Cylinder sleeve fatigue test device

A fatigue test, cylinder liner technology, applied in the direction of measuring device, engine test, mechanical parts test, etc., can solve the problems of cumbersome test process, high reliability, low efficiency, etc., to simplify the test components and expand the adjustment range , the effect of accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

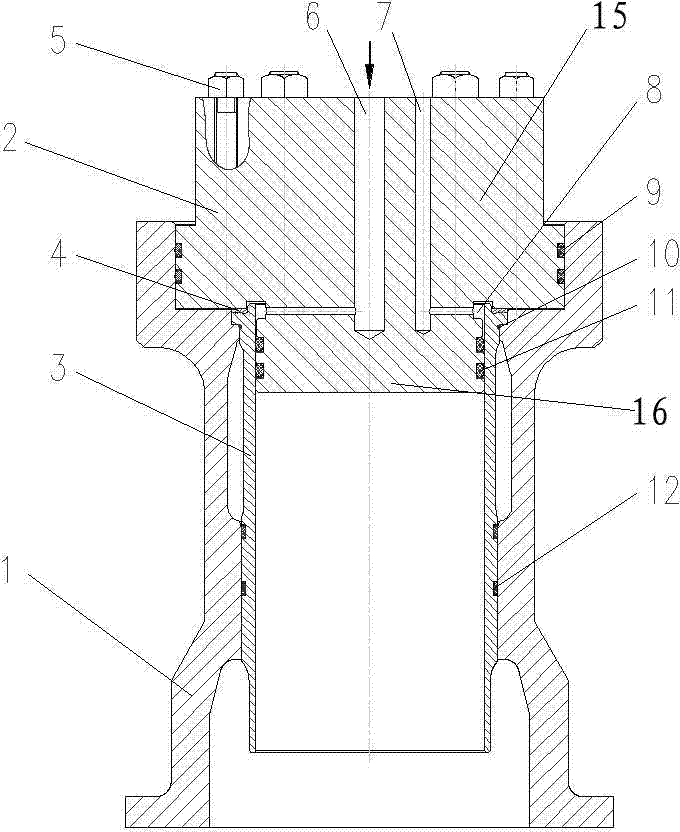

[0014] Such as figure 1 As shown, the pressure-bearing cylinder block 1 is the main support structure of the test device, which has the function of simulating the stiffness state of the body, supporting the test cylinder liner 3, connecting the combined cylinder head 2, and assisting the internal sealing of the cylinder. The lower part of the pressure-bearing cylinder is in the form of a flange and sits firmly on the floor of the laboratory, and can be fastened with anchor bolts; the inner cavity of the structure is designed in the form of a water jacket in the cylinder hole of the whole machine, and the upper and lower support and sealing structures of the cylinder liner are set. , forming a simulated water jacket to ensure that the support state of the test cylinder liner 3 is consistent with that of the whole machine. The cylinder head bolt holes designed around the pressure-bearing cylinder block 1 are arranged according to the requirements of the whole machine, so as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com