Automatic hydrate preventing device for deep water gas well test and preventing method

A technology of hydrate and measuring device, which is applied in surveying, earthwork drilling, wellbore/well components, etc., can solve the problems of hydrate prevention and control failure, manual reading error, low accuracy, etc., to achieve no manual operation delay, Reliable and responsive plant engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

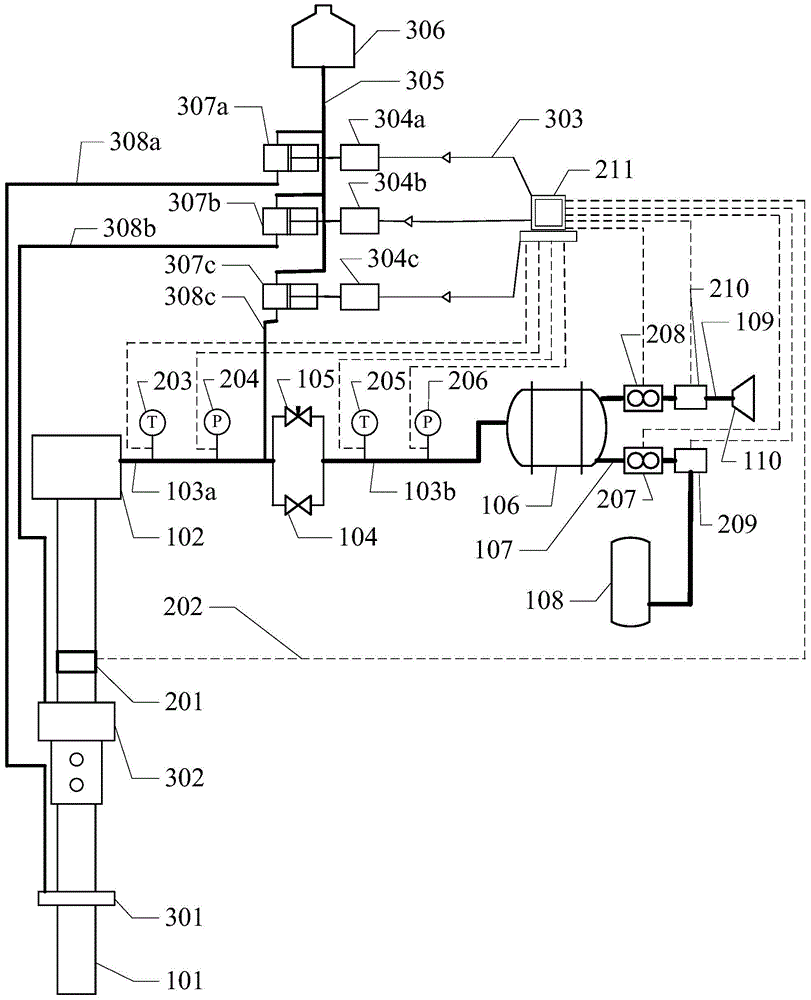

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

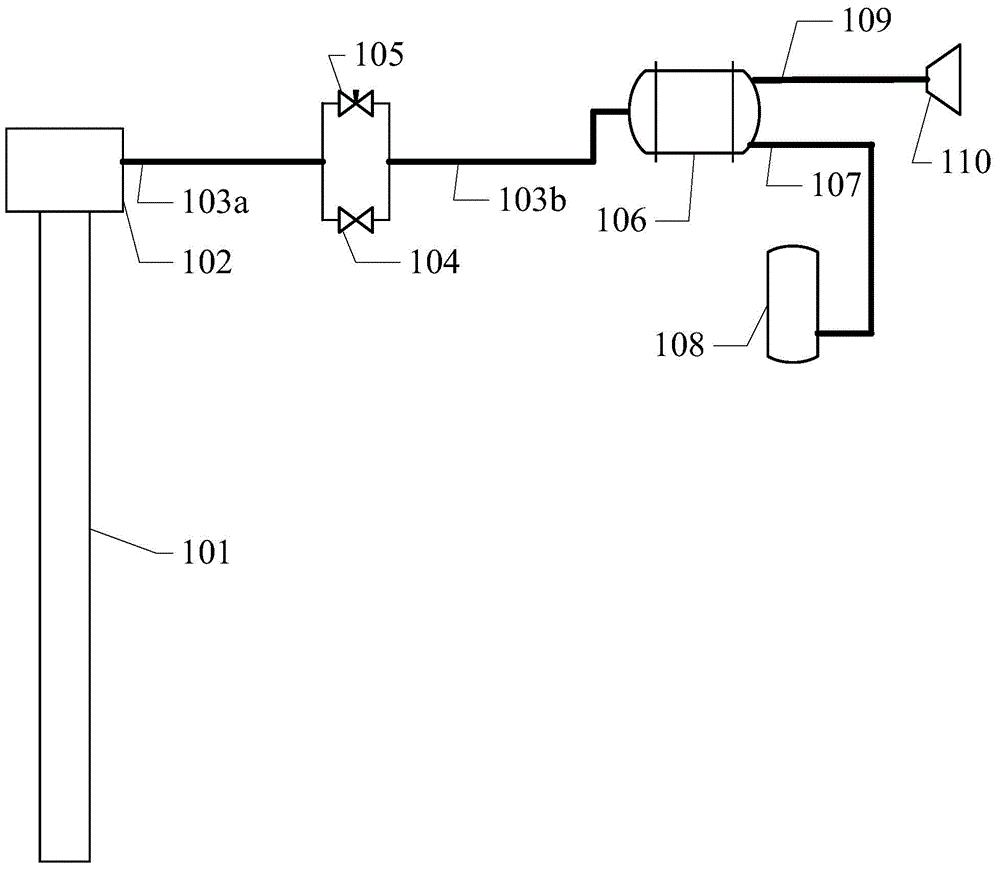

[0021] Such as figure 1 As shown, the deep-water gas well test downhole and surface devices include: test string 101, flow head 102, first surface flow pipeline 103a, second surface flow pipeline 103b, fixed nozzle 104, adjustable nozzle 105, gas-liquid two-phase Separator 106, liquid flow pipeline 107, liquid storage tank 108, gas flow pipeline 109 and combustion arm 110; flow head 102, as an intermediate device, is located at the top of the test column 101 and is connected with the test column 101 by threads;

[0022] Between the first surface flow pipeline 103a and the second surface flow pipeline 103b is a throttling manifold composed of a fixed nozzle 104 and an adjustable nozzle 105 connected in parallel; one end of the first surface flow pipeline 103a is connected to the flow head 102 through a union, The other end is connected to one end of the throttling mani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com