Steel panel used in fabricated Bailey truss in matching manner

A prefabricated, steel panel technology, applied to special pavements, bridge parts, roads, etc., can solve the problems of large amount of steel used in the structure, large safety factor, and failure to fully consider the reasonable force transmission of the Bailey truss structure. The force system is reasonable, the bearing capacity is strong, and it is beneficial to the effect of load transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings.

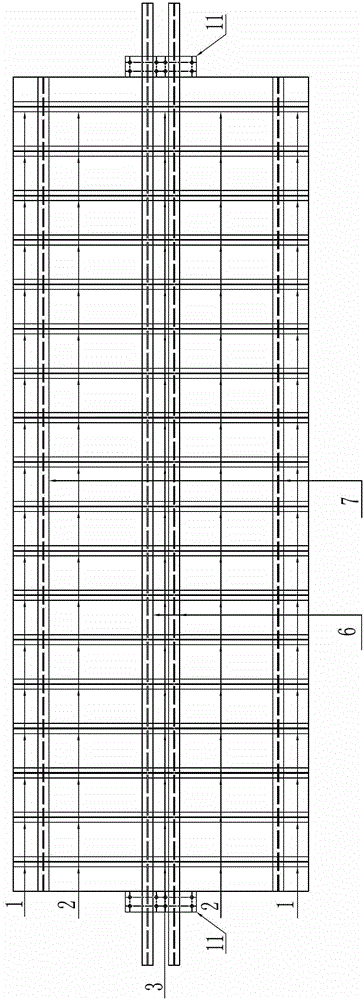

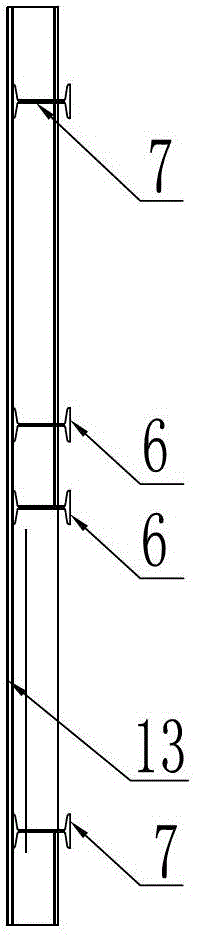

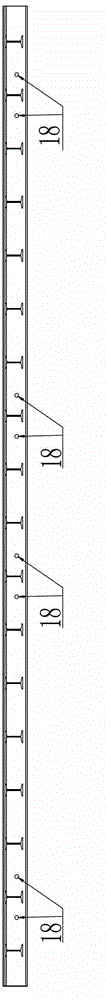

[0030] Such as Figure 1A , Figure 1B , Figure 1C , Figure 2A , Figure 2B , Figure 2C As shown, the main beam 6, main beam 7, main beam 8, main beam 9, and main beam 10 with different lengths are arranged under the checkered steel plate 13 according to the fulcrum of the oblique and vertical bars of the Bailey beam, and are connected with the checkered steel plate 13. The steel plate 13 is welded into one; the reinforced rib beam 1, reinforced rib beam 2, reinforced rib beam 3, reinforced rib beam 4, and reinforced rib beam 5 of different lengths are perpendicular to the direction of the main beam (in the same plane) inside) are uniformly arranged under the checkered steel plate 13 at a certain interval, and welded with the checkered steel plate 13, main girder 6, main girder 7, main girder 8, main girder 9, and main girder 10, thereby forming an A-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com