Patents

Literature

62results about How to "Realize reciprocating rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

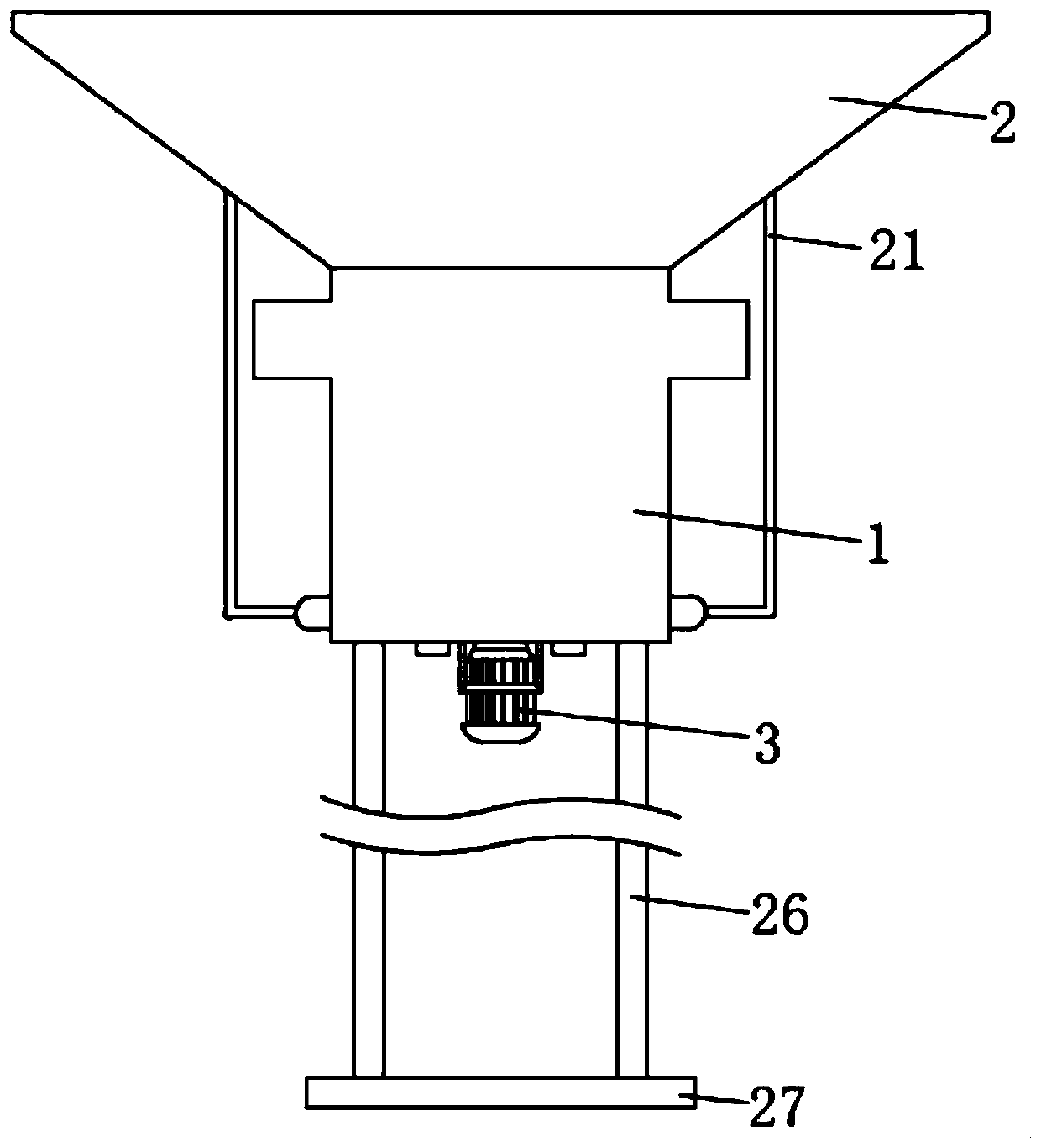

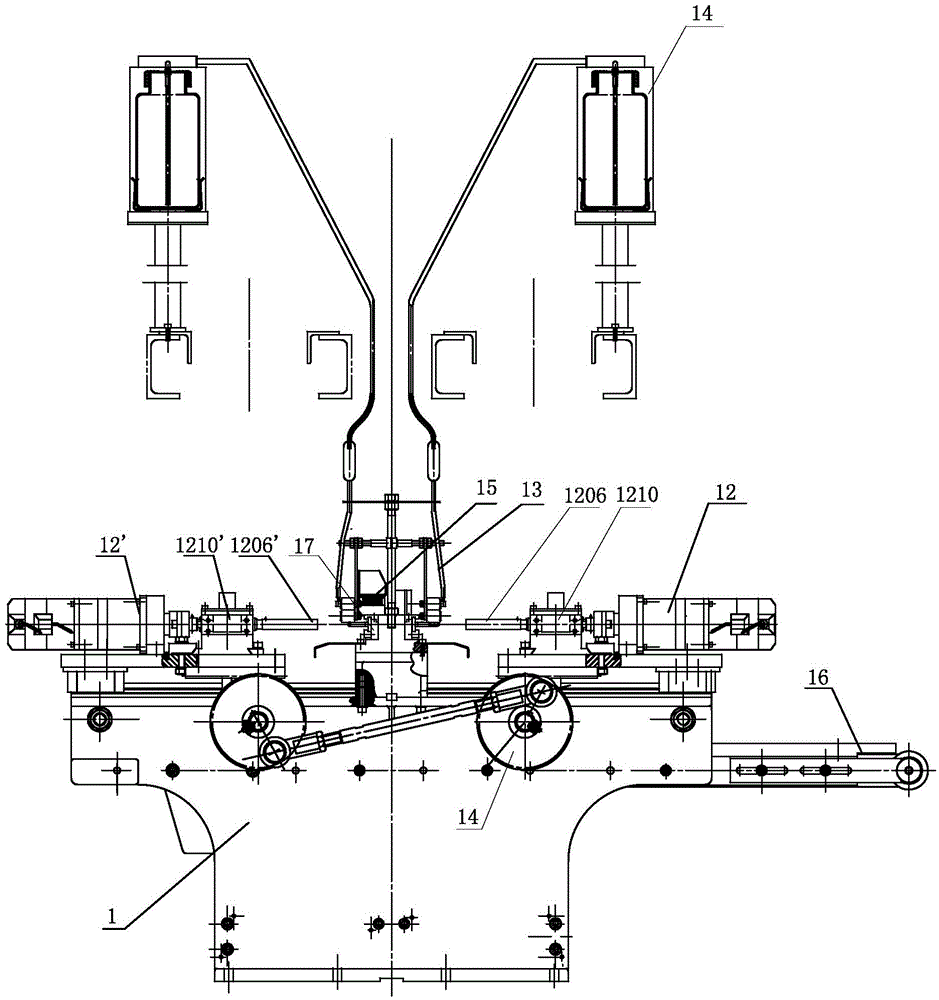

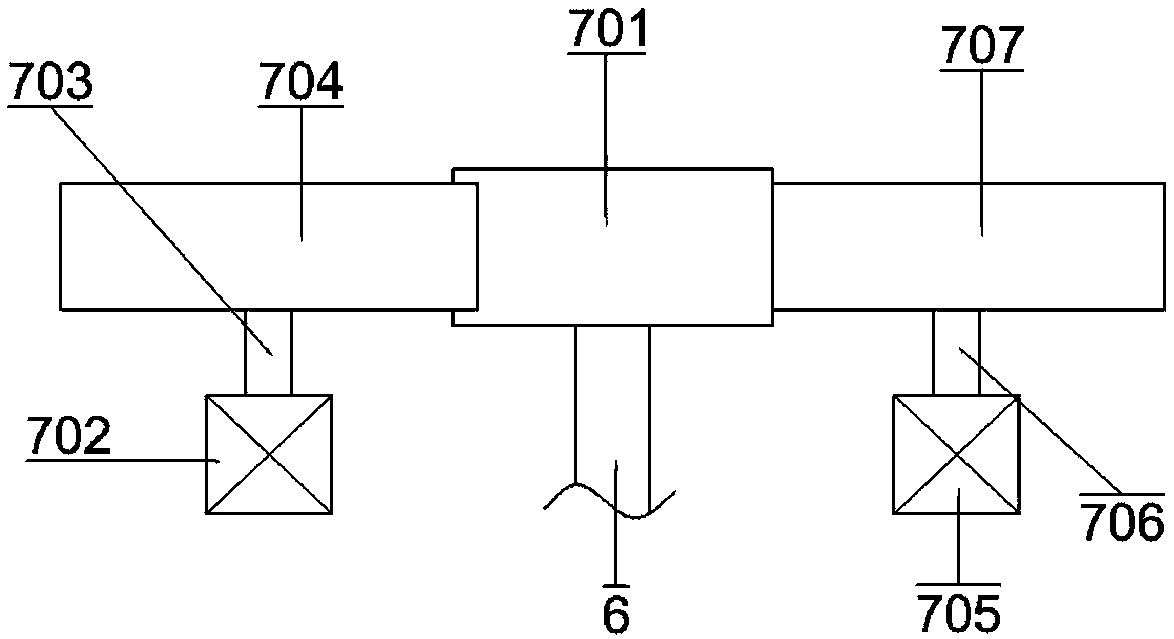

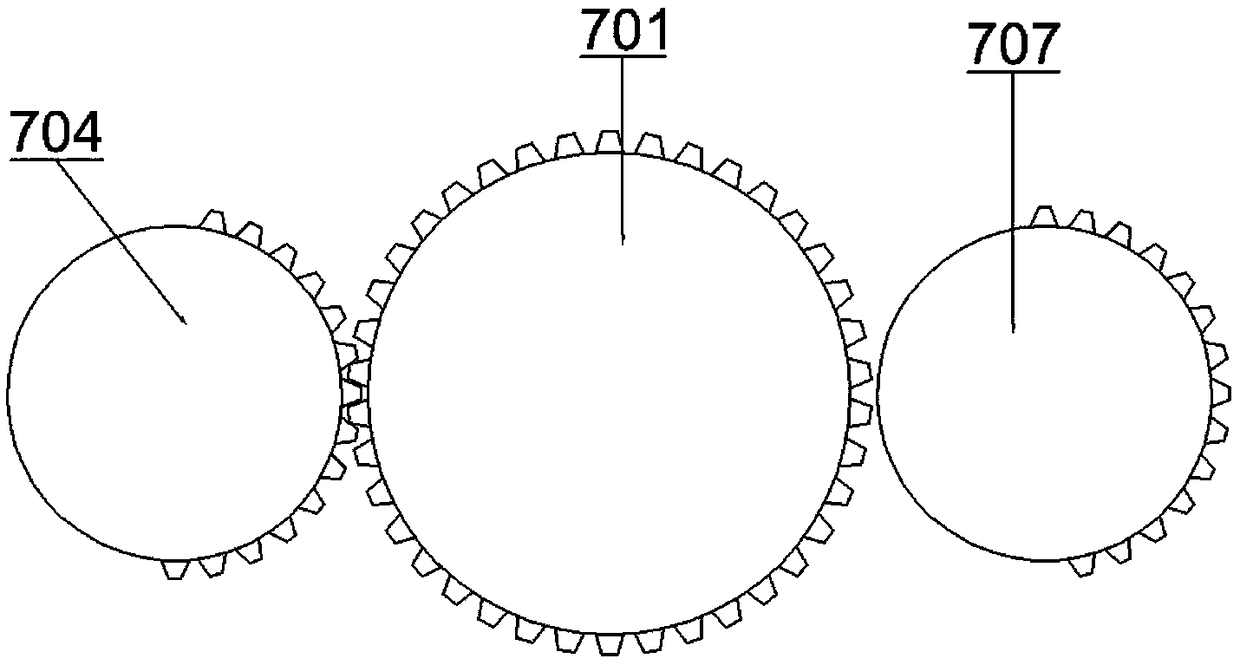

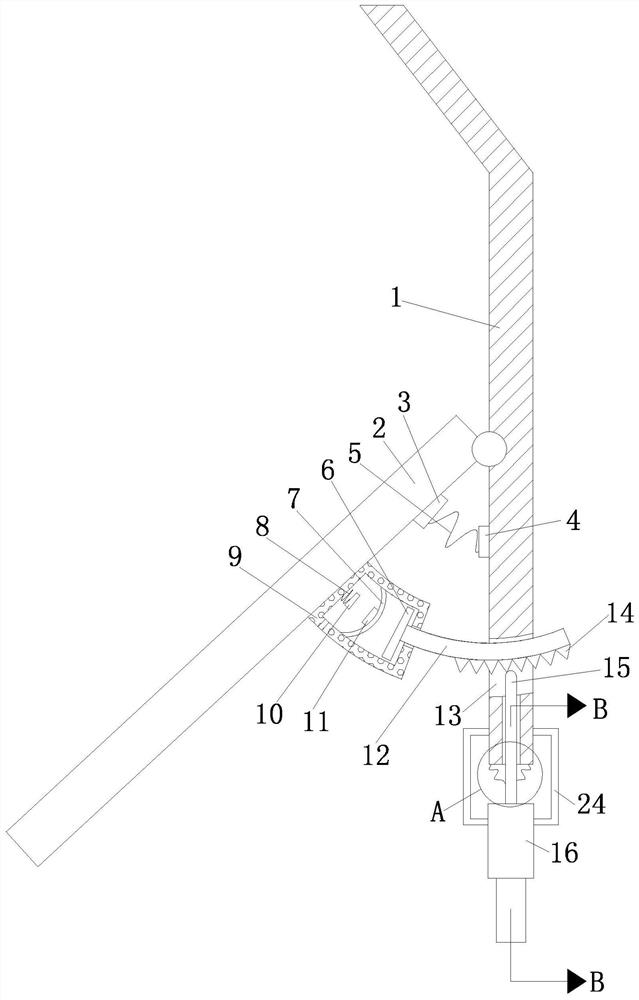

Electric rotation mechanism for seat

ActiveCN108556691ASimple structureReduce the number of partsMovable seatsGear wheelElectric machinery

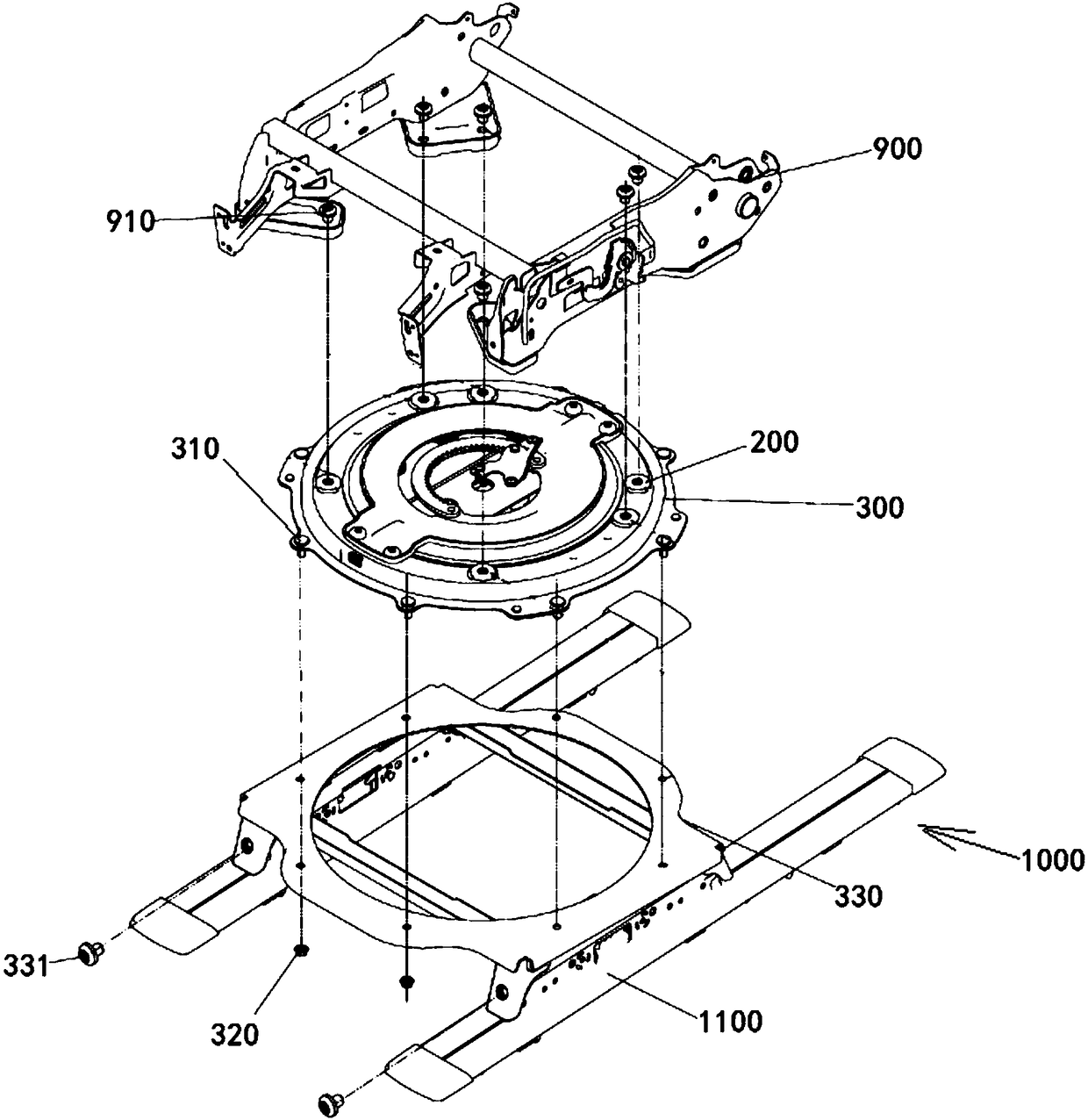

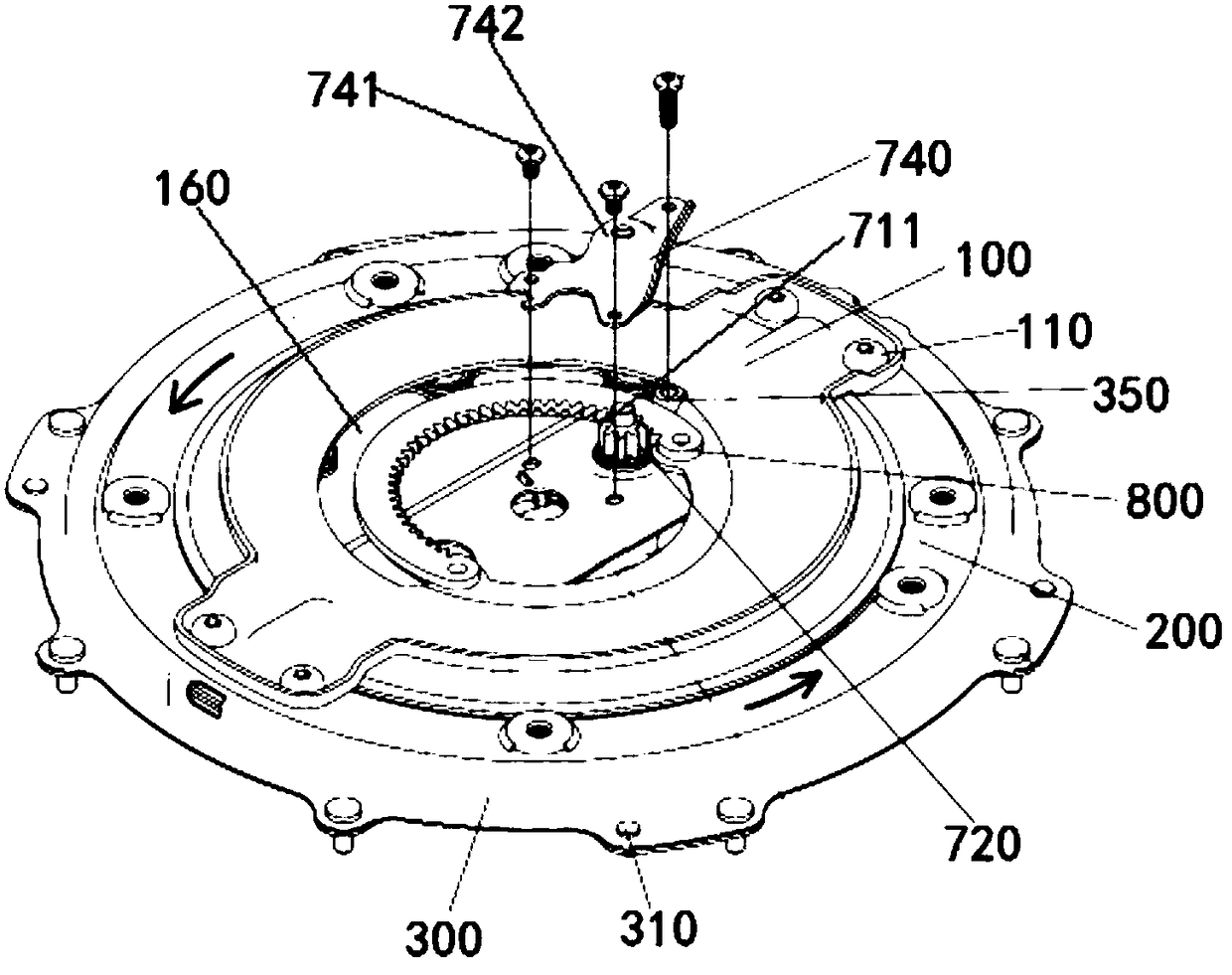

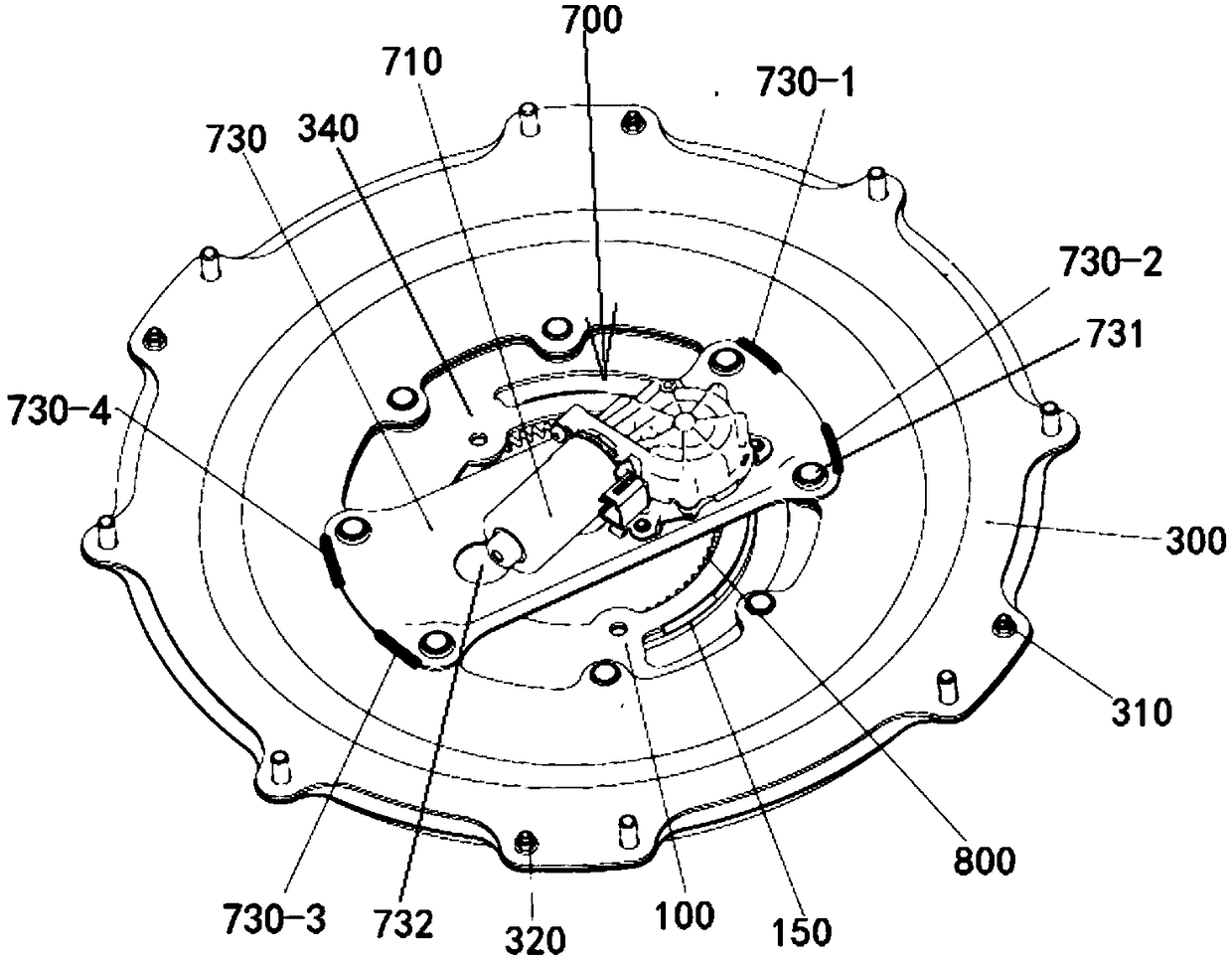

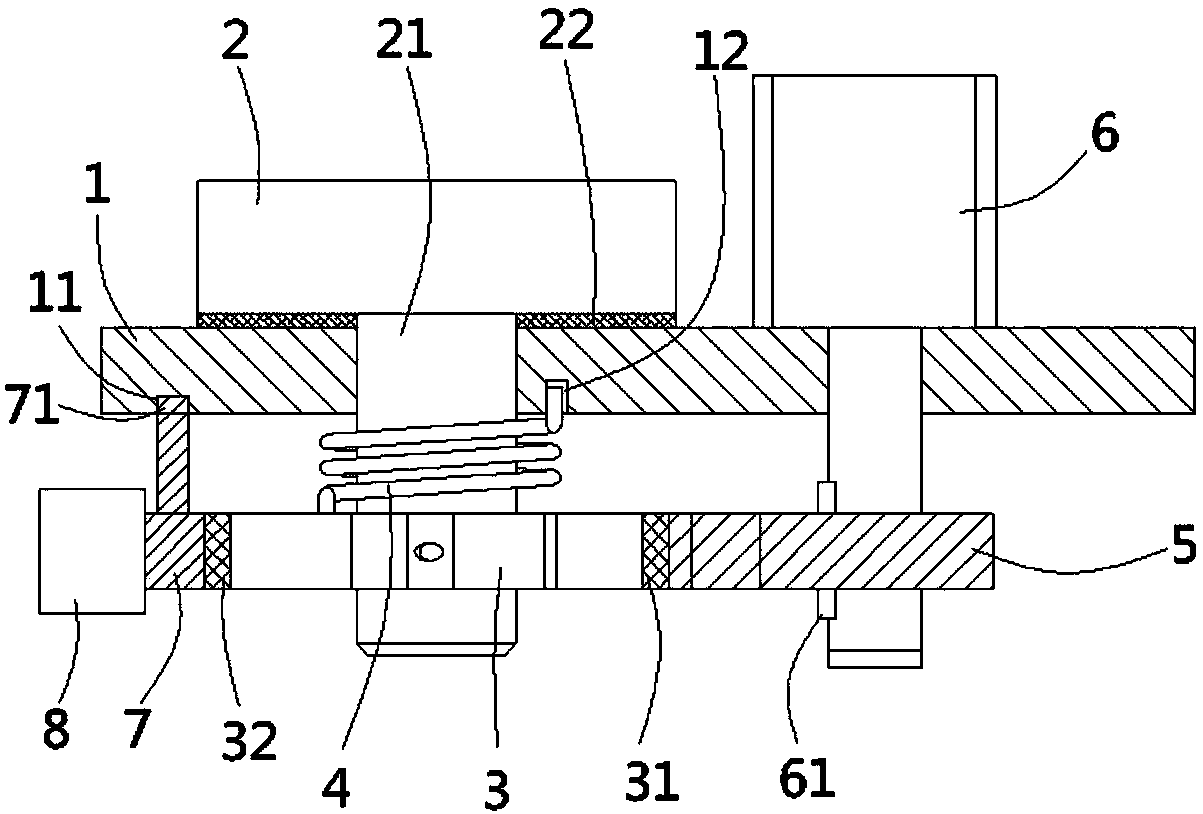

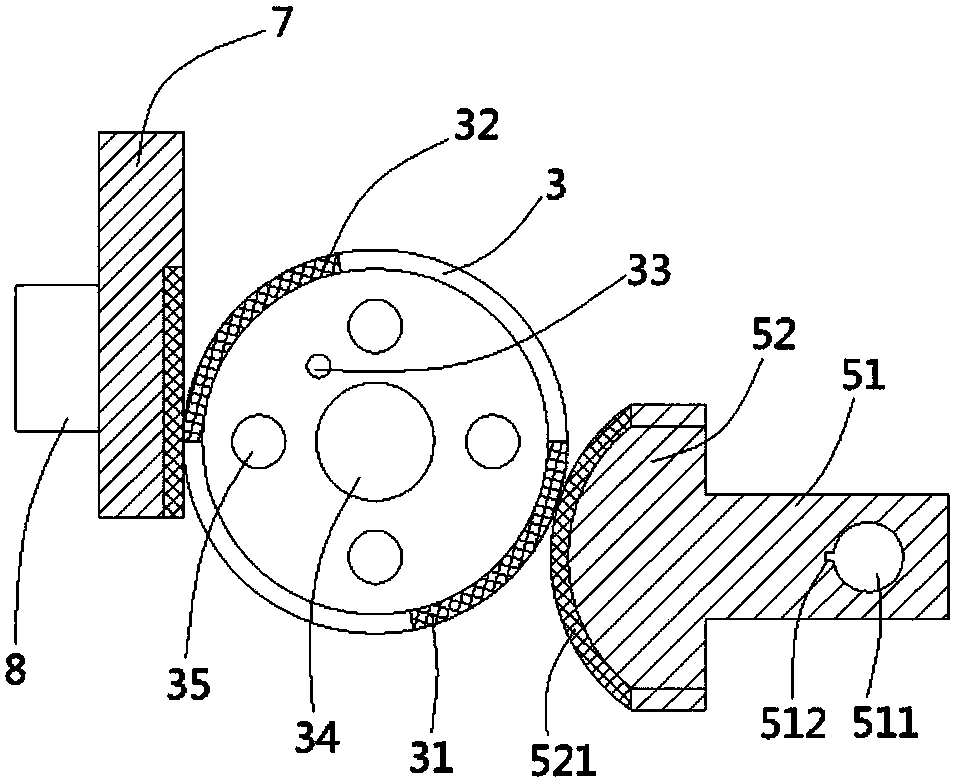

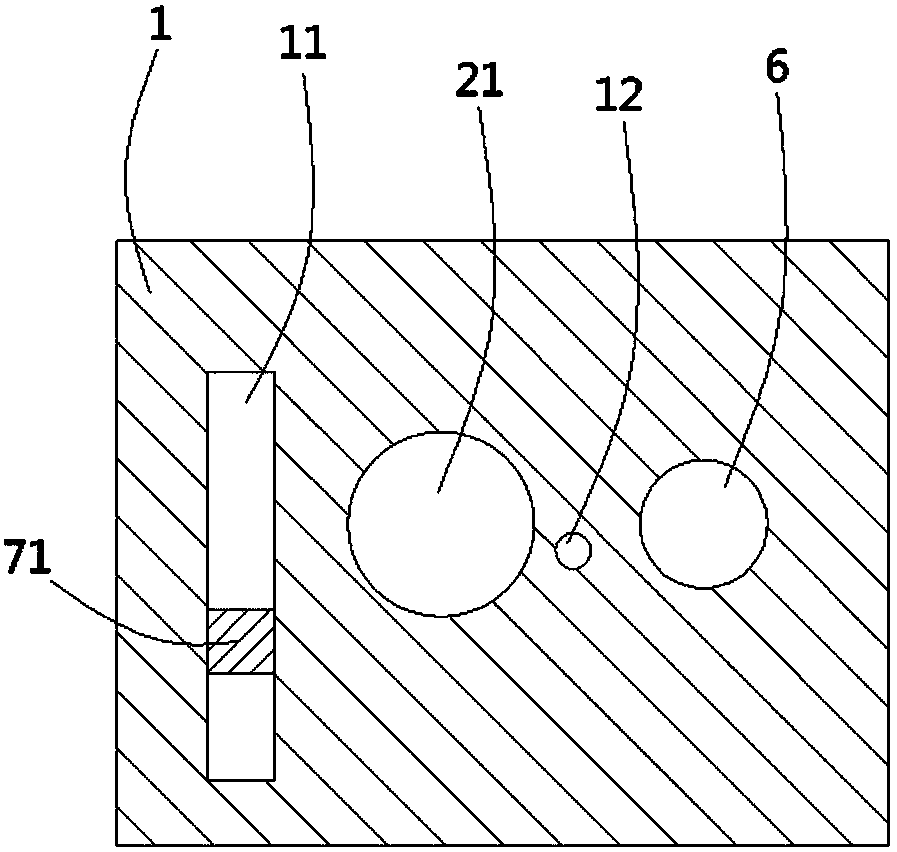

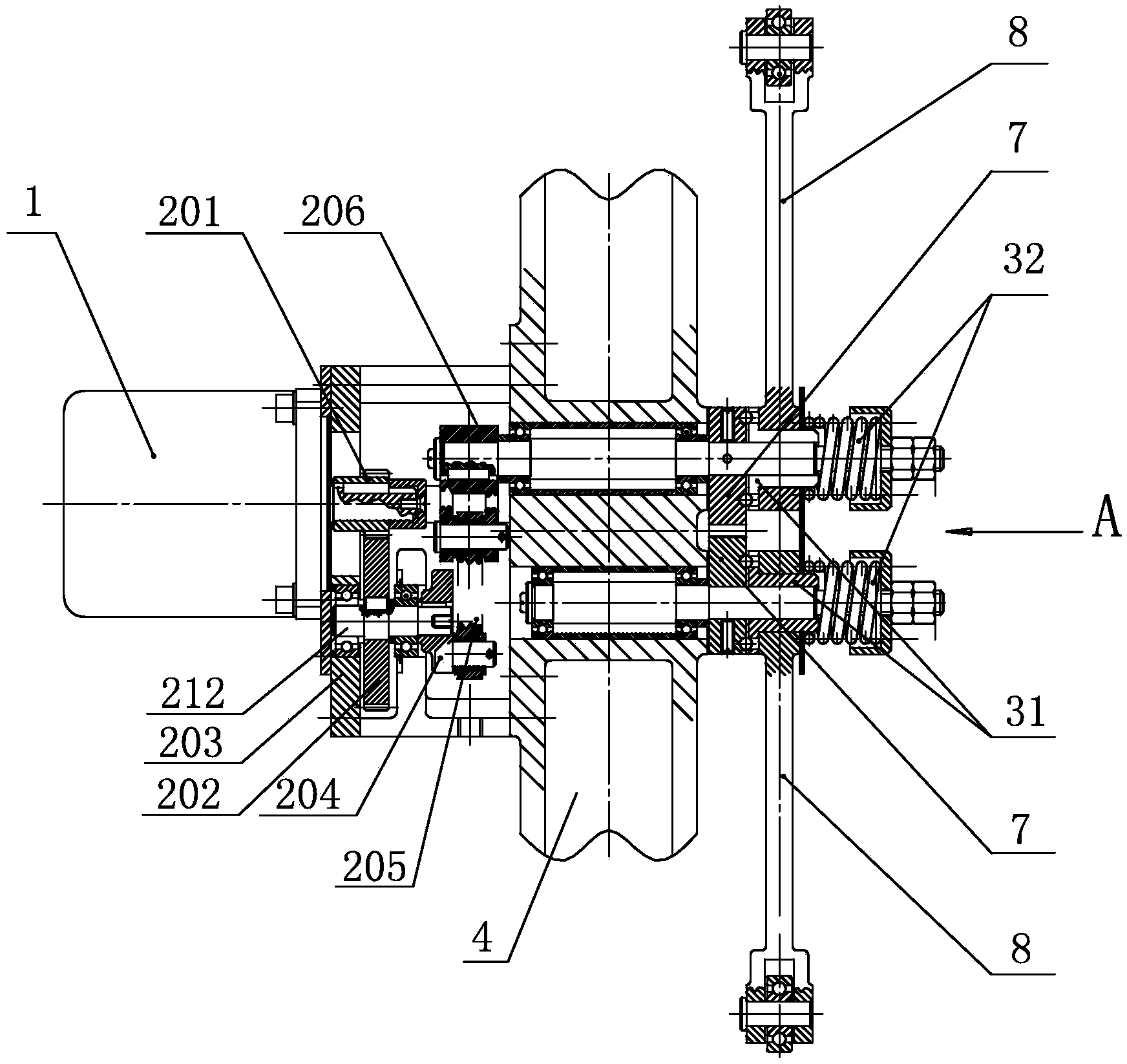

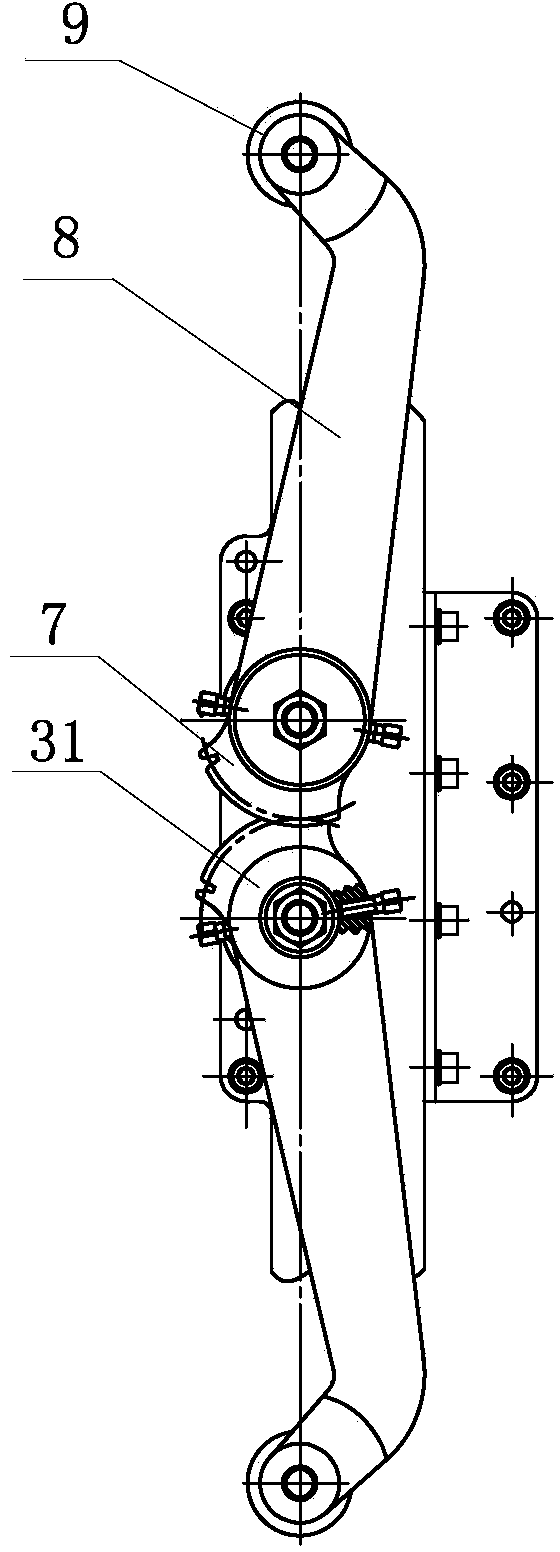

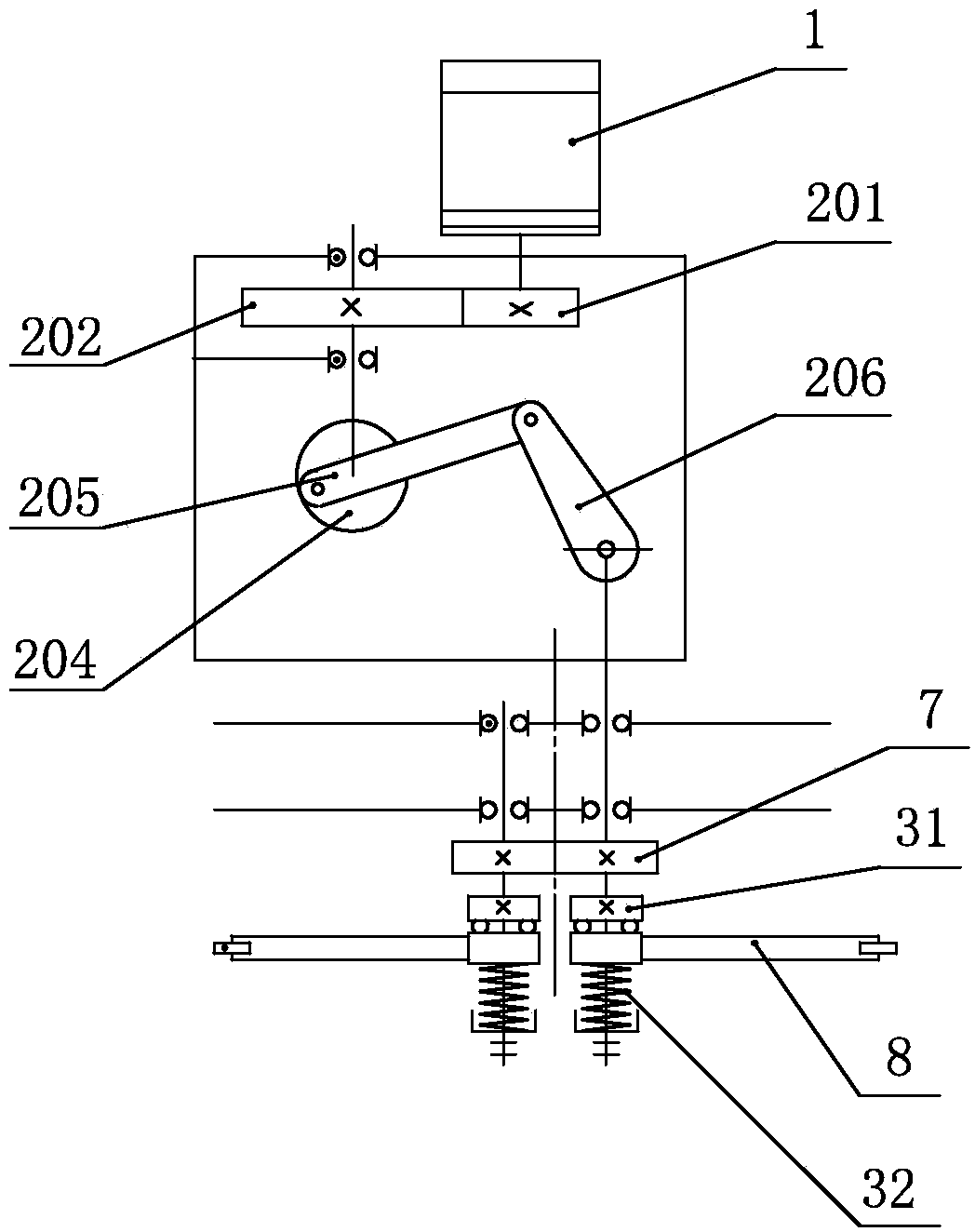

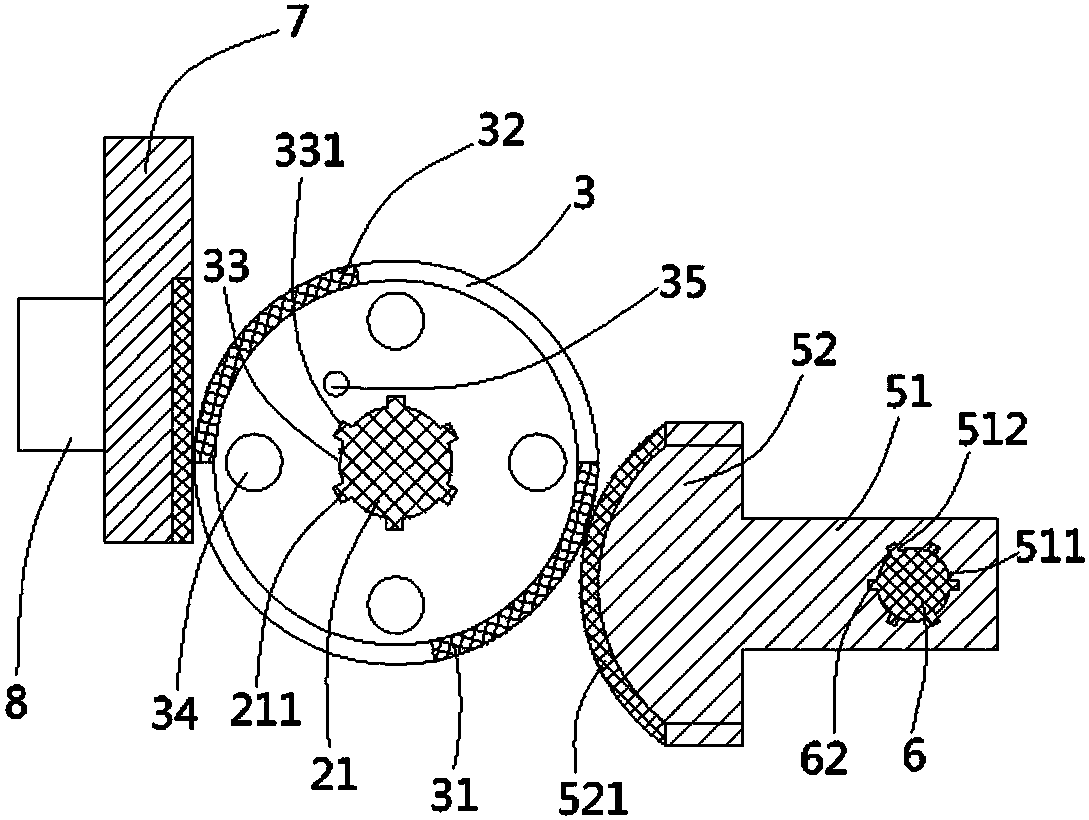

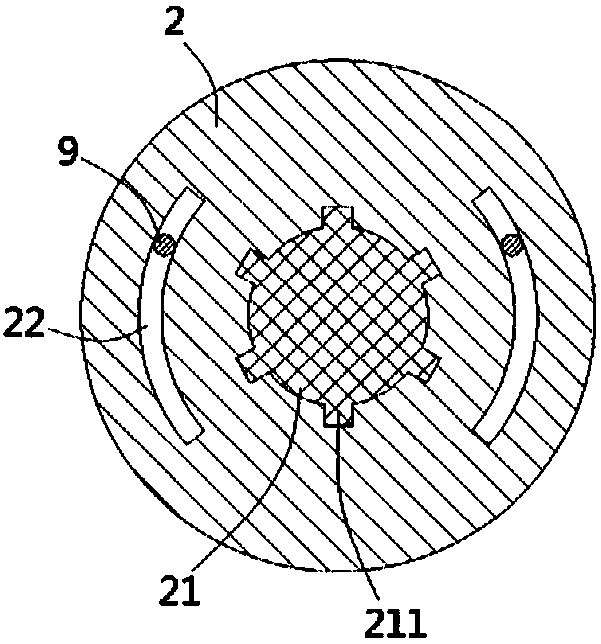

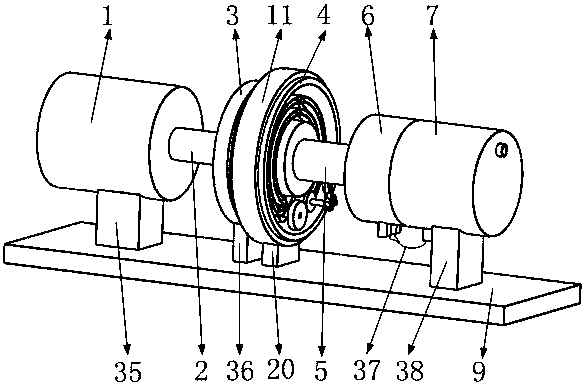

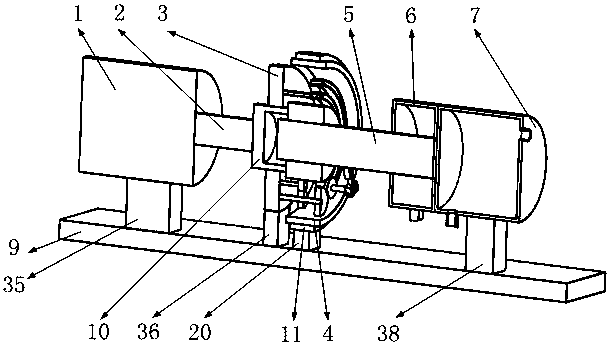

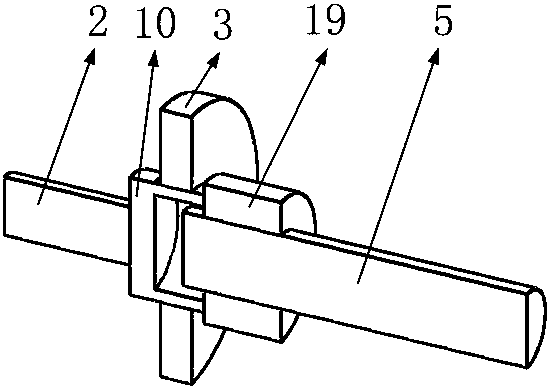

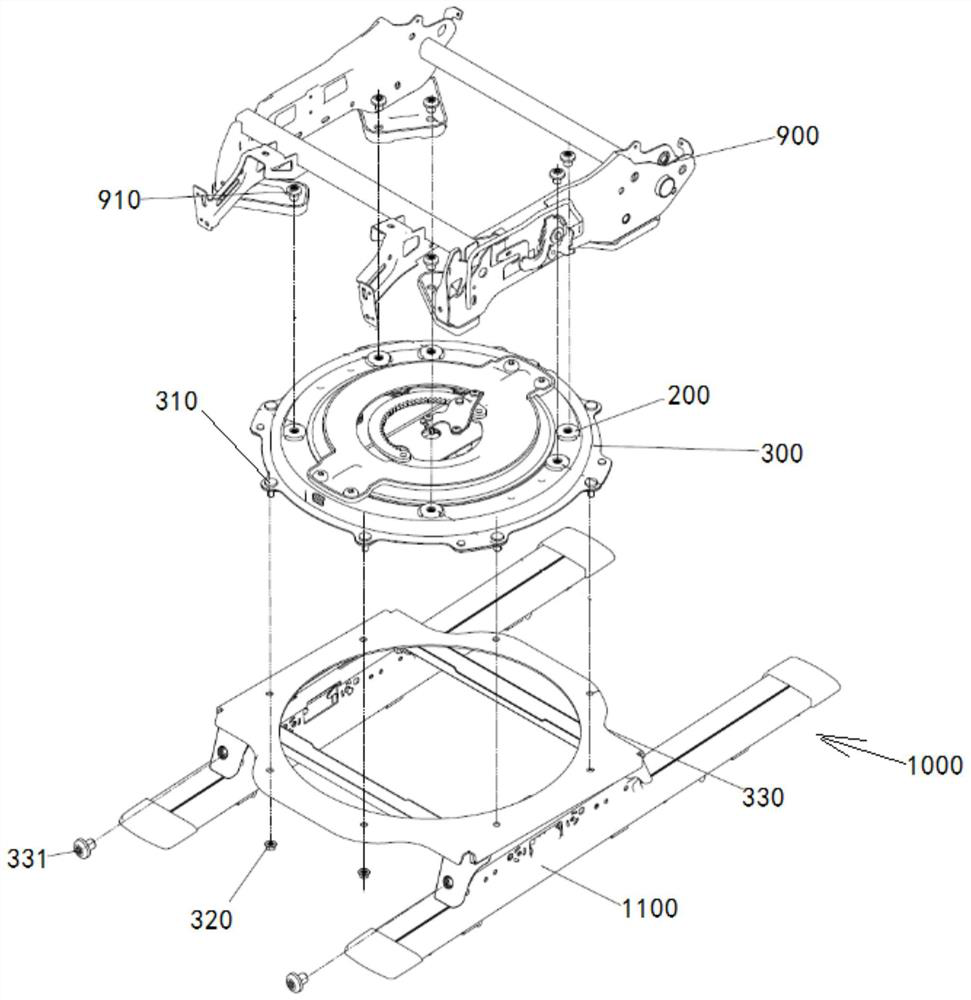

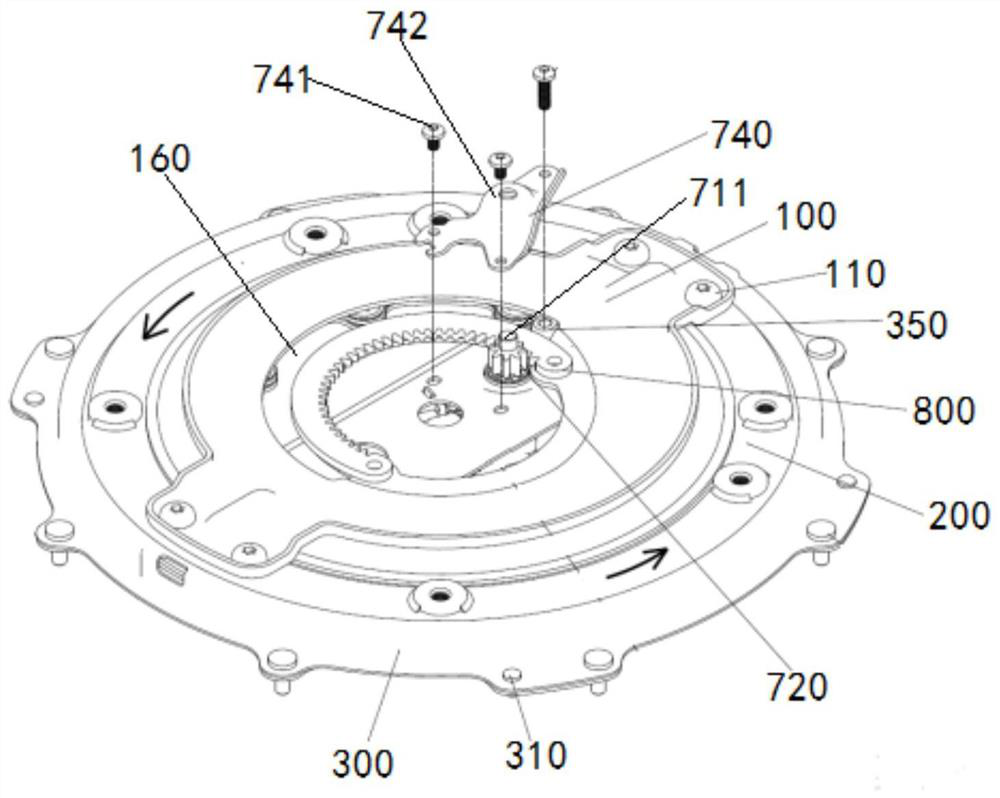

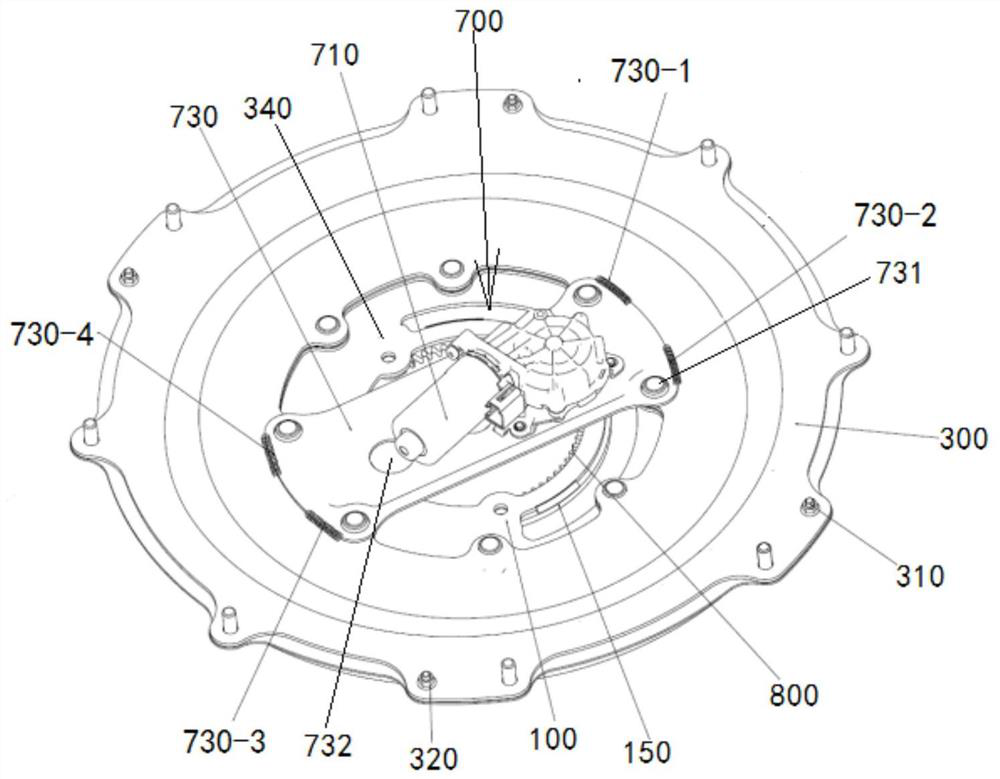

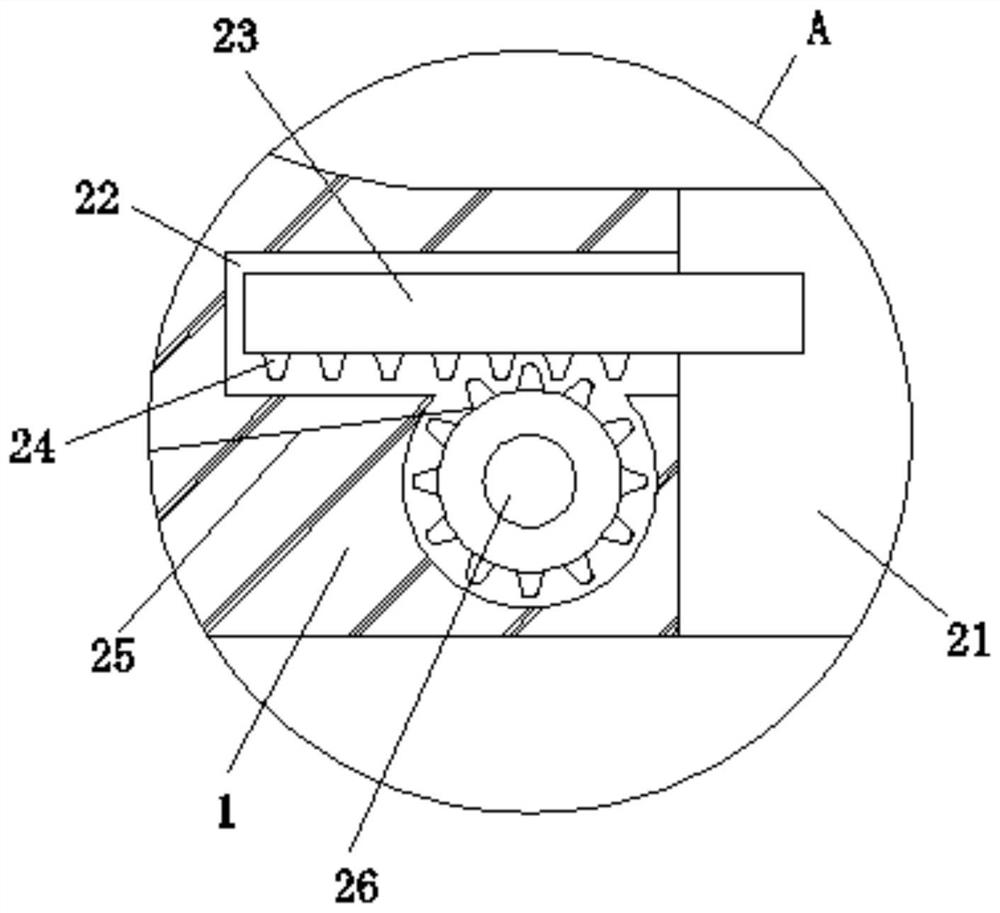

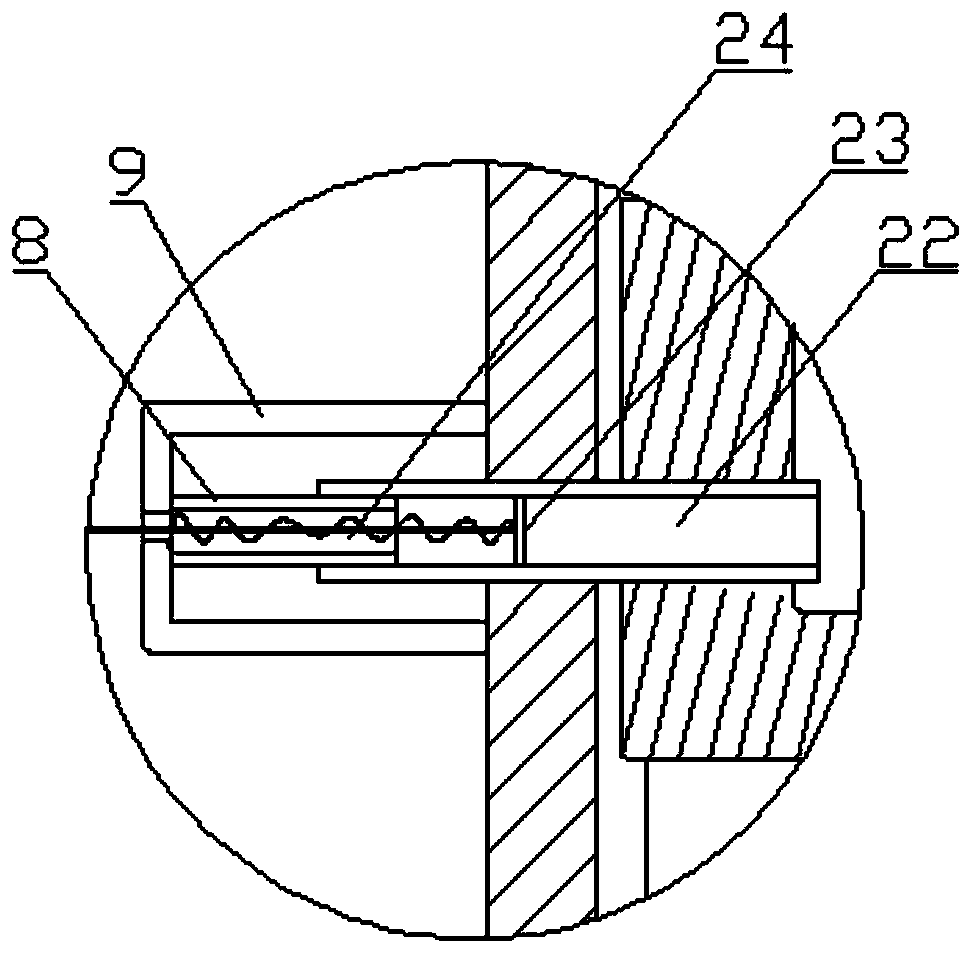

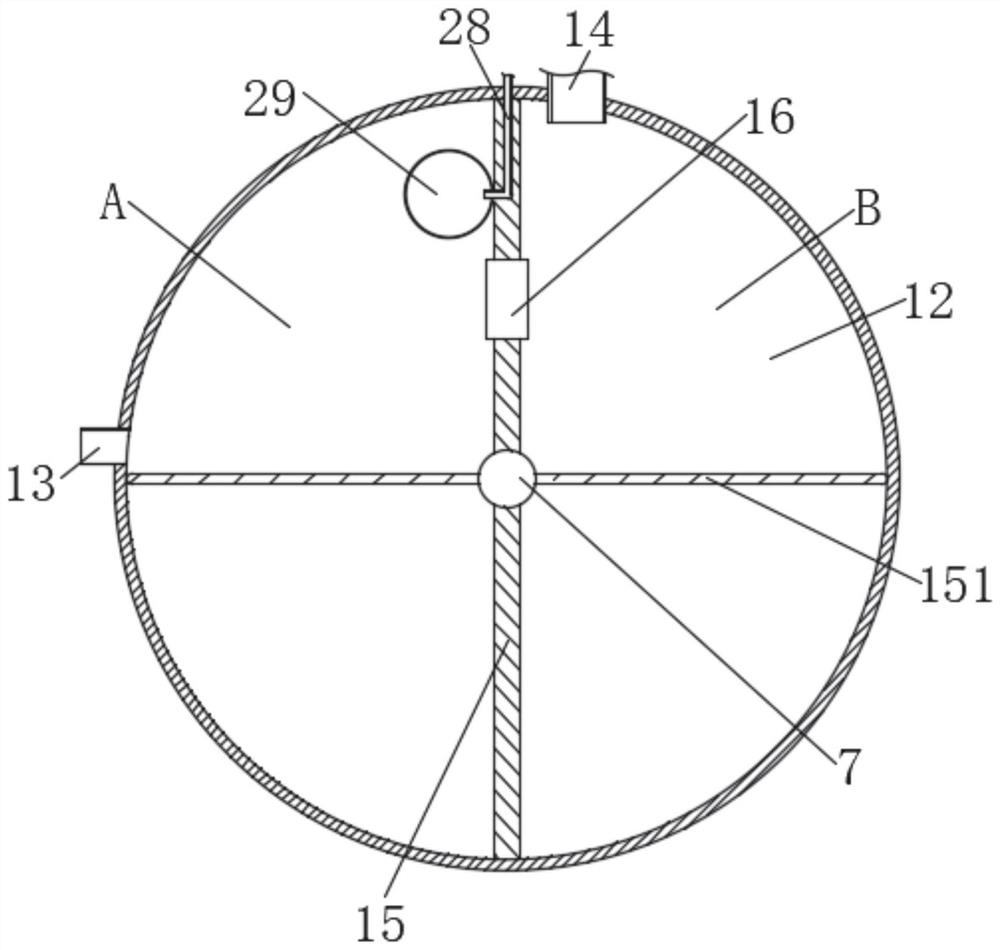

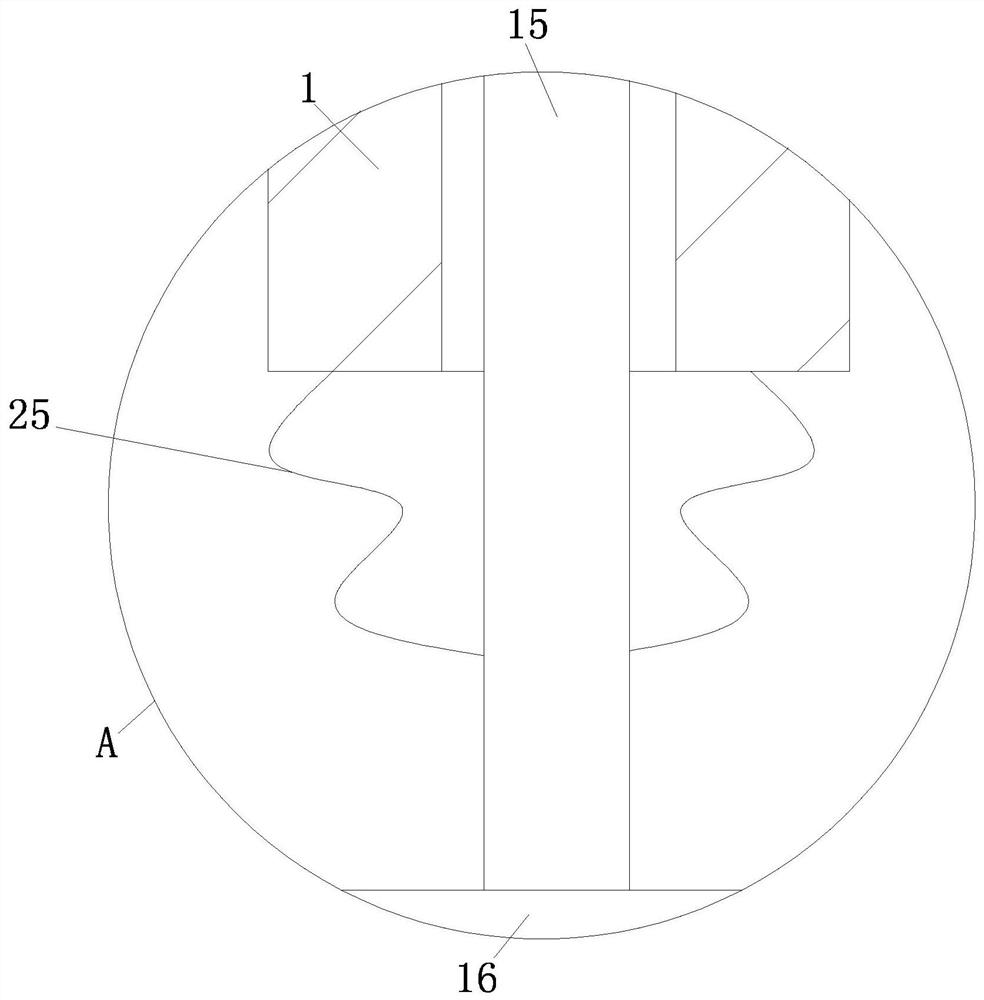

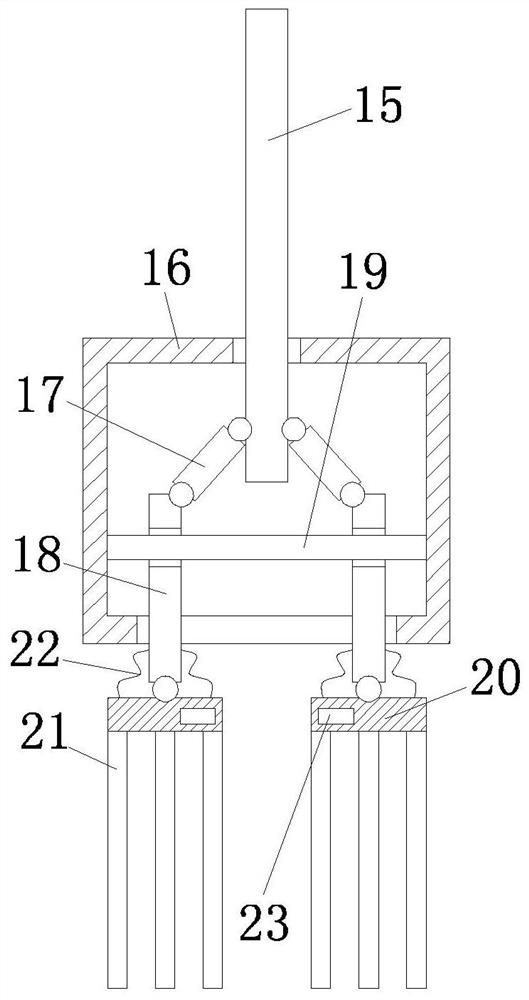

The invention discloses an electric rotation mechanism for a seat. The mechanism comprises a rotation support, a rotation disc, a fixing disc, a press disc, an upper ball assembly, a lower ball assembly, a driving motor assembly and a semi-circular rack. The driving motor assembly is installed on the fixing disc and comprises a driving gear; the semi-circular rack is installed on the rotation support, the circle center of the semi-circular rack coincides with the rotation center of the rotation support, and the semi-circular rack is meshed with the driving gear; the driving gear in the drivingmotor assembly drives the rotation support to rotate back and forth within 0-180 degrees through the semi-circular rack. According to the electric rotation mechanism for the seat, just through single-grade transmission of the driving motor assembly, the driving gear and the semi-circular rack, the seat can rotate back and forth within 0-180 degrees, and the mechanism has the advantage of small occupation space. Meanwhile, the situation is avoided that a wire harness of the seat rotates without limit and is twisted off.

Owner:YANFENG ADIENT SEATING CO LTD

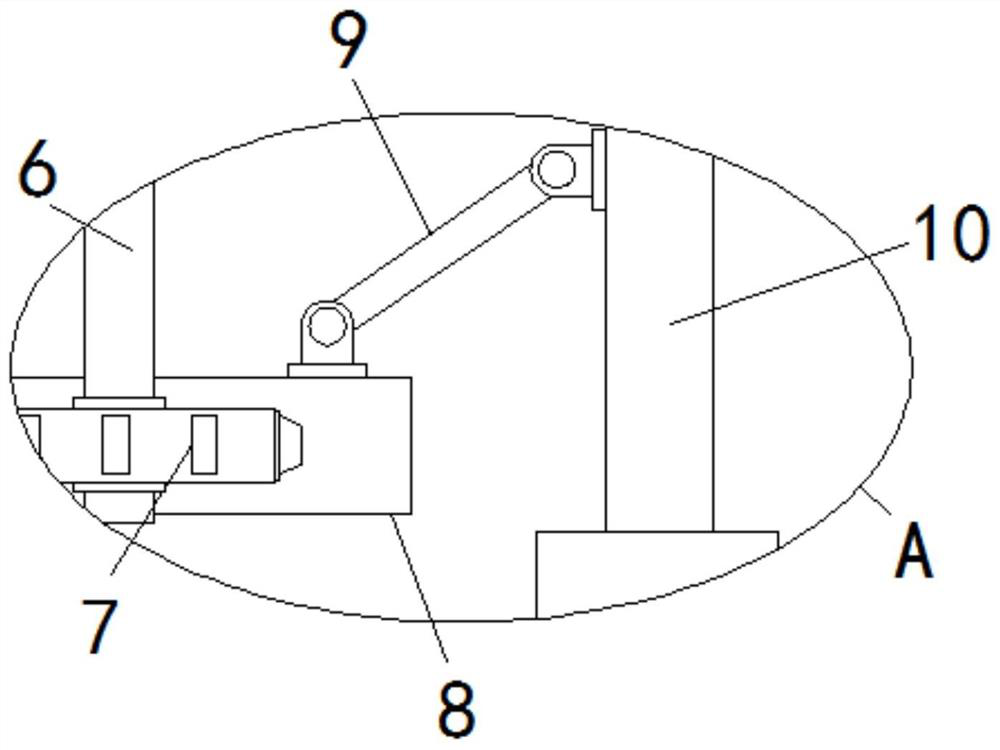

Nozzle reciprocating device on cleaning robot of freight car

InactiveCN107745385AThe reciprocating device can realize the reciprocating flushing of the nozzle without switching the rotation direction of the servo motorLow costCleaning using liquidsManipulatorEngineeringMechanical engineering

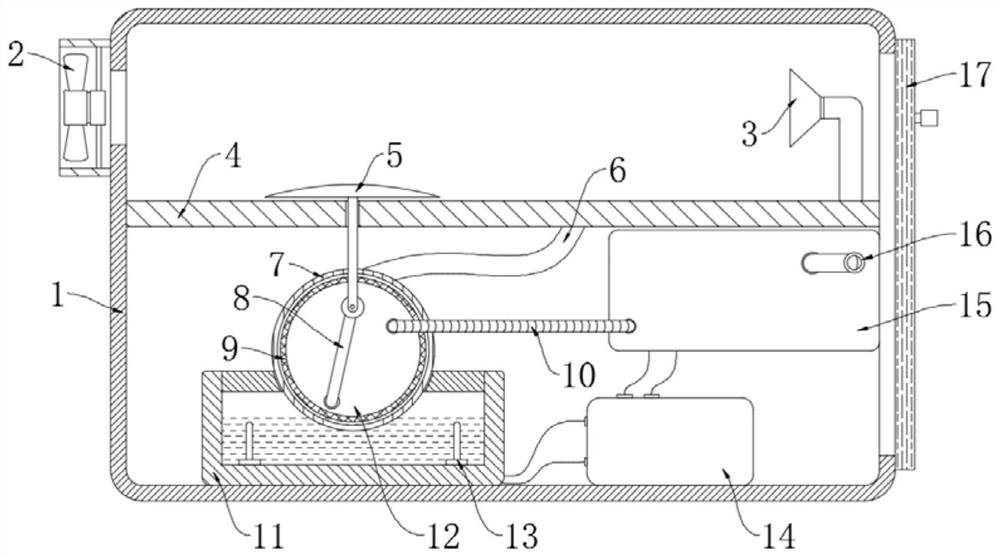

The invention discloses a nozzle reciprocating device on a cleaning robot of a freight car. The device comprises a mounting platform where a rotating seat is inserted; a central shaft that goes through a lower end surface of the mounting platform is formed on the rotating seat; a lower end of the central shaft is fixed by a rotating disk in a sleeved mode; the central shaft is sleeved by a reset torsional spring; a first fixing hole is formed in the rotating disk; a second fixing hole is formed in a lower end surface of the mounting platform; two ends of the reset torsion spring are fixed on inner walls of the first fixing hole and the second fixing hole; a first arc rack and a second arc rack which are projecting are formed on an outer side wall of the rotating disk; the first arc rack ismeshed and connected with a sector gear which is inserted and fixed on a rotating shaft of a motor; the second arc rack is meshed and connected with a second rack which is fixedly connected with a moving seat. The invention can realize the reciprocating flushing of the nozzle without the rotation direction switch of the servo motor, saves the cost and has high working efficiency.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

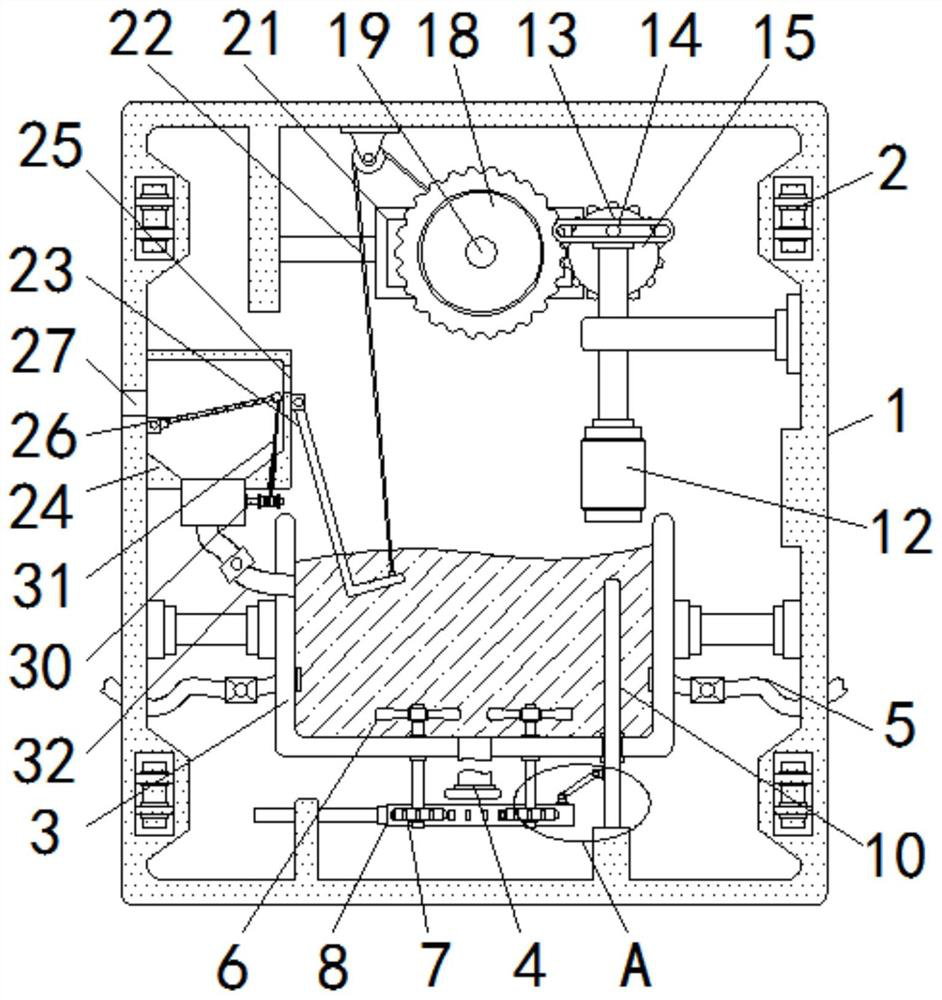

Dispensing subsequent glue removing device for electronic component

ActiveCN110936276AHigh glue removal efficiencyReasonable structureGrinding drivesGrinding machinesPillow block bearingGear wheel

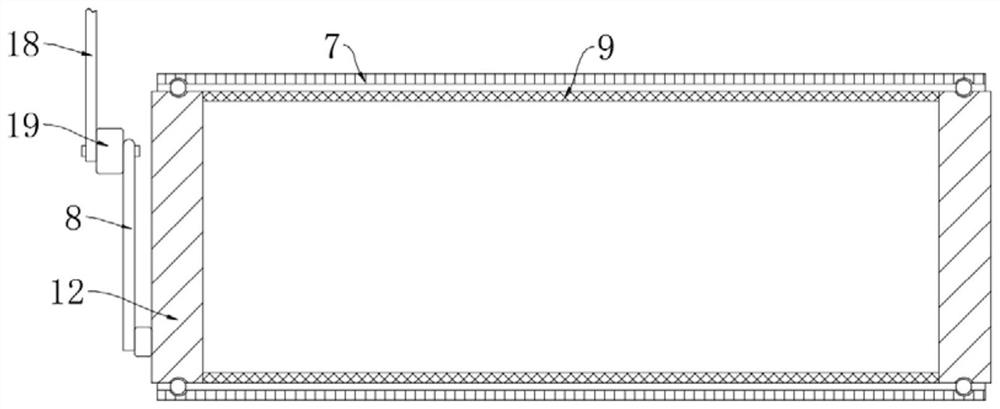

The invention relates to a machining device for electronic components and discloses a dispensing subsequent glue removing device for an electronic component, which comprises a fixed bottom plate. Support frames are mounted on two sides of the upper end of the fixed bottom plate; a fixed rack is installed at the top of the support frame; a guide column is arranged between the upper ends of the support frames; a sliding block is slidably connected to the middle of the guide column; a bearing seat is arranged in the sliding block; a rotating shaft is mounted in the bearing seat; a movable gear meshed with the fixed rack is mounted at the upper end of the rotating shaft; a glue removing grinding wheel is arranged at the bottom end of the rotating shaft; an air guiding box is installed in the middle of the left end of the support frame on the right side; a piston plate is installed in the air guiding box; an air guiding rod is installed on the left side of the piston plate; a sliding blockis connected to the left side of the air guiding rod; a lifting plate is installed between the inner sides of the support frames; and positioning clamping mechanisms are installed on the two sides ofthe upper end of the lifting plate. Reciprocating rotation of the glue removing grinding wheel is achieved, the glue removing efficiency of the electronic components is greatly improved, meanwhile, glue residues obtained after glue removing can be better blown away, and the glue removing efficiency is further improved.

Owner:肇庆益华电子科技有限公司

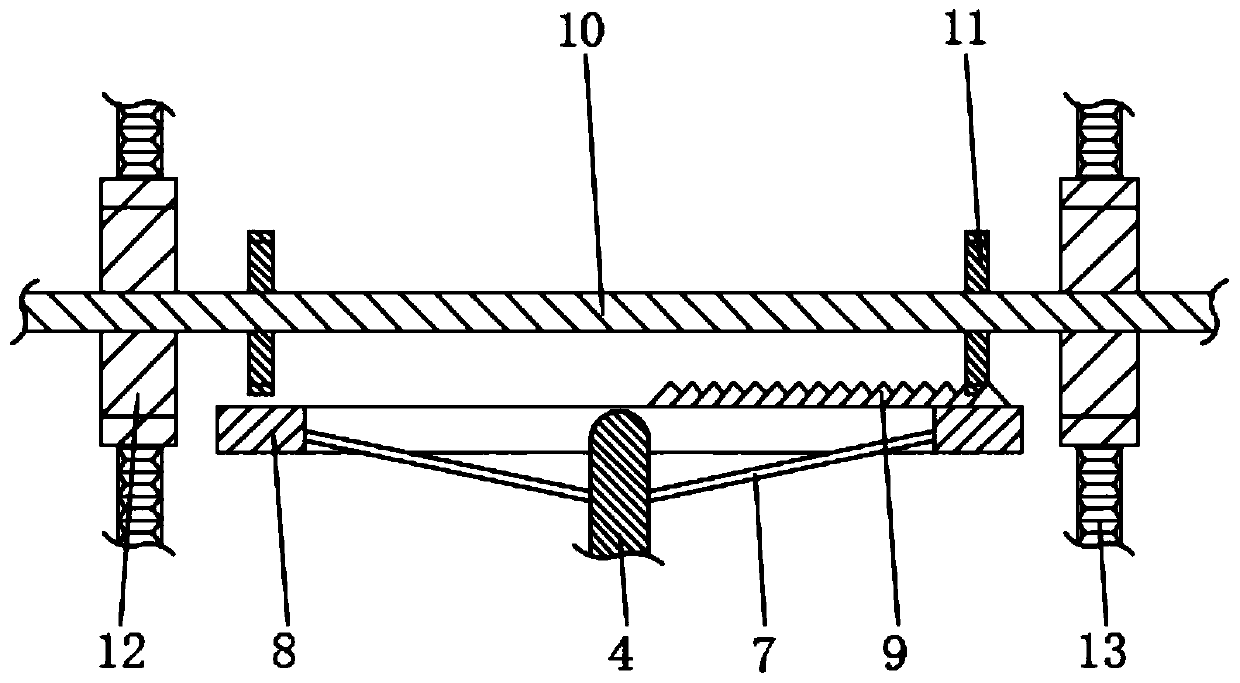

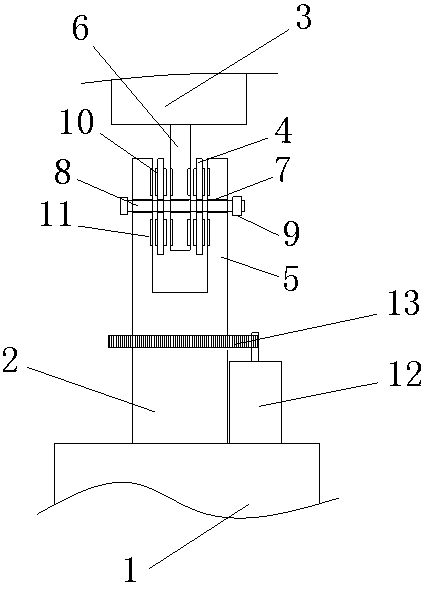

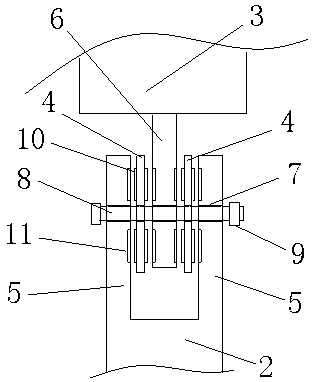

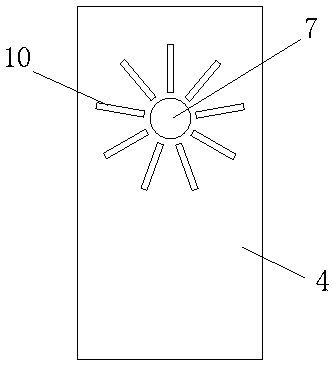

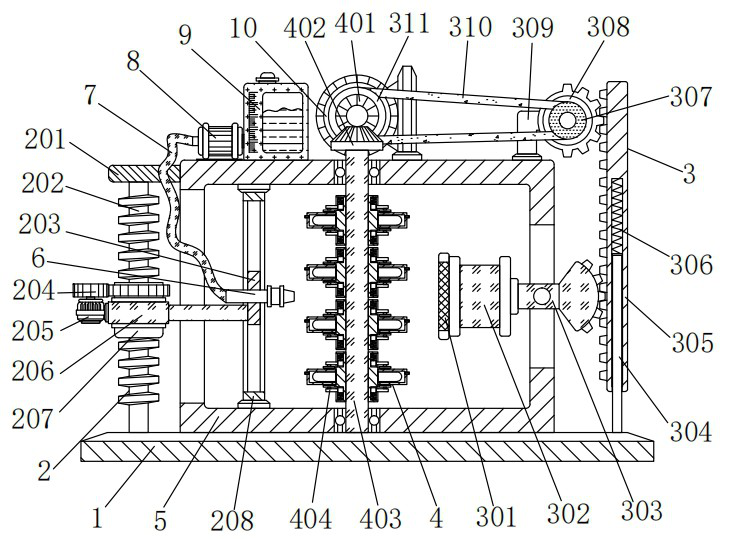

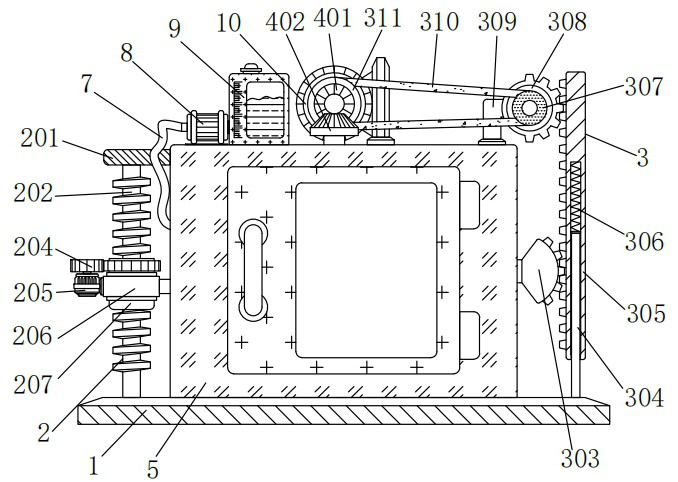

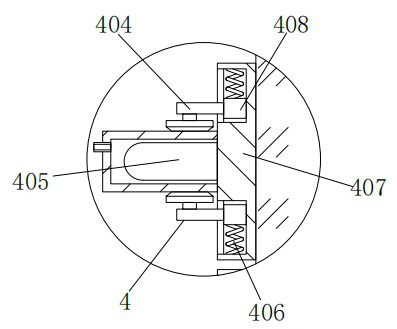

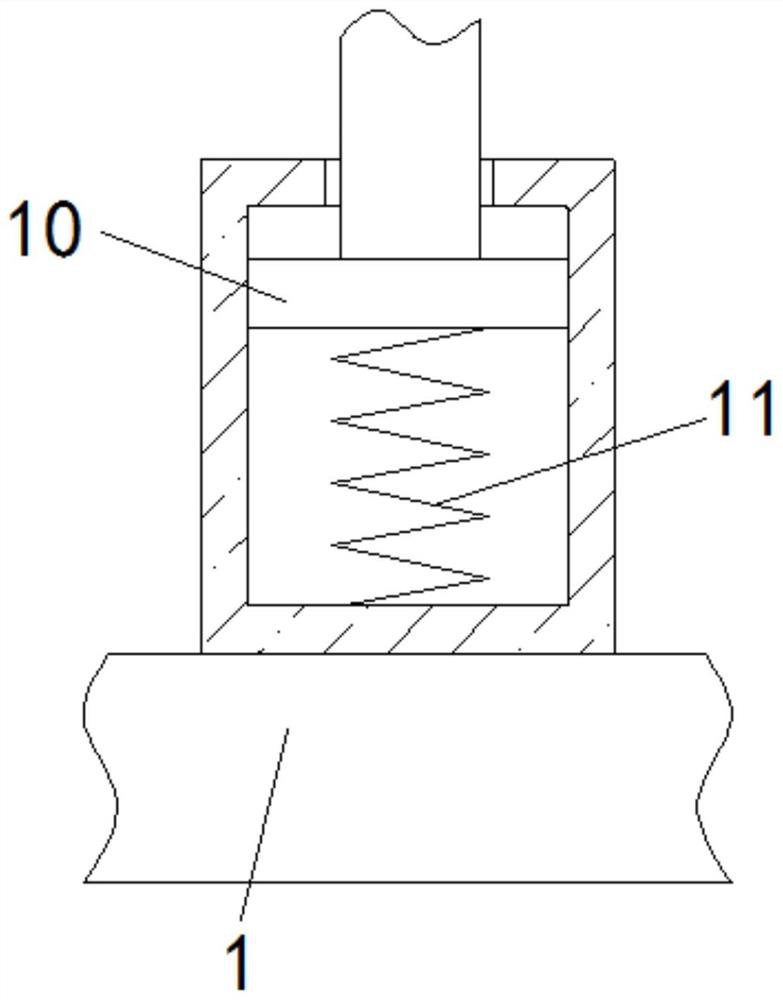

Mold bar push-out mechanism in capsule production system

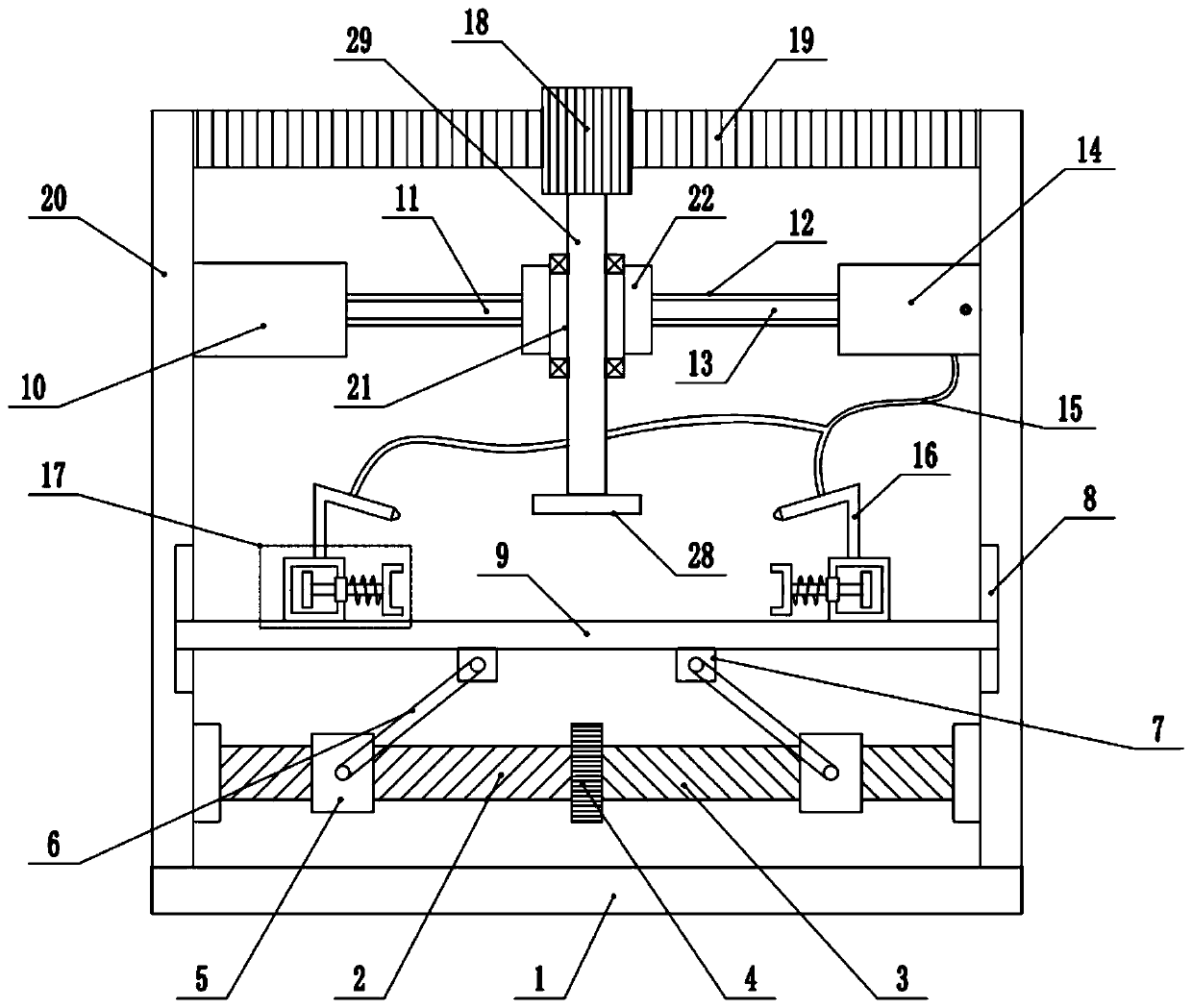

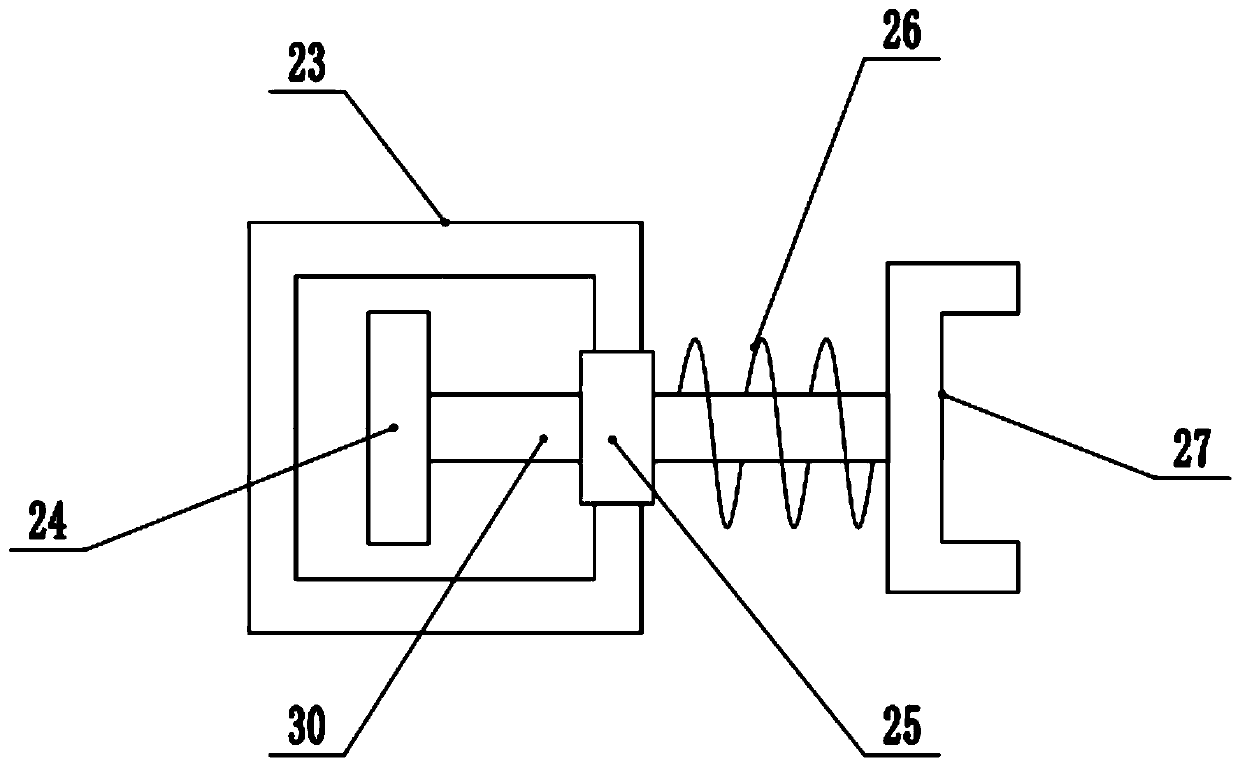

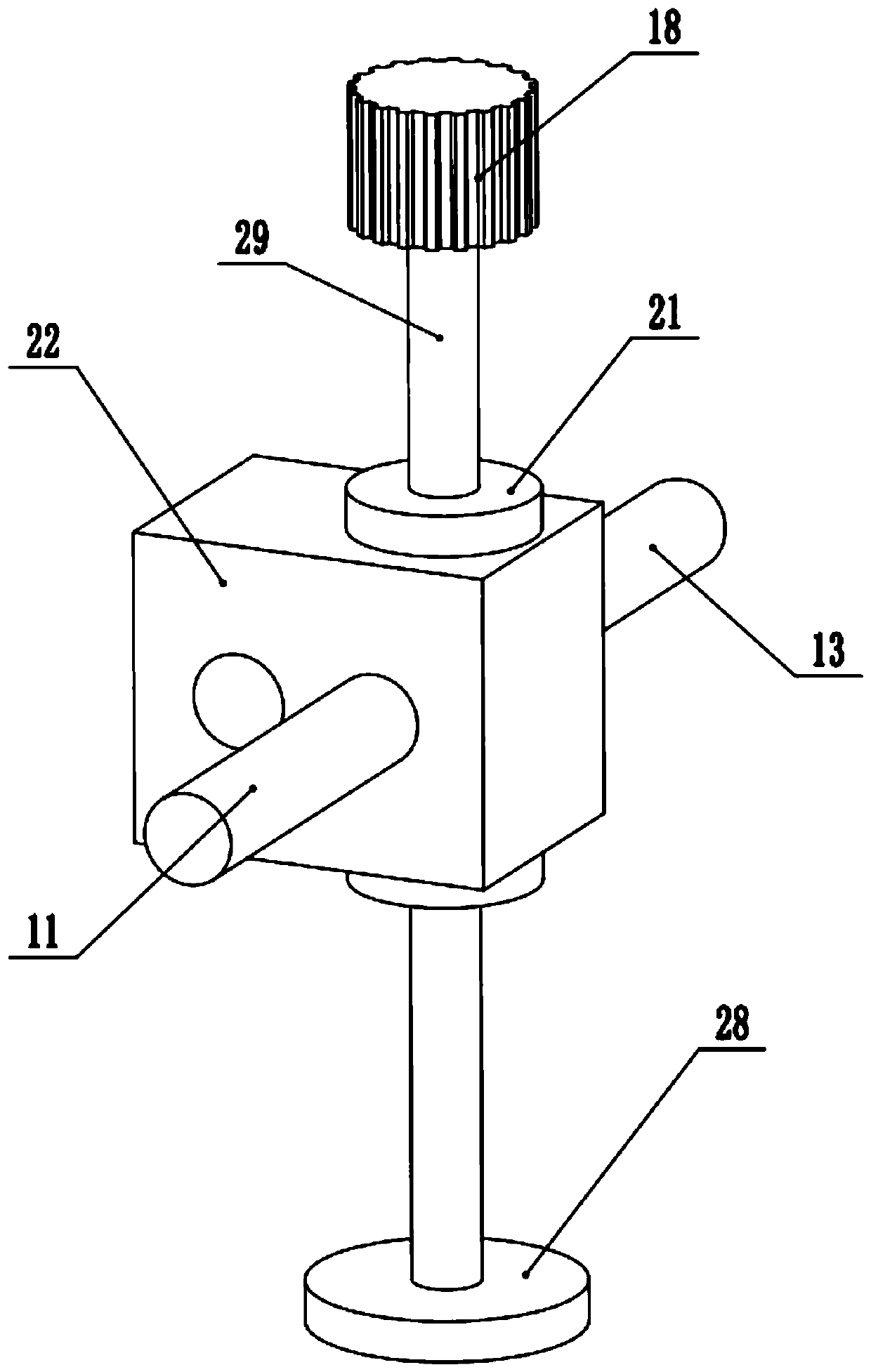

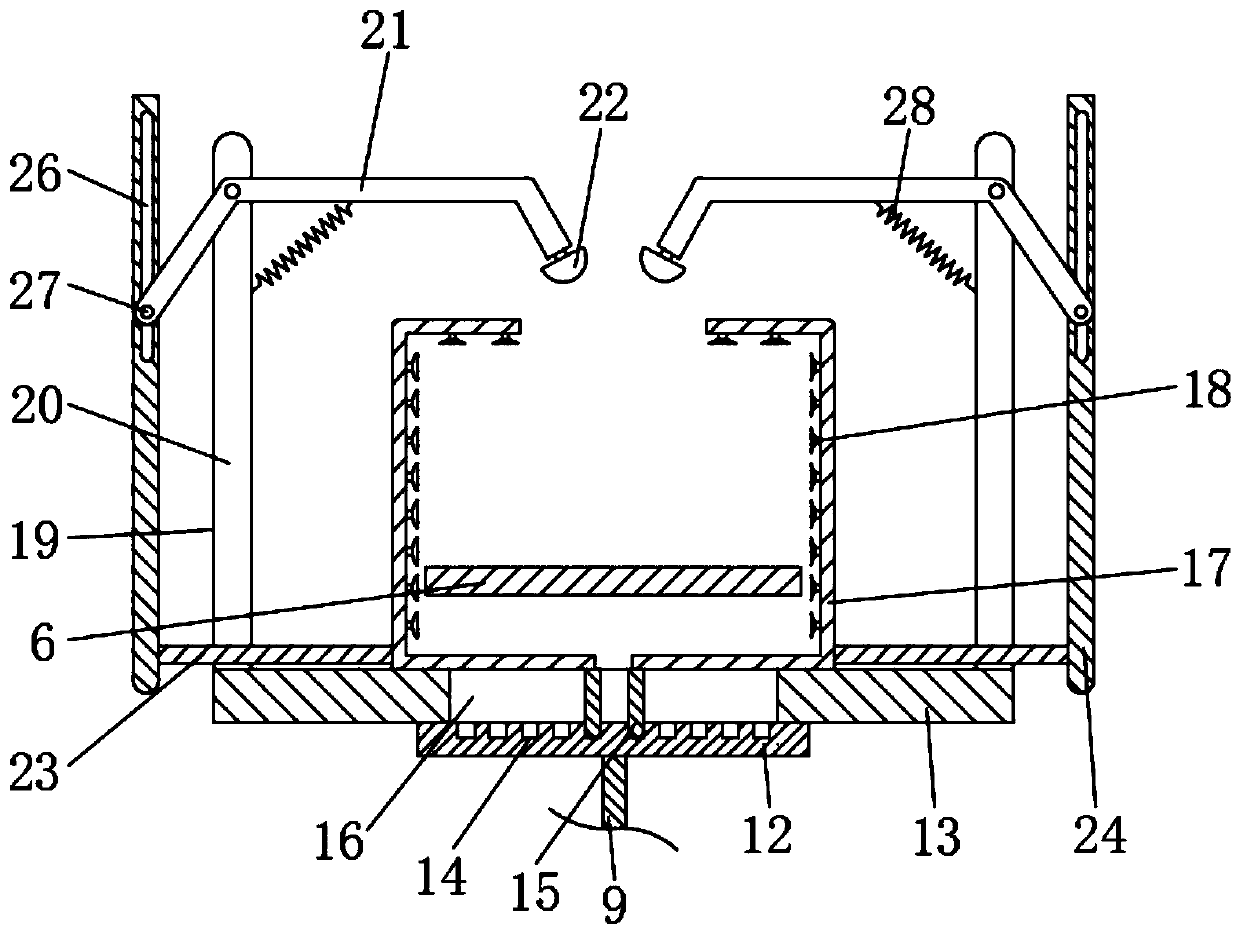

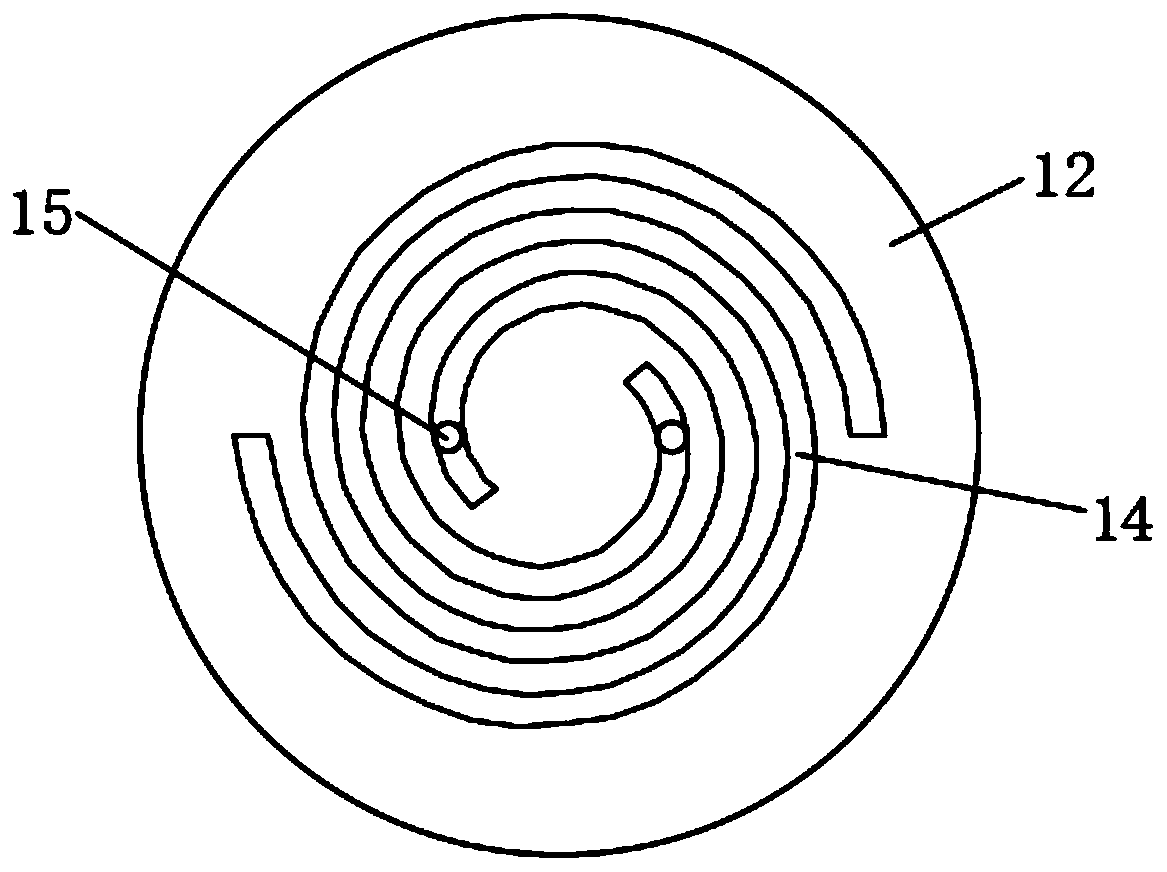

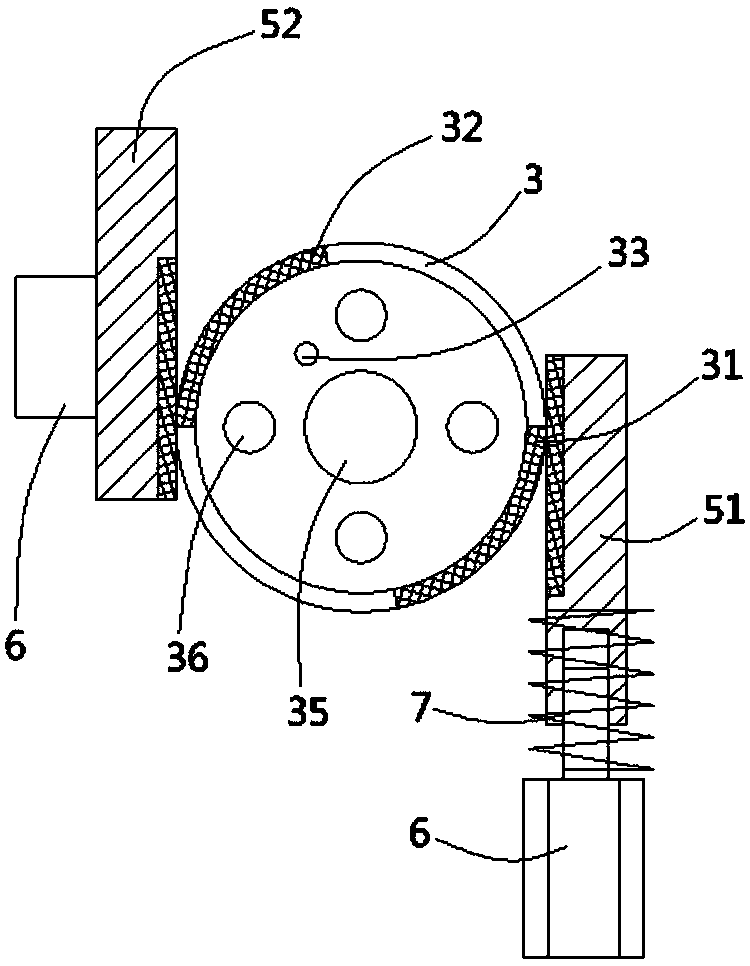

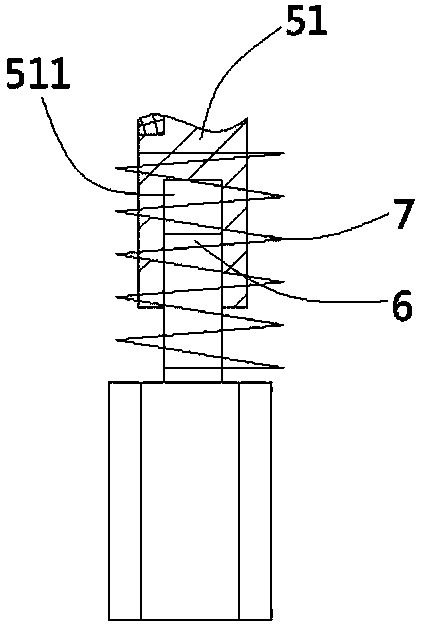

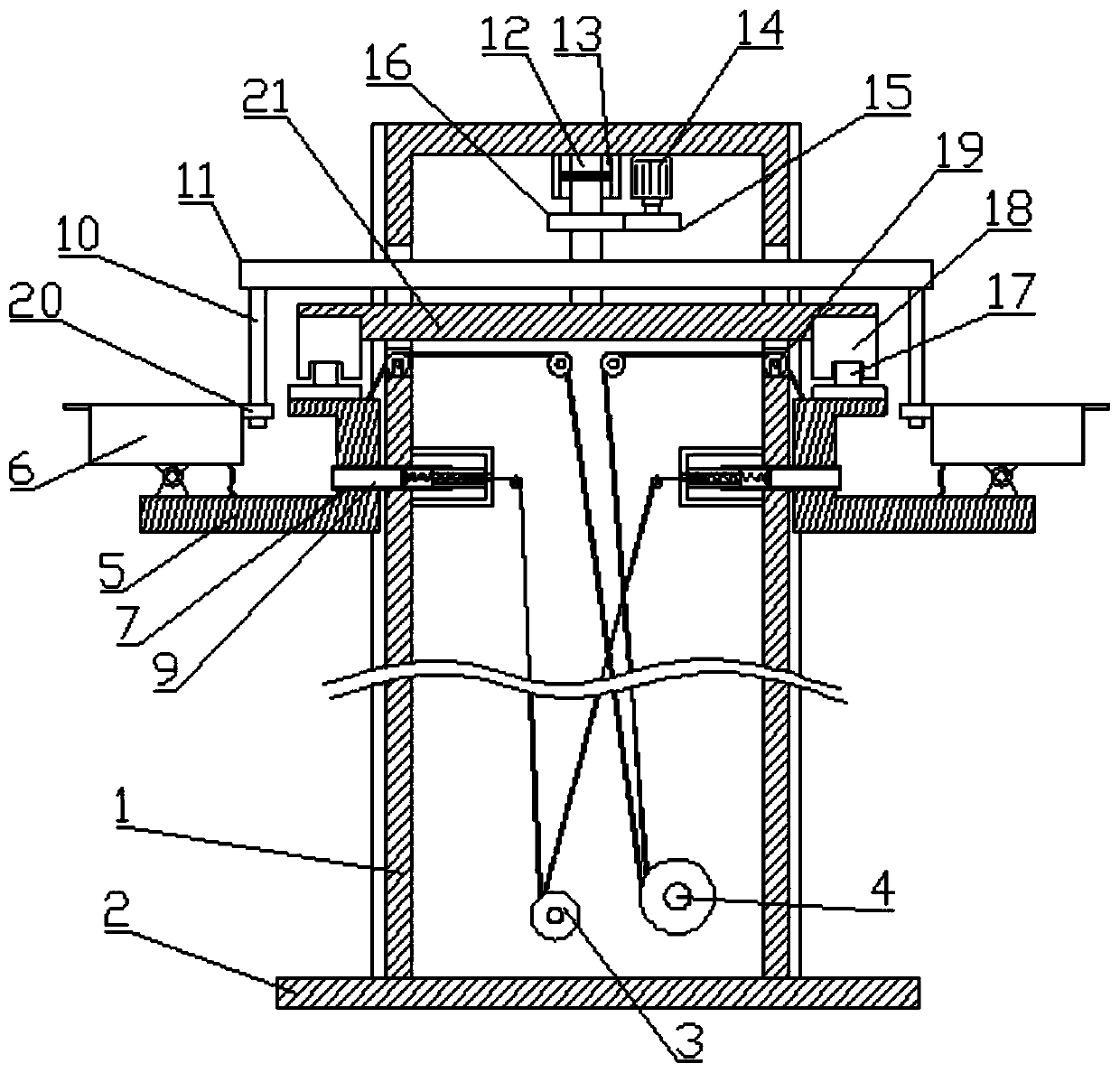

InactiveCN103711863AAvoid damageRealize reciprocating rotationGearingMechanical energy handlingProduction lineSteel ball

The invention discloses a mold bar push-out mechanism in a capsule production system, and belongs to the technical field of capsule production lines. The mechanism is installed on a push-out beam of a glue dipping machine and comprises a push-out motor, a transmission device, a driving push-out shaft, a driven push-out shaft, two push-out arms and overload protecting devices, wherein both the driving push-out shaft and the driven push-out shaft are installed on the push-out beam, one end of the driving push-out shaft and one end of the driven push-out shaft stretch out of the push-out beam, half teeth meshed to one anther are respectively installed at the end of the driving push-out shaft stretching out of the push-out beam and the end of the driven push-out shaft stretching out of the push-out beam, the two push-out arms are installed on the driving push-out shaft and the driven push-out shaft respectively, the overload protecting devices are installed on the end portion, where one push-out arm is installed, of the driving push-out shaft and the end portion, where the other push-out arm is installed, of the driven push-out shaft, and the other end of the driving push-out shaft stretches out of the push-out beam and is connected with the push-out motor through the transmission device. Through the mechanism, it can be guaranteed that the system is controlled to stop when faults happen. When the faults happen, steel balls roll out of overload disks so that the overload disks can drive the push-out arms to have displacement, real-time detection can be performed through a proximity switch, and therefore the mechanism is prevented from being damaged when the faults happen.

Owner:DANDONG JINWAN GRP

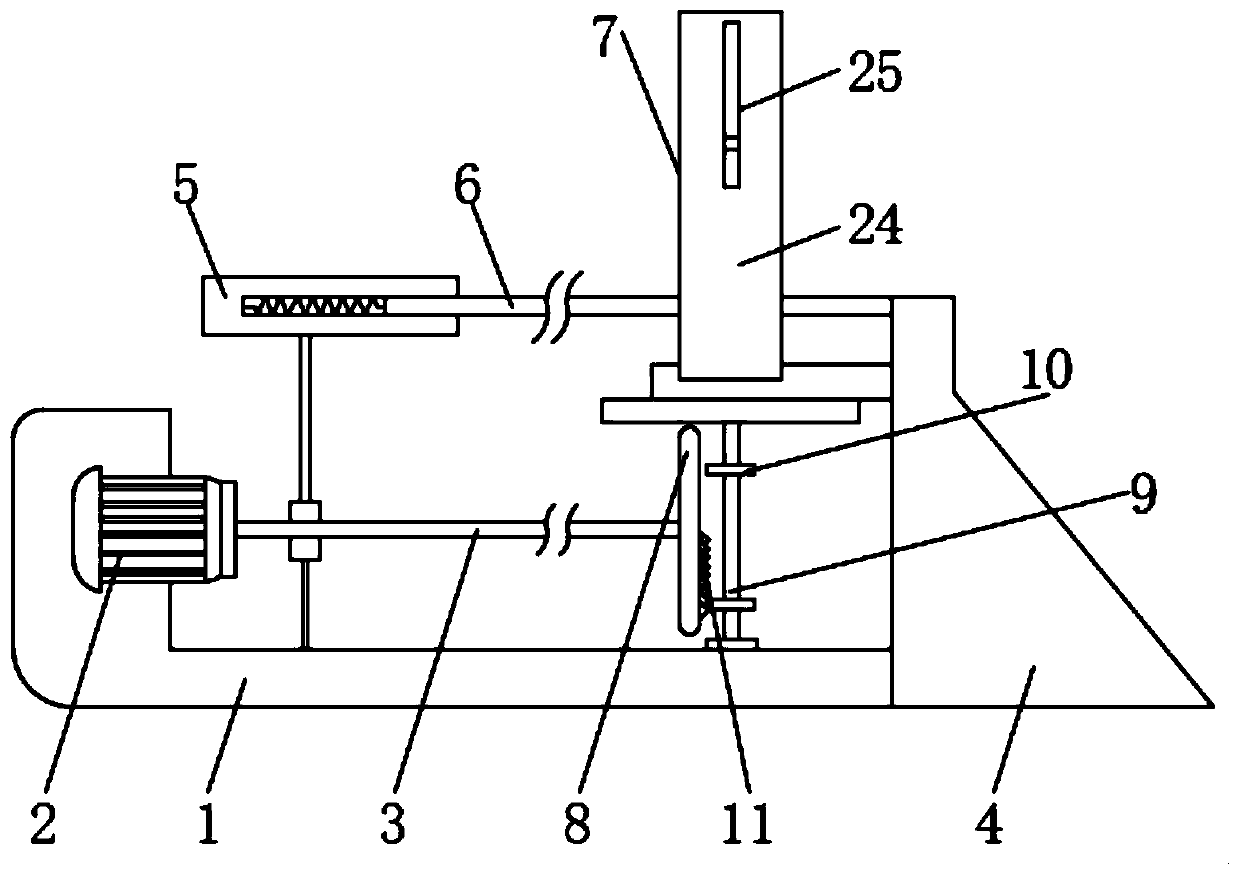

Grinding device for chemical powdery raw materials

InactiveCN111097575AImprove grinding effectReasonable structureGrain treatmentsReciprocating motionGear wheel

The invention relates to the technical field of chemistry engineering, and discloses a grinding device for chemical powdery raw materials. The grinding device comprises a fixed baseboard, wherein a grinding frame is installed in the middle of the upper end of the fixed baseboard, supporting frames are installed at the two sides of the upper end of the fixed baseboard, a fixed gear is installed between the top ends of the supporting frames, a grinding gear is meshed with the front end of the fixed rack, a grinding shaft is installed in the middle of the lower end of the grinding gear, a grinding disc is connected to the bottom end of the grinding shaft, and a plurality of grinding wheels are arranged in the middle of the bottom end of the grinding disc. A bearing cylinder is installed in the middle of the grinding shaft, a movement block is installed at the outer side of the bearing cylinder, a threaded part of a driving shaft is connected to the middle of the rear end of the movement block, the right end of the driving shaft penetrates through the supporting frames to be connected with a driving gear, a lifting rack is meshed with the rear end of the driving gear, and the bottom end of the lifting rack is provided with a reciprocating mechanism. By means of the grinding device, through the mutual cooperation of the reciprocating mechanism, the lifting rack and the driving gear,reciprocating rotation of the driving shaft is achieved, through the mutual cooperation of the movement block, the grinding shaft and the grinding gear, the grinding disc carries out reciprocating rotation while reciprocating left and right, and the grinding effect on the chemical powdery raw materials is enhanced.

Owner:王淑英

Spray pipe adjusting mechanism on freight van compartment cleaning robot

InactiveCN107804289ARealize reciprocating flushingLow costCleaning apparatus for railwaysCleaning using liquidsEngineeringTorsion spring

The invention discloses a spray pipe adjusting mechanism on a freight van compartment cleaning robot. The spray pipe adjusting mechanism comprises an installing platform, wherein a rotary seat is arranged on the installing platform, a central shaft penetrating through the installing platform is formed on the rotary seat, a first external spline is formed on the outer wall of the central shaft, a turntable sleeves and is fixed to the lower end of the central shaft in an inserted way, an installing hole is formed in the center of the turntable, a first internal spline matched with the first external spline is formed on the inner wall of the installing hole, a reset torsion spring sleeves the central shaft in an inserted way, a first arc-shaped rack and a second arc-shaped rack which protrudeare formed on the outer side wall of the turntable, the first arc-shaped rack is in meshed connection with a sector gear, the sector gear is insert-connected and fixed to a rotary shaft of a motor, the second arc-shaped rack is in meshed connection with a second rack, and a movable seat is fixedly connected to the second rack. The spray pipe adjusting mechanism can achieve reciprocating spray pipe flushing without switching of the rotary direction of the servo motor and save the cost.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Swing type air compressor

InactiveCN107676259ARealize reciprocating rotationExtended service lifeRotary/oscillating piston combinations for elastic fluidsOscillating piston pumpsGas compressorTransmitted power

The invention belongs to the technical field of air compressors, and particularly relates to a swing type air compressor. The air compressor comprises a motor, a driving rotating shaft, a sun gear, planetary gears, a gear ring and a transmission shaft; the motor transmits power to the sun gear through the driving rotating shaft; a sliding block gear moves along a guide rail which is composed of anouter ring guide rail, a transition guide rail and an inner ring guide rail under the driving of the sun gear, an auxiliary large gear and the gear ring, and the movement of the sliding block gear drives the transmission shaft to move through a rotation pair; and the movement of the transmission shaft drives a rotating air pressing plate to rotate in a reciprocating mode, after air in the air compressor is compressed to the high pressure air, the high-pressure air is stored in an air storage tank through air compressor one-way outlets and an air storage tank one-way inlet. The air compressingof the air compressor in a reciprocating and rotating mode is achieved, the friction between a rotor rotating continuously and a plunger doing reciprocating motions in a traditional plunger type aircompressor is avoided, the reciprocating motion of the plunger is omitted, so that the service life of the air compressor is prolonged; and the air compressor is simple in structure and convenient toinstall and maintain and has a good practical effect.

Owner:龚利芬

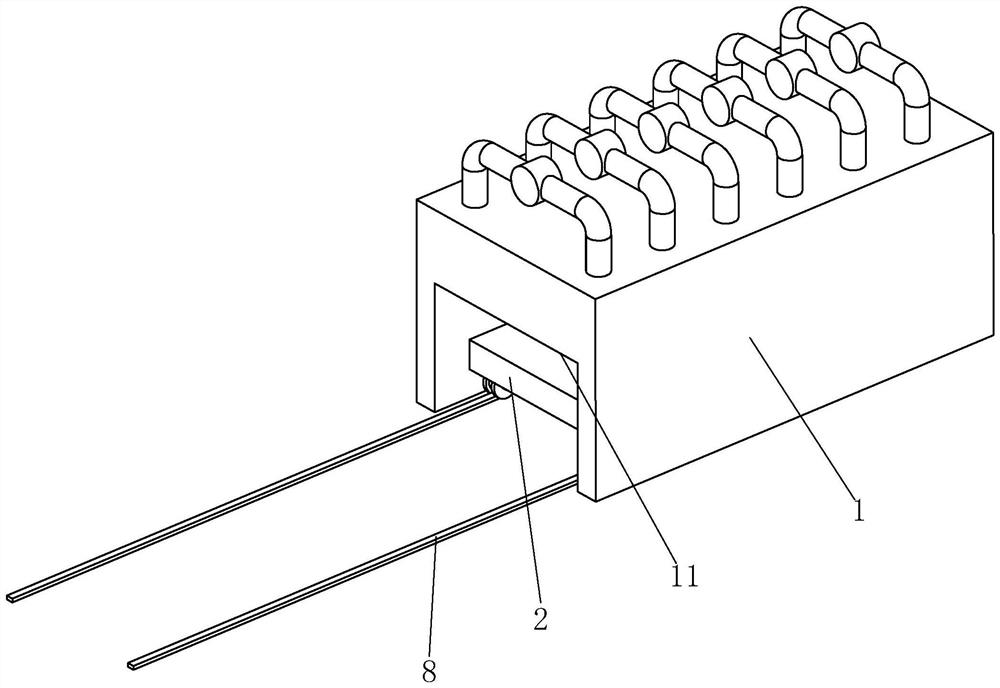

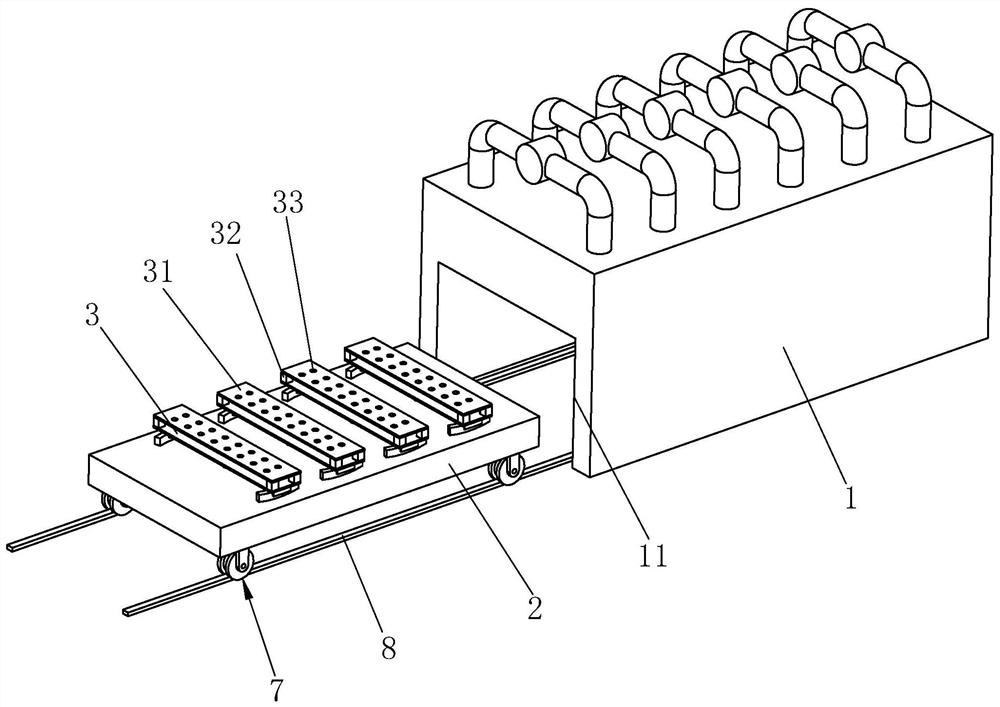

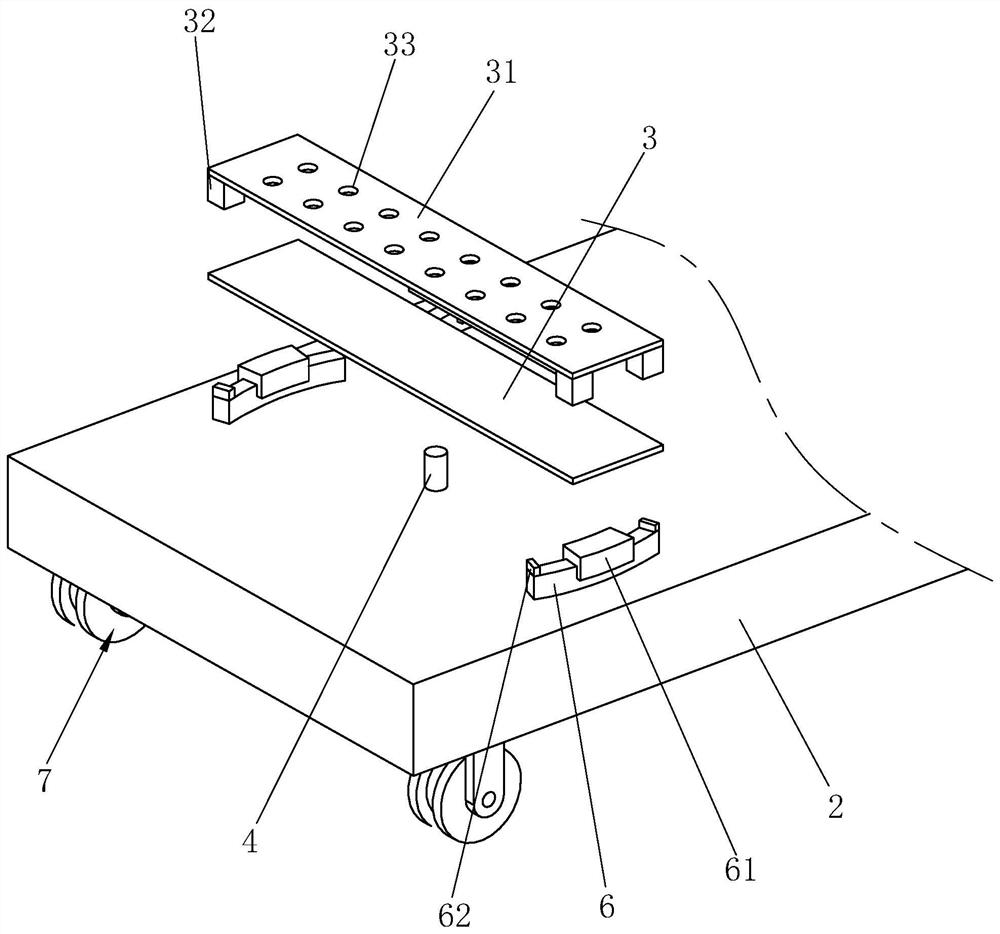

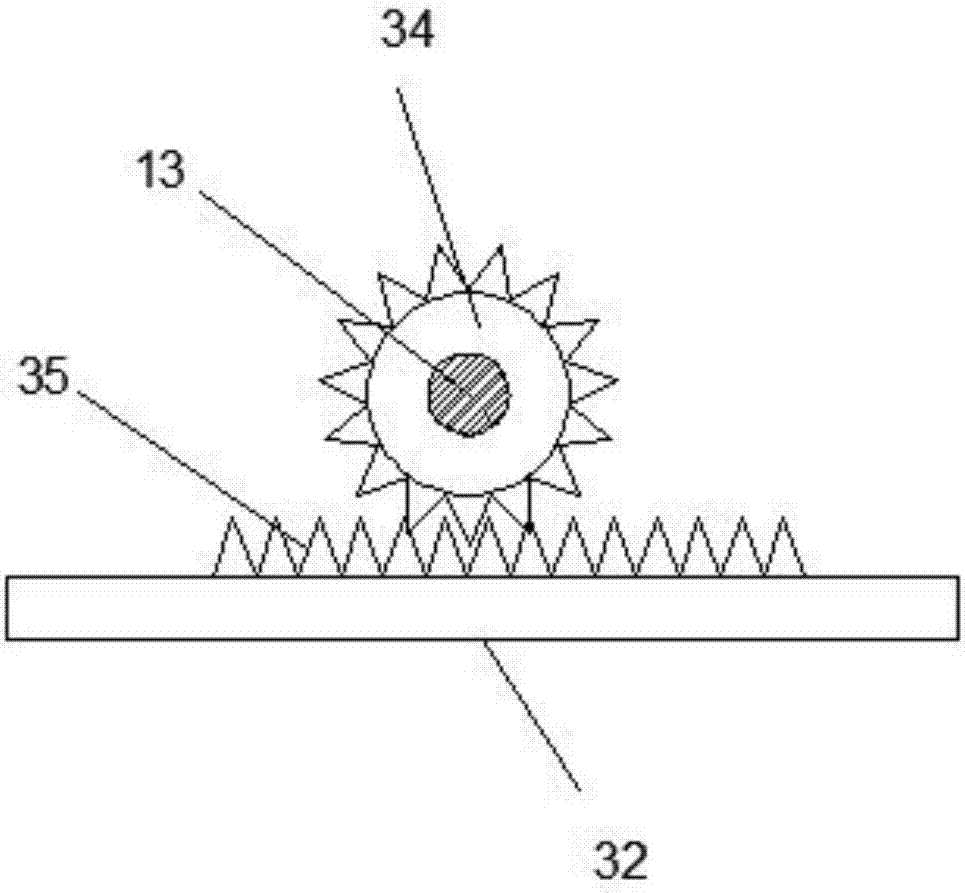

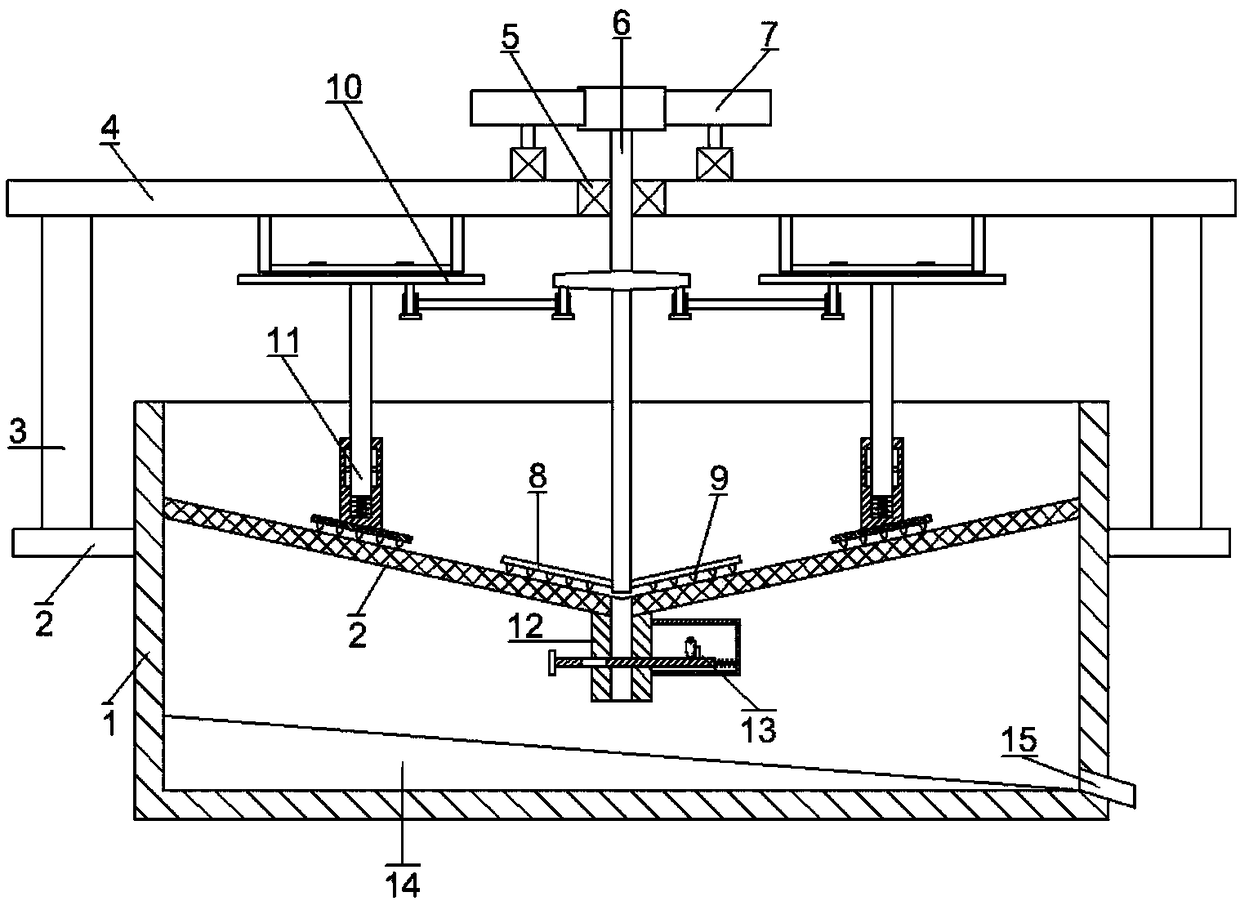

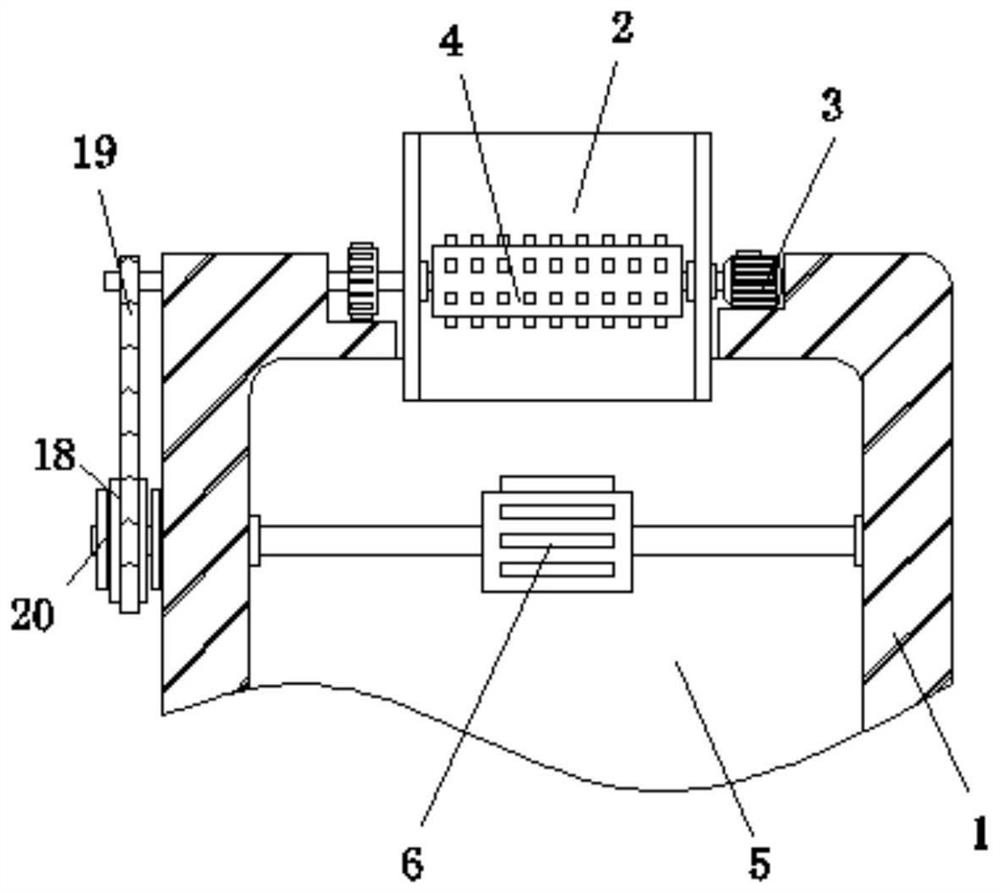

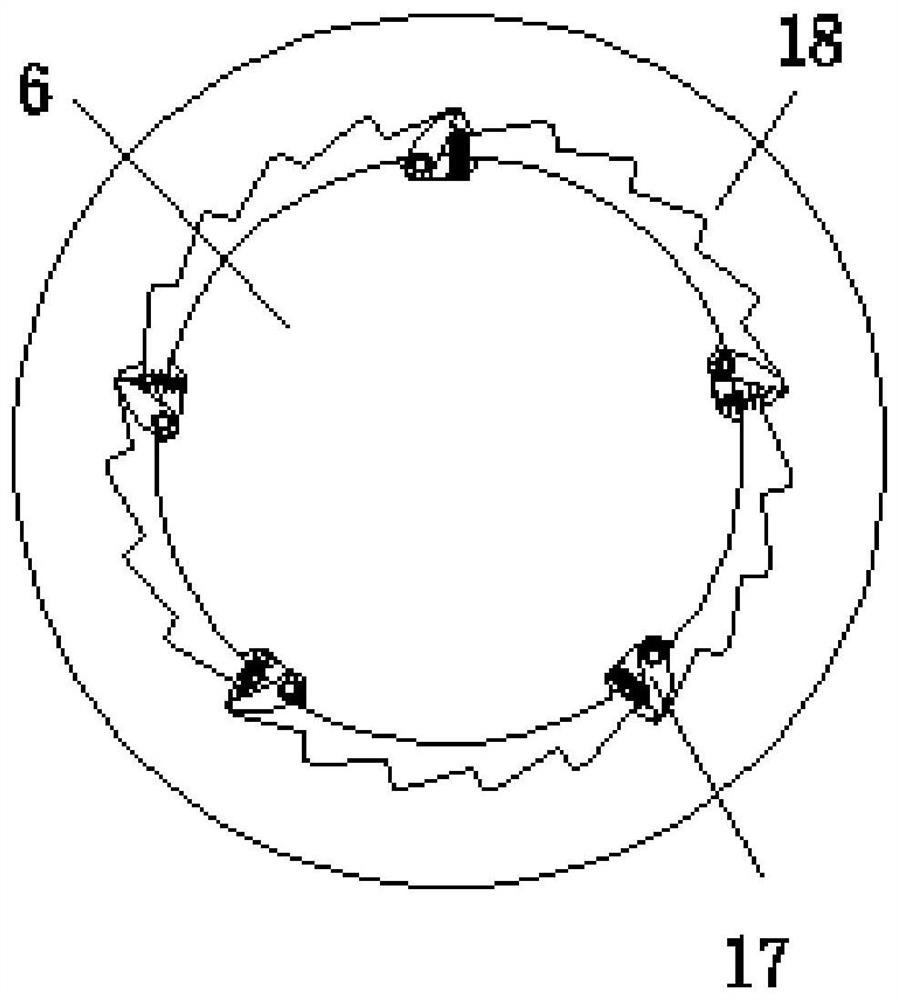

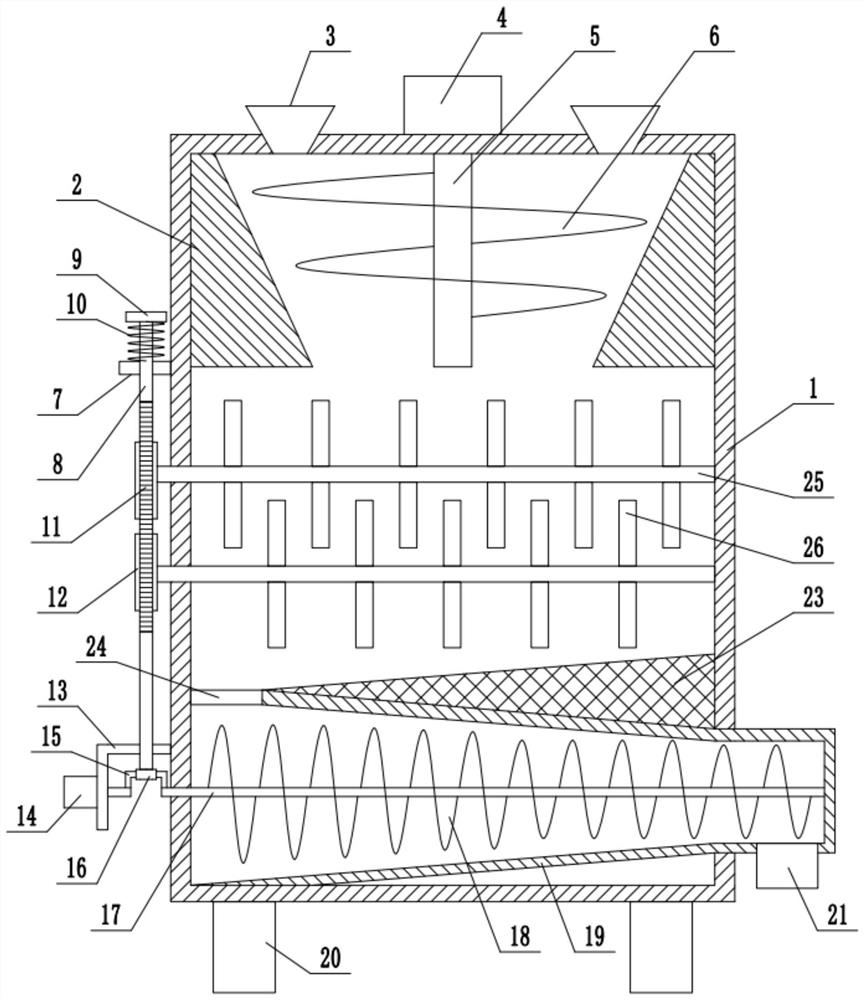

Sintering kiln and process of preparing regeneration bricks through sintering kiln

The invention relates to a sintering kiln and a process of preparing regeneration bricks through the sintering kiln. The sintering kiln comprises a kiln chamber and a kiln car arranged in the kiln chamber. The kiln car comprises base plates and rolling wheels rotatably connected below the base plates. The kiln chamber is internally provided with rails matched with the rolling wheels. The rolling wheels roll on the rails to make the kiln car slide in the kiln chamber. One side of the kiln chamber is provided with a kiln opening capable of allowing the kiln car to go in or out of the kiln chamber. The rails extend to the outer side of the kiln chamber from the kiln opening. The kiln car further comprises a plurality of bearing platforms arranged above the base and a plurality of swing shaftsfixedly arranged on the side, close to a base, of the bearing platforms and rotatably connected to the base. The plurality of bearing platforms are arranged in the length direction of the rails at intervals. A swing mechanism capable of driving the plurality of swing shafts to do reciprocating rotation along the axes of their own simultaneously. The sintering kiln has the advantages that brick bodies are heated uniformly in the sintering process, and the sintering effect of the brick bodies is good.

Owner:深圳市和志诚环保建材有限公司

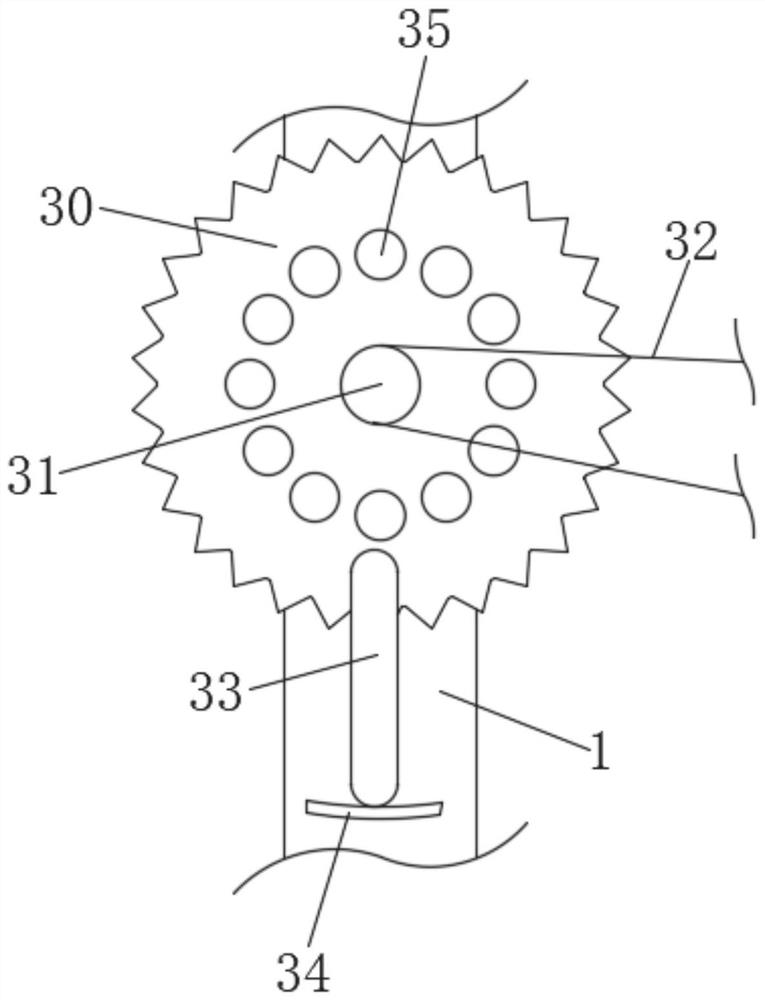

Insect capturing device for garden greening maintenance

ActiveCN111264491AEasy to inhaleRealize reciprocating rotationInsect catchers and killersElectric machineryEnvironmental engineering

The invention discloses an insect capturing device for garden greening maintenance. The device comprises a capturing shell, wherein exhaust holes are formed in the lower surface of the capturing shell; a tubular shell body is fixedly connected with the surface close to the top of the capturing shell; fine holes are formed in the inner edge surface of the tubular shell body; the tubular shell bodyis internally provided with an insect attraction propellant; a motor is fixedly connected with the bottom of the capturing shell; a shaft I is fixedly connected with the top of the output shaft of themotor; the surface of the shaft I penetrates through the capturing shell and is rotationally connected with the capturing shell; a negative pressure fan is fixedly connected with the side surface ofthe shaft I; an electric mesh is fixedly connected with the inner wall of the capturing shell; and a connecting rack is fixedly connected with the surface close to the top of the shaft I. With the cooperation and use of the structures, the problems that in the practical use process, the working intensity of operators in conventional insecticide spraying is large, a large amount of an insecticide needs to be spayed to a garden, the insect killing cost is high, and in addition, water and soil pollution can be easily caused, can be solved by using the insect capturing device.

Owner:湖南跳马园林有限公司

Logistics transporter capable of disinfecting during transportation and use method for logistics transporter

InactiveCN111514329AFully sterilized and disinfectedReduce security risksLavatory sanitoryAtomized substancesBacterial virusLogistics management

The invention discloses a logistics transporter capable of disinfecting during transportation and a use method for the logistics transporter. The logistics transporter comprises a base, wherein a motor is arranged on the surface of the base, the right end of an output shaft of the motor is fixedly connected with a lead screw, the right side of the base is fixedly connected with a stopper part, a nut mechanism is in screwed connection with the surface of the motor and is fixedly connected with a placement plate through a nut structure, a placement supporting plate is in sliding connection withthe internal wall of the placement plate, the right end of the lead screw is fixedly connected with a disinfection device, the disinfection device comprises a turntable I, and the right end of the lead screw is fixedly connected with the left side of the turntable I. According to the logistics transporter, through matched use among the above-mentioned structures, the problem during in-service usethat inconvenience is brought to use due to the fact that environments in contact with goods during transportation are complicated and diverse, the goods easily adhere various bacterial viruses, surface packages of the goods are difficultly subjected to disinfecting treatment timely by the traditional logistics transporters, and potential safety hazards are easily generated is solved.

Owner:谷雨

Cutting type tea rolling device

InactiveCN107136239AReasonable structureInnovative designPre-extraction tea treatmentDrive shaftGear wheel

The invention discloses a cutting type tea kneading device, which comprises a base, a kneading barrel connected to the middle part of the upper end of the support seat, a support frame connected to both sides of the top end of the kneading barrel, a feeding hopper connected to the middle part of the upper end of the support frame, and a middle part of the support frame connected by a bearing There is a cutting shaft, the upper middle part of the upper end of the cutting shaft is connected with the upper cutting tooth, the upper middle part of the cutting shaft is connected with the driven pulley, the right end of the driven pulley is connected with the driving pulley through the belt, and the lower part of the driving pulley is connected with the driving shaft, the driving shaft The middle part is connected with a driving gear, the left end of the driving gear is connected with a driven gear, the middle part of the left end of the driven gear is connected with a rotating shaft, the middle part of the rotating shaft is connected with a sliding sleeve, the lower end of the sliding sleeve is connected with a lifting column, and the front end of the middle part of the lifting column is connected with a lifting rack , the front end of the lifting rack is meshed with a rotating gear, and the left end of the rotating gear is connected with a rotating shaft. The present invention realizes the primary cutting-type rolling of the tea leaves, and also realizes the re-rolling of the tea leaves at the same time.

Owner:宫勋

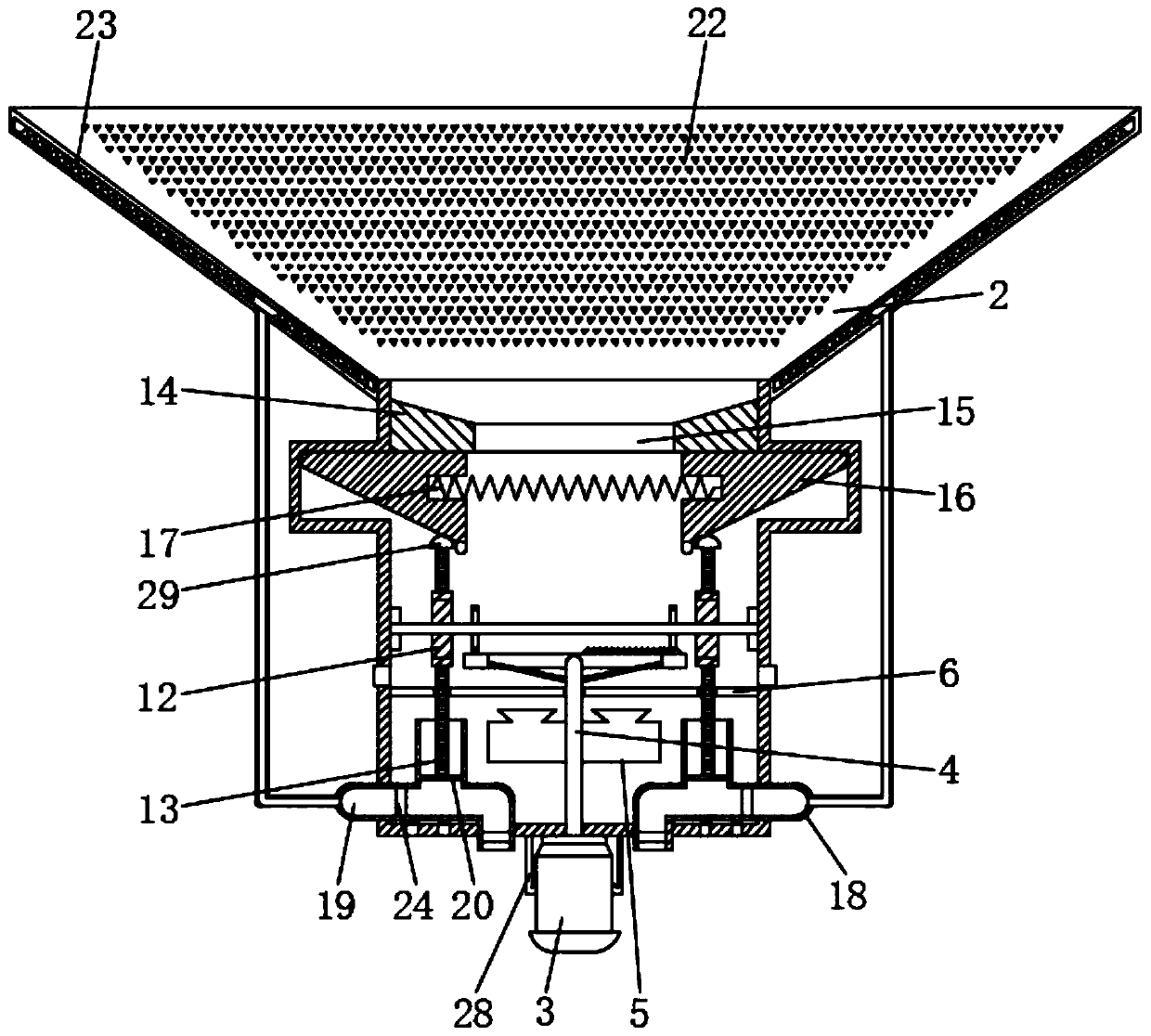

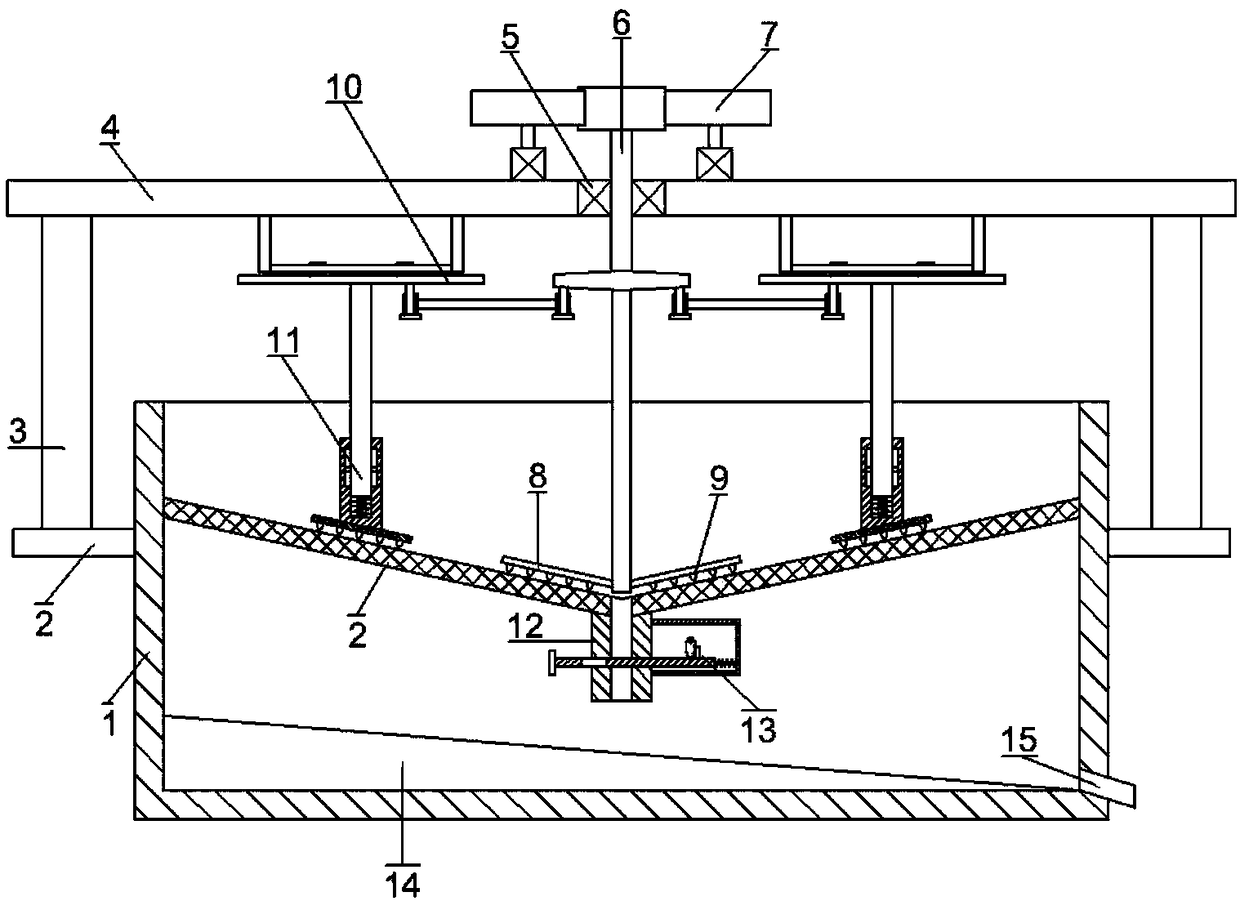

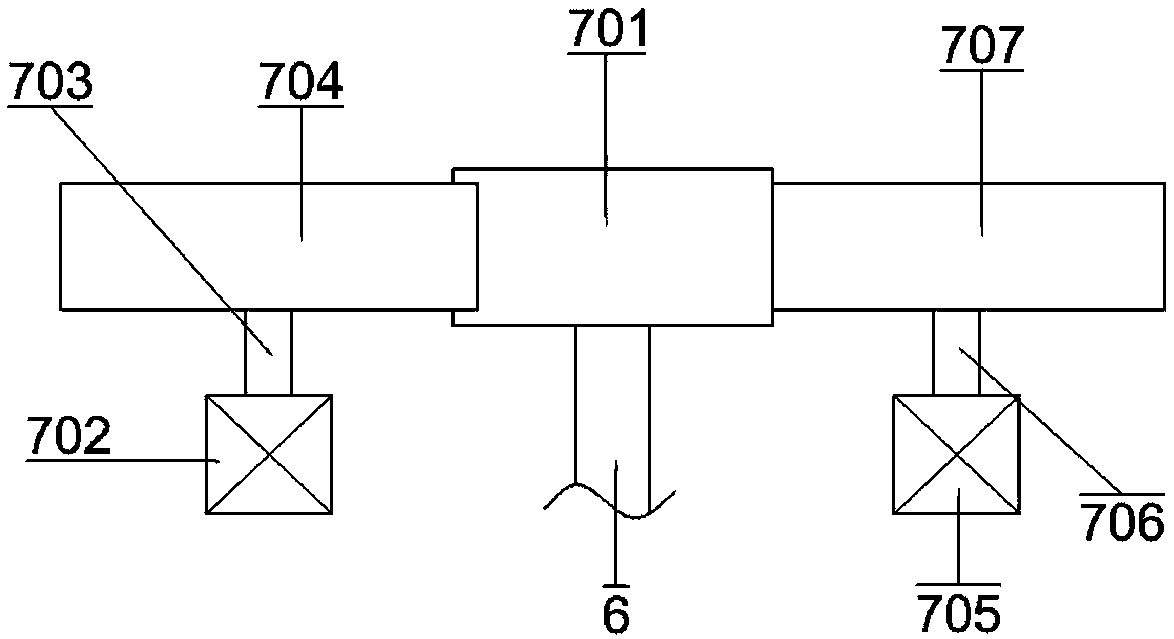

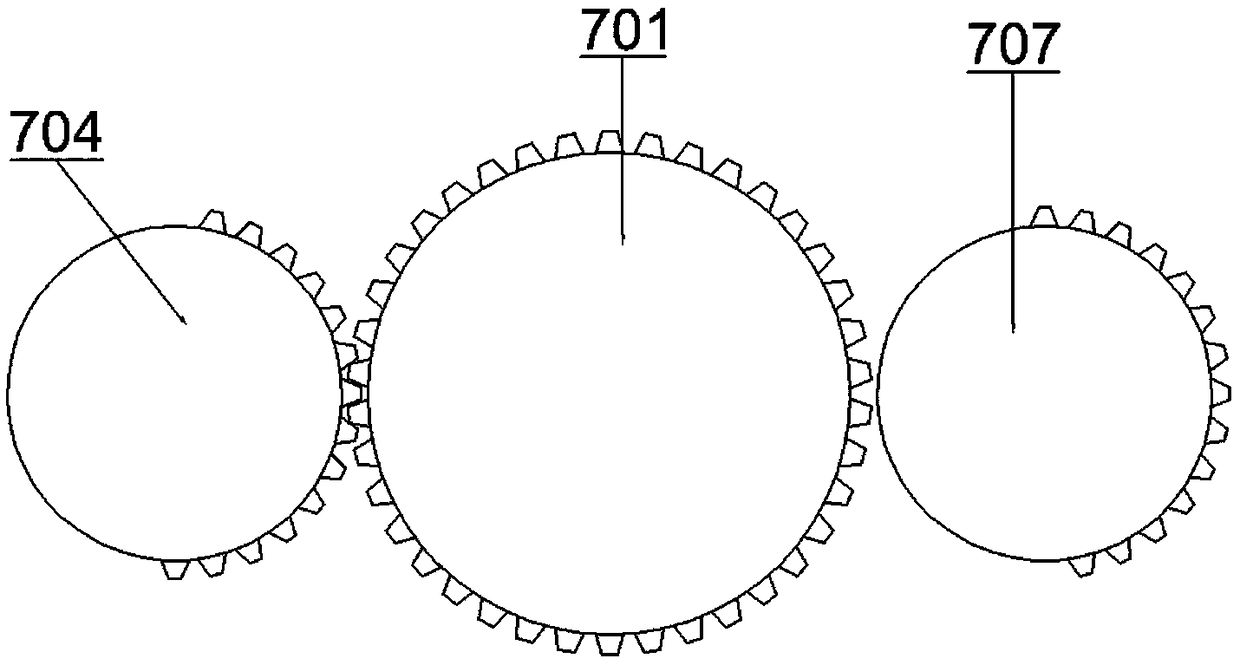

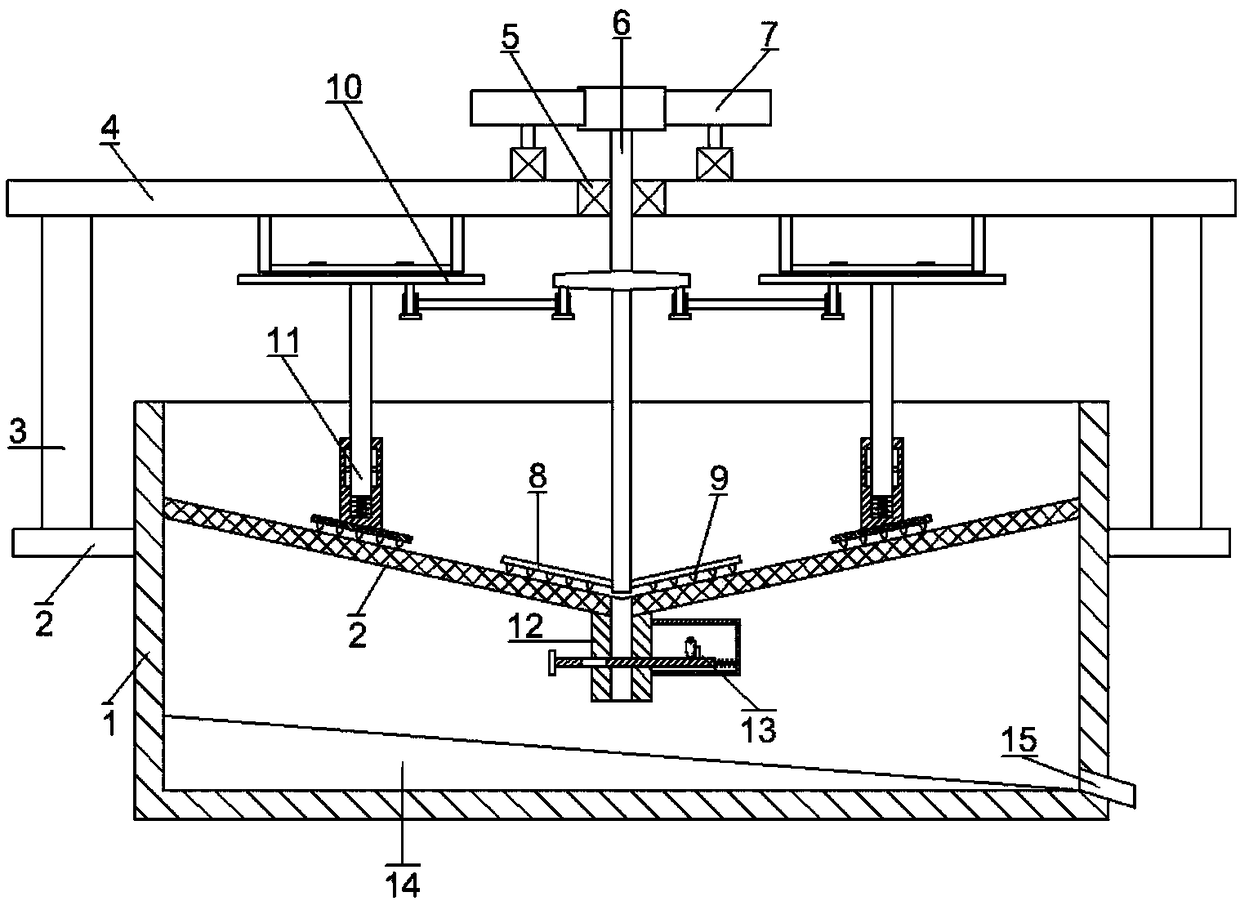

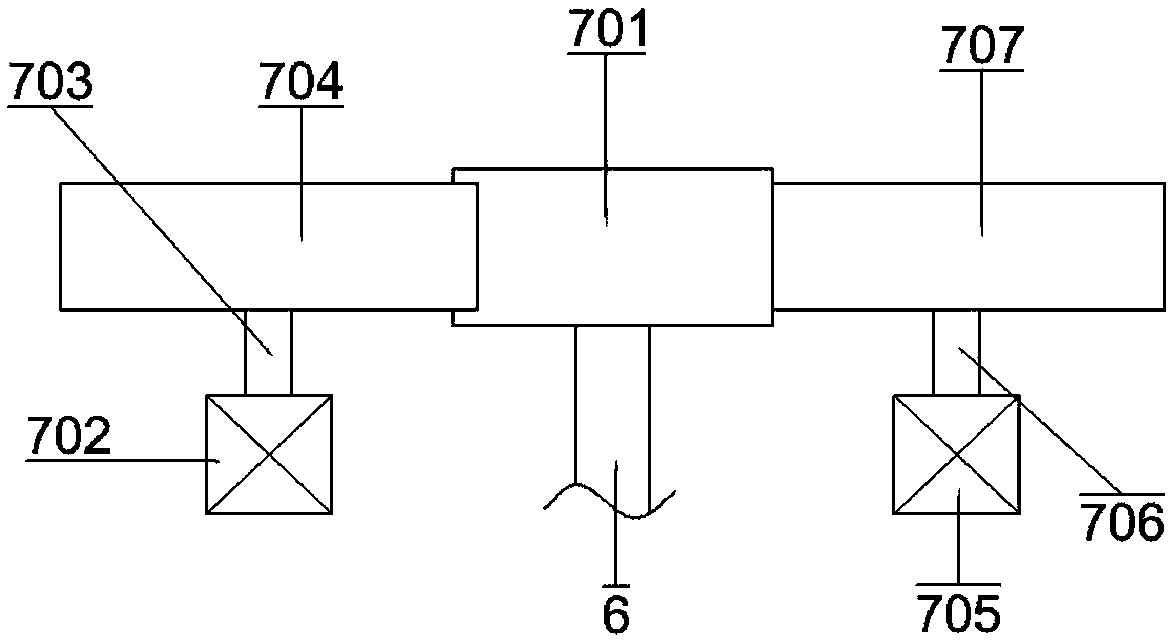

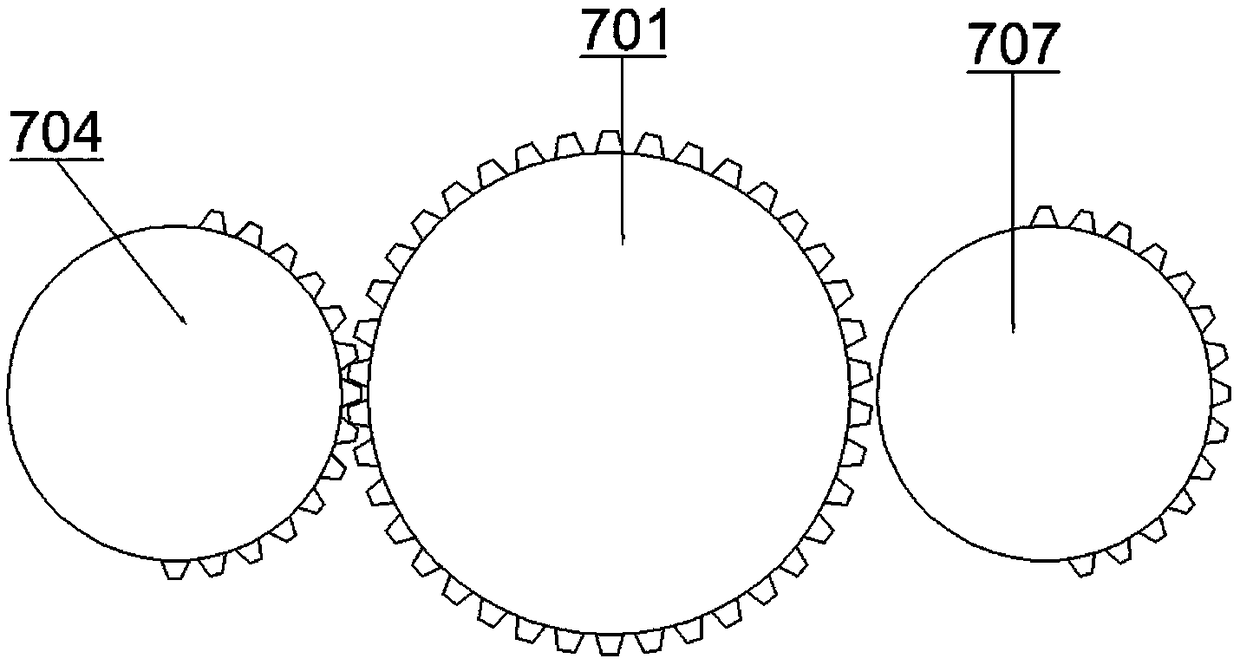

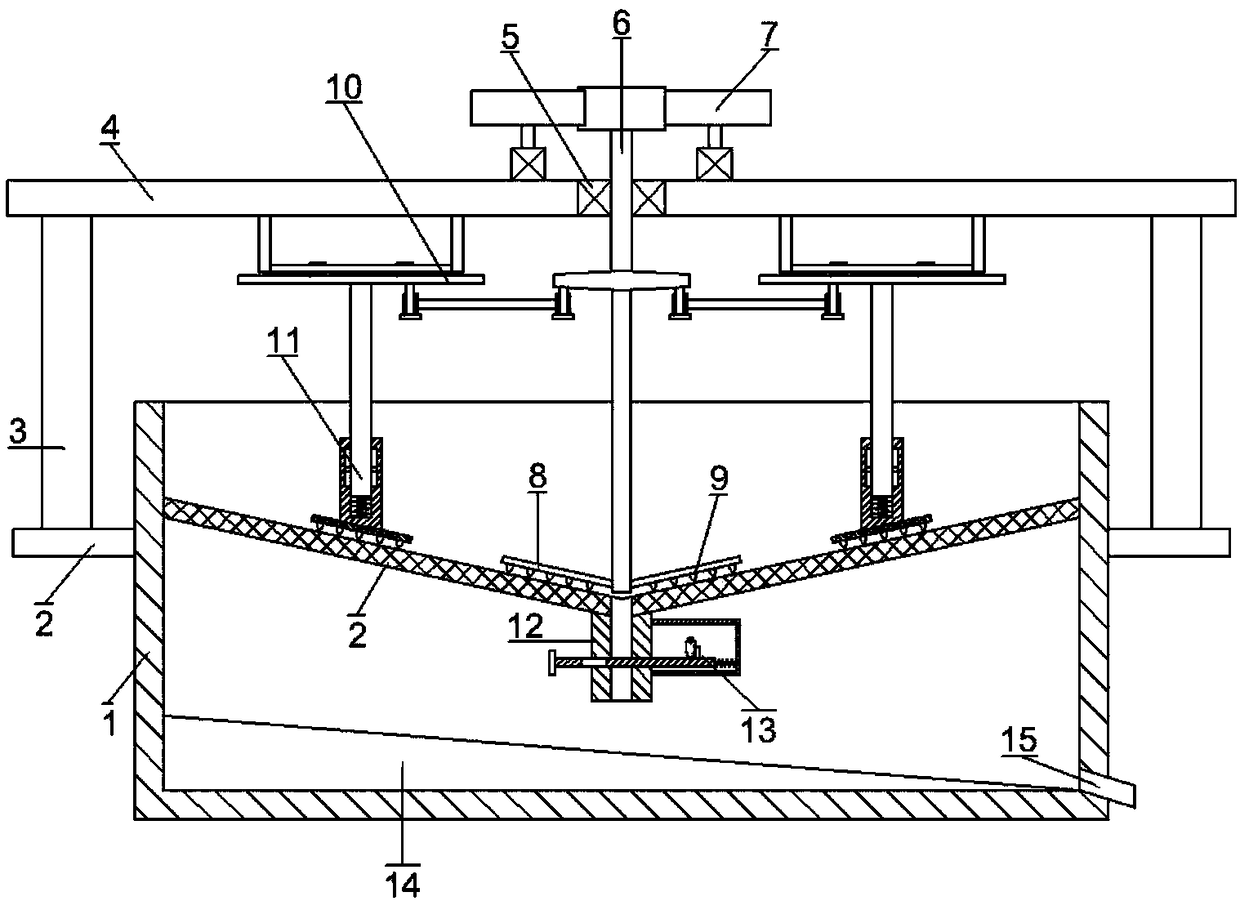

Particle material screening device with perturbation treatment

InactiveCN108745844ARealize reciprocating rotationEffective Disturbance HandlingSievingScreeningGear driveEngineering

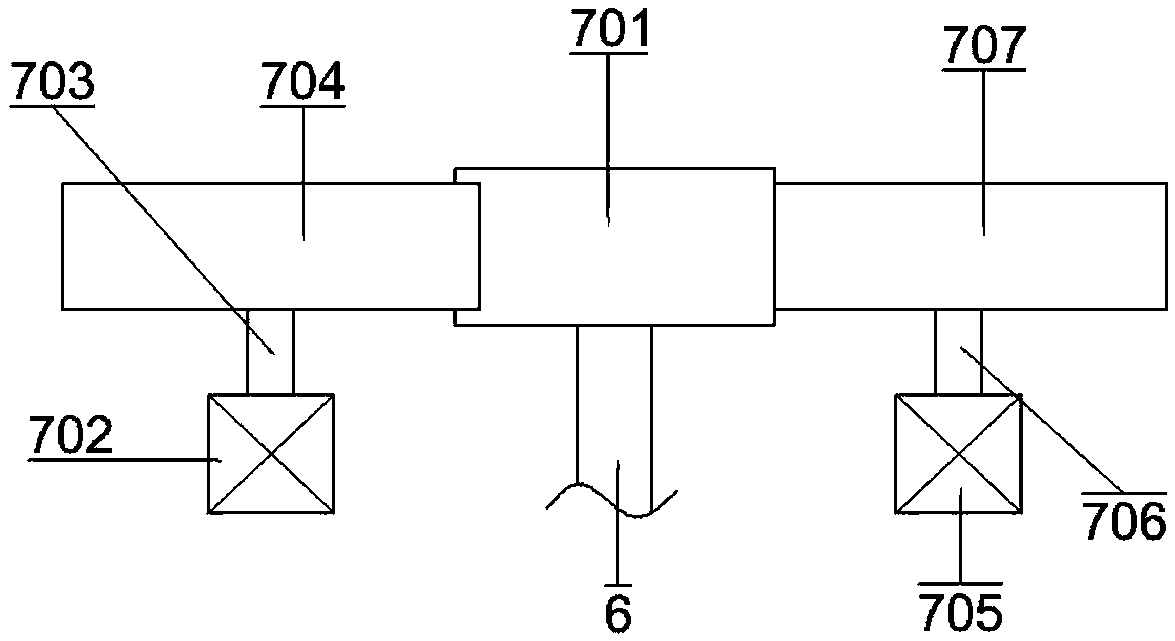

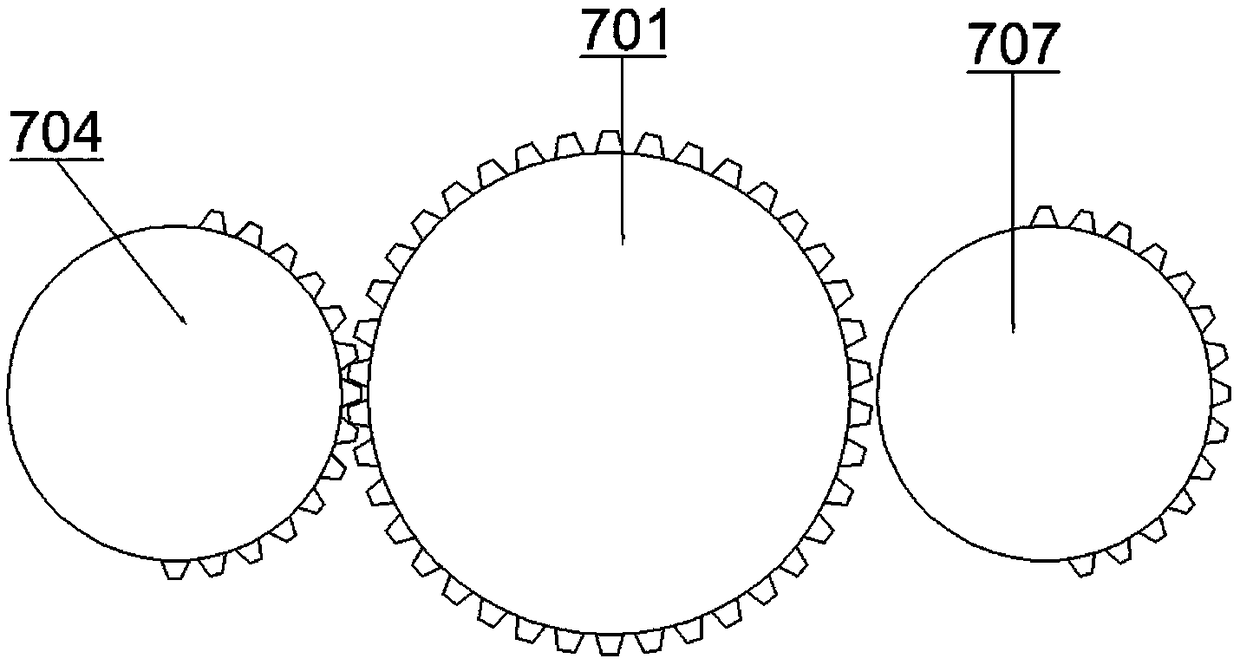

The invention provides a particle material screening device with perturbation treatment. A processing frame body is included, and the top of the processing frame body is in an open shape; a screen netis fixedly connected to the inner side wall of the processing frame body, and the cross section of the screen net is in a V shape; two horizontal bases are symmetrically and fixedly connected to theouter side wall of the processing frame body; supporting columns are fixedly connected with the upper sides of the horizontal bases; the top ends of the two supporting columns are jointly and fixedlyconnected with a supporting plate; and a bearing is embedded in the middle position of the supporting plate. The particle material screening device with perturbation treatment has the following beneficial effects when a left side half gear is engaged with an intermediate gear, a right side half gear is separated from the intermediate gear, and at the moment, the intermediate gear rotates in a clockwise direction; and when the left side half gear is engaged with the intermediate gear, the right side half gear is engaged with the intermediate gear, and at the moment, the intermediate gear rotates in the reverse direction; and reciprocating rotation of the intermediate gear can be achieved due to the repetition, and the intermediate gear drives a rotating rod to reciprocate.

Owner:泾县汇鼎锋建筑装饰工程有限公司

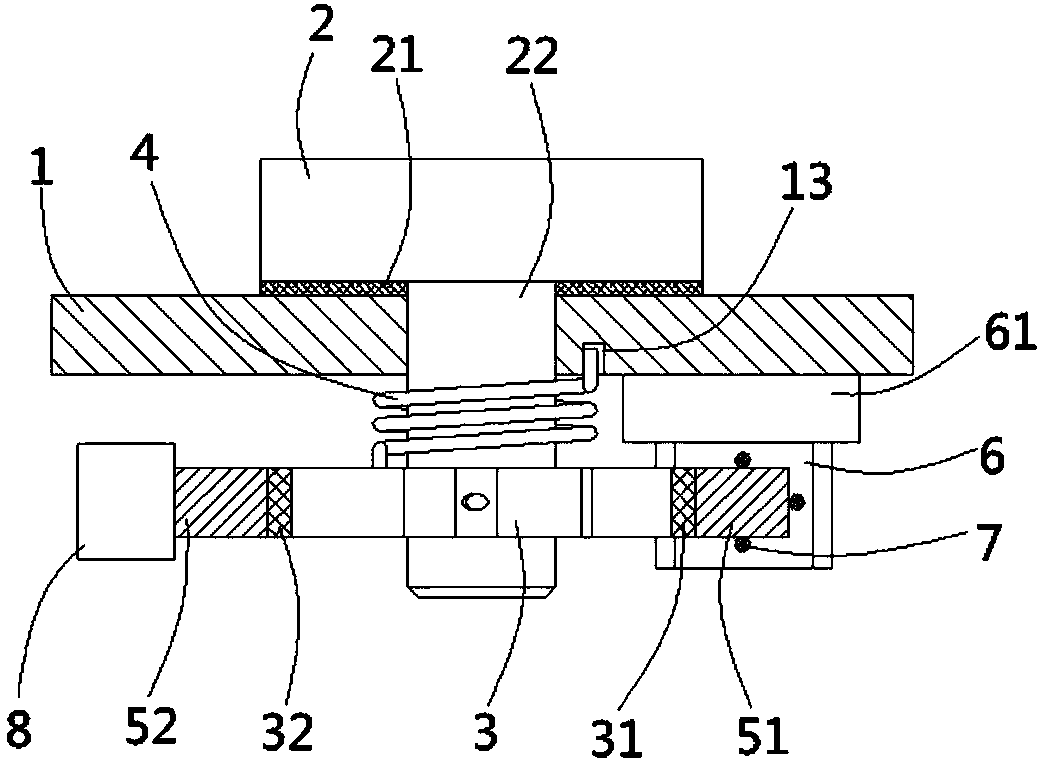

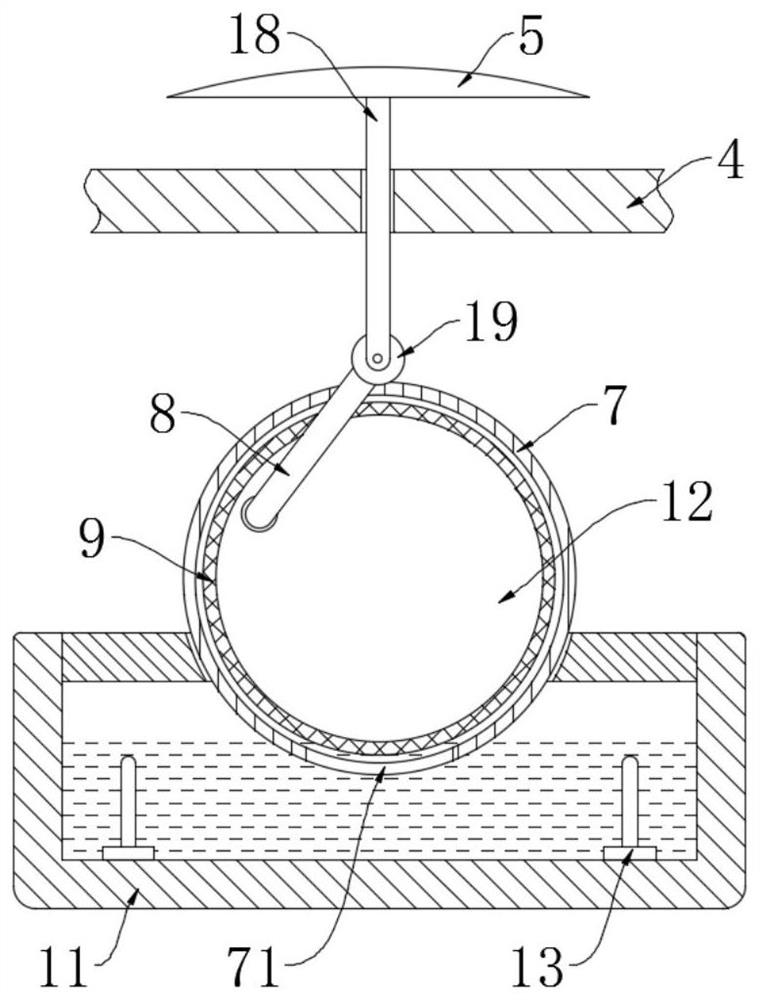

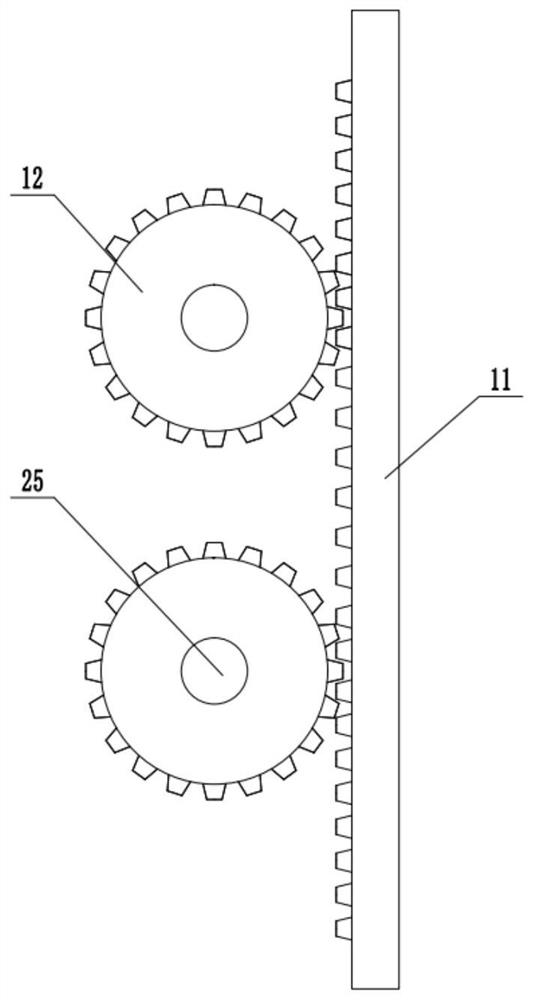

Seat electric rotation mechanism

The seat electric rotating mechanism disclosed in the present invention includes: a rotating bracket, a rotating disk, a fixed disk, a pressure plate, an upper ball assembly, and a lower ball assembly; it also includes: a driving motor assembly, which is installed on the fixed disk, The driving motor assembly includes a driving gear; a semicircular rack mounted on the rotating bracket, the center of the semicircular rack coincides with the center of rotation of the rotating bracket, and the semicircular rack meshes with the driving gear; in the driving motor assembly The driving gear drives the rotating bracket to rotate back and forth between 0° and 180° through a semicircular rack. The seat electric rotating mechanism of the present invention only needs a single-stage transmission of the driving motor assembly, the driving gear, and the semicircular rack to realize the reciprocating rotation of the seat between 0° and 180°, and has the advantage that the space occupied by the transmission mechanism is small . At the same time, avoid the unrestricted rotation of the seat wire harness and twist it off.

Owner:YANFENG ADIENT SEATING CO LTD

Equipment for rapidly screening particulate matter

InactiveCN108816715ARealize reciprocating rotationEffective Disturbance HandlingSievingScreeningParticulatesGear drive

The invention provides equipment for rapidly screening particulate matter. The equipment comprises a processing frame body, the top of the processing frame body is open, a screen mesh is fixedly connected to the inner side wall of the processing frame body, and the cross section of the screen mesh is in a V shape; two horizontal bases are symmetrically and fixedly connected to the outer side wallof the processing frame body, supporting columns are fixedly connected to the upper sides of the horizontal bases, a supporting plate is fixedly connected to the tops of the two supporting columns, and a bearing is embedded in the middle of the supporting plate. The equipment has the following advantages that when a left semi-gear is meshed with an intermediate gear, a right semi-gear is separatedfrom the intermediate gear, and the intermediate gear rotates clockwise at this time; when the left semi-gear is meshed with the intermediate gear, the right semi-gear is meshed with the intermediategear, the intermediate gear rotates counterclockwise at this time, in this way, the reciprocating rotation of the intermediate gear can be achieved repeatedly, and the intermediate gear drives a rotating rod to achieve reciprocating rotation.

Owner:安徽古耐家居有限公司

Resource utilization energy-saving recovery device for extracting metal from solid waste

PendingCN113117805ARealize up and down activitiesAchieve lateral reciprocationMagnetic separationGrain treatmentsElectric machineryBuoyant flow

The invention discloses a resource utilization energy-saving recovery device for extracting metal from solid waste. The device comprises a machine body, a motor, an electric push rod and a water pump, a feeding hopper is installed at the top of the machine body, a precipitation cavity is formed in the upper portion of the machine body, a tamping rod is welded to the bottom of a movable frame, and a positioning rod is fixed to the top of a guide plate. A first outlet is reserved in the side of the precipitation cavity, a second outlet is formed in the bottom of the precipitation cavity, a water outlet pipe is connected to the outer side of the first outlet, a recycling cavity is formed in the bottom of the machine body, and a water pump is fixed to the outer side of the bottom of the machine body through bolts. According to the resource utilization energy-saving recovery device for extracting the metal from the solid waste, wood chips, metal substances and broken stones in the crushed waste are separated and preliminarily guided out by utilizing buoyancy and impact force of water, meanwhile, the metal substances are thoroughly adsorbed and guided out, the water is recycled, and the operations of dust falling, buoyancy separation and impact discharging are realized.

Owner:何俊德

Candle wick fixing device

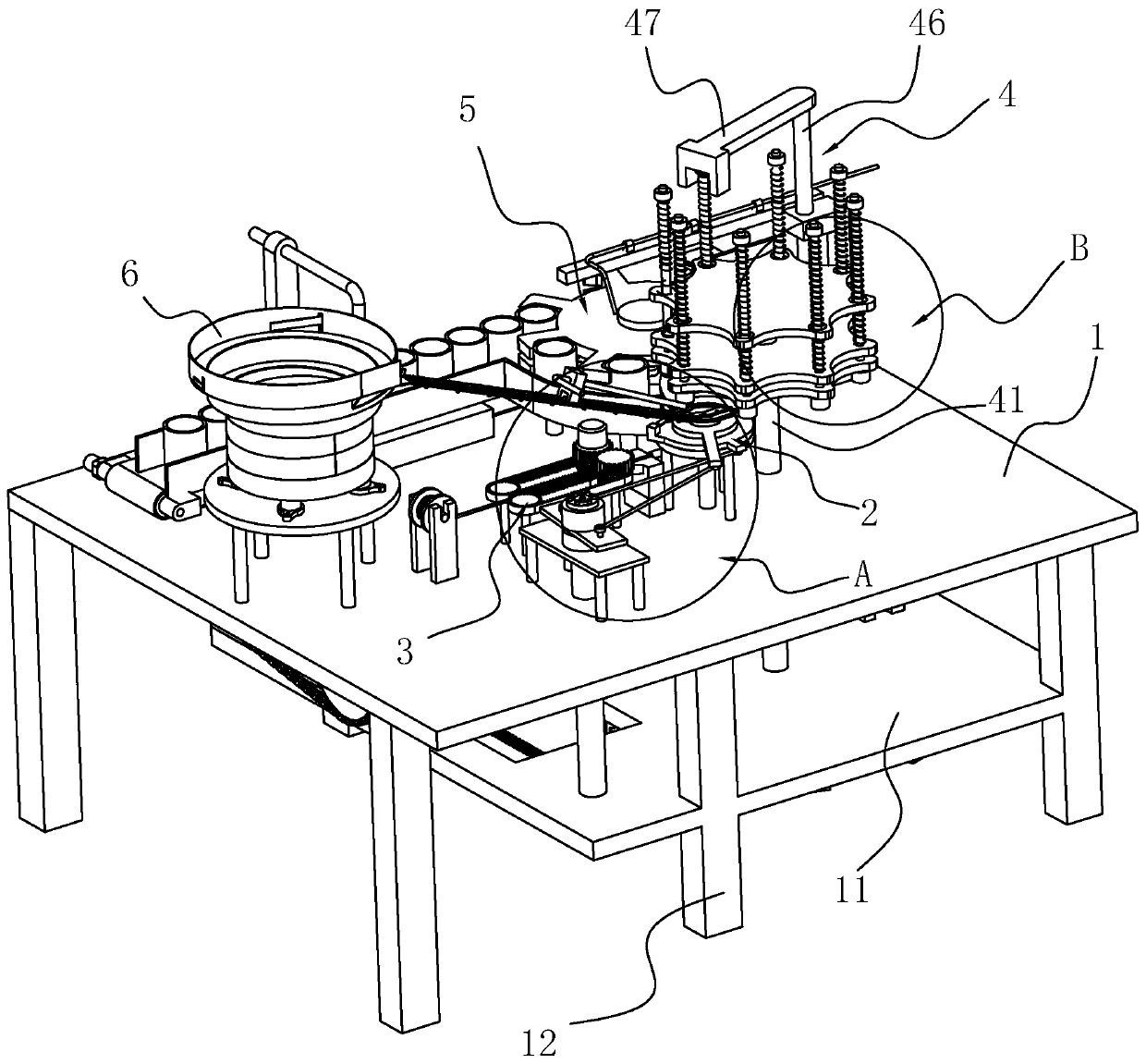

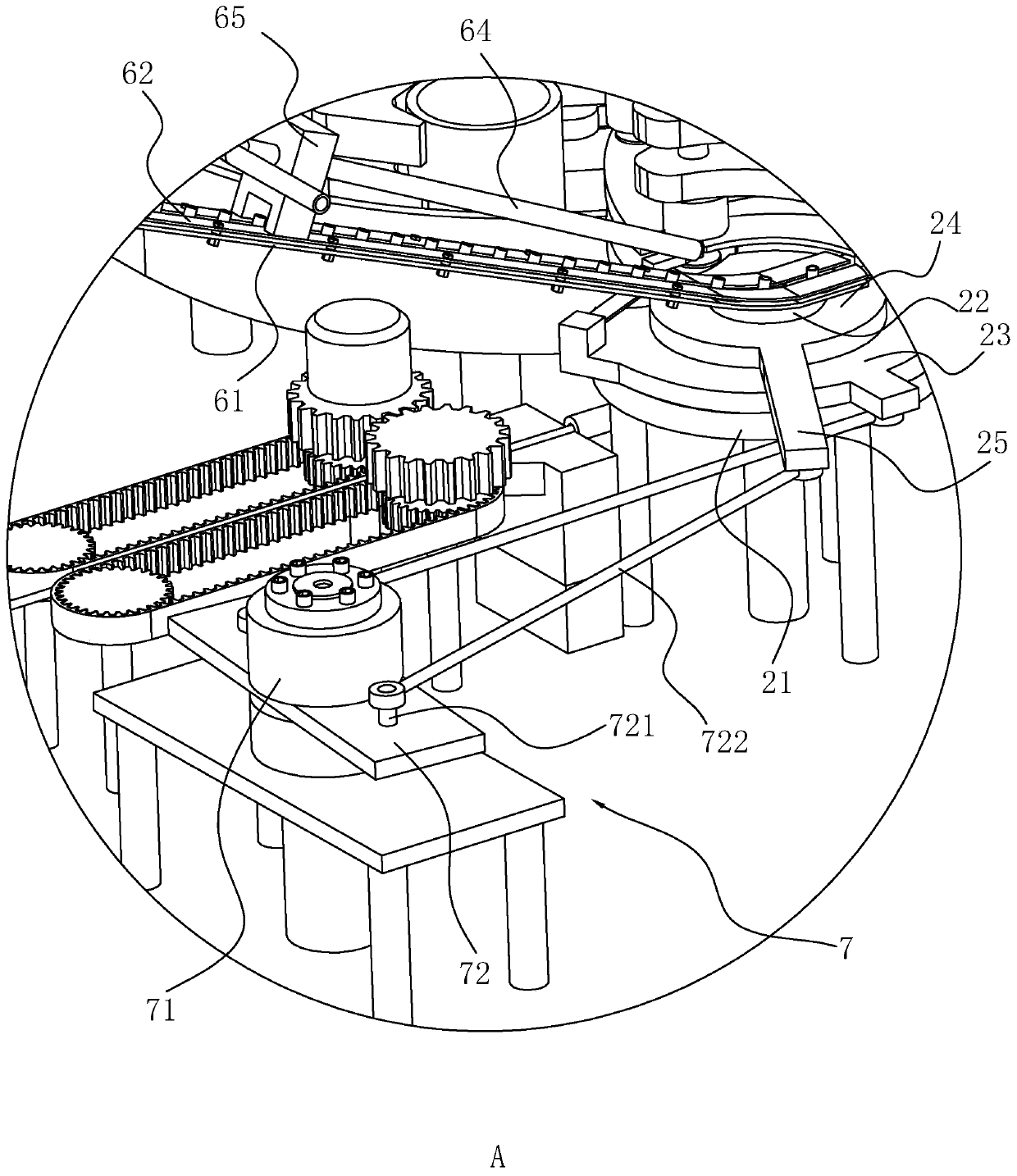

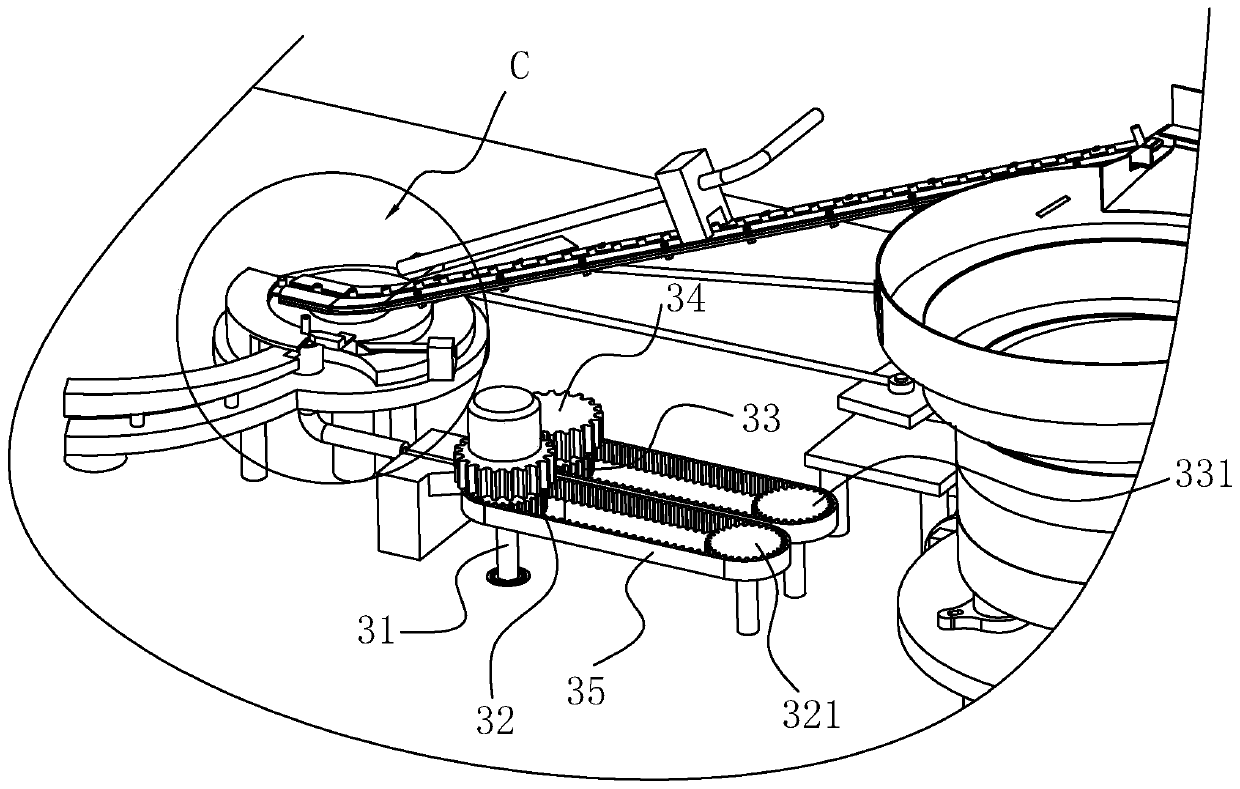

ActiveCN110862875ARealize reciprocating rotationRealize intermittent feedingCandle preparation apparatusAdhesiveMechanical engineering

The invention discloses a candle wick fixing device, and relates to the technical field of wax cup production. The problem that the operations of penetrating the candle wick through a wax block base and adhering the wax block of the wax cup base to the bottom of the wax cup are tedious and inconvenient in the prior art can be solved. The main point of the technical solution includes: the device comprises a worktable, a support table, a fixing shaft, a rotating block, a extrusion disk, a threading table, a vibration disk, a guide plate, a horizontal plate, a limiting plate, a support plate, a dial block, a extrusion block, a cutter, a pushing plate, a rotating disk, a transfer rod, and a adsorption block. The dial block moves the base of the wax block to the top of the threading table. Thecandle wick is inserted into the base of the wax block from the bottom of the threading table. The squeeze block and the dial block squeeze a limit tube, and the cutter cuts the wax wick. The adsorption block absorbs the base of the wax block, and then moves the base of the wax block to the top of the wax cup by a rotating disk, and then manually pushes the wax cup upwards, so that the base of thewax cup is contacted with an adhesive, and then pulls the wax cup downwards. The wax block base is detached from the adsorption block under the action of the adhesive, thereby making the operation tobe time-saving and labor-saving.

Owner:青岛欧亚自动化设备有限公司

Fan head angle adjusting structure

PendingCN107806434AImprove installation efficiencyEasy to adjustPump componentsPump controlAngular rangeAngle of rotation

The purpose of the present invention is to propose a fan head angle adjustment structure, which can easily adjust the fan head pitch angle and rotation angle, and reliably fix the fan head at a predetermined pitch angle, so as to satisfy users demand. The angle adjustment structure of the fan head of the present invention can make the pitch angle of the fan head better fixed and can be easily adjusted by adding an intermediate piece and making slight changes on the traditional clamping piece and inserting piece. The pitch angle of the fan head; at the same time, the present invention detects the rotation angle of the fan head in real time through a stepping motor, and compares the rotation angle with the input target angle value, thereby controlling the fan head to reverse when the fan head rotates to the limit angle. To rotate, to achieve the purpose of reciprocating rotation of the fan head within a predetermined angle range. To sum up, the present invention simultaneously realizes the adjustment of the pitch angle and the rotation angle of the fan head, and has good practicability.

Owner:XINYI HUIMEI ELECTRICAL APPLIANCES

Spraying pipe adjusting mechanism for freight compartment cleaning robot

InactiveCN107804290ARealize reciprocating flushingLow costCleaning apparatus for vehicle interiorsCleaning using liquidsMechanical engineeringPiston rod

The invention discloses a spraying pipe adjusting mechanism for a freight compartment cleaning robot. The spraying pipe adjusting mechanism for the freight compartment cleaning robot includes a mounting platform, a rotary base is inserted in the mounting platform, a central shaft penetrating out of the lower end face of the mounting platform is shaped on the rotary base, the lower end of the central shaft is fixed to a rotary disc in an inserted and sleeved mode, the central shaft is inserted in and sleeved with a restoration spring, the two ends of the restoration spring are fixed to the rotary disc and the mounting platform respectively, a first arc rack and a second arc rack are shaped on the rotary disc, the first arc rack mesh with a first rack in a meshing mode, an insertion groove is formed in one end of the first rack, a piston rod of a drive cylinder is inserted into the insertion groove, the piston rod of the drive cylinder and the first rack are inserted into and sleeved with pressure springs, the two ends of the pressure springs are fixed to the outer wall of the piston rod of the drive cylinder and the outer wall of the first rack respectively, the second arc rack meshes with the second rack, and a movable base is fixed to the second rack. By the adoption of the praying pipe adjusting mechanism for the freight compartment cleaning robot, washing of a spraying pipecan be conducted repeatedly without switching the rotation direction of a servo motor, the cost is saved, and the working efficiency is high.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

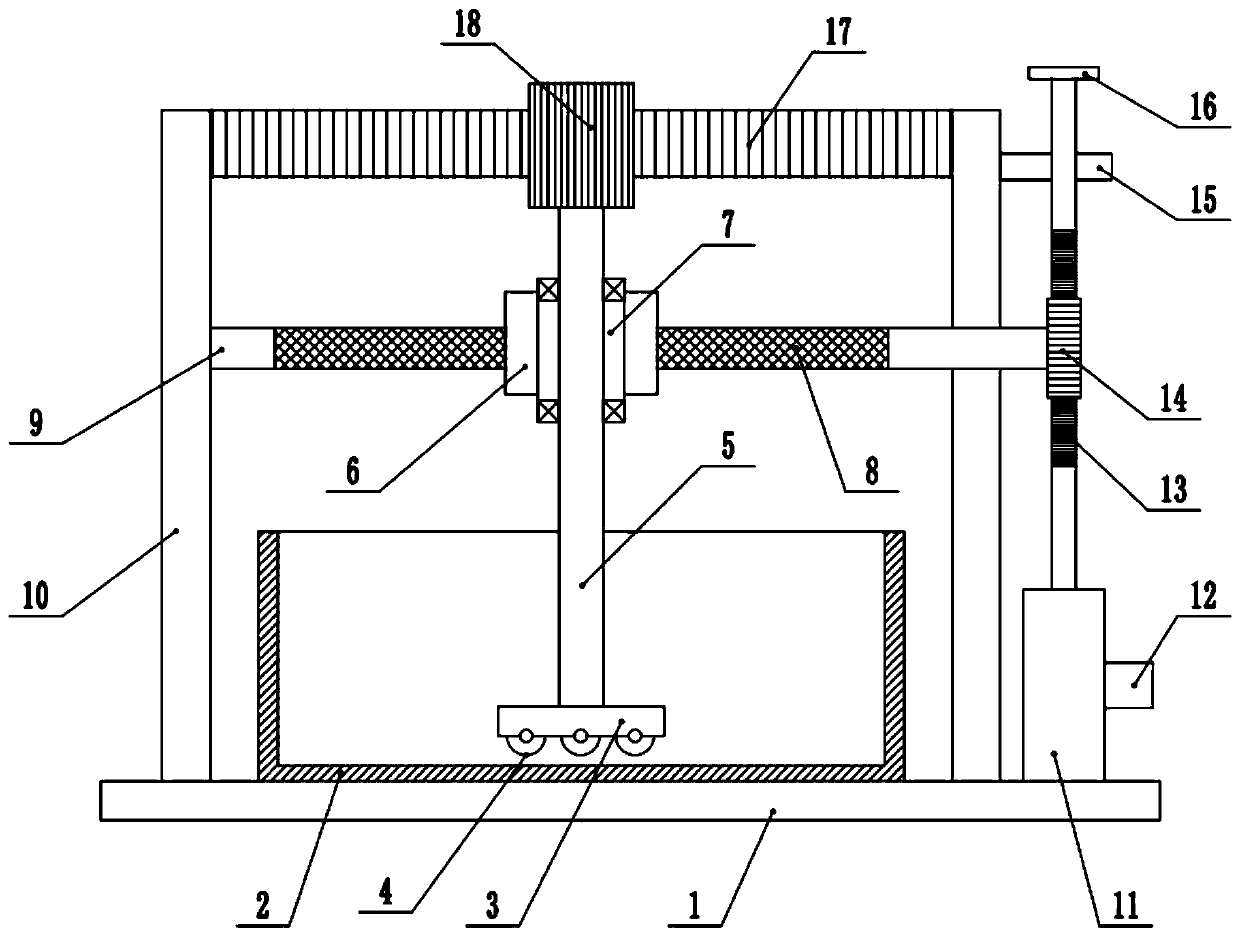

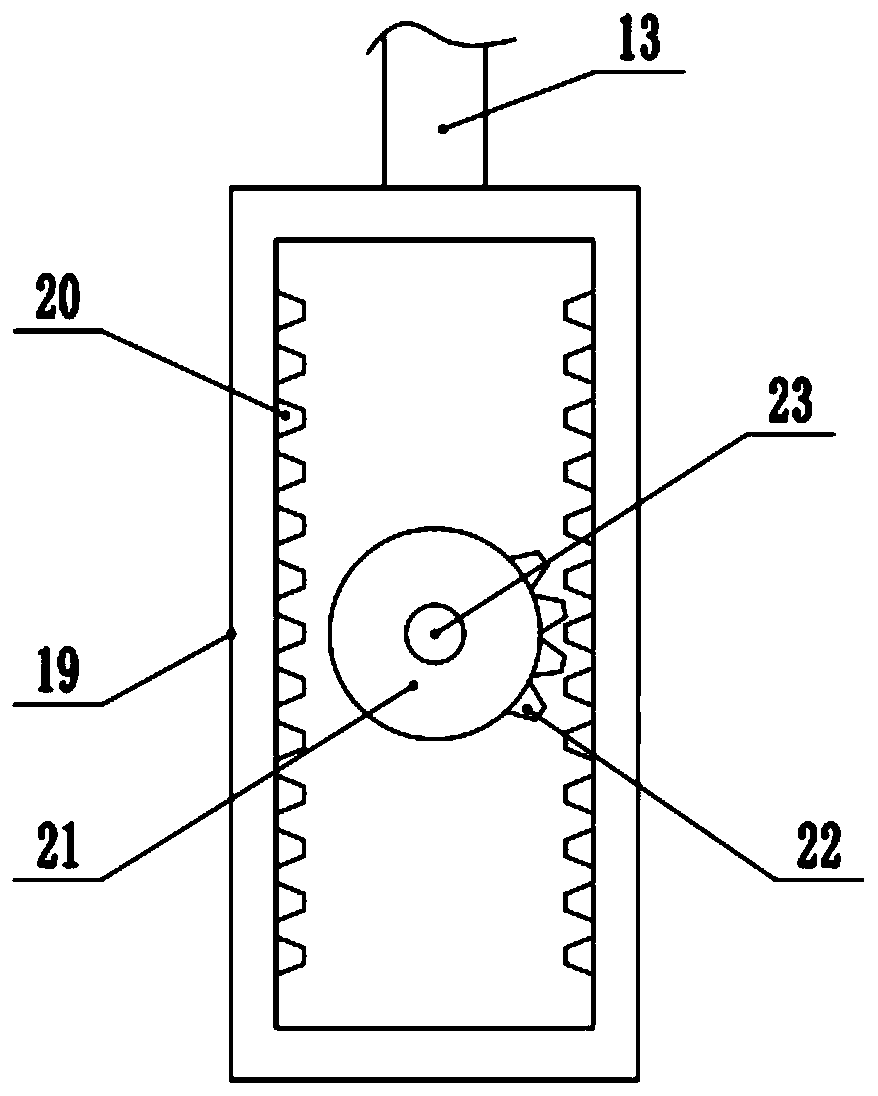

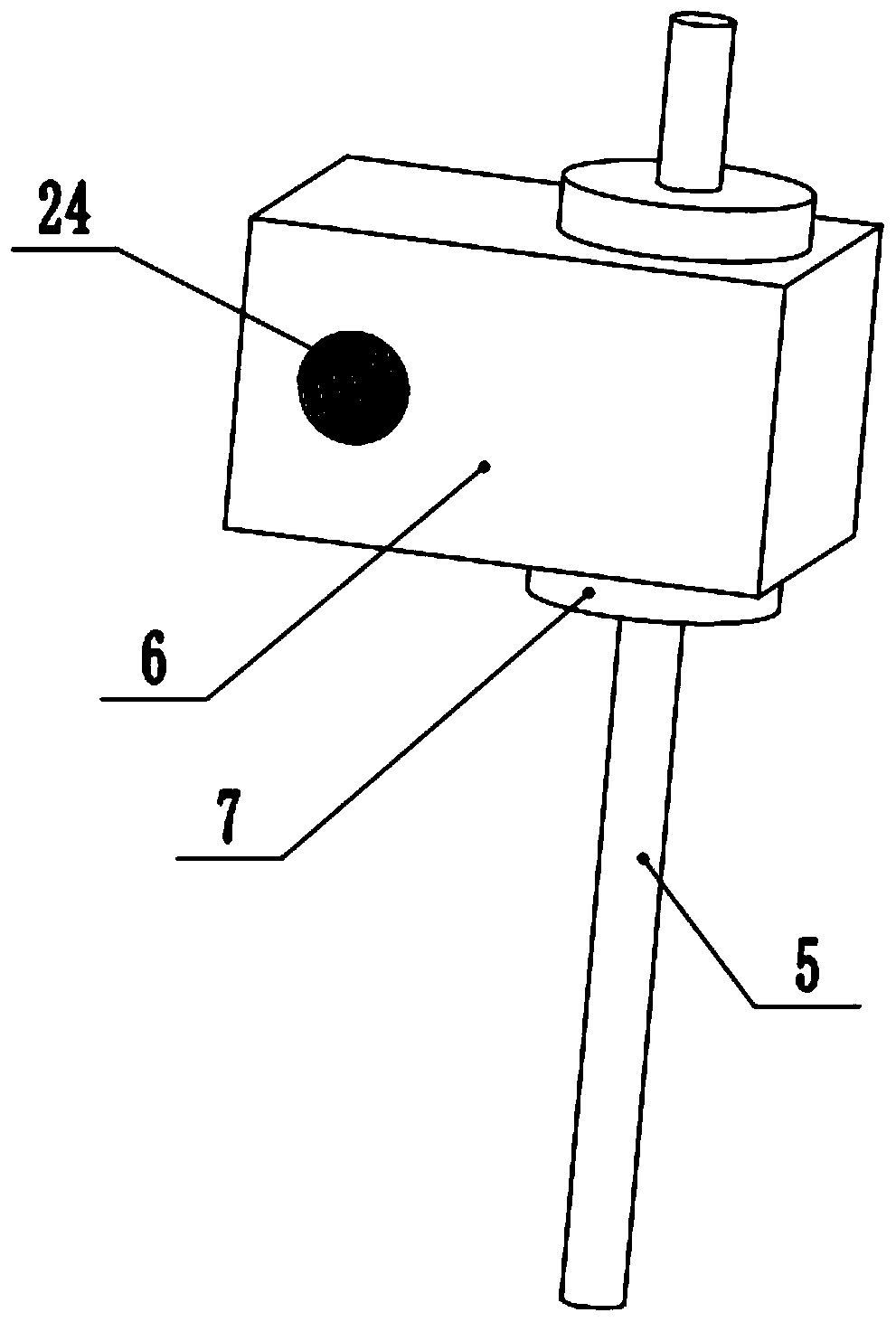

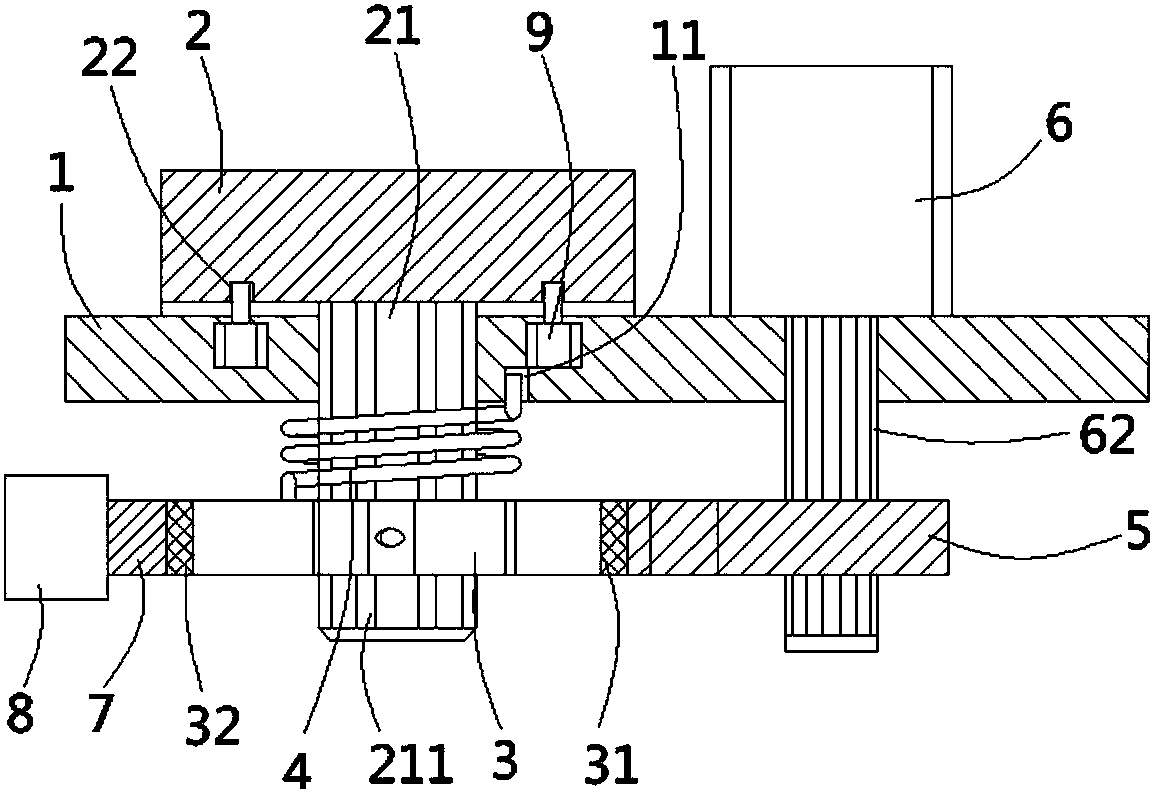

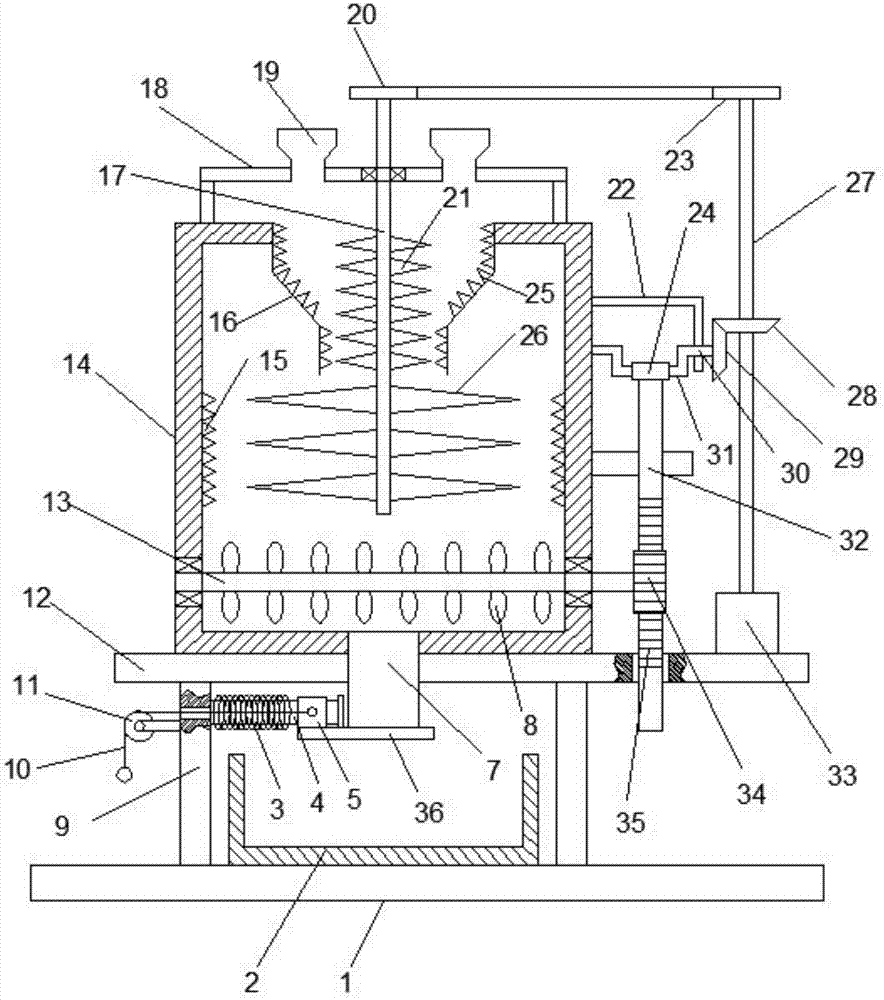

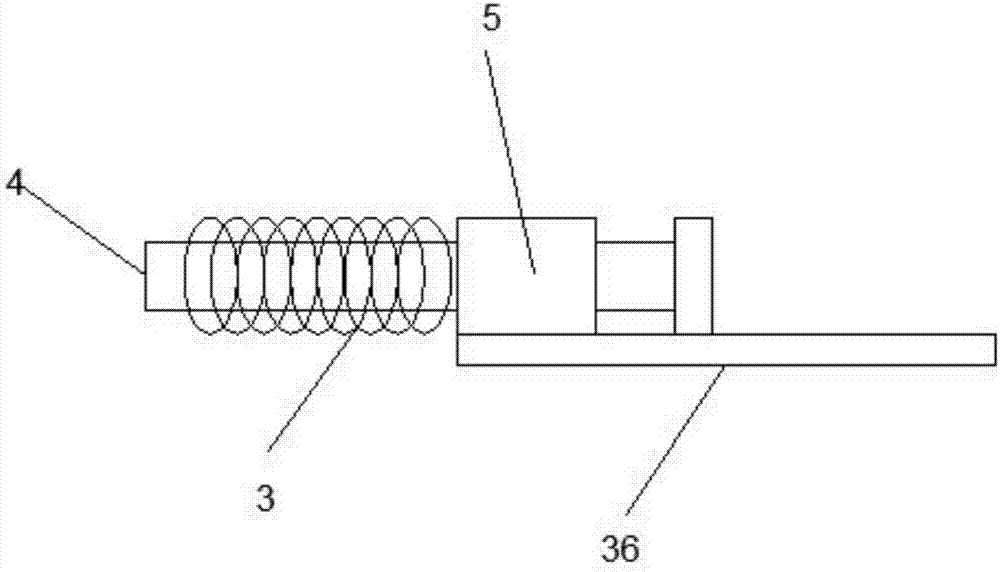

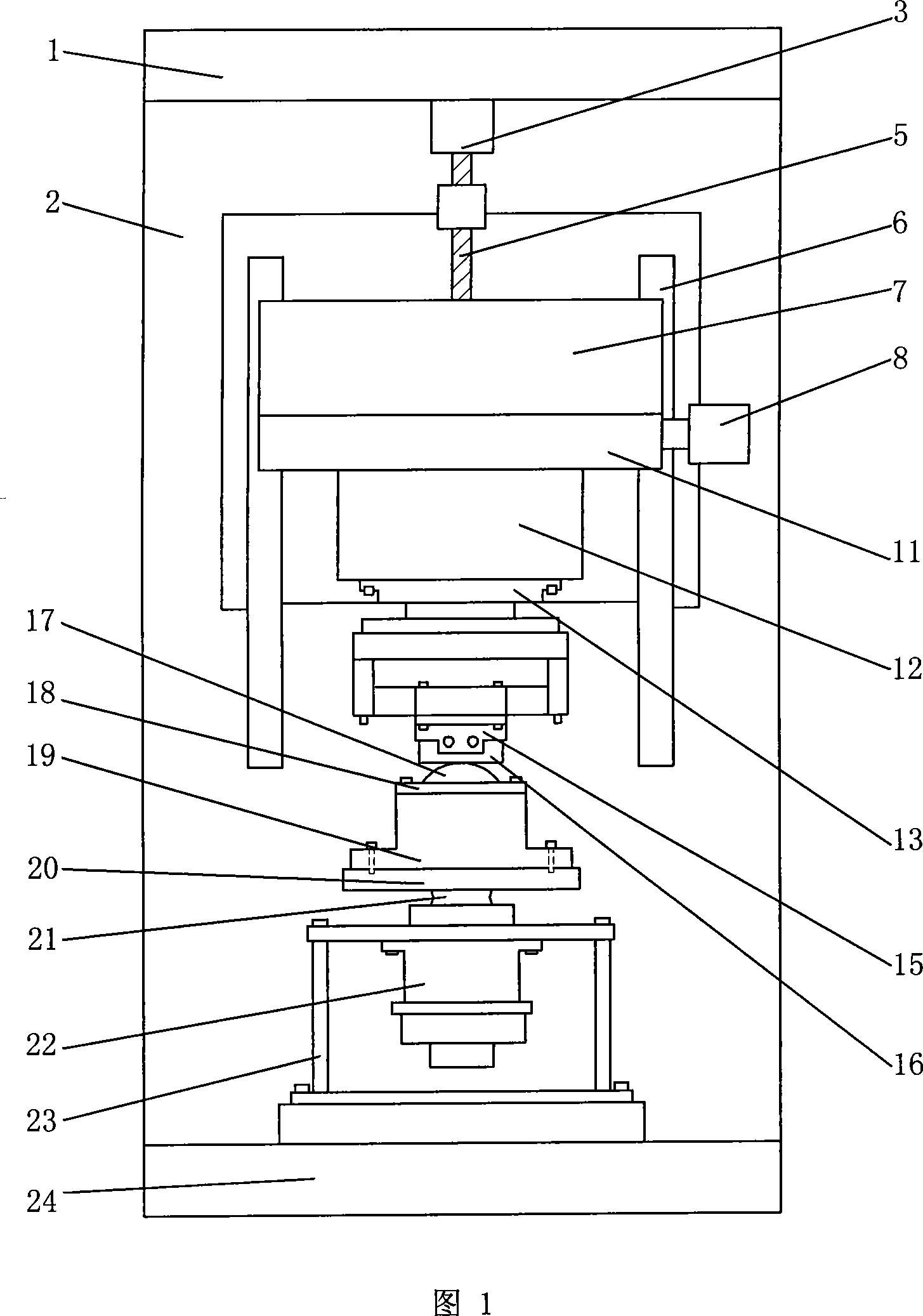

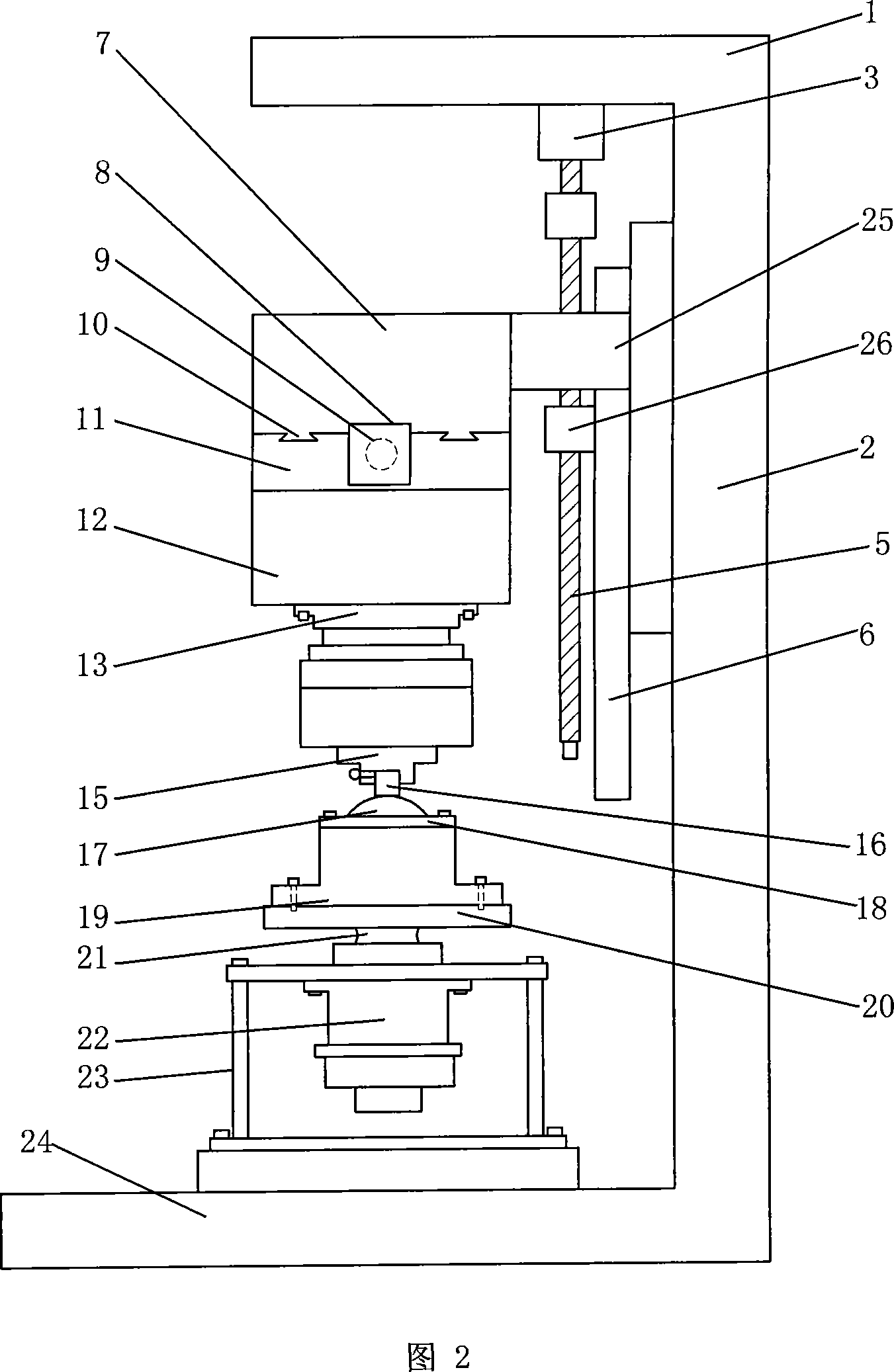

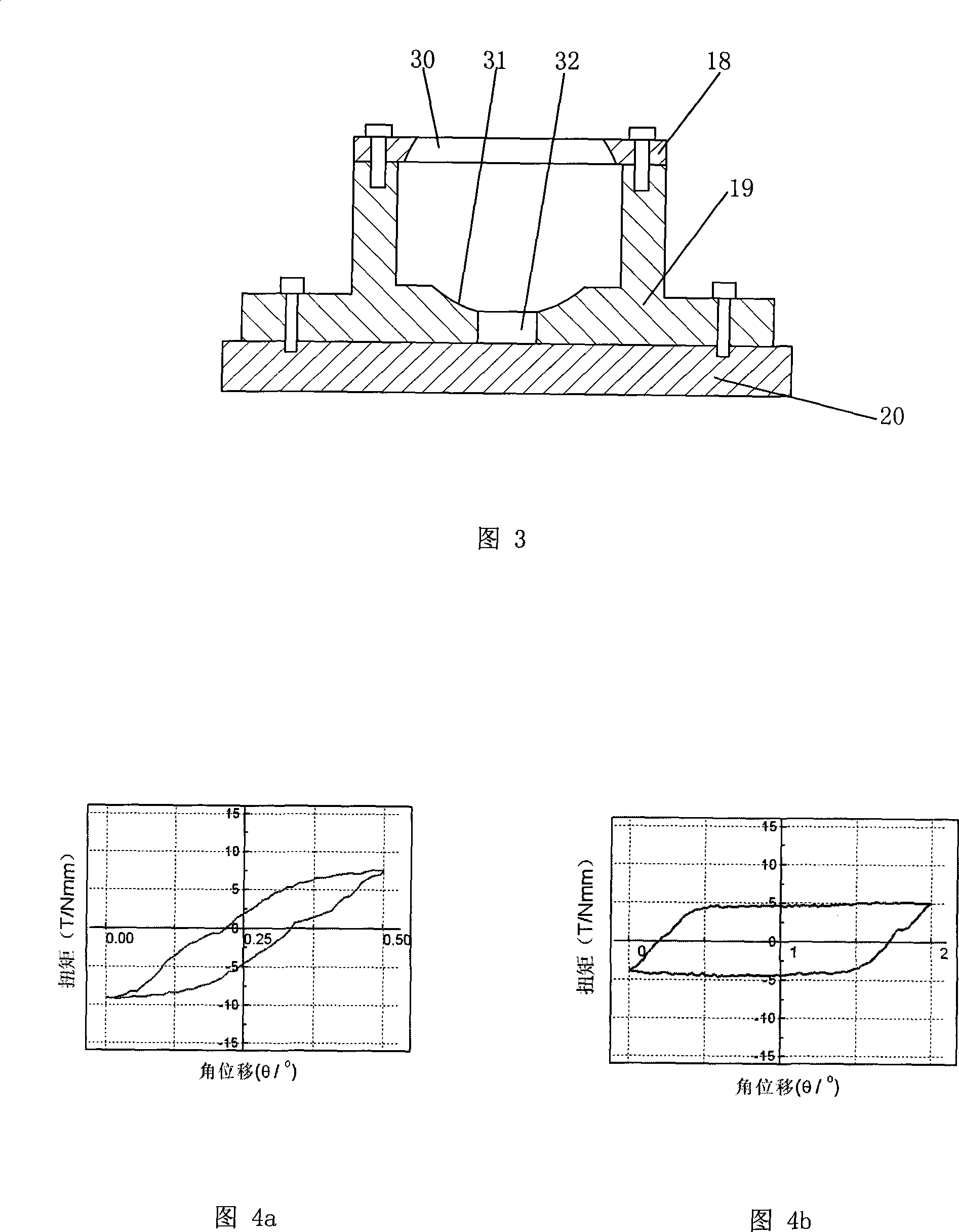

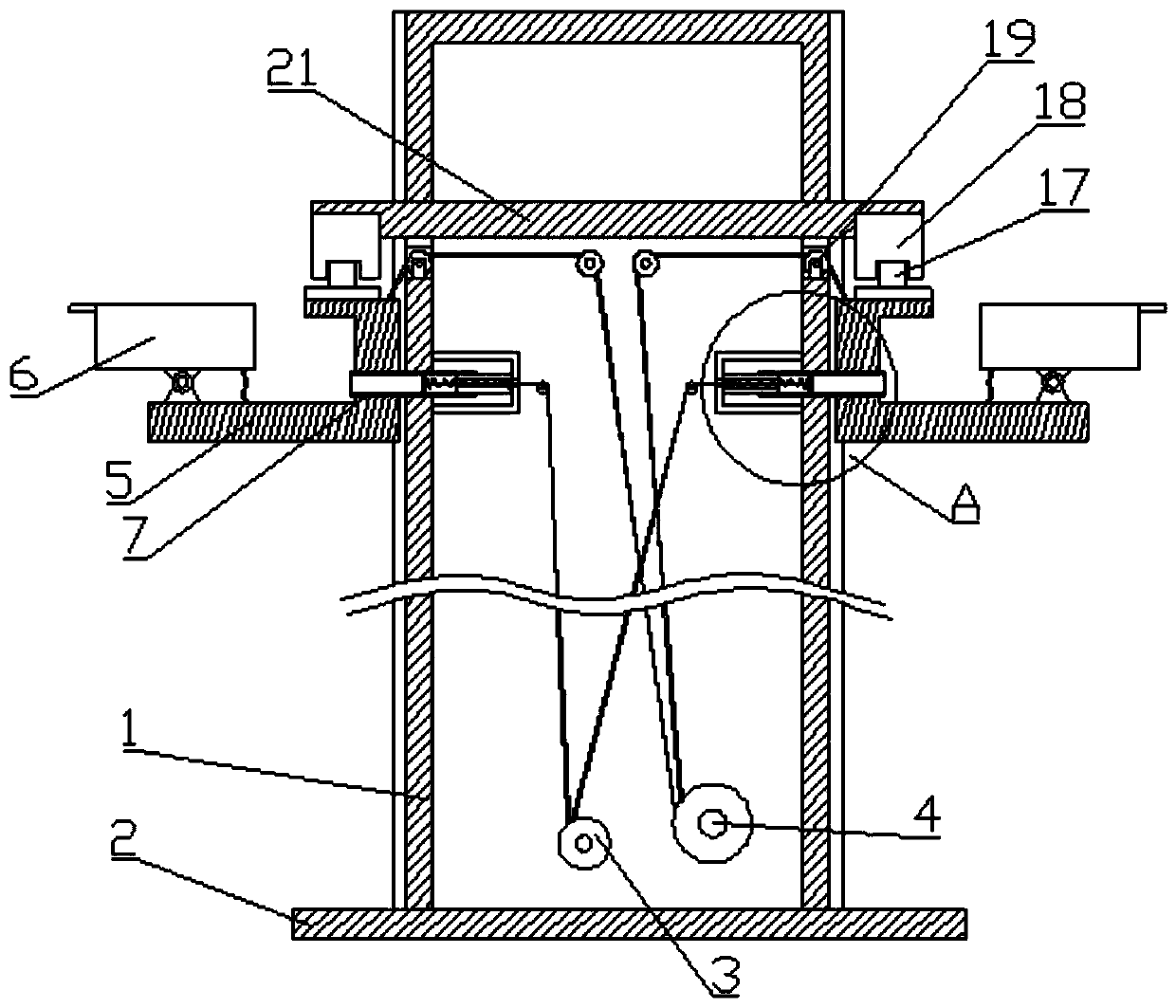

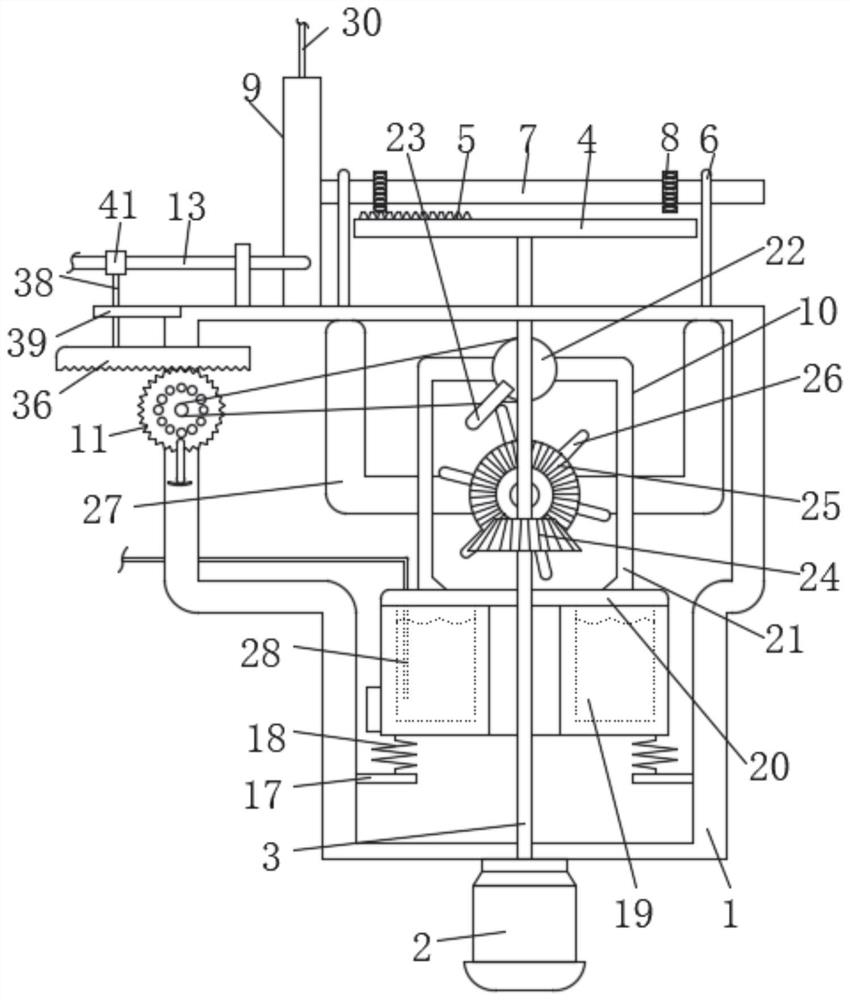

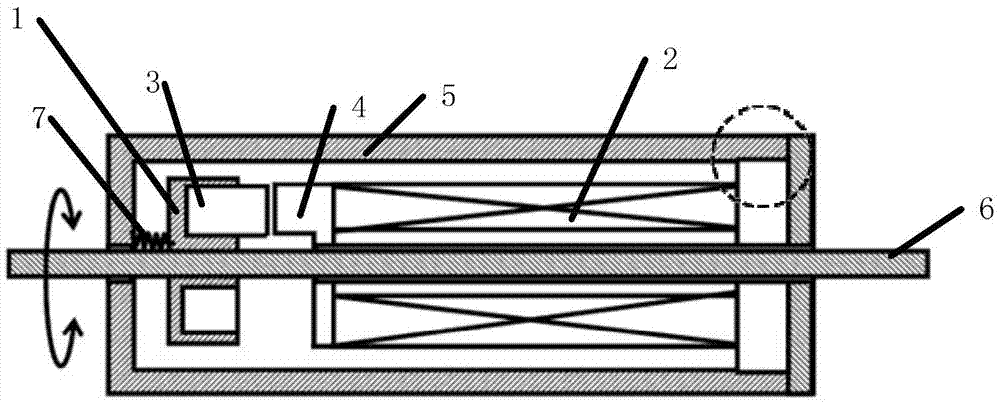

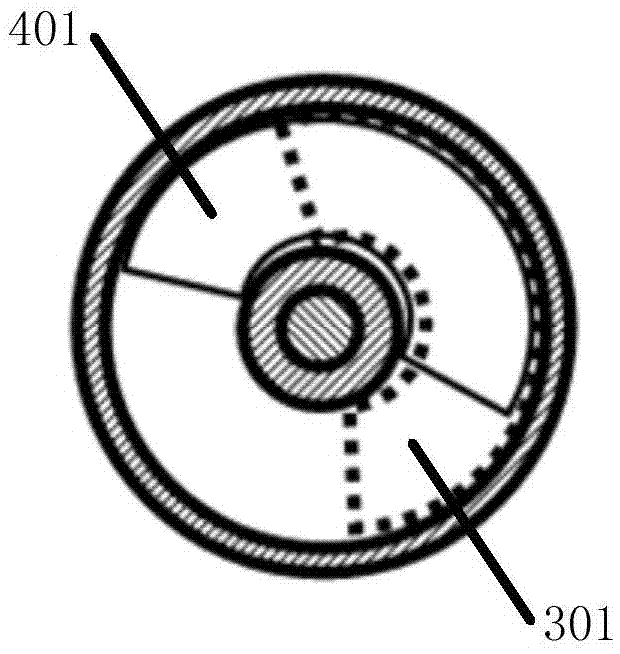

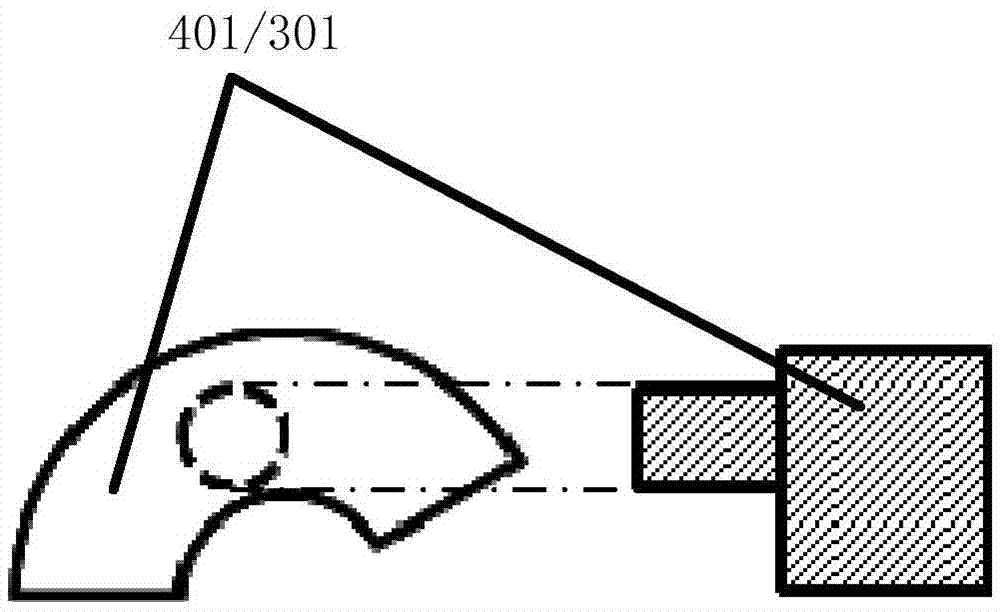

Twisting or micro-moving frictional wear test device

InactiveCN101178345BNo wear and tearAccurately characterize kinetic propertiesStructural/machines measurementInvestigating abrasion/wear resistanceFriction torqueLow speed

Owner:SOUTHWEST JIAOTONG UNIV

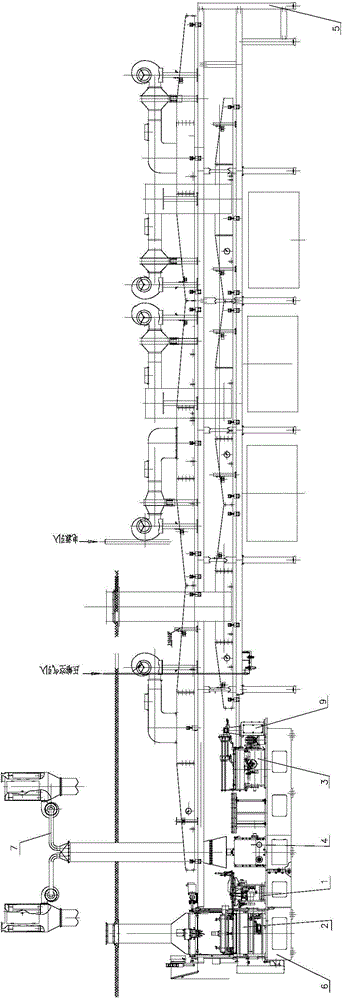

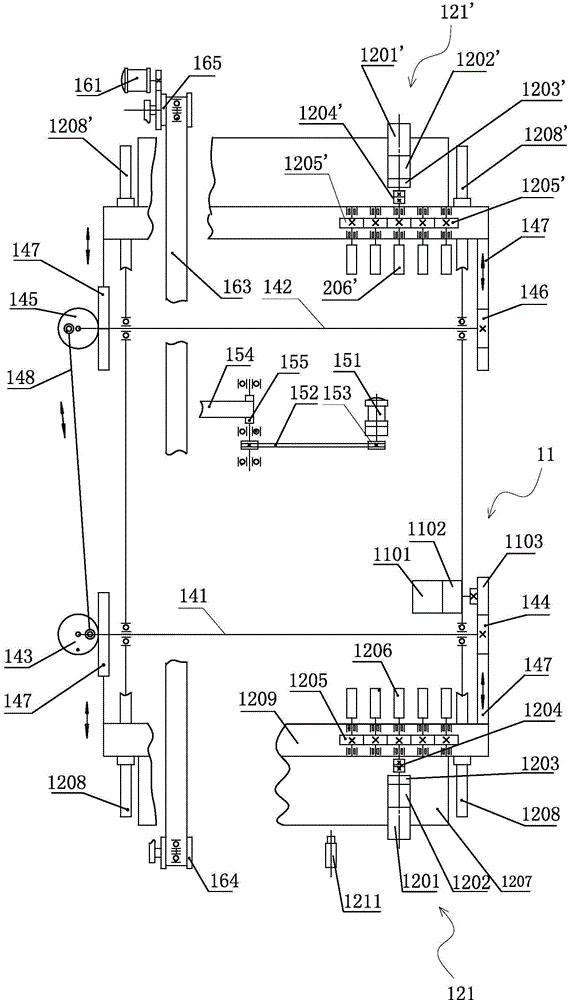

Capsule production line system

The invention relates to a capsule production system production line and belongs to the technical field of capsule production lines. The capsule production system production line comprises a mainframe base, a glue dipping machine, an oiling machine, an automat, a platform machine, a conveying drying device, a tail platform lifting mechanism, a waste material absorbing device, a large conveying belt device, a small conveying belt device and a main motor transmission case. The glue dipping machine, the oiling machine, the automat and the platform machine are arranged on the mainframe base side by side, the platform machine is installed between a lower pulling plate slideway of the conveying drying device and the automat, the main motor transmission case is connected with the platform machine, a T-shaped slide rail track is arranged between the automat and the platform machine, the glue dipping machine is respectively connected with an upper pulling plate slideway of the conveying drying device and a T-shaped sliding rail of the oiling machine, a platform machine pushing mechanism pushes die strips to respectively slide along a T-shaped sliding rail of the automat and the T-shaped sliding rail of the oiling machine and pushes the die strips having undergoing oiling to the glue dipping machine, and the die strips are dried through the conveying drying device and conveyed to the platform machine, are subject to capsule cutting and capsule peeling through the automat and are synthesized into integral capsules to be output. The capsule production system production line is driven by a servo motor, automatic production in the whole line is achieved, and the efficiency is high.

Owner:DANDONG JINWAN GRP

High-efficiency screening device

InactiveCN108906562ARealize reciprocating rotationEffective Disturbance HandlingSievingScreeningGear driveEngineering

The invention provides a high-efficiency screening device. The high-efficiency screening device comprises a processing frame body. The top of the processing frame body is open, a screen is fixedly connected to the inner side wall of the processing frame body, the section of the screen is V-shaped, and two horizontal seats are symmetrically and fixedly connected to the outer side wall of the processing frame body. The upper sides of the horizontal seats are fixedly connected with supporting columns, the top ends of the two supporting columns are fixedly connected with a supporting plate, and abearing is embedded in the middle of the supporting plate. The screening device has the advantage that when a left half gear is meshed with an intermediate gear, a right half gear is separated from the intermediate gear, and the intermediate gear rotates in one clock direction at the moment; when the left half gear and the intermediate gear are meshed, the right half gear is meshed with the intermediate gear, and the intermediate gear rotates in the opposite direction at the moment, thus achieving reciprocating rotation of the intermediate gear that intermediate gear drives a rotating rod to rotate in the reciprocating mode.

Owner:泾县狸宣文化用品有限公司

Square street lamp convenient to use

InactiveCN109855012ARealize moving up and downAchieve fixationLighting support devicesOutdoor lightingEngineeringElectronics

The invention discloses a square street lamp convenient to use, and relates to the technical field of electronics. The square street lamp comprises an installation rod, bases are arranged on the installation rod, lighting lamps are arranged on the bases, first joints are arranged at the upper ends of the bases, the first joints are matched with second joints on an installation plate by insertion,and a lifting structure for lifting the bases and a locking structure for fixing the bases are further arranged on the installation rod. The lifting structure comprises lifting ropes arranged on the bases, the lifting ropes penetrate through first guide wheels in first through holes to be connected to a second collection wheel in the installation rod, and the first through holes are formed in theside wall of the installation rod. The square street lamp is convenient to use, install and maintain.

Owner:覃天

Adsorption and decomposition integrated formaldehyde removal equipment

InactiveCN111672318AReduce volumeIncrease flow rateCombination devicesGas treatmentElectrolytic agentEngineering

The invention discloses adsorption and decomposition integrated formaldehyde removal equipment. The equipment comprises a machine shell, and an axial flow fan is installed on the outer side wall of the machine shell. An air inlet corresponding to the axial flow fan in position is formed in the side wall of the machine shell. A liquid storage box and a control piece are fixedly placed on the innerbottom wall of the machine shell. Electrolyte and two electrodes electrically connected with the control piece are contained in the liquid storage box. An outer cylinder is embedded in the top wall ofthe liquid storage box, a liquid inlet is formed in the bottom of the outer cylinder, an inner net cylinder is rotationally installed in the outer cylinder in a sealed mode, circular plates are fixedly installed at the two ends of the inner net cylinder in a sealed mode, and a linkage mechanism is arranged on one circular plate. Formaldehyde in air can be uninterruptedly transferred into a film layer, then formaldehyde is transferred into the electrolyte from the film layer to be decomposed, meanwhile, the purposes of adsorbing formaldehyde and decomposing formaldehyde are achieved, energy consumption of equipment is low, the use cost is low, and the purpose of efficiently removing formaldehyde can be achieved on the premise that the specification of an electrolytic tank is not enlarged.

Owner:吴建友

High-efficiency material screening and separation device with adaptive disturbance function

InactiveCN108906591ARealize reciprocating rotationEffective Disturbance HandlingSievingScreeningLeft halfGear wheel

The invention provides a high-efficiency material screening and separation device with an adaptive disturbance function. The material screening and separation device comprises a processing frame body.The top of the processing frame body is open, a screen is fixedly connected to the inner side wall of the processing frame body, the section of the screen is V-shaped, and two horizontal seats are symmetrically and fixedly connected to the outer side wall of the processing frame body. The upper sides of the horizontal seats are fixedly connected with supporting columns, the top ends of the two supporting columns are fixedly connected with a supporting plate, and a bearing is embedded in the middle of the supporting plate. The material screening and separation device has the advantage that when a left half gear is meshed with an intermediate gear, a right half gear is separated from the intermediate gear, and the intermediate gear rotates in one clock direction at the moment; when the lefthalf gear and the intermediate gear are meshed, the right half gear is meshed with the intermediate gear, and the intermediate gear rotates in the opposite direction at the moment, thus achieving reciprocating rotation of the intermediate gear that drives a rotating rod to rotate in the reciprocating mode.

Owner:合肥晶诺知识产权信息服务有限责任公司

Anesthesia apparatus disinfection device for anesthesia room

InactiveCN111973779AAchieve disinfectionAchieve fixationLavatory sanitoryChemicalsAnesthetic roomElectric machinery

The invention discloses an anesthesia apparatus disinfection device for an anesthesia room. The anesthesia apparatus disinfection device comprises a bottom plate, wherein a box body is fixedly connected to the top of the bottom plate; a square box is fixedly connected to the top of the box body; the lower part of the left side of the square box is communicated with a water inlet pipe of a water pump; a water outlet pipe of the water pump is communicated with a hose; the right end of the hose is communicated with a spray head; the right side of the top of the box body is fixedly connected witha motor seat preset on the right side of a first motor; and a fixing device is arranged below the box body. According to the anesthesia apparatus disinfection device for the anesthesia room, through cooperation of the bottom plate, the box body, the spray head, the hose, the water pump, the square box, the first motor and the fixing device, a cross rod is inserted into an apparatus, a first springdrives a sliding block to move inwards, and the water pump sprays alcohol in the square box out of the spray head along the hose, so that disinfection of the apparatus is realized, the apparatus doesnot need to be disinfected manually, the sharp part of the apparatus is prevented from hurting workers, and the safety of the workers is guaranteed.

Owner:米娜

Special rapid drainage monitoring equipment used after thyroid and breast surgery

InactiveCN112546310APlay a supporting roleReal-time monitoring of congestionMedical devicesVisible signalling systemsEngineeringDrainage tubes

The invention discloses special rapid drainage monitoring equipment used after a thyroid and breast surgery. The equipment comprises a supporting frame; a motor is fixedly connected to the lower surface of the supporting frame; a shaft I is fixedly connected to the top of an output shaft on the motor; the surface of the shaft I penetrates through the lower surface of the supporting frame and is rotationally connected with the supporting frame; the top of the shaft I penetrates through the upper surface of the supporting frame and is fixedly connected with a rotating plate; the upper surface ofthe rotating plate is fixedly connected with an arc-shaped rack; and the upper surface of the supporting frame is fixedly connected with two side plates. Through cooperative use of the structures, the problems that in the actual use process, due to the fact that in traditional drainage equipment, a drainage tube is extremely prone to being blocked, consequently drainage is not smooth, a traditional drainage device does not have the detection function, consequently the blockage of the drainage tube is difficult to find, and if treatment is not conducted in time, potential safety hazards are extremely prone to being generated, and secondary injury is brought to a patient are solved.

Owner:THE FIRST PEOPLES HOSPITAL OF NANTONG

Wisdom school solid waste recycling treatment device

The invention relates to the technical field of wisdom school waste treatment and discloses a wisdom school solid waste recycling treatment device comprising a treatment box. Smashing shafts are installed in the treatment box. The outside of each smashing shaft is provided with a plurality of smashing blades which are arranged in a staggered manner. The left side of each smashing shaft penetratesthrough the treatment box to be connected with a gear. A smashing cylinder is installed at the bottom end in the treatment box. A rotating shaft is installed in the smashing cylinder. The outside of the rotating shaft is provided with a rotating spiral. The left side of the rotating shaft penetrates through the treatment box to be connected with a crank. The middle of the crank is provided with asliding sleeve. The upper end of the sliding sleeve is provided with a lifting shaft. The middle of the lifting shaft is provided with a rack which is meshed with the gears. A feeding cylinder is installed in the upper end of the treatment box. A rotating shaft is installed in the feeding cylinder. The outside of the rotating shaft is provided with rotating blades. According to the wisdom school solid waste recycling treatment device, reciprocating rotation of the smashing shafts is achieved, and the smashing shafts cooperate with the staggered smashing blades to achieve effective smashing ofthe waste; and meanwhile, the rotating shaft and the rotating spiral which adopt the same power source are arranged and cooperate.

Owner:湖南省骏北科技有限公司

A seed soaking and accelerating germination device for biological breeding that can self-clean dry and floating seeds

ActiveCN112567924BFlip functionAutomate cleaningFiltration separationGerminating apparatusGermination

Owner:河北汉青种业有限公司

Rotation driving device capable of being implemented in a relatively high temperature environment

ActiveCN105449965AManufacturing and equipment simplificationShaft radial size reductionSynchronous machinesDislocationRotor magnets

The invention provides a rotation driving device capable of being implemented in a relatively high temperature environment. A rotation shaft stator and a rotation shaft rotor are coaxially or non-coaxially arranged, and opposite end surfaces of a stator magnet and a rotor magnet can rotate relative to each other between a dislocation position and a non-dislocation position. In the rotation driving device, a stator and a rotor can be arranged in the same axial direction, so that the radial size of a shaft is reduced; a coil magnet yoke and a rotor magnetic attraction body can be made of magnetic conduction material bodies so as to be different from a permanent magnet and can be used in a relatively high temperature environment; a rotor magnet yoke is formed by a plurality of small units which are embedded into a rotor structural body groove, the size of the yoke in a rotational direction can be conveniently adjusted according to a single cylinder and combination thereof; a plurality of stator and rotor pairs are combined in a series form, so that the rotation output torque can be multiplied; and when a coil in a stator comprises two coils, rotation in a reciprocating way can be achieved by making the two coils alternately energized and acting on an adjacent rotor.

Owner:杨斌堂

farming plow capable of turning soil

ActiveCN108551773BSimple structureRealize reciprocating rotationSoil-working equipmentsAgricultural engineeringStructural engineering

The invention discloses an agricultural plough capable of efficiently turning soil. The plough comprises a first connecting plate, and a second connecting plate is hinged to the side wall of the firstconnecting plate; the agricultural plough capable of efficiently turning the soil is simple in structure, and the first connecting plate is fixed to a carrier and can move leftwards along with the carrier to turn up the soil; when the second connecting plate rotates clockwise to a certain extent, a metal elastic sheet can be bent rightwards, a first conductive sheet is separated from a second conductive sheet to make a first electromagnet and a second electromagnet powered off, and a plurality of extruding blocks extrude a first sliding rod to make the first sliding rod move up and down relative to a mounting box; under the function of connecting rods, two second sliding rods move horizontally, and two third electromagnets are powered on and repel each other; through third springs, soil turning rods can vibrate, the soil turning area is larger, and the soil turning effect is improved.

Owner:惠安凯云石业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com