Patents

Literature

110results about How to "Minimal stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

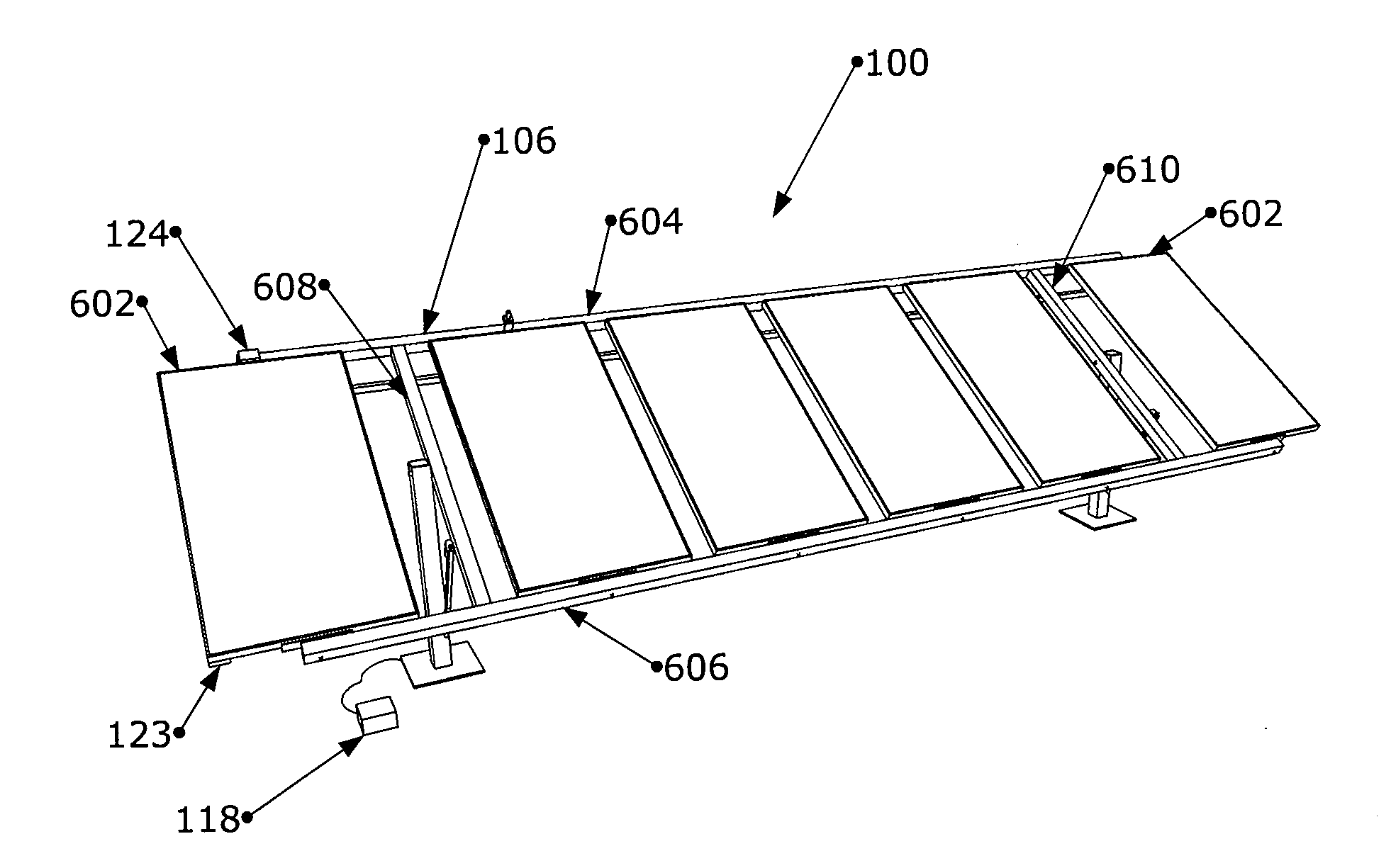

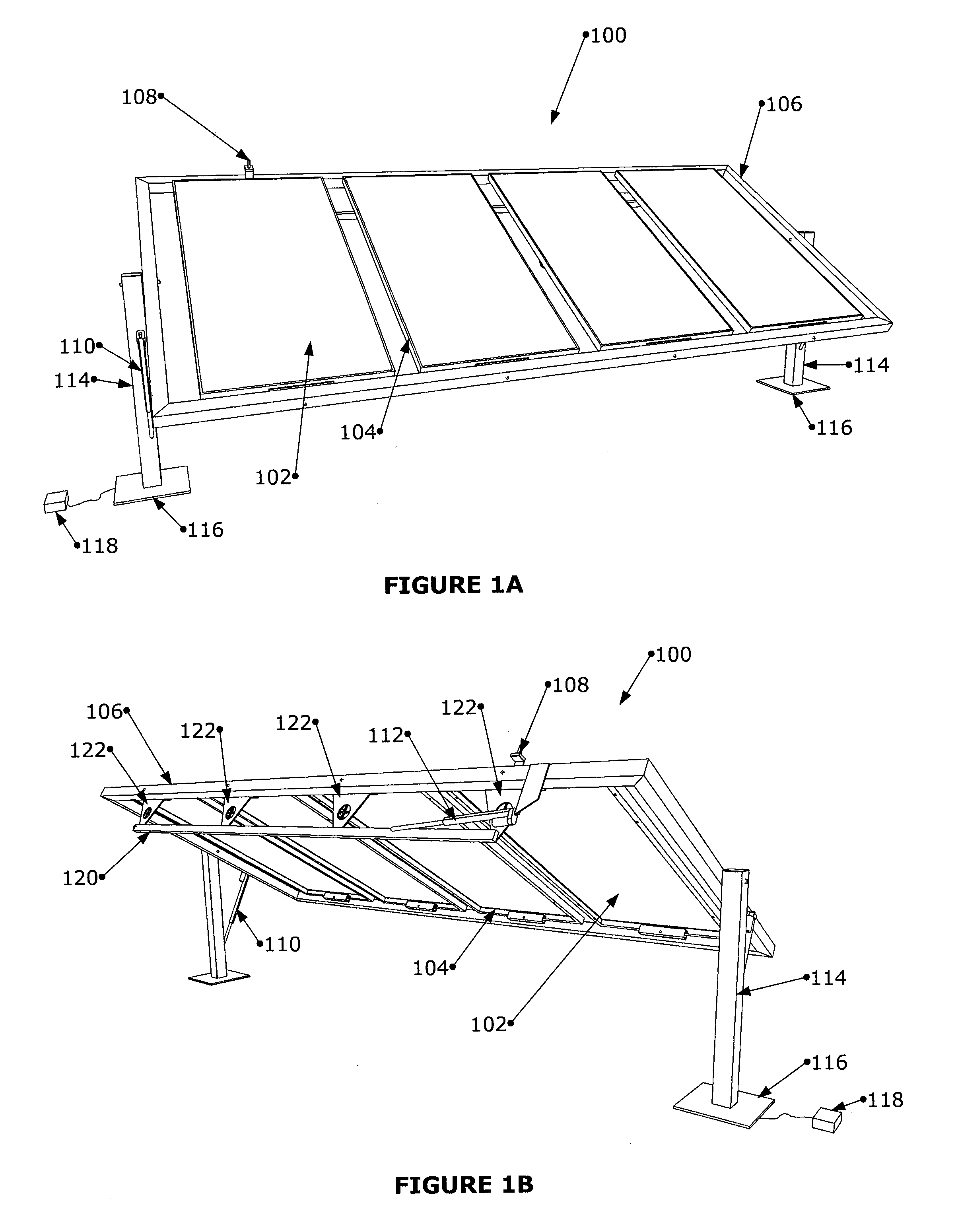

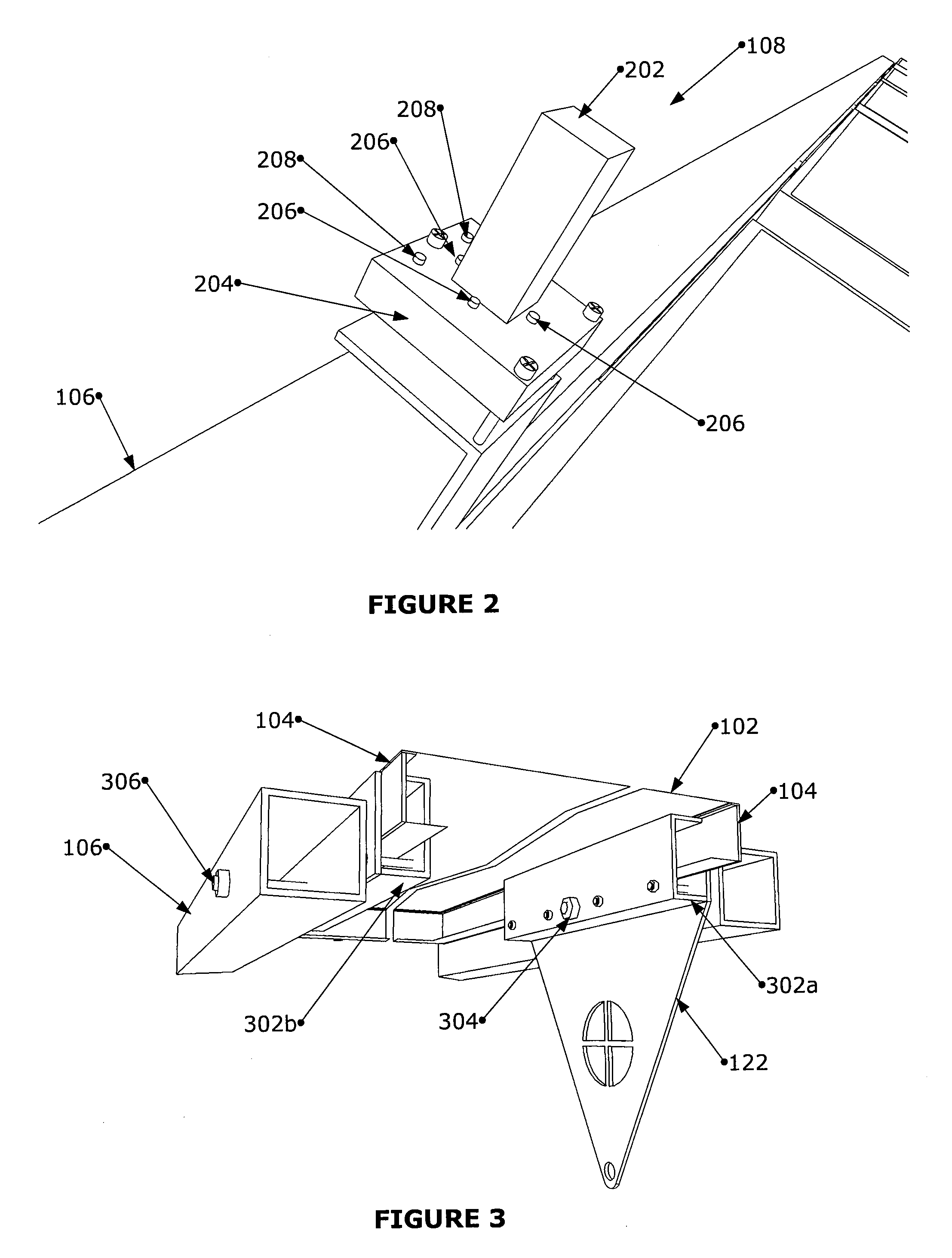

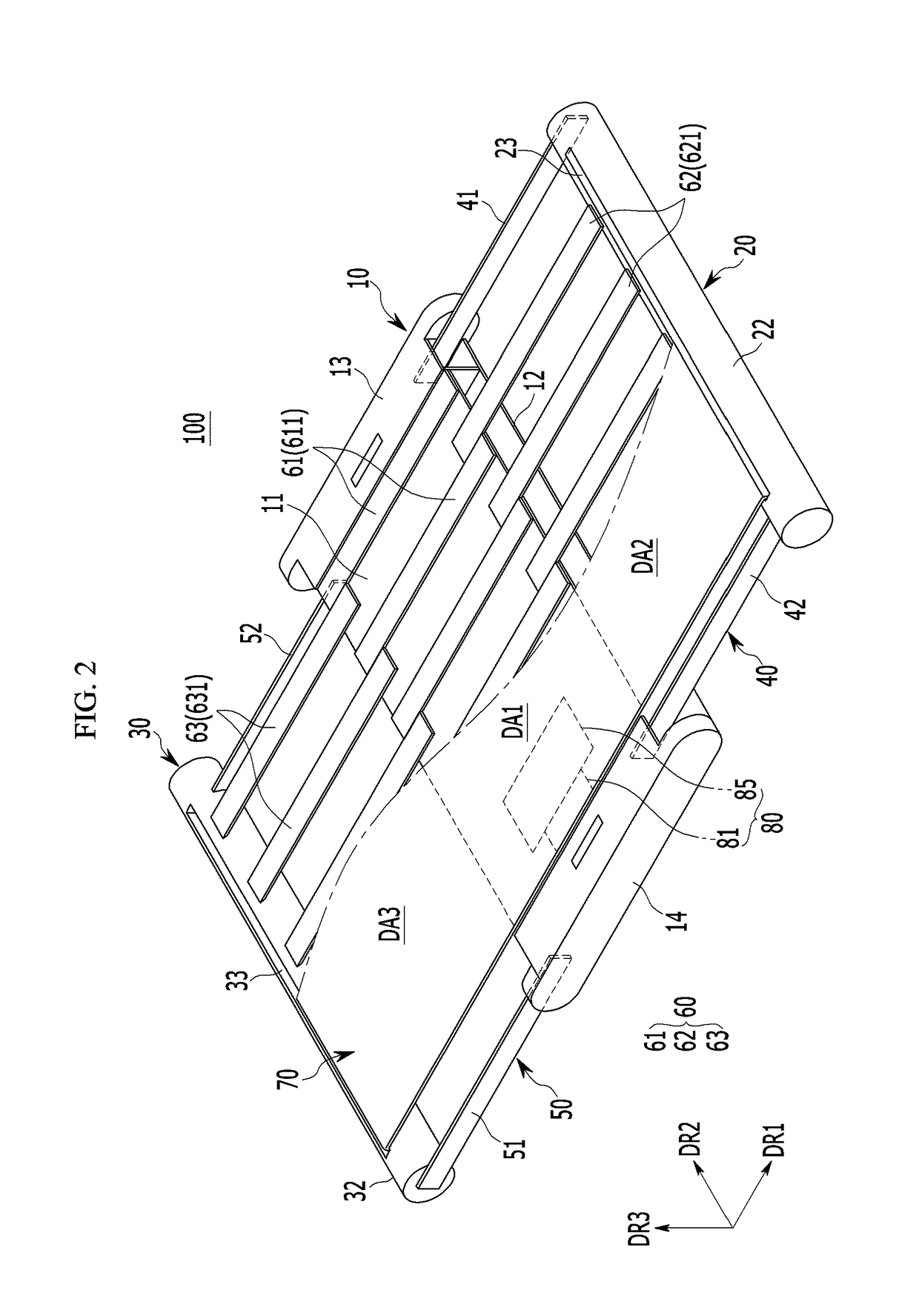

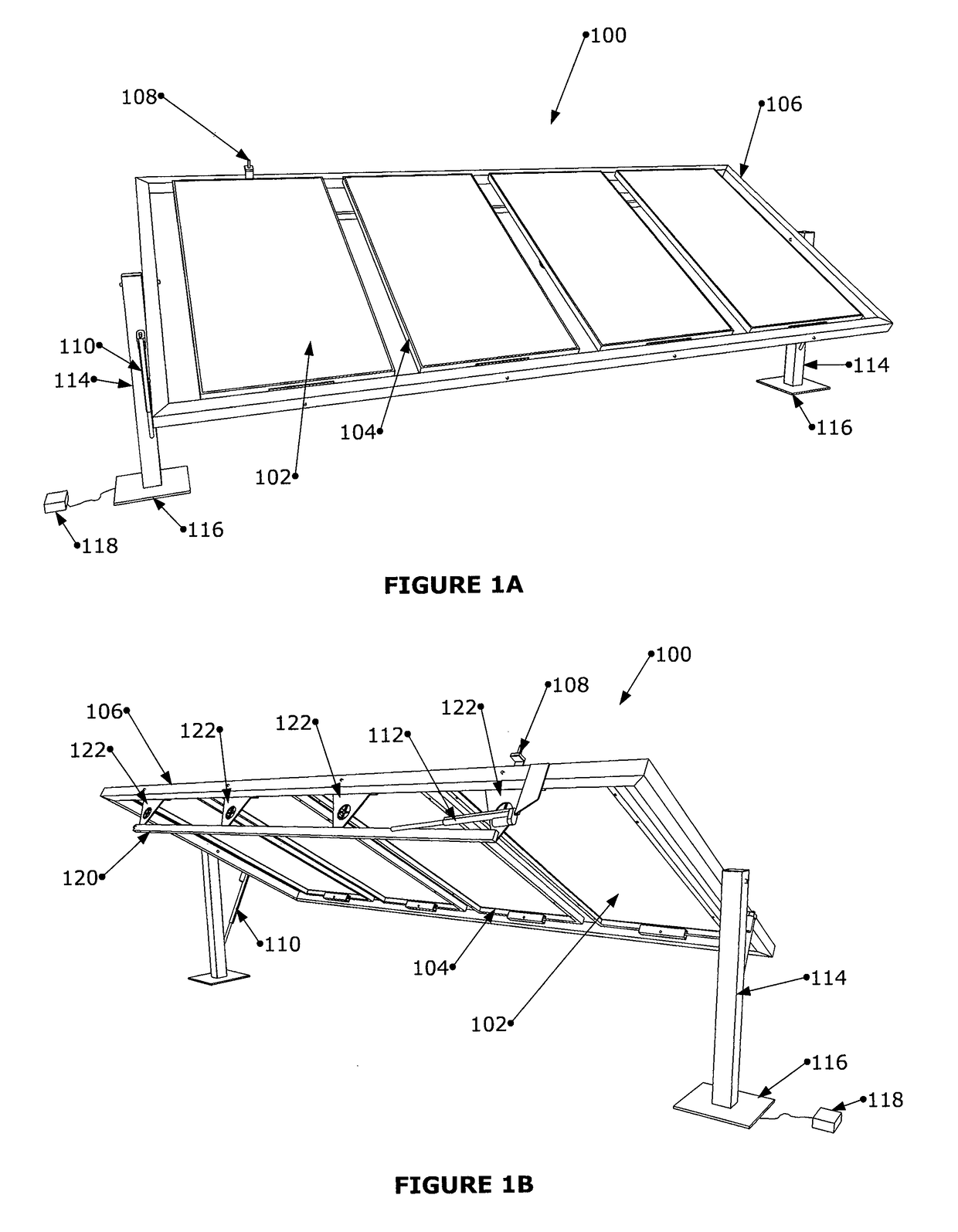

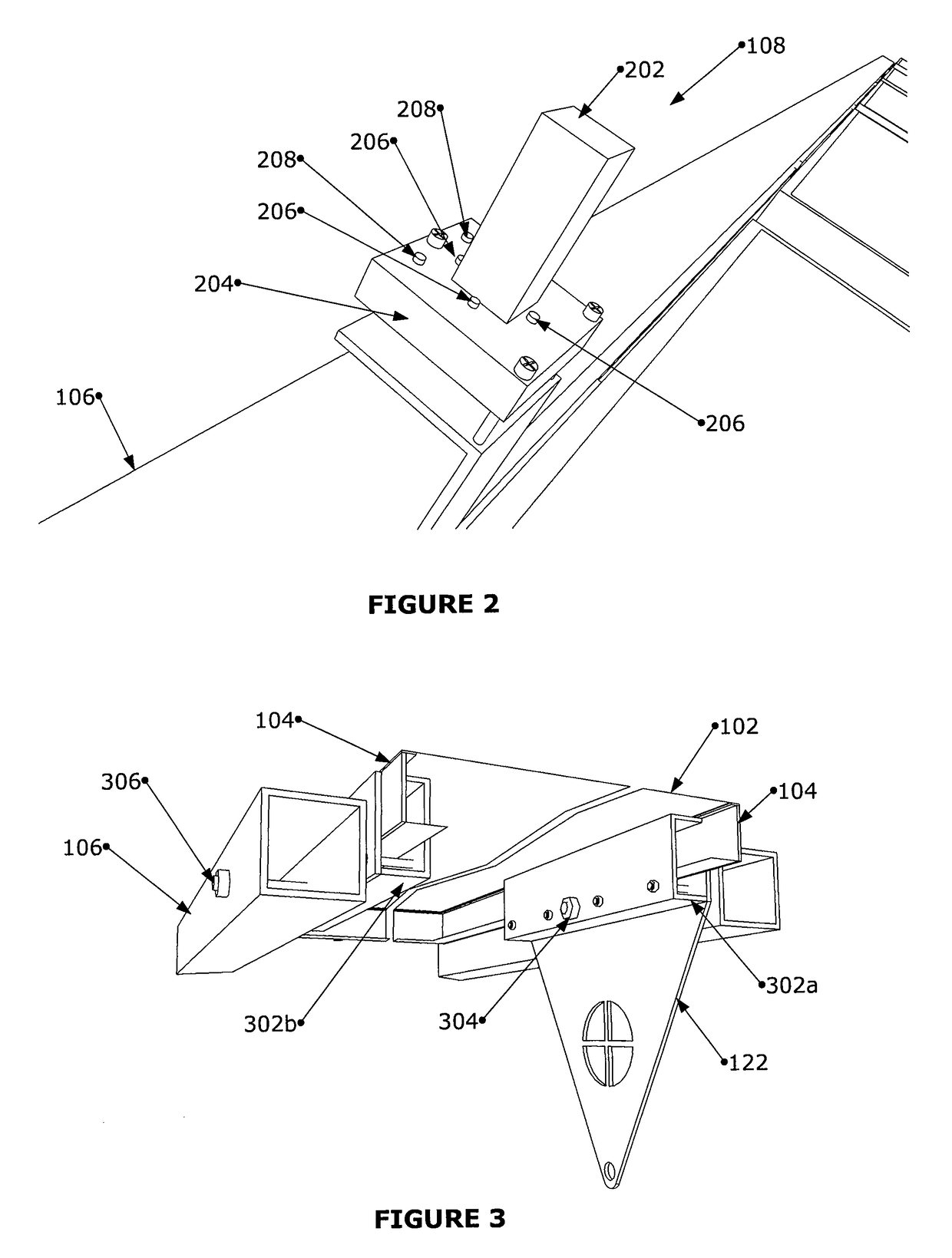

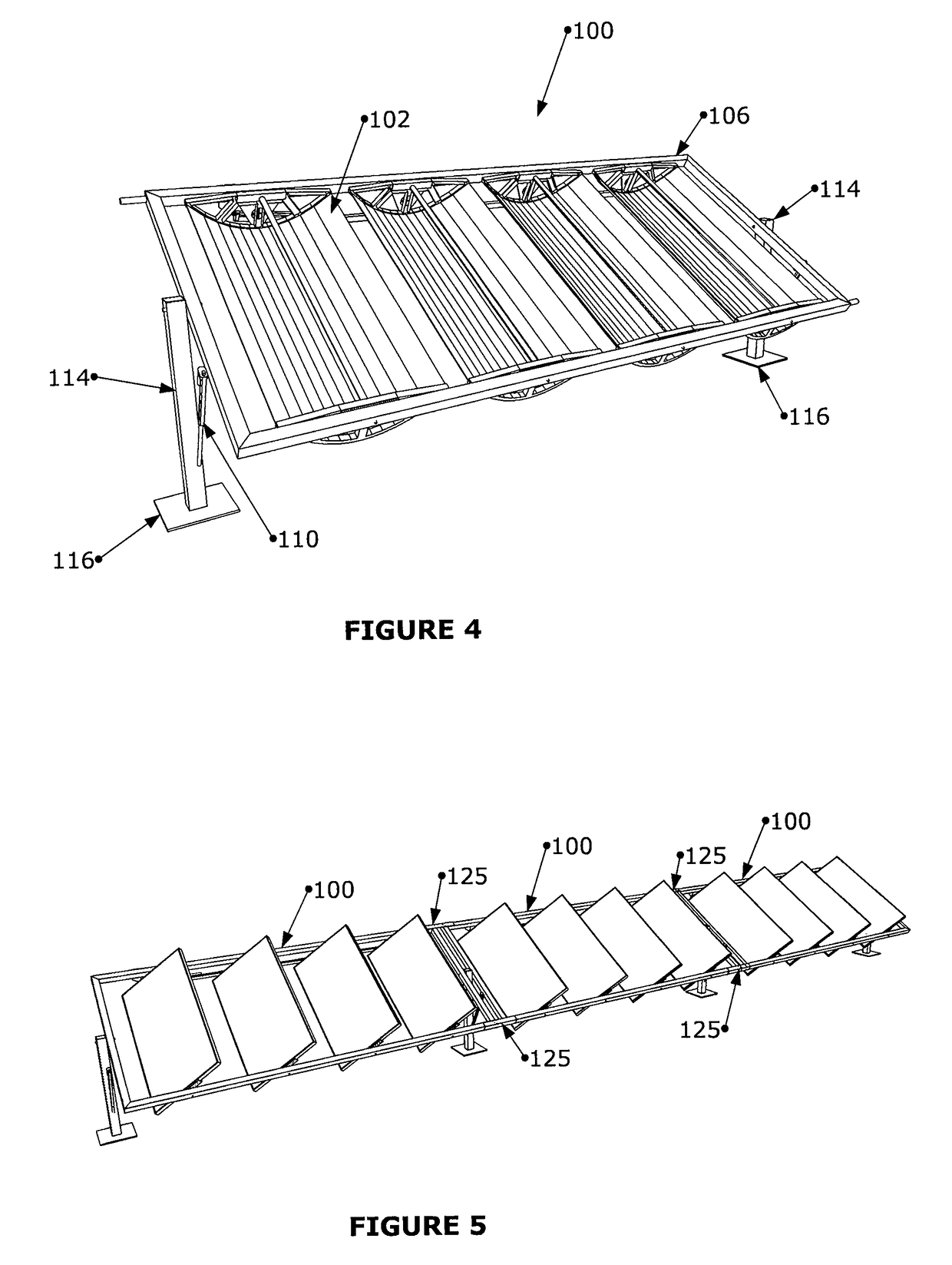

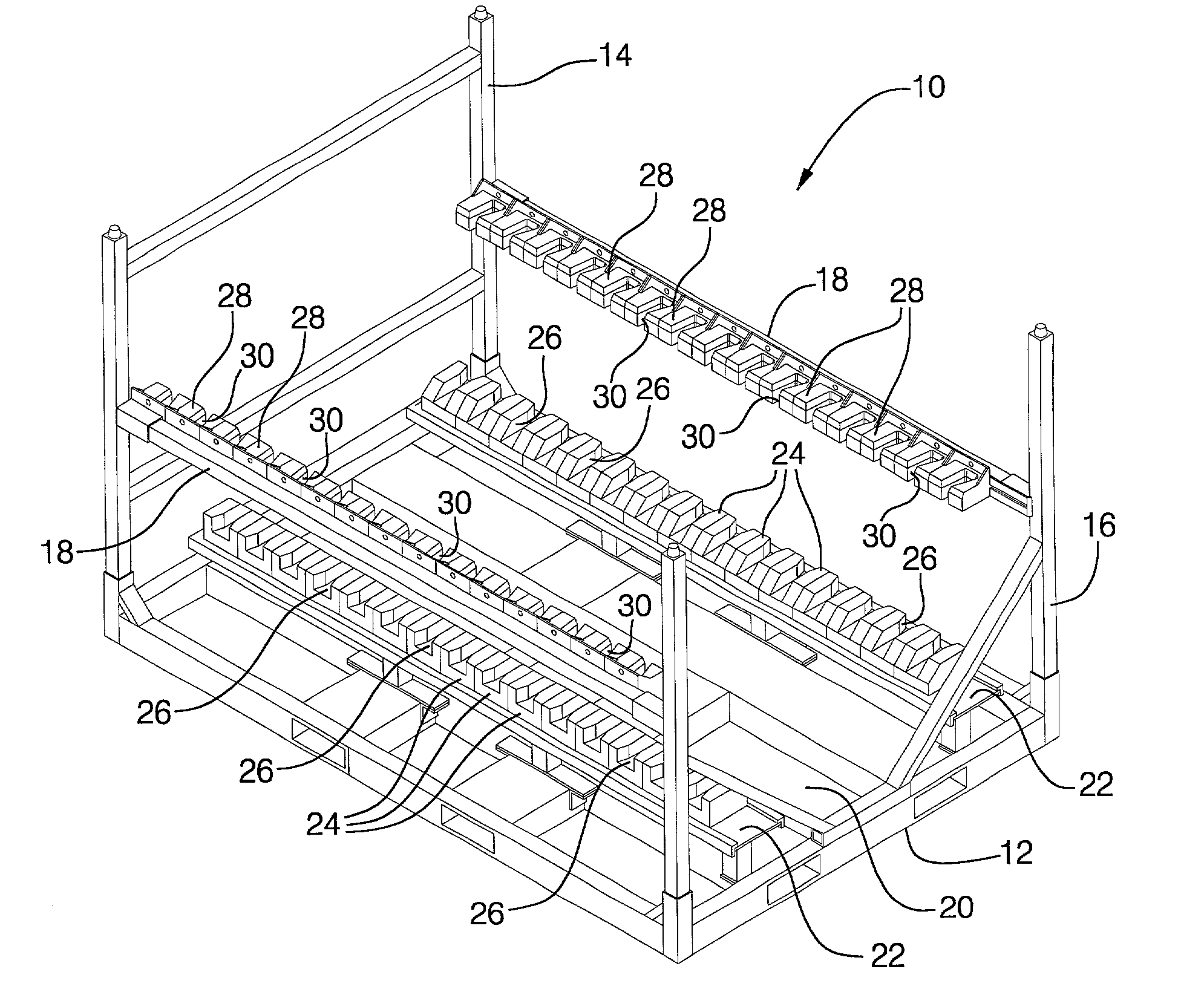

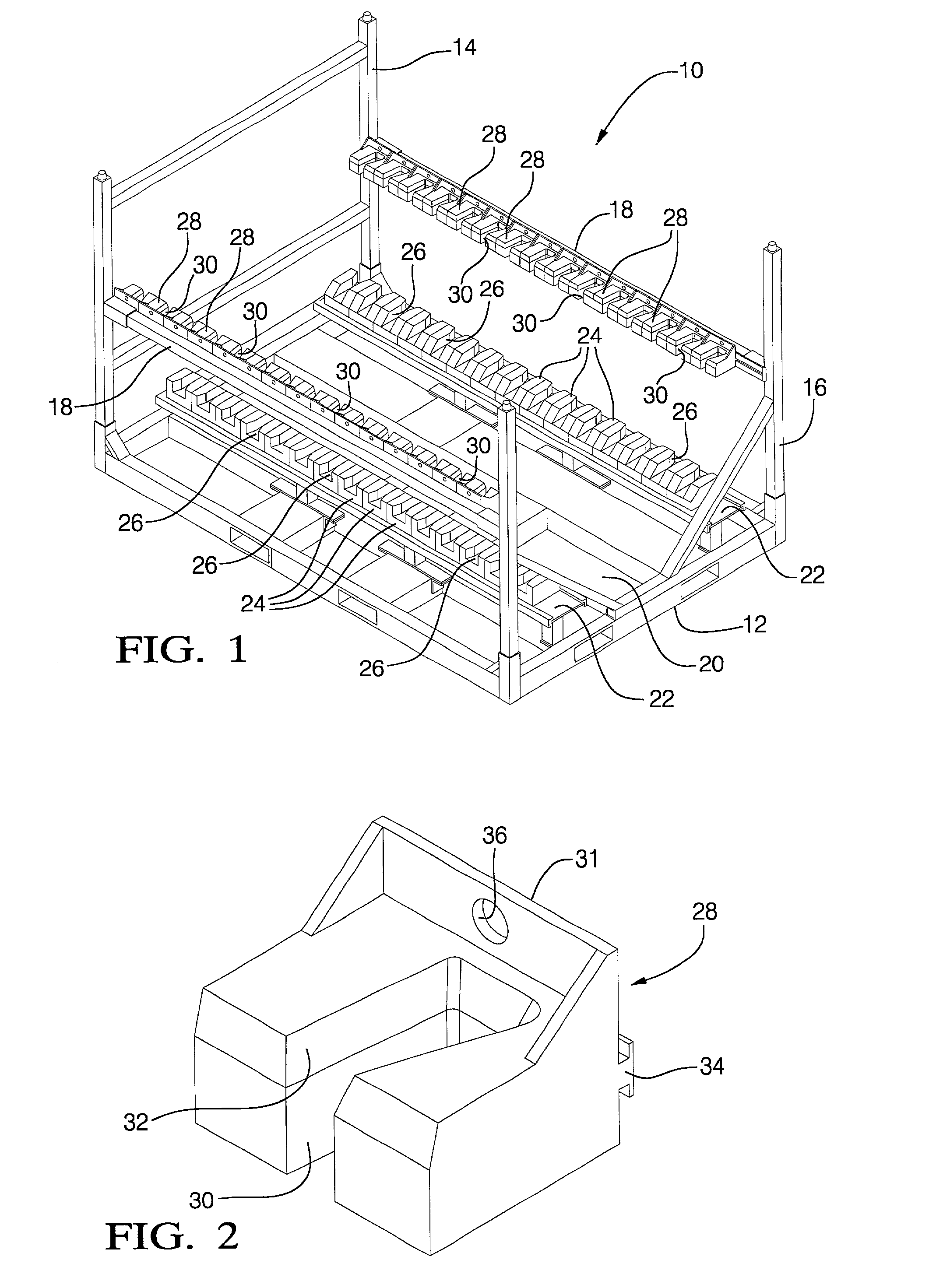

High efficiency counterbalanced dual axis solar tracking array frame system

ActiveUS20110073161A1Minimizes wind loadingReduce windOptical radiation measurementSolar heating energyPhotovoltaic solar energyShadowings

A high efficiency, environmentally friendly system comprising a plurality of photovoltaic solar collecting panels (PV panels) is disclosed. The system comprises an outer frame to which a plurality of inner frames are mounted to which the plurality of PV panels are attached. To minimize shadowing by the outer frame upon one or more PV panels, at least one PV panel may extend beyond an endpoint of the main frame. The system also comprises an outer frame rotation actuator that rotates the outer frame and an inner frame rotation actuator that rotates the inner frames and the plurality of PV panels. The solar tracking array frames disclosed herein help to improve the quality of the environment by conserving a variety of energy resources (e.g., fossil fuels, hydroelectric energy, etc.) The solar tracking array frames disclosed herein also help to reduce greenhouse gas emissions, as solar tracking array frames do not produce carbon dioxide byproducts.

Owner:SCANLON MARK +1

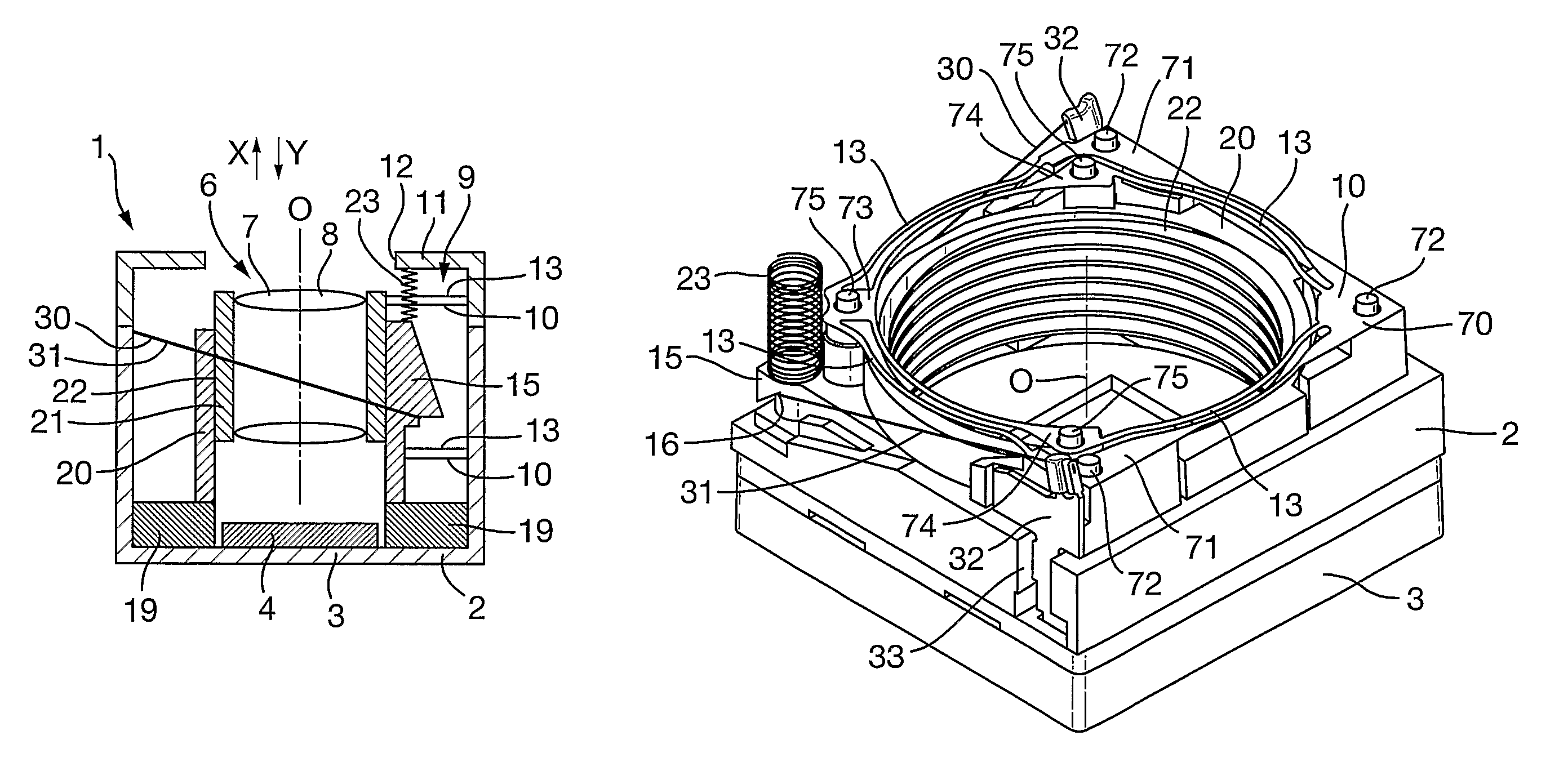

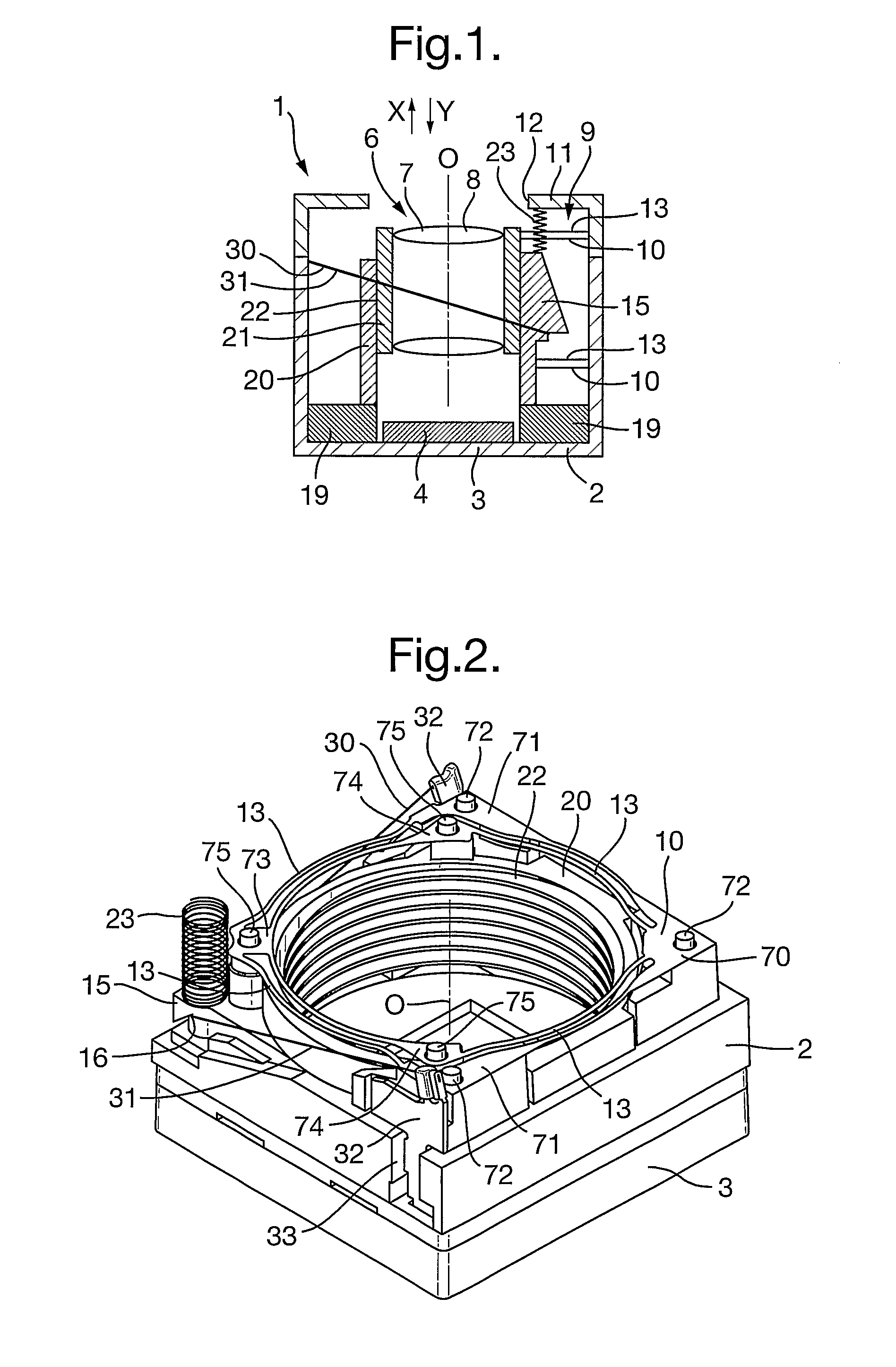

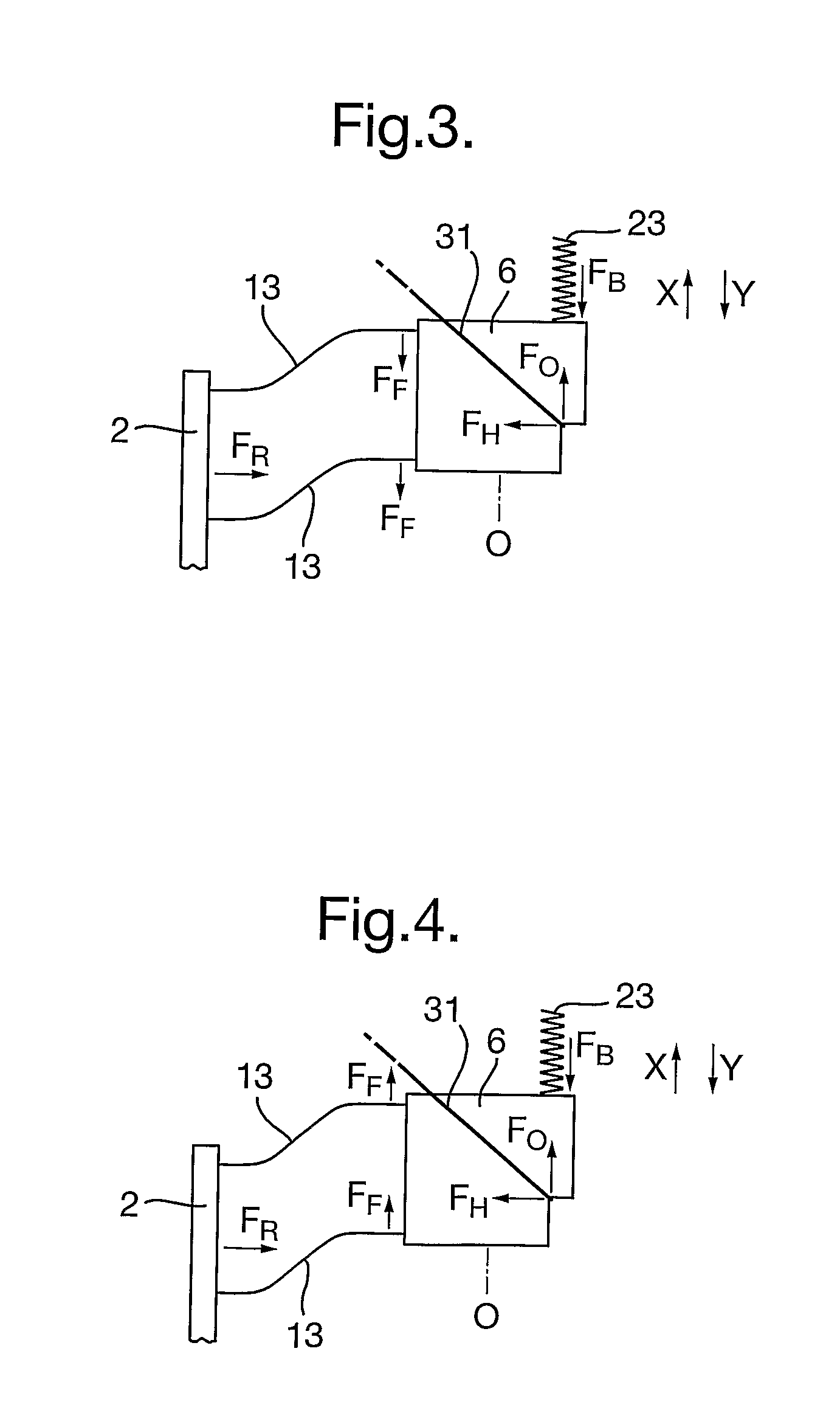

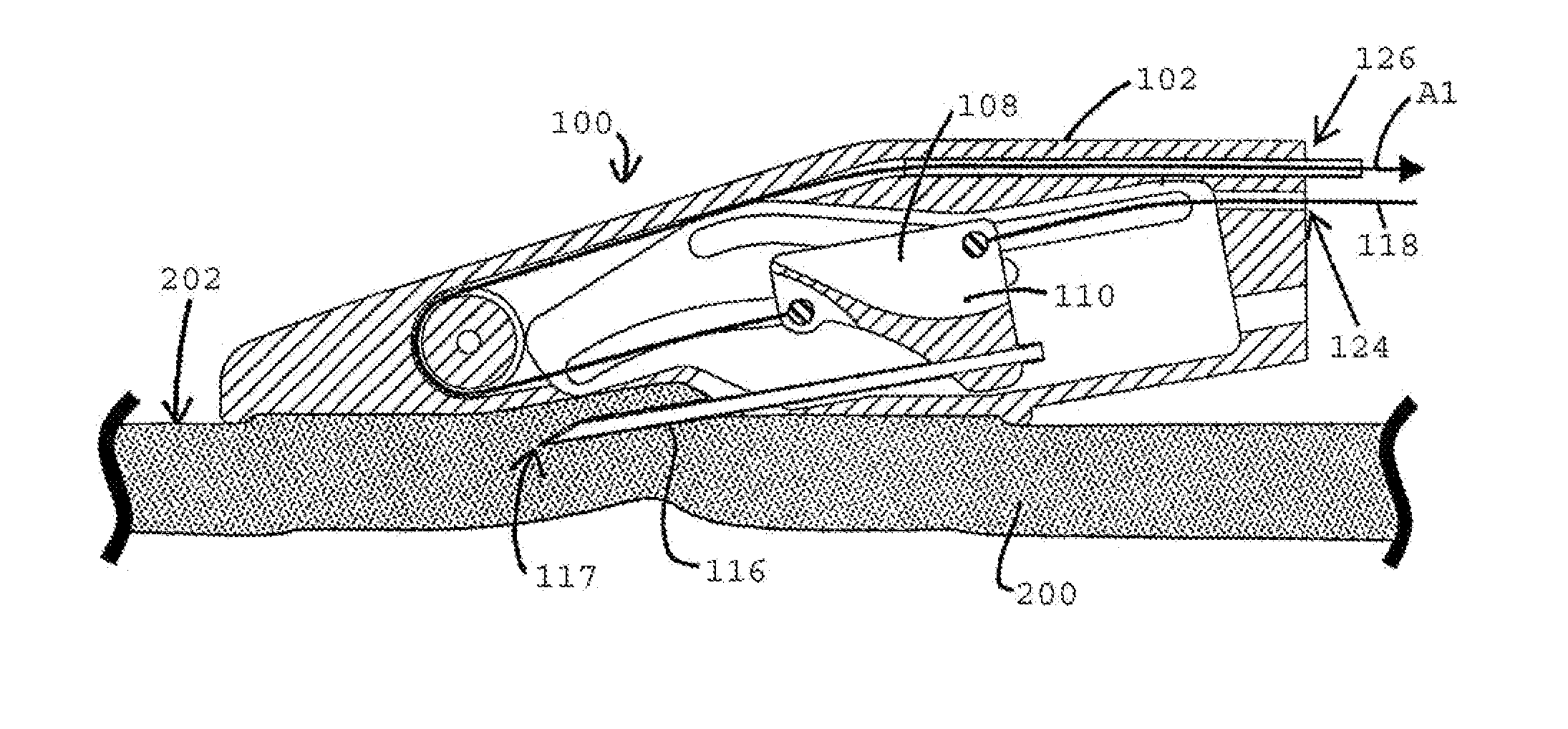

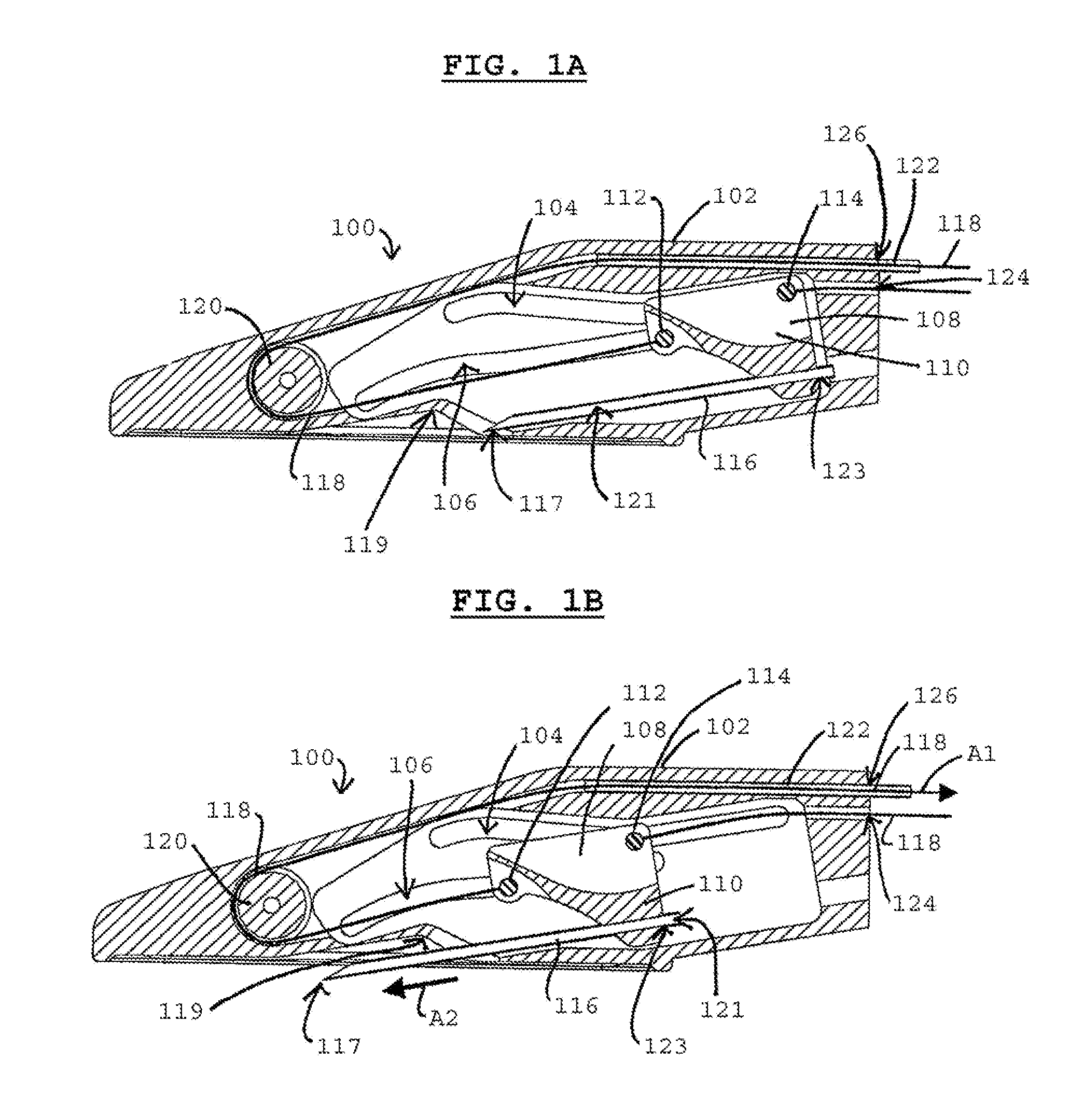

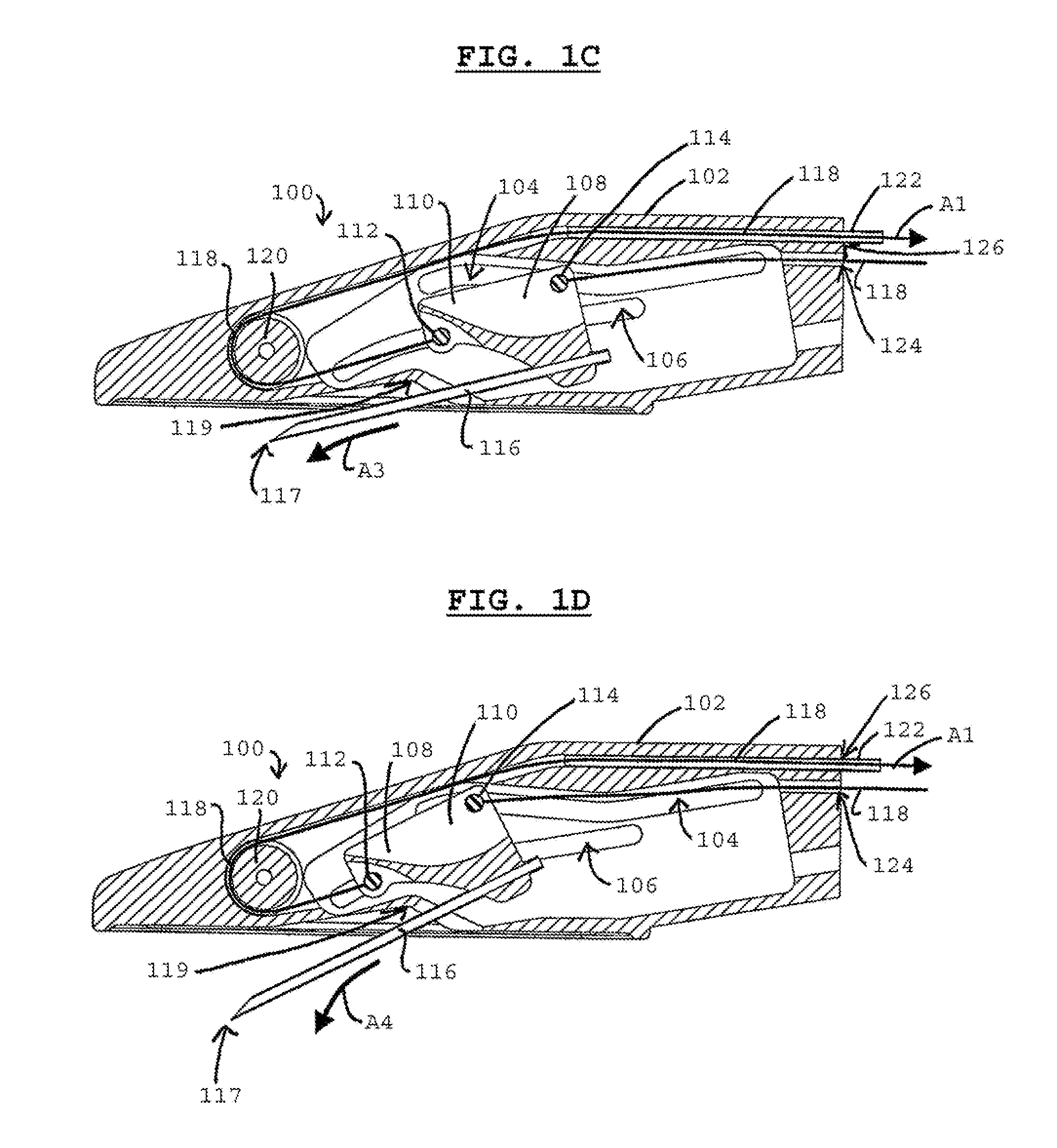

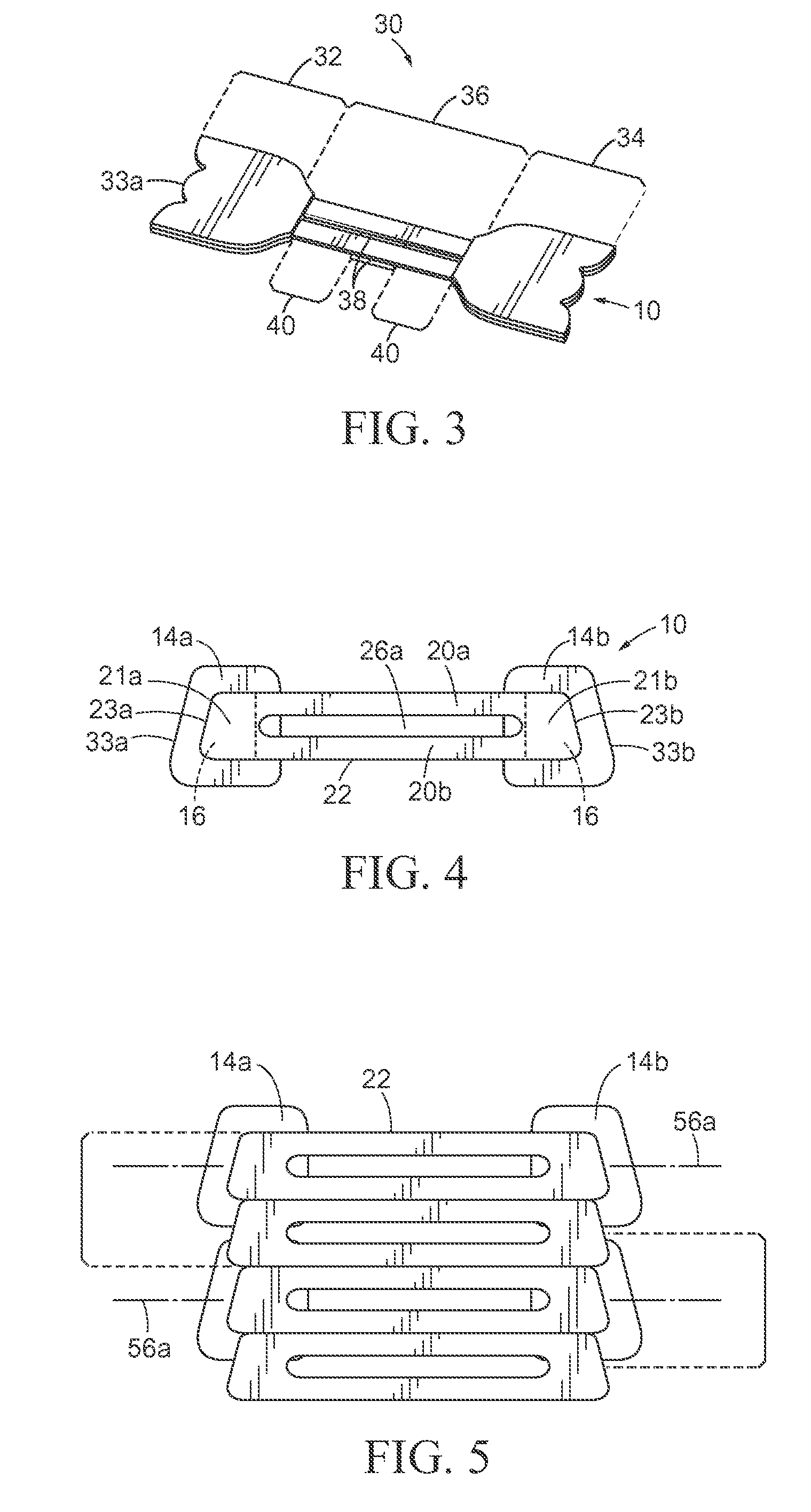

Shape memory alloy actuation apparatus

ActiveUS8441749B2Reduce maximum pressureReduce the applied forceTelevision system detailsProjector focusing arrangementCamera lensAcute angle

An SMA actuation apparatus comprises a camera lens element supported on a support structure by a plurality of flexures. An SMA wire at an acute angle to the movement axis and a biasing element are connected between the support structure and the movable element. A component of the force applied by the SMA wire perpendicular to the movement axis compresses the flexures causing them to apply a force to the movable element having a component along the movement axis in the same direction as the SMA wire. An end-stop limits the movement of the movable element, and the moment applied by the end-stop to the movable element about the center of stiffness is equal to the moment applied by the SMA wire about the center of stiffness at the point when the movable element loses contact with the end-stop on contraction of the SMA wire.

Owner:CAMBRIDGE MECHATRONICS

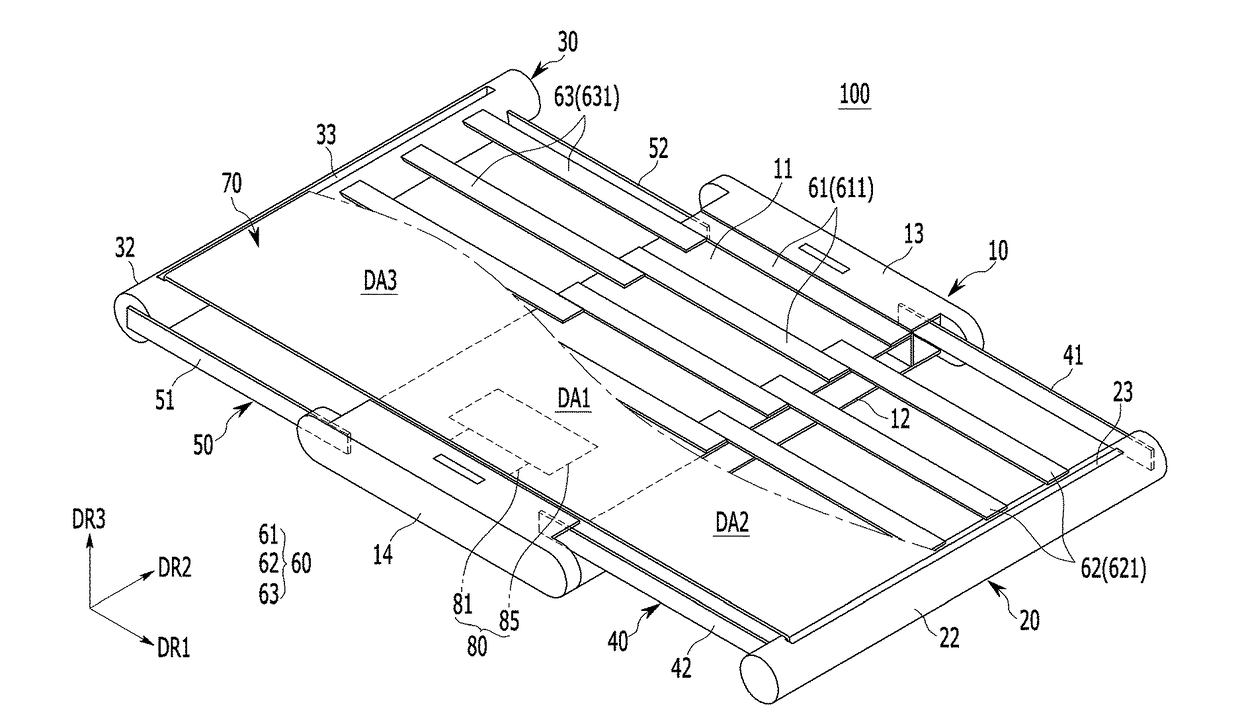

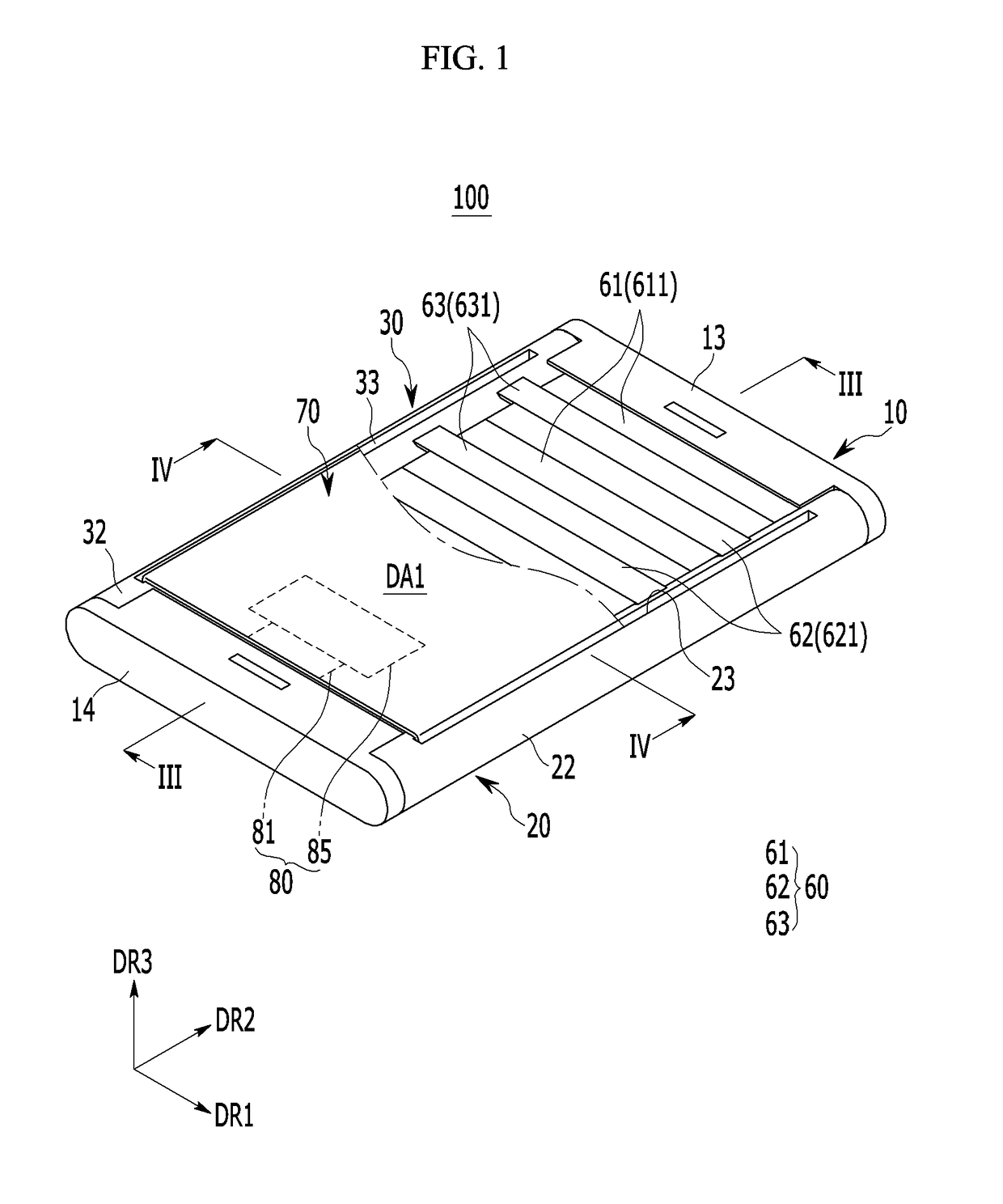

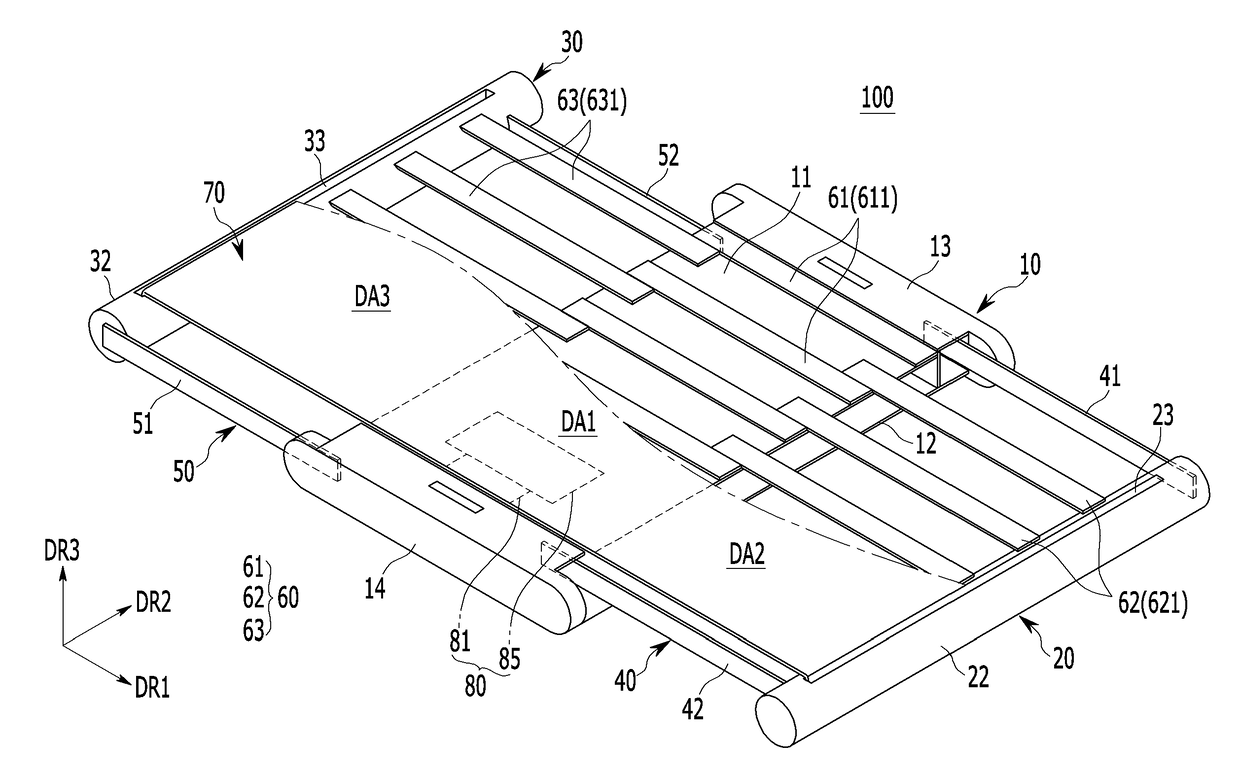

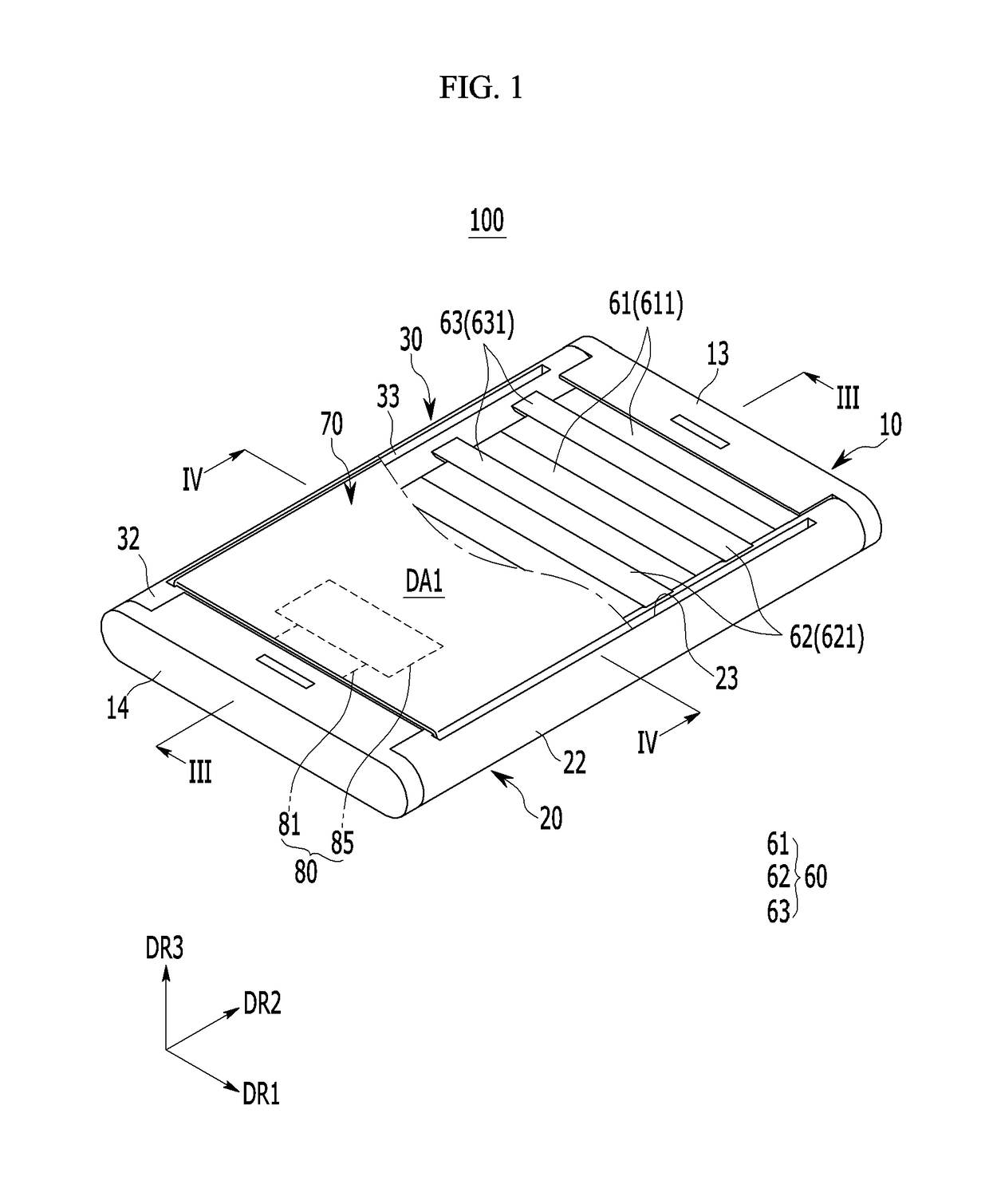

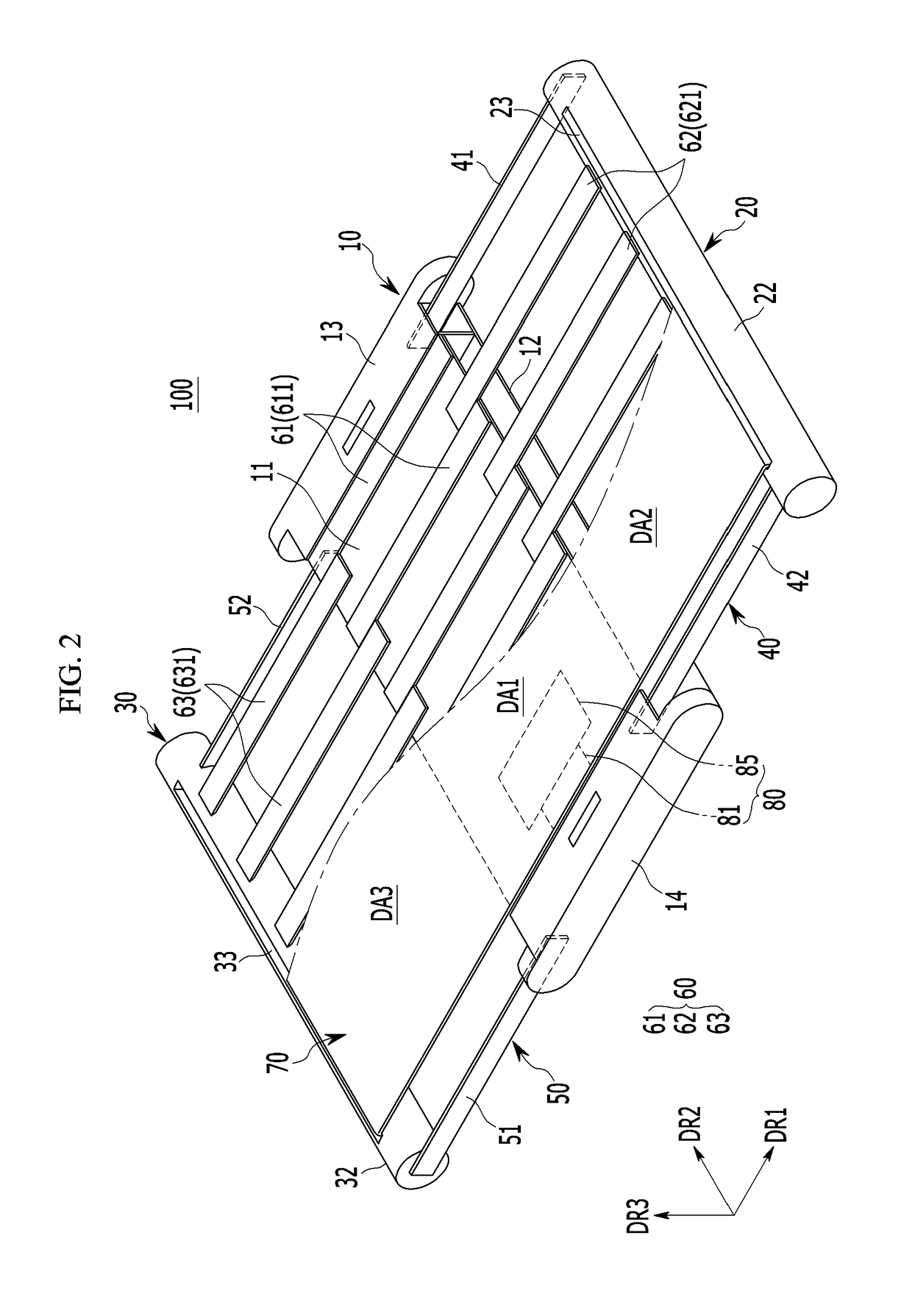

Display device

ActiveUS20180077808A1Maximize sizeMinimal stressDigital data processing detailsCasings with display/control unitsDisplay deviceComputer science

A display device may include a support plate, a first display unit, a second display unit, a third display unit, a pad, and a circuit board. The first display unit overlaps the support plate. The second display unit is connected to the first display unit. A portion of the second display unit may move relative to the support plate. The third display unit is connected through the first display unit to the second display unit. A portion of the third display may move relative to the support plate. The pad includes a pad electrode that is electrically connected to the first display unit. The circuit board is electrically connected to the pad. A first section of the circuit board is bent relative to a second section of the circuit board and is oriented perpendicular or oblique with respect to the first display unit.

Owner:SAMSUNG DISPLAY CO LTD

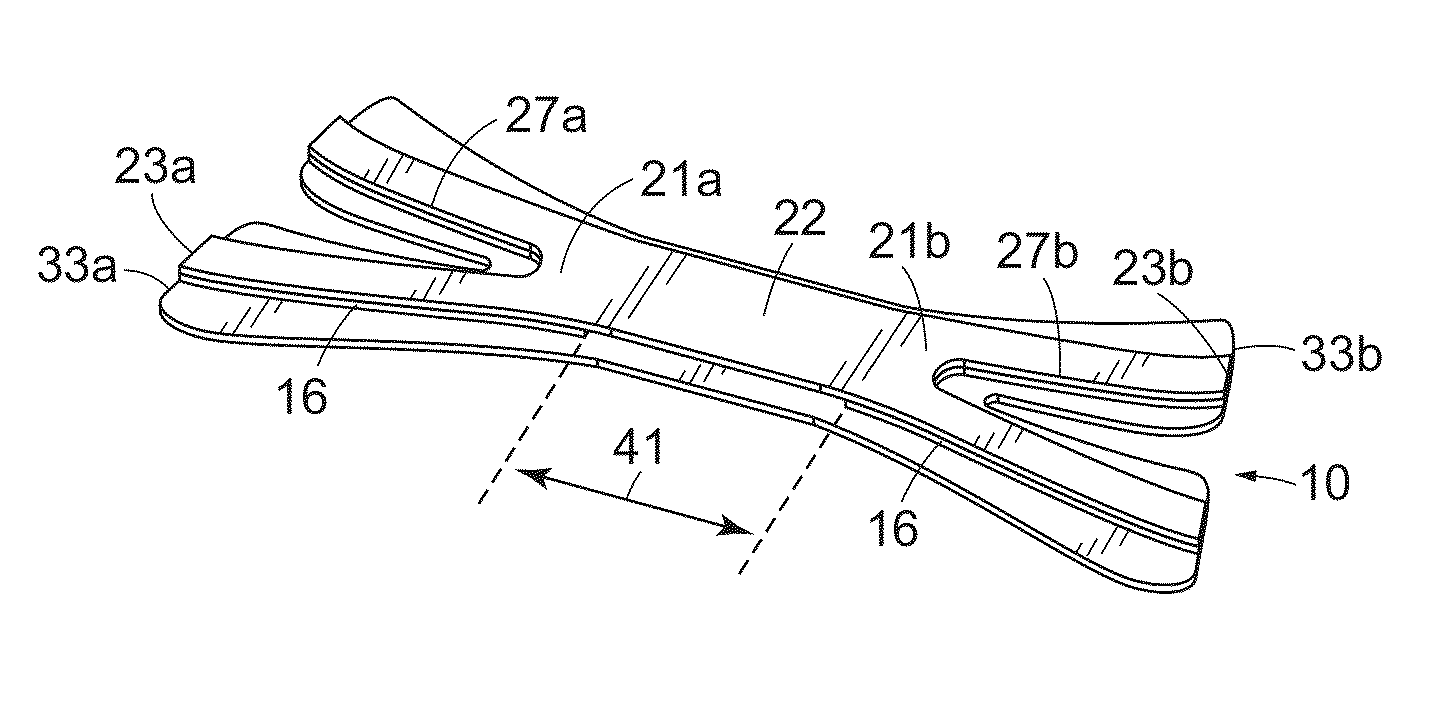

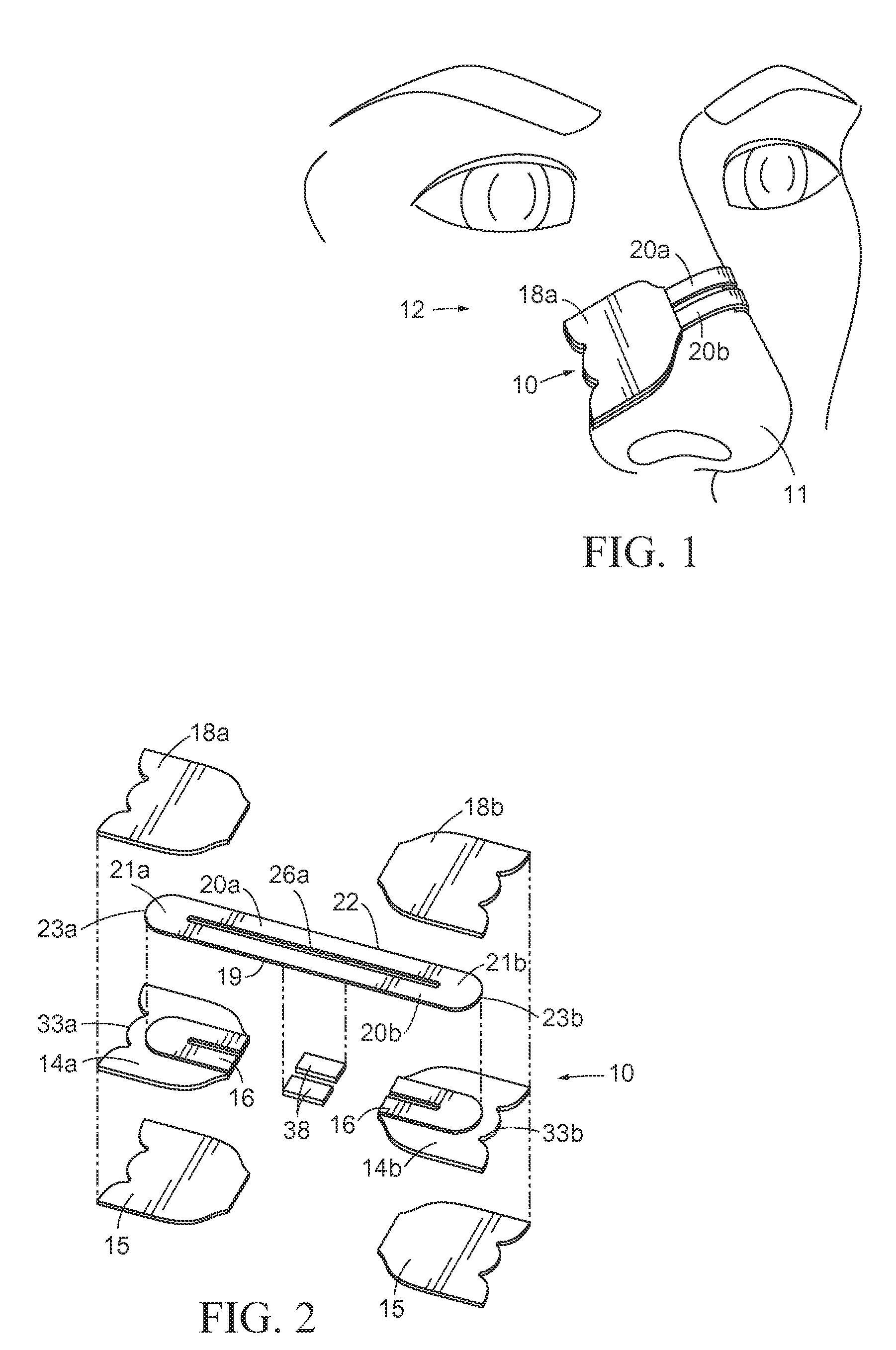

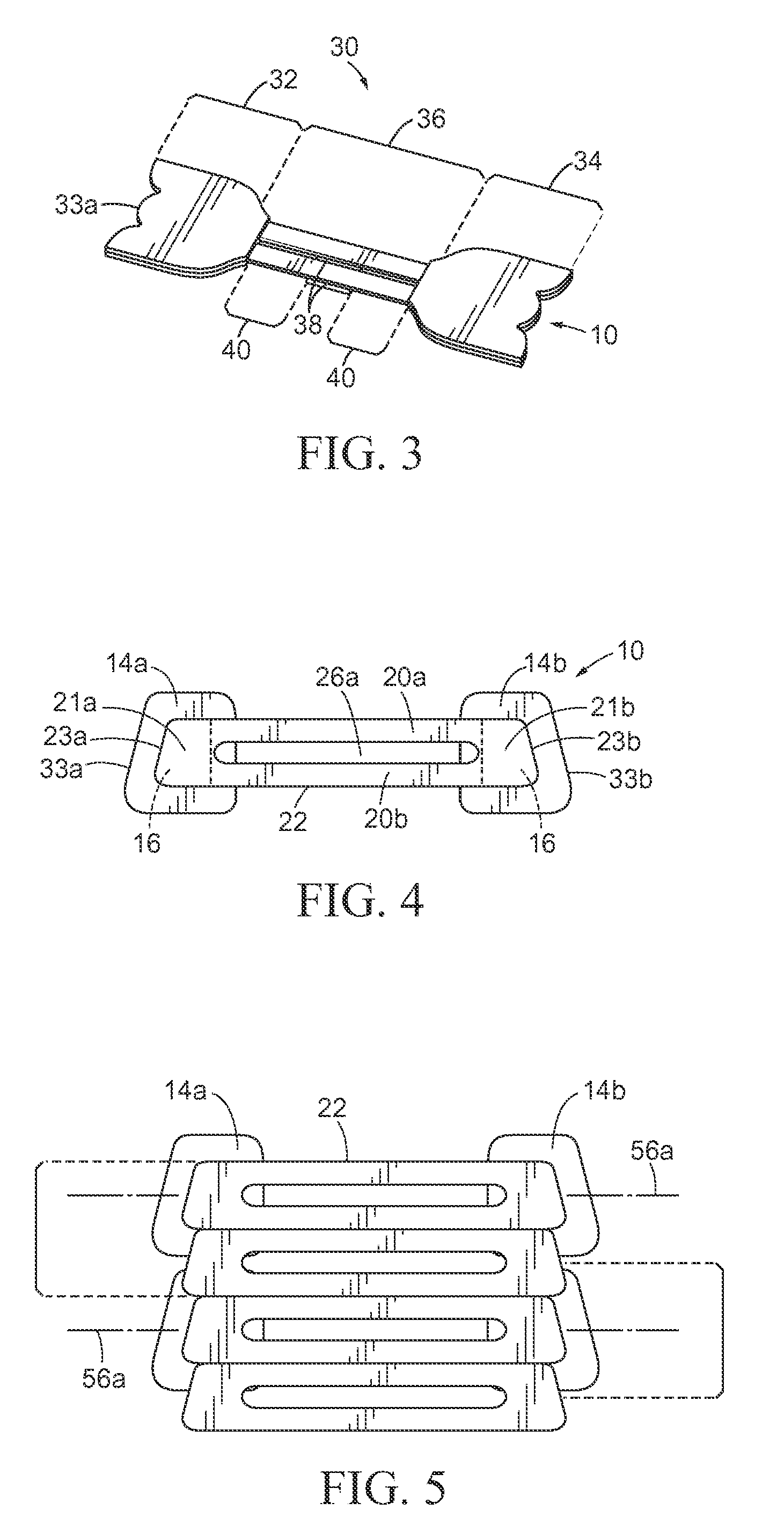

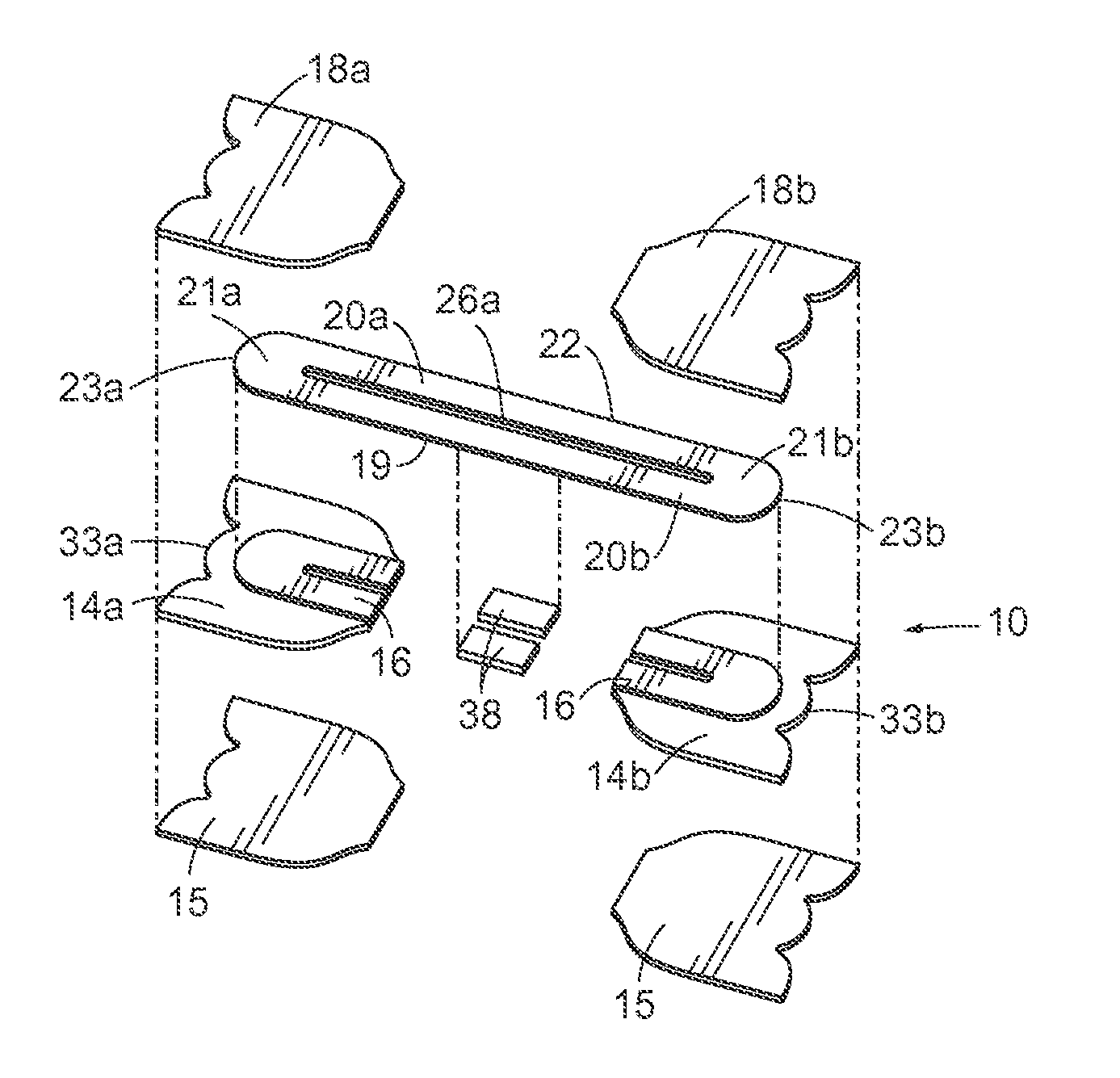

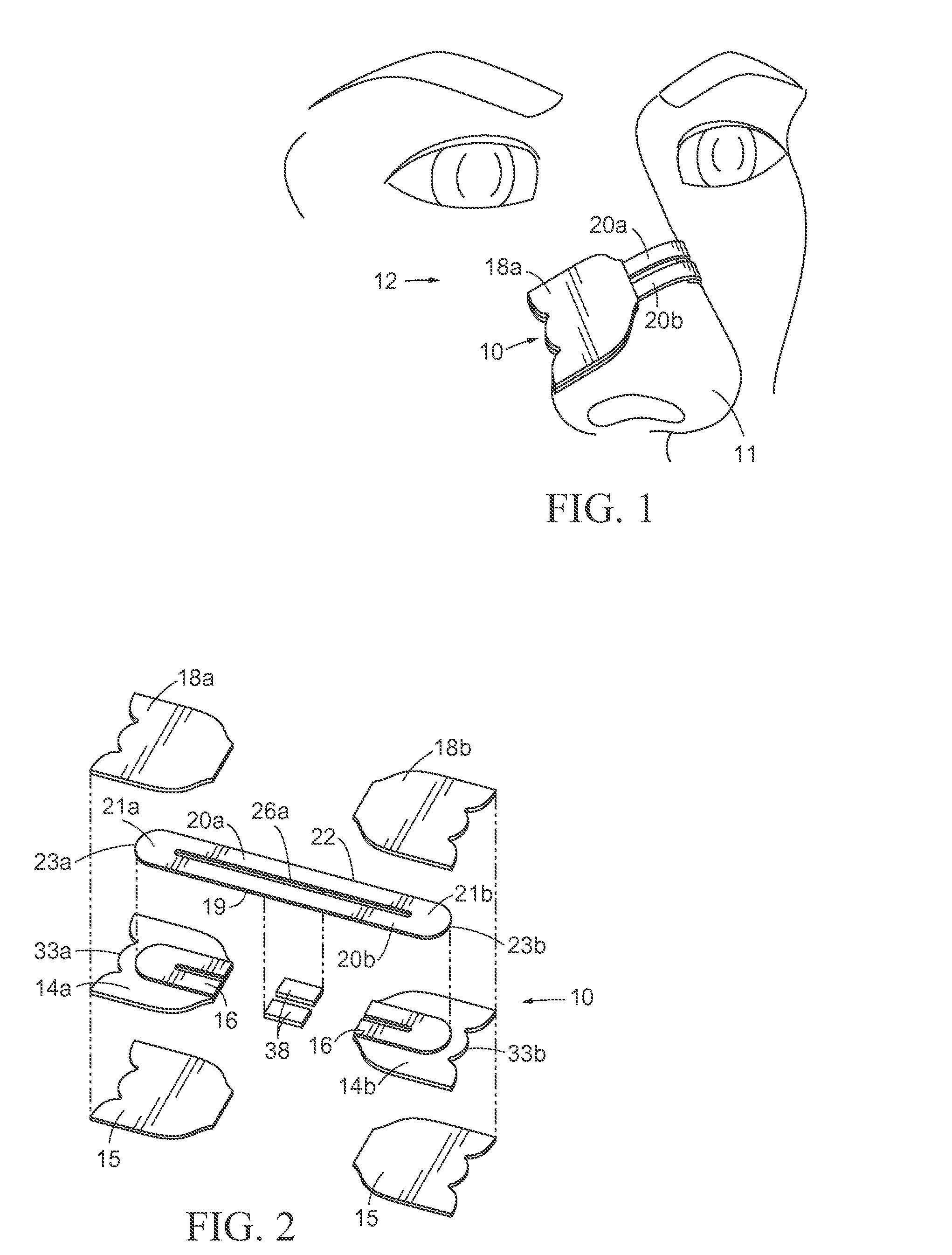

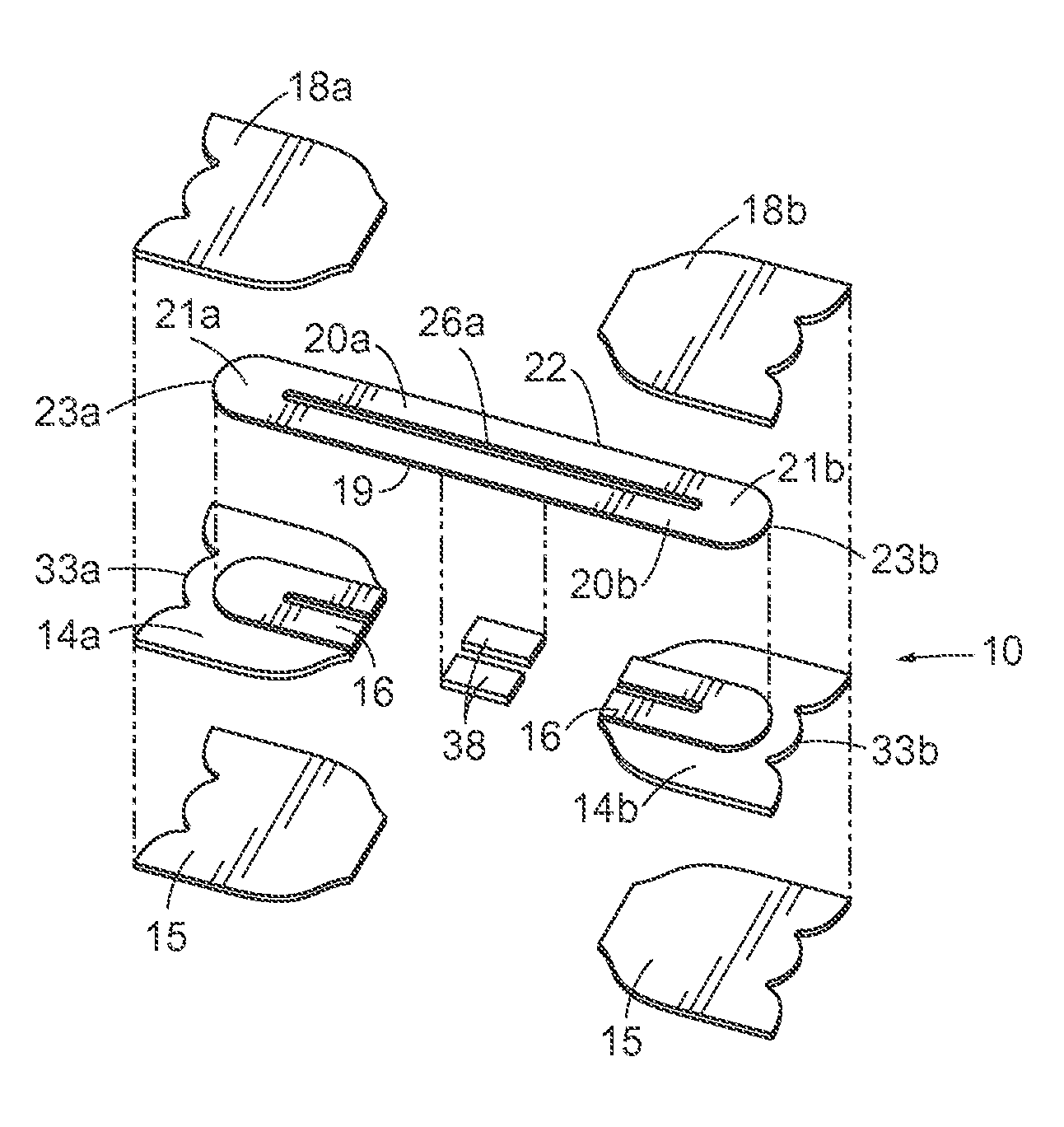

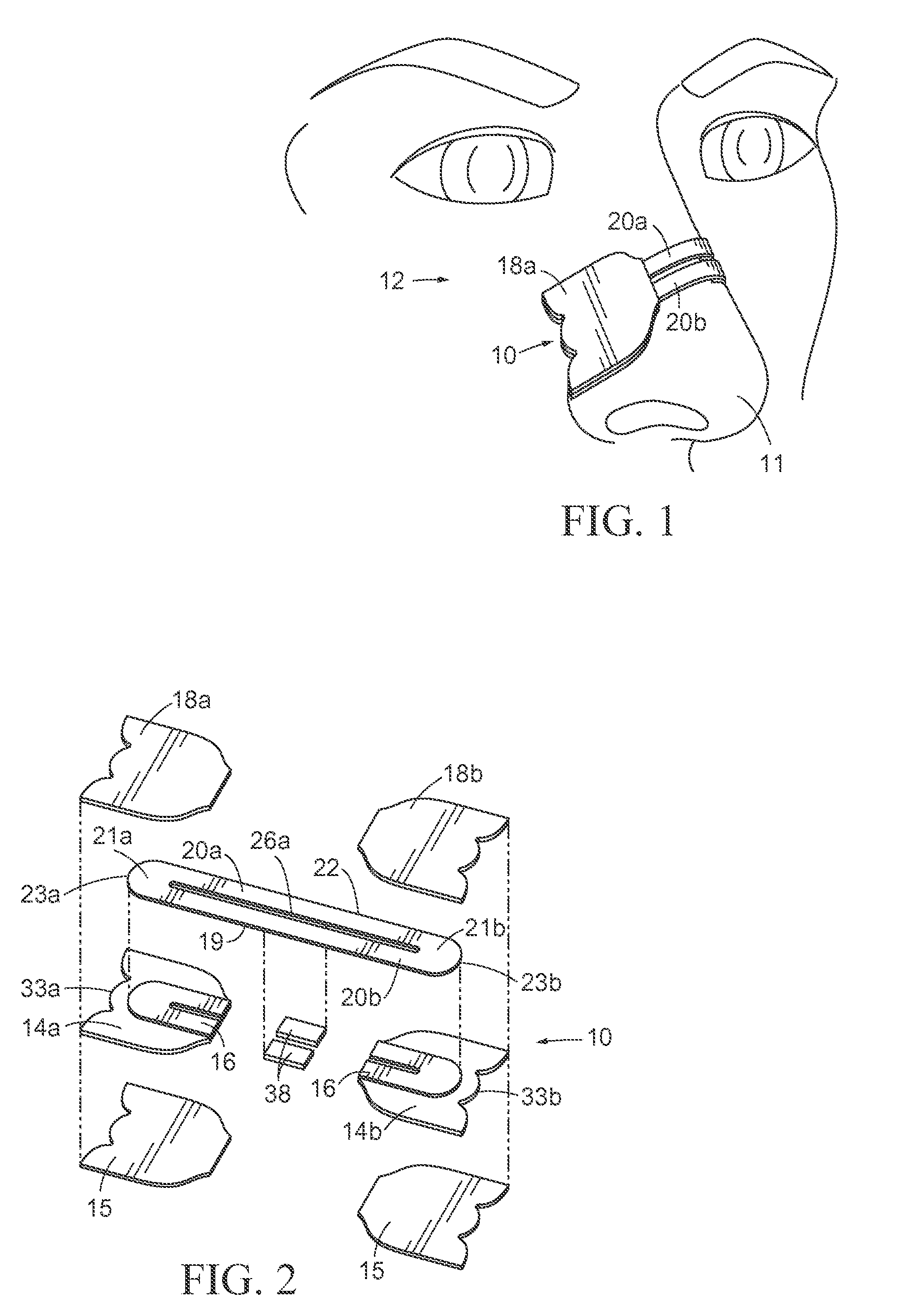

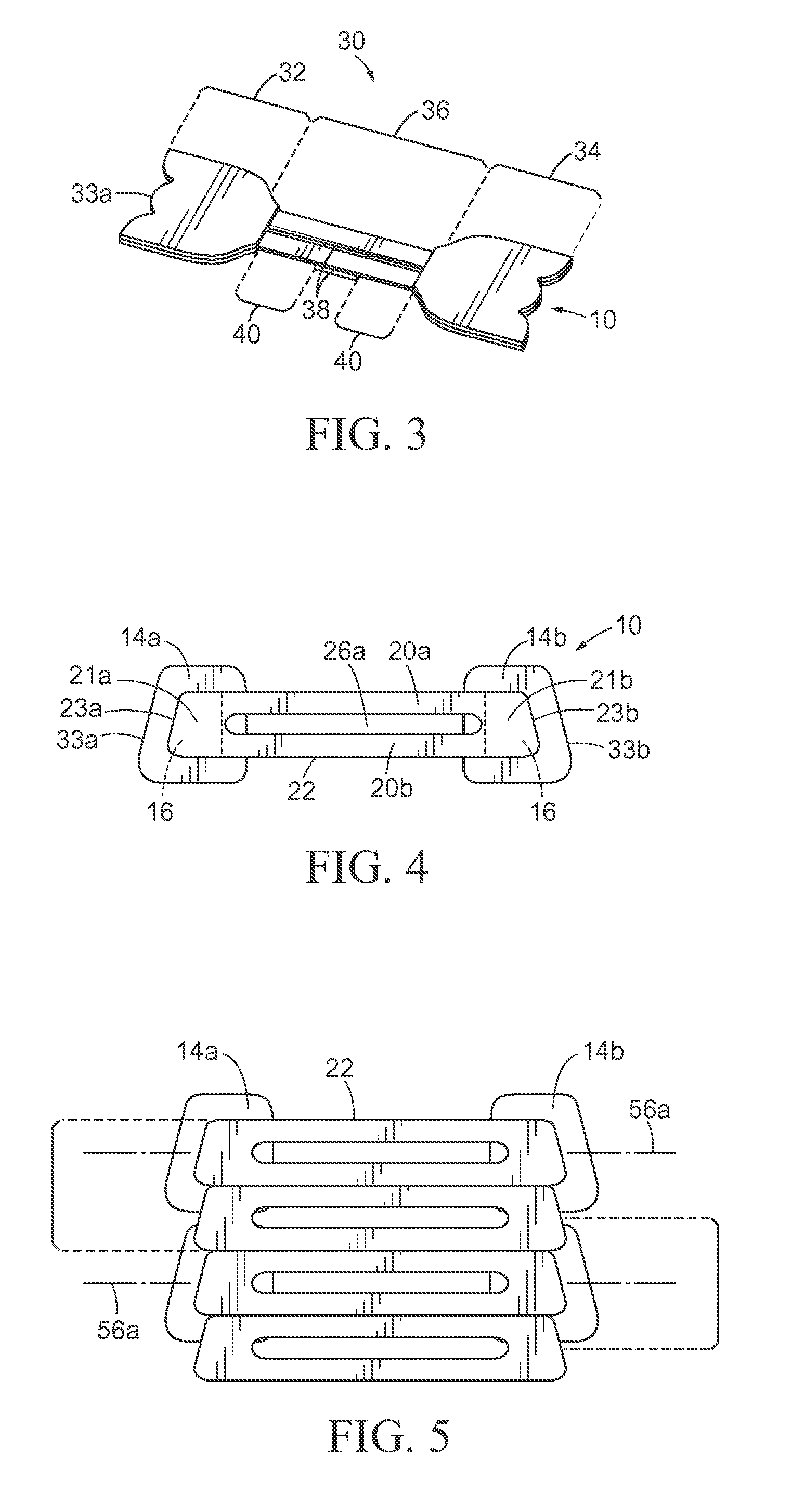

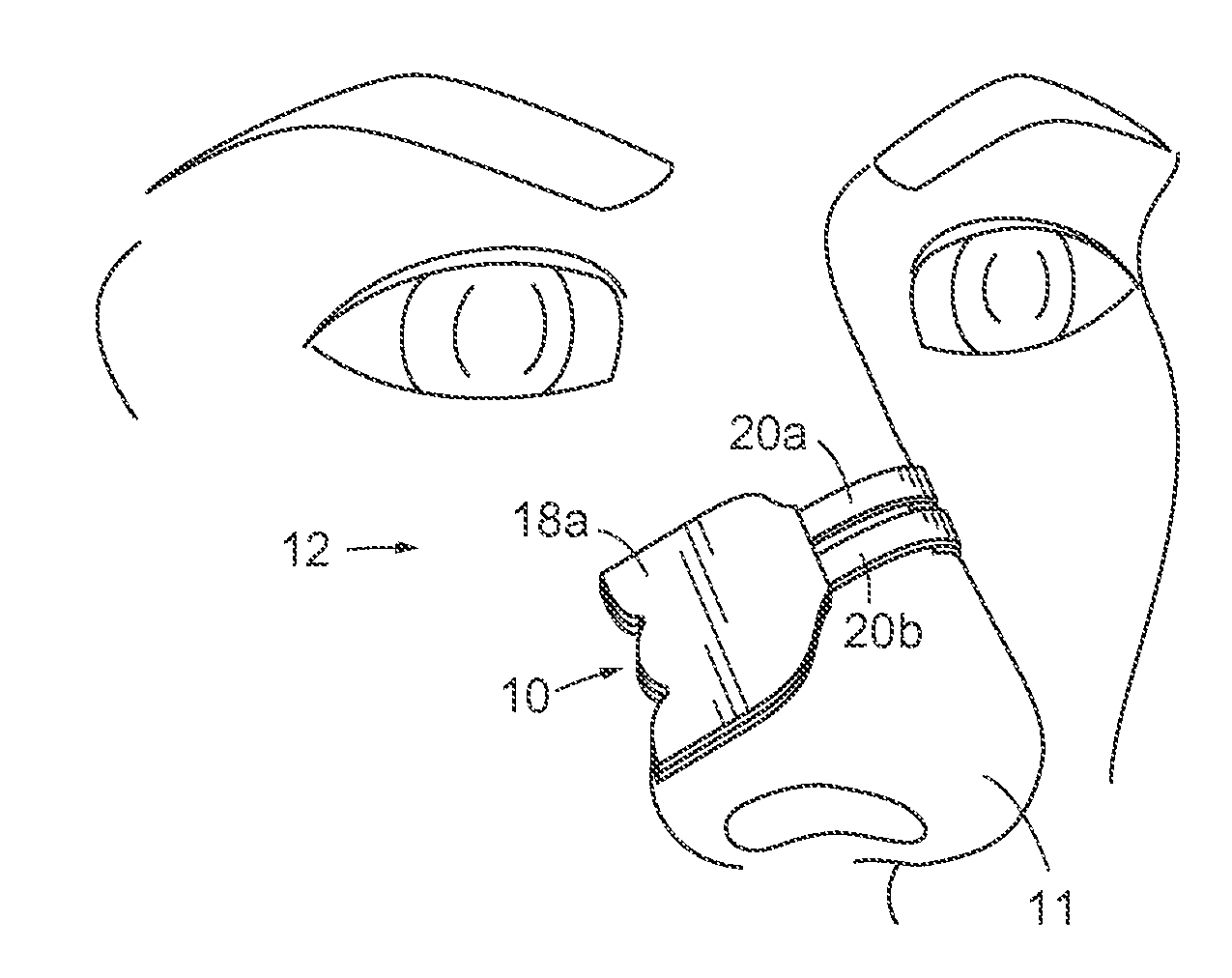

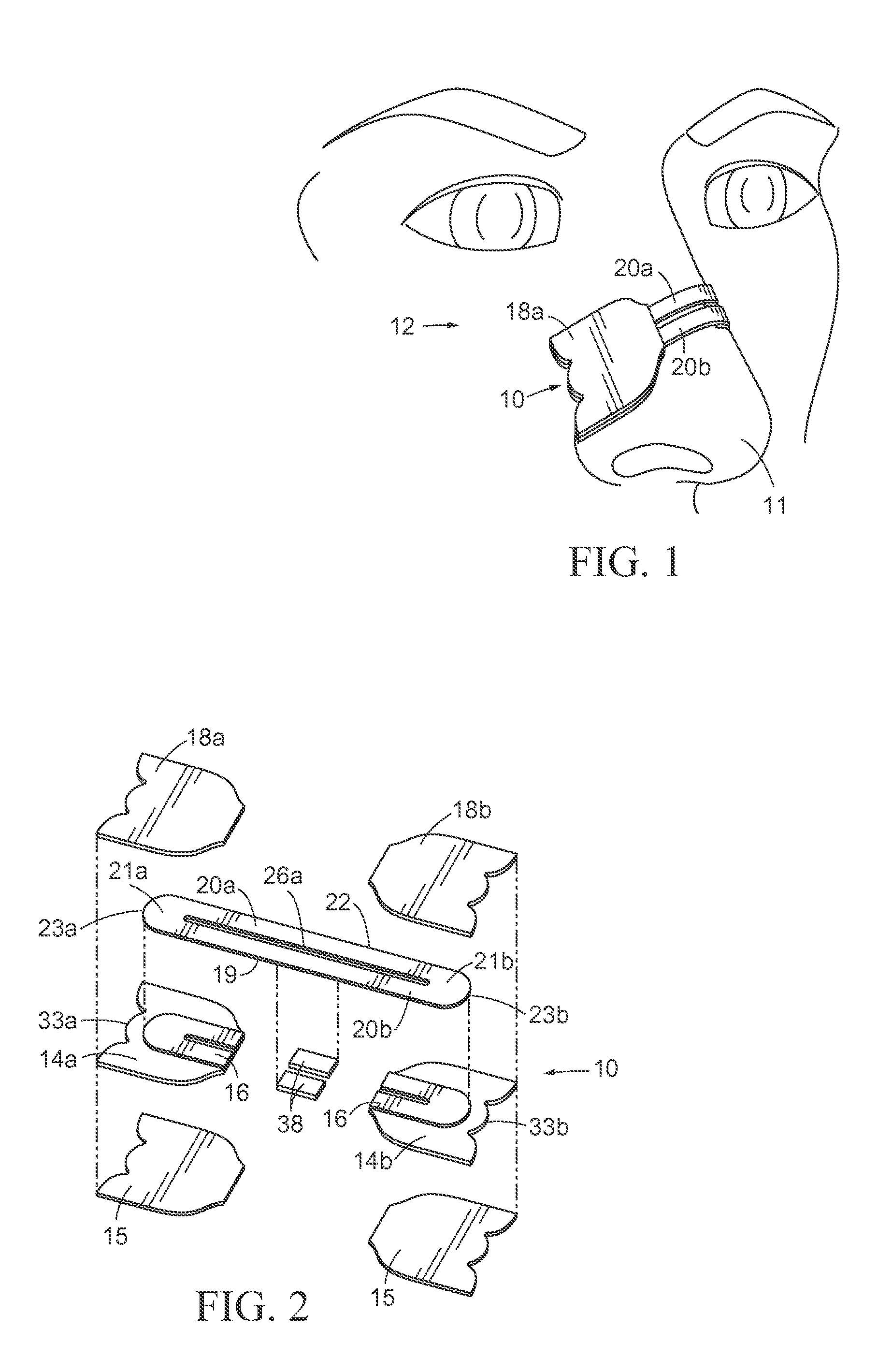

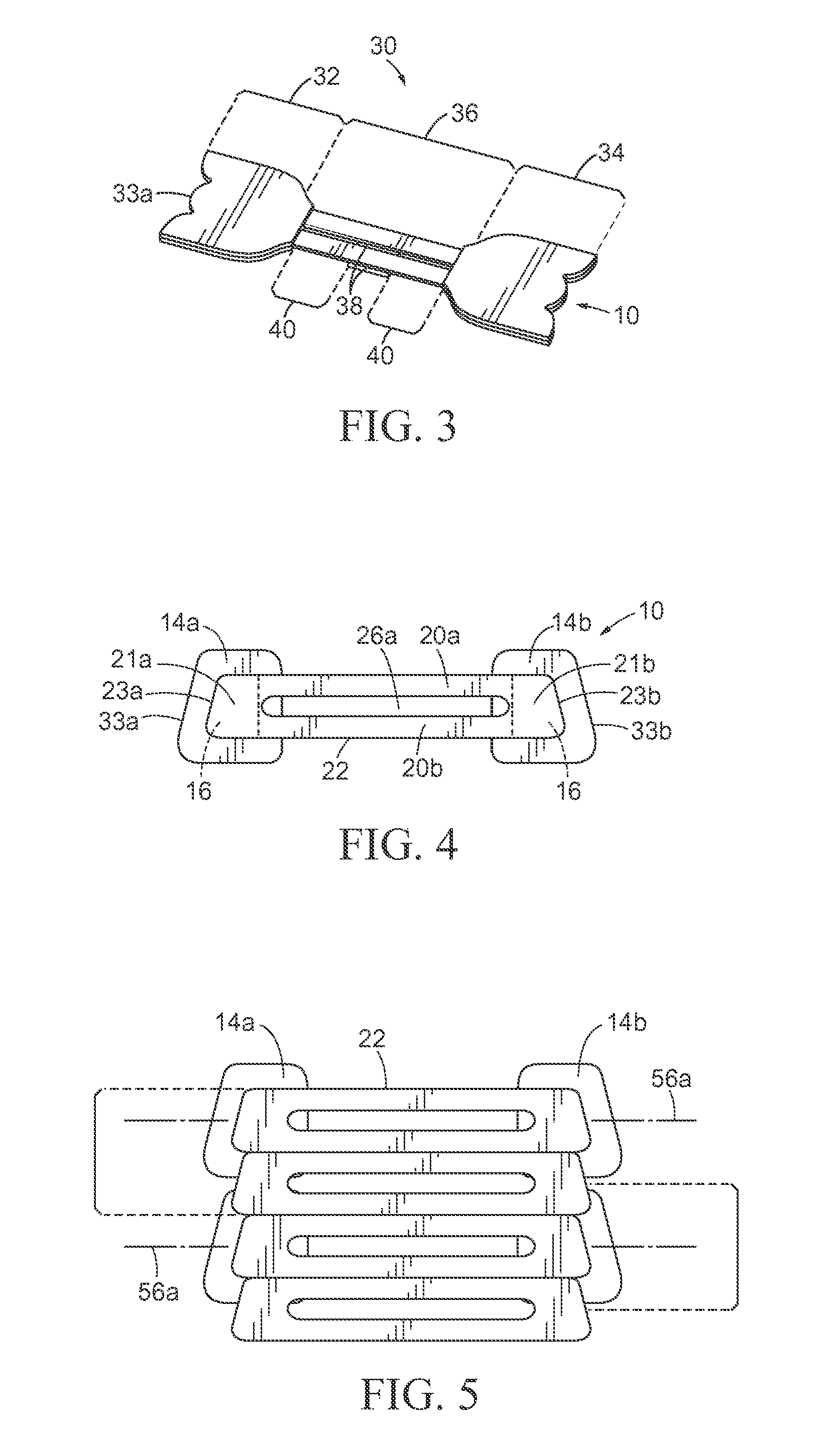

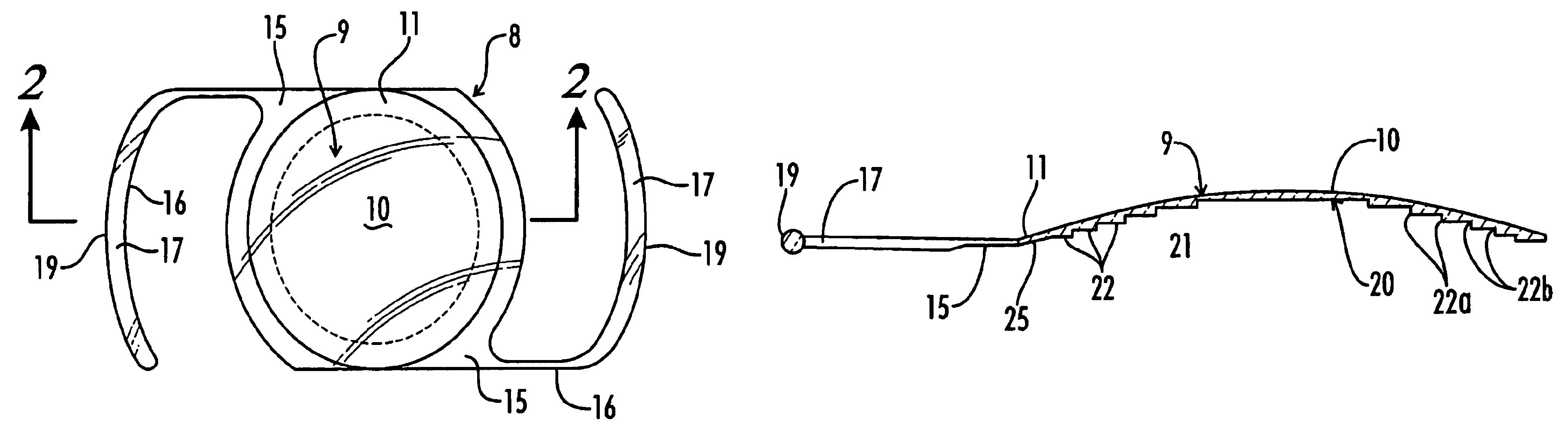

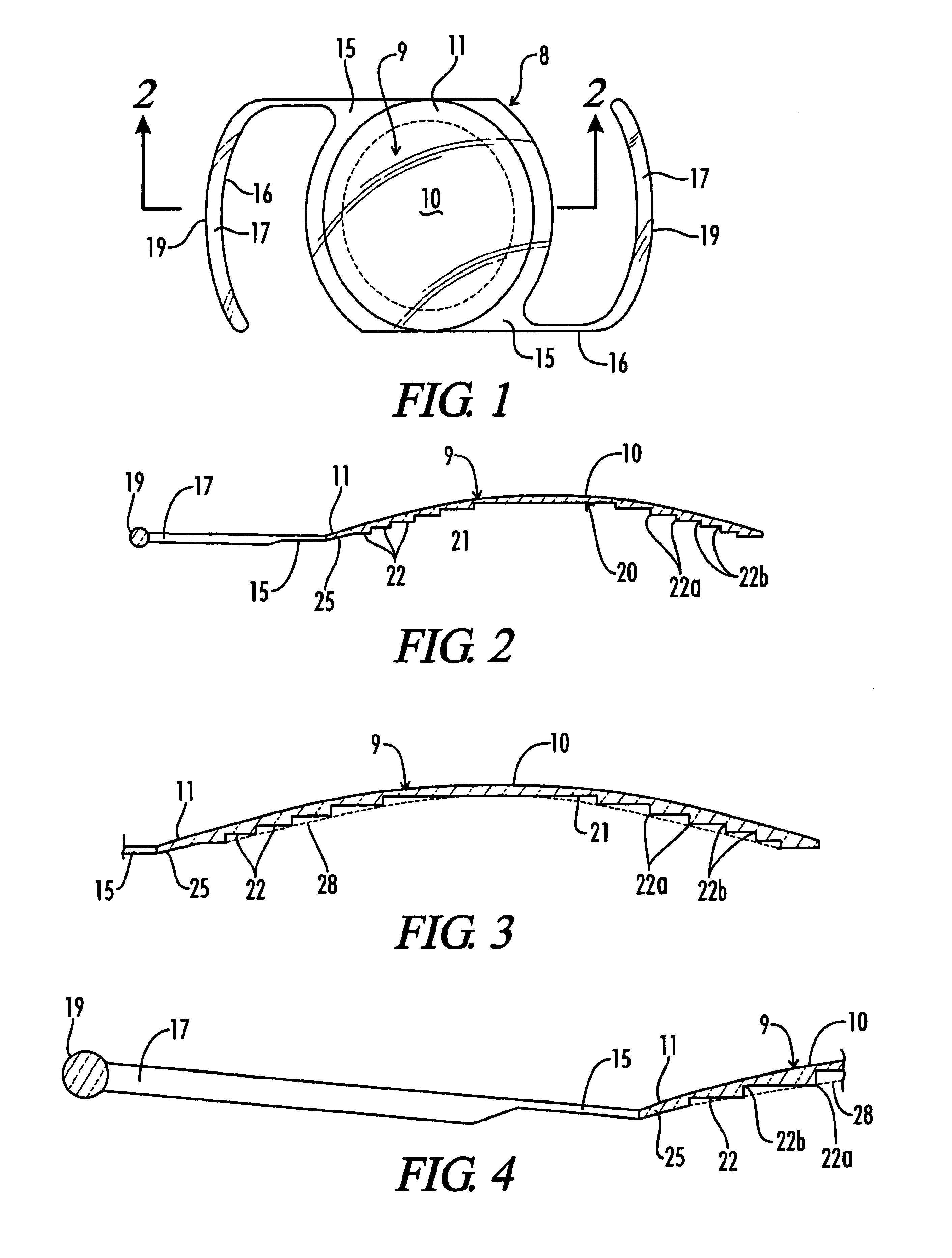

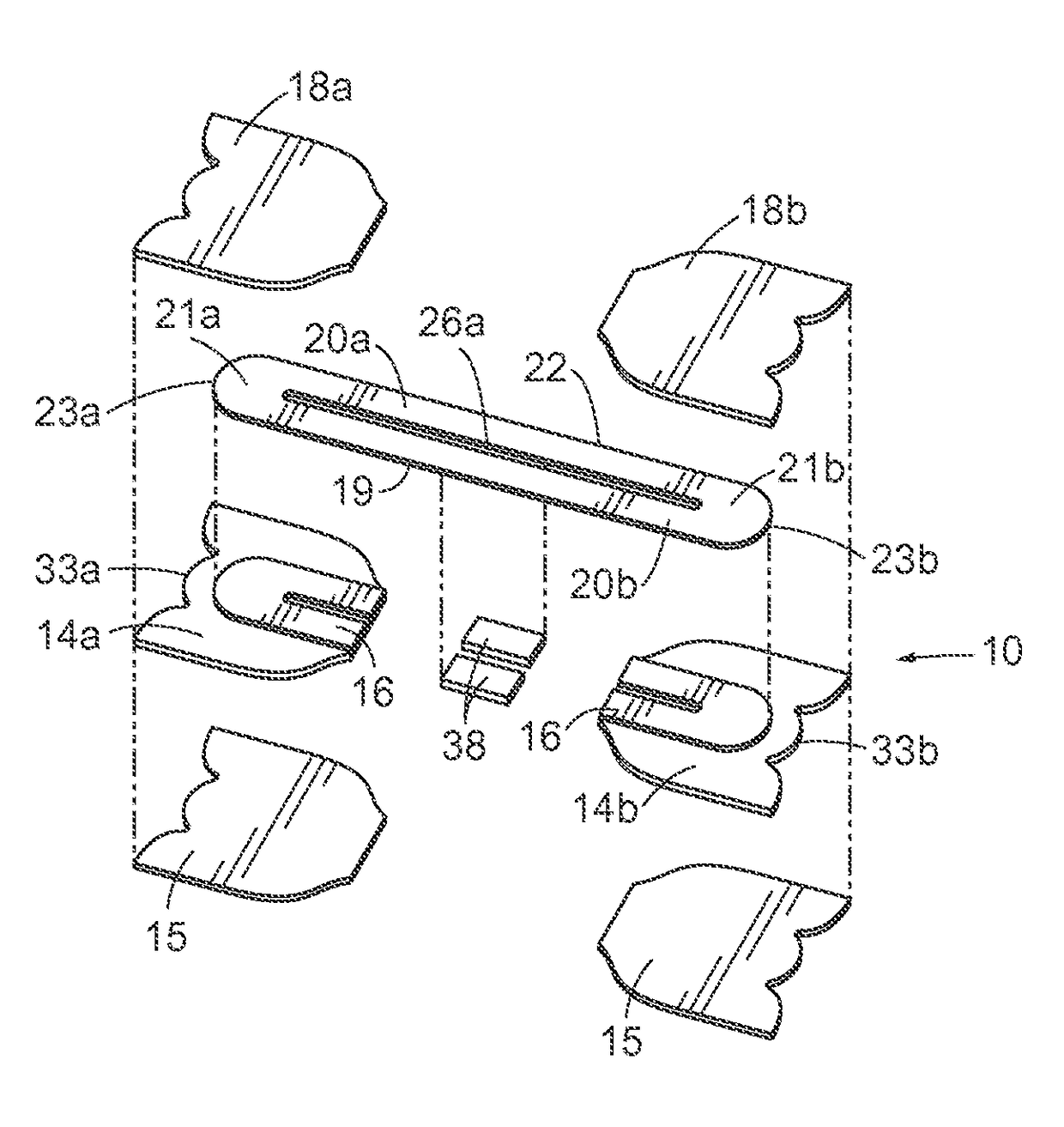

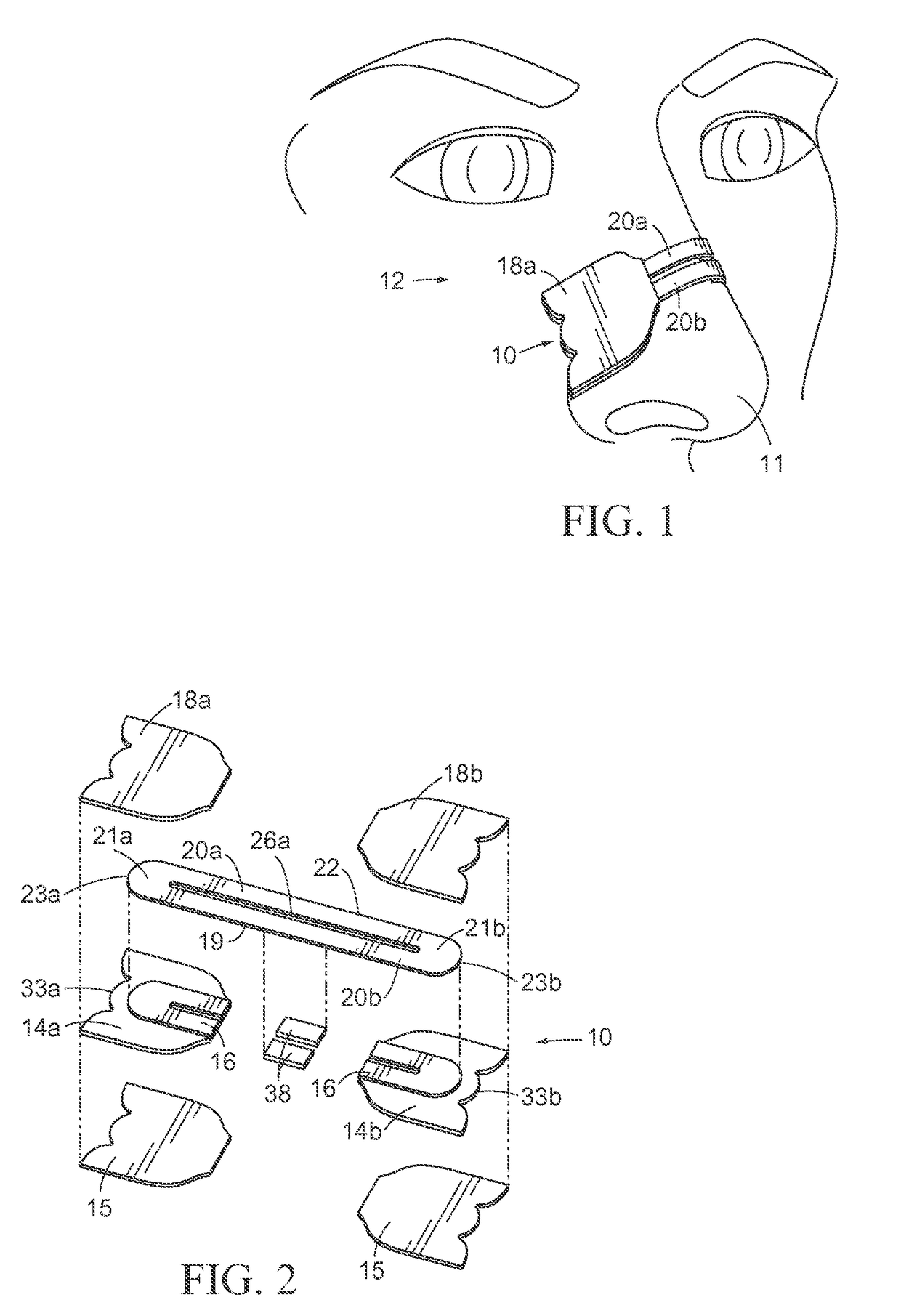

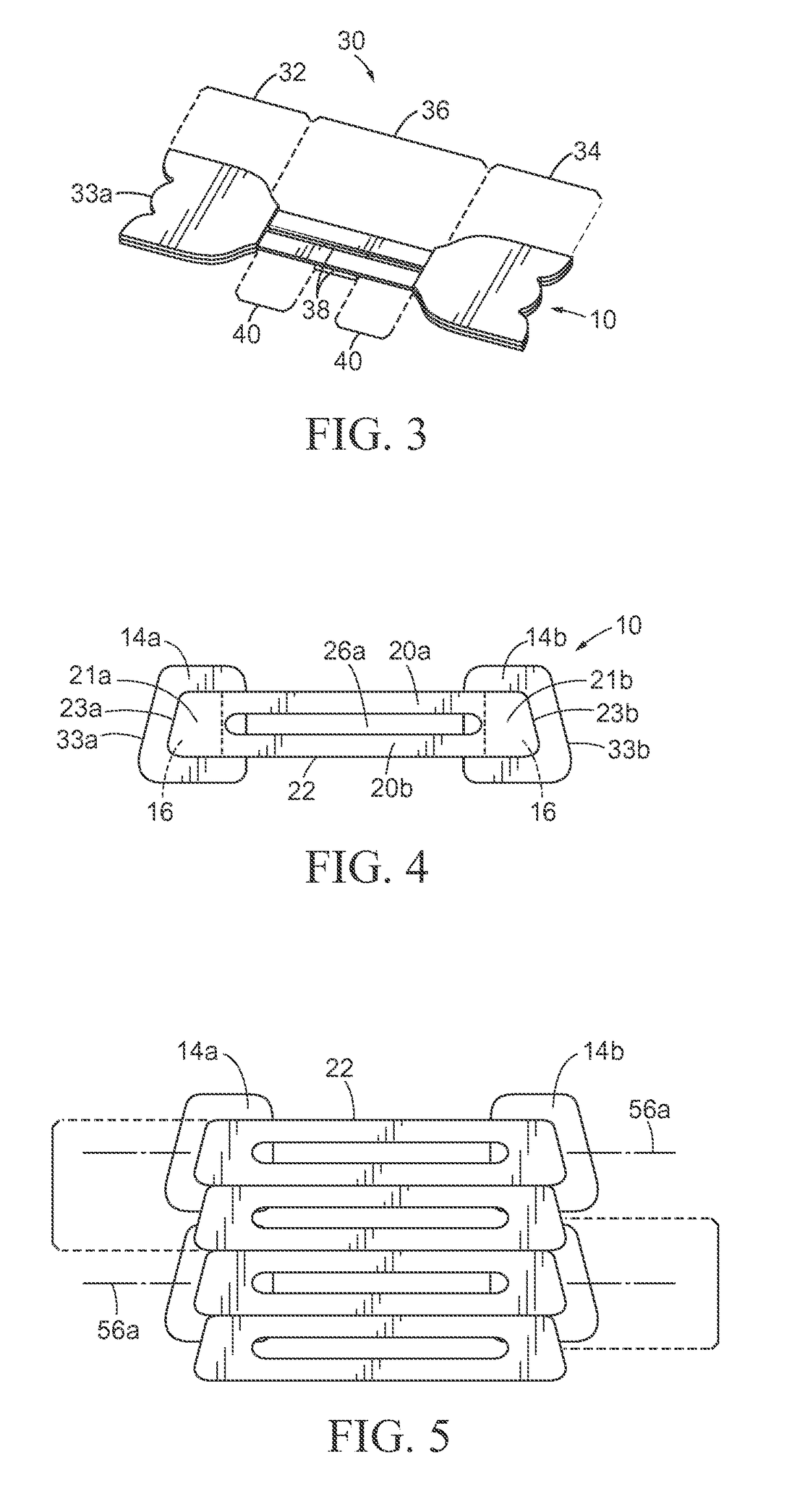

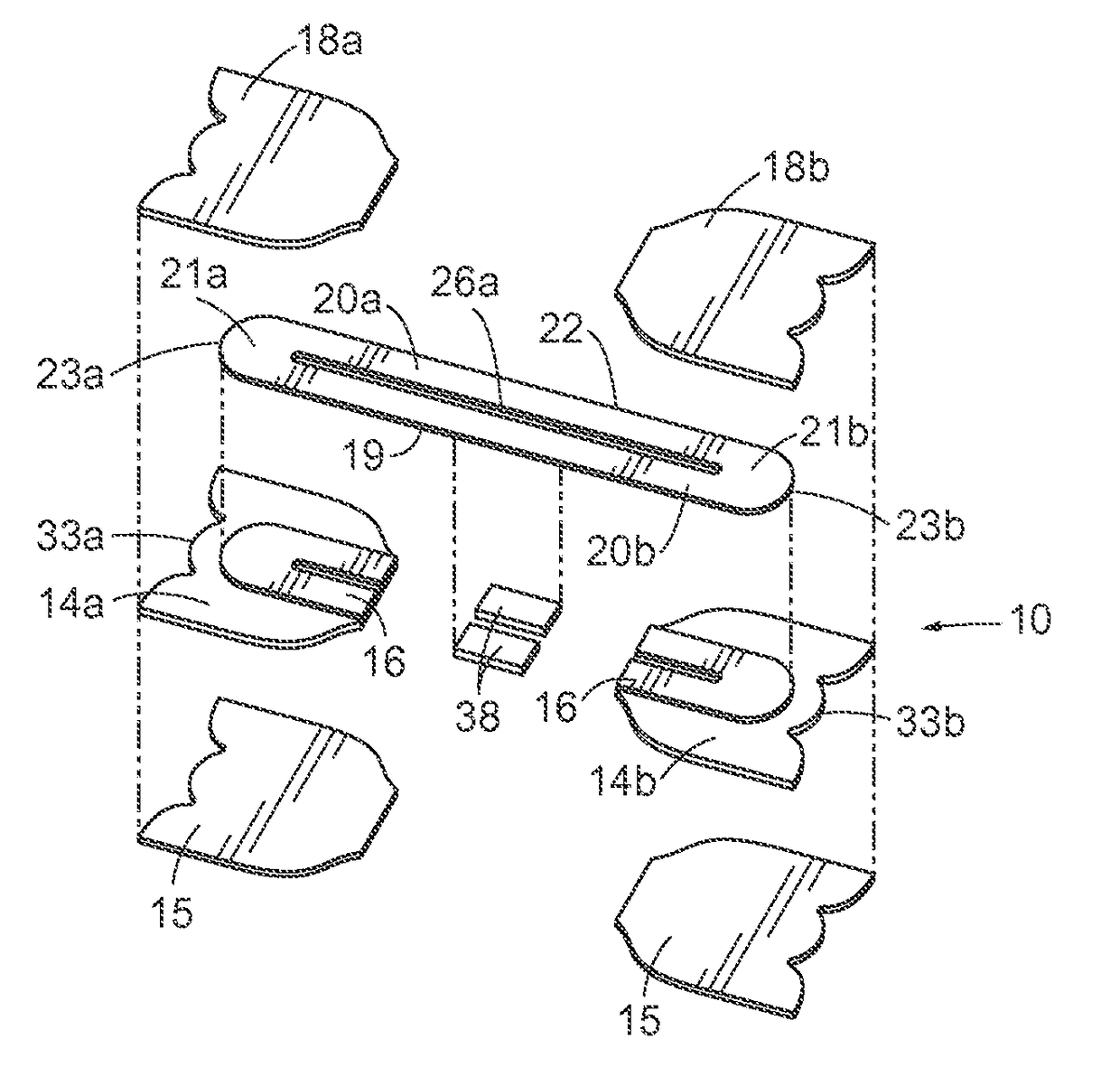

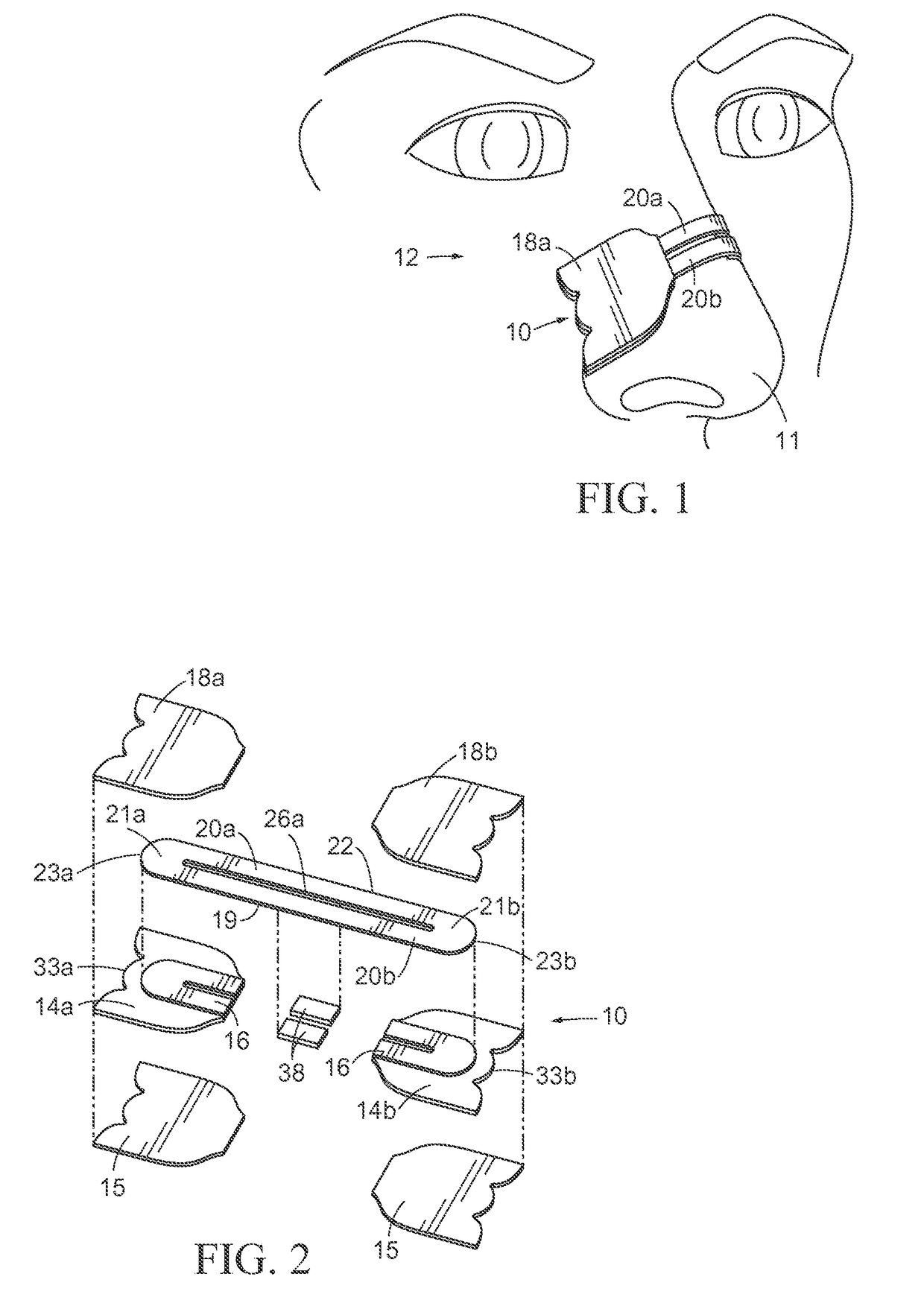

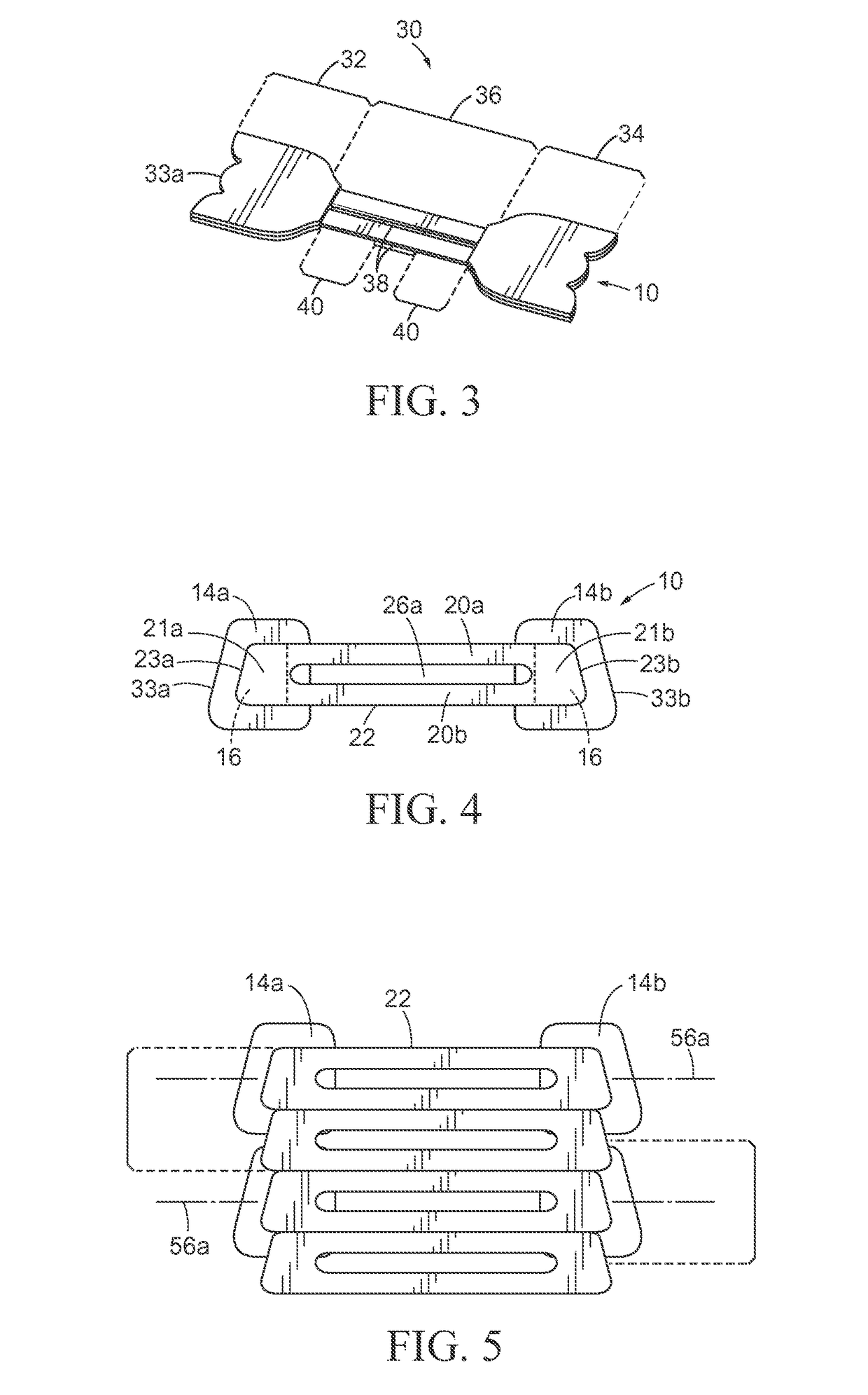

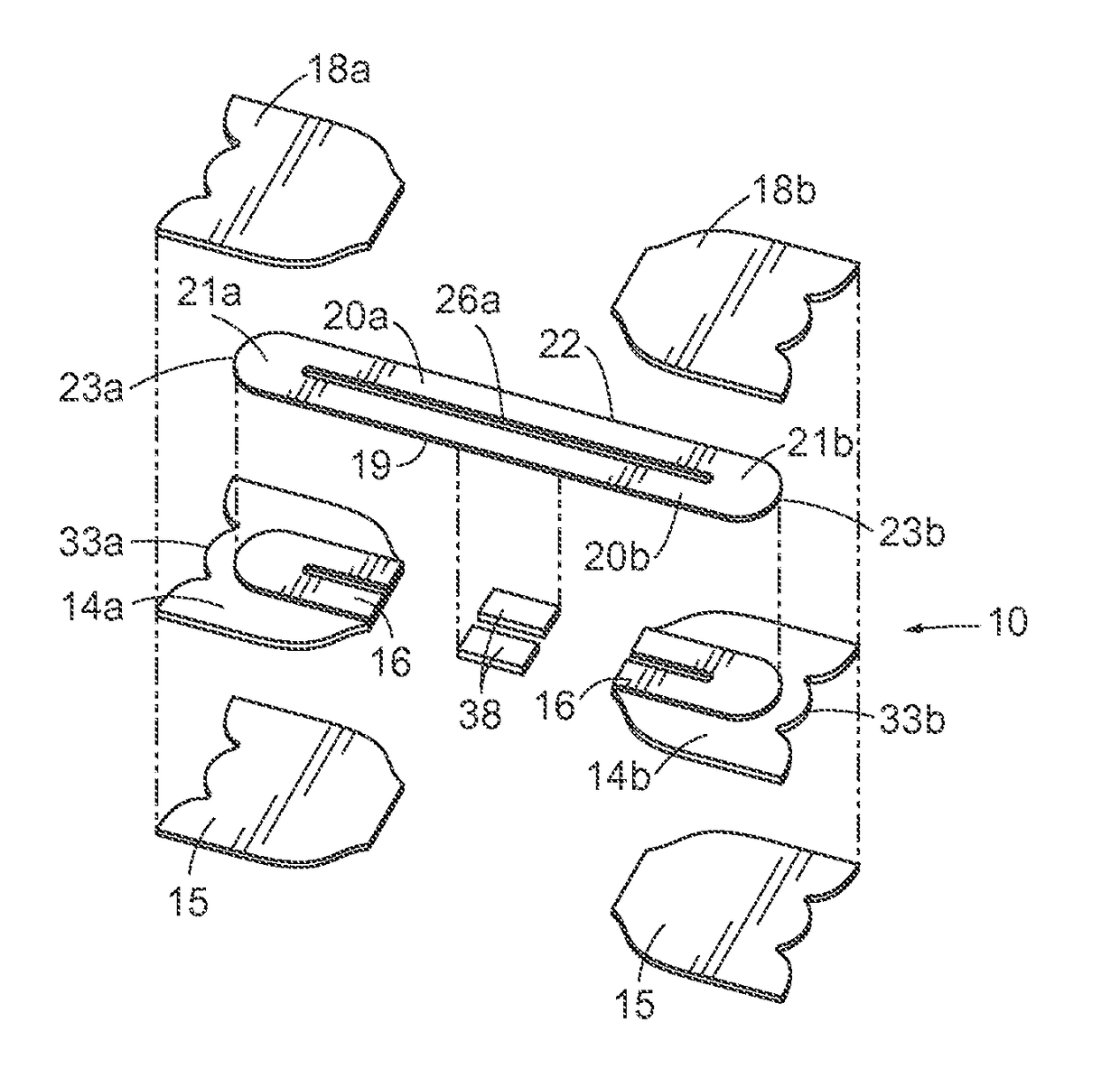

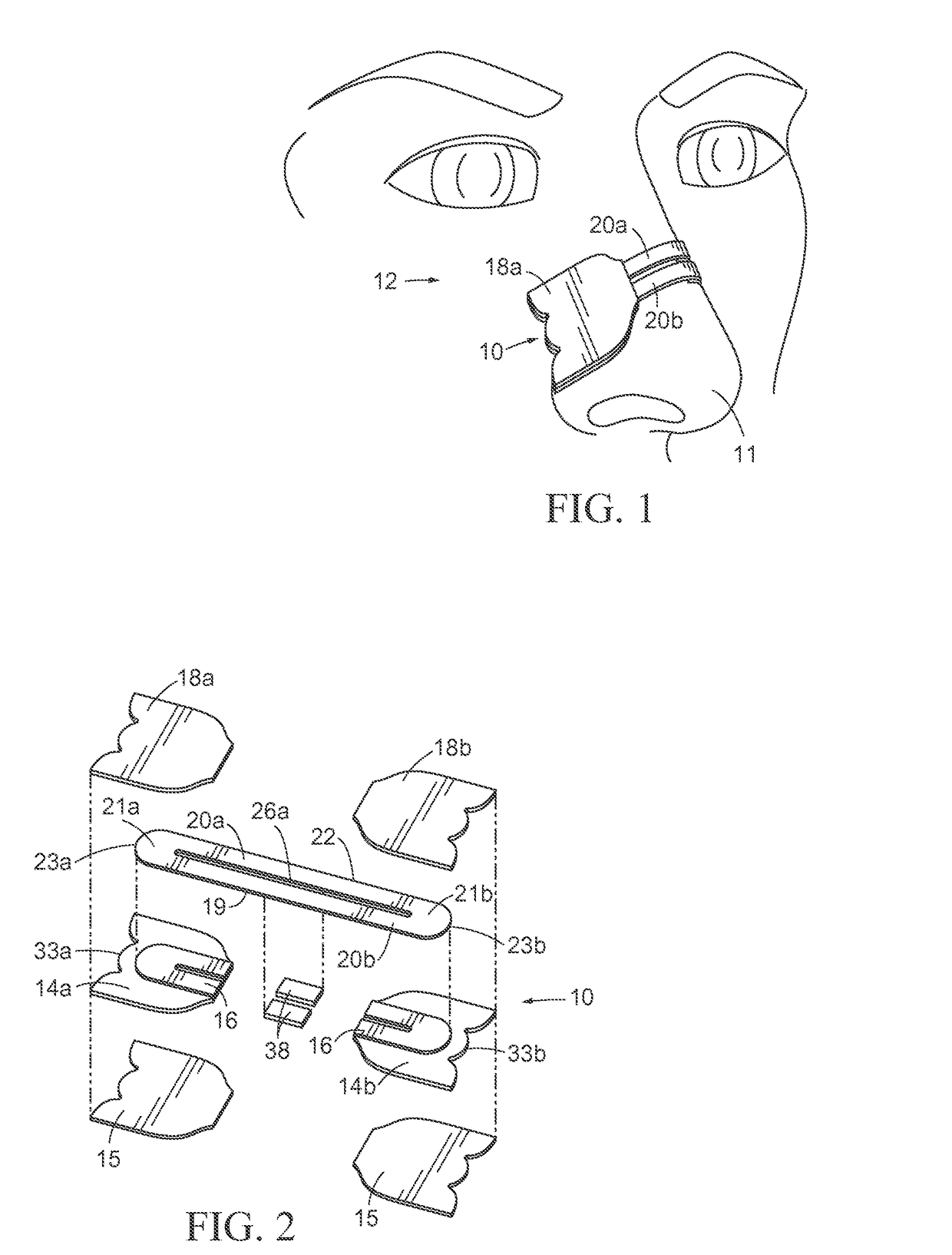

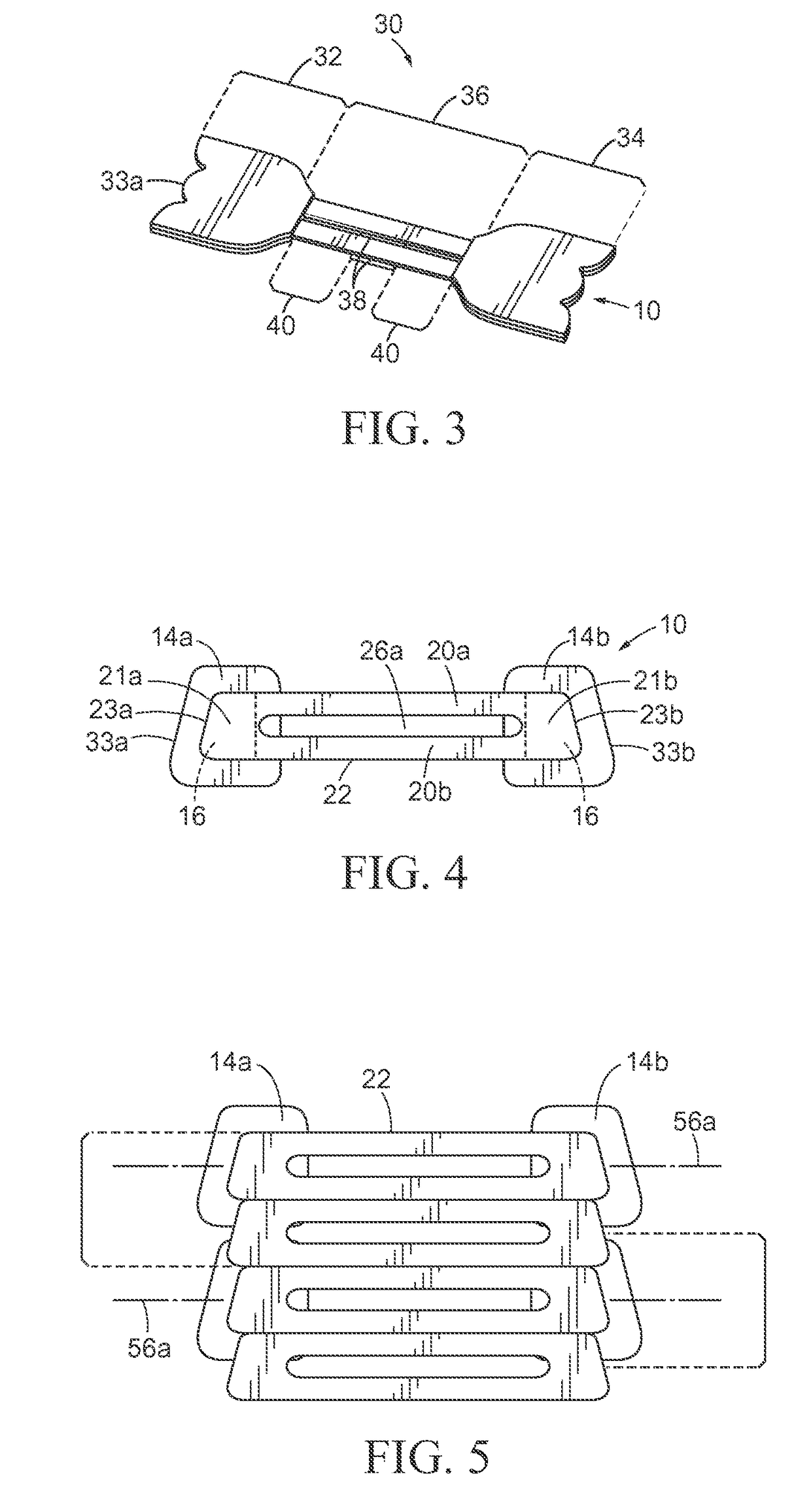

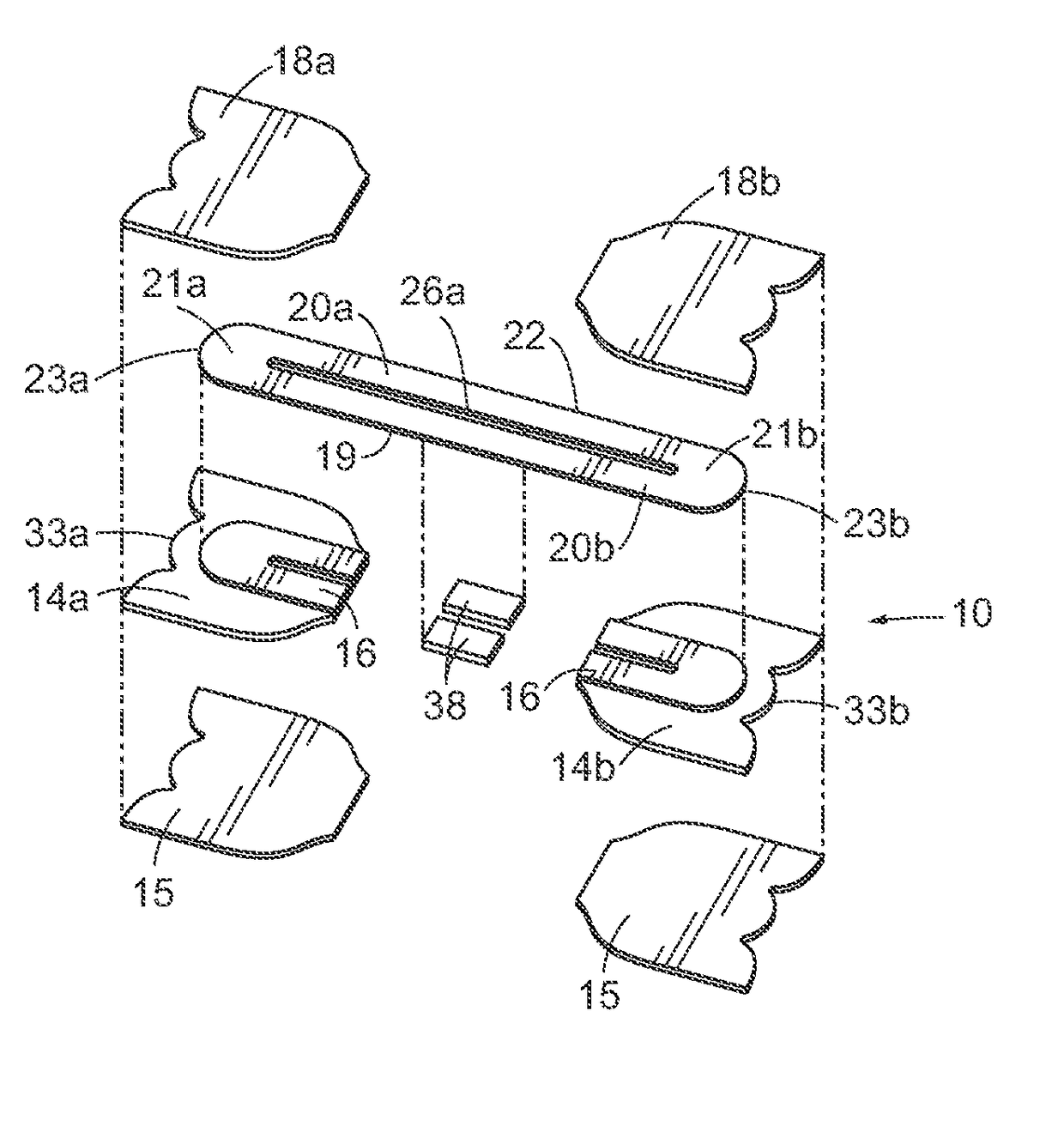

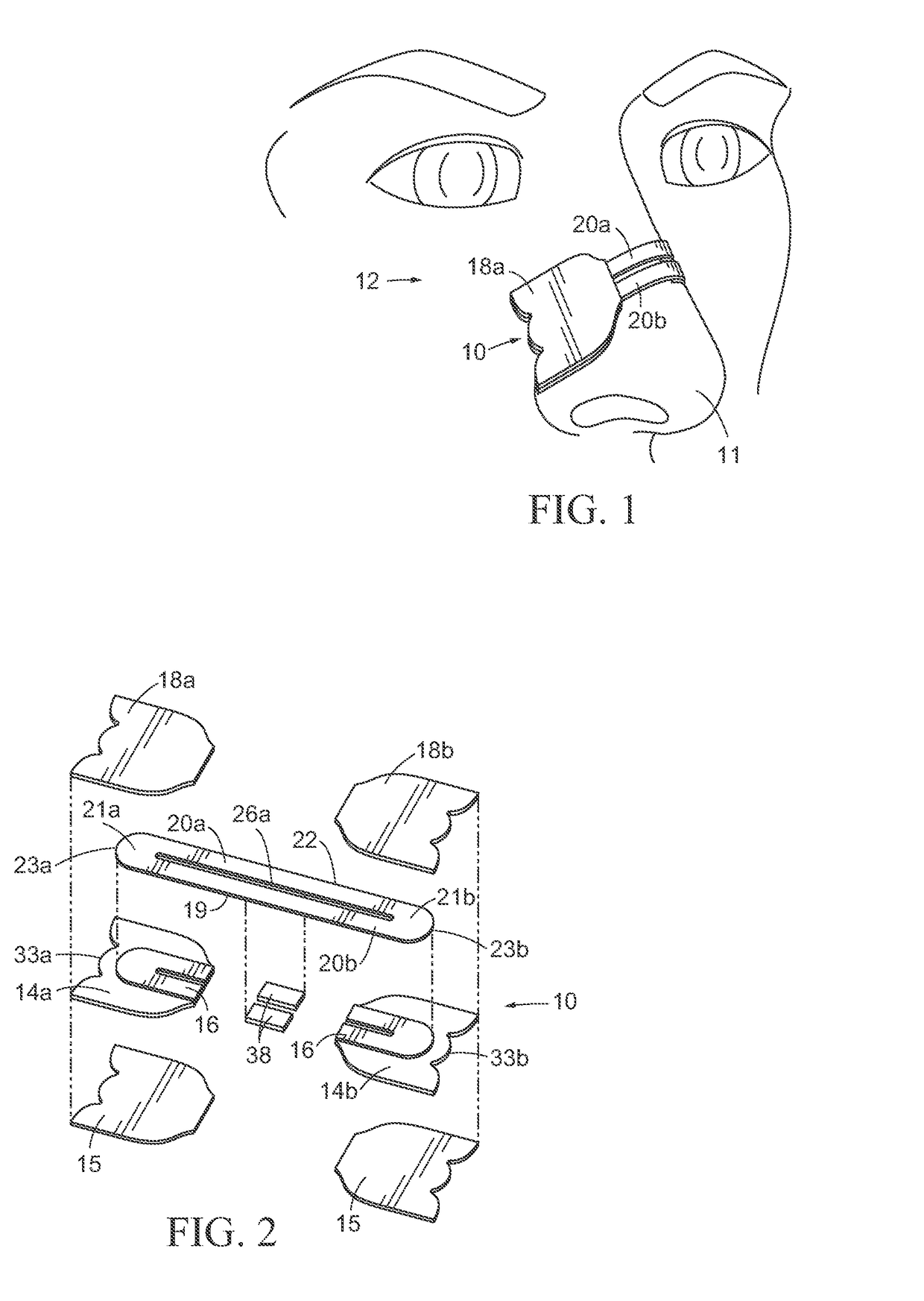

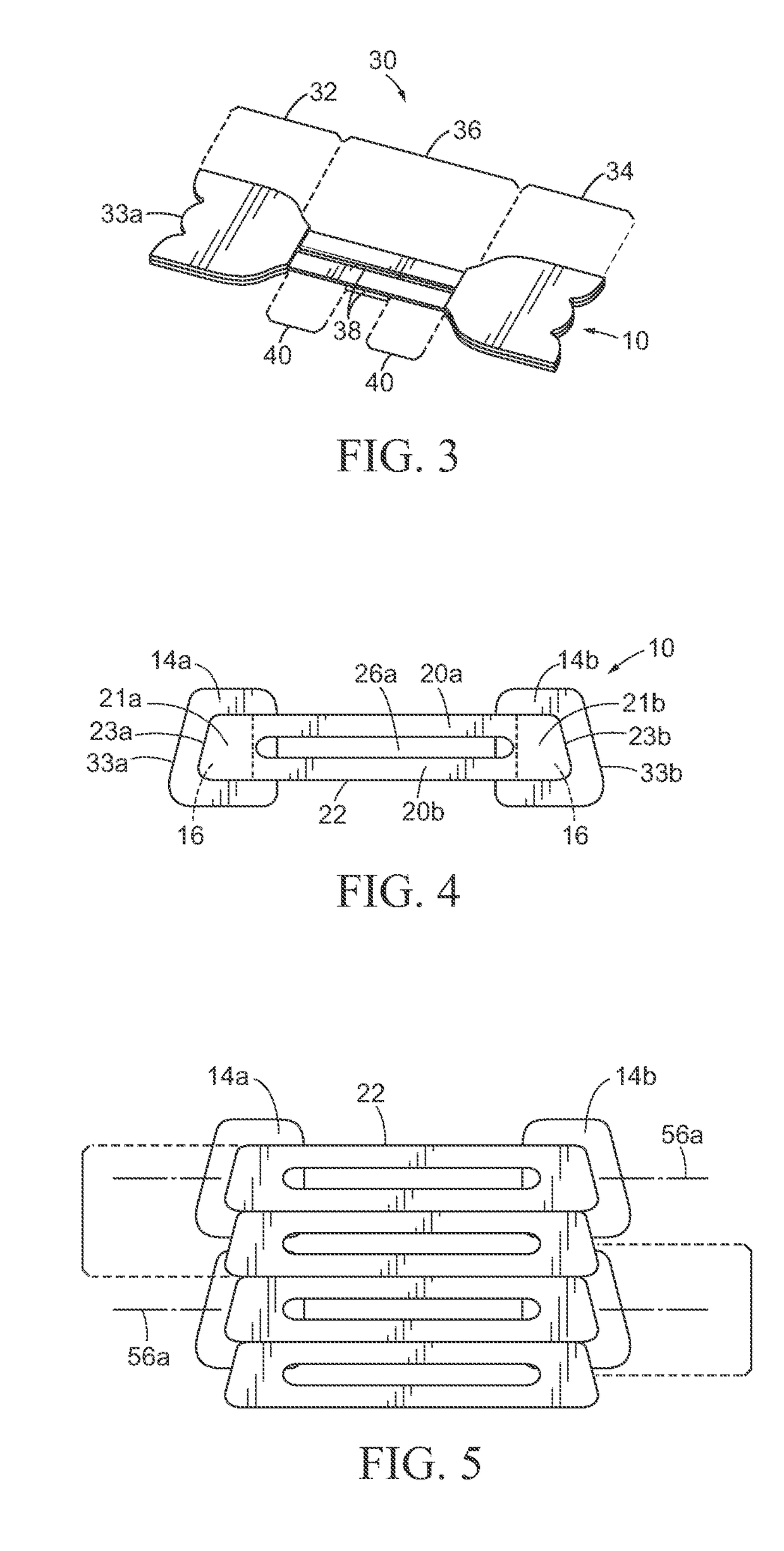

Economical nasal dilator and method of manufacture

ActiveUS8584671B2Facilitate assembly and applicationEasy to disassembleBreathing masksSurgeryNasal dilatorsMechanical engineering

A nasal dilator is formed as a unitary truss of laminated, vertically-stacked layers. A resilient layer provides stabilization and expansion of nasal wall outer tissues, while an adhesive layer attaches the dilator to the user's skin. Dilator component shapes are designed to facilitate manufacture with reduced material waste. Some embodiments can be assembled by the user to customize the size or configuration to personal preference.

Owner:HORIZON IP TECH LLC

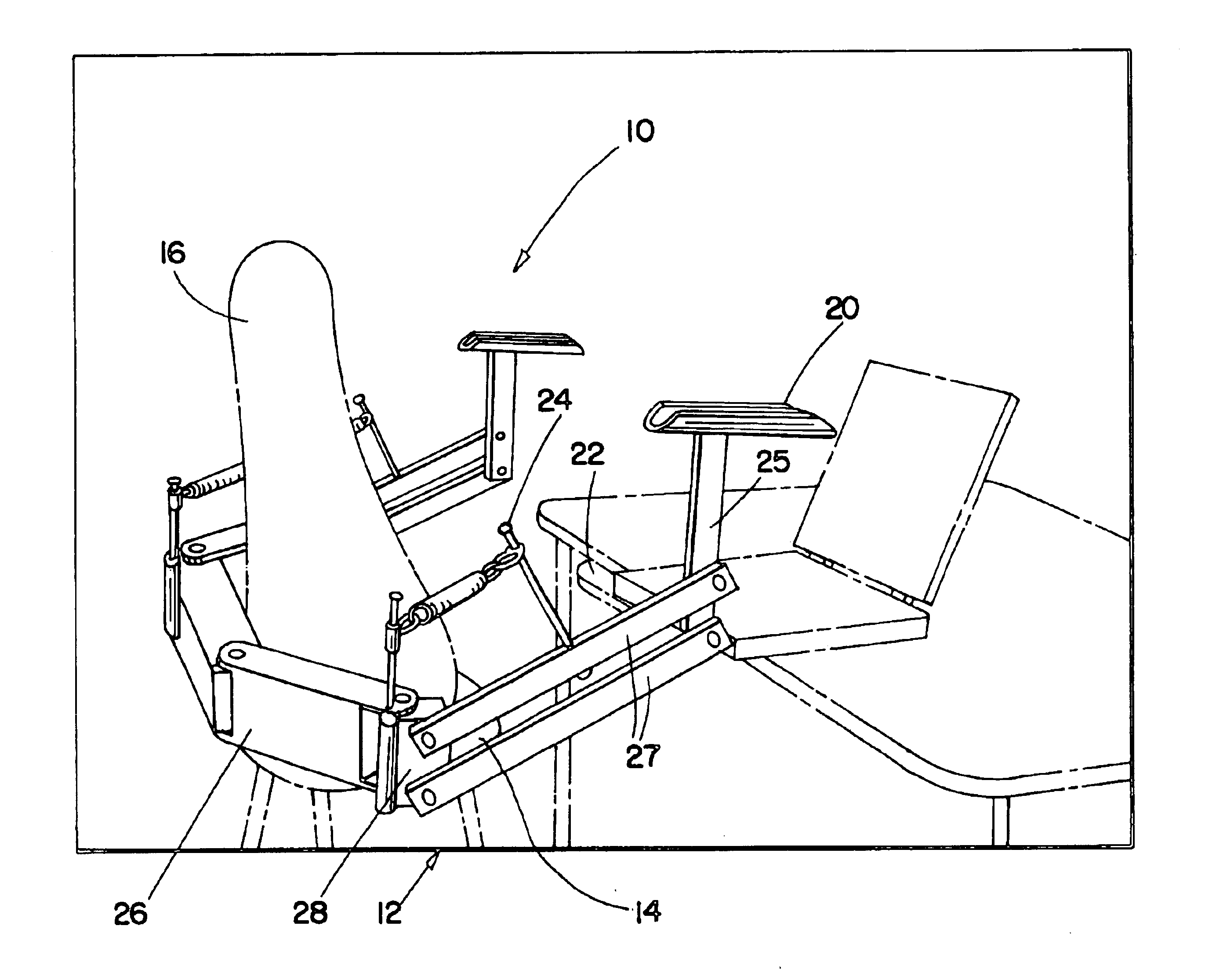

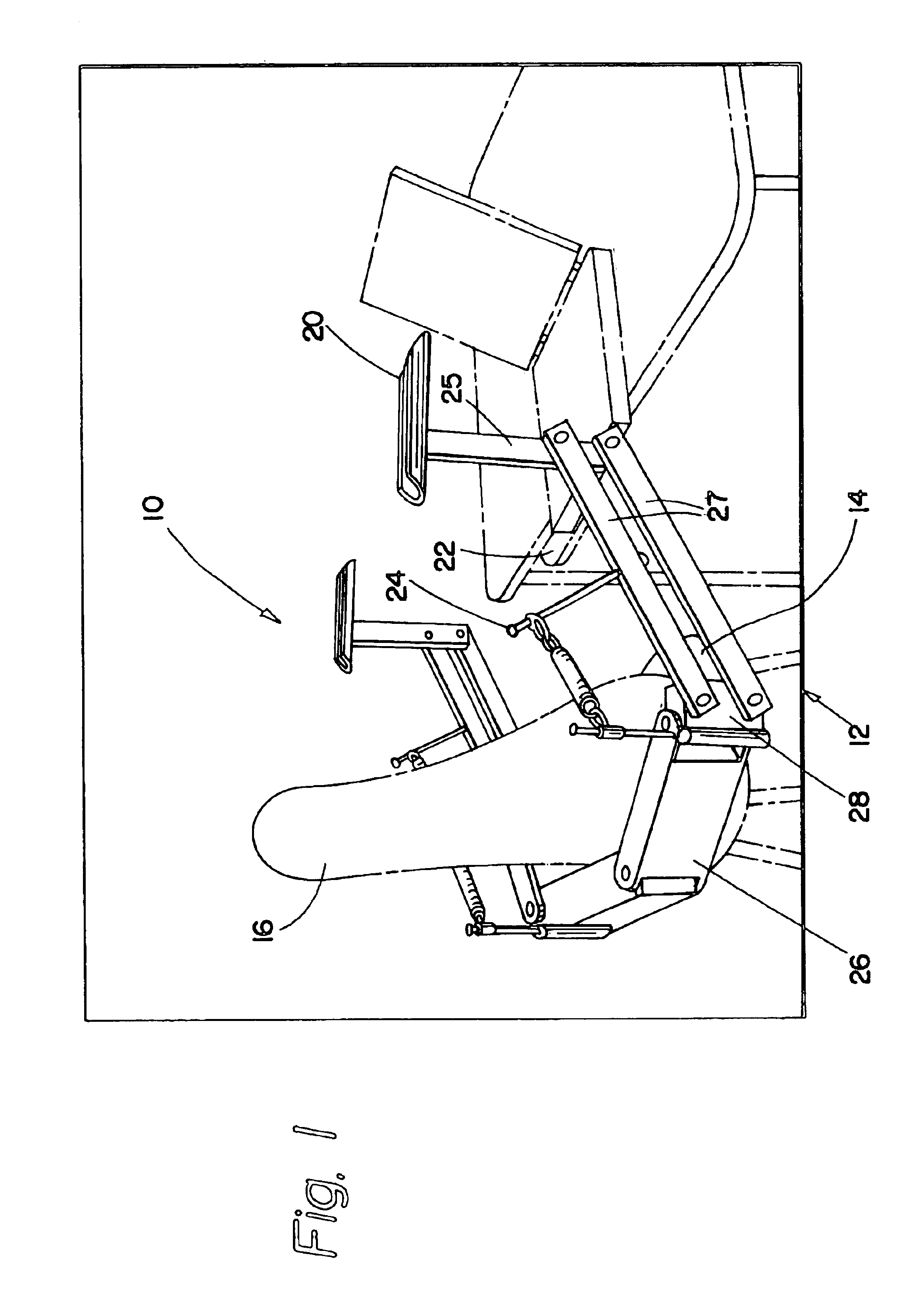

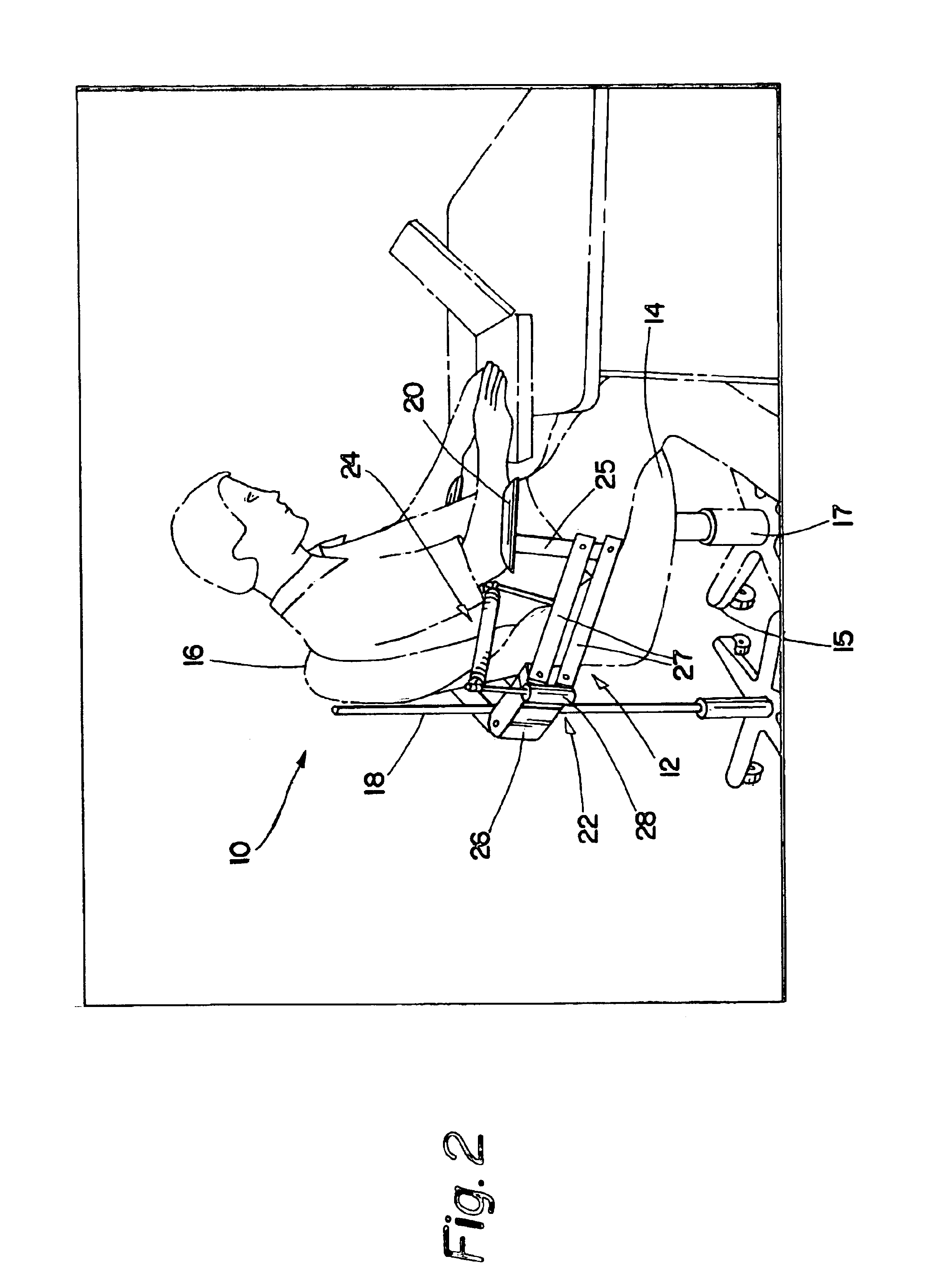

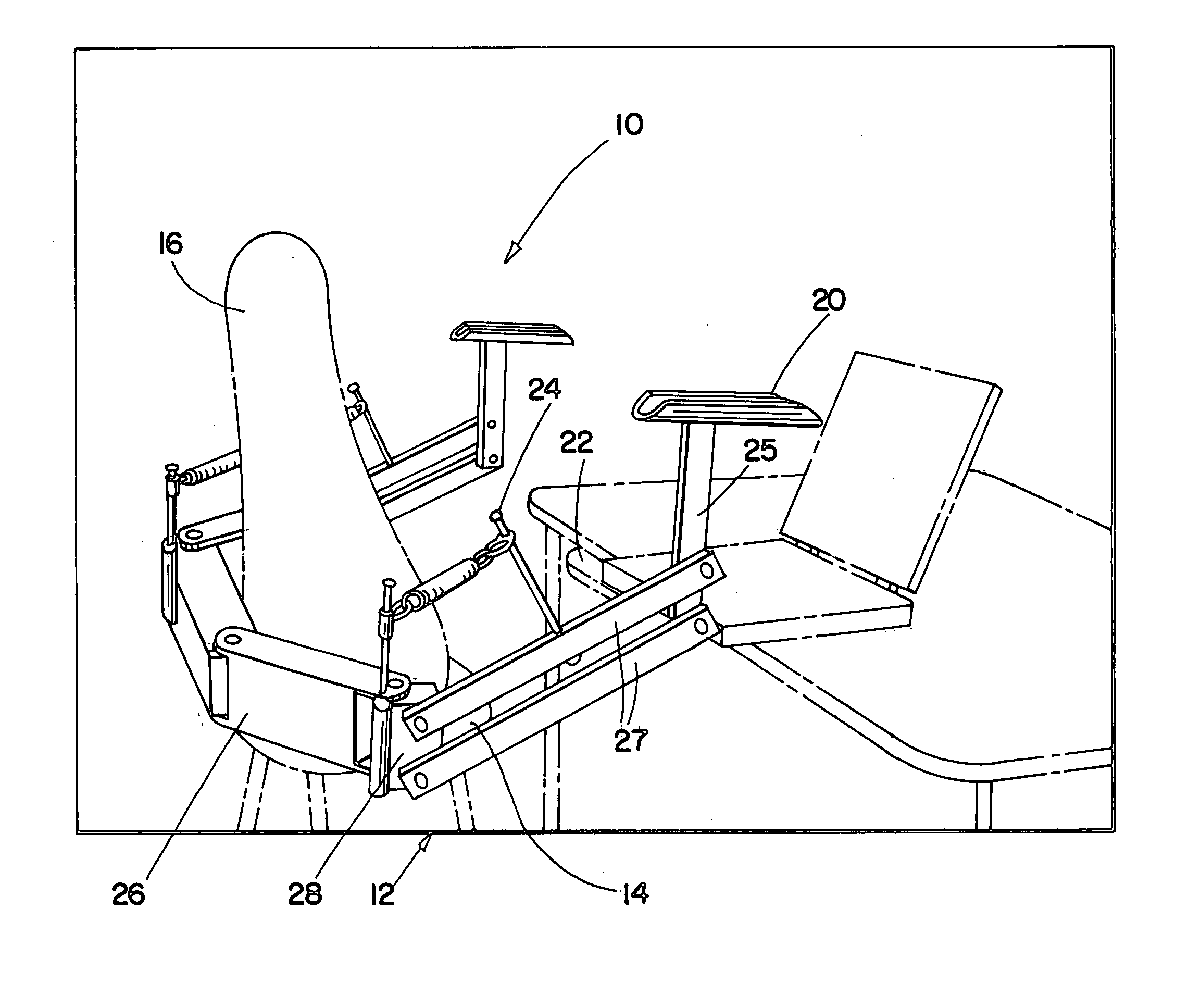

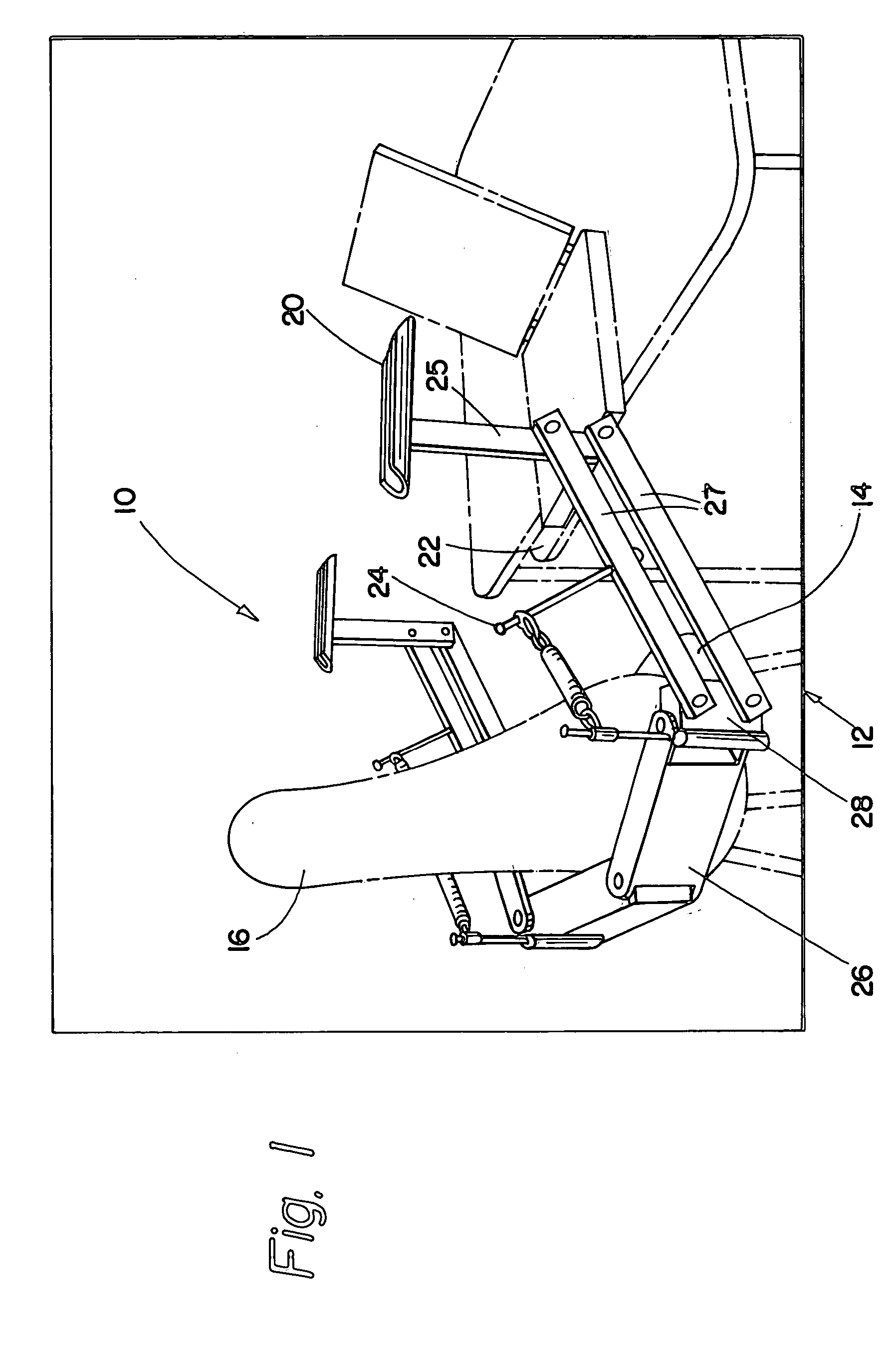

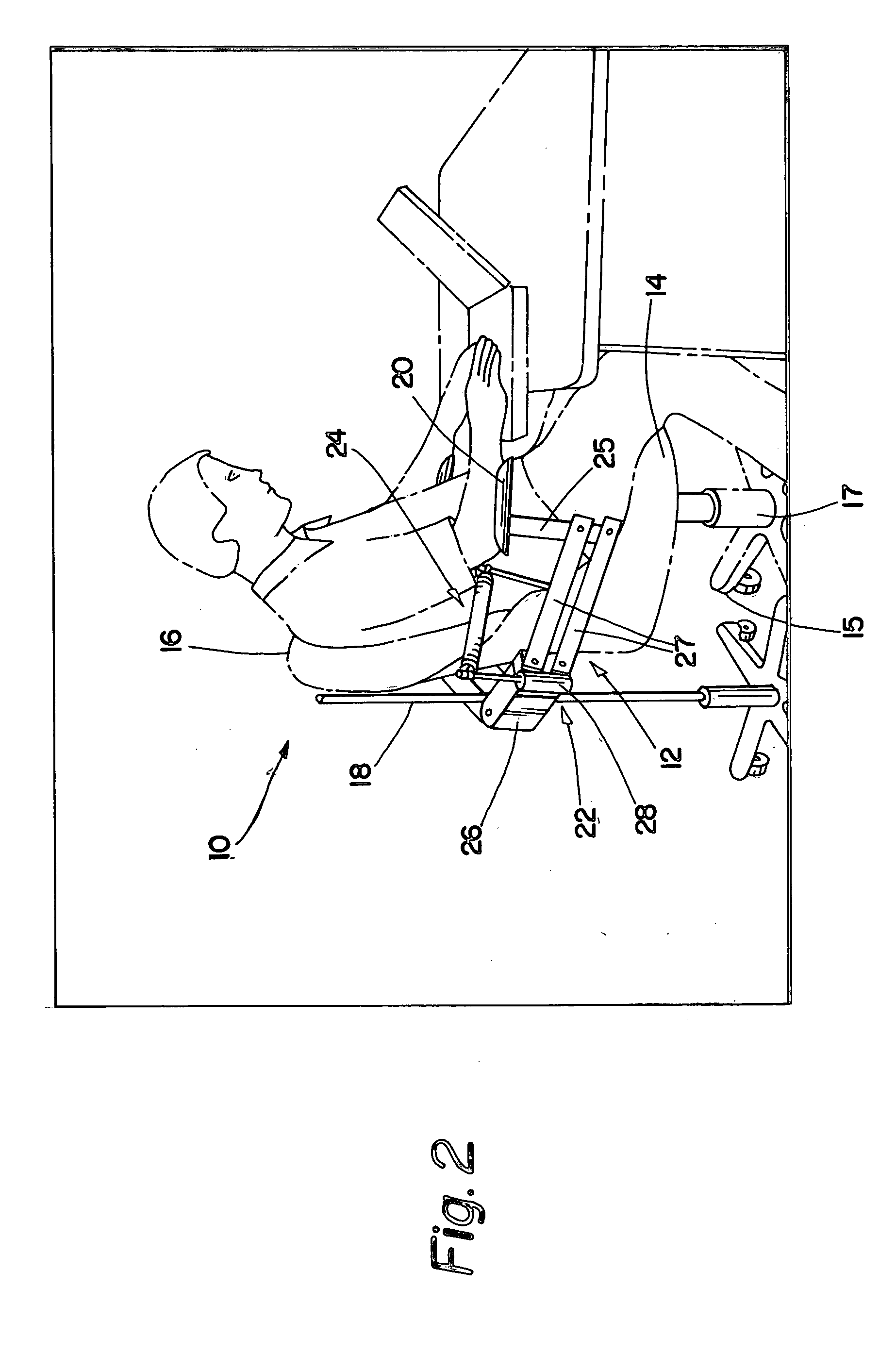

Ergonomically neutral arm support system

InactiveUS6923505B2Effectively weightlessNeutral body positionVehicle seatsWriting supportsSupporting systemDynamic balance

An ergonomic arm support system maintains a neutral position for the forearm. A mechanical support structure attached to a chair or other mounting structure supports the arms of a sitting or standing person. The system includes moving elements and tensioning elements to provide a dynamic balancing force against the forearms. The support structure is not fixed or locked in a rigid position, but is an active dynamic system that is maintained in equipoise by the continuous operation of the opposing forces. The support structure includes an armrest connected to a flexible linkage or articulated or pivoting assembly, which includes a tensioning element such as a spring. The pivoting assembly moves up and down, with the tensioning element providing the upward force that balances the downward force of the arm.

Owner:RGT UNIV OF CALIFORNIA

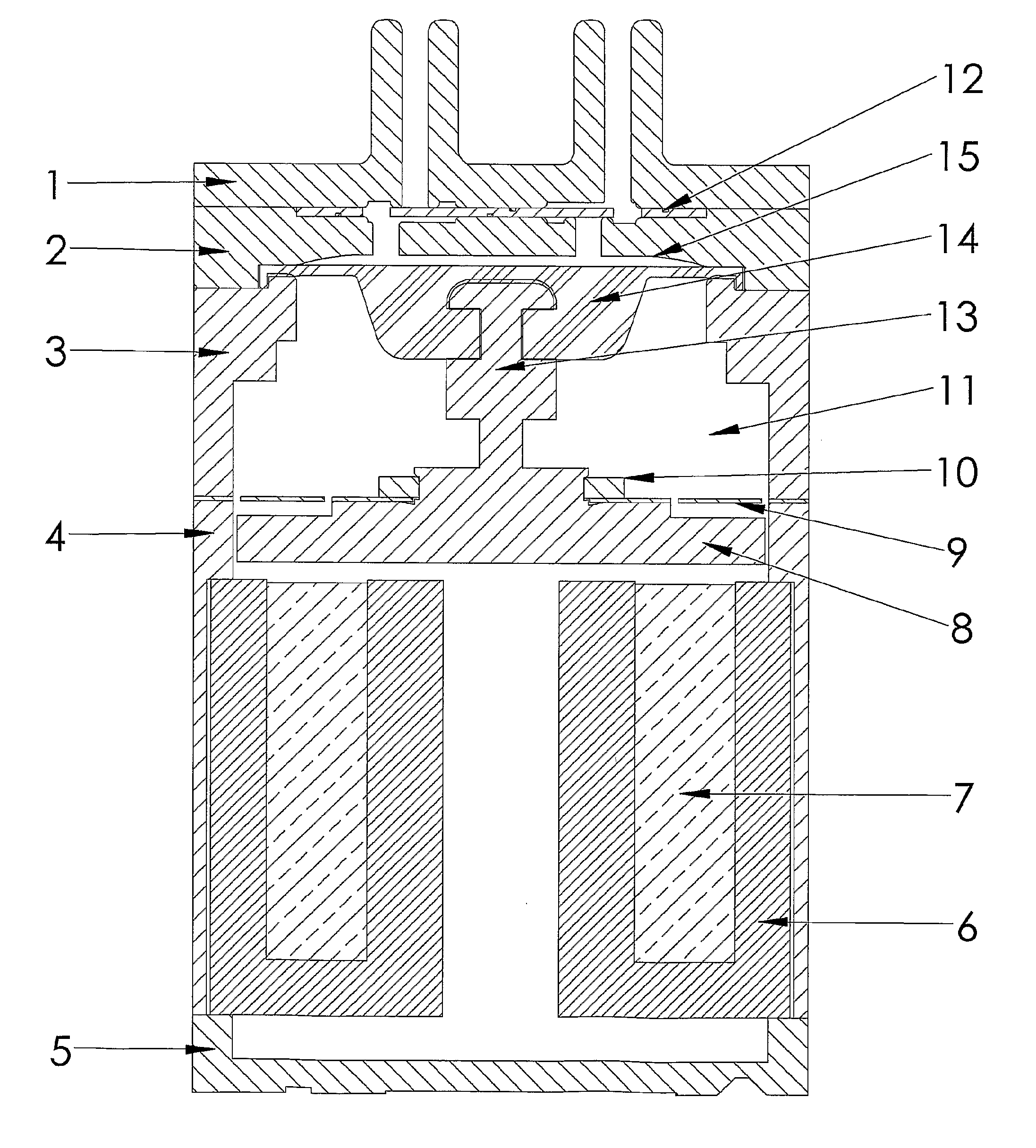

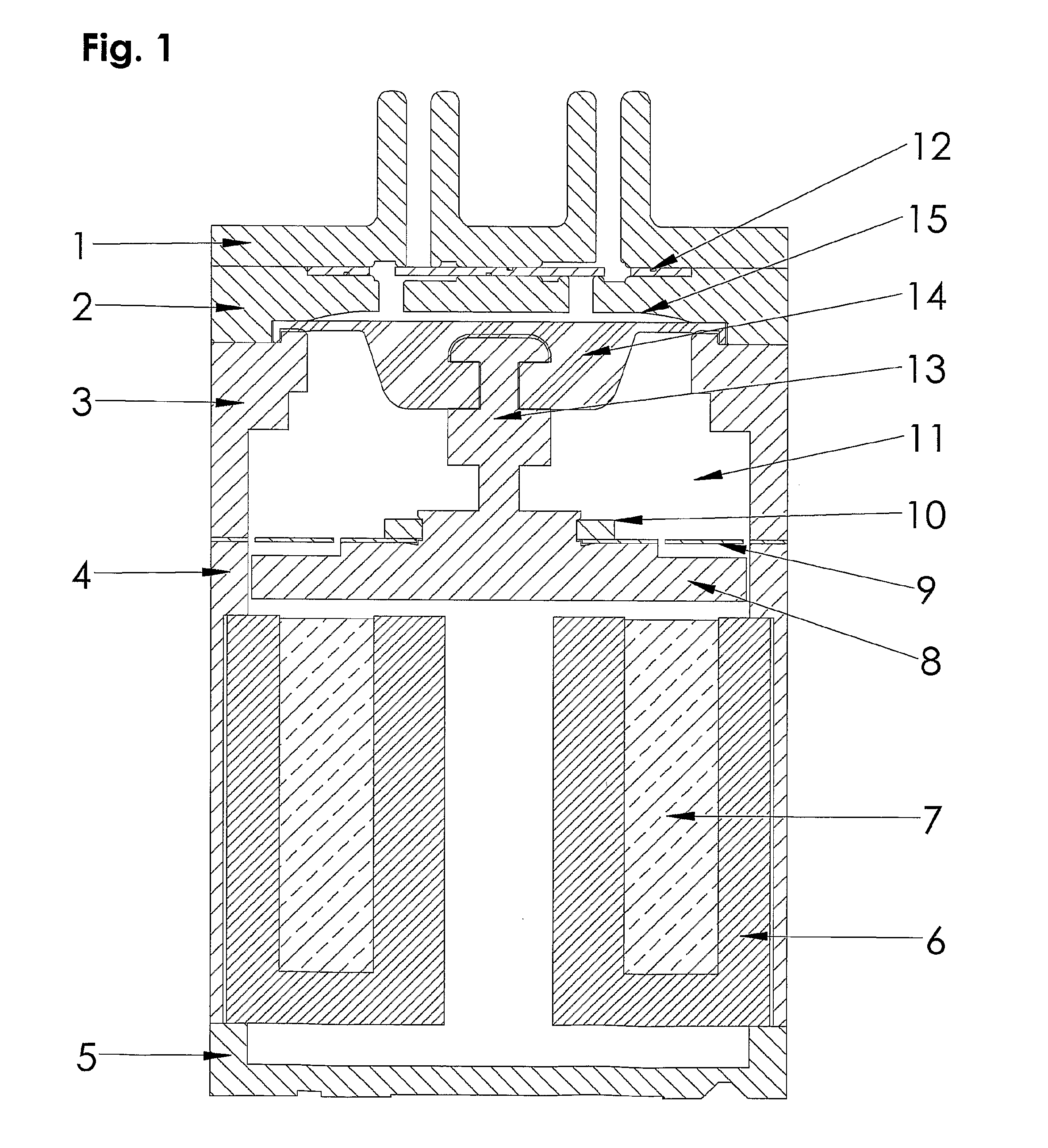

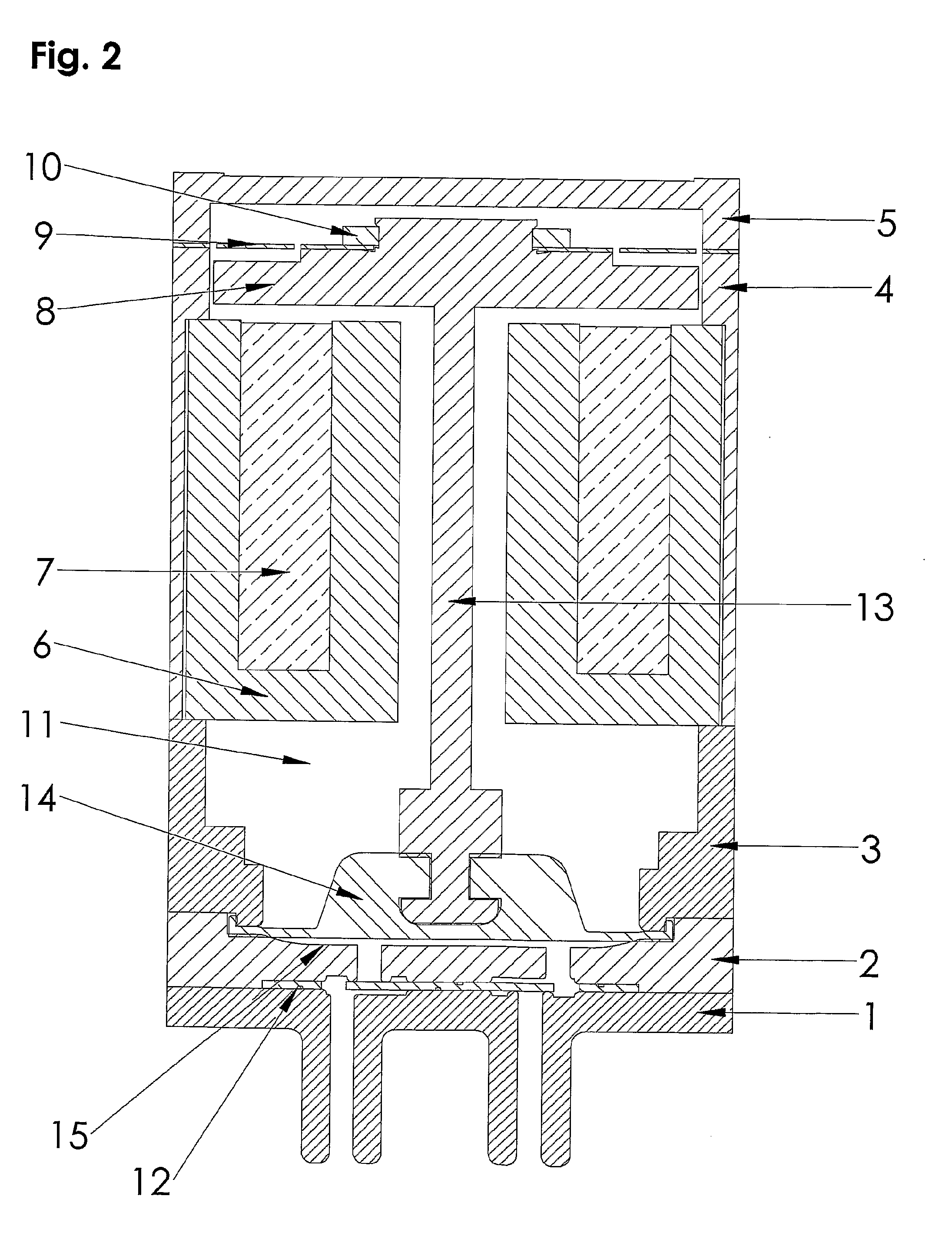

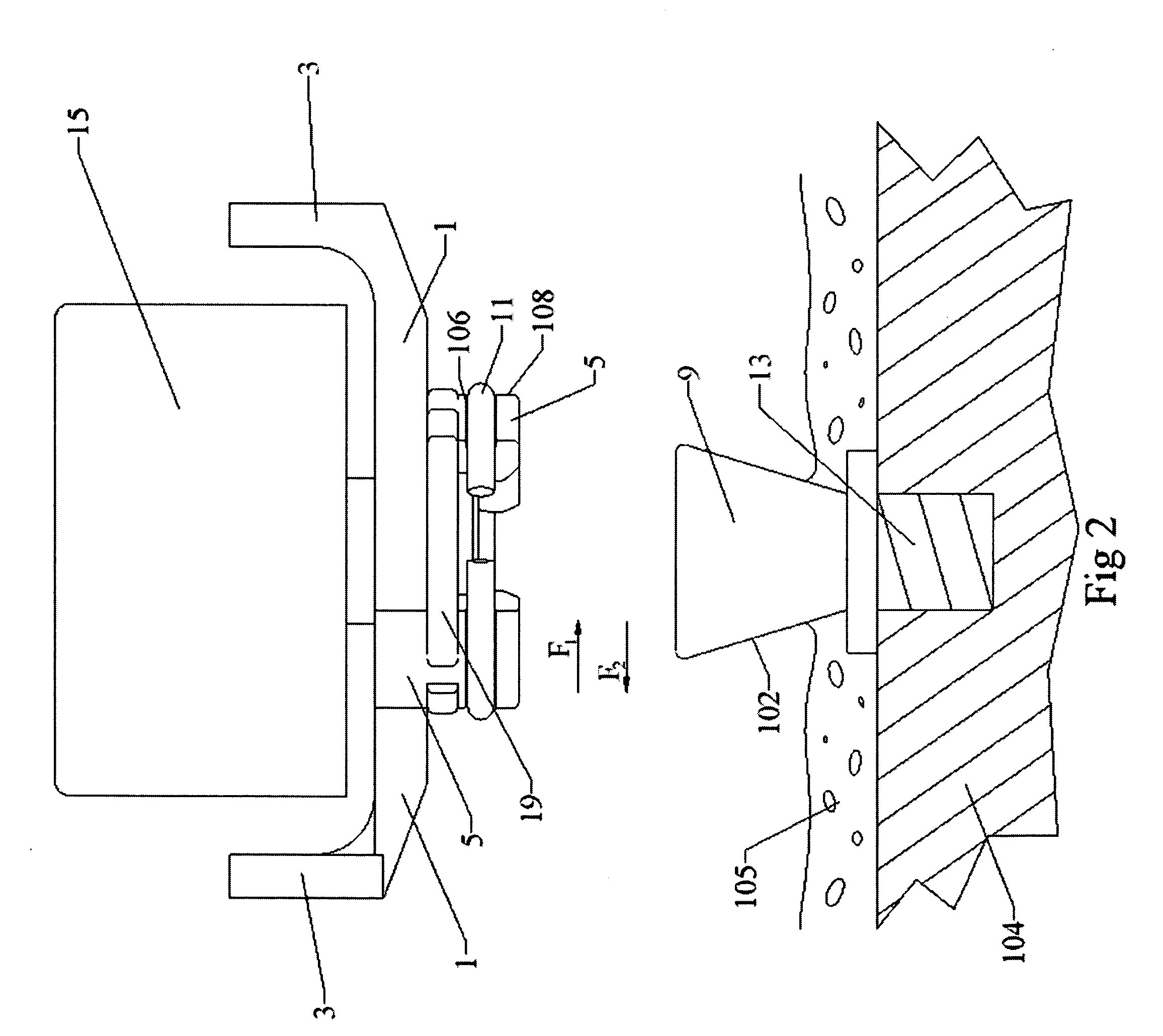

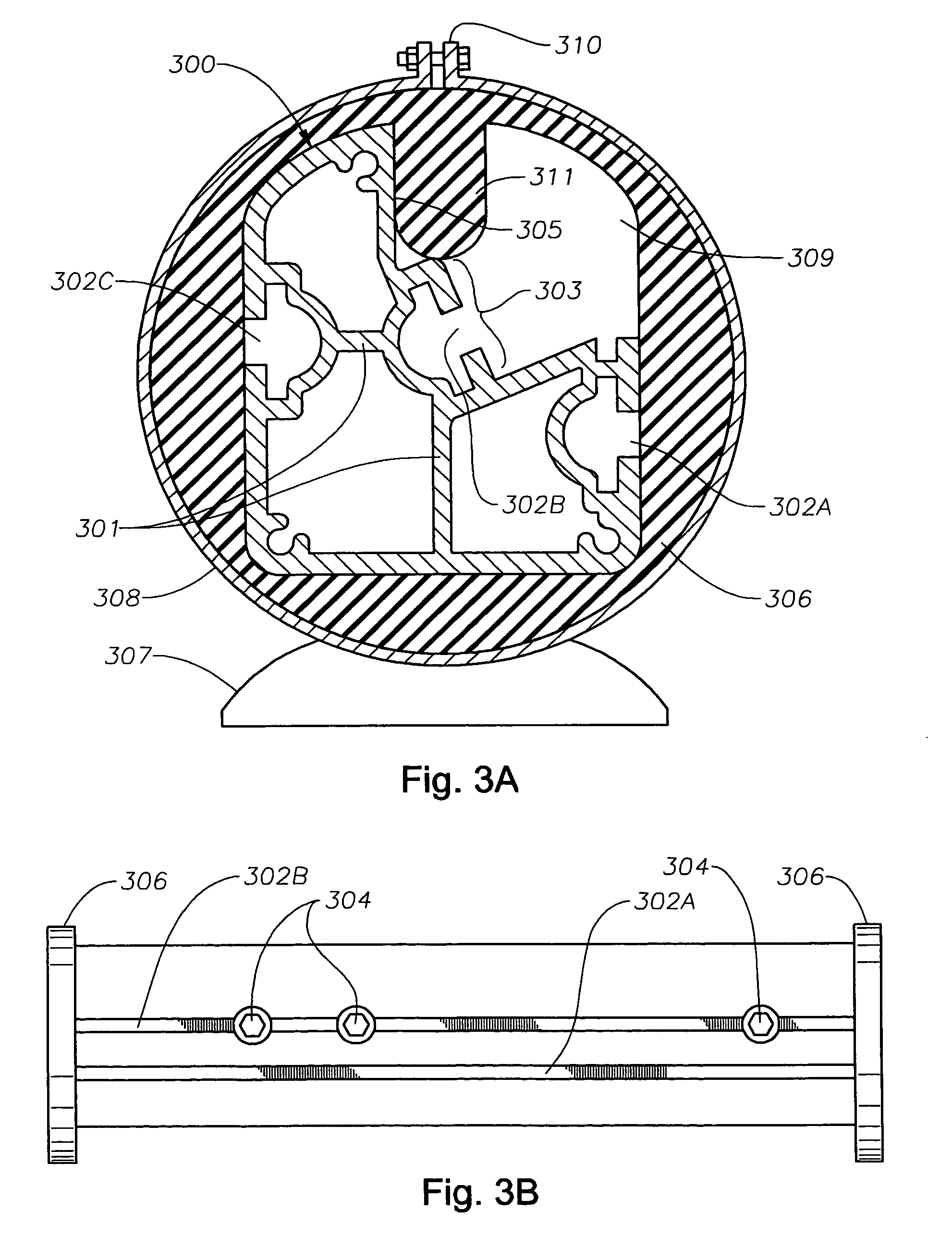

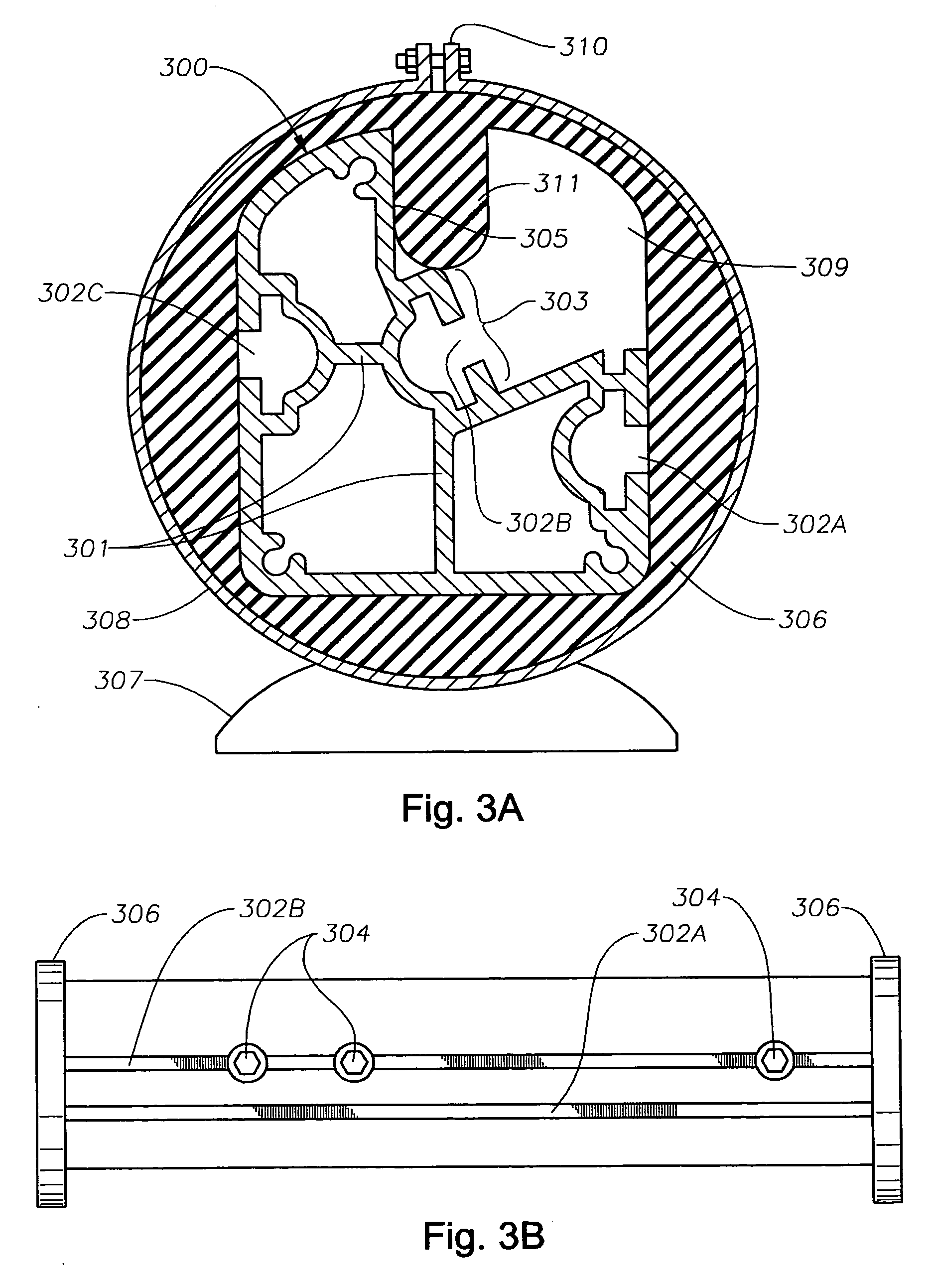

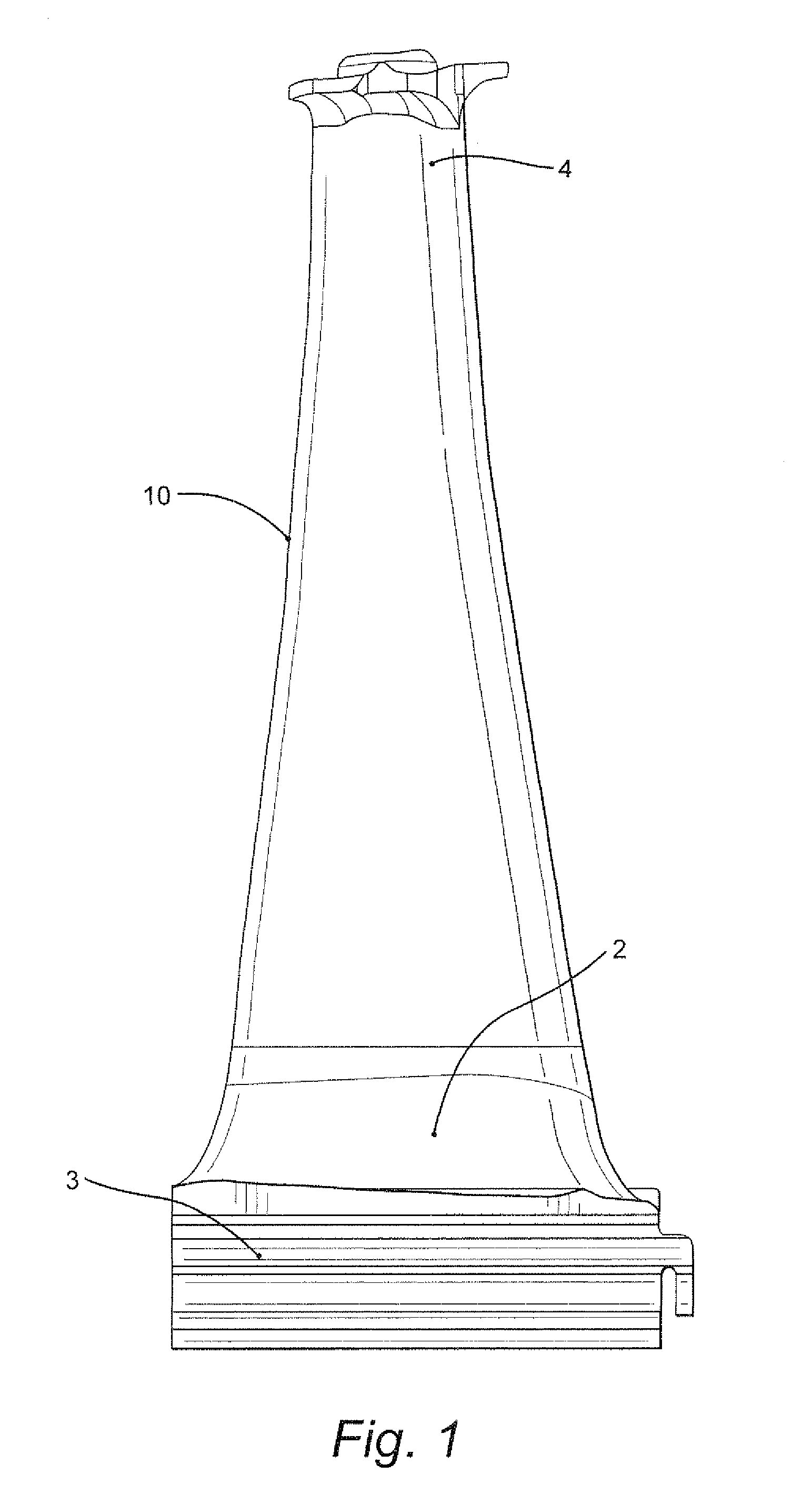

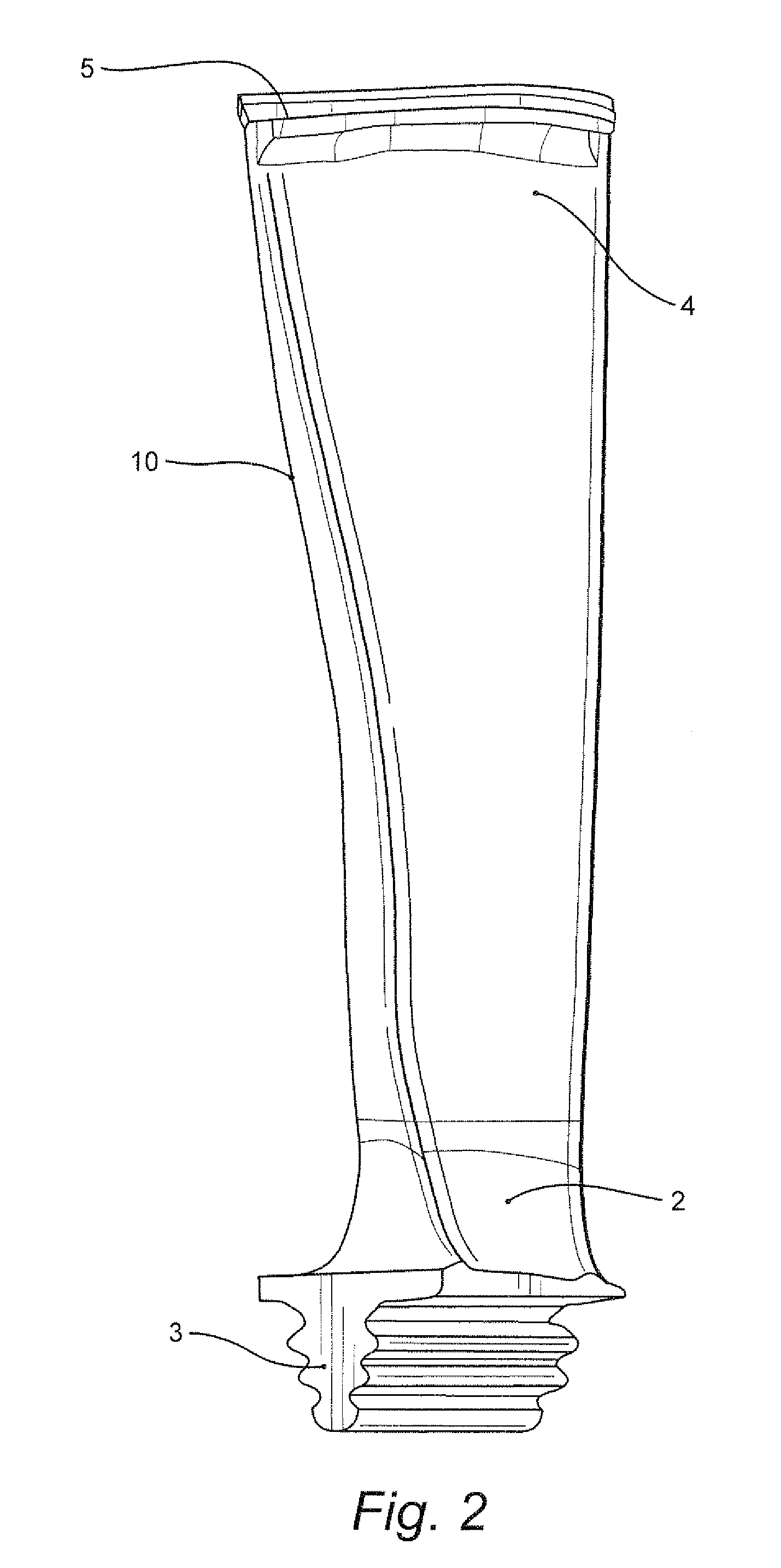

Membrane Pump

ActiveUS20090169402A1InexpensiveEasy to manufacturePositive displacement pump componentsFlexible member pumpsPump chamberEngineering

An electromagnetic driven membrane pump has a pump housing inside which at least one pump chamber (15) having at least one intake and outlet is formed and delimited between a gable (1) of the pump housing and at least one completely-sealed membrane (14) attached to a wall (4) of the pump housing and, in an axial direction of the pump housing, to a running axle (13) suspended in at least two separated suspensions in a longitudinal direction of the axle (13). At least one of the suspensions is composed of a flat spring (9) attached to the axle (13) in a radial direction out toward the wall (4) of the pump housing. The axle (13) is composed of magnetic material to be driven by a magnetic field from an electromagnet (7) for oscillation in its longitudinal direction and moving the membrane (14) in corresponding oscillating movement. The flat spring (9) is composed of an inner and at least one outer part, with the inner part attached to the axle (13) and the outer part(s) attached to the pump housing. These parts are connected with one another by two elastic legs, arranged at each side of the point where the spring is attached to the axle (13).

Owner:XAVITECH AB

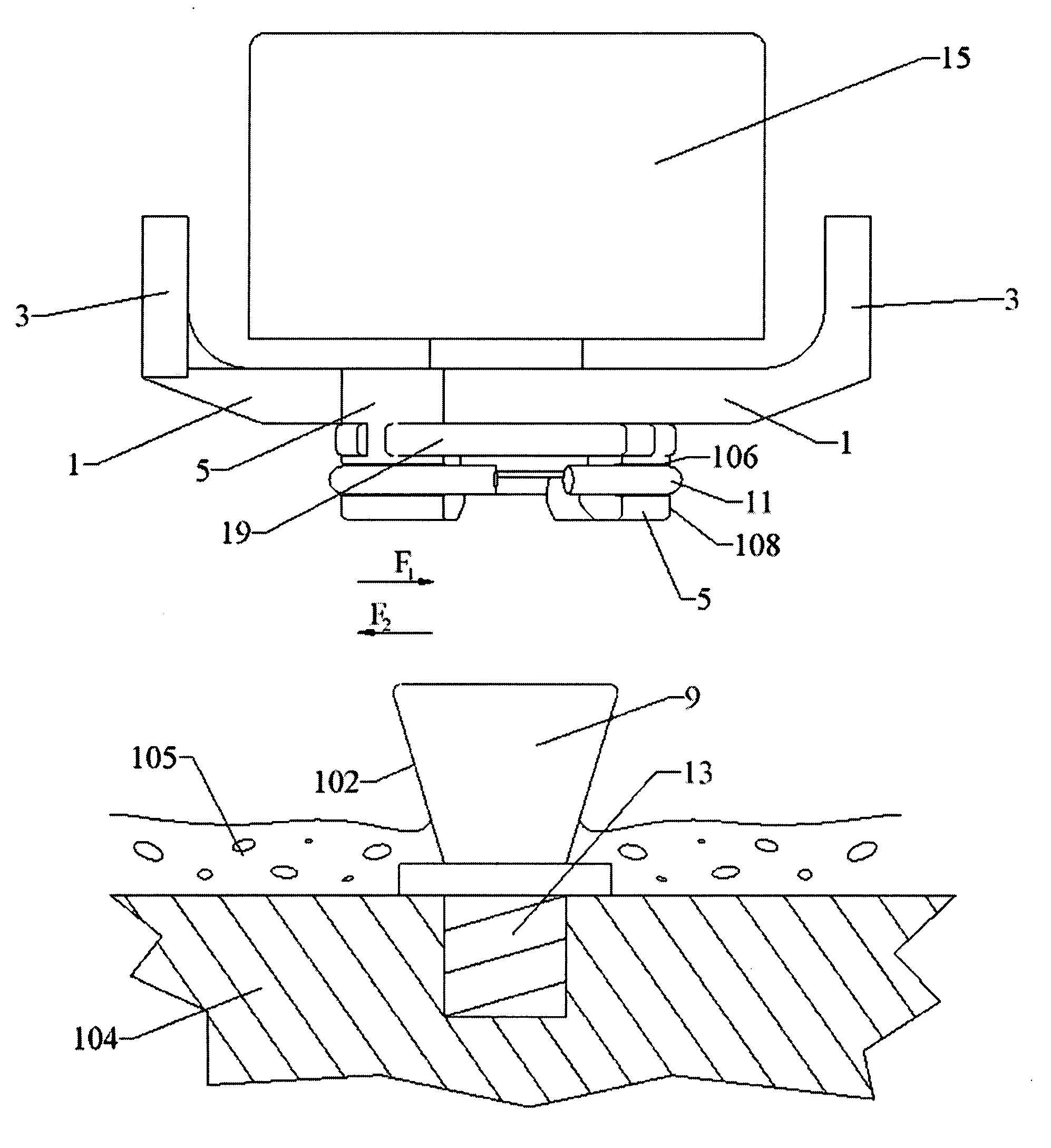

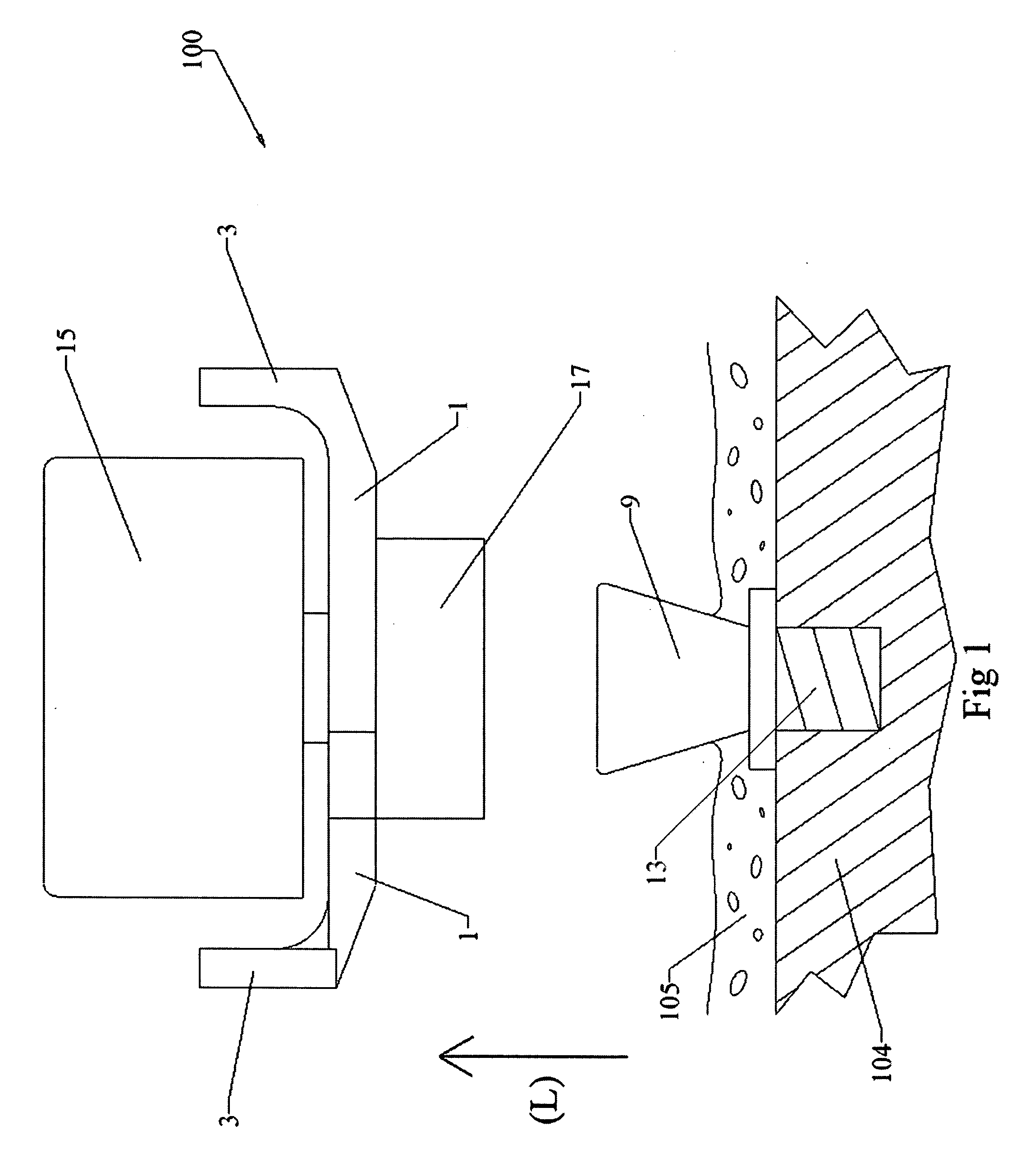

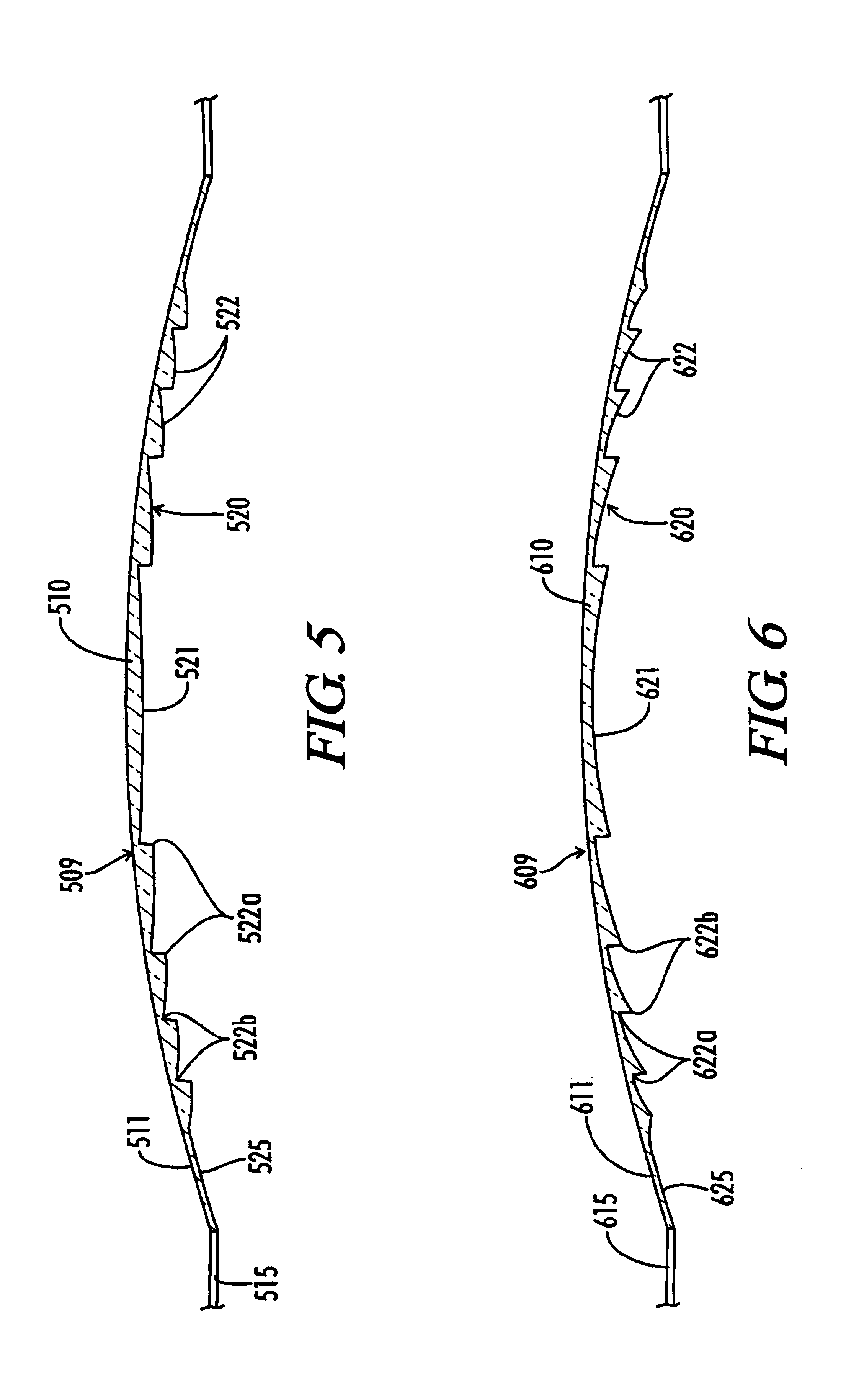

Arrangement for a hearing aid

ActiveUS20050249366A1Minimal stressHealth care can be savedBone conduction transducer hearing devicesImplantable hearing aidsControl armEngineering

The arrangement is for controlling the connection for a hearing aid (15) with a fixture (13) anchored in the skull bone. A control arm (1) extends from a connector (17), disposed between the hearing aid (15) and an abutment (9), to a handle (3) disposed at a side of the hearing aid (15) where the handle (3) is reachable by a patient. Biasing means provides a biasing force for biasing the control arm towards the connector (17). The control arm (1) is in operative engagement with the biasing means and movable in a direction to counter-act the biasing force of the biasing means to release the abutment (9) from the connector (17).

Owner:OTICON MEDICAL

Devices, methods and kits for forming tracts in tissue

InactiveUS20110125178A1Easy to useLimit likelihoodSurgical needlesSurgical veterinaryBlood vesselBiomedical engineering

Owner:ARSTASIS

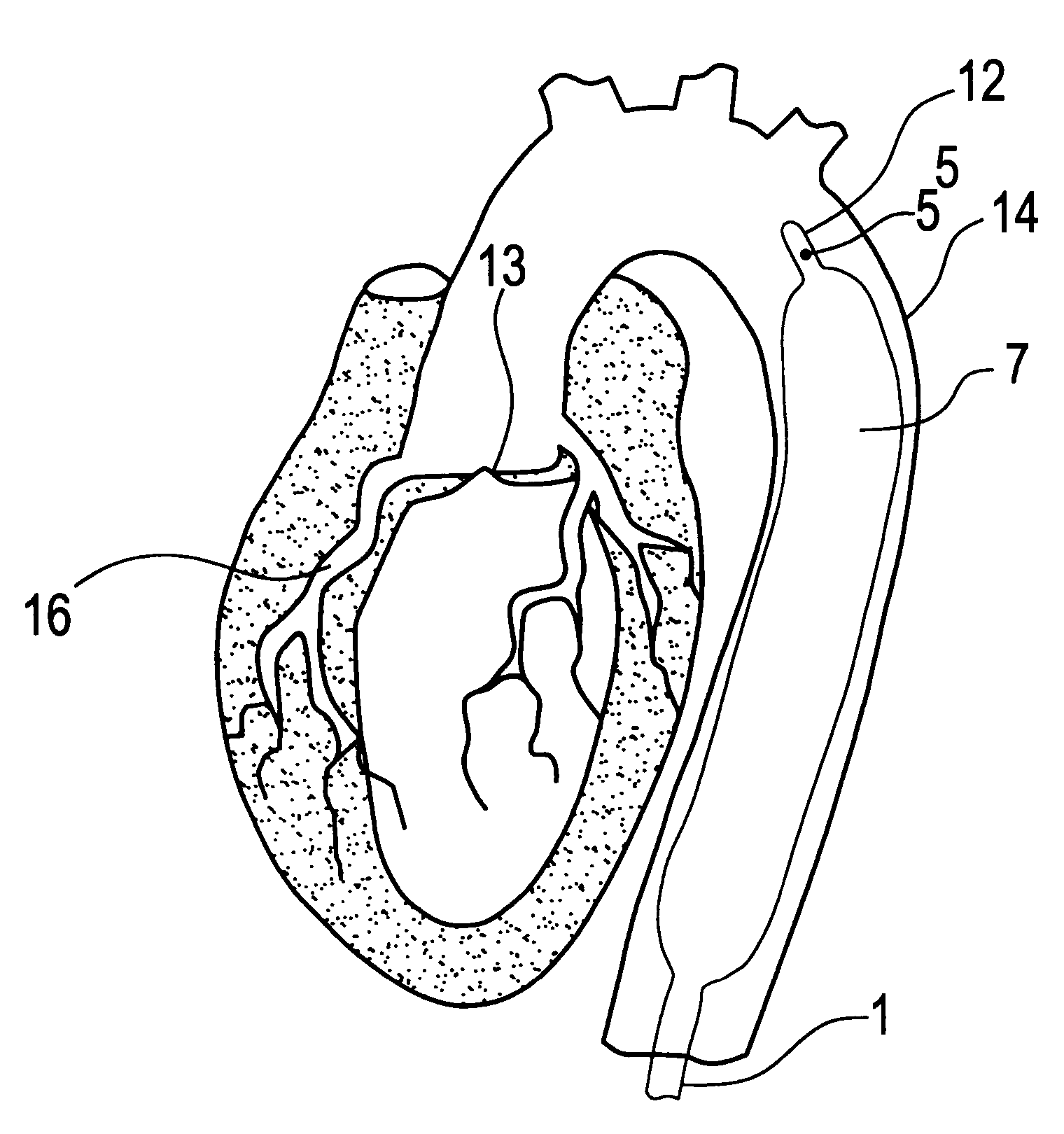

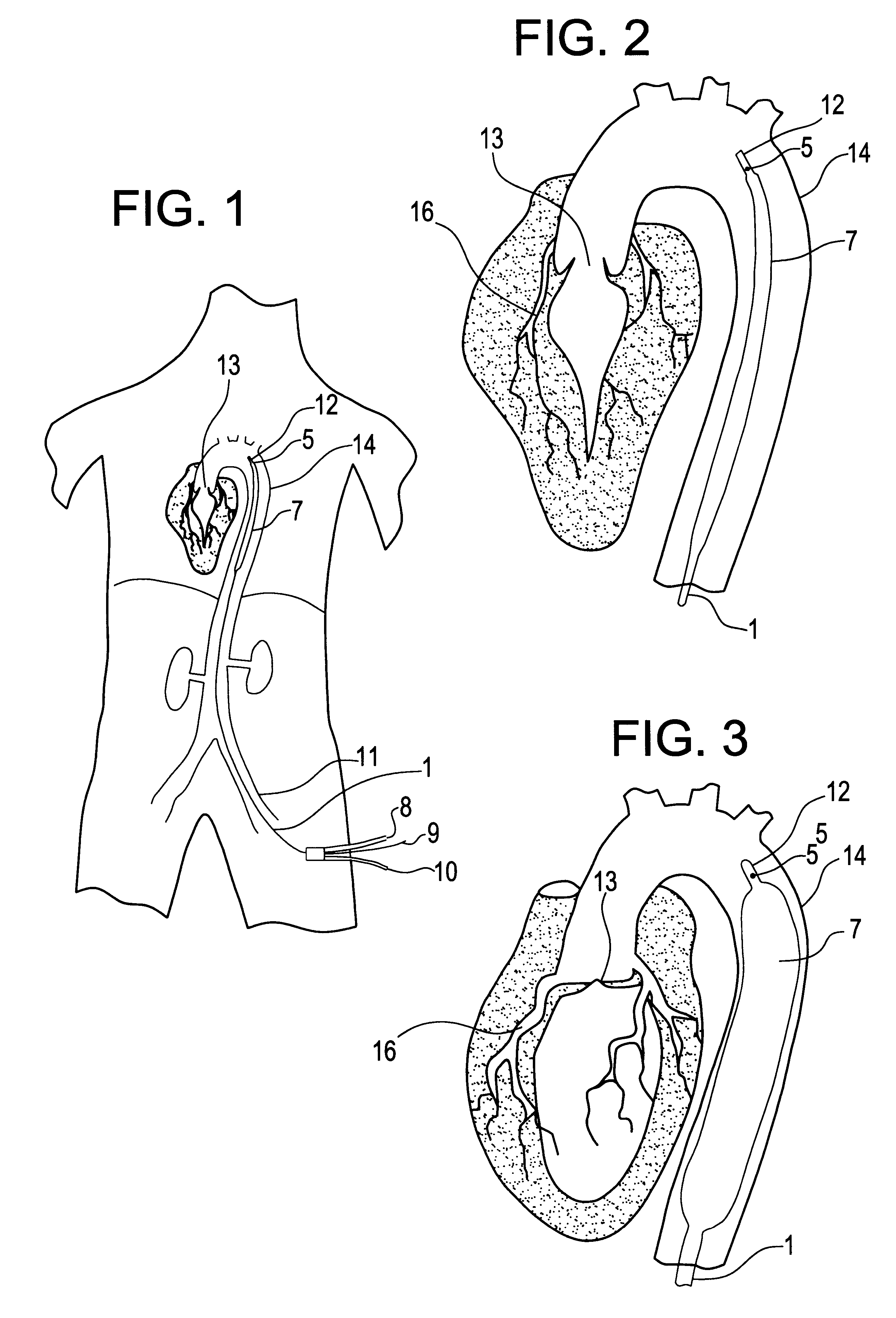

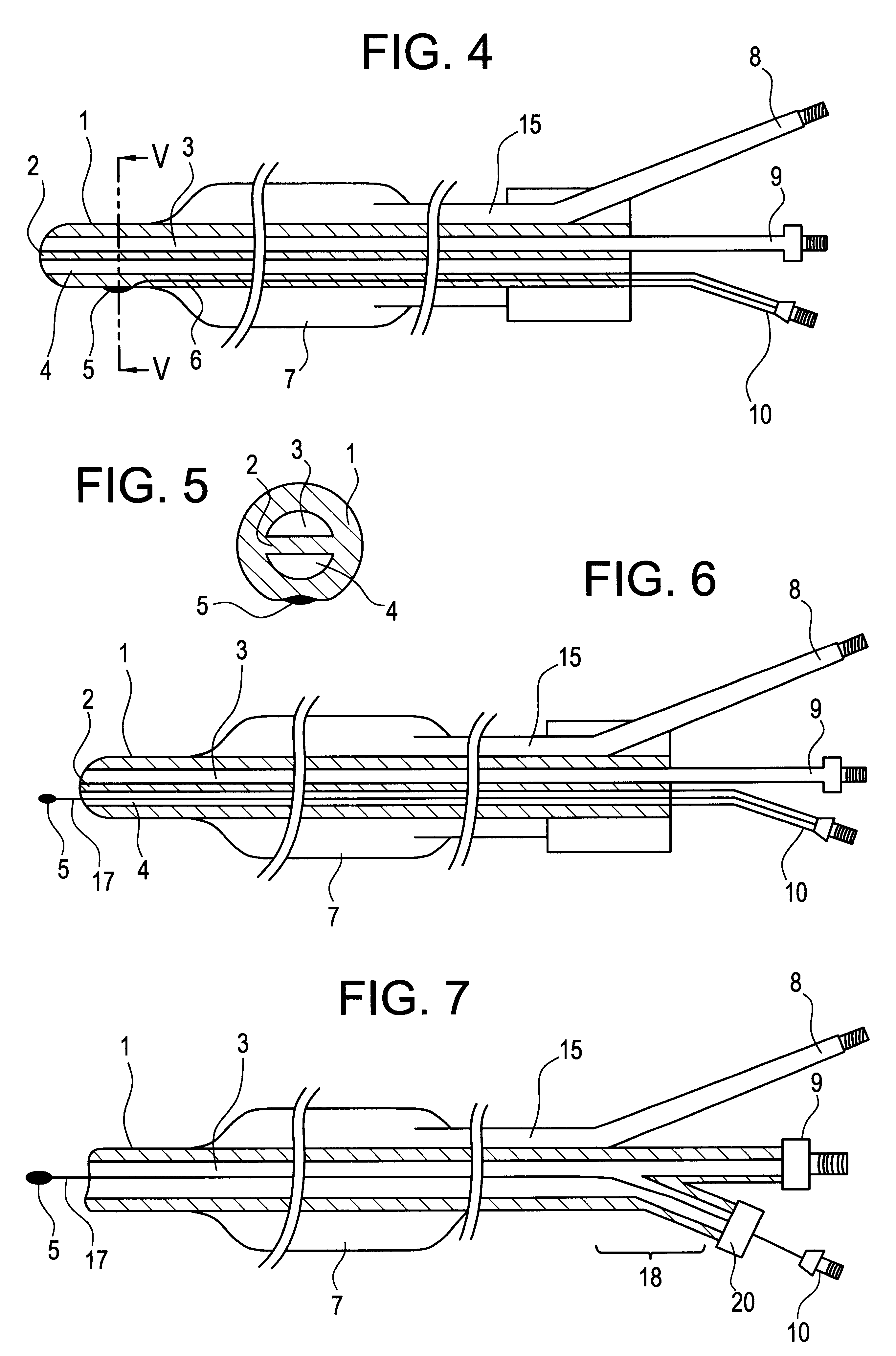

Combined catheter system for IABP and determination of thermodilution cardiac output

An intro-aortic balloon catheter system and method for determining cardiac output with the system including a distal end for insertion into an aorta and a proximal end opposed to the distal end, a balloon portion in proximity to the distal end which repeatedly expands and contracts so as to assist the pumping action of the heart, a catheter tube connected to the balloon portion with the catheter tube having a lumen introducing a pressurized gas into the balloon portion and leading the pressurized gas out from the balloon portion and a temperature sensor attached to the catheter tube and being electrically coupled to a connector at the proximal end of the catheter tube. The method includes inserting the temperature sensor into a lumen of the intra aortic balloon catheter system, advancing the temperature sensor until it projects freely into the aorta, injecting an injectate of a temperature different to that of the temperature of the patient's blood into the central vein of the patient, measuring the blood temperature profile versus time by means of the temperature sensor and calculating cardiac output and optionally the derived variables from the measured temperature profile.

Owner:PULSION MEDICAL SYST

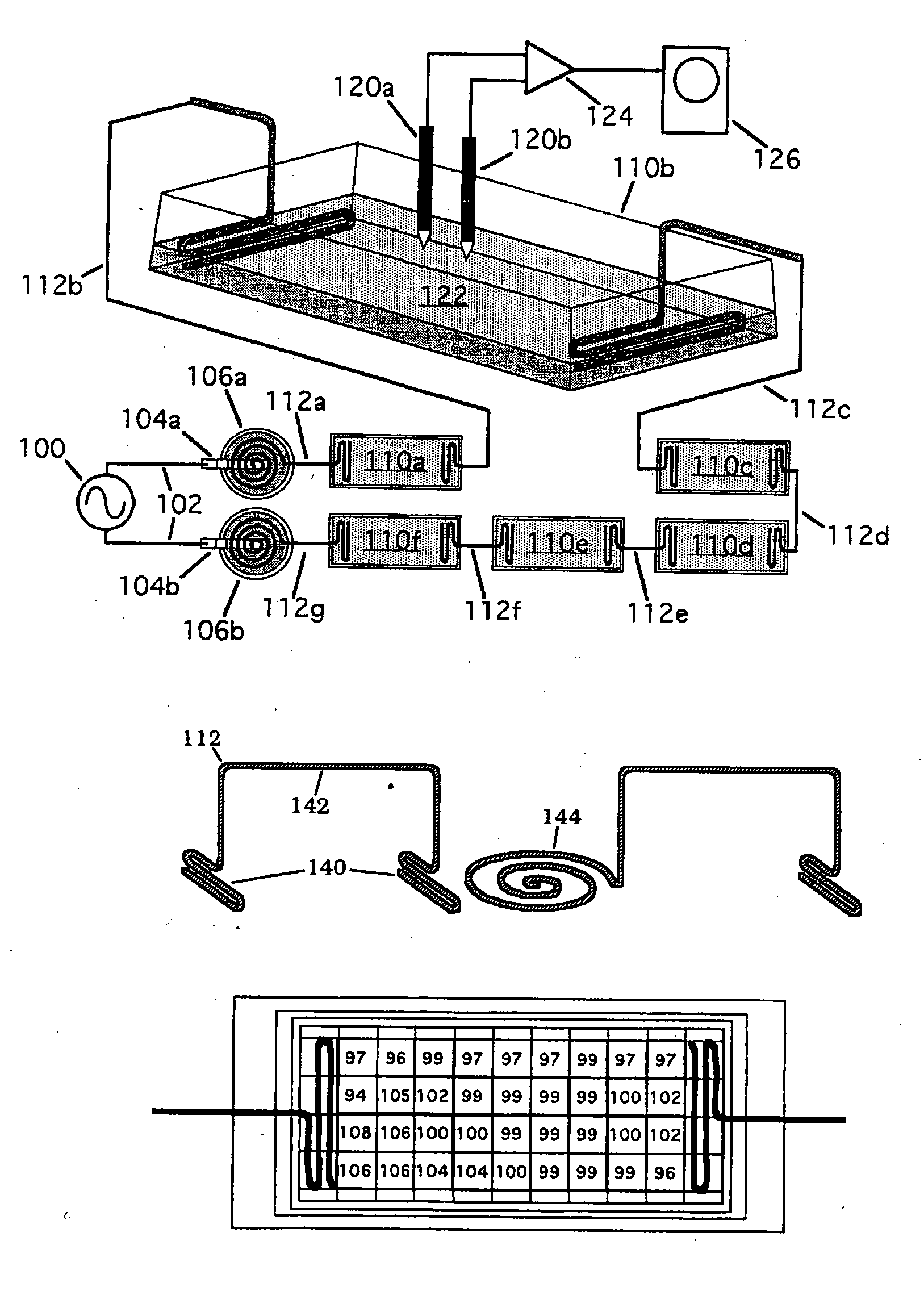

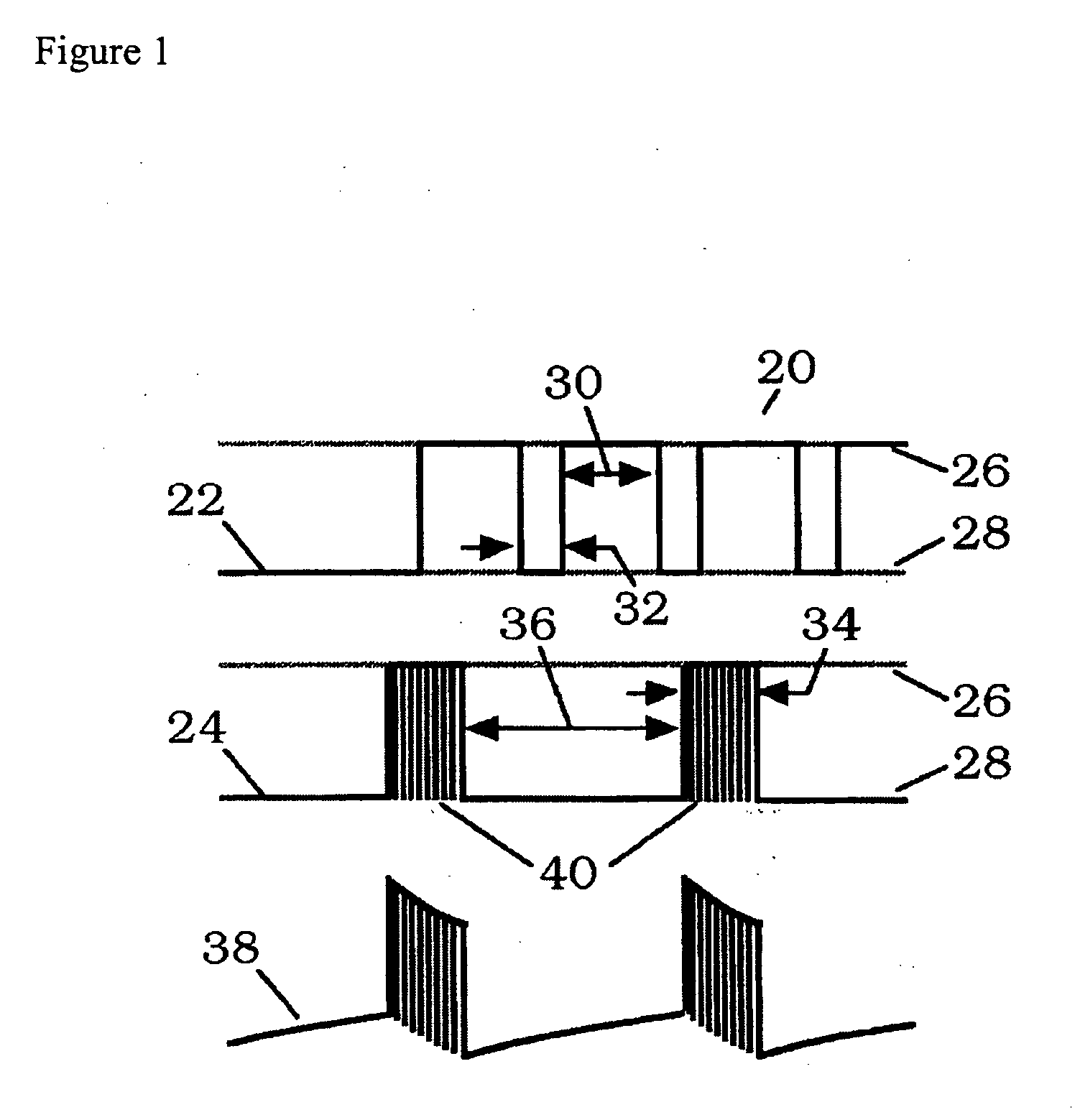

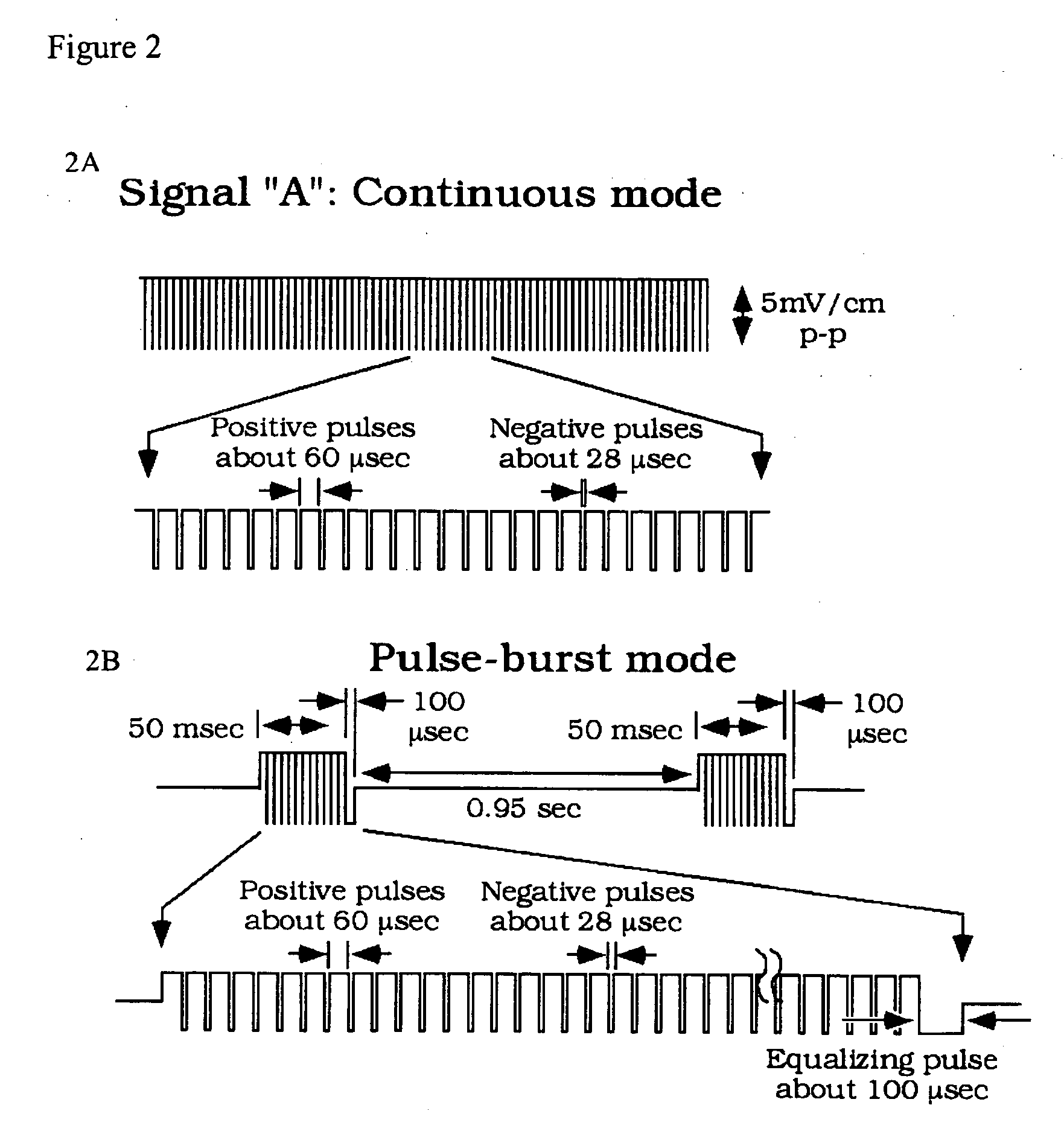

Methods for modulating osteochondral development using bioelectrical stimulation

ActiveUS20060293724A1Maximize utilizationMaximize applicationElectrotherapyStress based microorganism growth stimulationCo administrationOsteoblast

Compositions and methods are provided for modulating the growth, development and repair of bone, cartilage or other connective tissue. Devices and stimulus waveforms are provided to differentially modulate the behavior of osteoblasts, chondrocytes and other connective tissue cells to promote proliferation, differentiation, matrix formation or mineralization for in vitro or in vivo applications. Continuous-mode and pulse-burst-mode stimulation of cells with charge-balanced signals may be used. Bone, cartilage and other connective tissue growth is stimulated in part by nitric oxide release through electrical stimulation and may be modulated through co-administration of NO donors and NO synthase inhibitors. Bone, cartilage and other connective tissue growth is stimulated in part by release of BMP-2 and BMP-7 in response to electrical stimulation to promote differentiation of cells. The methods and devices described are useful in promoting repair of bone fractures, cartilage and connective tissue repair as well as for engineering tissue for transplantation.

Owner:MEDRELIEF

High efficiency counterbalanced dual axis solar tracking array frame system

ActiveUS8119963B2Improve efficiencyLittle powerOptical radiation measurementAuxillary drivesPhotovoltaic solar energyShadowings

A high efficiency, environmentally friendly system comprising a plurality of photovoltaic solar collecting panels (PV panels) is disclosed. The system comprises an outer frame to which a plurality of inner frames are mounted to which the plurality of PV panels are attached. To minimize shadowing by the outer frame upon one or more PV panels, at least one PV panel may extend beyond an endpoint of the main frame. The system also comprises an outer frame rotation actuator that rotates the outer frame and an inner frame rotation actuator that rotates the inner frames and the plurality of PV panels. The solar tracking array frames disclosed herein help to improve the quality of the environment by conserving a variety of energy resources (e.g., fossil fuels, hydroelectric energy, etc.) The solar tracking array frames disclosed herein also help to reduce greenhouse gas emissions, as solar tracking array frames do not produce carbon dioxide byproducts.

Owner:SCANLON MARK +1

Economical Nasal Dilator and Method of Manufacture

InactiveUS20150094758A1Easy to disassembleBroaden applicationNon-surgical orthopedic devicesNasal passageNasal passages

A nasal dilator comprises a laminate of vertically stacked layers each comprising at least one member or component. The layers form a unitary, or single body, truss. The truss features horizontal regions adapted to engage outer wall tissues of first and second nasal passages and to traverse the bridge of a nose therebetween. The dilator acts to stabilize and / or expand the nasal outer wall tissues and prevent said tissues from drawing inward during breathing. Dilator members, including components thereof, are configured to dimensional criteria suitable to engage and provide effective dilation to nasal passages, that create lateral and longitudinal registration of dilator members or components during manufacture, and that facilitate manufacture with minimal material waste. Methods of manufacture further include progressive steps that fabricate and assemble components into finished devices, including user assembly thereof. Embodiments further include a user-adjustable truss length, a truss which features a resilient member with divergent extensions and / or enlarged terminal ends, and a plurality of resilient members joined together at their end portions.

Owner:IERULLI JOSEPH V

Economical Nasal Dilator and Method of Manufacture

ActiveUS20150090398A1Easy to disassembleBroaden applicationLamination ancillary operationsPaper/cardboard articlesNasal passageNasal passages

A nasal dilator comprises a laminate of vertically stacked layers each comprising at least one member or component. The layers form a unitary, or single body, truss. The truss features horizontal regions adapted to engage outer wall tissues of first and second nasal passages and to traverse the bridge of a nose therebetween. The dilator acts to stabilize and / or expand the nasal outer wall tissues and prevent said tissues from drawing inward during breathing. Dilator members, including components thereof, are configured to dimensional criteria suitable to engage and provide effective dilation to nasal passages, that create lateral and longitudinal registration of dilator members or components during manufacture, and that facilitate manufacture with minimal material waste. Methods of manufacture further include progressive steps that fabricate and assemble components into finished devices, including user assembly thereof. Embodiments further include a user-adjustable truss length, a truss which features a resilient member with divergent extensions and / or enlarged terminal ends, and a plurality of resilient members joined together at their end portions.

Owner:HORIZON IP TECH LLC

Economical Nasal Dilator and Method of Manufacture

InactiveUS20150094757A1Easy to disassembleBroaden applicationNon-surgical orthopedic devicesNasal passageNasal passages

A nasal dilator comprises a laminate of vertically stacked layers each comprising at least one member or component. The layers form a unitary, or single body, truss. The truss features horizontal regions adapted to engage outer wall tissues of first and second nasal passages and to traverse the bridge of a nose therebetween. The dilator acts to stabilize and / or expand the nasal outer wall tissues and prevent said tissues from drawing inward during breathing. Dilator members, including components thereof, are configured to dimensional criteria suitable to engage and provide effective dilation to nasal passages, that create lateral and longitudinal registration of dilator members or components during manufacture, and that facilitate manufacture with minimal material waste. Methods of manufacture further include progressive steps that fabricate and assemble components into finished devices, including user assembly thereof. Embodiments further include a user-adjustable truss length, a truss which features a resilient member with divergent extensions and / or enlarged terminal ends, and a plurality of resilient members joined together at their end portions.

Owner:IERULLI JOSEPH V

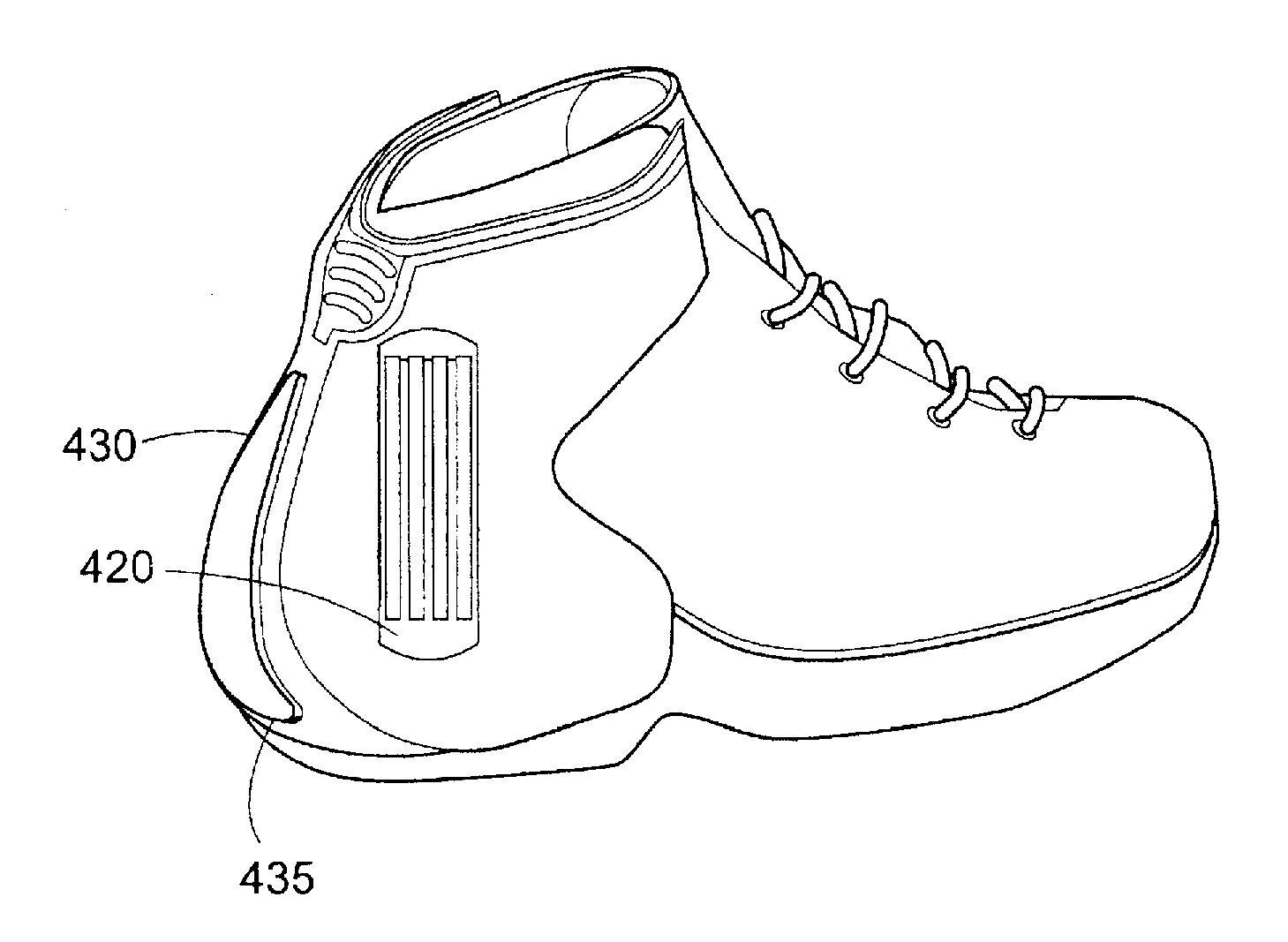

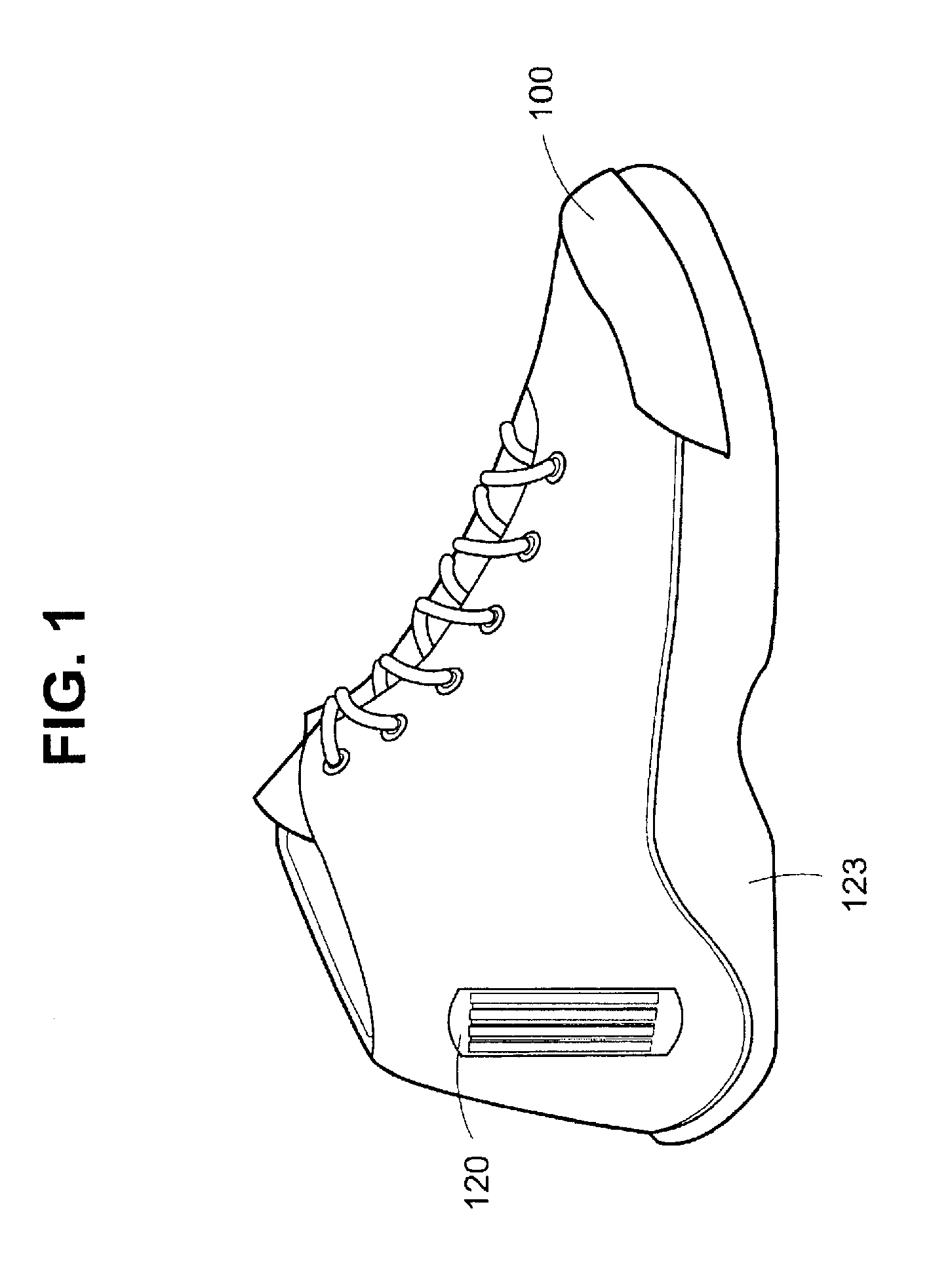

Footwear design personalizing

An article of footwear and a method making it. The footwear is configured for personalized design changes with the article of footwear comprising a base anchoring element with a first plurality of fastening elements. The base anchoring element is formed separately from existing footwear and then permanently attached to at least a portion of an outer surface of the existing footwear. The article of footwear further comprises at least two decorative elements each with a second plurality of fastening elements configured to individually releasably matingly engage with the first plurality of fastening elements. The first and second plurality of fastening elements are formed on the respective base anchoring element and each of the decorative elements, in mating registration with each other.

Owner:BAUM ASHER

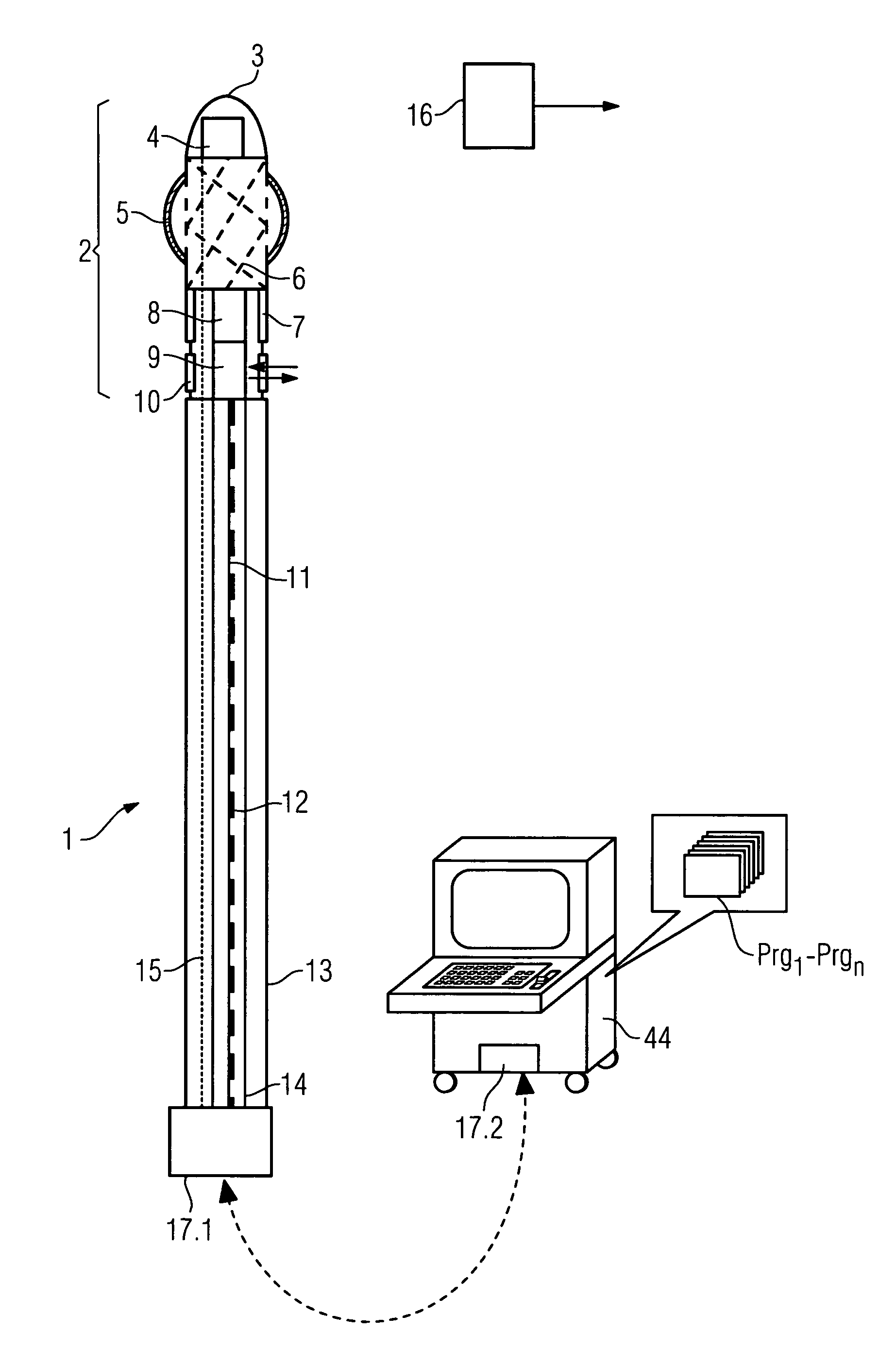

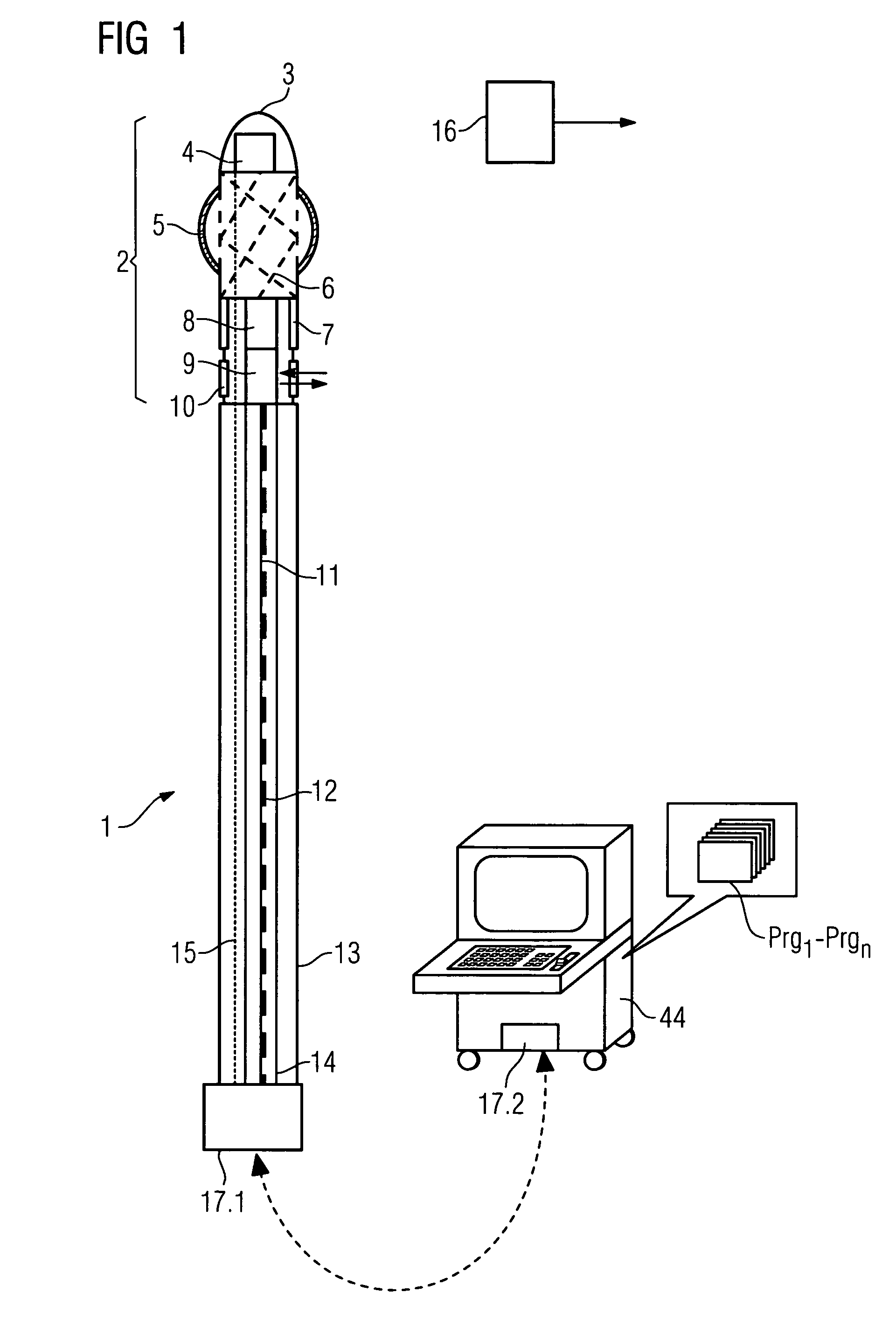

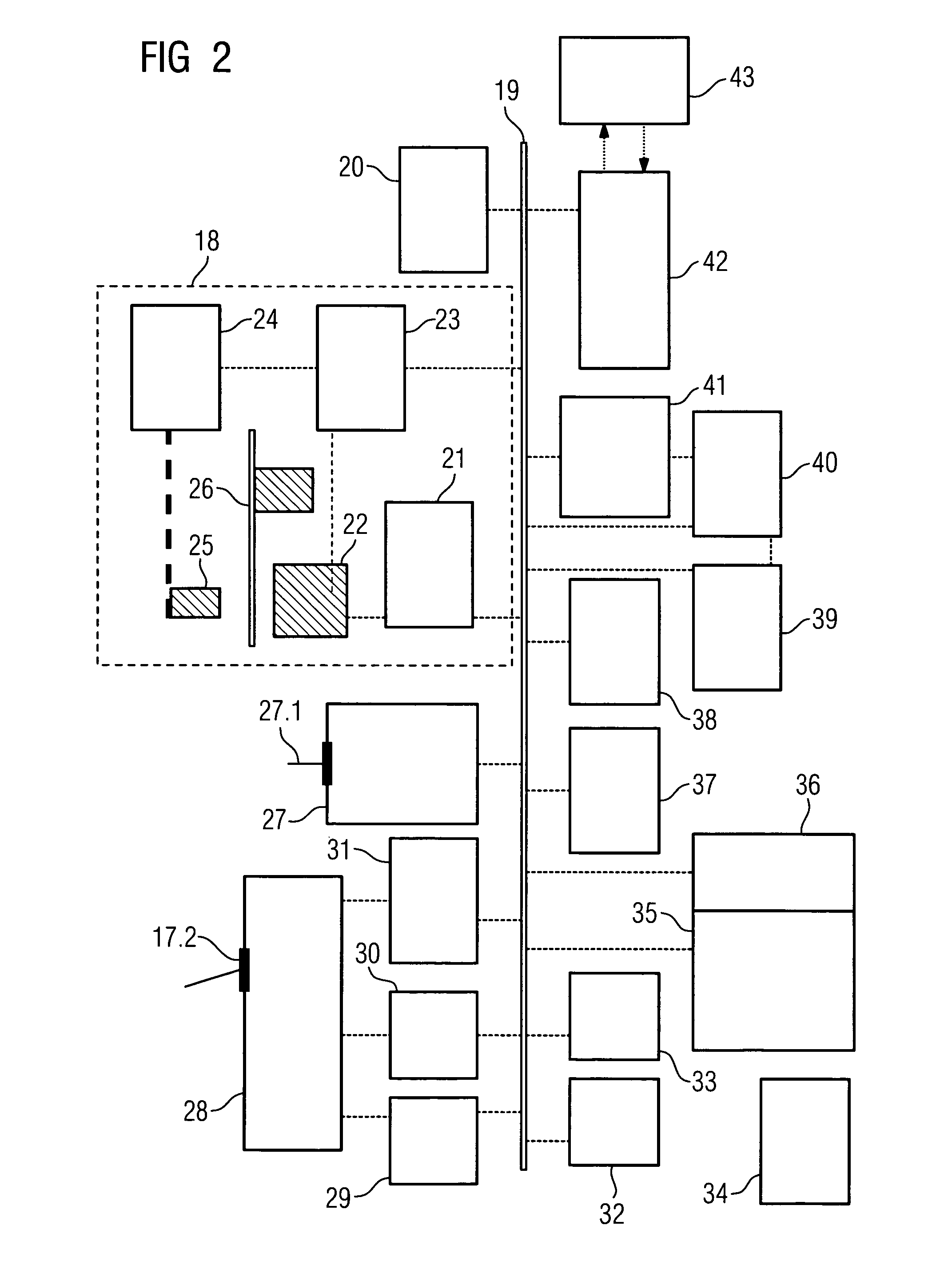

Medical catheter and system for inserting a catheter into a vessel

ActiveUS8126534B2Better assessmentMinimal stressUltrasonic/sonic/infrasonic diagnosticsEndoscopesUltrasound angiographyBlood vessel

The invention relates to a medical system for introducing a catheter into a blood vessel of a patient, having a computer and control unit, a means for creating a transparent general view of the position of the vessel, a catheter with a reversible inflatable balloon located in the front area, to the outside of which a stent can be fitted for implanting into the vessel, a position locating system for the catheter with position and location sensors that can determine the position and location of the catheter, the system with at least one OCT (optical coherence tomography) sensor at a catheter end for the close-up area, with at least one IVUS (intravascular ultrasound) imaging sensor at a catheter end for the remote area and the computer and control unit having image processing and image display functions for the image sensors.

Owner:SIEMENS HEALTHCARE GMBH

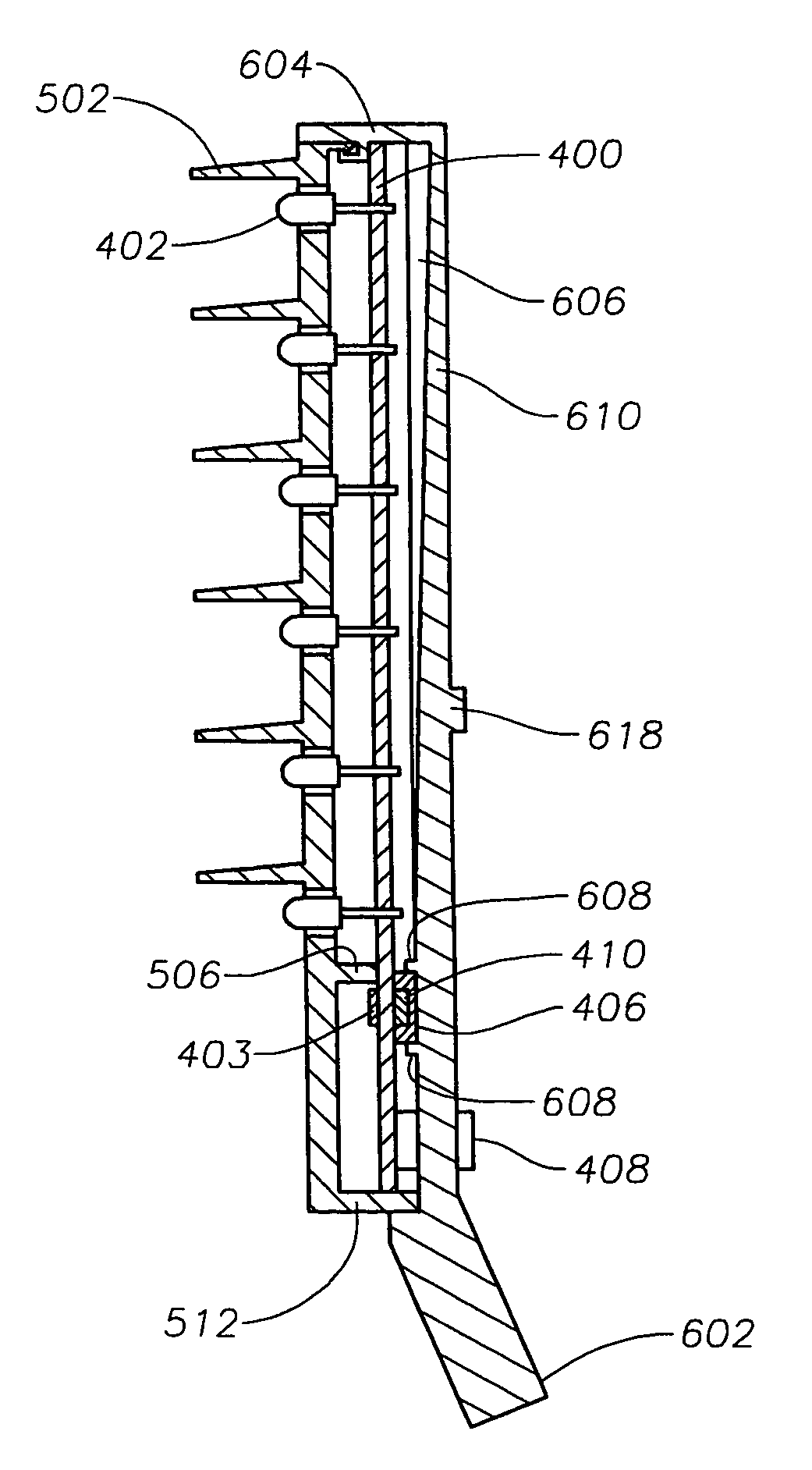

Deformable intraocular corrective lens

InactiveUS6921415B2Common problemStable positionEye surgeryIntraocular lensPhakic iolCorrective lens

A deformable, artificial intraocular contact lens for implantation into the human eye to correct normal-vision problems. The lens may be positioned posteriorly from the iris, resting against the anterior surface of the posterior capsule's natural lens. Alternatively, the lens may be positioned in the anterior chamber of the eye. The implanted lens works in conjunction with the cornea and natural lens to provide proper vision, as a substitute for regular contact lens, spectacles, and radial keratotomy. The lens may be designed from a rigid or semi-rigid material. Due to the thinness of the structure, the lens may be rolled and inserted into the eye, minimizing both the length of the corneal incision and the stretching of the cornea.

Owner:THINOPTX

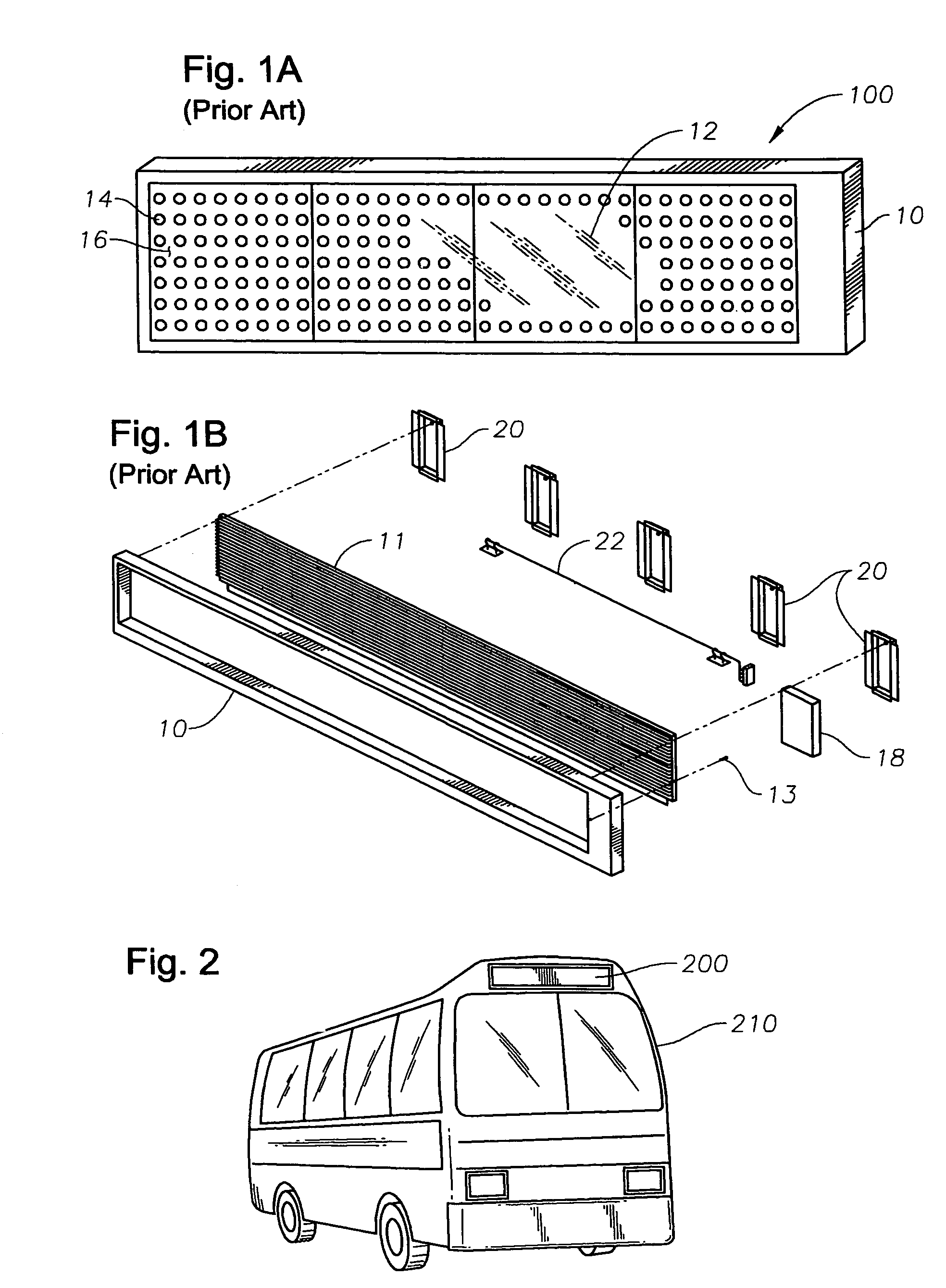

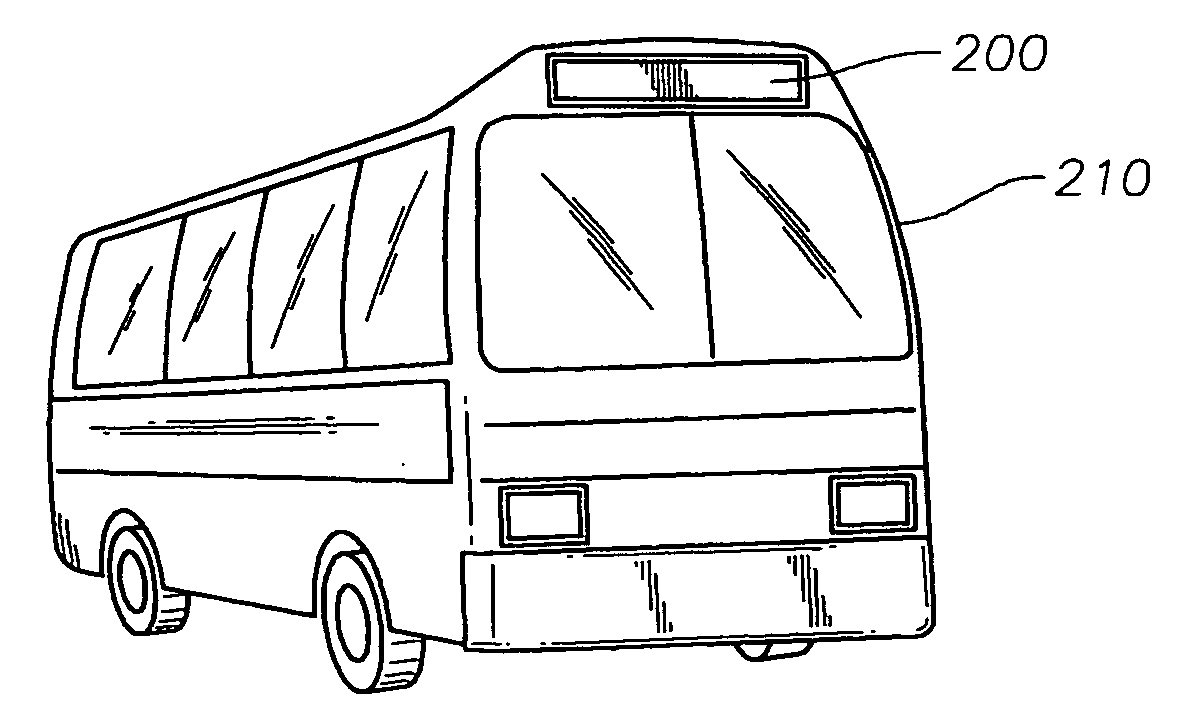

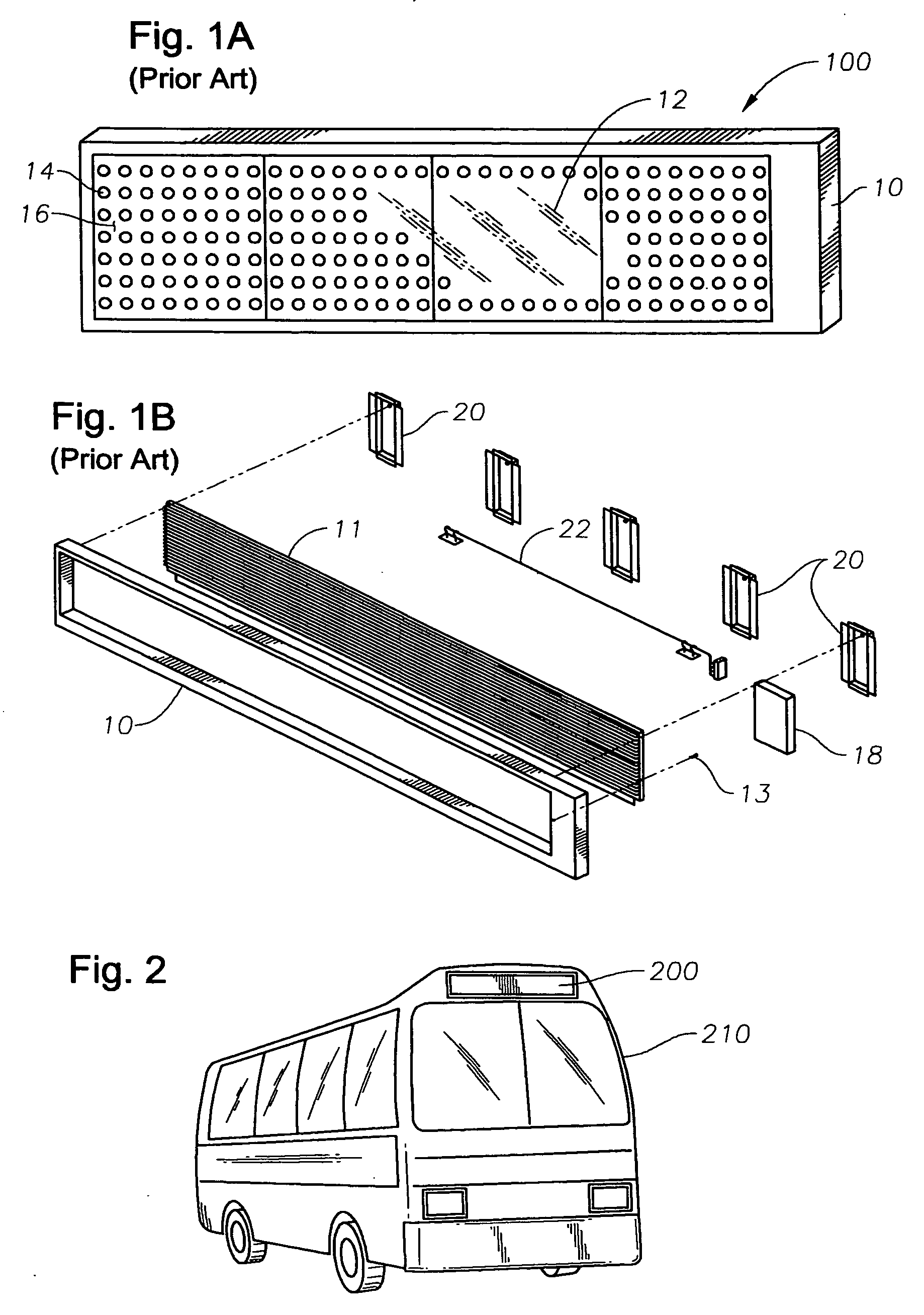

Display device with rail support

InactiveUS7131226B2Minimal stressLow failure rateStampsStatic indicating devicesWindow shutterDisplay device

Disclosed is a display device, elongate mount, and display module for displaying alphanumeric information to passengers of a mass transit vehicle. The display modules are mounted along a single edge to a elongate mount. The elongate mount includes at least one end cap which is made of a vibration dampening material. The louver of the display device includes a substantially continuous pressure member in order to place substantially continuous elongate contact to an area of an LED board that houses at least one heating element. The at least one heating element is covered by a thermally conductive foam that transmits heat from the elements to a heat sink of the display module.

Owner:LUMINATOR HLDG

Ergonomically neutral arm support system

InactiveUS20050012376A1Minimal stressEffectively weightlessVehicle seatsStoolsSupporting systemDynamic balance

An ergonomic arm support system maintains a neutral position for the forearm. A mechanical support structure attached to a chair or other mounting structure supports the arms of a sitting or standing person. The system includes moving elements and tensioning elements to provide a dynamic balancing force against the forearms. The support structure is not fixed or locked in a rigid position, but is an active dynamic system that is maintained in equipoise by the continuous operation of the opposing forces. The support structure includes an armrest connected to a flexible linkage or articulated or pivoting assembly, which includes a tensioning element such as a spring. The pivoting assembly moves up and down, with the tensioning element providing the upward force that balances the downward force of the arm.

Owner:RGT UNIV OF CALIFORNIA

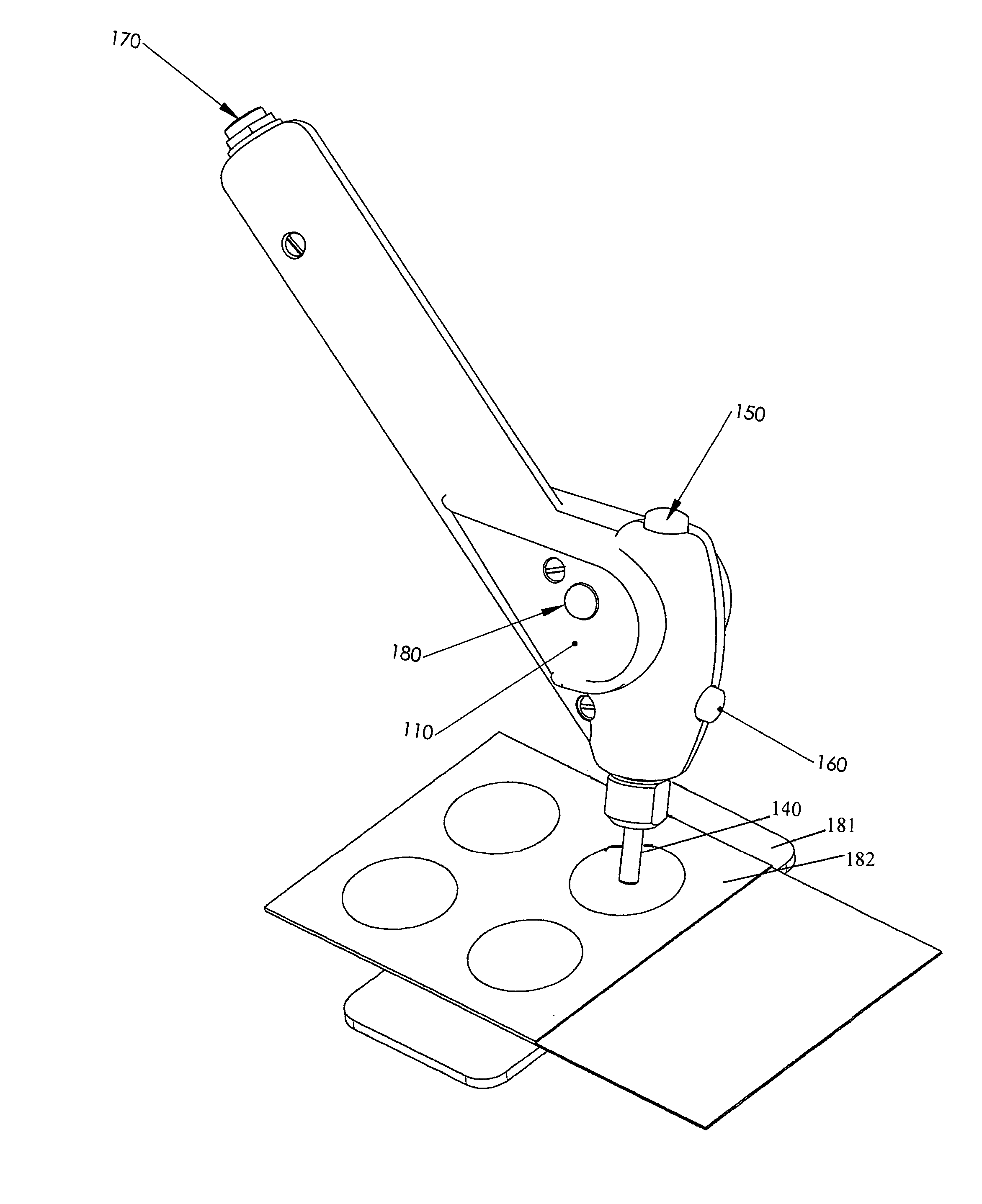

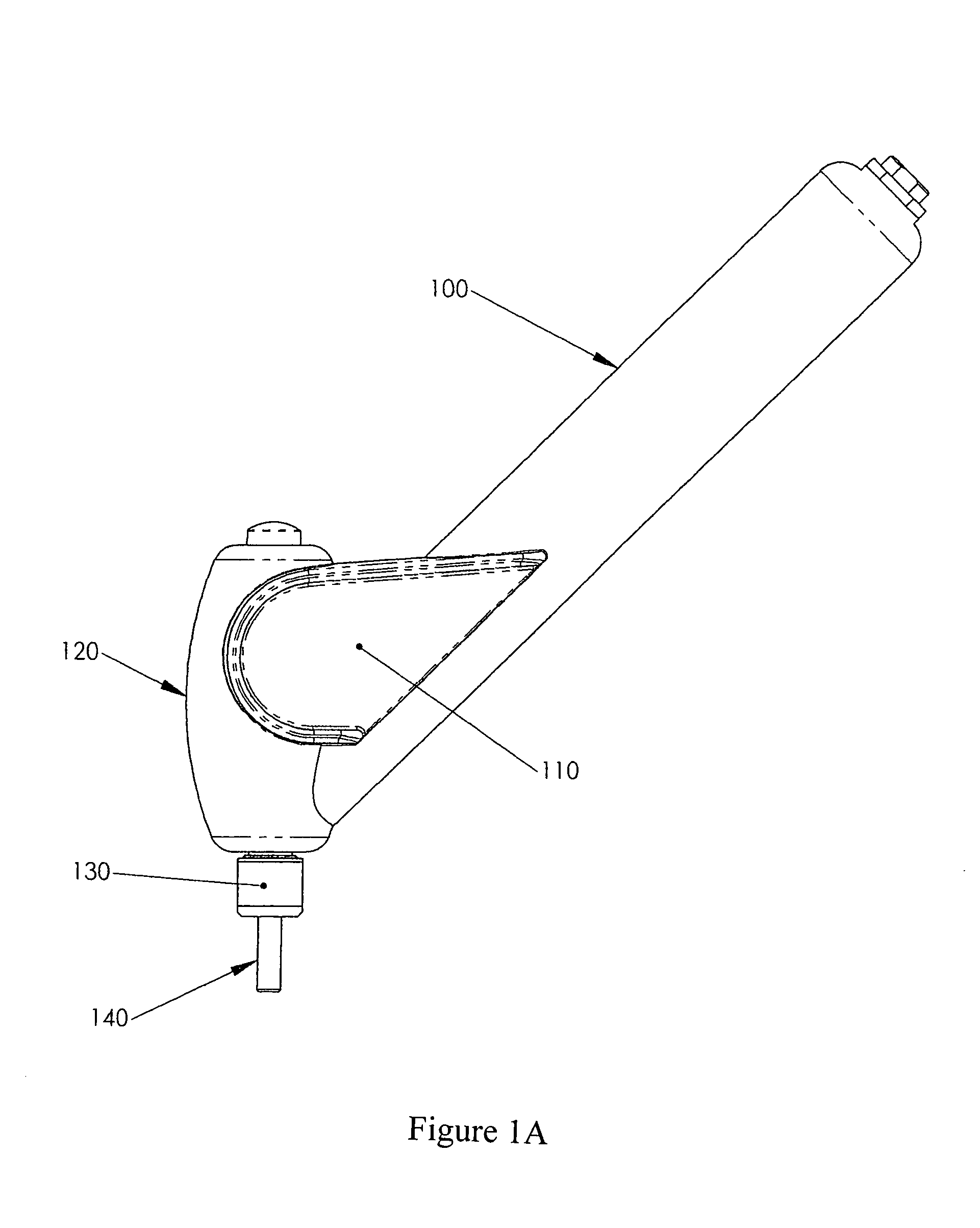

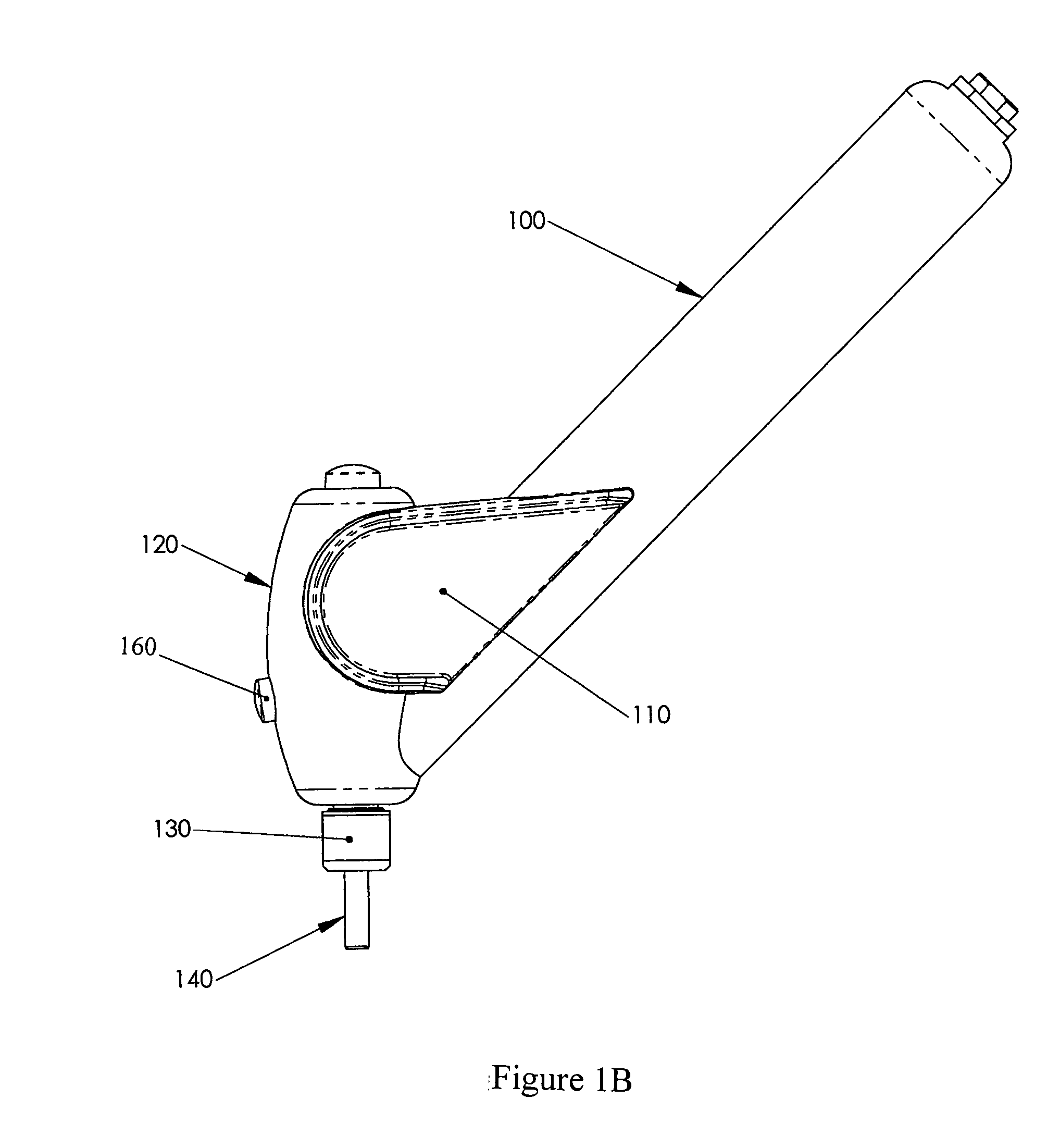

Motor driven sampling apparatus for material collection

InactiveUS20050044971A1Eliminates manual exertionReduce torqueWithdrawing sample devicesMotor driveSource material

An apparatus to excise a sample of material and temporarily store sample has a tubular clamshell casing at an angle to the horizontal, blended to a tubular boss under which is a tubular sample sleeve extending downwards from the boss. Within the casing an electric motor is housed which drives, via gears, the sample sleeve in a rotational manner. The end of the sleeve, distal from the boss, forms a cutting edge circumscribing a circular region. An ejection rod slides reciprocally within the sample sleeve between a stowed position and an expulsion position. When the ejection rod moves from the stowed position to the expulsion position, it will extend past the cutting edge and expel any sample of material contained within the cutting sleeve. A user cuts a sample from a source material using the cutting blade of the apparatus when the ejection rod is in the stowed position. The sample is cut when the cutting blade engages contact against the sample and gentle downward pressure is applied while a finger trigger activates the electric drive to rotate the cutting sleeve. Alternately a user may cut a sample from a source material by engaging contact between the cutting edge of the tubular sleeve and the source material, applying downward pressure against the source material thereby activating the electric drive to rotate the tubular cutting sleeve. Once the source material has been cut it is simultaneously extracted and lodged within the tubular sleeve. The extracted sample remains lodged in the tip of the tubular cutting sleeve until the user actuates the ejection rod through the sleeve to the expulsion position to eject the sample of source material. Return actuation of the eject rod is comprised of a coil spring that biases the rod in the retracted stowed position.

Owner:GE HEALTHCARE BIO SCI CORP

Economical Nasal Dilator and Method of Manufacture

ActiveUS20170112653A9Facilitate assembly and applicationEasy to disassembleLamination ancillary operationsMedical devicesNasal passageNasal passages

A nasal dilator comprises a laminate of vertically stacked layers each comprising at least one member or component. The layers form a unitary, or single body, truss. The truss features horizontal regions adapted to engage outer wall tissues of first and second nasal passages and to traverse the bridge of a nose therebetween. The dilator acts to stabilize and / or expand the nasal outer wall tissues and prevent said tissues from drawing inward during breathing. Dilator members, including components thereof, are configured to dimensional criteria suitable to engage and provide effective dilation to nasal passages, that create lateral and longitudinal registration of dilator members or components during manufacture, and that facilitate manufacture with minimal material waste. Methods of manufacture further include progressive steps that fabricate and assemble components into finished devices, including user assembly thereof. Embodiments further include a user-adjustable truss length, a truss which features a resilient member with divergent extensions and / or enlarged terminal ends, and a plurality of resilient members joined together at their end portions.

Owner:HORIZON IP TECH LLC

Economical Nasal Dilator and Method of Manufacture

ActiveUS20170143531A9Facilitate assembly and applicationEasy to disassembleLamination ancillary operationsMedical devicesNasal passagesNasal dilators

A nasal dilator comprises a laminate of vertically stacked layers each comprising at least one member or component. The layers form a unitary, or single body, truss. The truss features horizontal regions adapted to engage outer wall tissues of first and second nasal passages and to traverse the bridge of a nose therebetween. The dilator acts to stabilize and / or expand the nasal outer wall tissues and prevent said tissues from drawing inward during breathing. Dilator members, including components thereof, are configured to dimensional criteria suitable to engage and provide effective dilation to nasal passages, that create lateral and longitudinal registration of dilator members or components during manufacture, and that facilitate manufacture with minimal material waste. Methods of manufacture further include progressive steps that fabricate and assemble components into finished devices, including user assembly thereof. Embodiments further include a user-adjustable truss length, a truss which features a resilient member with divergent extensions and / or enlarged terminal ends, and a plurality of resilient members joined together at their end portions.

Owner:HORIZON IP TECH LLC

Economical Nasal Dilator and Method of Manufacture

InactiveUS20170151084A9Facilitate assembly and applicationEasy to disassembleMedical scienceNasal passageNasal passages

A nasal dilator comprises a laminate of vertically stacked layers each comprising at least one member or component. The layers form a unitary, or single body, truss. The truss features horizontal regions adapted to engage outer wall tissues of first and second nasal passages and to traverse the bridge of a nose therebetween. The dilator acts to stabilize and / or expand the nasal outer wall tissues and prevent said tissues from drawing inward during breathing. Dilator members, including components thereof, are configured to dimensional criteria suitable to engage and provide effective dilation to nasal passages, that create lateral and longitudinal registration of dilator members or components during manufacture, and that facilitate manufacture with minimal material waste. Methods of manufacture further include progressive steps that fabricate and assemble components into finished devices, including user assembly thereof. Embodiments further include a user-adjustable truss length, a truss which features a resilient member with divergent extensions and / or enlarged terminal ends, and a plurality of resilient members joined together at their end portions.

Owner:IERULLI JOSEPH V

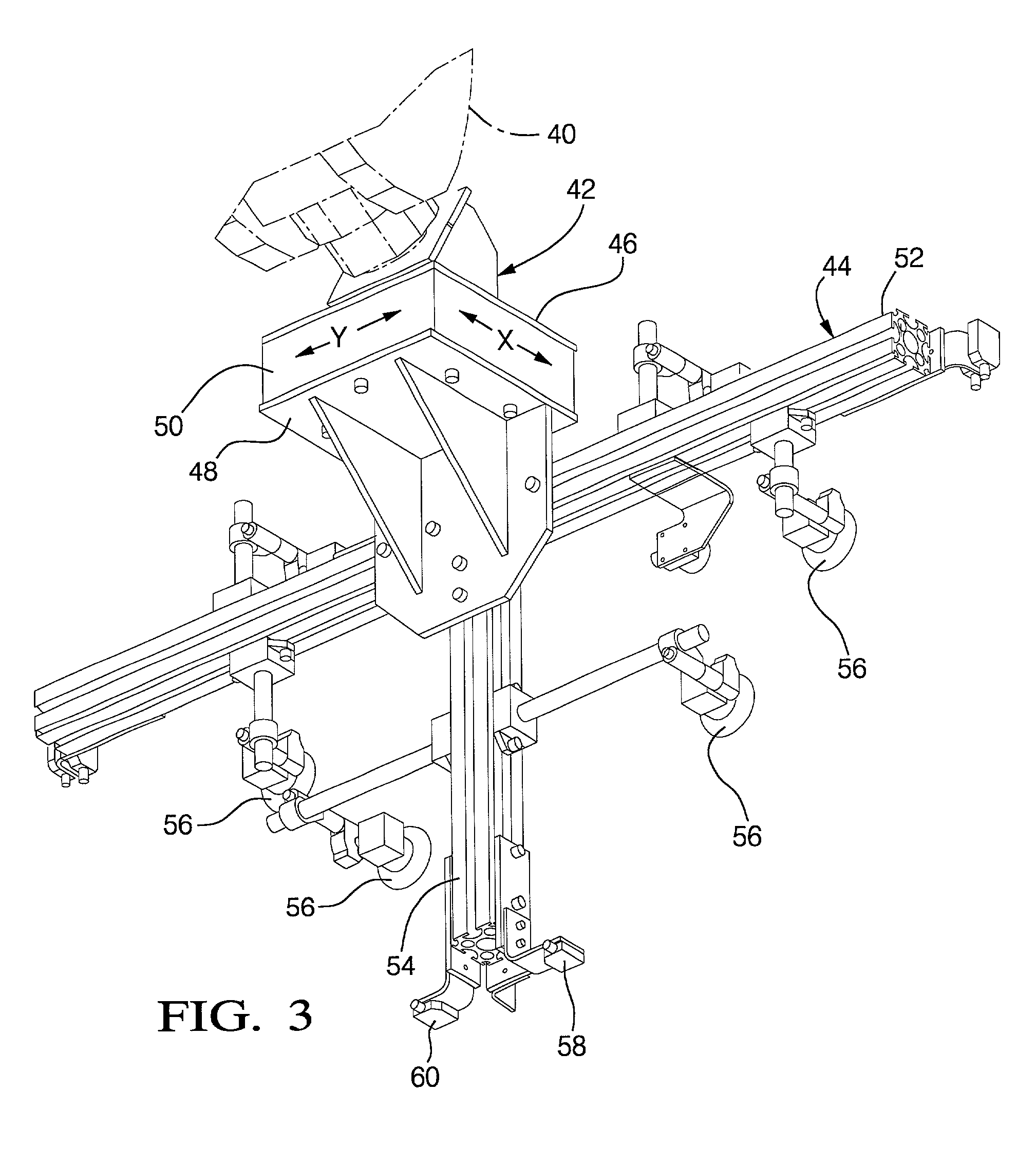

Robotic rack loading apparatus and method

Robotic rack loading apparatus and method include features and loading steps that provide essentially damage free rack loading of automotive panel assemblies into a specially designed rack. The rack includes dunnage elements containing sets of slots with lead-in upper edge angles and sensing holes associated with the slots. The robot carries a modified end of arm tool including a sensor to sense the location of a sensing hole to position a panel for loading into a corresponding set of slots. Another sensor preferably senses objects or structure in the rack to position the tool in a preload position. A compliant device allows lateral and longitudinal compliance of the end of arm tool to allow assemblies to be funneled into position in the slots without encountering damaging stress. A programmed robot can thus automatically load panel assemblies into the rack without damage.

Owner:GM GLOBAL TECH OPERATIONS LLC

Display device

ActiveUS10111346B2Maximize sizeMinimal stressStatic indicating devicesDigital data processing detailsDisplay deviceComputer science

Owner:SAMSUNG DISPLAY CO LTD

Display device with rail support

InactiveUS20050000126A1Minimal stressLow failure rateStampsMobile visual advertisingWindow shutterDisplay device

Disclosed is a display device, elongate mount, and display module for displaying alphanumeric information to passengers of a mass transit vehicle. The display modules are mounted along a single edge to a elongate mount. The elongate mount includes at least one end cap which is made of a vibration dampening material. The louver of the display device includes a substantially continuous pressure member in order to place substantially continuous elongate contact to an area of an LED board that houses at least one heating element. The at least one heating element is covered by a thermally conductive foam that transmits heat from the elements to a heat sink of the display module.

Owner:LUMINATOR HLDG

Economical Nasal Dilator and Method of Manufacture

InactiveUS20180028346A1Facilitate assembly and applicationEasy to disassembleMedical scienceNasal cavityNasal dilators

A nasal dilator comprises a laminate of vertically stacked layers each comprising at least one member or component. The layers form a unitary, or single body, truss. The truss features horizontal regions adapted to engage outer wall tissues of first and second nasal passages and to traverse the bridge of a nose therebetween. The dilator acts to stabilize and / or expand the nasal outer wall tissues and prevent said tissues from drawing inward during breathing. Dilator members, including components thereof, are configured to dimensional criteria suitable to engage and provide effective dilation to nasal passages, that create lateral and longitudinal registration of dilator members or components during manufacture, and that facilitate manufacture with minimal material waste. Methods of manufacture further include progressive steps that fabricate and assemble components into finished devices, including user assembly thereof. Embodiments further include a user-adjustable truss length, a truss which features a resilient member with divergent extensions and / or enlarged terminal ends, and a plurality of resilient members joined together at their end portions.

Owner:CORBETT LAIR INC

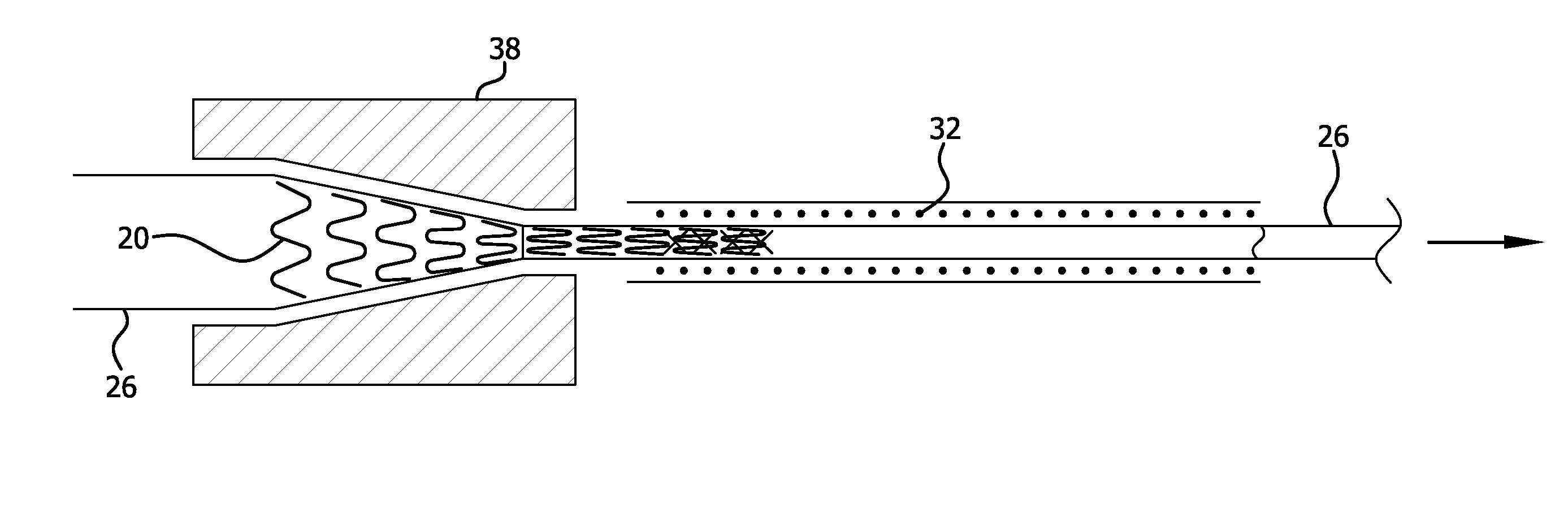

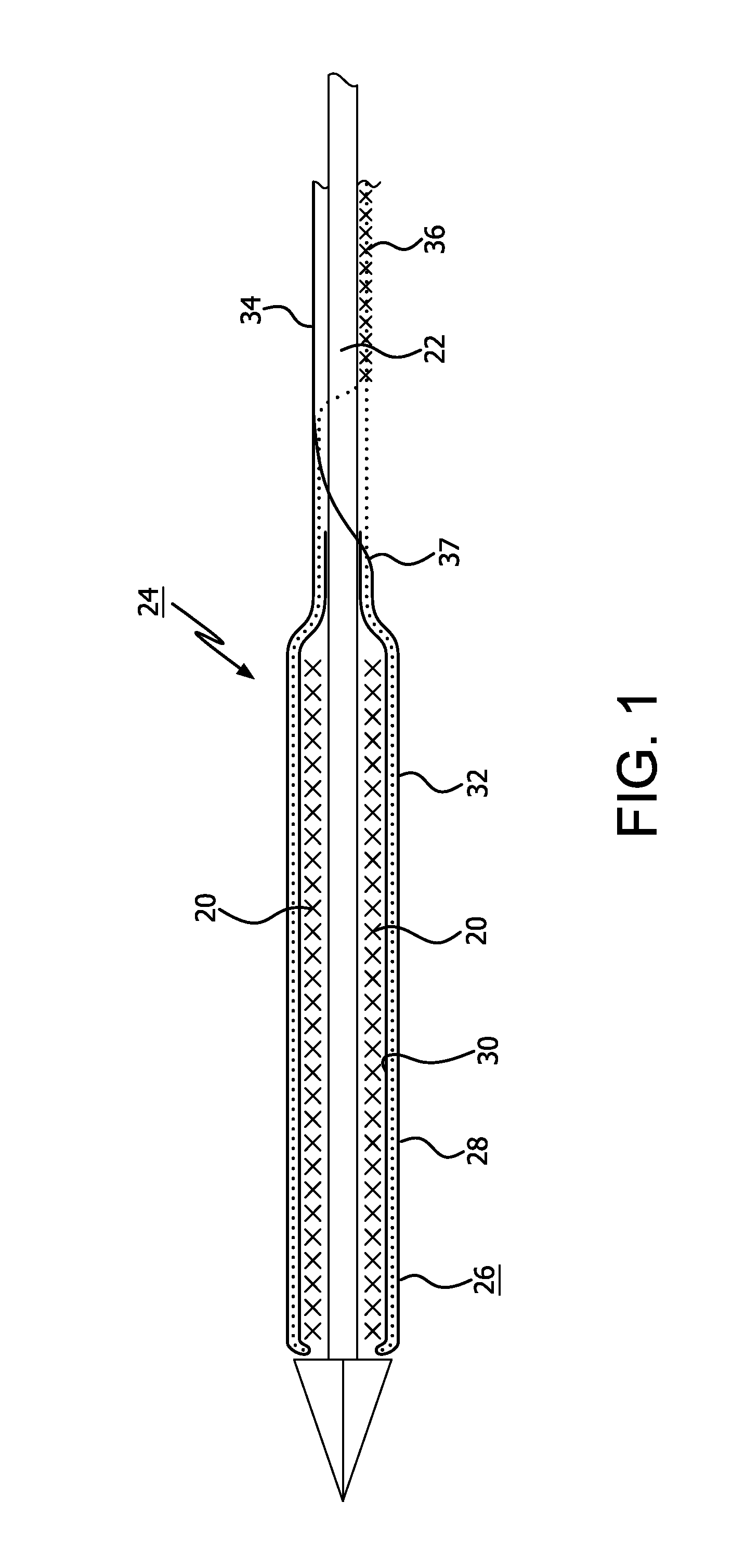

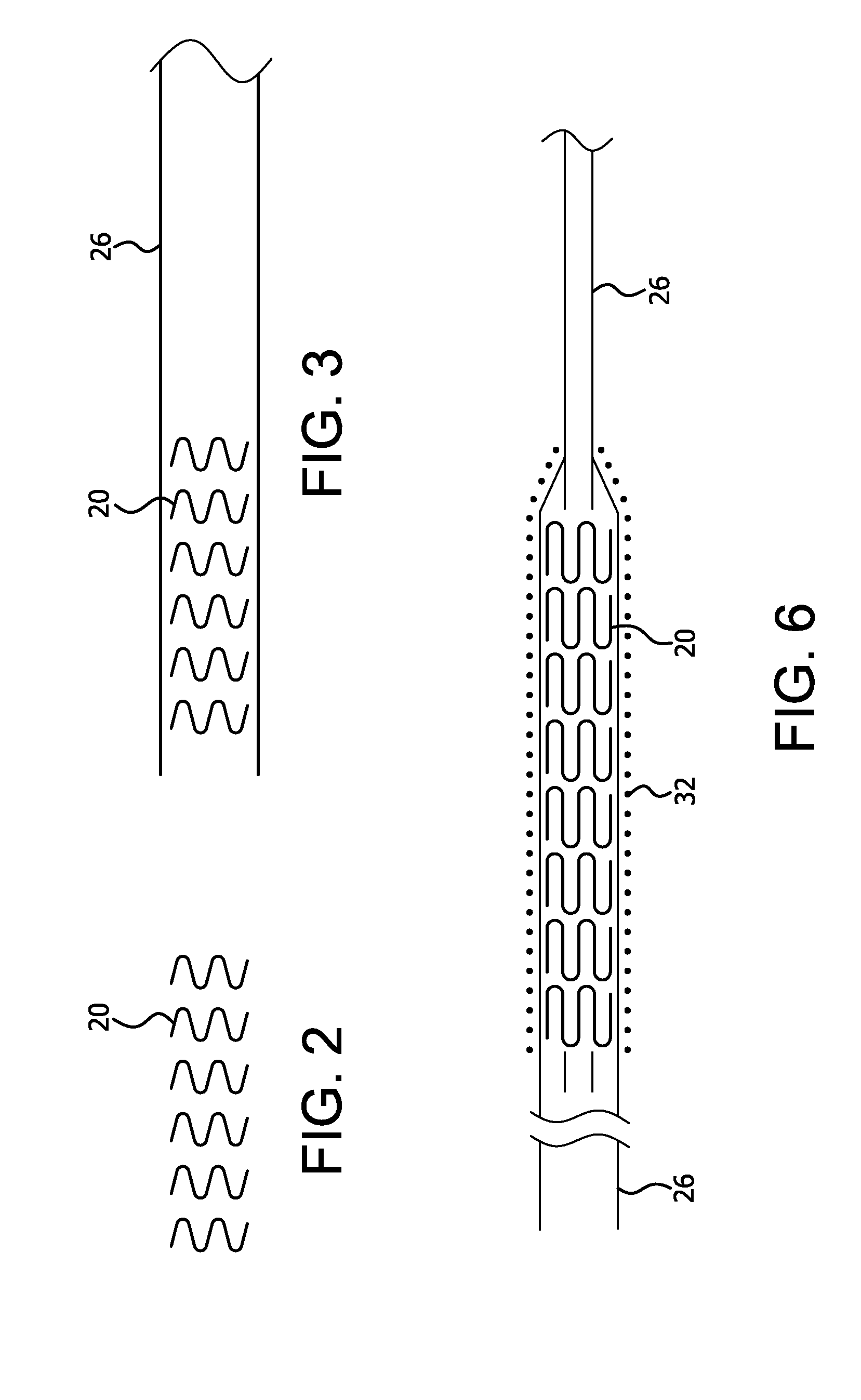

Implantable medical device constraint and deployment apparatus

ActiveUS20150250630A1Simple and accurate and reliable device deploymentProtection deliveryStentsEar treatmentProduction lineImplanted device

An implantable medical device deployment system is disclosed that employs both a sheath element and a constraint member to protect implantable medical devices during delivery in a body while providing simple, accurate, and reliable device deployment. The delivery system is configured so that loading and deployment forces are not directly related to device diameter, length, or design, thus allowing a more universal delivery system across various delivered device configurations and product lines. The deployment system can provide numerous benefits, include better protection for drug-coated implantable devices.

Owner:WL GORE & ASSOC INC

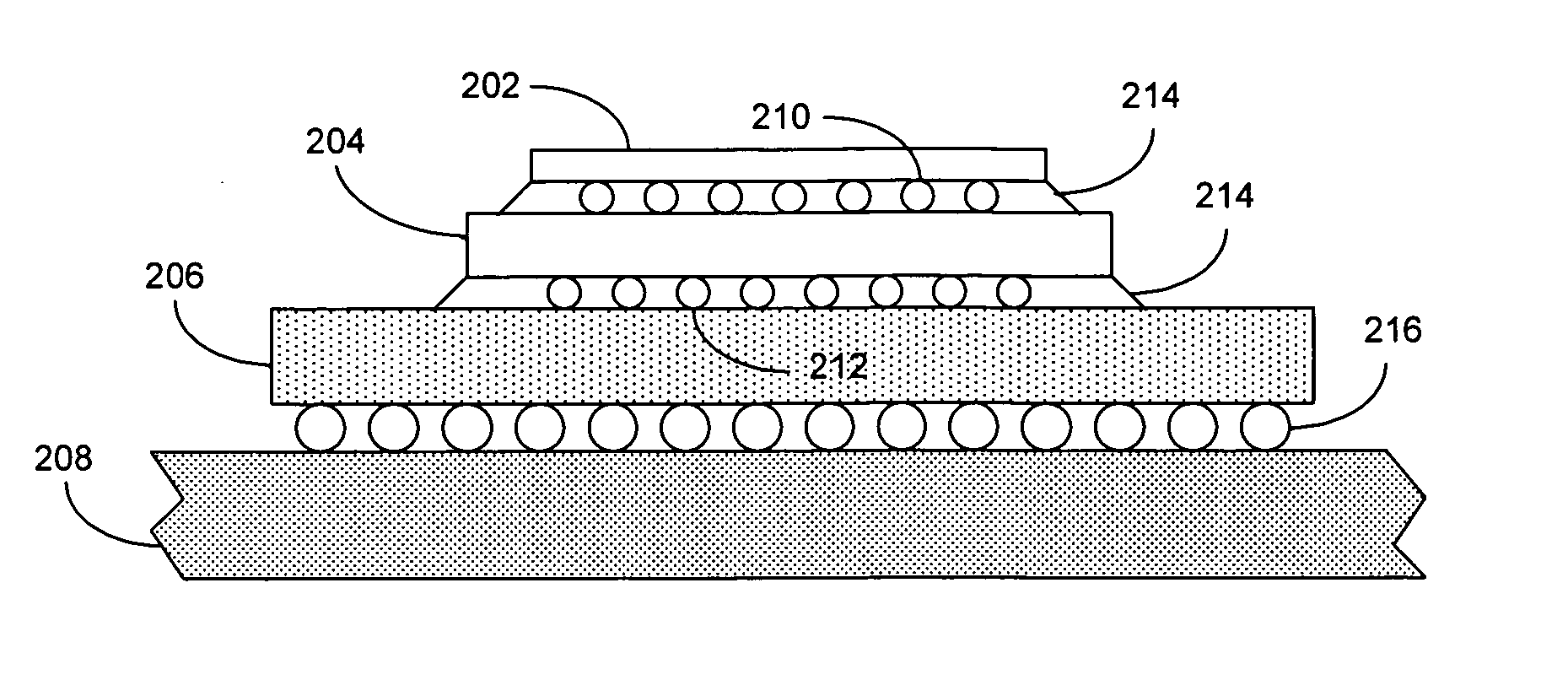

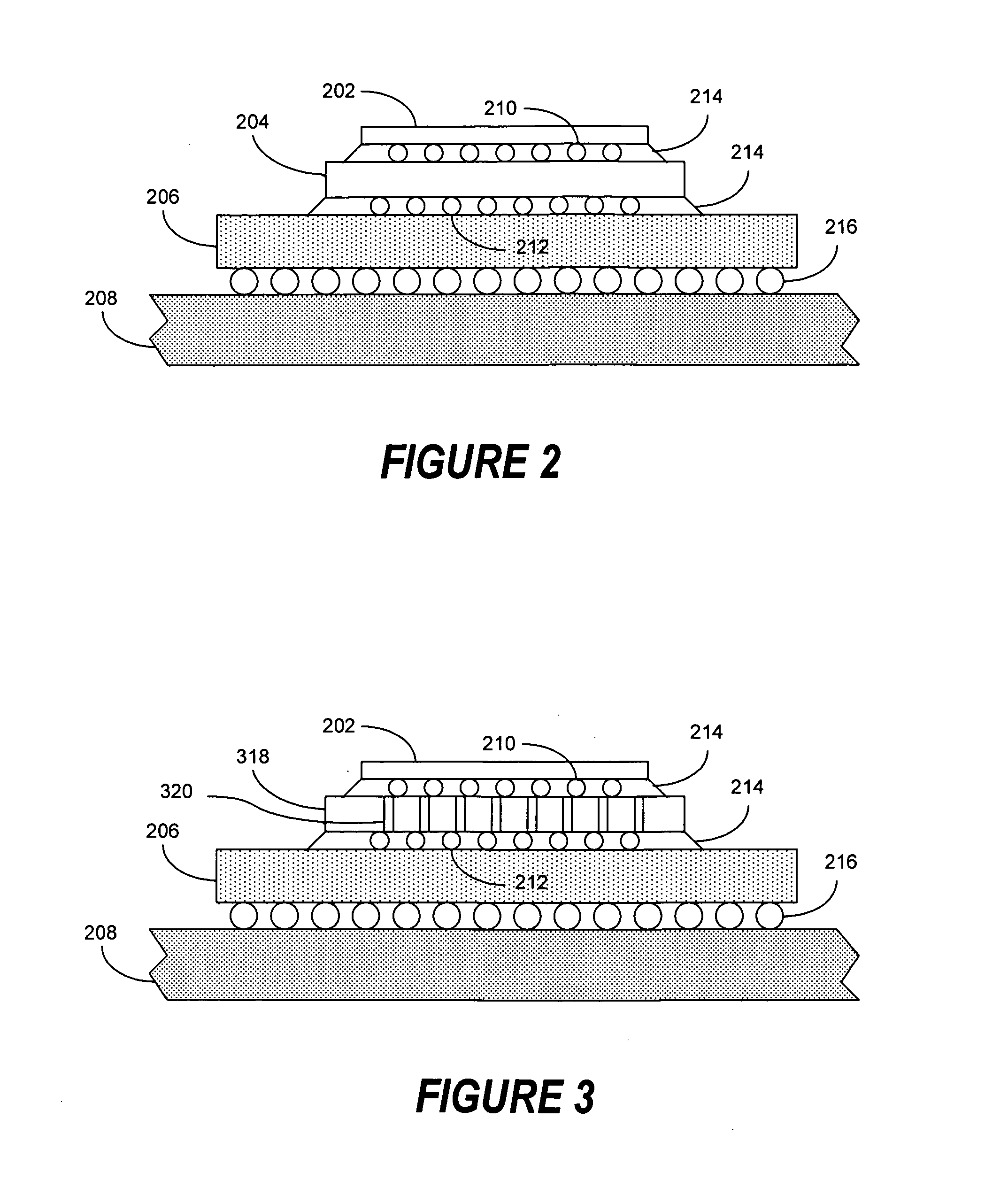

Thermal expansion compensation graded IC package

InactiveUS20070080441A1Relieve pressureStress on bumpSemiconductor/solid-state device detailsPrinted circuit aspectsElectrical connectionSemiconductor package

An apparatus and method for connecting one substrate, such as a semiconductor die, to an opposing substrate, such as a semiconductor package or circuit board, through a plurality of intermediate thermal compensator devices, each of which can incrementally and / or locally mitigate the stresses imposed by differences in the two substrate's thermal expansion characteristics. The compensator devices can be coupled to one another, with the resulting assembly attached to the first substrate on one side, and to the second substrate on the other side, through solder bump attach, or some equivalent method. The method of the invention provides electrical connection and thermal dissipation between the two substrates as well as providing mechanical protection by absorbing the stresses imposed by the difference in thermal expansion characteristics of the two substrates.

Owner:SUN MICROSYSTEMS INC

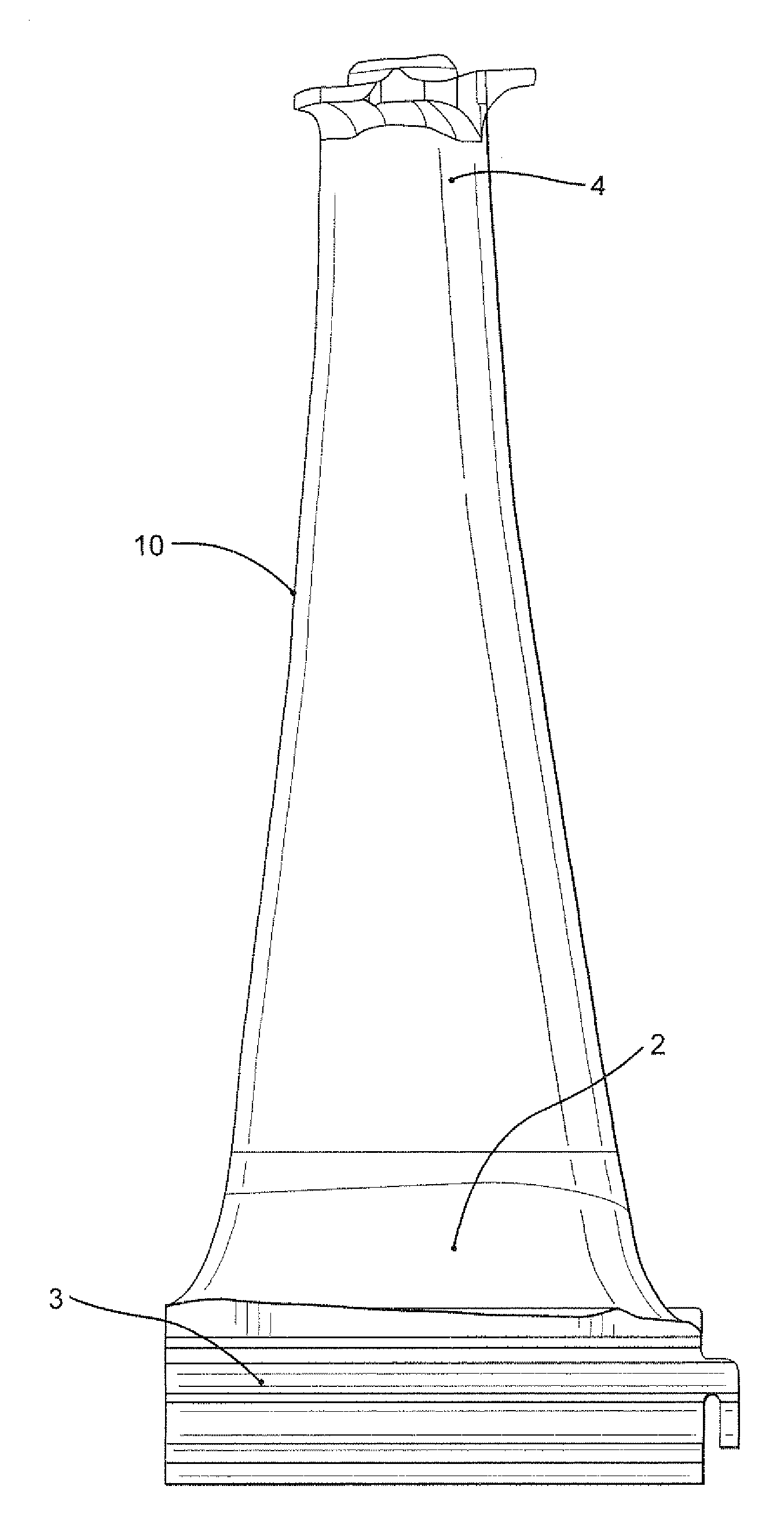

Steam Turbine Rotating Blade

ActiveUS20100021306A1Improve aerodynamic performanceImprove traffic distributionPropellersPump componentsEngineeringCentrifugal force

A rotating blade for a steam turbine includes a root section and an airfoil section contiguous with the root section. The airfoil section is shaped to optimize aerodynamic performance while providing optimized flow distribution and minimal centrifugal and bending stresses. The blade also includes a tip section continuous with the airfoil section, and a cover formed as part of the tip section. The cover defines a radial seal that serves to minimize tip losses. The rotating blade is capable of running at operating speeds between 5626 and 11250 rotations per minute.

Owner:NUOVO PIGNONE TECH SRL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com