Patents

Literature

89results about How to "Meet load-bearing requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

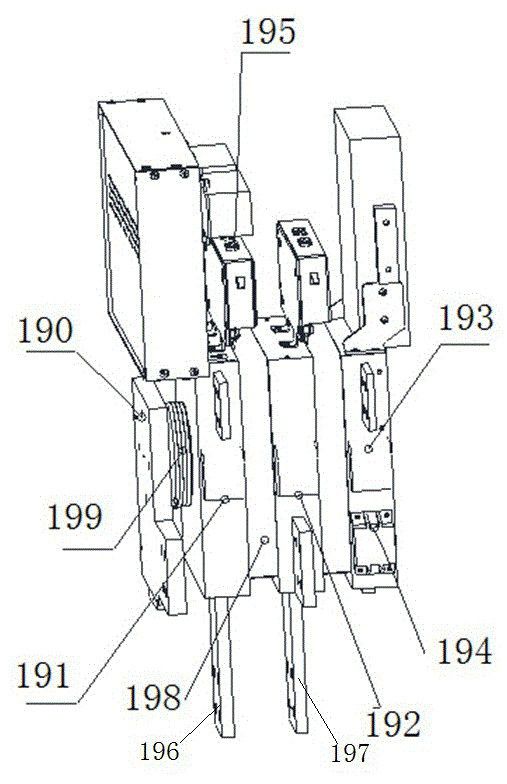

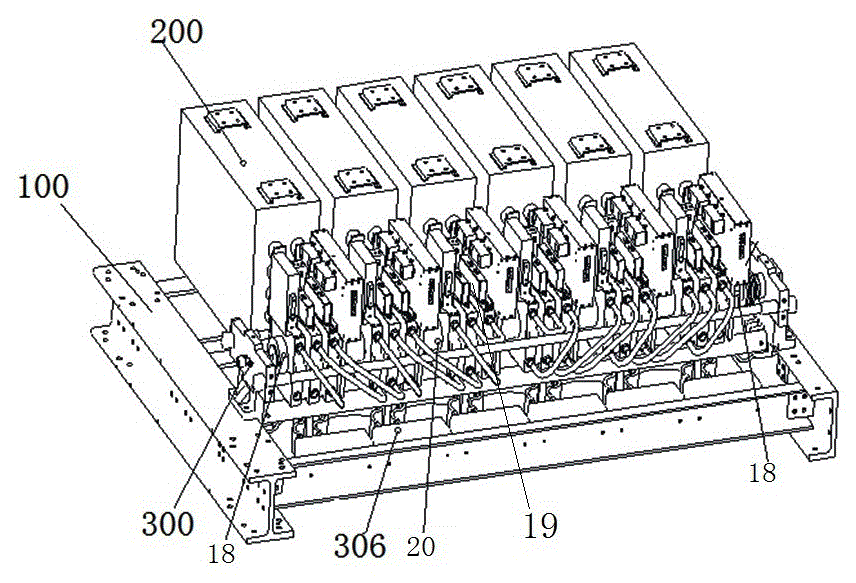

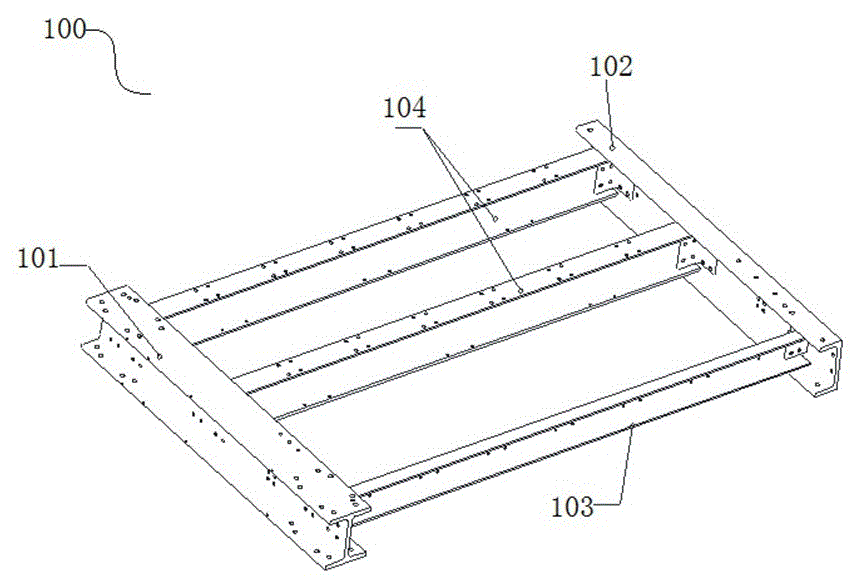

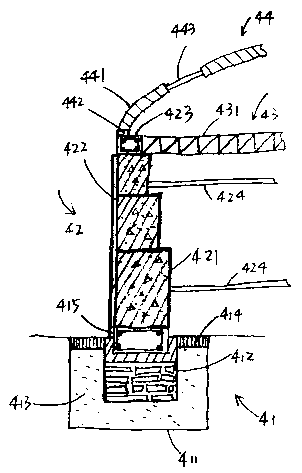

Converter valve component used for flexible DC power transmission and IGBT submodules thereof

ActiveCN105006474AImprove reliabilityExtended service lifeSemiconductor/solid-state device detailsSolid-state devicesThyratronComputer module

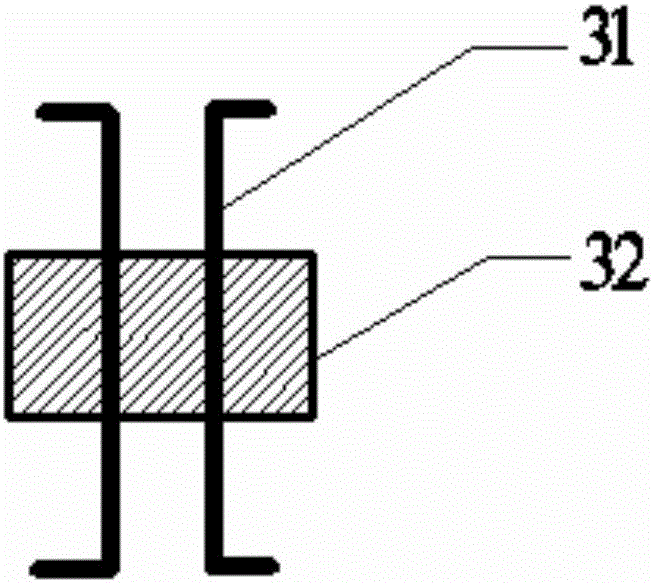

The invention provides a converter valve component used for flexible DC power transmission and IGBT submodules thereof. The converter valve component comprises an installing framework. A submodule crimping unit is fixedly arranged at the front part of the installing framework. The submodule crimping unit comprises an intermediate framework and two end plates. The intermediate framework is provided with at least two submodules and inter-module insulating stop blocks which are arranged in a spacing way along a left-and-right direction in turn. The two end plates are provided with two clamping devices. Each submodule comprises two IGBTs, three heat radiators and one thyristor. The two IBGTs and the three heat radiators are arranged in turn along the left-and-right direction in a mutual spacing way. One thyristor is arranged at the external side of the rightmost heat radiator. The corresponding fitting surface of the thyristor is fixedly installed at the external side surface of the rightmost heat radiator. The right side of the thyristor is provided with a conductive aluminum bar which is used for being matched with the rightmost heat radiator so as to clamp the thyristor. Multiple submodules can be connected in series and crimped via the two clamping devices in the submodule crimping unit so that the crimping and fixing structure of the submodules in the overall converter valve component can be effectively simplified.

Owner:XJ ELECTRIC +1

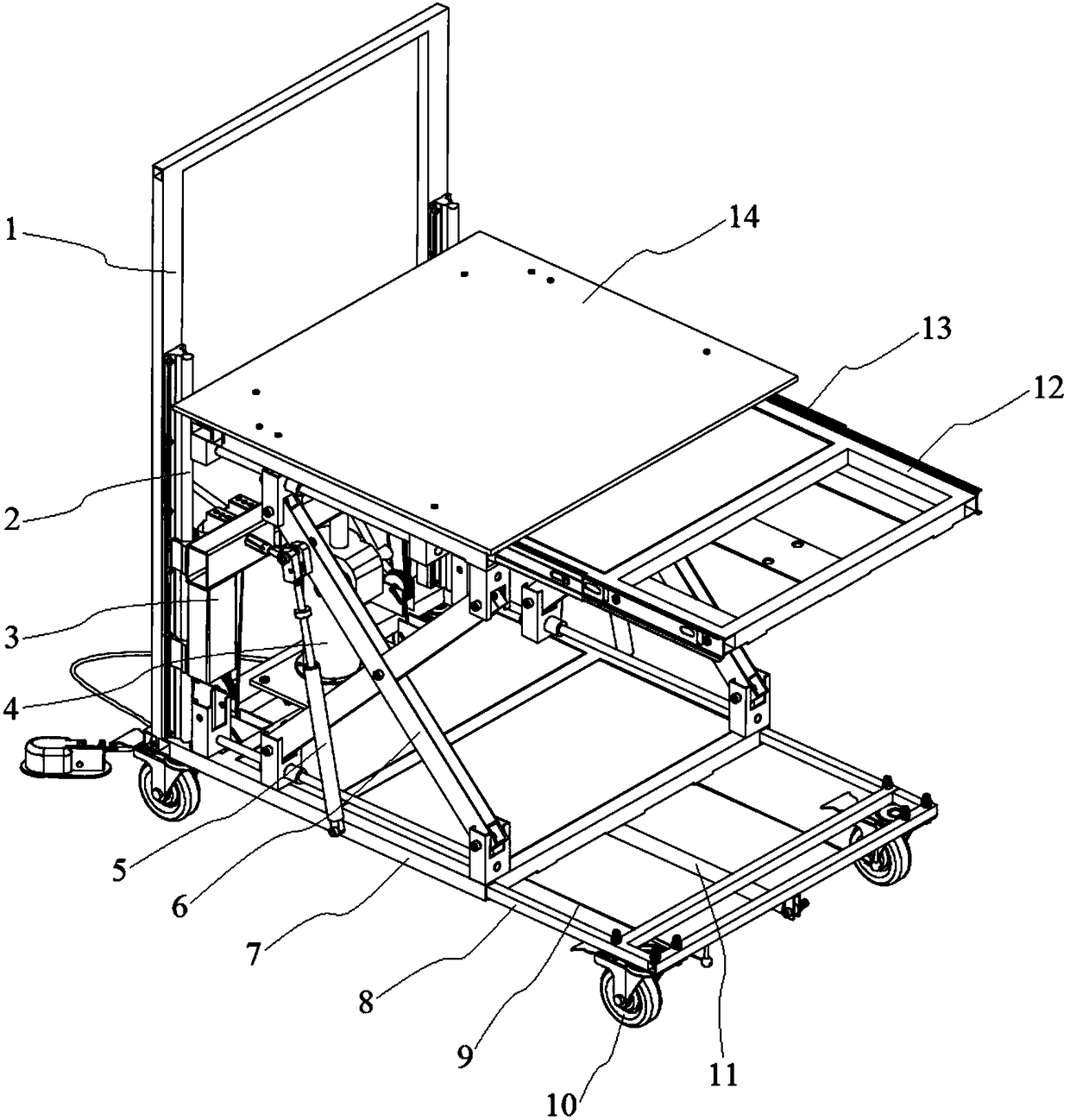

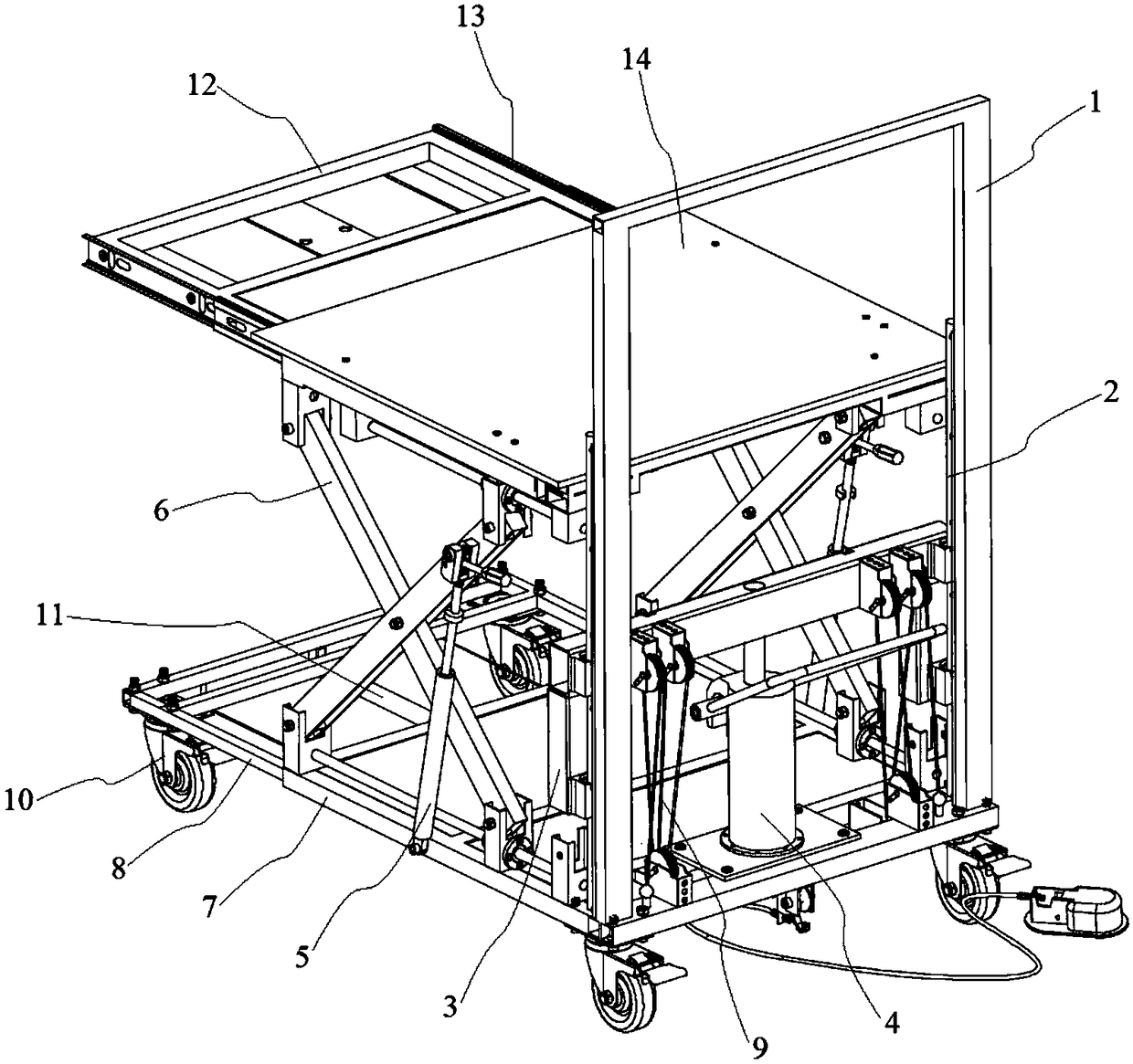

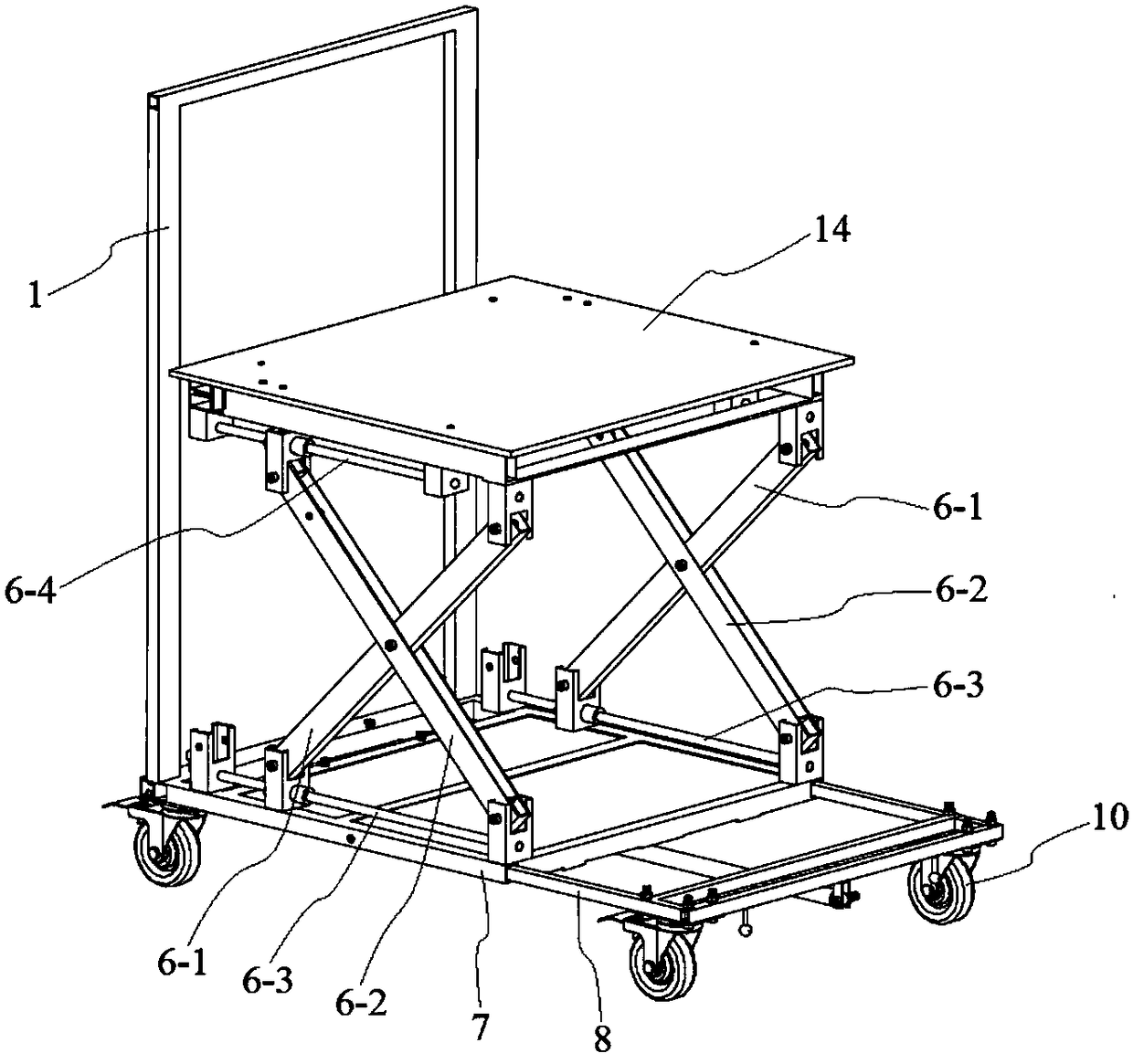

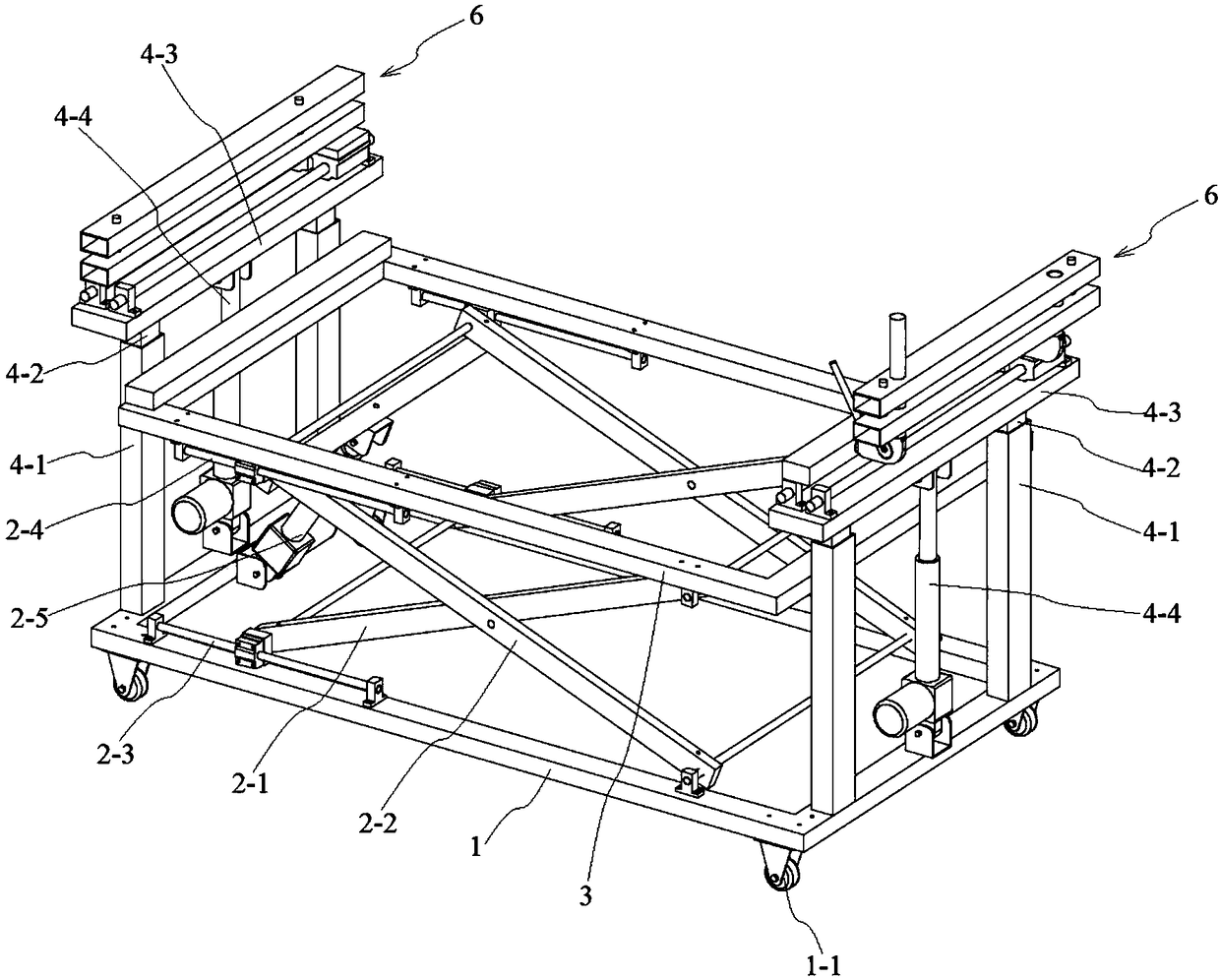

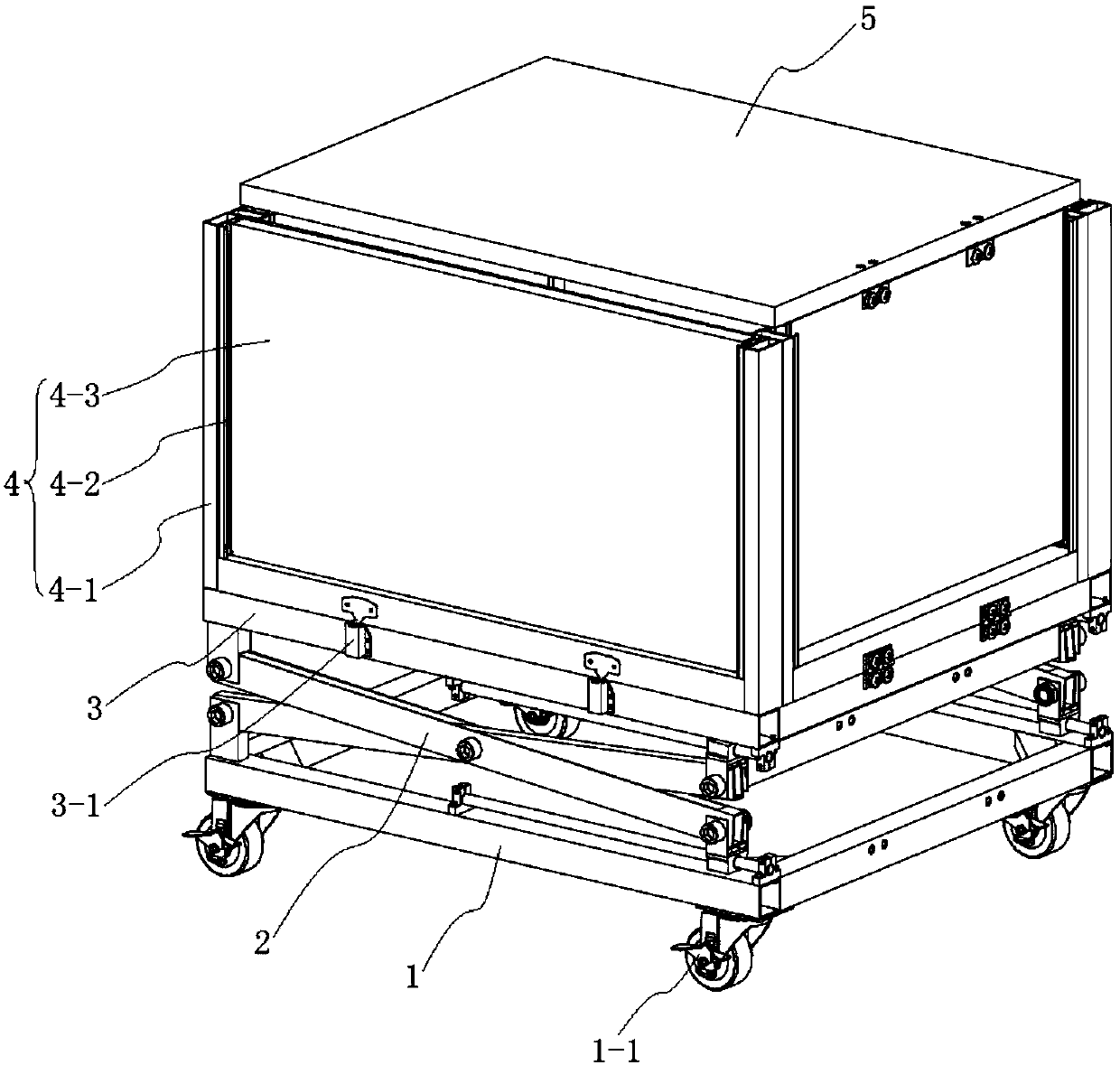

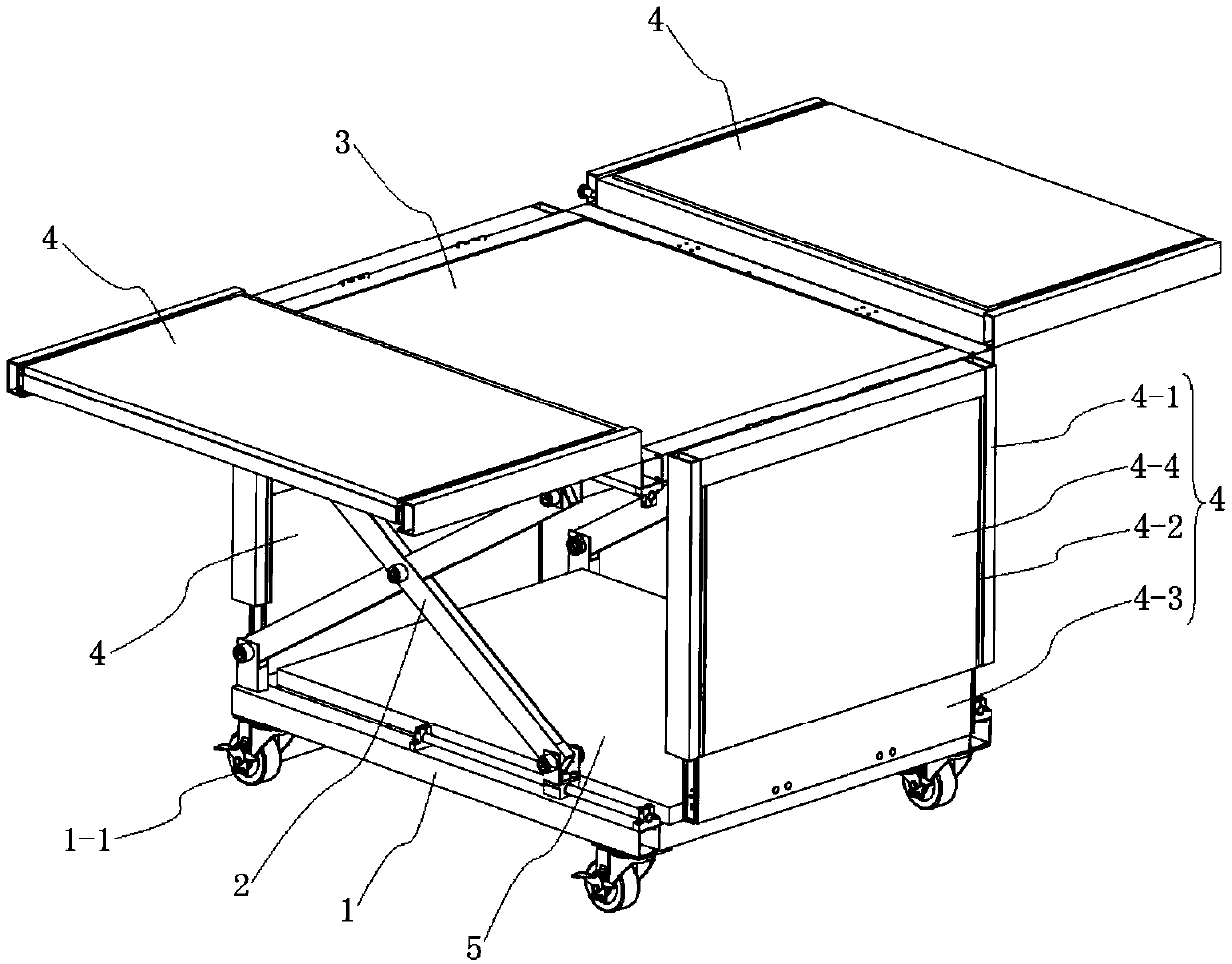

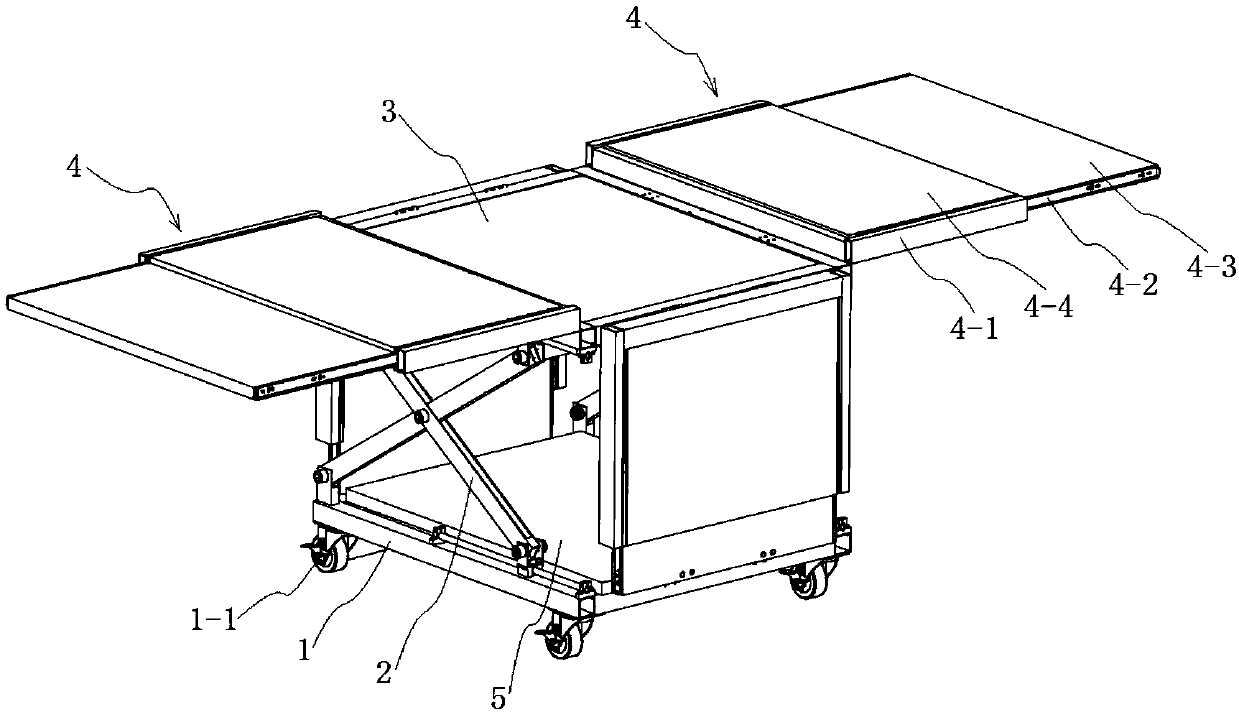

Multifunctional trolley with double-layer platform

ActiveCN108099980AIncrease loading capacityHarmonization of functionsLifting framesHand carts with multiple axesAir springEngineering

The invention discloses a multifunctional trolley with a double-layer platform, and belongs to the field of carrying tools. The trolley comprises an upper-layer platform body, a bottom-layer platformbody and a pushing hand, the pushing hand is fixed at the rear portion of the bottom-layer platform body, the upper-layer platform body is installed over the bottom-layer platform body through a scissor-type lifting mechanism, and the scissor-type lifting mechanism is further internally provided with an upper-layer locking air spring; the bottom-layer platform body comprises a bottom-layer platform fixing frame and a bottom-layer platform retractable frame which are retractably matched, the rear portion of the bottom-layer platform fixing frame and the front portion of the bottom-layer platform retractable frame are provided with rolling wheels, a bottom-layer retractable air spring for keeping the bottom-layer platform retractable frame elastically extending out is arranged between the bottom-layer platform fixing frame and the bottom-layer platform retractable frame, and the rear portion of the bottom-layer platform fixing frame is provided with a linkage mechanism for driving the bottom-layer platform retractable frame to retract back. By means of the trolley, the flexible use of the double-layer platform can be achieved; the loading capacity of the double-layer trolley is improved, and the trolley is flexible and convenient to use and easier to operate.

Owner:CHANGZHOU INST OF TECH

Critical-patient transfer bed with carrying function and application method thereof

The invention discloses a critical-patient transfer bed with a carrying function and an application method thereof and belongs to the field of medical equipment. The critical-patient transfer bed hasthe advantages that the critical-patient transfer bed is provided with a bed board which can ascend and descend and extend outwardly, sheet clamping mechanisms which can ascend and descend and extendoutwardly are arranged at the head and the tail of the transfer bed, the sheet clamping mechanism at one end has a turning function, a patient can be stably transferred between the transfer bed and ahospital bed by the coordination of the two sheet clamping mechanisms and the telescoping bed board, simple and reliable patient carrying is achieved, high carrying safety is achieved, the secondary damage problem during patient carrying is solved, and high carrying efficiency is achieved; in addition, first and second guard boards are arranged on two sides of an upper bed frame and can be horizontally spread to form expansion bed surfaces, the critical-patient transfer bed can be used as the hospital bed which can be used by the patient for a long time, and the critical-patient transfer bed is simple in structure, convenient to use, flexible to operate, low in manufacturing cost, good in market popularization value and the like.

Owner:CHANGZHOU INST OF TECH

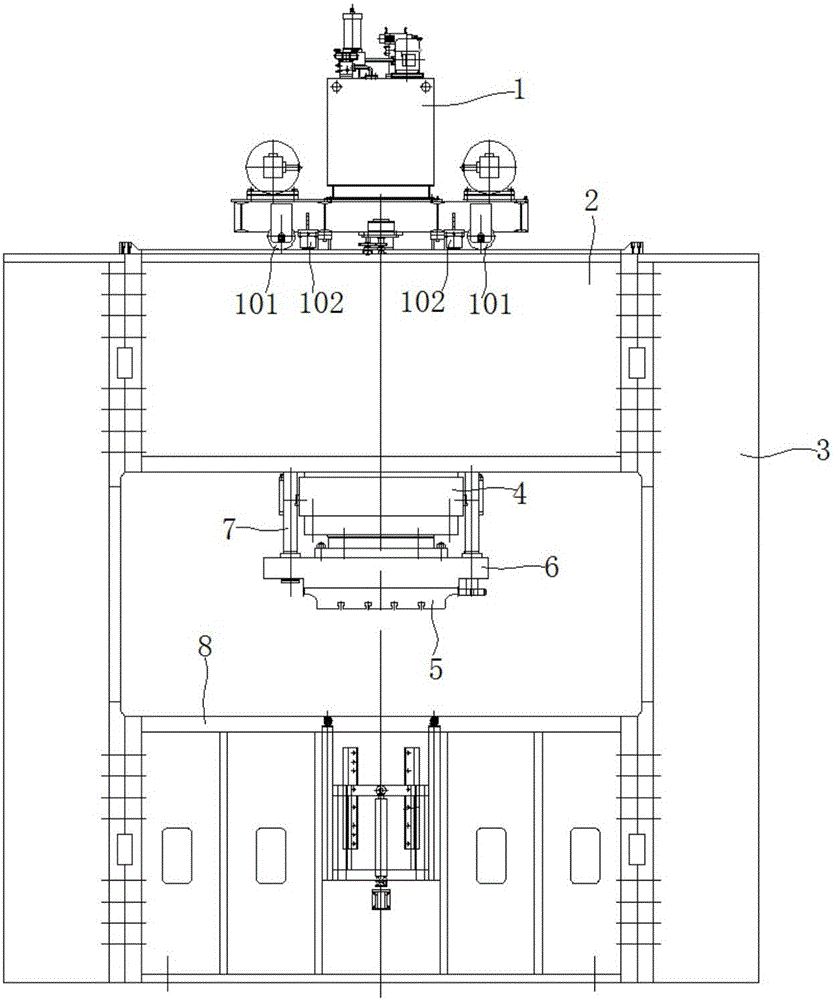

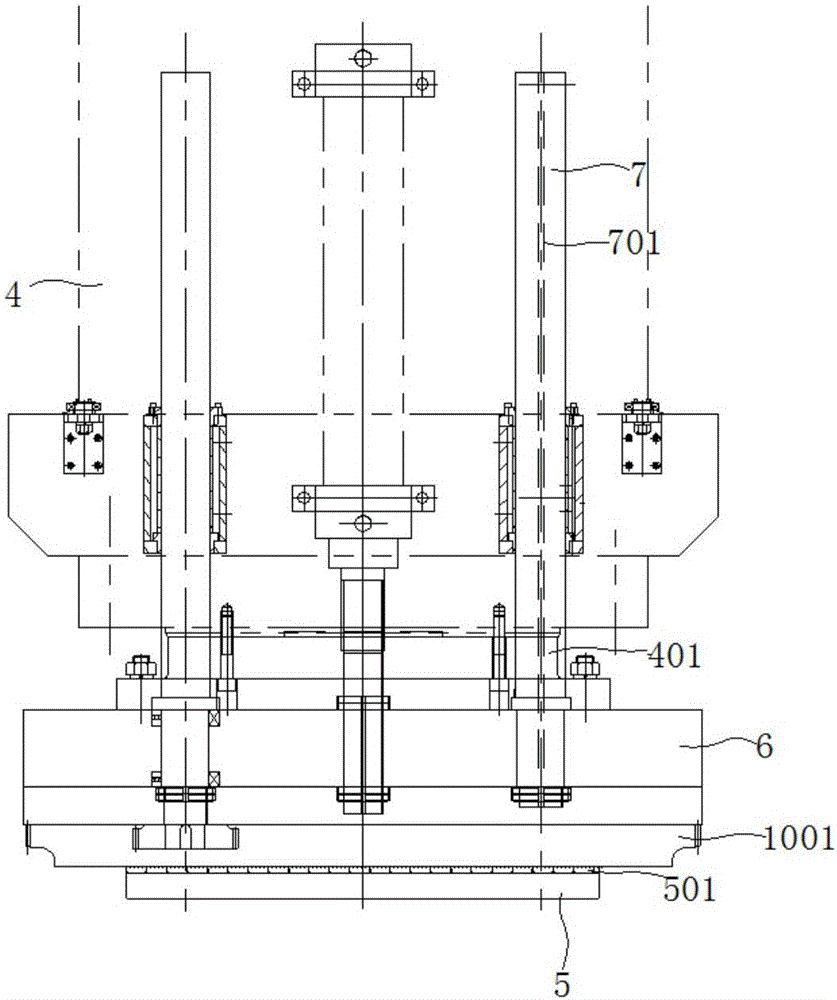

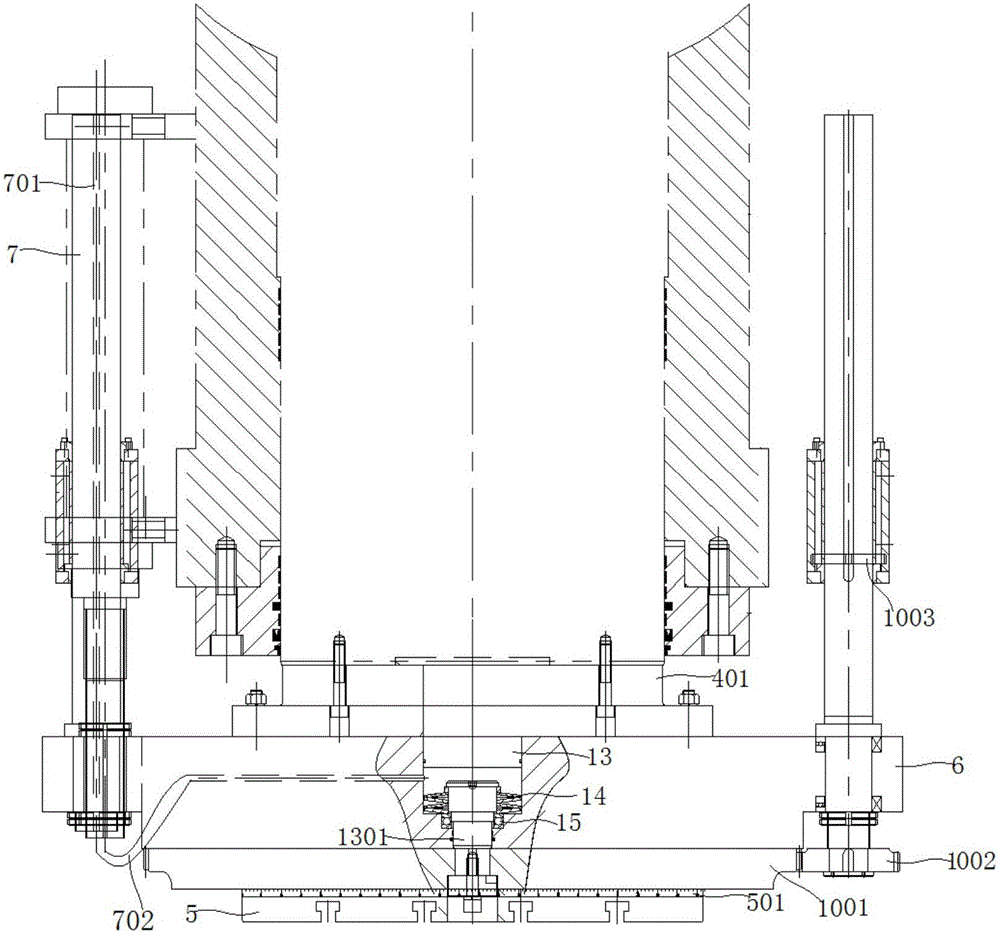

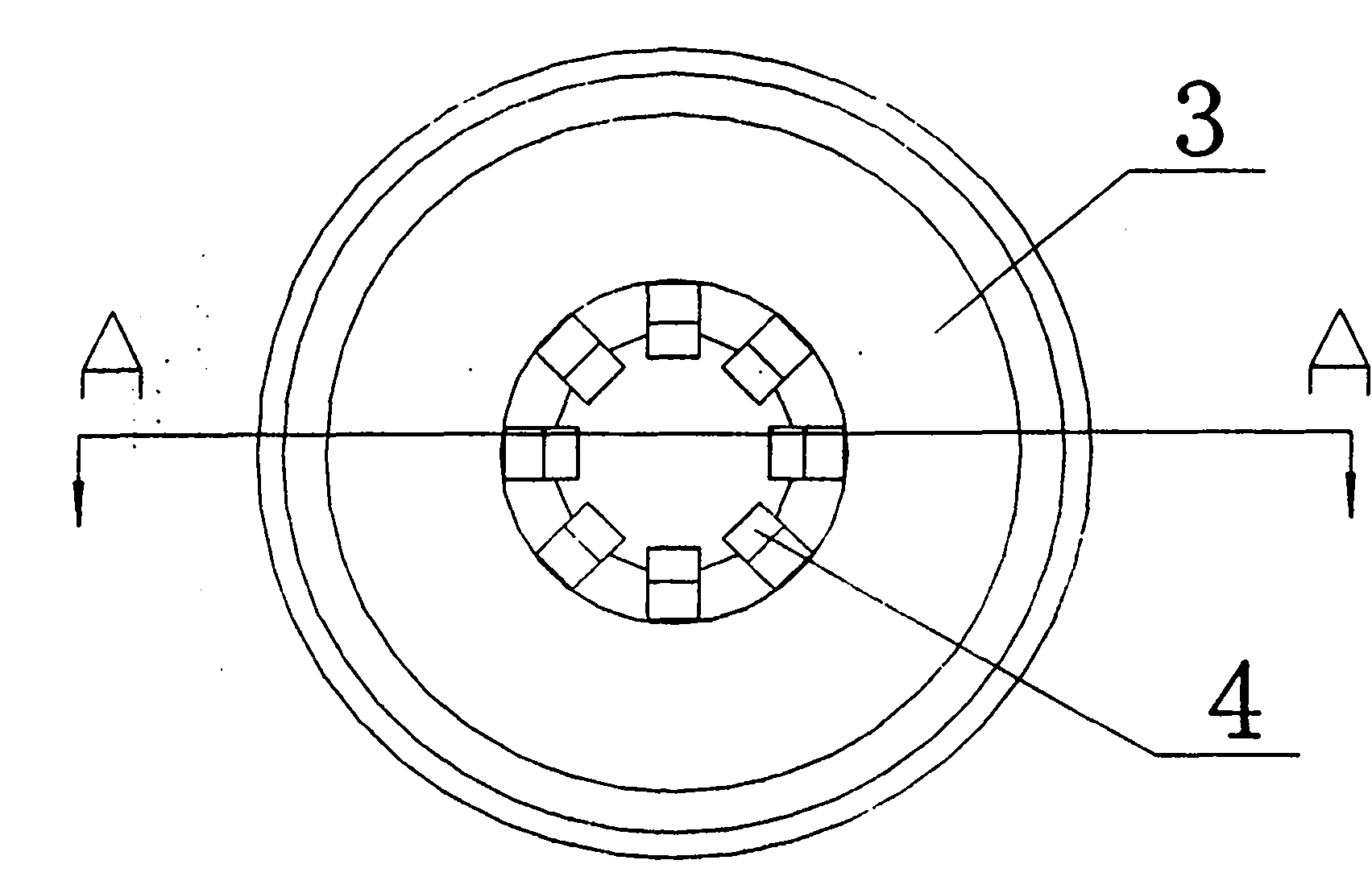

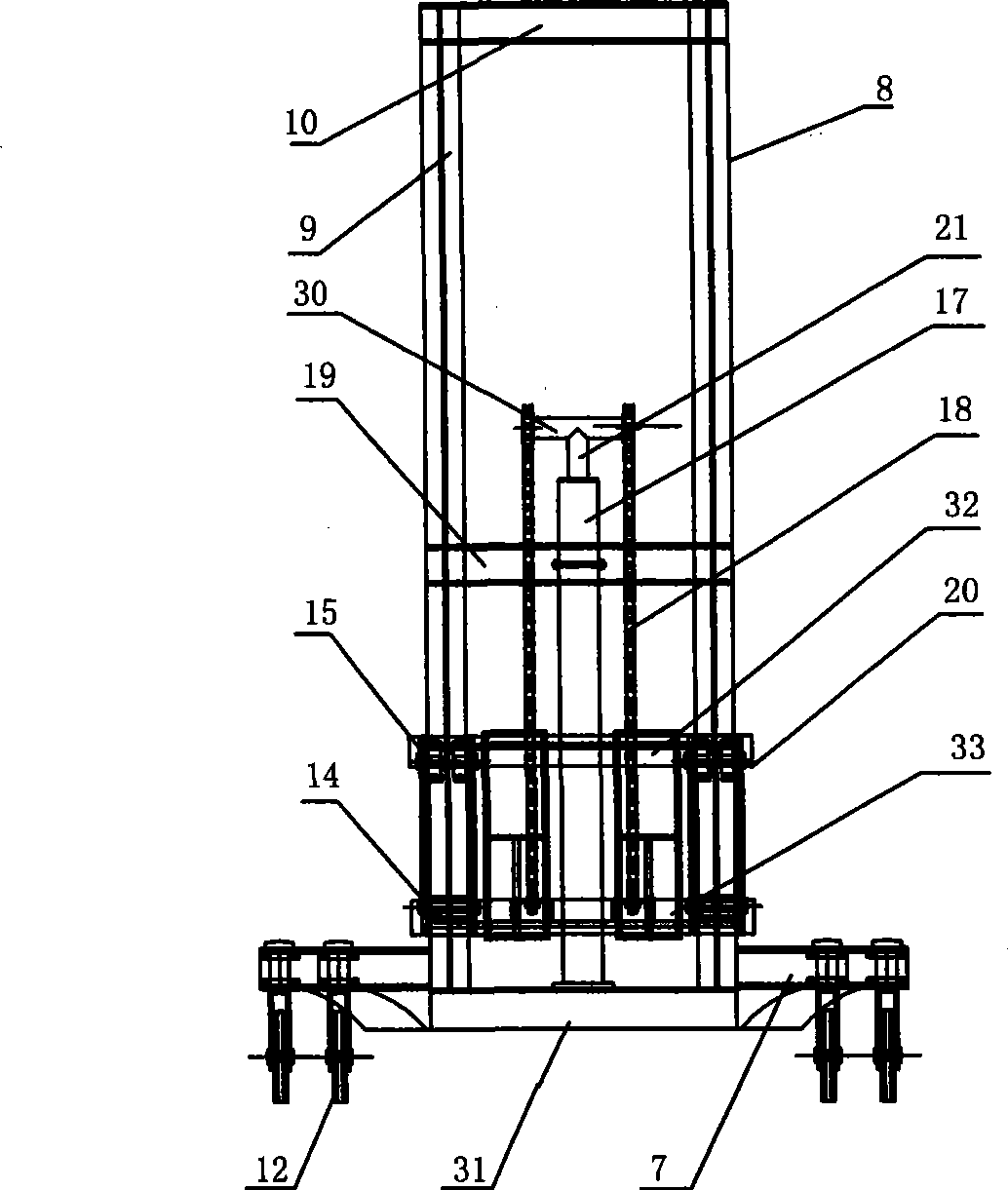

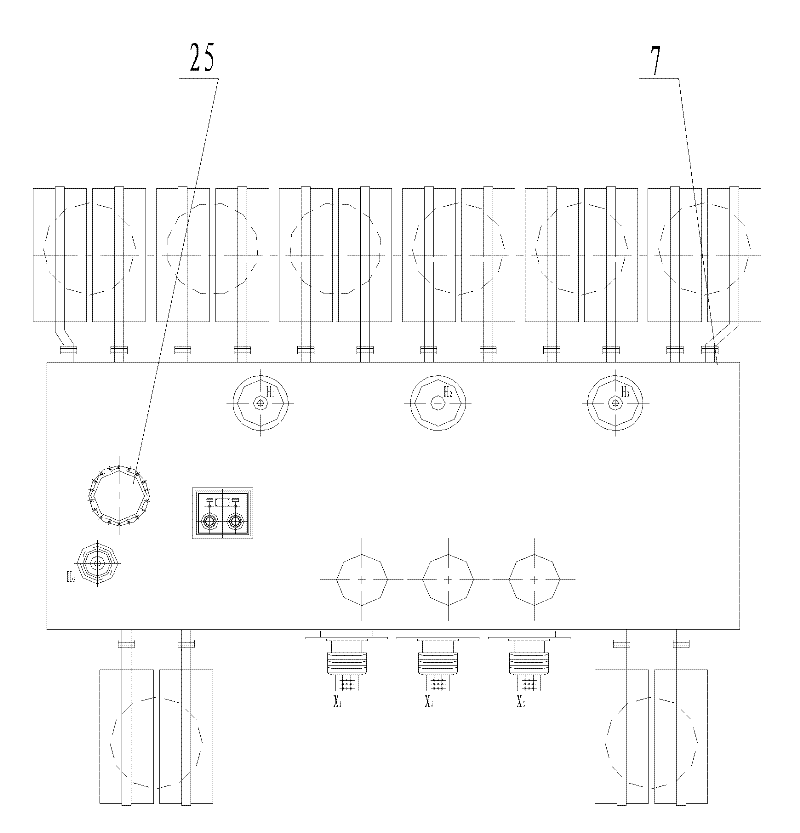

Large-tonnage rotation movement hydraulic machine

ActiveCN106003783AImprove machining accuracyIncrease productivityPress ramControl engineeringEngineering

The invention provides a large-tonnage rotation movement hydraulic machine, and belongs to the technical field of hydraulic machines. The large-tonnage rotation movement hydraulic machine comprises a hydraulic machine frame, a hydraulic station, a pressure head mechanism and a workbench, wherein the hydraulic machine frame comprises an upper beam, a lower beam and stand columns. The hydraulic station is located on the top of the hydraulic machine frame. The pressure head mechanism is hoisted below the hydraulic station. The workbench comprises a movement workbench and a rotation workbench, wherein the rotation workbench is located on an inner cavity of the movement workbench. Four travelling jack-up cylinders are symmetrically arranged below the movement workbench, three rotation jack-up cylinders which are evenly distributed are arranged below the rotation workbench in the circumferential direction of the rotation workbench, rolling wheels are arranged at the bottoms of the travelling jack-up cylinders, and rolling bearings are arranged between the rotation jack-up cylinders and the rotation workbench. The large-tonnage rotation movement hydraulic machine can be used for forming and machining large-tonnage plates, and the machining accuracy of the large-tonnage rotation movement hydraulic machine can be effectively guaranteed.

Owner:ANHUI DONGHAI MACHINE MFG CO LTD

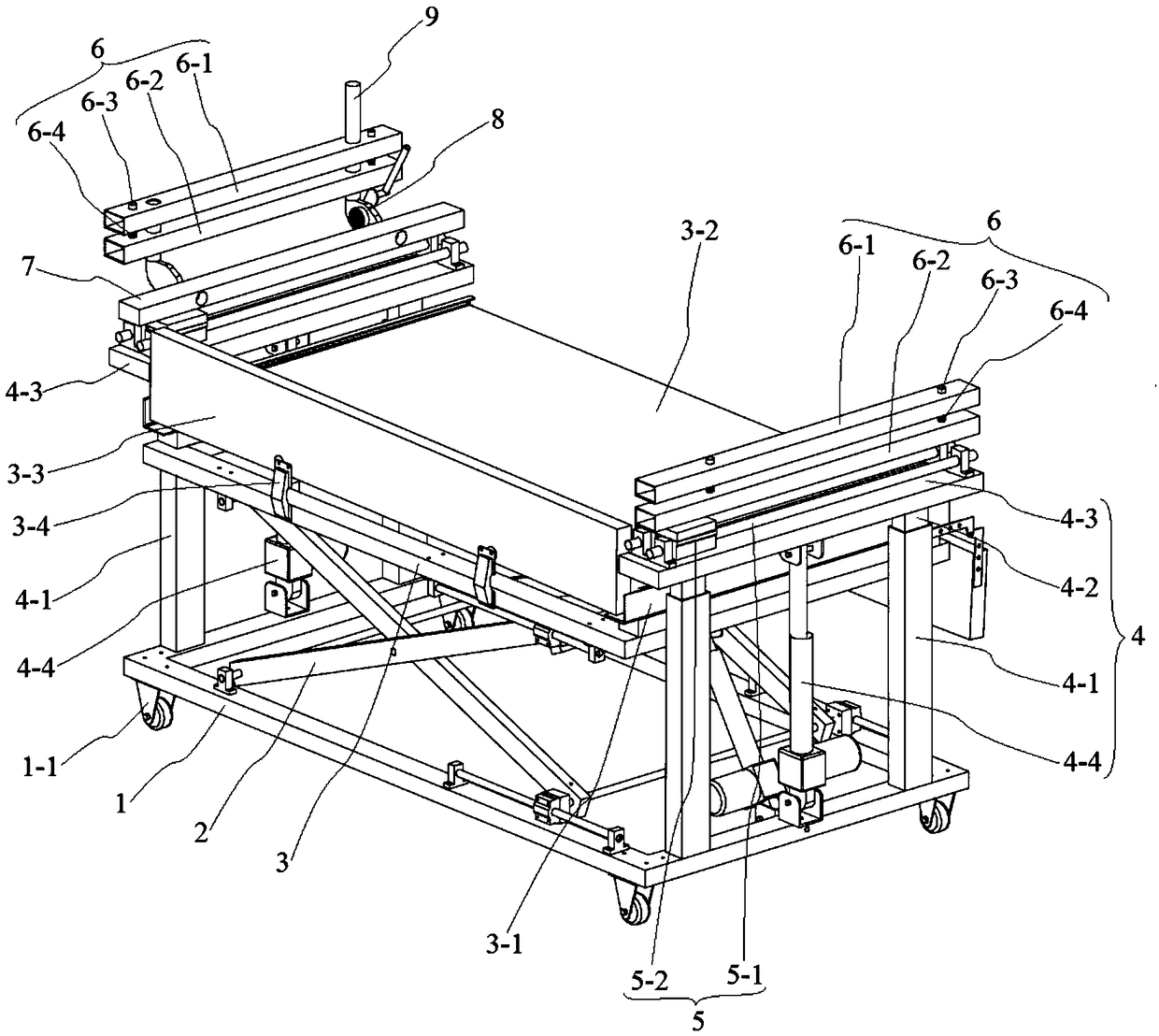

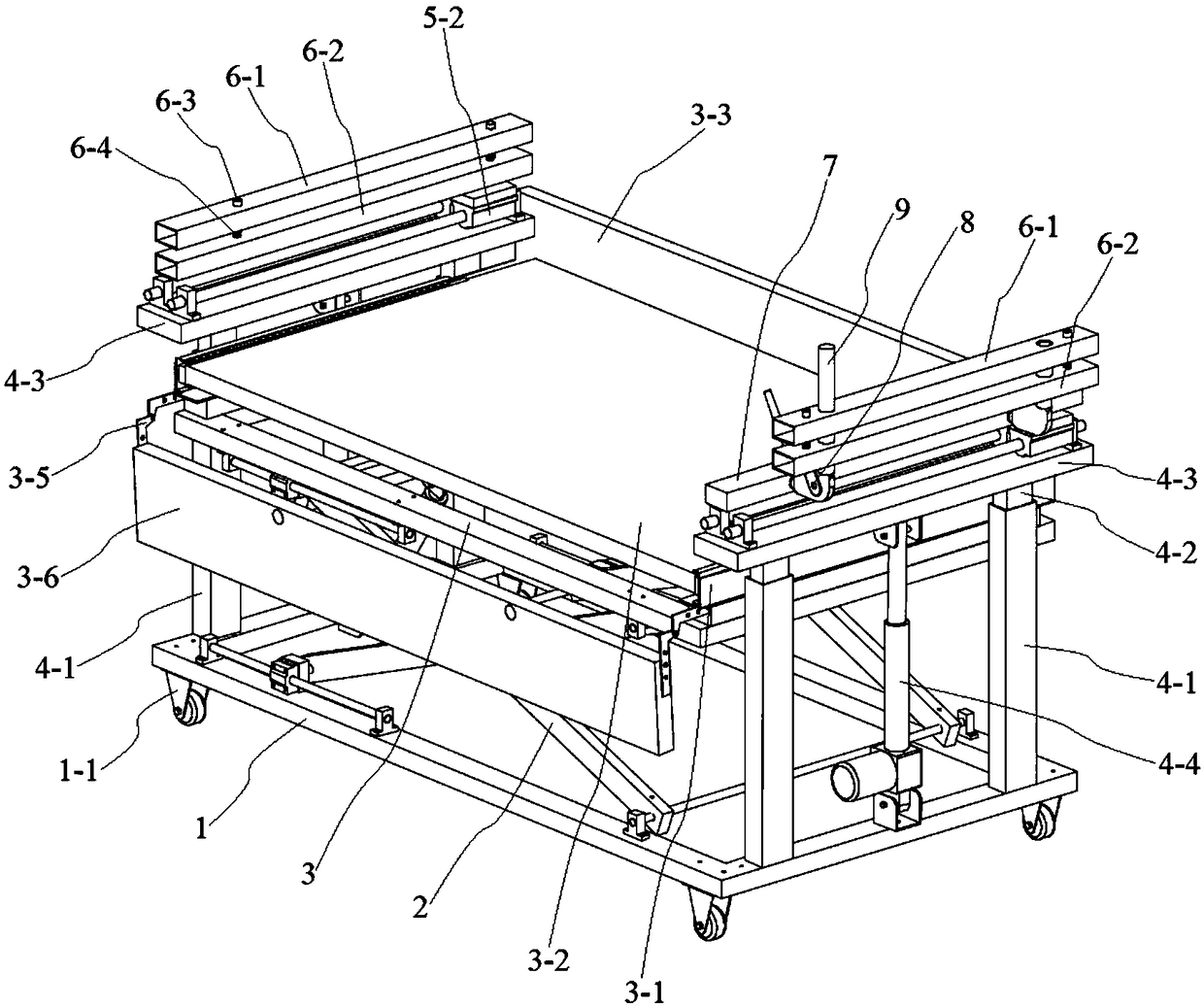

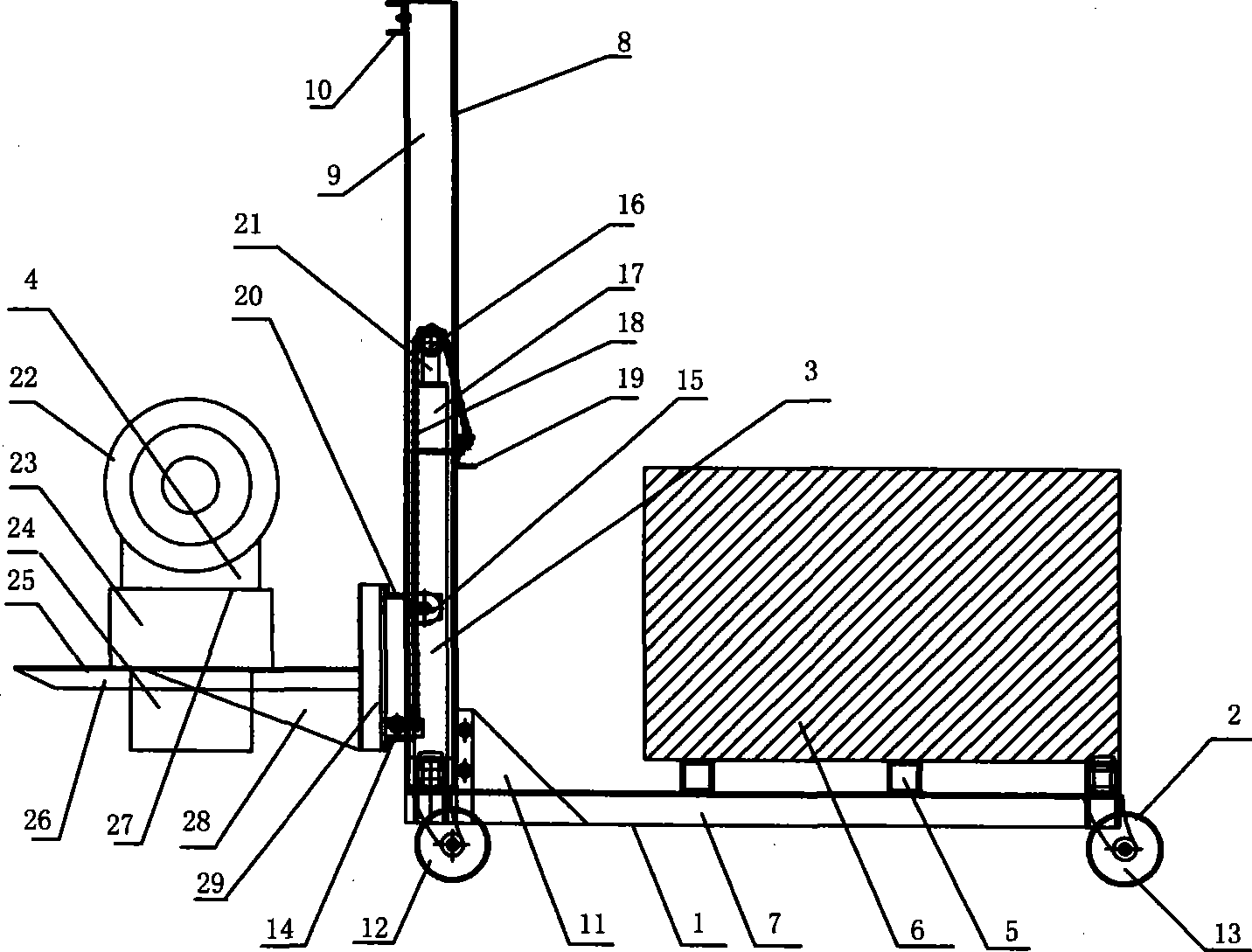

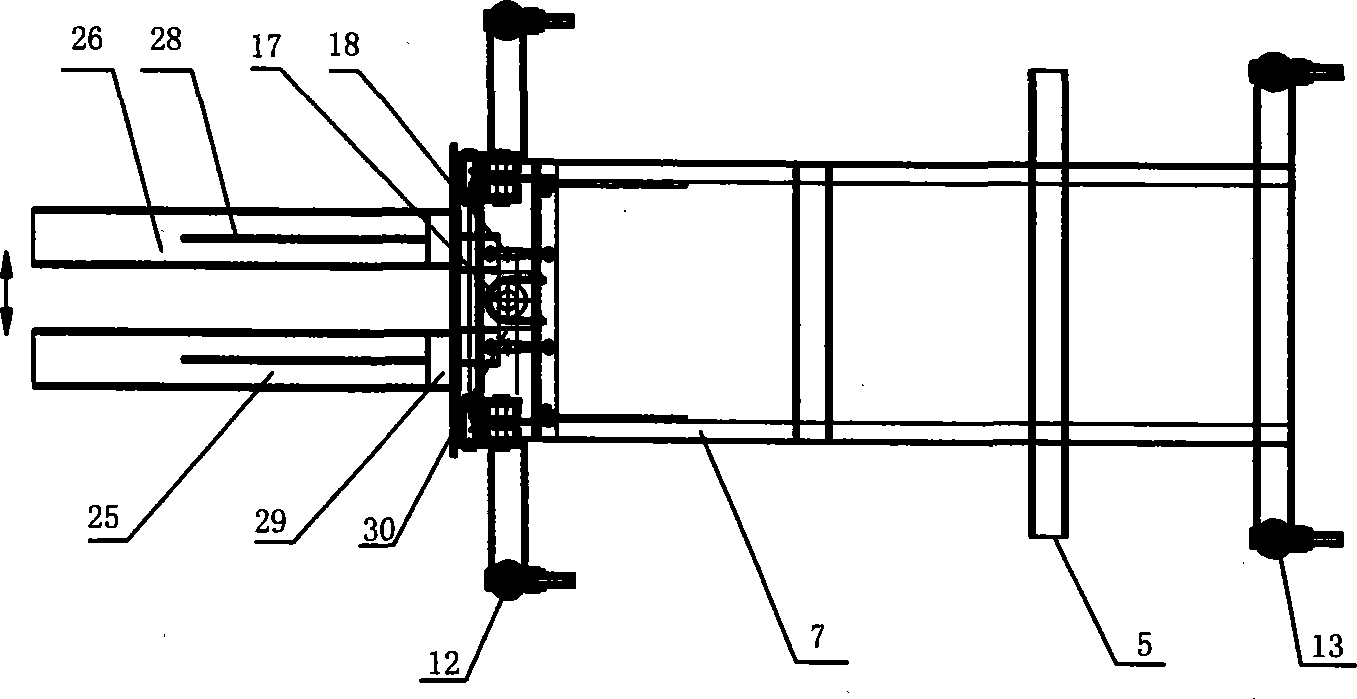

Machine packaging box that also can serve as expandable working table and using method of machine packaging box

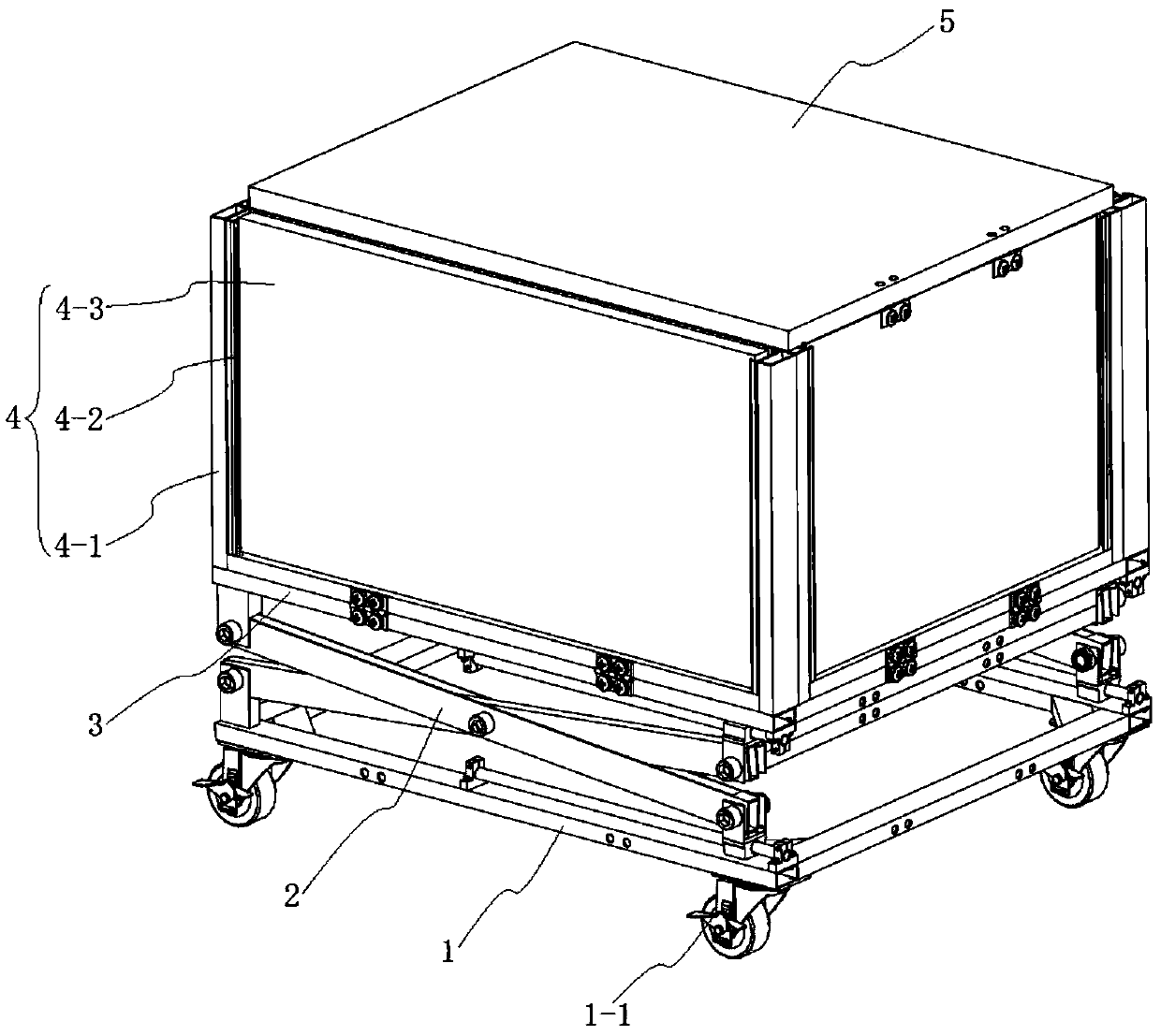

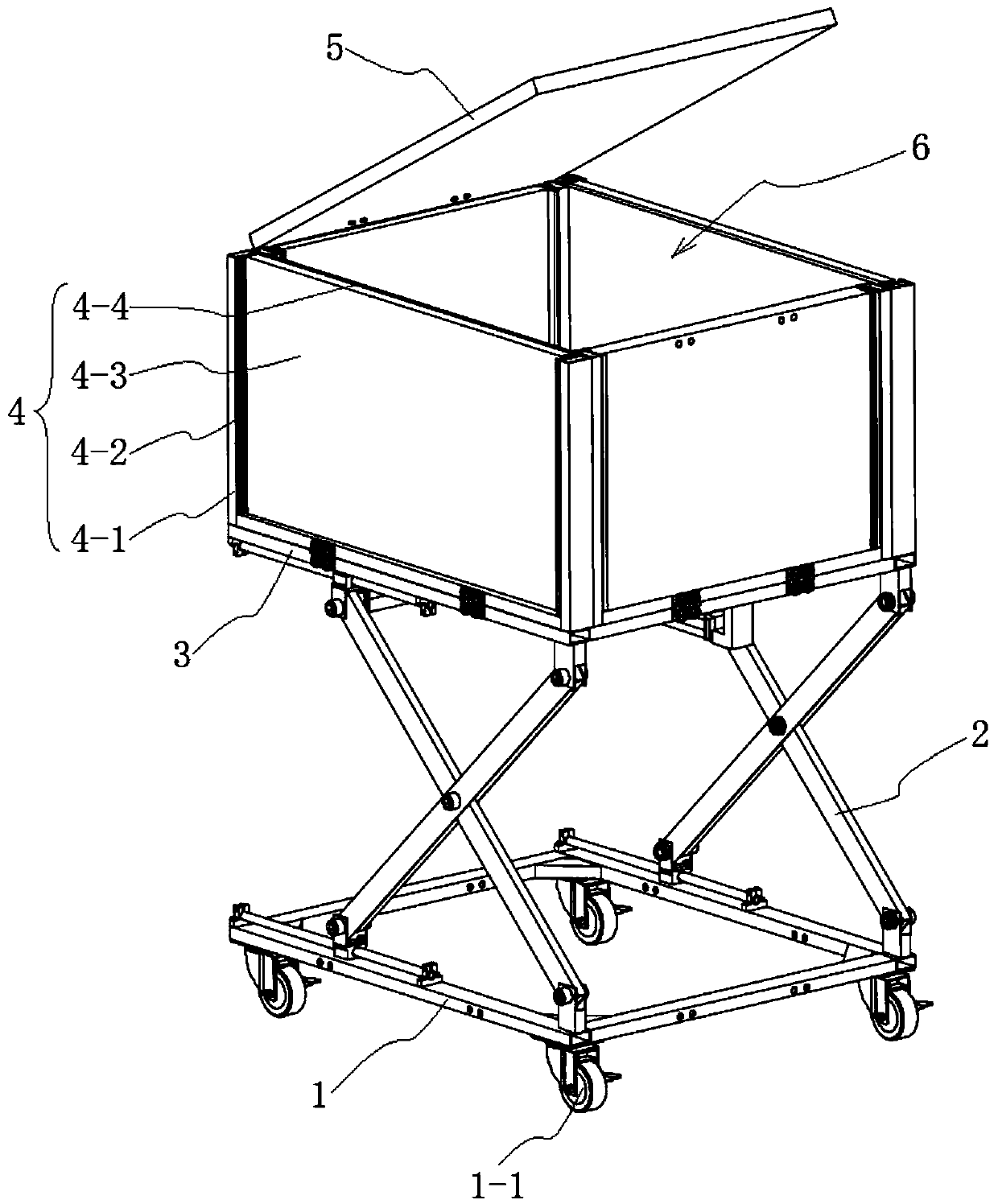

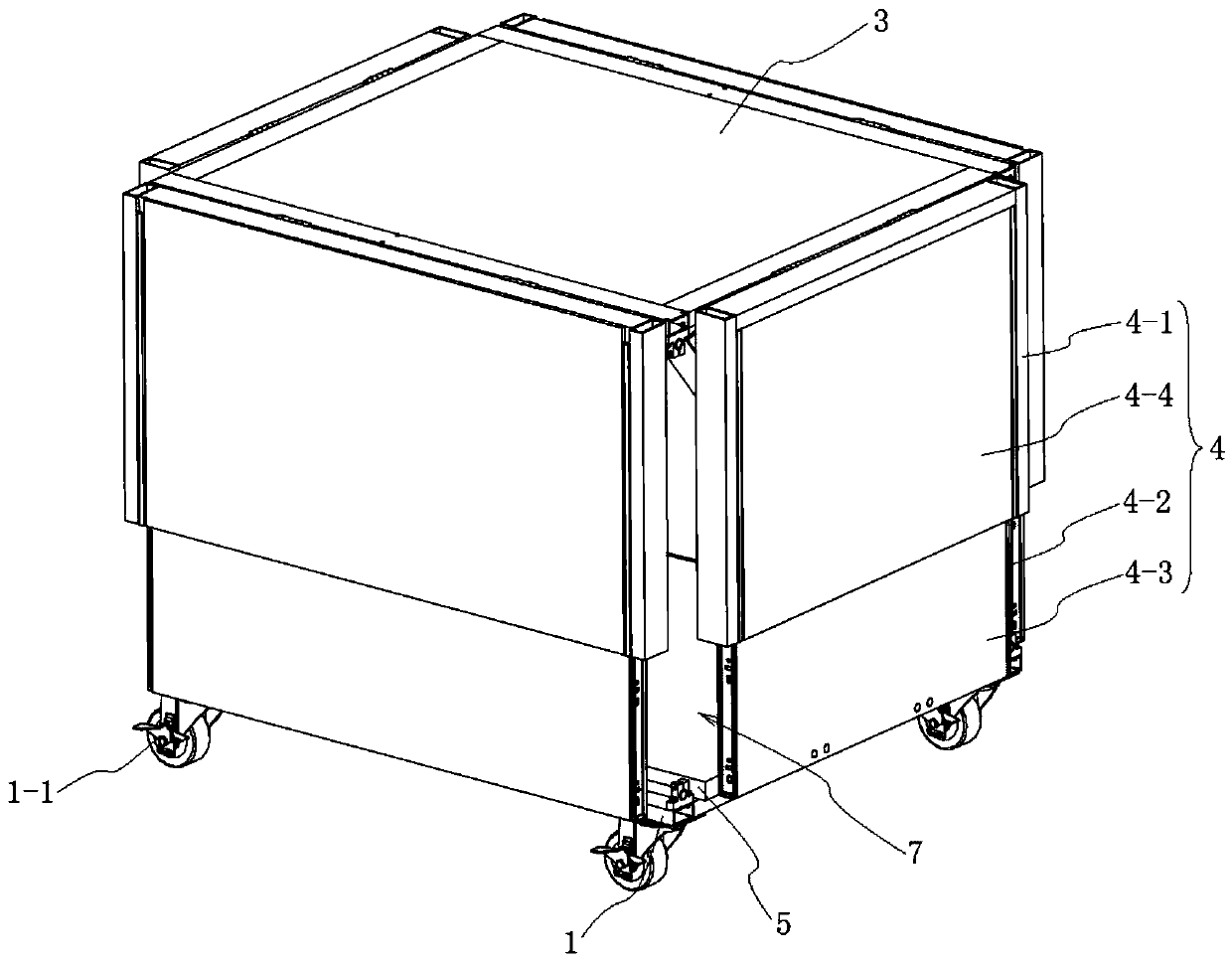

ActiveCN107934156ALow costIncrease the areaPackaging vehiclesContainers for machinesEngineeringShear mode

The invention discloses a machine packaging box that also can serve as an expandable working table and a using method of the machine packaging box and belongs to the technical field of packaging. Themachine packaging box comprises a base, a shear mode lifting mechanism and a packaging box main body, wherein the packaging box main body is mounted on the base through the shear mode lifting mechanism and is of a cuboid structure composed of a box body bottom plate, box body side plates and a box body top plate; the four sides of the box body bottom plate are rotatably connected with four groupsof box body side plates; the rotational angle of each of two groups of opposite box body side plates is 90 degrees; the rotational angle of each of the other two groups of opposite box body side plates is 180 degrees; and the box body top plate is rotatably connected with one of the other two groups of opposite box body side plates with the rotational angle being 180 degrees. According to the machine packaging box, the original structure deforms to form the working table, so that the packaging box can package transportation products, also can be used as the working table of a machine and realizes two purposes, so that the cost of purchasing another working table is saved, resource waste caused by discard of the packaging box is avoided, and the machine packaging box has high expansion performance and practical value.

Owner:CHANGZHOU INST OF TECH

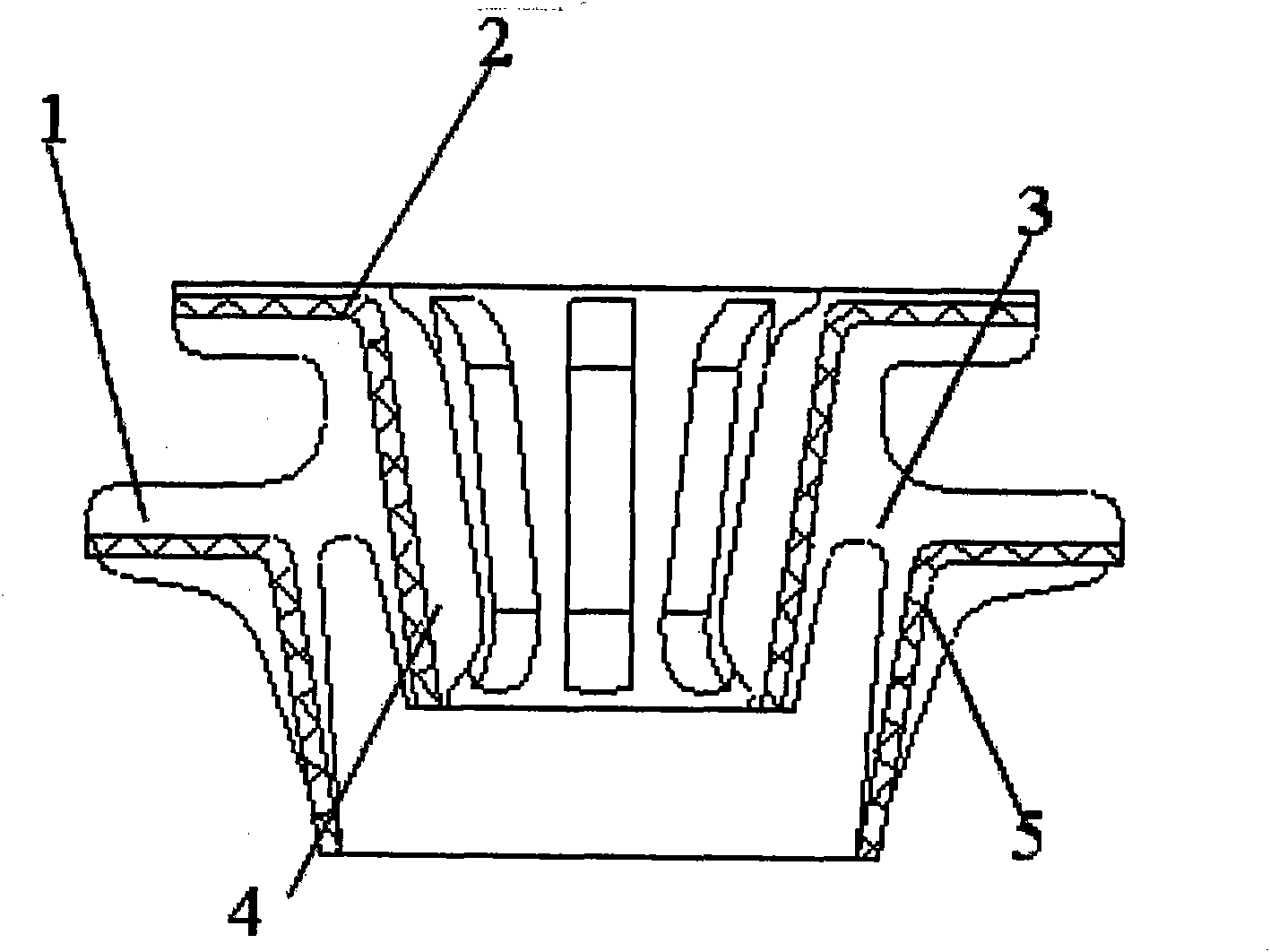

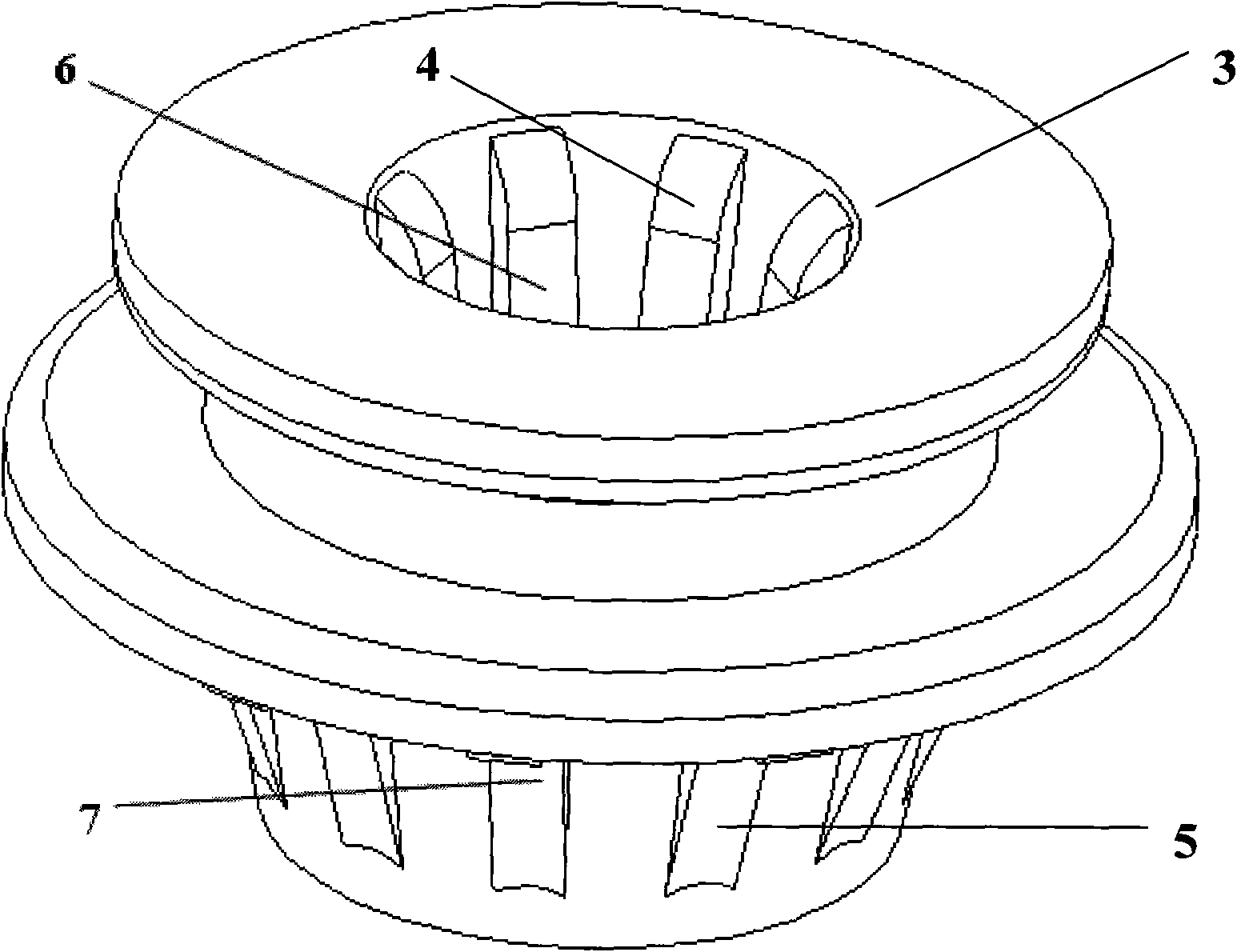

Rubber pad for automobile radiator

InactiveCN101865240AAvoid deformationReduce vibrationNon-rotating vibration suppressionPropulsion coolingEngineeringRelative motion

The invention discloses a rubber pad for an automobile radiator. The rubber pad comprises a shock absorbing ferrule body with two turned edges and is characterized in that an upper rigid ferrule with the turned edge is embedded into the upper part of the shock absorbing ferrule body; the inner wall on the upper part of the shock absorbing ferrule body is provided with a plurality of upper corrugates with inclination angles; a lower rigid ferrule with the turned edge is embedded into the lower part of the shock absorbing ferrule body; and the outer wall on the lower part of the shock absorbing ferrule body is provided with a plurality of lower corrugates with inclination angles. The rubber pad has the following advantages that: because the upper rigid ferrule and the lower rigid ferrule are connected through the shock absorbing ferrule body, the vibration transferred by a fan and an engine to the radiator is reduced by the relative motion of the upper rigid ferrule and the lower rigid ferrule in the shock absorbing ferrule body so as to reduce the vibration transferred by the radiator to the automobile body in the entire driving process, the rubber pad meets the requirements of the entire automobile on the bearing capacity, the shock absorption and the assembly, ensures reliable positioning of the radiator on the entire automobile and improves the comfort of the riding.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Aerated concrete

InactiveCN103342577AHigh compressive strengthMeet the load-bearing requirementsCeramicwareGypsumCalcium in biology

The invention relates to an aerated concrete. Each cubic meter of the concrete contains 300 to 350 kg of a siliceous material, 160 to 180 kg of a calcareous material and 0.3 to 0.5 kg of a foaming agent. The aerated concrete is characterized by further comprising ferroferric oxide and gypsum, wherein ferroferric oxide accounts for 5 to 10% of the total weight of the concrete, and the gypsum accounts for 2 to 3% of the total weight. According to the invention, ferroferric oxide is added into a conventional aerated concrete formula, so an aerated concrete brick prepared from the aerated concrete provided by the invention has effectively improved compressive strength, meets requirements of bearing and is a lightweight and anti-compression brick.

Owner:镇江崟鑫新型建材科技有限公司

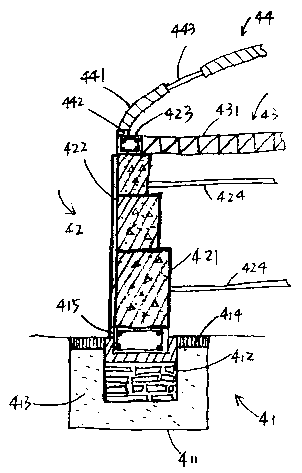

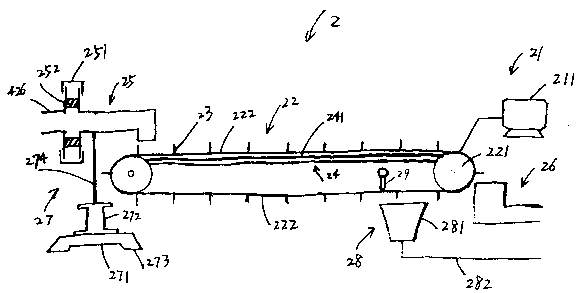

Stretching device of case beam in case

ActiveCN101435268AFacilitate installation alignmentRealize all-round positioningBuilding material handlingLifting capacityPre stress

The invention discloses a box girder box inside tension device, which is composed of a main structure system, a walk system, an elevating system, and a bearing system. The main structure system is an L-shaped steel structure composed of a plane truss and a vertical truss, and is provided with a balance weight. The walk system is arranged at the bottom of the plane truss. The elevating system is composed of a hydraulic oil cylinder, a chain, pulleys, and an elevating frame. The bearing system is composed of a bearing fork and a jack bracket. The invention adopts the hydraulic oil cylinder to elevate an oil pressure jack for tension, can accurately control the elongation of the hydraulic oil cylinder, is beneficial to the mounting and contraposition work of the oil pressure jack for tension, and can guarantee the construction safety. The device of the invention has strong adaptability, simple construction, convenient operation, and high work efficiency when tensioning in box girder box with multiple sections, has a maximum lifting capacity of 2t, a maximum lifting height of 1.9m (the distance from the working surface to the center of the jack), and high stability, not only is suitable for the tension in the box of straight web plate box girder, but also can be used for the box prestress tension of variable cross-section inclined box girder.

Owner:THE 5TH ENG MBEC

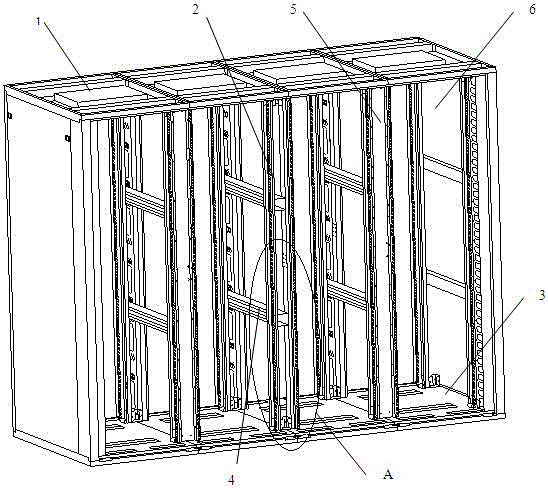

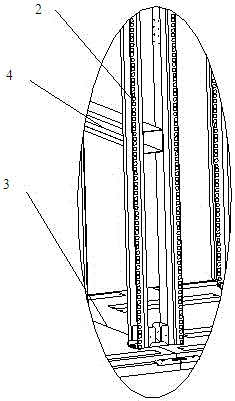

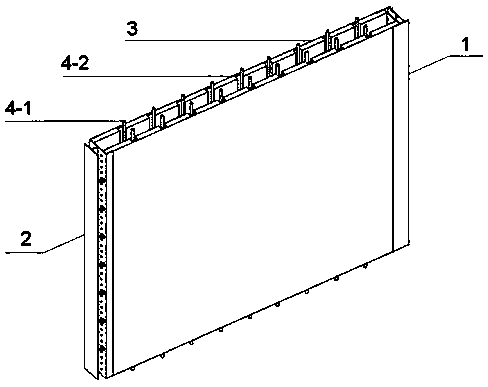

Integrated cabinet/ frame

InactiveCN105163558ALess materialPrevent turbulenceCircuit arrangements on support structuresRack/frame constructionEngineeringCold air

The invention provides an integrated cabinet / frame which comprises a top (1), a bottom (3), installation stand columns (2), front and back cross beams (4) and wire groove installation plates (5). The top (1) and the bottom (3) are in up and down connection and fixation through the installation stand columns (2); the two sides of each front and back cross beam (4) are connected with the adjacent installation stand columns (2) of two cabinets / frames respectively; and each wire groove installation plate (5) is connected with the adjacent installation stand columns (2) of the two cabinet / frame units to form one group, the size of which is equal to or larger than that of the existing two cabinet groups. The beneficial effects are that 1) the integrated cabinet / frame meets load-bearing requirement of the cabinet, and meanwhile, saves materials and reduces construction difficulty; 2) gap between the cabinets is enclosed, and thus front and back isolation of the cabinet is realized; 3) turbulence caused by hot and cold air is effectively prevented, and service efficiency of air conditioners in a machine room is greatly improved; and 4) a large vertical wire arrangement space can be obtained, and thus the current situation that the wire arrangement space of a common 600 mm cabinet is limited is changed, and convenience of wiring operation is allowed to be improved.

Owner:NANJING PUTIAN TELEGE INTELLIGENT BUILDING

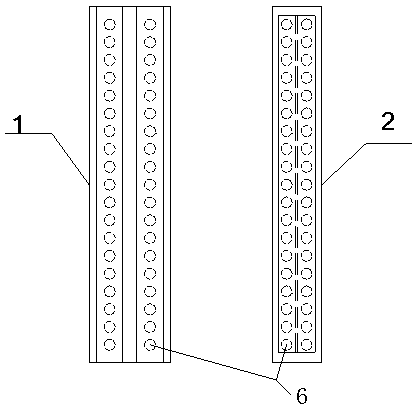

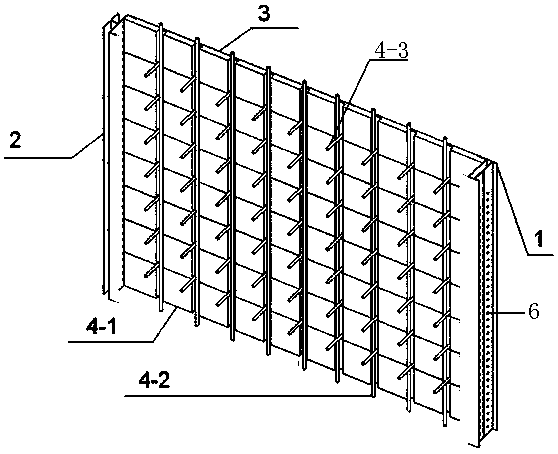

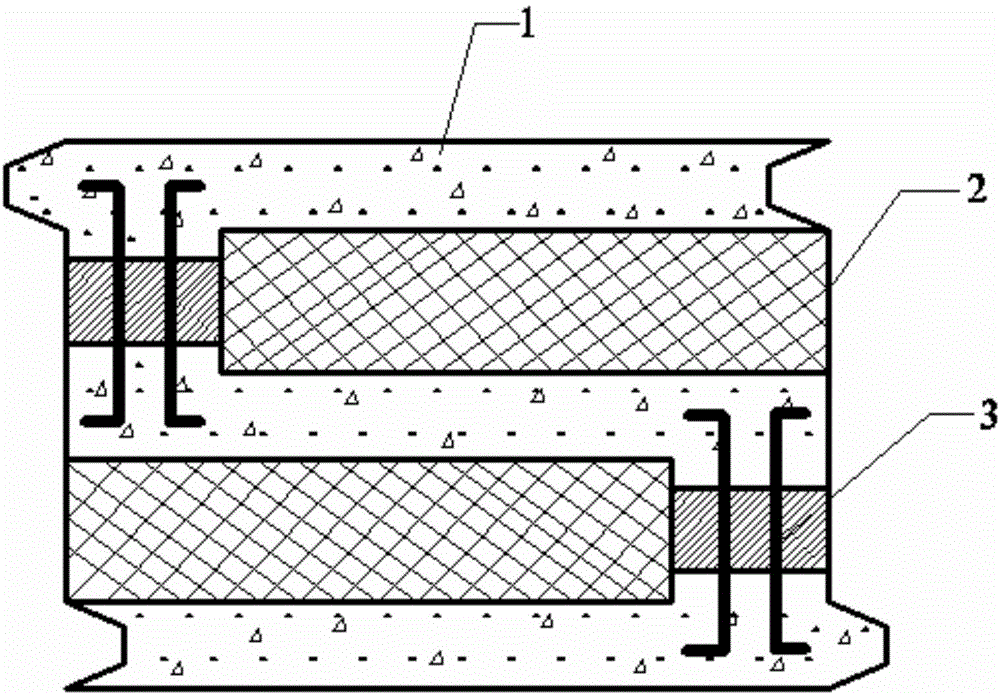

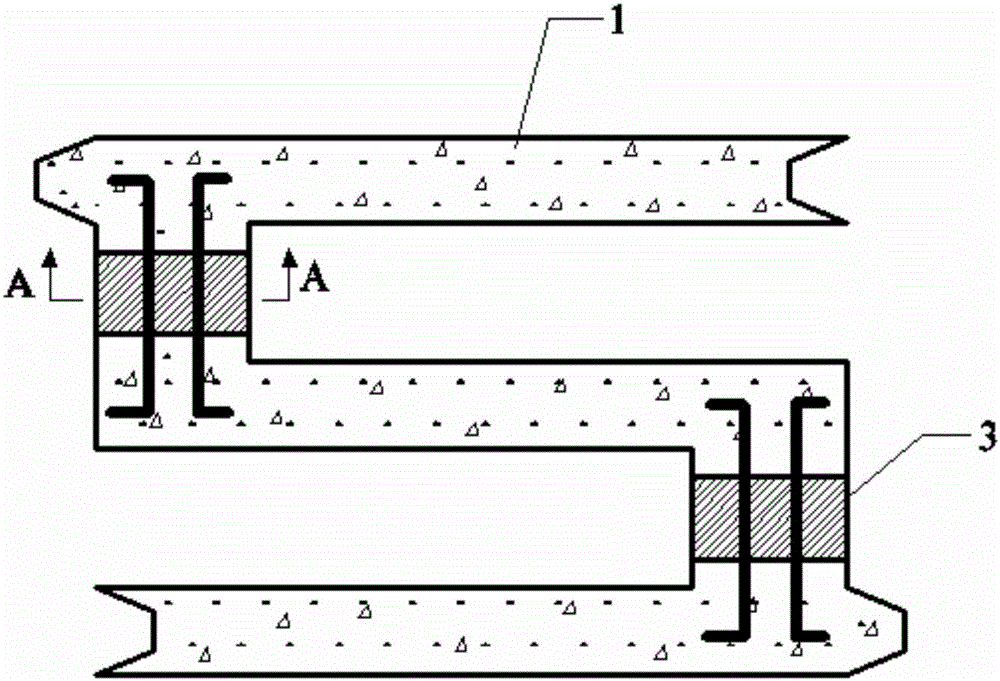

Prefabricated steel structural superposed shear wall and construction method thereof

The invention provides a prefabricated steel structural superposed shear wall and a construction method thereof. According to a prefabricated steel structural superposed shear wall plate, each shear wall comprises two double-faced heat preservation light wall plates; a deep longitudinal groove and a plurality of rows of transverse holes penetrating through the groove are formed in each wall plate;and self-locking components formed by welding a plurality of steel plates are arranged on the left and the right of a wall body, and the wall body can select different chaining lock catches and tailend lock catches according to different joints. The upper, lower, left and right portions of the wall body are all of symmetrical structures, a plurality of rows of transverse penetrating reinforcingsteel bars are arranged in the wall body, longitudinal reinforcing steel bars are connected with the transverse reinforcing steel bars in a lap joint or welded mode, and short bars are welded to the joint points of the transverse reinforcing steel bars and the longitudinal reinforcing steel bars. The construction method of the prefabricated steel structural superposed shear wall comprises the following steps that in-situ wire paying off is conducted, and temporary fixing frames are mounted; the shear wall is assembled and spliced in place, and connected and fixed to the temporary fixing frames; a prefabricated upper layer floor slab is placed in place; hidden beam steel plates and various additional reinforcing steel bars are arranged, and pipelines are arranged; high-fluidity free of vibration concrete is poured; and mounting construction of a next layer is entered in.

Owner:SHENYANG JIANZHU UNIVERSITY

Cable bridge supporting and fixing device

ActiveCN112117716AReduce usageLow costElectrical apparatusNon-rotating vibration suppressionShaped beamCable tray

The invention relates to the technical field of supporting and fixing devices, and discloses a cable bridge supporting and fixing device. The device comprises a cable bridge, a fixed frame arranged onone side of the cable bridge, an upper fixed base fixedly welded to the top of the fixed frame, a baffle fixedly welded to the top of the upper fixed base, and a connecting block movably clamped to one side of the upper fixed base; a suspension rod is fixedly welded to one end of the connecting block, a bolt sleeve is fixedly welded to one end of the suspension rod, a ring fixing buckle is fixedly installed on the periphery of the cable bridge, a locking bolt is fixedly connected between the two ends of the ring fixing buckle, square fixing buckles with opened right sides are fixedly installed on the two sides of the cable bridge respectively, and a fastening bolt is fixedly connected between the square fixing buckles. According to the supporting and fixing device, the connecting blocks are arranged on the two sides of the cable bridge, fixing and supporting of the cable bridge are achieved in a suspension mode through the suspension rods, the number of used I-shaped beam fixing frames is reduced, the construction difficulty is lowered, and the material cost is saved.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO YANTAI CITY FUSHAN DISTRICT POWER SUPPLY CO

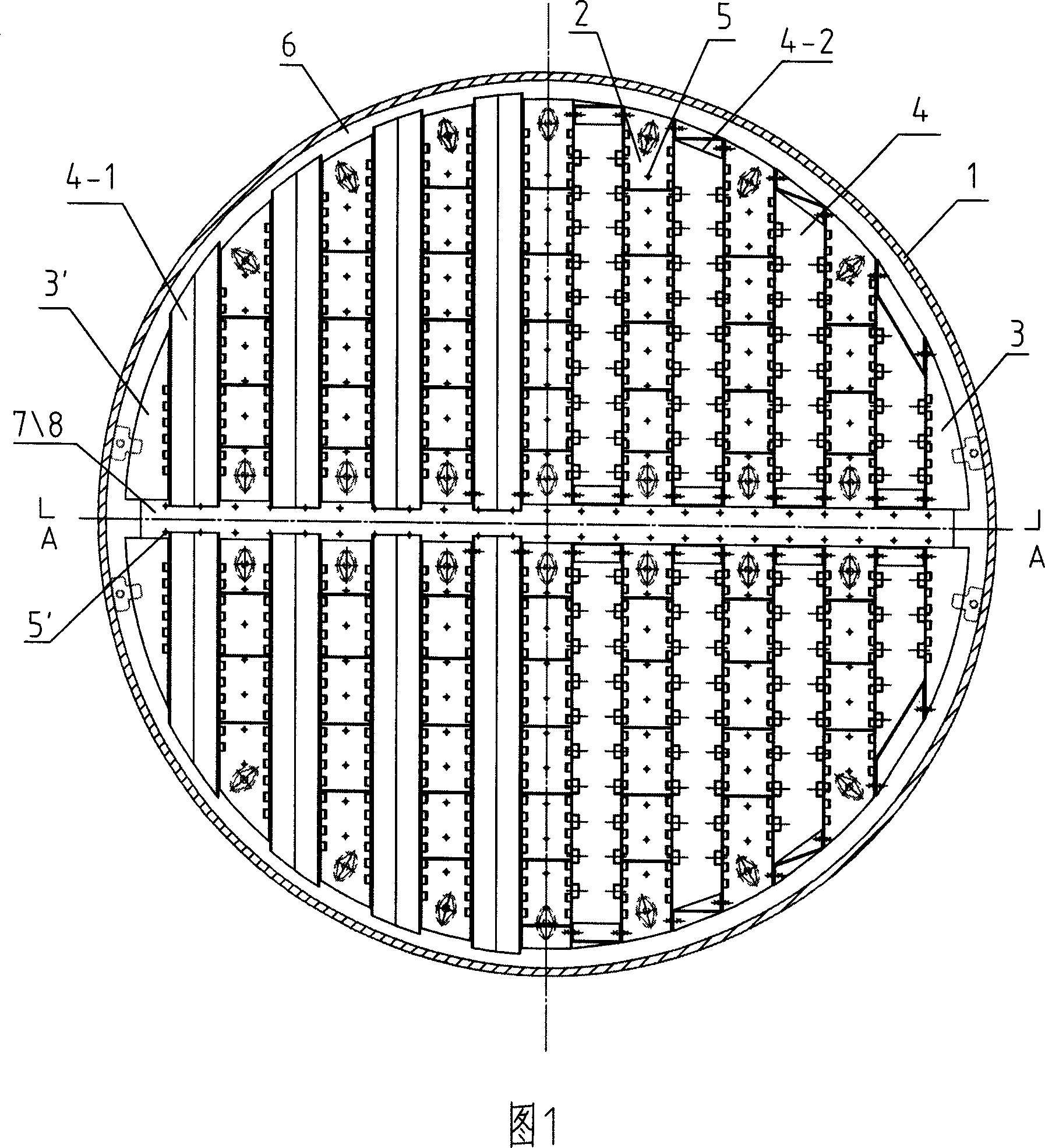

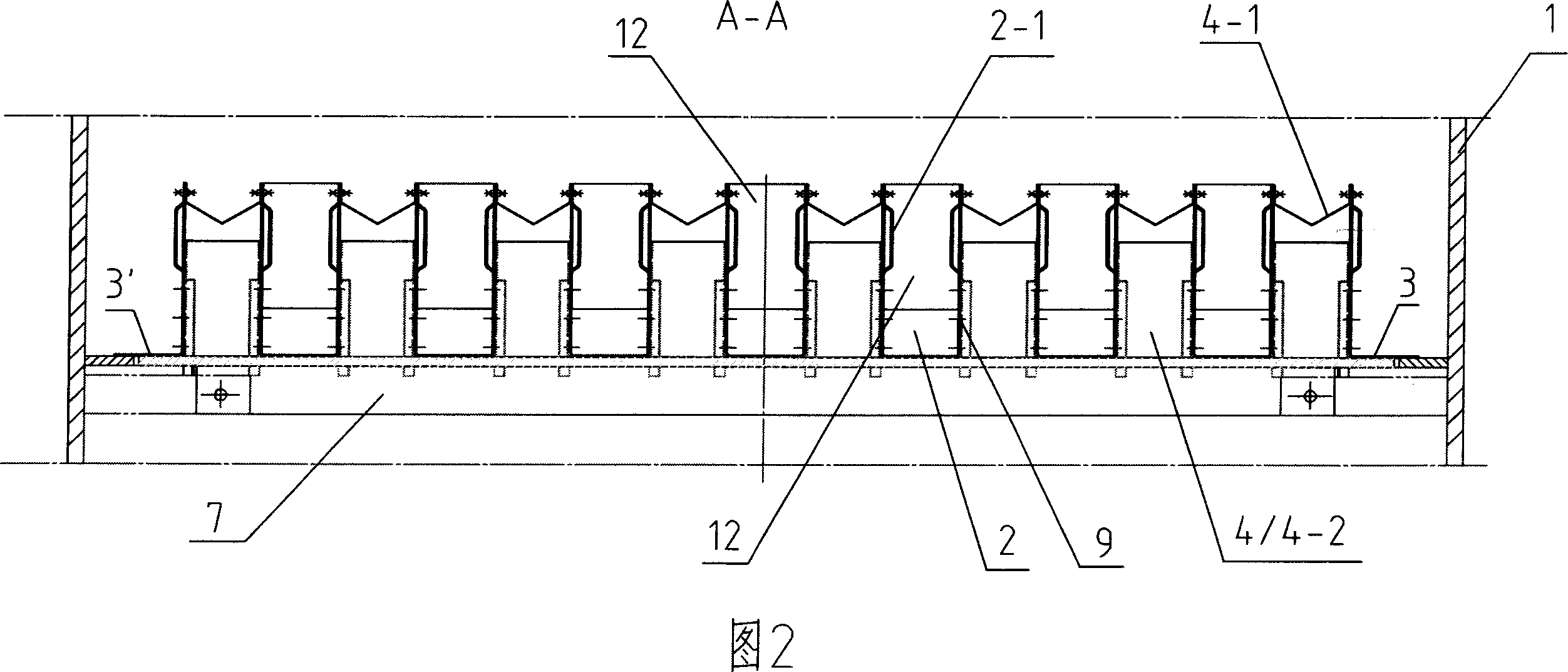

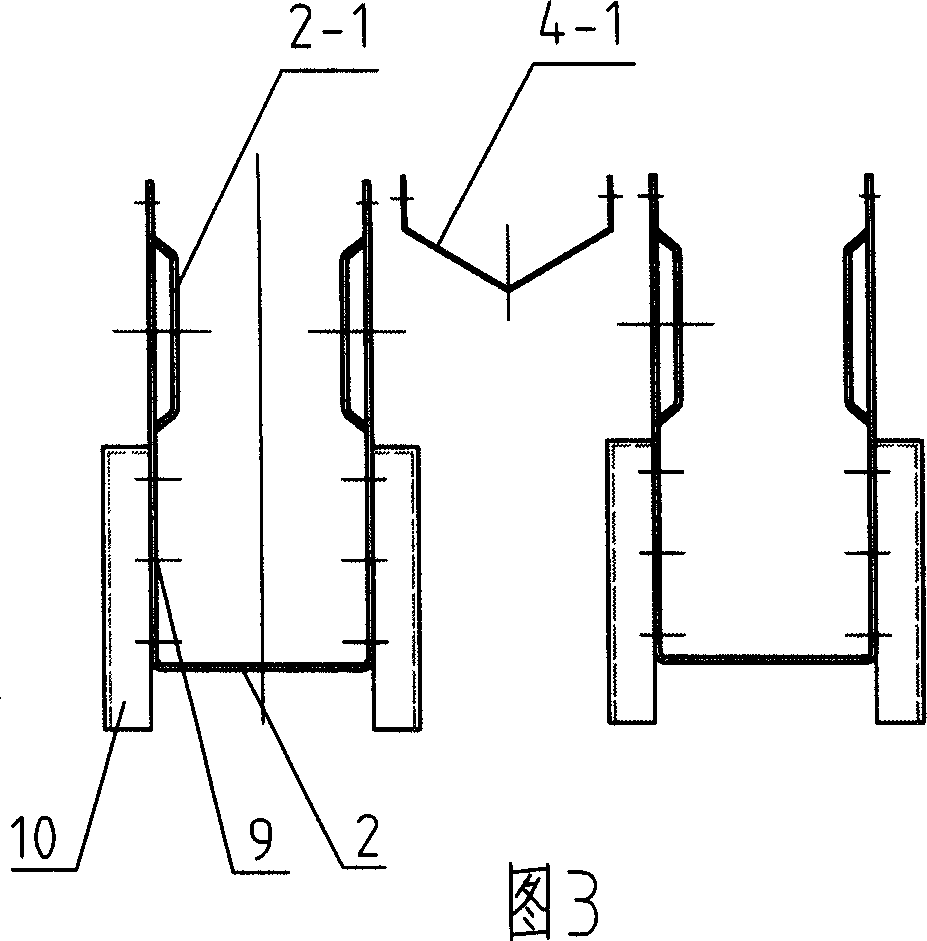

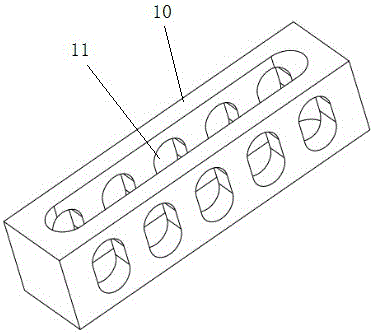

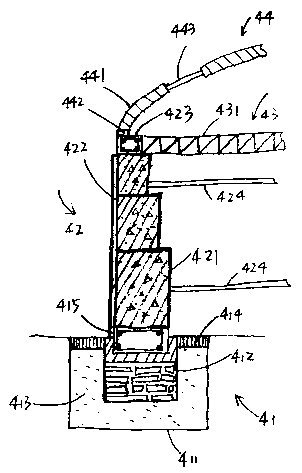

Gas-liquid allotter with supporting and mass transfer function

InactiveCN1919399ASimple structureEasy to makeDispersed particle separationFractional distillationMass transferEngineering

The invention discloses a gas-liquid distributor with support and mass transfer function, which consists of multiple liquid phase distributing grooves to arrange parallelly along radial direction and multiple liquid phase distributing semi-grooves on two sides of liquid phase distributing groove, wherein each gap of liquid phase distributing groove and semi-groove is gas phase distributing channel, which interconnects each liquid phase distributing groove and semi-groove, the mass transfer hole is opened on the liquid phase distributing groove and semi-groove, which is compatible with mass transfer function for distributor.

Owner:褚雅志

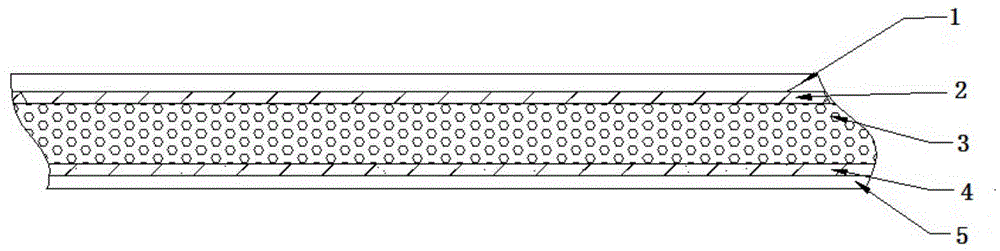

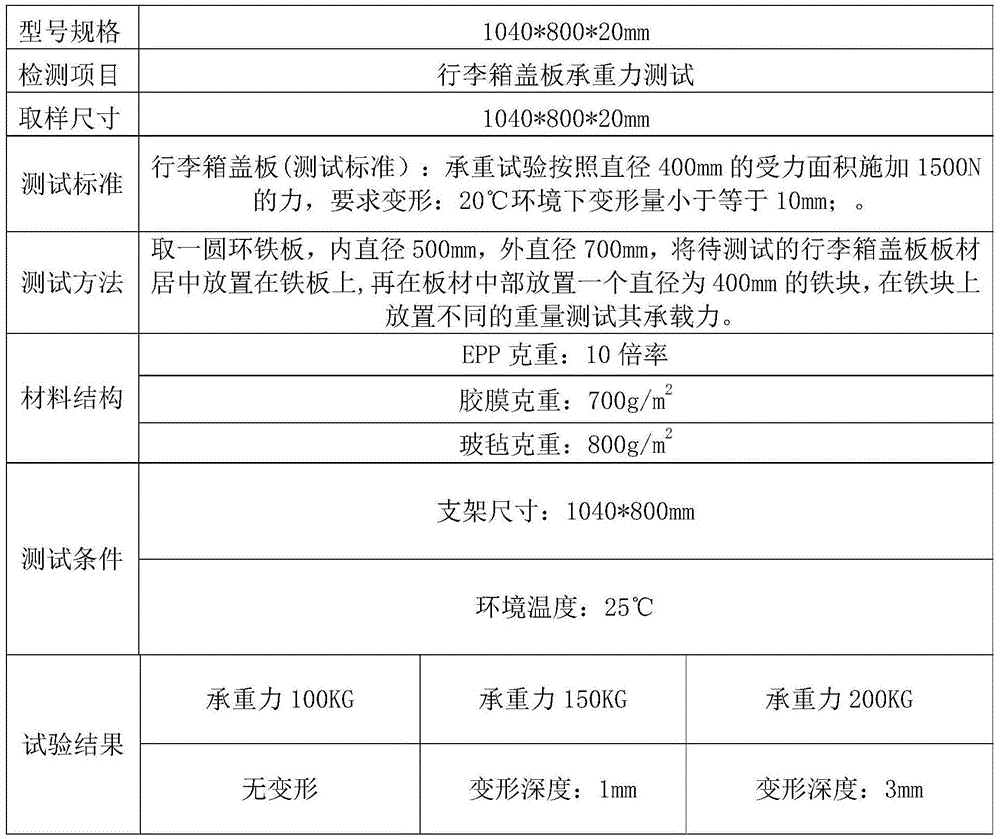

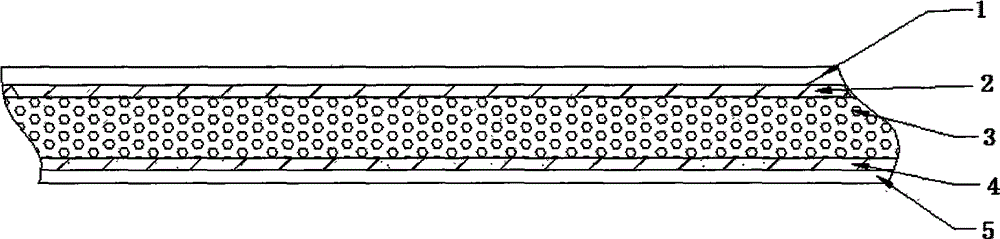

Novel car trunk cover plate and preparation method thereof

InactiveCN104527168AThe material is completely environmentally friendlyImprove lightweightSynthetic resin layered productsVehicle componentsEngineeringQuality assessment

The invention provides a novel car trunk cover plate and a preparation method thereof. The novel car trunk cover plate comprises an EPP foaming layer, wherein the surface of the EPP foaming layer is compounded with a first hot melt adhesive film layer, and the back of the EPP foaming layer is compounded with a second hot melt adhesive film layer; the outside of the first hot melt adhesive film layer is covered by a surface decorating layer, and the outside of the second hot melt adhesive film layer is covered by a bottom decorating layer. The used materials are completely environmentally friendly, and have no peculiar smell, any organic adhesive is not used in the production process, the in-car air quality assessment guideline is fully met, materials can be thoroughly recycled, and the lightweight of a product is enhanced by more than 50%; meanwhile, the load-bearing capacity of the product complies with the relevant weight load-bearing requirements of cars.

Owner:TIANJIN DALIN NEW MATERIAL TECH

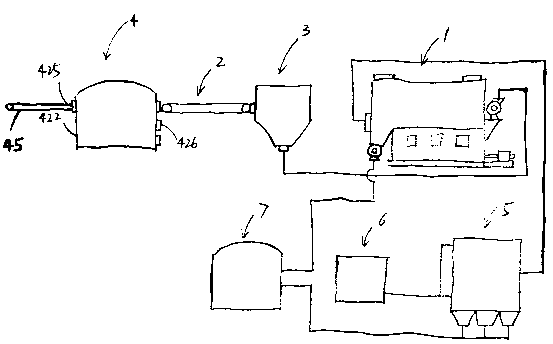

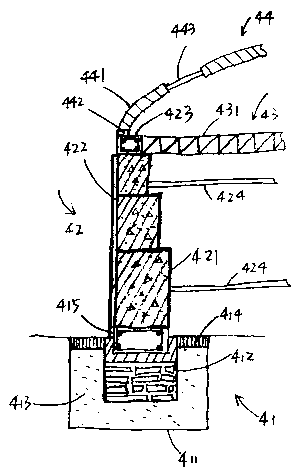

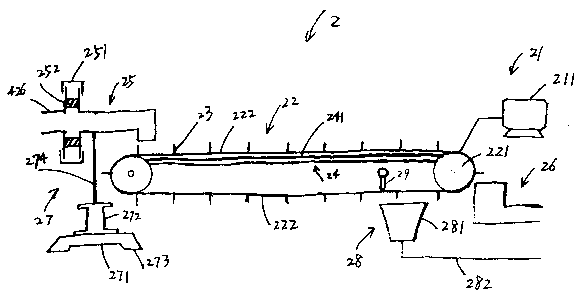

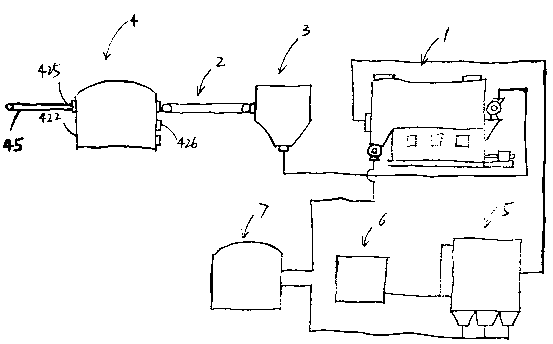

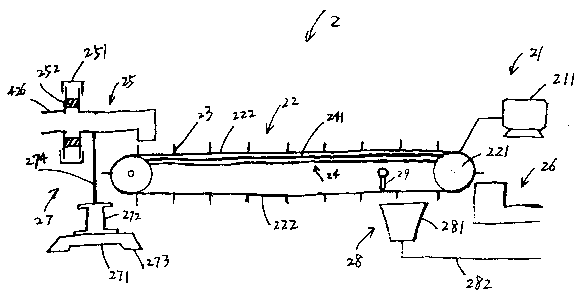

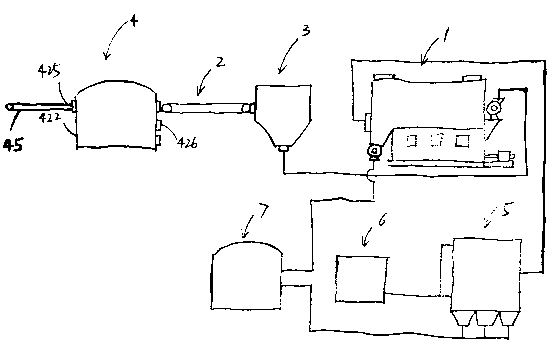

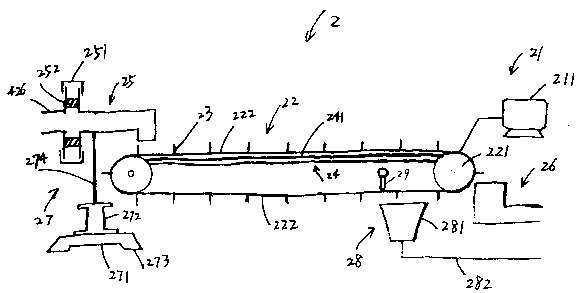

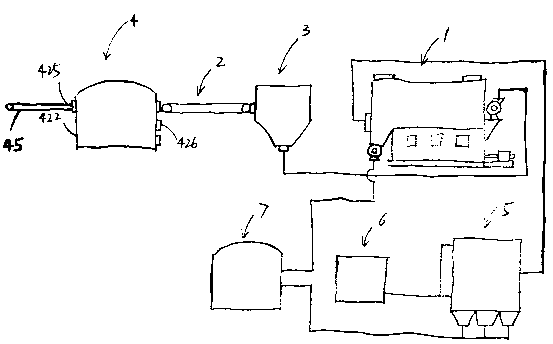

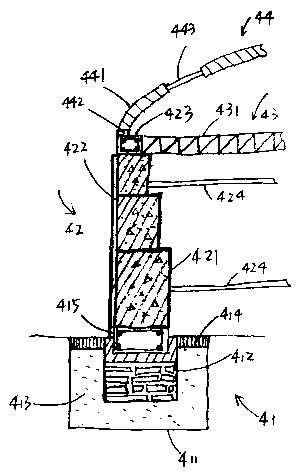

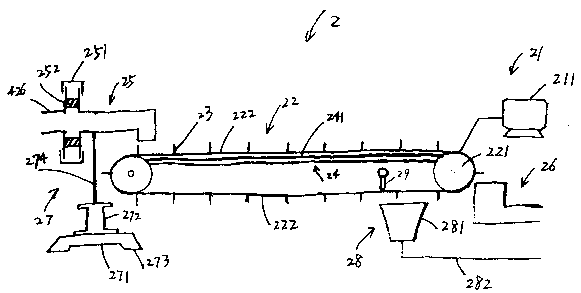

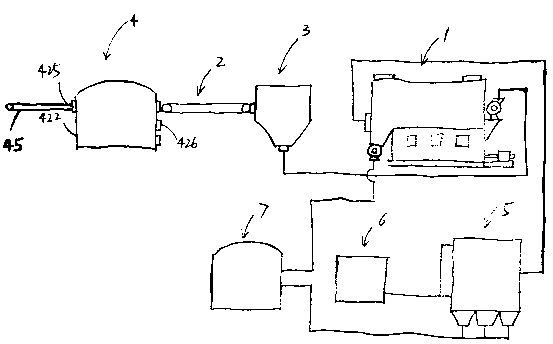

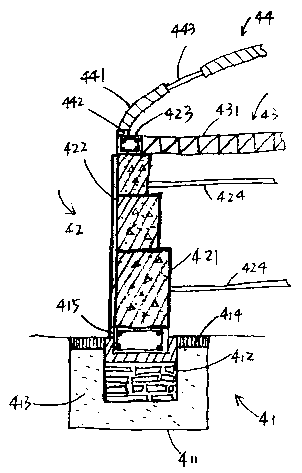

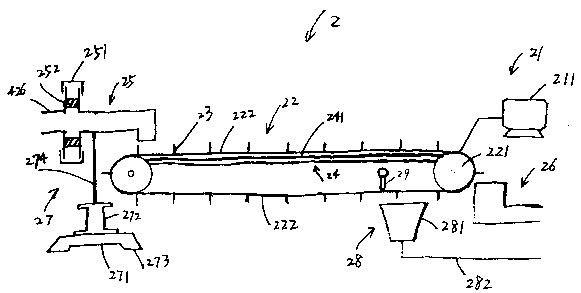

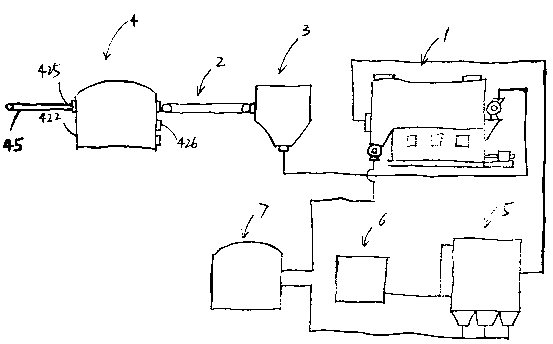

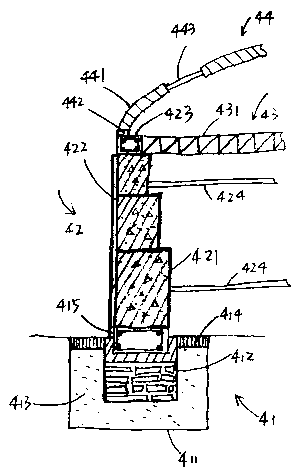

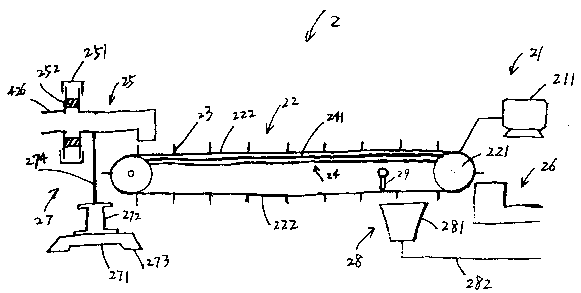

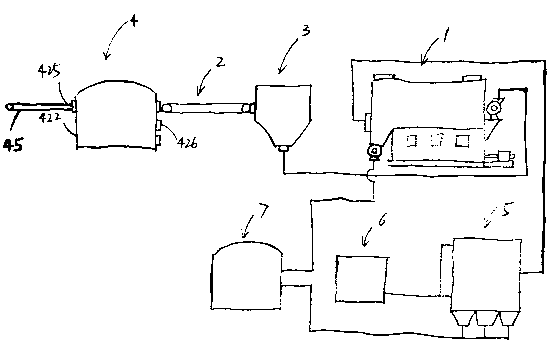

Production line used for drying coal slime

ActiveCN103134289AImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingLow noiseProduction line

The invention relates to a production line used for drying coal slime. The production line used for drying the coal slime is characterized by comprising a coal slime raw material repository, a scraper conveyor, a preparatory material storage bin, a coal slime drier, a coal dust gas dusting machine, a gas recycling device and a finished product repository, wherein reinforcing ribs arranged in a drying cabin of the coal slime drier of the production line can guarantee no deformation of the cabin body of the drying cabin in a high pressure environment; and thermal insulation cotton among the reinforcing ribs guarantees heat loss of the drying cabin to be as low as possible, realizes the energy-saving purpose and lowers the production cost. The production line used for drying the coal slime has the advantages of low energy consumption, low noise, strong structure stability, high processing efficiency, low equipment cost, strong equipment adaptability, no material blockage phenomenon, few production faults, low manufacturing cost and resource economization.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

Drying treatment system of slurry

ActiveCN103134284AImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingLoad torquePulp and paper industry

The invention relates to a drying treatment system of slurry. The drying treatment system is characterized by comprising a slurry raw material storing warehouse, a scraper conveying machine, a prepared material cabin, a slurry drying machine, a coal dust gas dusting machine, a gas recycling device and a finished product storing warehouse. A material raising shaft of the slurry drying machine in the treatment system is made of high-temperature-resisting materials and adopts a loading torque loop, so that the material raising shaft cannot deform under high-temperature, high-speed and large-torque operation, the material raising capability and the torque bearing capability of the material raising shaft are greatly improved, and the material raising efficiency and the working stability are greatly improved. The drying treatment system has the advantages of being low in energy consumption, low in noise, strong in structural stability, high in processing efficiency, low in device cost, strong in device adaptation, free of blocking, less in production failure, low in manufacture cost, and capable of saving resources.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

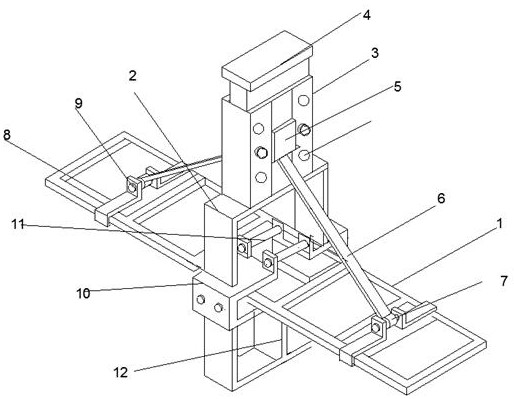

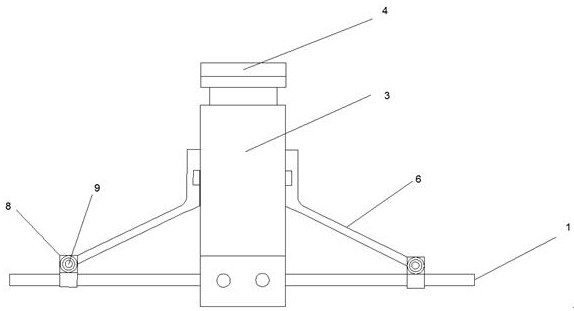

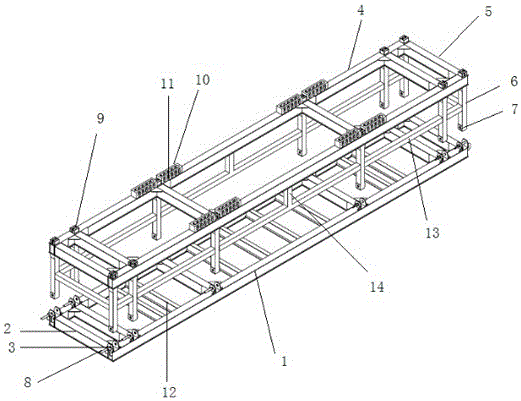

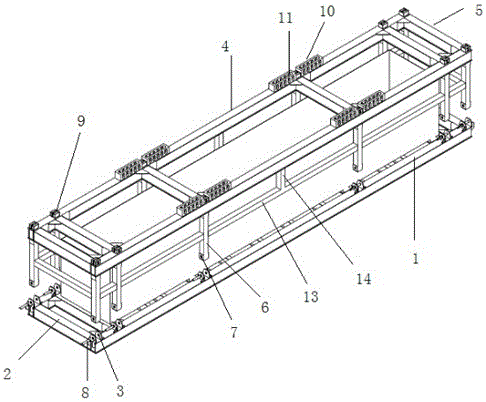

Load testing device and method of container crane

ActiveCN105800456AMeet load-bearing requirementsStable structureStructural/machines measurementLoad-engaging elementsContainer craneLoad testing

The invention discloses a load testing device and a method of a container crane. The device comprises a lower lifting frame and an upper lifting frame symmetrically arranged left and right; the lower lifting frame includes two first cross beams and multiple first longitudinal beams; the first cross beams and the first longitudinal beams are perpendicularly intersected; double-lug bases are arranged in the intersecting positions of the first cross beams and the first longitudinal beams; the upper lifting frame includes two second cross beams and multiple second longitudinal beams; the second cross beams and the second longitudinal beams are perpendicularly intersected; multiple stand columns are arranged at the lower parts of the intersecting positions of the second cross beams and the second longitudinal beams; fixed holes are formed in the bottoms of the stand columns; pin shafts penetrate through the fixed holes and the double-lug bases to connect the upper and lower lifting frames; container upper angle parts are arranged at the upper parts of the intersecting positions of the second cross beams and the second longitudinal beams on the left and right two sides; lifting lugs are arranged at the upper parts of the intersecting positions of the second cross beams and the second longitudinal beam at the middle part; and multiple lifting lug holes are formed in the lifting lugs. The device solves the technical problems of single purpose, incapability of adjusting lifting point positions and inconvenience for loading and unloading loads in a traditional crane load testing device.

Owner:HENAN WEIHUA HEAVY MACHINE

Production line used for drying coal slime

ActiveCN103134290AImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingLow noiseThermal insulation

The invention relates to a production line used for drying coal slime. The production line used for drying the coal slime is characterized by comprising a coal slime raw material repository, a scraper conveyor, a preparatory material storage bin, a coal slime drier, a coal dust gas dusting machine, a gas recycling device and a finished product repository, wherein an air speed adjusting valve which is convenient to control a flow speed of hot air in the coal slime drier is arranged at an air outlet of a blower of the coal slime drier of the production line, and a temperature control device which is convenient to control the temperature of the hot air flowing into the coal slime drier is arranged in a hot air inlet pipe, so that heat energy waste is avoided; and thermal insulation cotton is sleeved outside the hot air inlet pipe, so that heat loss is further reduced, and production cost is saved. The production line used for drying the coal slime has the advantages of low energy consumption, low noise, strong structure stability, high processing efficiency, low equipment cost, strong equipment adaptability, no material blockage phenomenon, few production faults, low manufacturing cost and resource economization.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

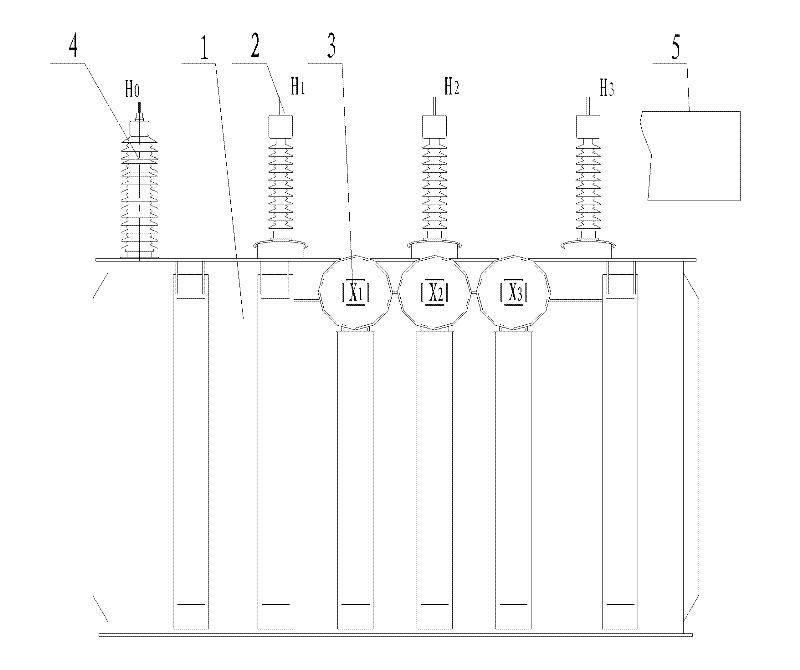

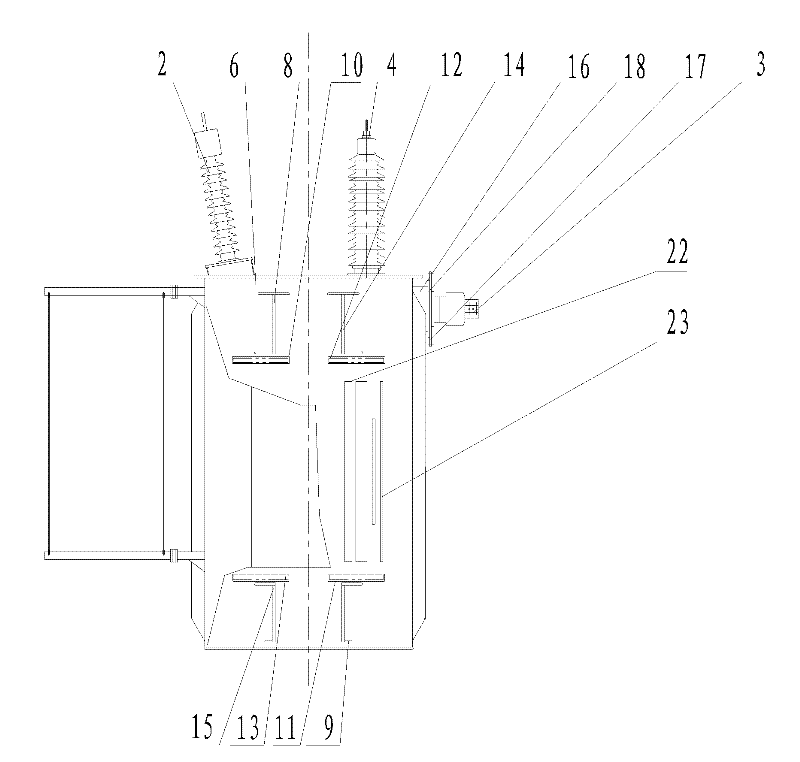

Transformer for realizing voltage change through changeover of leads

ActiveCN102543398AFirmly connectedMeet the technical parametersTransformers/inductances coolingTransformers/inductances coils/windings/connectionsLow voltageFuel tank

The invention relates to a transformer for realizing voltage change through changeover of leads. The transformer comprises a high voltage bushing, low voltage bushings, a high voltage neutral point bushing, an oil storage cabinet, an oil tank, a box cover, a cooling device and a tap-changer without excitation, wherein a three-phase three-column iron core structure is arranged in the oil tank; the three-phase three-column iron core is sleeved with a low voltage winding I, a high voltage winding, a voltage adjusting winding and a low voltage winding II from inside to outside respectively; the low voltage winding I is connected in series with the low voltage winding II; the low voltage winding I is wound leftwards; the low voltage winding II is wound rightwards; the two low voltage windings are connected end to head; the head part of the low voltage winding II is arranged at the upper end; and two low voltage windings are connected with a power generator by three low voltage bushings through changeover of the leads at the upper and lower parts. According to the invention, two low voltages are realized through changeover of two sets of leads, so that the two low voltages can be guaranteed to be connected with the power generator, and the technical parameters, the field external limitations, the foundation bearings and the weight requirements of the transformer in the prior art are satisfied at the same time.

Owner:特变电工山东沈变电气设备有限公司

Drying treatment system of slurry

ActiveCN103134288AImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingCouplingSlurry

The invention relates to a drying treatment system of slurry. The drying treatment system is characterized by comprising a slurry raw material storing warehouse, a scraper conveying machine, a prepared material cabin, a slurry drying machine, a coal dust gas dusting machine, a gas recycling device and a finished product storing warehouse. If a chain wheel of the scraper conveying machine in the treatment system needs to be replaced, users only need to detach a plurality of bolts instead of detaching a coupler, a bearing base, an end cover and a bearing, so that the chain wheel can be replaced, the replacing procedures are greatly reduced, and the replacing efficiency is greatly improved. The drying treatment system has the advantages of being low in energy consumption, low in noise, strong in structural stability, high in processing efficiency, low in device cost, strong in device adaptation, free of blocking, less in production failure, low in manufacture cost, and capable of saving resources.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

Novel car trunk cover plate and preparation method thereof

InactiveCN104527163AMeet load-bearing requirementsPlay a load-bearing roleSynthetic resin layered productsLaminationEngineeringHot-melt adhesive

The invention provides a novel car trunk cover plate and a preparation method thereof. The novel car trunk cover plate comprises an EPP foaming layer, wherein the surface of the EPP foaming layer is compounded with a first hot melt adhesive film layer, and the back of the EPP foaming layer is compounded with a second hot melt adhesive film layer; a surface decoration layer covers the first hot melt adhesive film layer; and a bottom decoration layer covers the second hot melt adhesive film layer. Materials are completely environmentally-friendly, do not have any odor and can be recycled by 100 percent, the lightweight of the cover plate is improved by over 50 percent, and the bearing capacity of the cover plate meets the related weight bearing requirement of automobiles.

Owner:北京长城华冠汽车技术开发有限公司

Drying process production line of coal slime

ActiveCN103123211AImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingResource savingCoal dust

The invention relates to a drying process production line of coal slime. The drying process production line of the coal slime is characterized by comprising a coal slime raw material storage warehouse, a scraper conveyer, a preparing storage bin, a coal slime drying machine, a coal dust gas dusting machine, a gas recycling device and a finished product storage warehouse. A stirring device of the coal slime drying machine in the production line is provided with a large torque starter. A motor can recover to a normal working state rapidly by the starter so that drying production efficiency of the coal slime materials can be improved, and meanwhile labor cost is saved. The drying process production line of the coal slime has the advantages of being low in energy consumption, low in noise, good in structure stability, high in processing efficiency, low in equipment cost, good in equipment adaptability, free from material blocking phenomenon, small in production malfunction, low in manufacturing cost and resource-saving.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

Drying treatment production line of slurry

ActiveCN103134282AImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingProduction lineSlurry

The invention relates to a drying treatment production line of slurry. The drying treatment production line is characterized by comprising a slurry raw material storing warehouse, a scraper conveying machine, a prepared material cabin, a slurry drying machine, a coal dust gas dusting machine, a gas recycling device and a finished product storing warehouse. A heat source control device is arranged on a hot air inlet portion of the slurry drying machine of the production line, hot air inlet amount can be regulated according to the moisture content of the fed materials of the drying device to achieve the aim of energy saving, and simultaneously, the drying treatment production line is convenient to adjust, easy to operate and capable of saving a large amount of manpower and time. The drying treatment production line has the advantages of being low in energy consumption, low in noise, strong in structural stability, high in processing efficiency, low in device cost, strong in device adaptation, free of blocking, less in production failure, low in manufacture cost, and capable of saving resources.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

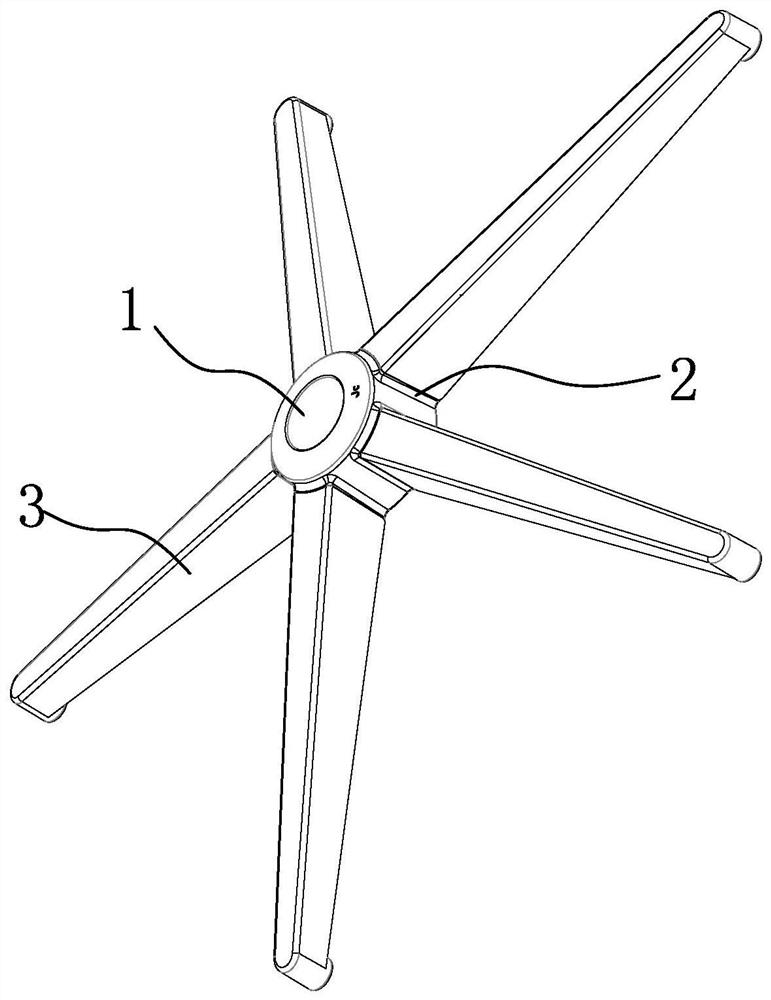

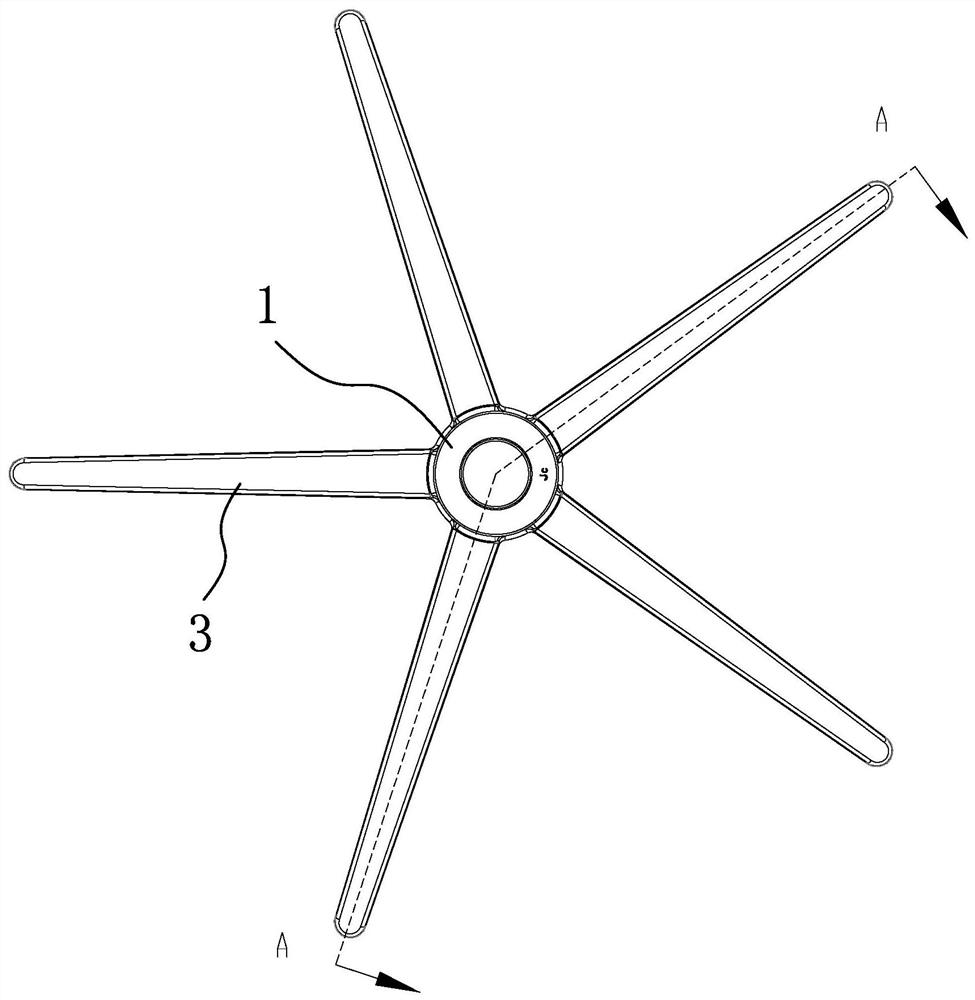

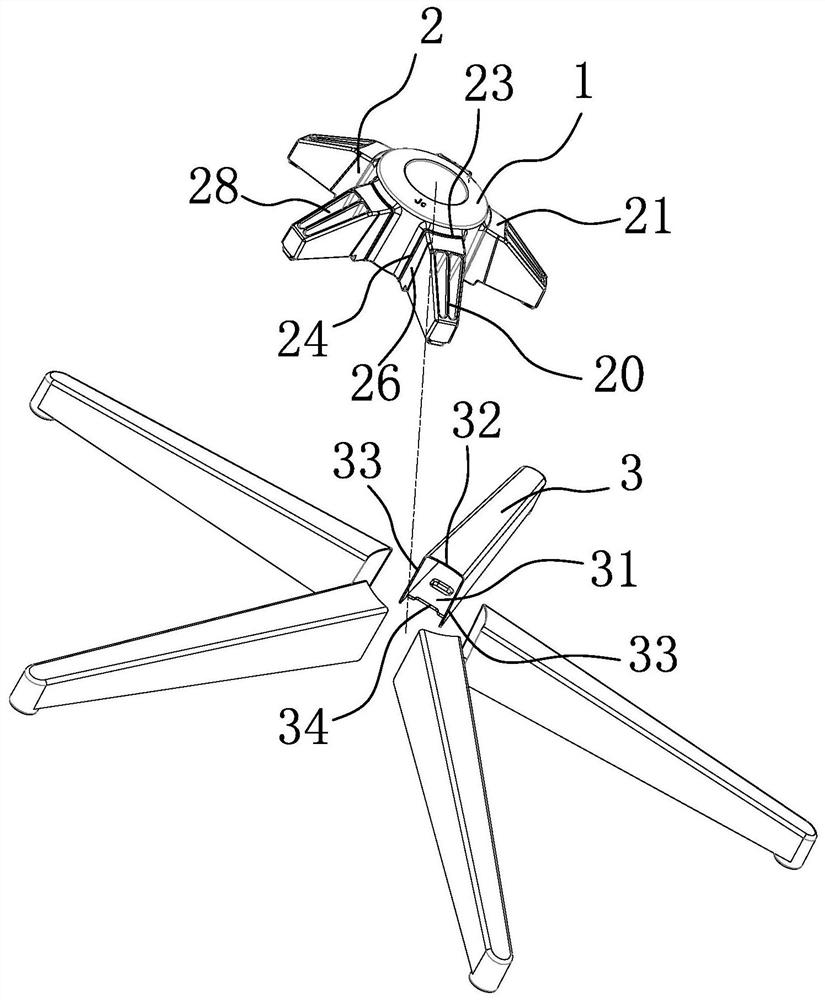

Combined detachable chair leg

PendingCN111631547AGood load-bearing performanceSimplify the assembly processStoolsChairsEngineeringPhysical therapy

A combined detachable chair leg comprises a middle disc seat and five single-foot connecting seats, and the five single-foot connecting seats are connected to the circumference of the middle disc seatand are uniformly distributed in the circumferential direction; the upper surface of each single-foot connecting seat is provided with an avoiding inclined plane and a matching inclined plane I whichare sequentially connected from outside to inside; the combined detachable chair leg also comprises five overturning assembly single feet in one-to-one correspondence with the single-foot connectingseats; matched inclined planes II are arranged on the inner walls of the upper sides of the ends, close to the single-foot connecting seats, of the overturning assembly single feet; an inner axial locking structure is arranged between the end, close to the middle disc seat, of each single-foot connecting seat and the end, close to the single-foot connecting seat, of the corresponding overturning assembly single foot, and when the overturning assembly single feet overturn upwards to enable the matching inclined planes I to be matched with the matching inclined planes II, the overturning assembly single feet can be limited from moving towards the side of the middle disc seat excessively in the axial direction of the single-foot connecting seats by inner axial locking structure, and an outeraxial concave-convex locking structure for preventing the corresponding overturning assembly single foot from being separated outwards along the axial direction of the corresponding single-foot connecting seat is arranged between one end, far away from the middle disc seat, of the lower surface of each single foot connecting seat and the lower side edge of the corresponding overturning assembly single foot.

Owner:李晨欢

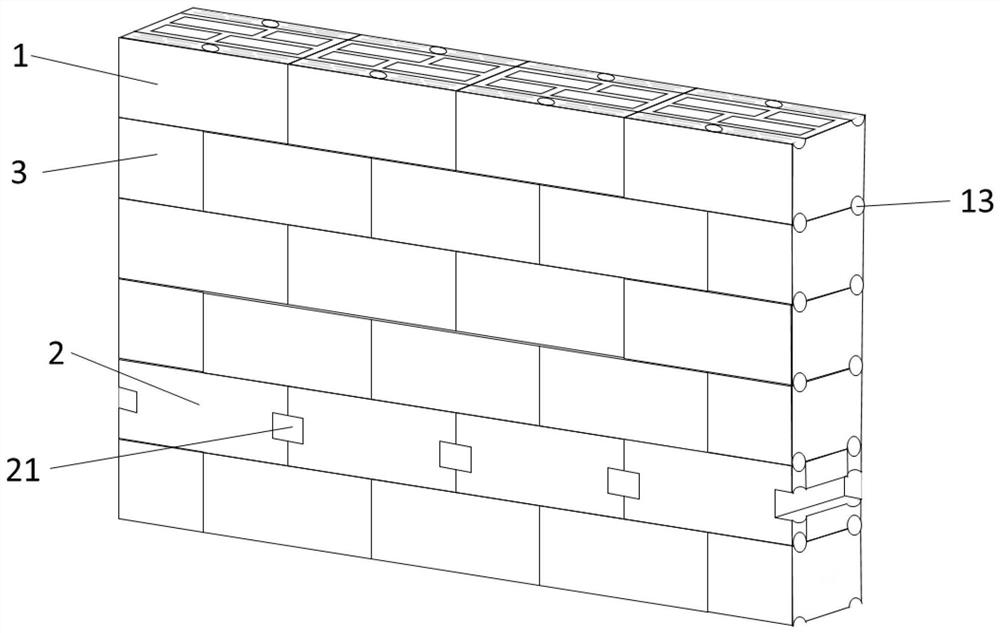

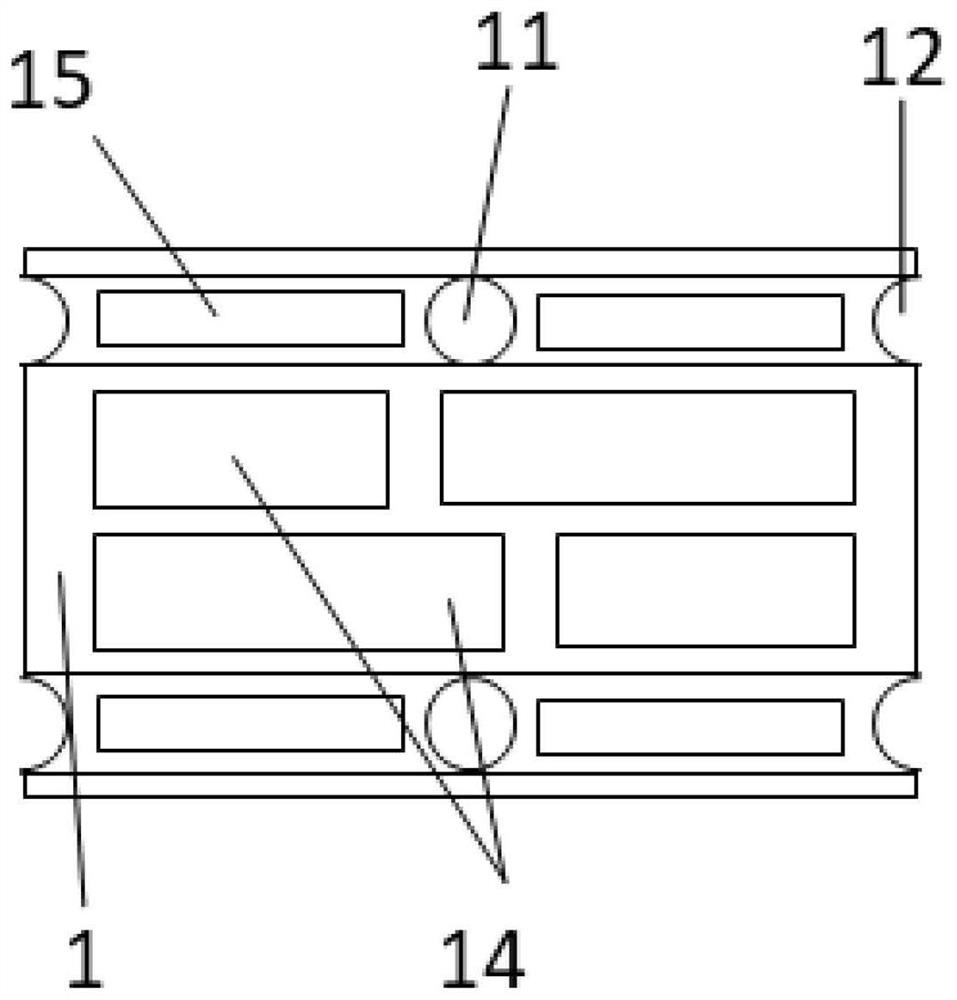

Prefabricated self-insulation recycled concrete house system and construction method thereof

PendingCN112554435AImprove integrityImprove bearing capacityStrutsWallsArchitectural engineeringStructural engineering

The invention discloses a prefabricated self-insulation recycled concrete house system and a construction method thereof. A wall body comprises a beam column system, a structural layer and a decorative layer, wherein the decorative layer is attached to one surface of the structural layer; the beam column system comprises an upper edge beam, a lower edge beam, a left side column and a right side column; the structural layer is a multilayer brickwork, and the multilayer brickwork comprises a plurality of layers of wall bodies which are built with main building blocks, a layer of wall body whichis built with auxiliary building blocks and end building blocks; the left side column and the right side column are respectively arranged on both ends of the lower edge beam; the structural layer is built on the lower side beam and is located between the left side column and the right side column; the upper edge beam is arranged on the top of the structural layer; a first concave opening and a first convex opening are respectively formed in the outer sides of the left side column and the right side column; and a second convex opening is formed in the top of the upper edge beam, and a second concave opening is formed in the bottom of the lower edge beam. A connecting piece is arranged so as to connect the structural layer and the decorative layer, so that the assembly is convenient, and thesplicing efficiency is greatly improved.

Owner:CHANGAN UNIV

Drying treatment system of slurry

ActiveCN103134287AImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingThermal insulationSlurry

The invention relates to a drying treatment system of slurry. The drying treatment system is characterized by comprising a slurry raw material storing warehouse, a scraper conveying machine, a prepared material cabin, a slurry drying machine, a coal dust gas dusting machine, a gas recycling device and a finished product storing warehouse. Material raising teeth of the slurry drying machine in the treatment system can effectively eliminate the phenomenon of journal sticking of sticky materials, and the drying treatment system of slurry is abrasion-resisting and thermal-insulation and can effectively improve production efficiency and prolong the service life. The drying treatment system has the advantages of being low in energy consumption, low in noise, strong in structural stability, high in processing efficiency, low in device cost, strong in device adaptation, free of blocking, less in production failure, low in manufacture cost, and capable of saving resources.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

Assembled thermal insulation decoration composite structure slab

InactiveCN104831886AWith heat preservation functionWith fire protection functionCovering/liningsBridge structural detailsCarrying capacityThermal insulation

The invention relates to an assembled thermal insulation decoration composite structure slab, which belongs to the field of slabs and comprises an end part, an upper structure layer, a middle structure layer, a core layer I, a core layer II, a lower structure layer and a decoration layer, wherein, the decoration layer is adhered to the lower surface of the lower structure layer and forms an integral structure together with three layers of steel plates of the upper structure layer, the middle structure layer and the lower structure layer through riveting or welding; the spaces between the structure layers are filled with the core layers and the core layers are thermal insulation layers or support layers formed by high label concrete; the composite structure slab has the advantages of no maintenance, lightweight, large carrying capacity, thermal insulation, sound insulation, seismic resistance, long service life, convenience in construction and the like.

Owner:SHANDONG YIBANG ENERGY TECH

Bridge-cutoff self-insulation concrete block and fabrication technology thereof

ActiveCN106812240AImprove insulation effectImprove mechanical propertiesConstruction materialClimate change adaptationGlass fiberBuilding energy

The invention relates to a bridge-cutoff self-insulation concrete block for building energy conservation and a fabrication technology of the block, and belongs to the technical field of building materials. The block is formed by combining a bridge-cutoff concrete hollow block provided with trapezoidal bulges and trapezoidal grooves and insulation materials, wherein the insulation materials are located in two cavities defined by the concrete hollow block; the concrete hollow block is fabricated from materials such as cement and fine stone, and provided with two bridge-cutoff connecting blocks to connect concrete; each bridge-cutoff connecting block consists of a plurality of glass fiber reinforcement ribs and polyurethane, and is fabricated in a bridge-cutoff connecting block mold; the glass fiber reinforcement ribs in the bridge-cutoff connecting blocks do not pass through the insulation materials of the block, so that the integrity of the insulation materials is kept. The block is applicable to construction of bearing and non-bearing walls, and has the advantages of high convenience in fabrication, good mechanical property, good insulation property, low cost and the like.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

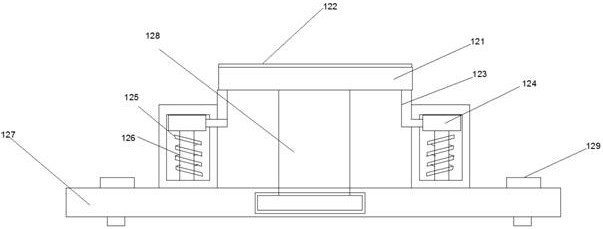

Machine packing case double as workbench and method of use thereof

The invention discloses a machine packaging box doubling as a workbench and a use method of the machine packaging box and belongs to the technical field of packaging. The machine packaging box doubling as the workbench comprises a base, a shear type lifting mechanism and a packaging box main body; the packaging box main body is installed on the base through the shear type lifting mechanism and isof a cuboid structure formed by a box body bottom plate, box body side plates and a box body top plate; the four side edges of the box body bottom plate are rotationally connected with four groups ofthe box body side plates respectively; and the box body top plate is rotationally connected with the side edge of one group of the box body side plate. As for the machine packaging box provided by theinvention, by arranging the lifting mechanism below the packaging box main body and utilizing original structure deformation of the packaging box main body, the machine packaging box has two purposesas being capable of packaging a transported product and being used by doubling as the workbench of a machine, lowers the cost of additionally purchasing the workbench, avoids resource waste caused bypackaging box abandoning, has very good practical value and is worthy of being widely popularized and used.

Owner:CHANGZHOU INST OF TECH

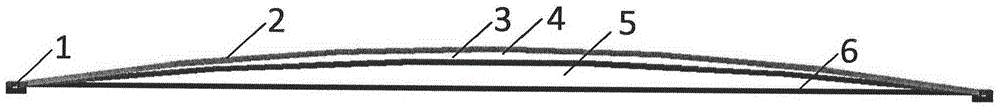

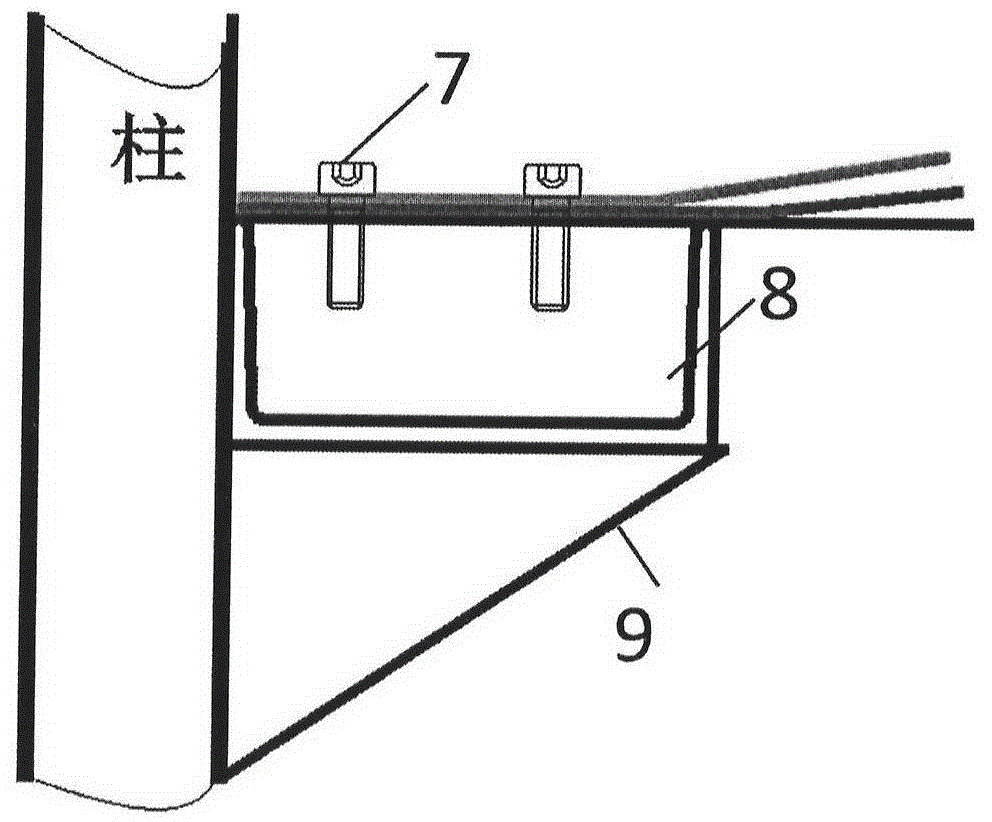

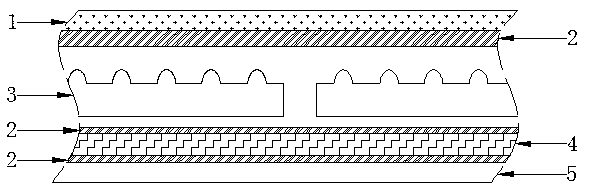

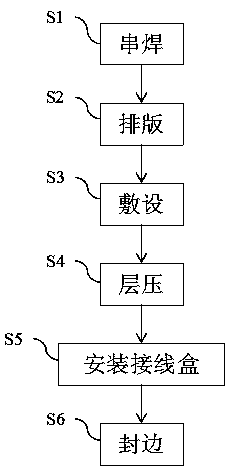

One-step molded light-duty PVT (photovoltaic-solar-thermal) assembly and preparation method therefor

PendingCN109494271AReduce weightMeet load-bearing requirementsPhotovoltaic energy generationSemiconductor devicesIsolation layerEngineering

The invention relates to a PVT (photovoltaic-solar-thermal) technical field, and specifically relates to a one-step molded light-duty PVT assembly and a preparation method therefor. The PVT assembly sequentially comprises a front protection layer, a photovoltaic cell string layer, an isolation layer and a thermal collection layer. Bonding layers are respectively disposed between two adjacent layers, and all layers of the PVT assembly are stacked and then the exterior of the stacked layers is provided with an edge sealing strip. The preparation method comprises the following steps: series welding- type setting-laying-laminating-wiring box installation-edge sealing. The PVT assembly takes the thermal collection layer as a support main body. Compared with a PVT assembly in the prior art, thePVT assembly reduces the weight by 50% or more, and solves a problem that a conventional PVT one-step molding of a photovoltaic assembly-thermal collection plate is difficult. The method provided by the invention optimizes the one-step molding technology, and reduces the production cost while simplifying the production process.

Owner:LINUO PV HIGH TECH

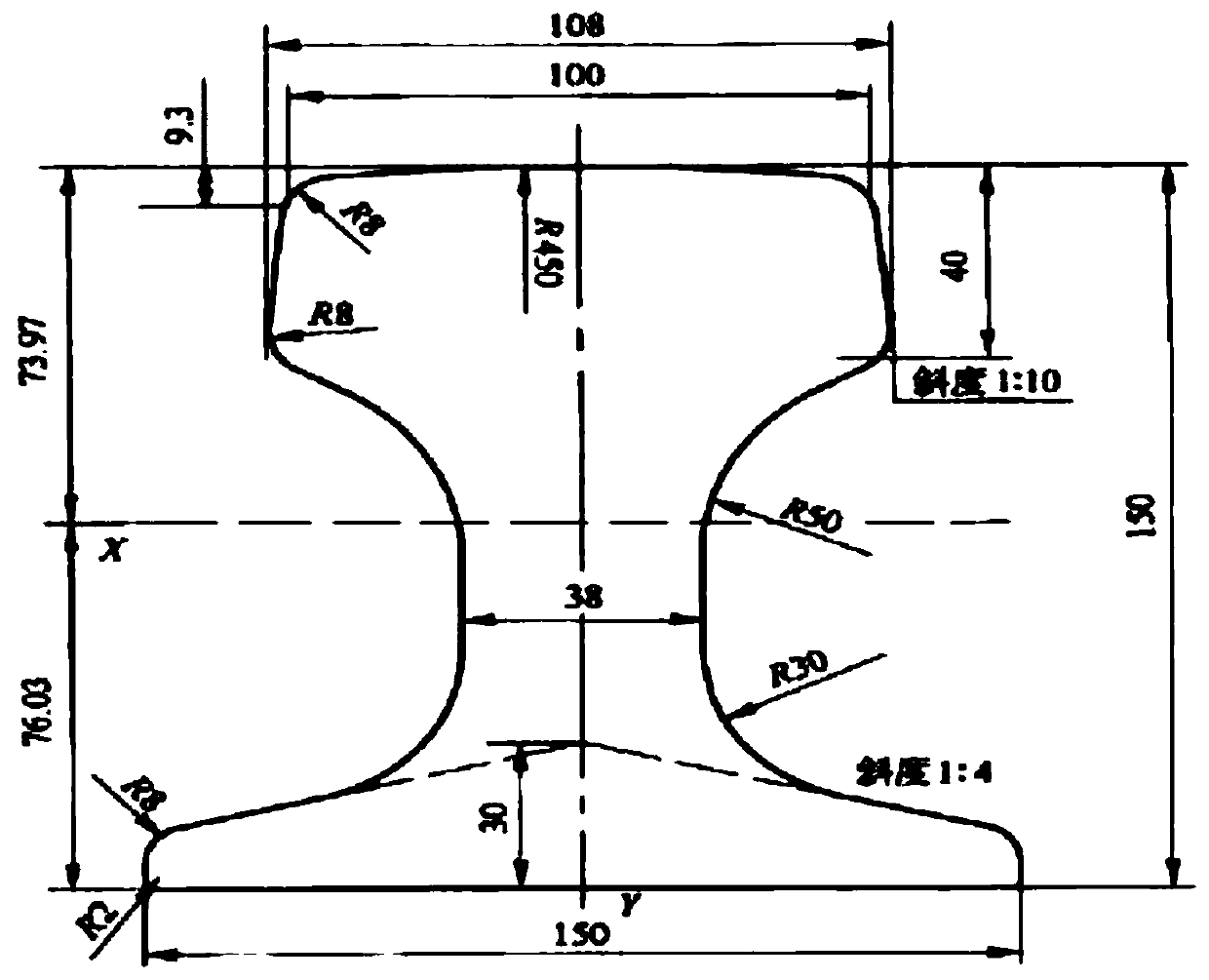

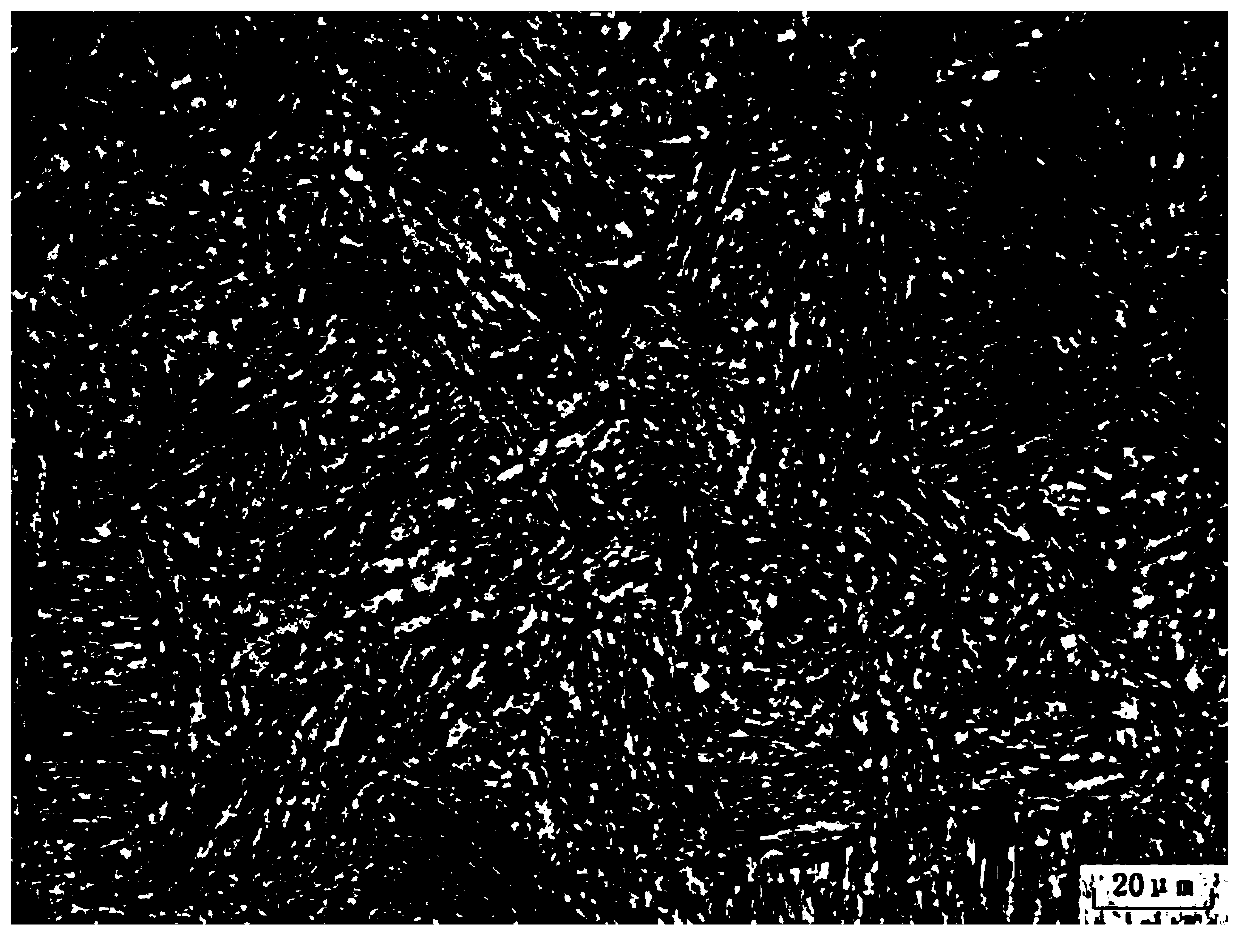

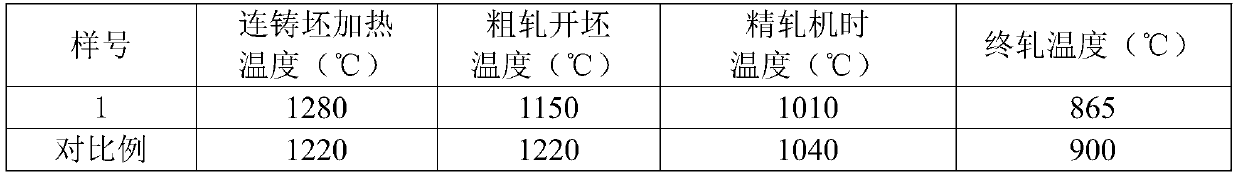

High strength and toughness steel rail for crane and manufacturing method thereof

InactiveCN110885950AImprove toughnessGood load-bearing requirementsFurnace typesMetal rolling arrangementsAustenite grainMetallurgy

The invention belongs to the technical field of steel rails, and particularly relates to a high strength and toughness steel rail for a crane and a manufacturing method thereof. The steel rail comprises the following components of, in percentage by weight, 0.15%-0.30% of C, 1.20%-1.70% of Si, 1.50%-2.50% of Mn, less than or equal to 0.025% of P, less than or equal to 0.015% of S, 0.30%-0.80% of Cr, 0.30%-0.70% of Mo, 0%-0.08% of Nb, 0%-0.020% of Ti, 0.20%-0.60% of Ni, the balance Fe, and unavoidable impurities; and the manufacturing method of the steel rail comprises the following steps that the soaking temperature of a continuous casting billet is 1280-1340 DEG C, the heat preservation time is 1-1.5 hours, two-stage rolling is carried out, straightening and heat-preserving are carried out, and then cooling is carried out. According to the manufacturing method, the production method is adopted, C-Si-Mn-Cr-Mo-Ni are utilized, microalloying elements such as Nb and Ti are added compositely, and the rolling interval time and the temperature of each steel rolling process are controlled, so that a refined austenite grain is obtained, and air cooling is carried out, so that the crane steel rail with a lath bainite structure with good strength and toughness is obtained.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com