Assembled thermal insulation decoration composite structure slab

A composite structure and prefabricated technology, which is applied in building structure, covering/lining, construction, etc., can solve the problems of increasing material consumption, prolonging the construction period, delaying the construction process, etc., so as not to fall off and hurt people, improve seismic performance, Guaranteed the effect of overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

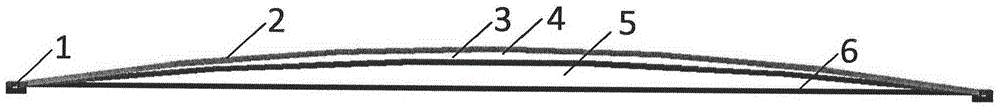

[0021] Such as figure 1 As shown, an assembled thermal insulation and decorative composite structural board includes an end portion 1, an upper structural layer 2, an intermediate structural layer 3, a core layer I4, a core layer II5, a lower structural layer 6 and a decorative layer; wherein, the upper structural layer , The middle structural layer and the lower structural layer are all steel plates, and the three-layer steel plates are all arched upwards in an arc shape, the decorative layer is bonded to the lower surface of the lower structural layer, and the decorative layer and the three-layer steel plates are formed by riveting or welding at the ends Integrated structure; the space between the upper structure layer and the middle layer fills the core layer I, the space between the middle layer and the lower structure layer fills the core layer II, and the core layer is an insulation layer.

[0022] The upper structural layer is a 2mm thick steel plate.

[0023] The midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com