Testing operation pipe column capable of achieving straight pushing well killing and formation testing method thereof

A technology for formation testing and operating pipe strings, which is applied in surveying, earthwork drilling, wellbore/well components, etc. It can solve the problems of long plugging operation time, poor mud passability, pipe string stuck, etc., and reduce economic losses , ensure safety and controllability, and ensure the effect of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

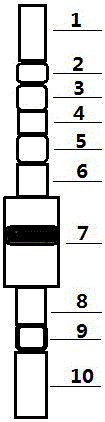

[0020] A test operation string that can realize direct push well killing, which is composed of oil pipe 1, normally closed valve 2, one-way shut-in circulation valve 3, normally open valve 4, pressure gauge holder 5, It consists of safety joint 6, RTTS packer 7, tubing 8, screen 9 and perforating gun 10.

[0021] A formation testing method that can realize direct pushing well killing. The technological process is as follows: after the pipe string is lowered to a predetermined depth → setting → changing the wellhead → replacing acid fluid through a normally open valve → closing the normally open valve by throwing a ball, performing perforation, Acidizing and blowout test operations → pressurize the annular space to operate the one-way shut-in circulation valve, shut down the well → positively inject plugging mud into the pipe string, kill the well, plugging → circulation → unsealing → trip out to obtain downhole data.

[0022] After the pipe string is lowered to a predetermined...

Embodiment 2

[0031] This embodiment further illustrates the present invention in conjunction with the accompanying drawings.

[0032] Through the dual pressure control mode of annulus + tubing, tubing 1 + normally closed valve 2 + one-way shut-in circulation valve 3 + normally open valve 4 + pressure gauge holder 5 + safety joint 6 + RTTS is used for isolation from top to bottom 7+Tube 8+Screen 9+Perforating gun 10. The string has the functions of perforating, acidizing, testing, downhole shut-in and repressurization, direct push and kill plugging, and acquisition of downhole temperature and pressure data.

[0033] The main process flow is as follows:

[0034] Run the above-mentioned combined pipe string as required, and measure the depth by electrical measurement.

[0035] Complete the setting of packer 7, pour out the wellhead blowout preventer device, reinstall the gas production wellhead, connect the ground testing process, and test the pressure of each equipment and pipeline one by o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com