Patents

Literature

182 results about "Transfer velocity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

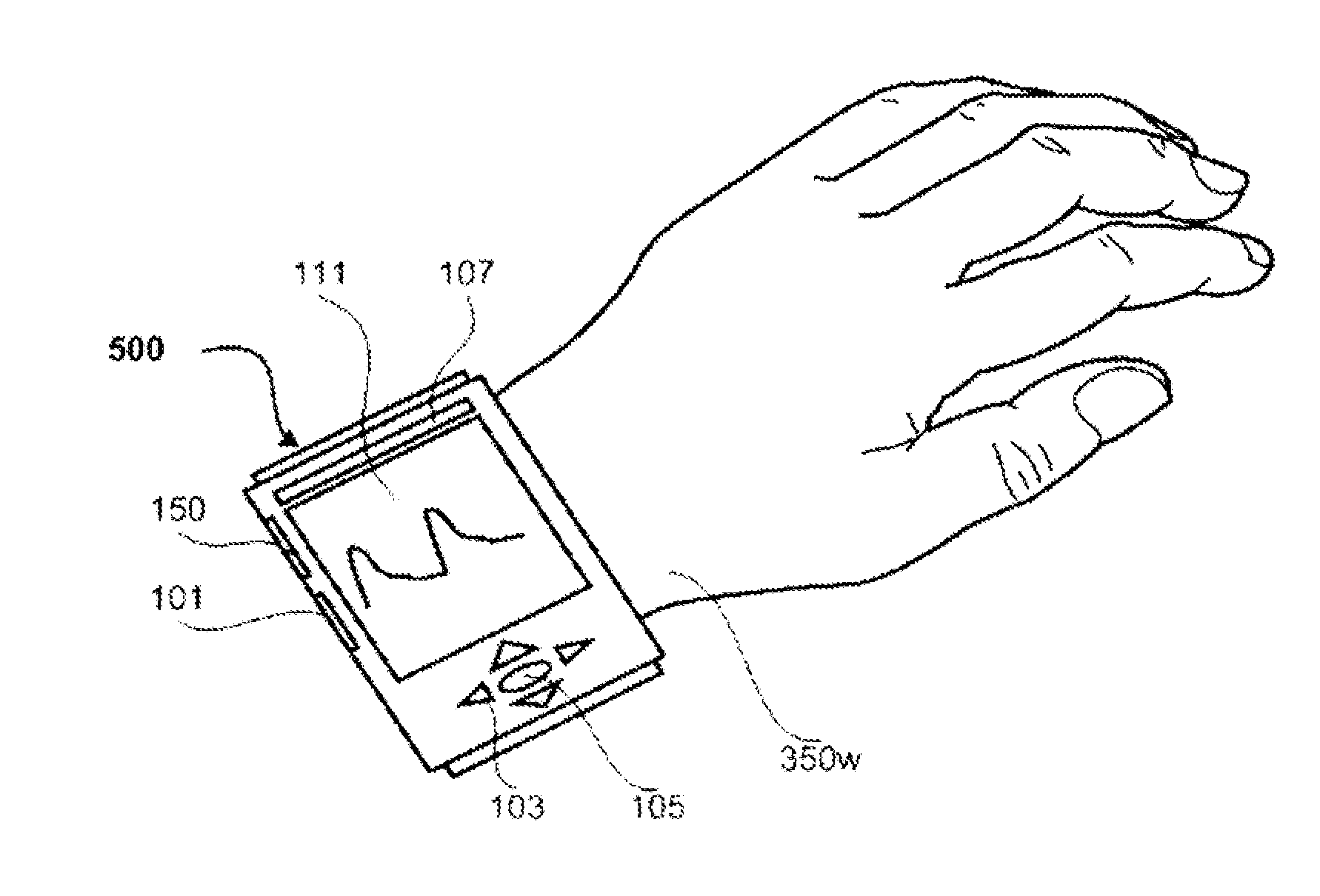

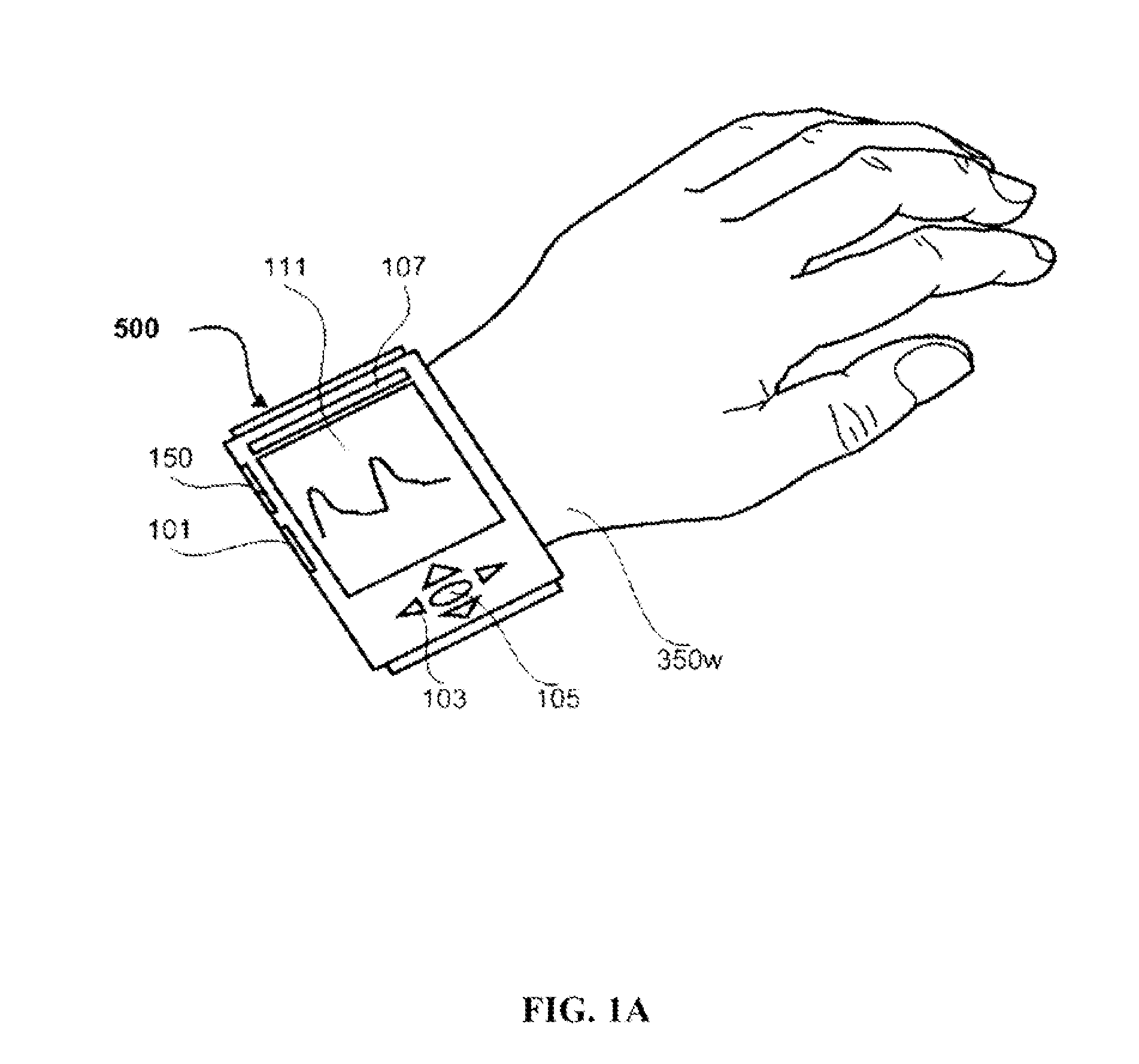

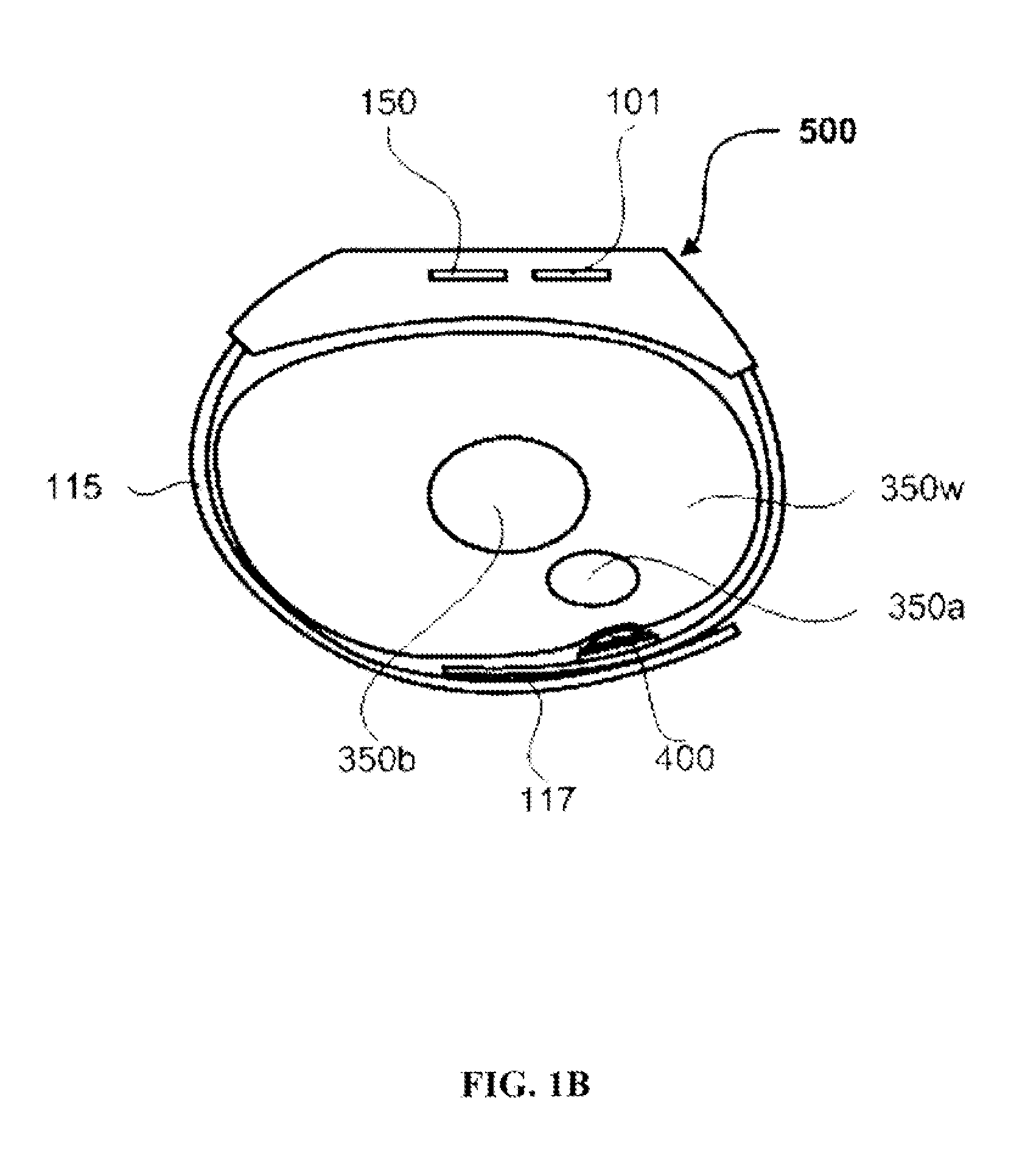

Apparatus and method for sensing radial arterial pulses for noninvasive and continuous measurement of blood pressure and arterial elasticity

InactiveUS20100210956A1Improve accuracyEvaluation of blood vesselsCatheterContinuous measurementReflected waves

Provided is a radial arterial pulse sensing apparatus for noninvasive and continuous measurement of blood pressure and arterial elasticity. The apparatus includes two pressure sensor for detecting radial arterial pulses, two cuffs that are disposed under the respective pressure sensors and expandable by application of external pressure, a motor unit for providing proper pressure to expandable pouches under the respective pressure sensors in a state where a wrist band having the pressure sensors is put on a wrist, a pulse wave velocity calculating unit that calculates a pulse wave transfer velocity to attain a blood pressure value using an output from the pressure sensors, and an augmentation index calculating unit that estimates the blood pressure value by finding a time point of a reflective wave of the pulses using the outputs from the pressure sensors.

Owner:GRAMPION GRP

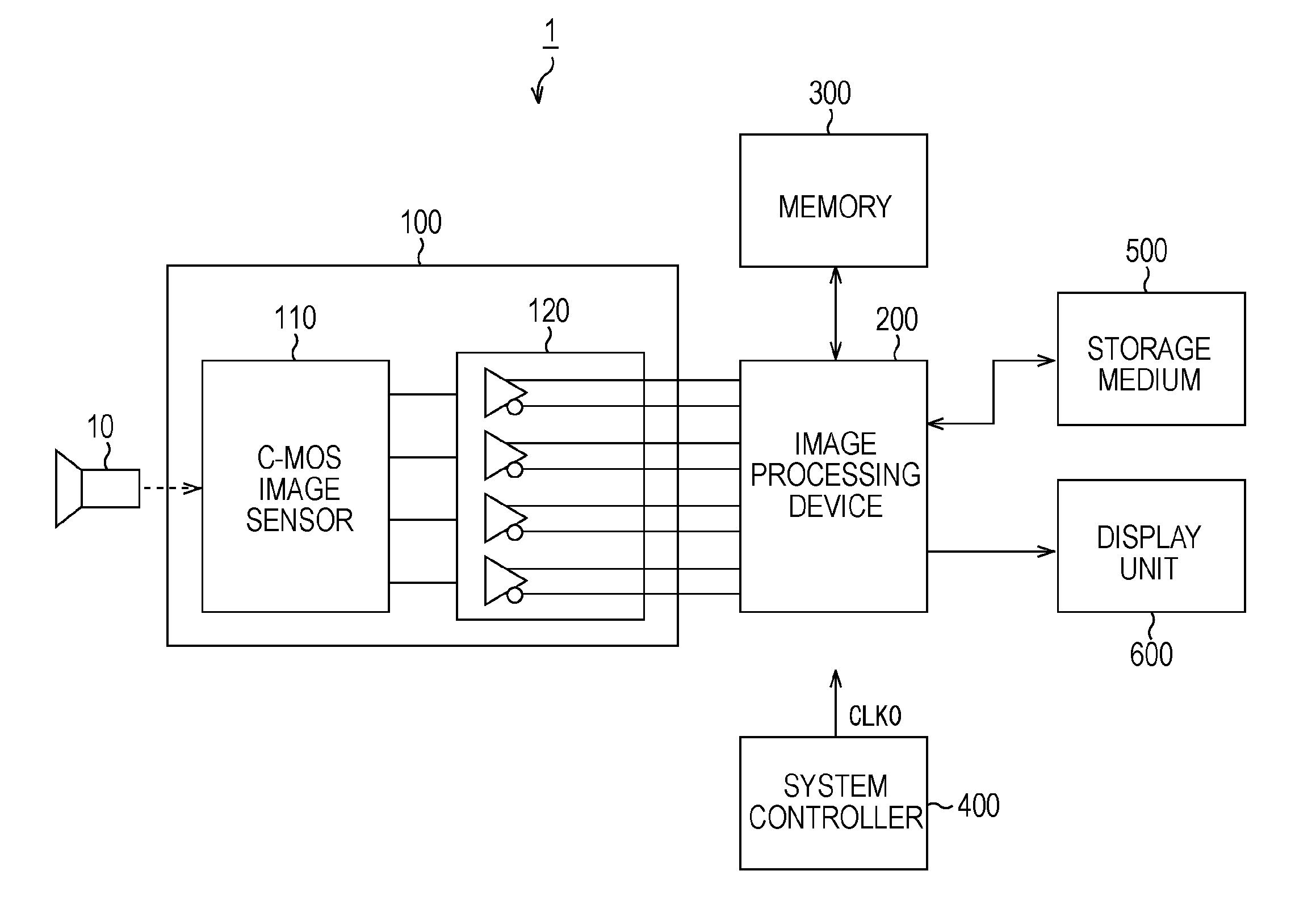

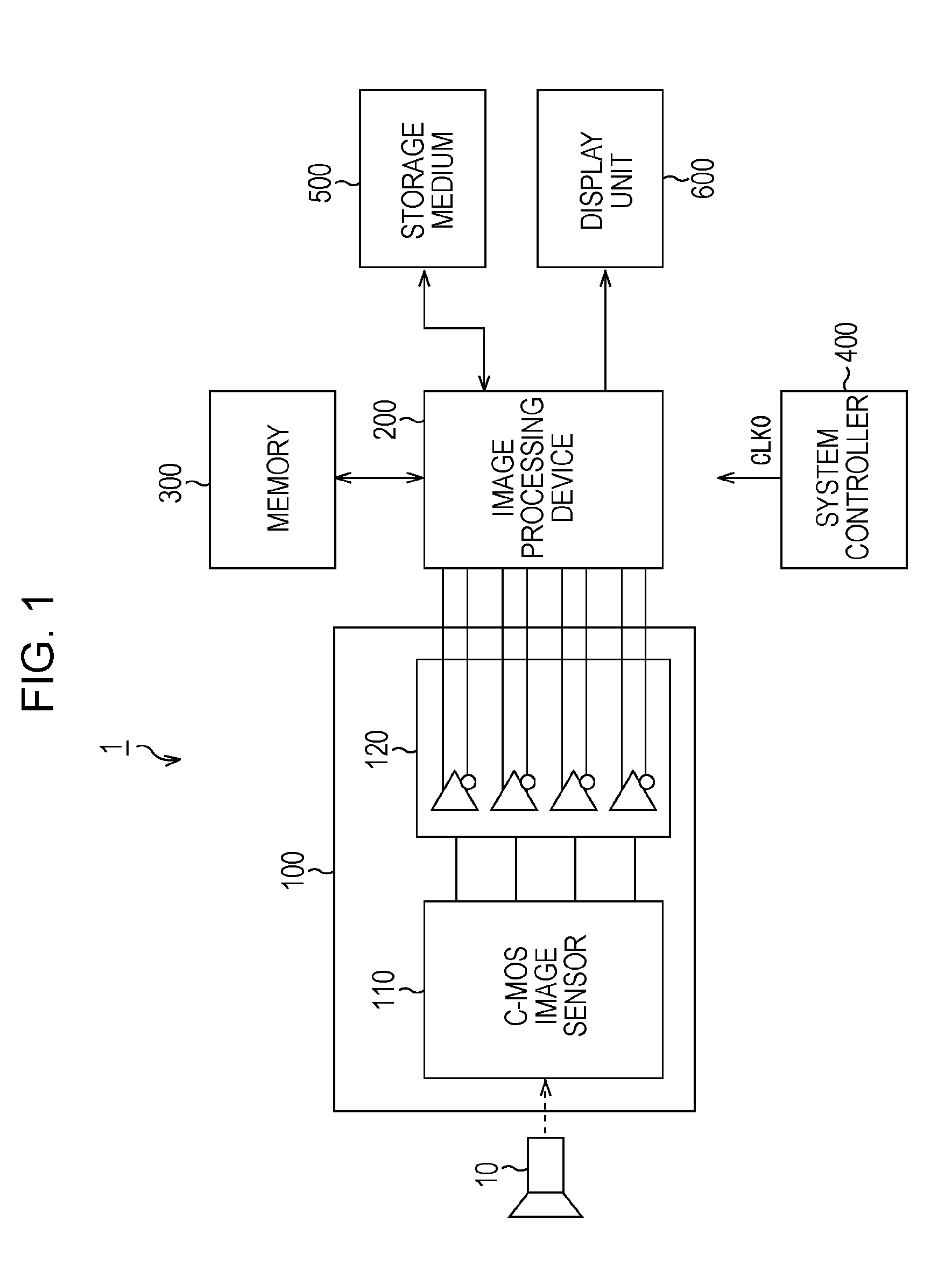

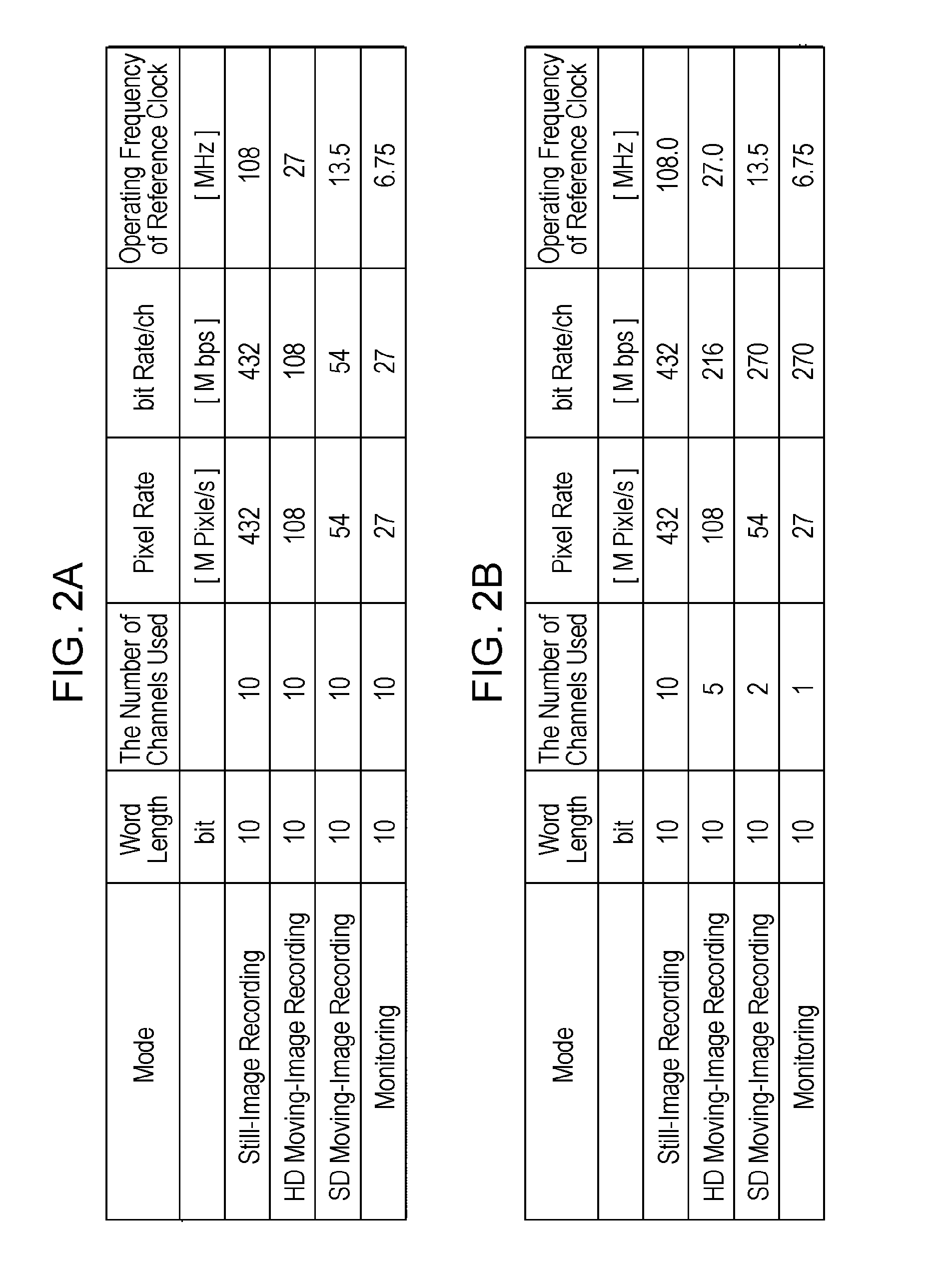

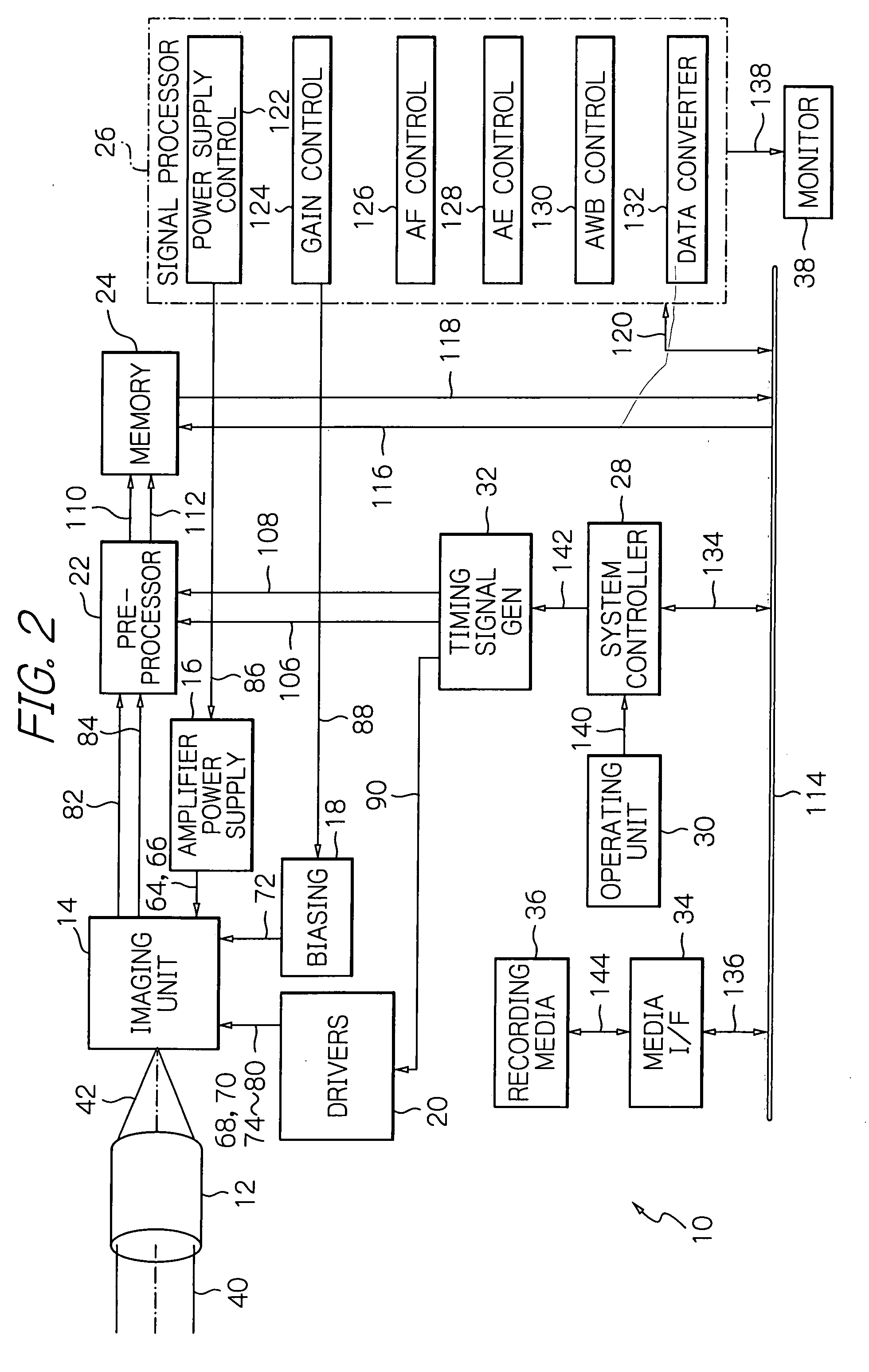

Solid-state image pick-up device, data transmission method, and image pickup apparatus

ActiveUS20100026814A1Increase frame rateElectric power consumption increaseTelevision system detailsSynchronisation information channelsElectric powerImaging data

A video camera (100) for transmitting image data from an image pickup device to an image processing device with reduced electric power includes a C-MOS image sensor (110) that reads captured image data on the basis of a reference clock CLK0, a frequency multiplying circuit (121) that generates a high-speed clock CLK1, a rearranging circuit (122) that transposes the captured image data into bit data sequences, a data output section (120) that causes each data transmitter (124) to sequentially transmit a corresponding bit data sequence to the outside on the basis of the high-speed clock CLK1, and a system controller (400) that drives data transmitters (124), the number of which is proportional to a transmission speed.

Owner:SONY CORP

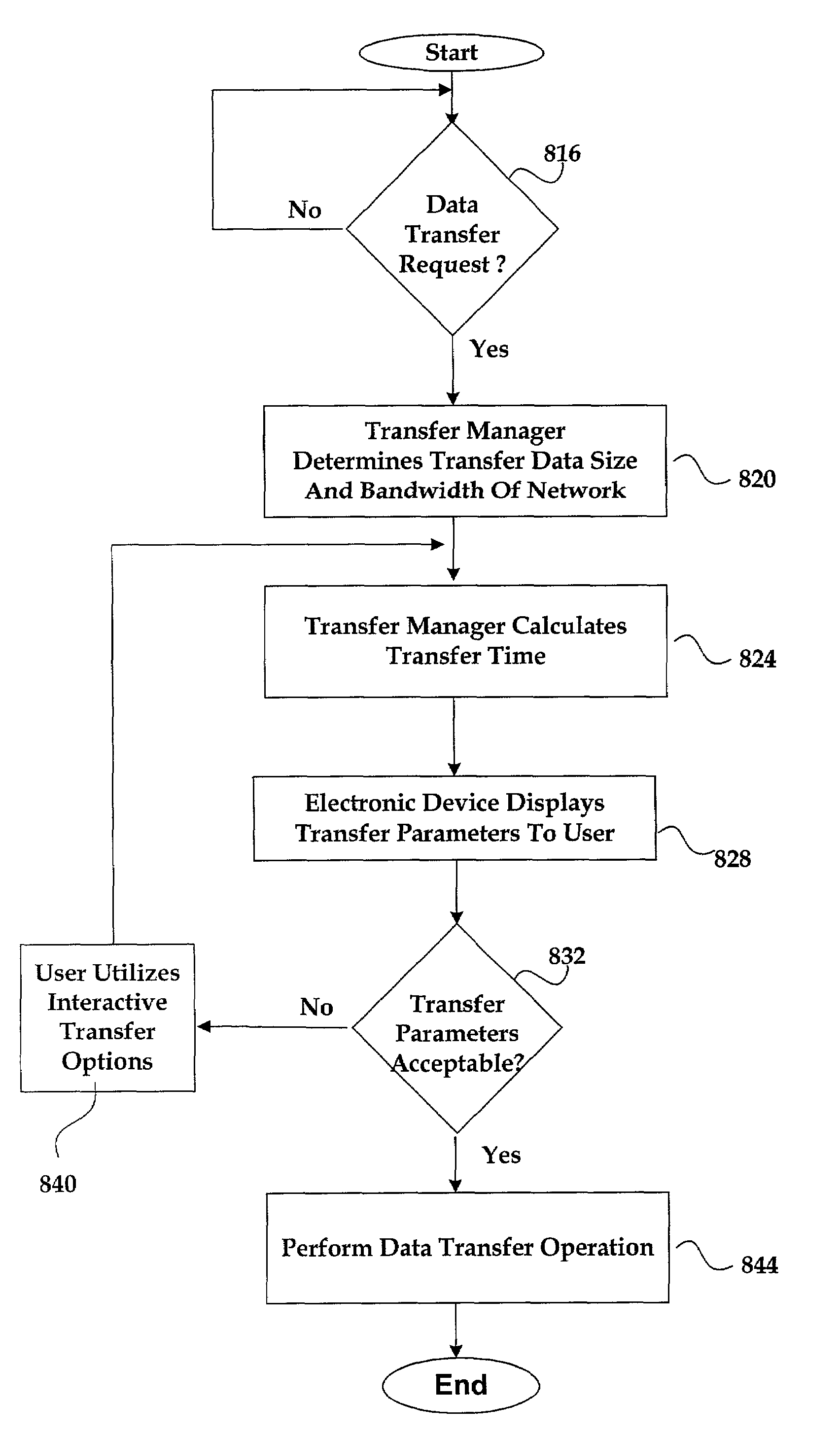

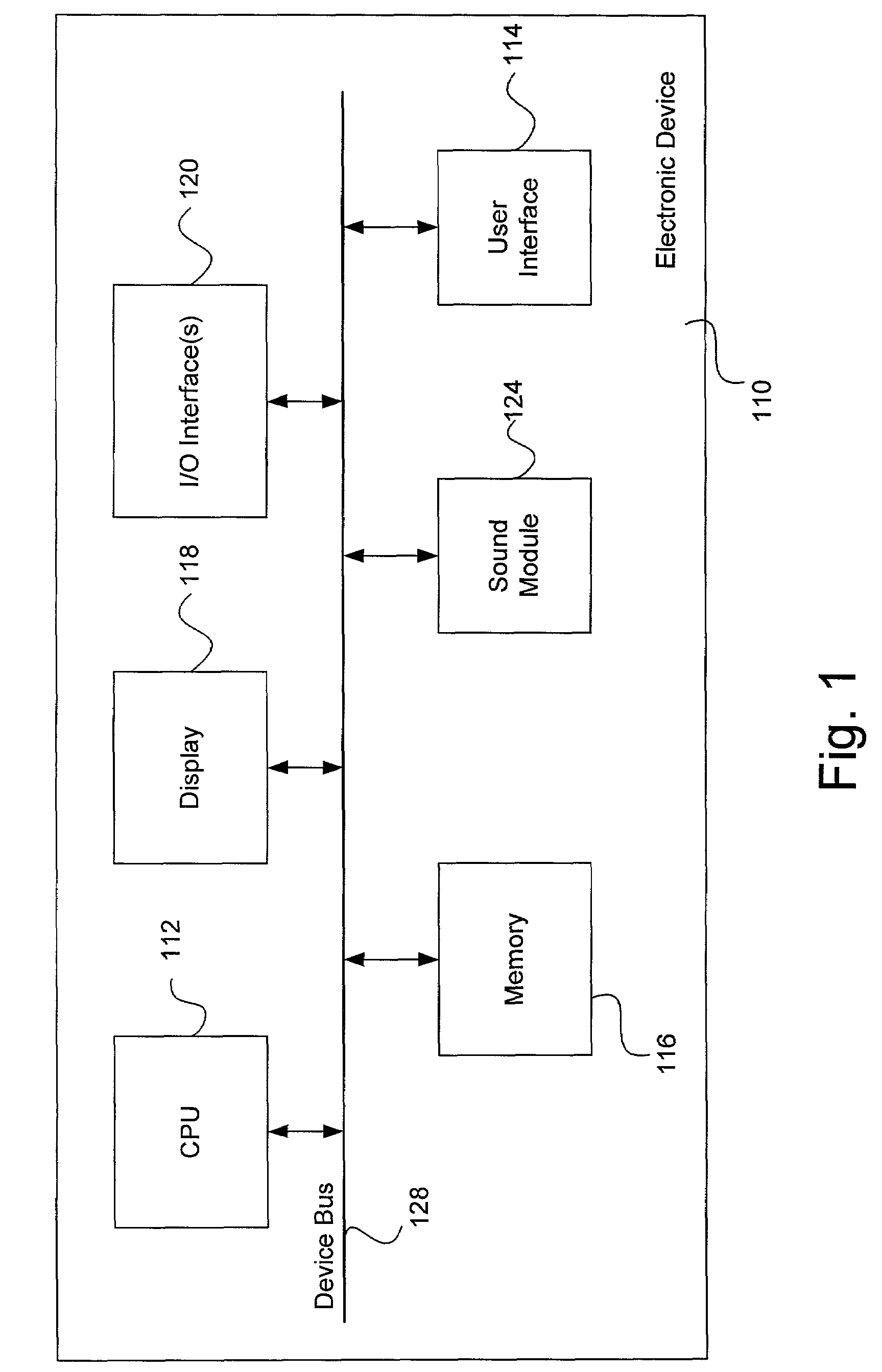

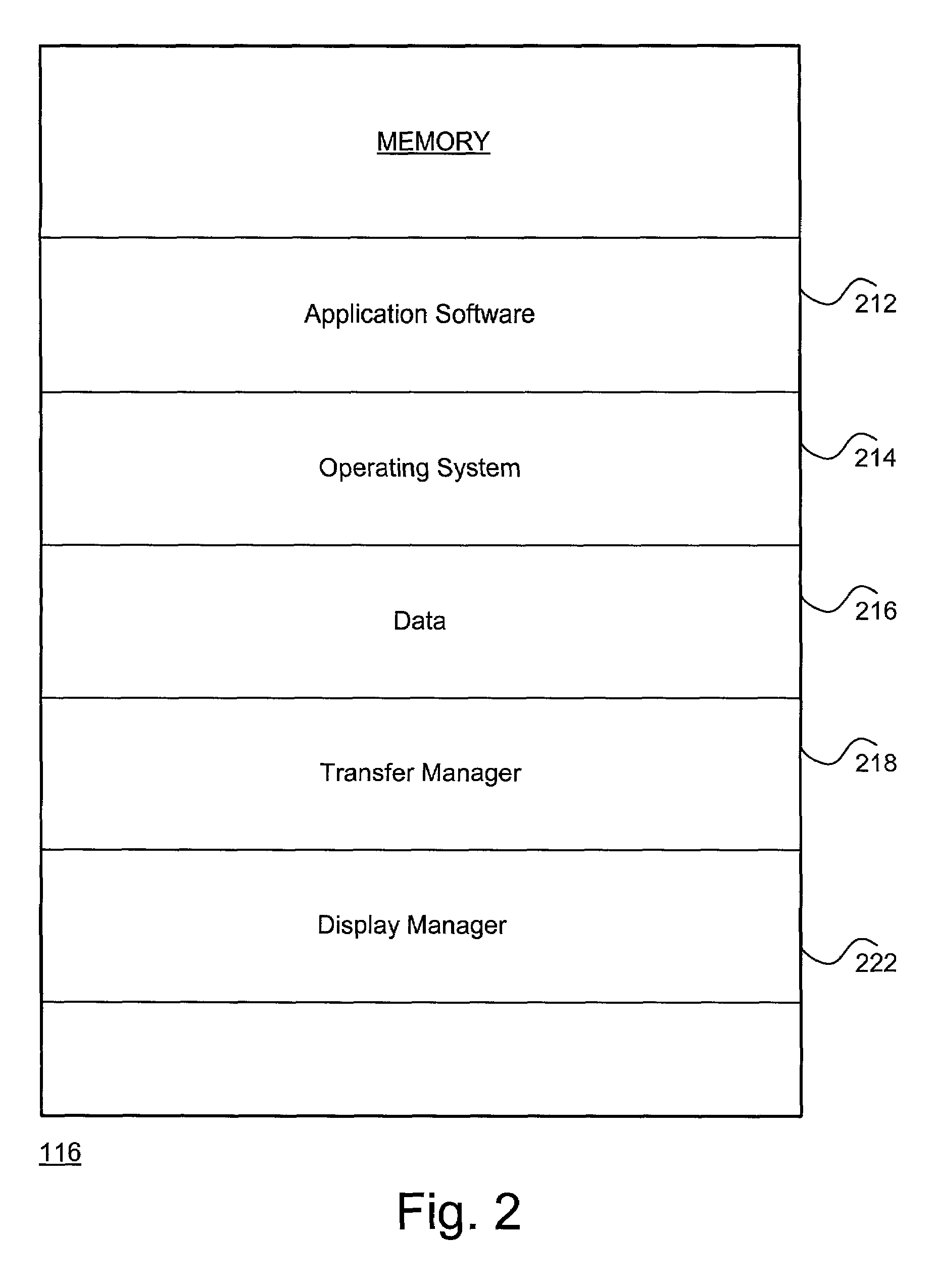

System and method for efficiently performing data transfer operations

InactiveUS7240099B2Improve performanceEfficient executionMultiple digital computer combinationsData switching networksData transmissionTransfer operation

A system and method for efficiently performing data transfer operations includes a source device for providing transfer data through a communication path or network to a destination device. The source device has a transfer manager that determines various transfer parameters including a transfer data size, a transfer speed, and a transfer duration. The transfer parameters are then presented on a user interface for interactive use by a system user to manipulate the transfer data with various transfer options to thereby perform the data transfer operation in an optimal manner under current transfer conditions.

Owner:SONY CORP +1

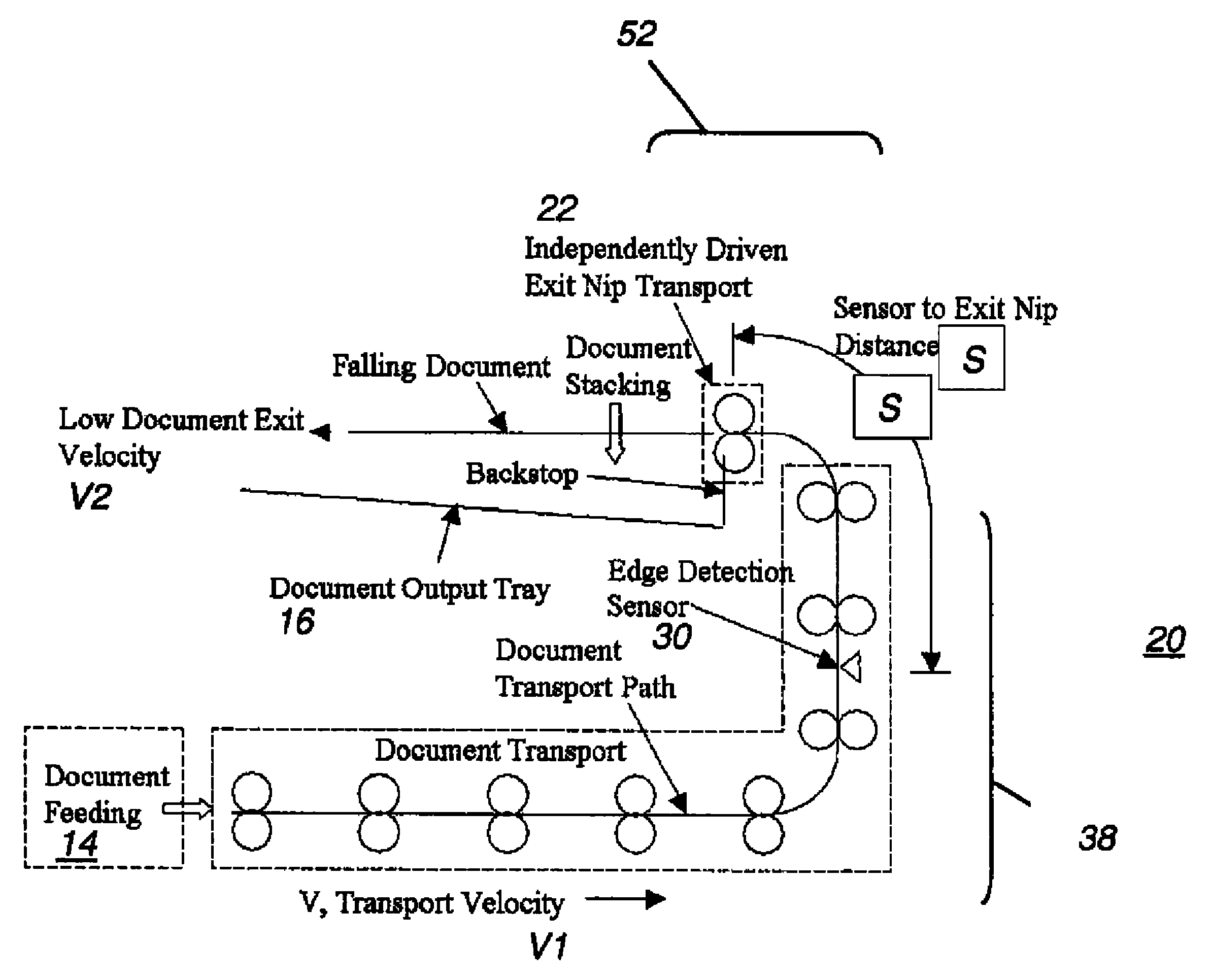

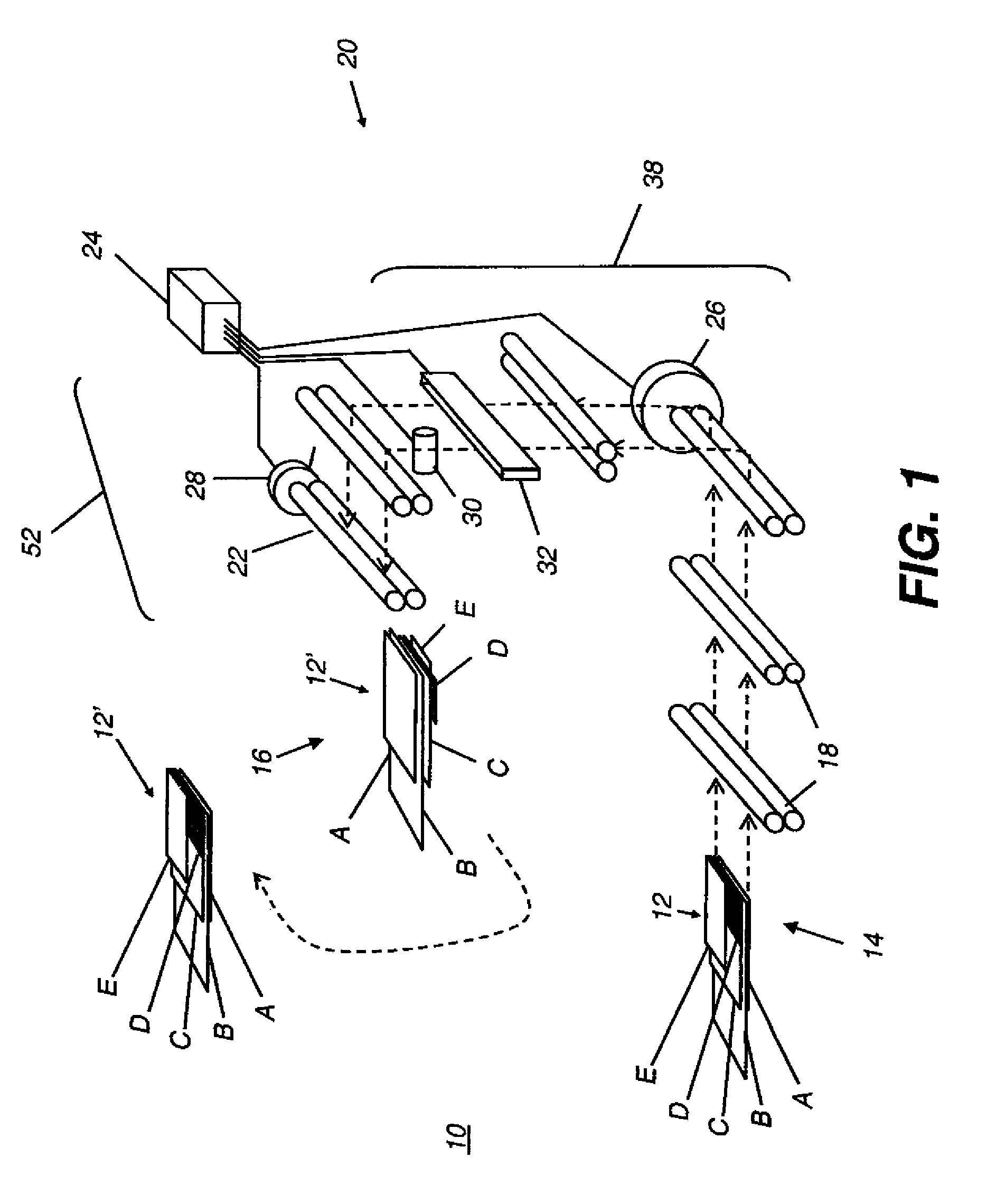

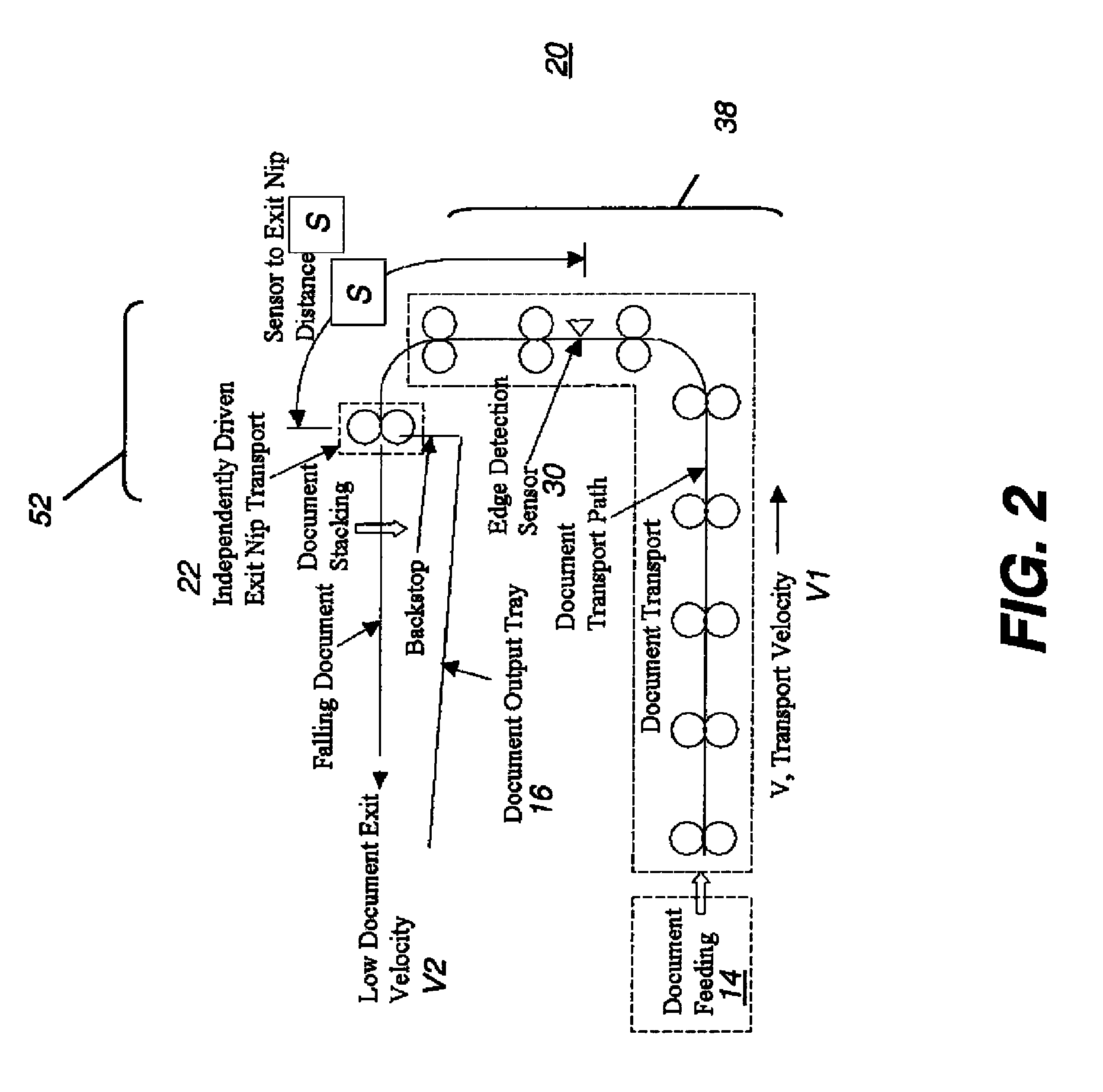

Document transport apparatus

ActiveUS7828279B2Preserving document stacking orderFilament handlingFunction indicatorsLeading edgePaper document

A method of scanning documents obtains the document that is to be scanned from an input tray, transports the document at a transport velocity past a scanner to obtain image data therefrom, and stacks each scanned document aligned with trailing-edge registration in a sloped output tray, in the order of scanning, by a sequence that detects the trailing edge of the scanned document, feeds the leading edge of the scanned document from an exit nip in a forward direction and above the sloped output tray at a transport velocity, then changes the speed at the exit nip to an exit velocity, different from the transport velocity, according to the timing of the trailing edge detection. The trailing edge of the scanned document is ejected at the exit velocity. The exit nip speed is restored to the transport velocity for feeding the leading edge of a subsequent document.

Owner:KODAK ALARIS INC

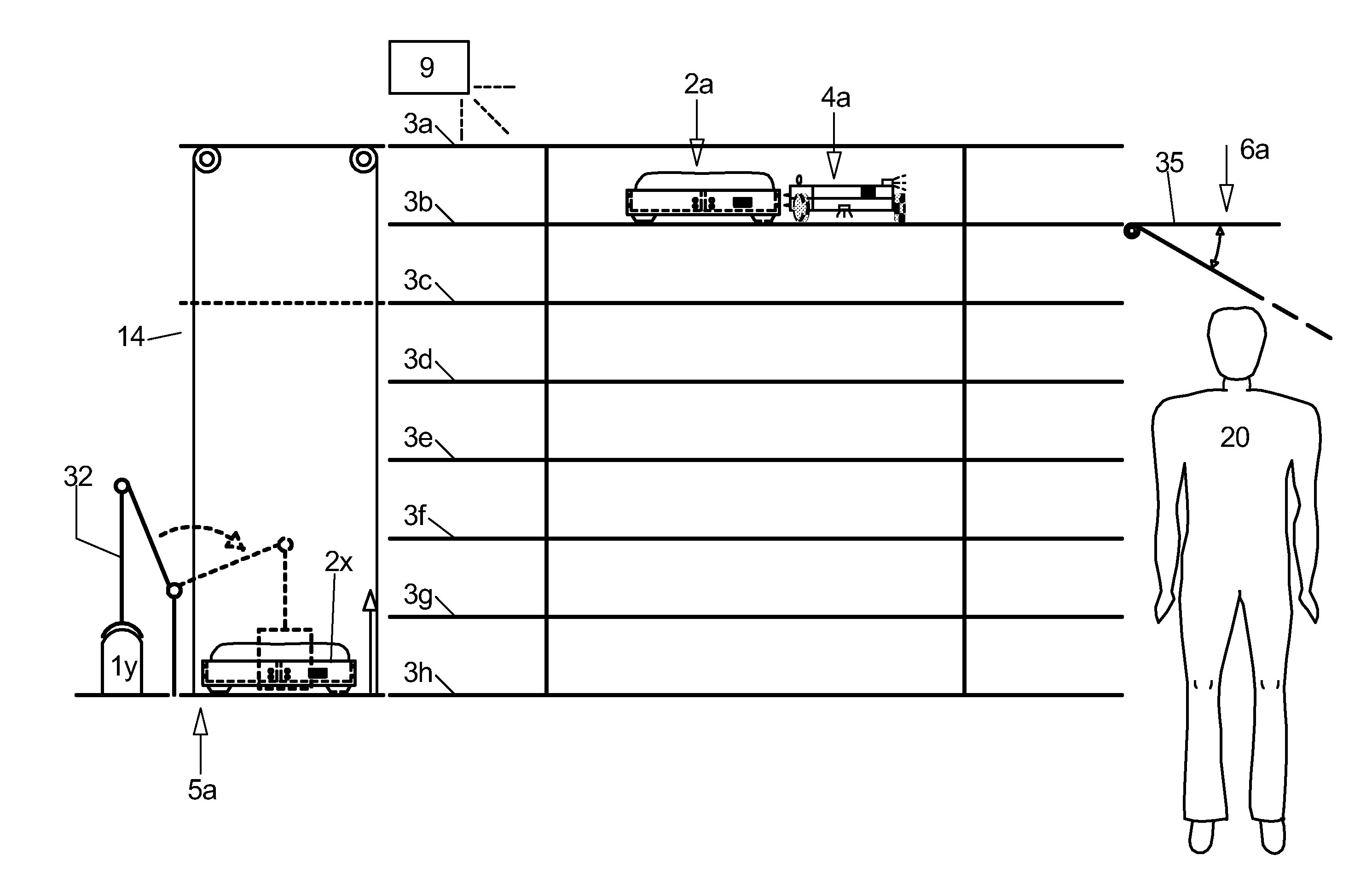

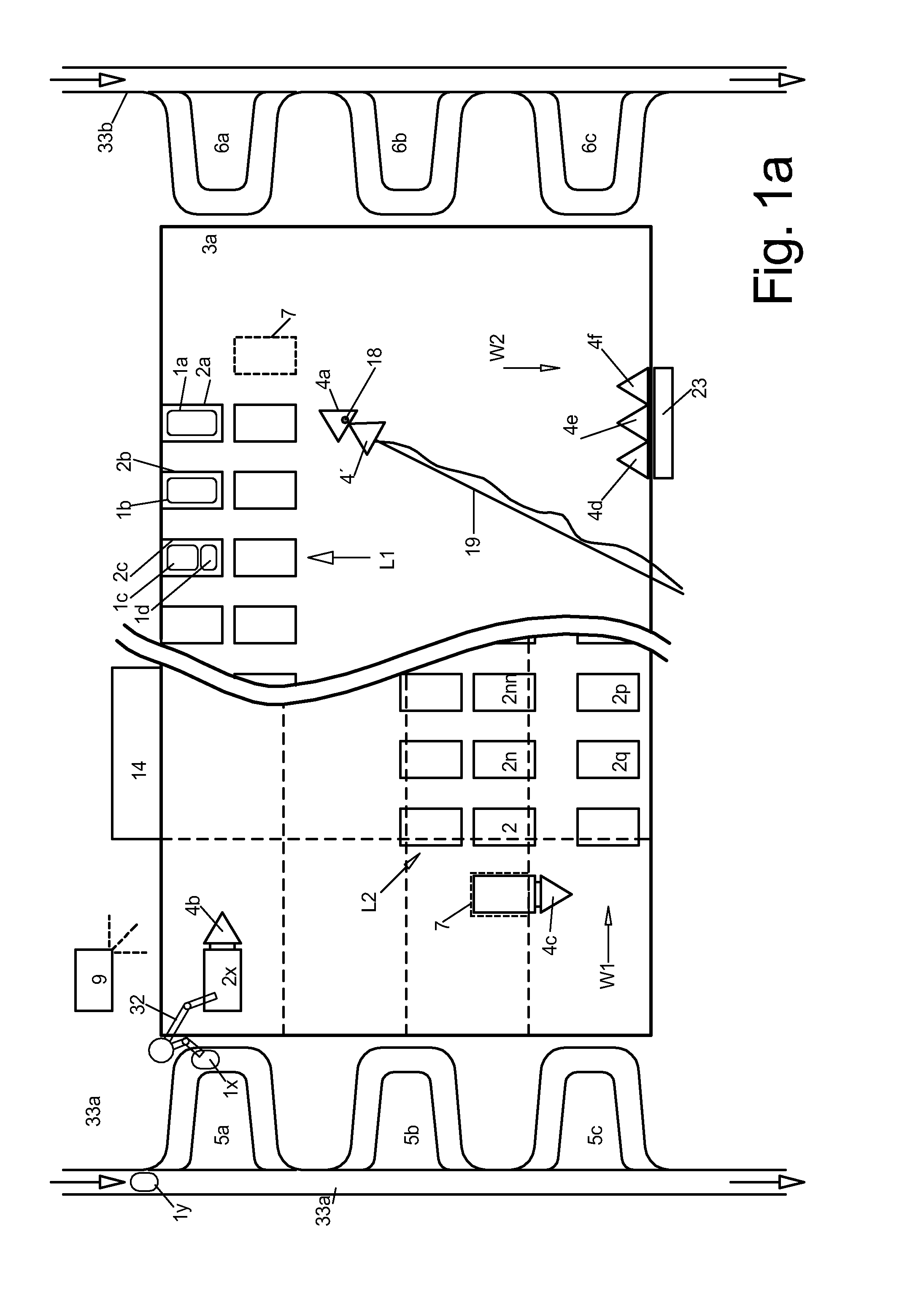

Storage systems comprising tractors and trailers

InactiveUS20120259482A1Easy to adaptLow costDigital data processing detailsSemiconductor/solid-state device manufacturingEngineeringTractor

Contrary to many storage systems in which the stored material is parked along rails and physical guides the instant invention includes self propelled tractors to move storage material arranged on trailers on a flat freely drivable storage surface to a desired position and parking it thereon. The slightly increased number of tractors which simultaneously perform storage and retrieval provide a high transfer speed.

Owner:TELEJET KOMMUNIKATIONS

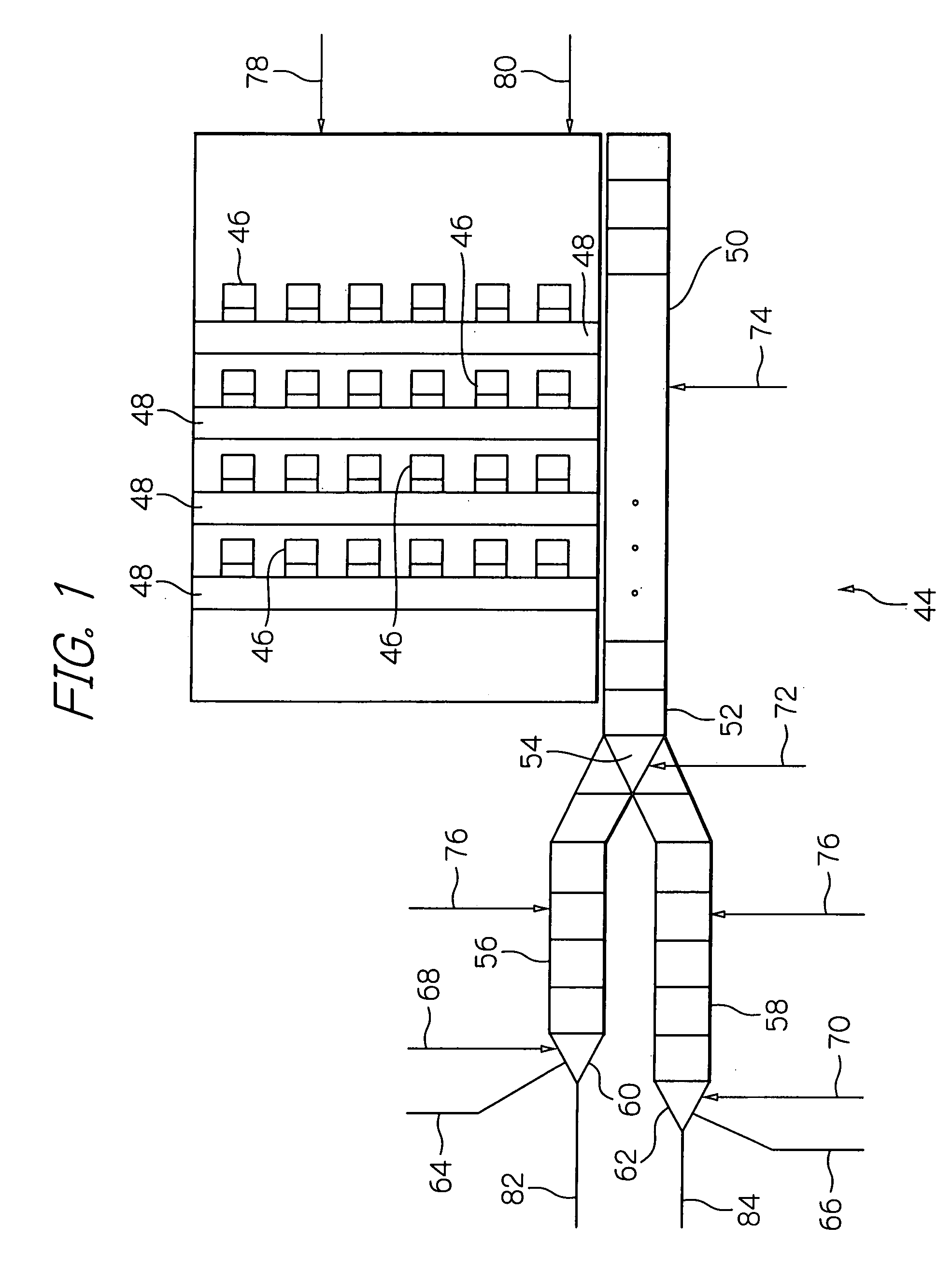

Solid state imaging device with horizontal transfer paths and a driving method therefor

InactiveUS20070229691A1Reduce noiseTelevision system detailsTelevision system scanning detailsAudio power amplifierVoltage

In a solid state imaging device, signal charges are branched to be output to in the form of one or plural outputs. At a horizontal transfer speed not lower than a predetermined transfer speed, the imaging device transfers signal charges of color attributes classified by a branching section, to plural horizontal transfer paths, where the signal charges are converted into analog voltage signals, which will be output synchronously. At a horizontal transfer speed lower than the predetermined transfer speed, the analog voltage signal converted is output from, e.g. the horizontal transfer path which has been selected. Output amplifiers arranged on the horizontal transfer paths are differentiated in sensitivities in detecting signal charges, depending on color attributes of signal charges supplied, and output the analog voltage signals.

Owner:FUJIFILM CORP

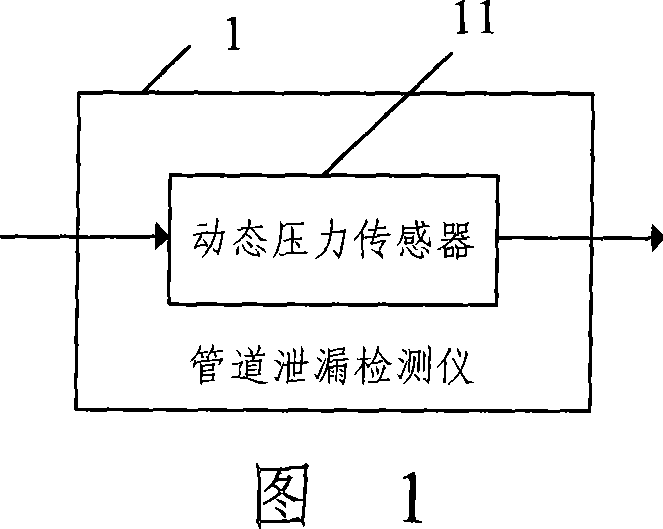

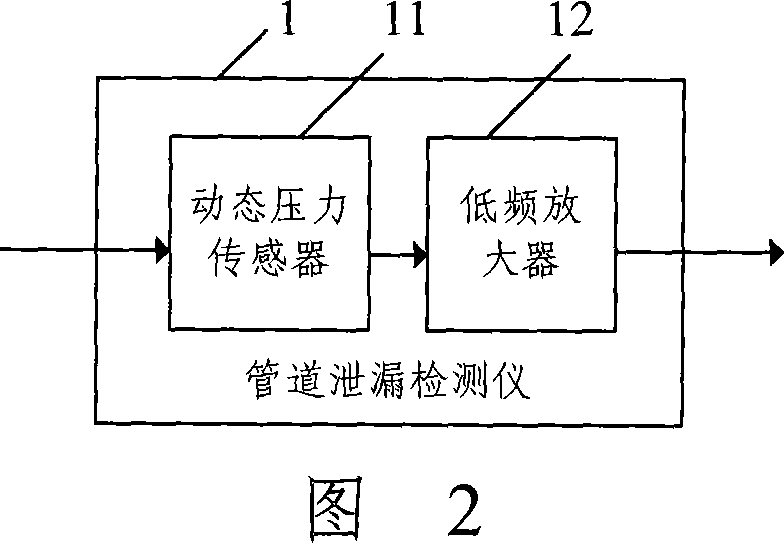

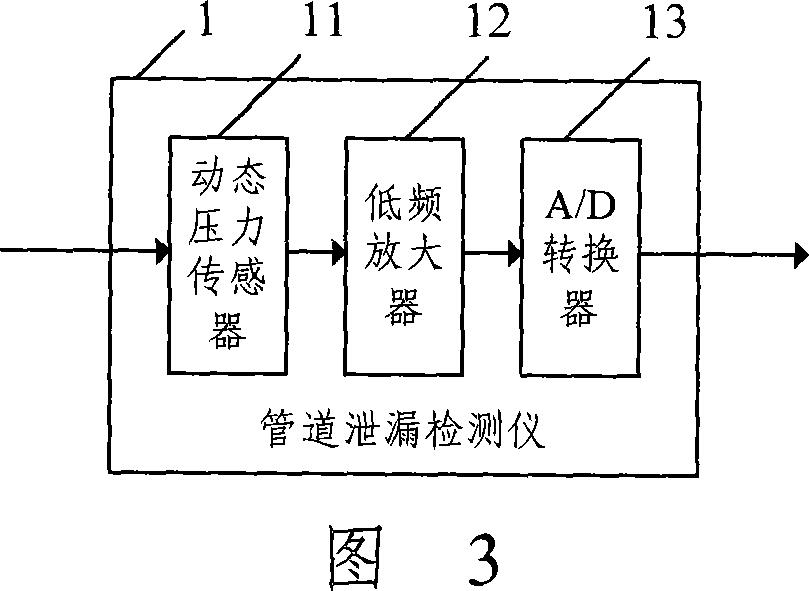

Pipe leakage detecting instrument, detecting device and detecting method based on dynamic low-frequency technology

The invention discloses a kind of conduit leakage detecting instrument, a detecting device and the method which base on the dynamic low-frequency technology. The conduit leakage detecting instrument includes a dynamic pressure sensor; the detecting device includes a conduit leakage detecting instrument, a base station, a central control station, and a GPS locating instrument and the conduit leakage detecting instrument connects with the central control station though the base station and the base station and the central station set up a locating instrument; the detecting method includes the following steps: the central station sets up the dynamic adjustable measuring range of the conduit leakage detecting instrument according to the get dynamic pressure variety; the GPS locating instrument can gets the time of the conduit leakage acoustic wave arriving the delivery first station or the delivery last station's conduit leakage detecting instrument individually; it can get the location of conduit leakage by plus-minus the time told above then multiply the transmission speed of the acoustic wave in the medium. It improves the measurement precision of the smaller pressure variety by adopting the detecting instrument and the detecting device and the method of the invention also can separate the leakage acoustic signal so it can determine the location of conduit leakage correctly.

Owner:陆国良

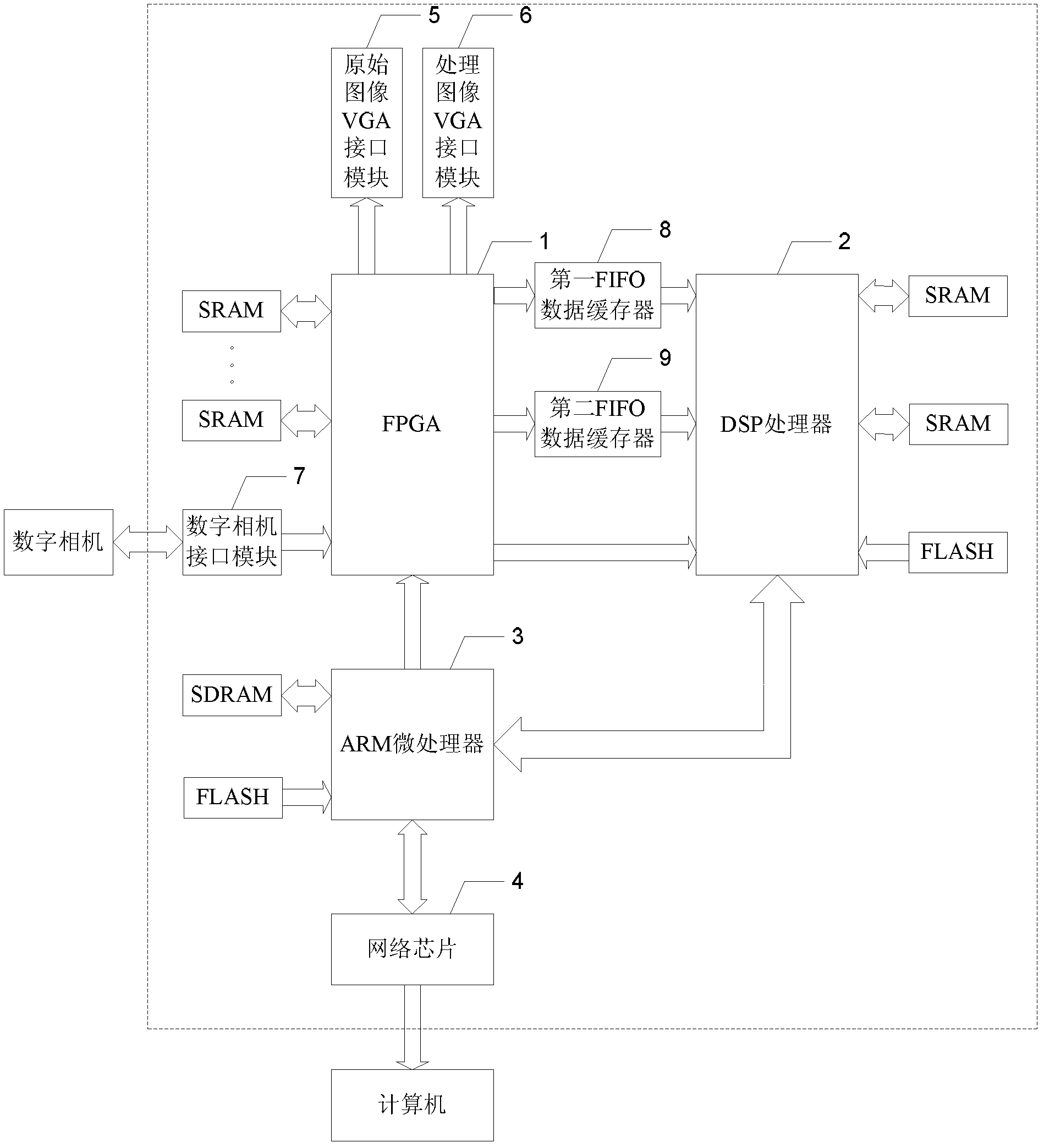

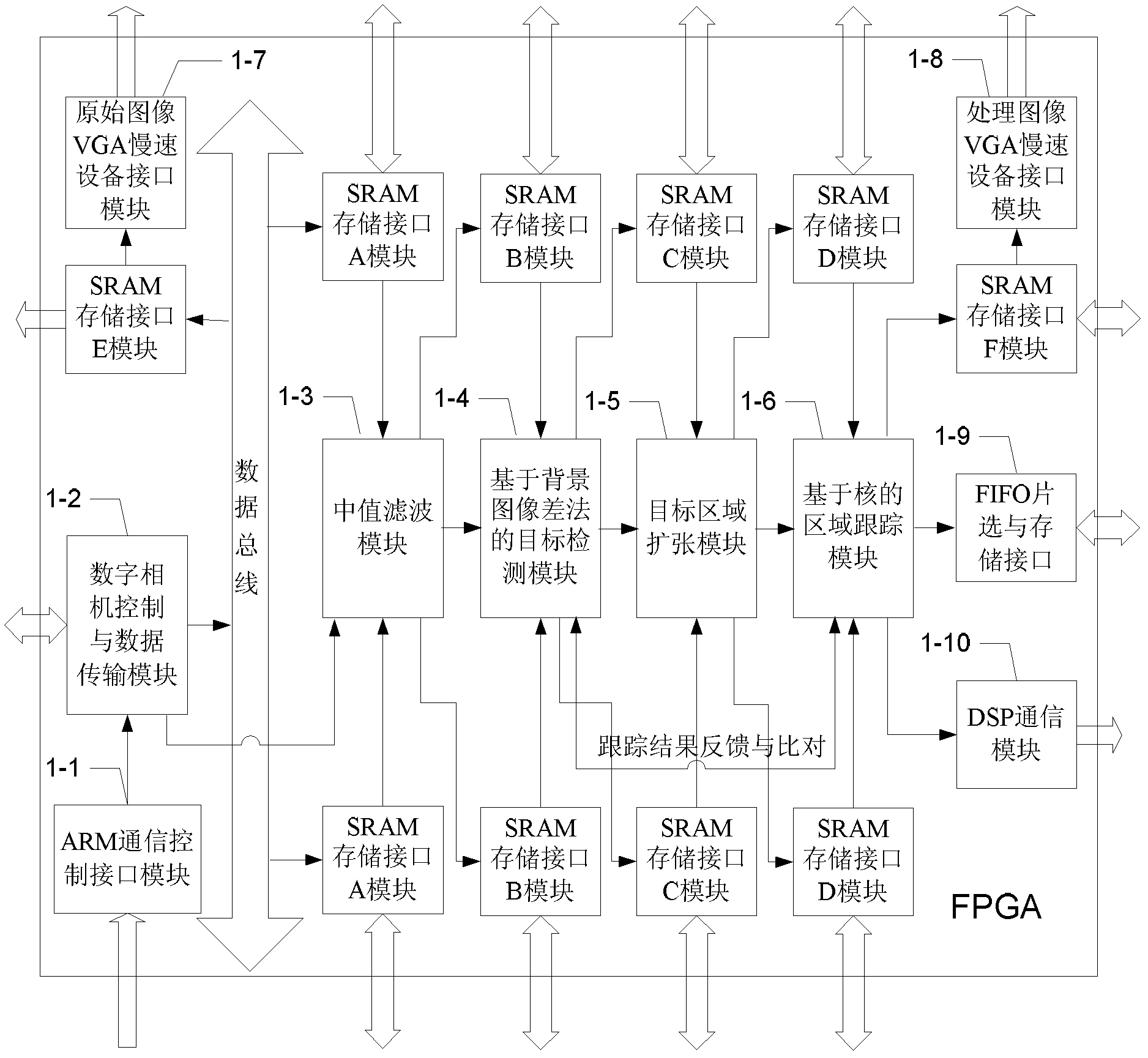

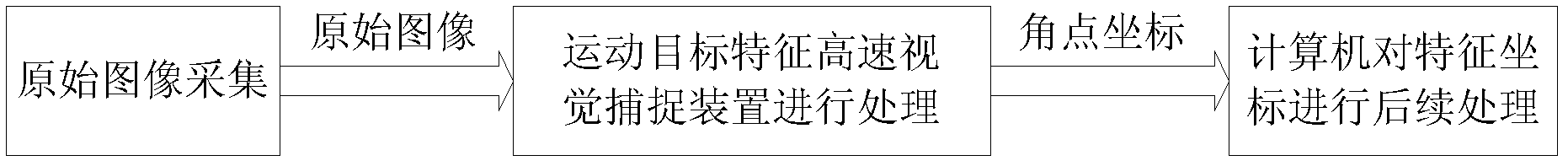

High-speed vision capture apparatus of moving object characteristic

ActiveCN102438118AProcessing speedEasy to handleTelevision system detailsImage analysisControl signalField-programmable gate array

A high-speed vision capture apparatus of a moving object characteristic belongs to the image processing field and the machine vision image measurement field. In the high-speed vision measurement, a real-time processing speed is not fast, a data volume is large and a transmission speed is low. By using the apparatus of the invention, the above problems can be solved. The apparatus comprises: a field-programmable gate array (FPGA), a digital signal processor (DSP), an advanced RISC machines (ARM) microprocessor, a network chip, an original image video graphics array (VGA) interface module, a processing image VGA interface module, a digital camera interface module, a first and a second first in first out (FIFO) data buffers. A digital camera collects an original image to the FPGA. The FPGA is connected with the original image VGA interface module and the processing image VGA interface module. A cached output terminal of the FPGA is connected with input terminals of the first and a secondFIFO data buffers respectively and is connected with the DSP. The DSP is connected with the ARM microprocessor. The ARM microprocessor is connected with a control signal input terminal of the FPGA. The ARM microprocessor is connected with a computer through the network chip.

Owner:HARBIN INST OF TECH

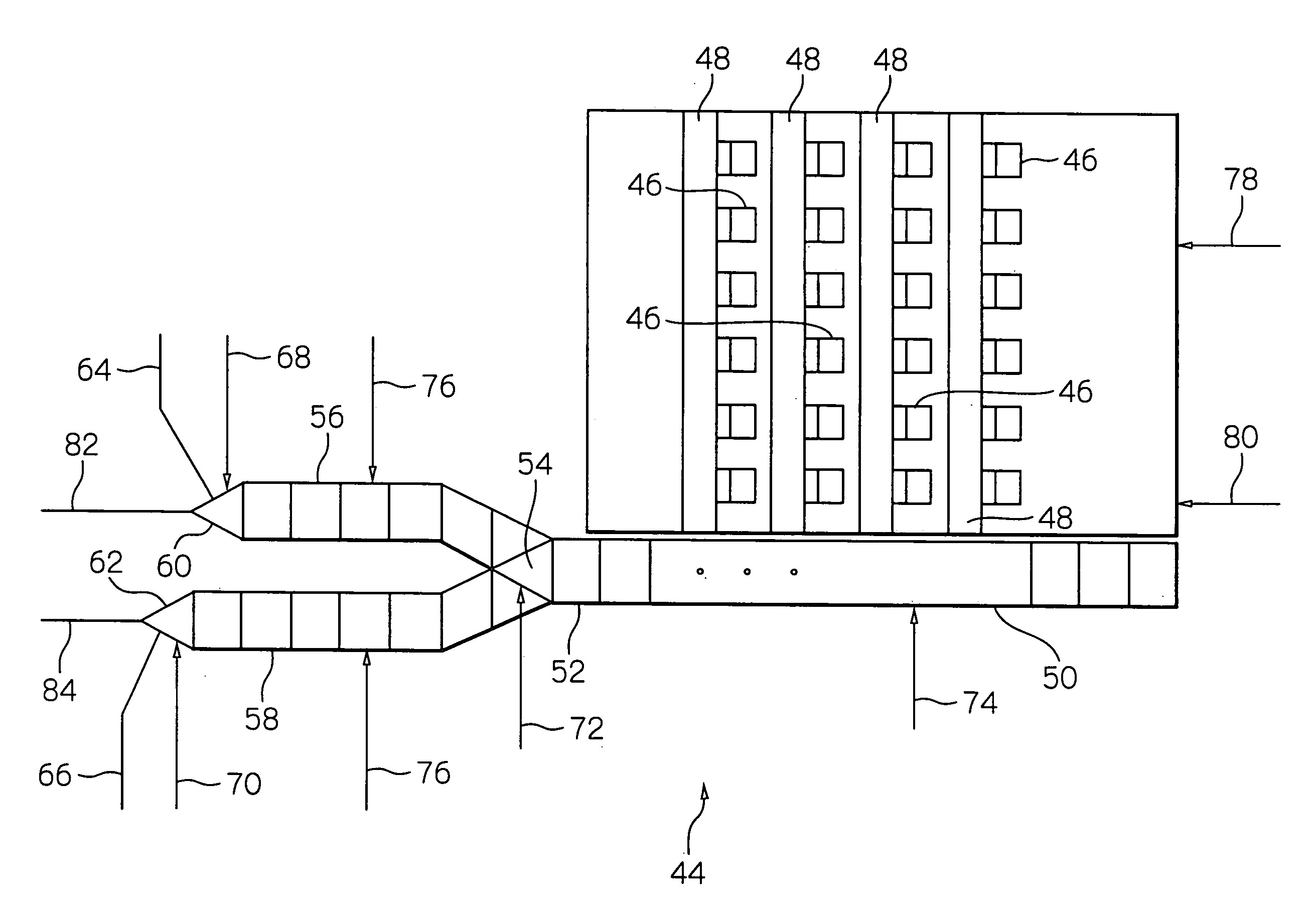

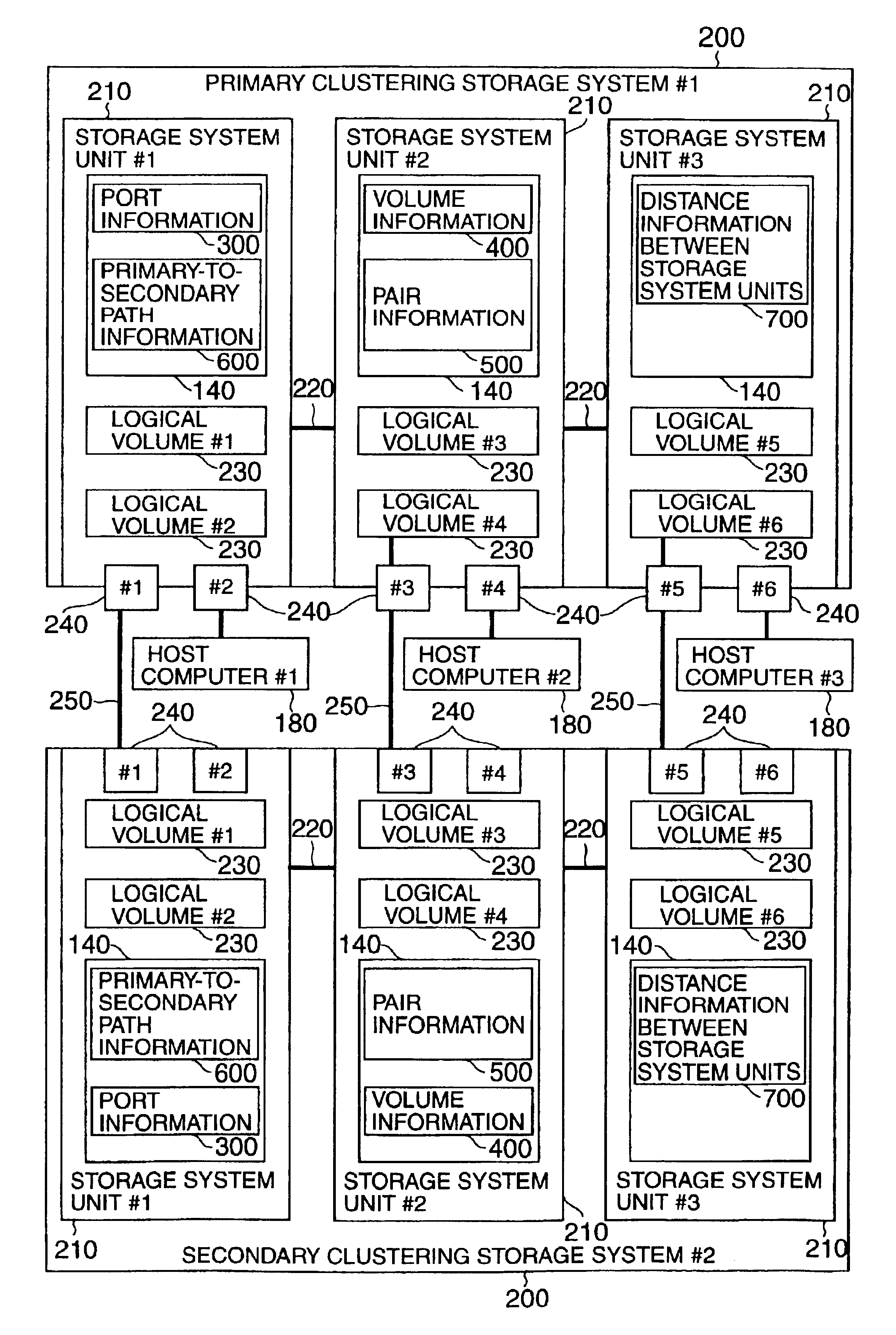

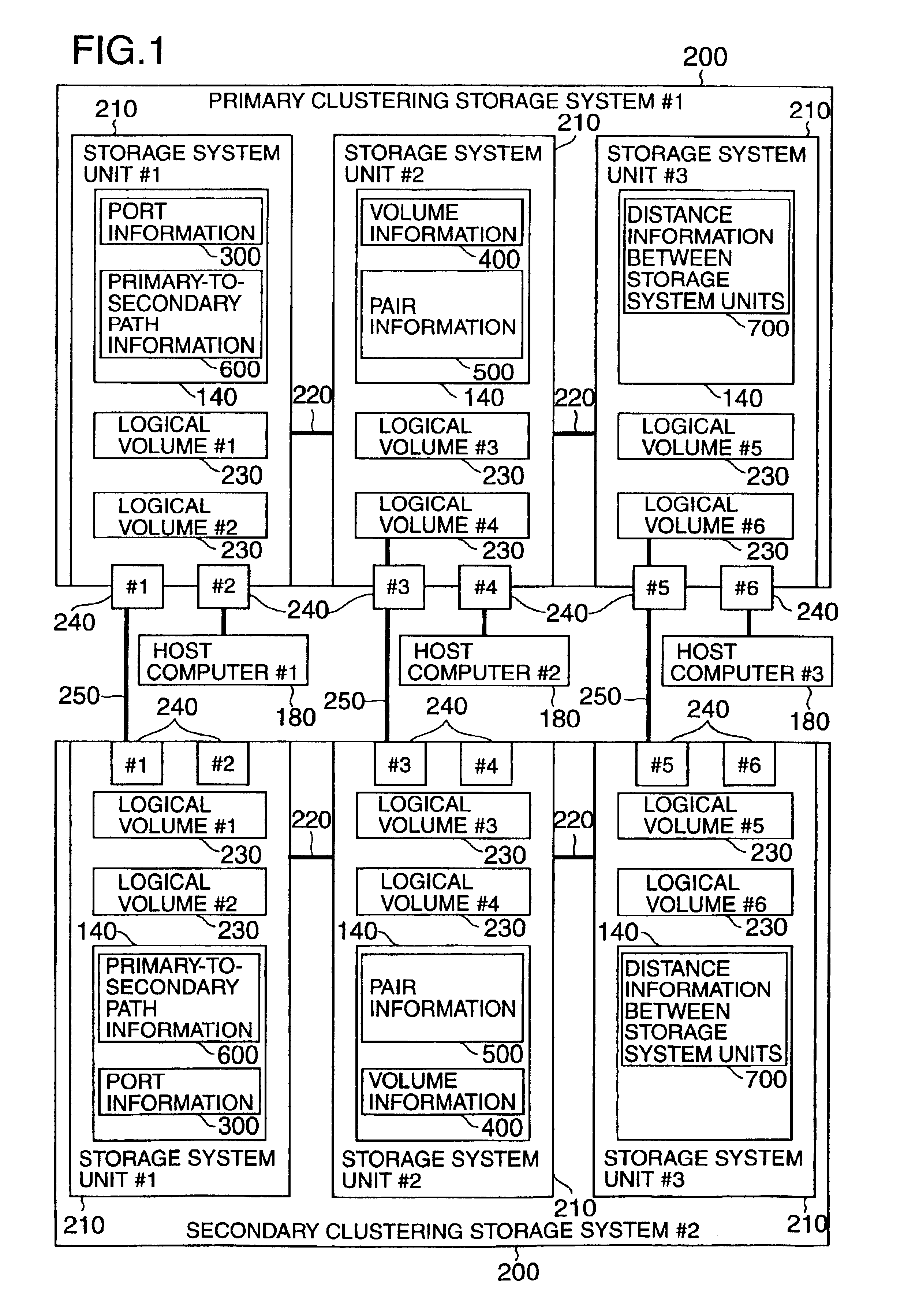

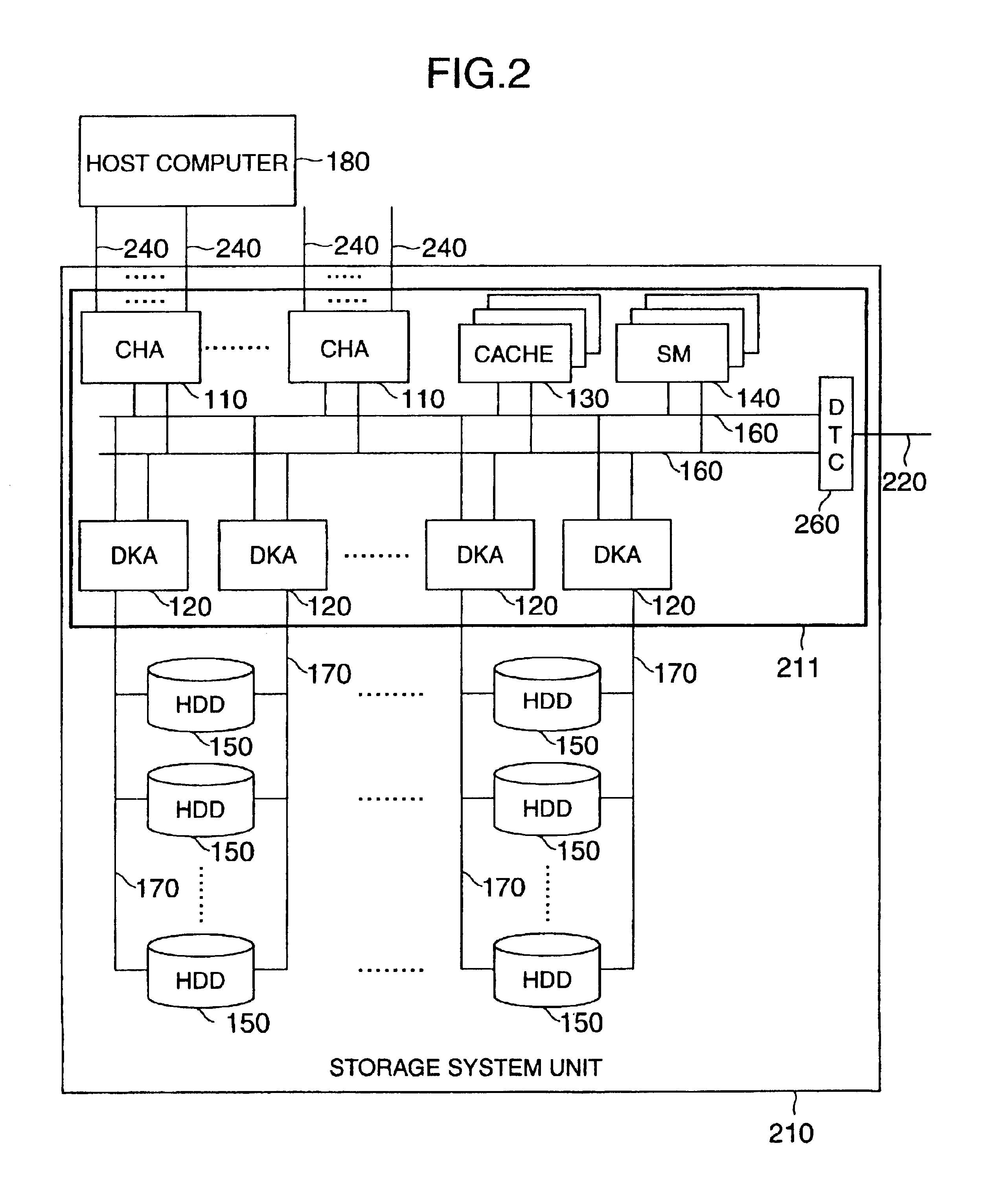

Clustering storage system

InactiveUS6922762B2Improve access performanceDrawback can be solvedInput/output to record carriersMultiple digital computer combinationsData connectionHybrid storage system

A clustering storage system, which enables to operate a plurality of storage system units as a single storage system, presents connection information between clustering storage systems to a user and receives data to be backed up and an instruction about a path between the clustering storage systems from the user. The clustering storage system uses load information or a transfer speed of a data connection line between the storage system units to determine a path between the clustering storage systems used for backup and a storage system unit for holding a backup copy so that the data transfer between the storage system units becomes minimum. Besides, the clustering storage system mainly uses the determined path for backing up the data.

Owner:HITACHI LTD

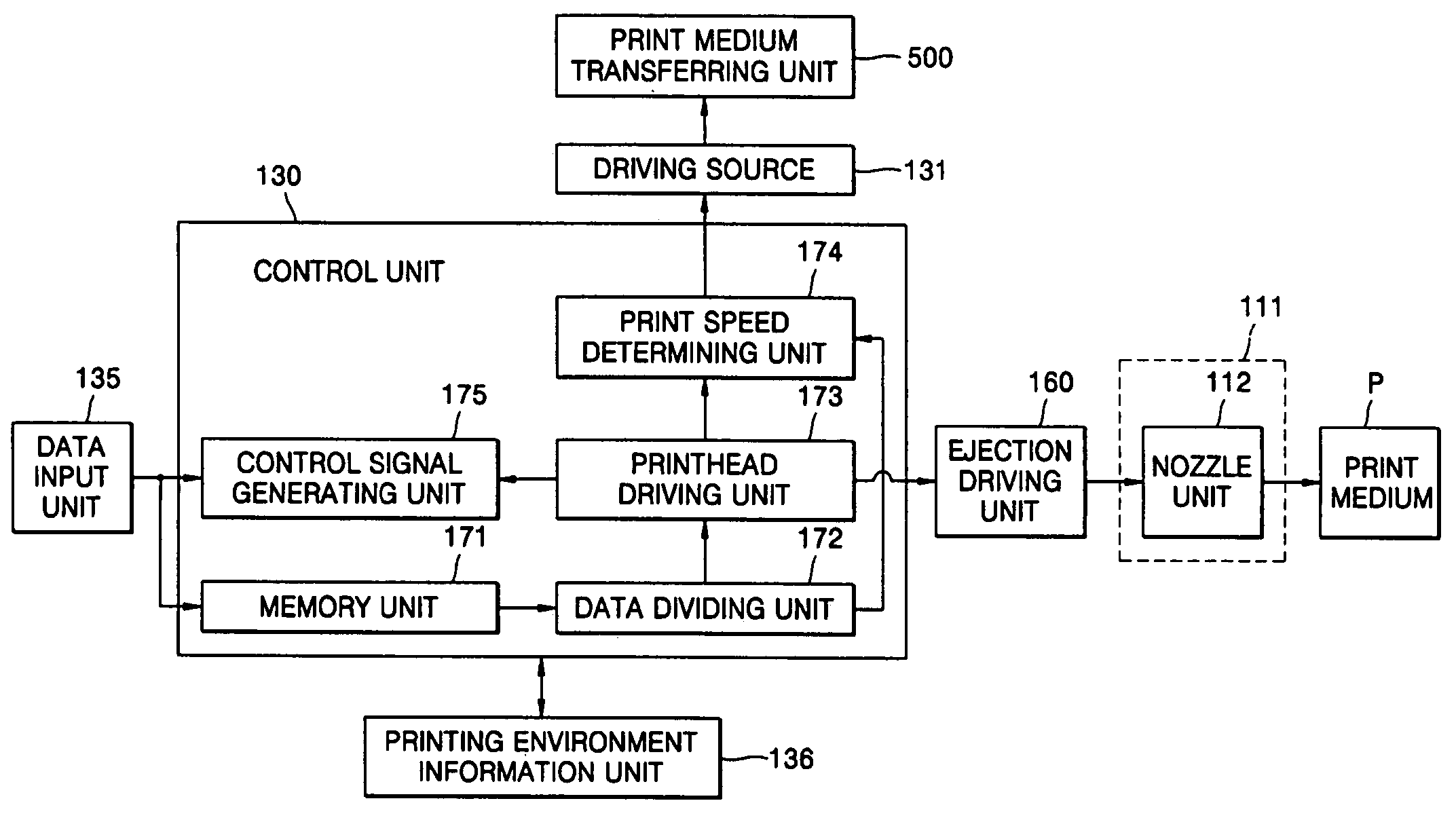

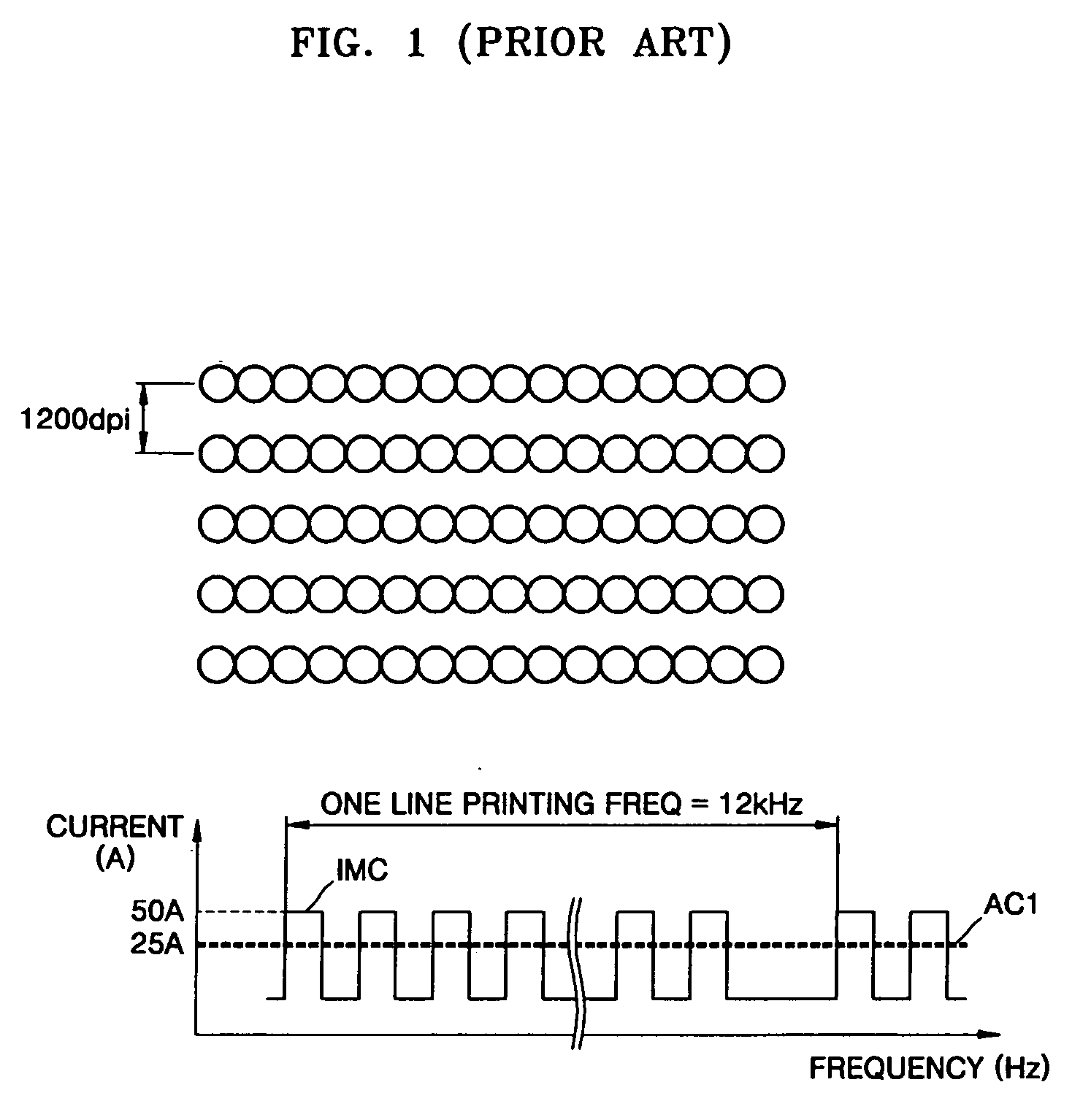

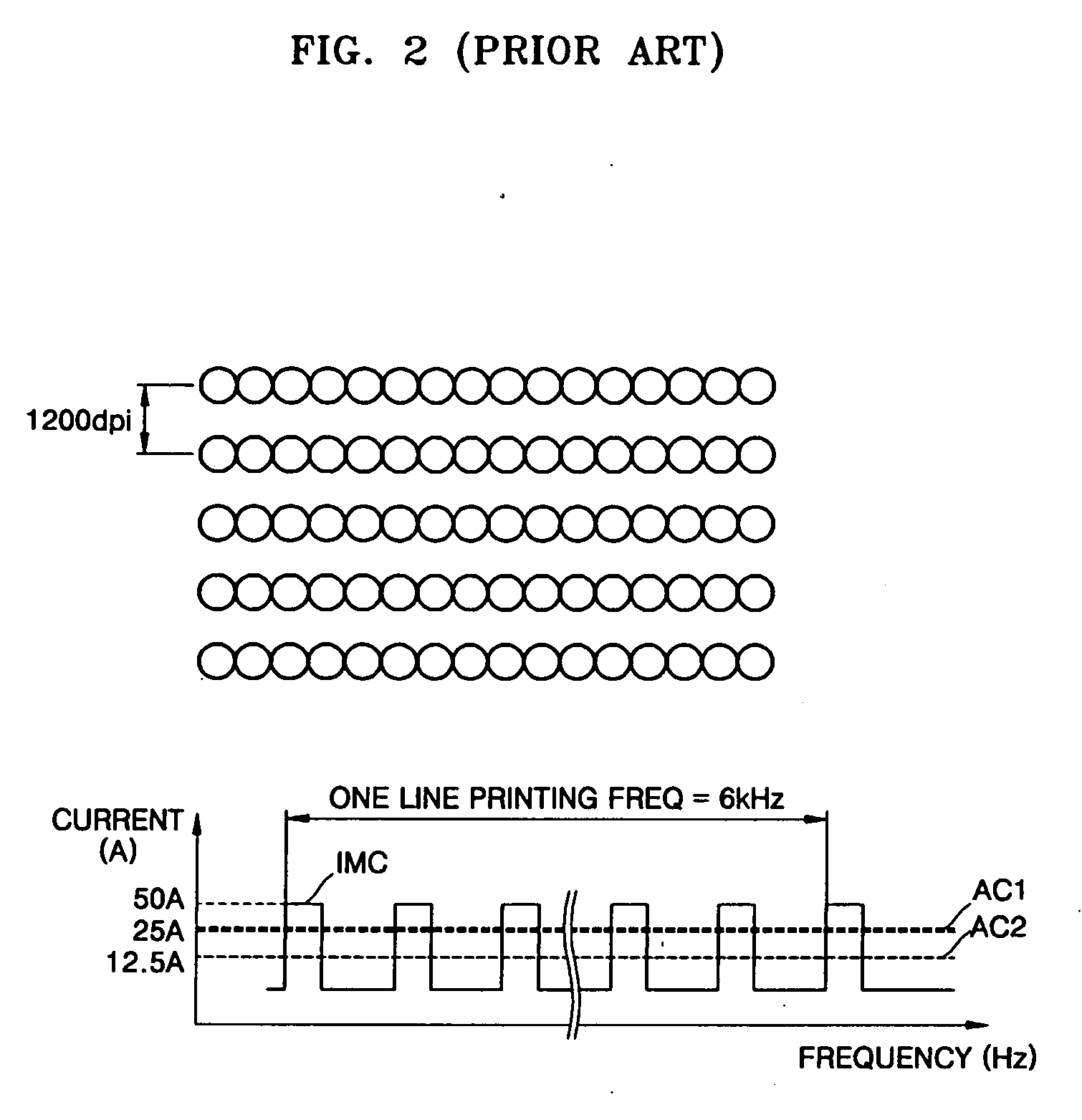

Inkjet image forming apparatus and printing method

InactiveUS20070024667A1Improve printing qualityReduce transfer speedInking apparatusOther printing apparatusImaging equipmentImaging data

An inkjet image forming apparatus and a printing method for the same. The printing method includes dividing image data to be printed in a single line into “n” groups, reducing a transferring speed of a print medium, and sequentially printing the divided “n” groups in “n” lines. The image data to be printed in the single line is divided and printed with a predetermined driving frequency. A transferring speed of the print medium is controlled to print the image data such that an instantaneous maximum consumption current and an average consumption current are reduced, resulting in the use of the smaller capacity power supply. The print medium is slowly transferred and the divided image data is sequentially printed, thereby enhancing printing quality.

Owner:SAMSUNG ELECTRONICS CO LTD

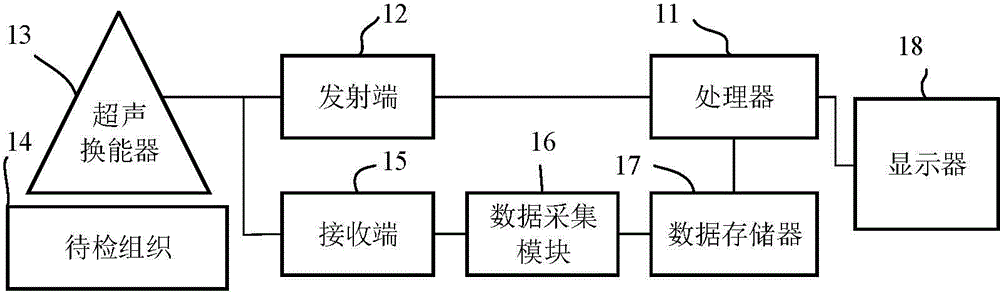

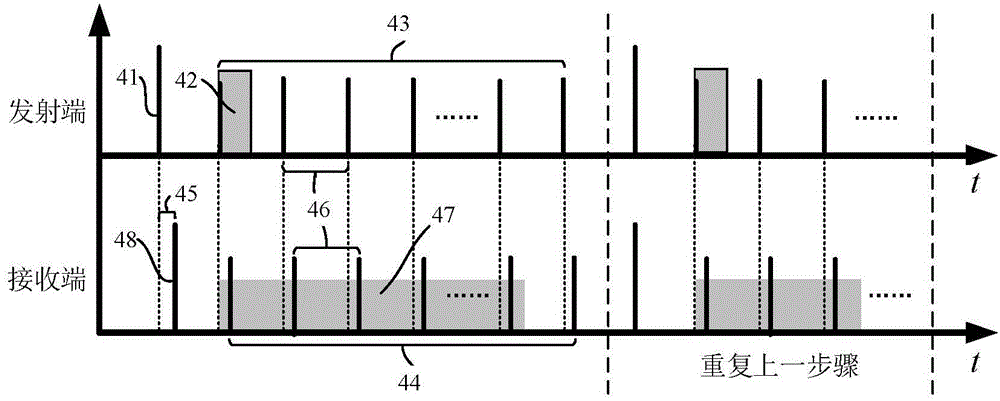

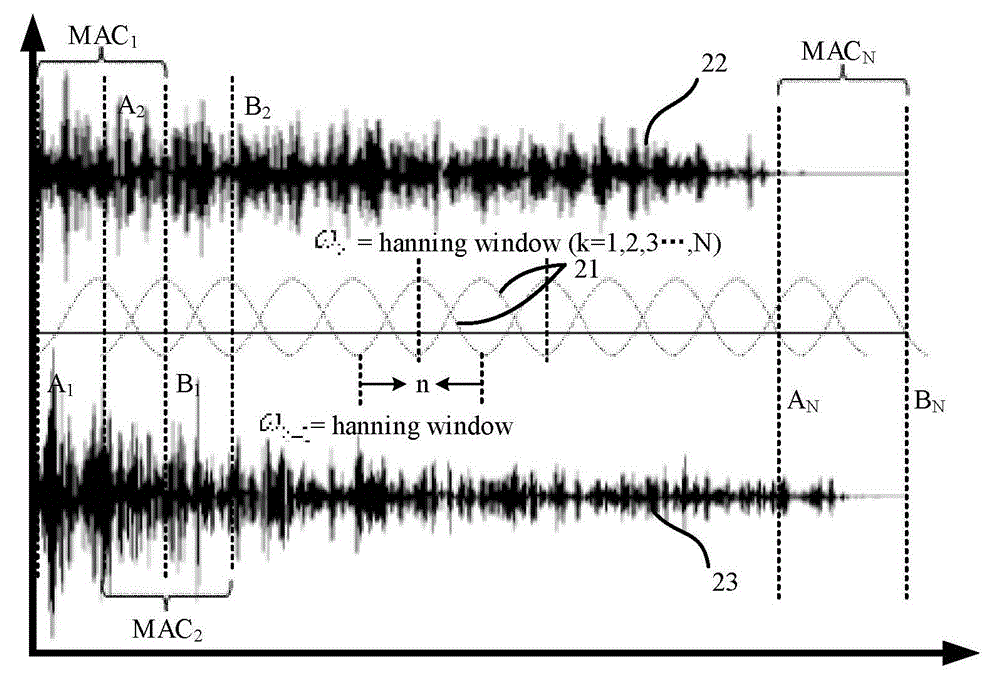

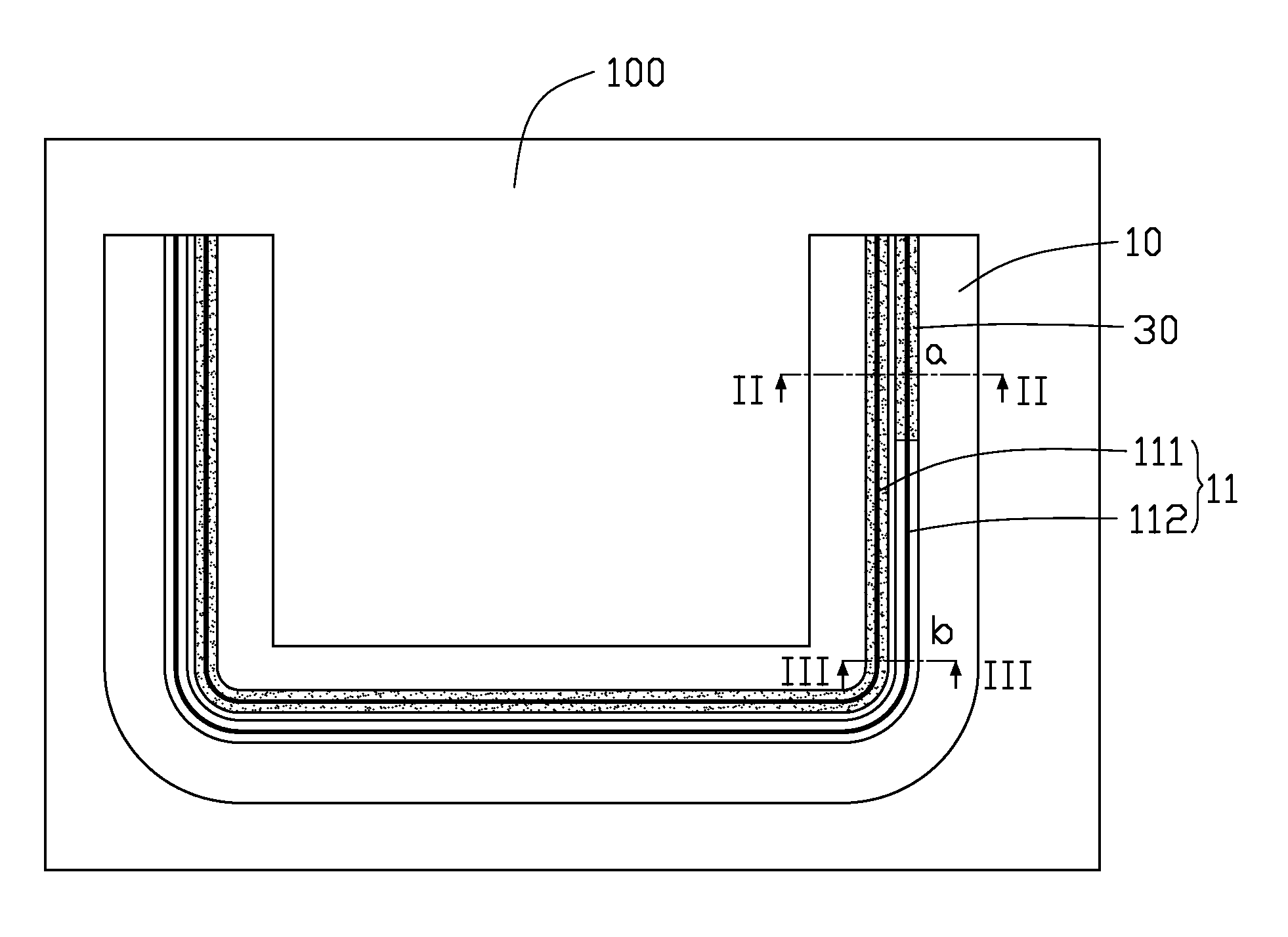

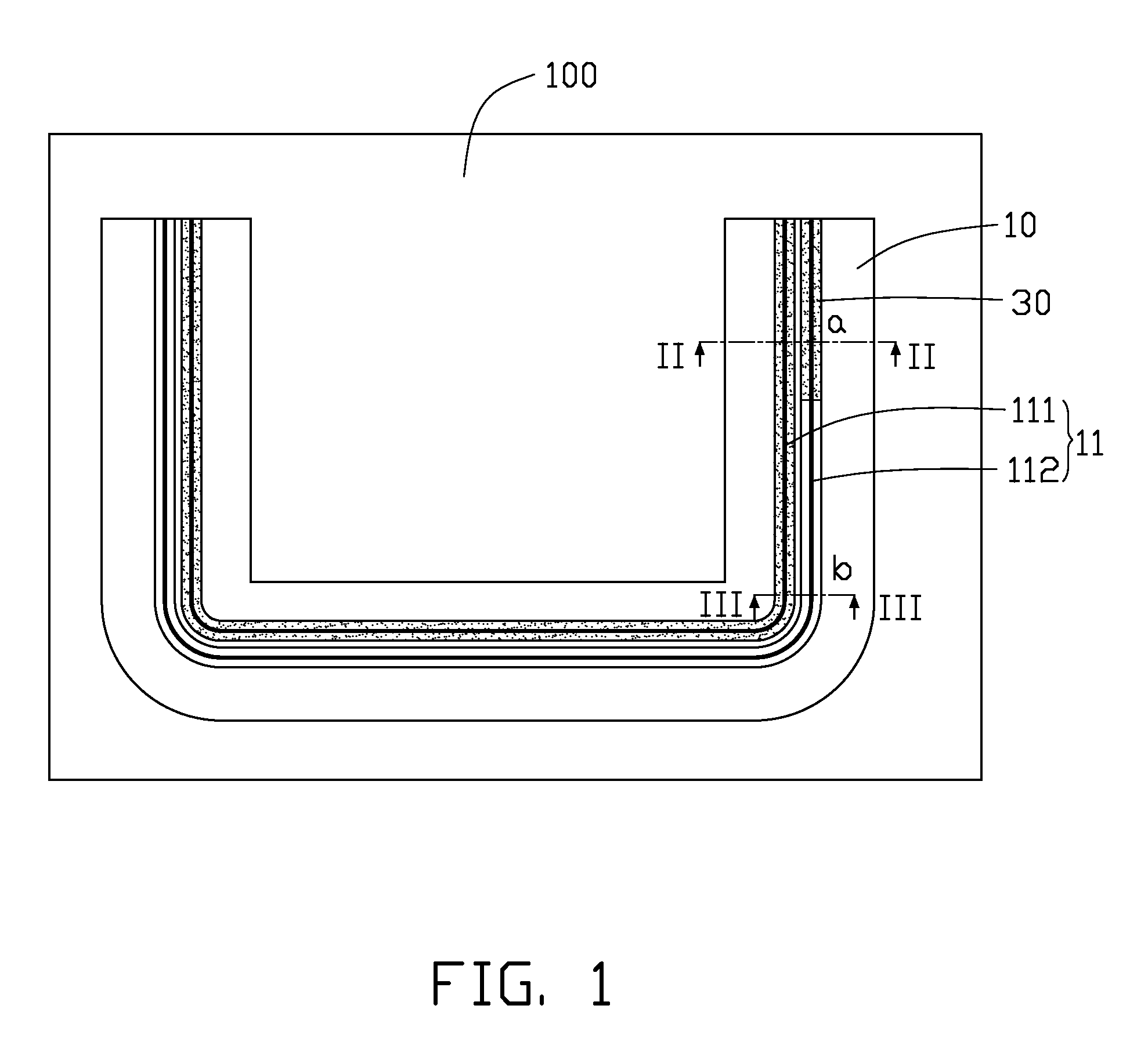

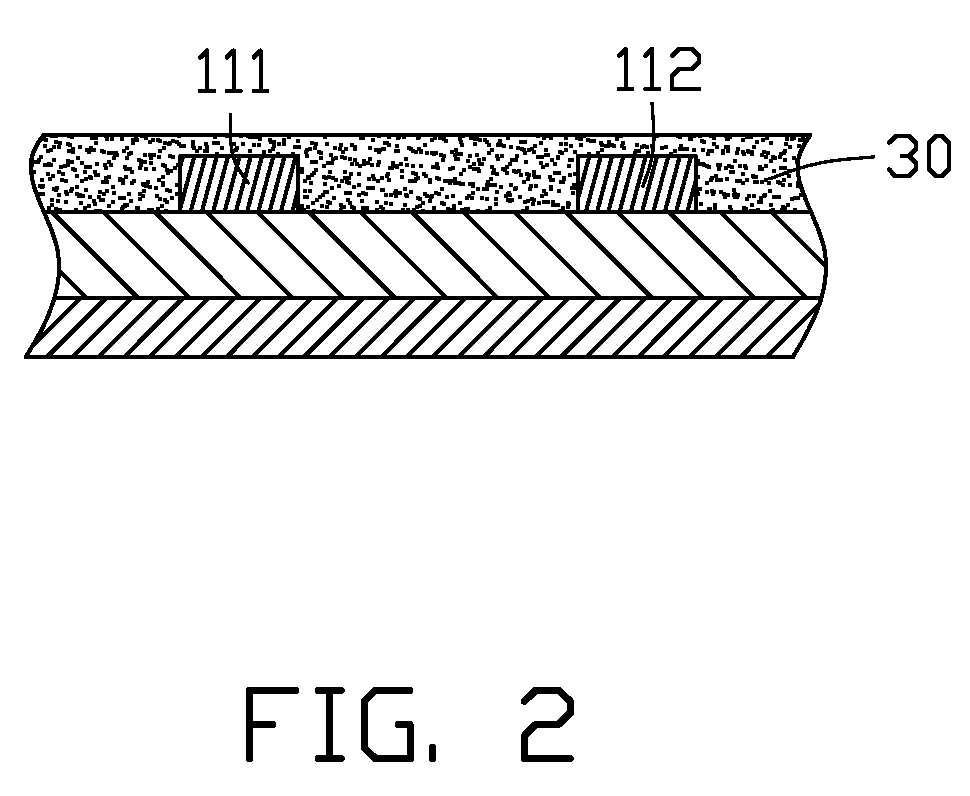

Method for detecting transmission speed of shear wave in biological tissue, method for detecting elasticity of biological tissue and method for biological tissue elasticity imaging

ActiveCN104605891AHigh resolutionAchieve early diagnosisOrgan movement/changes detectionInfrasonic diagnosticsShape changeElastography

The invention discloses a method for detecting transmission speed of a shear wave in biological tissue, a method for detecting elasticity of the biological tissue and a method for biological tissue elasticity imaging. The method for detecting the transmission speed of the shear wave in the biological tissue is characterized in that the distance of any two positions in the to-be-detected tissue in the shear wave transmission direction and time difference of MAC values of real-time echo signals and original echo signals changing on the two positions respectively are used for calculating the transmission speed of the shear wave between the two positions. The modal assurance criterion is used for tracking the shear wave, a fine shape change estimation of the issue under the action of the shear wave can be achieved, and the signal to noise ratio, the resolution ratio and the contrast degree of an image can be improved. The sensitivity is high. The modal assurance criterion serves as a time domain calculation method for ultrasound echo radio frequency signals, the consistency of calculating processes is better, multi-term continuous modality confidence divisor calculating tasks can be permitted to be concurrently operated in the same time, and that is, parallel calculating is performed to enable complex calculating operation of the whole elastic image to obtain a higher speed-up ratio. Accordingly, the method can effectively improve the calculating speed of an elastic imaging algorithm, and achieve real-time tracking of the shear wave in the transmission process.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

Differential signal transmission cable and method for compensating length offset thereof

InactiveUS20100237961A1Quality improvementPrinted circuit aspectsHigh frequency circuit adaptationsPermittivityTransmission time

A compensation method compensates for a length offset between a first transmission line and a second transmission line of a differential signal transmission. The compensation method includes calculating a transmission speed of a first signal in the first transmission line, measuring lengths of the first and second transmission lines, calculating a transmission time of the first signal in the first transmission line, and calculating a relationship between permittivity values of the first and second transmission lines. The compensation method further changes the permittivity values of the first and second transmission lines according to the relationship.

Owner:HON HAI PRECISION IND CO LTD

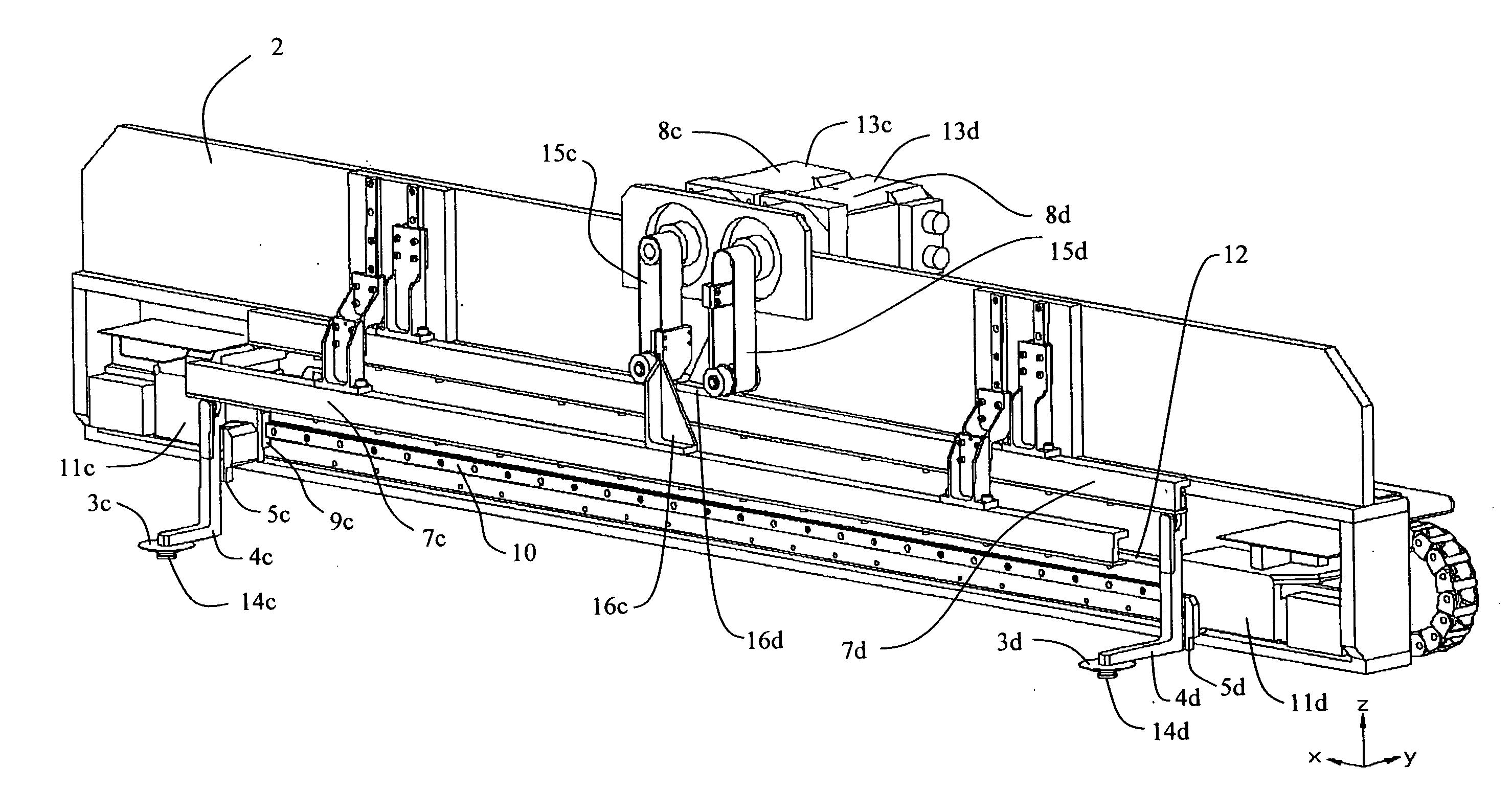

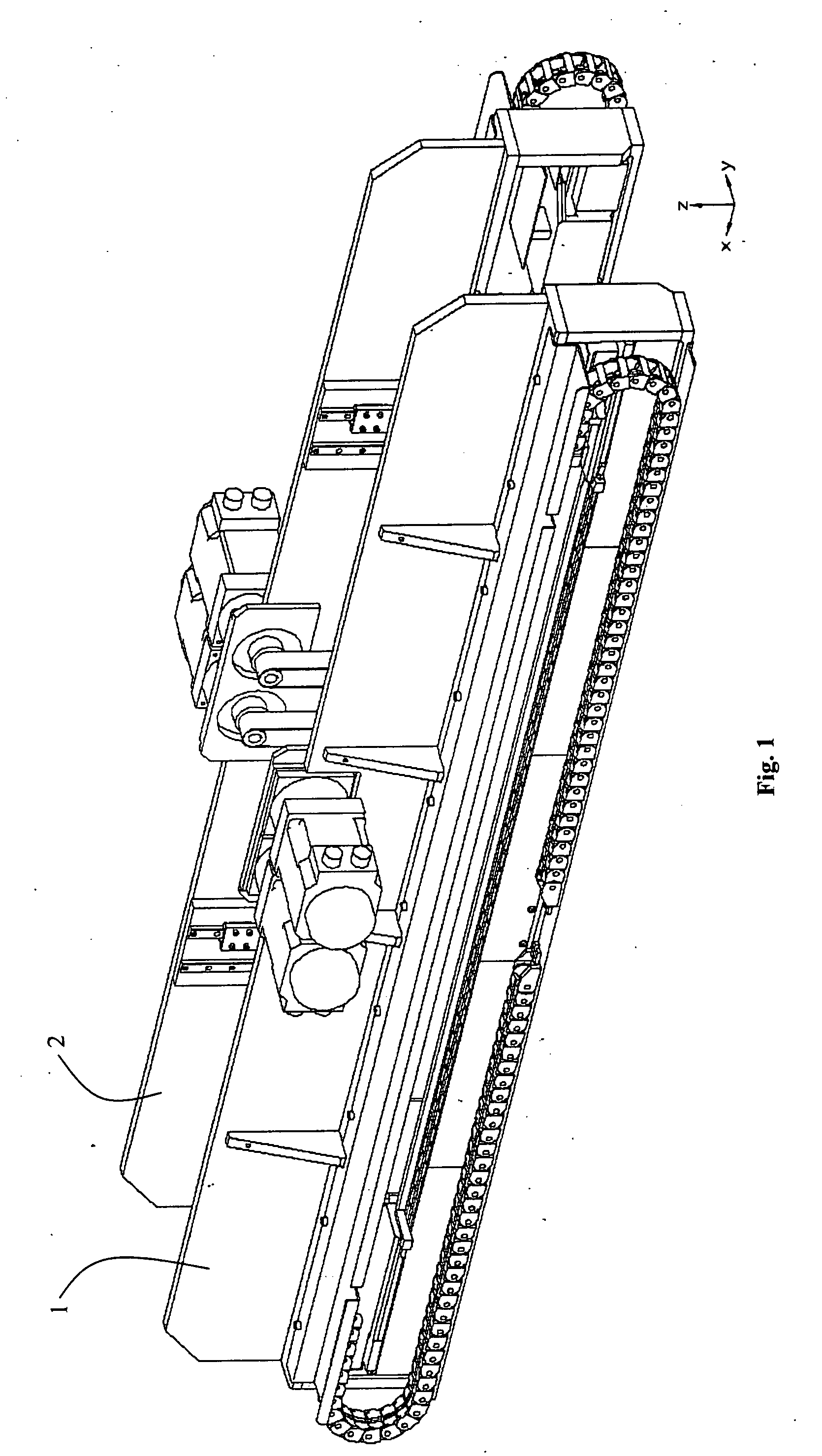

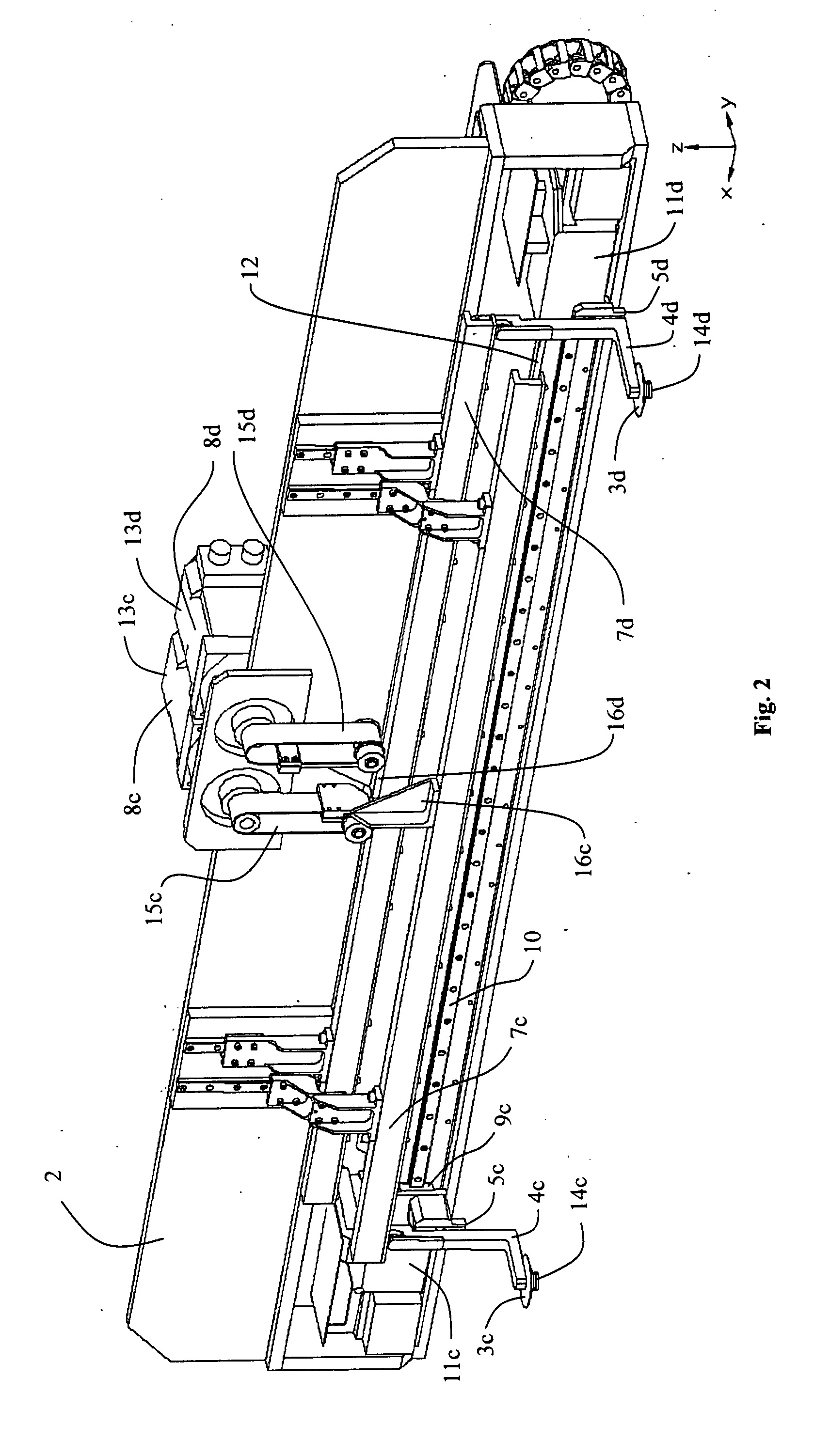

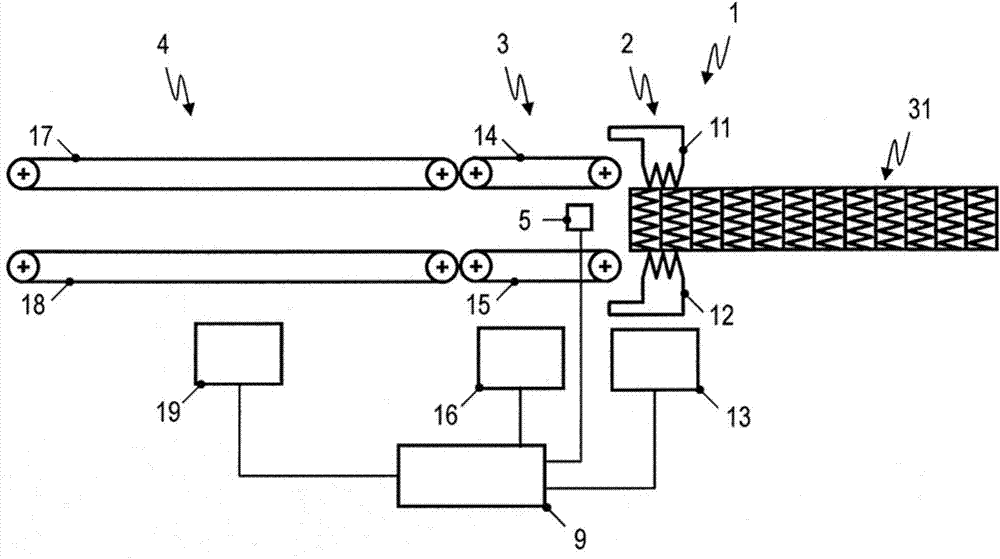

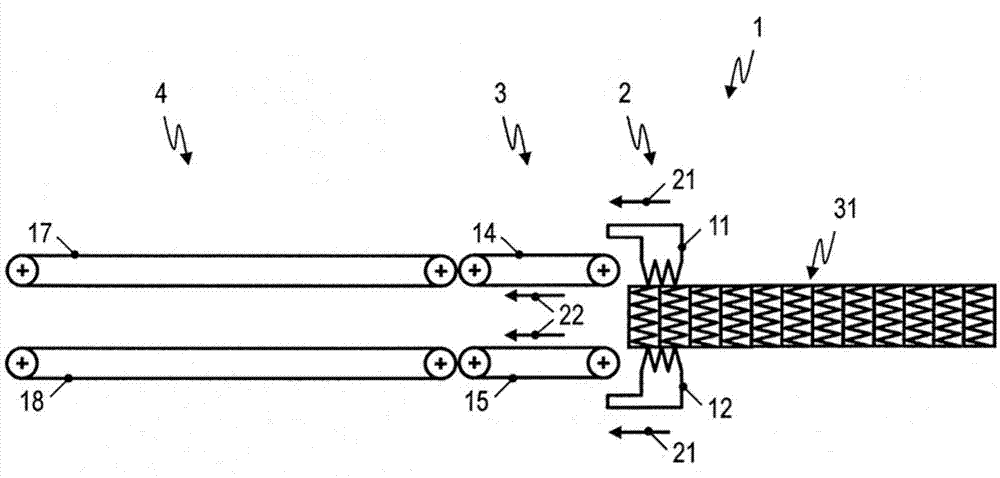

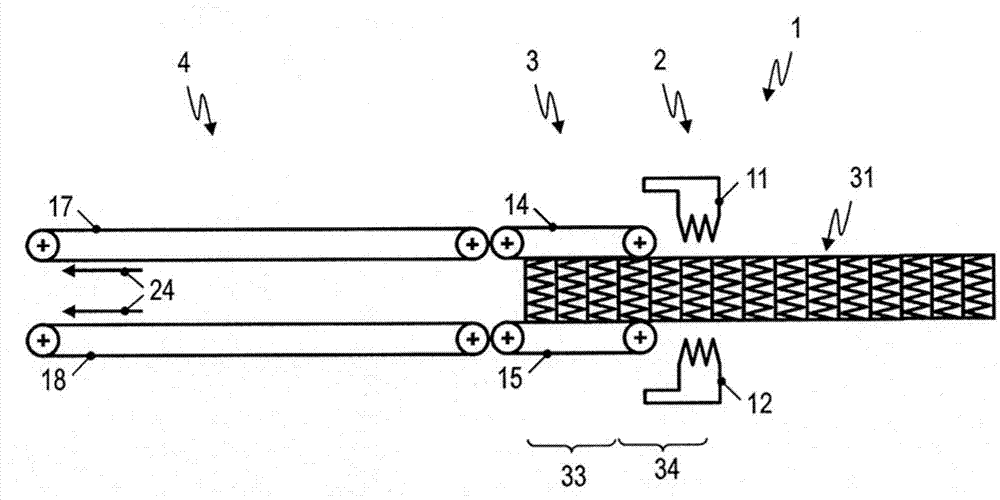

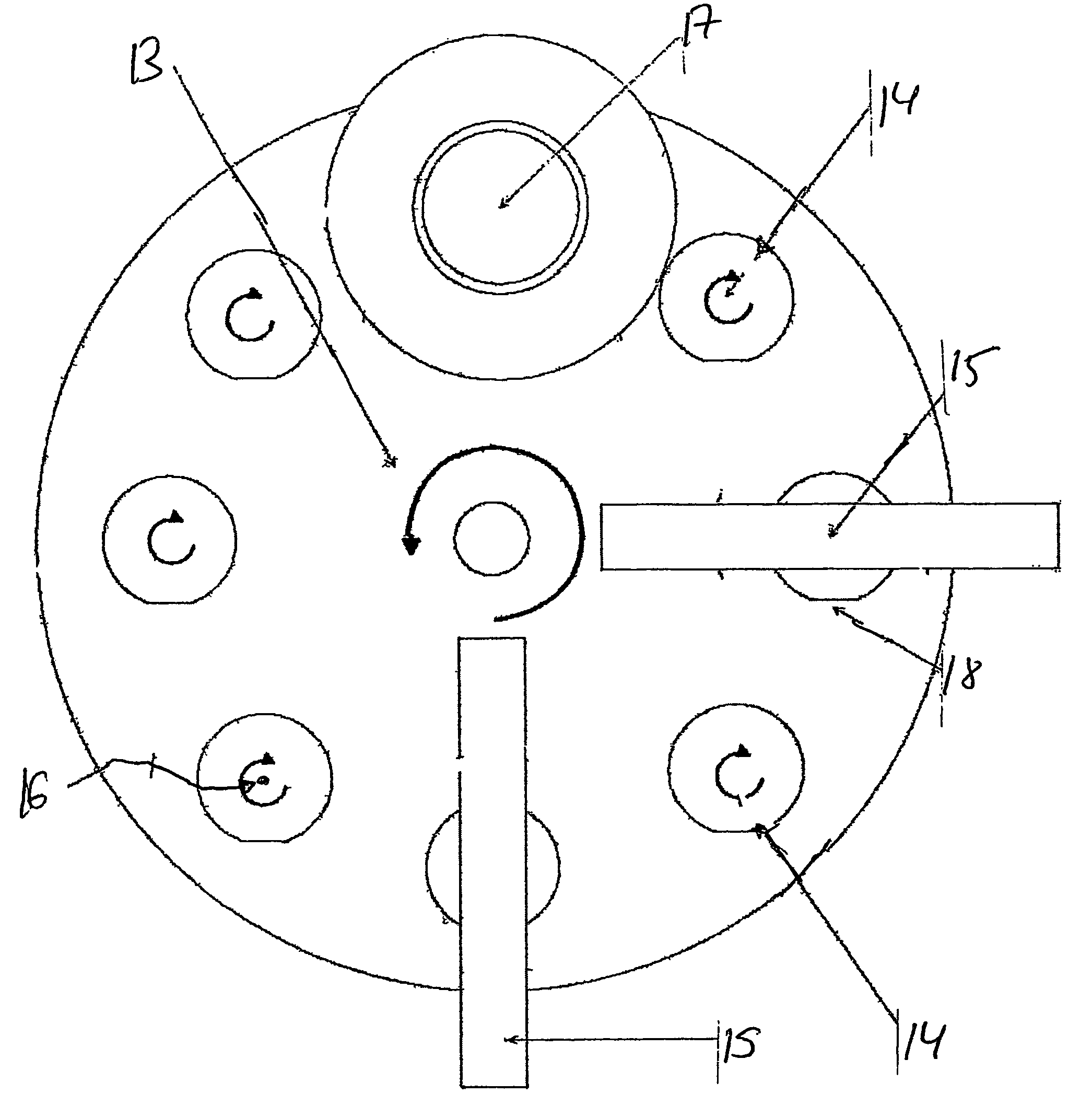

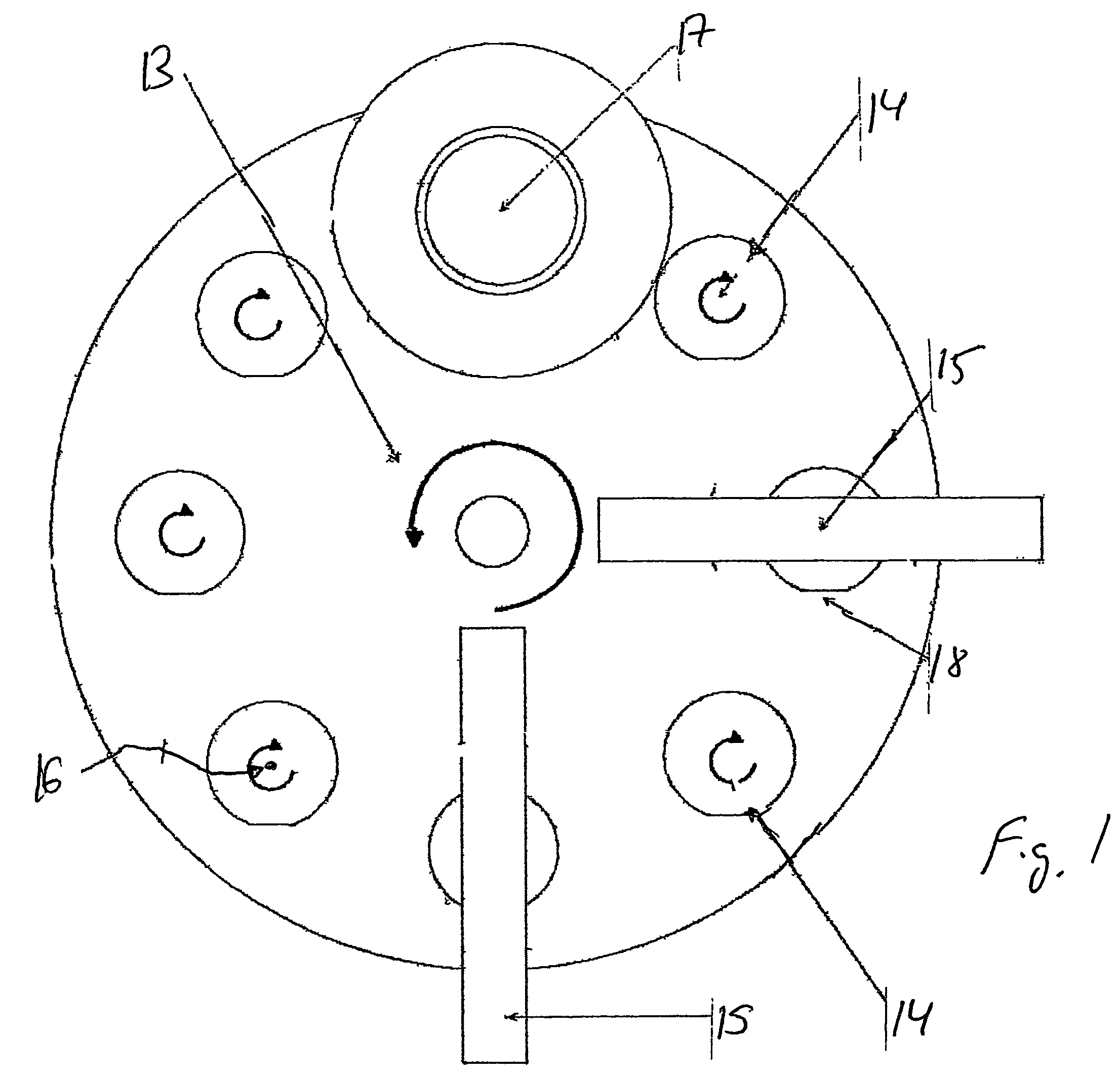

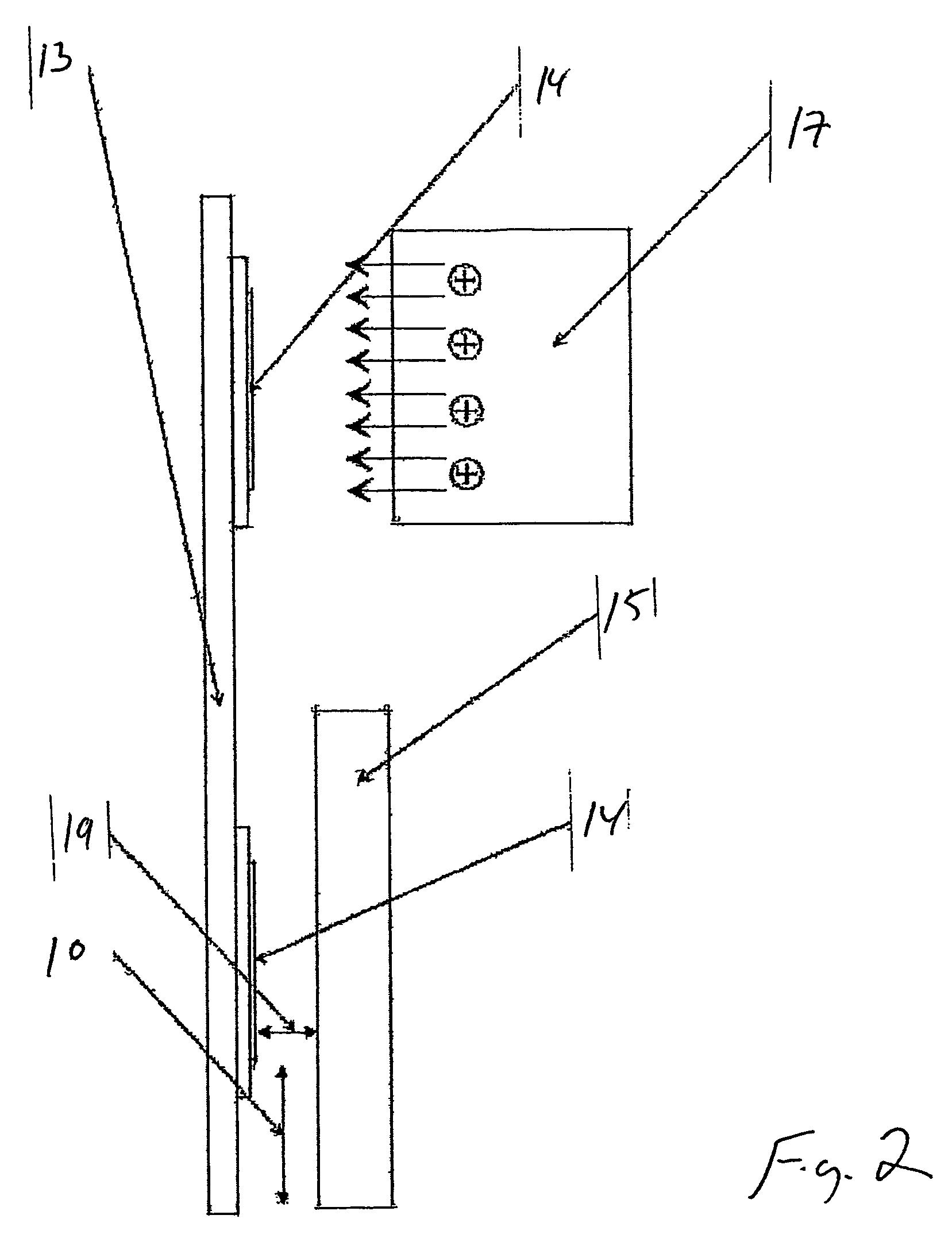

High speed linear pick-and-place

InactiveUS20080000756A1Increase transfer speedAvoid damageGripping headsFurniture partsSemiconductorTransfer velocity

A high-speed linear pick-and-place for increasing the speed of transfer of semiconductor electronic devices with accommodation for automated inspection or test. The invention includes two or more linear pick-and-place assemblies, each having two or more independently positionable pick-and-place nozzles. These assemblies are aligned such that the 4 or more nozzles can all pick and place to common shared locations. The 4 or more nozzles are operated so that they can pass by each other on their return stroke, except that nozzles sharing a rail cannot pass each other.

Owner:SYSTATION SEMICON

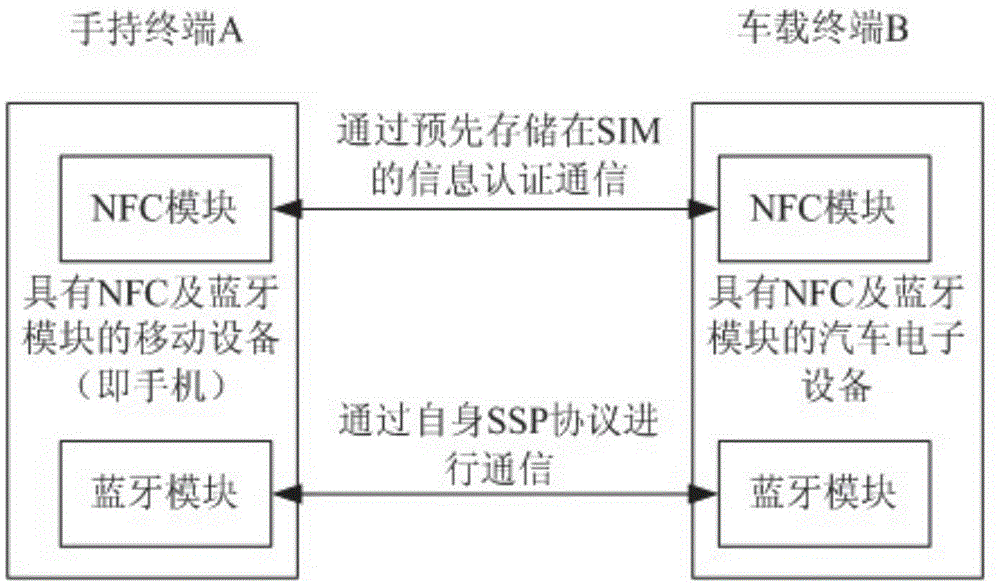

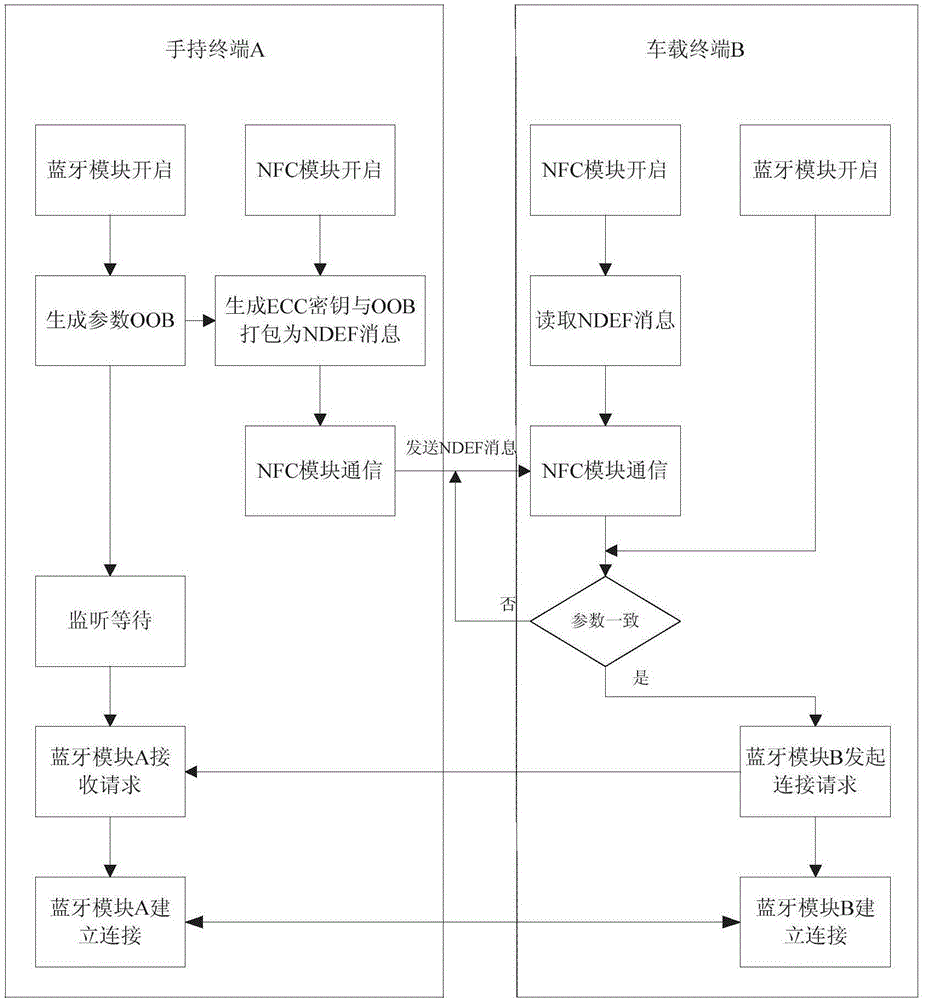

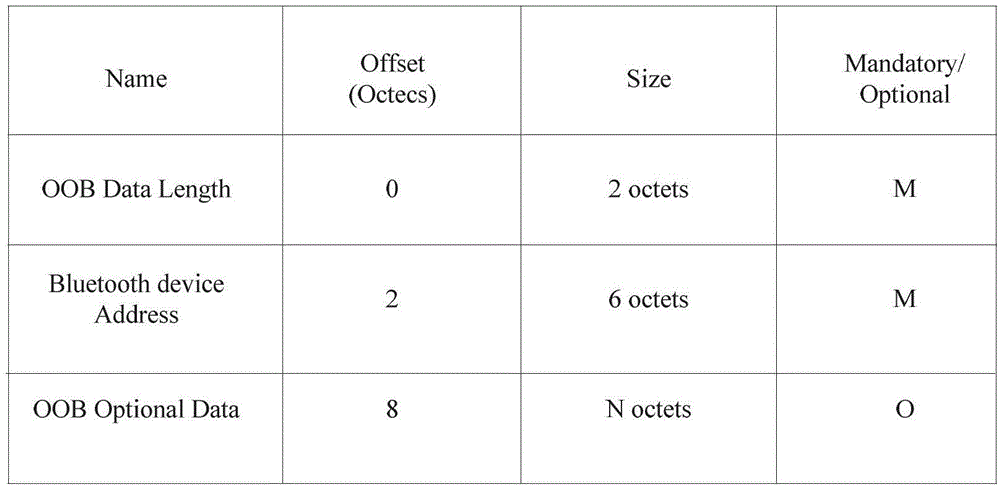

Scheme for optimizing automotive electronics application by utilizing NFC (Near Field Communication) and implementation method of scheme

ActiveCN104648321AIn line with the trend of intelligenceImprove experienceAnti-theft devicesRadio frequency signalEngineering

The invention discloses a scheme for optimizing an automotive electronics application by utilizing NFC (Near Field Communication) and an implementation method of the scheme, an NFC module of a handheld terminal A works under a point-to-point slave mode, and the NFC module arranged on a vehicle-mounted terminal B continuously sends a radio frequency signal in a polling manner under a point-to-point host mode; a user carries the handheld terminal A to be close to an automobile, at this time, the radio frequency signal excites the handheld terminal A provided with the NFC module in the radio frequency range, a sender starts communication under a certain protocol frame by appointment, and a receiver responds at the same transmission speed by utilizing load modulation data. According to the scheme and the implementation method thereof, the characteristic of simple NFC connection operation and the advantage of quick Bluetooth transmission speed are combined, so that the security of a system is maintained while the performance is better. According to the whole scheme, the user experience is improved and the scheme more conforms to the trend of automotive electronics intelligence.

Owner:常州佳迅信息技术有限公司

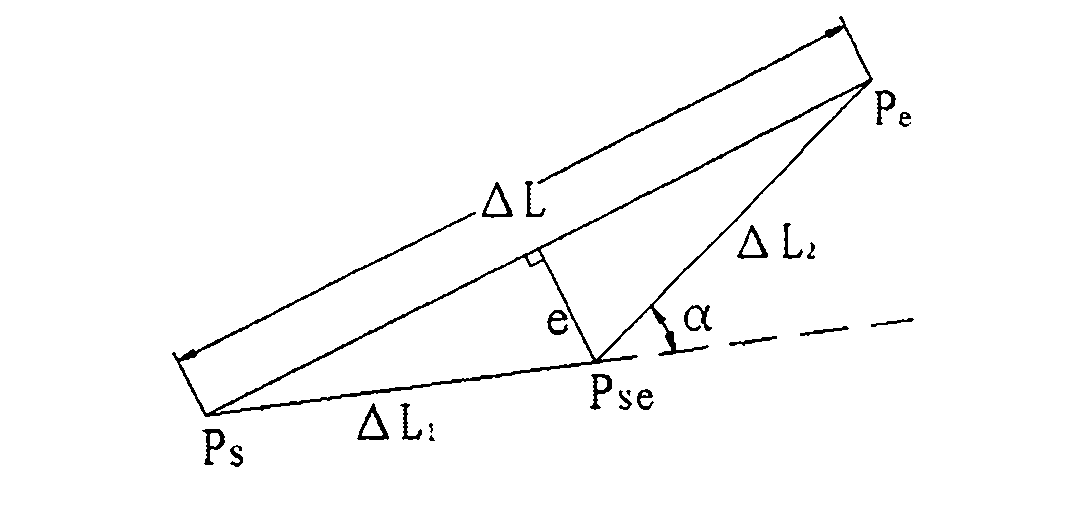

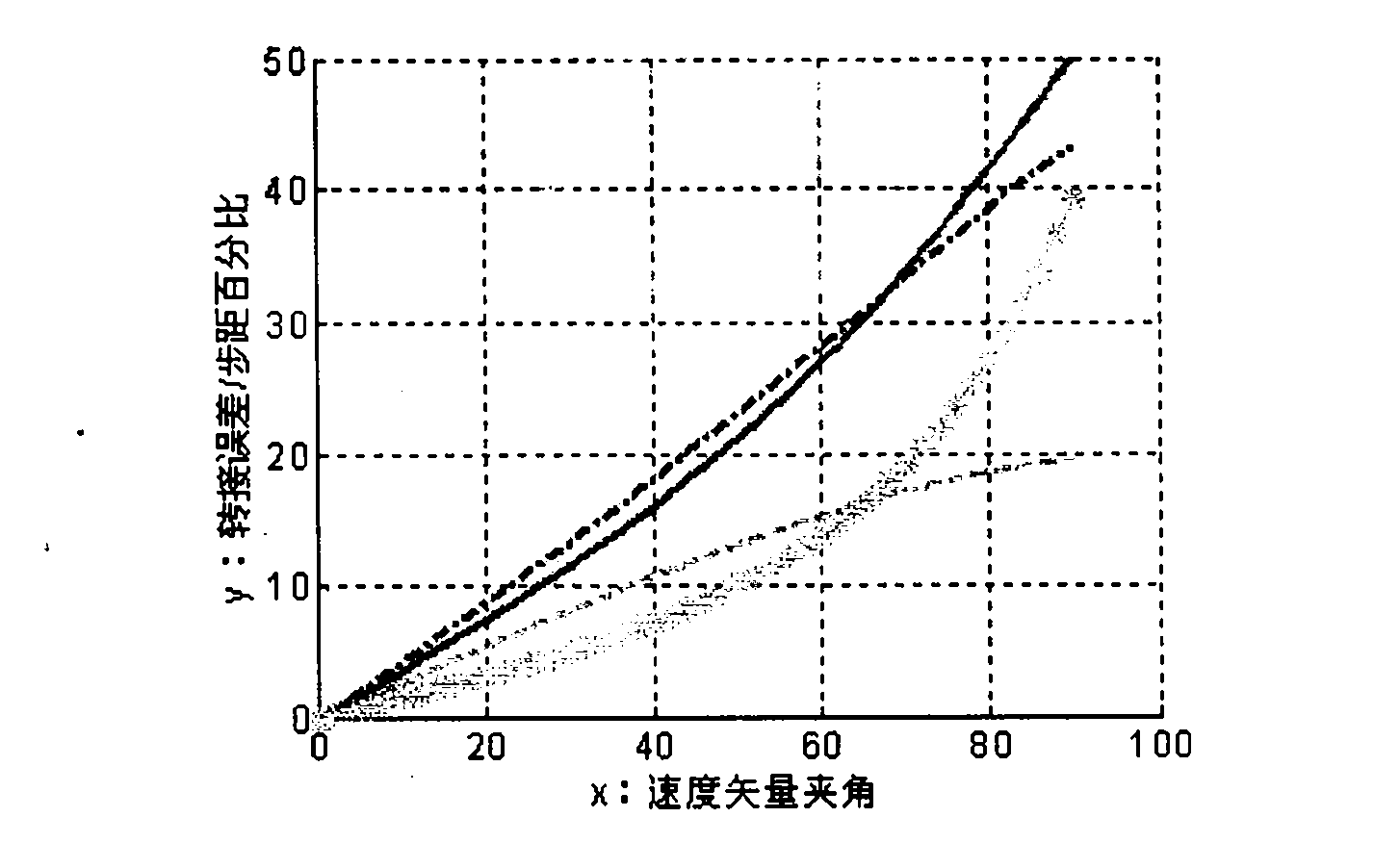

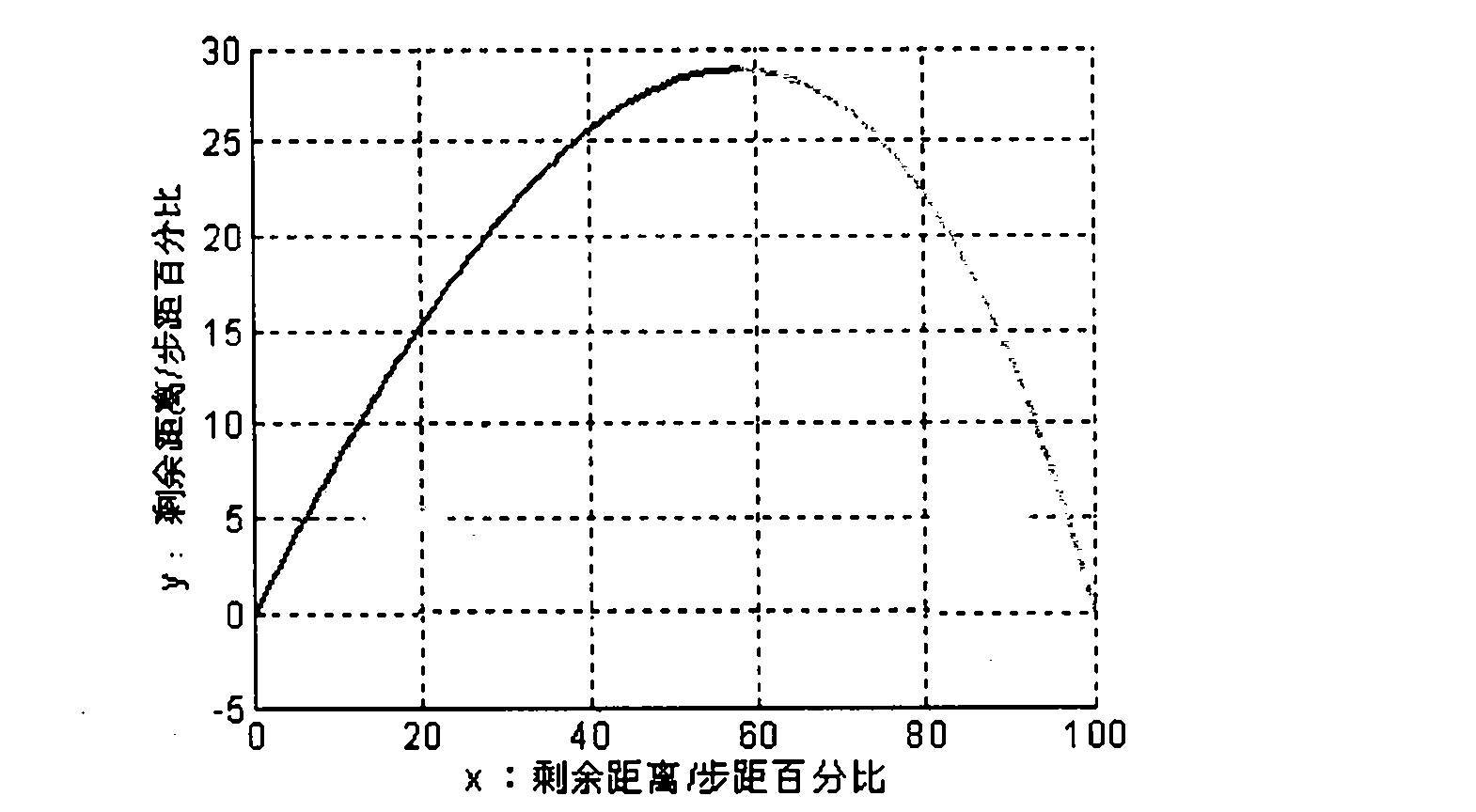

Precision error control based orbit segment transfer processing algorithm for numerical control machine tool

The invention provides a precision error control based orbit segment transfer processing algorithm for numerical control machine tool; elaboration and analysis are performed aiming at the current two transfer processing methods of connecting the orbit segment with a straight line and connecting the orbit segment with an arc and the error situation; for the error of the transfer processing of the orbit segment and the straight line, the change relation of the generated error and an interpolation surplus and an included angle is analyzed according to the difference of the velocity vector included angle; the transfer processing method and the error calculation of the orbit segment and the arc are elaborated based on two aspects of whether the orbit segment and the arc are on the same plane and the included angle of the orbit segment and the tangent line of the arc. Compared with the prior art, the analysis for the transfer processing method and the error are more complete; furthermore, the analysis for various transfer situations is more detailed and more thorough, and therefore, the higher transfer precision and the higher transfer velocity can be obtained.

Owner:KUNSHAN TIANDA JINGYI NUMERICAL CONTROL SCI &TECH DEV

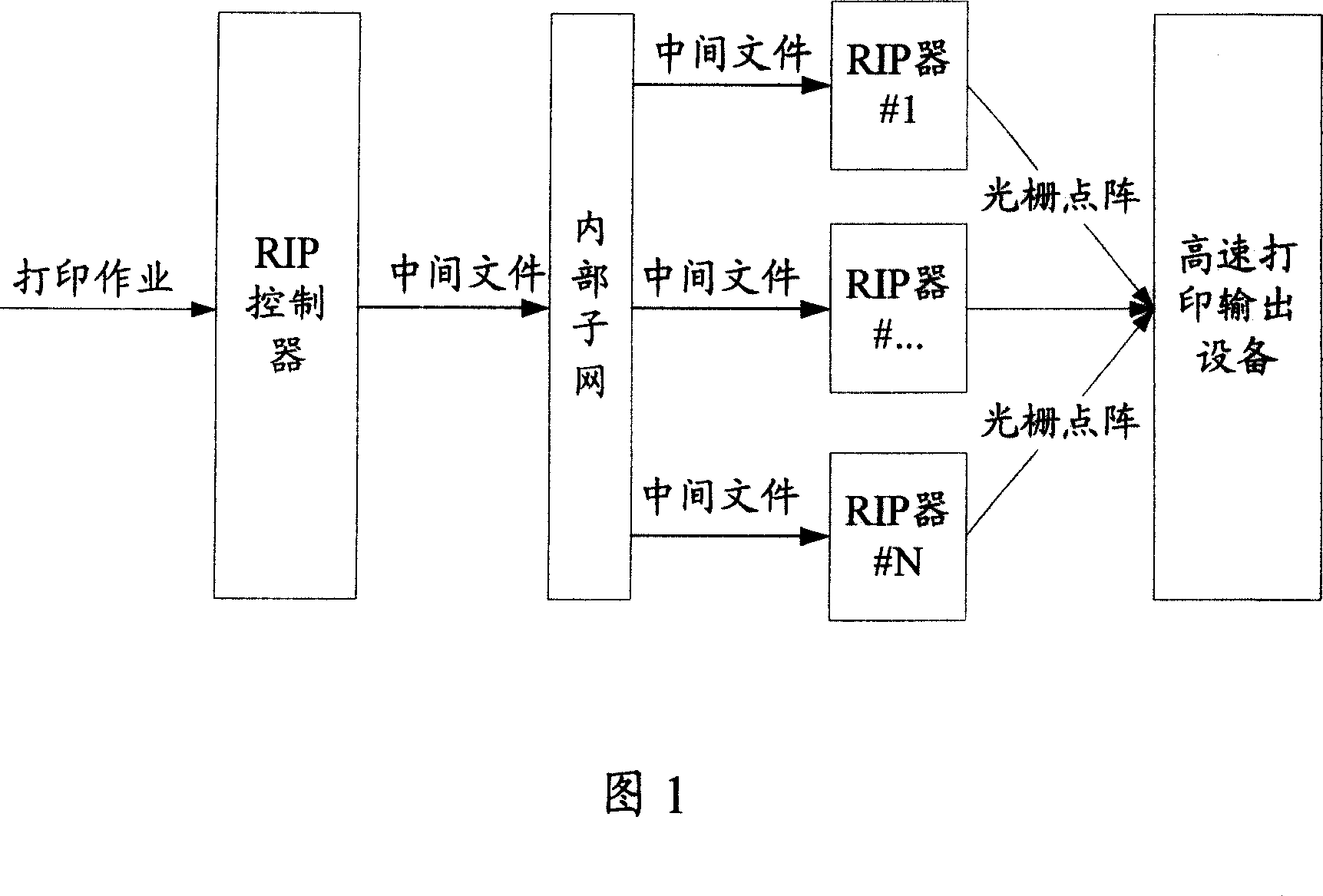

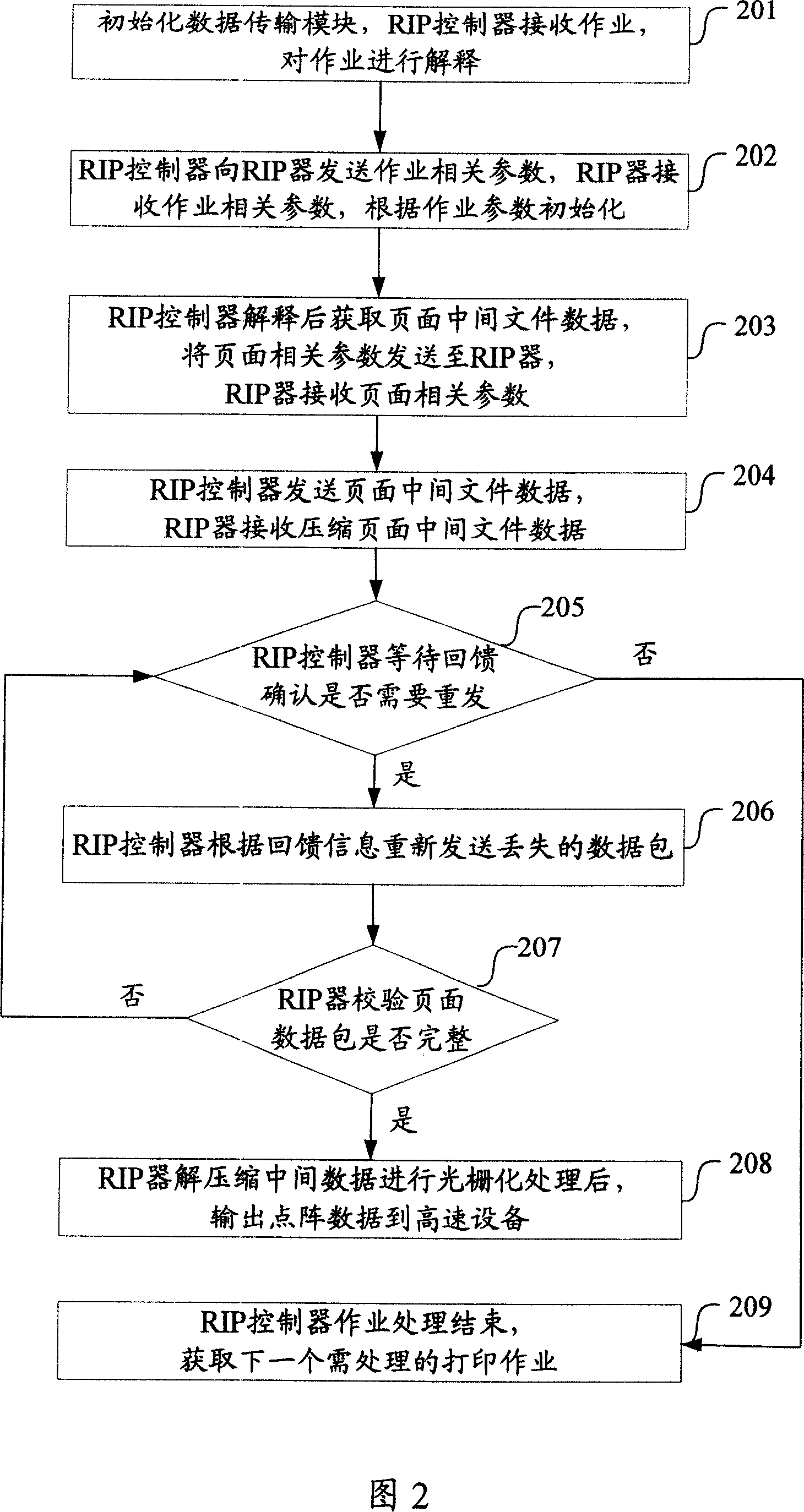

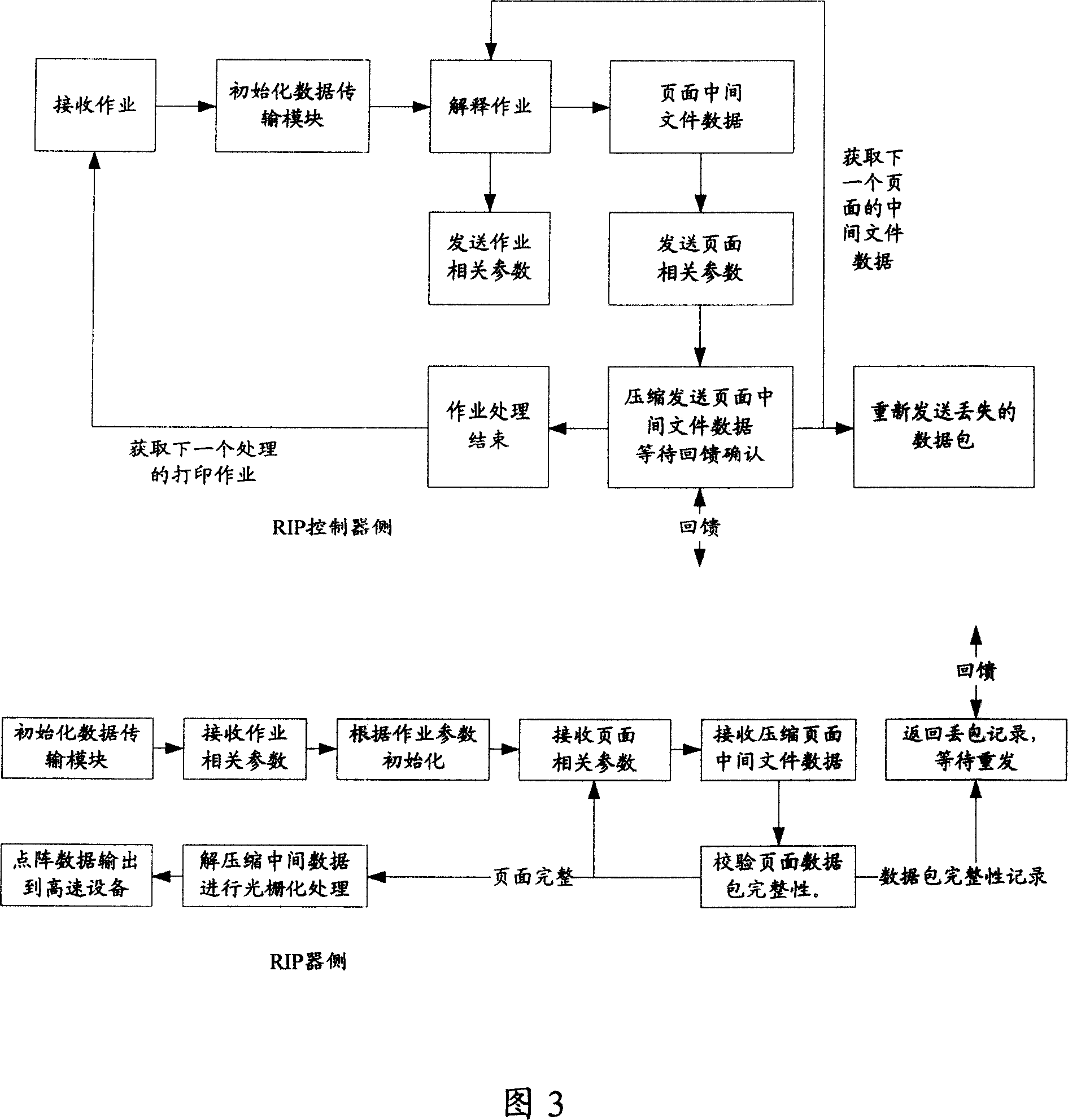

Data transmission system and method for distributed optical grating picture processing

InactiveCN101131626AReduce occupancyAcquisition speed is fastTransmissionDigital output to print unitsGratingOutput device

This invention discloses a kind of distributed grating image processing data transfer system of the figure and image printing treatment. In this invention method after the grating image processing controller interprets the printing describing language to the document data use the user data paper agreement to distribute it to the grating processor for grated process. In this invention system the grating image processing controller connects with the multiple grating image processor through the first data transfer module and the first transfer module is distributed to the grating image processor for grated process through the user data paper agreement after the first transfer module interprets the printing describing language to the document data in the grating image processing controller. By using this invention the transfer velocity is quicker and the occupation for the network resource is less and it improves the getting velocity of the grating image processing system for the processing work resource at the same time improves the processing velocity of the distributed grating processing system and it is satisfied for the requirement of high speed printing output device.

Owner:PEKING UNIV +1

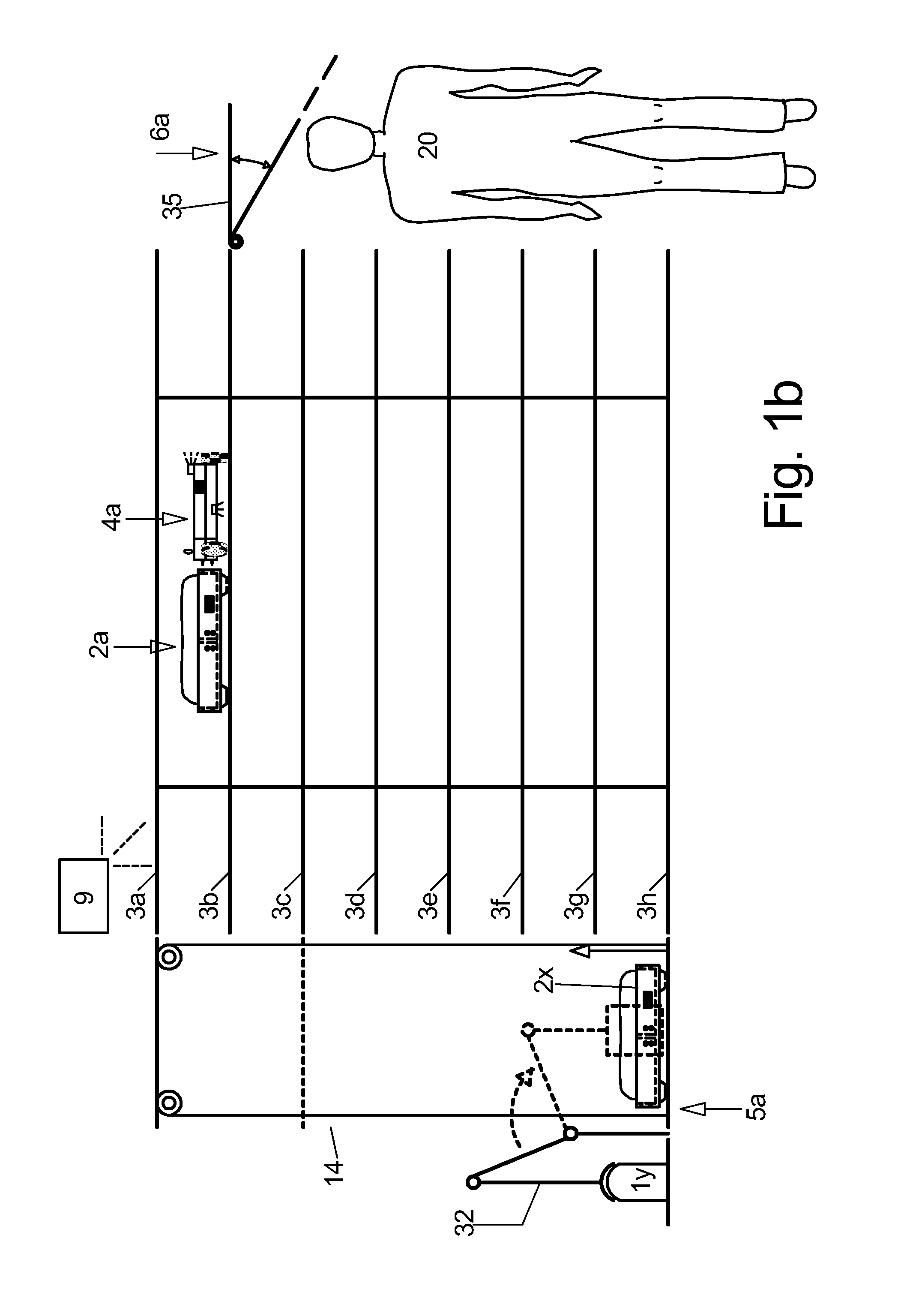

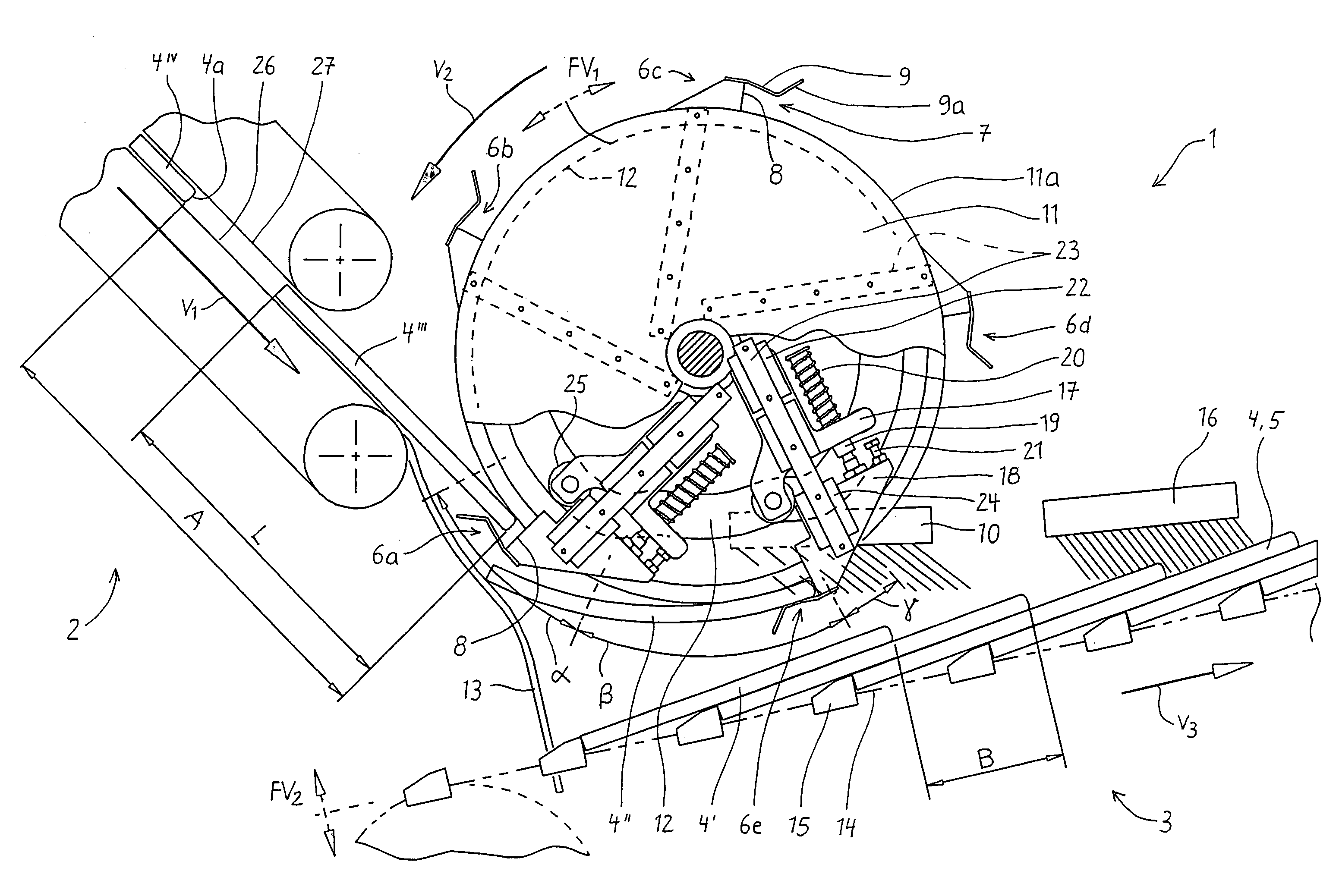

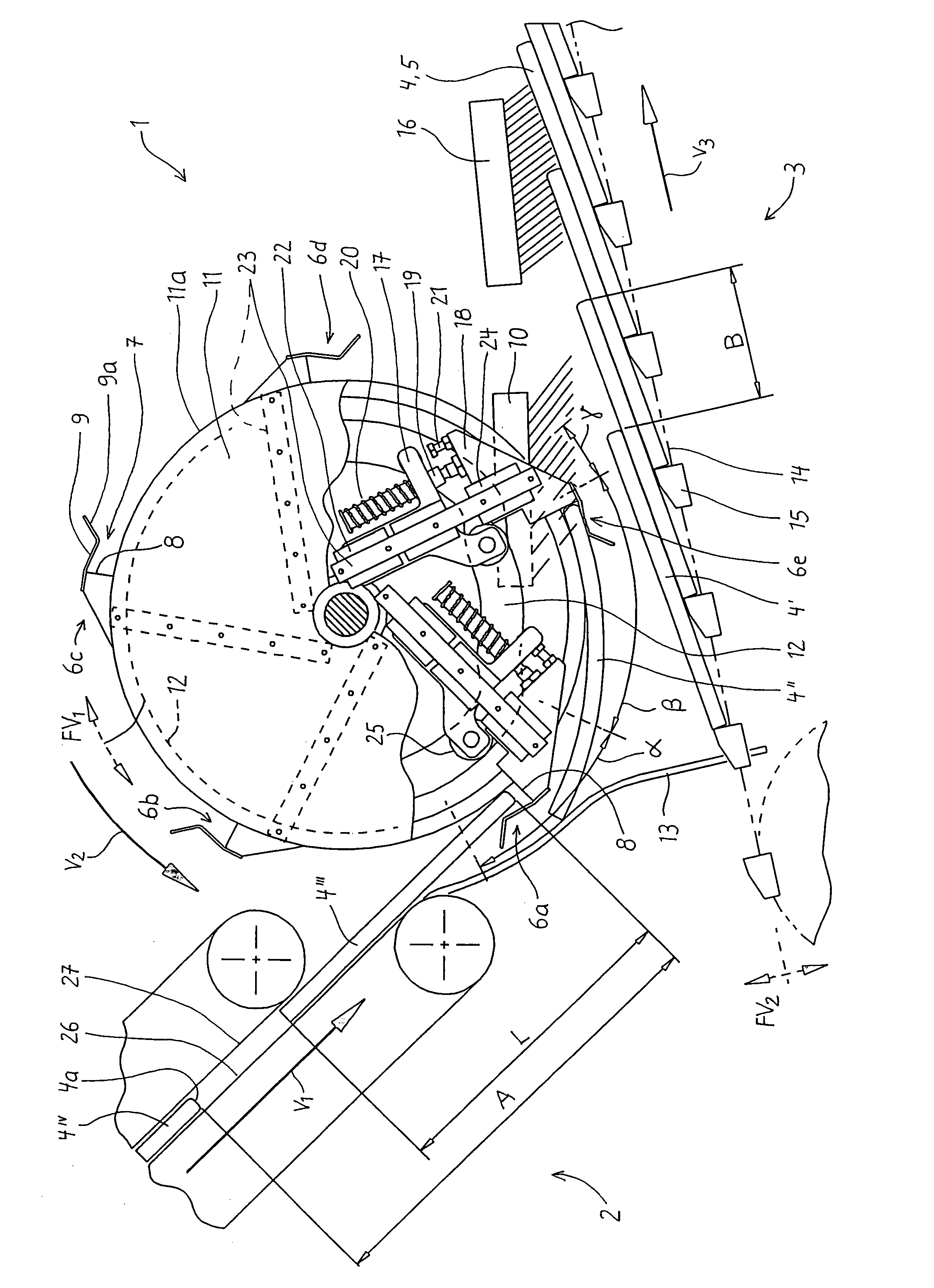

Device for depositing individual printed products, supplied in succession, in shingle formation

InactiveUS20070164501A1Reliably flawlessly deposit less-flexibleFast processingFunction indicatorsArticle deliveryEngineeringMechanical engineering

A device for depositing individual printed products (4), preferably magazines, brochures or book blocks, that are supplied in succession by means of a feed conveyor (2) on a downstream conveyor (3) with slower transport speed (v3) in shingle formation (5), wherein said device comprises a stream feeder (1) that receives the printed products (4) from the feed conveyor (2) by means of rotating grippers (6a to e) that are opened and closed in the appropriate cycle with the aid of a stationary cam (12) and deposits the printed products on the downstream conveyor (3). In order to reliably and flawlessly deposit the printed products, particularly thick and / or less flexible printing products, in shingle formation, the stream feeder includes a plurality of grippers (6a to e) that are rotatively driven with a slower speed (v2) than the feed speed (v1), wherein the grippers (6a to e), opened for receiving the printed products, respectively include a short pocket (7) with a bottom stop (8), with which the respectively supplied printed product (4) comes in contact due to the higher feed speed (v1). The clamped transport takes place within an angular range (β) of the rotational movement of the grippers, namely up to a defined distance upstream of a stripping element (10) for reliably releasing the printed products (4). They drop on the downstream conveyor (3) along a short path.

Owner:KOLBUS

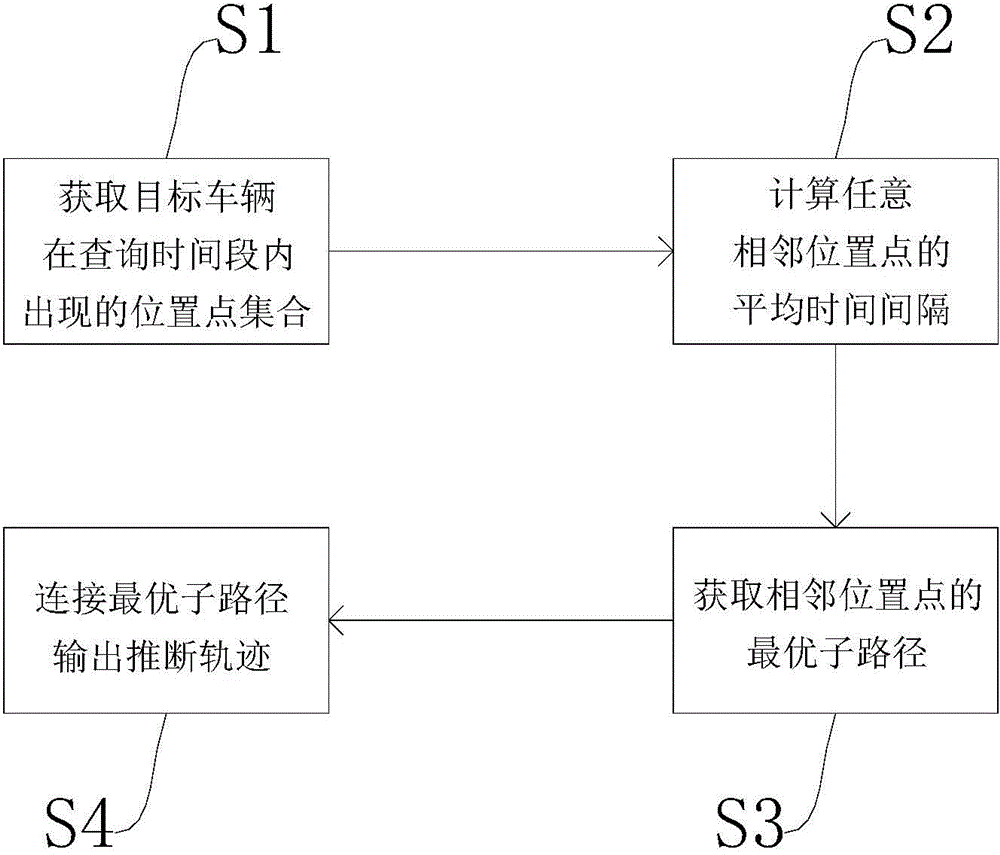

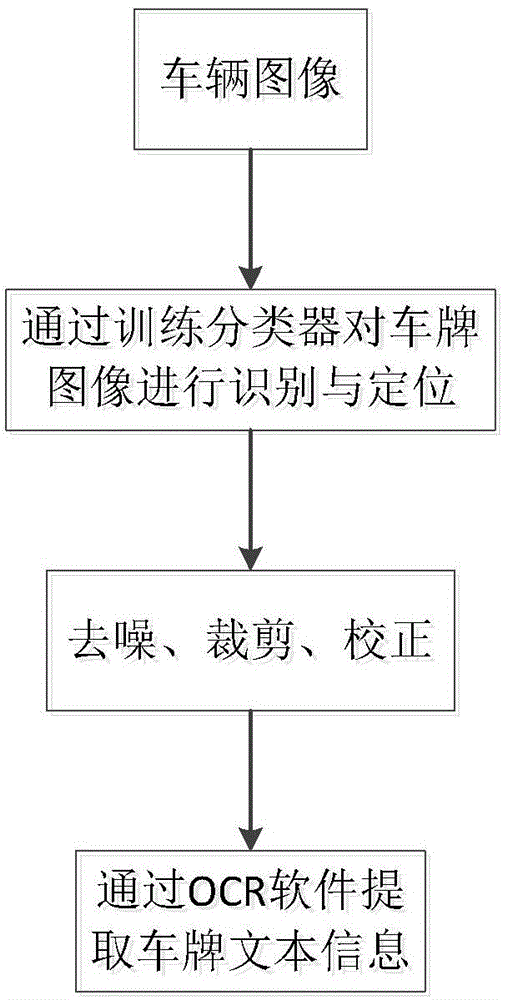

Predictive parsing method for track of vehicle

InactiveCN104318327AReduce overheadProcessing speedForecastingCharacter and pattern recognitionParsingNetwork cost

The invention discloses a predictive parsing method for track of vehicle, and the method comprises the steps as follows: obtaining the original video of the camera, having the information of the license plate number and recording the time of real time; obtaining the place point set of the target vehicle during the inquiring time region, calculating the average time interval of two adjacent place points and obtaining the best sub way of the adjacent place points, connecting to the best sub way for outputting predictive track. The predictive parsing method for track of vehicle fuses the surveillance video, information of the license plate number, time information and city topology for rationally forecasting the track of vehicle through the incomplete and discrete data; the video content analysis of the method is executed by each intelligent camera, the server pressure is reduced, the processing speed is fast; the camera sends the information of the license plate number to the server, the network cost is small and the transmission speed is fast.

Owner:BEIJING UNIV OF POSTS & TELECOMM

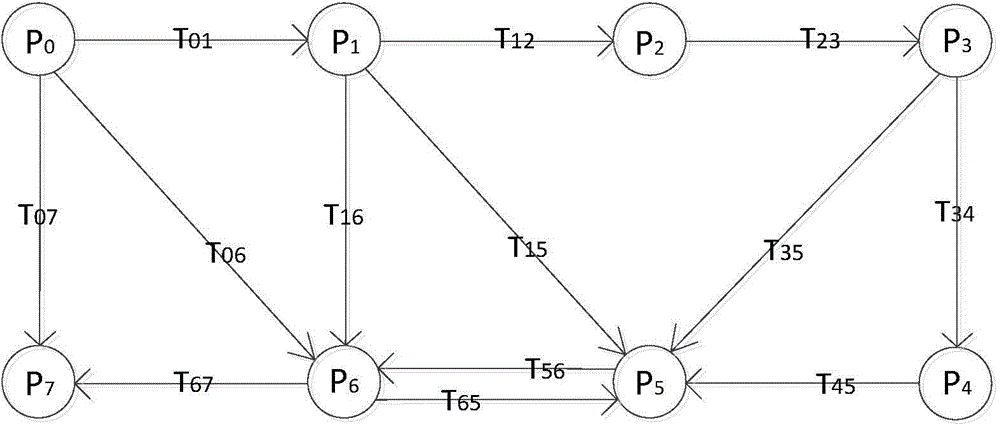

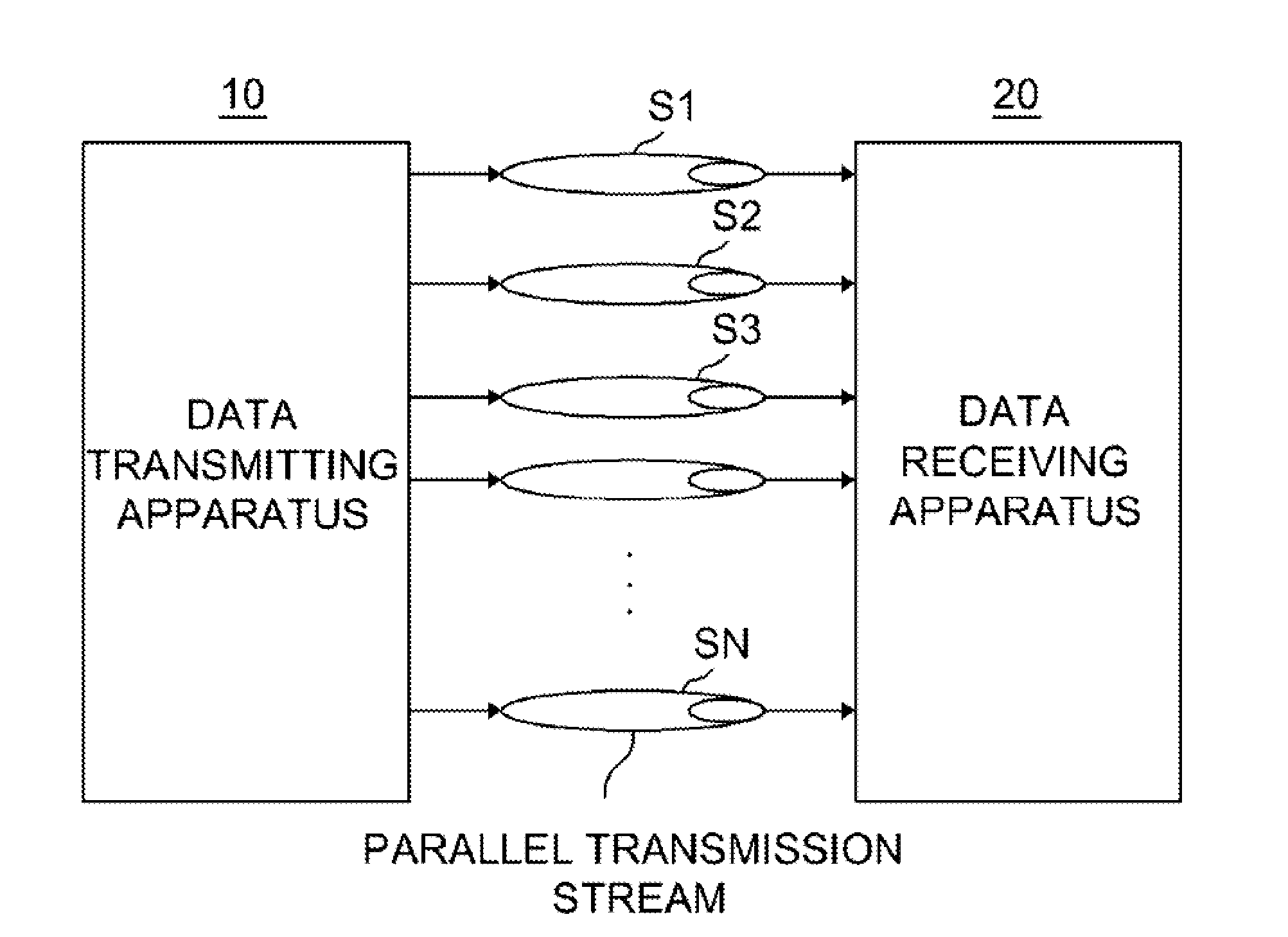

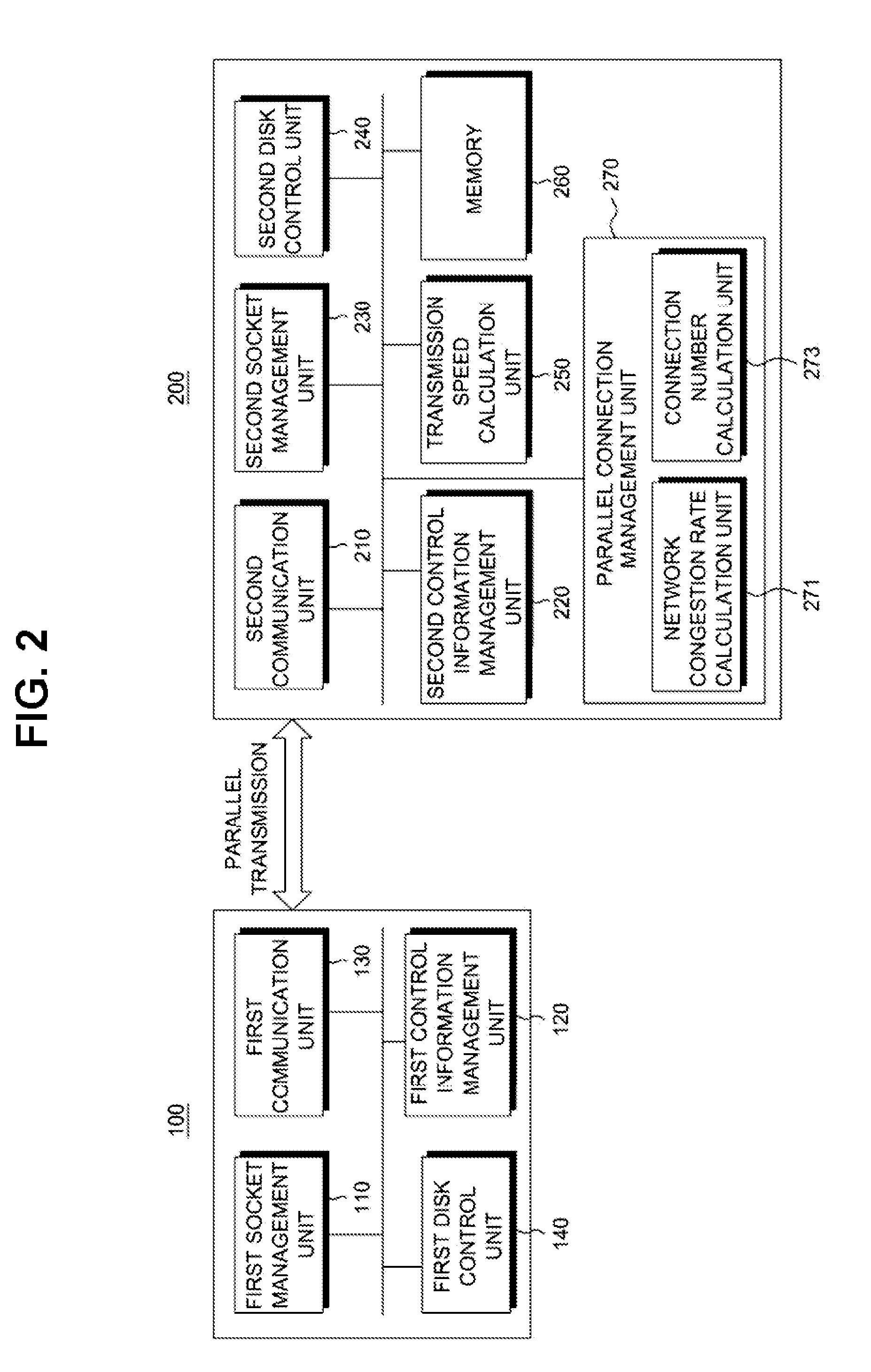

Method and apparatus for controlling stream to receive data in parallel

ActiveUS20120307636A1Increase speedEasy to calculateError preventionTransmission systemsDistributed computingNetwork congestion

Provided are a method and an apparatus for controlling streams to receive data in parallel. The method includes receiving data in parallel using a plurality of connected streams, calculating a network congestion rate using a change in a transmission speed of data received through each of the plurality of streams, adjusting a number of connections of the plurality of streams based on the calculated network congestion rate, and receiving the data in parallel using the adjusted number of streams.

Owner:SAMSUNG SDS CO LTD

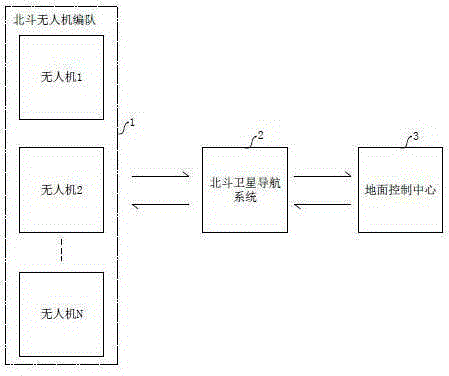

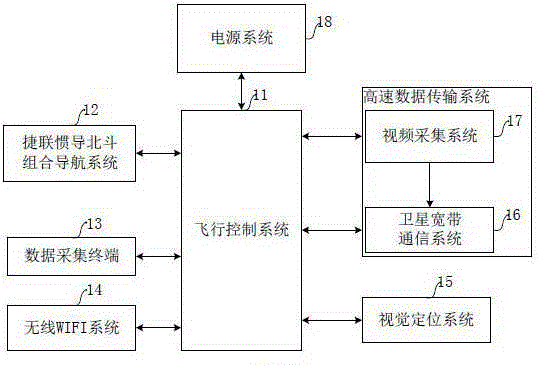

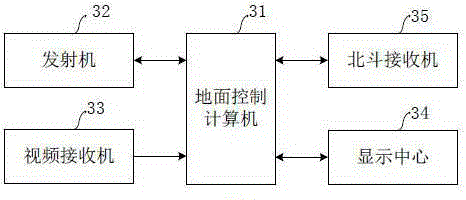

Apparatus for realizing device information acquisition in remote area through Beidou unmanned gyroplanes and data exchanging method

The invention discloses an apparatus for realizing device information acquisition in a remote area through Beidou unmanned gyroplanes and a data exchanging method. The system comprises a Beidou unmanned aerial vehicle (UAV) fleet, a Beidou satellite navigation system and a ground control center, wherein the Beidou UAV fleet is formed by unmanned gyroplanes with a serial inertial navigation system (SINS) Beidou combined navigation system and supports one-key return voyage and course optimization. The unmanned gyroplanes are powered by solar energy and storage battery, and video and data acquisition for an observation area is conducted through high-speed cameras. When no Beidou low altitude flight is avilable, a visual positioning system is used to sense the ground texture and relative height to realize stable flight. Wireless wifi is used for sharing information. The ground control center receives video information acquired by the UAV fleet to control the flight of the unmanned gyroplanes. In this way, the problem of low image transmission speed of UAVs, impossibility for stable flight when no Beidou and wireless communication network is available, poor cruising ability and small investigation scope of single UVA.

Owner:内蒙古信源信息技术有限公司

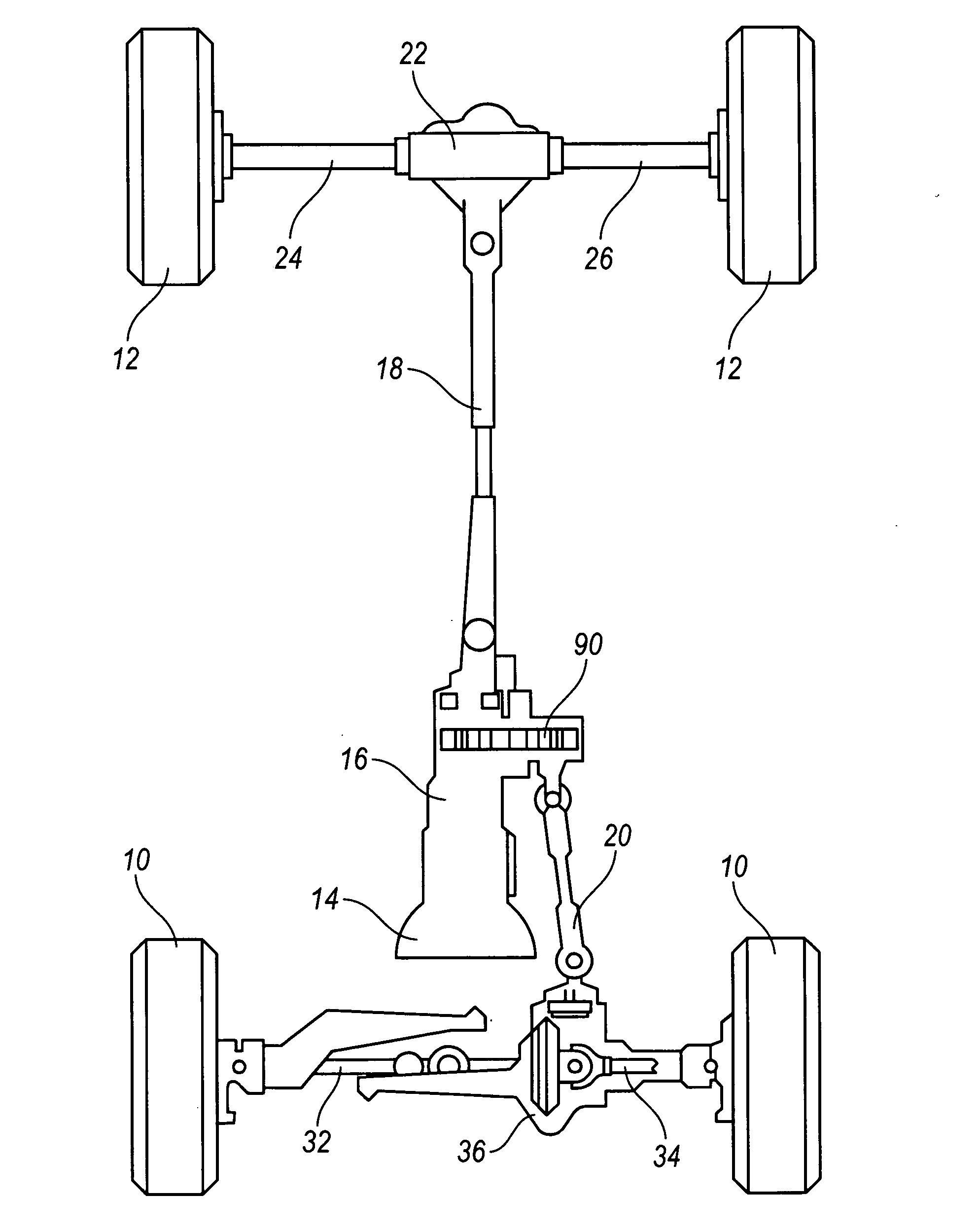

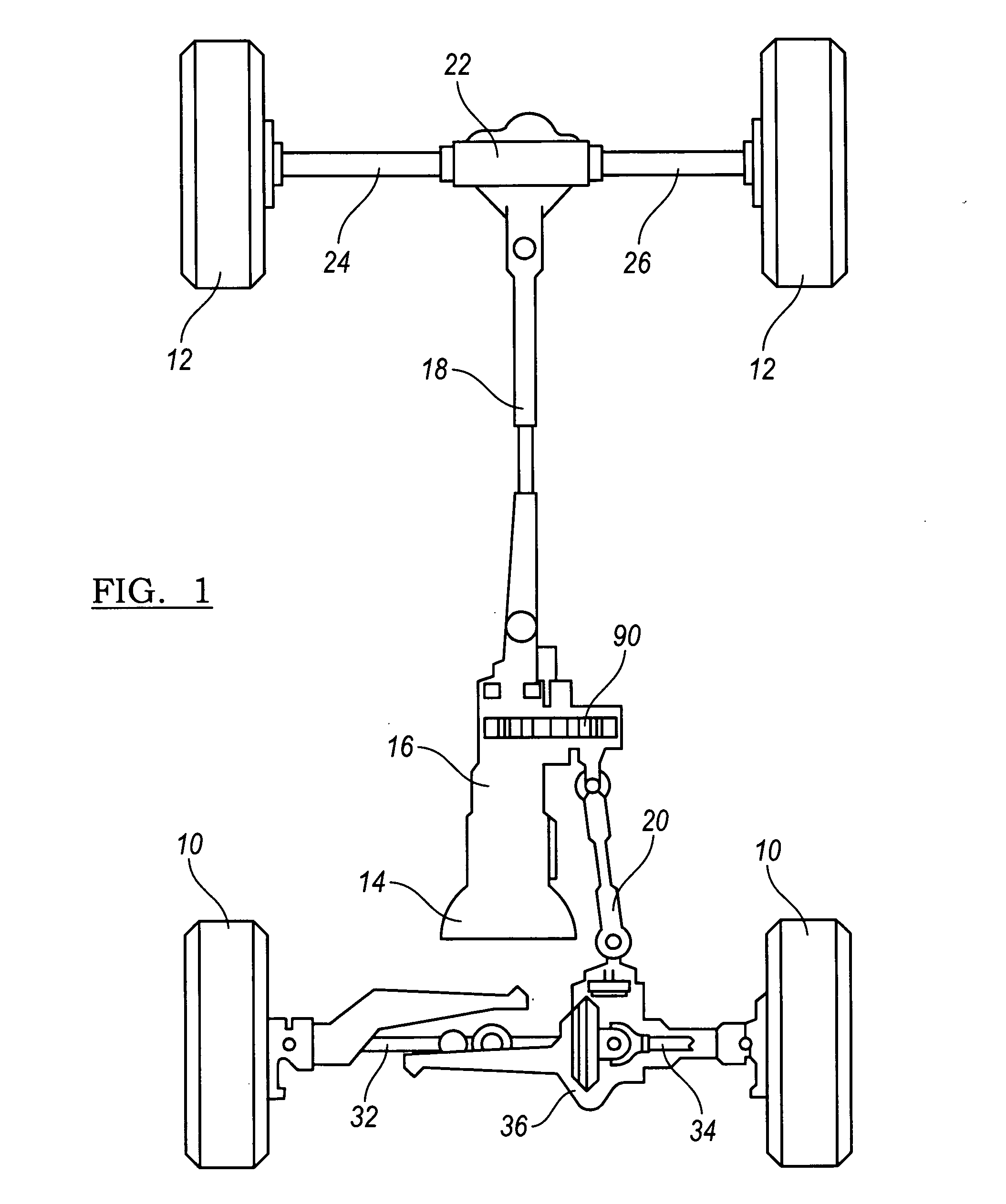

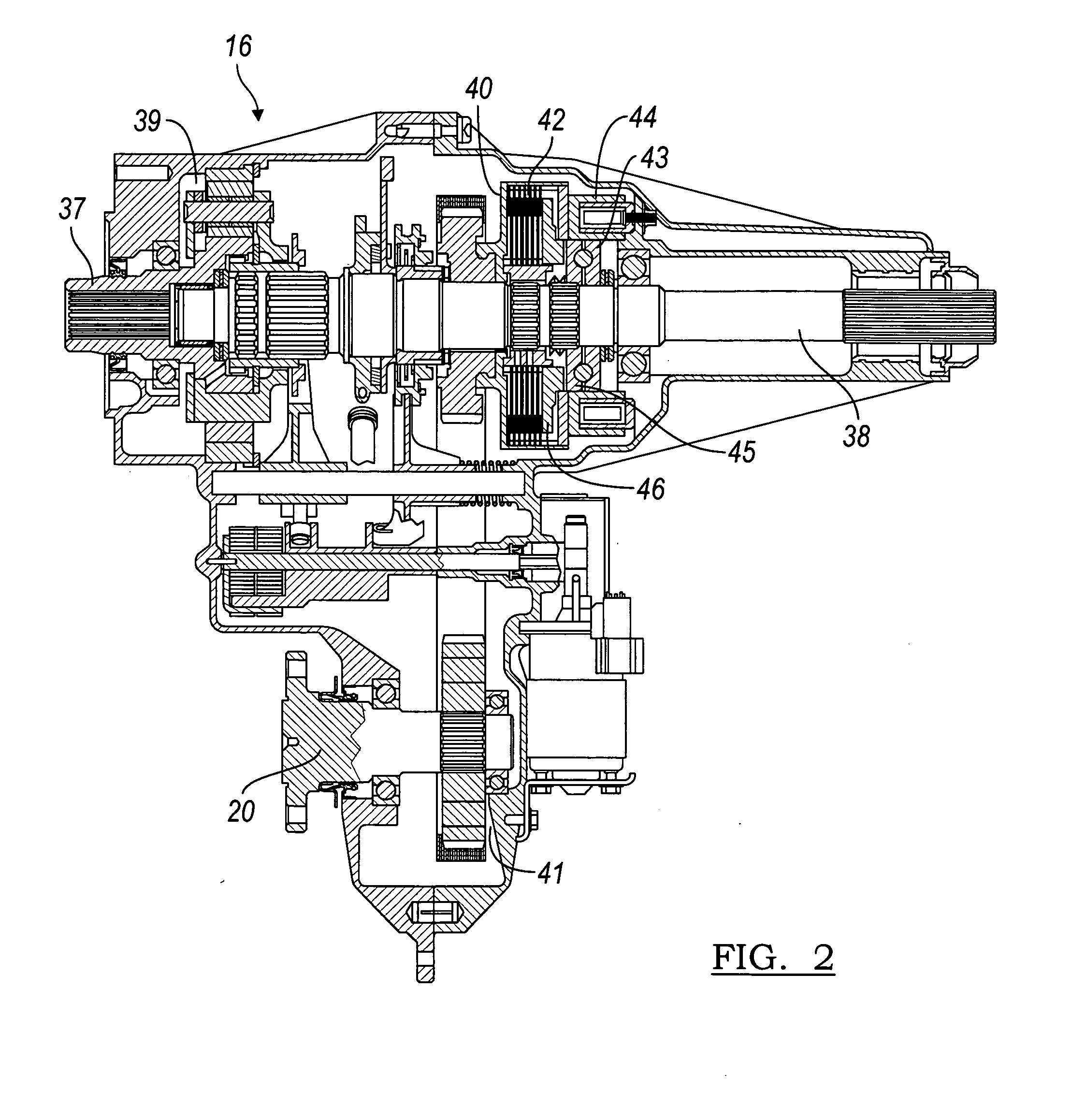

Prevention of inadvertent inertial engagement of a transfer case clutch

InactiveUS20070295548A1Minimal effectIncreased torque capacityClutchesDigital data processing detailsMobile vehicleTransfer case

A method for controlling operation of a transfer case in a motor vehicle driveline that includes by an engine controlled by a throttle having a variable position, and a transmission driveably connected to the engine for producing multiple ratios of the speed of a transmission input relative to the speed of a transmission output. The transfer case transmitting rotating power in response to an electric signal applied to a clutch. The method includes determining that the engine throttle position is less than a first reference throttle position during a period of predetermined length; determining that a speed of the vehicle speed is in a predetermined range; determining that the transmission is operating in a speed ratio greater than a reference speed ratio; determining that the engine throttle position is greater than a first reference throttle position; and increasing the torque capacity of the clutch for a predetermined period.

Owner:FORD GLOBAL TECH LLC

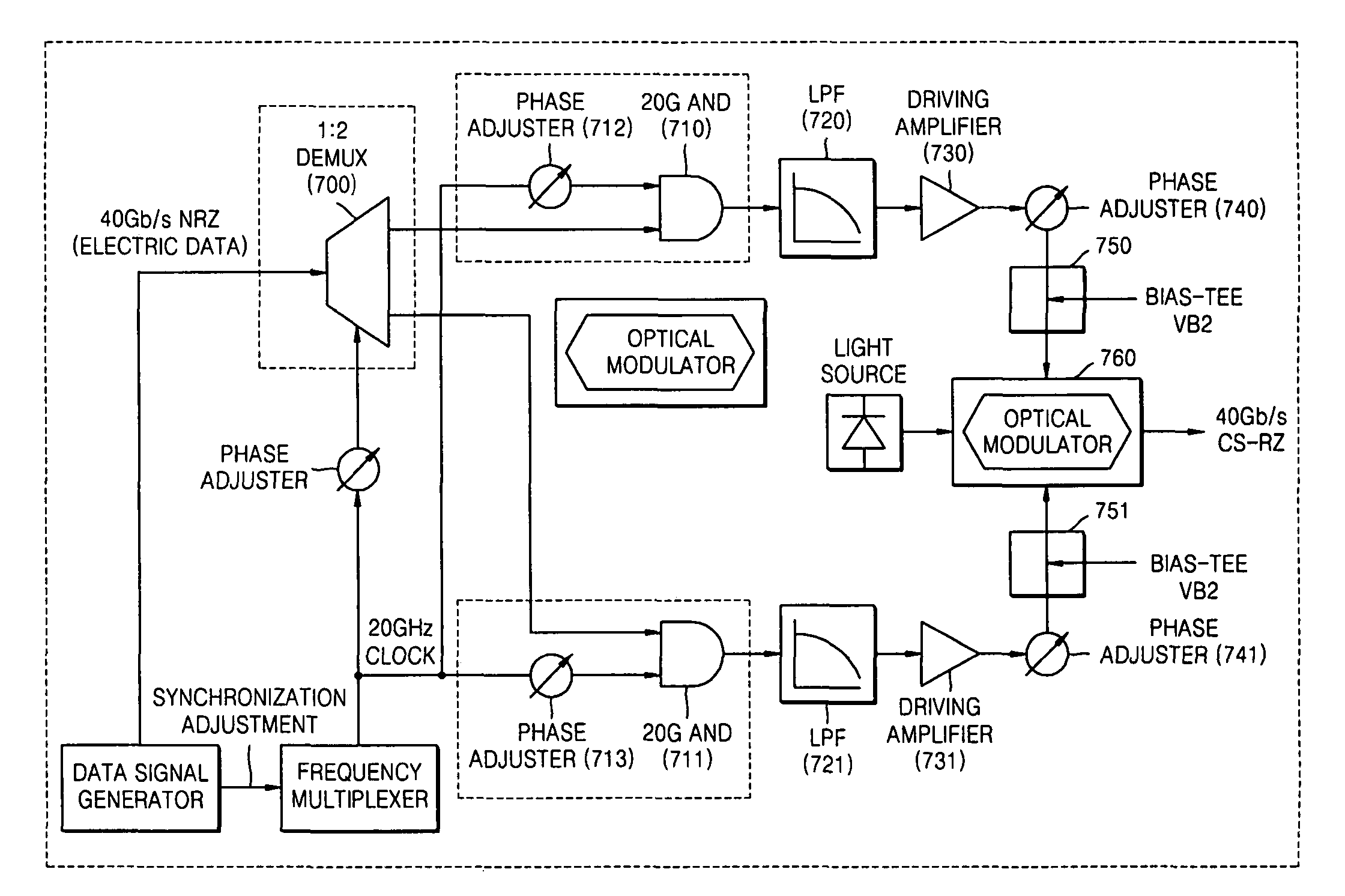

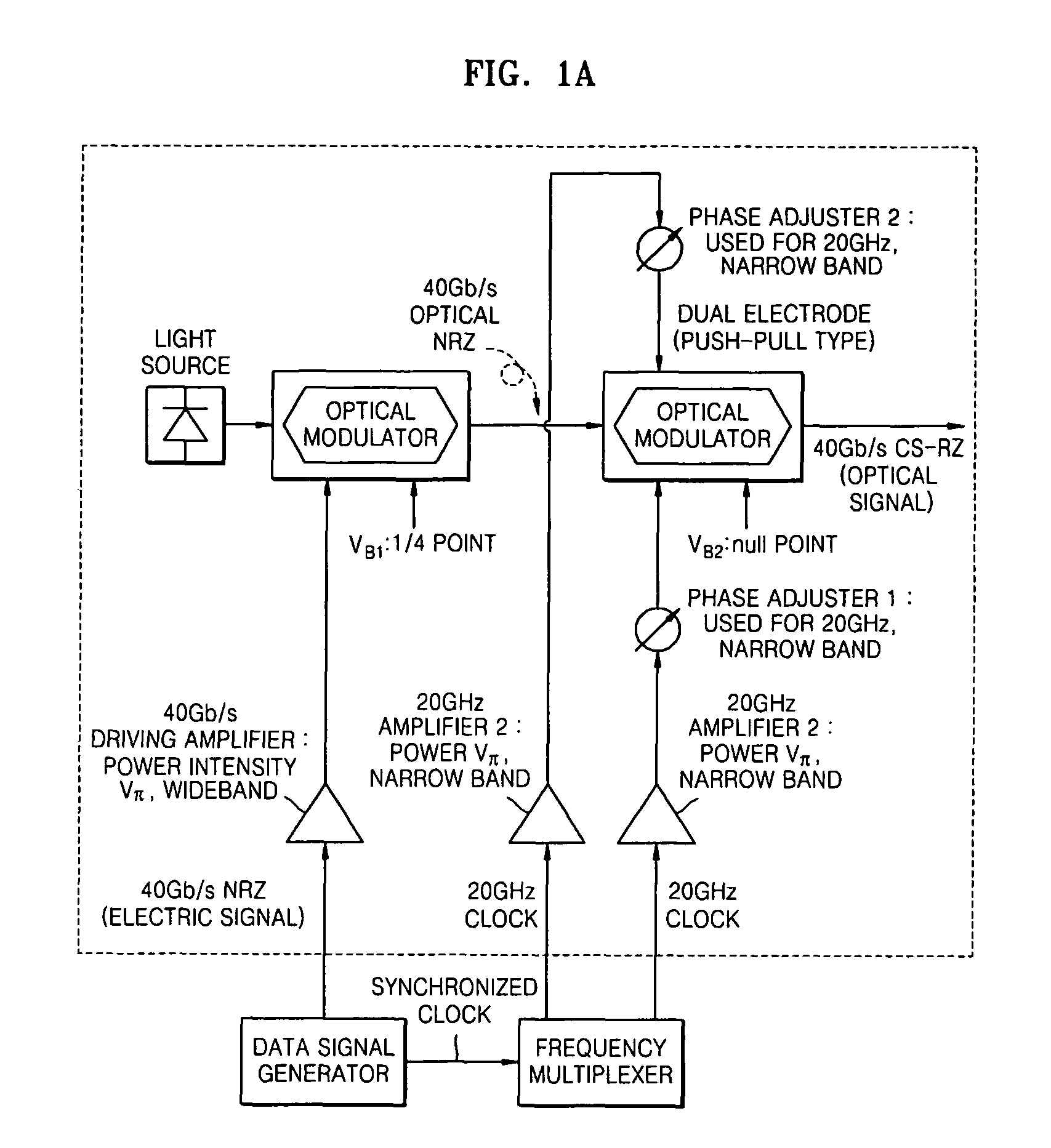

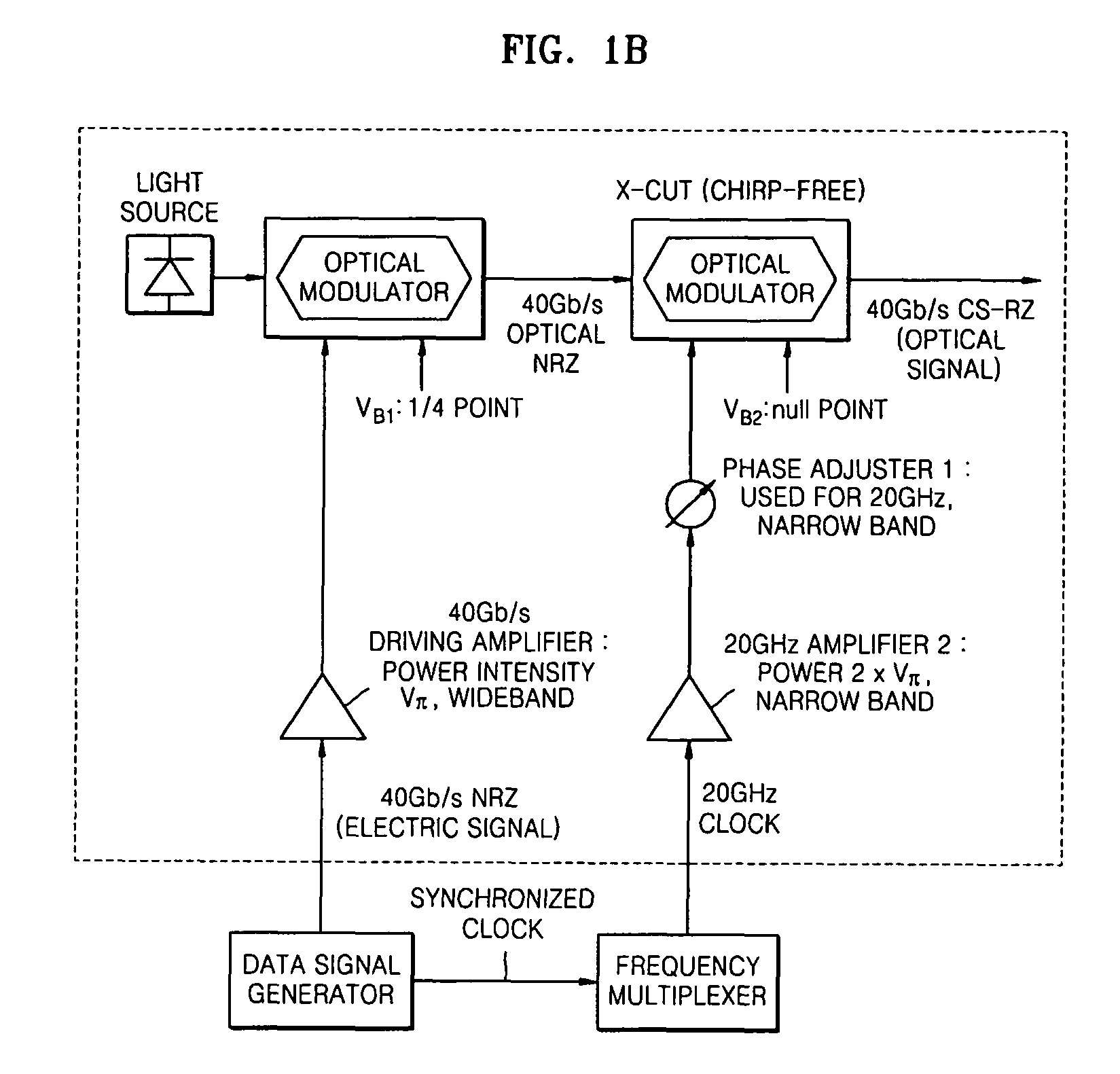

Apparatus and method to generate carrier suppressed-return to zero optical signal

Owner:ELECTRONICS & TELECOMM RES INST

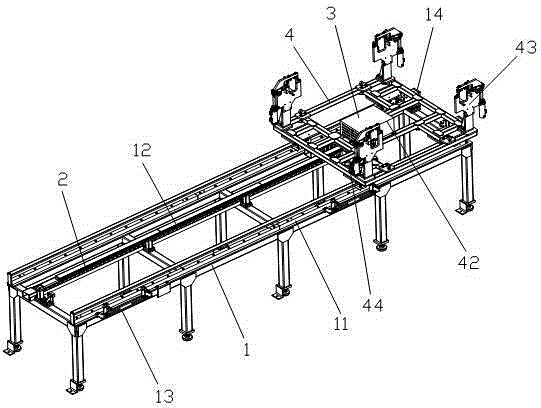

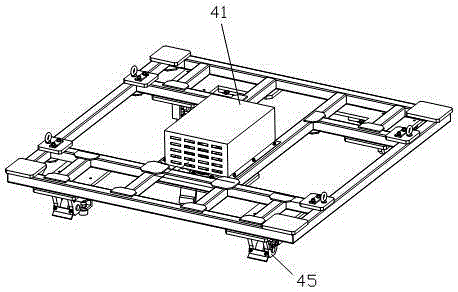

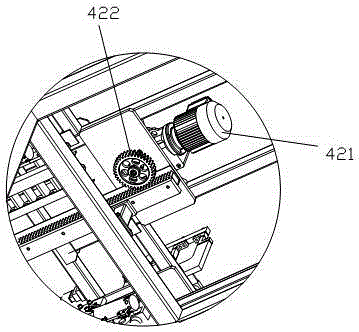

Automatic workpiece loading assembly based on robot workpiece pickup

InactiveCN105173589AFast Repeat Positioning AccuracyFast transmissionMechanical conveyorsAutomatic controlEngineering

The invention relates to an automatic workpiece loading assembly based on robot workpiece pickup, and belongs to the field of automobile parts. The automatic workpiece loading assembly based on robot workpiece pickup comprises a sliding table base, a manual workpiece loading device arranged at one end of the sliding table base, a robot workpiece grabbing device arranged at the other end of the sliding table base, and a sliding table walking car positioned on the position of the robot workpiece grabbing device, wherein the sliding table base comprises guide rails arranged at the two ends of the sliding table base, a sliding table gear rack arranged on the middle part of the sliding table base, an assembly switch arranged at one end of the sliding table base, and a sliding table guide limiting assembly arranged at the other end of the sliding table base. The automatic workpiece loading assembly based on robot workpiece pickup can realize rapid transportation of products among different assembly lines, saves labor power and time and improves efficiency. Repeated positioning precision for transportation is realized by virtue of mechanical locking and positioning, so that the automatic control is simplified, and the cost is saved; the mechanical structure is simple, and high-precision transportation at different distances can be realized by changing the lengths of the guide rails and the length of a transmission rack; and the repeated positioning precision is high and the transmission speed is high, so that the automatic workpiece loading assembly can be cooperated with automatic equipment such as a robot and the like very well in work.

Owner:HUBEI HENGLIDA WELDING EQUIP

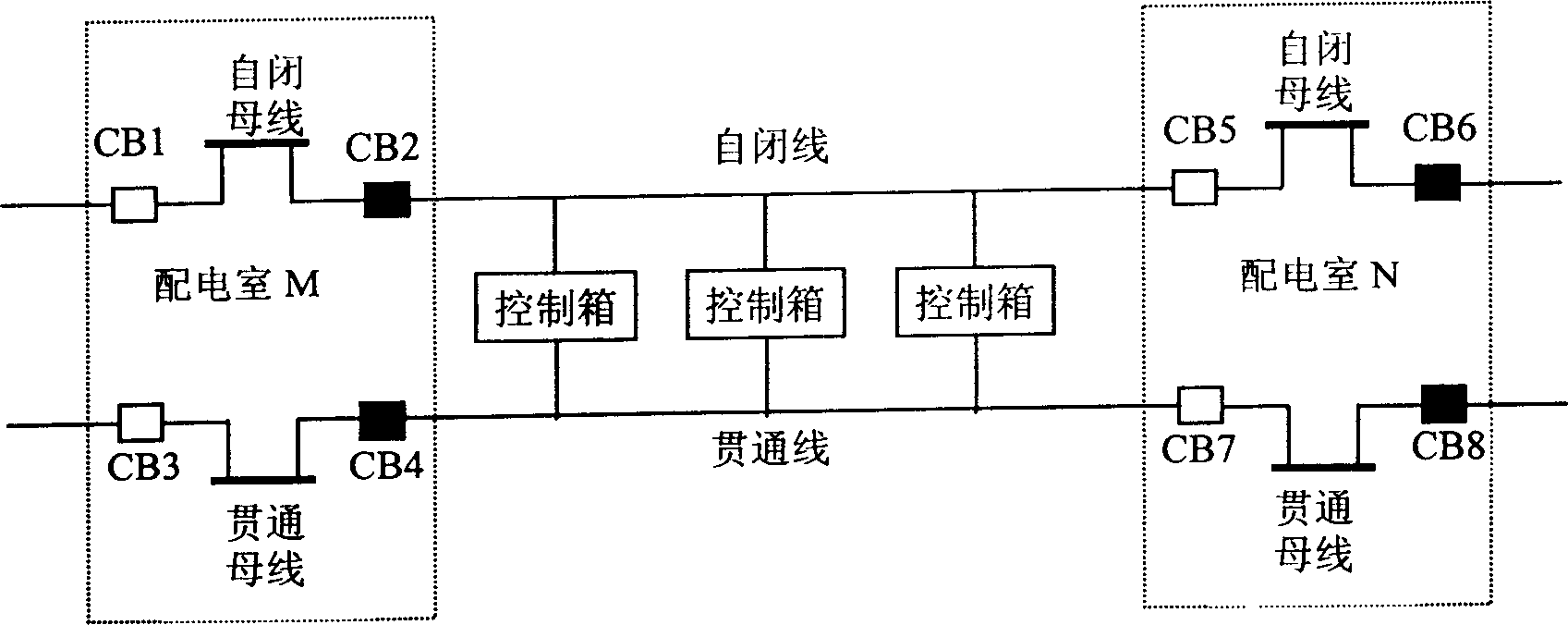

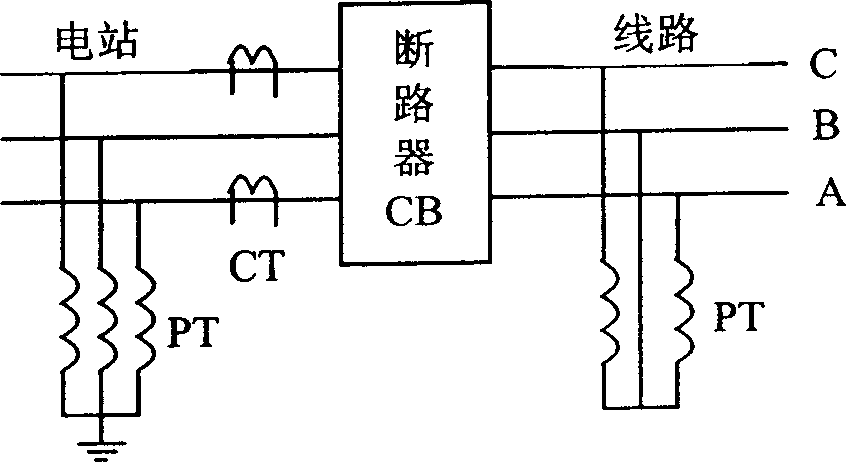

Railway self-closing/cut-through line-to-ground fault range count method

ActiveCN1689859AAccurate measurementSpeed of propagation is stablePower supply linesTransformerElectric power

The earth fault ranging method for automatic on / off circuit in railway belongs to the field of single phase earth fault locating method for small current earth system of electric power network. On-line detectors are installed on two ends of the line, and voltage traveling wave signal the small current earth system in failure generates is transmitted in the voltage signal transformers in the line. The on-line detectors detect the absolute time for the initial failure traveling wave to reach the voltage signal transformers on two ends, determine the time difference, and calculate the precise position in certain equation with the total line length and the traveling wave transmission speed. The present invention has the advantages of being fast and accurate, no influence of unstable electric arc and uneven load, etc.

Owner:SHANDONG KEHUI POWER AUTOMATION

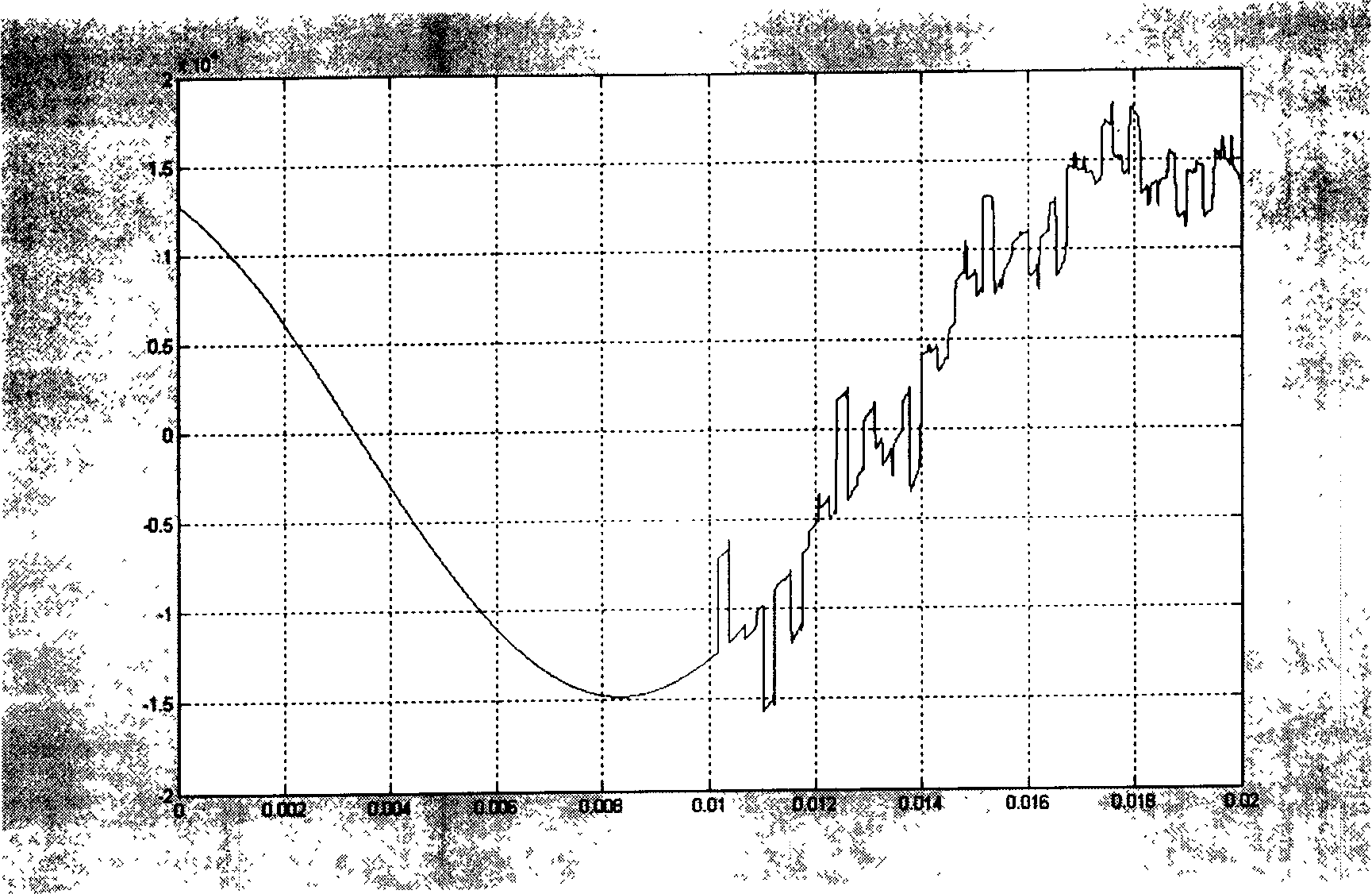

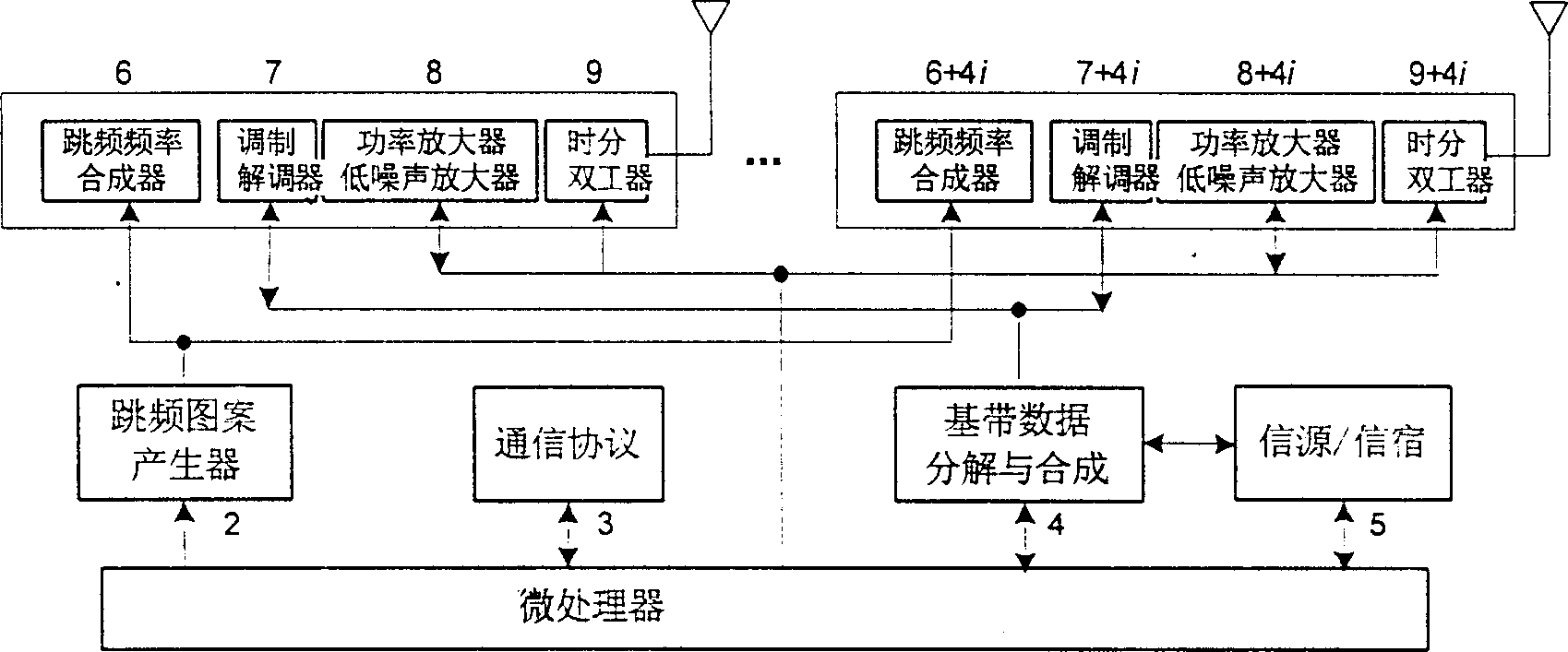

Multiplexer parallel transmission broadband high-speed frequency-hopping communication method and device thereof

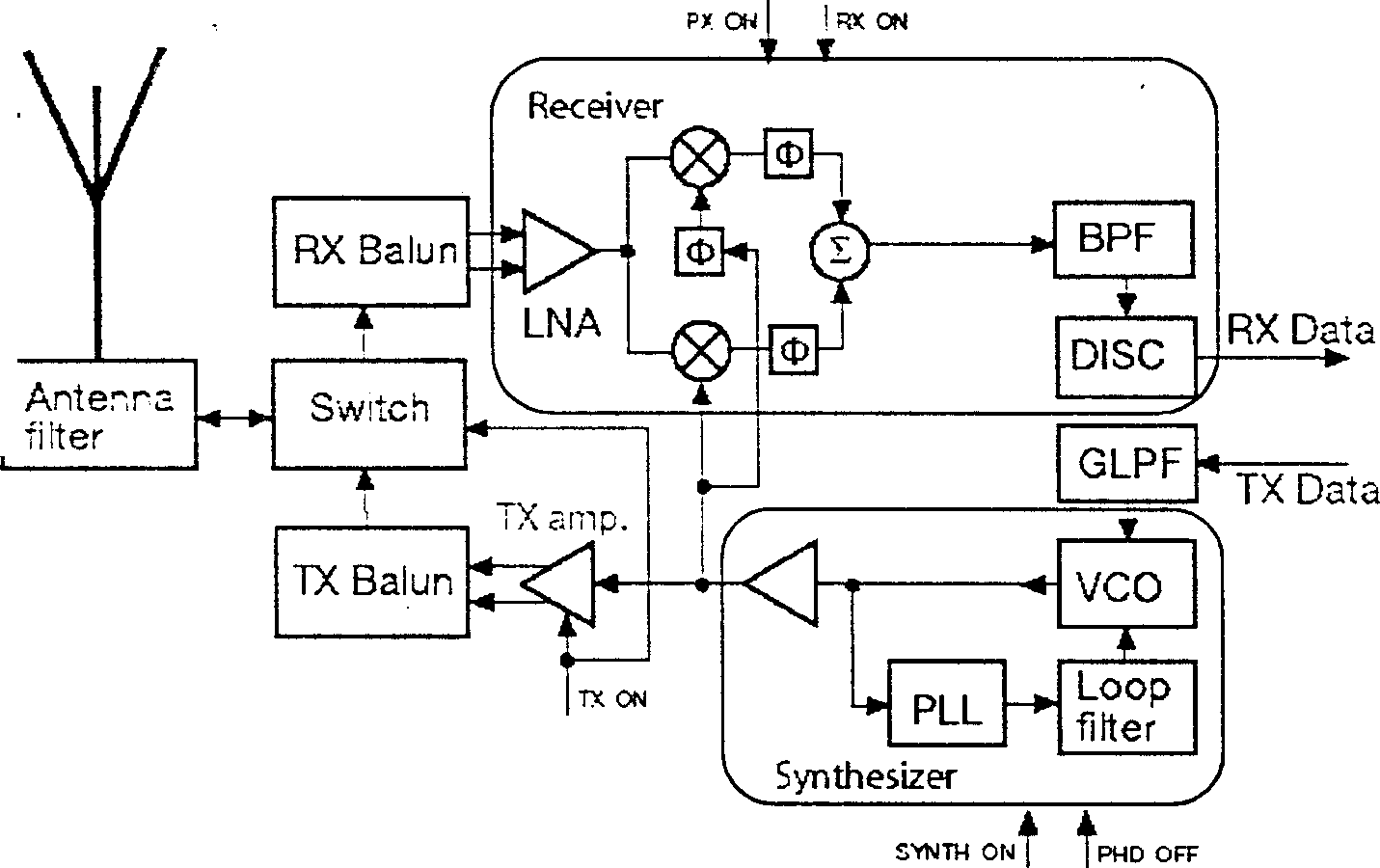

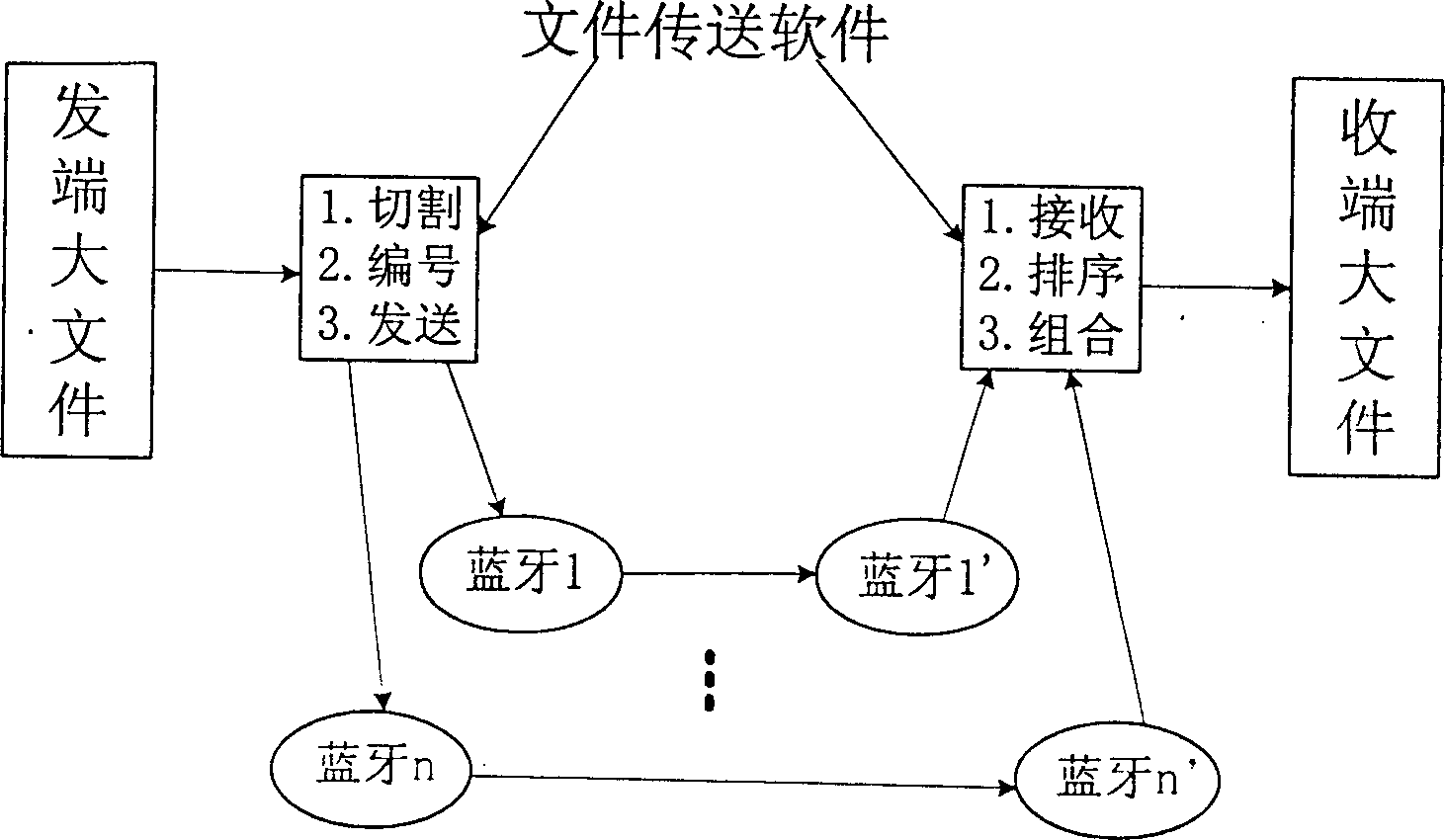

Broad band high speed transmission signal system using relative low speed chip is to set up multiple N corelated transmit and receive channels between source and sink to divide a "big file" be transmitted into N "small files" transmitted and receive in parallel, finally to be in composition to recover the original "big file", therefore increasing the transmitting speed by N times. The said deviceis composed of a micro-processor, frequency hopping graph generator, baseband data resolution and composition device, source and sink module, frequency hopping compositor, modem dynamic amplifier andtime division duplexes, making up multi-channels.

Owner:NANJING DONGDA MOBILE INTERCONNECTION TECH +1

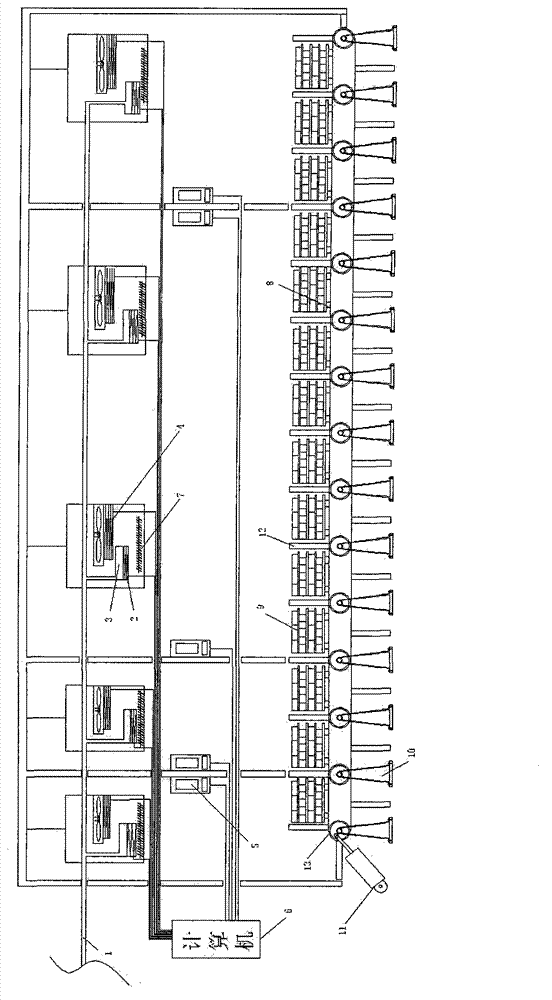

Novel intelligent automatic humidity and temperature kiln inside curing system and method for cement product

InactiveCN103029208AReduce lossDoes not affect transmissionCeramic shaping apparatusTemperature controlCarbonization

The invention provides a novel intelligent automatic humidity and temperature kiln inside curing system for a cement product. The system comprises a curing kiln; four heat-insulation soft spaced sections are arranged in a sealed kiln body and correspond to four curing periods of the cement product respectively; and the four curing periods include a pre-curing period, a heating period, a heat preservation period and a cooling period. The method comprises the following concrete steps: 1) determining the time of the four curing periods, setting the conveying speed of a plate conveying chain belt to be a constant value, and enabling the curing time ratio of the four heat-insulation soft spaced sections to be equal to the length ratio of the four heat-insulation soft spaced sections; and 2) setting the temperature and the humidity in each of the four heat-insulation soft spaced sections through a steam humidification device and a warm wind temperature control machine respectively. According to the curing system and method, the hydration and carbonization processes of the concrete cement product can be accelerated, the curing cycle can be shortened, and the problem of quality influence due to a series of factors such as cracking, deformation, collapse and the like can be solved.

Owner:天津恩赐晋华建材有限公司

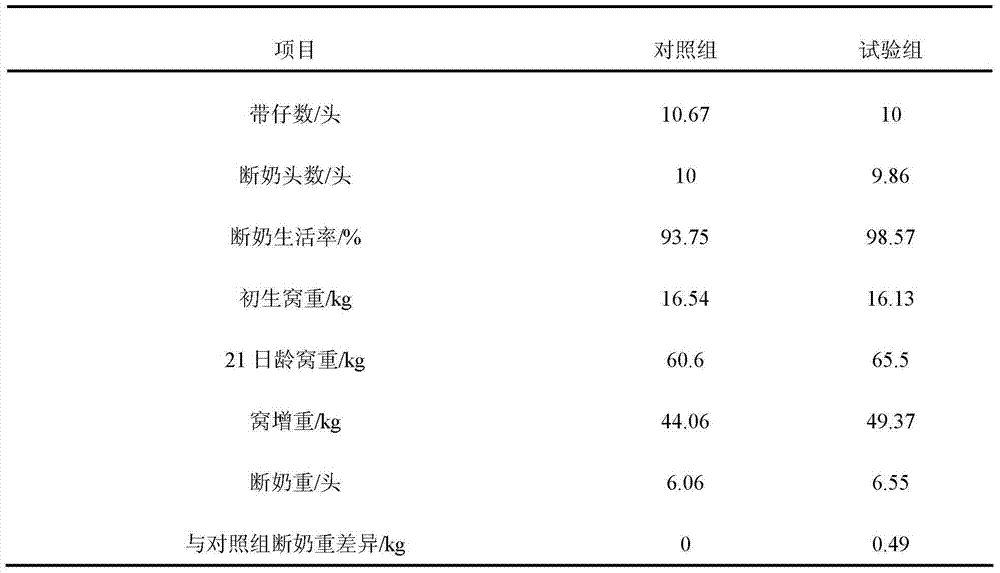

Feed water-soluble functional fatty powder

ActiveCN104222524AShort carbon chainIncrease polarityAnimal feeding stuffFood shapingDiseaseAnimal science

The invention relates to feed water-soluble functional fatty powder and solves the problems of low digestion and utilization rate and low energy supply speed of existing fat supplied to postnatal animals, diseased animals, young animals and the like. The feed water-soluble functional fatty powder comprises the following components in parts by mass: 20-30 parts of caprylic triglyceride, 25-35 parts of capric triglyceride, 3-5 parts of lysine, 1-3 parts of methionine, 1.5-2.5 parts of threonine, 1.5-3 parts of vitamin A, 1-3 parts of vitamin E, 1-5 parts of a composite emulsifier, 0.01-1.0 part of a composite antioxidant and 20-30 parts of a coating material. According to the feed water-soluble functional fatty powder, the digestion and utilization rate reaches up to 100% in animal bodies, the metabolism and transfer velocity in the animal bodies is high, the energy supply speed is 6 times that of long-chain fatty acid, and the energy can be quickly provided for the animals.

Owner:GUANGZHOU YOUBAITE FEED SCI & TECH

Device and method for conveying a spring serpentine

Owner:SPUHL AG

Method and apparatus for producing uniform isotropic stresses in a sputtered film

InactiveUS7153399B2Relieve stressSignificant stressCellsVacuum evaporation coatingSputteringFilm material

The invention provides a method and apparatus for producing uniform, isotropic stresses in a sputtered film. In the presently preferred embodiment, a new sputtering geometry and a new domain of transport speed are presented, which together allow the achievement of the maximum stress that the film material can hold while avoiding X-Y stress anisotropy and avoiding stress non-uniformity across the substrate.

Owner:ADVANTEST CORP

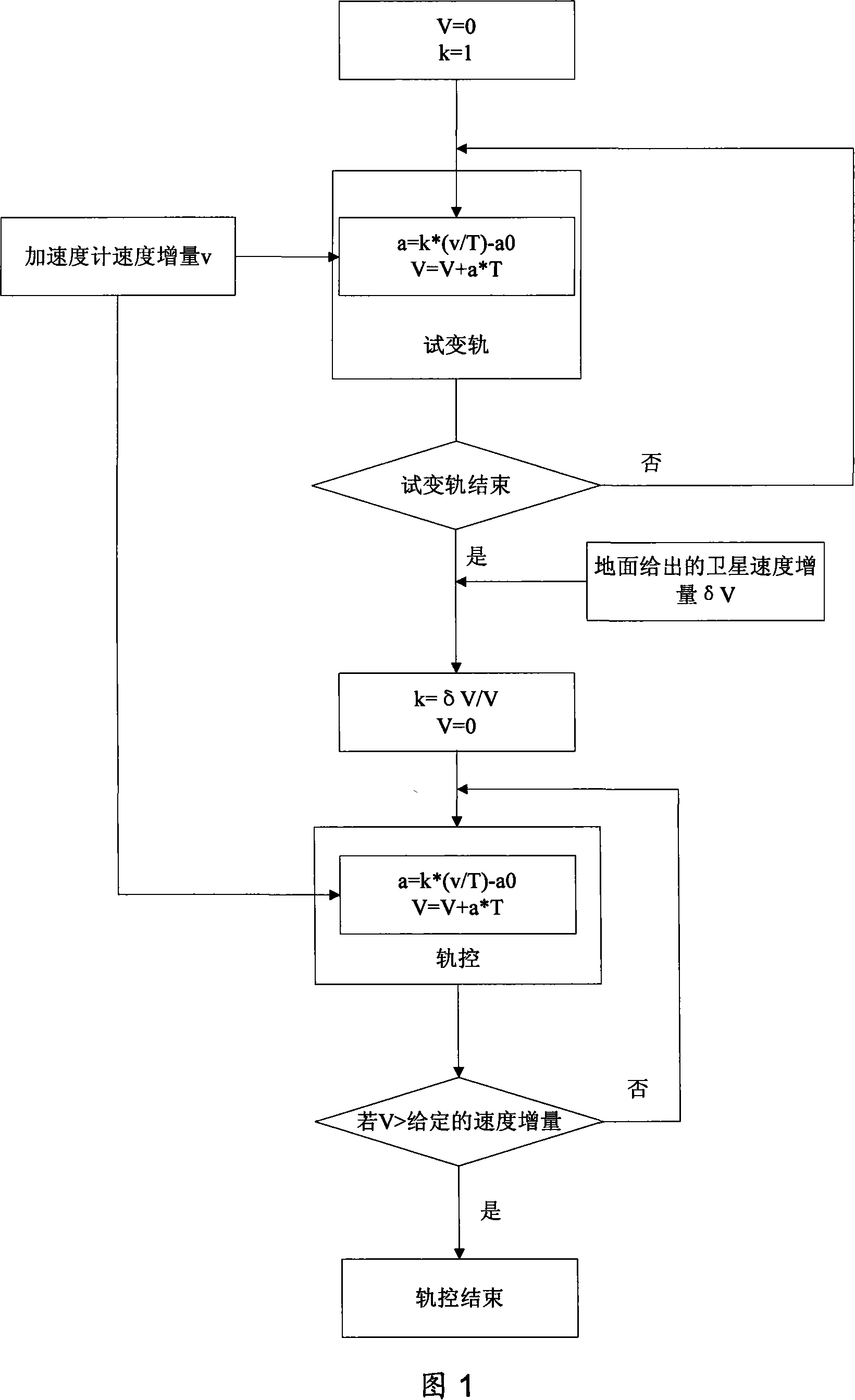

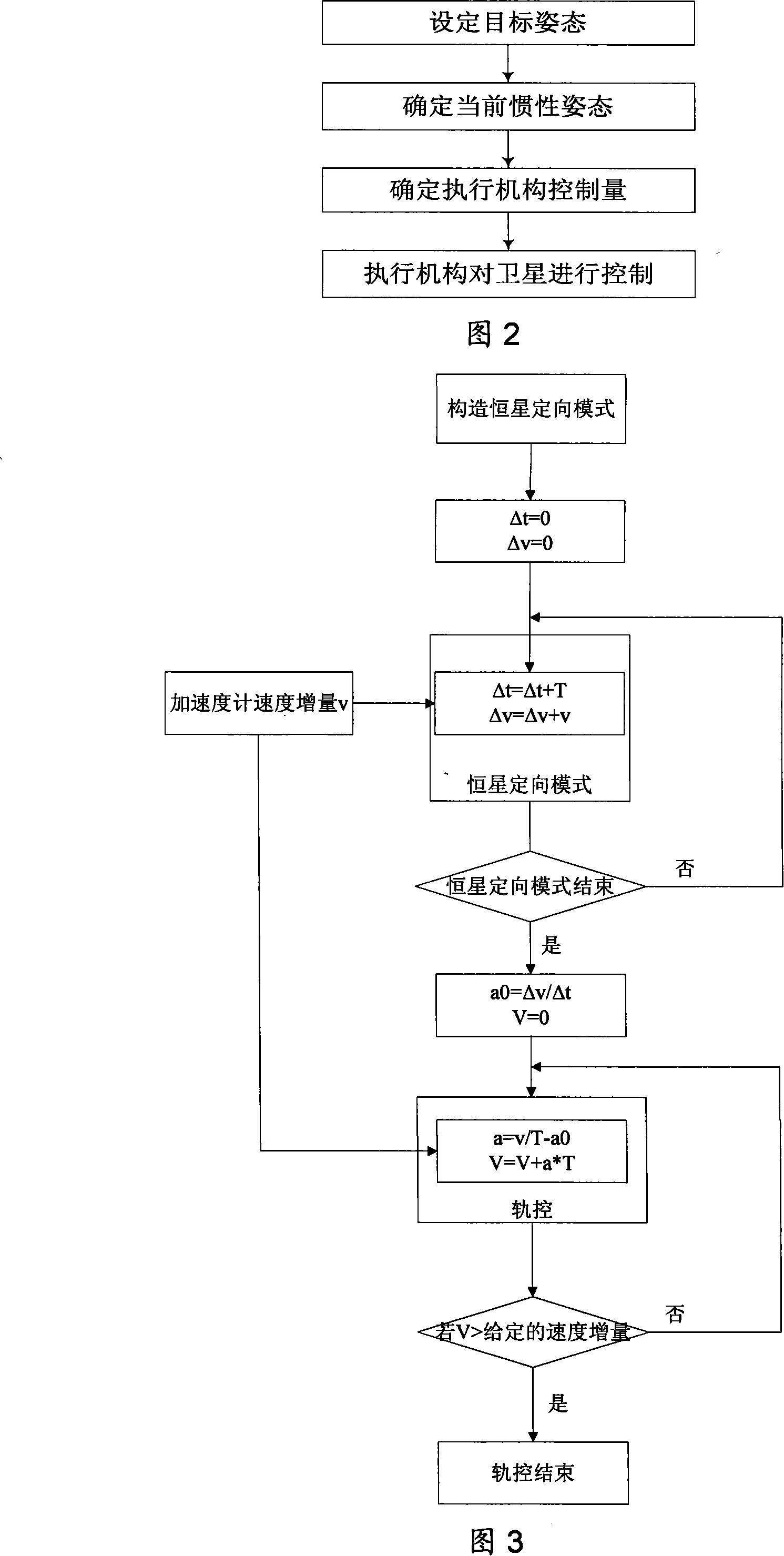

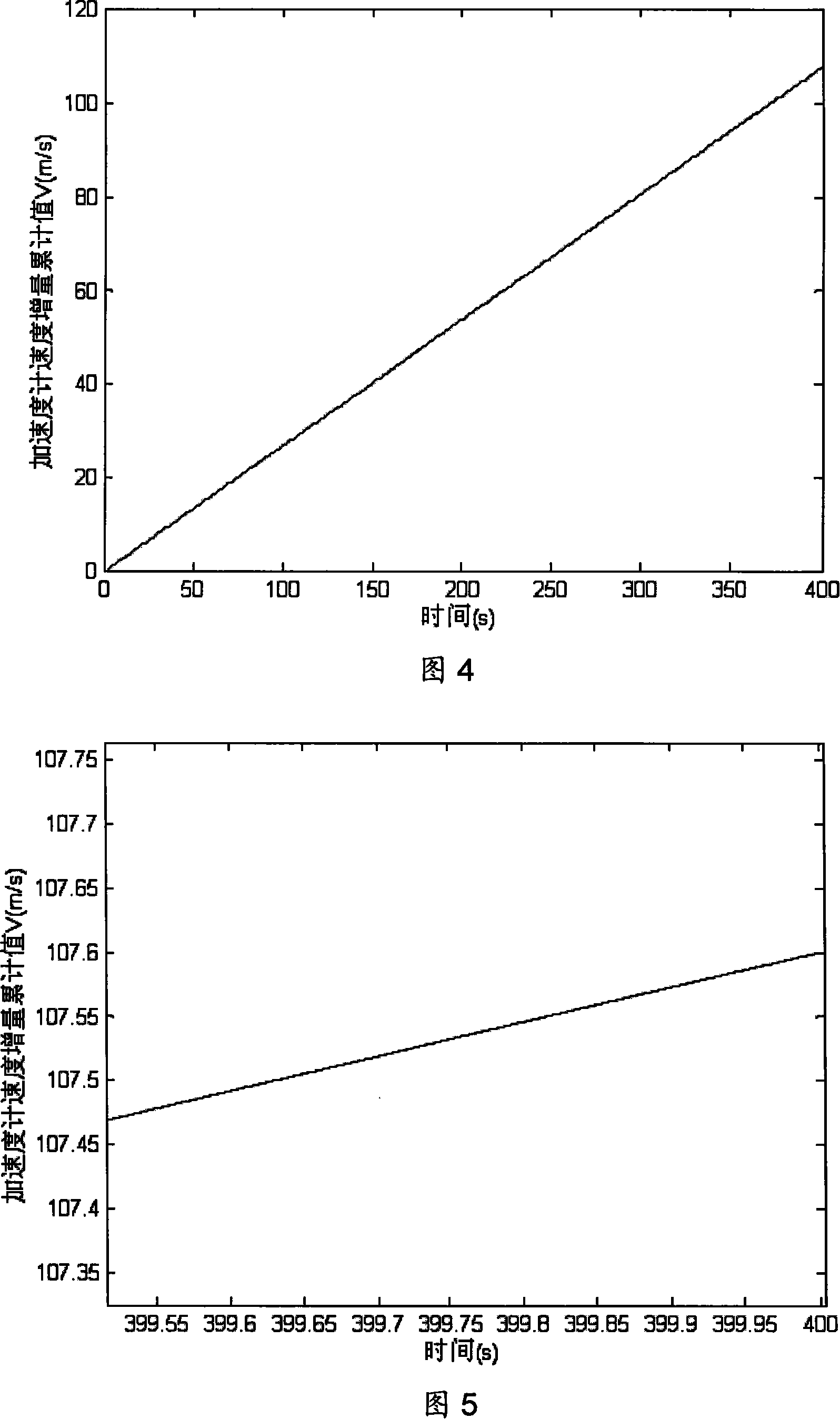

Method for calibrating accelerometer by using orbit determination data

InactiveCN101200221AImprove accuracyGuaranteed control accuracySpacecraft guiding apparatusDelta-vAccelerometer

Disclosed is a method to calibrate an accelerator through orbit determination data, which includes the following steps: make sure the zero offset calibration value of an accelerator before the satellite carry out trial orbit transfer and set the pulse equivalent calibration coefficient of the accelerator to 1; compensate the acceleration measured by the accelerator during the trial orbit transfer process; accumulate the velocity increment during the trial orbit transfer according to the compensated measured value by the accelerator; after the orbit transfer, calculate the pulse equivalent calibration value of the accelerator by velocity increment Delta V during the trial orbit transfer according to ground orbit measuring; during the orbit control process, compensate the accelerator measured value according to the obtained pulse equivalent calibration value and the zero offset calibration value of the accelerator before trial orbit transfer; calculate the velocity increment and compare the calculated velocity increment value with the orbit transfer velocity increment value before the orbit control, if the calculated velocity increment value is larger than the velocity increment value before orbit control, the orbit control can be stopped. If not, continue the execution from the orbit control process until the end.

Owner:BEIJING INST OF CONTROL ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com