Patents

Literature

51results about How to "Avoid job risk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

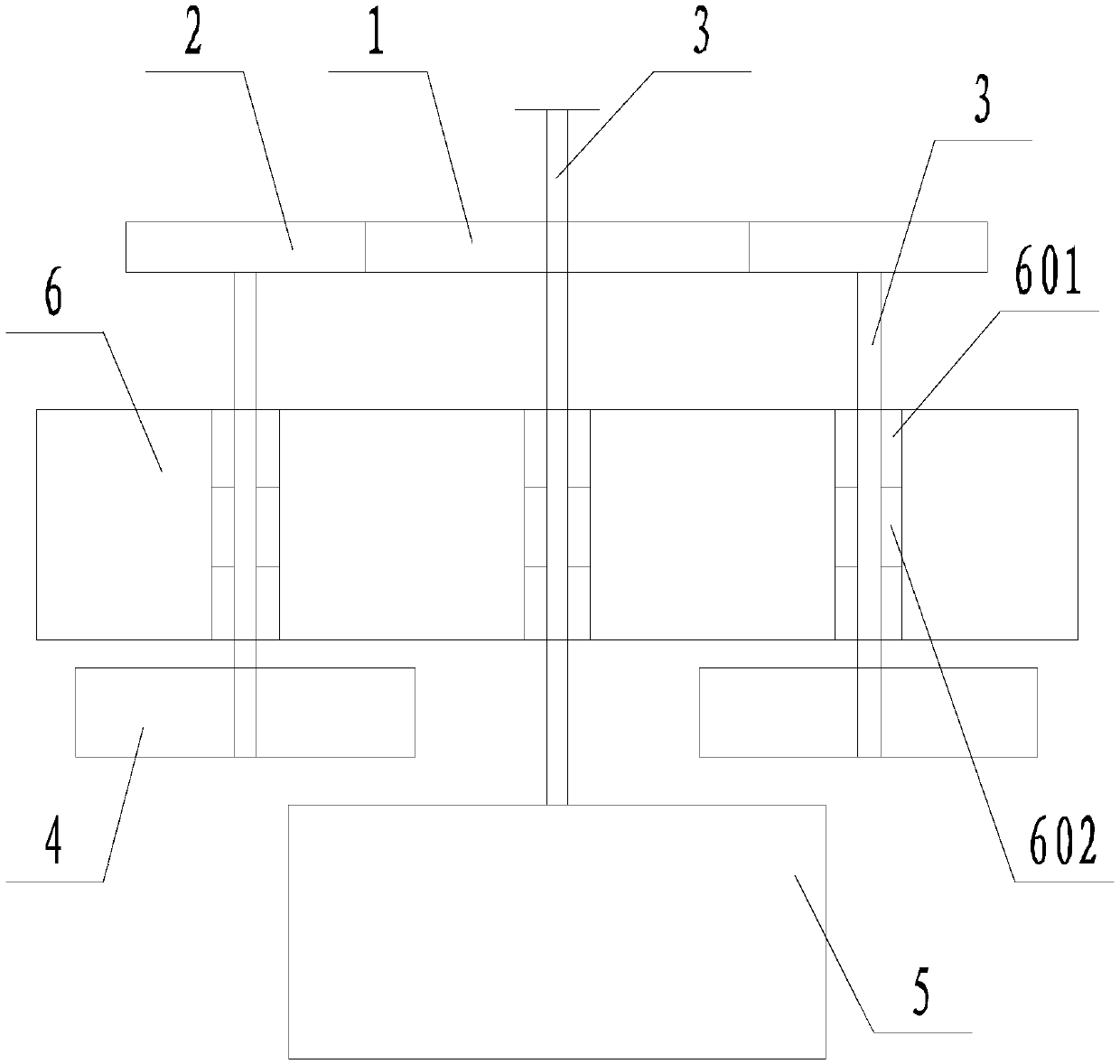

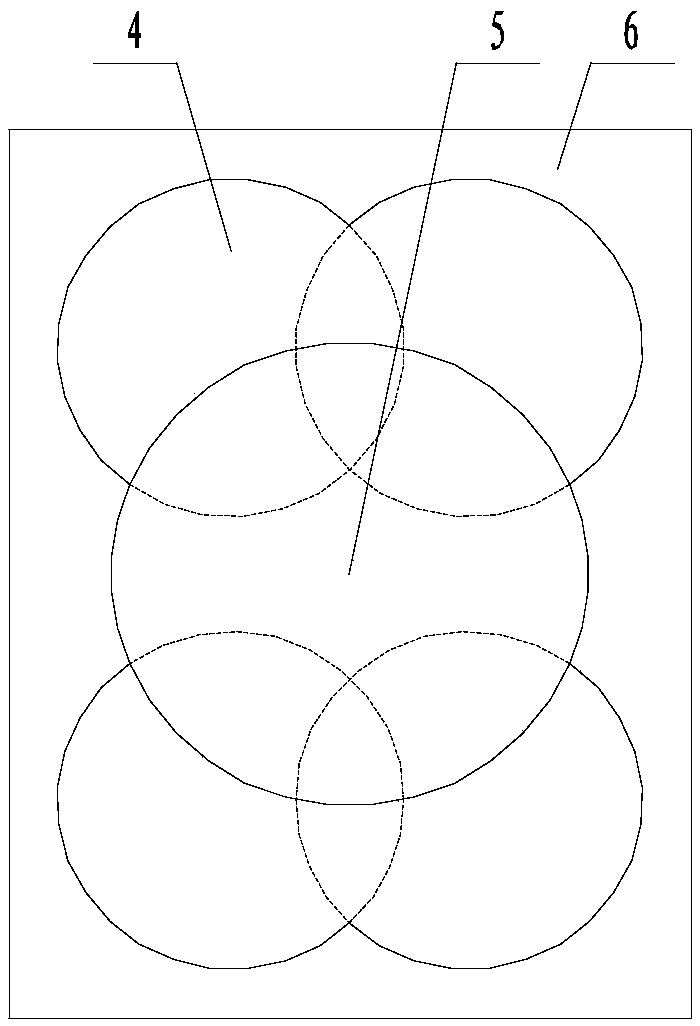

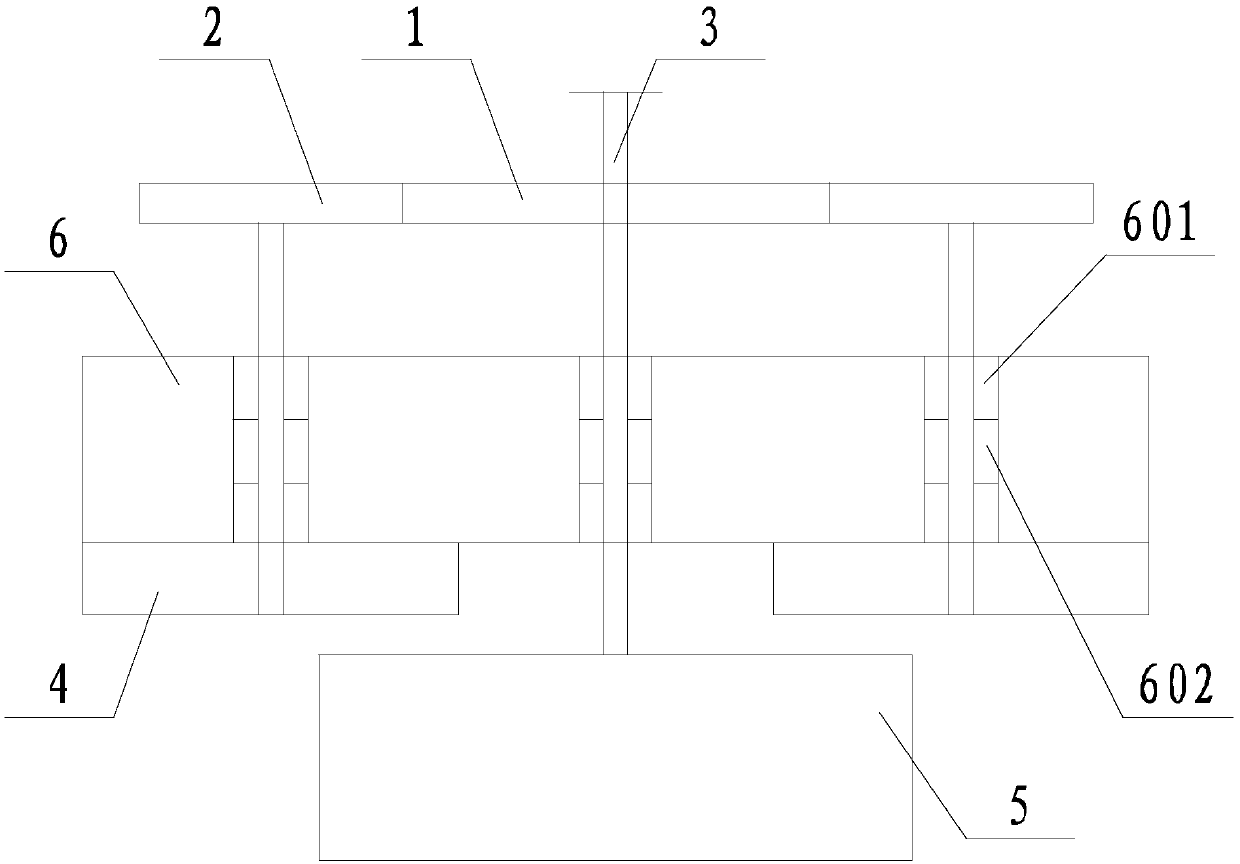

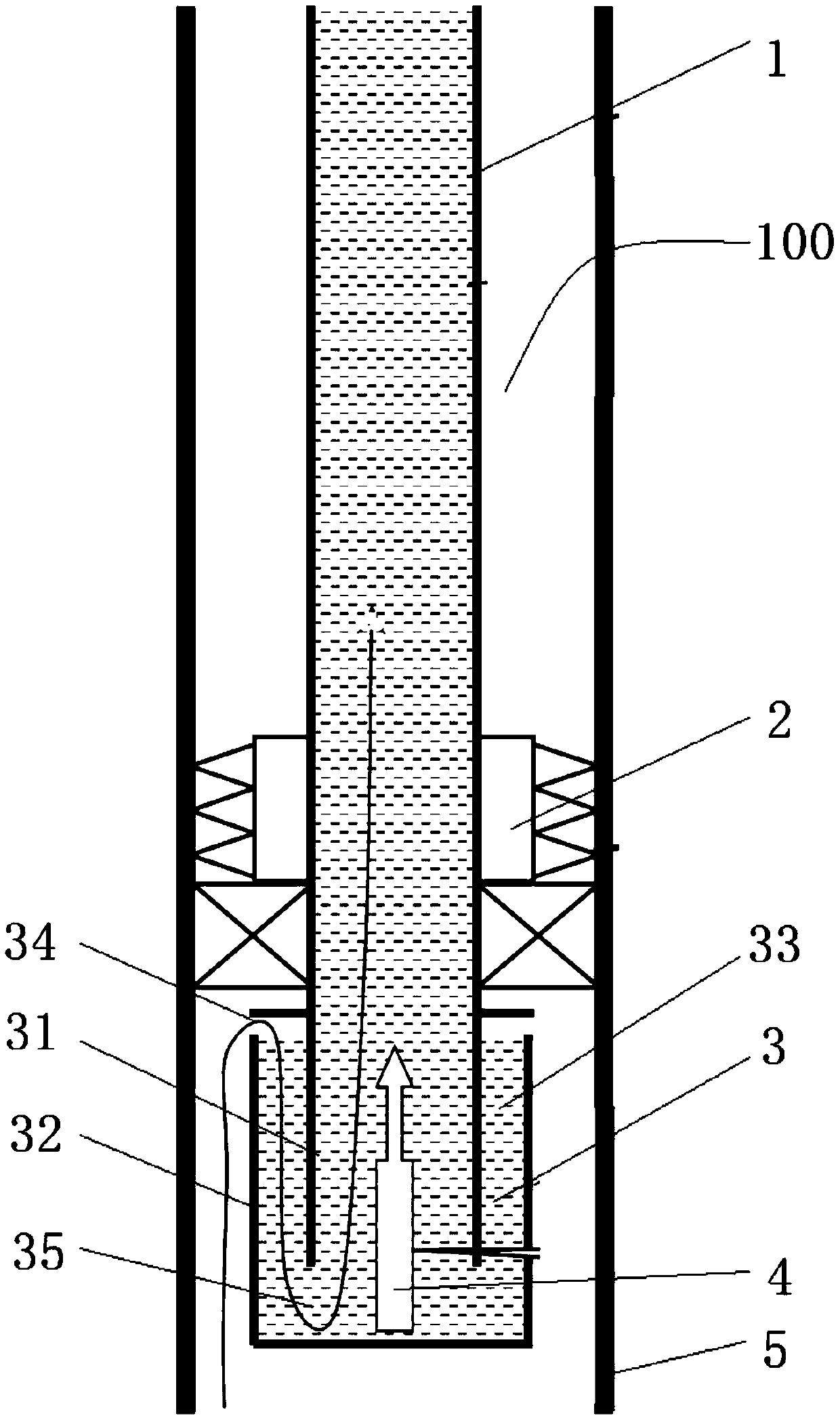

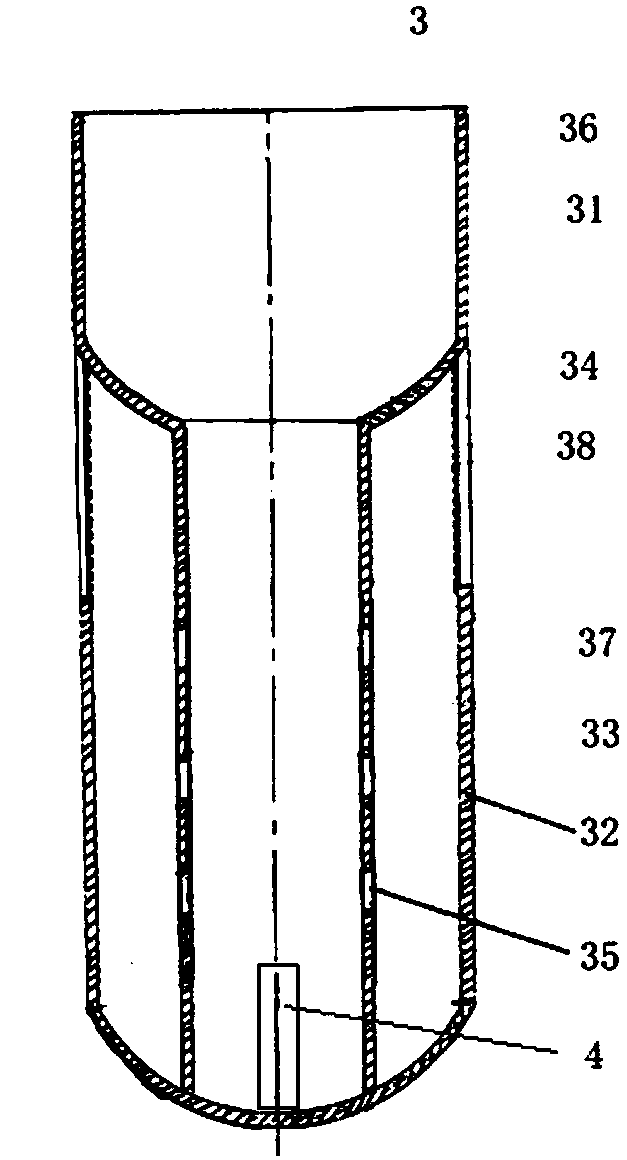

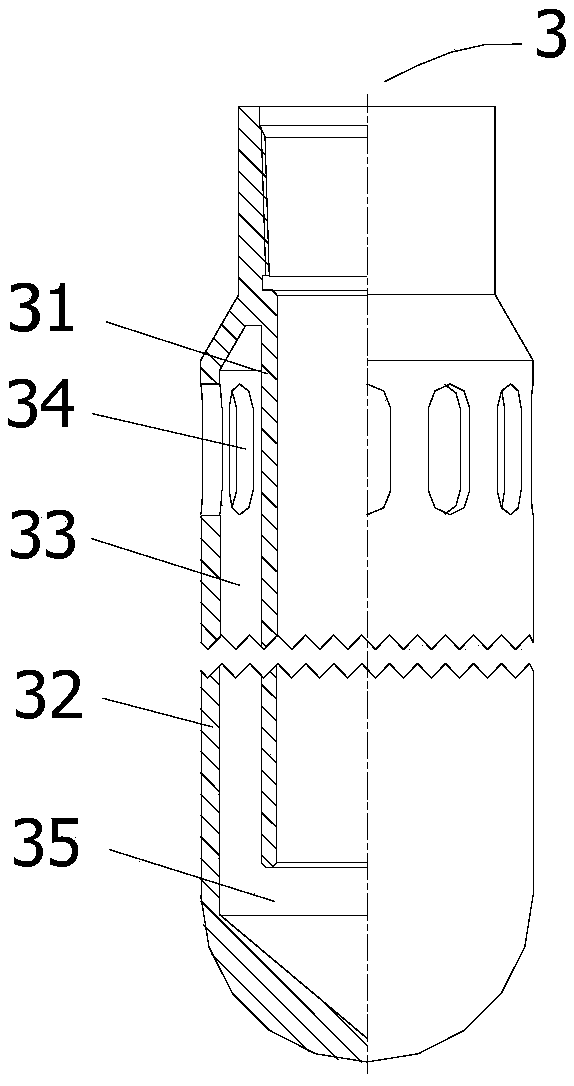

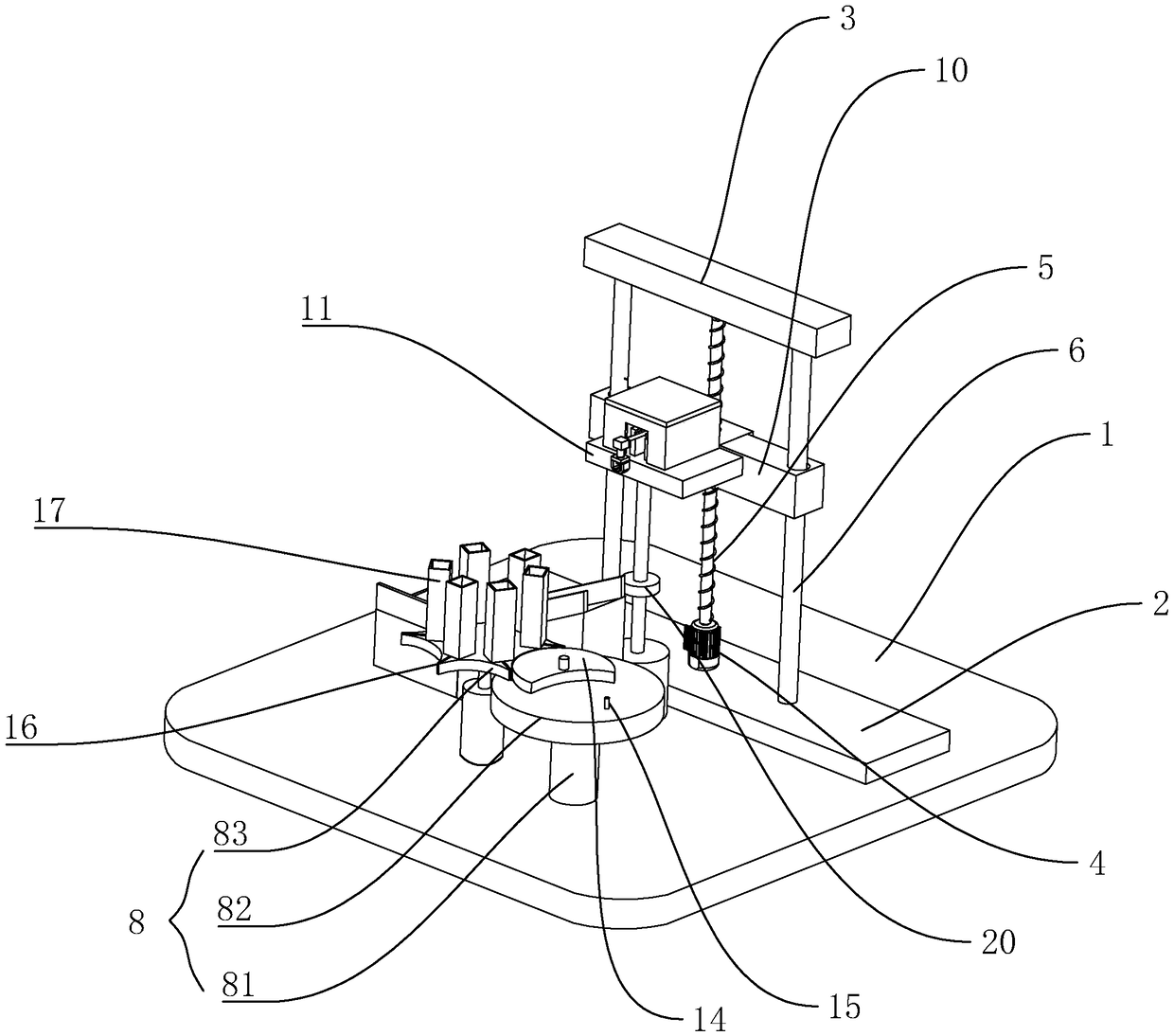

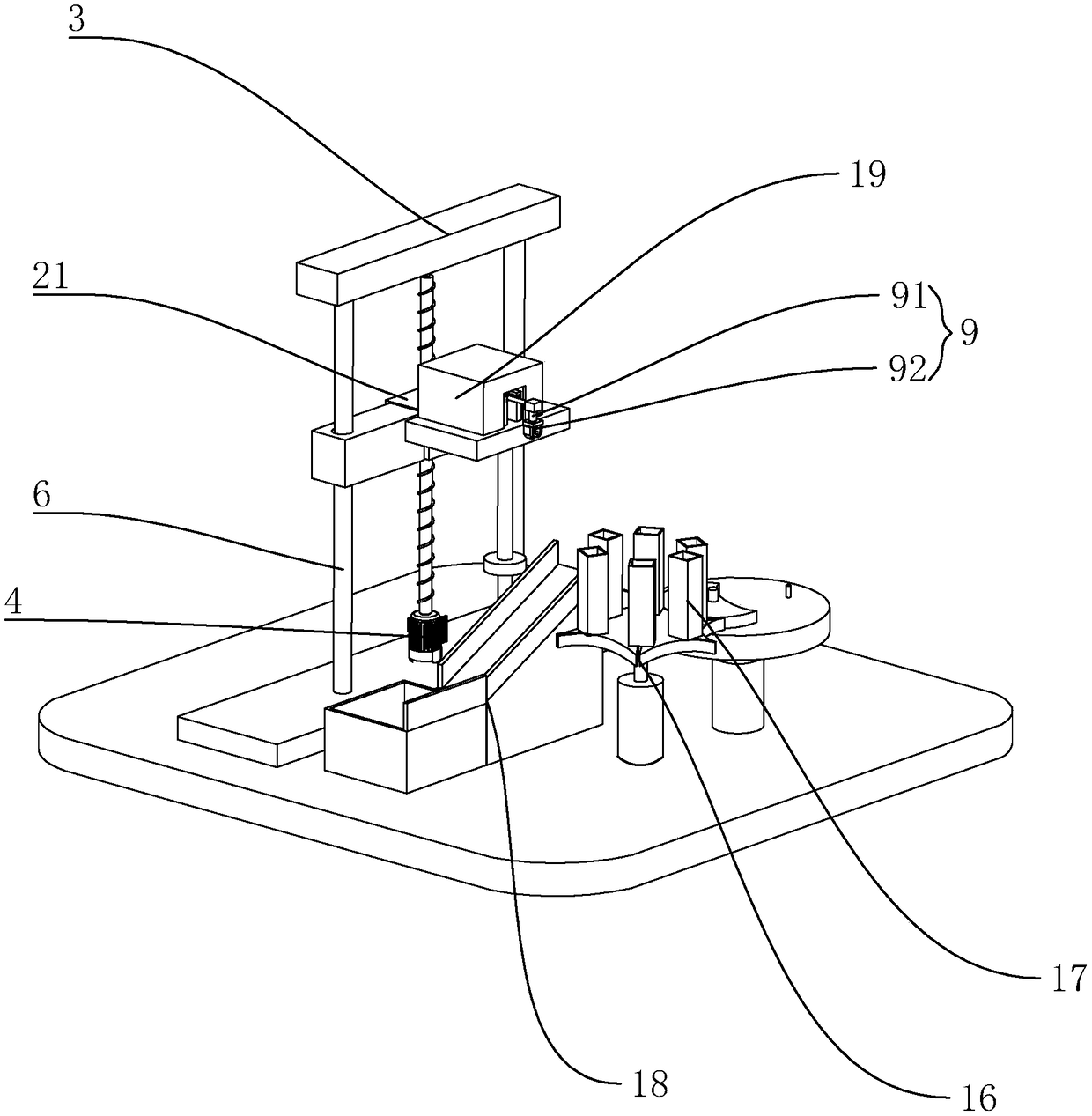

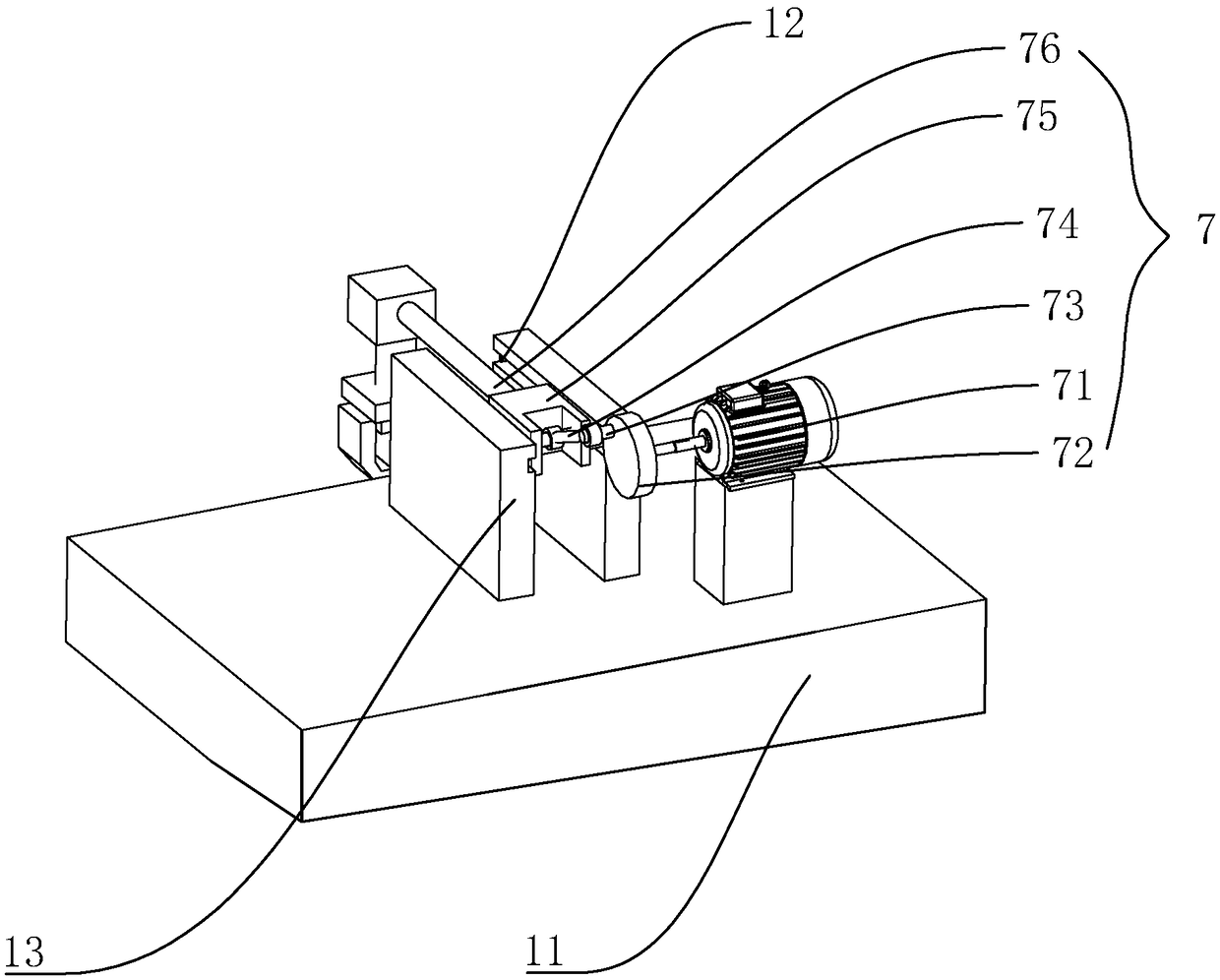

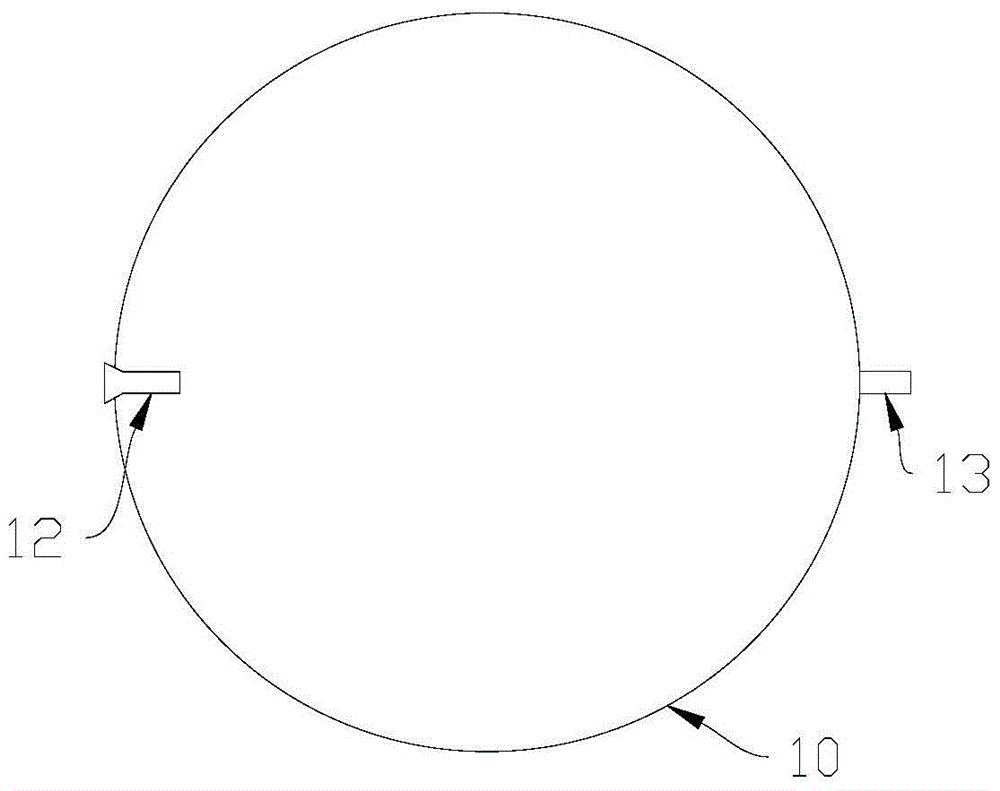

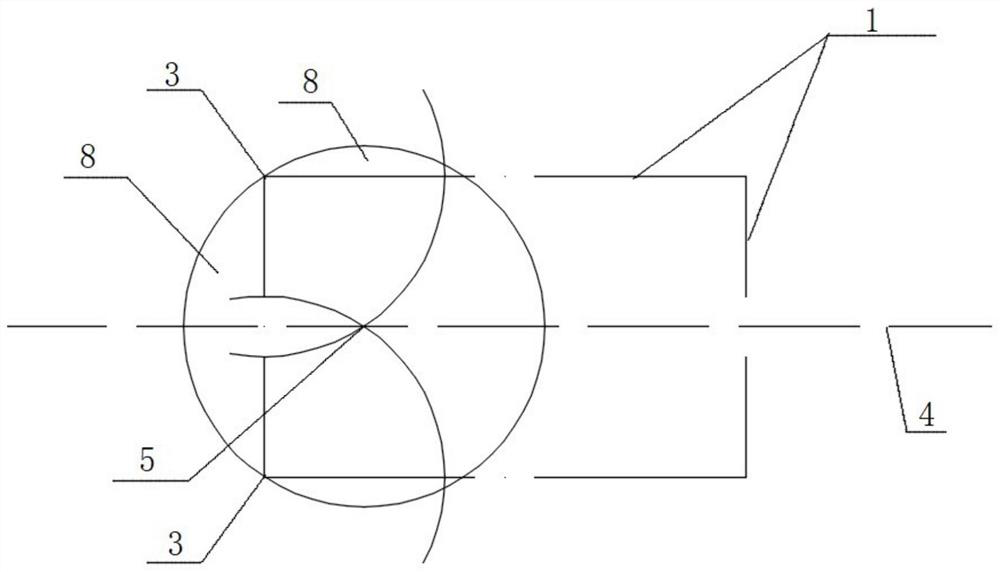

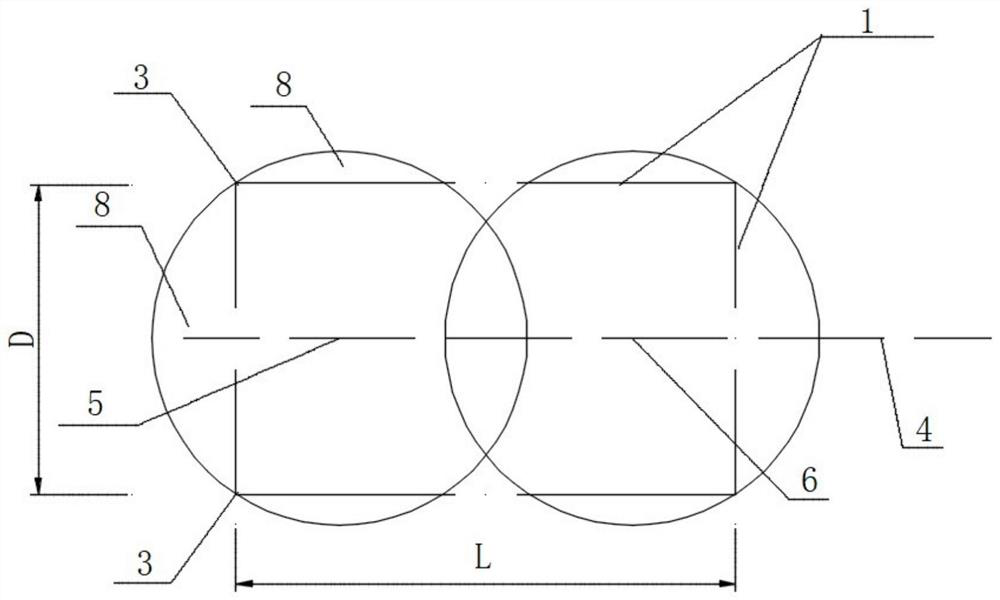

Square pile rotary drilling device for achieving square pore-forming and rotary drilling method thereof

PendingCN109681116ASolve the problem that can only be artificially formedReduce labor intensityDrill bitsDrilling machines and methodsDrilling machinesDrill bit

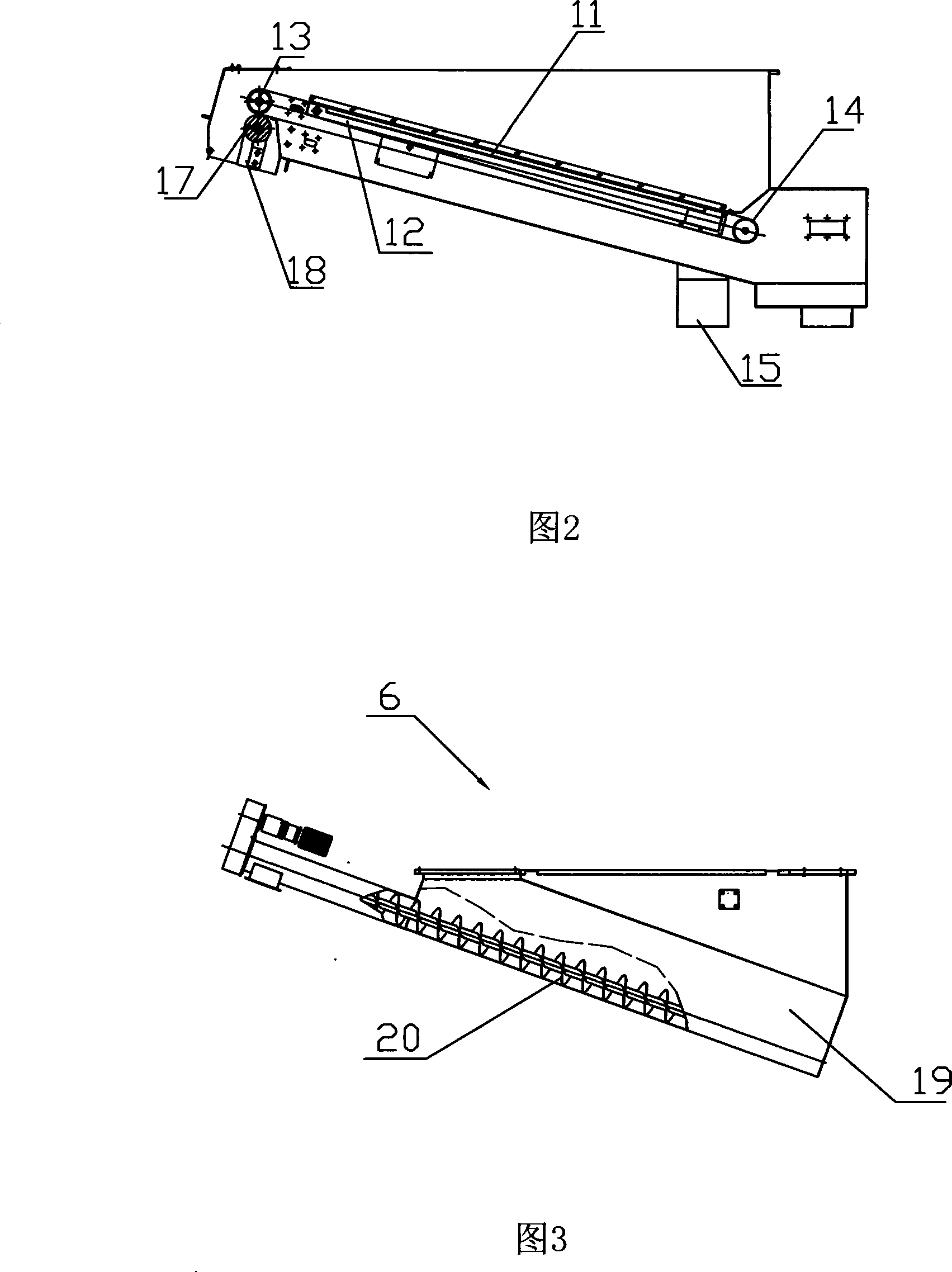

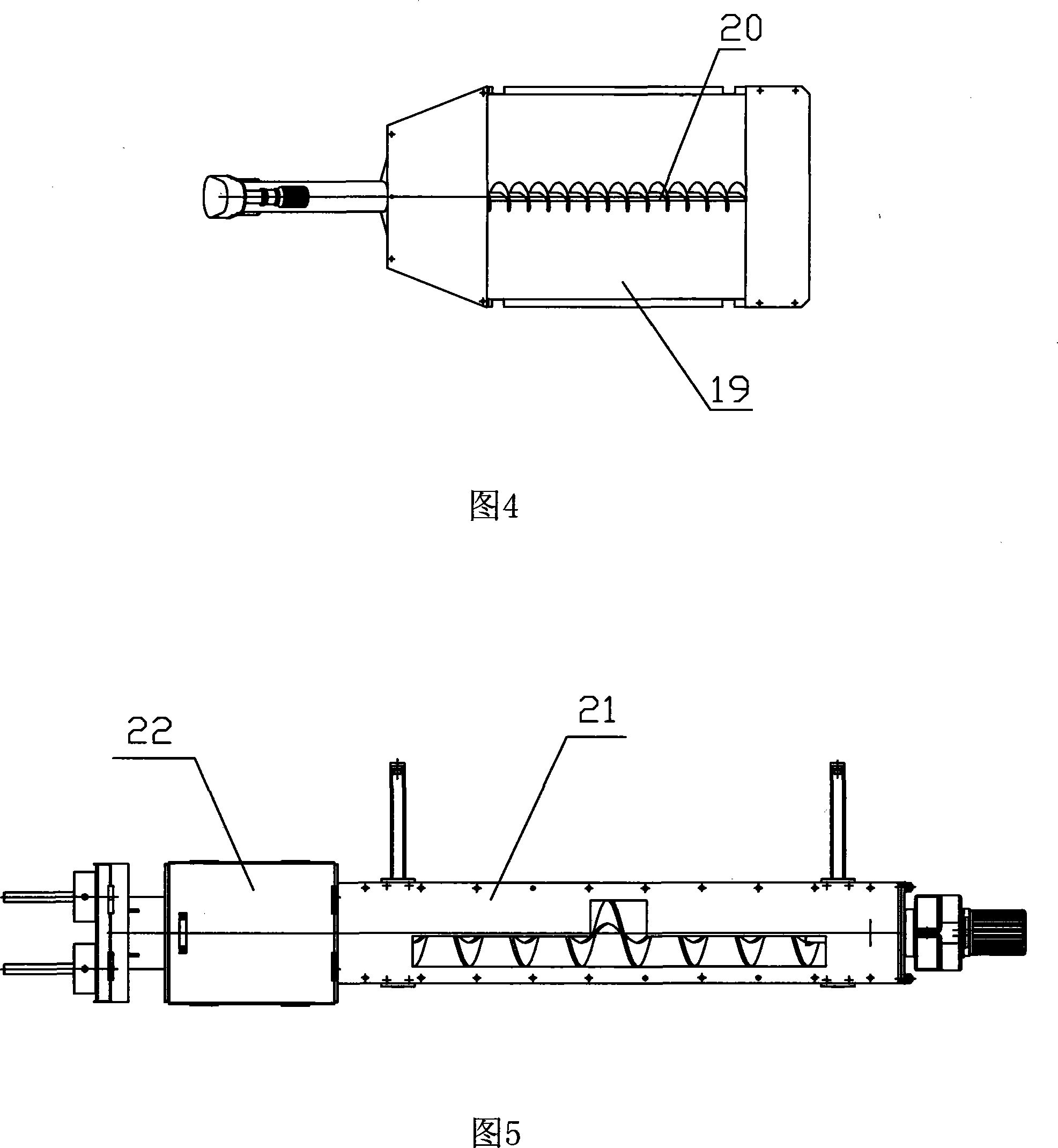

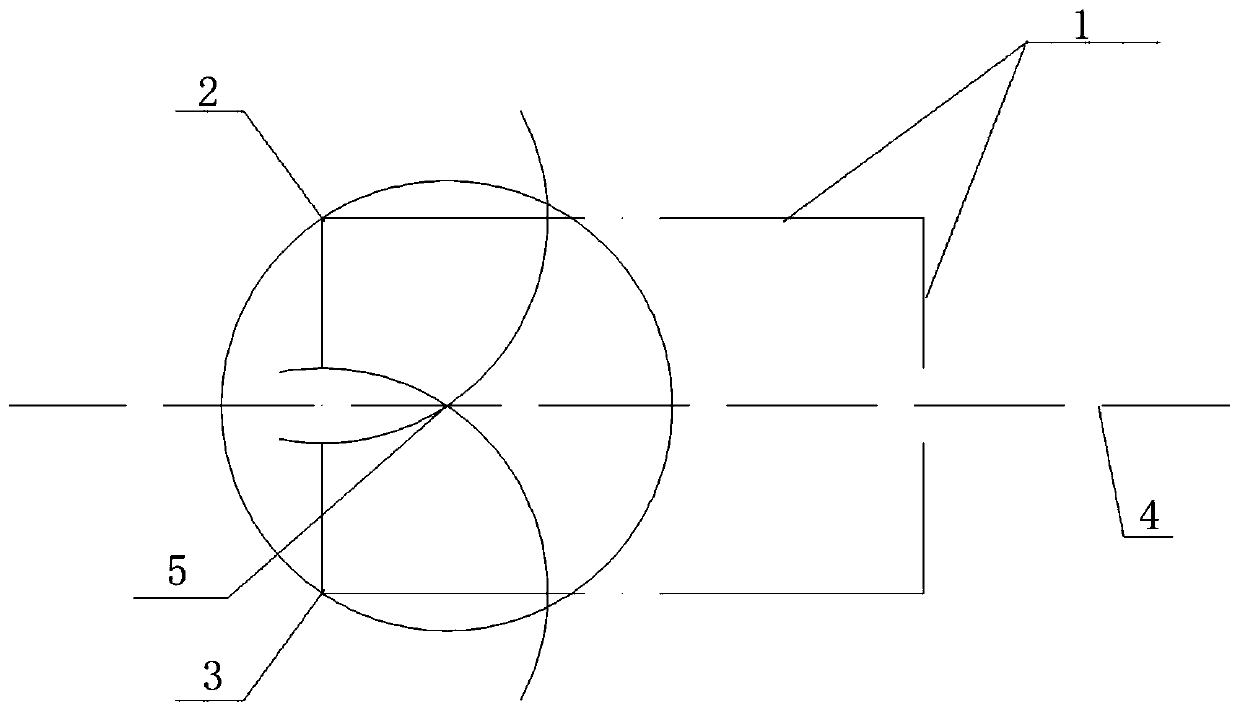

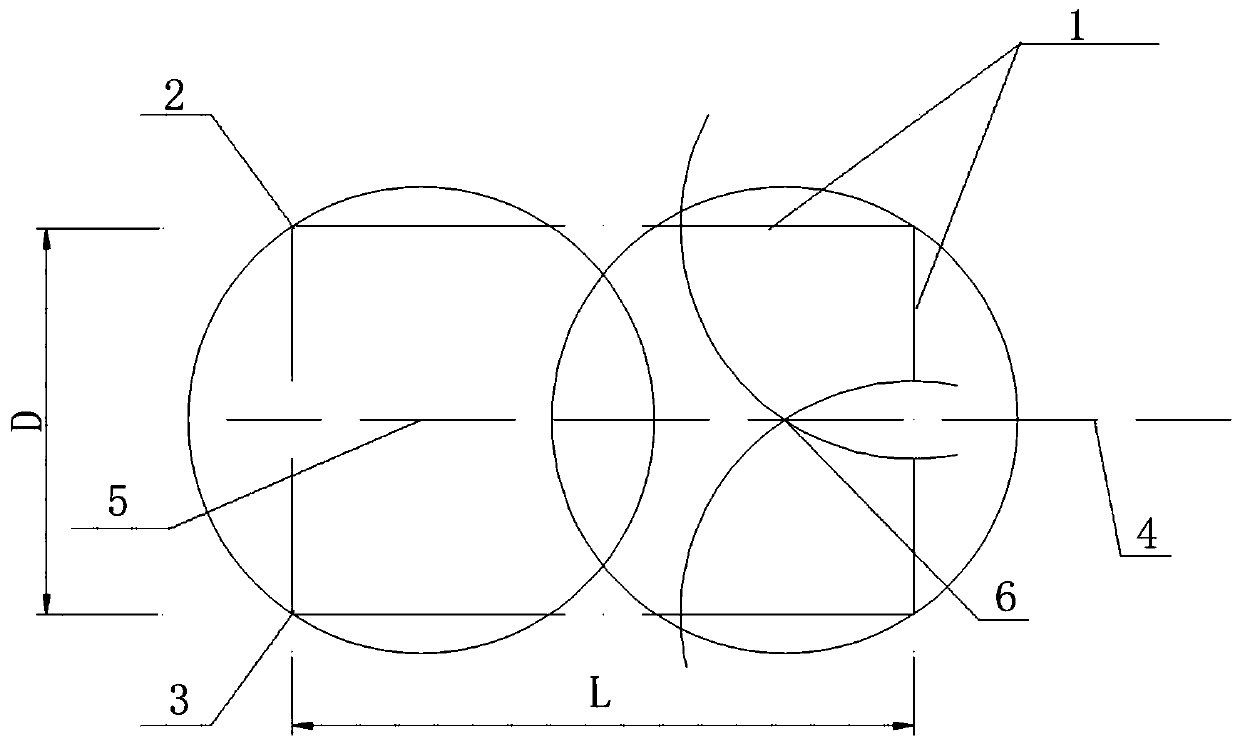

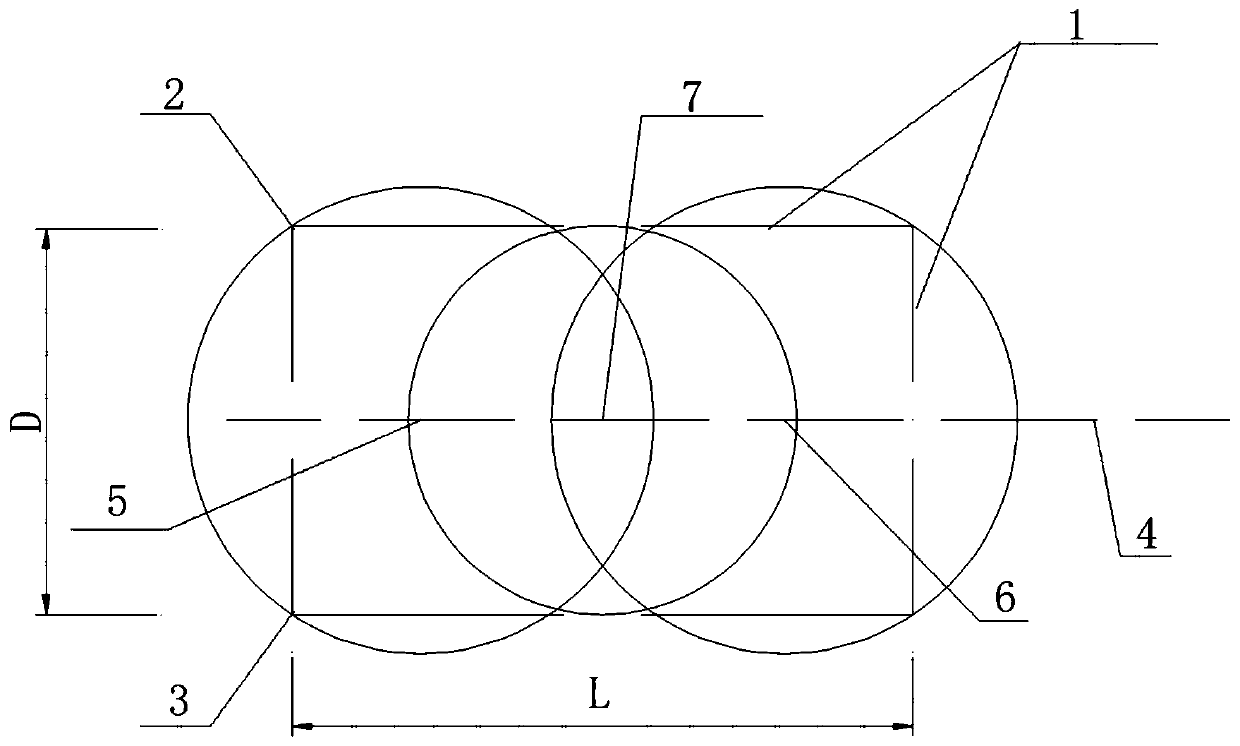

The invention discloses a square pile rotary drilling device for achieving square pore-forming and a rotary drilling method thereof. The device comprises a first rotating part and a plurality of second rotating parts which rotate along with the first rotating part, wherein rotating shafts of the first rotating part and the second rotating parts are in parallel, the first rotating part drives a main drill to rotate, each second rotating part drives an accessory drill to rotate, and all the accessory drills are located above the main drill; projections of the accessory drills in a rotating planeof the main drill partially coincide with the main drill; the device further comprises a square scraping part located above the accessory drills. The invention aims to provide the square pile rotarydrilling device for achieving square pore-forming and the rotary drilling method thereof to solve the problems that in the prior art, square pores cannot be formed by a rotary drilling machine directly, so that square pile construction is low in efficiency and unsafe; the purpose of forming the square pores directly through the rotary drilling machine to efficiently conduct cast-in-place square pile construction can be achieved.

Owner:四川省交通勘察设计研究院有限公司

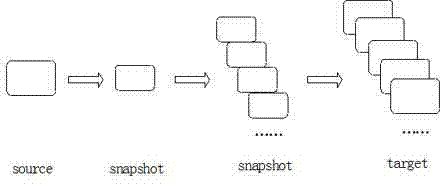

Method for deploying virtual machine rapidly in smart cloud OS (operating system)

InactiveCN102880515ASimplify work contentAvoid job risksResource allocationSoftware simulation/interpretation/emulationMultiple copyApplication software

The invention provides a method for deploying a virtual machine rapidly in a smart cloud OS (operating system). In the method, terminal Linux commands and a mode of homologous snapshots are used for deploying the virtual machine rapidly. The invention has the following technical scheme as follows: on the smart cloud OS, at first, a source virtual machine is created, an operating system is installed in the source virtual machine, application software is deployed in the system, then the source virtual machine is snapshot, multiple copies of a snapshot file are copied, corresponding UUID (universally unique identifier) numbers are separately given to the snapshot files through executing the corresponding commands in distributed storage, the snapshots of the source virtual machine are set as the mirror images of other virtual machines, and thus, the same rapid deployment of the virtual machines is finished through the method of homologous mirror images. By using the method, work content is simplified, work risks are avoided, and the disk space is greatly saved as the homologous files are used.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

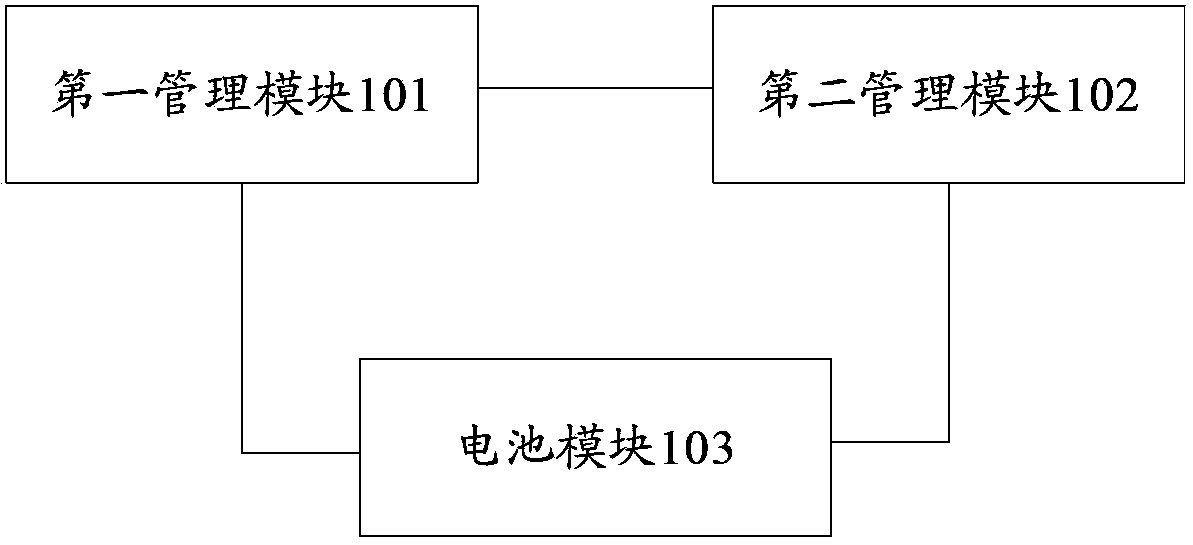

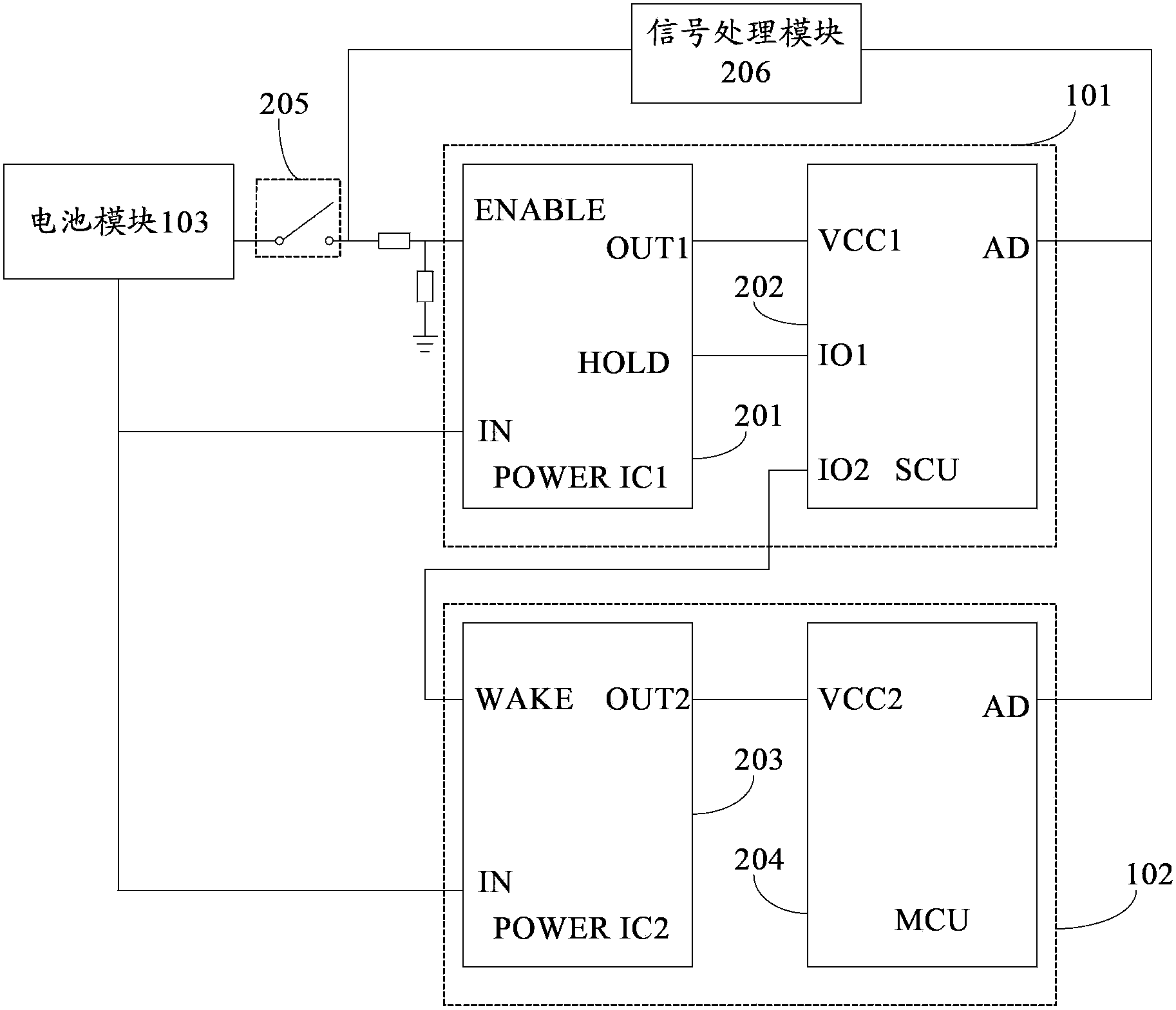

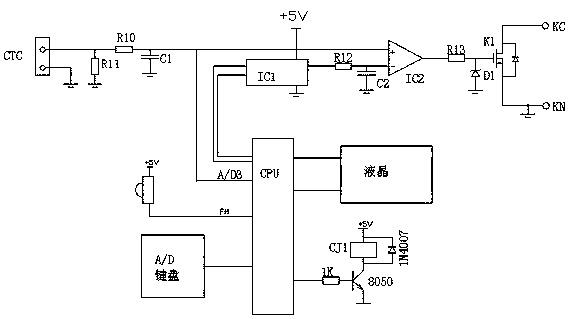

Electric car and power management device of electric car

ActiveCN103538486ARealize the function of power-on self-testImprove reliabilityElectric devicesDriver interactionsElectric vehicleEmbedded system

A power supply management device for electric vehicle and an electric vehicle with the power supply management device. The power supply management device comprises a first management module (101), a second management module (102) and a battery module (103), wherein, the first management module (101) is connected with the second management module (102) for controlling the delay power-on of the second management module (102) when the vehicle key is turned on, to implement the power-on self-test for the vehicle controller of the electric vehicle, and controlling the delay power-off of the second management module (102) when the vehicle key is turned off, to save the vehicle data information when the electric vehicle is power-off. The battery module (103) is connected with the first management module (101) and the second management module (102) respectively for supplying power to the first management module (101) and the second management module (102). The power supply management device improves the reliability and safety of the vehicle controller.

Owner:BEIQI FOTON MOTOR CO LTD

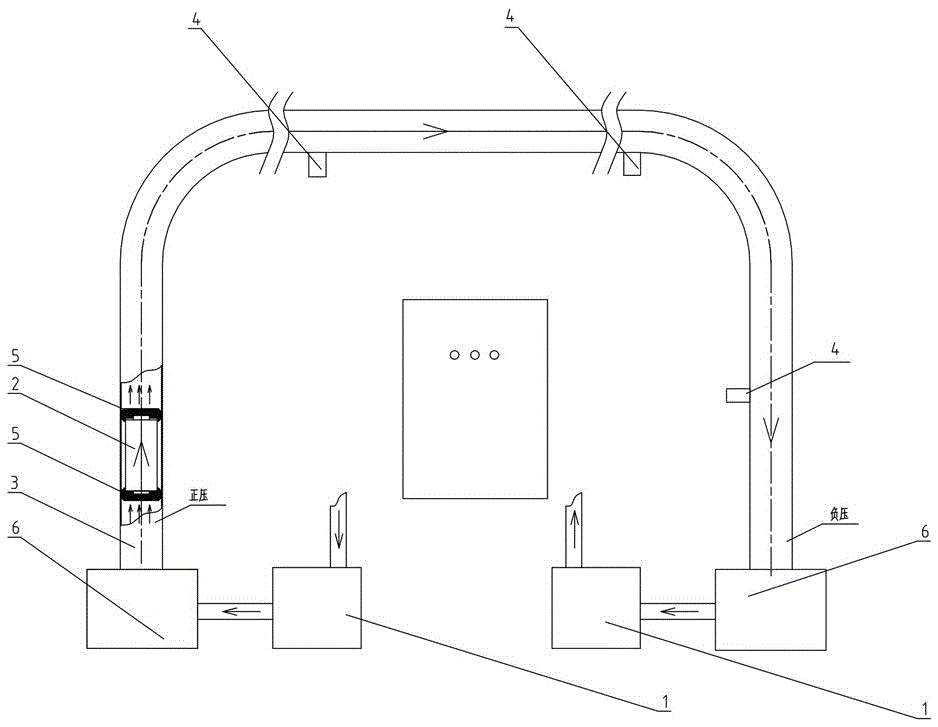

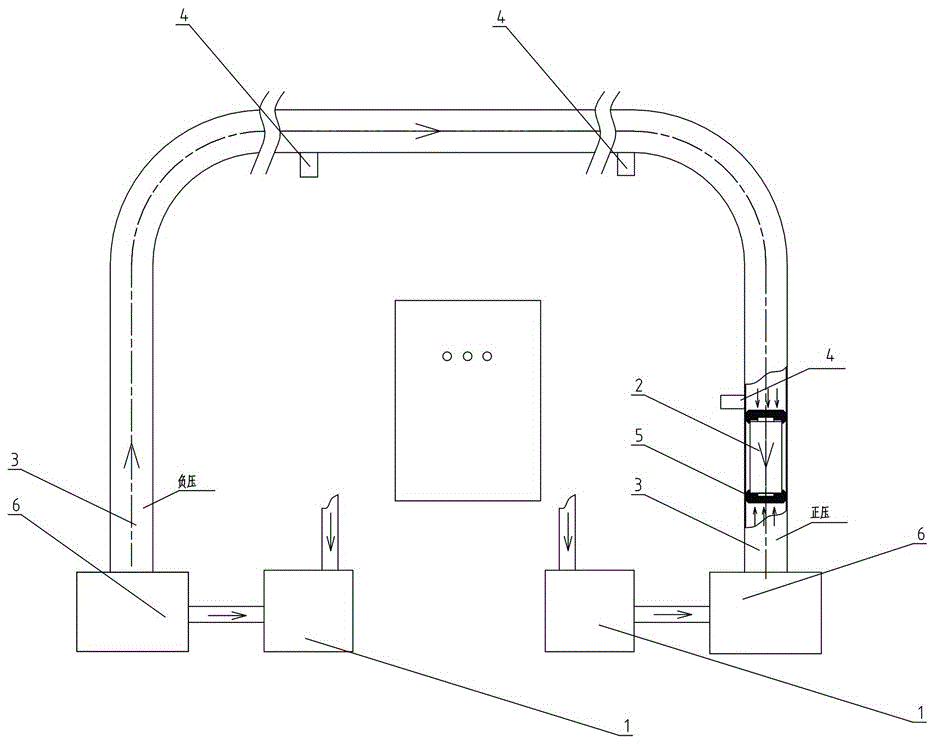

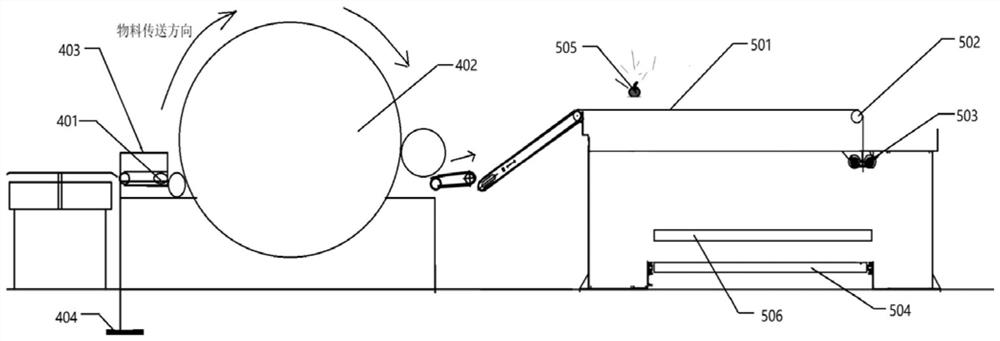

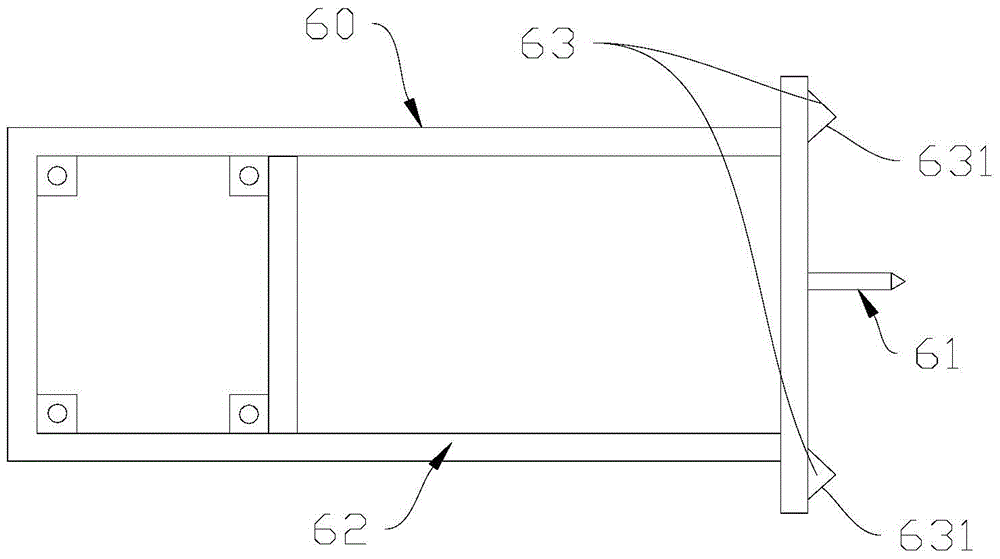

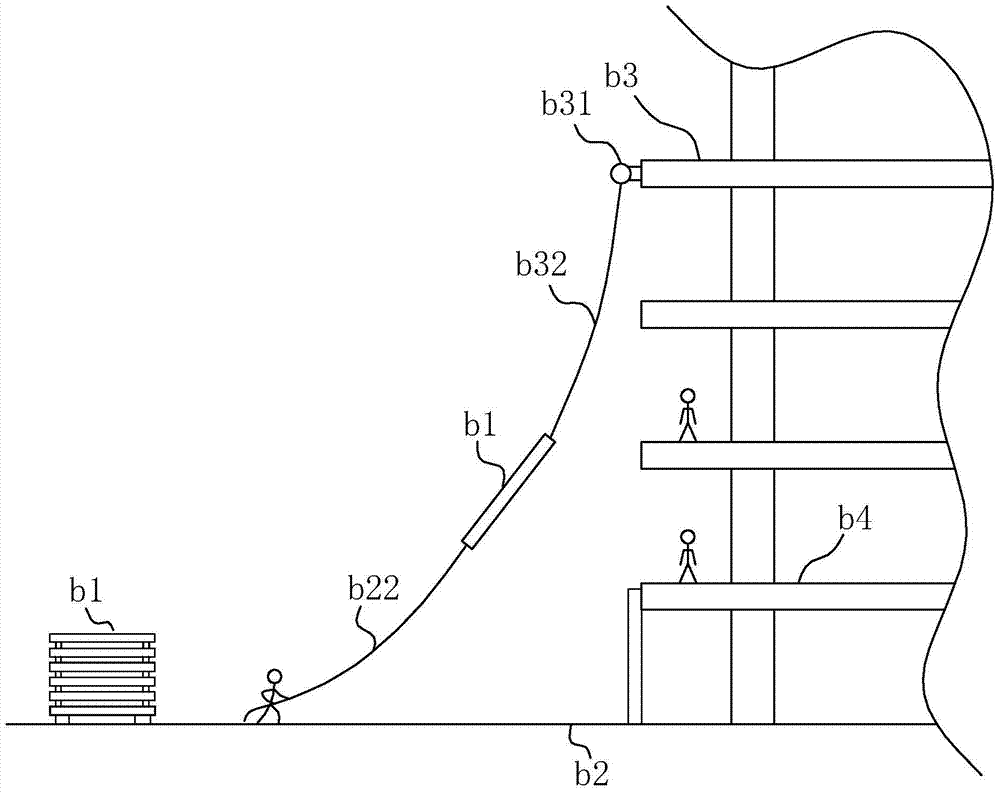

Bidirectional synergy driving material pneumatic conveying system

ActiveCN105600453AIncrease air pressure driving forceEfficient deliveryConveyorsEngineeringDriving mode

The invention discloses a bidirectional synergy driving material pneumatic conveying system which comprises driving gas source units and a transmission pipeline unit for conveying materials to be conveyed; the driving gas source units provide a blowing or suction gas source driving mode to the inside of the transmission pipeline unit to drive the materials to be conveyed to be pneumatically transmitted; two driving gas source units are respectively arranged at an initial end and a finish end of the transmission pipeline unit; the two driving gas source units are synergically matched to provide different gas source driving modes to the inside of the transmission pipeline unit, so as to reinforce a transmission speed of the materials to be conveyed at a transmission section and / or retard the transmission speed of the materials to be conveyed at a receiving section. The bidirectional synergy driving material pneumatic conveying system has the advantages that driving modes at both ends can be flexibly converted; not only can a very strong driving force be provided at the transmission section of a pipeline, but also a receiving impact force can be buffered at the receiving section of the pipeline.

Owner:HUNAN SUNDY SCI & TECH DEV

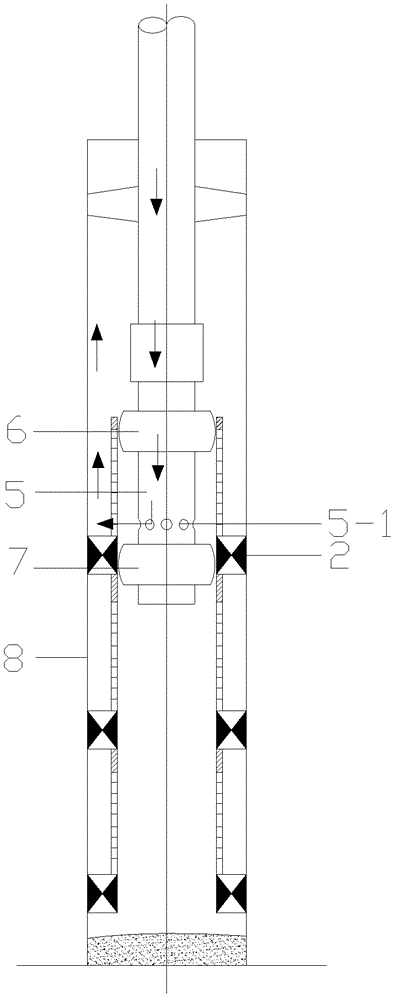

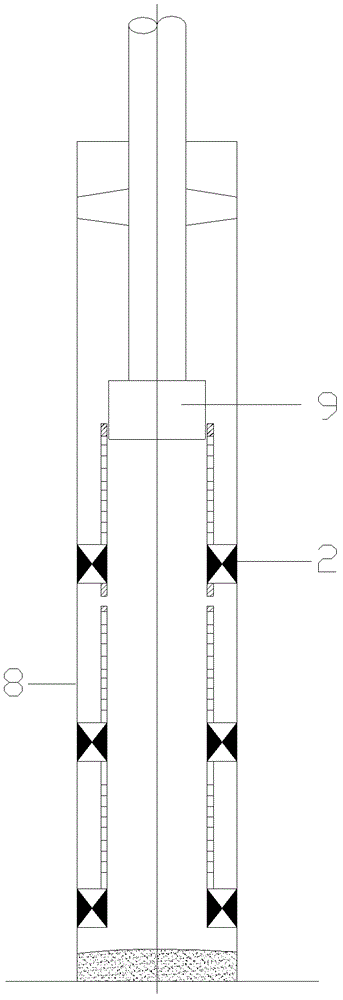

Well completing test pipe column and method for gas well

The invention provides a well completing test pipe column and method for a gas well. The pipe column comprises an oil pipe, a packer arranged on the outer wall of the oil pipe, a leak-proof device arranged at the tail end of the oil pipe and used for preventing well killing fluid in the oil pipe from leaking, and a pressure gauge arranged in an inner cavity of the leak-proof device or an inner cavity of the oil pipe. By using the pipe column, it can be ensured that gas well test and completing can be completed through one time of tripping in, it also can be ensured that the underground pressure gauge can be safely taken out, so that the pipe column can be effectively applied to the completing test of the gas well and is particularly suitable for a high-pressure gas well, the huge operationcost and the operation risk caused by operation on the pipe column are avoided, and the reliability of the pipe column is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

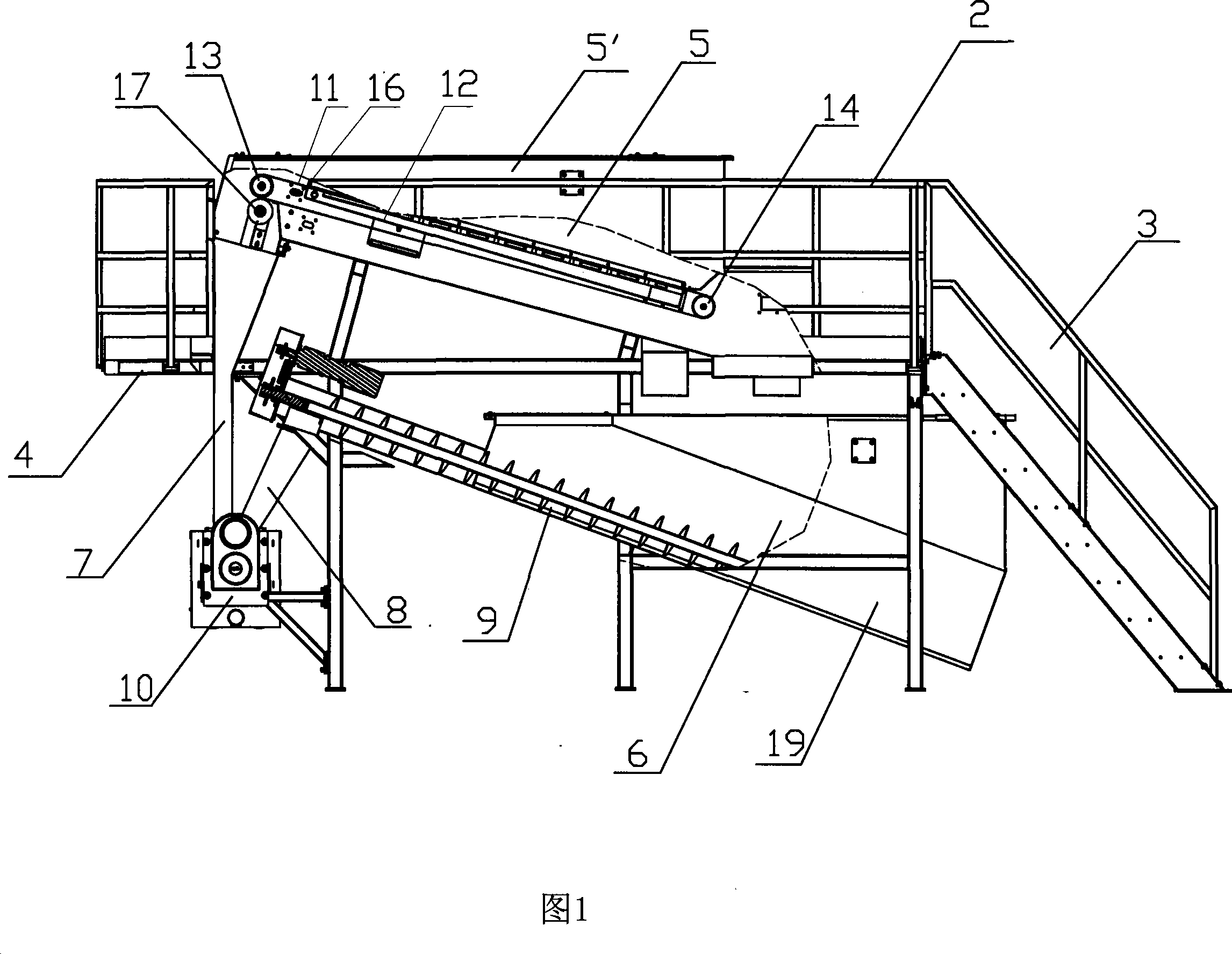

Device for treating polyester beverage bottle recycling sewage

InactiveCN101234811ASolve many problems in the recycling processAvoid secondary pollutionSludge treatment by de-watering/drying/thickeningWater/sewage treatment by flocculation/precipitationWater savingPolyester

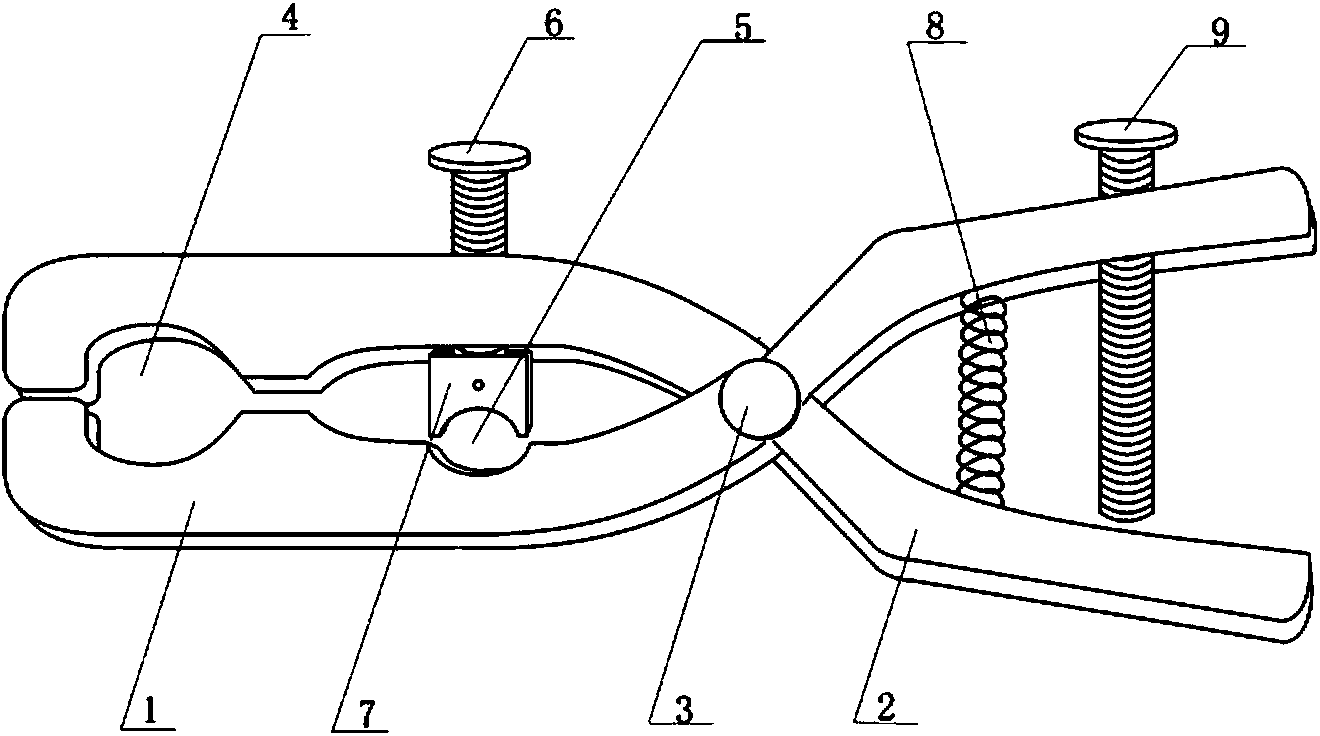

The invention relates to a sewage treatment device for reusing polyester beverage bottles, which comprises a chassis and a working platform arranged on the chassis, wherein, two sides of the work platform are provided with a guardrail, and the working platform is connected with stairs. The chassis is provided with a filtering equipment, an end of which is provided with a settling device beneath, and the other end of the filtering equipment is communicated with sludge collecting troughs; the settling device is provided with a transporting screw, an end of which is also connected with the sludge collecting troughs; the two sludge collecting troughs are both connected with a sludge presser. The sewage treatment device flocculates, settles, filters and presses the sewage generated in a cleaning process to change the sludge into clods; the pressed water is transferred to a filtering screen through a sewage pump for circulation, thus realizing reclaiming and reusing. The sewage treatment device completely solves a plurality of problems during the reusing process of beverage bottles, decreases the labor intensity, improves work efficiency, reduces work risks, saves water, solves the secondary pollution problem of sewage and waste residue completely, and meets the requirement of the development of circular economy.

Owner:杭州富兴环保机械有限公司

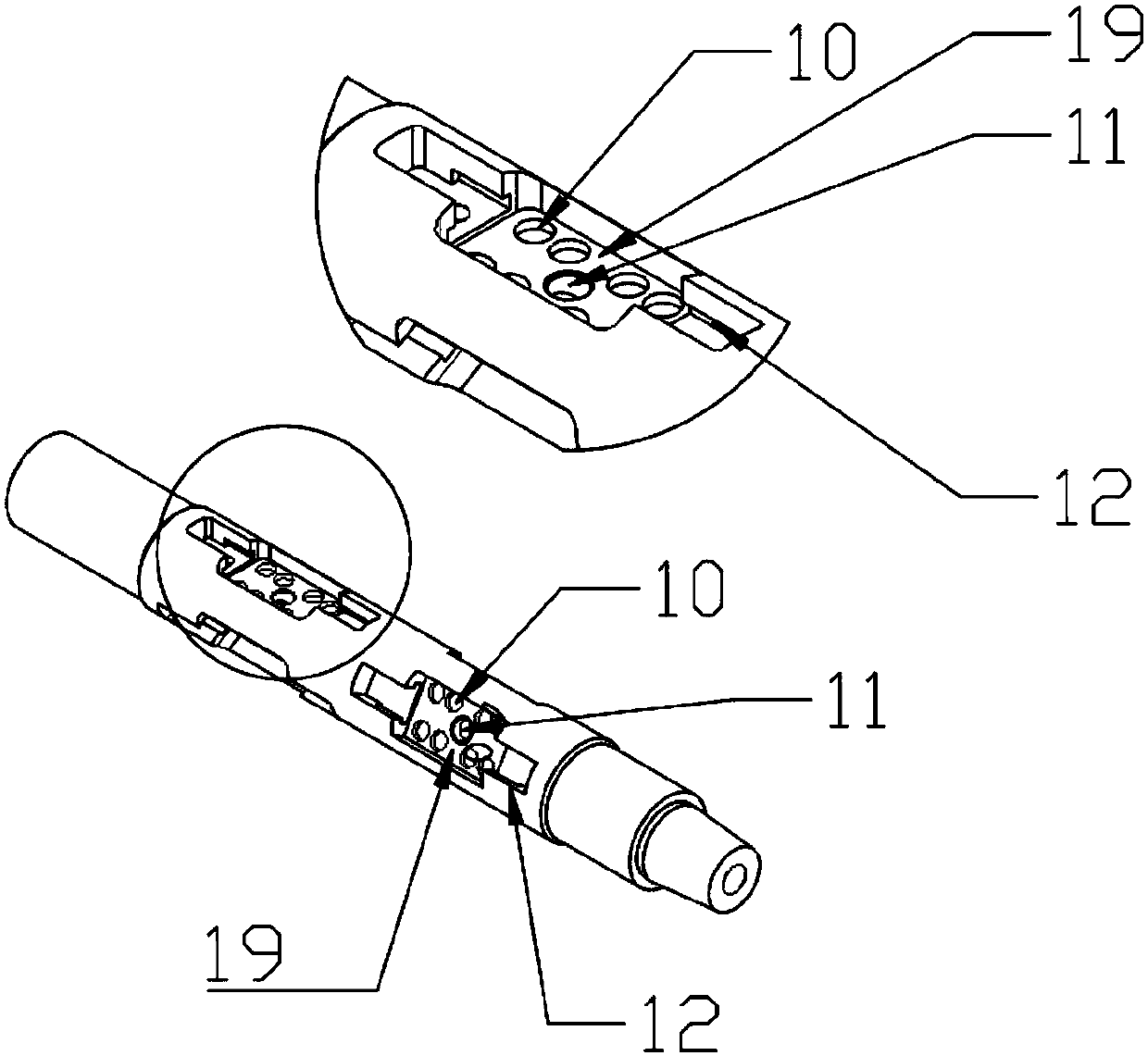

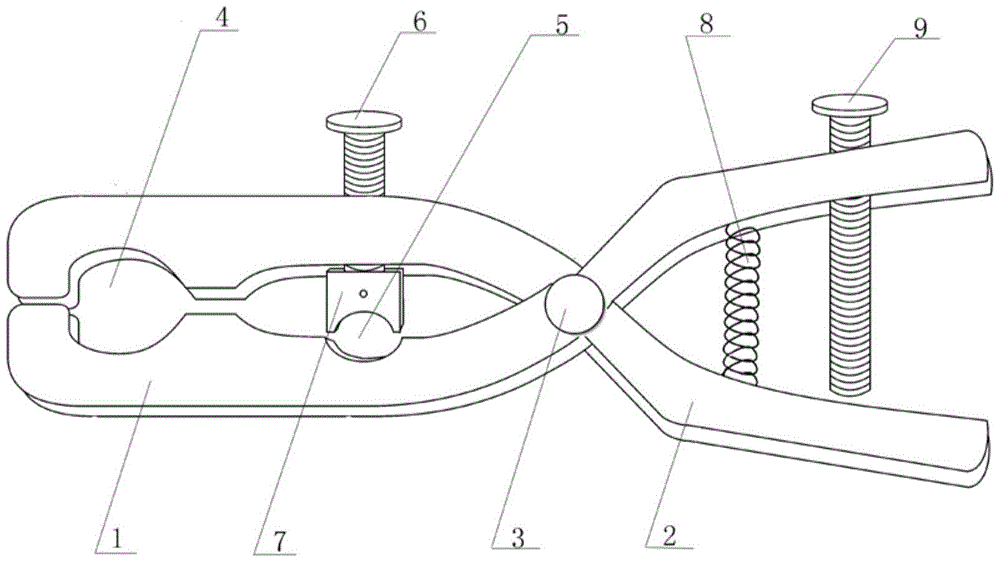

Method and device for 10 kV electrified work for connecting lead of branch connecting circuit

InactiveCN104143785AImprove live working methodsReduce labor intensityApparatus for overhead lines/cablesElectricityEngineering

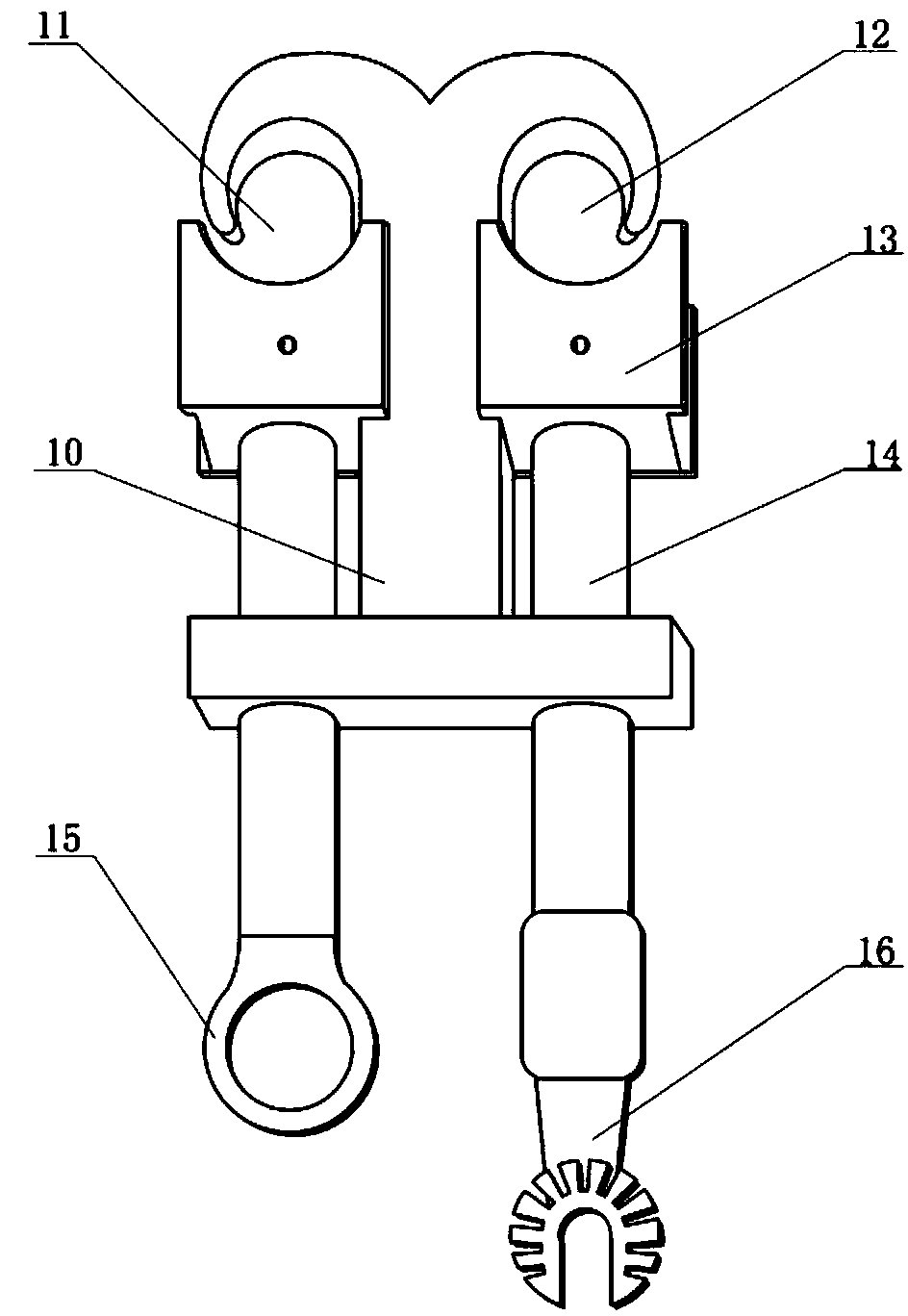

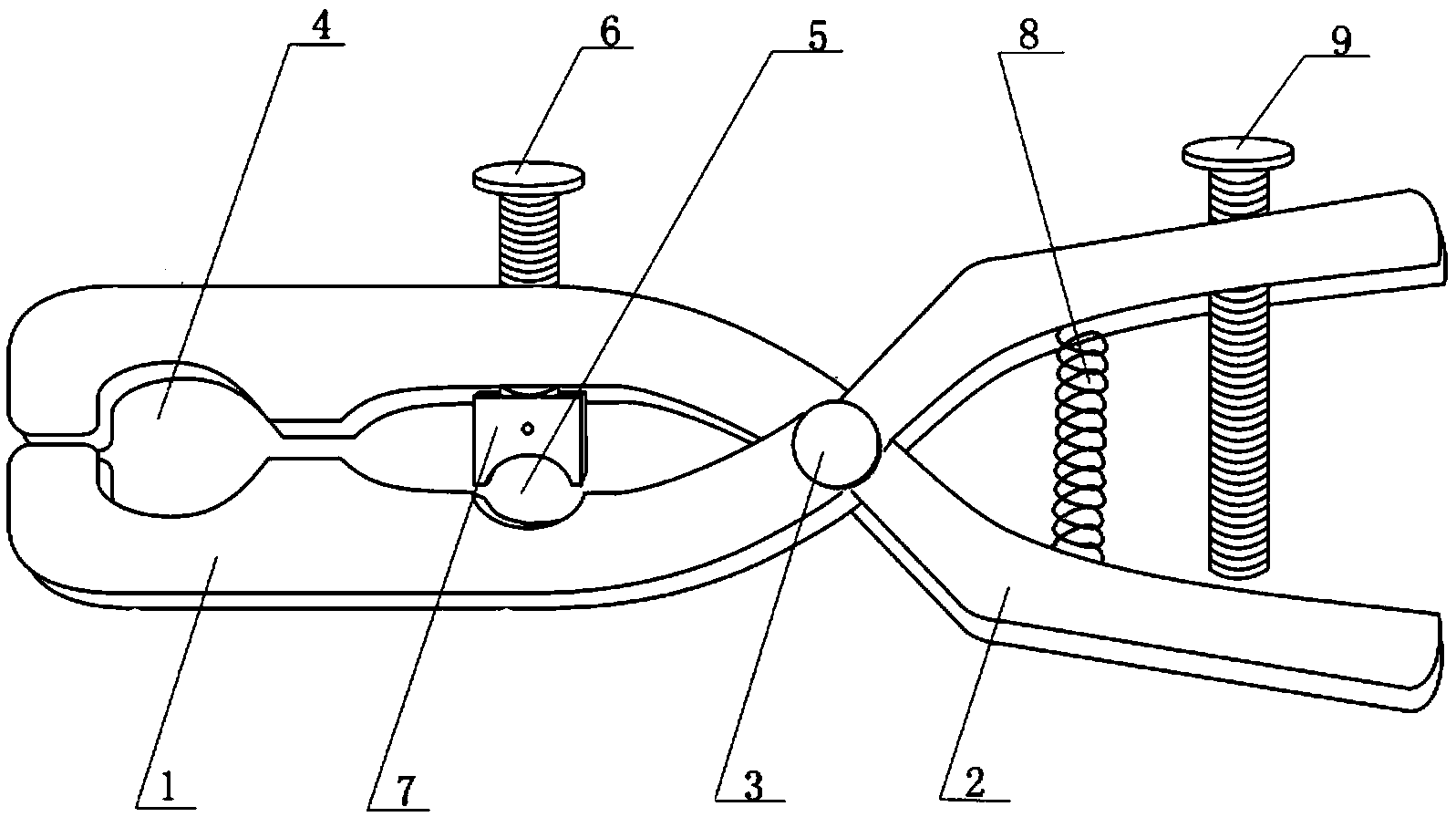

The invention discloses a method for 10 kV work for connecting a lead of a branch connecting circuit. A lead insulation fixer is used for fixing the lead and a main wire, and a double-screwing type connecting and leading wire clamp is used for conducting lead lap joint work. The lead insulation fixer is composed of a clamp body, an insulation handle and a hinge pin. The clamp body and the insulation handle which are integrated are symmetrically fixed together through the hinge pin to form a clamp-shaped structure. The double-screwing type connecting and leading wire clamp comprises a fixed hanging piece, a wire screwing mechanism and a lead screwing mechanism, the wire screwing mechanism and the lead screwing mechanism are connected with the fixed hanging piece through screws respectively. Compared with the prior art, the method has the advantages that a novel tool is adopted and the electrified working method is improved, so that labor intensity is lowered, working risks are avoided, and habituation violation work is eradicated; safety is high in practical application; the double-screwing type connecting and leading wire clamp is adopted, operation is convenient and fast, the method is suitable for an insulation glove work method and an insulation rod work method, the tool utilization amount is reduced, and the power supply reliability is improved.

Owner:STATE GRID CORP OF CHINA +1

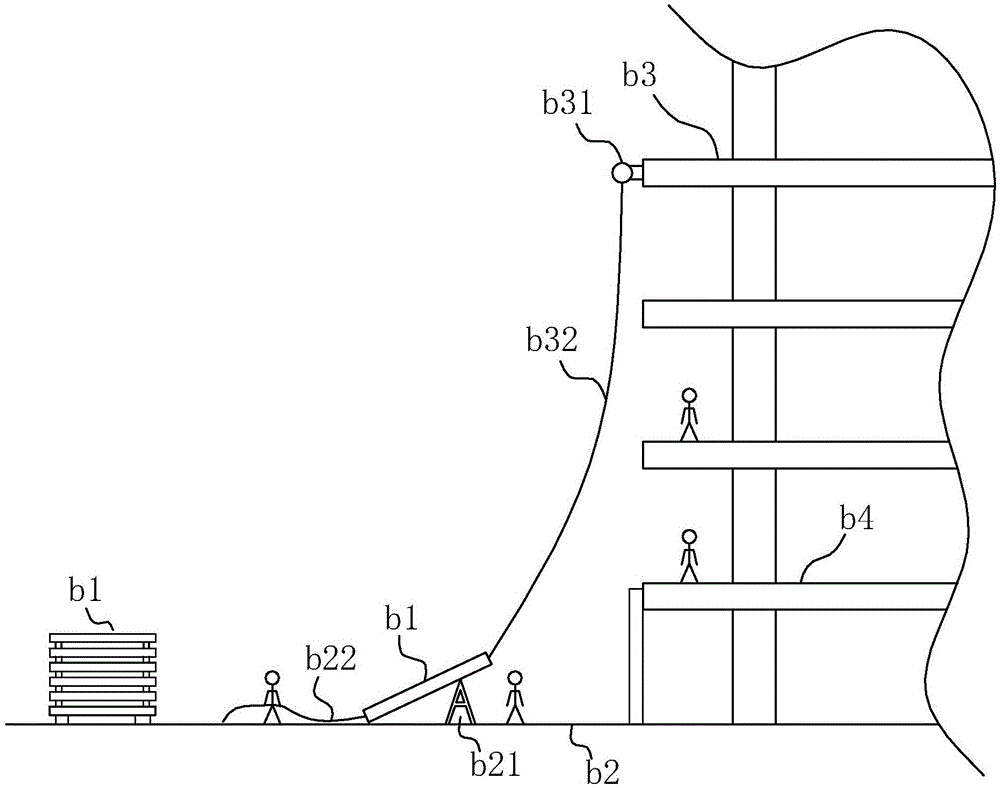

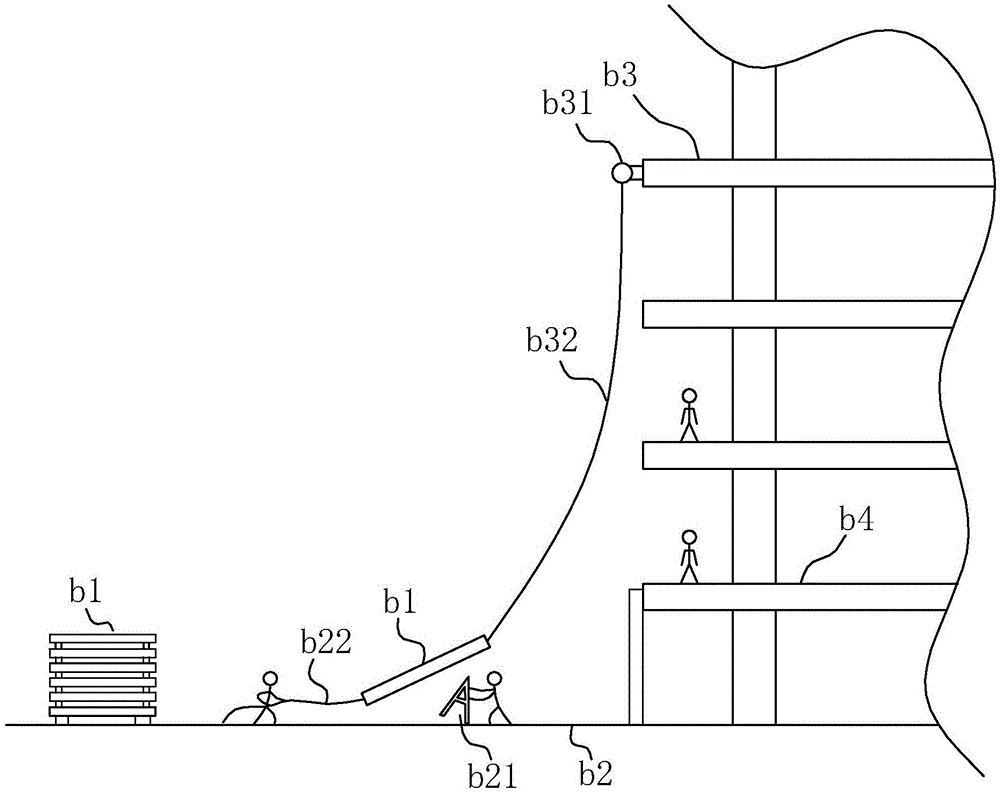

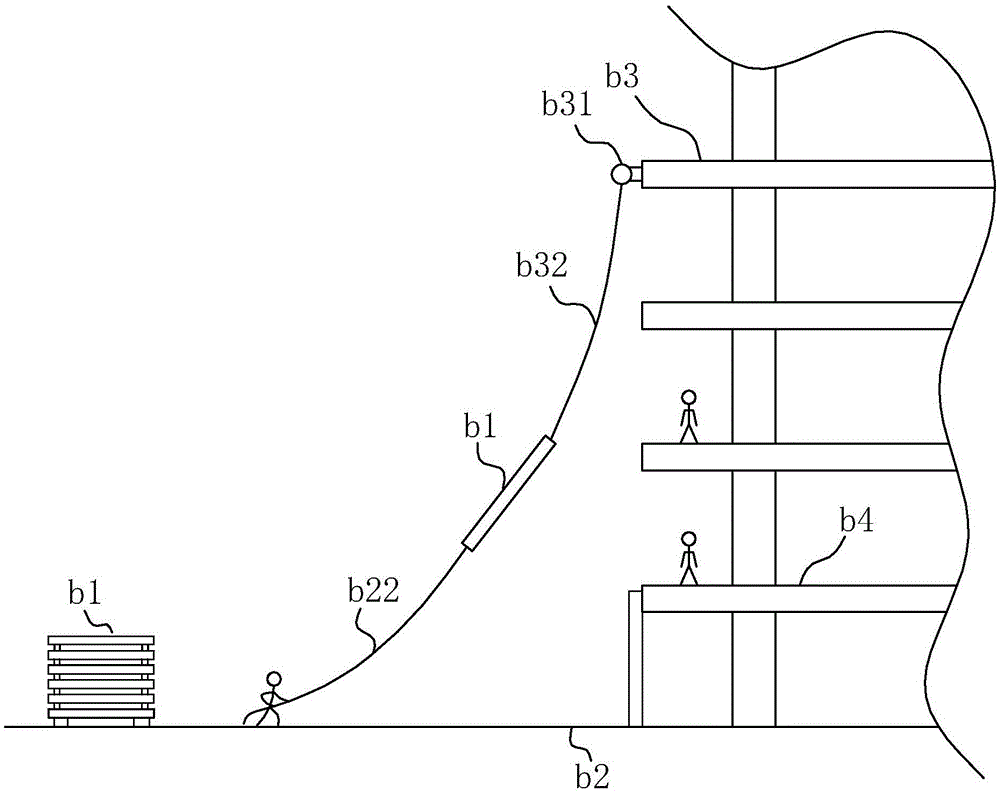

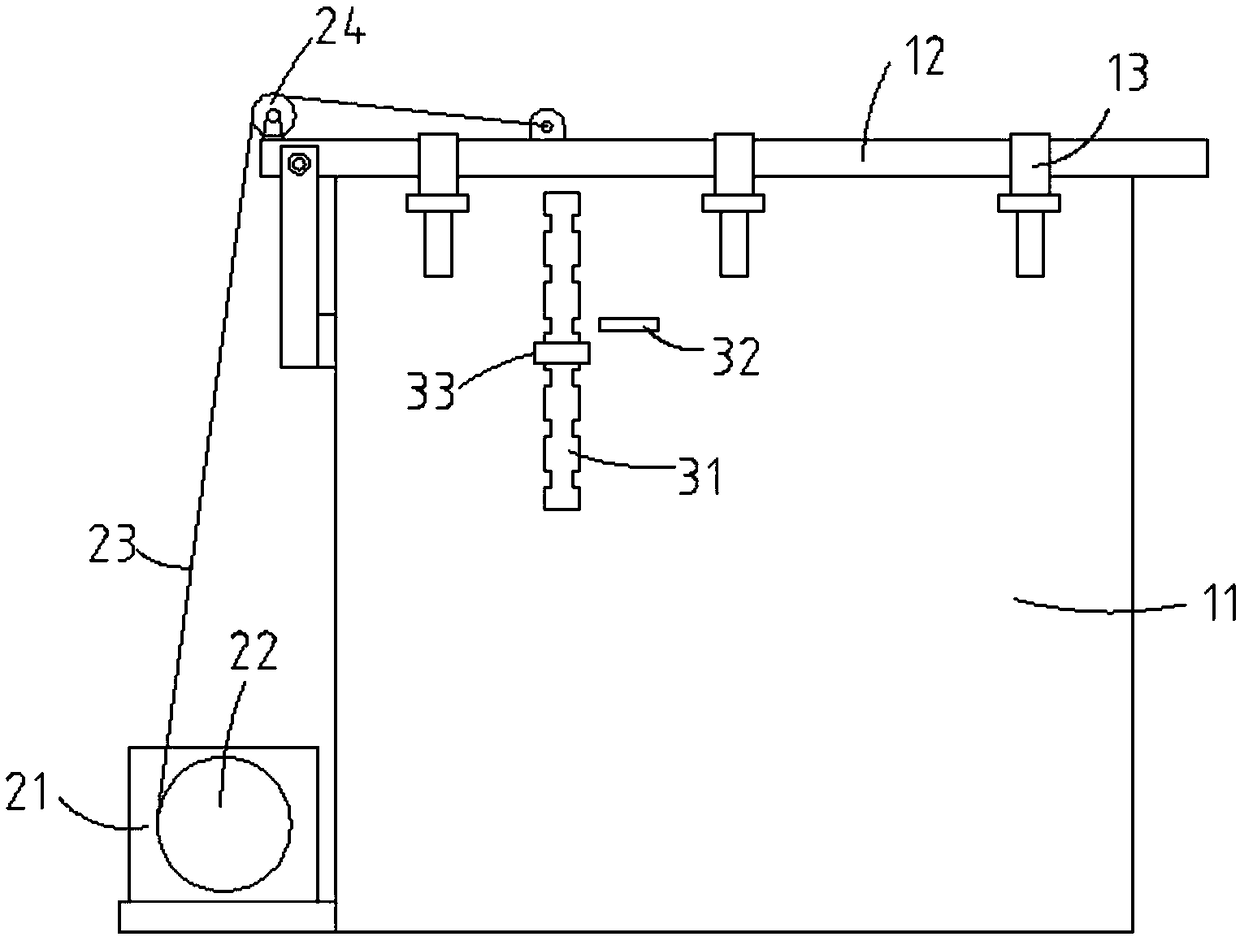

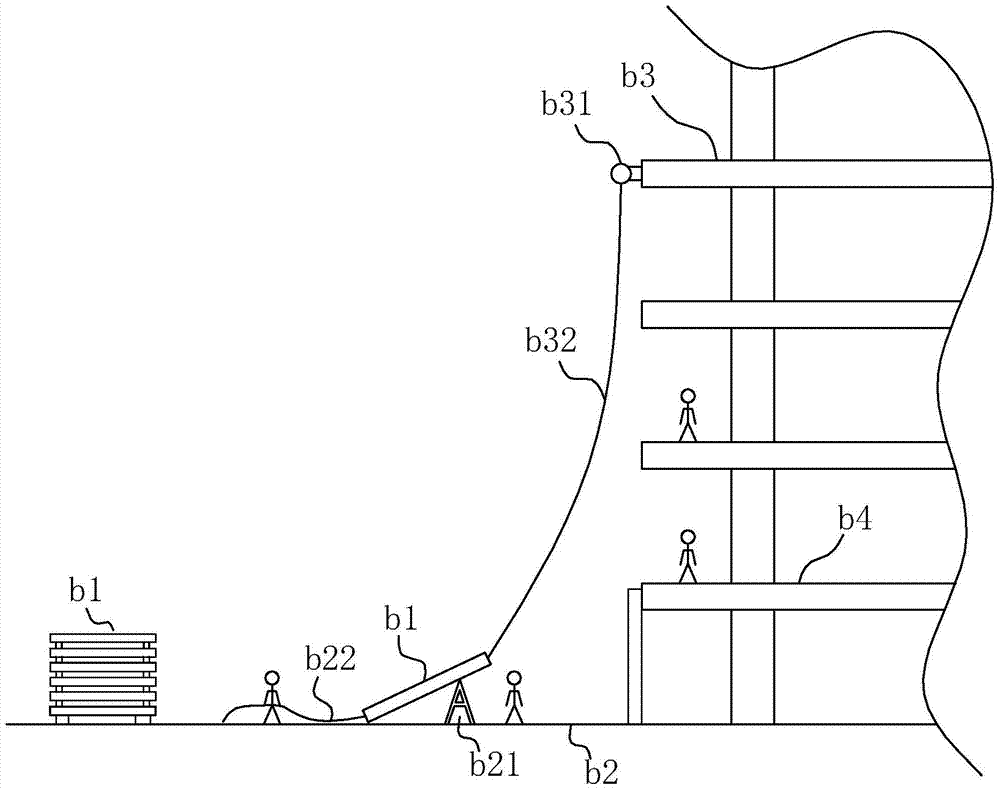

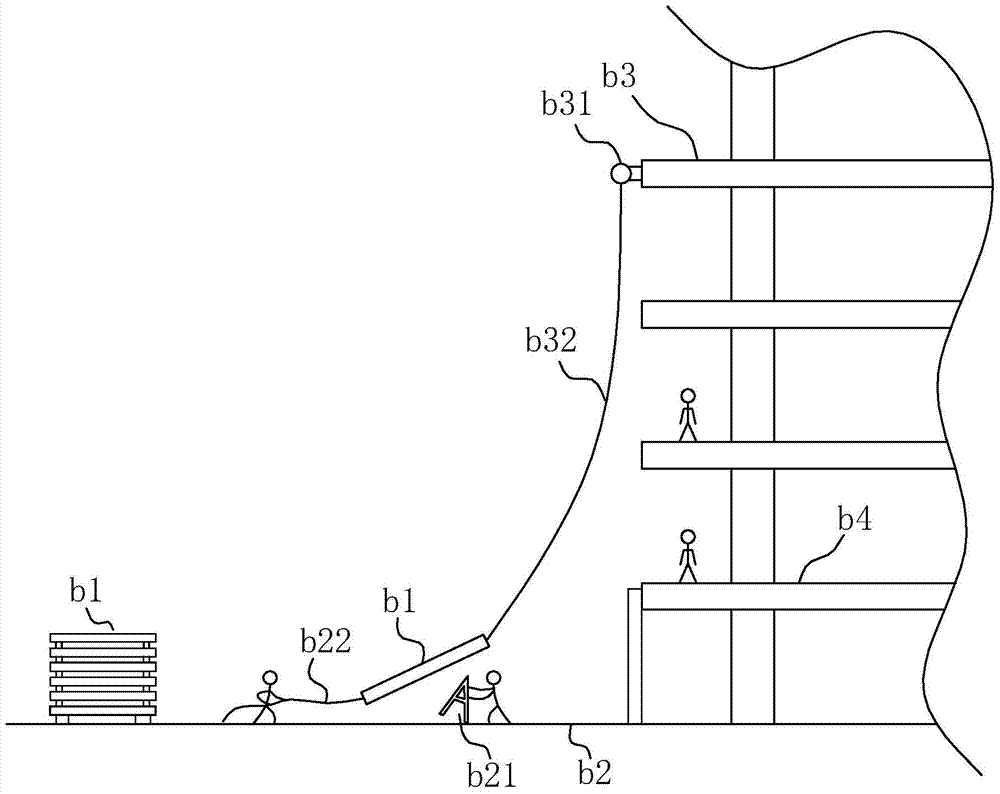

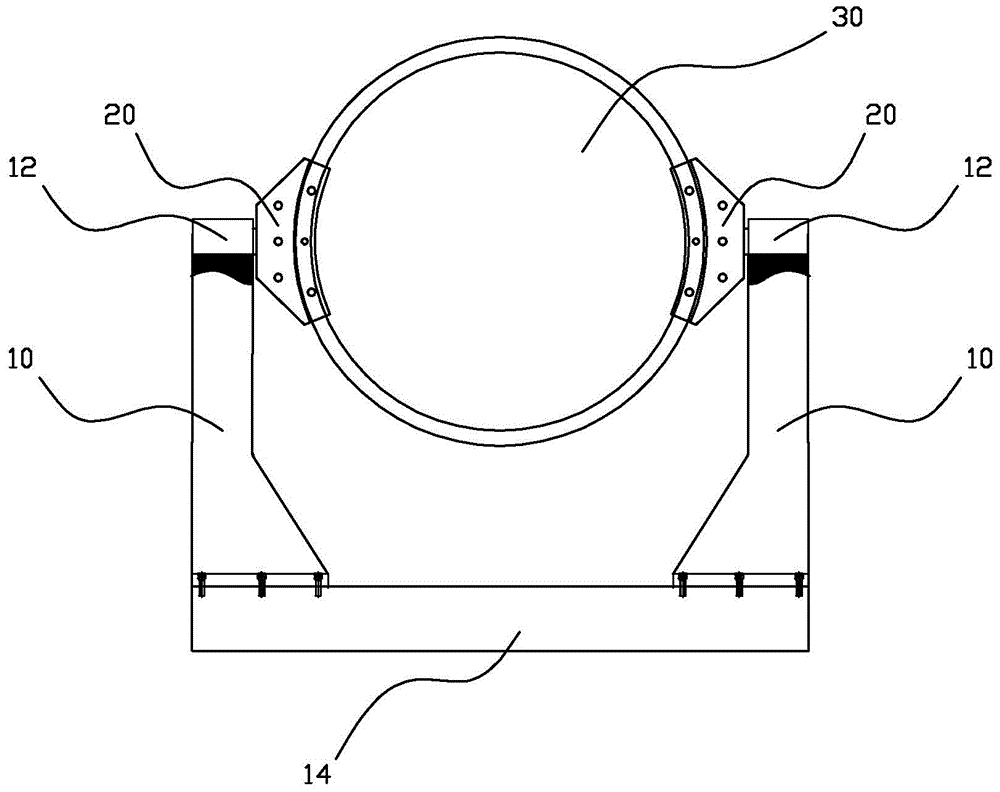

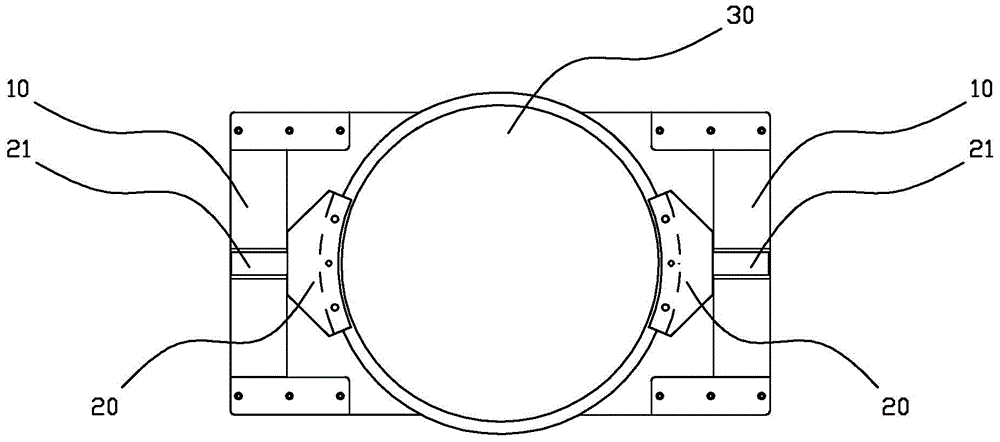

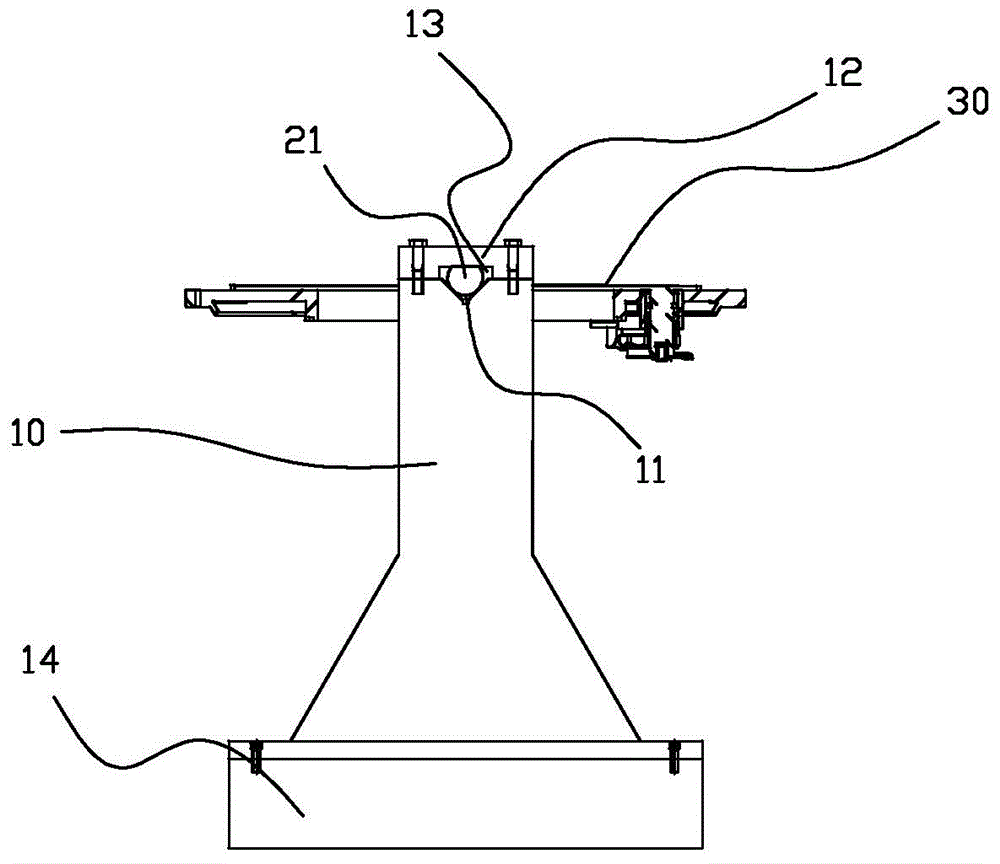

Construction method

ActiveCN105544993AAvoid job riskSlow pendulum motionWallsBuilding material handlingPendulumIndustrial engineering

Provided is a construction method and a carrier. A linear sliding rail and a sliding gasket pad part are additionally arranged on the carrier, the existing operation process of supporting unit plates by operators is replaced. The unit plates continuously bear supporting force of the linear sliding rail and the sliding pad part in the transition process that the unit plates become inclined from horizontal and then become vertical again, operation risks due to the fact that the operators are too close to the edge of a hoisting layer are avoided, meanwhile, pendulum motion generated when the operators instantly release the unit plates in the traditional hoisting process is buffered, the hoisting process of the unit plates is stable, and convenience and reliability are achieved.

Owner:JIANGSU JIAZE CONSTR CO LTD

High-speed mixer for easy opening and closing

InactiveCN108905871ARealize automatic opening and closingReduce work intensityTransportation and packagingMixer accessoriesEngineeringMechanical engineering

The invention discloses a high-speed mixer for easy opening and closing. A sealing cover is hinged to a cylinder of the high-speed mixer, a motor is placed outside the cylinder of the high-speed mixer, a rotating shaft of the motor is fixedly connected with a take-up reel, a reversing wheel is rotatably connected to the sealing cover, a pulling rope is placed on one side of the reversing wheel, one end of the pulling rope is fixedly connected with the sealing cover, and the other end is wound around the take-up reel; a support rod is inserted on the outer wall of the cylinder of the high-speedmixer, a positioning insert plate is inserted on the support rod, and the positioning insert plate is positioned on the cylinder of the high-speed mixer. The high-speed mixer can realize the automatic opening and closing of the sealing cover of the high-speed mixer, and the sealing cover of the conventional high-speed mixer needs to be manually moved to realize cleaning of the cylinder of the high-speed mixer. The high-speed mixer can effectively reduce the work intensity of workers, improves work efficiency, and avoids work risks.

Owner:南京真宸科技有限公司

Drug delivery device for fumigating granary and drug delivery method

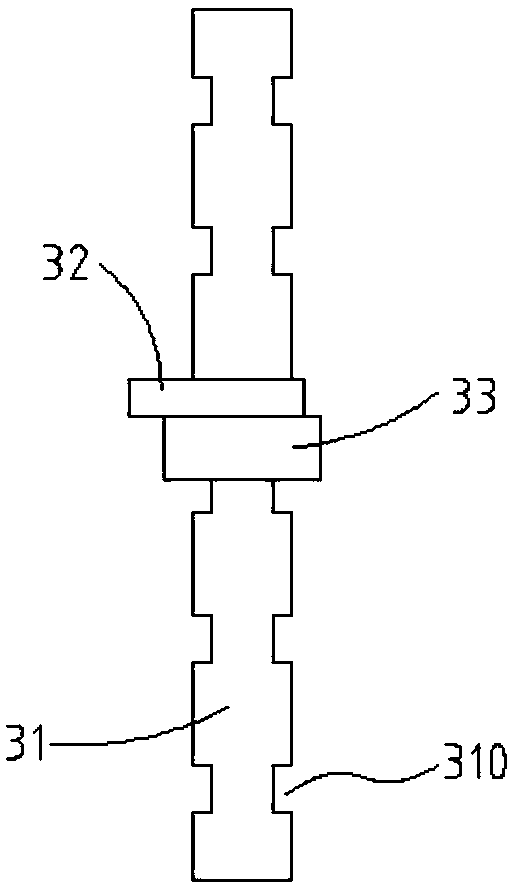

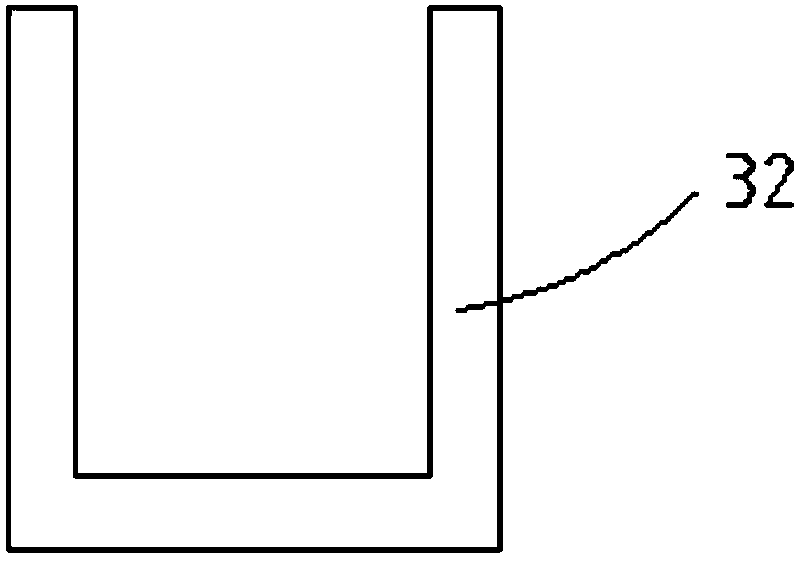

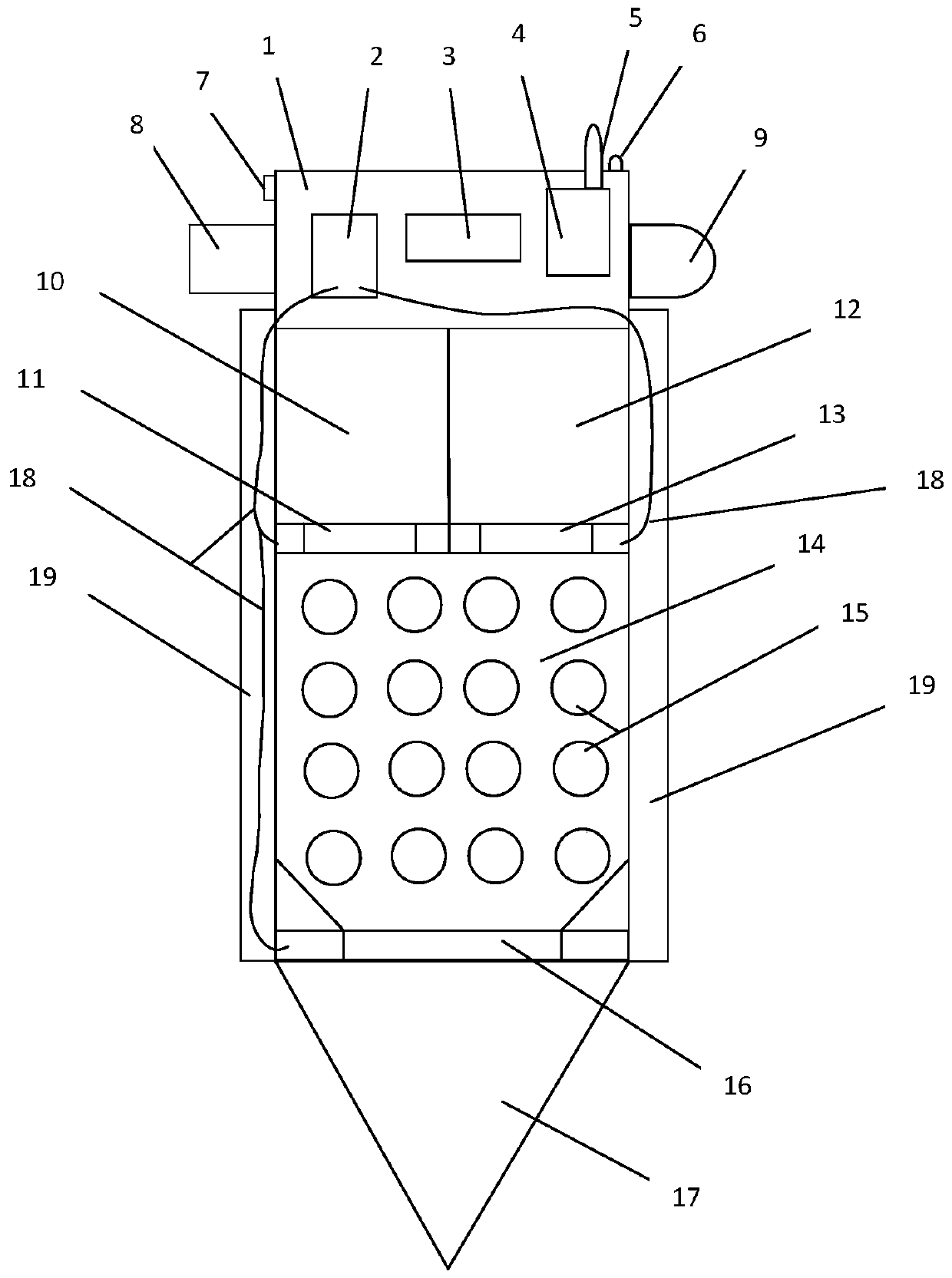

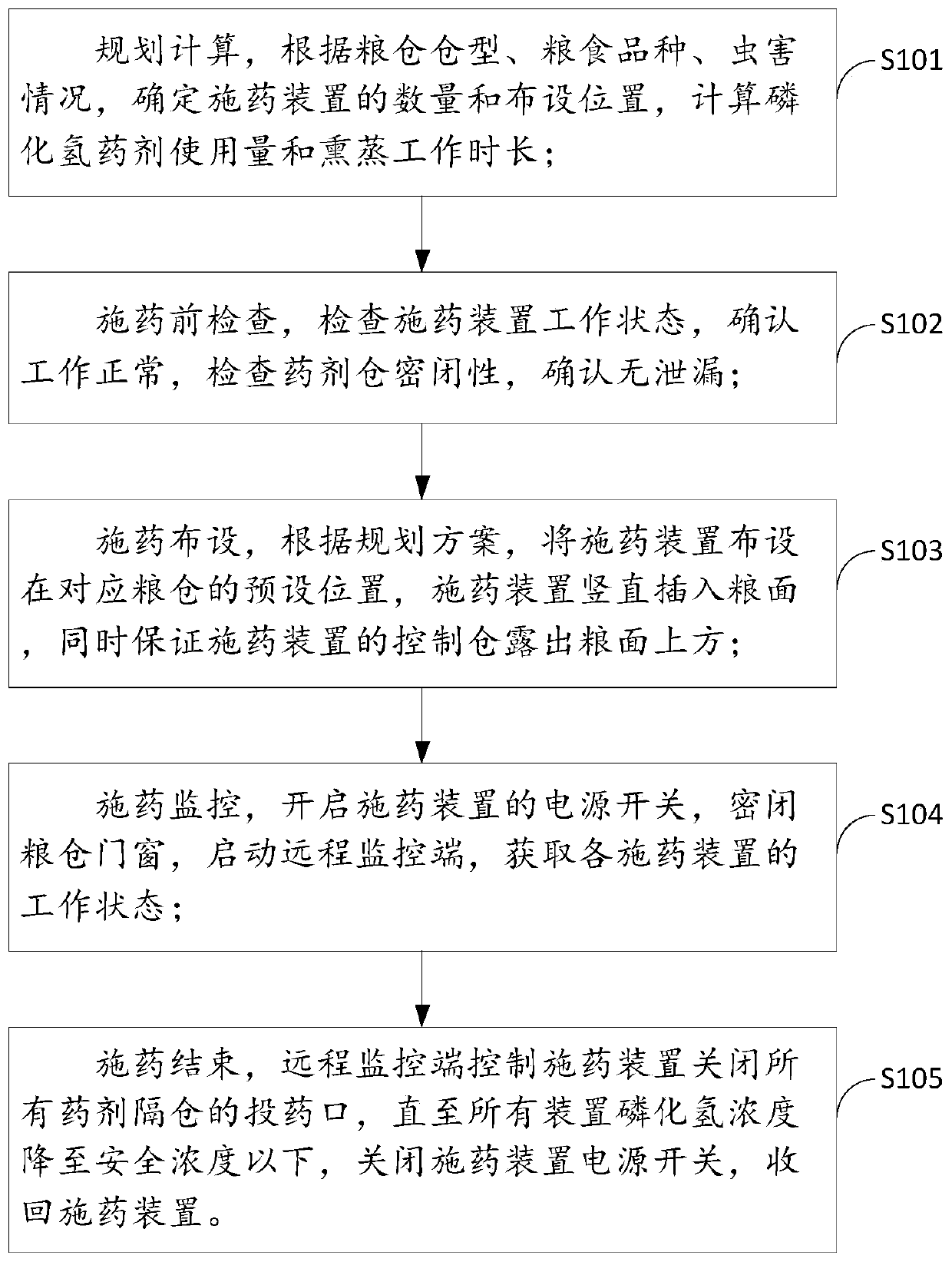

PendingCN109730051AAvoiding Risks to Personnel OperationsImprove the effect of fumigation and insecticideFumigatorsDrug deliveryMaterial resources

The invention discloses a drug delivery device for fumigating a granary. The drug delivery device comprises a control bin, a medicament bin and a drug delivery bin below the medicament bin, wherein aresidue receiving bin is arranged below the drug delivery bin, a control module, a power supply module, a wireless communication module and a wireless communication antenna are arranged in the controlbin. The drug delivery device is in communication interconnection with a remote monitoring terminal in a wireless communication manner and can be remotely monitored. The invention further discloses adrug delivery method based on the drug delivery device. According to the drug delivery device, the automatic hydrogen phosphide fumigation can be realized without unattended operation, the concentration of hydrogen phosphide gas in the granary can be monitored in real time, the automatic supplemental drug delivery can be carried out, the drug delivery concentration of the whole fumigation cycle can be guaranteed, the fumigation precision is increased, the personnel security is guaranteed, the manpower and material resources are saved, and the device has good economic and social benefits.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

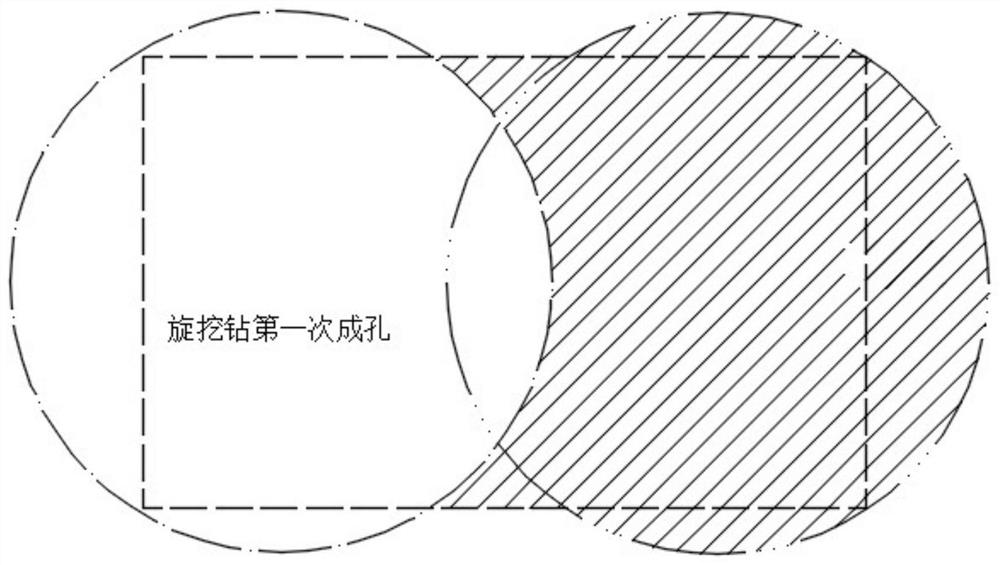

Efficient and safe fast hole formation method adopting rotary excavating machinery for slide-resistant piles

ActiveCN110820729AIncrease construction costsEasy to operateRotary drillingRotary-drilling machinesRebarEnvironmental geology

The invention discloses an efficient and safe fast hole formation method adopting rotary excavating machinery for slide-resistant piles. The method comprises the following steps that A, paying off andpositioning of slide-resistant pile holes or site lofting is carried out; B, hole digging by a rotary excavating pile machine is carried out according to pile core serial number and position or the holes are formed adopting rotary excavating machinery; C, excess earthwork on a side wall is cleaned and sediment at the bottom of the pile is removed; D, a reinforcement cage is lowered; and E, the slide-resistant piles are formed through pouring concrete. According to the efficient and safe fast hole formation method adopting rotary excavating machinery for the slide-resistant piles, the problemsthat the efficiency of manual hole digging pile breaking into a rock is low, no blasting excavation is allowed under complex environment and the hole formation construction is very difficult are solved, on the one hand, the fact that hole formation adopting machinery can be carried out without using a pile casing and retaining wall is realized, so that the construction cost is greatly reduced; and on the other hand, the slide-resistant pile construction is completed quickly in the limited time when the self-stabilizing capacity of a hole wall after hole formation adopting machinery supports until the concrete pouring forming, and the construction safety and quality are ensured.

Owner:YUNNAN JIANTOU FOUND ENG CO LTD

Method and device for 10 kV electrified work for breaking lead on falling type fuse

ActiveCN104143784AReduce labor intensityAvoid job riskApparatus for overhead lines/cablesIndustrial engineeringUltimate tensile strength

The invention relates to a method and device for 10 kV electrified work for breaking a lead on a falling type fuse. A lead insulation fixer is adopted for fixing the lead and a main wire, and the method and device are suitable for the work manner that a lead connecting clamp is adopted in lead lap joint. The lead insulation fixer is composed of a clamp body, an insulation handle and a hinge pin. The clamp body and the insulation handle which are of the integral type are symmetrically fixed together through the hinge pin, and a clamp-shaped structure is formed. A wire fixing groove and a lead fixing groove are formed in the clamp body. Compared with the prior art, the method and device for the 10 kV electrified work have the advantages that a novel tool is adopted and the electrified working method is improved, so that labor intensity is lowered, working risks are avoided, and habituation violation work is eradicated; in practical application, the safety accident rate of 10 kV electrified work for breaking the lead on the falling type fuse more than 200 times all the year round is zero, and safety is high; operation is convenient, working efficiency is improved, the method and device for the 10 kV electrified work are suitable for an insulation glove work method and an insulation rod work method, the tool utilization amount is reduced, and the power supply reliability is improved.

Owner:ANSHAN POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER COMPANY +1

Automatic material loading and unloading mechanical arm

PendingCN109015611AQuick loading and unloadingReduce manual operationsProgramme-controlled manipulatorBall screwEngineering

The invention discloses an automatic material loading and unloading mechanical arm and aims to provide the mechanical arm capable of clamping workpieces rapidly. The automatic material loading and unloading mechanical arm is characterized by comprising a base, the base is provided with a material loading mechanism, one side of the material loading mechanism is provided with a first supporting plate fixed to the base, the first supporting plate is provided with a first driving motor fixedly connected, an output shaft of the first driving motor is provided with a rolling-ball screw rod, the other end of the rolling-ball screw rod is fixedly connected with a second supporting plate, two sides of the screw rod are provided with supporting racks fixed with the first supporting plate and the second supporting plate, the rolling-ball screw rod is provided with a sliding block, two sides of the sliding block are provided with an extension plate fixedly connected, the supporting racks run through the extension plate, the side, close to the material loading mechanism, of the sliding block is provided with a fixed plate fixedly connected, the fixed plate is provided with a grabbing mechanism,and one side of the grabbing mechanism is provided with a driving mechanism capable of moving the grabbing mechanism front and back.

Owner:WUXI XINGUANG COMP INSTALLATION

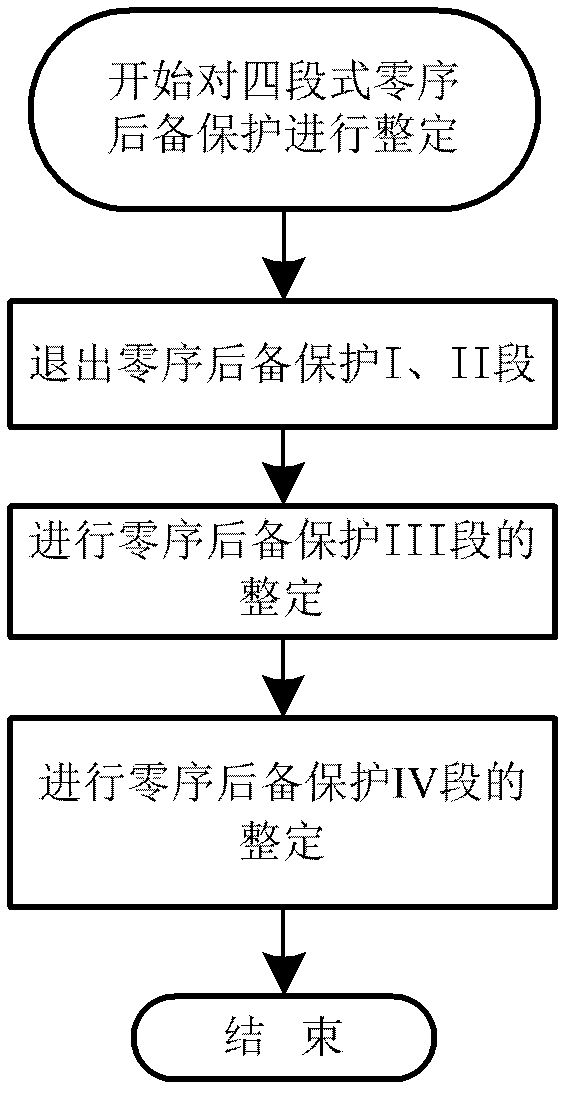

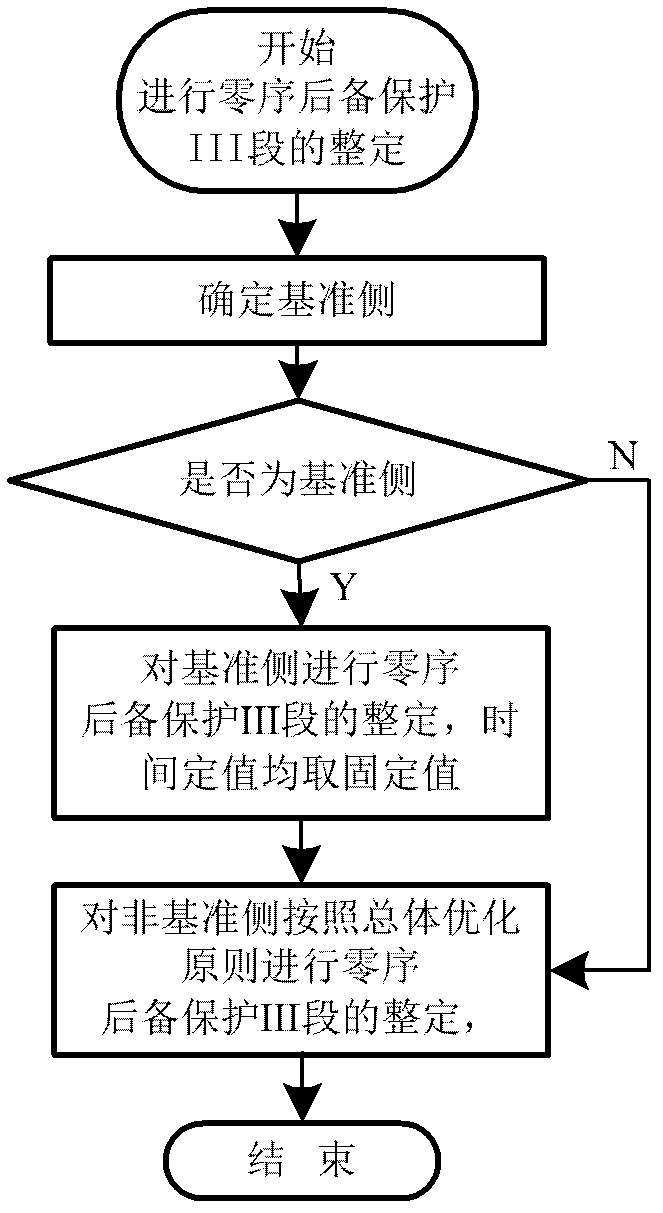

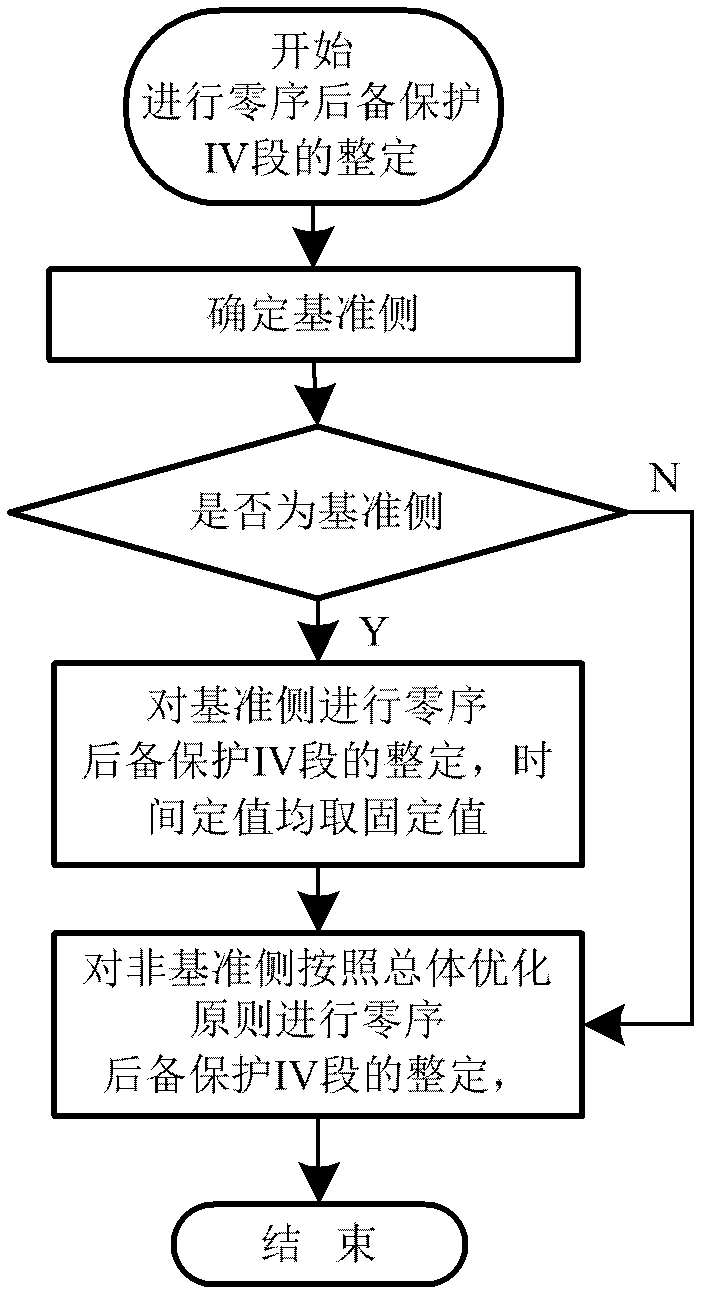

Zero-sequence backup protection setting method for ultra-high voltage transmission line

ActiveCN102545173AImprove adaptabilityGuaranteed stabilityEmergency protective circuit arrangementsUltra high voltagePower grid

The invention provides a zero-sequence backup protection setting method for an ultra-high voltage transmission line. The method comprises the following steps of: (1) configuring zero-sequence backup protection in a four-section form, deleting a zero-sequence backup protection I section and a zero-sequence backup protection section II, and reserving a zero-sequence backup protection section III and a zero-sequence backup protection section IV; (2) dividing the zero-sequence backup protection section III into a reference-side zero-sequence backup protection section III and a non-reference-side zero-sequence backup protection section III and respectively performing setting by utilizing a reference side; and (3) dividing the zero-sequence backup protection section IV into a reference-side zero-sequence backup protection section IV and a non-reference-side zero-sequence backup protection section IV and respectively performing setting by utilizing the reference side, wherein the reference side refers to any station end, of which an opposite station end adopts optical differential protection for all outgoing lines, on the transmission line. On the premise of no increase of the security risk of a power grid, the adaptability of a constant value to power grid change is improved, the protection constant value regulation caused by coordinating with constant value regulation is reduced and the workload of the setting calculation is greatly reduced simultaneously.

Owner:GUANGDONG POWER GRID POWER DISPATCHING CONTROL CENT +1

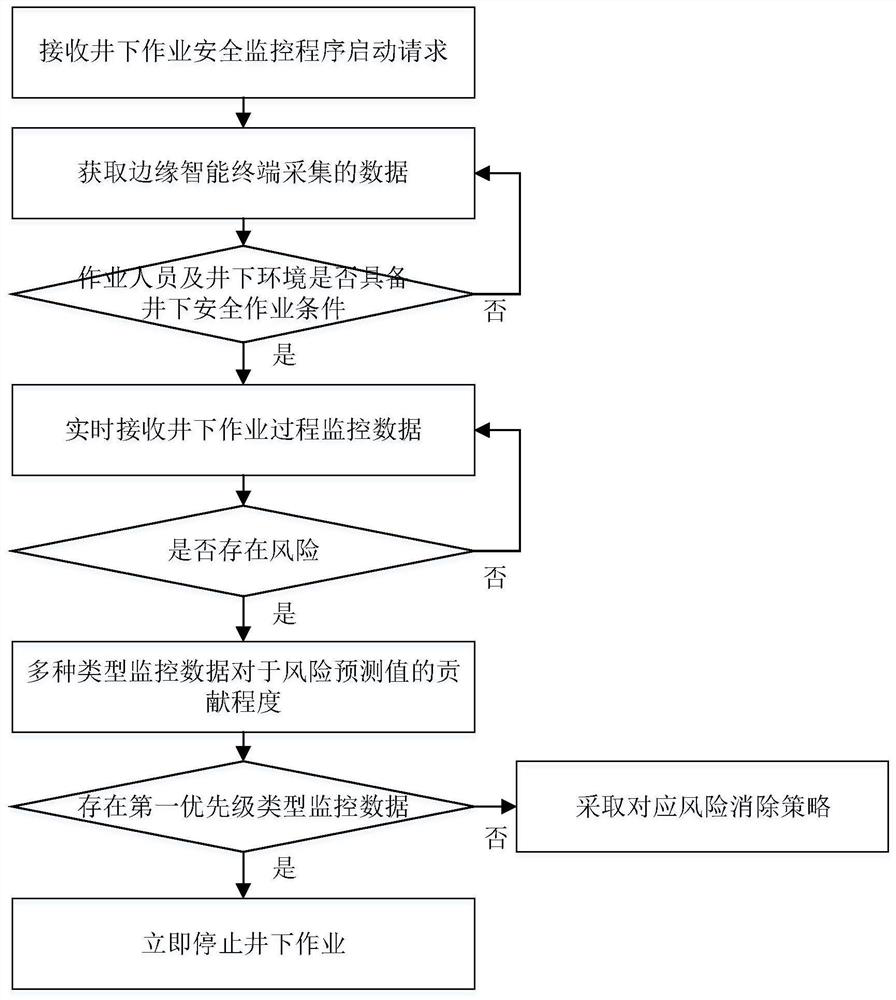

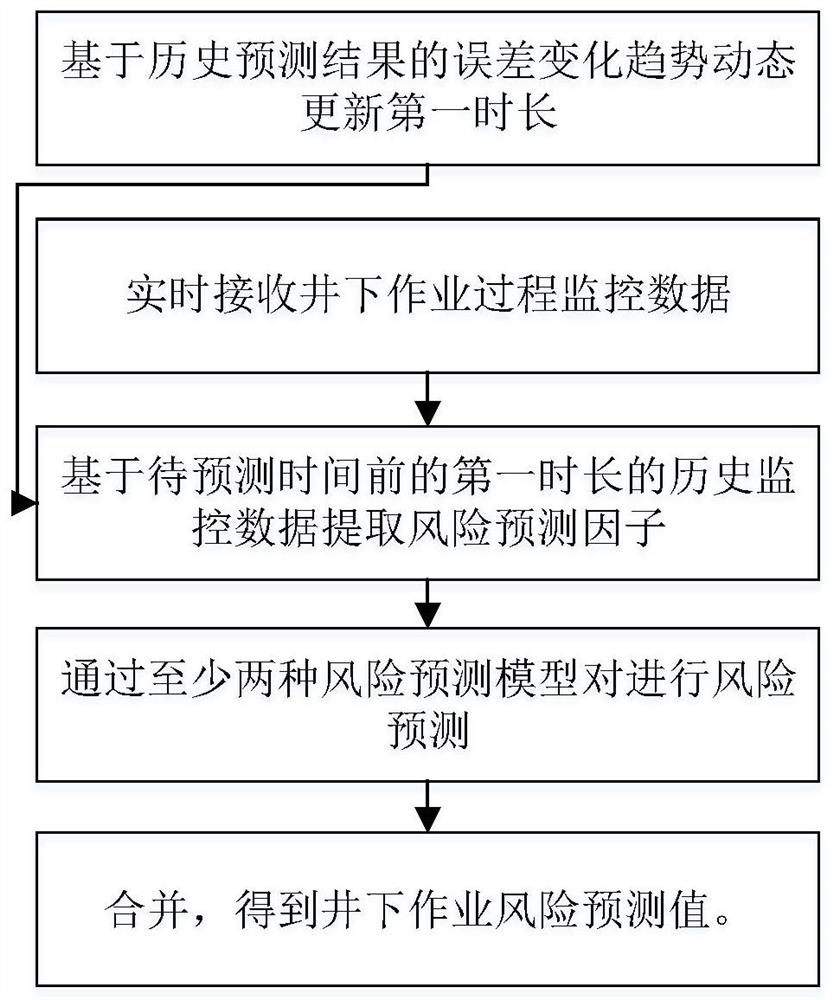

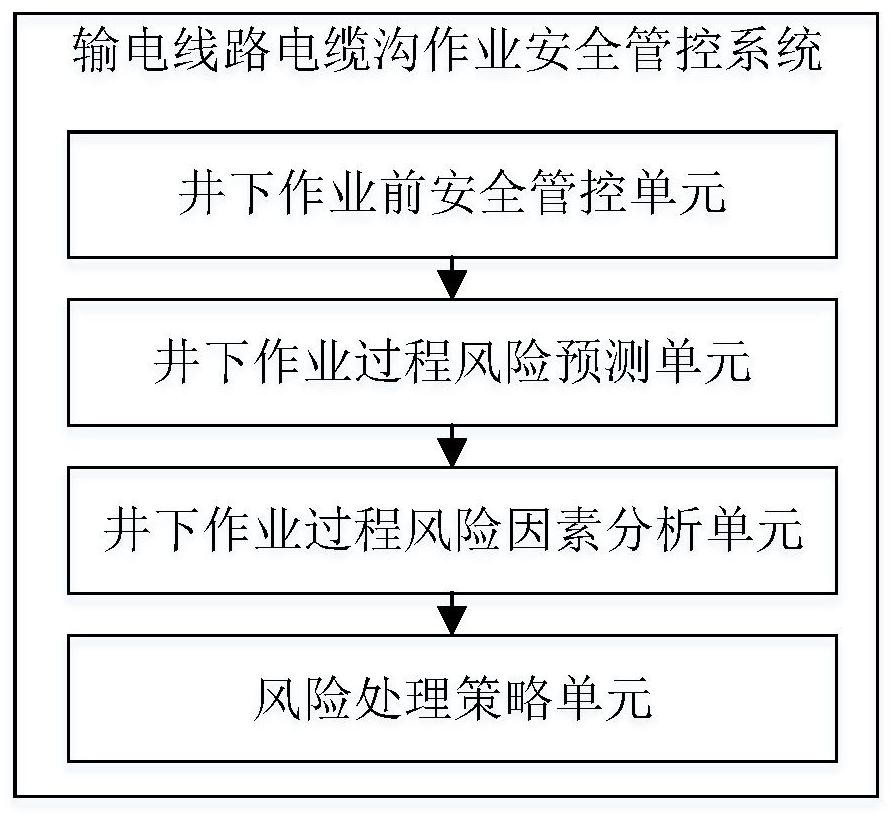

Power transmission line cable trench operation safety management and control method and system based on edge computing

PendingCN113743726AImprove the efficiency of operation safety management and controlAvoid job riskResource allocationResourcesEdge computingData acquisition

The invention discloses a power transmission line cable trench operation safety management and control method and system based on edge computing. The method comprises the steps of obtaining data collected by an edge intelligent terminal and determining that an operator and an underground environment have underground safety operation conditions; sending an underground operation process monitoring data acquisition instruction to the edge intelligent terminal, receiving underground operation process monitoring data in real time, and performing underground operation risk prediction; when it is determined that there is a risk, analyzing contribution degrees of various types of monitoring data to a risk prediction value; and obtaining the priority corresponding to the monitoring data type with the contribution degree larger than a second preset threshold, and if there is monitoring data of the first priority type, sending first safety warning information to an operator, the first safety warning information being used for indicating the operator to stop underground operation. Omnibearing cable trench operation safety management and control are realized, the efficiency of cable trench operation safety management and control is improved, and cable trench operation risks are avoided to the greatest extent.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +1

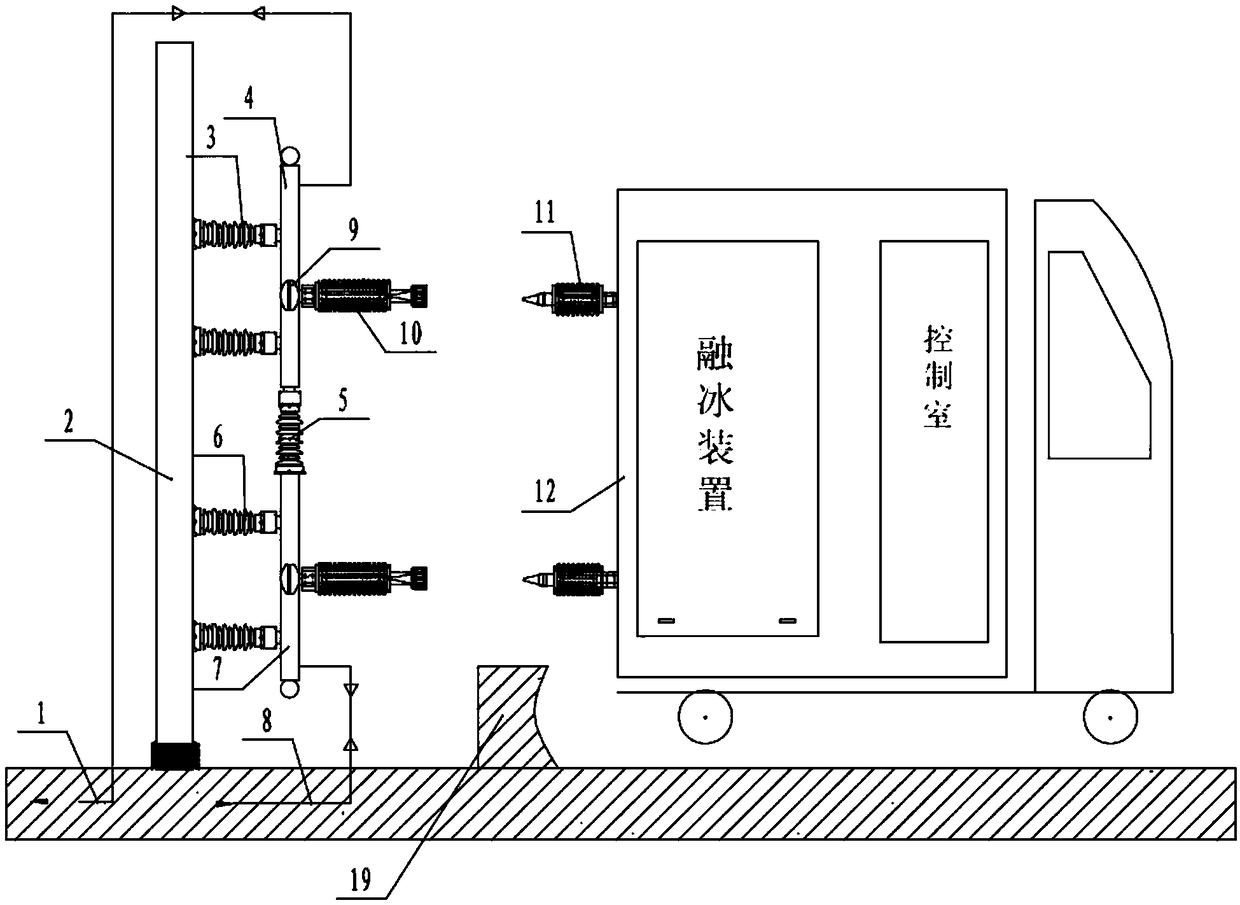

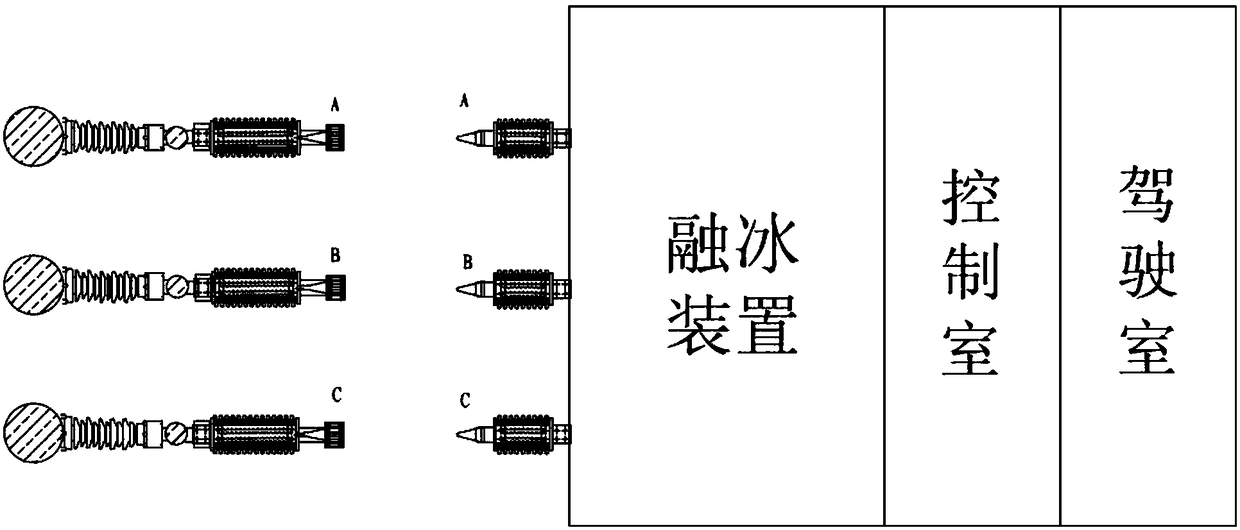

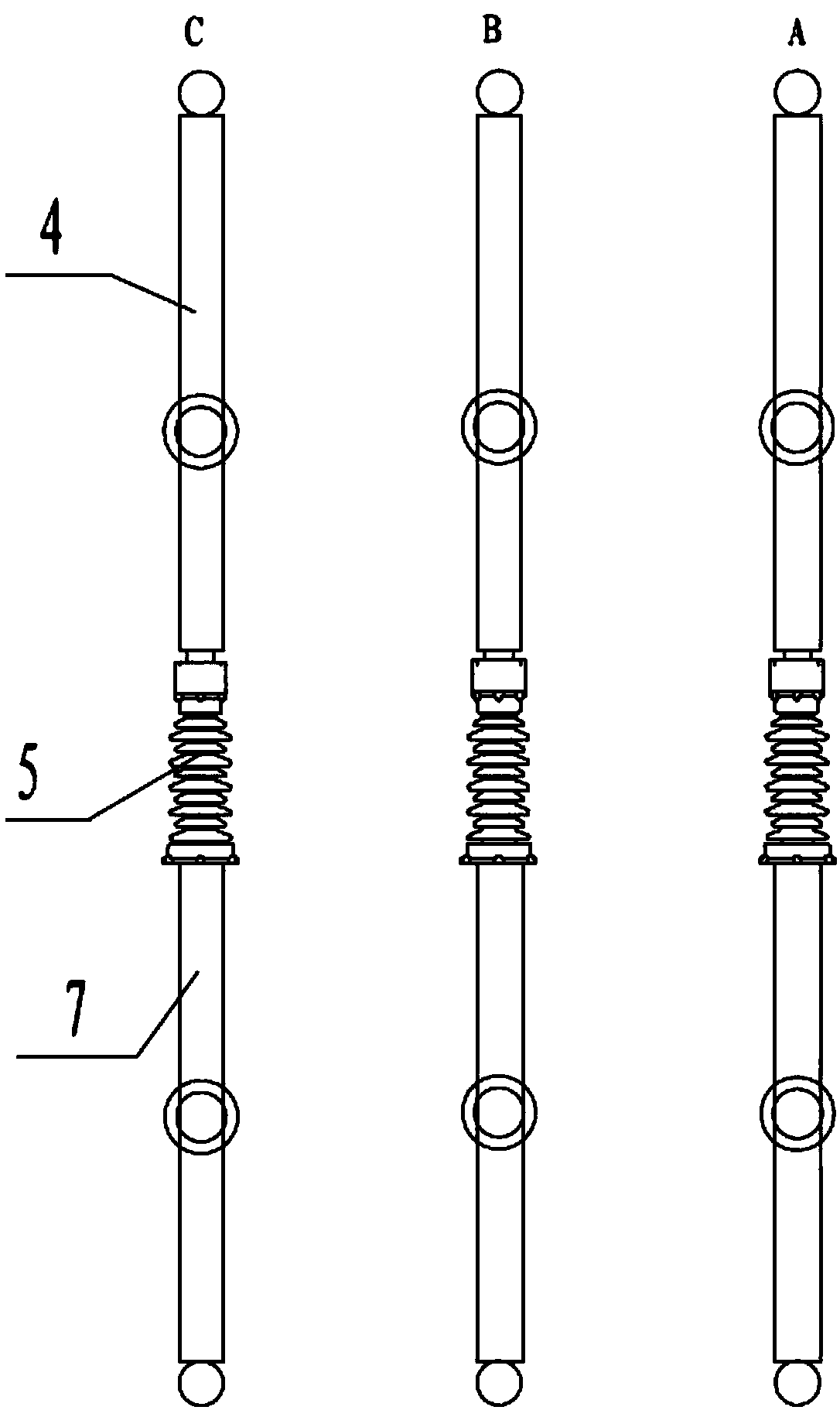

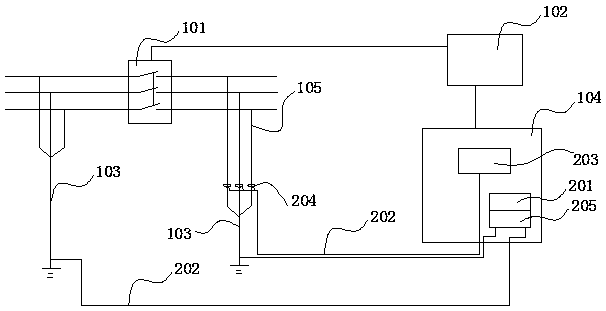

Mobile direct-current deicing horizontal access device

PendingCN108336688AShorten the timeAvoid job riskOverhead installationCoupling contact membersEmbedded systemOperations security

The invention discloses a mobile direct-current deicing horizontal access device. The mobile direct-current deicing horizontal access device comprises an electric pole fixedly connected onto the ground, a post insulator I, an isolated insulator, a direct-current bus, a post insulator II, an alternating-current bus and fixed contacts and moving contacts which are matched with each other, wherein the direct-current bus and the alternating-current bus are vertically fixedly connected onto the electric pole through the horizontal post insulator I and the horizontal post insulator II respectively;the direct-current bus and the alternating-current bus are connected through the isolated insulator; the fixed contacts are mounted on the direct-current bus and the alternating-current bus respectively; the moving contacts corresponding to the fixed contacts are mounted on a vehicle-mounted direct-current deicing device; the alternating-current bus is switched in an alternating-current power supply through an alternating-current input cable; and the direct-current bus is switched in a deiced circuit through a direct-current output cable. Without the need of manual wiring, the labor intensityis greatly reduced, the time and labor are saved preferably, the mounting efficiency is greatly improved, the mounting reliability is higher, and the operational safety is higher.

Owner:GUIZHOU POWER GRID CO LTD

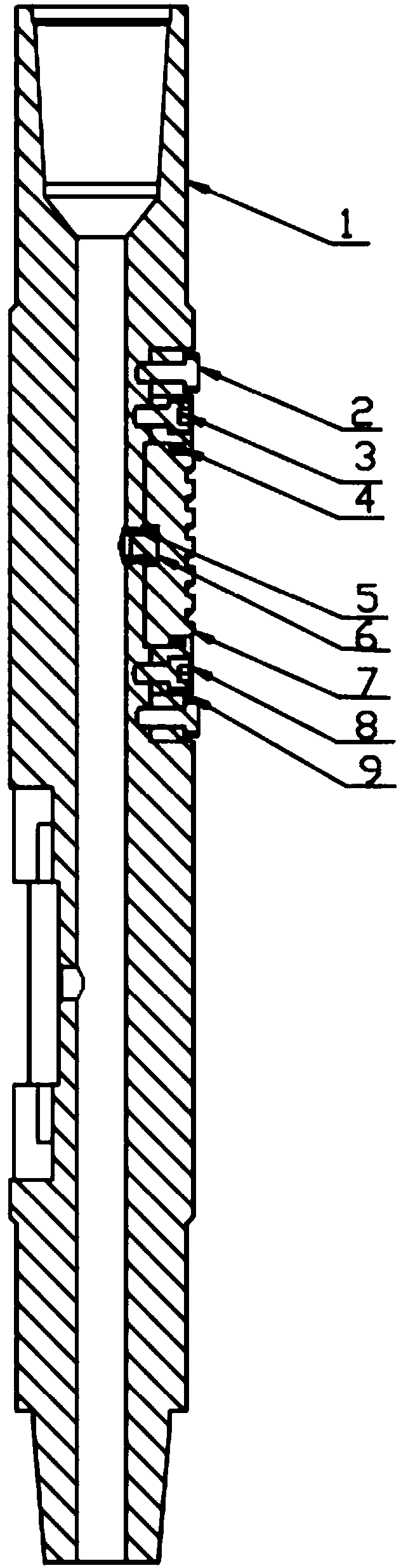

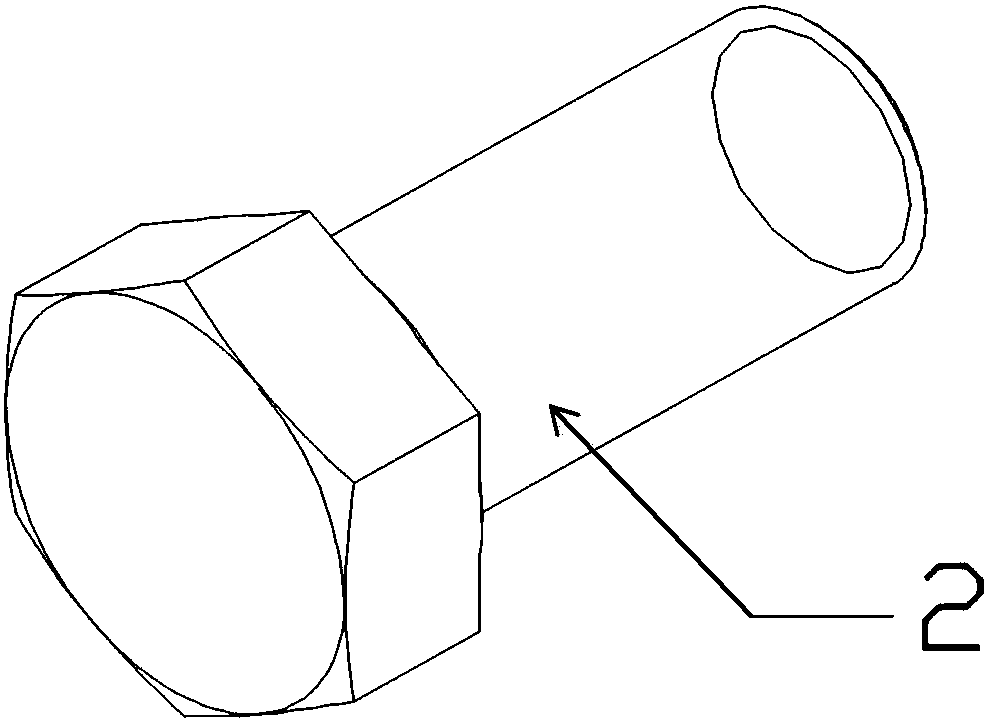

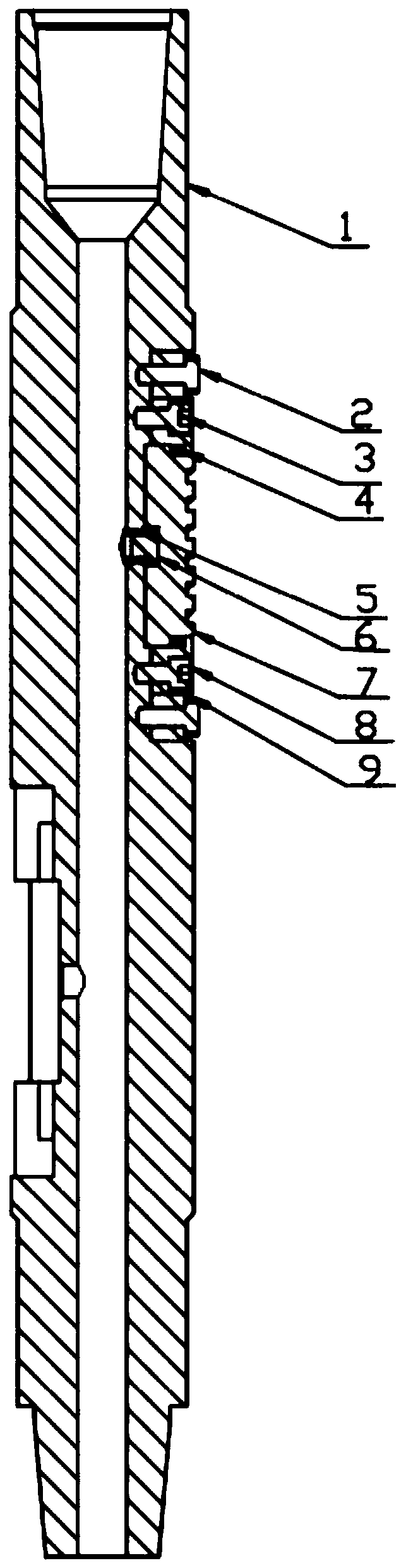

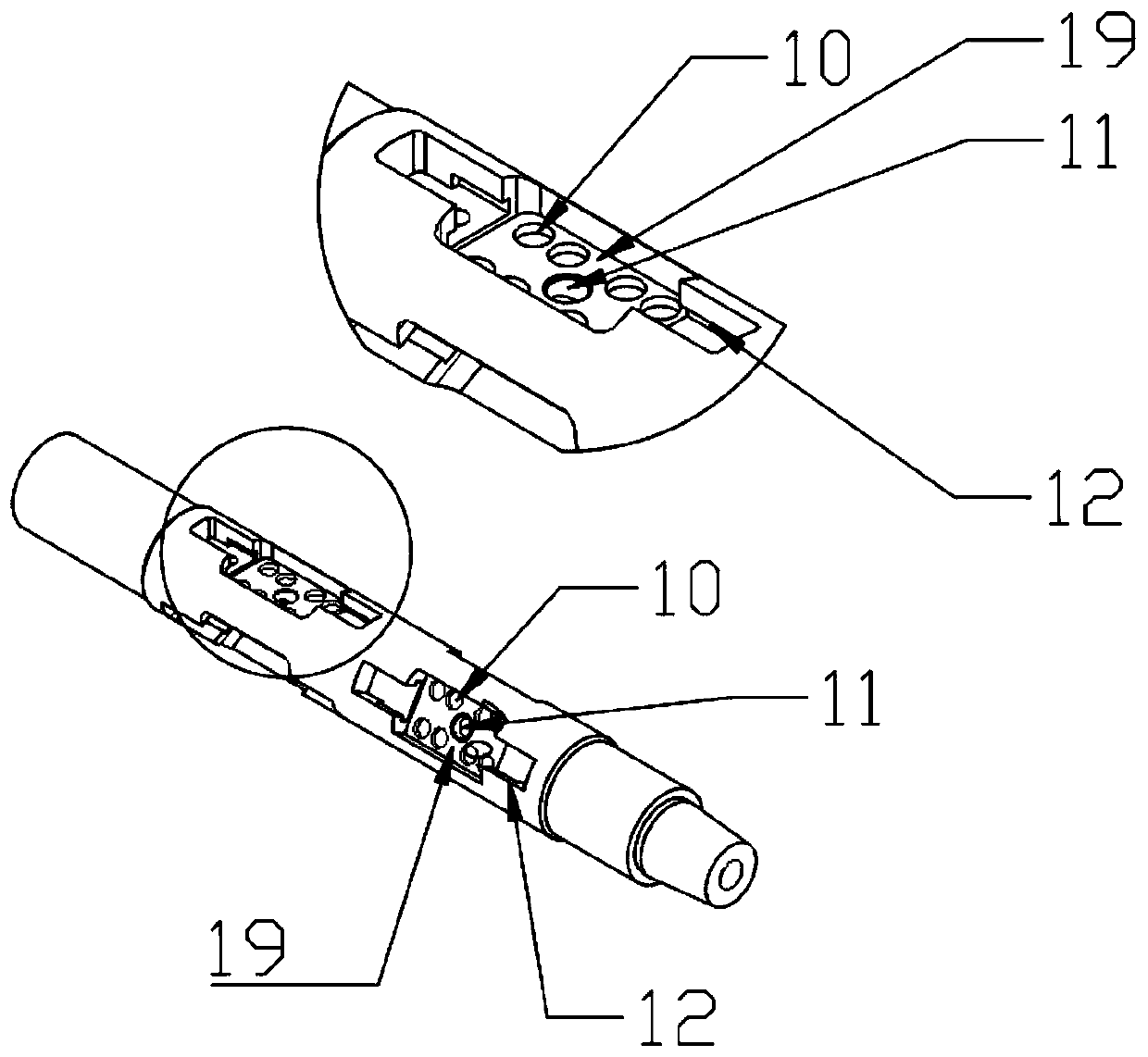

One-piece ball-throwing and segmenting wall scraper

Disclosed is a one-piece ball-throwing and segmenting wall scraper with an aim to mainly solve problems that an existing wall scraper is limited in application and complicated in technology. The one-piece ball-throwing and segmenting wall scraper is characterized by being composed of a body, compression springs, a pressure bearing plug, an inner sleeve, sliders, pressure blocks and the like; grooves used for placing scraper bodies are formed in the body, and each scraper body is located at the bottom of each groove under the initial state and is fixed through each pressure block and a slider mechanism; the lower side of each scraper body is provided with the spring, and a ratchet structure formed by the inner sleeve and the pressure bearing plug can allow the scraper bodies to be opened orclosed by compressing and restoring the springs. By the arrangement, segmenting wall scraping can be realized, cleaning effect is improved, damage to sleeves can be effectively prevented, and servicelife of the sleeves is prolonged; operations such as grinding, wall scraping and pigging can be completed with one pipe column, operation time is effectively reduced, and operation cost is lowered.

Owner:NORTHEAST GASOLINEEUM UNIV

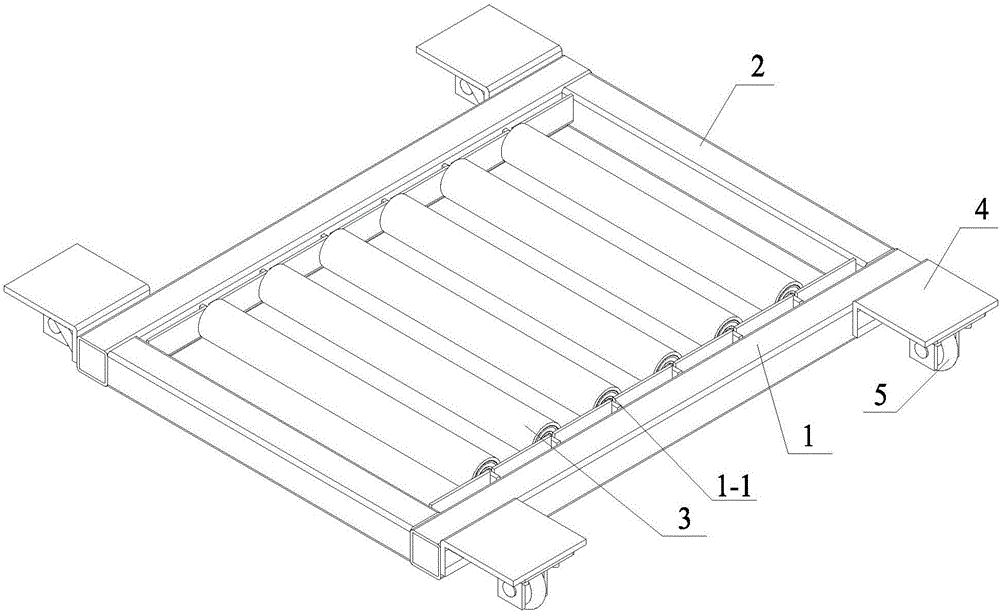

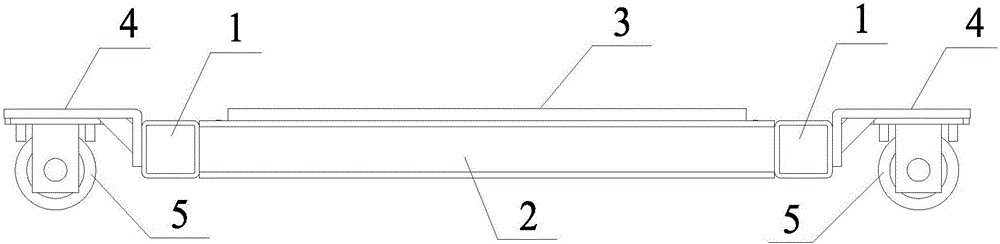

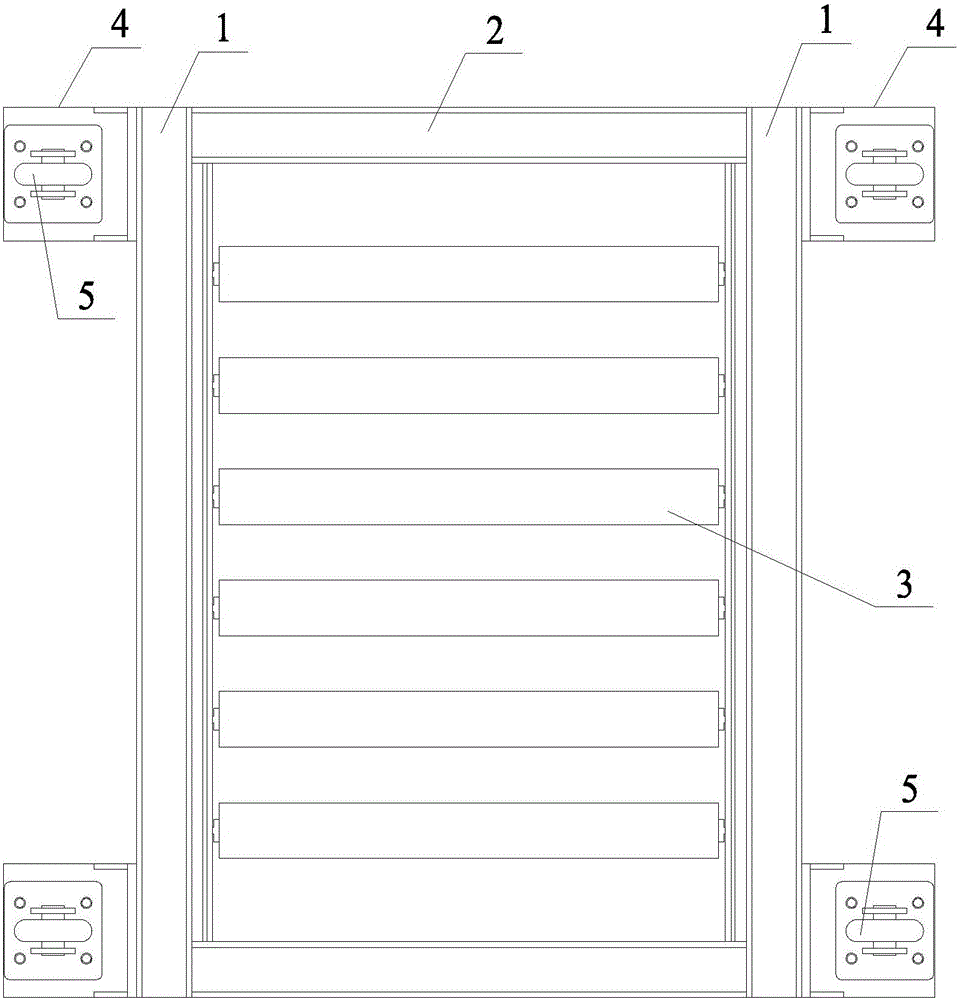

Transporting device for CRH5A motor train unit fifth-level-overhaul electrical cabinet

InactiveCN106081469AReduce labor intensityIncrease productivityManual conveyance devicesTransportation technologyUltimate tensile strength

The invention discloses a transporting device for a CRH5A motor train unit fifth-level-overhaul electrical cabinet and belongs to the technical field of electrical cabinet transportation. The transporting device comprises two longitudinal beams, two cross beams, six rolling bars, four L-shaped supporting plates an four universal wheels. The two longitudinal beams and the two cross beams are perpendicularly welded in a pairwise manner to form a rectangular bottom frame. Six grooves are formed in the inner side of each of the two longitudinal beams at equal intervals. The two ends of rotating shafts of the six rolling bars are arranged in the twelve grooves correspondingly. The rolling bars are connected with the longitudinal beams in a rolling manner. The four L-shaped supporting plates are located at the four corners of the rectangular bottom frame correspondingly and are correspondingly welded to the outer sides of the two longitudinal beams. The four universal wheels are fixed to the lower surfaces of the four L-shaped supporting plates correspondingly. The upper surfaces of the six rolling bars and the upper surfaces of the four L-shaped supporting plates are located in the same horizontal plane and are higher than the upper surface of the rectangular bottom frame. By the adoption of the transporting device, the labor intensity of operators is lowered, the production efficiency is improved, and operation risks are avoided.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

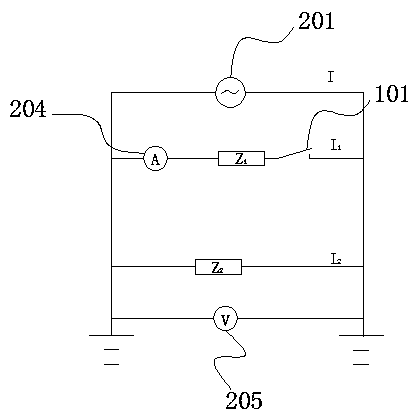

Double-side grounding type online testing system and testing method for switchgear

PendingCN109143051AReduce the number of opening and closingExtended service lifeMachine part testingCircuit interrupters testingCurrent sensorSwitchgear

The invention discloses a double-side grounding type online testing system and a double-side grounding type online testing method for switchgear, which relate to the technical field of power equipmenttests, and particularly to the double-side grounding type online testing system and the double-side grounding type online testing method for conducting comprehensive tests on switchgear of power transmission, transformation and distribution lines. The double-side grounding type online testing system comprises the tested switchgear and an action driver controlling the tested switchgear to switch on and switch off, and further comprises a host, a connecting cable, grounding wires and a current sensor, wherein the grounding wires connected with a wiring terminal on the same side of the tested switchgear are electrically connected with the same grounding welding pile, and the grounding welding pile is electrically connected with constant current source output ends in the host by means of theconnecting cables. The invention aims to provide the online testing system and testing method for improving the power failure test efficiency of the switchgear, optimizing the test flow and reducing the operational risk.

Owner:STATE GRID CORP OF CHINA +1

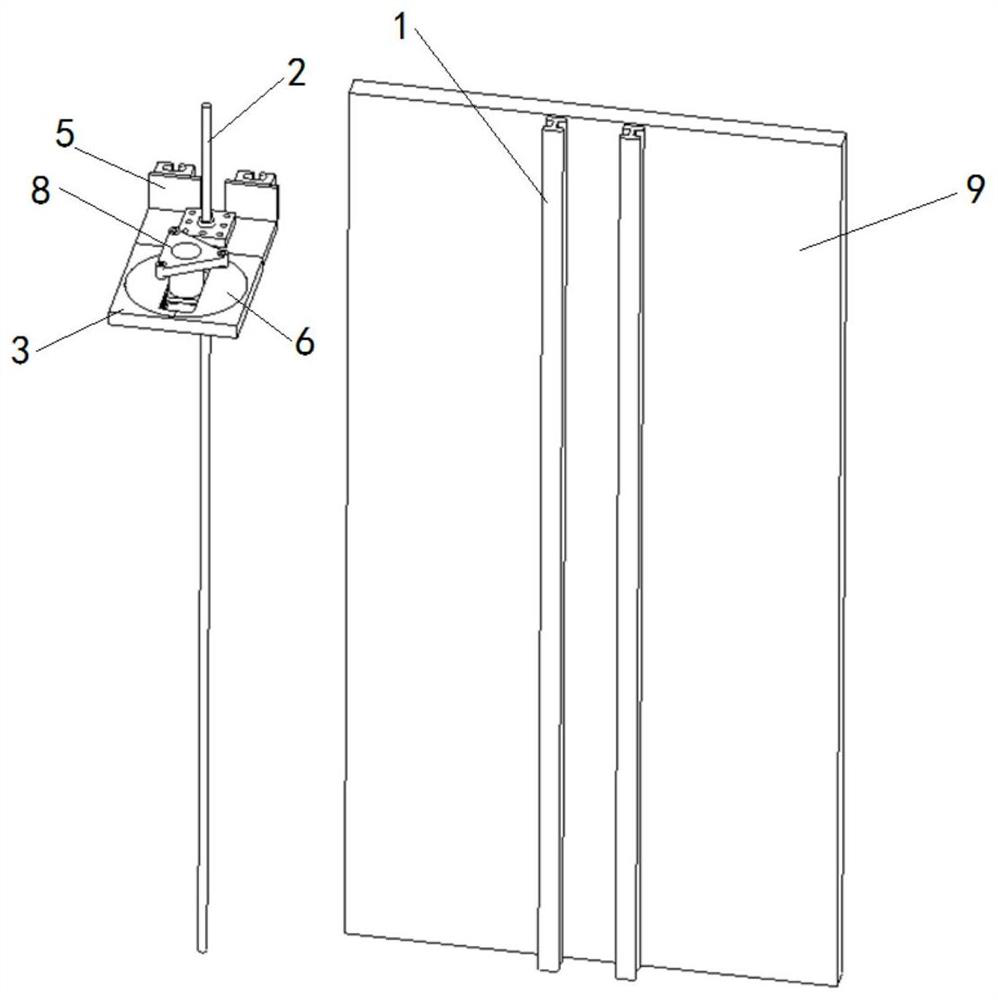

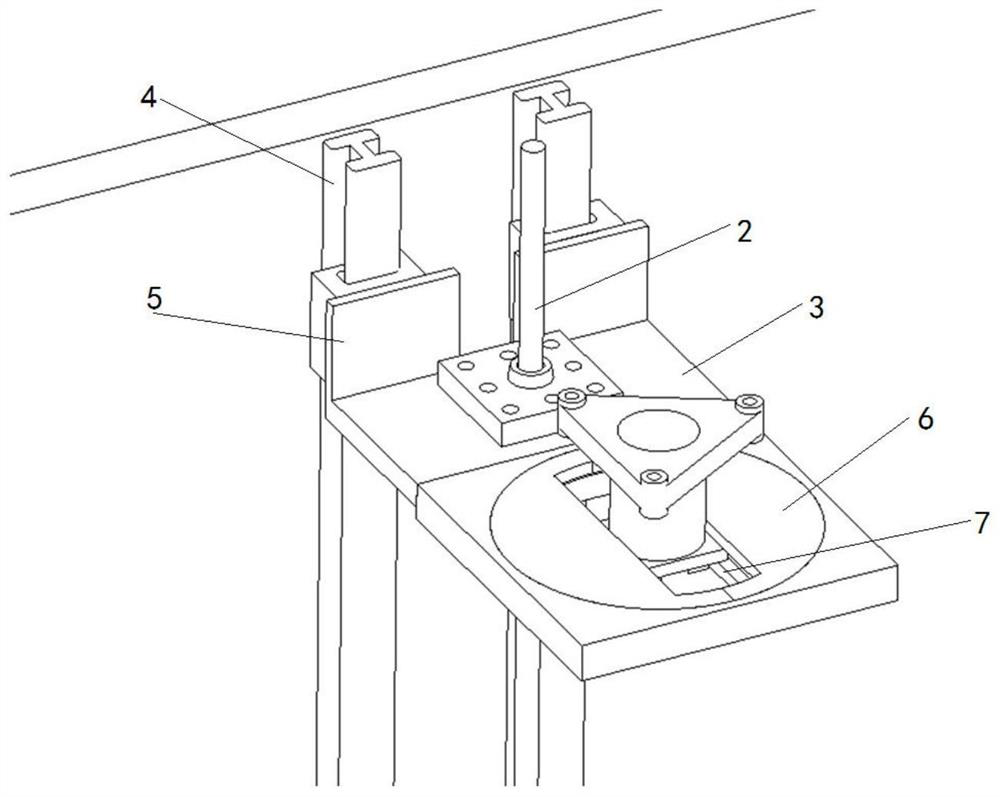

Rapid centering device for high-altitude total station and use method of rapid centering device

PendingCN114739371AEasy to moveGuaranteed alignment requirementsSurveying instrumentsVehicular energy storageStructural engineeringTotal station

The invention provides a rapid centering device for a high-altitude total station. The rapid centering device comprises two guide rails; a positioning shaft; the positioning seat is connected with the positioning shaft and the two guide rails in an up-down sliding manner; the rotating device is arranged on the positioning seat; and the total station base is arranged on the rotating device. The invention further discloses a using method of the rapid centering device for the high-altitude total station. The device is easy and convenient to operate, intelligent, effective, safe, stable, high in practicability, easy and convenient to install and capable of being turned over, operation risks caused by high-altitude tripod erecting can be avoided, the measurement efficiency of the total station is greatly improved, the labor cost is reduced, and unnecessary risks are avoided.

Owner:THE THIRD CONSTR OF CHINA CONSTR EIGHTH ENG BUREAU

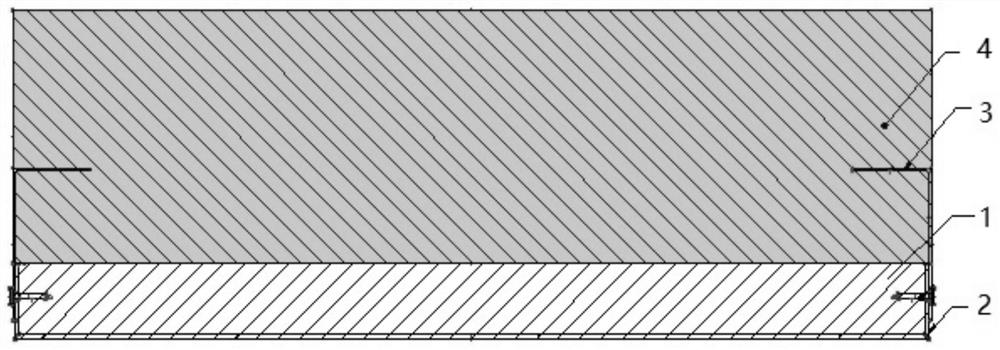

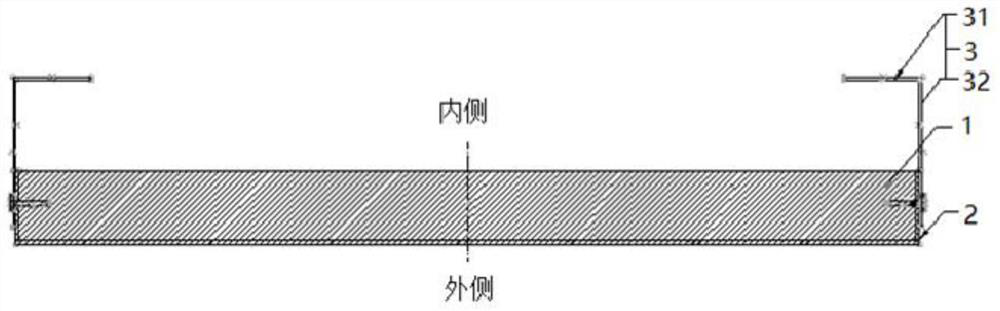

A prefabricated building exterior wall

ActiveCN112031265BEasy constructionQuality is easy to controlDischarging arrangementFeeding arrangmentsFiberThermal insulation

The invention provides an exterior wall of a prefabricated building, which includes a thermal insulation board, a cover layer, an L-shaped embedded part and a cement layer. For all the panels except the inner panels, the L-shaped embedded parts include intersecting inner arms and outer arms. The length of the outer arms is greater than the thickness of the insulation board. On the wall, the end connecting the inner arm faces the cement layer inside the insulation board, the free end of the inner arm is inserted into the cement layer, and the insulation board, cover layer, L-shaped embedded part and cement are connected through the connecting piece pierced by the L-shaped embedded part. Layers are connected as one. The insulation board includes 100 parts of inorganic fiber and 1-13 parts of phenolic resin. The prefabricated building exterior wall in the present invention, through a reasonable structural layout, makes the structure of the prefabricated exterior wall simple, the exterior wall processing is convenient, combined with the new thermal insulation material, the fire prevention, isolation and mechanical properties are greatly improved.

Owner:BEIJING SATELLITE MFG FACTORY

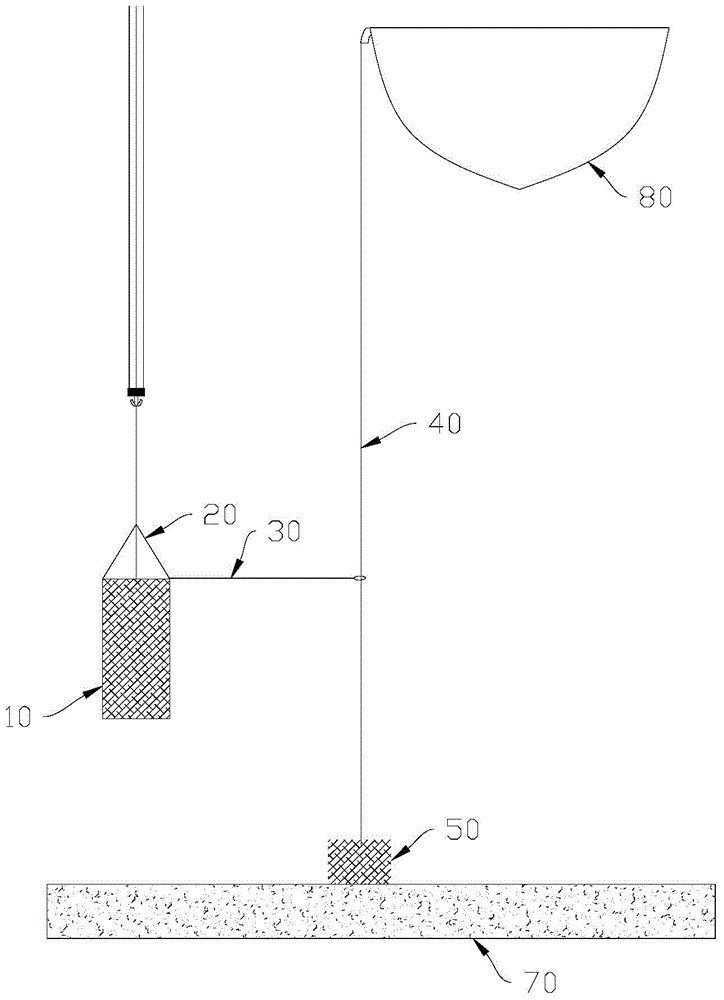

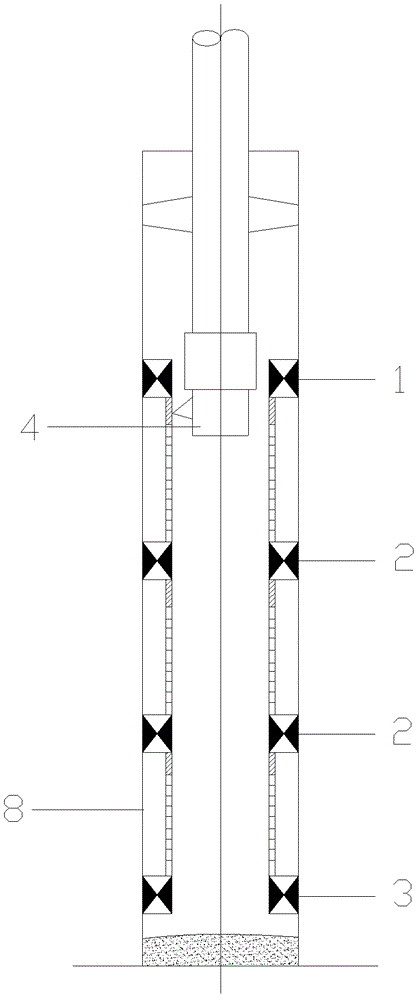

Heading Control and Adjustment Method of Lowering Anchor Pile

ActiveCN105002876BPrevent rotationEnsure that the heading is not biasedArtificial islandsUnderwater structuresStructural engineeringSeabed

Owner:SHENZHEN OFFSHORE OIL ENG UNDERWATER TECH CO LTD

Working method of breaking the upper lead wire of 10kv live drop-out fuse

ActiveCN104143784BImprove live working methodsReduce labor intensityApparatus for overhead lines/cablesCalipersUltimate tensile strength

The invention relates to an operation method for breaking the upper lead wire of a 10kV live-line drop-out fuse, which uses a lead wire insulation fixer to fix the lead wire and the main lead wire, and is suitable for the operation method of using a lead wire clip for overlapping the lead wire; the lead wire insulation fixer is composed of Composed of a pliers body, an insulating handle and a pin shaft; the integrated pliers body and insulating handle are symmetrically fixed together by the pin shaft to form a pincer-shaped structure; the pliers body is provided with wire fixing grooves and lead wire fixing grooves. Compared with the prior art, the beneficial effects of the present invention are as follows: 1) By applying new tools and tools, the live working method is improved, labor intensity is reduced, operation risks are avoided, and habitual illegal operations are eliminated. 2) In actual application, the safety accident rate of the 10kV live wire breaking and dropping top lead wire operation more than 200 times throughout the year is 0, and the safety is high. 3) It is easy to operate and improves working efficiency. It is suitable for the working method of insulating gloves and the working method of insulating poles, reduces the amount of tools used, and improves the reliability of power supply.

Owner:ANSHAN POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER COMPANY +1

Construction method

ActiveCN105544993BHanging stableAvoid job riskWallsBuilding material handlingPendulumIndustrial engineering

Provided is a construction method and a carrier. A linear sliding rail and a sliding gasket pad part are additionally arranged on the carrier, the existing operation process of supporting unit plates by operators is replaced. The unit plates continuously bear supporting force of the linear sliding rail and the sliding pad part in the transition process that the unit plates become inclined from horizontal and then become vertical again, operation risks due to the fact that the operators are too close to the edge of a hoisting layer are avoided, meanwhile, pendulum motion generated when the operators instantly release the unit plates in the traditional hoisting process is buffered, the hoisting process of the unit plates is stable, and convenience and reliability are achieved.

Owner:JIANGSU JIAZE CONSTR CO LTD

Overturning clamp for large cover of crystal growing furnace

InactiveCN104593859ASimple and convenient operationTroubleshoot flippingPolycrystalline material growthFrom frozen solutionsSapphireEngineering

A related overturning clamp for a large cover of a crystal growing furnace comprises two symmetrically-arranged bracing frames, and fixed ox-horn-shaped members arranged on the bracing frame in a rotation way; each fixed ox-horn-shaped member comprises a rotation shaft, a movable clamping sheet and a bearing block; one end of the rotation shaft is connected with the corresponding bracing frame in a rotation way, and the other end of the rotation shaft is connected with the bearing block; the bearing block and the movable clamping sheet form a fixing area; the large cover is clamped in the fixing area; and two rotation bearings are coaxially arranged. The overturning clamp is capable of effectively controlling the overturning process of the large cover of the jewel furnace, is simple and convenient to operate, helps to effectively solve the problem that the large cover of the sapphire crystal growing furnace is difficult to overturn, helps to effectively improve hoisting, adjusting, cleaning and afresh assembling processes of a thermal field, and helps to greatly shorten the sapphire crystal growth period, improve production power and reduce sapphire crystal growth cost, thereby improving working efficiency, simplifying working process and reducing working risk.

Owner:福建鑫晶精密刚玉科技有限公司

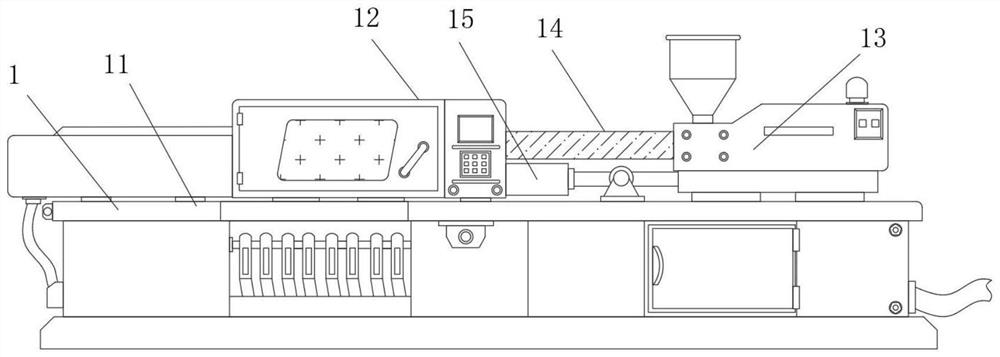

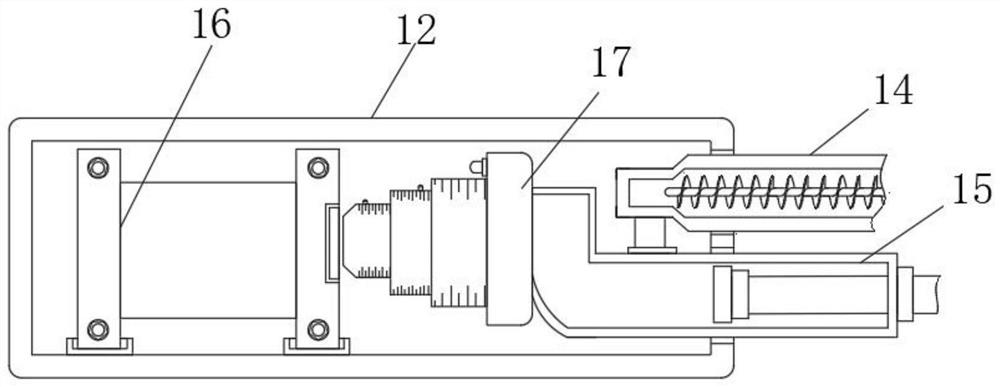

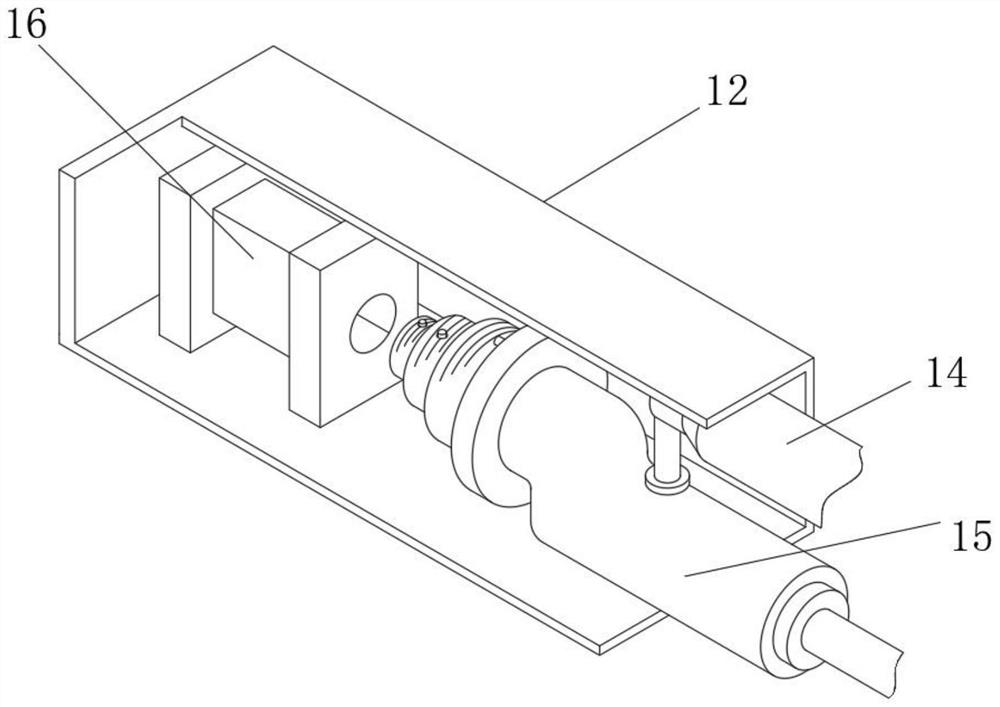

Screw extrusion equipment for producing graphene composite high polymer material

PendingCN114379024AGuaranteed tightnessAvoid work intensity and injection molding failureComposite materialManufacturing engineering

The invention relates to the technical field of injection molding machines, in particular to screw extrusion equipment for graphene composite high polymer material production, which comprises a frame body, the frame body comprises a workbench, the surface of the workbench is connected with a processing box, one end of the surface of the workbench far away from the processing box is provided with an injection molding device, and the surface of the injection molding device is connected with an injection molding rod. According to the injection molding device, a worker adjusts the position of a telescopic adjusting plate to move, then the injection rate of raw materials during injection molding of the device is adjusted, and it is guaranteed that the polarization situation caused by too high pressure is avoided when a third injection molding head and a second injection molding head or a first injection molding head abut against an injection molding opening; and therefore, it is guaranteed that the device can conduct sealed injection molding on different molds under the condition that different injection molding heads are not replaced, the sealing performance during injection molding is guaranteed, the risks of working intensity and injection molding failures caused when workers replace the injection molding heads are also avoided, the use range of the device is effectively widened, and the use effect of the device is improved.

Owner:HEBEI NORTH UNIV

Sand washing type fishing technology for sand prevention pipe string

The invention discloses a sand washing type fishing technology for a sand prevention pipe string, which comprises the steps of 1) cutting off a blind pipe of a top sand prevention pipe section; 2) recovering a top packer; 3) running a sand washing pipe string into the residual sand prevention pipe string of the top sand prevention pipe section; 4) slowly putting down the sand washing pipe string, and simultaneously, circulating washing liquid to conduct sand washing for annular space between the top sand prevention pipe section and a casing pipe; 5) cutting off a blind pipe which is close to the lower portion of an intermediate isolation packer on the top currently; 6) fishing the residual sand prevention pipe string of the top sand prevention pipe section and an intermediate isolation packer at the bottom of the top sand prevention pipe section; and 7) repeating steps 3) -6) to fish out the residual sand prevention pipe string of the next sand prevention pipe section and an intermediate isolation packer at the bottom of the next sand prevention pipe section until all the sand prevention pipe sections and packers are fished out. The sand washing type fishing technology can solve the problem that conventional casing milling is difficult to adopt due to the small annular space between a screen pipe and the casing pipe, effectively speed up the fishing schedule, accelerate the operation effectiveness for a given period of time, control the expenses in a work period and save the operation cost.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Integrated pitching segmental wall scraper

Integral pitch segment scraper. The main purpose of the invention is to solve the problems of limited application and complicated process existing in the existing wall scraper. It is characterized in that: the tool is mainly composed of a body, a compression spring, a pressure-bearing plug, an inner sleeve, a slider, a pressing block, etc.; the body is provided with a groove for placing the scraper body, and the scraper body is located in the groove in the initial state. The bottom is pressed and fixed by the pressing block and the slider mechanism; a spring is placed under the scraper body, and the ratchet structure composed of the inner sleeve and the pressure plug can realize the opening and closing of the scraper body by compressing and restoring the spring. This integrated ball-pitching segmented wall scraper can realize the process of segmented wall scraping, increase the cleaning effect, and at the same time can effectively prevent the problem of casing damage and increase the service life of the casing; realize drilling, grinding, and wall scraping in one trip And drilling and other operations, effectively reducing operating time and reducing operating costs.

Owner:NORTHEAST GASOLINEEUM UNIV

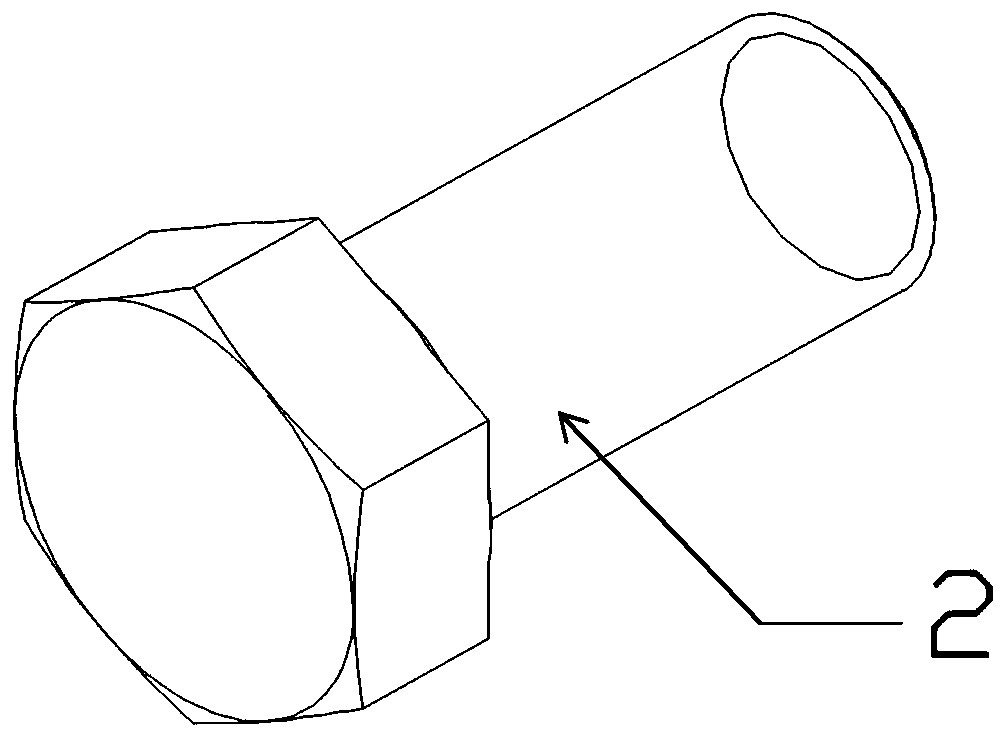

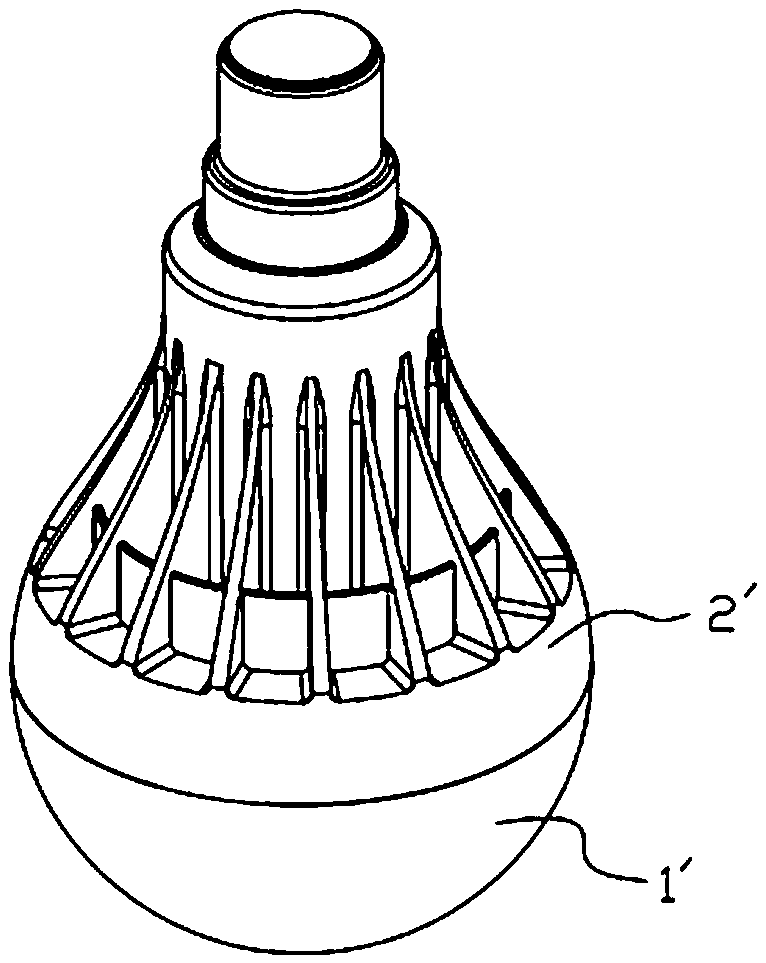

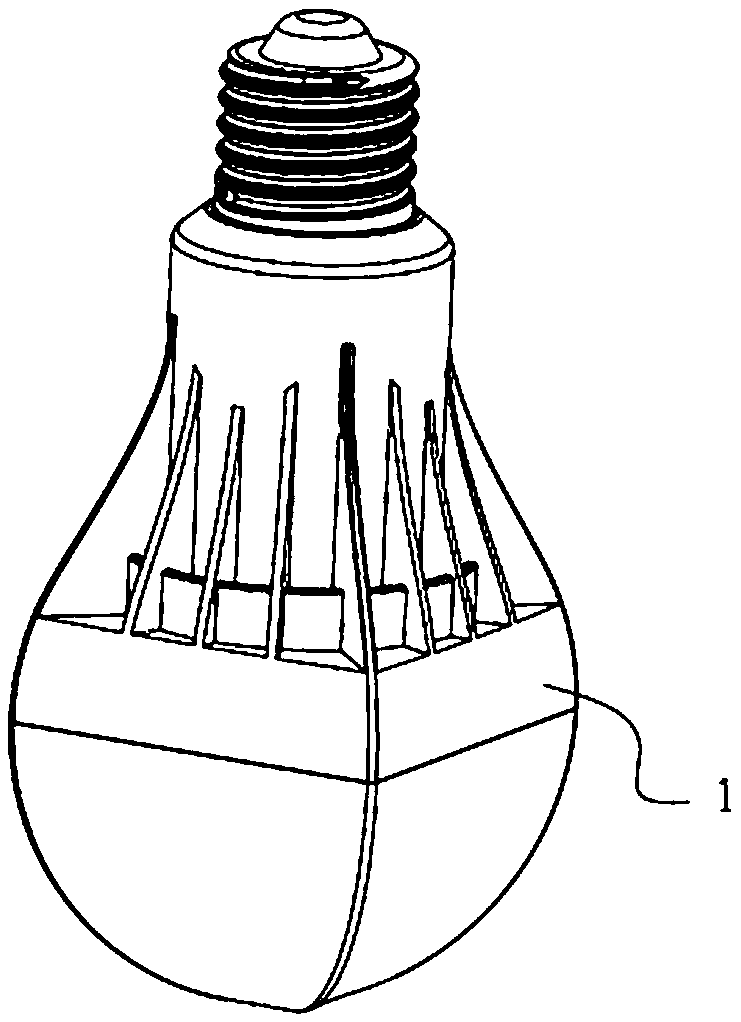

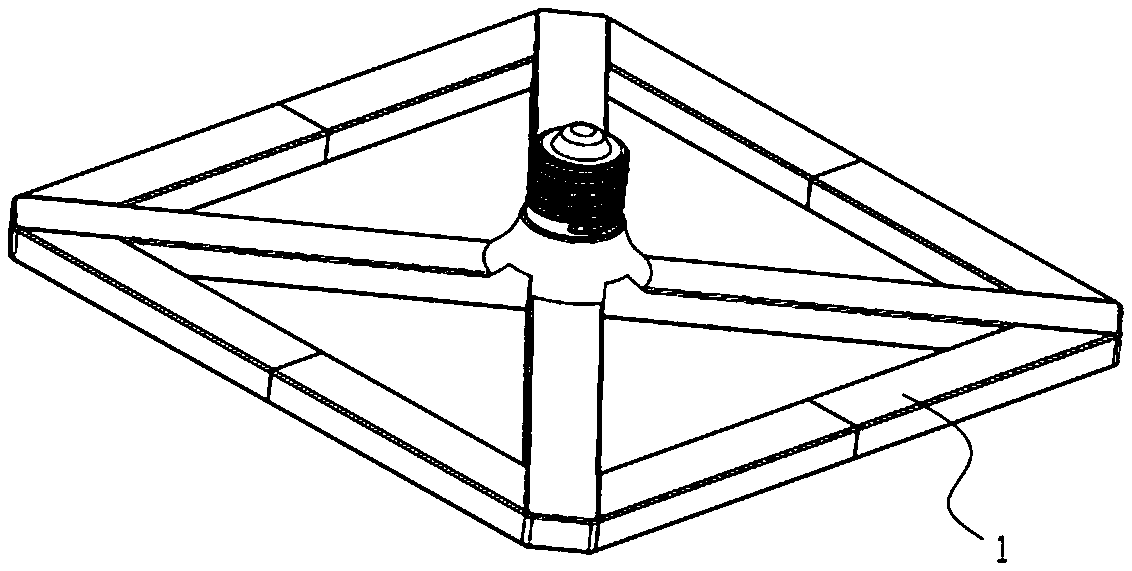

Bulb with clamping-connection structure and special non-contact dismounting and mounting tool of bulb

The invention discloses a bulb with a clamping-connection structure. The bulb comprises a bulb body. The outer contour of the bulb body is arranged in a polygon or oval shape, or the bulb body is provided with a polygonal or oval clamping-connection protrusion. The bulb of the design is provided with the clamping-connection structure facilitating dismounting and mounting, thus, non-contact or remote dismounting and mounting of the bulb can be achieved conveniently in combination with special dismounting and mounting tools during replacement, and the bulb has the characteristics of being safe in dismounting and mounting, simple and practical in structure and low in maintaining cost.

Owner:徐勇

An Improved Simple Rectangular Anti-sliding Pile Mechanical Rapid Hole-forming Construction Method

ActiveCN110820733BReduce security risksIncrease construction costsBulkheads/pilesDrilling machines and methodsClassical mechanicsMachine

The invention discloses an improved simple and simple rectangular anti-sliding pile mechanical rapid hole-forming construction method, which specifically includes the steps: A. setting out and positioning the rectangular pile hole; B. making a rectangular steel casing; C. rotating the pile machine according to the pile core Excavate the hole with serial number and position; D. Use the hydraulic vibratory hammer to lower the rectangular steel casing into the rectangular pile hole to remove excess earthwork; E. Pour concrete in the over-excavation area outside the steel casing; F. Lift the steel casing with the hydraulic vibratory hammer ; G. Lower the rectangular steel cage and pour concrete to form anti-slide piles. The construction method of the invention solves the problems of slow construction progress and great difficulty in forming holes for manual hole-digging piles, and has the advantages of convenient operation, safe construction, high efficiency and wide applicability.

Owner:YUNNAN JIANTOU FOUND ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com