Fiber bragg grating hydrogen sensor based on femtosecond laser micromachining and preparation method for fiber bragg grating hydrogen sensor

A fiber grating and femtosecond laser technology, which is applied in laser welding equipment, metal processing equipment, clad optical fiber, etc., can solve the problems of low sensitivity and short film life, and achieve high sensitivity, low cost and improved film life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

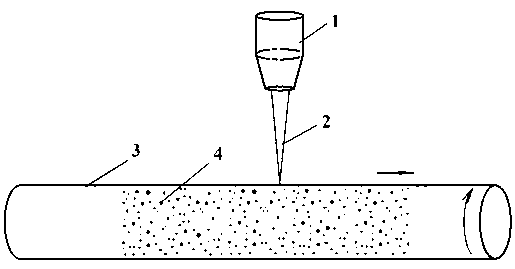

[0029] Describe in detail below in conjunction with accompanying drawing:

[0030] Such as figure 1 As shown in the figure, as a pretreatment process for three-dimensional microstructure processing, a femtosecond laser is used to prepare irregularly distributed surface micropits. The femtosecond laser is focused by the laser focusing lens 1 , and the focus of the femtosecond laser beam 2 is aligned with the surface of the fiber grating (cladding) 3 . In order to avoid damaging the spectral characteristics of the core grating, the femtosecond laser beam is offset from the fiber core by 25-35um. The laser energy density is set in the interval slightly higher than the ablation threshold (critical vaporization point) of the quartz material. Let the optical fiber rotate at a constant speed under the drive of the rotating fixture, and at the same time, the worktable drives the optical fiber to move slowly along the axial direction, so that the laser scans the cladding cylindrical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com