Patents

Literature

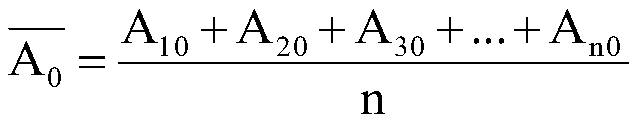

84results about How to "Reduce maximum pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

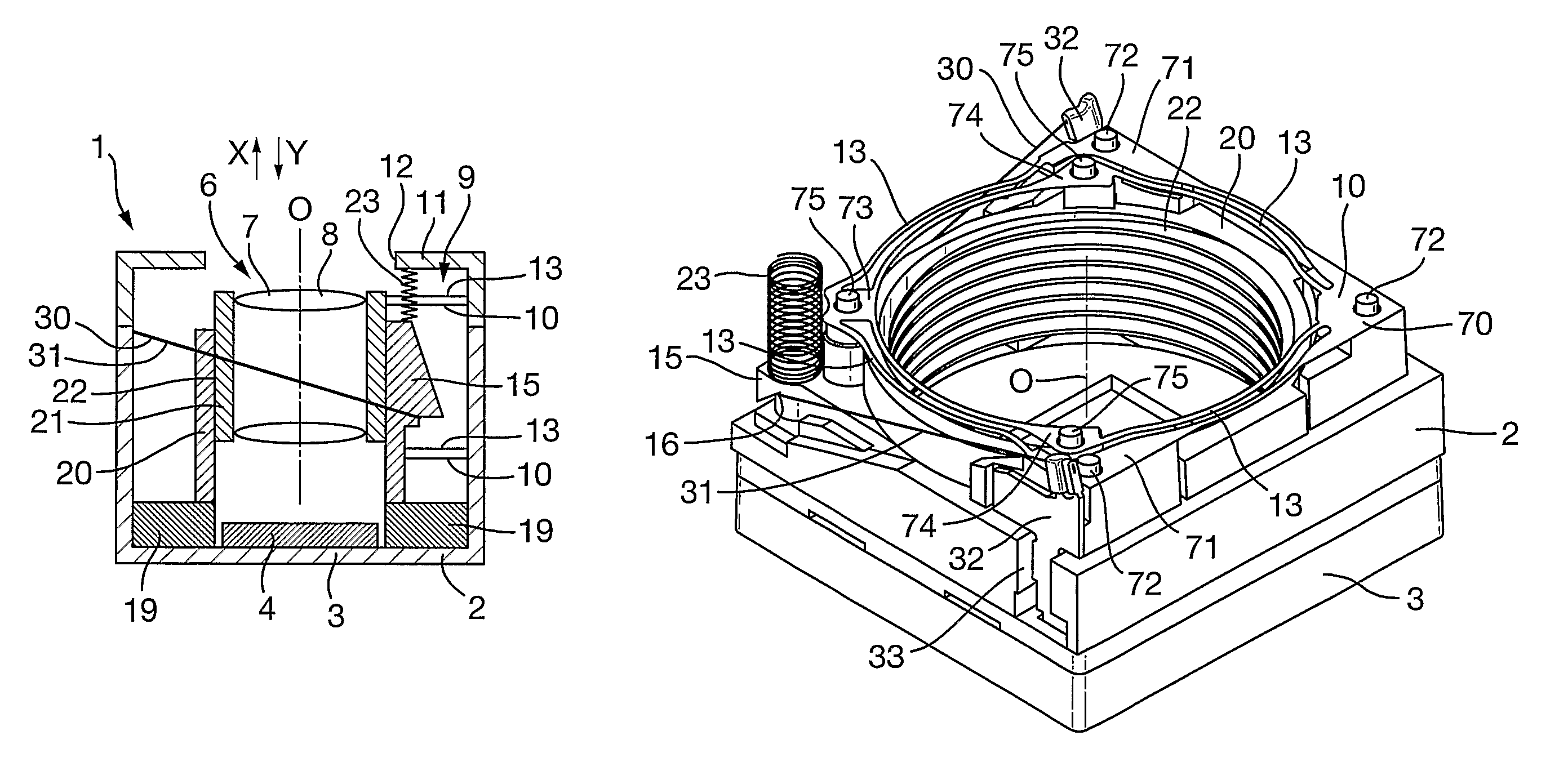

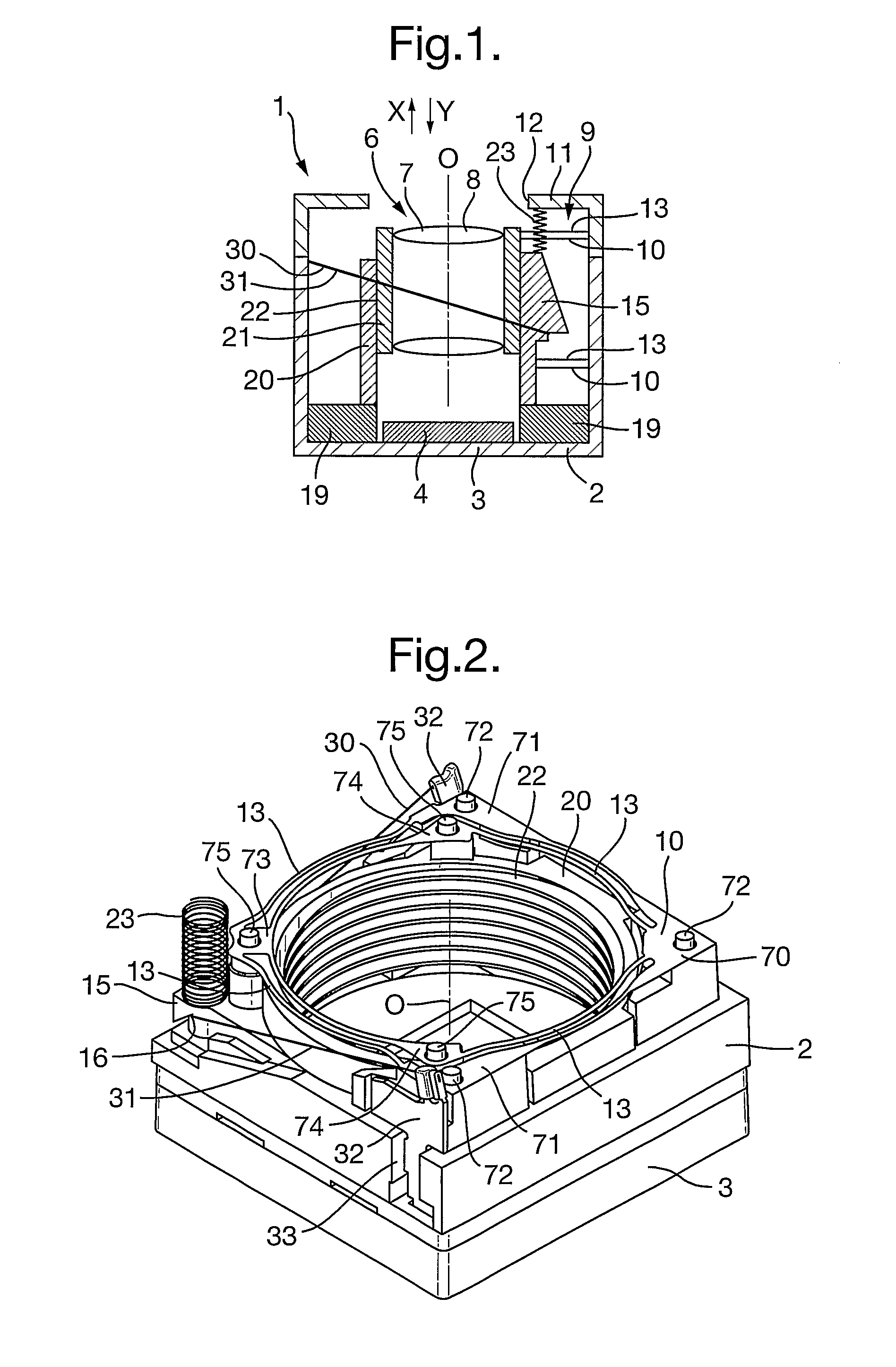

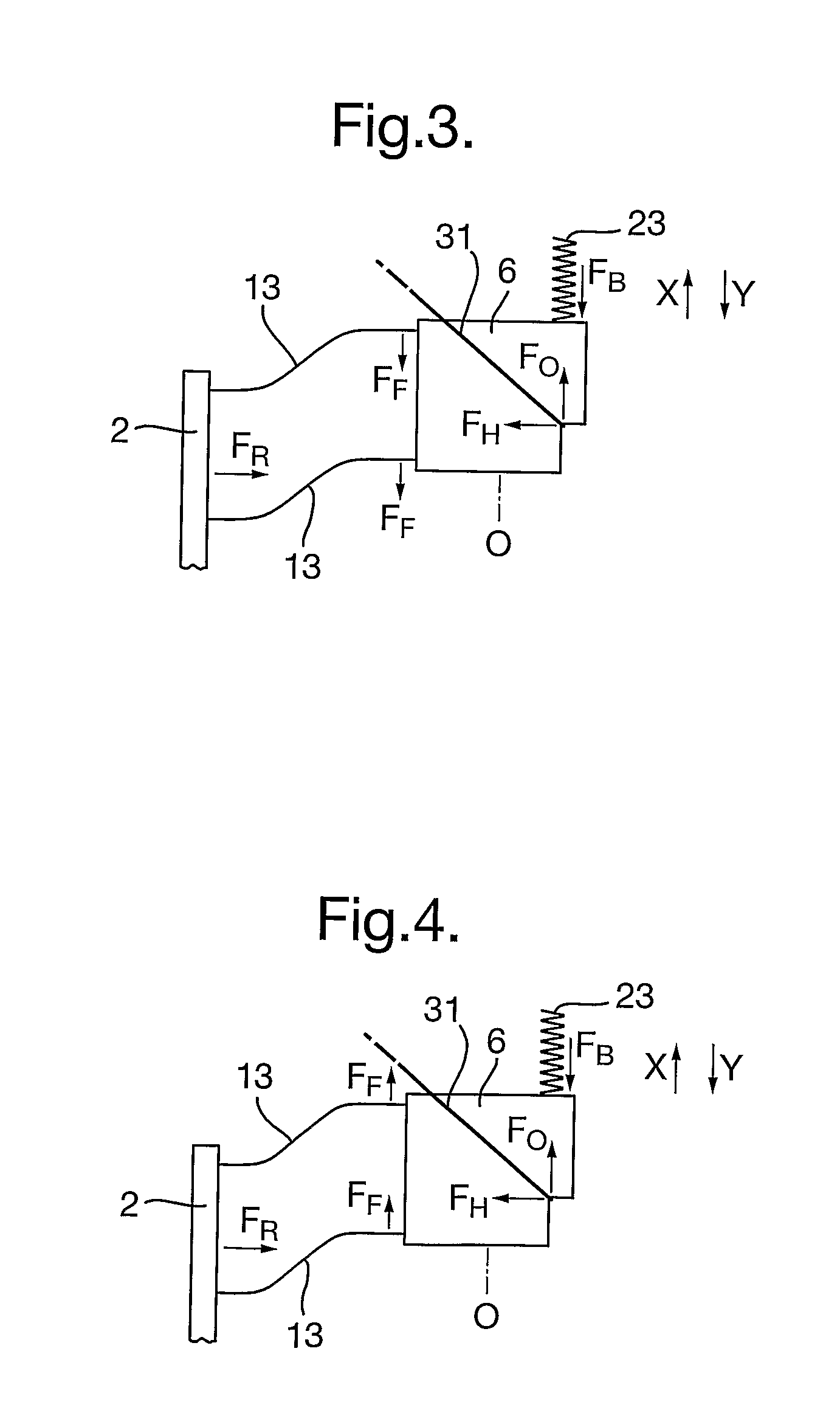

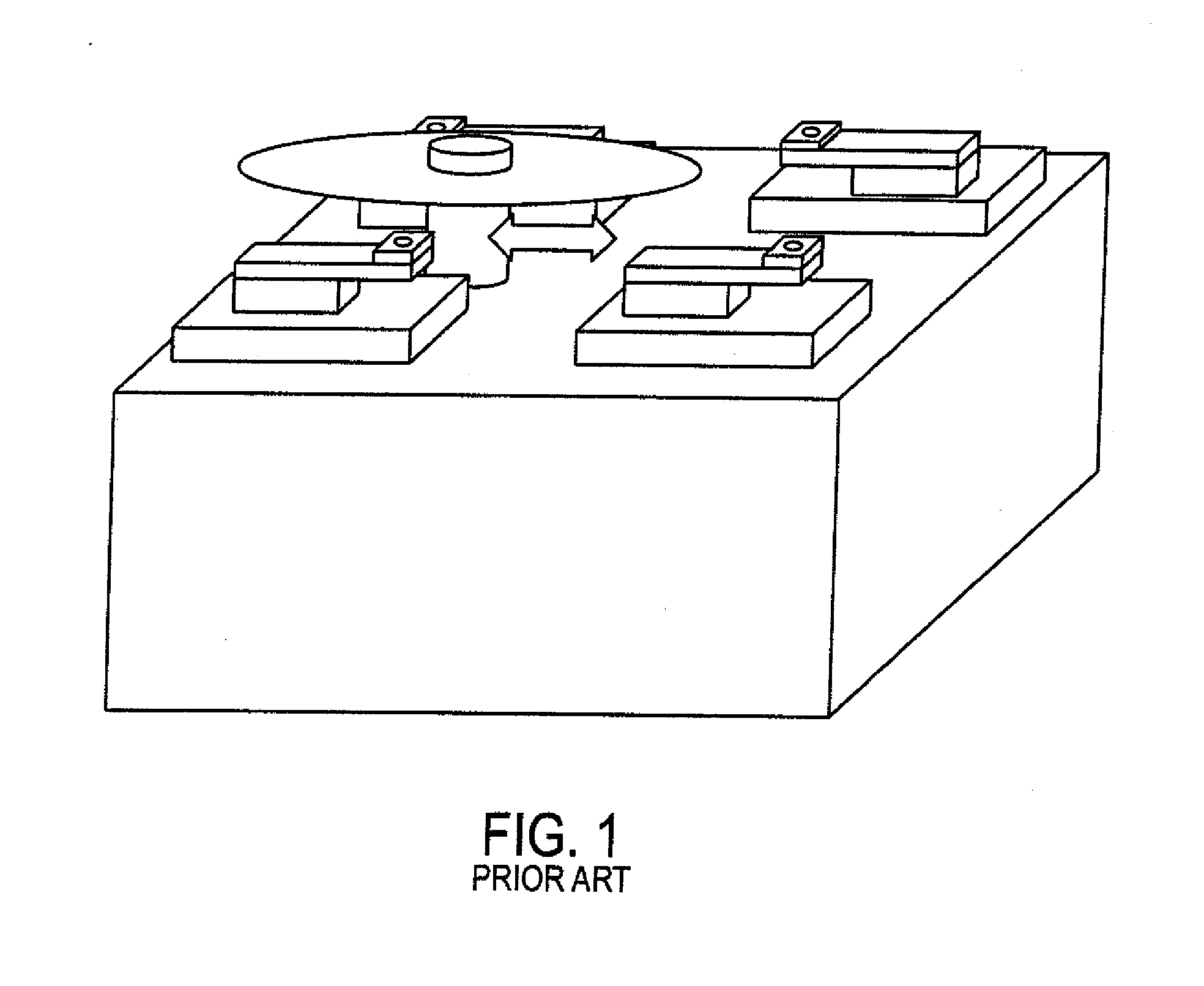

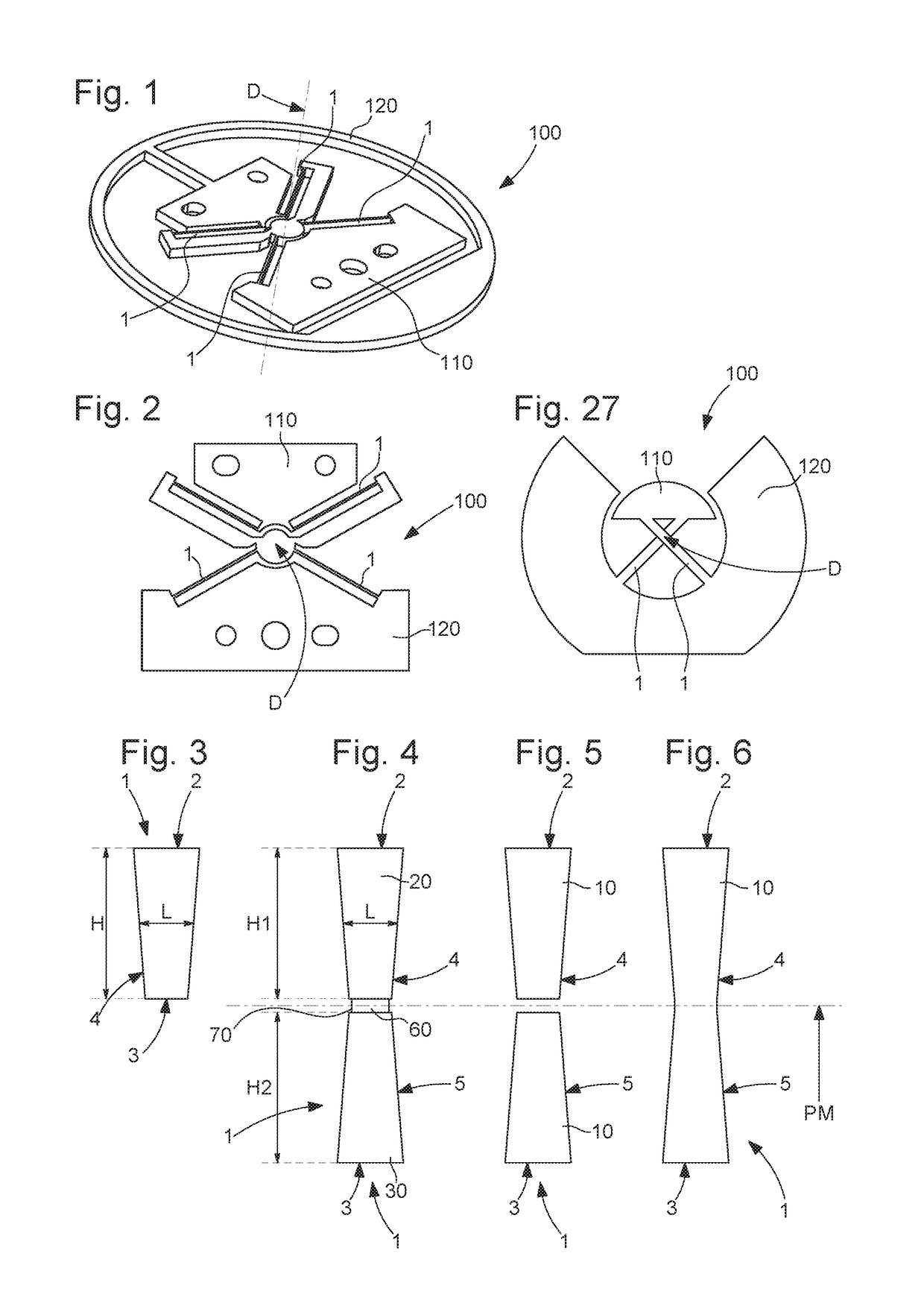

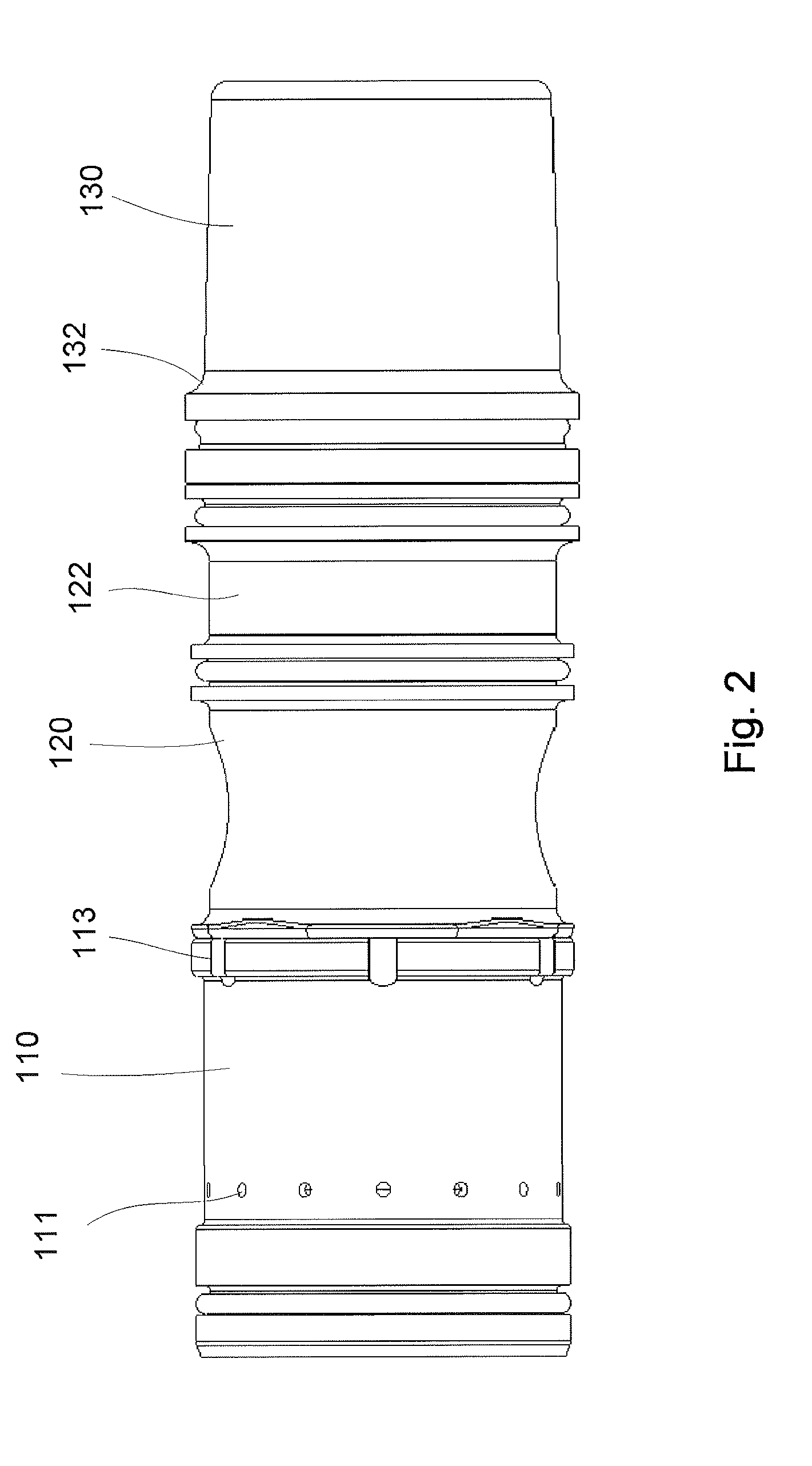

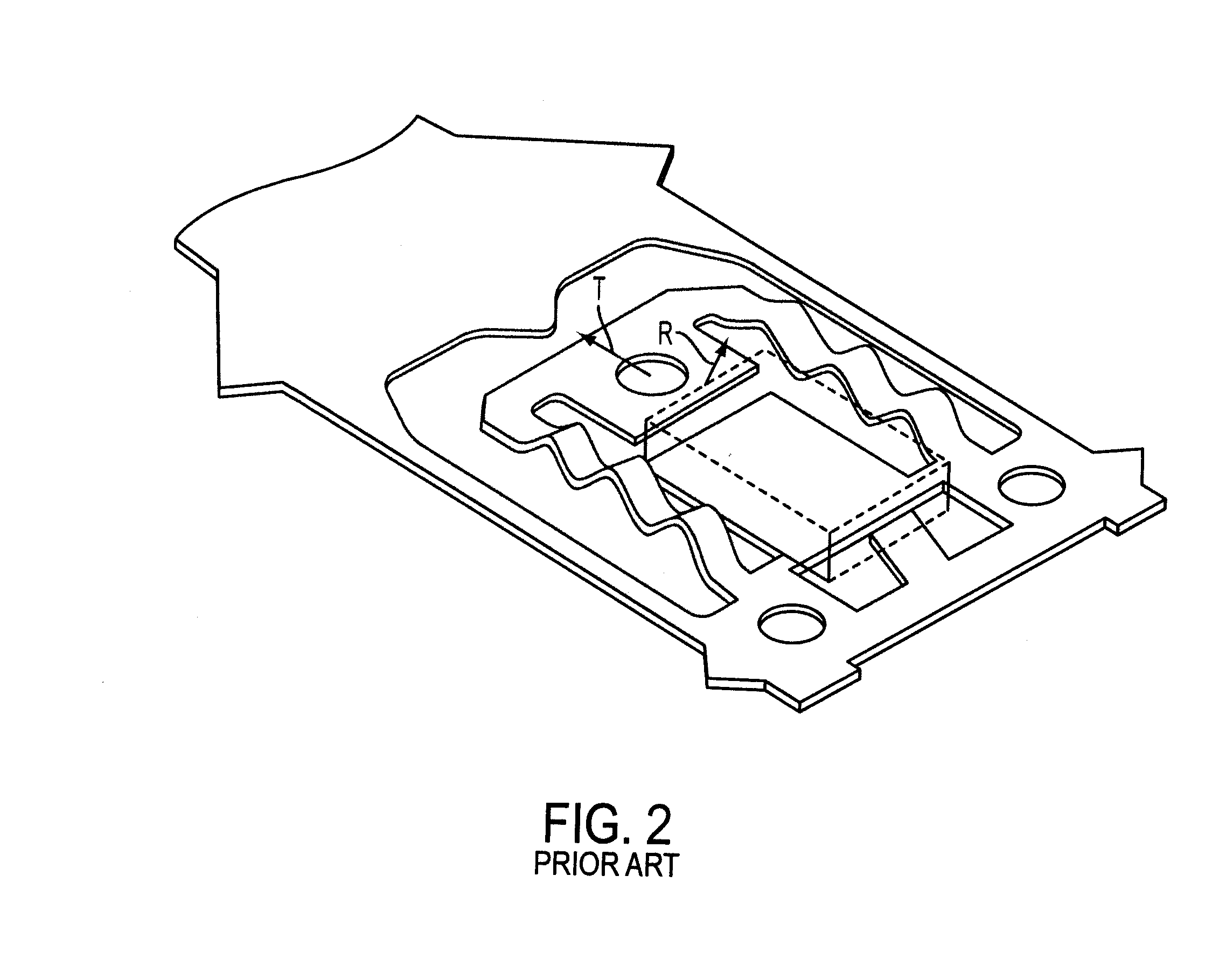

Shape memory alloy actuation apparatus

ActiveUS8441749B2Reduce maximum pressureReduce the applied forceTelevision system detailsProjector focusing arrangementCamera lensAcute angle

An SMA actuation apparatus comprises a camera lens element supported on a support structure by a plurality of flexures. An SMA wire at an acute angle to the movement axis and a biasing element are connected between the support structure and the movable element. A component of the force applied by the SMA wire perpendicular to the movement axis compresses the flexures causing them to apply a force to the movable element having a component along the movement axis in the same direction as the SMA wire. An end-stop limits the movement of the movable element, and the moment applied by the end-stop to the movable element about the center of stiffness is equal to the moment applied by the SMA wire about the center of stiffness at the point when the movable element loses contact with the end-stop on contraction of the SMA wire.

Owner:CAMBRIDGE MECHATRONICS

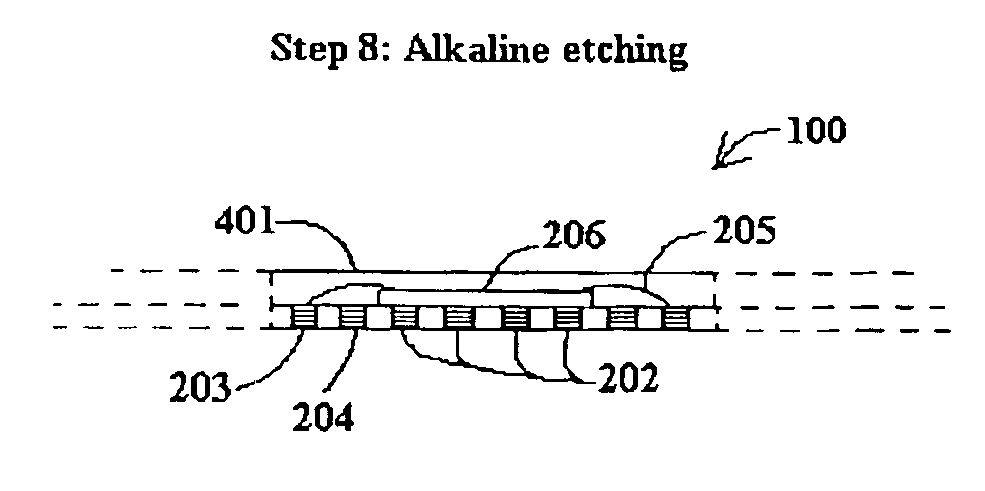

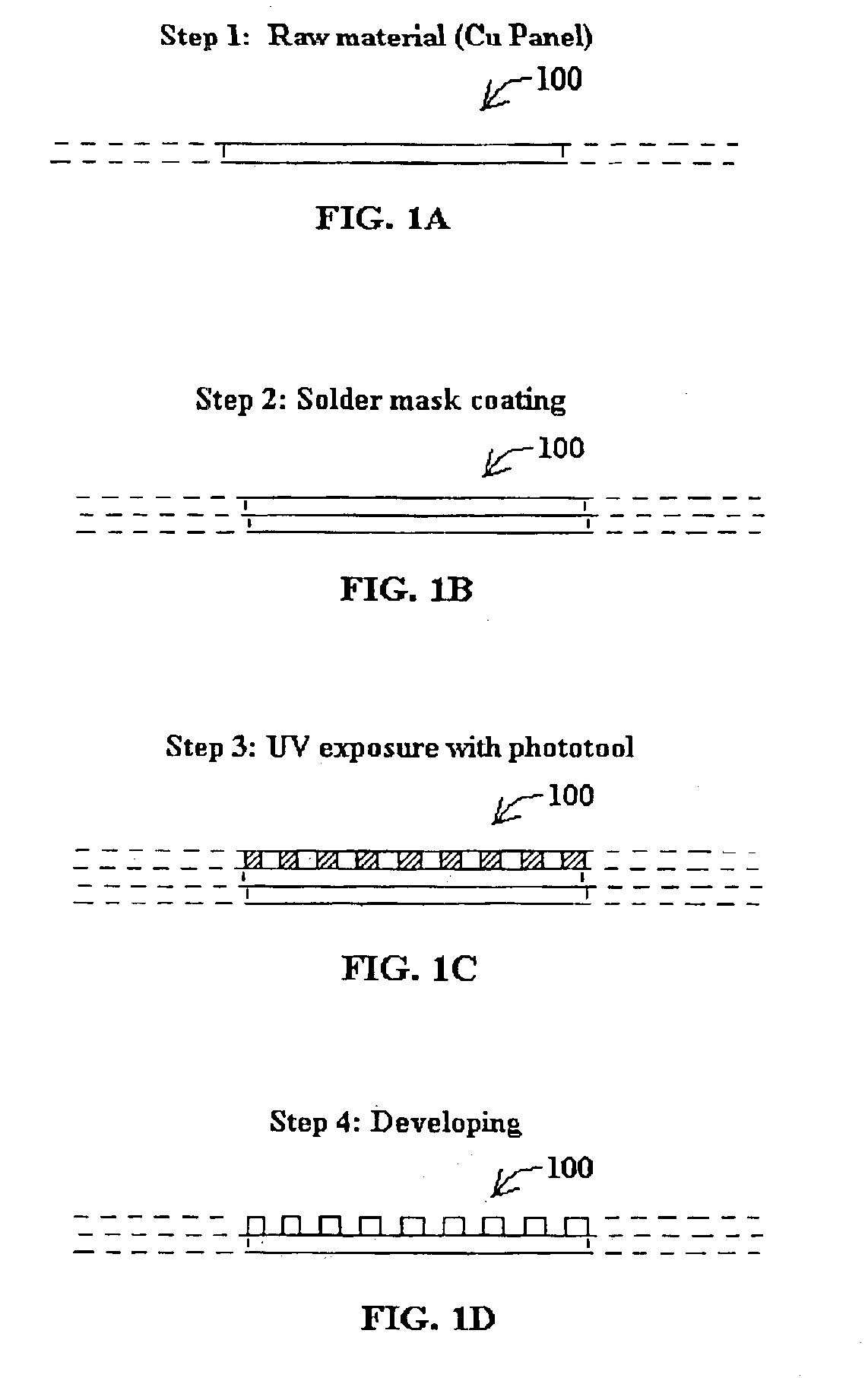

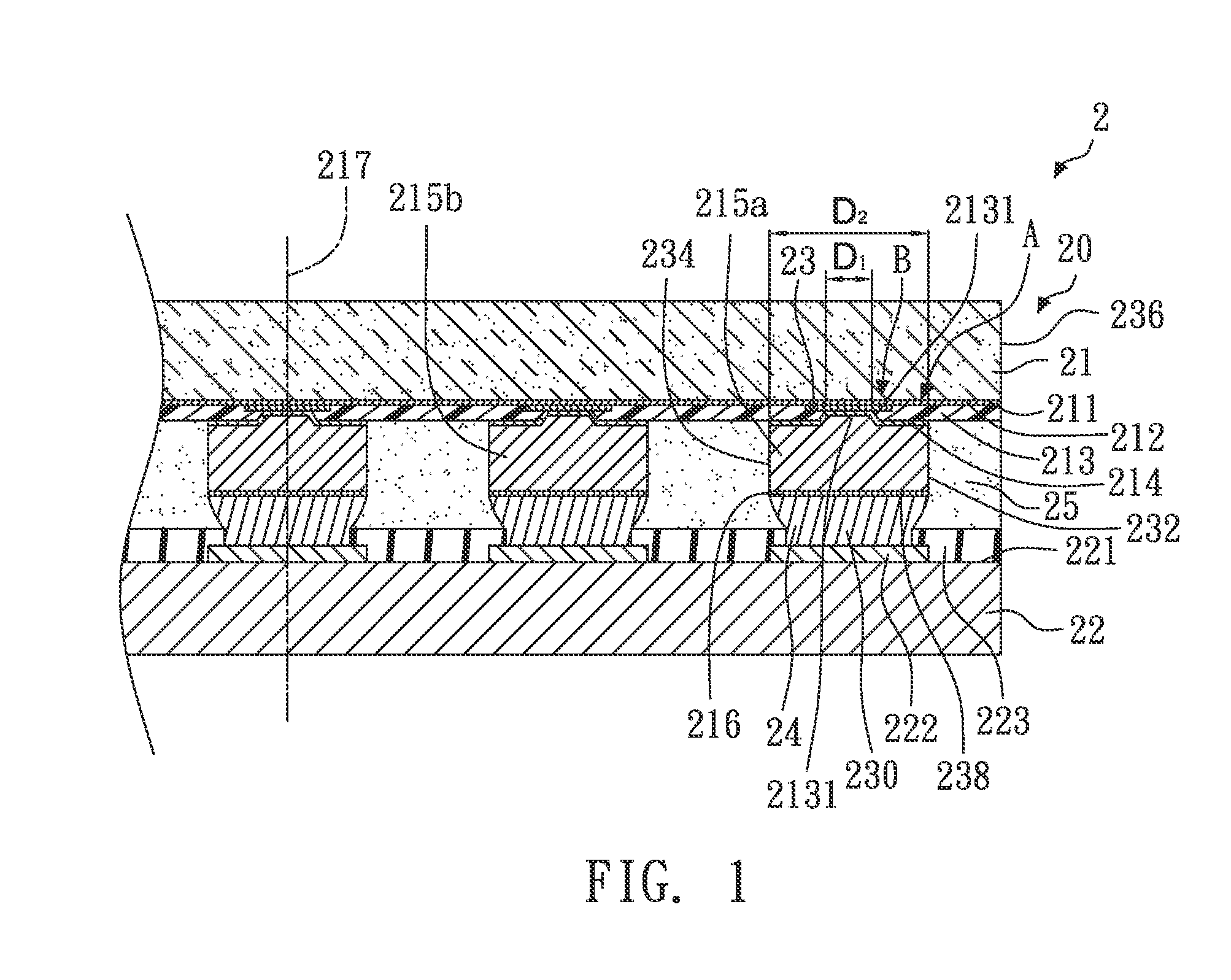

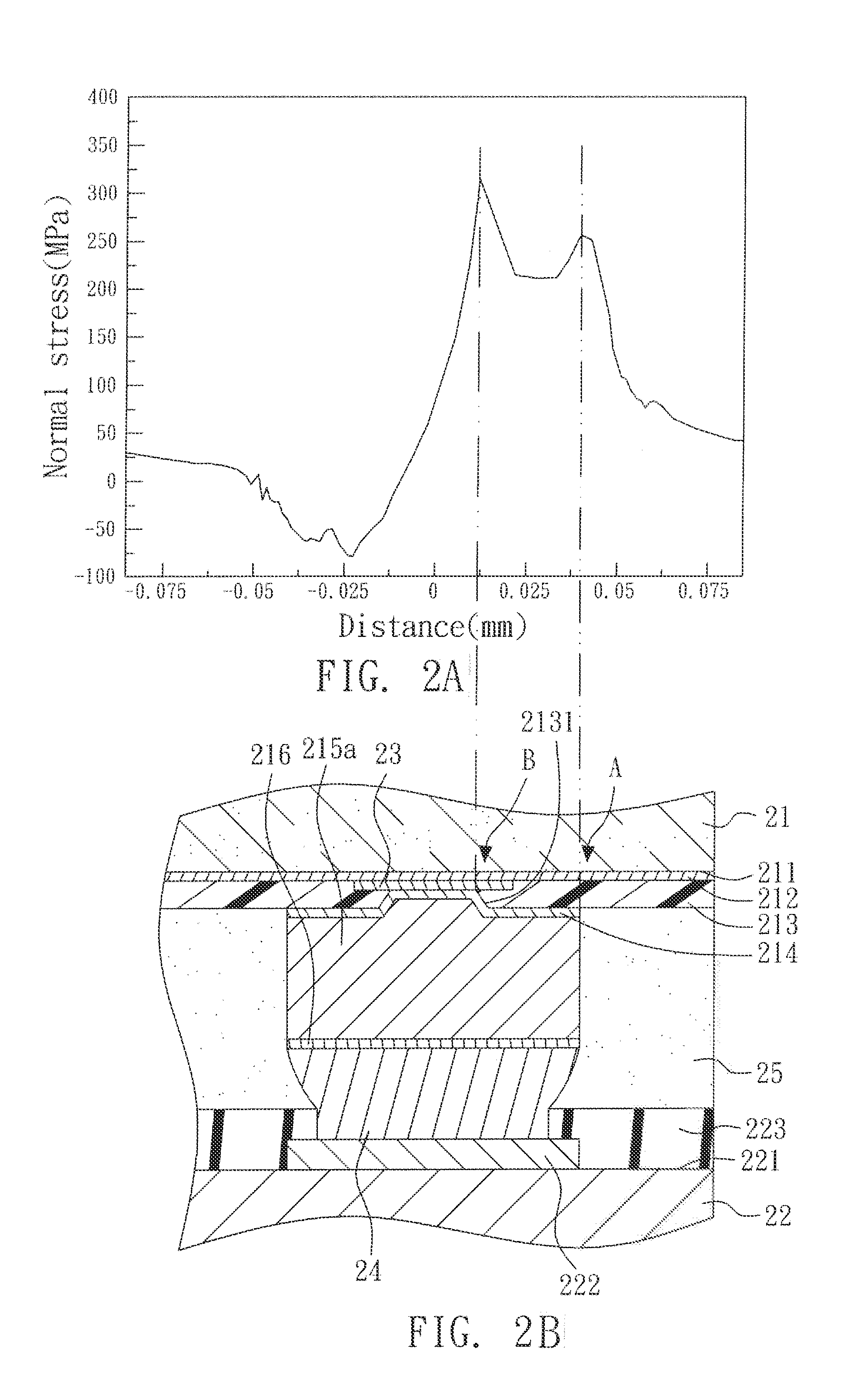

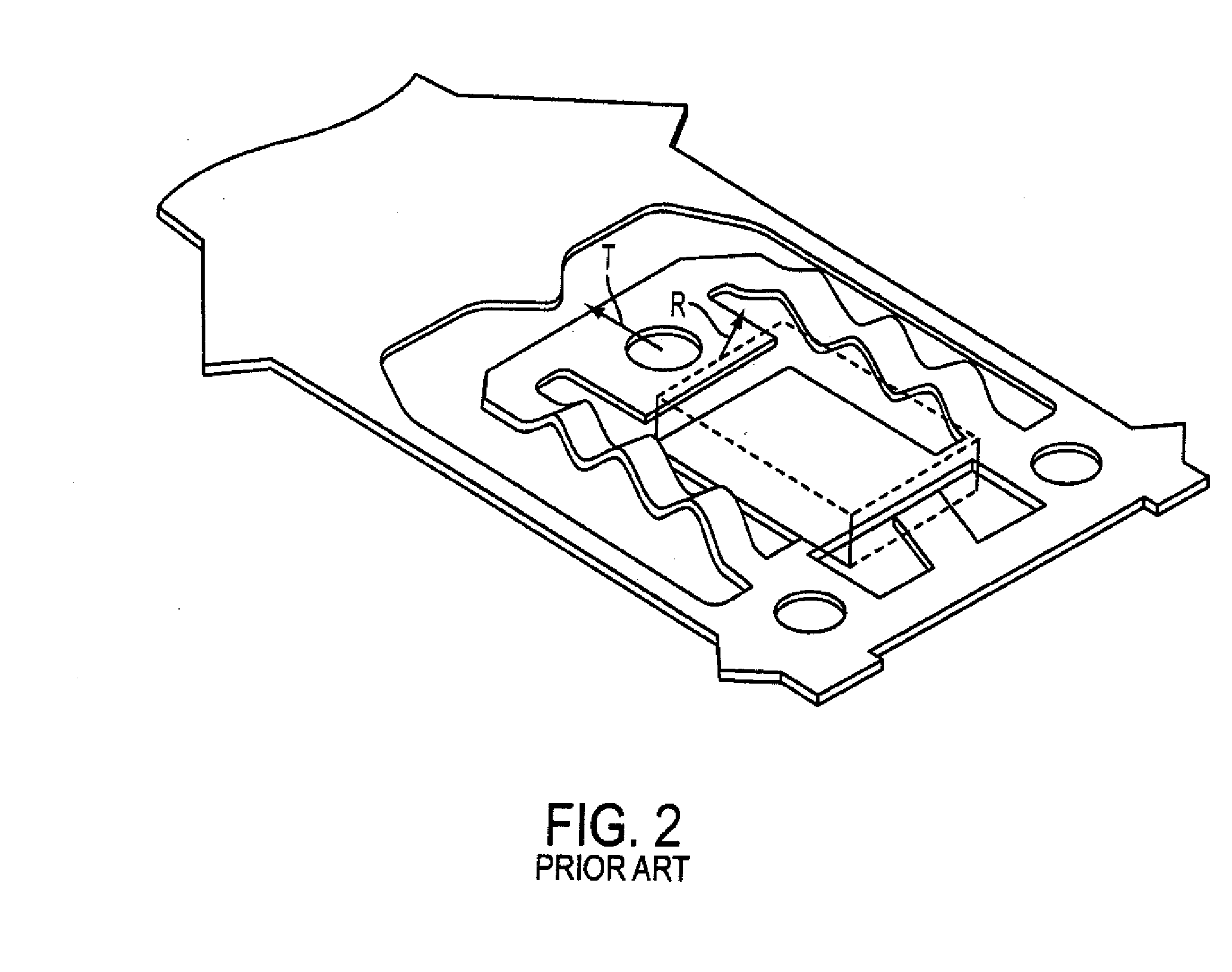

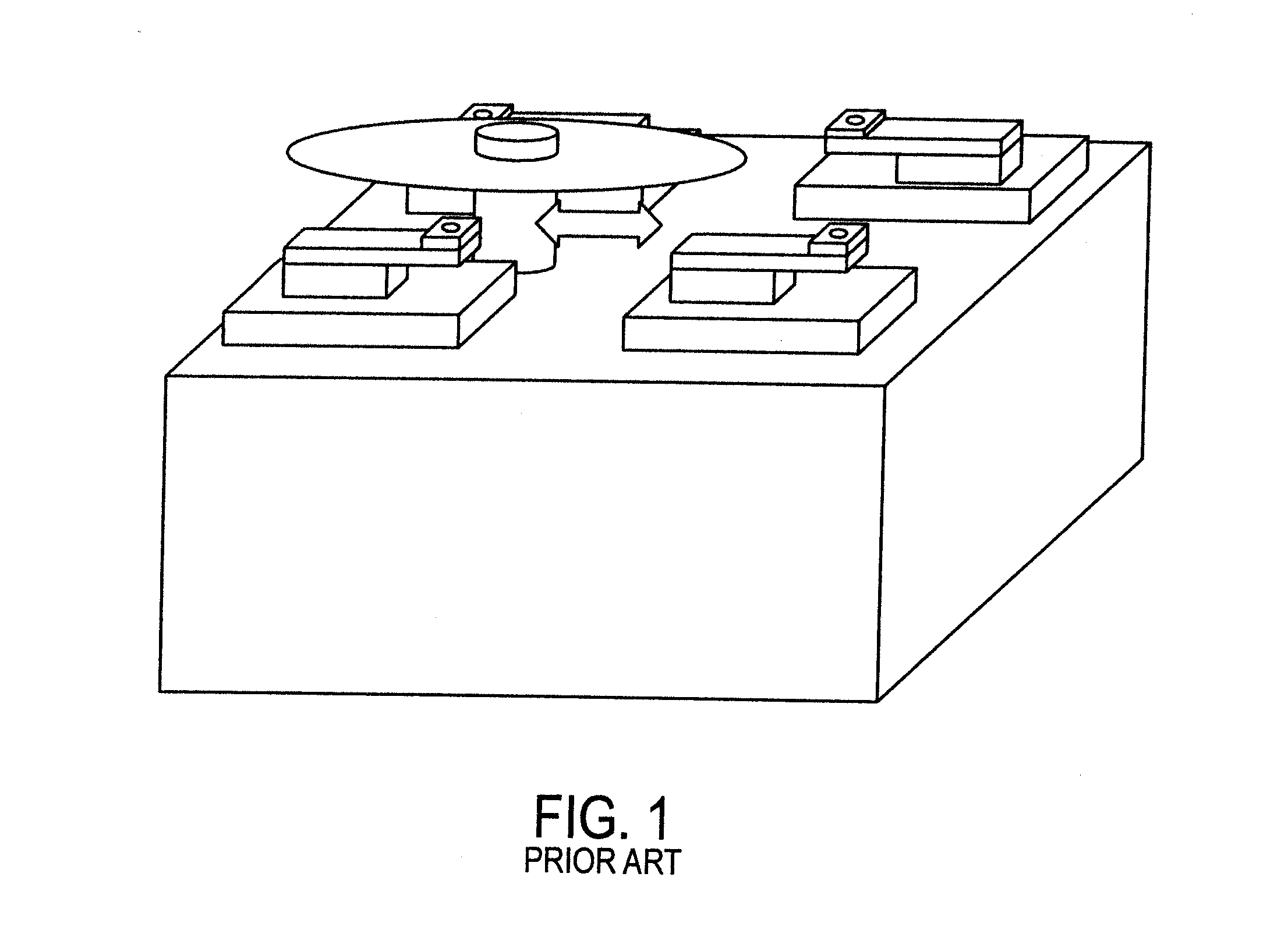

Leadless plastic chip carrier with etch back pad singulation and die attach pad array

InactiveUS6872661B1Mitigate internal stressReduces lineSemiconductor/solid-state device detailsSolid-state devicesContact padEngineering

A leadless plastic chip carrier has a plurality of die attach pads on which a singulated semi-conductor die is mounted. At least one row of contact pads circumscribes the plurality of die attach pads and a power / ground ring is intermediate the contact pads and the die attach pads. Wire bonds connect the semiconductor die, the contact pads and the power / ground ring. An overmold covers the semi-conductor die, the die attach pads, the power / ground ring and the contact pads such that each of the die attach pads and the contact pads has one exposed surface.

Owner:UTAC HEADQUARTERS PTE LTD

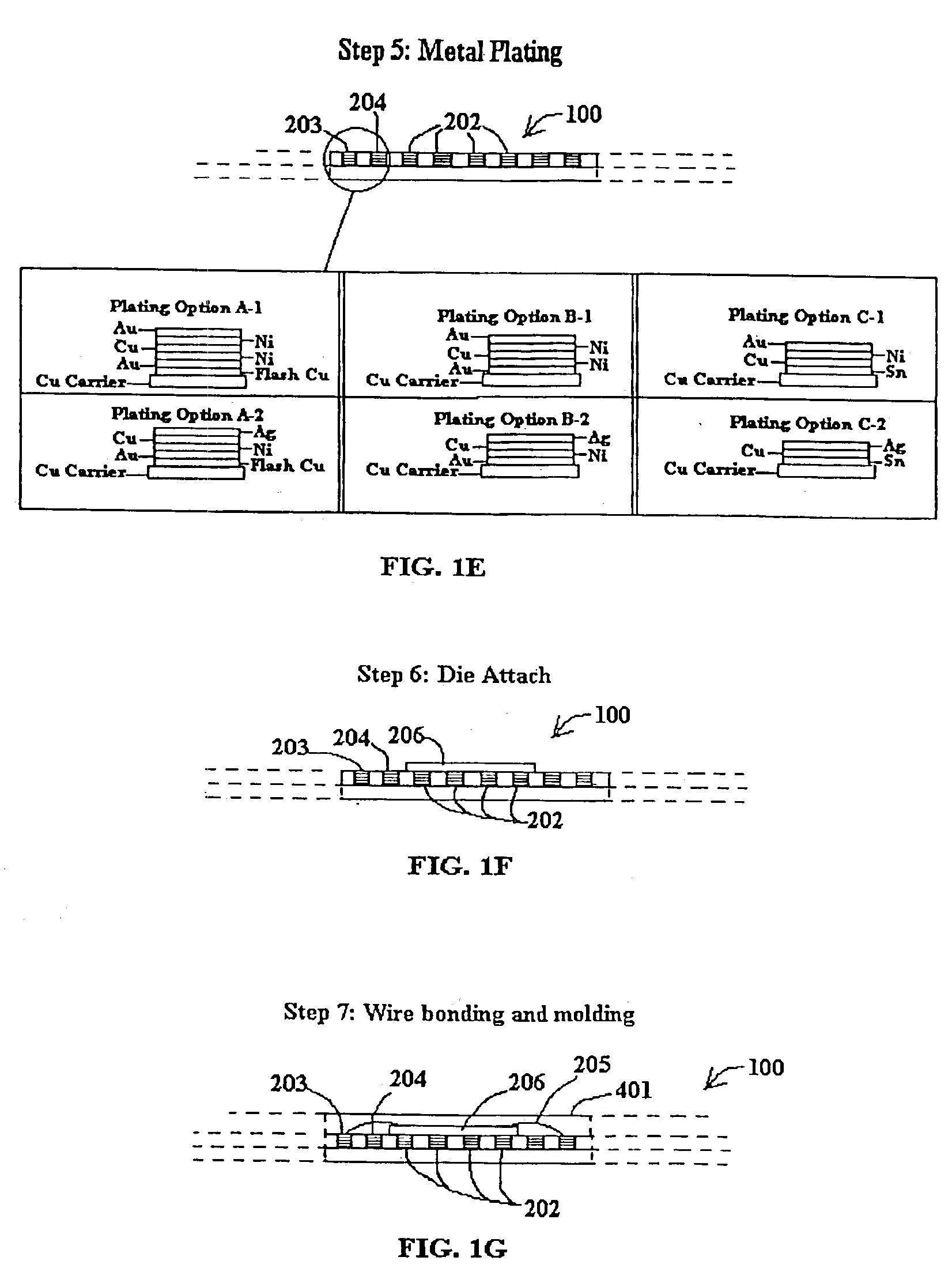

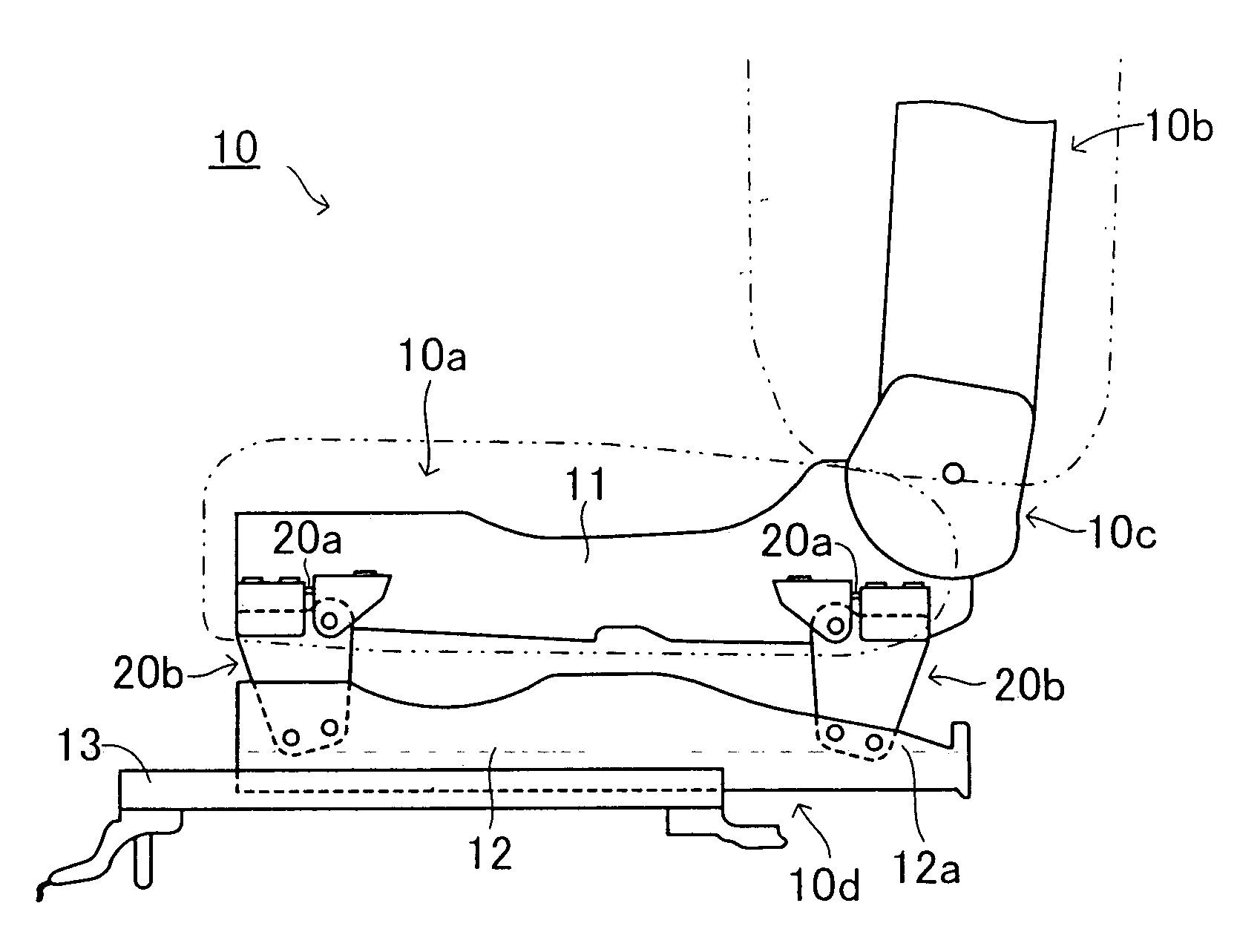

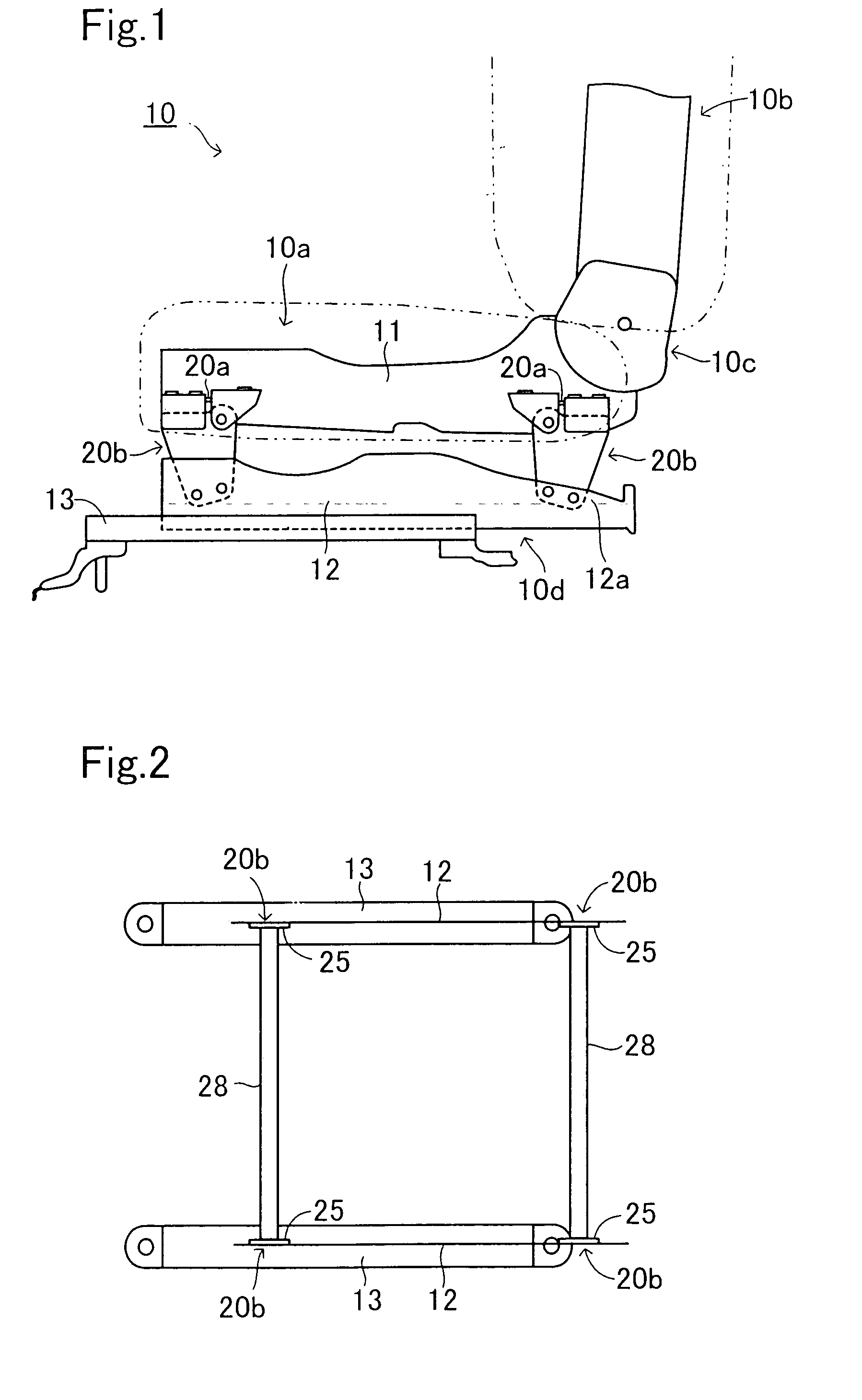

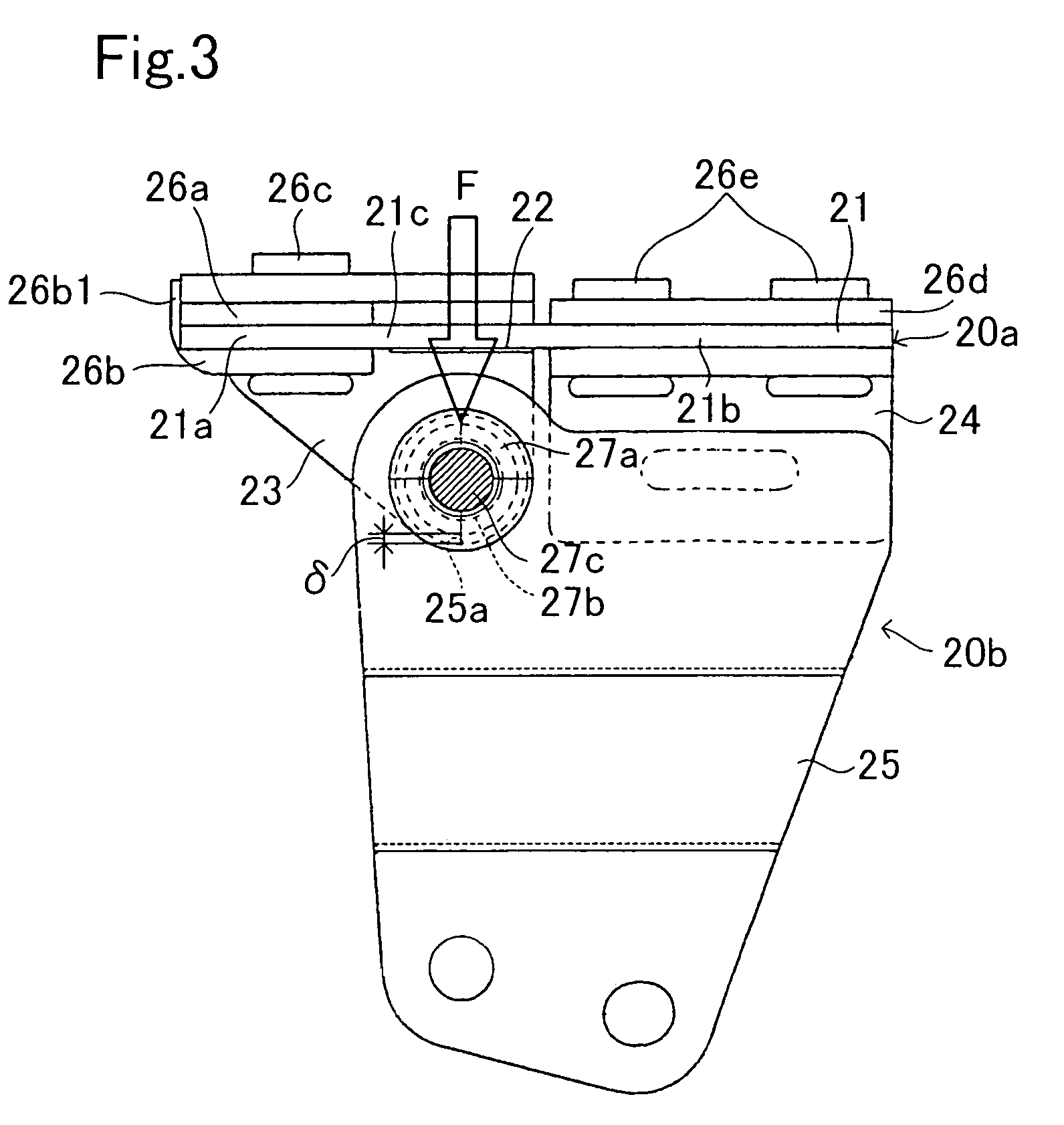

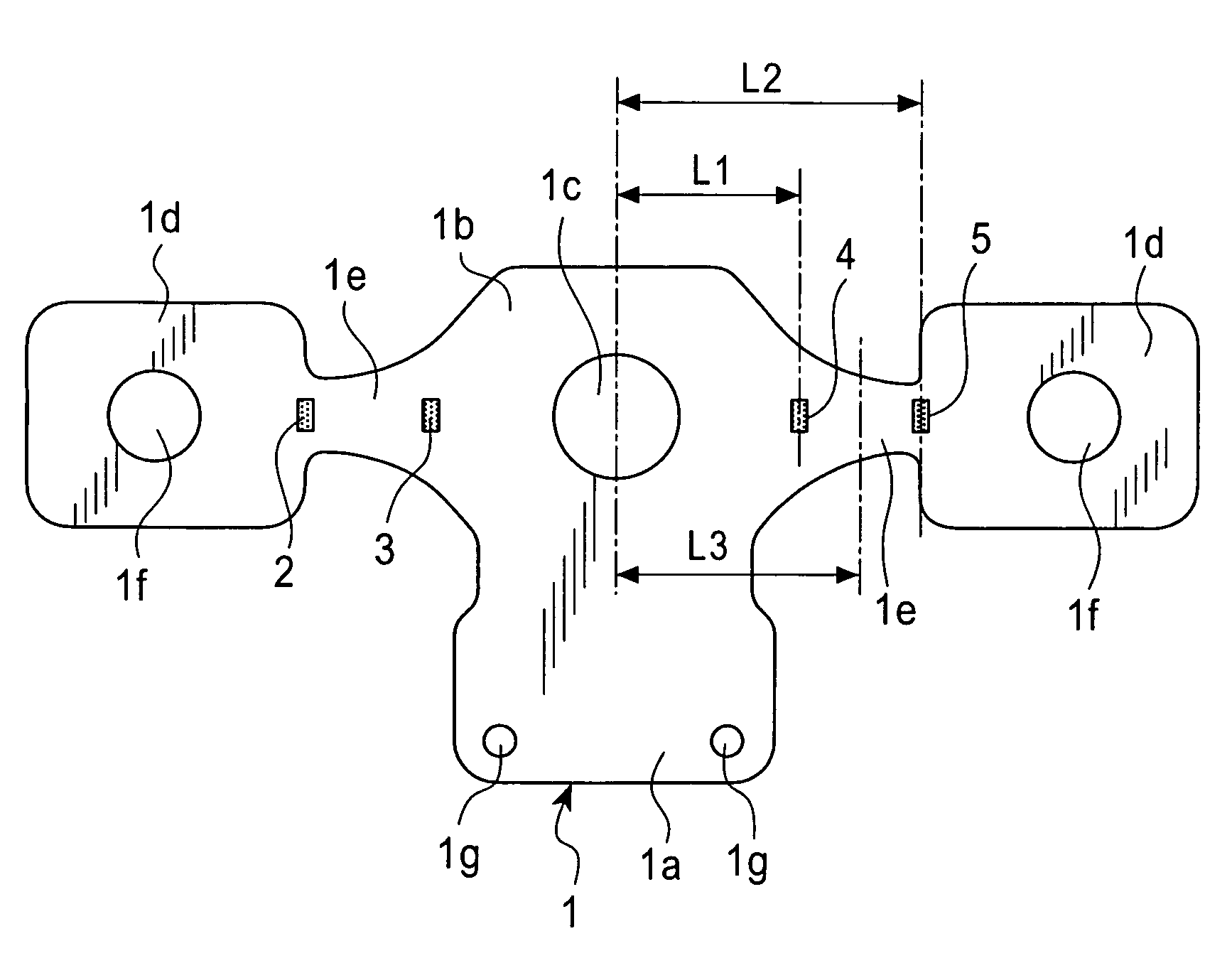

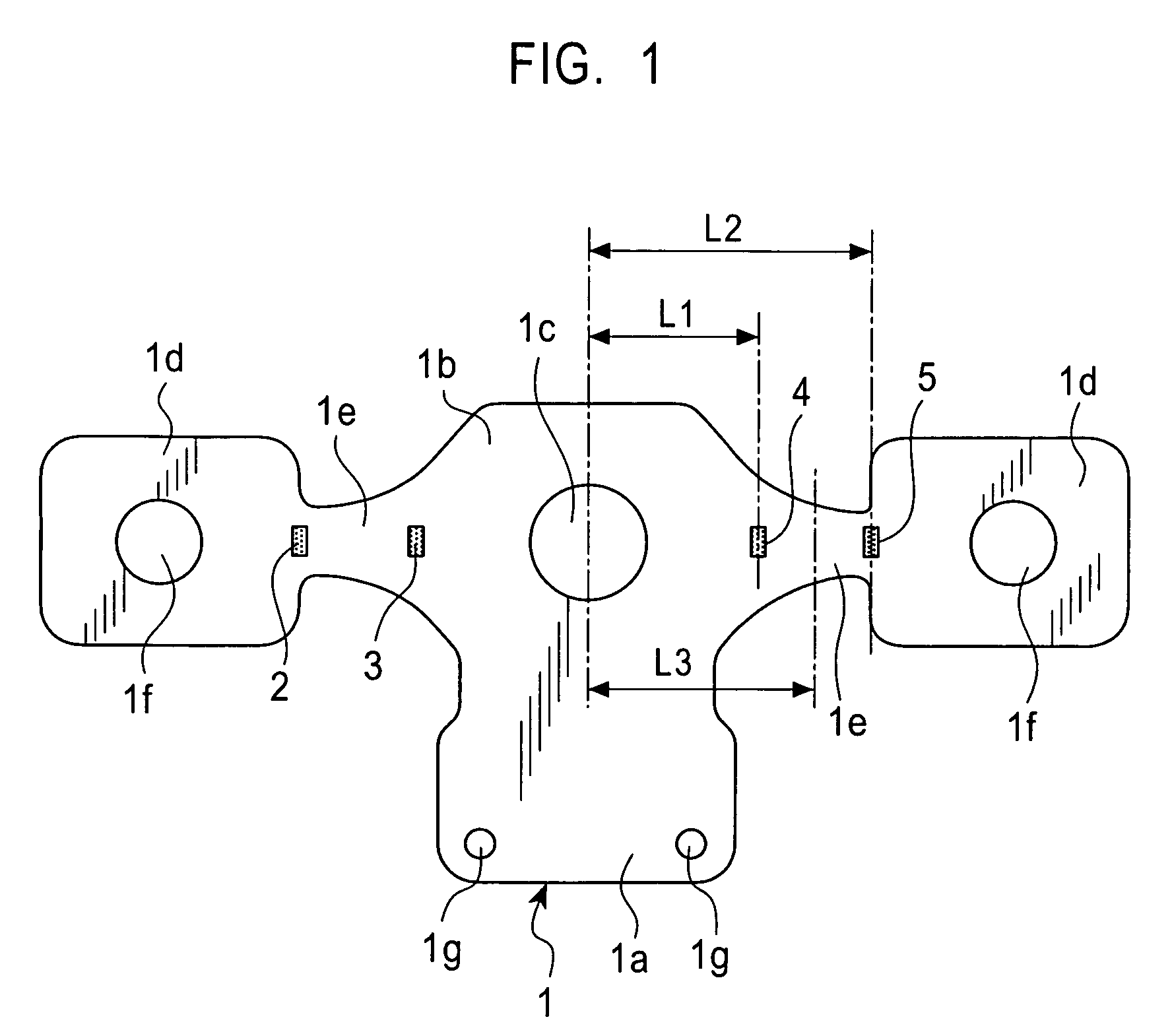

Attachment structure of a load sensor for a vehicle seat

InactiveUS6981717B2Accurate weighingReduce weightVehicle seatsBelt retractorsStrain gaugeAutomotive engineering

Owner:AISIN SEIKI KK

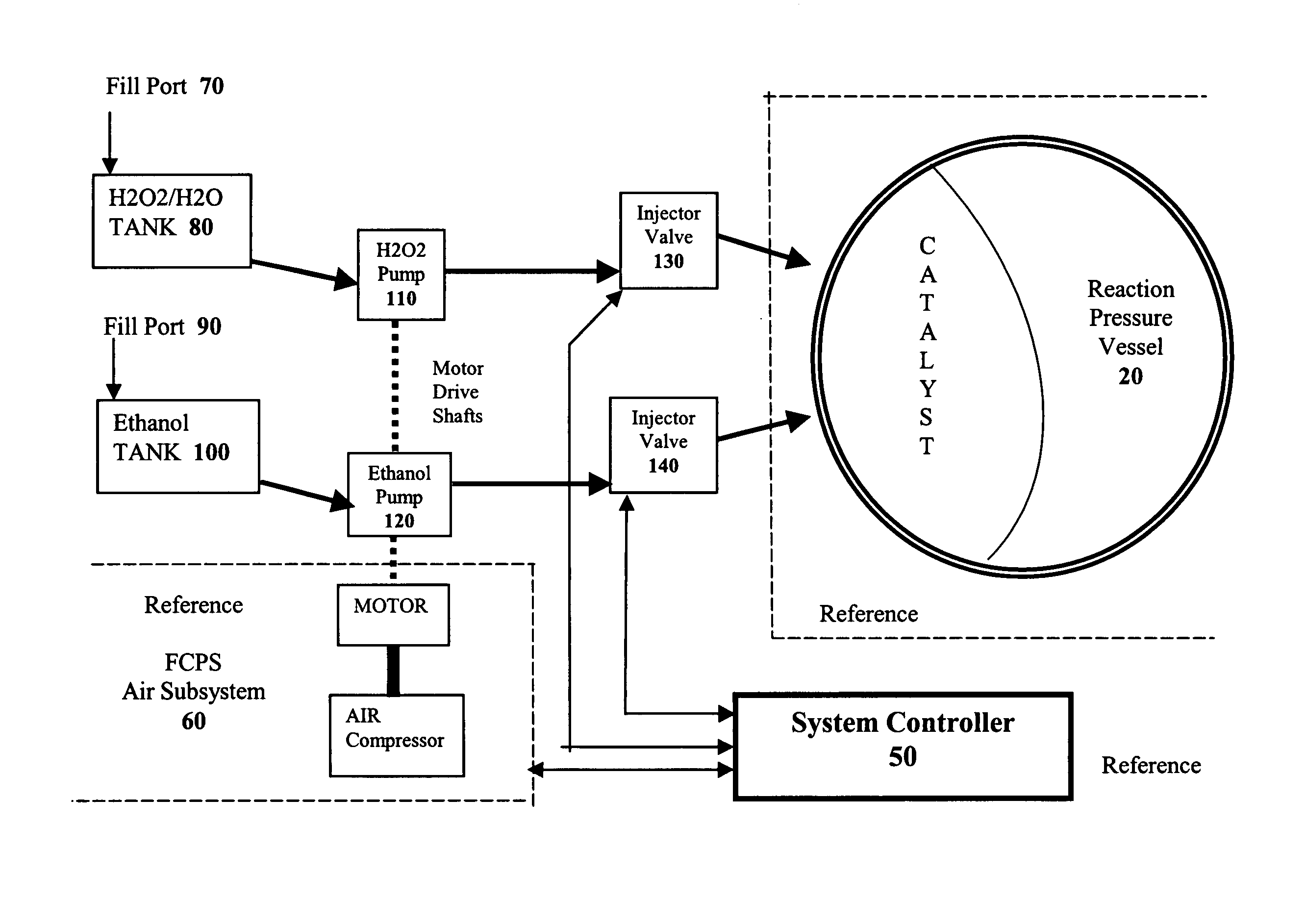

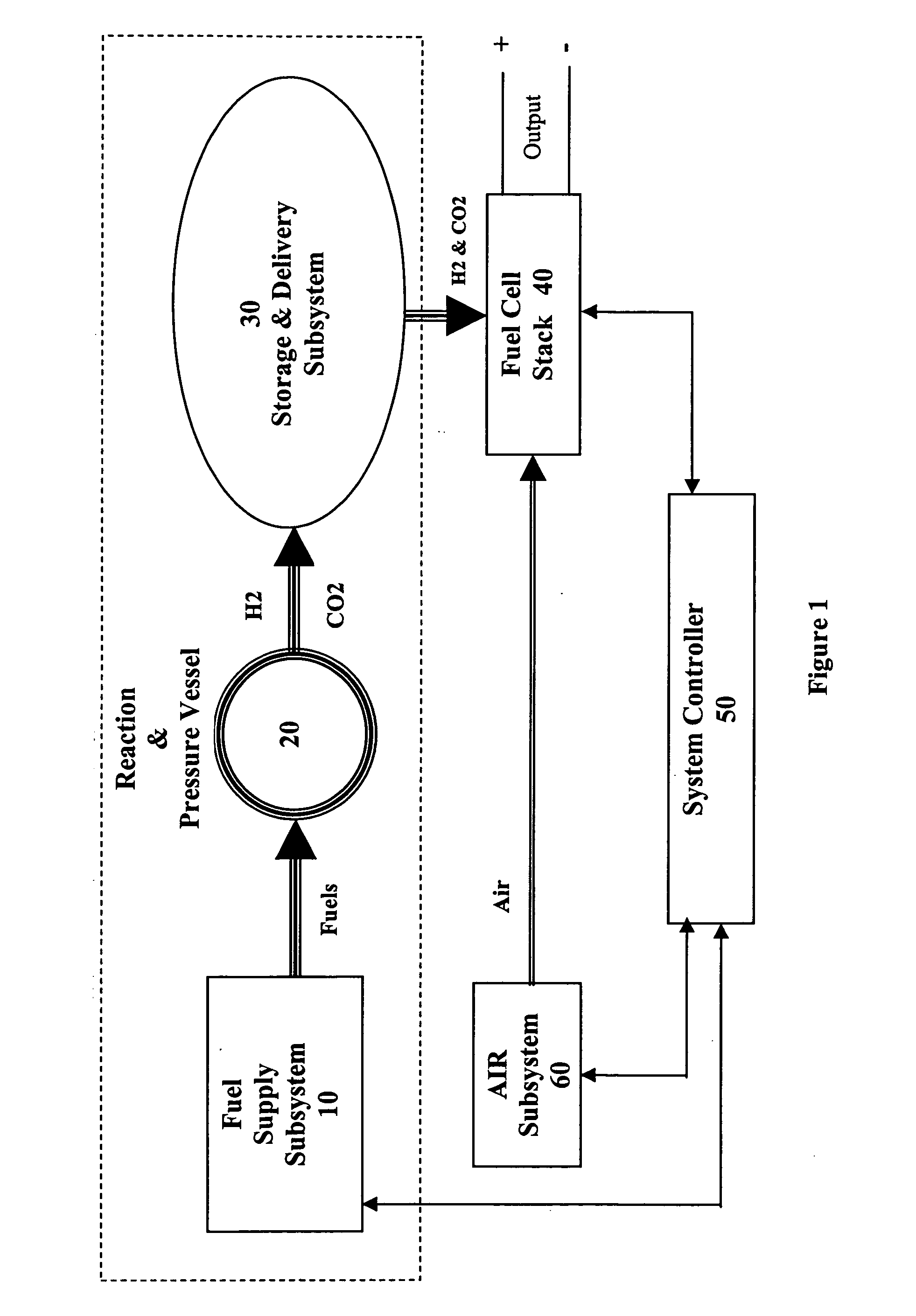

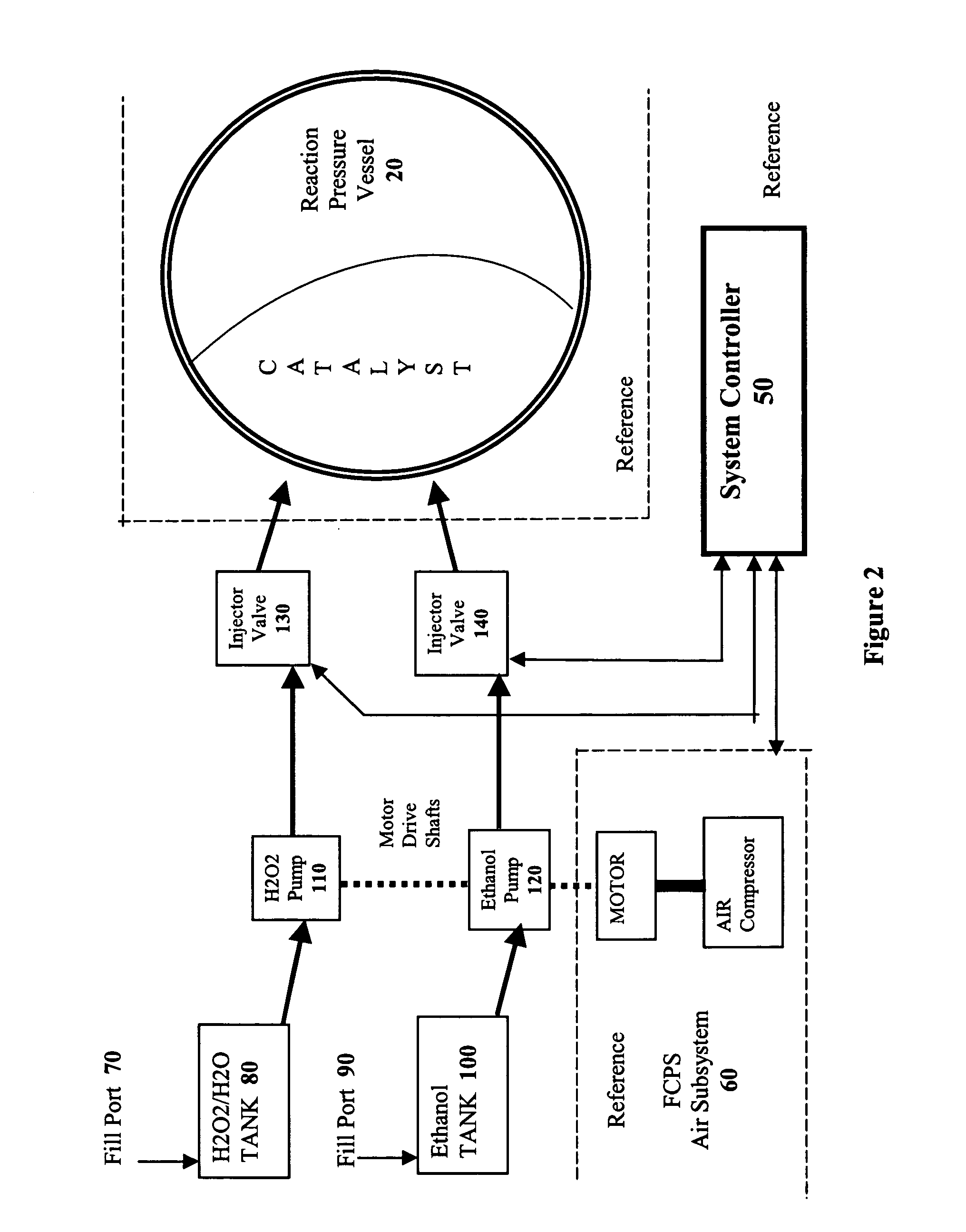

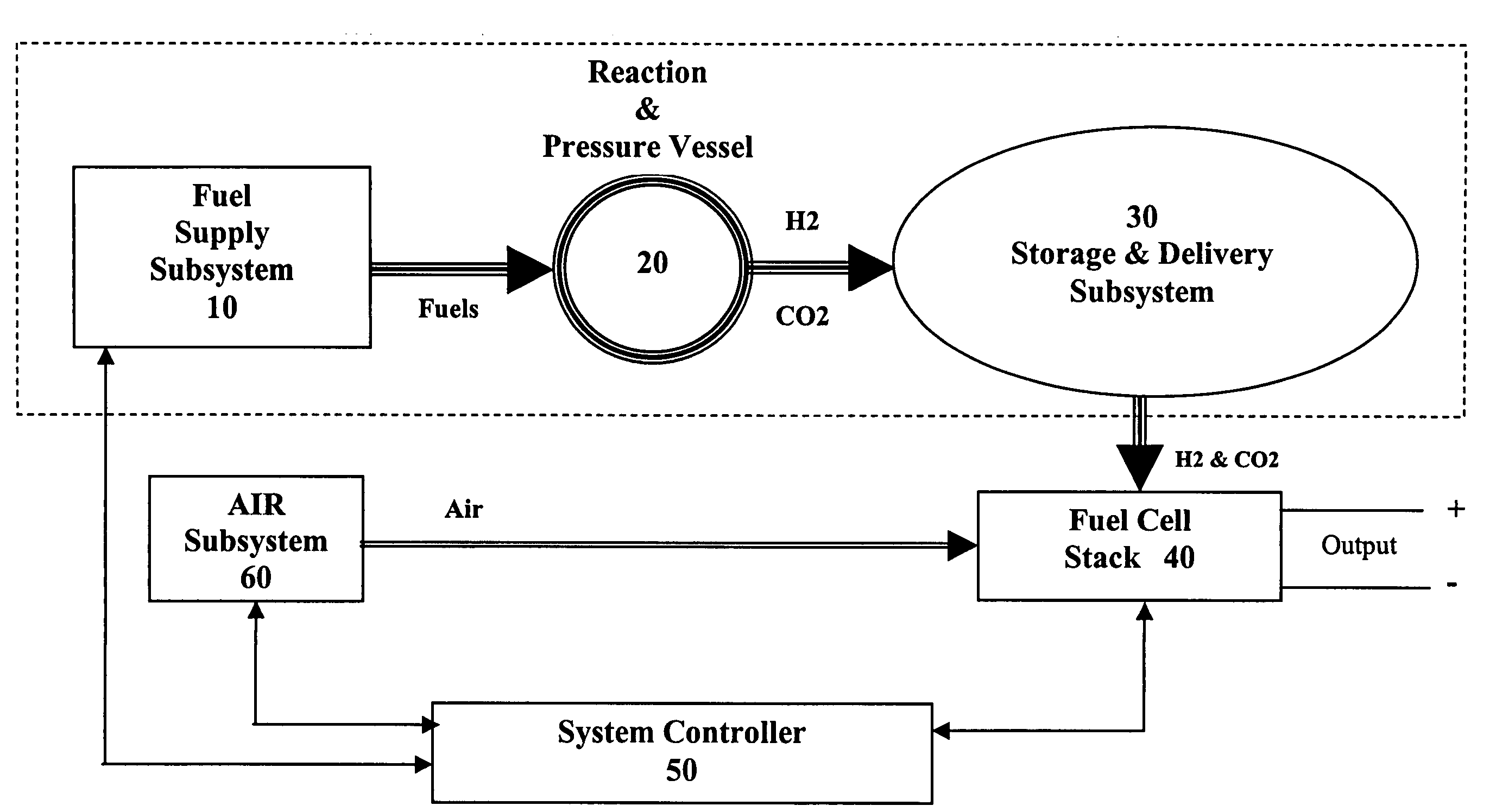

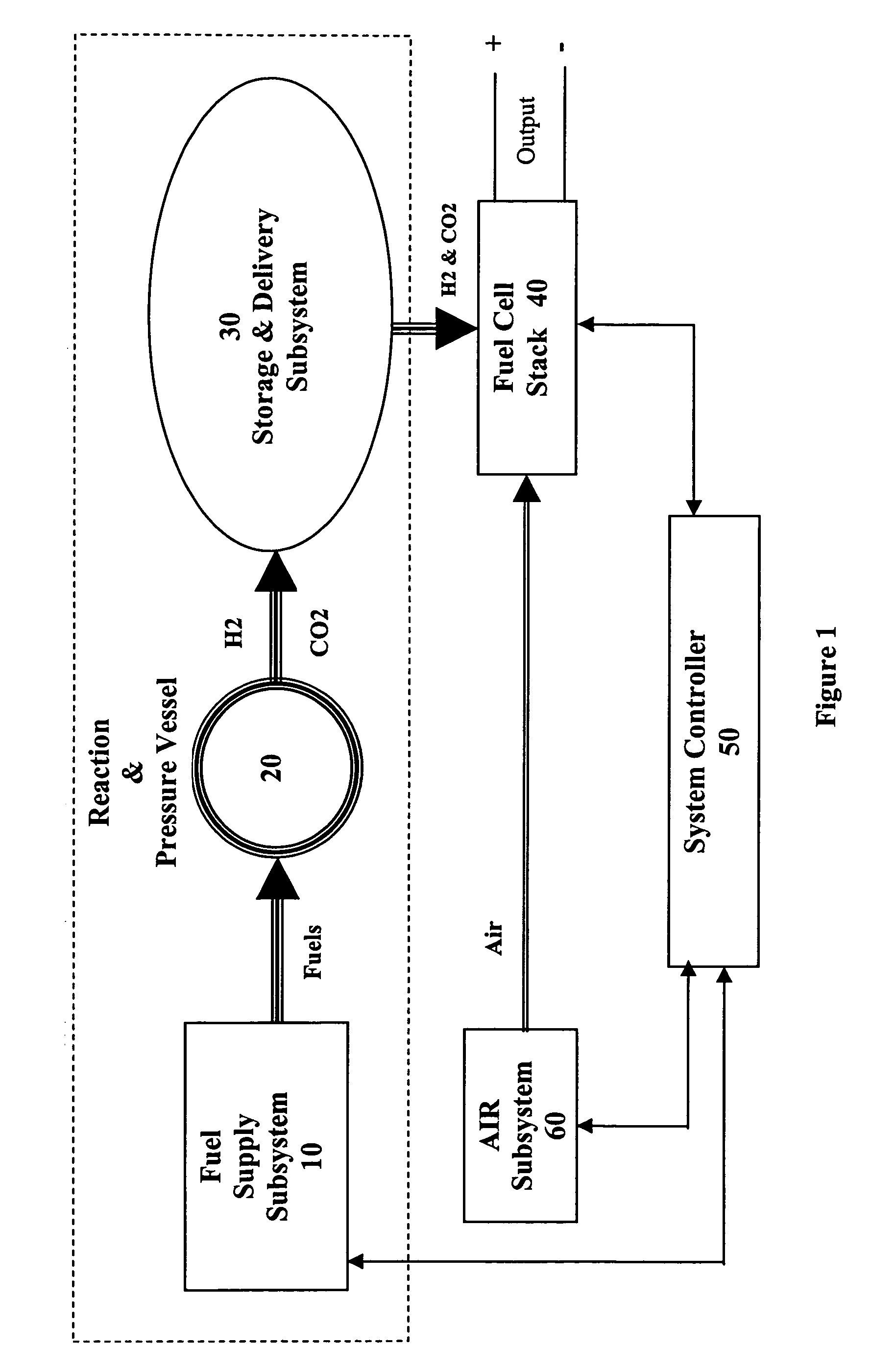

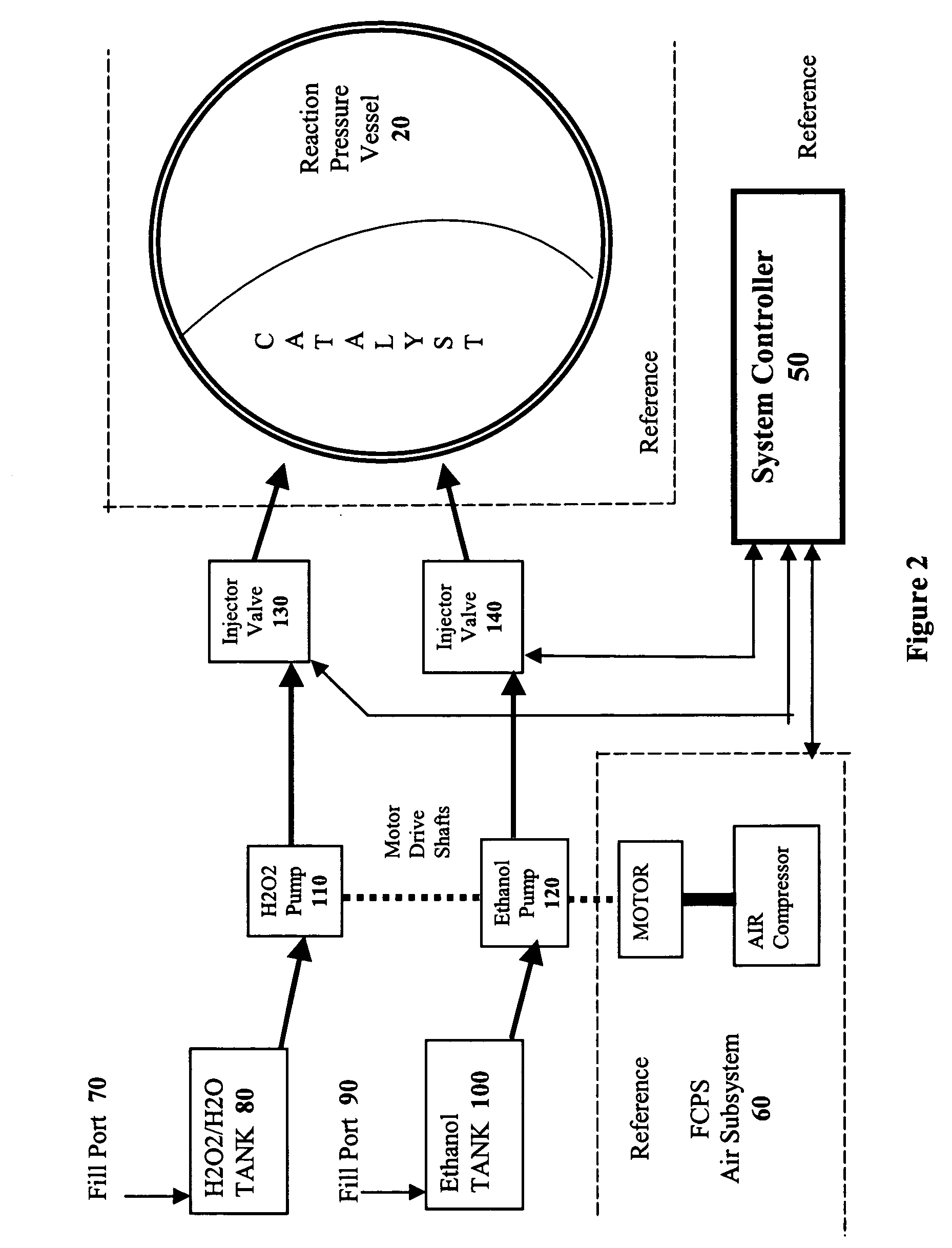

Hypergolic hydrogen generation system for fuel cell power plants

InactiveUS20050031918A1Increased electrical power densityIncrease pressureHydrogen separation using solid contactFuel cell auxillariesHydrocotyle bowlesioidesOxygen

The invention provides a controlled hypergolic approach to using concentrated hydrogen peroxide in combination with certain hydrocarbons such as ethanol, methanol, methane as well as more common fuels such as gasoline, diesel, DME, JP5, JP8 and the like to generate a gas mixture primarily composed of hydrogen and carbon dioxide. Because air is not used as the oxygen source, this novel process does not allow the formation of nitrous oxide (NOx) compounds, thereby avoiding the primary source of nitrogen contamination as well. The process is executed in a constraining system on a micro scale such that the resulting hydrogen supply is self-pressurizing. This enables the incorporation of an “on-demand” hydrogen fuel source for a variable output fuel cell power plant such as those proposed for use in automobiles, marine vessels and stationary power sources. In another embodiment of the present invention hydrogen peroxide is catalytically, or thermally reacted to provide H2O vapor and O2. When this gaseous stream is introduced to the cathode of the fuel cell, the percent concentration of oxygen is increased with no corresponding increase in the parasitic power demand made by an air-moving device. This use of H2O2 as an oxygen source may be continuous, intermittent or limited to specific instances when peak power output demands or high transient loads are placed upon the FCPS.

Owner:CBH2 TECH

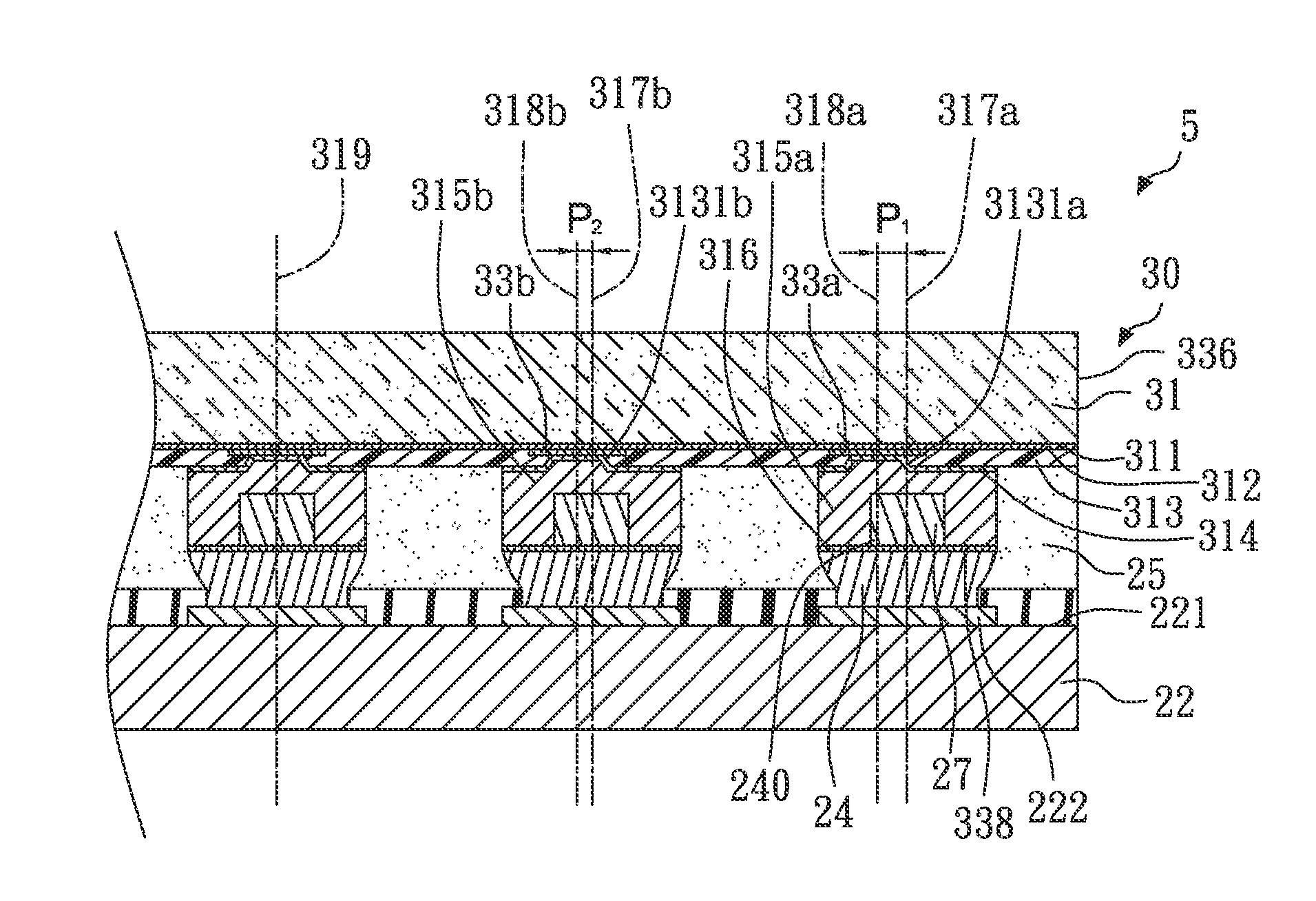

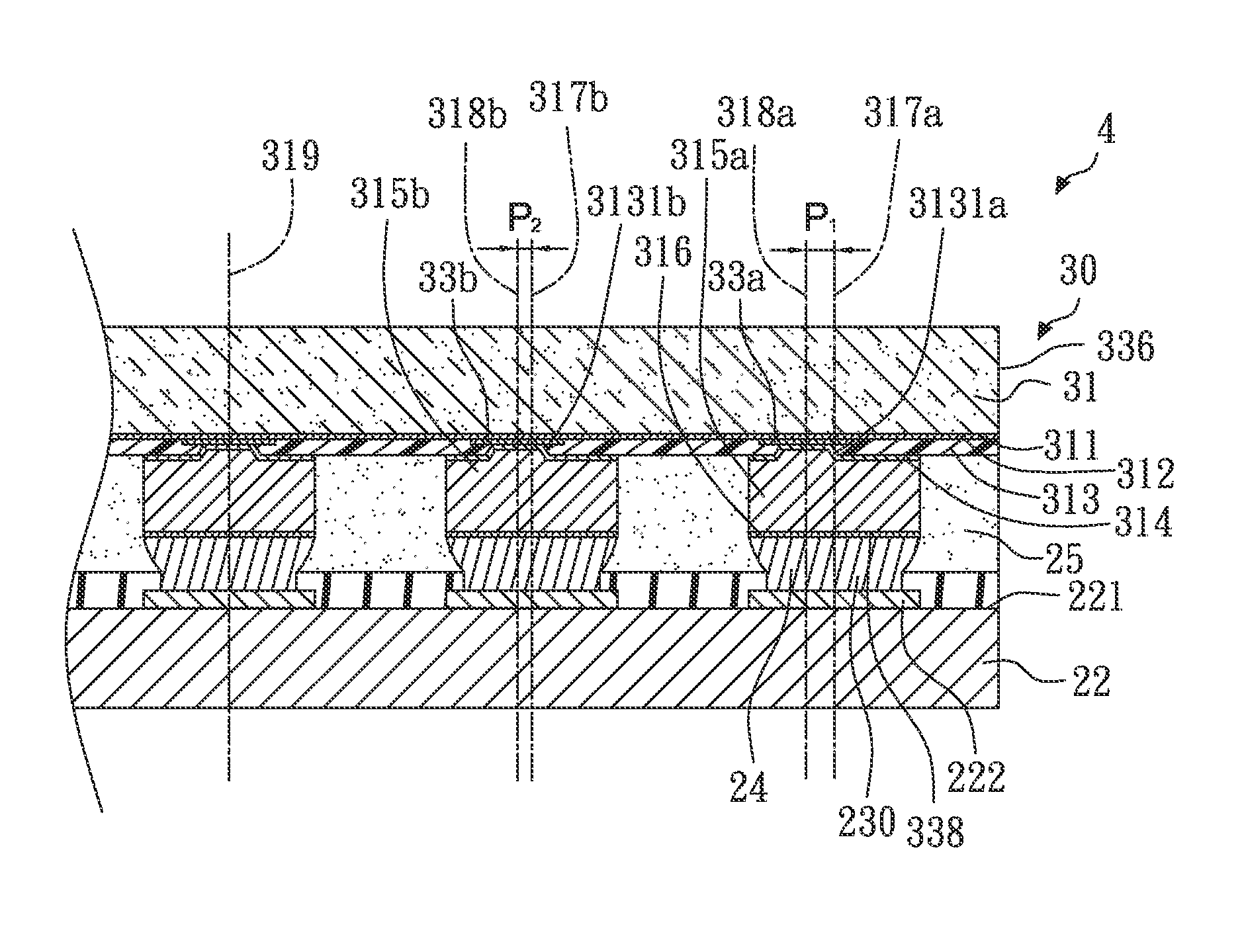

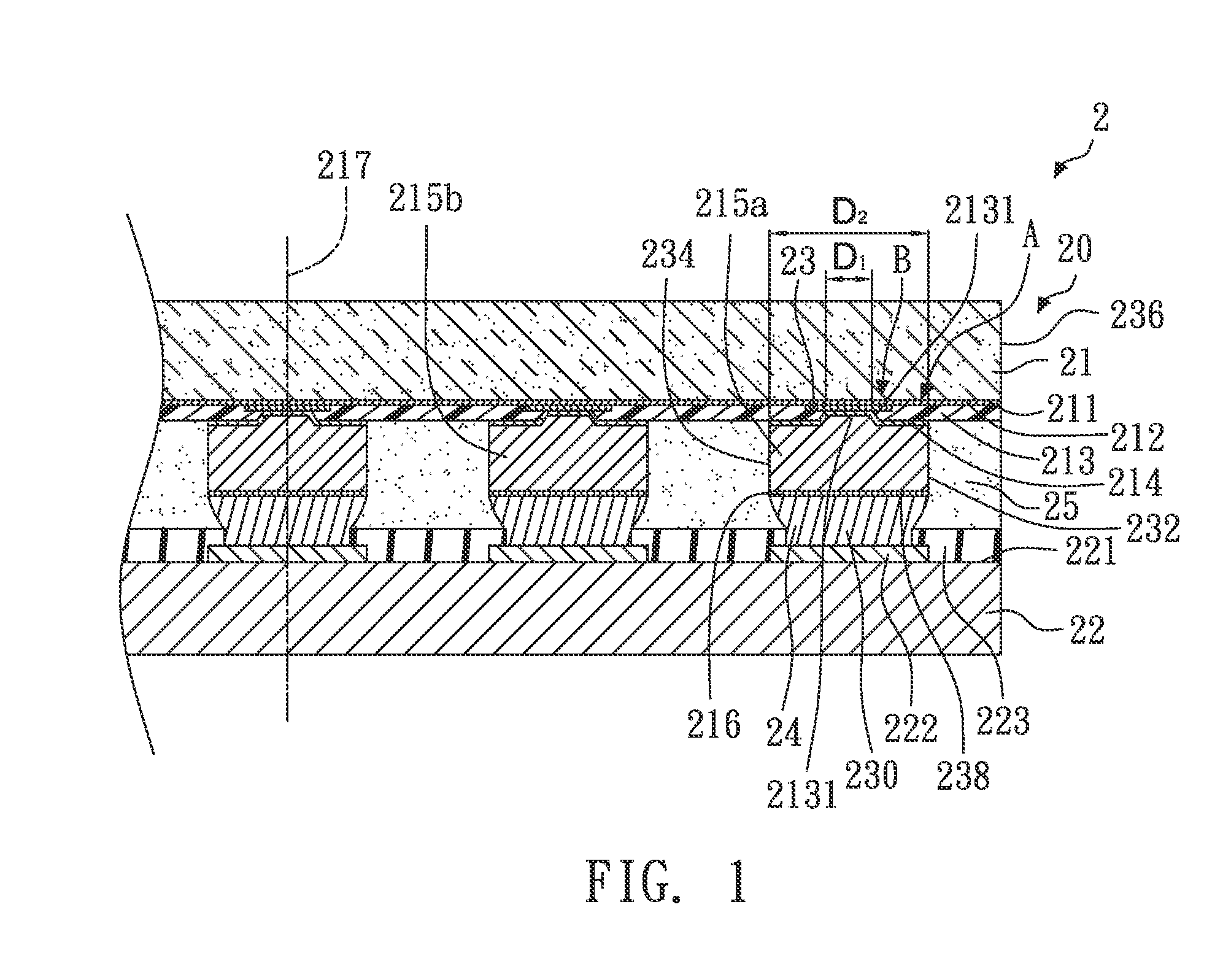

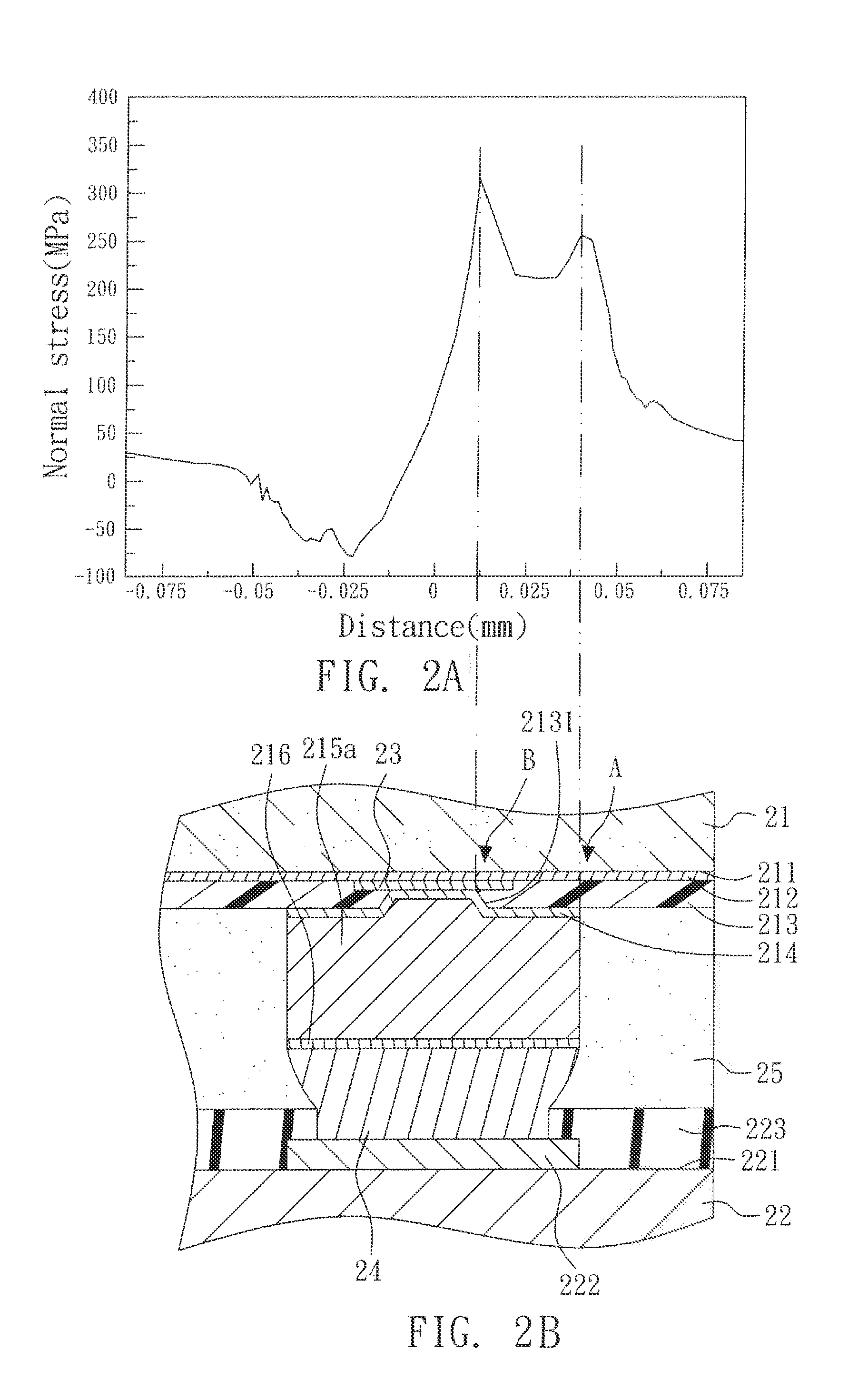

Semiconductor package with integrated metal pillars and manufacturing methods thereof

ActiveUS20120074532A1Reduce maximum pressureSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

A semiconductor package includes a substrate and a semiconductor device. The semiconductor device includes a body having a center, a layer disposed adjacent to the body, and a plurality of conductive pillars configured to electrically connect the semiconductor device to the substrate. The layer defines a plurality of openings. Each of the plurality of conductive pillars extends at least partially through a corresponding one of the plurality of openings. An offset between a first central axis of the each of the plurality of conductive pillars and a second central axis of the corresponding one of the plurality of openings varies with distance between the first central axis and the center of the body. The second central axis of the corresponding one of the plurality of openings is disposed between the first central axis of the each of the plurality of conductive pillars and the center of the body.

Owner:ADVANCED SEMICON ENG INC

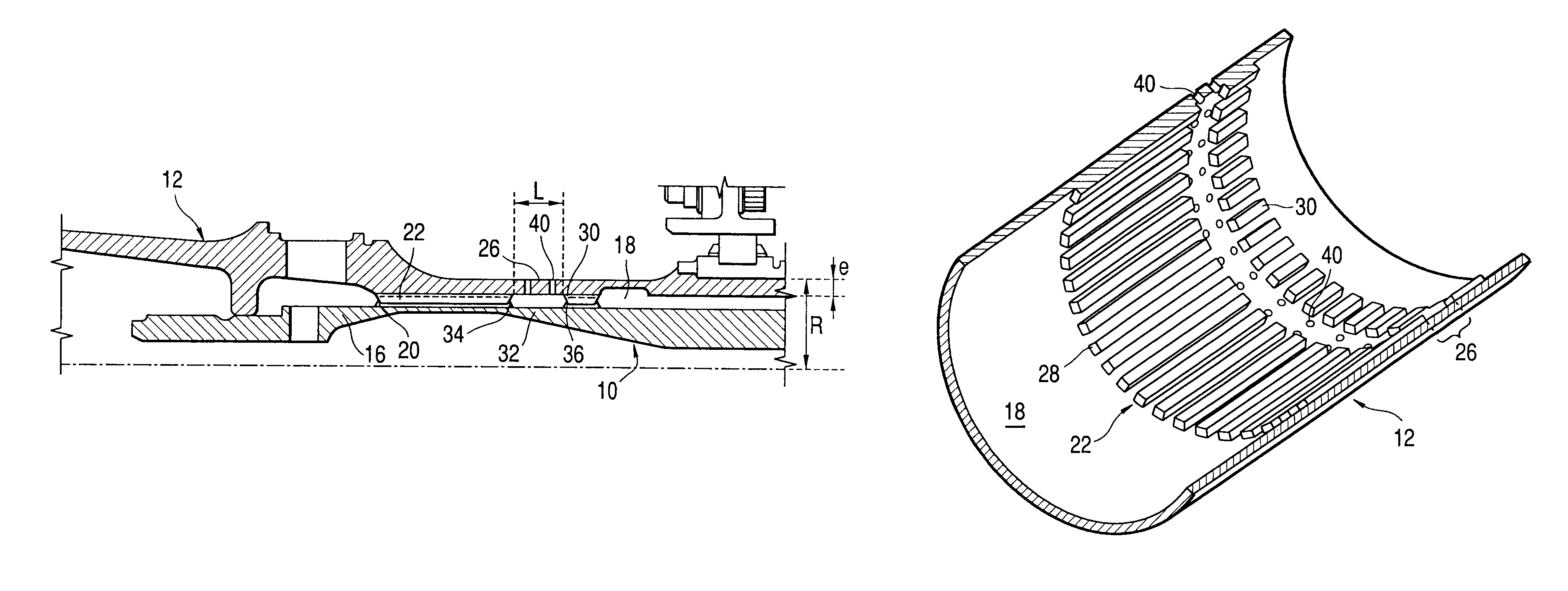

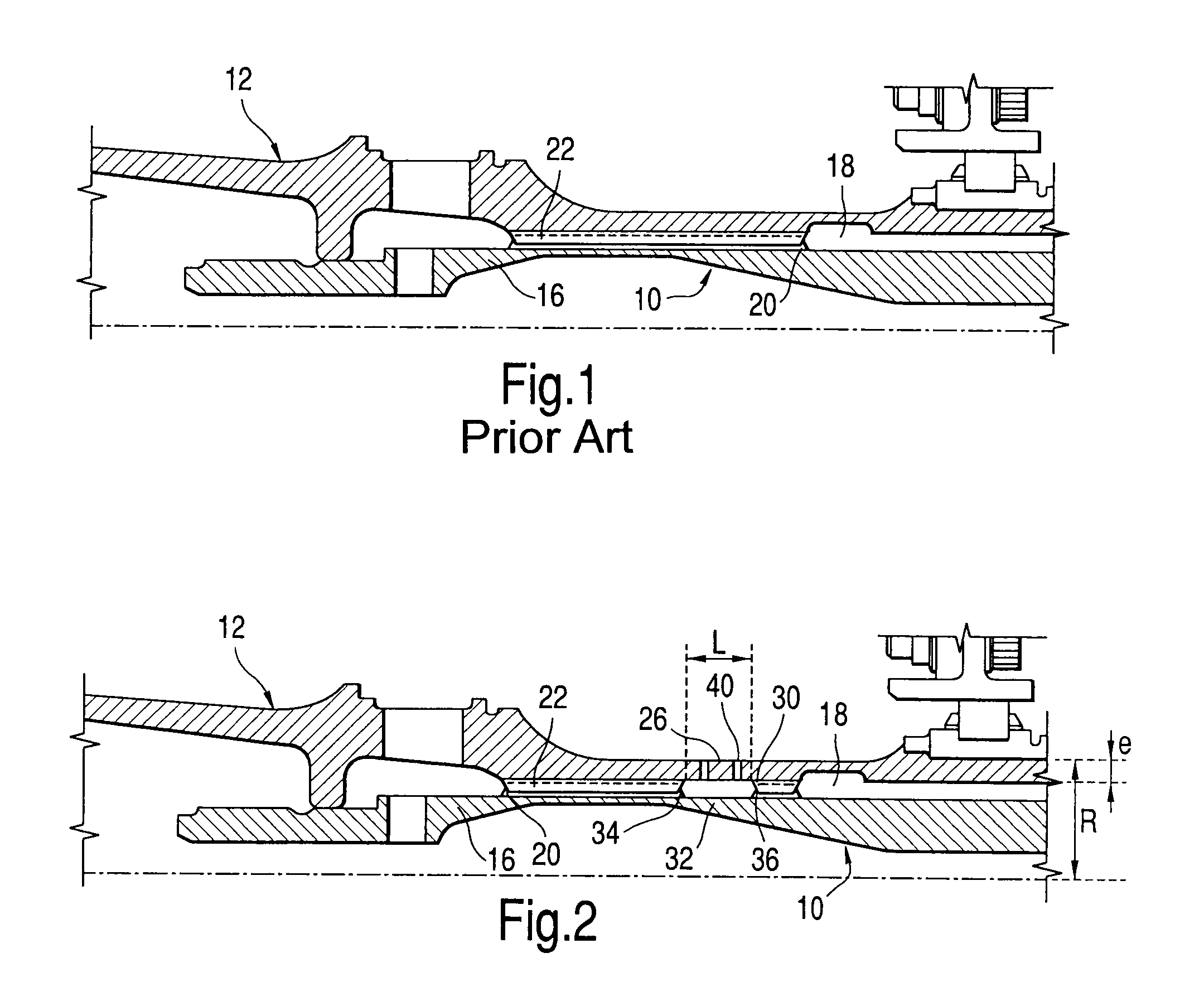

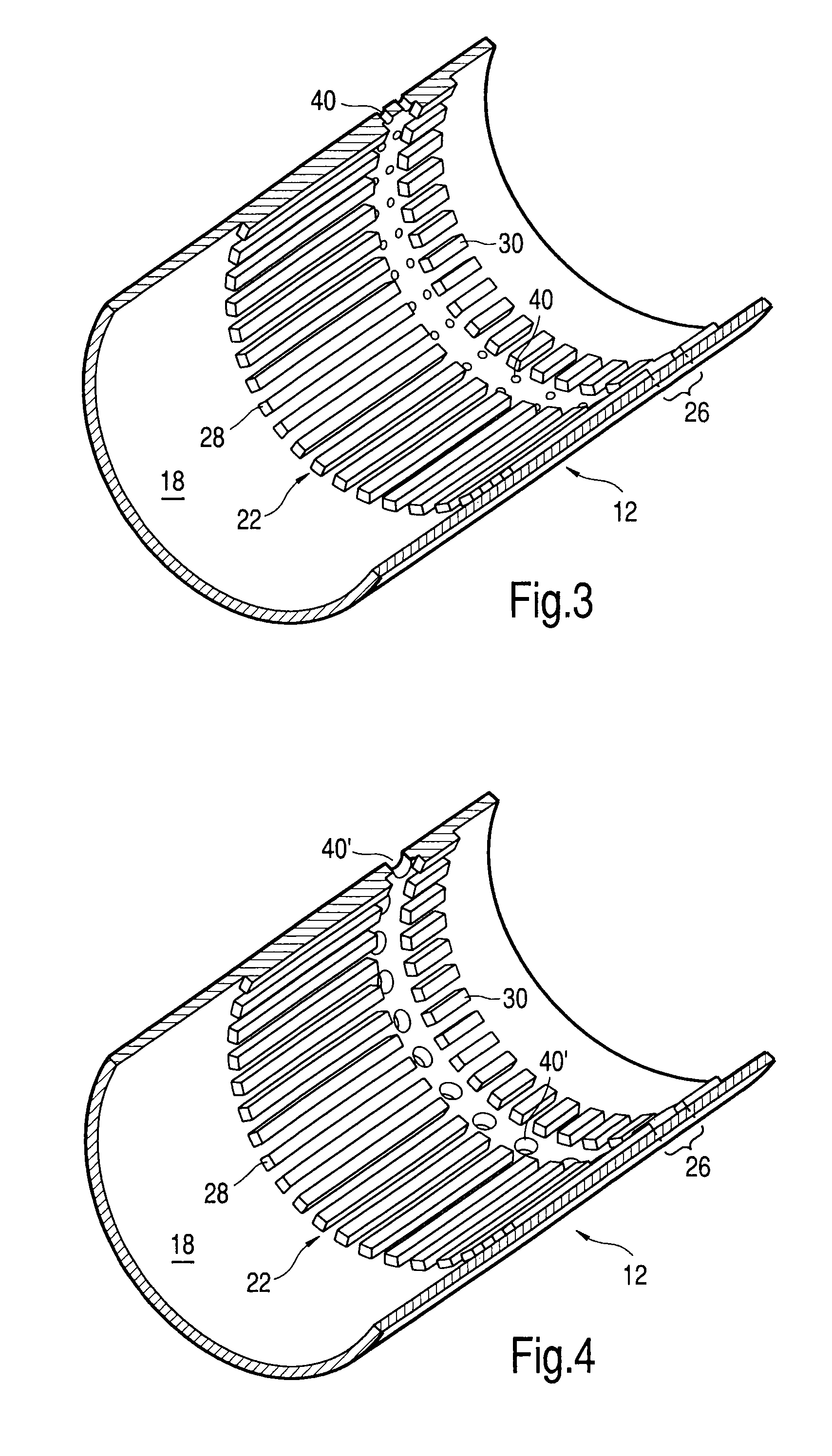

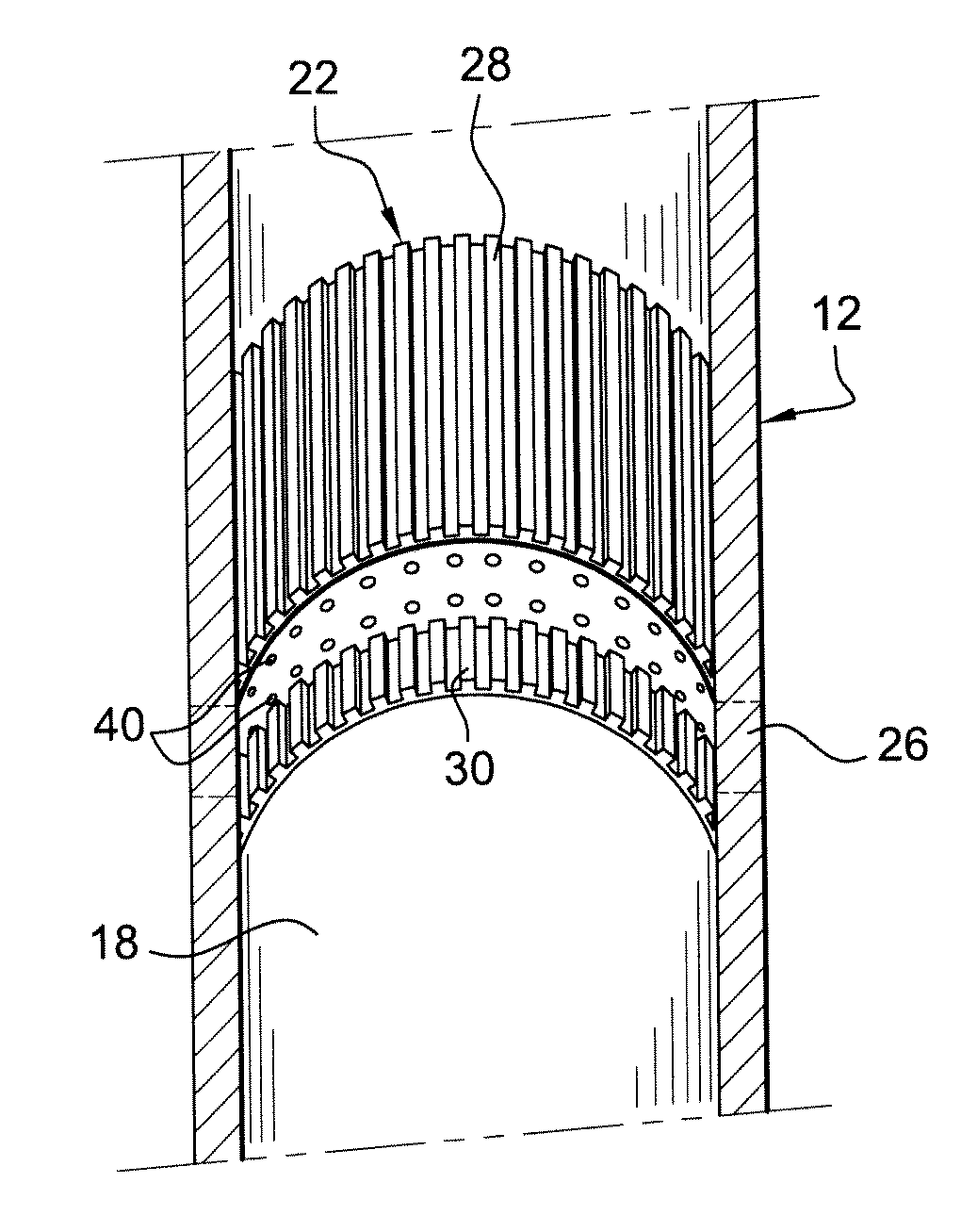

Device for connecting two rotating shafts, in particular in a turbomachine

ActiveUS7736083B2Simple and effective and economic solutionIncrease flexibilityYielding couplingBlade accessoriesRotational axisDrive shaft

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

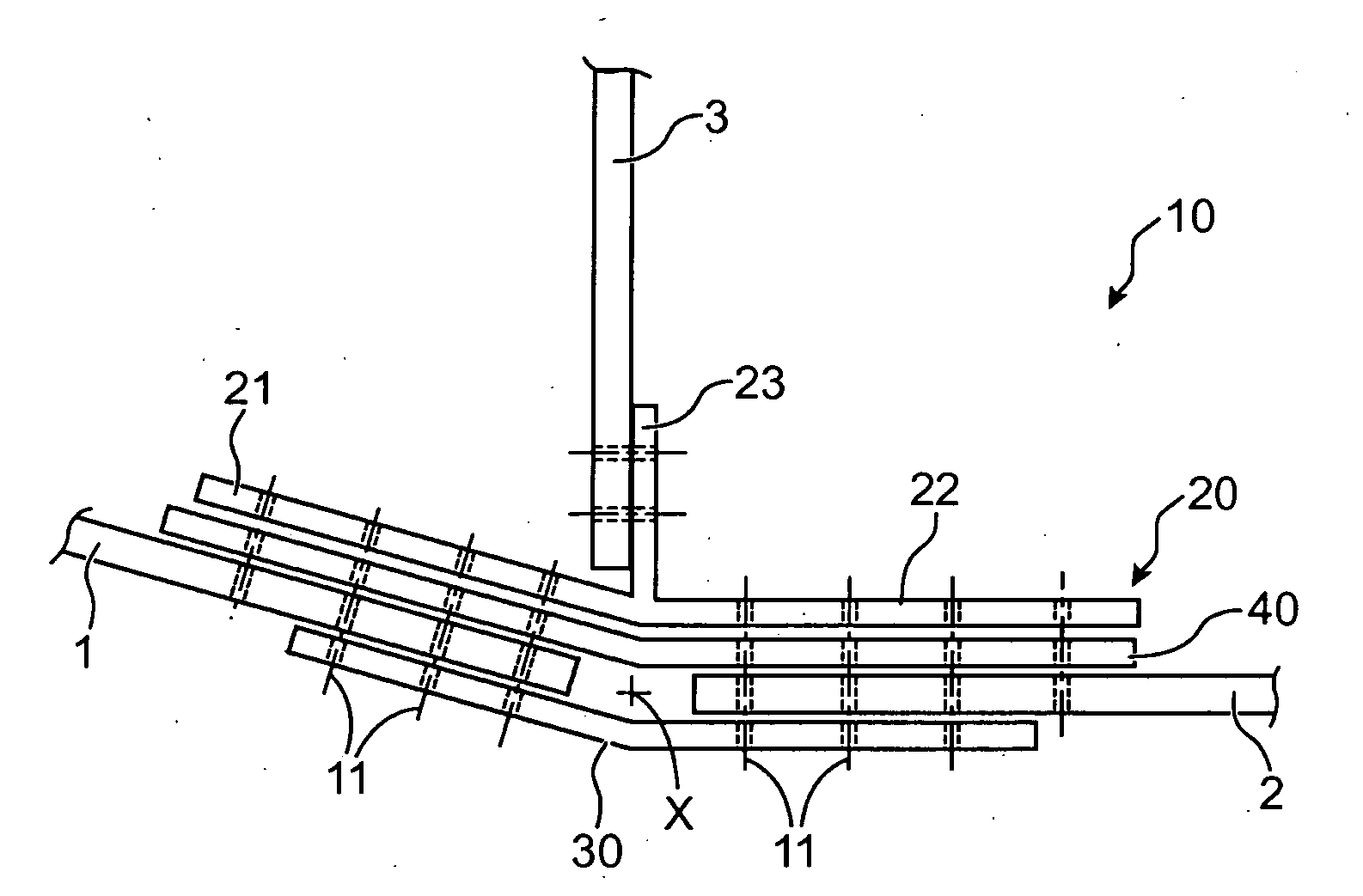

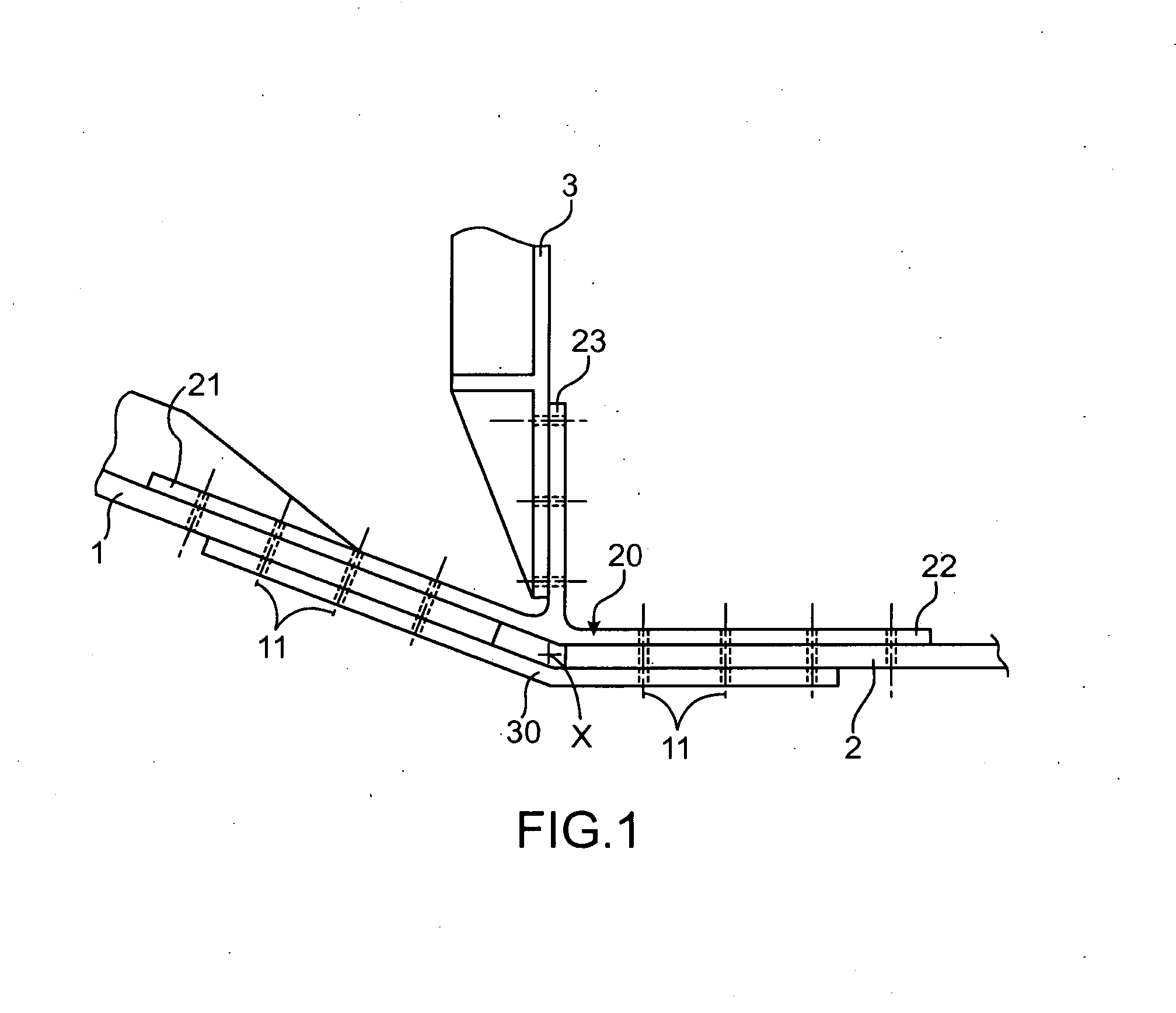

Fish joint device having an improved mechanical hold

ActiveUS20140263836A1Improve mechanical propertiesMaintaining and reducing massFuselage framesRopes and cables for vehicles/pulleyEngineeringStructural element

Owner:AIRBUS OPERATIONS (SAS)

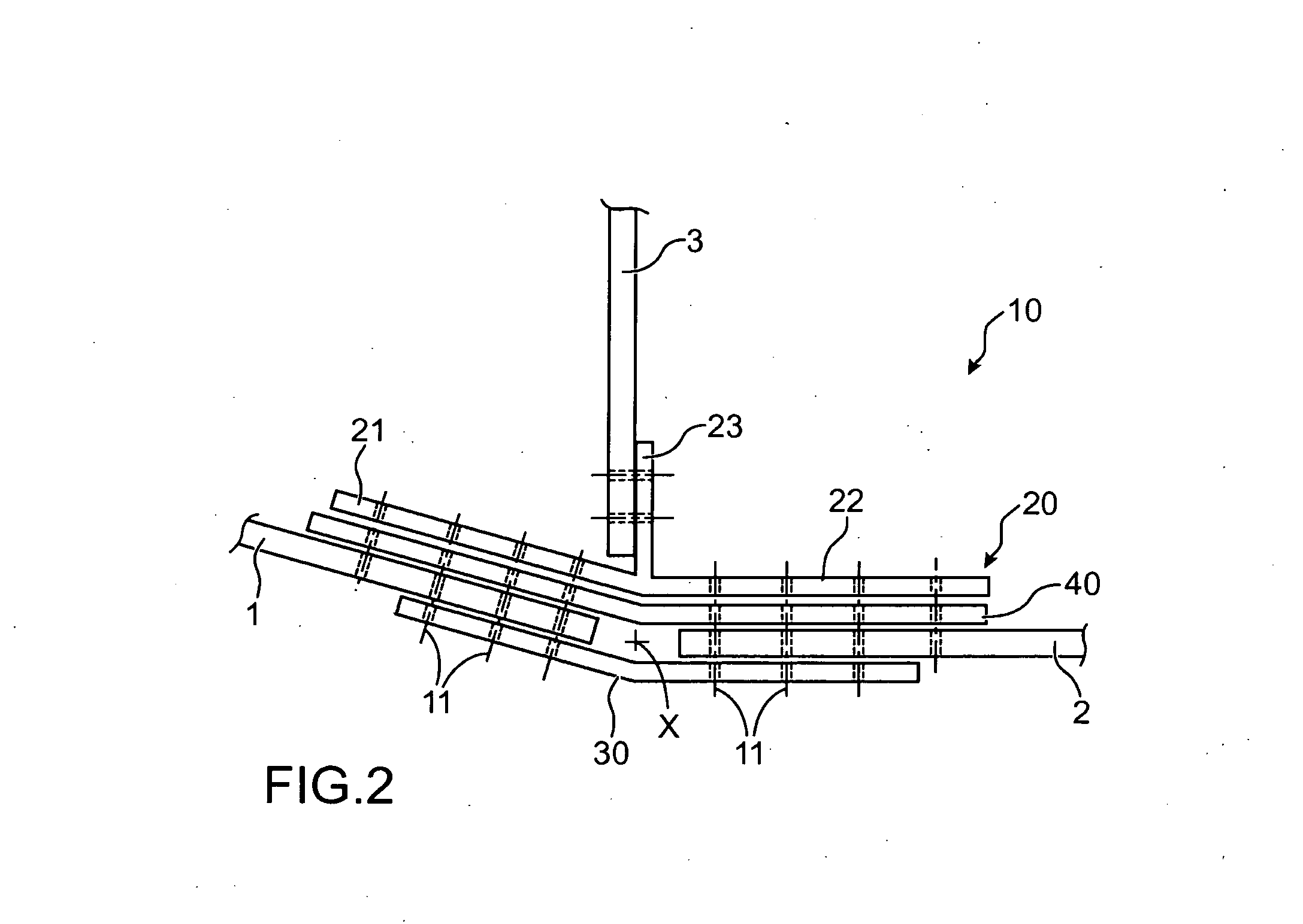

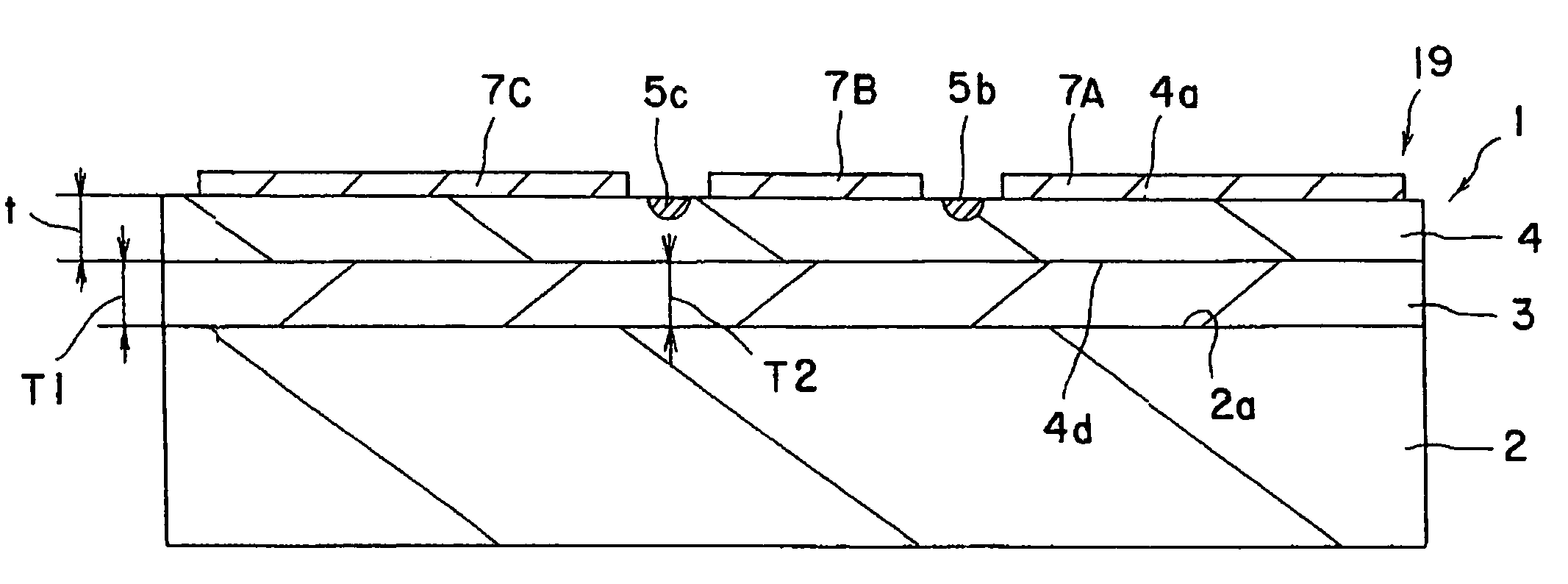

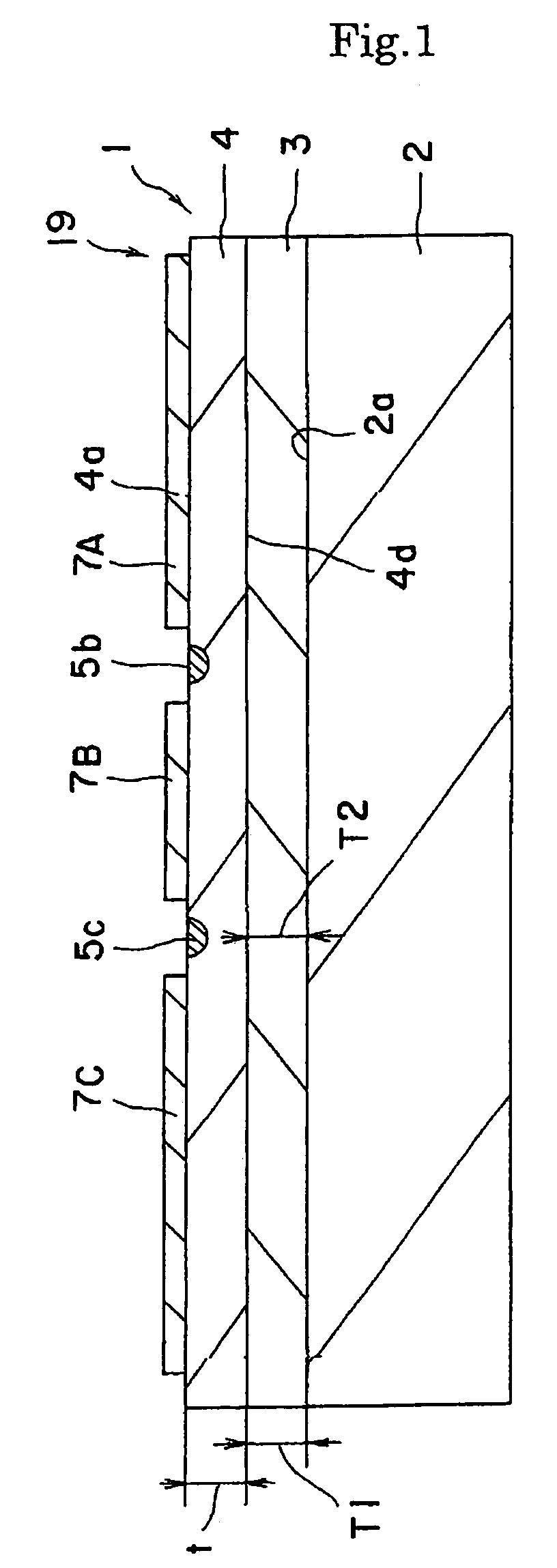

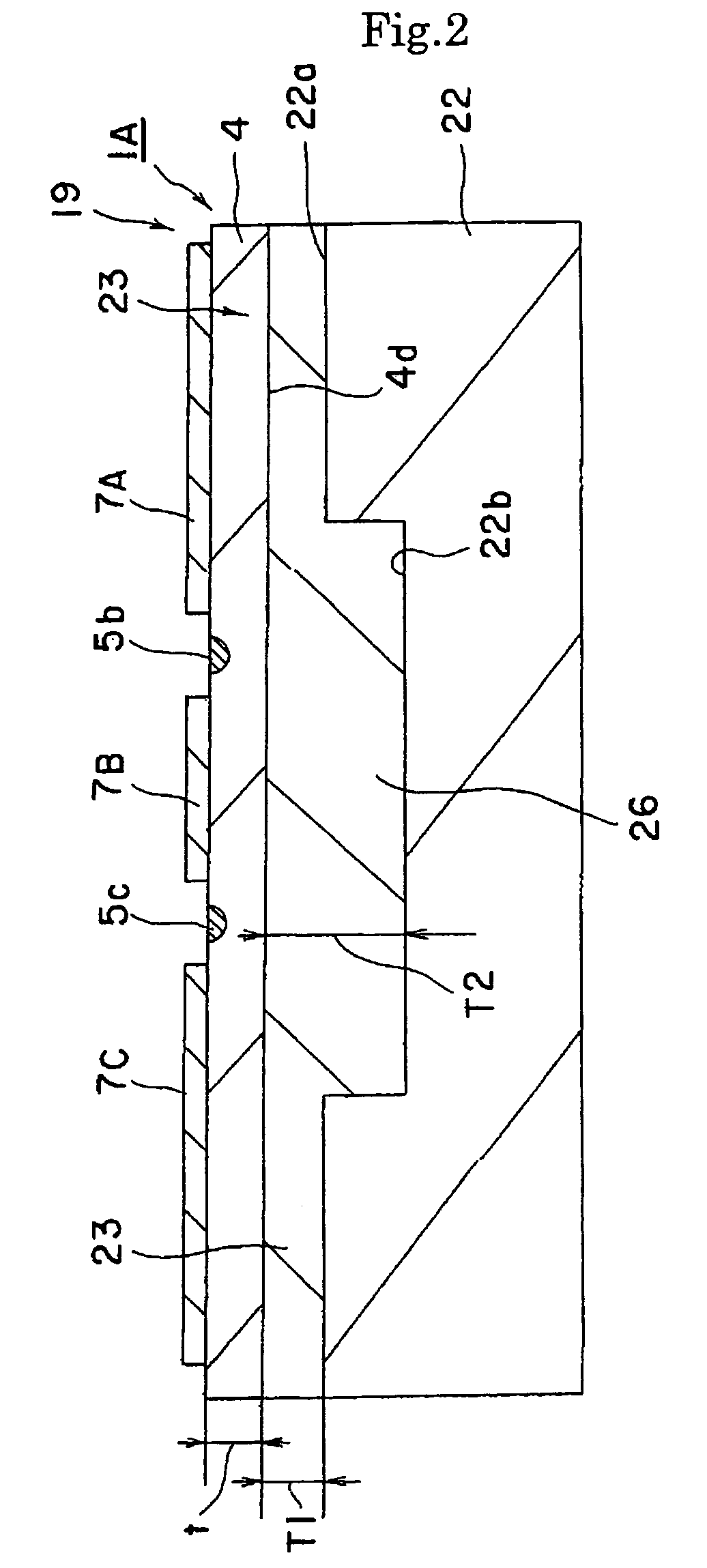

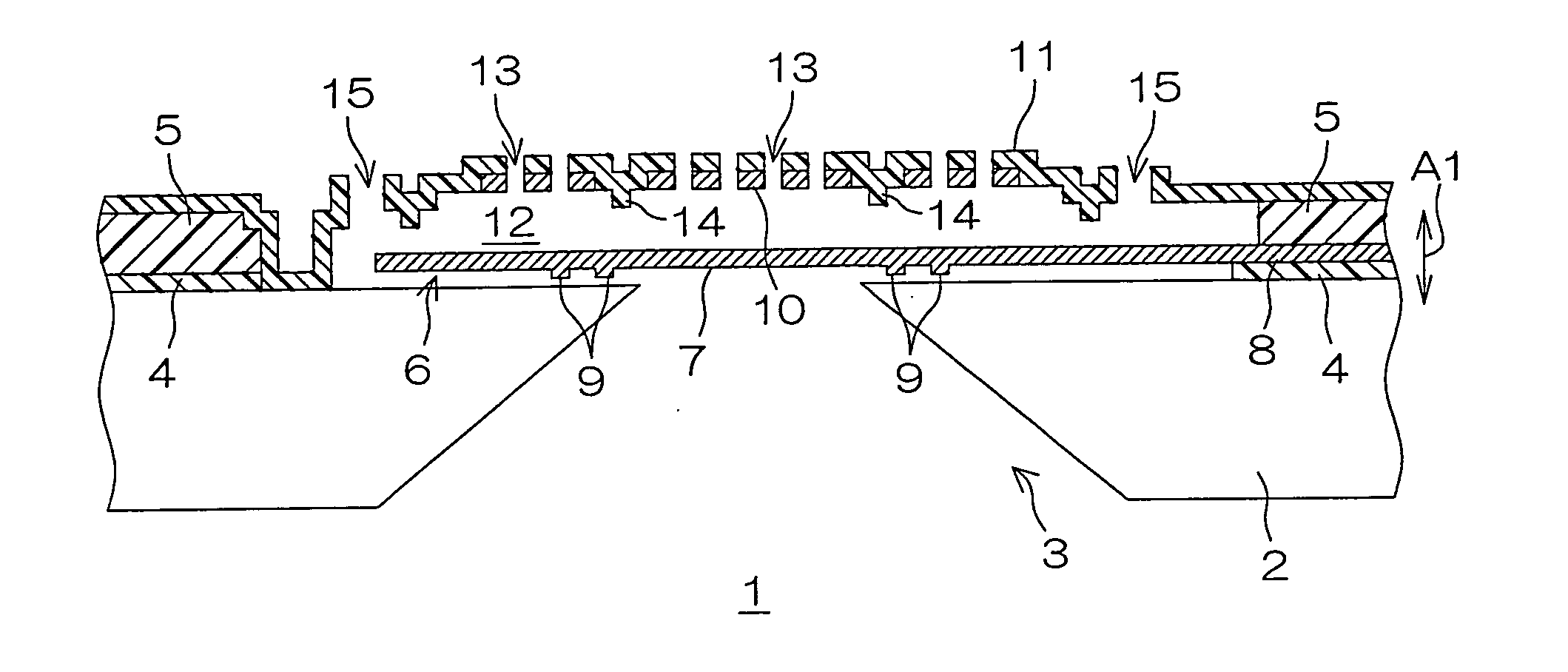

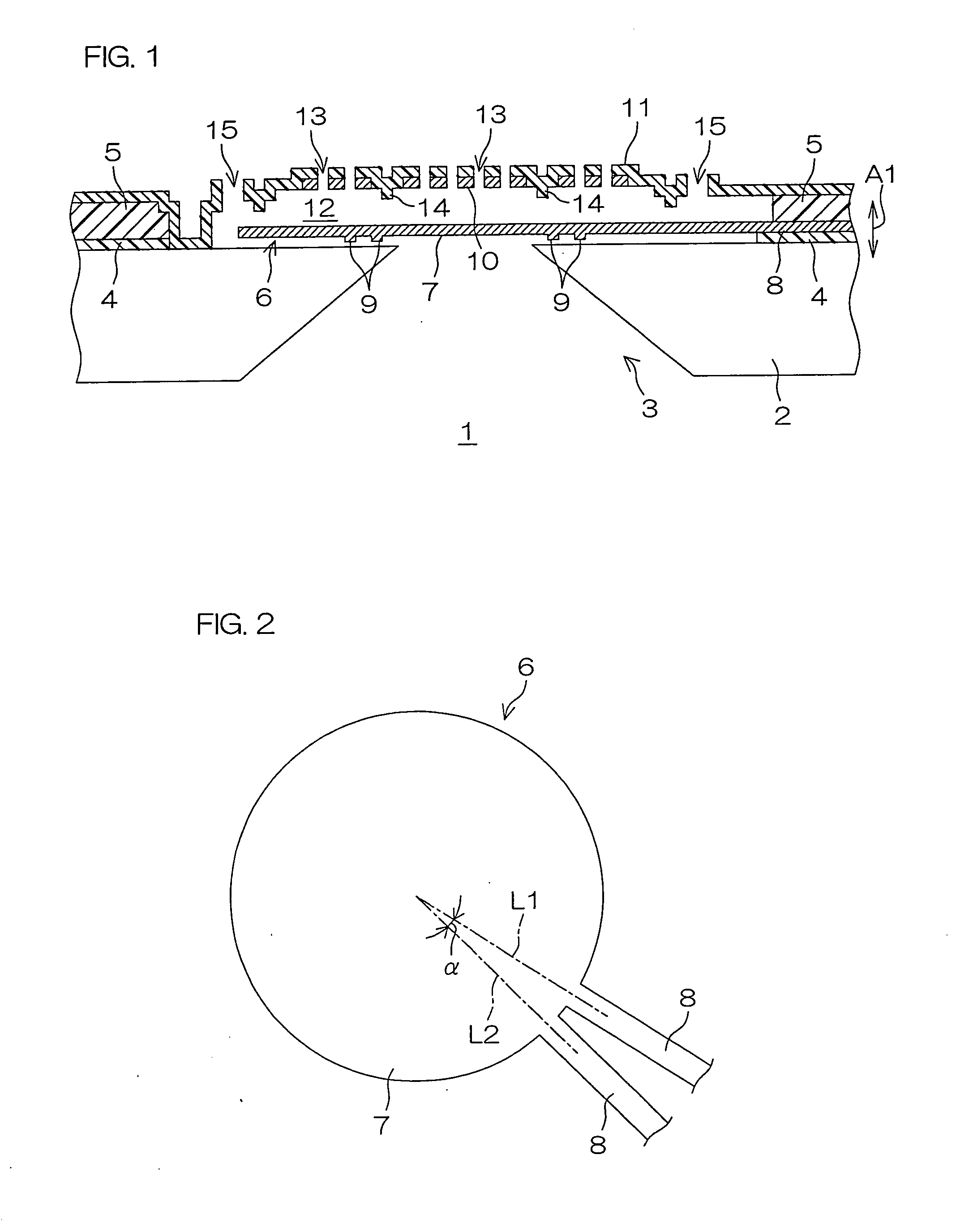

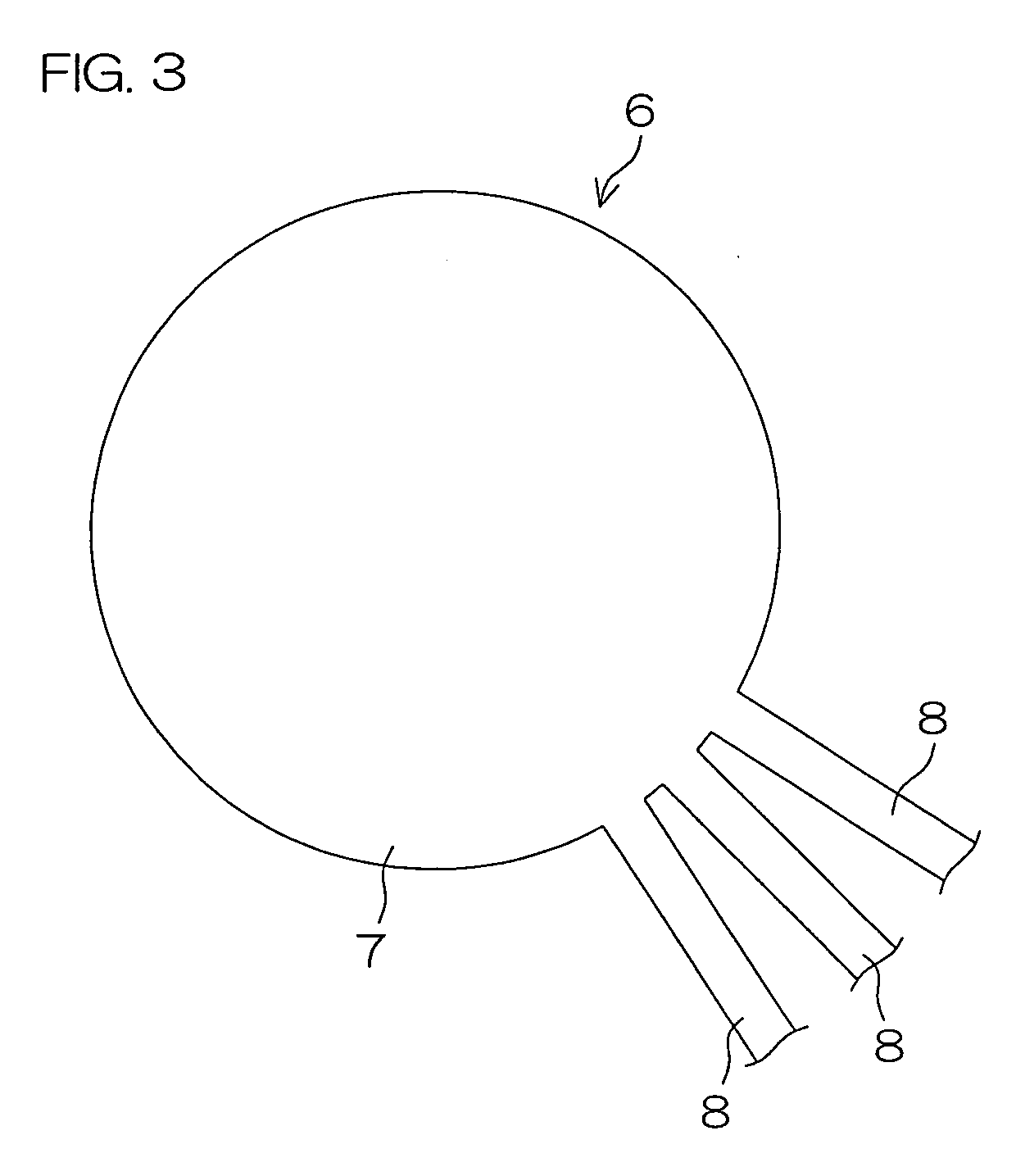

Optical waveguide device, and a travelling wave form optical modulator

InactiveUS7035485B2Temperature driftInhibit deteriorationCoupling light guidesOptical waveguide light guideWave formWaveguide

An optical waveguide device 1 has an optical waveguide substrate 19, a supporting body 2 for supporting the substrate 19 and a joining layer 3 for joining the substrate 19 and the supporting body 2. The substrate 19 has a flat plate-shaped main body 4 made of an electro-optic material with a thickness of 30 μm or smaller and having first and second main faces 4a and 4b opposing each other, an optical waveguide provided on the side of the first main face 4a of the main body 4, and electrodes 7A to 7C provided on the side of the first main face 4a of the main body 4. The joining layer 3 joins the supporting body 2 at a joining face 4d and the second main face 4d of the main body 4. The joining face 2a of the supporting body 2 is substantially flat. Alternatively, the joining layer 3 has a thickness of 200 μm or lower.

Owner:NGK INSULATORS LTD

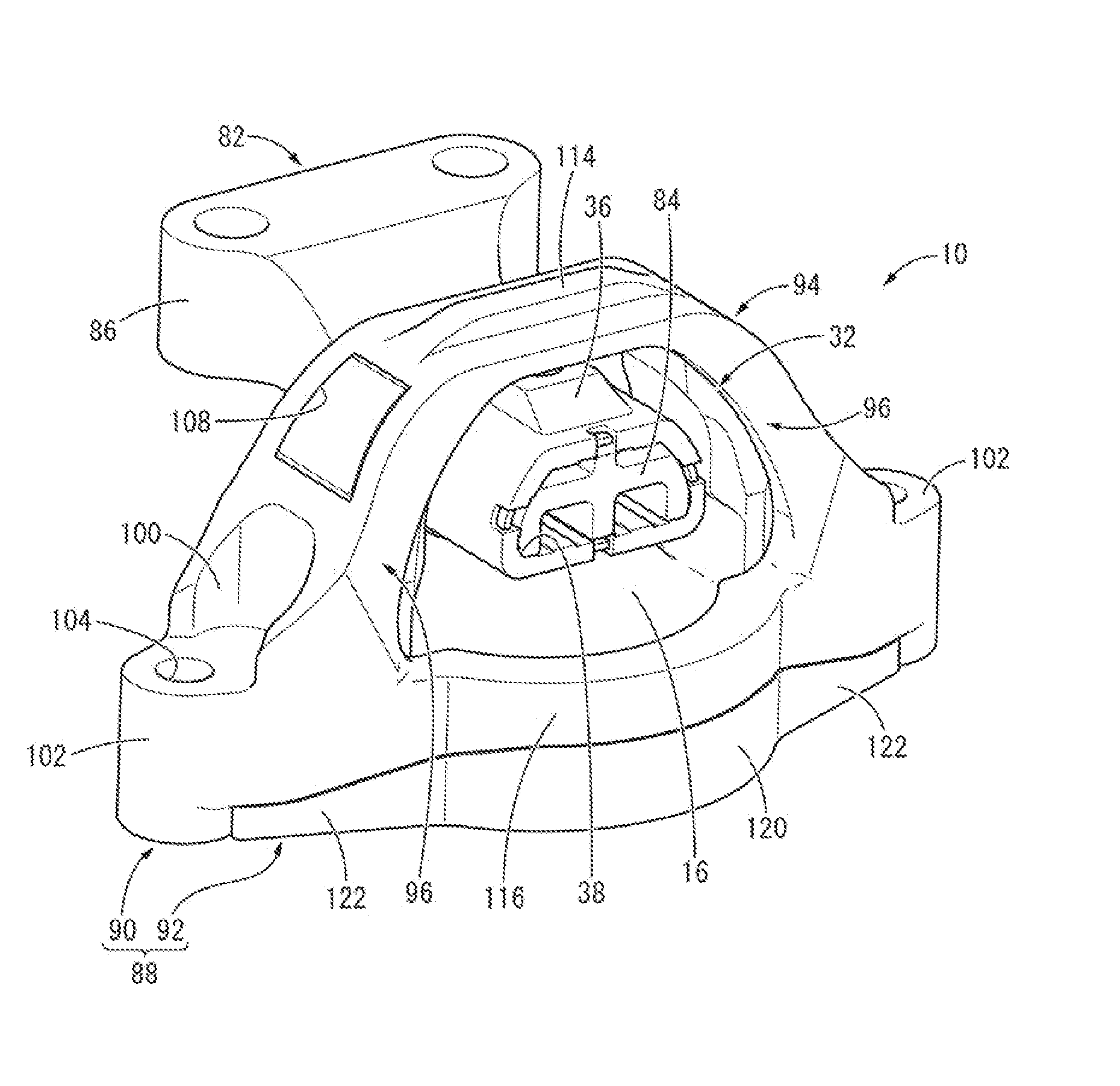

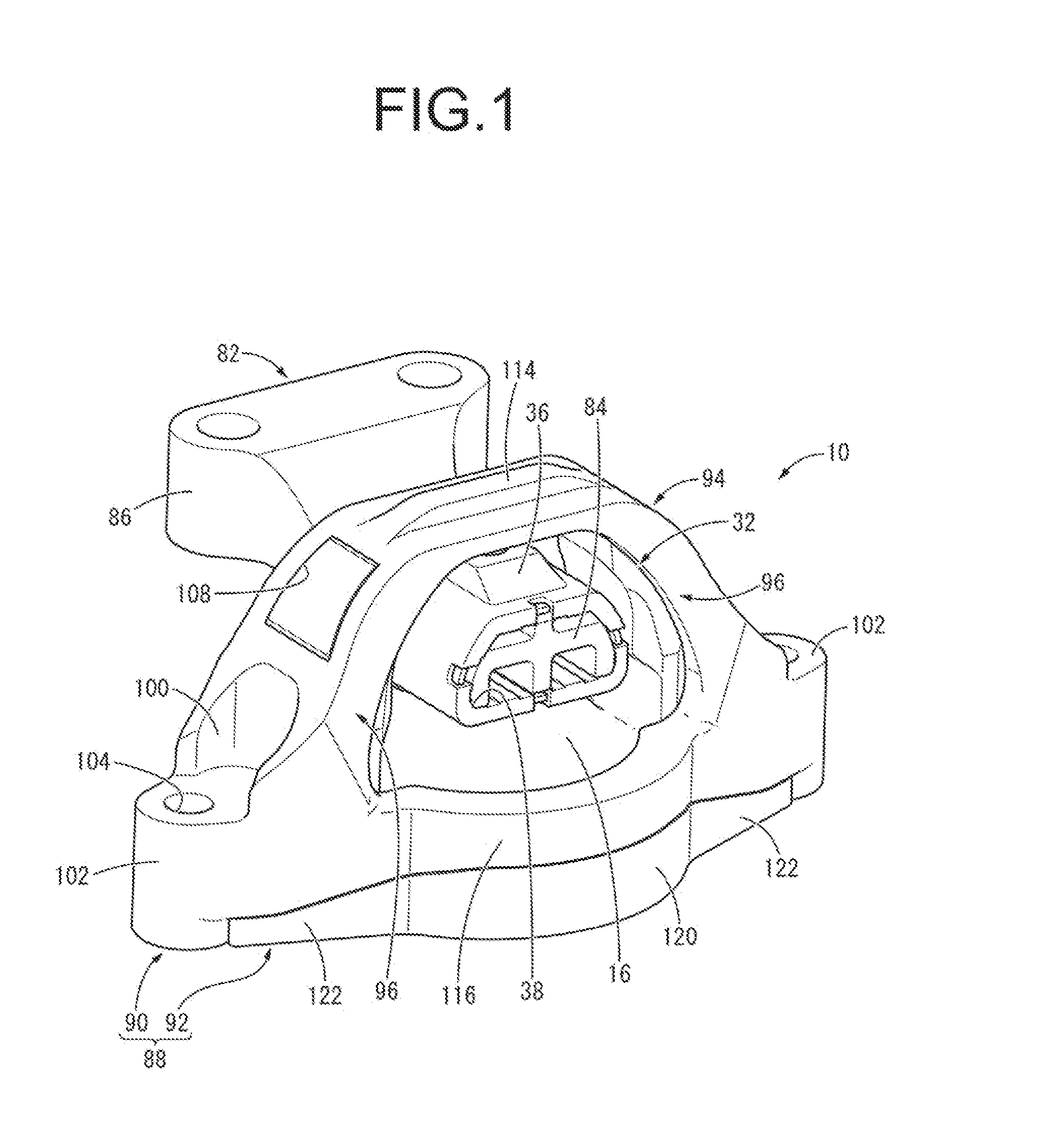

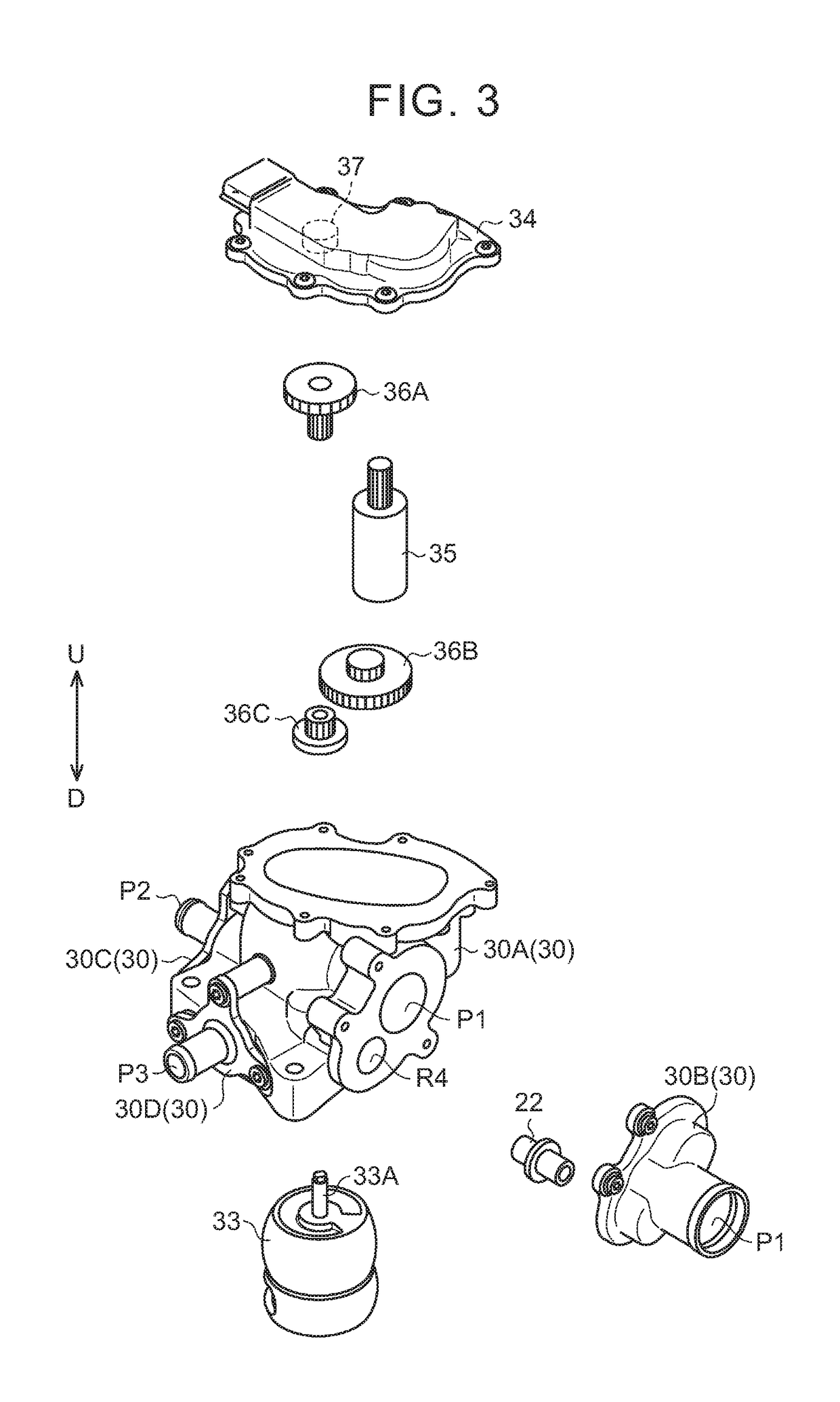

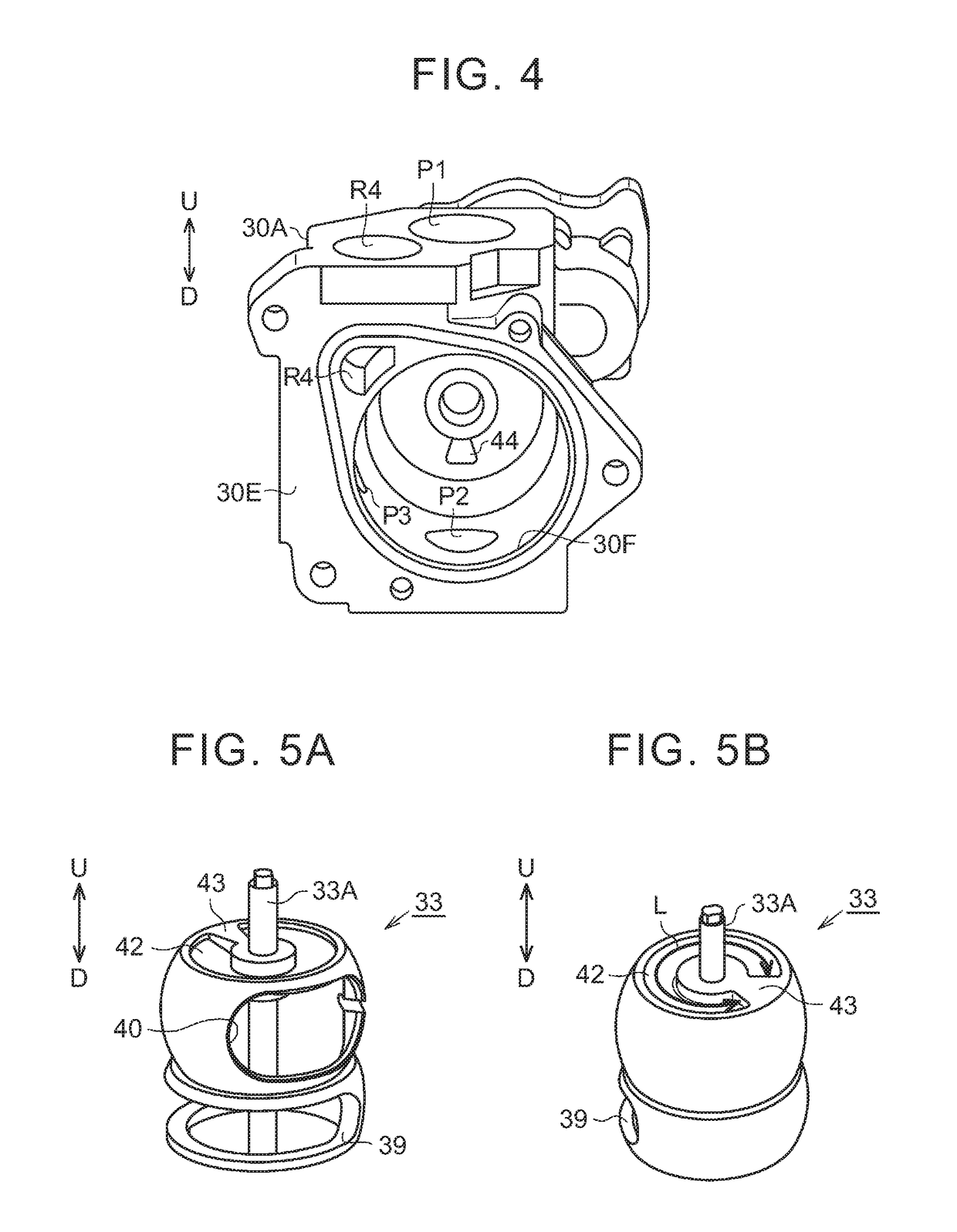

Vibration damping device

InactiveUS20150276010A1Increased durabilityReduce the amount requiredSpringsNon-rotating vibration suppressionAbutmentMechanical engineering

A vibration damping device including first and second mounting members elastically connected to each other by a main rubber elastic body, and a bracket member mounted to the second mounting member and providing a stopper for restricting displacement of the first mounting member relative to the second mounting member by means of abutment between the first mounting member and the bracket member. The second mounting member includes an input portion that faces the first mounting member at a given distance. The bracket member includes an abutting portion that faces the first mounting member with the input portion being interposed therebetween. An abutting rubber layer is provided on a surface of the input portion overlapped on the abutting portion. The stopper is constituted, by abutment between the first mounting member and the abutting portion via the input portion.

Owner:SUMITOMO RIKO CO LTD

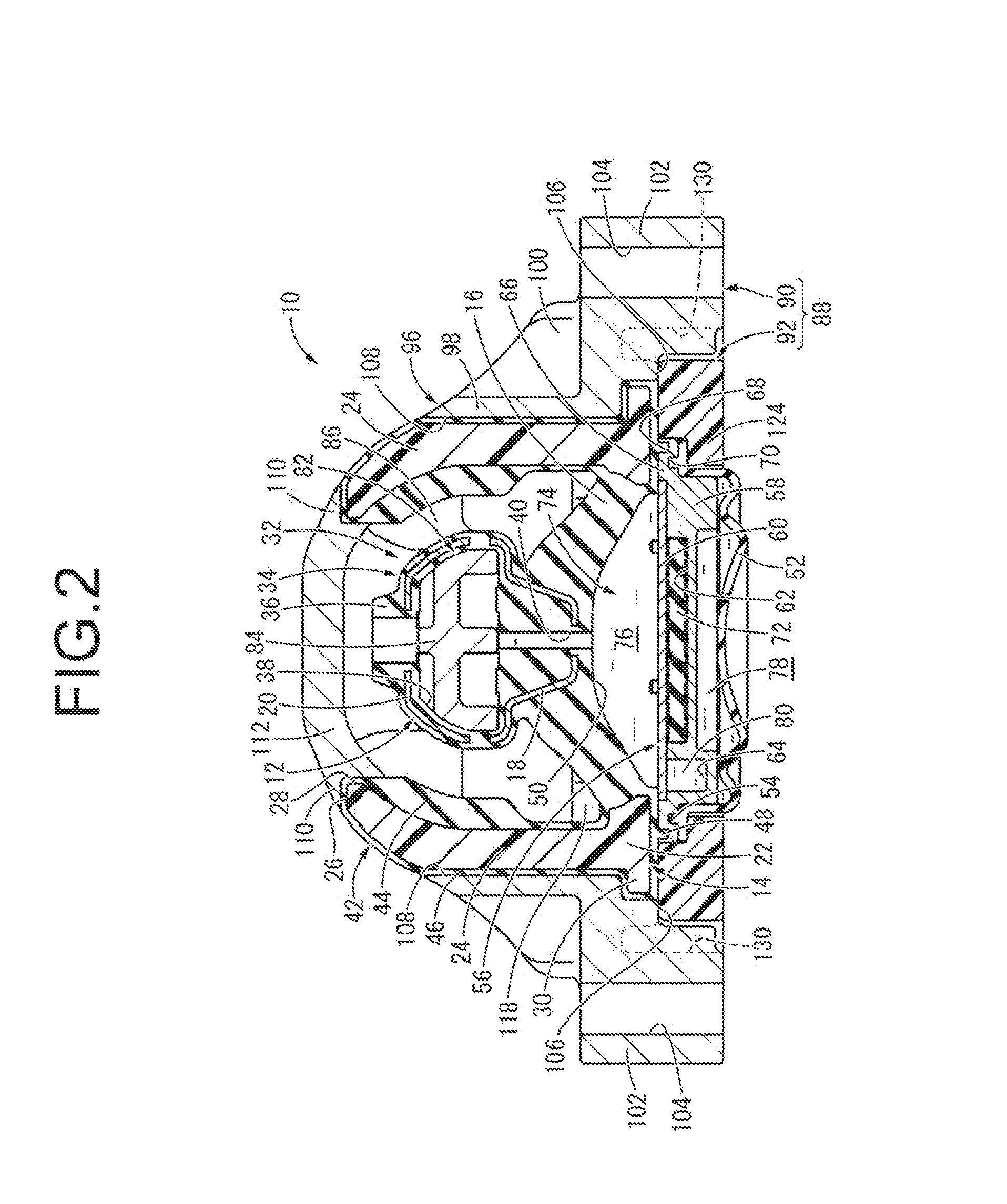

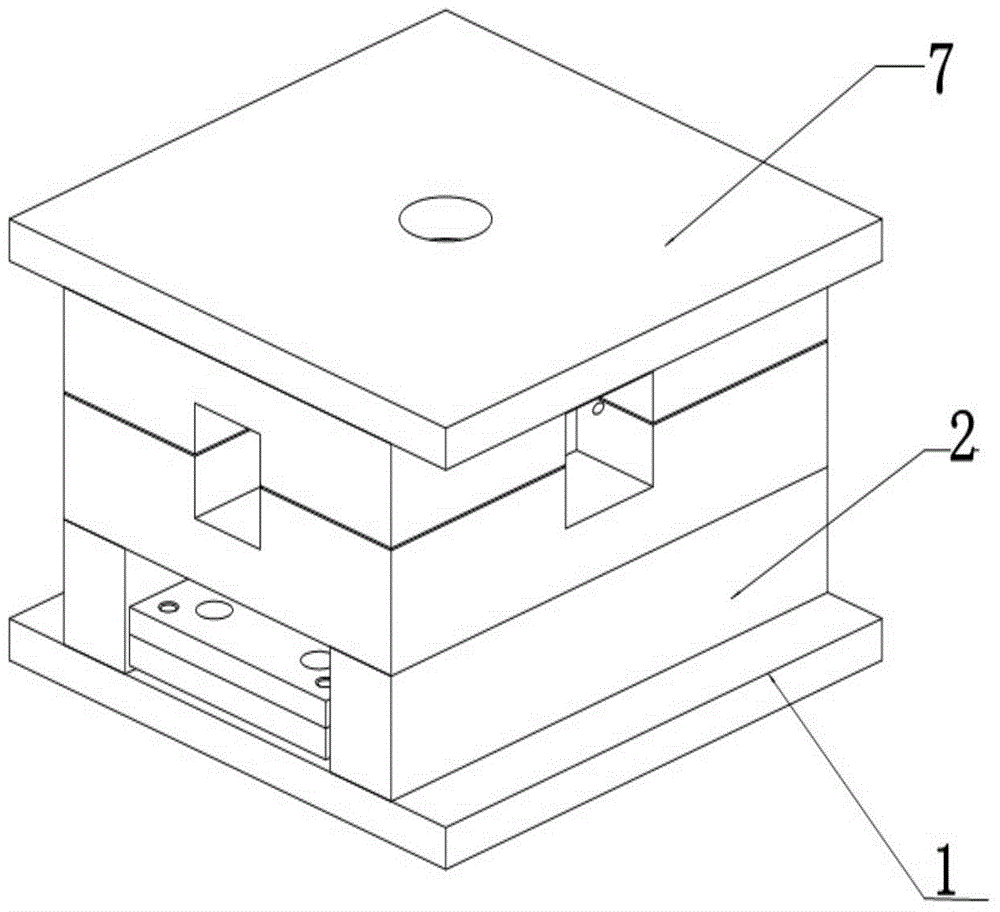

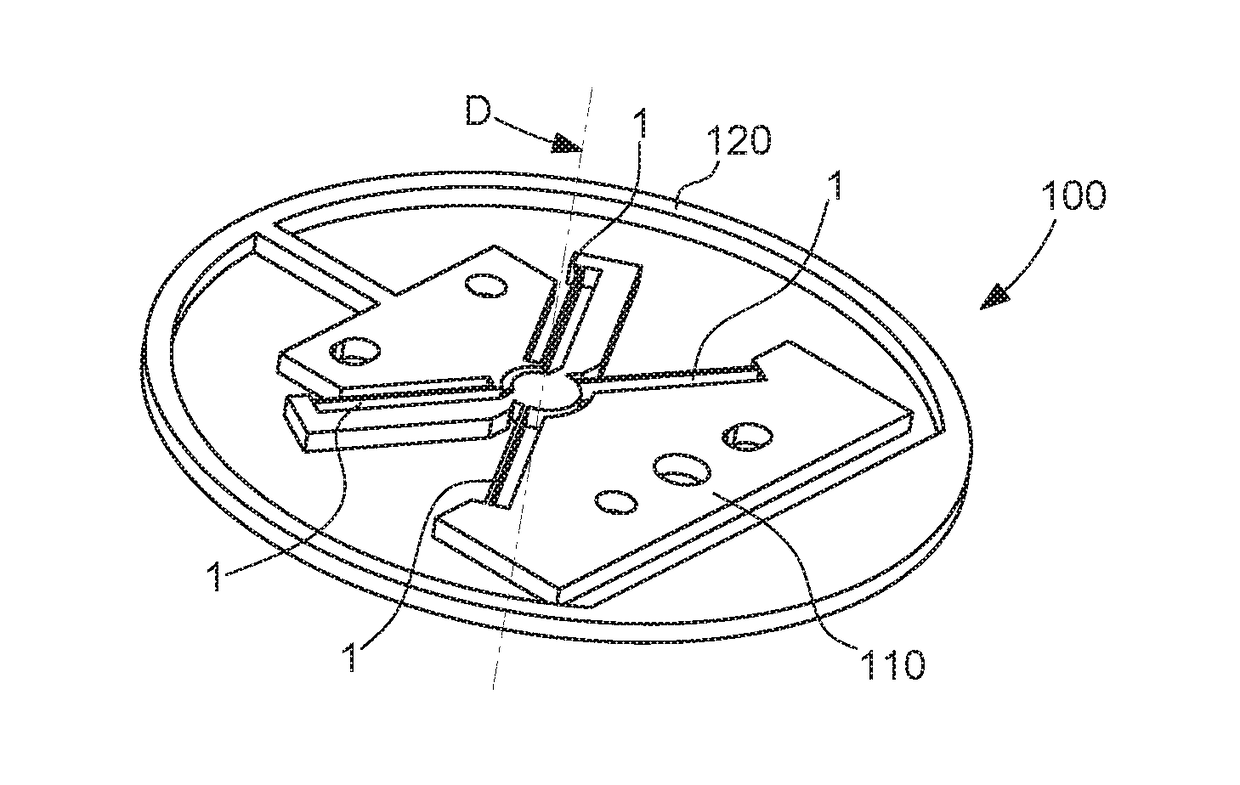

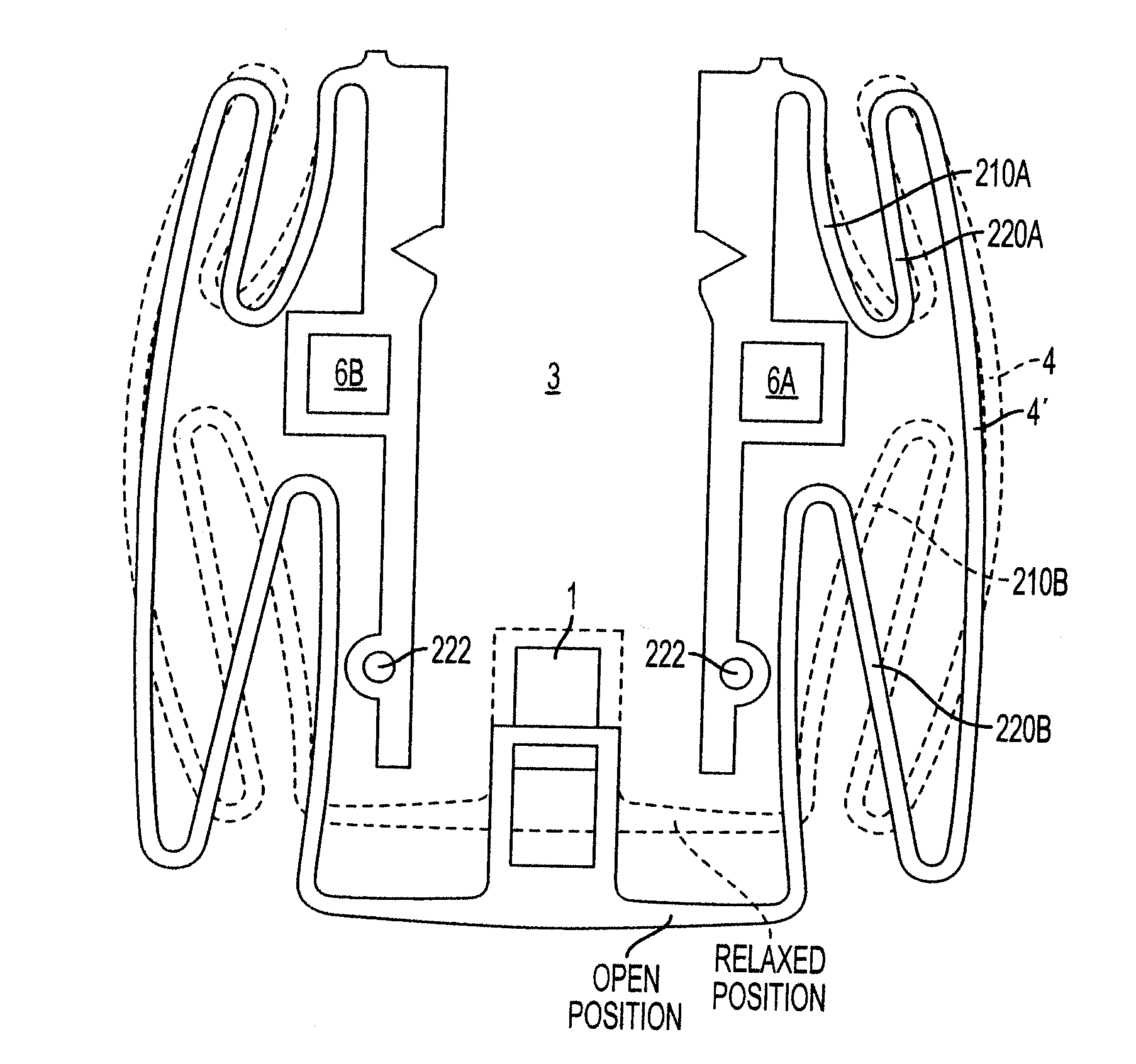

Planar slider test socket

InactiveUS20120033318A1Reduce maximum pressurePrevent rotationDisposition/mounting of recording headsRecord information storageHard disc driveElectricity

The present application is directed to a slider supporting apparatus for flying a slider of a hard disk drive in the manufacturing process to provide electrical performance characteristics. The present invention discloses an integrated design including the electrical interconnect, the gimballing mechanism, the preload mechanism and the slider supporting mechanism integrated into a single supporting structure.

Owner:XYRATEX TECH LTD

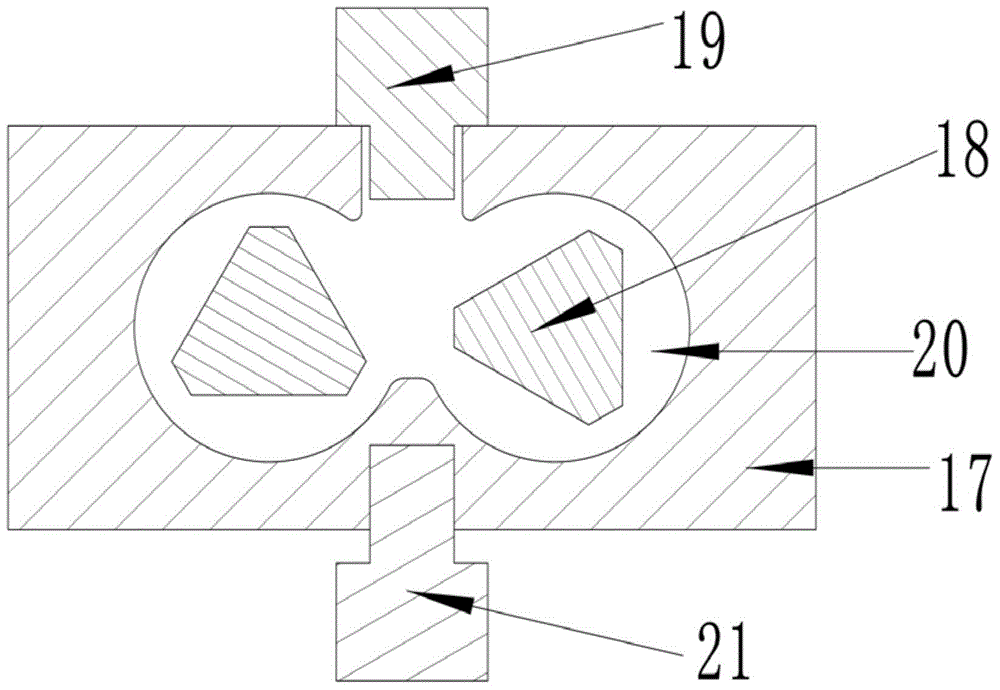

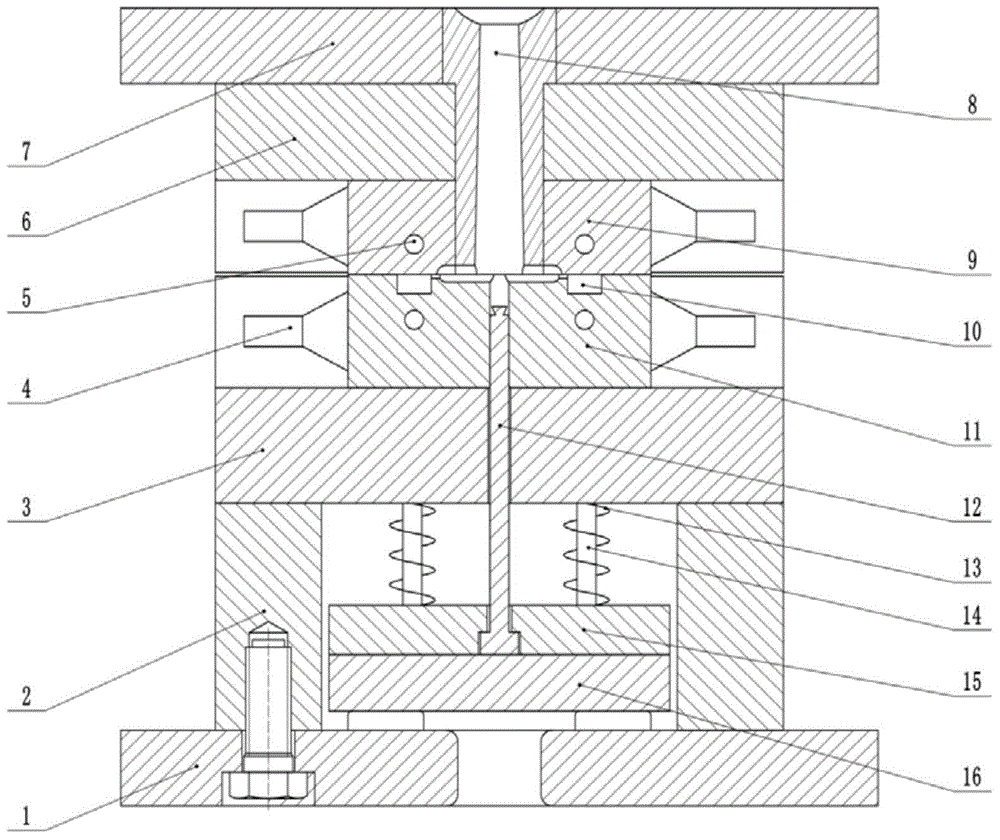

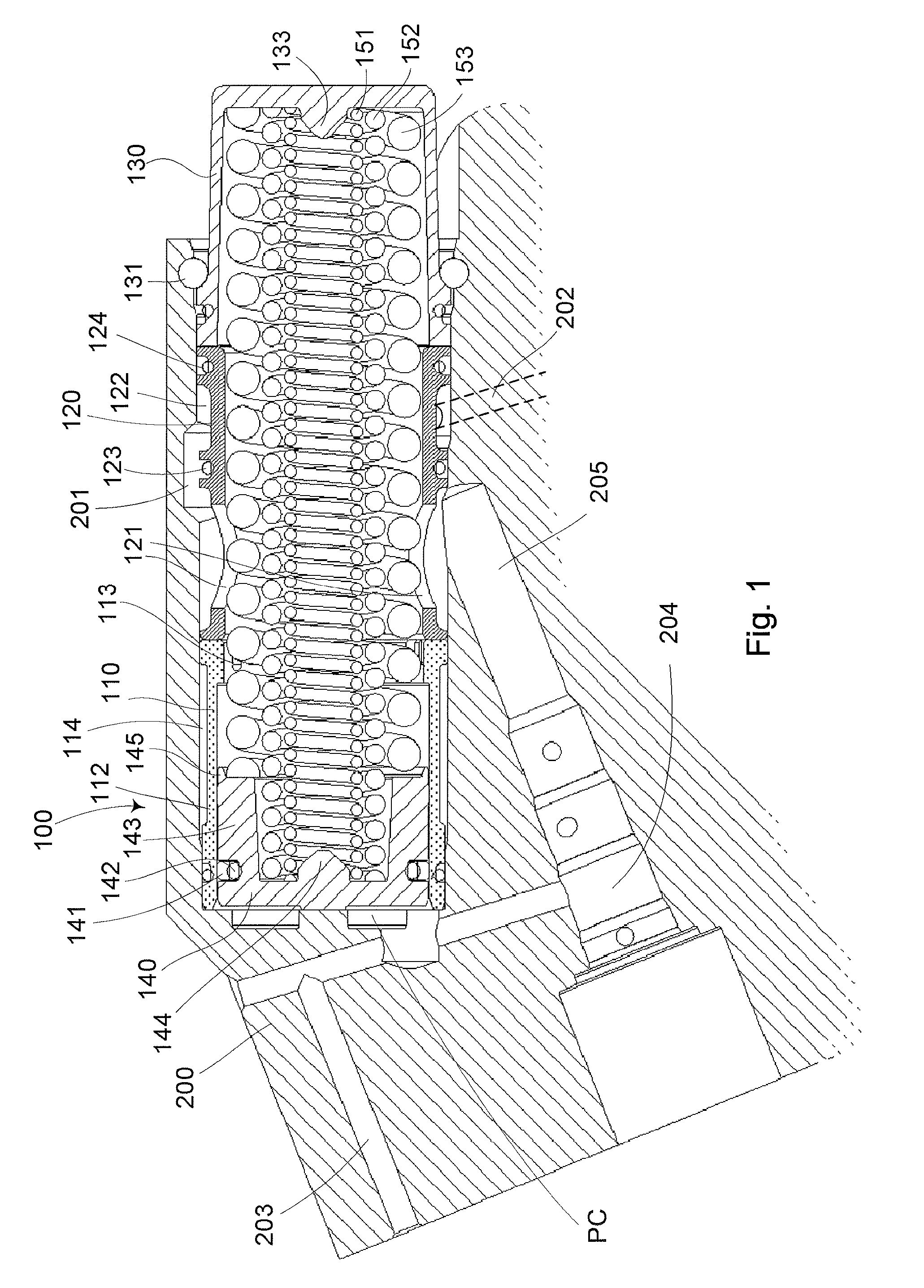

Ultrasonic assisted powder injection molding device and method

ActiveCN104525953AChange rheologyReduce maximum pressureCeramic shaping apparatusComposite materialUltrasonic generator

The invention relates to an ultrasonic assisted powder injection molding device and method. The device comprises an internal mixing device and an injection molding device. An internal mixing cavity is formed inside a shell of the internal mixing device, and a feeding hole communicated with the internal mixing cavity is formed in the surface of the shell. A rotor is arranged in the internal mixing cavity of the internal mixing device. A pressing weight is arranged at the feeding hole and is suitable for sealing the feeding hole. The injection molding device comprises a threaded rod injection molding machine and an injection mold. The feedstock obtained by internal mixing through the internal mixing device is injected into the injection mold through the threaded rod injection molding machine, and blanks are obtained by molding. A first energy converter is connected with the internal mixing device, and a second energy converter is connected with the injection mold. The first energy converter and the second energy converter are connected with an ultrasonic generator respectively, and are suitable for driving the internal mixing device and the injection mold respectively for supersonic vibration. The ultrasonic assisted powder injection molding device and method can effectively remove the agglomeration phenomenon in the mixing process and lower the mixing temperature, and are especially suitable for the feedstock made of metal or ceramic powder, of irregular shapes or high-carrying capacity, which is hard to inject.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Device for connecting two rotating shafts, in particular in a turbomachine

ActiveUS20080124168A1Simple and effective and economicSimple and effective and economic solutionYielding couplingBlade accessoriesRotational axisEngineering

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Semiconductor package with integrated metal pillars and manufacturing methods thereof

ActiveUS8698307B2Reduce maximum pressureSemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor package

A semiconductor package includes a substrate and a semiconductor device. The semiconductor device includes a body having a center, a layer disposed adjacent to the body, and a plurality of conductive pillars configured to electrically connect the semiconductor device to the substrate. The layer defines a plurality of openings. Each of the plurality of conductive pillars extends at least partially through a corresponding one of the plurality of openings. An offset between a first central axis of the each of the plurality of conductive pillars and a second central axis of the corresponding one of the plurality of openings varies with distance between the first central axis and the center of the body. The second central axis of the corresponding one of the plurality of openings is disposed between the first central axis of the each of the plurality of conductive pillars and the center of the body.

Owner:ADVANCED SEMICON ENG INC

Hypergolic hydrogen generation system for fuel cell power plants

InactiveUS7344789B2High densityIncrease pressureHydrogen separation using solid contactFuel cell auxillariesOxygenContamination

The invention provides a controlled hypergolic approach to using concentrated hydrogen peroxide in combination with certain hydrocarbons such as ethanol, methanol, methane as well as more common fuels such as gasoline, diesel, DME, JP5, JP8 and the like to generate a gas mixture primarily composed of hydrogen and carbon dioxide. Because air is not used as the oxygen source, this novel process does not allow the formation of nitrous oxide (NOx) compounds, thereby avoiding the primary source of nitrogen contamination as well. The process is executed in a constraining system on a micro scale such that the resulting hydrogen supply is self-pressurizing. This enables the incorporation of an “on-demand” hydrogen fuel source for a variable output fuel cell power plant such as those proposed for use in automobiles, marine vessels and stationary power sources. In another embodiment of the present invention hydrogen peroxide is catalytically, or thermally reacted to provide H2O vapor and O2. When this gaseous stream is introduced to the cathode of the fuel cell, the percent concentration of oxygen is increased with no corresponding increase in the parasitic power demand made by an air-moving device. This use of H2O2 as an oxygen source may be continuous, intermittent or limited to specific instances when peak power output demands or high transient loads are placed upon the FCPS.

Owner:CBH2 TECH

MEMS sensor

InactiveUS20110227177A1Reduce maximum pressureReduce sensitivitySemiconductor electrostatic transducersElectrostatic transducer microphonesMems sensorsAcoustics

Owner:ROHM CO LTD

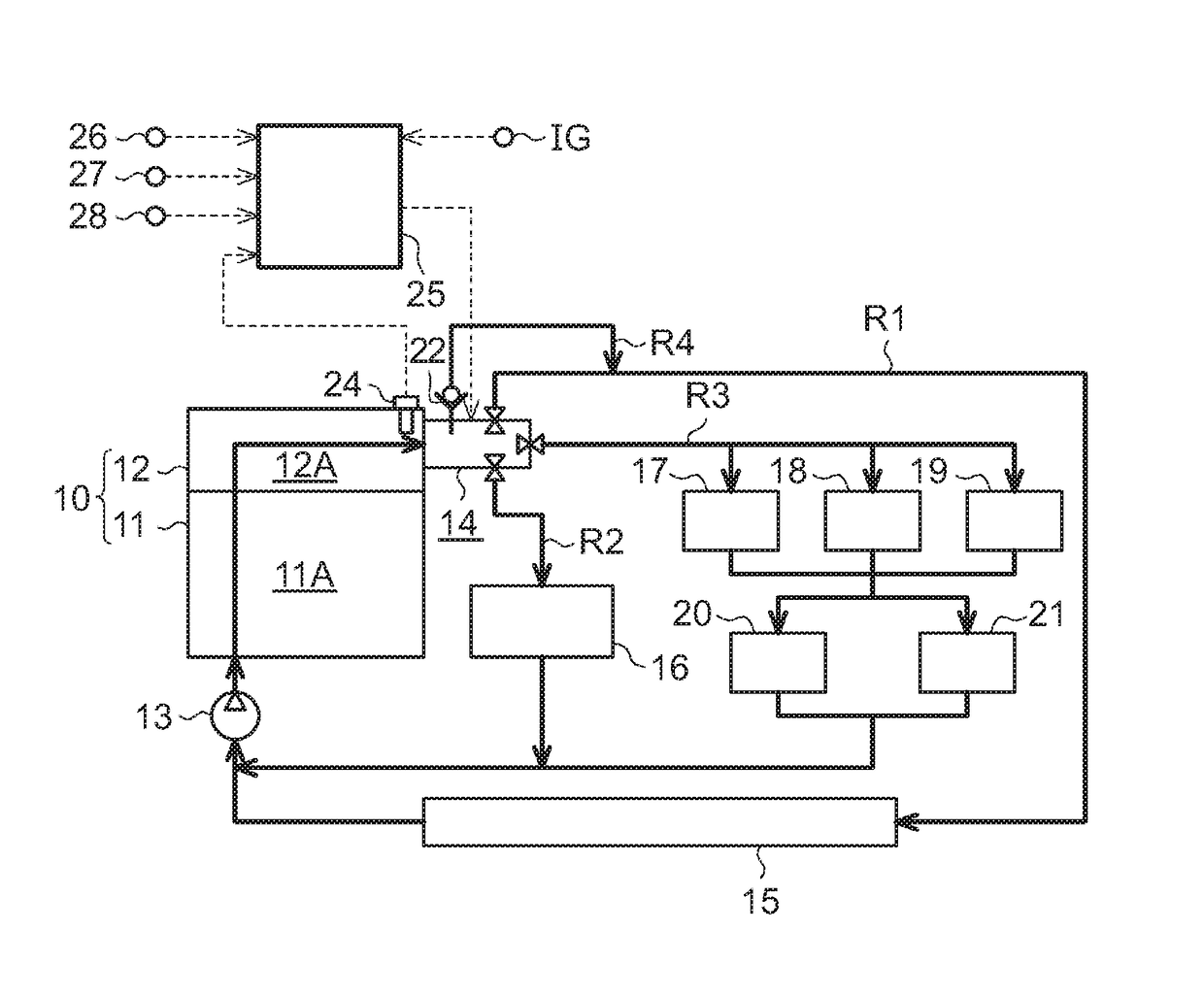

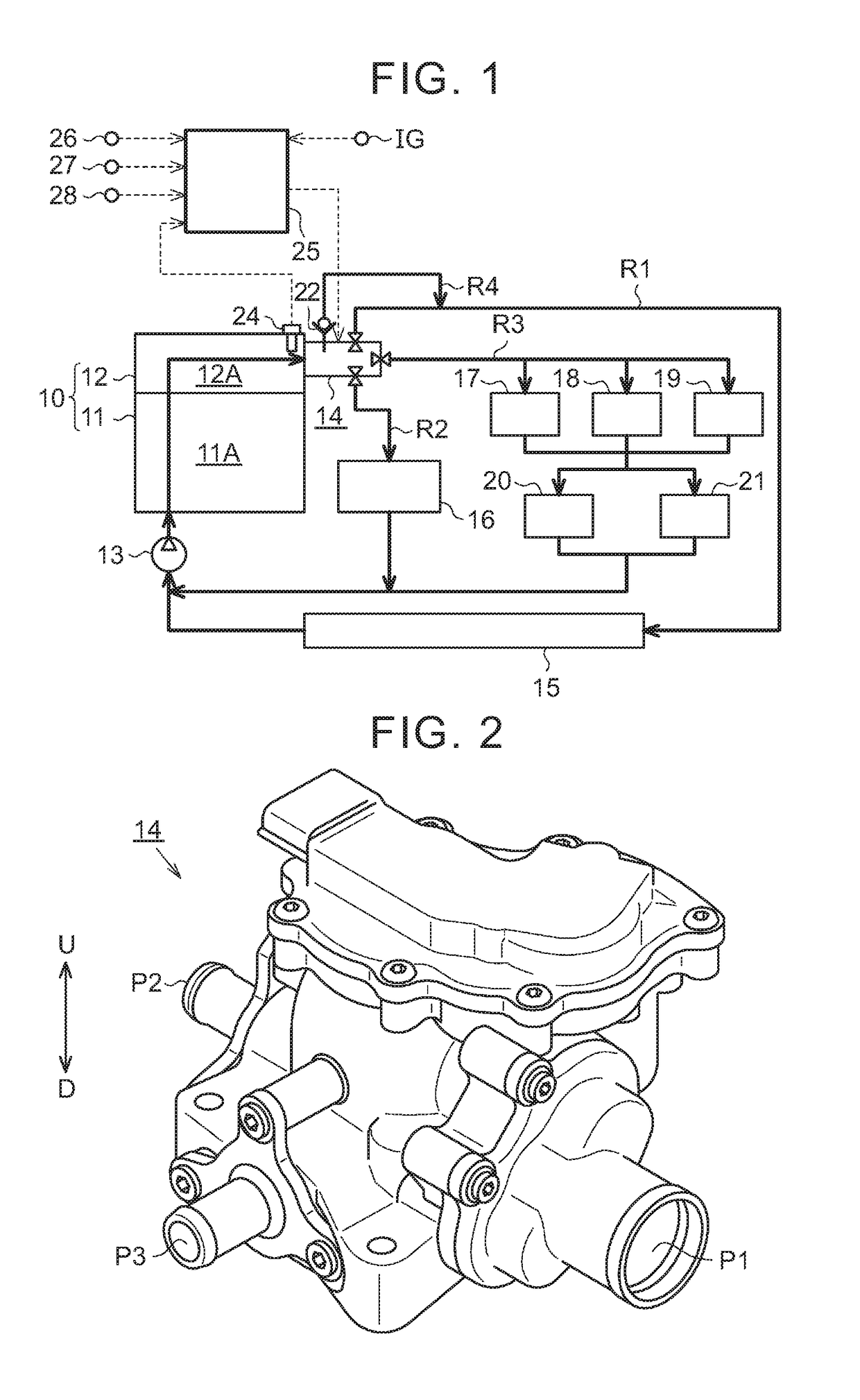

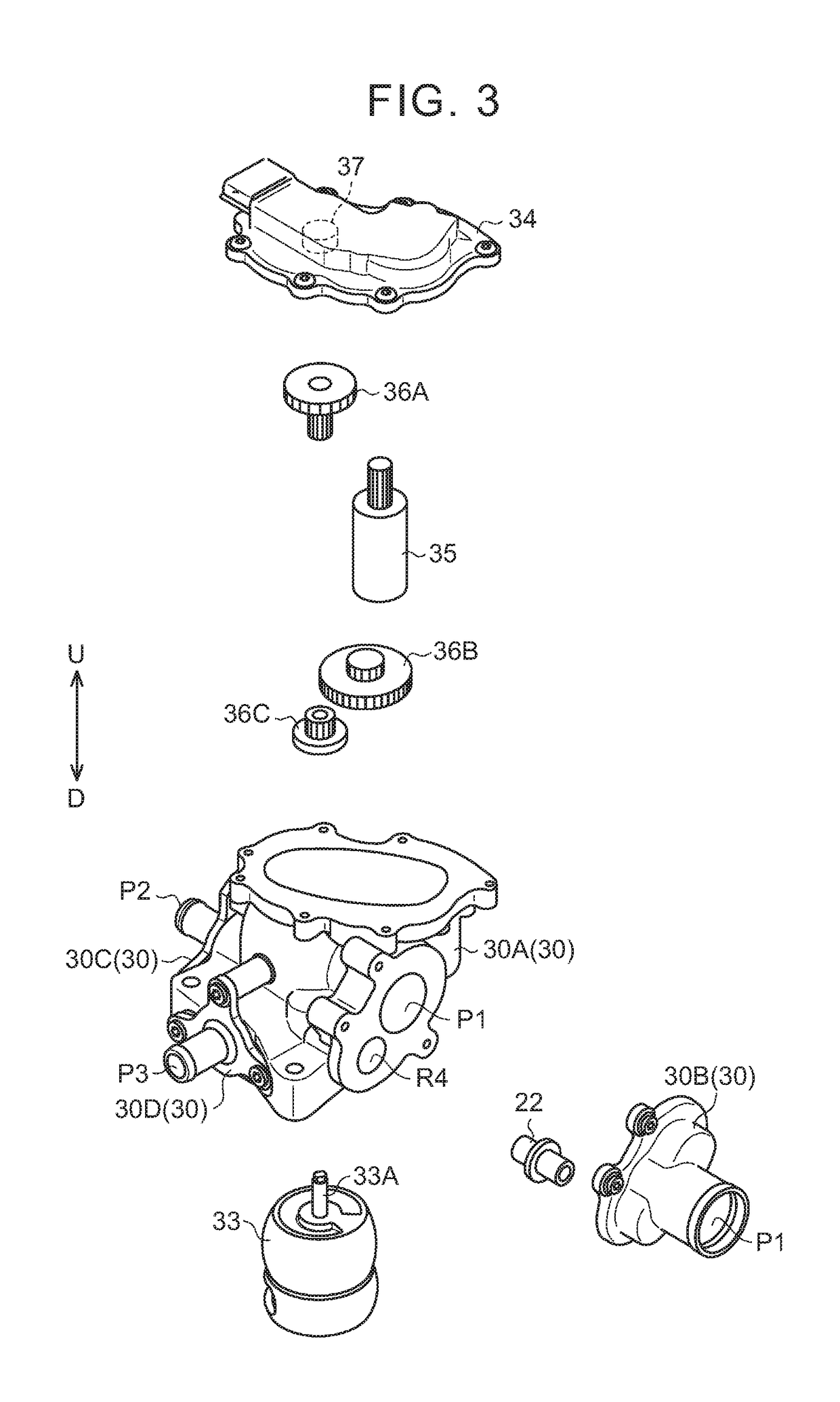

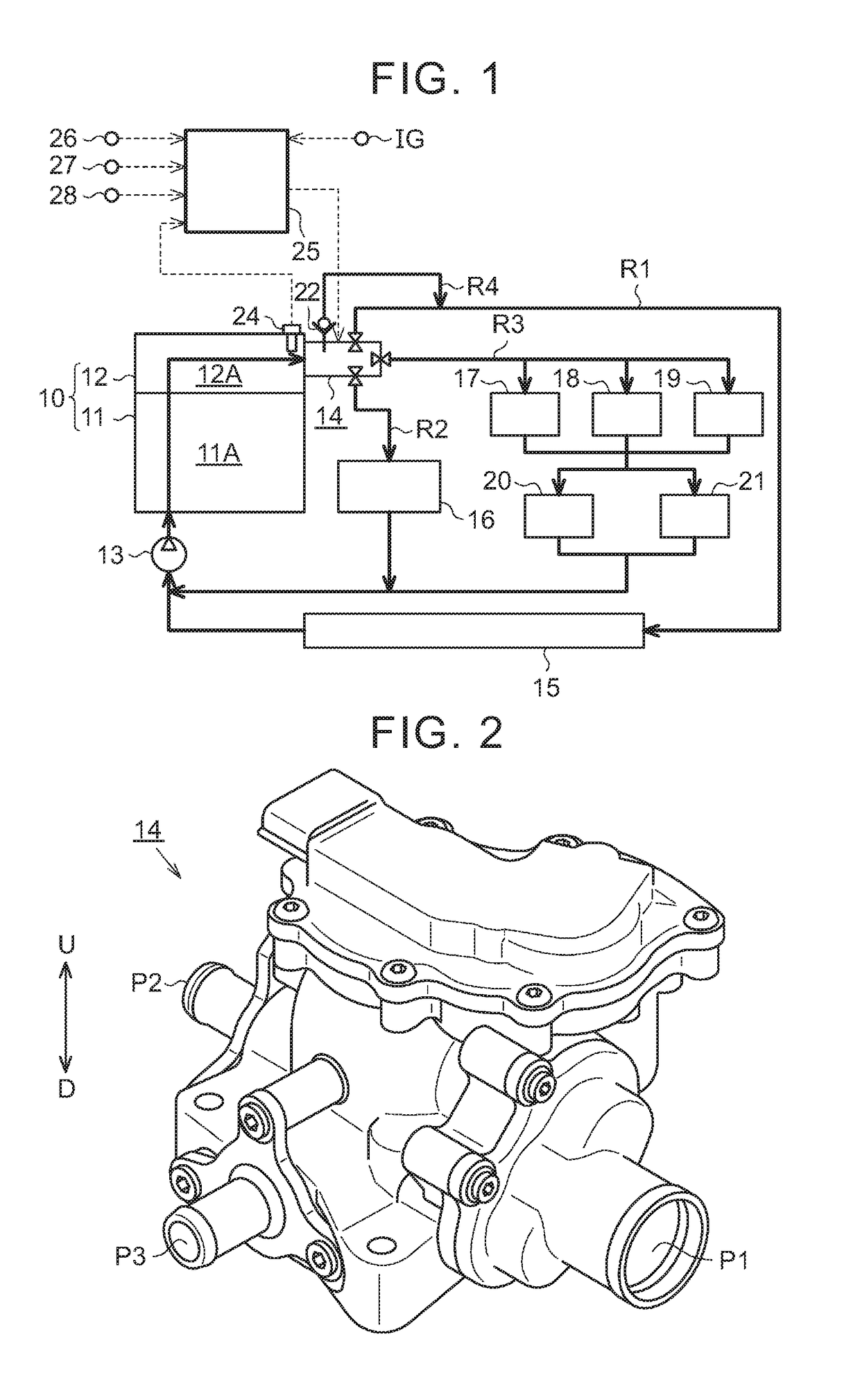

Cooling device and cooling method for engine

A cooling device for an engine includes a radiator route passing through a radiator, that are merged together after being branched on the downstream side from the inside of the engine in a coolant circuit configured to allow a coolant to flow from a pump through the inside of the engine and return to the pump. An at-stop control section provided in the cooling device controls a multiway valve that has three discharge ports, including a radiator port connected to the radiator route, so as to close the radiator port and open at least one of the other discharge ports when an ignition switch is turned off.

Owner:TOYOTA JIDOSHA KK

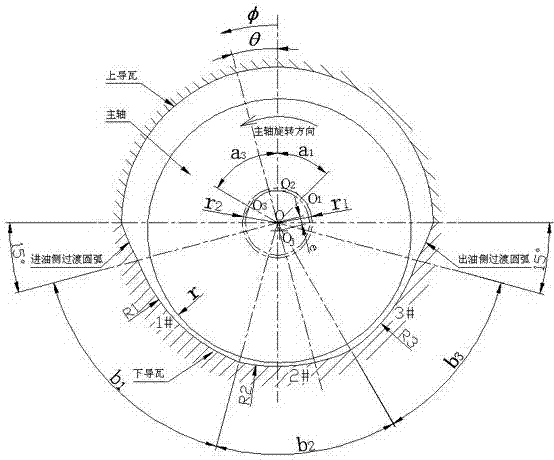

Radial sliding bearing

InactiveCN103075425AIncreased bearing areaReduce maximum pressureBearing componentsBearingsEllipseDistribution characteristic

The invention relates to a radial sliding bearing, which comprises a main shaft, an upper bearing liner and a lower bearing liner, and is characterized in that the inner wall of the lower bearing liner of the radial sliding bearing is formed by jointing three arcs, radiuses of the three arc are set to be equal or unequal; opposite to the bearing center and along a main shaft rotation direction, a preset eccentric distance of the first arc is more than preset eccentric distances of the second arc and the third arc; the preset eccentric distances of the second arc and the third arc are the same; the circle center of the second arc is positioned on a vertical direction of the bearing; after pressure distribution characteristics and thickness distribution characteristics of design requirements are defined, an included angle formed by a connection line of the first arc circle center and the bearing center with the bearing vertical line and an included angle formed by a connection line of the third arc circle center and the bearing center with the bearing vertical line can be calculated according to an oil film thickness formula (1) and a Reynolds equation (2); after the included angles of every arc are defined, the preset eccentric distances of the arcs can be calculated according to the thickness calculation formula and oil film wedge shape requirements, such that the three non-concentric arcs form three continuous wedge oil films having similar shapes and the same oil film thickness during the operation process so as to achieve a multi-oil wedge bearing effect, such that the original elliptical or cylindrical sliding bearing can be lowered.

Owner:浙江富春江水电设备有限公司

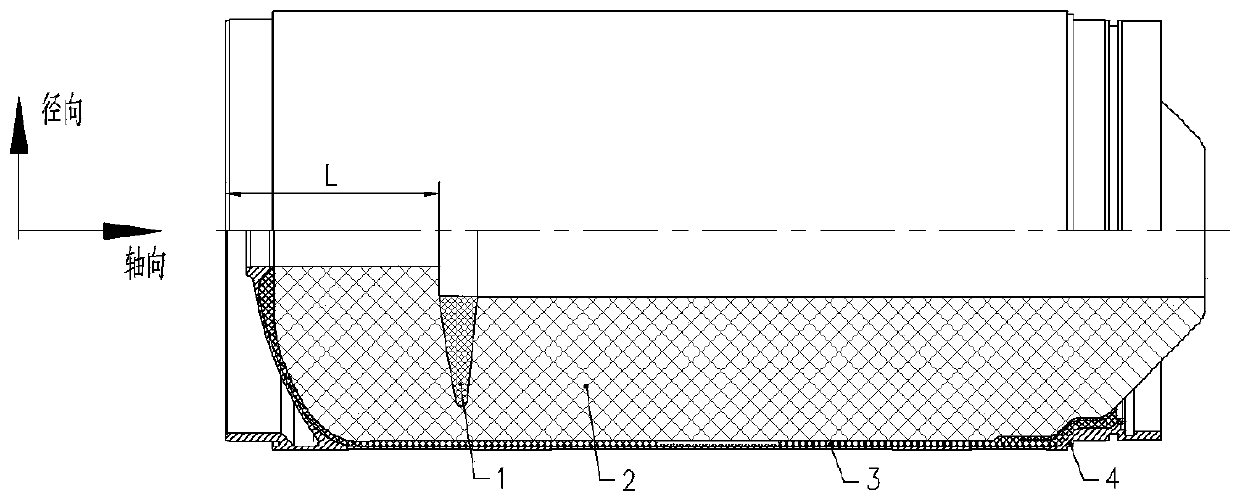

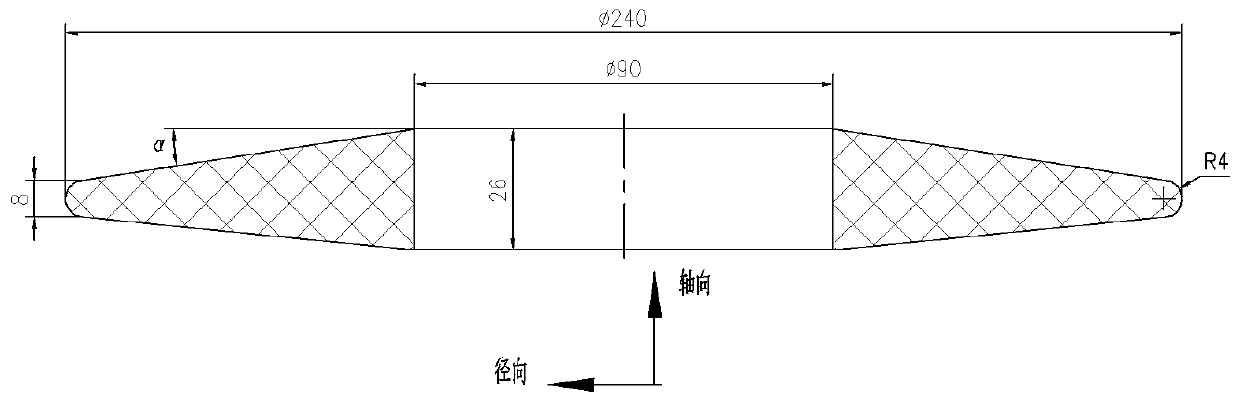

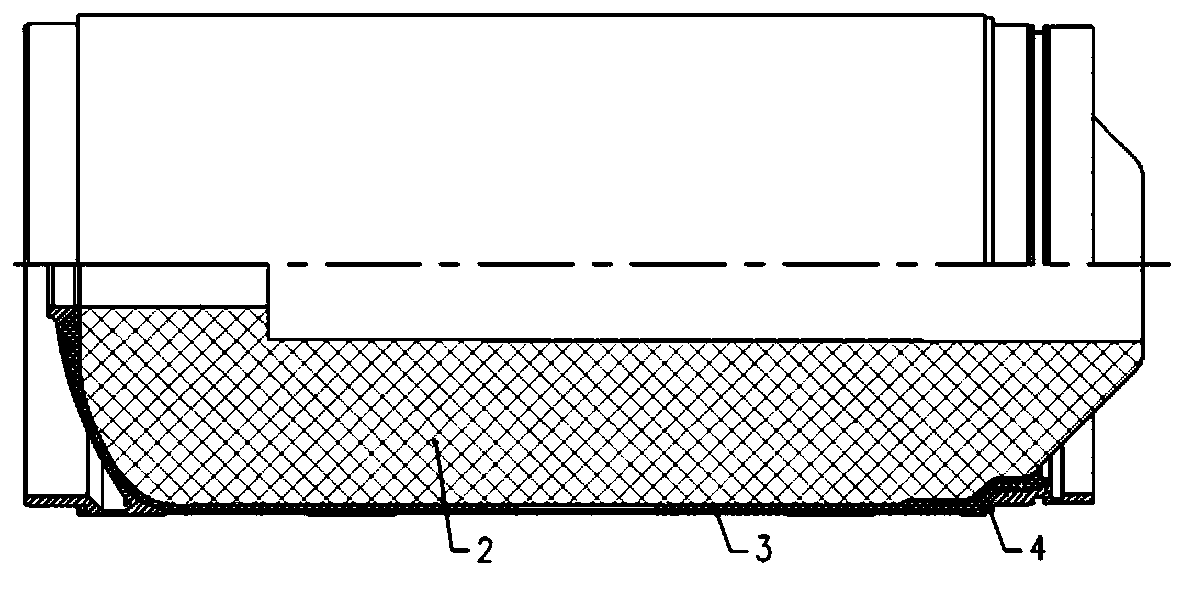

Tubular inner-hole charge structure with inner cavity partition and used for solid rocket engine, and method

ActiveCN110145411AImprove surface increaseReduce maximum pressureRocket engine plantsCombustion chamberWorking pressure

The invention discloses a tubular inner-hole charge structure with an inner cavity partition and used for a solid rocket engine. The inner cavity partition is arranged in the combustion chamber chargestructure of the solid engine, and the inner cavity partition is made from a polyurethane foam material. The tubular inner-hole charge structure with the inner cavity partition and used for the solidrocket engine has the beneficial effects of being capable of effectively improving the progressive performance of the solid rocket engine in a working process, reducing the maximum working pressure of the engine, reducing the design thickness of a shell body, reducing the passive mass of the missile engine, and increasing the missile range.

Owner:SHANGHAI XINLI POWER EQUIP RES INST

Flexible strip for horology and method for manufacturing the same

ActiveUS20180143591A1Improve out-of-plane stiffnessIncrease stiffnessGearworksFrequency stabilisation mechanismEdge surfaceResonator

A method for manufacturing a flexible strip, including forming a plate of the required thickness with one or more micromachinable substrate wafers; affixing, on either side of the plate, an upper mask with an upper window and a lower mask with a lower window, of identical geometry; etching the plate, at least to mid-thickness, from the upper side of each upper etching window, and from the side of each lower etching window; removing the upper mask and the lower mask, to delimit a flexible strip having a height equal to the thickness of the plate, and whose edges are as-etched. A flexible strip made of micromachinable material, including, between two parallel upper and lower surfaces, two peripheral, tapered and reverse-tapered edge surfaces, for a flexible pivot, a resonator, a movement or a watch.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

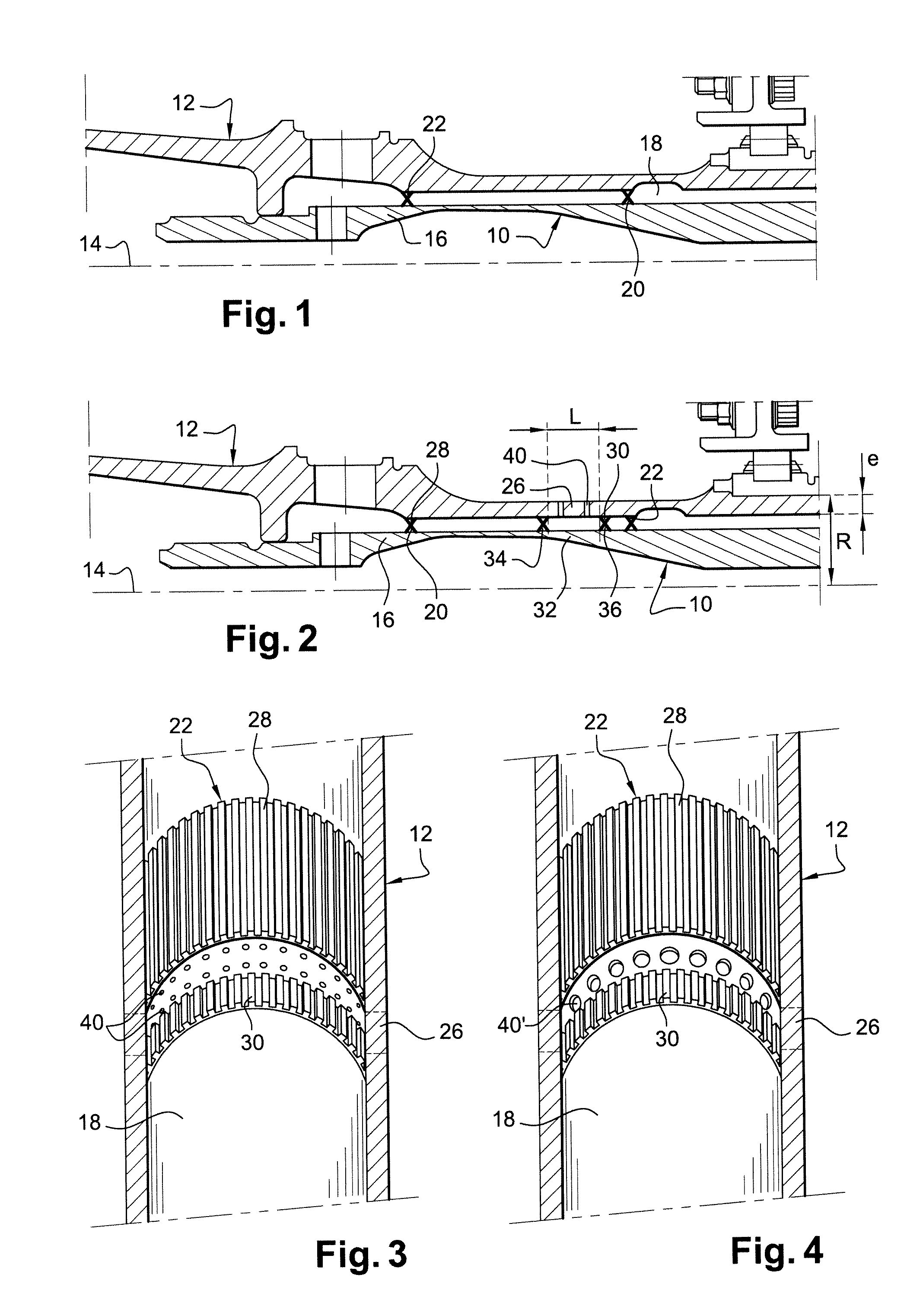

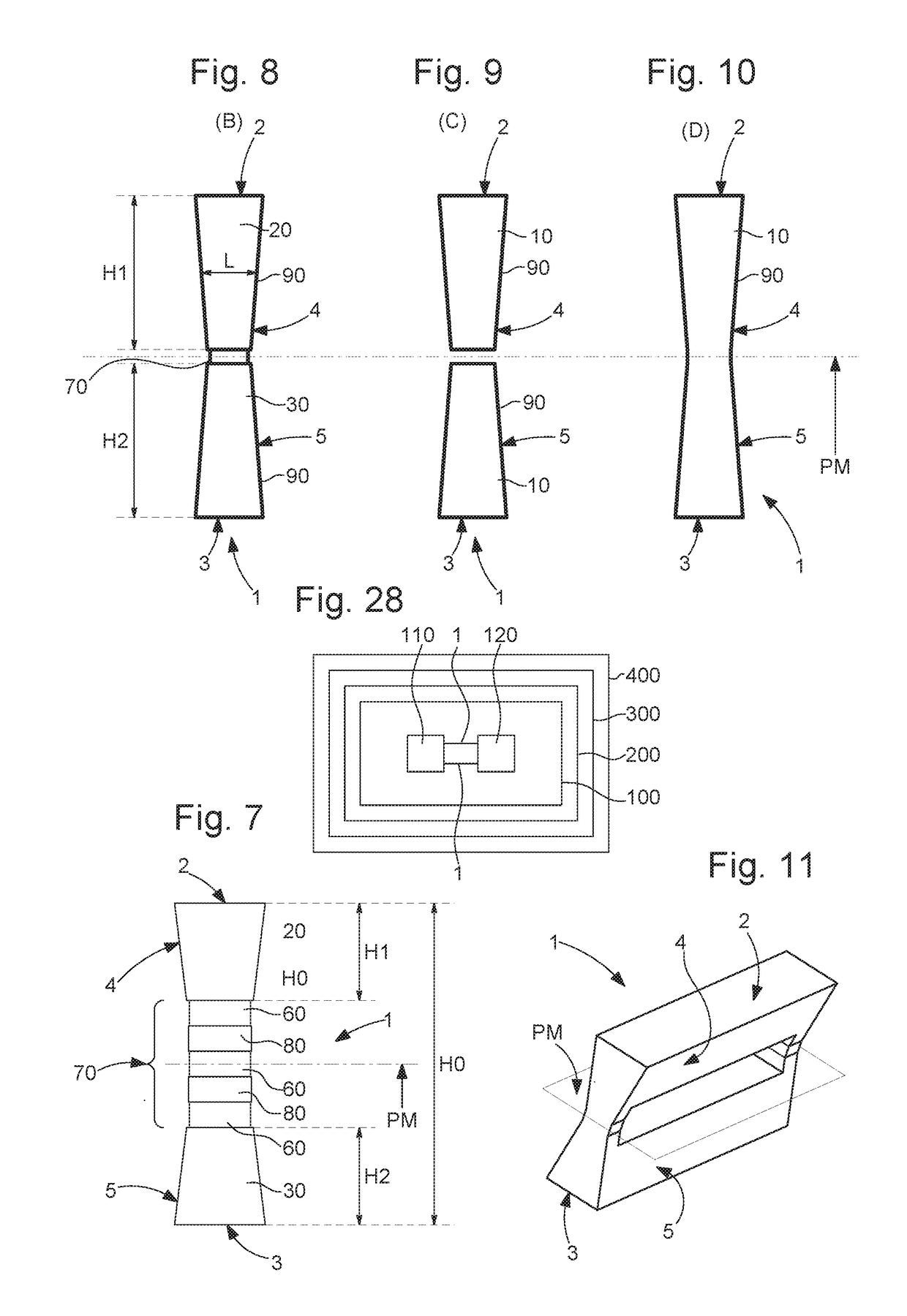

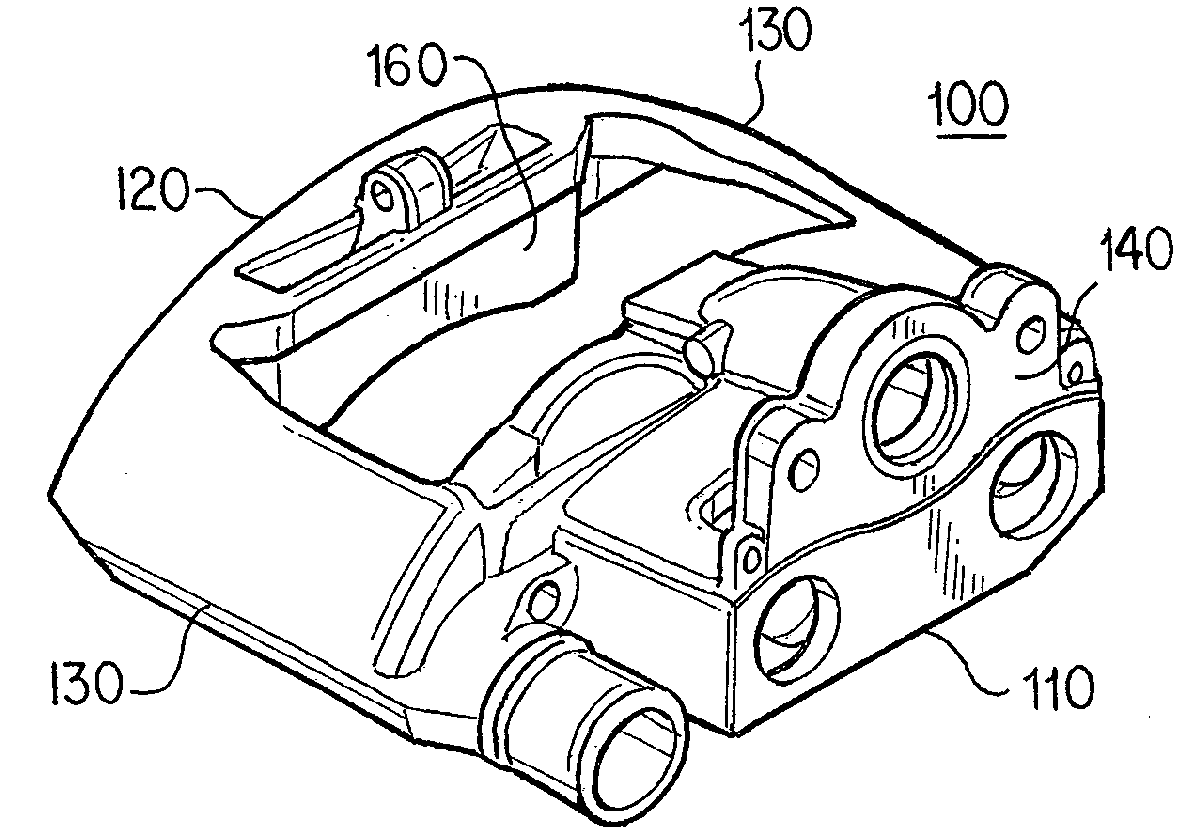

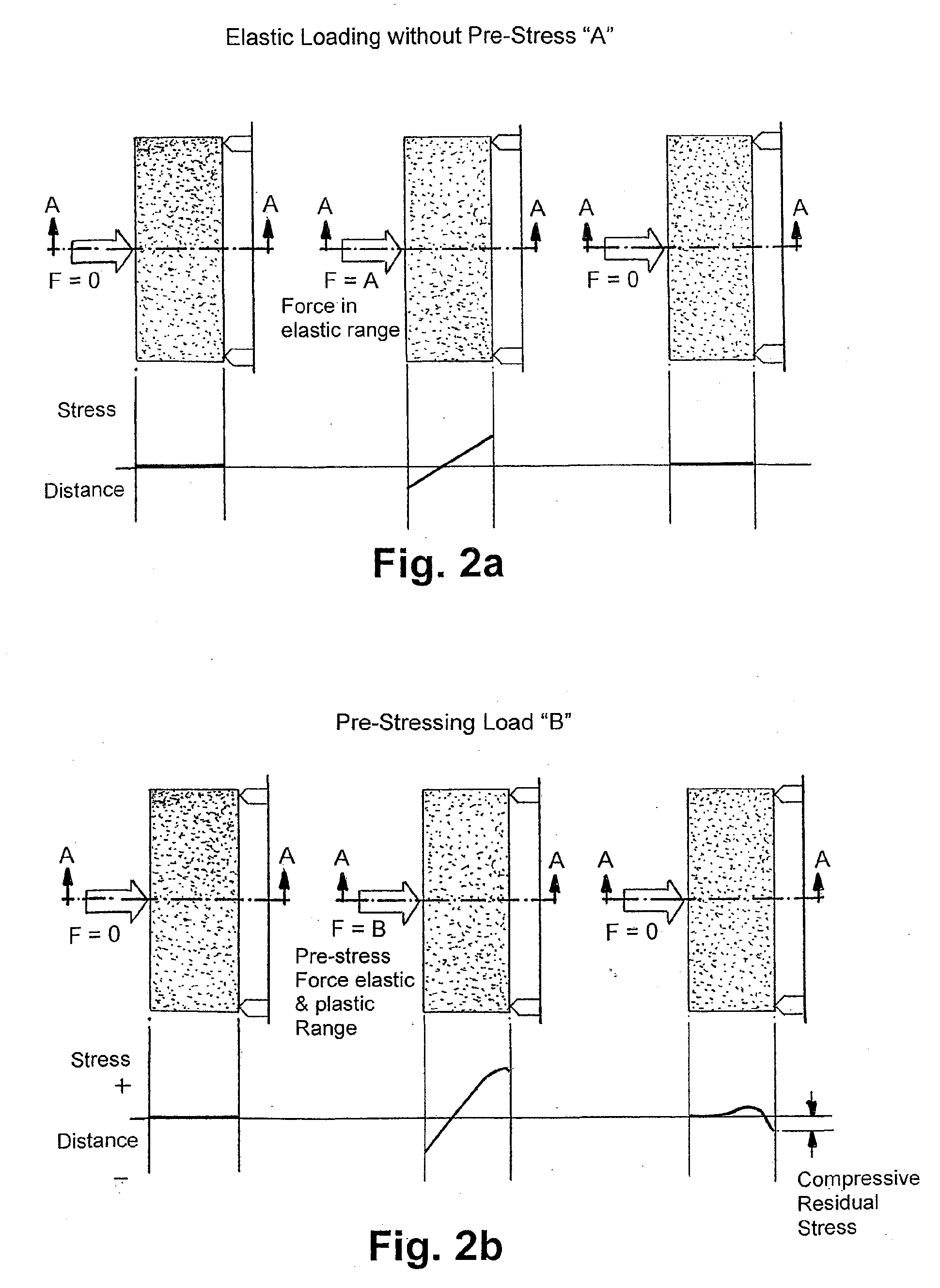

Air Disk Brake Caliper Pre-Stressing Method and Pre-Stressed Caliper Apparatus

ActiveUS20100236875A1Increase fatigue lifeLow peak stressAxially engaging brakesForce measurementCast ironStress range

Owner:BENDIKS SPAJSER FAUNDEJSHN BREJK LLK

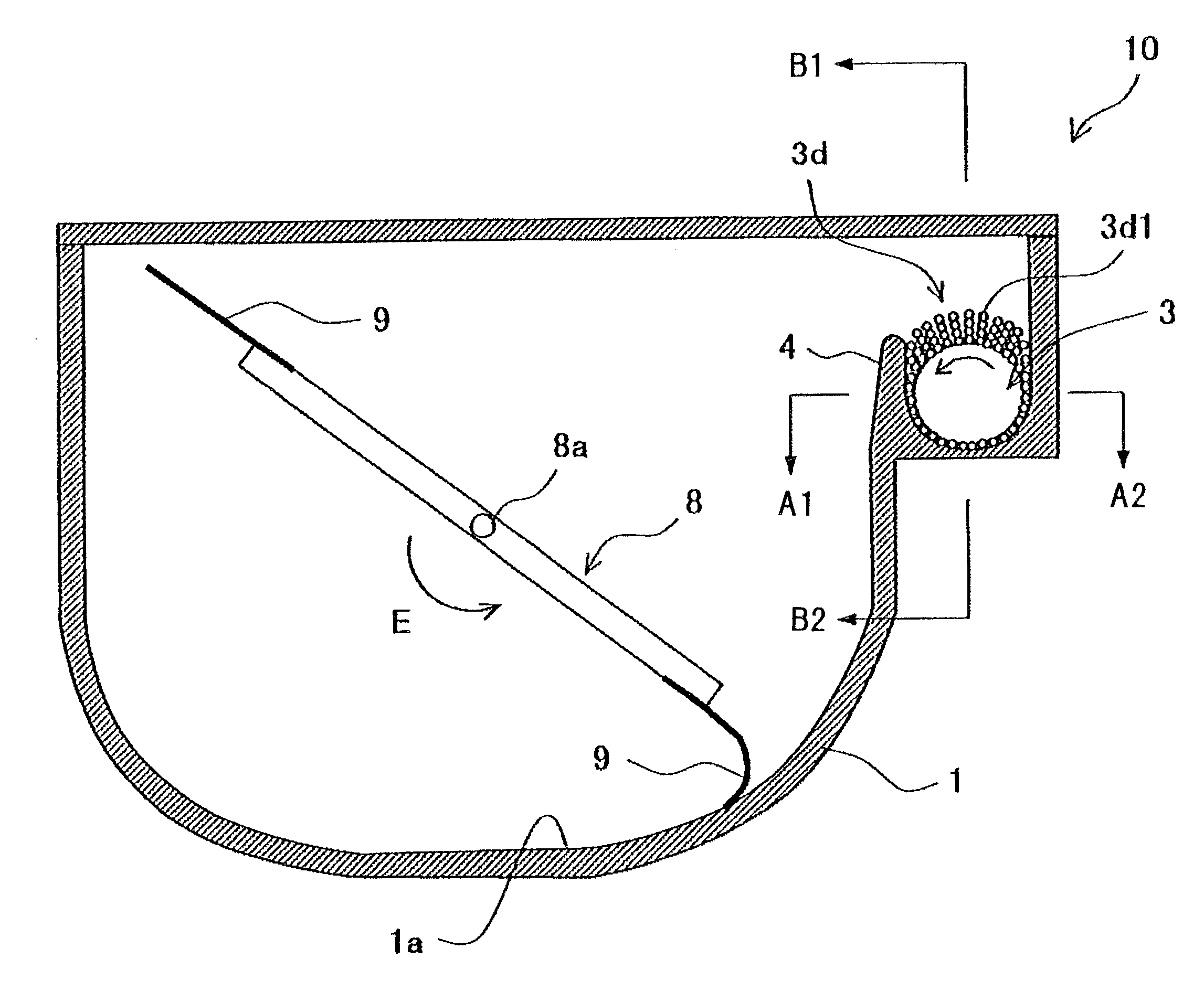

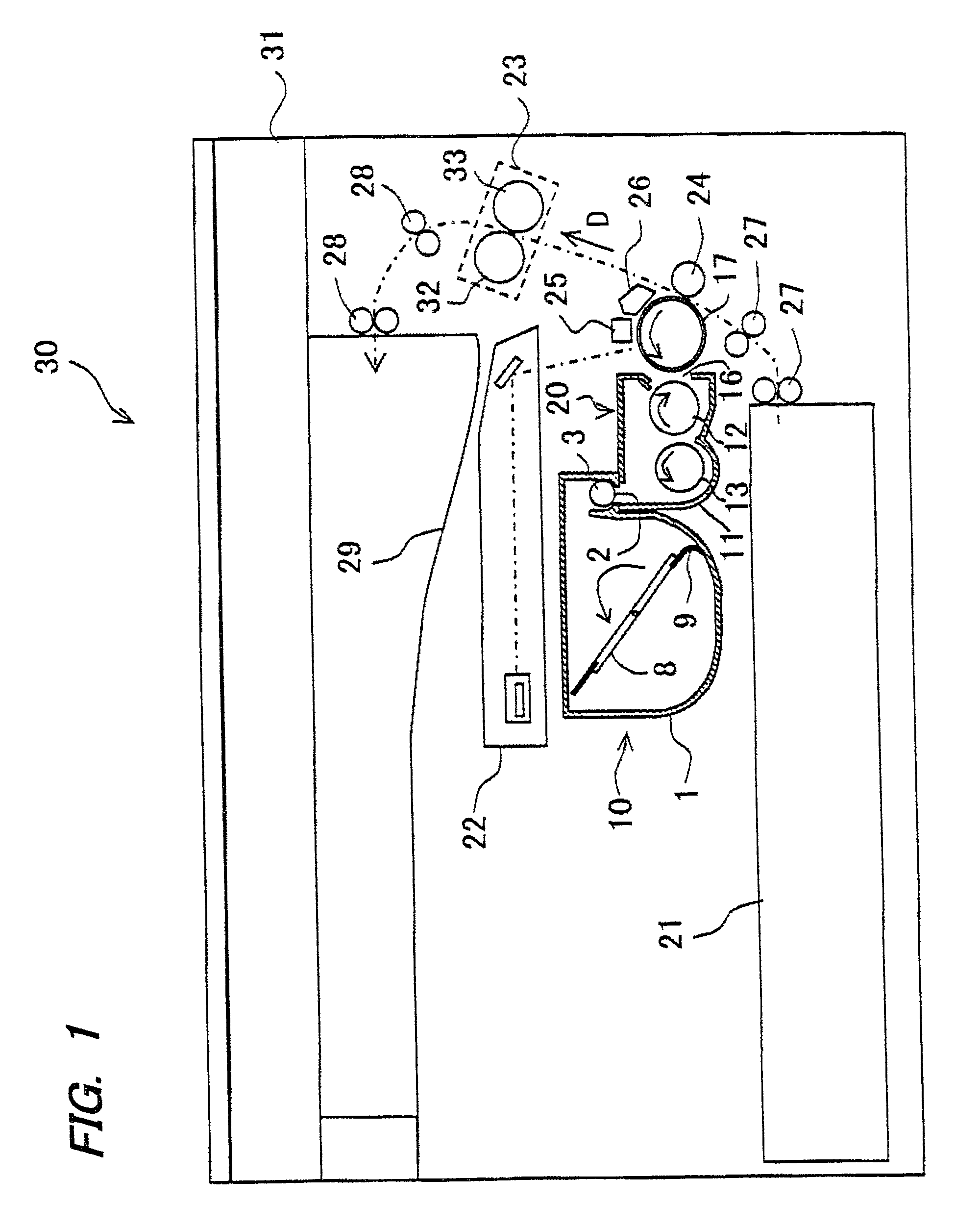

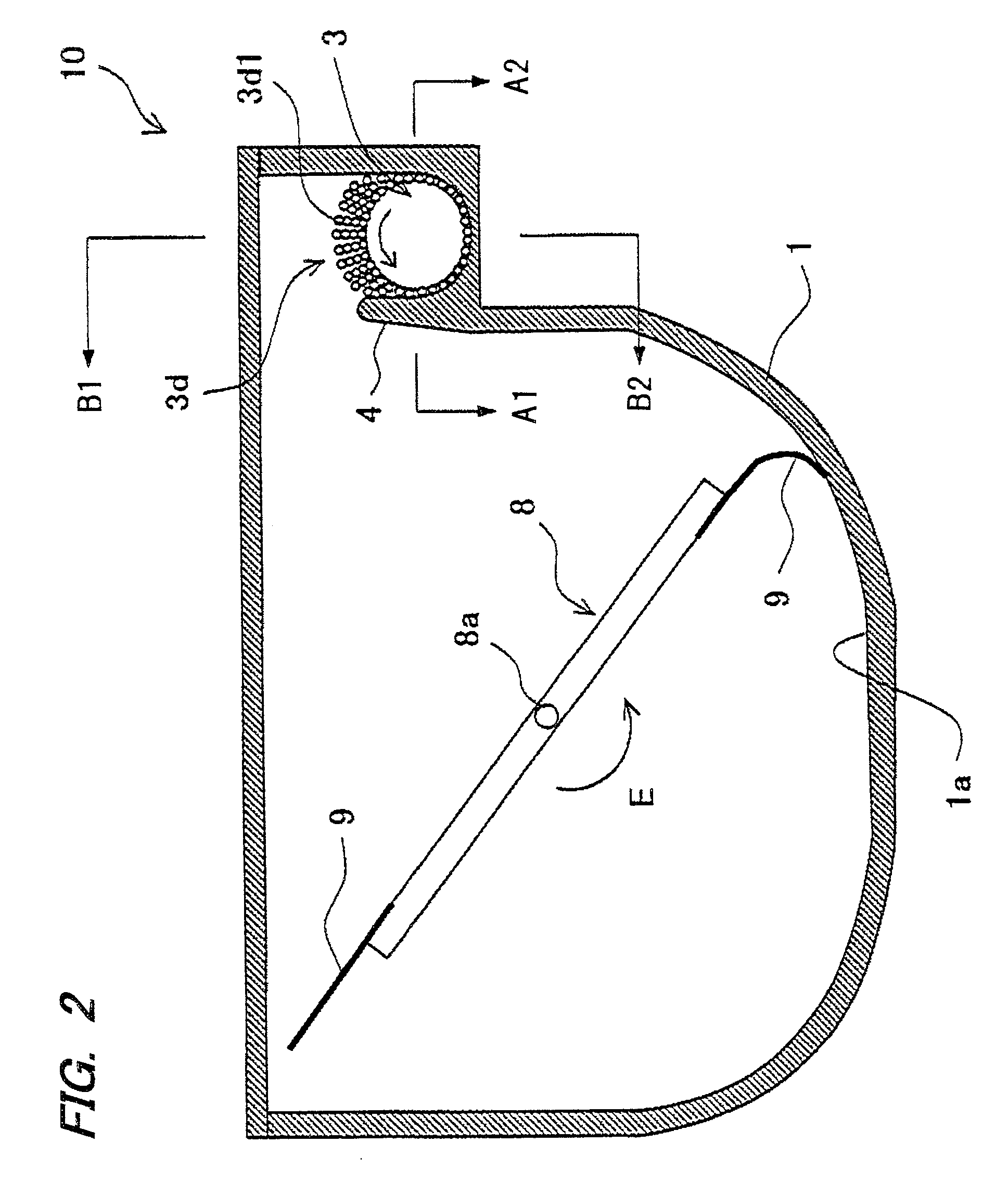

Toner cartridge and image forming apparatus using the same

ActiveUS20100061772A1Avoid performance degradationDamage suppressionElectrographic process apparatusEngineeringDischarger

An image forming apparatus includes a photoreceptor drum, a charger, an exposure device, a developing device, a toner cartridge for supplying toner to the developing device, a transfer device and a fixing device. The toner cartridge includes: a toner container, a toner discharge port, a toner discharger having a toner agitator. The toner discharger includes a toner discharger rotary shaft, around which a helical magnet is provided; and magnetic particles that form a helical magnetic brush along the magnet on the surface of the toner discharger rotary shaft.

Owner:SHARP KK

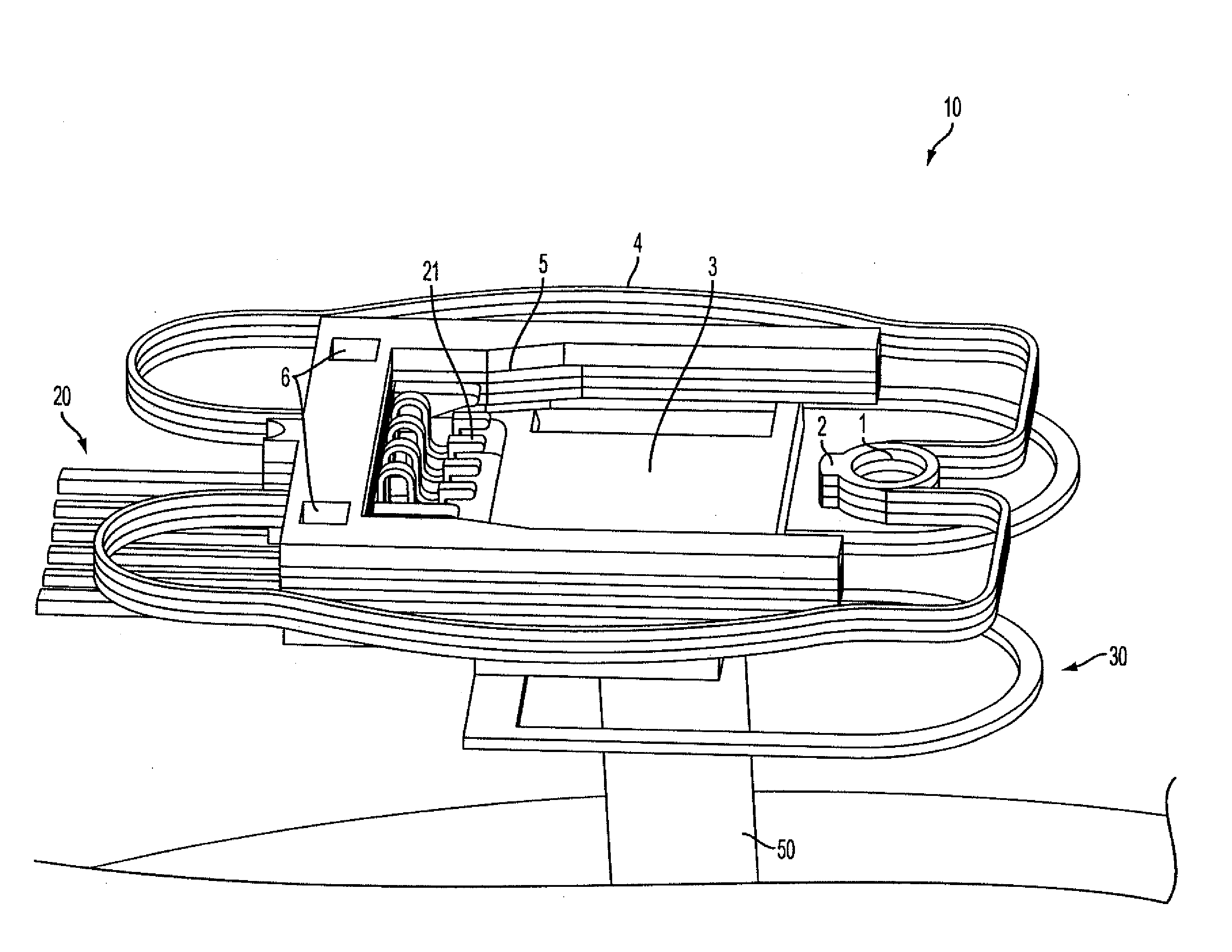

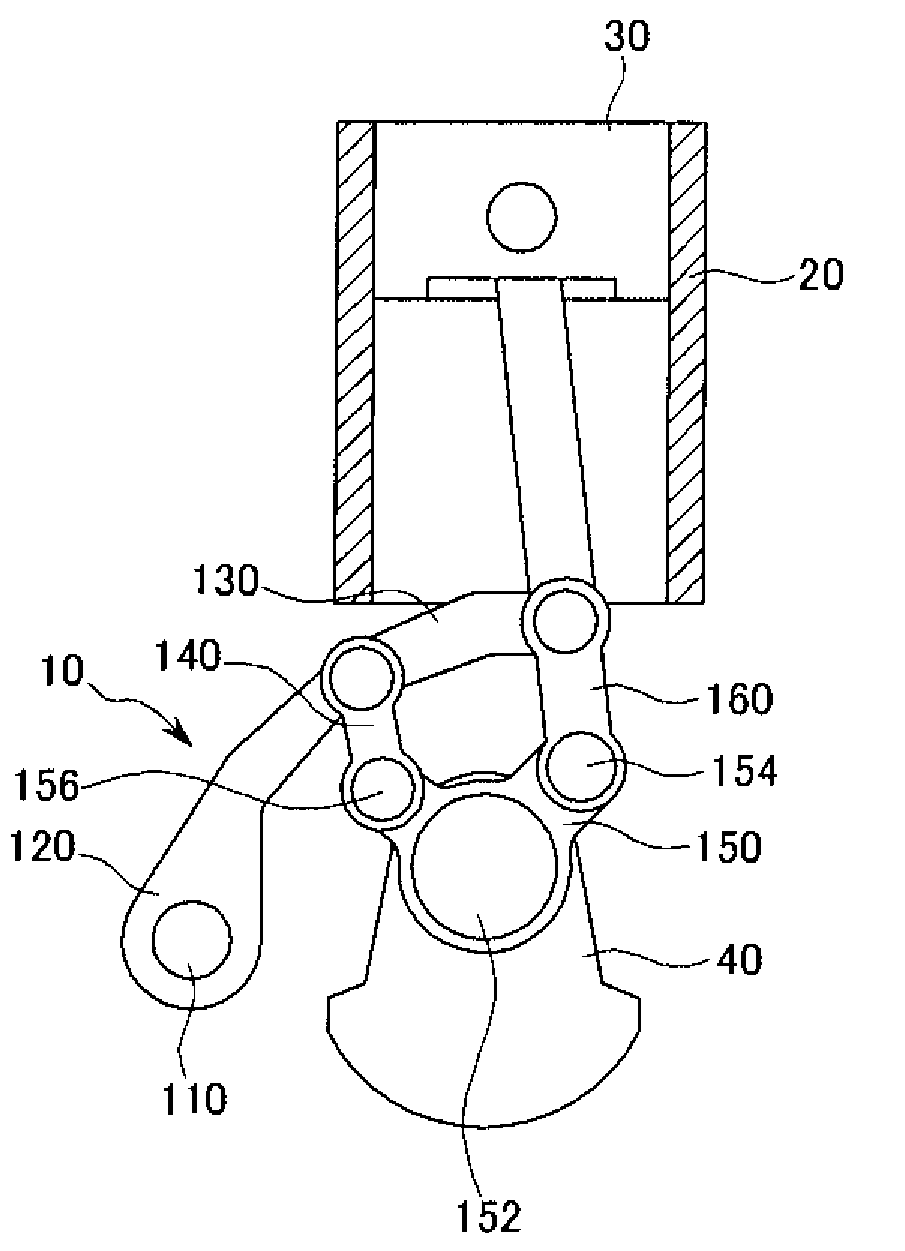

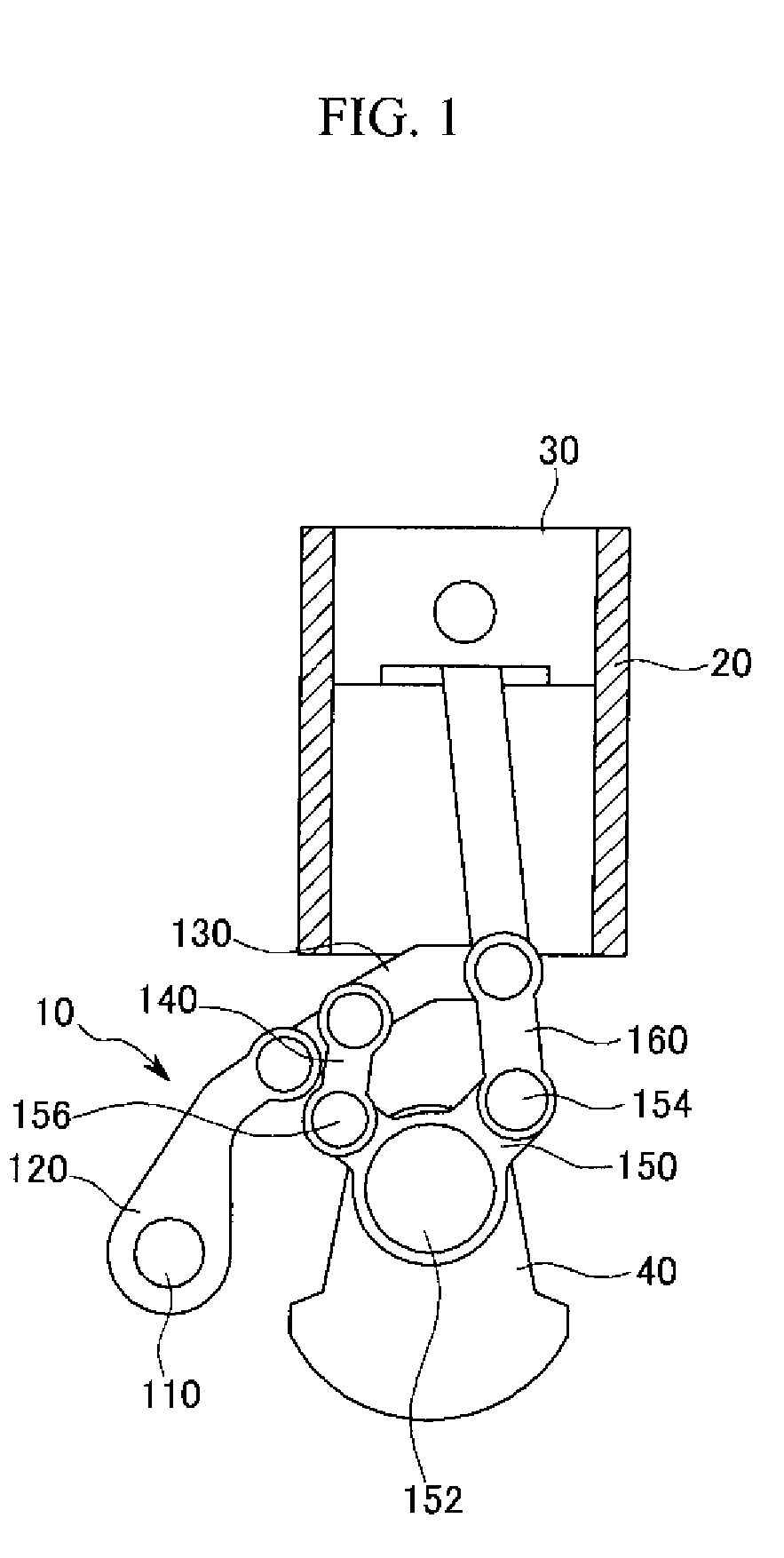

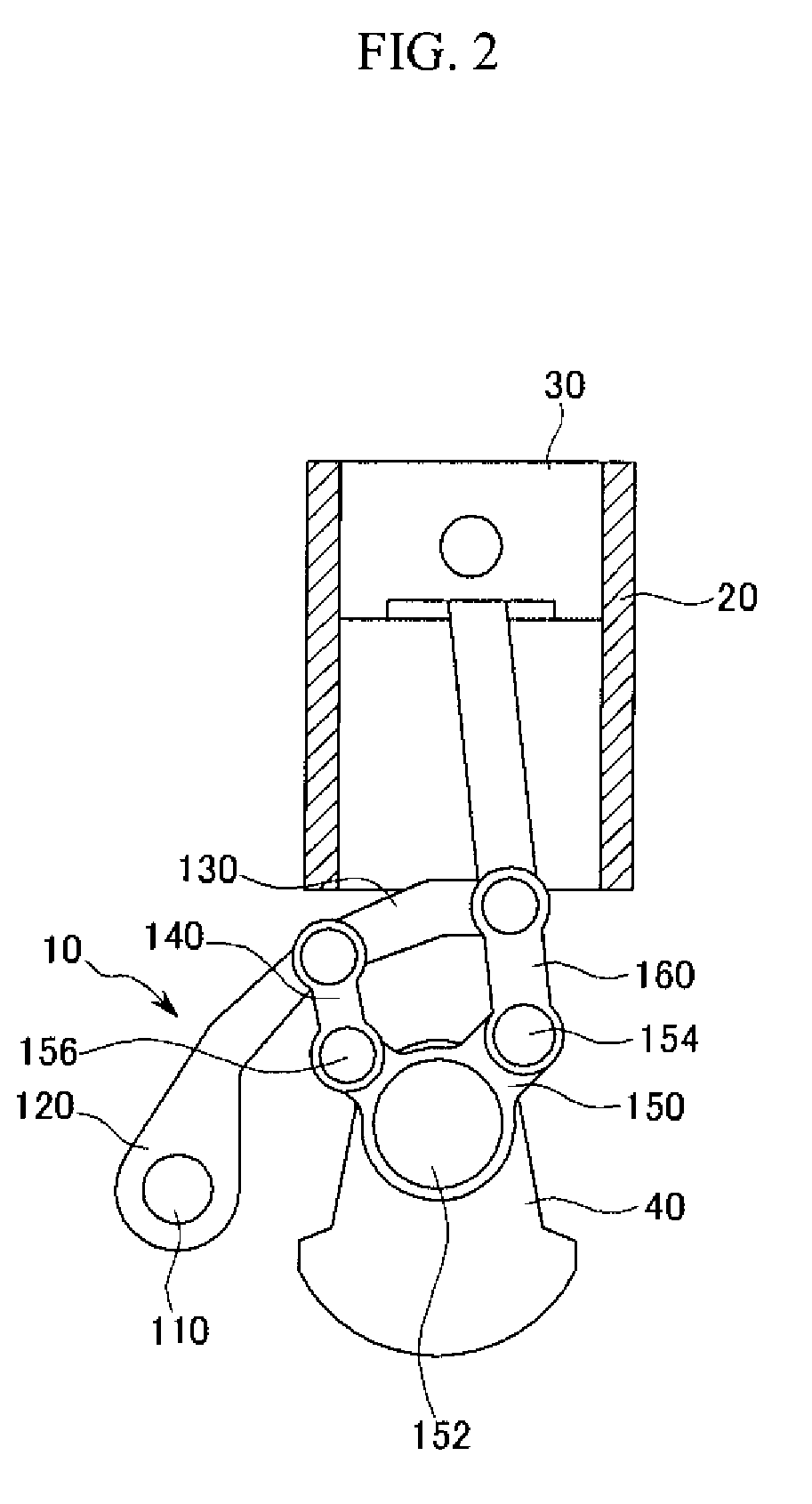

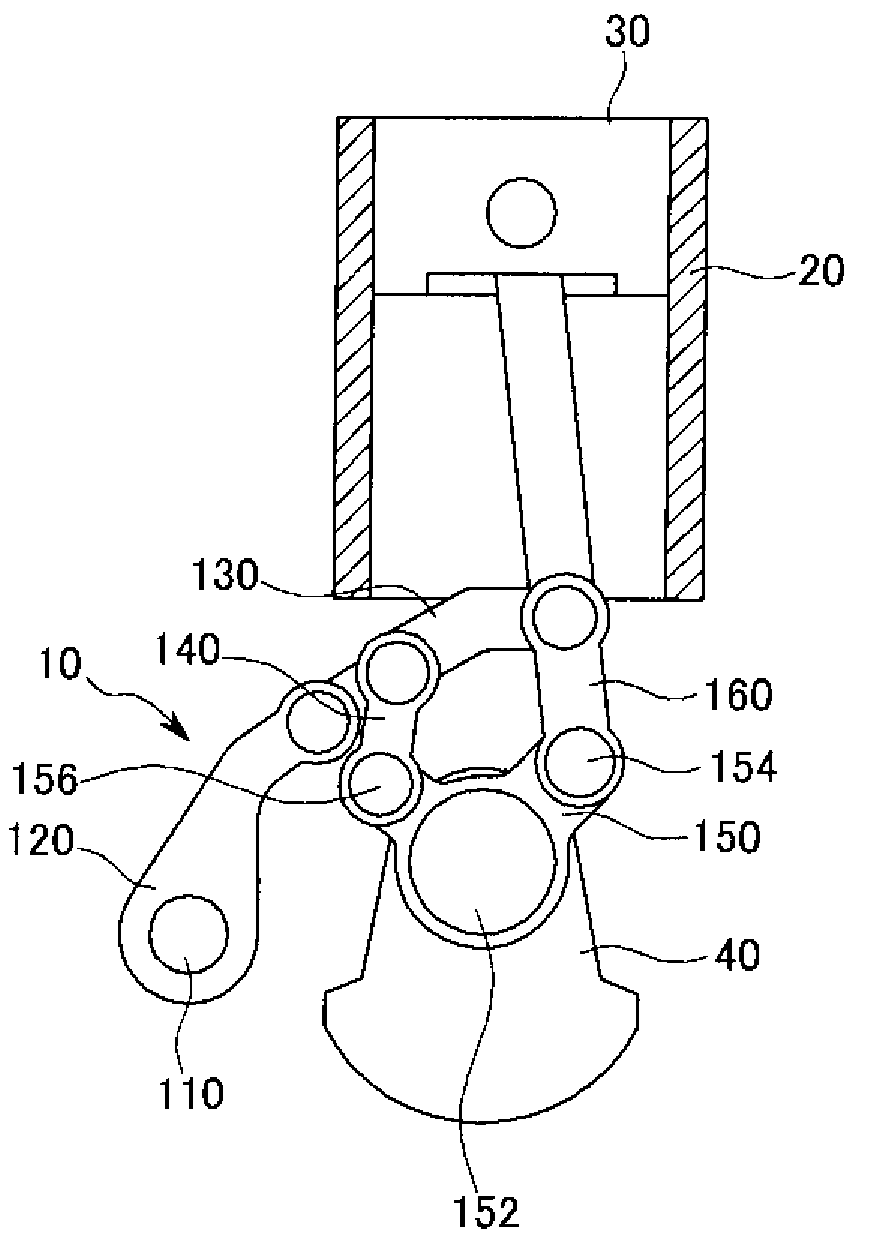

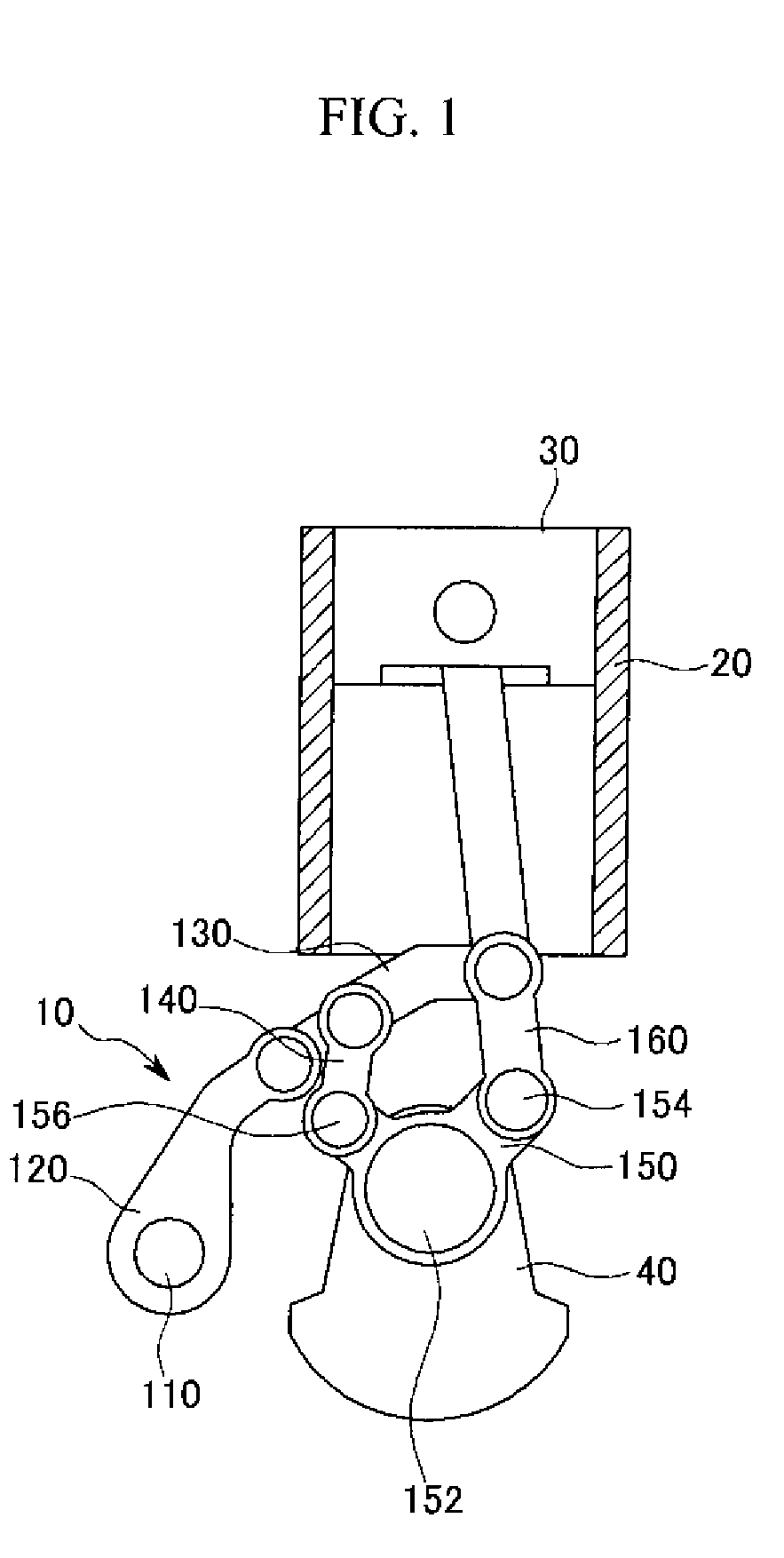

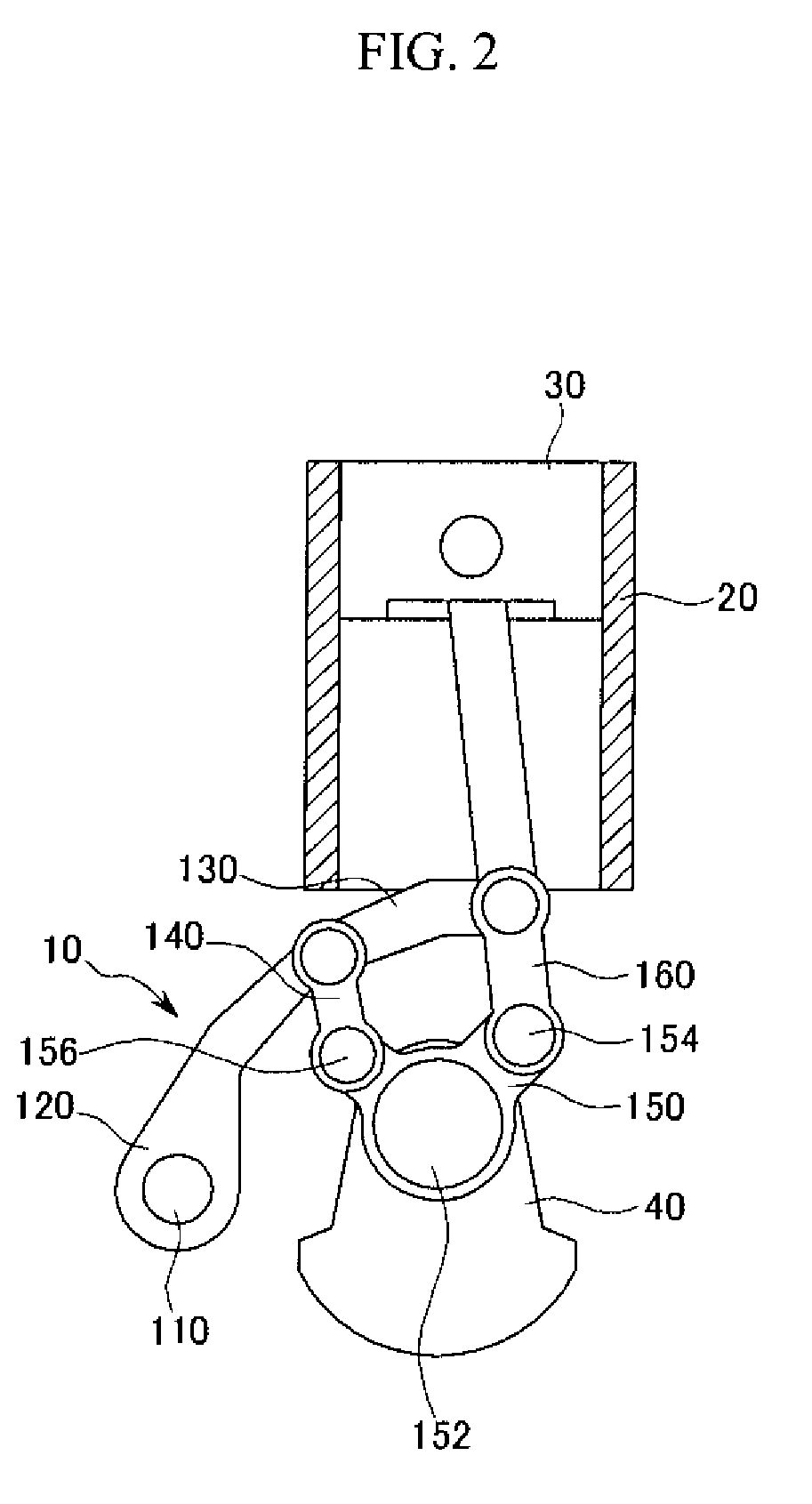

Variable compression ratio apparatus

InactiveUS20090139492A1Reduce maximum stressReduce maximum pressureEngine controllersMachines/enginesRotational axisCombustion chamber

A variable compression ratio apparatus that changes the compression ratio of an air-fuel mixture in a combustion chamber according to a driving state of an engine, enablements may include a connecting rod receiving the combustion force from the piston; a pin link receiving a part of the combustion force from the connecting rod and rotating the crankshaft; a support link disposed substantially in parallel with the connecting rod; a division link receiving a part of the combustion force from the connecting rod and transmitting the part of the combustion force to the support link; a control link provided with one end coupled to the division link in order to change position of one end of the division link; and an eccentric camshaft coupled to other end of the control link in order to change position of a rotational axis of the control link.

Owner:HYUNDAI MOTOR CO LTD

Accumulator

InactiveUS20090064674A1Rapid responseSmall sizeFluid couplingsAccumulator installationsPistonHigh pressure

An accumulator for a hydraulic system, wherein the accumulator comprises a liner, a piston and a housing, that defines a pressure chamber, for receiving hydraulic fluid at high pressure, wherein the piston is biased towards an end position of the pressure chamber for interacting with the hydraulic fluid in the pressure chamber, and the piston is movable in a predetermined range for accumulating hydraulic fluid. The accumulator has at least one outlet port in a sidewall of the liner, which outlet port is covered by the piston in the predetermined range and is uncovered when the piston has moved a predetermined distance from the end position. A hydraulic system is also provided that comprises the above accumulator and an all-wheel drive system comprising the above hydraulic system. A method for de-airing an accumulator according to above is also provided.

Owner:BORGWARNER TORQ TRANSFER SYSTEMS AB

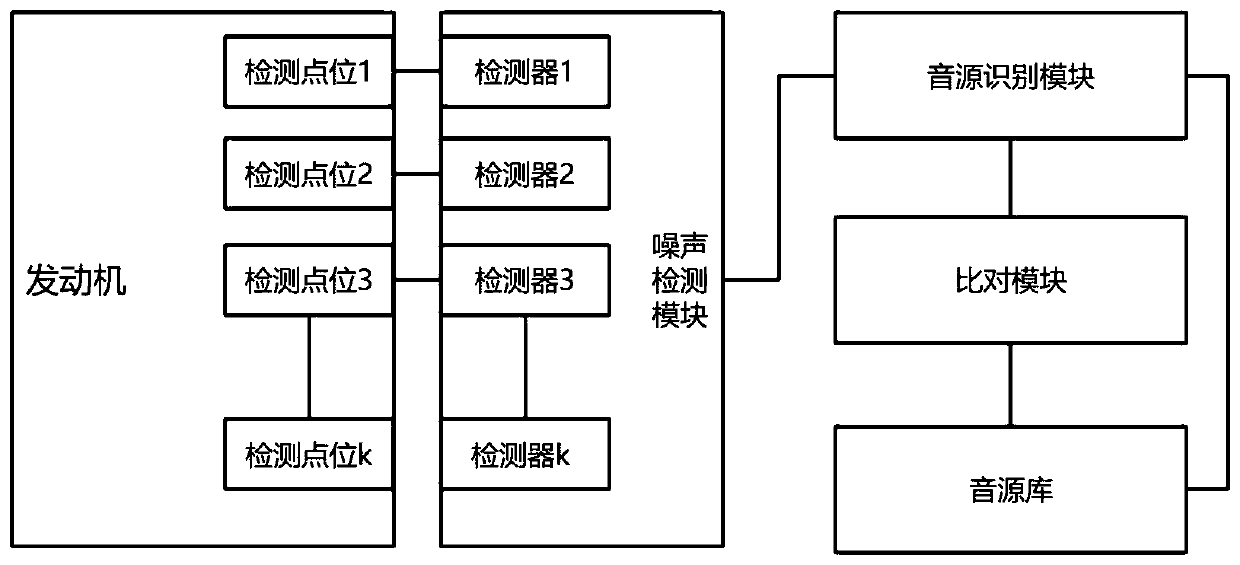

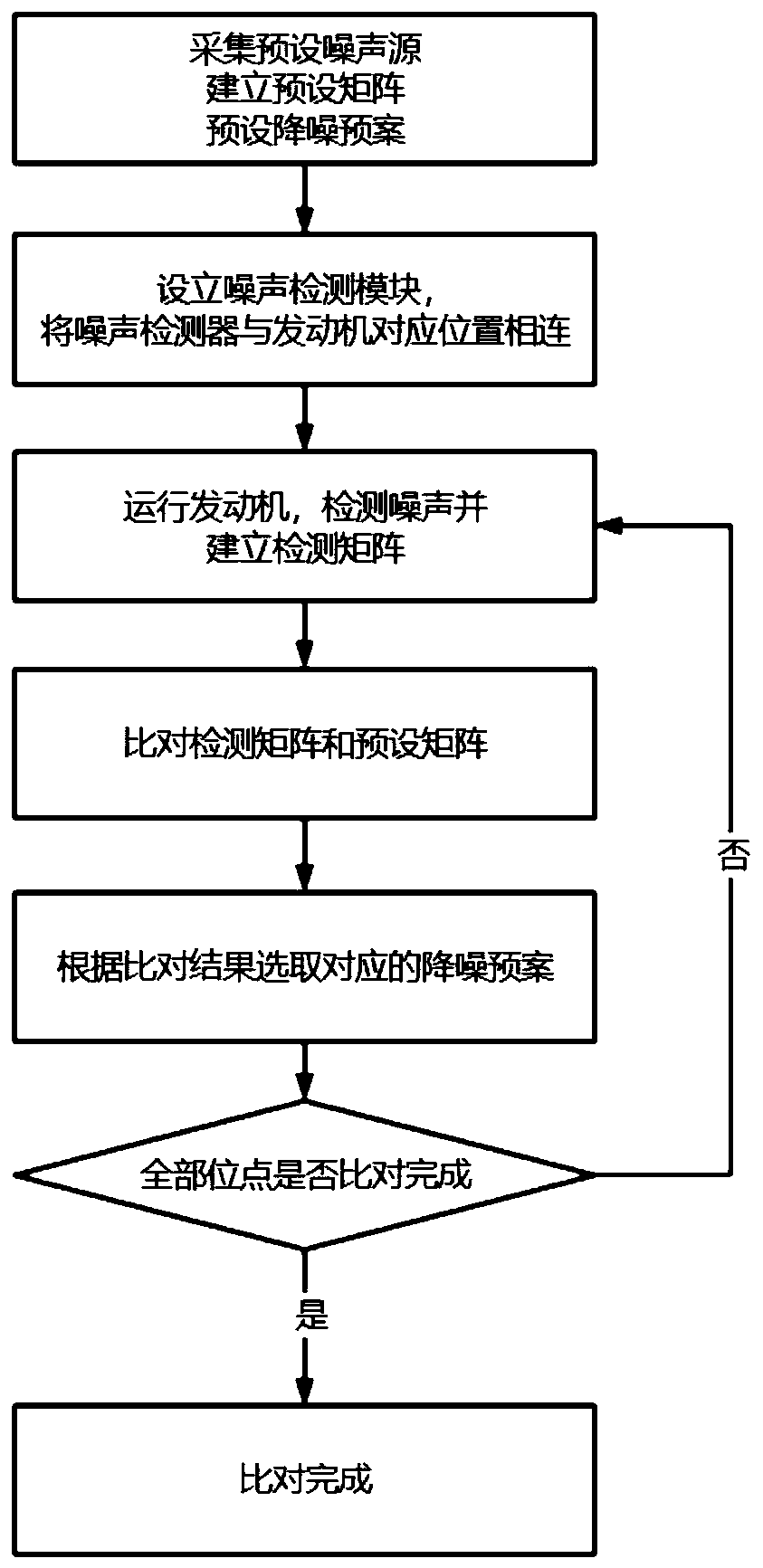

Generator set shock absorption and noise reduction method based on noise source recognition

ActiveCN111243613AImprove shock absorption efficiencyComprehensive detectionSpeech analysisSound sourcesNoise detection

The invention relates to a generator set shock absorption and noise reduction method based on noise source recognition. The method comprises the steps that a preset noise source is collected, a presetmatrix is established, and a noise reduction plan is preset; a noise detection module is arranged, and a noise monitor is connected with the corresponding position of the generator set; operating thegenerator set, detecting noise and establishing a detection matrix; comparing the detection matrix with a preset matrix; and selecting a corresponding noise reduction plan according to the detectionresult. According to the invention, different types of standard noise sources are pre-recorded; taking the noise source as a judgment reference; according to the method, the preset matrix is set to store the specified parameters in the noise into the sound source library, the types of the detected noise can be accurately judged by sequentially comparing the detected noise with the preset noise, the specific noise reduction method is used in a targeted mode according to the types of the noise, and the shock absorption efficiency of the method on the generator set can be effectively improved.

Owner:福建省煜坤强威电机有限公司

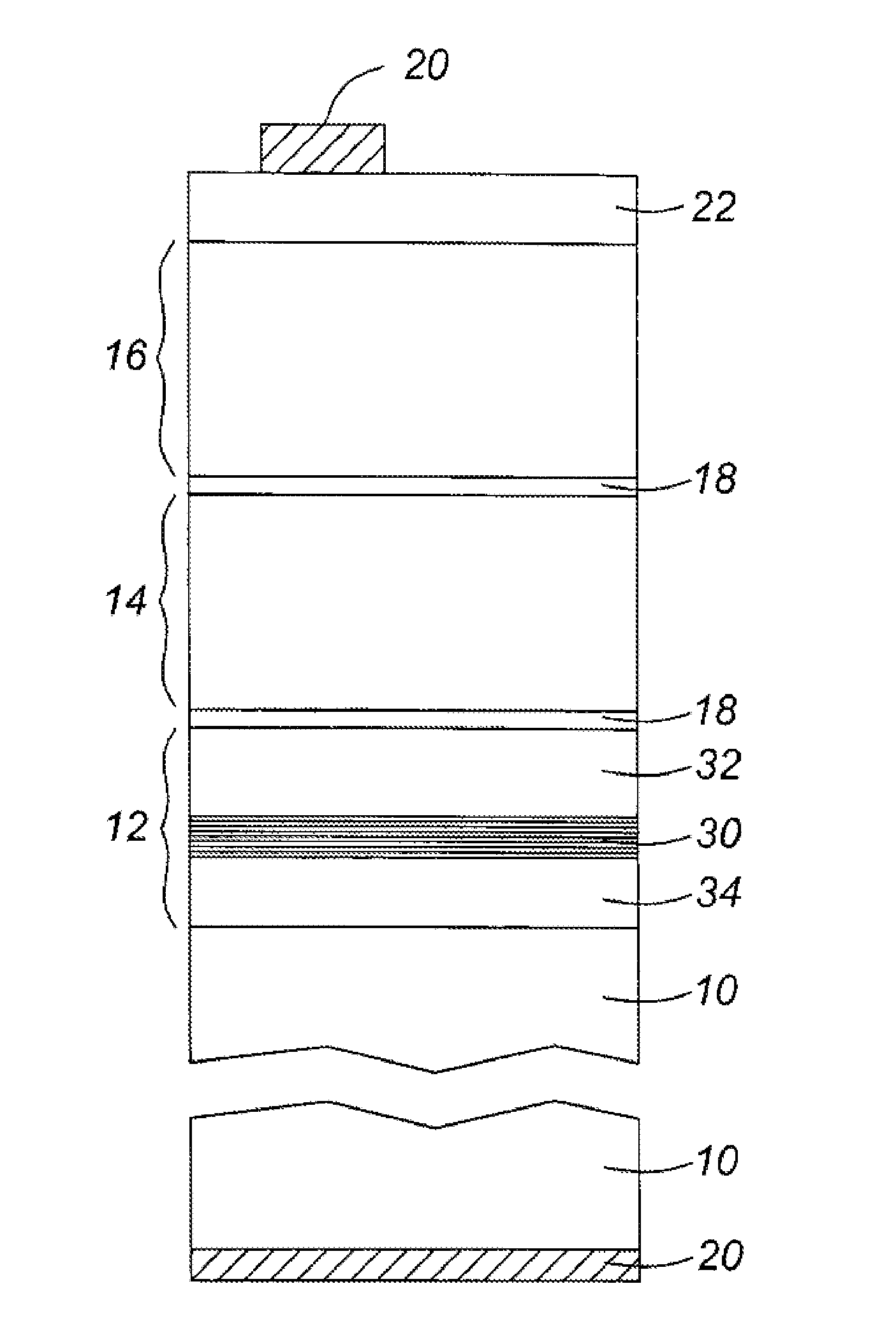

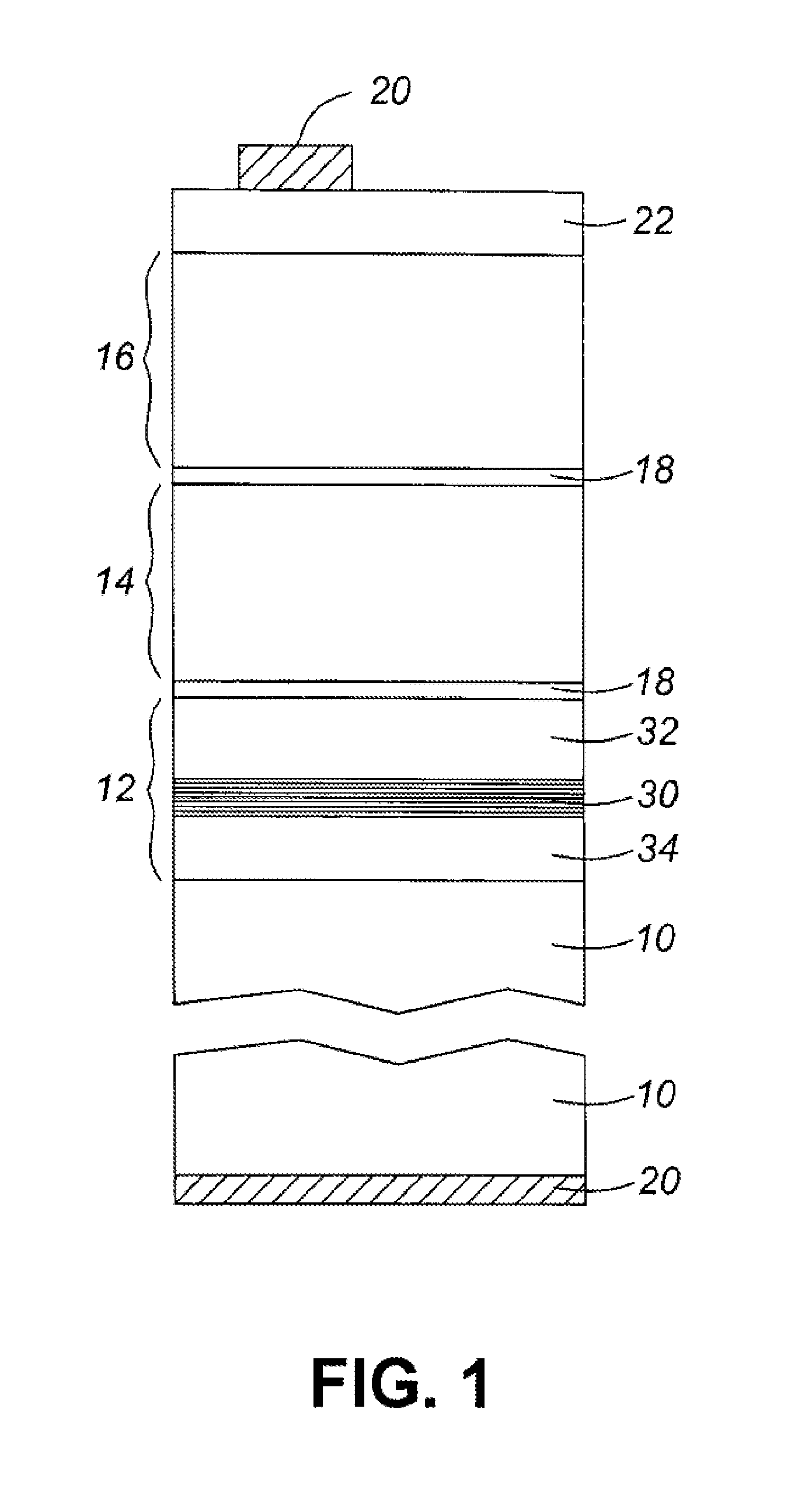

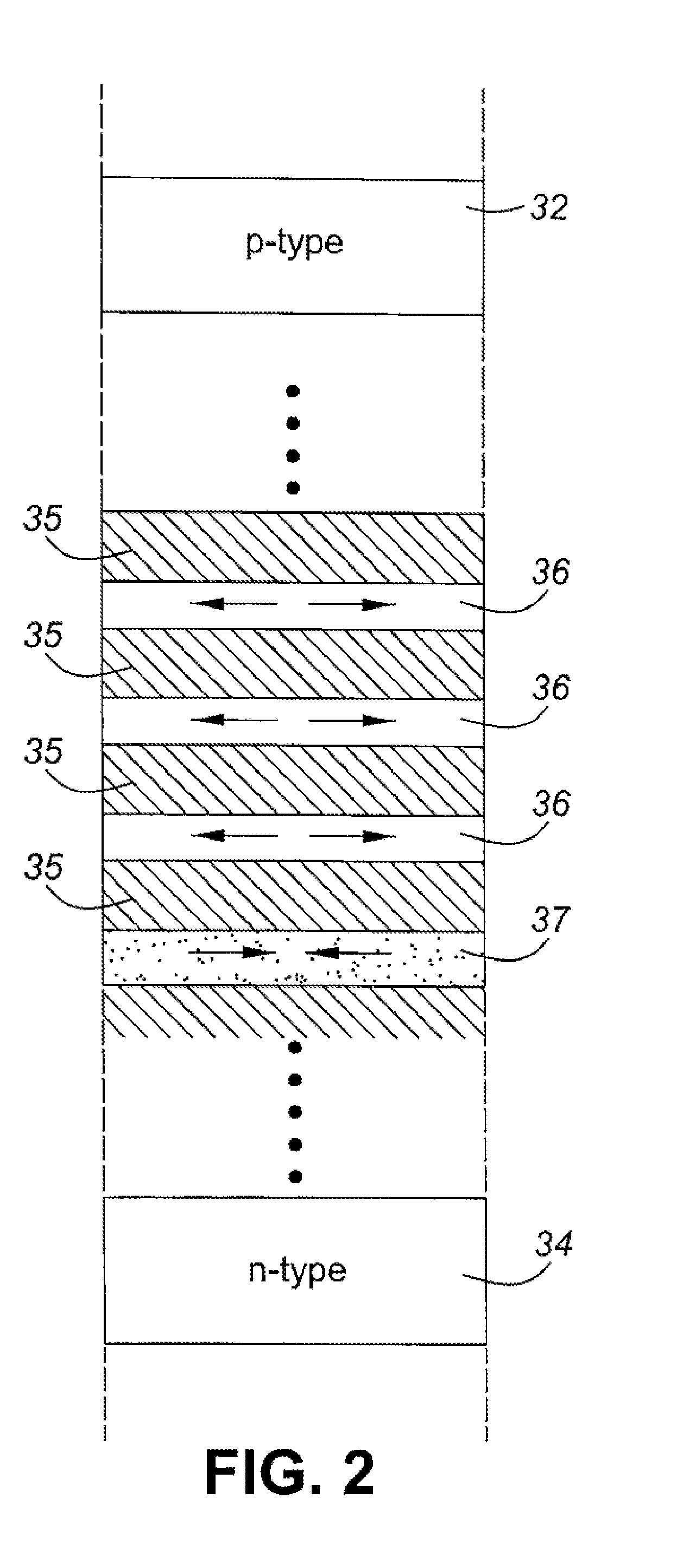

Photovoltaic junction for a solar cell

ActiveUS20130269760A1Reducing degree of shiftLong wavelengthSemiconductor/solid-state device manufacturingNanoopticsPhysicsStatic force

A photovoltaic junction for a solar cell is provided. The photovoltaic junction has an intrinsic region comprising a multiple quantum well stack formed from a series of quantum wells separated by barriers, in which the tensile stress in some of the quantum wells is partly or completely balanced by compressive stress in the others of the quantum wells. The overall elastostatic equilibrium of the multiple quantum well stack may be ensured by engineering the structural and optical properties of the quantum wells only, with the barriers having the same lattice constant as the materials used in the oppositely doped semiconductor regions of the junction, or equivalently as the actual lattice size of the junction or intrinsic region, or the bulk or effective lattice size of the substrate. Alternatively, the barriers may contribute to the stress balance.

Owner:LUMENTUM OPERATIONS LLC

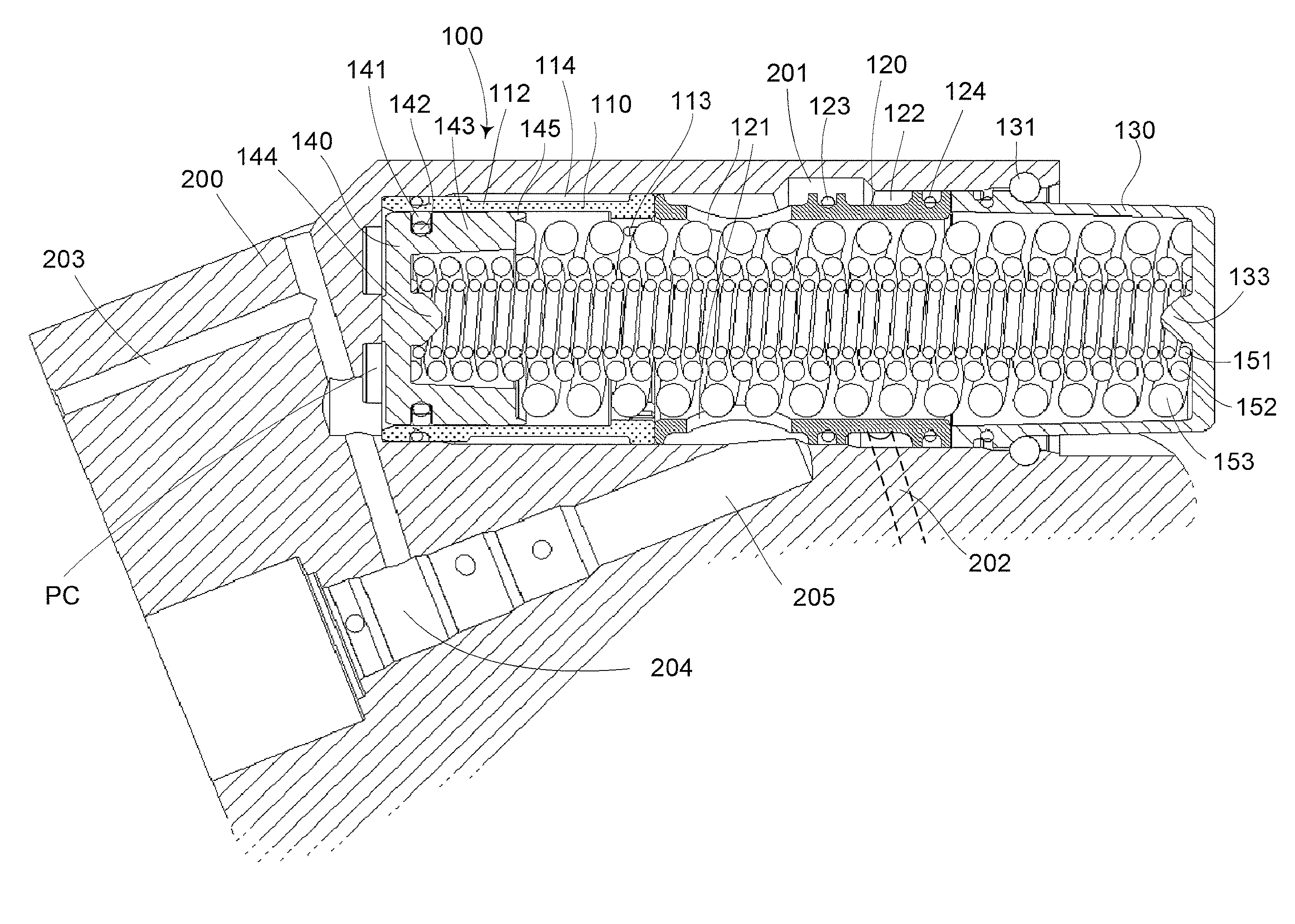

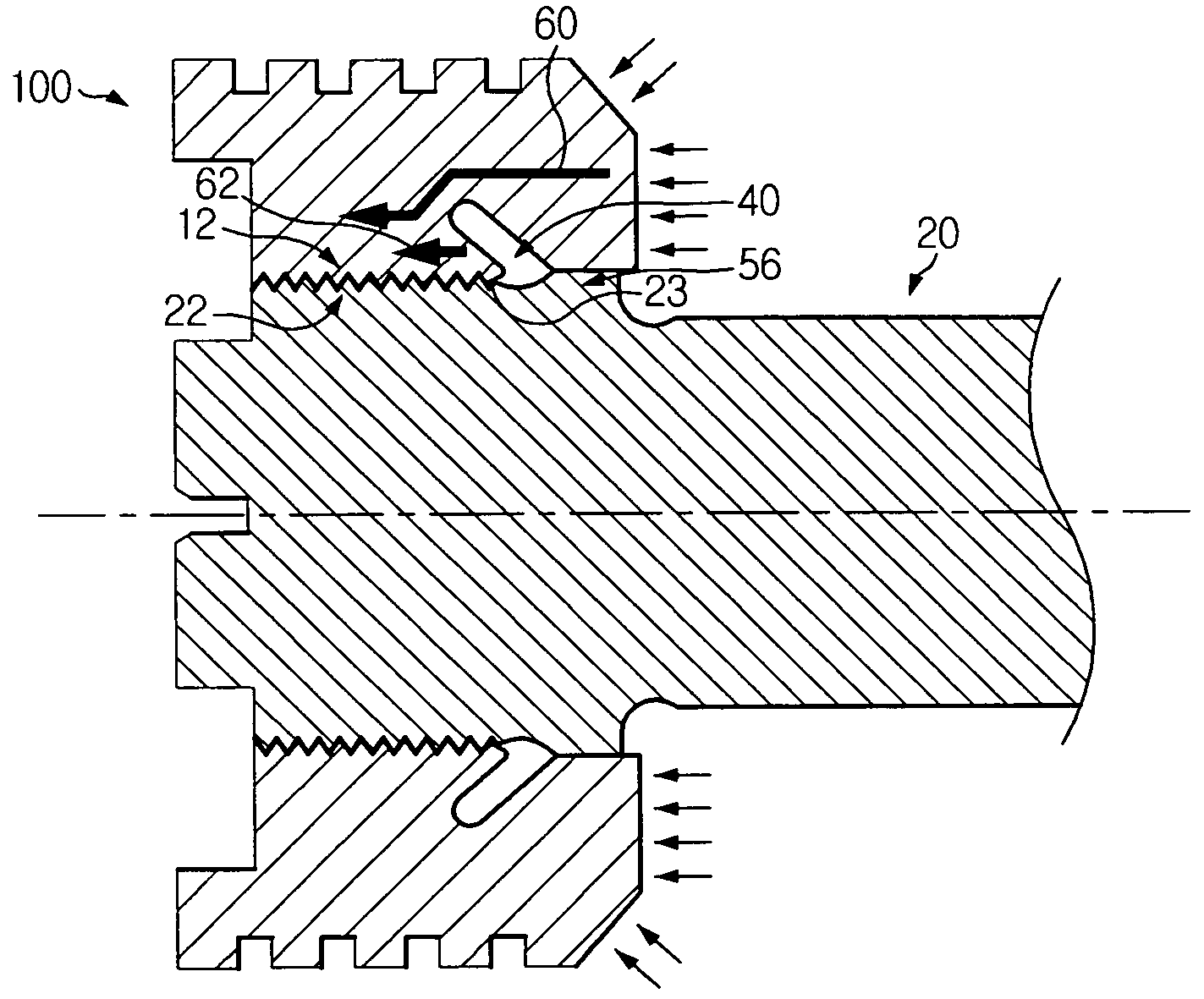

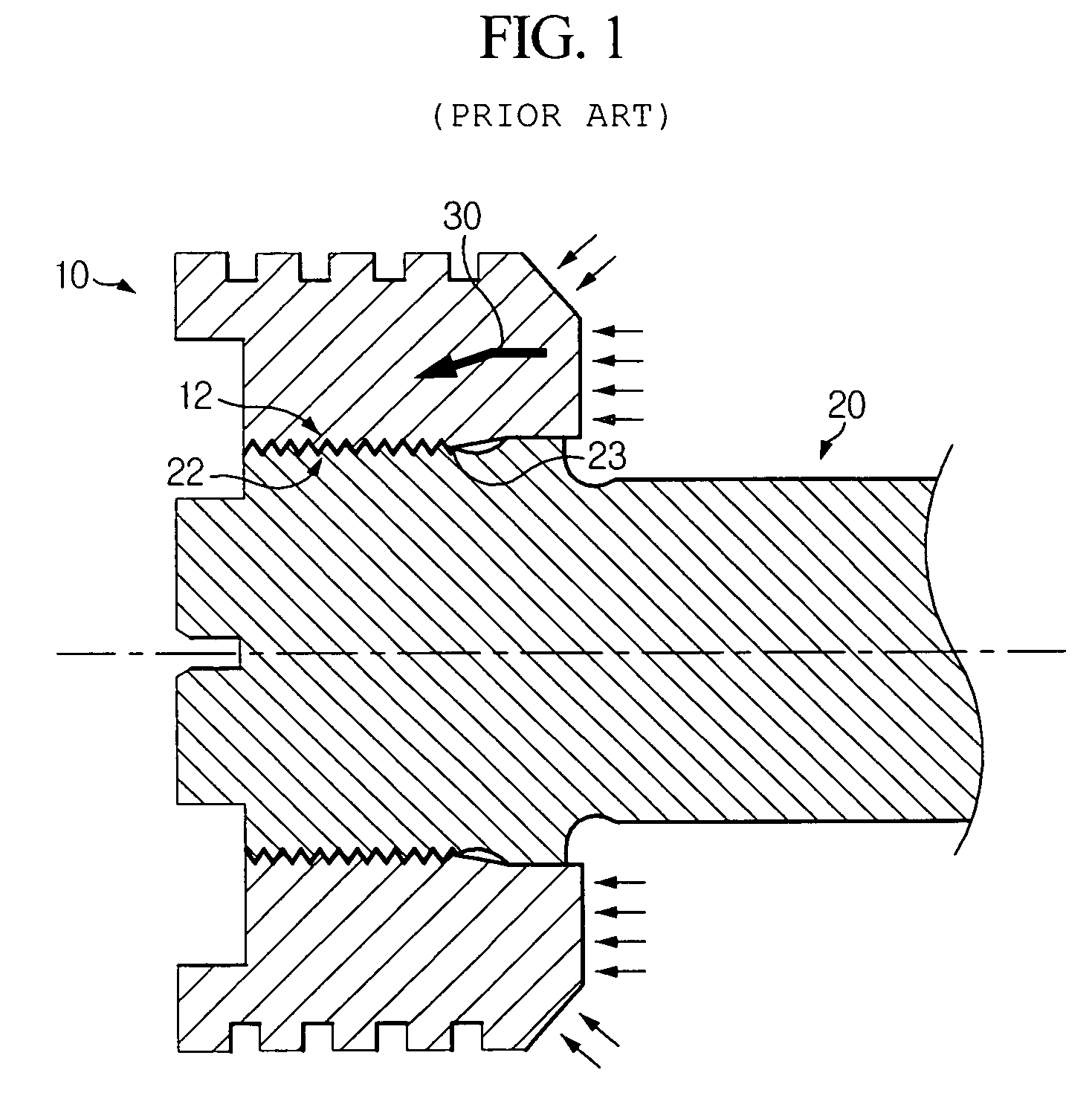

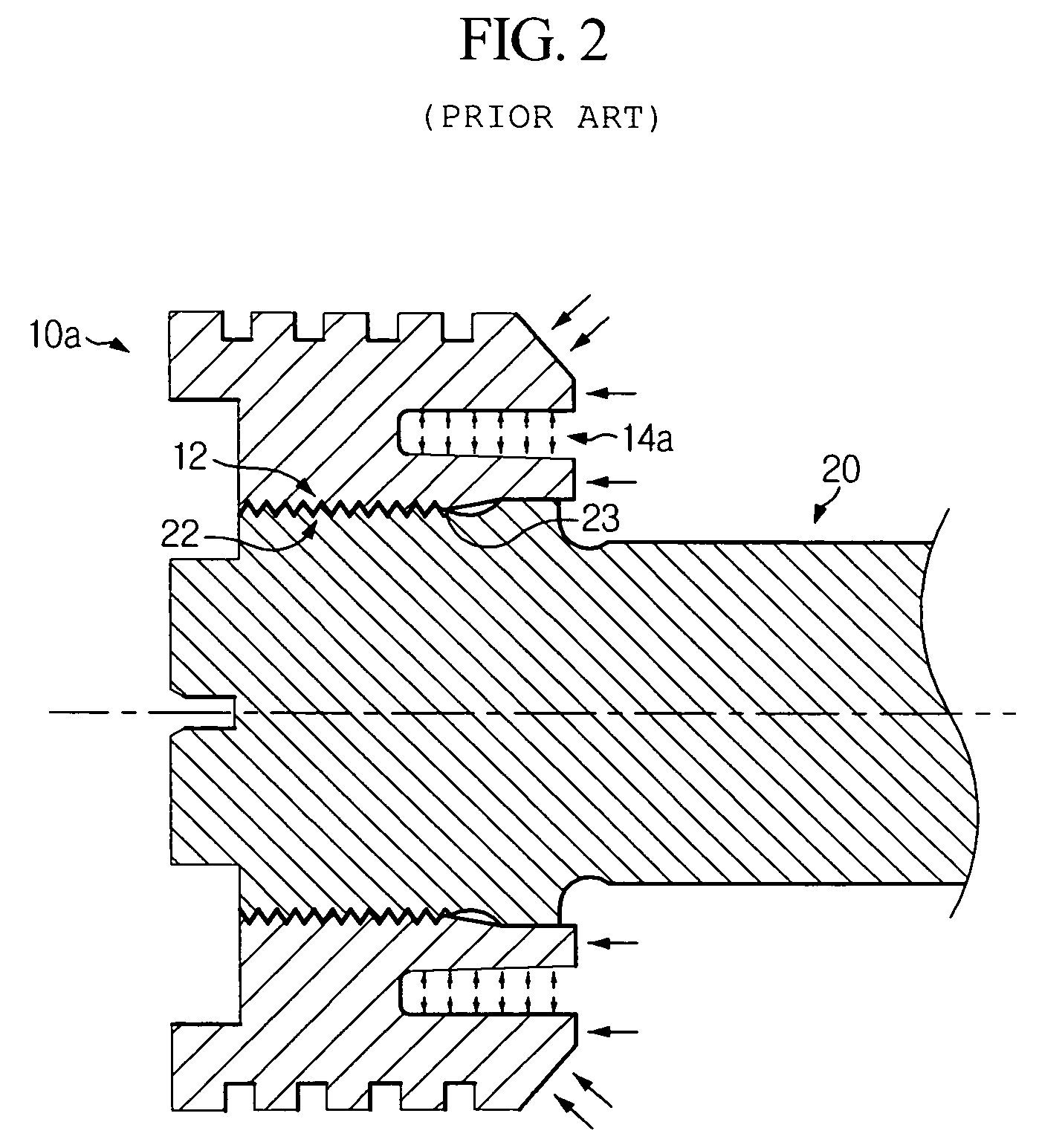

Piston head for hydraulic injection molding machine

ActiveUS7513191B2Reduce maximum pressurePrevent inflowPlungersPipe elementsHydraulic cylinderEngineering

Owner:LS MTRON LTD

Cooling device and cooling method for engine

A cooling device for an engine includes a radiator route passing through a radiator, that are merged together after being branched on the downstream side from the inside of the engine in a coolant circuit configured to allow a coolant to flow from a pump through the inside of the engine and return to the pump. An at-stop control section provided in the cooling device controls a multiway valve that has three discharge ports, including a radiator port connected to the radiator route, so as to close the radiator port and open at least one of the other discharge ports when an ignition switch is turned off.

Owner:TOYOTA JIDOSHA KK

Variable compression ratio apparatus

InactiveUS7966980B2Reduce maximum pressureSmall sizeEngine controllersMachines/enginesRotational axisCombustion chamber

A variable compression ratio apparatus that changes the compression ratio of an air-fuel mixture in a combustion chamber according to a driving state of an engine, enablements may include a connecting rod receiving the combustion force from the piston; a pin link receiving a part of the combustion force from the connecting rod and rotating the crankshaft; a support link disposed substantially in parallel with the connecting rod; a division link receiving a part of the combustion force from the connecting rod and transmitting the part of the combustion force to the support link; a control link provided with one end coupled to the division link in order to change position of one end of the division link; and an eccentric camshaft coupled to other end of the control link in order to change position of a rotational axis of the control link.

Owner:HYUNDAI MOTOR CO LTD

Fly capable slider test socket

ActiveUS20120008226A1Reduce maximum pressurePrevent rotationDisposition/mounting of recording headsRecord information storageHard disc driveSingle support

The present application is directed to a slider supporting apparatus for flying a slider of a hard disk drive in the manufacturing process to provide electrical performance characteristics. The present invention discloses an integrated design including the electrical interconnect, the gimballing mechanism, the preload mechanism and the slider supporting mechanism integrated into a single supporting structure.

Owner:XYRATEX TECH LTD

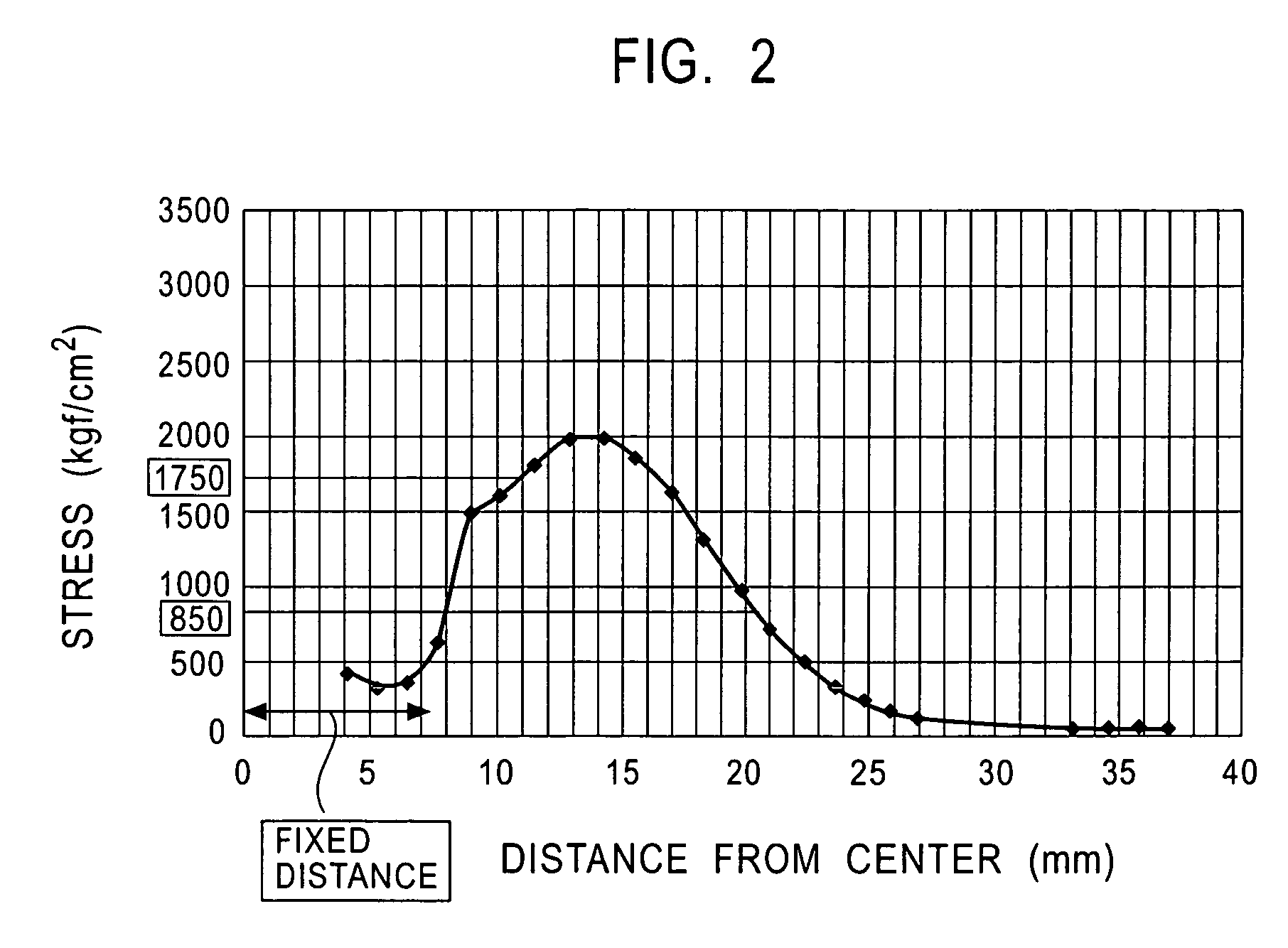

Load sensor

InactiveUS7077016B2Reduce maximum pressureReduce the cross-sectional areaPedestrian/occupant safety arrangementUsing electrical meansEngineeringStrain sensor

A load sensor includes a resilient member including a stationary segment, a load-receiving segment extending outward from the stationary segment, and an arm segment between the load-receiving segment and the stationary segment. Moreover, first and second strain-sensor elements are disposed on the same surface of the arm segment. The first strain-sensor element is adjacent to the load-receiving segment and the second strain-sensor element is adjacent to the stationary segment. The arm segment is tapered such that the cross-sectional area of the arm segment decreases from the stationary segment to the load-receiving segment. The narrowest portion of the arm segment has the first strain-sensor element disposed thereon. Accordingly, when a load generated by an impact is applied to the load-receiving segment, the maximum stress is reduced, and moreover, a difference between a stress applied to the first strain-sensor element and a stress applied to the second strain-sensor element is minimized.

Owner:ALPS ALPINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com