Patents

Literature

93 results about "Upholstered furniture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

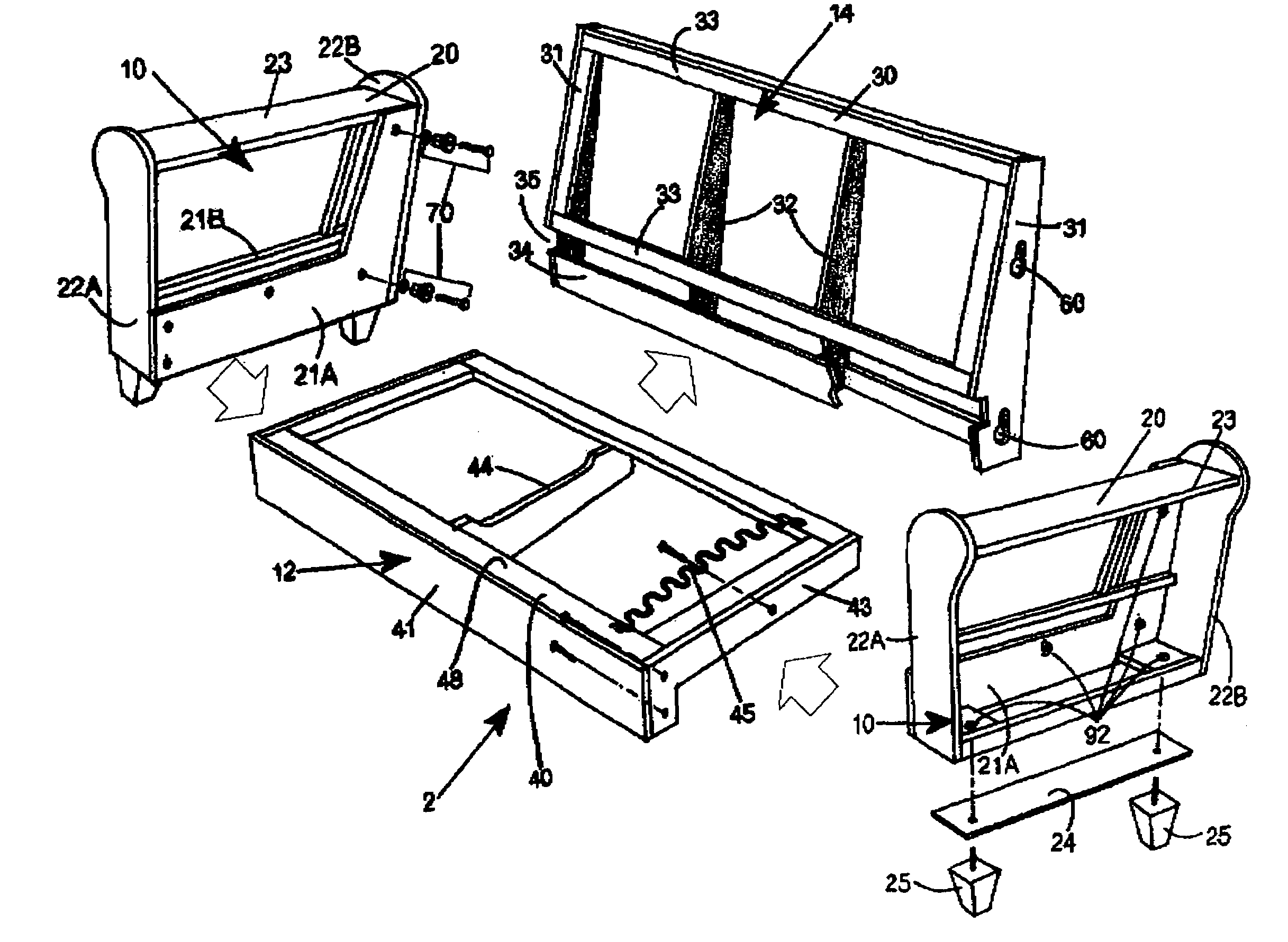

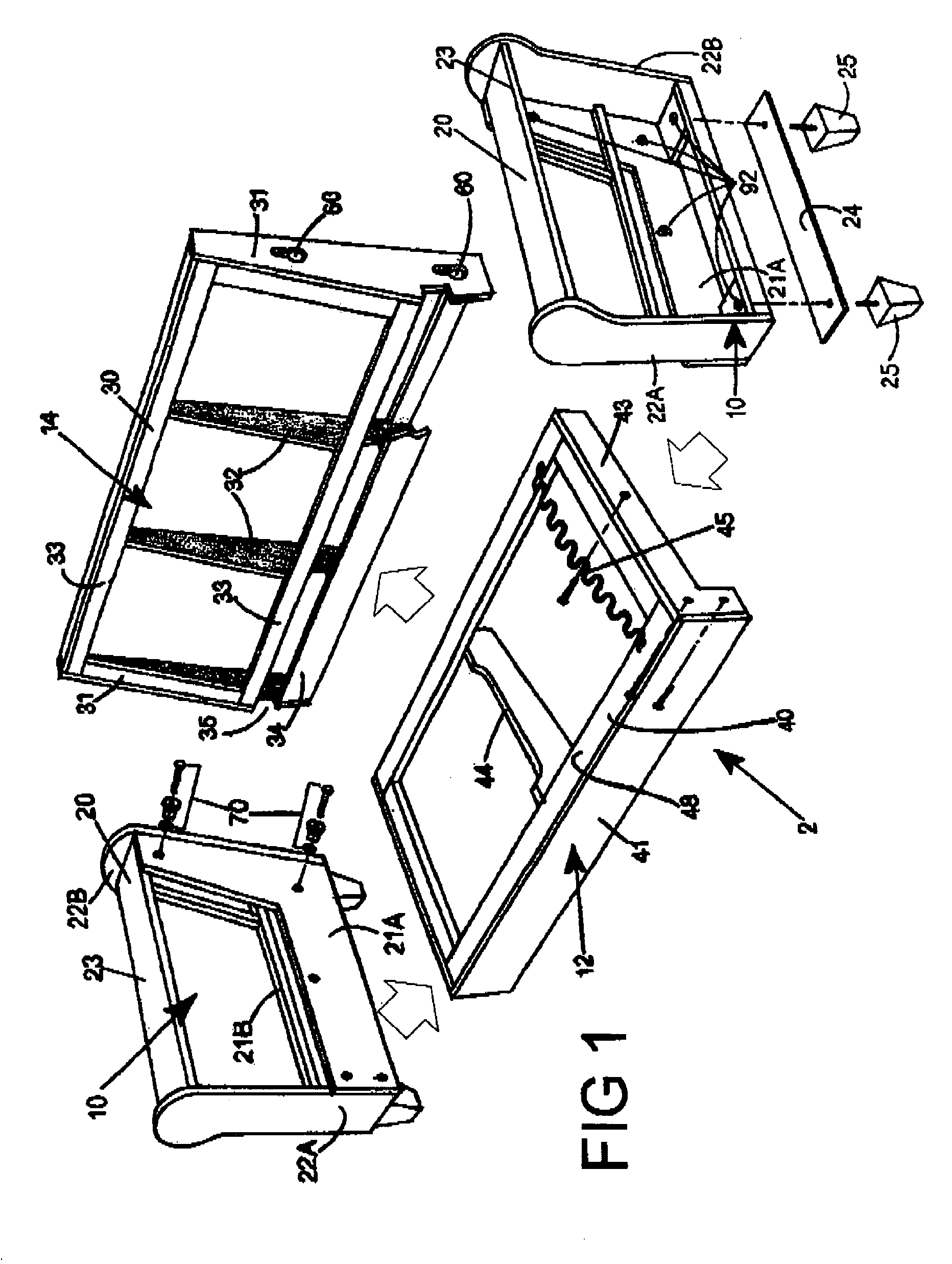

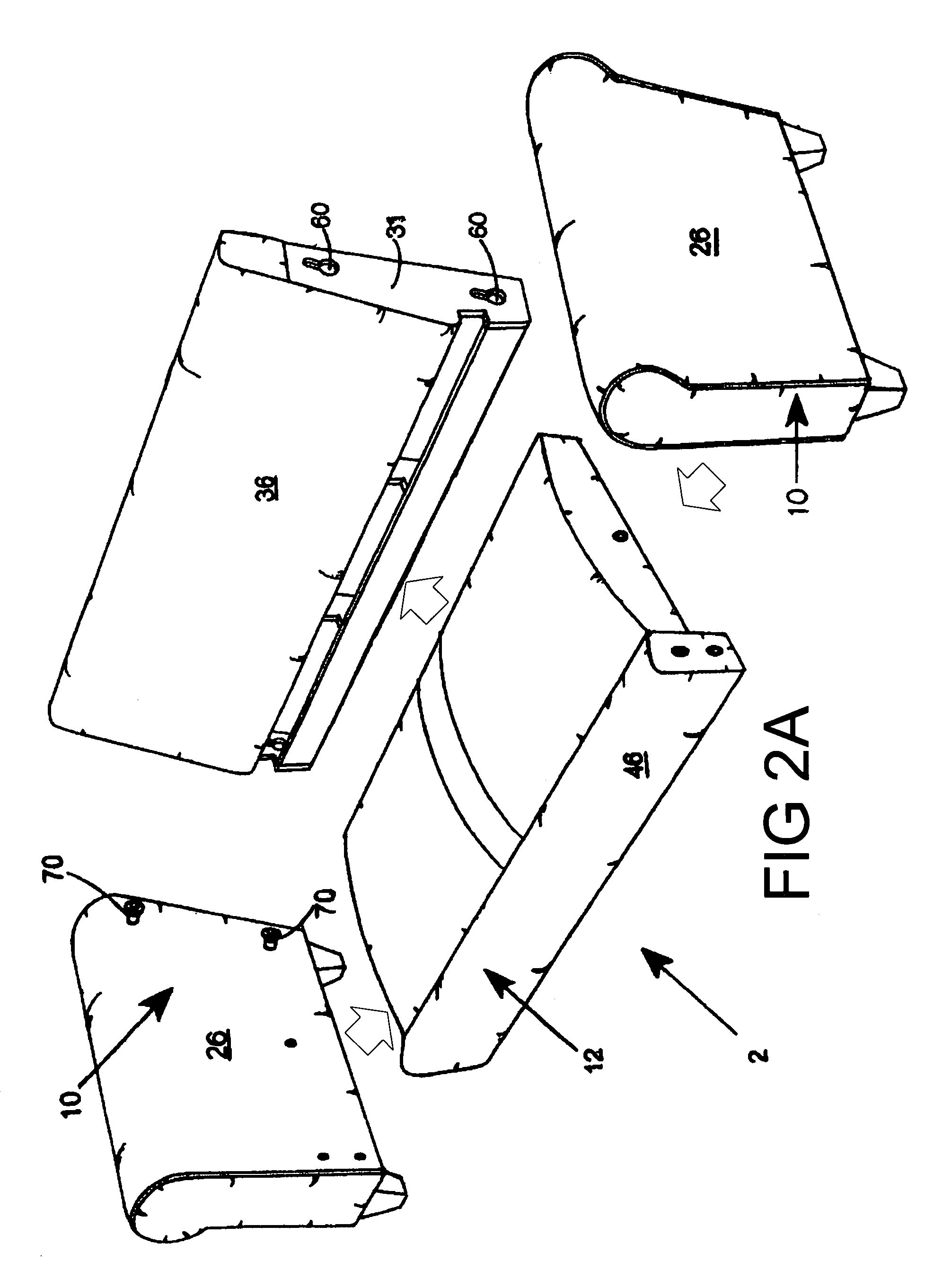

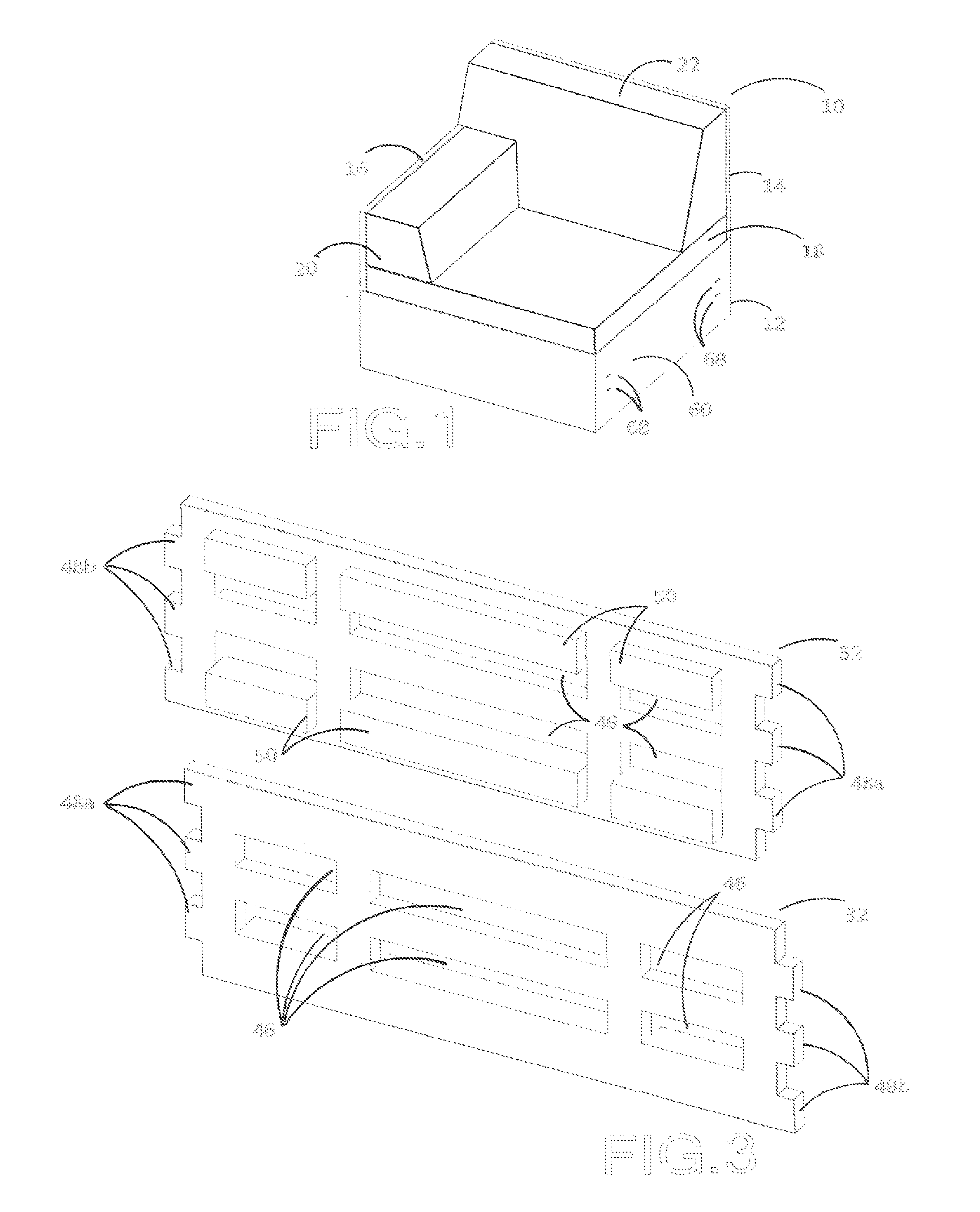

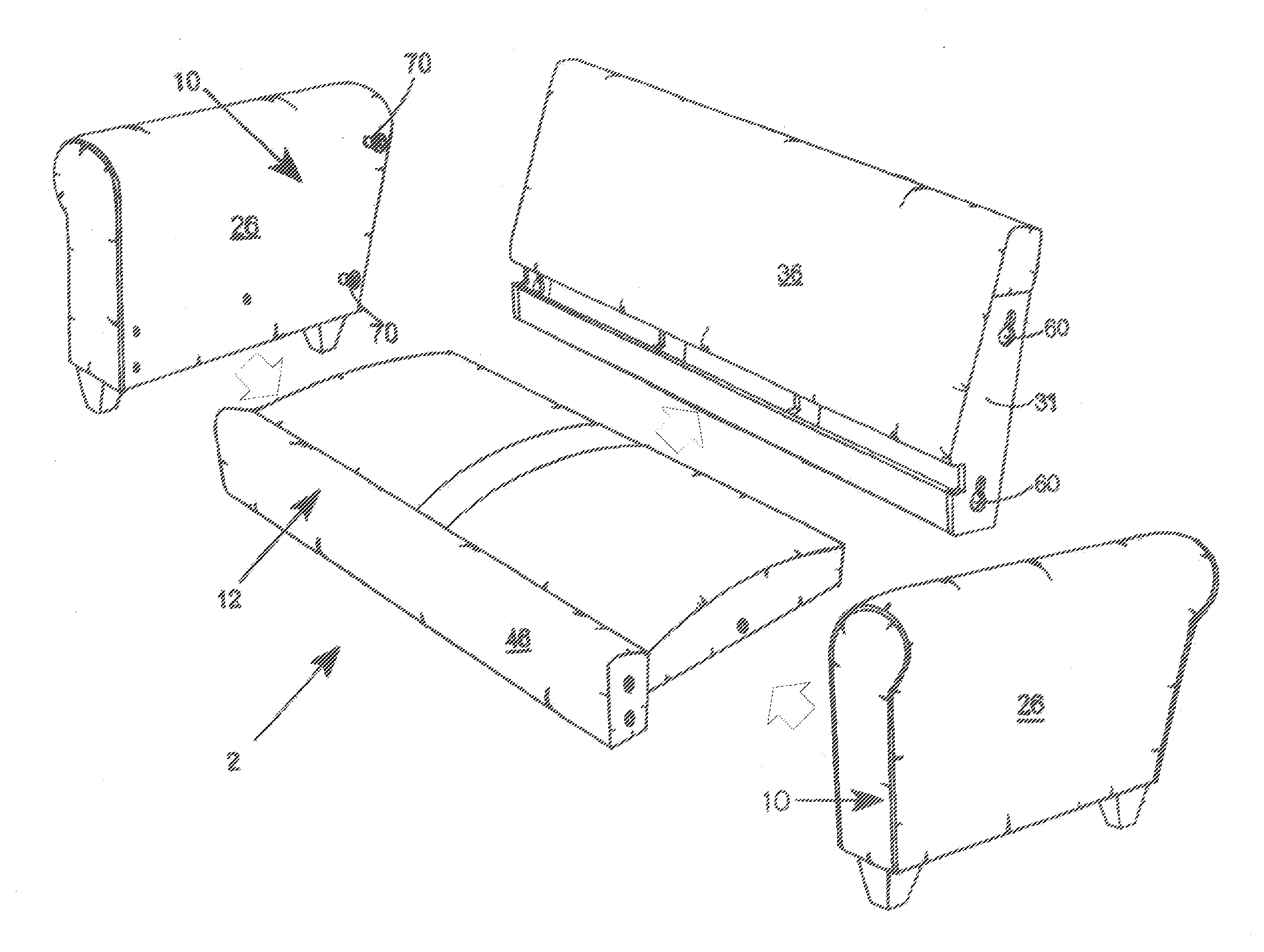

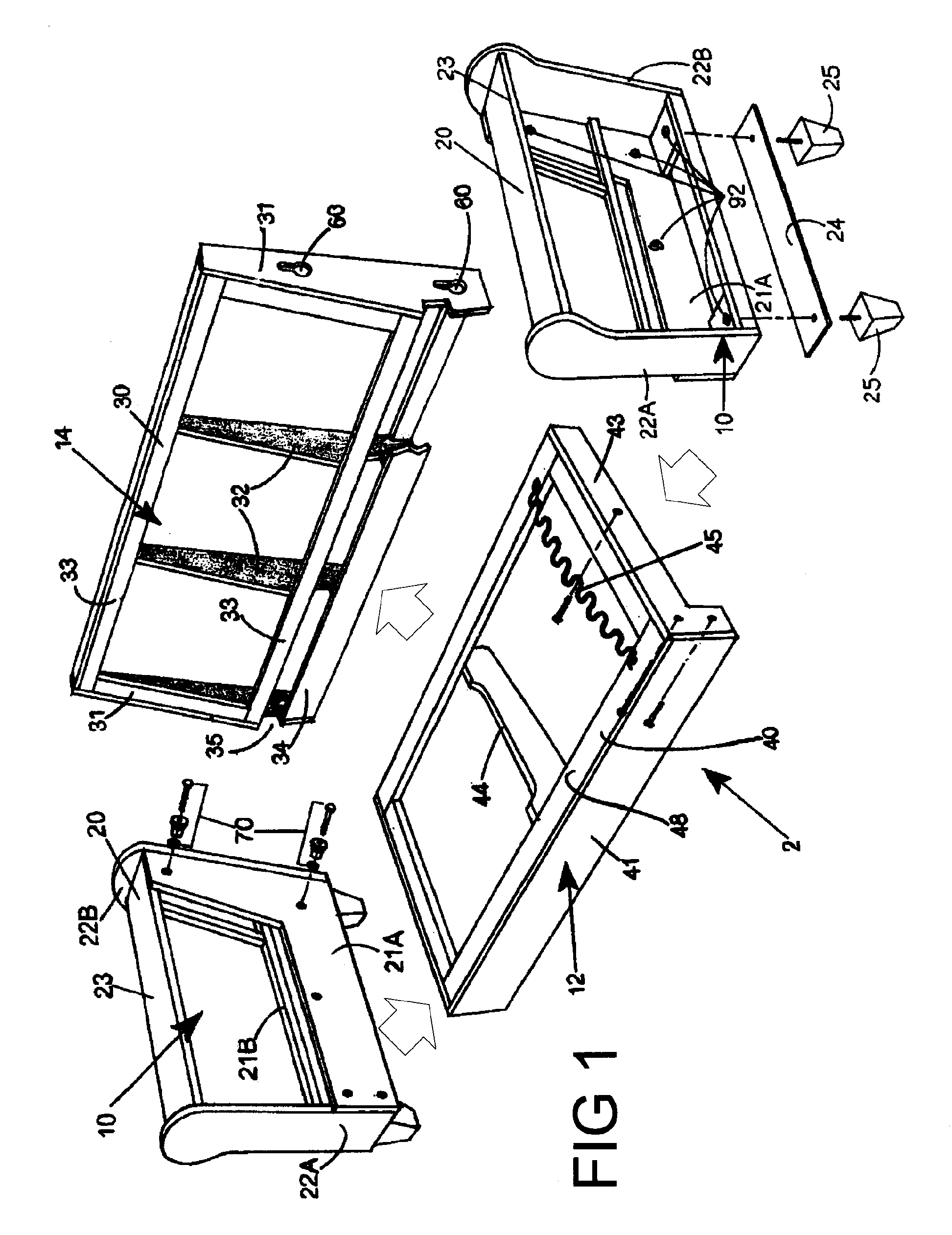

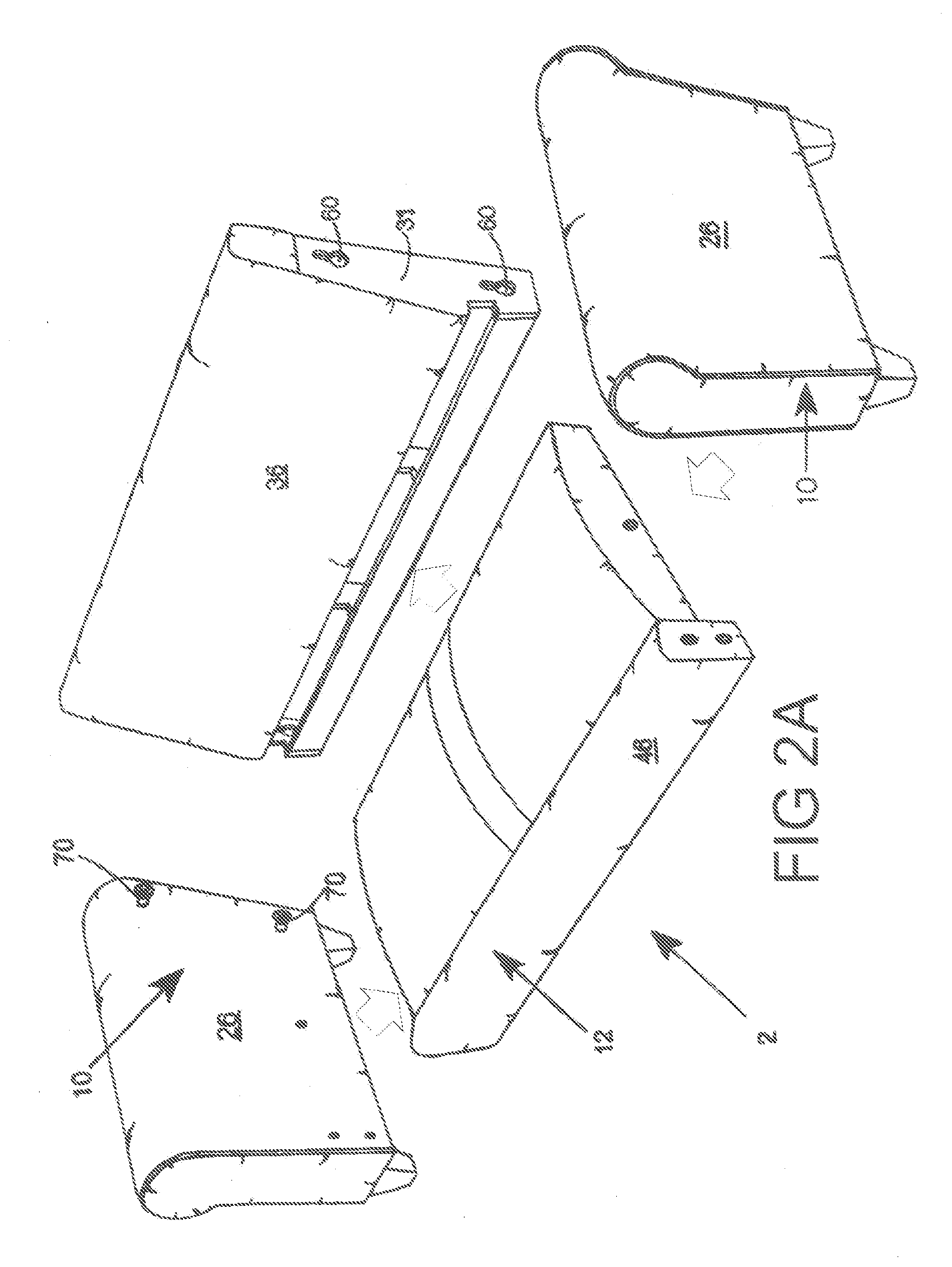

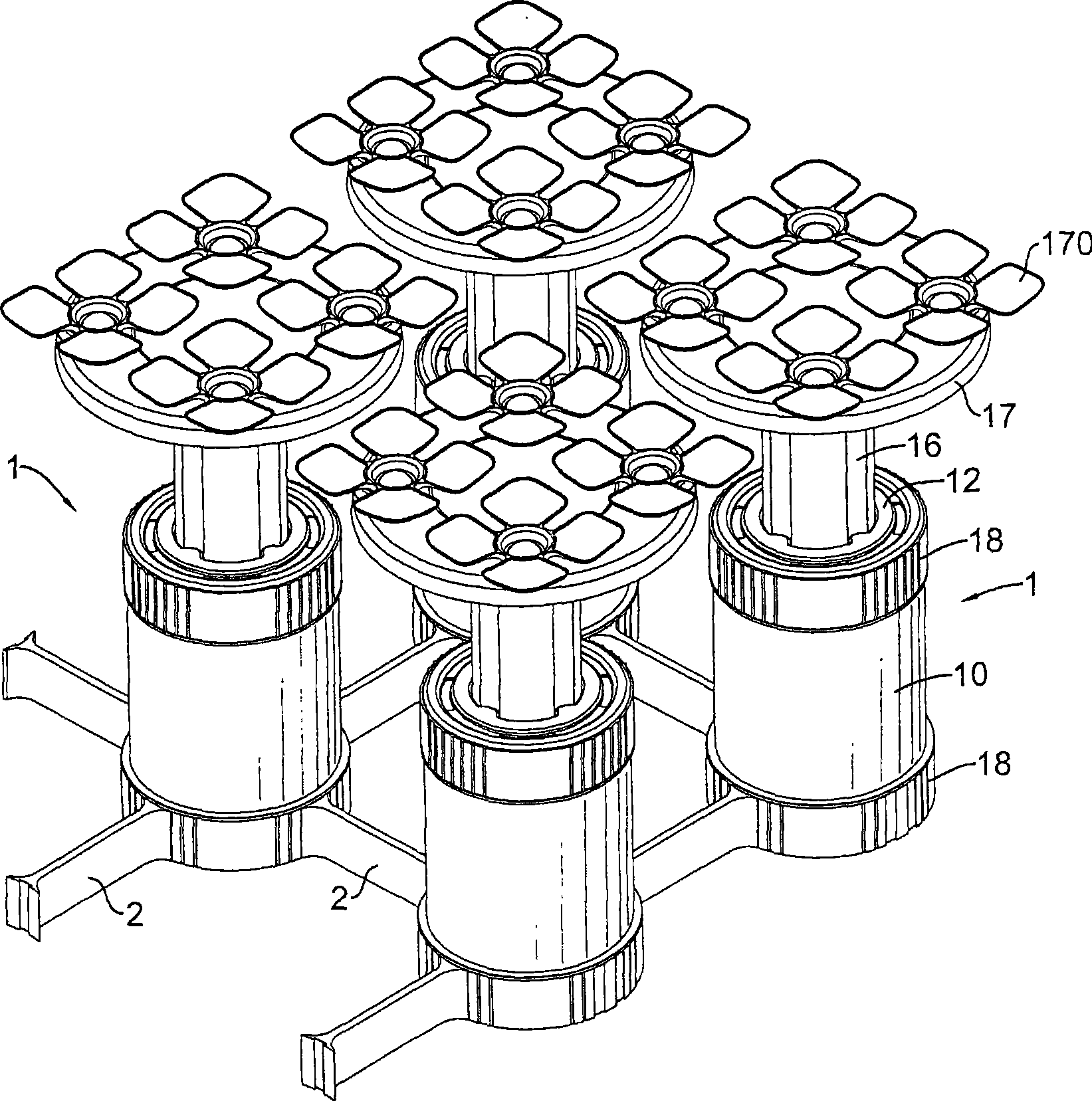

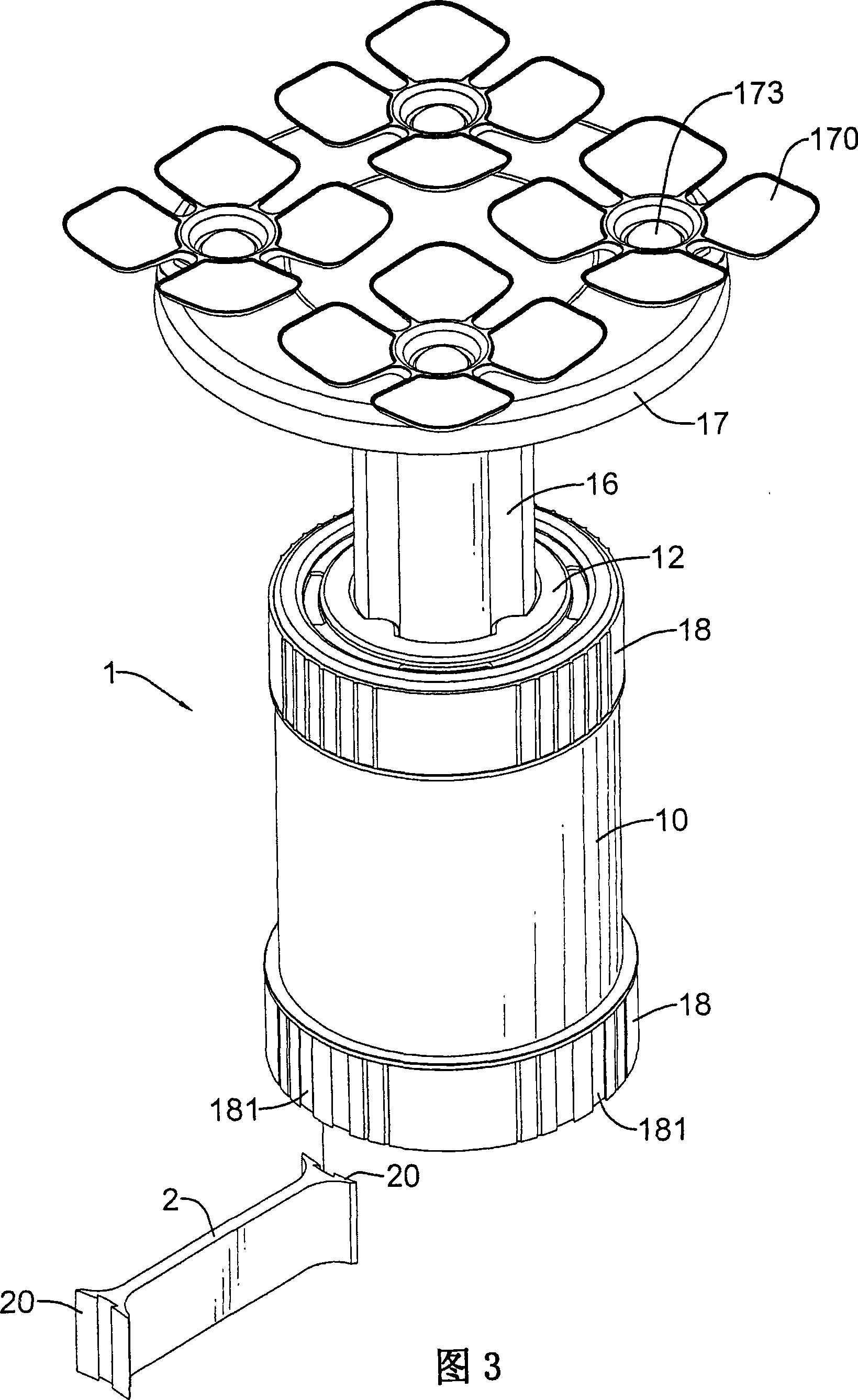

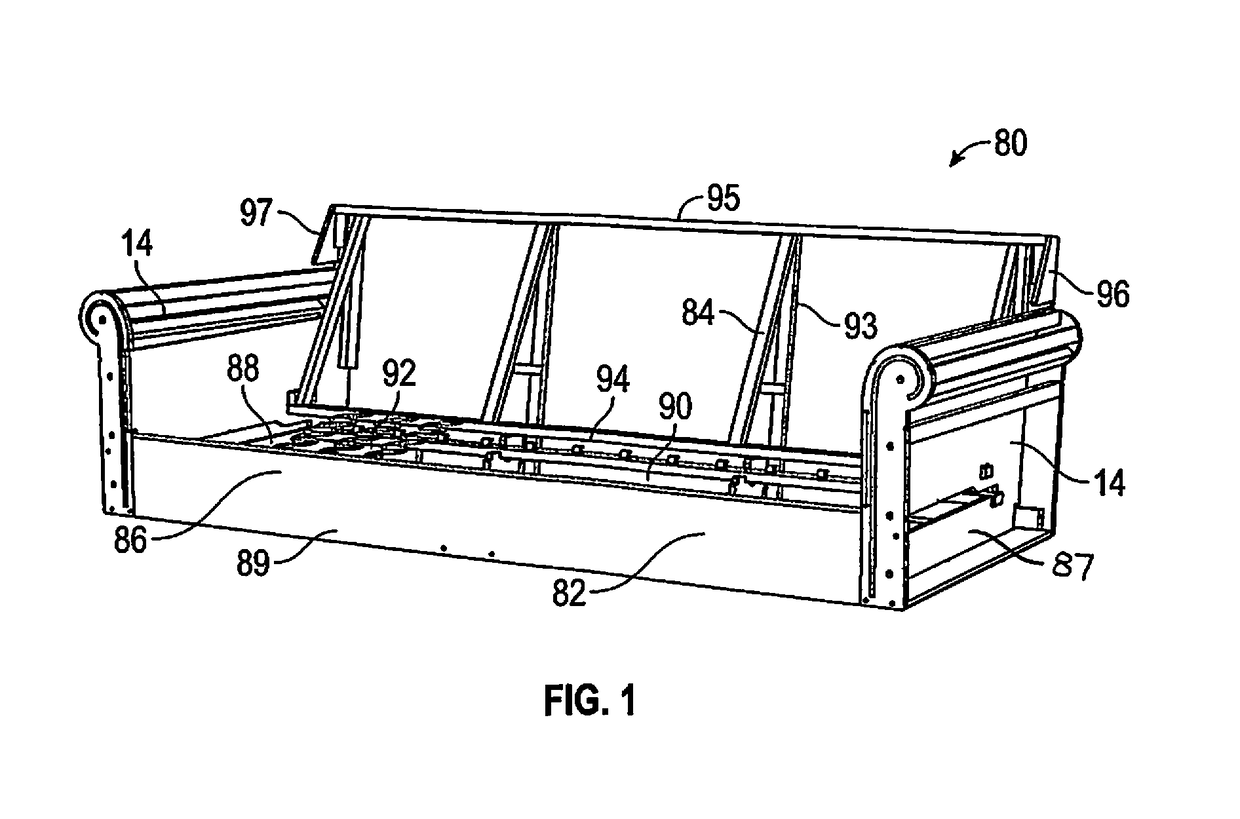

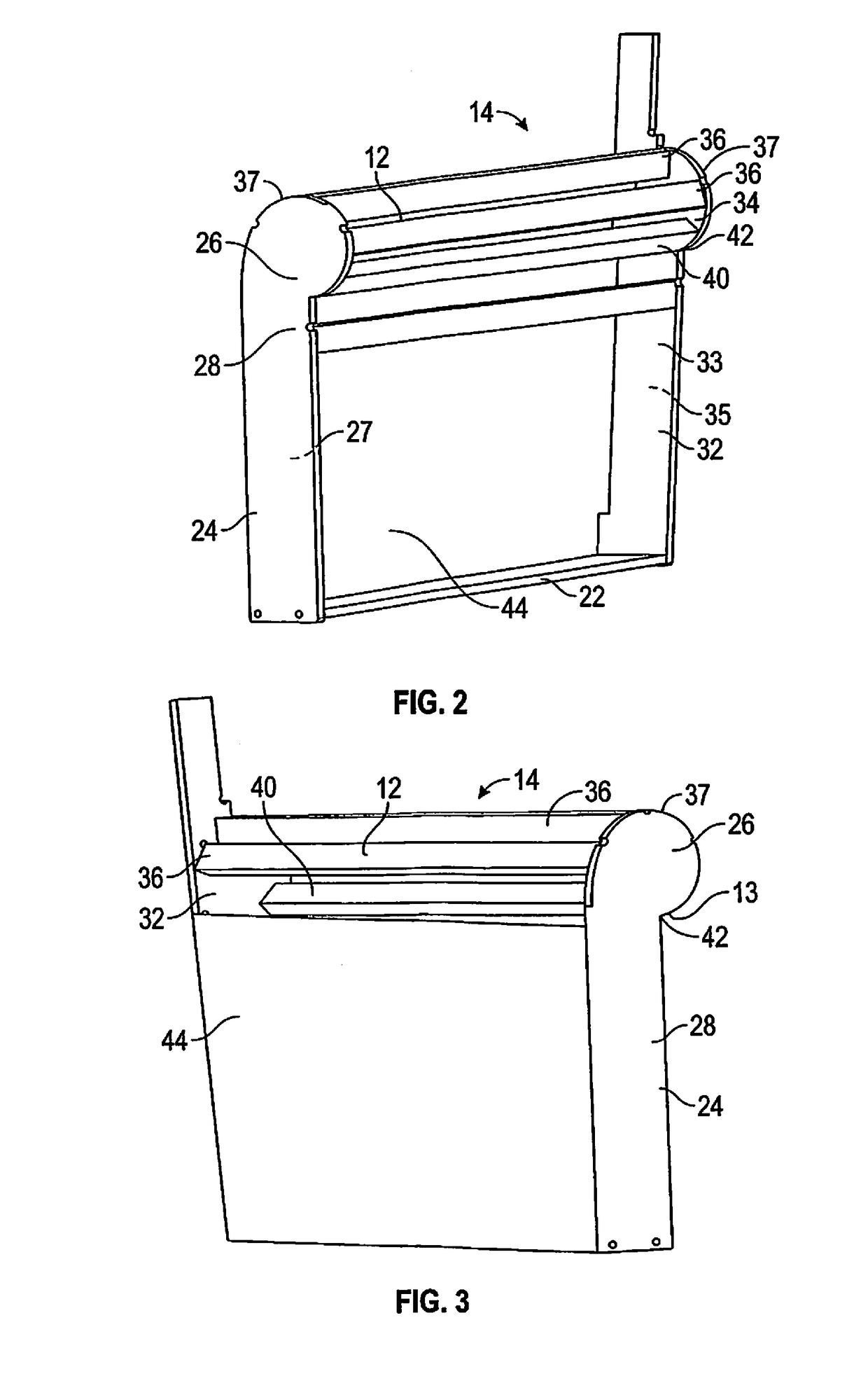

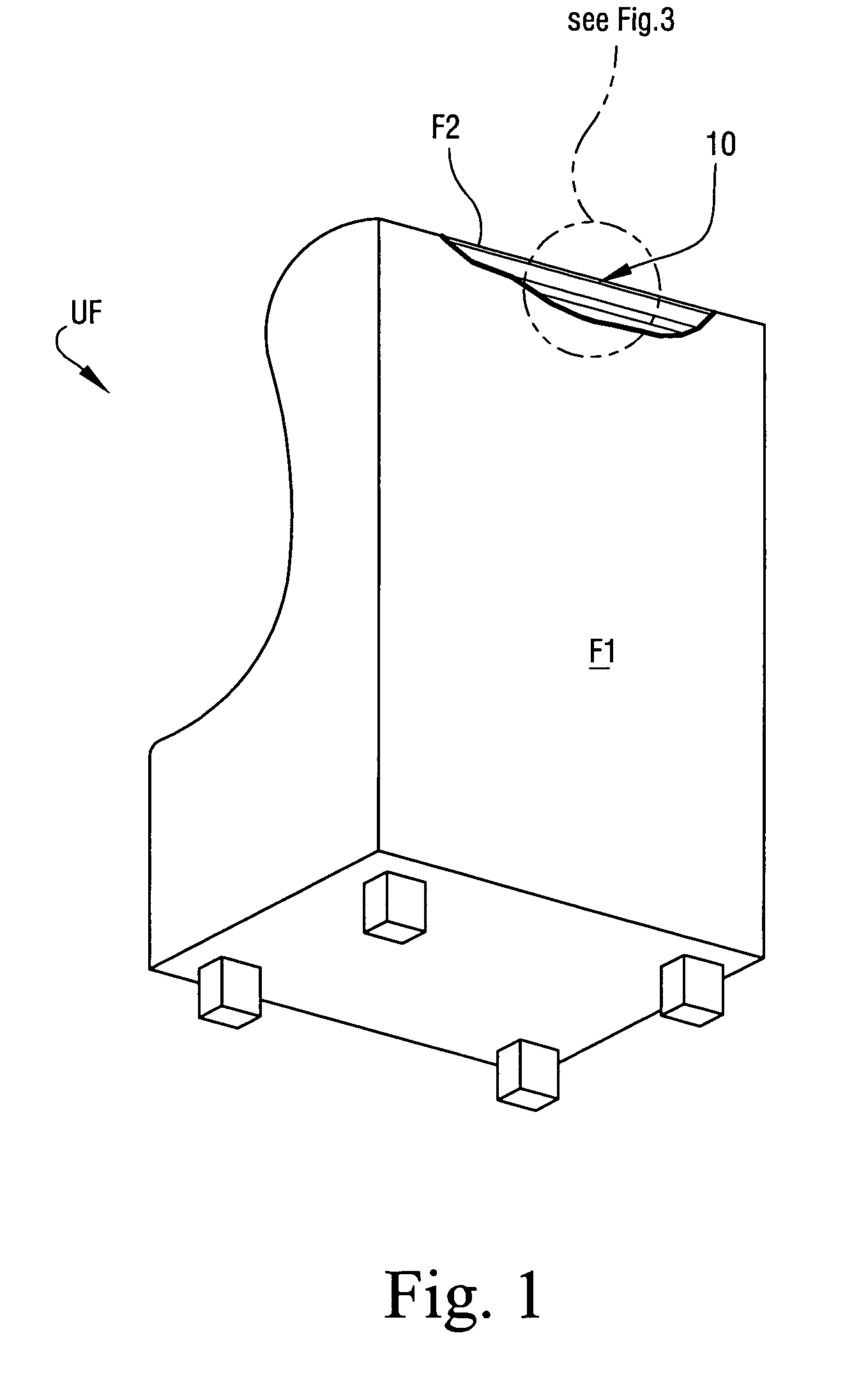

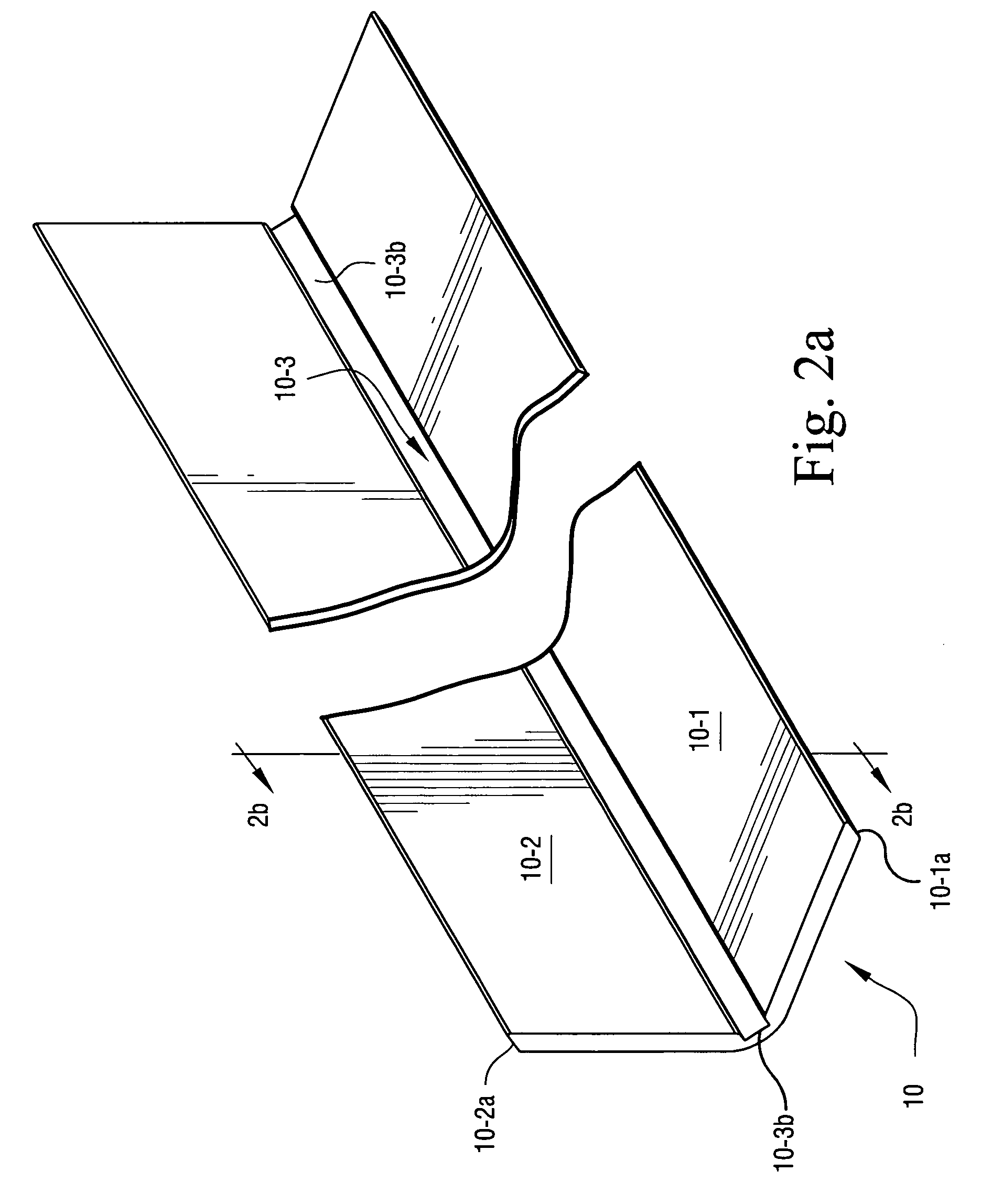

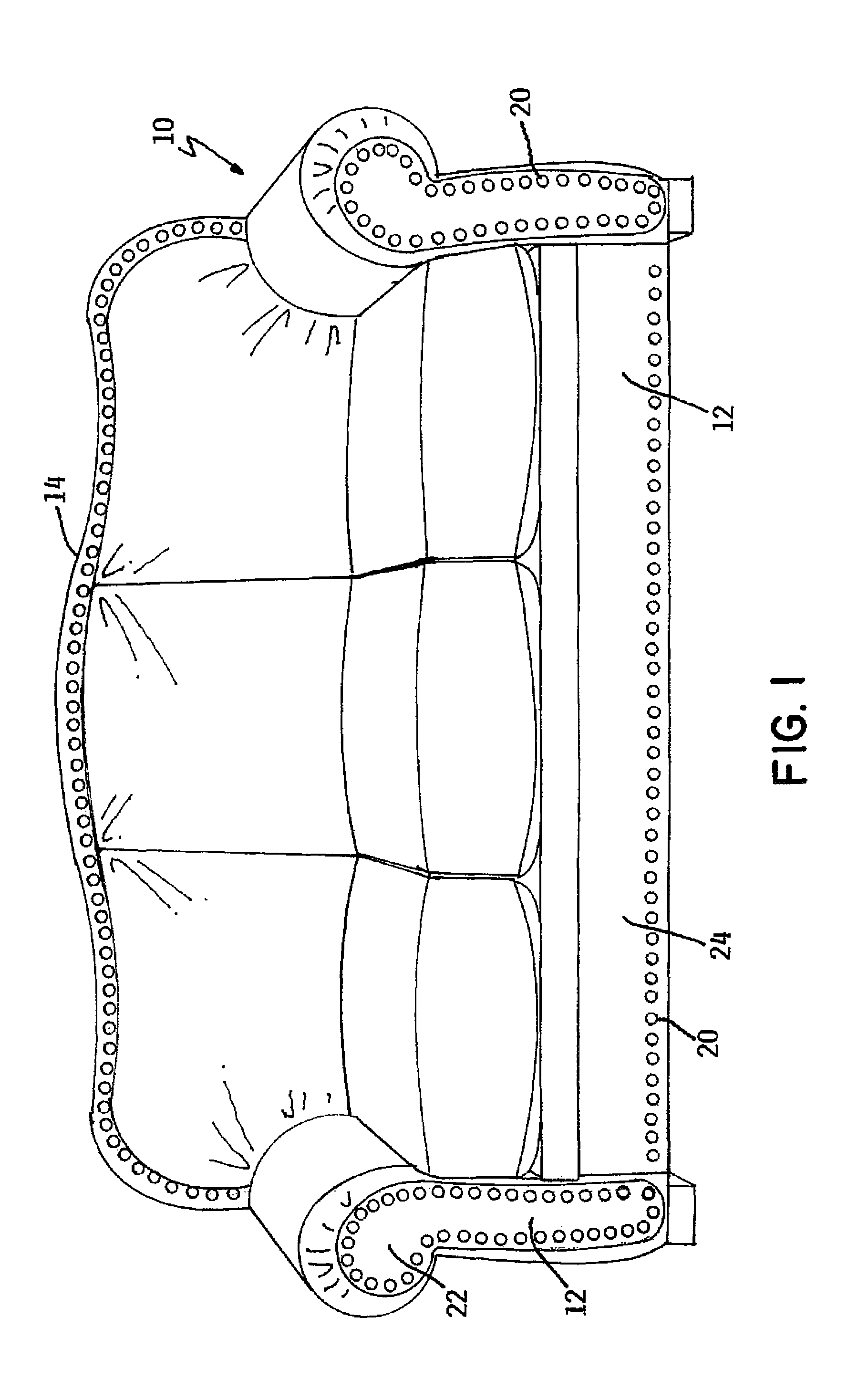

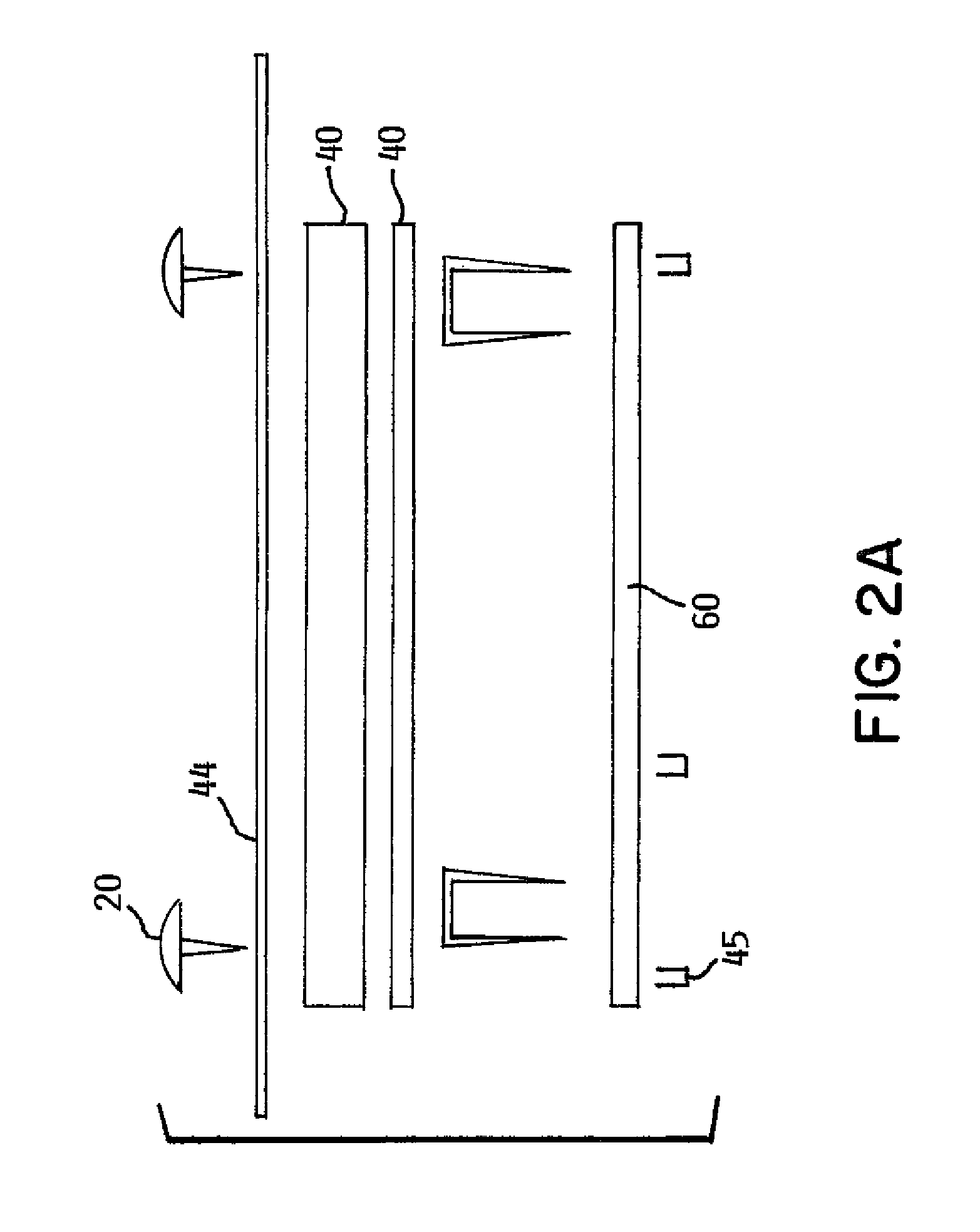

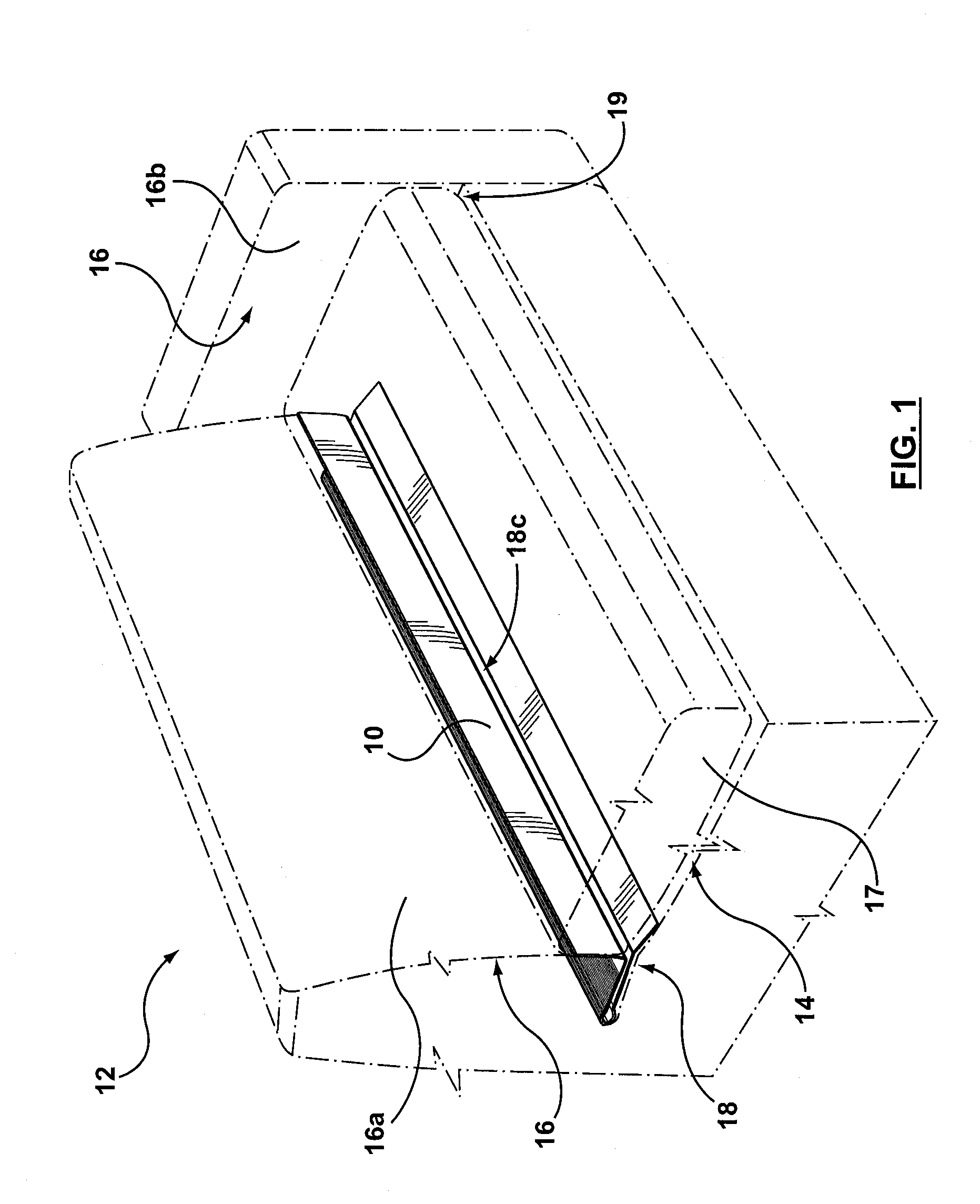

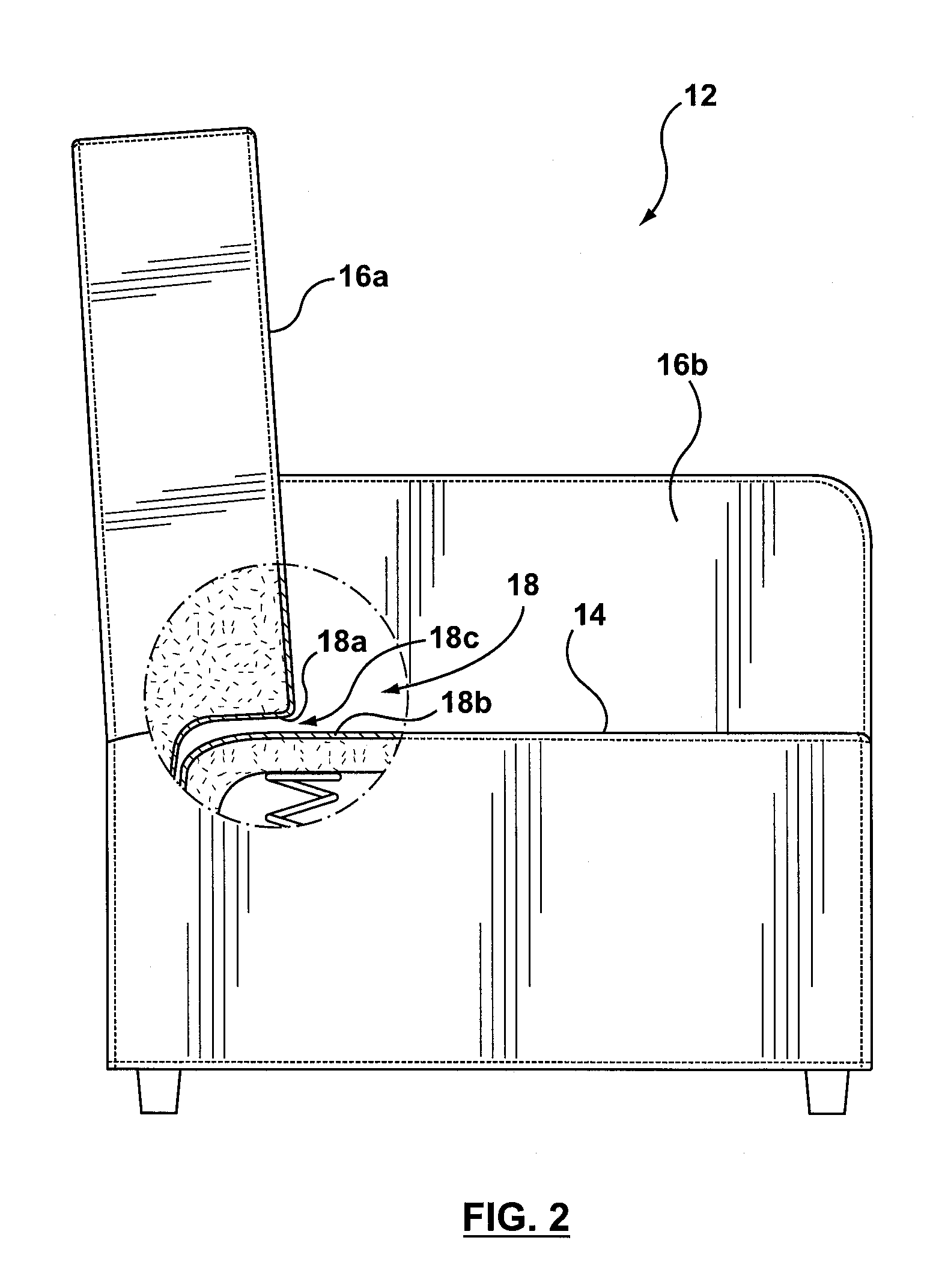

Assembly apparatus for modular components especially for upholstered furniture

InactiveUS8356954B2Easy to transportEasy to disassembleRopes and cables for vehicles/pulleyDismountable chairsEngineeringUpholstered furniture

A connector assembly is used to connect subassemblies such as parts of a knockdown or modular sofa or similar item of furniture. The furniture item can be an upholstered item in which the multiple components are stackable into a volume that is smaller than the assembled item of furniture for shipping. The connector assembly includes a keyhole slot on a frame member in one component and a male connector assembly on a frame member in the other assembly. The male connector includes a sleeve with a cylindrical shank and an adjacent enlarged or conical portion, and the sleeve, which may be plastic, is mounted the bolt. The narrow section of the keyhole slot has a beveled surface and as the sleeve progresses into the narrow section, engagement of the conical sleeve section with the beveled slot surface tightens the two members being attached.

Owner:KC TECH

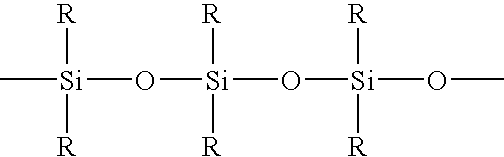

High resilient silicone foam and process for preparing same

A method for producing a novel silicone foam by reaction of a polyisocyanate with a silicone oligomer having a plurality of functional end groups with active hydrogens, optionally in the presence of fire-retardants, under foam forming conditions which creates a new silicone foam for use in items such as residential upholstered furniture industry, seat cushions and bedding etc., and specifically for use in applications that require, high resilience and fire-retardant properties such as aircraft and surface transportation seat cushioning, military and shipboard mattresses etc.

Owner:CHESTNUT RIDGE FOAM

Slickened or siliconized flame resistant fiber blends

InactiveUS20060160454A1Extinguish any residual flameMinimal shrinkageDomestic upholsteryFibre treatmentFiberPolymer science

The invention relates to slickened or siliconized flame resistant fiber blends that are well suited for use in mattresses, boxsprings, upholstered furniture, fiber-filled bed clothing, transportation seating or any end use application where a soft materials are desired for flame resistant (FR) purposes. Some of the fibers in the blend are slickened. The FR fibers incorporated into these blends include both char forming FR fibers and oxygen depleting FR fibers. FR char-forming fibers are those which exhibit little shrinkage when exposed to direct flame and are not spun from polymers manufactured with halogenated monomers. Oxygen depleting FR fibers are spun from polymers manufactured with halogenated monomers.

Owner:BEIJING CARINAE MATERIAL TECH CO LTD

Nonwoven highloft flame barrier

InactiveUS7259117B2Stringent testGuaranteed to continue to useStuffed mattressesSynthetic resin layered productsPolymer scienceNonwoven fabric

The invention relates to a nonwoven highloft flame barrier well suited for use in mattress, upholstered furniture and other end use applications where a highloft nonwoven material is desired for flame barrier purposes. A preferred nonwoven highloft flame barrier of the invention comprises a blend of fibers, that are inherently fire resistant and essentially nonshrinking to direct flame, with melamine fibers being preferred either alone or in conjunction with, for example, viscose rayon based fibers, fibers extruded from polymers made with halogenated monomers and preferably low-melt binder fibers, which are thermally activated in a highloft manufacturing process to provide low bulk density, resiliency and insulation properties in the end use application. The preferred fiber blends are designed to withstand extended periods of time exposed to open flame with minimal shrinkage of the char barrier; thereby preventing a flames from “breaking through” the char barrier and igniting underlying materials. Other component fibers can also, optionally, be included such as: natural fibers, to improve product economics in the end use application. The highloft flame barrier of this invention also allows for the manufacture of open flame resistant composite articles, while also permitting the continued use of conventional non-flame retardant dress cover fabrics, conventional non-flame retardant fiberfills and conventional non-flame retardant polyurethane foams.

Owner:BEIJING CARINAE MATERIAL TECH CO LTD

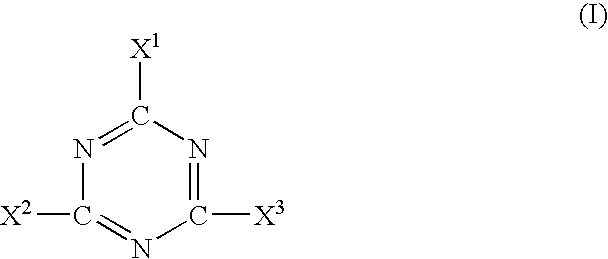

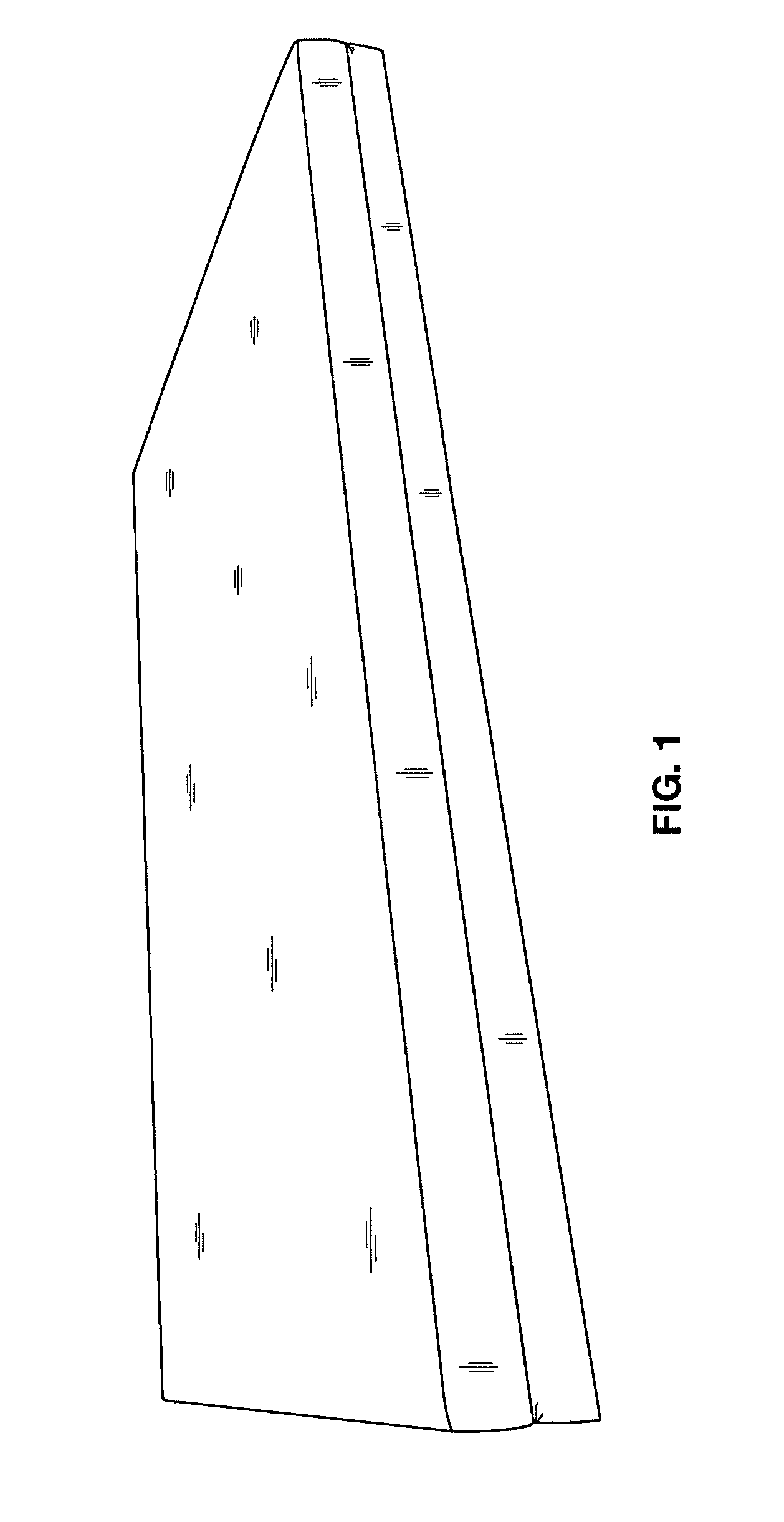

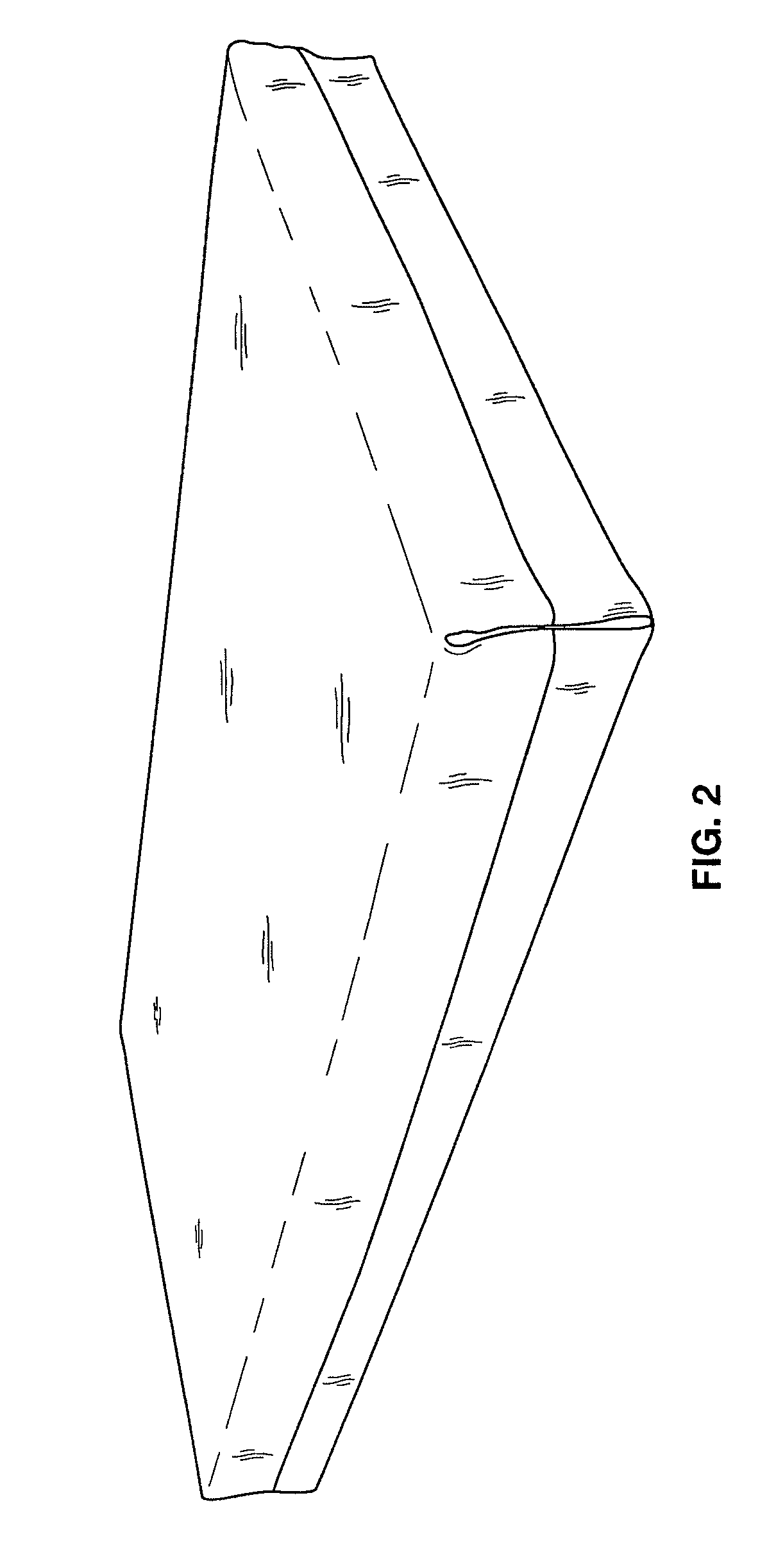

Fire retardant cover for mattresses

A retrofit cover for fully or partially enclosing a mattress, wherein the cover is formed of a unitary, integrally formed fabric having a fire barrier element. The cover is capable of rendering mattresses, mattress foundations, upholstered furniture article and other articles filled with resilient cushioning materials that were not originally manufactured to meet a full-scale open flame standard capable of passing such newly mandated standard for performance in newly manufactured items. When tested in accordance with the flame resistance test protocols of 16 CFR 1633 or TB 603, the item encased in the retrofit cover has a maximum heat release rate of less than 200 kW and a total energy release of less than 25 MJ in the first five minutes of the test.

Owner:MURTZCO

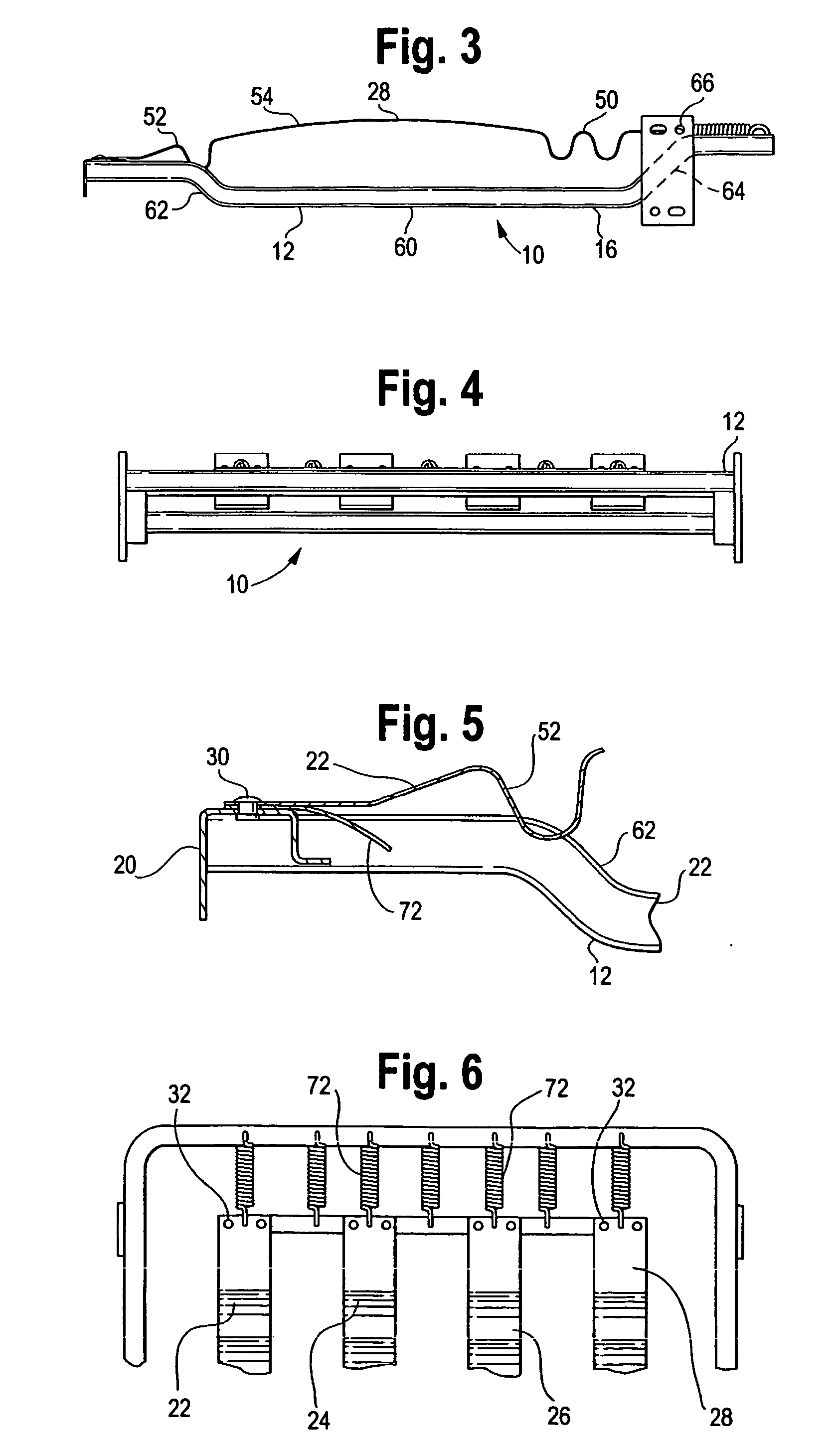

After-treatment method for oil-and water-repellency of fibrous substrates

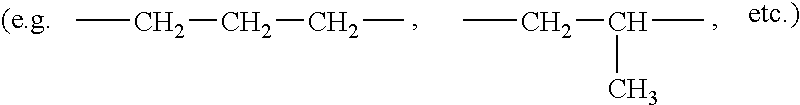

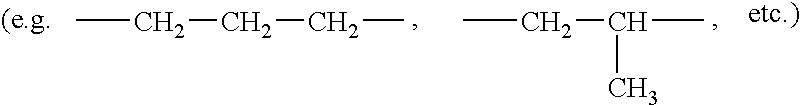

A method is provided for after-treating fabric with a fluoroacrylate emulsion by spraying or immersion. The immersion can be carried out in a laundering process (preferably in a late cycle of the process) or even under poorly-controlled conditions (e.g. field conditions). The spraying embodiment of this method is useful for treating large, previously manufactured items comprising fabric (e.g. upholstered furniture, tents, awnings, and the like) with an aerosol spray containing micrometer or submicrometer-sized droplets of a diluted version of the fluoroacrylate emulsion. In all embodiments, the fluoroacrylate emulsion contains, dispersed therein with the aid of a surfactant system, essentially a single hydrophobic component comprising a particulate fluoroacrylate copolymer having repeating units of the formulas I and II wherein Rf is a C8-rich fluorinated alkyl radical; R and R1 are hydrogen or alkyl; and R2 is hydrogen or substituted or unsubstituted alkyl. The aqueous dispersion further contains, in addition to the surfactant system, a minor amount of polar organic liquid. Depending upon the melting or softening point of the fluoroacrylate copolymer, drying under heat can be optional and in any event can be carried out at temperatures below 100 DEG C.

Owner:MOODY RICHARD J

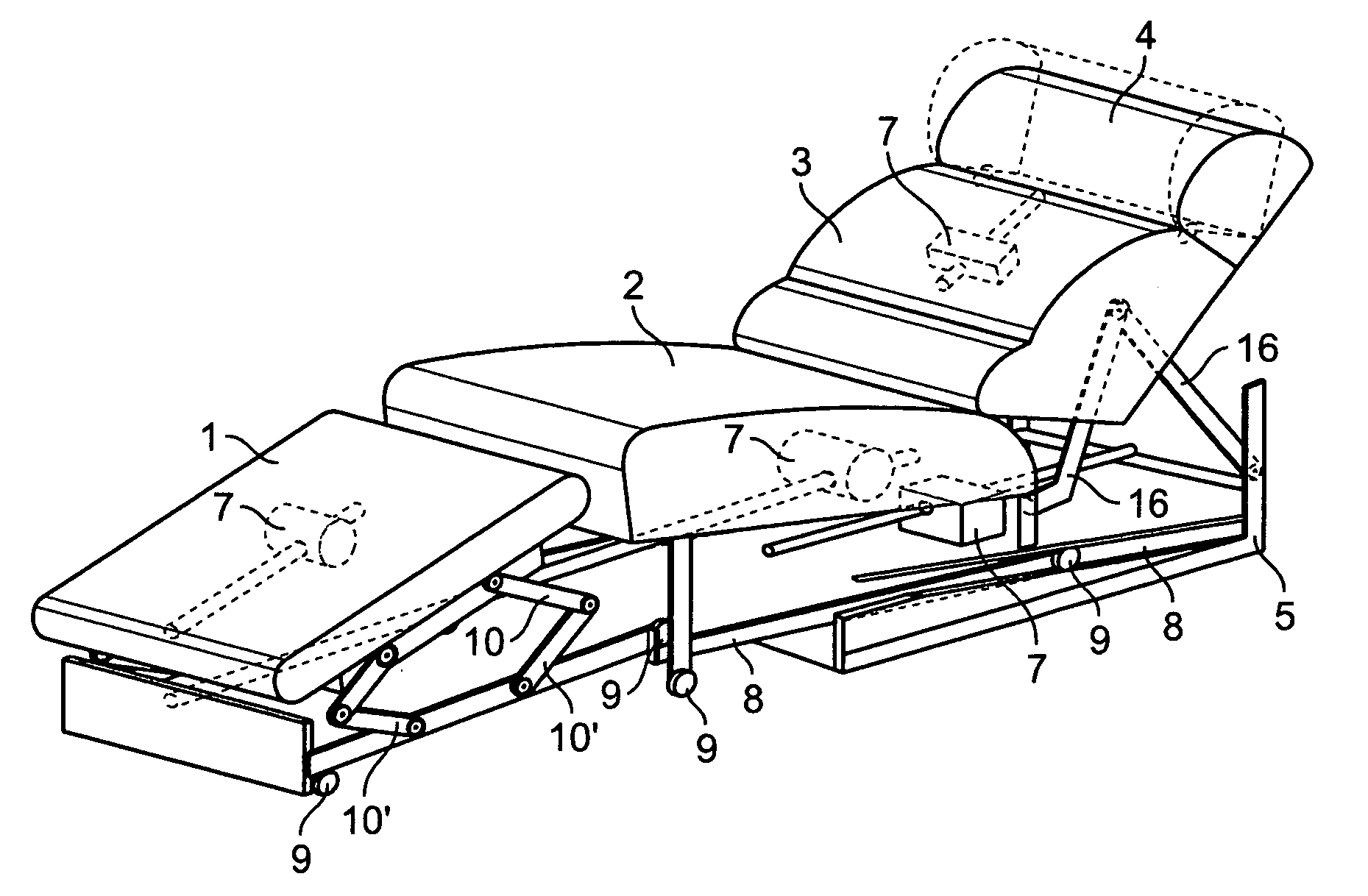

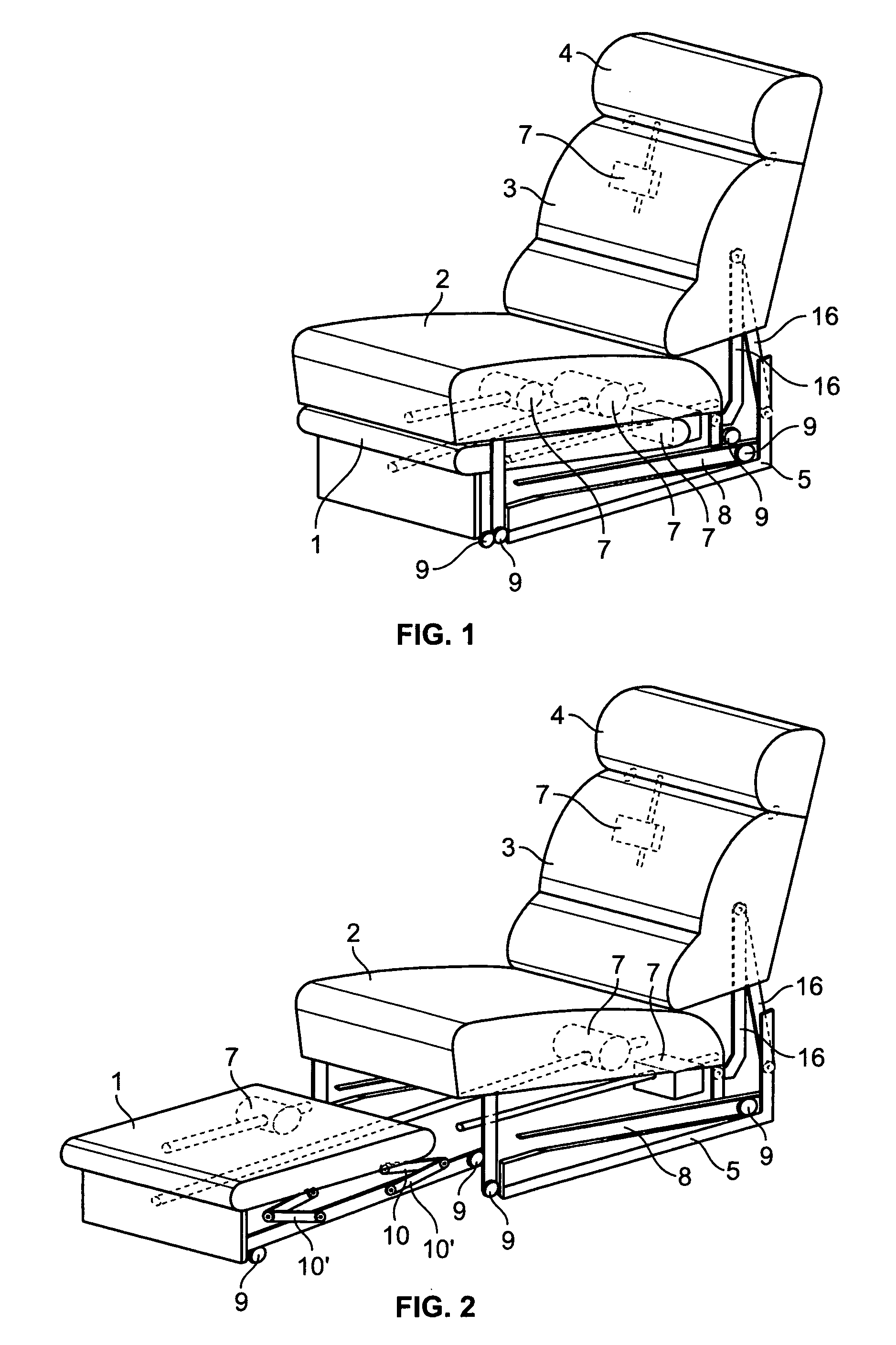

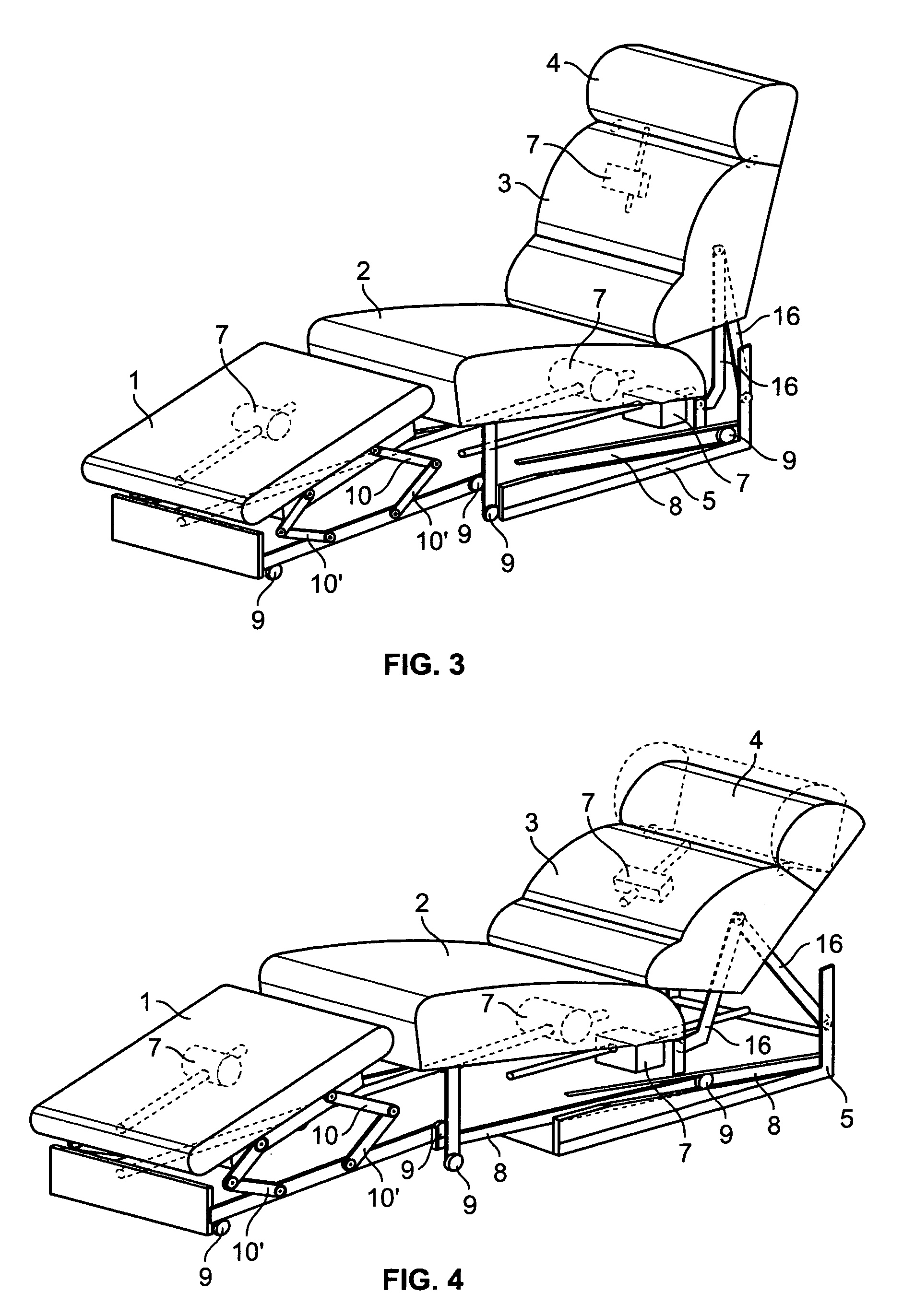

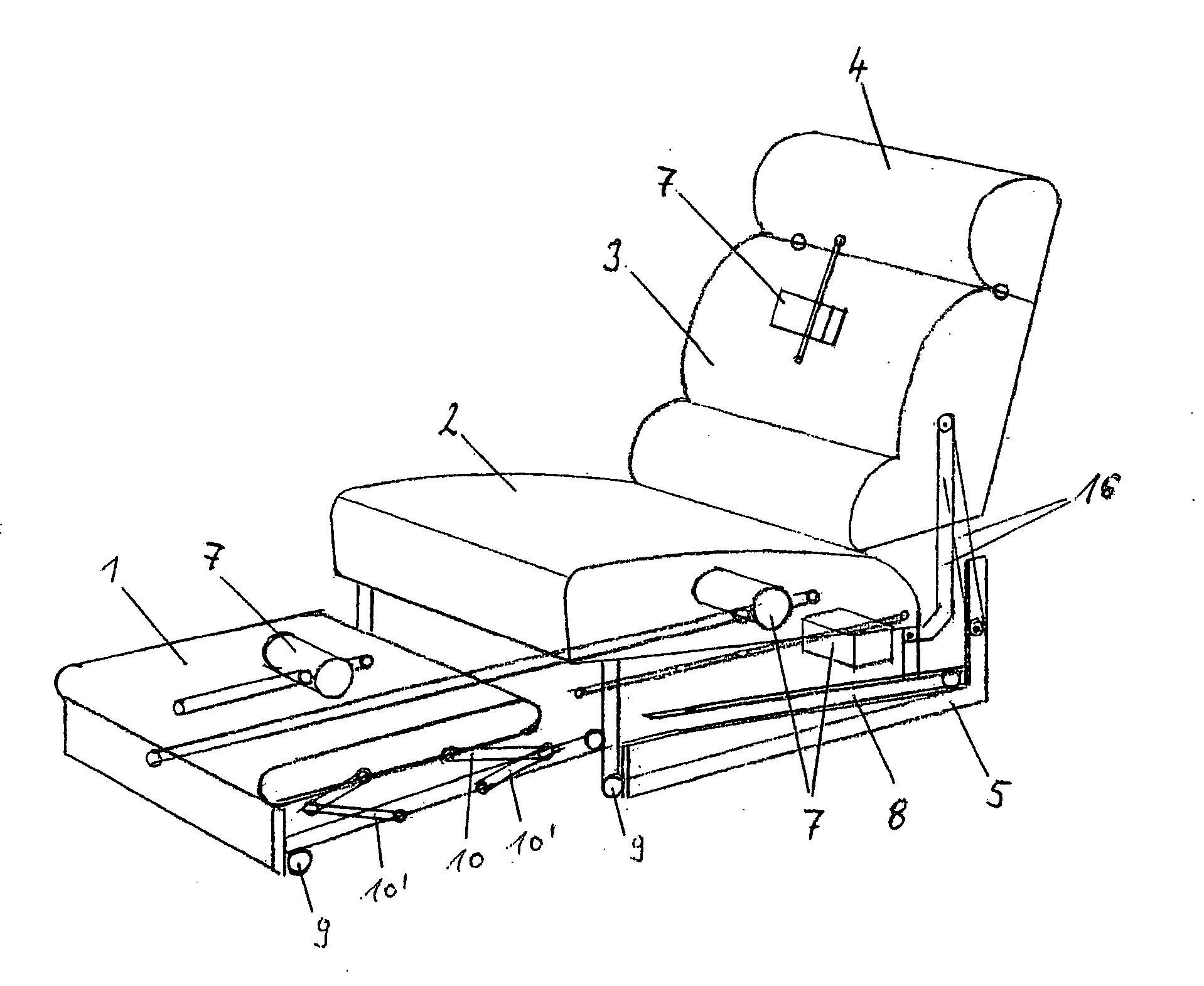

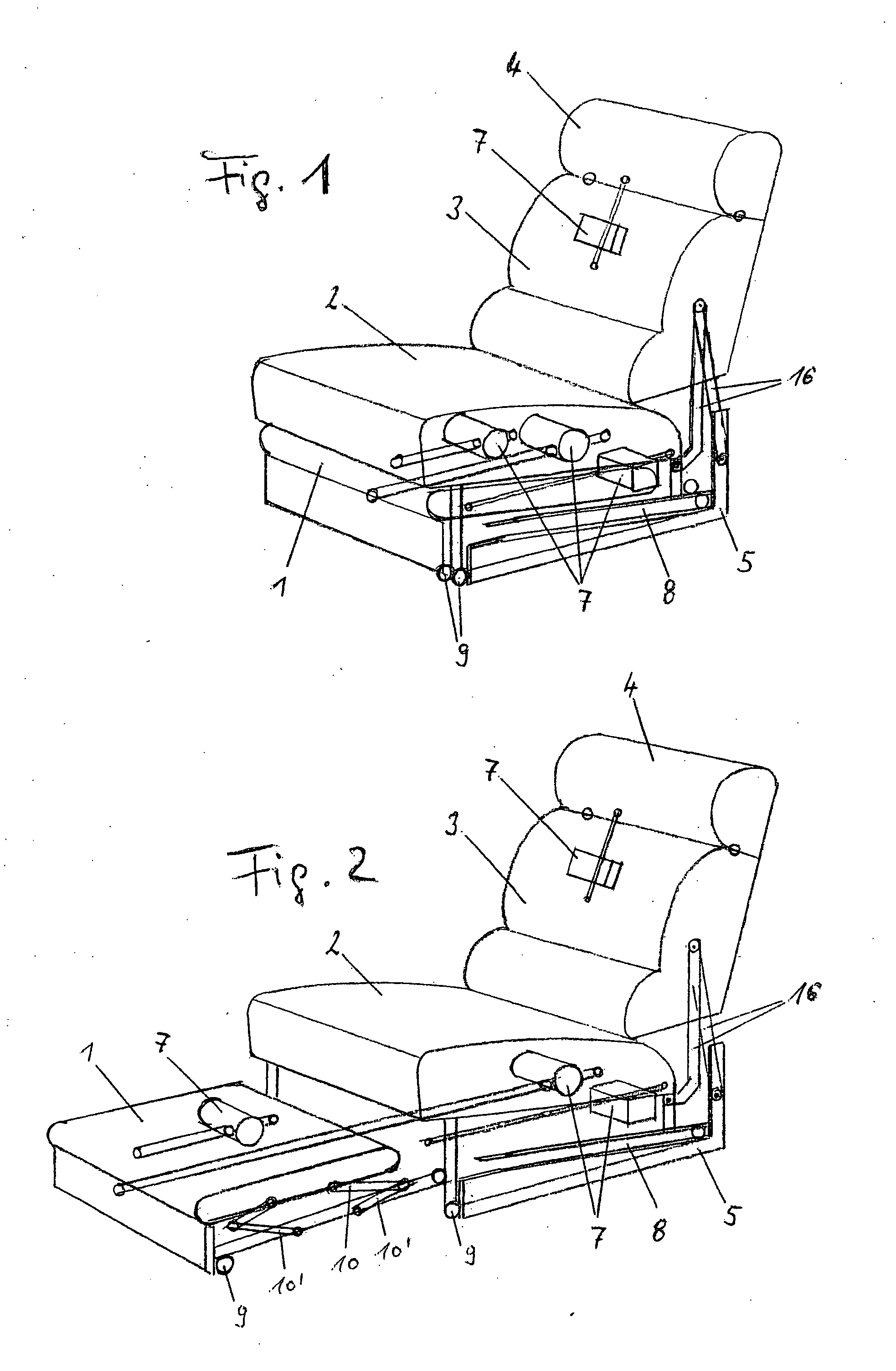

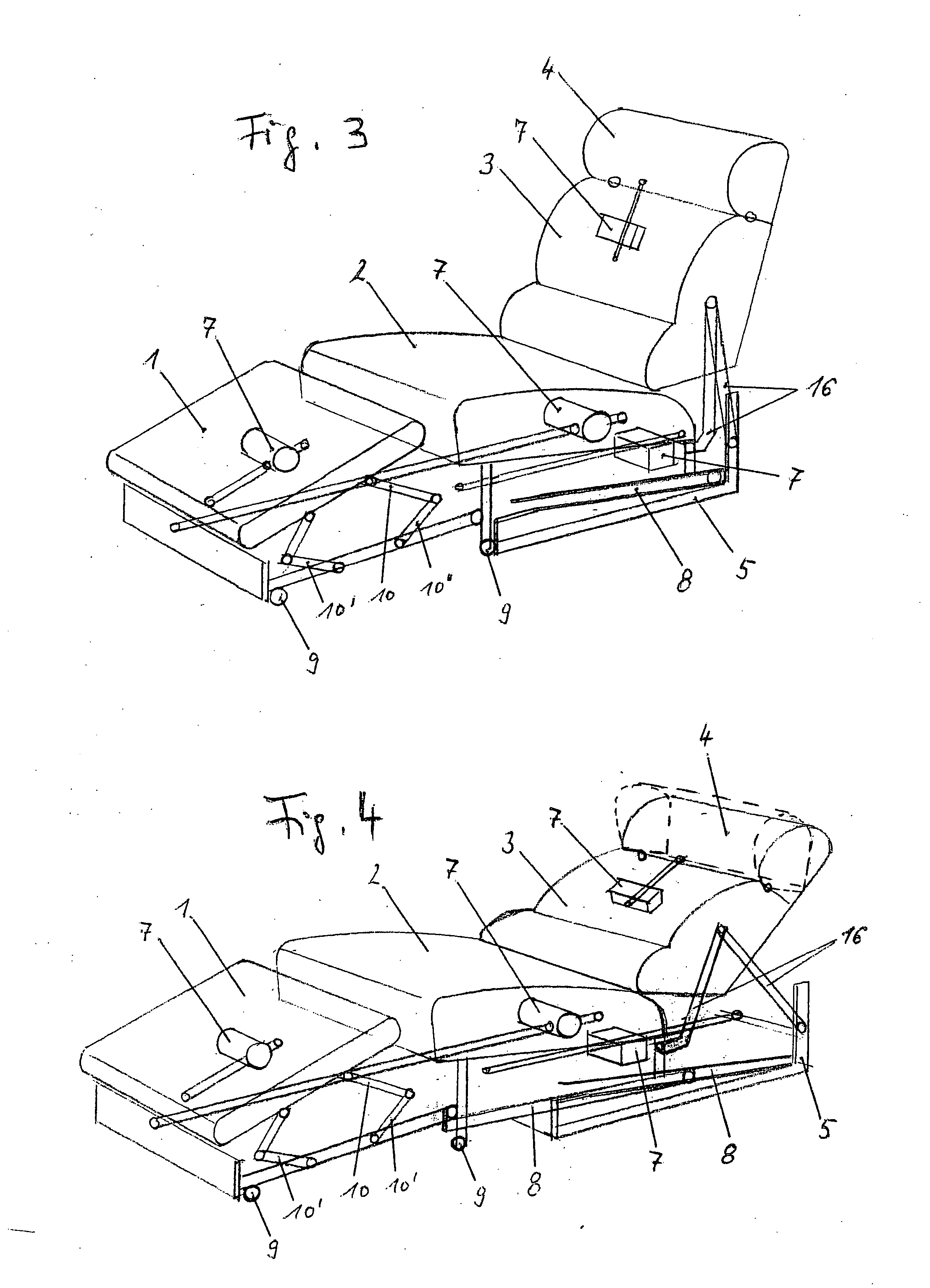

Convertible piece of upholstered furniture with chair and bed function

InactiveUS7083235B2Fully stressedEasy and step-less and wall-free conversion capabilityOperating chairsSofasMotor driveIntermediate stage

A convertible piece of upholstered furniture can be converted via motorized conversion aids from a seat function into a bed, by way of any desired number of intermediate stages, and vice versa. All movable parts can be fully stressed by a person during conversion, even when a person is sitting or lying on the piece of furniture. These changes can take place even when the piece is being used by a person, whereby each movable part of the piece of upholstered furniture can be changed by means of a motor drive having a control. The footrest and the seat part are configured so that they can move out of a base frame with their metal fittings. A lever construction arranged on the metal fitting of the footrest and a motor drive adjusts the height and angle of the footrest and moves the piece of furniture to the various positions.

Owner:FIEDLER HANS

Fire retardant cover for mattresses

A retrofit cover for fully or partially enclosing a mattress, wherein the cover is formed of a unitary, integrally formed fabric having a fire barrier element. The cover is capable of rendering mattresses, mattress foundations, upholstered furniture article and other articles filled with resilient cushioning materials that were not originally manufactured to meet a full-scale open flame standard capable of passing such newly mandated standard for performance in newly manufactured items. When tested in accordance with the flame resistance test protocols of 16 CFR 1633 or TB 603, the item encased in the retrofit cover has a maximum heat release rate of less than 200 kW and a total energy release of less than 25 MJ in the first five minutes of the test.

Owner:MURTZCO

Convertible piece of upholstered furniture with chair and bed function

InactiveUS20050052067A1Fully stressedImprove stressOperating chairsSofasMotor driveIntermediate stage

A convertible piece of upholstered furniture can be converted via motorized conversion aids from a seat function into a bed, by way of any desired number of intermediate stages, and vice versa. All movable parts can be fully stressed by a person during conversion, even when a person is sitting or lying on the piece of furniture. These changes can take place even when the piece is being used by a person, whereby each movable part of the piece of upholstered furniture can be changed by means of a motor drive having a control. The footrest and the seat part are configured so that they can move out of a base frame with their metal fittings. A lever construction arranged on the metal fitting of the footrest and a motor drive adjusts the height and angle of the footrest and moves the piece of furniture to the various positions.

Owner:FIEDLER HANS

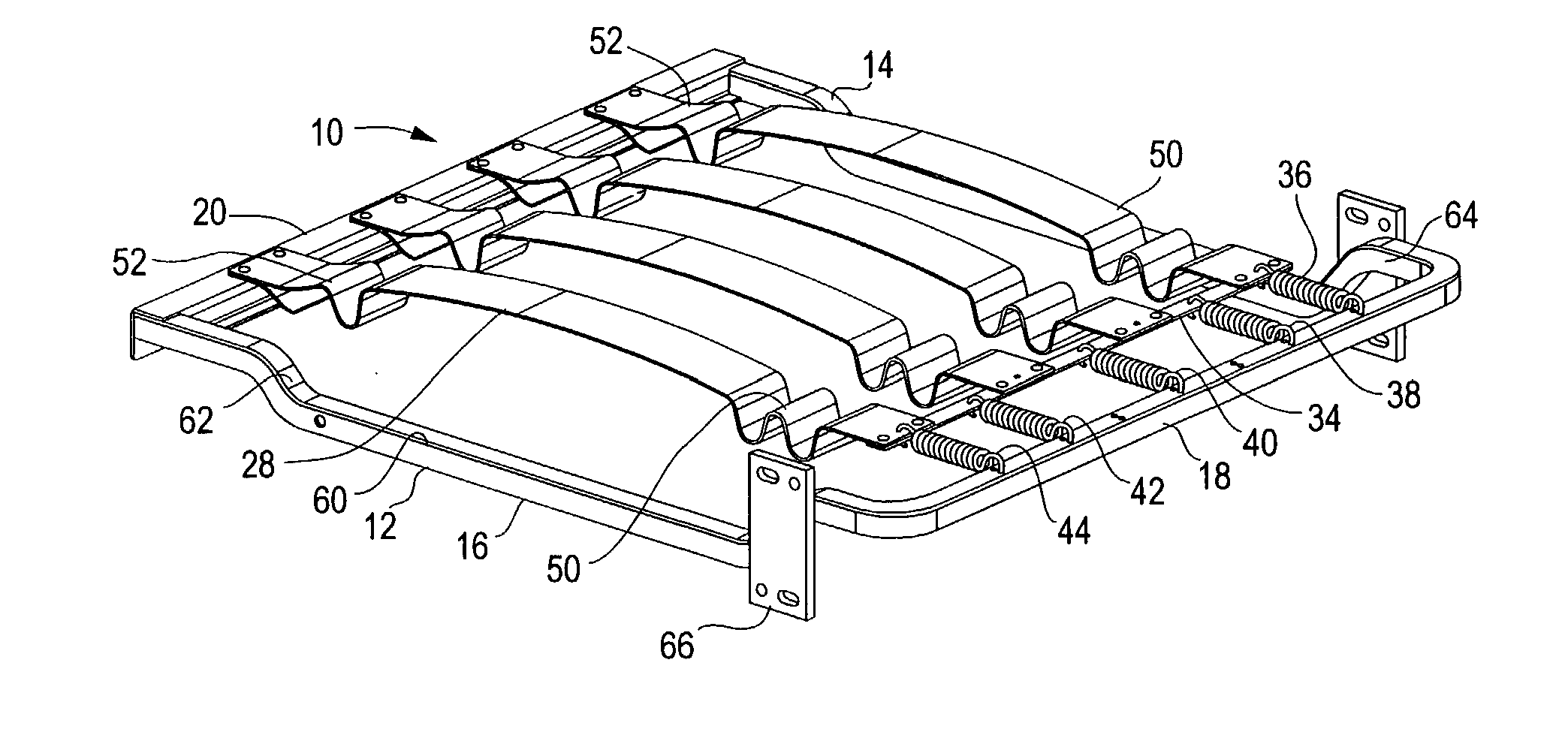

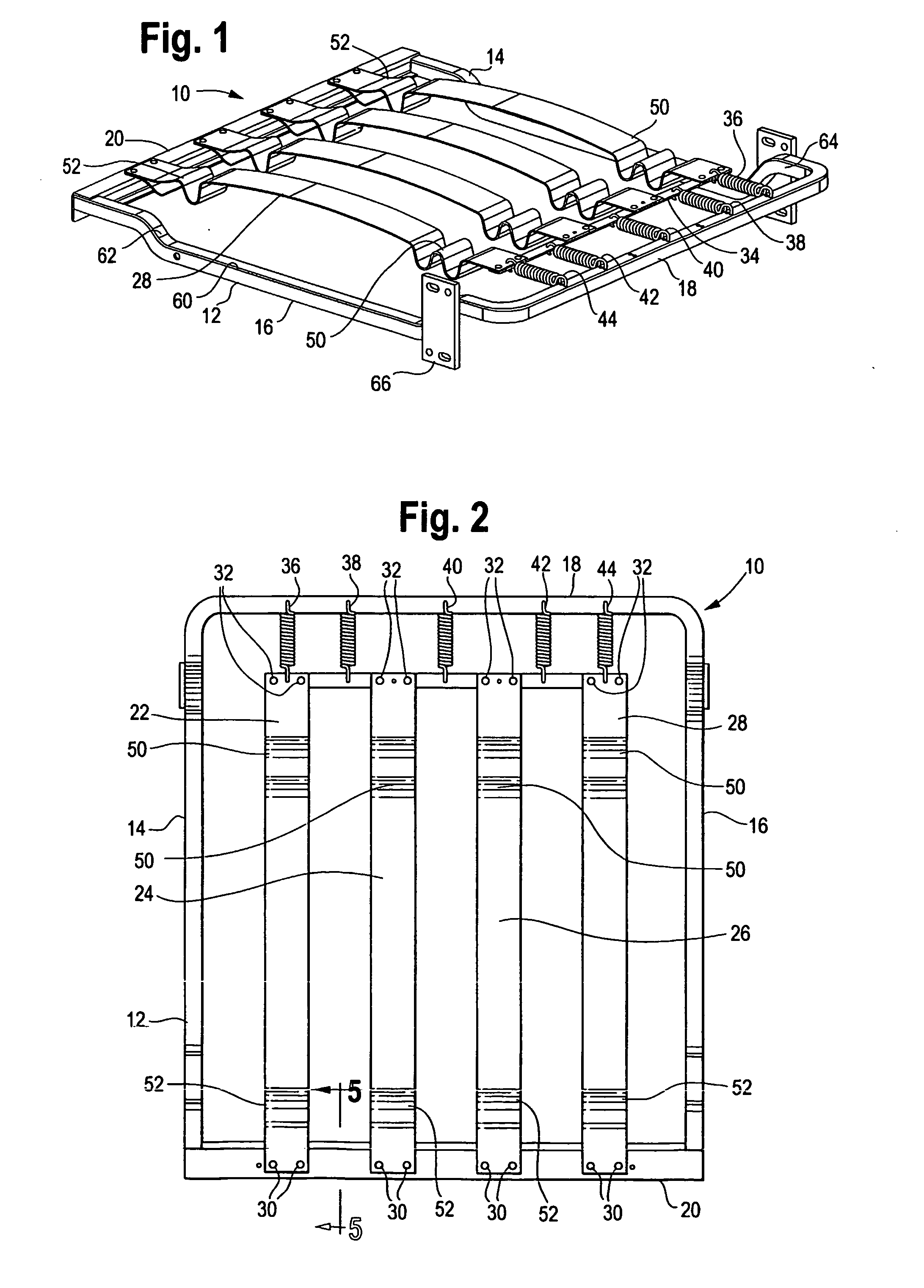

Double spring function upholstered furniture spring assemblies

A double spring function seat spring assembly combines a U-shaped frame with a closed front, a number of leaf springs (26-28) connected between the front and a cross piece and a plurality of coil springs (36, 38, 40) supporting the cross piece from the frame, the leaf springs formed with a series of W and V arches to enable flexing and extension for improved durability and comfort.

Owner:FLEXSTEEL INDS INC

Flame resistant matelasse fabrics utilizing spun and filament flame resistant yarns

InactiveUS20070004302A1Efficient use ofReduce flammabilityWeft knittingDomestic upholsteryConus californicusUpholstered furniture

The invention relates to the use of a flame resistant (FR) three-layer double-knit fabric, also know as a matelasse fabric. The top layer is of standard non-FR face yarn, the middle layer is of a FR filler spun yarn and the bottom layer is of a FR spun yarn or FR filament yarn. This FR matelasse fabric can be used to protect a mattress, foundation, upholstery cushion, pillow, office panel, transportation seat or any other article requiring FR protection. In this invention, a matelasse fabric is formed by circular double knitting a FR spun or FR filament yarn into the bottom portion of the fabric, utilizing a heavy cotton count FR filler spun yarn for the middle layer and using conventional non-FR yarns for the top layer. The invention has particular applicability in the formation of FR mattresses and foundations that require passage of large open flame tests such as CPSC's 16 CFR Part 1633, California's Test Bulletin 603 and Test Bulletin 129 and in the formation of FR upholstered furniture that requires passage of California's Test Bulletin 133 or British Standard 5852 using the crib 5 ignition source or higher.

Owner:MCKINNON LAND

Slickened or siliconized flame resistant fiber blends

InactiveUS7589037B2Desirable soft and comfortable propertyLess testingDomestic upholsteryFibre treatmentFiberPolymer science

Owner:BEIJING CARINAE MATERIAL TECH CO LTD

After-treatment method for imparting oil-and water-repellency to fabric

A method is provided for after-treating fabric with a fluoroacrylate emulsion by immersion, typically under poorly-controlled conditions (e.g. field conditions), and a second embodiment of this method is provided for treating large, previously manufactured items comprising fabric (e.g. upholstered furniture, tents, awnings, and the like) with an aerosol spray containing micrometer or submicrometer-sized droplets of a diluted version of the fluoroacrylate emulsion. In both embodiments, the fluoroacrylate emulsion contains, dispersed therein with the aid of a surfactant system containing an amphoteric surfactant, essentially a single particulate fluoroacrylate copolymer having repeating units of the formulas I and II wherein Rf is a fluorinated alkyl radical; R and R1 are hydrogen or alkyl; and R2 is hydrogen or substituted or unsubstituted alkyl. The aqueous dispersion further contains, in addition to the surfactant system, a minor amount of polar organic liquid. In the first embodiment, drying under heat is optional and in any event can be carried out at temperatures below 55 DEG C. In the second embodiment, drying under heat is highly impractical but is also unnecessary.

Owner:MOODY RICARD J

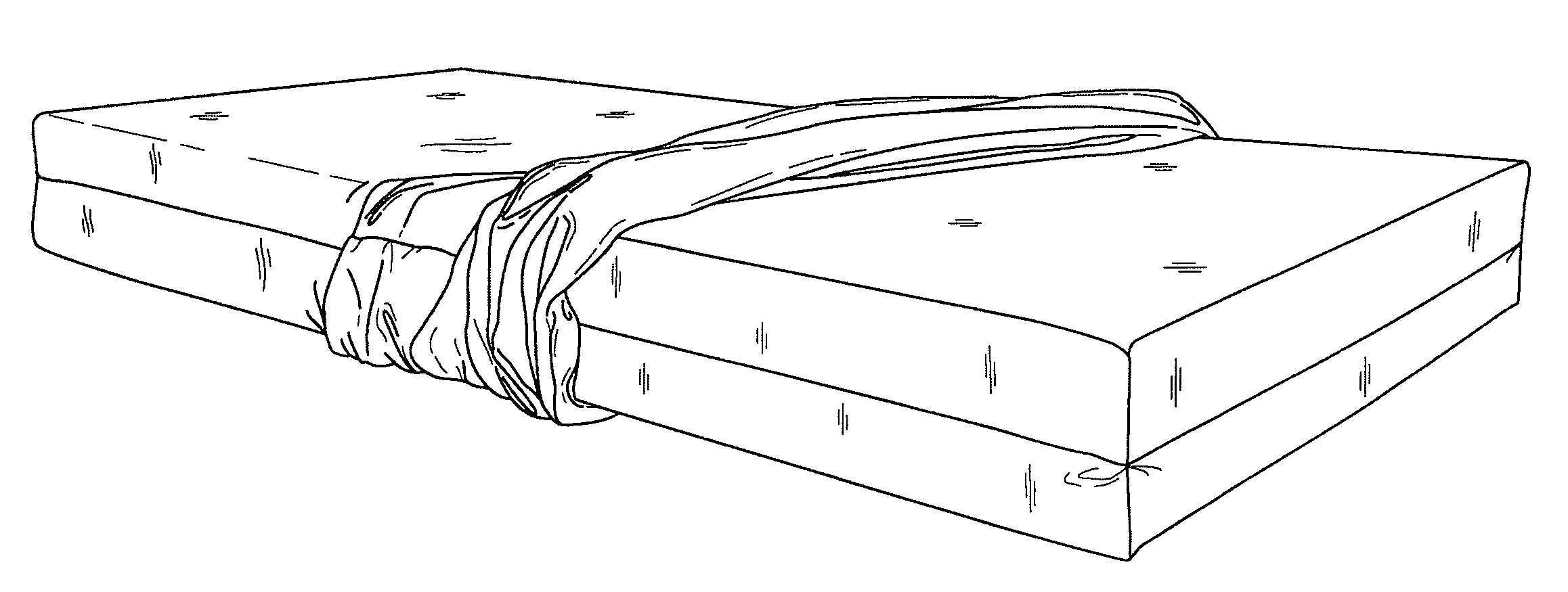

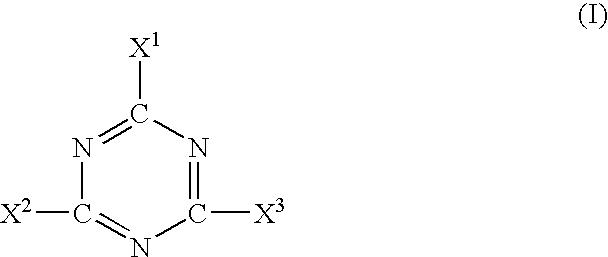

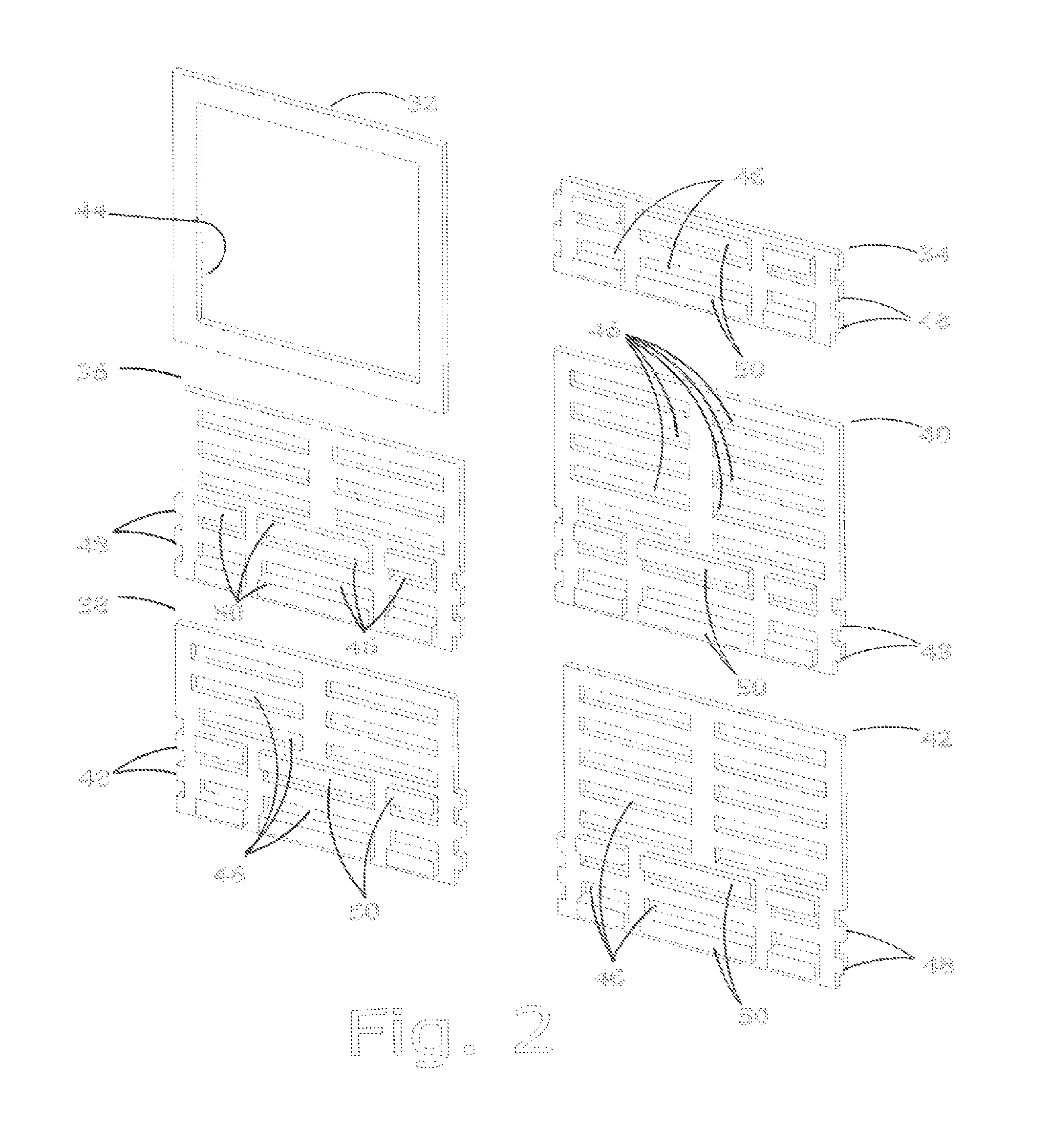

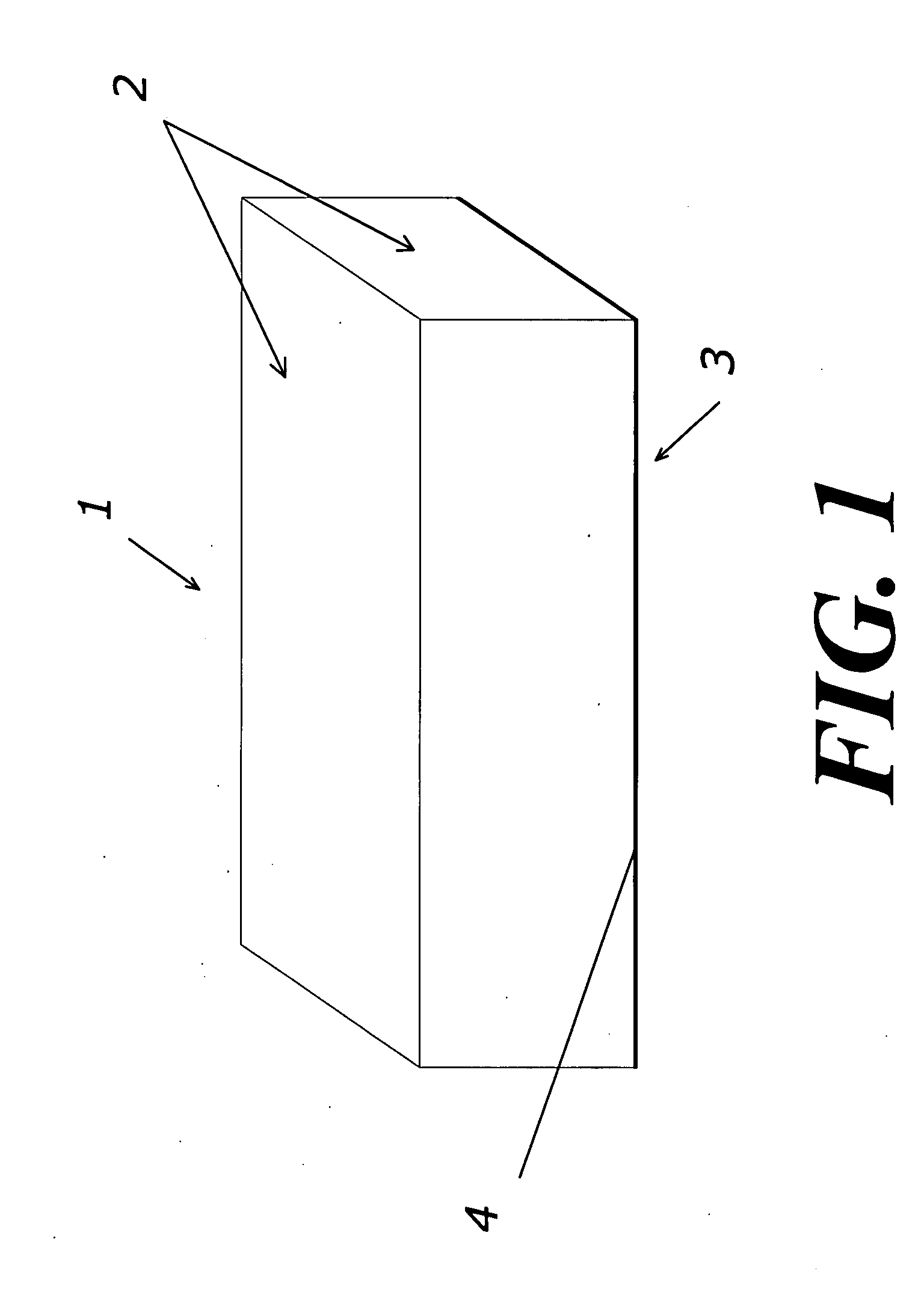

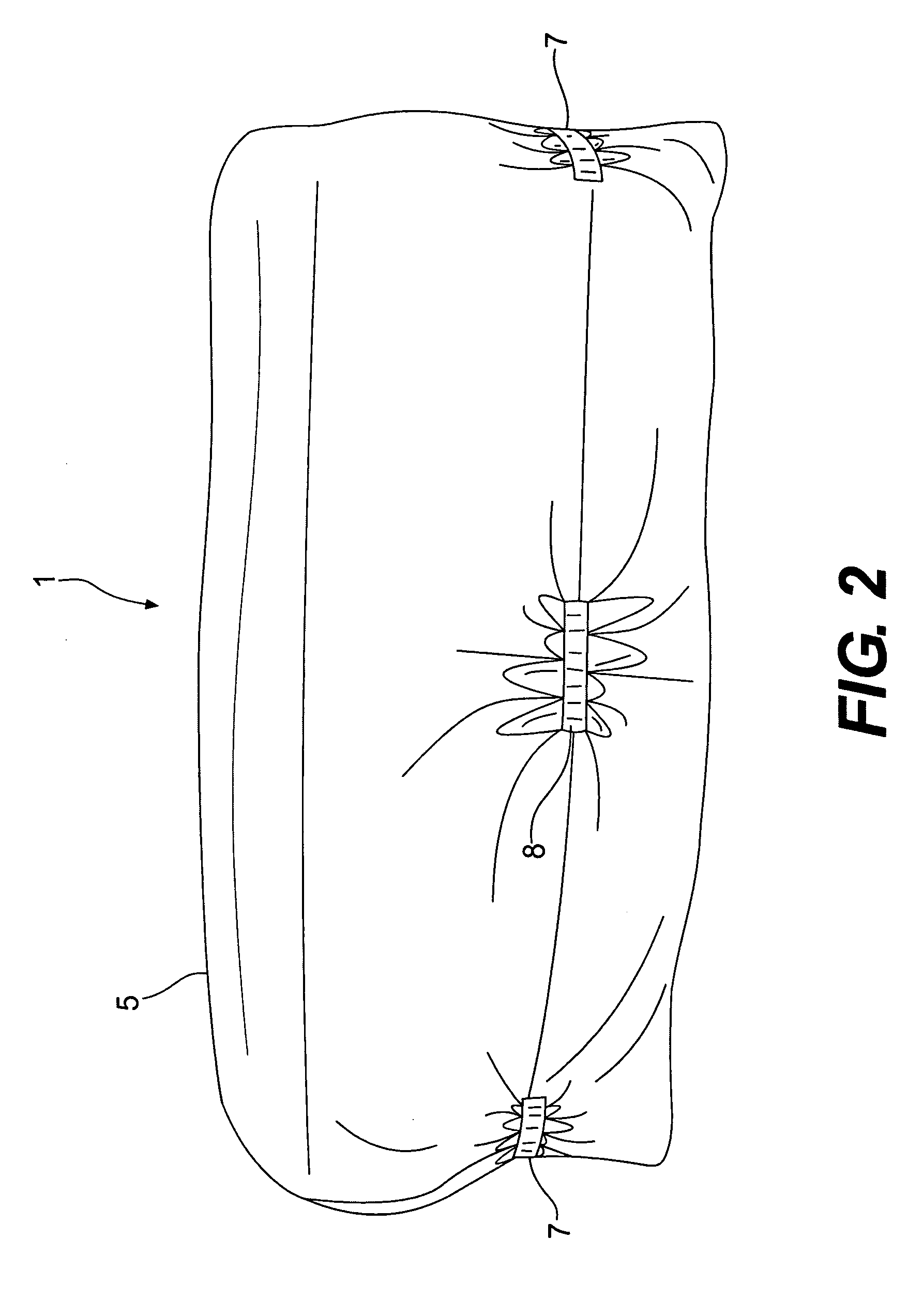

Modular knock-down upholstered furniture

A knock-down, modular furniture frame including a plurality of panels having interlocking sides and at least one tensioning device having a band that girds the plurality of panels to secure the plurality of panels together under tension into an interlocking relationship.

Owner:BLAIR MICHAEL

Flame-retardant mattress

ActiveUS20060090272A1Improve flame retardant performanceTexture and comfortSynthetic resin layered productsWarp knittingPolyesterPolymer science

There is provided a flame-retardant knit fabric which can exhibit texture and comfort inherent to materials such as cotton and urethane foam used for upholstered furniture such as a mattress and chair and bedding products such as a pillow, mattress pad and bedding, the flame-retardant knit fabric which can provide these products with high flame retardance. The internal structure of a mattress is covered with a flame-retardant knit fabric that comprises at least two fibers selected from the group consisting of (A) a halogen-containing fiber, (B) a cellulosic fiber, (C) a flame-retardant cellulosic fiber and (D) a polyester fiber, has a weight per unit area of at least 140 g / m2 and a thickness of at least 0.5 mm, and contains a flame retardant at a ratio of at least 2% by weight based on the while fabric.

Owner:KANEKA CORP

Polyol formulation for producing latex-like flexible polyurethane foam

A polyol formulation is disclosed, the formulation including: (a) 80 to 99 parts by weight (pbw) of a polymer polyol comprising a base polyol having a molecular weight in the range of from 2,500 to 6,500, an average nominal functionality (Fn) of at least 2.0, an ethylene oxide content of 50 to 80%, and a primary hydroxyl content of at least 40% and a polymer stably dispersed therein; and, up to a total of 100 pbw, (b) 1 to 20 pbw of a hydrophilic polyol having a molecular weight in the range of from 2,000 to 5,500, an ethylene oxide content of at least 40% by weight and a primary hydroxyl content of at least 50%. The formulation may further include a tin catalyst and optionally a crosslinking agent and is very useful for producing latex-like polyurethane foams. These foams may be suitably applied in cushions (in e.g. car seats and upholstered furniture) or mattresses.

Owner:SHELL OIL CO

Stitchbonded inherently flame resistant fabrics

InactiveUS20080085651A1Small shrinkagePrevent spontaneous combustionLayered productsWarp knittingYarnGlass fiber

The invention relates to an inherently flame resistant (FR) stitchbonded nonwoven fabric for mattresses, boxsprings, upholstered furniture, top-of-the-bed, office panel, transportation seating or any end use application where a FR textile material is desired. Two of the preferred forms of this invention include: 100% cotton. 100% rayon, 100% lyocell, cotton / non-FR fiber blends, rayon / non-FR fiber blends or lyocell / non-FR fiber blend battings that are stitchbonded with flame resistant fiberglass core-spun yarn. 100% cotton, 100% rayon, 100% lyocell, cotton / non-FR fiber blends, rayon / non-FR fiber blends or lyocell / non-FR fiber blend battings that are stitchbonded with FR spun yarn.

Owner:BEIJING CARINAE MATERIAL TECH CO LTD +1

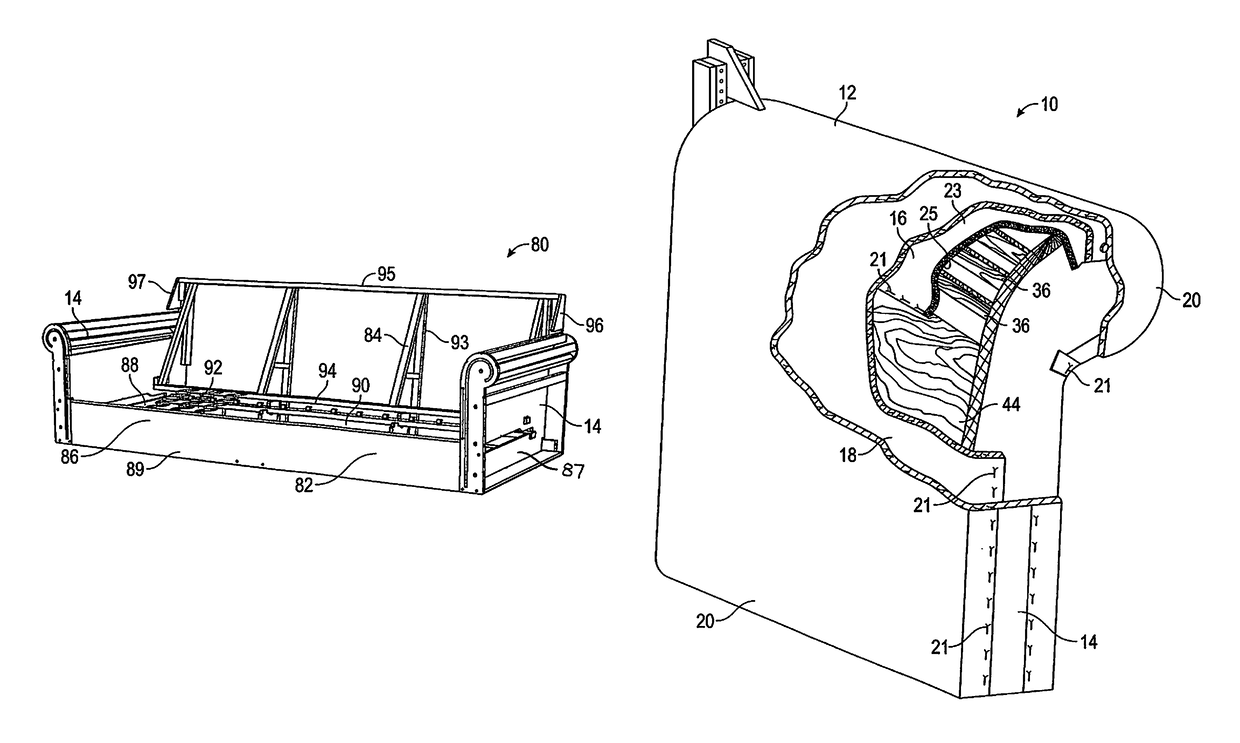

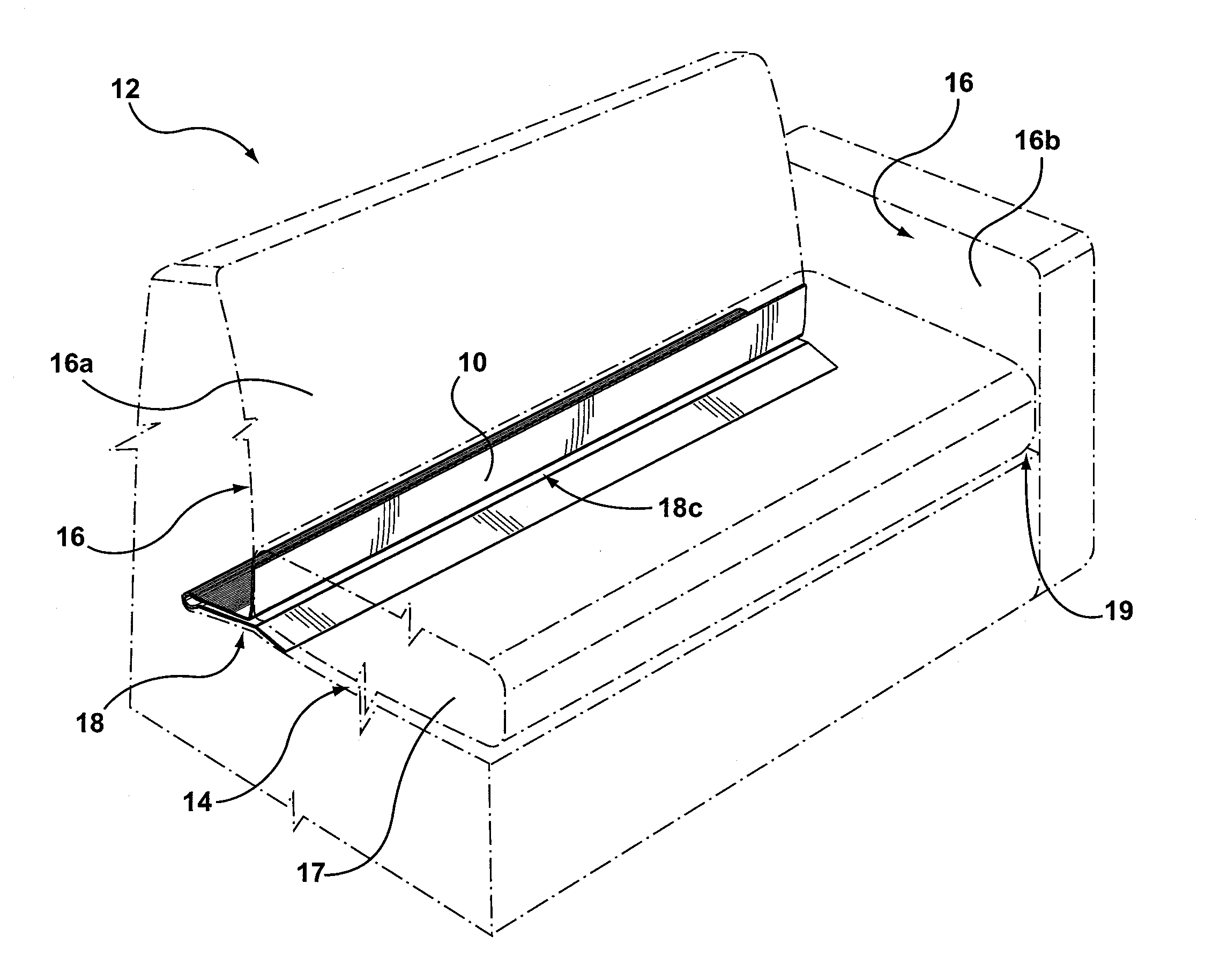

Assembly Appaatus for Modular Components Especially for Upholstered Furniture

InactiveUS20130134763A1Easy to transportEasy to disassembleDismountable chairsFoldable chairsUpholstered furnitureMechanical engineering

A connector assembly is used to connect subassemblies such as parts of a knockdown or modular sofa or similar item of furniture. The furniture item can be an upholstered item in which the multiple components are stackable into a volume that is smaller than the assembled item of furniture for shipping. The connector assembly includes a keyhole slot on a frame member in one component and a male connector assembly on a frame member in the other assembly. The male connector includes a sleeve with a cylindrical shank and an adjacent enlarged or conical portion, and the sleeve, which may be plastic, is mounted the bolt. The narrow section of the keyhole slot has a beveled surface and as the sleeve progresses into the narrow section, engagement of the conical sleeve section with the beveled slot surface tightens the two members being attached.

Owner:KOCH JON RUSSELL

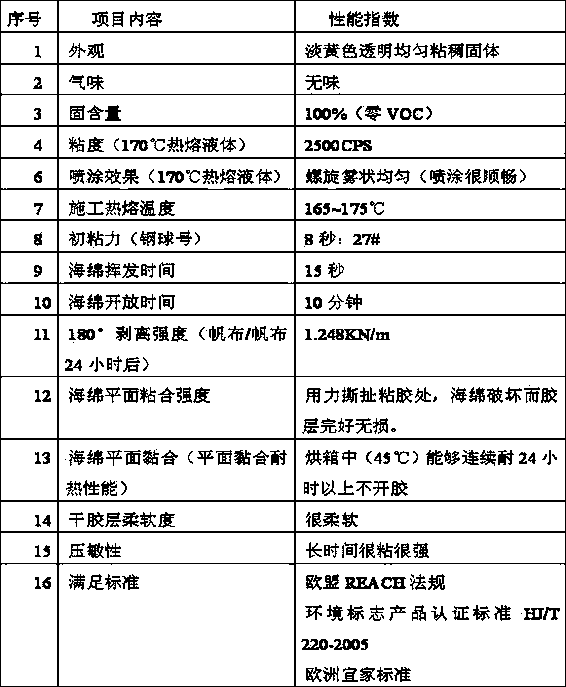

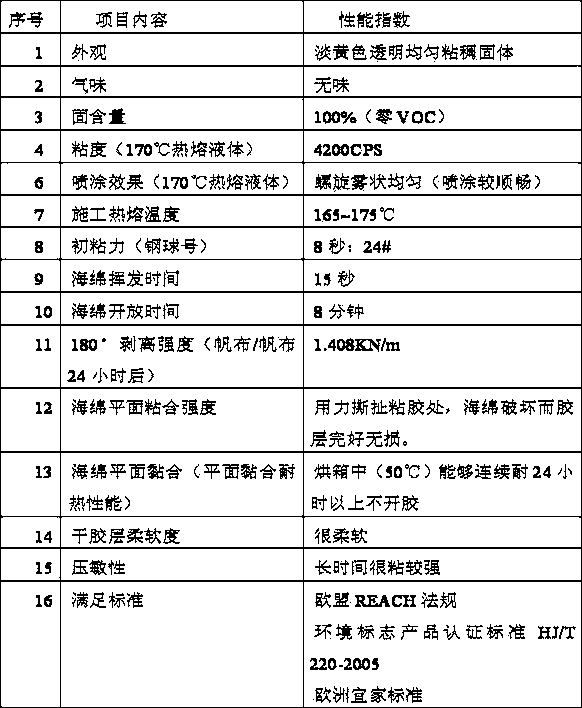

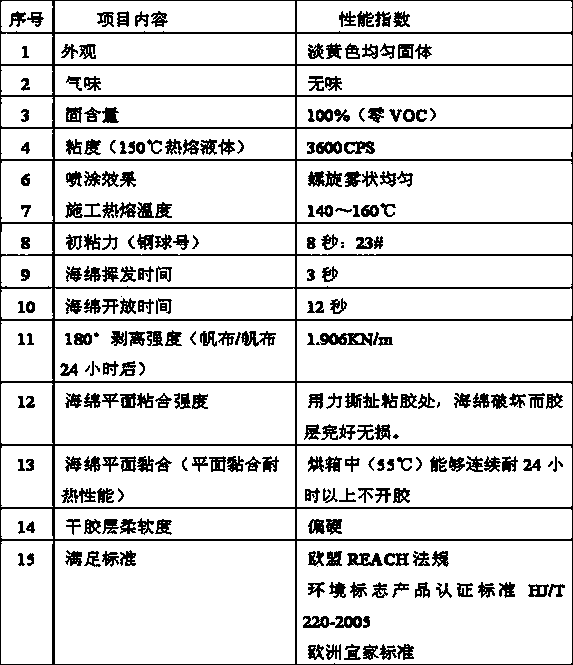

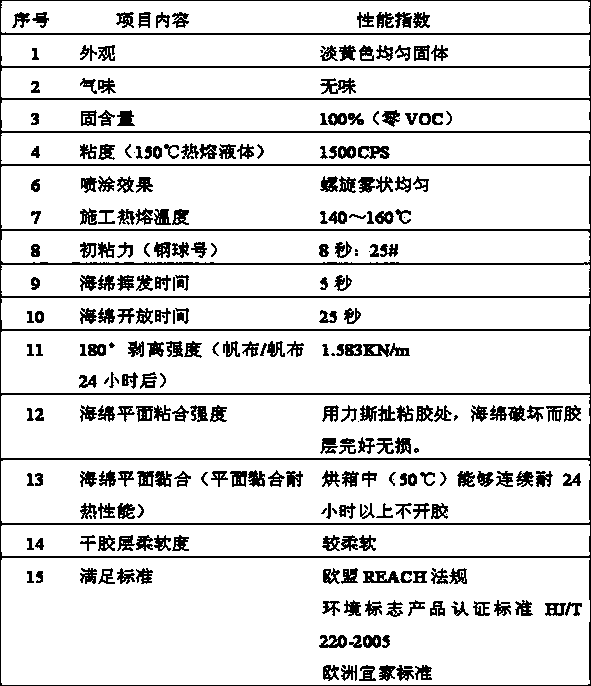

Environment-friendly hot-melt pressure-sensitive adhesive capable of being sprayed and preparation method thereof

ActiveCN103805112AReduce usageGet rid of severe constraintsMineral oil hydrocarbon copolymer adhesivesRosin adhesivesThermoplasticPolymer science

The invention discloses an environment-friendly hot-melt pressure-sensitive adhesive capable of being sprayed and a preparation method thereof. The hot-melt pressure-sensitive adhesive comprises the following main components in percentage by weight: 20 percent of SIS (Styrene Isoprene Styrene) thermoplastic styrene isoprene copolymer rubber of which the melt index is 6, 8 percent of SBS (Styrene Butadiene Styrene) thermoplastic butadiene styrene rubber of which the melt index is 8, 7 percent of water-white hydrogenated rosin, 10 percent of white disproportionated hydrogenated rosin glycerol ester, 8 percent of pale yellow modified terpene resin, 5 percent of C5 petroleum resin, 7.5 percent of white tackifying resin, 3 percent of polyisobutene and 4 percent of sasol wax. The environment-friendly hot-melt pressure-sensitive adhesive disclosed by the invention contains no organic solvent, zero VOC (volatile organic compounds), no heavy metals and no smell, is totally green, environment-friendly and nontoxic, has the advantages of being excellent in adhesive property, large in peel strength, high in drying speed, long in opening time, glue-saving, convenient for construction, low in cost, fireproof, safe and the like, and is widely applied to upholstered furniture industries such as mattresses, sofas, swivel chairs, pillows, screens and the like as well as sanitation product industries such as diapers, sanitary towels and the like, especially suitable for application in Europe and America environment-friendly high-grade export products and products for children.

Owner:深圳市顾康力化工有限公司

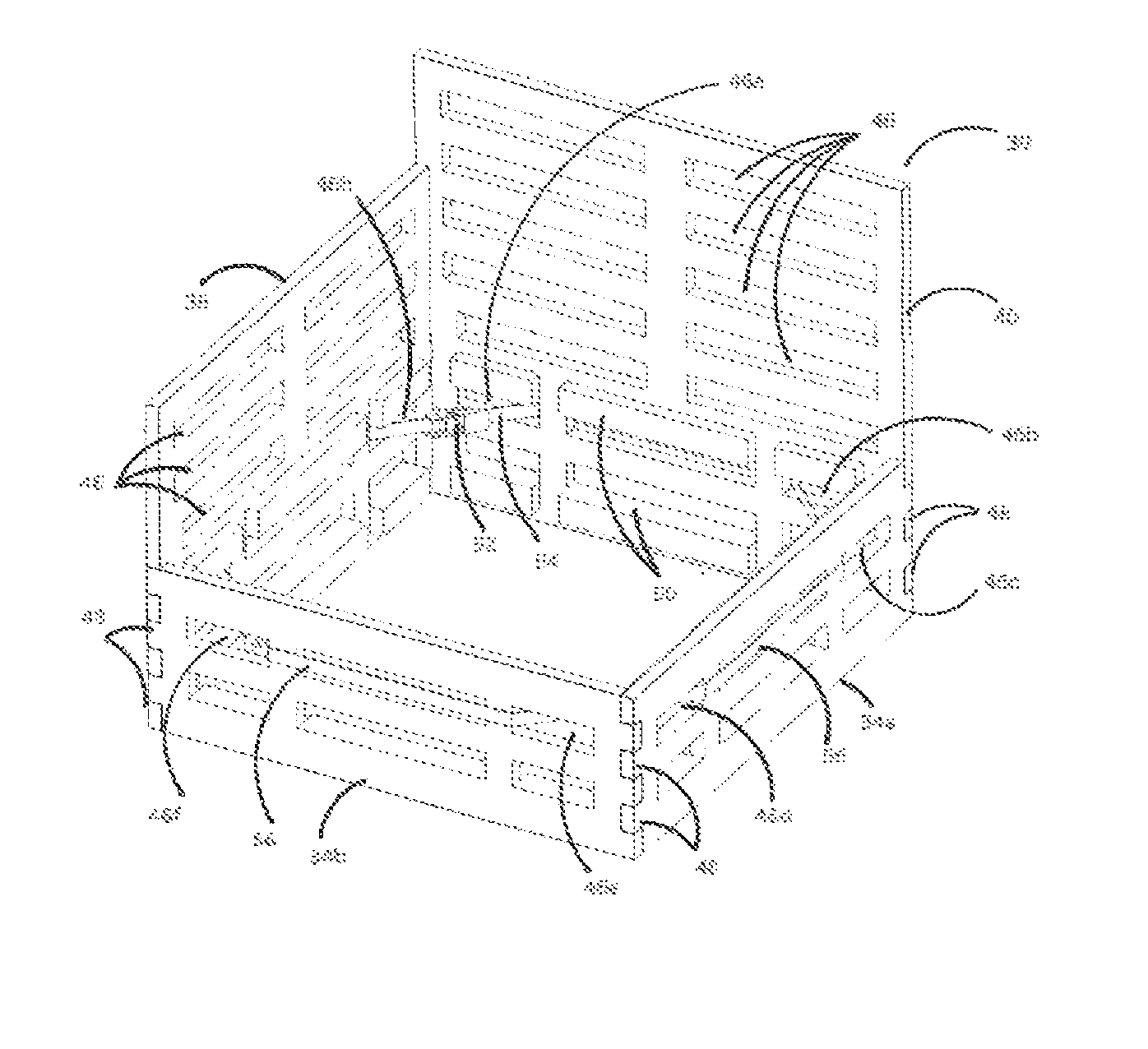

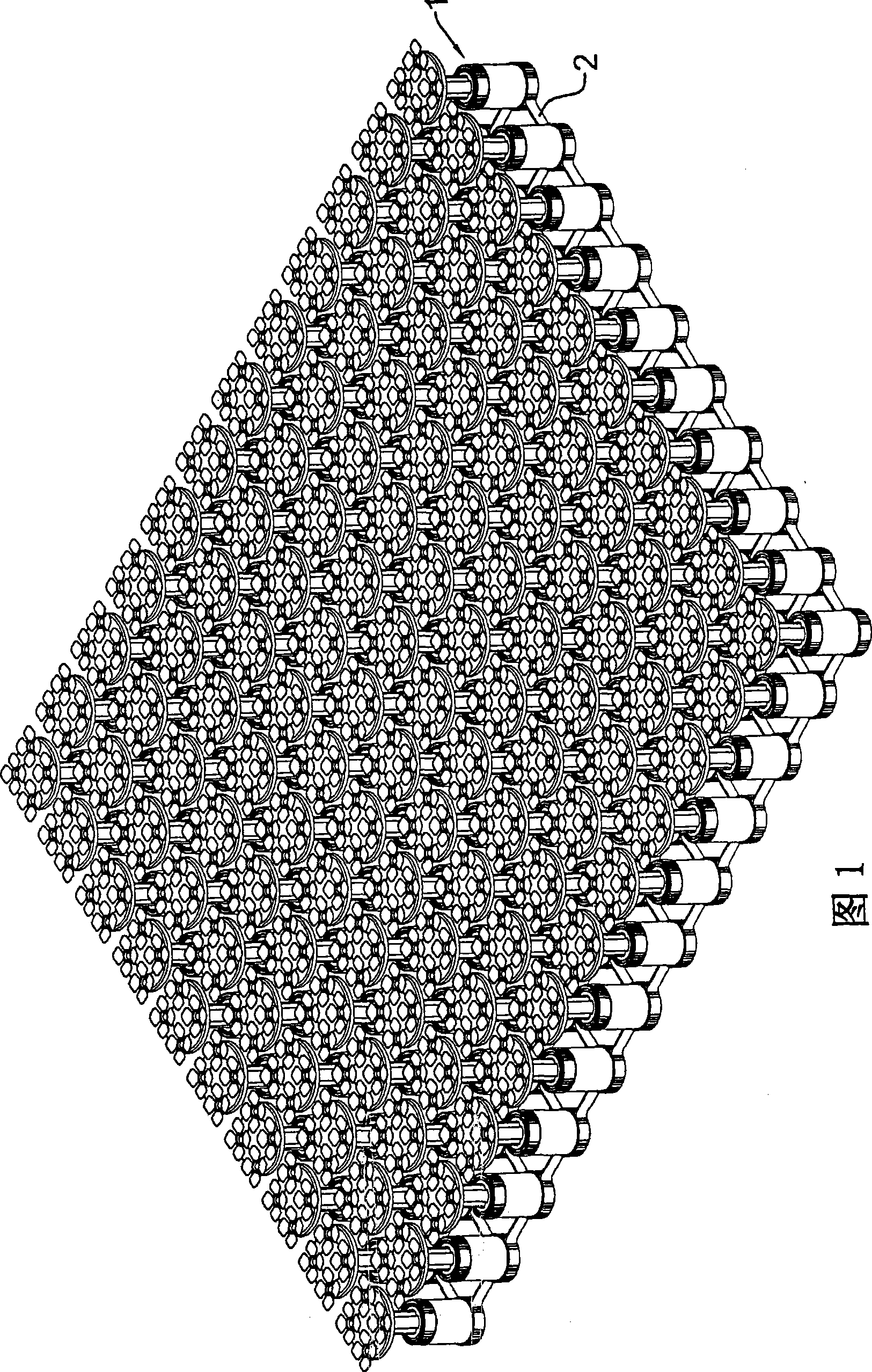

Magnetic levitation cushion and magnetic levitation device thereof

InactiveCN101411570AExtended service lifeSimple structureStuffed mattressesSpring mattressesRepulsion forceUpholstered furniture

The invention relates to a magnetic levitation cushion and support barrels thereof. The cushion has a plurality of support barrels capable of assembling with each other, each support barrel is at least provided with one fixed lower magnet and one upper magnet arranged in polarities rejecting to the lower magnet and movable relative to the fixed lower magnet, and the upper magnet is connected with a telescopic shaft extending at the top of the support barrel. At least a pad is provided at a top end of each shaft for constituting a supporting pad which takes the repulsion force produced by opposite polarities as a support force. The magnetic levitation cushion is used as a cushion for upholstered furniture such as chairs, beds and sofas.

Owner:许 荦彬

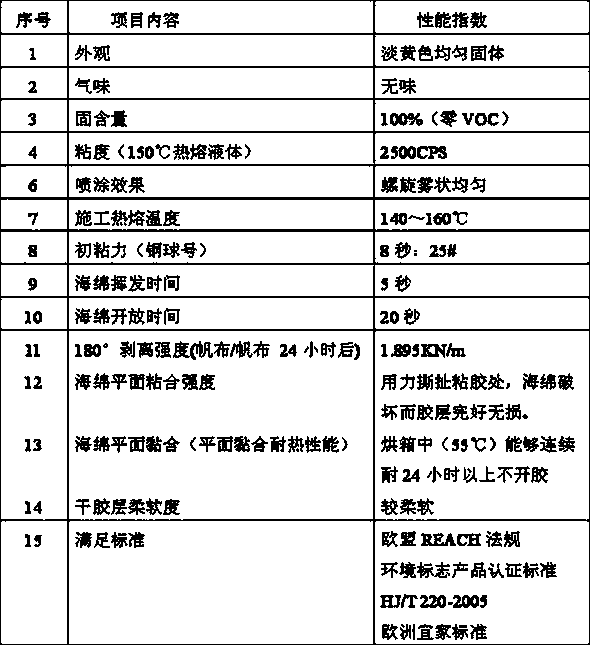

Sprayable environment-friendly hot melt glue and preparation method thereof

ActiveCN103805098AReduce usageGet rid of severe constraintsMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesMicrocrystalline waxEngineering

The invention discloses sprayable environment-friendly hot melt glue and a preparation method thereof. The spray glue mainly comprises the following components in percentage by weight: 12% of EVA thermoplastic resin with melting index 30, 18% of EVA thermoplastic resin with melting index 65, 10% of water-white rosin, 12% of water-white hydrogenated rosin, 8% of C9 petroleum resin, 14.5% of white tackifying resin, 5% of polyisobutene and 8% of microcrystalline wax. The sprayable environment-friendly hot melt glue disclosed by the invention has comprehensive advantages in multiple aspects such as environmental friendliness and no toxin, no organic solvent, zero VOC, no heavy metal or odor, good initial viscous force, high bonding strength, high permanent adhesion, heat and aging resistance, high drying speed, large spray area of unit weight (saving glue) and efficient and quick spraying construction, and has the advantages of complete environmental friendliness, improvement of the operation and construction environment, low cost, no odor, fire safety and the like, and is widely applied to the upholstered furniture industries such as sofa, swivel chairs, mattress, pillows and screens and especially applicable to the European and American environment-friendly high-grade exported products and children products.

Owner:深圳市顾康力化工有限公司

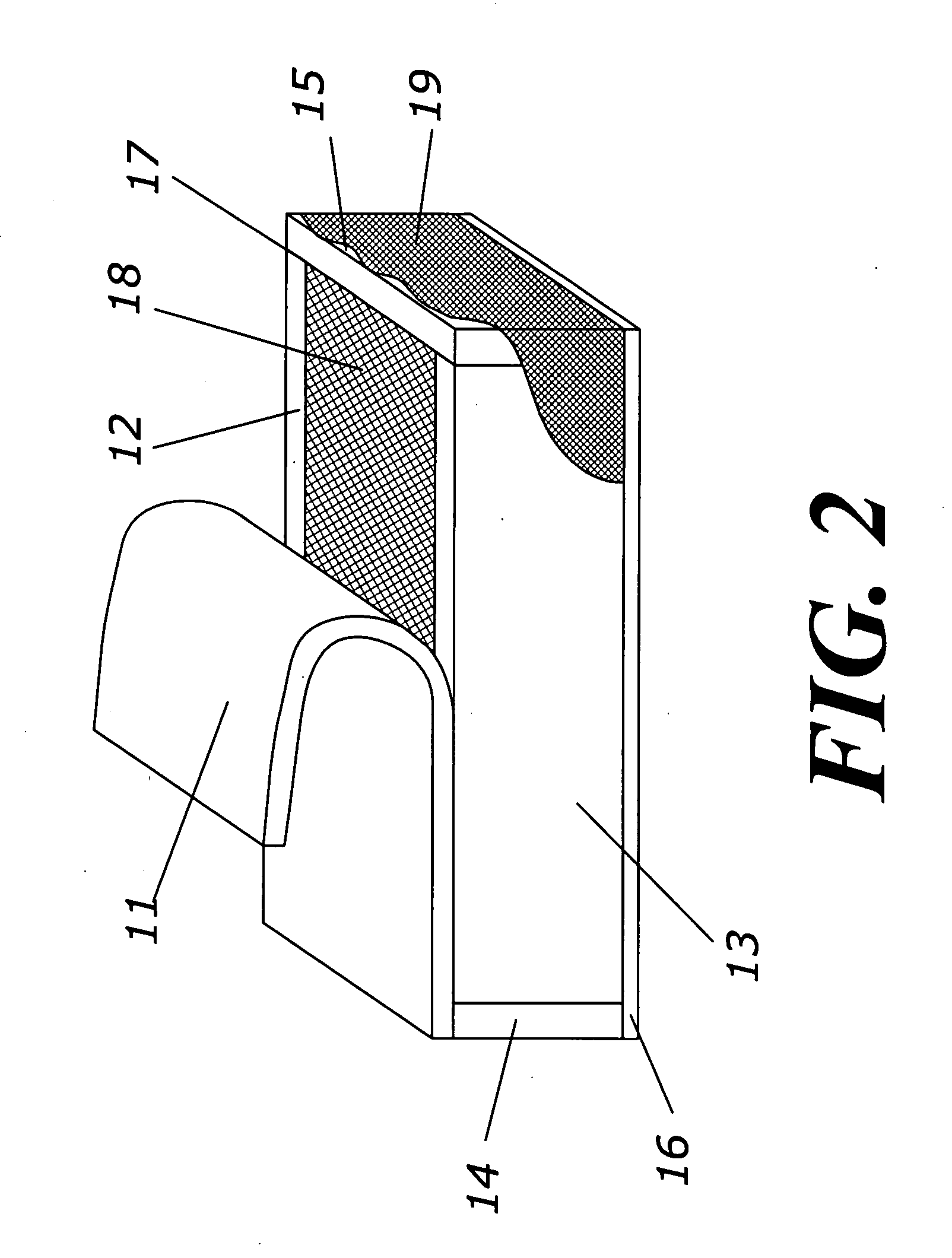

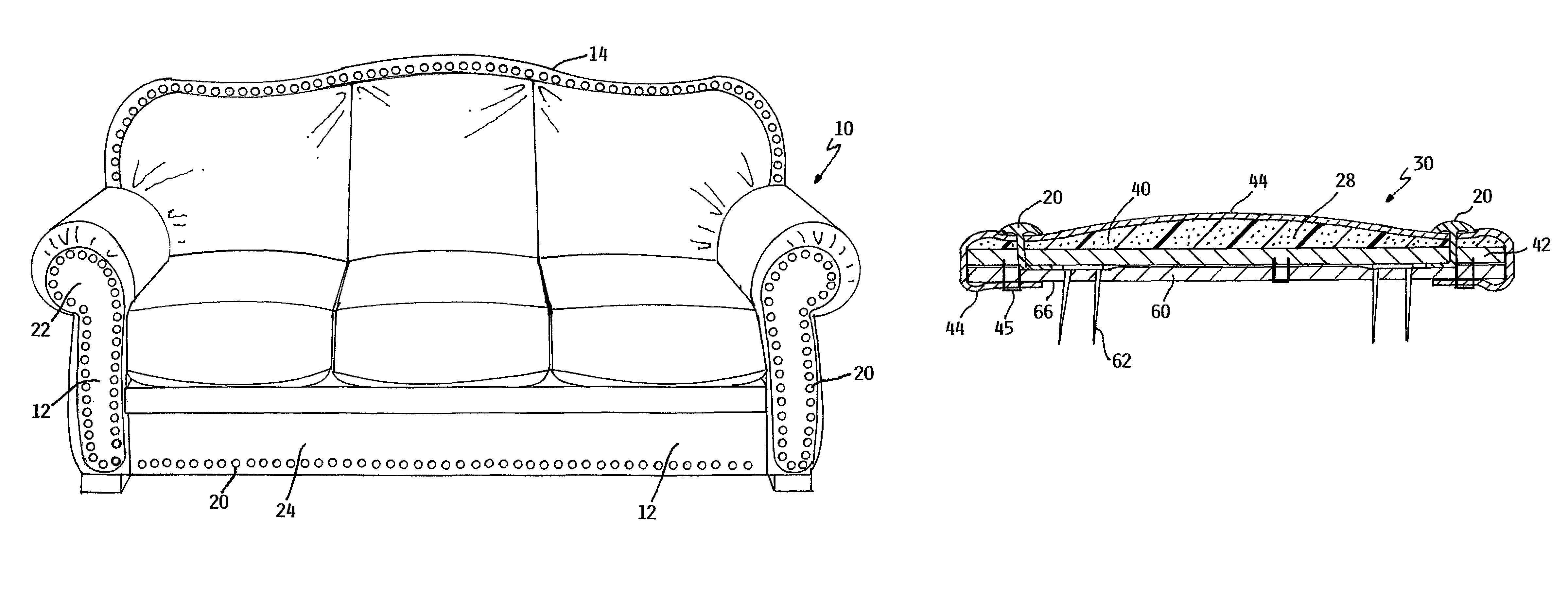

Upholstered furniture piece having upholstered arm panels

A sofa with an upholstered arm panel has an arm frame with a layered composition comprising an underlayment material layer, a fiber material layer positioned on top of and contacting the underlayment material layer, and a covering upholstery material layer positioned on top of and contacting the fiber material layer. The underlayment material layer is comprised a planar sheet of Ethylene-vinyl acetate closed cell foam. The EVA foam extends forwardly on the arm frame to create a forward extending lip. The use of EVA foam reduces the number of structural and cushioning materials, fasteners, and labor currently required in arm panel construction.

Owner:ASHLEY FURNITURE IND INC

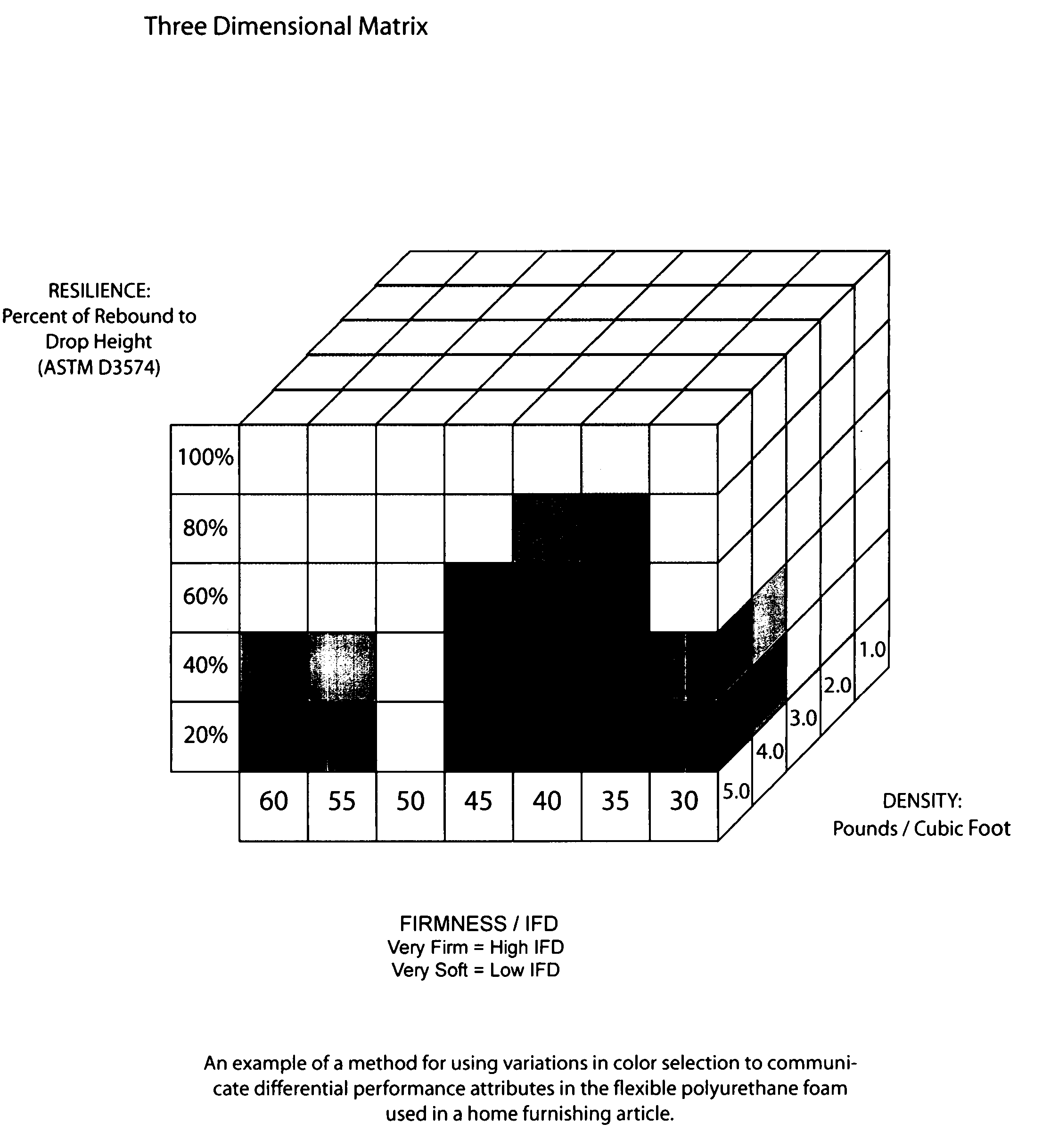

Method for communicating performance attributes

ActiveUS20080301983A1Efficient communicationReduce colorUpholstery manufactureStampsCushioningUpholstered furniture

A method of using color or color schemes to simplify the communication to consumers of complex information regarding the combinations and interactions of technically oriented performance attributes that describe the degree of comfort as found in mattresses, mattress foundations, upholstered furniture articles and other articles filled with cushioning materials. Additionally the selected method of using color as a communication tool may be of further benefit in the interaction with consumers by developing strong emotional ties to the consumers purchase decision.

Owner:KICKBALL CONCEPTS

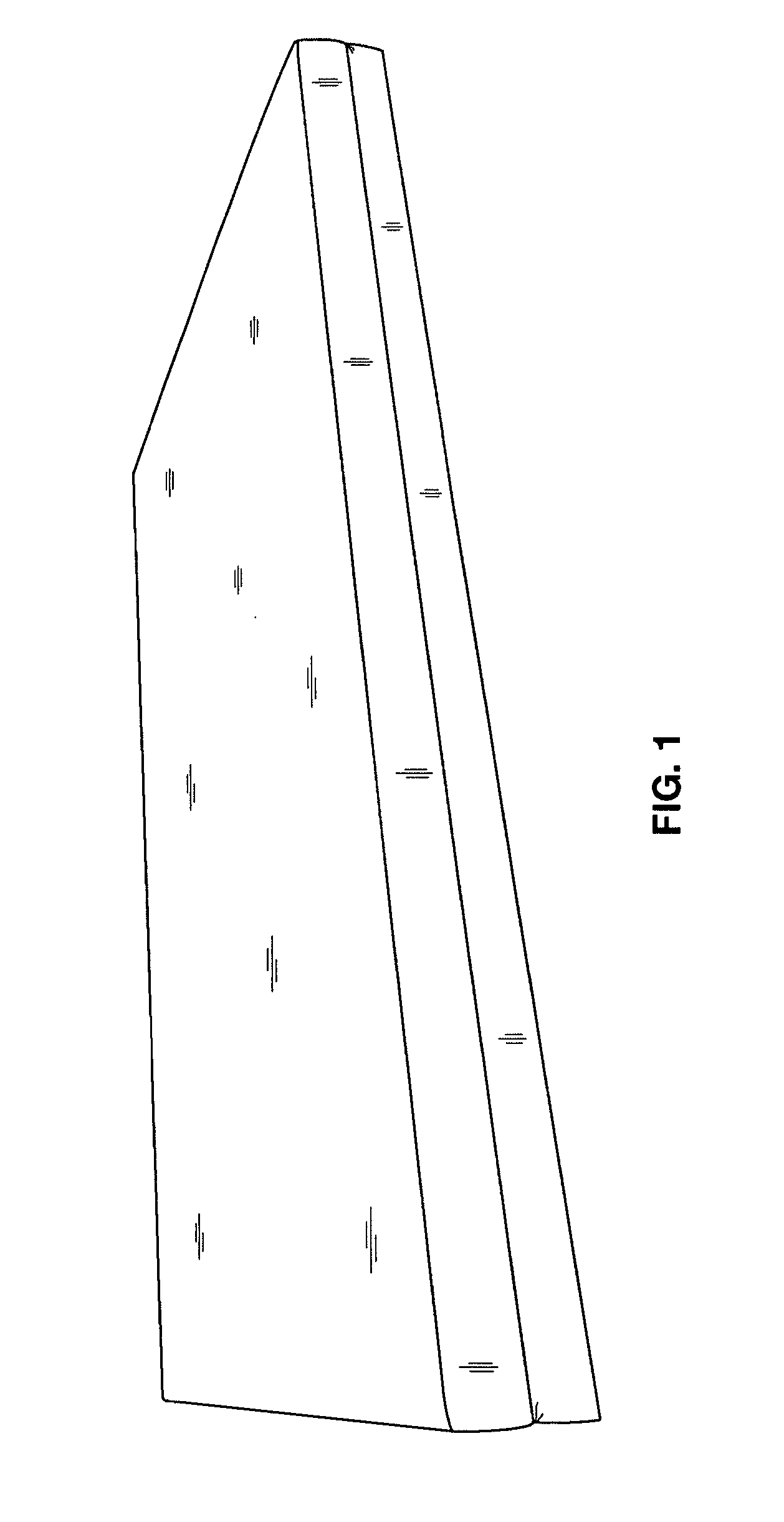

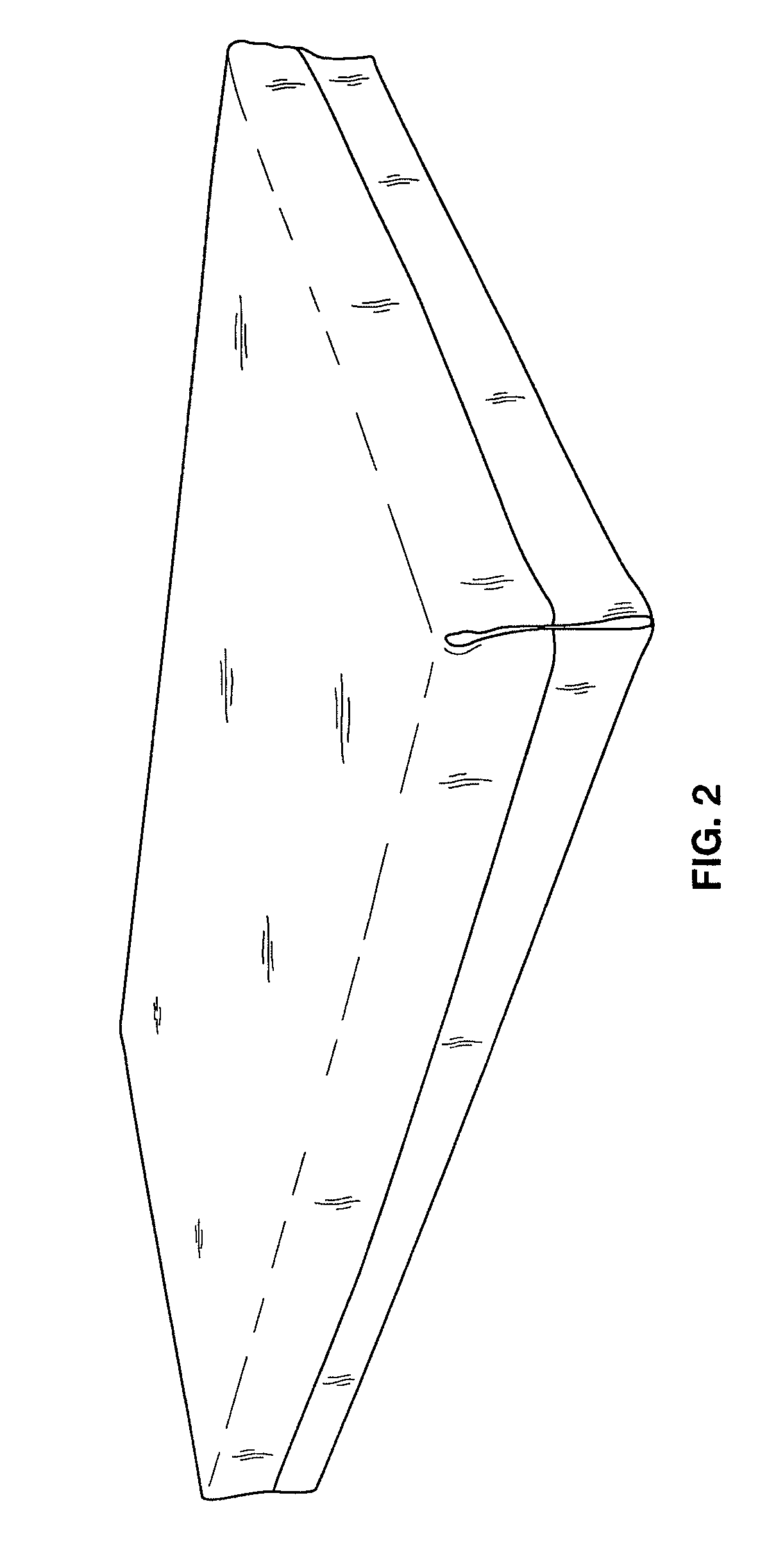

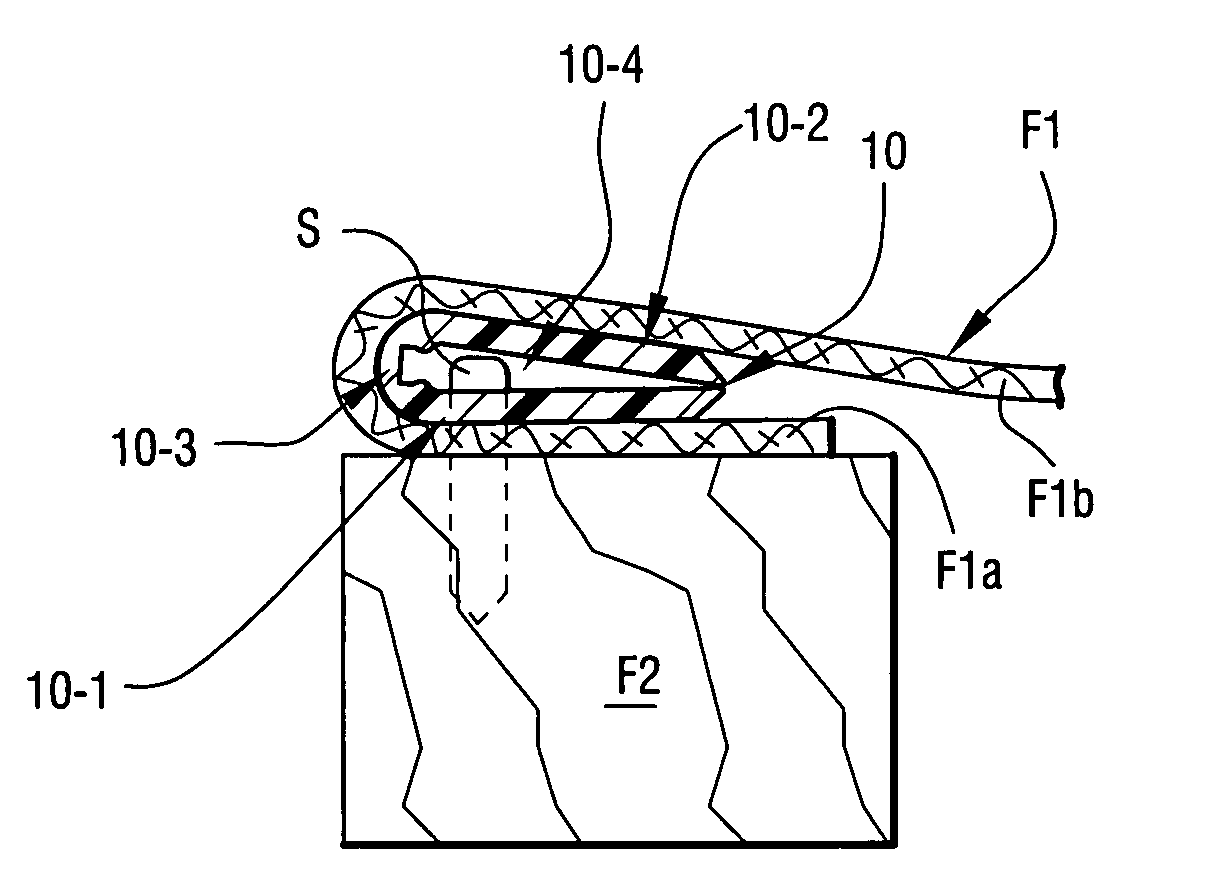

Protective strips for use in the manufacture of upholstered furniture

ActiveUS7419212B2Prevent (orAvoid contactStuffed mattressesSpring mattressesUpholstered furnitureFastener

Protective strips for use in the manufacture of upholstered furniture include a fastening strip portion, a cover strip portion and a hinge portion which flexibly connects the fastening and cover strip portions to one another. In use, the protective strips may be positioned such that a portion of the upholstery fabric is sandwiched between the fastening strip portion thereof and a portion of the furniture frame to which the fabric is to be attached. Suitable fasteners (e.g., staples, tacks, nails, brads and like fasteners) may then be physically driven through the fastening strip portion and the underlying fabric portion into the furniture frame and thereby fasten the fabric portion physically to the frame. Once the fastening strip portion has been fastened to the furniture frame, the remaining fabric portion may be doubled over the fastened tail portion which in turn causes the cover strip portion to be folded over the fastening strip portion. In such a manner, the heads of the fasteners are physically covered by the cover strip portion so as to prevent contact with the overlaid fabric. As such, rubbing of the fabric against the fastener heads is prevented so as to thereby preclude (or at least substantially minimize) fabric abrasion and wear.

Owner:3 D LLC

Flame-retardant waterproof stretchable composite fabric, pillow or mattress protector using said fabric and use of said fabric as a protective screen

The composite fabric is suitable as a flame barrier for different articles, such as mattresses, pillows, seats and upholstered furniture and is made from a plurality of joined breathable layers including at least one textile layer and one impervious layer joined including a knitted textile layer made of cellulose fibres of natural renewable origin including at least 50% of cellulose flame-retardant fibres, and the impervious layer including an halogen free plastic material selected among polyurethane or polyester incorporating a known flame-retardant or inhibitor additive.

Owner:MFR IND DE TORTELLA

Furniture with decorative fasteners

ActiveUS8764115B2Efficiently and safely shippedEfficient and cost-effectiveUpholstery manufactureUpholstered panelsEngineeringUpholstered furniture

A method of assembling an upholstered furniture piece comprising decorative fasteners comprising providing an underlayment material layer, a foam material layer and a covering material layer. The foam material layer is positioned between the underlayment material layer and the covering material layer. The covering material layer extends beyond the underlayment material layer and the foam material layer. Fasteners are used to fasten the underlayment material layer, the foam material layer and the covering material layer together forming a layered component. A template may be used to guide positioning of the fasteners. The fasteners are decorative fasteners. Excess covering material that extends beyond the fasteners is stretched around the edges of the layered component and is affixed to a bottom surface of the layered component, thereby forming a layered assembly. The layered assembly is affixed to an upholstered furniture piece.

Owner:ASHLEY FURNITURE IND INC

Flame retardant knit fabric

There is provided a flame-retardant knit fabric that sufficiently provides texture and amenity inherent in cotton or urethane foam as a material used in upholstered furniture such as mattresses and chairs, bedding products such as pillows, mattress pads, and futon, and the like, and can make these products highly flame-retardant. The present invention relates to a knit fabric comprising at least two fibers selected from the group consisting of (A) a halogen-containing fiber, (B) a cellulosic fiber, (C) a flame-retardant cellulosic fiber, and (D) a polyester fiber, the knit fabric having a weight per unit area of 150 g / m2 or more, having a thickness of 0.5 mm or more, and having a content of a flame retardant in the whole knit fabric of 2 wt % or more, wherein (weight per unit area of the knit fabric (g / m2))×(thickness of the knit fabric (mm))×(content of the flame retardant in the whole knit fabric (wt %) / 100)=10 or more.

Owner:KANEKA CORP

Formaldehyde-free adhesive and method for producing formaldehyde-free palm fiber mattress by using same

InactiveCN102618210ALow costSolve formaldehyde releaseStuffed mattressesProtein adhesivesCross-linkYarn

The invention discloses a formaldehyde-free adhesive and a method for producing a formaldehyde-free palm fiber mattress by using the formaldehyde-free adhesive. The formaldehyde-free adhesive is produced by using formaldehyde-free raw materials which are vegetable protein, a cross-linking agent, an auxiliary material and water. According to the method for producing the formaldehyde-free palm fiber mattress by using the formaldehyde-free adhesive, a palm fiber raw material is a natural coconut palm fiber yarn or a natural arenga engleri fiber yarn and is sequentially subjected to working procedures of felting, needling, glue spraying, drying, slicing, hot-pressing, side shearing and checking. The palm fiber mattress, the release amount of the free formaldehyde of which is far less than 0.050mg / m<2>.h (stated in QB1952.2-2004 spring soft mattress of upholstered furniture), can be produced according to the method. The free formaldehyde of the palm fiber mattress is only derived from the natural palm fiber, thereby the problem of formaldehyde release of the palm fiber mattress is fundamentally solved.

Owner:田志壮

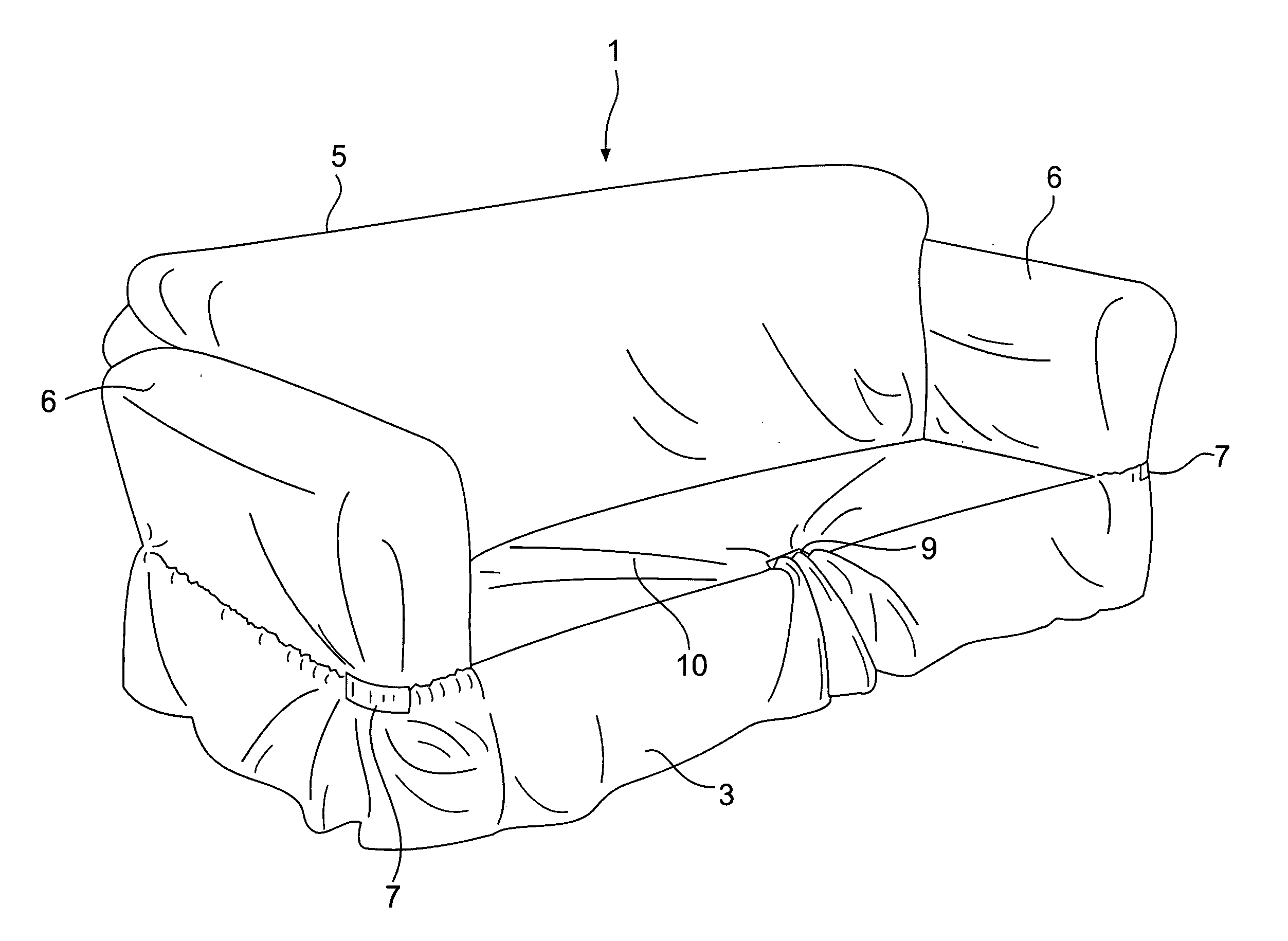

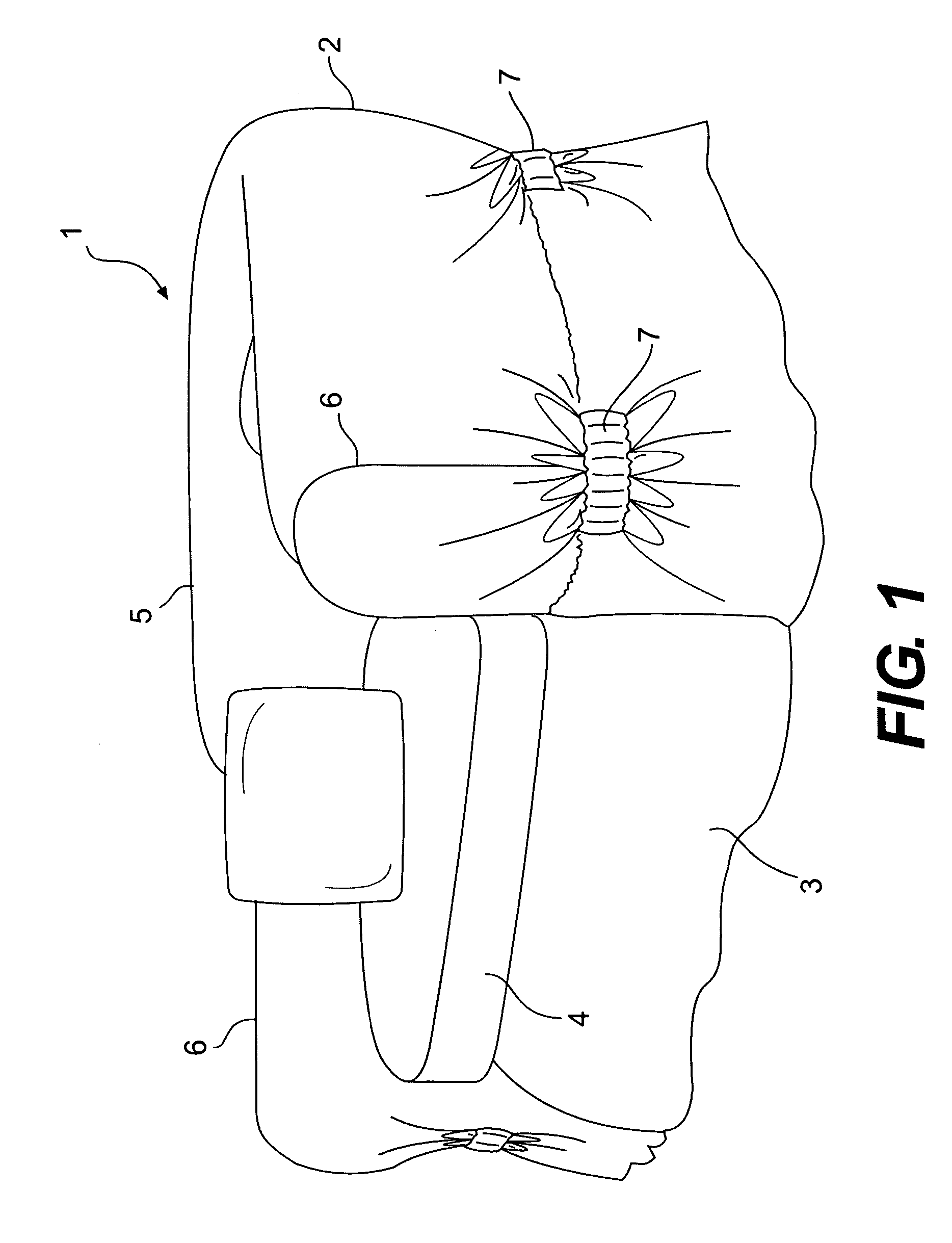

Slipcover with secured corners for upholstered furniture

A one-piece or two-piece slipcover for covering upholstered furniture has a gathering device at each corner to gather any excess material of the slipcover to provide a neat, tailored look to the slipcover. The gathering device may be an elastic strip, a fabric tab having hook and loop fasteners secured to the surfaces thereof, or a drawstring.

Owner:MAYTEX MILLS

Catching device for use with upholstered furniture

A catching device for use with a piece of upholstered furniture having a base portion, at least one wall portion extending upwardly from the base portion, and a crevice between the base portion and the at least one wall portion. The catching device includes an elongated receptacle sized and shaped for insertion into the crevice. The receptacle has a length selected to extend along at least a portion of the crevice, an upper sidewall shaped to extend along a wall side of the crevice, a lower sidewall shaped to extend along a base side of the crevice, and an end portion shaped for flexibly coupling the lower sidewall to the upper sidewall so as to form a closed end of the receptacle. The upper sidewall and lower sidewall are biased apart from each other such that when the receptacle is inserted into the crevice, the upper sidewall sealingly engages the wall portion and the lower sidewall sealingly engages the base portion. The catching device also includes a retaining flange flexibly coupled to a top portion of the upper sidewall and being sized and shaped such that when the receptacle is inserted into the crevice, the retaining flange protrudes outwardly from the crevice and away from the lower sidewall to engage a wall surface of the at least one wall portion to secure the receptacle in the crevice.

Owner:KATCHALL4U

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com