Patents

Literature

33results about How to "Effective force transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

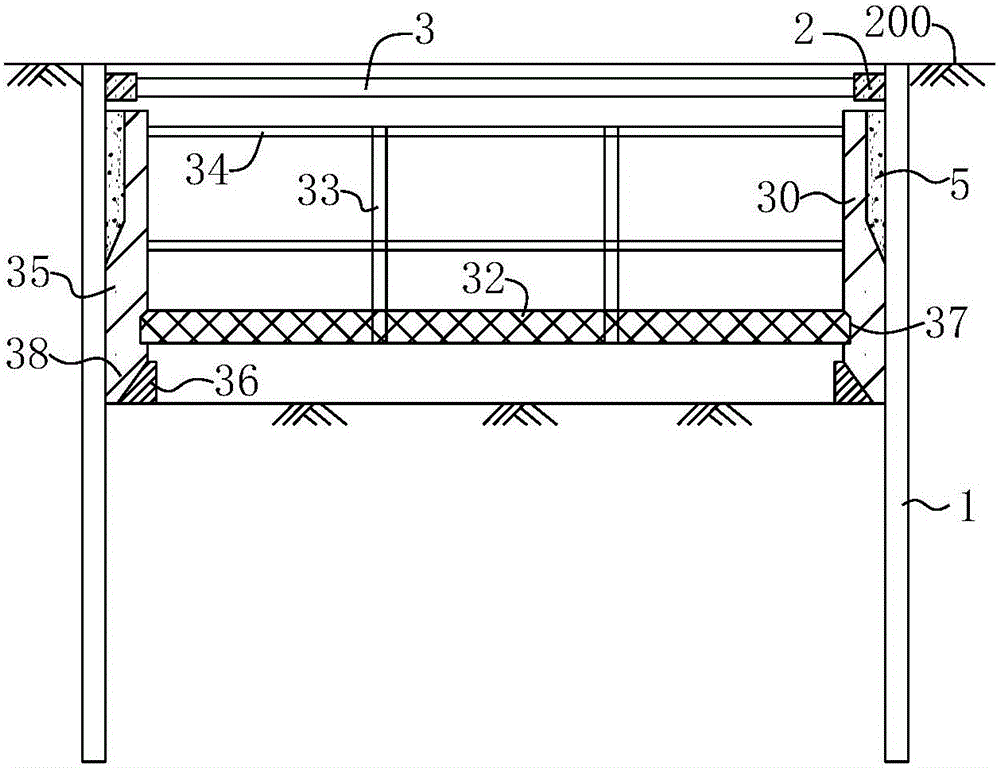

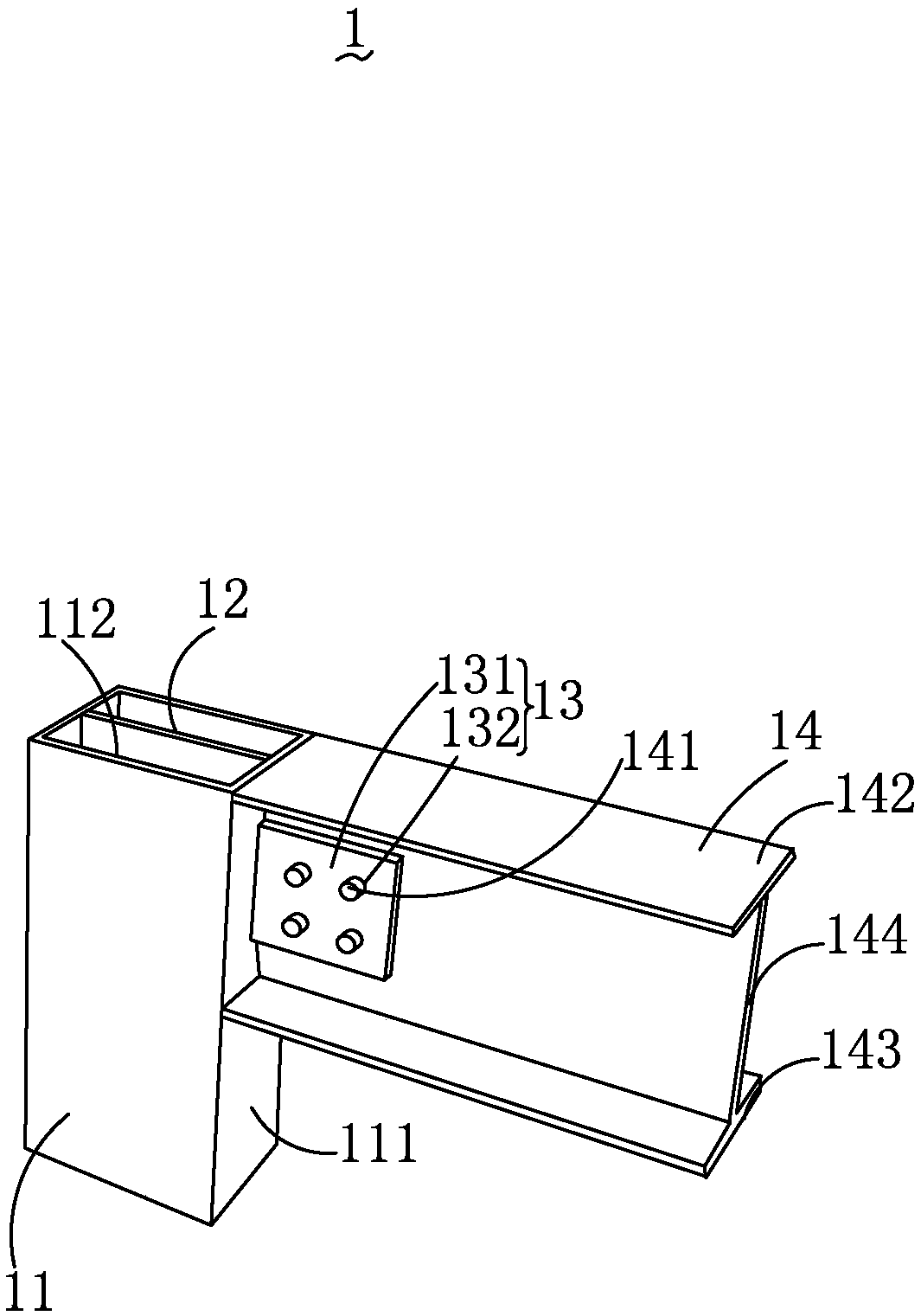

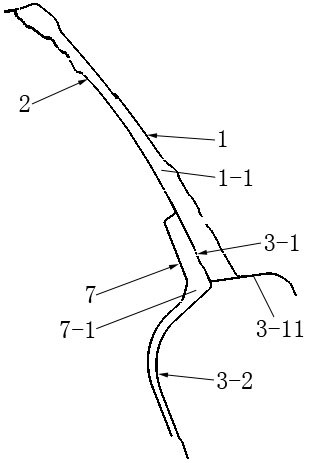

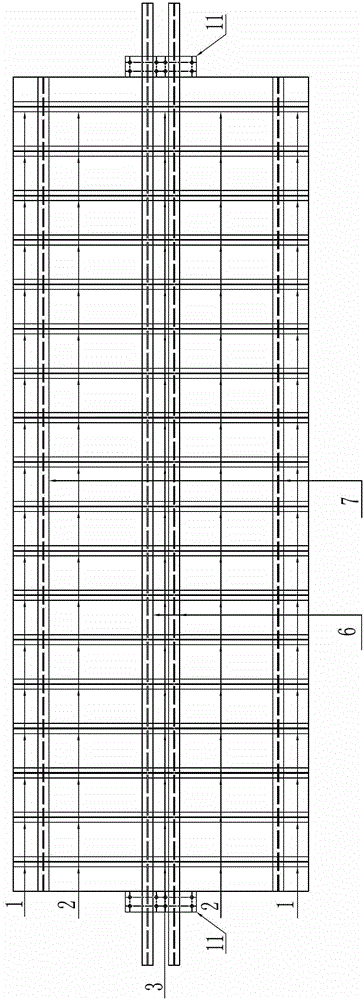

Assembled reinforced concrete beam-slab structural system with cast-in-situ layer in building structure

ActiveCN106065663AReduce workloadImprove standardizationFloorsLoad-supporting elementsReinforced concreteEngineering

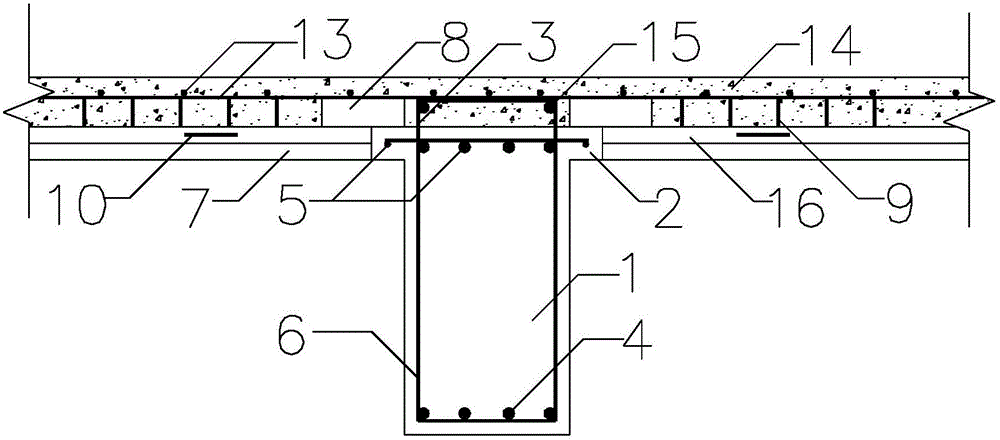

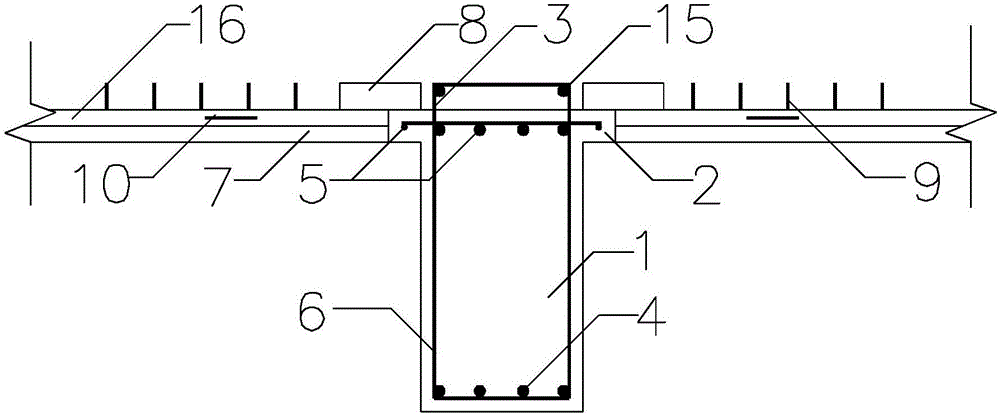

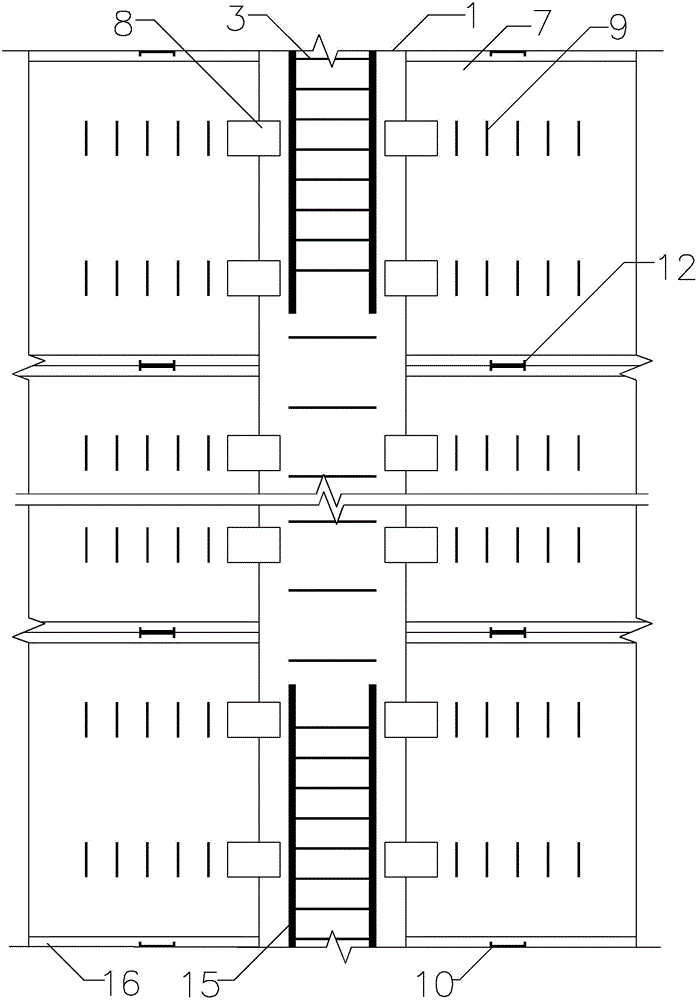

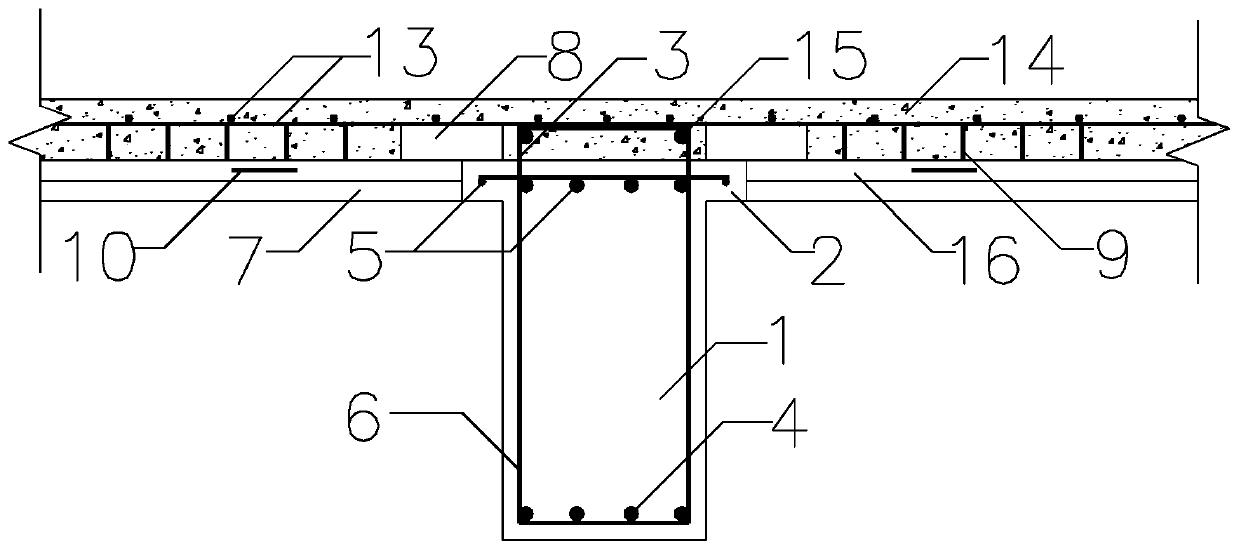

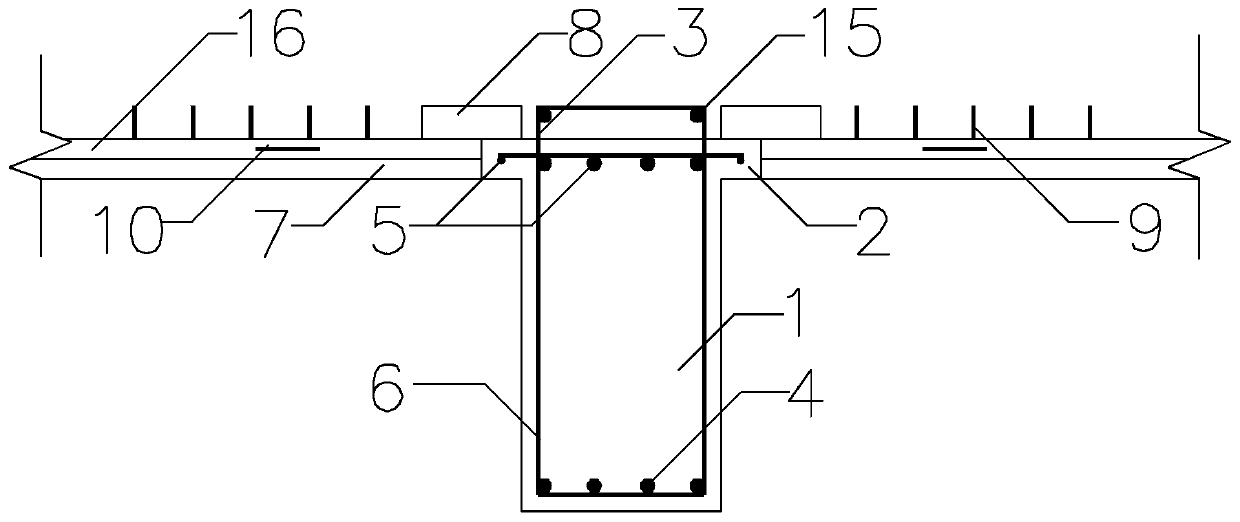

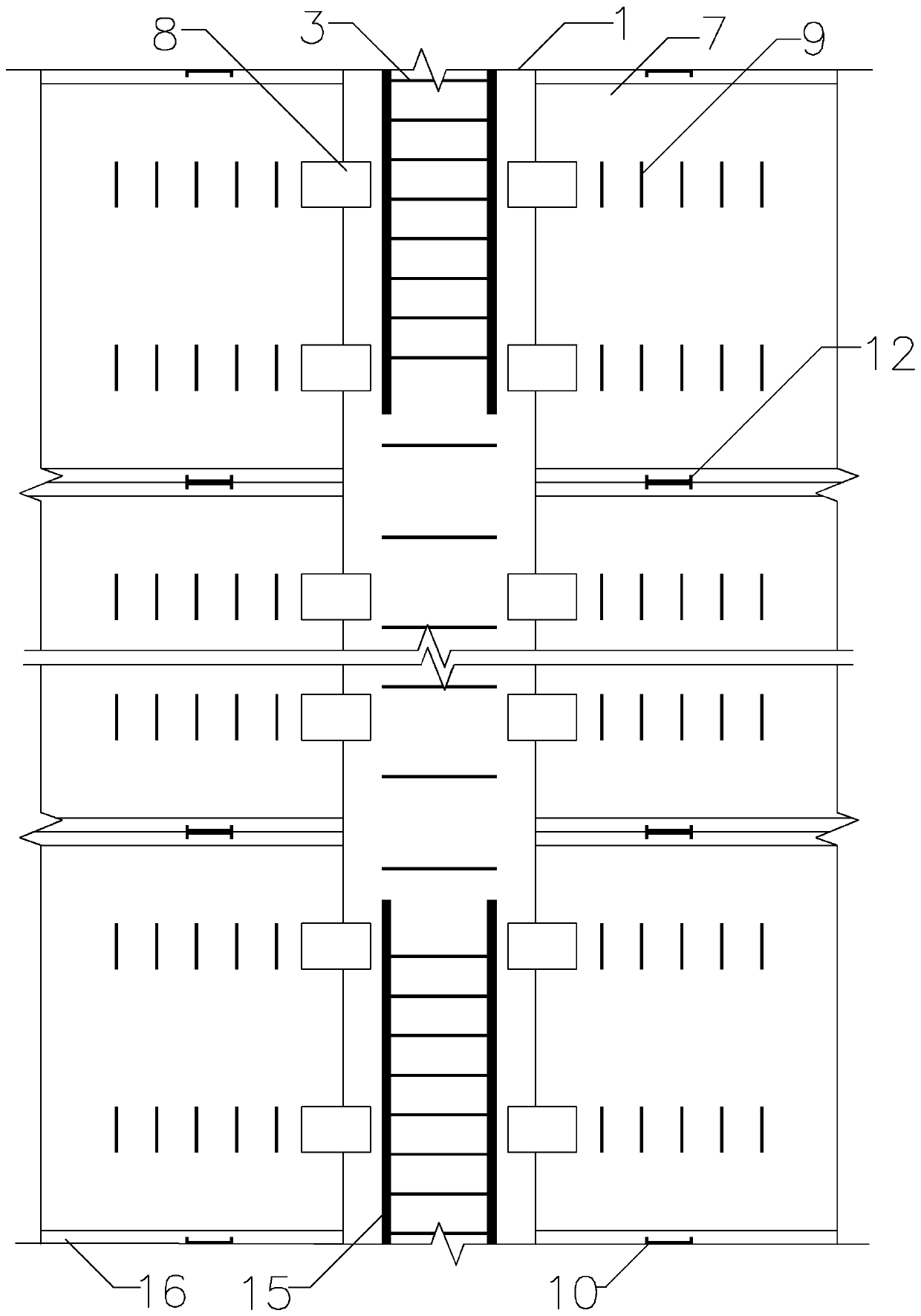

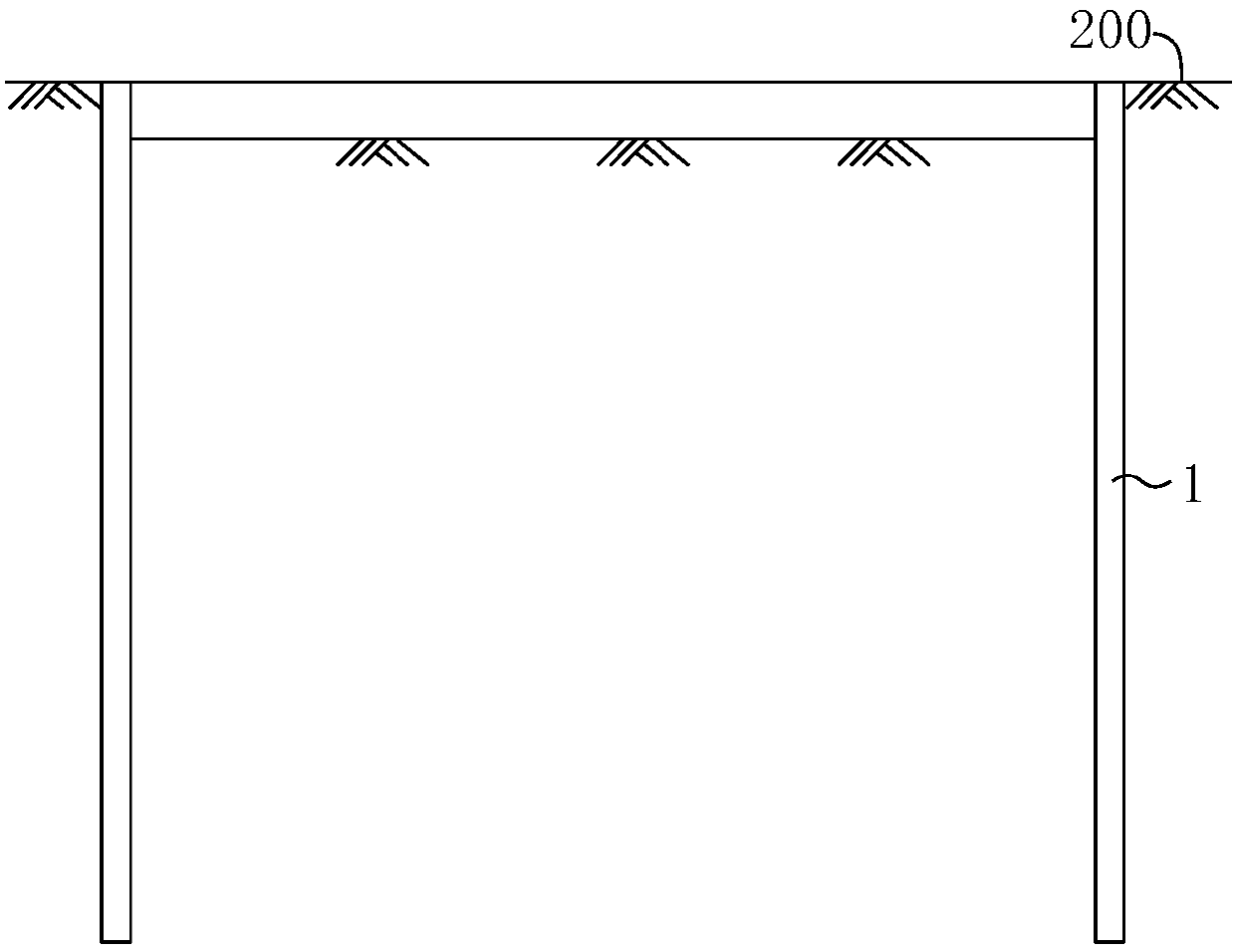

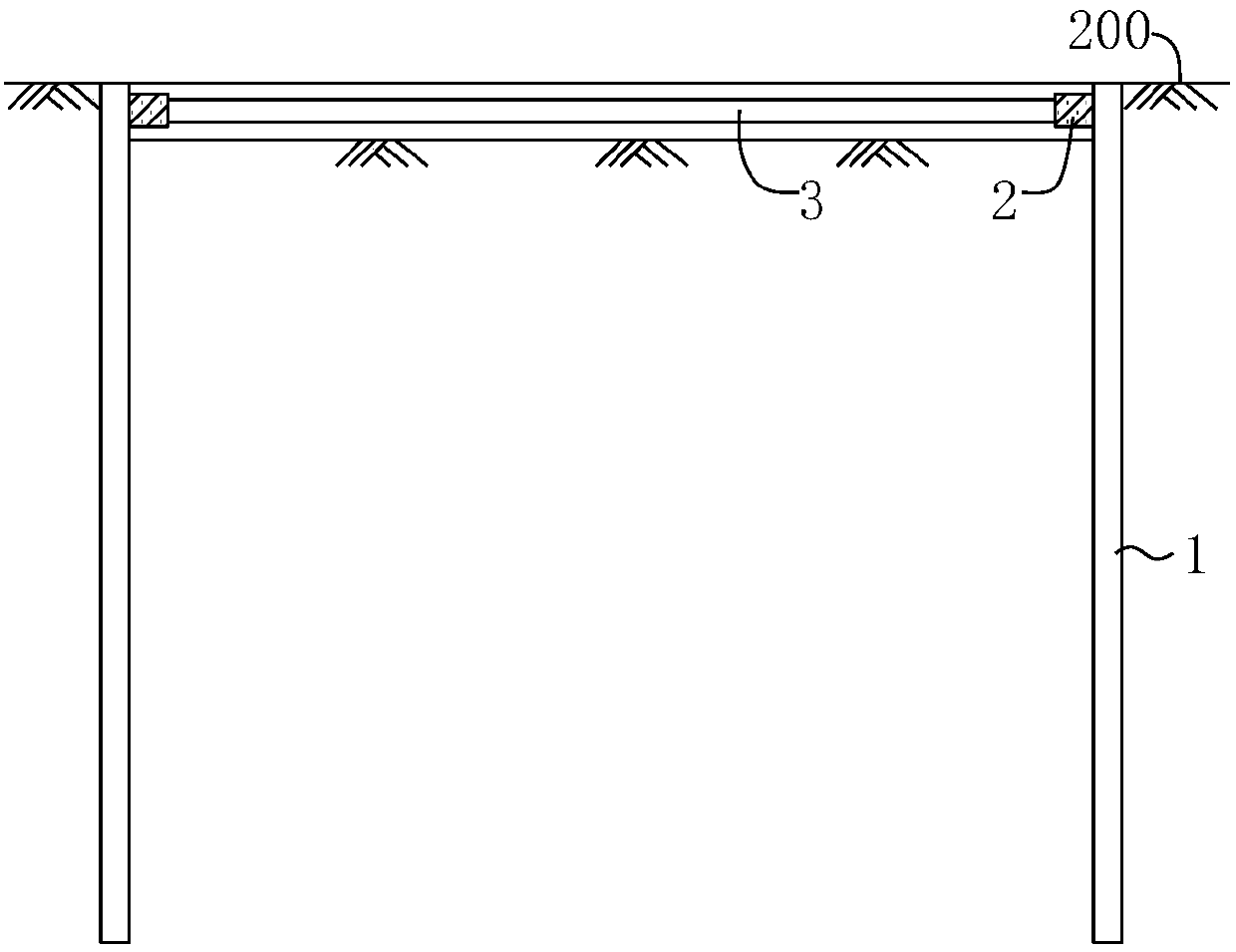

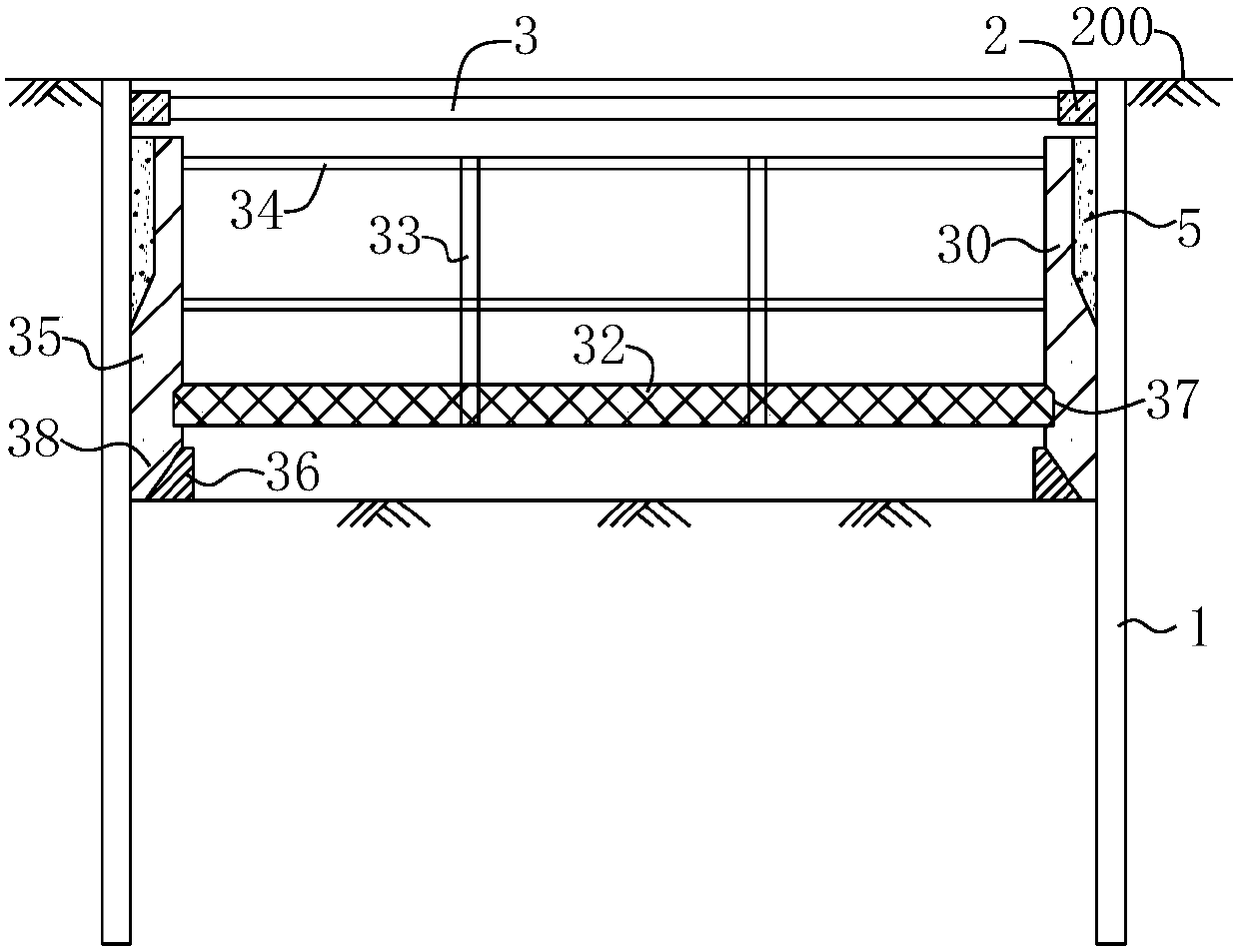

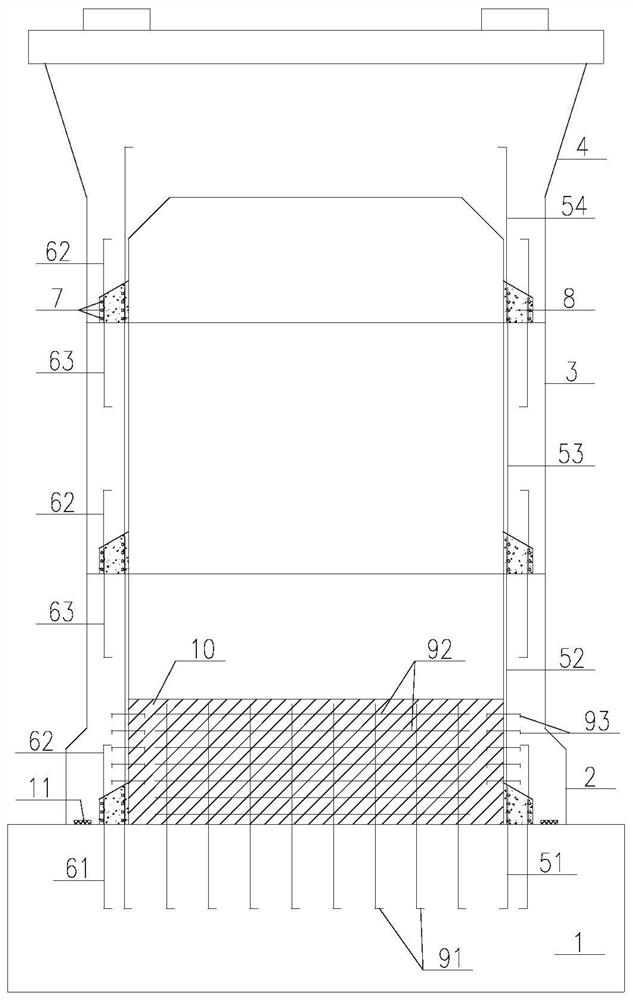

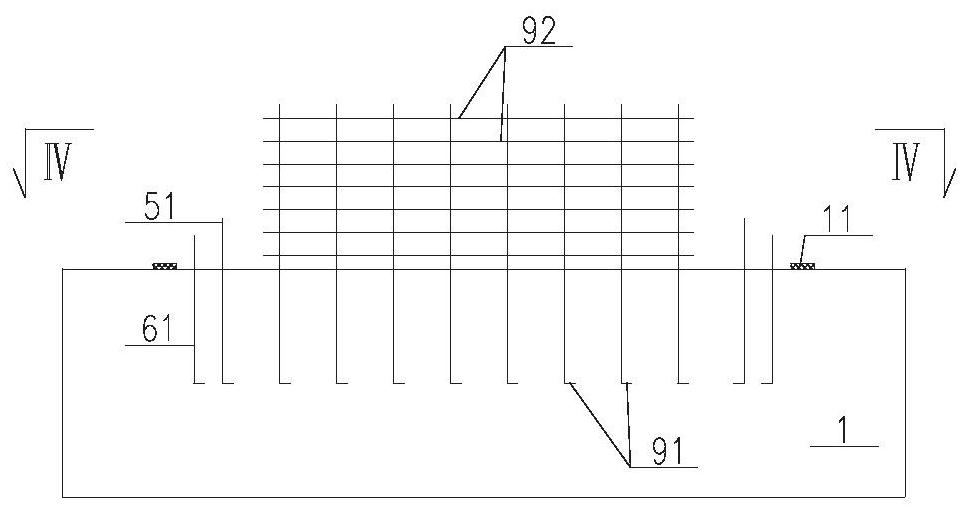

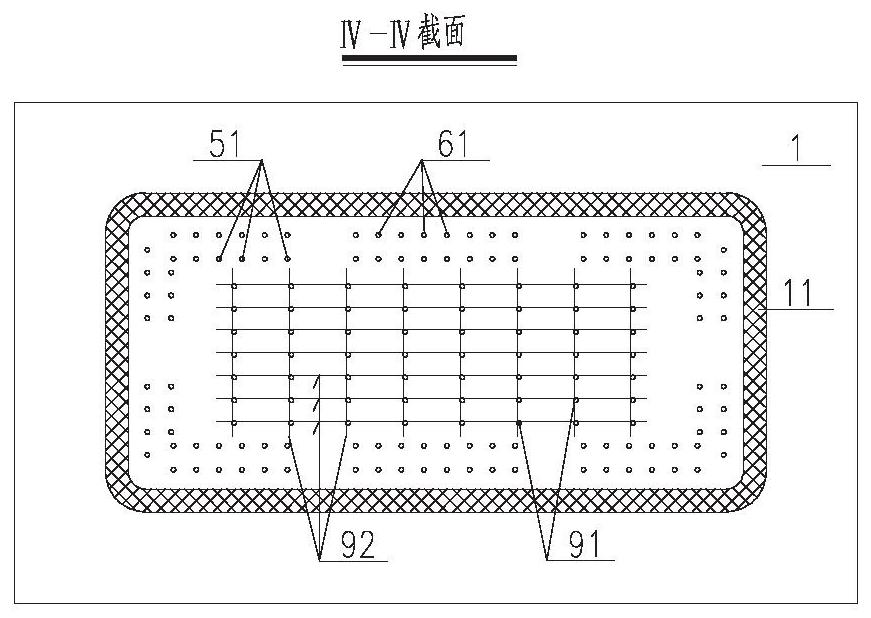

The invention discloses an assembled reinforced concrete beam-slab structural system with a cast-in-situ layer in a building structure. The assembled reinforced concrete beam-slab structural system comprises a superposed beam, a superposed slab, reinforcing mesh pieces, the cast-in-situ concrete superposed layer and beam negative reinforcements, wherein the superposed beam is a reinforced concrete precast beam; outwardly projecting tongue-and-grooves are formed in two sides of the upper part of the superposed beam; the superposed slab is horizontally arranged and is a reinforced concrete precast slab; cover-plate-type tongue-and-grooves are formed at the positions, corresponding to the outwardly projecting tongue-and-grooves, on two sides of the superposed slab, and overlapped on the outwardly projecting tongue-and-grooves; the reinforcing mesh pieces and the beam negative reinforcements are horizontally arranged above the superposed beam and the superposed slab; the reinforcing mesh pieces are bundled up with corresponding reinforcements in the superposed beam and the superposed slab; the beam negative reinforcements are bundled up with corresponding reinforcements in the superposed beam; after arrangement of the reinforcing mesh pieces and the beam negative reinforcements, concrete is poured to form the cast-in-situ concrete superposed layer. The assembled reinforced concrete beam-slab structural system has favorable integrity and mechanical property, and the integrity and the anti-seismic property can be improved.

Owner:广东省建科建筑设计院有限公司

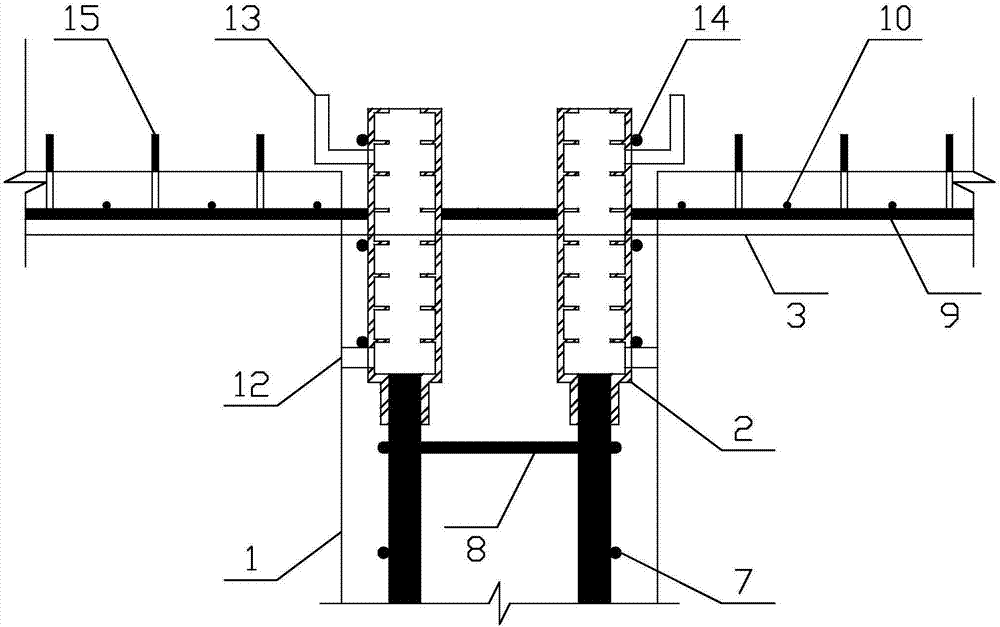

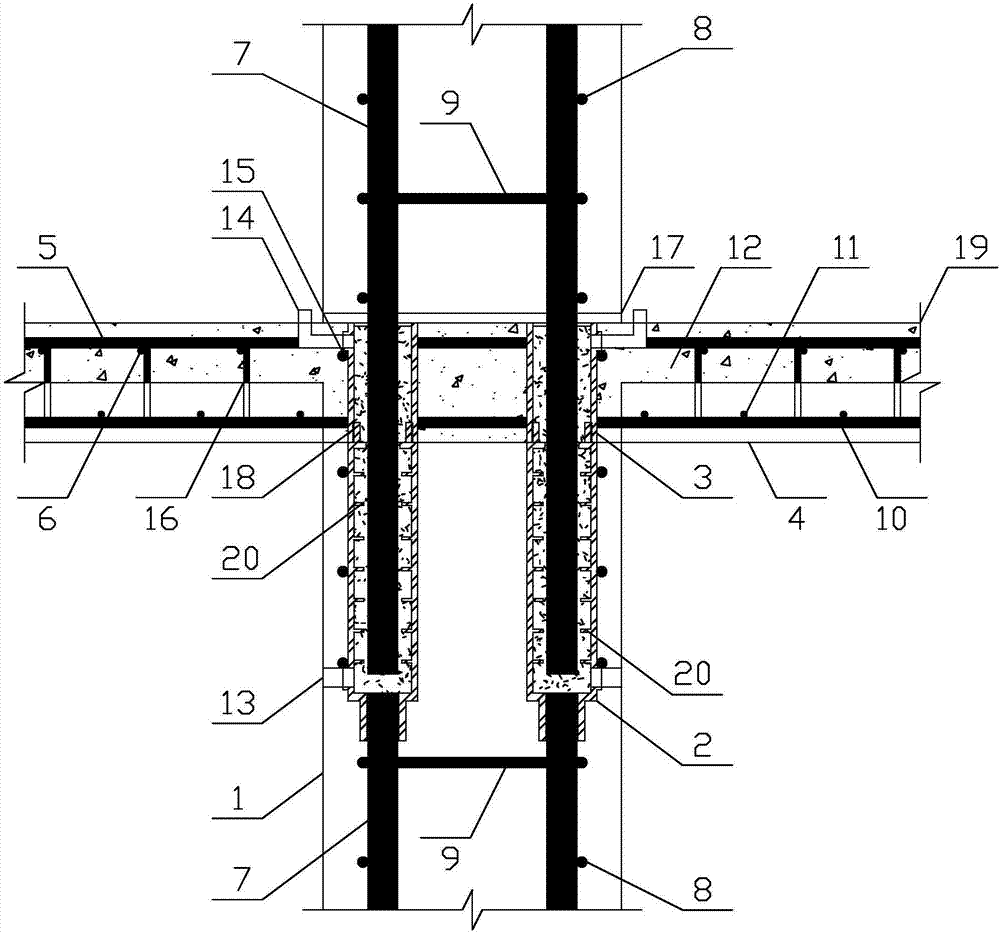

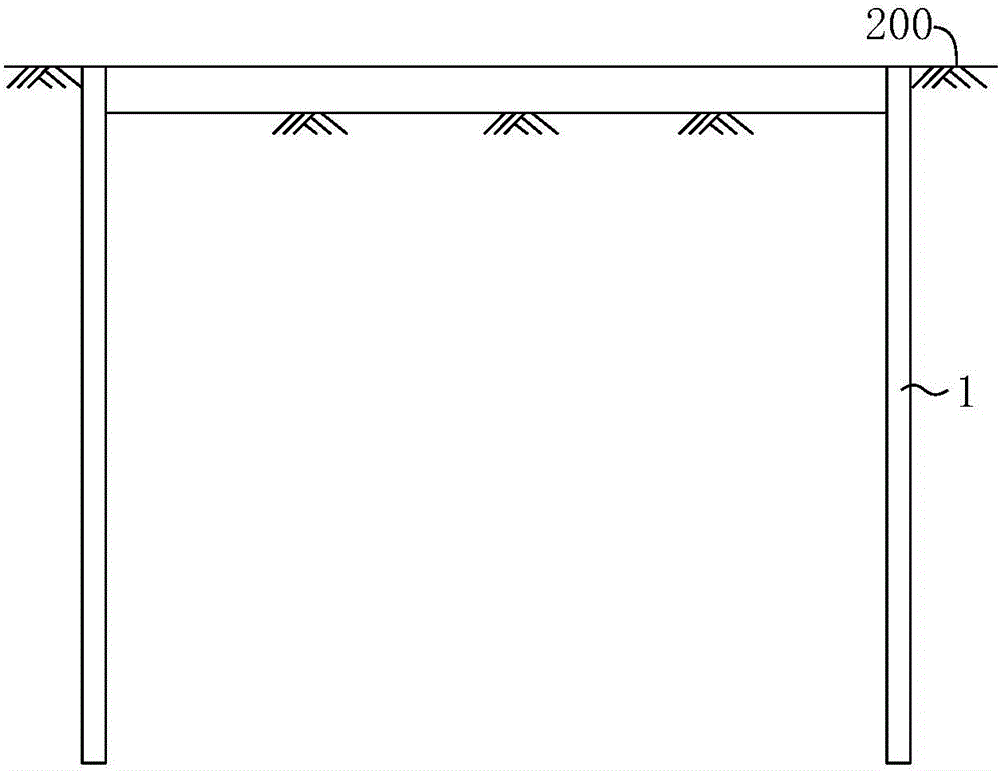

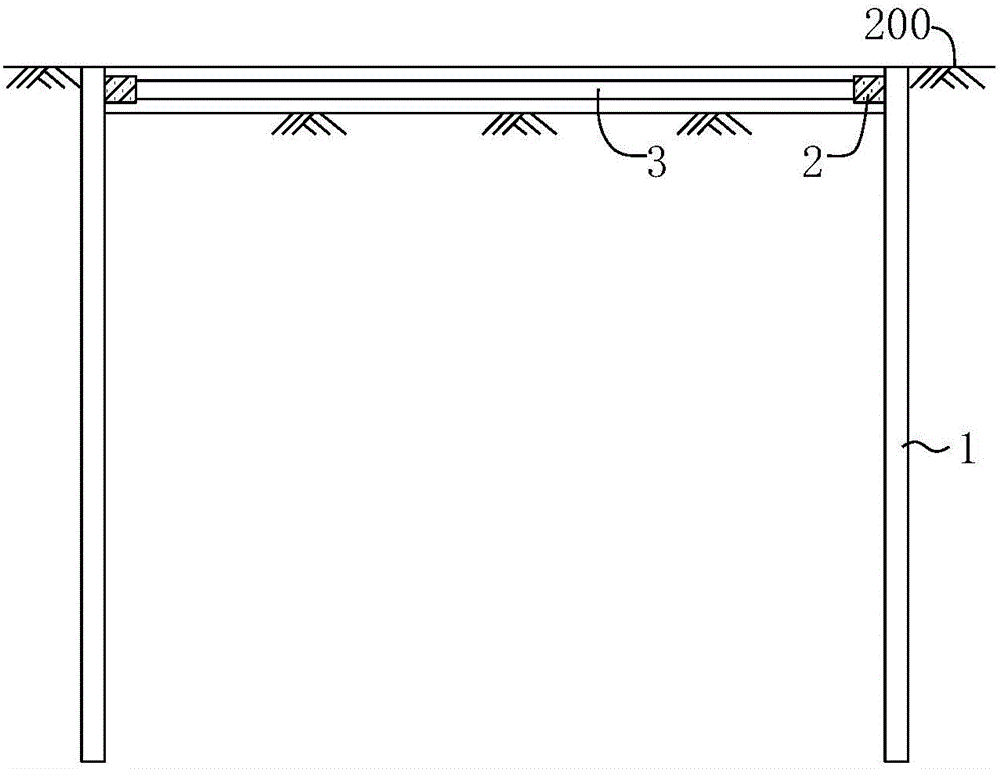

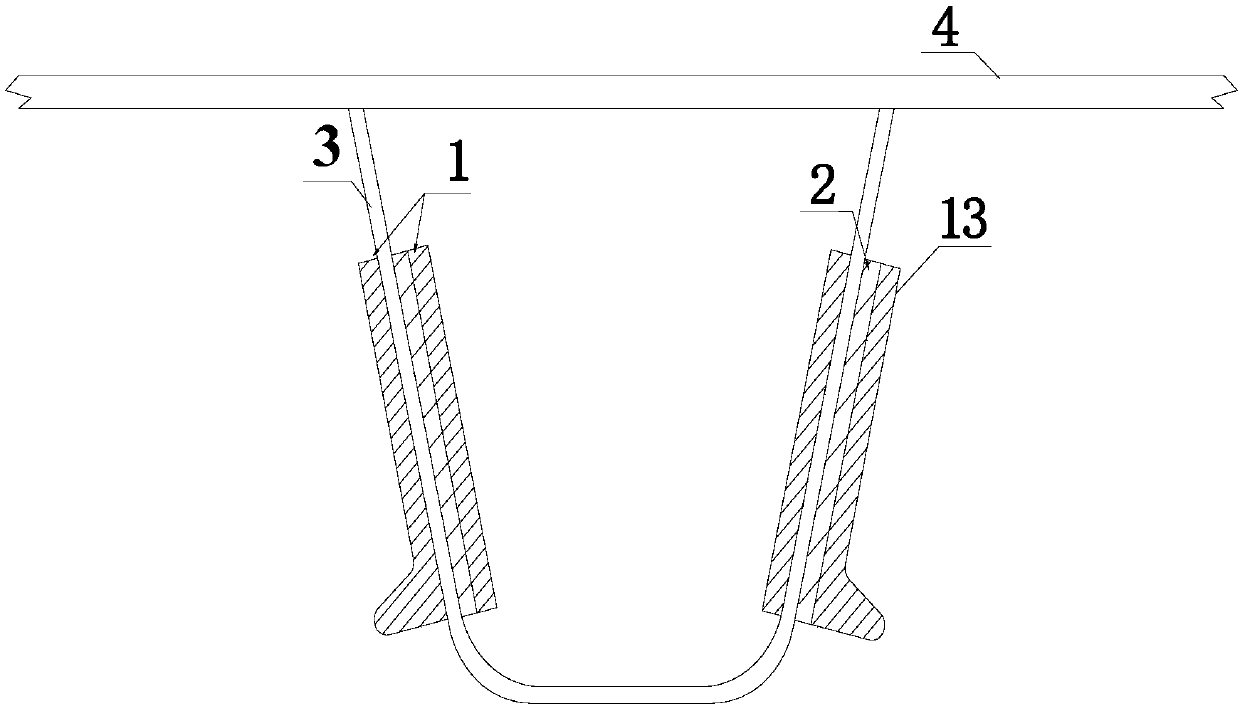

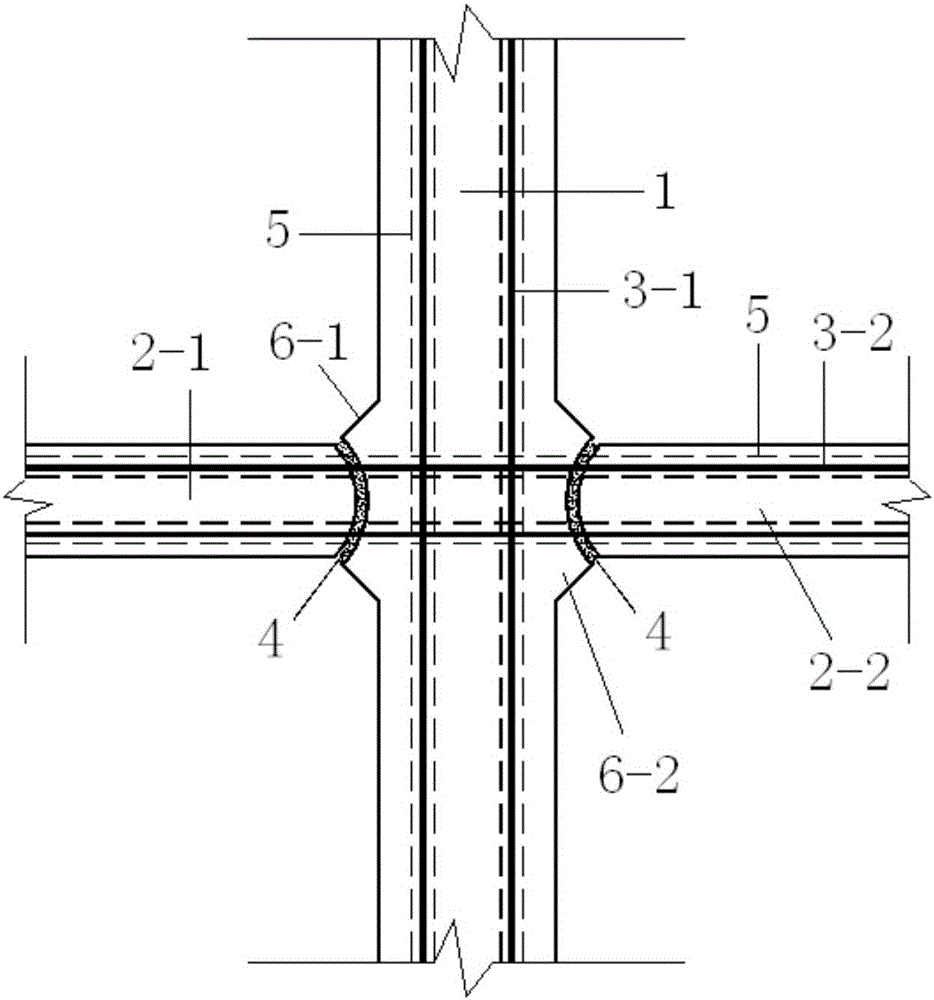

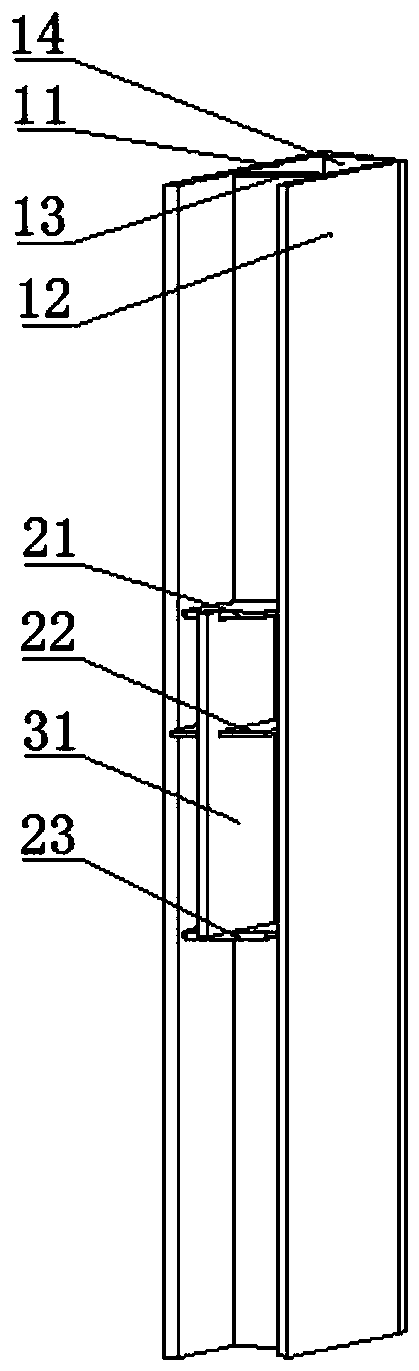

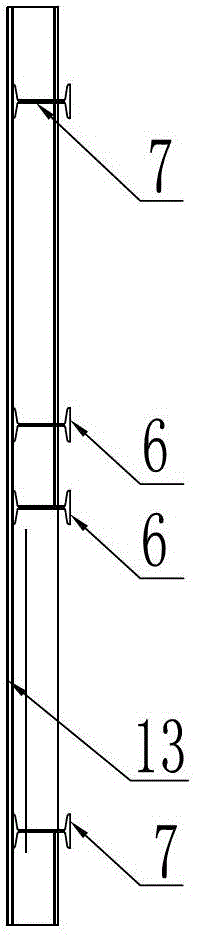

Fabricated prefabricated shear wall and laminated slab node

PendingCN107100290AAvoid the situation of pulling offImprove integrityWallsProtective buildings/sheltersSlurryShock resistance

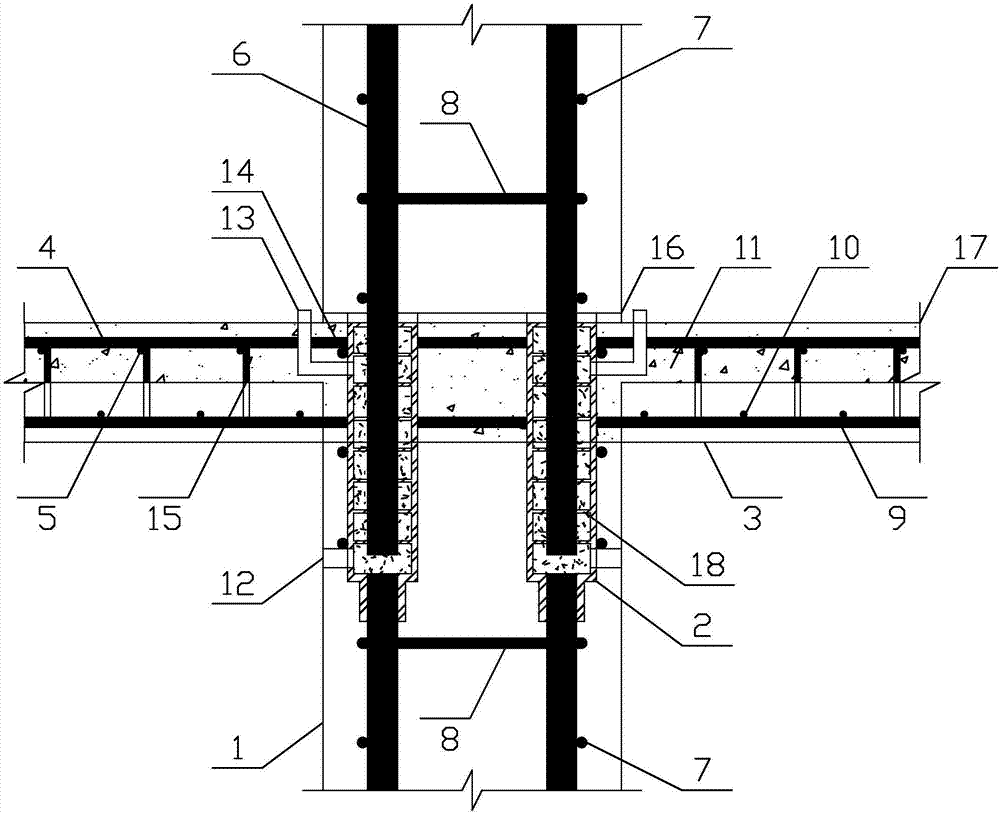

The invention discloses a fabricated prefabricated shear wall and laminated slab node. The fabricated prefabricated shear wall and laminated slab node comprises a prefabricated shear wall and a laminated slab; a grouting sleeve is arranged at a node body of the prefabricated shear wall and the laminated slab, the lower portion of the grouting sleeve is buried in the upper end of the prefabricated shear wall, and the rest part of the grouting sleeve is located in a post-poured concrete laminated layer of the laminated slab; the bottom end of the grouting sleeve is arranged at the top ends of vertical steel bars located in the prefabricated shear wall, the vertical steel bars downwards and outwards extend out of a prefabricated shear wall located on an upper floor, and the vertical steel bars are inserted into the grouting sleeve from the top end of the grouting sleeve; and a slurry discharging pipe and a grouting pipe are arranged on the upper portion and the lower portion of the grouting sleeve correspondingly, and a grouting material is poured into the grouting sleeve from the grouting pipe till the grouting material overflows from the slurry discharging pipe to enable the grouting sleeve to be completely filled with the grouting material. The grouting sleeve is a connecting piece of the upper-layer shear wall and the lower-layer shear wall, and a plastic hinge is formed at the bottom of the grouting sleeve. The prefabricated shear wall and a prefabricated plate form the wall plate node in an engaged mode through mutual connecting and binding among the grouting sleeve, a steel bar net piece and the post-poured concrete, and integrality and shock resistance of the node are improved.

Owner:广东省建科建筑设计院有限公司 +1

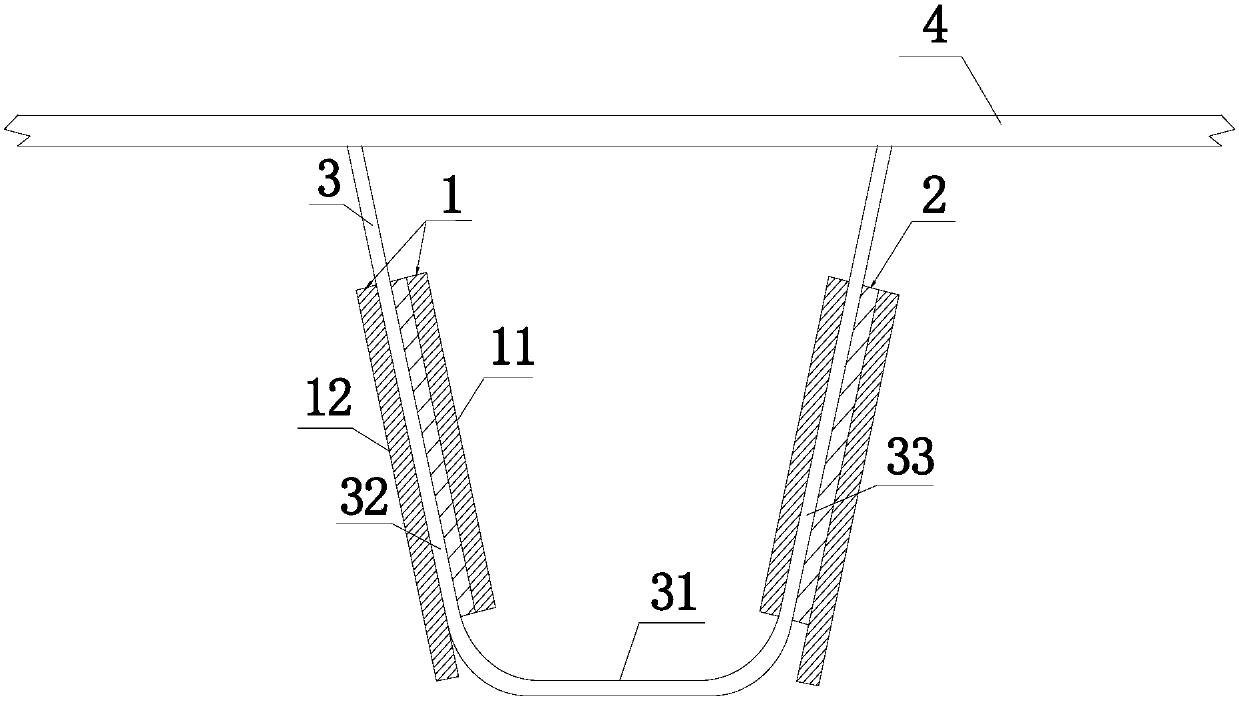

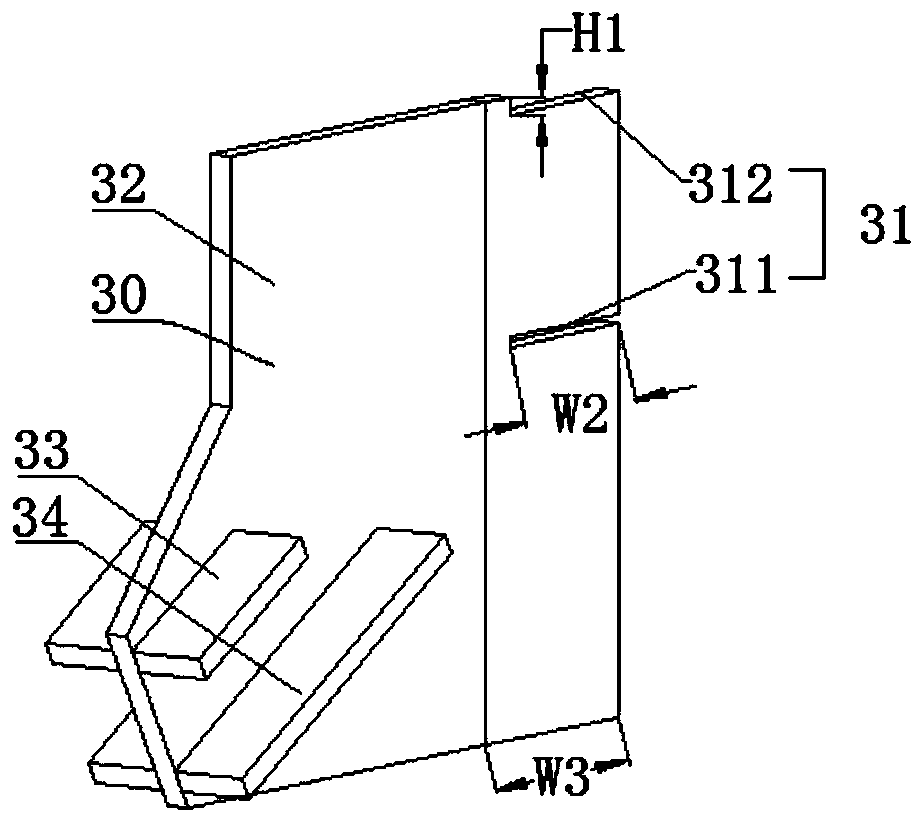

Joint of fabricated precast shear wall and laminated slab connected with fabricated precast shear wall by combined grouting sleeves

PendingCN106968381AImprove seismic performanceIncrease production capacityFloorsBuilding reinforcementsSteel barPlastic hinge

The invention discloses a joint of a fabricated precast shear wall and a laminated slab connected with the fabricated precast shear wall by combined grouting sleeves. The combined grouting sleeves are arranged at the joint. Each combined grouting sleeve comprises a first section sleeve body and a second section sleeve body; the top ends of the first section sleeve bodies are connected with the bottom ends of the second section sleeve bodies; the bottom ends of the first section sleeve bodies are connected on the top ends of vertical steel bars in the precast shear wall and completely pre-buried in the top ends of the precast shear wall, and the second section sleeve bodies are pre-buried in post-poured concrete laminated layers; the vertical steel bars extend downward out of the precast shear wall on the last storey, the vertical steel bars are inserted in the second section sleeve bodies from the top ends of the second section sleeve bodies and extend into the first section sleeve bodies; and mortar discharging pipes are arranged on the upper portions of the second section sleeve bodies, and grouting pipes are arranged on the lower portions of the first section sleeve bodies. The combined grouting sleeves serve as connecting pieces of the shear wall on the upper layer and the shear wall on the lower layer. Shear wall members form plastic hinges at the bottom. The shear wall and the precast slab form the joint through mutual connection and bonding occlusion among the sleeve bodies, steel bar meshes and post-poured concrete, and the integrity and anti-seismic performance of the joint are improved.

Owner:广东省建科建筑设计院有限公司 +1

Steel sheet pile support construction method for building underground garage open caisson

ActiveCN106013053AReduce the risk factorAvoid cumbersomeArtificial islandsExcavationsPurlinArchitectural engineering

The invention discloses a steel sheet pile support construction method for building an underground garage open caisson to reduce the construction complexity and improve the construction efficiency during open caisson building and reduce the building expenditure for the open caisson. According to the construction method, open caisson construction is carried out in an area defined by a steel sheet wall, wherein building of a wall of the open caisson is carried out in a manner of segment-by-segment construction from bottom to top. The building method comprises the steps that steel sheet piles are sunk, and the continuous steel sheet pile wall is formed; a certain of earthwork is excavated in the area defined by the steel sheet pile wall, then, a pile block enclosure purlin is erected on the top of the steel sheet pile wall, and horizontal braces are built on the inner side of the pile block enclosure purlin; and then, open caisson building is finished through a method that earthwork is excavated segment by segment, the wall is poured segment by segment and sinking is carried out.

Owner:JIANGSU DONGHENAN GEOTECHNICAL TECH CO LTD

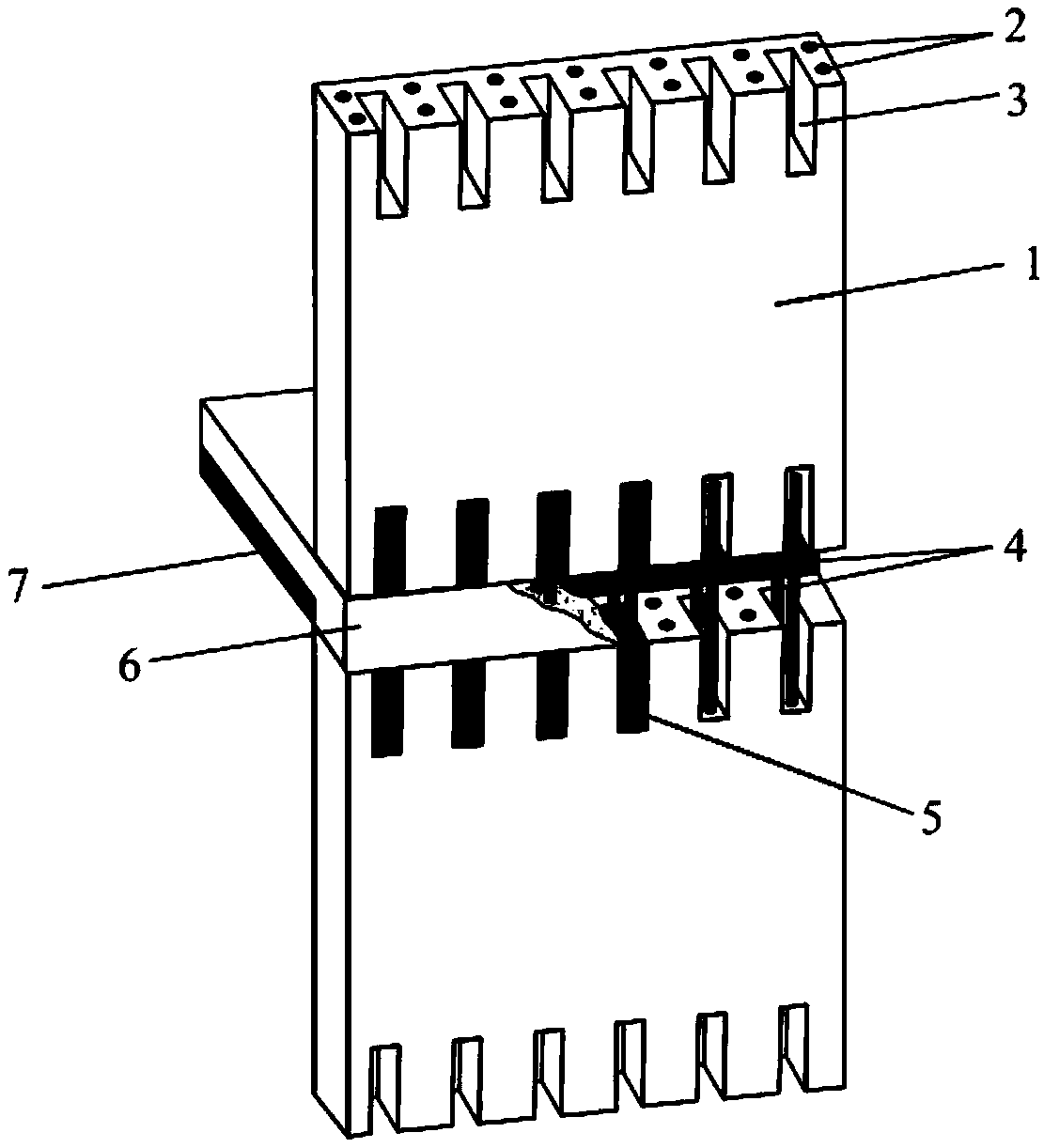

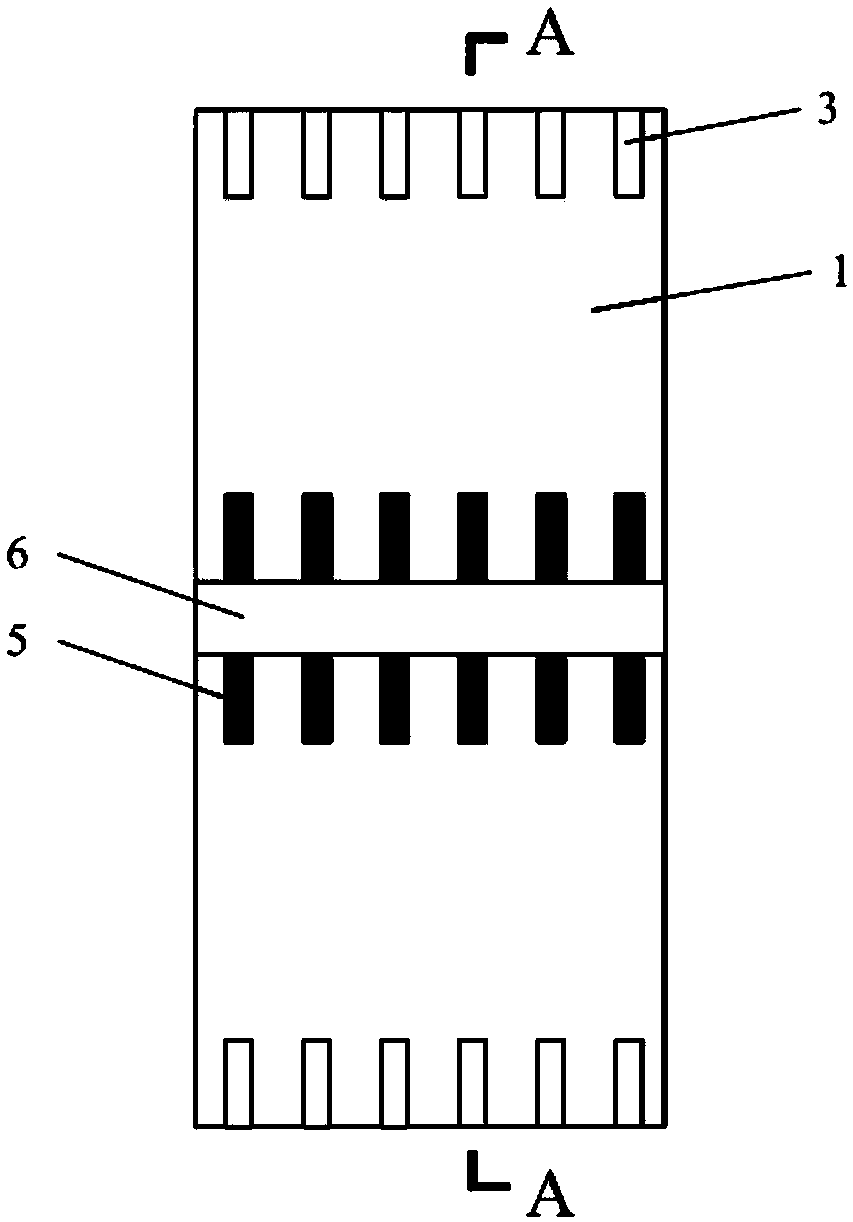

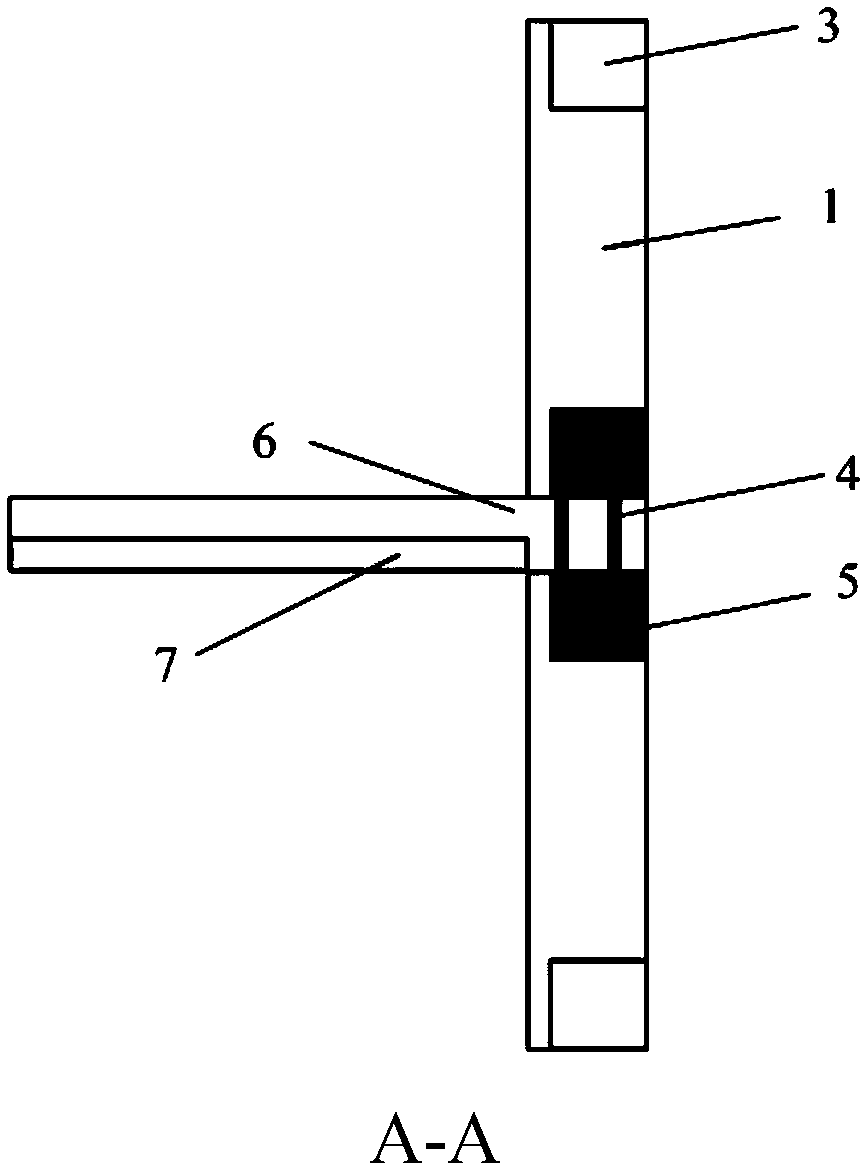

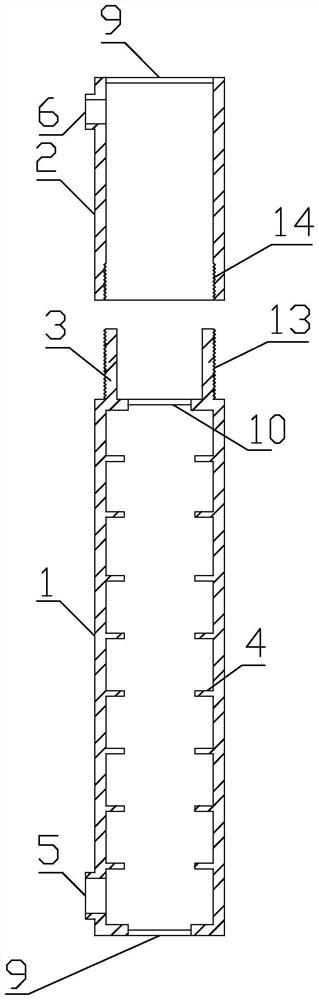

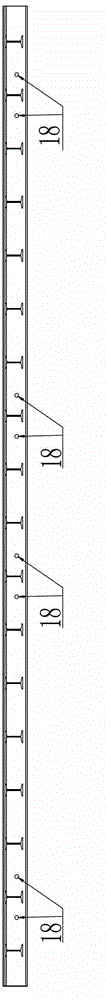

Vertical connection structure of prefabricated concrete shear wall and construction method thereof

InactiveCN109372155APull-out phenomenon does not occurImprove connection strengthWallsRebarPrecast concrete

The invention relates to a vertical connection structure of a prefabricated concrete shear wall and a construction method thereof, and belongs to the technical field of a building structure. The vertical connection structure comprises a prefabricated concrete shear wall, additional steel bars, hole filling cement-based cementing materials and cement concrete post-pouring strips, wherein one row ofstrip-shaped slot holes are reserved at each of the top and the bottom of the prefabricated concrete shear wall; the slot holes are distributed between vertical stress steel bars in the wall; when the prefabricated wall bodies are vertically spliced, the slot holes of the upper and lower layers of wall bodies are aligned and communicated in the splicing seam positions; the through length additional steel bars are put into the slot holes; and the cement-based cementing materials are poured for fixation. The concrete is cast in situ in the horizontal splicing seam positions to form the post-pouring strips. The upper layer prefabricated concrete shear wall and the lower layer prefabricated concrete shear wall are firmly connected in the vertical direction through the additional steel bars, the hole filling cement-based cementing materials and the concrete post-pouring strips; and the force is reliably transferred. The vertical connection structure of the prefabricated concrete shear wallhas the advantages that the connection performance is identical to that of the existing grouting sleeve connection structure; the integrality and the safety of the structure are effectively ensured;the stress mechanism is clear; the construction is convenient; and economic performance and practicability are realized.

Owner:TSINGHUA UNIV +1

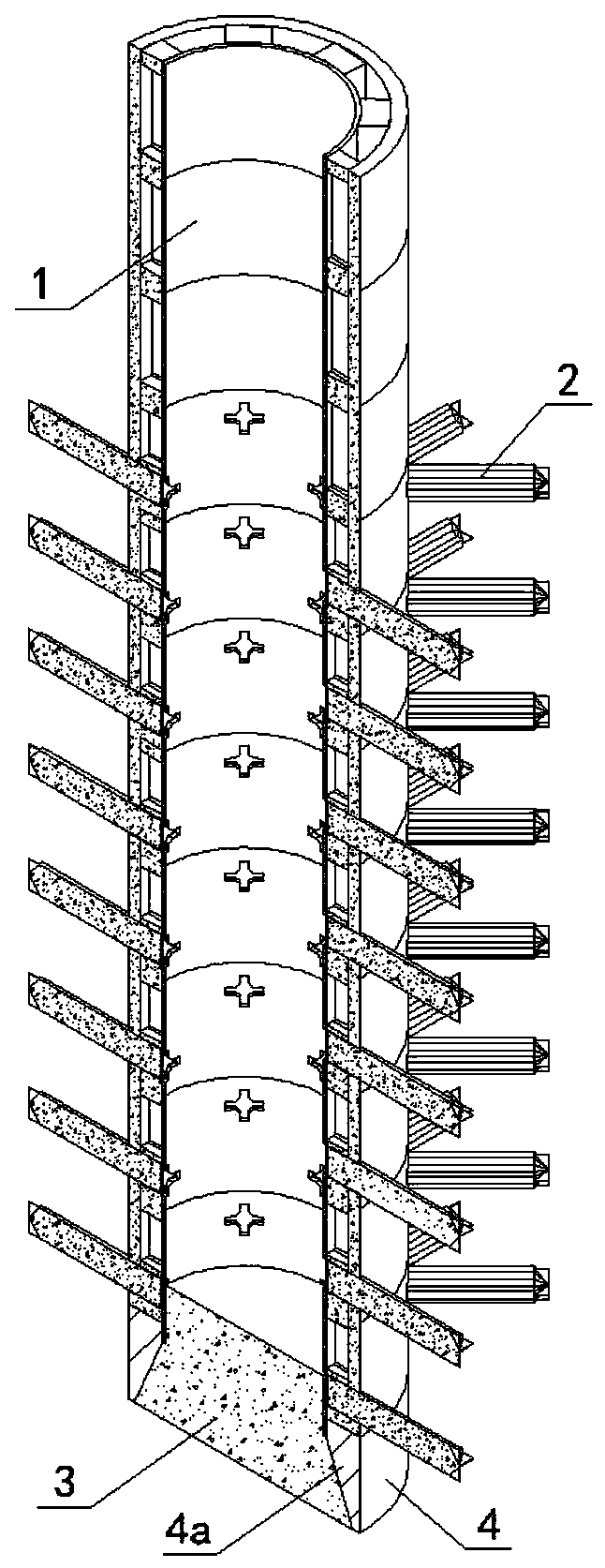

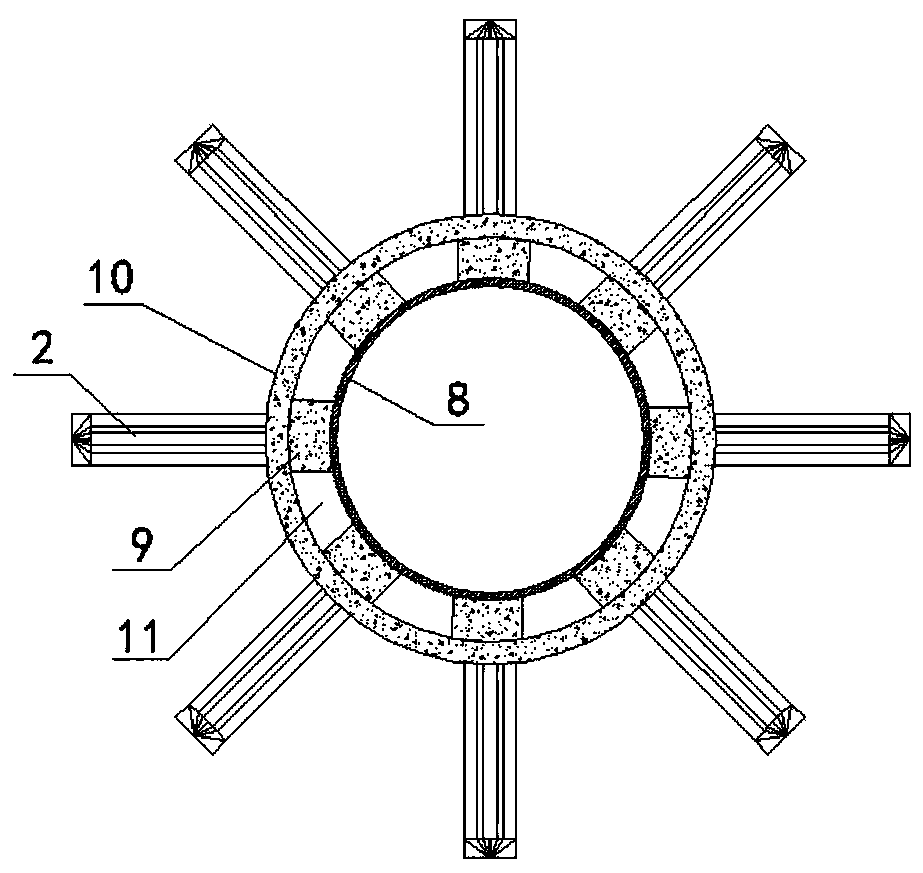

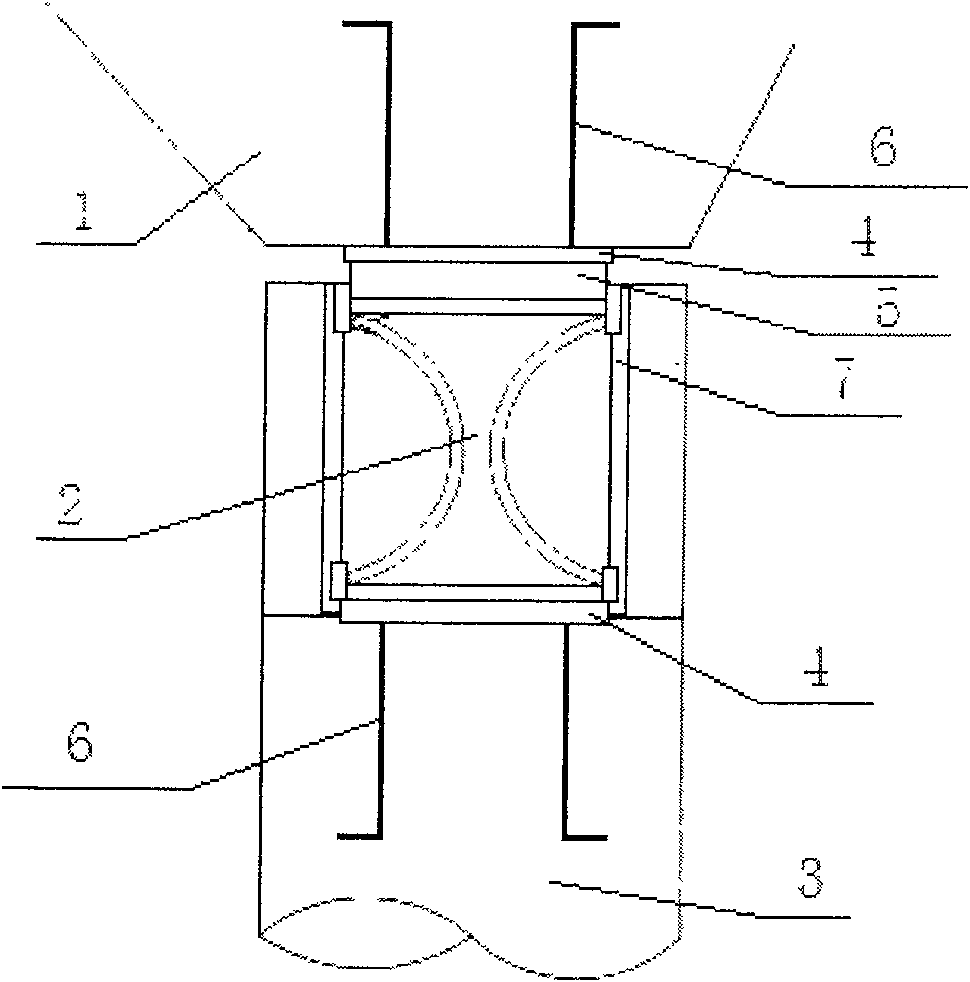

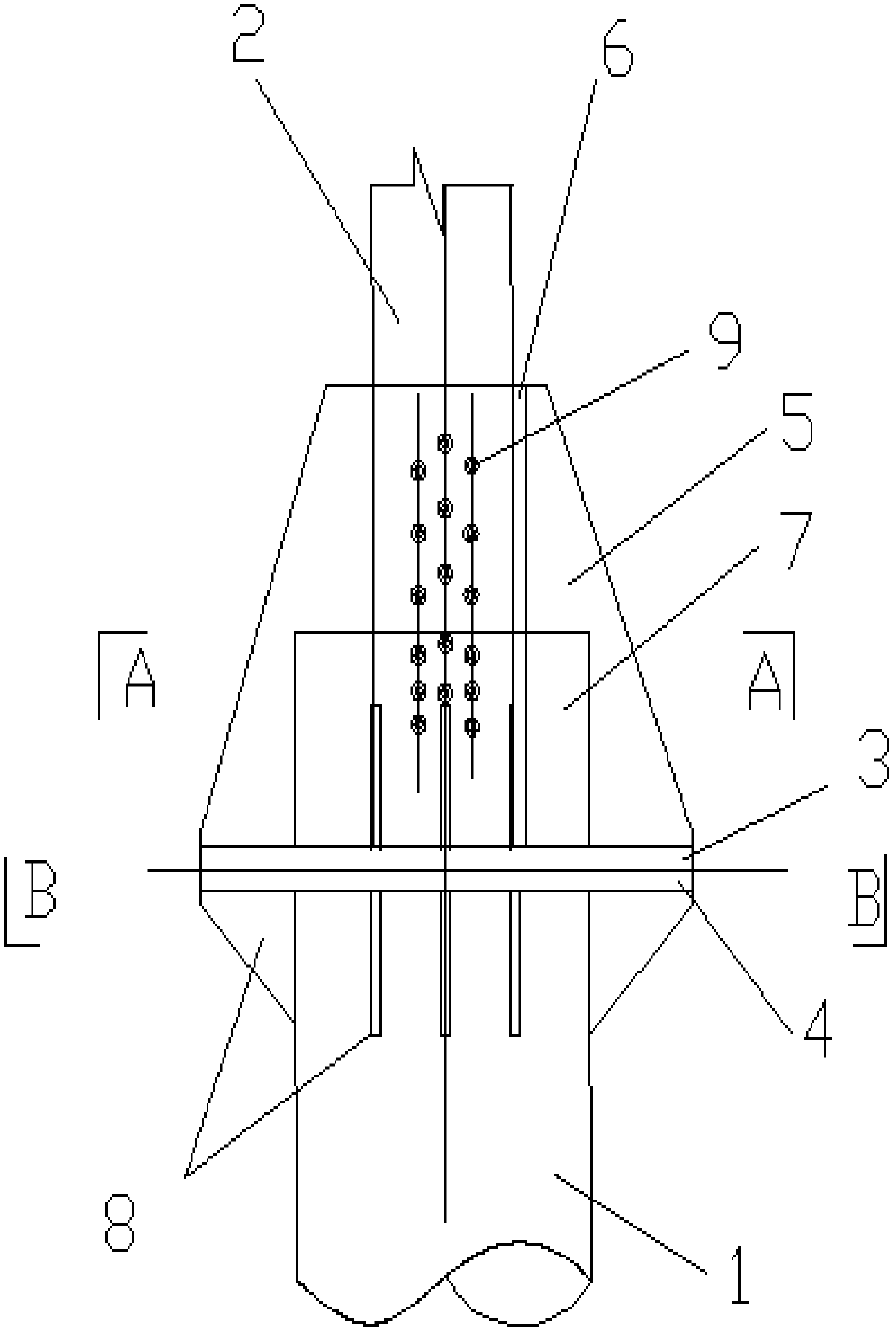

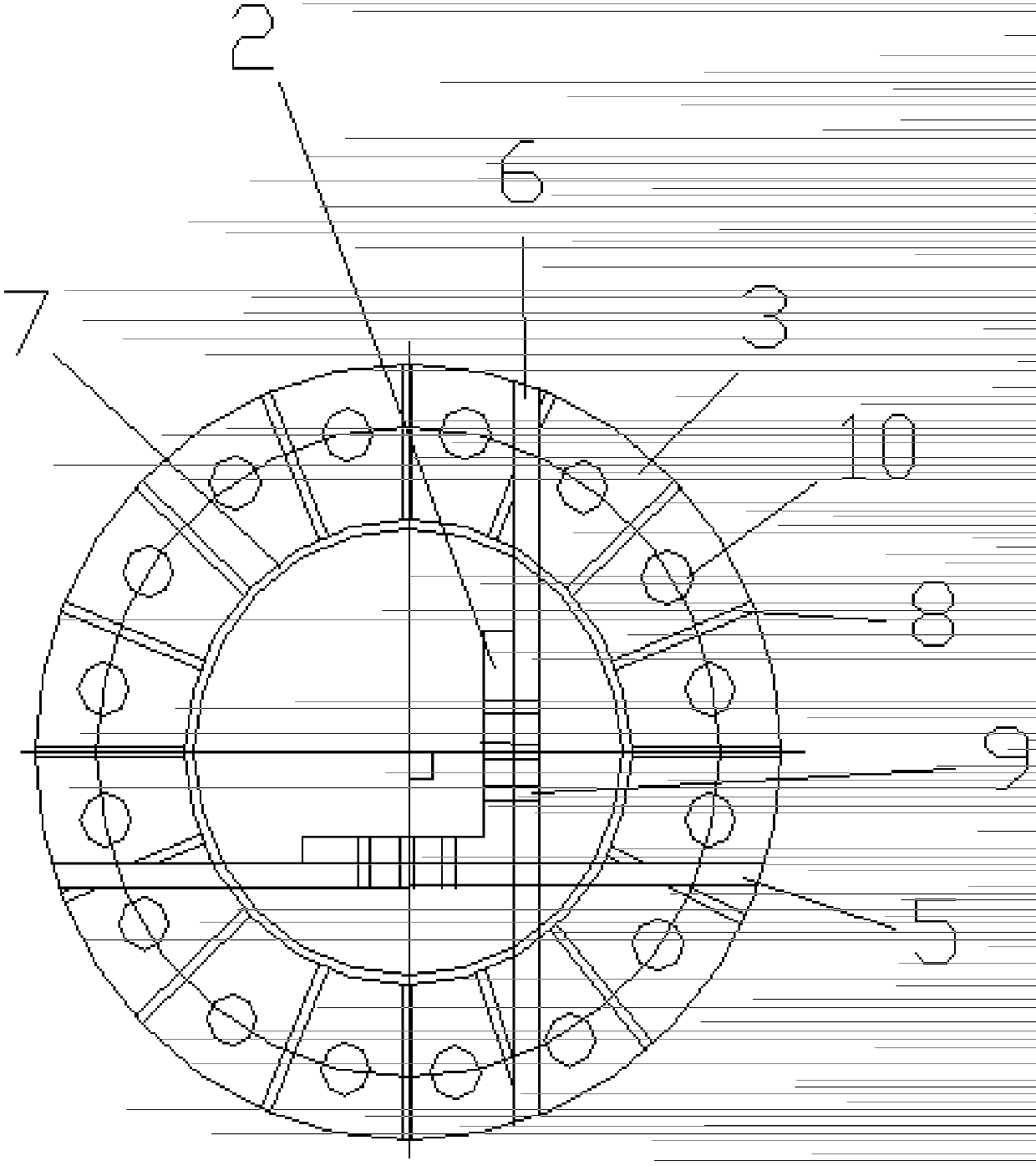

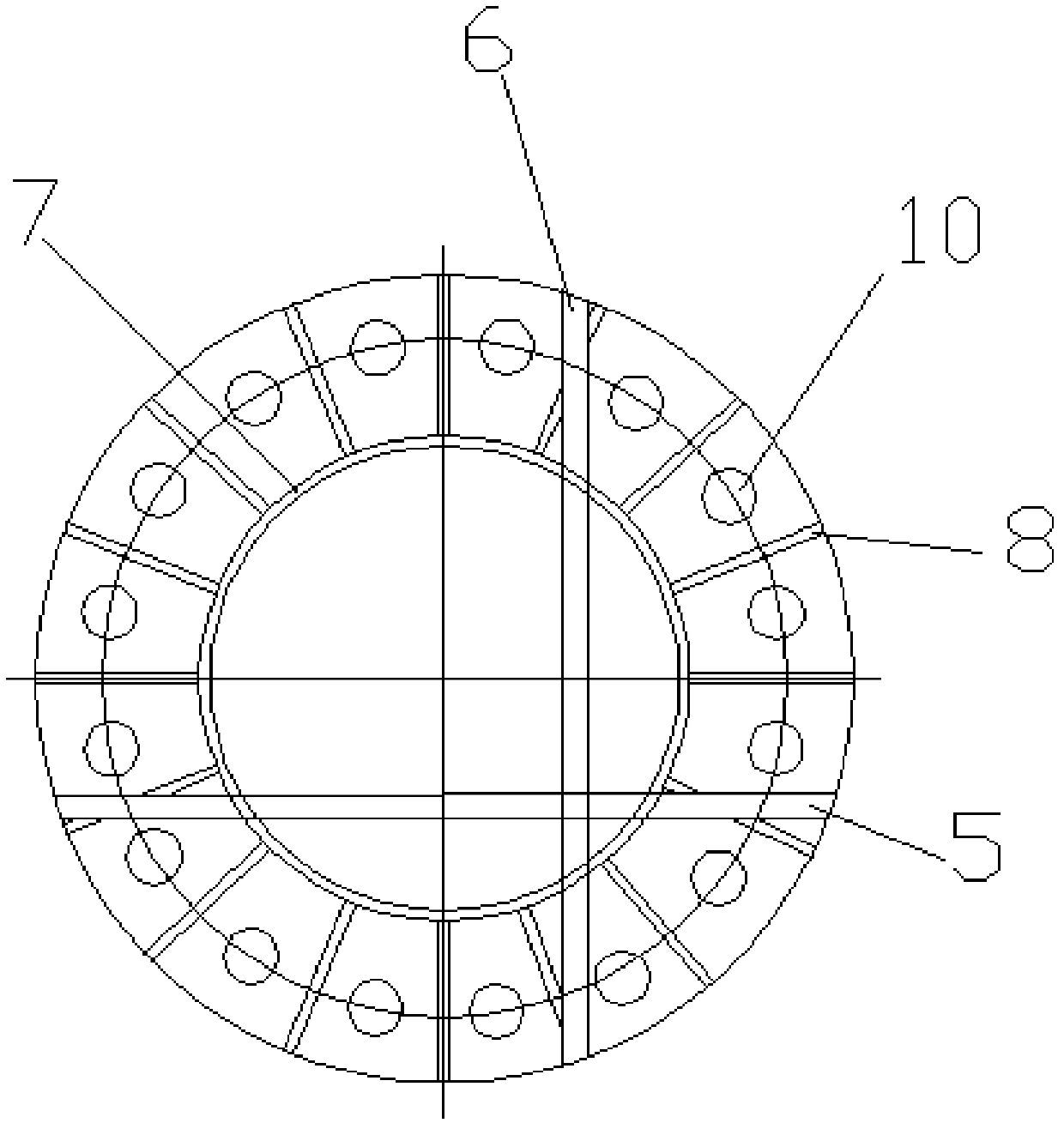

Two-wall hollow fabricated root-type open caisson foundation

PendingCN110093942AEffective force transmissionAvoid stress concentrationCaissonsEconomic benefitsDouble wall

The invention discloses a two-wall hollow fabricated root-type open caisson foundation. The two-wall hollow fabricated root-type open caisson foundation is composed of a shaft, root keys and a back cover, the shaft is of an annular tubular structure with two hollow walls, and is composed of a shaft inner wall, a rib wall and an outer wall in the radial direction, and a formed cavity between the well walls communicates vertically so that mud sucking equipment can be lowered and moved in the cavity between the well walls; bottom feet of the shaft are blade feet, and root keys are arranged on thepositions, penetrating through the shaft inner wall, the rib wall and the outer wall and protruding and extending from the outer wall, of the shaft; the shaft is formed by connection of a bottom segment and a plurality of standard segments in the vertical direction, the bottom segment is in a blade shape, and the blade feet are formed; and for the shaft which is completely jointed and sunk in place, the root keys are arranged in the shaft, and then the bottom of the shaft is poured to form the back cover. According to the two-wall hollow fabricated root-type open caisson foundation, main components are connected by prefabricated components correspondingly, the structure is simple, fast and accurate sinking of an open caisson can be realized, the construction difficulty is effectively lowered, the operational safety factor is improved, industrial mass production is facilitated, and economic benefits are obvious.

Owner:ANHUI TRANSPORTATION HLDG GRP CO LTD

Orthotropic deck plate bolt welding joint and external wide splice plate

InactiveCN107630402AEasy to manufactureEasy to processBridge structural detailsArchitectural engineeringWheel load

The invention discloses an orthotropic deck plate bolt welding joint and an external wide splice plate. The external wide splice plate comprises inside splice plates and outside splice plates, whereinthe inside splice plates are fixed onto the inner side of a U rib web plate, the outside splice plates are fixed onto the outer side of the U rib web plate, and the U rib web plate is provided with afirst side, a flat plate and a second side. The inside splice plates are fixedly arranged on the inner side of the first side and the inner side of the second side, the outside splice plates are fixedly arranged on the outer side of the first side and the outer side of the second side, the upper edges, the front end faces and the rear end faces of the inside splice plates are flush with those ofthe outside splice plates, and the lower edges of the outside splice plates are not lower than those of the flat plate of the U rib web plate. The wheel load stress of the lower edges of the splice plates is reduced, and the anti-fatigue performance of the structure detail of the bolt welding joint is improved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

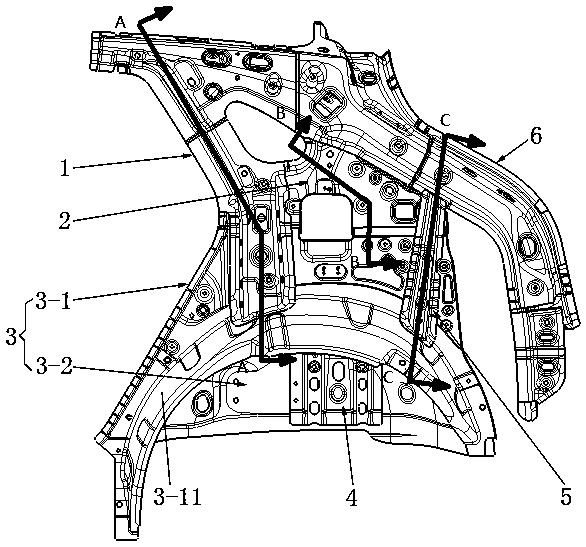

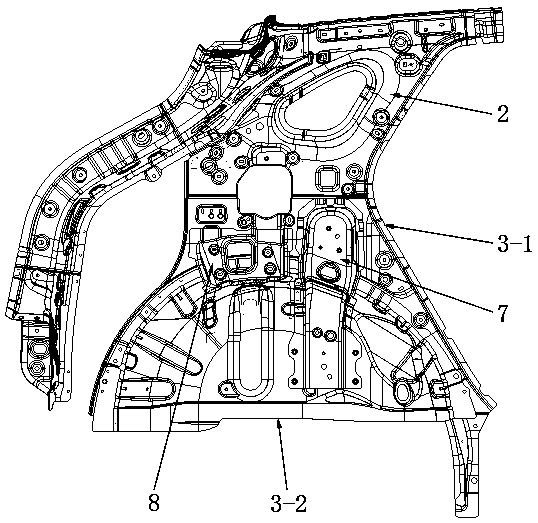

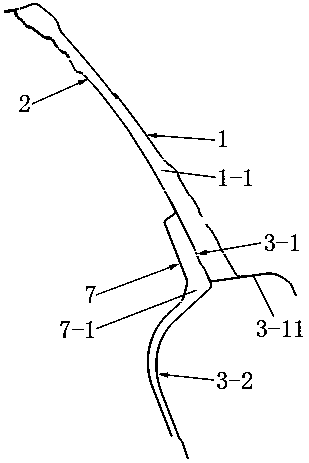

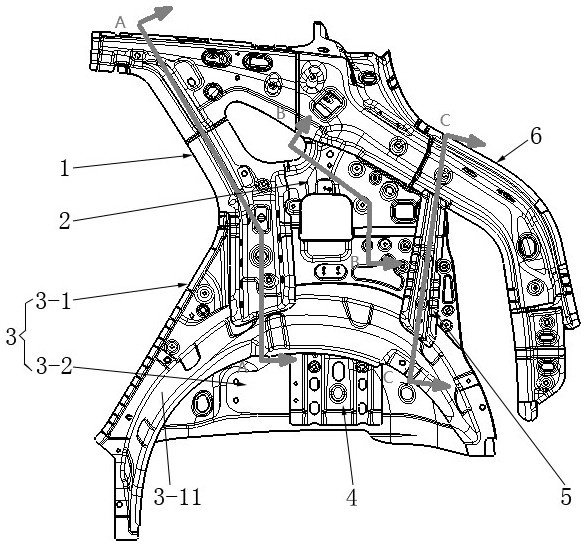

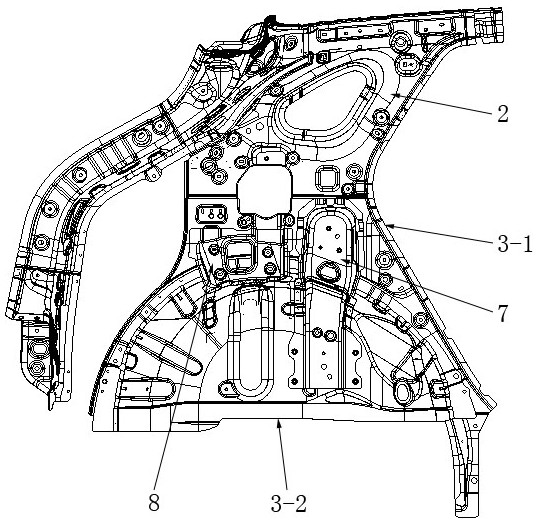

Force transmission assembly of automobile rear shock absorber

ActiveCN111055926AExtended delivery pathEfficient deliverySuperstructure subunitsResilient suspensionsShock absorber

The invention discloses a force transmission assembly of an automobile rear shock absorber, which relates to the technical field of automobile bodies. The force transmission assembly of the automobilerear shock absorber comprises a rear side wall inner plate, a C-column reinforcing plate, a D-column assembly, a rear wheel cover and a rear shock absorber mounting plate arranged in the rear wheel cover, a first force transmission cavity is formed among the C-column reinforcing plate, the rear side wall inner plate and a rear wheel cover outer plate, and the first force transmission cavity extends to an arch cover part of the rear wheel cover outer plate; a second force transmission cavity is formed in the D-column assembly and is communicated with the first force transmission cavity; a rearside wall reinforcing beam is fixedly connected to the outer side of the rear side wall inner plate, one end of the rear side wall reinforcing beam is connected with the D-column assembly, and the other end of the rear side wall reinforcing beam is connected with the arch cover part of the rear wheel cover outer plate; the rear side wall reinforcing beam, the rear side wall inner plate, the D-column assembly and the rear wheel cover outer plate define a third force transmission cavity. The problem that an existing automobile rear side wall structure cannot effectively decompose and absorb force transmitted from a rear shock absorber can be solved.

Owner:DONGFENG LIUZHOU MOTOR

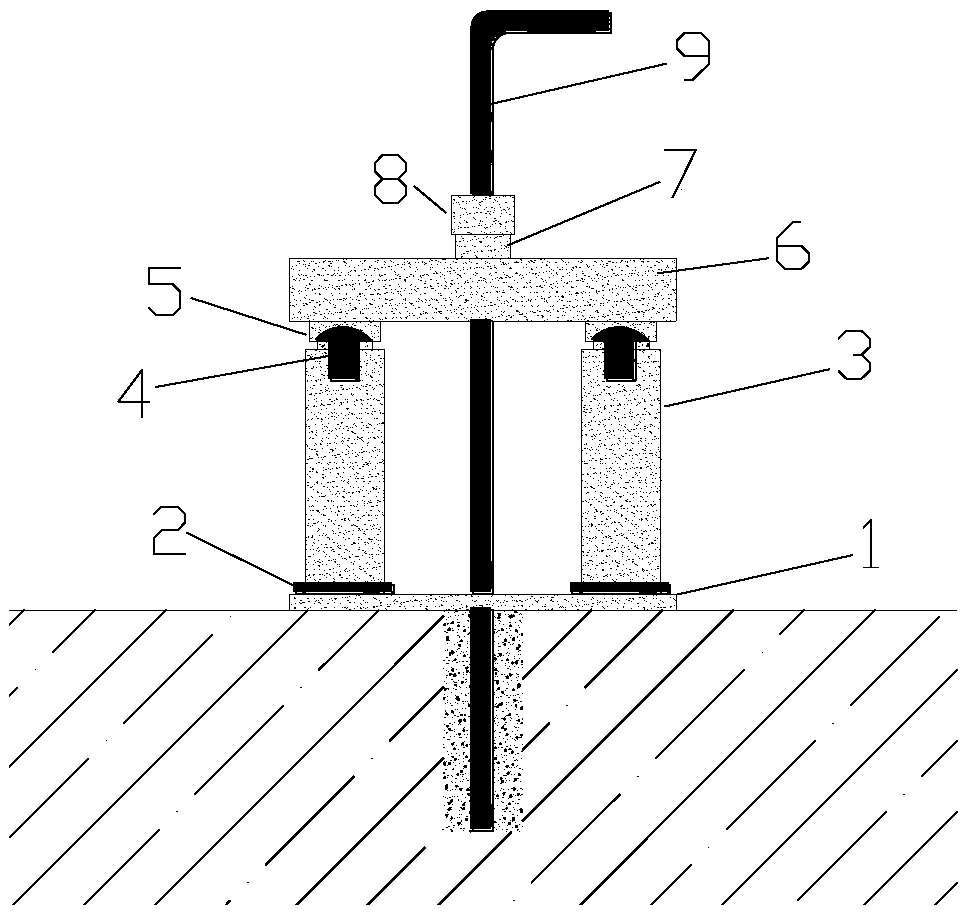

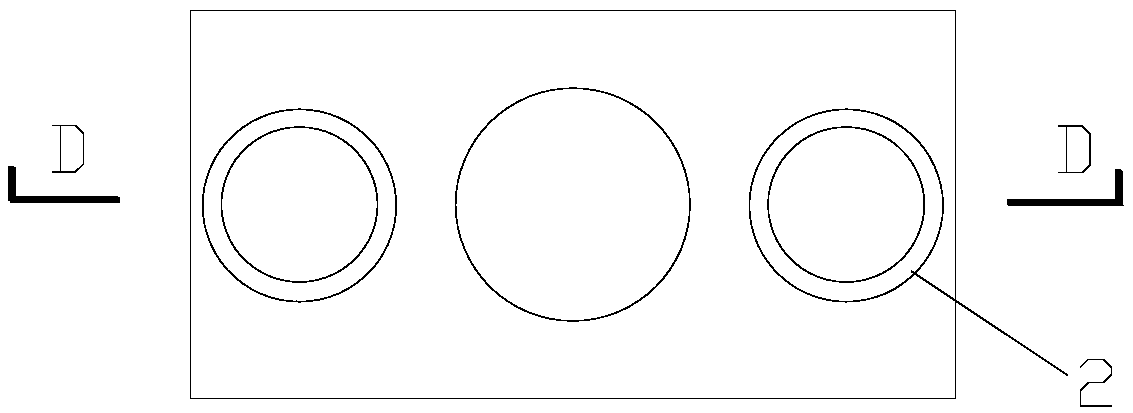

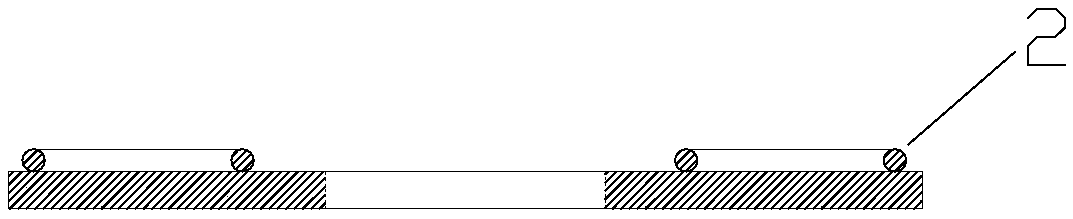

Anti-pulling test device for anchor rod

InactiveCN109024714AAvoid destructionReduce volumeFoundation testingBulkheads/pilesEngineeringPressure sensor

The invention discloses an anti-pulling test device for an anchor rod. The anti-pulling test device comprises an anchorage device, a pressure sensor, a pressure bearing member and a supporting jackingassembly. The anchorage device, the pressure sensor and the pressure bearing member are disposed in the same axis with the anchor rod, and the anchorage device is anchored on the anchor rod. One endof the pressure bearing member is connected to the supporting jacking assembly, and the other end of the pressure bearing member is connected to the anchorage device. The pressure sensor is disposed between the anchorage device and the pressure bearing member. The supporting jacking assembly includes at least two jacking members, and the supporting jacking assembly is used for jacking up the pressure bearing member to be displaced upwards to drive the anchor rod to move upwards. The anti-pulling test device utilizes a lever principle to realize an anti-pulling test of a foundation of a rock anchor rod of transmission line engineering, avoids the damage to a rock anchor rod body during the anti-pulling test of the anchor rod, and has the characteristics of small size, light weight, convenient transportation and the like.

Owner:CHINA ELECTRIC POWER RES INST +1

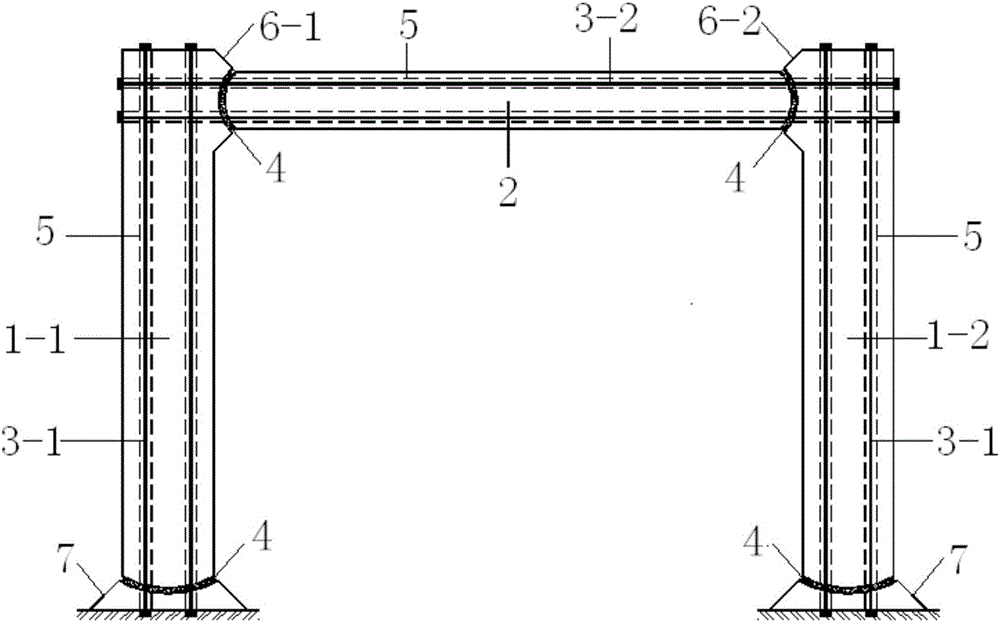

Prestressed fabricated concrete joint curved surface connecting structure

ActiveCN106193287AReduce compressive stressIncrease contact areaBuilding constructionsPre stressConvex side

The invention discloses a prestressed fabricated concrete joint curved surface connecting structure which comprises prefabricated columns and prefabricated beams. Joint overhanging arms are arranged at joints of the prefabricated columns and the prefabricated beams, each joint overhanging arm is of a variable-section structure, sections at the joints of the joint overhanging arms and the prefabricated columns are large while those at the joints of the joint overhanging arms and the prefabricated beams are small, and end faces connected with the prefabricated beams are concave surfaces; connecting end faces of the prefabricated beams and the joint overhanging arms are convex surfaces, and the convex surfaces and the concave surfaces on the joint overhanging arms are equal in curvature. Prefabricated beams prestressed rebars sequentially penetrate prestressed rebar holes in the prefabricated beams, the joint overhanging arms and the prefabricated columns to be pre-tightened to connect the prefabricated beams, the joint overhanging arms and the prefabricated columns to form a whole. The prestressed fabricated concrete joint curved surface connecting structure is stable in structure and long in service life.

Owner:WUHAN UNIV OF TECH

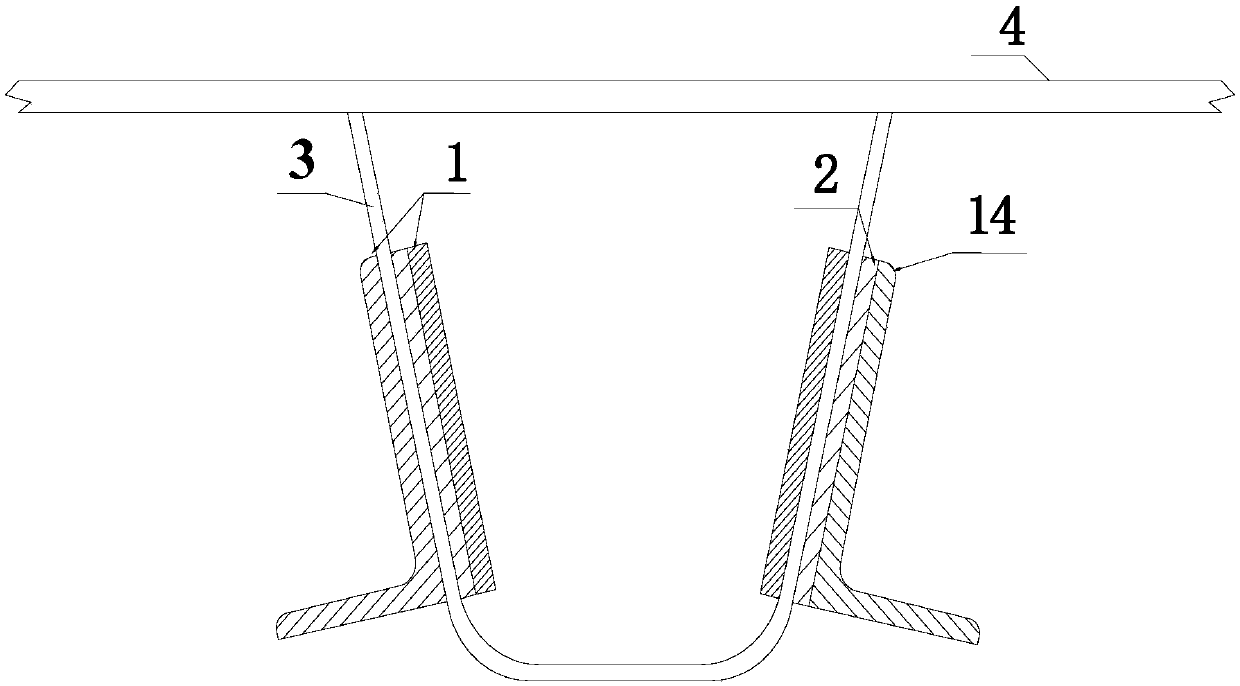

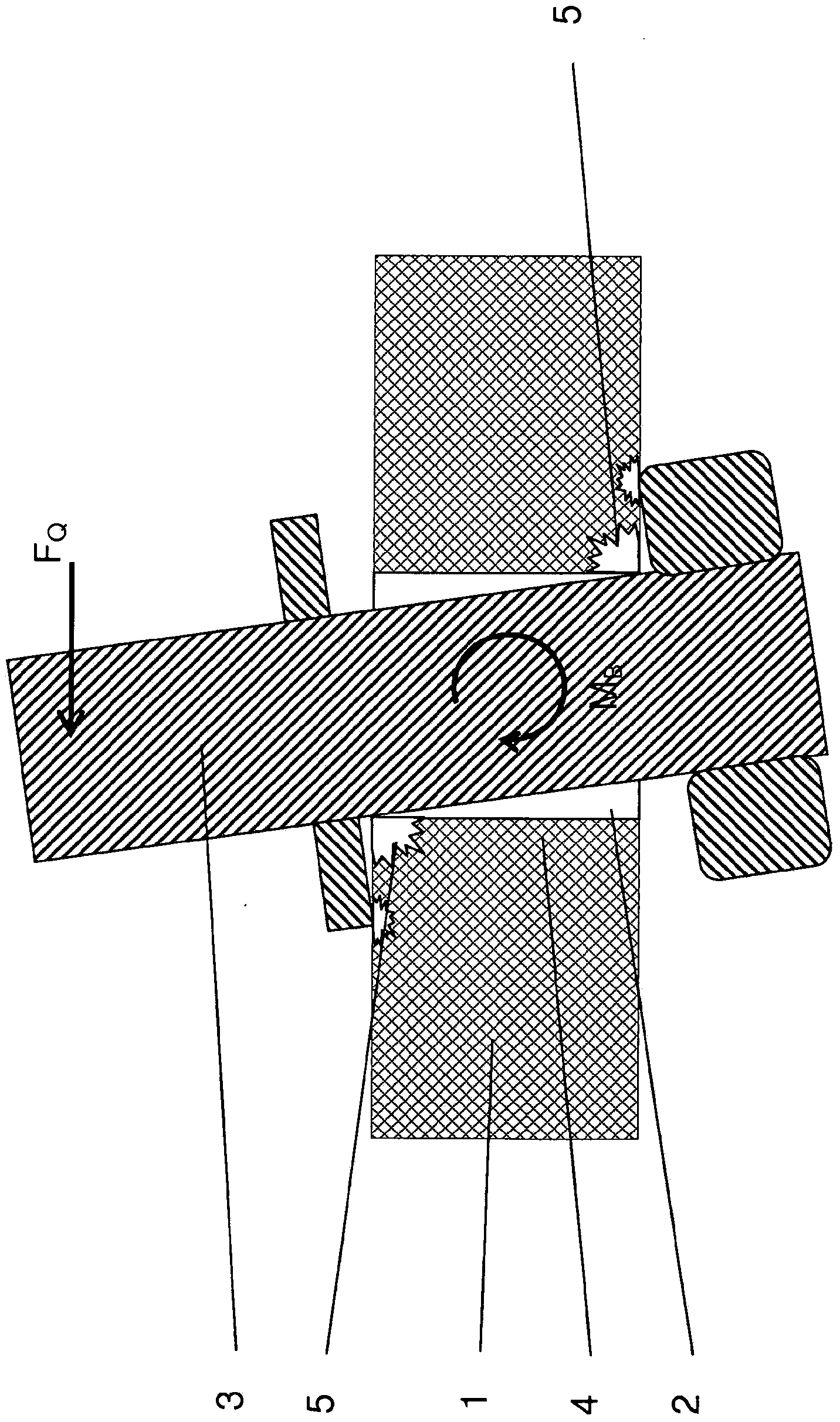

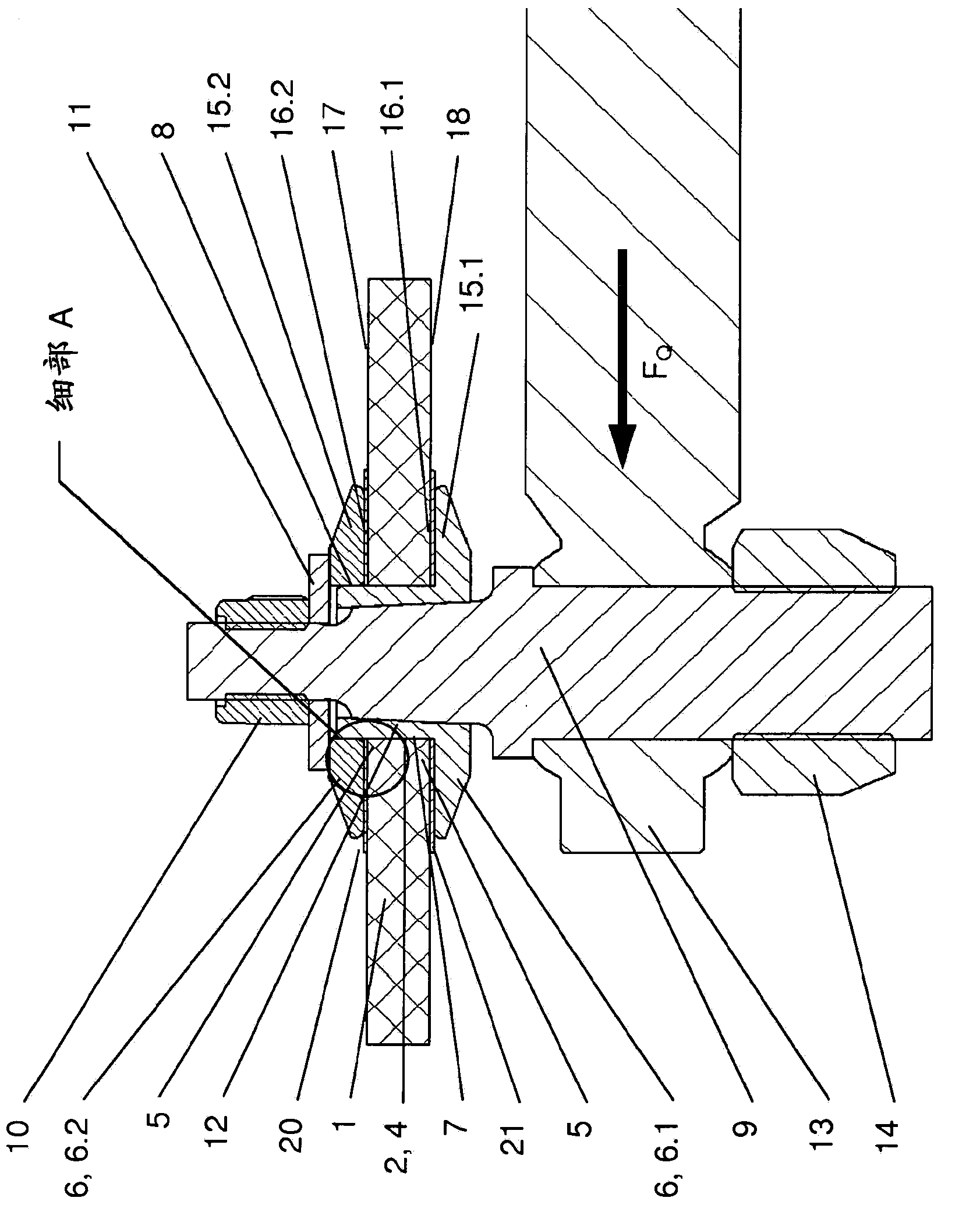

Device for introducing force into a component of fibre composite material

The invention relates to a device for introducing force into a component of fiber composite material by means of a screw connection having a bolt-like connecting element arranged in a passage of the component. The invention is based in particular on the object of improving the durability of the screw connection on the component of fiber composite material. The object is achieved in that the screw connection has a two-part bush (6) which borders the passage (2) of the component (1) and accommodates the connecting element (9), wherein the first and the second bush part (6.1, 6.2) of the bush (6) are designed to engage in one another in axial extension, and each bush part (6.1, 6.2) has a radially extended union collar (15.1, 15.2) with a collar side (16.1, 16.2) facing the component (1), on which side a sliding surface is formed.

Owner:LEICHTBAU ZENT SACHSEN

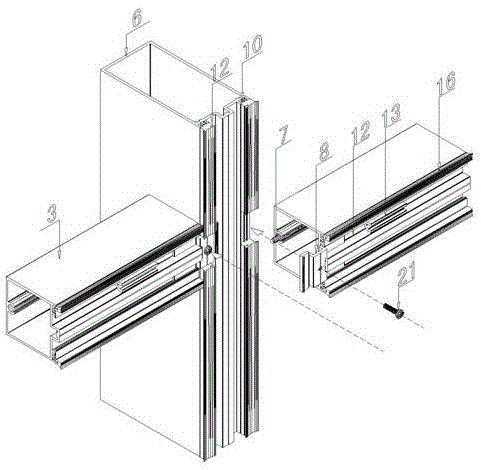

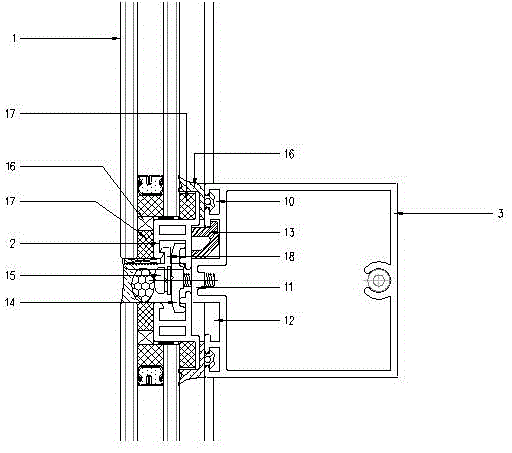

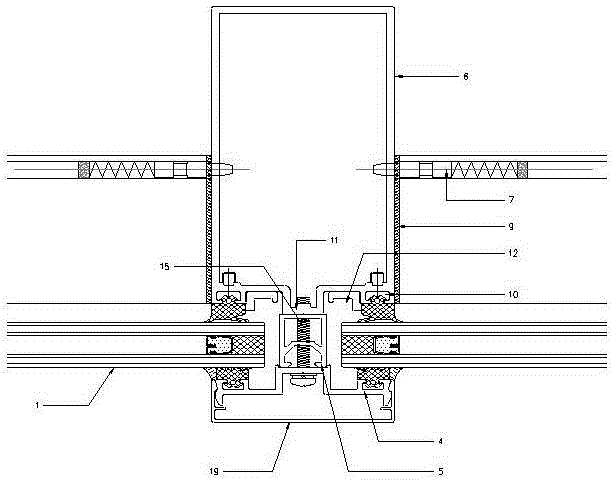

Semi-hidden frame curtain wall system device

The invention belongs to the technical field of curtain wall tools, and particularly relates to a semi-hidden frame curtain wall system device. The semi-hidden frame curtain wall system device comprises an exposed frame part and a hidden frame part, the hidden frame part comprises glass, the glass is connected with a stand column or a beam through an auxiliary frame, and the end is fixed to the stand column through threads; in the hidden frame part, the auxiliary frame is arranged on a flange and containing cavities of the stand column or the beam and fixed to the flange of the stand column or the beam through threads by means of press blocks; in the exposed frame part, one end of a heat insulation strip is arranged on the flange of the stand column or the beam, the other end of the heat insulation strip is fixed to a press plate through threads, and being held by the press plate, the glass is fixed to the stand column or the beam. The semi-hidden frame curtain wall system device has the advantages that the semi-hidden frame glass curtain wall system device is an exposed-hidden combination which is convenient to install and capable of simplifying the construction technology, reducing cost, and improving safety.

Owner:ZHEJIANG JIEFANG DECORATION ENG

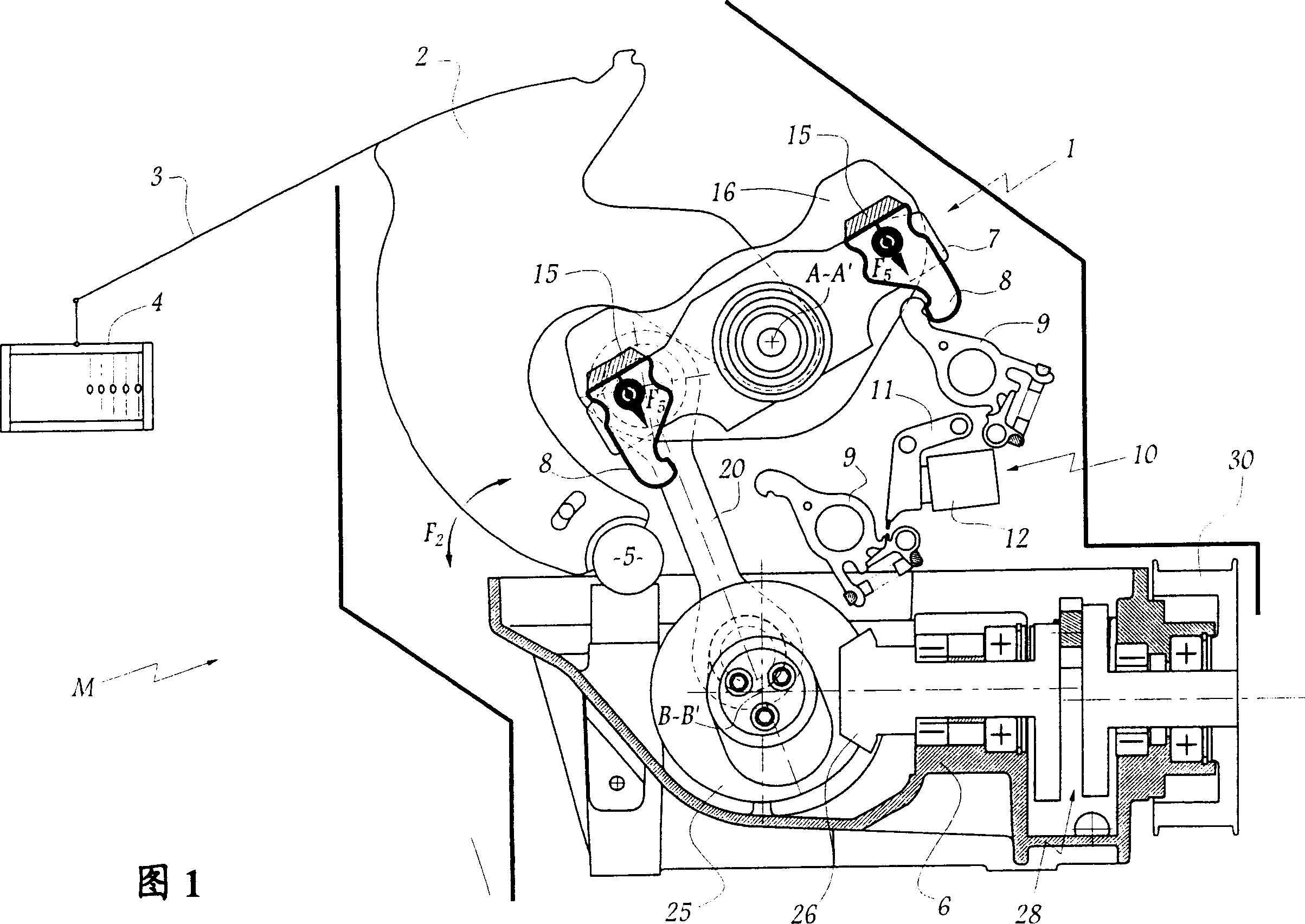

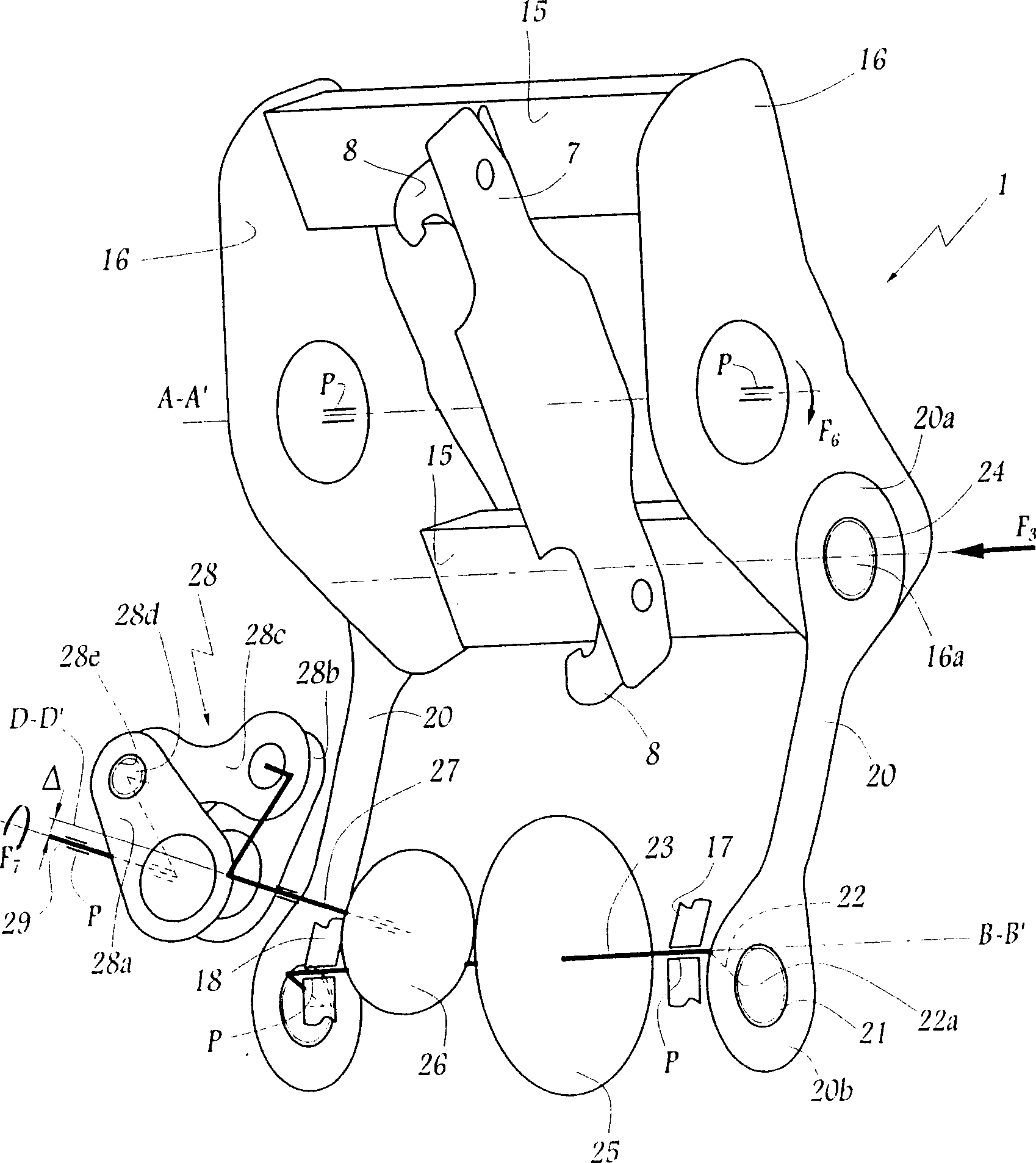

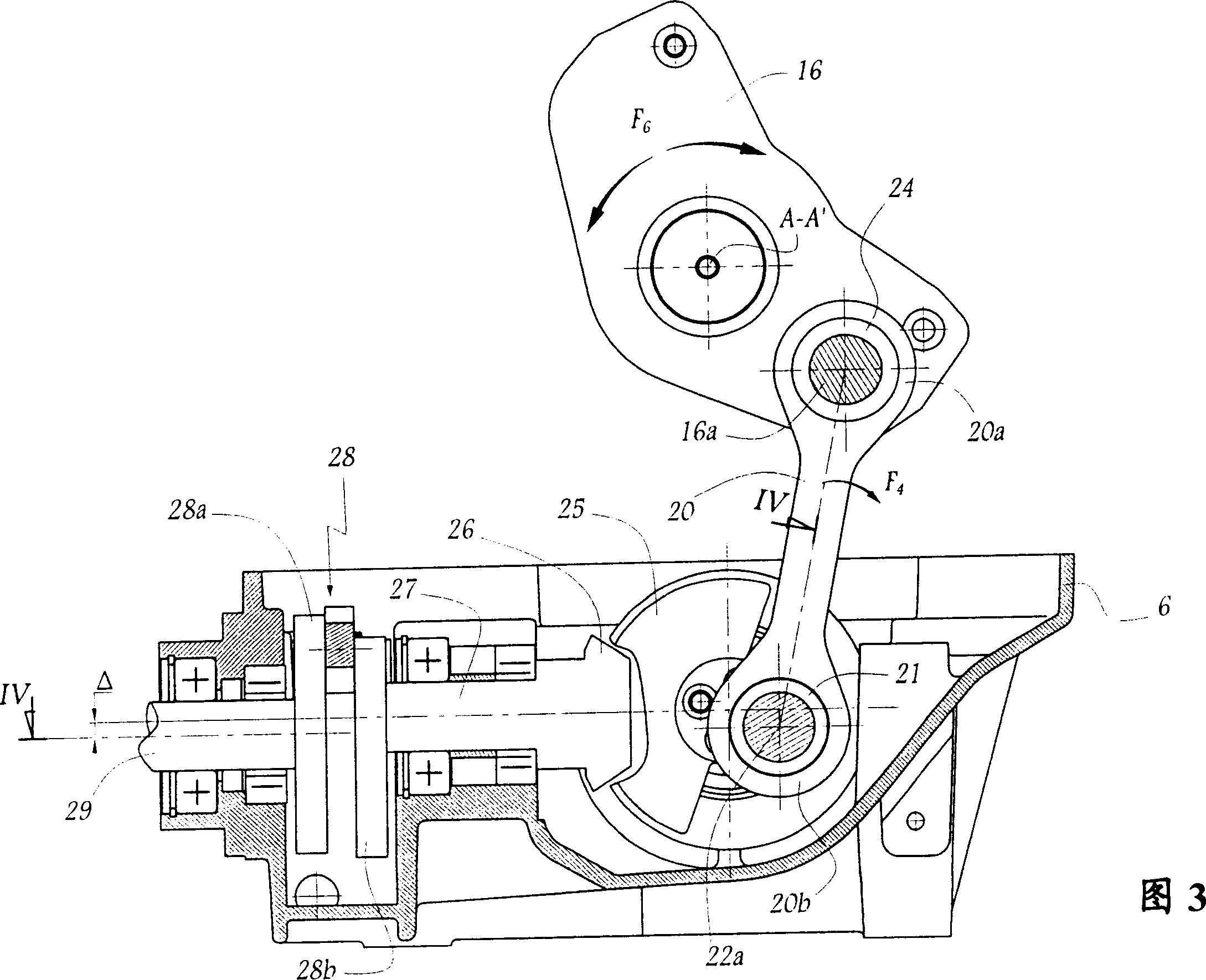

Dobby loom and loom mounted with said dobby loom

The loom dobby (1) consists of oscillating levers linked kinematically to a heddle frame, each lever being equipped with a balance arm (7) with hooks (8) and actuated by pushers (15) supported by drivers (16). Each driver is pivoted by an arm (20) connected to a crank (22) on the end of a shaft (23) that rotates about a fixed geometrical axis (B-B') in relation to the heddle frame and is equipped with a torque receiver (25). The latter is in the form of a gear meshing with a second gear (26) on the output shaft (27) of a modulator (28) for the rotary motion. The two gears have conical teeth and their shafts are basically orthogonal to one another.

Owner:STAUBLI HANGZHOU PRECISION MACHINERY ELECTRONICS CO LTD

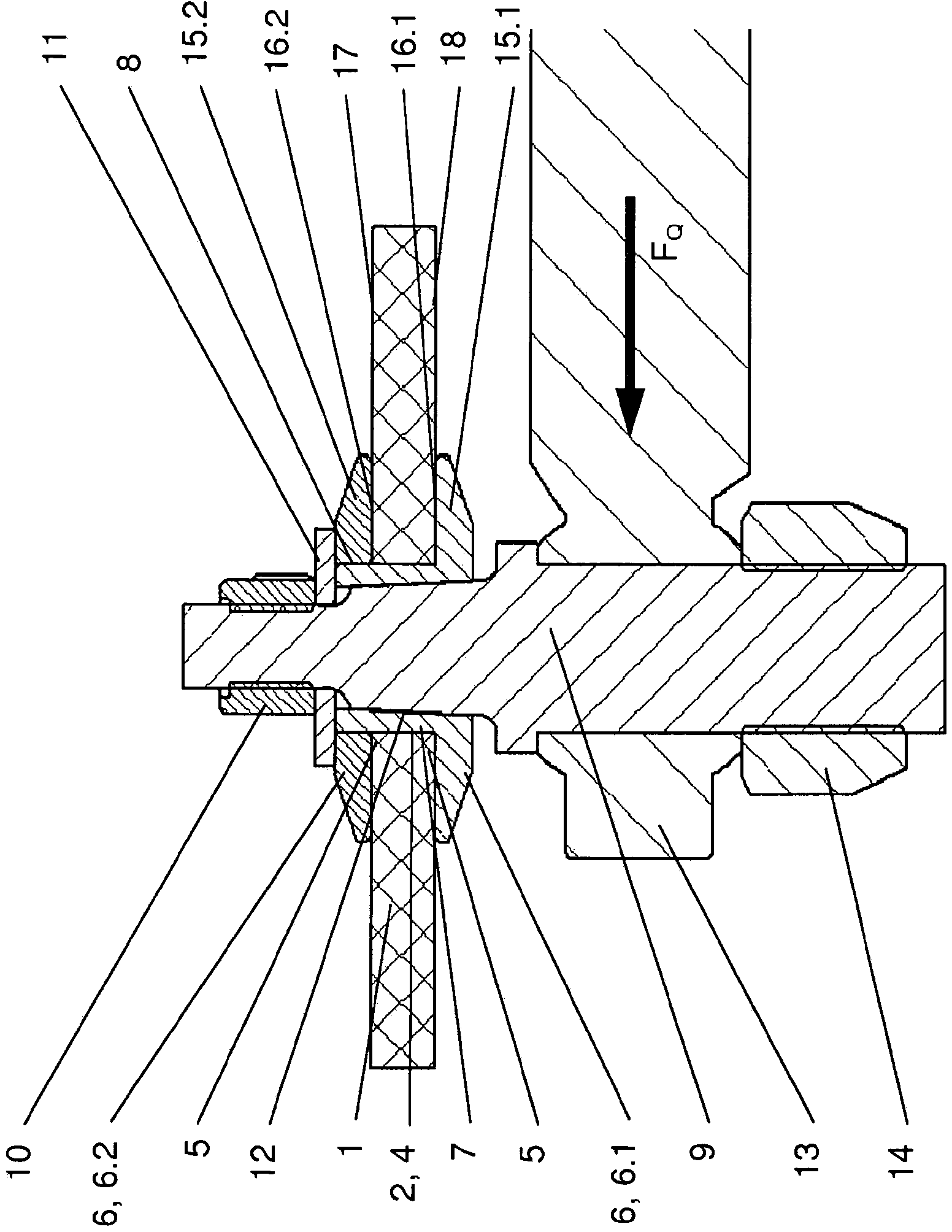

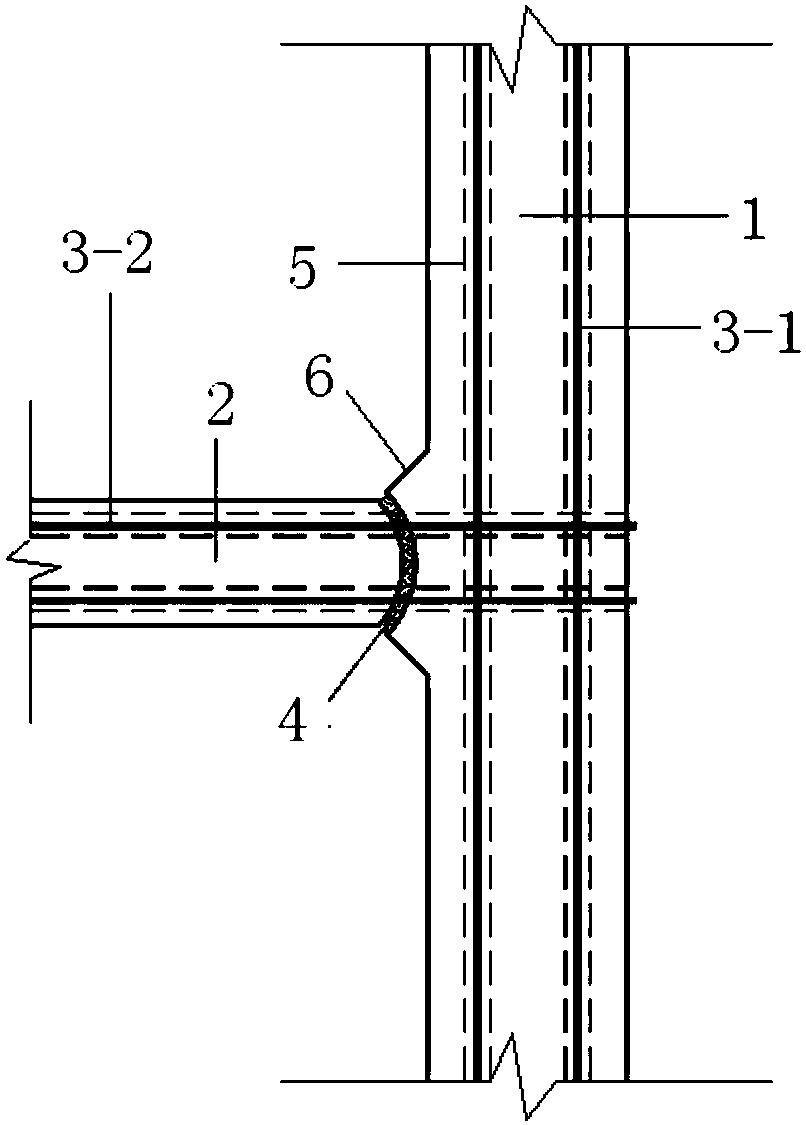

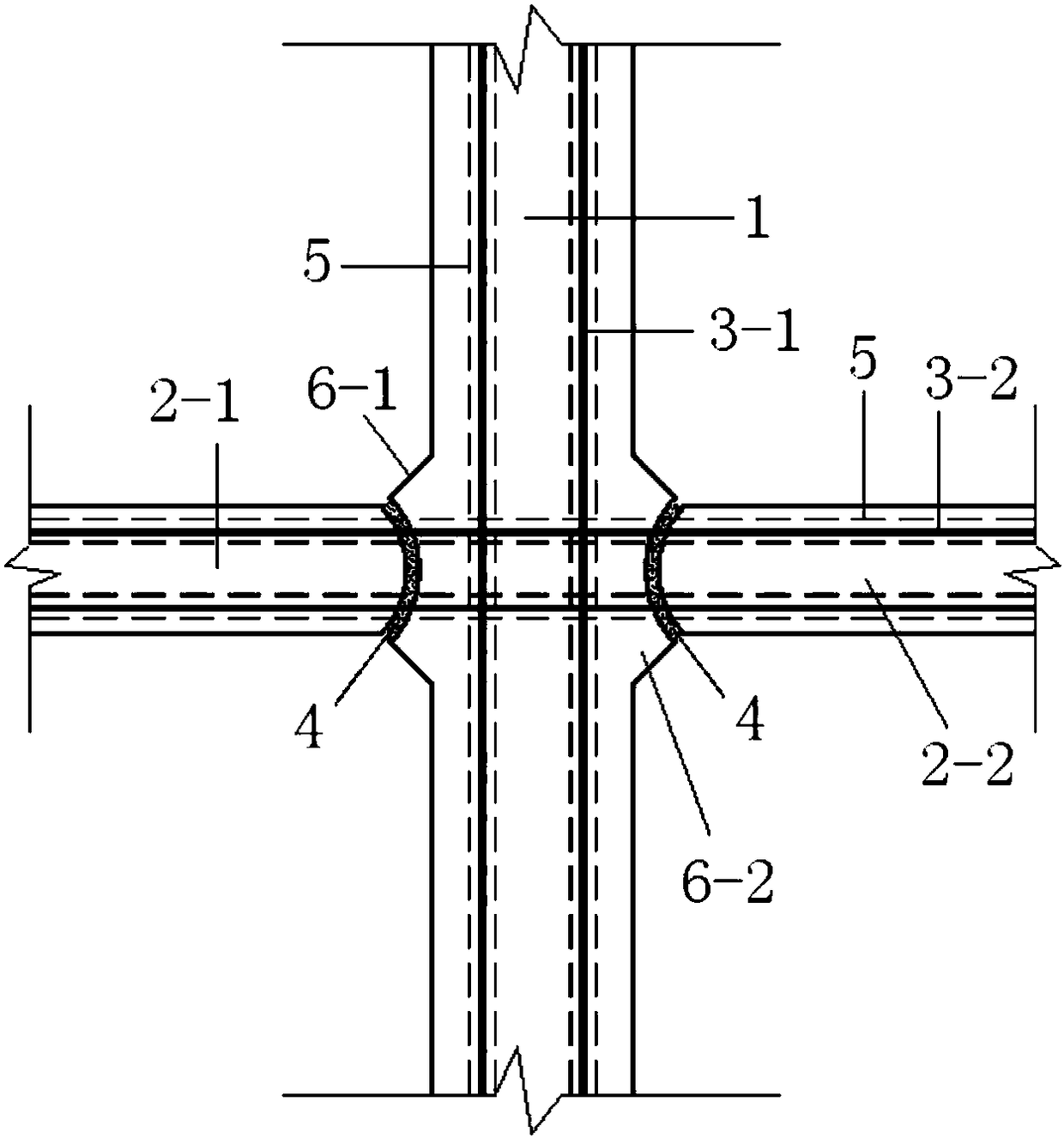

Vertical baffle and beam column connecting joint applied to steel tube column

InactiveCN109113176AActive connectionEffective transmission of compressive stressProtective buildings/sheltersShock proofingThick plateEngineering

The invention provides a vertical baffle and beam column connecting joint applied to a steel tube column. The vertical baffle and beam column connecting joint applied to the steel tube column comprises a tube pipe column body, vertical baffles, a beam column connecting plate and a steel beam, and the vertical baffles are arranged in the relative interior of the tube pipe column body. The tube pipecolumn body comprises a thick plate column wall, the thick plate column wall is arranged on the side portion of the tube pipe column body, and the beam column connecting plate and the tube beam are connected with the thick plate column wall. According to the vertical baffle and beam column connecting joint applied to the tube pipe column, a connecting mode of vertically being arranged the baffles, the effective connecting of the steel beam and a concrete filled steel tubular column is realized, and the requirement of construction method of pouring concrete is met.

Owner:罗纯艳

Prefabricated reinforced concrete beam-slab structure system with cast-in-place floors in building structures

ActiveCN106065663BReduce workloadImprove standardizationFloorsLoad-supporting elementsReinforced concreteTongue and groove

The invention discloses an assembled reinforced concrete beam-slab structural system with a cast-in-situ layer in a building structure. The assembled reinforced concrete beam-slab structural system comprises a superposed beam, a superposed slab, reinforcing mesh pieces, the cast-in-situ concrete superposed layer and beam negative reinforcements, wherein the superposed beam is a reinforced concrete precast beam; outwardly projecting tongue-and-grooves are formed in two sides of the upper part of the superposed beam; the superposed slab is horizontally arranged and is a reinforced concrete precast slab; cover-plate-type tongue-and-grooves are formed at the positions, corresponding to the outwardly projecting tongue-and-grooves, on two sides of the superposed slab, and overlapped on the outwardly projecting tongue-and-grooves; the reinforcing mesh pieces and the beam negative reinforcements are horizontally arranged above the superposed beam and the superposed slab; the reinforcing mesh pieces are bundled up with corresponding reinforcements in the superposed beam and the superposed slab; the beam negative reinforcements are bundled up with corresponding reinforcements in the superposed beam; after arrangement of the reinforcing mesh pieces and the beam negative reinforcements, concrete is poured to form the cast-in-situ concrete superposed layer. The assembled reinforced concrete beam-slab structural system has favorable integrity and mechanical property, and the integrity and the anti-seismic property can be improved.

Owner:广东省建科建筑设计院有限公司

A kind of steel sheet pile support construction method for building underground garage caisson

The invention discloses a steel sheet pile support construction method for building an underground garage open caisson to reduce the construction complexity and improve the construction efficiency during open caisson building and reduce the building expenditure for the open caisson. According to the construction method, open caisson construction is carried out in an area defined by a steel sheet wall, wherein building of a wall of the open caisson is carried out in a manner of segment-by-segment construction from bottom to top. The building method comprises the steps that steel sheet piles are sunk, and the continuous steel sheet pile wall is formed; a certain of earthwork is excavated in the area defined by the steel sheet pile wall, then, a pile block enclosure purlin is erected on the top of the steel sheet pile wall, and horizontal braces are built on the inner side of the pile block enclosure purlin; and then, open caisson building is finished through a method that earthwork is excavated segment by segment, the wall is poured segment by segment and sinking is carried out.

Owner:JIANGSU DONGHENAN GEOTECHNICAL TECH CO LTD

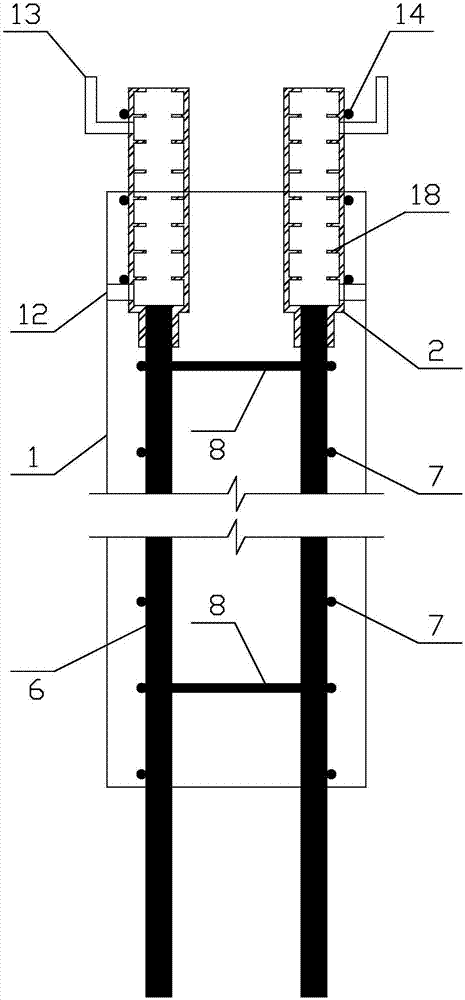

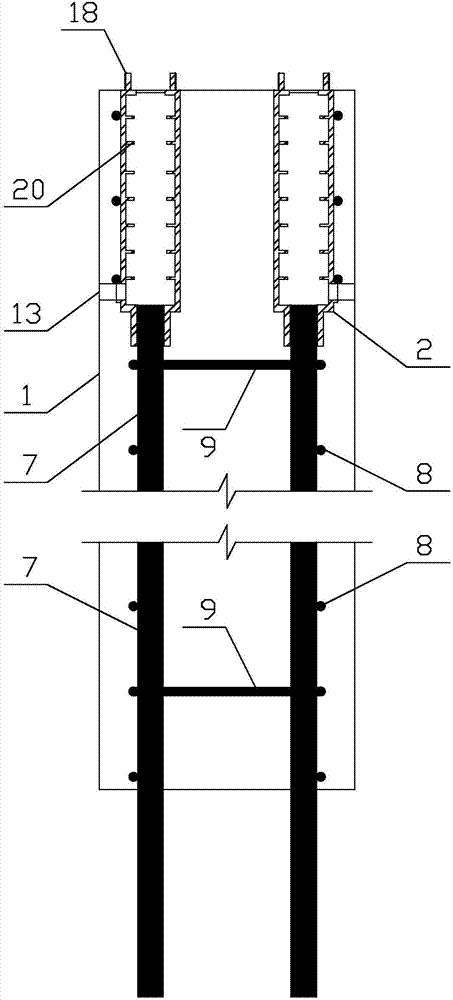

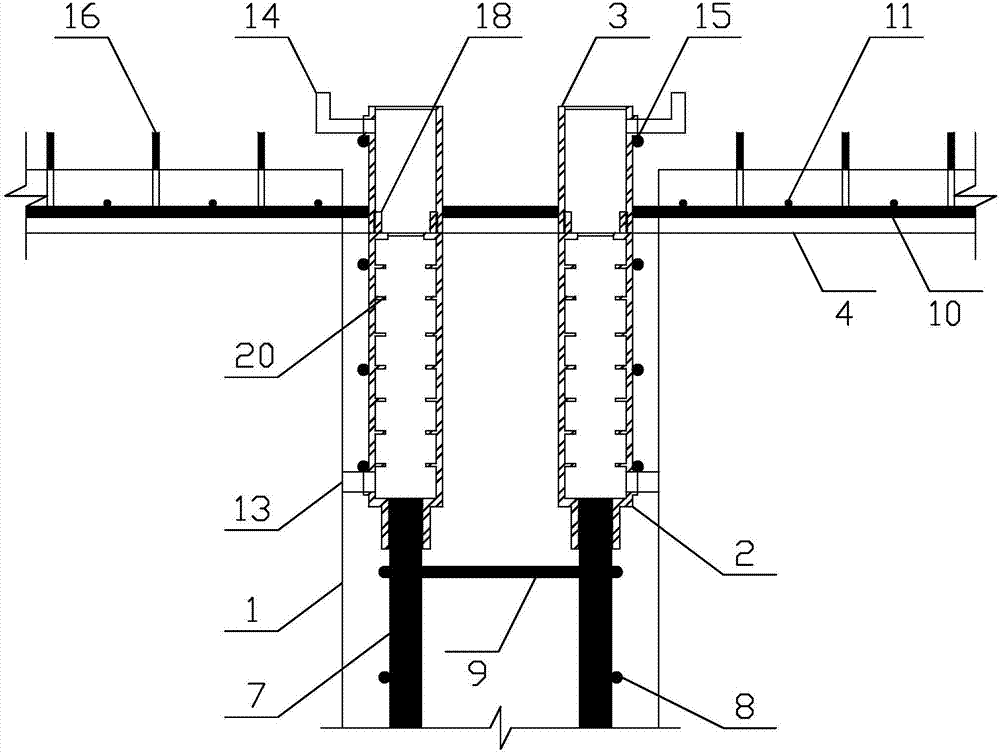

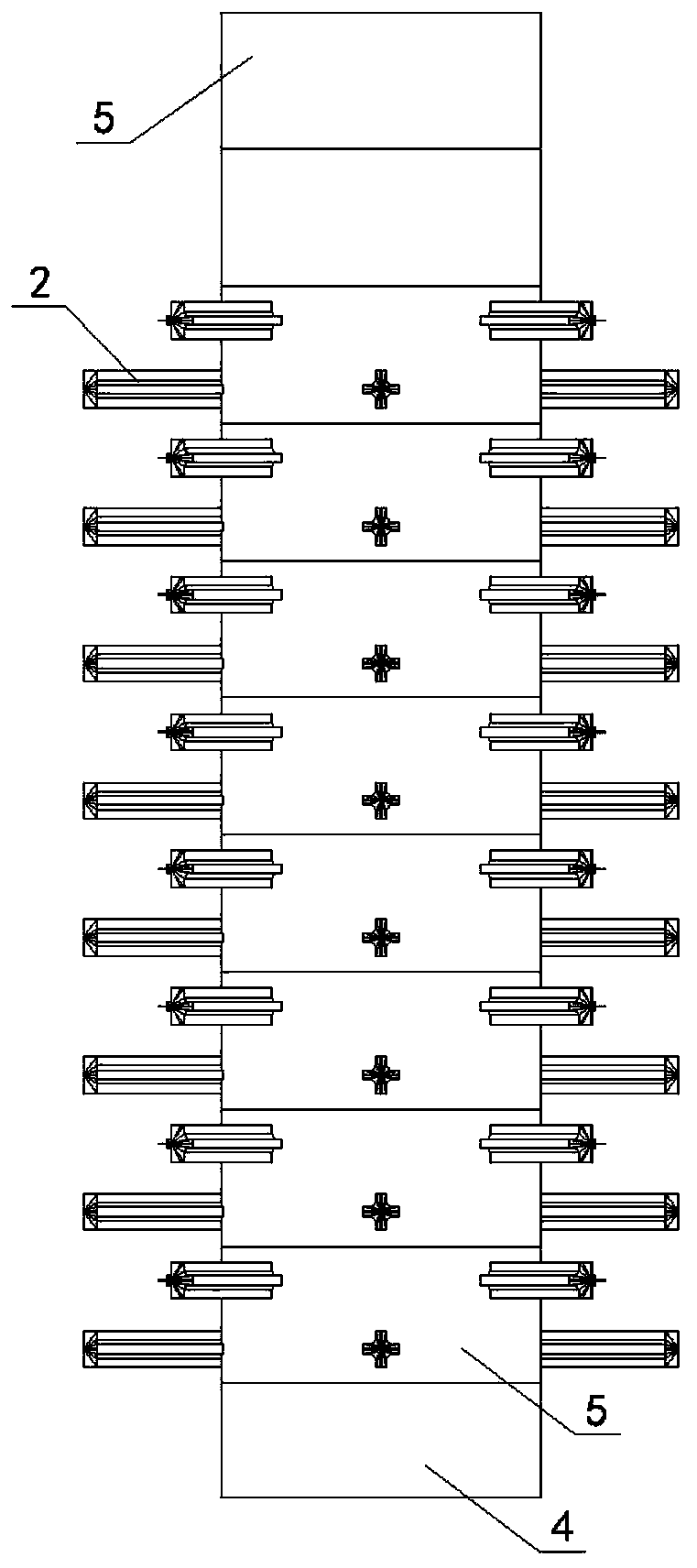

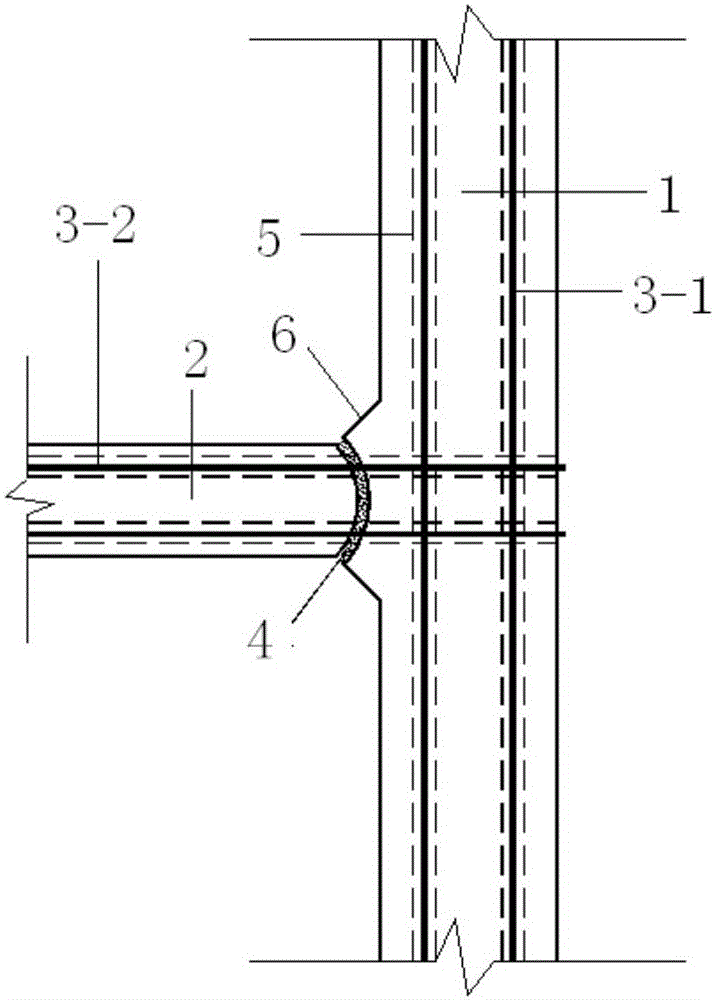

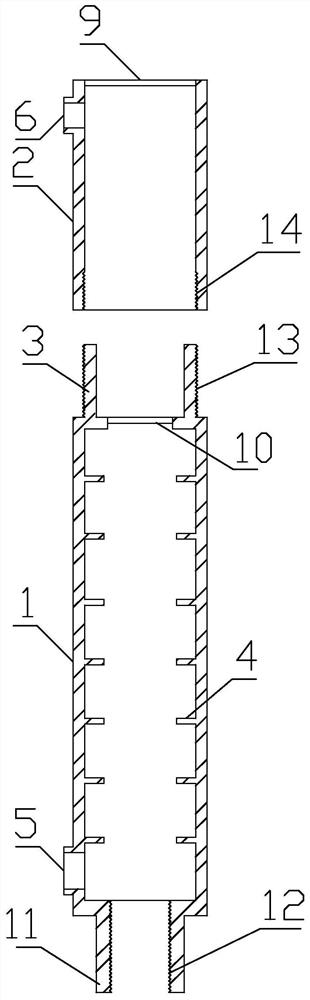

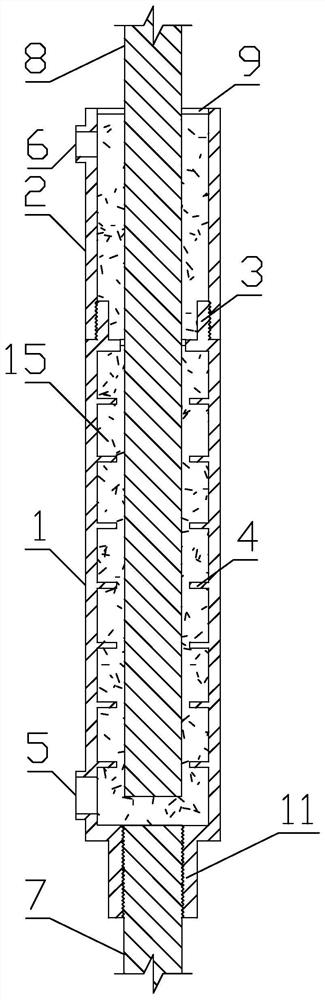

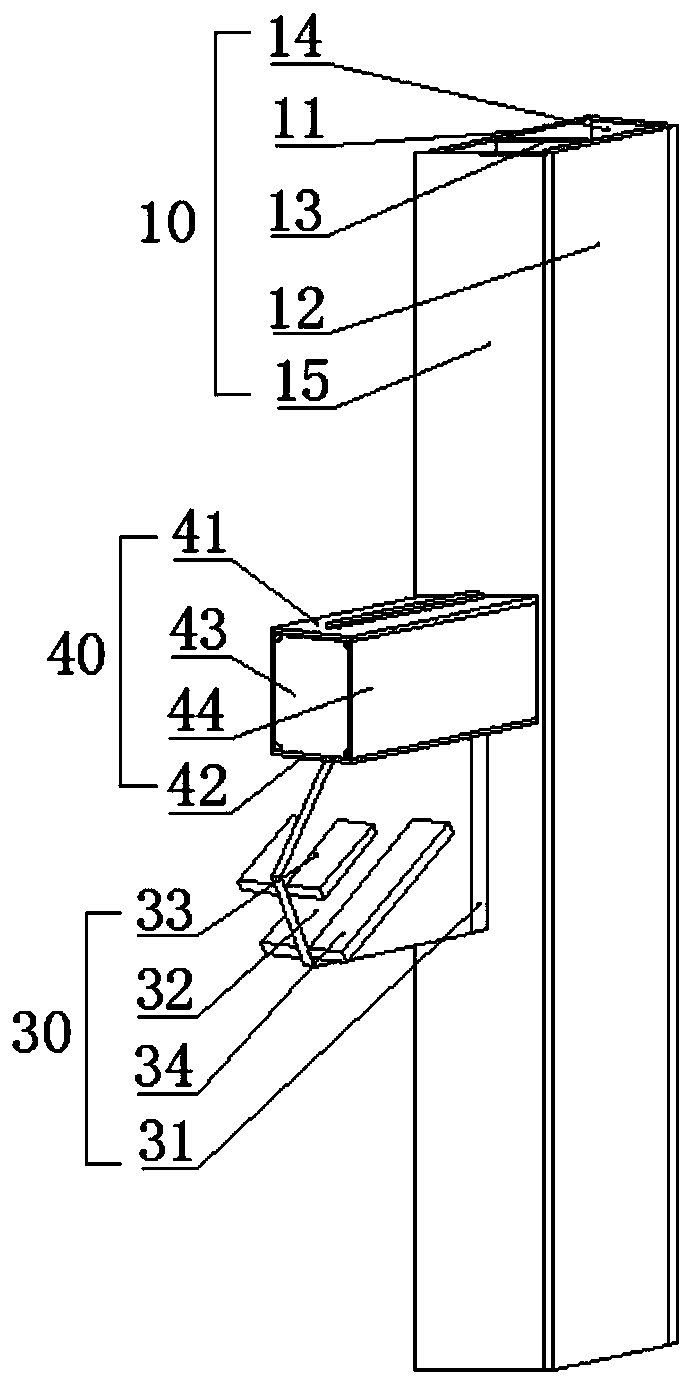

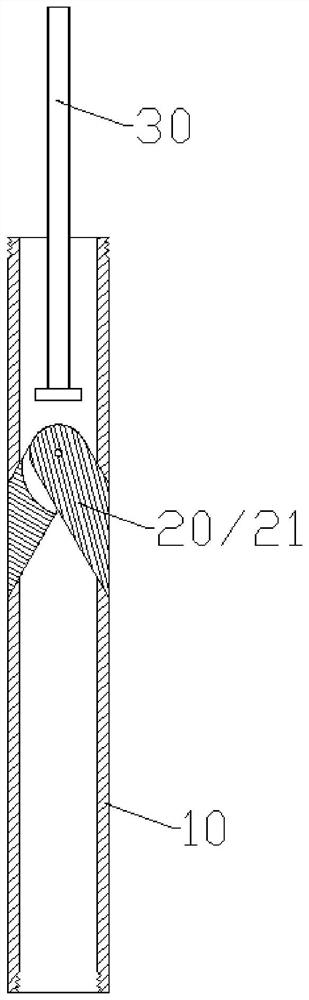

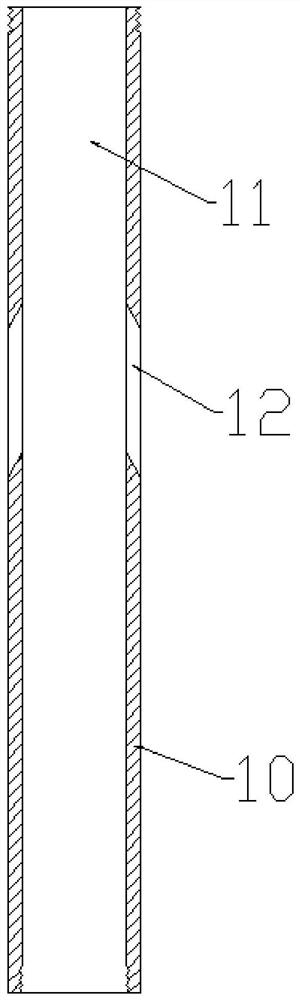

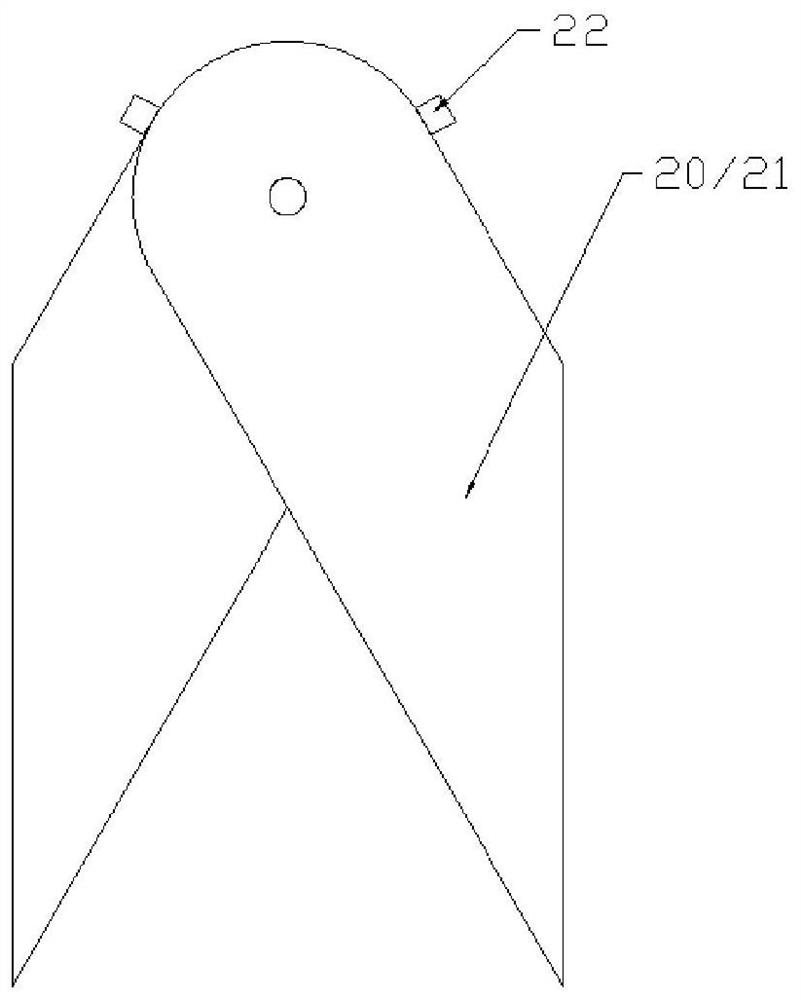

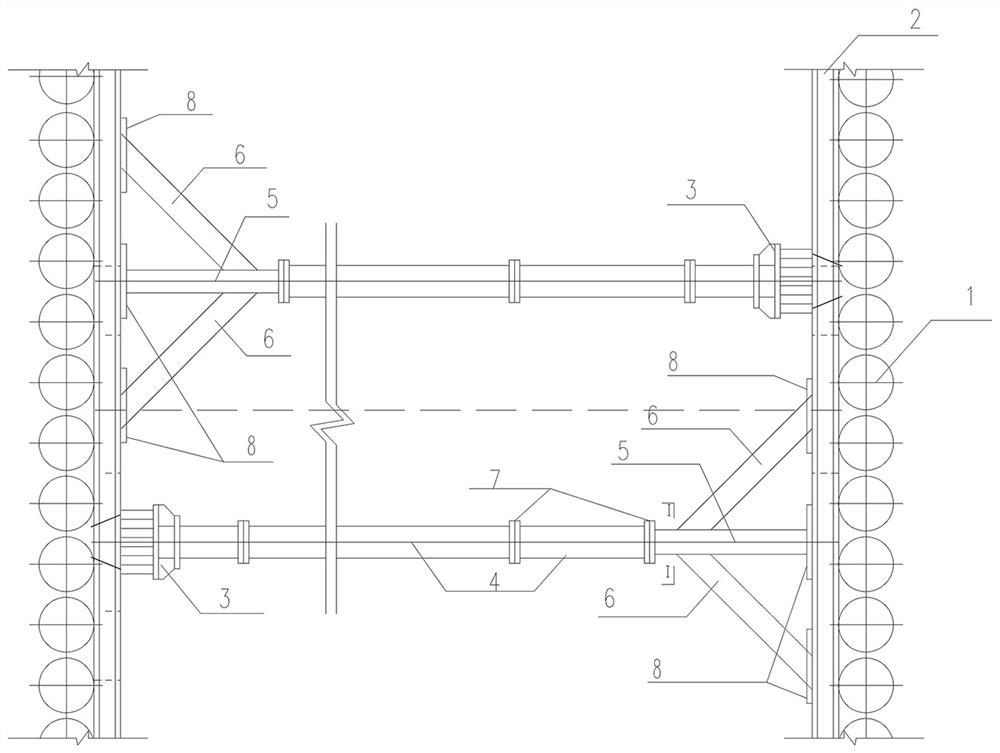

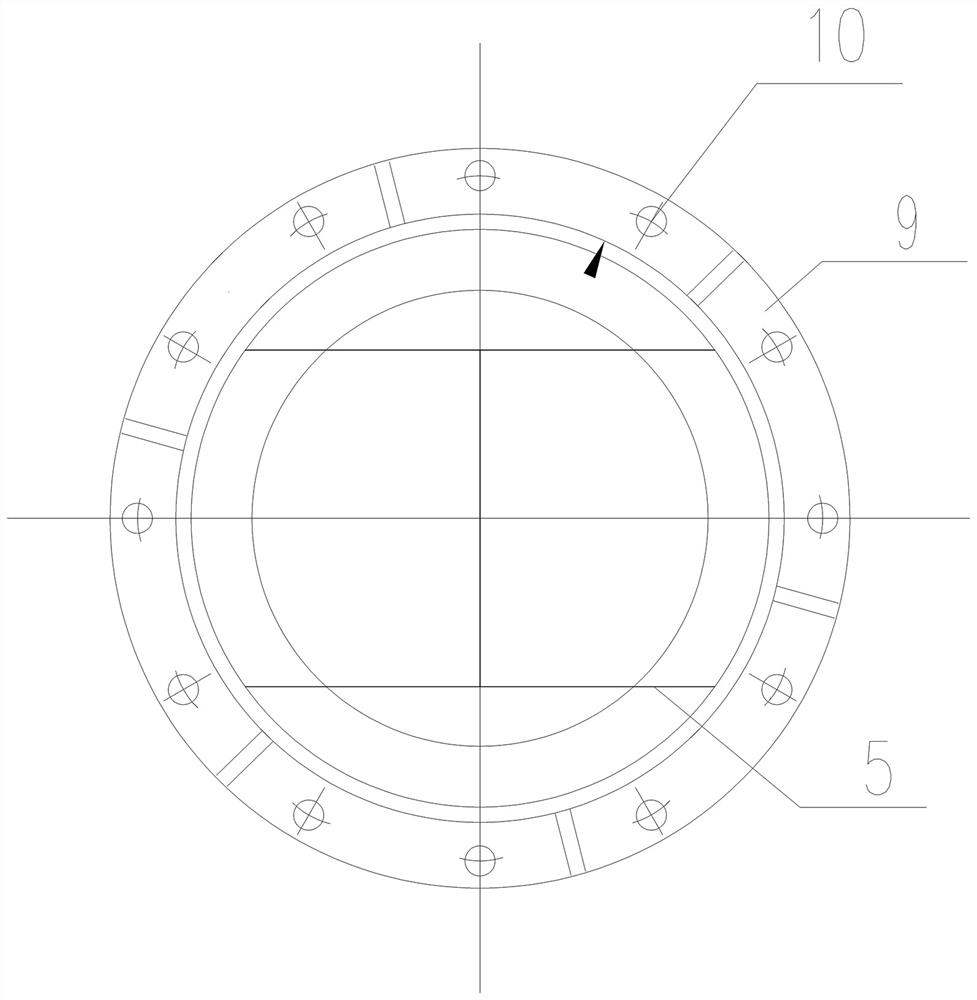

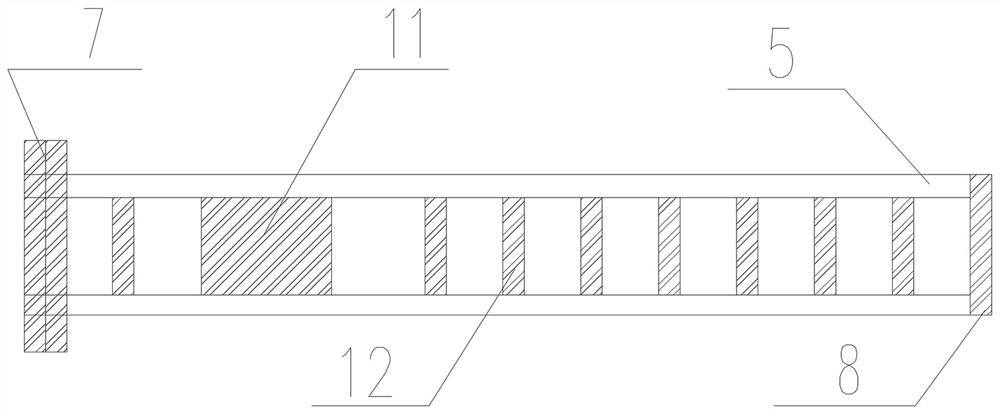

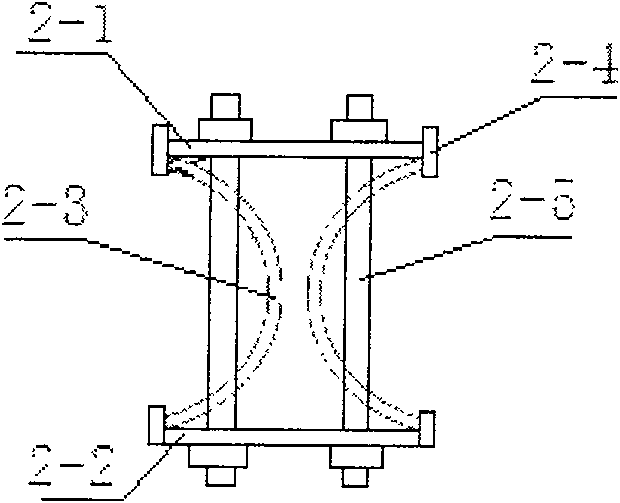

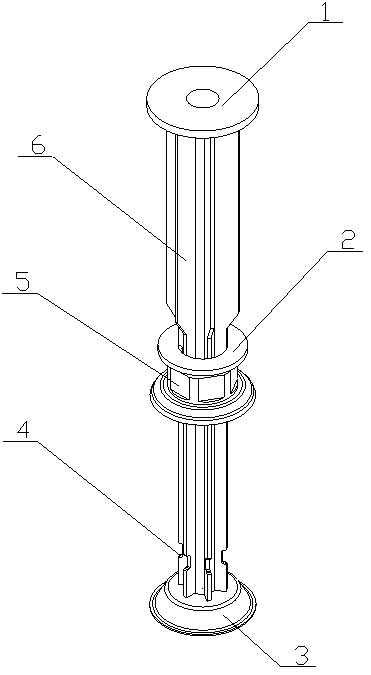

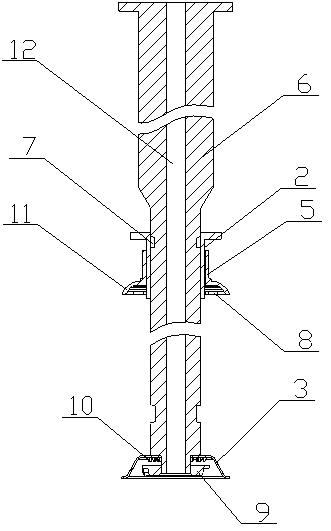

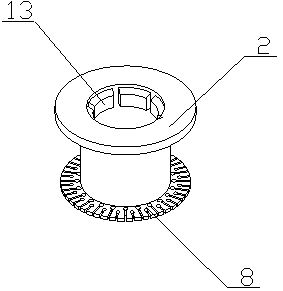

A steel grouting sleeve for ductile connection of prefabricated concrete structures

ActiveCN107023121BEnhance the anti-seismic performance of nodesEffective force transmissionProtective buildings/sheltersBuilding reinforcementsArchitectural engineeringRebar

The invention discloses a steel bar grouting sleeve for ductile connection of fabricated concrete structures, comprising two sections of the sleeve, a grouting hole and a grouting hole. The first section of the grouting sleeve is used as a connector for steel bars and is used to connect different components The second section of the through sleeve is the through tube of the steel bar, which is used for the steel bar to pass through the post-cast layer, and the two sections of the sleeve are connected by threads. The grouting hole is located at the lower part of the first section of the grouting sleeve, and the grouting hole It is arranged on the upper part of the second through-sleeve. The biggest feature of the steel bar grouting sleeve provided by the present invention is that the grouting sleeve is a combined type, and the overhanging steel bar of one prefabricated component passes through the post-cast layer through the second section through the sleeve, and is inserted into the first section of another prefabricated component. The grouting sleeve is then grouted to connect the steel bars between different prefabricated components to ensure that the longitudinal steel bars can effectively transmit force, so that the position of the grouting sleeve can also make the connection part have the required plastic deformation capacity when it enters the plastic state. In addition, using the steel bar grouting sleeve provided by the invention also has the functions of fast, efficient, simple and convenient for construction operations, thereby ensuring construction quality, improving construction efficiency and reducing construction difficulty.

Owner:广东省建科建筑设计院有限公司

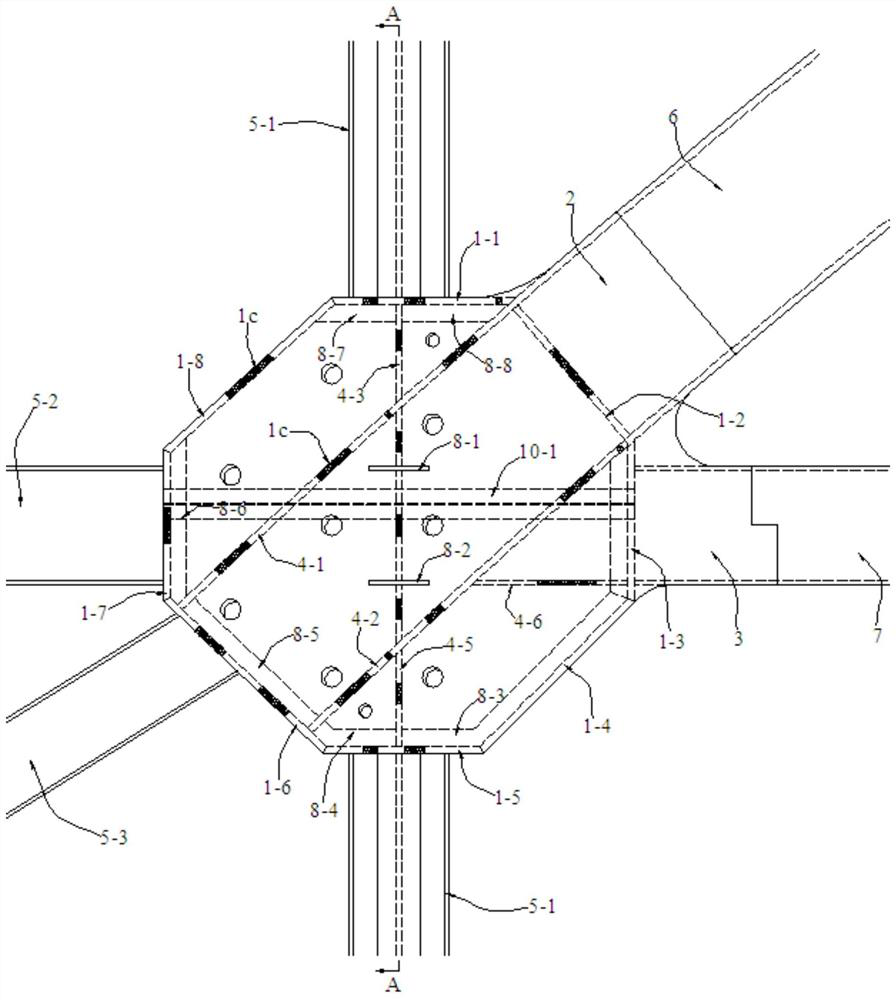

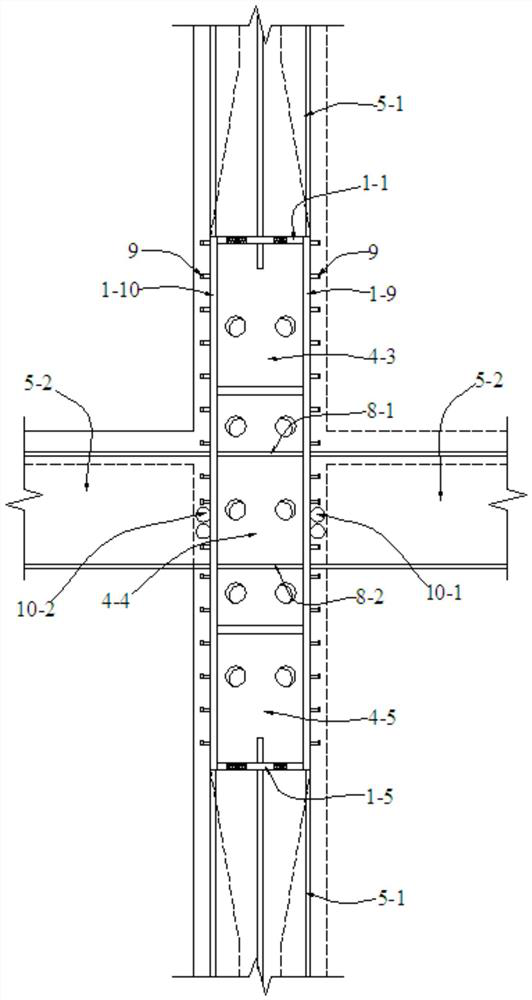

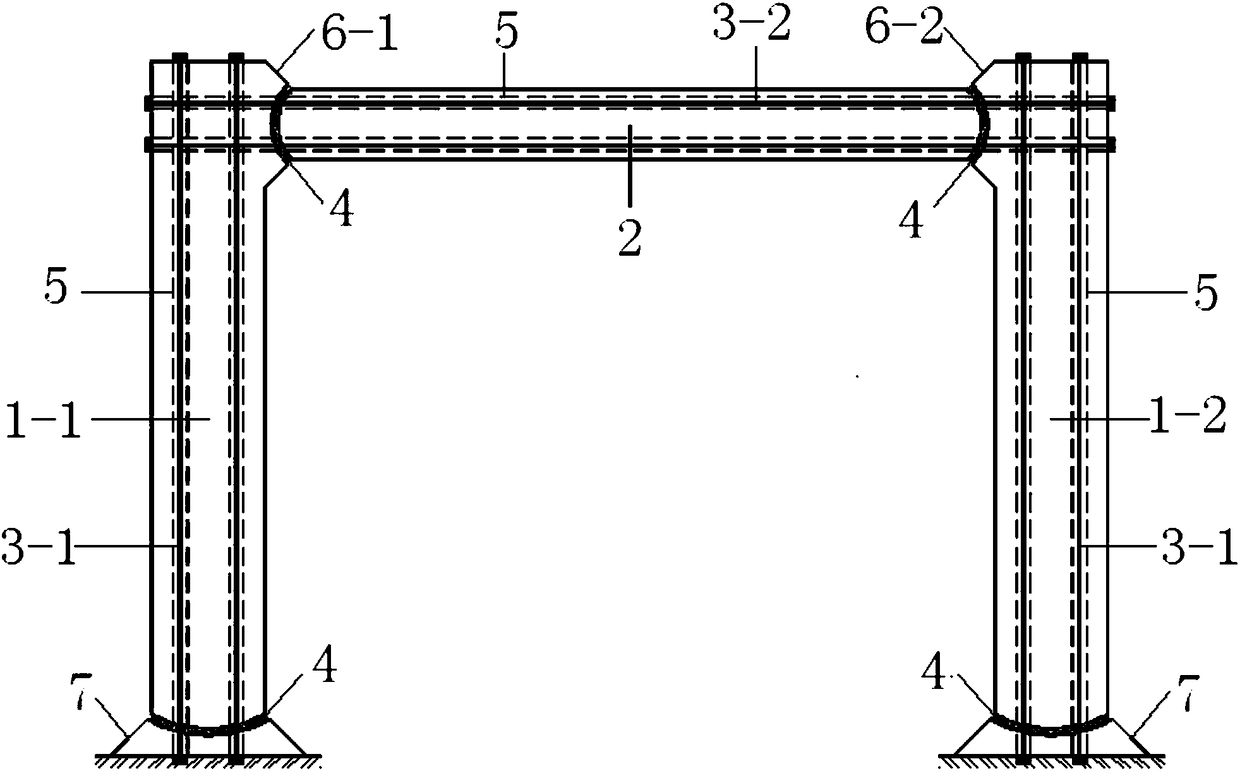

Node with buckling-restrained braced connecting plate penetrating through beam column and manufacturing method thereof

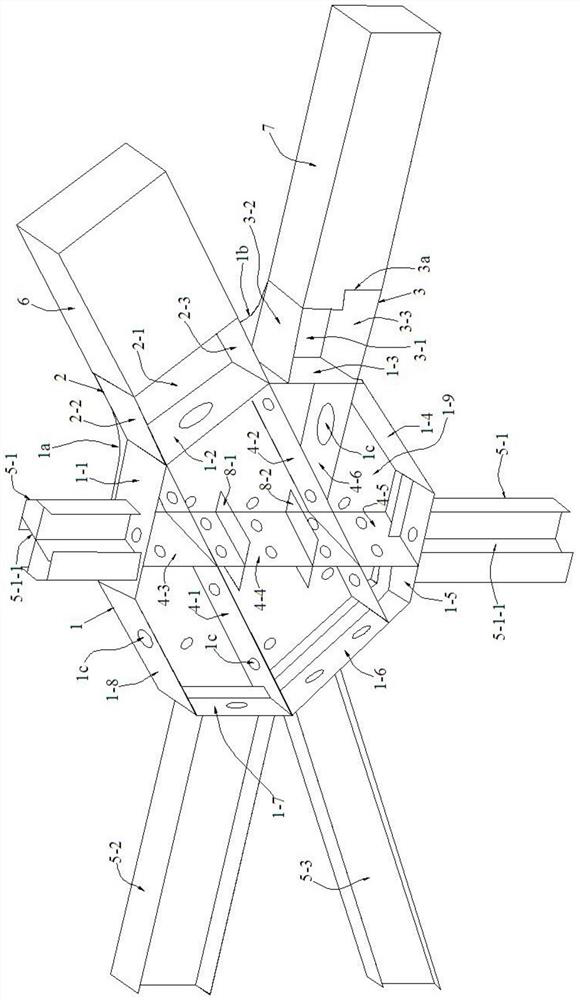

PendingCN110424562APower transmission is simpleEffective force transmissionProtective buildings/sheltersShock proofingChinese charactersBuckling-restrained brace

The invention provides a node with a buckling-restrained braced connecting plate penetrating through a beam column. The node with the buckling-restrained braced connecting plate penetrating through the beam column comprises a steel column shaped like a Chinese character "ri", a steel column interior stiffening structure, a buckling-restrained braced connecting structure and a box girder. The steelcolumn interior stiffening structure is embedded inside the steel column shaped like the Chinese character "ri" and arranged perpendicular to the steel column shaped like the Chinese character "ri".The buckling-restrained braced connecting structure comprises a connecting plate and an outer connection plate which are arranged in an integrally connected manner. One end of the connecting plate penetrates through the steel column shaped like the Chinese character "ri" and is connected with the steel column interior stiffening structure in a clamped and fixed manner and is in contact with the inner side wall of the steel column shaped like the Chinese character "ri". The other end of the connecting plate is arranged in a manner that the other end of the connecting plate is outward-bulging onthe outer wall of the steel column shaped like the Chinese character "ri". The outer connection plate is arranged in an outward-extending manner along the end face of the side, away from the steel column shaped like the Chinese character "ri", of the connecting plate. The outer connection plate and the connecting plate are connected side by side. The box girder penetrates through the outer connection plate and is arranged perpendicular to the connecting plate. One end of the box girder is connected with the outer wall of the steel column shaped like the Chinese character "ri". The invention further provides a manufacturing method for the node with the buckling-restrained braced connecting plate penetrating through the beam column. The node with the buckling-restrained braced connecting plate penetrating through the beam column is simple in design and structure, easy to operate and high in universality; and force transferring is simpler.

Owner:MCC TIANGONG GROUP

Prefabricated assembled hollow pier based on UHPC joints and construction method

PendingCN113123221AConvenient pre-embeddedPre-buried connection is reliableBridge structural detailsBridge erection/assemblyArchitectural engineeringRebar

The invention discloses a prefabricated assembled hollow pier based on UHPC joints and a construction method of the pier, the prefabricated assembled hollow pier comprises a pier column and a base, the pier column is a hollow pier column, the pier column is sequentially composed of a pier bottom section, a middle section and a top cap section from bottom to top, the pier bottom section is located at the top of the base, steel bar connectors are embedded between the pier bottom section and the base, between the pier bottom section and the middle section and between the middle section and the top cap section, reinforcing stirrups are arranged outside the steel bar connectors, and connection is achieved through post-pouring of UHPC joints. According to the invention, the steel bar connectors between the sections are easy to position and connect, the height of the joints is remarkably reduced, and the using amount of joint concrete is small; the segment construction tolerance is large, and the precision requirement is low; joints are free of vibration, self-compaction is achieved, pouring is convenient, and construction is simple; and the assembled pier is excellent in overall performance, high in joint durability, rapid to assemble, short in field operation time and high in efficiency.

Owner:CHINA RAILWAYS CORPORATION +1

Drum-shaped combined steel box joint, arch frame joint structure and construction method thereof

PendingCN113323152AGuarantee the effectiveness of force transmissionGuaranteed connection qualityArched structuresVaulted structuresPre stressMechanical engineering

The invention discloses a drum-shaped combined steel box joint, an arch frame joint structure and a construction method thereof, which can realize multi-angle intersection welding connection among a steel framework, an arch rib and an arch bottom pull rod of a support cylinder. A first inner partition and a second inner partition are arranged, so that the stress transmission effectiveness of the arch rib is guaranteed; a third inner partition, a fourth inner partition and a fifth inner partition are arranged, so that the stress transmission effectiveness of upper and down vertical steel ribs is guaranteed; three horizontal steel ribs and an inclined steel rib of the support cylinder can directly transmit stress through a joint box, so that the connecting quality among the steel framework, the arch rib and the arch bottom pull rod is guaranteed; in addition, a plurality of pouring communication holes are formed, so that the compactness of steel box concrete in an inner cavity of the joint box is guaranteed; and in addition, the arch effect of the drum-shaped combined steel box joint is utilized, so that the prestressing force of an external prestressed cable can be directly transmitted to the drum-shaped combined steel box joint.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

Relay

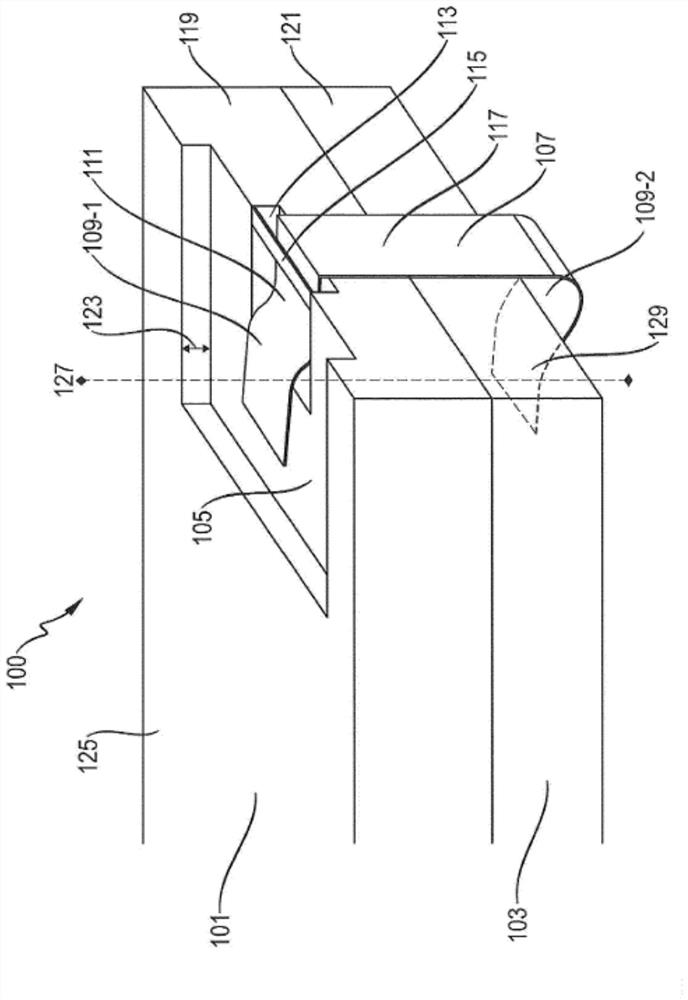

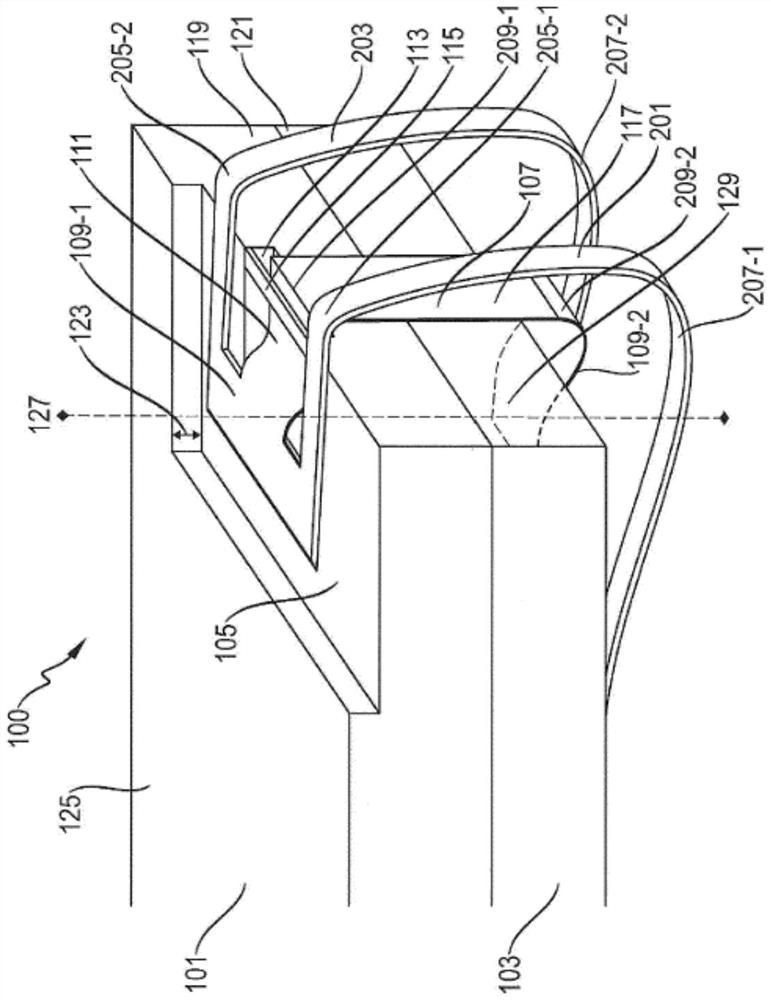

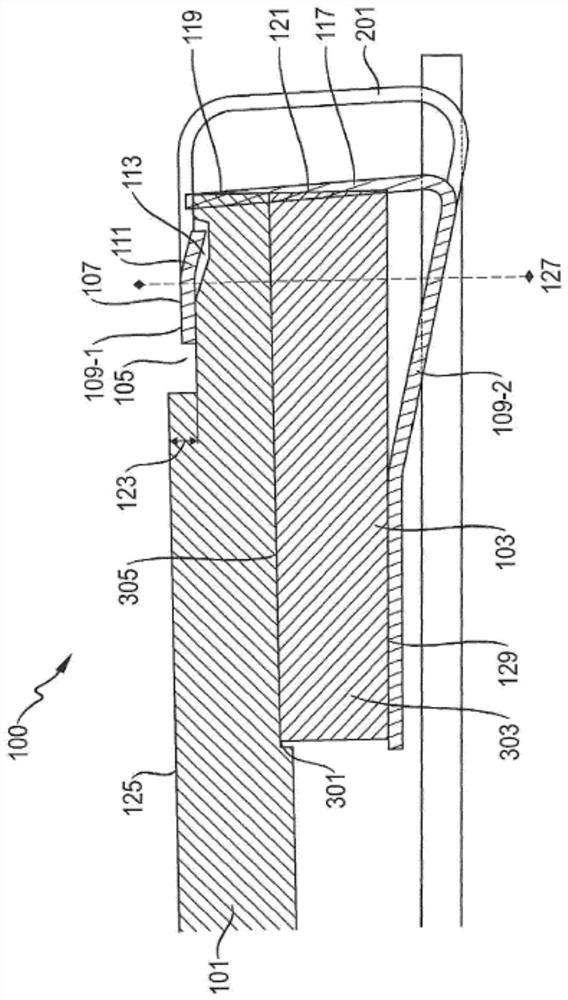

PendingCN112262452AMeet the height limit requirementsStructure height flushElectromagnetic relay detailsEngineeringMechanical engineering

The invention relates to a relay (100), comprising an armature (101) and a yoke (103) which can be electromagnetically coupled to the armature (101). The armature (101) lies flat at least partly on the yoke (103), and a receiving depression (105) is partly formed in the armature (101). The relay also comprises a bracket-shaped clamping spring (107) which surrounds the armature (101) and the yoke (103) on the end face in order to fix the armature (101) on the yoke (103). The bracket-shaped clamping spring (107) has a first clamping limb (109-1), which is arranged in the receiving depression (105), and a second clamping limb (109-2), which lies on the yoke (103). The first clamping limb (109-1) has an angled tab (111) which engages elastically into a recess (113) formed in the receiving depression (105) of the armature (101).

Owner:PHOENIX CONTACT GMBH & CO KG

Steel pipe pile structure

PendingCN113774899AStrengthen connectionIncrease end bearing capacityFoundation repairBulkheads/pilesSteel tubeEngineering

The invention provides a steel pipe pile structure. The steel pipe pile structure comprises a steel pipe pile and a bracket, wherein a through hole for communicating the inside and outside of a pipe cavity of the steel pipe pile is formed in the side wall of the steel pipe pile; and the bracket can extend out of the pipe cavity in a sliding manner and is inserted into the through hole. The steel pipe pile structure provided by the invention is simple in structure and convenient to use; after the steel pipe pile is arranged in place, the tail end of the bracket is pushed from the interior of the pipe cavity of the steel pipe pile through an execution piece, the bracket is forced to stretch out of the steel pipe pile from the through hole, then a bracket structure for connecting the steel pipe pile and the foundation is formed, construction is convenient, damage is small, and cost is low.

Owner:BEIJING AEROSPACE GEOTECHN ENG INST

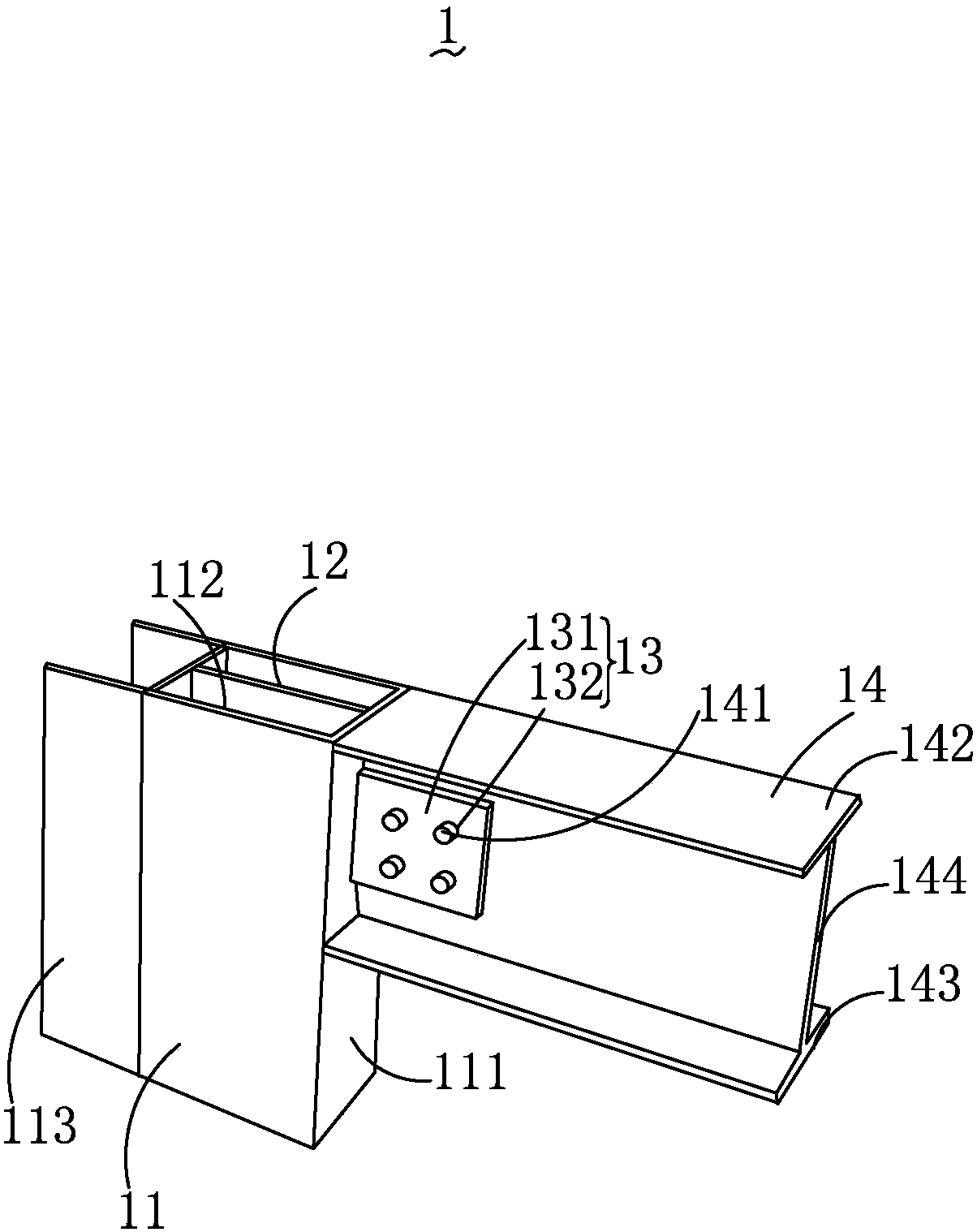

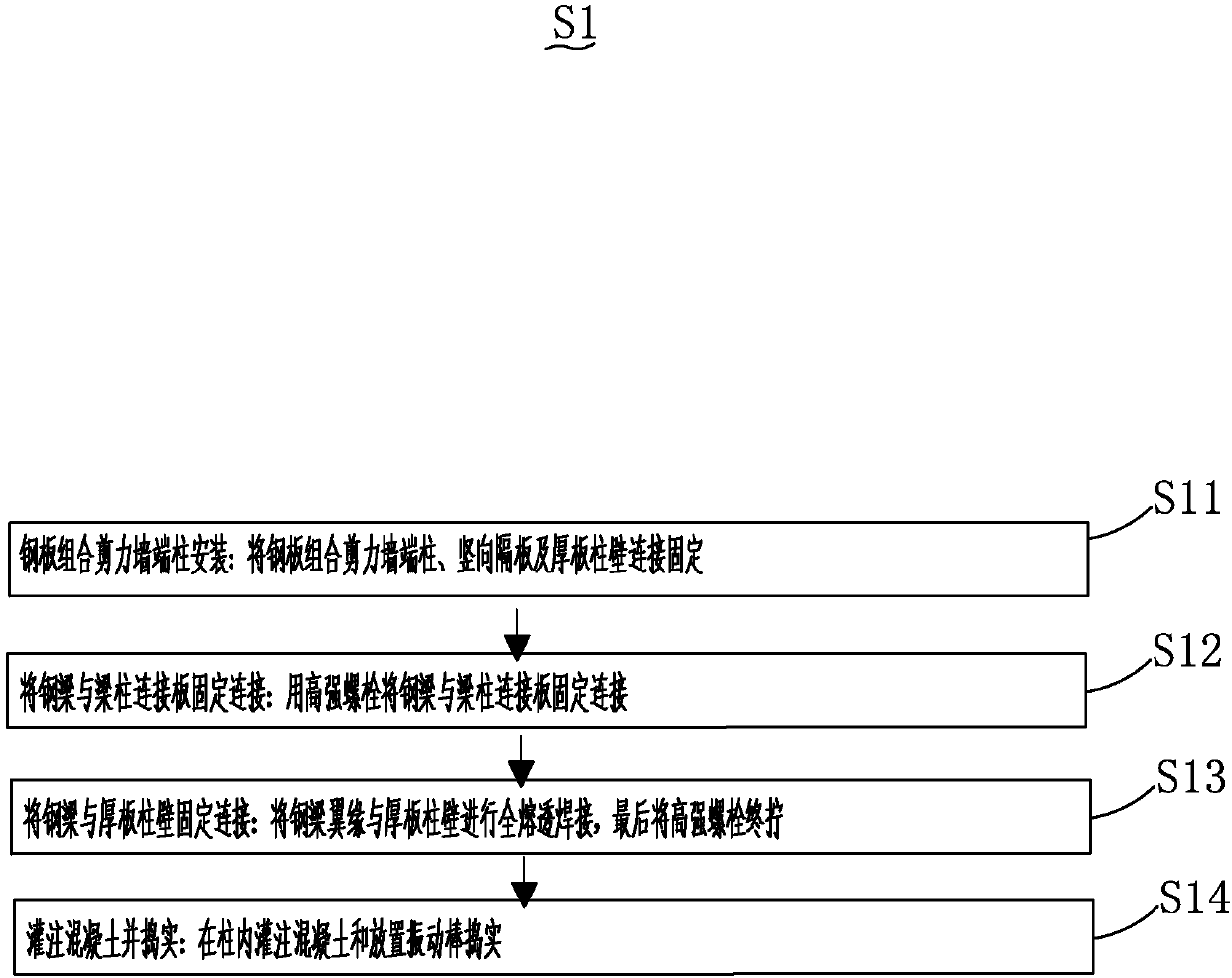

Vertical partition plate beam and column connection joint applicable to composite steel plate shear wall end column and construction method for applying vertical partition plate beam and column connection joint

PendingCN107642181ASolve problems such as perfusion inconvenienceActive connectionWallsSheet steelThick plate

The invention provides a vertical partition plate beam and column connection joint applicable to a composite steel plate shear wall end column and a construction method for applying the vertical partition plate beam and column connection joint. The vertical partition plate beam and column connection joint applicable to the composite steel plate shear wall end column comprises the composite steel plate shear wall end column, a vertical partition plate, a beam and column connection plate and a steel beam. The vertical partition plate is vertically arranged in the opposite insides of the composite steel plate shear wall end column, the composite steel plate shear wall end column comprises a thick plate column wall, the thick plate column wall is arranged on a side of the composite steel plateshear wall end column, and the beam and column connection plate is connected with the steel beam and the thick plate column wall. The vertical partition plate beam and column connection joint applicable to the composite steel plate shear wall end column and the construction method have the advantages that the vertical partition plate beam and column connection joint in a connection mode is provided with the vertical partition plate, accordingly, the steel beam can be effectively connected with a composite steel plate shear wall, and requirements of pouring concrete construction methods can bemet.

Owner:HUNAN ARCHITECTURAL DESIGN INST +1

Prestressed Prestressed Prefabricated Concrete Node Surface Connection Structure

ActiveCN106193287BReduce compressive stressIncrease contact areaBuilding constructionsRebarConcave surface

The invention discloses a prestressed fabricated concrete joint curved surface connecting structure which comprises prefabricated columns and prefabricated beams. Joint overhanging arms are arranged at joints of the prefabricated columns and the prefabricated beams, each joint overhanging arm is of a variable-section structure, sections at the joints of the joint overhanging arms and the prefabricated columns are large while those at the joints of the joint overhanging arms and the prefabricated beams are small, and end faces connected with the prefabricated beams are concave surfaces; connecting end faces of the prefabricated beams and the joint overhanging arms are convex surfaces, and the convex surfaces and the concave surfaces on the joint overhanging arms are equal in curvature. Prefabricated beams prestressed rebars sequentially penetrate prestressed rebar holes in the prefabricated beams, the joint overhanging arms and the prefabricated columns to be pre-tightened to connect the prefabricated beams, the joint overhanging arms and the prefabricated columns to form a whole. The prestressed fabricated concrete joint curved surface connecting structure is stable in structure and long in service life.

Owner:WUHAN UNIV OF TECH

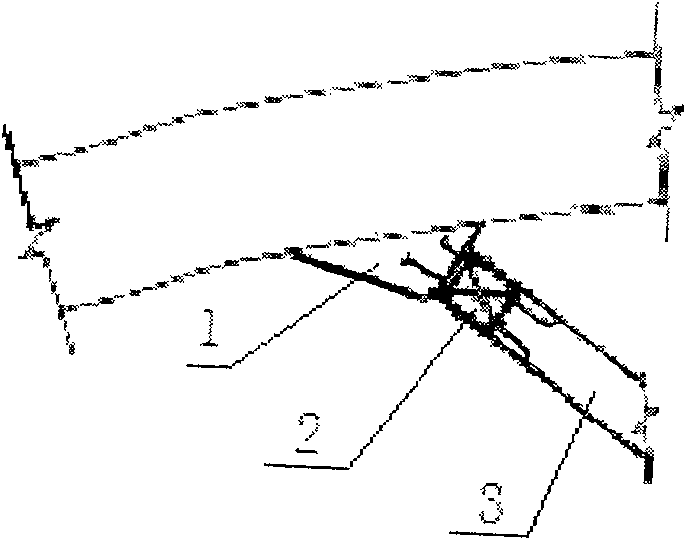

Foundation pit supporting system based on splayed I-shaped steel and construction method thereof

The invention relates to a foundation pit supporting system based on splayed I-shaped steel and a construction method thereof. The system comprises an inner support horizontally arranged in a foundation pit, wherein the inner support comprises two sections, namely a splayed I-shaped steel support and a steel pipe support; the splayed I-shaped steel support comprises a diagonal support and diagonal braces symmetrically arranged on two sides of the diagonal support; one end of each diagonal brace is fixed to a surrounding purlin or a crown beam in the foundation pit, and the other end of each diagonal brace is fixed to the side face of the diagonal support; one end of the diagonal support is fixed to the surrounding purlin or the crown beam in the foundation pit, and the other end of the diagonal support is connected with the steel pipe support; and the other end of the steel pipe support is fixed to the surrounding purlin or the crown beam in the foundation pit through a movable head. The novel inner support with one or two ends made of the splayed I-shaped steel is designed, so that the action range of each steel support is widened, the number of the inner supports is reduced, the cost is reduced, and the construction period is shortened; and meanwhile, the operation space in the foundation pit can be enlarged, more abundant operation conditions are reserved for large machinery, the earthwork outward transport and material feeding and discharging efficiency is improved, and a more efficient and economical foundation pit steel support system is realized.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

Jacking force-adjustable prestressed resilient support structure and construction method thereof

InactiveCN100582373CStructural Internal Force OptimizationEasy constructionBridge erection/assemblyBridge strengtheningPre stressSpring steel

A prestressing force elastic support structure convenient for regulating the prestressing force, is characterized in that a rigidization strip is casted at the bridge bearing point position to be reinforced, and a support pier stud is casted beneath the rigidization strip; the rigidization strip is in fixed connection with the support pier stud through a prestressing force elastic steel bearing; two spring steel sheets have a certain radian and the arc tops are relative to each other, which are arranged between the upper steel plate and the lower steel plate, the spring steel sheets and the common edge of the upper steel plate and the lower steel plate are welded and fastened on a locating steel plate, the upper steel plate and the lower steel plate are connected through a long bolt, a prestressing force is added to the spring steel sheet as a deformation margin, thereby the object of regulating the prestressing force can be achieved by adjusting the bolt. The invention has beneficial technique effects of simple construction, reliable structure and adjustable prestressing force.

Owner:CHONGQING JIAOTONG UNIVERSITY

Automotive rear shock absorber force transmission components

ActiveCN111055926BExtended delivery pathEfficient deliverySuperstructure subunitsResilient suspensionsShock absorberEngineering

The invention discloses an automobile rear shock absorber force transmission assembly, which relates to the technical field of automobile body, and comprises a rear side wall inner panel, a C-pillar reinforcement plate, a D-pillar assembly, a rear wheel cover and a rear wheel cover arranged in the rear wheel cover. The rear shock absorber mounting plate, the C-pillar reinforcement plate, the rear side wall inner panel and the rear wheelhouse outer panel form the first force transmission chamber, and the first force transmission chamber extends to the arch of the rear wheelhouse outer panel; D There is a second force transmission cavity in the column assembly, and the second force transmission cavity communicates with the first force transmission cavity; a rear side wall reinforcement beam is fixedly connected to the outer side of the rear side wall inner panel, and one end of the rear side wall reinforcement beam is connected to the D The column assembly is connected, and the other end is connected with the arch of the rear wheelhouse outer panel; the rear side wall reinforcement beam is enclosed with the rear side wall inner panel, the D-pillar assembly and the rear wheelhouse outer panel to form a third force transmission chamber. The invention solves the problem that the existing automobile rear side wall structure cannot effectively decompose and absorb the force transmission from the rear shock absorber.

Owner:DONGFENG LIUZHOU MOTOR

Steel panel used in fabricated Bailey truss in matching manner

ActiveCN103306202BExtreme forceEasy to connectTemporary pavingsBridge structural detailsTransmission pointSteel plates

Owner:THE 2ND ENG CO LTD MBEC +1

Interlayer cleaner for double-layer box body

InactiveCN110756531AAdapt to the cracksEffective force transmissionHollow article cleaningBrush deviceMechanical engineering

The invention discloses an interlayer cleaner for a double-layer box body, and discloses a cleaning brush device which can be used in cooperation with an existing steel wire ball and can clean the twosides of a box body crack at the same time through a push pipe wrapping the steel wire ball. The interlayer cleaner for the double-layer box body is characterized in that one end of the push pipe issleeved with a front pressing cover, wherein the diameter of the front pressing cover is gradually increased from top to bottom; the bottom edge of the front pressing cover is bent towards the outer side in the horizontal direction; a plurality of clamping teeth are arranged on the inner wall of the top of the front pressing cover; a lower fastening nut is arranged at one end of the push pipe in ascrewed mode and positioned in the front pressing cover; a push plate is arranged at the other end of the push pipe; a plurality of rib plates are arranged on the outer wall of the push pipe at equalangles and positioned between the front pressing cover and the push plate; the two ends of each rib plate are connected with the front pressing cover and the push plate respectively; a distance is reserved between every two adjacent rib plates; each rib plate is divided into an upper section and a lower section; the width of the upper section of each rib plate is larger than that of the lower section of each rib plate; and the joint of the upper section and the lower section of each rib plate is in slope transition.

Owner:XUZHOU LISTON IND DESIGN CO LTD

Connection joint for steel tube and angle steel in steel tube tower of transmission line

The invention relates to a connection structure of a steel tube and angle steel mixed iron tower of a transmission line, and particularly relates to a connection joint of changing a steel tube into angle steel in a steel tube tower of a transmission line. The connection joint comprises a steel tube, angle steel and a flange, wherein the flange comprises an upper end flange and a lower end flange which have equal diameters, one end of the upper end flange is connected with one end of the lower end flange, the other end of the lower end flange is connected with the steel tube to form a lower end flange joint, an annular reinforcing pipe is connected to the other end of the upper end flange in the axial direction, the upper end flange and the annular reinforcing pipe form an upper end flange joint, the angle steel passes through the annular reinforcing pipe, and the angle steel is fixed by depending on a gusset plate I and a gusset plate II arranged on the upper end flange, wherein plate surfaces of the gusset plate I and the gusset plate II are mutually vertical and crossed. The connection joint is reliable in force transfer, and can be used in connection of a variable cross-section part in the steel tube and angle steel mixed iron tower.

Owner:CHINA ELECTRIC POWER RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com