Externally-mounted prefabricated sandwich type thermal-insulation concrete wallboard and assembling system and construction method thereof

A technology of prefabricated concrete and thermal insulation wall panels, applied in passive houses, climate sustainability, building components, etc., can solve problems such as insufficient strength of connection structures, and achieve the effects of high rigidity, improved integrity, and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

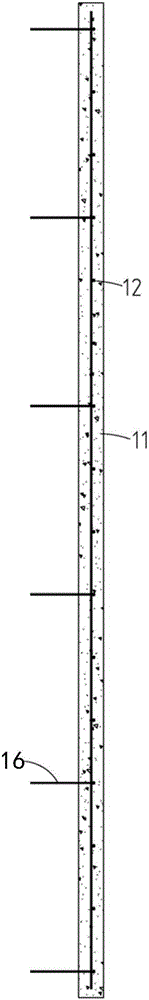

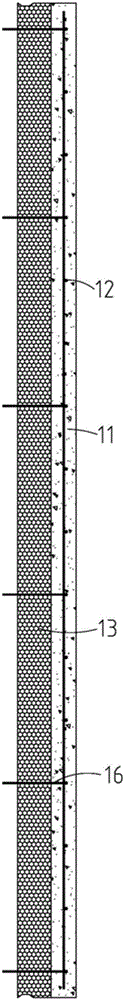

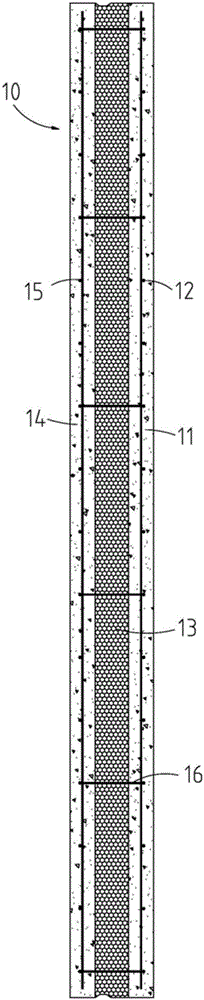

[0060] For the benefit of understanding of the present invention, below in conjunction with accompanying drawing Figure 4 to Figure 18 and examples are described.

[0061] The invention provides an externally hung prefabricated concrete sandwich insulation wall panel, an assembly system and a construction method thereof.

[0062] see Figure 4 to Figure 6 , illustrating the structure of the thermal insulation wallboard of the present invention, the wallboard 20 mainly includes an outer blade 21, a layer of thermal insulation material 23 and an outer leaf reinforcement mesh 22, and the outer blade 21 is provided with an outer blade reinforcement mesh 22. The inner leaf plate 24 is provided with an inner leaf steel mesh 25, and the thermal insulation material layer 23 is arranged between the outer leaf plate 21 and the inner leaf plate 24 and a steel bar truss is inserted; the steel bar truss is a planar steel bar truss structure , which includes continuously bent truss webs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com