A prefabricated corrugated steel plate lattice enclosure structure and construction method thereof

A corrugated steel plate, prefabricated assembly technology, applied in the direction of fences, building types, buildings, etc., can solve non-structural, shortened construction period, labor and other problems, achieve high manufacturing precision, give full play to material strength, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings.

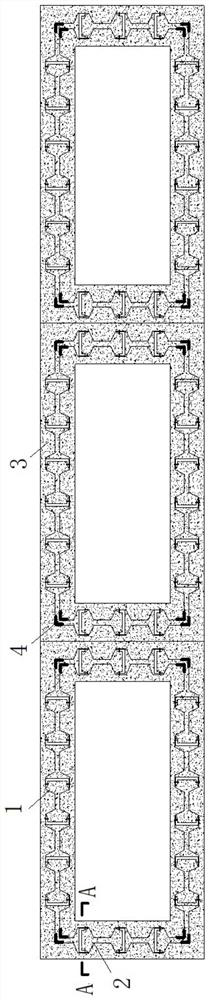

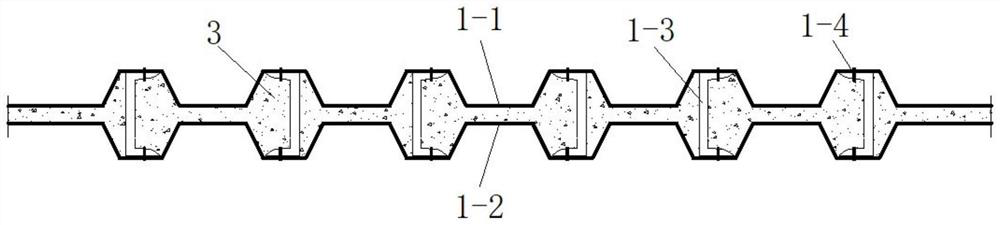

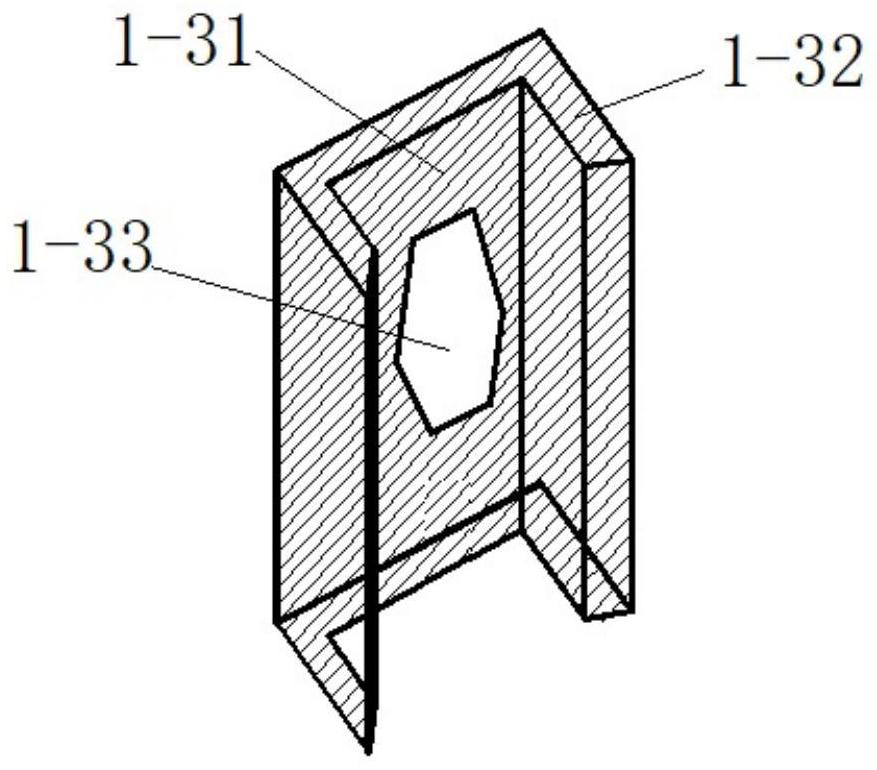

[0032] This embodiment provides a figure 1 The prefabricated corrugated steel lattice envelope shown. The enclosure structure includes a number of enclosure units in a frame structure ( figure 1 Only three enclosure units are shown in the figure), each enclosure unit includes a transverse enclosure part and a longitudinal enclosure part filled with concrete, and a truss 1 as a bending part is arranged inside the transverse enclosure part (such as figure 2 shown), a lattice column 2 (as shown in Figure 4 shown), the truss 1 and the lattice column 2 are connected to each other and bonded with the concrete 3 to form a whole, and the truss 1 and the lattice column 2 are preferably connected by welding angle steel 4 . Both the truss 1 and the lattice column 2 are made of two corrugated steel plates and several channel steels (such as image 3 or Figure 5 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com