Patents

Literature

112results about How to "Significant stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

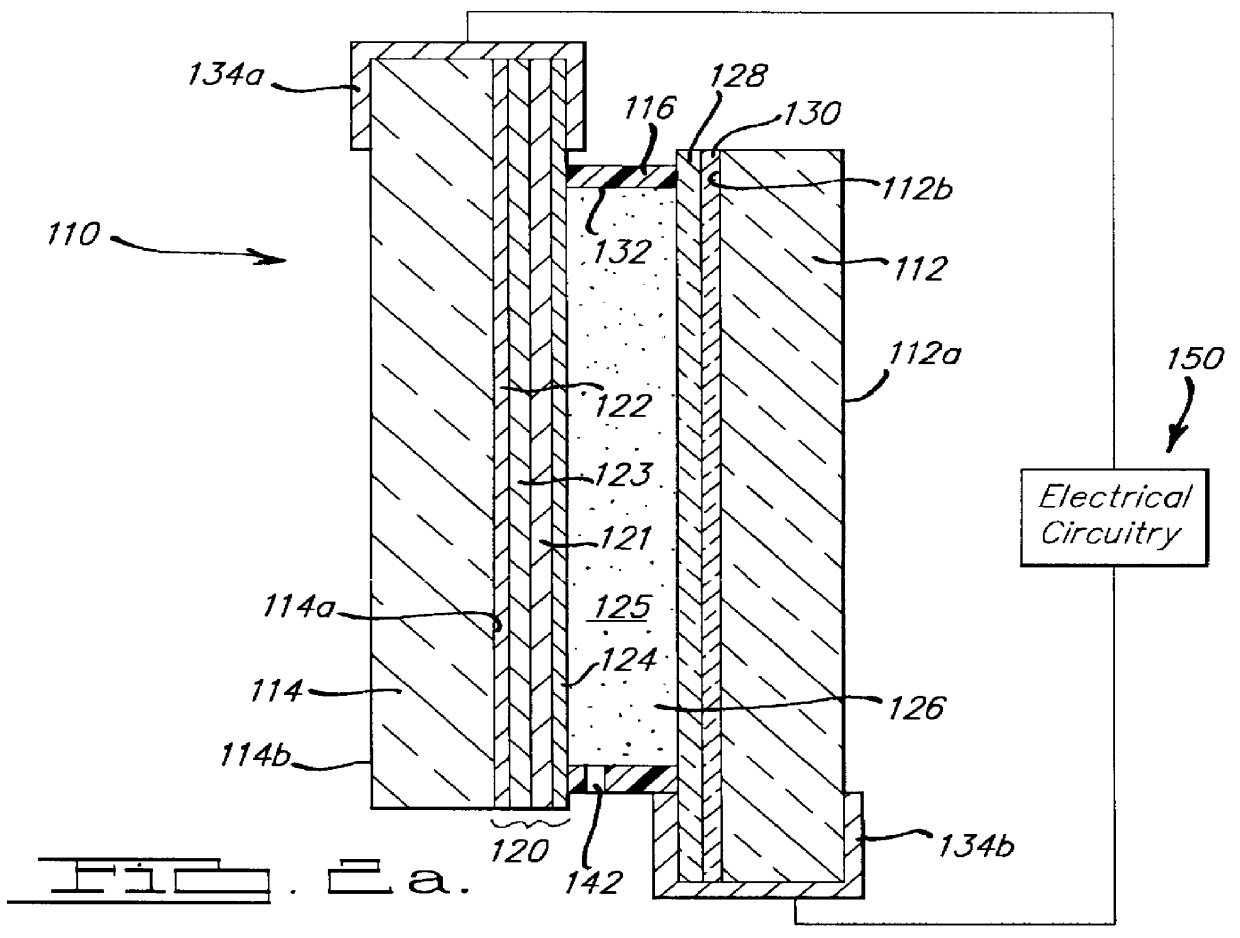

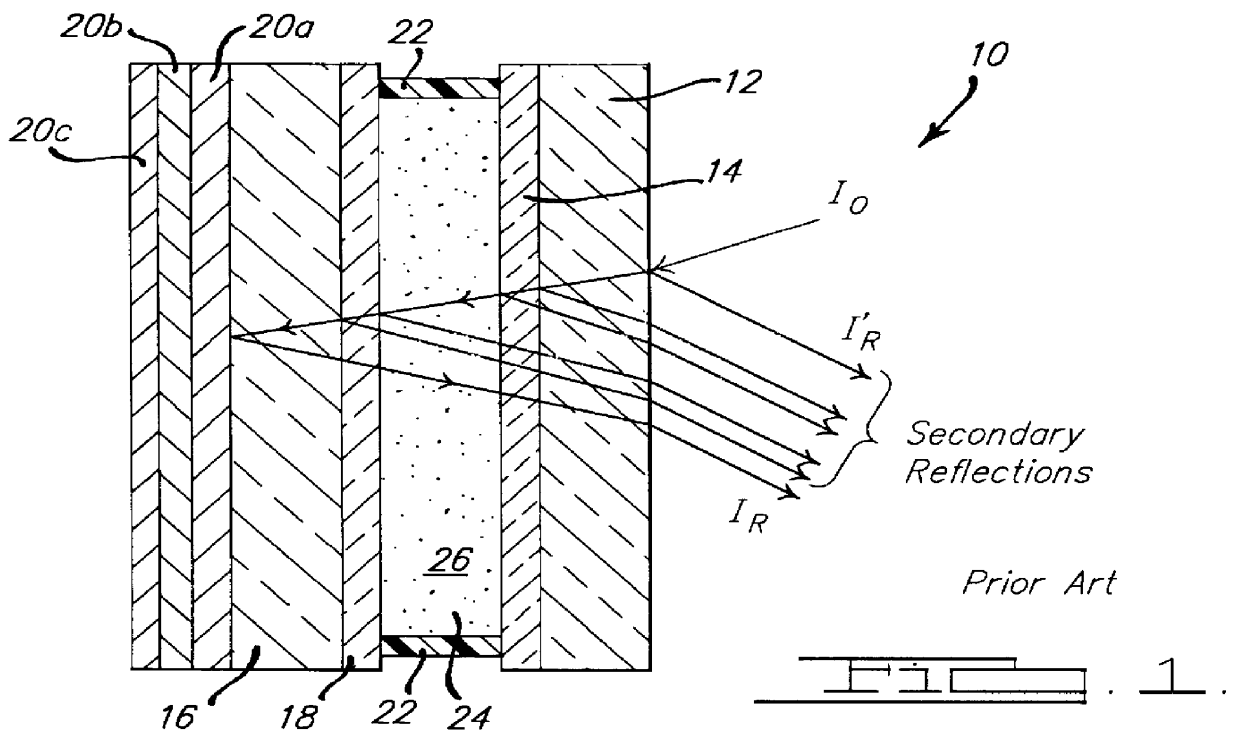

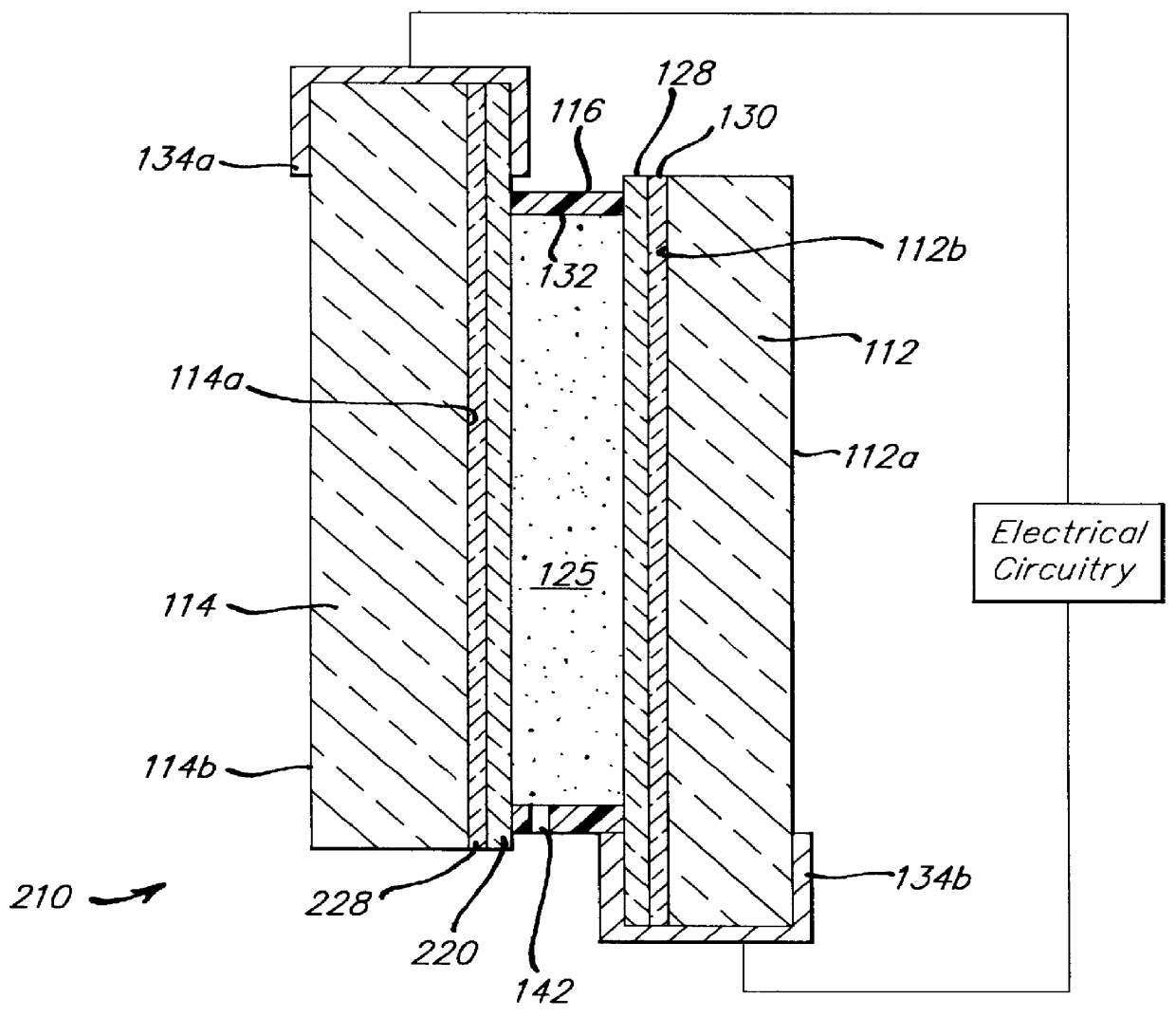

Seal for electrochromic devices

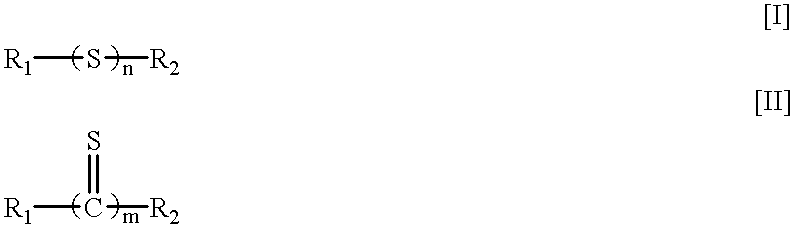

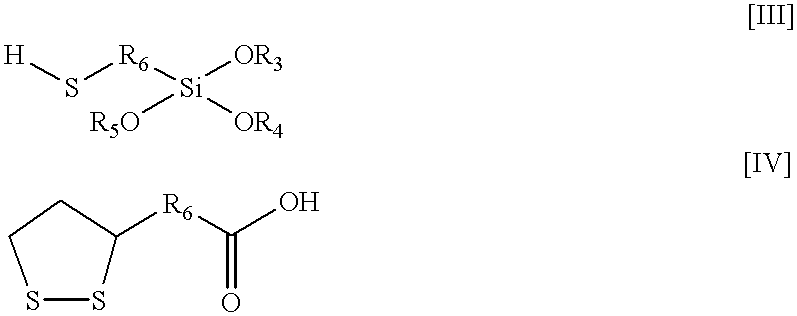

An improved seal member is provided as a part of an electrochromic device to bond two glass elements together in a spaced-apart relationship. In one embodiment the seal member provides improved adhesion to a reflector / electrode on the third surface of an electrochromic mirror, or to a layer of metal on the second or third surface for an electrochromic light filter. This seal member comprises a mixture of an organic resin sealing system and an adhesion promoter, where the adhesion promotor comprises a first and a second region, where the first region interacts with the reflector / electrode or the metal layer, and a second region that interacts with the organic resin sealing system, and may even chemically react with the organic resin sealing system. In another embodiment the seal member is provided with a coefficient of thermal expansion that is closer to glass than a standard epoxy sealing system.

Owner:GENTEX CORP

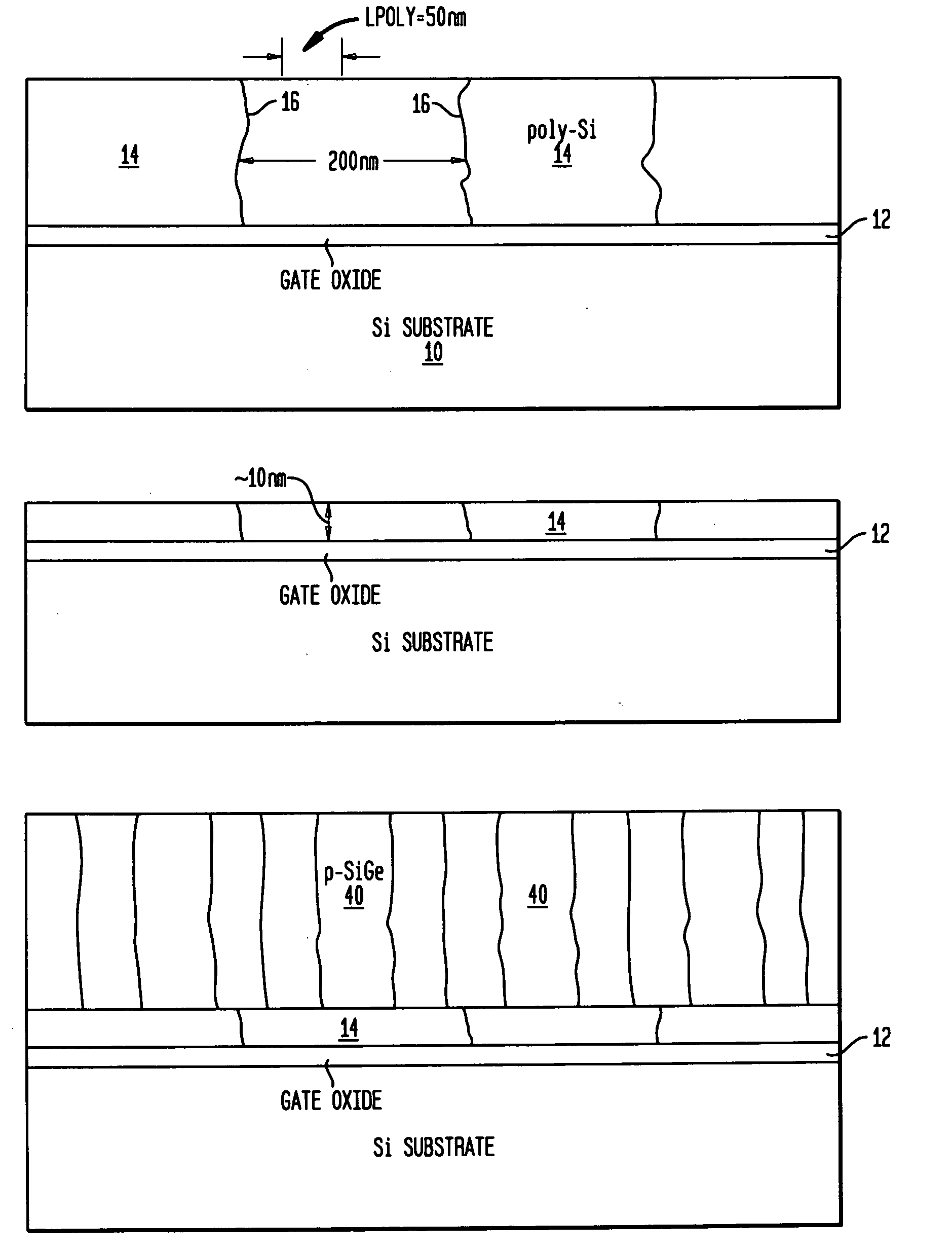

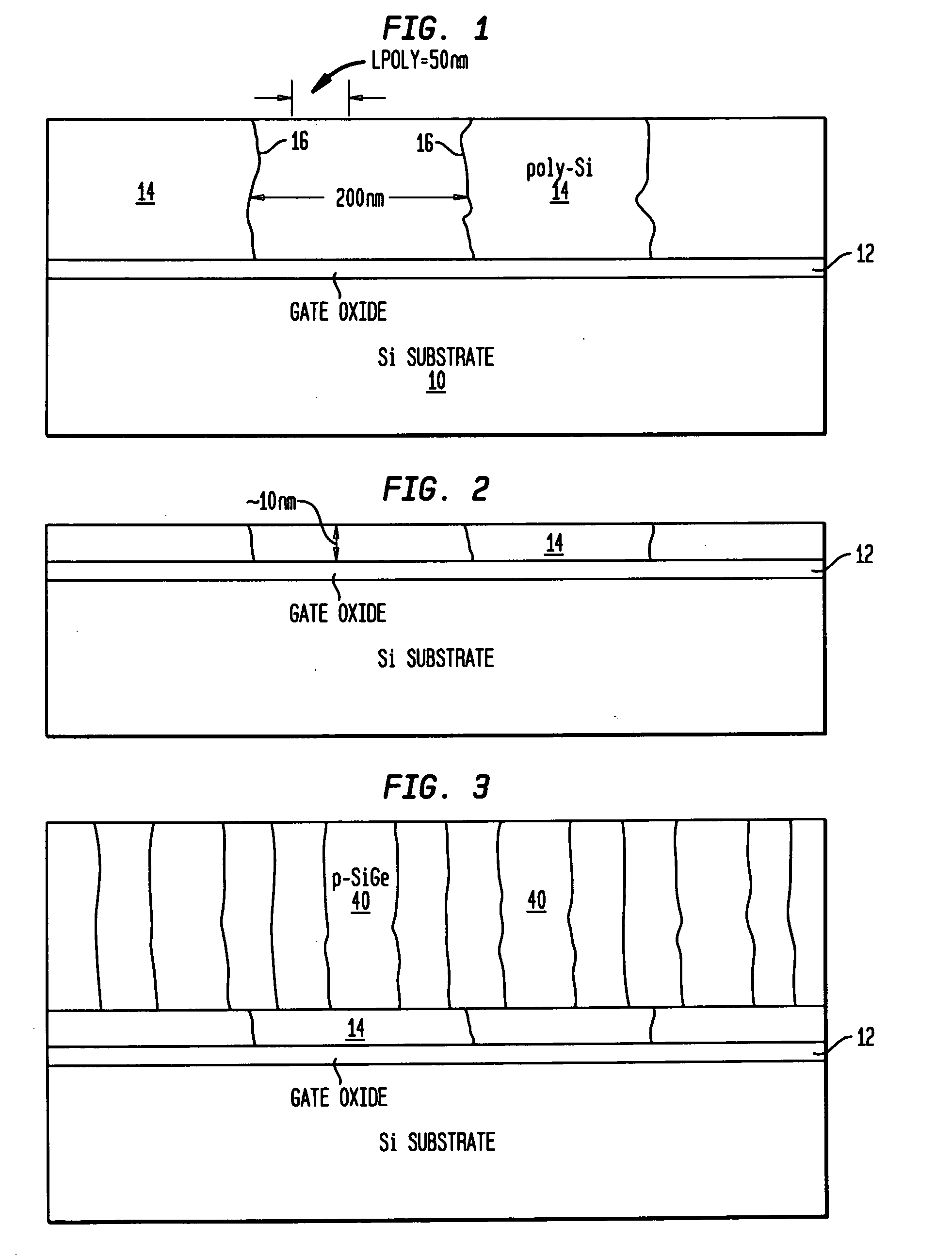

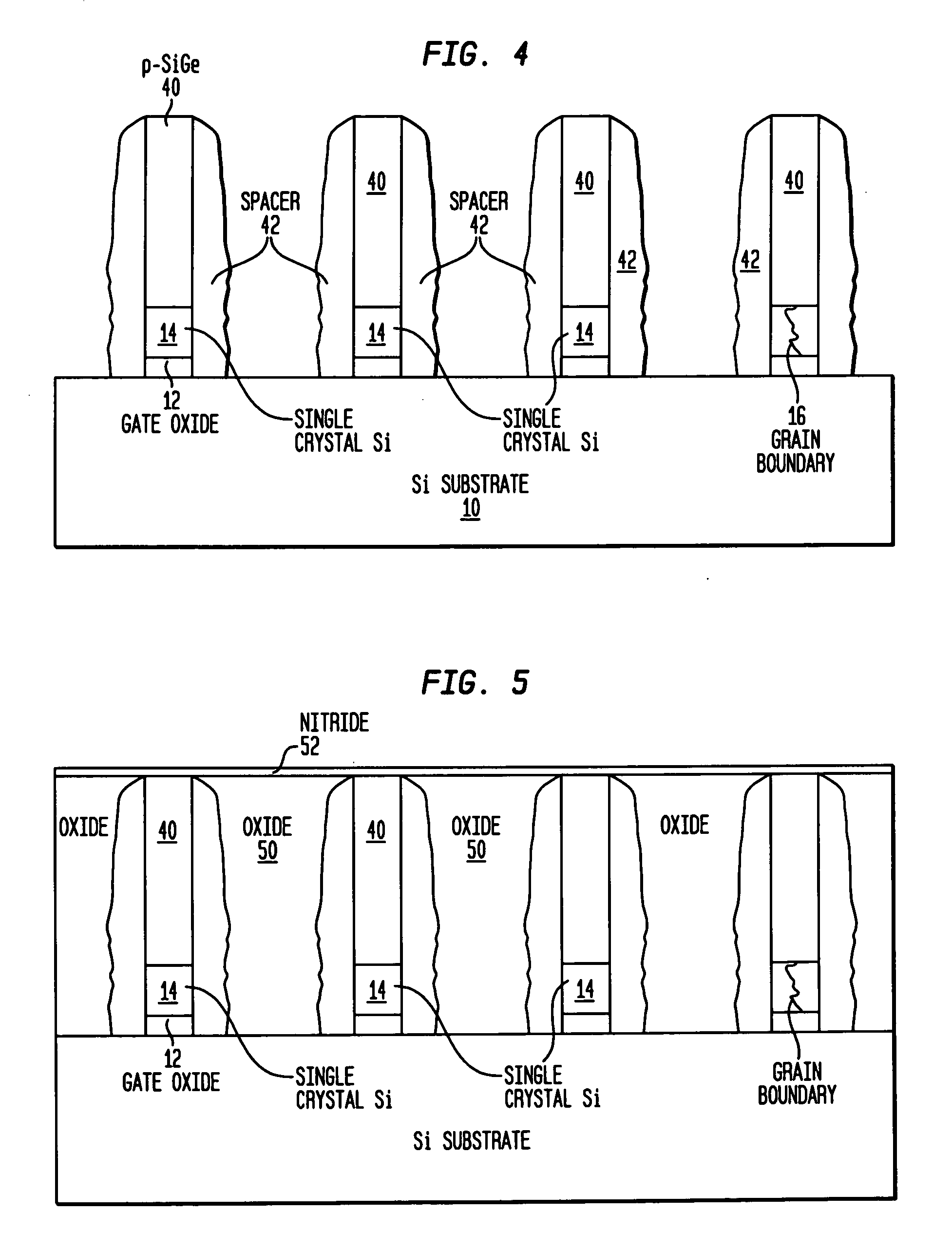

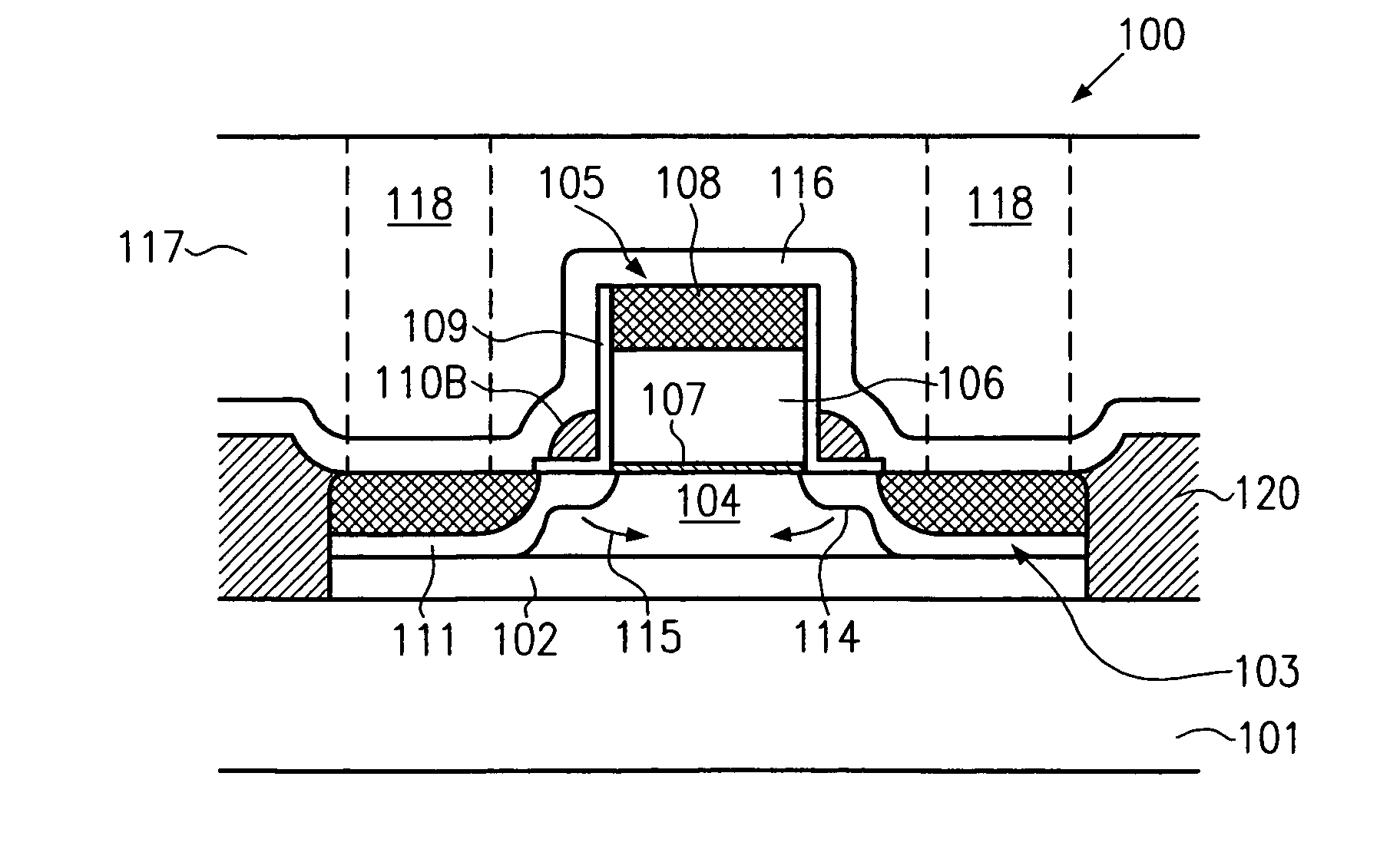

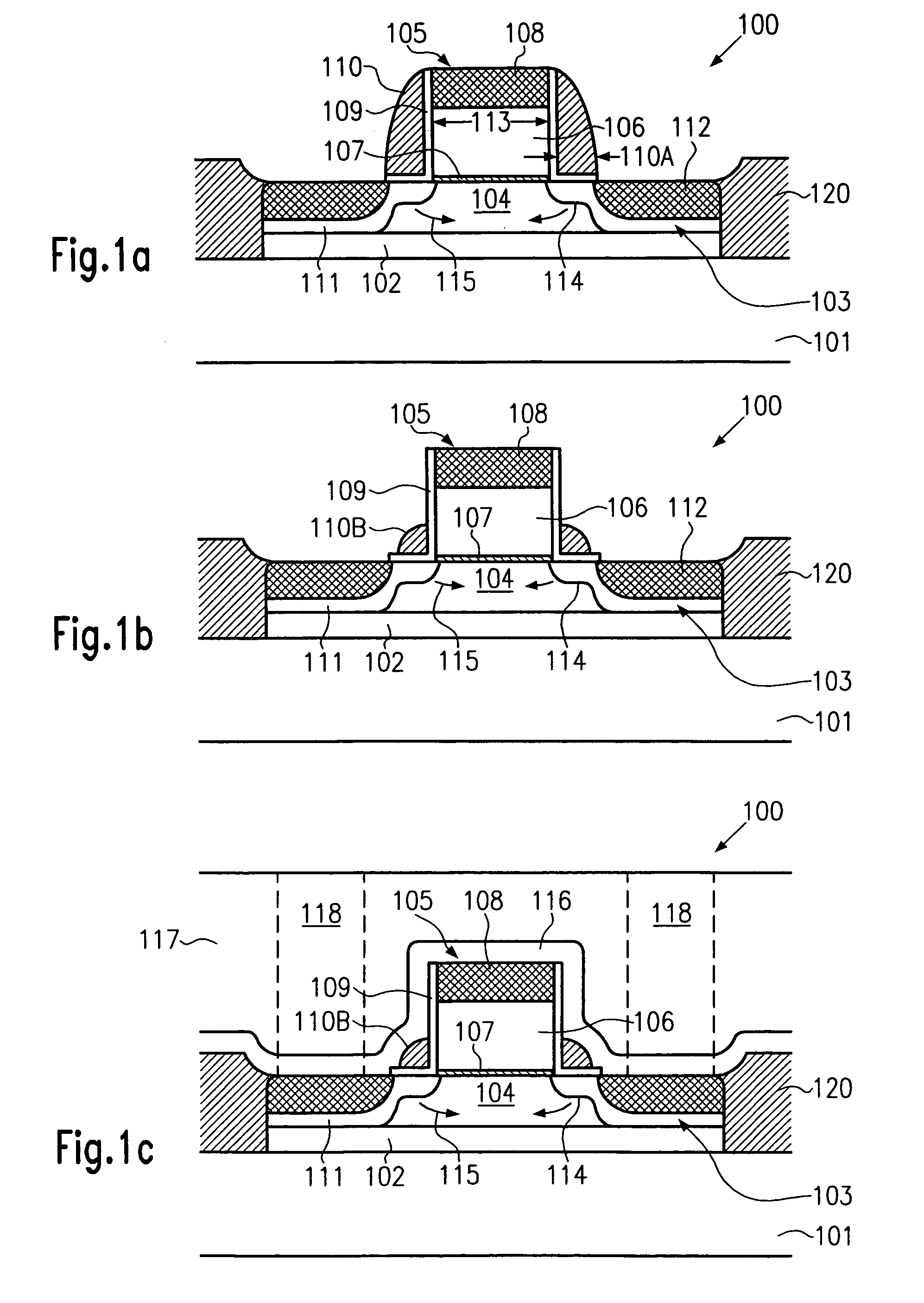

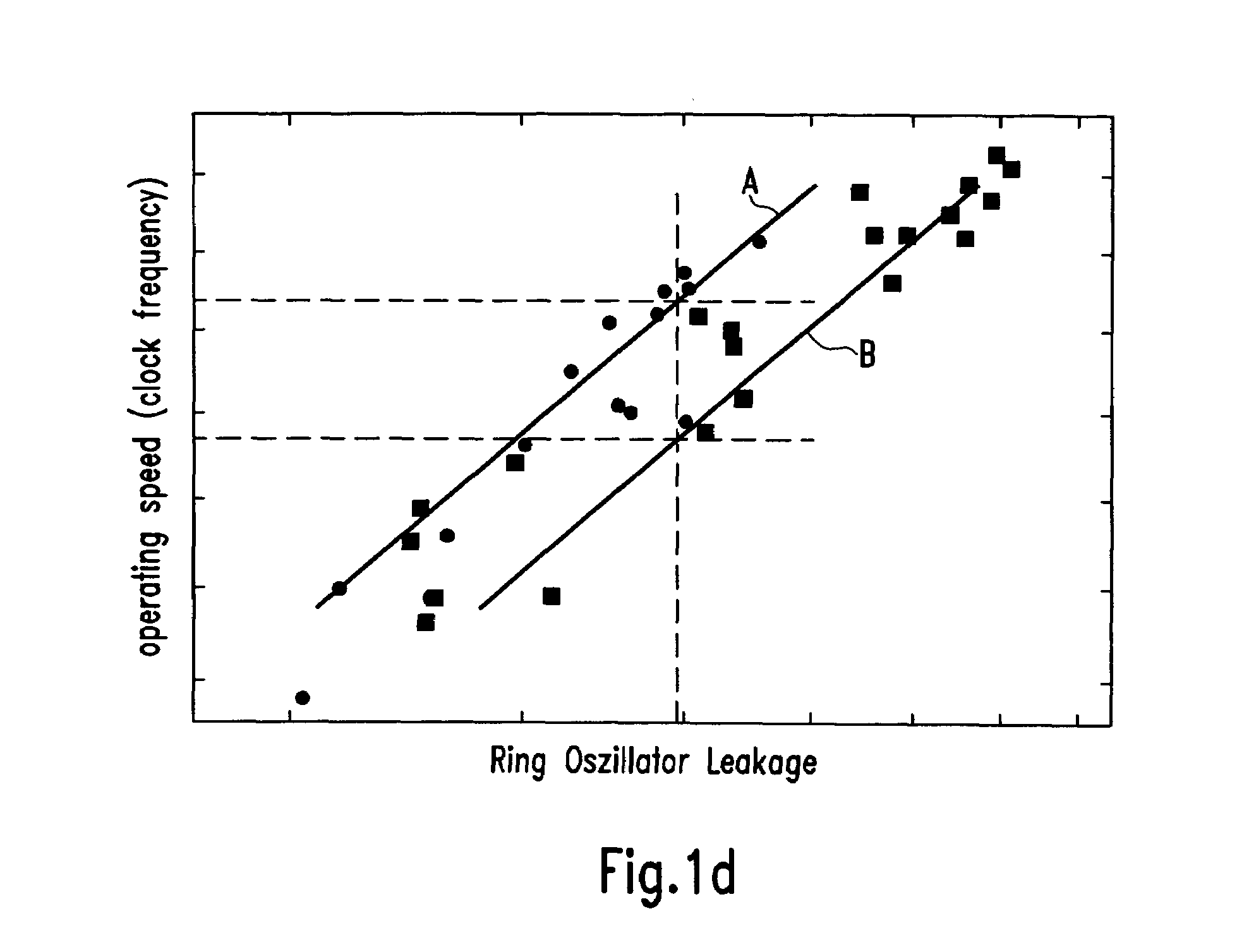

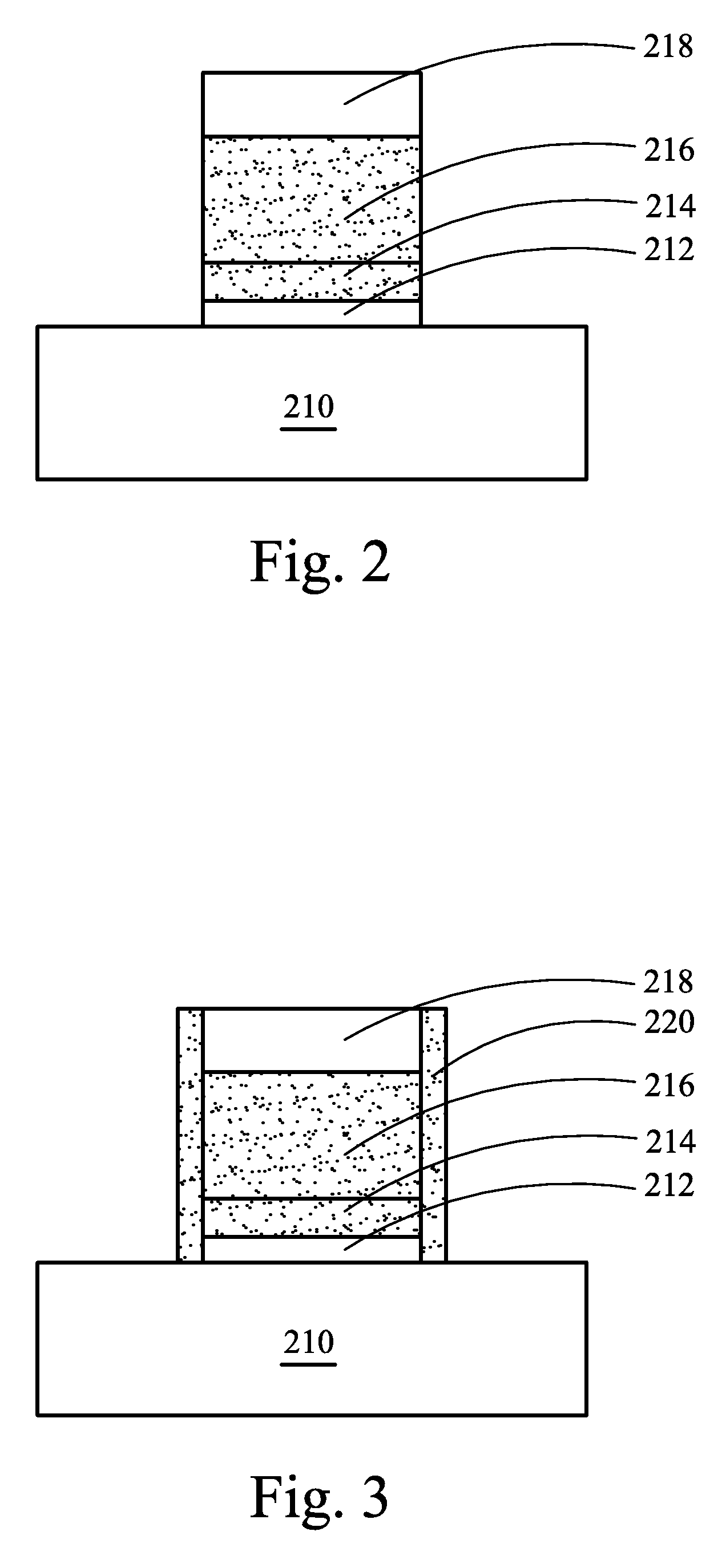

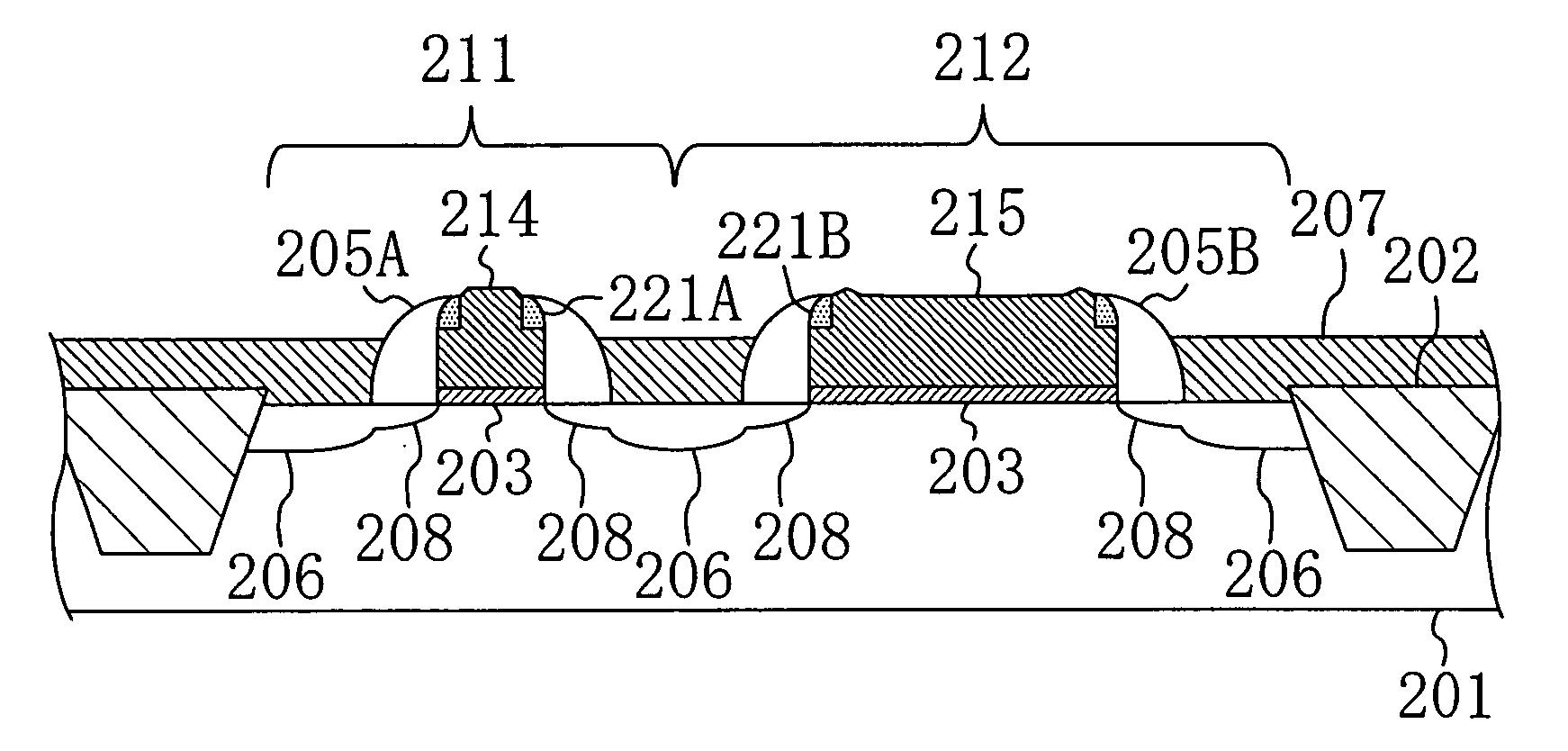

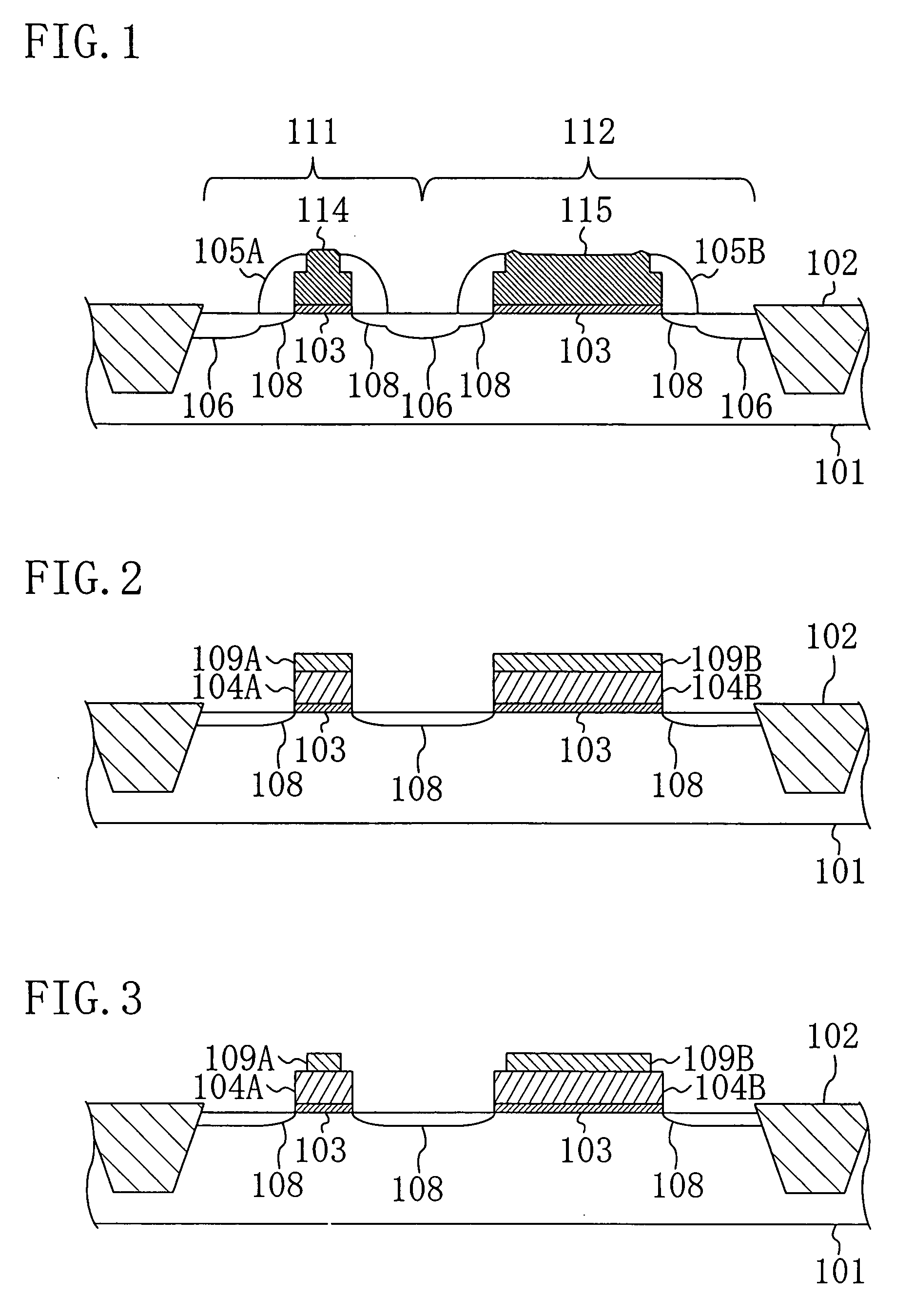

STRUCTURES AND METHODS FOR MANUFACTURING OF DISLOCATION FREE STRESSED CHANNELS IN BULK SILICON AND SOI CMOS DEVICES BY GATE STRESS ENGINEERING WITH SiGe AND/OR Si:C

ActiveUS20050236668A1Avoid misalignmentReduce generationTransistorSemiconductor/solid-state device detailsSoi cmosCMOS

Structures and methods of manufacturing are disclosed of dislocation free stressed channels in bulk silicon and SOI (silicon on insulator) CMOS (complementary metal oxide semiconductor) devices by gate stress engineering with SiGe and / or Si:C. A CMOS device comprises a substrate of either bulk Si or SOI, a gate dielectric layer over the substrate, and a stacked gate structure of SiGe and / or Si:C having stresses produced at the interfaces of SSi(strained Si) / SiGe or SSi / Si:C in the stacked gate structure. The stacked gate structure has a first stressed film layer of large grain size Si or SiGe over the gate dielectric layer, a second stressed film layer of strained SiGe or strained Si:C over the first stressed film layer, and a semiconductor or conductor such as p(poly)-Si over the second stressed film layer.

Owner:GLOBALFOUNDRIES US INC

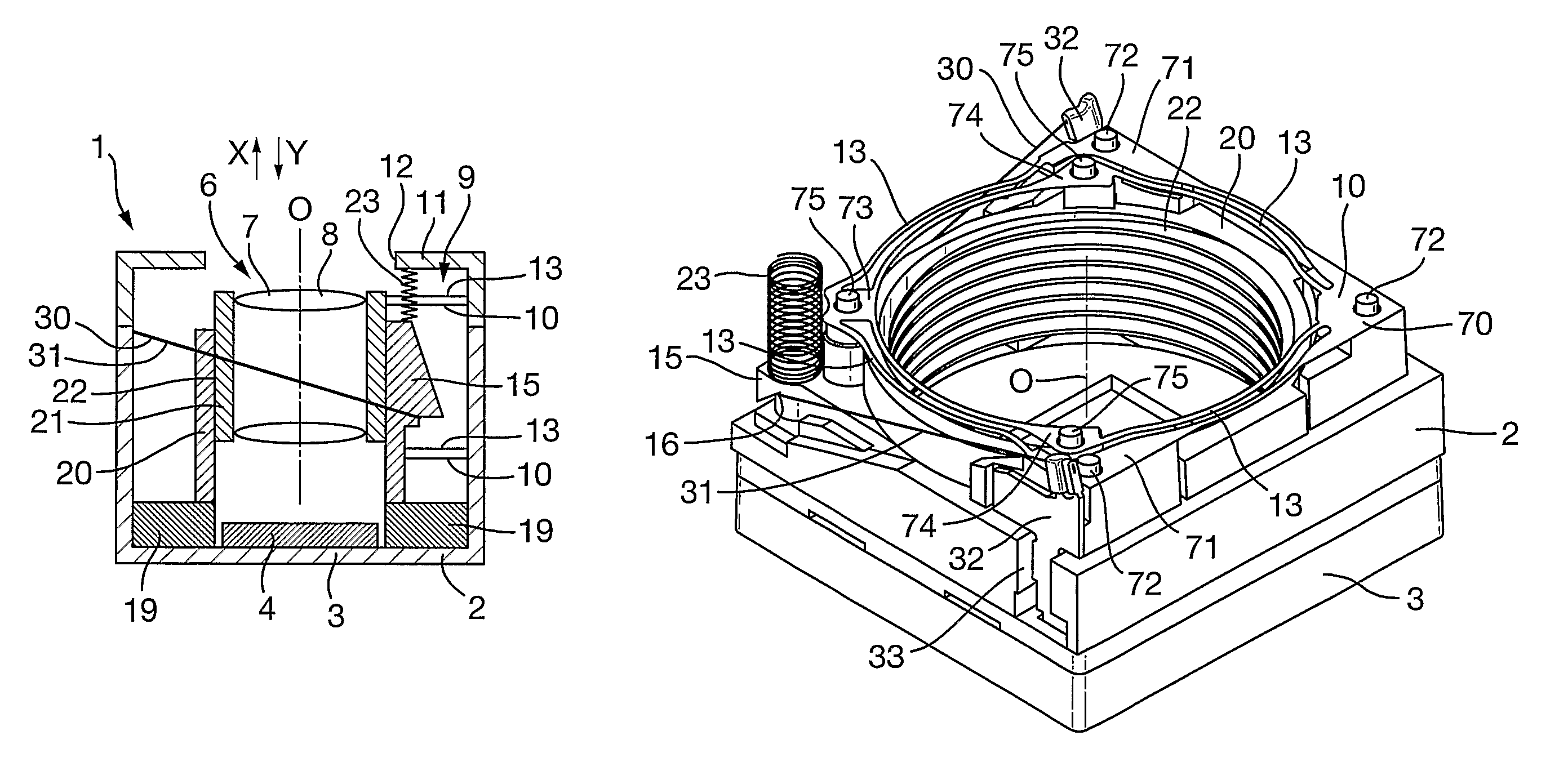

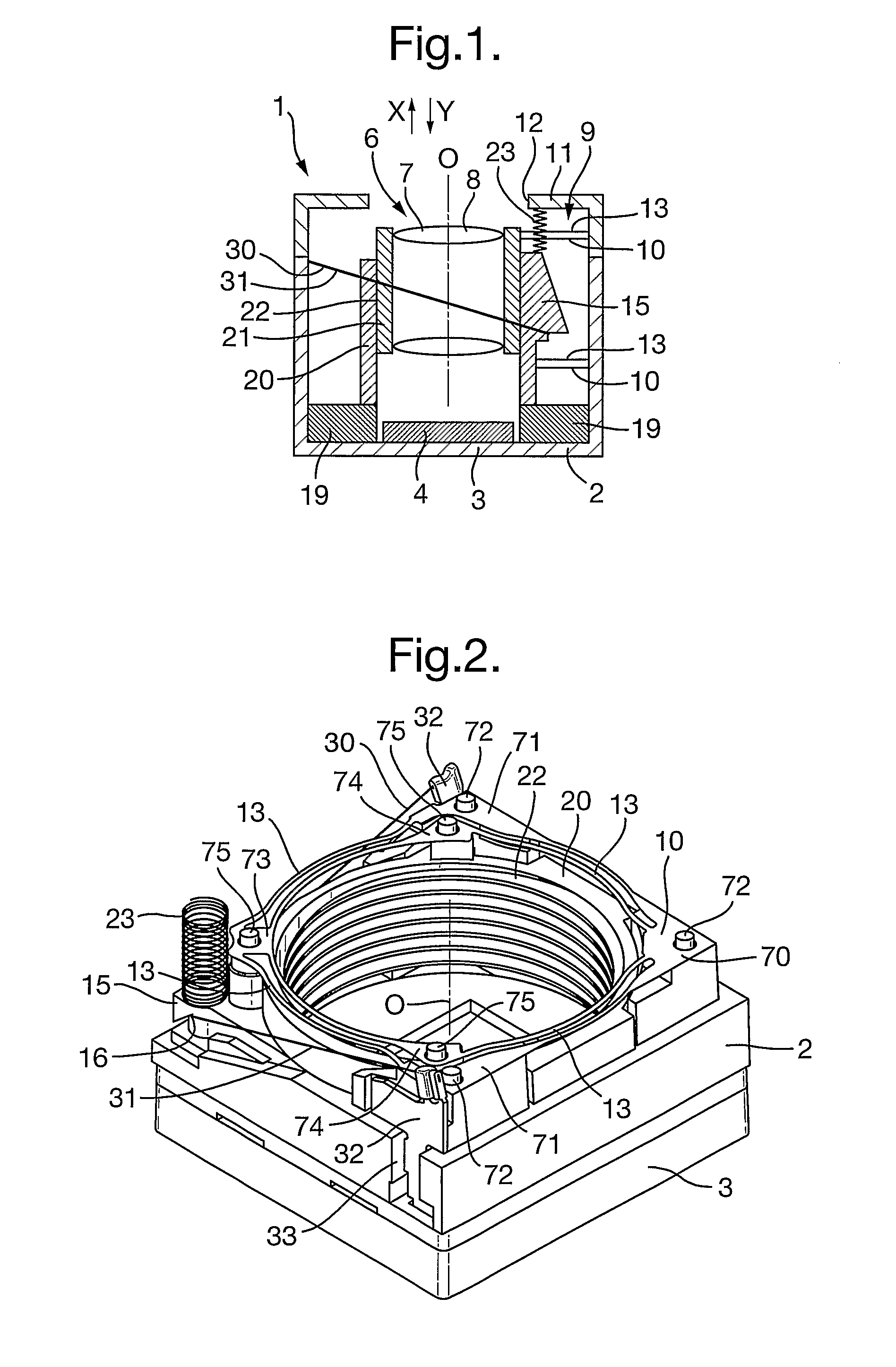

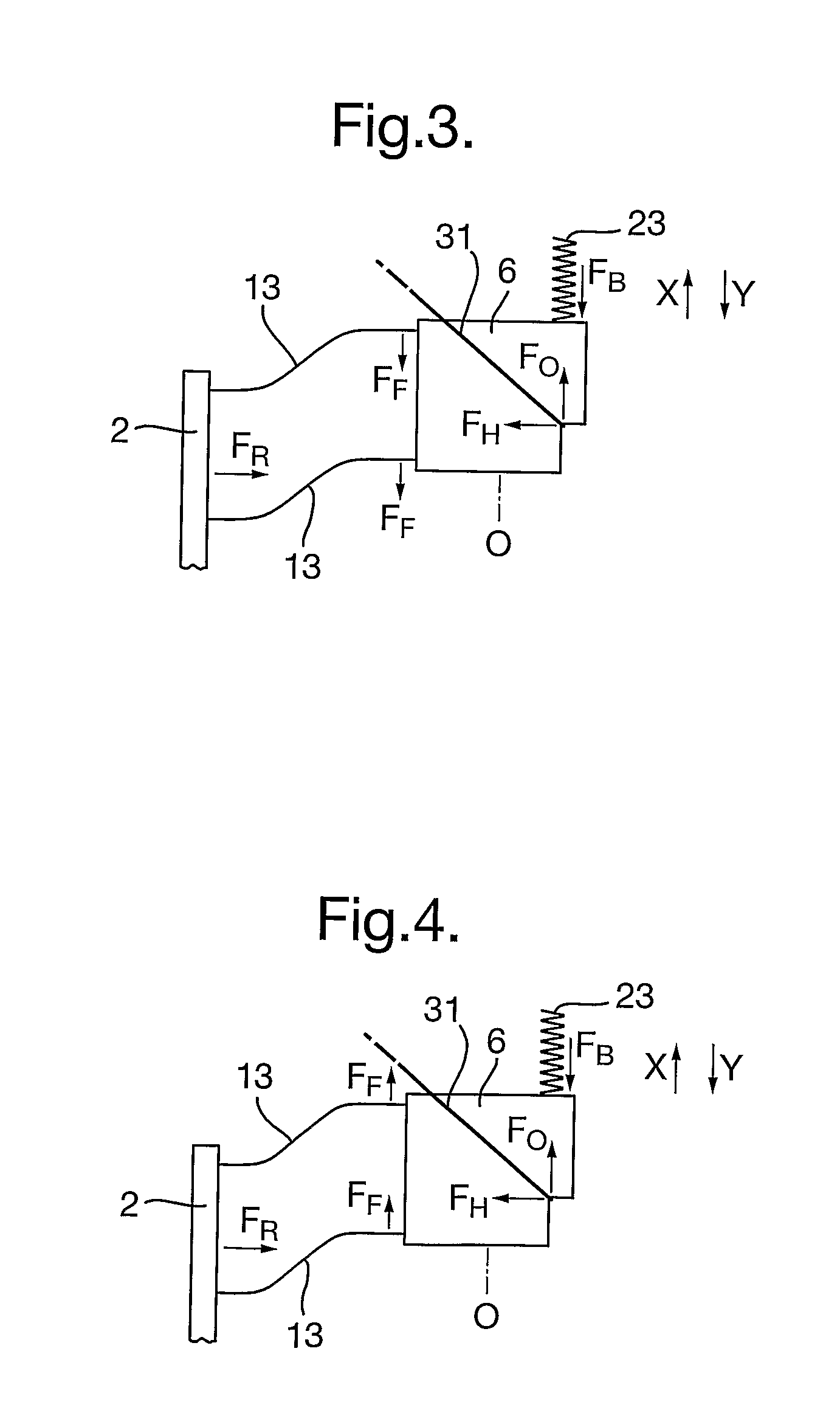

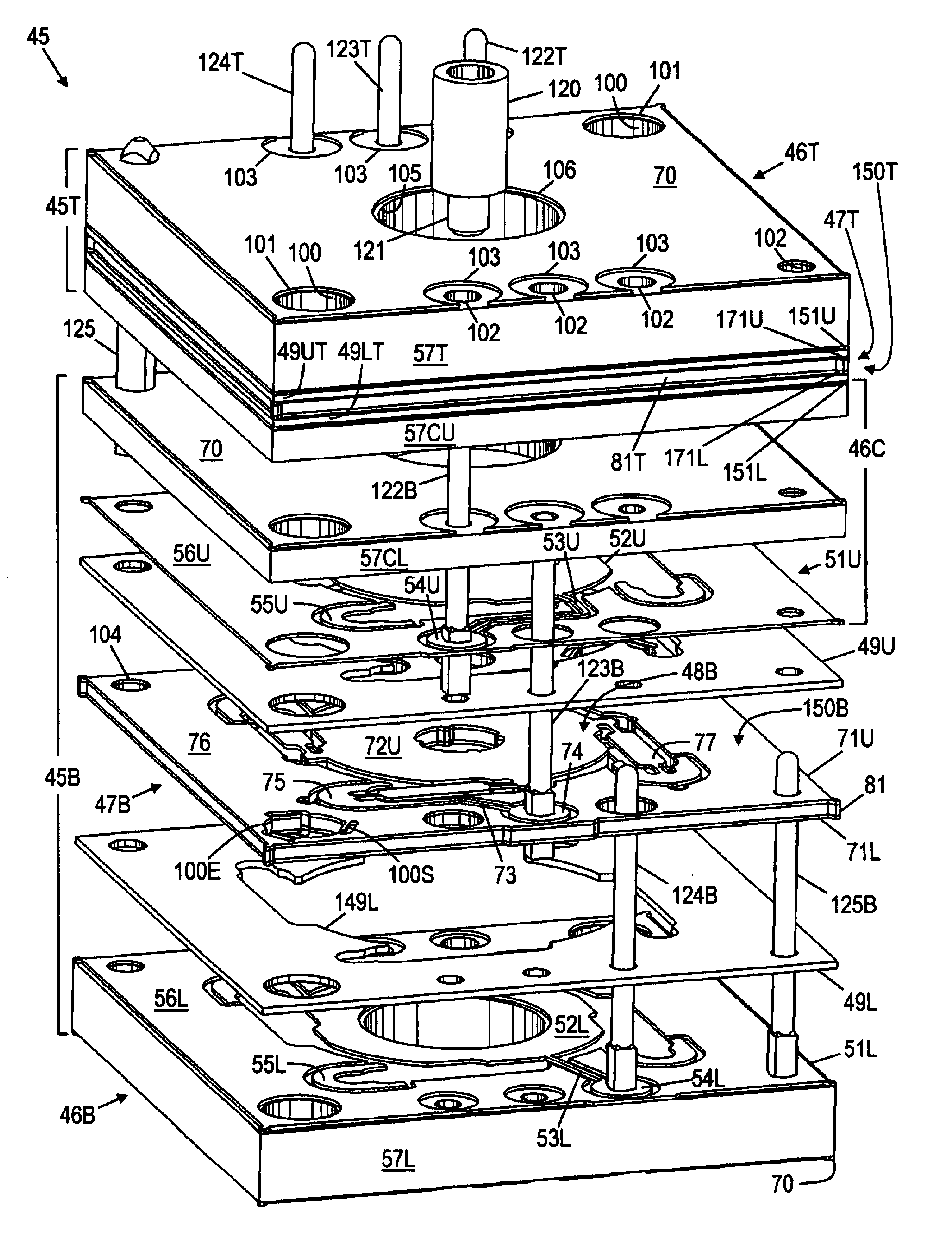

Shape memory alloy actuation apparatus

ActiveUS8441749B2Reduce maximum pressureReduce the applied forceTelevision system detailsProjector focusing arrangementCamera lensAcute angle

An SMA actuation apparatus comprises a camera lens element supported on a support structure by a plurality of flexures. An SMA wire at an acute angle to the movement axis and a biasing element are connected between the support structure and the movable element. A component of the force applied by the SMA wire perpendicular to the movement axis compresses the flexures causing them to apply a force to the movable element having a component along the movement axis in the same direction as the SMA wire. An end-stop limits the movement of the movable element, and the moment applied by the end-stop to the movable element about the center of stiffness is equal to the moment applied by the SMA wire about the center of stiffness at the point when the movable element loses contact with the end-stop on contraction of the SMA wire.

Owner:CAMBRIDGE MECHATRONICS

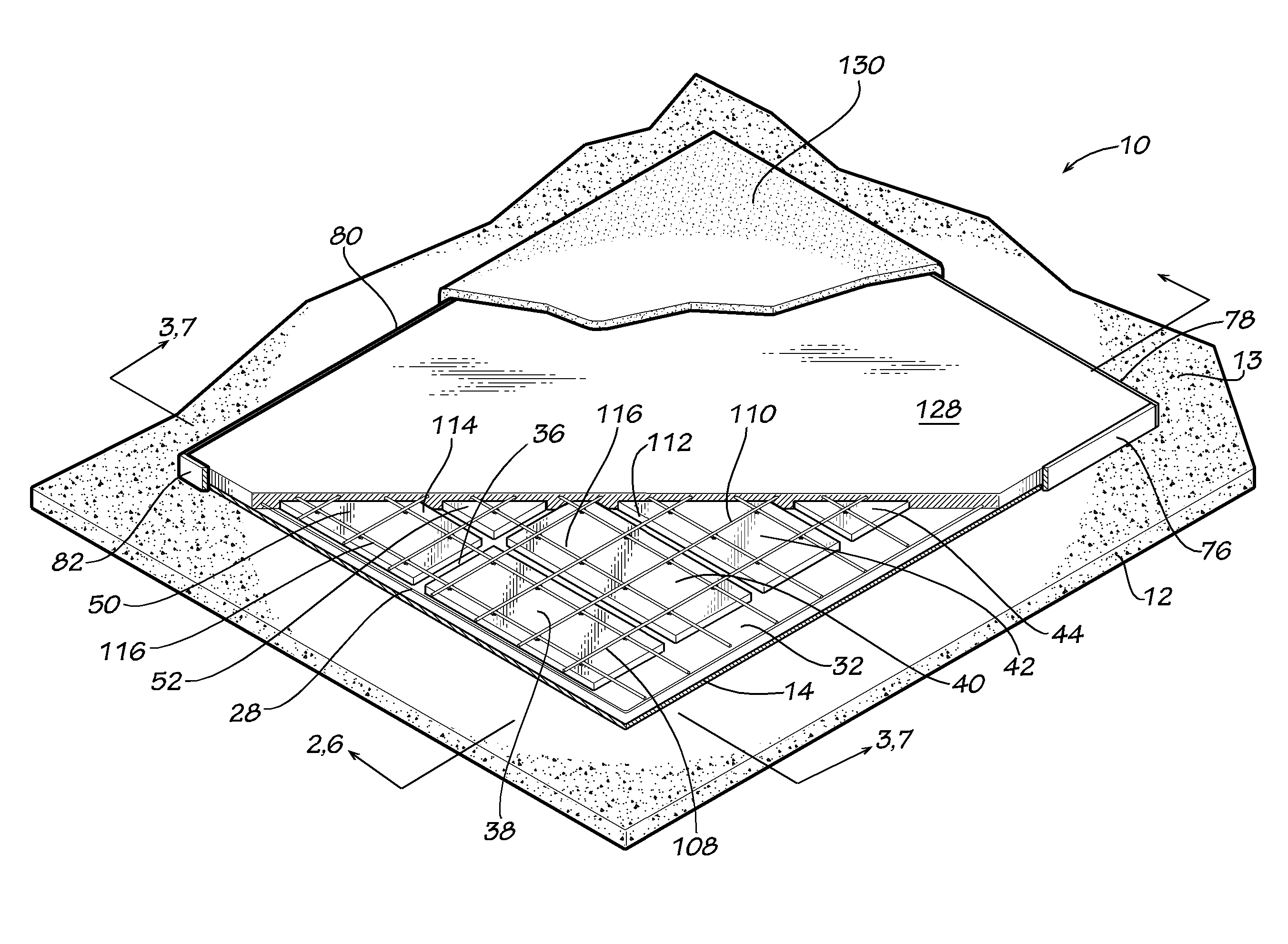

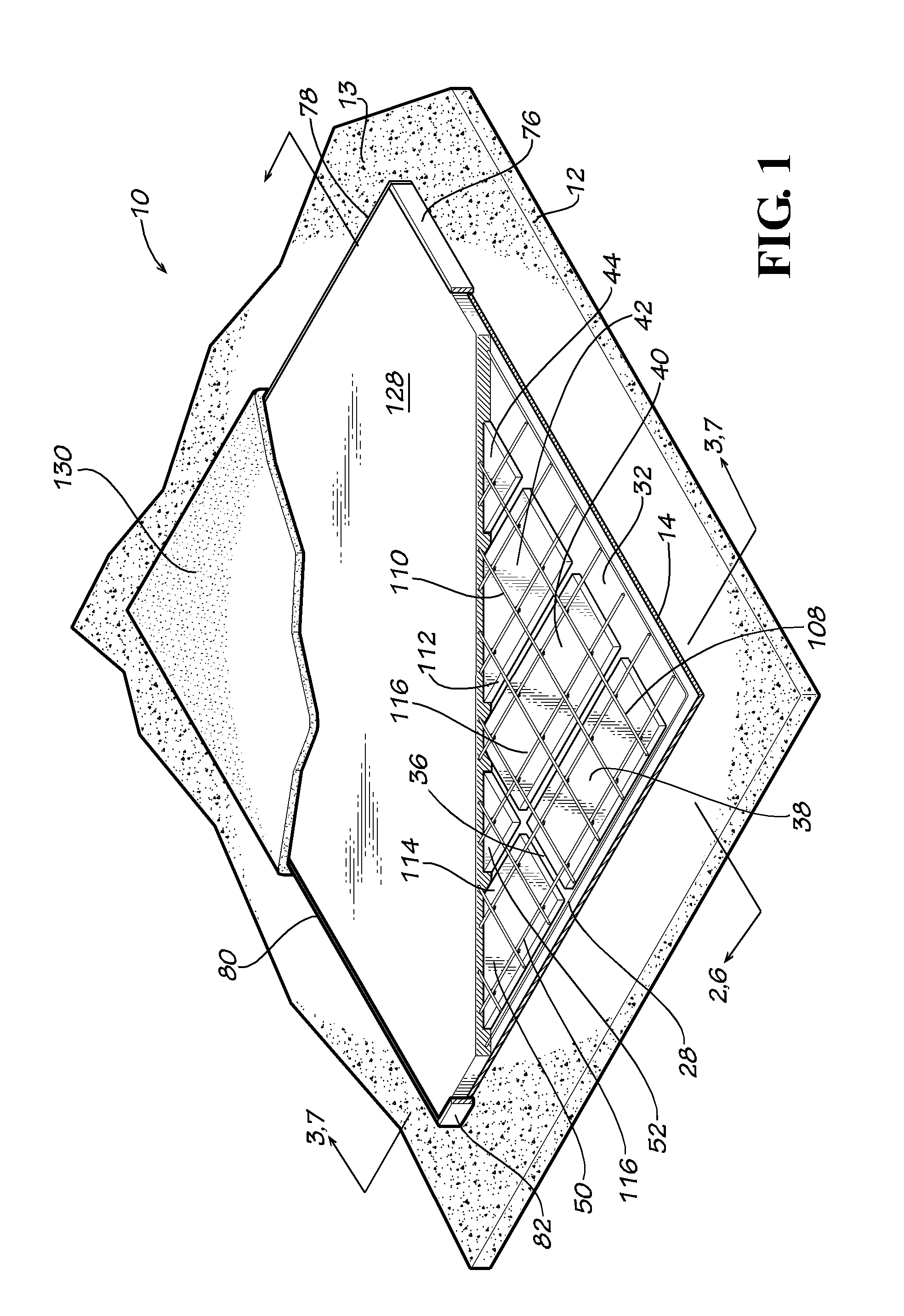

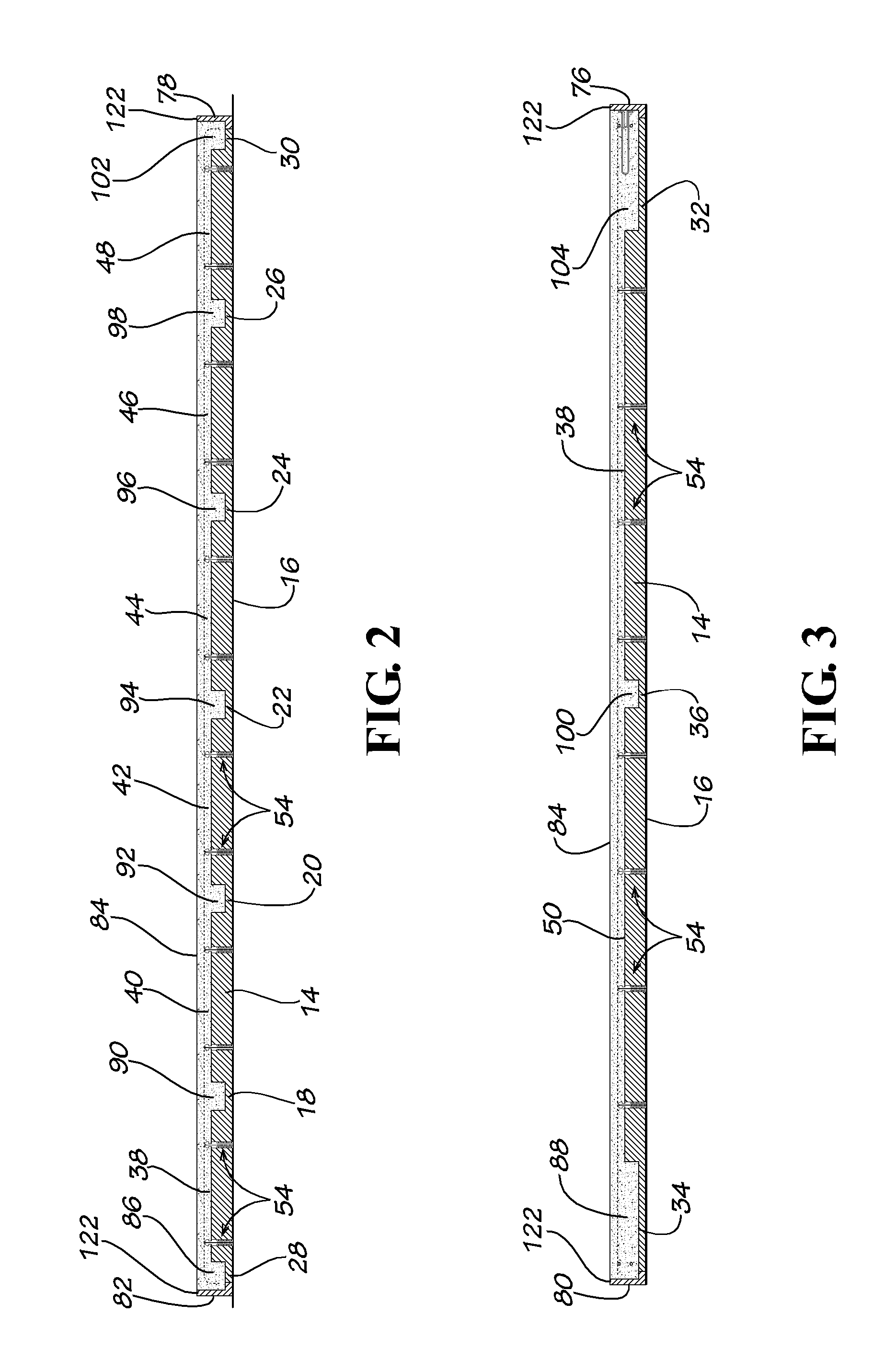

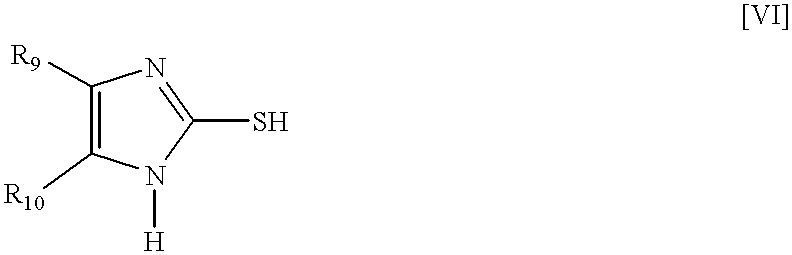

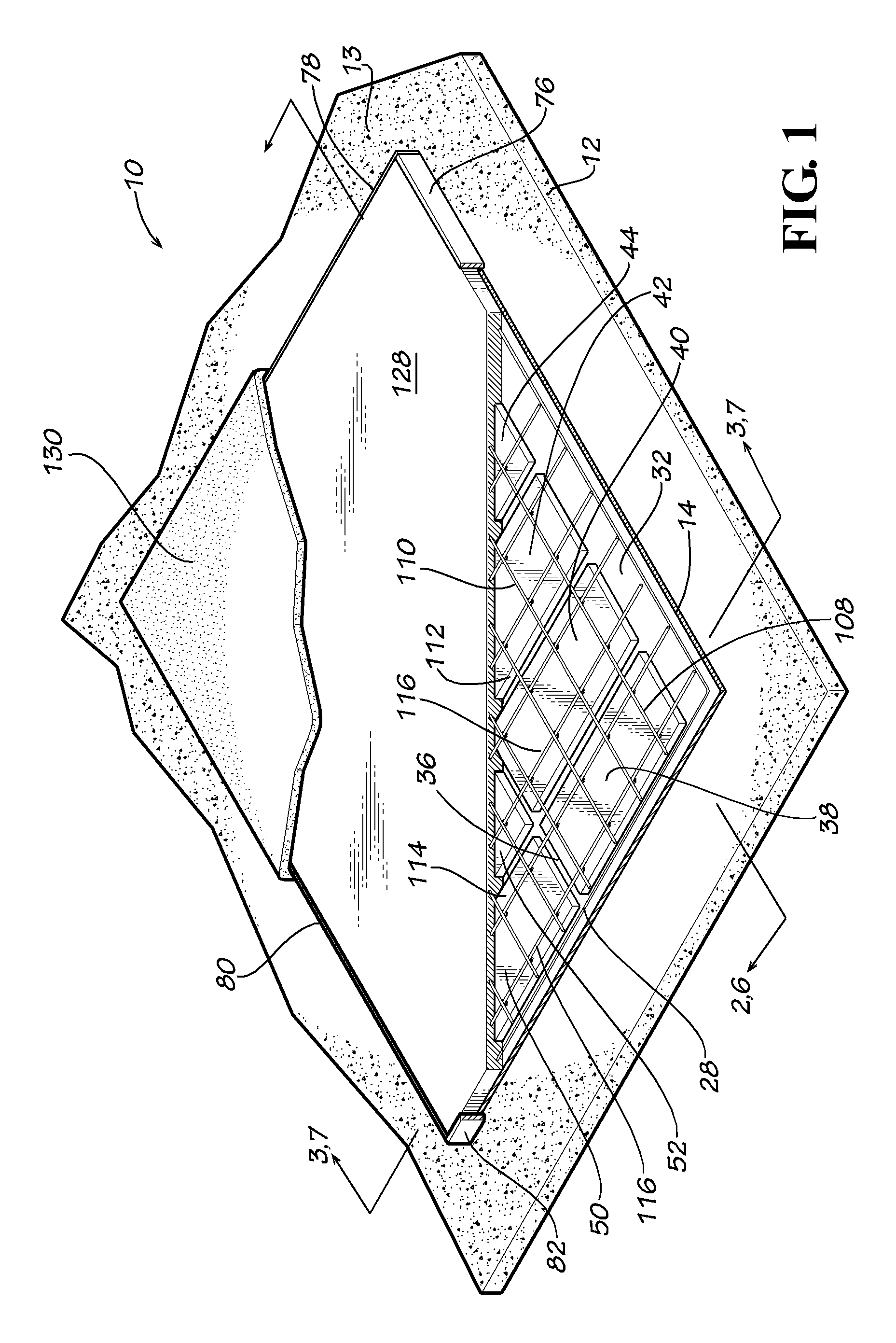

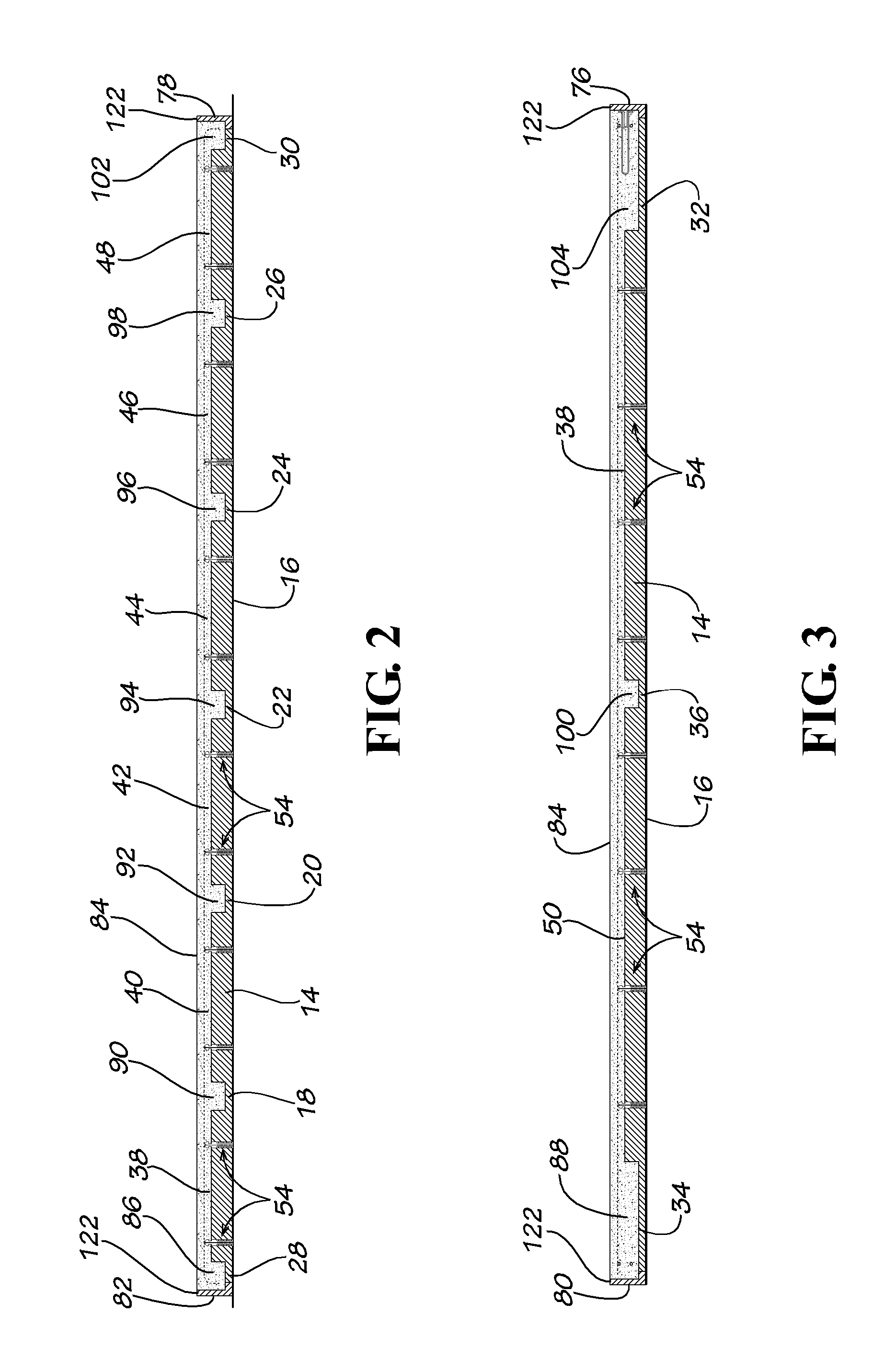

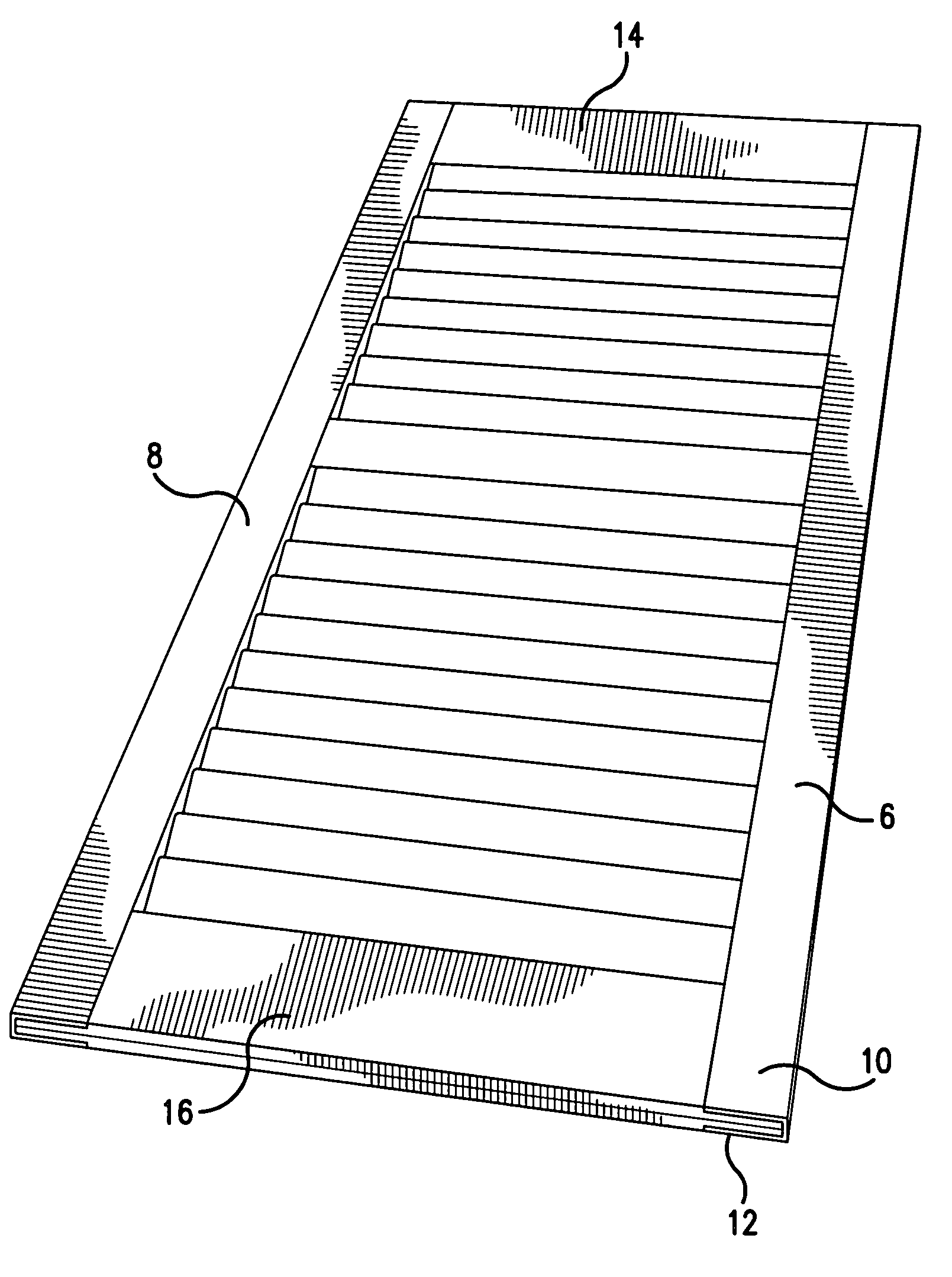

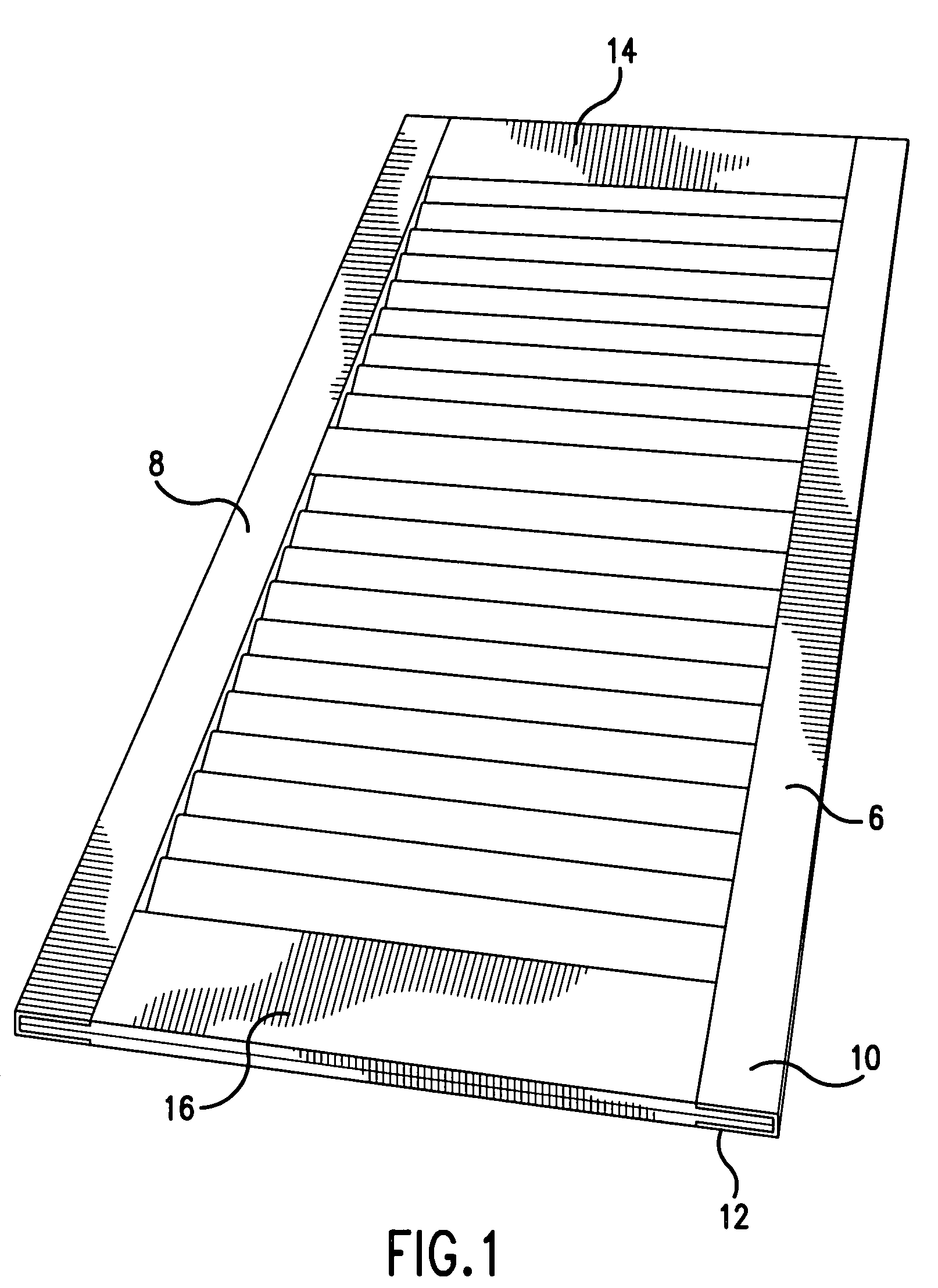

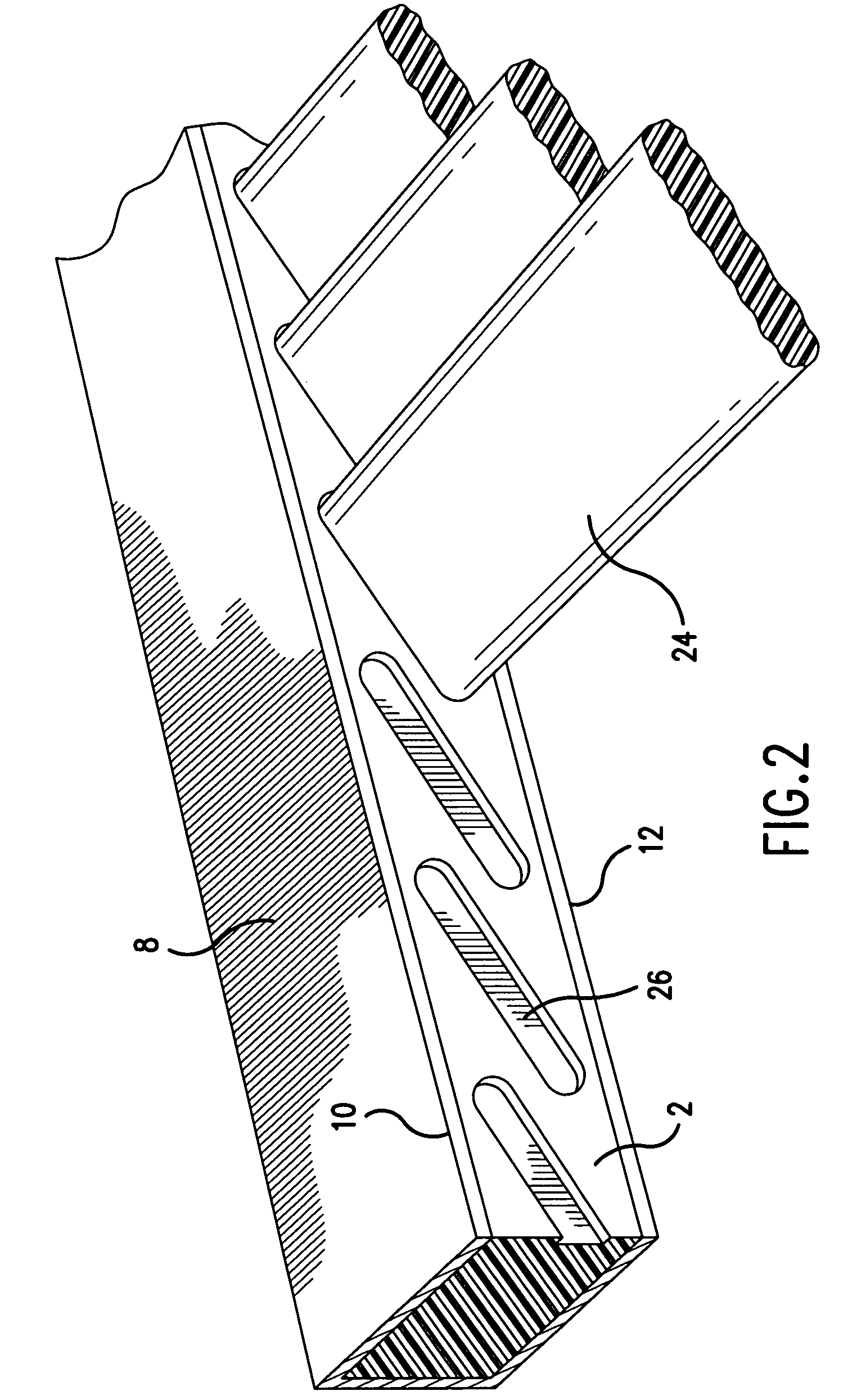

High performance, reinforced insulated precast concrete and tilt-up concrete structures and methods of making same

Owner:CIUPERCA ROMEO ILARIAN

Seal for electrochromic devices

An improved seal member is provided as a part of an electrochromic device to bond two glass elements together in a spaced-apart relationship. In one embodiment the seal member provides improved adhesion to a reflector / electrode on the third surface of an electrochromic mirror, or to a layer of metal on the second or third surface for an electrochromic light filter. This seal member comprises a mixture of an organic resin scaling system and an adhesion promoter, where the adhesion promotor comprises a first and a second region, where the first region interacts with the reflector / electrode or the metal layer, and a second region that interacts with the organic resin sealing system, and may even chemically react with the organic resin sealing system. In another embodiment the seal member is provided with a coefficient of thermal expansion that is closer to glass than a standard epoxy sealing system.

Owner:GENTEX CORP

High performance, reinforced insulated precast concrete and tilt-up concrete structures and methods of making same

Owner:CIUPERCA ROMEO ILARIAN

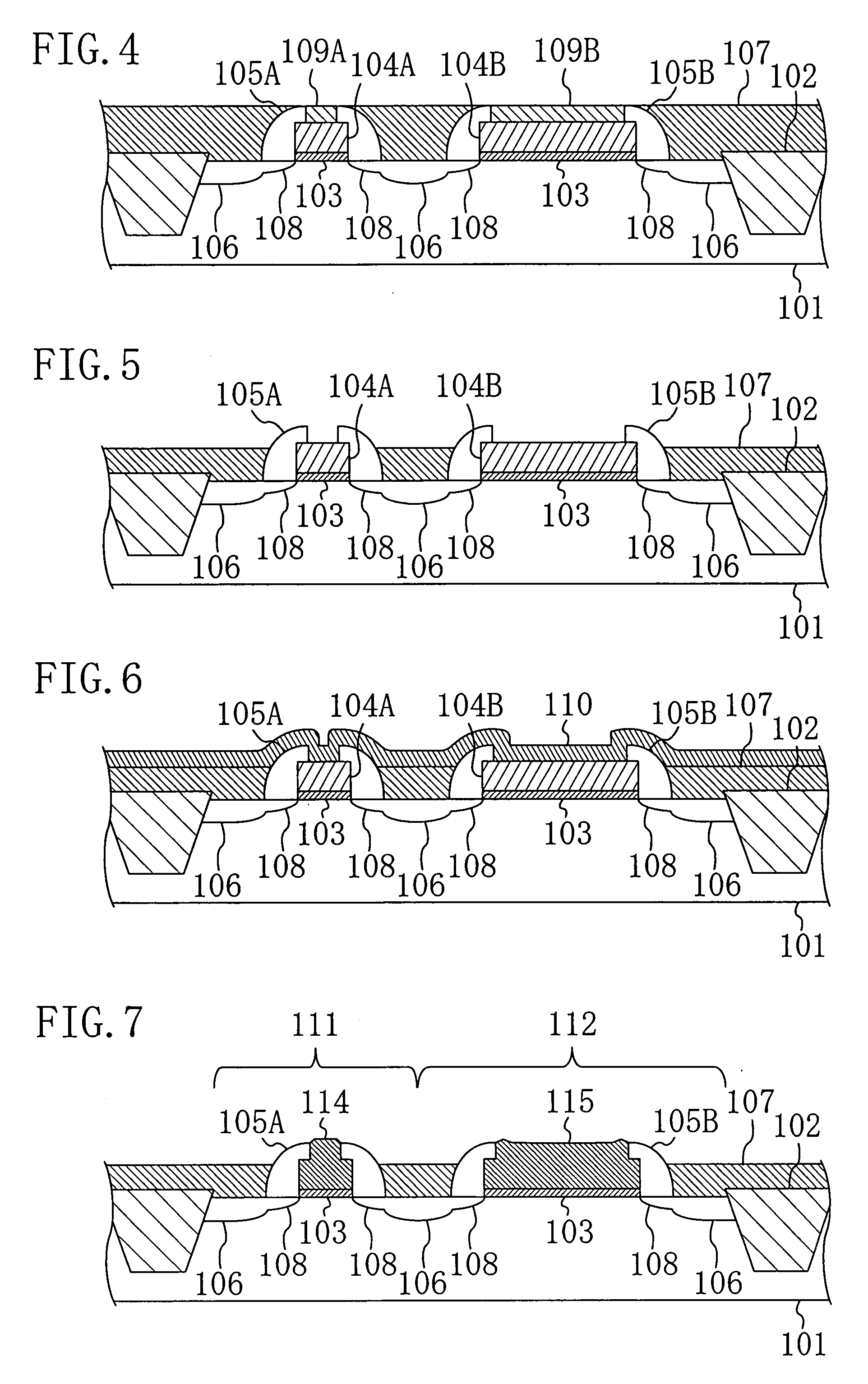

Technique for controlling mechanical stress in a channel region by spacer removal

ActiveUS7314793B2Significant stressLittle elasticitySemiconductor/solid-state device manufacturingSemiconductor devicesCouplingEngineering

During the formation of a transistor element, sidewalls spacers are removed or at least partially etched back after ion implantation and silicidation, thereby rendering the mechanical coupling of a contact etch stop layer to the underlying drain and source regions more effective. Hence, the mechanical stress may be substantially induced by the contact etch step layer rather than by a combination of the spacer elements and the etch stop layer, thereby significantly facilitating the stress engineering in the channel region. By additionally performing a plasma treatment, different amounts of stress may be created in different transistor devices without unduly contributing to process complexity.

Owner:GLOBALFOUNDRIES US INC

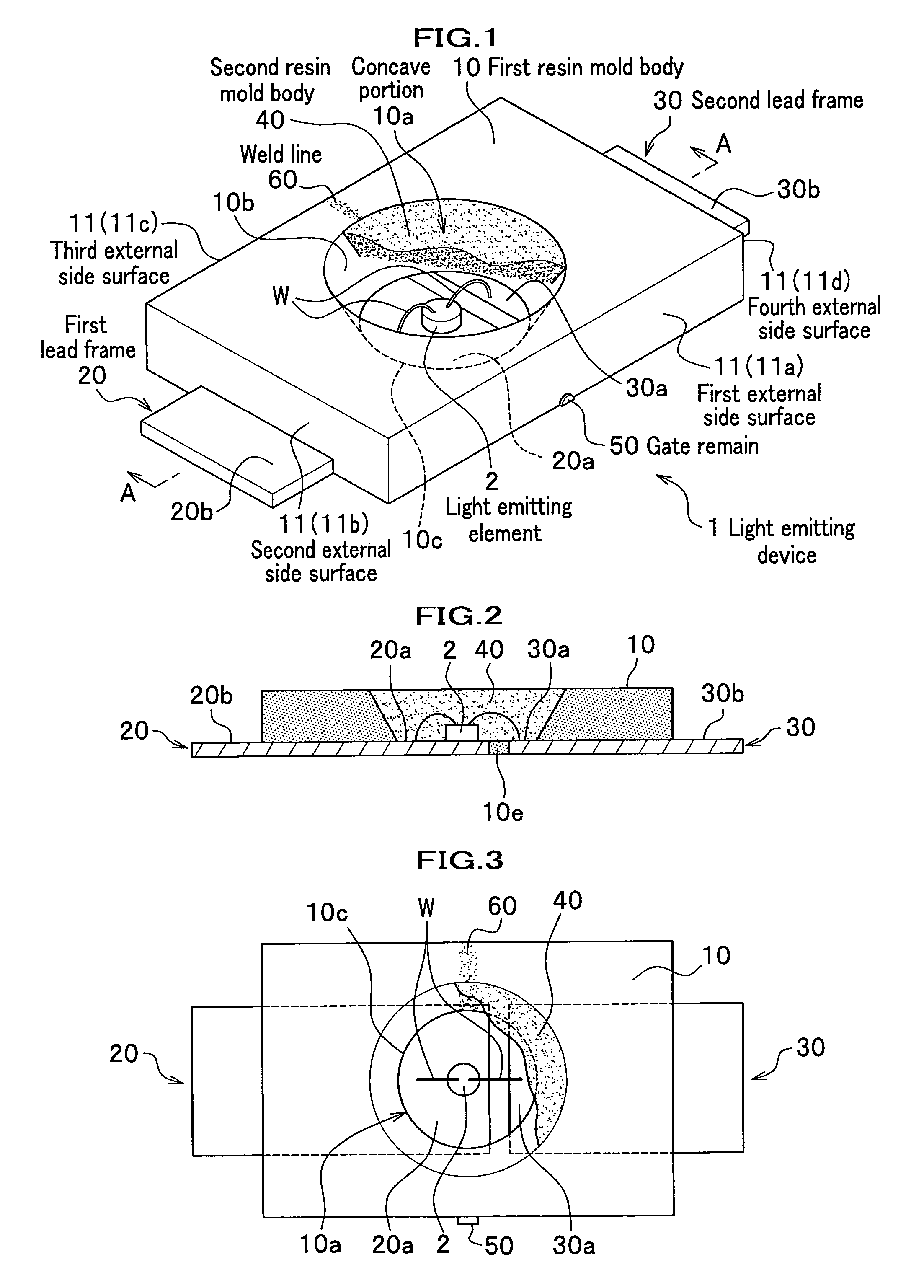

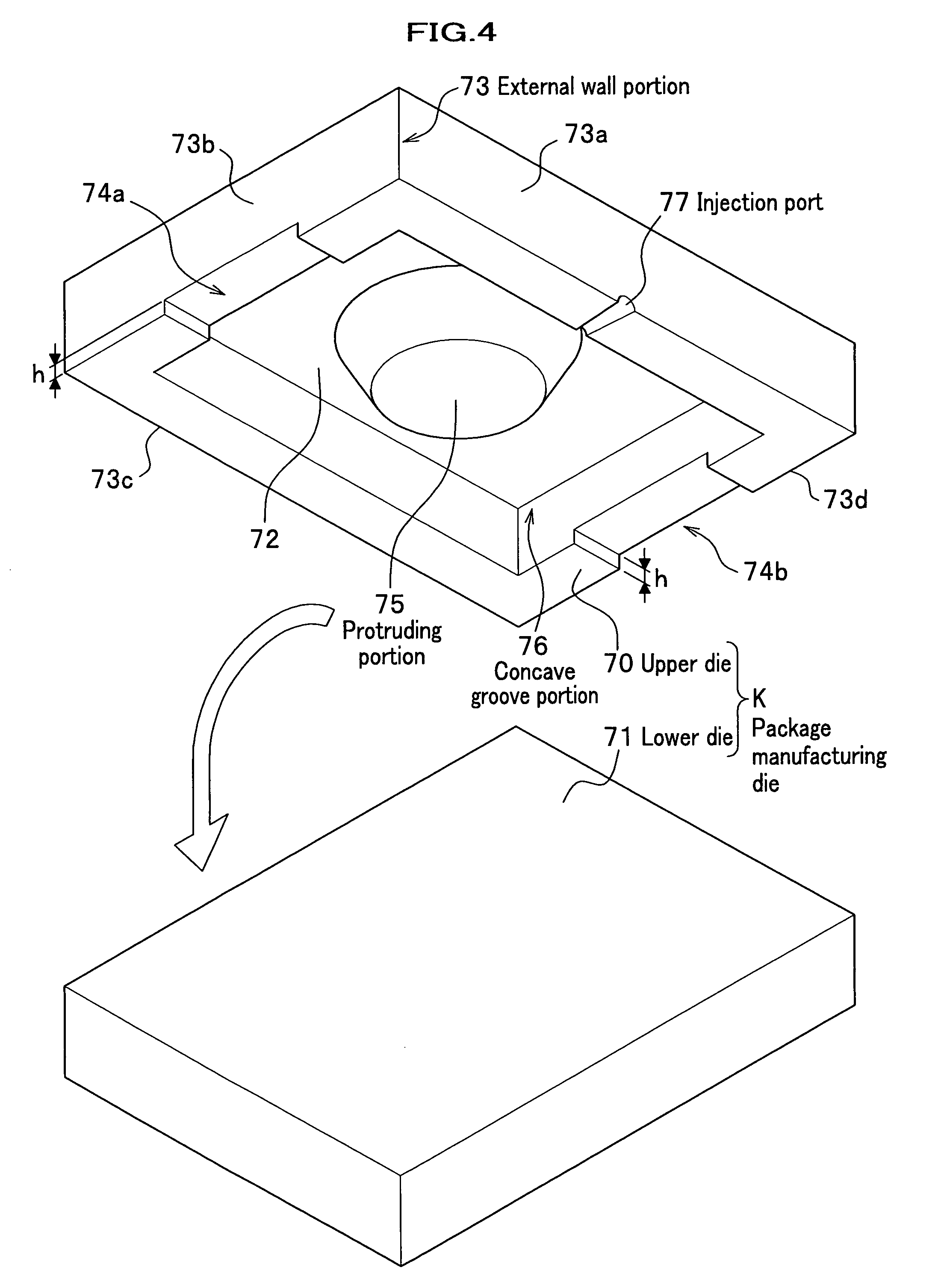

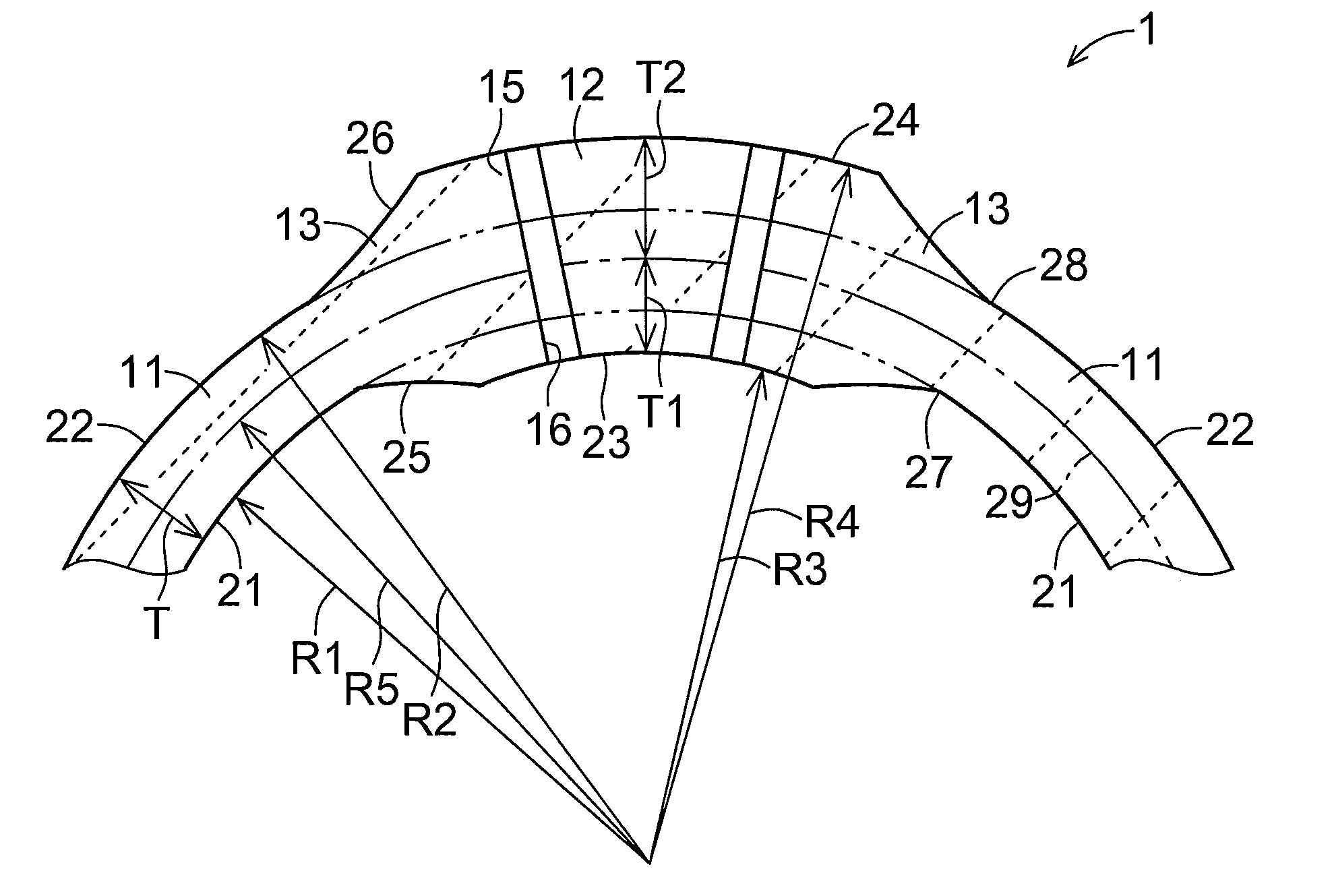

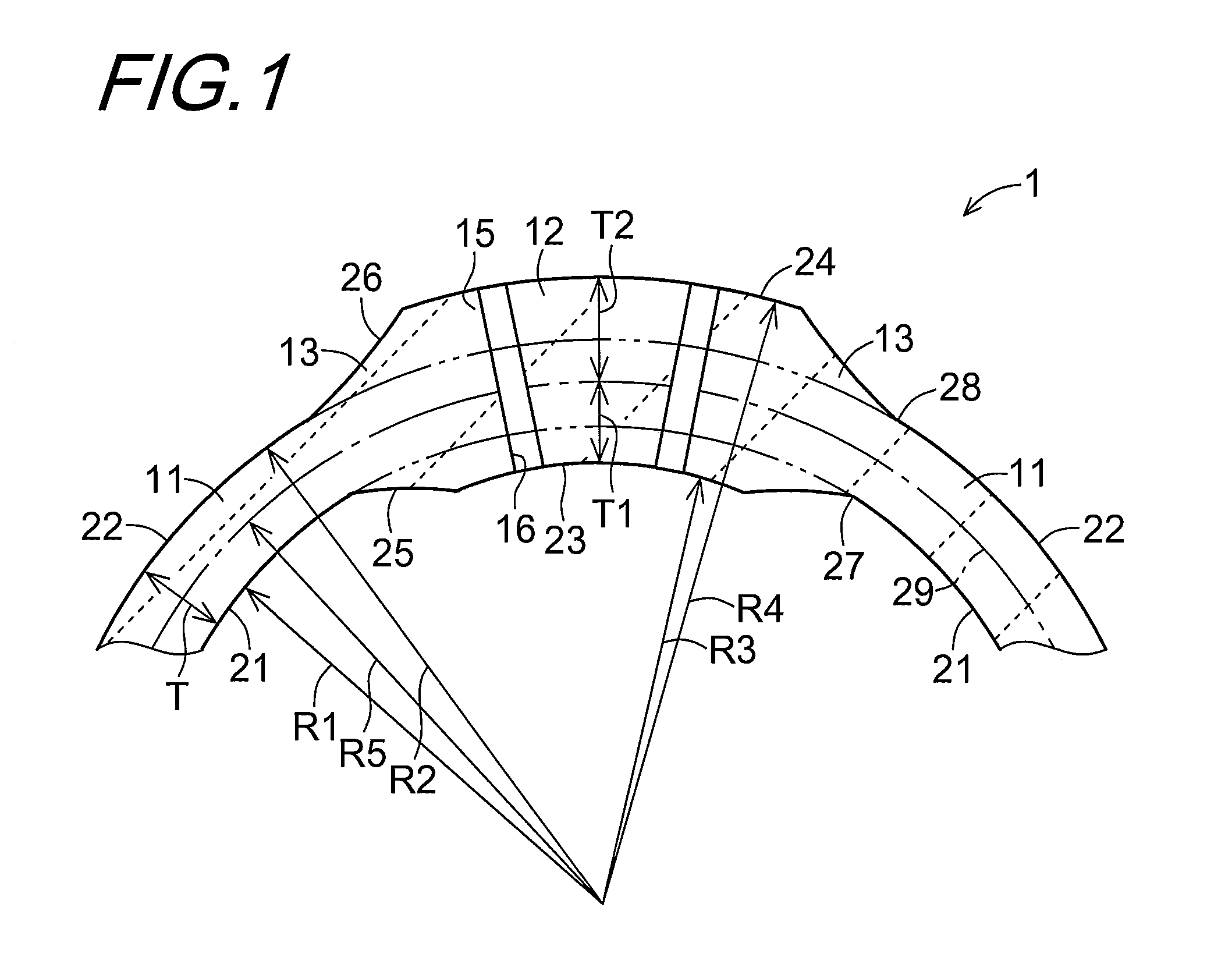

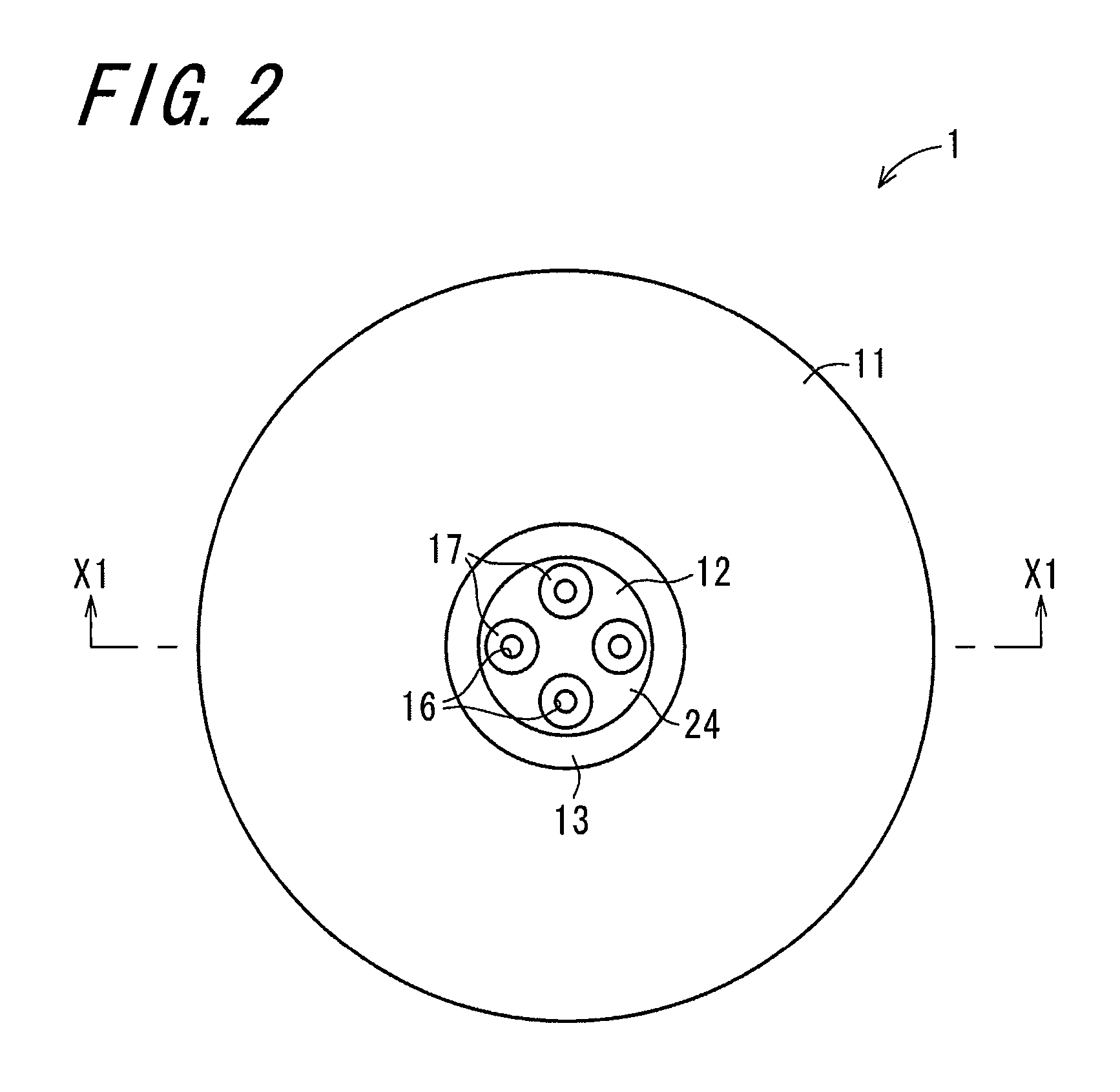

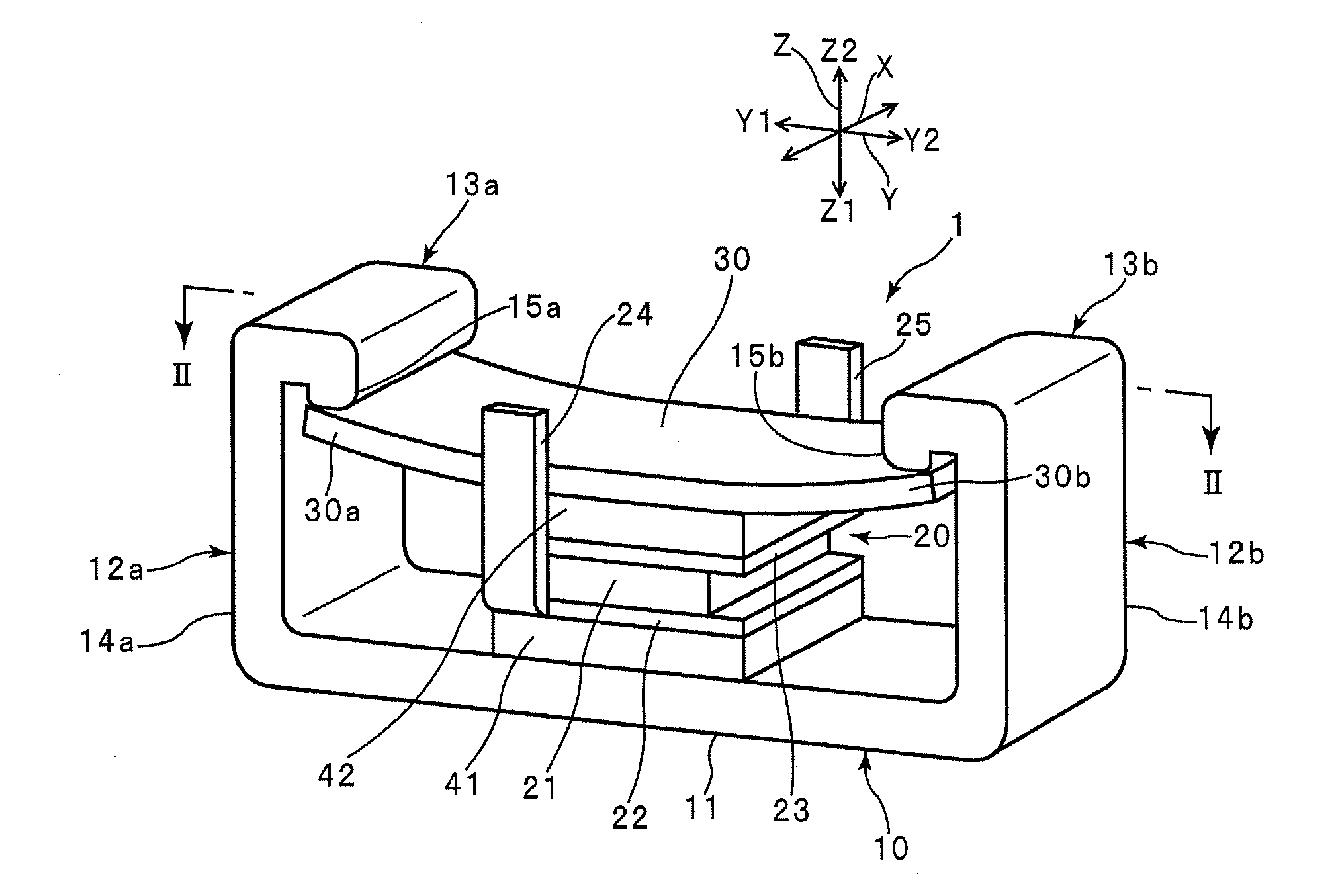

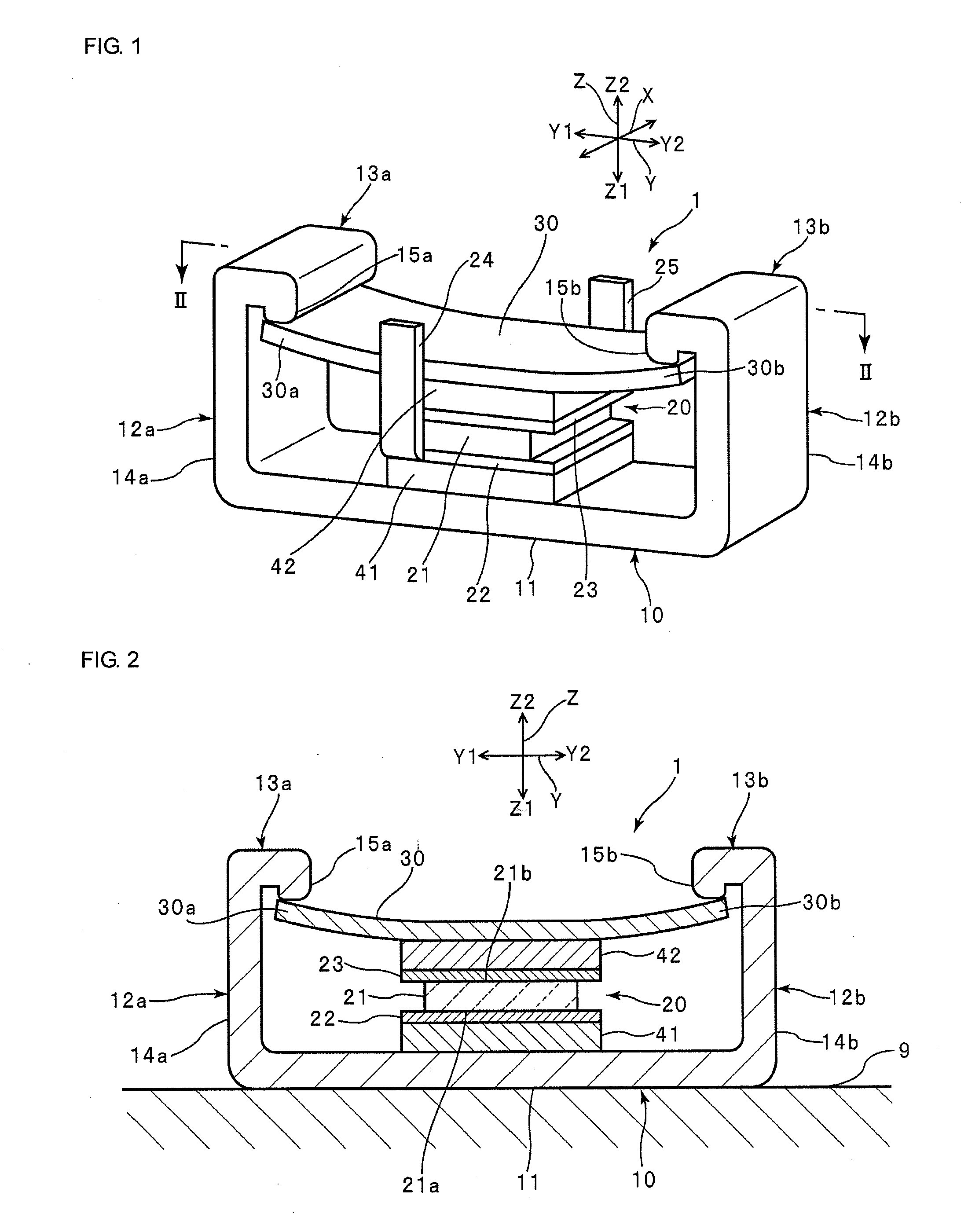

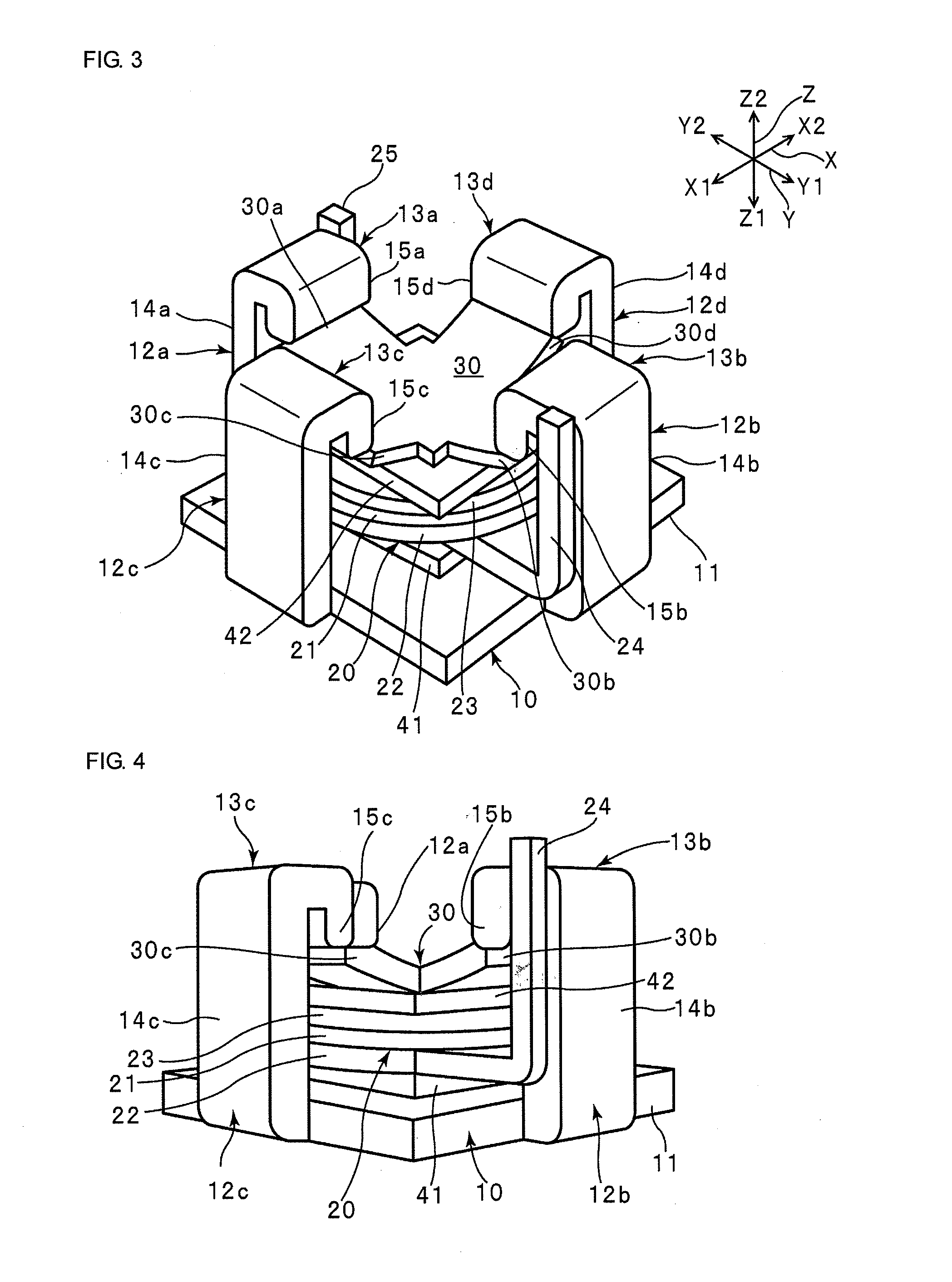

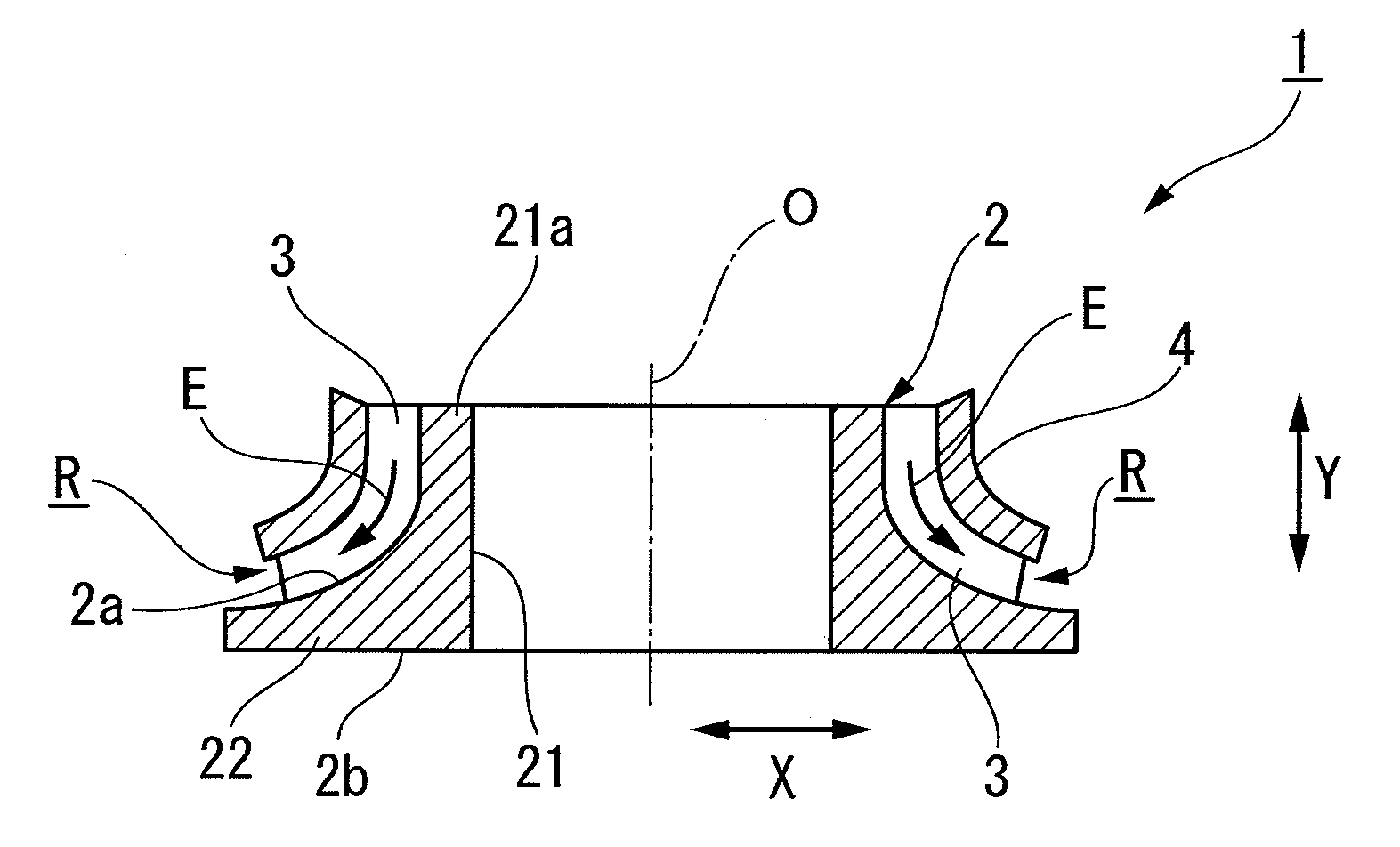

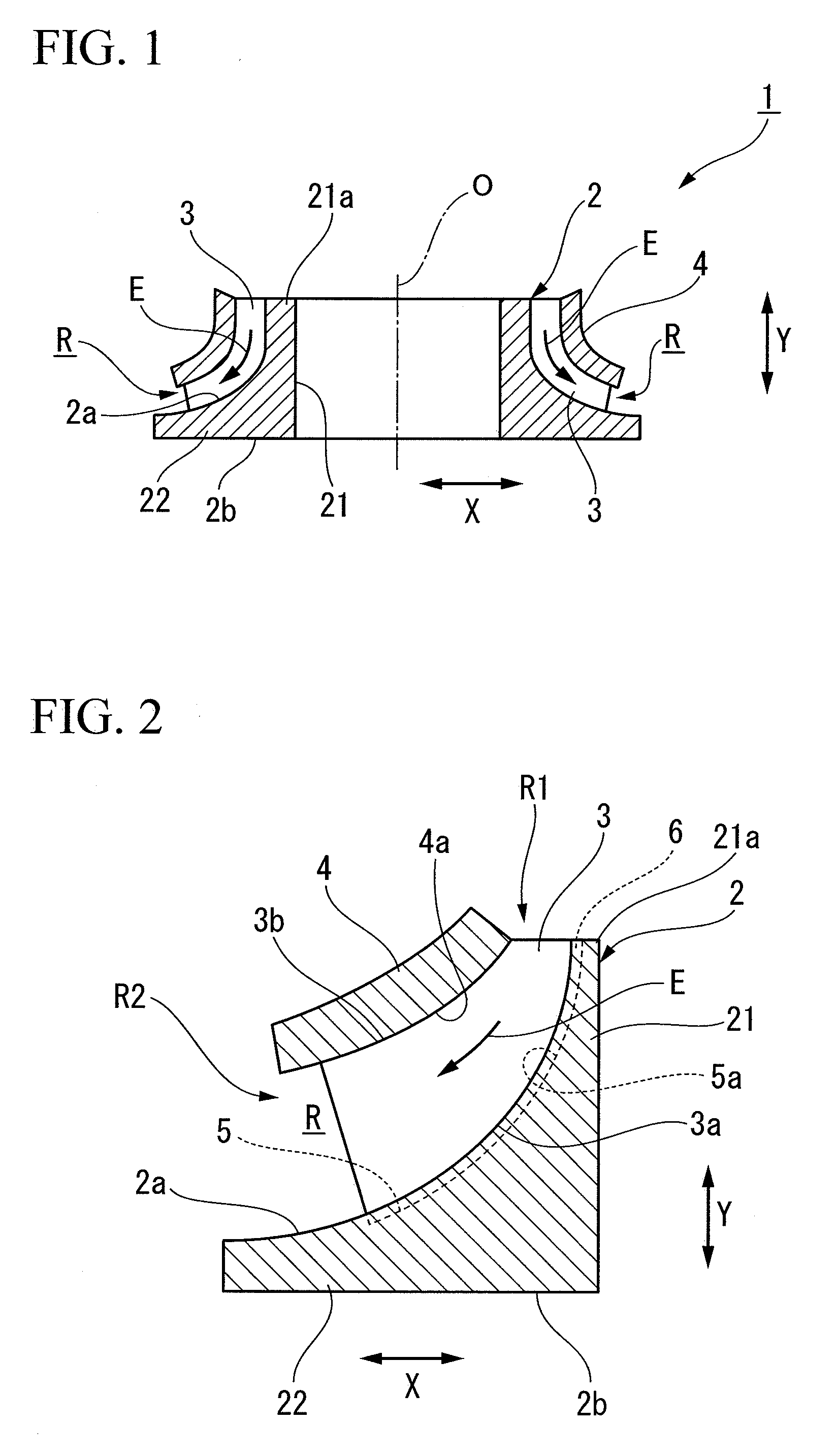

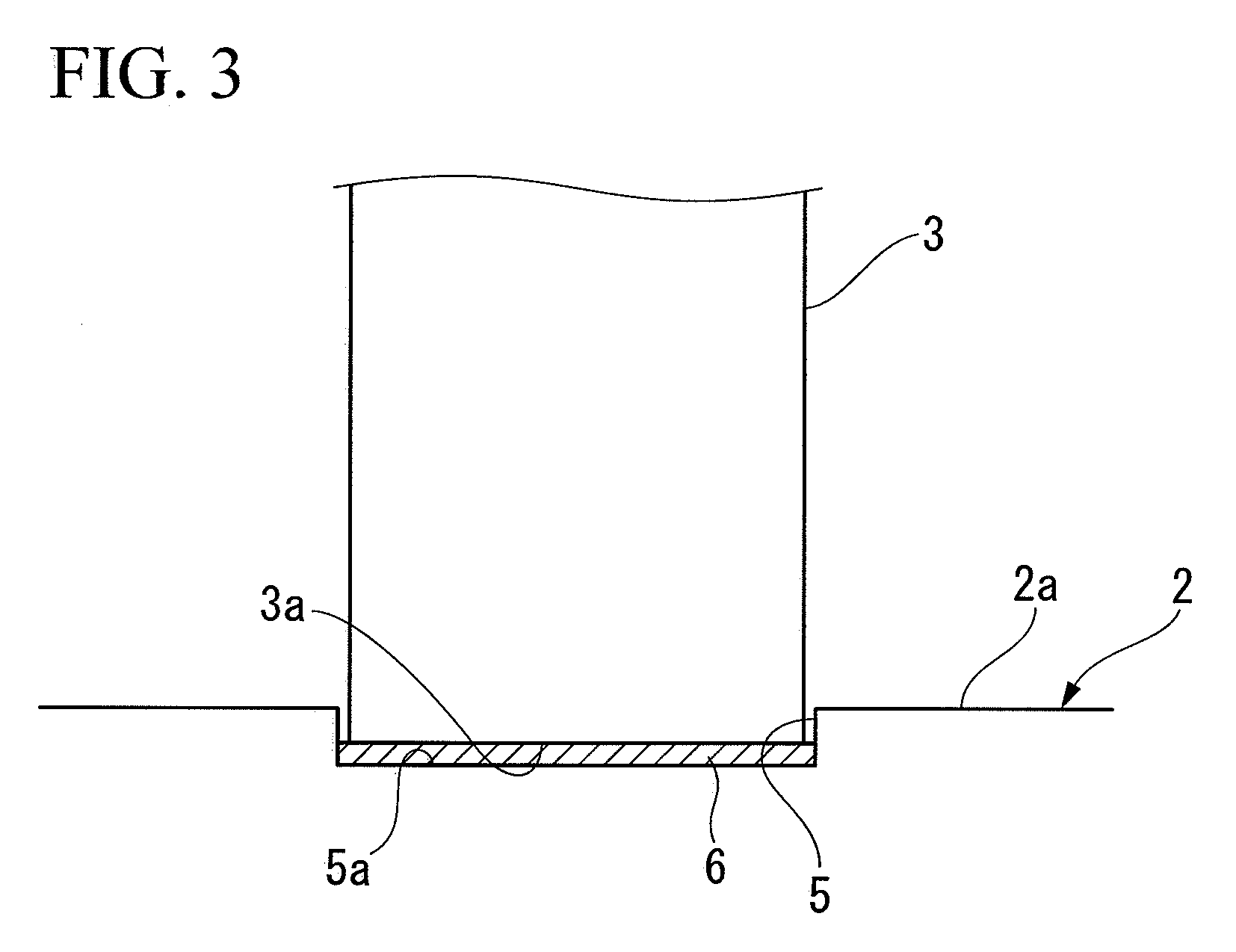

Light emitting device, package, light emitting device manufacturing method, package manufacturing method and package manufacturing die

ActiveUS8217414B2Significant stressAvoid crackingSemiconductor/solid-state device detailsSolid-state devicesEngineeringLight emitting device

Provided is a light emitting device wherein a resin molded body having a circular or an oval recessed section at the center suppresses generation of cracks. A light emitting device (1) is provided with a light emitting element (2); a first resin molded body (10) having a plurality of outer surfaces (11), and a recessed section (10a) at the center; a first lead (20) and a second lead (30) electrically connected to the light emitting element (2); and a second resin molded body (40) applied in the recessed section (10a). The light emitting element (2) is place on the first lead (20), and the surface of the second resin molded resin (40) is permitted to be a light emitting surface. A gate notch (50) obtained by cutting a gate formed on the outer surface (11) of the first resin molded body (10) is formed on an extended line of a normal line on one point on a circular cross-section of the recessed section (10a) in the normal nine direction.

Owner:NICHIA CORP

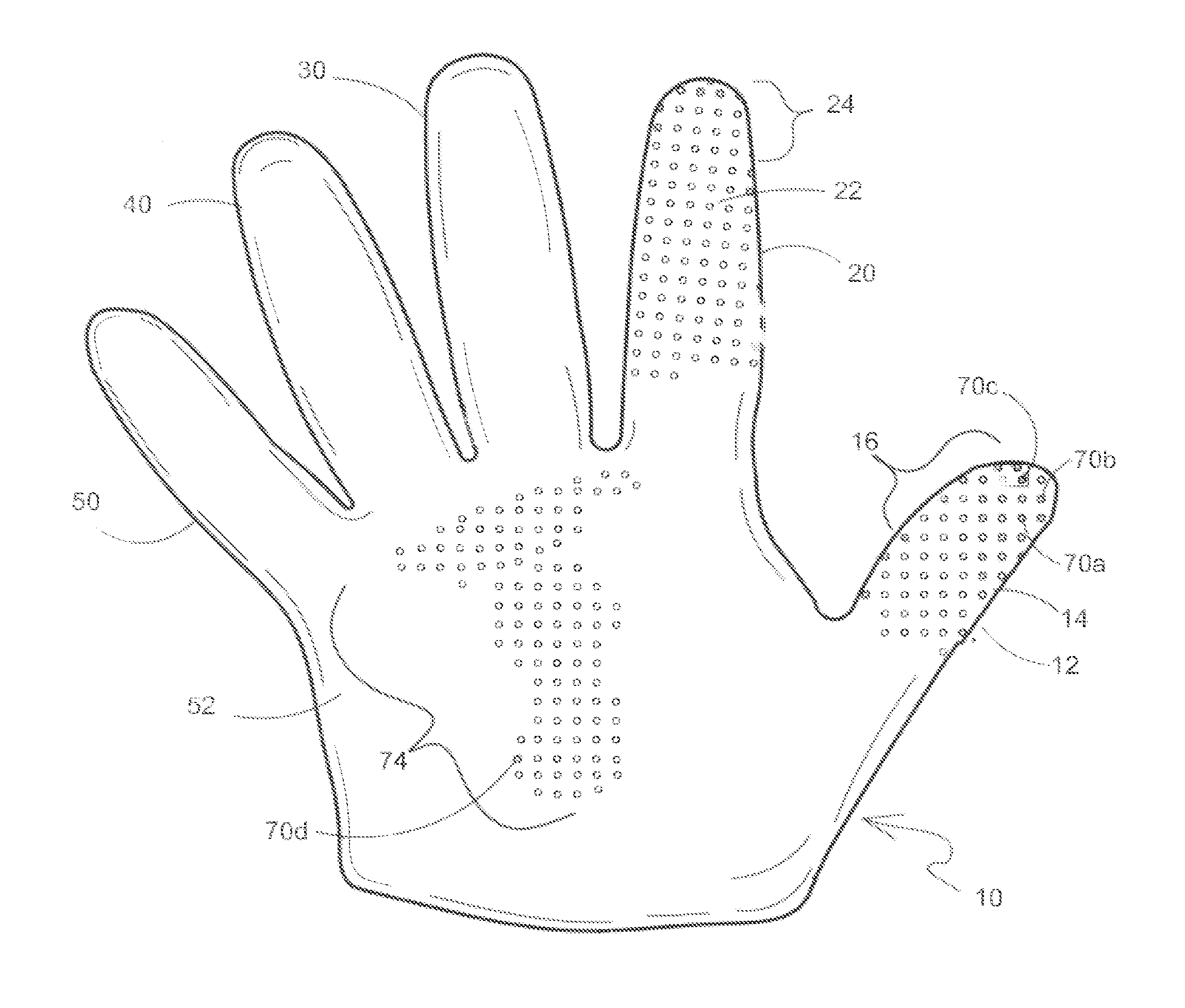

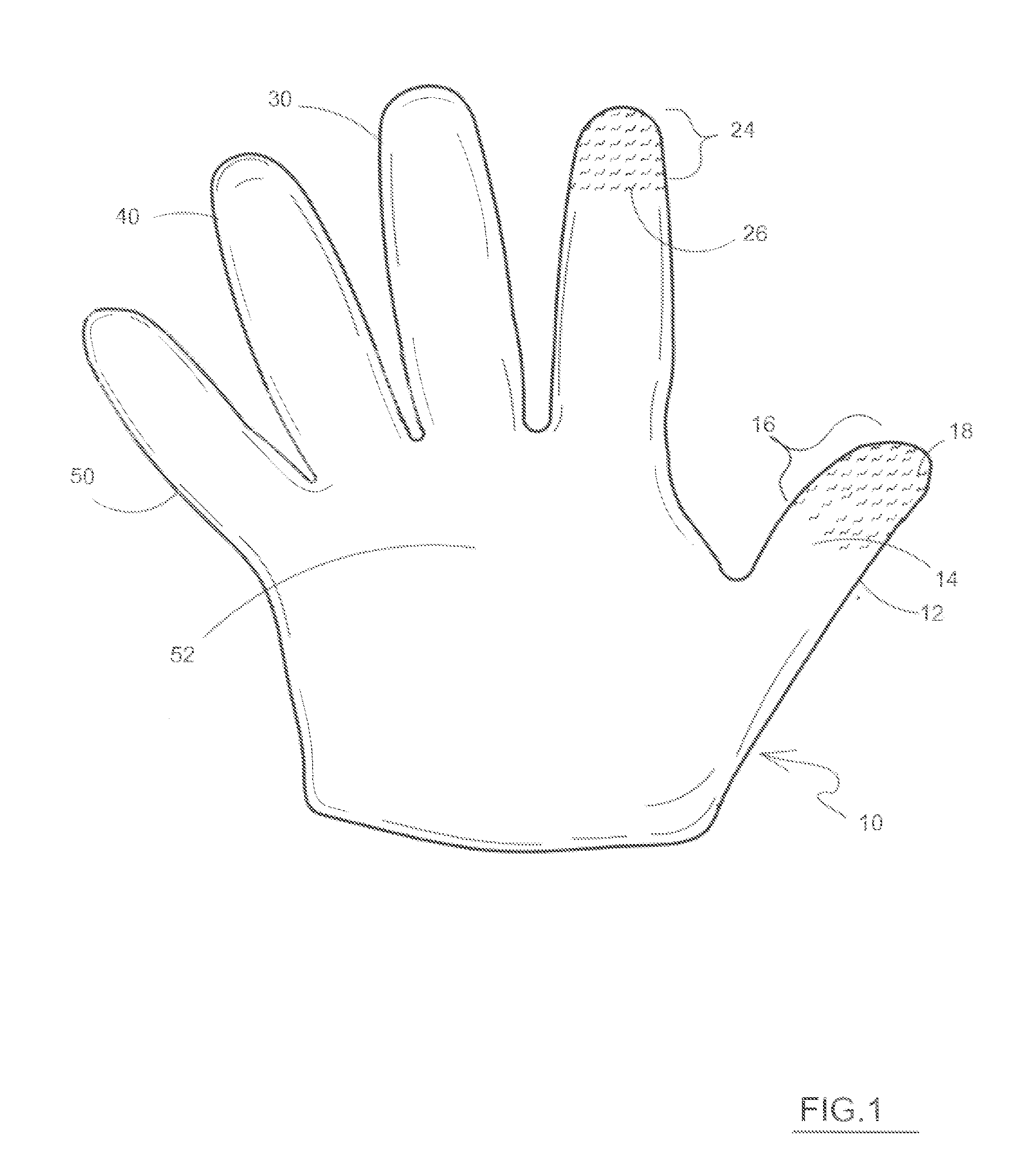

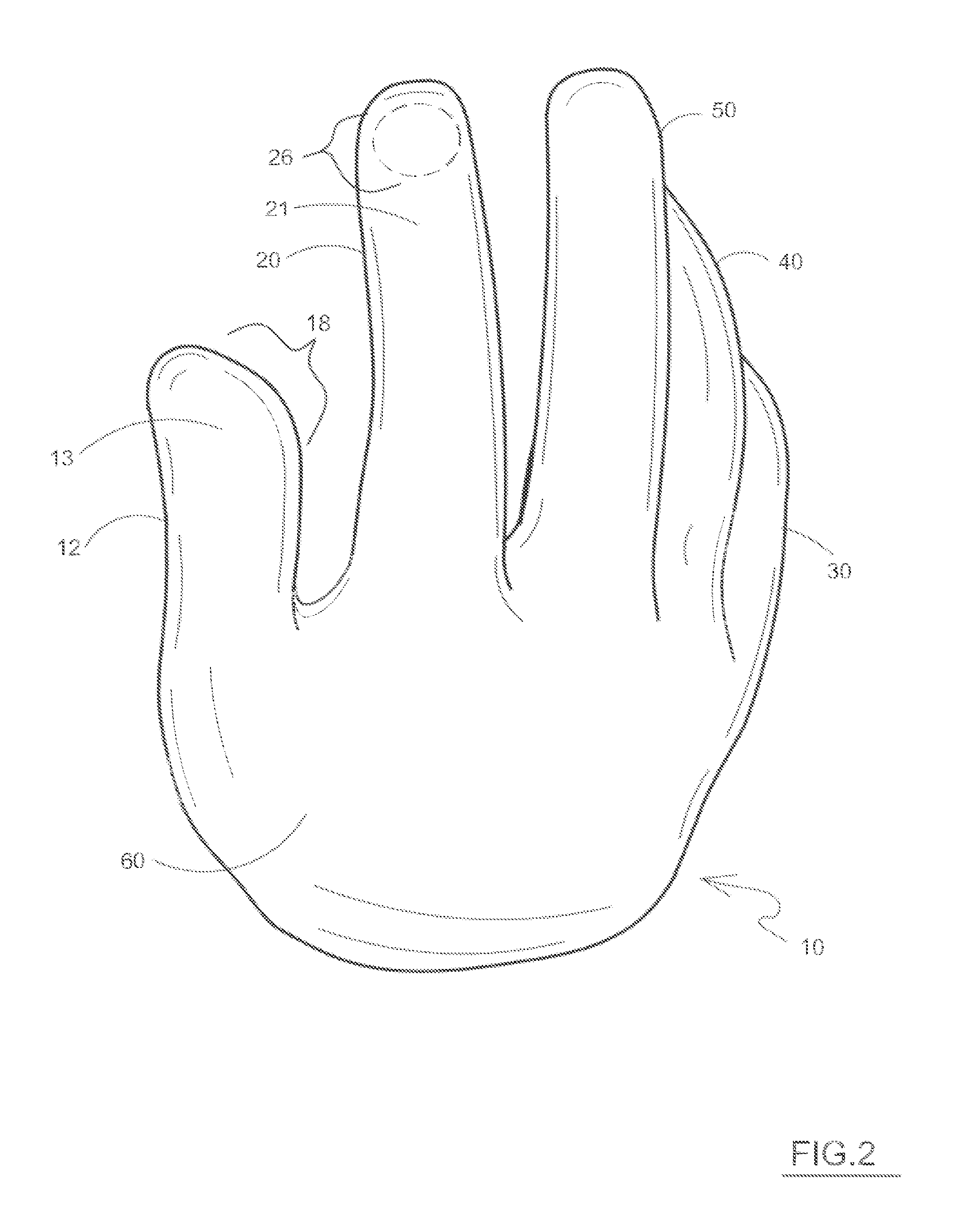

Knit Gloves with Conductive Finger Pads

The seamless knit glove has electrically conductive finger regions, either defined by pads or thread. The glove is worn by a user to enable operation of a capacitive touch screen on an electronic device. The seamless knit glove finger sleeves, anterior palm side and posterior “back side” are knit as a unitary structure which has a high degree of stretch. The glove needs no finger-linking operation to attach the sleeves to the anterior and posterior glove regions. In one, electrically conductive yarn is deployed over at least an anterior tip region of the thumb and the index finger sleeve to enable the user to activate a capacitive touch screen of an electronic device. The user's electrical skin condition is transferred via the conductive threads to the capacitive touch screen. In another, a multiplicity of printed-on conductive ink pads is disposed over the anterior surfaces of the thumb and index sleeves.

Owner:NOLAN GLOVE CO

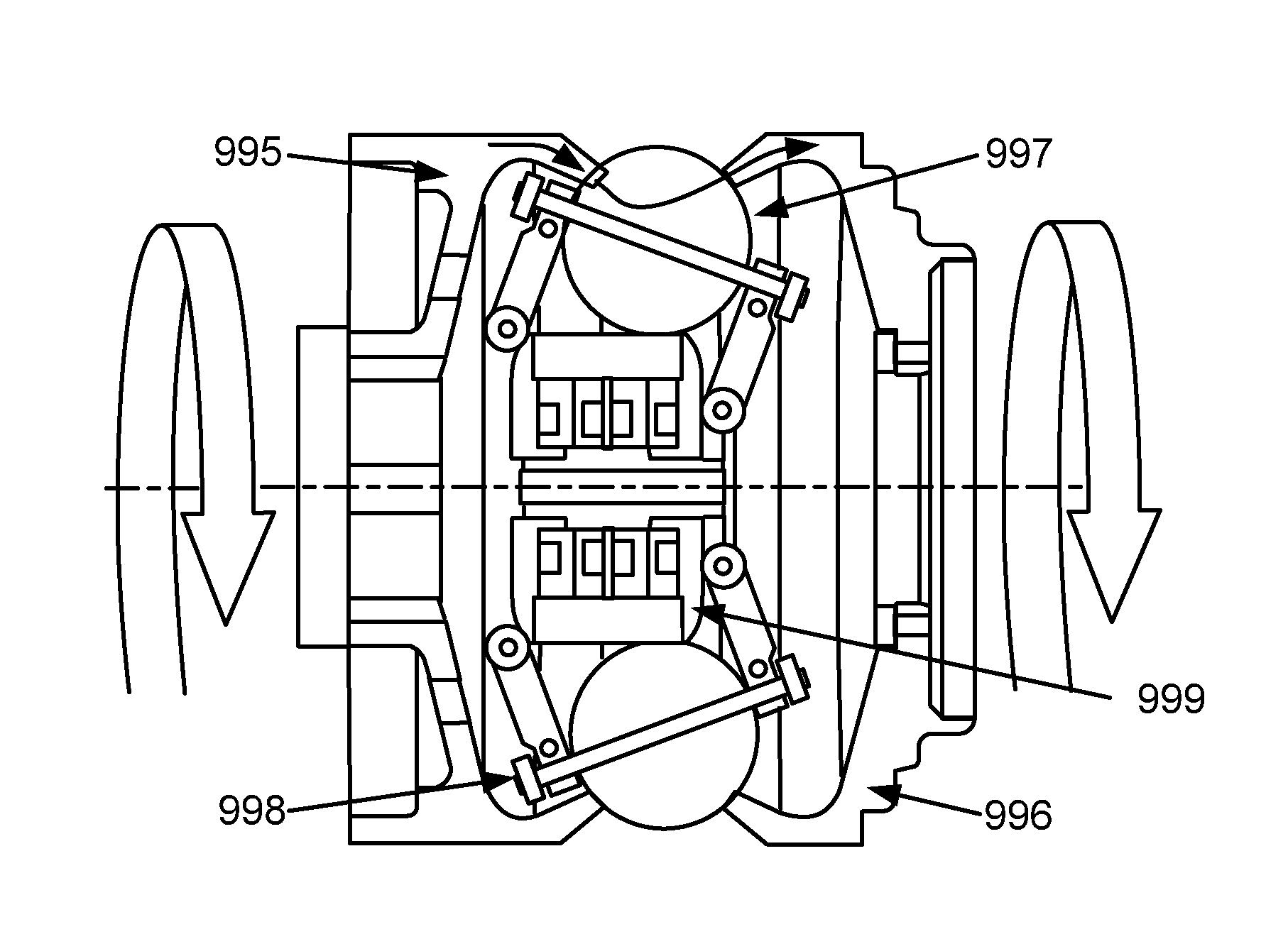

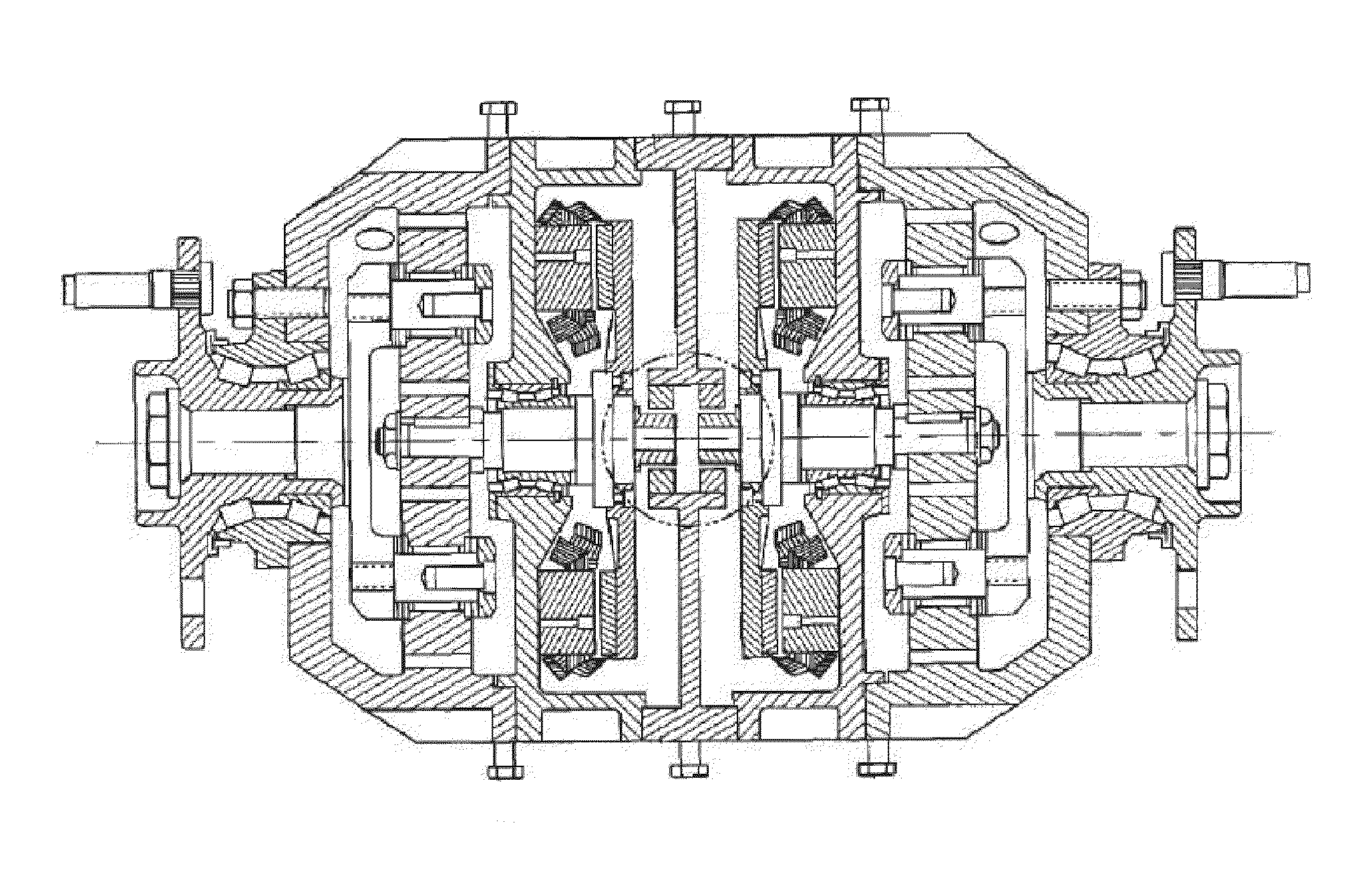

Variable-radius contact geometry for traction drives

A ball-type variator having a variable contact patch geometry wherein the variator efficiency is improved when the effect of spin is reduced under light load. Said ball-type variator having said variable contact patch geometry wherein the maximum stresses are reduced at high loads.

Owner:DANA CORP

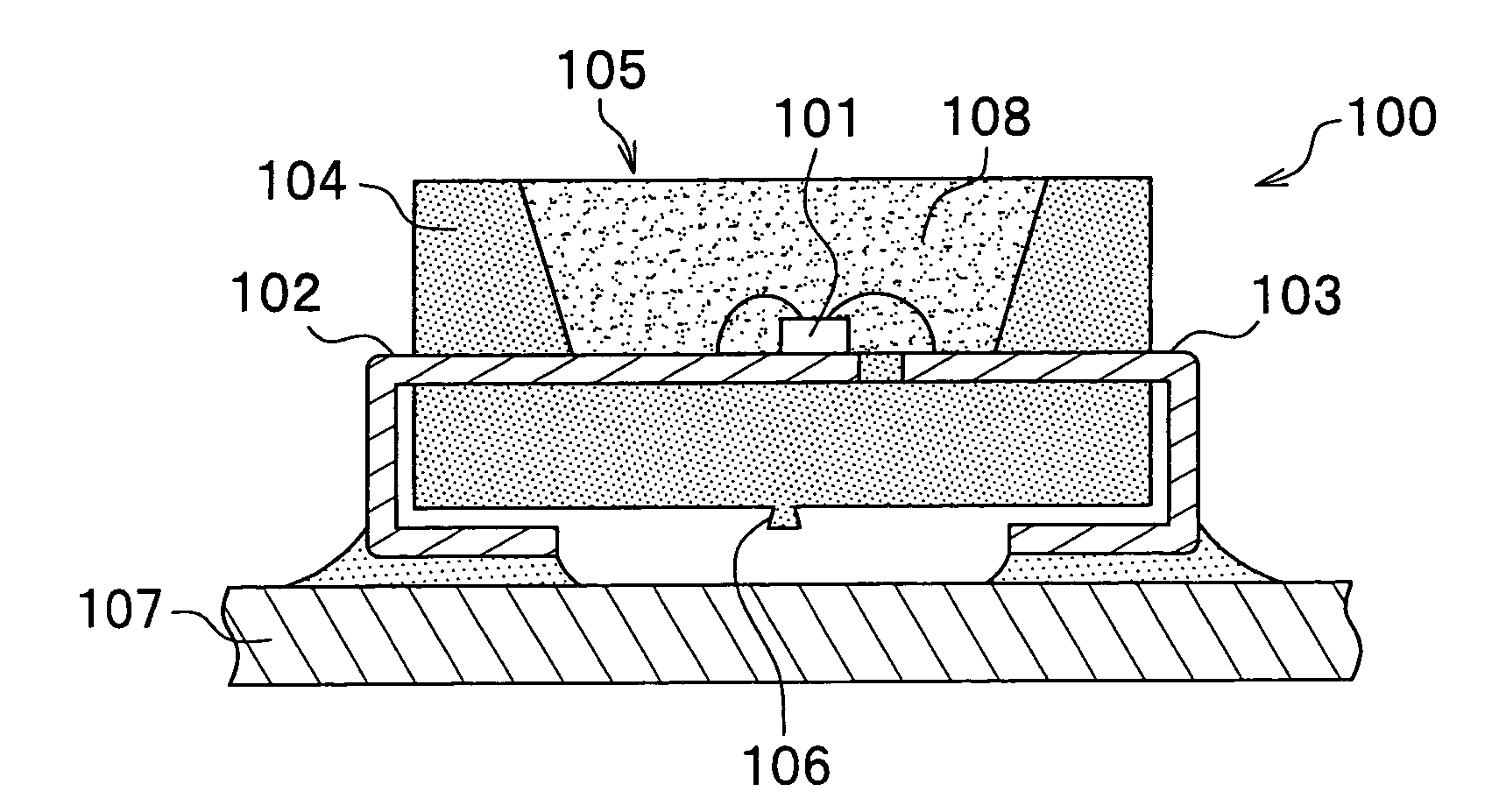

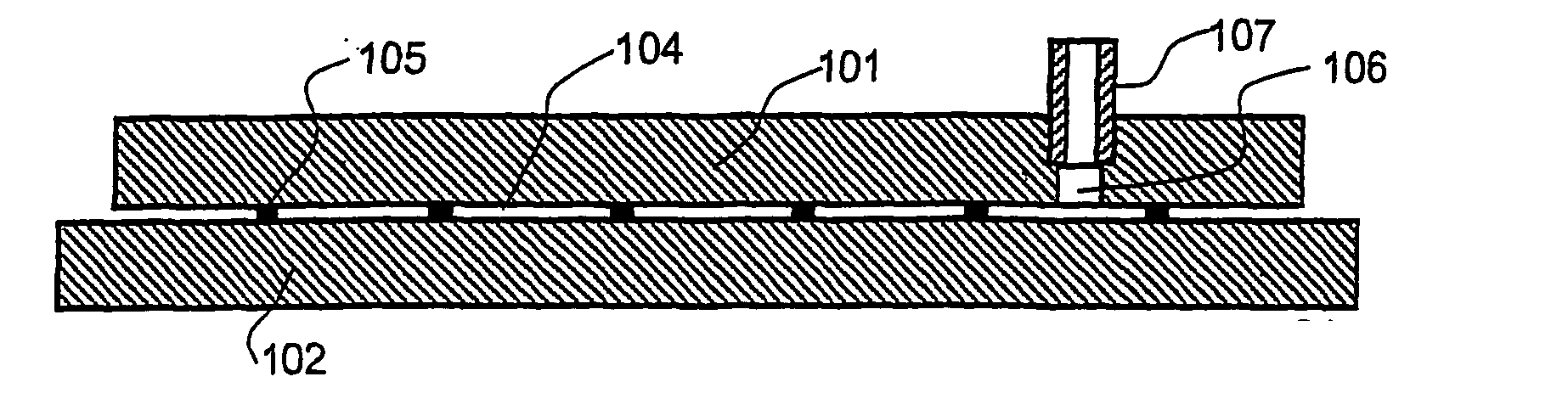

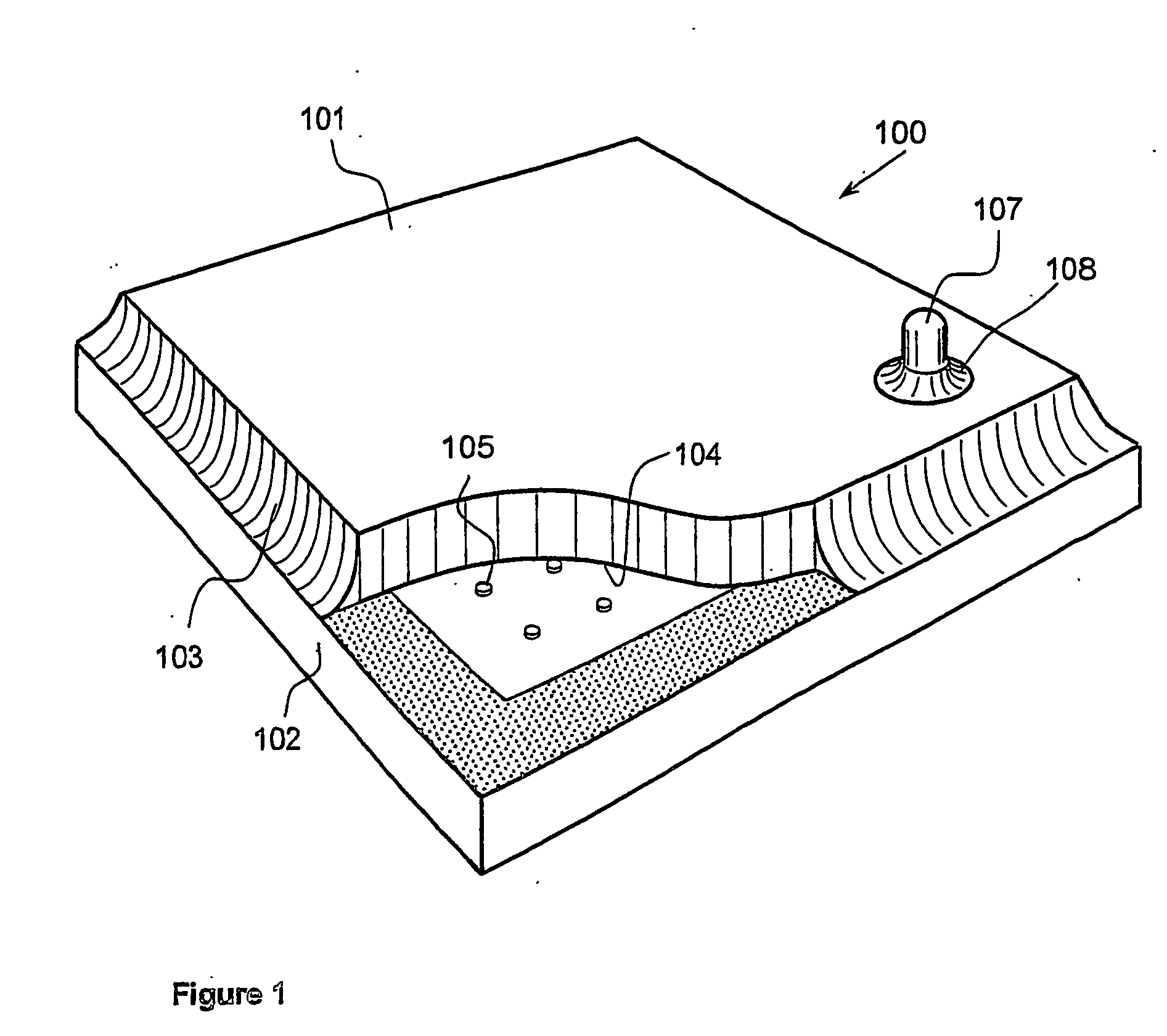

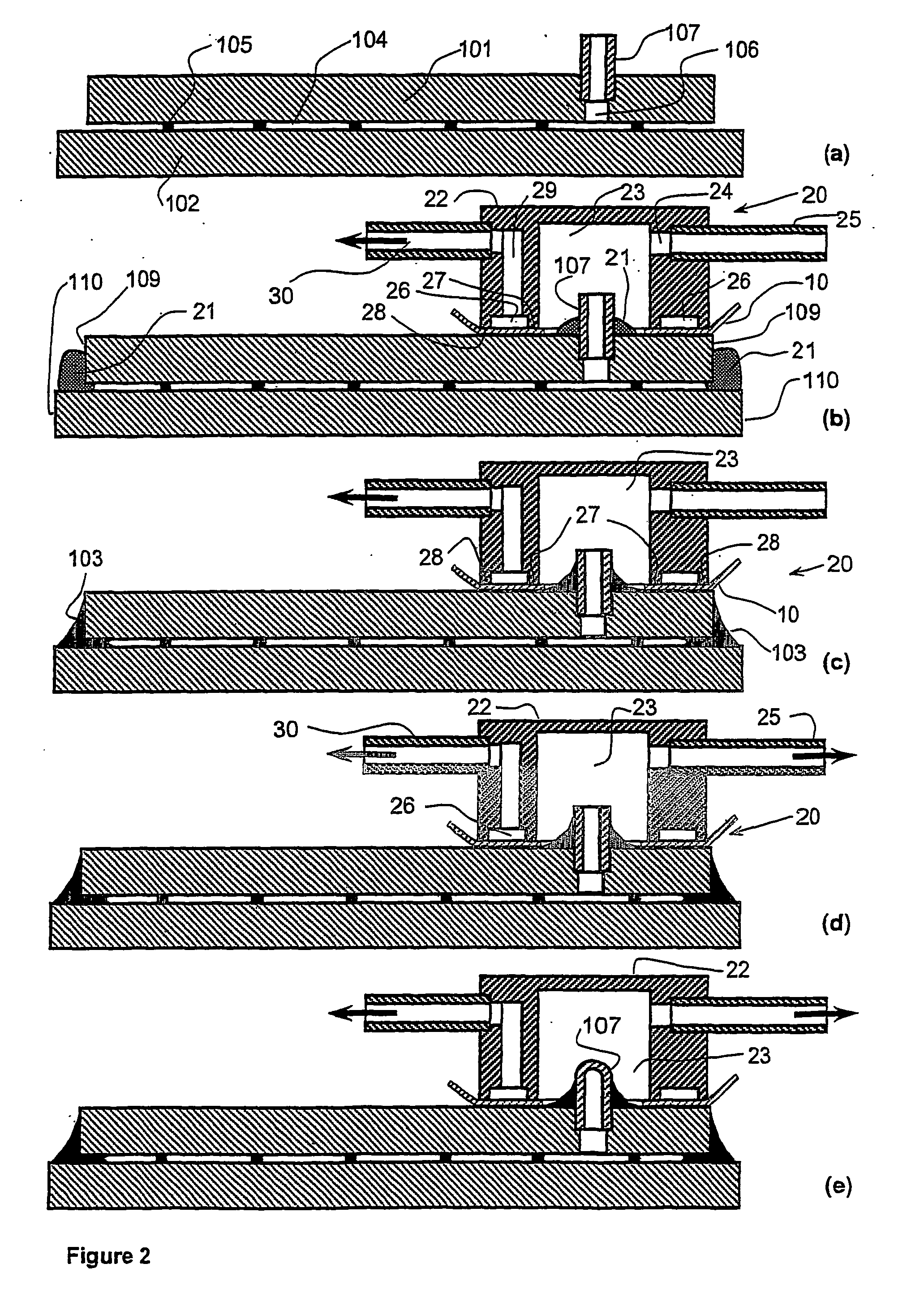

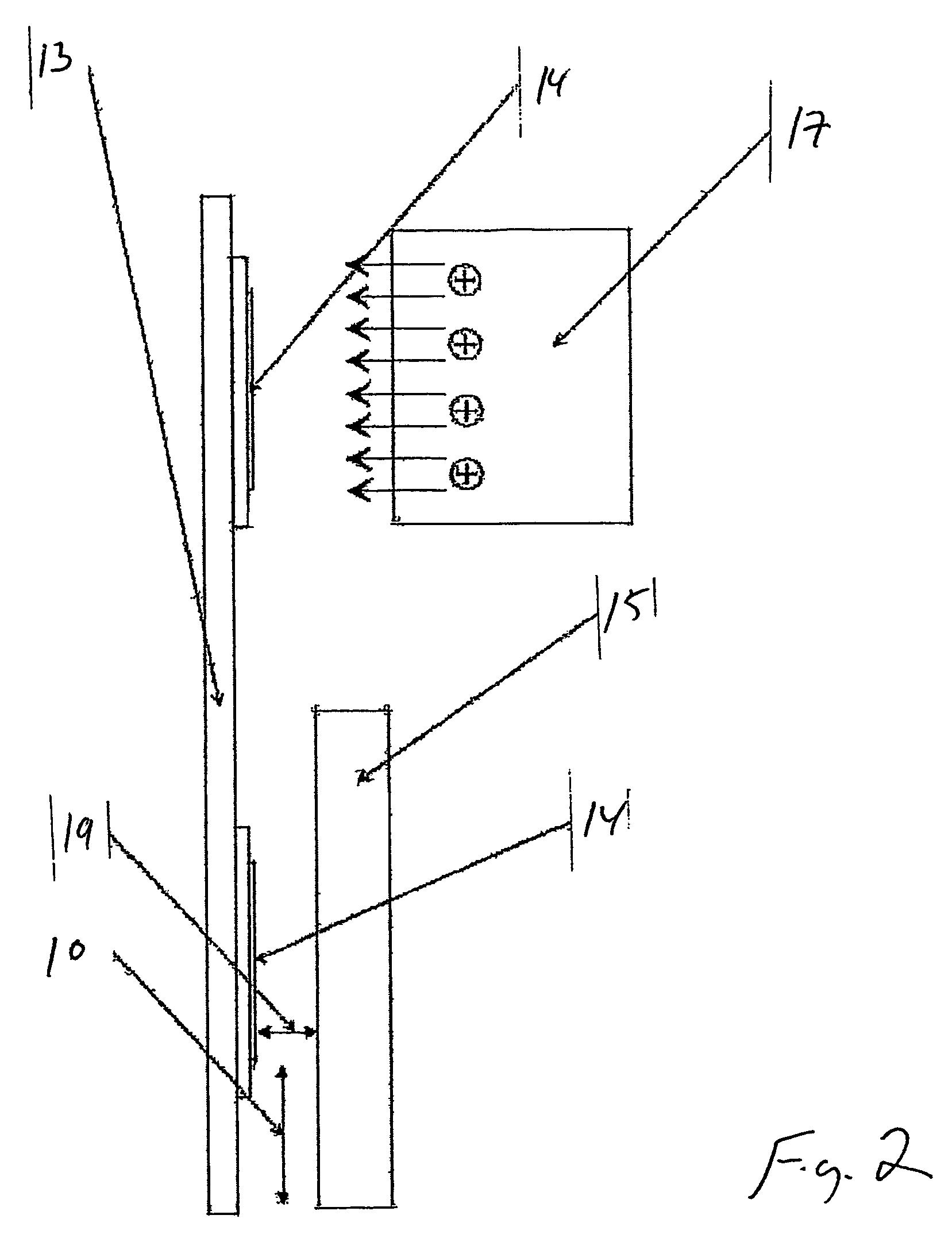

Sealing arrangement for use in evacuating a glass chamber

InactiveUS20060175767A1Degrade quality of vacuumSuppress mutationEngine sealsElectric discharge tubesEngineeringGlass sheet

A gasket (10) is provided for an evacuation head assembly (20) to evacuate a chamber (104) defined by two glass sheets (101, 102). The gasket (10) may be made from a metal foil such as aluminium and has opposite sealing surfaces (14, 15, 19) that are profiled with a series of fine grooves (17) and wherein the variation in thickness between the sealing surfaces is less than 1 μm.

Owner:THE UNIV OF SYDNEY

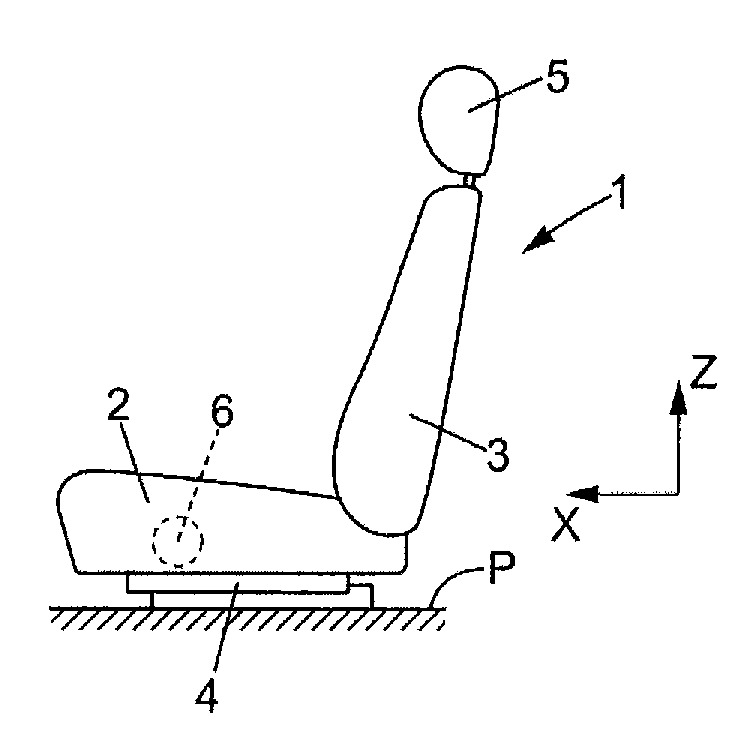

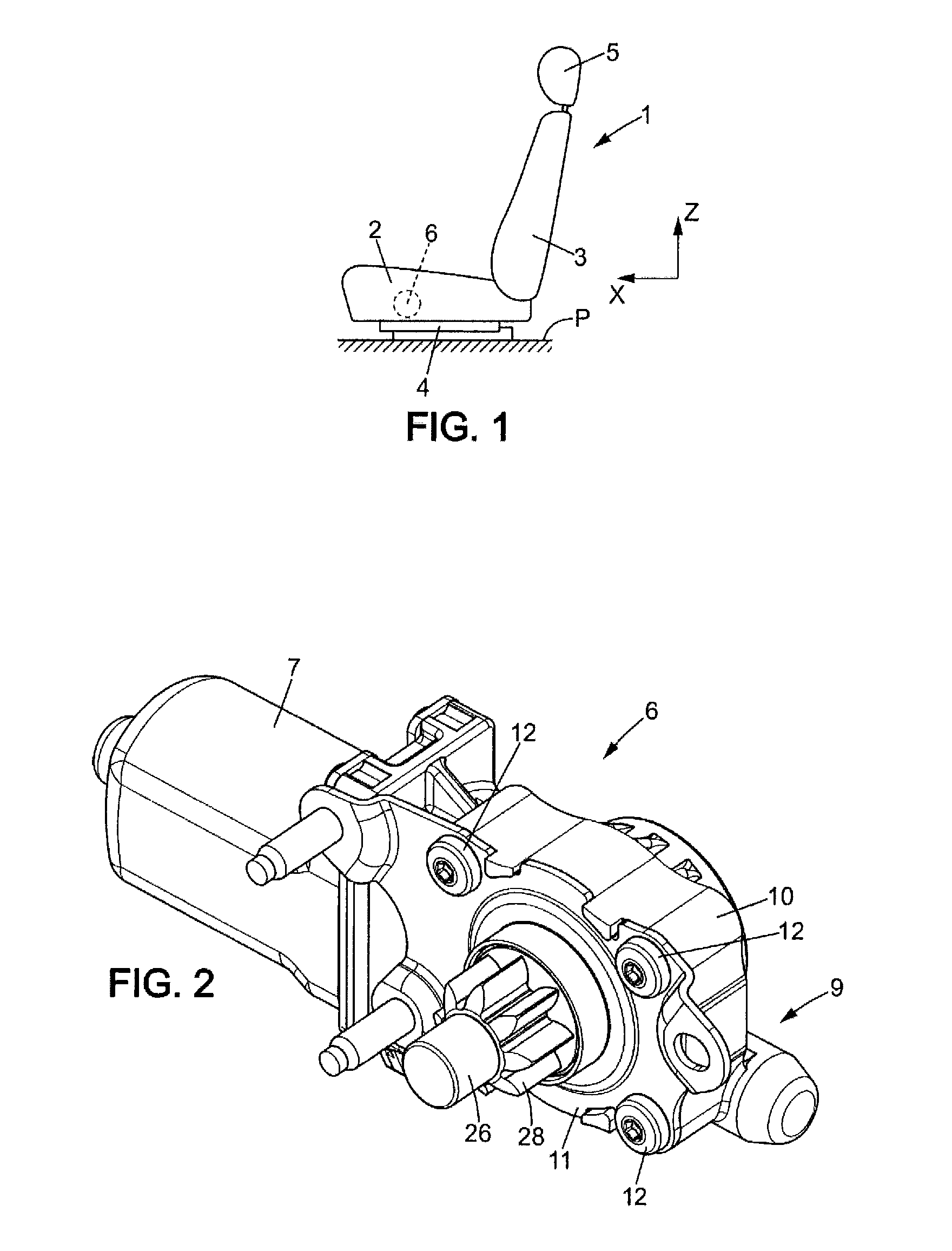

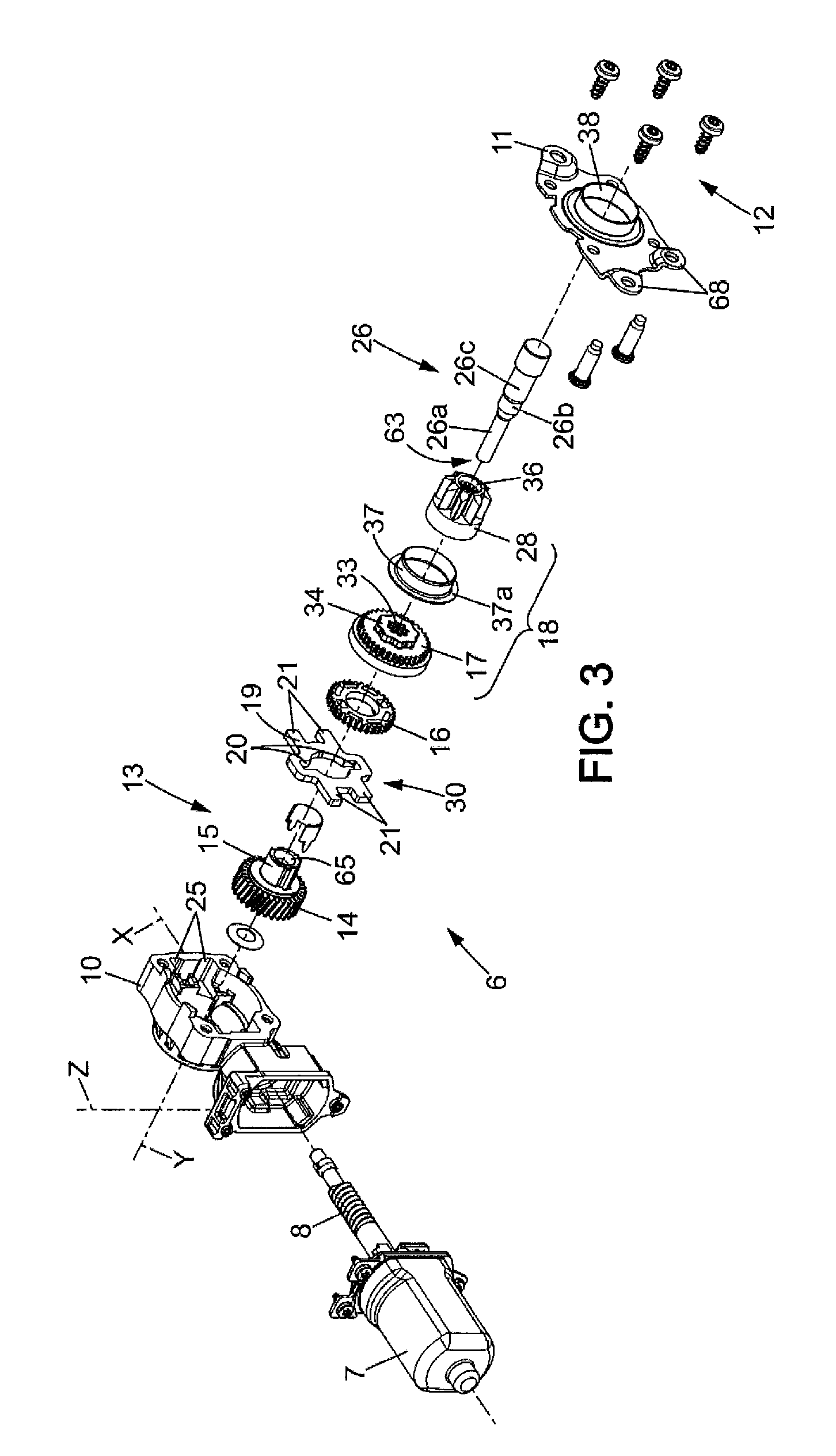

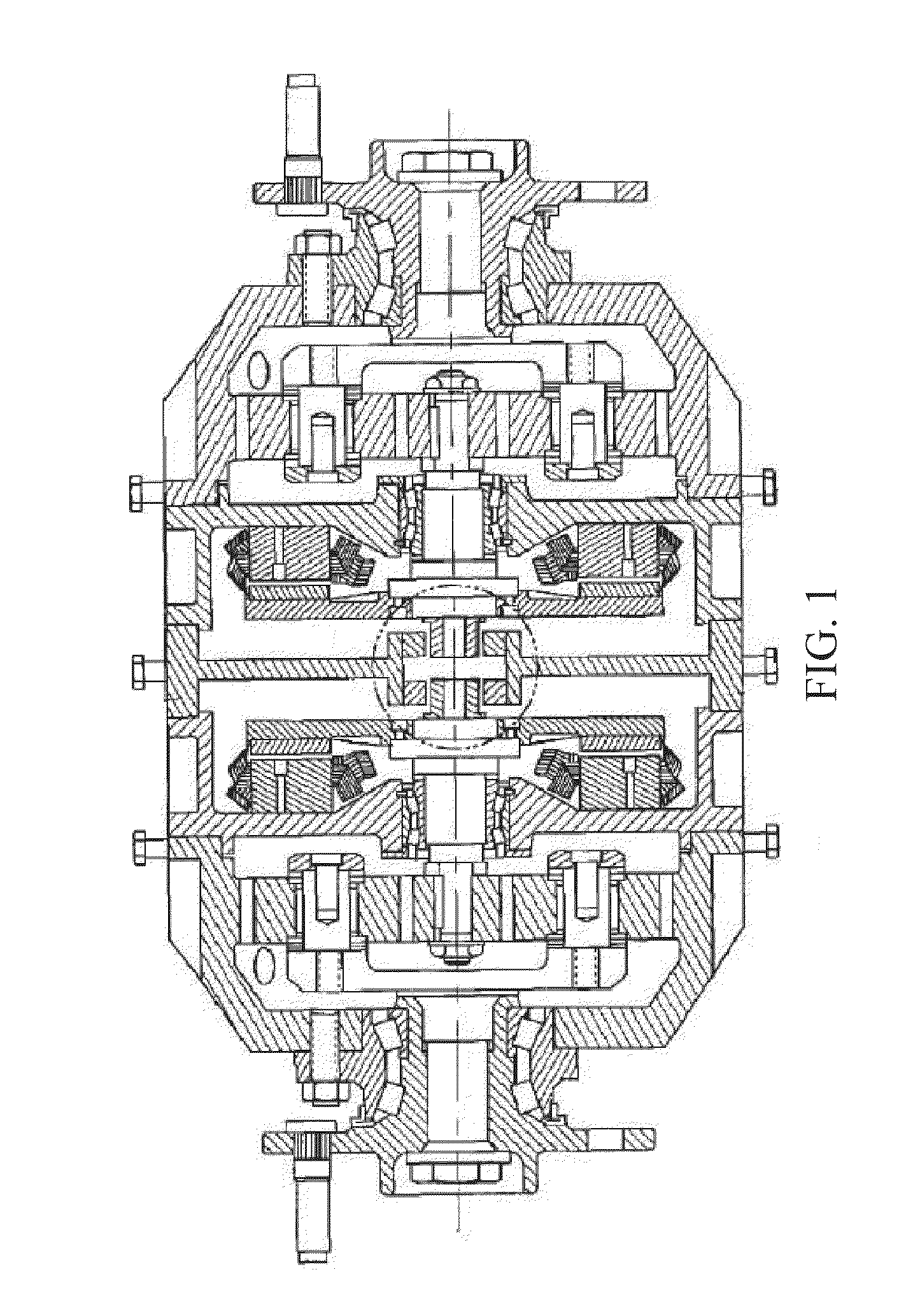

Adjustment mechanism for vehicle seat, vehicle seat comprising such a mechanism

An adjustment mechanism for vehicle seat, comprising a gearbox, an eccentric element driven by a driving unit, an eccentric gear wheel rotatably mounted on the eccentric element, a drive output unit equipped with an inner gear ring which cooperates with the eccentric gear wheel by partial engagement of the teeth, a sliding block equipped with a first and a second longitudinal guide, the sliding block cooperating with the eccentric gear wheel by the first longitudinal guide, the sliding block cooperating with the gearbox by the second longitudinal guide, the material of the second longitudinal guide having a lower hardness than the hardness of the material of the eccentric gear wheel.

Owner:FAURECIA

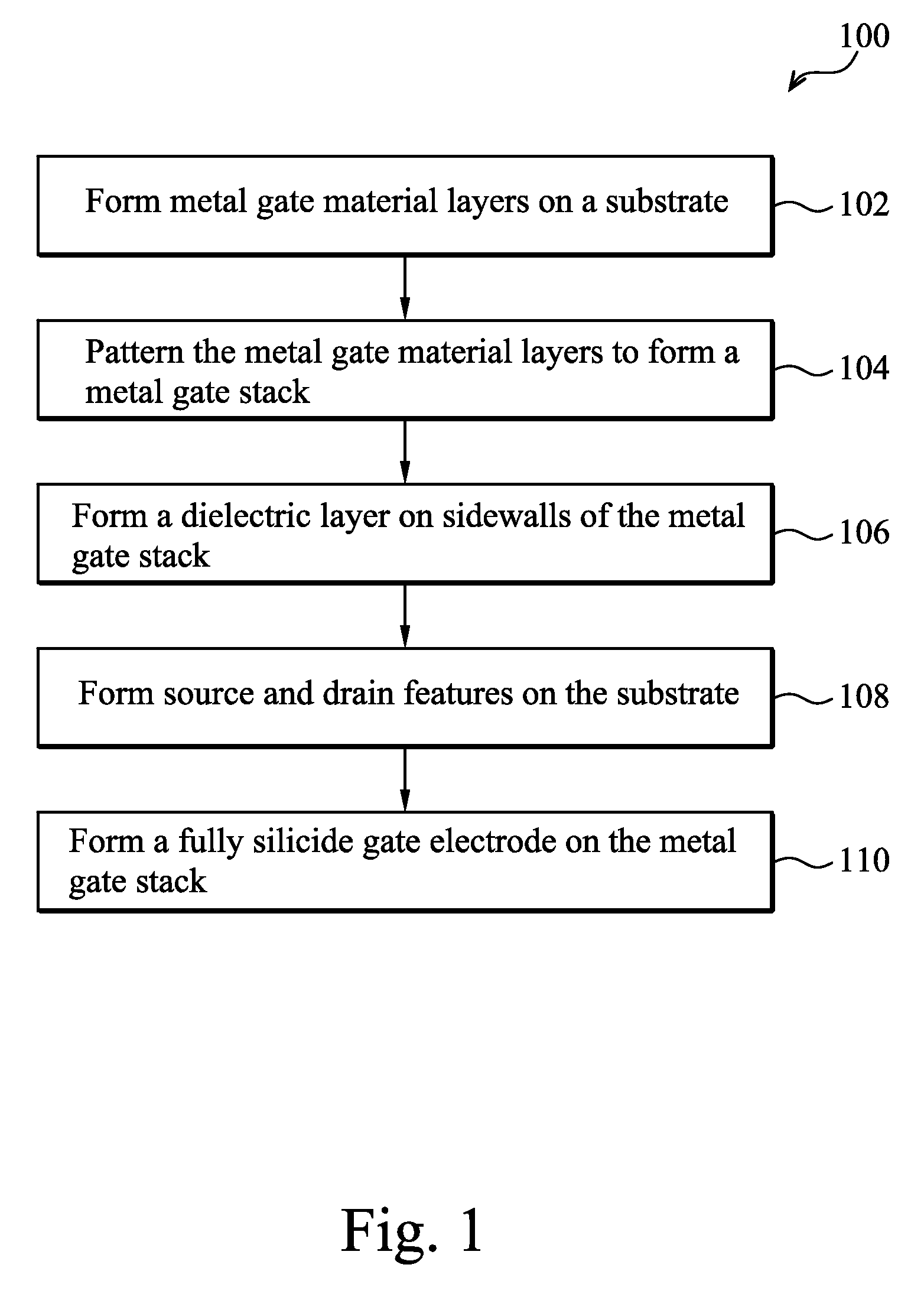

Transistor performance improving method with metal gate

ActiveUS20100078733A1Improve mobilityImprove device performanceTransistorSemiconductor/solid-state device manufacturingGate stackSemiconductor

The present disclosure provides a method for making a semiconductor device having metal gate stacks. The method includes forming a high k dielectric material layer on a semiconductor substrate; forming a first metal layer on the high k dielectric material layer; forming a silicon layer on the first metal layer; patterning the silicon layer, the first metal layer and the high k dielectric material layer to form a gate stack; and performing a silicidation process to fully change the silicon layer into a silicide electrode.

Owner:TAIWAN SEMICON MFG CO LTD

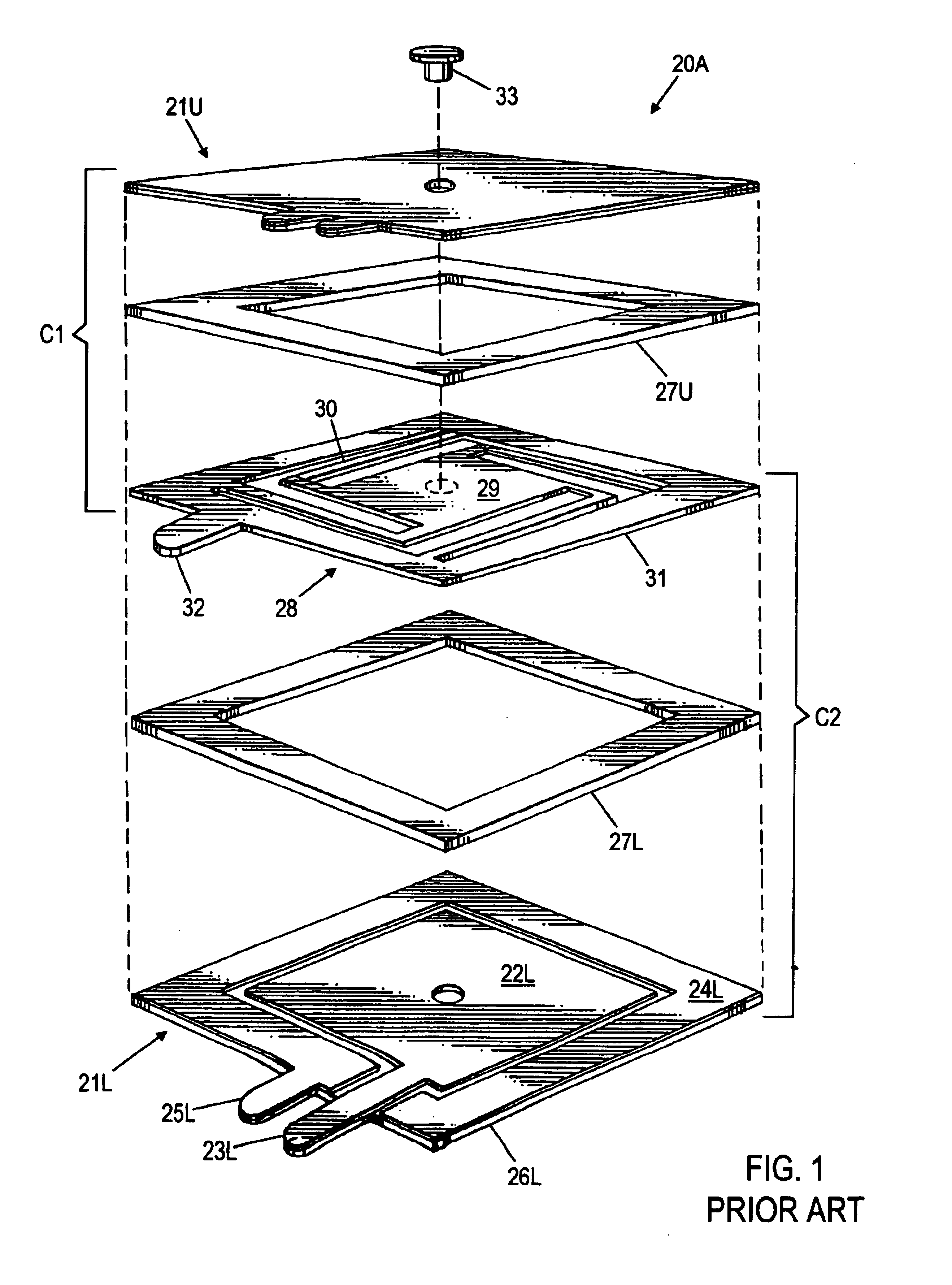

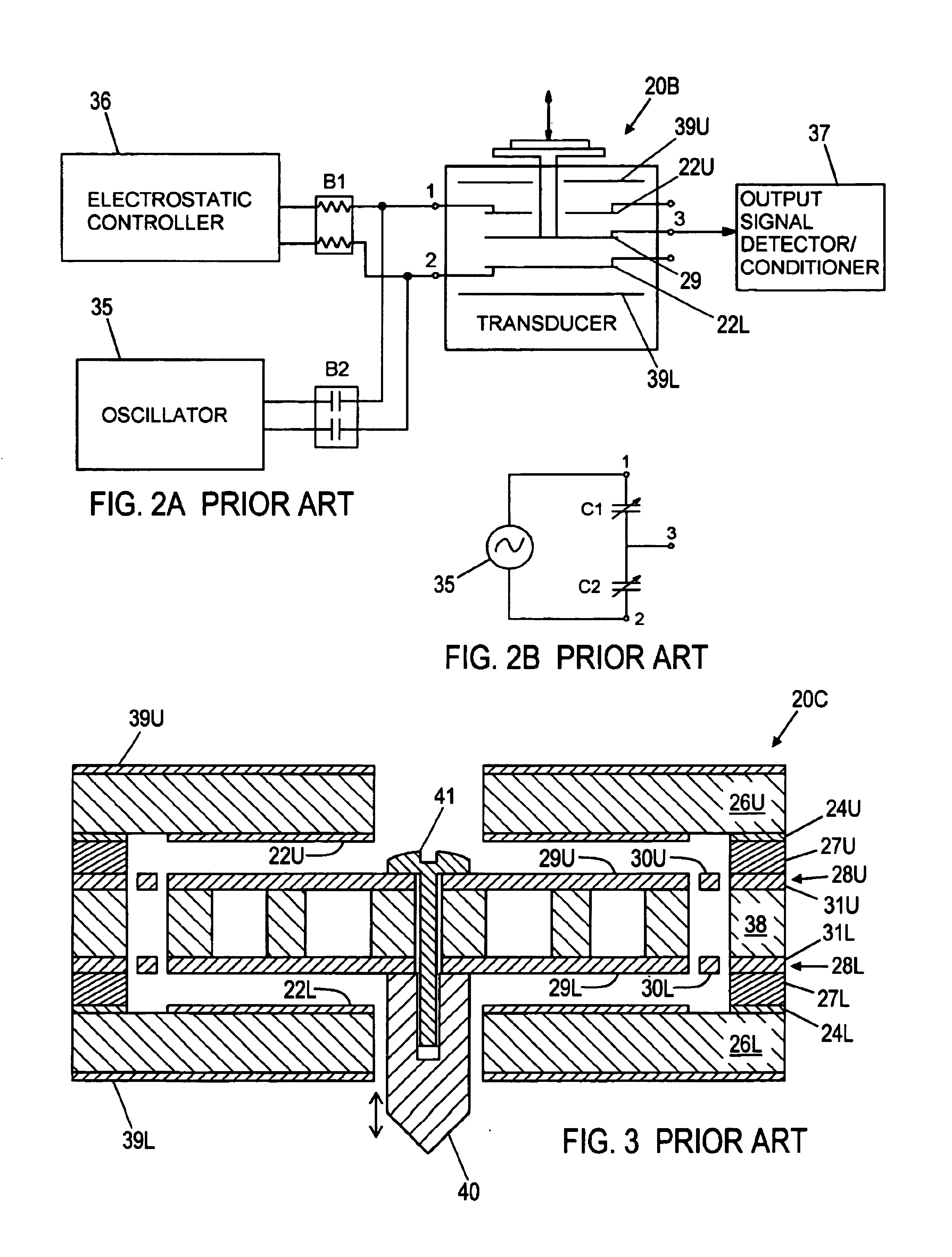

Multi-layer capacitive transducer

InactiveUS7046497B1Reduce thicknessImprove the immunityCapacitor with electrode area variationCapacitor with electrode distance variationHysteresisMechanical engineering

A capacitive transducer of multi-layer construction includes two rotor plates supported by flexible springs, the plates being spaced apart and rigidly connected by a stem. One rotor plate my be used as either a pickup electrode or a grounded target electrode for determining position, displacement, or load force. The second rotor plate may be used for electrostatic actuation without interfering with or destroying circuitry associated with the first rotor plate. A number of improvements are disclosed including a hollow rotor plate structure for reduced moving mass, buckling resistant features for the springs, improved spring anchor joint design for reduced creep and hysteresis, and material selection and matching for reduced thermal sensitivity.

Owner:BONIN WAYNE

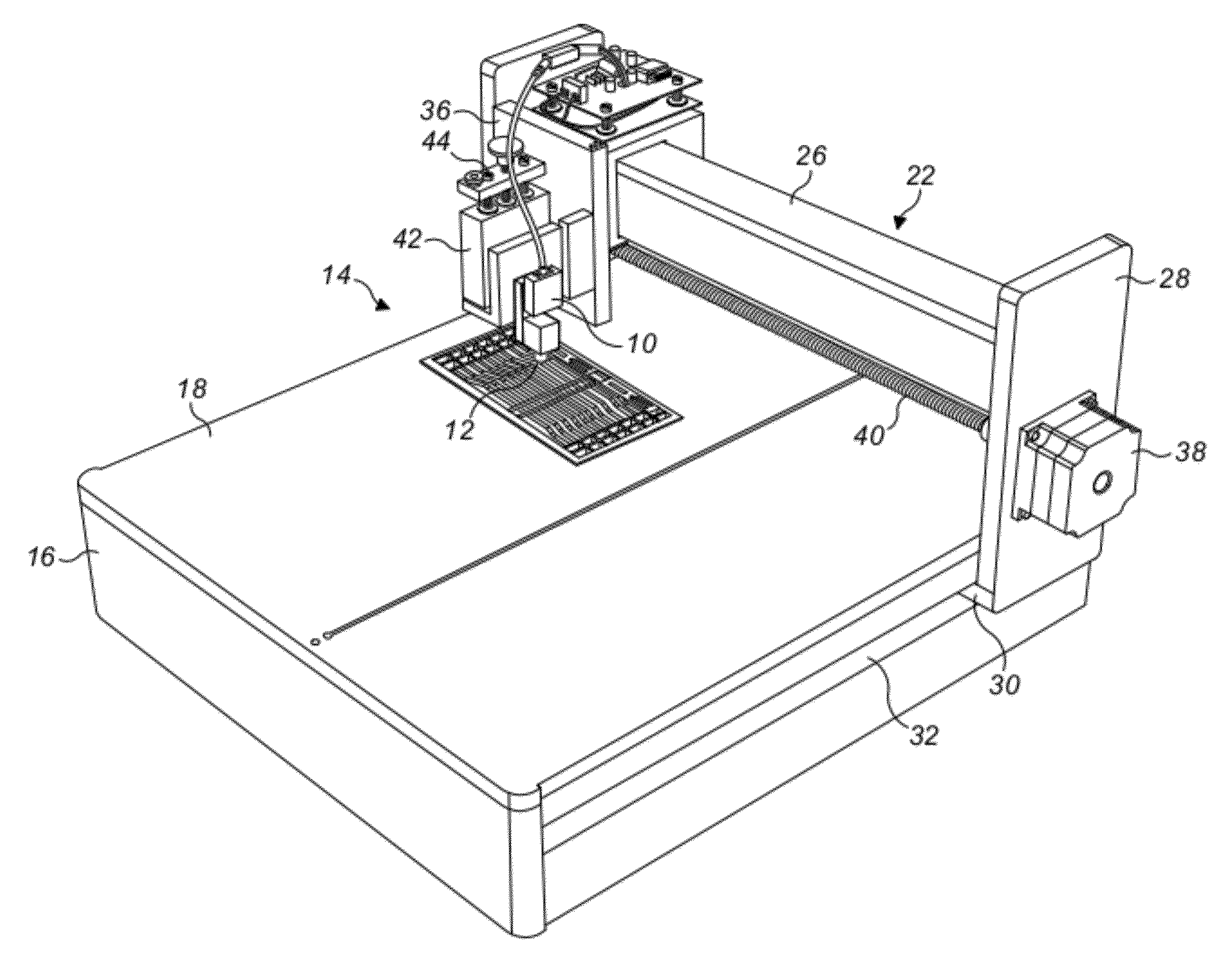

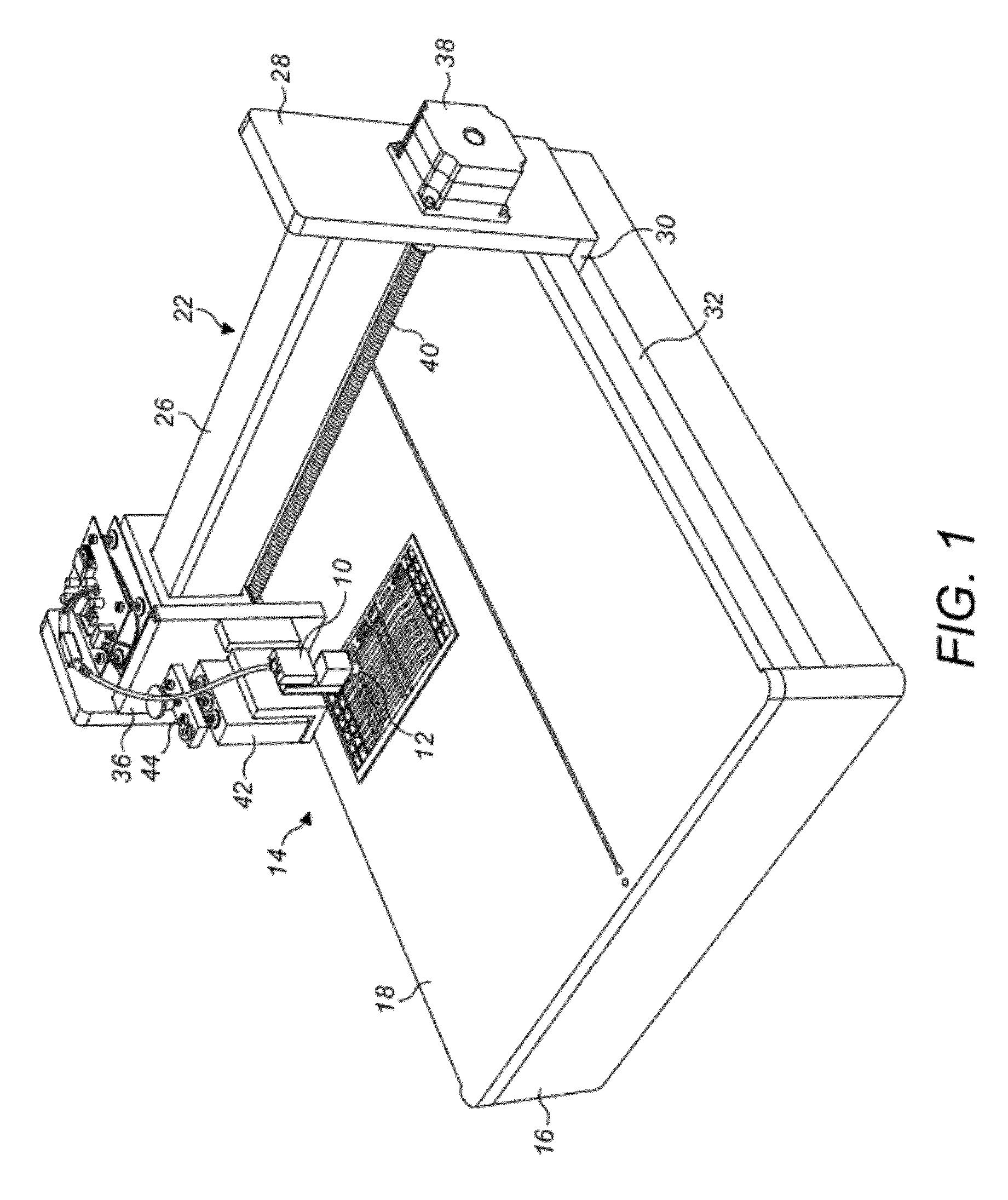

Apparatus and method for measuring charge density distribution

ActiveUS20120323513A1Significant stressResistance/reactance/impedenceVoltage-current phase angleCapacitanceDigital recording

The invention provides a method and apparatus for the detection of charge density distribution at the surface of a material sample. The apparatus comprises an electric potential sensor for measuring surface charge on a material sample, wherein the electrical potential sensor includes a probe for capacitively coupling the electric potential sensor to the surface of the material sample, an amplifier for generating a measurement output, the probe being connected to an input of the amplifier and the measurement output being supplied at an output of the amplifier, and a feedback arrangement driven from the output of the amplifier for enhancing the input impedance of the amplifier. A positioning system mounts the probe of the electric potential sensor above the material sample and moves the probe at a constant height over a surface of the said sample, and a processing system receives and processes the measurement output of the electric potential sensor for generating a digital record of the charge density distribution at the surface of the material sample.

Owner:THE UNIV OF SUSSEX

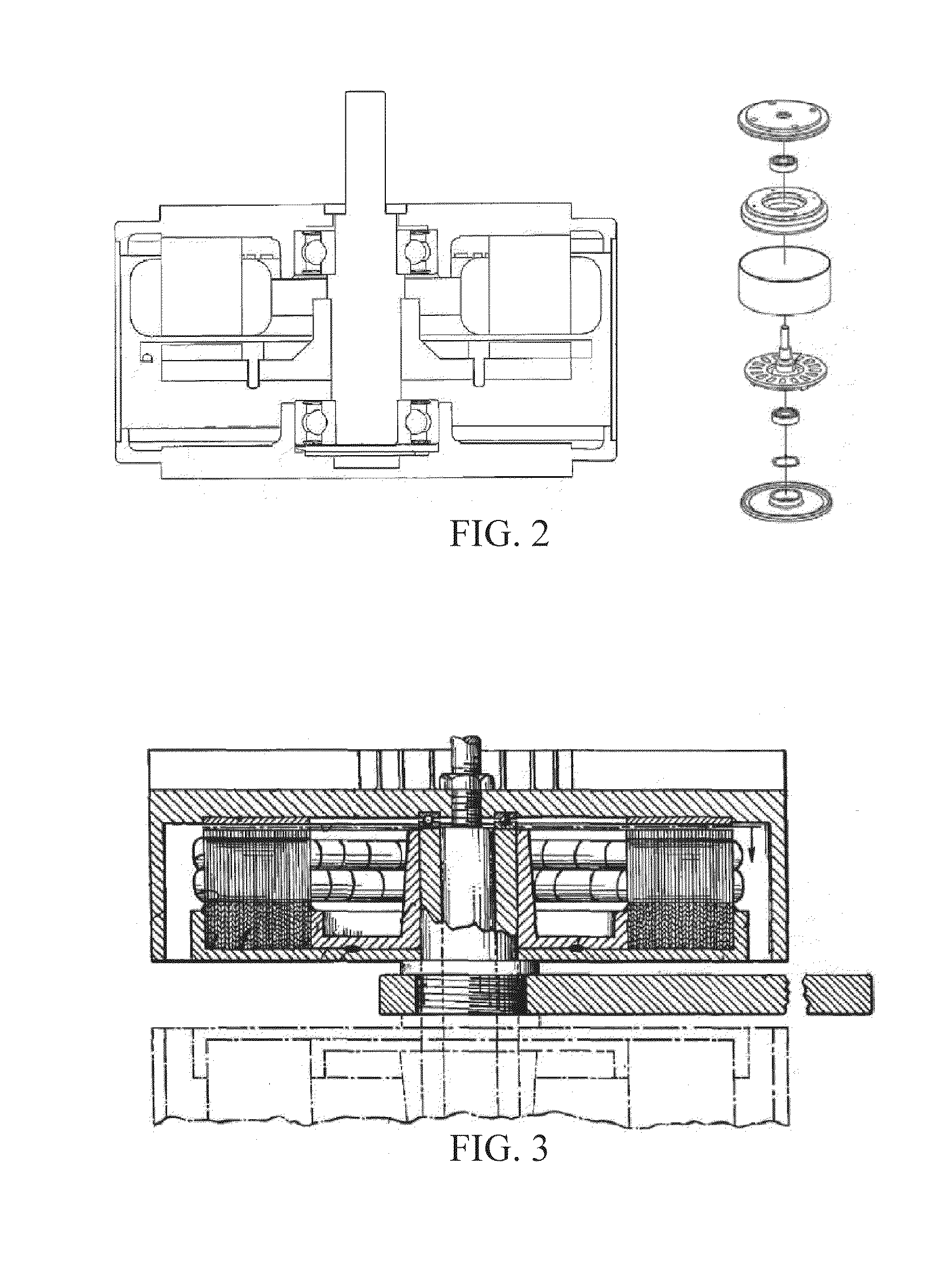

Stator assembly structure for axial flux electric machine

ActiveUS20130140920A1Promote generationImprove competitivenessMagnetic circuit stationary partsManufacturing dynamo-electric machinesElectric machineEngineering

A stator assembly structure for an axial flux electric machine is designed. The back iron for each silicon steel disk stator is formed into a specific structure with tooth-like protrusions for allowing the same to be integrated with the disk-type stator seat, while the disk-type stator seat is made of a material suitable for casting or mold forming. A coil is mounted on the disk stator, and a stator assembly is achieved by integrating the stator, the coil and the stator seat. The stator and the disk-type stator seat of the stator assembly are manufactured by using a one-piece cast or one-piece mold forming method so as to enable the contact surfaces of the stator and the stator seat to engage with each other even more tightly, and consequently enable the heat generated from the coil to be transmitted rapidly from the disk stator to the disk-type stator seat.

Owner:IND TECH RES INST

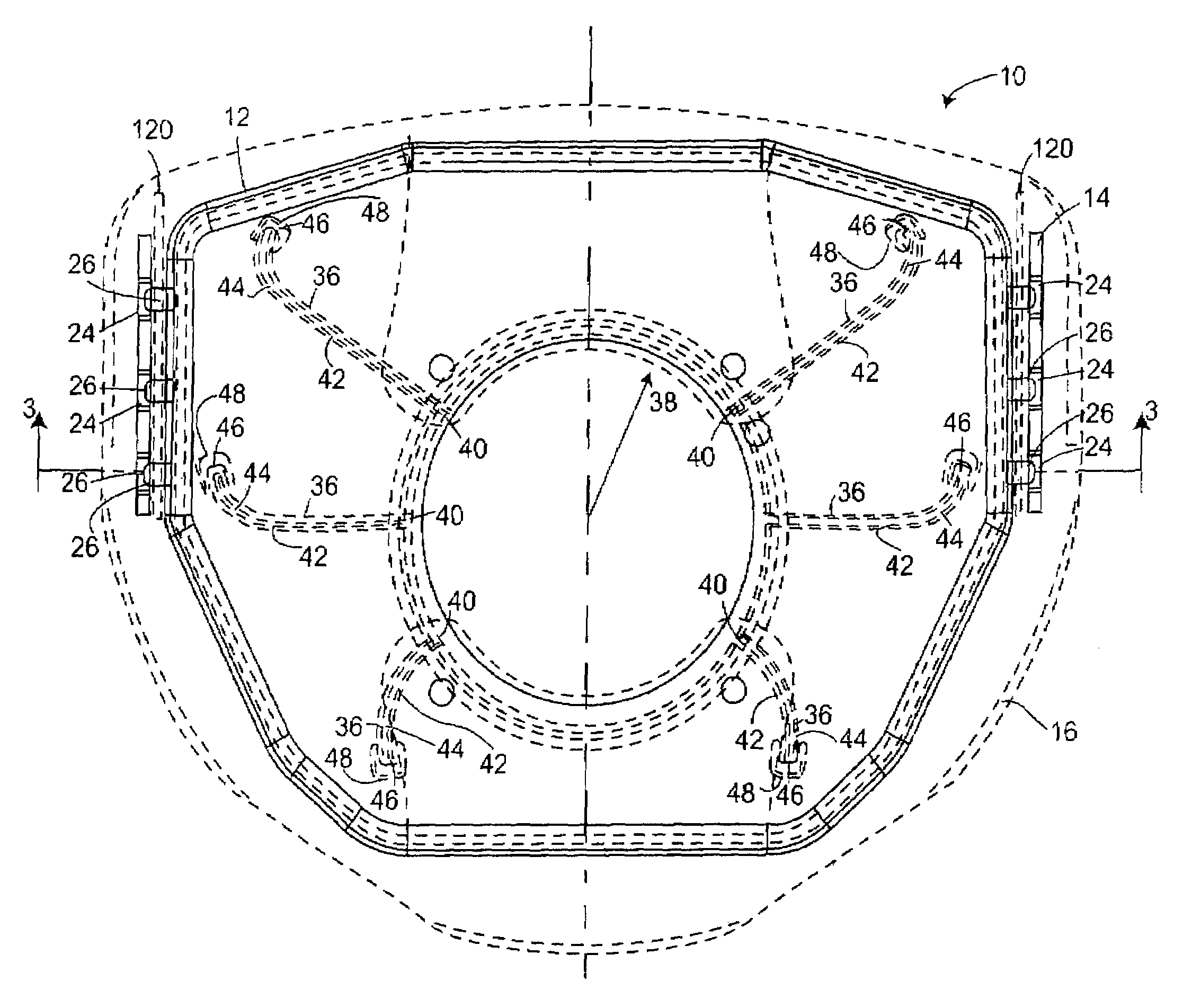

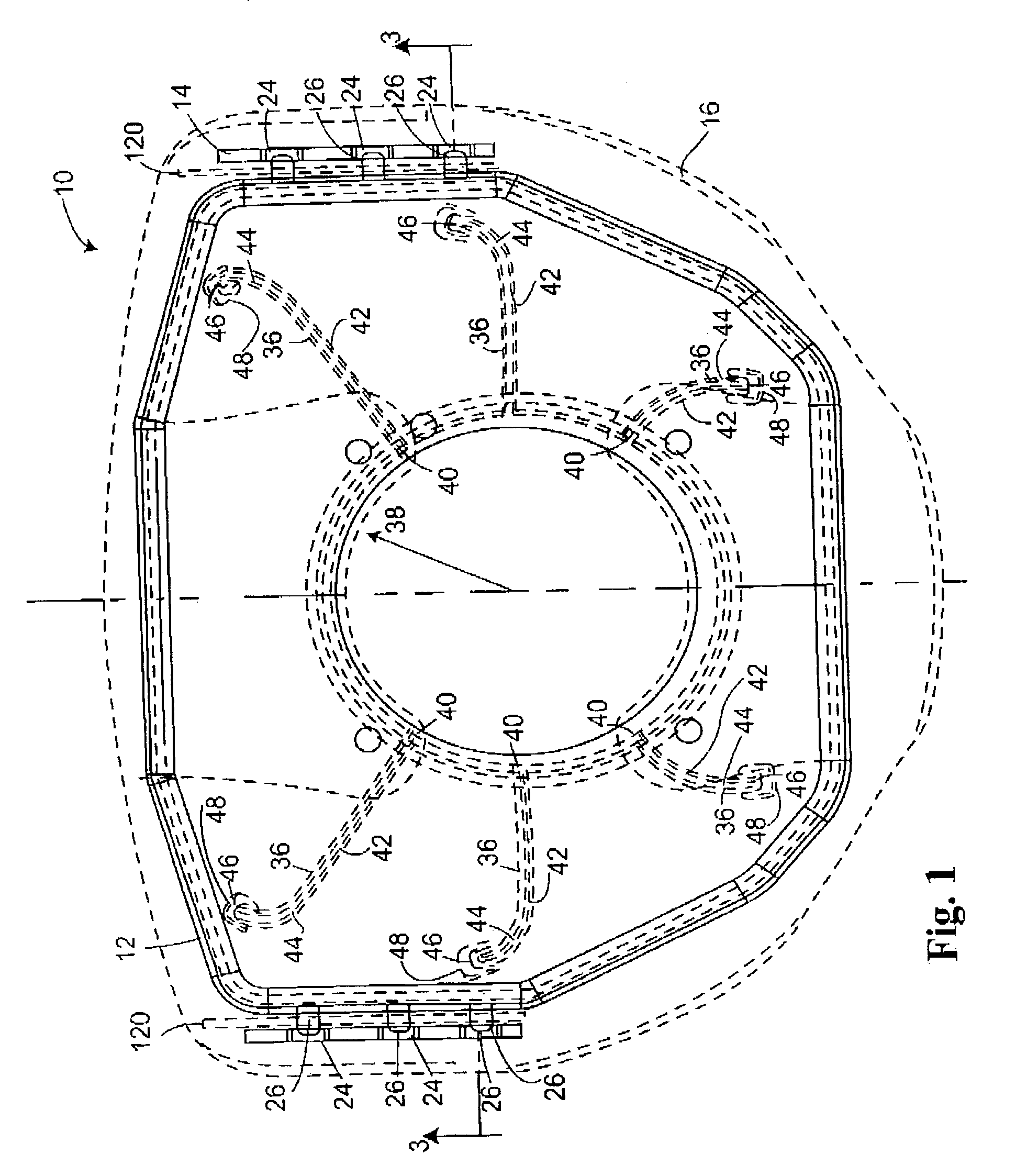

Air bag cover with articulated tear seam

InactiveUS6994372B2Reduced integrityLess forcePedestrian/occupant safety arrangementSteering wheelEngineering

A steering wheel assembly having a fastenerless air bag module assembly is disclosed. This assembly employs a housing with a projection and a steering wheel armature configured to receive the projection. The cover is retained between the housing and the steering wheel armature. Furthermore, the present invention provides a steering wheel cover with a tear seam that permits the air bag to deploy more efficiently with less damage to the occupants.

Owner:KEY SAFETY SYST

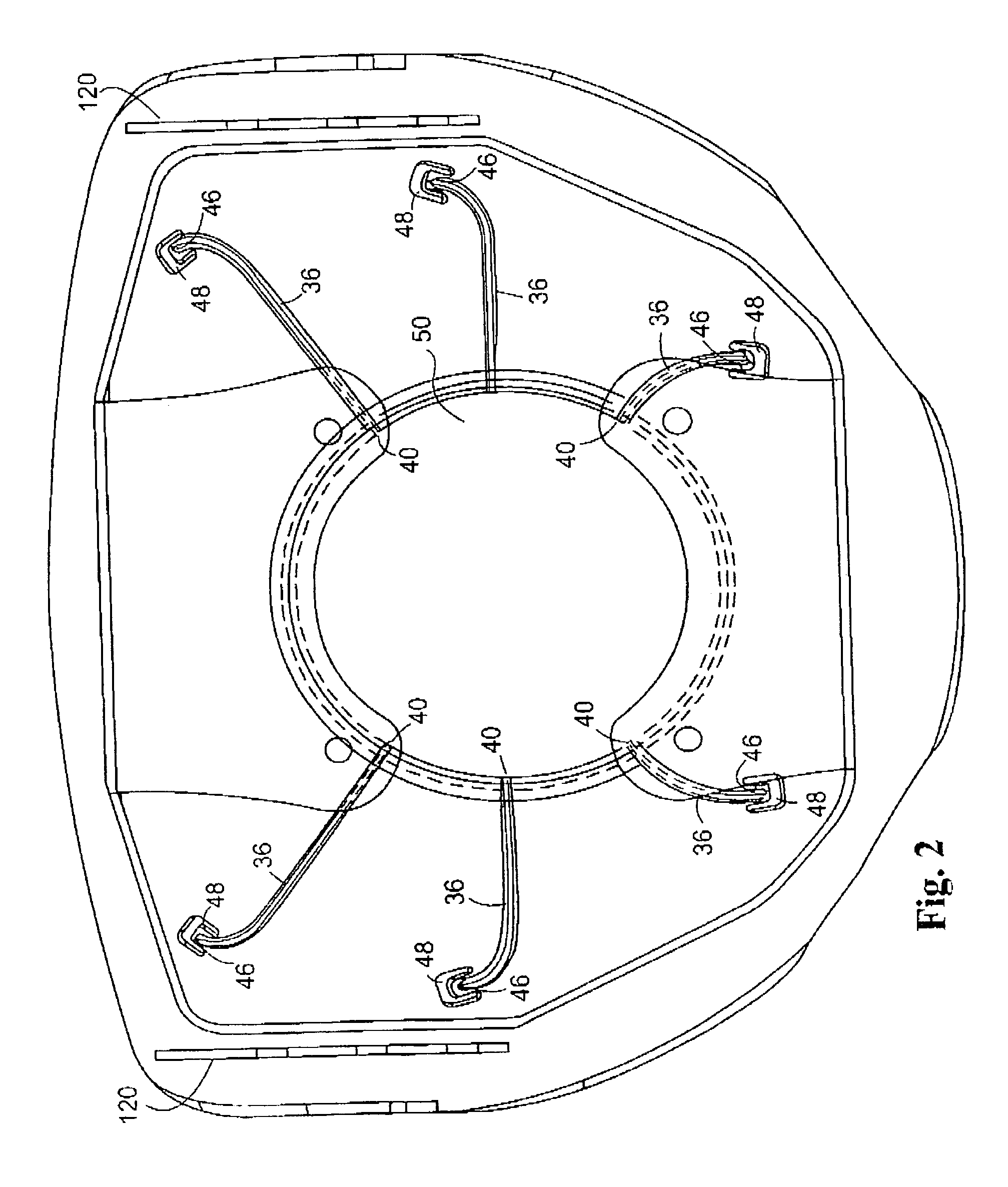

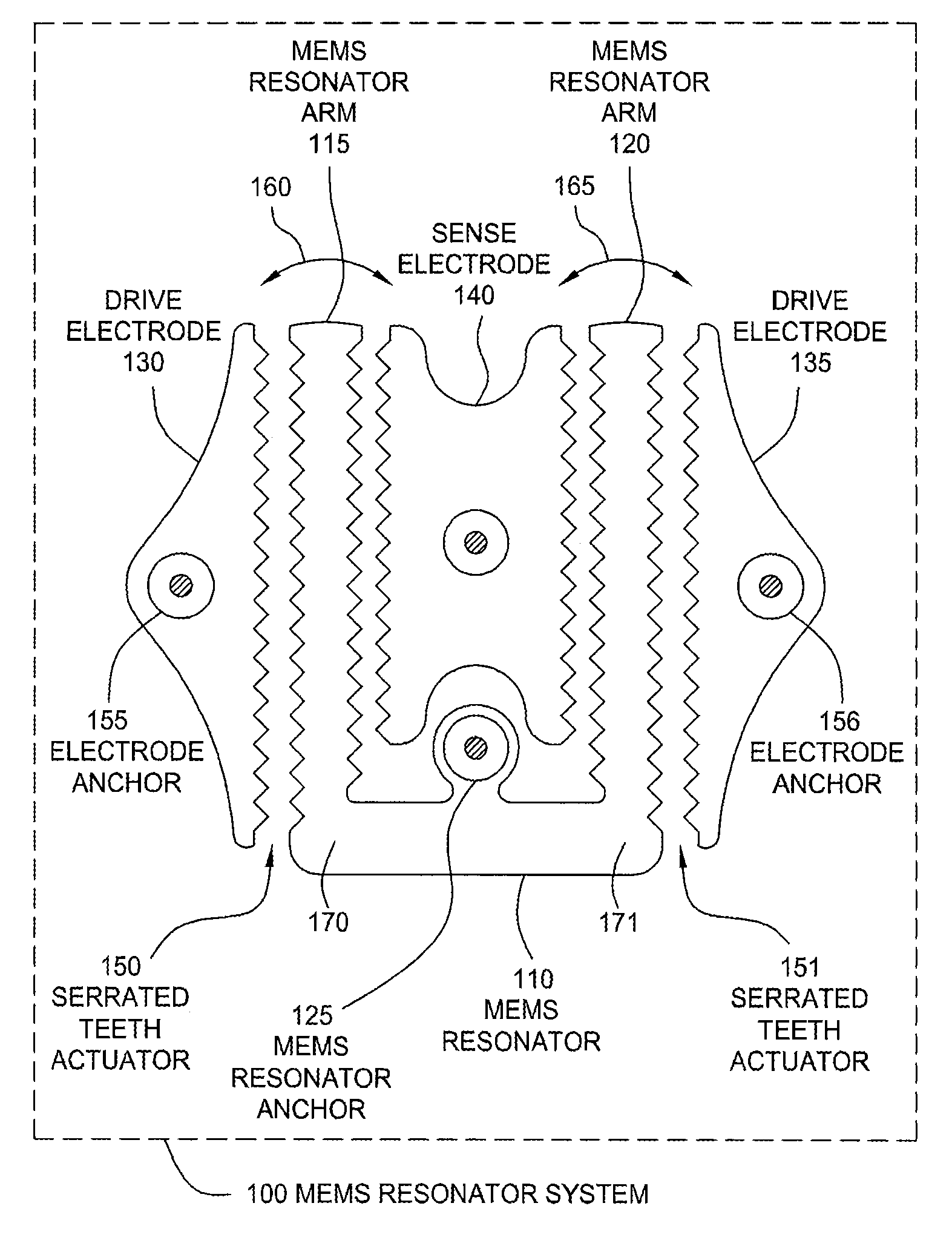

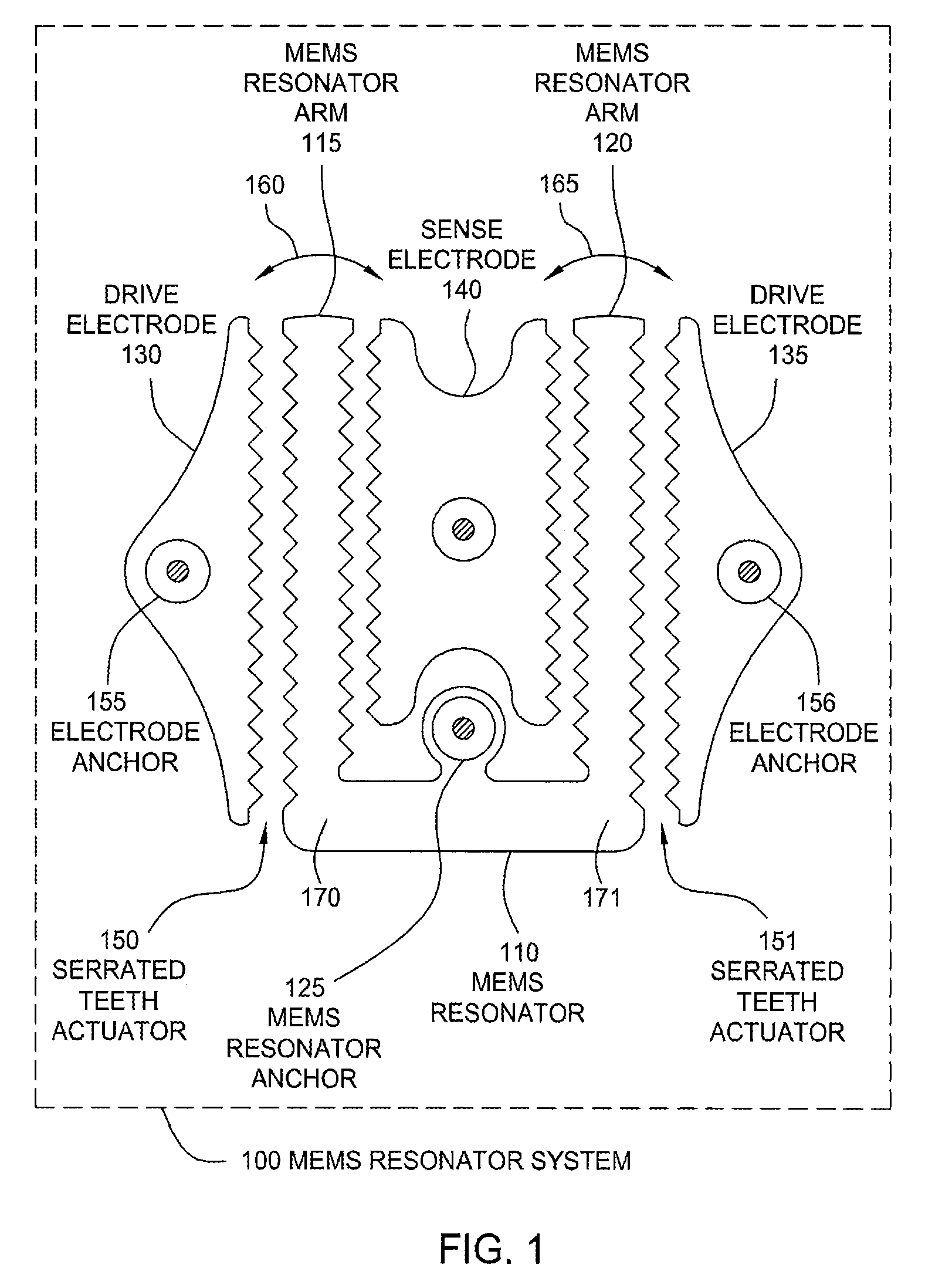

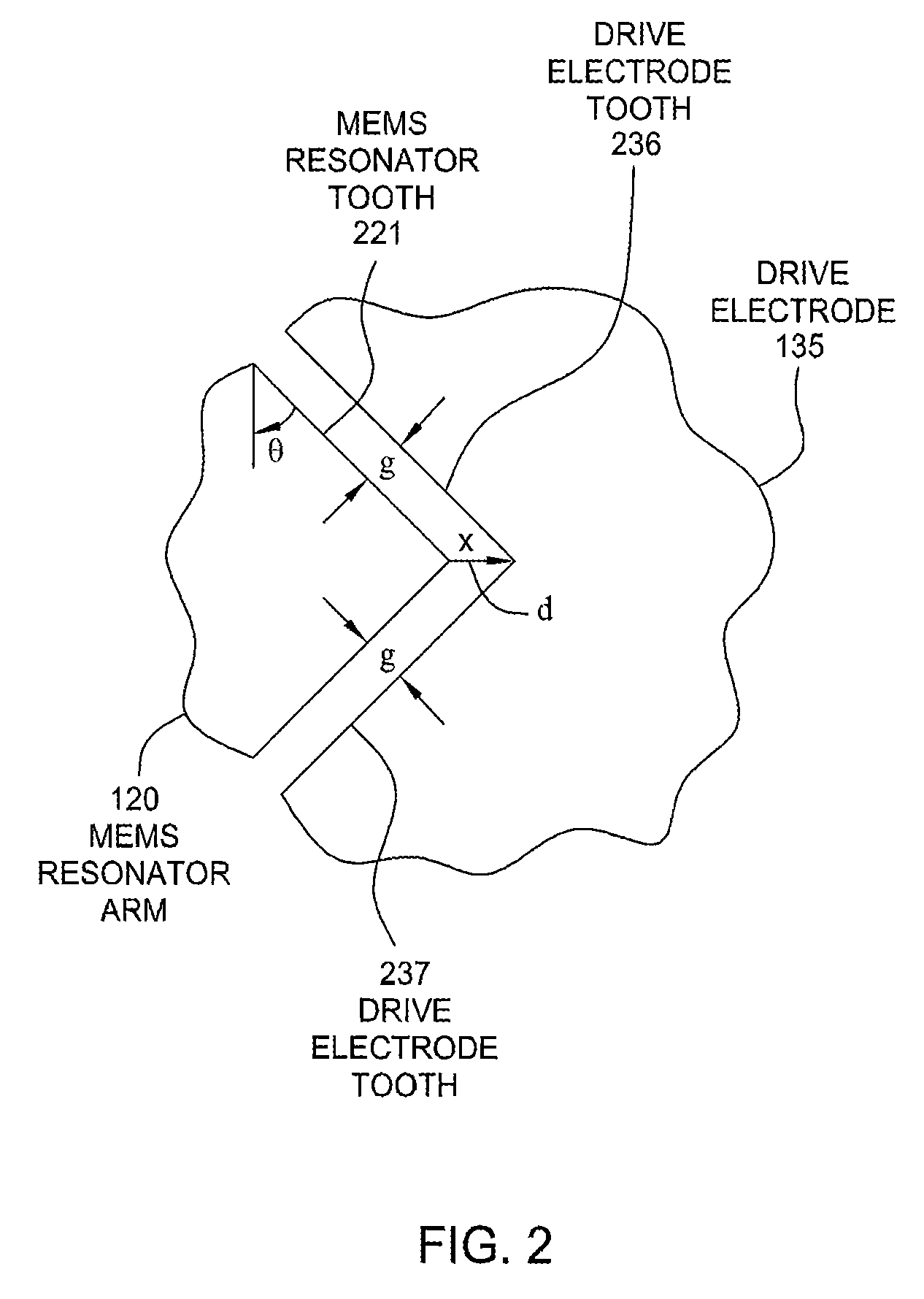

Serrated MEMS resonators

ActiveUS7545239B2Enhanced signalCompromise performanceImpedence networksPiezoelectric/electrostriction/magnetostriction machinesActuatorControl theory

One embodiment of the present invention sets forth a serrated tooth actuator for driving MEMS resonator structures. The actuator includes a fixed drive electrode having a serrated tooth surface opposing a MEMS resonator arm also having a serrated tooth surface, where the MEMS resonator arm is configured to rotate towards the drive electrode when an AC signal is applied to the drive electrode. Such a configuration permits higher amplitude signals to be applied to the drive electrode without the performance of the actuator being compromised by nonlinear effects. In addition, the serrated tooth configuration enables a sufficiently high actuating force to be maintained even though the distance traversed by the MEMS resonator arm during operation is quite small. Further, the serrated configuration allows a MEMS resonator system to withstand larger fluctuations in voltage and larger substrate stresses without experiencing a substantial shift in resonant frequency.

Owner:SITIME

Shell of pressure-resistant container, pressure-resistant container, and exploratory apparatus

InactiveUS20130026172A1High strengthReduce crackingVessel geometry/arrangement/sizeLarge containersThick wallUltimate tensile strength

Owner:JAPAN AGENCY FOR MARINE-EARTH SCIENCE AND TECHNOLOGY +1

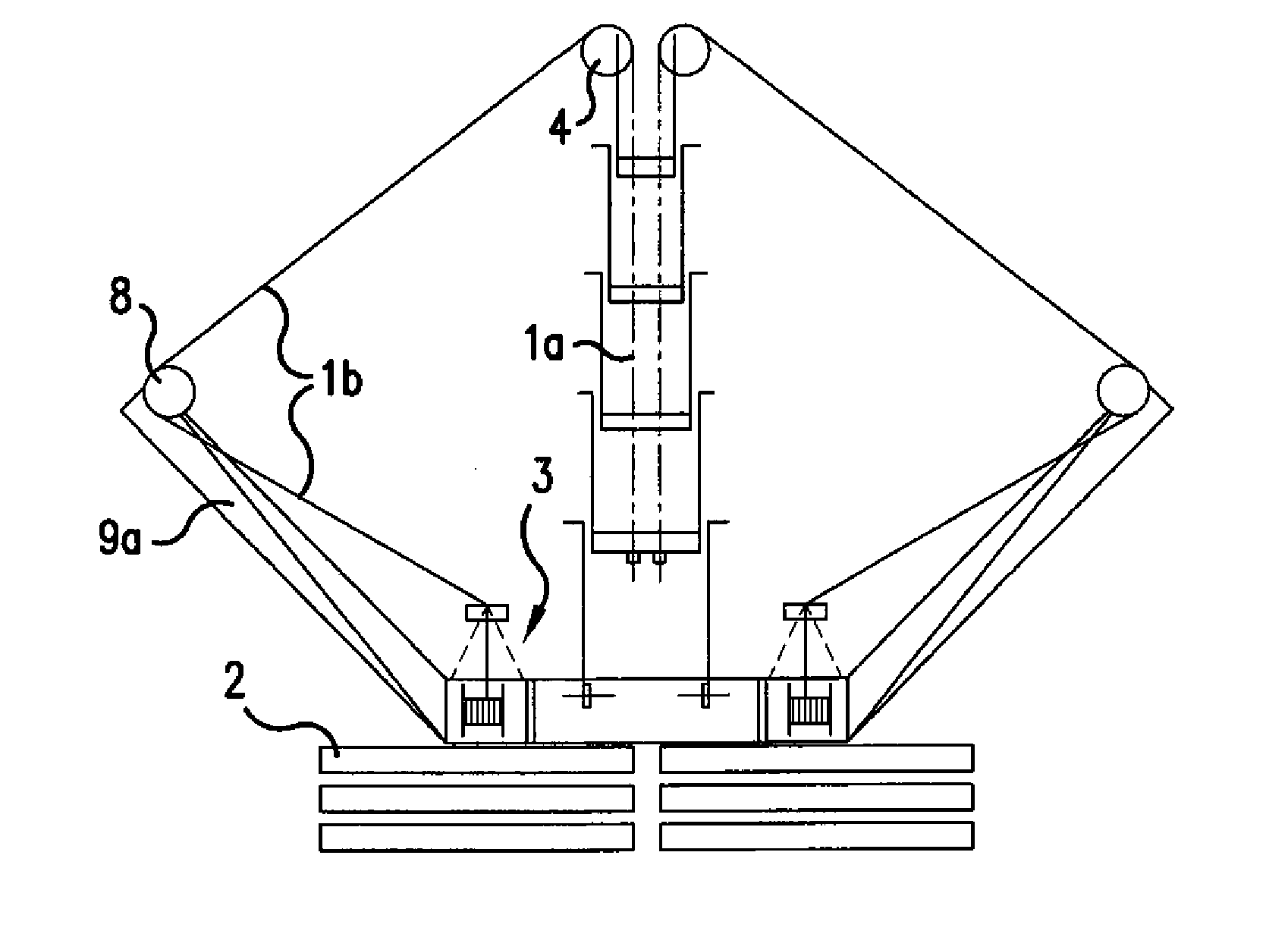

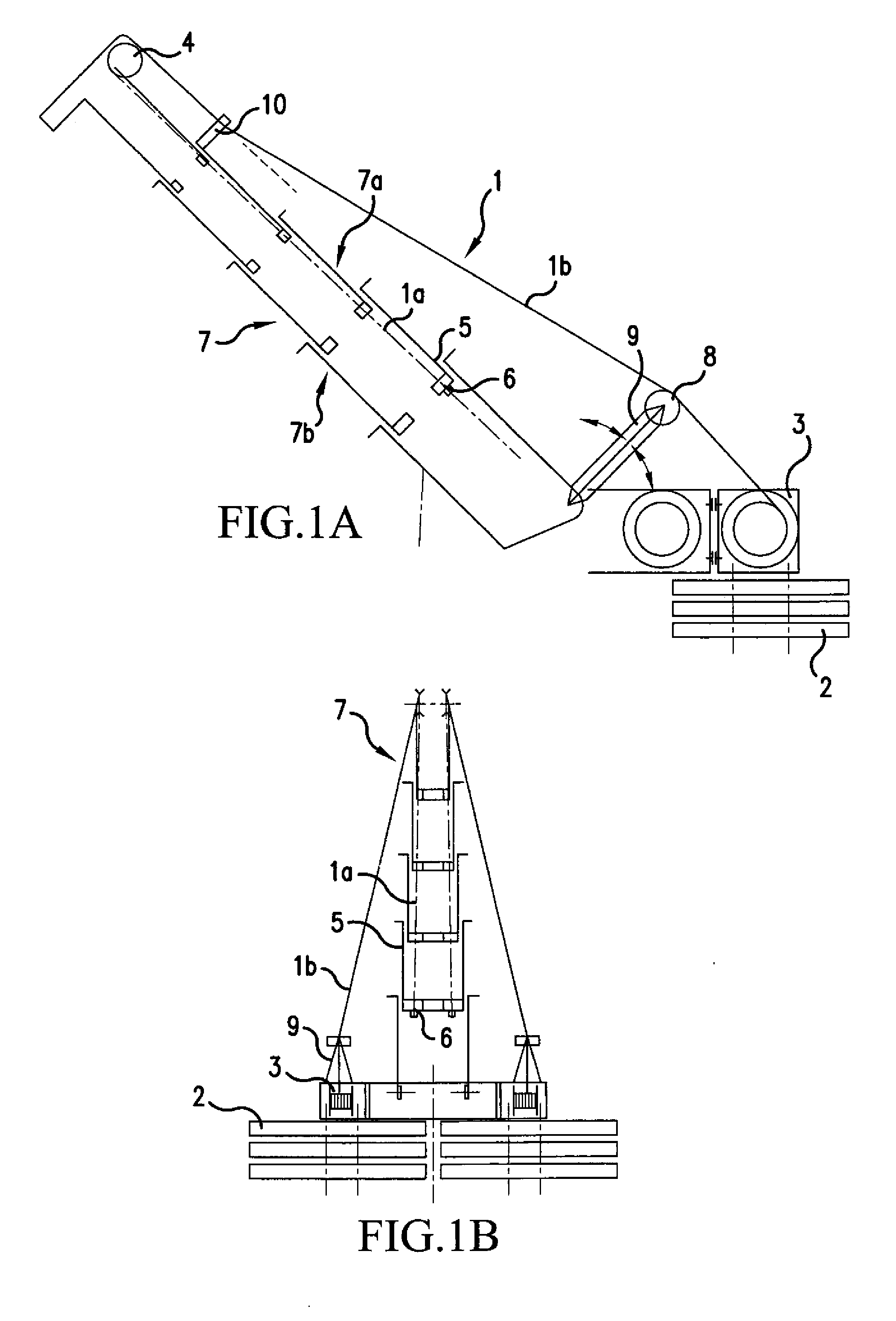

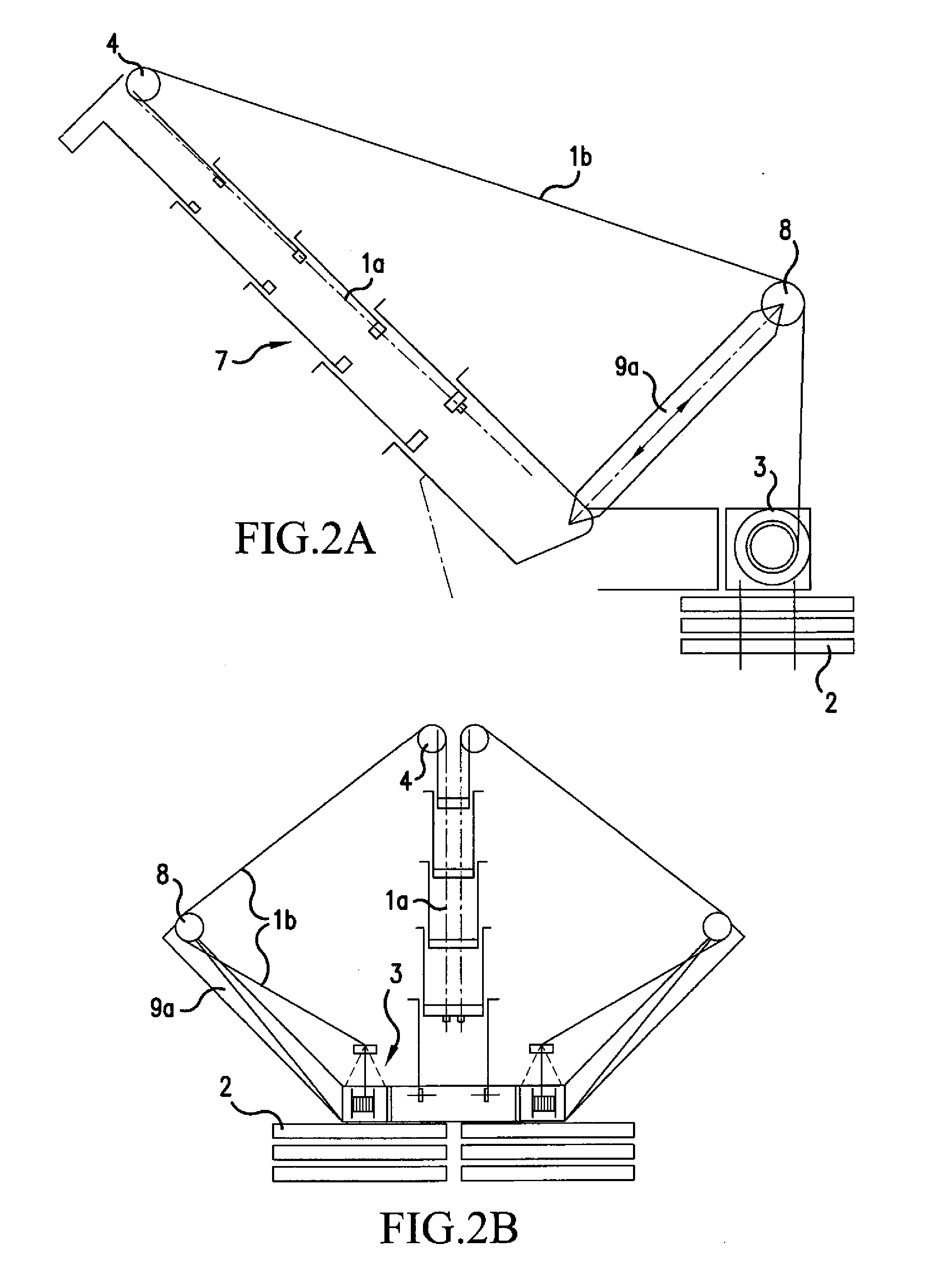

Tensioning System for a Mobile Telescopic Crane

InactiveUS20080023432A1Point becomes highHigh material strengthCargo handling apparatusPassenger handling apparatusEngineeringWinch

A tensioning system for a mobile telescopic crane having a telescopic mast includes at least one tensioning cable for bracing the telescopic mast and at least one tensioning winch mounted on the crane superstructure for tensioning the cable. The tension in the cable creates a pressure bias within the mast. The winch is movable with respect to said superstructure of the crane and movement of the winch relative to the superstructure also imposes tension on the tensioning cable.

Owner:GROVE US LLC

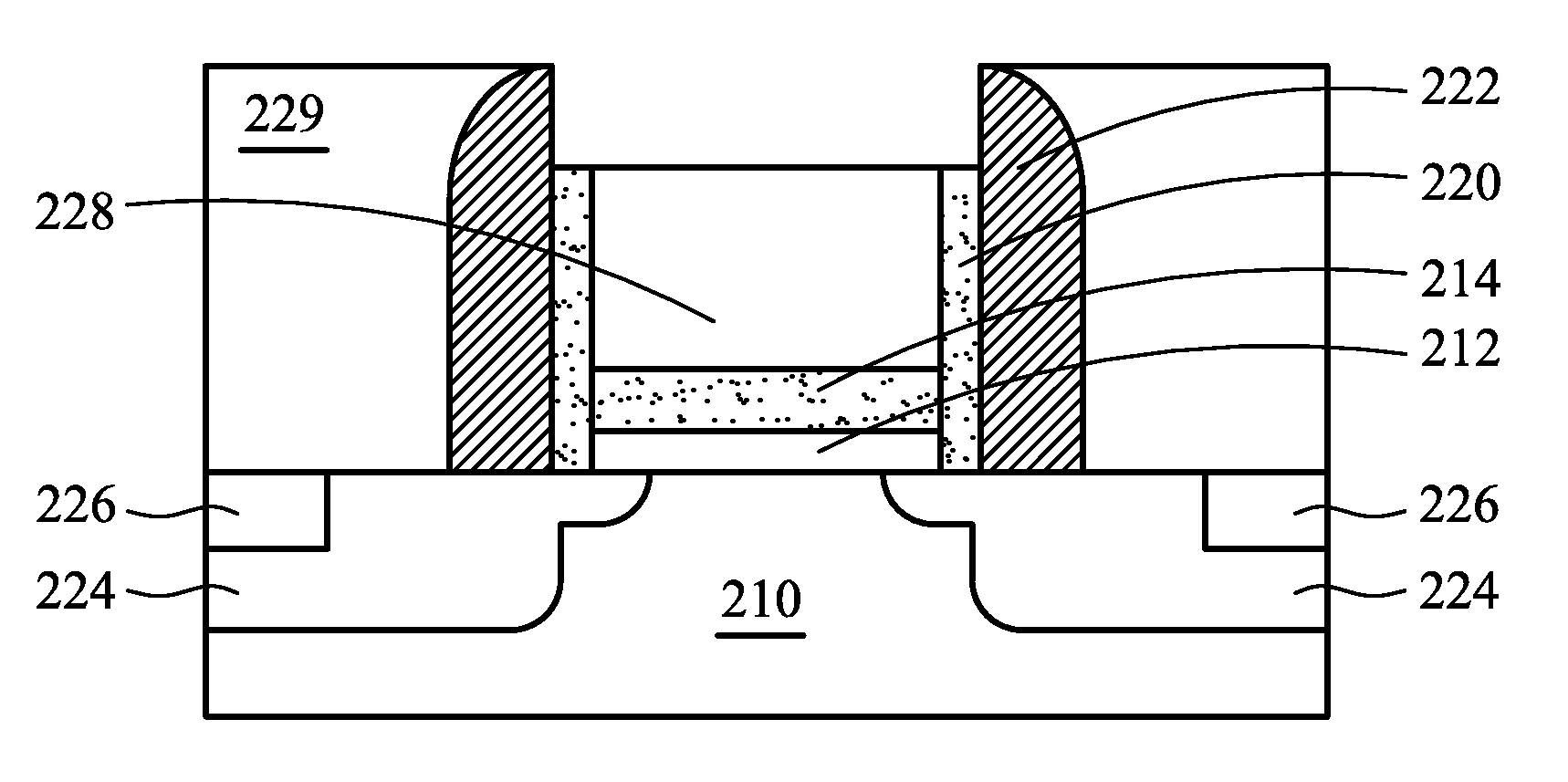

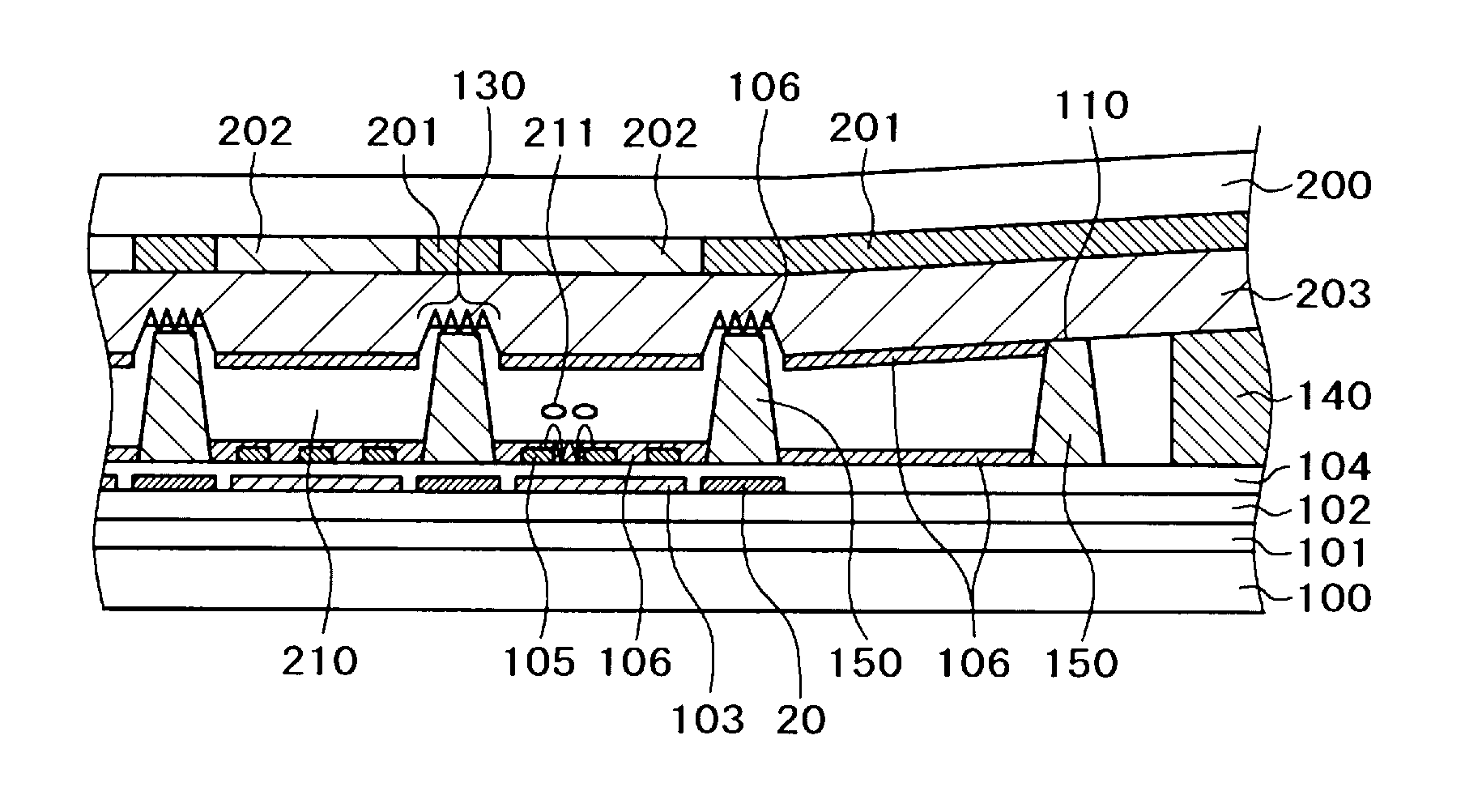

Semiconductor device and method for manufacturing the same

InactiveUS20080073733A1Effective placementEasy to controlSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringSemiconductor

A semiconductor device includes a MIS transistor having a gate electrode which is fully silicided with metal. The edge parts of the gate electrode are lower in height than the other part thereof. Sidewall spacers are formed to cover the side and top surfaces of the edge parts of the gate electrode.

Owner:PANASONIC CORP

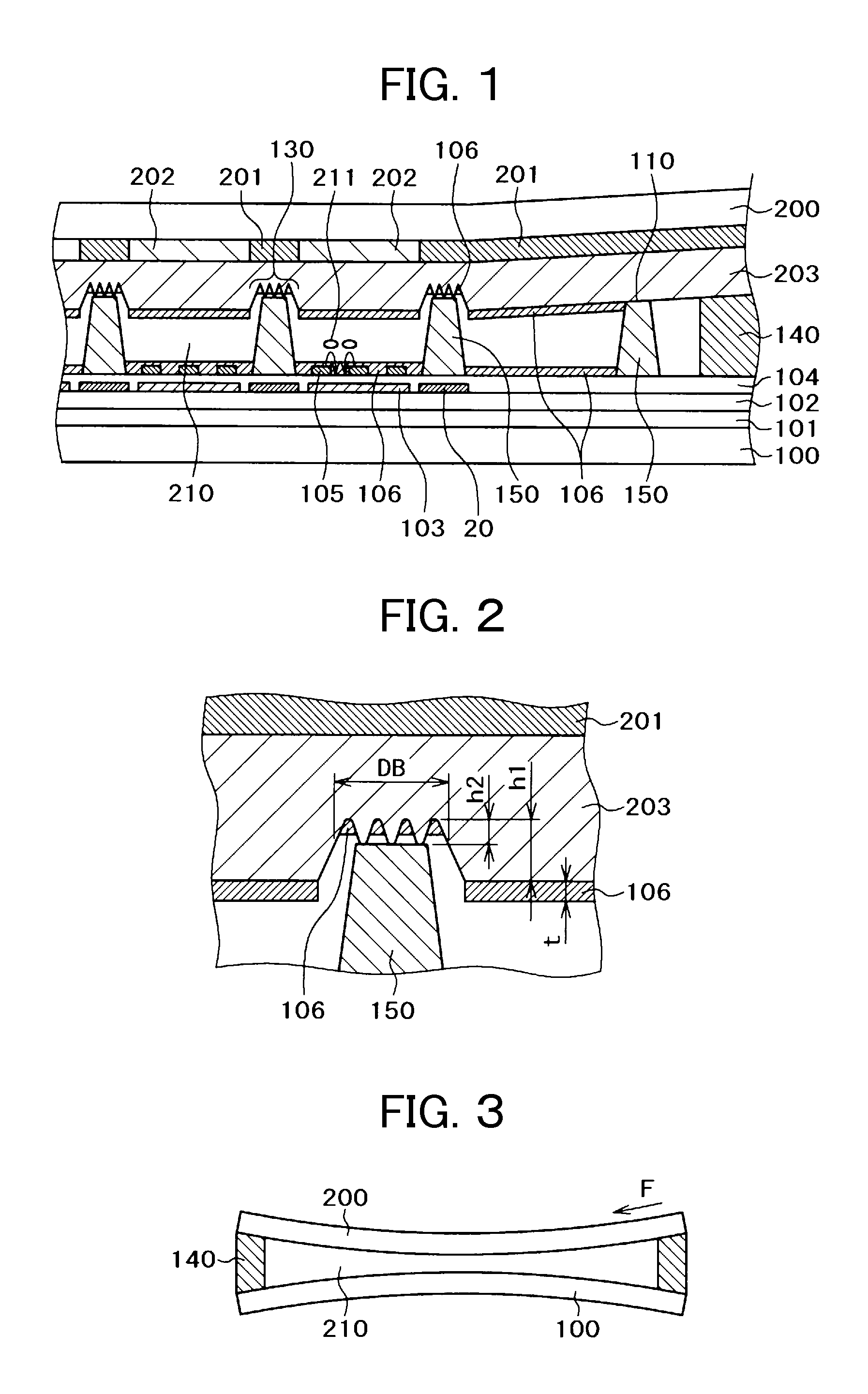

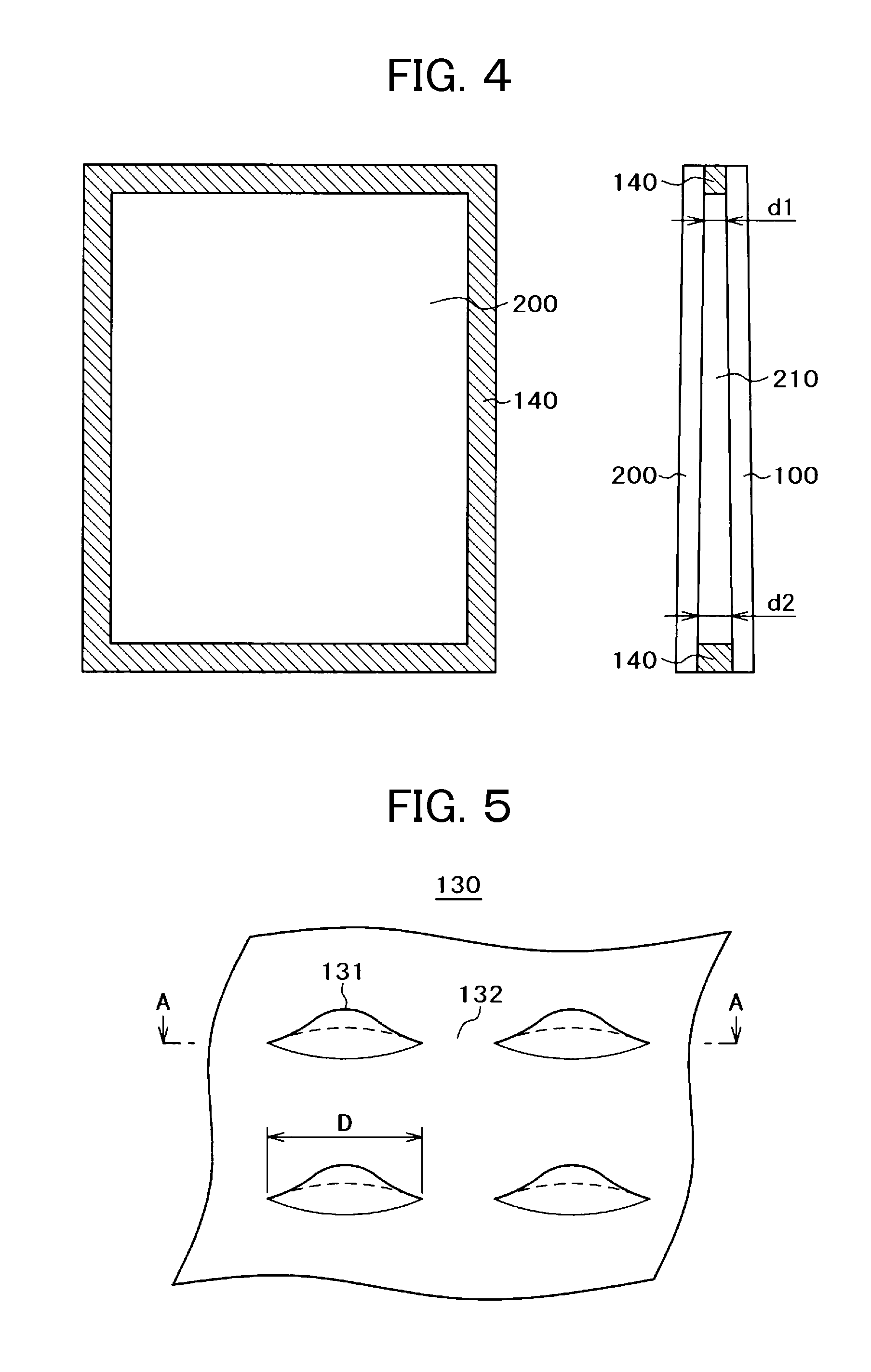

Liquid crystal display device

InactiveUS20130057820A1Prevent the scraping of the oriented filmAvoid it happening againNon-linear opticsLiquid-crystal displayEngineering

In a liquid crystal display device using a cylindrical spacer to define the gap between a TFT substrate and a counter substrate, the TFT substrate does not include an organic passivation film, in which the cylindrical spacer is formed on an inorganic passivation film. An overcoat film is formed to cover a black matrix and color filters in the counter substrate. A concavo-convex mount is formed in the overcoat film. The top of the cylindrical spacer is brought into contact with the concavo-convex mount. The oriented film is not attached to the top of the cylindrical spacer and the convex portion of the concavo-convex mount. Thus, even if horizontal displacement occurs in the TFT substrate or the counter substrate, it is possible to prevent the occurrence of bright spots due to the scraping of the oriented film caused by the friction between the TFT substrate and the counter substrate.

Owner:JAPAN DISPLAY INC

Corrosion resistant window shutter

InactiveUS7131241B2Test may passSignificant stressShutters/ movable grillesVentilation arrangementWindow shutterEngineering

Owner:BLACKWELL GROVER M +1

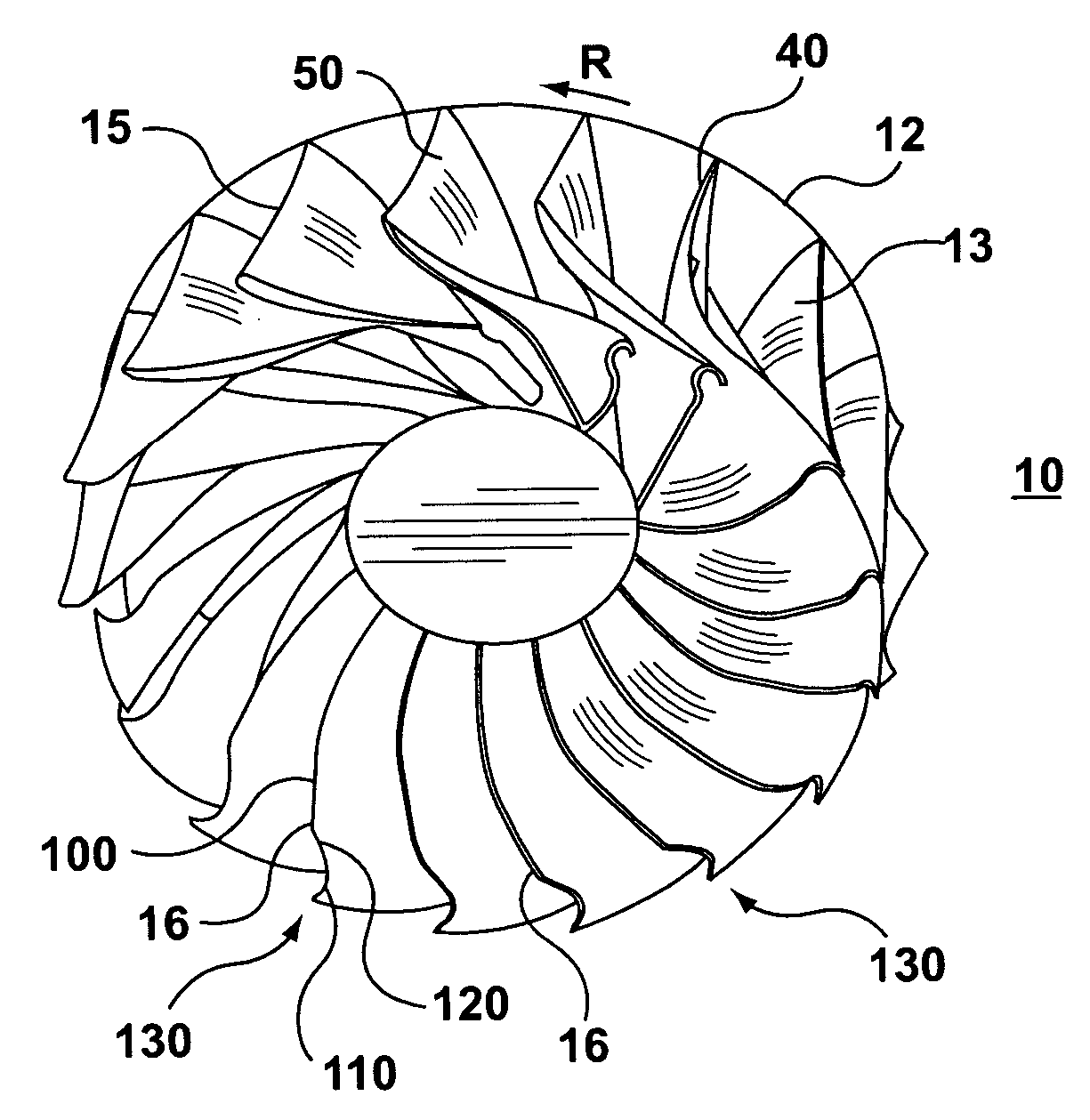

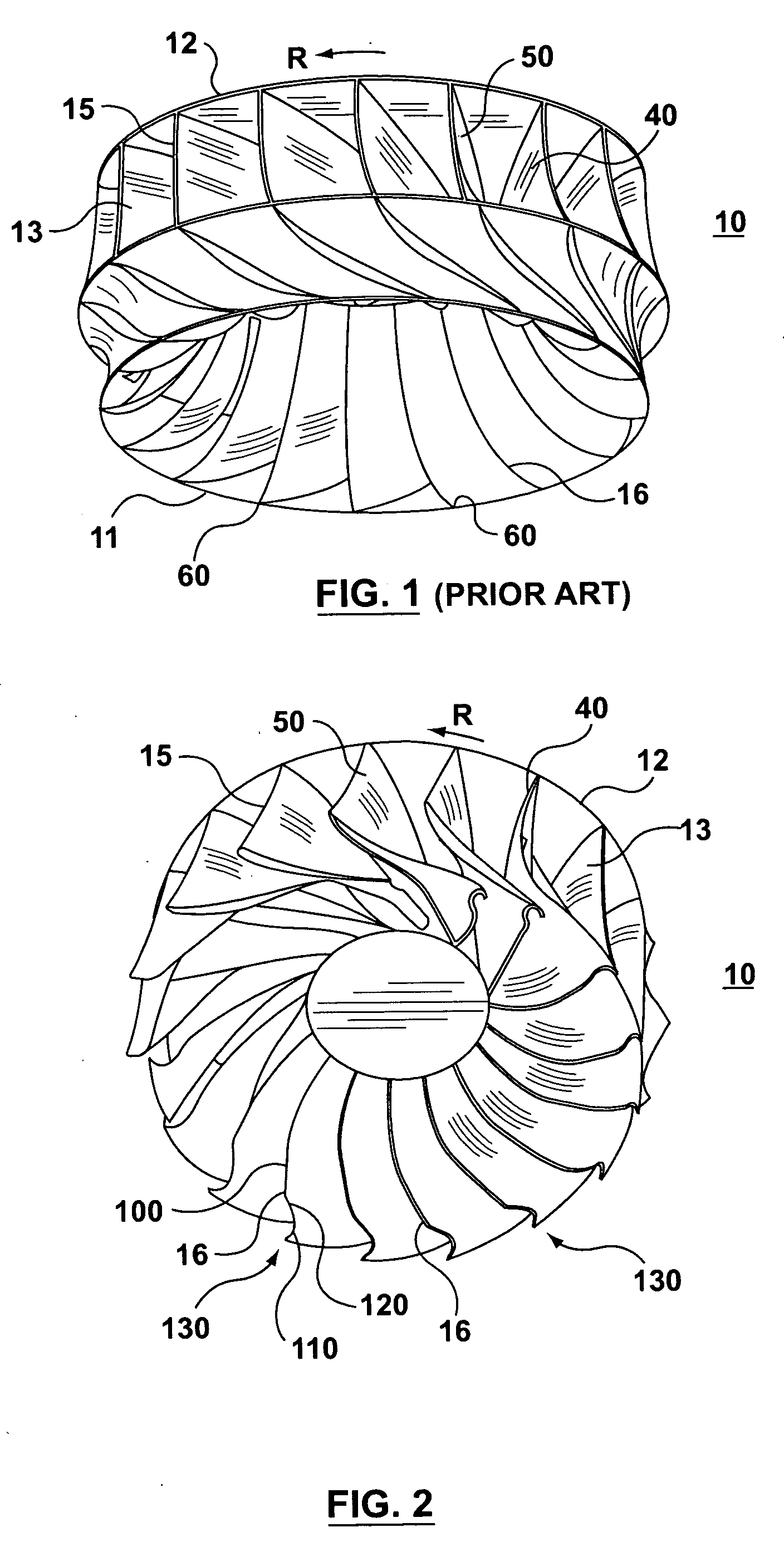

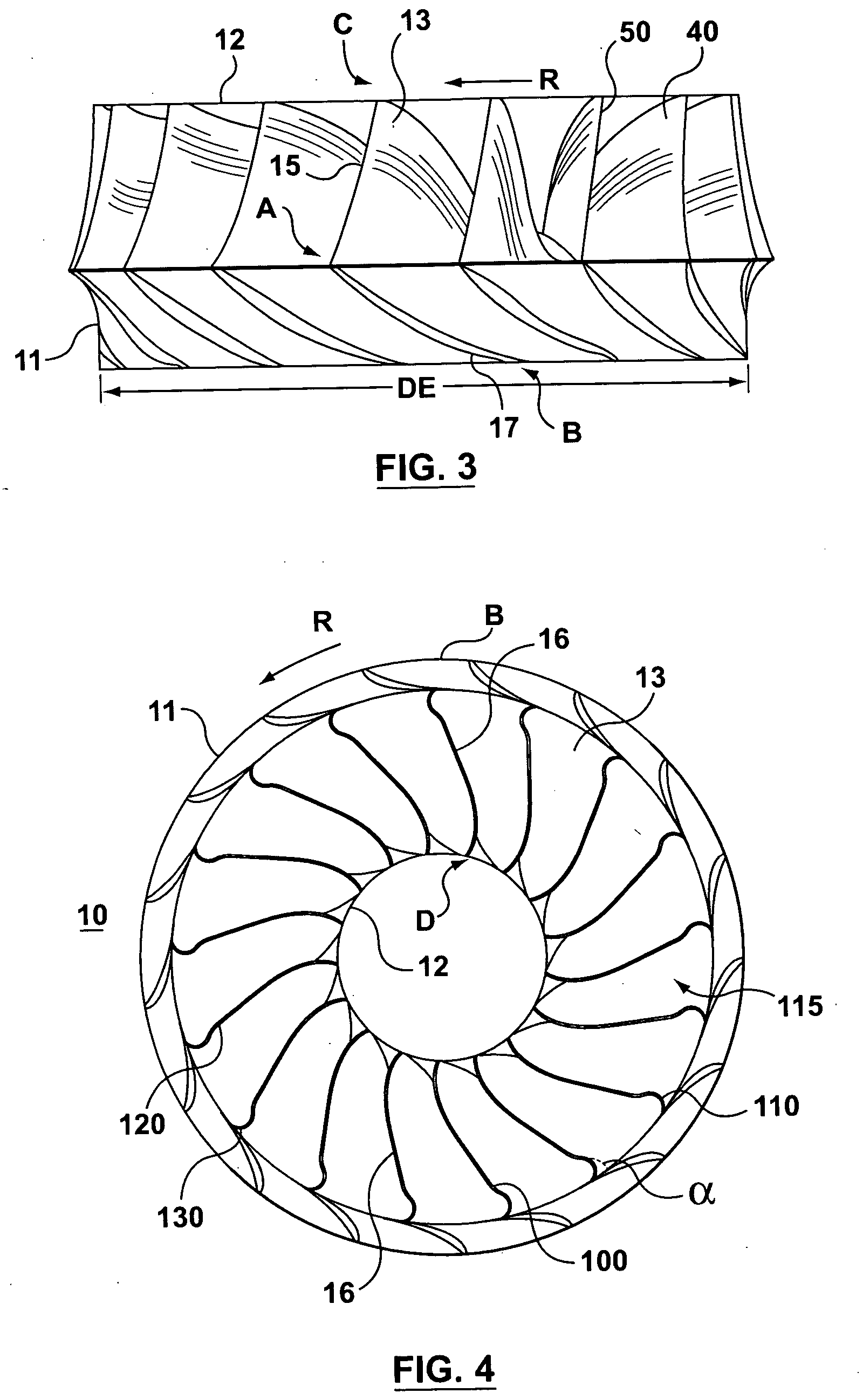

Runner for francis type hydraulic turbine

InactiveUS20060115357A1No negative impact on hydraulic performance or cavitation behaviorReduce stress concentrationPump componentsStatorsStress concentrationWater turbine

There is disclosed a runner for a Francis-type hydraulic turbine where each runner blade has a outlet edge comprising a deflected edge portion. The deflected edge portion is located adjacent to the junction or attachment point of the outlet edge to the band of the runner to define a stress reducing tip extension portion of the blade adjacent the band. This tip extension portion reduces stress concentration adjacent where the outlet edge joins the runner band.

Owner:GENERAL ELECTRIC CANADA MISSISSAUGA

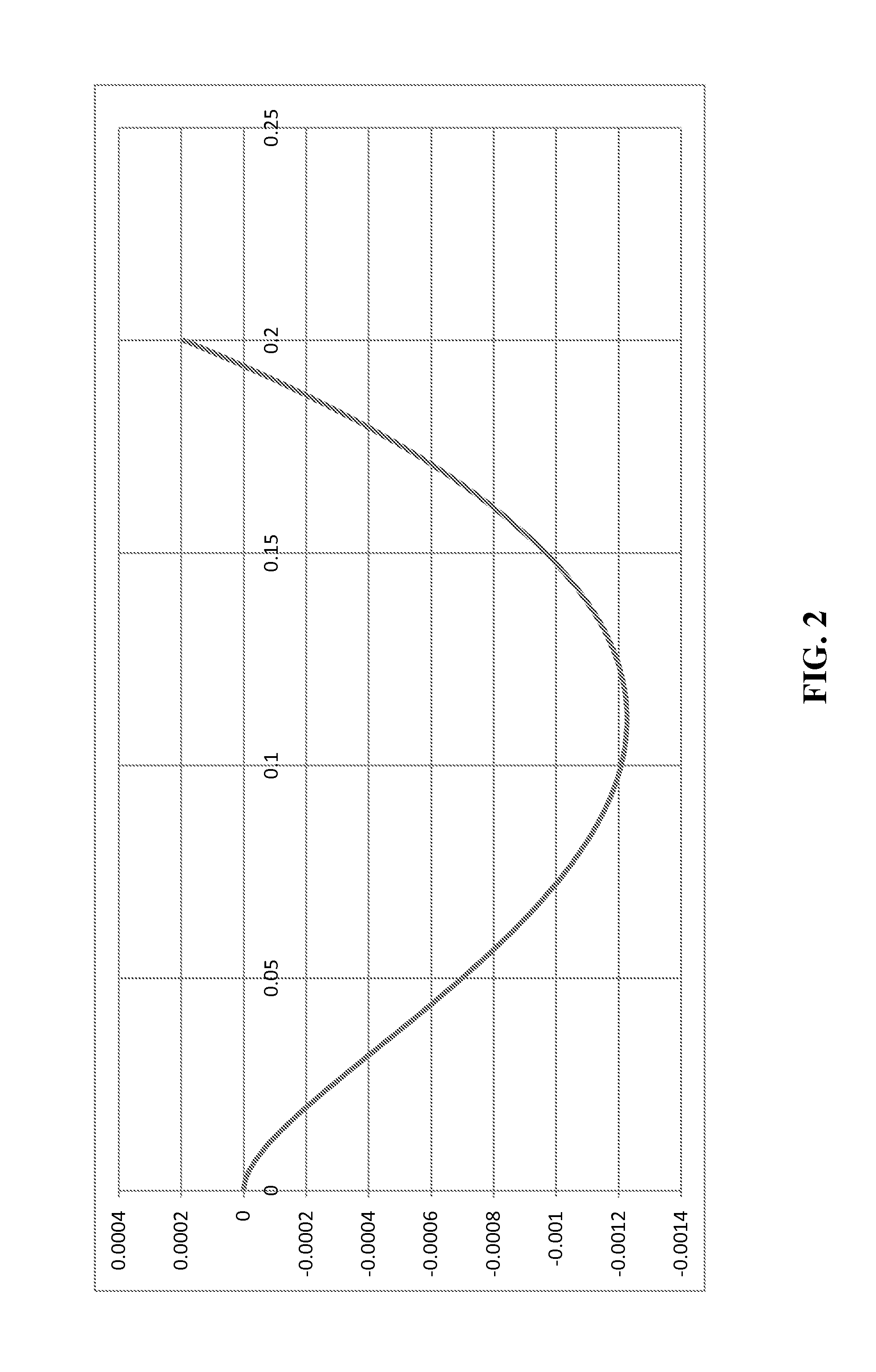

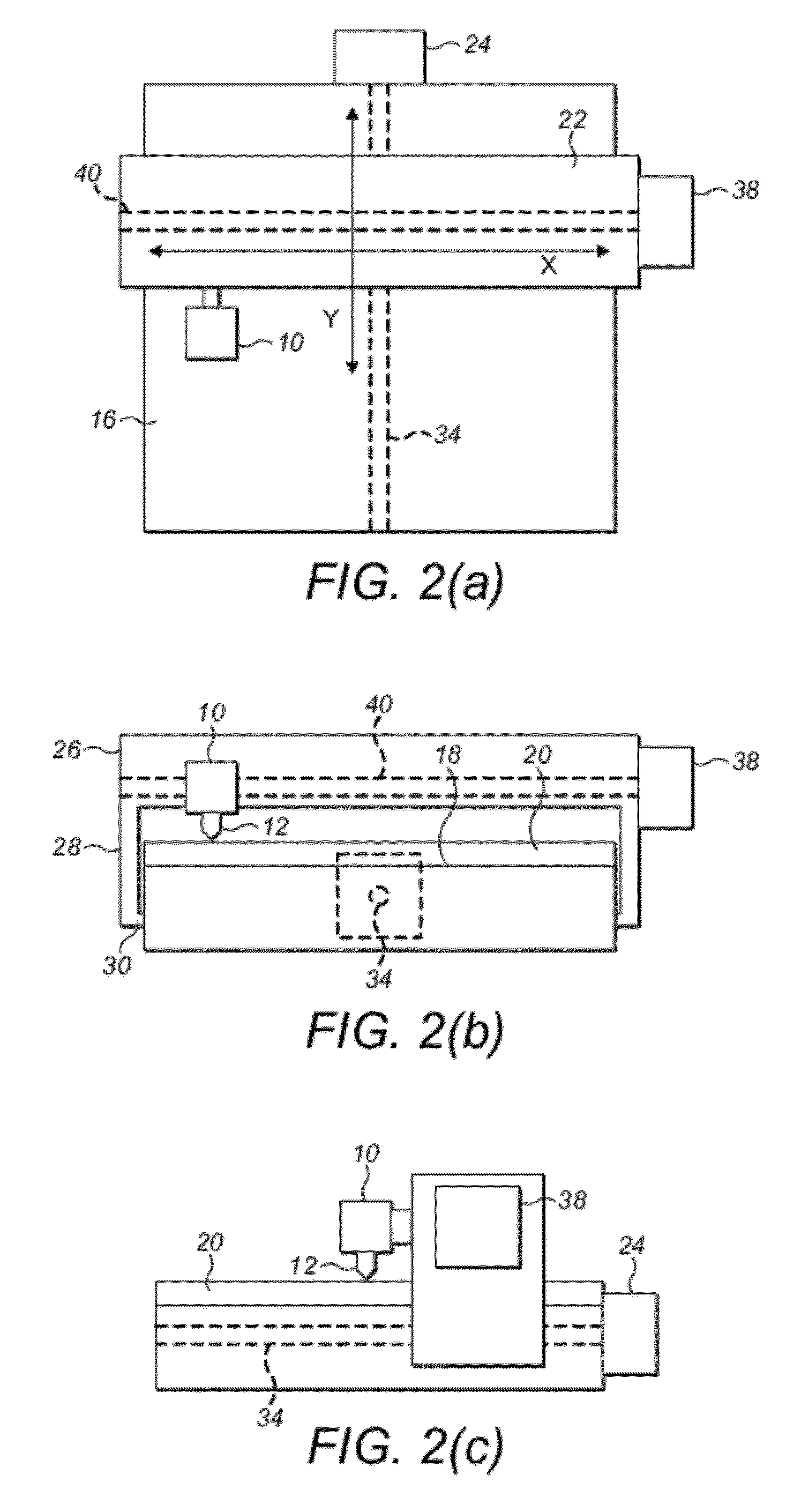

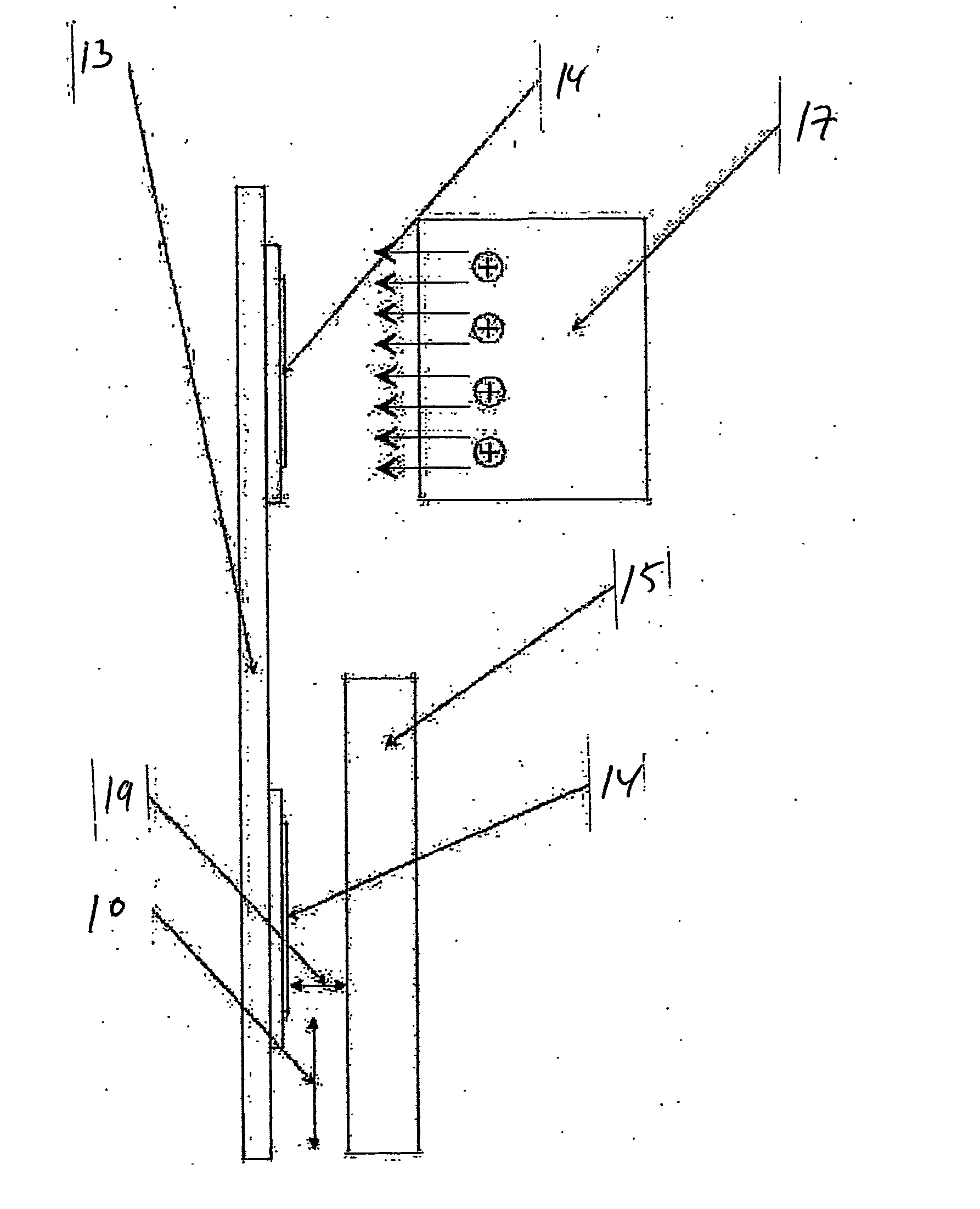

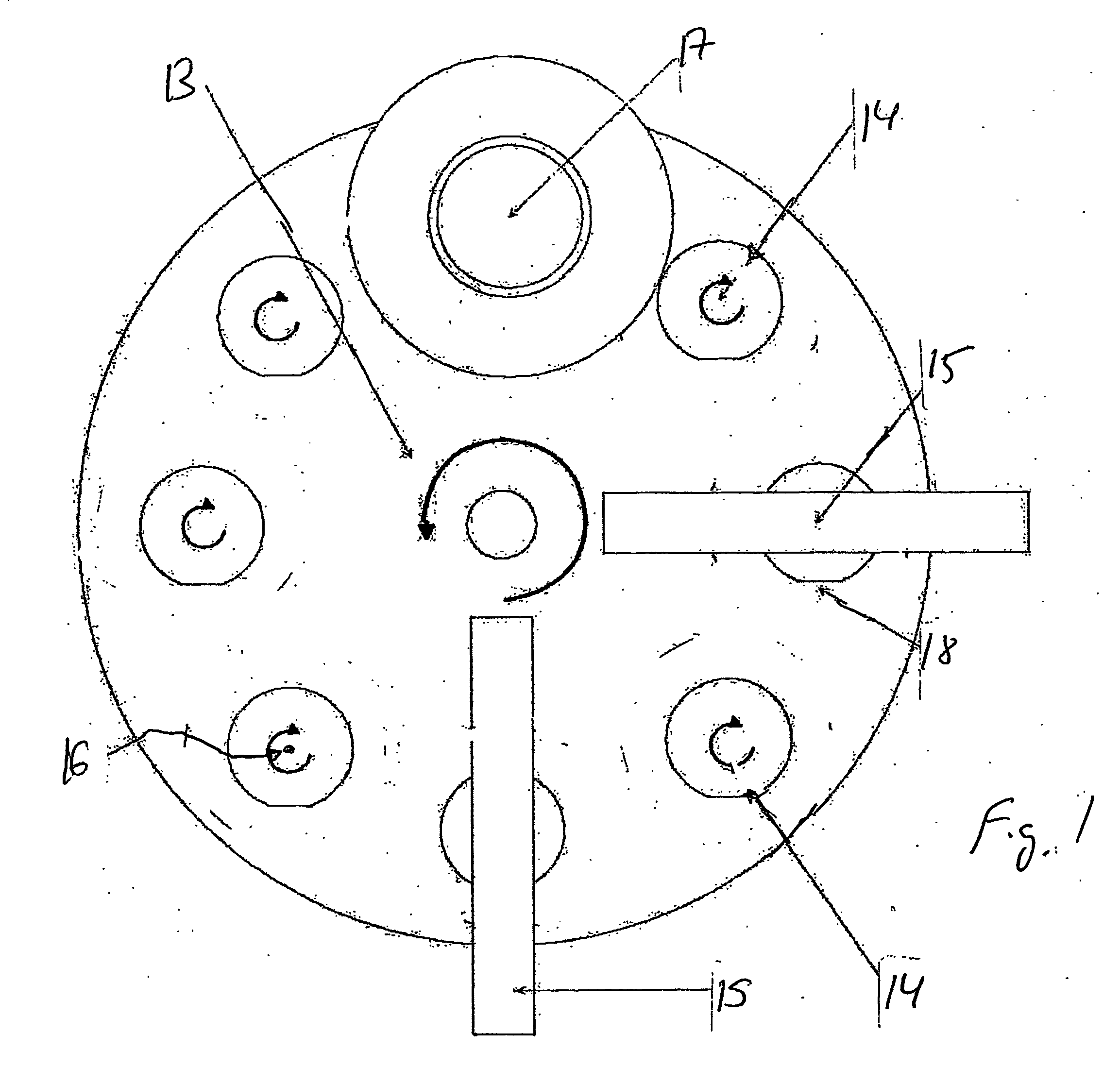

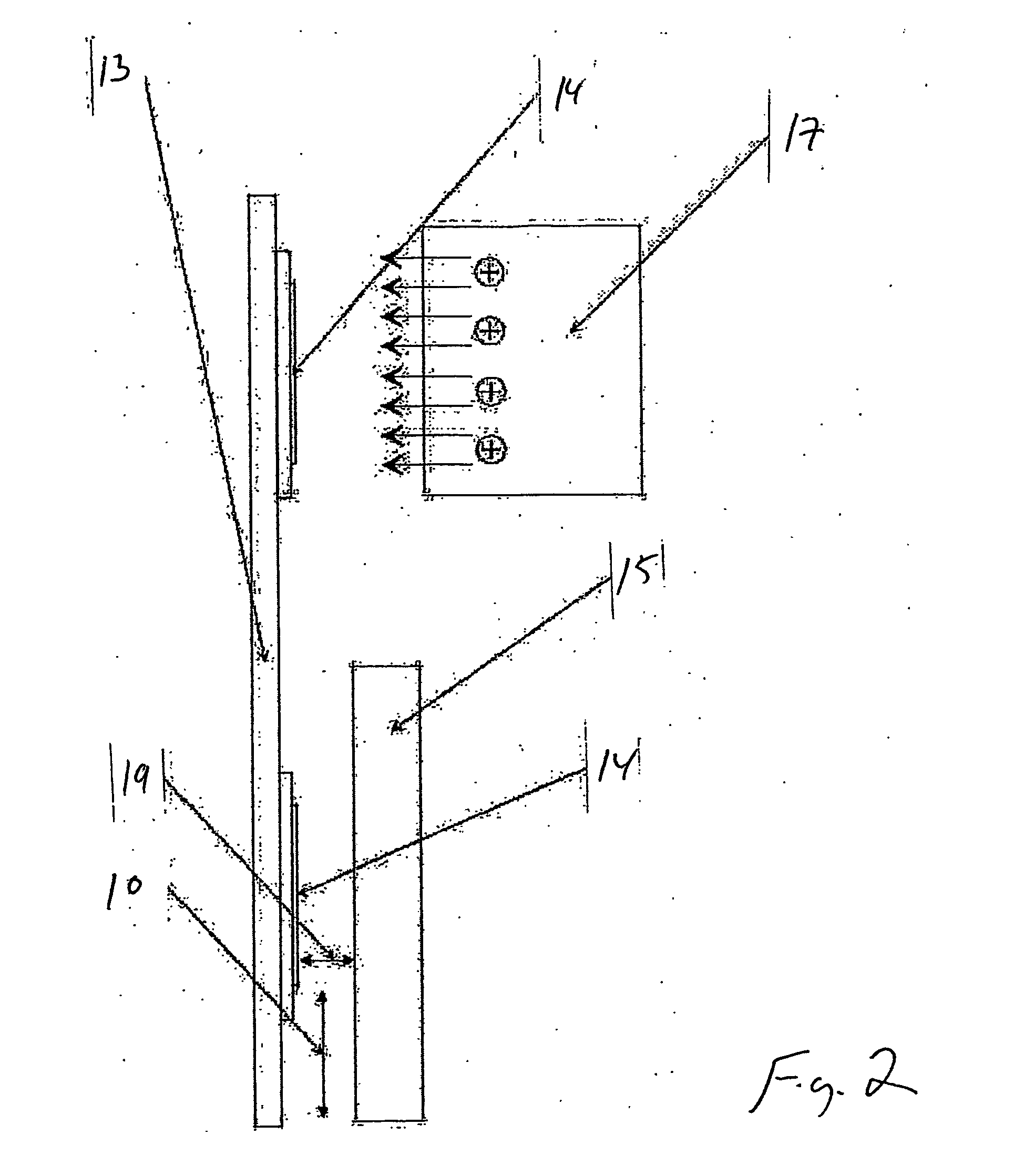

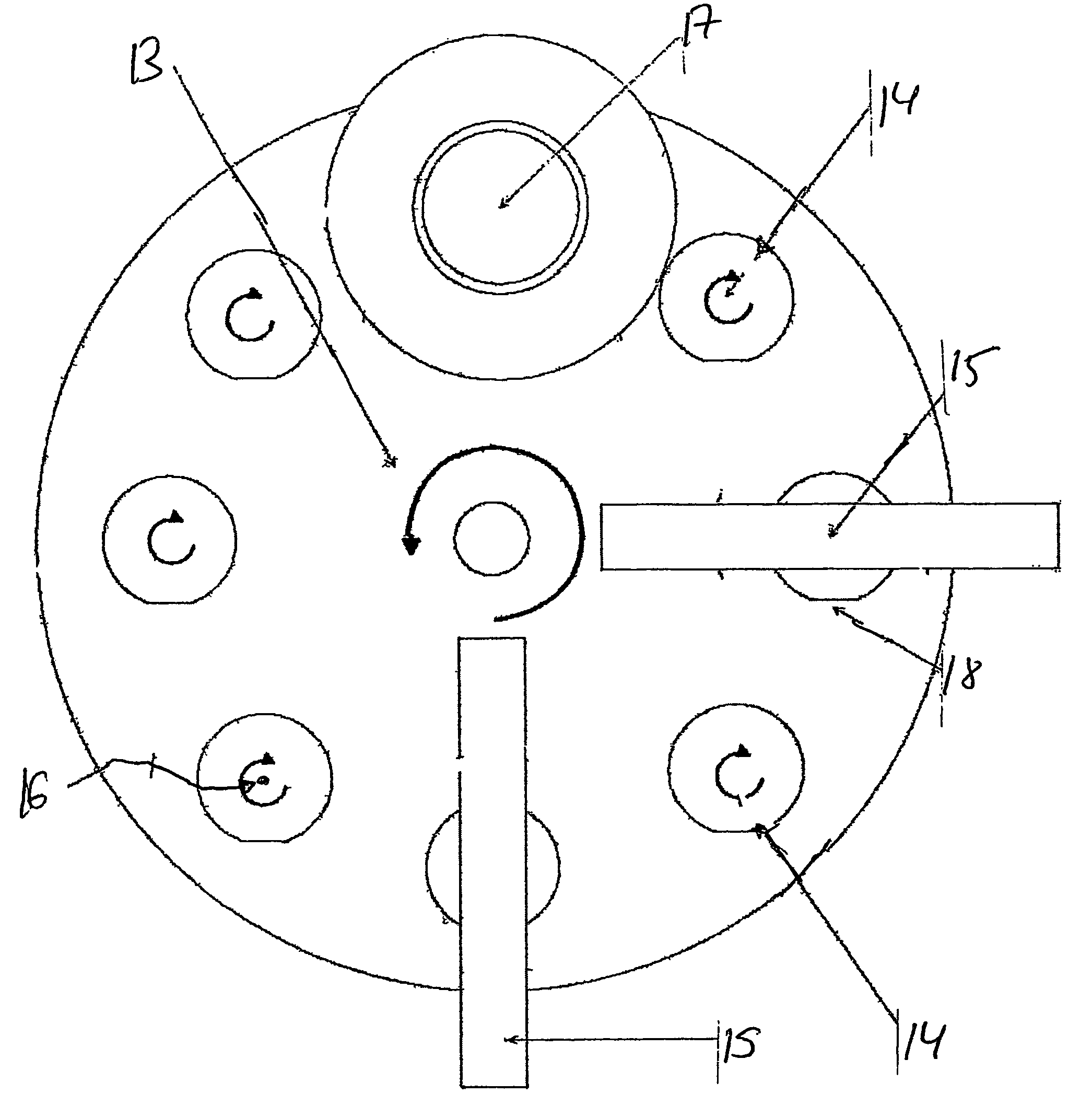

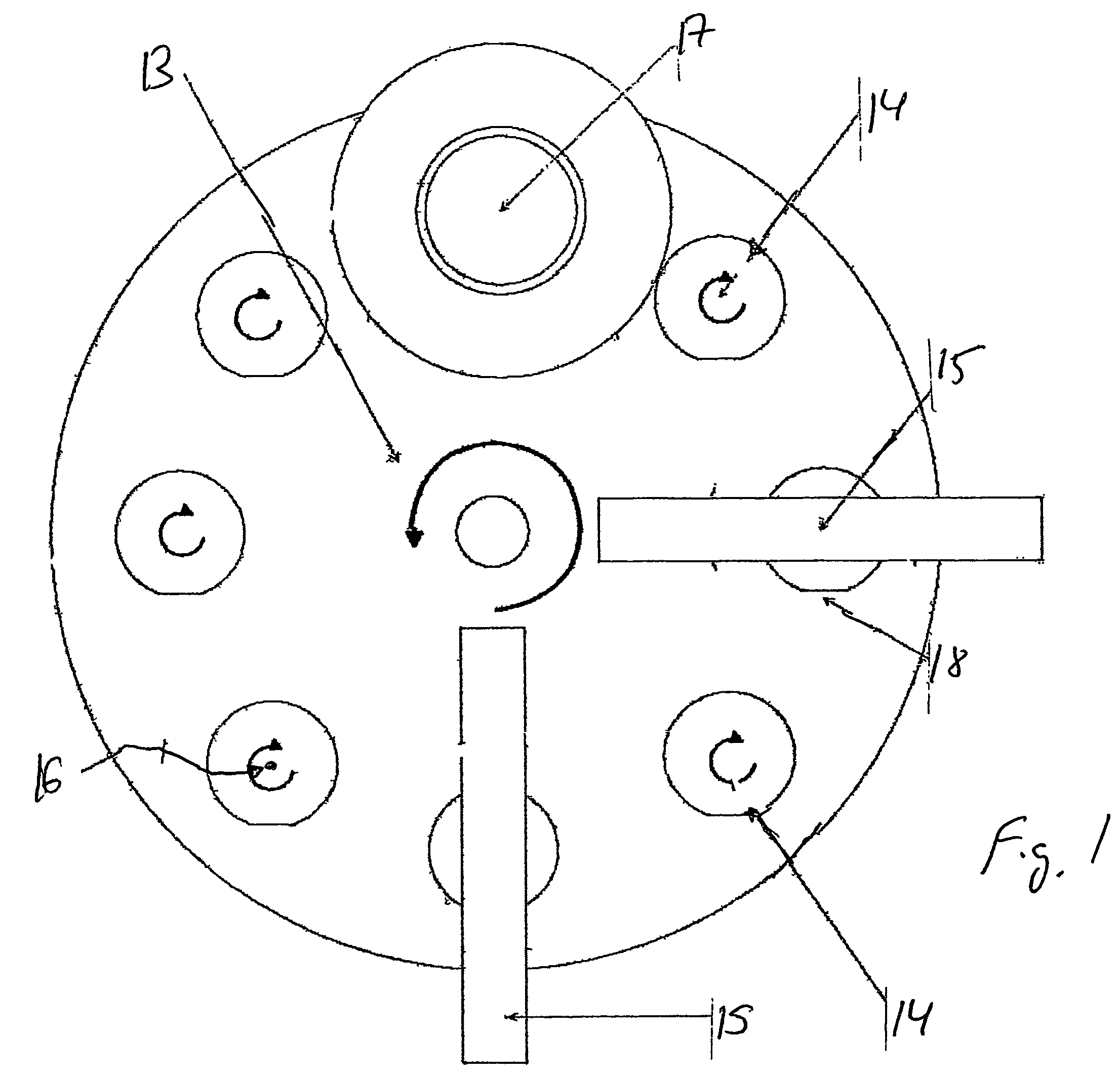

Method and apparatus of producing uniform isotropic stresses in a sputtered film

InactiveUS20050003196A1Relieve stressSignificant stressCellsVacuum evaporation coatingSputteringFilm material

The invention provides a method and apparatus for producing uniform, isotropic stresses in a sputtered film. In he presently preferred embodiment, a new sputtering geometry and a new domain of transport speed are presented, which together allow the achievement of the maximum stress that the film material can hold while avoiding X-Y stress anisotropy and avoiding stress non-uniformity across the substrate.

Owner:ADVANTEST CORP

Piezoelectric Power Generator

ActiveUS20110148256A1Improve power generation efficiencyImprove vibration efficiencyPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesElectricityEngineering

Owner:MURATA MFG CO LTD

Method and apparatus for producing uniform isotropic stresses in a sputtered film

InactiveUS7153399B2Relieve stressSignificant stressCellsVacuum evaporation coatingSputteringFilm material

The invention provides a method and apparatus for producing uniform, isotropic stresses in a sputtered film. In the presently preferred embodiment, a new sputtering geometry and a new domain of transport speed are presented, which together allow the achievement of the maximum stress that the film material can hold while avoiding X-Y stress anisotropy and avoiding stress non-uniformity across the substrate.

Owner:ADVANTEST CORP

Method of manufacturing impeller, impeller, and compressor having impeller

InactiveUS20100196163A1Reduce stress concentrationEnhanced advantagePropellersPump componentsImpellerEngineering

A method of manufacturing an impeller including a substantially disk-shaped disk, a cover facing the disk, and a blade provided between the disk and the cover, the method includes: forming a groove in a blade attachment surface of the disk or the cover so as to correspond to the shape of an edge tip of the blade; and bonding an inner surface of the groove to the edge tip of the blade through a bonding agent after inserting the edge tip of the blade into the groove.

Owner:TAYLOR MADE GOLF +1

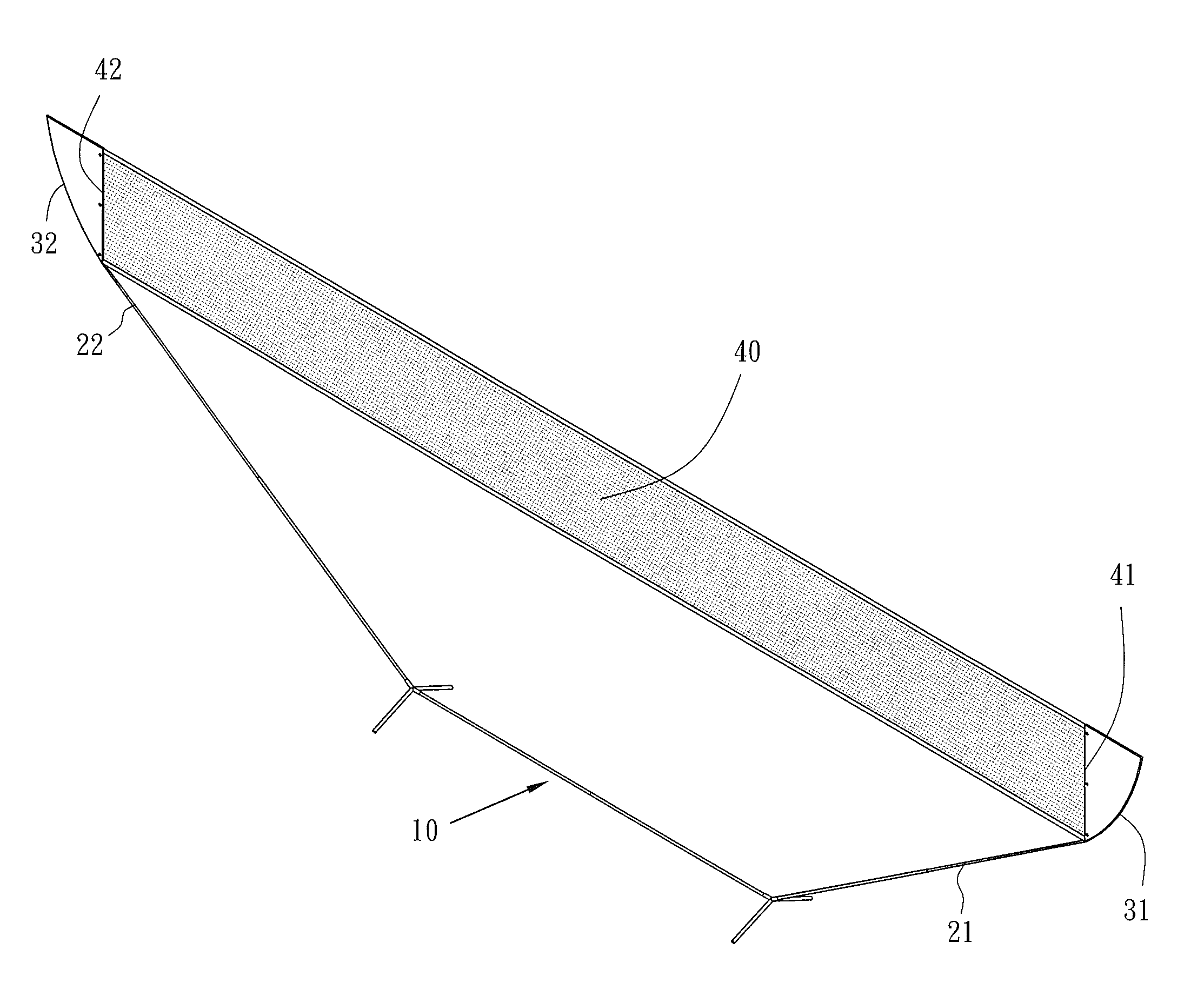

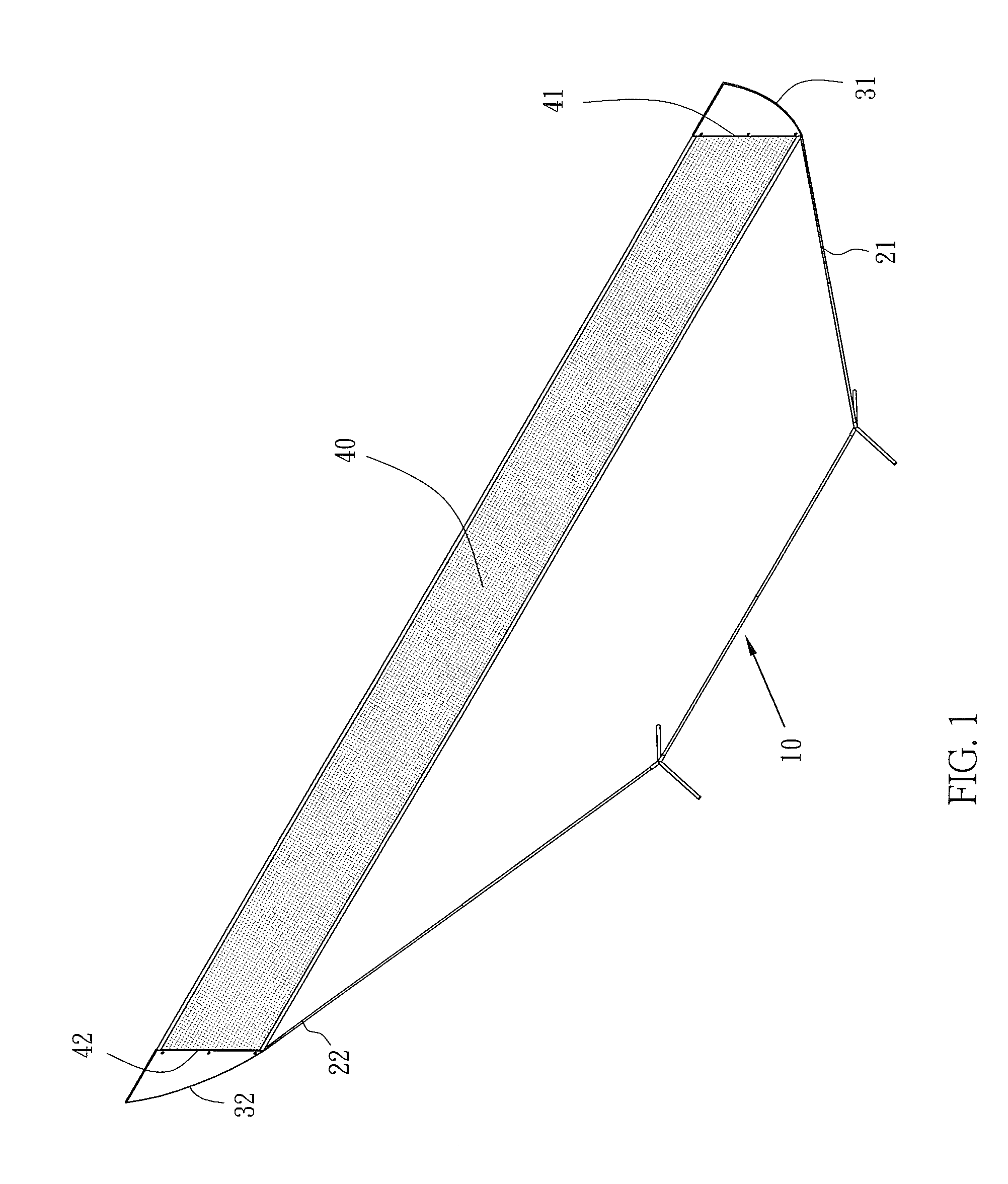

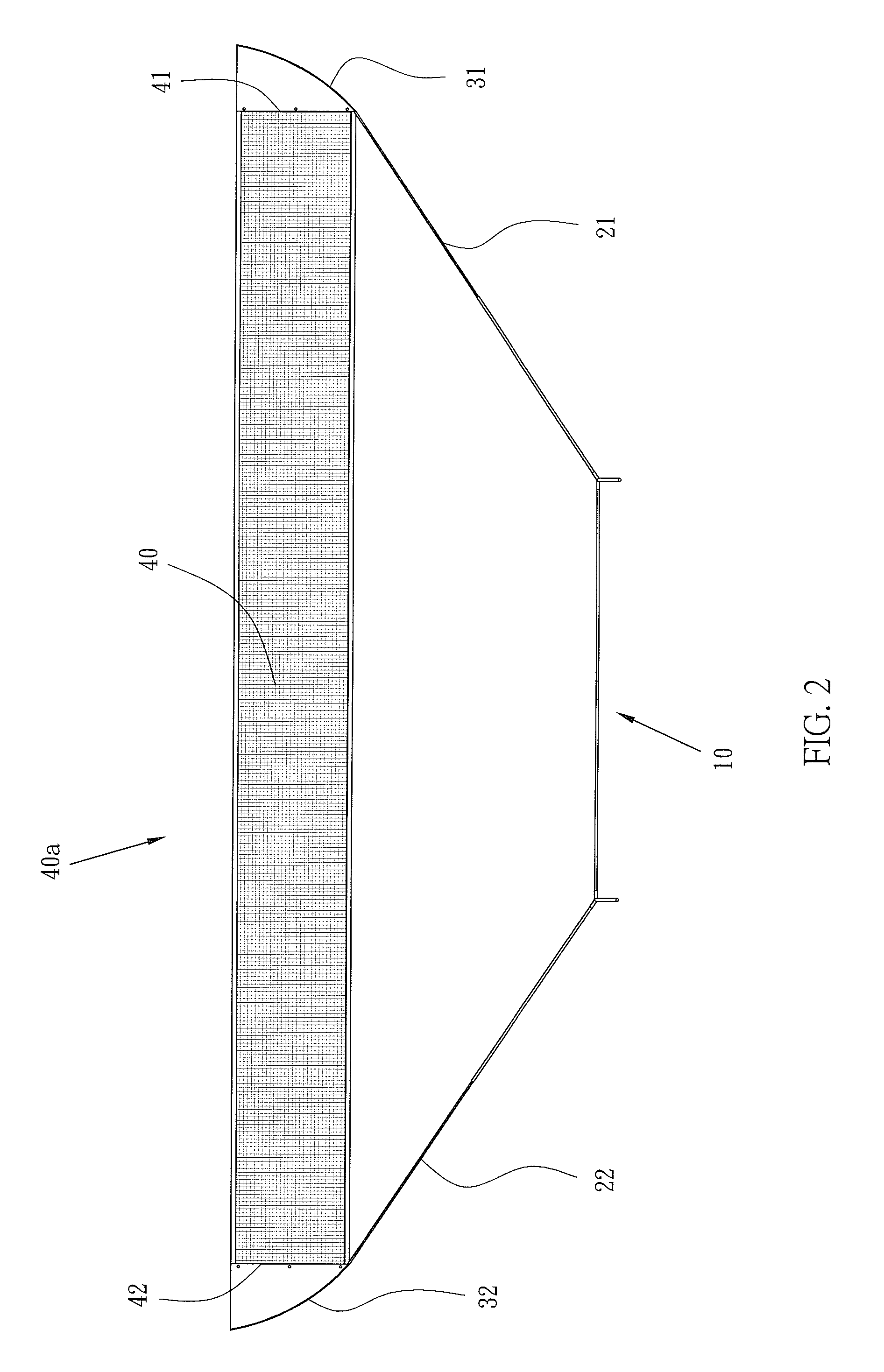

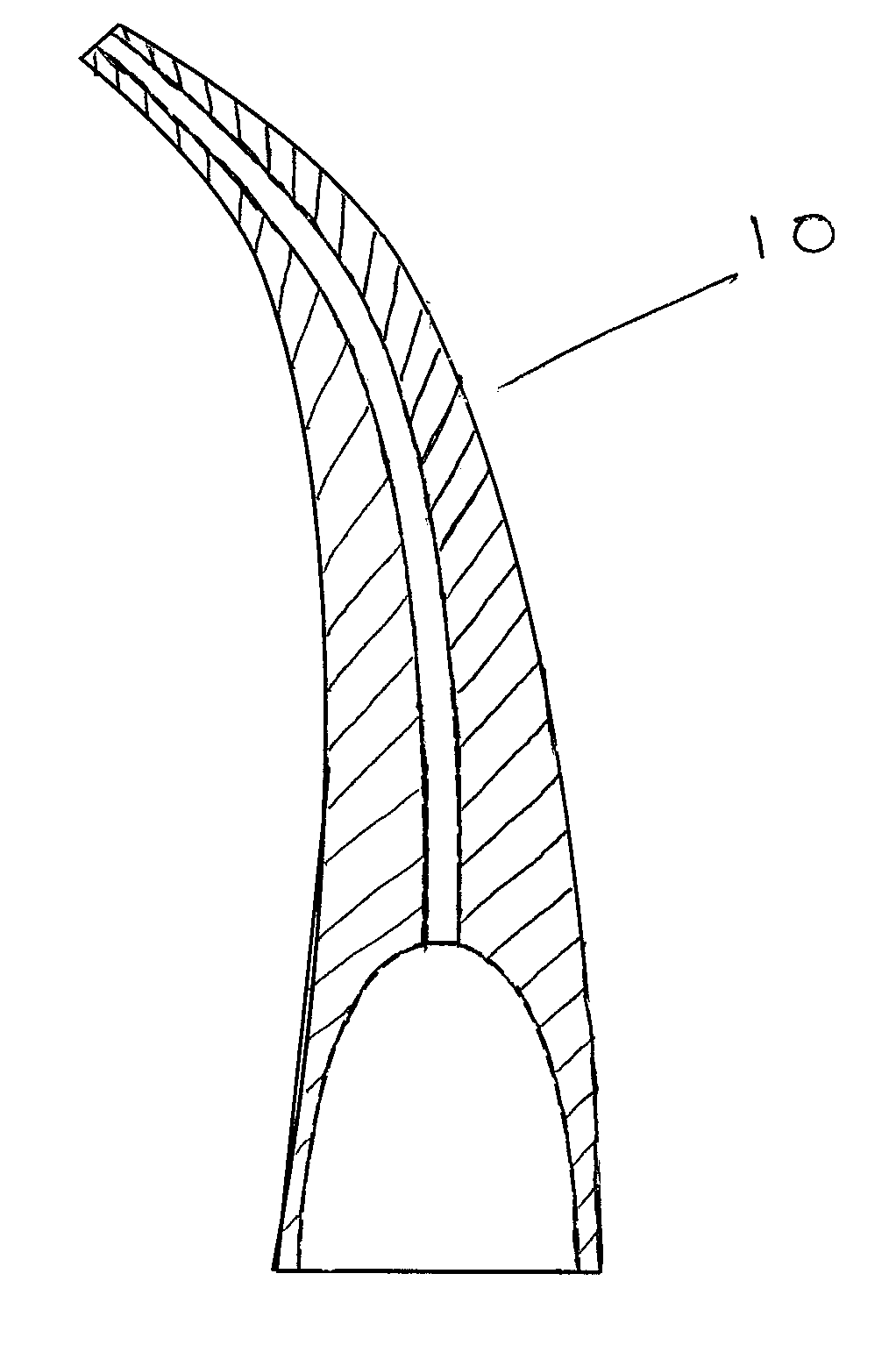

Ball Net Structure

InactiveUS20150057109A1Uniform stress distributionExtended service lifeTennisBall sportsPull forceEngineering

Owner:CHEN BENJAMIN

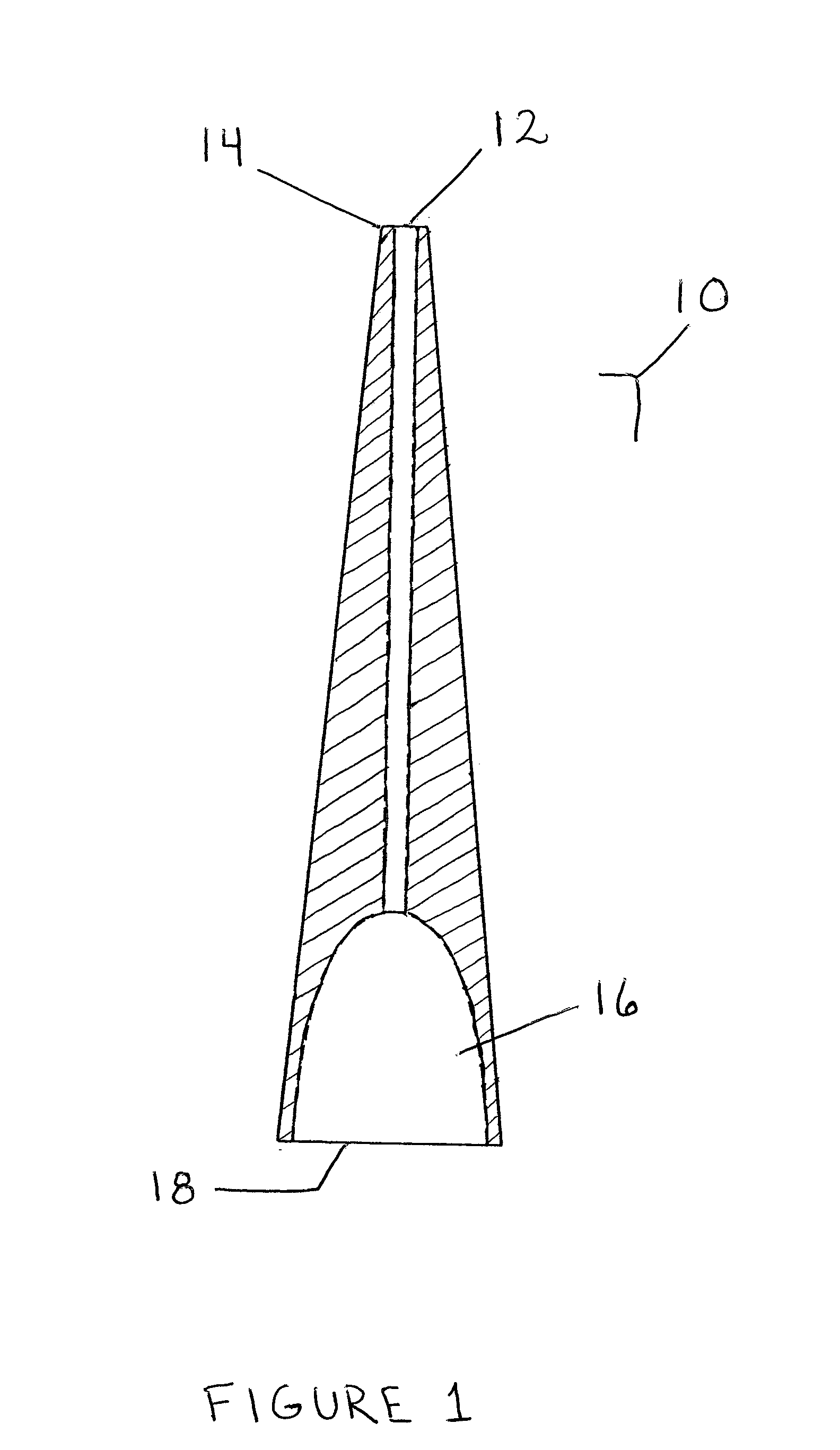

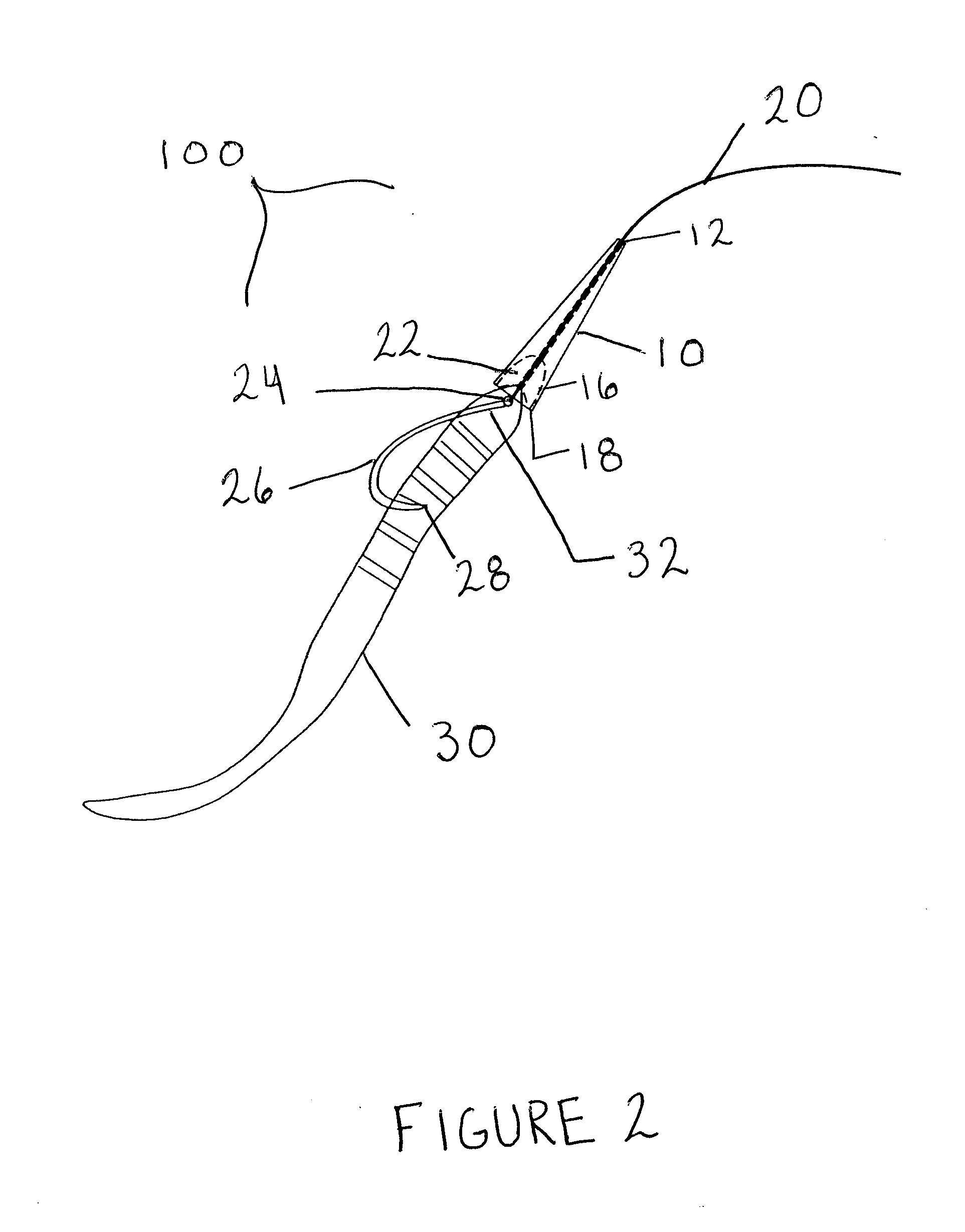

Fishing lure

The present invention is generally directed toward an artificial fishing lure component. In particular the present invention is directed toward a fishing lure component simulating a worm's head, which may be used as a slip sinker, a pegged sinker, or simply as an addition to a traditional, artificial worm lure to facilitate the natural movement of live bate in weeds, brush, twigs, and stone. The present invention is conically shaped and composed of soft flexible material with a cavity for snugly encapsulating a weighted sinker. The present invention may be used in a variety of configurations including both Texas and Carolina Rigs.

Owner:YOUNG EDWARD RAY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com