Patents

Literature

230 results about "Well kill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A well kill is the operation of placing a column of heavy fluid into a well bore in order to prevent the flow of reservoir fluids without the need for pressure control equipment at the surface. It works on the principle that the hydrostatic head of the "kill fluid" or "kill mud" will be enough to suppress the pressure of the formation fluids. Well kills may be planned in the case of advanced interventions such as workovers, or be contingency operations. The situation calling for a well kill will dictate the method taken.

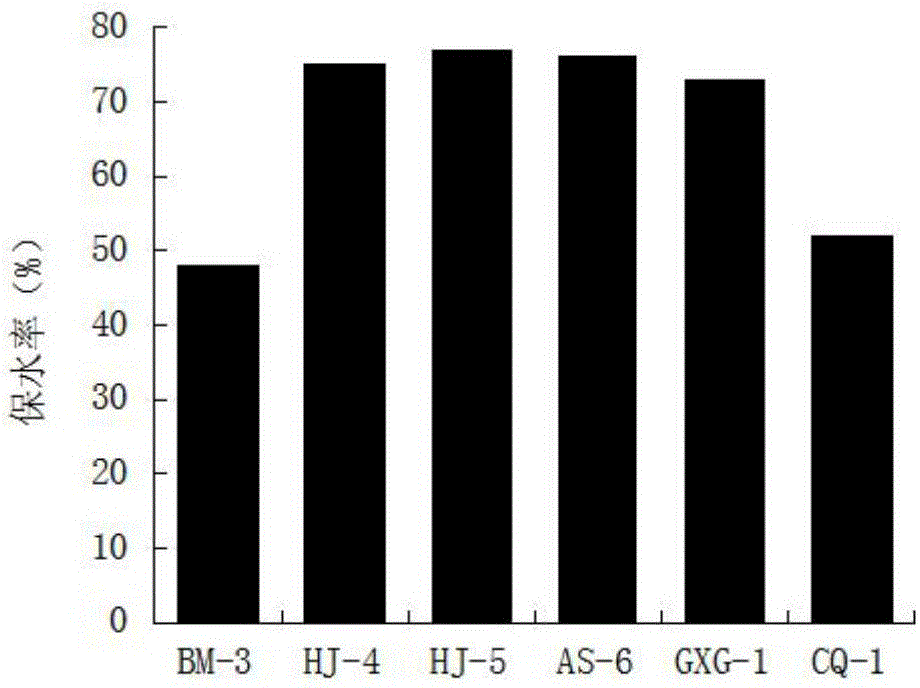

Foam washing fluid and preparation method thereof

The invention relates to foam washing fluid, which is applied to an oilfield development and washing work process. The foam washing fluid is characterized by comprising the following components by weight: 3.5 to 6 percent of hexadecyl-octadecyl trimethyl ammonium chloride, 18 to 30 percent of thioalcohol polyoxyethylene ether SSA-80, 8 to 12 percent of polyoxyethylene (10) octyl phenol ether, 1 to 2 percent of potassium chloride, 0.05 to 0.1 percent of fluorocarbon surfactant FC-3B, 0.5 to 1 percent of vitamin A, 0.05 to 0.1 percent of fluorocarbon surfactant FN-3, and the balance of water. The foam washing fluid has the effects that: when an oil well is thermally washed, the foam washing fluid is added into well washing fluid, and the oil well does not generate well killing phenomenon; and when a water injection well is washed, the foam washing fluid is evenly added into injection fluid, then dead oil in a shaft can be thoroughly washed out, and simultaneously, the aim of eliminating the pollution of a near wellbore zone is achieved.

Owner:PETROCHINA CO LTD

Ultra High Viscosity Pill and Methods for Use with An Oil-Based Drilling System

A fluid pressure transmission pill (FPTP) having an ultra-high viscosity for use in association with hydrocarbon drilling and exploration operations, particularly, managed pressure drilling (MPD) operations, is described. The ultra-high viscosity pill is a weighted pill composition that includes a hydrocarbon fluid, a thixotropic viscosifying agent, one or more activators, an emulsifier / wetting agent, a fluid loss control additive, and a weighting material. In accordance with selected aspects of the described fluid pressure transmission pill, the ratio of the amount of the thixotropic viscosifying agent to the activator is a ratio of about 7:1, and the weighting material is a barium-containing solid-phase material. Also described are methods of use of such FPTP products in subterranean operations, such as well killing operations during managed pressure drilling.

Owner:TEXAS UNITED CHEM CORP

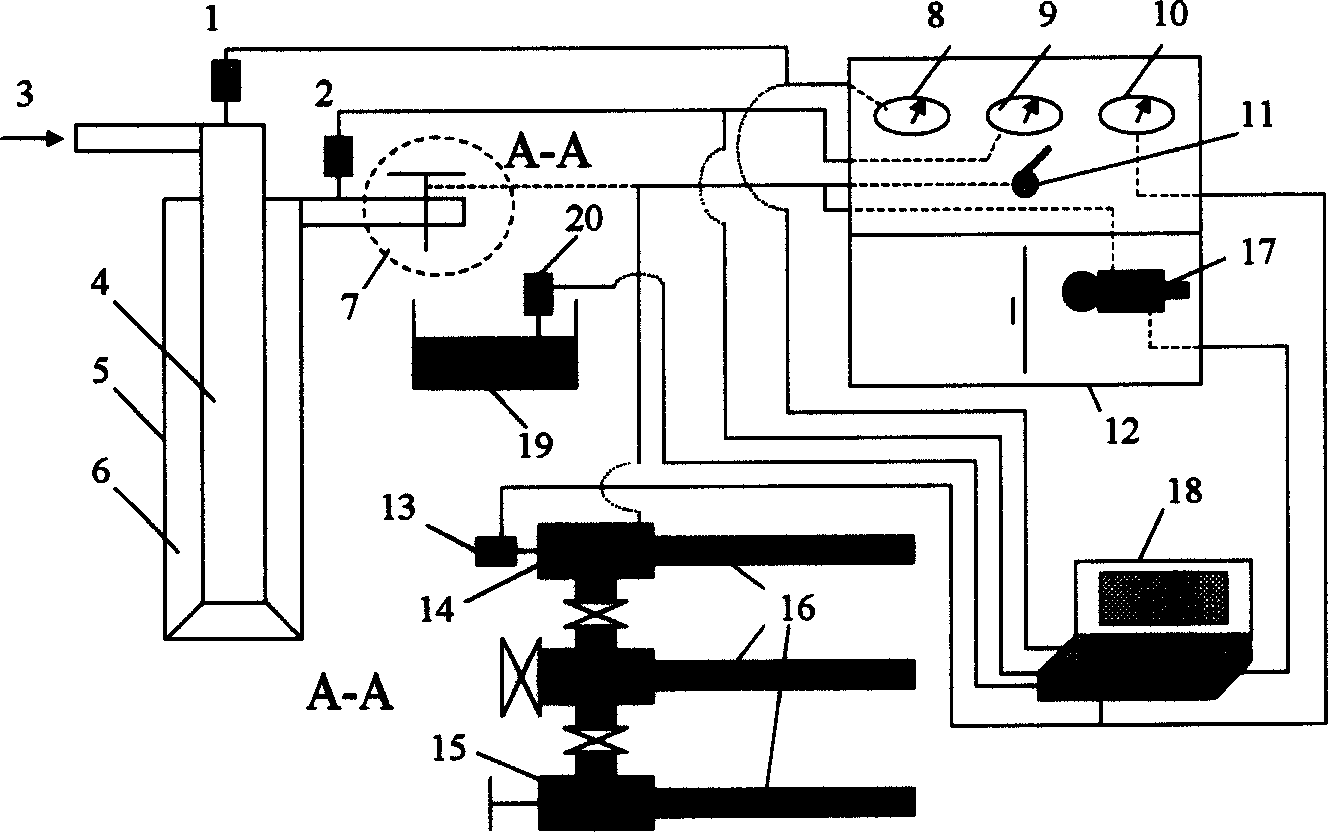

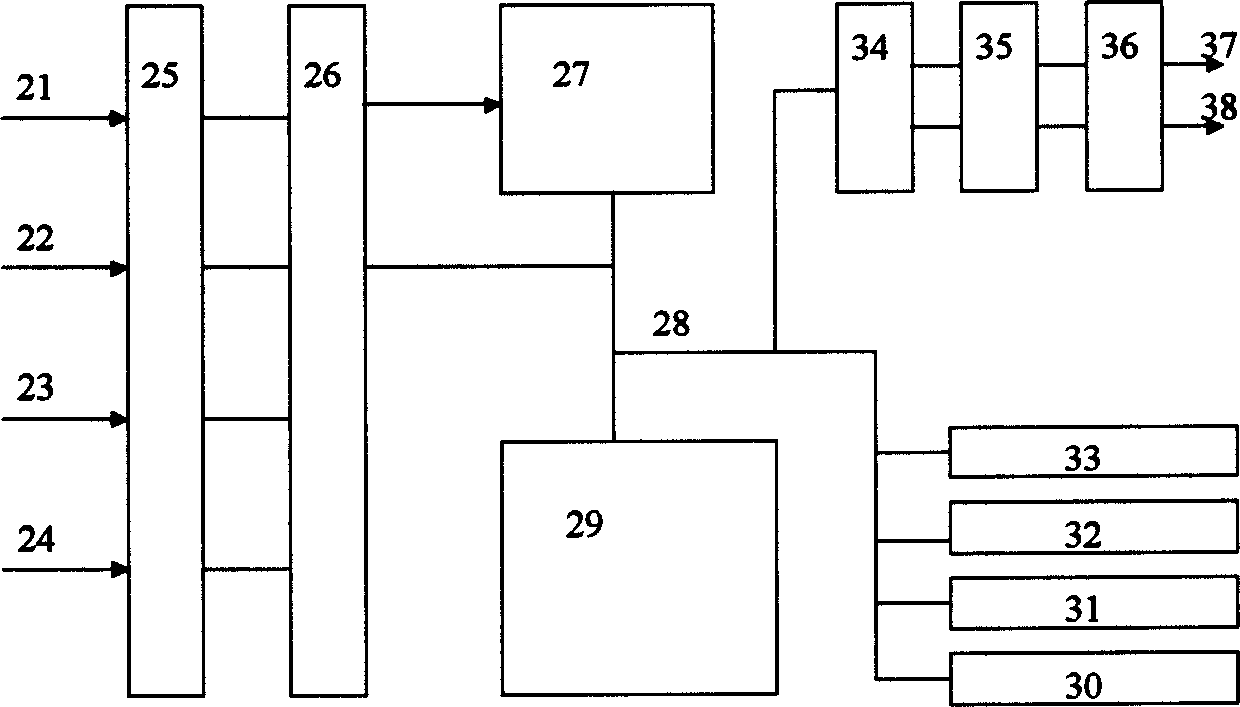

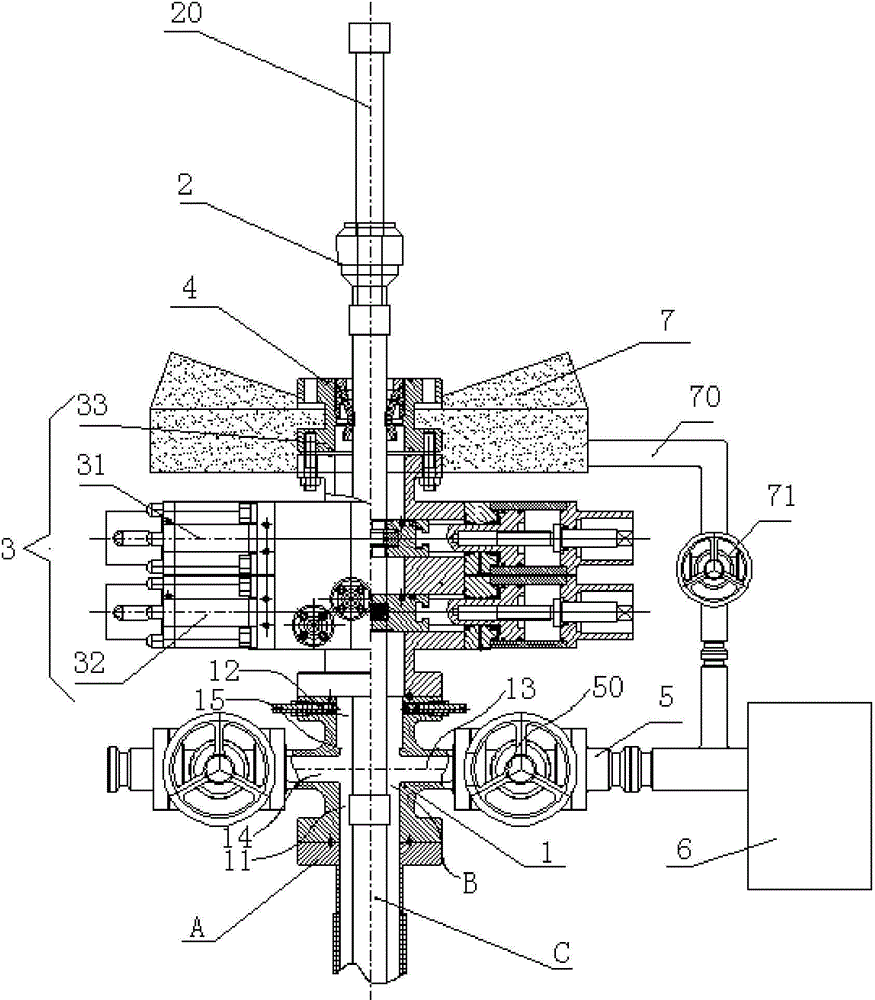

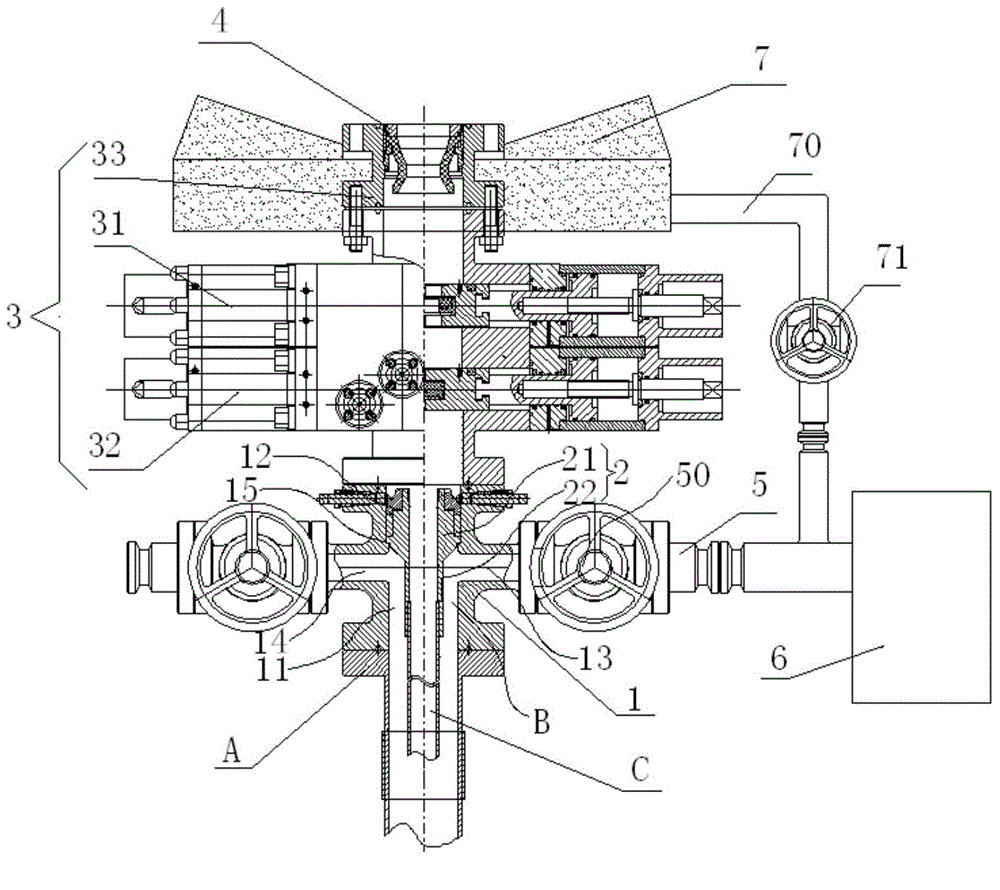

Automic control system for throttle well killing

InactiveCN1538036ARealize automatic controlAvoid downhole pressure fluctuationsFluid removalFluid pressure controlWell killThrottle control

An automatic control system for throttle well killing fracture for automatically controlling the throttle circulation pressure is composed of vertical-fracture sensor, sleeve-fracture sensor, well-fracture liquid, drilling column, well, ring space, throttle pipes, vertical-fracture meter, sleeve-fracture meter, valve openness meter, manual three-position four-way valve, electric three-position four-way valve, throttle control box, valve sensor, hydraulic throttle valve, manual throttle valve, spraying pipeline, computer, sludge pool and level sensor for sludge pool. Its control method is also disclosed.

Owner:雷宗明

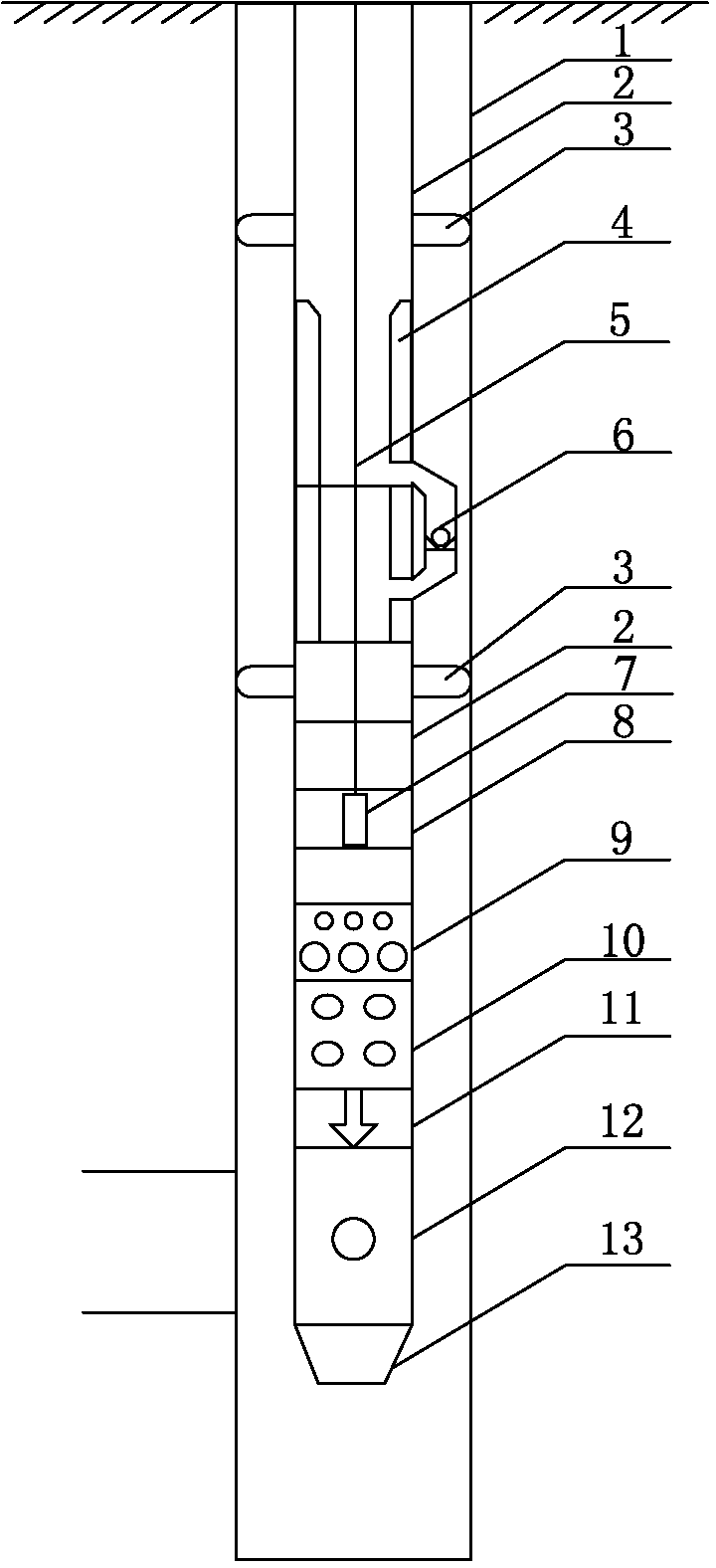

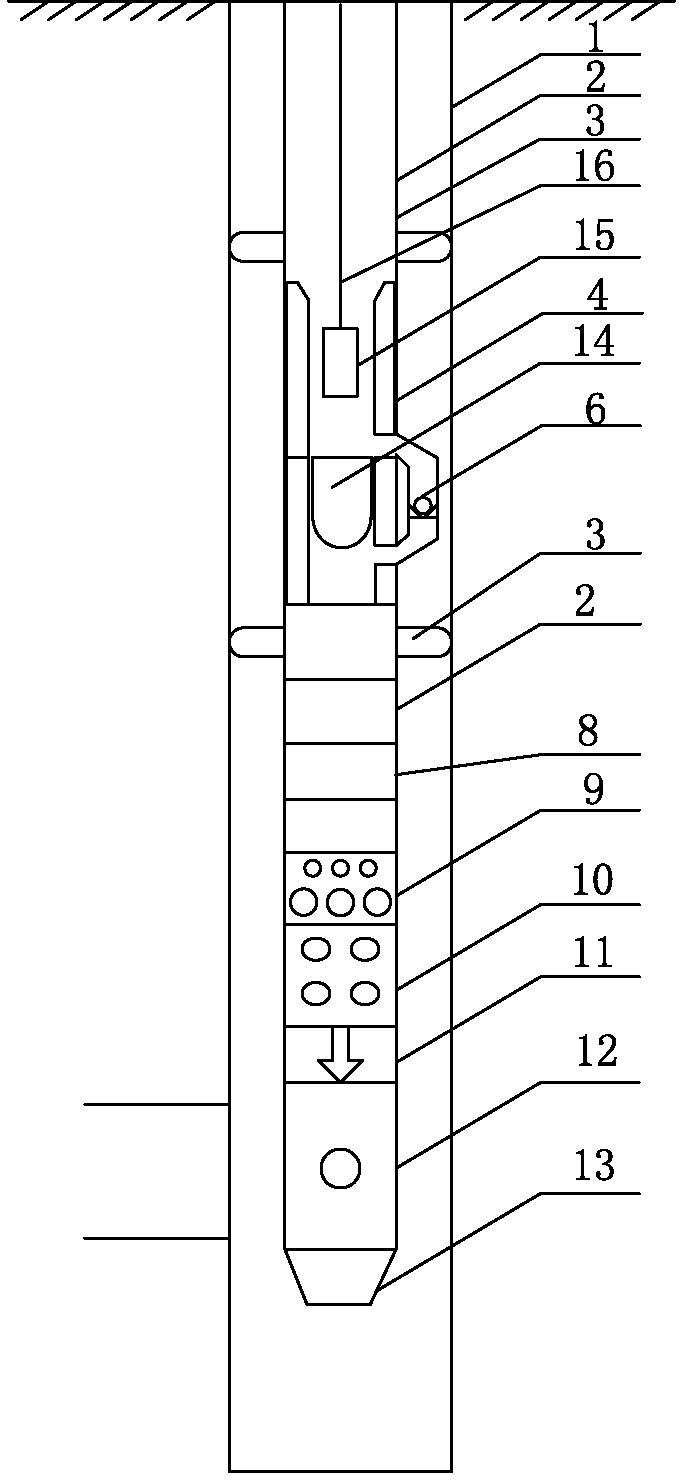

Small-diameter tubular pump pump-passing depth checking perforating and pumping combined production method

ActiveCN103410484AAvoid pollutionIncrease the effective diameterSurveyFluid removalWell killGas oil ratio

The invention relates to a small-diameter tubular pump pump-passing depth checking perforating and pumping combined production method. The method includes adopting a perforating and pumping combined pump and a small-diameter gamma depth checking gauge, tripping in a standing valve along with a perforating and pumping combined tubing string and a pumping-down tool to a design position, tripping in the small-diameter gamma depth checking gauge for pump-passing depth checking, adjusting the tubing string to enable a perforating gun to align to a perforating formation, tripping in a pumping rod plunger and a blanking plug, performing pump bumping and well completion, then performing annulus pressure perforating, and starting to pump and produce after perforating. By the technology, the purposes for accurate located perforating of oil sheets and pumping after perforating are achieved, oil layers are protected effectively, well control safety in construction is improved, and technical support is provided for well-killing-free production of high-pressure oil wells and high-gas-oil-ratio oil wells.

Owner:CHINA PETROLEUM & CHEM CORP +1

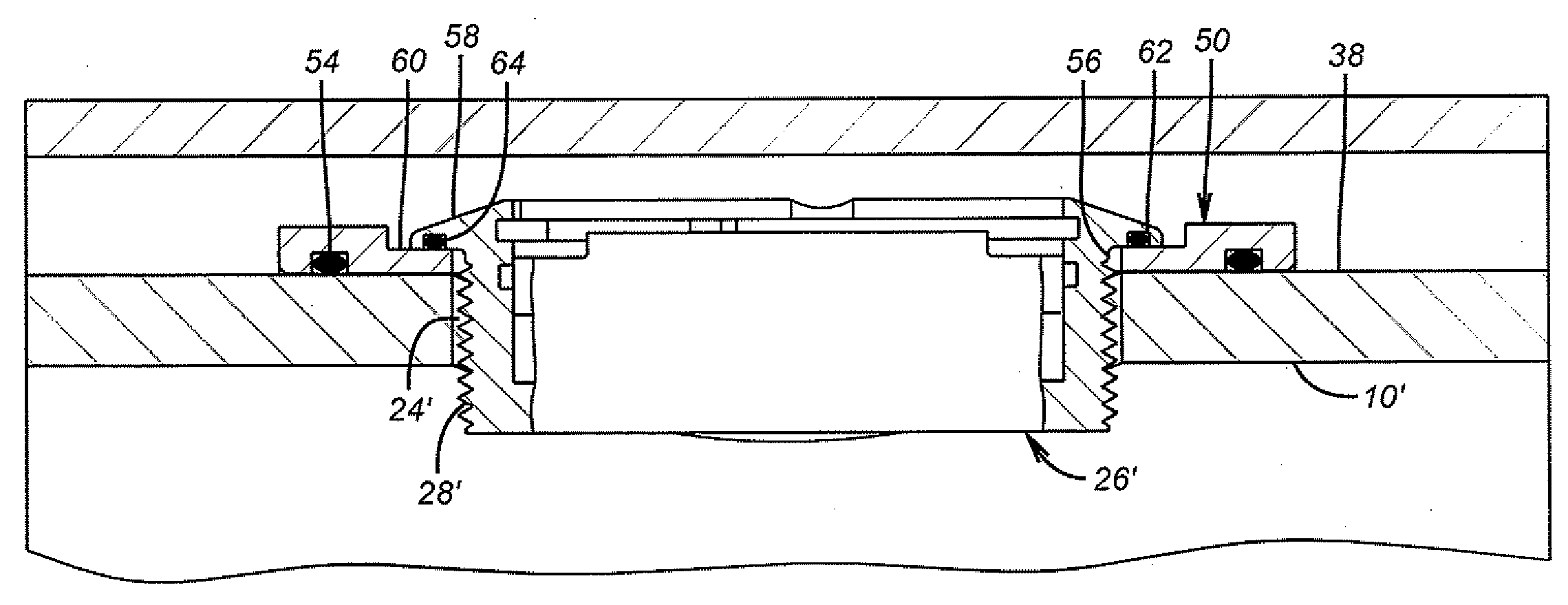

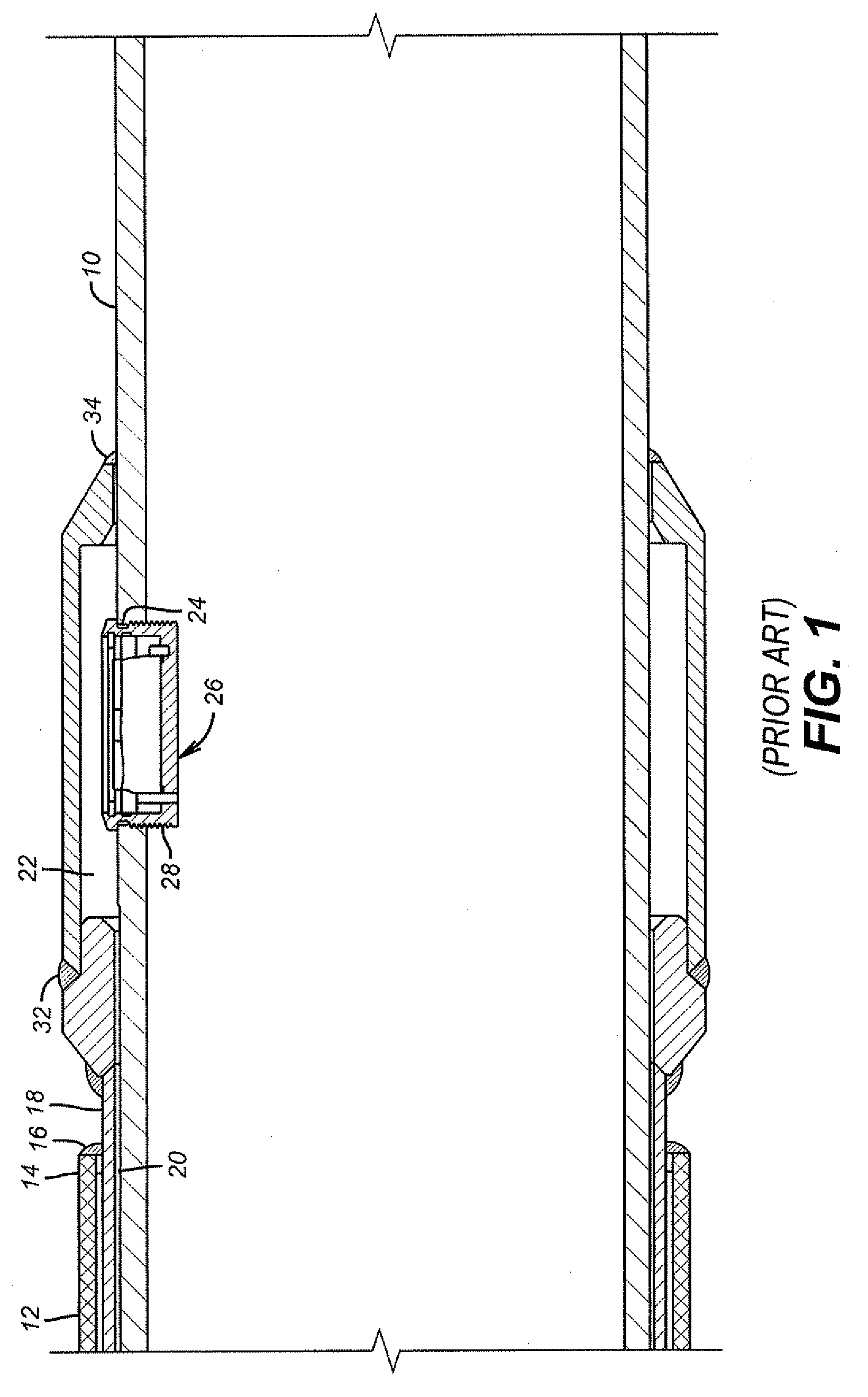

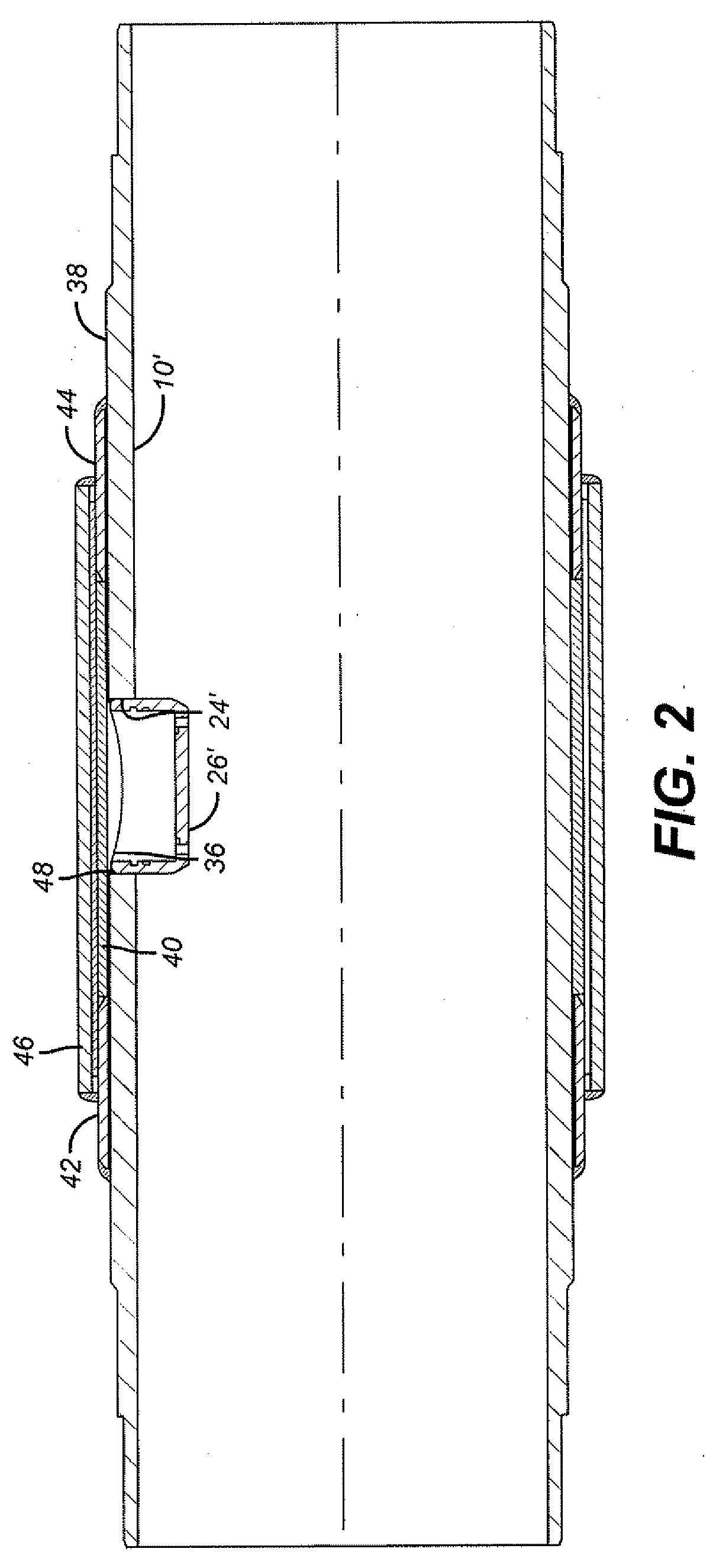

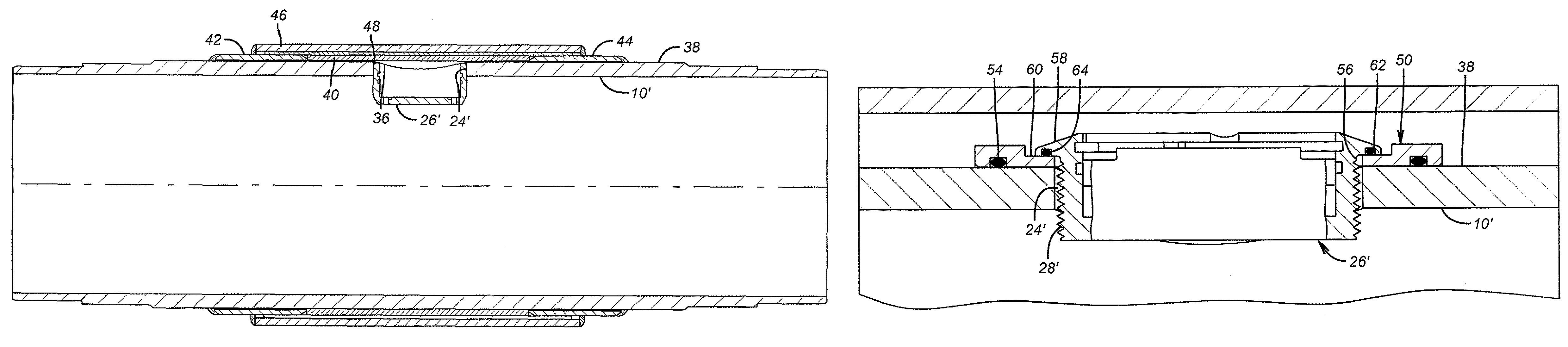

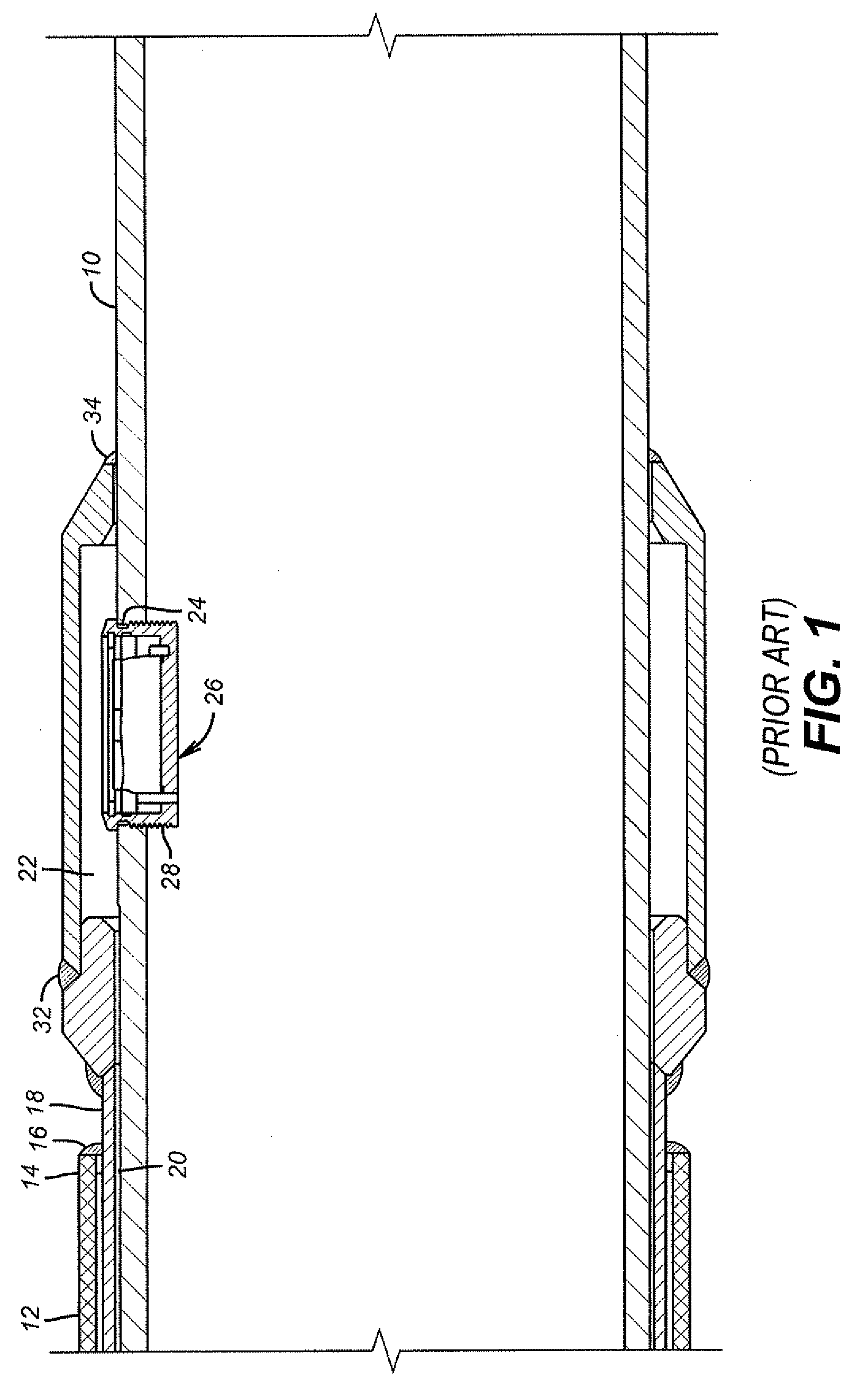

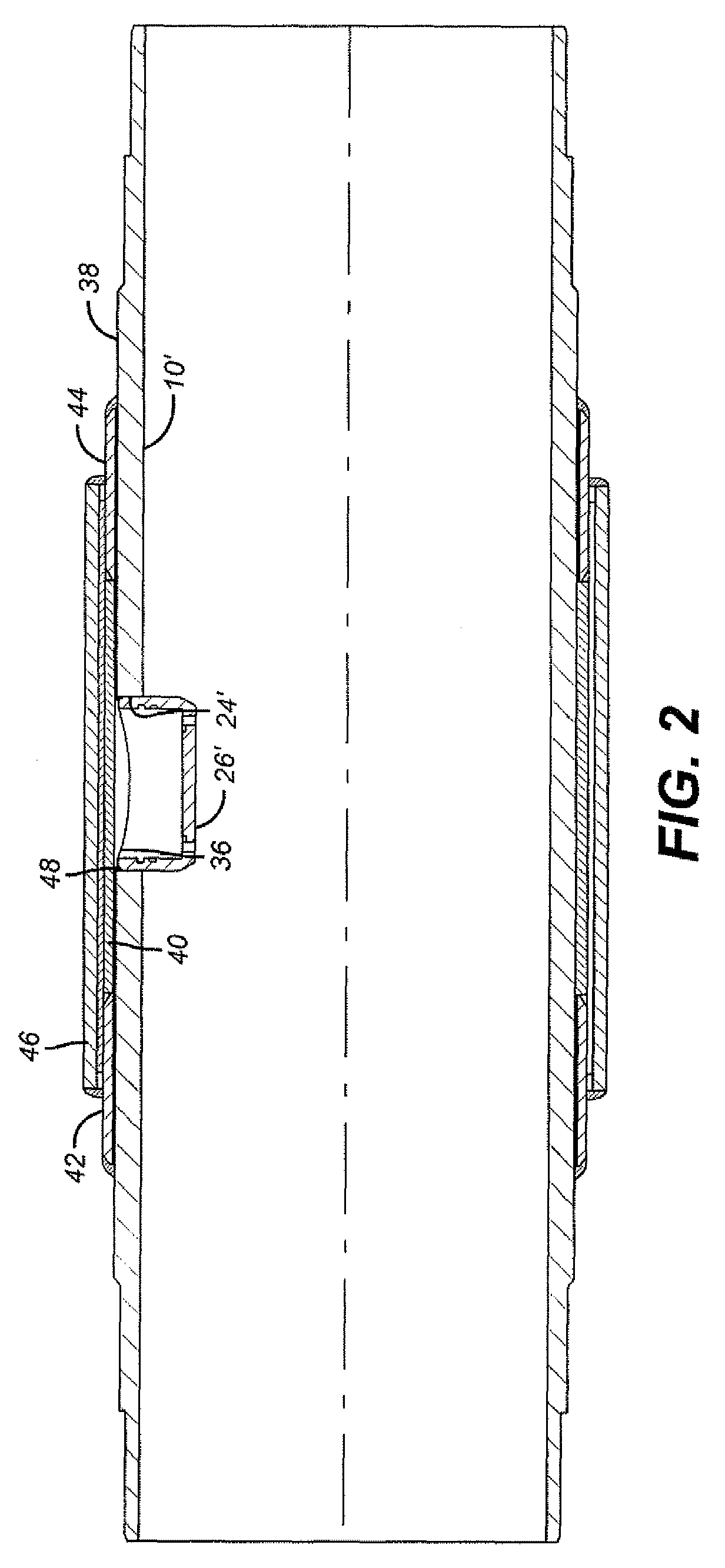

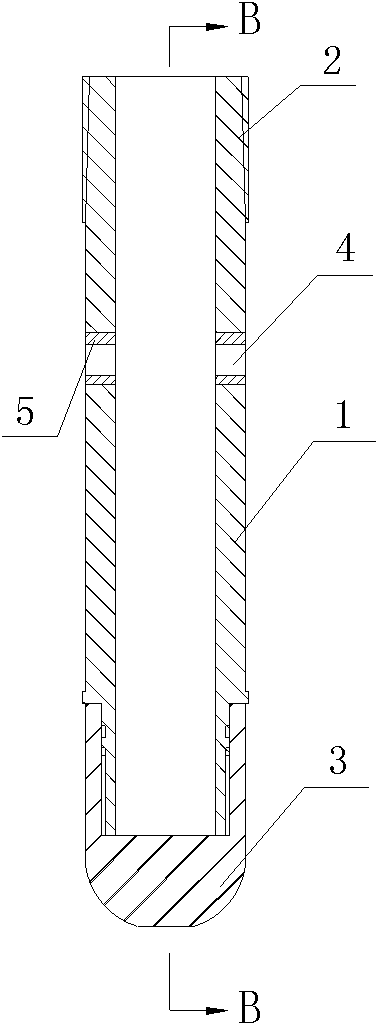

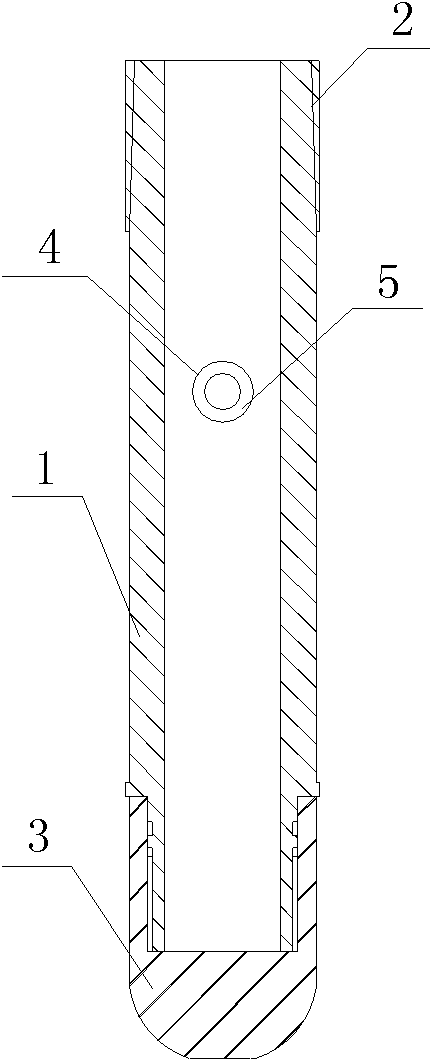

Restrictor Valve Mounting for Downhole Screens

ActiveUS20080264628A1Shorten assembly timeLow costFluid removalWell/borehole valve arrangementsWell killSlurry

In one aspect of the invention a valve that operates in association with a downhole screen is threaded into the wall of a base pipe after being inserted through a saddle. When the valve body is threaded in, the engagement into the wall threads in the base pipe acts as a sealing force on a ring seal between the saddle and the base pipe and between the valve body and the saddle. The valve itself can be outfitted with a cover with openings that can be integral or removable and disposed at the end of the valve that is innermost to the base pipe. Preferably a series of elongated slots are used that can catch slurry if the well is to be killed while allowing subsequent production to drive the accumulated solids from well killing back into the base pipe. Another feature places the valve in a base pipe opening under a cylindrical screen section to reduce assembly time and cost of constructing an adjacent housing to one side of the cylindrical screen section to accommodate the valve.

Owner:BAKER HUGHES INC

Restrictor valve mounting for downhole screens

ActiveUS7644758B2Low costShorten the timeFluid removalWell/borehole valve arrangementsWell killPusa hispida

In one aspect of the invention a valve that operates in association with a downhole screen is threaded into the wall of a base pipe after being inserted through a saddle. When the valve body is threaded in, the engagement into the wall threads in the base pipe acts as a sealing force on a ring seal between the saddle and the base pipe and between the valve body and the saddle. The valve itself can be outfitted with a cover with openings that can be integral or removable and disposed at the end of the valve that is innermost to the base pipe. Preferably a series of elongated slots are used that can catch slurry if the well is to be killed while allowing subsequent production to drive the accumulated solids from well killing back into the base pipe. Another feature places the valve in a base pipe opening under a cylindrical screen section to reduce assembly time and cost of constructing an adjacent housing to one side of the cylindrical screen section to accommodate the valve.

Owner:BAKER HUGHES HLDG LLC

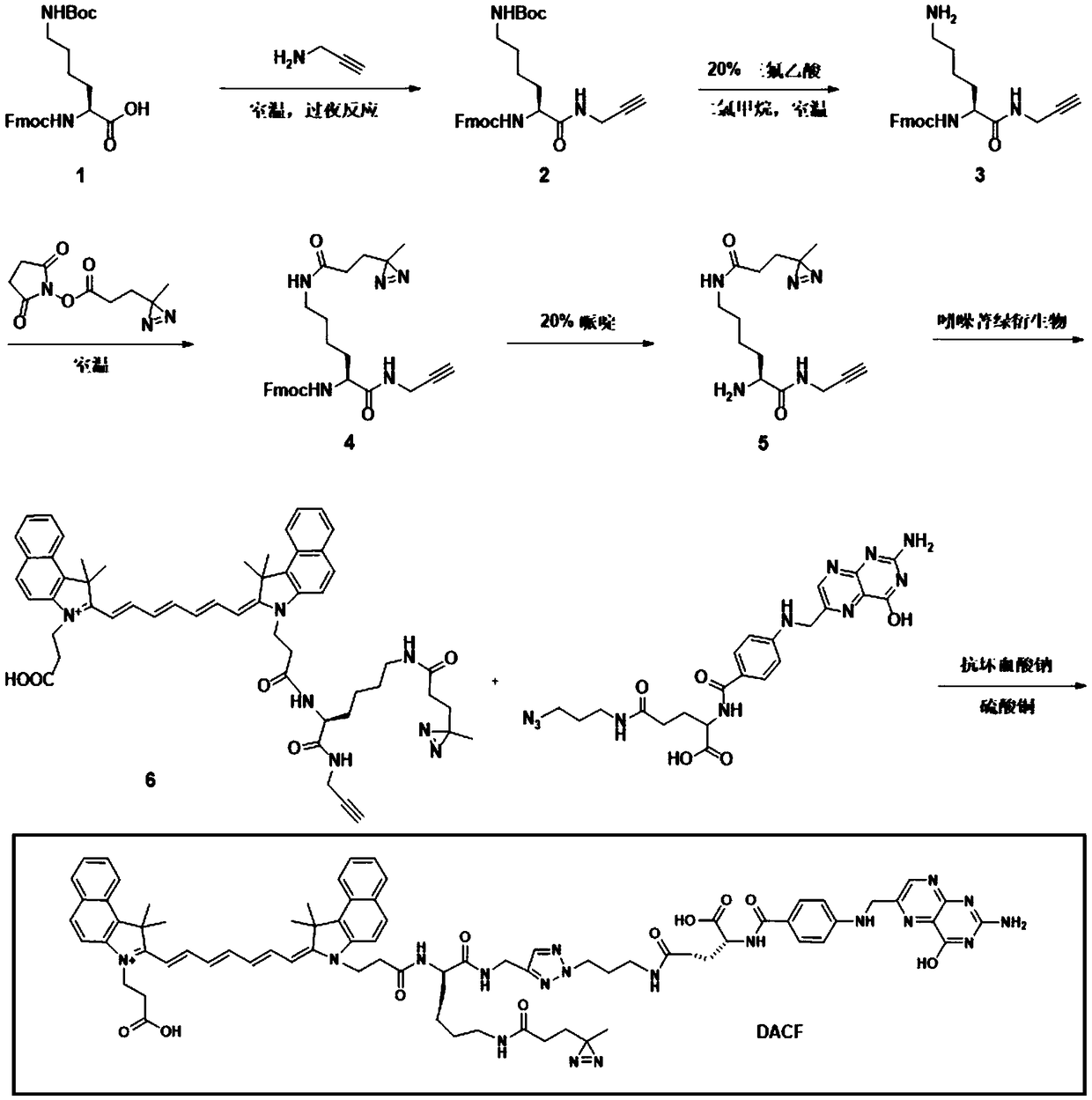

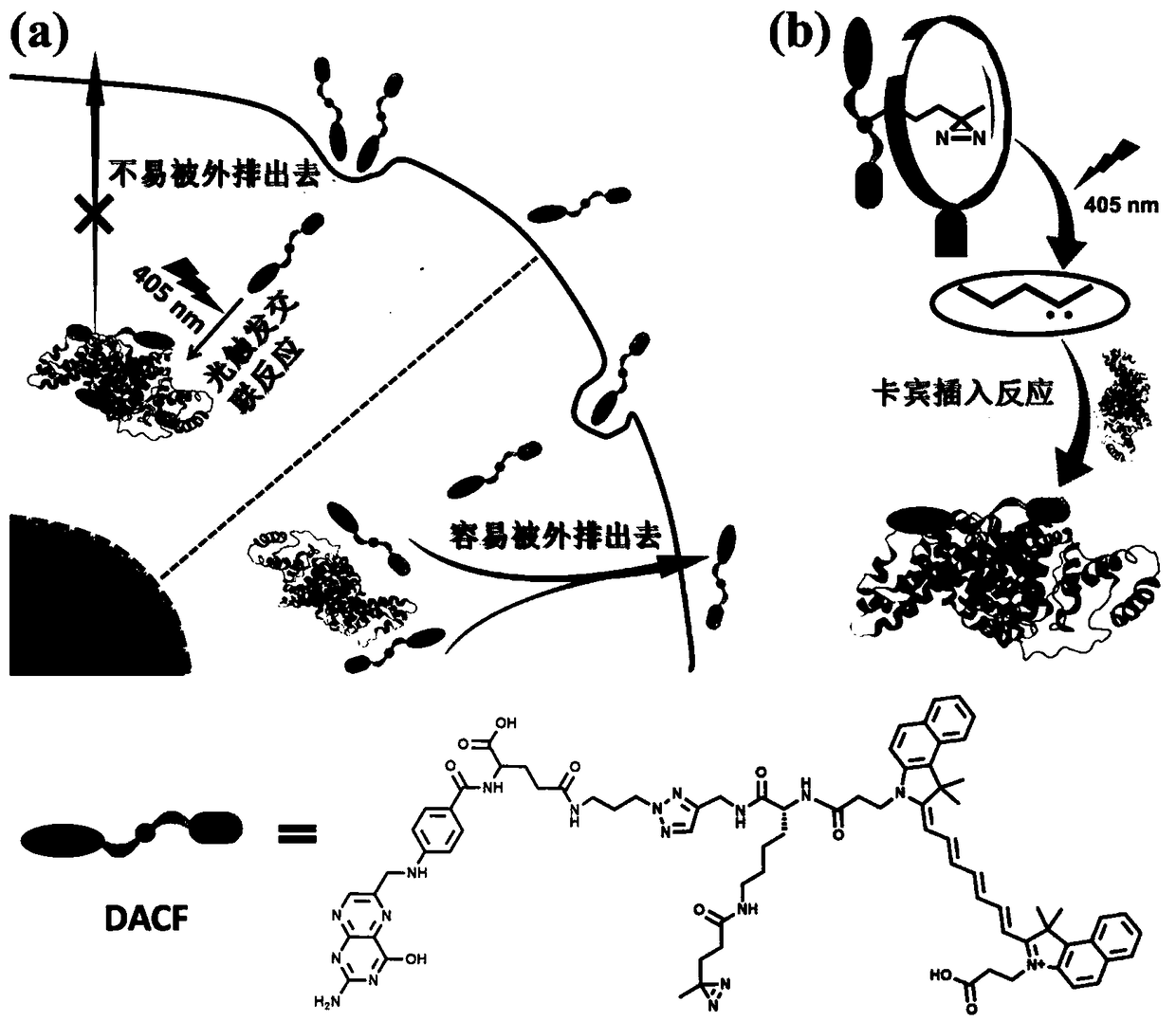

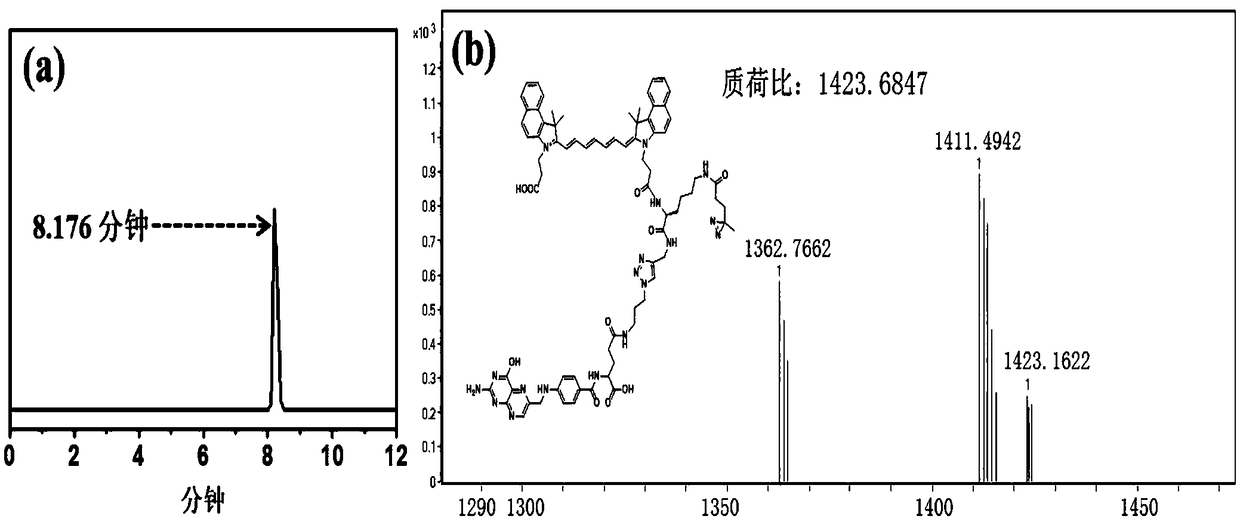

Ultraviolet light-triggered crosslinking near-infrared molecular probe as well as preparation method and application thereof

ActiveCN109180680AMild light trigger conditionsLight trigger conditions are simpleOrganic active ingredientsOrganic chemistryWell killUltraviolet lights

The invention discloses an ultraviolet light-triggered croslinking near-infrared molecular probe as well as a preparation method and application of the molecular probe. Particularly, the preparation method comprises the following steps: constructing and synthesizing a photo-crosslinking near-infrared molecular probe DACF; and causing the photo-crosslinking near-infrared molecular probe DACF to crosslink in cells under the triggering of ultraviolet light. The probe is irradiated by light with a specific wavelength to generate a Carbene intermediate with high activity and is bound with an intracellular biomolecule covalent bond, so that the intake of the probe in the cell is remarkably increased, the residence time is prolonged, and the long-term tracking of tumor cells can be realized. Meanwhile, the tumor cells can be well killed by virtue of the photothermal effect of the probe. According to the photo-crosslinking near-infrared molecular probe prepared by virtue of the preparation method, the accumulation amount of the probe in a living tumor can be effectively increased, the residence time can be effectively prolonged, the diagnosis and treatment integration of the tumor is realized, and the molecular probe has important scientific research values and economic values.

Owner:SUZHOU UNIV

Injecting-plugging method during under-well work

ActiveCN103603628ASolve the injection problemReduce operating costsSealing/packingWell killCement slurry

The invention discloses an injecting-plugging method during under-well work. The method is characterized by comprising the following steps: a. killing a well to steady by clear water and then measuring the balance liquid level in the well; b. pulling out an original tube string from the well, throwing a casing rubber plug, and conveying the casing rubber plug to the designed depth by an injecting-plugging tube string; c. pumping cement slurry from the injecting-plugging tube string, then pumping clear water to substitute for cement slurry, and directly pulling the injecting-plugging tube string to the measured balance liquid level after the pumping is finished, wherein the liquid level in the well descends gradually after achieving the highest working liquid level until restoring to balance; and d. standing the cement slurry for waiting for solidifying, and forming a cement plug after the cement slurry is solidified. The method is especially applicable to ultra low pressure oil-gas wells prone to leakage, and capable of directly accomplishing injecting-plugging without stopping leakage or throwing a bridge plug when the level of a well killing fluid in the well is far away from the mouth of the well; the injecting-plugging difficulty of the ultra low pressure wells prone to leakage is effectively overcome.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

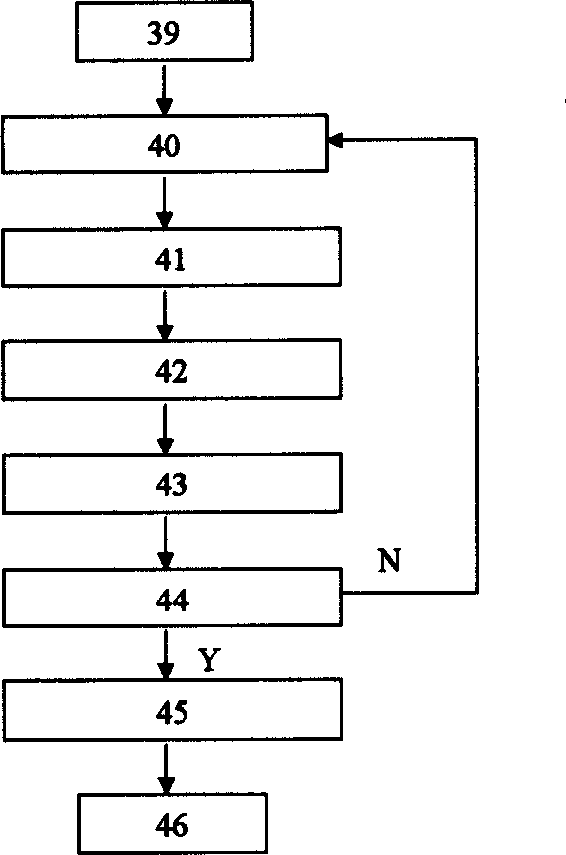

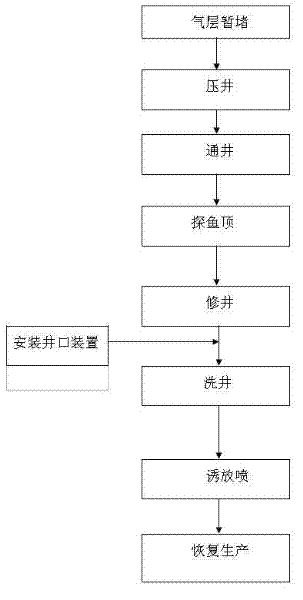

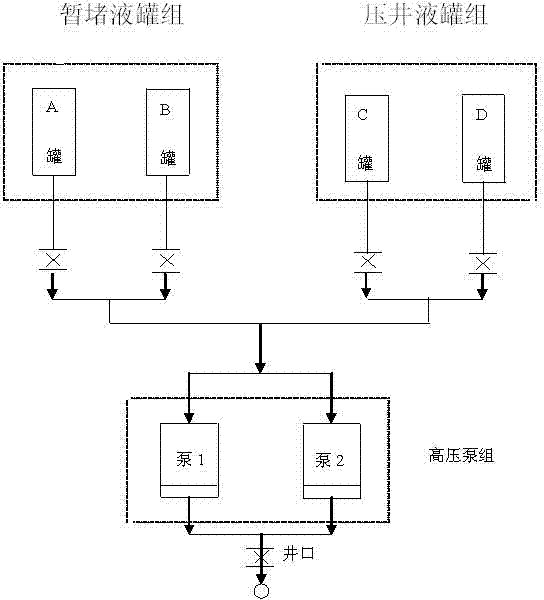

Well killing treatment method for well kick in process of pulling out of hole

The invention discloses a well killing treatment method for well kick in the process of pulling out of a hole. A well is shut in, and a mass flow meter is connected in a throttle manifold; the stratum pressure is calculated by means of the hydraulic parameter and other parameters in the drilling process; by controlling the opening degree of a throttle valve and combining the reading value of the mass flow meter, first time of operation of drilling with pressure is conducted; whether a drill bit meets a gas cut drilling fluid or not is judged; the well killing drilling depth and the density of a well killing fluid are determined; well killing is conducted through an engineer method, and the gas cut drilling fluid in the well is circulated out of the well in a circular week; and well killing drilling depth calculating, density determining and well killing through the engineer method are conducted circularly, till the gas cut drilling fluid is overall circulated out of the well. Well kick in the drilling process can be subjected to well killing design, by means of theoretical calculation and process operation, the time that the drill bit reaches the top of the gas cut drilling fluid is judged, accordingly the start time of well killing is determined, and guarantee is provided for safely and effectively circulating out the gas cut drilling fluid in the well.

Owner:CHINA PETROCHEMICAL CORP +3

Well kill additive, well kill treatment fluid made therefrom, and method of killing a well

InactiveUS20060011343A1Well mixedReduced volume flowDrilling compositionSealing/packingFiberWell kill

Owner:BURTS BOYCE DONALD III

Sand blasting, perforating and fracturing method

Owner:ANTON OILFIELD SERVICES (GRP) LTD

Well killing method using solid water particles as kill fluid

The invention is a well killing method using solid water particles as well killing liquid, its character: making according to the steps: 1, prepare clear water or salt water; 2, add in the drugs such as corrosion inhibitor, discharging assistant, clay stabilizing agent, etc, to protect oil-gas well; 3, add in solidification initiator and colloid protective agent; 4, add in strong water absorbing resin material to fully and uniformly mix to form solid particles; 5, press the solid particles into the well tube by slurry pump or crusher in a forward or reverse circulating mode; 6, after killing well, circulate a cycle, observe for 48 hours, and when the well is stable, open well mouth to make underpit construction; 7, discharge the solid particles in the well tube by pumping or air lifting, etc, and put into production.

Owner:廖中健

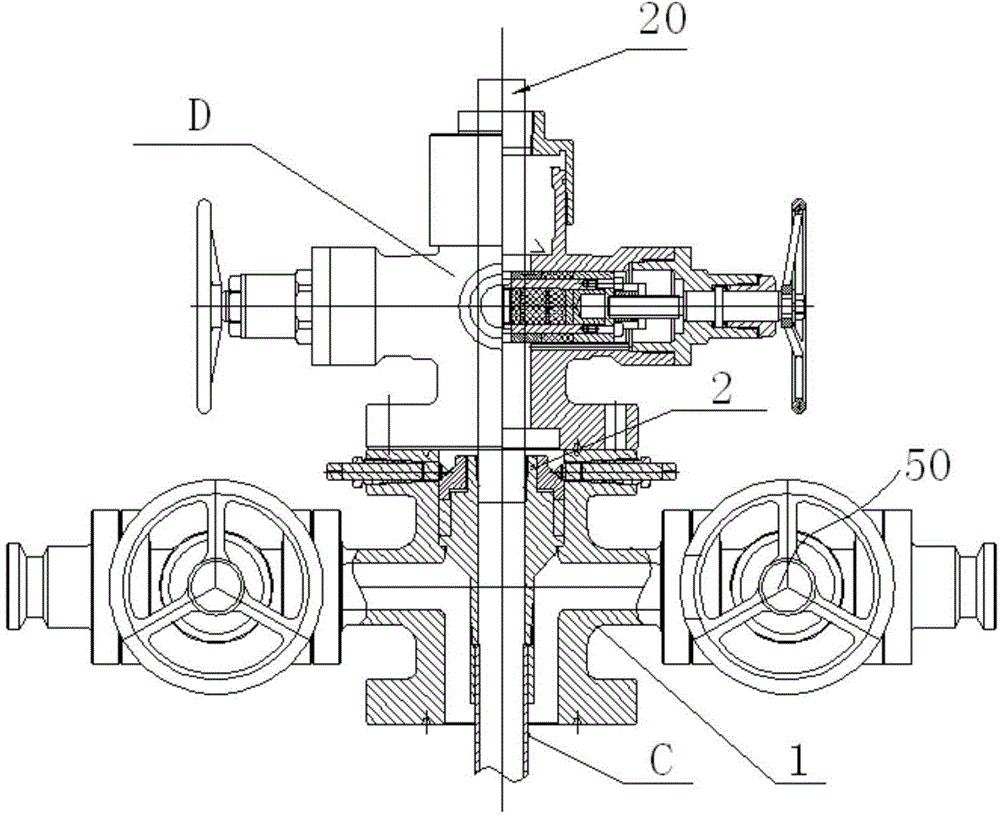

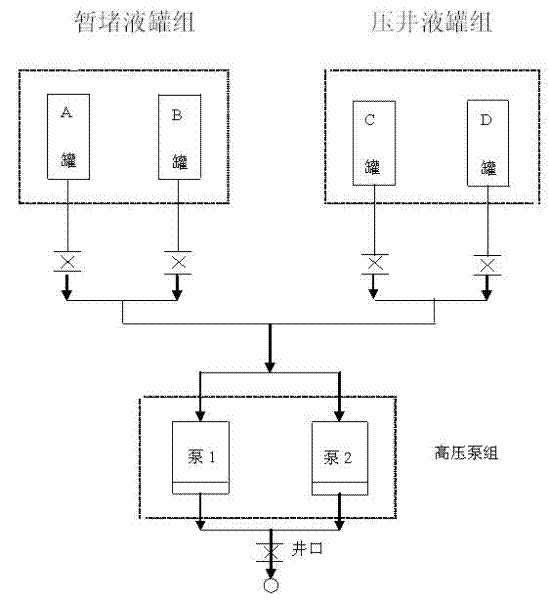

Device and technological method for pulling lower oil tube

The invention discloses a device and a technological method for pulling a lower oil tube. The device comprises a large cross, a hanger, a hanger plug, a double ram type preventer and a sealing piece. The large cross comprises a first channel, a second channel, a third channel and a fourth channel, wherein the first channel is connected with a well mouth flange in a sealing mode, and the second channel is connected with the double ram type preventer in a sealing mode. A hanger seat is arranged at the position of the second channel, an open flow pipeline is arranged on the third channel and / or the fourth channel, and a first valve is arranged on the open flow pipeline. A liquid flow channel is formed between the hanger and the large cross, the hanger is provided with a first matching part and a second matching part opposite to the first matching part, the first matching part is matched with the hanger seat, and the second matching part is used for fixing the oil tube. The lower end of the hanger plug is fixed to the hanger in a sealing mode. The double ram type preventer is connected with a containing seat in a sealing mode. The sealing piece is arranged in the containing seat. The device and the technological method for pulling the lower oil tube are suitable for non-well killing operation, high in operation efficiency and low in cost.

Owner:PETROCHINA CO LTD

Unidirectional temporary plugging agent for natural gas wells and application method thereof

The invention relates to a unidirectional temporary plugging agent used for extracting natural gas from wells of an oil field and an application method. The temporary plugging agent comprises hydrophilic high polymer powder, wherein a polymeric monomer of the hydrophilic high polymer powder is one from or a combination of several from acrylamide, acrylate, propylene sulfonate, ethylene sulfonate,2-acrylamido-2-methyl propane sulfonic acid (AMPS) and vinyl pyrrolidone. The temporary plugging agent is matched with well killing fluid for use after being made into temporary plugging fluid, can form a leakage-free working fluid system with a differential pressure of 30MPa, and can be completely suitable for low pressure natural gas wells of which the pressure coefficient is between 0.2 and 0.5, the temperature is not higher than 180 DEG C and the differential pressure is not larger than 30MPa.

Owner:SHENGLI OIL FIELD FANGYUAN CHEM IND

Vertical well orientated hydraulic jet multi-stage fracturing method for oil and gas well

InactiveCN108952664APrecise location of perforationEasy alignmentFluid removalWell killSand blasting

The invention discloses a vertical well orientated hydraulic jet multi-stage fracturing method for an oil and gas well. The method includes the following steps of well flushing, well killing and drifting scrapping. A guiding head, a rotatable casing collar locator, a repeatable-setting packer, an oriented hydraulic jet gun, a safety joint, an oriented pup joint and an oil tube oriented hydraulic jet multi-stage fracturing string are sequentially connected to the tail end of an oil tube; after the string enters the well, the position of the jetting tool is localized accurately through the rotatable casing collar locator; the string is rotated at the mouth of the well to determine the orientation corresponding to a spray nozzle of the oriented hydraulic jet gun; after orientation is determined, setting of the repeatable-setting packer is performed, perforating fluid enters from an oil tube pump to perform sand blasting perforation, and oil jacket annular space sand fracturing is performed; after fracturing construction is ended, the oil tube is lifted to unpack the repeatable-setting packer. With the method, the operation period is short, the demand that during fracturing, crack initiation is performed in the minimum main stress direction can be met, construction pressure is decreased, and the recovery efficiency of the oil and gas well is substantially improved.

Owner:CNPC BOHAI DRILLING ENG

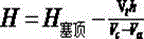

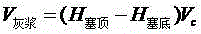

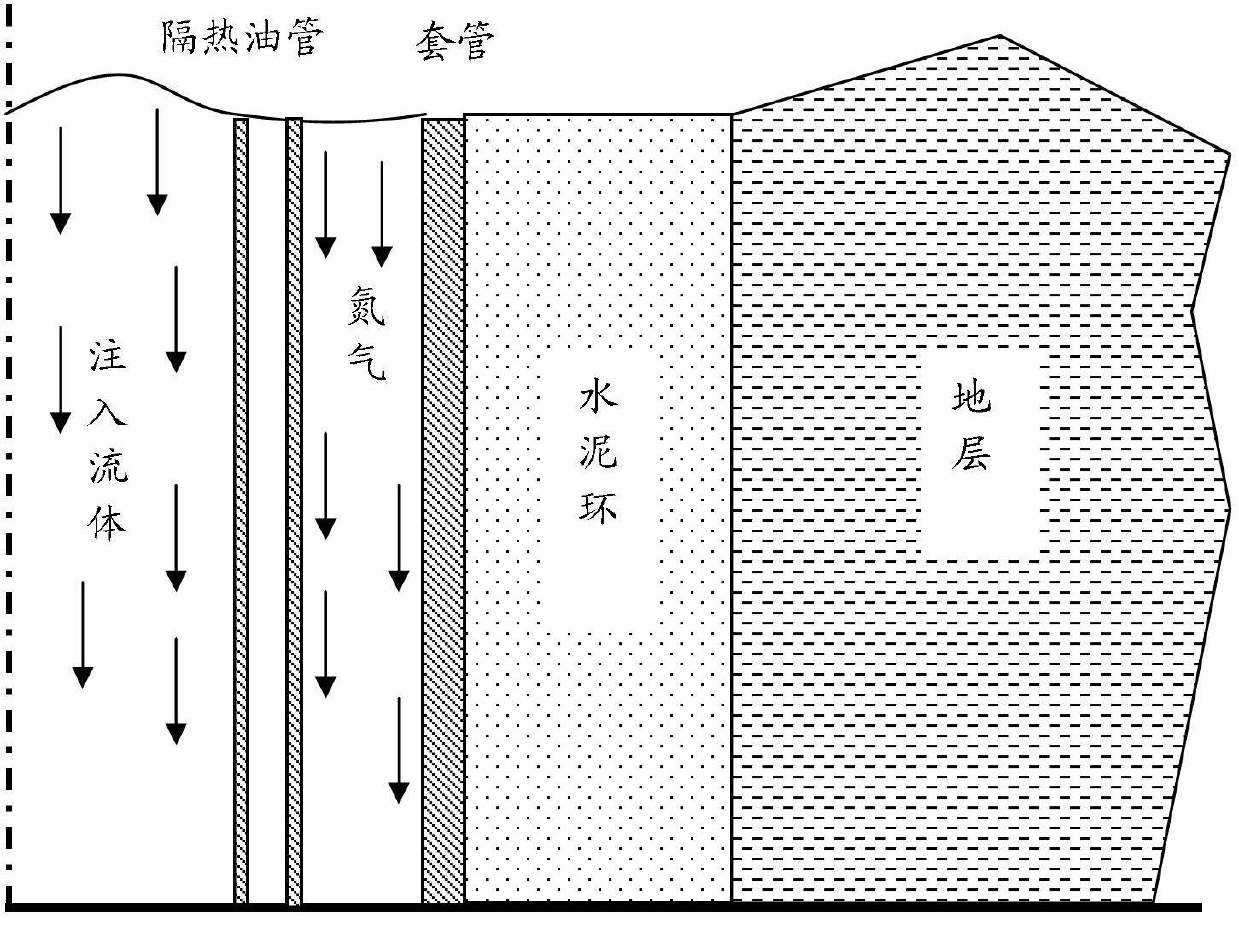

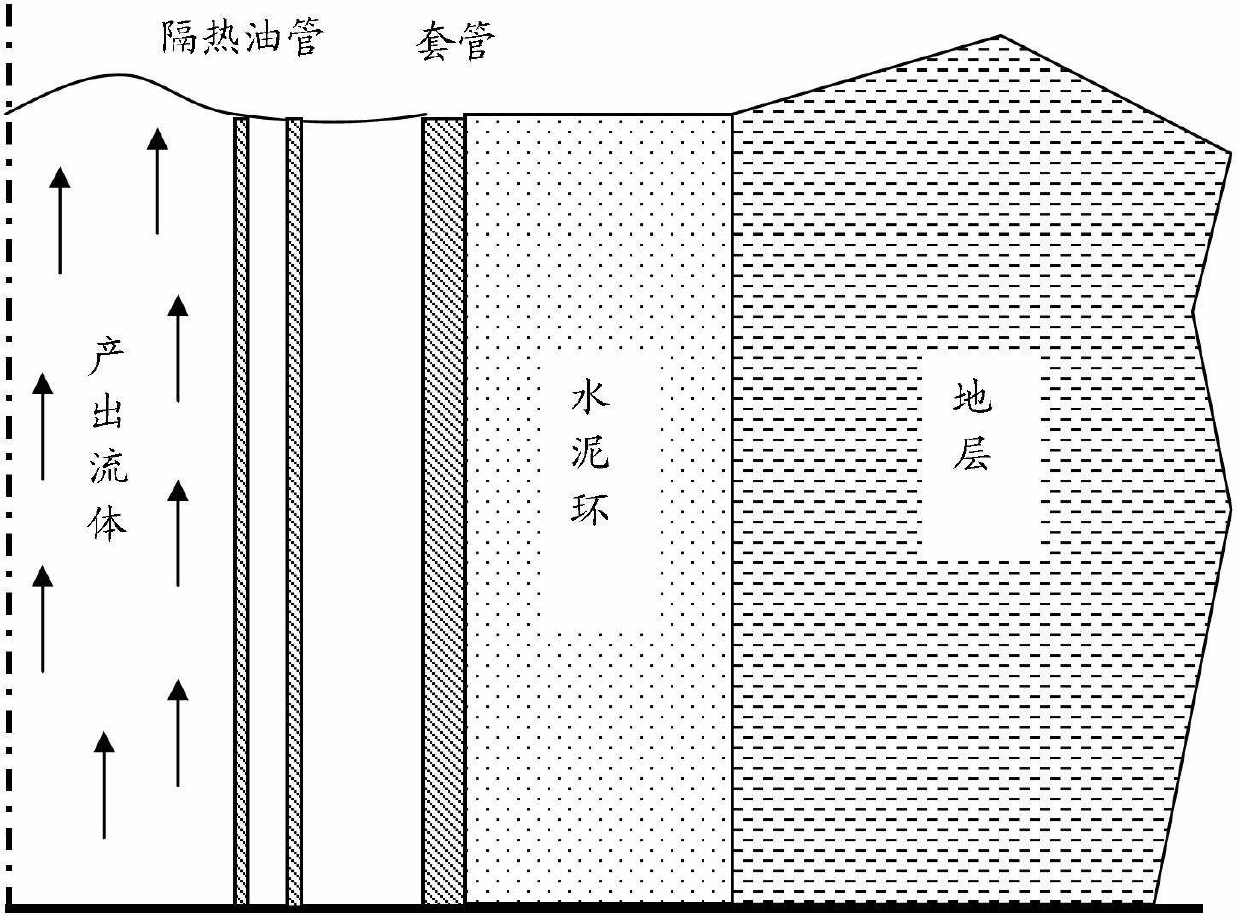

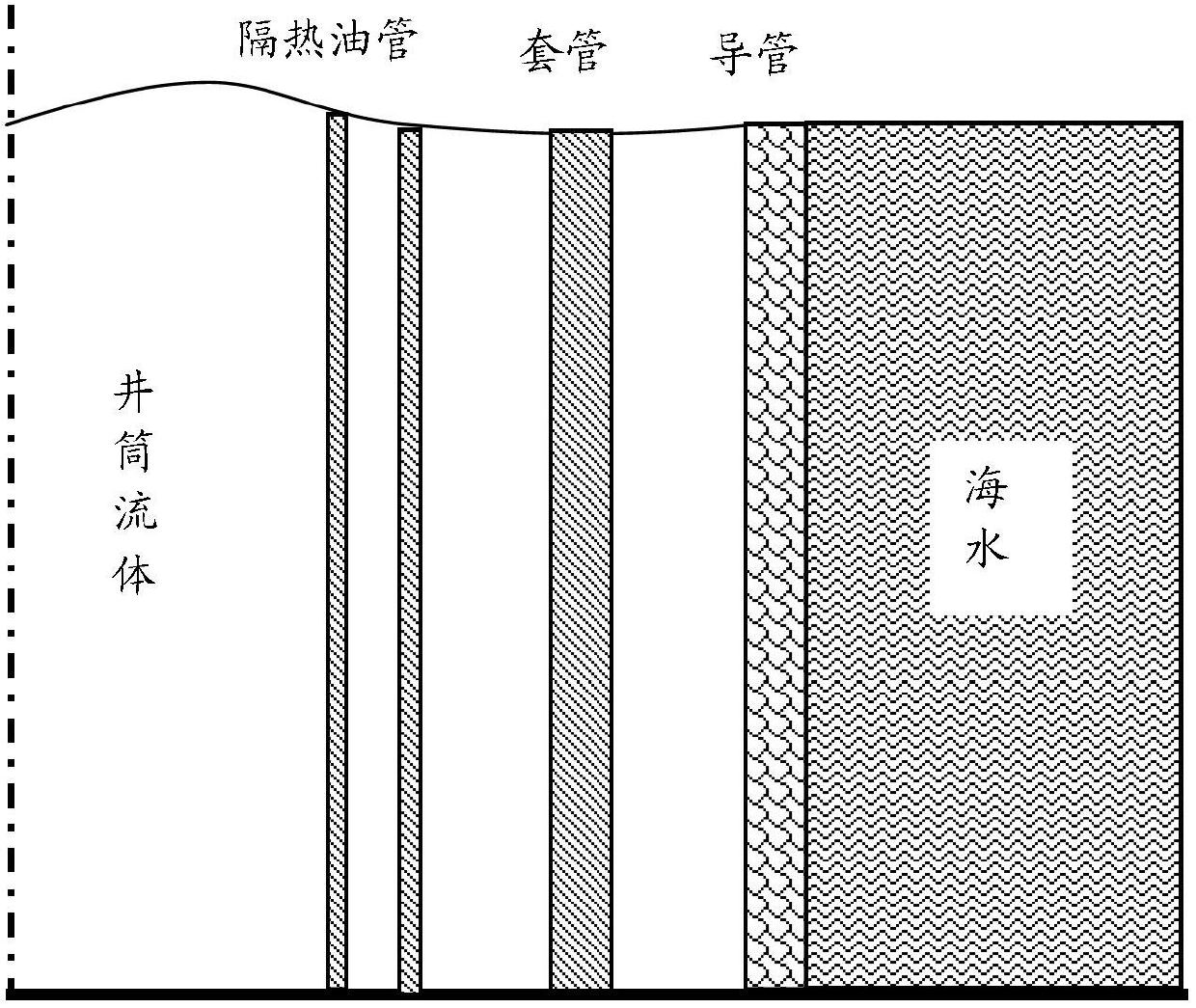

Injection-production two-trip pipe string balanced well killing control method

The invention provides an injection-production two-trip pipe string balanced well killing control method. The method comprises the following steps of: (1) calculating productivity and formation pressure during the flow period of a multiple thermal fluid huff-puff well; (2) determining the well killing time; (3) calculating the bottom hole pressure during well killing; (4) calculating the density of well killing fluid and selecting the well killing fluid; (5) calculating the using quantity of the well killing fluid; and (6) determining the well killing way. According to the method provided by the invention, the multiple thermal fluid huff-puff well can be timely converted from oil flow production to mechanical oil production, and the energy in the injection formation can be fully utilized; and simultaneously, the time effectiveness of the well intervention operation can be minimized, the pollution of an oil layer and the heat loss of the formation can be reduced to the greatest extent, and the high-speed and high-efficient development of an offshore heavy oil field can be kept.

Owner:CHINA NAT OFFSHORE OIL CORP +2

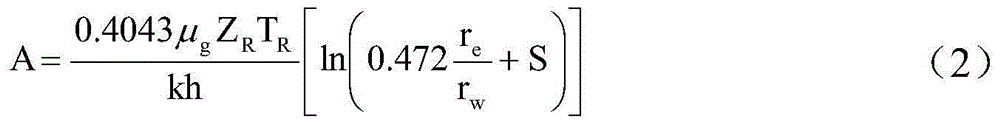

Determination method of well killing occasion of pressing-back method for gas well

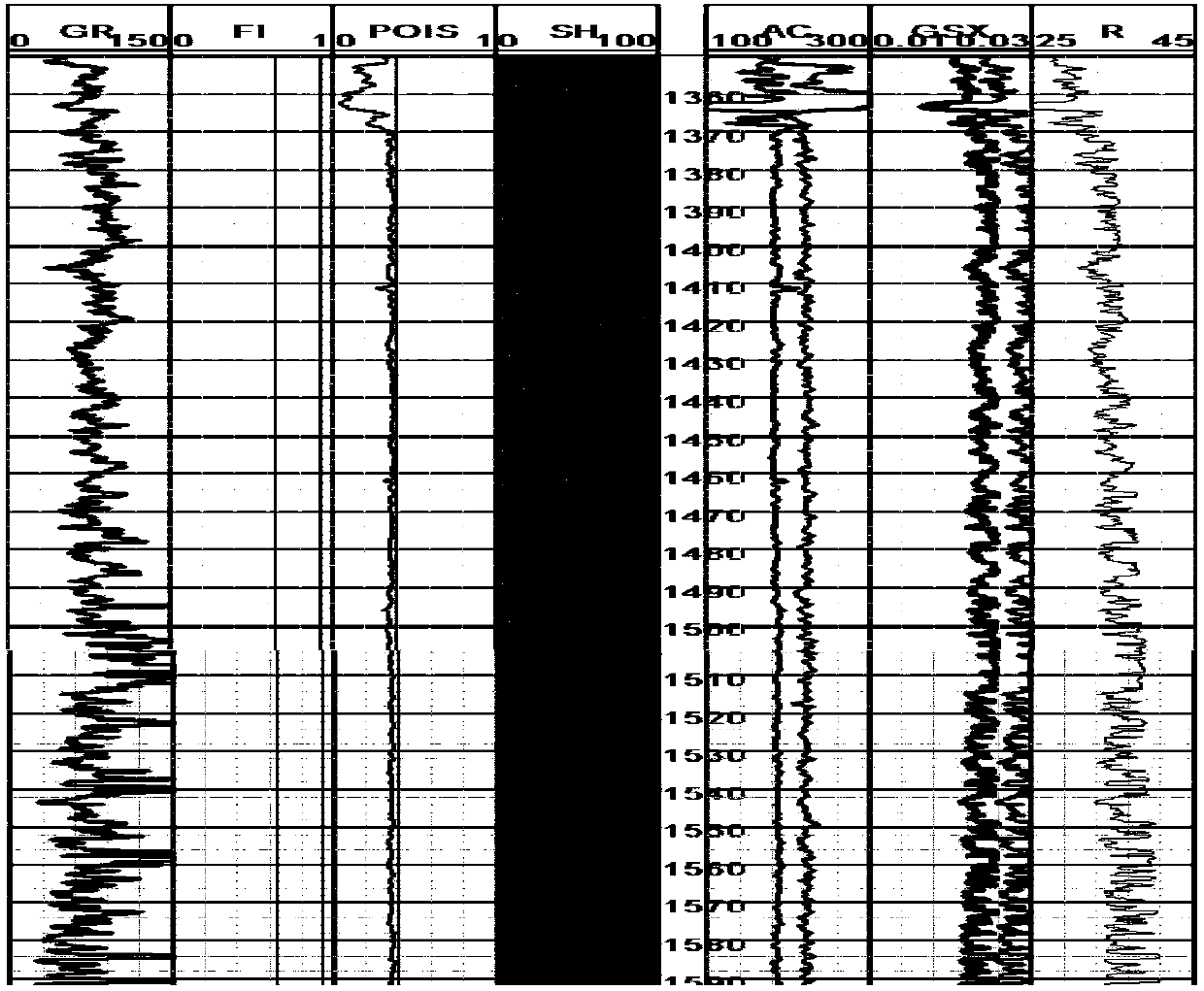

ActiveCN105756660AEliminates the risk of pressure exceeding the maximum allowable wellhead pressureReduced risk of pressure exceeding the maximum allowable wellhead pressureSurveyWell killBottom hole pressure

The invention discloses a determination method of a well killing occasion of a pressing-back method for a gas well. The determination method of the well killing occasion of the pressing-back method for the gas well comprises the following steps of collecting the physical property parameters of a stratigraphic rock and a fluid through geological logging and the data of an adjoining well; drawing an IPR (Inflow Performance Relationship) curve of the gas well by a formula through the collected data; drawing an OPR (Outflow Performance Relationship) curve of a relationship between a pit shaft gas yield and bottom hole pressure; drawing the IPR curve and the OPR curve in the same coordinate system; calculating an allowable maximum well shut-in time; calculating a wellhead pressure function when the well killing is started at some moment after well shut-in; solving wellhead maximum pressure; judging latest time when the well killing is started. The method is applicable to the conditions that the circulating well killing cannot be carried out due to the well blowout of the gas well and the pressing-back method is adopted to carry out the well killing; the latest well killing time that the well is successfully killed by using the pressing-back method after the well shut-in can be calculated; therefore, the risk that wellhead pressure generated in a well killing process exceeds maximum allowable wellhead pressure can be removed; the theoretical guidance is provided for the success of the well killing. The method is uncomplicated in calculation process, simpler in operation technique, and suitable for field use.

Owner:CHINA PETROCHEMICAL CORP +3

Pressing expansion type downhole annular blowout preventer and communication method thereof

The invention discloses a pressing expansion type downhole annular blowout preventer, and belongs to the technical field of downhole blowout prevention. The pressing expansion type downhole annular blowout preventer mainly comprises a communication module, a control module, a power module and an execution module. A rubber barrel of the execution module of the pressing expansion type downhole annular blowout preventer can be expanded when liquid is pressed in through a pressing sliding block, so that setting is realized. When a discharging passage communicates with the rubber barrel, the liquid in the rubber barrel flows out through the discharging passage, so that deblocking is realized. The pressing expansion type downhole annular blowout preventer can be used repeatedly, and is rapid in response, suitable for a full-well section and various well types, high in safety coefficient, long in service life, capable of achieving communication with a novel circulation passage after setting, and favorable for subsequent well killing operation.

Owner:SOUTHWEST PETROLEUM UNIV

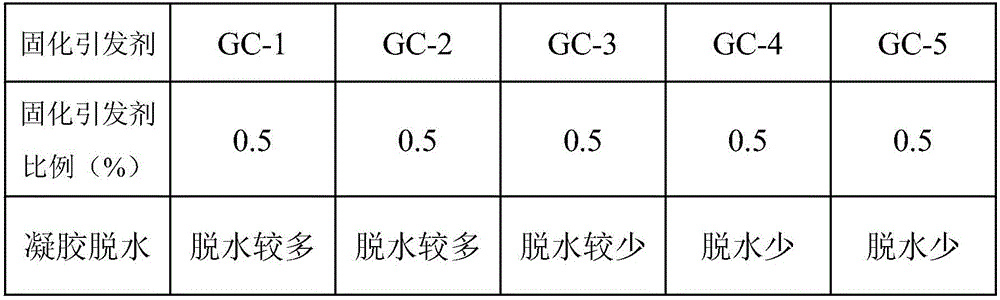

Solidified water temporary plugging well-killing working fluid and preparation method and draining method thereof

ActiveCN106833572AEasy to prepareSimple preparation processDrilling compositionSealing/packingWell killWorking fluid

The invention provides solidified water temporary plugging well-killing working fluid. The solidified water temporary plugging well-killing working fluid is prepared from 10 to 40 percent of solidified water system and 60 to 90 percent of anti-swelling stabilizing fluid, wherein the solidified water system is prepared from the following components in percentage by mass: 1.1 to 1.5 percent of main agent, 0.3 to 0.5 percent of solidification initiator and the balance of water. The preparation method of the working fluid comprises the following steps: 1), taking the main agent in an amount determined in a formula; 2) taking the solidification initiator and the anti-swelling agent in amounts determined in the formula; 3) injecting clear water into a container in an amount determined in the formula, adding the main agent and the solidification agent initiator in amounts determined in the formula in sequence, and uniformly stirring to obtain the solidified water system; 4) adding the anti-swelling stabilizing fluid in an amount determined in the formula to obtain the solidified water temporary plugging well-killing working fluid. A draining method combining acidifying-demulsifying and liquid nitrogen drainage is adopted. The working fluid is simple in preparation process, a colloid protective agent is not needed, the plugging efficiency is increased greatly, the plugging cost is lowered, damage to strata is reduced, and the problems of coexistence of collapse and leakage and low reservoir protection performance in a gas well construction process are solved. The solidified water temporary plugging well-killing working fluid has important practical significance to increase of the oil gas exploration and development speeds.

Owner:PETROCHINA CO LTD

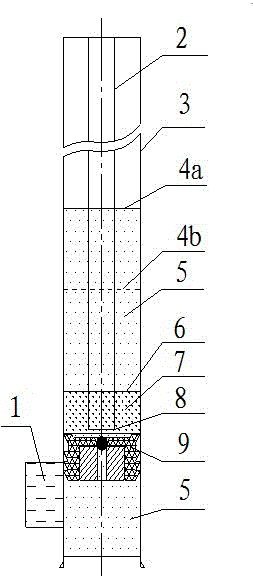

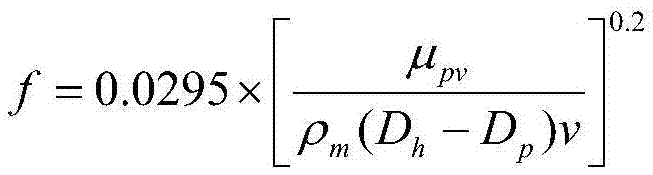

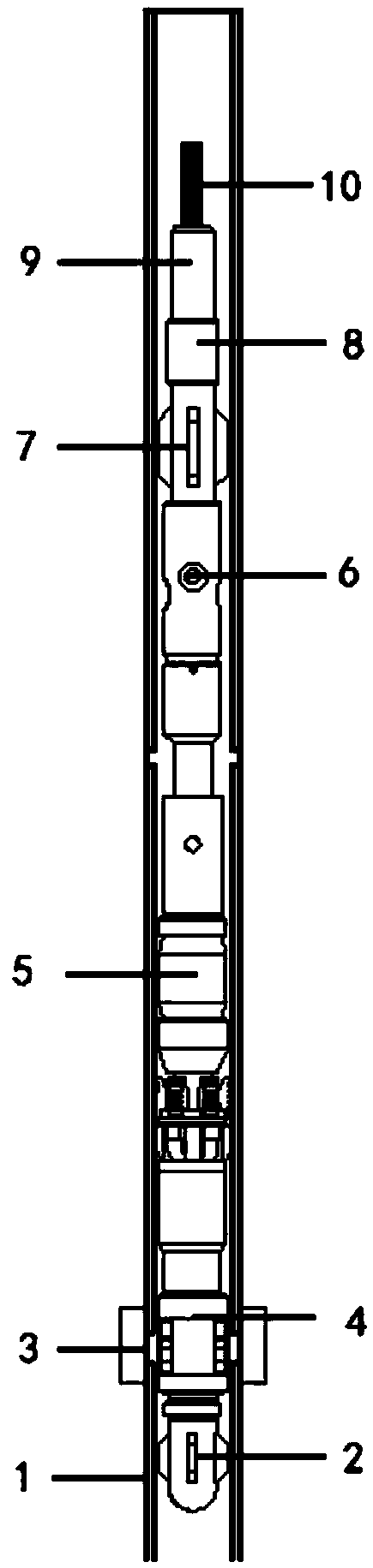

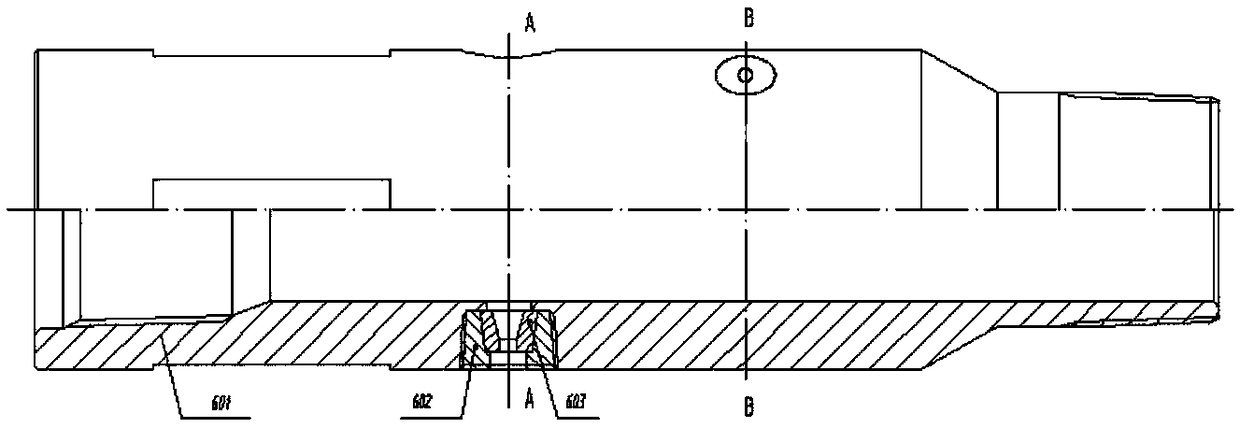

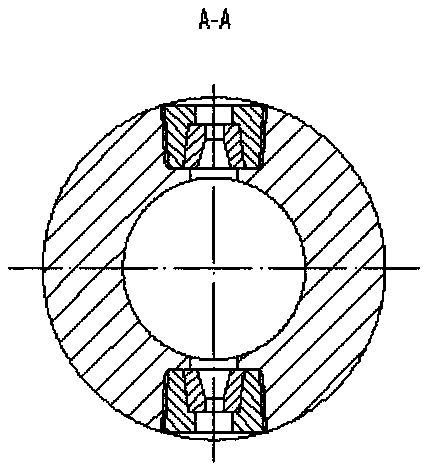

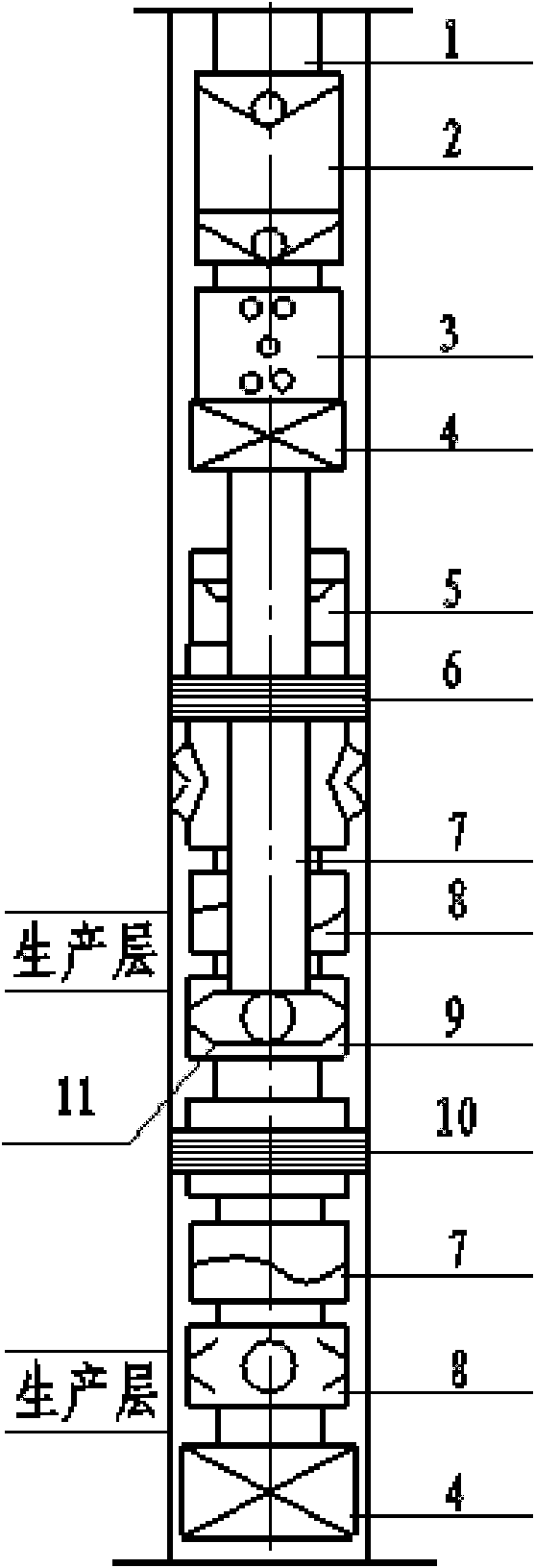

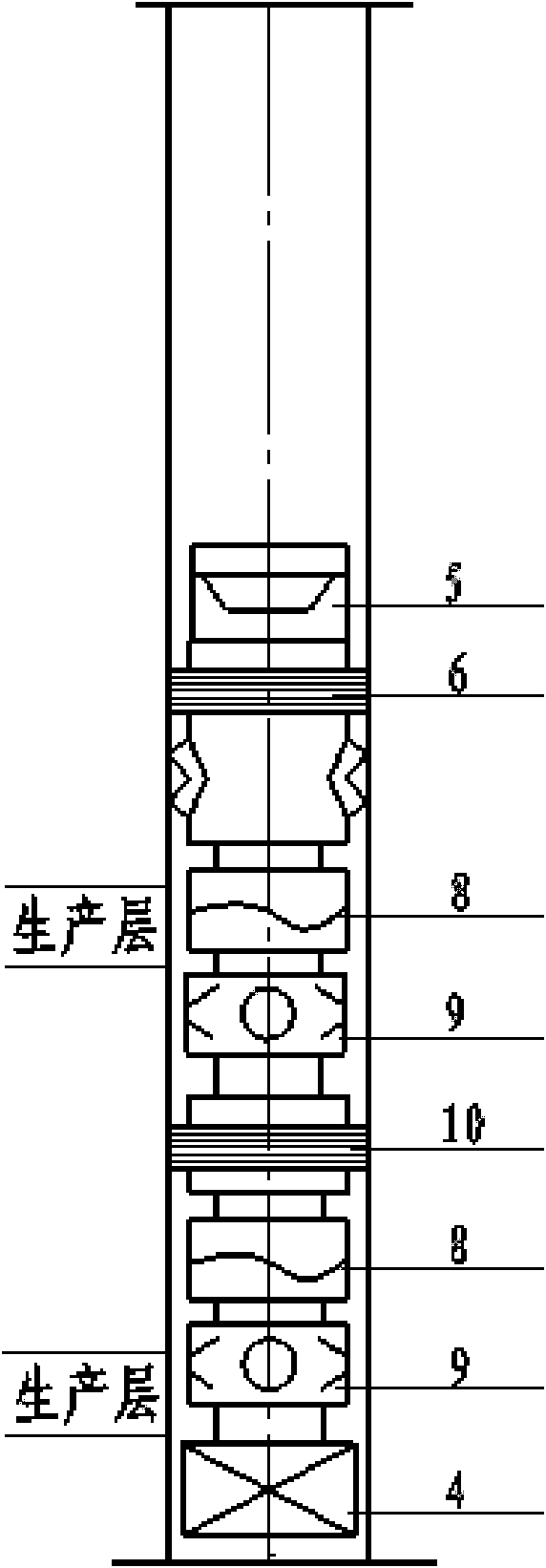

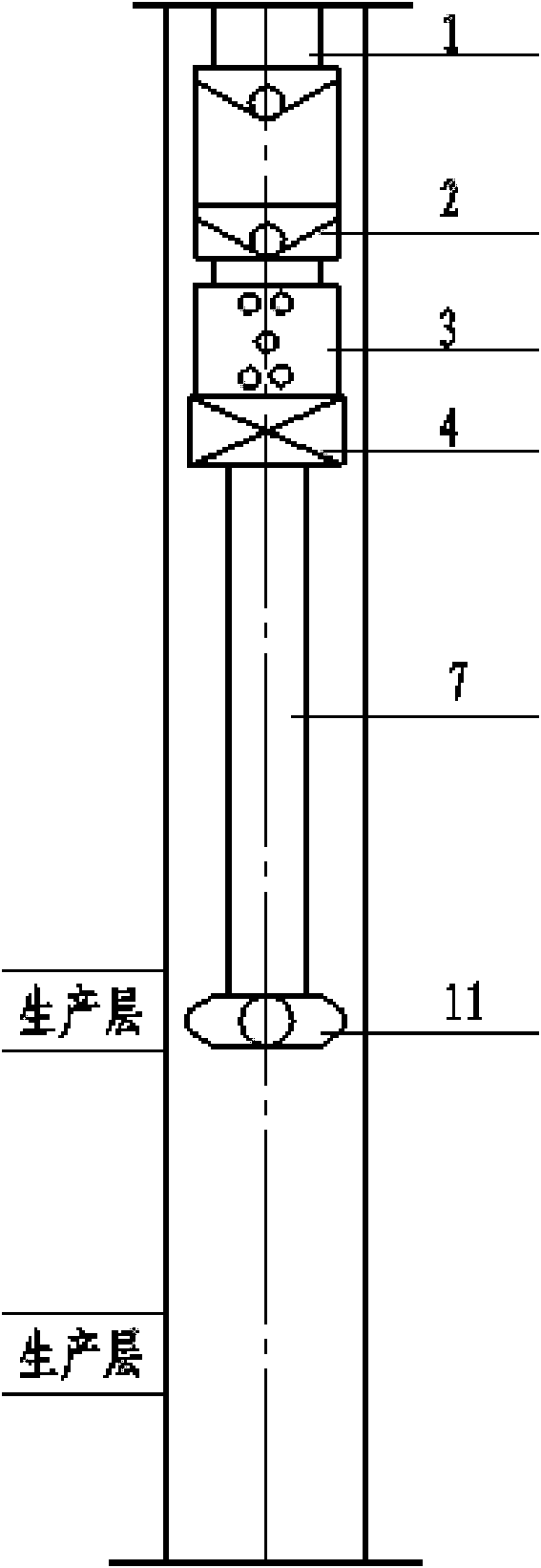

Separate zone production technical string capable of protecting oil reservoirs

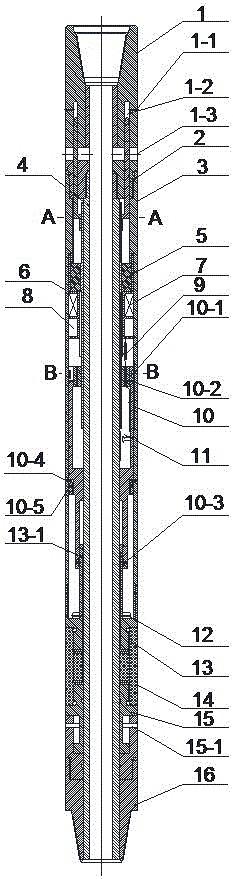

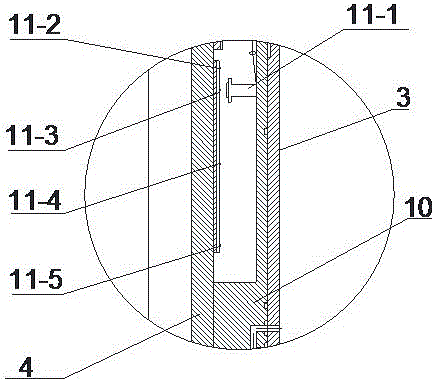

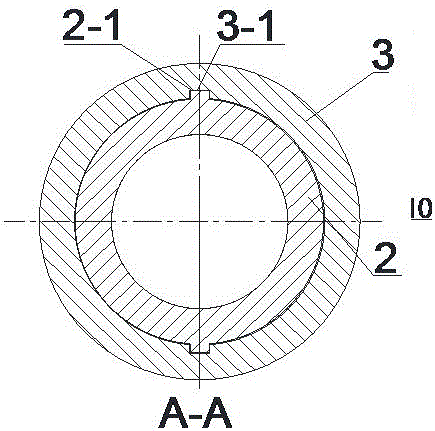

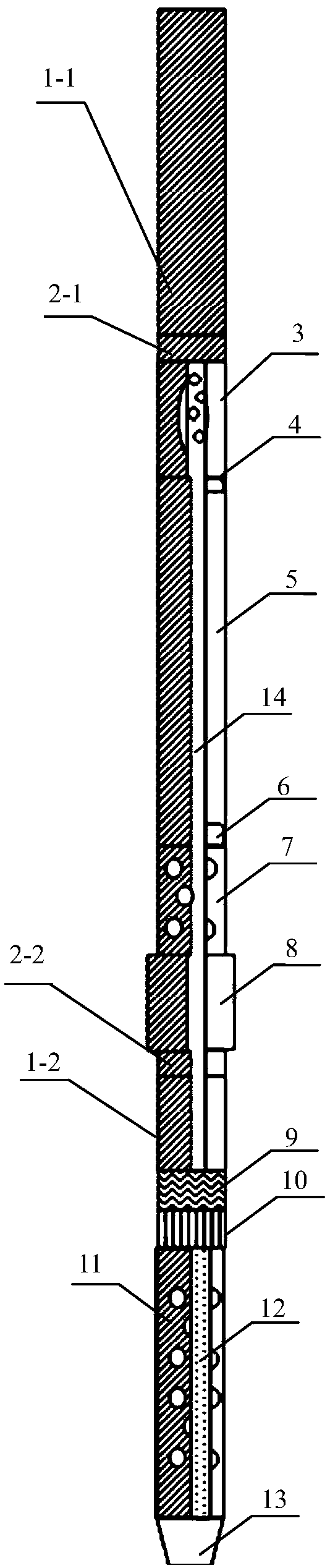

InactiveCN102852467AReasonable structural designPractical structural designDrilling rodsFluid removalWell killOil well

The invention relates to a separate zone production technical string capable of protecting oil reservoirs. The separate zone production technical string consists of a pumping string and an oil reservoir protecting releaser string. The oil reservoir protecting releaser string consists of a plug (4), an oil reservoir protector (9), a safety joint (8), a Y341 type self-examining packer (10), a Y441 type packer (6) and a releaser head (5) which are fixedly connected from bottom to top. A pumping string switch (11) is plugged into the oil reservoir protector (9) of the oil reservoir protecting releaser string and can be used for opening any production layers, and is convenient to switch on and switch off accurately. The string is simple, reasonable, convenient and practical in structural design, and can close a stratum without well killing during pump inspection, prevent flushing fluid or well killing fluid from entering the oil reservoirs to pollute the same and protect the oil reservoirs, and accordingly production efficiency can be increased, effective production periods of the oil reservoirs are prolonged, any oil reservoir can be opened during oil well production, and zone replacement production of oil well can be achieved without removing the jammed releaser string.

Owner:PETROCHINA CO LTD

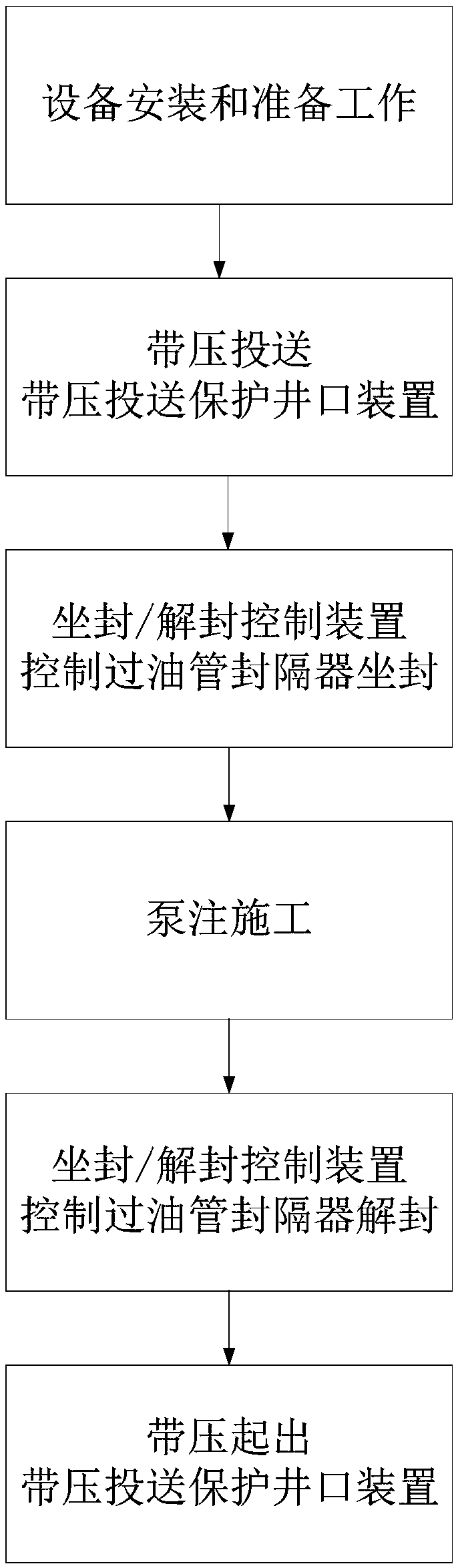

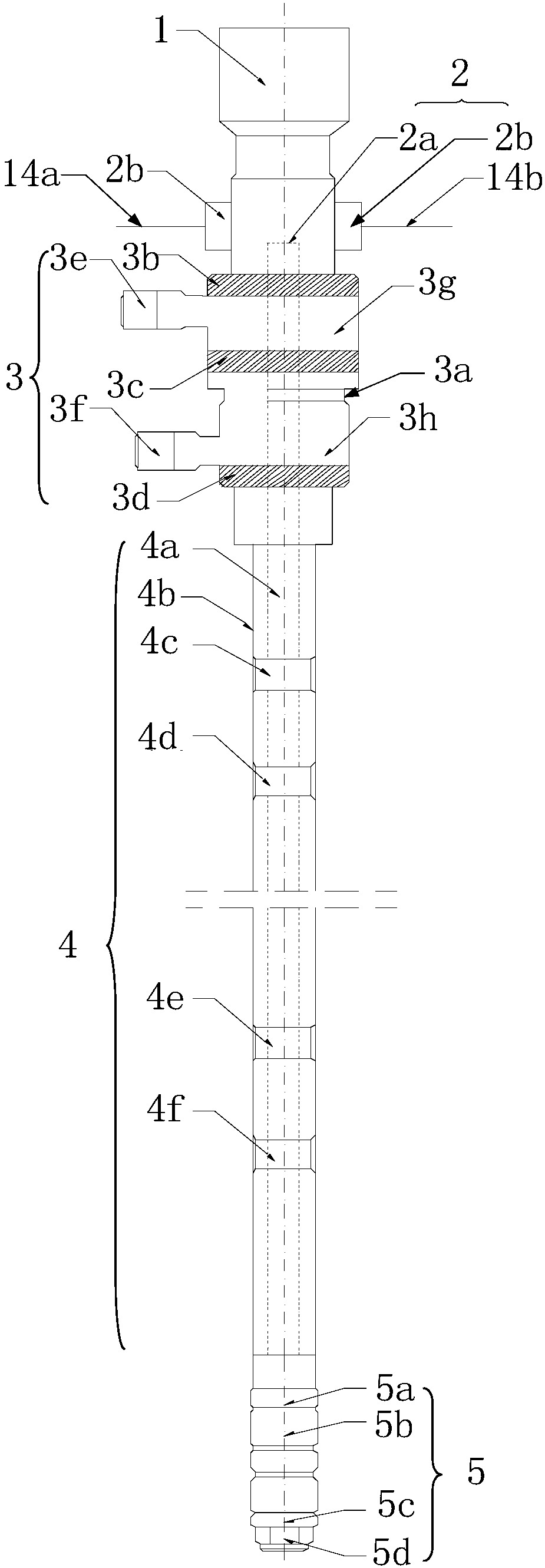

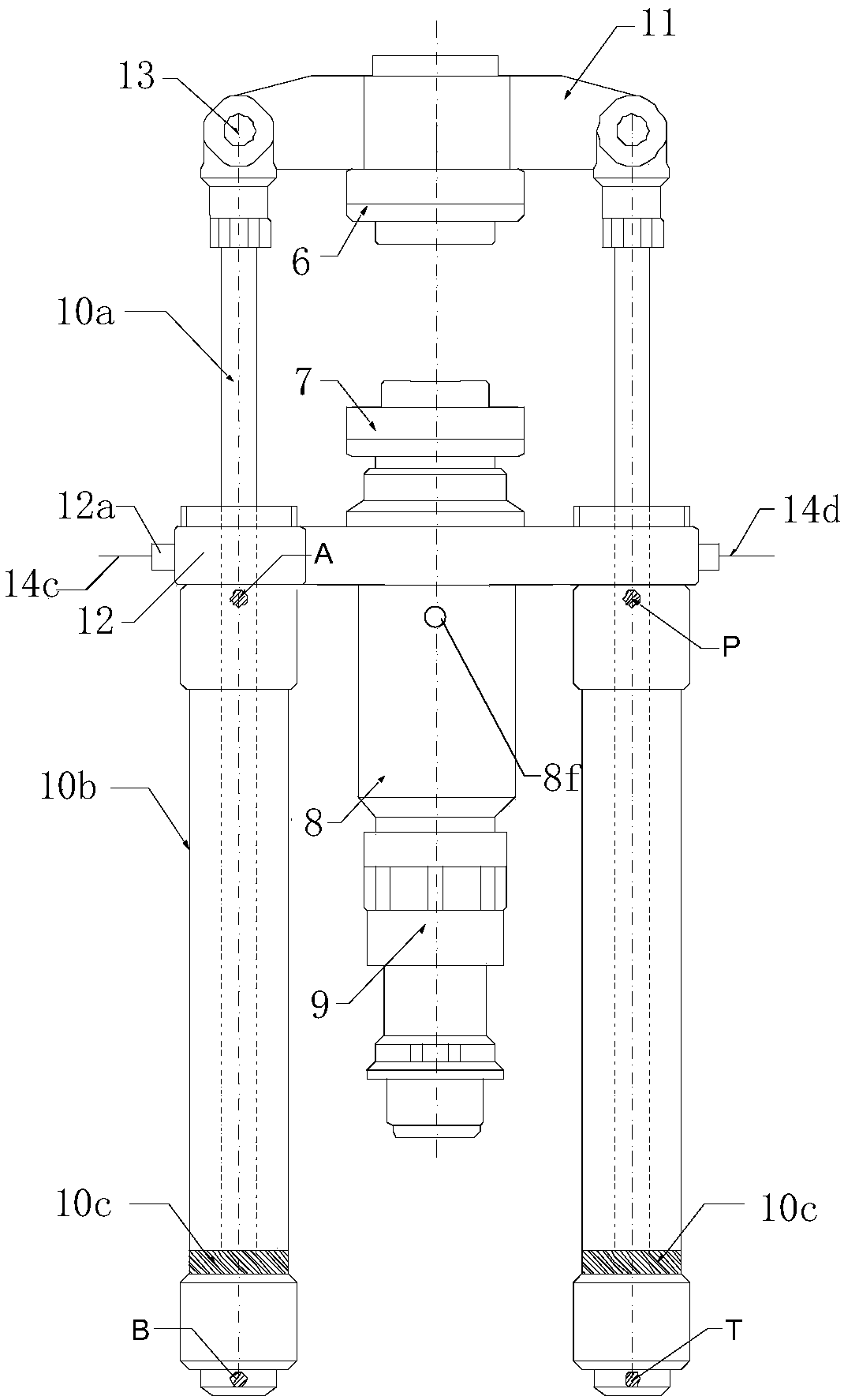

Construction method for conducting pipe interior under-pressure plugging on production pipe string

ActiveCN108019178AIncrease construction pressure limitReduce pollutionSealing/packingWell killDual stage

The invention discloses a construction method for conducting pipe interior under-pressure plugging on a production pipe string. According to the construction method, through an under-pressure delivering wellhead protecting device, through the five steps of under-pressure delivering, packer setting, pumping injection construction, packer unsetting and under-pressure pulling-out in sequence, an oilpassing pipe packer is plugged on the inner wall of the preset position of the production pipe string to achieve under-pressure construction operation, and a corresponding matched device is matched with a delivery oil pipe under the effect of a dual-stage hydraulic propeller through a floatable locking mechanism and a fixed locking mechanism to achieve the situation that the oil passing pipe packer is delivered to the preset position in the production pipe string under the situation of a Christmas tree is under pressure, then through a setting / unsetting control device, setting of the oil passing pipe packer is achieved, and thus bi-directional limiting fixing is conducted on the whole delivering device to complete the delivery operation process of the whole under-pressure delivering device. According to the construction method, effective isolation of Christmas tree upper hangers can be achieved, ground construction pressure limitation during pumping injection is improved, reservoir pollution brought by well killing operation is reduced, and the situation that the good effect is achieved on oil field development is ensured.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

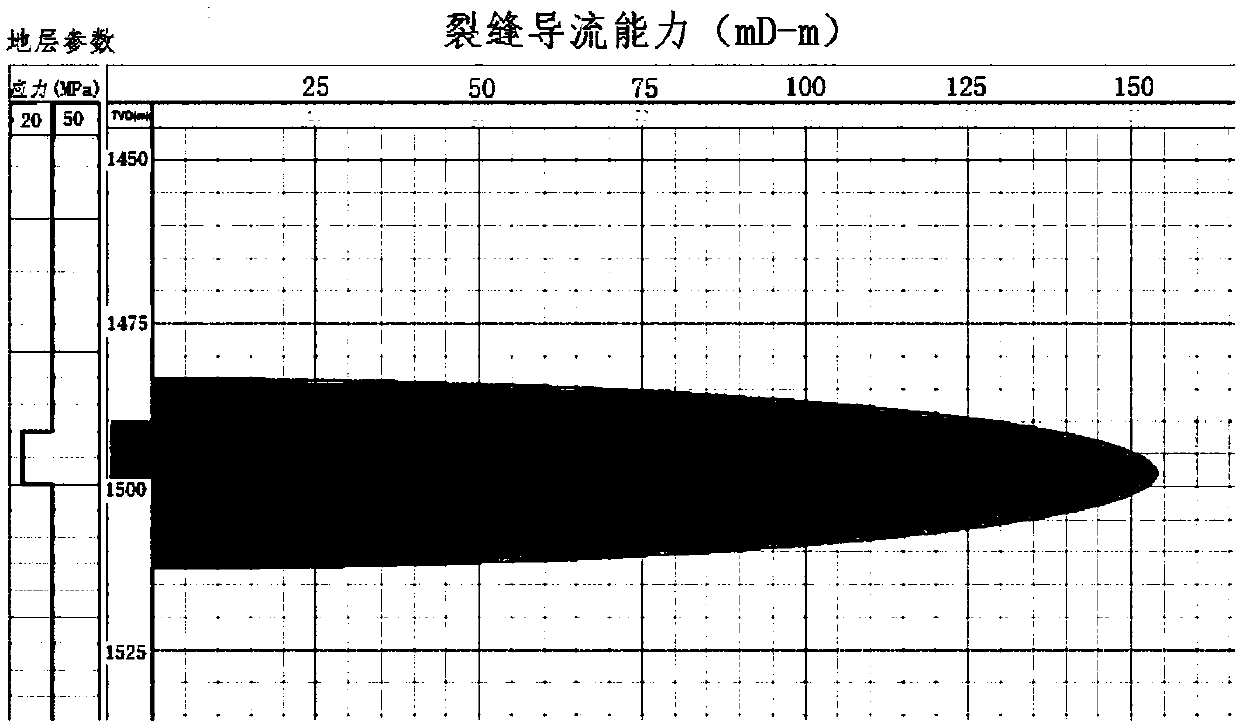

Low-permeability thick-oil oil reservoir fracturing method

ActiveCN107762474AReduce cold damageImprove the transformation effectFluid removalWell killFracturing fluid

The invention provides a low-permeability thick-oil oil reservoir fracturing method. The low-permeability thick-oil oil reservoir fracturing method comprises the following steps that reservoir rock mechanical parameters and logging data are obtained, the fracturing crack parameters are obtained through simulation, and the needed viscosity-decreasing liquid preparation quantity is obtained throughcalculation; according to data of adjacent wells and the logging data, the stratum fracture pressure of a transformed layer section of a fracturing well is calculated, and the highest injection displacement Qmax of viscosity-decreasing liquid when a reservoir is not fractured open is calculated; the viscosity-decreasing liquid is prepared from hot water, the viscosity-decreasing liquid is injectedinto the reservoir at the injection displacement being 0.9 time the Qmax at the matrix injection stage, after the matrix injection stage is finished, the injection displacement is increased to fracture the reservoir open, and the remaining viscosity-decreasing liquid continues being injected into the reservoir to enable the impact range of the viscosity-decreasing liquid to be larger than that ofhydraulic cracks; and after injection of the viscosity-decreasing liquid is finished, well kill is conducted for 2-5 days, then fracturing liquid is prepared from warn water, fracturing transformingis conducted on a thick-oil well according to the end sand removal transforming mode, and after fracturing transforming is finished, the well is closed for 2 h to conduct rapid back flow.

Owner:PETROCHINA CO LTD

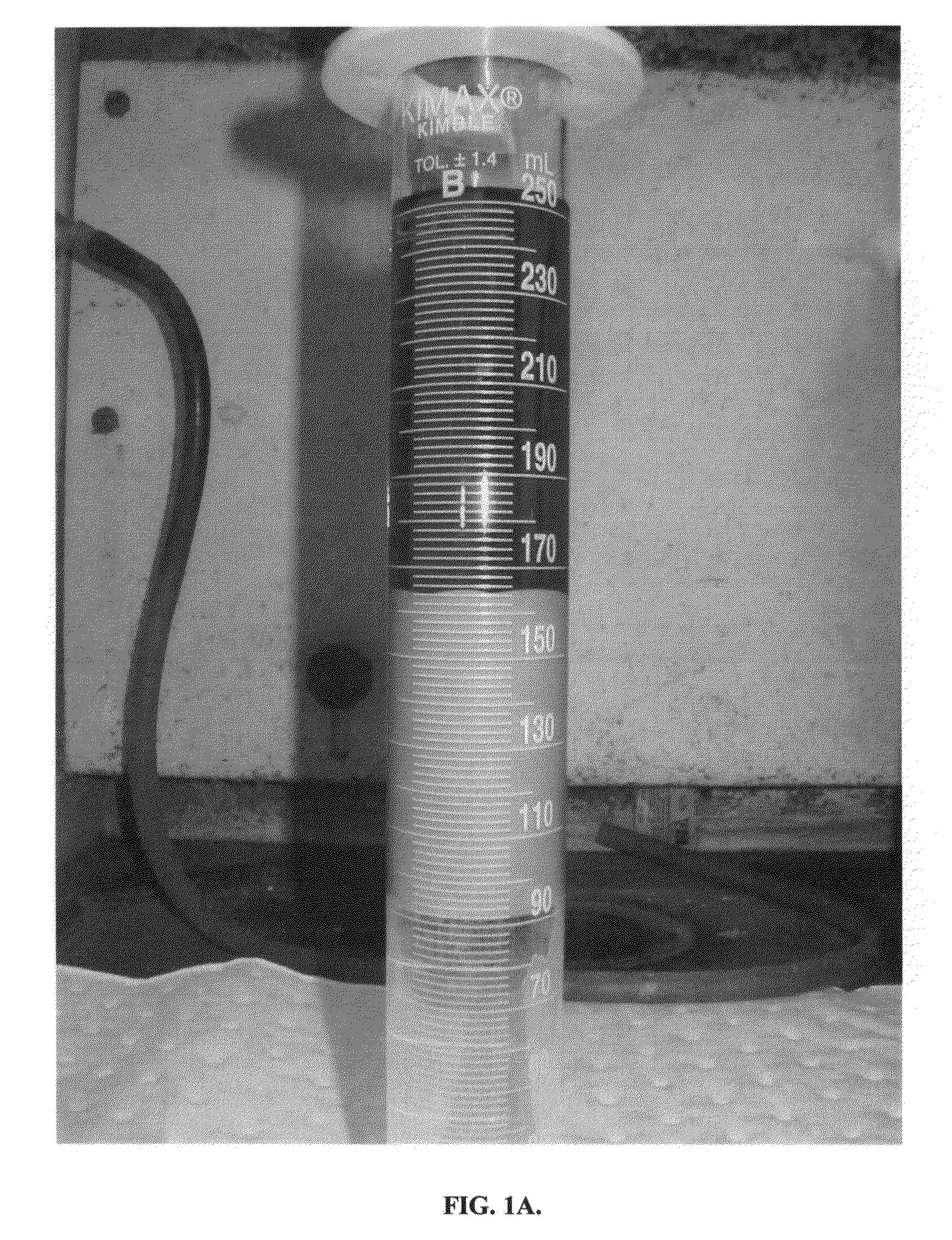

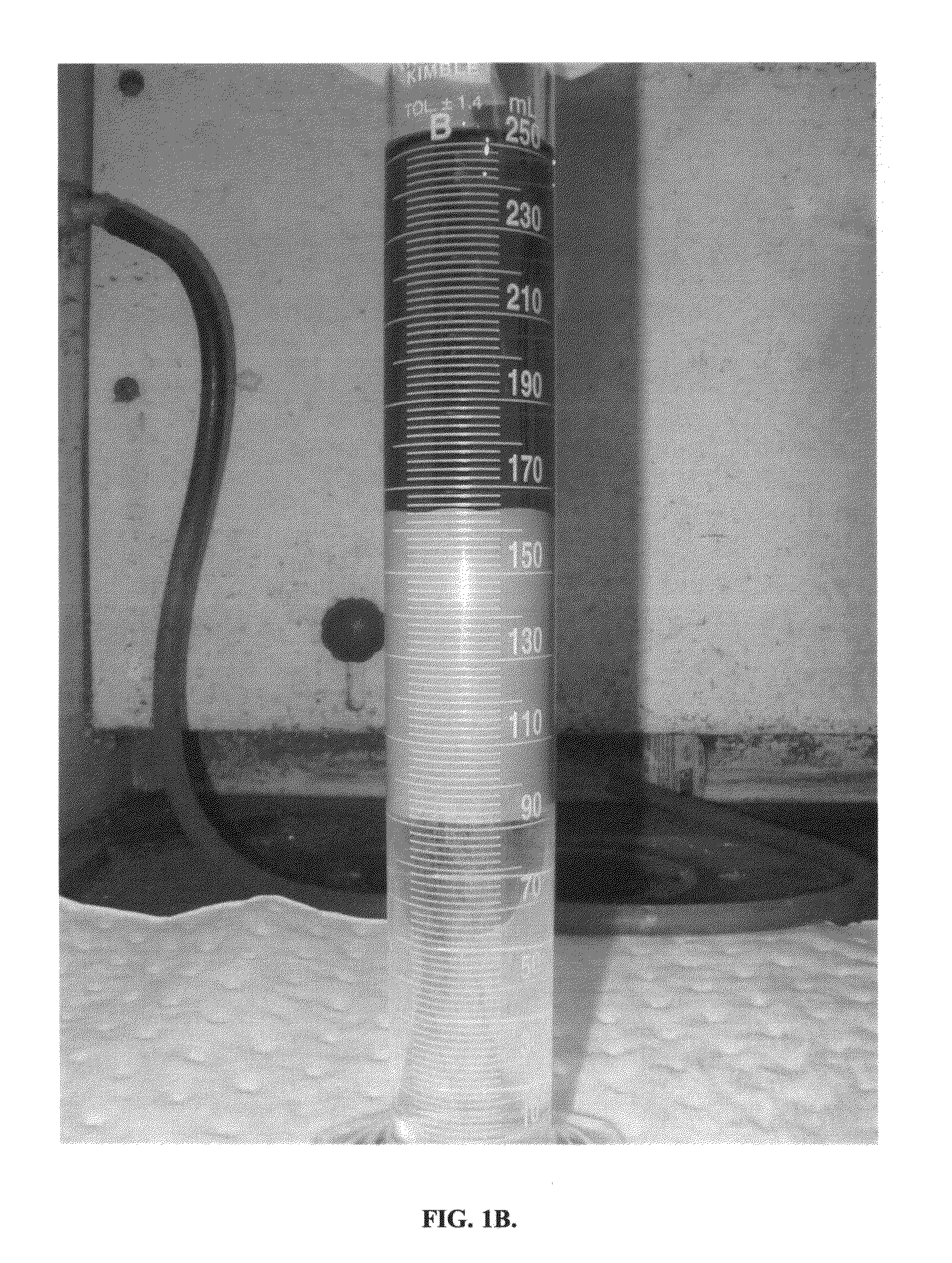

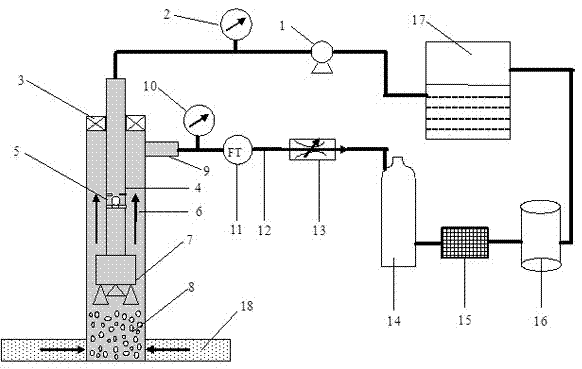

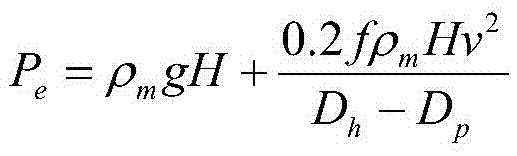

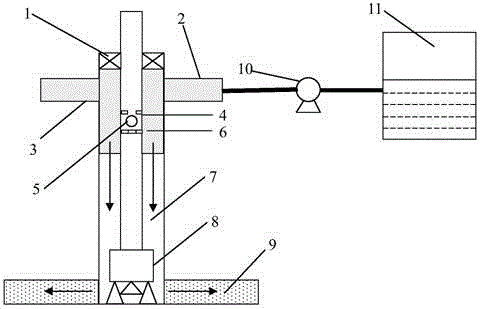

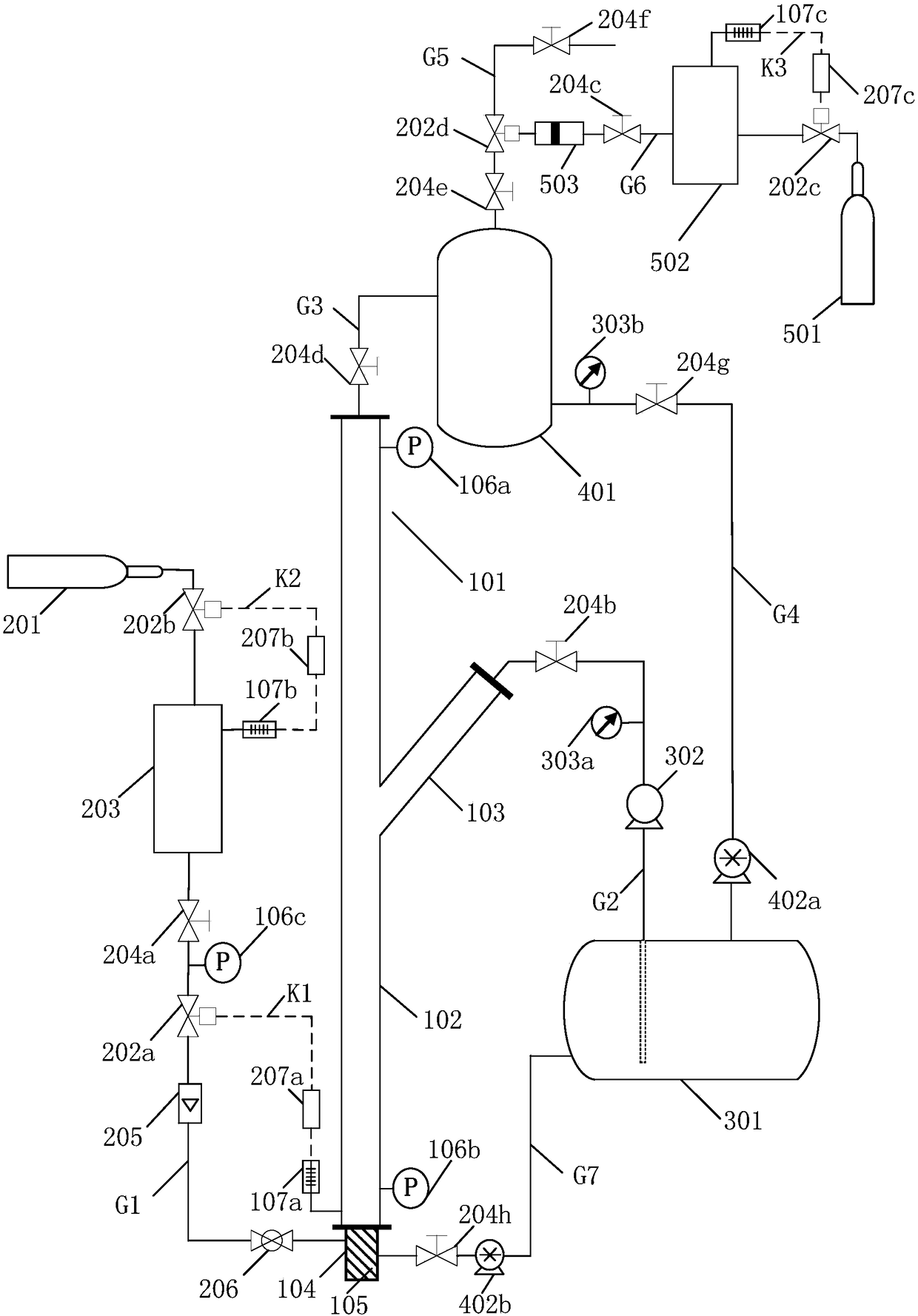

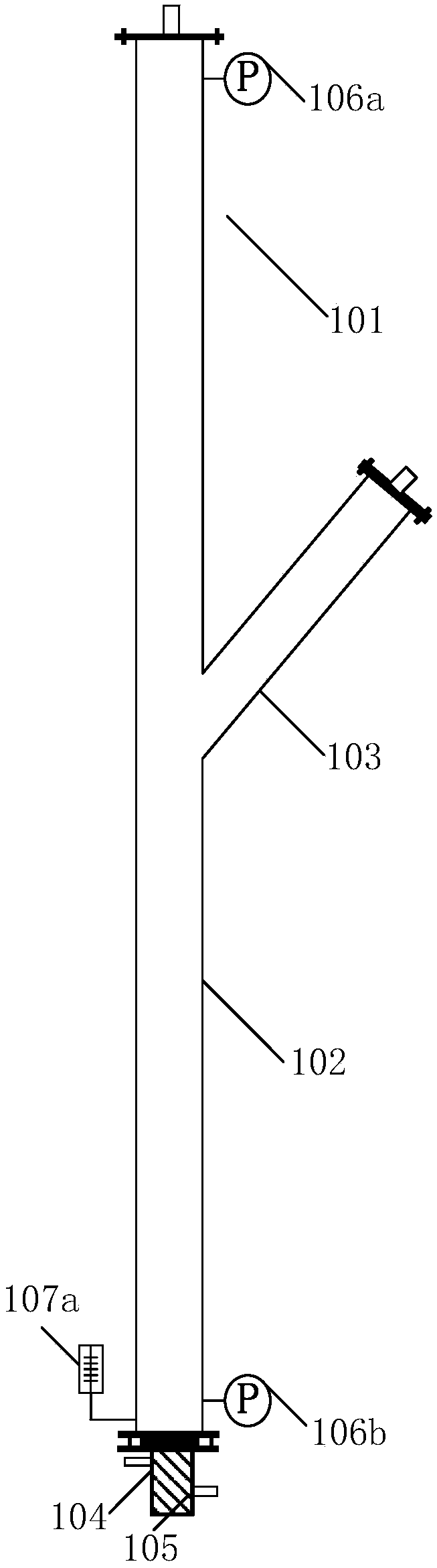

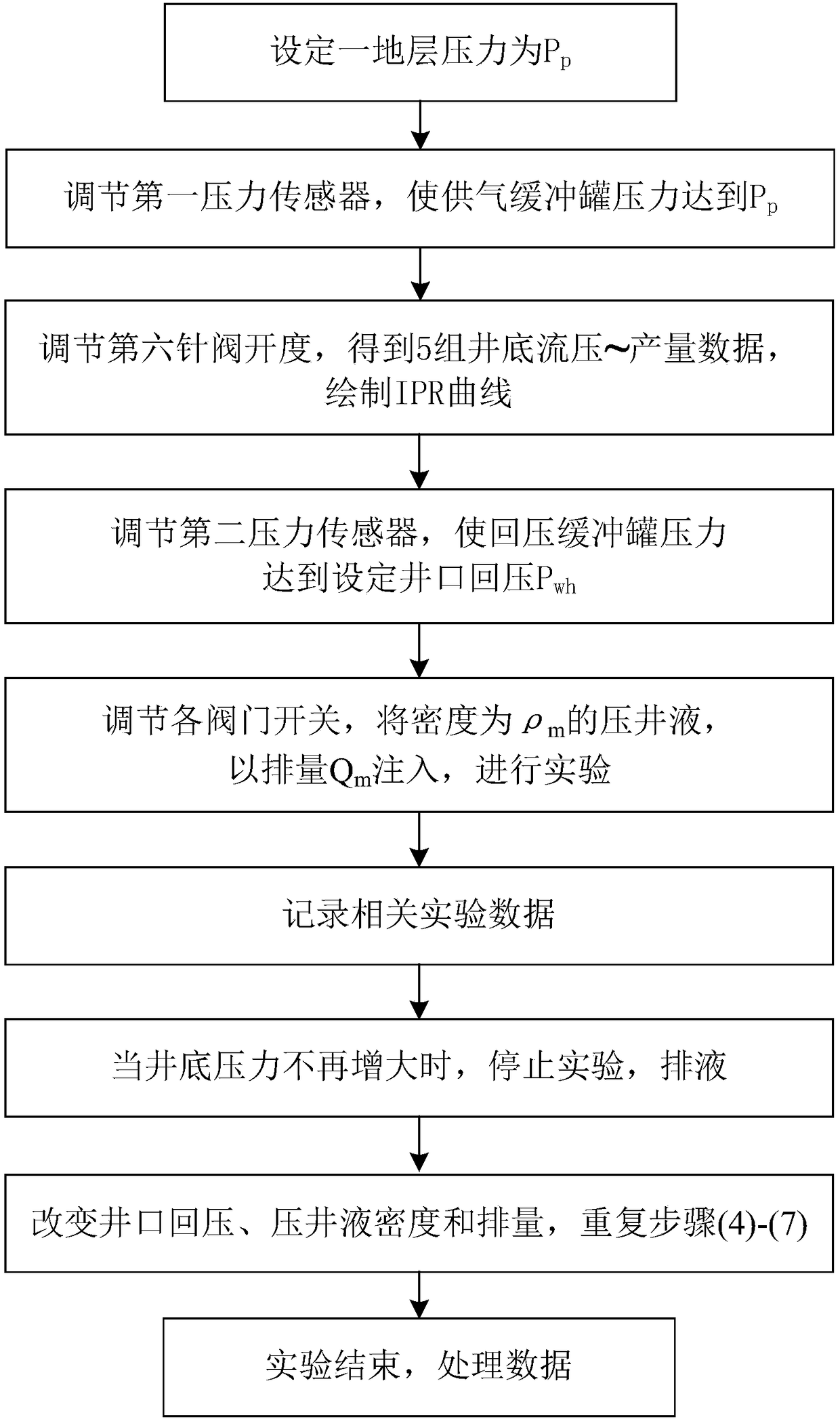

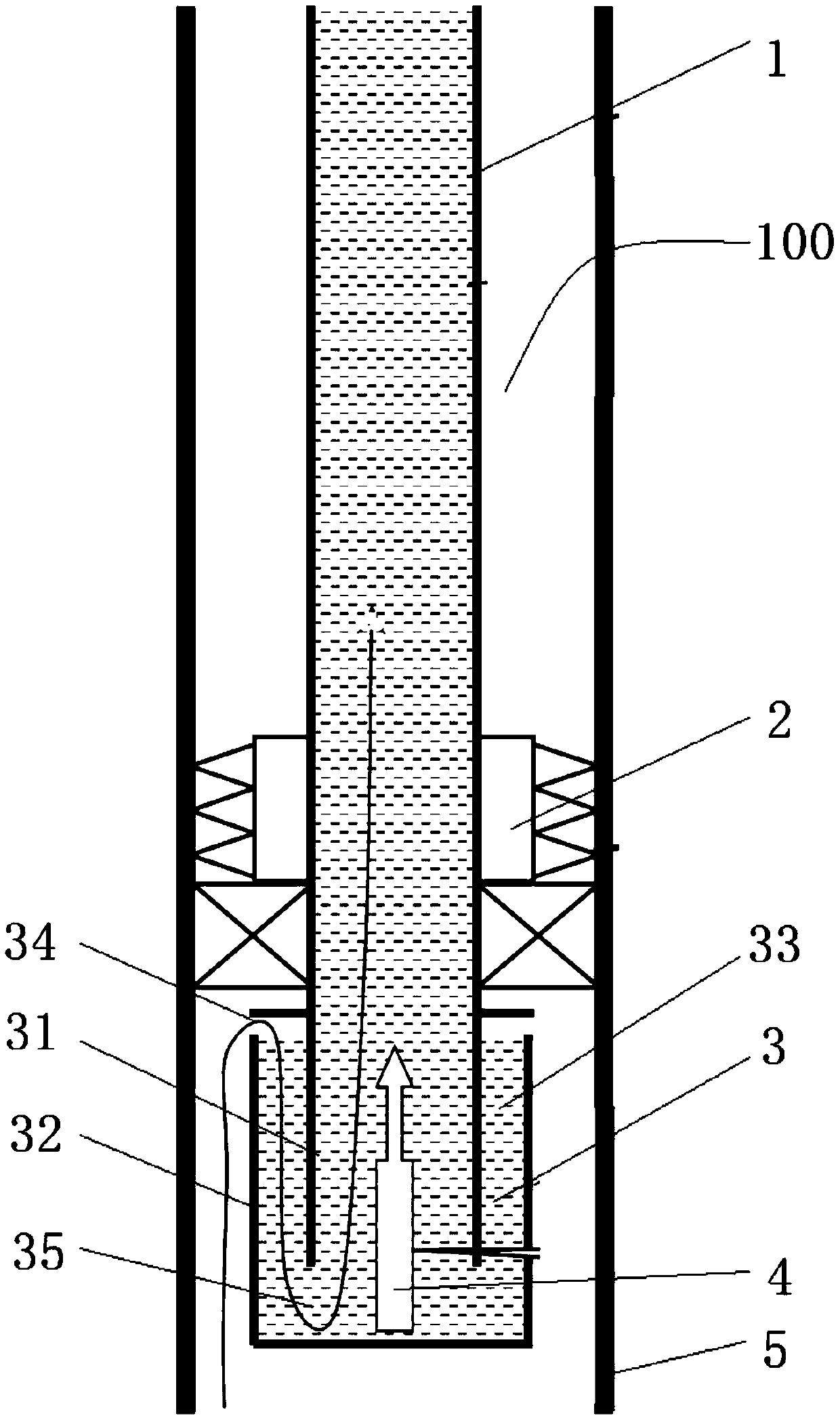

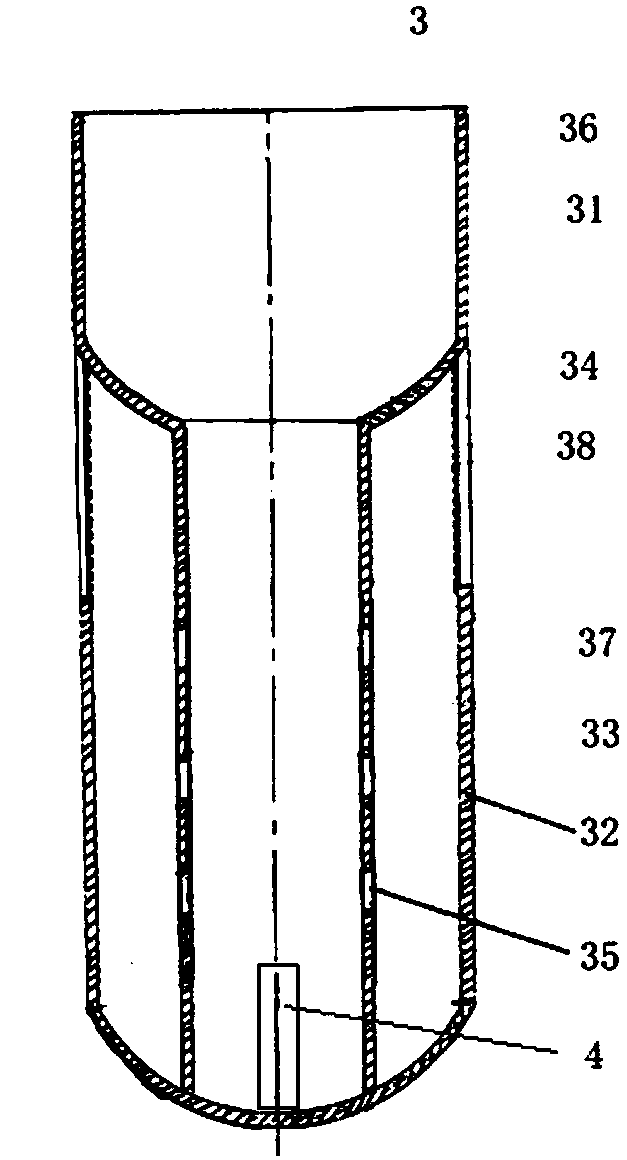

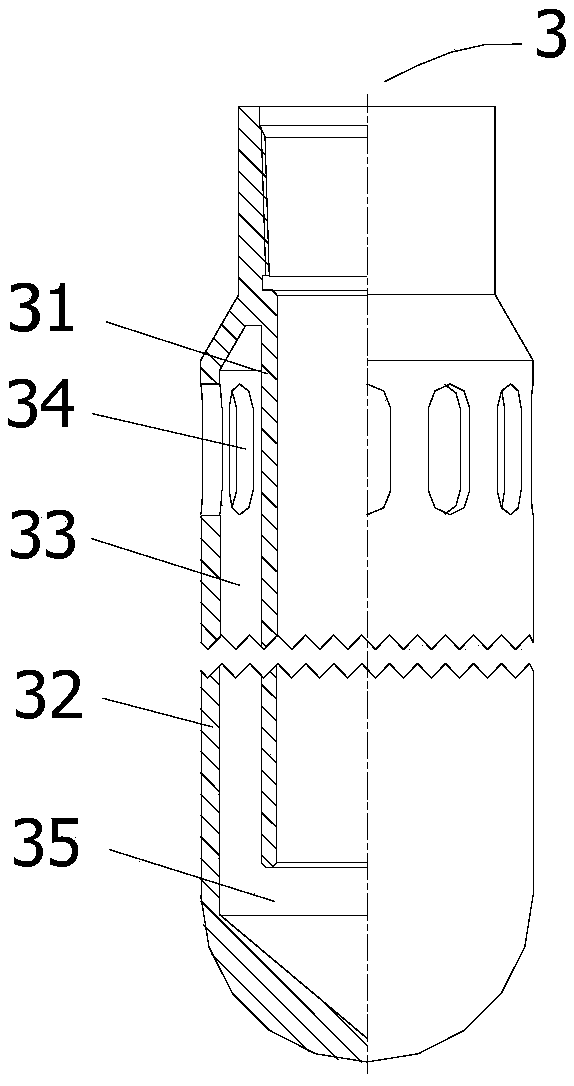

Rescue well well-kill simulation experimental device and method

ActiveCN108222926AGas production rate keeps decreasingBorehole/well accessoriesWell killControl system

The invention relates to a rescue well well-kill simulation experimental device. The rescue well well-kill simulation experimental device comprises an experimental shaft, a gas injection system, a liquid injection system, a gas-liquid separation system, a back-pressure control system and a liquid discharging system; the gas injection system and the liquid injection system correspondingly inject gas and liquid into the experimental shaft, the experimental shaft simulates the gas-liquid two-phase flow condition in an accident well, a mixed fluid is subjected to gas and liquid separation throughthe gas-liquid separation system after flowing out of the experimental shaft, the back-pressure control system controls the back pressure size of a wellhead, and after an experiment is completed, liquid discharging is conducted by the liquid discharging system; and the gas injection system automatically adjusts the gas injection speed according to the pressure change of the well bottom of the experimental shaft, and the process of constantly decreasing of the gas well production in the well kill process is truly reflected, and thus, the coupling simulation between the shaft and a stratum is realized. The invention provides a set of rescue well well-kill simulation device and method, the pressure change of the well bottom of the accident well under different well-kill parameters can be simulated, and model parameters and experimental data are provided for design and study of rescue well well-kill construction parameters.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

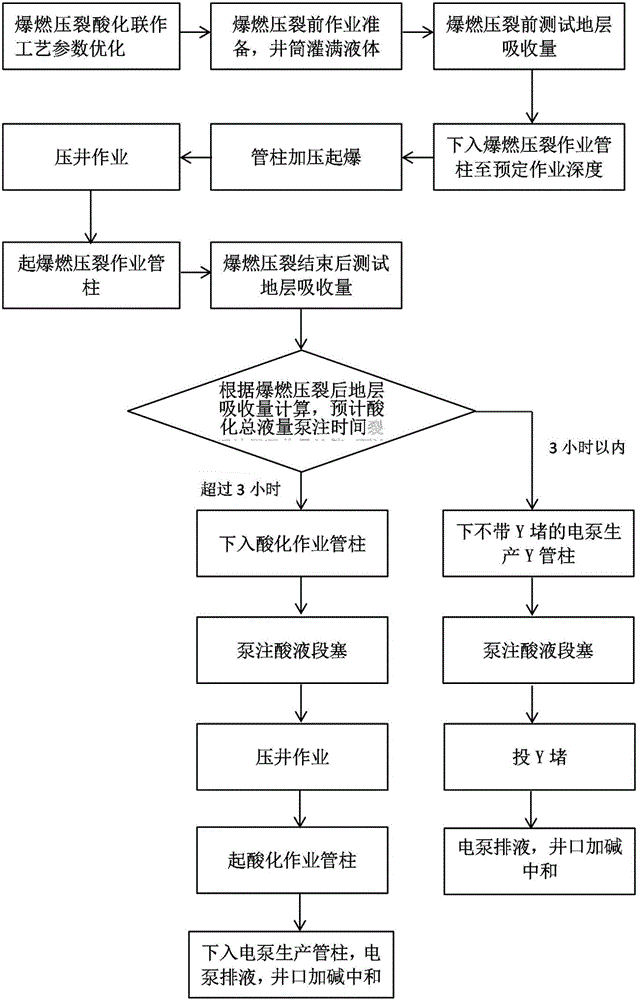

Method for detonation fracture acidizing combined operation

ActiveCN106246156AEnhancing the effectiveness of deflagration fracturingGuaranteed work effectFluid removalDrilling compositionWell killDetonation

The invention discloses a method for detonation fracture acidizing combined operation. The method comprises the steps of optimizing detonation fracture acidizing combined operation process parameters, performing operation preparation before detonation fracture and filling a pitshaft with liquid, testing stratum absorption amount before the detonation fracture, placing a detonation fracture operation tubular column to a predetermined operation depth, performing pressurization detonation of the tubular column, performing well killing operation, detonating the fracture operation tubular column, testing the stratum absorption amount after the detonation fracture, placing an acidizing operation tubular column, performing pumping injection acid liquid slug, lifting the acidizing operation tubular column, placing an electric pump production tubular column and performing electric pump liquid drainage and well opening alkalifying neutralization, placing an electric pump production Y tubular column without a Y tubular column, performing pumping injection of acid liquid slug, placing the Y tubular column, performing electric pump liquid drainage and well opening alkalifying neutralization and the like. The method has the advantages that detonation fracture and acidizing effects can be further enhanced, the acid liquid injection capability is enhanced, the acidizing radius is expanded, crack closure is further avoided, and a physical effect is enhanced; a detonation fracture effect can be enhanced, a follow-up acidizing step is selected flexibly, and the operation step is omitted while an operation effect can be guaranteed.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Well kill additive, well kill treatment fluid made therefrom, and method of killing a well

For well kill treatment to prevent the intrusion of formation fluids into the wellbore while the well is open, a well kill additive including a dry mixture of water soluble crosslinkable polymer, a crosslinking agent, filter aid, and optionally, a reinforcing material of fibers and / or comminuted plant materials. The method of forming a well kill fluid includes contacting the additive with water or an aqueous solution, with a method of conforming the formation further including the step of injecting the fluid into the wellbore.

Owner:BURTS III BOYCE DONALD

Testing operation pipe column capable of achieving straight pushing well killing and formation testing method thereof

ActiveCN106522918AMeet the needs of plugging construction operationsSimple structureSurveyConstructionsWell killIndustrial engineering

The invention discloses a testing operation pipe column capable of achieving straight pushing well killing and a formation testing method thereof. The formation testing method comprises the technological processes that the pipe column is put downwards to the predetermined depth; seat sealing is conducted; well head replacing is conducted; acid liquor is replaced through a normally open valve; the normally open valve is closed by throwing balls, and perforating, acidifying and open flow testing operation are conducted; a one-way well shut-in type circulation valve is operated through annulus pressure, and downhole shut-in is conducted; leaking stoppage mud is positively injected into the pipe column, and well killing and leaking stoppage are conducted; circulating is conducted; deblocking is conducted, and downhole information is obtained after the pipe column is lifted out. According to the testing operation pipe column capable of achieving straight pushing well killing and the formation testing method thereof, the multiple functions such as perforating, acidifying, testing, downhole shut-in re-pressing, and straight pushing well killing leaking stoppage can be achieved; the structure is simple and feasible; great convenience is mainly provided for well killing leaking stoppage operation in the later period, and the safe and reliable effects are achieved; and thus, the requirements for well killing leaking stoppage construction operation of a reservoir prone to leakage are met, economic losses brought by the complexity caused by well killing leaking stoppage and the like are decreased, and the effect that construction is safe and controllable is ensured.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Well completing test pipe column and method for gas well

The invention provides a well completing test pipe column and method for a gas well. The pipe column comprises an oil pipe, a packer arranged on the outer wall of the oil pipe, a leak-proof device arranged at the tail end of the oil pipe and used for preventing well killing fluid in the oil pipe from leaking, and a pressure gauge arranged in an inner cavity of the leak-proof device or an inner cavity of the oil pipe. By using the pipe column, it can be ensured that gas well test and completing can be completed through one time of tripping in, it also can be ensured that the underground pressure gauge can be safely taken out, so that the pipe column can be effectively applied to the completing test of the gas well and is particularly suitable for a high-pressure gas well, the huge operationcost and the operation risk caused by operation on the pipe column are avoided, and the reliability of the pipe column is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

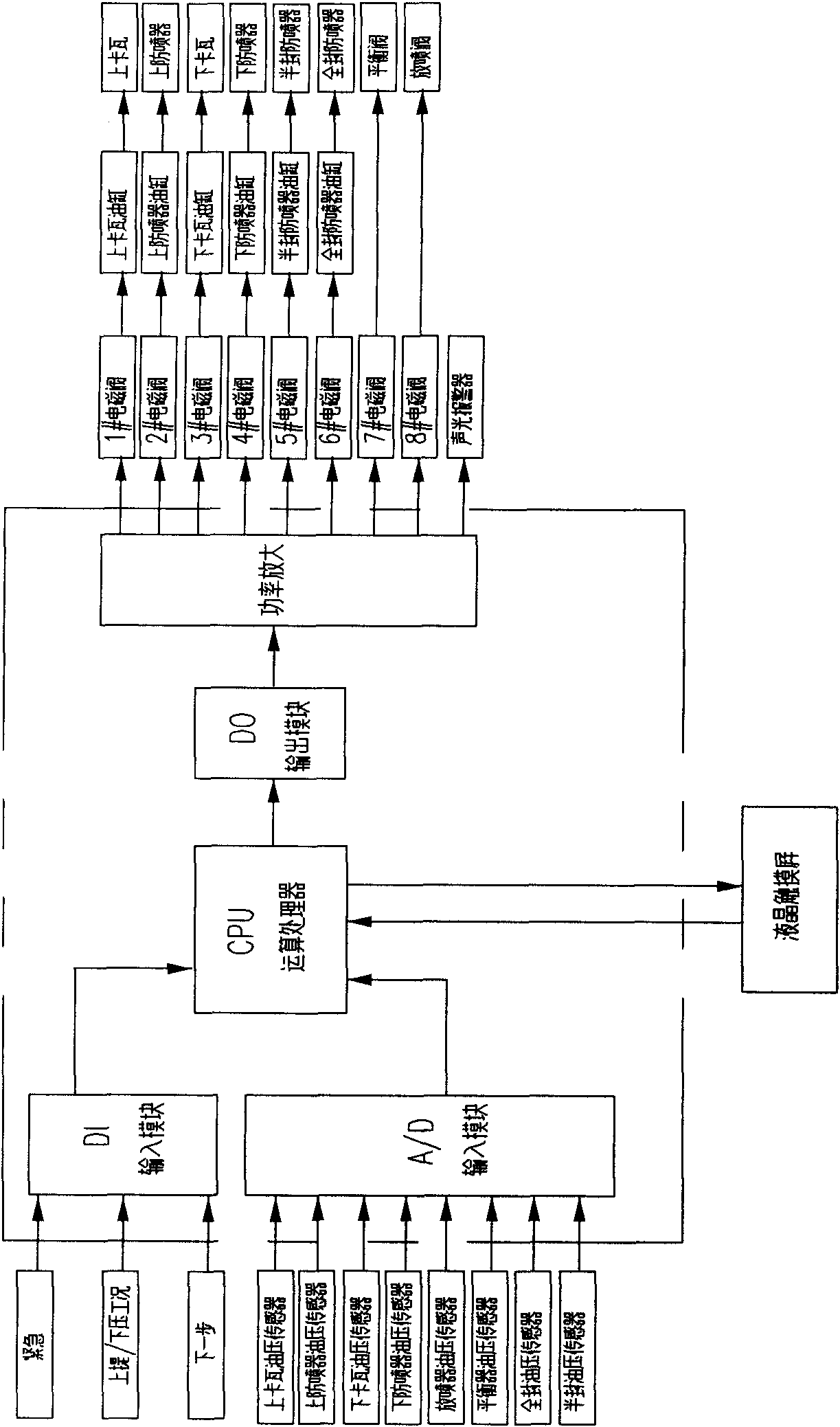

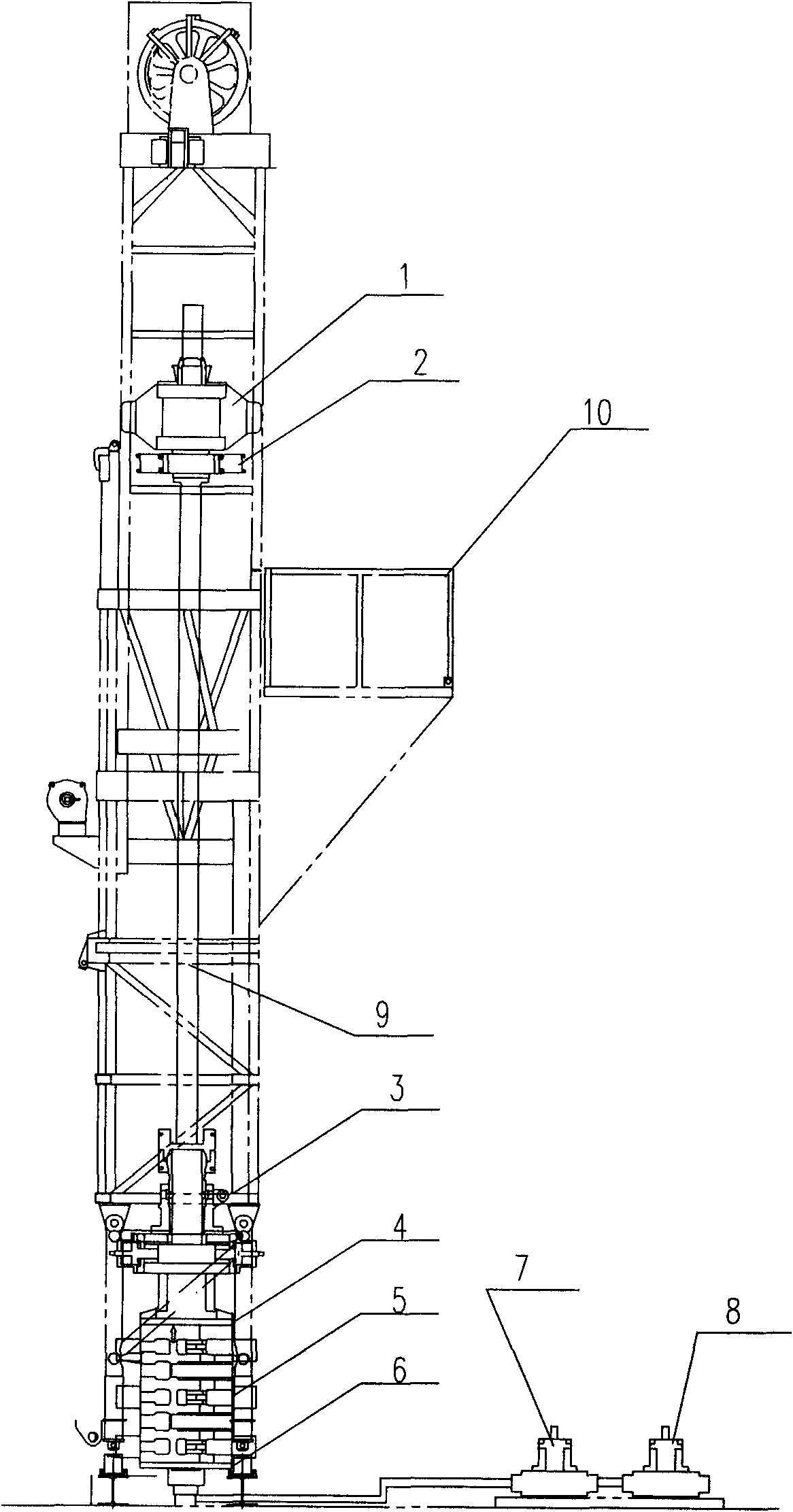

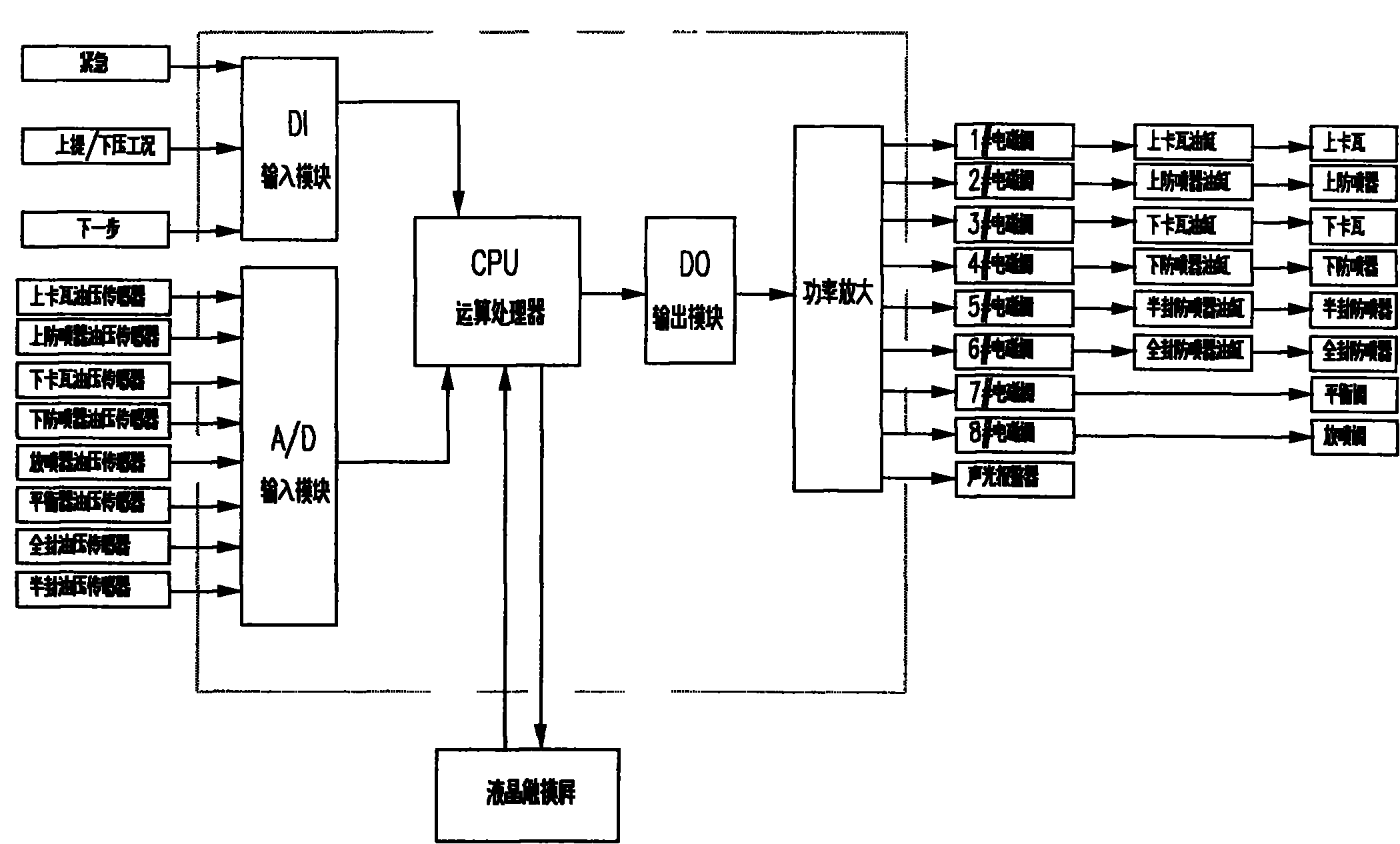

Automatic control device of oil pipe clamping mechanism of non-well killing workover rig

ActiveCN101818639ARealize automatic controlImprove securityTubing catchersAutomatic control for drillingWell killAutomatic control

The invention relates to an automatic control device of an oil pipe clamping mechanism of a non-well killing workover rig, belonging to the field of non-well killing workover operation equipment. The automatic control device is used for the non-well killing workover operation equipment and comprises a control device, a plurality of electromagnetic valves, oil pressure sensors and hydraulic oil cylinders, wherein the control device takes a controller loading self-authoring software as a core; the oil pressure sensors are the same as the electromagnetic valves in number; and the hydraulic oil cylinders are the same as the electromagnetic valves in number. The automatic control device is characterized in that a data processing device comprises a DI (Data Input) module, a CPU operation processor, a DO (Data Output) module, a power amplifier, an A / D (Analog / Digital) input modules and a CPU, wherein the DI module, the CPU operation processor, the DO module and the power amplifier are sequentially connected, and the A / D input module is connected with the CPU; an executive device comprises eight electromagnetic valves, six hydraulic oil cylinders, two hydraulic valves and a clamping mechanism; and the input end of the A / D input module is also connected with eight oil pressure sensors, and the oil pressure sensors are connected with oil inlet pipelines of the hydraulic oil cylinders orthe hydraulic valves one by one. The invention solves the problem of equipment safety caused by the complexity and the easy error of the manual operation of the oil pipe clamping mechanism and reduces the labor intensity of operators.

Owner:中石化四机石油机械有限公司 +1

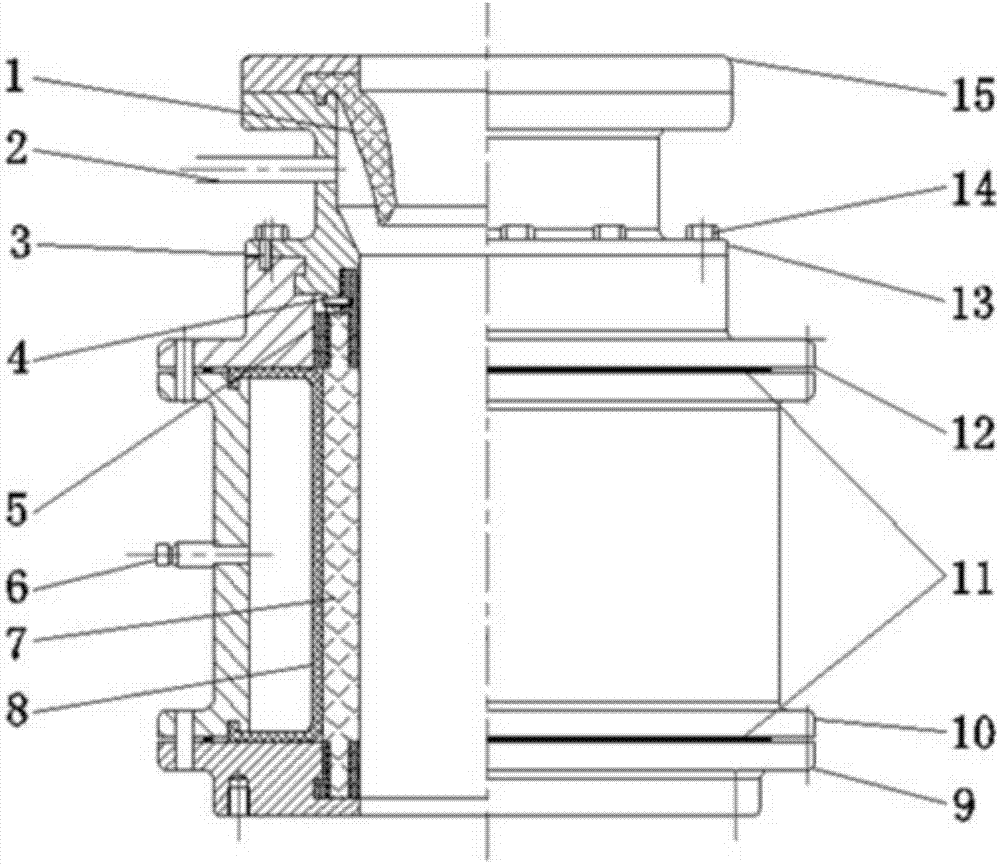

Annular blowout preventer

The invention discloses an annular blowout preventer. The annular blowout preventer comprises a first shell body, a gas bag and a gas inflating opening. According to the technical schemes of the annular blowout preventer, gas serves as a power medium to push the gas bag to embrace an oil tube tightly, the gas is inflated between the first shell body and the gas bag through a gas inflating valve, the gas bag is deformed and embraces the oil tube tightly, so that annular sealing between the oil tube and a sleeve tube is achieved; when the oil tube is needed to be lifted upwardly during minor repairing operation, due to the fact that compressibility of the gas is good, the gas bag can be squeezed by an oil tube coupling, the gas located between the gas bag and the first shell body is squeezed and deformed, so that space in the middle of the gas bag allows the oil tube coupling to pass through directly; and compared with the prior art, time for waiting opening and closing of a hydraulic annular blowout preventer is saved, so that oil tube uplifting time in minor repairing operation is shortened, and time of minor repairing operation is reduced accordingly, the efficiency of minor repairing operation is improved, and reservoir in non-well killing operation is protected.

Owner:CHINA UNITED COALBED METHANE +1

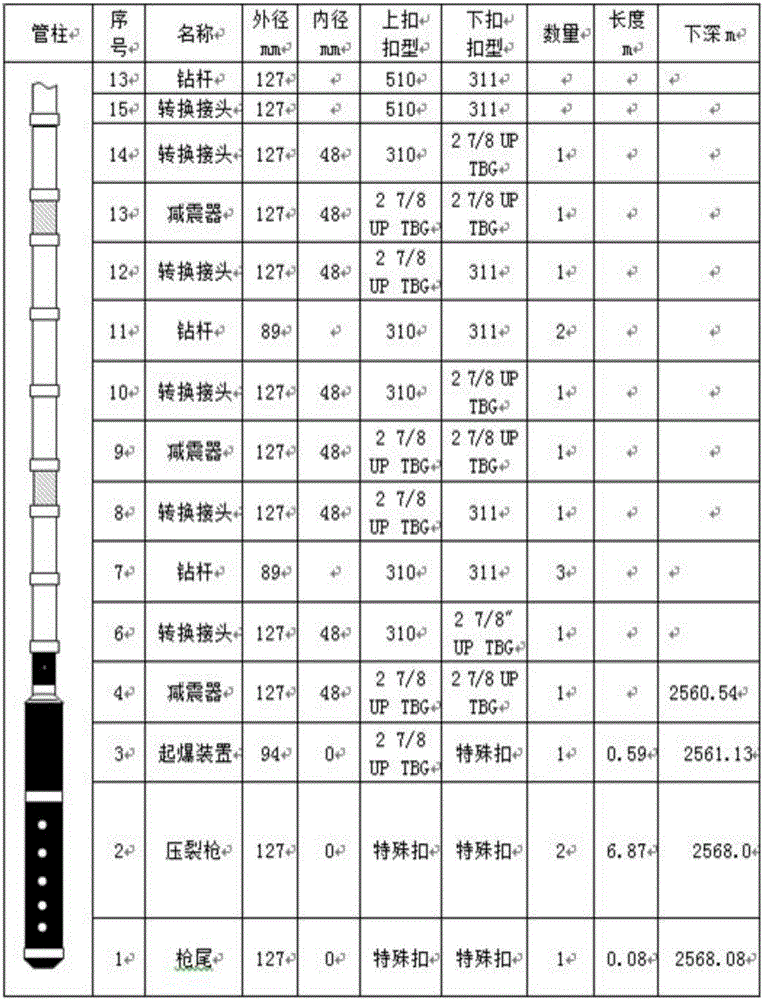

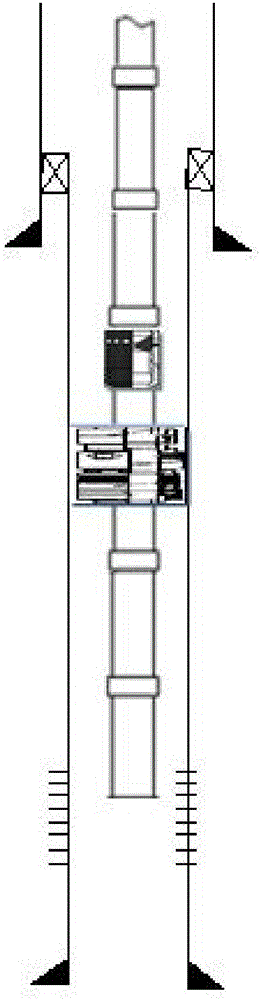

Deflagration fracturing and hydraulic impact fracturing combination pipe column and combination method

The invention belongs to the technical field of oil and gas field reservoir reconstruction and discloses a deflagration fracturing and hydraulic power impact fracturing combination pipe column and combination method. The combination pipe column is connected in series with a hydraulic power impact fracturing device and a deflagration fracturing device through an oil pipe or a drill pipe and an adapter buckle. A central tube is built in the hydraulic power impact fracturing device and is used for transmitting liquid pressure applied by a ground pump through the combination pipe column so as to perform deflagration fracturing operation; according to the combination method, the combination pipe column is lowered to a predetermined working position, deflagration fracturing operation is first performed, and then the hydraulic power impact fracturing operation is performed; the value of liquid pressure applied in the deflagration fracturing operation needs to be smaller than the value of liquid pressure applied in the hydraulic power impact fracturing operation; after reverse circulation well killing operation, the combination pipe column is taken out. Via the deflagration fracturing andhydraulic impact fracturing combination pipe column and combination method, deflagration fracturing and hydraulic impact fracturing combination of the pipe column can be realized in one trip, work trip frequency can be reduced, crack expansion and extension can be facilitated after the deflagration fracturing operation, and pipe column and work safety can be realized.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com