Patents

Literature

33results about How to "Guarantee in place" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

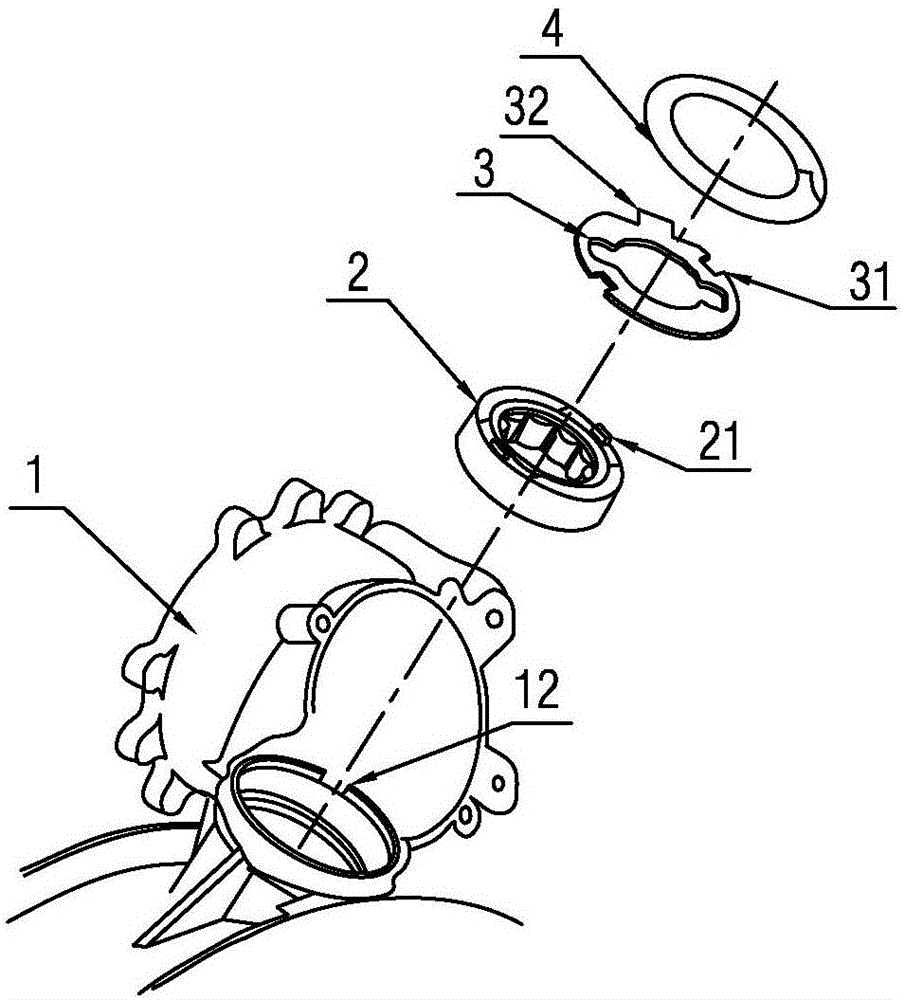

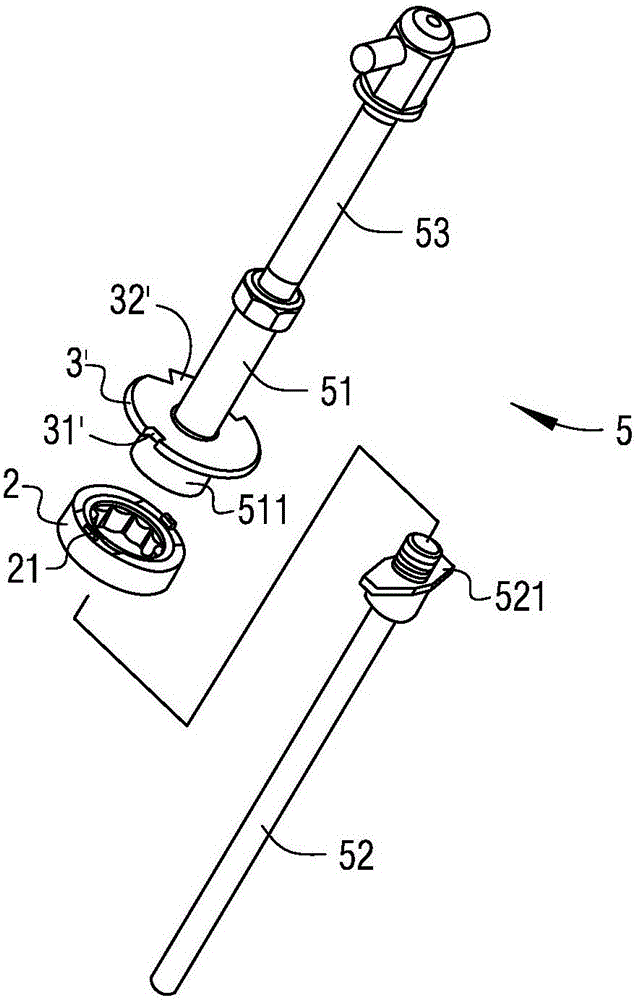

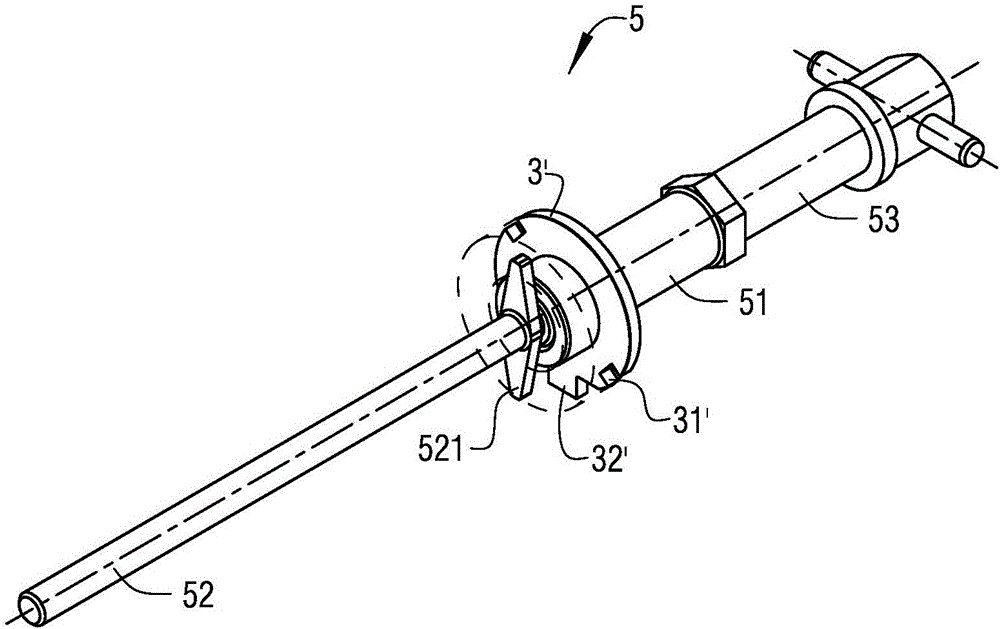

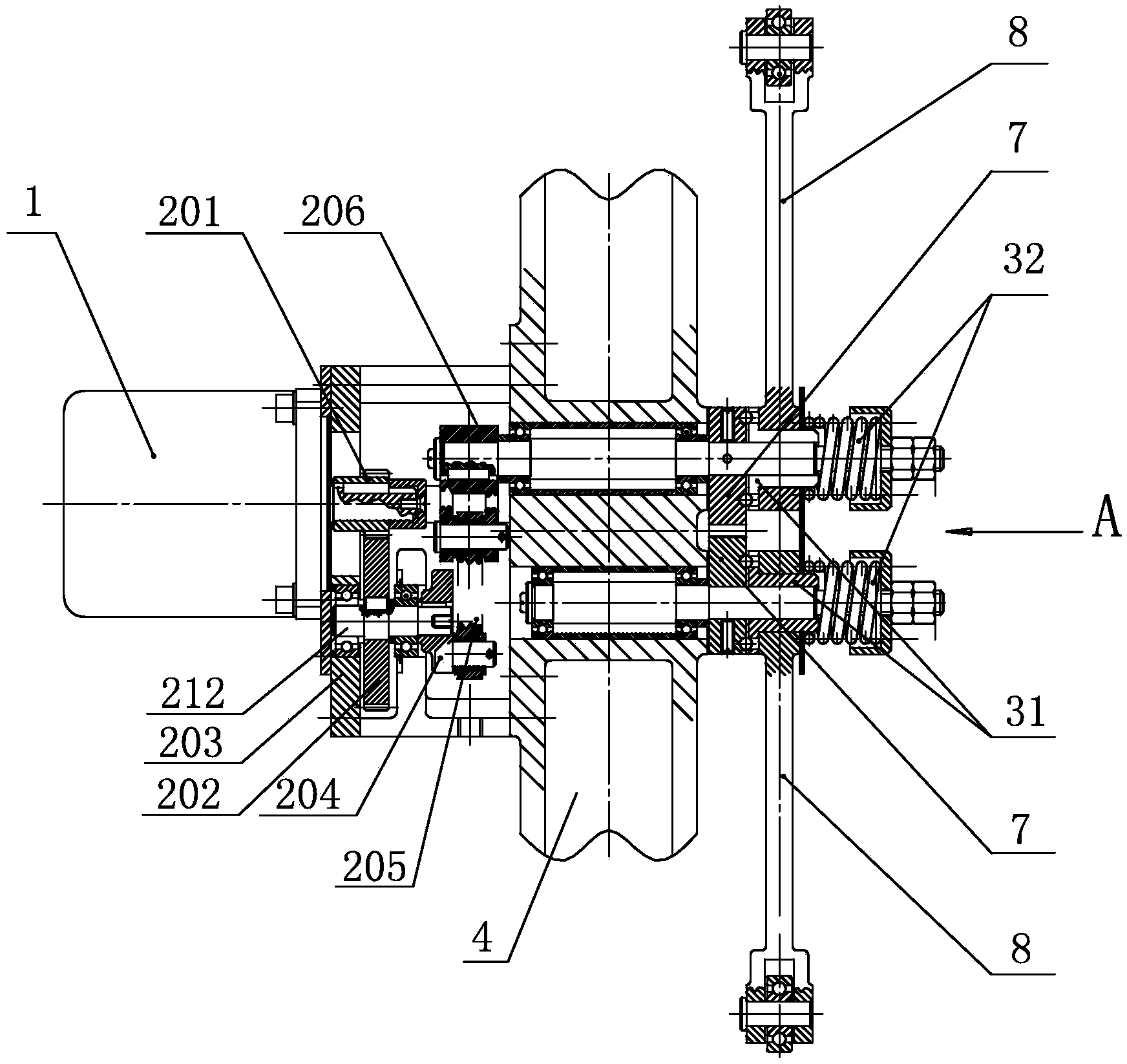

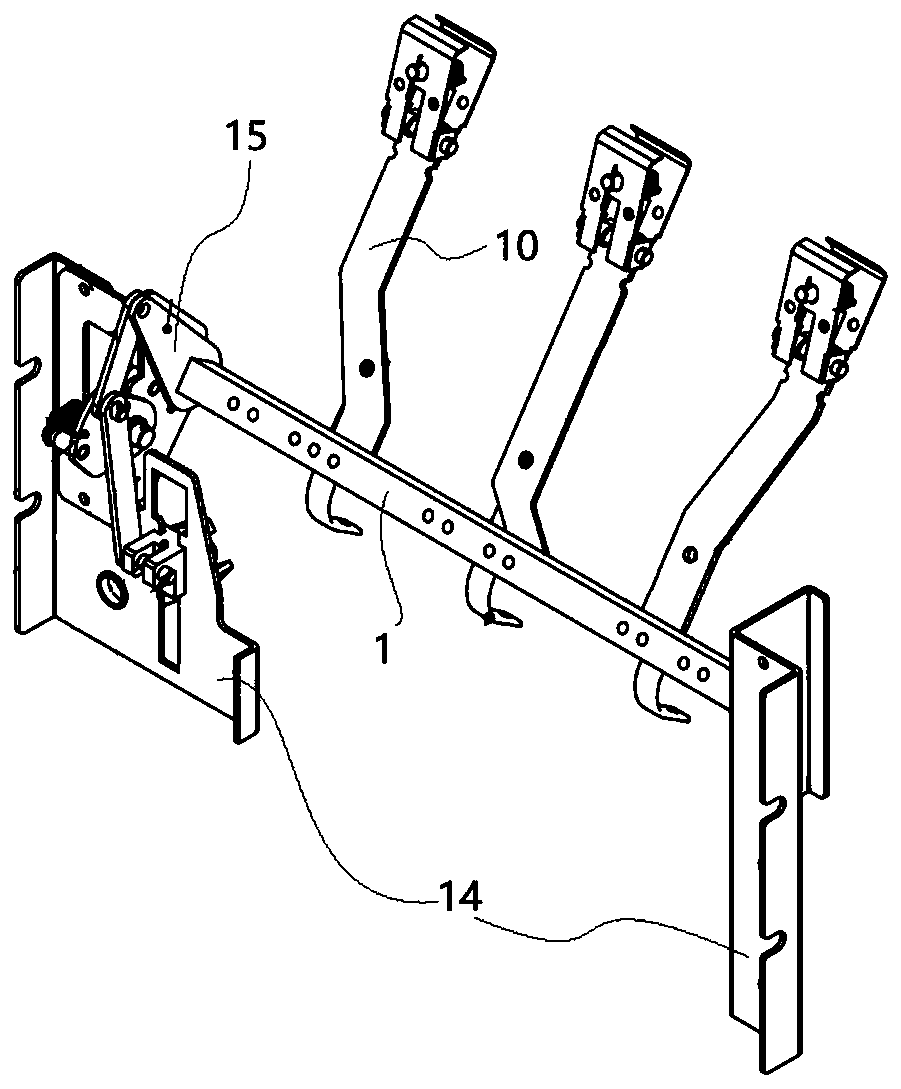

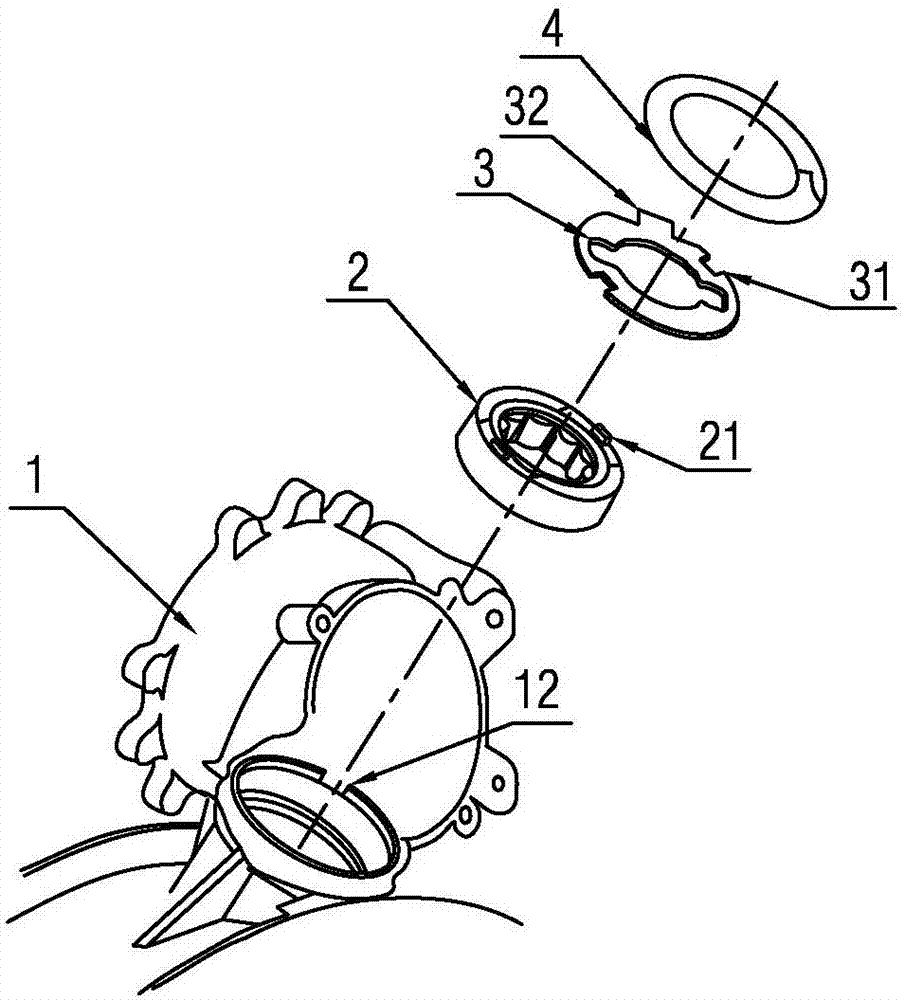

Bearing assembly method

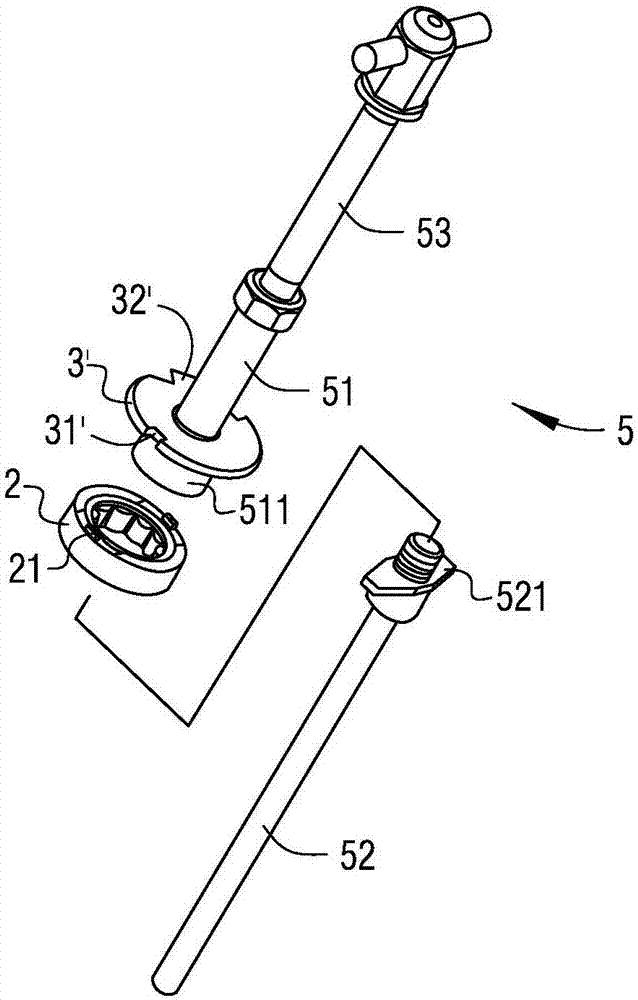

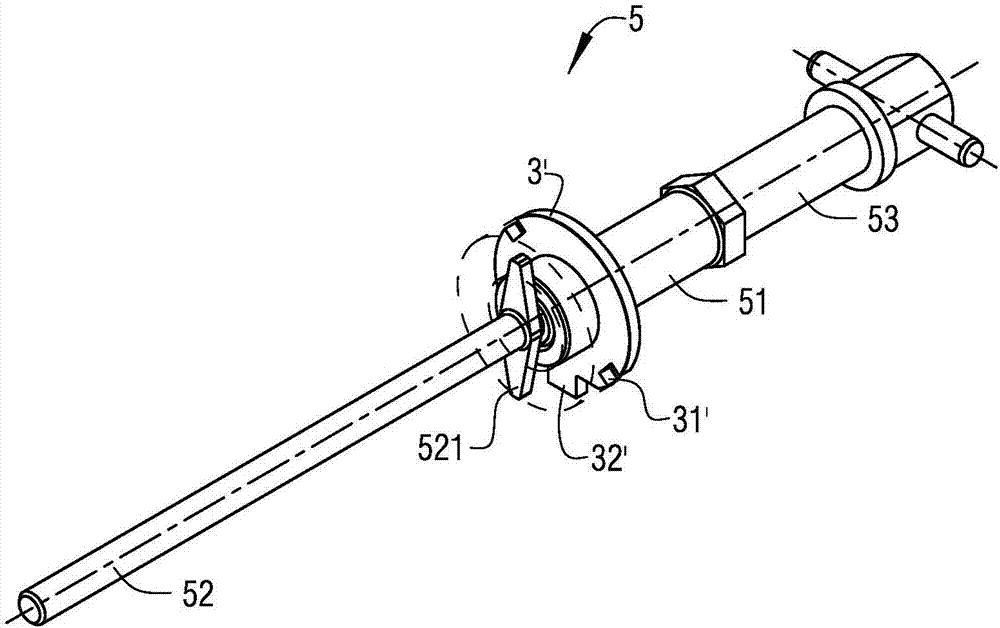

The invention relates to a bearing assembly method used for assembling a bearing without an inner ring on an intermediate case of an aircraft engine. The method includes the following steps: A, providing an assembly tool, sleeving a cylindrical portion with a bearing bush, enabling a boss to match and align with a first notch, rotationally connecting an ejector rod with a first pressure rod, and clamping the bearing with an ejector blade and a disc; B, after heating a case hole of the intermediate case or cooling the bearing, enabling a first projection to align with a case notch, and then assembling the bearing in place; disconnecting the ejector rod with the first pressure rod, taking out the ejector rod from the intermediate case, and then taking the first pressure rod out of the bearing; C, mounting a collar and a spiral retaining ring in sequence to finish assembling of the bearing. The bearing assembly method greatly improves assembly and disassembly efficiency and quality.

Owner:CHINA HANGFA SOUTH IND CO LTD

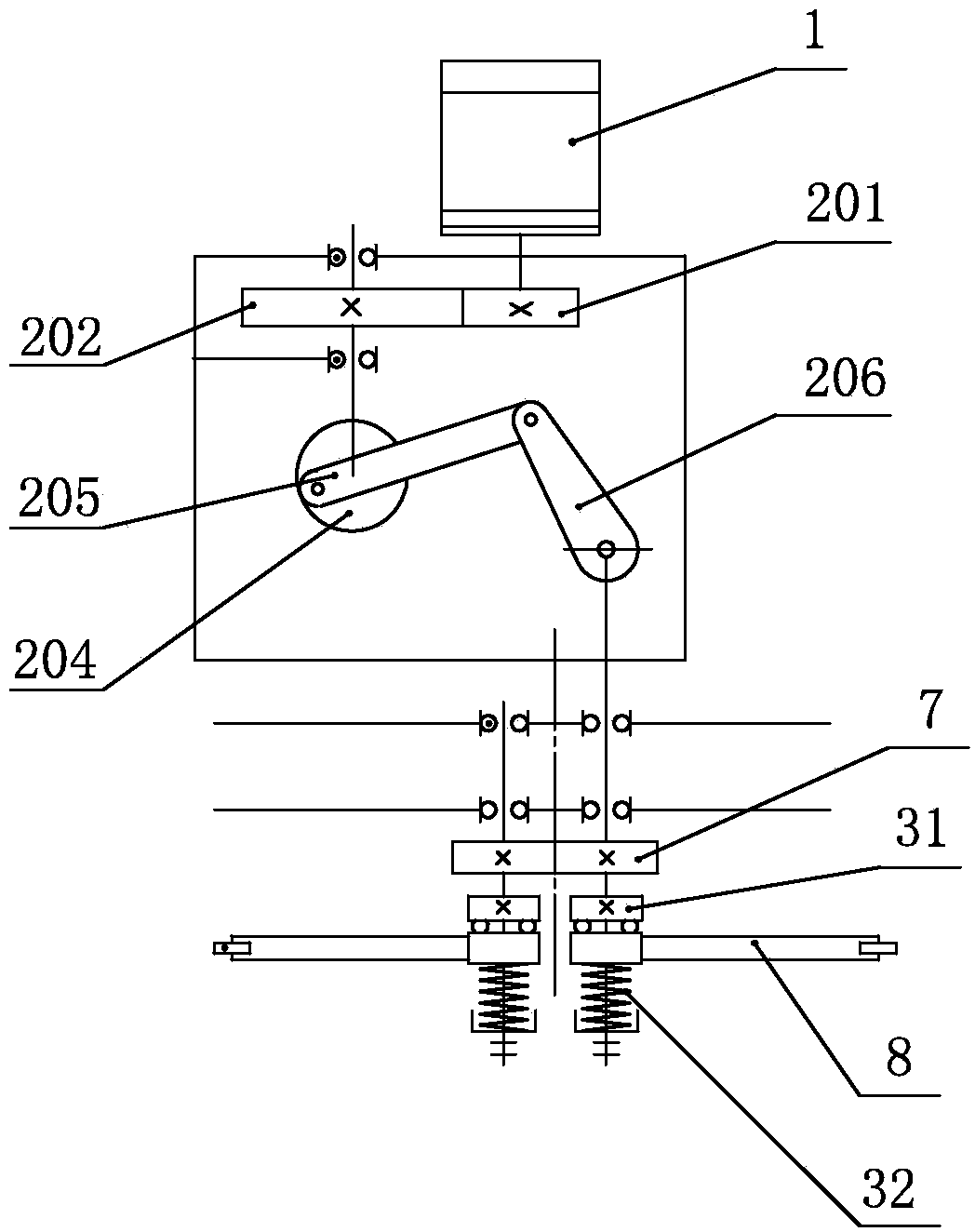

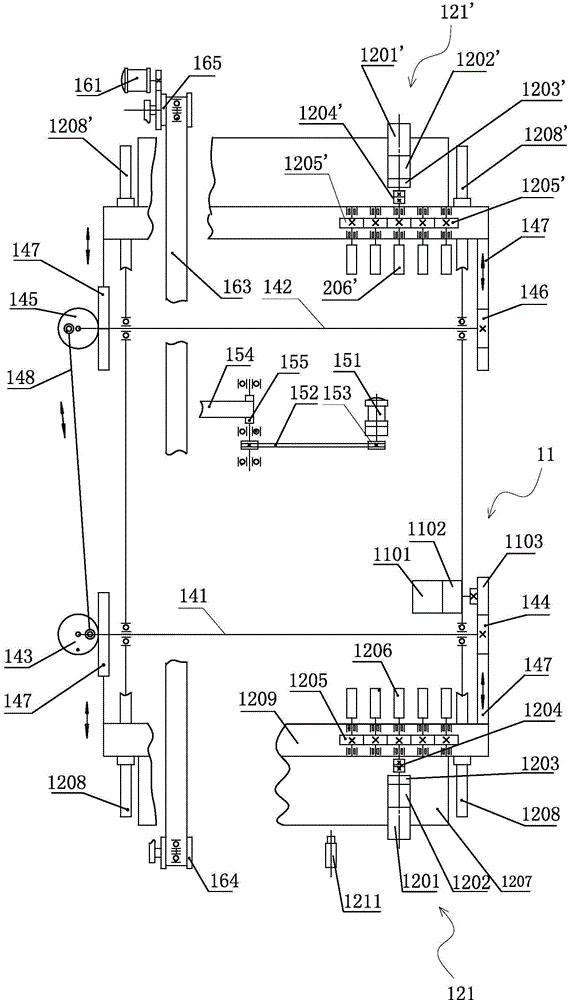

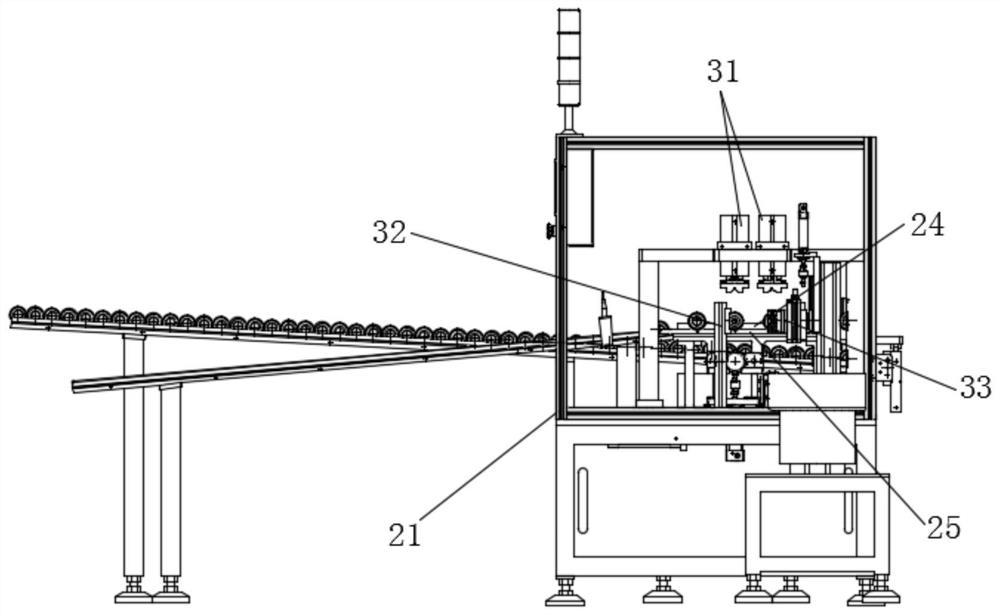

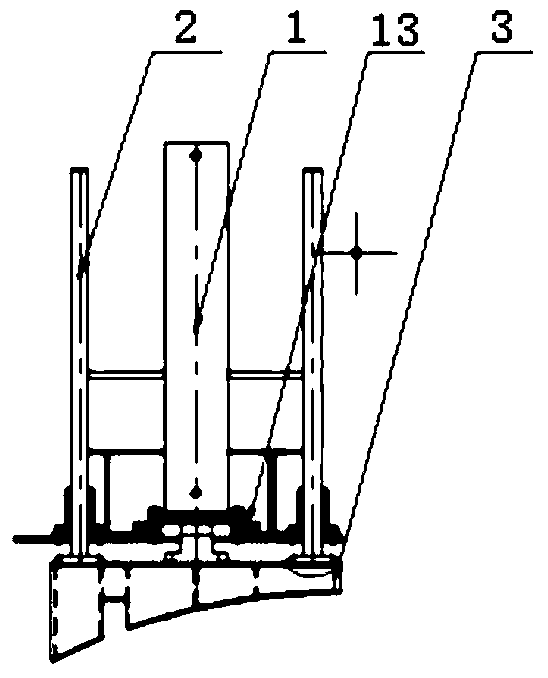

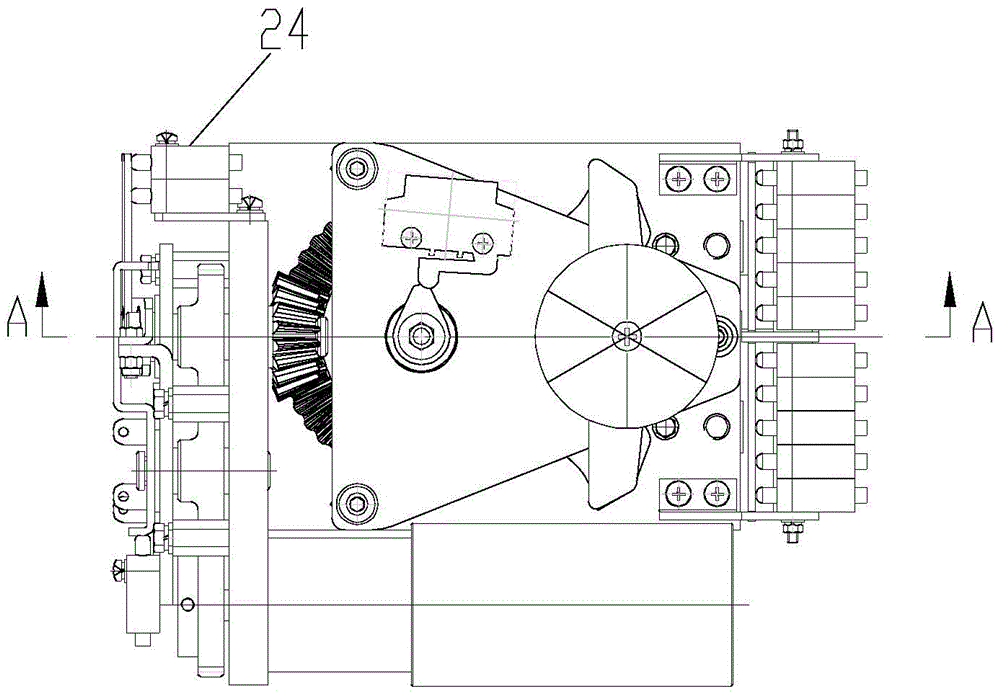

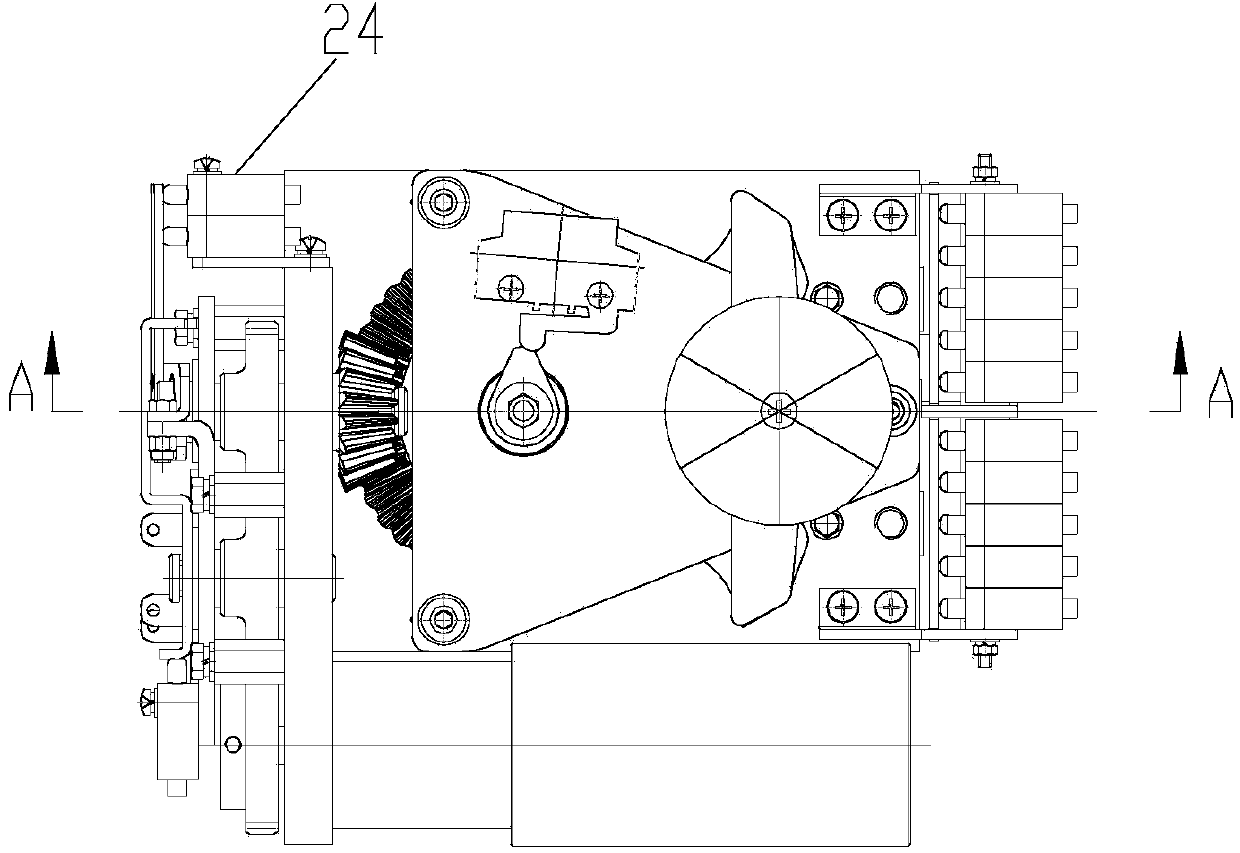

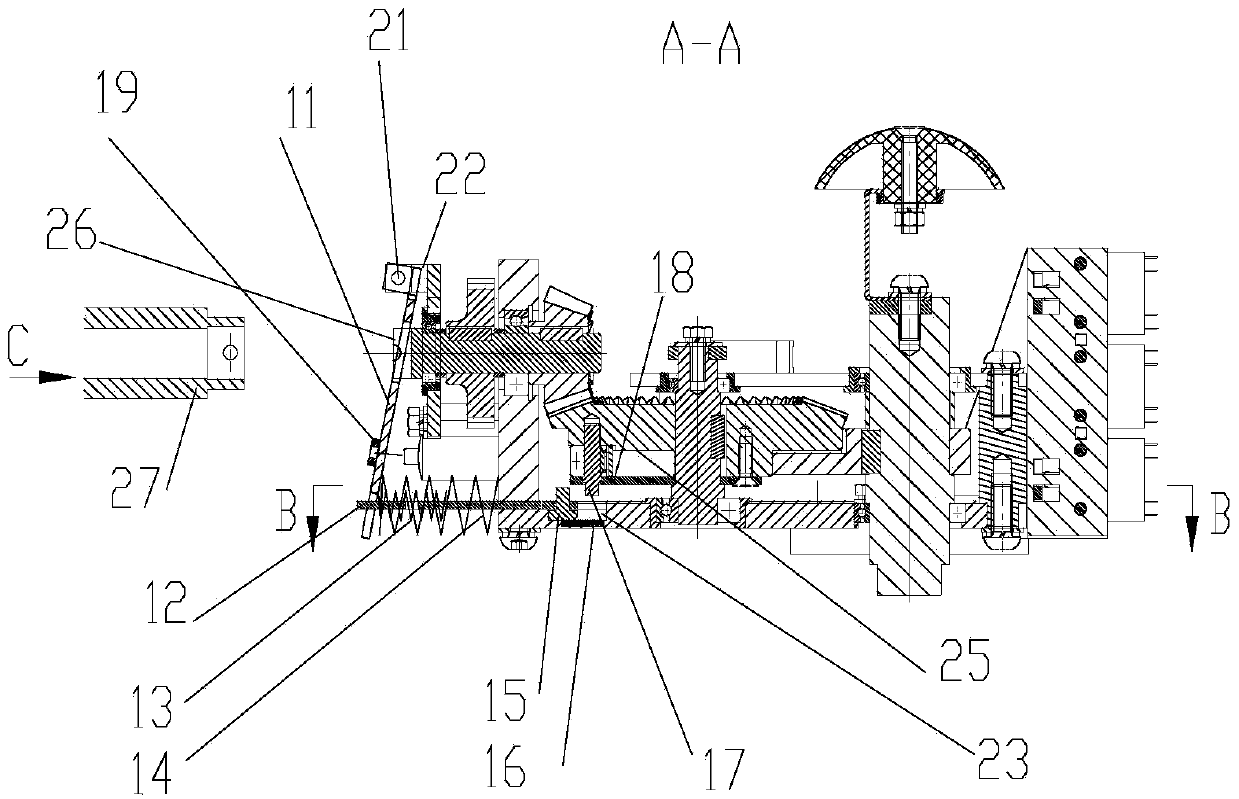

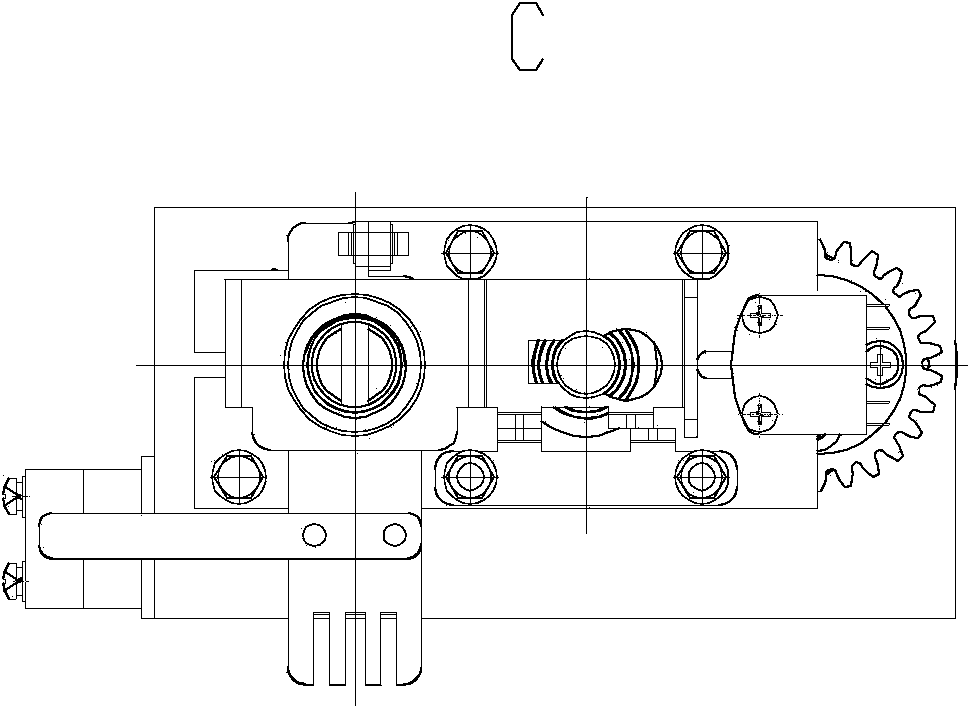

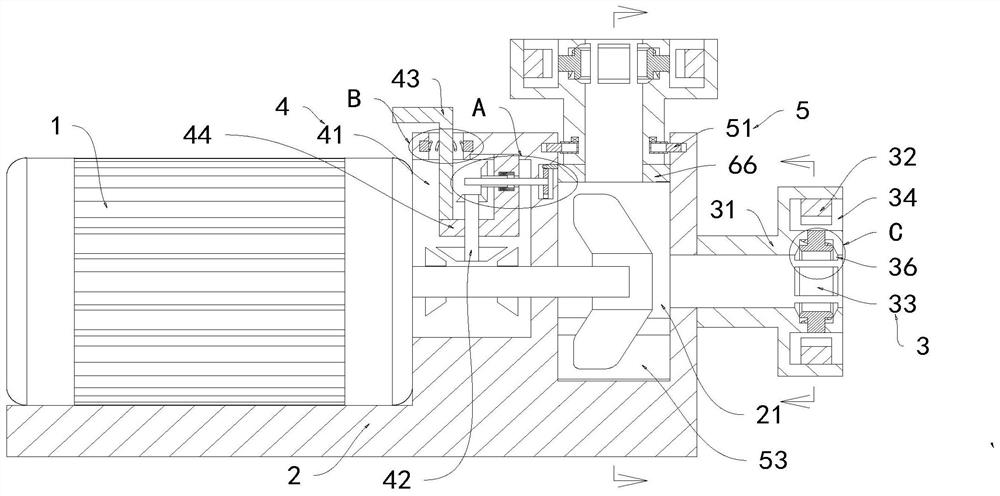

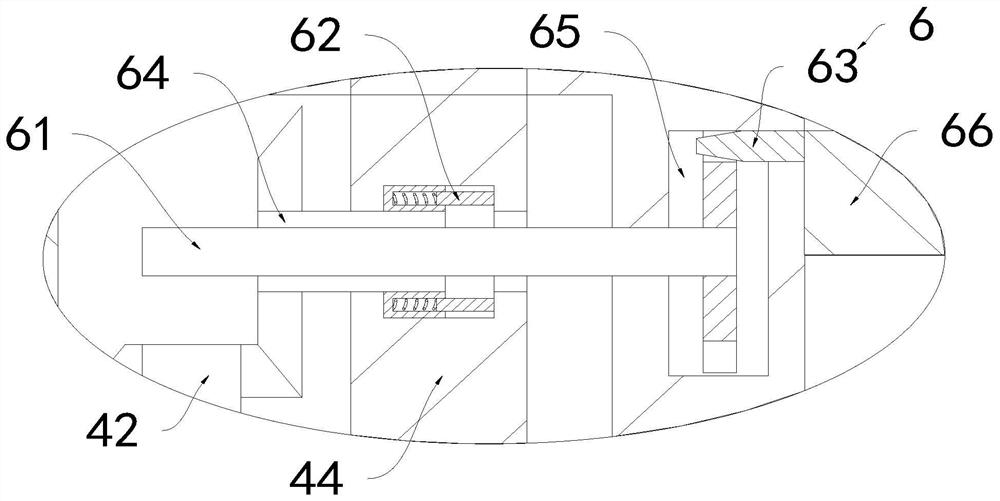

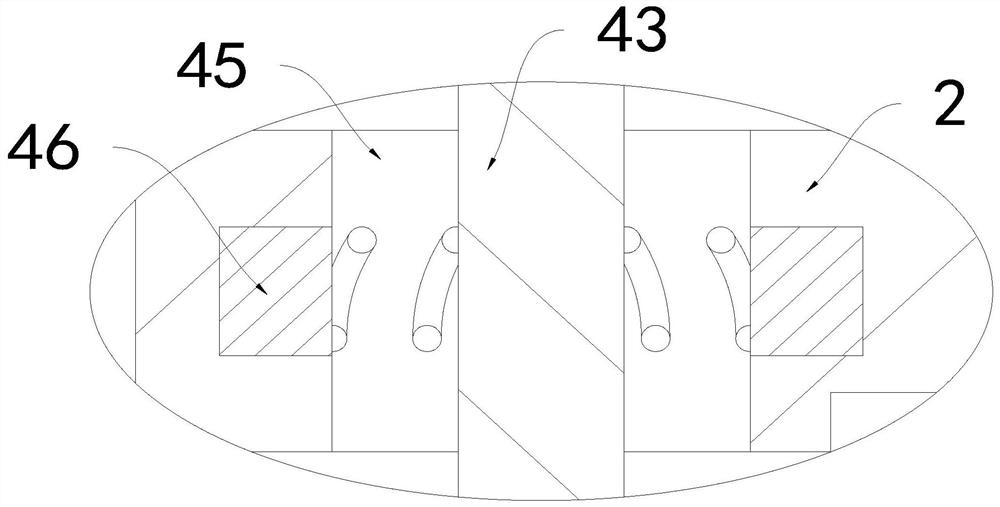

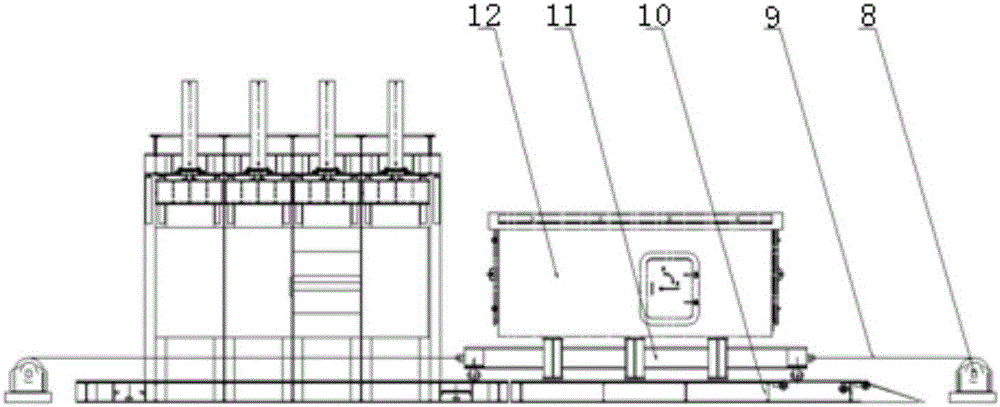

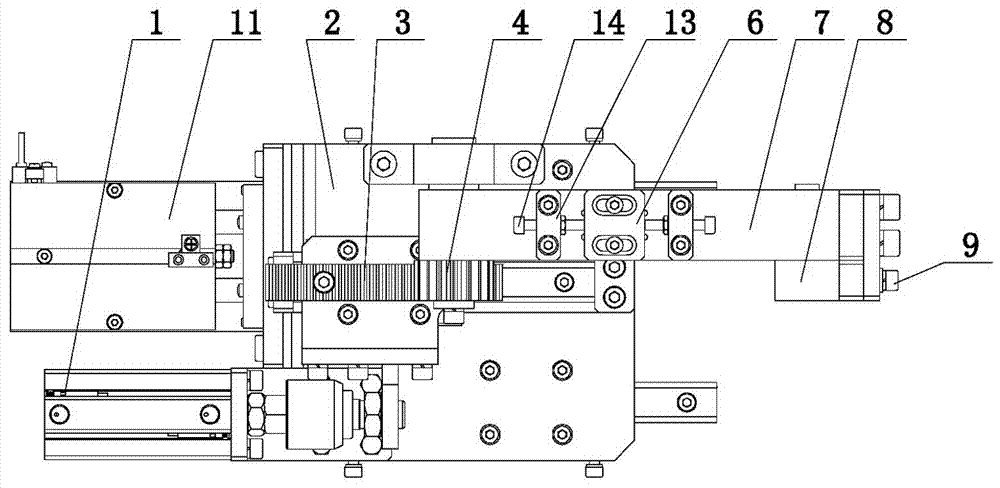

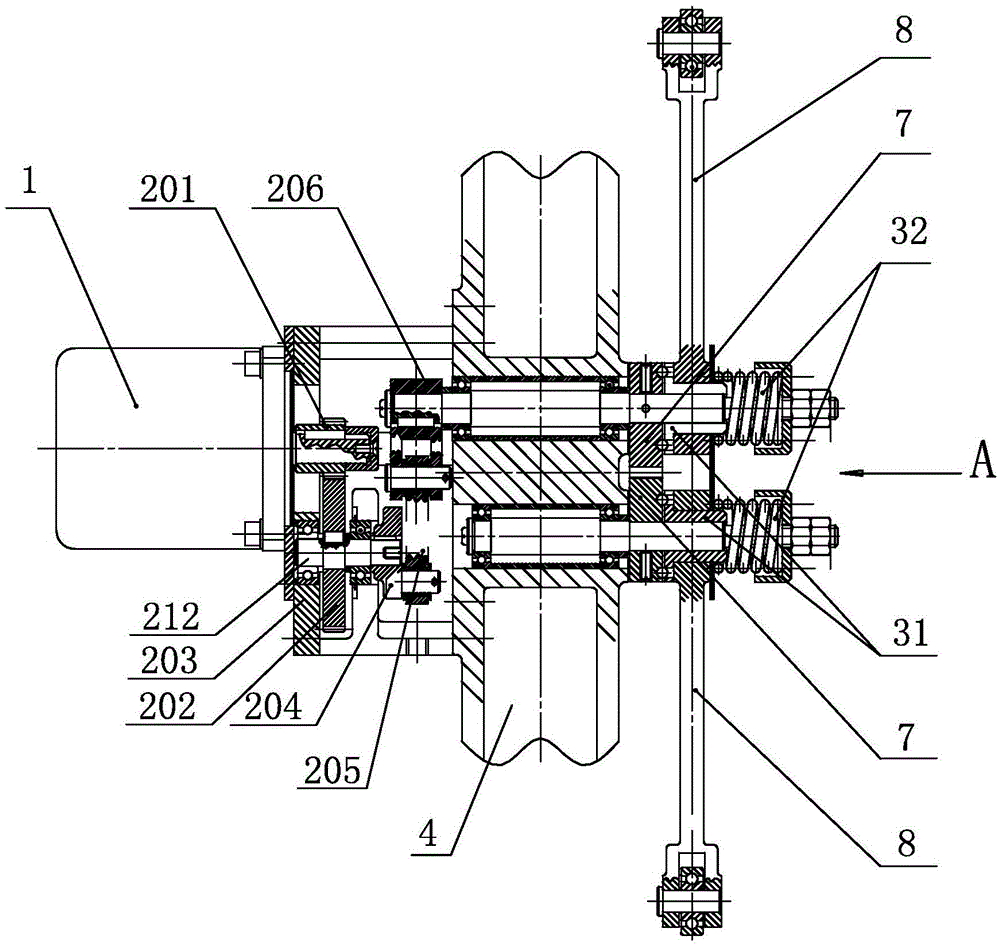

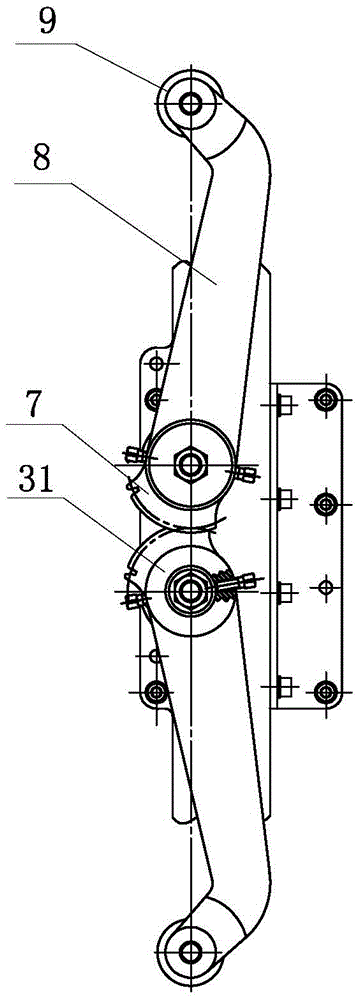

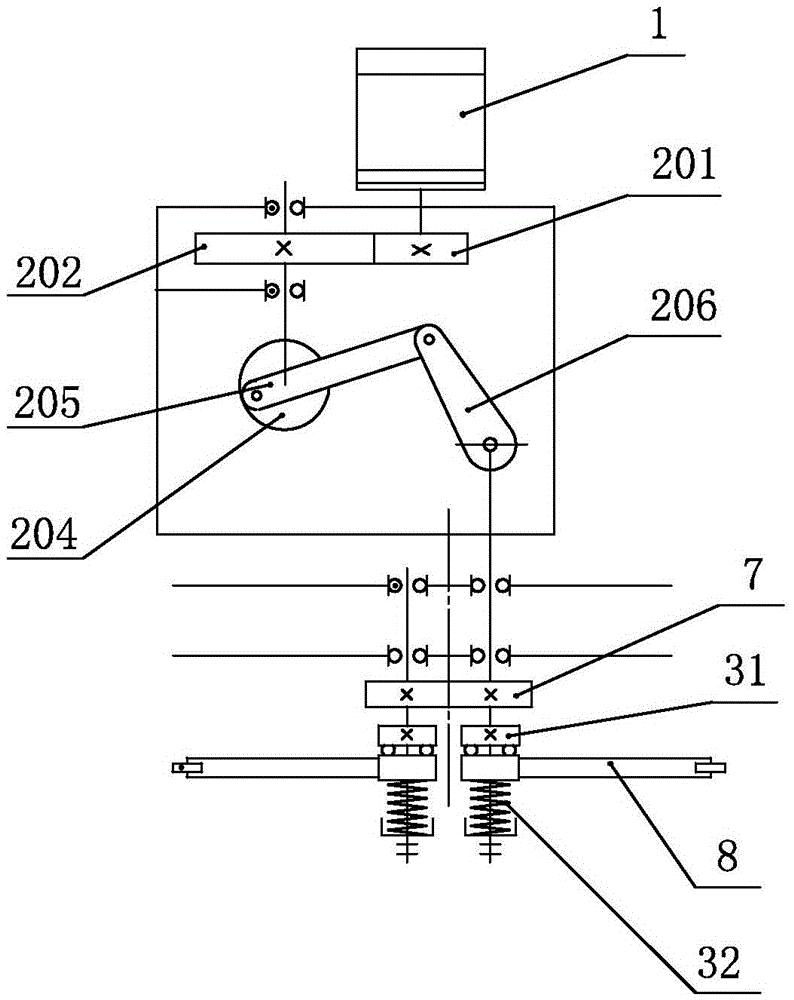

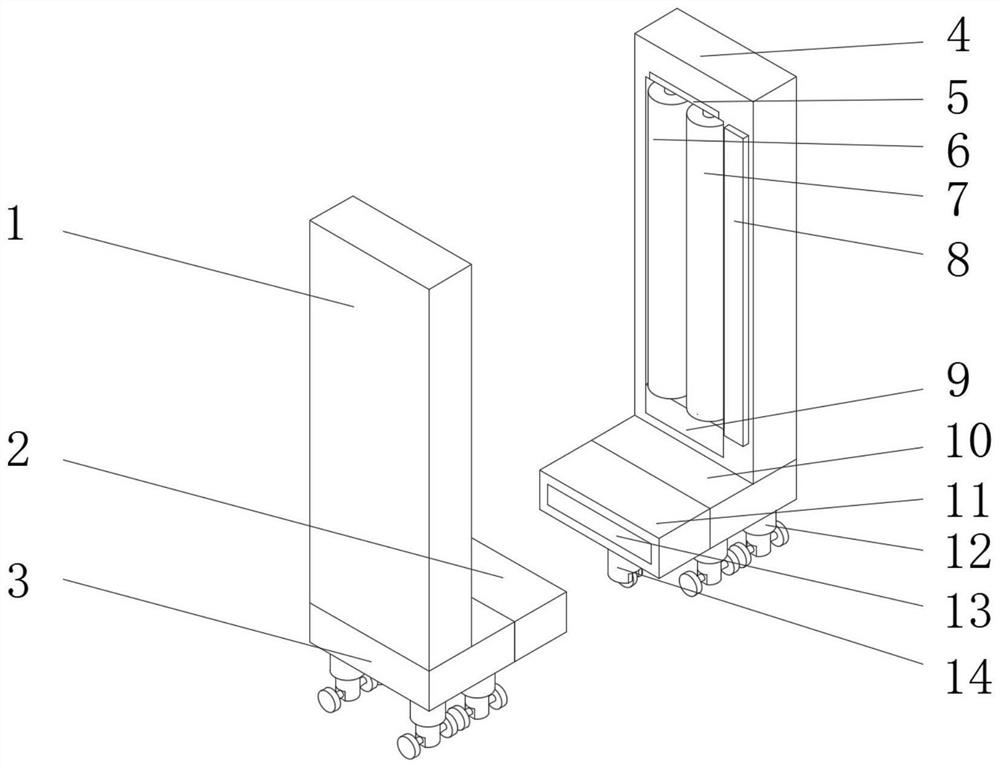

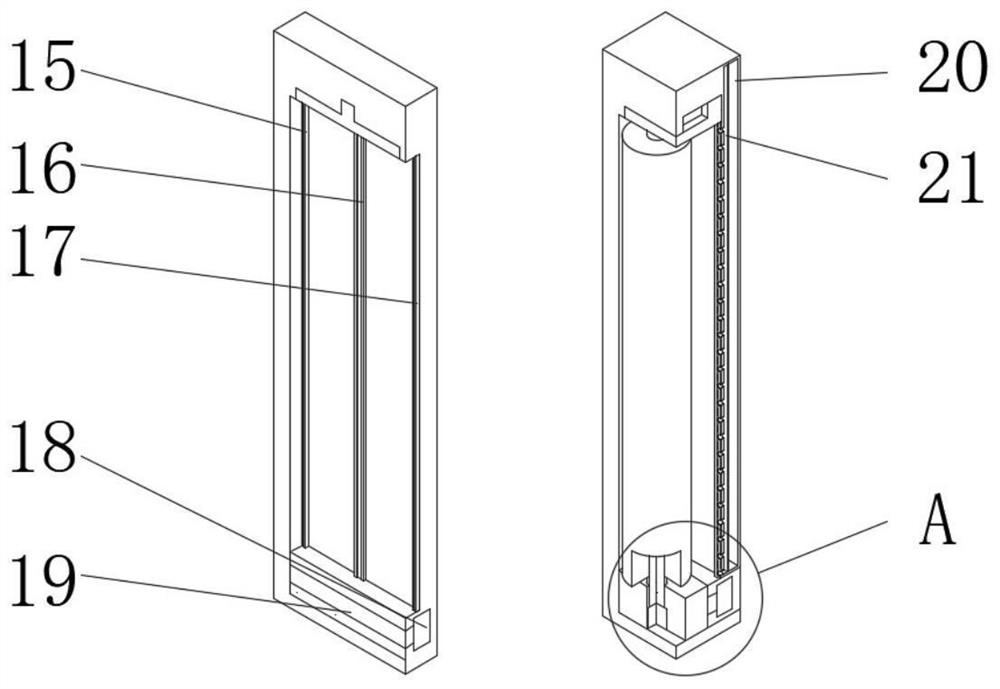

Mold bar push-out mechanism in capsule production system

InactiveCN103711863AAvoid damageRealize reciprocating rotationGearingMechanical energy handlingProduction lineSteel ball

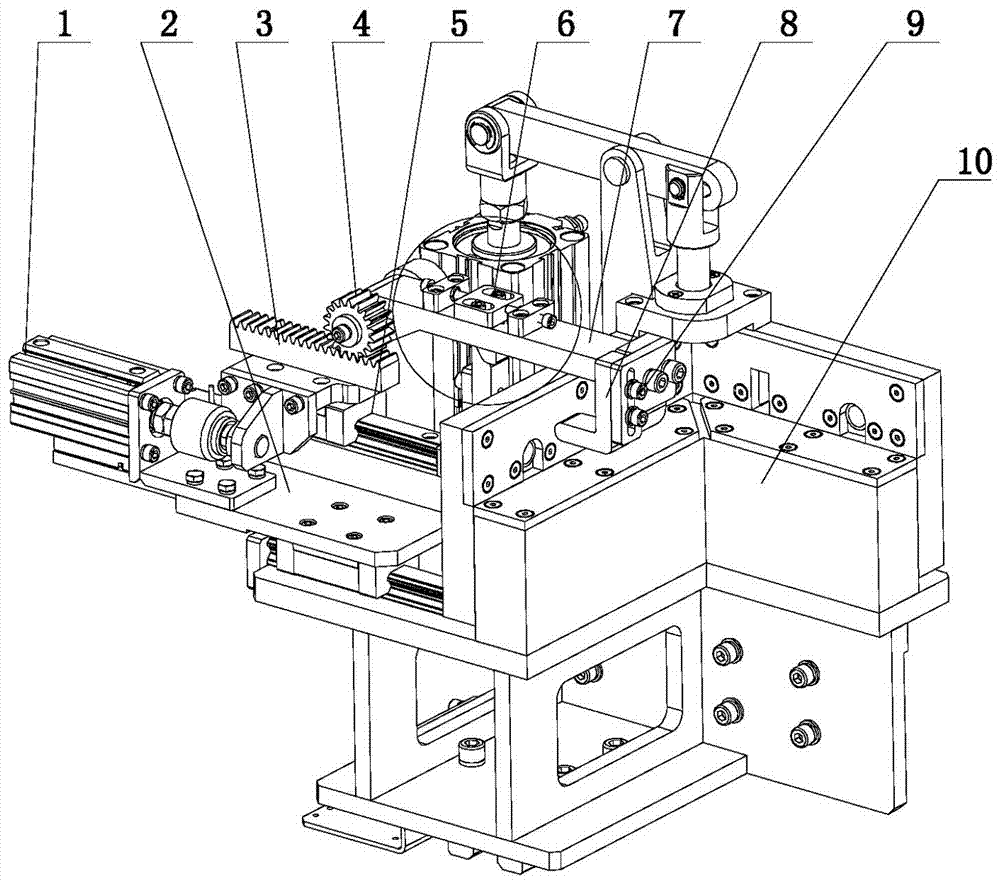

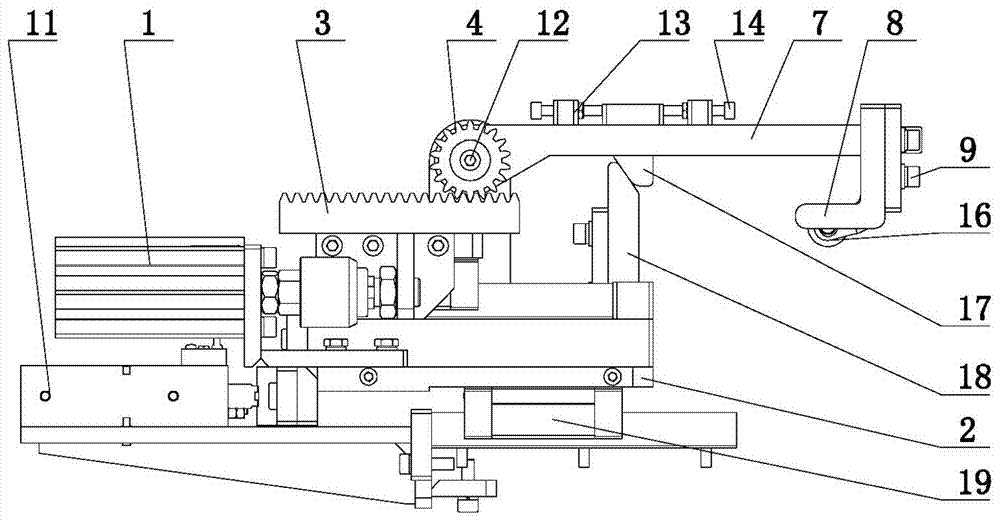

The invention discloses a mold bar push-out mechanism in a capsule production system, and belongs to the technical field of capsule production lines. The mechanism is installed on a push-out beam of a glue dipping machine and comprises a push-out motor, a transmission device, a driving push-out shaft, a driven push-out shaft, two push-out arms and overload protecting devices, wherein both the driving push-out shaft and the driven push-out shaft are installed on the push-out beam, one end of the driving push-out shaft and one end of the driven push-out shaft stretch out of the push-out beam, half teeth meshed to one anther are respectively installed at the end of the driving push-out shaft stretching out of the push-out beam and the end of the driven push-out shaft stretching out of the push-out beam, the two push-out arms are installed on the driving push-out shaft and the driven push-out shaft respectively, the overload protecting devices are installed on the end portion, where one push-out arm is installed, of the driving push-out shaft and the end portion, where the other push-out arm is installed, of the driven push-out shaft, and the other end of the driving push-out shaft stretches out of the push-out beam and is connected with the push-out motor through the transmission device. Through the mechanism, it can be guaranteed that the system is controlled to stop when faults happen. When the faults happen, steel balls roll out of overload disks so that the overload disks can drive the push-out arms to have displacement, real-time detection can be performed through a proximity switch, and therefore the mechanism is prevented from being damaged when the faults happen.

Owner:DANDONG JINWAN GRP

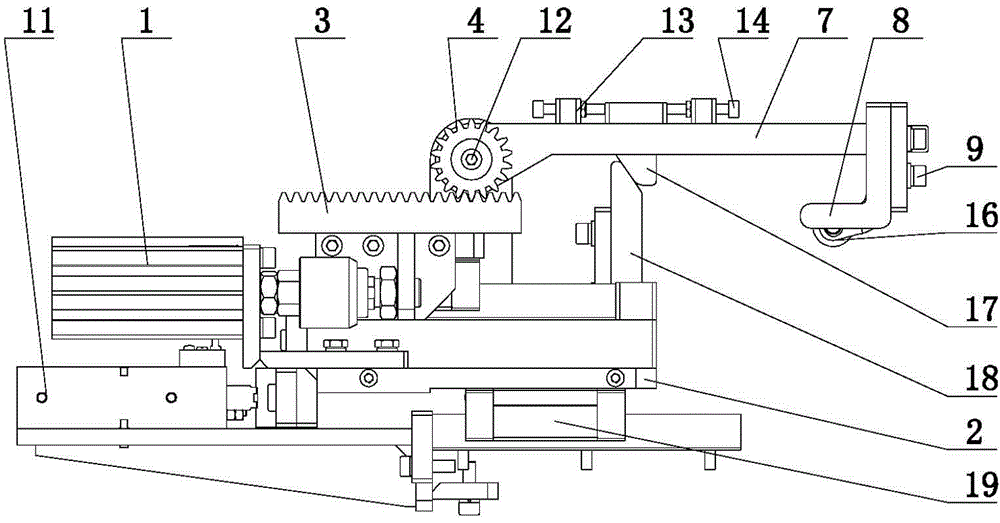

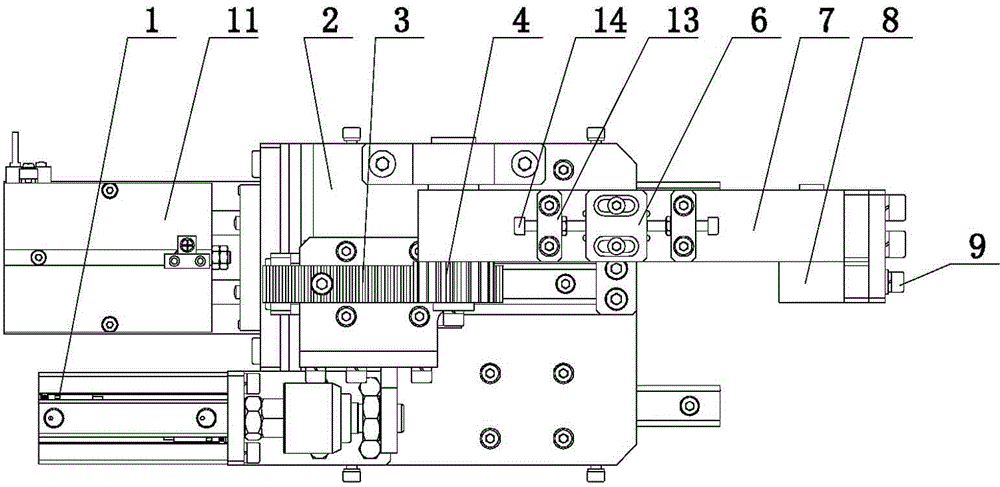

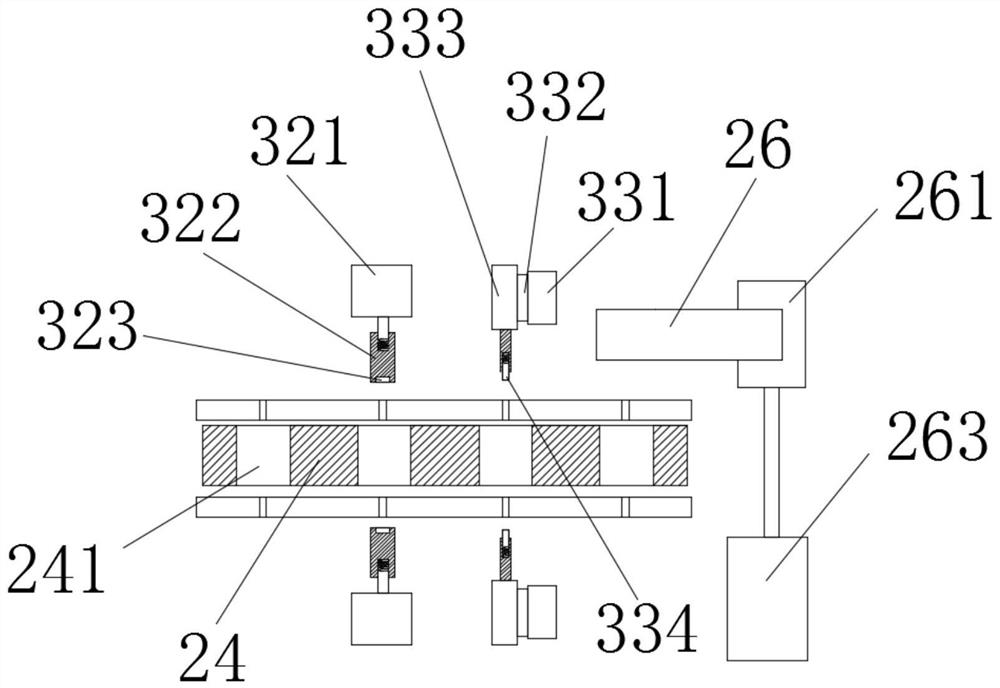

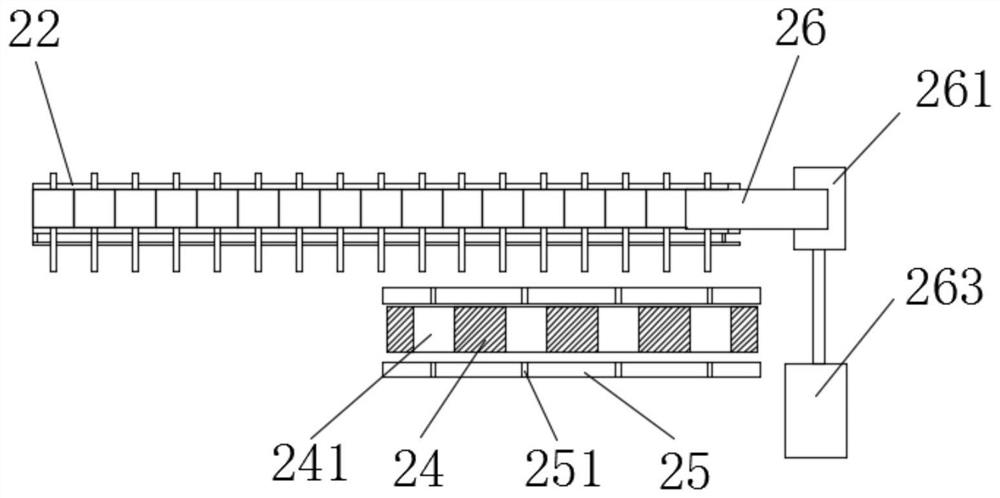

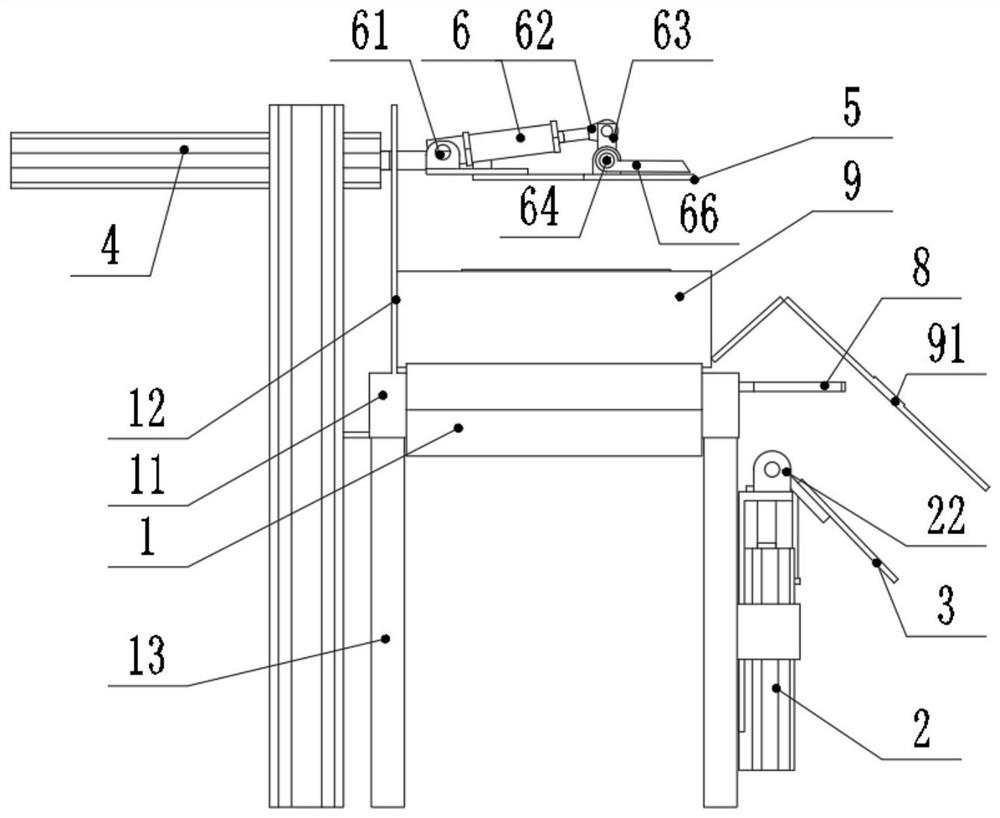

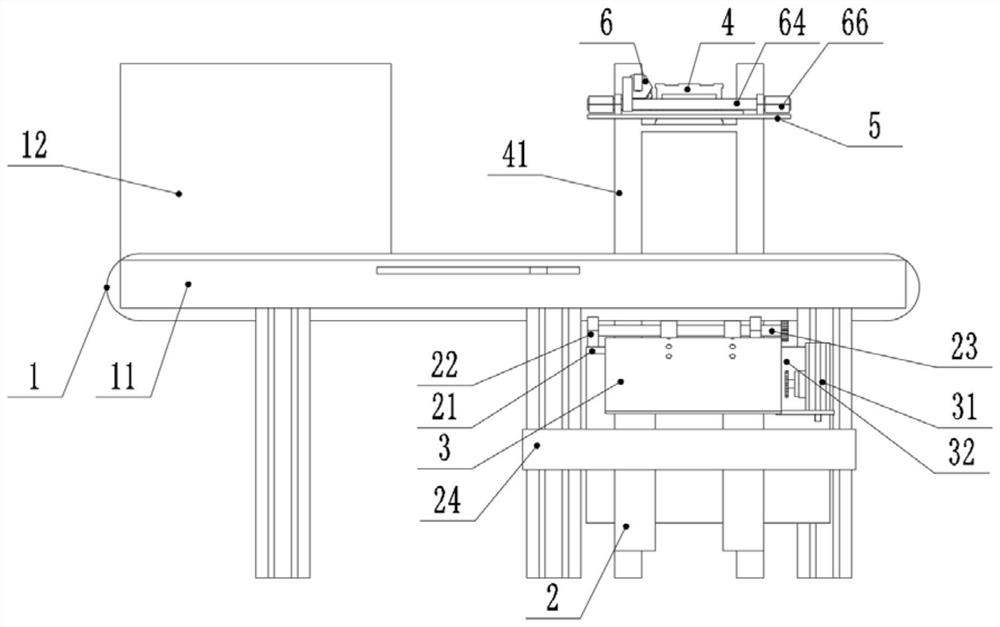

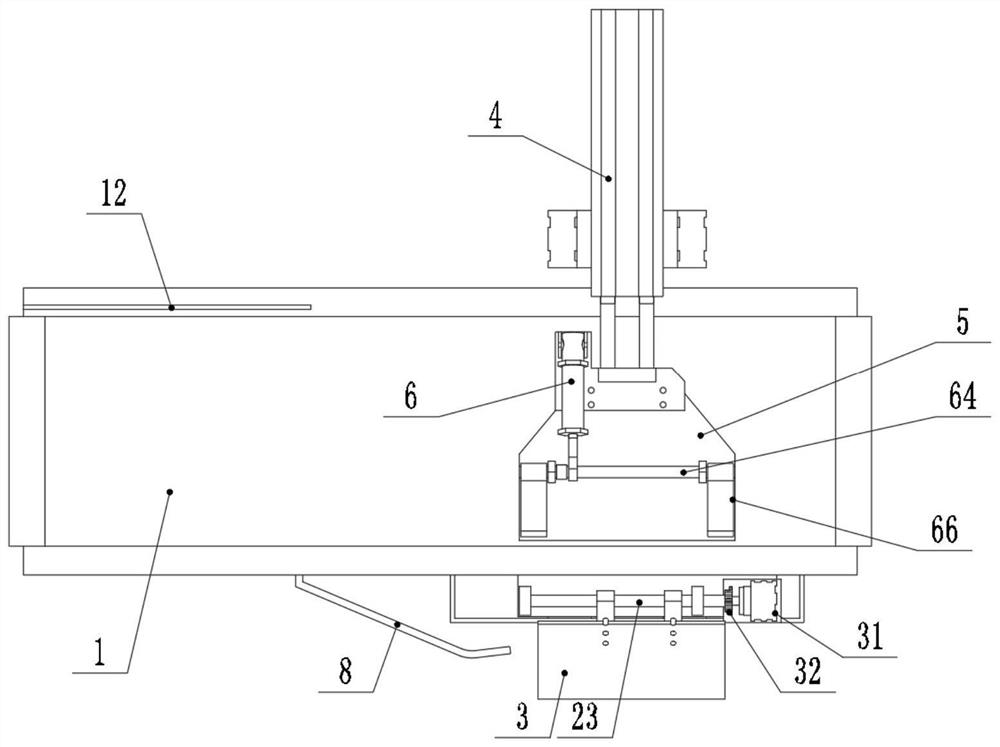

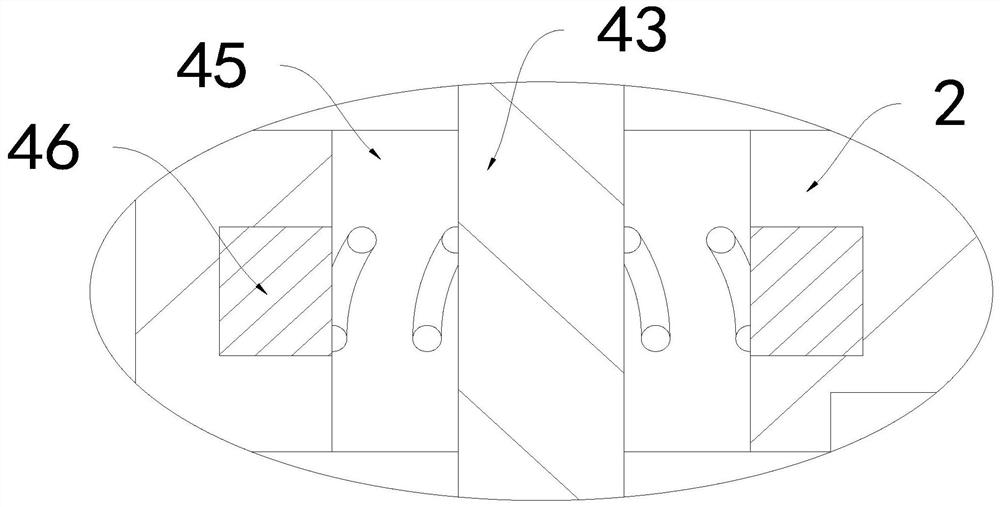

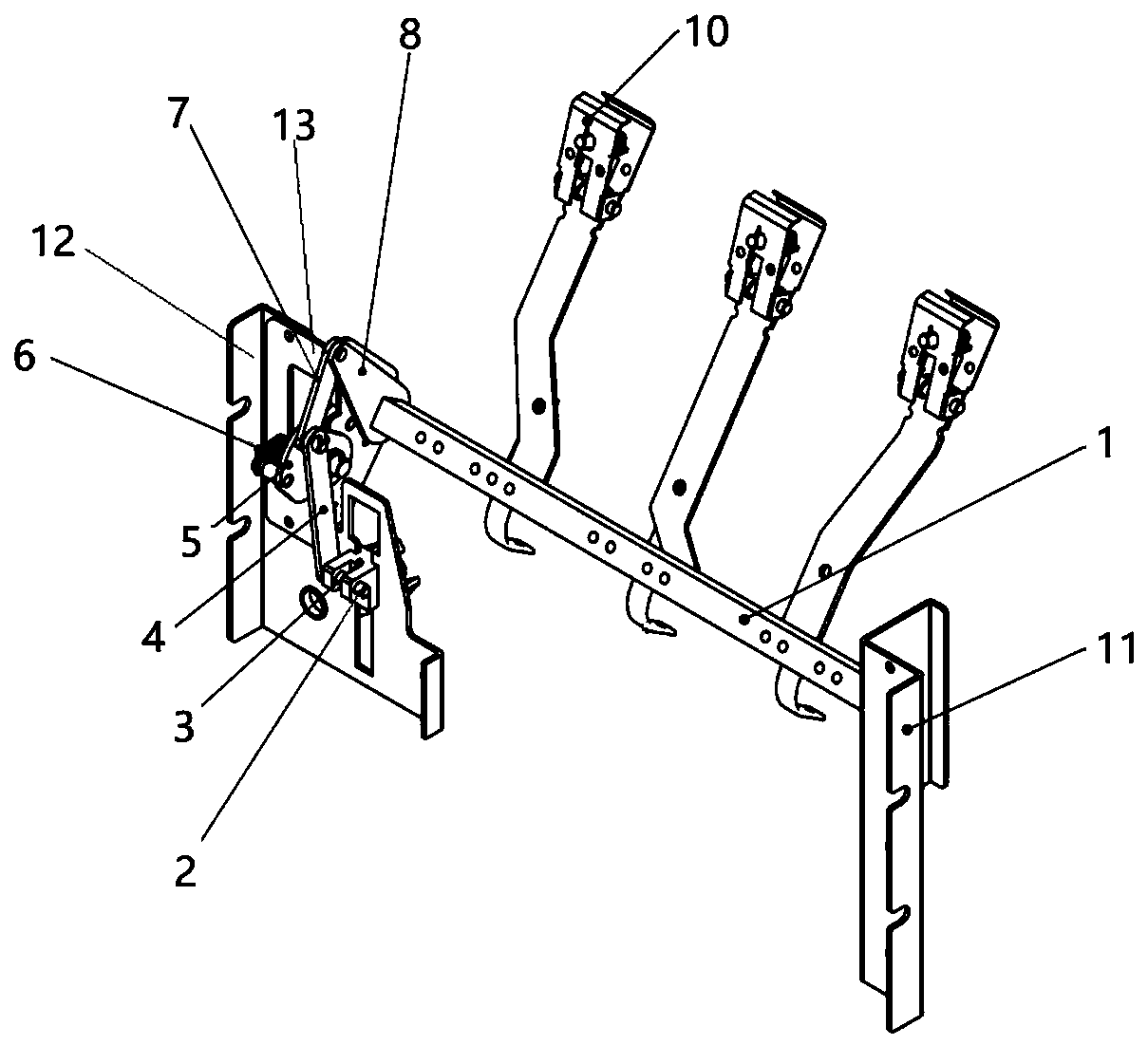

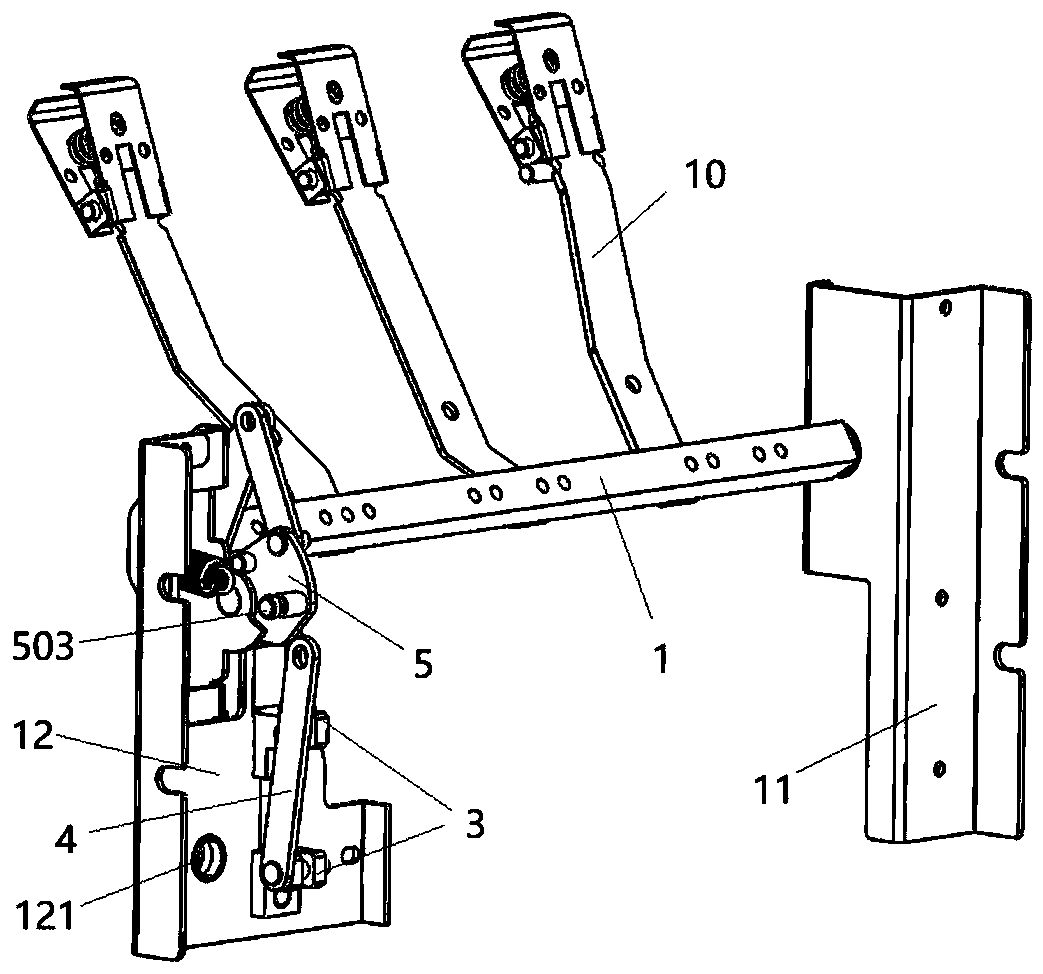

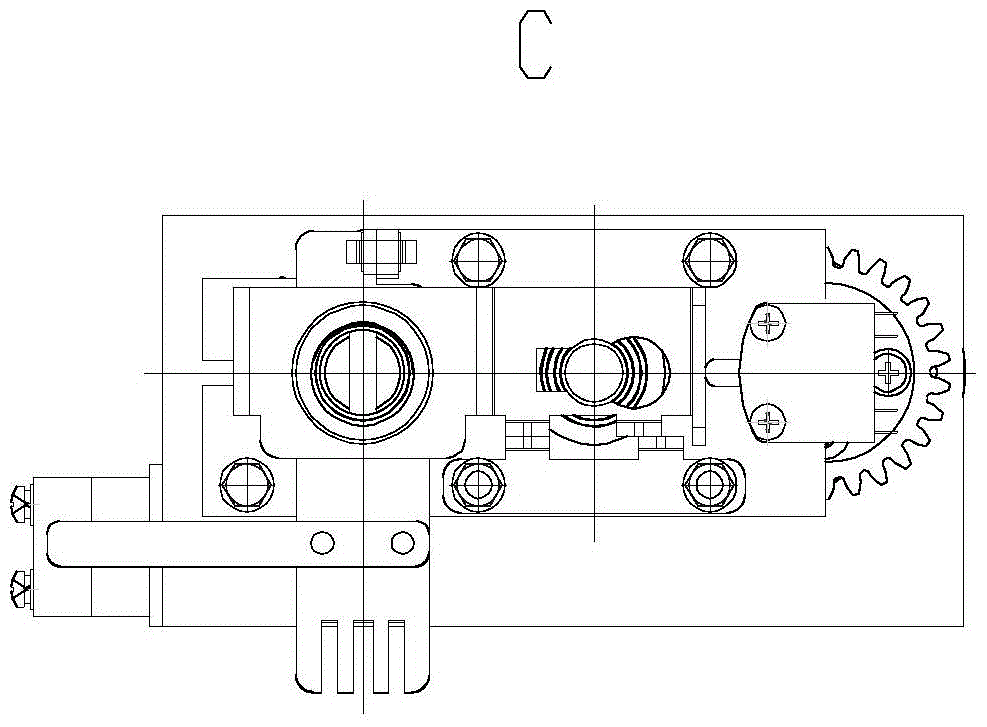

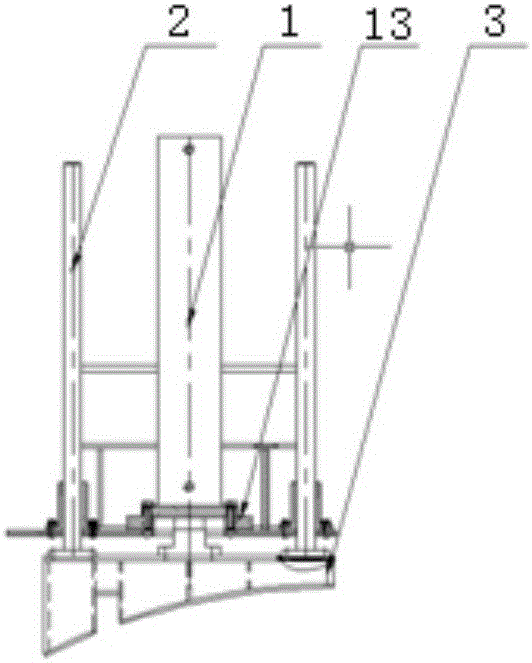

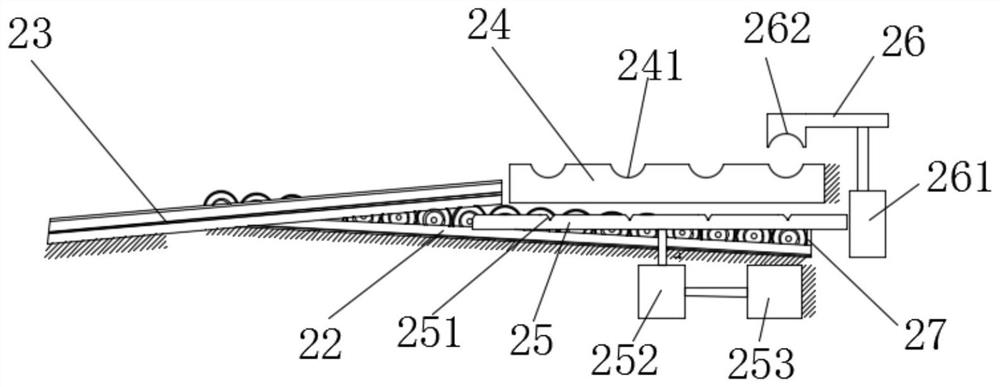

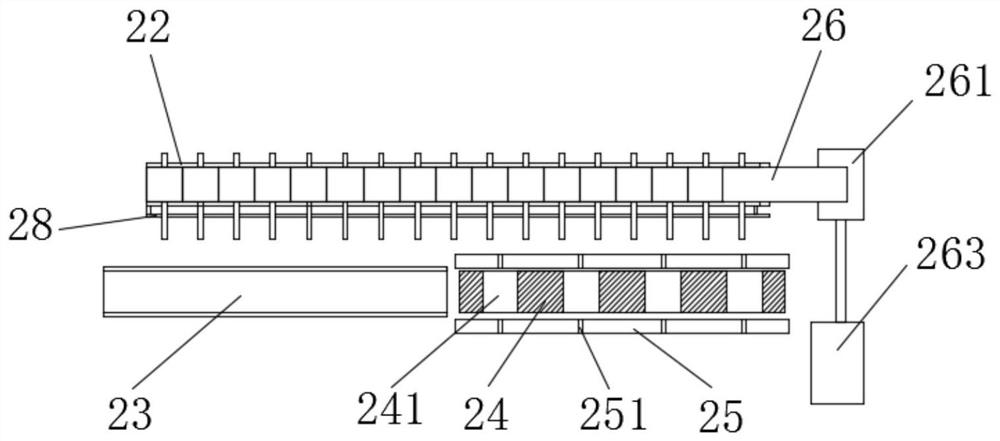

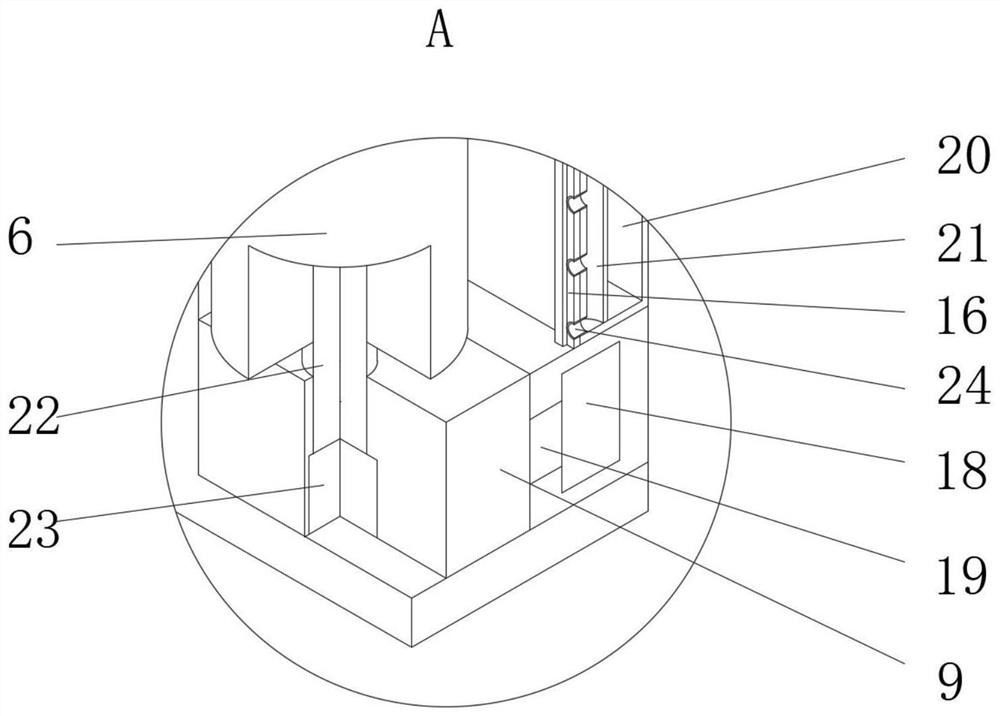

Photovoltaic module section bar straightening and backboard flattening mechanism

ActiveCN105470340AGuarantee in placeDo not interfere with transportFinal product manufactureSemiconductor devicesGear wheelBackplane

The invention provides a photovoltaic module section bar straightening and backboard flattening mechanism, belongs to the technical field of photovoltaic module automatic production equipment and specially relates to the photovoltaic module section bar straightening and backboard flattening mechanism applied to a frame combiner. The invention provides the photovoltaic module section bar straightening and backboard flattening mechanism which improves production efficiency and allows product uniformity to be good. The mechanism comprises a telescopic cylinder and is characterized in that the telescopic cylinder is connected with a movable frame; the movable frame is provided with a turn-over cylinder; the turn-over cylinder is connected with a toothed bar on the movable frame; the movable frame is provided with a turn-over arm through a turn-over shaft; the end portion of the turn-over arm is provided with a claw hook; a gear engaged with the toothed bar is arranged at the place of the turn-over shaft of the turn-over arm; and the lower surface of the turn-over claw hook is provided with a press roller.

Owner:CHINT NEW ENERGY TECH (HAINING) CO LTD

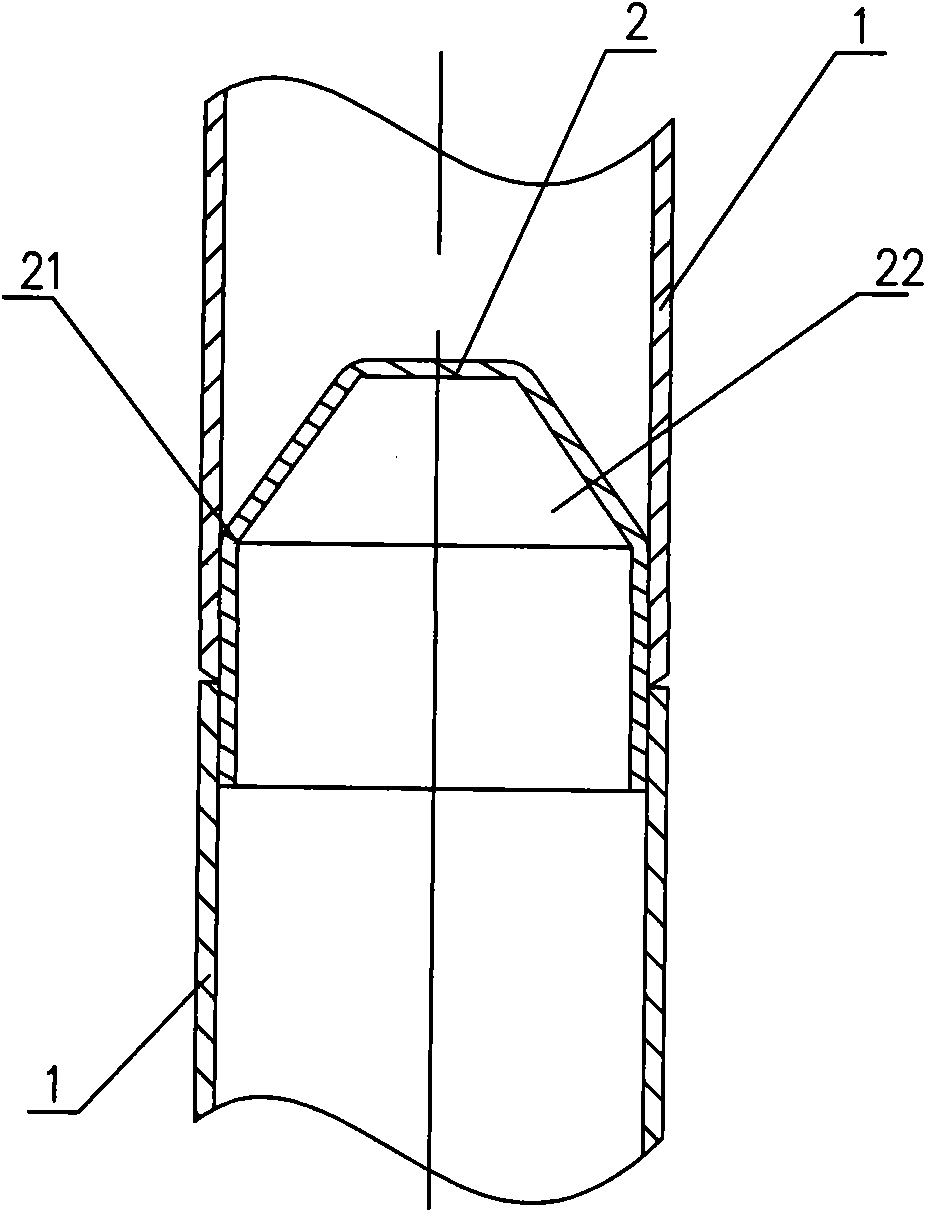

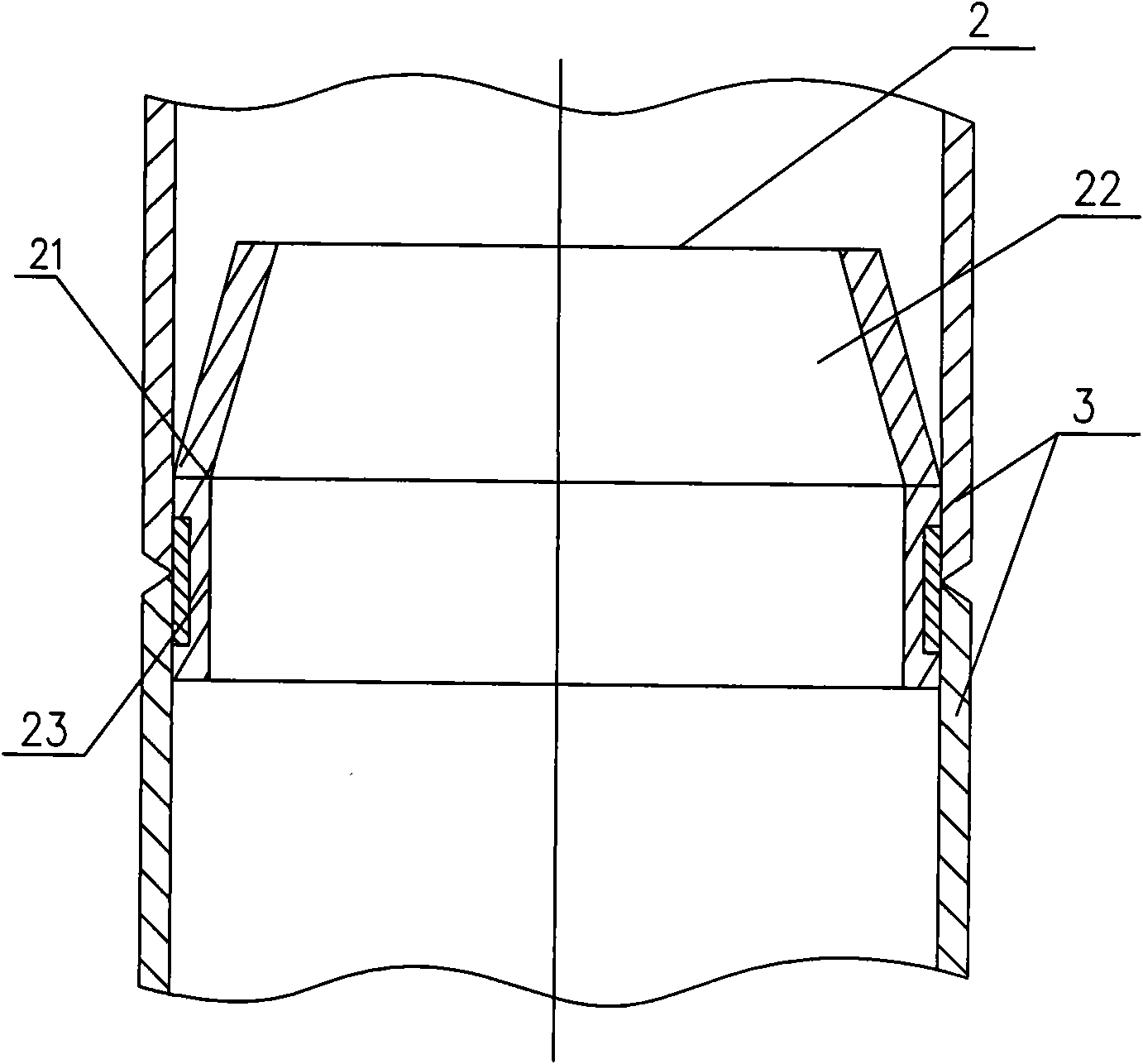

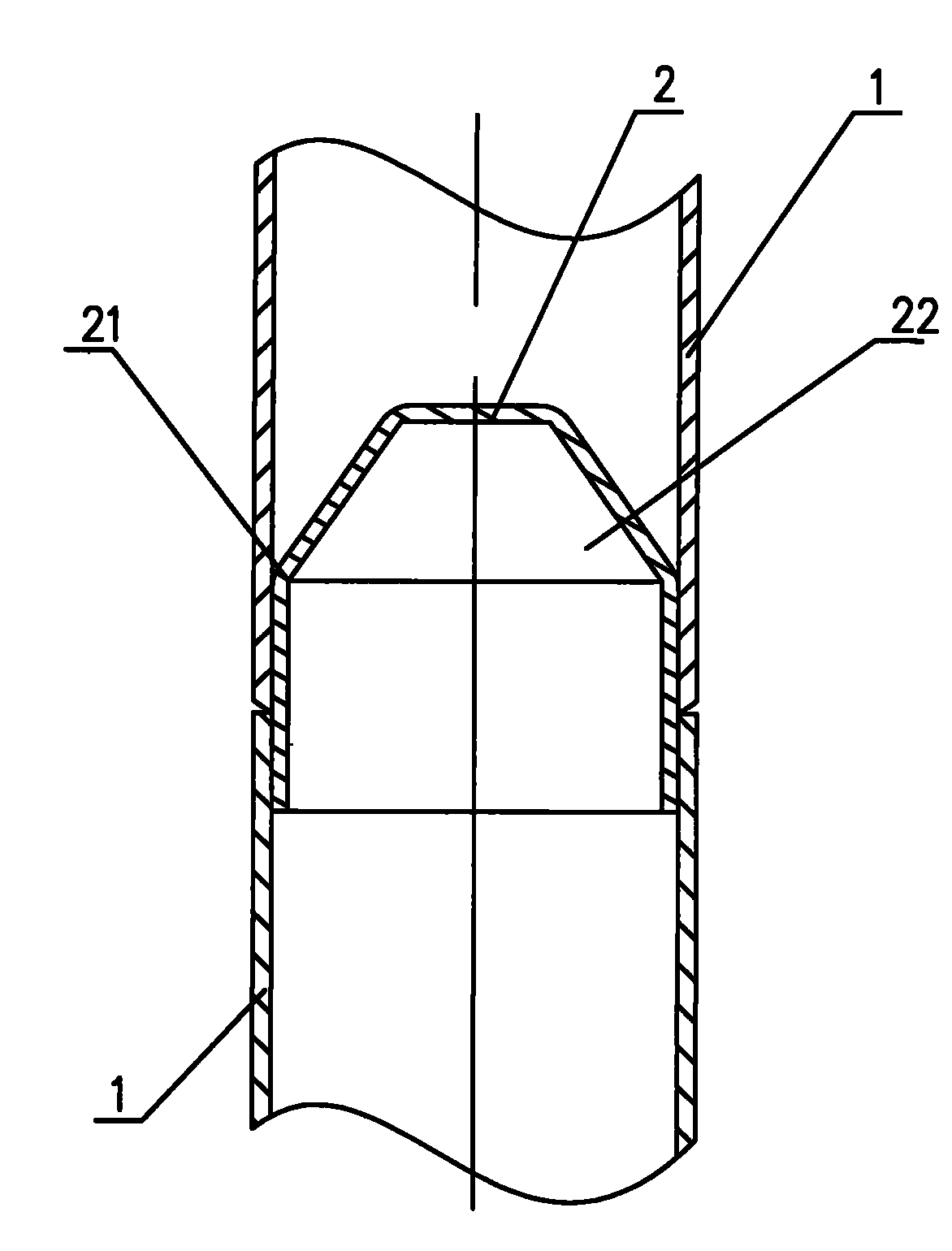

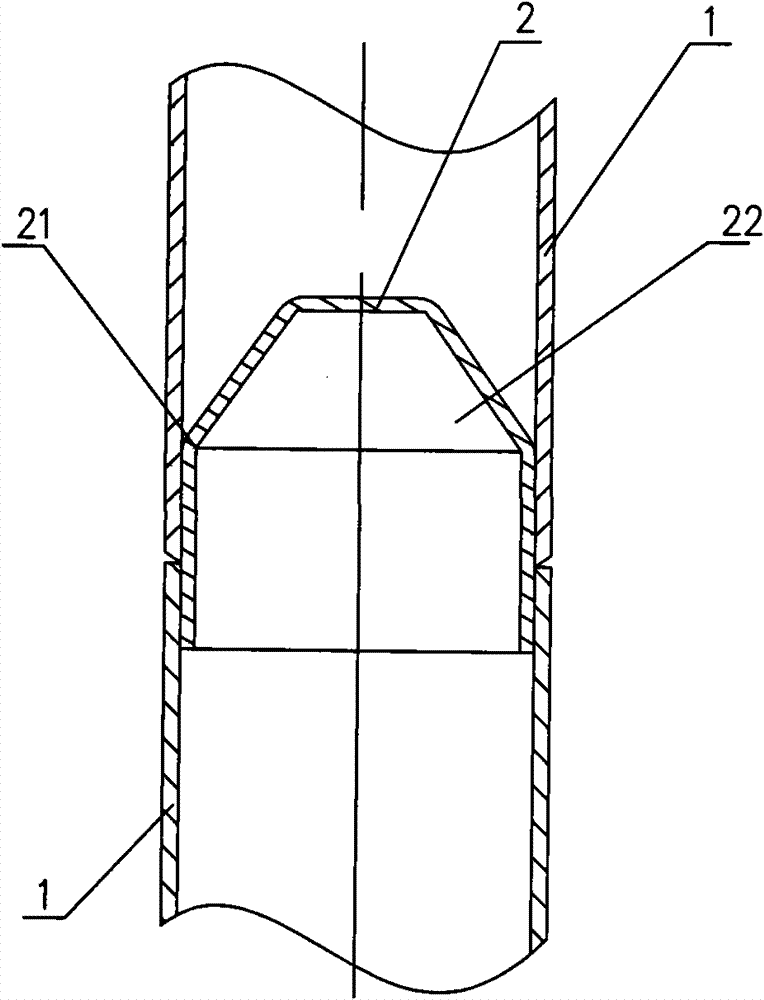

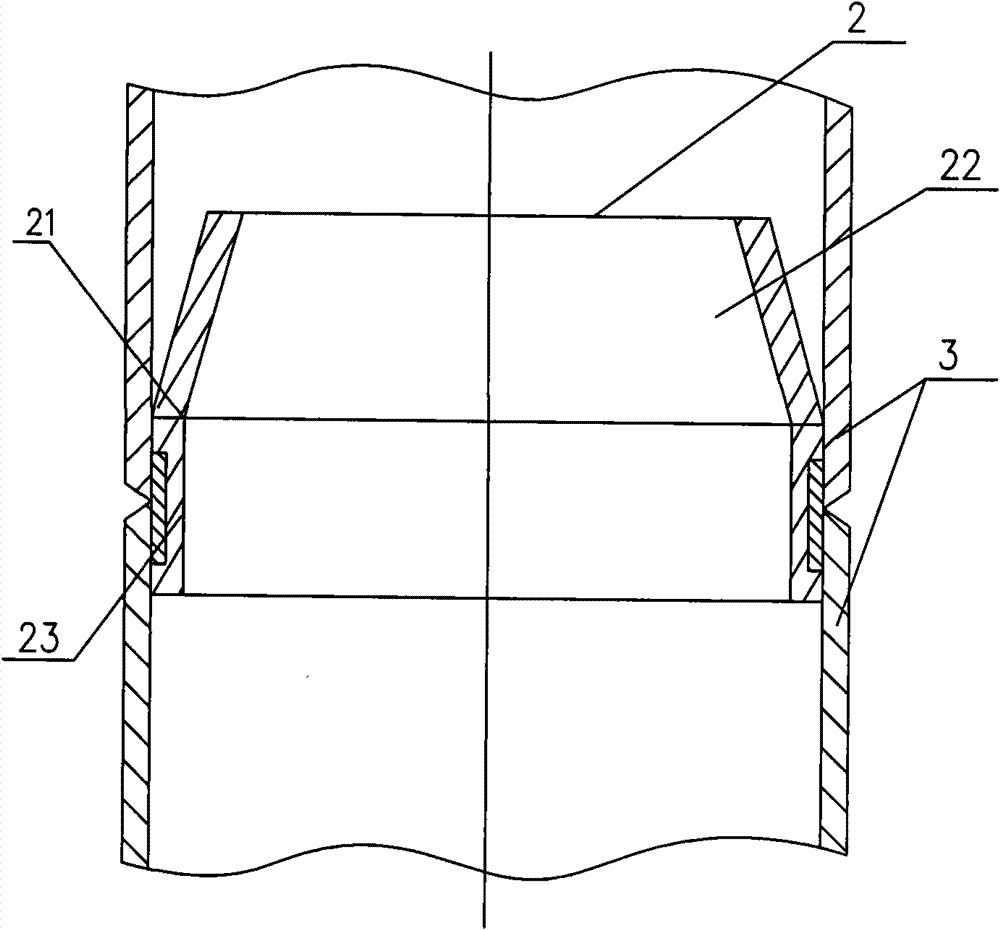

Connecting structural component for air-separation cold box and method for integrally assembling cold box

ActiveCN101832314AMeet quality requirementsAvoid misalignmentSolidificationLiquefactionEngineeringAir separation

The invention discloses a connecting structural component of an air-separation cold box, which comprises a conjunct connector capable of being arranged on a joint of an frame steel tube or fractionating tower body consisting of involutory upper and lower parts in the cold box, and is characterized in that: the guide connector consists of at least one section of inner cylinder fixed on the inner wall of the joint end of a steel tube and used for docking guidance, and a cone connected on the inner cylinder. Compared with the prior art, the connecting structural component has the characteristics of having simple structure and convenient use and installation, meeting the quality requirement on integrally assembled cold box on site, preventing the malposition of the fractionating tower body which cannot be corrected artificially, guaranteeing the alignment of the fractionating tower and the proper position of a welding plate, and the like.

Owner:杭州杭氧低温液化设备有限公司

Die elevating device applied to tube bending machine

The invention discloses a die elevating device applied to a tube bending machine. The die elevating device comprises a machine body, wherein a die base which can slide up and down is installed on the machine body; a wedge block which can slide horizontally is installed at the bottom part of the machine body; stairs are arranged on the surface of the wedge block; the die base is provided with a roller; and the roller is arranged on the stairs of the wedge block. The wedge block horizontally slides so as to push the roller to be positioned in stairs of different layers. The wedge block adopts a fixing mode that two oil cylinders are connected tail to tail. The die base is pushed to move up and down by using the horizontal movement of the wedge block, such mode of push is more stable and unlikely to damage compared with a screw rod mode; and the fixation mode that two oil cylinders are connected tail to tail ensures that the wedge block is stable and positioned in place.

Owner:张家港和升数控机床制造有限公司

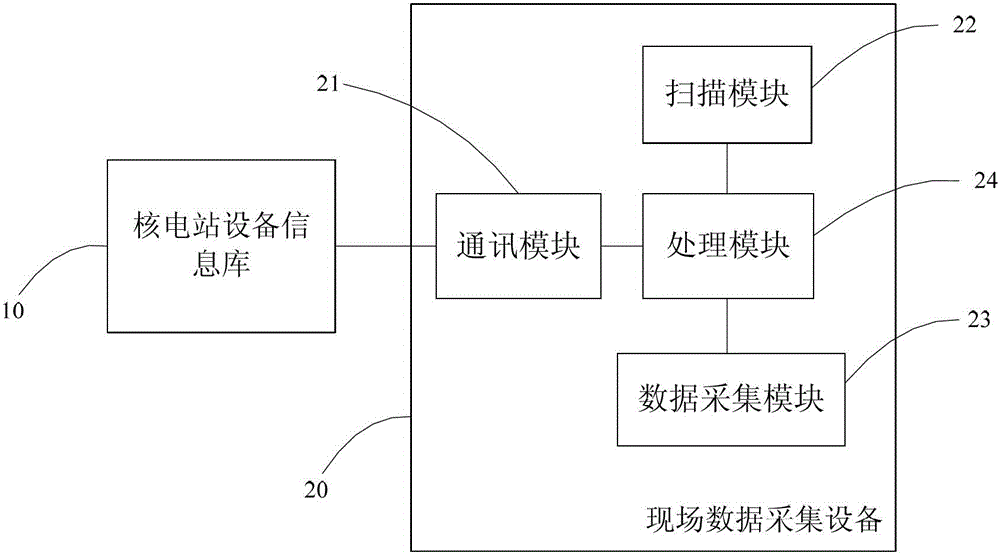

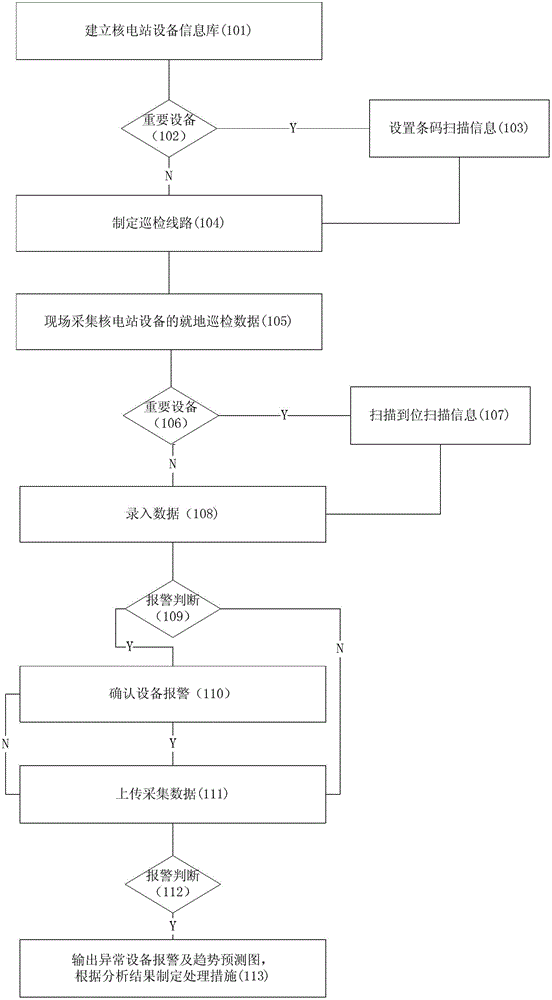

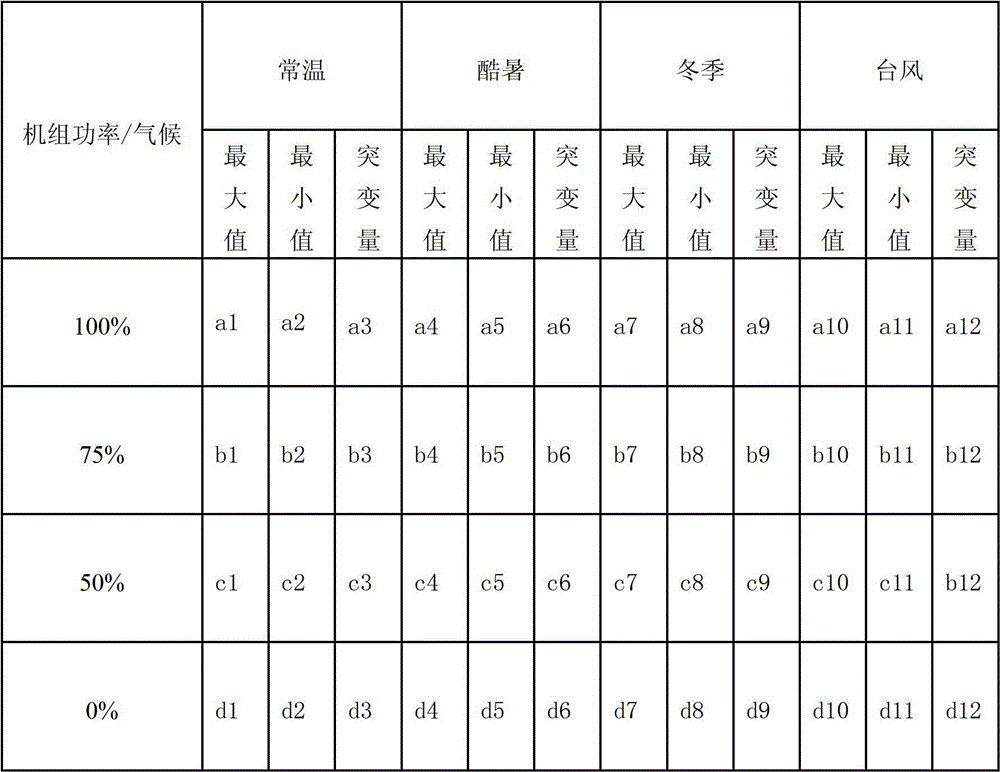

Method, system and device for warning routing inspection of nuclear power station field device

ActiveCN102968878BGuarantee in placeSafe and stable operationAlarmsInformation repositoryNuclear power

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +1

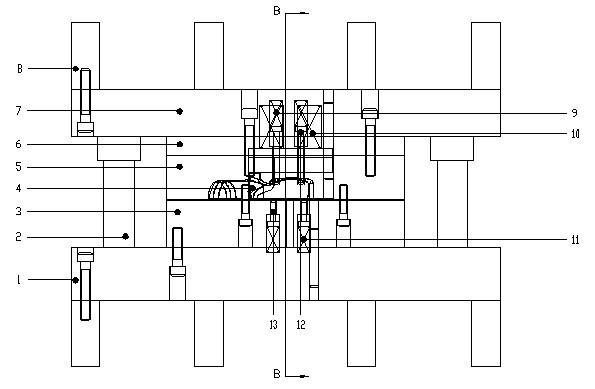

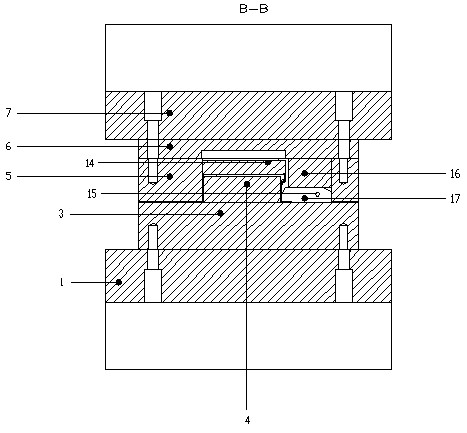

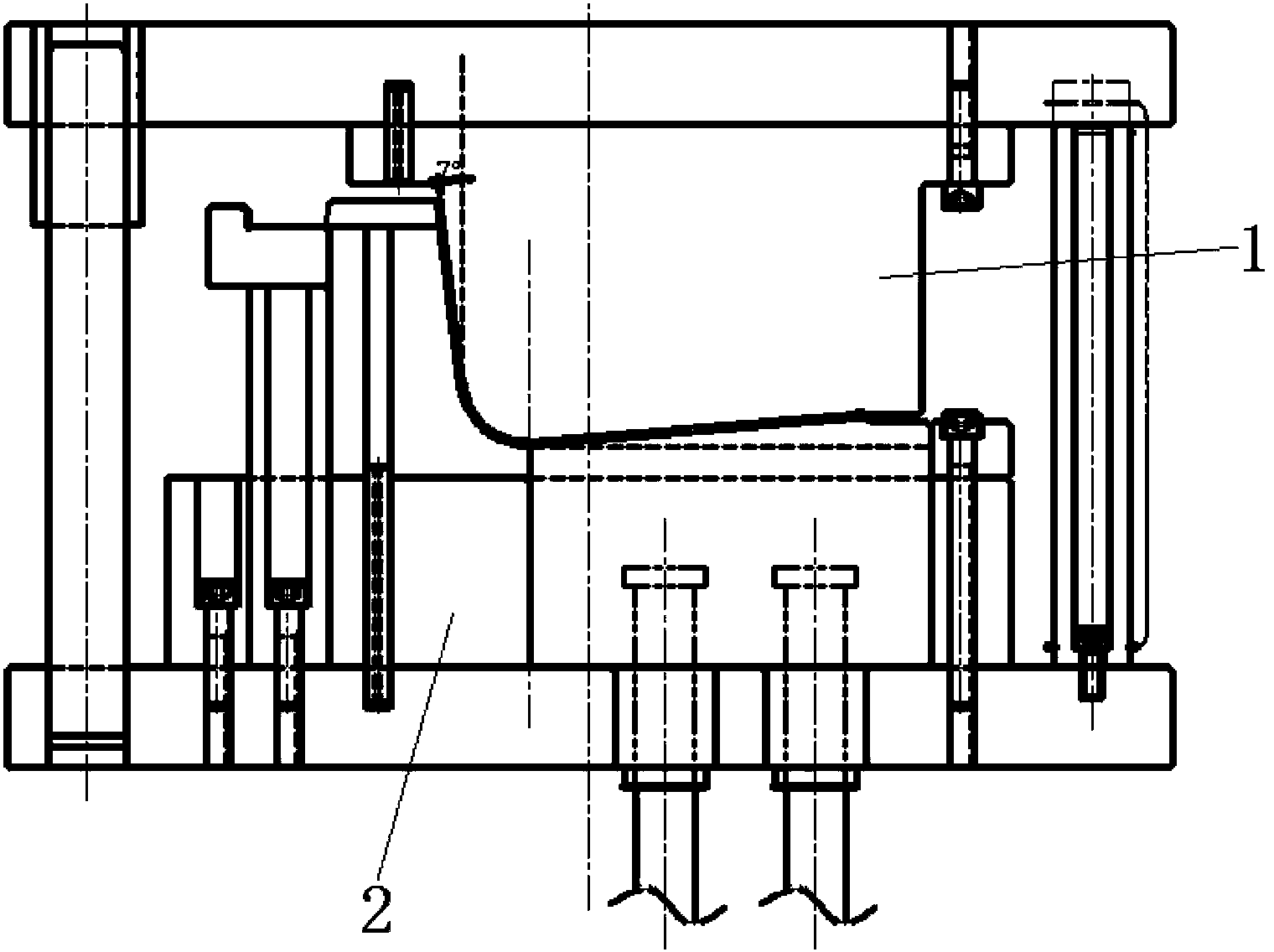

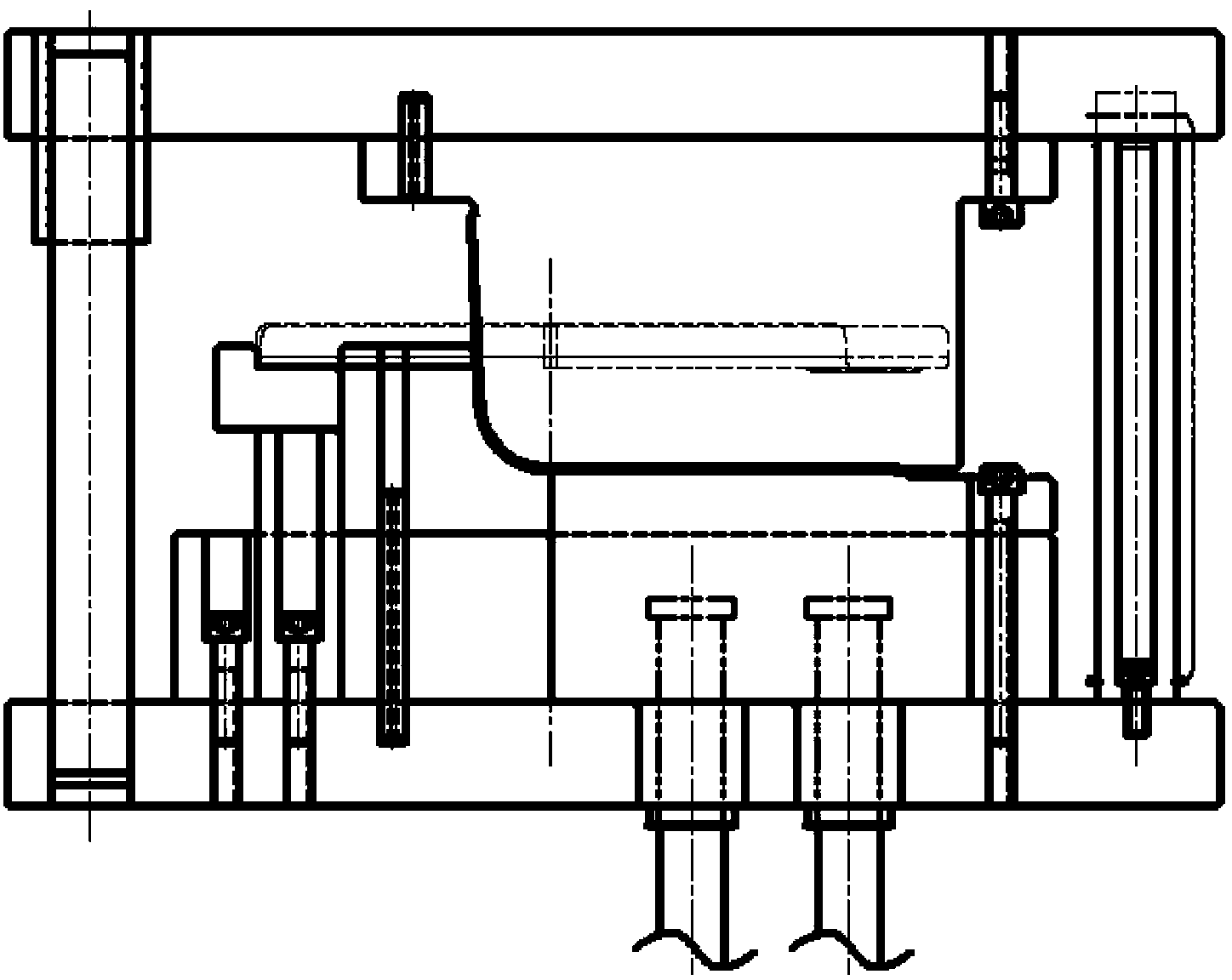

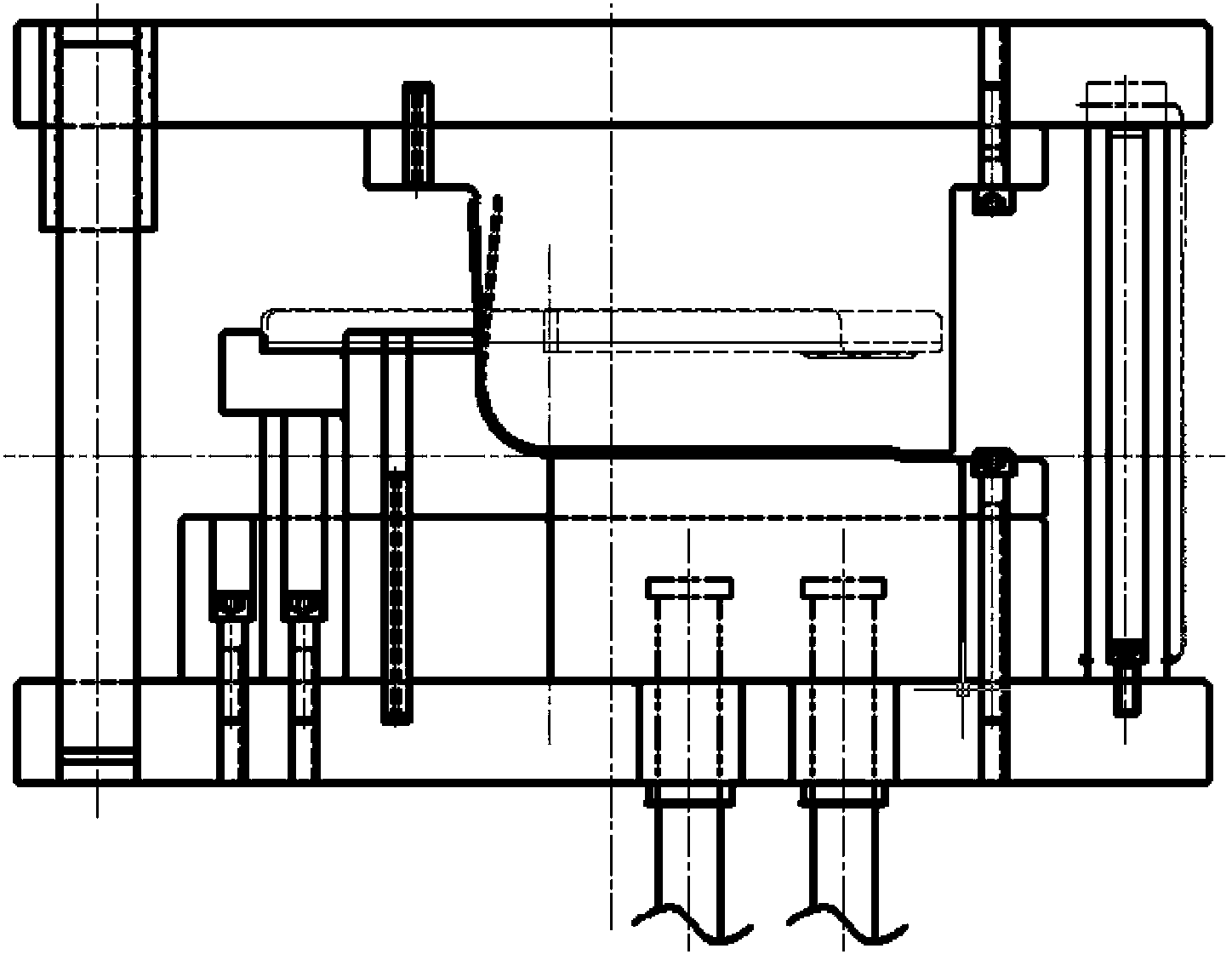

Leveling die of automobile exhaust gas recycling cooling system diffuser

InactiveCN102527844AAvoid interferenceGuarantee in placeShaping toolsEngineeringMechanical engineering

The invention discloses a leveling die of an automobile exhaust gas recycling cooling system diffuser, which comprises an upper die structure and a lower die structure. The upper die structure comprises an upper template and a leveling upper die; the leveling upper die is fixed at the lower part of the upper template through an upper backing plate; a cavity for enveloping the largest outer peripheral surface of a work piece to be machined is formed on the surface of the leveling upper die; the lower die structure comprises a lower template; a leveling lower die is installed on the lower template; a work piece positioning block is arranged on the surface of the leveling lower die; the outer molded surface of the work piece positioning block is matched with the inner peripheral molded surface of the work piece to be machined; the lower die structure also comprises a leveling movable block; the leveling movable block is embedded at the bottom of an upper die embedded block; the rear end of the leveling movable block is connected with the upper die embedded block through a rotary pin; the upper die embedded block is embedded on the leveling upper die; an upper part ejecting pin is installed at the upper part of the leveling movable block in the upper die embedded block; and a lower part ejecting pin is installed in the leveling lower die in a position corresponding to the upper part ejecting pin.

Owner:WUXI DAWN DIE & STAMPING

Connecting structural component for air-separation cold box and method for integrally assembling cold box

ActiveCN101832314BMeet quality requirementsAvoid misalignmentSolidificationLiquefactionEngineeringAir separation

The invention discloses a connecting structural component of an air-separation cold box, which comprises a conjunct connector capable of being arranged on a joint of an frame steel tube or fractionating tower body consisting of involutory upper and lower parts in the cold box, and is characterized in that: the guide connector consists of at least one section of inner cylinder fixed on the inner wall of the joint end of a steel tube and used for docking guidance, and a cone connected on the inner cylinder. Compared with the prior art, the connecting structural component has the characteristicsof having simple structure and convenient use and installation, meeting the quality requirement on integrally assembled cold box on site, preventing the malposition of the fractionating tower body which cannot be corrected artificially, guaranteeing the alignment of the fractionating tower and the proper position of a welding plate, and the like.

Owner:杭州杭氧低温液化设备有限公司

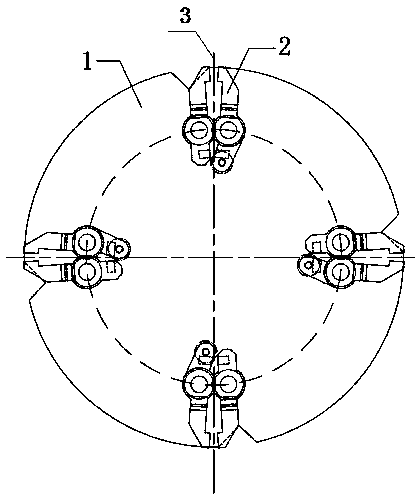

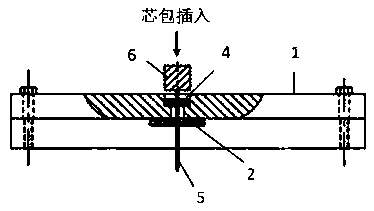

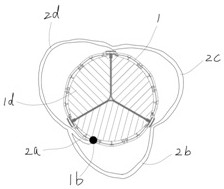

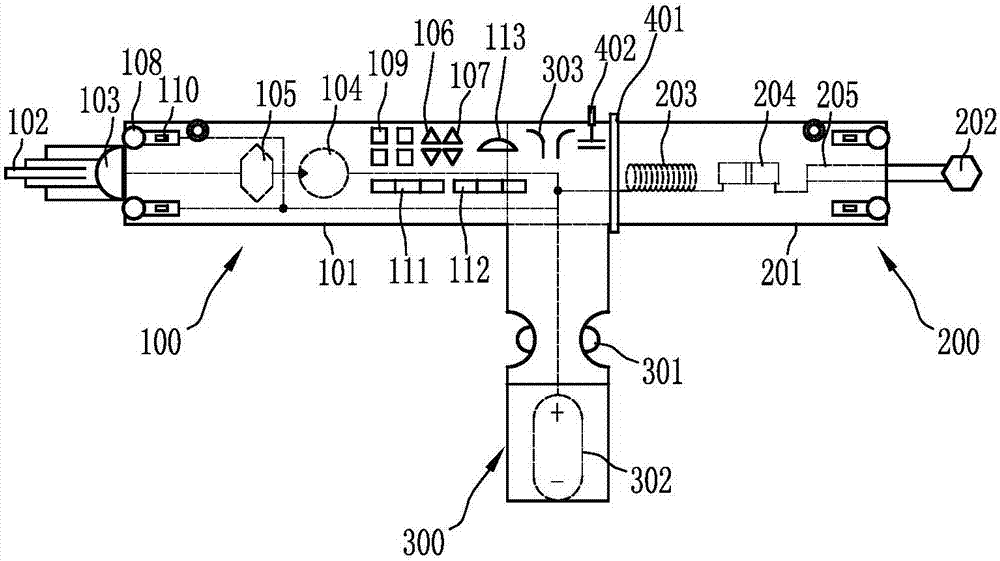

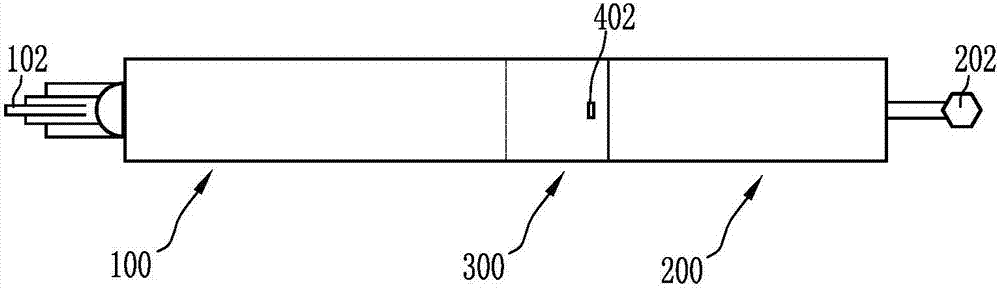

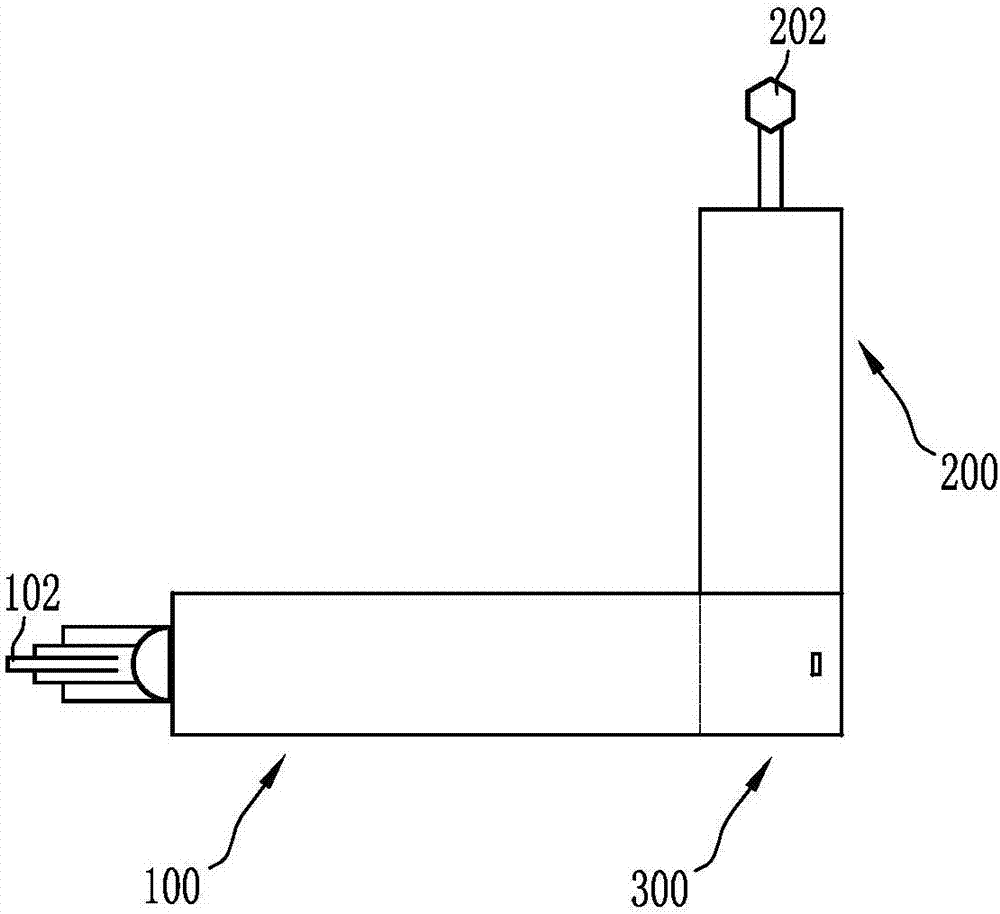

Integrated multi-station plate and automatic guide pin clamping device for assembling aluminum electrolytic capacitors

PendingCN108962603AReduce in quantitySimplify combination assembly proceduresCapacitor terminalsCapacitor manufactureManipulatorAluminum foil

The invention discloses an integrated multi-station plate and automatic guide pin clamping device for assembling aluminum electrolytic capacitors. According to the invention, multiple groups of guidepin clamping manipulators are arranged at equal intervals in the circumferential direction at the bottom of an integrated multi-station plate, the clamping end of each guide pin clamping manipulator is located at the edge of the multi-station plate, a rubber cover is arranged below the integrated multi-station plate and located at a position perpendicular to the clamping end, and a core cladding guide pin of the small aluminum electrolytic capacitor passes through the rubber cover and then clamped and fixed by the clamping end. The device disclosed by the invention enables the multi-station plate to be molded at one time by using an integrated multi-station technology, is convenient to assembly and easy to be in place accurately, and improves the working efficiency; and the automatic accurate positioning guide pin clamping device at the bottom of the multi-station plate enables a core cladding to move stably in the assembling process, thereby greatly reducing the possibility of damaging a riveting part between an aluminum foil and a guide pin of the core cladding.

Owner:SHENZHEN JIANGHAO ELECTRON

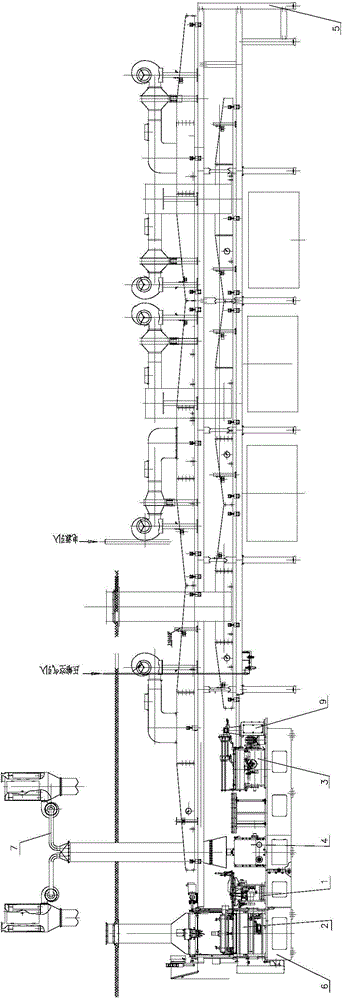

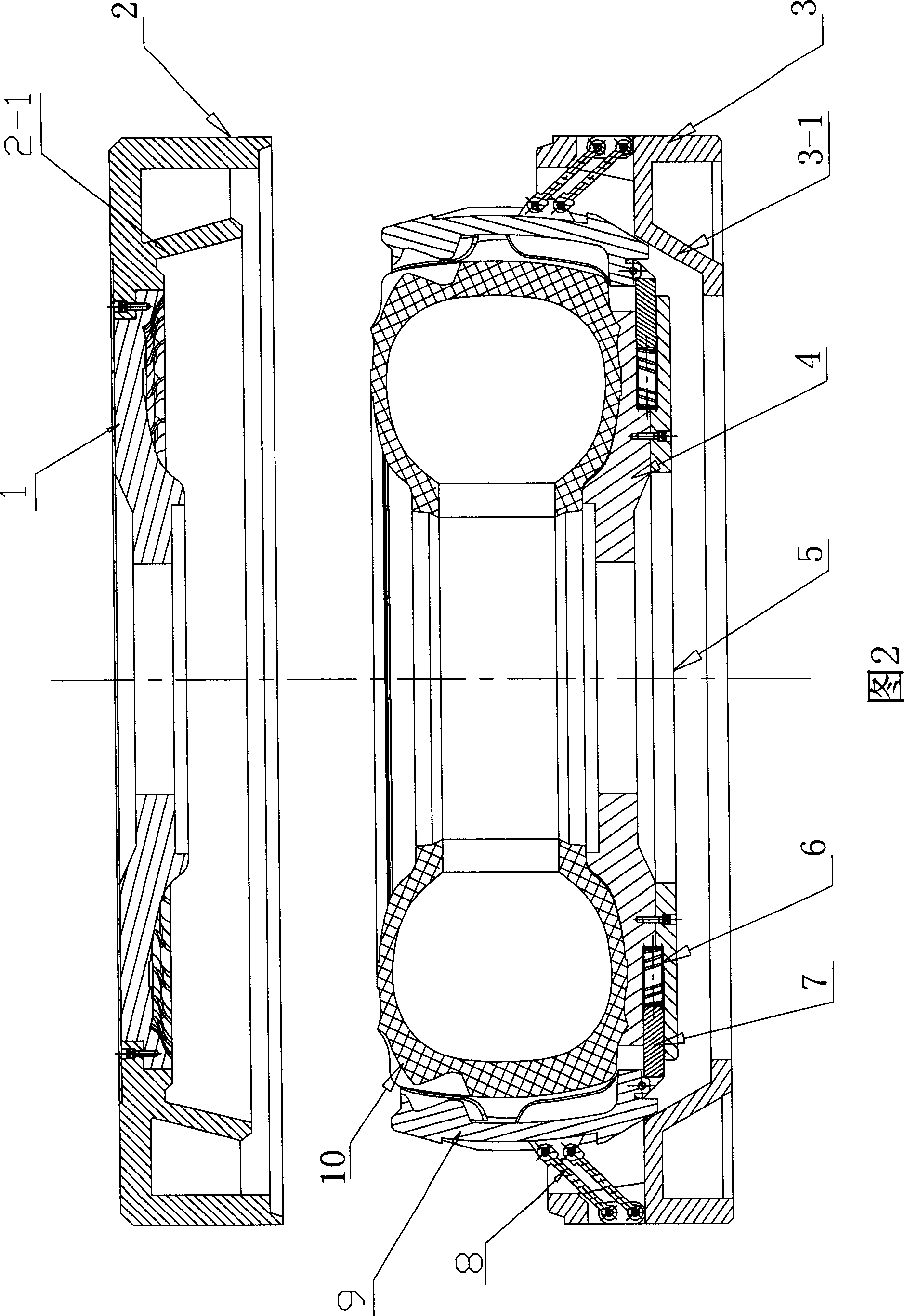

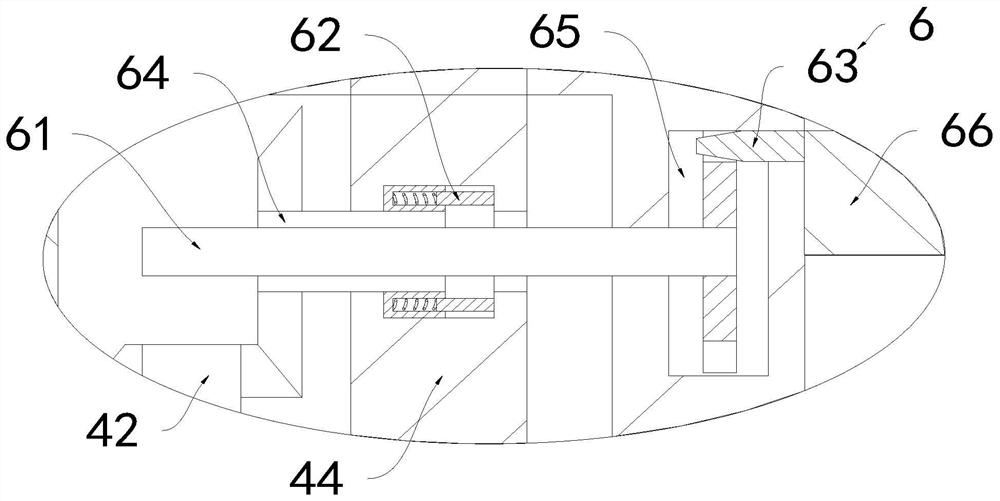

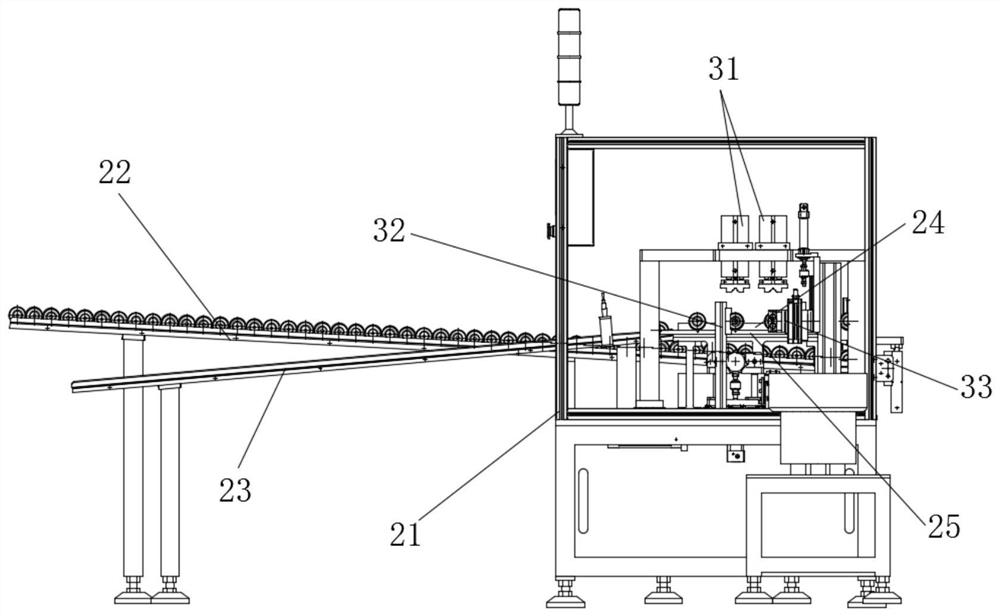

Capsule production line system

The invention relates to a capsule production system production line and belongs to the technical field of capsule production lines. The capsule production system production line comprises a mainframe base, a glue dipping machine, an oiling machine, an automat, a platform machine, a conveying drying device, a tail platform lifting mechanism, a waste material absorbing device, a large conveying belt device, a small conveying belt device and a main motor transmission case. The glue dipping machine, the oiling machine, the automat and the platform machine are arranged on the mainframe base side by side, the platform machine is installed between a lower pulling plate slideway of the conveying drying device and the automat, the main motor transmission case is connected with the platform machine, a T-shaped slide rail track is arranged between the automat and the platform machine, the glue dipping machine is respectively connected with an upper pulling plate slideway of the conveying drying device and a T-shaped sliding rail of the oiling machine, a platform machine pushing mechanism pushes die strips to respectively slide along a T-shaped sliding rail of the automat and the T-shaped sliding rail of the oiling machine and pushes the die strips having undergoing oiling to the glue dipping machine, and the die strips are dried through the conveying drying device and conveyed to the platform machine, are subject to capsule cutting and capsule peeling through the automat and are synthesized into integral capsules to be output. The capsule production system production line is driven by a servo motor, automatic production in the whole line is achieved, and the efficiency is high.

Owner:DANDONG JINWAN GRP

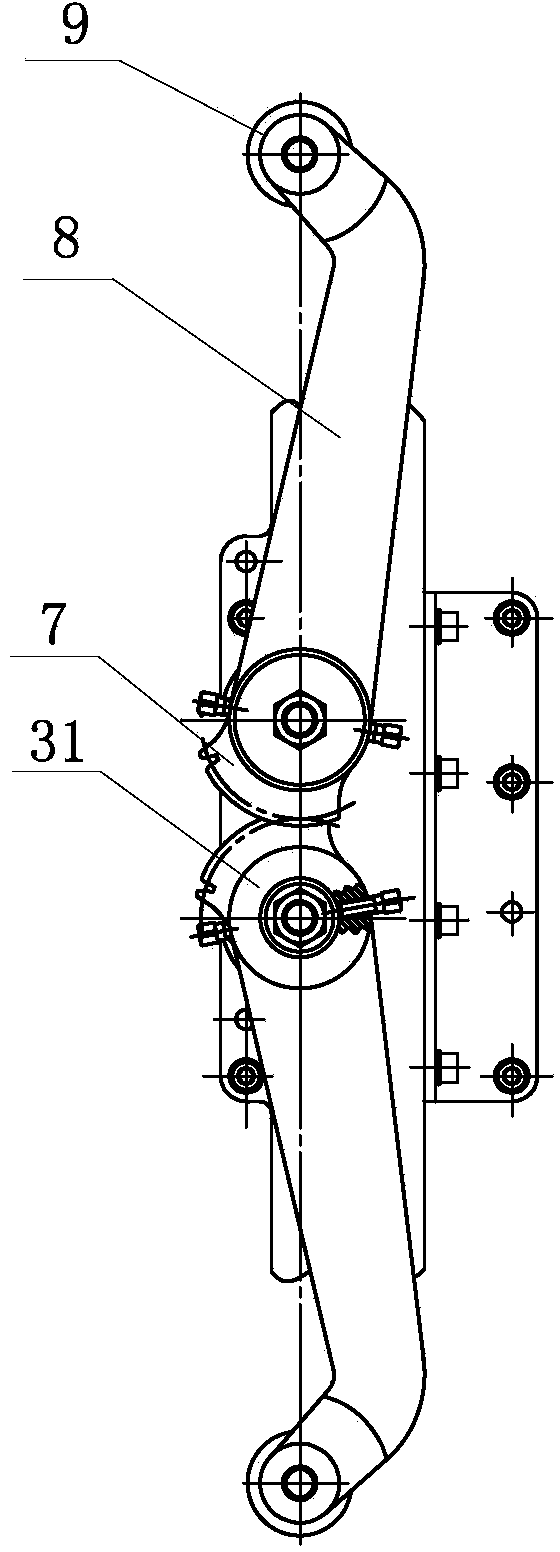

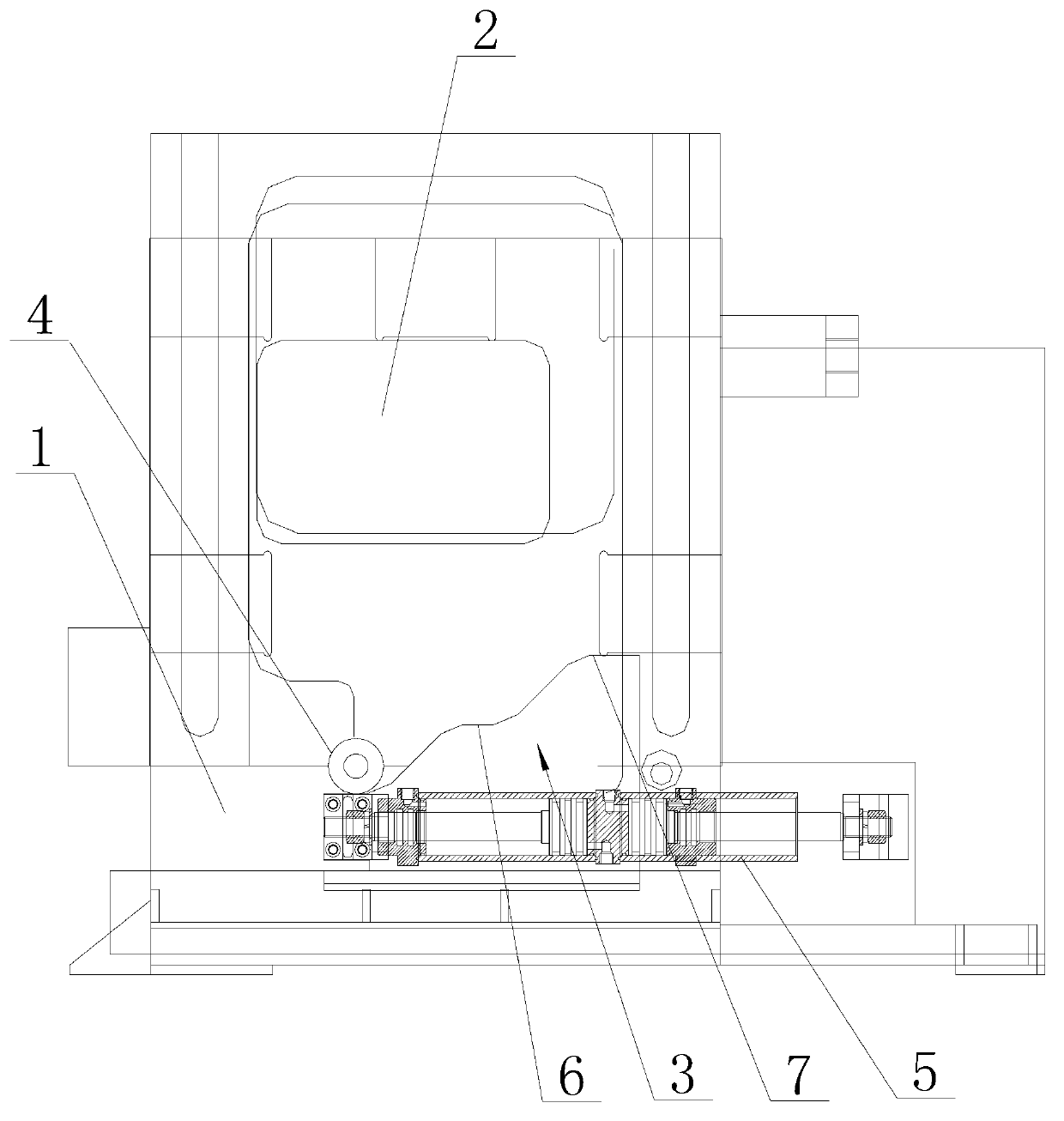

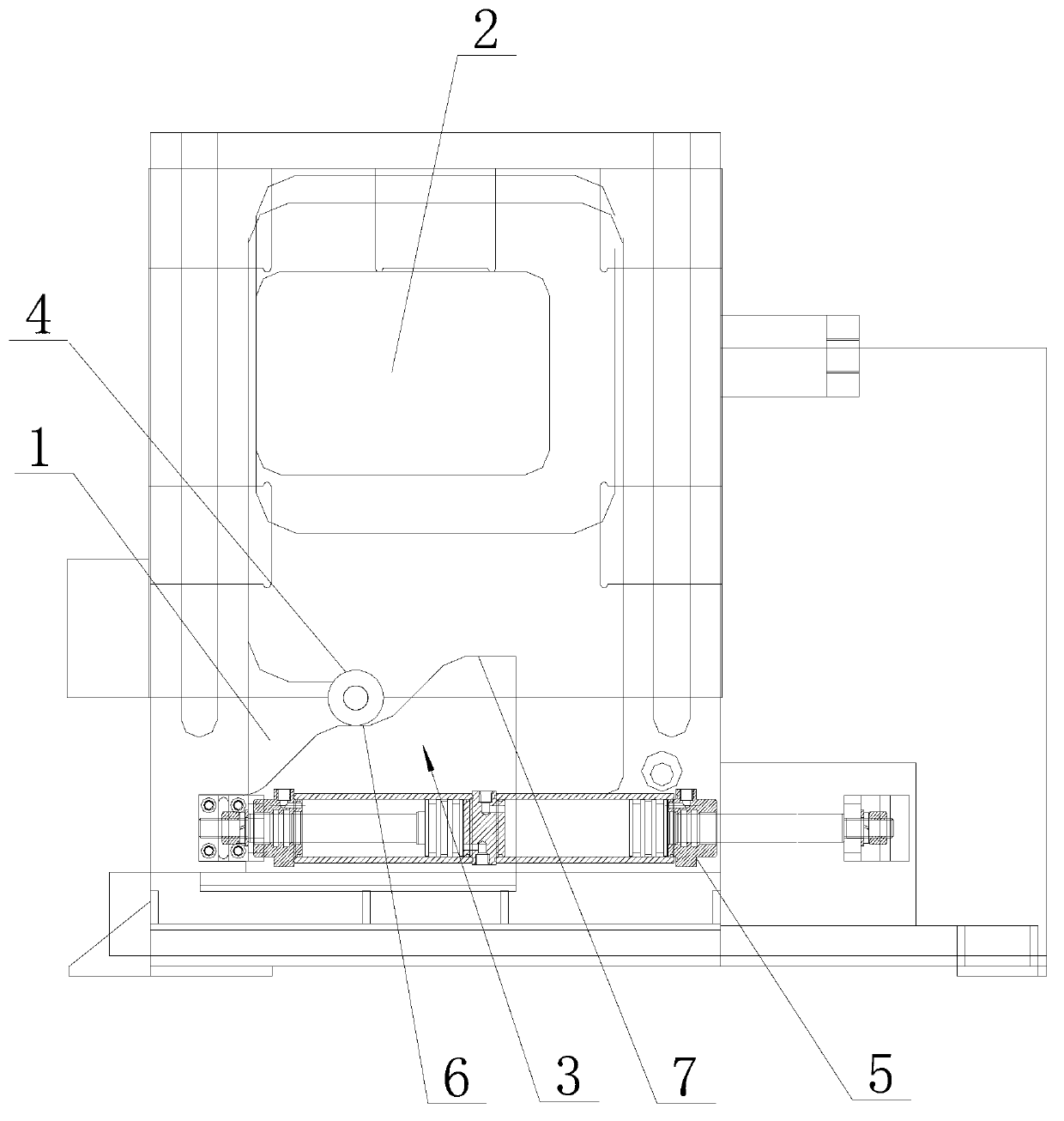

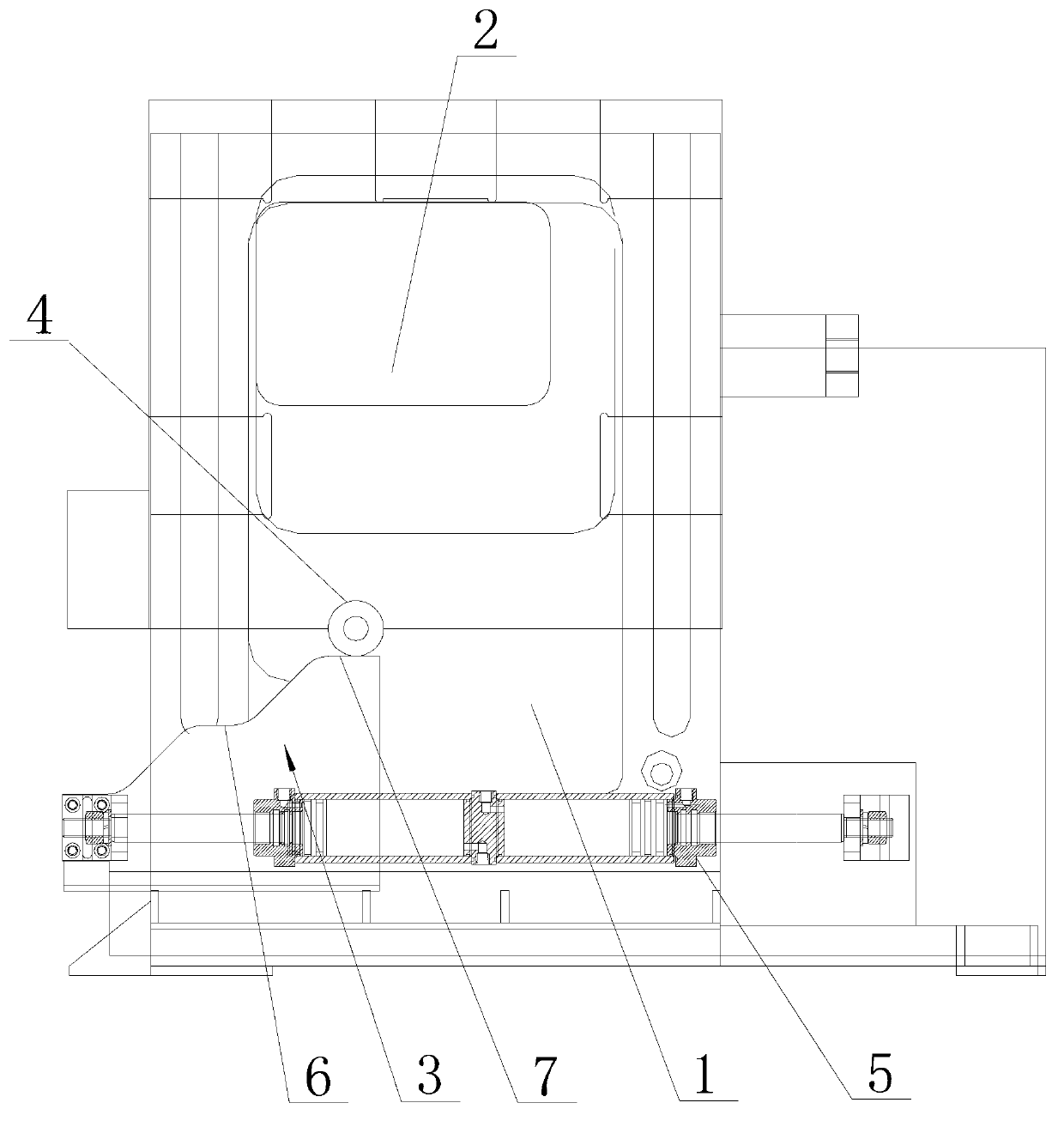

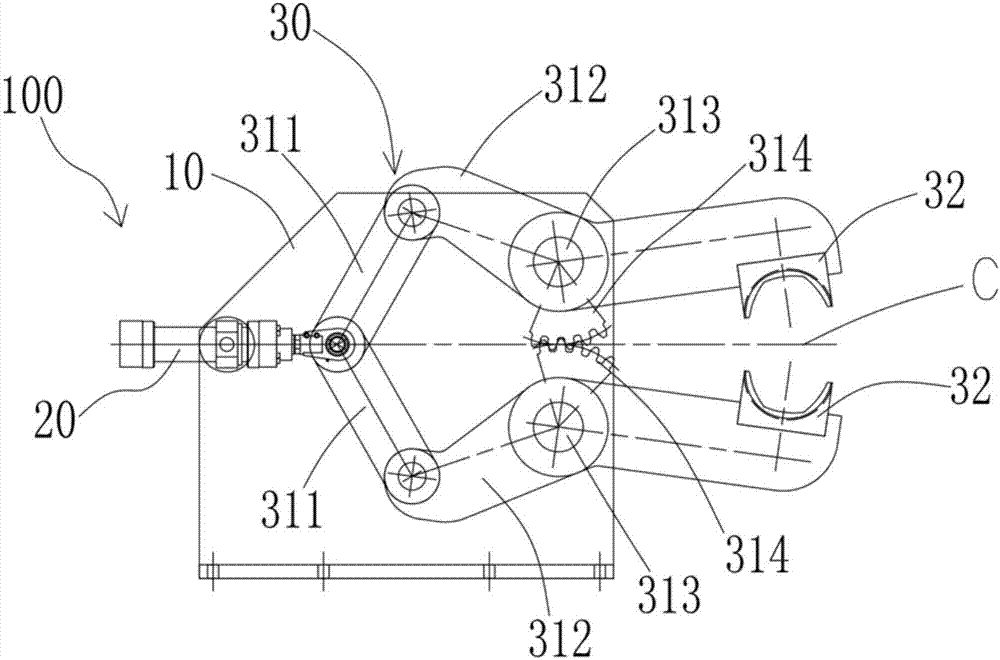

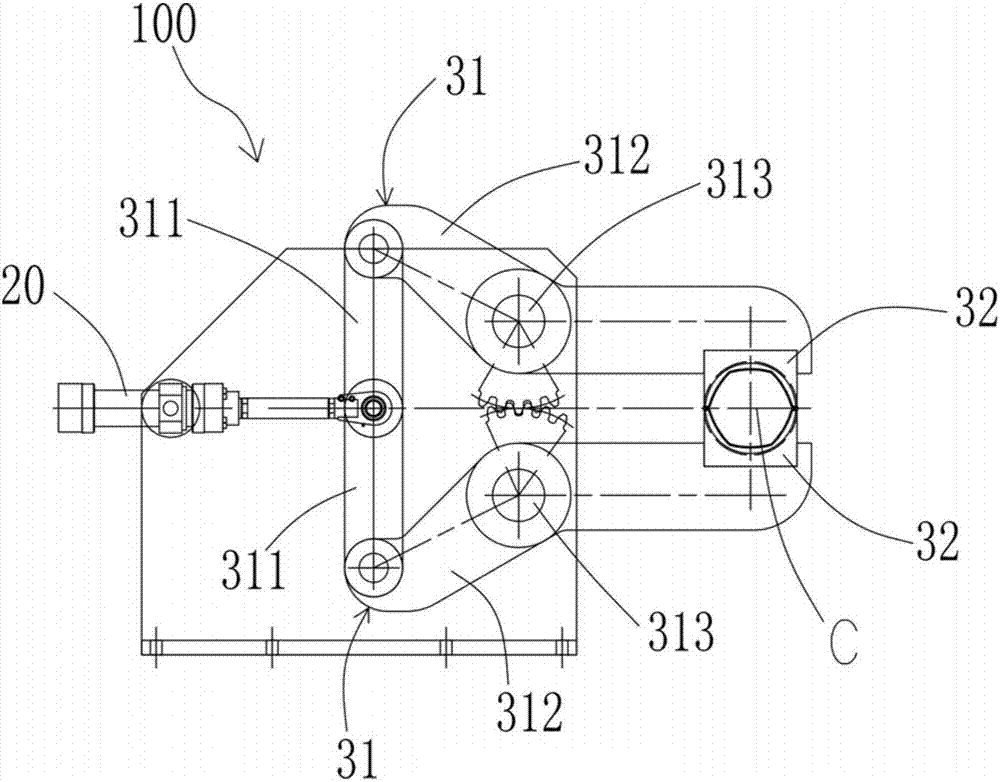

Pressurizing type necking machine

PendingCN107497954ASimple equipment structureQuick responseShaping toolsEngineeringHydraulic cylinder

The invention provides a pressurizing type necking machine and relates to the technical field of steel rolling devices. The pressurizing type necking machine at least comprises a machine frame, a hydraulic cylinder and a synchronous swinging unit, wherein the hydraulic cylinder and the synchronous swinging unit are installed on the machine frame. The synchronous swinging unit comprises two swinging assemblies. Each swinging assembly comprise a pull rod, a swing arm, a mandrel and a sector tooth, wherein the swinging arm is hinged to the machine frame through the mandrel, one end of the swinging arm is hinged to the pull rod, the other end of the swinging arm is provided with a necking die, one end of the pull rod is hinged to a cylinder head of the hydraulic cylinder, the other end of the pull rod is hinged to the swinging arm, the sector tooth is arranged on the mandrel in a sleeving manner and fixedly connected with the swinging arm, an interval exists between the two swinging arms. The two sector teeth are mutually meshed. The two swinging assemblies are driven by the hydraulic cylinder to be synchronously opened and closed. The pressurizing type necking machine completes the necking action through one hydraulic cylinder, and the pressurizing type necking machine is simple structure and rapid in response.

Owner:BEIJING JINGCHENG RUIXINCHANGCAI ENG TECH +1

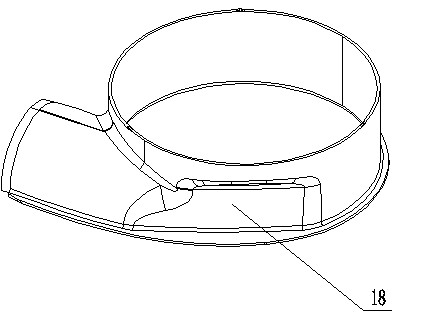

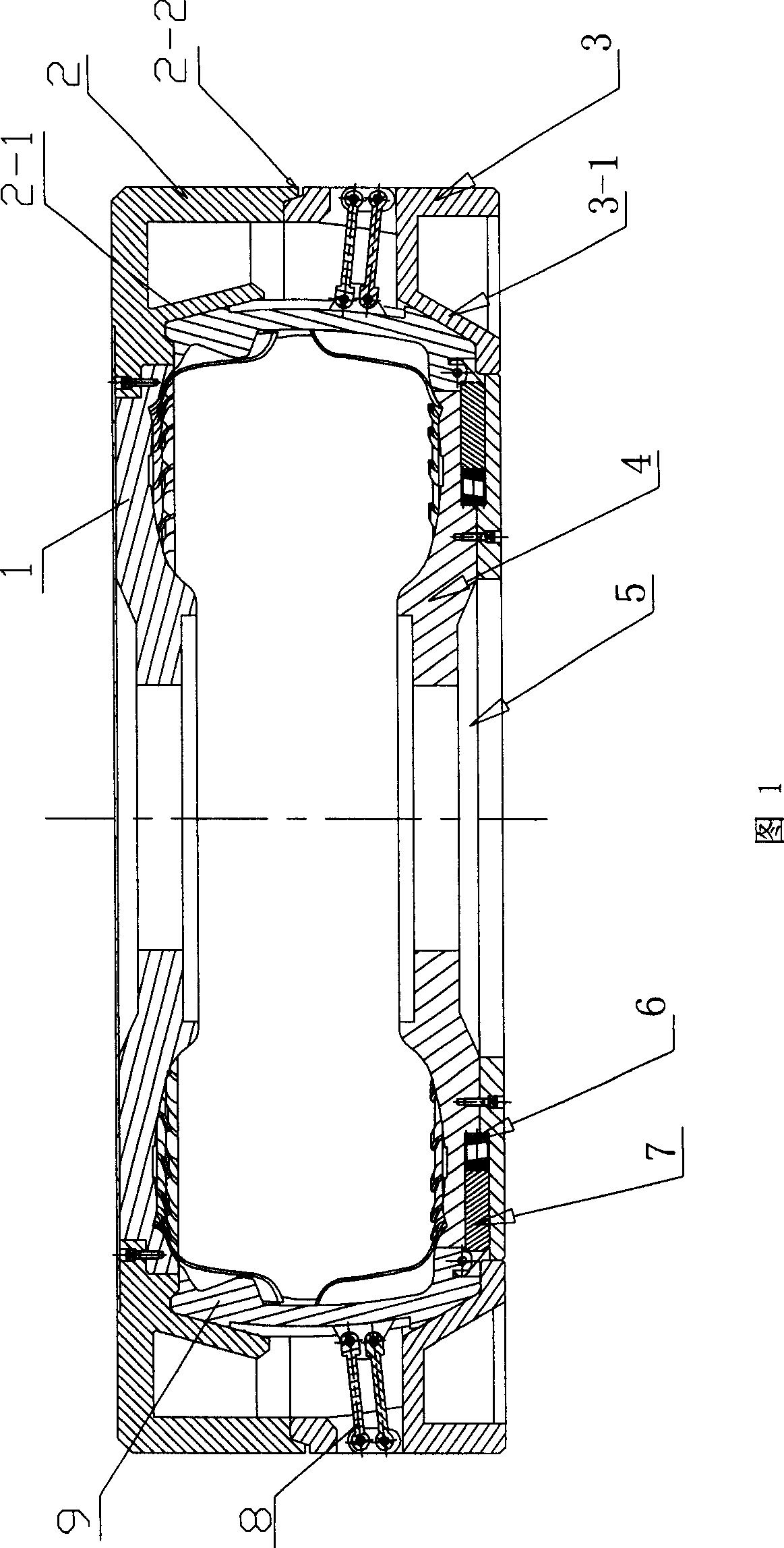

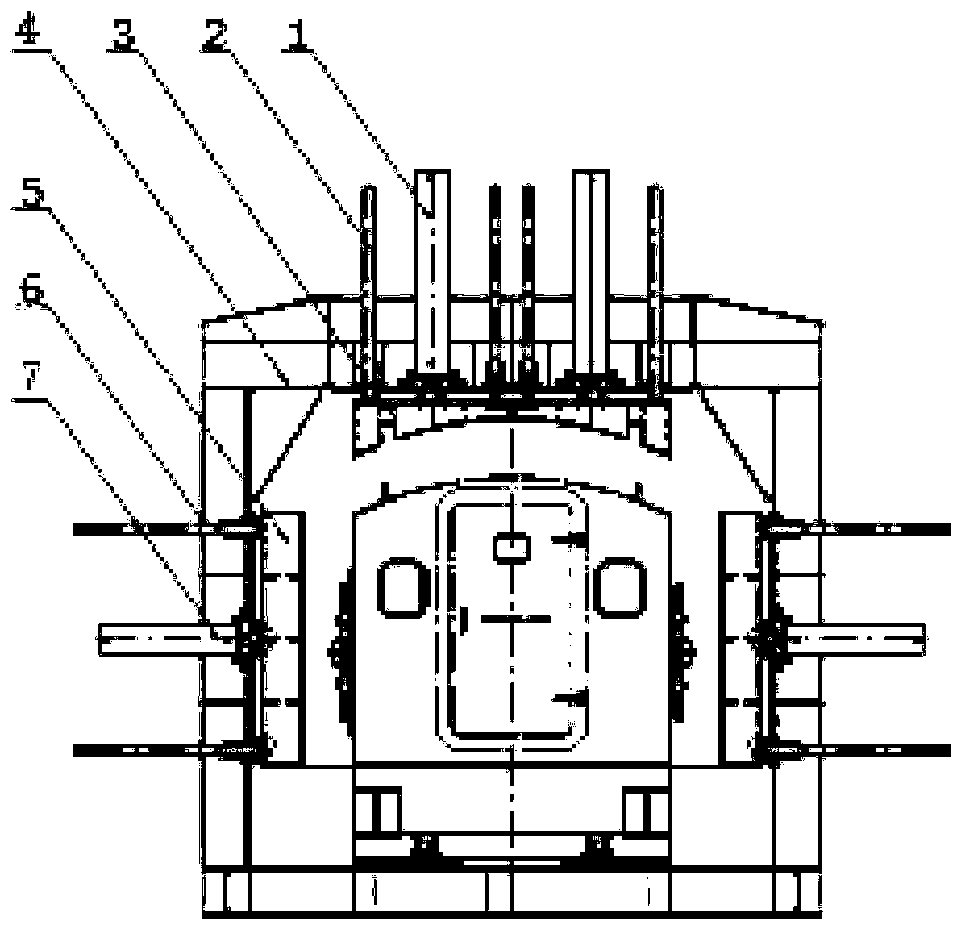

Giant tire activating mold

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

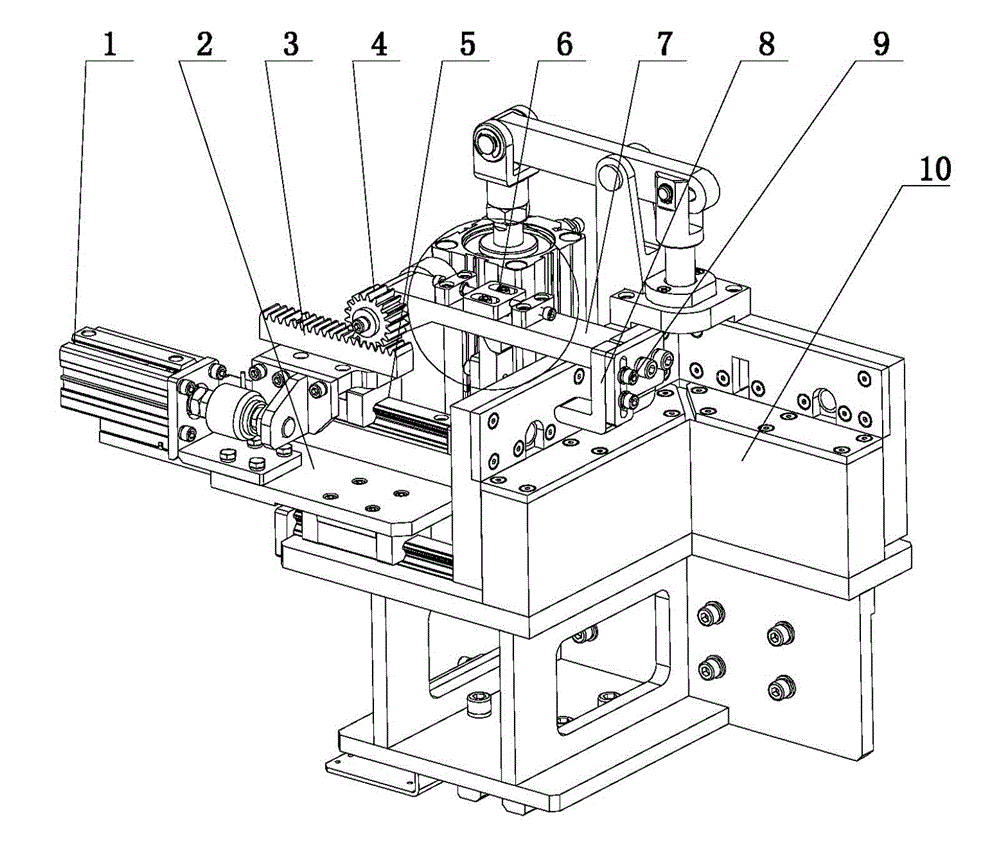

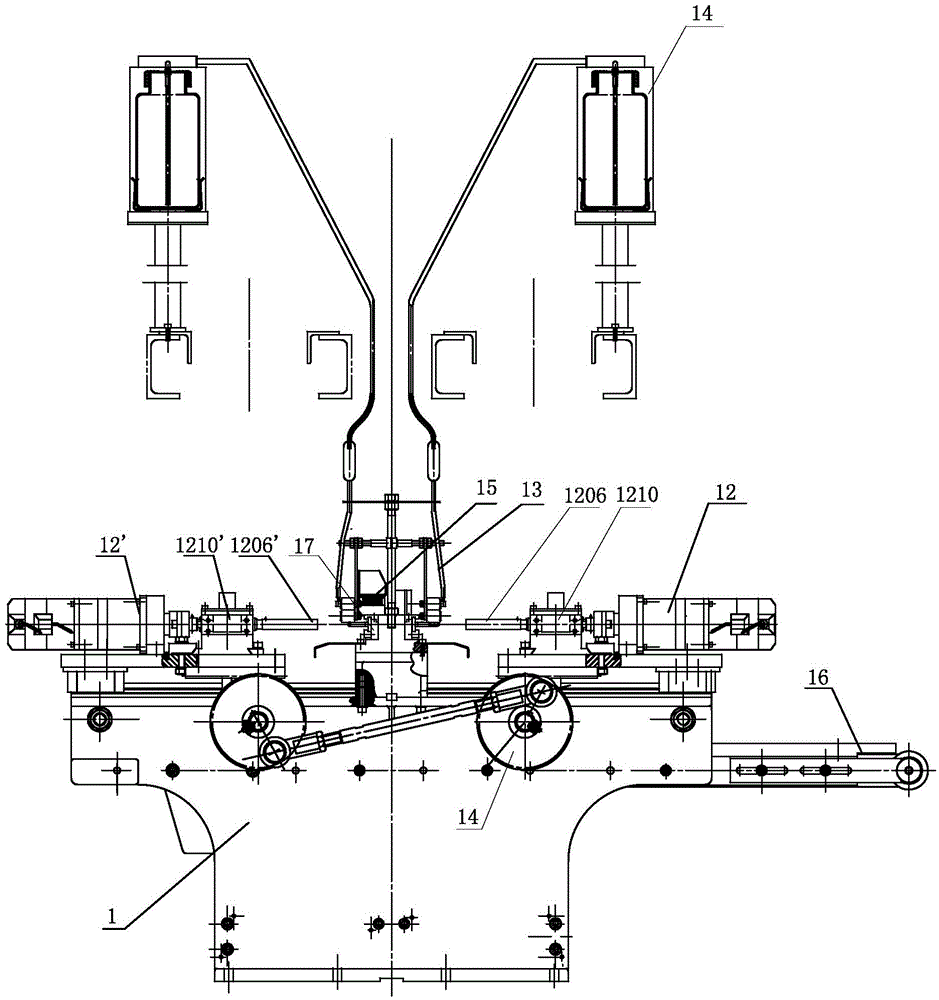

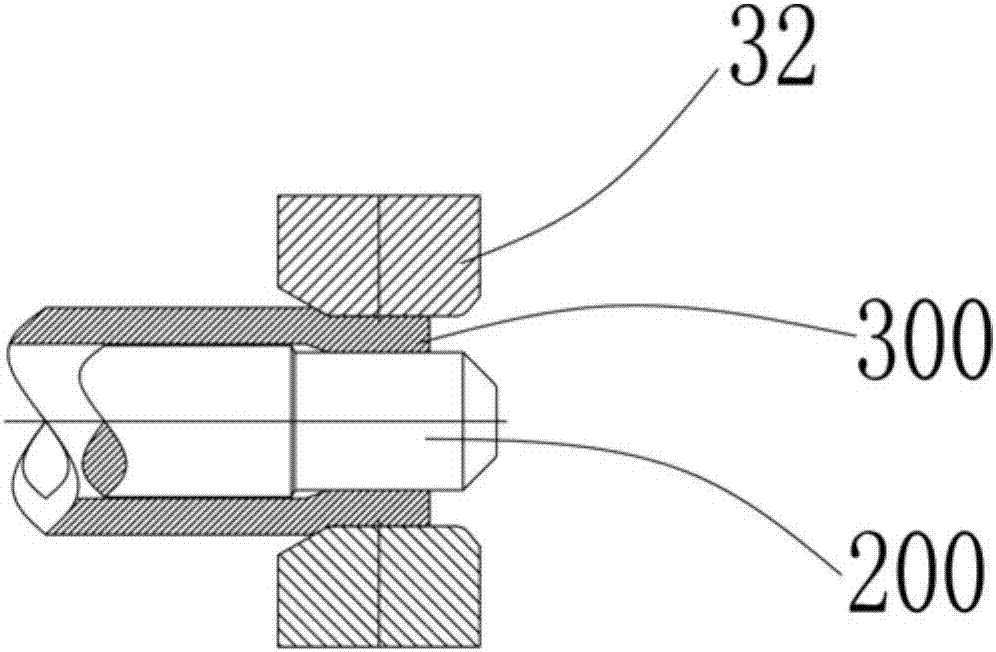

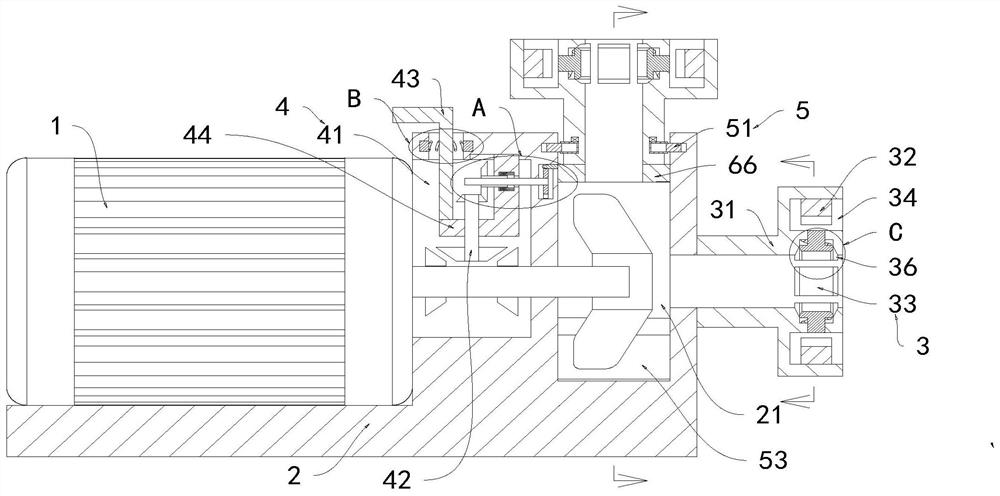

Motor rotor shaft sleeve press-in machine

ActiveCN112701866AGuarantee in placeIncrease productivityManufacturing stator/rotor bodiesElectric machineMachine

The invention provides a motor rotor shaft sleeve press-in machine which comprises a rack, a motor rotor positioning block is fixed to the rack, a shaft sleeve sleeve-in device and a shaft sleeve press-in device are symmetrically arranged on the two sides of the motor rotor positioning block, and a motor rotor pressing block is arranged above the motor rotor positioning block. The motor rotor pressing block is used for pressing a motor rotor positioned on the motor rotor positioning block, the shaft sleeve sleeve-in device is used for grabbing a shaft sleeve and preliminarily sleeving the shaft sleeve on a shaft of the motor rotor, and the shaft sleeve press-in device is used for pressing the preliminarily sleeved shaft sleeve into a specified position. The shaft sleeve press-in process is divided into two steps, namely a sleeve-in step and a press-in step, direct pressing of a shaft sleeve clamp on the shaft sleeve is replaced, the shaft sleeve is sleeved in place, two shafts of a motor rotor can be pressed at the same time, and the production efficiency is improved.

Owner:HANGZHOU WEIGUANG ELECTRONICS

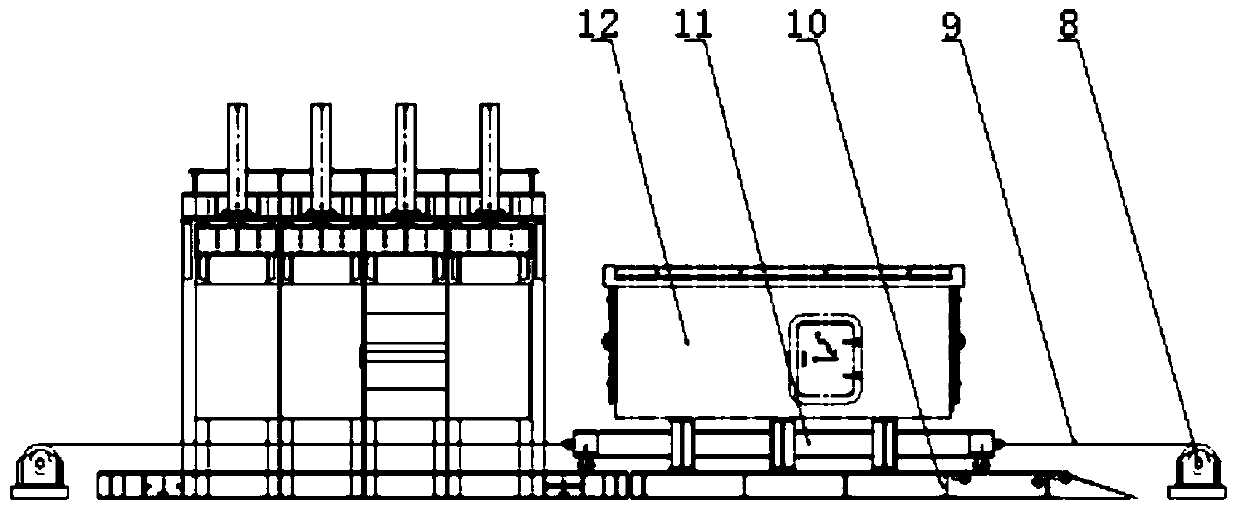

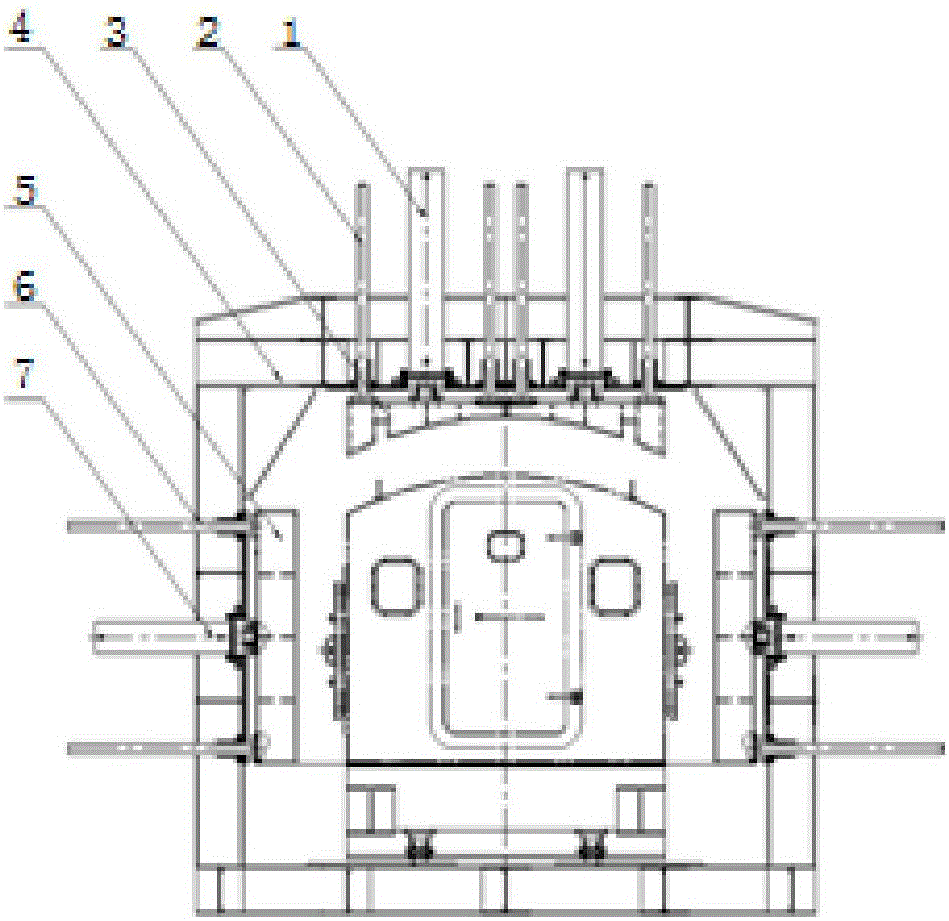

A test platform and method for the protection capability of a tunnel construction rescue cabin

ActiveCN106092624BImprove adaptabilityGuaranteed stabilityStructural/machines measurementHydraulic cylinderEngineering

The invention belongs to the matching technical field of tunnel construction rescue and discloses a platform and method for testing the protective capability of a tunnel construction rescue capsule body. The testing platform comprises a bearing stand, a traction device, multiple vertical loading executing mechanisms, and multiple horizontal loading execution mechanisms. The traction device comprises a traction trestle, two winches, a steel wire, and a traction vehicle. The bearing stand is provided with a stopping block. Each vertical loading executing mechanism comprises a vertical hydraulic cylinder and a vertical pressure block. The hydraulic rod of the vertical hydraulic cylinder is disposed vertically. The multiple horizontal loading execution mechanisms are arranged in a left row and a right row. The testing method comprises performing a test for simulating uniformly distributed dead load, a test for simulating impulse load, and a test for simulating local and single-side bias load on the rescue capsule body and the whole rescue capsule. The bearing stand, as the main force-bearing member of the platform, bears the reactive force of loaded static force in a test and may well disperse the reactive force of the loaded static force in the test.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Cigarette circulation box sealing device

PendingCN112896579ARealize automatic lid sealingImprove work efficiencyPackaging cigaretteWrapper twisting/gatheringElectrical connectionConveyor belt

The invention provides a cigarette circulation box sealing device. The device comprises a conveying belt used for conveying a circulation box, wherein the side face of the circulation box is provided with an opening, the opening is connected with a box cover made of cloth, the top face of the circulation box and the box cover are connected with hook-and-loop fasteners which match each other correspondingly, a jacking air cylinder with an upward output shaft is connected to the lower portion of the side face of the conveying belt, the output shaft end of the jacking air cylinder is connected with a jacking plate, a horizontal box closing rotating shaft is rotatably connected to the upper portion of the jacking plate, a box closing supporting plate is connected to the outer side face of the box closing rotating shaft, one end of the box closing rotating shaft is connected with a rotating air cylinder, one side of the conveying belt is connected with a photoelectric sensor, the device further comprises a PLC, and the PLC is electrically connected with the photoelectric sensor, the jacking air cylinder and a rotating air cylinder. The device can realize automatic cover closing and box sealing of the circulation box, saves time and labor, and is high in working efficiency and good in box sealing effect.

Owner:SHANDONG QINGDAO TOBACCO

An intelligent fire pump

ActiveCN113565726BFirmly connectedAchieve stabilityPositive displacement pump componentsFire rescueElectric machineryWater flow

The invention discloses an intelligent fire pump, which belongs to the field of fire pumps. An intelligent fire pump, including a fire pump motor, a protective seat cover, a working chamber, two connecting main parts for connecting with fire hose joints, a transmission main part, a stabilizing main part and an adjusting main part; the working chamber is located in the protection Inside the seat cover; the fire pump motor is fixed on the protective seat cover, and the motor shaft of the fire pump motor is provided with an impeller, and the impeller is located in the working chamber; the two connecting main parts are located on the protective seat cover and connected to the working chamber Connected, a connecting main part is fixed on the side end surface of the protective seat cover, it can effectively limit the position of the joint according to the increase of the actual water pressure after connecting the fire hose joint and the fire joint through the connecting main part, and Carry out clamping, especially after the water flow pressure is higher after the fire pump is pressurized, in order to better ensure the connection between the joints of the two, to achieve the stability of the water flow transmission.

Owner:ZHEJIANG BETTER PUMP CO LTD

Grounding switch

ActiveCN110444436AGuarantee in placeAvoid short circuit failureContact driving mechanismsAir-break switch detailsEngineeringDriving mode

A grounding switch includes a contact terminal assembly, a square rotating shaft, a mounting and fixing assembly, and a driving assembly. The contact terminal assembly is connected with a moving contact terminal of the grounding switch to control the grounding switch to be switched on or grounded. The contact terminal assembly is connected to the square rotating shaft; the square rotating shaft isused to control the rotation of the contact terminal assembly; the mounting and fixing assembly is used to fix the driving assembly and the square rotating shaft, the mounting and fixing assembly isdivided into two parts, one of the two parts is used to fix the driving assembly while the other part is connected with the rotatable square rotating shaft in a sleeving manner, the driving assembly is used to drive the square rotating shaft to rotate, the square rotating shaft is provided with power to rotate by the driving assembly through a connecting rod driving mode, the driving assembly is fixed on the mounting and fixing assembly, and the driving assembly is connected with the rotatable square rotating shaft is a sleeving manner. The grounding switch disclosed in the invention can be free of limitation by the driving assembly during usage and is advantageous in that jamming cannot be caused.

Owner:北京清畅新企电力设备有限公司

Rectification method for improper flanging angle and uneven flanging surface of automobile L-shaped stamping parts

The invention discloses a correcting method of misplacement of a flanging angle and unevenness of a flanging face of an automotive L-shaped stamping part. According to the method, a negative angle is avoided in the subsequent correcting by rotating a process angle and reserving a rebounding process remainder, and the right placement and the subsequent correctable property of the flanging angle are guaranteed; and through the improvement of the structure of a die, a workpiece is totally located in a female groove, the flanging face is uniformly stressed in the same direction in the flanging process, and the evenness of the flanging face is guaranteed, so that the precision of the stamping part is guaranteed.

Owner:CHERY AUTOMOBILE CO LTD

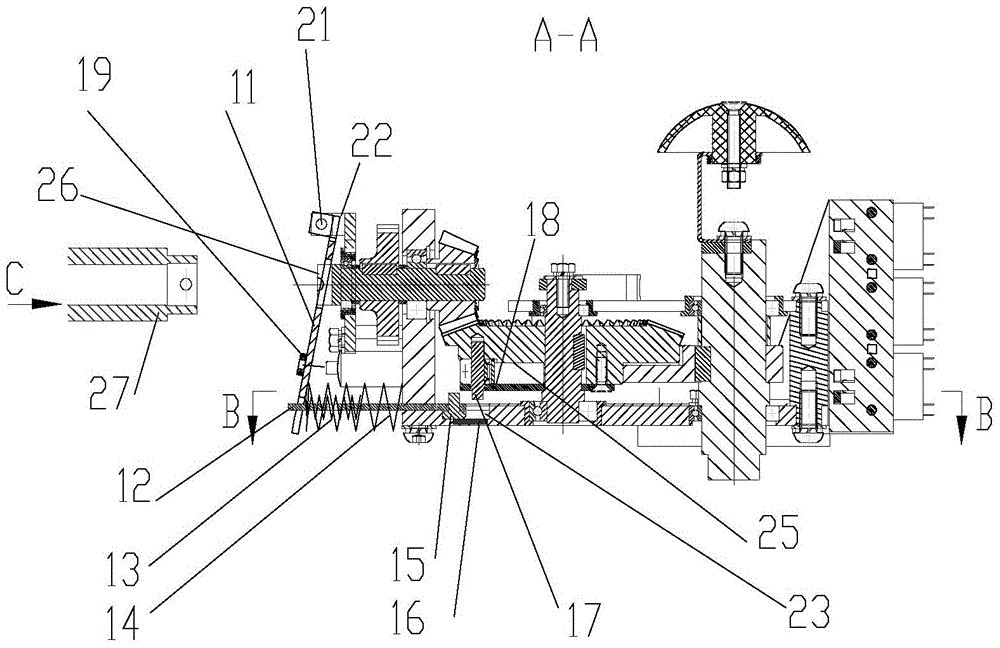

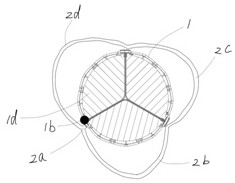

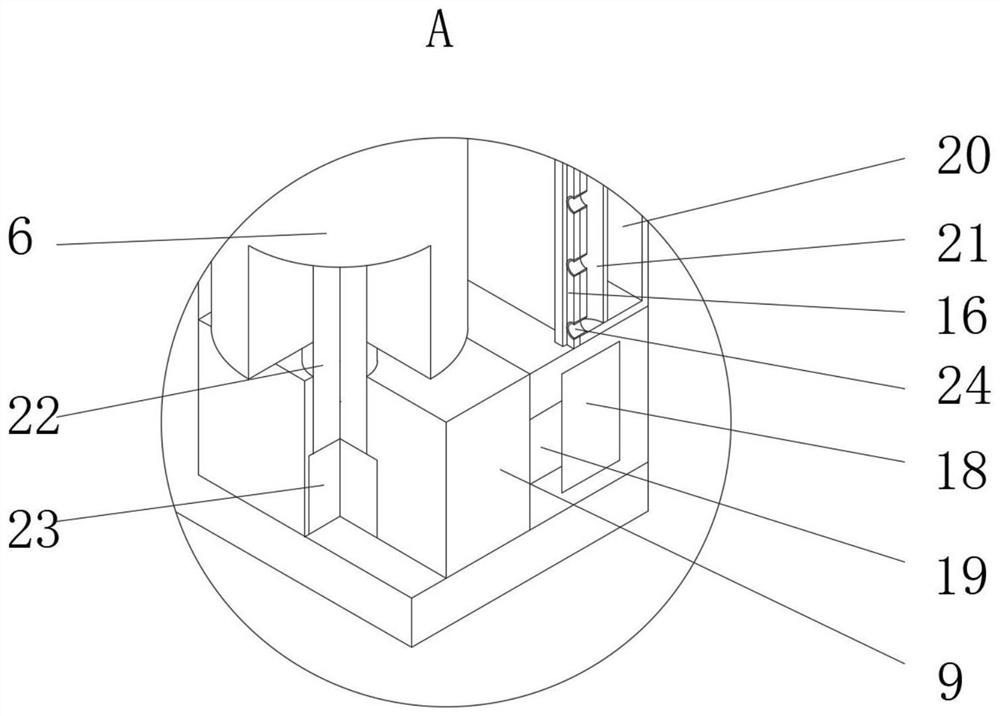

A Limiting Structure of Operating Mechanism Based on Magnetic Suspension Technology

ActiveCN104576097BRealize the locking function in placeAvoid misuseContact driving mechanismsLong axisEngineering

Disclosed is an operating mechanism limiting structure based on the magnetic suspension technology. An operating mechanism is provided with a rotating part and located inside a shell. Three layers of groove cavities are formed in a base or shell base plate (23) below the horizontal rotating part. A small rectangular groove or hole (31) is formed in the bottommost layer, and a guiding permanent magnet (16) in the same shape as the small rectangular groove is fixedly arranged inside the small rectangular groove. A large rectangular groove (32) is formed in the middle layer, and the long end of the large rectangular groove deforms to form the triangular groove. A T-shaped groove (33) is formed in the upmost layer, and the long end of the T-shaped groove extends to the edge of the base (23). The long axes of the three grooves coincide. A downward-protruding sliding stop block (15) is fixedly arranged on the bottom face of the horizontal rotating part and corresponds to the three layers of groove cavities when rotating. The operating mechanism limiting structure further comprises a sliding plate (12), the sliding stop block (15) and a rotating pressing plate (11). According to the operating mechanism limiting structure based on the magnetic suspension technology, and particularly the GIS three-station switch operating mechanism limiting structure based on the magnetic suspension technology, the design is more flexible and simpler, the structure is compact, the occupied space is small, and the cost is low.

Owner:GUANGZHOU BAIYUN ELECTRIC EQUIP

Operating mechanism limiting structure based on magnetic suspension technology

ActiveCN104576097ARealize the locking function in placeAvoid misuseContact driving mechanismsMagnetLong axis

Disclosed is an operating mechanism limiting structure based on the magnetic suspension technology. An operating mechanism is provided with a rotating part and located inside a shell. Three layers of groove cavities are formed in a base or shell base plate (23) below the horizontal rotating part. A small rectangular groove or hole (31) is formed in the bottommost layer, and a guiding permanent magnet (16) in the same shape as the small rectangular groove is fixedly arranged inside the small rectangular groove. A large rectangular groove (32) is formed in the middle layer, and the long end of the large rectangular groove deforms to form the triangular groove. A T-shaped groove (33) is formed in the upmost layer, and the long end of the T-shaped groove extends to the edge of the base (23). The long axes of the three grooves coincide. A downward-protruding sliding stop block (15) is fixedly arranged on the bottom face of the horizontal rotating part and corresponds to the three layers of groove cavities when rotating. The operating mechanism limiting structure further comprises a sliding plate (12), the sliding stop block (15) and a rotating pressing plate (11). According to the operating mechanism limiting structure based on the magnetic suspension technology, and particularly the GIS three-station switch operating mechanism limiting structure based on the magnetic suspension technology, the design is more flexible and simpler, the structure is compact, the occupied space is small, and the cost is low.

Owner:GUANGZHOU BAIYUN ELECTRIC EQUIP

Asymmetric artificial aortic valve using eccentric limiting keys for intervention

PendingCN113303946AShorten the lengthAssurance controlHeart valvesBiomedical engineeringNeoaortic valve

The invention discloses an asymmetric artificial aortic valve using eccentric limiting keys for intervention. The asymmetric artificial aortic valve comprises an asymmetric straight-barrel-shaped short stent main body containing a valve leaflet structure and an eccentric limiting component fixed on the outer side of the stent main body through a single connecting point. The stent main body with the valve leaflet is used for replacing the original diseased valve. The eccentric limiting structure fixed on the outer side of the stent in a single point mode is used for adapting to the position of an implantation system to naturally guide positioning of the main stent valve and providing support to prevent the main stent valve from sliding down.

Owner:黄健兵

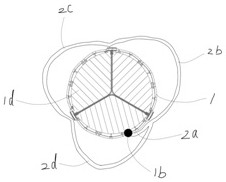

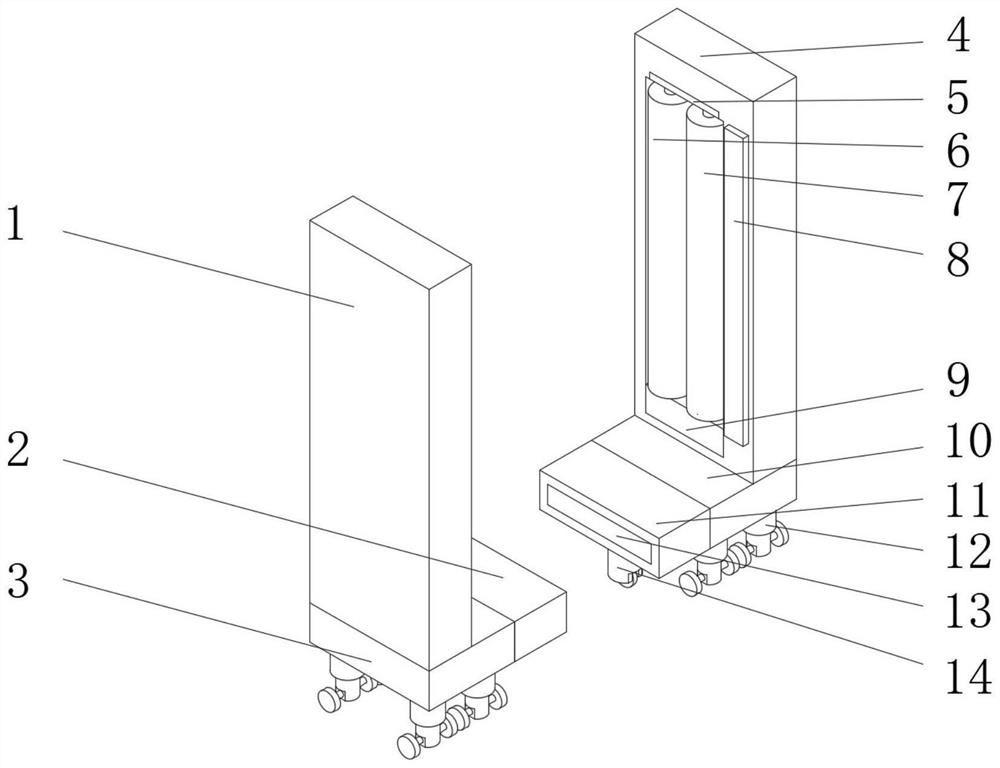

Lubricating oil filling device for elevator car guide rail

Owner:株洲畅爽石化有限公司

Reliable and stable intelligent fire pump

ActiveCN113565726AFirmly connectedAchieve stabilityPositive displacement pump componentsFire rescueControl engineeringElectric machinery

The invention discloses a reliable and stable intelligent fire pump, and belongs to the field of fire pumps. The reliable and stable intelligent fire pump comprises a fire pump motor, a protection seat sleeve, a working cavity, two connecting main pieces used for being connected with a fire hose connector, a transmission main piece, a stabilizing main piece and an adjusting main piece, wherein the working cavity is arranged in the protective seat sleeve; the fire pump motor is fixedly arranged on the protection seat sleeve, an impeller is arranged on a motor shaft of the fire pump motor, and the impeller is located in the working cavity; the two connecting main pieces are both arranged on the protection seat sleeve and communicate with the working cavity, one connecting main piece is fixedly arranged on the side end face of the protection seat sleeve, and after the fire hose connector and a fire connector are connected through the connecting main pieces, the position of the connector can be effectively limited and clamped according to the increase of actual water pressure, particularly, the pressure of the water flow pressurized by the fire pump is higher, and the connection of the position of the fire hose connector and the fire connector is ensured so as to achieve the stability of water flow transmission.

Owner:ZHEJIANG BETTER PUMP CO LTD

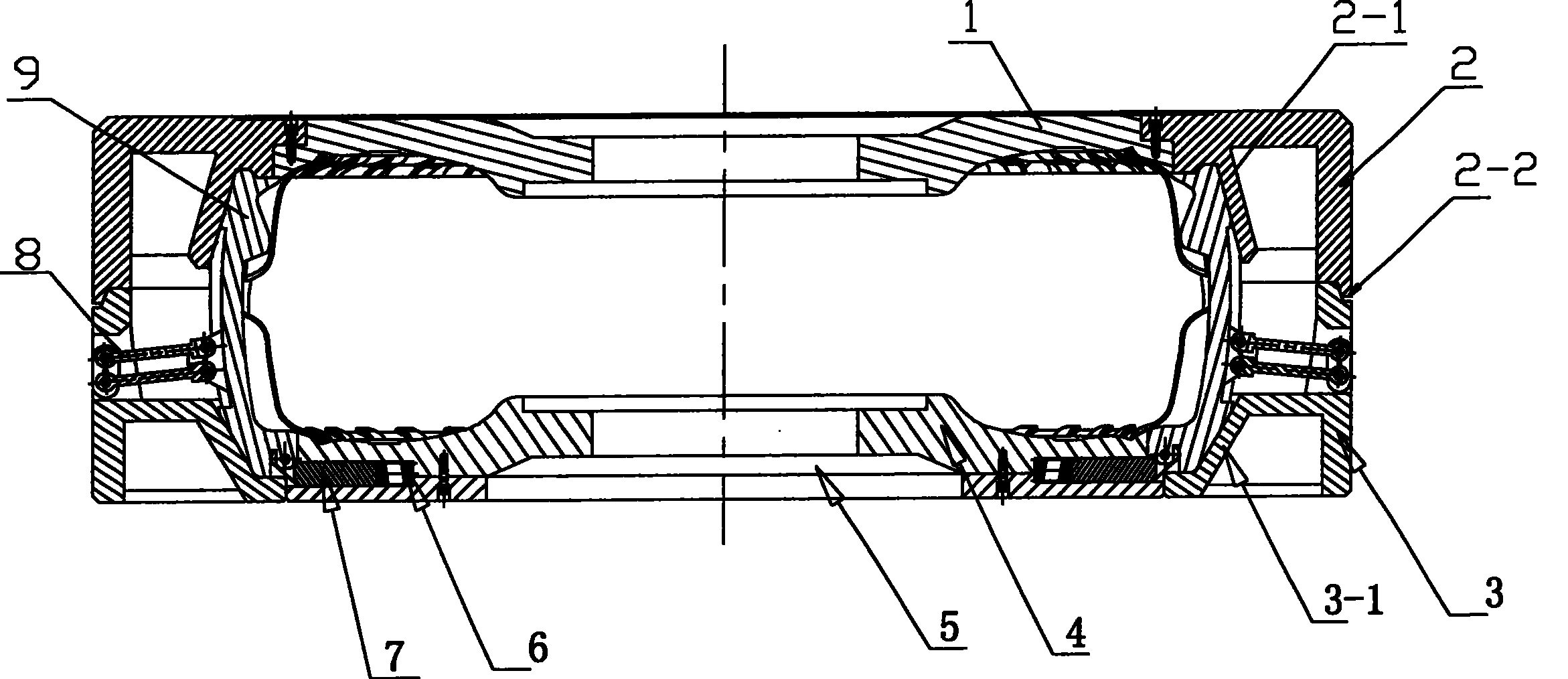

Platform and method for testing protective capability of tunnel construction rescue capsule body

ActiveCN106092624AImprove adaptabilityGuaranteed stabilityStructural/machines measurementHydraulic cylinderEngineering

The invention belongs to the matching technical field of tunnel construction rescue and discloses a platform and method for testing the protective capability of a tunnel construction rescue capsule body. The testing platform comprises a bearing stand, a traction device, multiple vertical loading executing mechanisms, and multiple horizontal loading execution mechanisms. The traction device comprises a traction trestle, two winches, a steel wire, and a traction vehicle. The bearing stand is provided with a stopping block. Each vertical loading executing mechanism comprises a vertical hydraulic cylinder and a vertical pressure block. The hydraulic rod of the vertical hydraulic cylinder is disposed vertically. The multiple horizontal loading execution mechanisms are arranged in a left row and a right row. The testing method comprises performing a test for simulating uniformly distributed dead load, a test for simulating impulse load, and a test for simulating local and single-side bias load on the rescue capsule body and the whole rescue capsule. The bearing stand, as the main force-bearing member of the platform, bears the reactive force of loaded static force in a test and may well disperse the reactive force of the loaded static force in the test.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

A bearing assembly method

The invention relates to a bearing assembly method used for assembling a bearing without an inner ring on an intermediate case of an aircraft engine. The method includes the following steps: A, providing an assembly tool, sleeving a cylindrical portion with a bearing bush, enabling a boss to match and align with a first notch, rotationally connecting an ejector rod with a first pressure rod, and clamping the bearing with an ejector blade and a disc; B, after heating a case hole of the intermediate case or cooling the bearing, enabling a first projection to align with a case notch, and then assembling the bearing in place; disconnecting the ejector rod with the first pressure rod, taking out the ejector rod from the intermediate case, and then taking the first pressure rod out of the bearing; C, mounting a collar and a spiral retaining ring in sequence to finish assembling of the bearing. The bearing assembly method greatly improves assembly and disassembly efficiency and quality.

Owner:CHINA HANGFA SOUTH IND CO LTD

Photovoltaic module profile straightening and back plate flattening mechanism

ActiveCN105470340BGuarantee in placeDo not interfere with transportFinal product manufactureSemiconductor devicesEngineeringMechanical engineering

Owner:正泰新能科技股份有限公司

Die bar push-out mechanism in capsule production system

InactiveCN103711863BAvoid damageRealize reciprocating rotationGearingMechanical energy handlingEngineeringPush out

The invention discloses a mold bar push-out mechanism in a capsule production system, and belongs to the technical field of capsule production lines. The mechanism is installed on a push-out beam of a glue dipping machine and comprises a push-out motor, a transmission device, a driving push-out shaft, a driven push-out shaft, two push-out arms and overload protecting devices, wherein both the driving push-out shaft and the driven push-out shaft are installed on the push-out beam, one end of the driving push-out shaft and one end of the driven push-out shaft stretch out of the push-out beam, half teeth meshed to one anther are respectively installed at the end of the driving push-out shaft stretching out of the push-out beam and the end of the driven push-out shaft stretching out of the push-out beam, the two push-out arms are installed on the driving push-out shaft and the driven push-out shaft respectively, the overload protecting devices are installed on the end portion, where one push-out arm is installed, of the driving push-out shaft and the end portion, where the other push-out arm is installed, of the driven push-out shaft, and the other end of the driving push-out shaft stretches out of the push-out beam and is connected with the push-out motor through the transmission device. Through the mechanism, it can be guaranteed that the system is controlled to stop when faults happen. When the faults happen, steel balls roll out of overload disks so that the overload disks can drive the push-out arms to have displacement, real-time detection can be performed through a proximity switch, and therefore the mechanism is prevented from being damaged when the faults happen.

Owner:DANDONG JINWAN GRP

Special tools for handcart switch and grounding knife switch operation

InactiveCN105914634BLarge torqueGuarantee in placeSwitchgear with withdrawable carriageControl mannerDrive motor

The invention discloses a handcart switch and grounding switch operation special tool, which comprises a handcart switch operation mechanism, a grounding switch operation mechanism and a handle, wherein the handcart switch operation mechanism comprises a handcart switch sleeve; a handcart switch operation head is arranged at the outer end of the handcart switch sleeve in a rotating mode; a tension overload automatic release is arranged between the handcart switch operation head and the handcart switch sleeve; the handcart switch sleeve is internally provided with a driving motor; the grounding switch operation mechanism comprises a grounding switch sleeve; a grounding switch operation head is arranged at the outer end of the grounding switch sleeve in a rotating mode; a spring energy storage mechanism is arranged inside the grounding switch sleeve; and a rotating lock switch and an operation head switch are arranged between the grounding switch operation mechanism and the handcart switch operation mechanism. Corresponding operation of the handcart switch or the grounding switch is realized in an electric or manual control mode, the operation and the use are convenient, and the working efficiency is improved.

Owner:WULIAN COUNTY POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO +1

A motor rotor shaft sleeve assembly machine

ActiveCN112701865BGuarantee in placeIncrease productivityManufacturing stator/rotor bodiesElectric machineryControl theory

Owner:HANGZHOU WEIGUANG ELECTRONICS

Lubricating oil filling device for elevator car guide rails

The invention provides a lubricating oil filling device for elevator car guide rails. The device comprises a first smearing plate, wherein a first bottom plate is fixedly connected to the bottom of the first smearing plate, and a first connecting plate is fixedly connected to the rear end of the first bottom plate. According to the lubricating oil filling device, the lengths of two first rotatingbrushes and the lengths of two second rotating brushes exceed the height of the elevator guide rails, and then the tops and bottoms of the elevator guide rails can be simultaneously filled with lubricating oil in a non-dead-angle manner; three atomizing bodies are used for atomizing the lubricating oil at the same time and matched with the rotating brushes for cleaning, so that the cleaning is conducted more thoroughly; and meanwhile pushing sheets are used for further uniform treatment after oil product filling for removing residual stains and impurities on the surfaces of the elevator guiderails to ensure in-place of the lubricating oil and assist in cleaning of impurities adhering to the guide rails.

Owner:株洲畅爽石化有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com