Intelligent well killing method and device for complex pressure system stratum

A formation and pressure technology, which is applied in earthwork drilling, wellbore flushing, wellbore/well components, etc., can solve the problems of relying on manual experience, low success rate, high risk, etc., and achieve no manual operation delay, timely monitoring, Engineering Reliable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

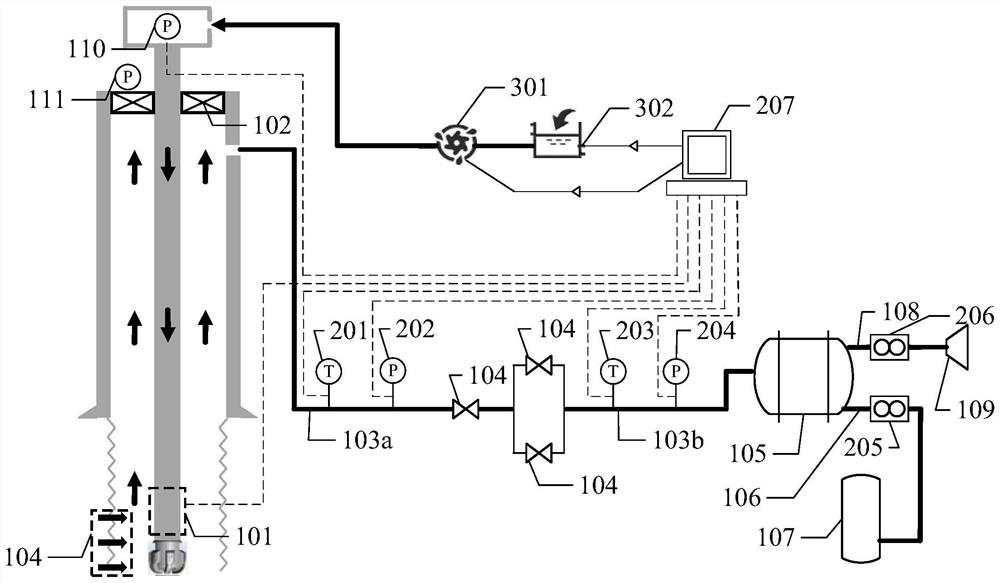

[0155] An intelligent well killing method for complex pressure system formations, comprising the following steps:

[0156] (1) Real-time monitoring of downhole-surface real-time information, including inlet / outlet drilling fluid flow difference, drilling fluid temperature, density, mud resistivity, standpipe pressure, mud pool increment, hook load;

[0157] (2) Process the real-time downhole-surface real-time information monitored in step (1) to judge downhole working conditions. If downhole abnormalities occur, real-time inversion of formation pressure and formation permeability, and real-time inversion of the wellbore multiphase flow model Uncertain parameters in the middle, dynamic simulation calculation of wellbore pressure distribution;

[0158] (3) Send out control signals, intelligently optimize and design throttling control parameters, including throttle valve connection mode and pressure drop distribution scheme, adjust wellhead pressure in real time to maintain const...

Embodiment 2

[0160] According to a kind of complex pressure system stratum intelligent killing method described in embodiment 1, its difference is:

[0161] In step (2), processing the downhole-surface real-time information monitored in step (1) in real time, and judging the downhole working condition means: combining the downhole real-time data for early overflow monitoring, the specific steps are as follows:

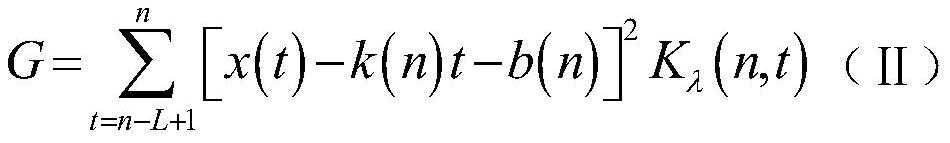

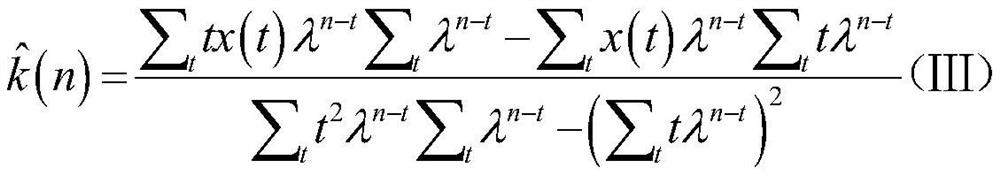

[0162] Collect overflow monitoring data X=[X from downhole PWD101 1 ,X 2 ,…X i ,…X m ],X i are different overflow detection parameters, which are discrete data sequences varying with time t, also denoted as x i (t), i=1,2,...,m, m is the length of the collected data, for a certain time interval t∈[n-L+1,n], L is the time window, and n is an arbitrarily selected time interval The starting point of , and its corresponding x(t) is approximated by the local linear regression model as formula (I):

[0163] x(t)=k(n)t+b(n) (I)

[0164] In the formula (I), k(n) is the slope of the ...

Embodiment 3

[0189] According to a kind of complex pressure system stratum intelligent killing method described in embodiment 1, its difference is:

[0190] In step (2), real-time inversion of formation pressure and formation permeability refers to:

[0191] After gas kick occurs during drilling, the reservoir fluid entering the wellbore will cause changes in the fluid composition and flow rate in the annular space. By measuring parameters such as pressure and flow rate, the reservoir parameters can be deduced in reverse. The gas invasion process is similar to the unstable well testing process, so certain formation information can be represented based on changes in gas invasion response parameters (vertical pressure, outlet flow, mud pool increment, etc.), so as to realize formation information inversion before well shut-in.

[0192]Since the gas invasion is slow and the expansion rate is very small in the early stage of gas invasion, the gas production rate at the bottom hole can be obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com