Well completing test pipe column and method for gas well

A technology for testing pipes and gas wells, applied in wellbore/well components, measurement, drilling pipes, etc., can solve the problems of increased risk of test failure, high risk of well control, loss of kill fluid, etc., to avoid operating costs and operations. risk, improve work reliability, and reduce wellhead pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing.

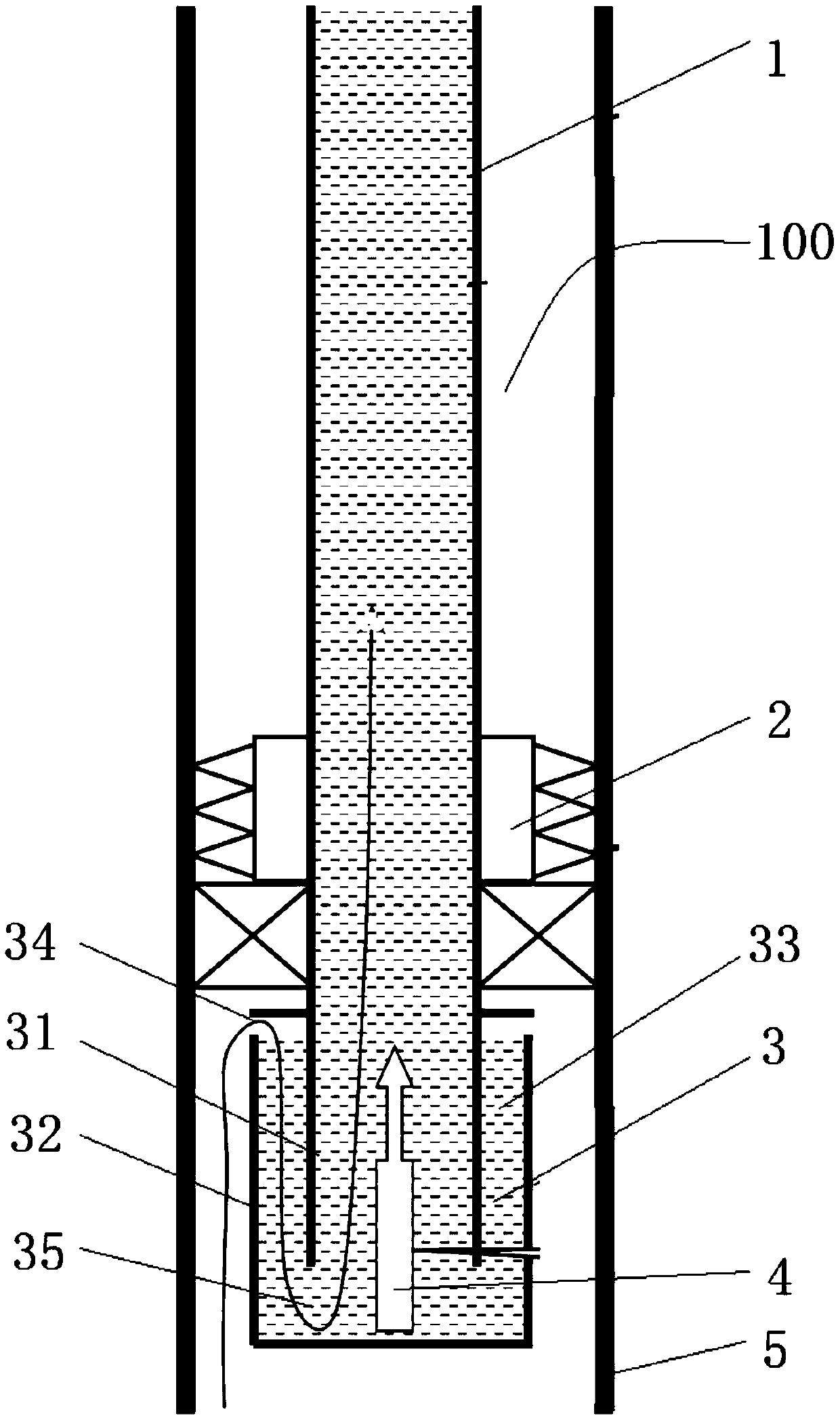

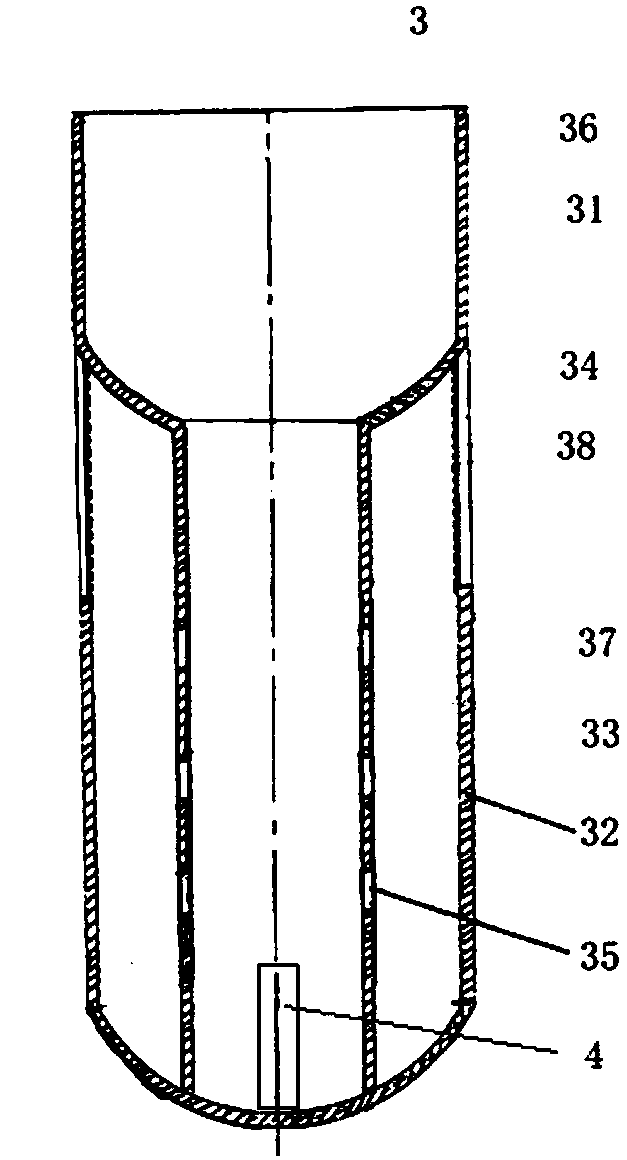

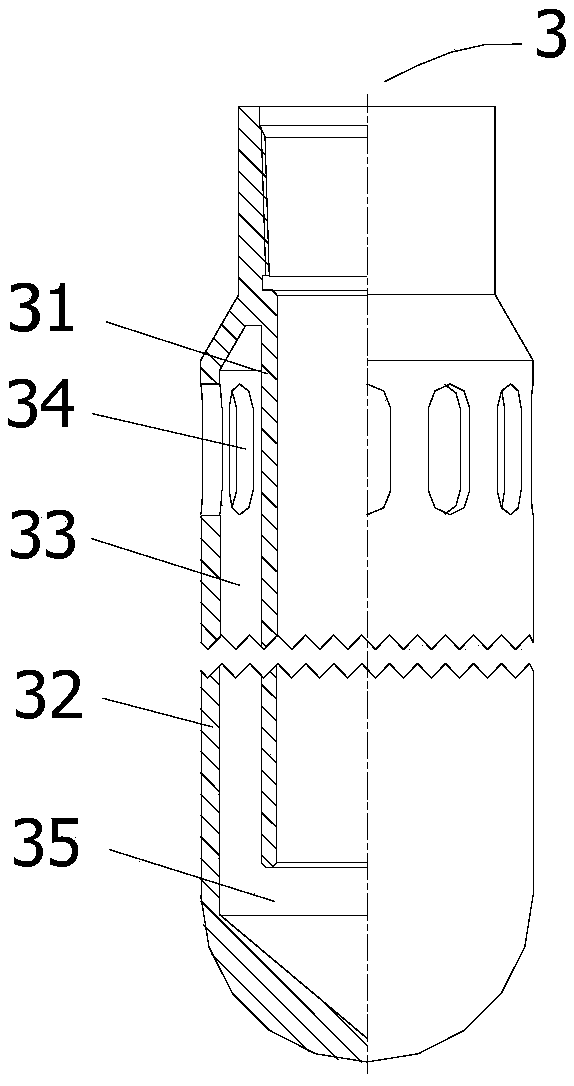

[0034] figure 1 A completion test string 100 for a gas well according to the present invention is shown. Such as figure 1 As shown, the tubing string 100 includes a tubing 1 , a packer 2 , a leakage prevention device 3 and a pressure gauge 4 . Wherein, the oil pipe 1 plays the role of connection and transportation, and is used for running the pipe string 100 into the gas well. The packer 2 is arranged on the outer wall of the tubing 1 . After the tubing string 100 is run in place, the packer 2 is set to seal off the annulus between the tubing 1 and the casing 5 . The anti-leakage device 3 is arranged at the end of the oil pipe 1 . During the well killing operation, the anti-leakage device 3 is used to prevent the loss of the killing fluid in the tubing 1 and prevent gas from entering the tubing 1 to cause gas invasion. The pressure gauge 4 is arranged in the inner cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com