Solar cell conductive silver paste free of silicone oil and application thereof

A technology for solar cells and conductive silver paste, applied in conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc. , to achieve the effect of improving the linear aspect ratio, improving the viscosity characteristics, and improving the conductivity and plasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

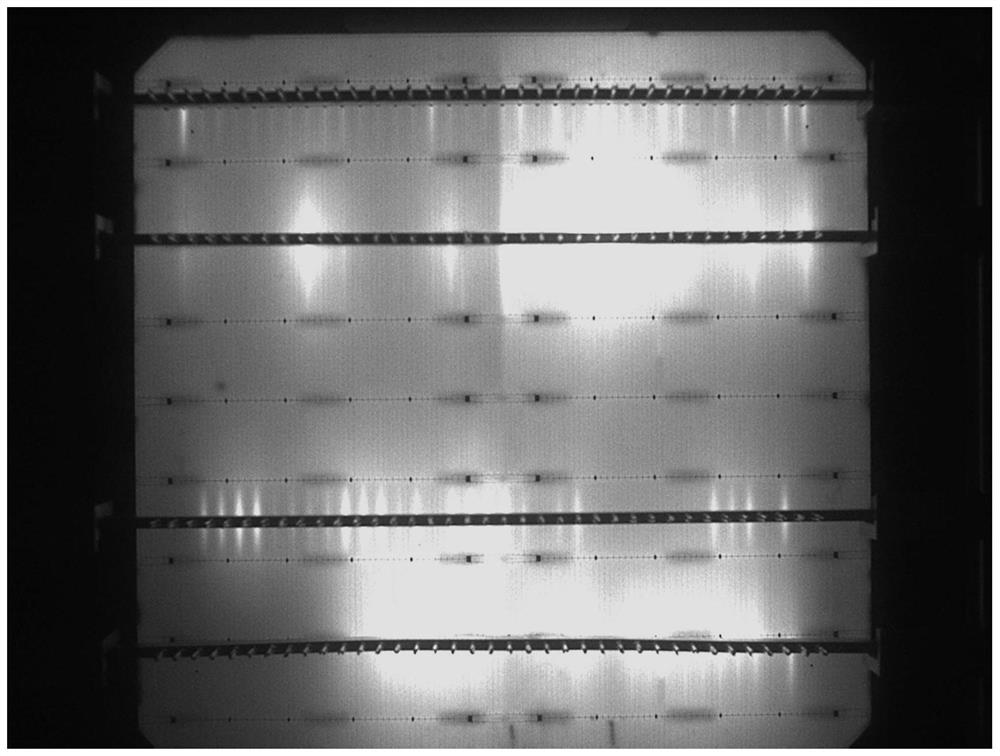

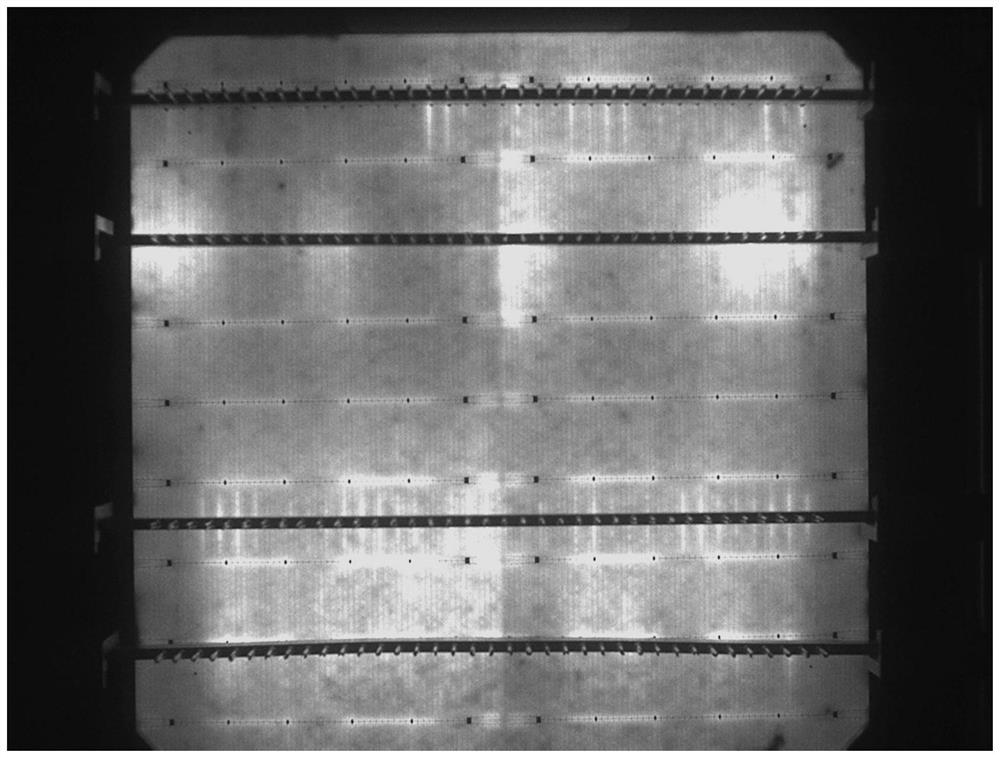

Image

Examples

Embodiment 1

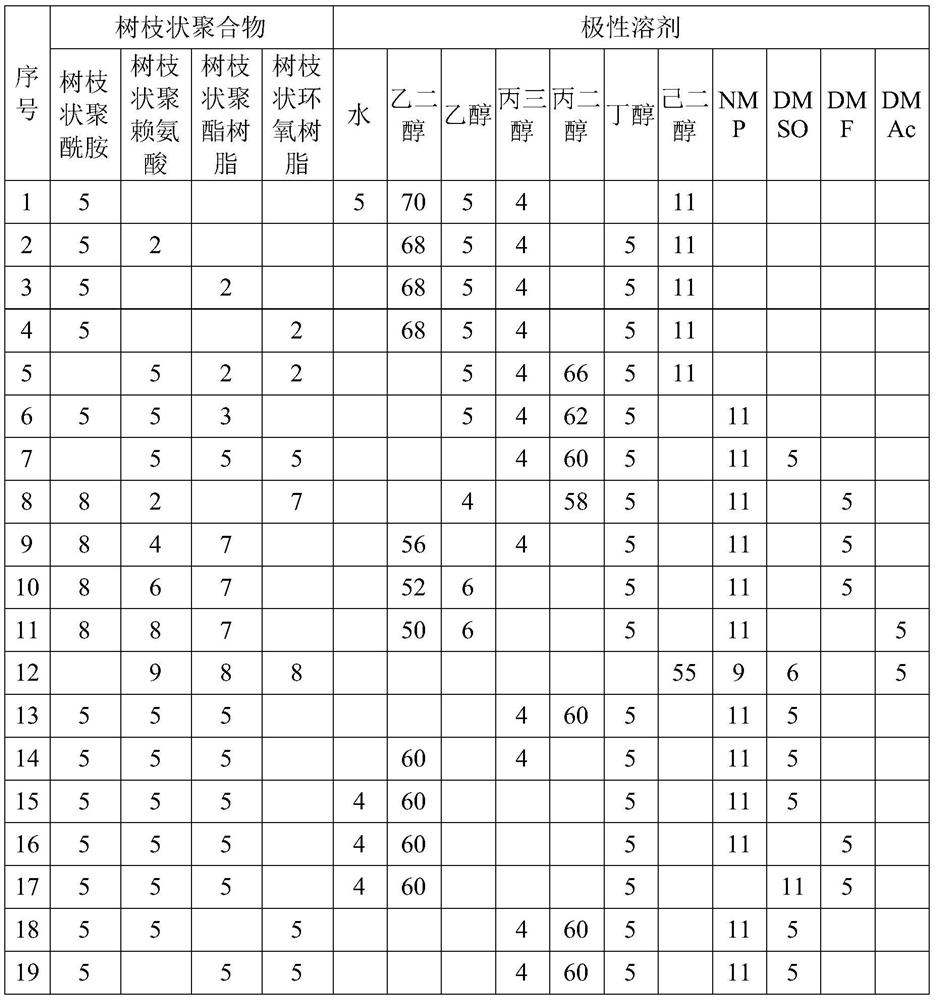

[0032]This embodiment provides a series of polymer additives, and the raw material composition of each polymer additive is shown in Table 1 in parts by weight.

[0033] Table 1

[0034]

[0035] The preparation method of the above-mentioned polymer additive is as follows: uniformly mixing the dendritic polymer and the polar solvent according to the ratio to obtain the polymer additive.

Embodiment 2

[0037] This embodiment provides a series of conductive silver pastes. The raw material composition of each conductive silver paste is shown in Table 2, based on the total weight of the silver paste raw materials as 100%. Among them, the numbers corresponding to the organic resin, organic solvent, thixotropic agent and dispersant are the parts by weight of each component in the organic vehicle, for example: in formula combination 1, the organic vehicle is composed of a weight ratio of 10:75:5 : 10 organic resins, organic solvents, thixotropic agents and dispersants, and the weight ratio of the organic vehicle in the raw materials is 14.5%. The polymer additives in Table 2 can be any one or a combination of two or more of the polymer additives shown in Table 1.

[0038] The glass powder used in Table 2 is a tellurite glass powder composition with an average particle size of 0.1 μm-5 μm and a softening point of 200°C-600°C; the silver powder is spherical silver powder with a tap ...

Embodiment 3

[0045] This embodiment provides the test results of the viscosity characteristics, plastic characteristics, sintering ability and tensile ability of the conductive silver paste, which are summarized in Table 3.

[0046] Example samples 5-1 to 5-5 in table 3 represent the conductive silver paste obtained according to the formula composition in table 2, and the polymer additives used are respectively the raw materials whose serial numbers are 3, 6, 9, 12 and 18 in table 1 composition. The preparation method of conductive silver paste is: mix silver powder, glass powder, organic vehicle and polymer additive according to a certain proportion, grind and disperse through three-roll mill after mixing, and control the average scraper fineness of silver paste to below 10 μm, preferably controlled The fineness reaches below 5μm.

[0047] For example, the preparation method of embodiment sample 5-1 is:

[0048] 1. Mix dendritic polyamide, dendritic polyester resin, ethylene glycol, eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com