Patents

Literature

49results about How to "Fully stressed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

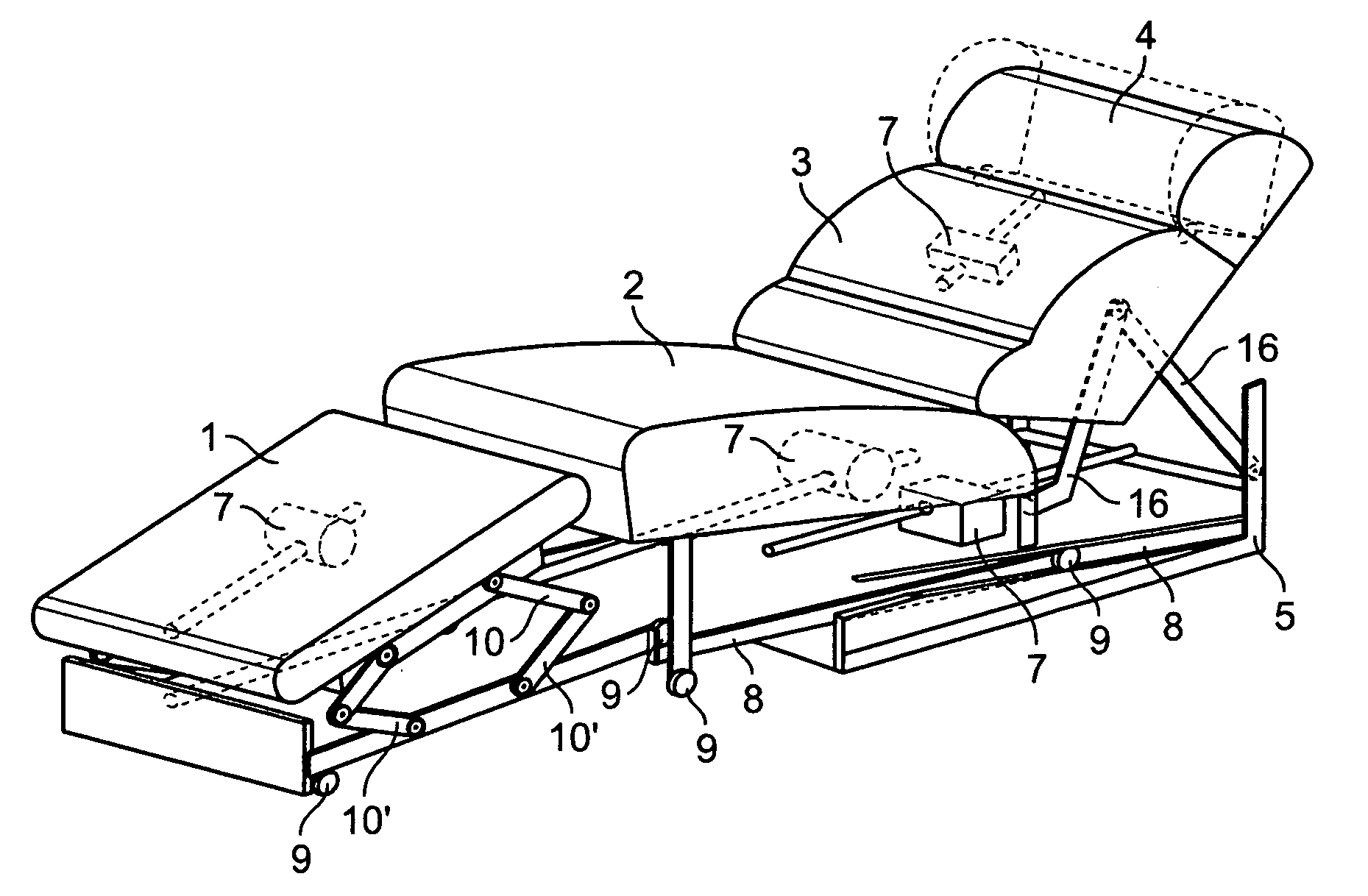

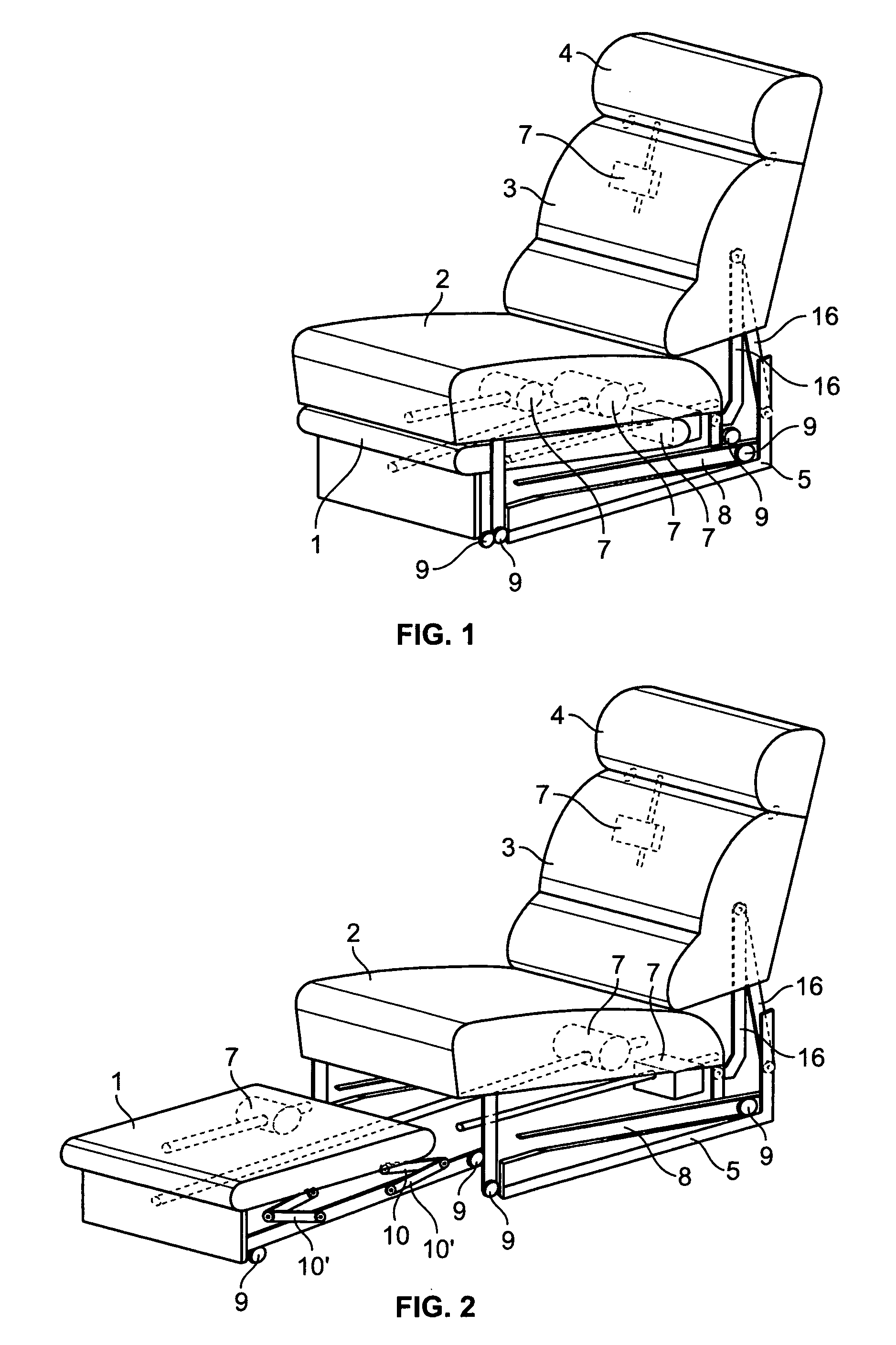

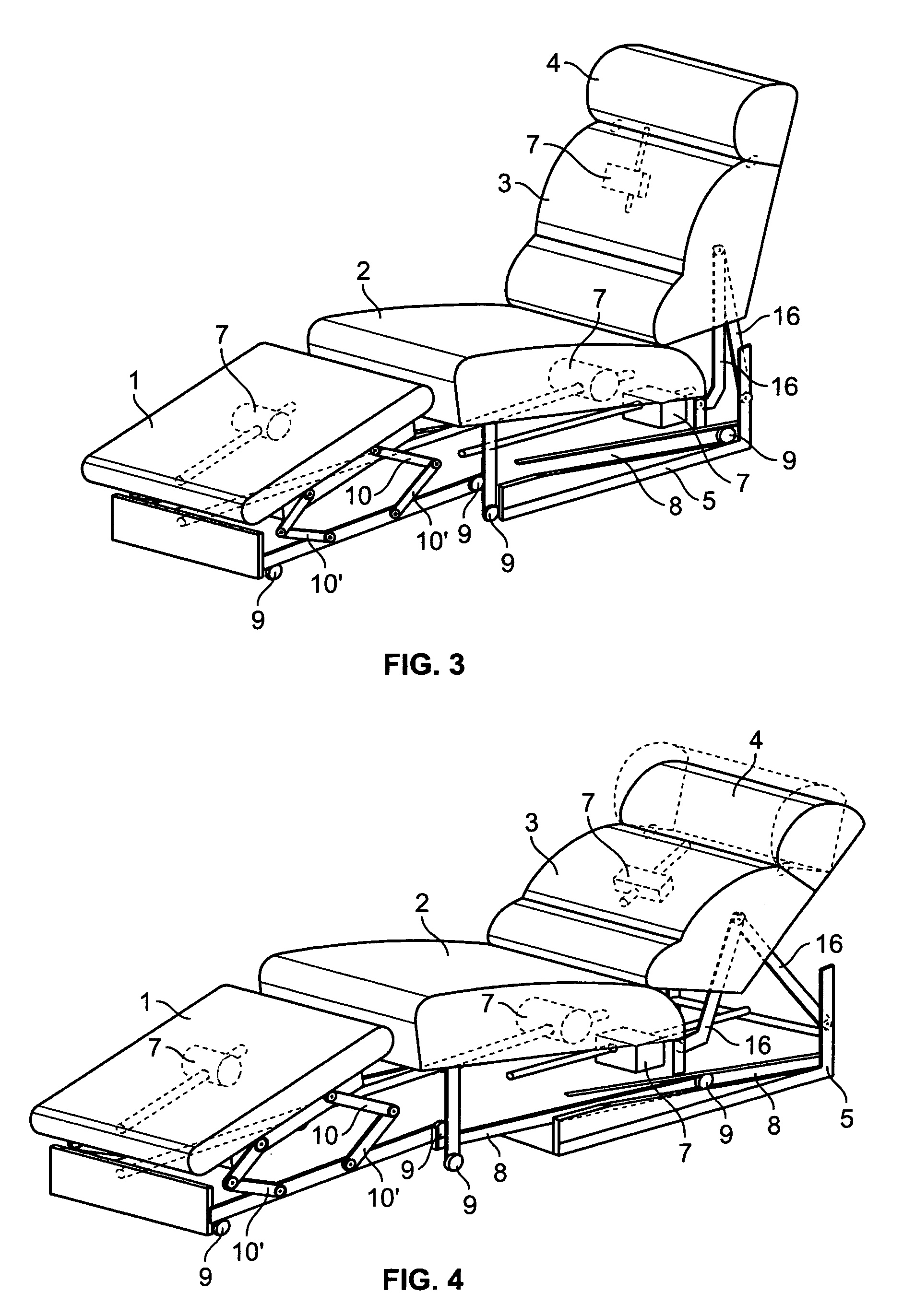

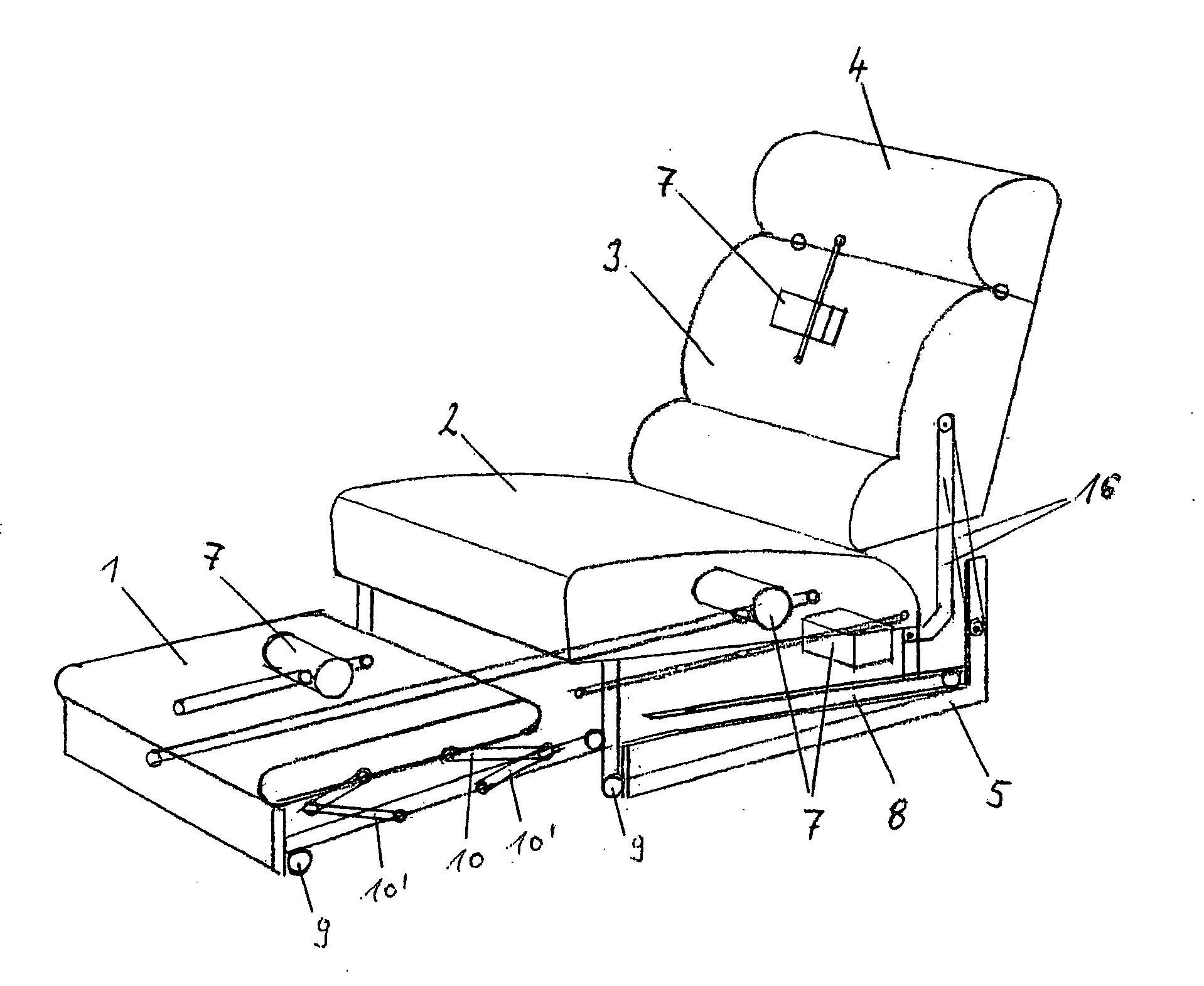

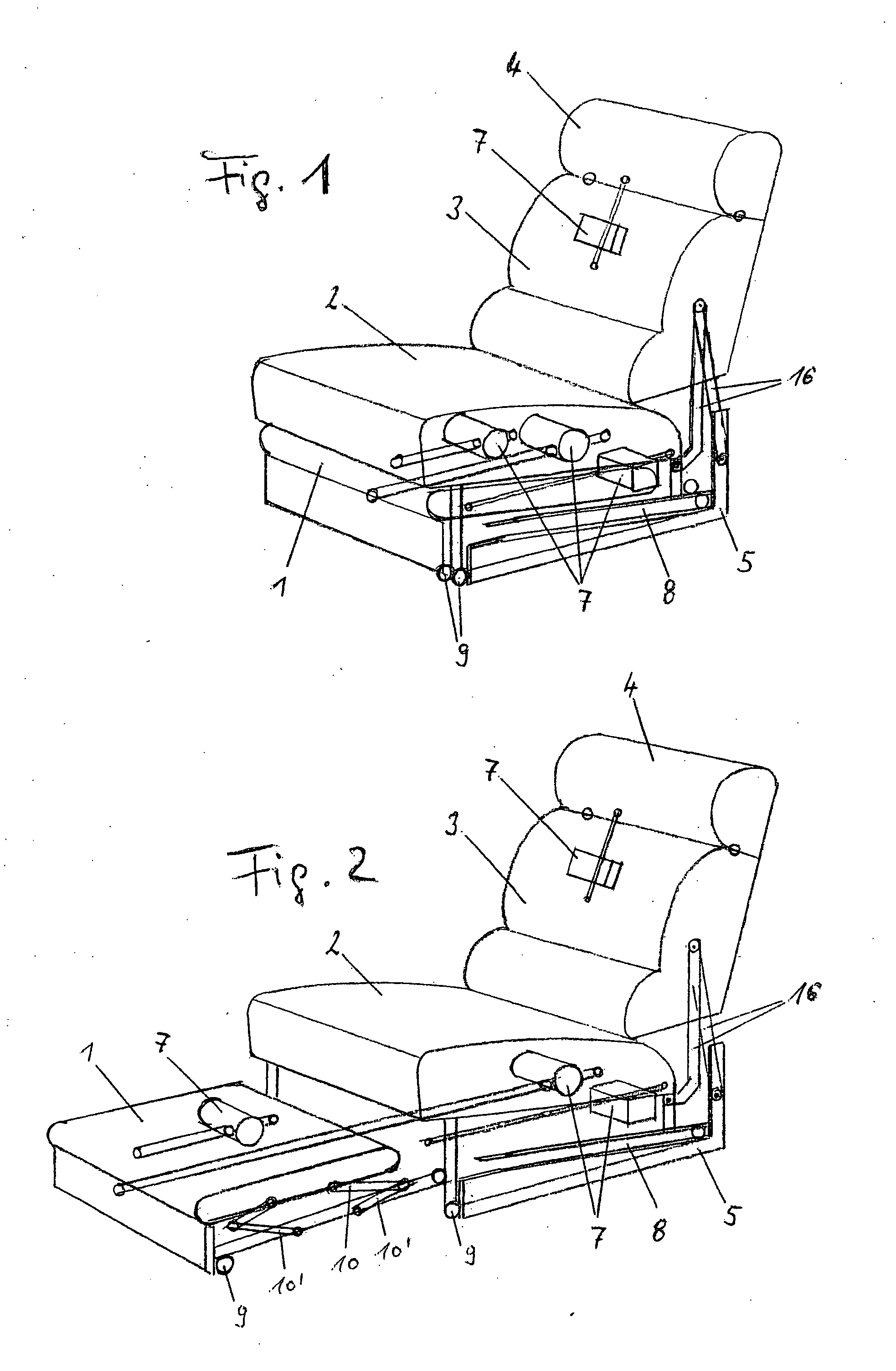

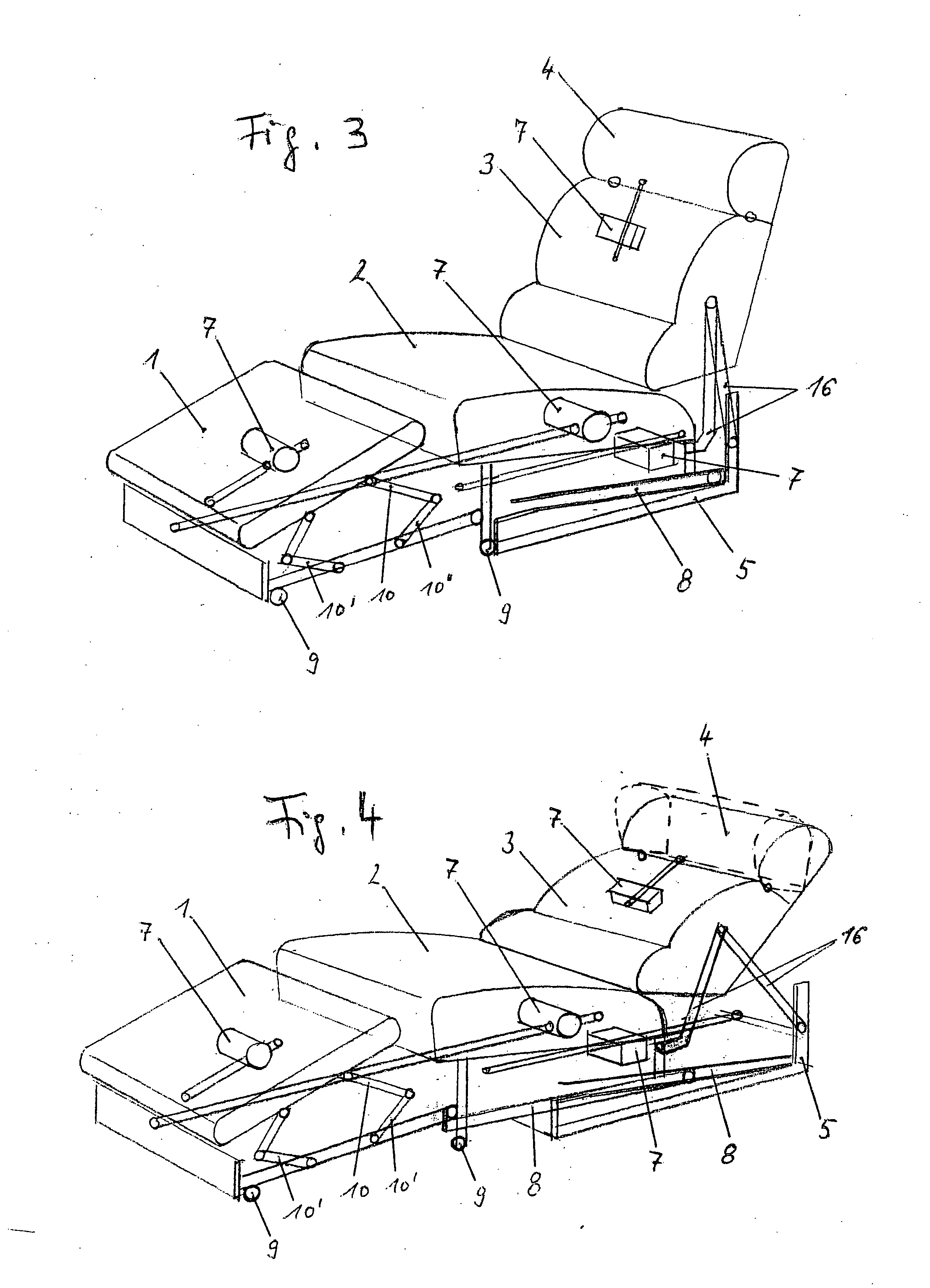

Convertible piece of upholstered furniture with chair and bed function

InactiveUS7083235B2Fully stressedEasy and step-less and wall-free conversion capabilityOperating chairsSofasMotor driveIntermediate stage

A convertible piece of upholstered furniture can be converted via motorized conversion aids from a seat function into a bed, by way of any desired number of intermediate stages, and vice versa. All movable parts can be fully stressed by a person during conversion, even when a person is sitting or lying on the piece of furniture. These changes can take place even when the piece is being used by a person, whereby each movable part of the piece of upholstered furniture can be changed by means of a motor drive having a control. The footrest and the seat part are configured so that they can move out of a base frame with their metal fittings. A lever construction arranged on the metal fitting of the footrest and a motor drive adjusts the height and angle of the footrest and moves the piece of furniture to the various positions.

Owner:FIEDLER HANS

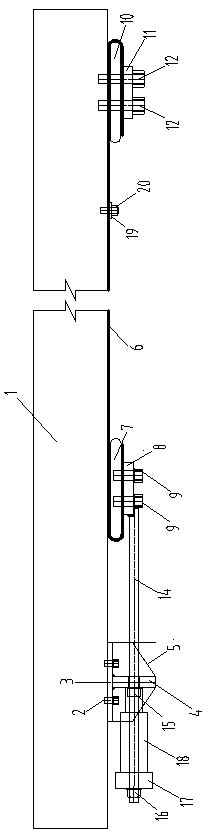

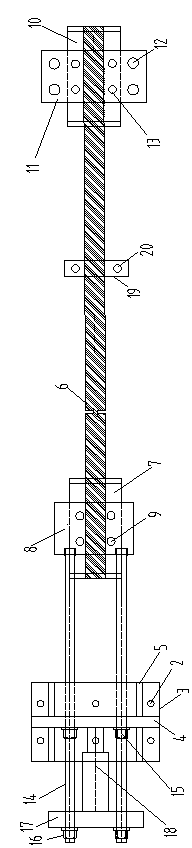

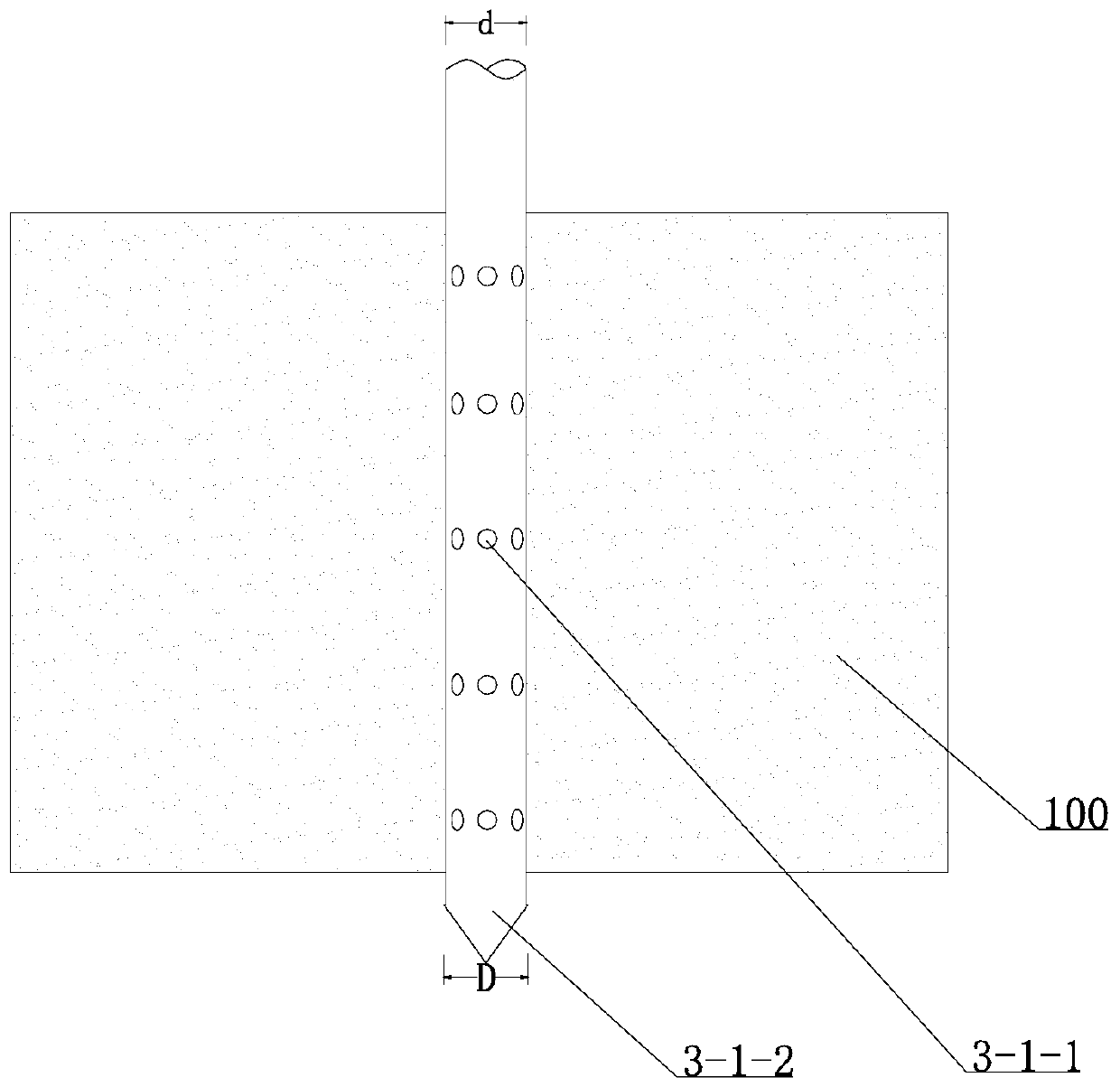

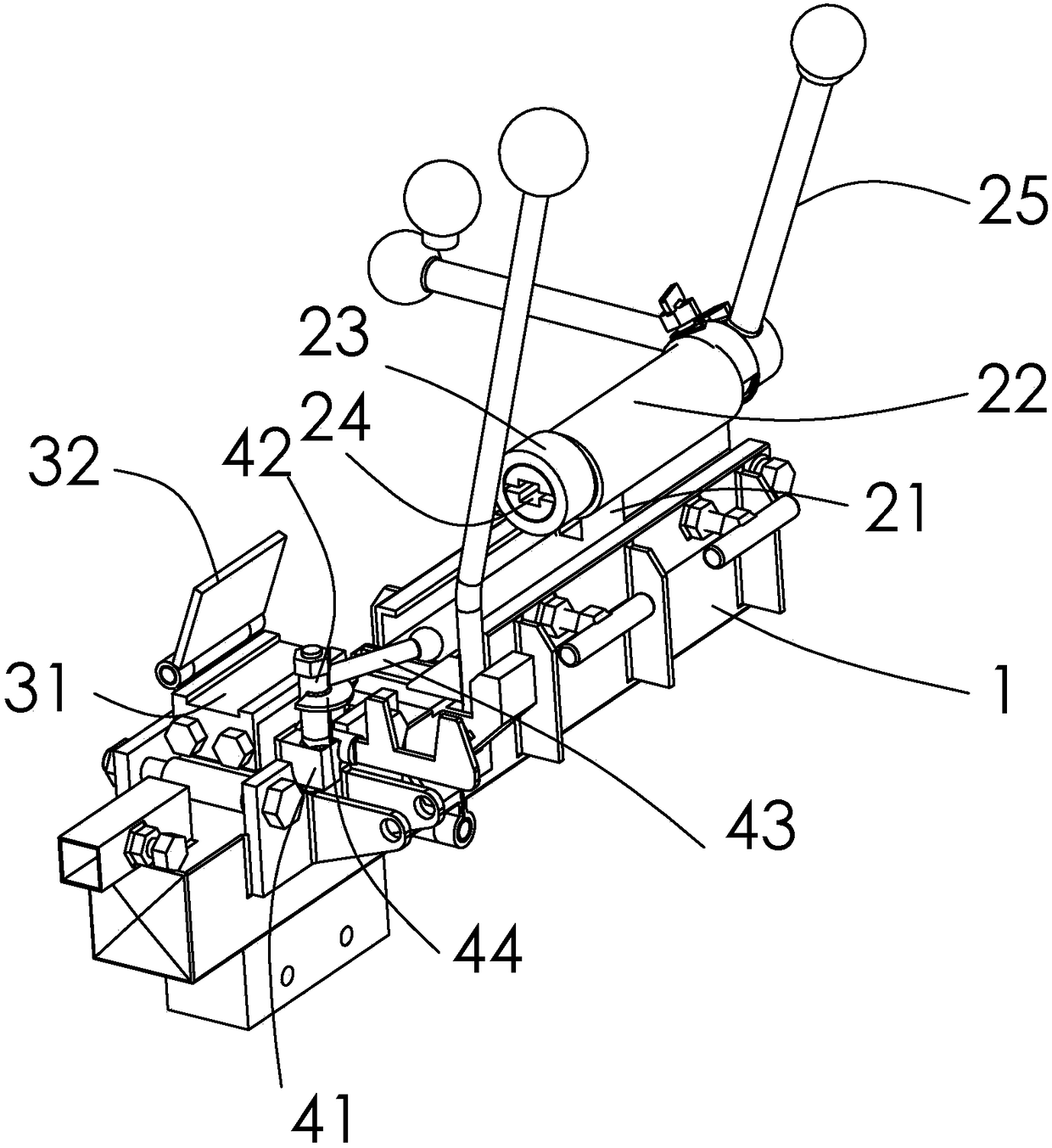

Construction method of reinforcing large-span concrete structure with prestressed carbon fiber sheet

InactiveCN103321430AWidely applicable reinforcementImprove mechanical performanceBridge erection/assemblyBuilding material handlingFiberCarbon fibers

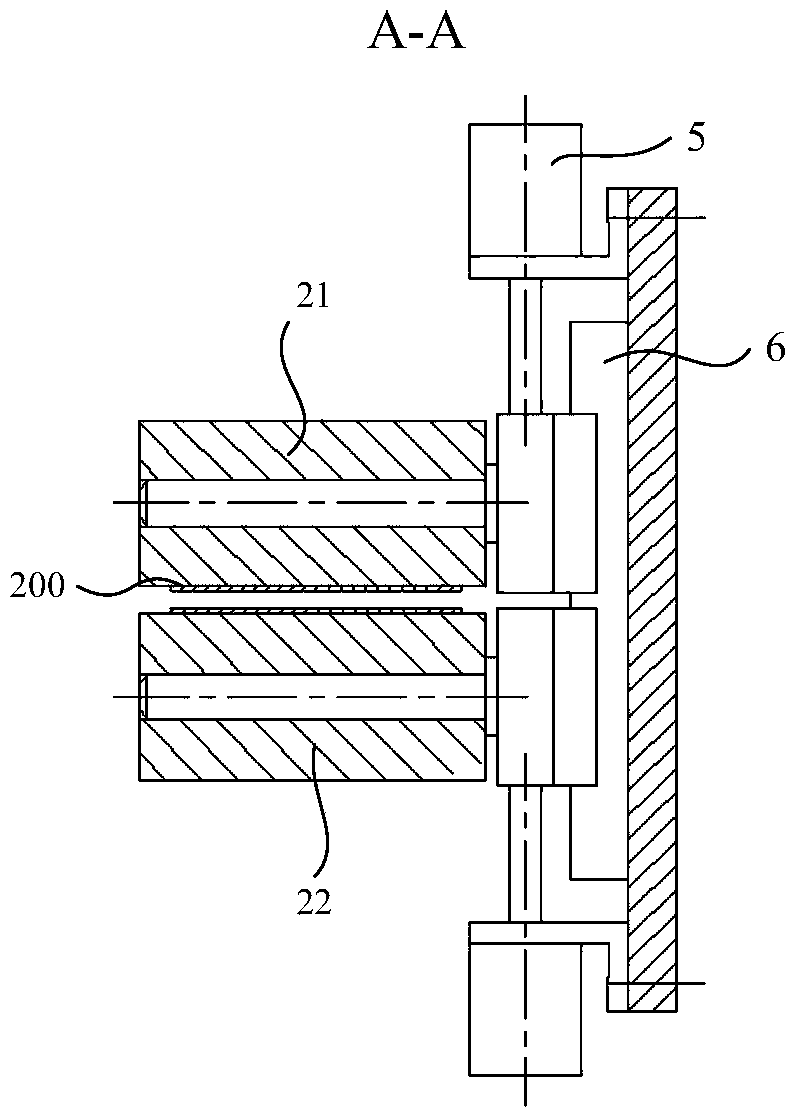

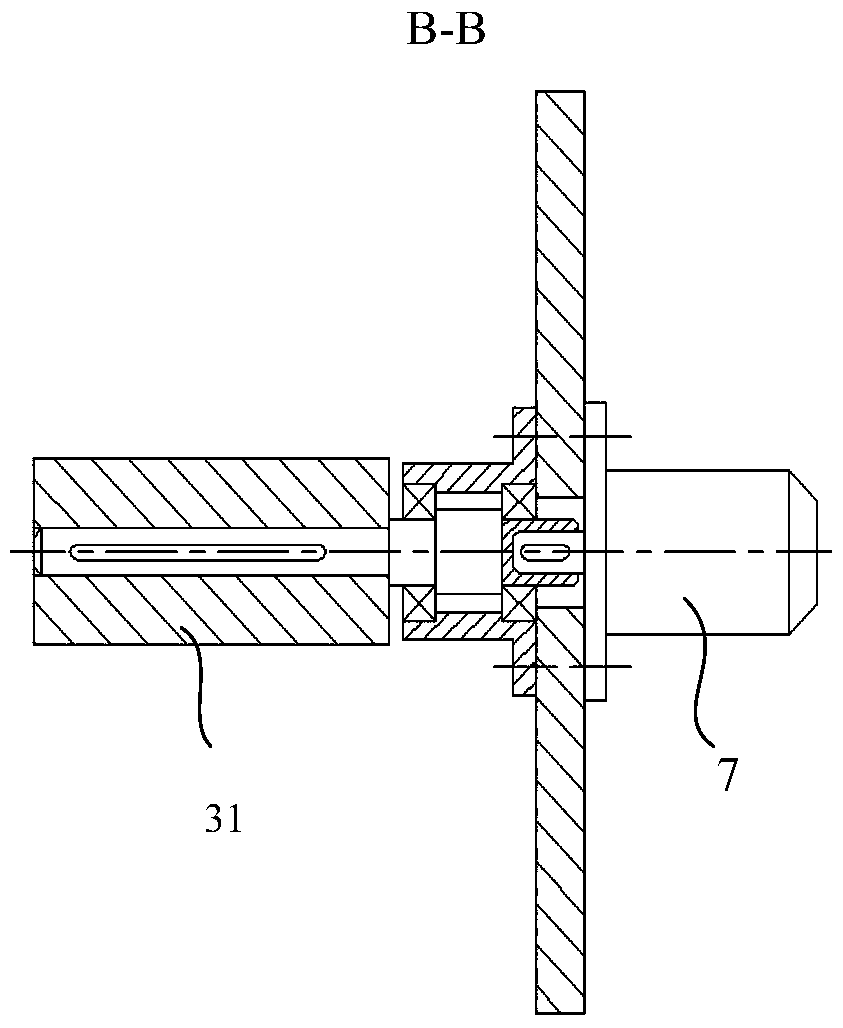

A construction method of reinforcing a large-span concrete structure with prestressed carbon fiber sheet comprises the following steps of forming bolt embedding holes on the side surface to be reinforced of the large-span concrete structure, and embedding high-strength bolts of different specifications into the bolt embedding holes through adhesive glue; fabricating stretch sheet fixing portions, stretch sheet moving portions and stretch power fixing portions; mounting the stretch sheet fixing portions, stretch sheet moving portions, stretch sheet assembling units, stretch power fixing portions and stretch power portions, wherein the stretch sheet assembling units, the stretch power fixing portions and the stretch power portions are made of carbon fiber materials; stretching stretch sheet; and removing stretching power and tightly pressing and adhering the stretch sheet onto the surface of the large-span concrete structure. The construction method of reinforcing the large-span concrete structure with the prestressed carbon fiber sheet can achieve the gapless adhesion between the prestressed stretch sheet and the concrete structure to be reinforced, facilitate the coordination of the uniform stress force of the same sections of the carbon fiber filaments of the stretch sheet, improve the integral stress performance of the prestressed carbon fiber sheet and the coordination deformation capability of the prestressed carbon fiber sheet and the concrete structure and give full play to the high-strength characters of the carbon fiber sheet.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER +1

Convertible piece of upholstered furniture with chair and bed function

InactiveUS20050052067A1Fully stressedImprove stressOperating chairsSofasMotor driveIntermediate stage

A convertible piece of upholstered furniture can be converted via motorized conversion aids from a seat function into a bed, by way of any desired number of intermediate stages, and vice versa. All movable parts can be fully stressed by a person during conversion, even when a person is sitting or lying on the piece of furniture. These changes can take place even when the piece is being used by a person, whereby each movable part of the piece of upholstered furniture can be changed by means of a motor drive having a control. The footrest and the seat part are configured so that they can move out of a base frame with their metal fittings. A lever construction arranged on the metal fitting of the footrest and a motor drive adjusts the height and angle of the footrest and moves the piece of furniture to the various positions.

Owner:FIEDLER HANS

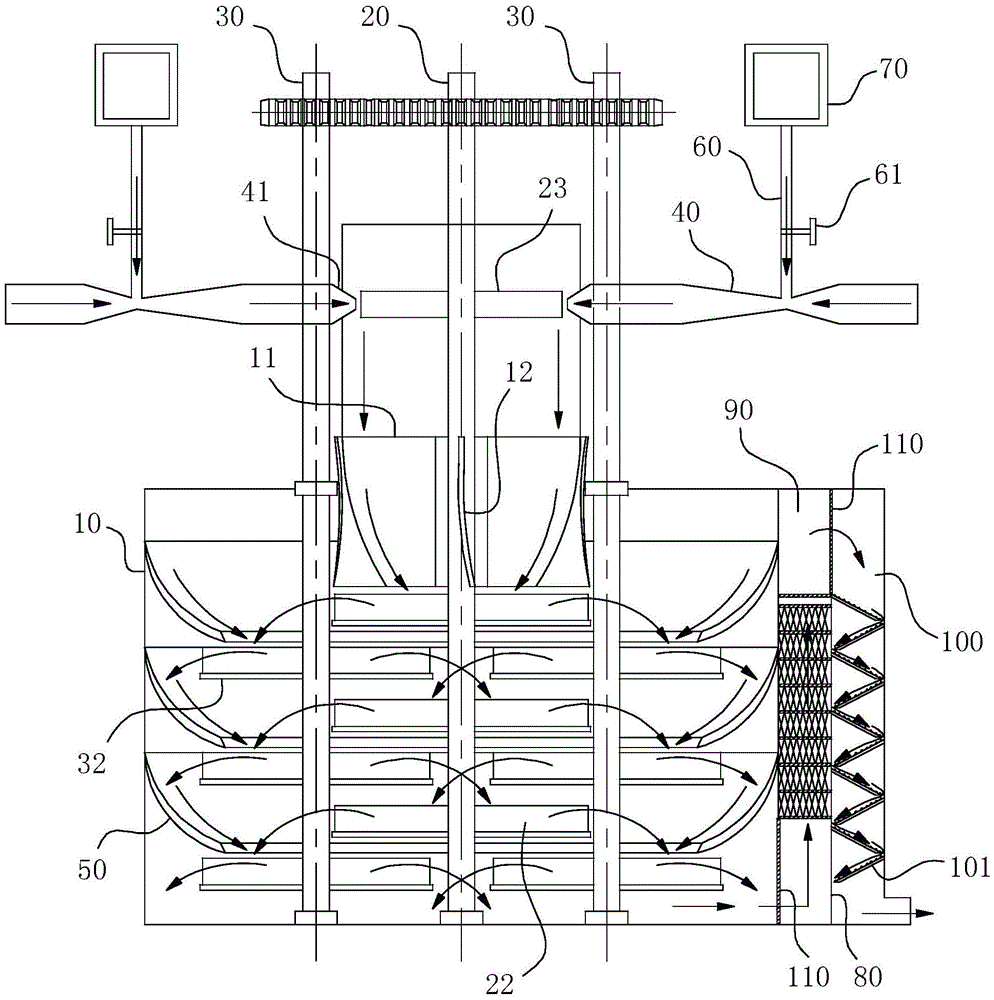

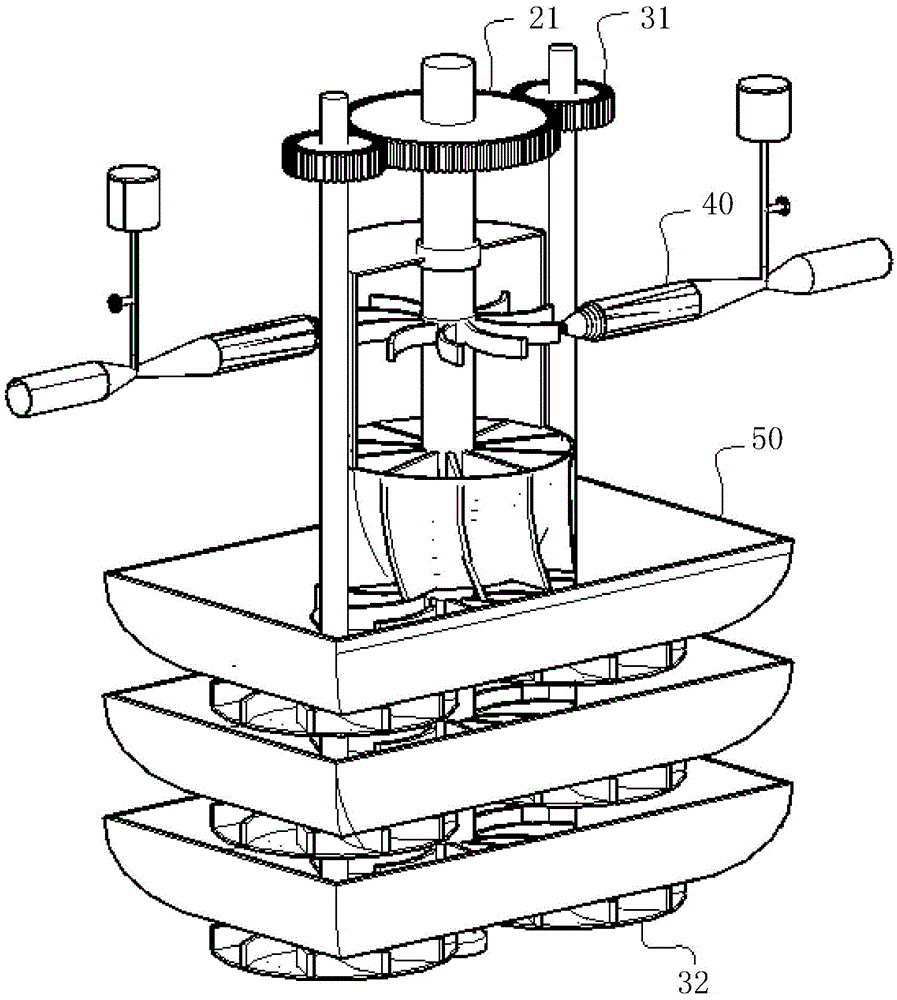

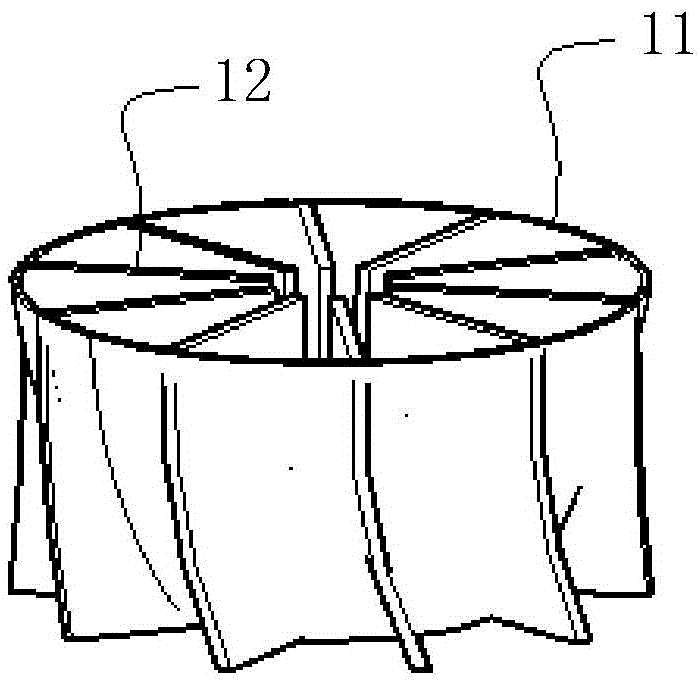

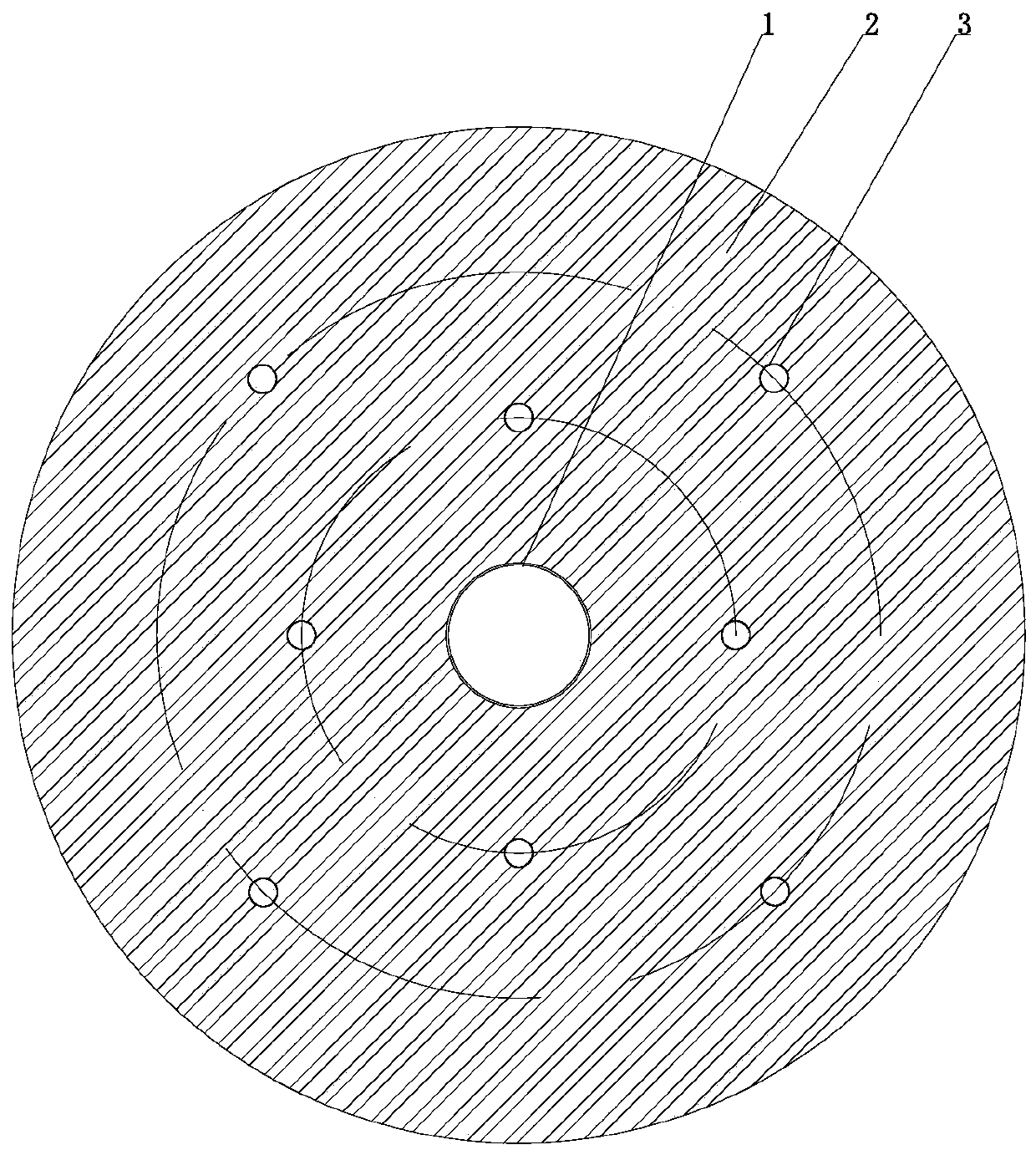

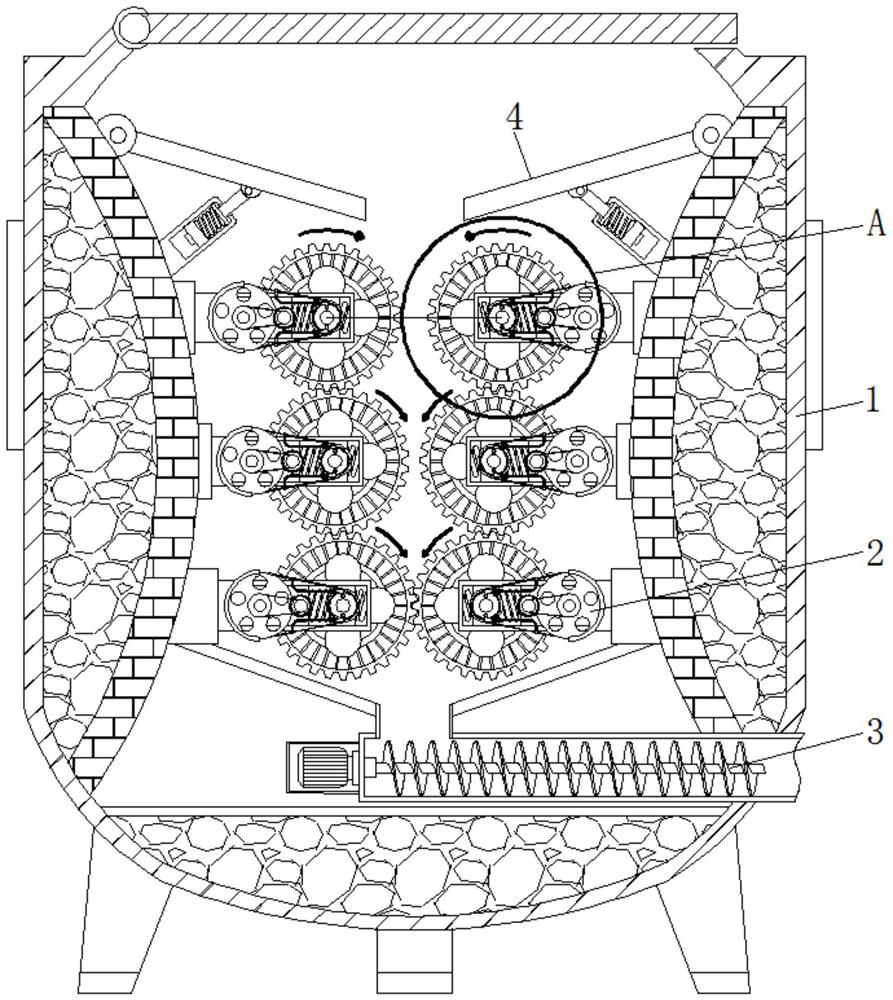

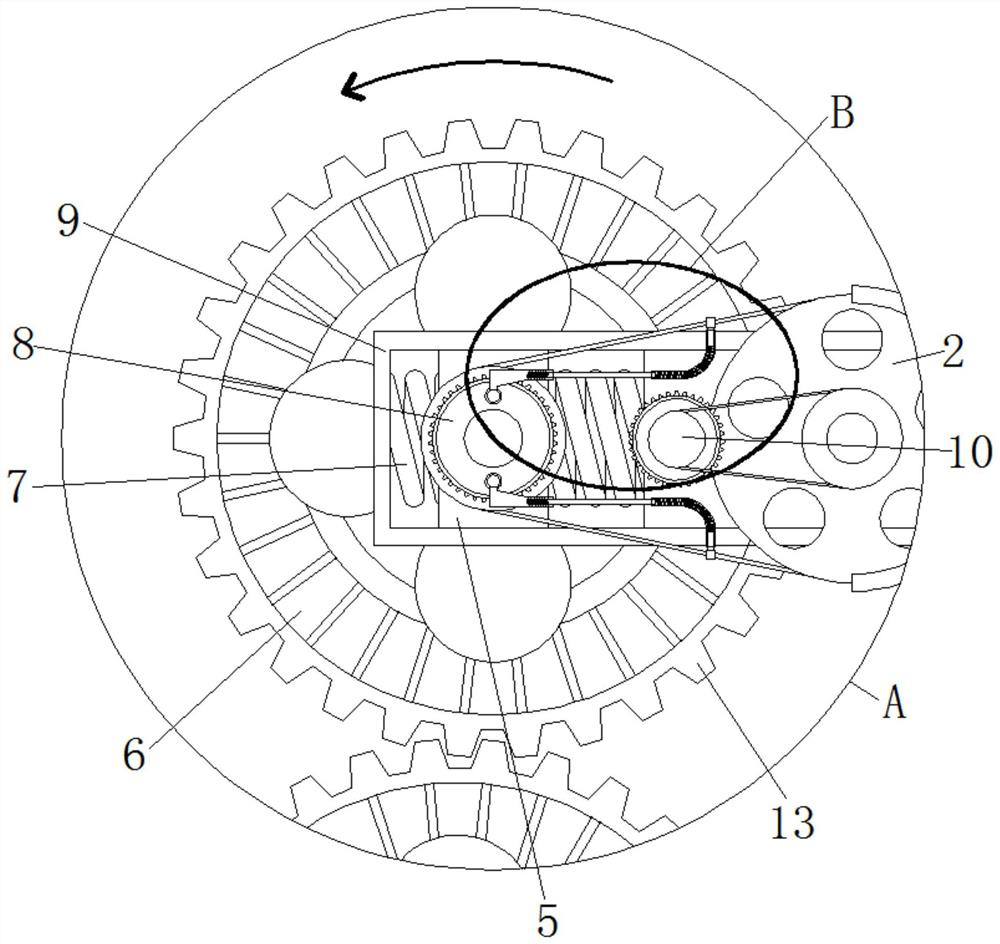

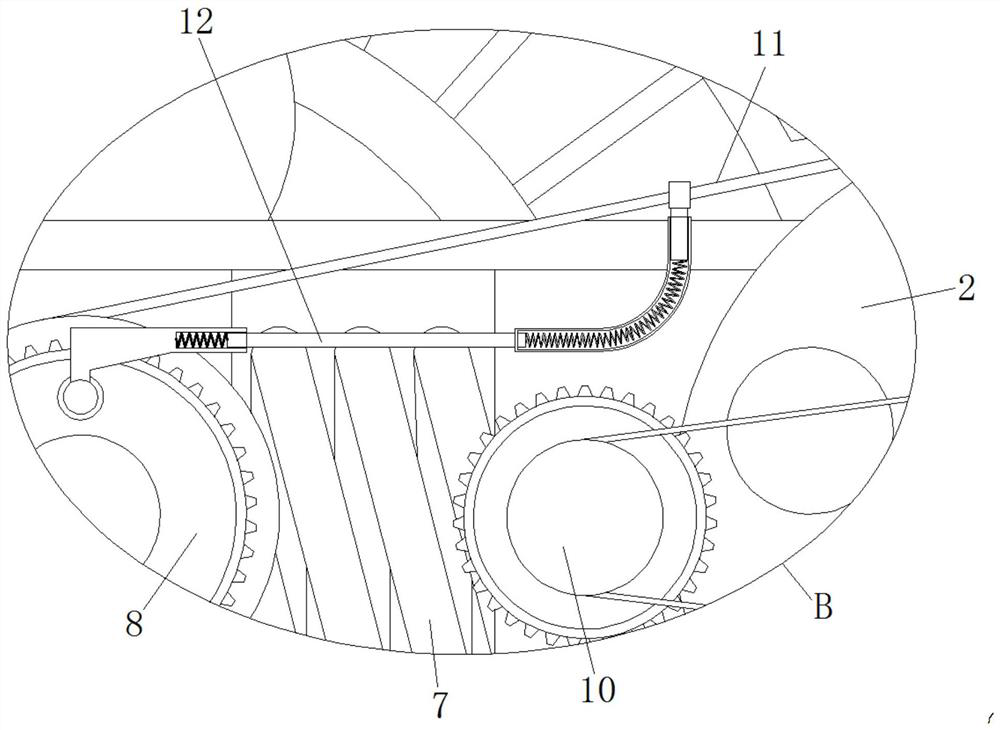

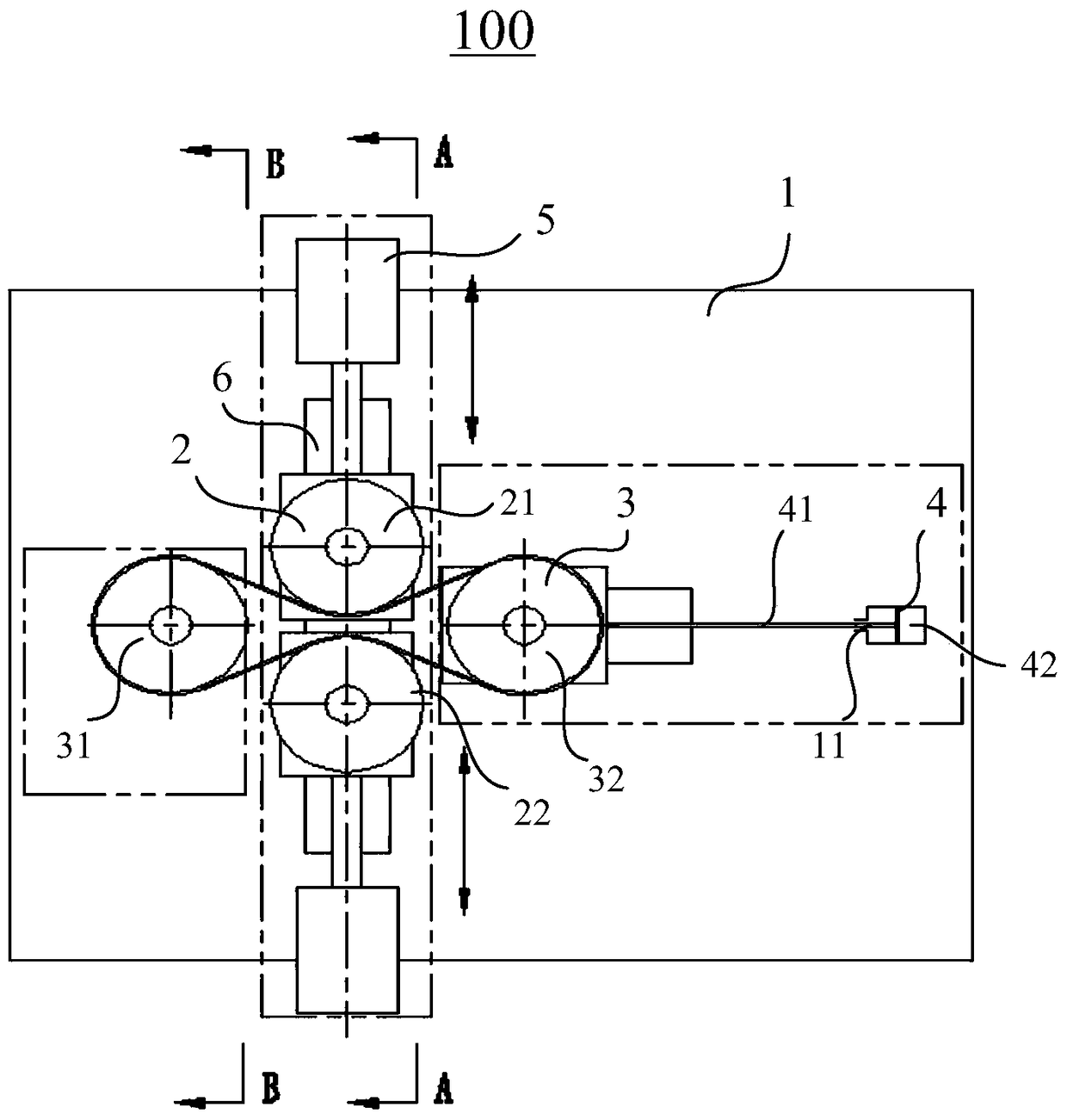

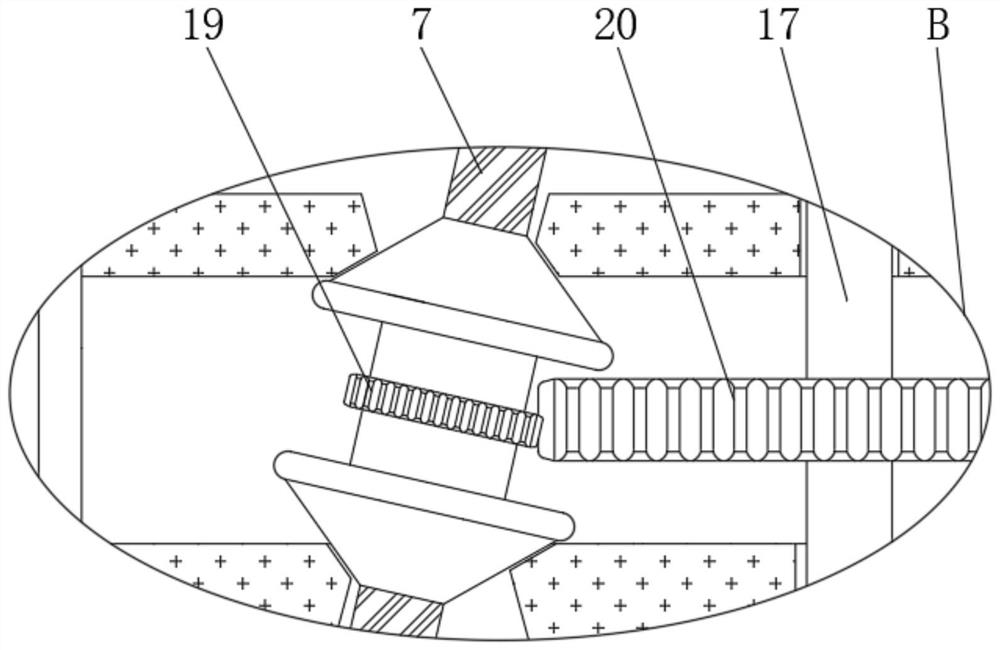

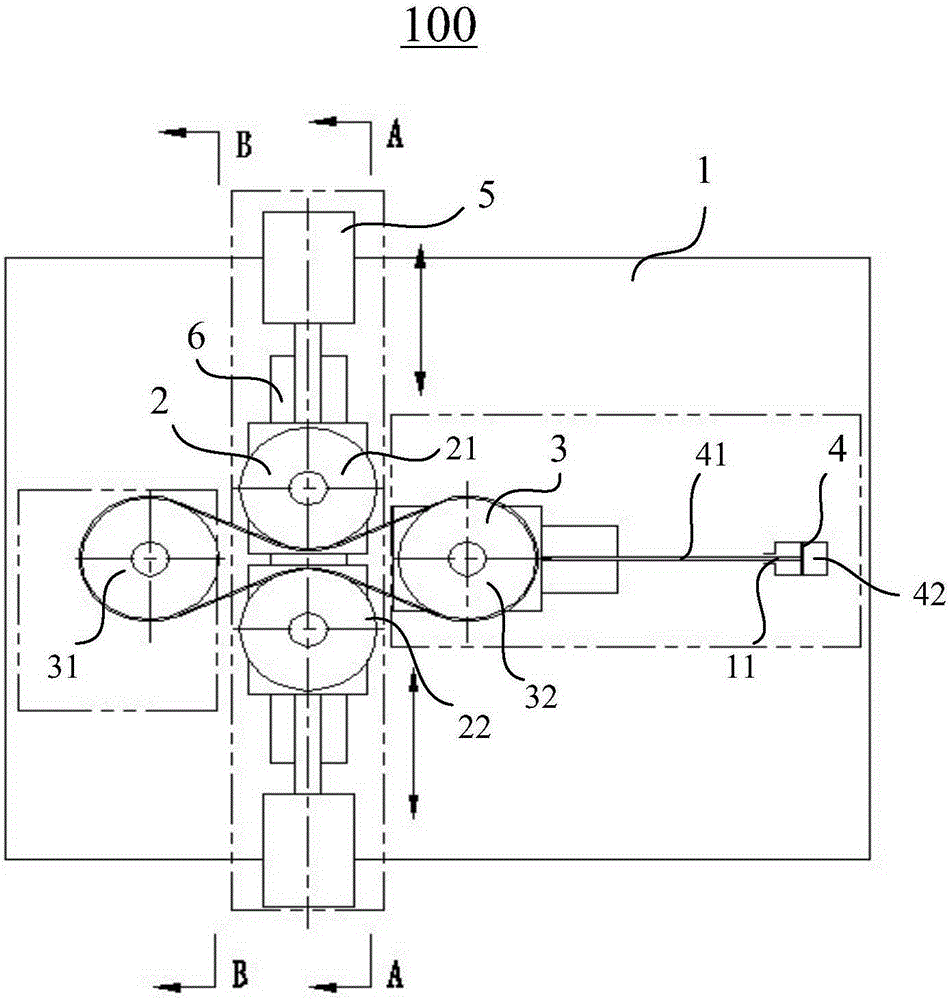

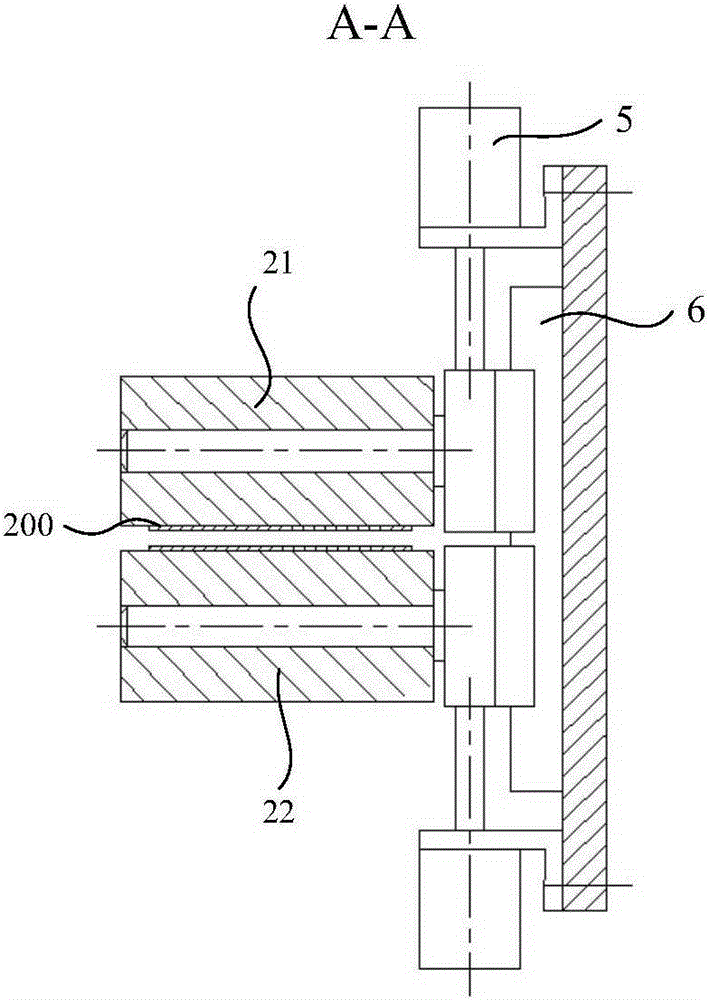

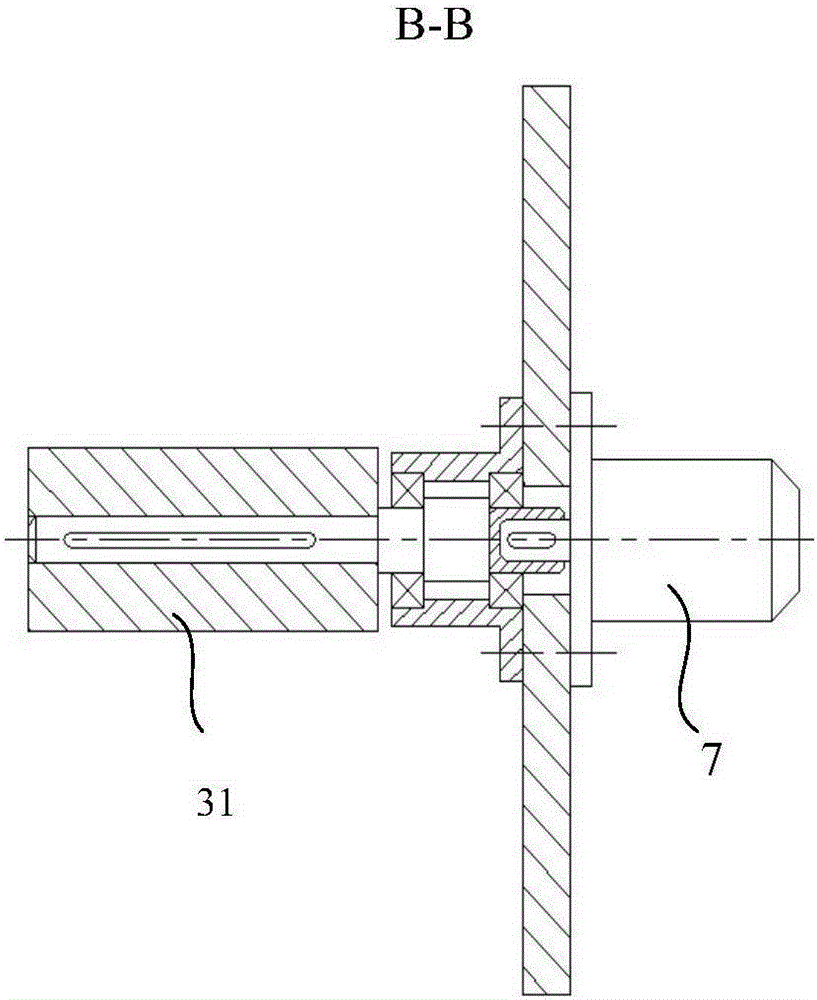

Multi-impeller mixed flow field ore pulp preprocessor based on ore pulp pipeline pressure drive

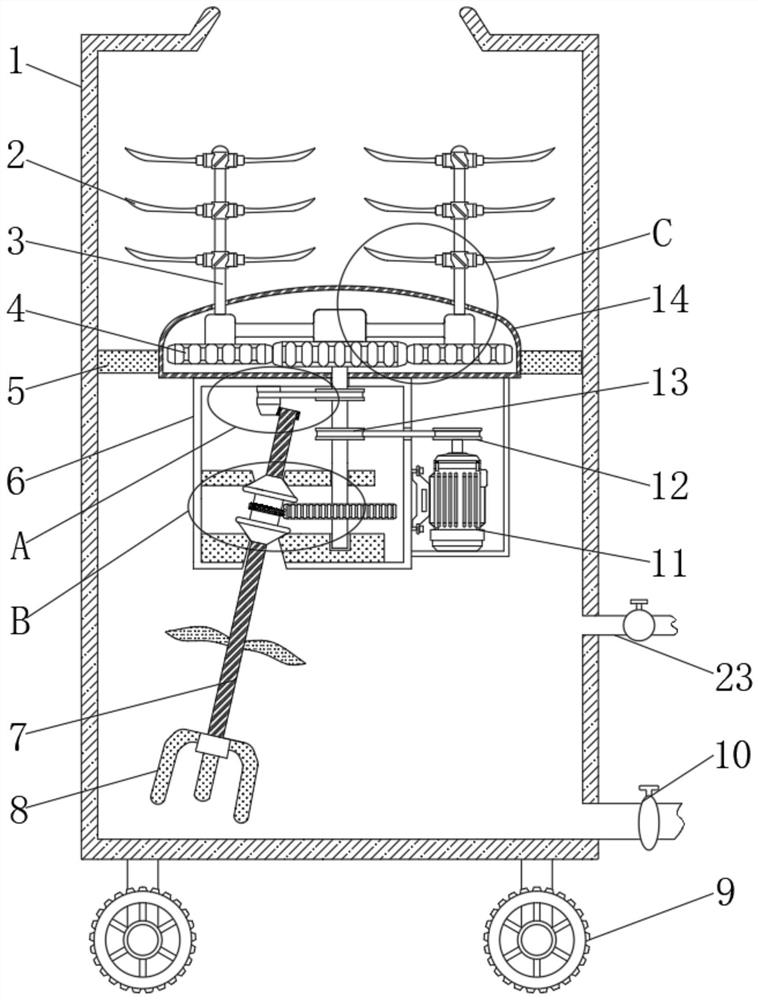

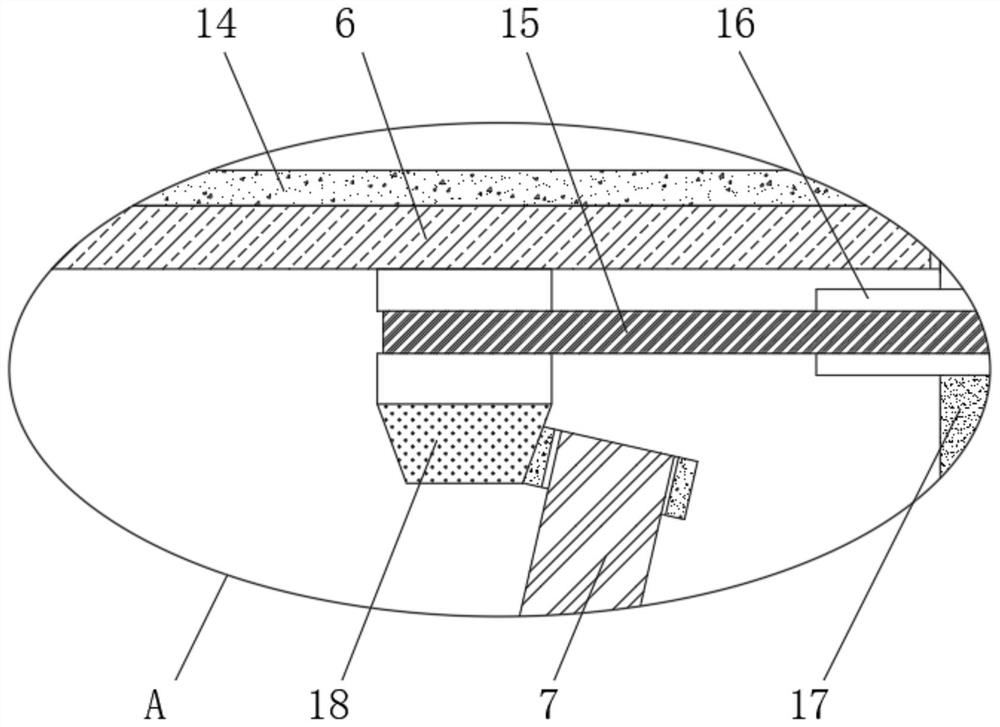

ActiveCN105536610AReduce consumption costImprove the mixing effectRotary stirring mixersTransportation and packagingImpellerMixed flow

The invention relates to the field of coal slurry pretreatment, in particular to a multi-impeller mixed flow field ore pulp preprocessor based on ore pulp pipeline pressure drive. The multi-impeller mixed flow field ore pulp preprocessor comprises a mixing box, a driving rotary shaft and a driven rotary shaft. A driving gear is coaxially arranged on the driving rotary shaft, and a driven gear is arranged on the driven rotary shaft to form the meshing relation. A driving turbine is further coaxially arranged on the driving rotary shaft. A group of stirring impellers is fixed to the driving rotary shaft, and a group of stirring wheels is fixed to the driven rotary shaft respectively in a coaxial and mutual equal-height mode. In the vertical direction, the stirring impellers and projections of the stirring impellers produce intersections. A guide sleeve is arranged under the driving turbine. Guide blades are arranged inside the guide sleeve in a circinate mode, and the rotating direction of the mixed liquid guided by the guide blades is mutually identical to the rotating direction of the stirring impellers under the guide blades. The multi-impeller mixed flow field ore pulp preprocessor can play a very good hardening and tempering effect on floated coal slime, is especially suitable for slurry-mixing and quality-improving demands of fine coal difficult to float and is high in working efficiency, and the preprocessing process is quick and convenient.

Owner:ANHUI UNIV OF SCI & TECH

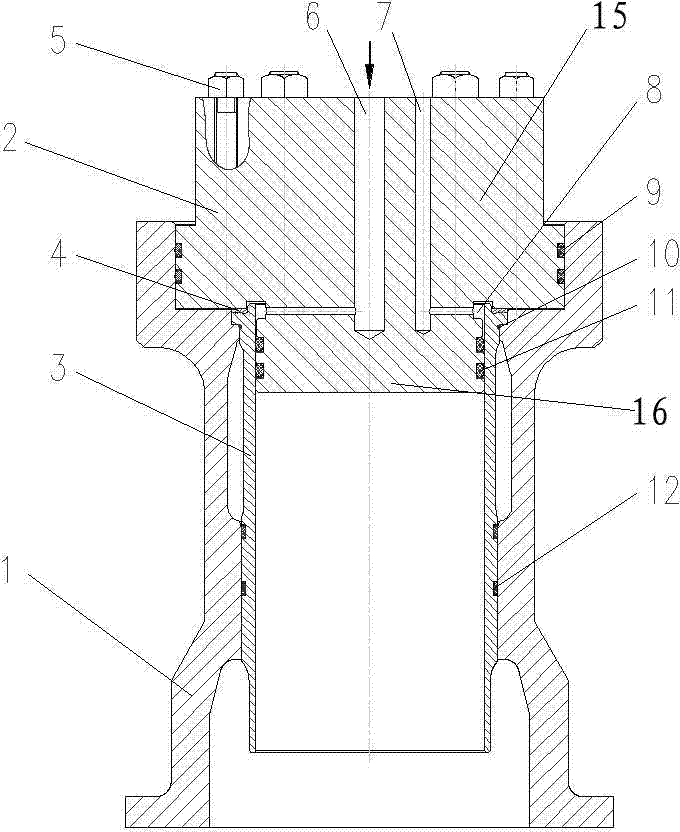

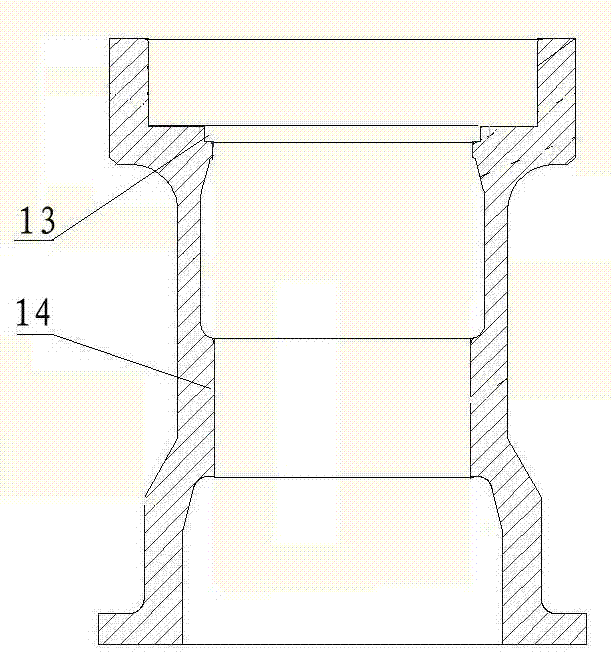

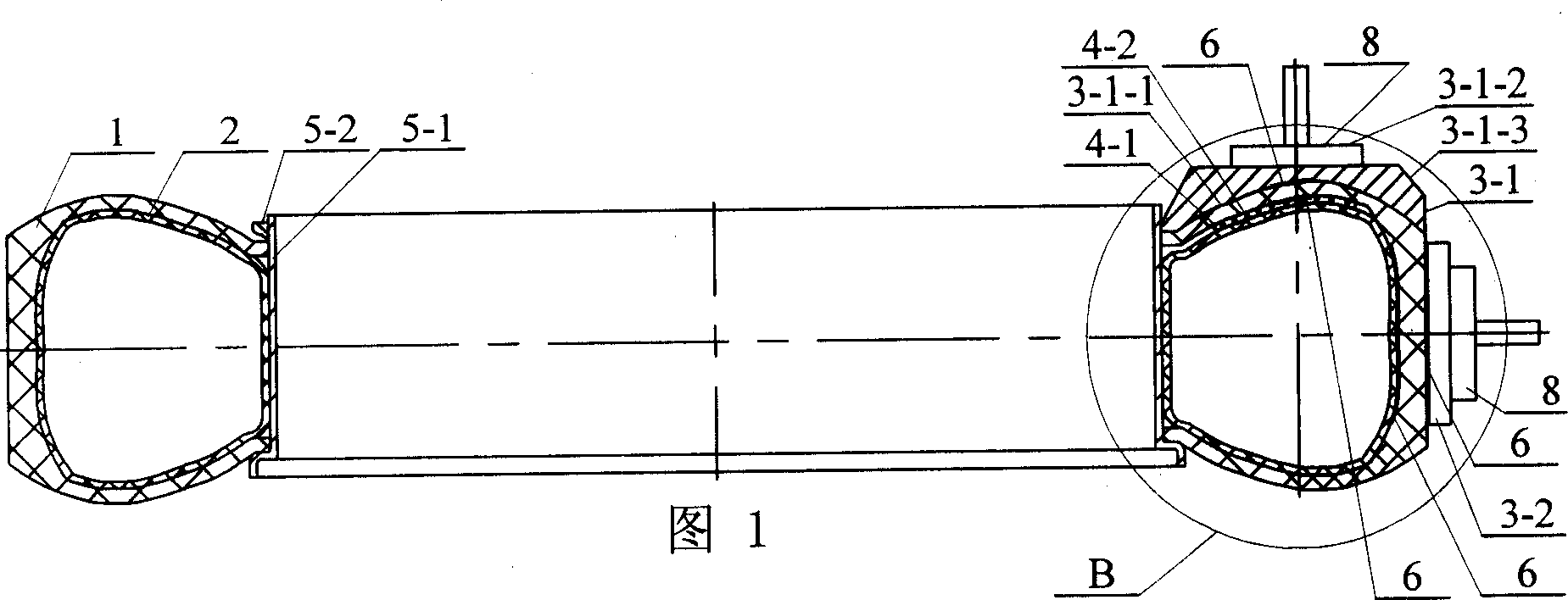

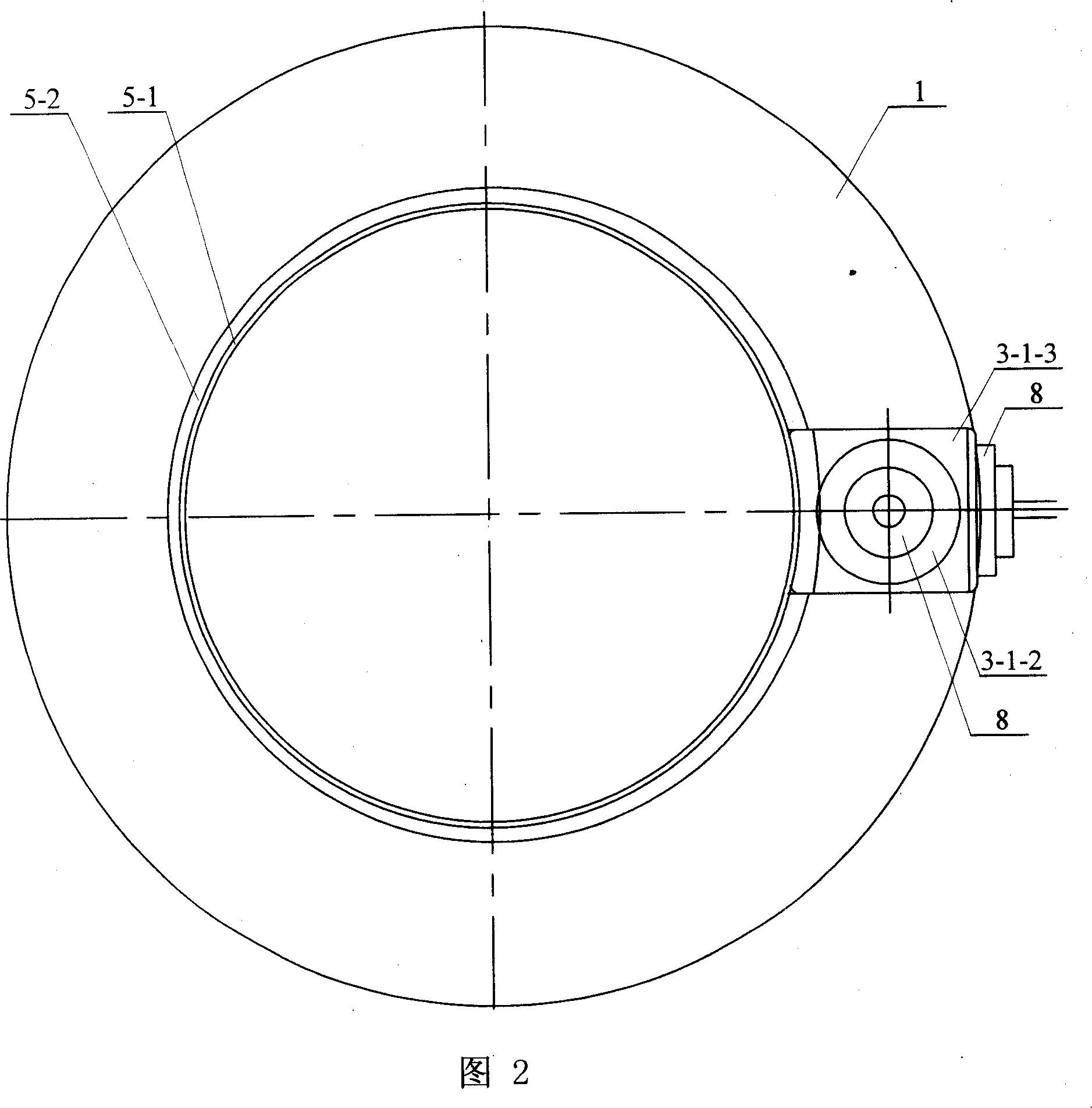

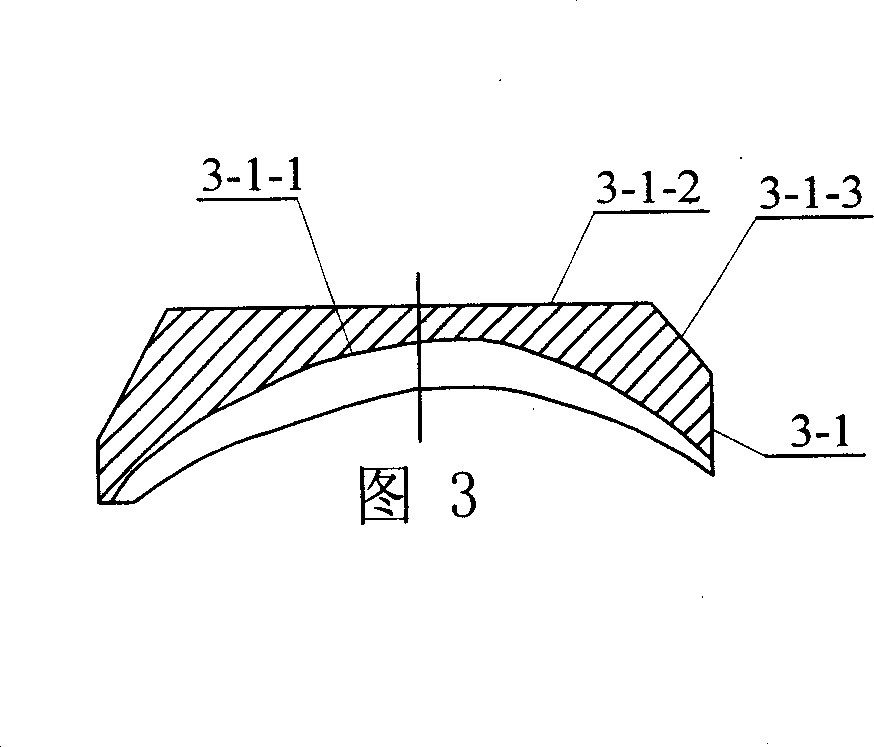

Cylinder sleeve fatigue test device

ActiveCN103759926ASimplify test componentsEliminate hidden dangers in the cylinderMachine part testingEngine testingCombustion chamberEngineering

The invention relates to a cylinder sleeve fatigue test device. An annular sunk groove (13) and an annular sealing protrusion (14) used for supporting a cylinder sleeve (3) are arranged on a bearing cylinder body (1), a counter bore matched with a combined cylinder cover (2) is formed in an upper opening of the cylinder body, an oil inlet port and a sensor port are formed in an oil inlet (6) and an upper port of a pressure monitoring hole (7) in the cylinder body respectively, the cylinder sleeve (3) is arranged in the bearing cylinder body (1), the combined cylinder cover (2) is arranged in the counter bore of the combined cylinder cover (2) and the cylinder sleeve (3) in a sealing sleeved mode, a cylinder cushion (4) is arranged at the position where the combined cylinder cover (2) is connected with the cylinder sleeve (3), and an upper edge opening of the cylinder sleeve (3) and a simulation combustor cavity form a simulation combustor (8). According to the cylinder sleeve fatigue test device, sealing hidden troubles in the cylinder body are eliminated, stability of the test process is improved, the adjusting range of the pressure in the cylinder body is enlarged, and a cylinder sleeve fatigue examination and a fault reappearance test are facilitated.

Owner:CHINA NORTH ENGINE INST TIANJIN

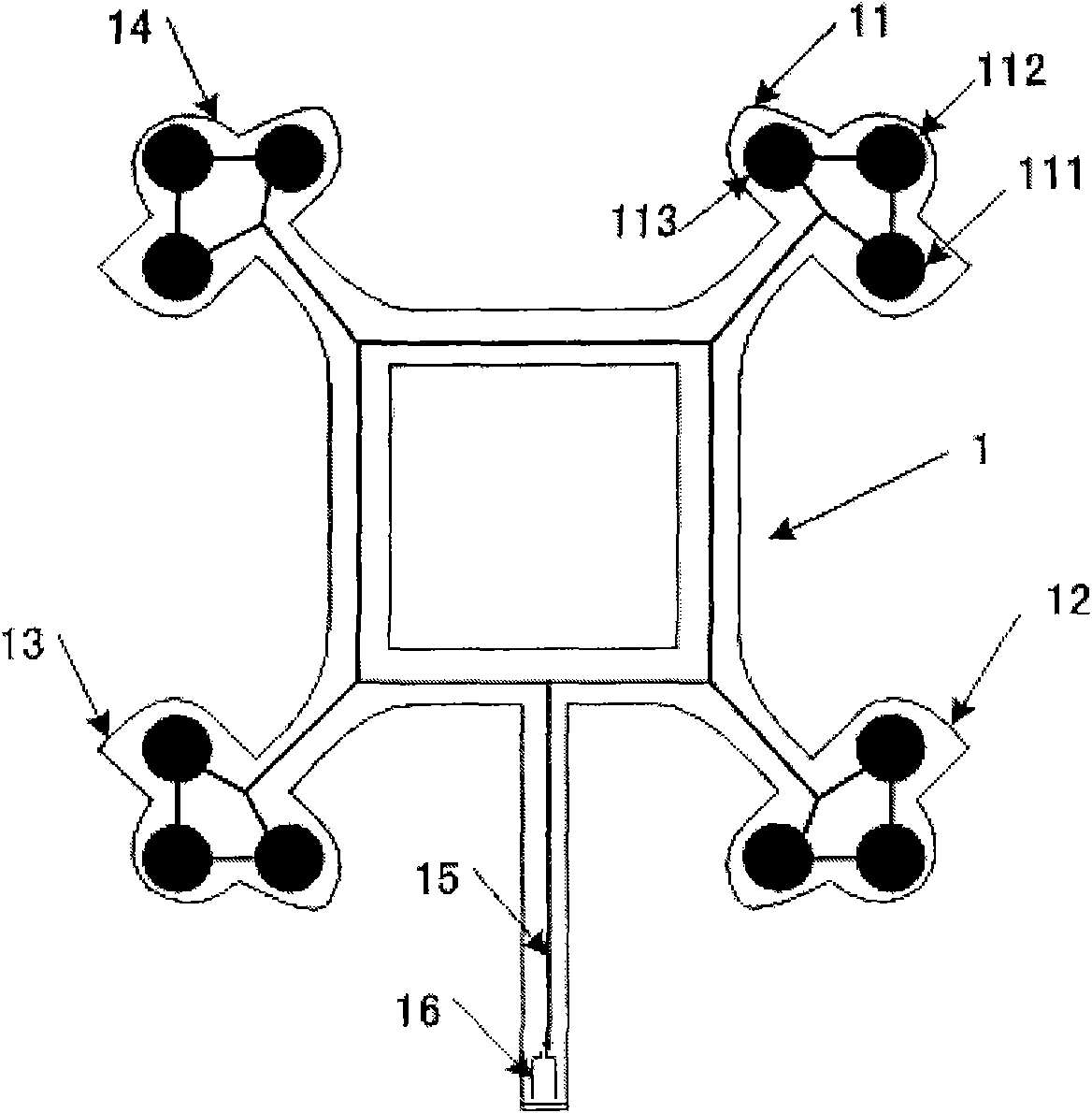

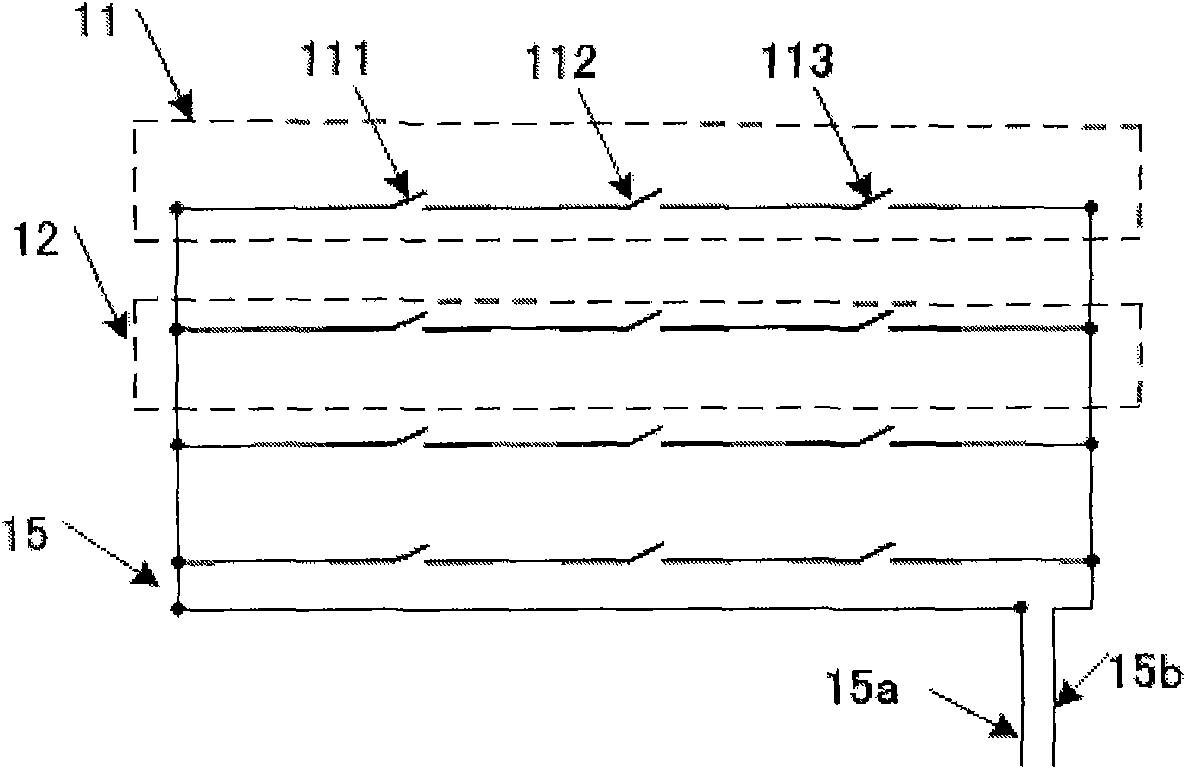

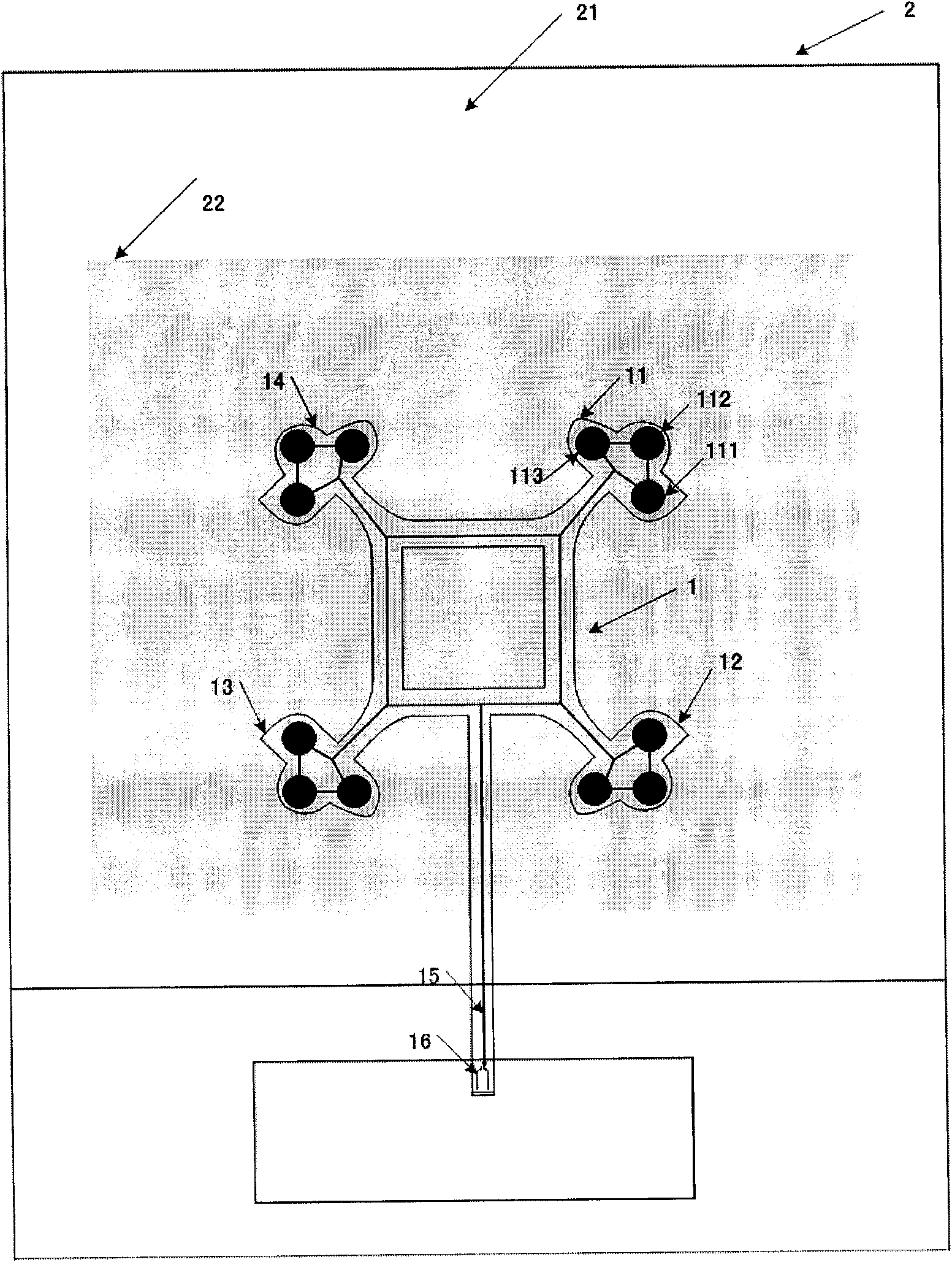

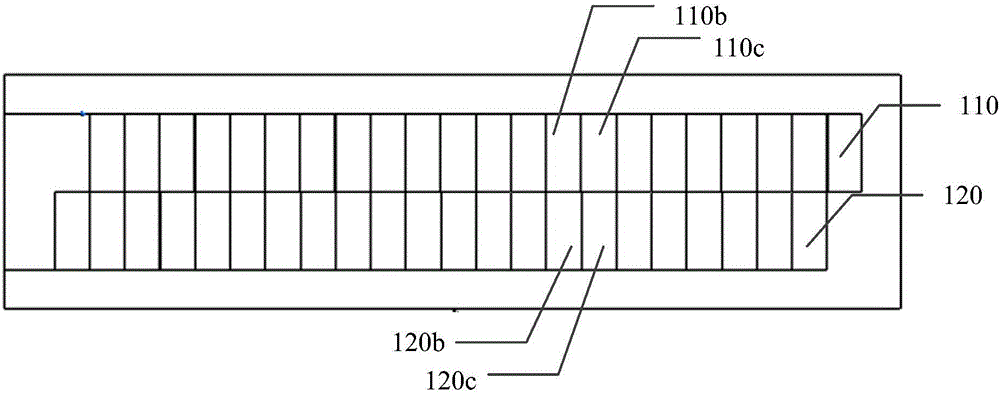

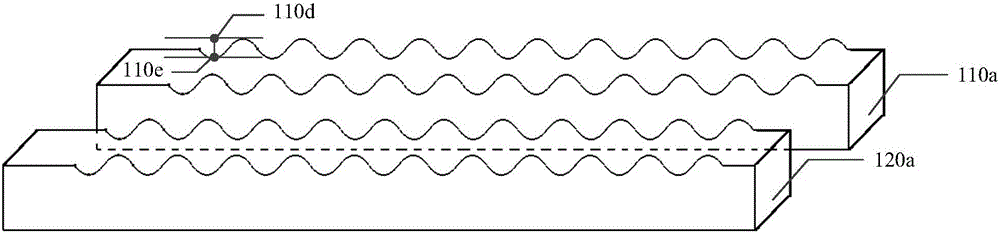

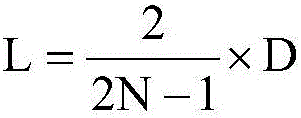

Sensor for determining the occupancy of vehicle seats

InactiveCN101556197AAvoid interferenceFully stressed at the same timePedestrian/occupant safety arrangementMultiple fluid pressure valves simultaneous measurementElectrical resistance and conductanceTransport infrastructure

The invention belongs to the field of transport infrastructure technology and specifically relates to a sensor for determining the occupancy of vehicle seats. The sensor comprises a plurality of pressure sensing units. The force area of a vehicle seat surface is divided into several sub-regions and the pressure sensing units are divided into the pressure sensing unit groups with the number equivalent to that of the sub-regions, and each pressure sensing unit group is exclusively arranged into a sub-region. The parallel connection as the circuit connection is applied to different sensing unit groups and the series connection is applied for the connection in a sensing unit group. When the pressure sensing unit of a sensing unit group is adequately pressed, the output resistance value of the sensor is less than a threshold value; otherwise, the output resistance value of the sensor is higher than the threshold value. By comparing the output resistance value of the sensor with the threshold value, the seat occupancy information can be known.

Owner:舒少龙 +1

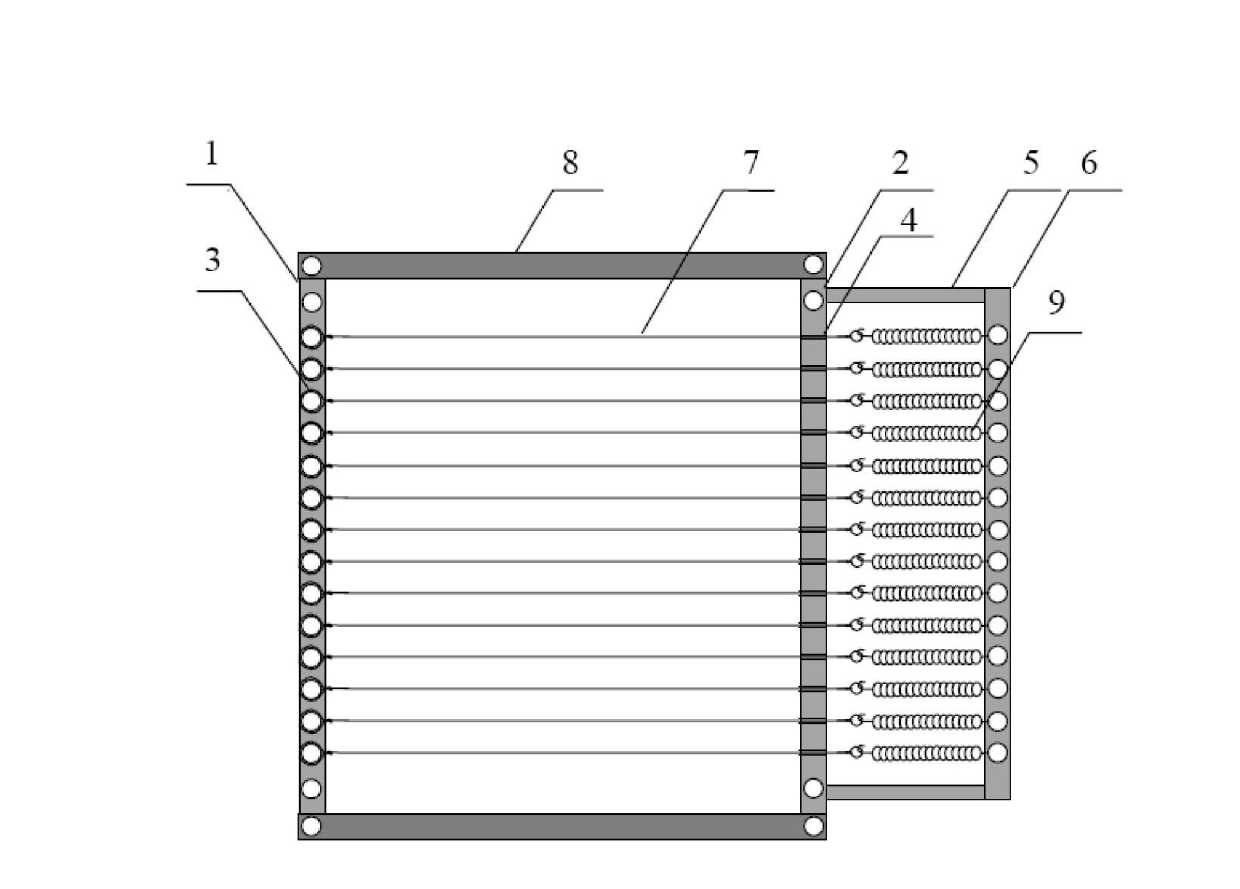

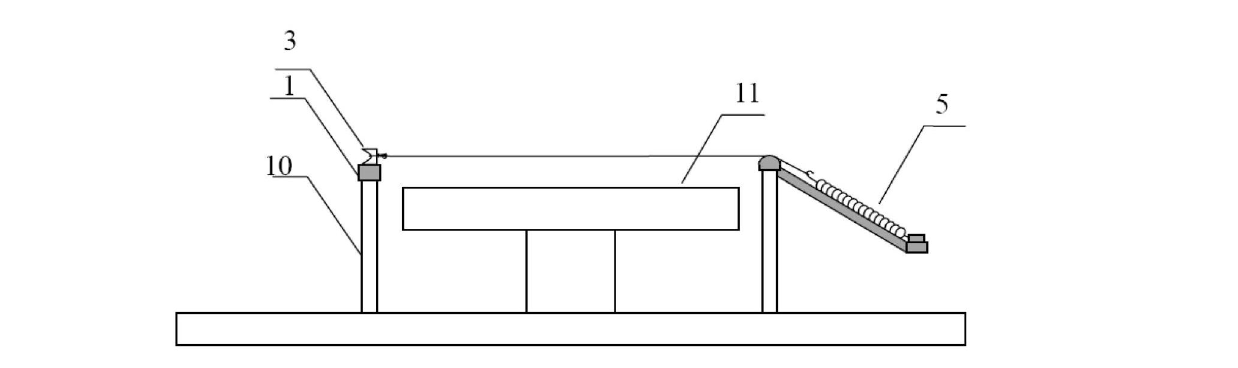

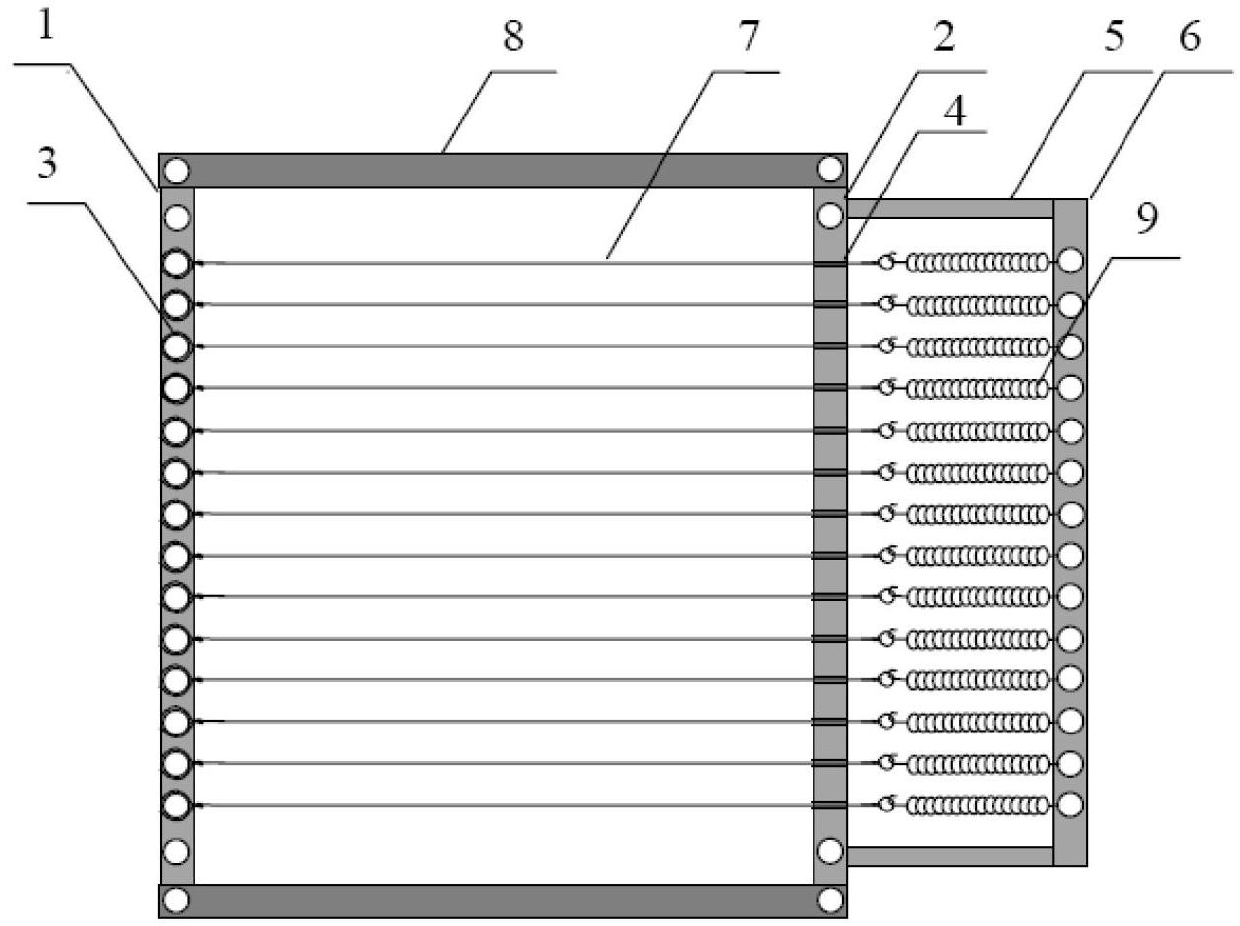

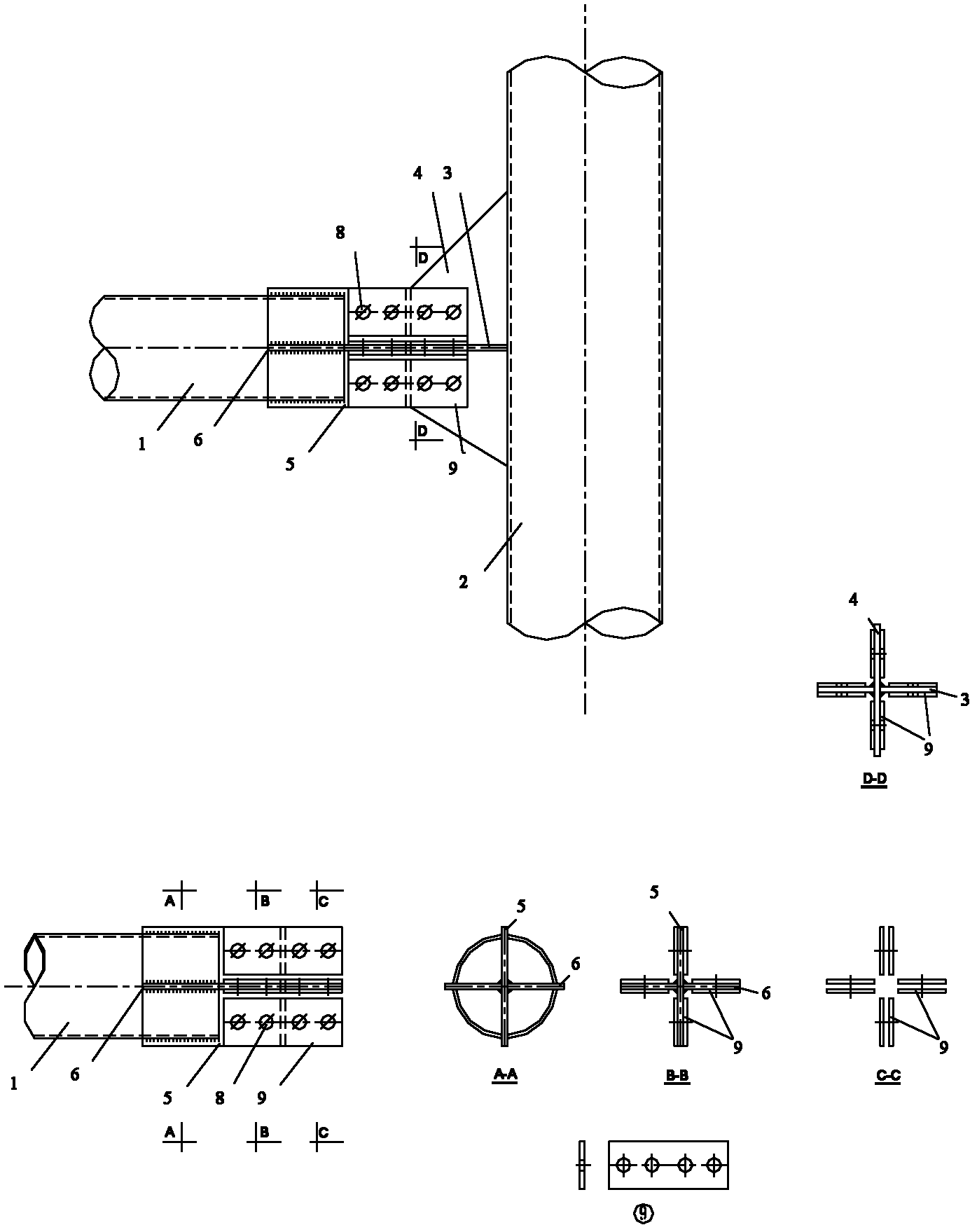

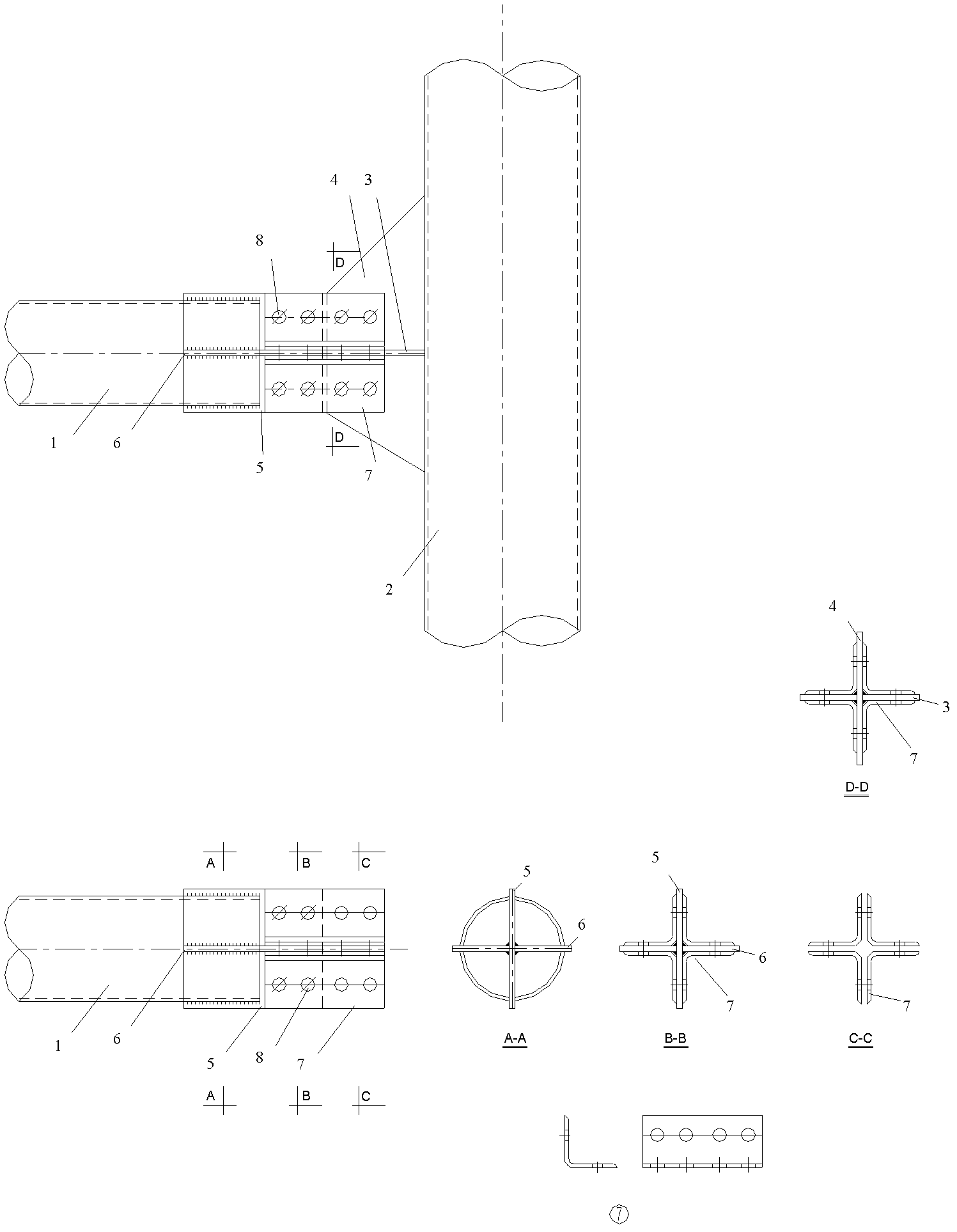

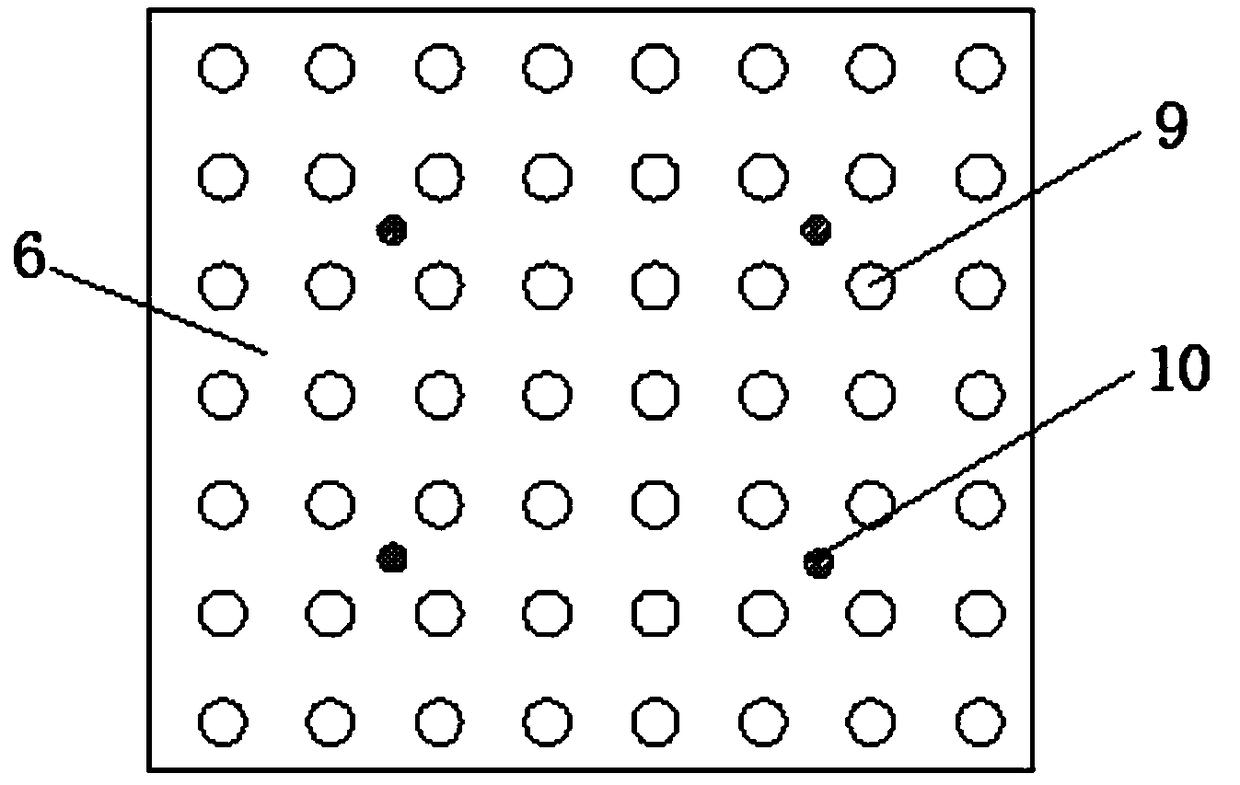

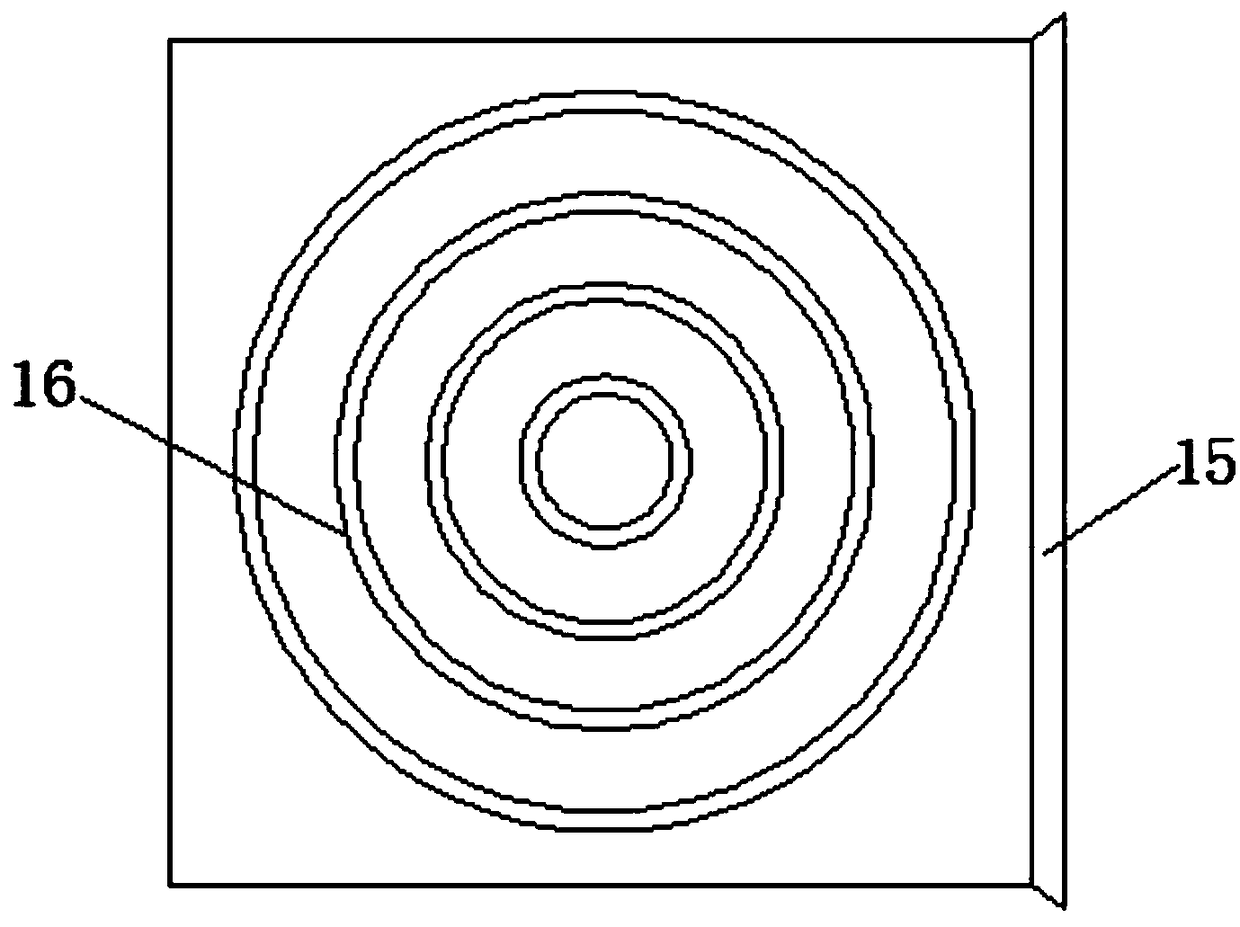

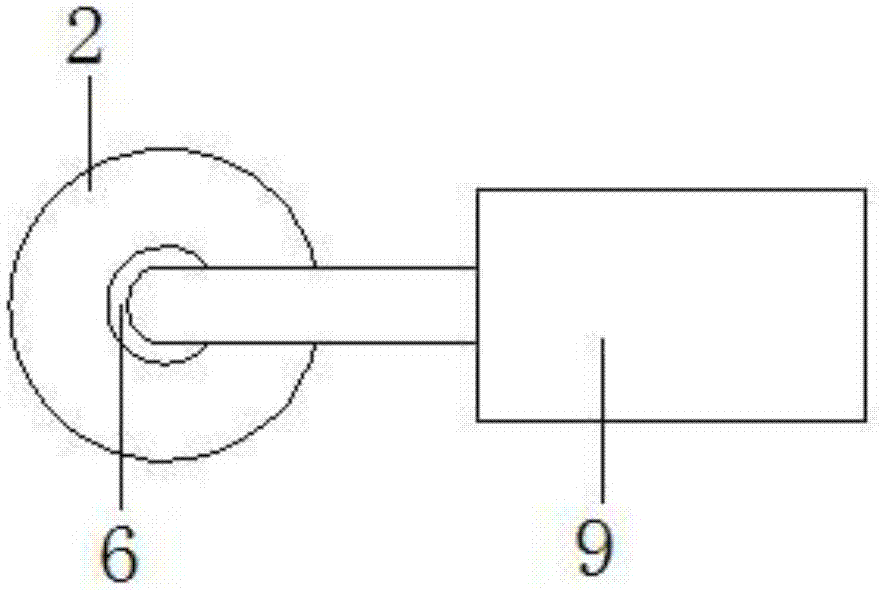

Hot filament rack for large-area deposited diamond film and manufacturing method of hot filament rack

InactiveCN102634770AFully stressedAvoid coolingChemical vapor deposition coatingGas phaseCopper electrode

The invention relates to the field of chemical-vapor-deposited diamond films, particularly relates to a hot filament rack in a hot filament chemical vapor deposition device and a manufacturing method of the hot filament rack. The hot filament device comprises a left molybdenum electrode (1), a right molybdenum electrode (2), a pin with a groove (3), an arc-shaped groove (4), a spring bracket (5), an outer edge strip (6), a plurality of equally long filaments (7), two support rods (8) and a spring (9). The entire hot filament rack is firstly integrally installed outside a deposition chamber; after all the filaments are arranged, the entire filament array is placed in a reaction chamber; the left and the right molybdenum electrodes and four water-cooled copper electrode pillars (10) are connected; after the hot filament rack is fixed, the two support rods (8) are removed and then the chamber is closed for experiments. The hot filament rack provided by the invention can overcome some technical defects in the prior art, improve the utilization rate and stability of hot filaments, and can be used for preparing large-area diamond films.

Owner:UNIV OF SCI & TECH BEIJING

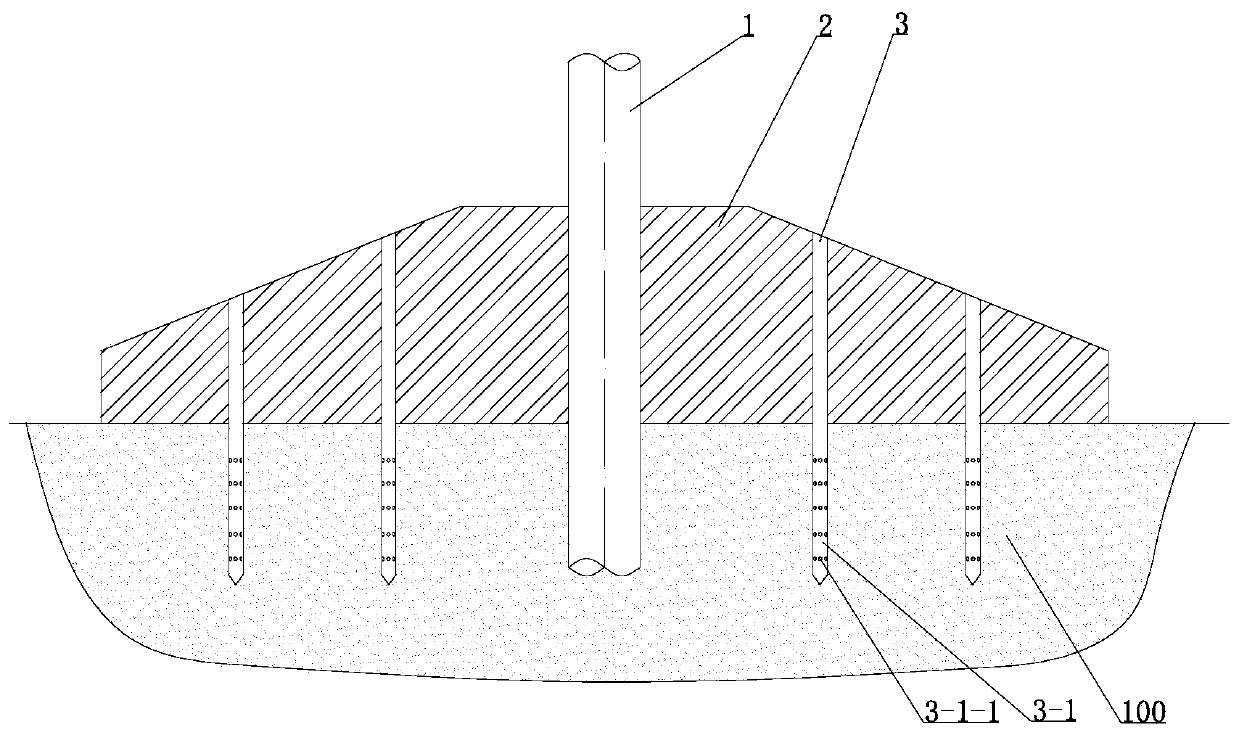

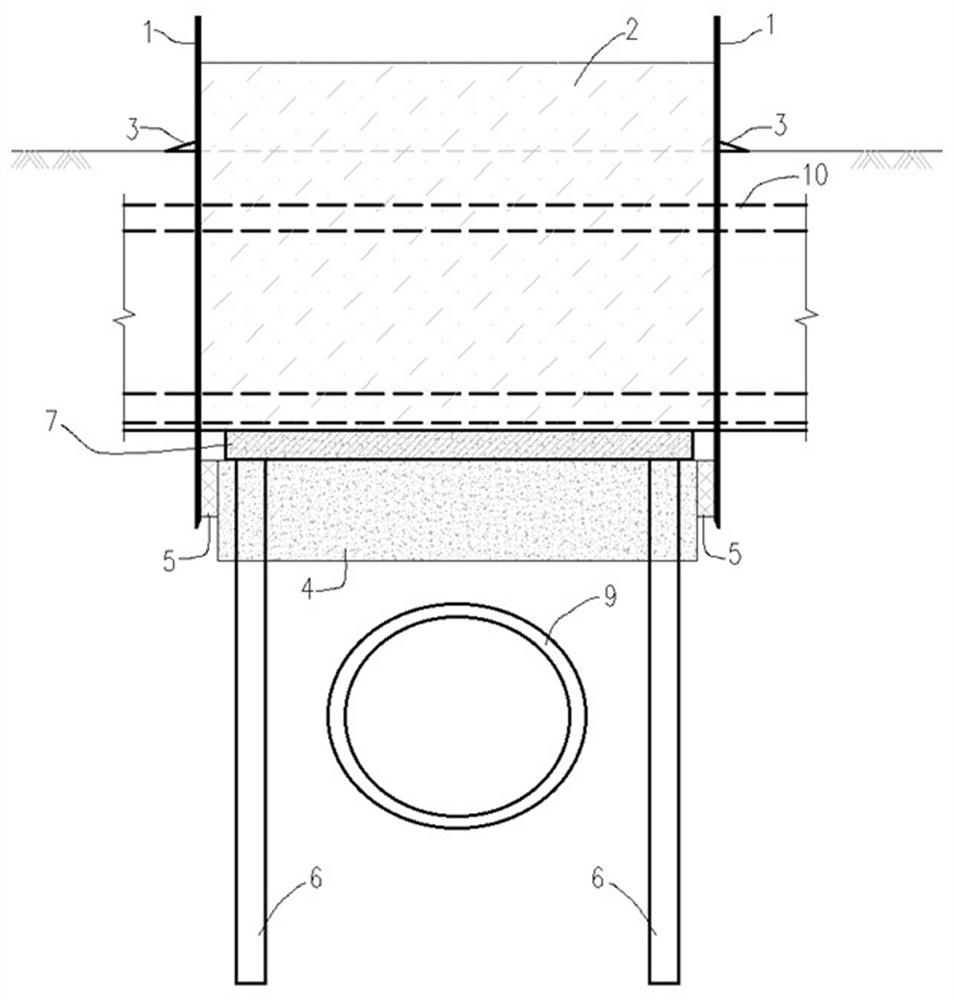

Offshore wind turbine composite foundation and foundation reinforcement construction method

ActiveCN111501814AIncrease contact areaImprove carrying capacityBulkheads/pilesSoil preservationRebarSteel tube

The invention relates to an offshore wind turbine composite foundation and a foundation reinforcement construction method. The composite foundation comprises a single-pile foundation body and a peripheral friction body, wherein the peripheral friction body is of a concrete integrated pouring structure with built-in steel bars and is in a circular truncated cone shape; the single-pile foundation body is sleeved with the peripheral friction body; the peripheral friction body makes contact with the upper end of a foundation soil body; vertical construction hole channels which communicate the upper end with the lower end and are used for achieving grouting are formed in the peripheral friction body; a plurality of vertical construction hole channels are evenly distributed on one or more circles of circumference; and a steel pipe nail is connected into each vertical construction hole channel in a pouring mode or fixedly inserted into each vertical construction hole channel, the lower section of each steel pipe nail extends out of the lower end of the peripheral friction body and is inserted into the foundation soil body, and guniting holes are evenly distributed in the pipe wall of eachsteel pipe nail. According to the composite foundation, the contact area between the foundation and a subgrade is increased, grouting reinforcement treatment can be conducted on the soft soil foundation, thus the bearing capacity of the subgrade and the foundation can be improved, integrated construction is achieved, and seabed pretreatment is reduced.

Owner:HEBEI UNIV OF TECH

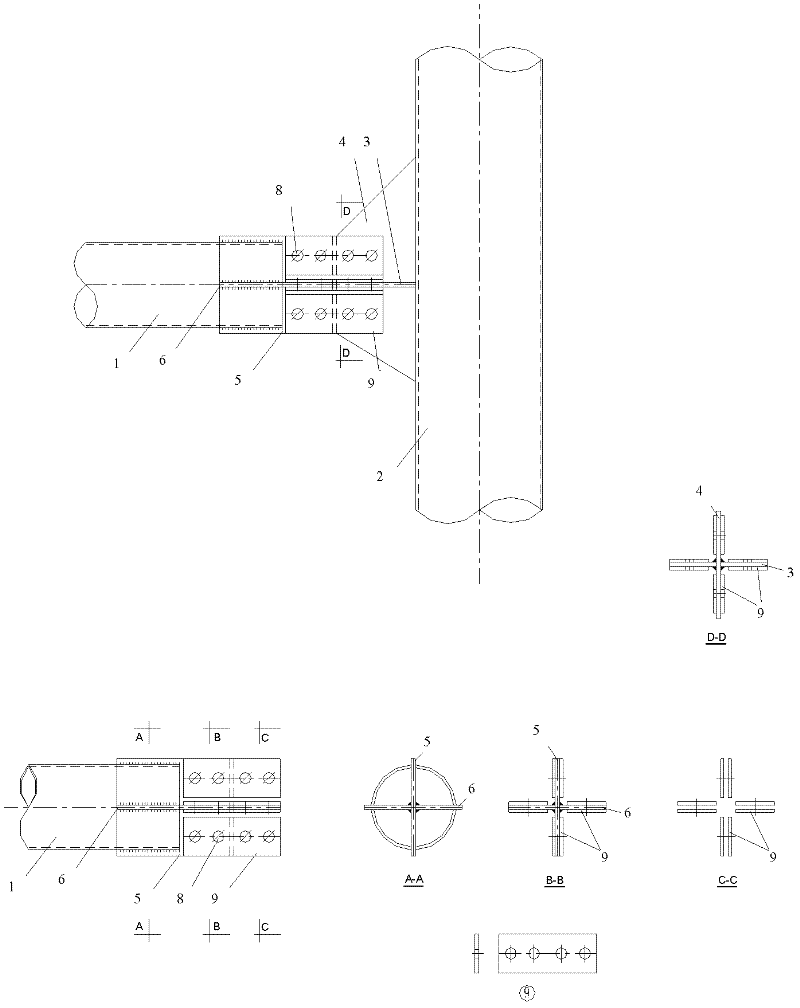

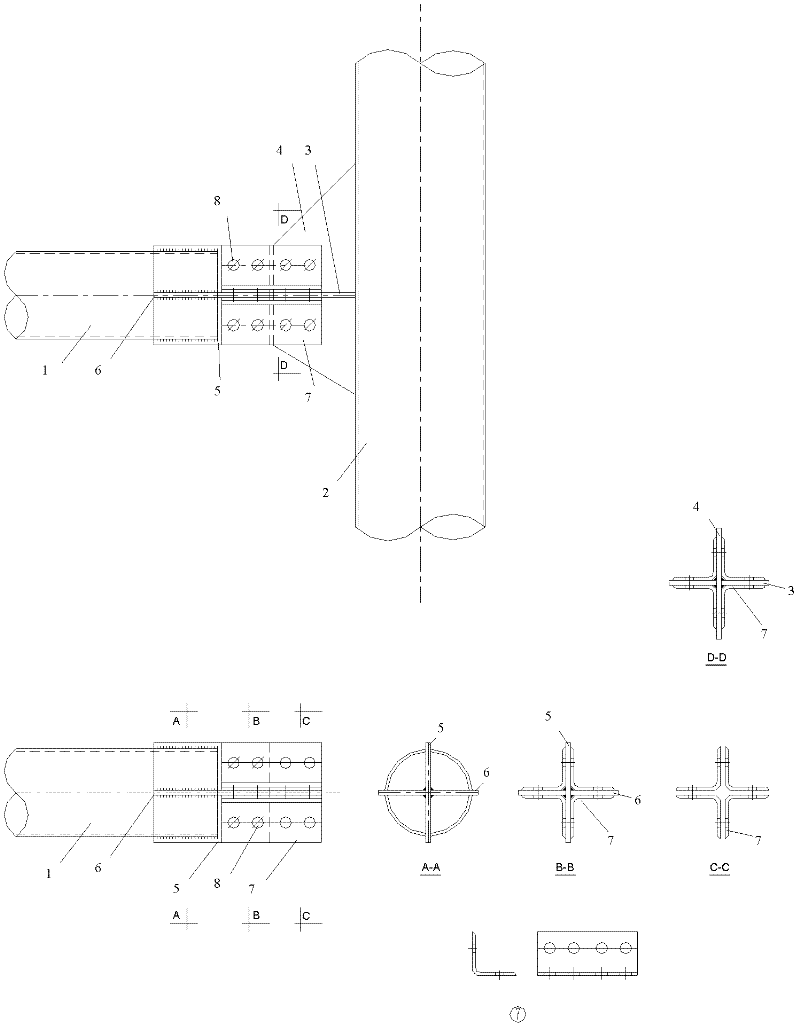

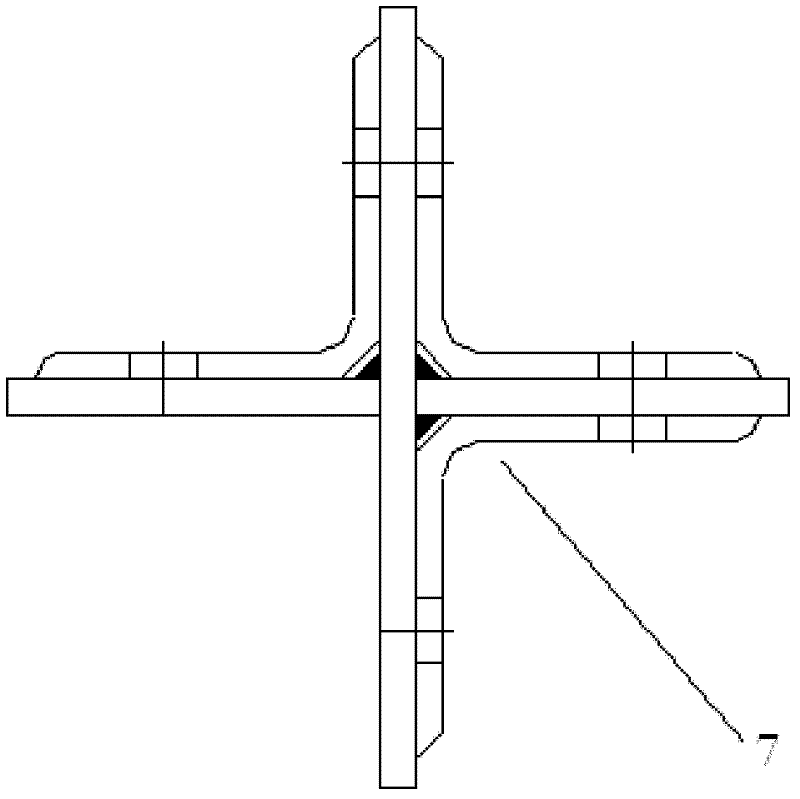

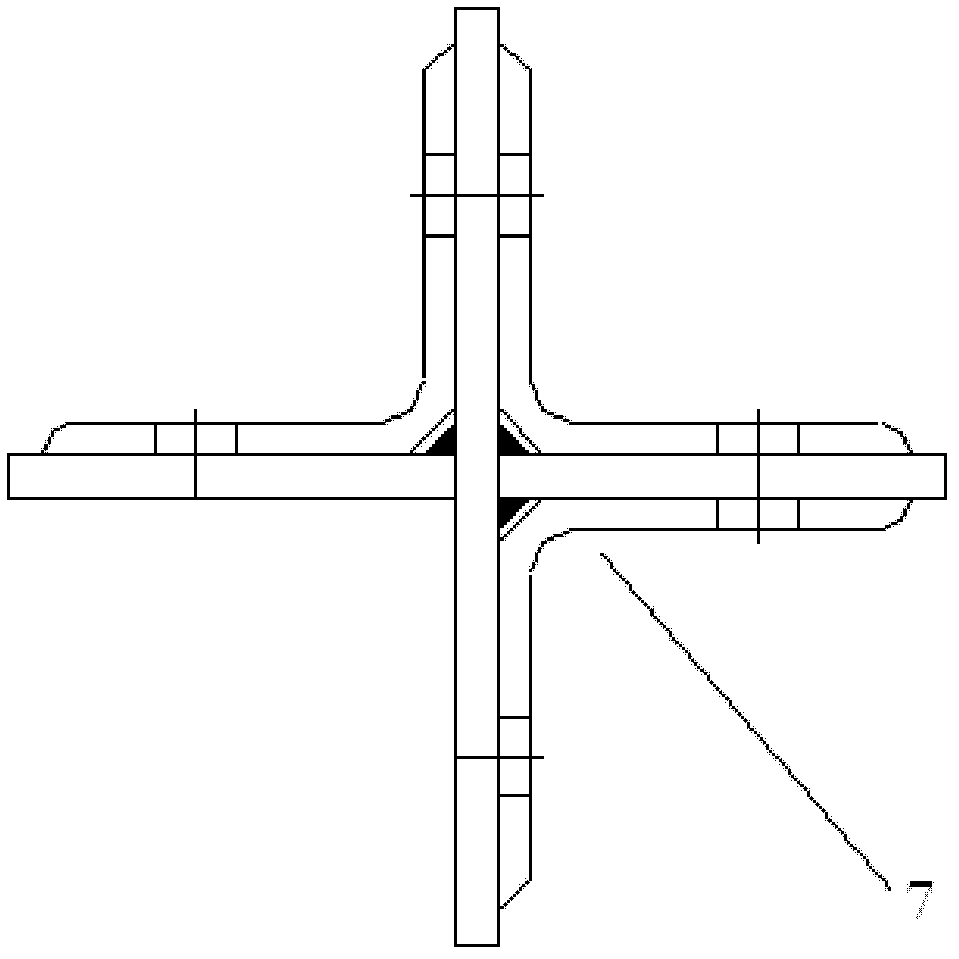

Plug-in connection components and steel pipe towers for transmission lines

The invention discloses a plug-in board connection assembly and a steel pipe tower of a power transmission line. The plug-in board connection assembly includes two gusset plates arranged in a cross shape as a gusset plate joint and two plug plates arranged in a cross shape as a plug-in board joint, and the gusset plate The joint and the plug-in board joint are butt-connected together by using fasteners through the connecting member, and the connecting member includes two, three or four angled pieces, wherein the two angled pieces are symmetrically arranged with respect to the center of the plugged-in board connection assembly. Through the plug-in plate connection assembly of the present invention, the advantages of simple connection, good structural force coordination, strong stability and sufficient force of angle steel or bent plate are realized.

Owner:CHINA ELECTRIC POWER RES INST +1

Inserted plate connection assembly and power transmission line steel pipe tower

The invention discloses an inserted plate connection assembly and a power transmission line steel pipe tower. The inserted plate connection assembly comprises two gusset plates and two inserted plates, wherein the two gusset plates are arranged in a cross shape to form a gusset plate joint; the two inserted plates are arranged in a cross shape to form an inserted plate joint; the gusset plate joint and the inserted plate joint are abutted by a connection component through a fastener; the connection component comprises two, three or four bent plates; and two bent plates are symmetrically arranged relative to the center of the inserted plate connection assembly. The inserted plate connection assembly disclosed by the invention realizes the advantages of simple connection, high structure stress coordination, strong stability and sufficient stress of angle iron or the bent plates.

Owner:CHINA ELECTRIC POWER RES INST +1

Method for vulcanizing inflated cover tyre

A hot repairing method for the inflatable tyre includes such steps as abrading the damaged position, sticking the hot-repairing rubber pads onto its inner and outer surfaces, attaching a heating belt to the inner surface, inflating internal tube, installing it in steel basin, putting a module on the outer surface of damaged position, putting a sulfurizing machine on the module, and inflating internal tube to 2.5-6 Kg / sq.cm while electrically heating it to 140-150 deg.C for 25-120 min.

Owner:周启君

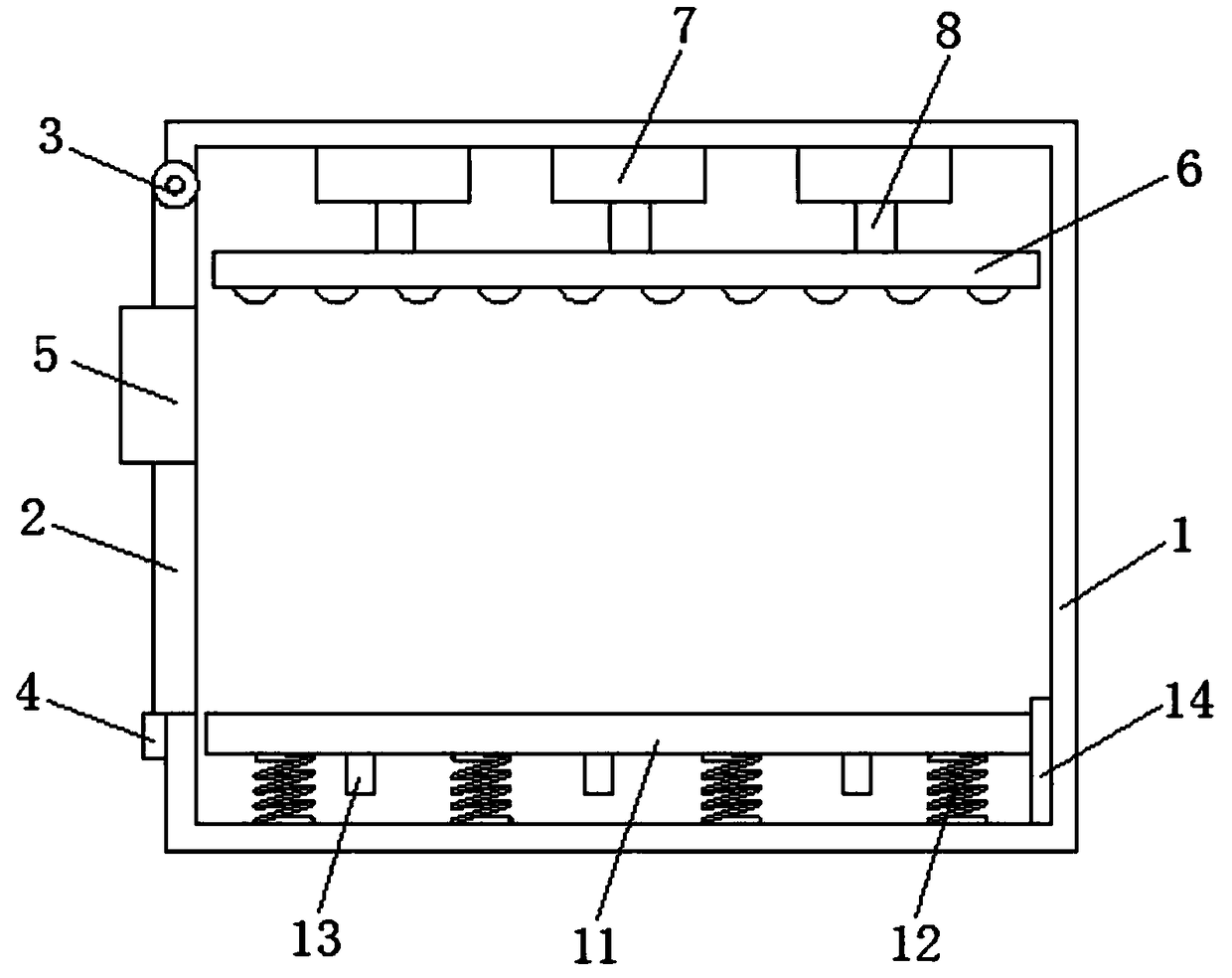

Filling and pressing device for building decoration waste materials

InactiveCN108773616AAvoid relative slidingCompactionRefuse transferringStorage devicesTelescopic cylinderEngineering

The invention discloses a filling and pressing device for building decoration waste materials. The filling and pressing device comprises a box body, a movable plate and an upper pressing plate, hydraulic telescopic cylinders and a bottom plate, wherein the movable plate is rotationally connected to the opening of the box body through a hinge seat, the bottom end of the movable plate is fixedly connected with a buckle used for being fixedly clamped with the bottom end of the box body, a garbage inlet is formed in the position, close to the hinge seat, of the middle of the movable plate, one side of the upper pressing plate is fixedly arranged at the ends of supporting arms of the hydraulic telescopic cylinders, anti-skid granular protrusions are arranged on the other side of the upper pressing plate, the other ends of springs are fixedly arranged on the bottom surface of the inner side of the box body, six anti-collision columns are evenly and fixedly arranged on the bottom surface of the bottom plate, and the springs and anti-collision columns are arranged below the bottom plate, so that the solid waste can be stably stressed in the compaction process, the garbage can be bounced upby a certain distance through the counter-acting force of the springs, the garbage can be conveniently taken out and transported, and the device is simple and practical.

Owner:安徽稀饭智能家居有限公司

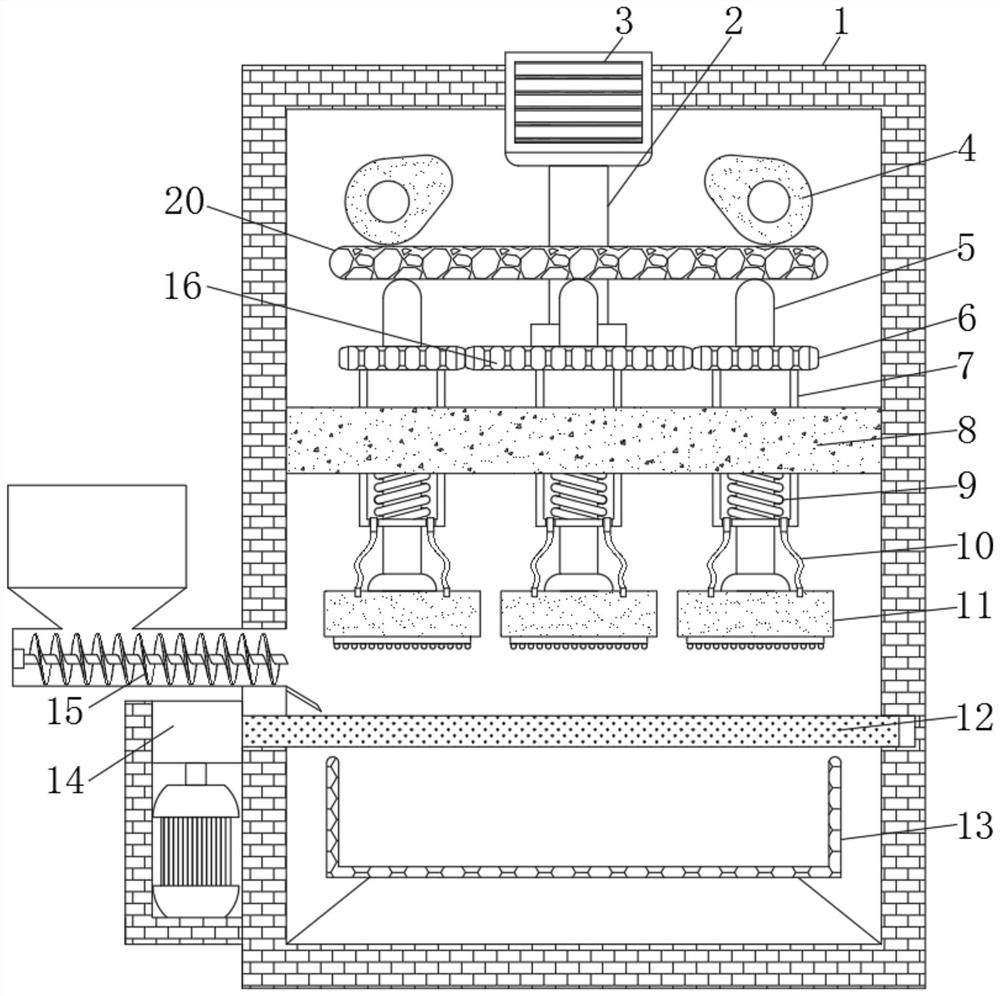

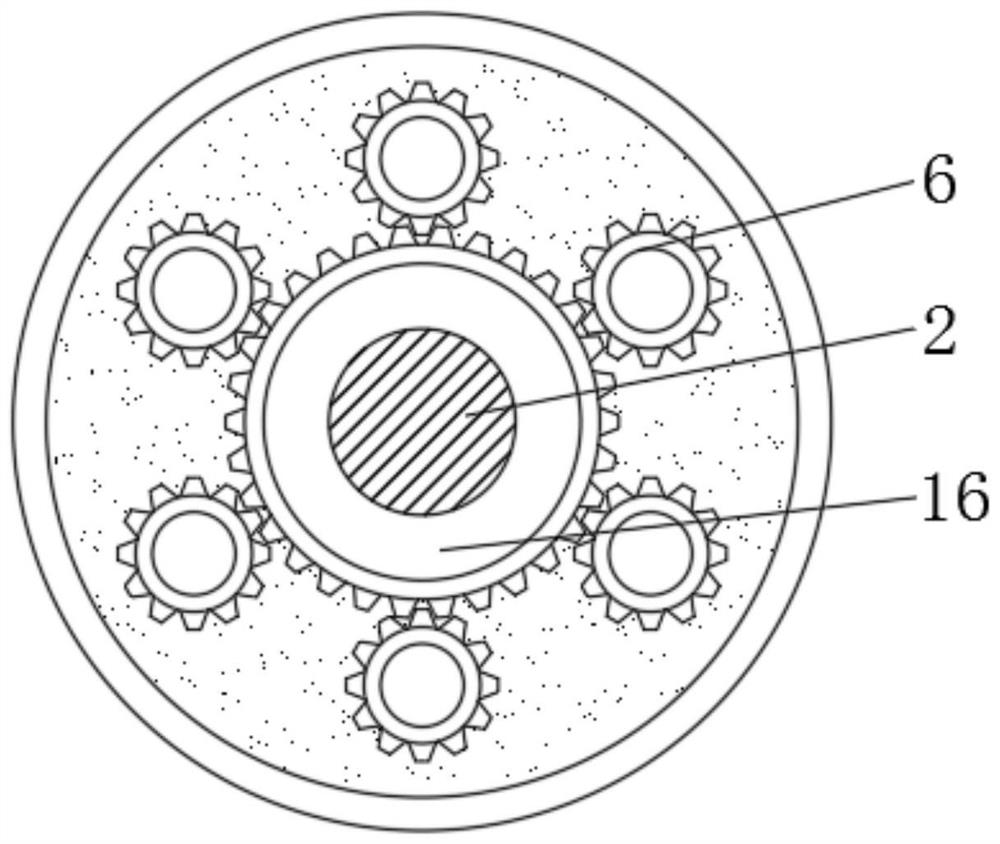

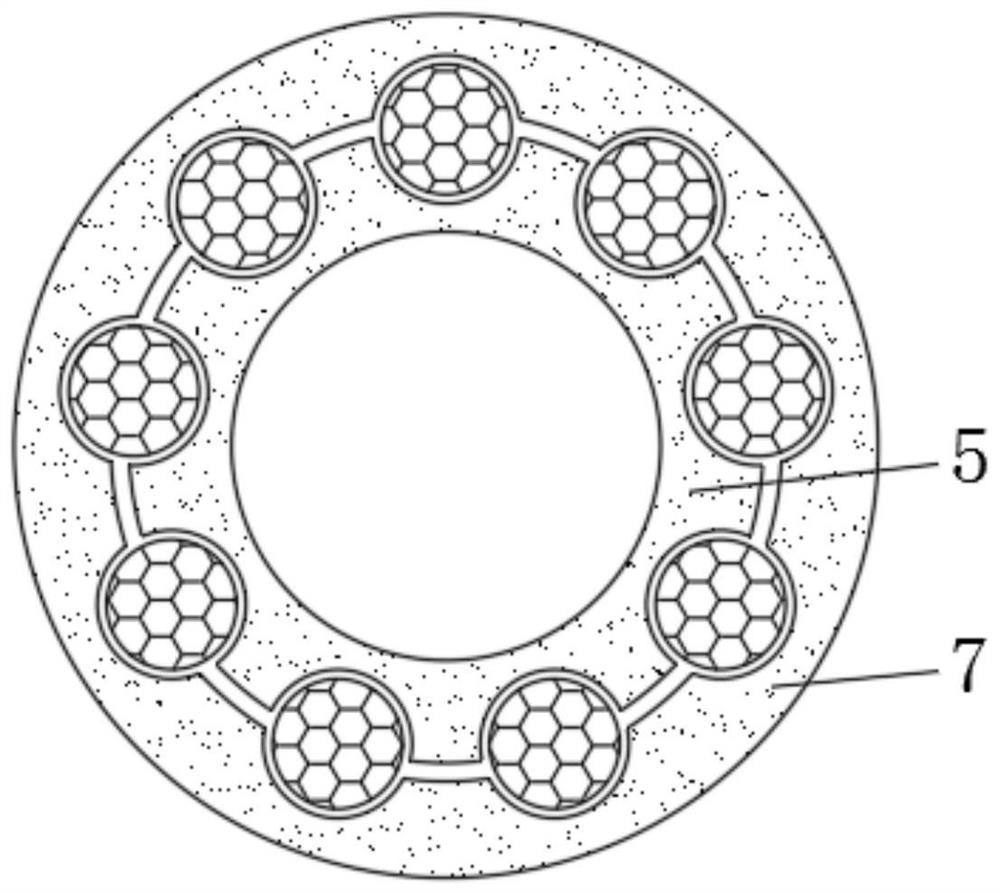

Device for recycling building waste

InactiveCN113210399AImprove crushing capacityImprove the crushing effectConstruction waste recoverySolid waste disposalWaste treatmentHigh torque

The invention relates to the technical field of solid waste treatment, and discloses a device for recycling building waste. The device comprises a rack, wherein the inner wall of the rack is fixedly connected with a crushing bracket; a slide block is connected inside the crushing bracket in a sliding mode; the front surface of the slide block is movably connected with a crushing gear; the outer wall of the crushing gear is movably connected with a transmission gear; the back surface of the crushing gear is movably connected with a belt; the outer wall of the belt is movably connected with a drive disc; the opposite end of the slide block is movably connected with a crushing roller; and the outer wall of the crushing roller is movably connected with a crushing tooth sleeve. According to the device for recycling building waste disclosed by the invention, the crushing roller drives the slide block to extrude a return spring towards the two sides, the slide block drives the crushing gear to be engaged with the transmission gear, and the transmission gear drives the crushing gear to rotate with high torque at low speed, so that crushing ability of the crushing roller is improved, and the building waste is prevented from blocking the crushing device to burn a motor.

Owner:刘道述

Iron plate twisting device

Owner:江苏悍威汽车有限公司

Gear machining and heat treatment process

InactiveCN105714040AAdd depthImprove heating uniformitySolid state diffusion coatingMetal working apparatusGear grindingProduct inspection

The present invention discloses a gear machining and heat treatment process, and the gear machining process successively comprises forging, normalizing, quenching and tempering, vertical machining, gear shaping, annealing, vertical machining, gear shaping, vertical milling, stabilizing aging, gear grinding, nitriding and finished product inspection, wherein the step of normalizing is normalizing at (880 + / -10) DEG C for (3-4) h, and then cooling in air; the step of quenching and tempering is quenching and tempering at (850 + / -10) DEG C for (3-4) h, quenching with water, and cooling with oil; the step of the annealing is annealing at (530 + / -10) DEG C for (3-4) h, cooling in a furnace in the heating and cooling rate of less than or equal to 50 DEG C / h; the step of stabilizing aging is stabilizing aging at (510 + / -10) DEG C for (3-4) h, and cooling in the furnace in the heating and cooling rate of less than or equal to 2 5 DEG C / h; and the step of nitriding is nitriding at (510 + / -10) DEG C for (10-12) h, and cooling in the furnace in the heating and cooling rate of less than or equal to 2 5 DEG C / h. The gear machining and heat treatment process is more reasonable, and can reduce distortion after nitriding to improve the overall performance of a gear.

Owner:CHONGQING YUANHUANG MACHINERY MFG CO LTD

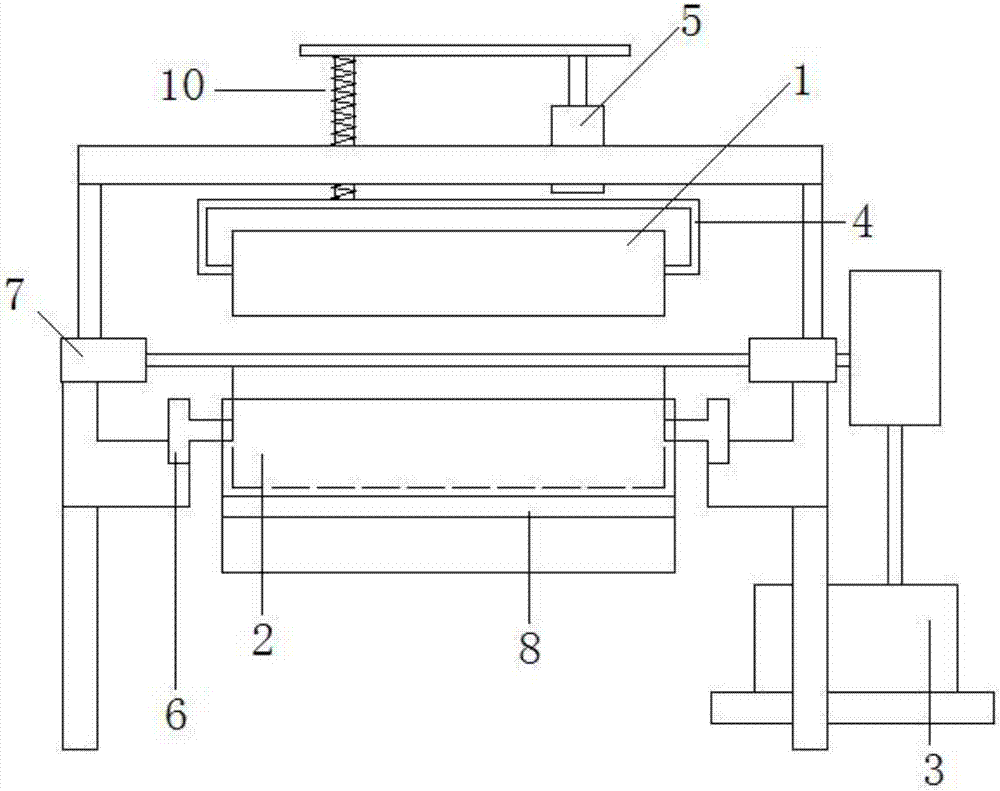

Profile modeling winding technology and profile modeling winding machine

The invention discloses a profile modeling winding technology and a profile modeling winding machine. According to the profile modeling winding technology and the profile modeling winding machine, in the winding process, yarn material gaps can be effectively removed, bubbles can be removed, and the process from the attaching state to the winding completing state can be maintained. The profile modeling winding machine comprises a machine frame, an upper roller, a lower roller and a vacuumizing pump, the upper roller is in rotation connection with a pushing frame, a pushing air cylinder is arranged on the machine frame, a lower support is arranged on the machine frame, the lower roller is in rotation connection with the lower support, locking heads are arranged between the pushing frame and the lower support, a profile modeling pressing strip is arranged between the locking heads and fixed by the locking heads, a ventilation pipeline connected with the vacuumizing pump is arranged in one locking head, and a working table plate is arranged on the machine frame. The profile modeling winding technology and machine have the advantages that the winding process is mechanically completed, and is stable and efficient, tight scraping operation is carried out before winding, the yarn material can be attached in a compact mode, the stress area in rolling is large, stress is sufficient, it is effectively ensured that the clearance can be removed, and the high-quality yarn material workblank is wound.

Owner:TONGXIANG BONNY SCI & TECH COMPOSITE +1

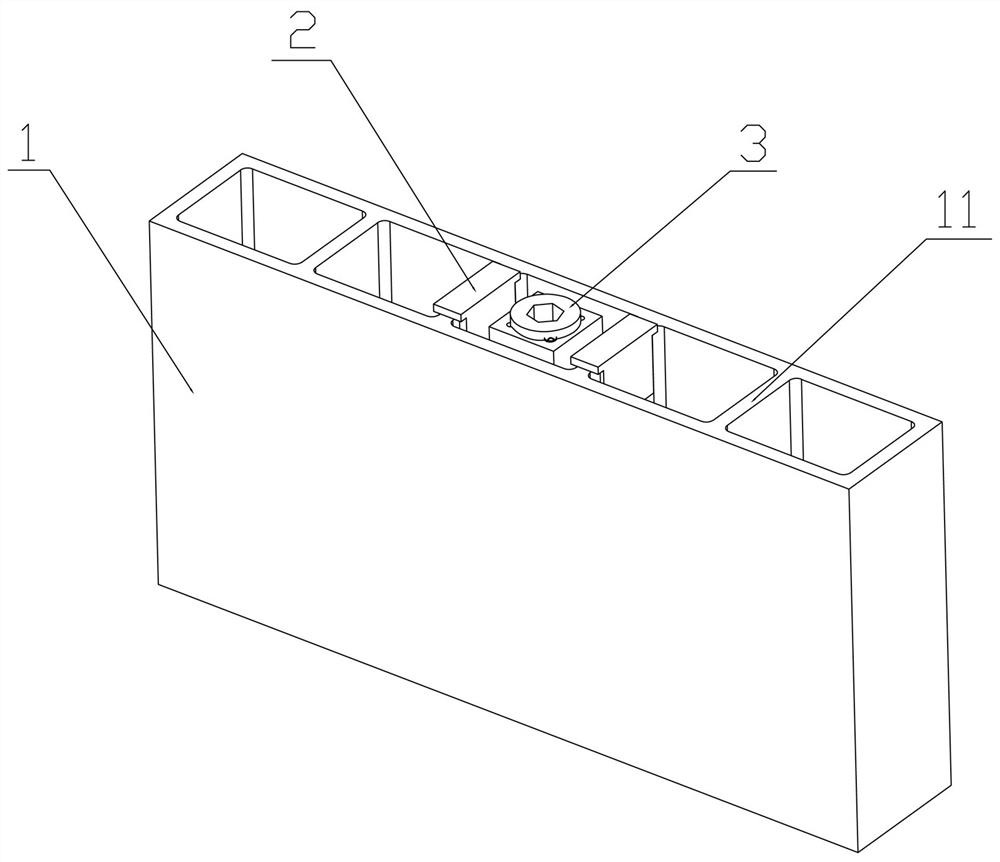

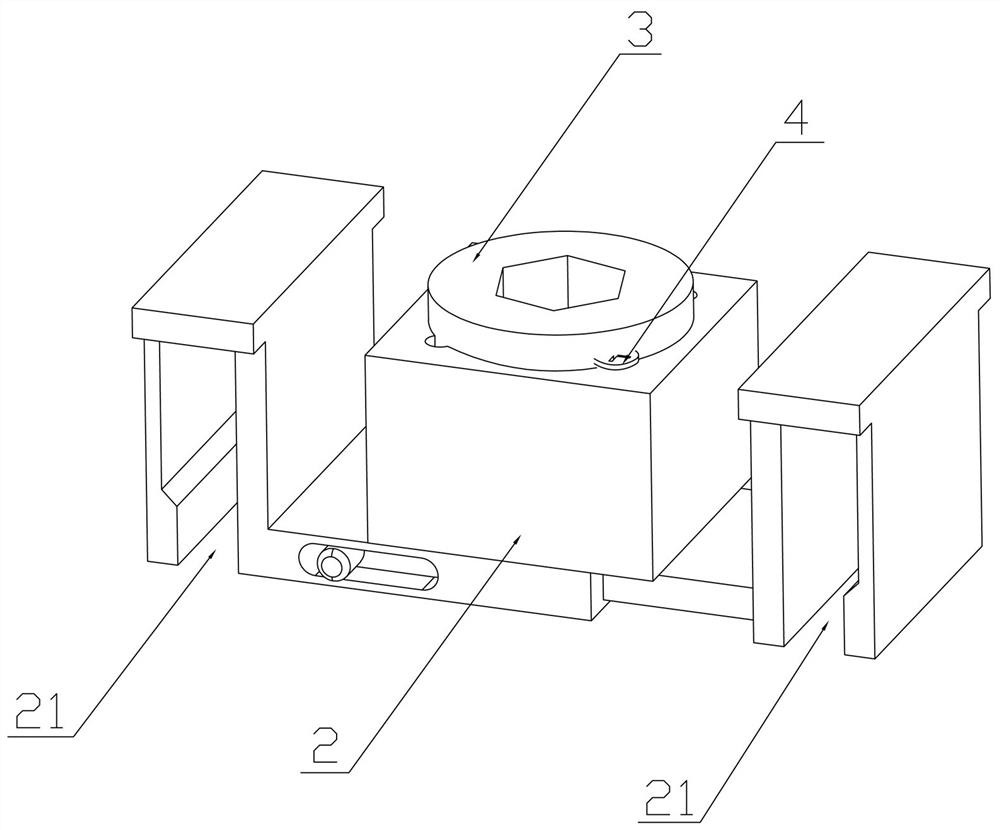

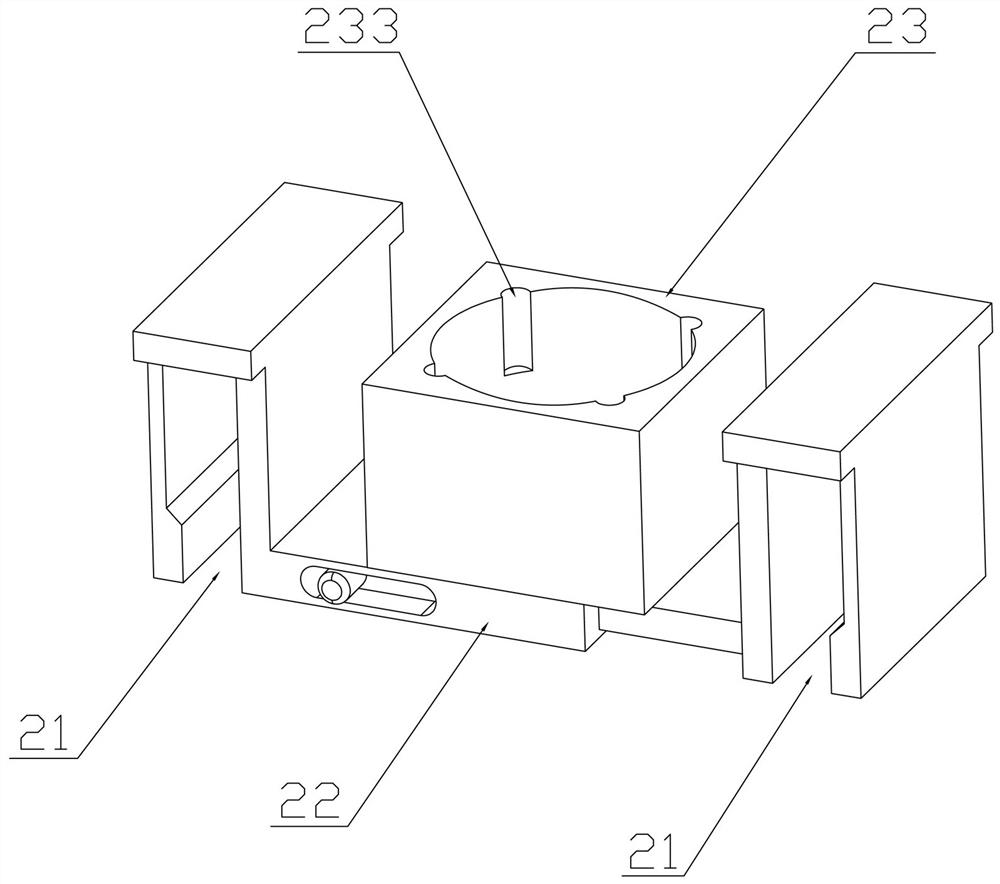

Assembly type bathroom wallboard height adjusting mechanism

PendingCN113898222AHeight adjustableIncrease heightSpecial buildingBuilding componentsComposite substrateEngineering

The invention relates to and discloses an assembly type bathroom wallboard height adjusting mechanism, and relates to the technical field of bathrooms. The assembly type bathroom wallboard height adjusting mechanism specifically comprises a base used for being fixedly connected with a ceramic tile composite substrate, and an adjusting column used for adjusting the height of the adjusting column on the base; clamping grooves connected with two rib plates of a cavity of the ceramic tile composite substrate in an inserted mode are formed in the two sides of the base correspondingly, the two clamping grooves are connected with the two rib plates of the cavity of the ceramic tile composite substrate in an inserted mode correspondingly and used for fixedly connecting the base to the ceramic tile composite substrate, a threaded hole is formed in the base, and an external thread matched with the threaded hole is arranged on the adjusting column. According to the assembly type bathroom wallboard height adjusting mechanism, the base is fixedly connected with the ceramic tile composite substrate, the threaded hole is formed in the base, then the adjusting column provided with the external thread is in threaded connection with the threaded hole, the height of the adjusting column on the base is adjusted, the height of the ceramic tile composite substrate can be extended through the height of the adjusting column, and therefore when the height of the adjusting column on the base is adjusted, the height of the ceramic tile composite substrate can be adjusted.

Owner:ZHEJIANG YASHA DECORATION

Energy-saving and environment-friendly equipment for re-filtering edible oil squeezing material

InactiveCN112375618AEven by forceIncrease profitFatty-oils/fats refiningFatty-oils/fats productionDrive shaftGear wheel

The invention relates to the technical field of edible oil, and discloses energy-saving and environment-friendly equipment for re-filtering an edible oil squeezing material. The energy-saving and environment-friendly equipment comprises a rack, a servo motor is fixedly connected to the top wall of the rack, a driving shaft is inserted into the bottom of the servo motor, a driving gear is fixedly connected to the bottom end of the driving shaft, the outer wall of the driving gear is engaged with a transmission gear, the bottom surface of the transmission gear is fixedly connected with a transmission shaft, and the outer wall of the transmission shaft is movably connected with a fixing plate. According to the energy-saving and environment-friendly equipment for re-filtering the edible oil squeezing material, the transmission shaft drives a pressing rod to rotate, the pressing rod drives a grinding disc fixedly connected with the bottom end to rotate, a pressing plate extrudes the pressing rod downwards, the pressing rod drives a piston and the grinding disc to move downwards to make contact with oil residues, the rotating grinding disc enables the oil residues at the bottom to be dispersed and staggered, the oil residues are stressed more uniformly at all angles, the utilization rate of oil is high, and the equipment is more energy-saving and environment-friendly.

Owner:温州立卓建材有限公司

Device and method for detecting mechanical properties of cold-rolled steel strip

ActiveCN105241766BFully stressedImprove accuracyMaterial strength using repeated/pulsating forcesWeld seamEngineering

Owner:武汉钢铁有限公司

Crushing and stirring device for producing poultry feed

InactiveCN112090350AFully stressedGood crushing effectFeeding-stuffRotary stirring mixersFeed processingAgricultural engineering

The invention relates to the technical field of feed processing, and discloses a crushing and stirring device for producing a poultry feed. The crushing and stirring device comprises a rack, a sieve plate is fixedly connected to the inner wall of the rack, a crushing bin is fixedly connected to the outer wall of the sieve plate, and a transmission shaft is inserted into the crushing bin; and the top end of the transmission shaft is fixedly connected with a first transmission gear, the outer wall of the first transmission gear is engaged with a second transmission gear, a crushing shaft is inserted into the second transmission gear, and the outer wall of the transmission shaft is sleeved with a first rotary disc. According to the crushing and stirring device for producing the poultry feed,the first transmission gear drives the second transmission gear to rotate so as to drive a crushing shaft to rotate, the crushing shaft drives a crushing cutter to cut raw materials in a bin body, a fixing rod drives the crushing shaft to rotate, and revolution and autorotation of a crushing assembly are combined, so that the raw materials are stressed more sufficiently, the crushing effect is better, and the crushing time is shorter.

Owner:湖州南浔双林兴祥蚕蛹饲料有限公司

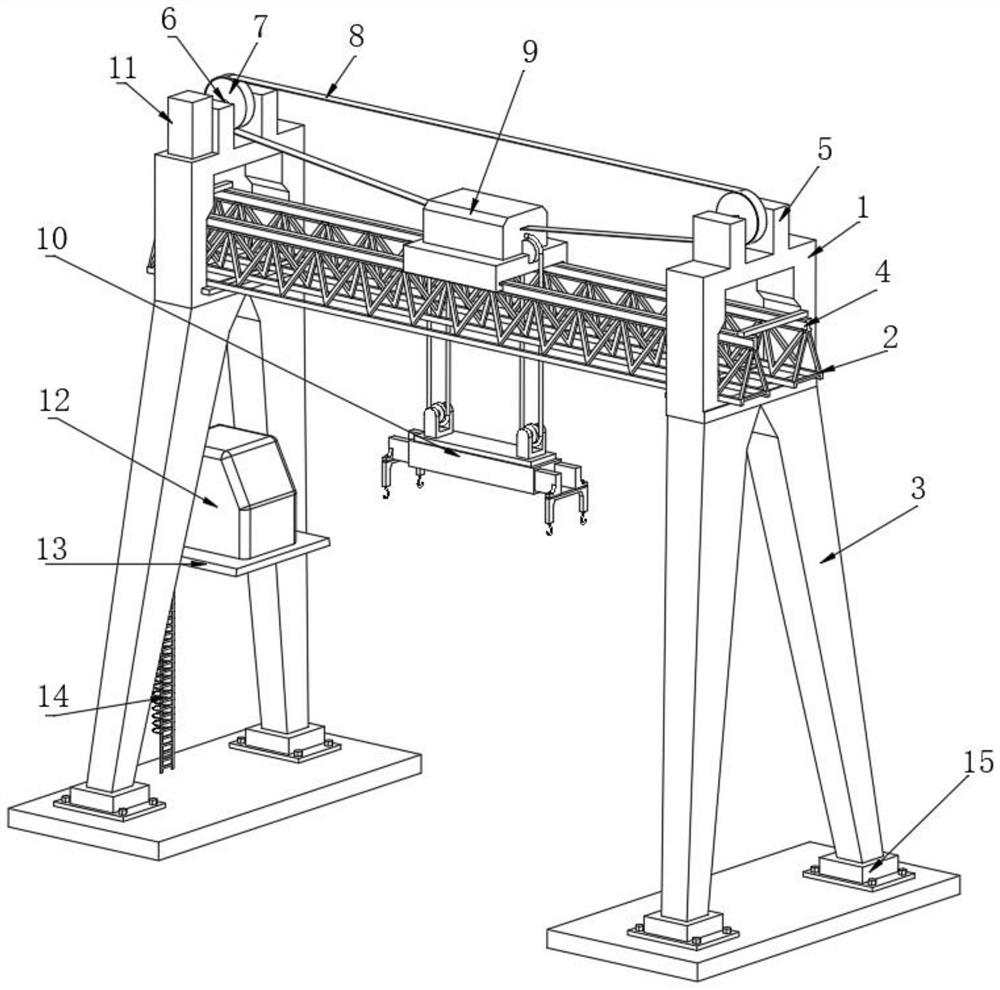

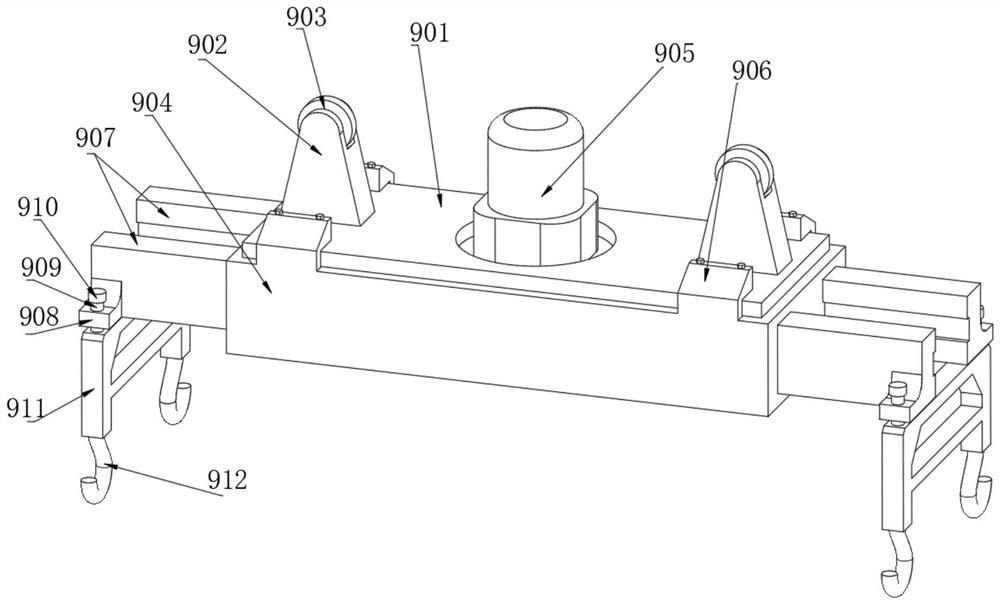

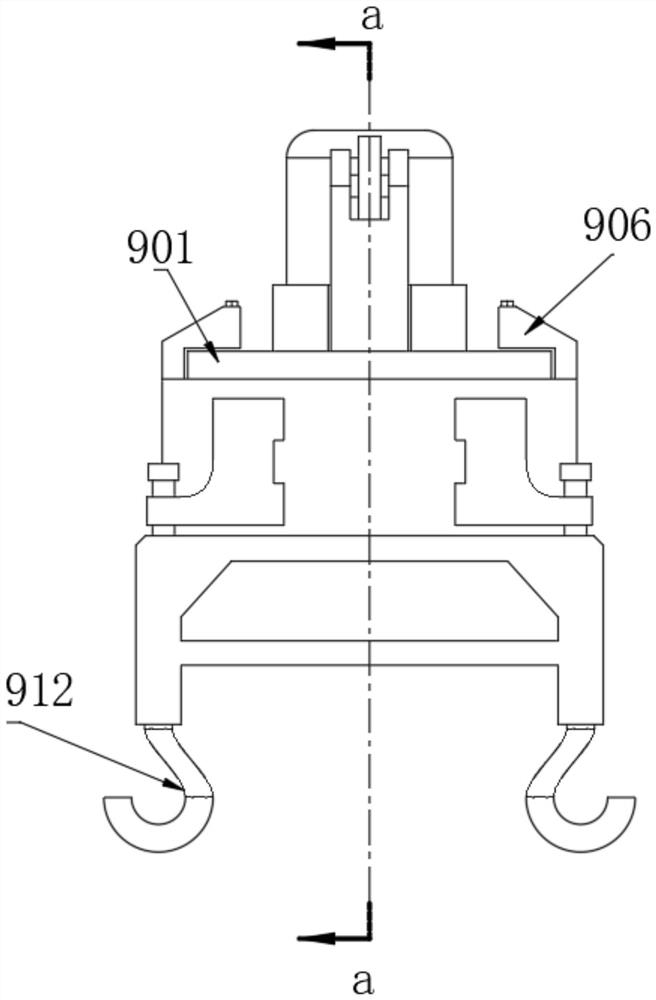

Gantry crane for large special equipment

PendingCN113955644AAchieve the effect of lifting hook assemblyStable structureBase supporting structuresBraking devices for hoisting equipmentsGear wheelElectric machinery

The invention provides a gantry crane for large special equipment, and relates to the technical field of gantry cranes. The gantry crane comprises two slide rail fixing frames, two parallel triangular slide rail trusses penetrate through the two slide rail fixing frames, and two transverse moving turntables are rotationally connected through a transverse moving chain belt; and the lower end of a lifting assembly is movably connected with a hook claw assembly used for grabbing objects. A motor driving bevel gear on an adjusting box motor rotating output shaft is meshed with a synchronizing shaft bevel gear to drive an adjusting synchronizing shaft to rotate, so that synchronous rotating gears at the two ends rotate at the same time, four adjusting claw hook supporting rods at the two ends are driven to stretch out and draw back, and therefore the distance between two hook claw frames at the lower end can be adjusted, and aim of adjusting the object hooking length can be achieved. Compared with an existing gantry crane frame, the gantry crane has the advantages that when large containers are hooked, due to the fact that the sizes of the containers are different, stress in the vertical direction of the hook claws is more sufficient by adjusting the length of the hook claws.

Owner:重庆望江特种装备有限公司

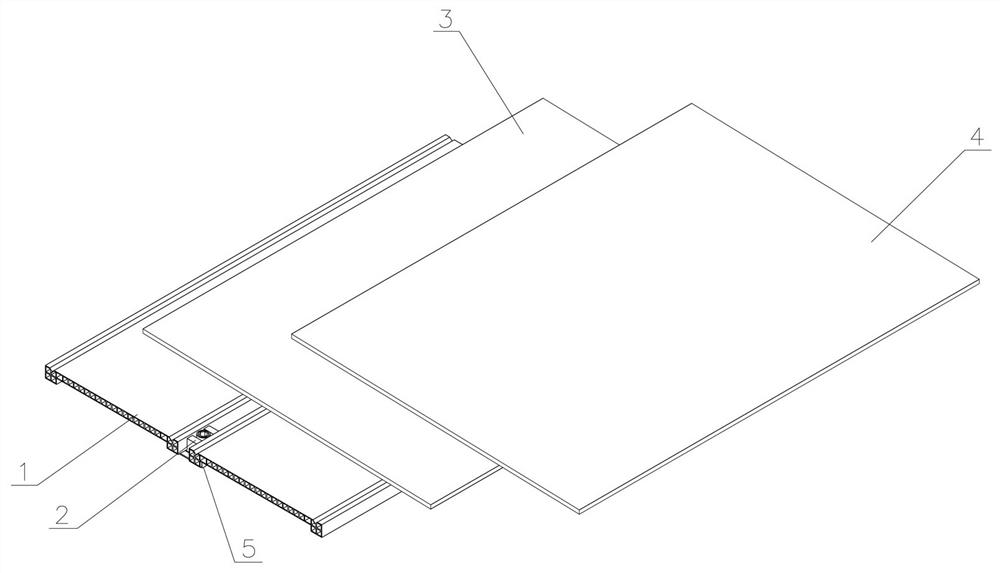

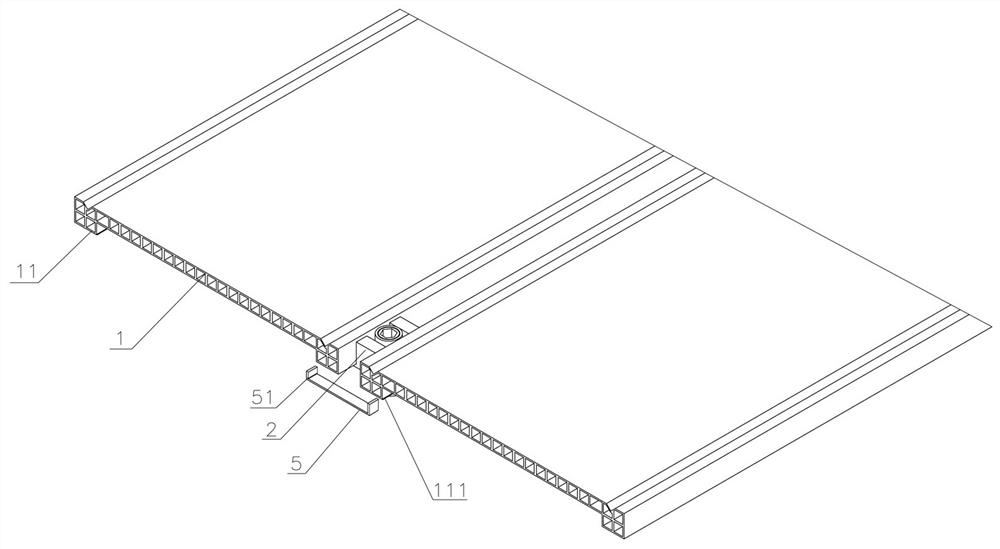

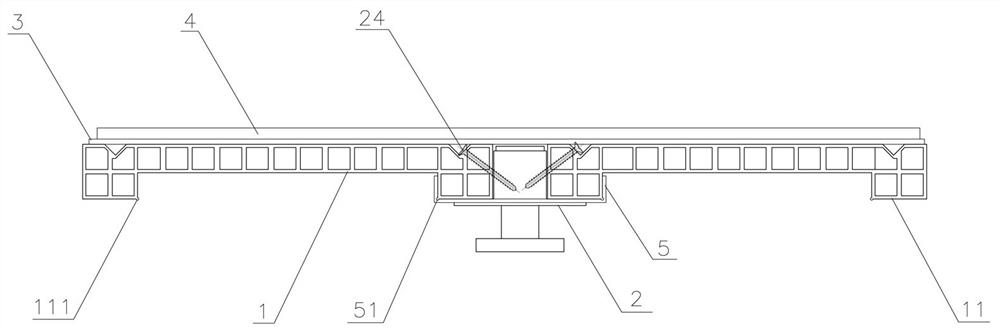

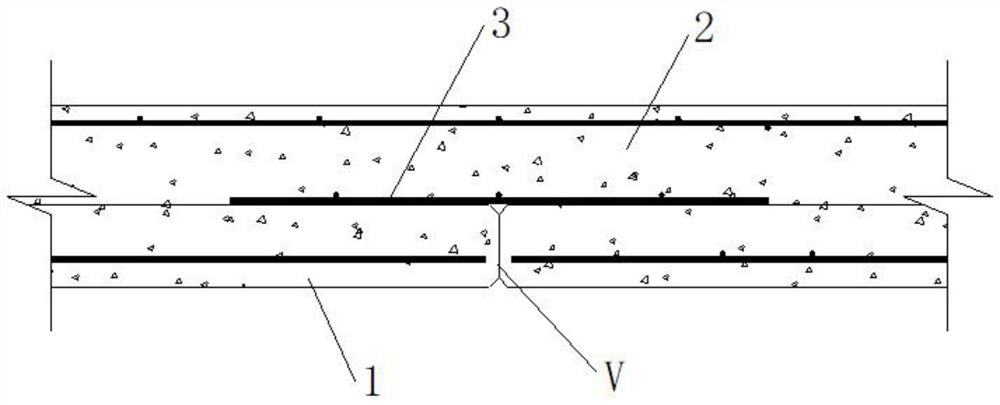

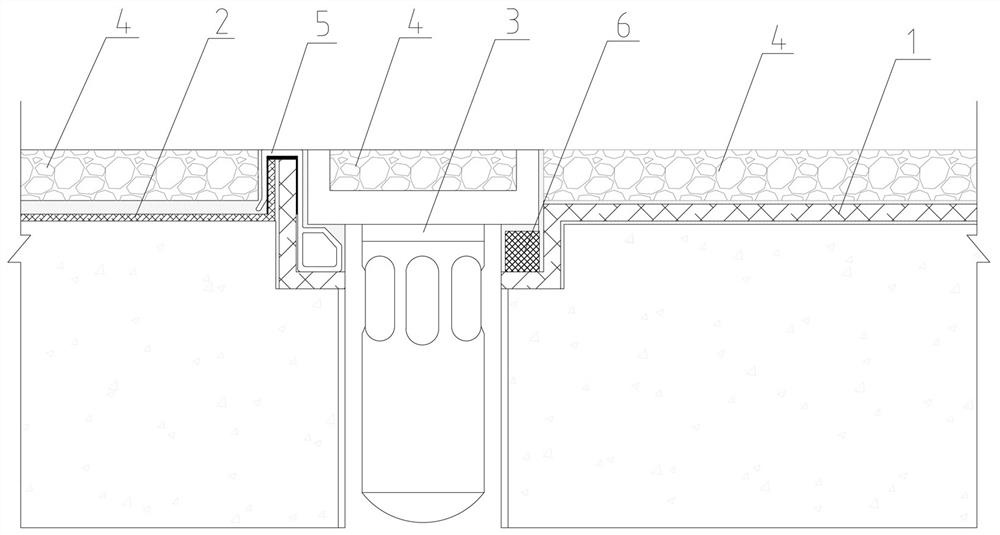

Fabricated ground and mounting method

PendingCN113250413AImprove stabilityExtended service lifeFalse floorsCeramic tilesGeotechnical engineering

The invention discloses a fabricated ground and a mounting method, and relates to the technical field of architectural decoration. The fabricated ground specifically comprises bearing base plates, adjusting feet and a fixed device, wherein the bottoms of the adjusting feet abuts against the ground, the tops of the adjusting feet is used for bearing the two adjacent bearing base plates, and the fixed device is used for fixing the bearing base plates to the adjusting feet; when the adjusting feet adjust the height of the adjusting feet, the two adjacent bearing base plates are leveled; the fabricated ground further comprises a balance layer and a surface layer, wherein the bearing base plate is covered with the balance layer, and the balance layer is covered with the surface layer. According to the fabricated ground, one ends of the two adjacent bearing base plates are carried on the adjusting feet, then the bearing base plates are fixed to the adjusting feet through the fixed device, the bottoms of the adjusting feet abut against the ground, and then the self-heights of the adjusting feet are adjusted, so that leveling of the two adjacent bearing base plates is achieved; finally, the bearing base plate is covered with the balance layer made of cement fiber plates, tiles or wood floors are laid on the cement fiber plates to serve as panels, and laying of the fabricated ground is completed.

Owner:ZHEJIANG YASHA DECORATION

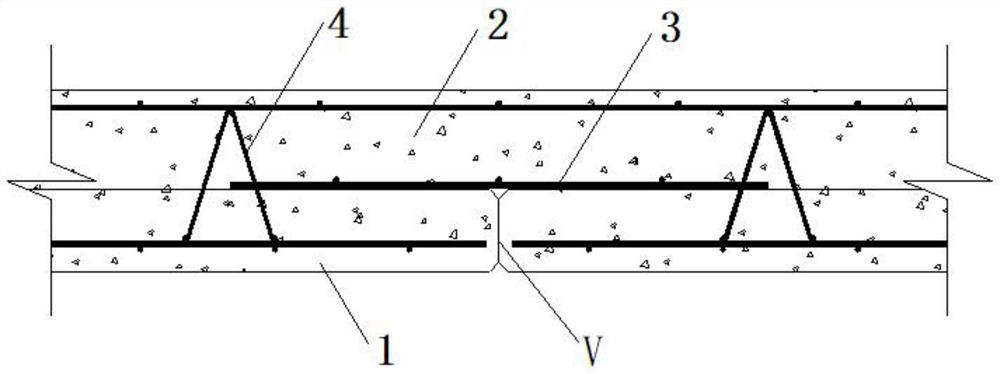

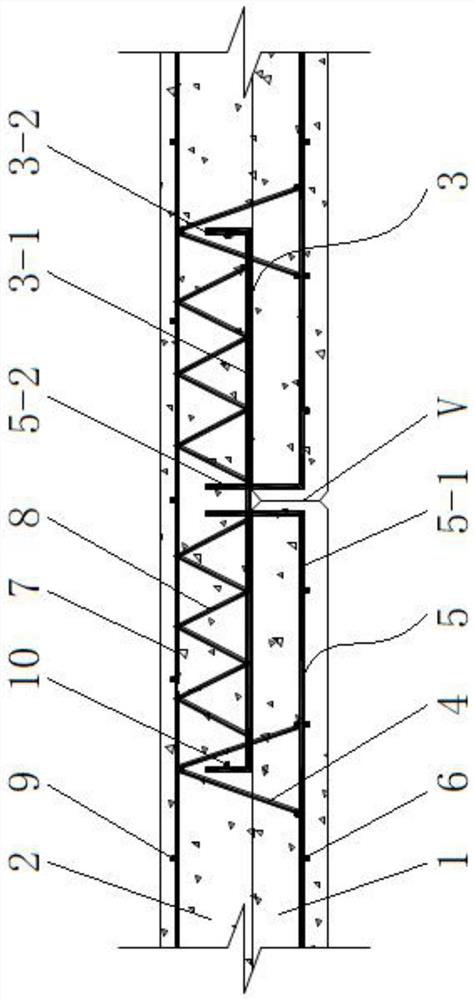

Bidirectional laminated slab dense splicing strong seam construction process and structure

PendingCN112922205AAvoid tear damageImprove integrityFloorsBuilding material handlingRebarMechanical engineering

The invention discloses a bidirectional laminated slab dense splicing strong seam structure. The bidirectional laminated slab dense splicing strong seam structure comprises a prefabricated slab and a cast-in-place layer, wherein bottom plate steel bars and bottom plate connecting bars are arranged in the prefabricated slab, the bottom plate steel bars comprise bottom plate load-bearing steel bars and bottom plate fixing steel bars, the bottom plate fixing steel bars are close to a splicing seam of the prefabricated slab, bent upwards and extend out of the surface of the prefabricated slab, additional steel bars and top plate compression steel bars are longitudinally laid in the cast-in-place layer, every two adjacent additional steel bars are connected to one top plate compression steel bar through a connecting web bar, the additional steel bars are perpendicular to the abutted seam, additional fixing steel bars are further arranged at the two ends of the additional steel bars and arranged in the vertical direction, and top plate connecting ribs and the top plate compression steel bars are laid in the transverse direction and in an overlapped mode. The bidirectional laminated slab dense splicing strong seam construction structure is high in integrality and bearing capacity, and the stability of the laminated slab near the abutted seam is high.

Owner:重庆中科建筑科技(集团)有限公司

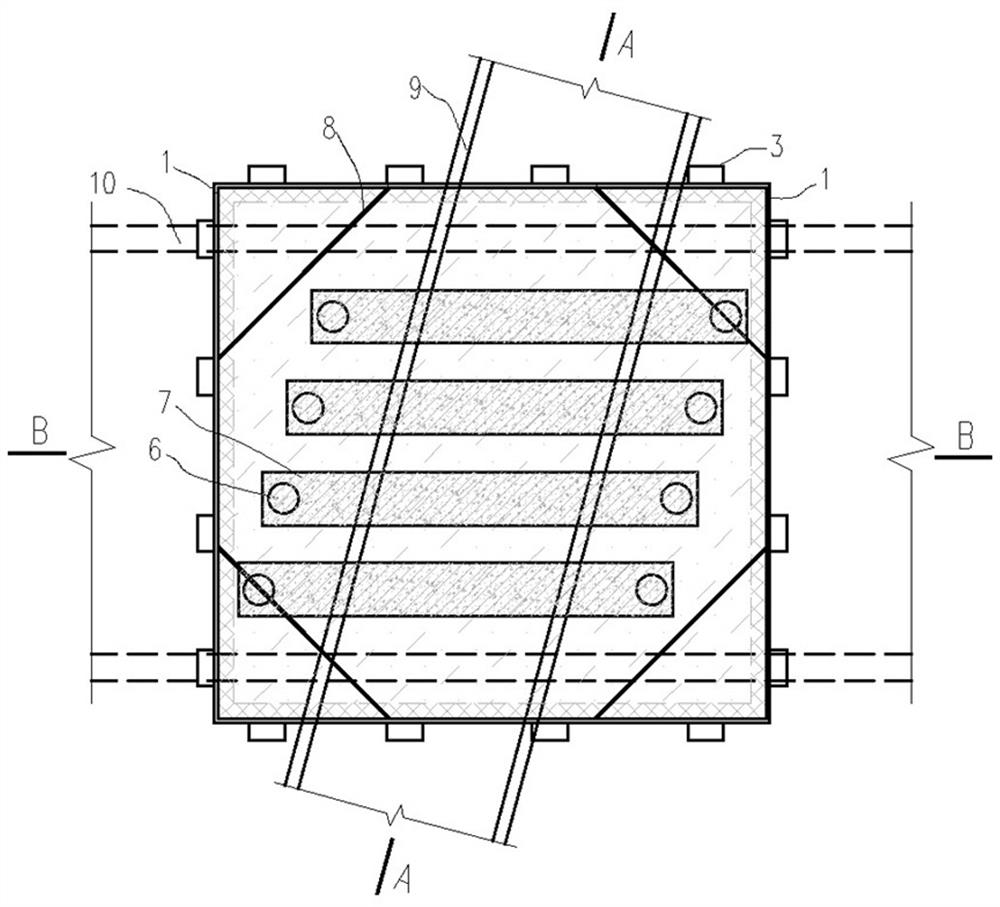

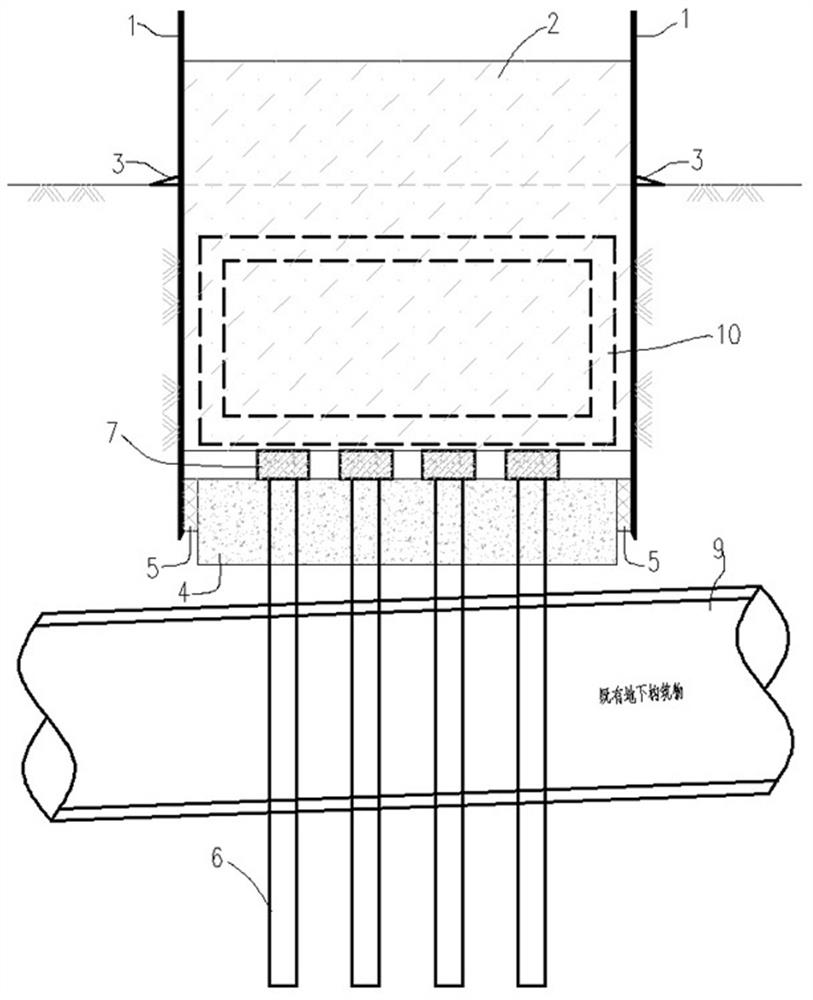

Compensation type construction structure for underground engineering construction and construction method thereof

PendingCN114775687ASolving the time-space exposure problemControl the floating situationArtificial islandsUnderwater structuresSteel jacketArchitectural engineering

The invention relates to the technical field of foundation pit engineering, in particular to a compensation type construction structure for underground engineering construction and a construction method thereof.The construction structure comprises a steel jacket box, the steel jacket box covers the construction range of a to-be-built structure, a central reinforcing area is arranged at the bottom of the steel jacket box, anchor piles are arranged in the central reinforcing area, and the steel jacket box covers the construction range of the to-be-built structure. The anchor piles are arranged on the two sides of the existing underground structure, the anchor piles are connected through anchor plate beams arranged at the tops to form a door type frame structure, proper slurry is injected into the steel jacket box according to the soil taking amount, and equivalent pressure compensation is generated for an unexcavated area. The method has the advantages that the impervious layer is formed by combining the foundation stratum reinforcing area with the jet grouting pile seam sealing, the generated load pressure is controlled by combining the height of the slurry liquid level in the steel jacket box, and the stratum stress at the position of the existing underground structure is kept unchanged.

Owner:CHINA RAILWAY SHANGHAI DESIGN INST GRP

Cold-rolled steel belt mechanical property detection device and method

ActiveCN105241766AFully stressedImprove accuracyMaterial strength using repeated/pulsating forcesWeld seamEngineering

The invention discloses a cold-rolled steel belt mechanical property detection device and method. The detection device comprises a body; a bended roller, which is slidingly fixed on the body, wherein the bended roller can rise or descend relative to the body and is provided with an upper bended roller and a lower bended roller for clamping a cold-rolled steel belt; a tension roller, which is arranged on the body and can horizontally slide relative to the body, wherein the tension roller comprises a driving roller, which is fixed relative to the body is capable of rotating around the core shaft of the driving roller, and a driven roller, which is fixed on the body and is capable of horizontally sliding relative to the body; and a tension assembly, which is connected to the driven roller so as to apply a constant tensile force on the driven roller. In the prior art, the tests on bending fatigue strength of cold-rolled steel belt are not accurate, the actual stress state of weld seams during the production process of steel belt production cannot be simulated, and the provided device and method solve the problems mentioned above and are capable of precisely measuring the bending fatigue strength of cold-rolled steel belt.

Owner:武汉钢铁有限公司

A construction method of reverse prefabricated frame jacking of oil roof on variable slope

The invention discloses a jacking construction method for a prefabricated frame with an inversely arranged oil top on a variable ramp. The method comprises the following steps: arranging a weak transition section at a gradient change point, namely breaking a concrete slide way to form a weak section of a soil foundation; inversely arranging the oil top at one end of the prefabricated frame, arranging a rear seat of the oil top in a mode of backing on the prefabricated frame, connecting a piston column of the oil top with a force transfer member bar on the back, applying jacking force to the back through the oil top, and enabling the rear seat of the oil top to push the prefabricated frame to move forward for jacking; and jacking the prefabricated frame, dismounting the force transfer member bar, performing following up pouring on step type concrete rear seats, mounting the force transfer member bar, jacking the prefabricated frame, dismounting the force transfer member bar, performing following up pouring on step type concrete rear seats, mounting the force transfer member bar, continuing to jack, and executing the processes circularly until the prefabricated frame is jacked in place according to the design. The jacking construction method for the prefabricated frame with the inversely arranged oil top on the variable ramp, disclosed by the invention, can be used for ensuring continuous and stable jacking construction of the prefabricated frame on the variable ramp.

Owner:中铁二十五局集团第三工程有限公司 +1

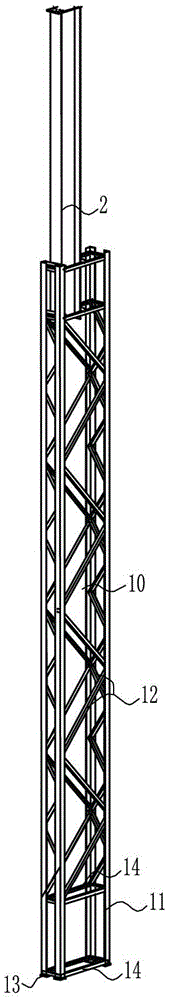

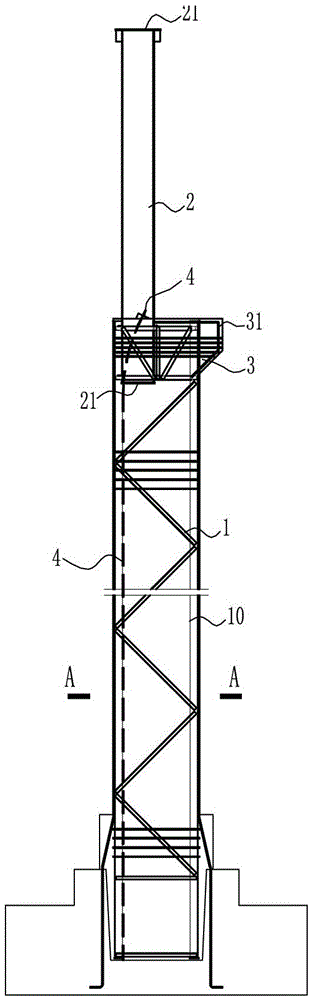

A composite column of lattice type steel column and reinforced concrete and its construction method

ActiveCN102852282BIncrease stiffnessReduce steel consumptionStrutsBuilding material handlingReinforced concreteSteel columns

Owner:杨众 +1

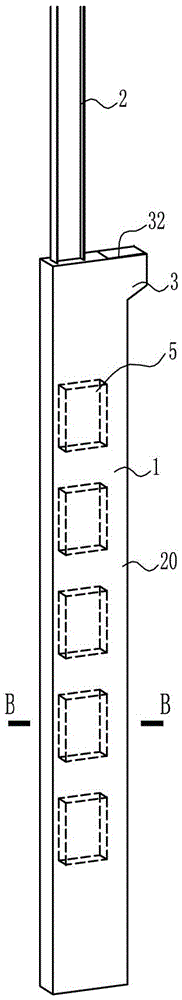

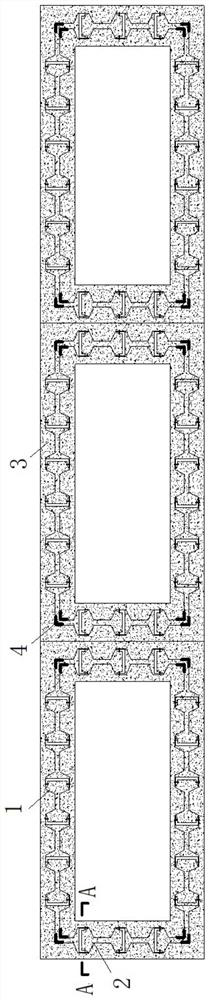

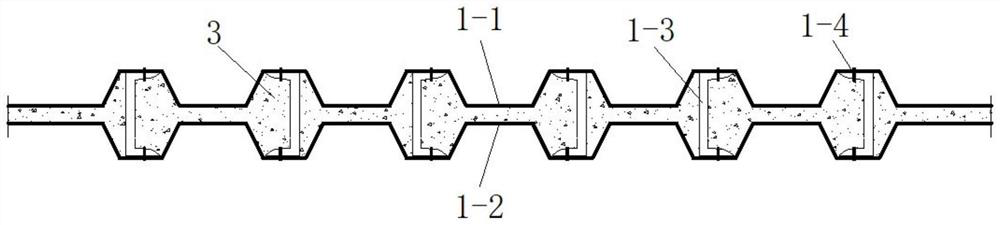

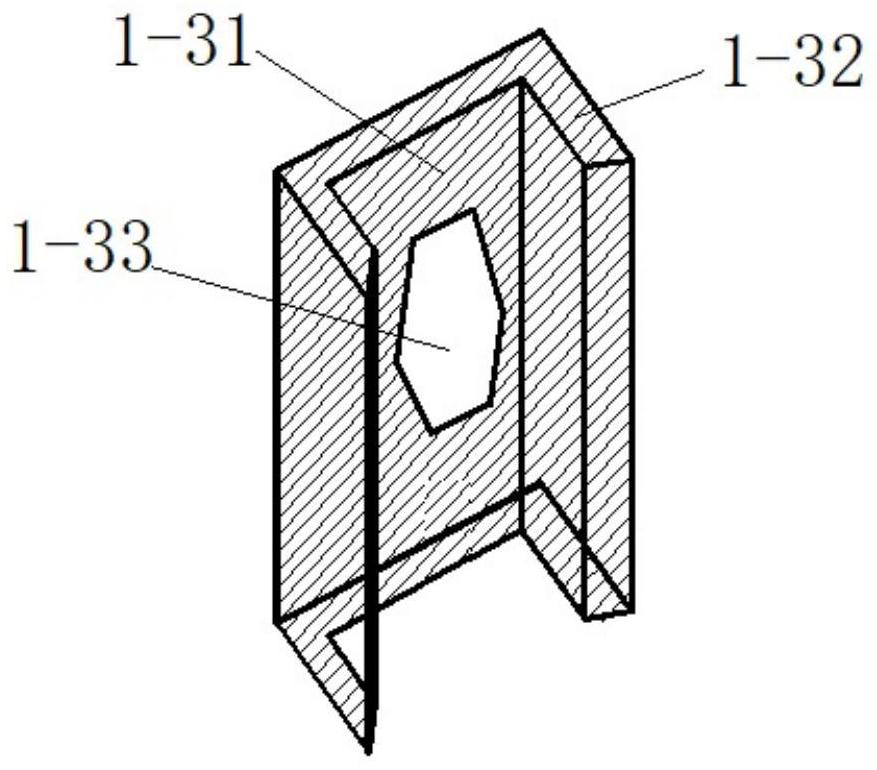

A prefabricated corrugated steel plate lattice enclosure structure and construction method thereof

ActiveCN112983116BPlay the role of tension reinforcementIncrease contact surfaceFencingClassical mechanicsAxial force

The invention discloses a prefabricated corrugated steel plate lattice-type enclosure structure and a construction method thereof. The structure includes a number of frame-structured enclosure units, each enclosure unit includes a transverse enclosure portion and a longitudinal enclosure portion filled with concrete, and a truss as a bending component is arranged inside the transverse enclosure portion. The interior of the enclosure is provided with a lattice column as an axial force-bearing member. The truss and the lattice column are connected to each other and bonded with the concrete to form a whole. It is composed of channel steel, a channel steel is arranged in the cavity formed by each peak-to-peak part, the flange of the channel steel is connected with the wave crest in the cavity, and the opening direction of the channel steel in the adjacent cavity is opposite. The invention solves the problem that the envelope structure is only regarded as a non-structure in the traditional building form, is convenient for timely replacement when damaged, and ensures that the structure has good mechanical properties.

Owner:CHANGZHOU INST OF TECH

Vehicle wheel bearing assembly

InactiveCN106092618AFully stressedFull stress reliefVehicle steering/rolling behaviourResonanceStress relief

The invention discloses a vehicle wheel bearing assembly and belongs to the field of vehicle design. The vehicle wheel bearing assembly comprises a first bearing part and a second bearing part. Upper surfaces of the first bearing part and the second bearing part are provided with sine surfaces of the same cycle length. The cycle length of the sine surfaces is correlated with the sprung mass resonance frequency of a vehicle of a predetermined type. The first bearing part and the second bearing part provide travel section for the vehicle at the same time, wherein the first bearing part is designed to enable a left tire of the vehicle to travel, and the second bearing part is designed to enable a right tire of the vehicle to travel. The vehicle wheel bearing assembly solves the problem that the stress relief of a vehicle plate spring is insufficient when the bumpy road test on vehicles of various types is conducted on the same bumpy road, and can carry out the bumpy road test by determining a suitable bumpy road for a vehicle based on the sprung mass resonance frequency of the vehicle, thereby achieving the effect of fully releasing stress of a vehicle plate spring.

Owner:CHERY AUTOMOBILE CO LTD

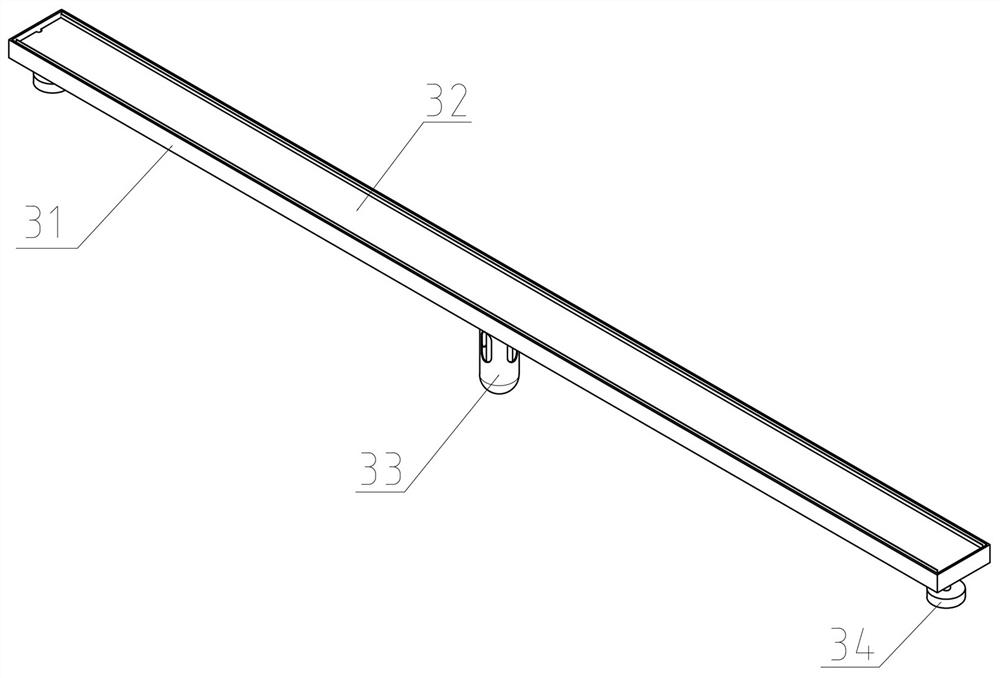

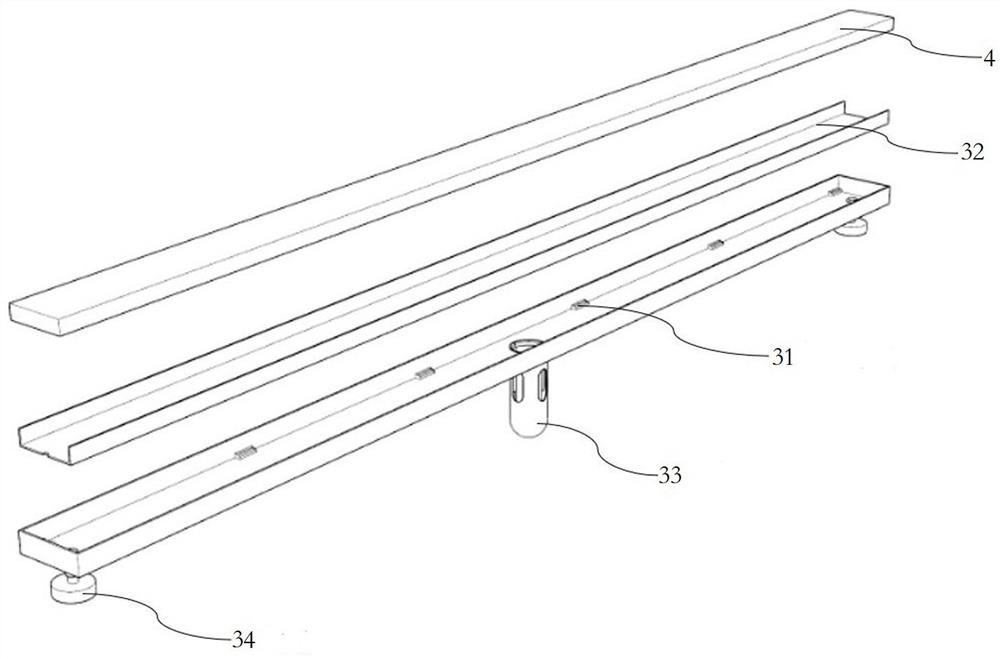

Mounting system for height-difference-free dry and wet areas of fabricated toilet

PendingCN113356503AAvoid cloggingAchieve the purpose of hidingSewerage structuresFlooringMechanical engineeringToilet booth

The invention relates to and discloses a mounting system for height-difference-free dry and wet areas of a fabricated toilet, and relates to the technical field of bathrooms. The mounting system specifically comprises a plastic bottom box mounted in the wet area of the toilet and a flexible bottom box mounted in the dry area of the toilet; the junction of the dry area and the wet area is surrounded by abutting of the vertically-arranged plastic bottom box and the vertically-arranged flexible bottom box; and the mounting system further comprises a linear floor drain mounted in the plastic bottom box and close to the junction of the plastic bottom box and the flexible bottom box, and veneers covering the plastic bottom box and the flexible bottom box. According to the invention, the dry area and the wet area of the toilet are separated through the plastic bottom box mounted in the wet area of the toilet and the flexible bottom box mounted in the dry area of the toilet; the linear floor drain is mounted in the plastic bottom box and is used for discharging water in the wet area; and the veneers cover the plastic bottom box and the flexible bottom box, and the tops of the veneers are flush, so that the problem of height difference at the junction of the dry and wet areas is solved, and barrier-free access of bathroom ground is achieved.

Owner:ZHEJIANG YASHA DECORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com