Bidirectional synergy driving material pneumatic conveying system

A technology for pneumatic conveying and materials, applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of the impact of objects to be conveyed, large pressure loss in one-way driving, slow operation, etc., to prolong the service life of equipment, increase the driving force of air pressure, The effect of slowing down the transfer speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

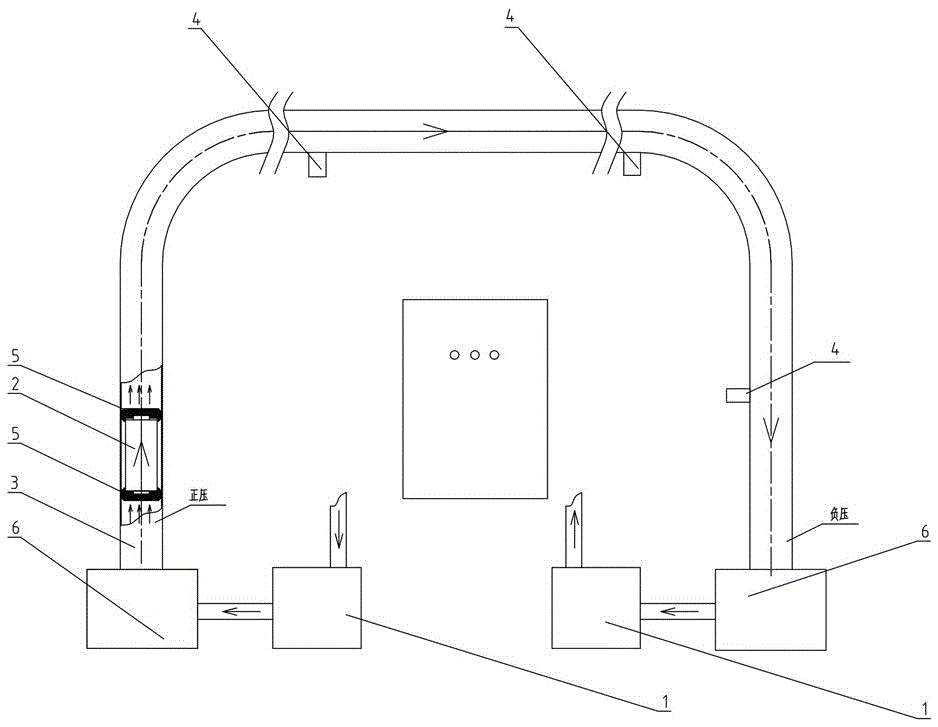

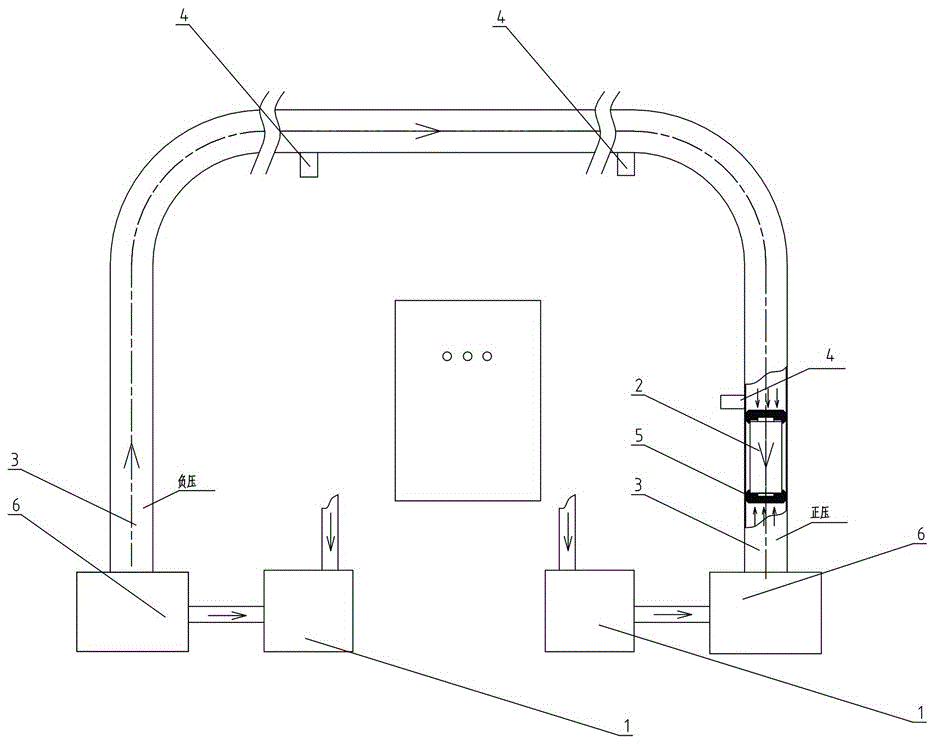

[0026] Such as figure 1 , figure 2 As shown, the present invention provides a two-way cooperatively driven material pneumatic conveying system, including a driving air source unit 1 and a transmission pipeline unit 3 for transporting the object to be conveyed 2 (in the following description, for the convenience of corresponding description, the object to be conveyed 2 An example is a sample bottle, of course, in other embodiments, the object to be conveyed 2 can also be other devices or objects to be conveyed, which should all belong to the protection scope of the present invention), and the driving air source unit 1 provides The air source driving mode of blowing or sucking air drives the pneumatic transmission of the object 2 to be conveyed. There is a driving air source unit 1 at the beginning and end of the transmission pipeline uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com