Pipe leakage detecting instrument, detecting device and detecting method based on dynamic low-frequency technology

A technology of pipeline leakage and detector, which is applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of short response time, reduced output data attenuation, inability to distinguish leaking sonic signals, etc., and achieve accurate judgment. , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

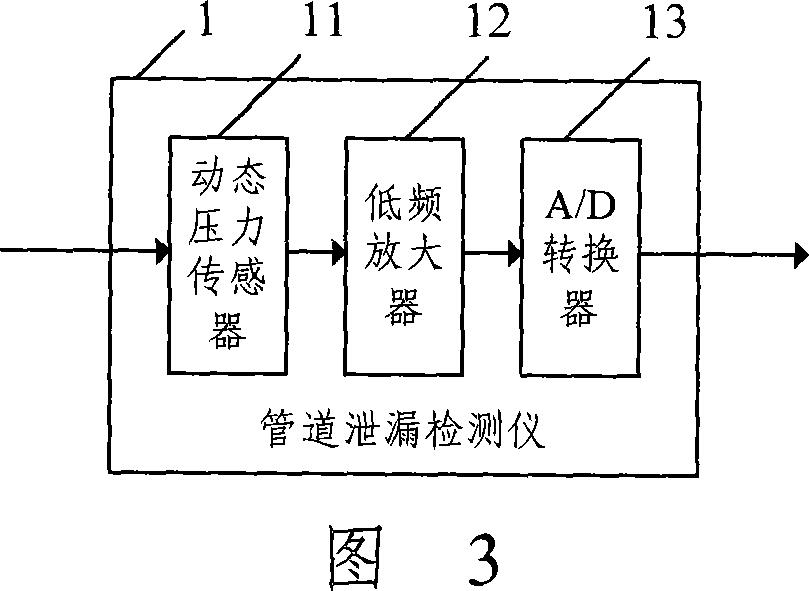

[0055] Based on the principle of Fig. 3, the dynamic pressure sensor 11 is connected with the A / D converter 13 through the low-frequency amplifier 12, and the dynamic pressure sensor 11, the low-frequency amplifier 12 and the A / D converter 13 adopted are specifically:

[0056] The dynamic pressure sensor 11 used has a working frequency range of 0-1000 Hz, and the rise time, that is, the response time is greater than 2 μs. The response time of the dynamic pressure sensor 11 is greater than 2 μs, which ensures the dynamic response of the dynamic pressure sensor 11.

[0057] The low-frequency amplifier 12 matched with the dynamic pressure sensor 11 collects low-frequency data signals, adjusts the measurement range with multiple gears, and adjusts the measurement range of the pipeline leak detector 1 according to the dynamic pressure change in pipeline operation, and adopts a full scale of 0-5V output, the measured frequency range is below 20Hz.

[0058] The selection requirement ...

Embodiment 2

[0064] As shown in Figure 6, a pipeline leak detection device based on dynamic low-frequency technology includes two pipeline leak detectors 1a and 1b, two base stations 2a and 2b, a central control station 3, and three GPS locators 4a and 4b and 4c.

[0065] The pipeline leak detectors are installed at the first station of the pipeline and the last station of the pipeline, respectively, the pipeline leak detector 1a at the first station of the pipeline and the pipeline leak detector 1b at the last station;

[0066] The pipeline leakage detector 1a at the first station of transportation is connected to the central control station 3 through the first base station 2a, the pipeline leakage detector 1b at the last station of transportation is connected to the central control station 3 through the second base station 2b, and the first base station 2a is connected to the central control station 3 to carry out remote communication to detect the output value of the pipeline leakage de...

Embodiment 3

[0075] A certain pipeline has a total length of 100.3km, the operating pressure of the first station is 2.2Mpa, the operating pressure of the last station is 0.25Mpa, the amount of oil and gas transported is 220m3 / h, and the diameter of the pipeline is 426mm.

[0076] Based on the principle of Figure 7, this embodiment adopts the pipeline leak detector shown in Figure 3 and the pipeline leak detection device shown in Figure 6, the full scale of the pipeline leak detector is 5000mV, a pipeline leak detection based on dynamic low frequency technology method, including the following steps:

[0077] Step 201: through the dynamic response of the dynamic pressure sensor 11 in the pipeline leakage detector 1 to the dynamic pressure variation, and the low-frequency amplifier 12 matched with it, the low-frequency pipeline leakage sound wave signal is collected, and the signal is converted by the A / D converter 13; The leak detector 1 includes a pipeline leak detector 1a at the first del...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com