Integrated multi-station plate and automatic guide pin clamping device for assembling aluminum electrolytic capacitors

An aluminum electrolytic capacitor, multi-station technology, applied in the direction of capacitors, capacitor manufacturing, capacitor terminals, etc., can solve the problems of affecting product qualification rate, damage to electrode aluminum foil riveting, excessive leakage current, etc., to simplify the assembly process. , speed up the production progress, the effect of strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

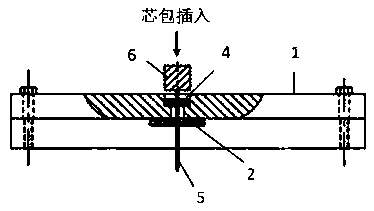

[0019] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0020] It should be noted that the embodiments provided by the present invention are only for effectively explaining the technical features of the present invention, and the positioning words such as left, right, upper end, and lower end are only for better understanding of the embodiments of the present invention. The description should not be regarded as a limitation on the technical solution of the present invention.

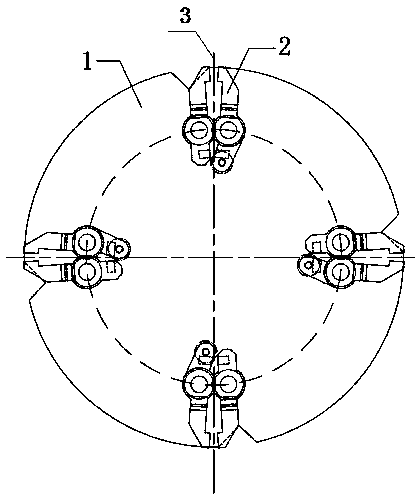

[0021] The invention discloses an aluminum electrolytic capacitor assembly integrated multi-station disk and an automatic clip guide device. Four clip guide manipulators 2 are arranged equidistantly around the bottom of the integrated multi-station disk 1. Here Limiting the number of guide needle m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com