Patents

Literature

37results about How to "Common force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

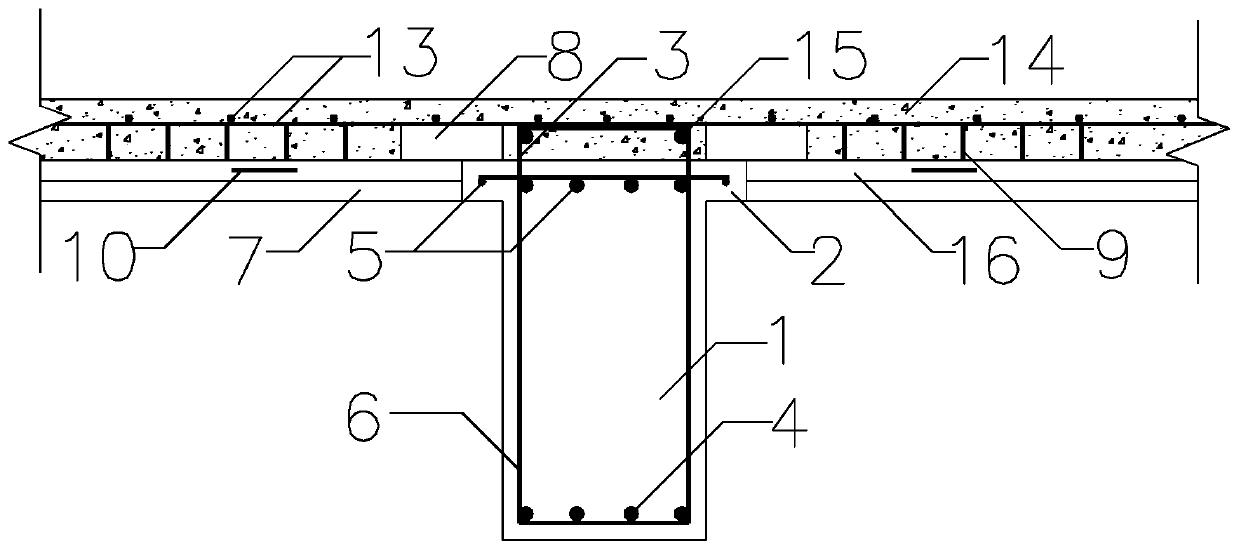

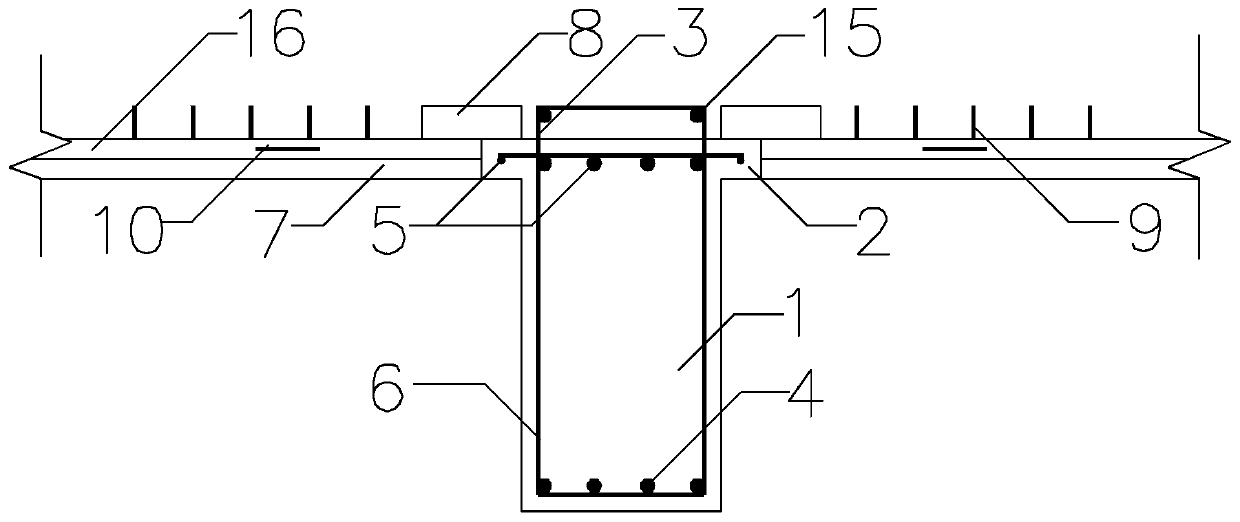

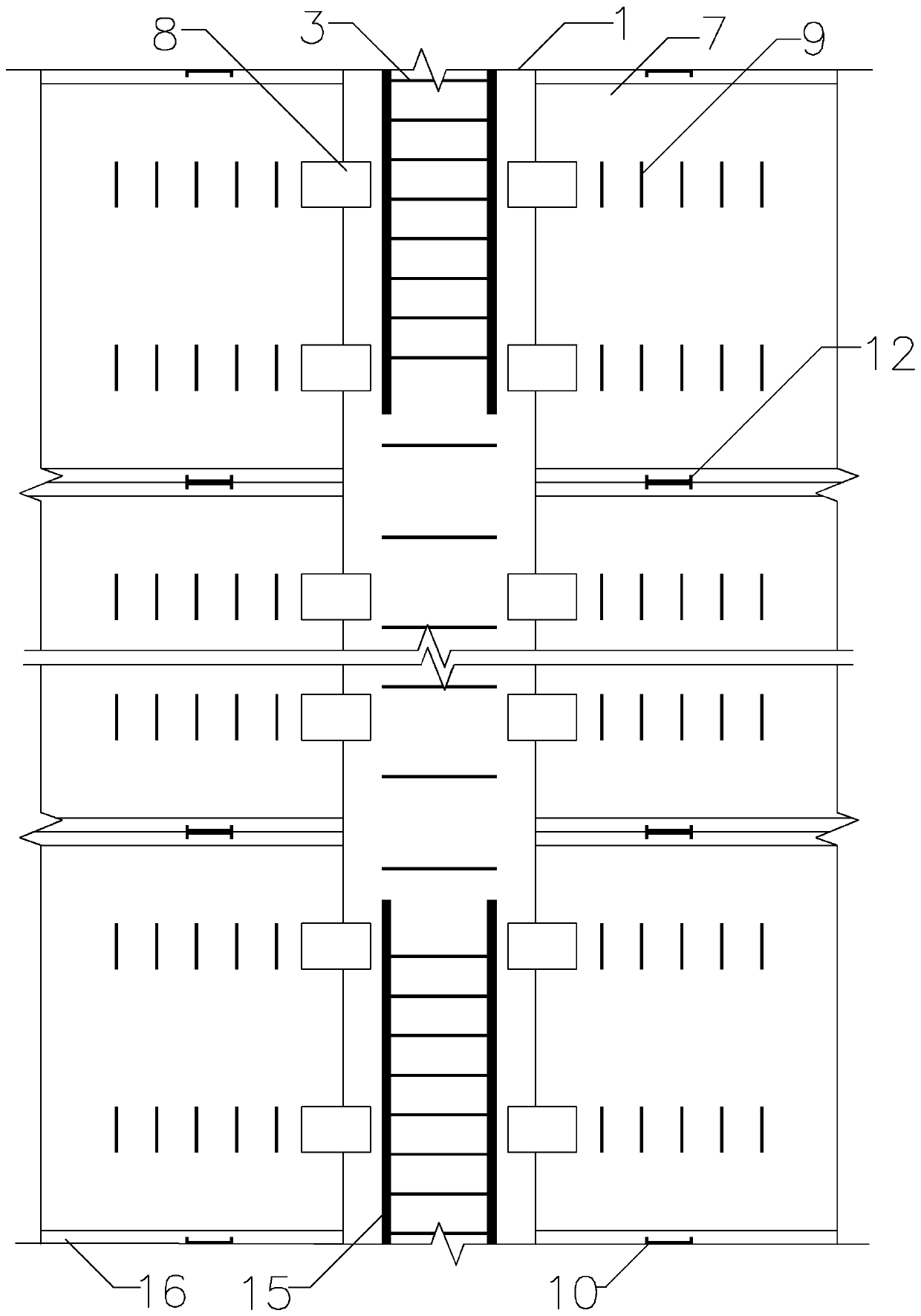

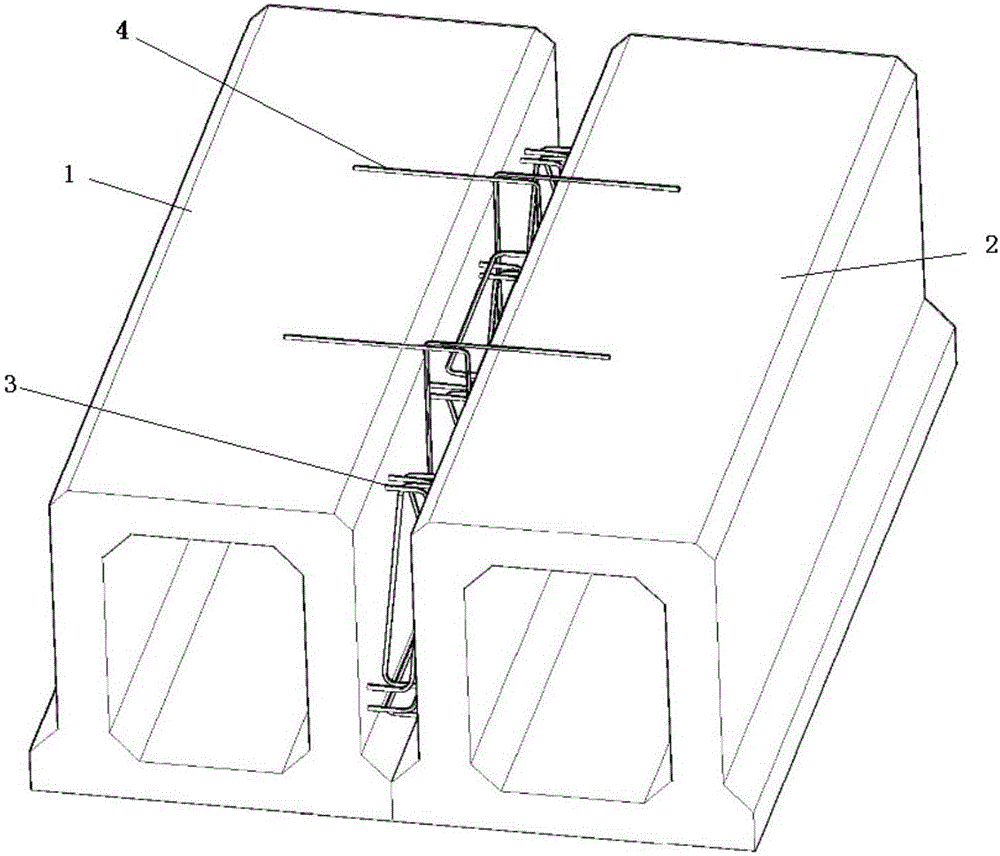

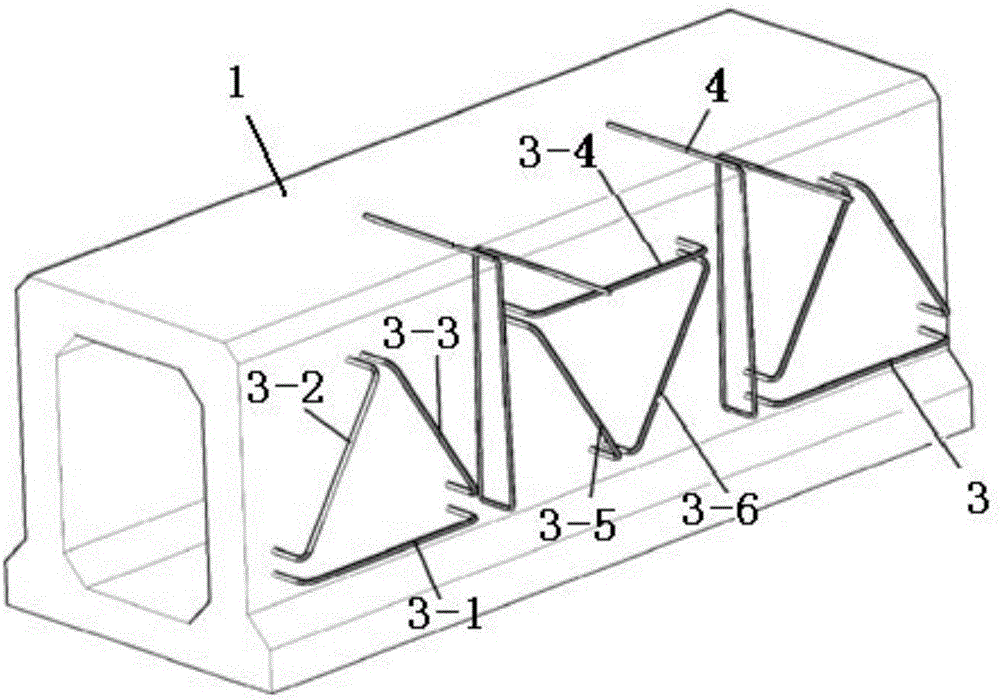

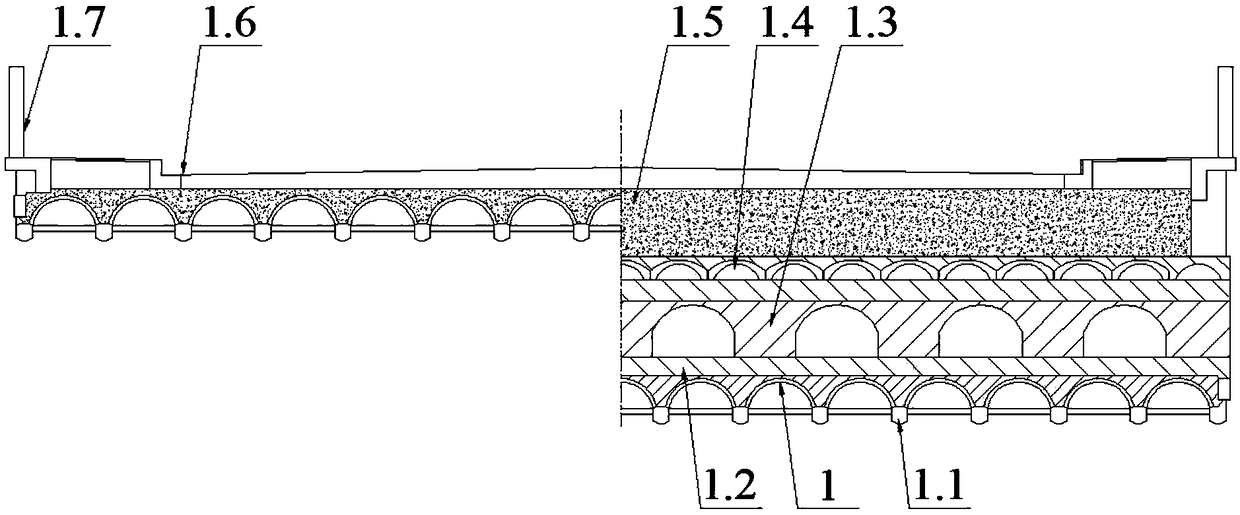

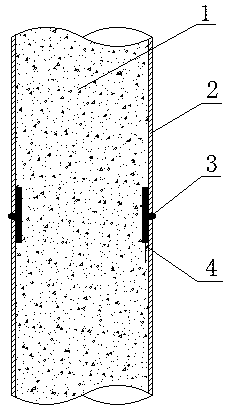

Assembled reinforced concrete beam-slab structural system with cast-in-situ layer in building structure

ActiveCN106065663AReduce workloadImprove standardizationFloorsLoad-supporting elementsReinforced concreteEngineering

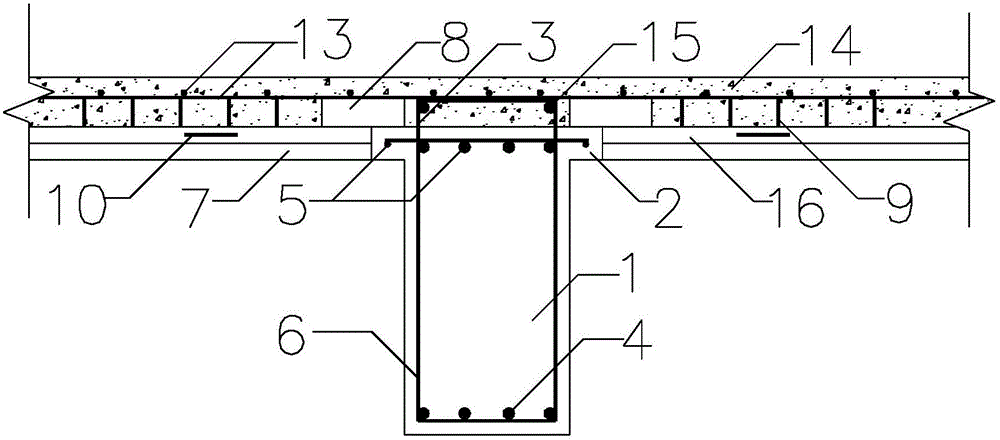

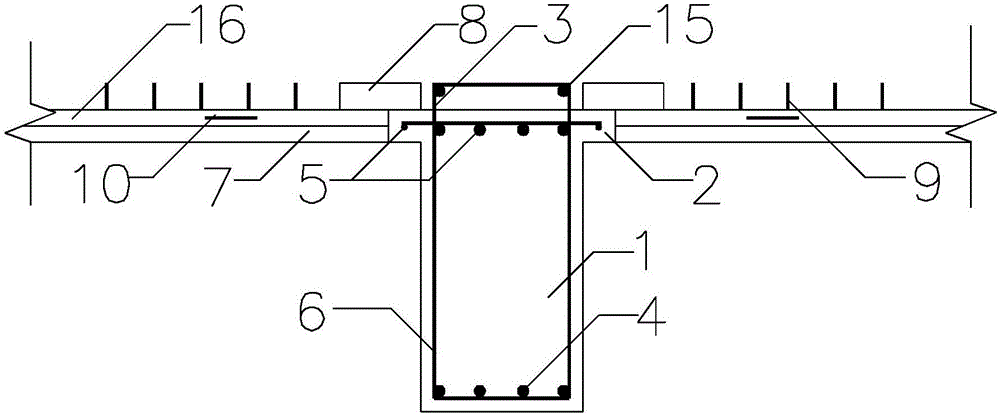

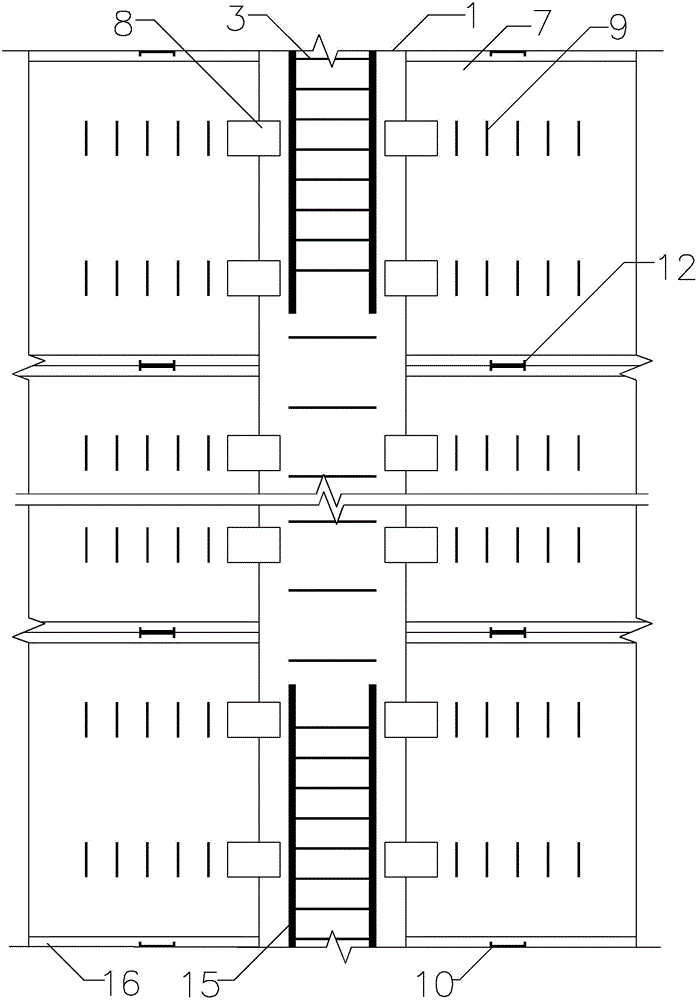

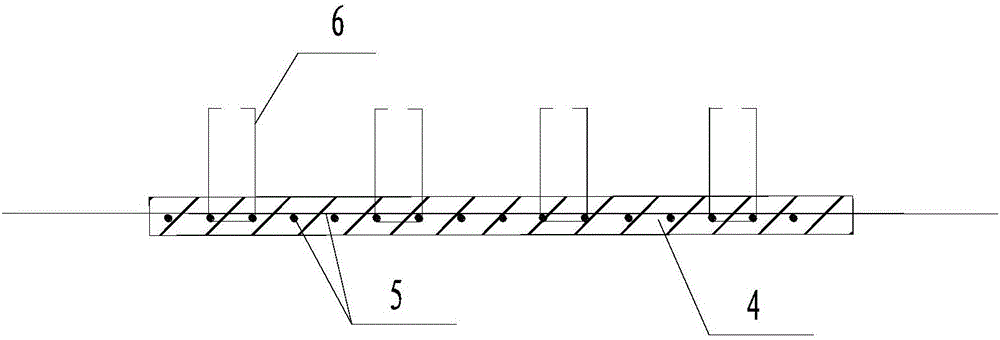

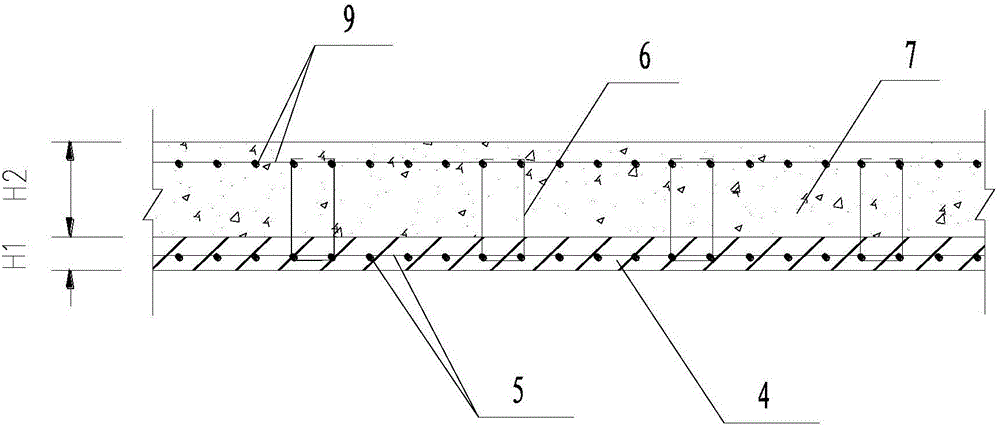

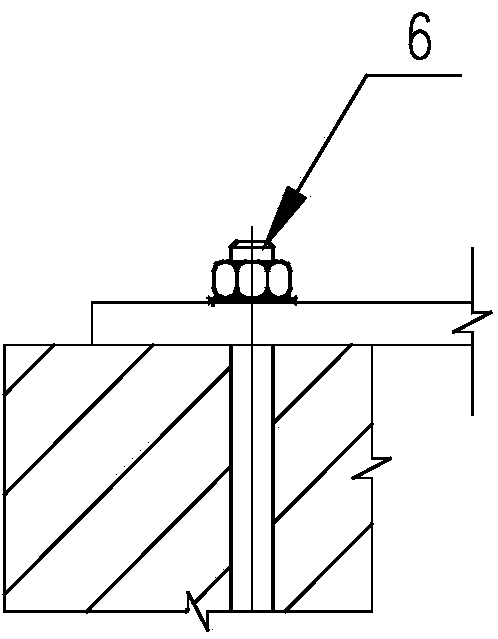

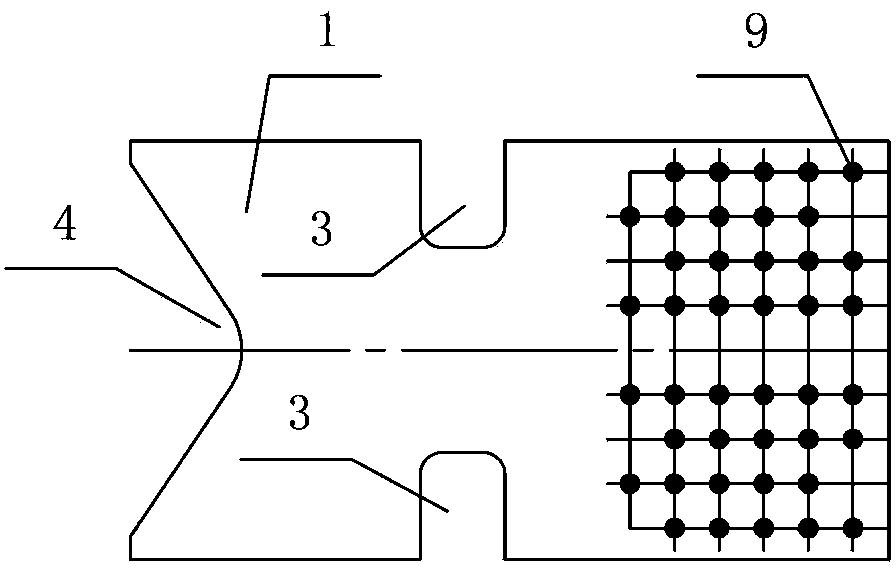

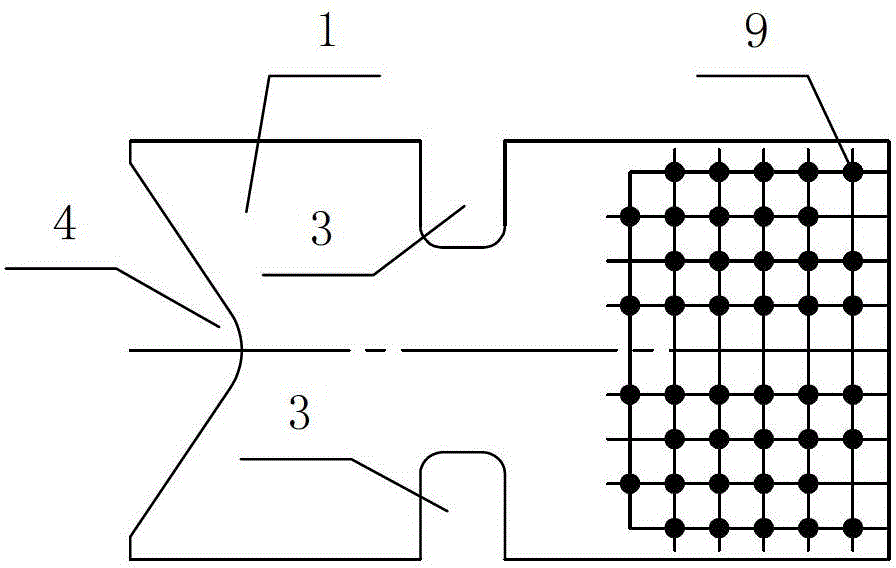

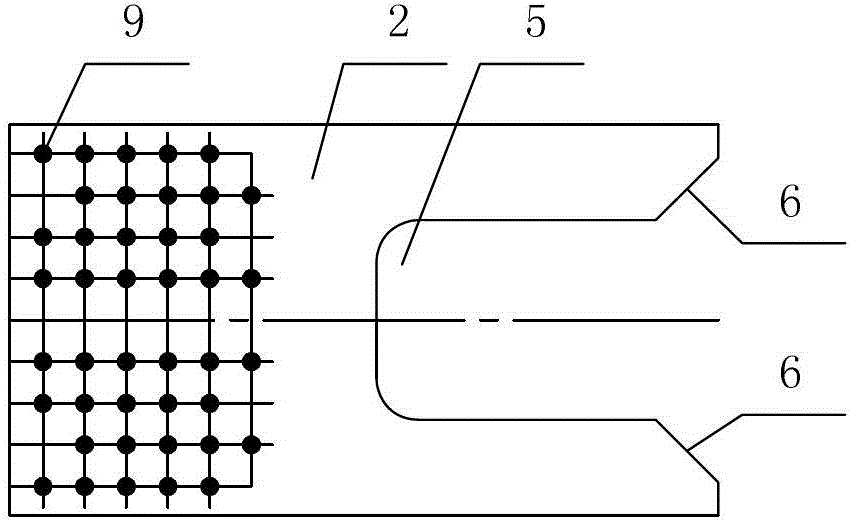

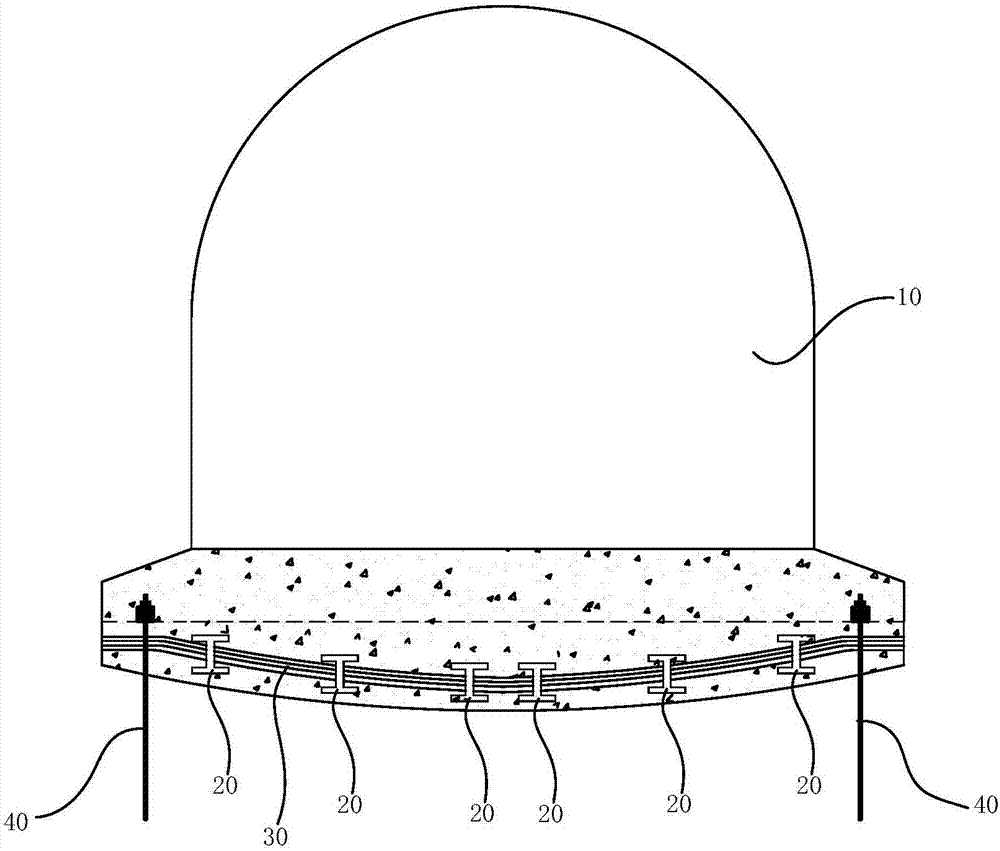

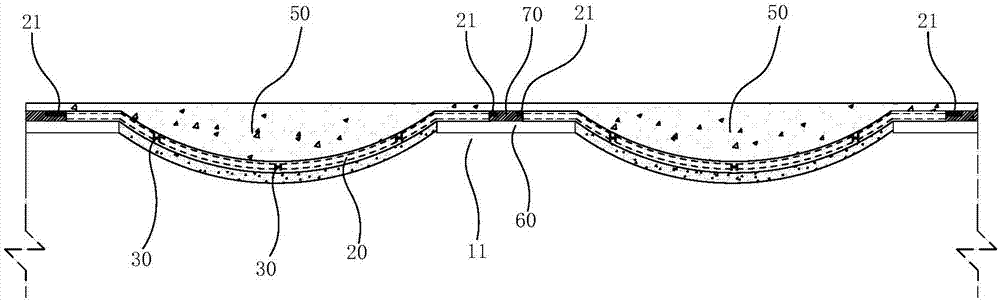

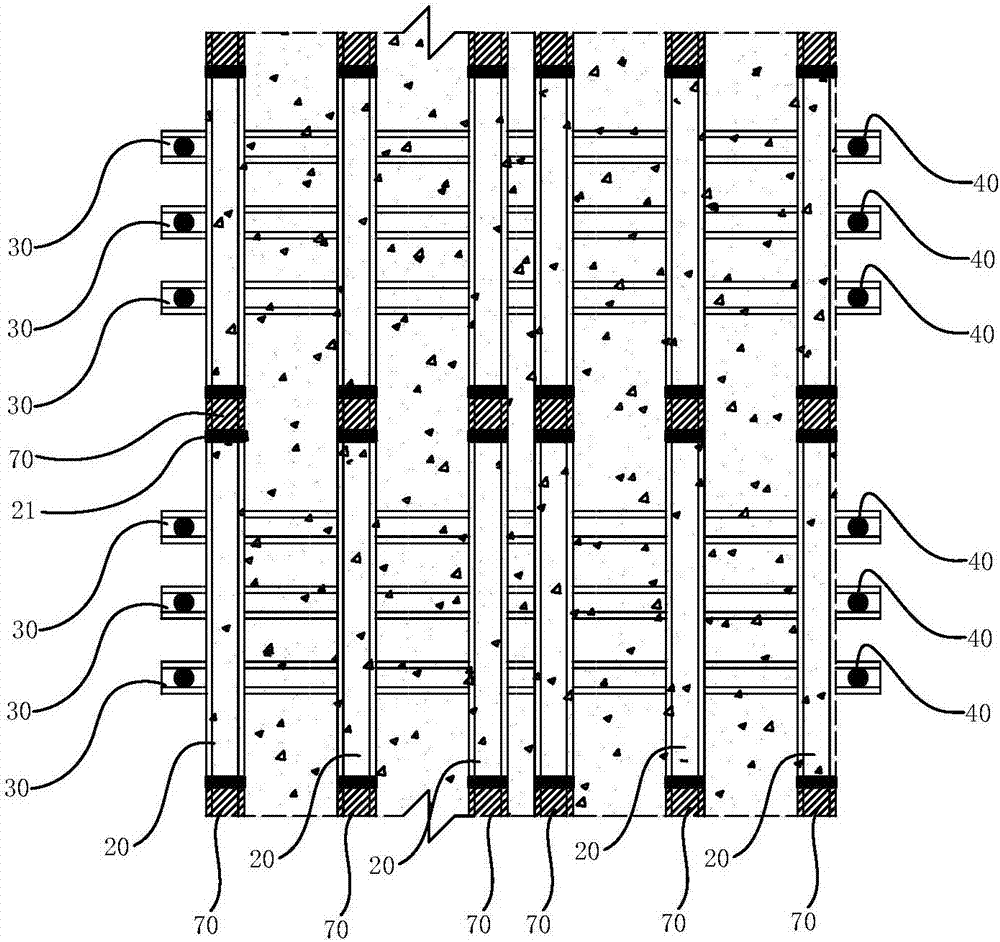

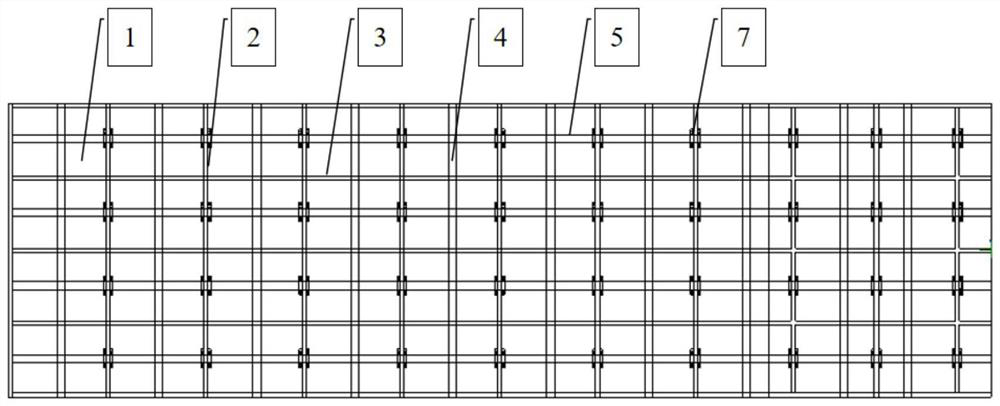

The invention discloses an assembled reinforced concrete beam-slab structural system with a cast-in-situ layer in a building structure. The assembled reinforced concrete beam-slab structural system comprises a superposed beam, a superposed slab, reinforcing mesh pieces, the cast-in-situ concrete superposed layer and beam negative reinforcements, wherein the superposed beam is a reinforced concrete precast beam; outwardly projecting tongue-and-grooves are formed in two sides of the upper part of the superposed beam; the superposed slab is horizontally arranged and is a reinforced concrete precast slab; cover-plate-type tongue-and-grooves are formed at the positions, corresponding to the outwardly projecting tongue-and-grooves, on two sides of the superposed slab, and overlapped on the outwardly projecting tongue-and-grooves; the reinforcing mesh pieces and the beam negative reinforcements are horizontally arranged above the superposed beam and the superposed slab; the reinforcing mesh pieces are bundled up with corresponding reinforcements in the superposed beam and the superposed slab; the beam negative reinforcements are bundled up with corresponding reinforcements in the superposed beam; after arrangement of the reinforcing mesh pieces and the beam negative reinforcements, concrete is poured to form the cast-in-situ concrete superposed layer. The assembled reinforced concrete beam-slab structural system has favorable integrity and mechanical property, and the integrity and the anti-seismic property can be improved.

Owner:广东省建科建筑设计院有限公司

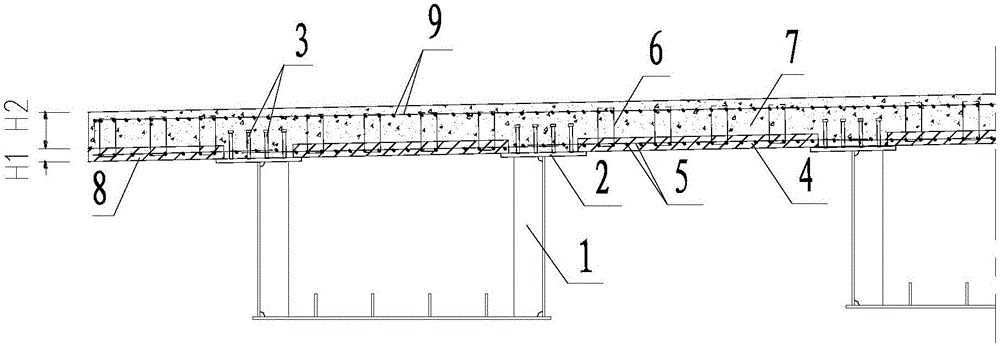

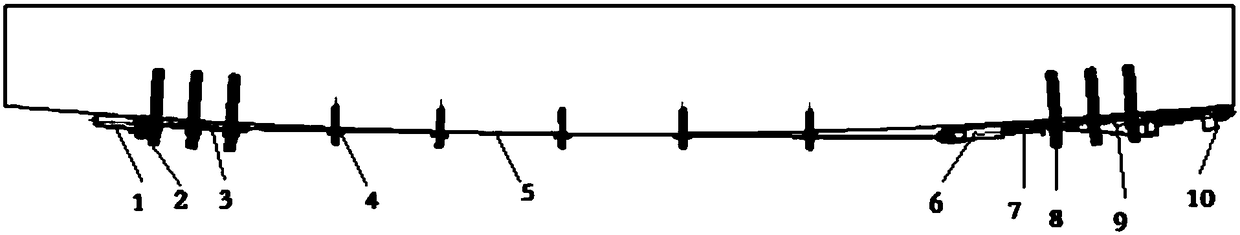

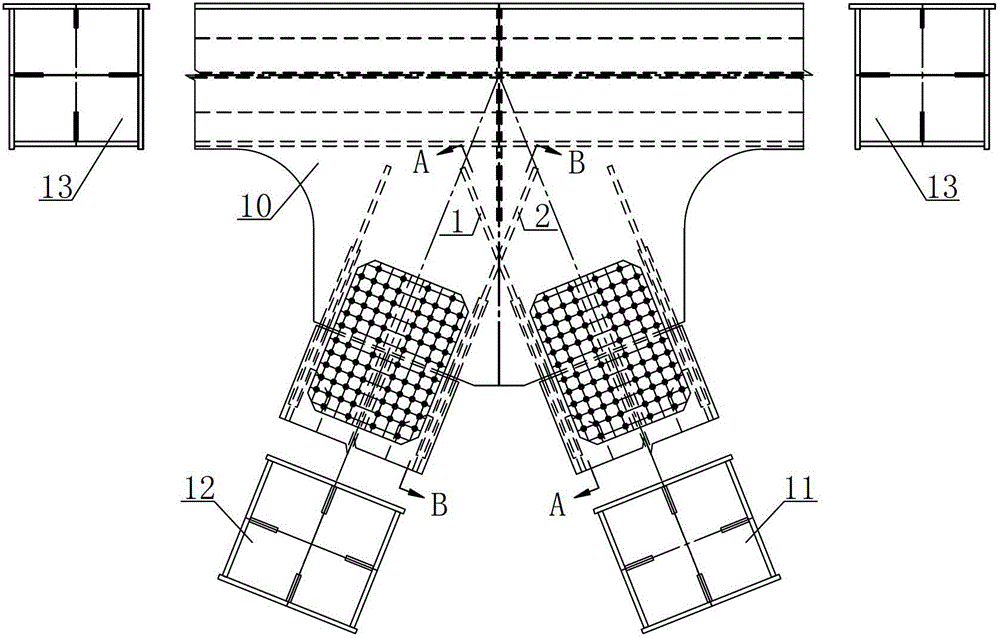

UHPC-common-concrete-lamination composite bridge-deck-slab construction and constructing method thereof

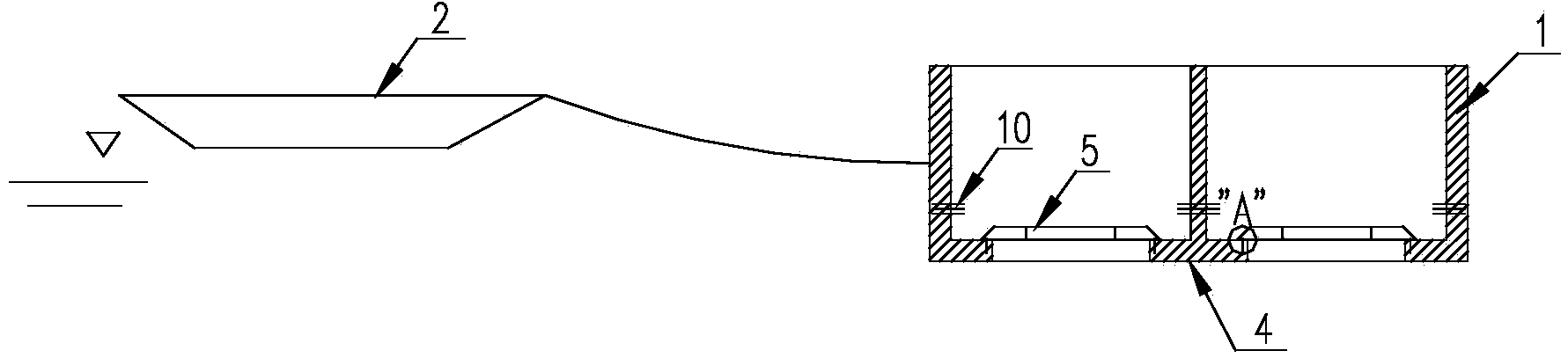

ActiveCN106638304ACancellation of transverse prestressRealize no support constructionBridge structural detailsBridge erection/assemblyBridge deckRebar

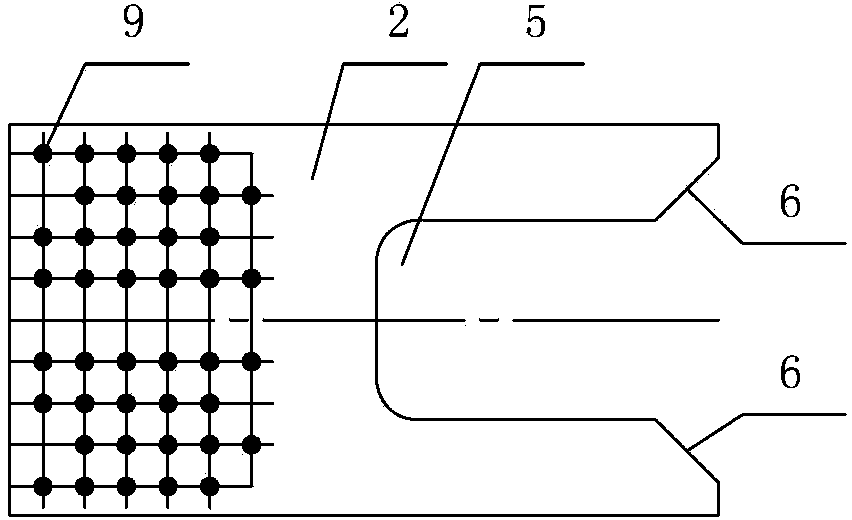

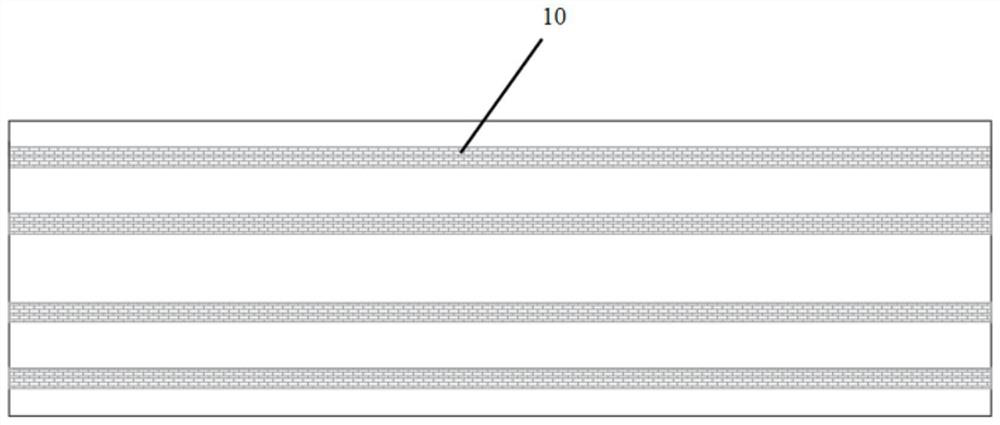

The invention discloses a UHPC-common-concrete-lamination composite bridge-deck-slab construction and a constructing method thereof. The UHPC-common-concrete-lamination composite bridge-deck-slab construction comprises UHPC prefabricated slabs, horizontal pre-embedded reinforcing steel bars, U-shaped vertical pre-embedded bars, lamination cast-in-place concrete, vertical-and-horizontal whole reinforcing steel bar nets, wet-connection-band concrete and steel-beam-flange-slab shearing nails. The steel-beam-flange-slab shearing nail are welded on the surfaces of flange slabs of steel beams, the UHPC prefabricated slabs are supported on the flange slabs of the steel beams, and the horizontal pre-embedded reinforcing steel bars between the adjacent UHPC prefabricated slabs are in lap joint; the vertical-and-horizontal whole reinforcing steel bar nets are arranged on the flange slabs of the steel beams and the UHPC prefabricated slabs and poured with the lamination cast-in-place concrete, and the UHPC prefabricated slabs are poured with the wet-connection-band concrete. A UHPC-common-concrete-lamination composite bridge deck slab has the advantages that the structural stress performance is excellent, the weight of the bridge deck slab is light, the performance cost ratio is high, shear transferring is continuous, transverse prestress is not required, and support-free constructing can be achieved, cooperative work of the steel beams and the concrete bridge deck slab can be achieved, and carrying capacities of composite beams are improved.

Owner:SOUTHEAST UNIV

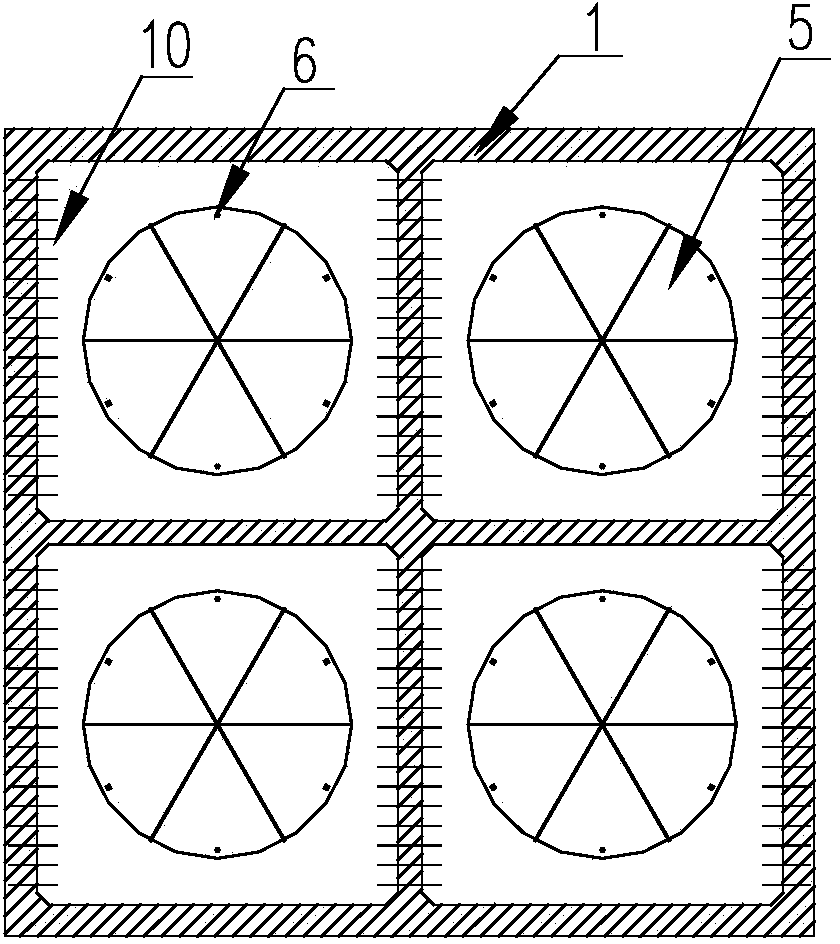

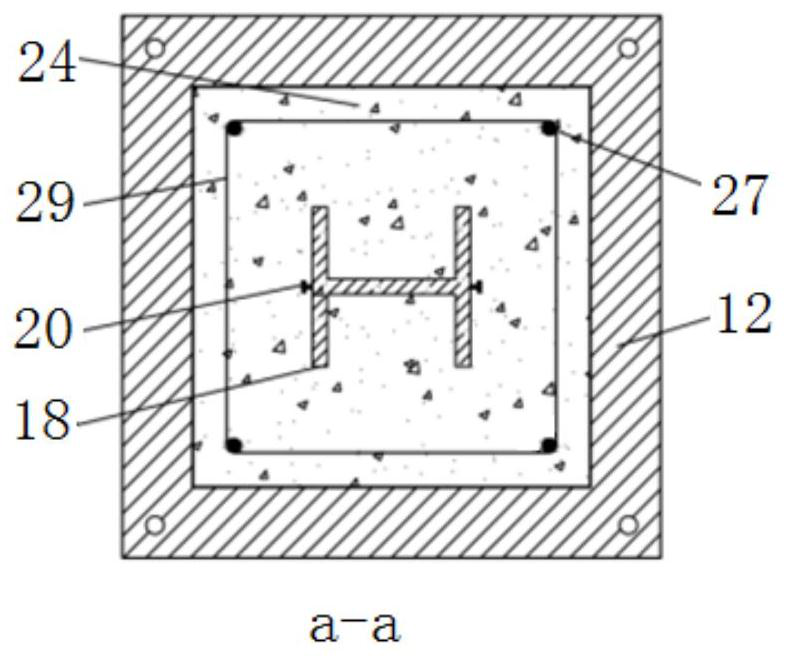

Prefabricated bearing platform suitable for large-diameter tubular column foundation of sea bridge and construction method thereof

InactiveCN103590415ATake advantage ofSave construction investmentFoundation engineeringEngineeringRebar

The invention relates to a prefabricated bearing platform suitable for a large-diameter tubular column foundation of a sea bridge and a construction method of the prefabricated bearing platform. The prefabricated bearing platform is of a multi-box lattice type concrete structure, and a box chamber and the large-diameter tubular column foundation are uniform in arrangement. Movable steel bottom plates are arranged at positions, corresponding to tubular columns, of bottom plates, and connecting reinforcing steel ribs are arranged on the inner wall of the prefabricated bearing platform. The construction method includes the steps of prefabricating the bearing platform in a dry dock on the bank side, filling the dry dock with water after the bearing platform is prefabricated, enabling the prefabricated platform to float by itself, opening a lock when the water level inside the dock is flush with the water level of the sea surface, and dragging the prefabricated bearing platform to the position of a pier; filling the prefabricated bearing platform with water so that the prefabricated bearing platform can sink onto a temporary support, and erecting an operating platform on the top of the prefabricated bearing platform; taking down the movable steel plates, conducting tubular column sinking construction, pouring underwater bottom sealing concrete, pumping water, bonding the reinforcing steel ribs, pouring bearing platform concrete, and forming a complete bearing platform structure. According to the prefabricated bearing platform and the construction method, platform erecting expenses can be saved, materials are used completely, construction investment and time are saved, and the prefabricating bearing platform can bear force together with later period bearing platform concrete.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

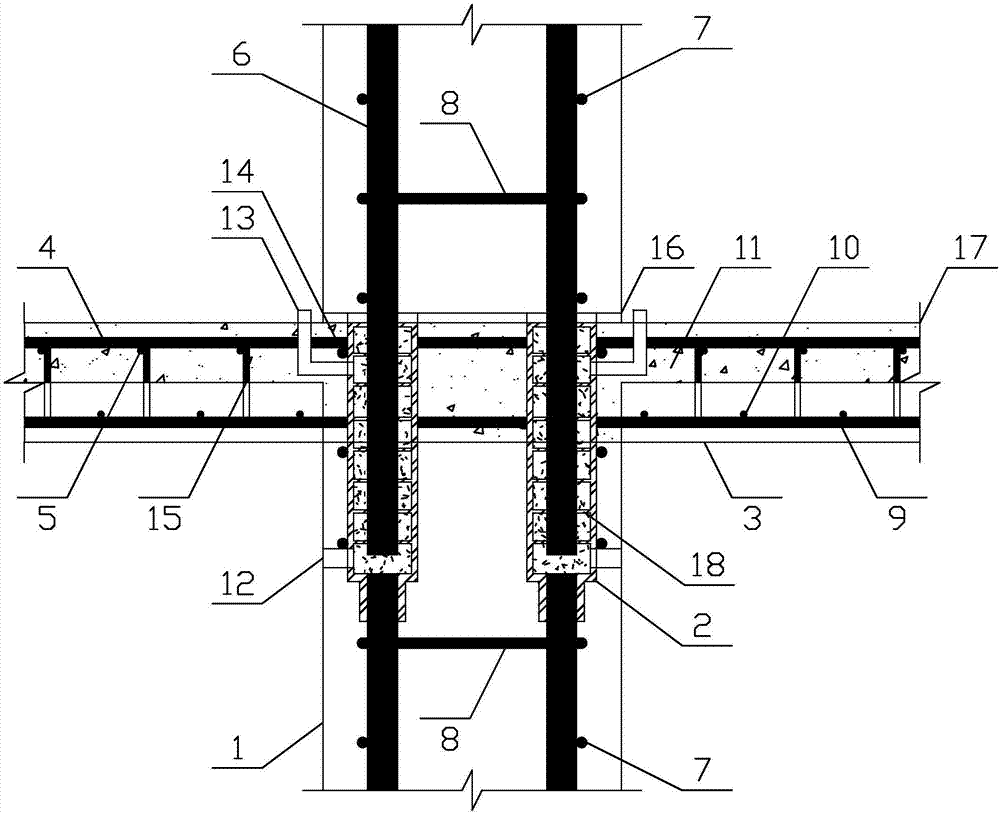

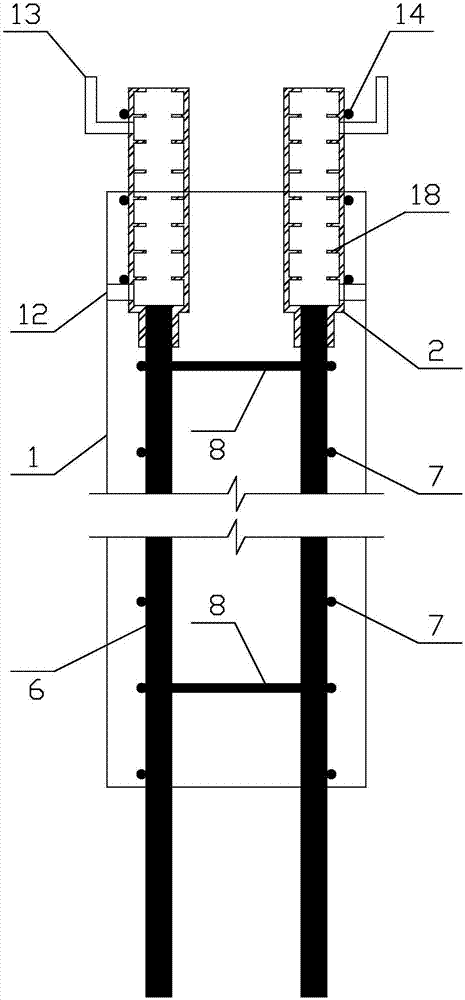

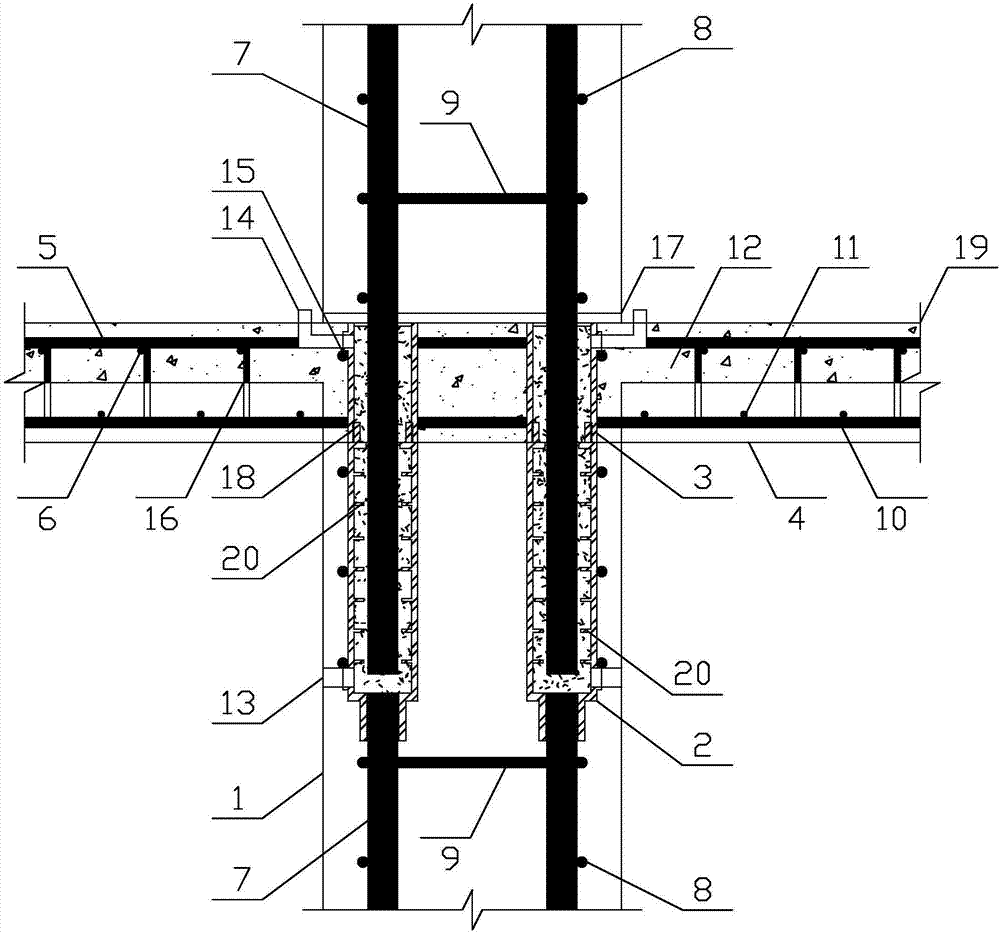

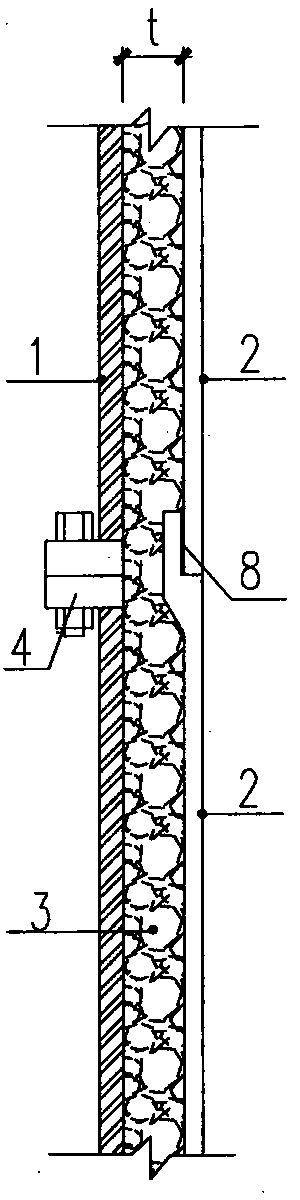

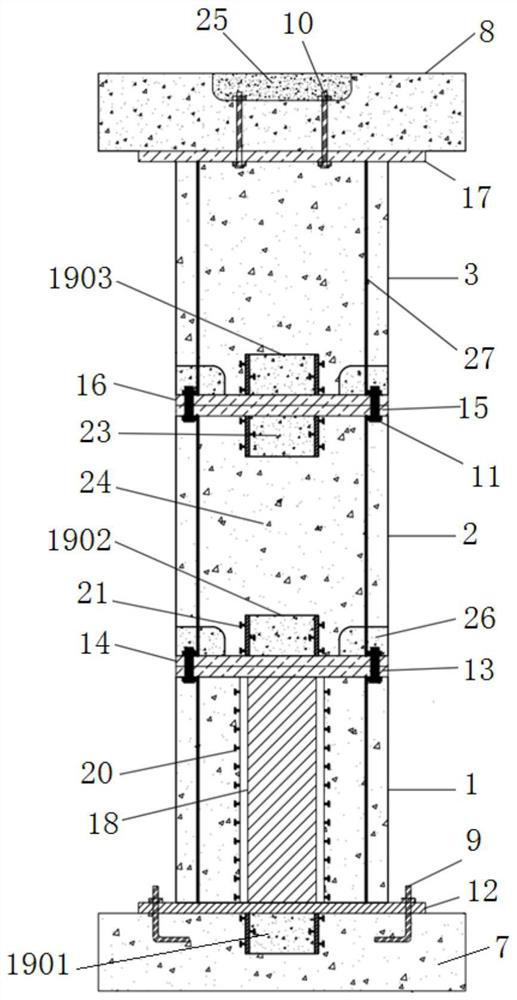

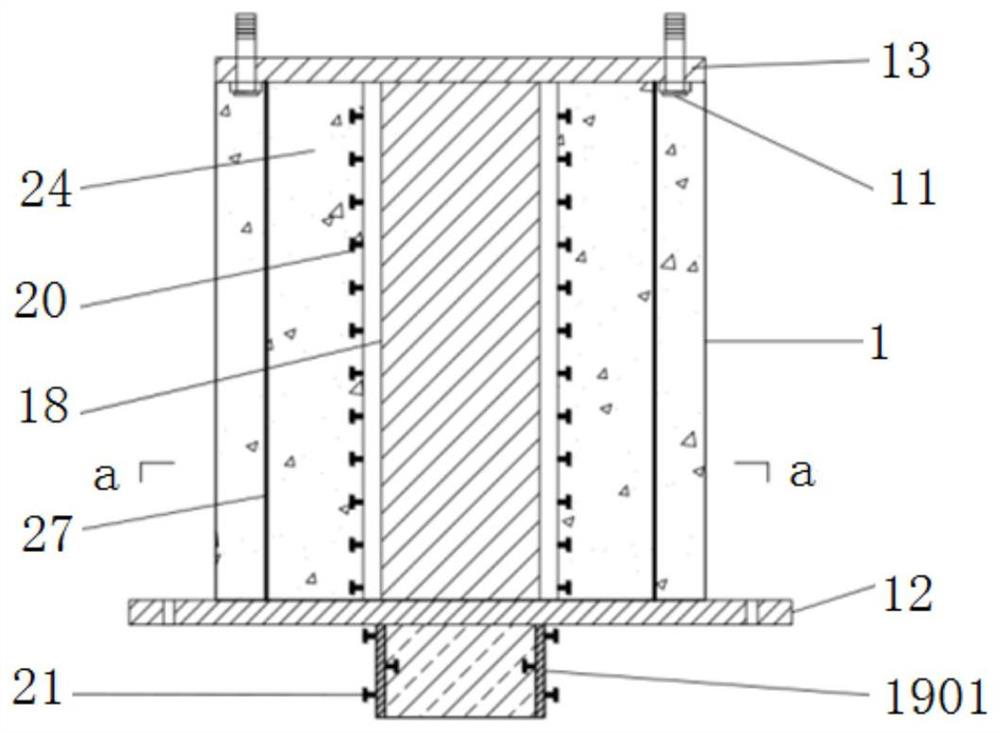

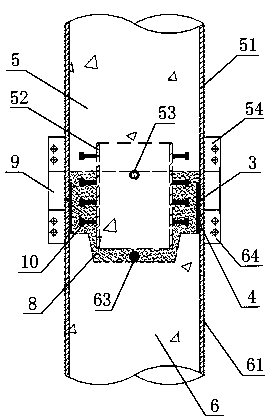

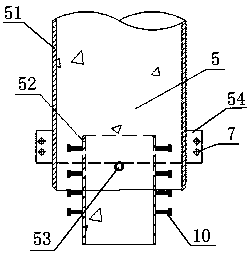

Connecting structure of fabricated concrete-filled steel tubular column body

The invention discloses a connecting structure of a fabricated concrete-filled steel tubular column body. The connecting structure comprises a first steel tubular column section and a second steel tubular column section; the first steel tubular column section is in butt joint with the second steel tubular column section, an inner steel tube is inserted into an inserting groove in a second outer steel tube, and a liner tube is arranged at the connecting position of a first outer steel tube and the second outer steel tube; the first outer steel tube, the second outer steel tube and the liner tube are welded into one through V-shaped groove welding; cementing materials are poured into gap areas in the first outer steel tube and the second outer steel tube, and air in the gap areas is exhausted though exhaust vents; and connecting plates are mounted on a first lug plate and a second lug plate through bolts. The connecting structure has the advantages that the shear-bearing ability of the connecting parts is improved, so that the column body reaches the normal section compression-bending bearing force and the shear-bearing ability which are not less than those of cast-in-place concrete,mounting is easy and convenient, the production and construction efficiency is improved, dust and noise pollution is further reduced, and the environmental-friendly requirements of green buildings are met.

Owner:重庆大学建筑规划设计研究总院有限公司

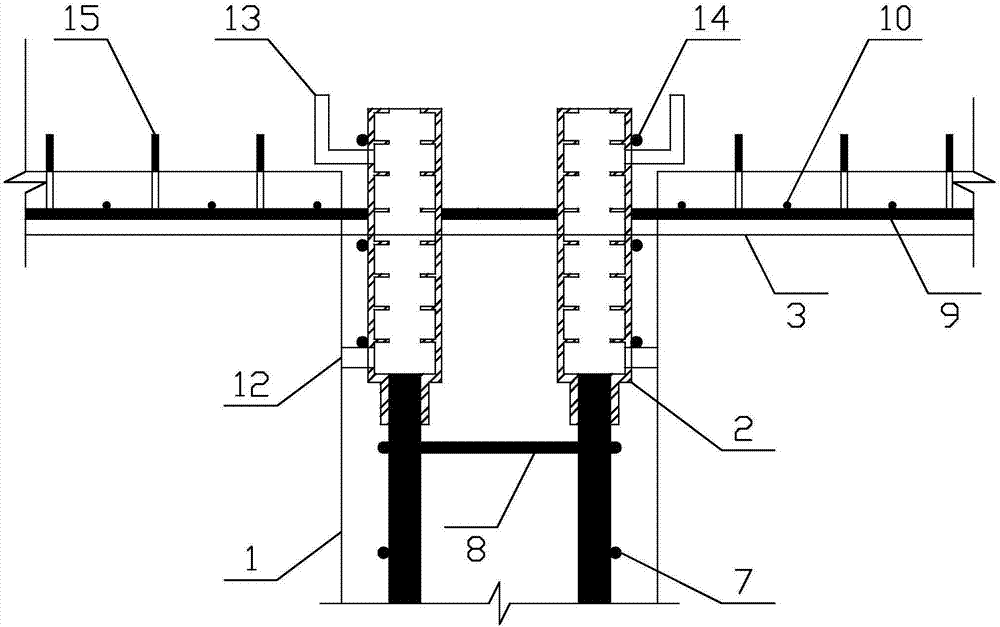

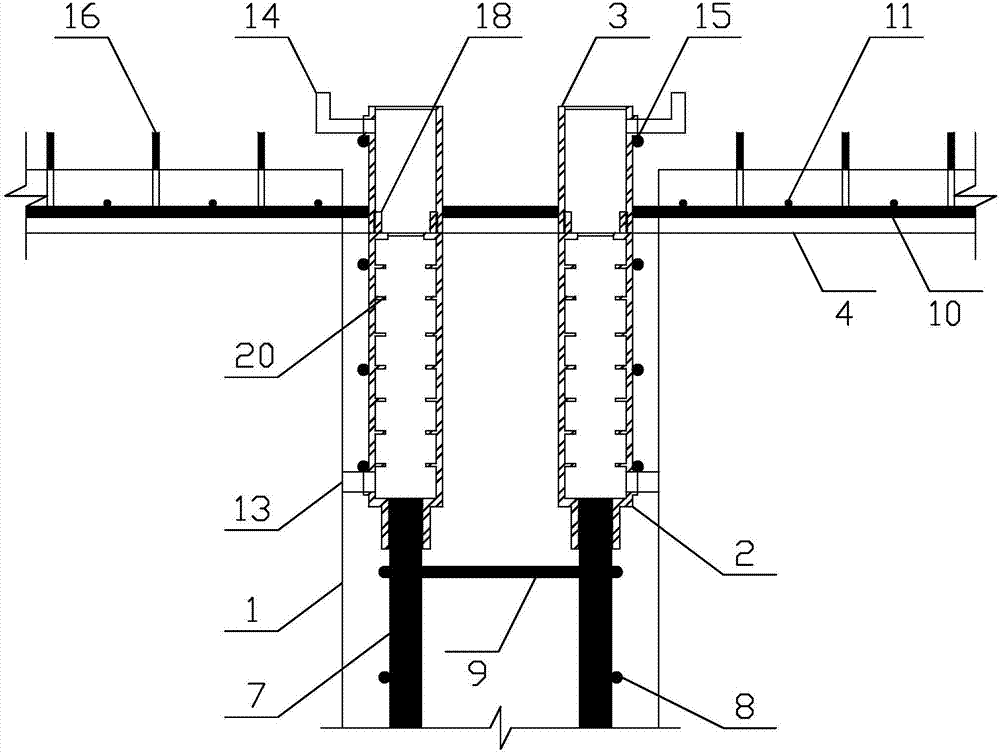

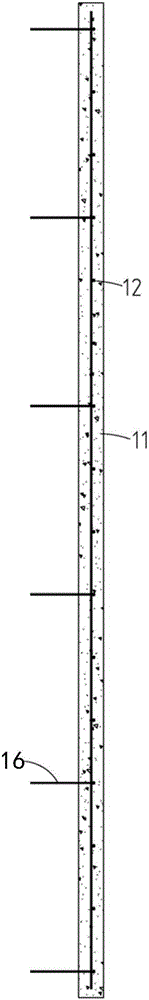

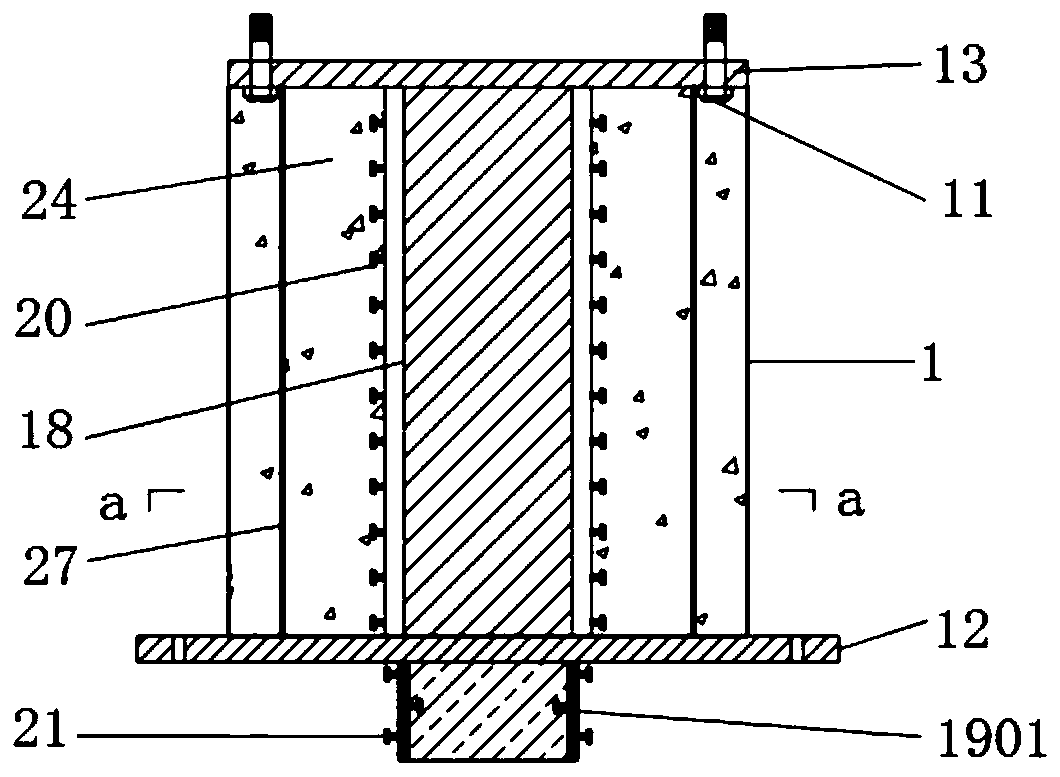

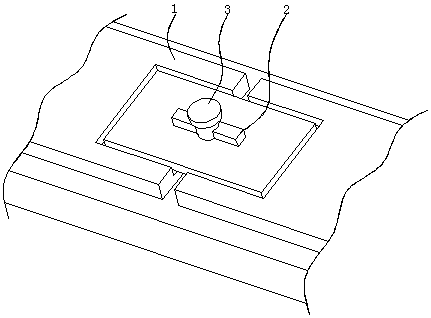

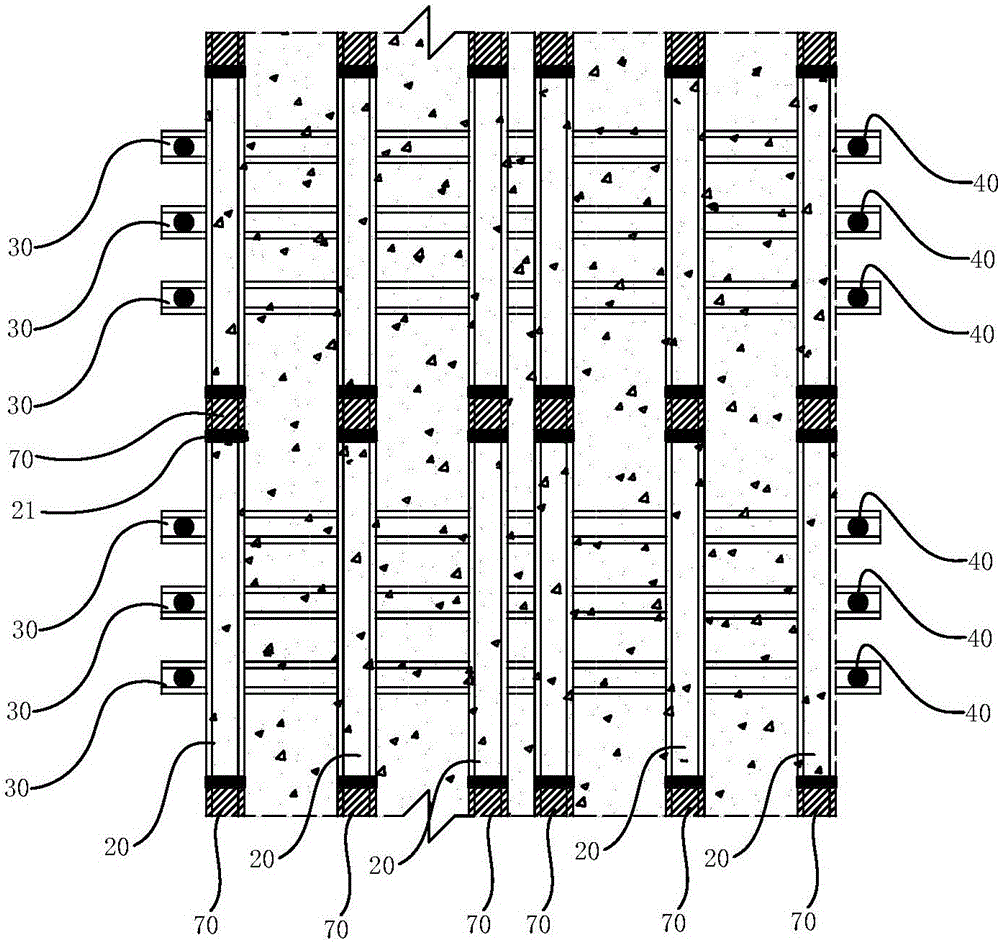

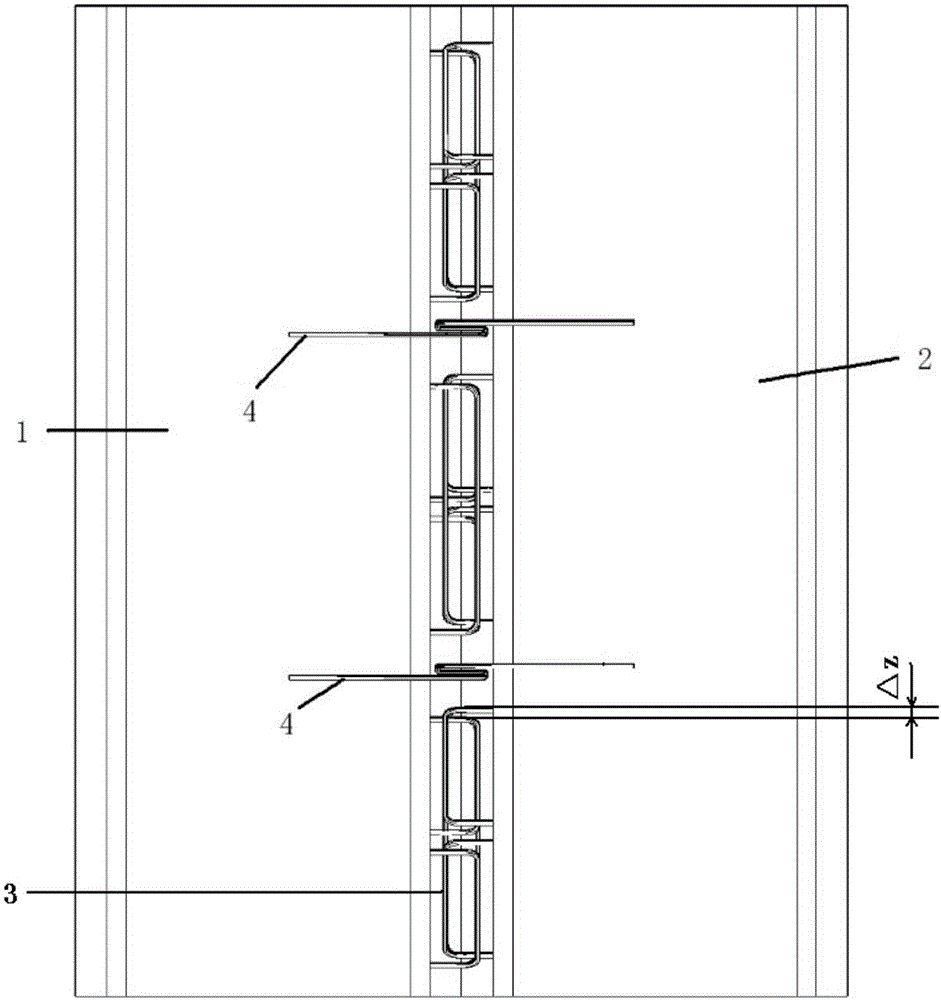

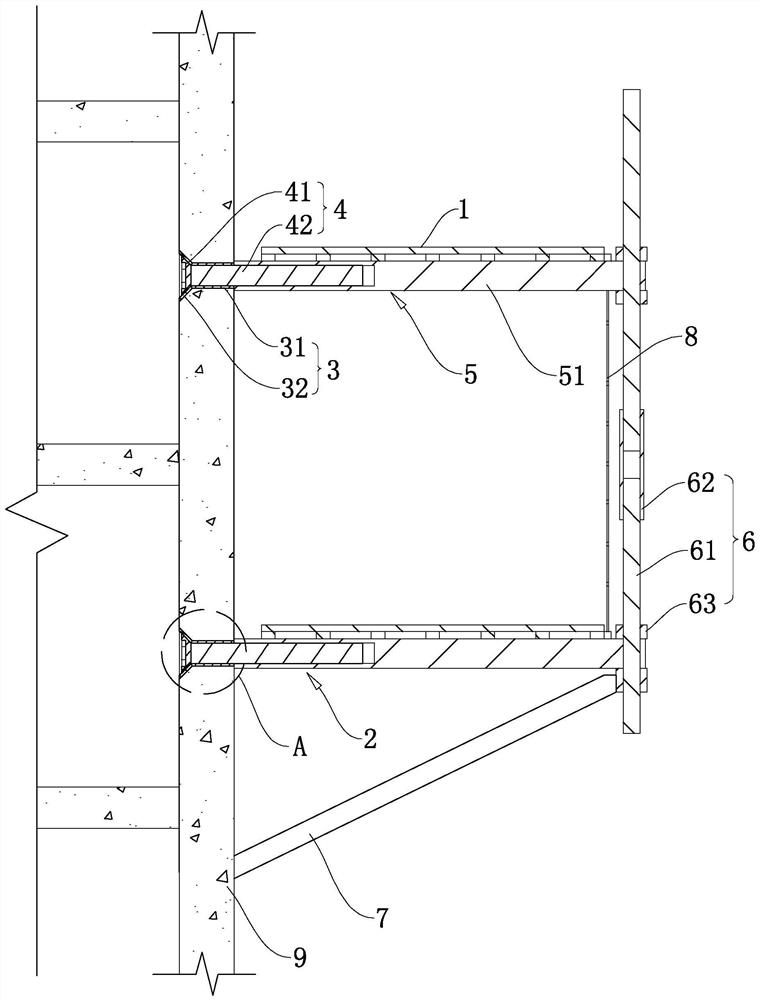

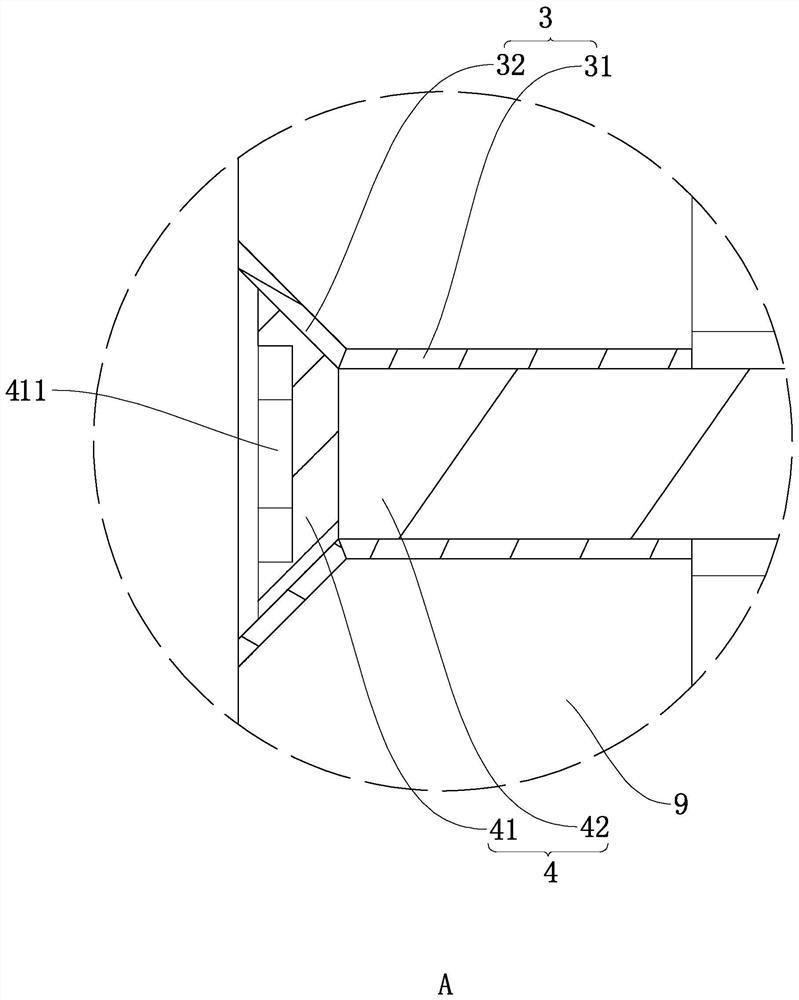

Fabricated prefabricated shear wall and laminated slab node

PendingCN107100290AAvoid the situation of pulling offImprove integrityWallsProtective buildings/sheltersSlurryShock resistance

The invention discloses a fabricated prefabricated shear wall and laminated slab node. The fabricated prefabricated shear wall and laminated slab node comprises a prefabricated shear wall and a laminated slab; a grouting sleeve is arranged at a node body of the prefabricated shear wall and the laminated slab, the lower portion of the grouting sleeve is buried in the upper end of the prefabricated shear wall, and the rest part of the grouting sleeve is located in a post-poured concrete laminated layer of the laminated slab; the bottom end of the grouting sleeve is arranged at the top ends of vertical steel bars located in the prefabricated shear wall, the vertical steel bars downwards and outwards extend out of a prefabricated shear wall located on an upper floor, and the vertical steel bars are inserted into the grouting sleeve from the top end of the grouting sleeve; and a slurry discharging pipe and a grouting pipe are arranged on the upper portion and the lower portion of the grouting sleeve correspondingly, and a grouting material is poured into the grouting sleeve from the grouting pipe till the grouting material overflows from the slurry discharging pipe to enable the grouting sleeve to be completely filled with the grouting material. The grouting sleeve is a connecting piece of the upper-layer shear wall and the lower-layer shear wall, and a plastic hinge is formed at the bottom of the grouting sleeve. The prefabricated shear wall and a prefabricated plate form the wall plate node in an engaged mode through mutual connecting and binding among the grouting sleeve, a steel bar net piece and the post-poured concrete, and integrality and shock resistance of the node are improved.

Owner:广东省建科建筑设计院有限公司 +1

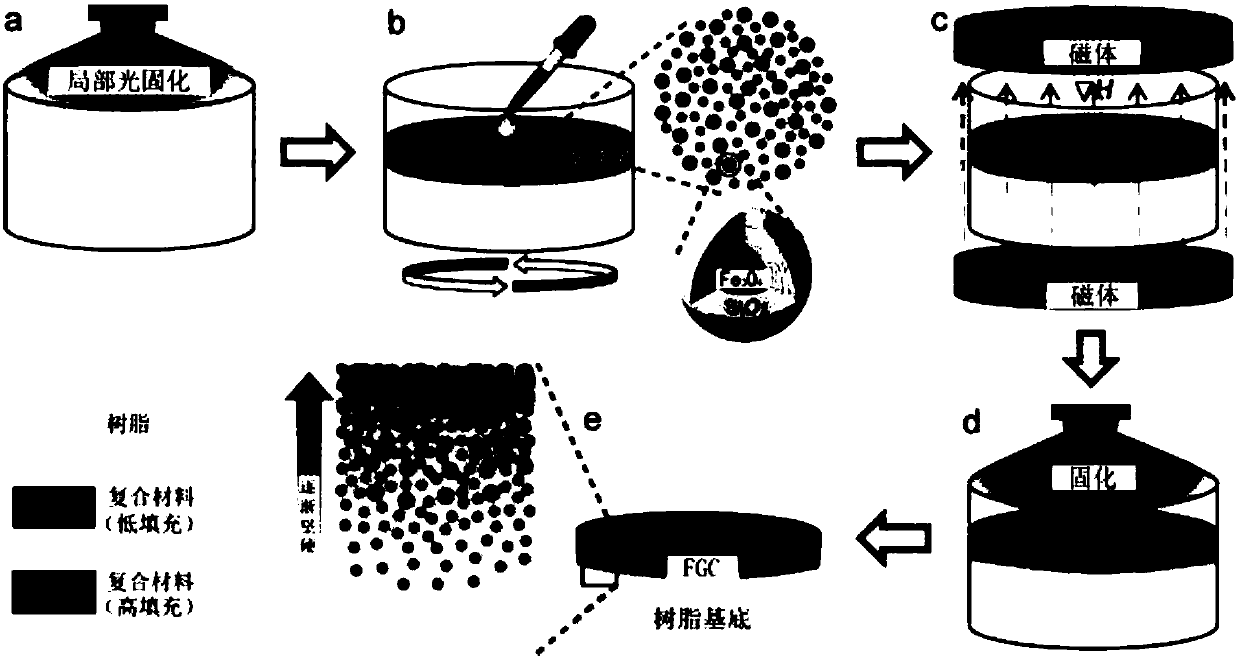

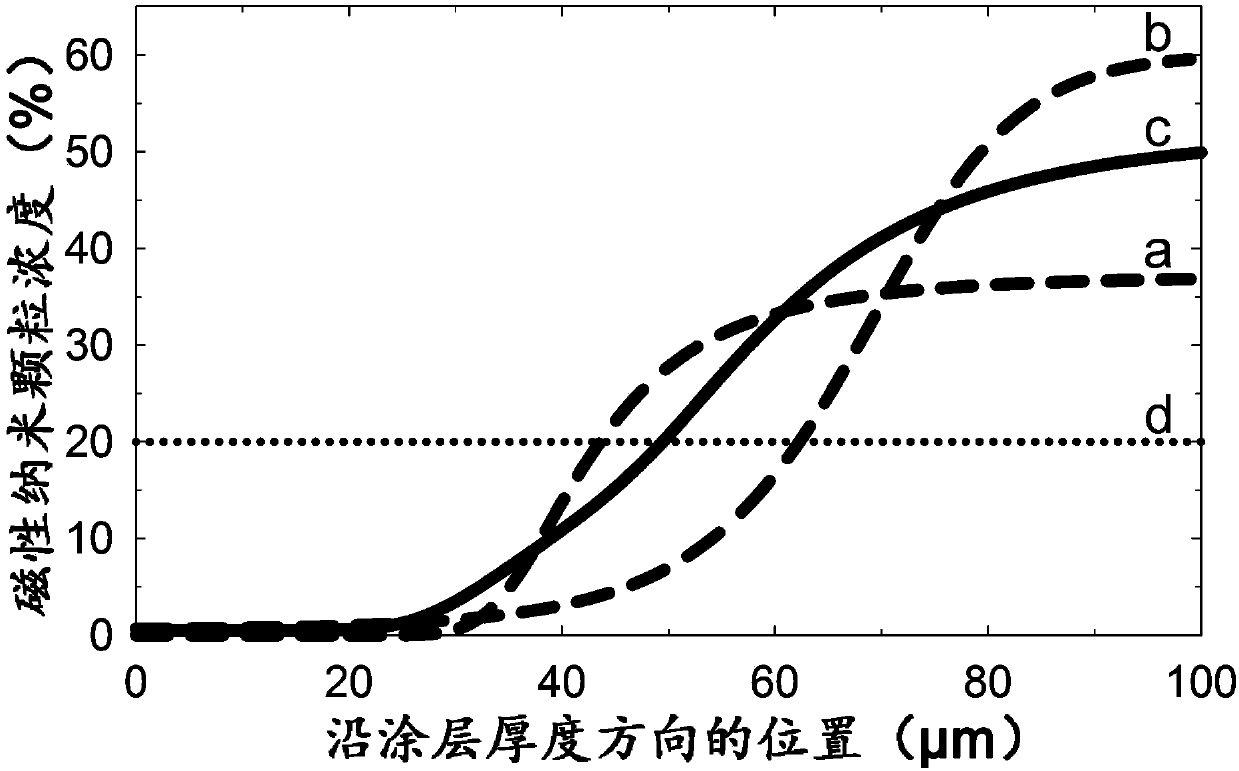

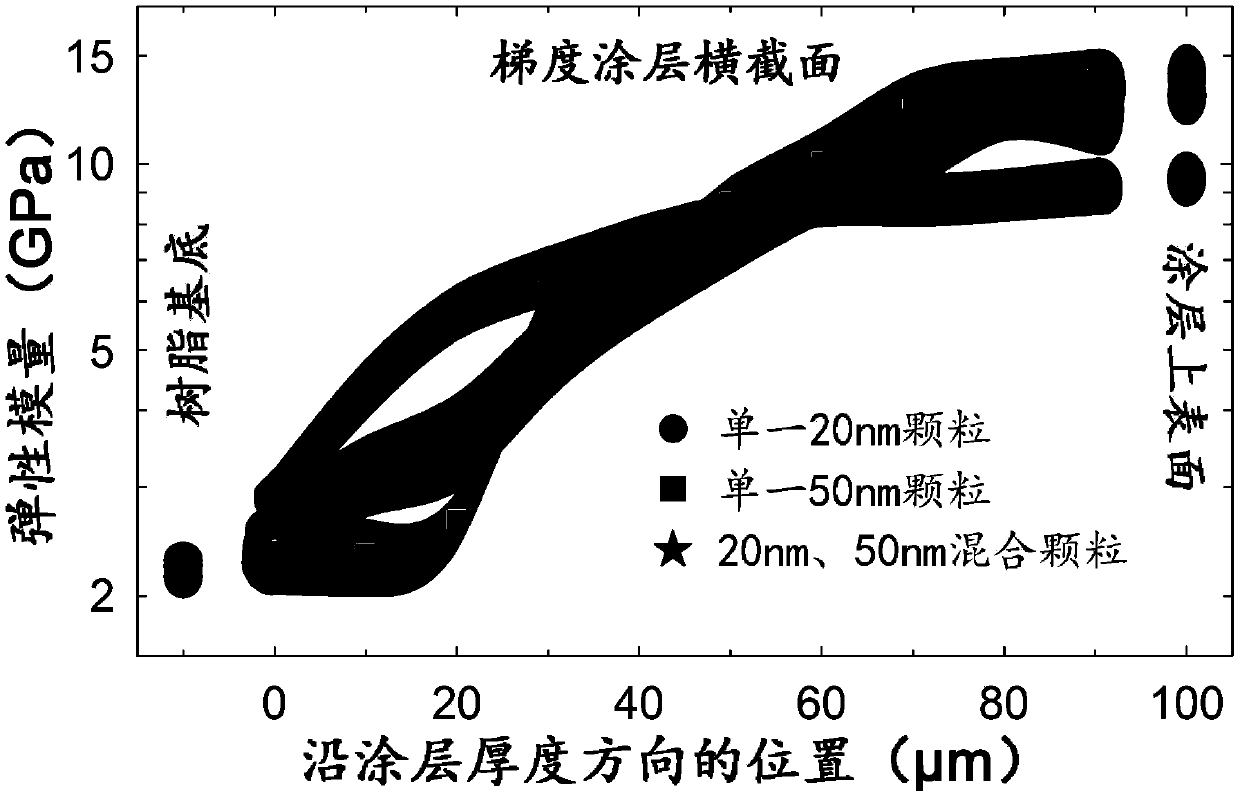

Method for preparing biomimetic functional gradient coating

InactiveCN109554012AImprove wear resistanceImprove toleranceMagnetic paintsPretreated surfacesMagnetite NanoparticlesLarge size

The invention relates to a method for preparing a biomimetic functional gradient coating. The method comprises the following steps: (1) coating a resin substrate with a mixed solution containing magnetic nanoparticles so as to form a product I, wherein the magnetic nanoparticles comprise particles with an outer diameter of 15-25 nm and particles with an outer diameter of 45-55 nm; (2) applying a magnetic field in the vertical direction so as to redistribute the magnetic nanoparticles inside the product I to form a product II; and (3) performing full curing on the product II so as to obtain thebiomimetic functional gradient coating. The prepared biomimetic functional gradient coating has the advantages that the concentrations of the magnetic nanoparticles in interfaces of the coating havegentler gradient distribution from top to bottom due to small-size particles, and the magnetic nanoparticles possessed by the interface with the most magnetic nanoparticles have a larger concentrationvalue and a higher elastic modulus due to large-size particles.

Owner:WUHAN UNIV

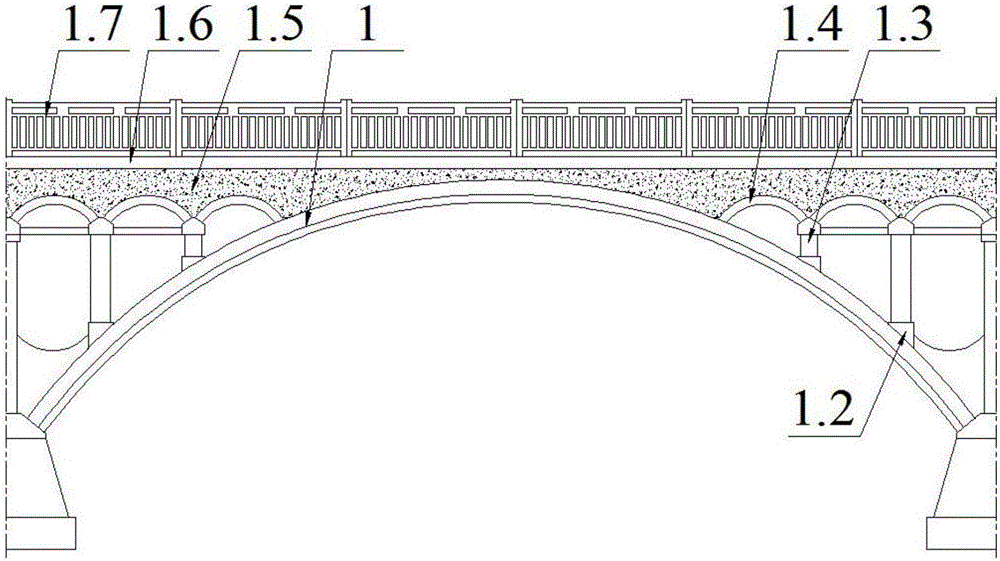

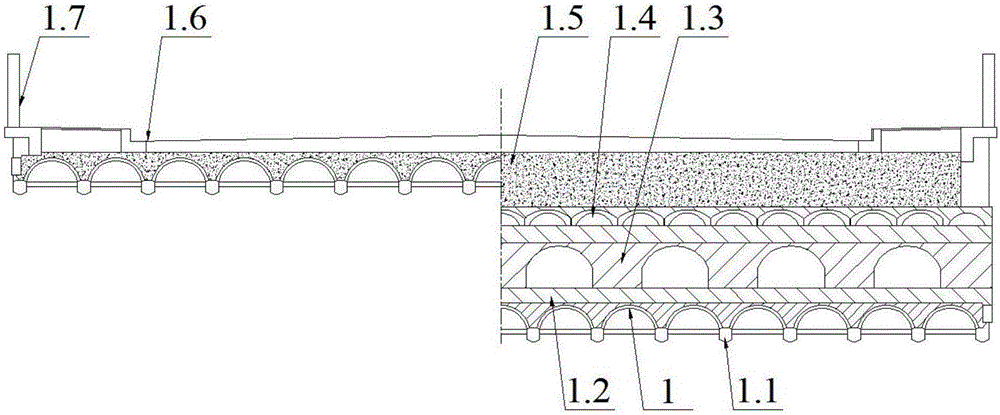

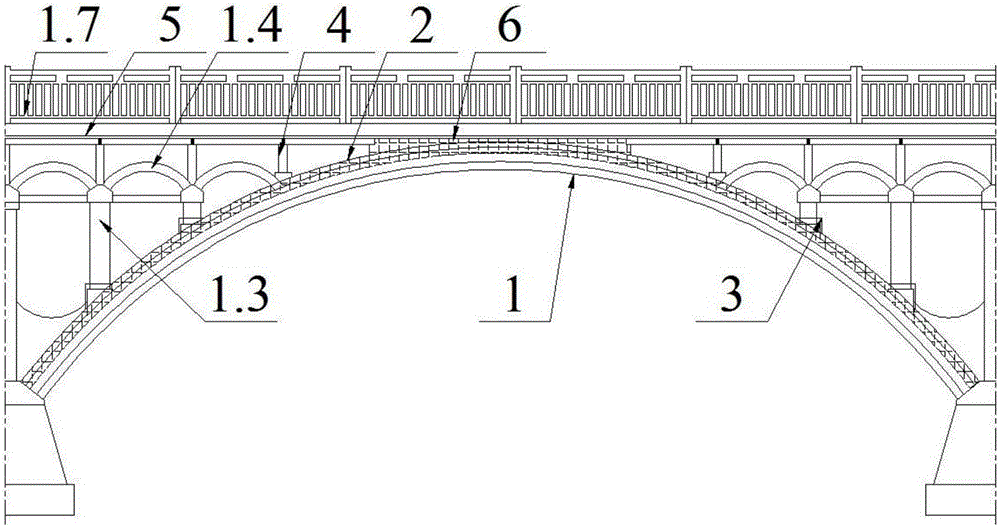

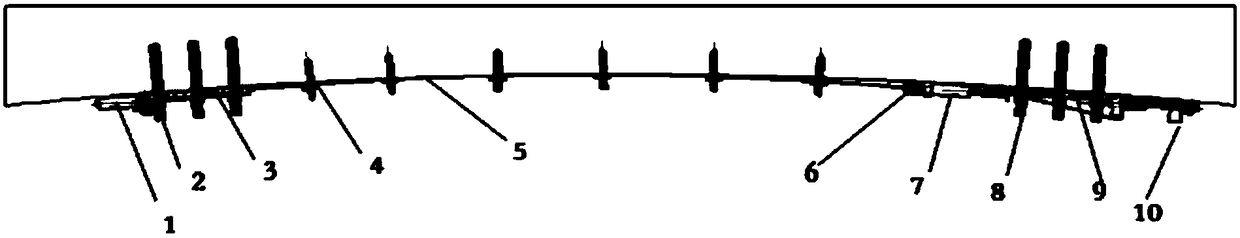

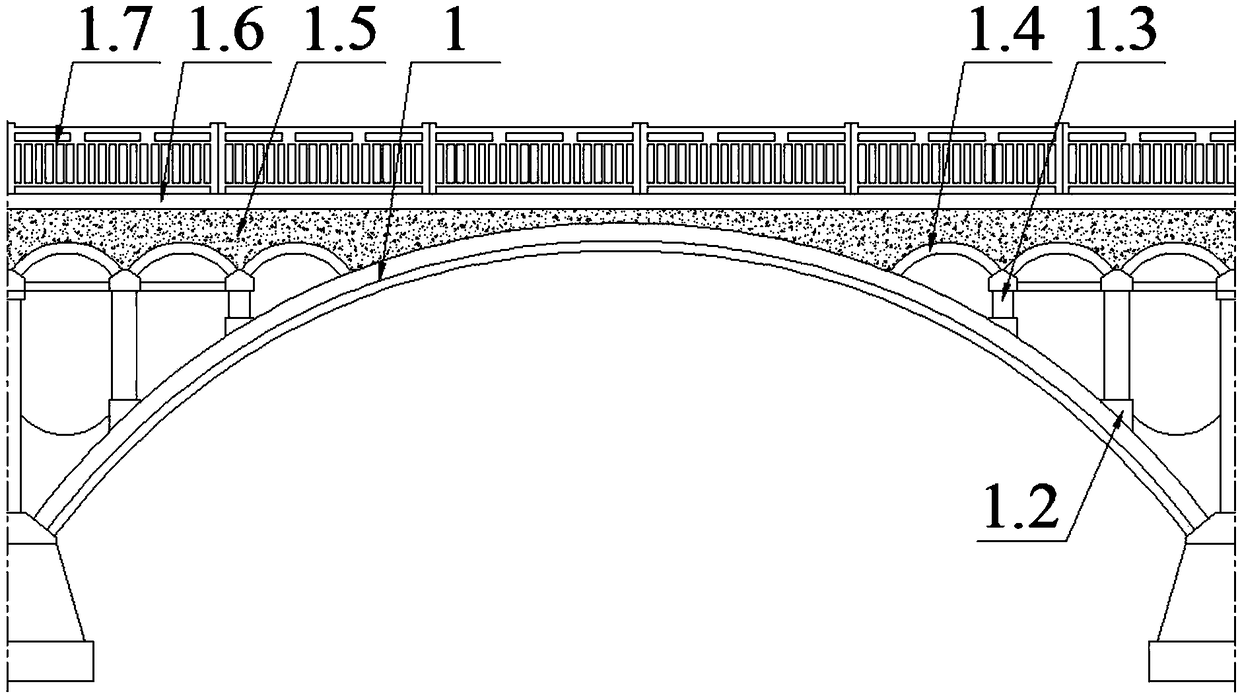

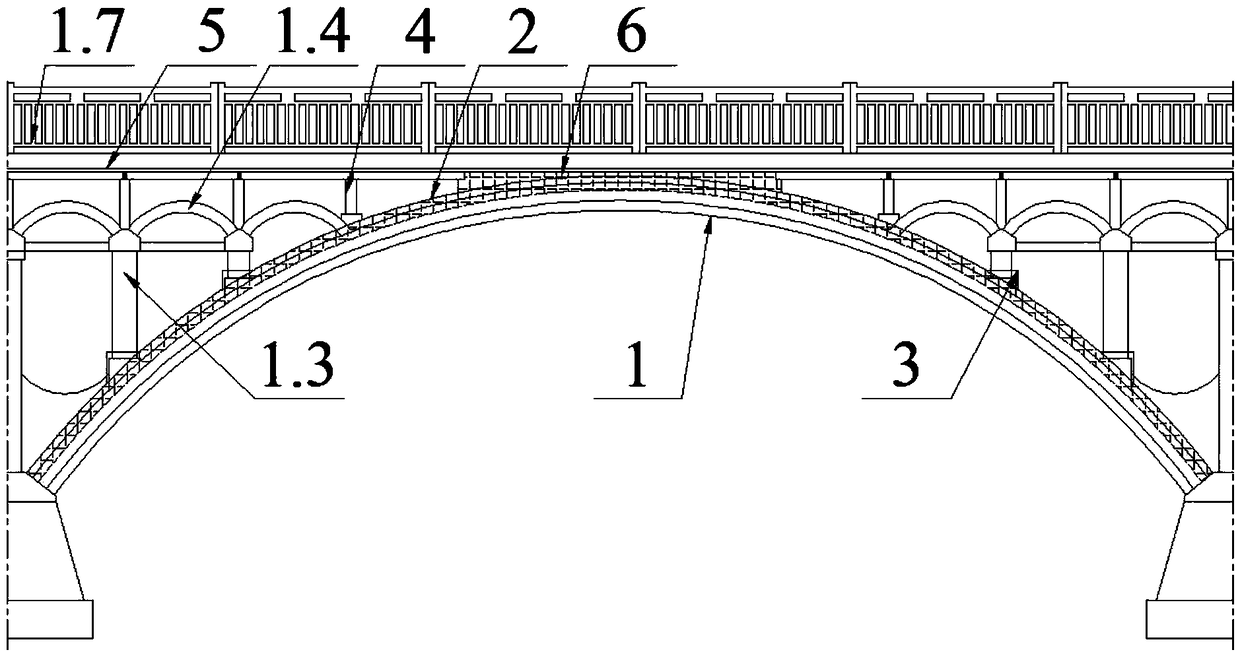

Composite cover arch reinforcing method for arches of two-way curved arch bridge

ActiveCN106284106AImprove adaptabilityEasy to operateBridge erection/assemblyBridge strengtheningStructural engineeringUltimate tensile strength

The invention relates to the technical field of bridge repairing structures, in particular to a composite cover arch reinforcing method for arches of a two-way curved arch bridge. The composite cover arch reinforcing method for the arches of the two-way curved arch bridge comprises the step that a plurality of arch concrete reinforcing ribs which are as long as a main arch ring are obtained by pouring on the arch back of the two-way curved arch bridge in the bridge direction, and the structural strength of the main arch ring is enhanced through the reinforcing ribs which are arranged at intervals and protrude out of the arch back. According to the composite cover arch reinforcing method for the arches of the two-way curved arch bridge, by constructing the reinforcing ribs on the arch back of the main arch ring, a new arch rib structure located on the arch ring is formed, and the structural strength of the whole arch ring is enhanced; and navigation and traffic below the bridge are not affected, the overall appearance structure of the bridge is not damaged, and the composite cover arch reinforcing method has extremely high promotional value.

Owner:CCCC ROAD & BRIDGE SPECIAL ENG

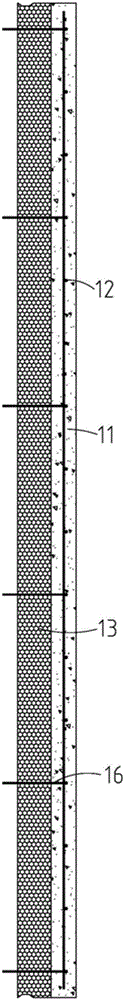

Joint of fabricated precast shear wall and laminated slab connected with fabricated precast shear wall by combined grouting sleeves

PendingCN106968381AImprove seismic performanceIncrease production capacityFloorsBuilding reinforcementsSteel barPlastic hinge

The invention discloses a joint of a fabricated precast shear wall and a laminated slab connected with the fabricated precast shear wall by combined grouting sleeves. The combined grouting sleeves are arranged at the joint. Each combined grouting sleeve comprises a first section sleeve body and a second section sleeve body; the top ends of the first section sleeve bodies are connected with the bottom ends of the second section sleeve bodies; the bottom ends of the first section sleeve bodies are connected on the top ends of vertical steel bars in the precast shear wall and completely pre-buried in the top ends of the precast shear wall, and the second section sleeve bodies are pre-buried in post-poured concrete laminated layers; the vertical steel bars extend downward out of the precast shear wall on the last storey, the vertical steel bars are inserted in the second section sleeve bodies from the top ends of the second section sleeve bodies and extend into the first section sleeve bodies; and mortar discharging pipes are arranged on the upper portions of the second section sleeve bodies, and grouting pipes are arranged on the lower portions of the first section sleeve bodies. The combined grouting sleeves serve as connecting pieces of the shear wall on the upper layer and the shear wall on the lower layer. Shear wall members form plastic hinges at the bottom. The shear wall and the precast slab form the joint through mutual connection and bonding occlusion among the sleeve bodies, steel bar meshes and post-poured concrete, and the integrity and anti-seismic performance of the joint are improved.

Owner:广东省建科建筑设计院有限公司 +1

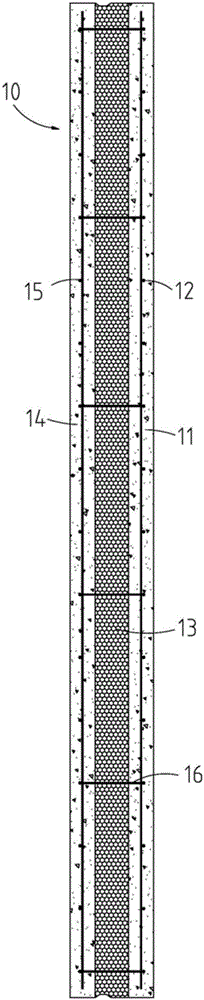

Externally-mounted prefabricated sandwich type thermal-insulation concrete wallboard and assembling system and construction method thereof

ActiveCN106760158AImprove structural strengthIncrease stiffnessPassive housesBuilding componentsFloor slabThermal insulation

The invention provides an externally-mounted prefabricated sandwich type thermal-insulation concrete wallboard and an assembling system and construction method thereof. The technical problem that a connecting structure between vane boards on the two sides of an existing thermal-insulation wallboard is insufficient in strength is solved by enabling steel bar truss web bars in a continuously-bent status to be connected to longitudinal reinforcing bars on an inner vane board and an outer vane board of the thermal-insulation wallboard. In addition, the externally-mounted wallboard is in assembling connection with a steel beam and a floorslab through a pre-buried bolt technical means or a split bolt technical means. Meanwhile, the self-characteristics of a steel structure are considered, and the assembly structure strength between the wallboard and the steel beam as well as between the wallboard and the floorslab is guaranteed.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

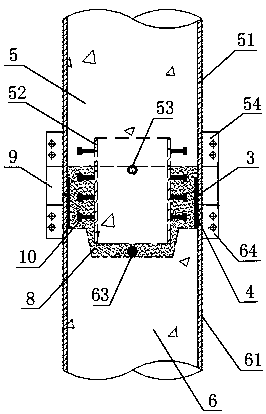

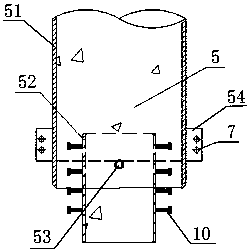

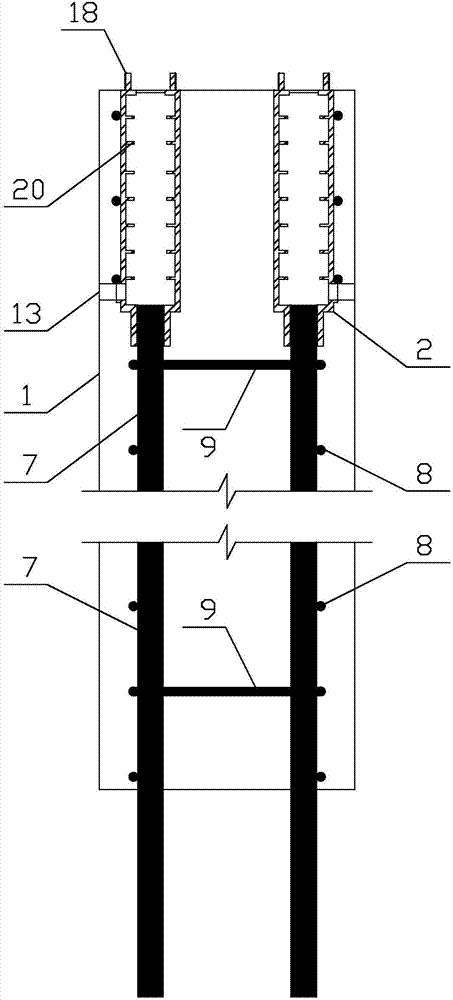

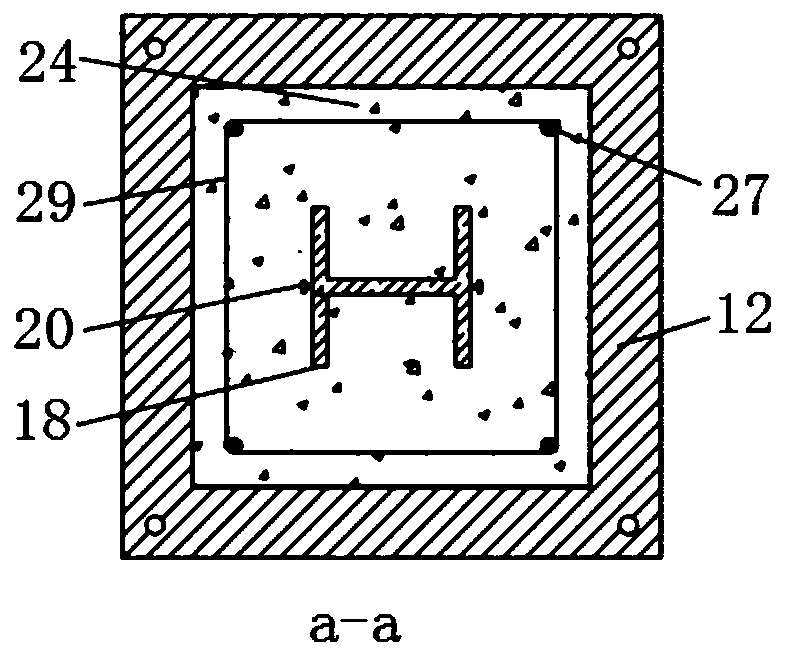

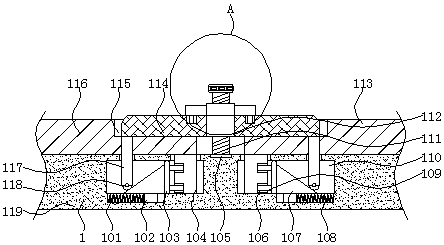

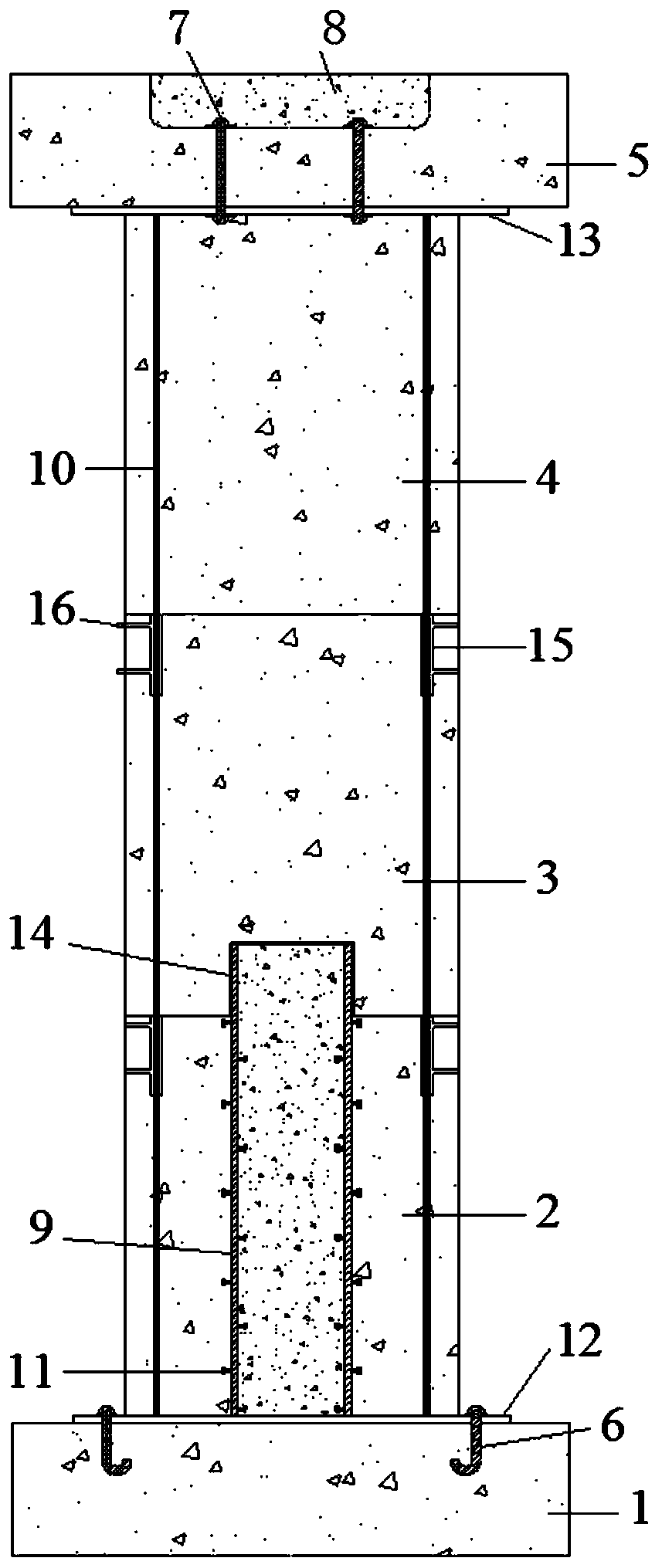

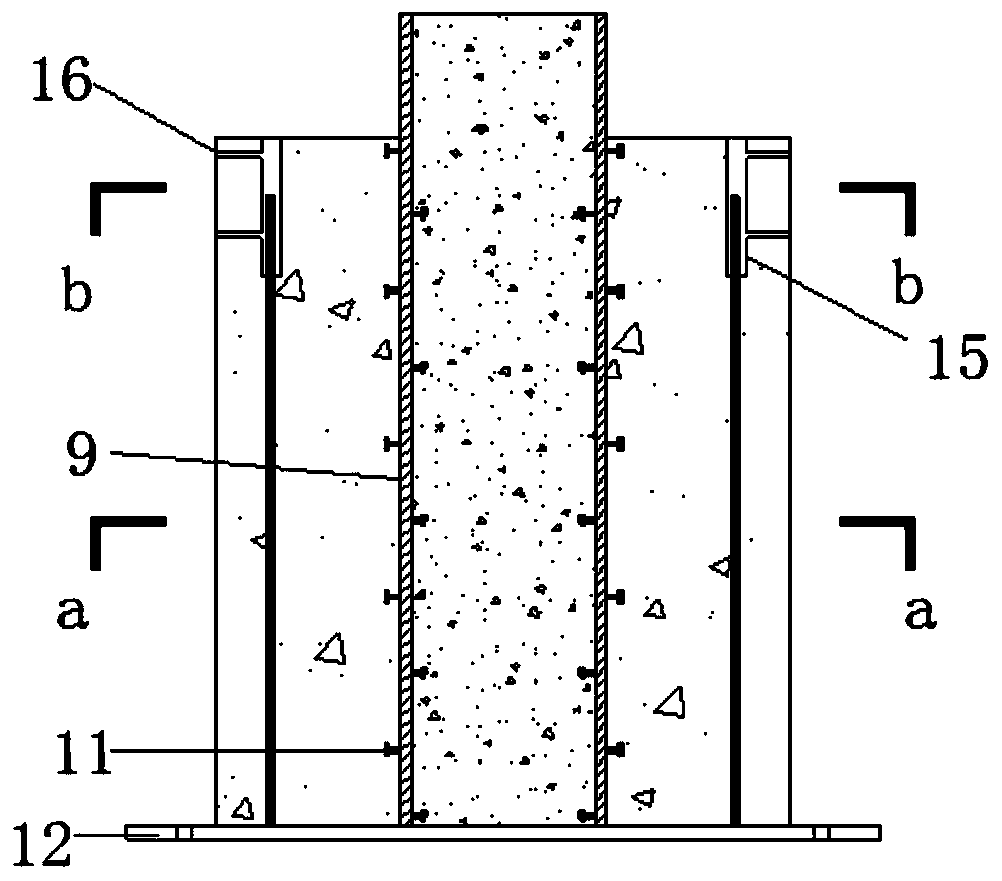

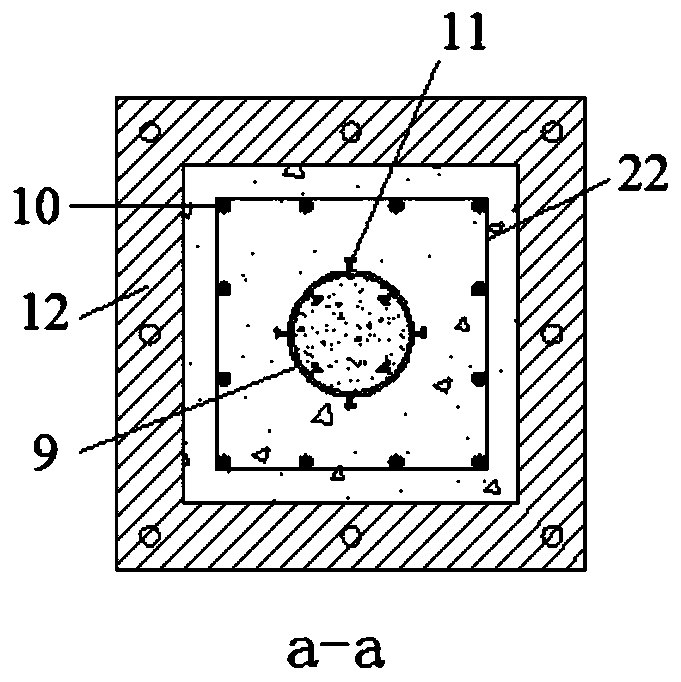

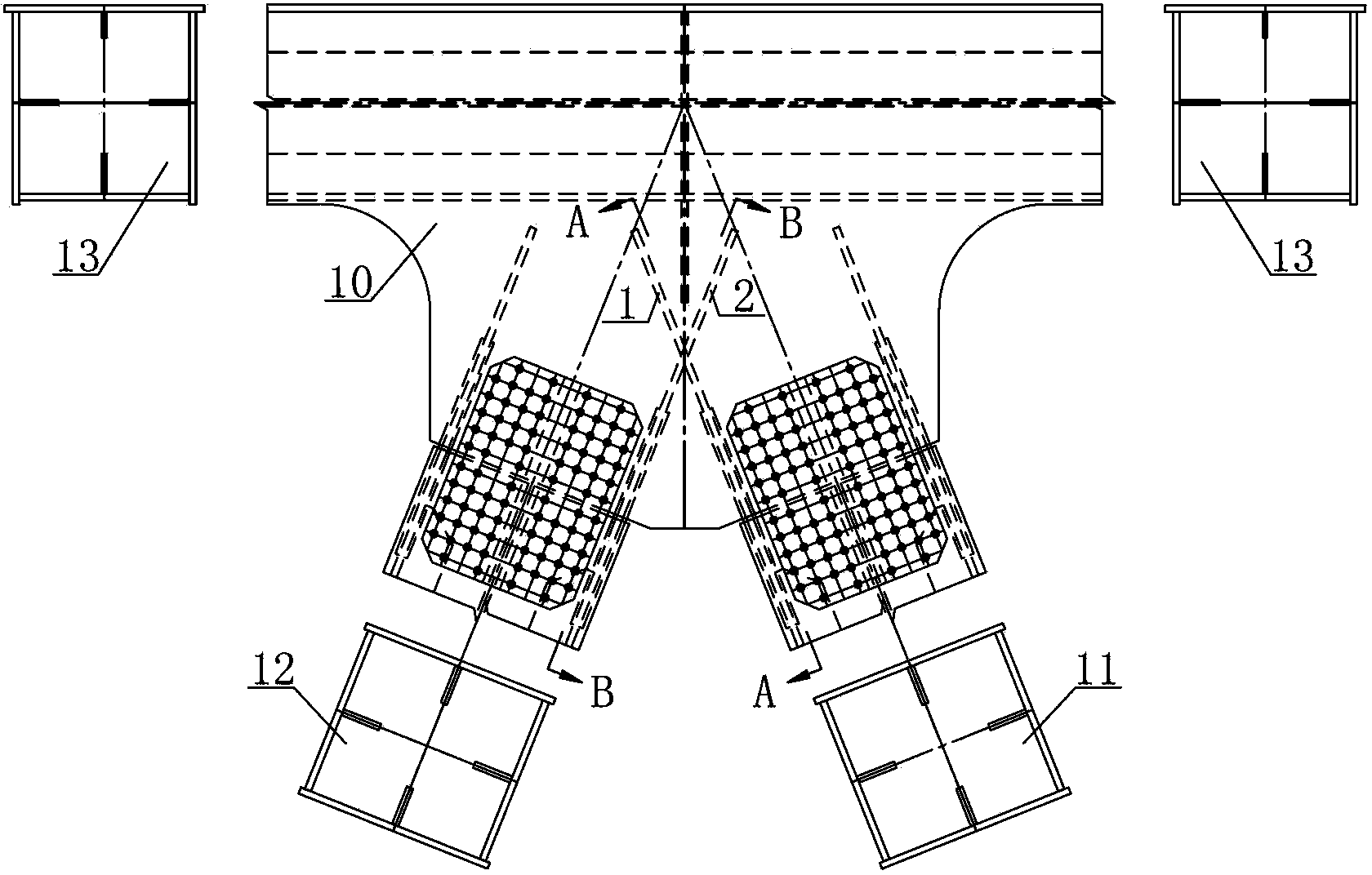

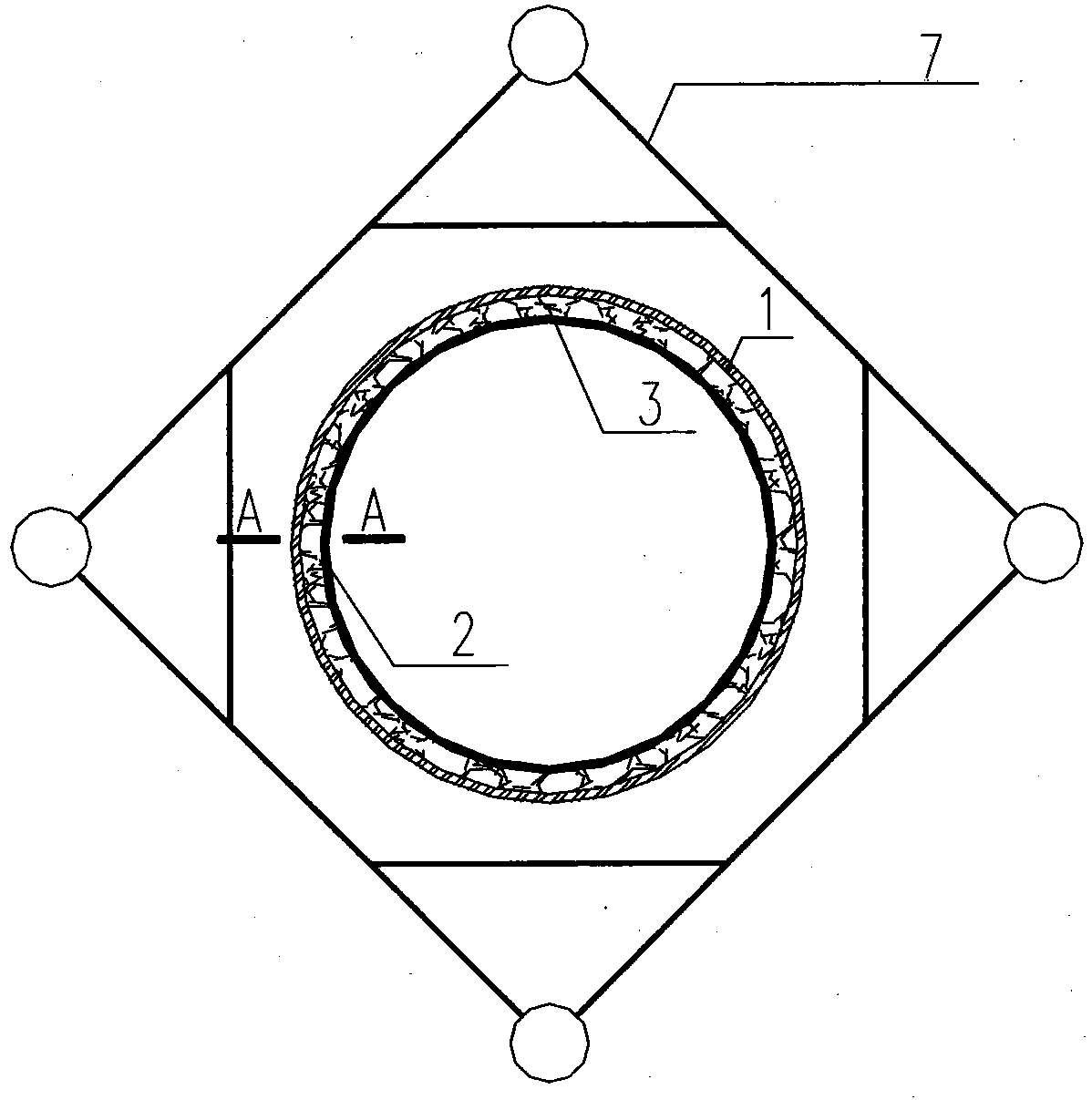

Prefabricated steel reinforced concrete and reinforced concrete assembled pier and construction process

ActiveCN110952440AFast constructionLow construction noiseBridge structural detailsBridge erection/assemblyReinforced concreteArchitectural engineering

Prefabricated steel reinforced concrete and reinforced concrete assembled bridge piers are provided with two connecting modes including bolt connection and connector connection, and each assembled bridge pier connected through bolts comprises a foundation, a first bottom section, a first middle section, a first top section and a bent cap. The assembled pier connected through the connectors comprises a foundation, a second bottom section, a second middle section, a second top section and a bent cap. The construction process of the prefabricated steel reinforced concrete and reinforced concreteassembled pier comprises the following steps that 1, components are manufactured, specifically, the first bottom section, the first middle section, the first top section and the bent cap are prefabricated, or the second bottom section, the second middle section, the second top section and the bent cap are prefabricated; 2, the components are mounted. The designed connection technology of the prefabricated sections and the foundation, the connection technology of the prefabricated sections and the connection technology of the prefabricated sections and the bent cap can guarantee that all the prefabricated parts are connected into a whole, and the structure is jointly stressed and deformed harmoniously.

Owner:NORTHEASTERN UNIV

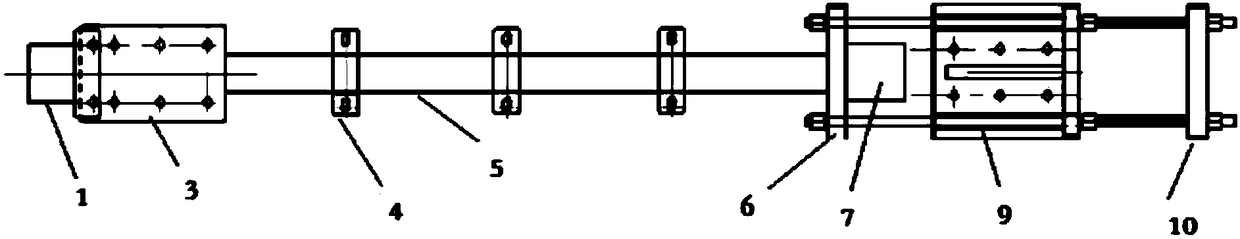

Method for reinforcing curved bridge through prestressed carbon plate

InactiveCN108487090ARealize surface constructionReach bondBridge erection/assemblyBridge strengtheningFiberAdhesive

The invention relates to a method for reinforcing a curved bridge through a prestressed carbon plate. The method comprises the following steps that S1, line drawing and perforating are carried out, holes are cleaned, and a concrete base face is cleaned; S2, a fixed end anchor head and a fixed end anchor plate are fixed to the fixed end of the concrete base face, a stretching end anchor head and astretching end anchor plate are fixed to the stretching end of the concrete base face, a stretching end baffle, a stretching end anchor plate and a stretching tool baffle are connected through a high-strength screw rod, a hydraulic jack is placed between the stretching end anchor plate and the stretching tool baffle, one end of a carbon fiber plate is fixed into the fixed end, the other end of thecarbon fiber plate is located at the stretching end, and the middle of the carbon fiber plate is fixed through a pressing plate; S3, the portion between the concrete base face and the carbon fiber plate is coated with an adhesive, the hydraulic jack is driven to drive the stretching end anchor head and the stretching end anchor plate to move through pushing counter-force, after prestress tensionof the carbon fiber plate is in place, an anchoring nut at the stretching end is screwed down, finally a corresponding device is torn down, and the reinforcing process on the curved bridge is completed.

Owner:CARBON COMPOSITESTIANJIN CO LTD

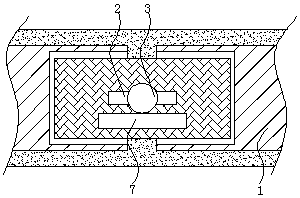

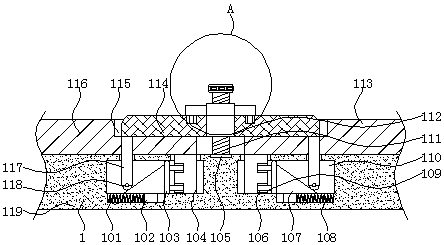

Shock-absorbing device for bridge widening construction

The invention discloses a shock-absorbing device for bridge widening construction, and relates to the technical field of bridge construction. The shock-absorbing device comprises a fixing mechanism, and a fiber mechanism is arranged at the upper part of the fixing mechanism. The fixing mechanism comprises a tension spring, a first sliding block, push plates, a fixing column, a bearing, limiting grooves, inclined blocks, a first sliding groove, limiting rods, a cavity, a threaded rod, a loop ring, an old bridge, a press plate, a groove, a new bridge, a push rod, a roller and channel steel. According to the shock-absorbing device for the bridge widening construction, during use, a worker turns the threaded rod, so that the loop ring drives the press plate to move down to simultaneously pressthe new bridge and the old bridge, and therefore the first step fixation is achieved; then, the press plate pushes the push rod to move down, so that the push rod extrudes the inclined blocks and thetwo inclined blocks approach each other, two push plates push two groups of limiting rods to be inserted into two groups of limiting grooves, and therefore the second step fixation for the new bridgeand the old bridge is achieved; thus, the whole can enable the new bridge and the old bridge to bear force together, and the deflection difference between the new bridge and the old bridge is reduced.

Owner:张鹏 +12

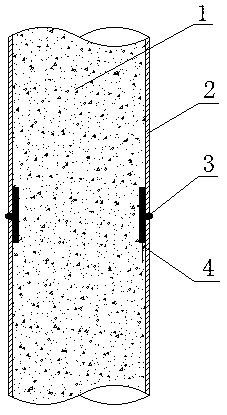

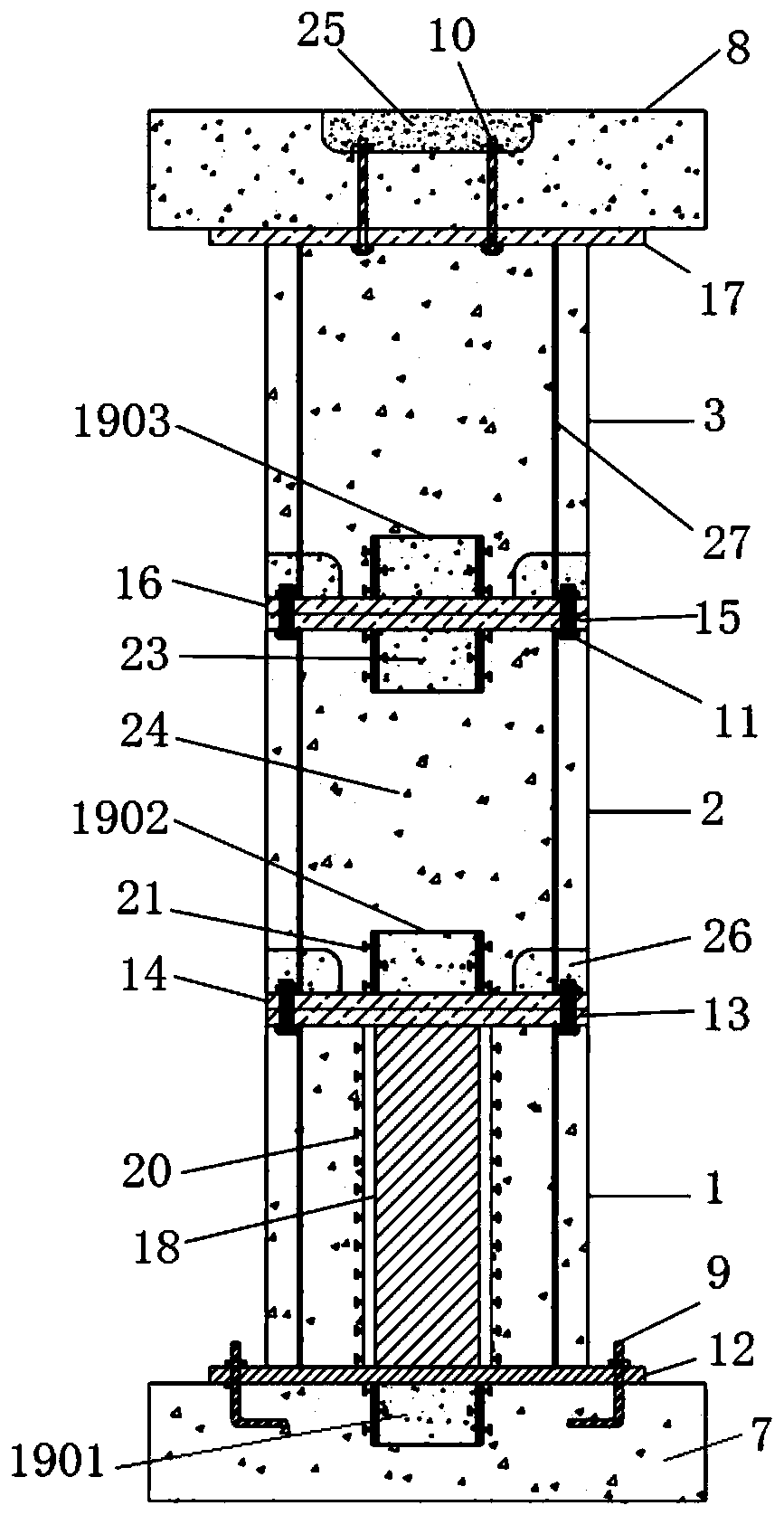

Prefabricated stiff concrete-filled steel tube and reinforced concrete assembled pier and construction process thereof

InactiveCN110924291AFast constructionImprove bearing capacityBridge structural detailsBridge erection/assemblyReinforced concreteArchitectural engineering

Disclosed are a prefabricated stiff concrete-filled steel tube and a reinforced concrete assembled bridge pier which are respectively in two forms of connecting with a grouting sleeve connector and aconnecting steel plate. The assembled pier connected with the grouting sleeve connector comprises a first bottom section, a first middle section, a first top section, a foundation and a bent cap. Theassembled pier connected through the connecting steel plates comprises a second bottom section, a second middle section, a second top section, a foundation and a bent cap. The invention relates to a construction process thereof. The construction process comprises the following steps: step 1, component manufacturing: manufacturing a first bottom section, a first middle section, a first top section,a foundation and a bent cap or a second bottom section, a second middle section, a second top section, a foundation and a bent cap; step 2, mounting components. The connecting technology of the prefabricated sections and the foundation, the connecting technology of the prefabricated sections and the connecting technology of the prefabricated sections and the bent cap are designed, it is guaranteed that all the prefabricated parts are connected into a whole, and the structure is jointly stressed and deformed harmoniously.

Owner:NORTHEASTERN UNIV

Web member intersecting and split joint connector structure in positions of steel truss girder bridge nodes

The invention relates to a web member intersecting and split joint connector structure in the positions of steel truss girder bridge nodes. The middle section of a groove opening of a first U-type groove of a first connector plate penetrates through a second U-type groove of a second connector plate, the space of the first connector plate and the space of the second connector plate intersect and are staggered, the connector plates are welded with node plates in the position of the steel truss girder bridge nodes, and the node plates are welded with chord members; then the connector plates are in bolt joint connection with the member ends of web members through split joint plates and high-strength bolts to form an integrated structure and jointly bear force. Because the intersecting split joint connector plates are welded to the node plates after being mutually staggered in space, and are then in bolt joint connection with the member ends of the web members through the split joint plates and the high-strength bolts to form the integrated structure and jointly bear force, the force can be reasonably borne. The web member intersecting and split joint connector structure in the positions of the steel truss girder bridge nodes can avoid the problems of excessively centralized stress and welding fatigue which are caused by direct intersecting and welding of web member connector plates, can reduce sizes of the node plates and save steel materials, and is obvious in large-internal-force and large-size web member end split joint effect.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

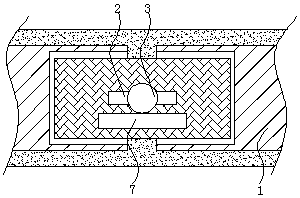

Combined structure of reinforced concrete reverse arch and anchor rods and for managing roadway bottom swelling and construction method of combined structure

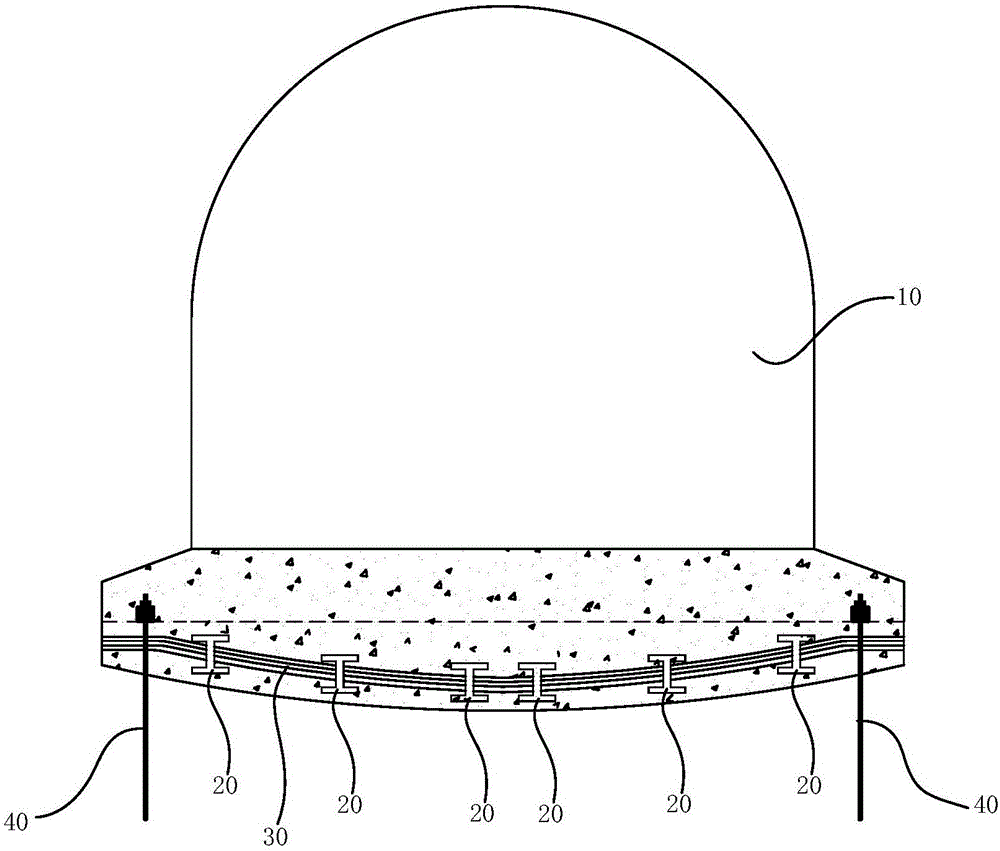

ActiveCN106437780ACommon forceGood governanceUnderground chambersTunnel liningReinforced concreteRock bolt

The invention relates to a combined structure of a reinforced concrete reverse arch and anchor rods and for managing roadway bottom swelling. The combined structure comprises first I-shaped steel beams arranged along the length direction of a roadway baseplate, notches of sliding grooves on two sides of the first I-shaped steel beams are horizontally arranged, the first I-shaped steel beams are arranged along the width direction of a roadway at intervals, second I-shaped steel beams are arranged along the width direction of the baseplate of the roadway and along the length direction of the first I-shaped steel beams at intervals and are of a frame-shaped structure integrally, notches of sliding grooves on two sides of the second I-shaped steel beams are arranged vertically, the anchor rods are penetratingly arranged at two ends of the second I-shaped steel beams and fixedly connected with baseplate surrounding rock of the roadway, and concrete is poured on the combined structure to form a concrete layer. Stress in the vertical direction of the baseplate of the roadway is transferred towards the length direction and the width direction of the roadway, the combined structure of the reinforced concrete reverse arch and the anchor rods form a whole, and the reinforced concrete reverse arch and the anchor rods are jointly stressed, so that the combined structure is convenient and quick to construct and good in bottom swelling managing effect.

Owner:ANHUI UNIV OF SCI & TECH

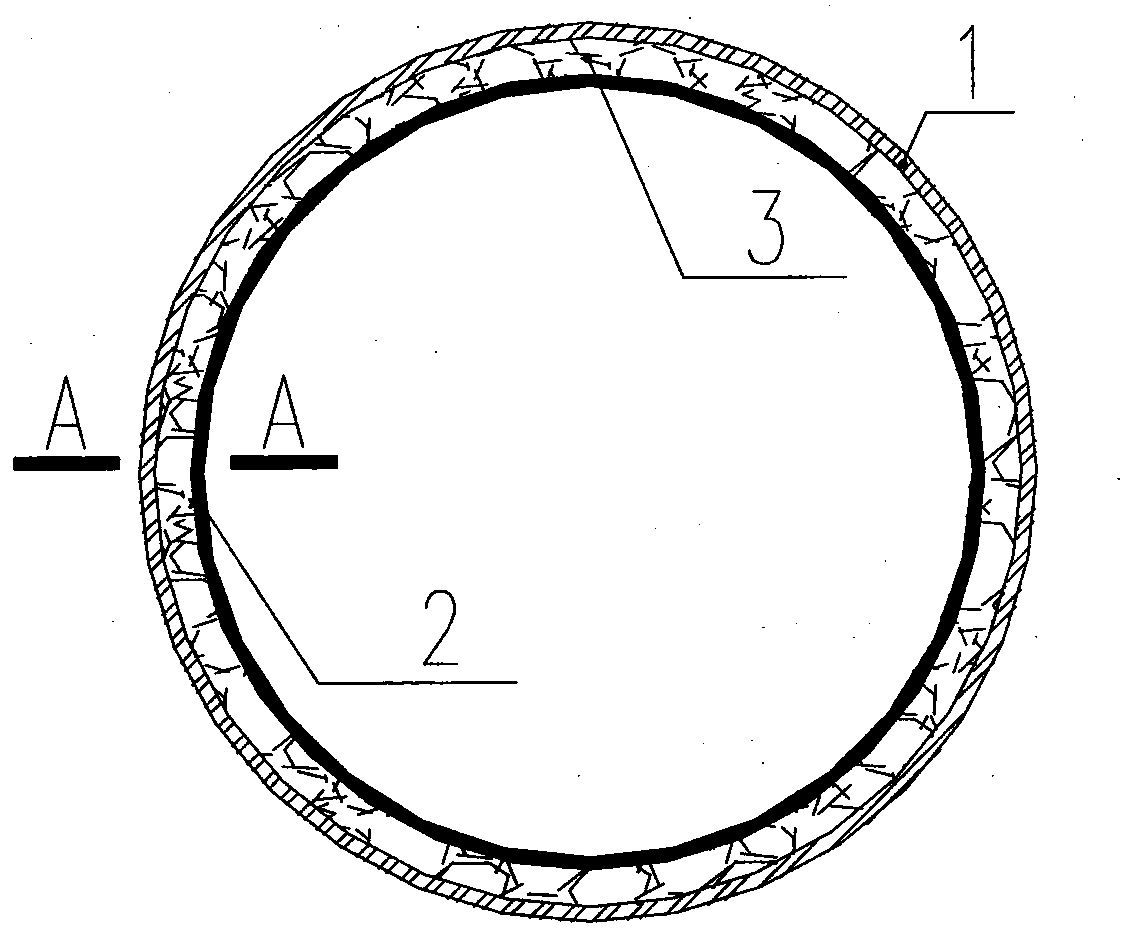

Steel-fiberglass composite smoke discharging facility

The invention discloses a steel-fiberglass composite smoke discharging facility. The steel-fiberglass composite smoke discharging facility is characterized in that the steel-fiberglass composite smokedischarging facility comprises a steel outer cylinder and a fiberglass inner cylinder which are different in diameter, the fiberglass inner cylinder is arranged in the steel outer cylinder matched with the fiberglass inner cylinder, and a bearing ring is arranged on the steel outer cylinder; and the bottom of the fiberglass inner cylinder is arranged on the bearing ring, and the steel outer cylinder and the fiberglass inner cylinder are connected in a composite mode through a polymer foaming material. According to the steel-fiberglass composite smoke discharging facility, the structure is simple, joint stress can be achieved, the structure strength requirement is met, and meanwhile the anti-corrosion requirement is met; good heat-preservation performance is achieved, and a heat-preservation layer does not need to be additionally arranged; and the steel-fiberglass composite smoke discharging facility is specially suitable for transformation of an existing steel inner cylinder chimney,the anti-corrosion purpose is achieved by utilizing the existing structure under the premise that the existing steel inner cylinder is not dismounted, thus the engineering manufacturing cost can be greatly reduced, and economic benefits are remarkable.

Owner:上海必立结构设计事务所有限公司

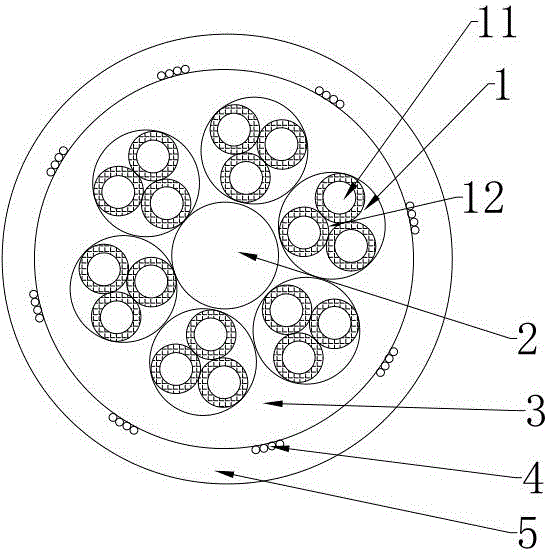

Tensile anti-torsion cable

PendingCN106710677AExtended service lifeImprove tensile propertiesInsulated cablesInsulated conductorsEngineeringHigh intensity

The invention discloses a tensile anti-torsion cable comprising conductors, a filling core, an inner sheath and an outer sheath, and an anti-torsion layer; the three conductors are twisted to form a cable core; the filling core is arranged in the cable center; the cable core surrounds the filling core; the inner sheath extrudes around the cable core in an embedded manner; the outer sheath is filled outside the inner sheath; the anti-torsion layer is added between the inner and outer sheaths. The tensile anti-torsion cable can realize conductor grouped cabling, is filled with high strength tensile aramid fibers, and the sheath is filled with aramid fiber braided fabrics; the tensile anti-torsion cable is tensile and anti-torsion, and long in service life.

Owner:拓柔电缆(上海)有限公司

Prefabricated reinforced concrete beam-slab structure system with cast-in-place floors in building structures

ActiveCN106065663BReduce workloadImprove standardizationFloorsLoad-supporting elementsReinforced concreteTongue and groove

The invention discloses an assembled reinforced concrete beam-slab structural system with a cast-in-situ layer in a building structure. The assembled reinforced concrete beam-slab structural system comprises a superposed beam, a superposed slab, reinforcing mesh pieces, the cast-in-situ concrete superposed layer and beam negative reinforcements, wherein the superposed beam is a reinforced concrete precast beam; outwardly projecting tongue-and-grooves are formed in two sides of the upper part of the superposed beam; the superposed slab is horizontally arranged and is a reinforced concrete precast slab; cover-plate-type tongue-and-grooves are formed at the positions, corresponding to the outwardly projecting tongue-and-grooves, on two sides of the superposed slab, and overlapped on the outwardly projecting tongue-and-grooves; the reinforcing mesh pieces and the beam negative reinforcements are horizontally arranged above the superposed beam and the superposed slab; the reinforcing mesh pieces are bundled up with corresponding reinforcements in the superposed beam and the superposed slab; the beam negative reinforcements are bundled up with corresponding reinforcements in the superposed beam; after arrangement of the reinforcing mesh pieces and the beam negative reinforcements, concrete is poured to form the cast-in-situ concrete superposed layer. The assembled reinforced concrete beam-slab structural system has favorable integrity and mechanical property, and the integrity and the anti-seismic property can be improved.

Owner:广东省建科建筑设计院有限公司

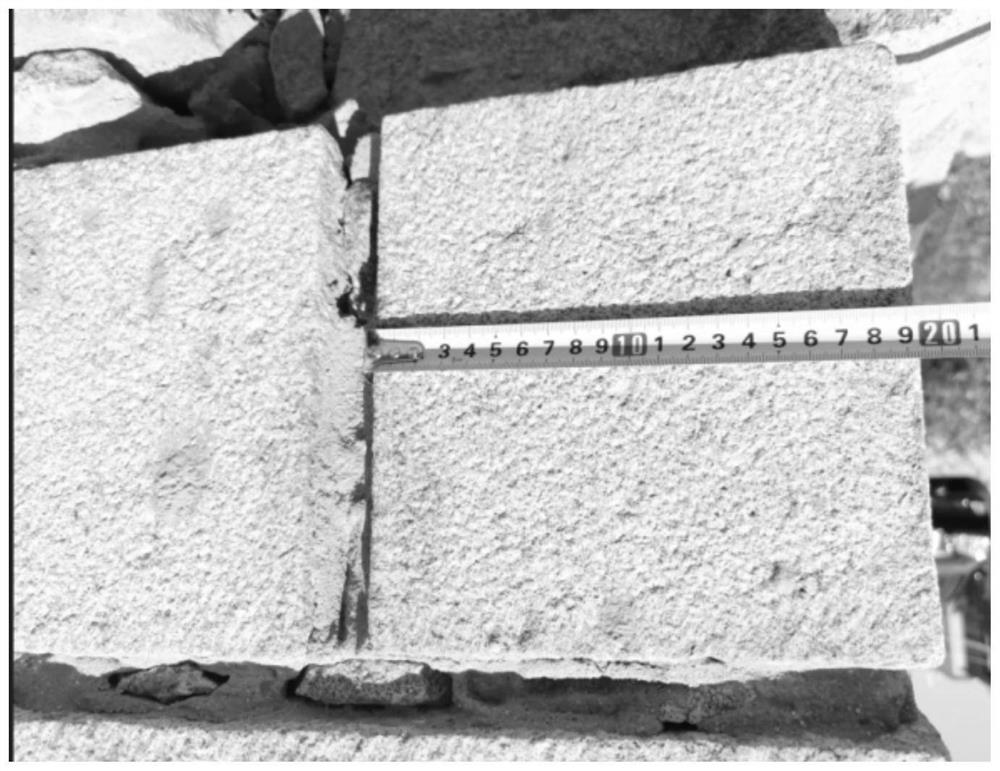

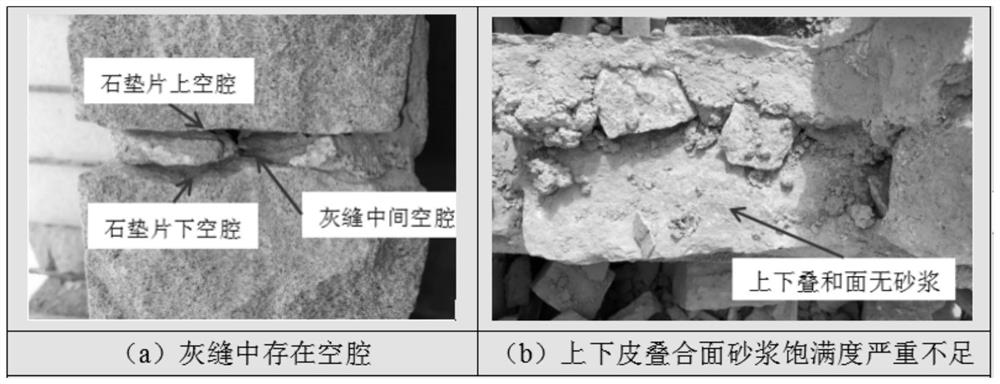

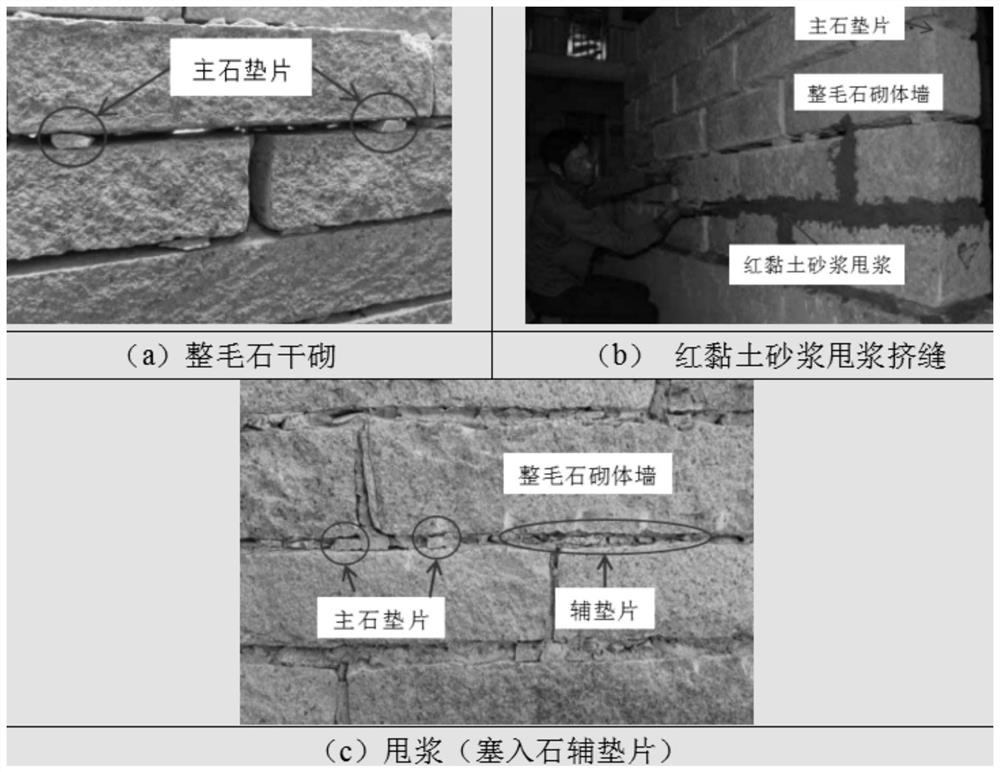

UHPC (Ultra High Performance Concrete) material for reinforcing existing whole rubble wall and reinforcing method thereof

ActiveCN114163190APromotes early hydrationImprove mechanical propertiesSolid waste managementBuilding repairsFiberCarboxylic acid

The invention discloses an existing whole rubble wall reinforcing UHPC material and a reinforcing method thereof, and belongs to the technical field of wall reinforcing, the existing whole rubble wall reinforcing UHPC material comprises 550-600 kg / m < 3 > of Portland cement, 180-200 kg / m < 3 > of white silica fume, 510-530 kg / m < 3 > of limestone powder, 715-735 kg / m < 3 > of quartz sand, 60-75 kg / m < 3 > of iron ore tailing particles, 50-60 kg / m < 3 > of pumice particles, 15-30 kg / m < 3 > of a polycarboxylic acid water reducer, 230-255 kg / m < 3 > of water and 25-35 kg / m < 3 > of POM fibers; the improved novel UHPC section increasing method and the steel bar binding method are combined to reinforce the existing whole rubble wall body, the thickness of the whole rubble wall body can be increased, and the stability of the whole rubble wall body is improved; and the anti-seismic property and durability are remarkably improved, and the method is convenient to construct and can be widely applied to anti-seismic reinforcement of the whole rubble wall.

Owner:FUZHOU UNIV

Intersection joint structure of web members at nodes of steel truss bridges

The invention relates to a web member intersecting and split joint connector structure in the positions of steel truss girder bridge nodes. The middle section of a groove opening of a first U-type groove of a first connector plate penetrates through a second U-type groove of a second connector plate, the space of the first connector plate and the space of the second connector plate intersect and are staggered, the connector plates are welded with node plates in the position of the steel truss girder bridge nodes, and the node plates are welded with chord members; then the connector plates are in bolt joint connection with the member ends of web members through split joint plates and high-strength bolts to form an integrated structure and jointly bear force. Because the intersecting split joint connector plates are welded to the node plates after being mutually staggered in space, and are then in bolt joint connection with the member ends of the web members through the split joint plates and the high-strength bolts to form the integrated structure and jointly bear force, the force can be reasonably borne. The web member intersecting and split joint connector structure in the positions of the steel truss girder bridge nodes can avoid the problems of excessively centralized stress and welding fatigue which are caused by direct intersecting and welding of web member connector plates, can reduce sizes of the node plates and save steel materials, and is obvious in large-internal-force and large-size web member end split joint effect.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

A prefabricated corrugated steel plate lattice enclosure structure and construction method thereof

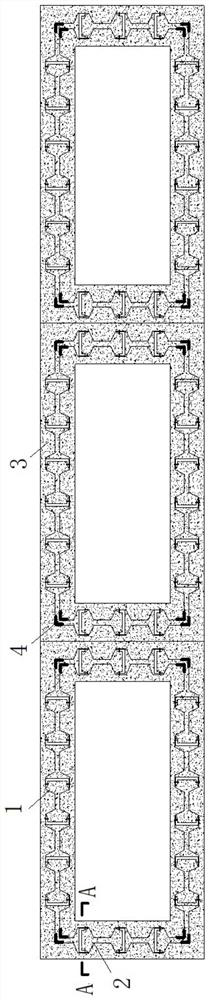

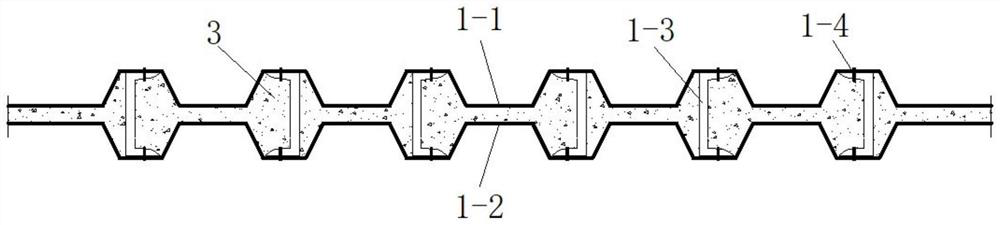

ActiveCN112983116BPlay the role of tension reinforcementIncrease contact surfaceFencingClassical mechanicsAxial force

The invention discloses a prefabricated corrugated steel plate lattice-type enclosure structure and a construction method thereof. The structure includes a number of frame-structured enclosure units, each enclosure unit includes a transverse enclosure portion and a longitudinal enclosure portion filled with concrete, and a truss as a bending component is arranged inside the transverse enclosure portion. The interior of the enclosure is provided with a lattice column as an axial force-bearing member. The truss and the lattice column are connected to each other and bonded with the concrete to form a whole. It is composed of channel steel, a channel steel is arranged in the cavity formed by each peak-to-peak part, the flange of the channel steel is connected with the wave crest in the cavity, and the opening direction of the channel steel in the adjacent cavity is opposite. The invention solves the problem that the envelope structure is only regarded as a non-structure in the traditional building form, is convenient for timely replacement when damaged, and ensures that the structure has good mechanical properties.

Owner:CHANGZHOU INST OF TECH

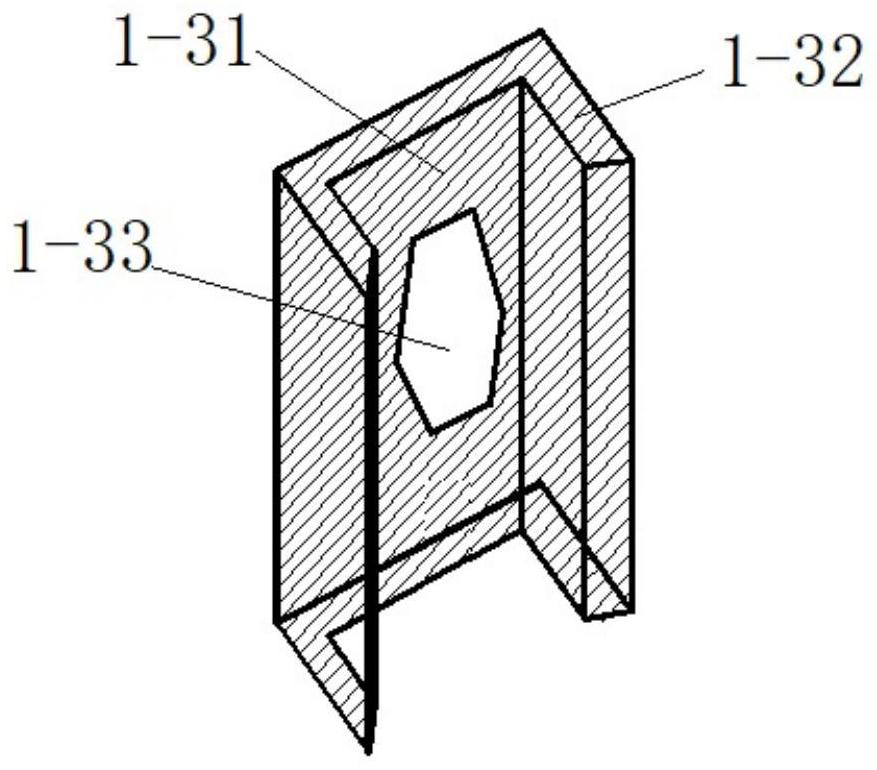

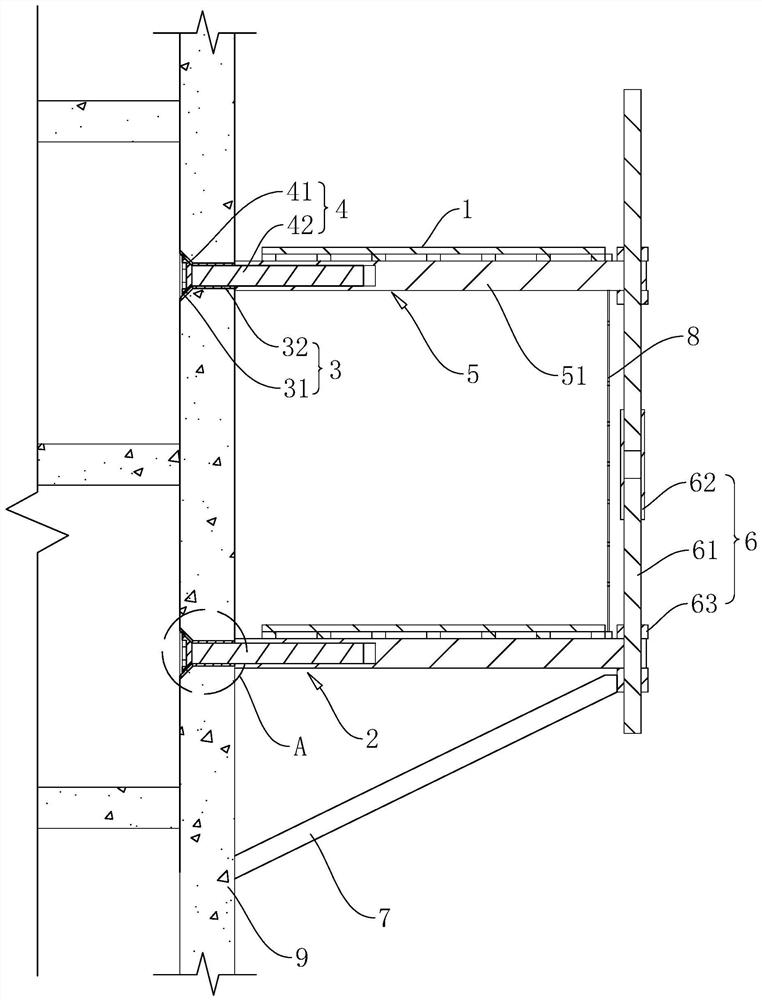

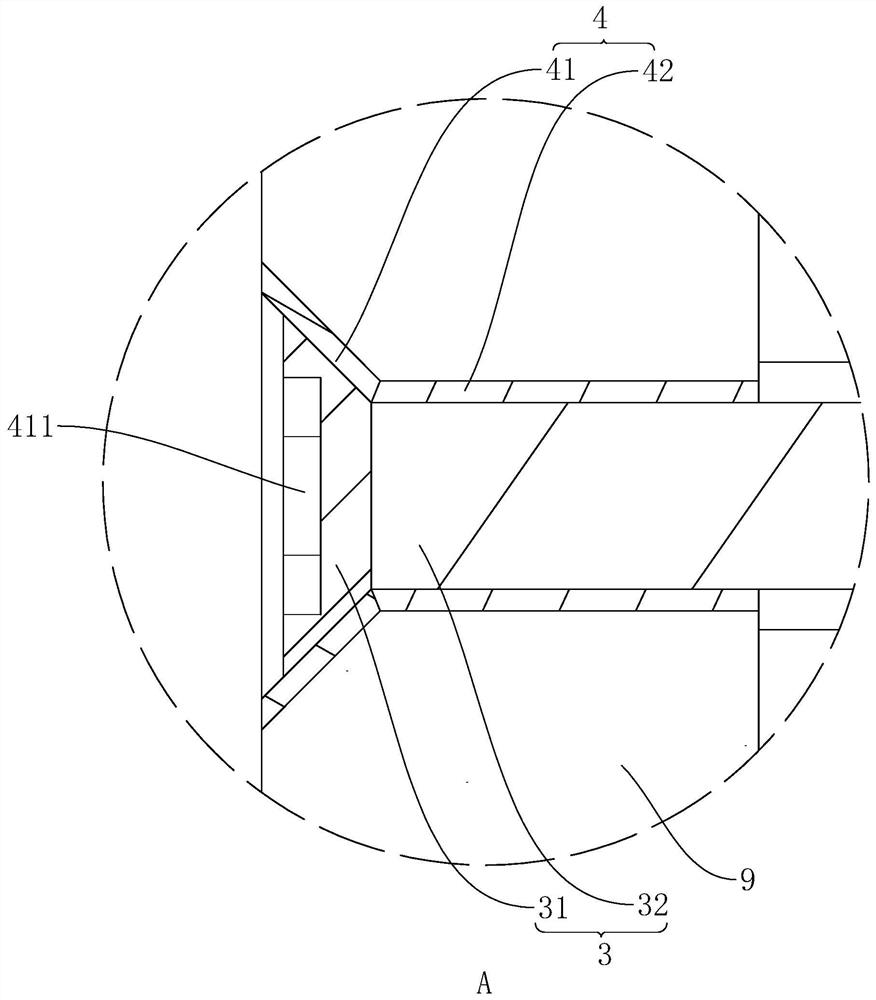

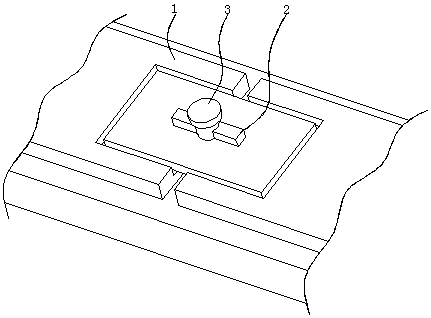

Overhanging type external scaffold facilitating wall repairing and construction method thereof

ActiveCN112593693AReduce the difficulty of repairReduce workloadScaffold accessoriesBuilding support scaffoldsClassical mechanicsExternal cladding

The invention relates to an overhanging type external scaffold facilitating wall repairing and a construction method thereof, in particular to the technical field of building construction. The overhanging type external scaffold comprises a scaffold body and a plurality of wall connecting pieces, wherein the wall connecting pieces are installed on the outer wall, needing overhanging, of a buildingand comprise first mounting pieces, second mounting pieces and third mounting pieces, the first mounting pieces are perpendicular to the outer wall and pre-buried in the outer wall, the two ends of the first mounting pieces are correspondingly flush with the two side walls in the thickness direction of the outer wall, the second mounting pieces are arranged in the first mounting pieces in a penetrating manner and are in sealed connection with the first mounting pieces, one ends of the second mounting pieces extend out of the building outer wall, one ends of the third mounting pieces sleeve onesides, extending out of the outer walls, of the second mounting pieces and are detachably connected with the second mounting pieces, and the scaffold body is correspondingly erected on the third mounting pieces on the same layer. The overhanging type external scaffold has the advantages that the repairing difficulty is low, and therefore the workload of repairing the outer wall body is reduced conveniently.

Owner:江苏天德建设工程有限公司

Damping device for bridge widening construction

ActiveCN109371830BSmooth rotationPrevent rotationBridge structural detailsArchitectural engineeringScrew thread

The invention discloses a shock-absorbing device for bridge widening construction, and relates to the technical field of bridge construction. The shock-absorbing device comprises a fixing mechanism, and a fiber mechanism is arranged at the upper part of the fixing mechanism. The fixing mechanism comprises a tension spring, a first sliding block, push plates, a fixing column, a bearing, limiting grooves, inclined blocks, a first sliding groove, limiting rods, a cavity, a threaded rod, a loop ring, an old bridge, a press plate, a groove, a new bridge, a push rod, a roller and channel steel. According to the shock-absorbing device for the bridge widening construction, during use, a worker turns the threaded rod, so that the loop ring drives the press plate to move down to simultaneously pressthe new bridge and the old bridge, and therefore the first step fixation is achieved; then, the press plate pushes the push rod to move down, so that the push rod extrudes the inclined blocks and thetwo inclined blocks approach each other, two push plates push two groups of limiting rods to be inserted into two groups of limiting grooves, and therefore the second step fixation for the new bridgeand the old bridge is achieved; thus, the whole can enable the new bridge and the old bridge to bear force together, and the deflection difference between the new bridge and the old bridge is reduced.

Owner:张鹏 +12

A joint structure and arrangement method of hinged steel bar connectors for concrete girder bridges

ActiveCN106049258BGuaranteed shear performanceImprove shear resistanceBridge structural detailsBridge erection/assemblyConcrete beamsInverted triangle

Owner:HEBEI PROVINCIAL COMM PLANNING & DESIGN INST

A Method for Reinforcing Composite Arches of Double-curved Arch Bridges

ActiveCN106284106BImprove adaptabilityEasy to operateBridge erection/assemblyBridge strengtheningEngineeringStructural engineering

Owner:CCCC ROAD & BRIDGE SPECIAL ENG

Combination structure of steel-concrete anti-arch and anchor rod used to control roadway underside and construction method of the combination structure

ActiveCN106437780BCommon forceGood governanceUnderground chambersTunnel liningReinforced concreteRock bolt

The invention relates to a combined structure of a reinforced concrete reverse arch and anchor rods and for managing roadway bottom swelling. The combined structure comprises first I-shaped steel beams arranged along the length direction of a roadway baseplate, notches of sliding grooves on two sides of the first I-shaped steel beams are horizontally arranged, the first I-shaped steel beams are arranged along the width direction of a roadway at intervals, second I-shaped steel beams are arranged along the width direction of the baseplate of the roadway and along the length direction of the first I-shaped steel beams at intervals and are of a frame-shaped structure integrally, notches of sliding grooves on two sides of the second I-shaped steel beams are arranged vertically, the anchor rods are penetratingly arranged at two ends of the second I-shaped steel beams and fixedly connected with baseplate surrounding rock of the roadway, and concrete is poured on the combined structure to form a concrete layer. Stress in the vertical direction of the baseplate of the roadway is transferred towards the length direction and the width direction of the roadway, the combined structure of the reinforced concrete reverse arch and the anchor rods form a whole, and the reinforced concrete reverse arch and the anchor rods are jointly stressed, so that the combined structure is convenient and quick to construct and good in bottom swelling managing effect.

Owner:ANHUI UNIV OF SCI & TECH

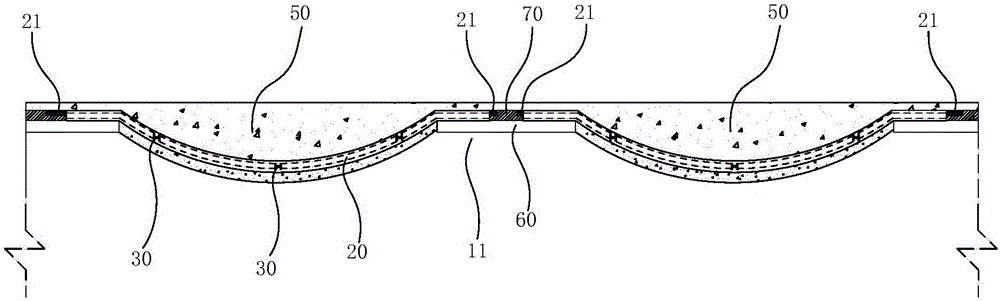

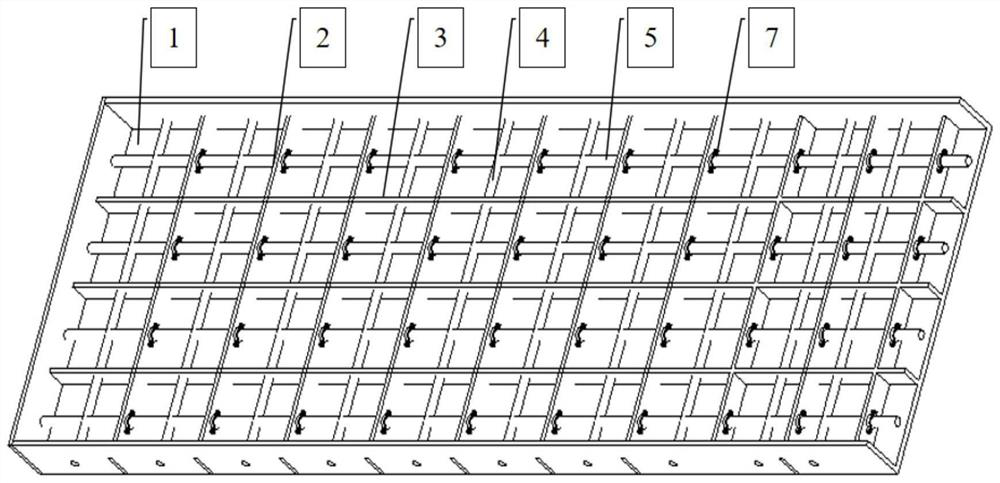

FRP (Fiber Reinforced Plastic) reinforced PVC (Polyvinyl Chloride) plate-concrete composite floor

The invention relates to the technical field of building structures, in particular to an FRP reinforced PVC plate-concrete composite floor which comprises an FRP reinforced PVC formwork system, stress bars and distribution bars inserted into a formwork in a penetrating mode and concrete poured in the PVC formwork system, the FRP reinforced PVC formwork system comprises a PVC formwork body, FRP cloth and FRP partition plates, and the FRP partition plates comprise FRP transverse partition plates and FRP longitudinal partition plates. The FRP longitudinal partition plates are connected with the bottom plate of the PVC formwork body through insertion connection of the T-shaped ribs and the closed grooves, the FRP longitudinal partition plates are connected with the FRP transverse partition plates through insertion connection of the T-shaped blocks and the T-shaped grooves, and the distribution steel bars and the longitudinal load-bearing steel bars penetrate through the holes to be installed. And the bolts are rotated to enable the metal semicircular rings to fix the distributed steel bars and the longitudinal load-bearing steel bars, so that the FRP cloth is adhered to the bottom plate of the PVC template main body, the defect of low bearing capacity of the PVC template is overcome, the integrity of the structure is enhanced, the bearing capacity of the structure is improved, and the service life of the structure is prolonged.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Prefabricated Steel Concrete and Reinforced Concrete Assembled Piers and Construction Technology

ActiveCN110952440BFast constructionLow construction noiseBridge structural detailsBridge erection/assemblyReinforced concreteArchitectural engineering

Prefabricated steel concrete and reinforced concrete assembled piers are divided into two connection methods, one is bolt connection, and the other is connector connection. The bolt-connected assembled pier includes the foundation, the first bottom segment, the first middle segment, the second A top segment and cover beam; the assembled bridge pier connected by the connector includes a foundation, a second bottom segment, a second middle segment, a second top segment and a cover beam; the construction of prefabricated steel concrete and reinforced concrete assembled bridge piers The process includes the following steps: Step 1, making components, prefabricating the first bottom segment, the first middle segment, the first top segment and the cap beam or prefabricating the second bottom segment, the second middle segment, and the second top Sections and cap beams; step 2, component installation. The designed prefabricated section and foundation connection technology, the connection technology between prefabricated sections, and the prefabricated section and cover beam connection technology can ensure that the prefabricated components are connected as a whole, so that the structure is jointly stressed and deformed in coordination.

Owner:NORTHEASTERN UNIV LIAONING

A cantilevered external scaffold for easy wall repair and its construction method

ActiveCN112593693BReduce the difficulty of repairReduce workloadScaffold accessoriesBuilding support scaffoldsConstruction engineeringExternal cladding

The application relates to a cantilevered external scaffolding for easy wall repair and its construction method, which relates to the technical field of building construction, which includes a frame body and several wall-connecting parts, and the wall-connecting parts are installed on the external wall of the building that needs to be cantilevered , the wall connecting piece includes a first installation piece, a second installation piece and a third installation piece. The first installation piece is vertical to the exterior wall and embedded in the exterior wall. The walls are correspondingly flush; the second mounting part is passed through the first mounting part and sealed with the first mounting part, and one end of the second mounting part extends out of the outer wall of the building; one end of the third mounting part is sleeved on the second The mounting part extends out of one side of the outer wall and is detachably connected with the second mounting part; the frame body is erected correspondingly on the third mounting part on the same floor. The application has the effect of lower repairing difficulty, thereby facilitating the reduction of the workload of external wall repairing.

Owner:江苏天德建设工程有限公司

A connection structure of prefabricated steel tube concrete column body

The invention discloses a connecting structure of a fabricated concrete-filled steel tubular column body. The connecting structure comprises a first steel tubular column section and a second steel tubular column section; the first steel tubular column section is in butt joint with the second steel tubular column section, an inner steel tube is inserted into an inserting groove in a second outer steel tube, and a liner tube is arranged at the connecting position of a first outer steel tube and the second outer steel tube; the first outer steel tube, the second outer steel tube and the liner tube are welded into one through V-shaped groove welding; cementing materials are poured into gap areas in the first outer steel tube and the second outer steel tube, and air in the gap areas is exhausted though exhaust vents; and connecting plates are mounted on a first lug plate and a second lug plate through bolts. The connecting structure has the advantages that the shear-bearing ability of the connecting parts is improved, so that the column body reaches the normal section compression-bending bearing force and the shear-bearing ability which are not less than those of cast-in-place concrete,mounting is easy and convenient, the production and construction efficiency is improved, dust and noise pollution is further reduced, and the environmental-friendly requirements of green buildings are met.

Owner:重庆大学建筑规划设计研究总院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com