Installation method of building wall space facing materials

A technology of facing material and installation method, which is applied in the field of building wall decoration, can solve the problems of high consumption of steel materials, poor thermal insulation performance, poor reliability, etc., and achieves production cost reduction, simple structure, and easy manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

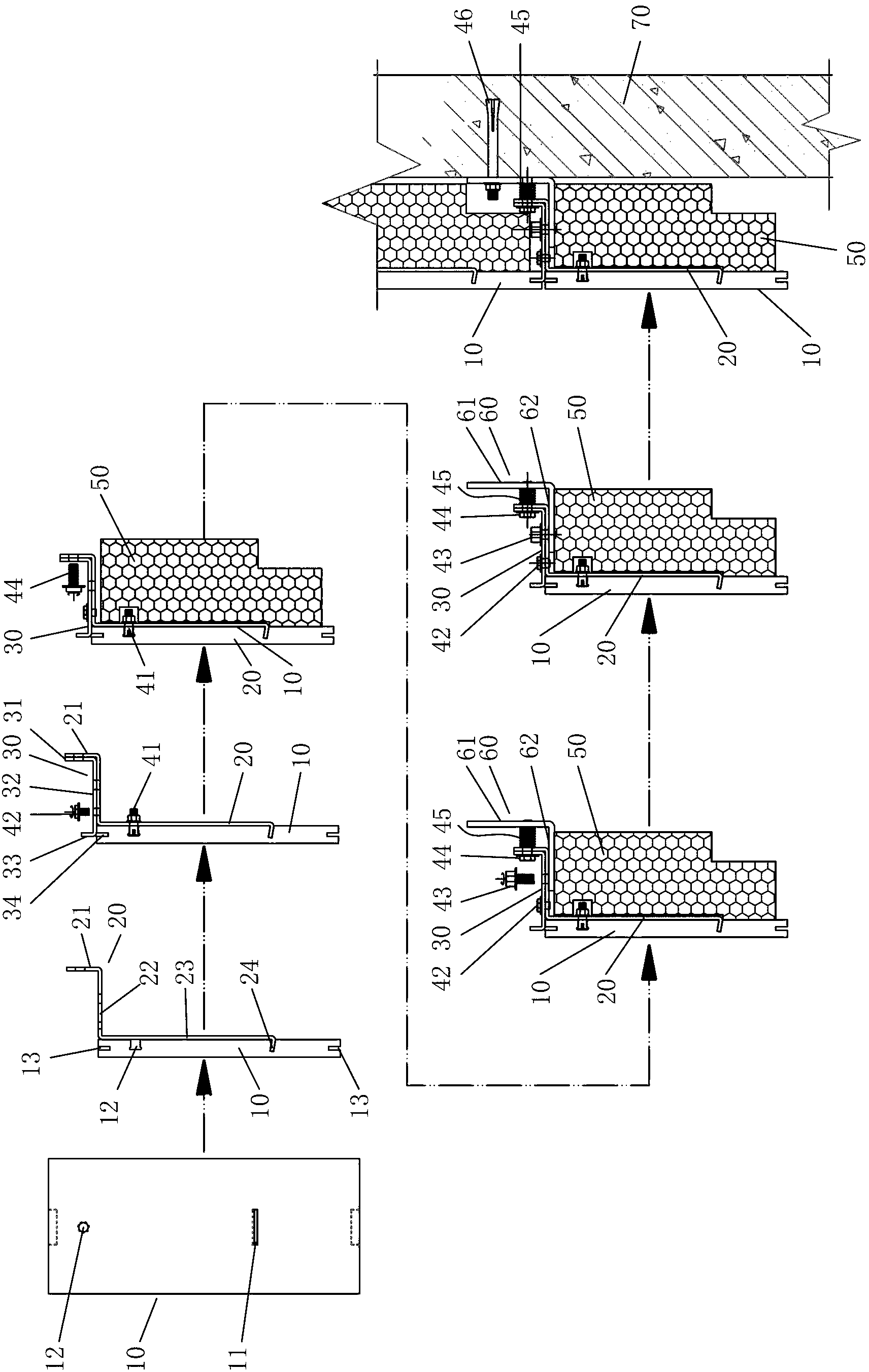

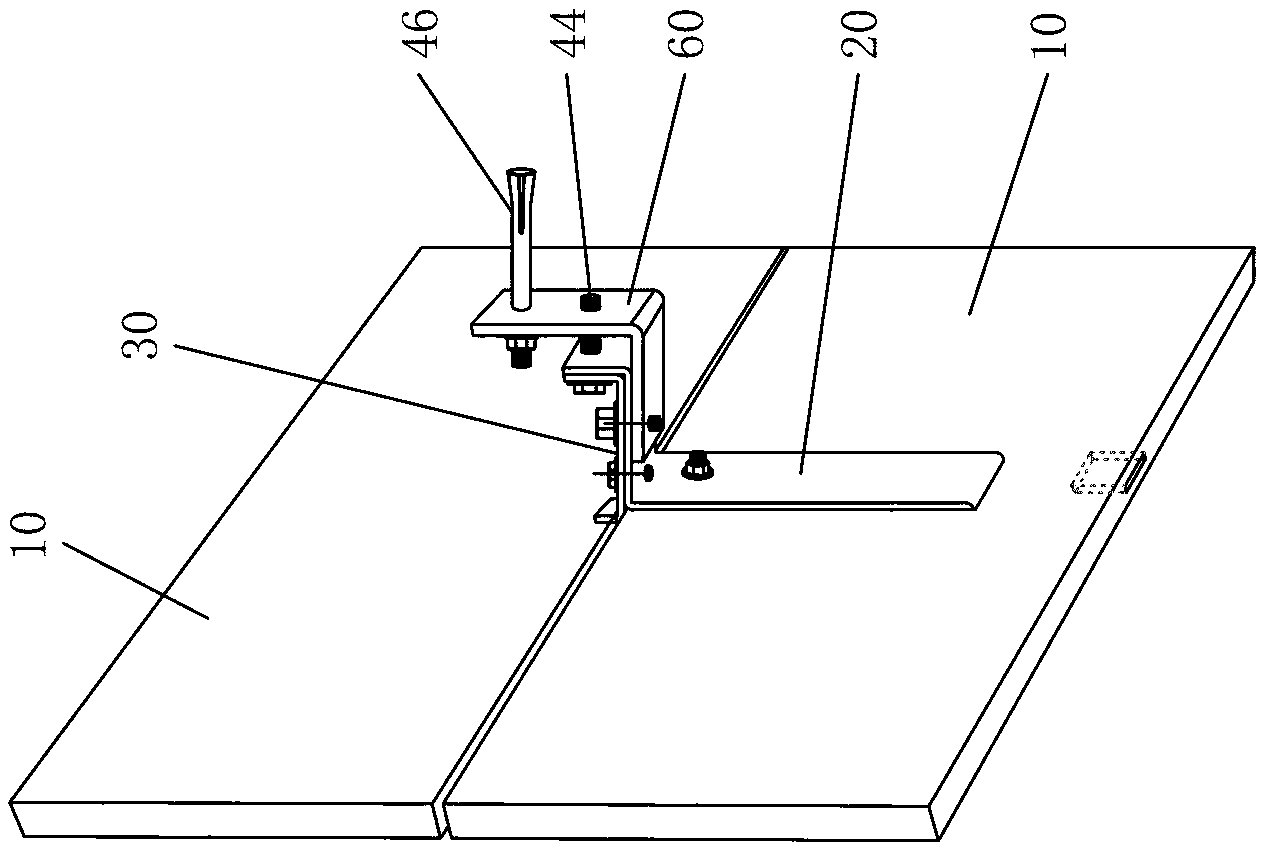

[0032] Example 1, see figure 1 — image 3 :

[0033] The installation method of building wall decoration materials includes the following steps:

[0034] (1) Make panel 10 and open chute 11 or chute 11 and straight slot 13 on the design position of panel 10, and install blind hole 12 for back bolt;

[0035] (2) Install the metal pendant:

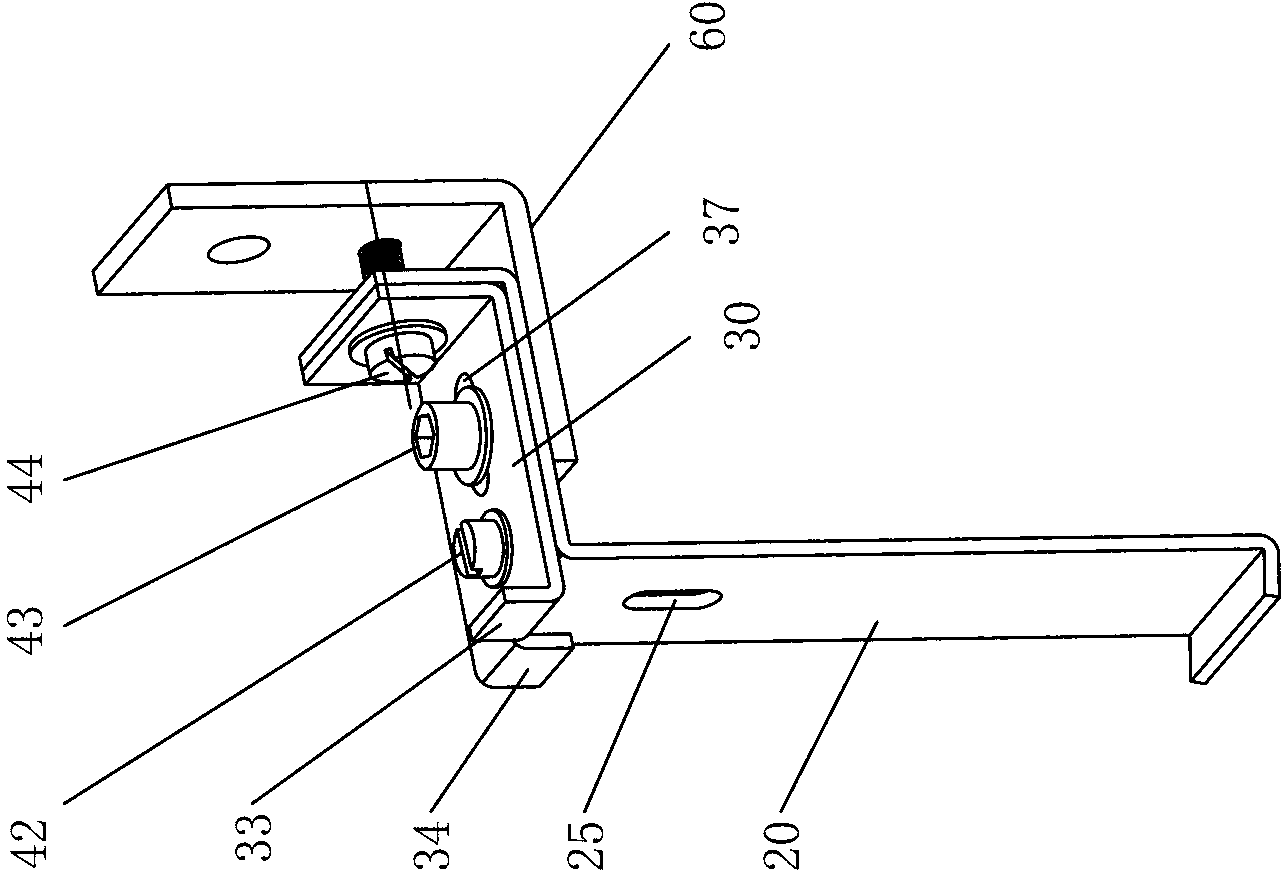

[0036] 1) Put the exposed horizontal part 22 of the pendant one 20 upward, hang the oblique hook 24 of the pendant one 20 on the chute 11, pass the back bolt 41 through the mounting hole on the pendant one 20 and fix it on the panel 10 superior;

[0037] 2) First, make the upper horizontal part 32 and 22 of the upper end of the second pendant 30 and the first pendant 20 fit together, and then fit the upper flange 31 and 21 on the inner side, and then install the second pendant 30 on the upper horizontal part 22 of the upper end of the first pendant 20 with screws 42 superior;

[0038] (3) On the back of the panel 10 where the pendant i...

Embodiment 2

[0046] Example 2, see Figure 4 — Figure 6 :

[0047] The structure of embodiment 2 is basically the same as that of embodiment 1, the difference is:

[0048] The slotting described in step (1) is to open the inclined slot 12 only on the back of the panel 10 .

[0049] The right angle flanging of the outer end of the pendant two 30 is only the upward flanging 38, and the pendant three 80 with only the bent part 81 and the oblique hook 82 is also provided, and the oblique hook 82 of the pendant three 80 is hung upward on the pendant On the chute 12 on the lower side of the first 20, use the back bolt 41 to pass through the installation hole on the third pendant 80 and fix it on the panel 10, wherein: the right-angled flanging is a flanging of approximately 90 degrees, not specifically 90 degrees The flanging, for example: the angle of the right-angle flanging is 95-90 degrees or 85-90 degrees or 90 degrees.

[0050] When the pendant 3 80 is installed on the above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com