Method for preparing biomimetic functional gradient coating

A technology of gradient coating and bionic function, which is applied in coatings, devices for coating liquid on the surface, magnetic coatings, etc., can solve the problems of coating wear resistance and insufficient tolerance, and achieve high elastic modulus, Effect of high wear resistance and resistance, high interface durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

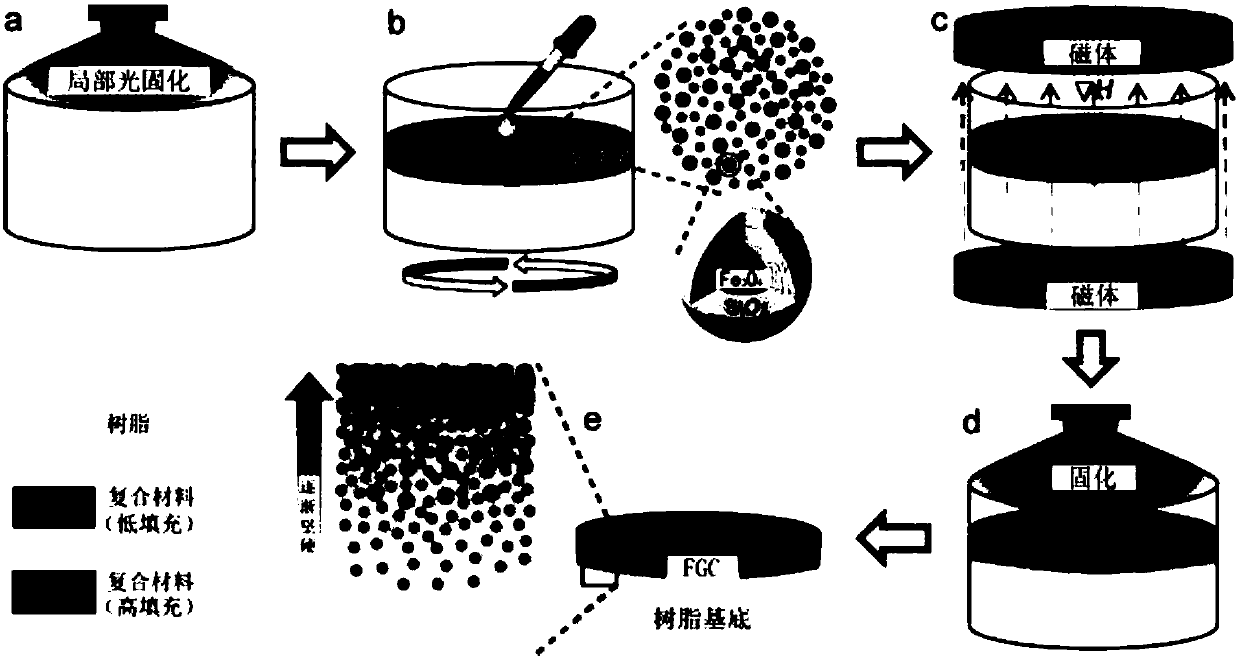

[0023] Such as figure 1 As shown, a preparation method of a biomimetic functionally graded coating in Embodiment 1 of the present invention comprises the following steps:

[0024] Step 1: Coating a mixed solution containing magnetic nanoparticles on a resin substrate to form product I; wherein the magnetic nanoparticles include particles with an outer diameter of 15-25 nm and particles with an outer diameter of 45-55 nm;

[0025] Step 2: applying a magnetic field in the vertical direction of the product I to redistribute the magnetic nanoparticles inside the product I to form product II;

[0026] Step 3: The product II is completely cured to obtain a biomimetic functionally gradient coating.

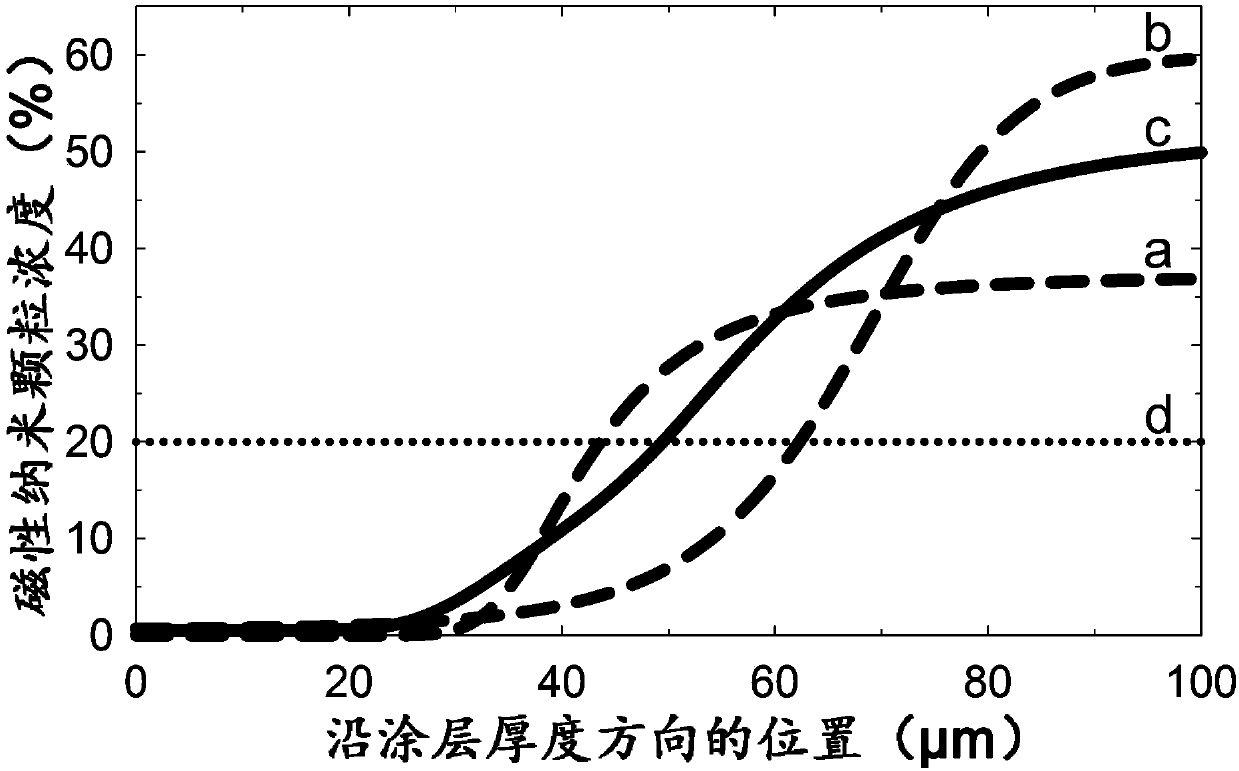

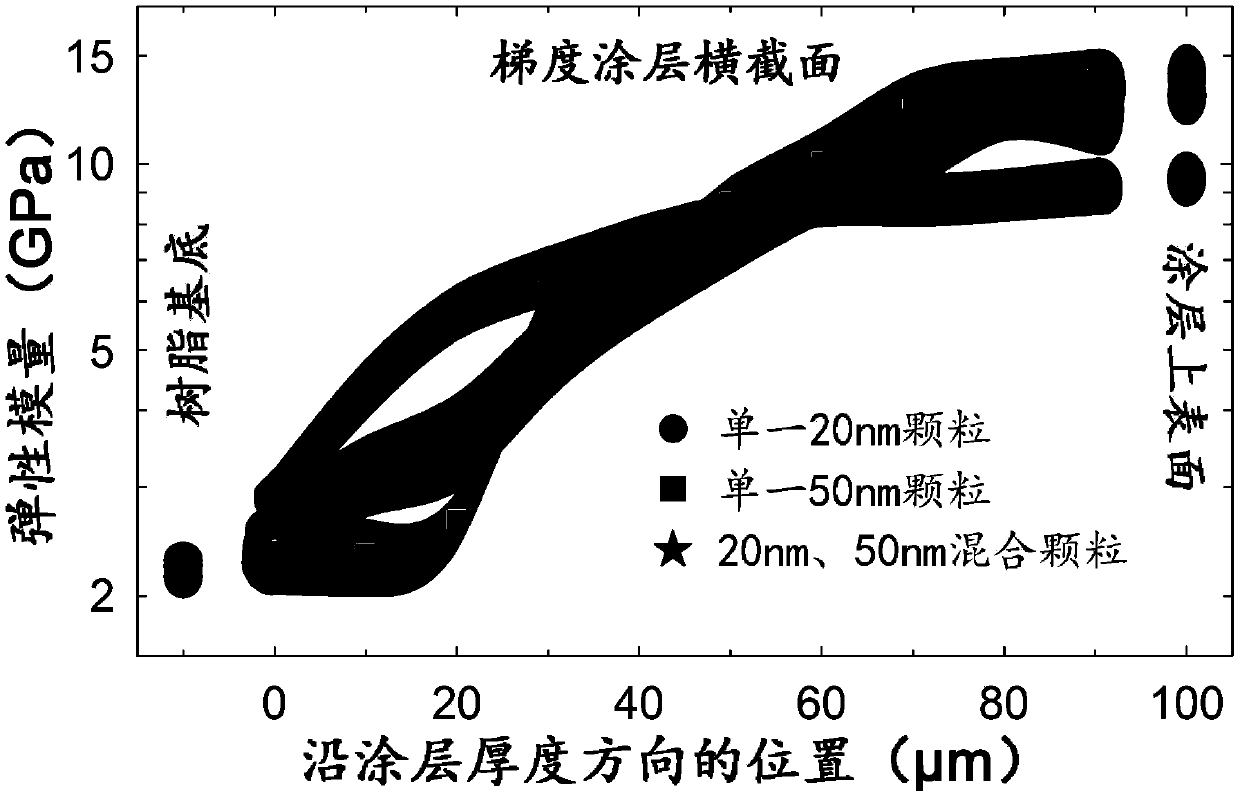

[0027] figure 2 is the concentration diagram of magnetic nanoparticles in each interface of the coating; wherein, curves a-c are the mixed solution containing only 20nm magnetic nanoparticles, the mixed solution containing only 50nm magnetic nanoparticles and the mixed solution of 20n...

Embodiment 2

[0031] Example 2 of the present invention is a preparation method of a bionic functionally graded coating. On the basis of Example 1, the mass fraction of magnetic nanoparticles in the mixed solution is 15%-25%.

Embodiment 3

[0032] Embodiment 3 of the present invention is a preparation method of a bionic functionally graded coating. On the basis of Embodiment 1 or 2, the magnetic nanoparticles are Fe, Fe 2 o 3 , Fe 3 o 4 One or more of , Co and Ni.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com