Transverse supporting assembly for container equipment

A technology of container equipment and horizontal support, which is applied in the direction of mechanical equipment, supporting machines, machine platforms/supports, etc., can solve the problems of non-adjustable length of horizontal support rods and uneven load bearing of container equipment, and achieve simple structure and uniform load bearing , The effect of convenient installation and layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

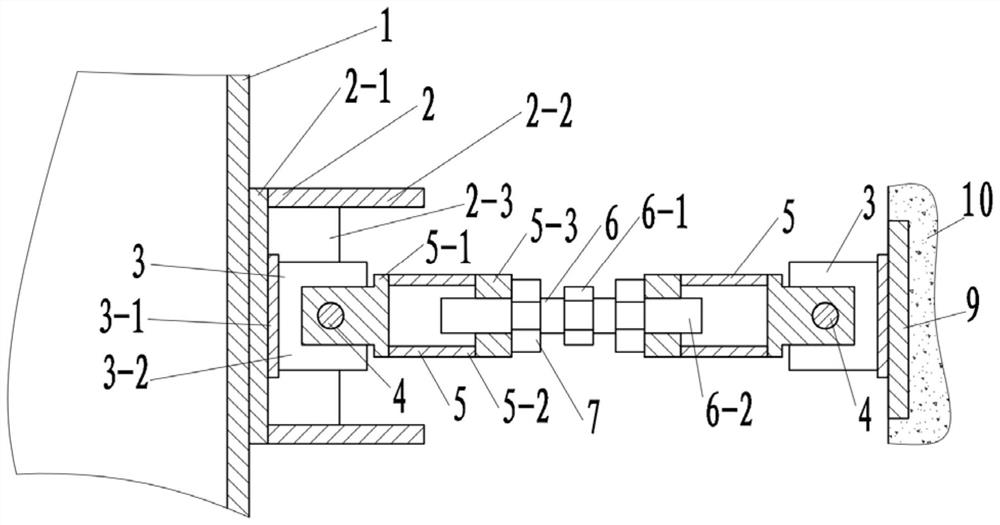

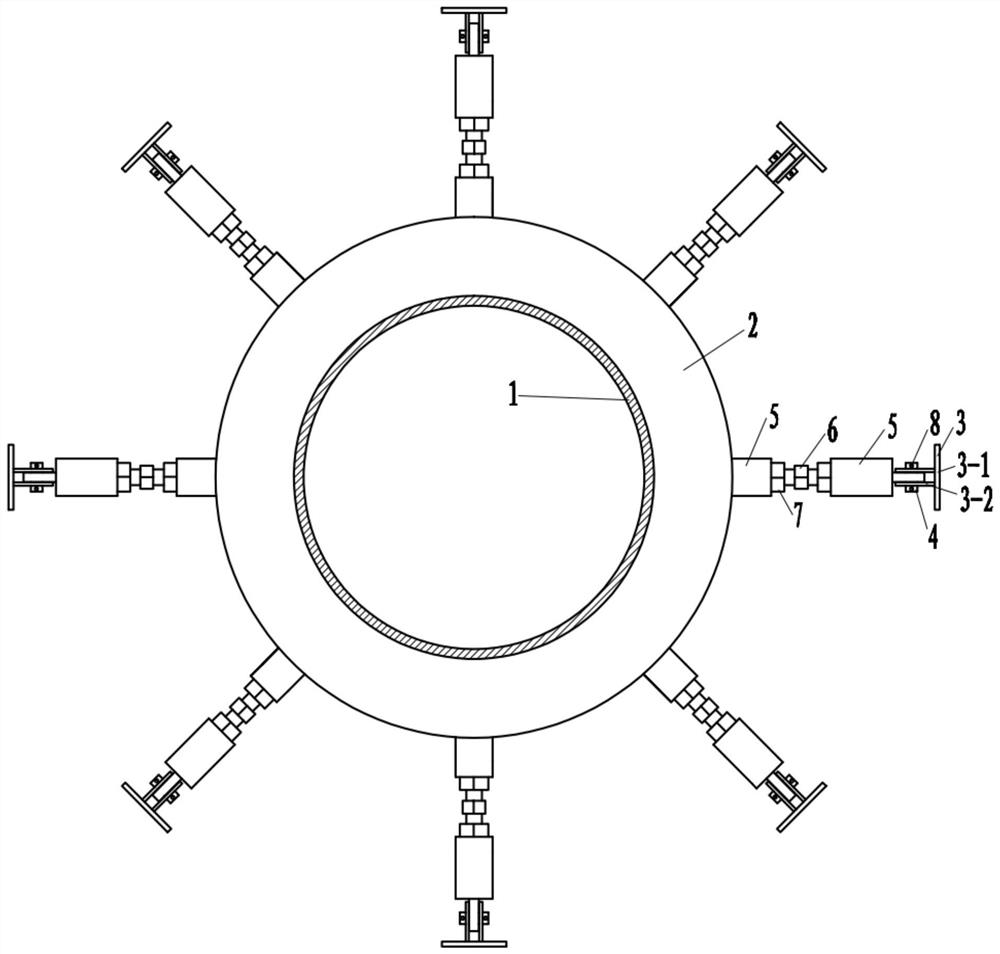

[0024] Such as figure 2 As shown, the present invention discloses a horizontal support assembly of container equipment, including a support 3, a pull rod assembly 5 and an adjustment assembly; the support 3 is hinged to the pull rod assembly 5; Easy to install and fix on site. The adjustment assembly realizes the adjustment of the distance between the two supports 3 by adjusting the distance between the two pull rod assemblies 5; the two supports 3 are respectively connected to the container equipment and the wall. Such as figure 1 As shown, the lateral support components are evenly arranged in the circumferential direction of the container equipment to achieve lateral support for the container equipment.

[0025] The tie rod assembly 5 includes a connecting head 5-1, a connecting pipe 5-2 and a threaded section 5-3; the connecting head 5-1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com