Radial sliding bearing

A radial sliding, bearing technology, applied in the directions of bearings, bearing components, shafts and bearings, etc., can solve the problem of peak pressure increase in the load-bearing area, the minimum critical safety speed of oil film thickness, the difficulty of installation of block tilting guide bearings, and the difficulty of oil film. Problems such as high peak pressure, to achieve the effect of simple assembly, reducing the maximum pressure, and increasing the thickness of the oil film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

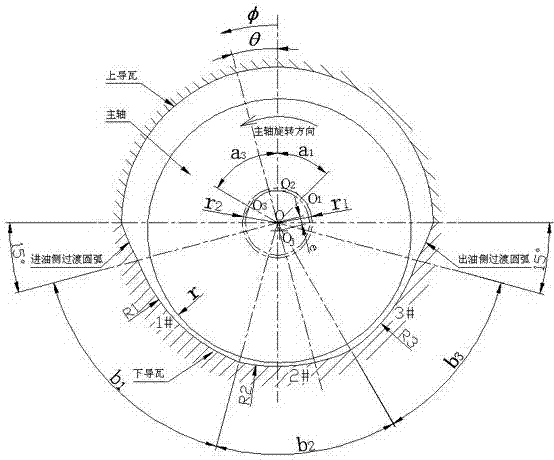

[0023] combined with figure 1 Further explanation: During the operation of the unit, there is a vertical downward load on the main shaft. When the radial sliding bearing reaches static stability, the main shaft will deviate from the center of the bearing. Three independent and connected wedge-shaped oil films are produced between them, and the film thickness equations of these three oil films are:

[0024] the

[0025] the

[0026] the

[0027] The bearing oil film area of this bearing is: , it can be obtained that the expression of the bearing oil film thickness is:

[0028] the Time:

[0029] the Time:

[0030] the Time:

[0031] The equation characterizing the oil film pressure distribution characteristics of hydrodynamic lubricated sliding bearings is the Reynolds equation. The Reynolds equation of this bearing is as follows:

[0032] the

[0033] In the formula, is the oil density, is the dynamic viscosity of lubricating oil, is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com