Elliptical compression spring structure and upholstered furniture elastic structure thereof

A compression spring, elliptical technology, applied in the field of elliptical compression spring structure and the elastic structure of upholstered furniture, can solve the problems that it is difficult to reach 80,000 times or just reach 80,000 times, which affects the service life of the product, and achieves simple structure, The effect of prolonging the service life and increasing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

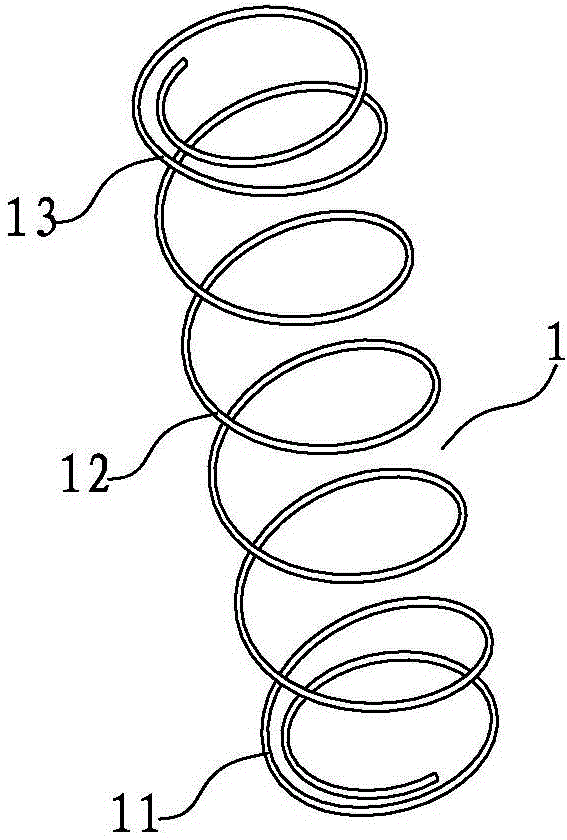

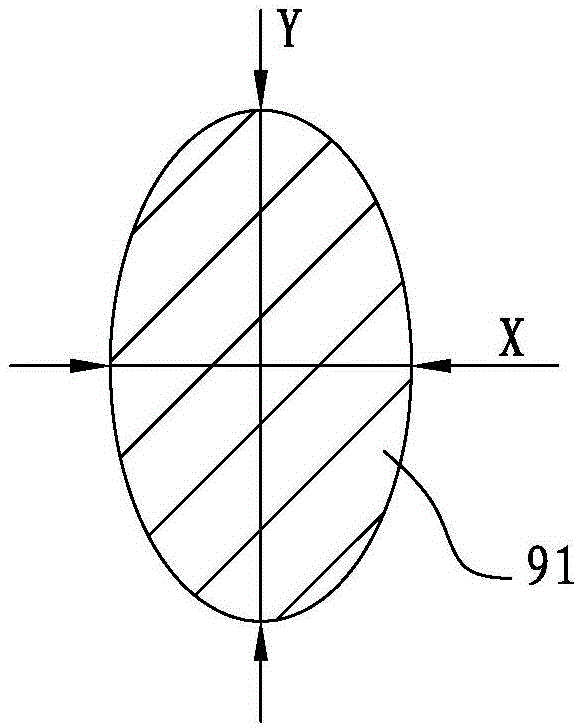

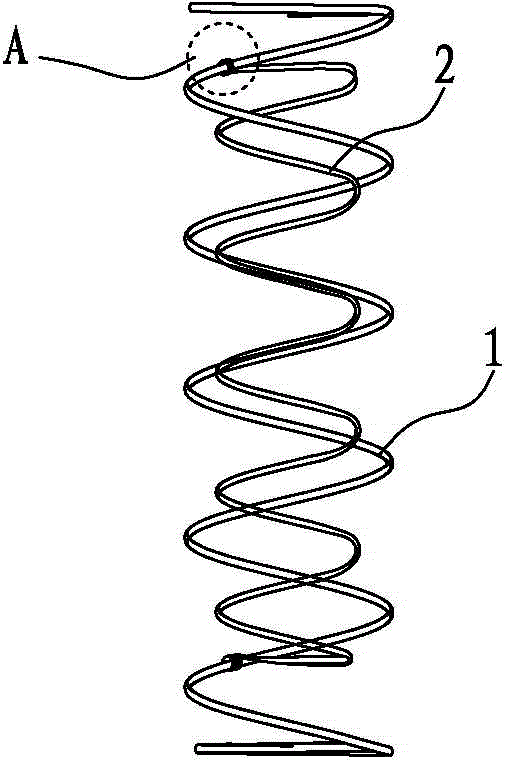

[0033] Such as Figure 1~Figure 4 As shown, an elliptical compression spring structure includes an elastic body 1 helically wound with a metal wire, the cross section of the metal wire is an elliptical cross section, and the minor axis X of the elliptical cross section is perpendicular to the compression direction, The major axis Y of the elliptical section is parallel to the compression direction; the metal wire generally adopts stainless steel wire, alloy steel wire 91 (such as figure 2 ) and other metal materials, since the spring structure adopts an elliptical cross-section, its long axis Y is parallel to the compression direction and is used to bear pressure, that is to say: in the actual winding process, ensure that the long axis of the ellipse Y is always parallel to the compression force direction, so that when the Y axis is under pressure, since the length...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com