Patents

Literature

32results about How to "High glue removal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

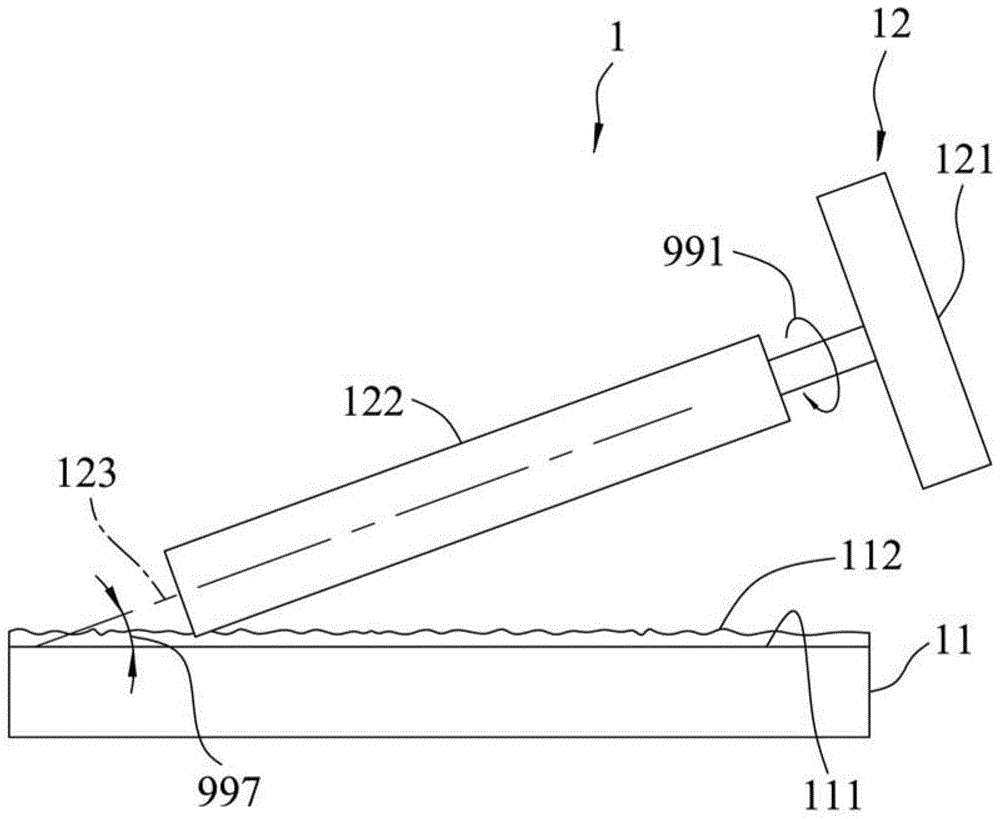

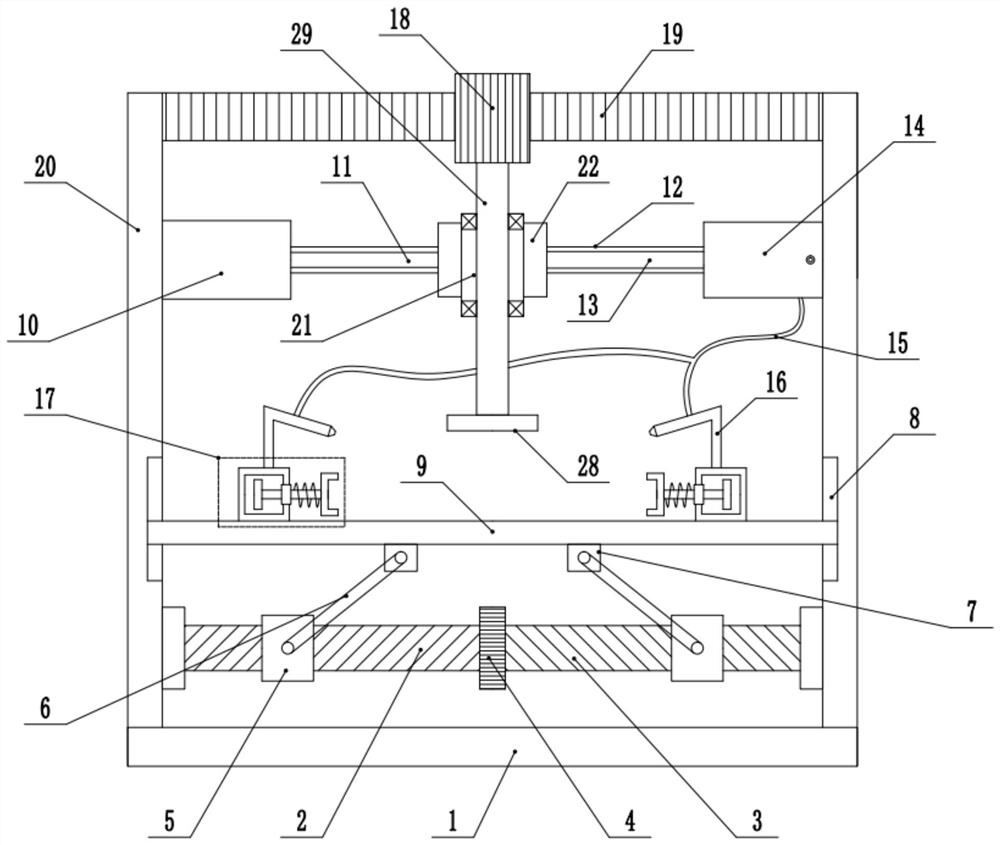

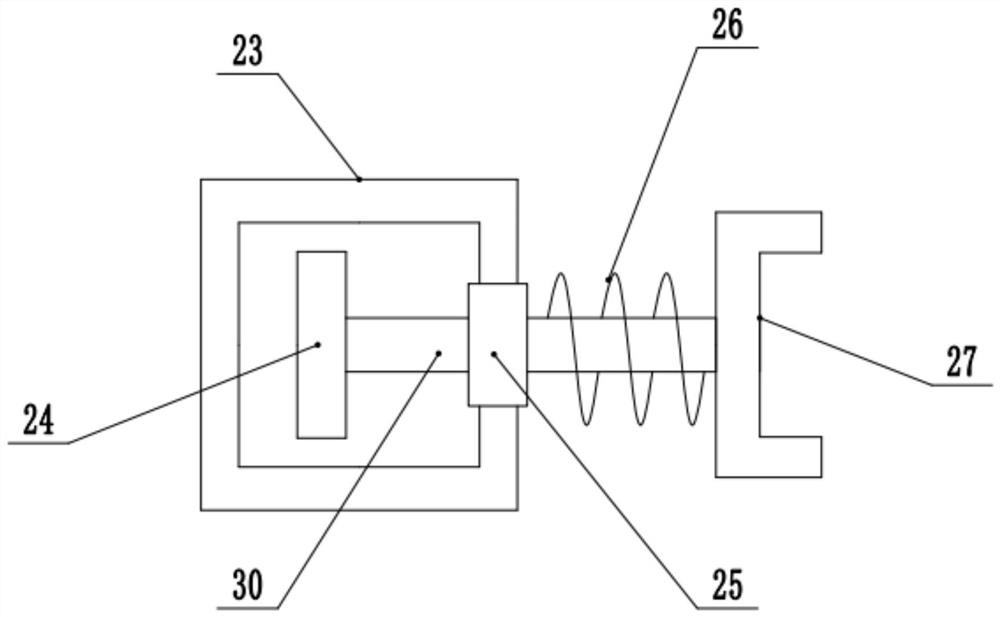

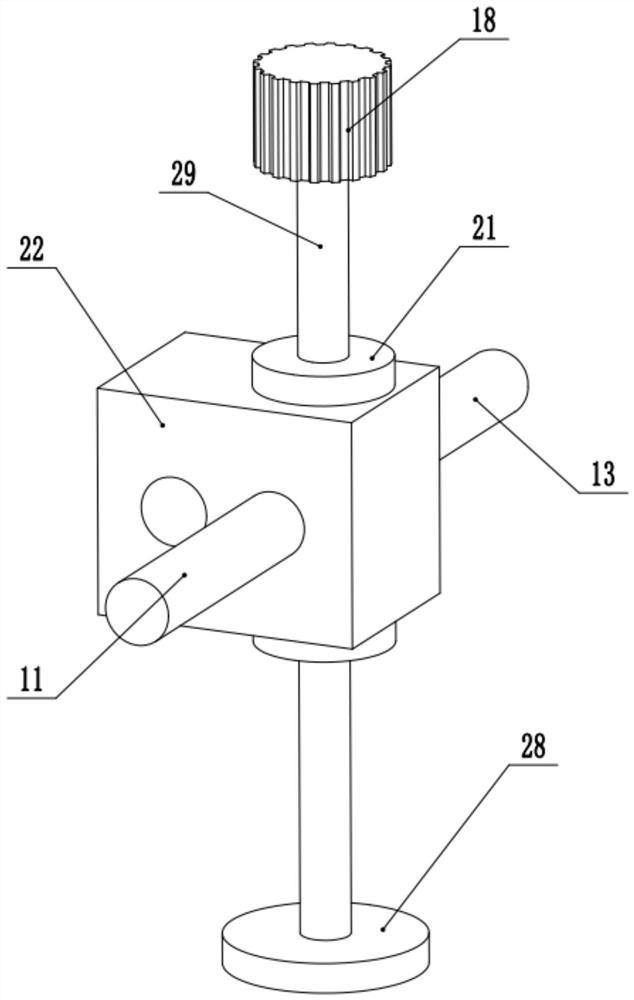

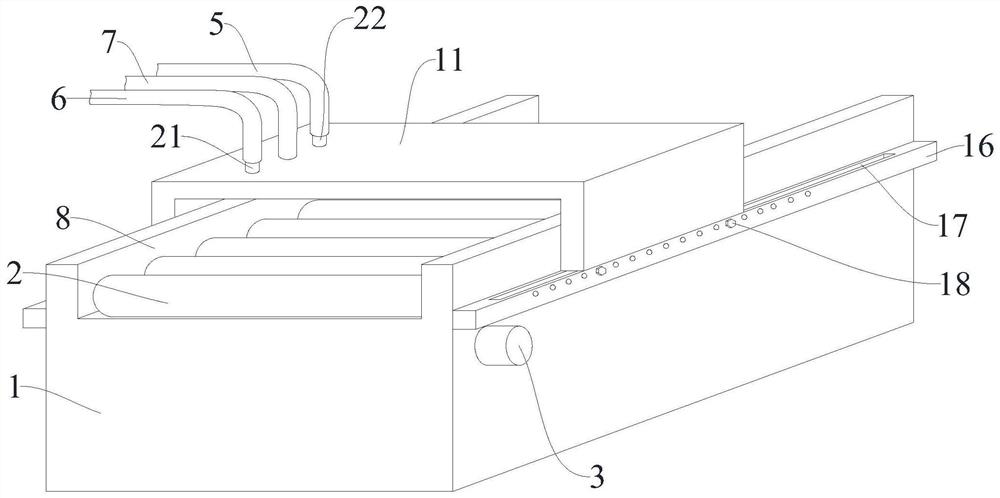

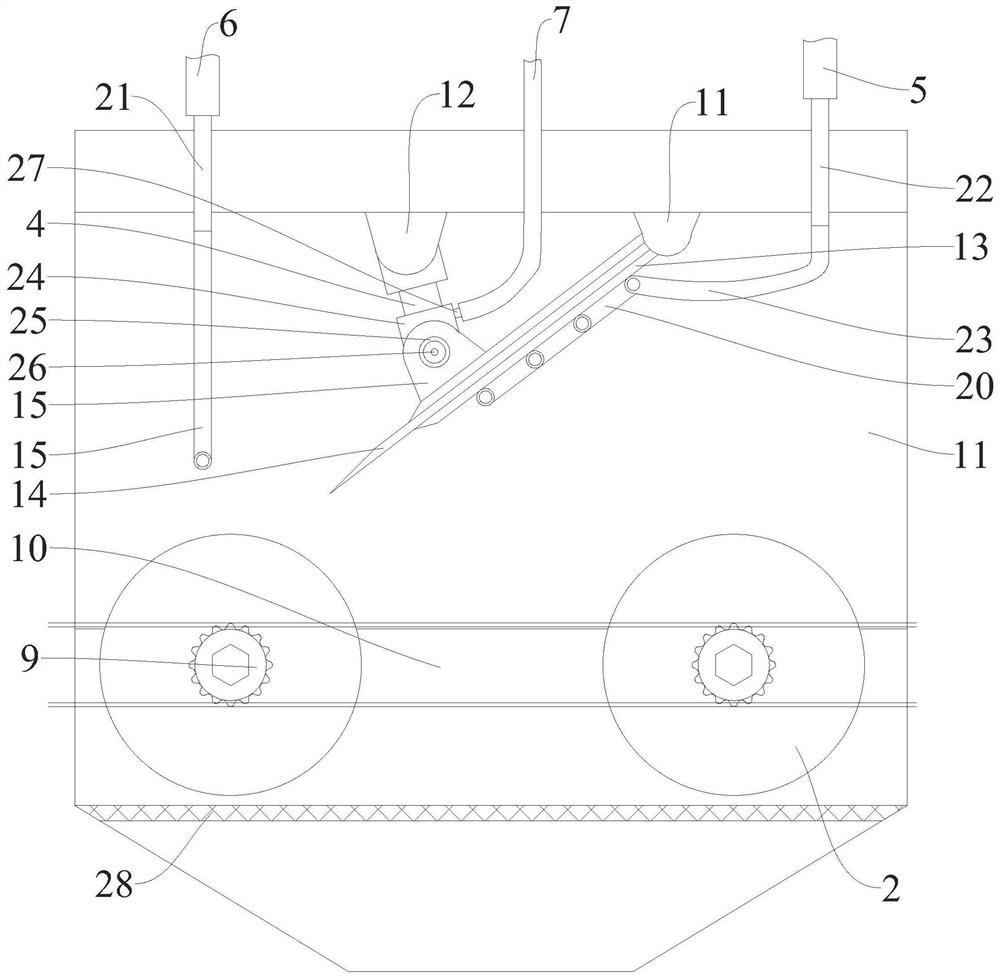

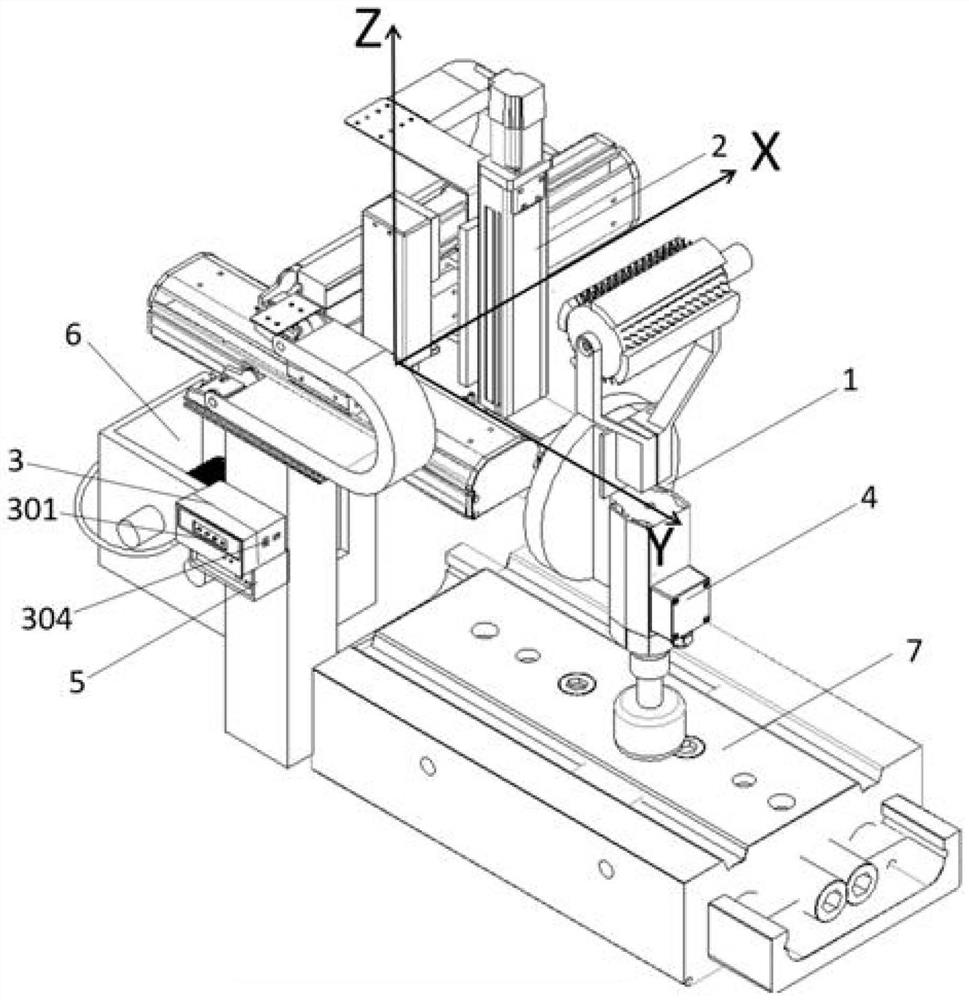

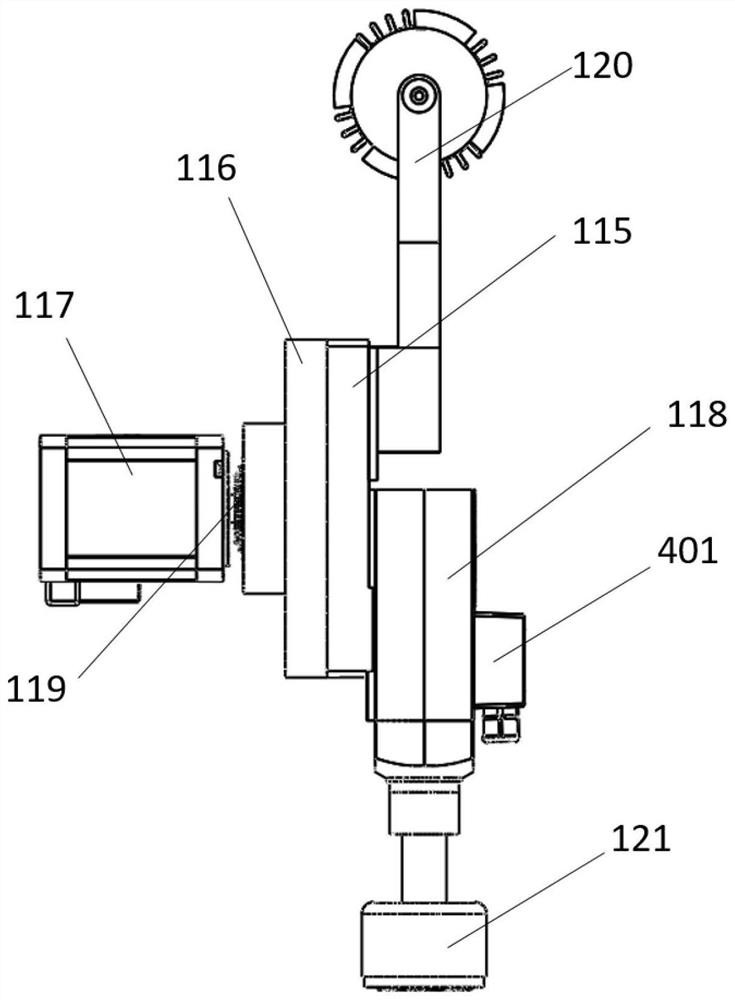

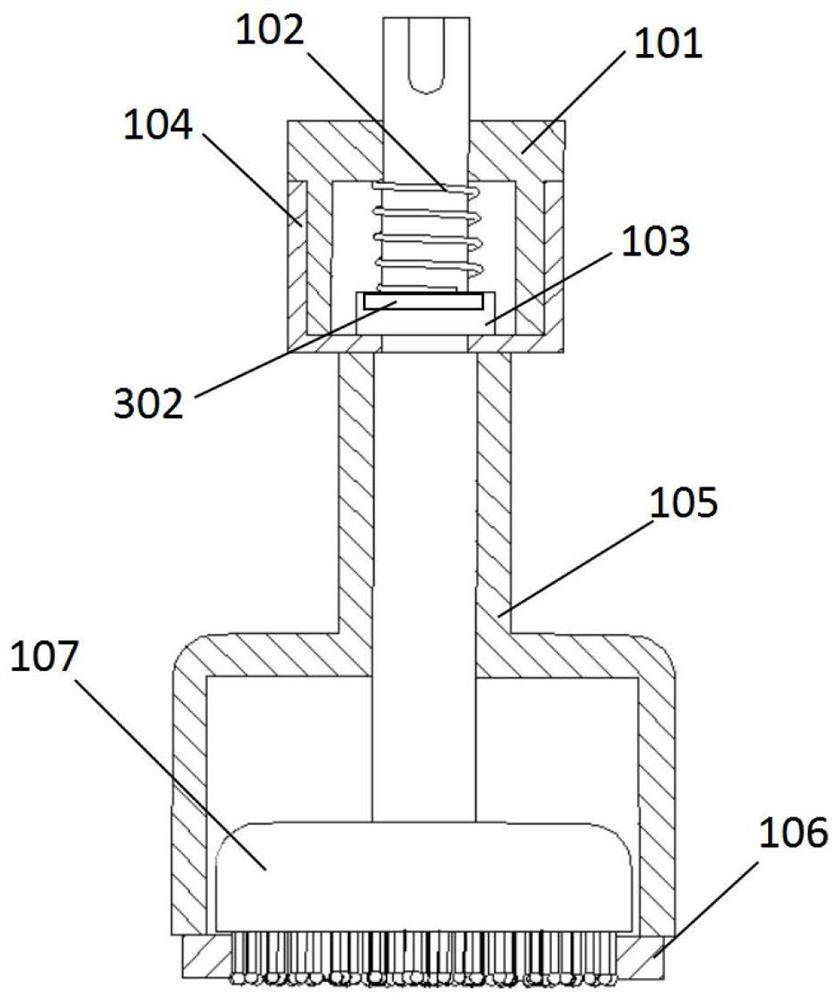

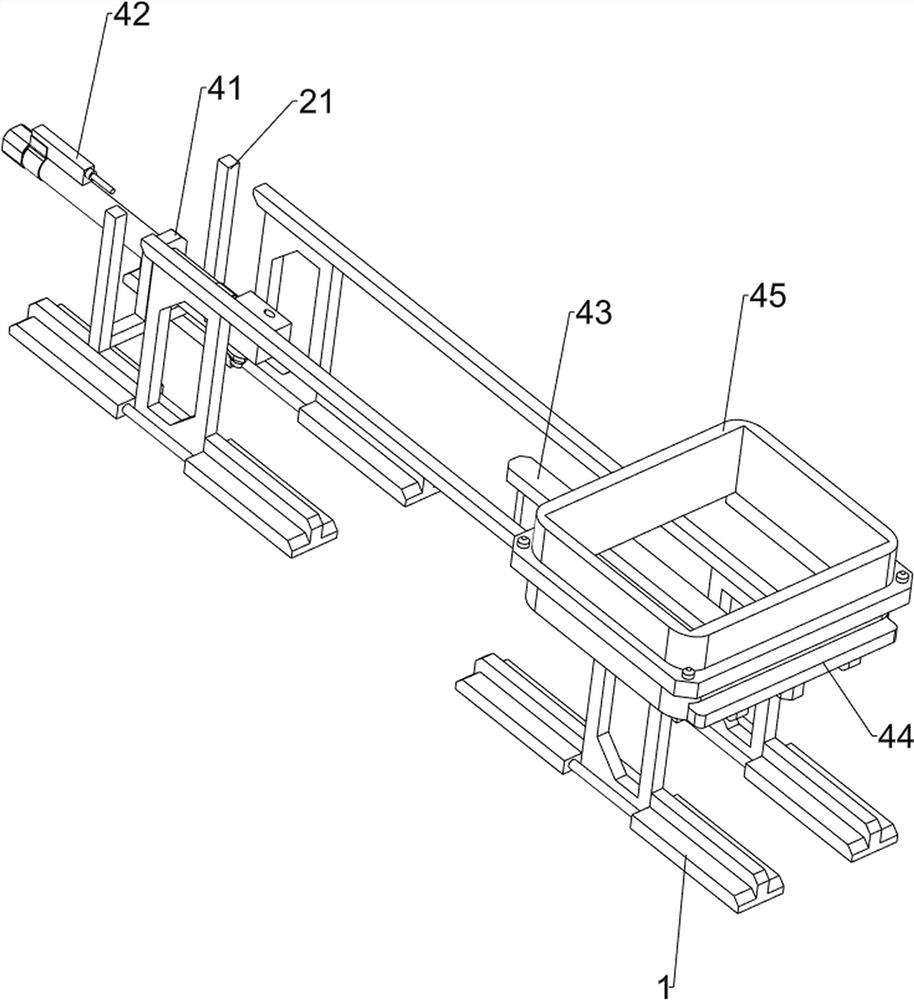

Dispensing subsequent glue removing device for electronic component

ActiveCN110936276AHigh glue removal efficiencyReasonable structureGrinding drivesGrinding machinesPillow block bearingGear wheel

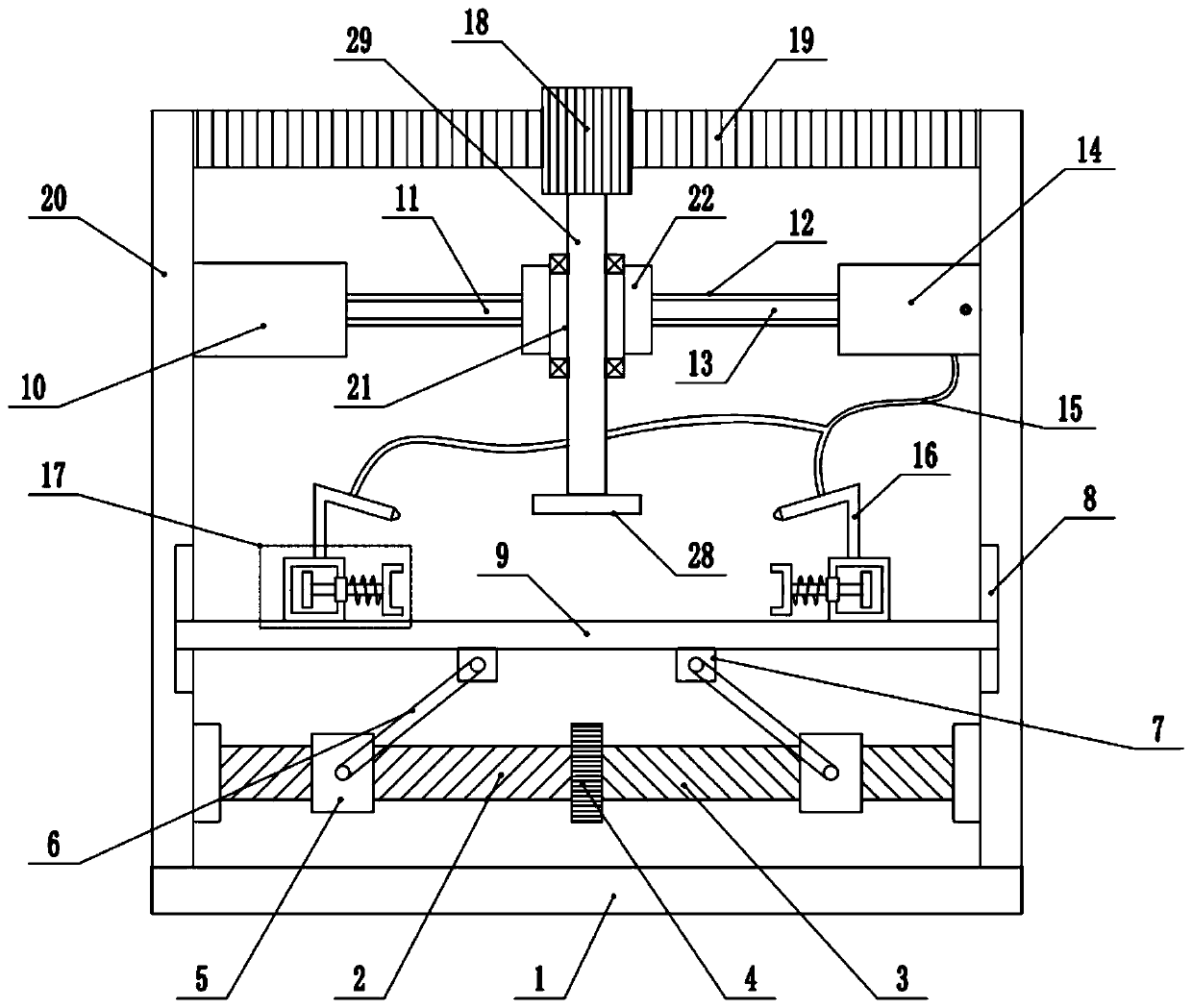

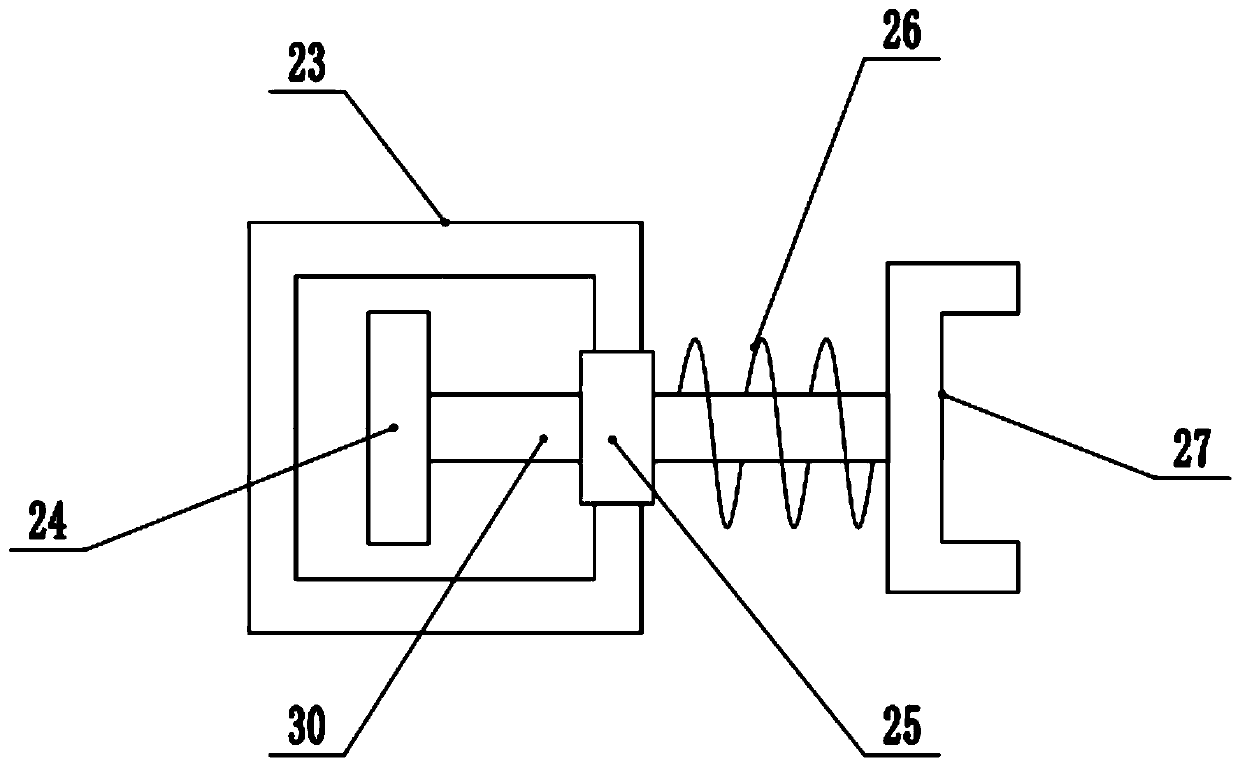

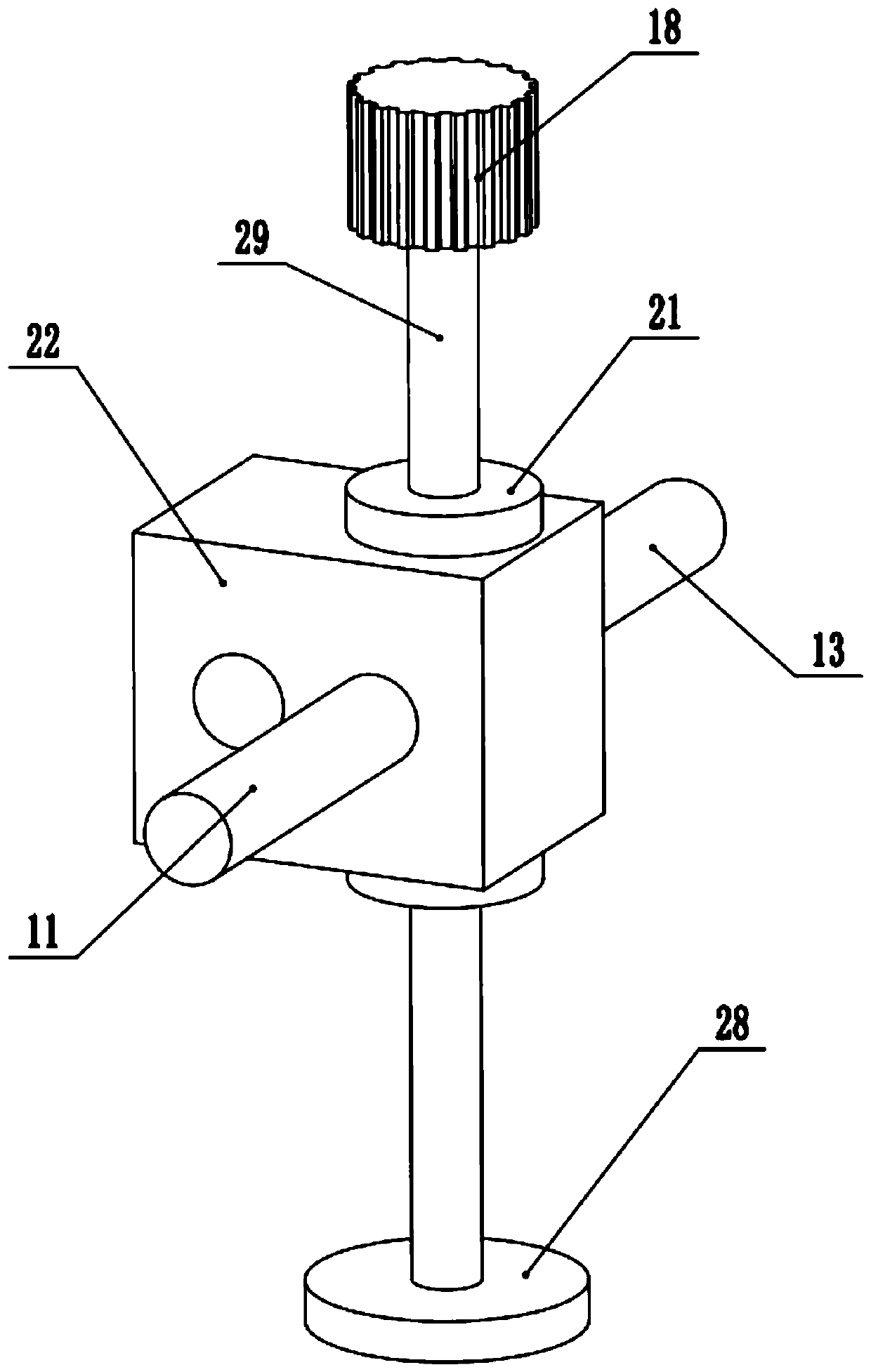

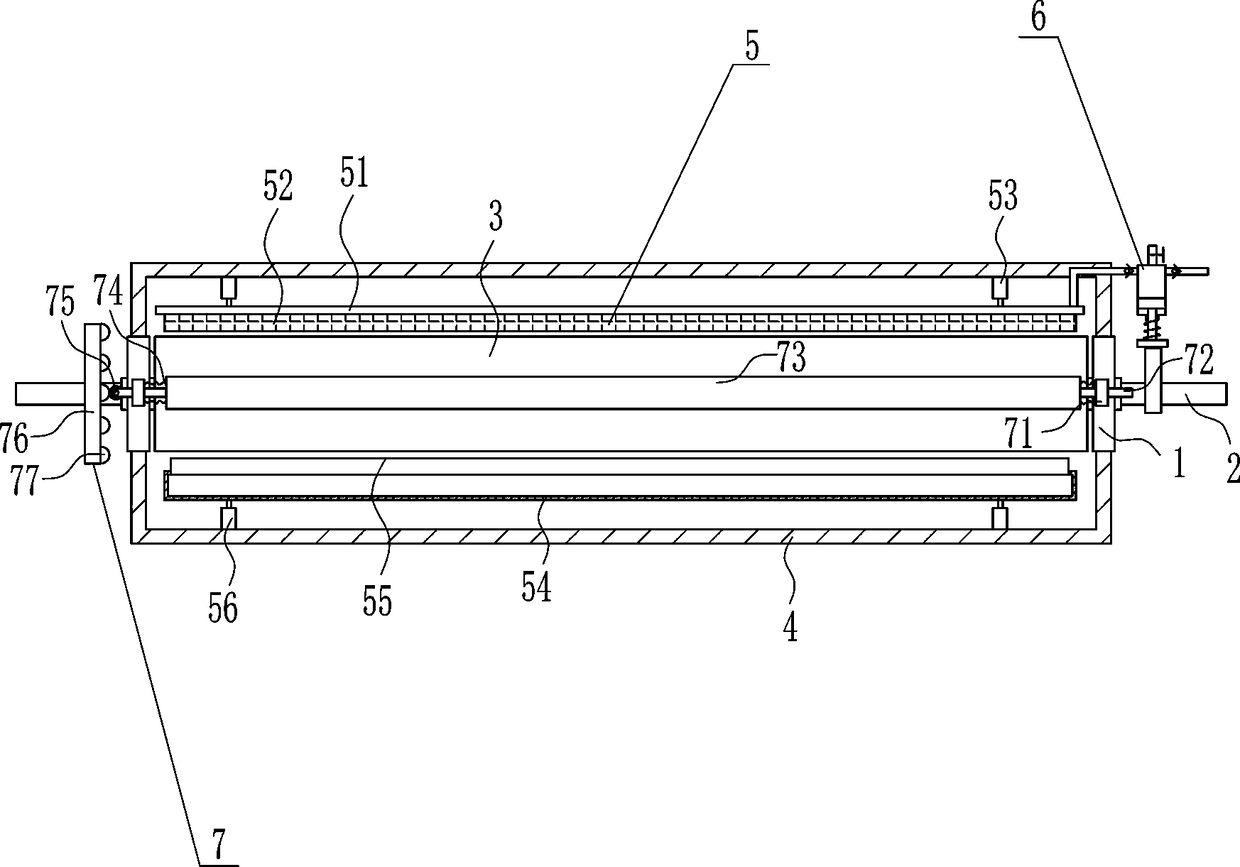

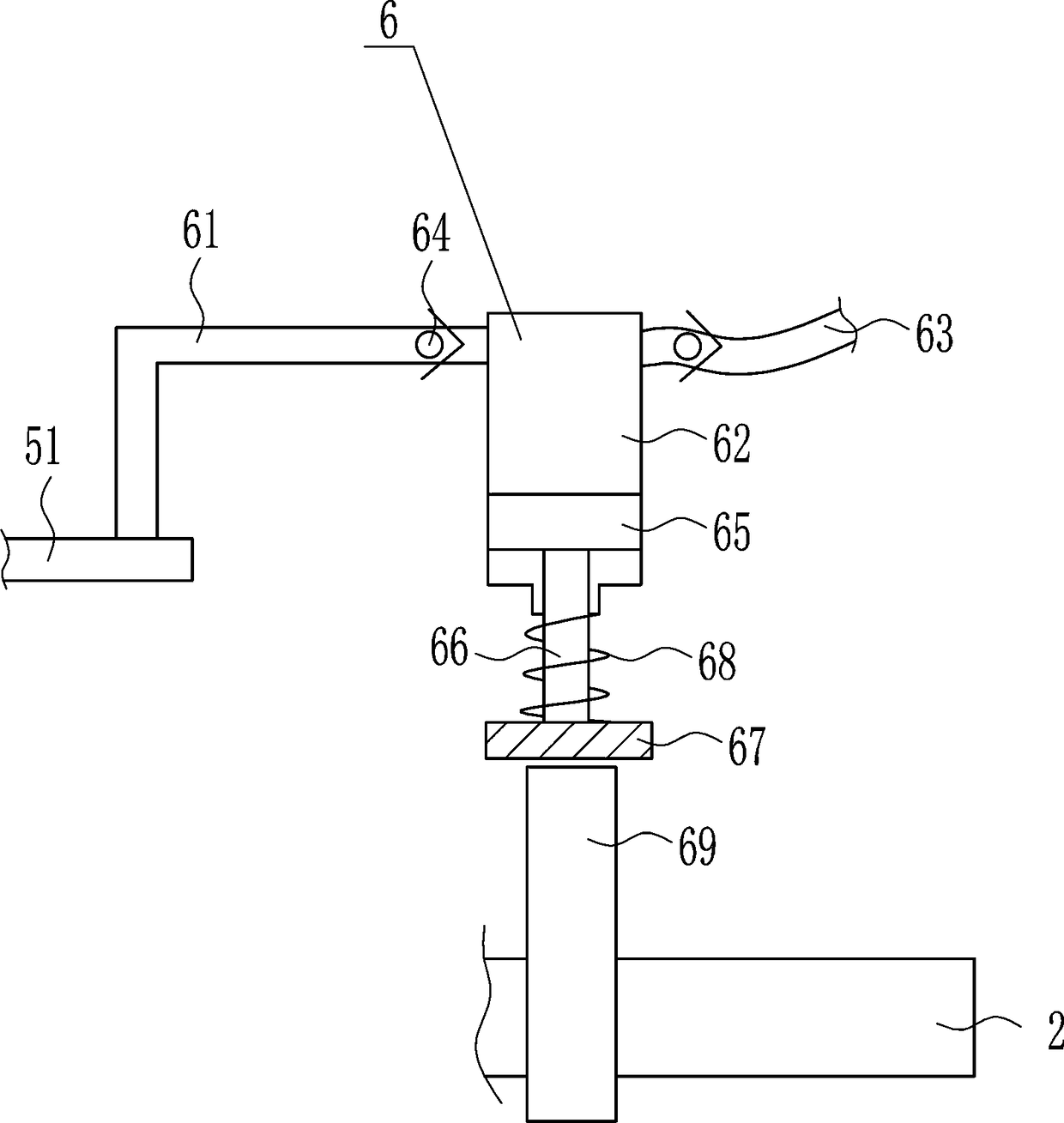

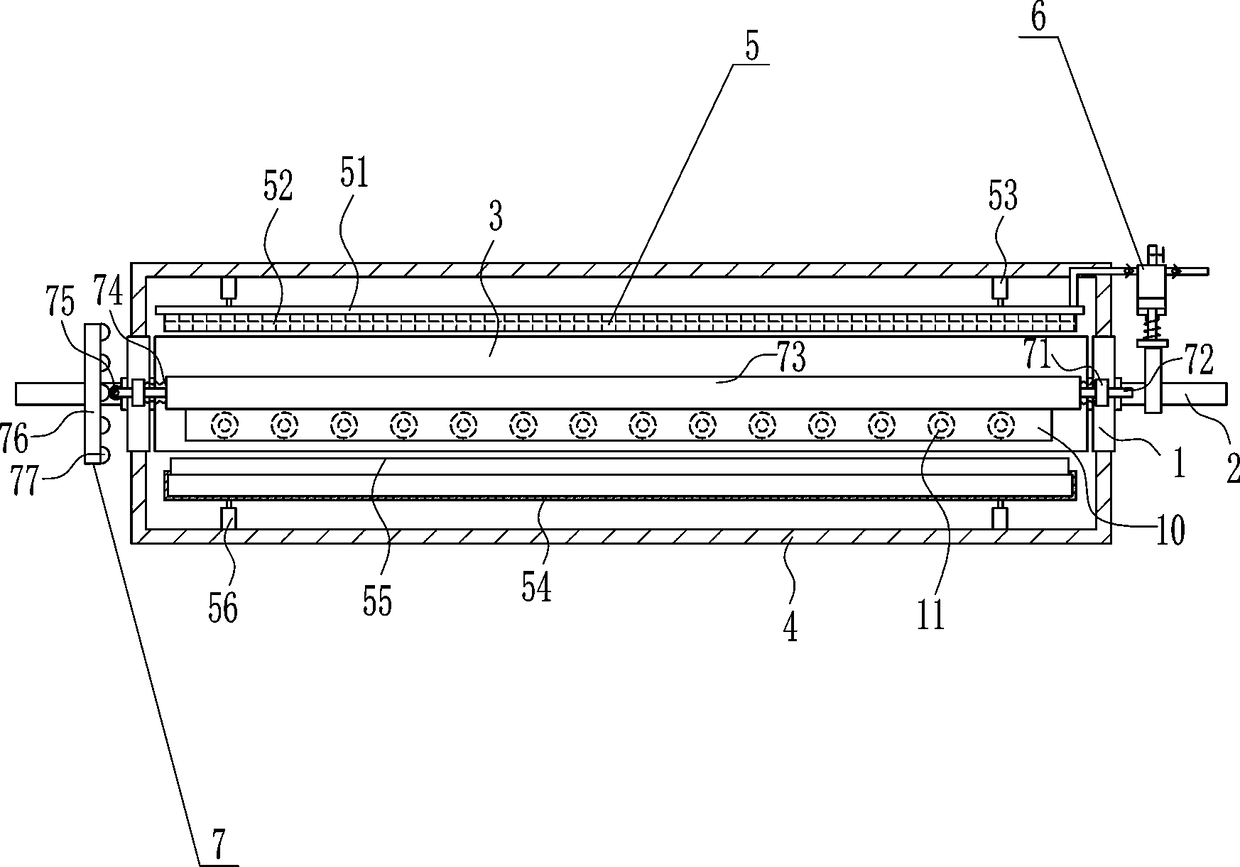

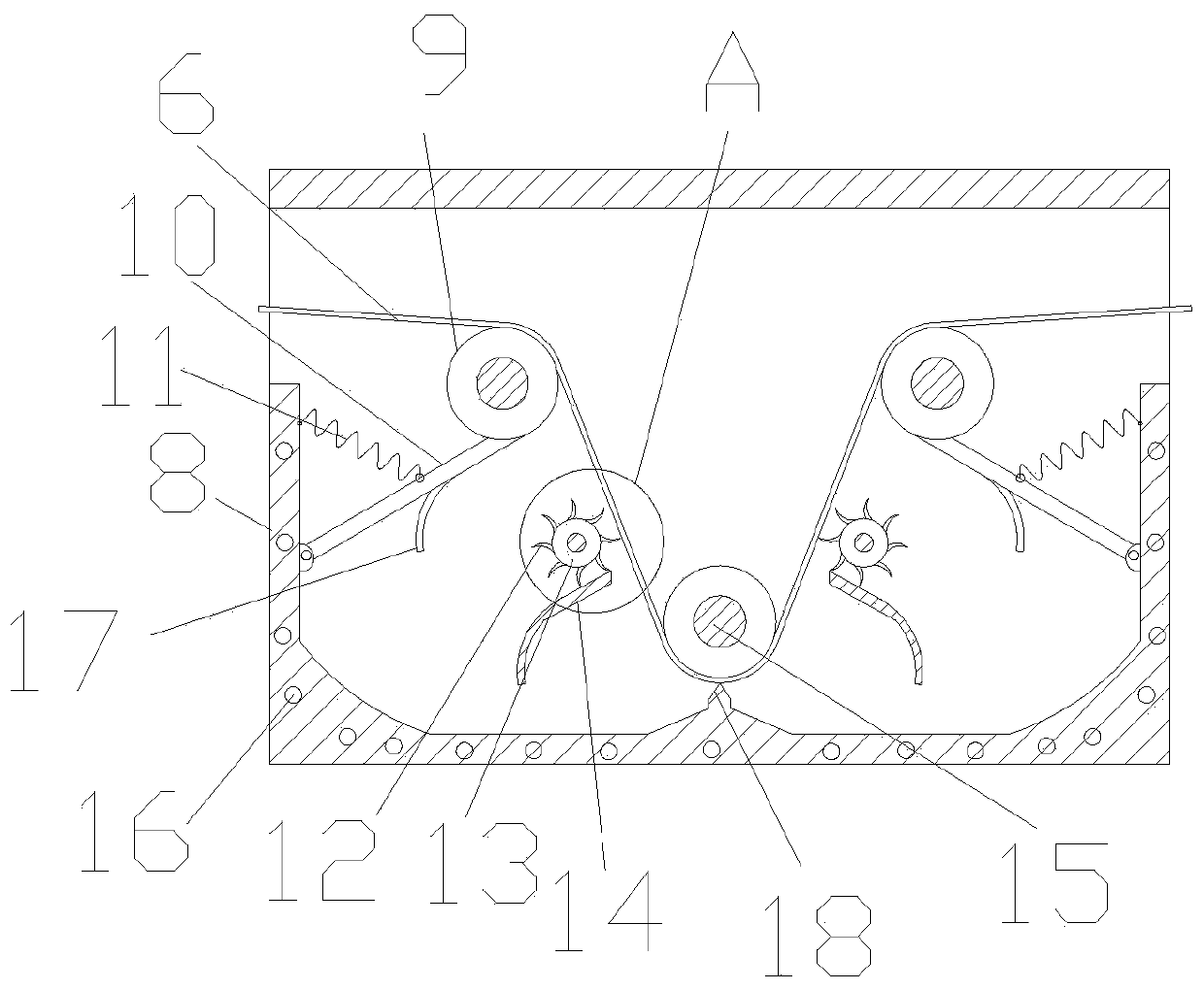

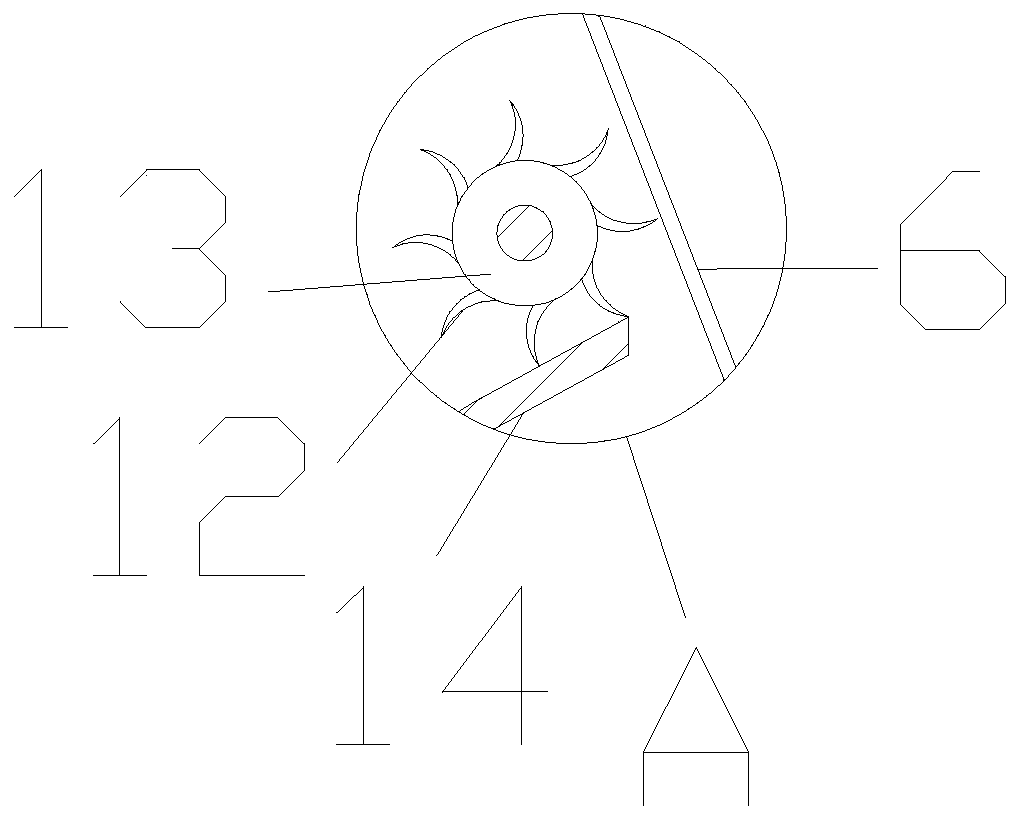

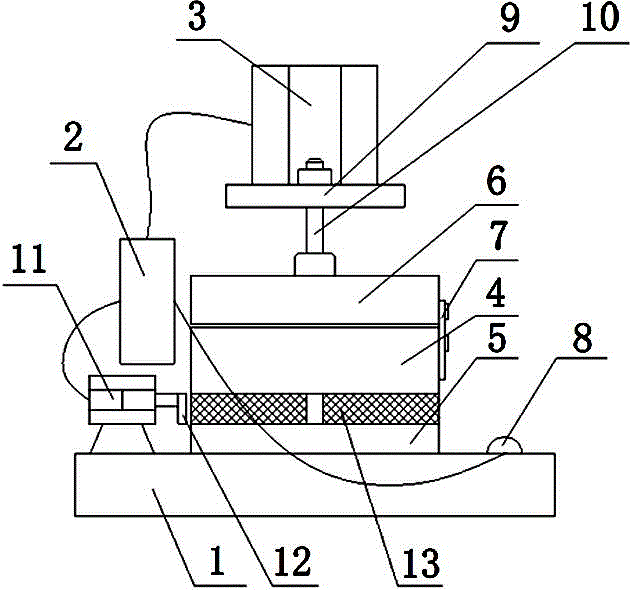

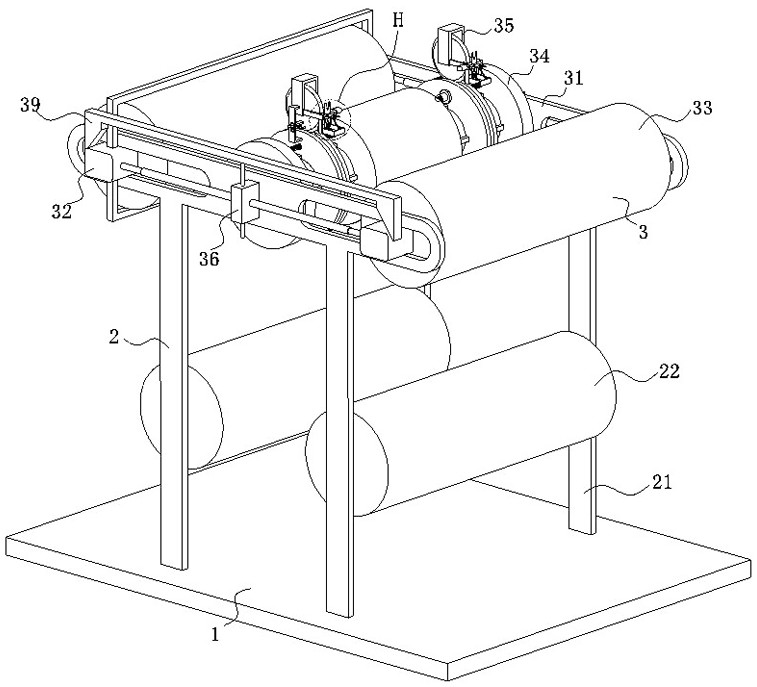

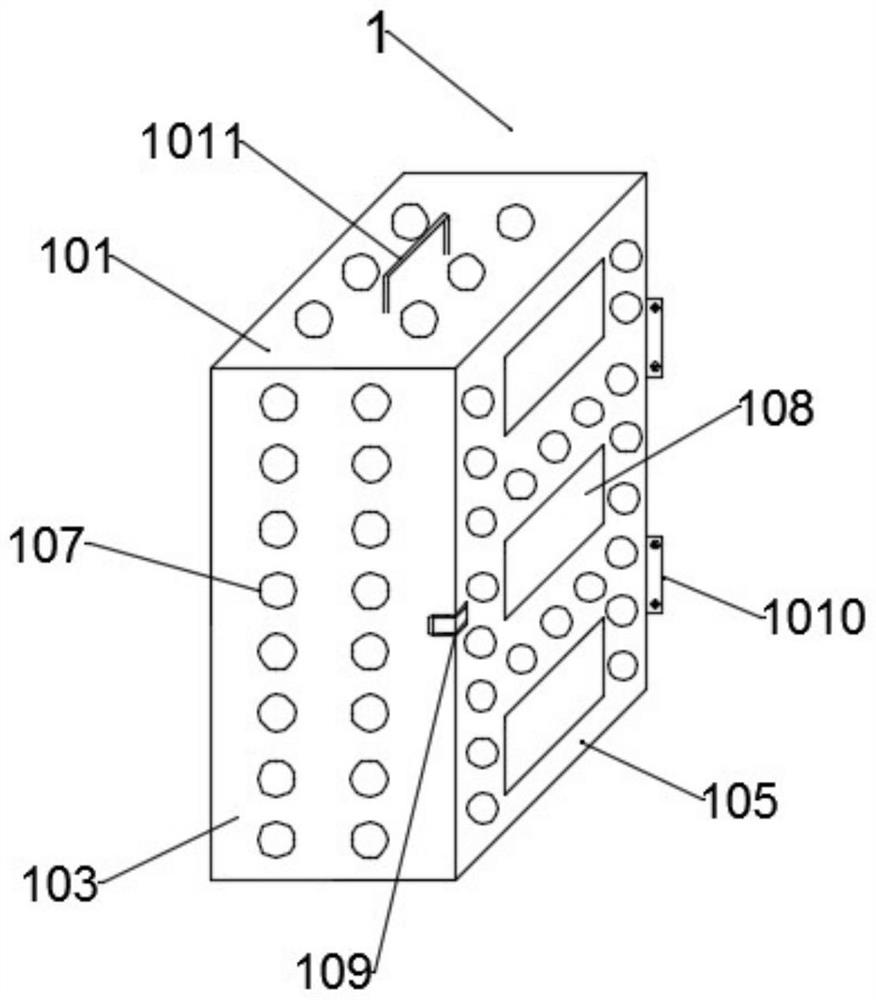

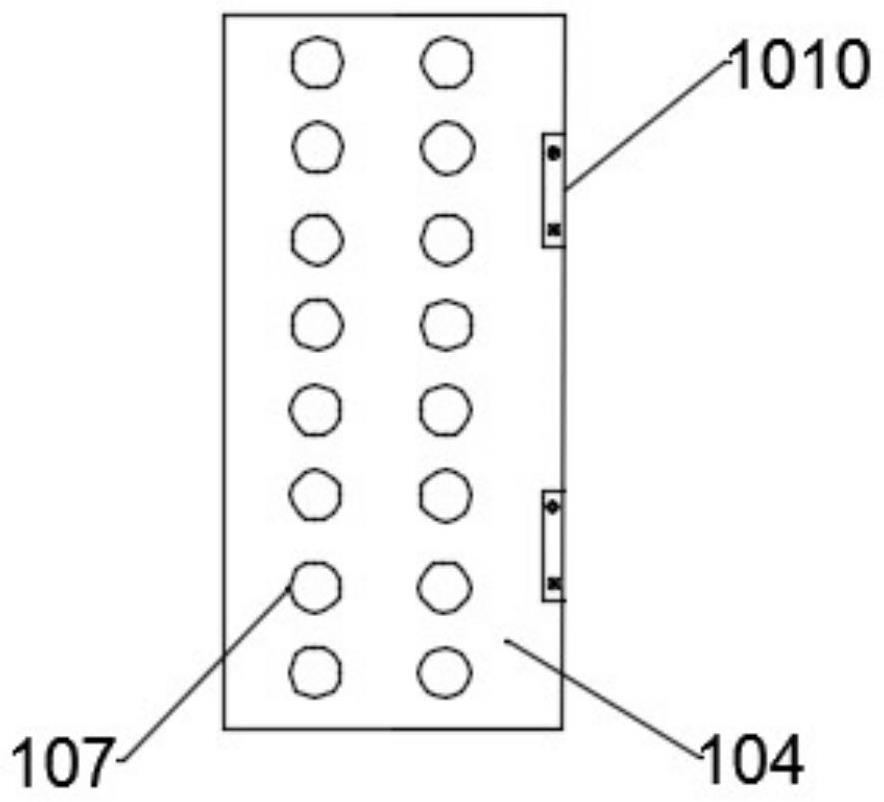

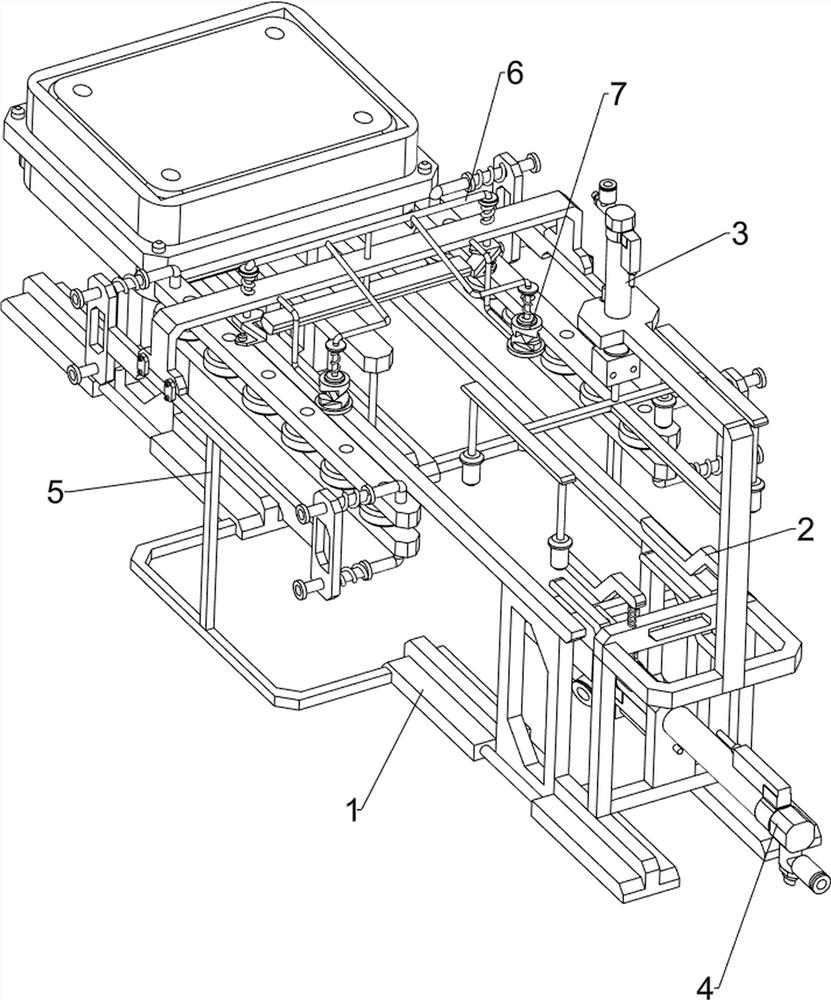

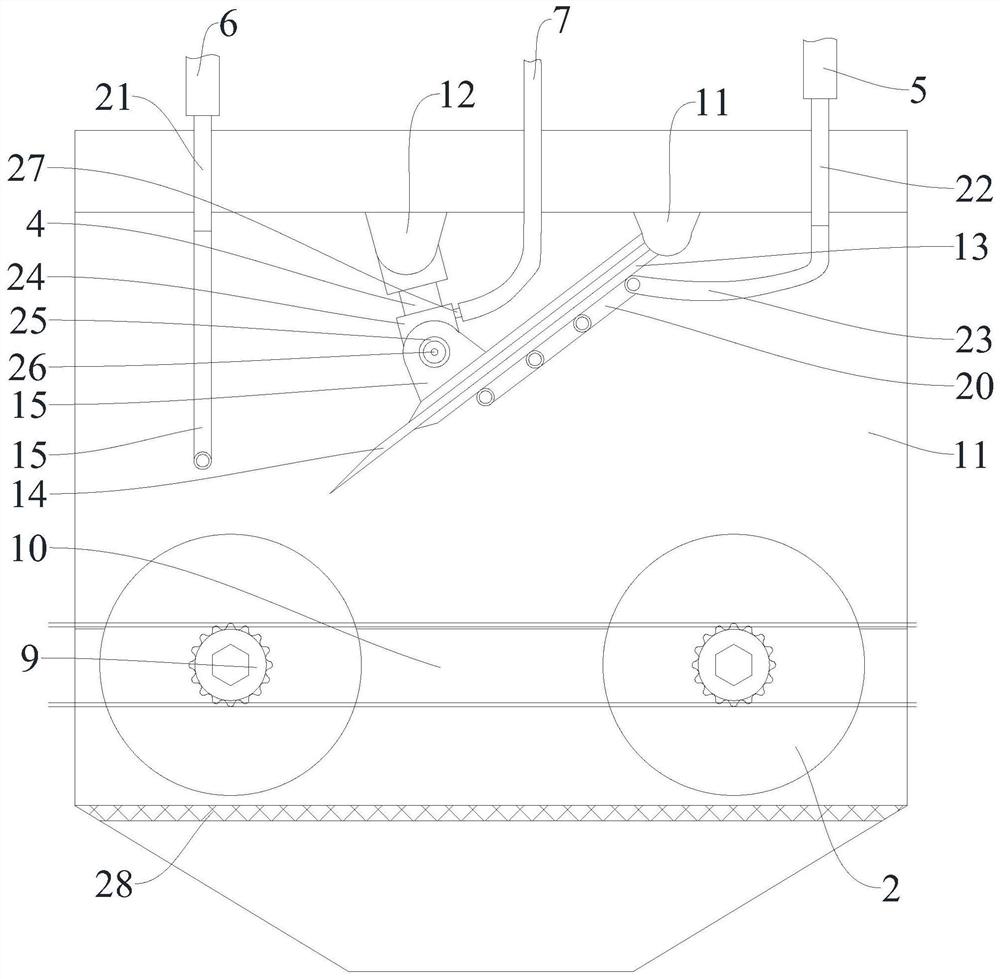

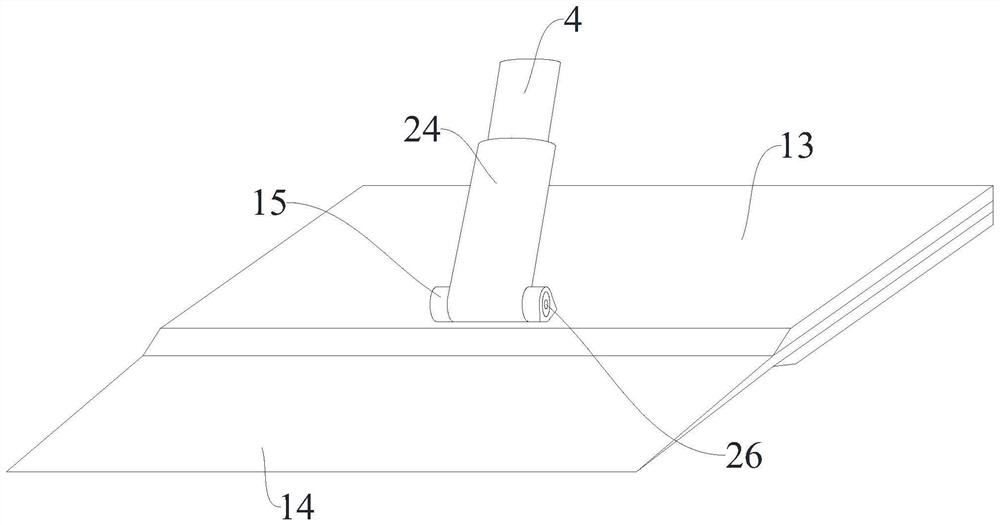

The invention relates to a machining device for electronic components and discloses a dispensing subsequent glue removing device for an electronic component, which comprises a fixed bottom plate. Support frames are mounted on two sides of the upper end of the fixed bottom plate; a fixed rack is installed at the top of the support frame; a guide column is arranged between the upper ends of the support frames; a sliding block is slidably connected to the middle of the guide column; a bearing seat is arranged in the sliding block; a rotating shaft is mounted in the bearing seat; a movable gear meshed with the fixed rack is mounted at the upper end of the rotating shaft; a glue removing grinding wheel is arranged at the bottom end of the rotating shaft; an air guiding box is installed in the middle of the left end of the support frame on the right side; a piston plate is installed in the air guiding box; an air guiding rod is installed on the left side of the piston plate; a sliding blockis connected to the left side of the air guiding rod; a lifting plate is installed between the inner sides of the support frames; and positioning clamping mechanisms are installed on the two sides ofthe upper end of the lifting plate. Reciprocating rotation of the glue removing grinding wheel is achieved, the glue removing efficiency of the electronic components is greatly improved, meanwhile, glue residues obtained after glue removing can be better blown away, and the glue removing efficiency is further improved.

Owner:肇庆益华电子科技有限公司

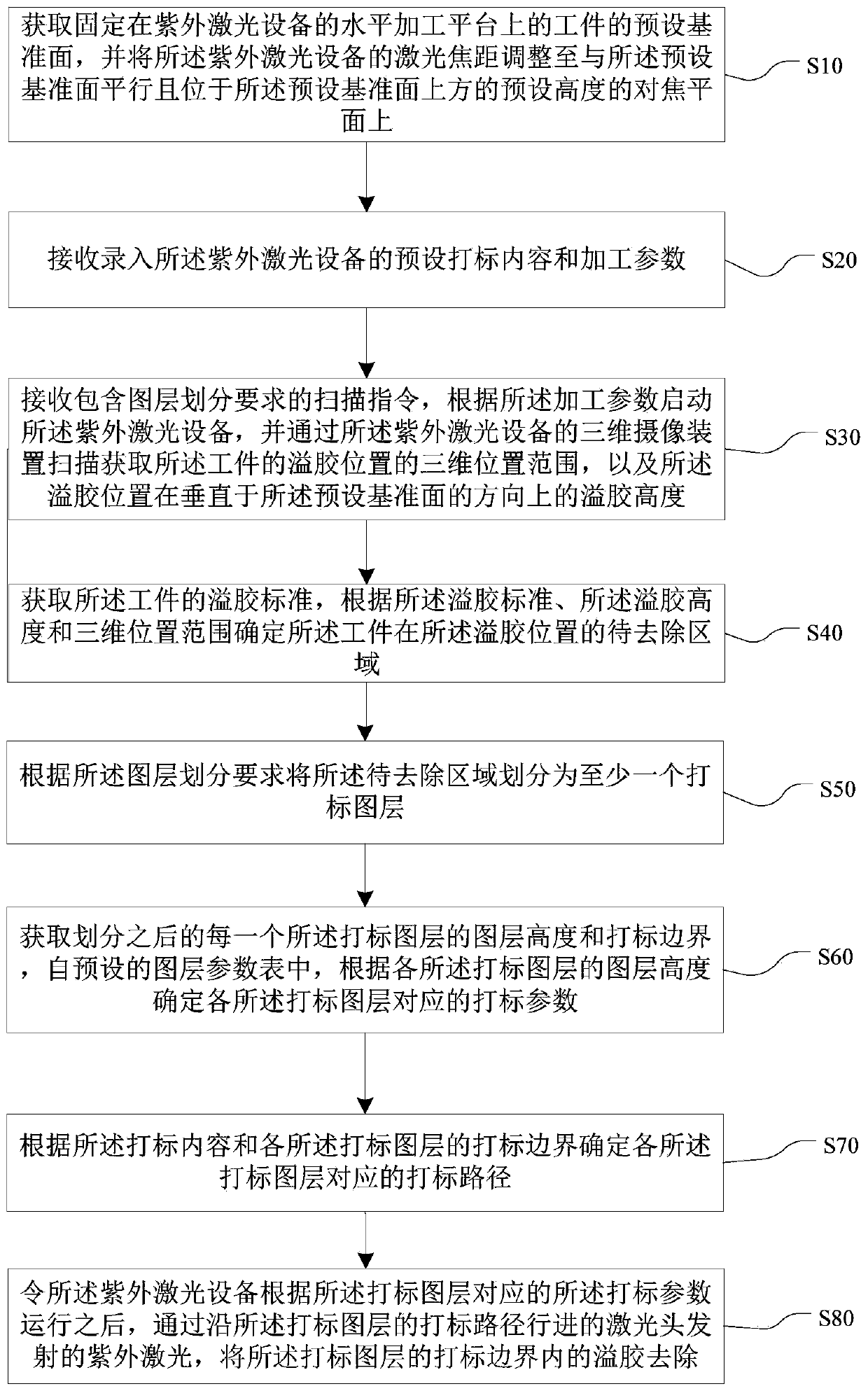

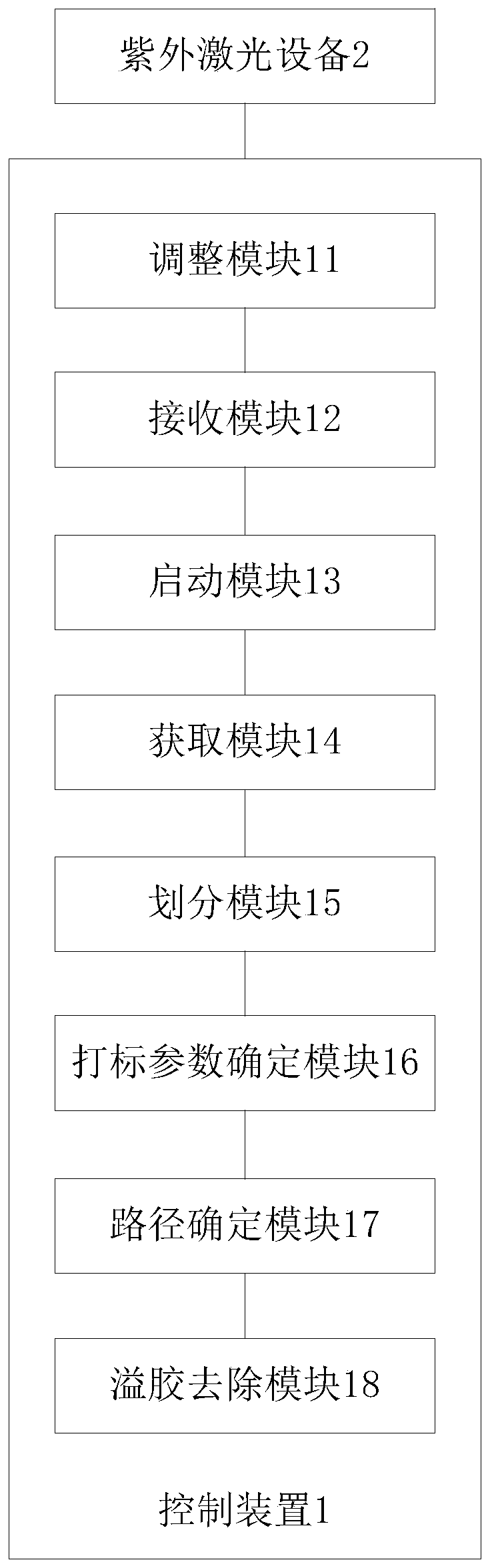

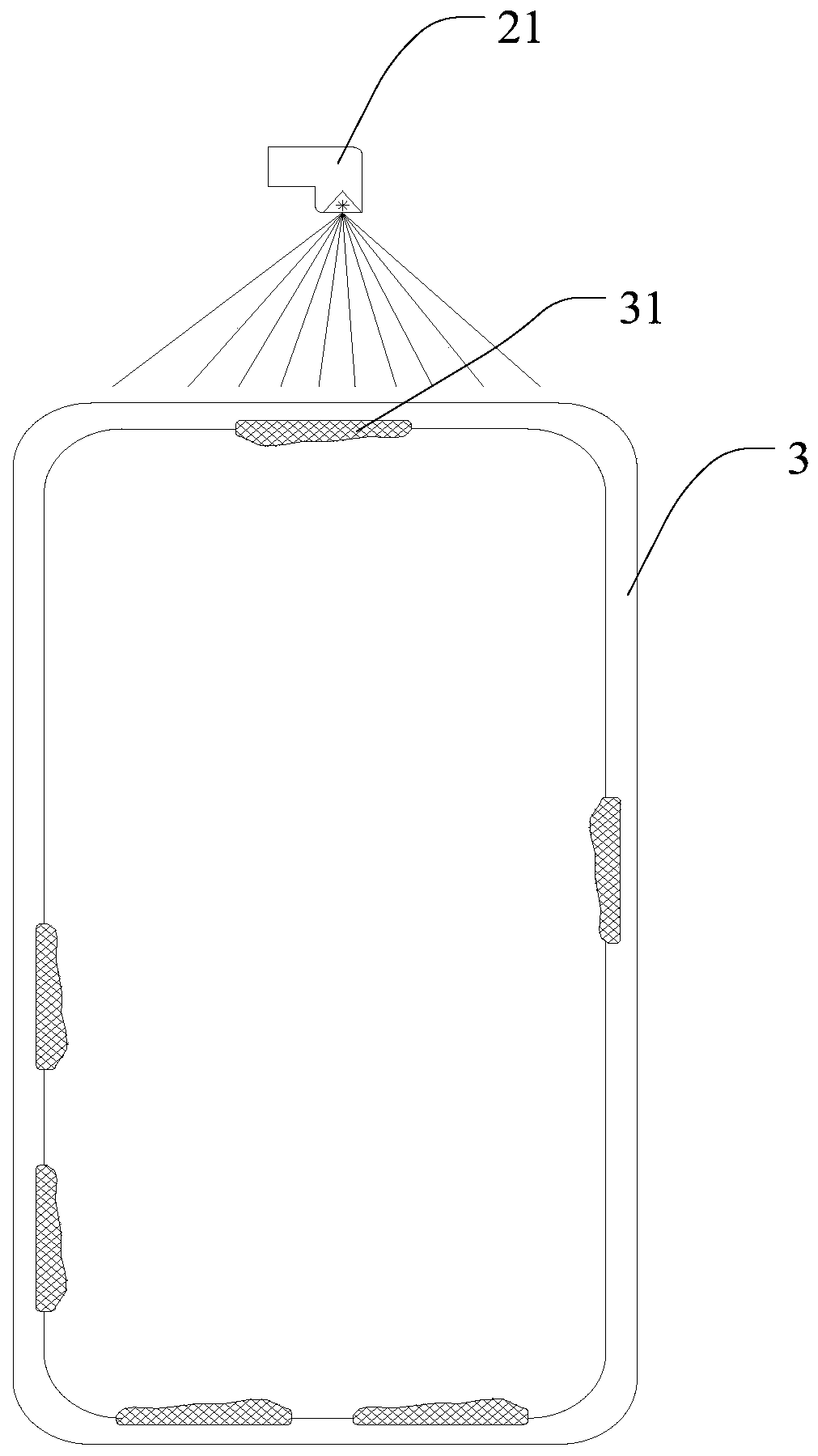

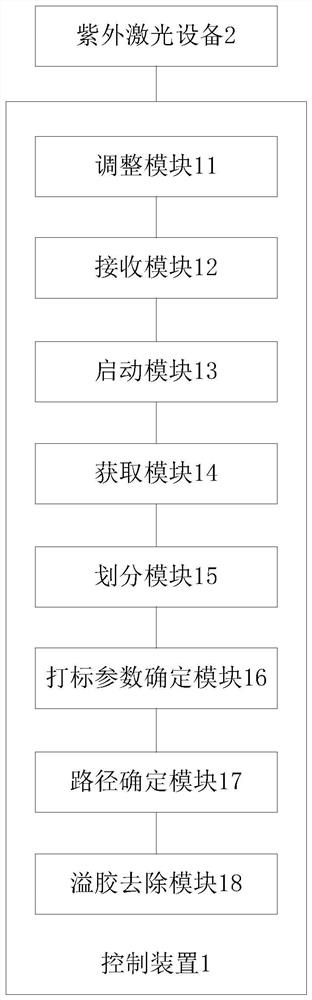

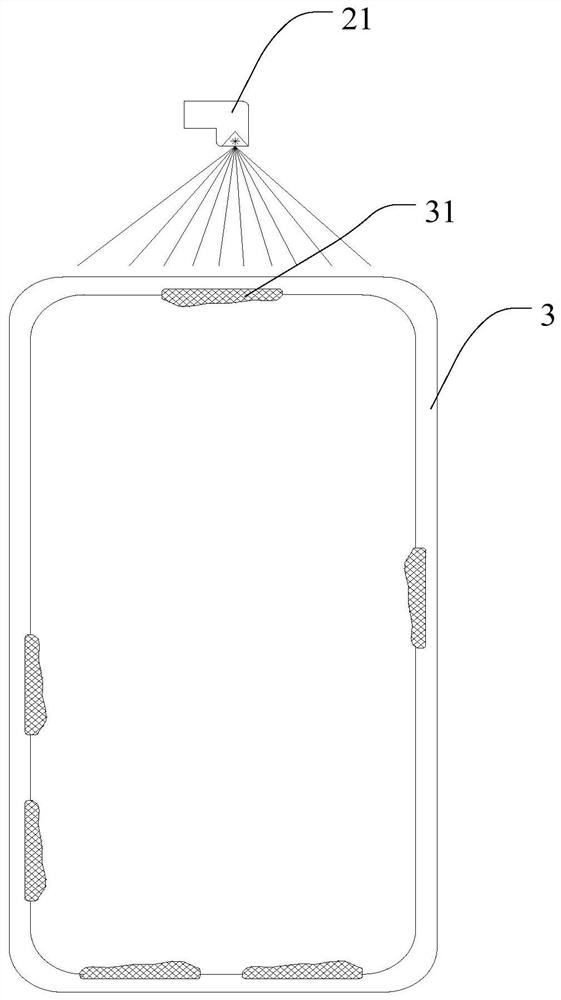

Ultraviolet laser glue removal method and system

ActiveCN110102900AHigh degumming precisionReduce labor costsLaser beam welding apparatusEnvironmental resistanceUltraviolet

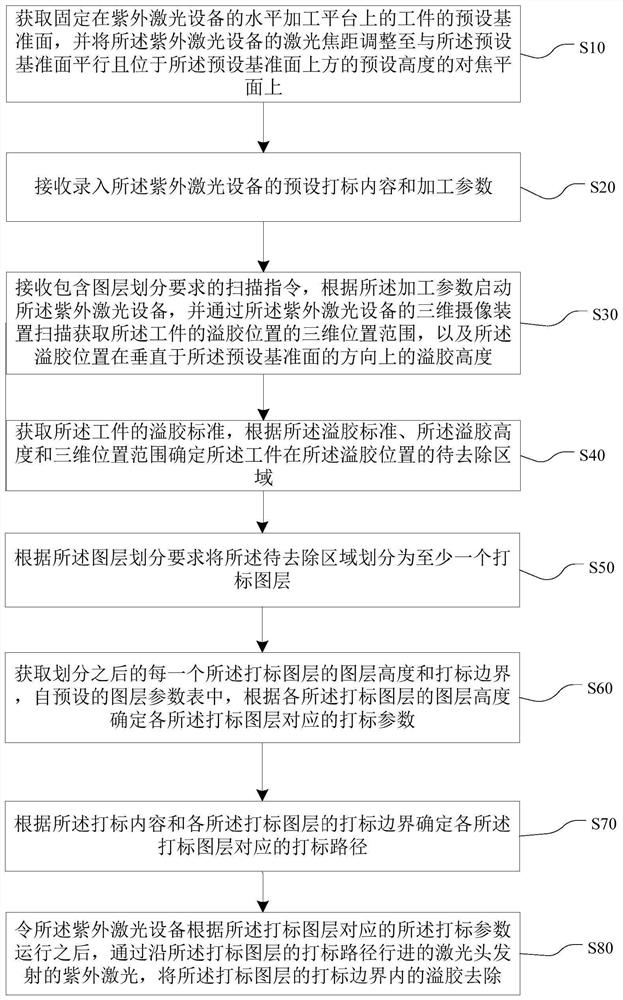

The invention provides an ultraviolet laser glue removal method and system. The method comprises the steps that the three-dimensional position range and the glue overflowing height of a glue overflowing position of a workpiece are scanned by a three-dimensional camera device; according to overflowing standards, the glue overflowing height and the three-dimensional position range, the area to be removed at the glue overflowing position of the workpiece is determined; the layer height and marking boundary of each marking layer after partition are obtained, and the marking parameters corresponding to each marking layer are determined according to the layer height of each marking layer; according to the marking content and the marking boundary of each marking layer, the corresponding marking path of each marking layer is determined; and after ultraviolet laser equipment operates according to the marking parameters corresponding to the marking layers, overflowing glue in the marking boundaries of the marking layers is removed by ultraviolet lasers emitted by a laser head traveling along the marking paths of the marking layers. The ultraviolet lasers are utilized to remove the overflowing glue, the labor cost is reduced, the glue removal efficiency is promoted, the amount of glue removal is controllable, the glue removal precision is high, and the glue removal process is environmentfriendly.

Owner:HANS LASER TECH IND GRP CO LTD

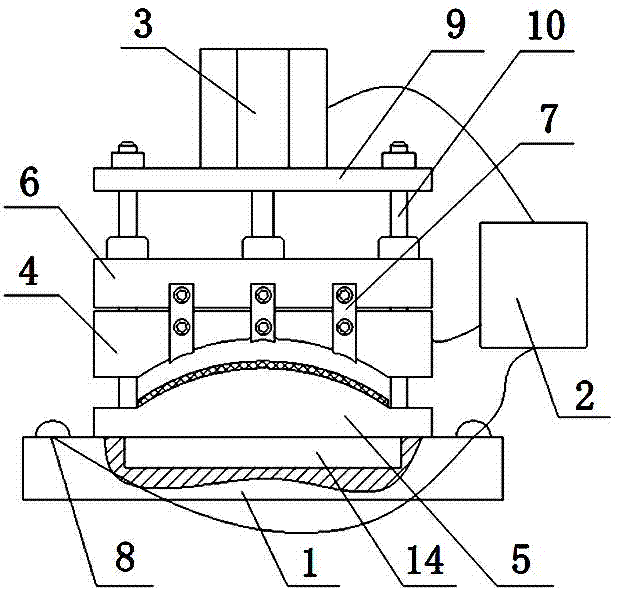

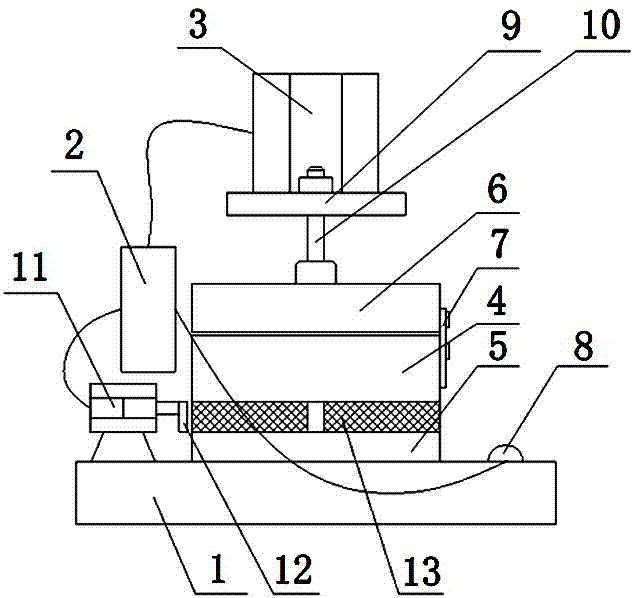

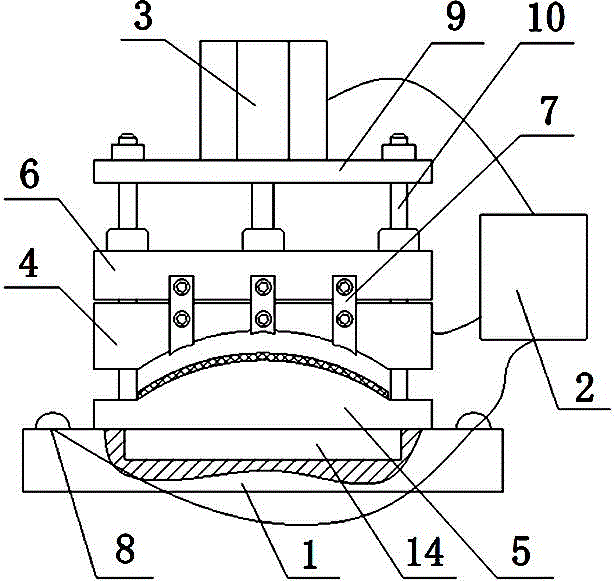

Automatic gate removing equipment

ActiveCN102962965ACause safety accidentEasy to operateMetal working apparatusEngineeringMechanical engineering

The invention relates to automatic gate removing equipment. The equipment comprises a base (1), guide rails (10), a cylinder A (3), a plurality of blades (7) and an upper die (4), wherein a cylinder seat (9) is fixedly arranged at the tops of the guide rails (10), and the cylinder A (3) is arranged on the cylinder seat (9); a knife rest (6) and the upper die (4) are arranged on the guide rails (10) in a sliding manner; the plurality of blades (7) are arranged on one side of the knife rest (6); a spindle of the cylinder A (3) penetrates through the cylinder seat (9) and is connected with the knife rest (6); a lower die (5), switches (8) and a cylinder B (11) are arranged on the base (1); a push block (12) is arranged on the cylinder B (11); and a control box (2) is connected with the cylinder A (3), the switches (8) and the cylinder B (11) respectively. The automatic gate removing equipment has the advantages of being safe and reliable, being simple to operate, and having a high gate removing efficiency and a good cutting appearance effect.

Owner:CHENGDU HOMIN TECH

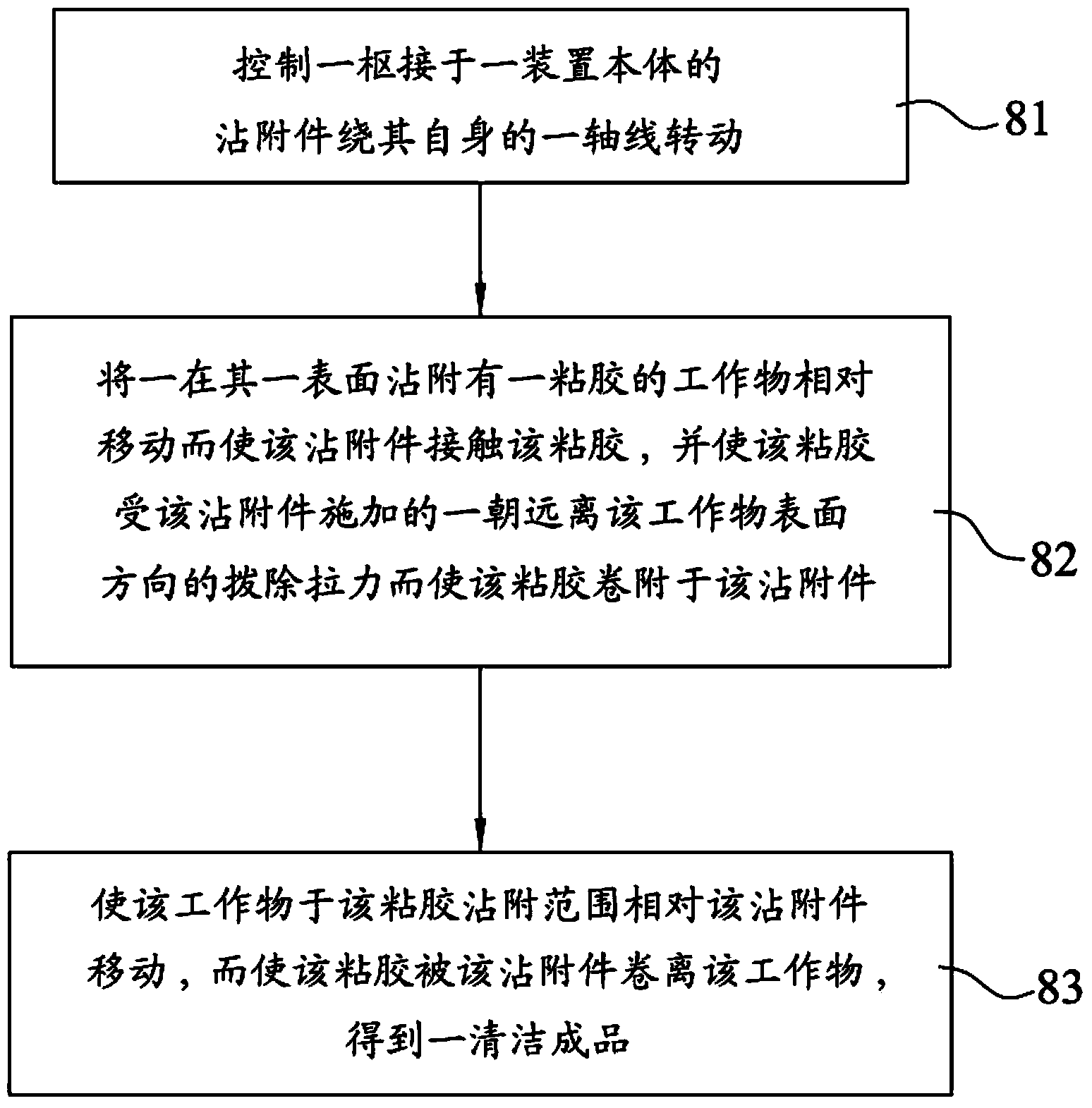

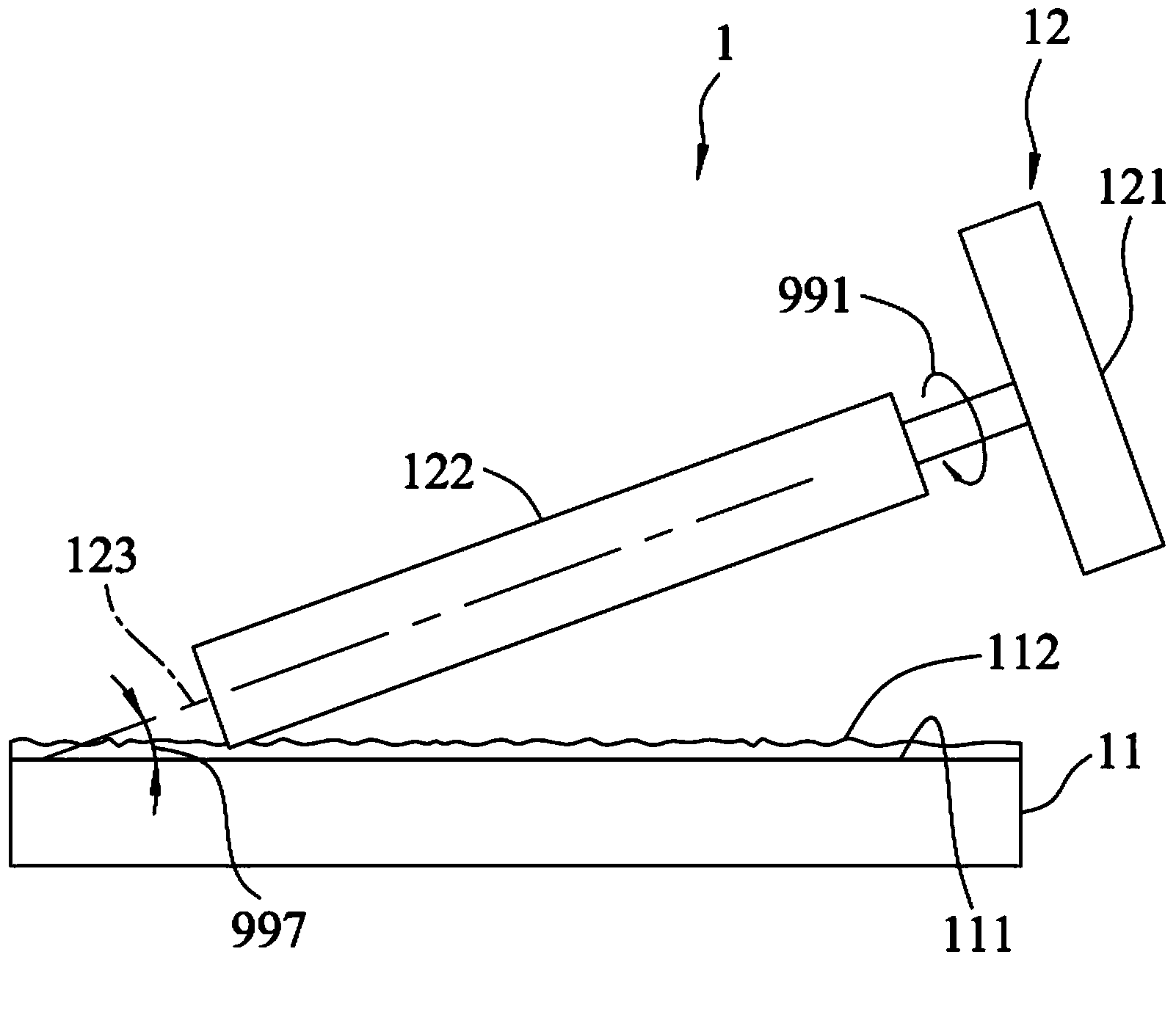

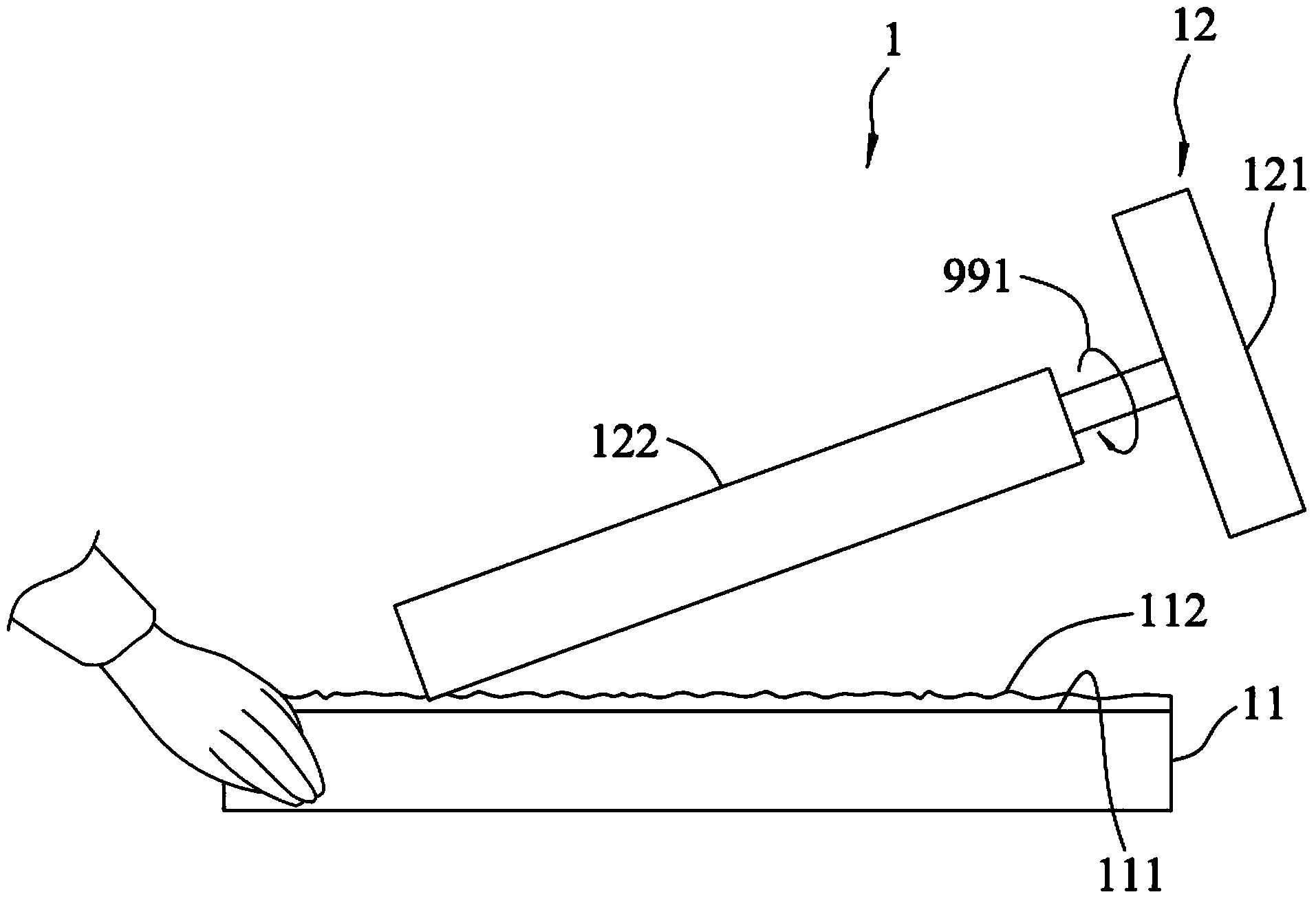

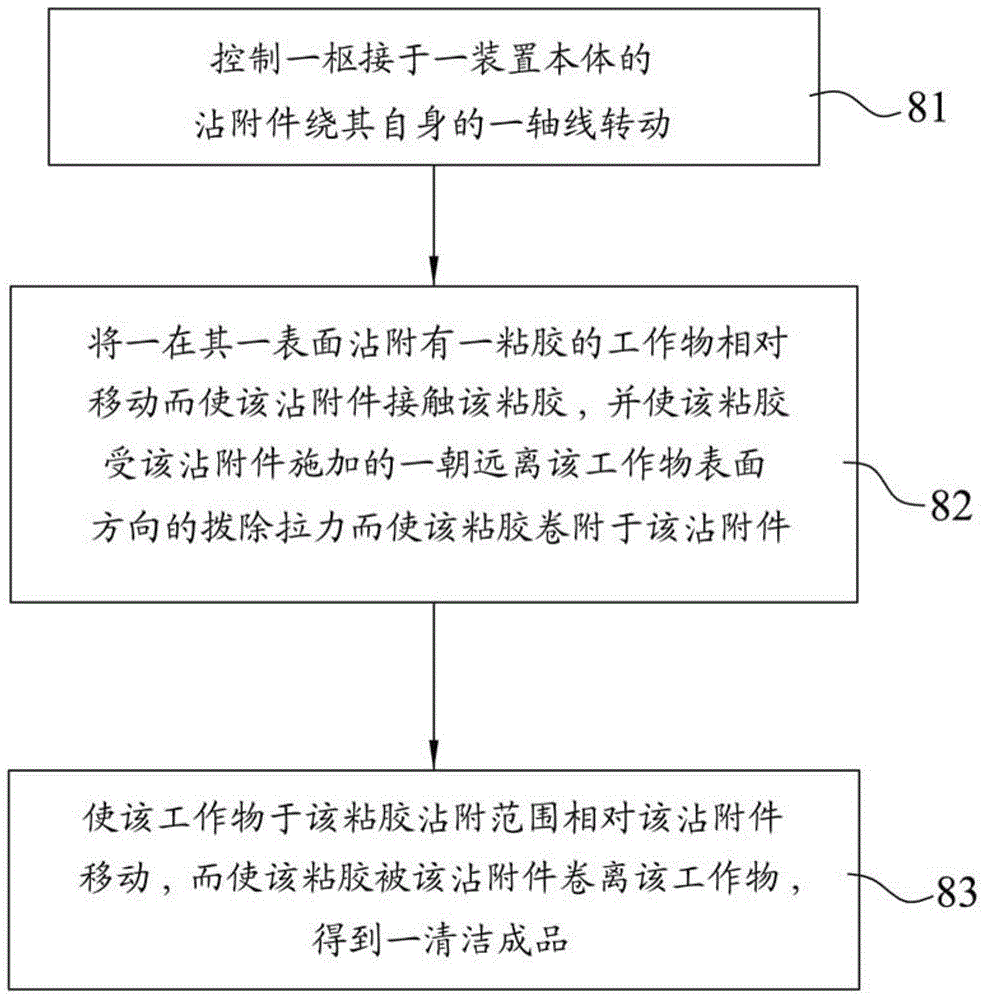

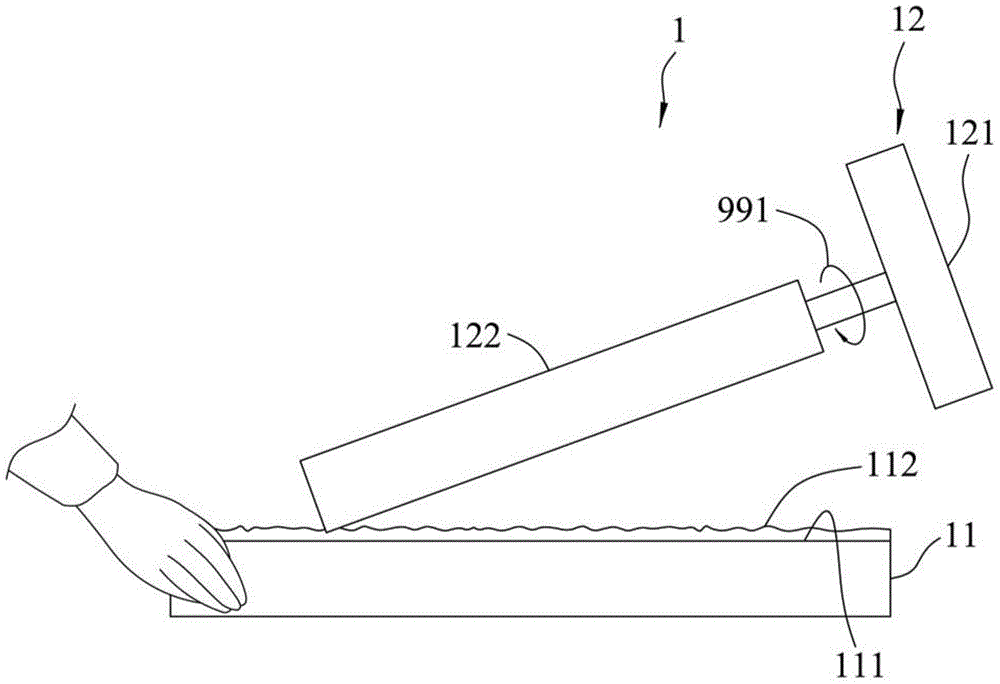

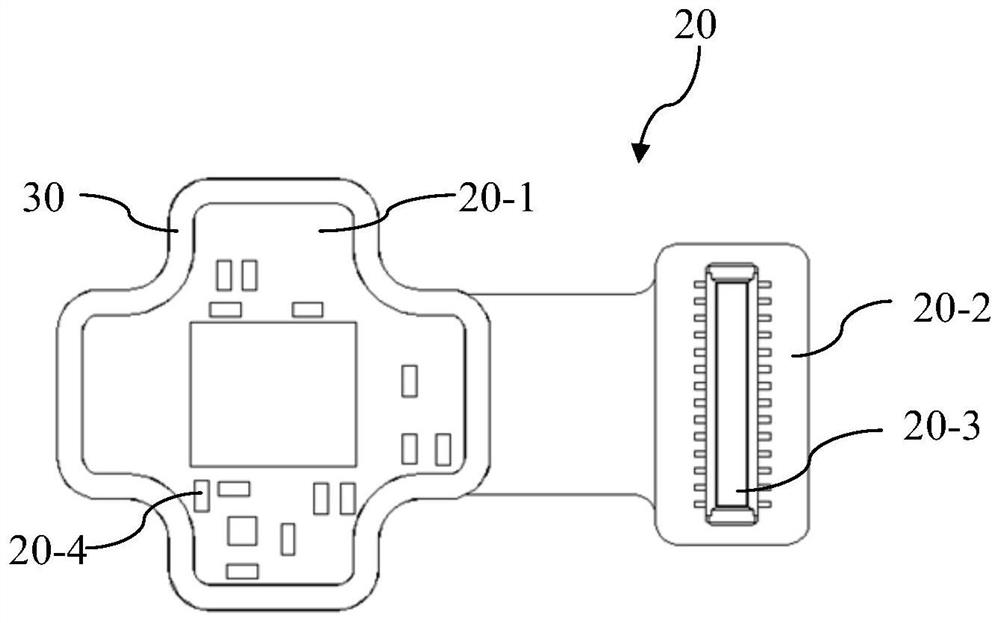

Method and system for removing gel and thereof

InactiveCN104227768AAvoid destructionHigh glue removal efficiencyMetal working apparatusPull forceDisplay device

The present invention discloses a method and a system for removing gel. The method comprises steps of controlling a gel pasting attachment pivoted to the device body to rotate around the axis; allowing an operating element with gel pasted, such as a touch control device element or a display device element to move relative to the gel pasting attachment to allow the gel pasting attachment to contact the gel, allowing the gel to be coiled and attached to the gel pasting attachment through a pulling force in the direction far from the surface of the operating element and applied on the gel pasting attachment; and moving the operating element to move relative to the gel pasting attachment in the scope of the gel pasting attachment, allowing the gel to be coiled to be departed from the operating element to obtain a clean finished product. Furthermore, the present invention also provides a system for removing gel. The method and the system can efficiently remove the gel, and prevent damage to the operating element in the gel removal process.

Owner:DAXIN MATERIALS

Corrugated paper bonding compression roller for carton production

ActiveCN108790280ANot easy to damageHigh glue removal efficiencyBox making operationsPaper-makingInterference fitCarton

The invention relates to a compression roller, in particular to a corrugated paper bonding compression roller for carton production and aims to achieve the technical purpose of providing the corrugated paper bonding compression roller for carton production, wherein the glue removing efficiency is relatively high, and paper is not prone to being damaged while glue removing is carried out. Accordingto the technical scheme, the corrugated paper bonding compression roller for carton production comprises bearing pedestals and the like; the left and the right of a first rotating shaft are connectedwith the bearing pedestals in an interference fit manner, and the upper parts and the lower parts of the left bearing pedestal and the right bearing pedestal are provided with n-shaped frames; and the middle of the first rotating shaft is provided with a compression roller body, the compression roller body is located between the two n-shaped frames, the inner sides of the n-shaped frames are provided with a glue removing device, and a movable component of the glue removing device is provided with a liquid spraying device. According to the corrugated paper bonding compression roller for cartonproduction, corrosion liquid is sprayed to the compression roller body through the glue removing device, then, the glue on the compression roller body is removed, the liquid spraying device sprays the corrosion liquid to a glue removing component of the glue removing device, and therefore the effects that the glue removing efficiency is relatively high, and the paper is not prone to being damagedwhen glue removing is carried out are achieved.

Owner:义乌市义心科技有限责任公司

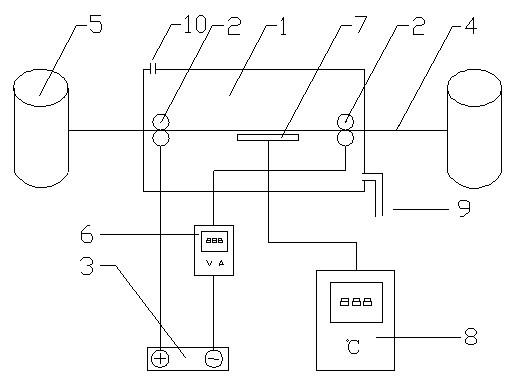

Colloid quick removing method for carbon fiber

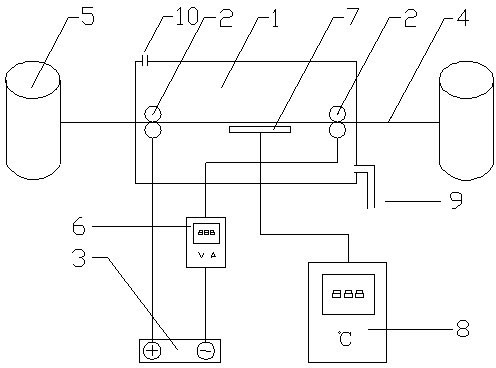

InactiveCN102330326AAvoid surface damageSmall mechanical propertiesPhysical treatmentFiberCarbon fibers

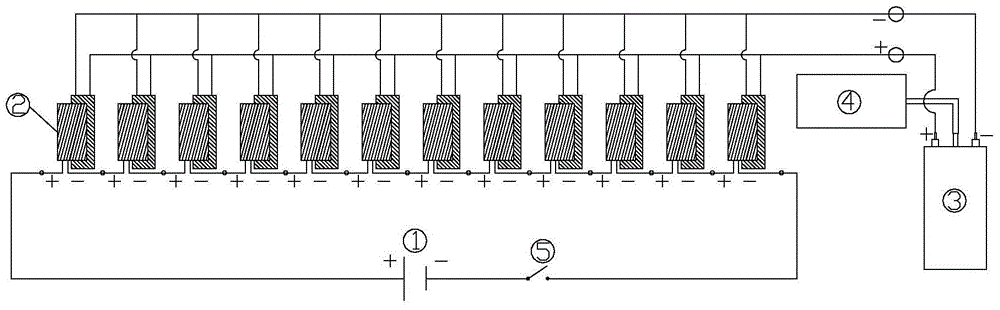

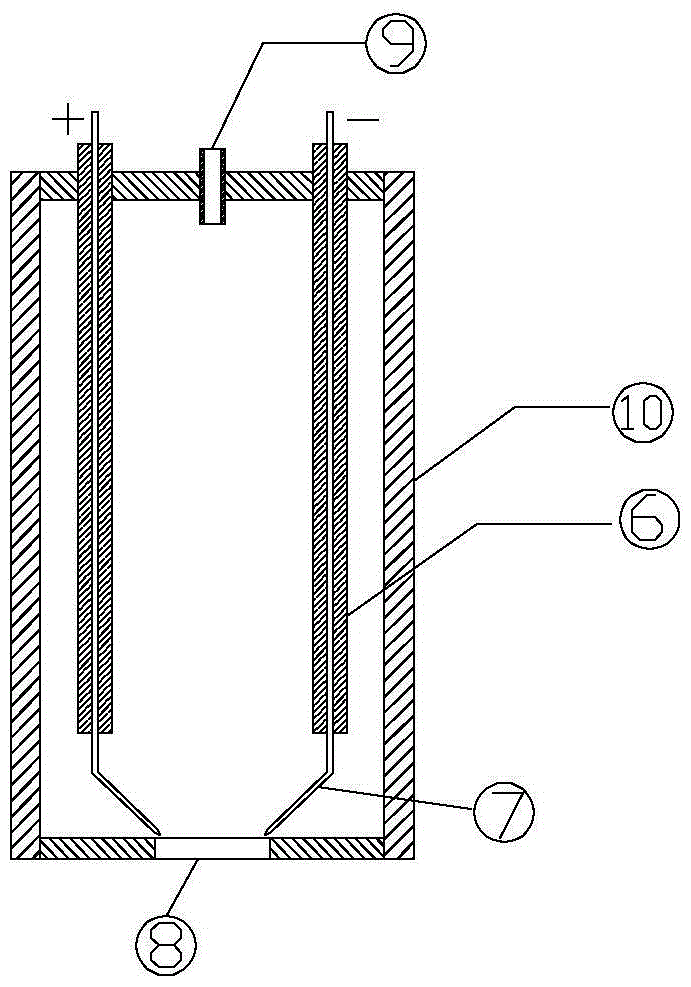

The invention discloses a colloid quick removing method for a carbon fiber, comprising the following steps of: a, connecting two ends of the carbon fiber, which is needed to remove the colloid, to the anode and the cathode of a power supply; b, electrifying the carbon fiber to emit heat; c, measuring the surface temperature of the carbon fiber via a temperature sensor; d, controlling the current so as to control the surface temperature of the carbon fiber, thereby enabling the temperature to satisfy a condition of quickly melting and volatilizing the surface colloid without reducing the mechanical properties of the carbon fiber; e, controlling the colloid removing time, and rolling up the carbon fiber after removing the colloid. On one hand, the surface colloid is melted and volatilized by the heat emitted by the carbon fiber, which solves the defects of long temperature rise time, low colloid removing efficiency, energy wastage and the like of the conventional gaseous oxidation colloid removing mode in which a heat source is arranged at outside of the heated carbon fiber and the heat transfer is finished by convection, radiation and conduction, and is economic and environmentally friendly; on the other hand, the carbon fiber is heated under protective atmosphere, the heating temperature is high, the colloid is removed completely, simultaneously, damage on the surface of the carbon fiber is avoided, the mechanical properties of the carbon fiber are not changed greatly, and strength of the carbon fiber used as a composite material reinforcement is guaranteed.

Owner:CHINA ZHONGWANG

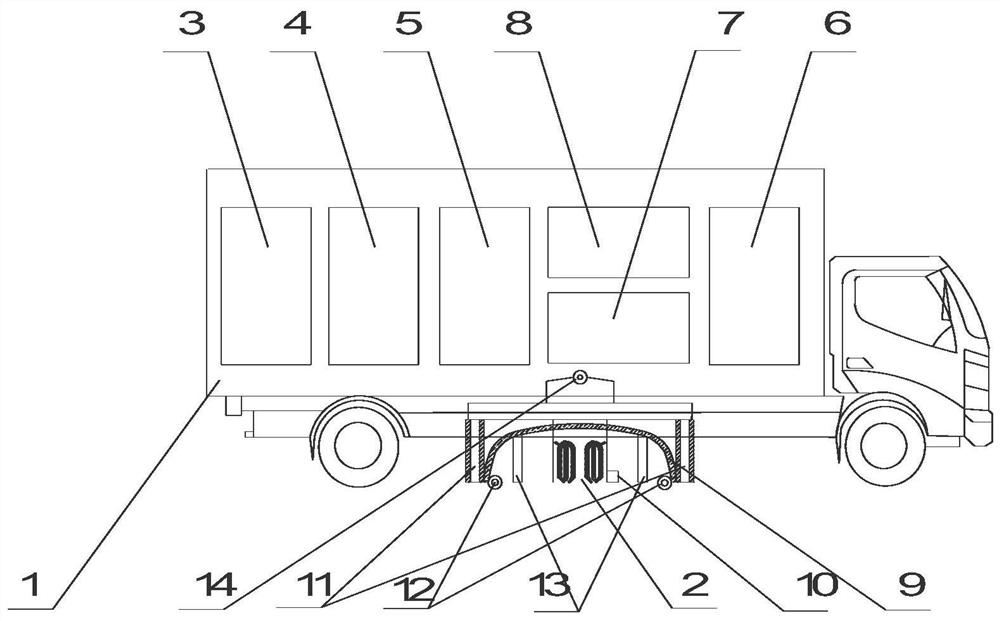

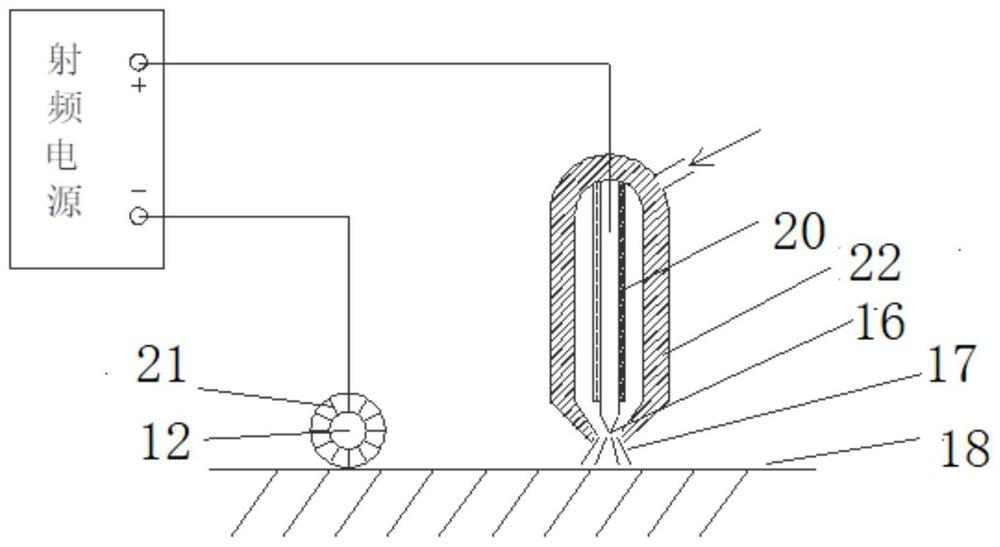

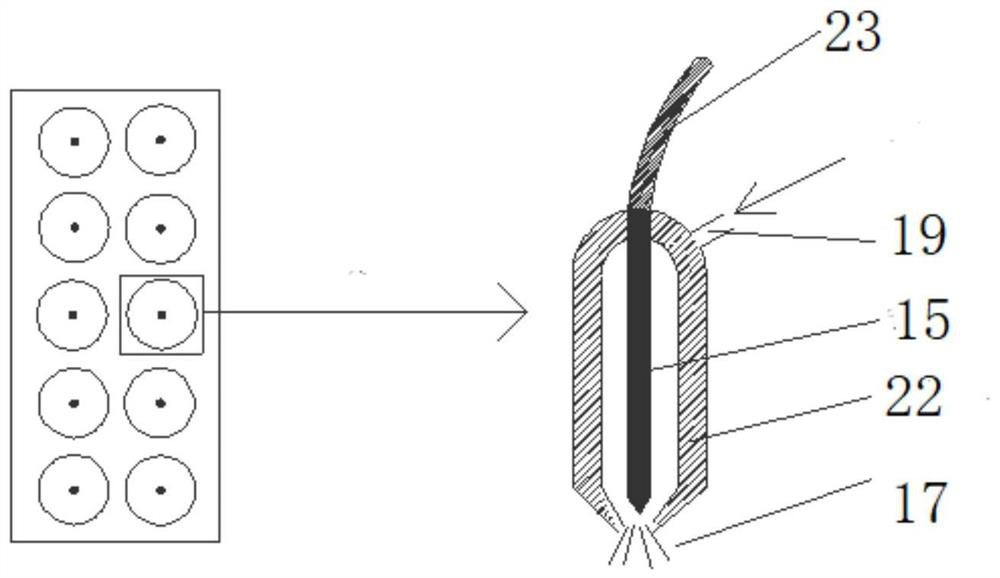

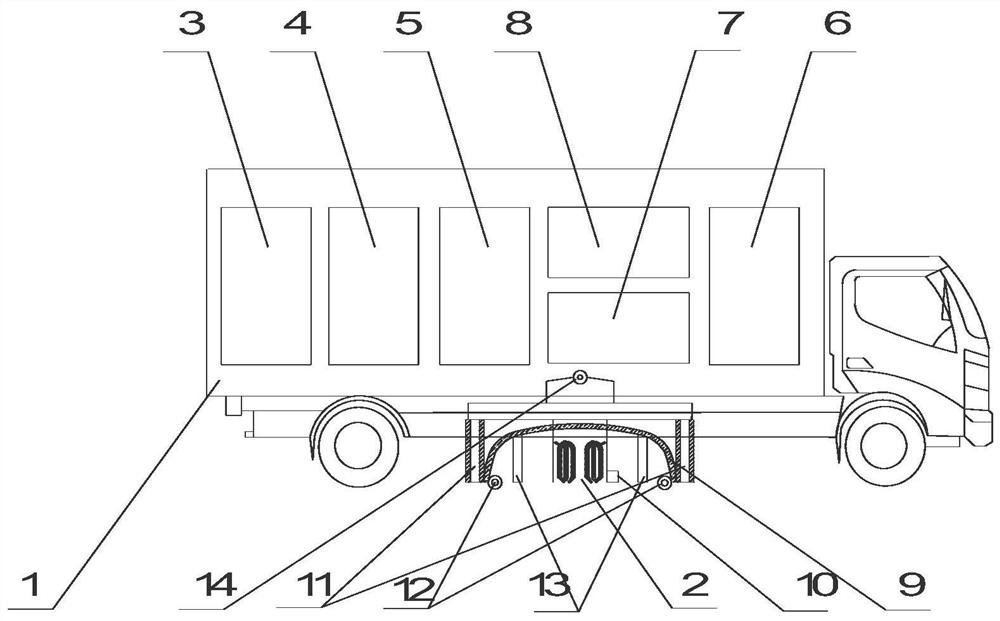

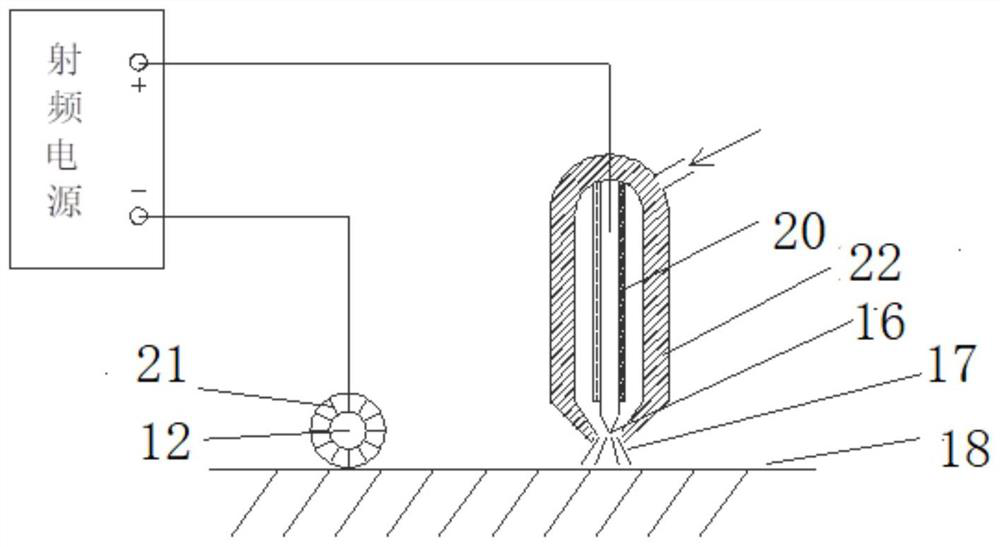

Plasma degumming equipment for airfield runway

ActiveCN113106903AClean up thoroughlyReduce neutralizationDispersed particle separationDirt cleaningDirect couplingRoad surface

The invention provides plasma degumming equipment for an airport runway. The plasma degumming equipment comprises a carrying vehicle body, a rolling electrode mounted at the bottom of the carrying vehicle body, and a discharge electrode assembly, an oxygen generator, a radio frequency power supply and a control unit which are mounted in the carrying vehicle body; the rolling electrode is connected with the negative electrode of the radio frequency power supply, and is in rolling contact with a pavement rubber layer of the airfield runway during use, and is used for temporarily polarizing the pavement rubber layer of the airfield runway to form a temporary discharge electrode of the discharge electrode assembly; the discharge electrode assembly and a pavement rubber layer of the airport runway are directly coupled to discharge and excite oxygen ejected from the oxygen generator to generate high-concentration plasma, so that the pavement rubber layer is gasified; the oxygen generator is used for preparing oxygen by taking air as a raw material; the radio frequency power supply is used for providing a high-voltage and high-frequency power supply for the discharge electrode assembly; and the control unit is used for controlling the operation of the rolling electrode, the discharge electrode assembly, the oxygen generator and the radio frequency power supply. Plasma is generated through direct coupling type discharge, the glue removing efficiency is high, glue removing is thorough, and the road surface is not damaged.

Owner:林强

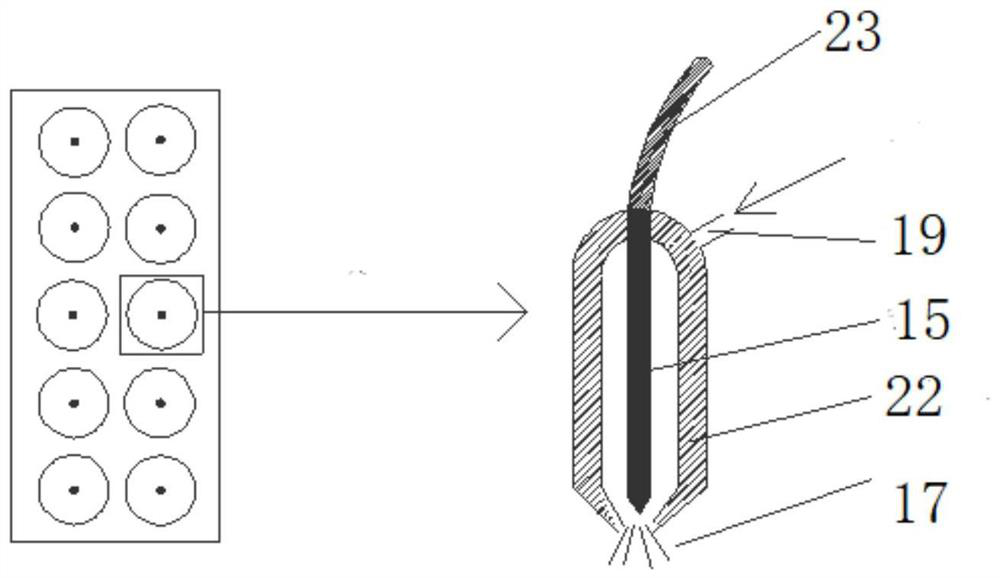

Lens cleaning equipment

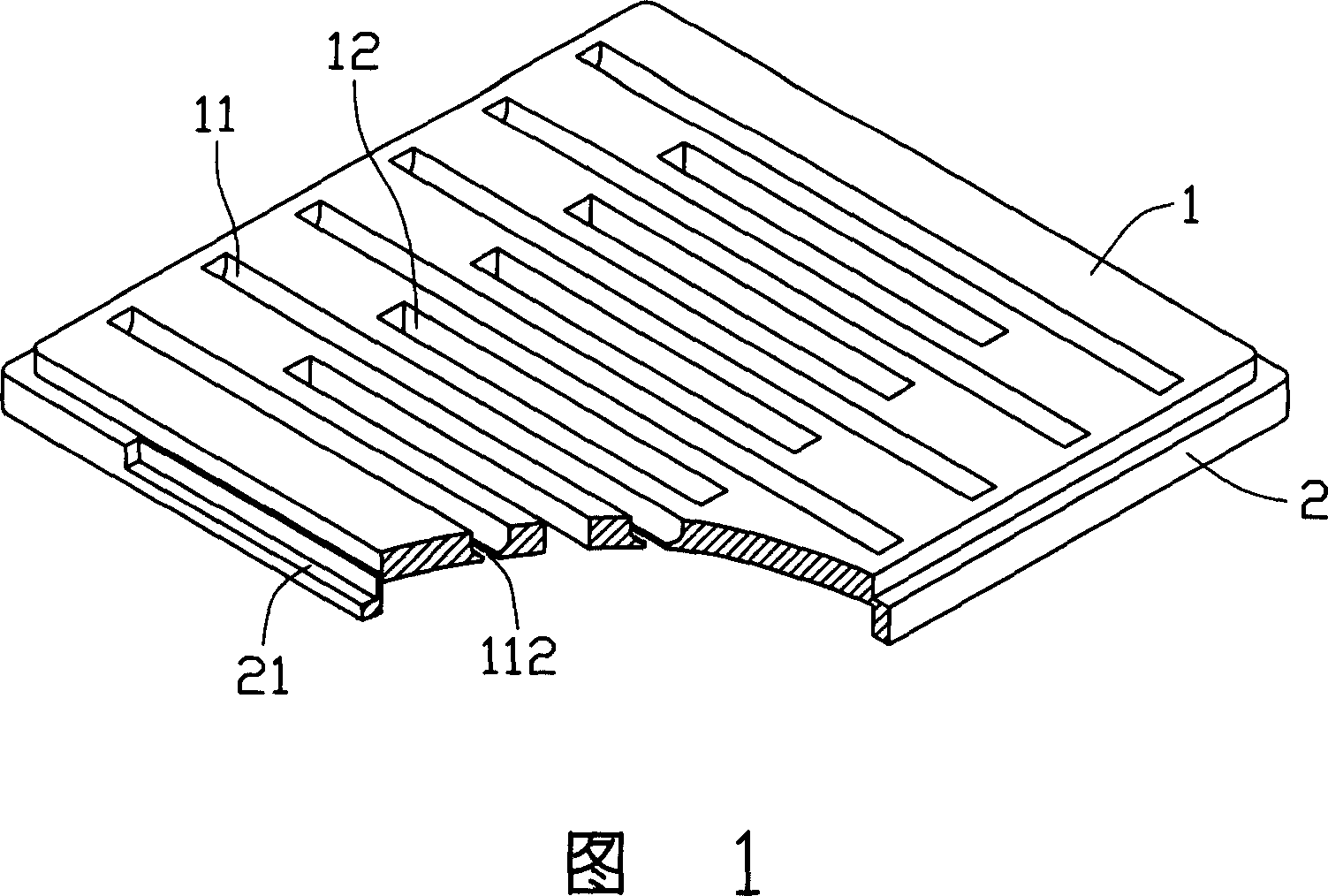

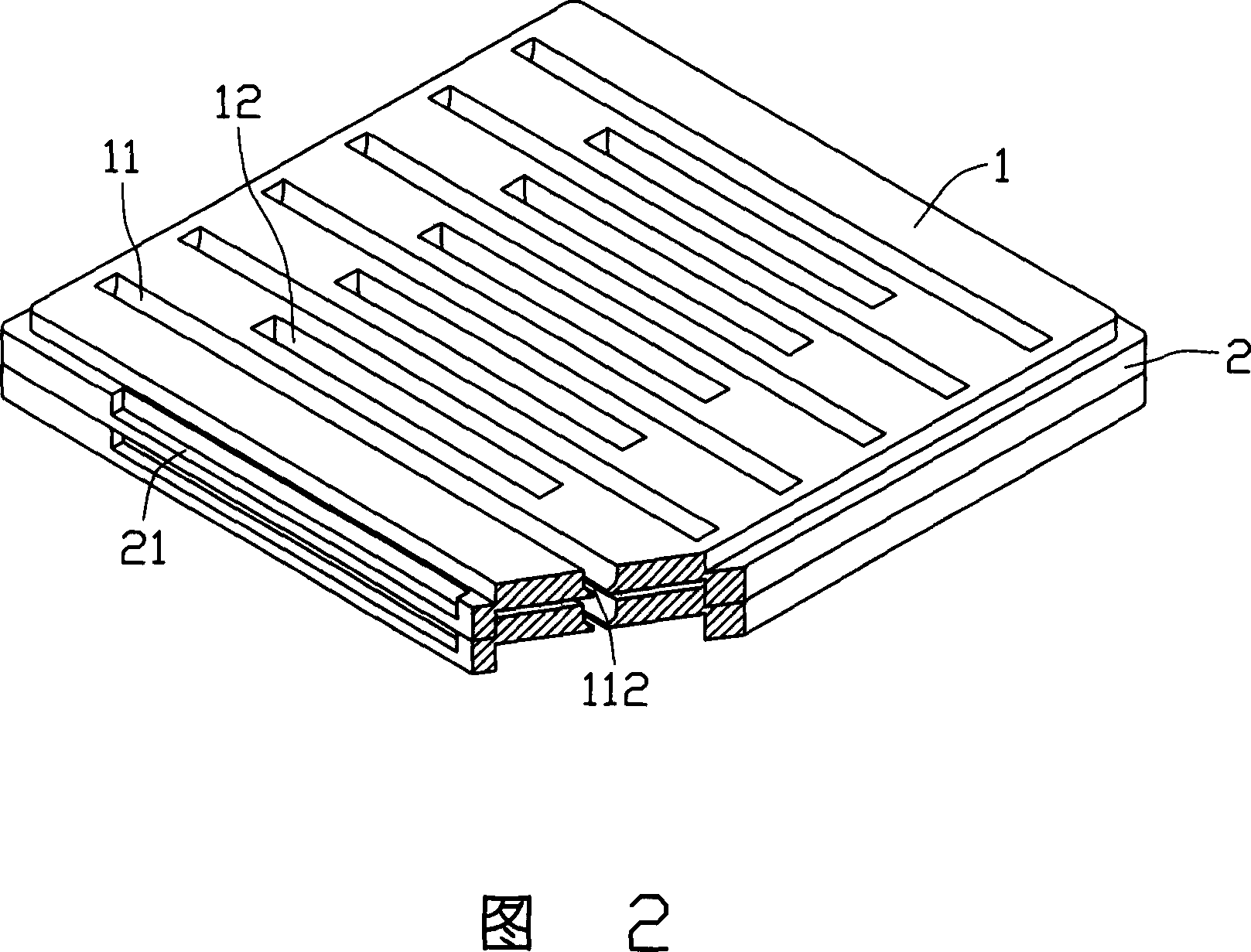

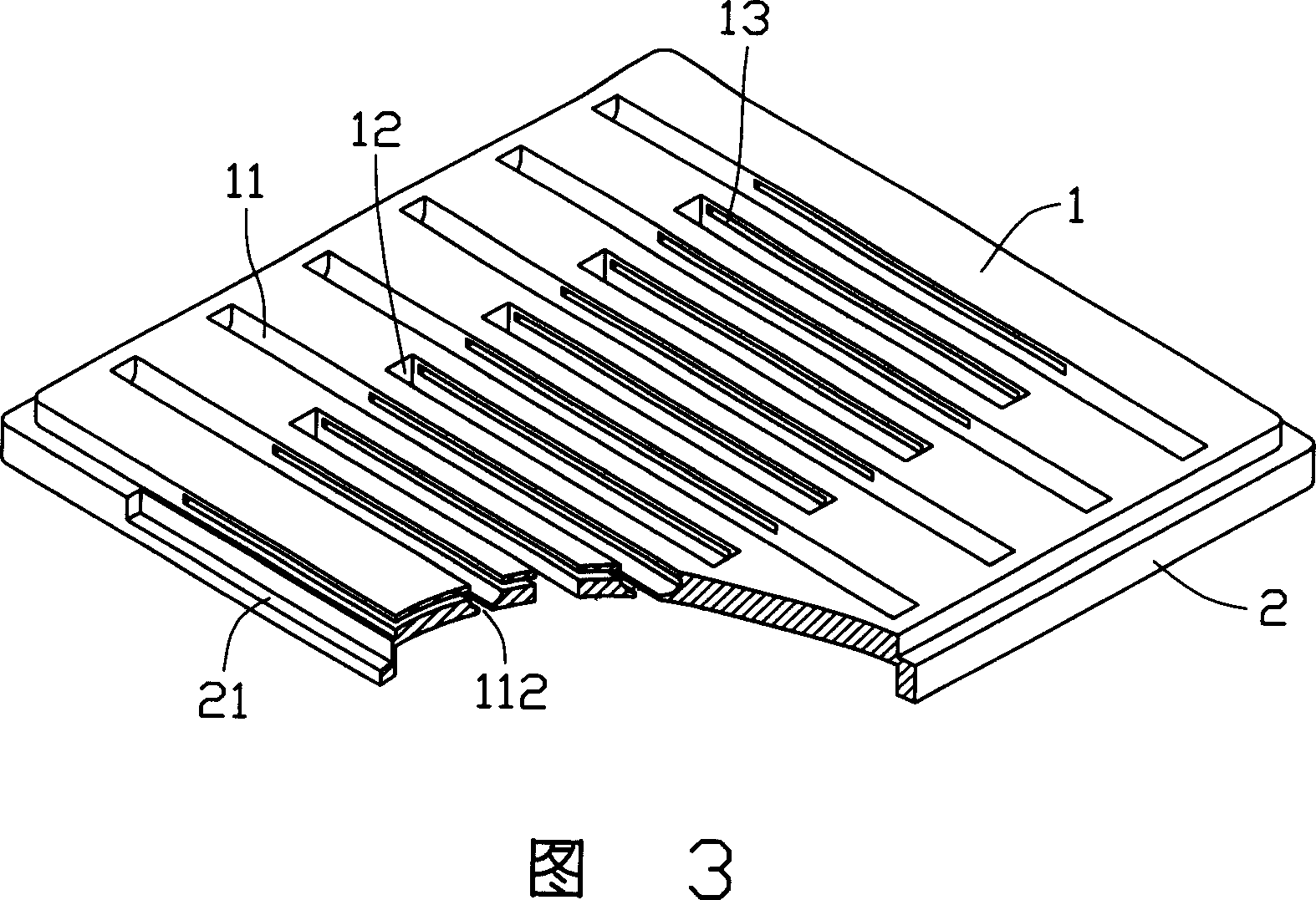

InactiveCN1990128AHigh glue removal efficiencyOrderly rowsWork holdersFlexible article cleaningLens plateEngineering

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

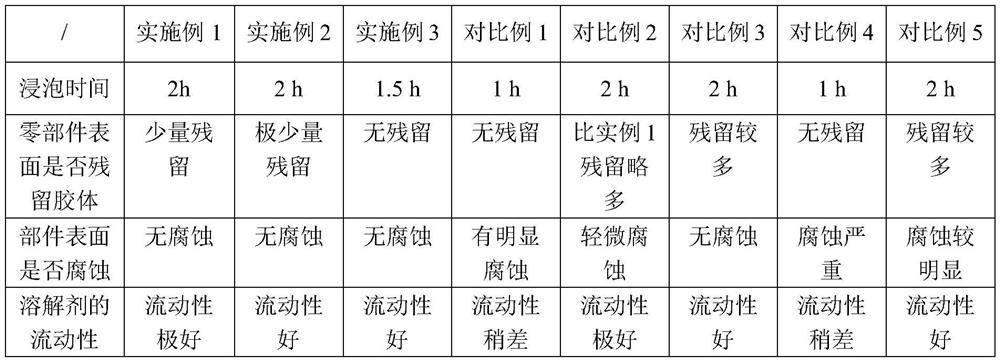

A kind of dissolving agent for removing cured silicone rubber and preparation method thereof

The invention discloses a dissolving agent for removing cured silicone rubber, which comprises 30%-60% C 2 ~C 4 Monohydric alcohol or dihydric alcohol, 1% to 8% of strong alkali, 1% to 10% of dimethicone, 1% to 10% of metal slow release agent, and the balance is solvent oil. The invention also discloses a method for preparing the dissolving agent, which comprises the following steps: 2 ~C 4 Monohydric alcohol or dihydric alcohol, strong base and dimethicone are mixed, stirred and heated at 50~80℃ for 0.5~2h, and the obtained reaction product is then mixed with corresponding weight percentage of solvent oil and metal slow-release agent, to get Silicone rubber dissolving agent. The silicone rubber dissolving agent of the invention has high degumming efficiency, and the cured silicone rubber on the parts or components can be removed after soaking for 0.5 to 2 hours; the dissolving agent will not corrode the parts or elements during the soaking process, and can achieve non-damaged degumming .

Owner:JIANGSU LOPALTECH

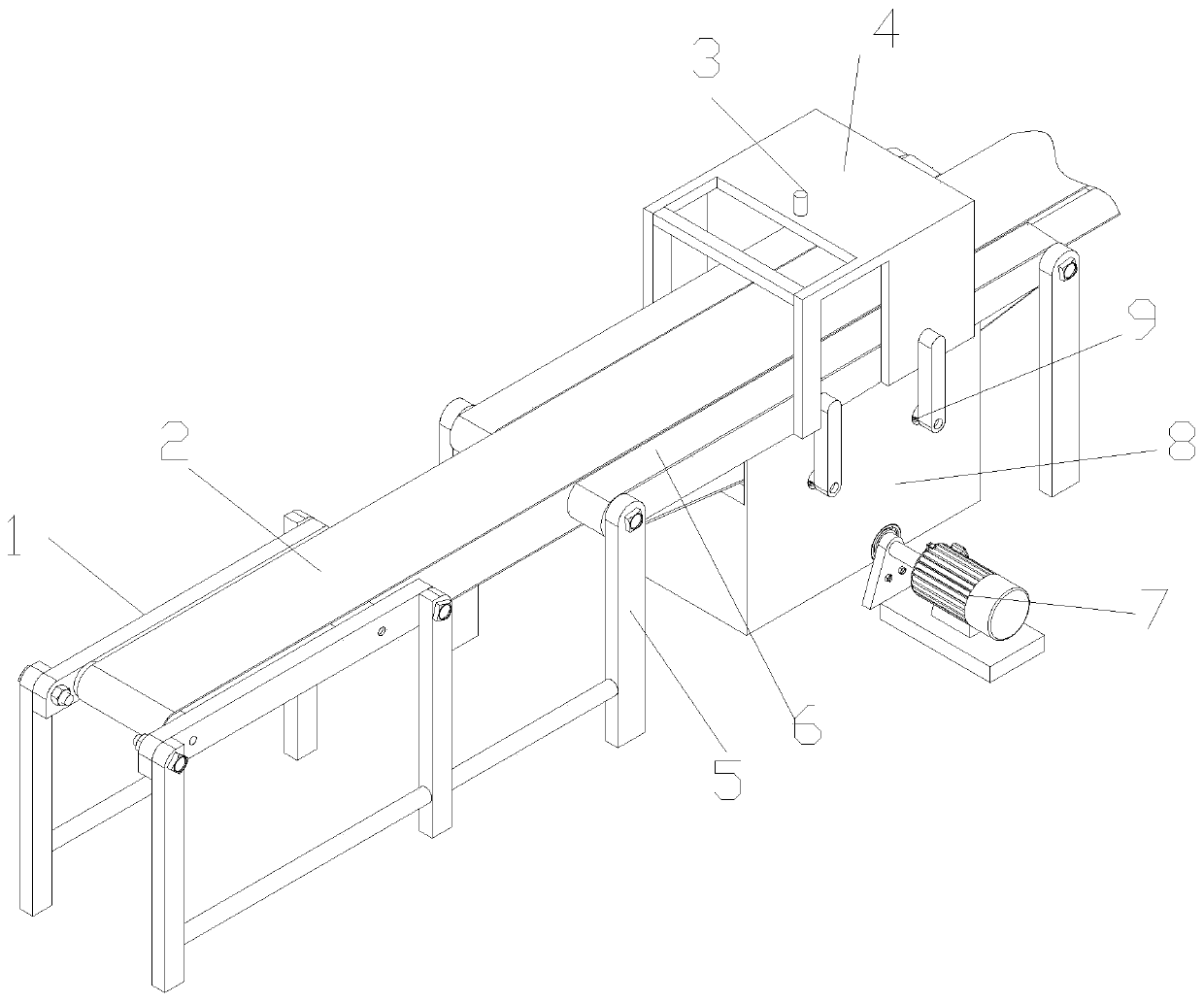

Glue spraying mechanism of hot-melting compounding machine

InactiveCN110481142AAvoid accumulationEasy to remove glueLaminationLamination apparatusHot meltEngineering

The invention discloses a glue spraying mechanism of a hot melting compounding machine. The mechanism comprises a first supporting frame, wherein a conveying belt is mounted at the upper end of the first supporting frame; a hot melting compounding machine is mounted on the conveying belt; a glue spraying head is arranged at the front end of the hot melting compounding machine; second supporting frames are arranged on the two sides of the bottom of the hot melting compounding machine; edge conveying belts are installed on the second supporting frames; the edge conveying belts are arranged on the two sides of the conveying belt; glue removing chambers are arranged at the bottom of the second supporting frames; glue removing scrapers are arranged in inner cavities of the glue removing chambers; a driving roller is arranged at the bottom of the glue removing chambers; and a first driving motor is installed on one side of the driving roller. Because the edge conveying belts are arranged onthe two sides of the conveying belt, redundant glue can be sprayed to the edge conveying belts, and scraped by the glue removing scrapers to achieve automatic glue removing, glue accumulation is prevented, normal use is achieved, glue removing is convenient and rapid, the working efficiency is improved, and the labor intensity is reduced.

Owner:ANHUI ZHICHENG ELECTROMECHANICAL SPARE PARTS

Automatic glue removal equipment

ActiveCN102962965BCause safety accidentEasy to operateMetal working apparatusEngineeringMechanical engineering

The invention relates to automatic gate removing equipment. The equipment comprises a base (1), guide rails (10), a cylinder A (3), a plurality of blades (7) and an upper die (4), wherein a cylinder seat (9) is fixedly arranged at the tops of the guide rails (10), and the cylinder A (3) is arranged on the cylinder seat (9); a knife rest (6) and the upper die (4) are arranged on the guide rails (10) in a sliding manner; the plurality of blades (7) are arranged on one side of the knife rest (6); a spindle of the cylinder A (3) penetrates through the cylinder seat (9) and is connected with the knife rest (6); a lower die (5), switches (8) and a cylinder B (11) are arranged on the base (1); a push block (12) is arranged on the cylinder B (11); and a control box (2) is connected with the cylinder A (3), the switches (8) and the cylinder B (11) respectively. The automatic gate removing equipment has the advantages of being safe and reliable, being simple to operate, and having a high gate removing efficiency and a good cutting appearance effect.

Owner:CHENGDU HOMIN TECH

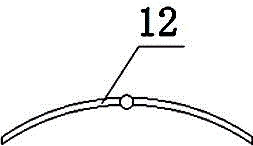

Water-based adhesive remover applied to OCA on mobile phone cover plate and preparation method of water-based adhesive remover

PendingCN113943610AHigh glue removal efficiencyGood effectOrganic detergent compounding agentsNon-ionic surface-active compoundsSolventChemistry

The invention provides a water-based adhesive remover applied to an OCA on a mobile phone cover plate. The water-based adhesive remover is prepared from the following components in percentage by mass: 10 to 25 percent of methyl salicylate, 35 to 55 percent of solubilizer, 0.2 to 0.8 percent of penetrant, 3 to 5 percent of softener, 1.5 to 3 percent of odor masking agent, 0.2 to 1.5 percent of PH value regulator and 10 to 40 percent of water; and the water-based adhesive remover is neutral. According to the water-based adhesive remover applied to the OCA on the mobile phone cover plate and the preparation method of the water-based adhesive remover of the invention, the methyl salicylate, the solubilizer, the penetrant, the softener, the odor masking agent and the pH regulator are scientifically proportioned, so that the functions of all the components are combined and cooperated, the OCA can be easily removed, the adhesive removal efficiency is high, the effect is good, the adhesive can be completely removed by 100%, no residue exists, the corrosion damage to black oil on the cover plate is avoided, and the practicability is high.

Owner:广州亦盛环保科技有限公司

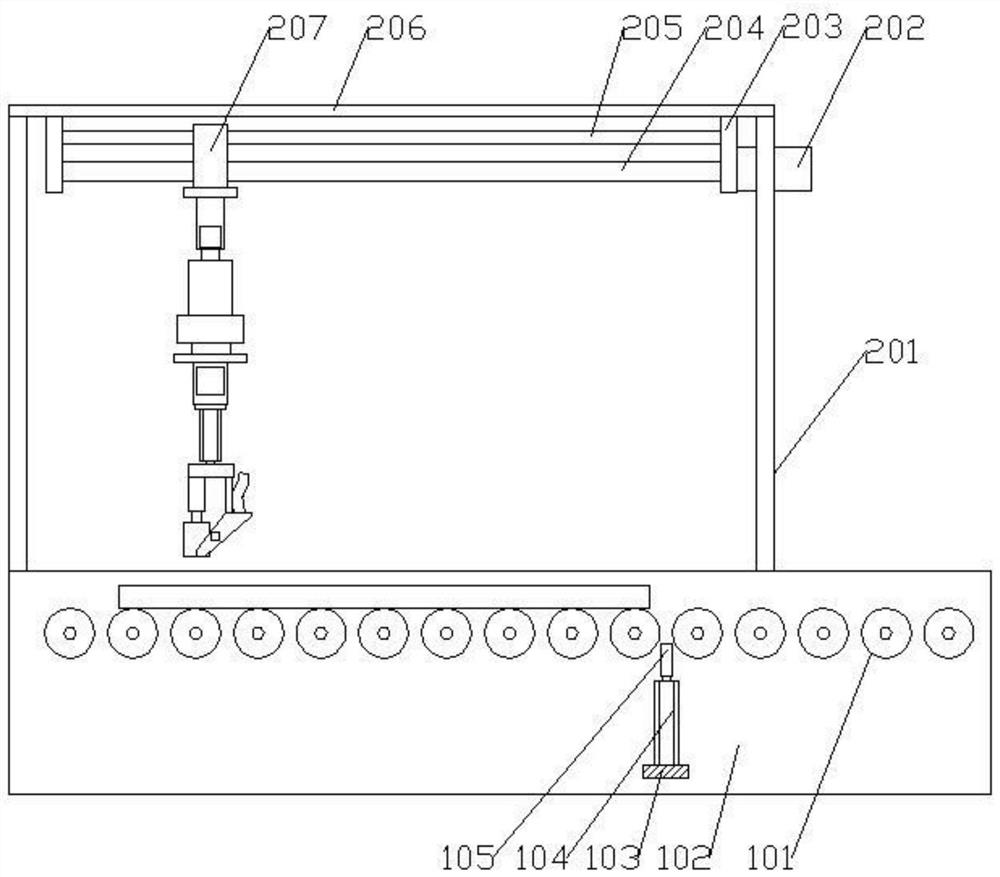

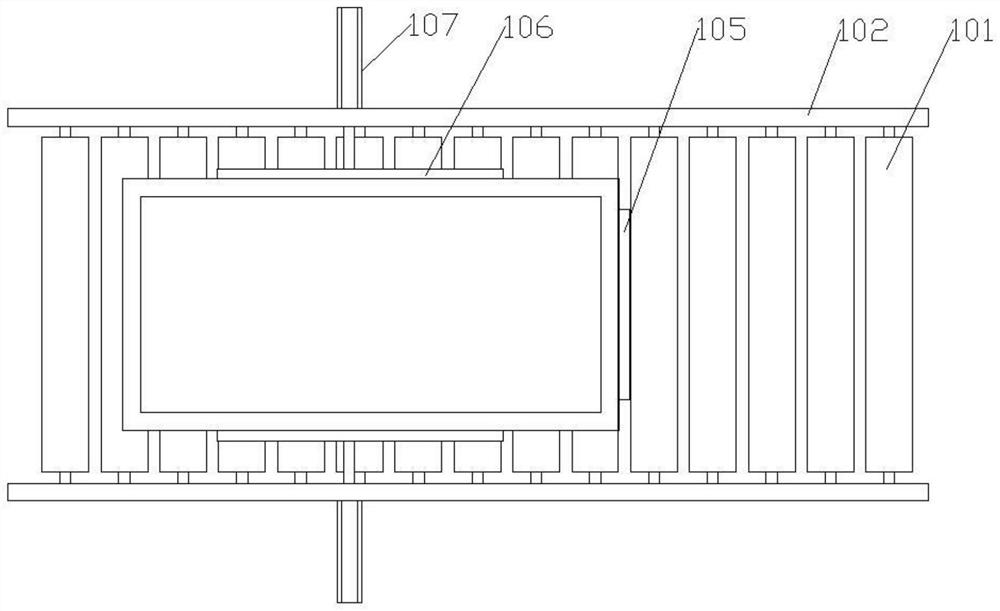

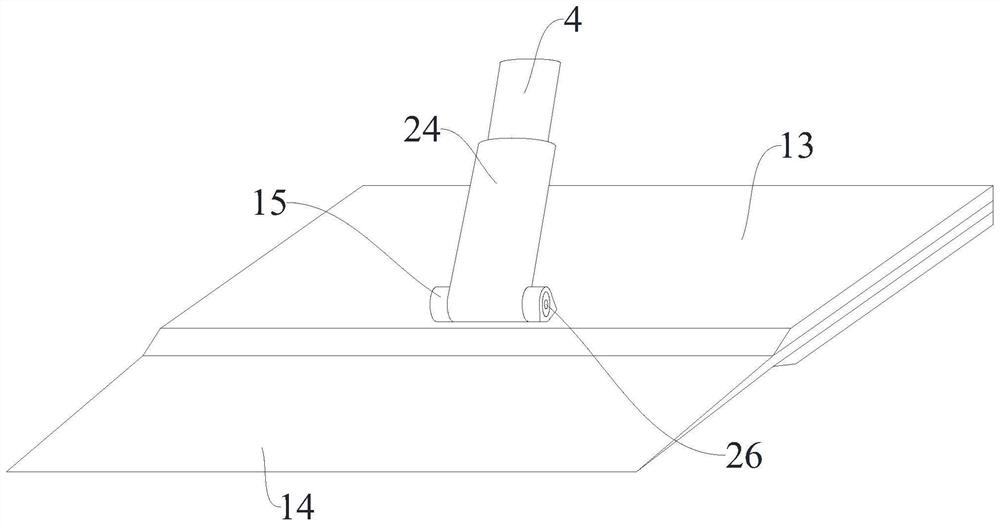

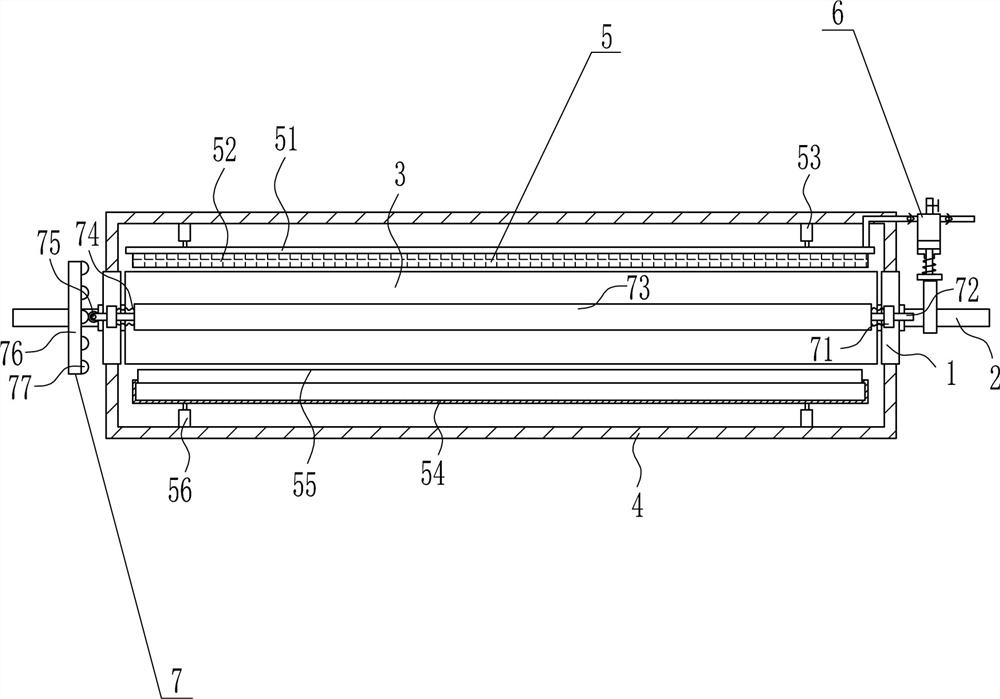

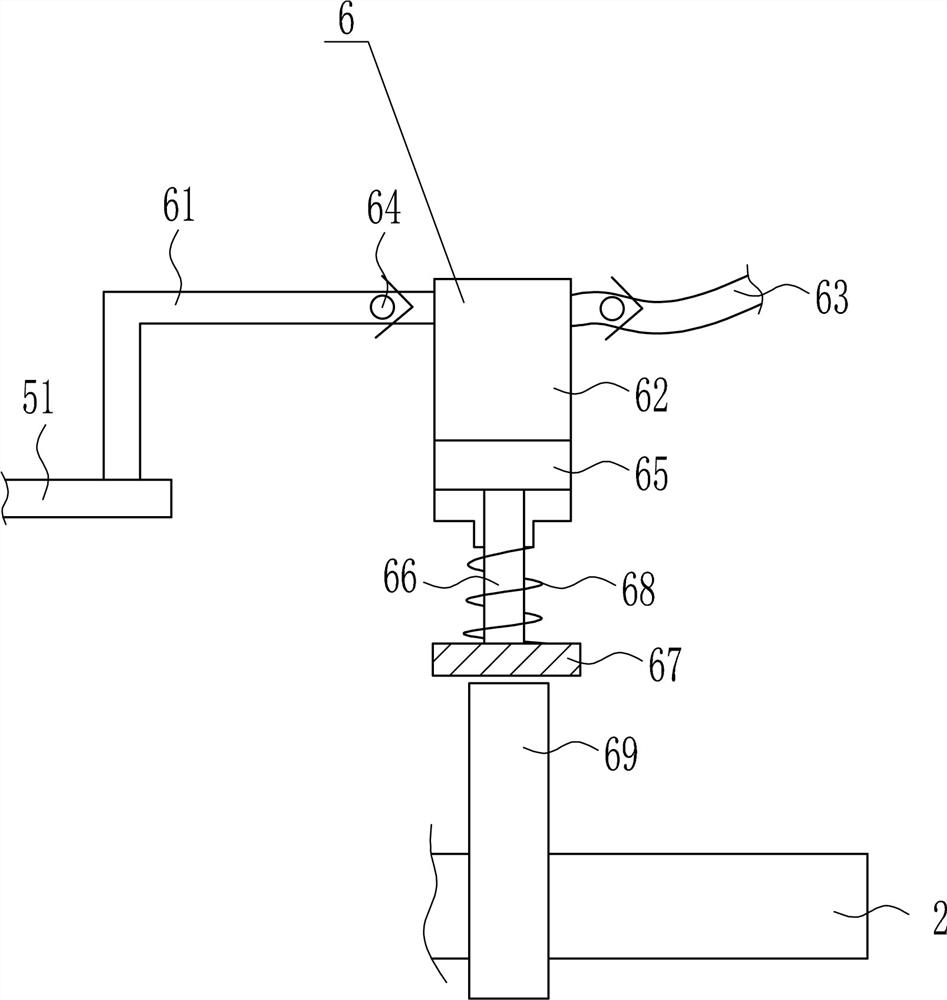

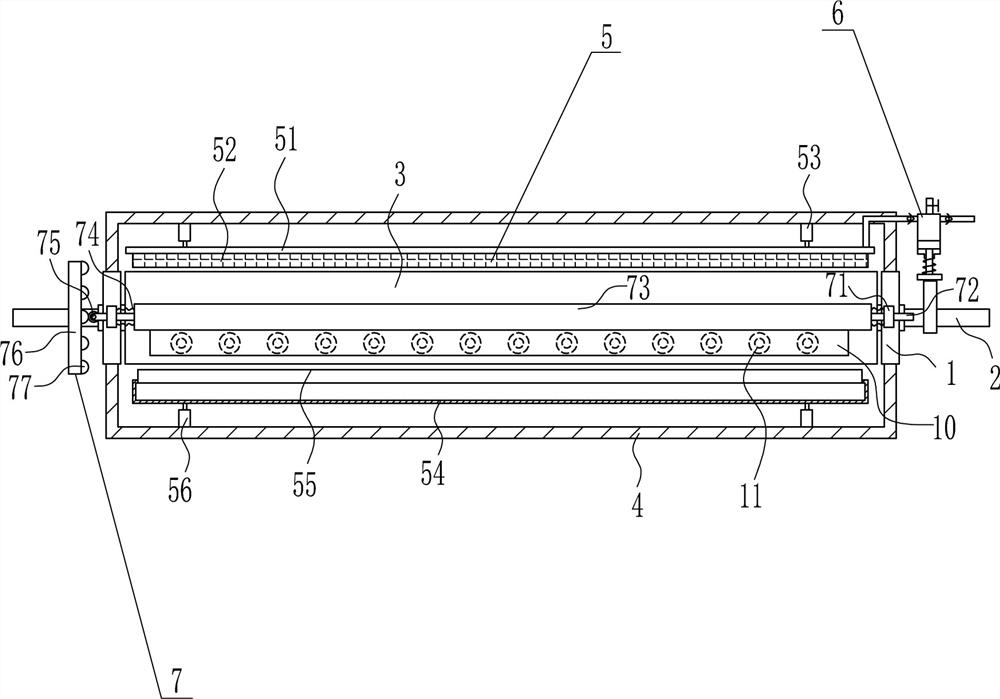

Surface treatment device and method for a photovoltaic module

ActiveCN112934768BImprove processing efficiencyImprove seal protection effectCleaning using toolsCleaning using liquidsMechanical engineeringPhysics

The present invention provides a surface treatment device and method for a photovoltaic module, which includes conveying component 1, conveying component 2 and conveying component 3 arranged in sequence along the same conveying direction. The upper end of the module two is provided with a cleaning assembly for cleaning the surface of the photovoltaic module, and the upper end of the conveying assembly three is provided with a film assembly for applying a film to the photovoltaic module. The processing device provided by the invention realizes the automation of glue removal and improves the removal Glue efficiency, reduce defects, high processing efficiency, replace manual and automatic completion of the follow-up process of photovoltaic modules, and improve the delivery speed of finished products.

Owner:ANHUI POLYTECHNIC UNIV

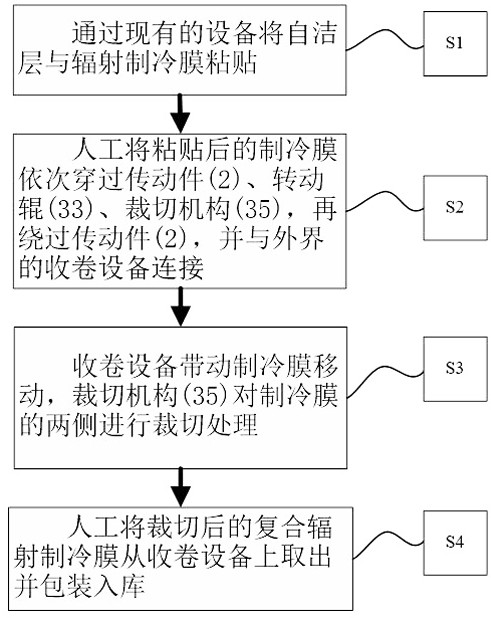

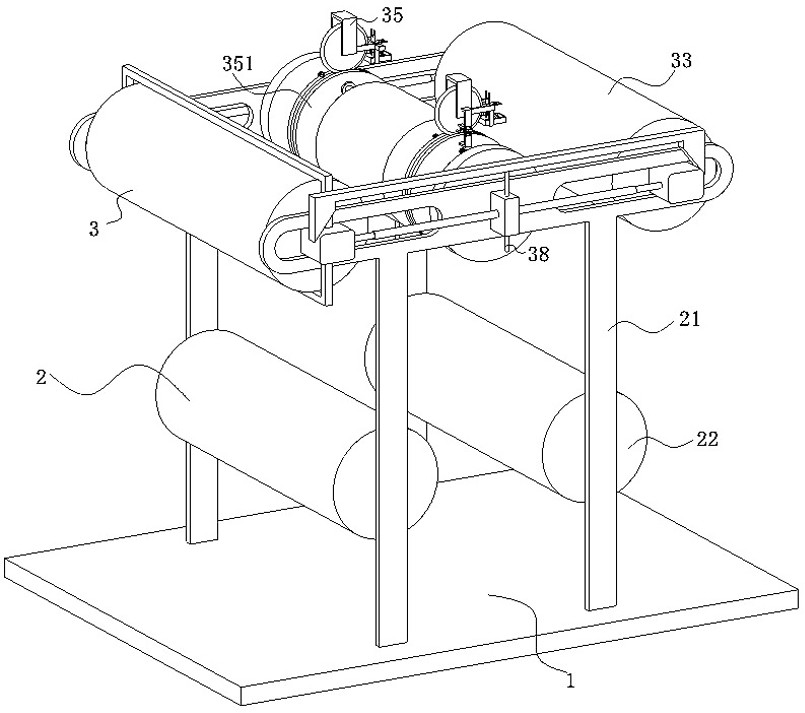

A kind of composite radiation refrigeration film production method

ActiveCN114348750BHigh glue removal efficiencyGuaranteed aestheticsMetal working apparatusArticle deliveryThermodynamicsEngineering

The invention relates to the technical field of refrigerating film manufacturing, in particular to a method for producing a composite radiation refrigerating film, comprising a placing plate, a transmission part and a cutting part; The upper end of the piece is jointly installed with a cutting piece. In the existing method, when removing the excess glue on both sides of the refrigeration film, the sides of the refrigeration film are usually cut off directly, but the existing equipment cannot clamp the two sides of the refrigeration film, and the refrigeration film is easy to be cut during the cutting process. Deformation occurs, resulting in uneven incision at the cutting place of the refrigeration film, thereby reducing the aesthetics of the refrigeration film. The cutting mechanism adopted in the production method of the composite radiation refrigeration film provided by the present invention can clamp the cutting part of the refrigeration film, so that the incision of the refrigeration film is flat and smooth, and the aesthetics of the refrigeration film after being formed is ensured.

Owner:广东鑫亿帆材料科技有限公司

Airport pavement plasma degumming device

InactiveCN105040612BNo damageHigh glue removal efficiencyRoad cleaningEngineeringHigh pressure water

Owner:CIVIL AVIATION UNIV OF CHINA

Ultraviolet laser adhesive removal method and system

ActiveCN110102900BHigh degumming precisionReduce labor costsLaser beam welding apparatusUltravioletEngineering

The invention provides an ultraviolet laser glue removal method and system. The method comprises the steps that the three-dimensional position range and the glue overflowing height of a glue overflowing position of a workpiece are scanned by a three-dimensional camera device; according to overflowing standards, the glue overflowing height and the three-dimensional position range, the area to be removed at the glue overflowing position of the workpiece is determined; the layer height and marking boundary of each marking layer after partition are obtained, and the marking parameters corresponding to each marking layer are determined according to the layer height of each marking layer; according to the marking content and the marking boundary of each marking layer, the corresponding marking path of each marking layer is determined; and after ultraviolet laser equipment operates according to the marking parameters corresponding to the marking layers, overflowing glue in the marking boundaries of the marking layers is removed by ultraviolet lasers emitted by a laser head traveling along the marking paths of the marking layers. The ultraviolet lasers are utilized to remove the overflowing glue, the labor cost is reduced, the glue removal efficiency is promoted, the amount of glue removal is controllable, the glue removal precision is high, and the glue removal process is environmentfriendly.

Owner:HANS LASER TECH IND GRP CO LTD

Method and system for removing colloids

InactiveCN104227768BAvoid destructionHigh glue removal efficiencyMetal working apparatusPull forceDisplay device

The invention discloses a method and system for removing colloid. The method includes: first controlling a staining part pivotally connected to a device body to rotate around its own axis. Then, a workpiece, such as a touch device component, a display device component, etc., with an adhesive attached to one surface thereof, is moved relative to the adhesion part so that the adhesion part contacts the adhesive, and the adhesive is affected by the adhesive. The removing pulling force exerted by the staining part in a direction away from the surface of the workpiece causes the adhesive roll to be attached to the staining part. Finally, the workpiece is moved relative to the staining part within the adhesive adhesion range, so that the adhesive is rolled away from the workpiece by the staining piece, thereby obtaining a clean finished product. In addition, the present invention also provides a system for removing colloids. The invention can efficiently remove adhesive and avoid damage to the workpiece during the adhesive removal process.

Owner:DAXIN MATERIALS

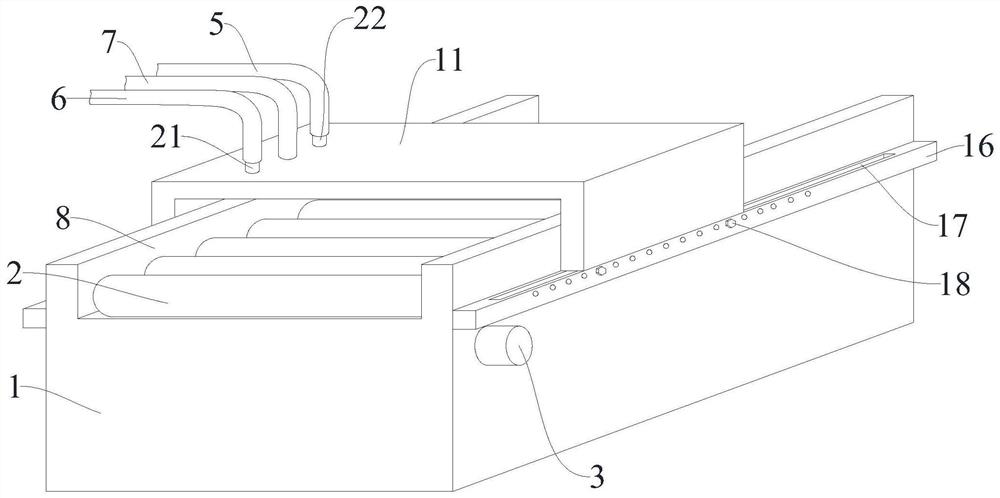

A glue dispensing subsequent glue removal device for electronic components

ActiveCN110936276BHigh glue removal efficiencyReasonable structureGrinding drivesGrinding machinesPillow block bearingGear wheel

The invention relates to a processing device for electronic components, and discloses a glue dispensing and subsequent glue removal device for electronic components, which includes a fixed bottom plate, a support frame is installed on both sides of the upper end of the fixed bottom plate, a fixed rack is installed on the top of the support frame, and the support frame The guide column is installed between the upper ends, the middle part of the guide column is slidably connected with the sliding block, the bearing seat is installed inside the sliding block, the rotating shaft is installed inside the bearing seat, the movable gear meshing with the fixed rack is installed on the upper end of the rotating shaft, and the bottom end of the rotating shaft is installed Rubber grinding wheel, the air-inducing box is installed in the middle of the left end of the support frame on the right side, the piston plate is installed in the air-inducing box, the air-inducing rod is installed on the left side of the piston plate, the sliding block is connected to the left side of the air-inducing rod, and the lifting is installed between the inner sides of the supporting frame. plate, positioning and clamping mechanisms are installed on both sides of the upper end of the lifting plate. The present invention realizes the reciprocating rotation of the glue removal grinding wheel, greatly increases the glue removal efficiency of electronic components, and at the same time makes the glue residue after glue removal can be better blown away, further increasing the glue removal efficiency.

Owner:肇庆益华电子科技有限公司

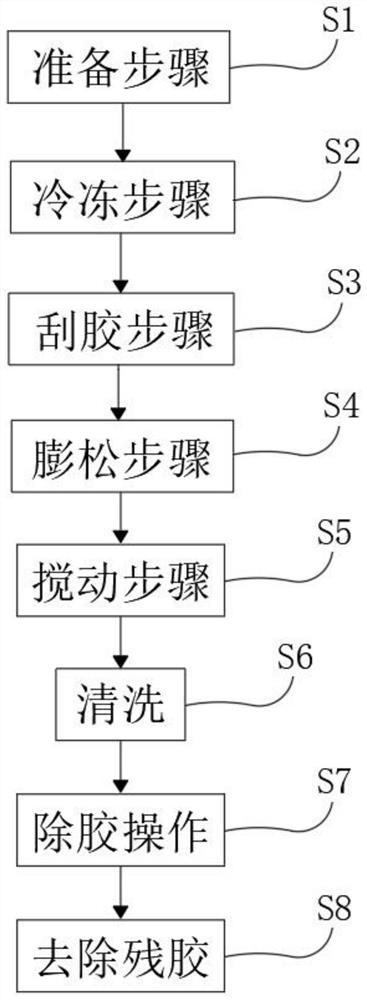

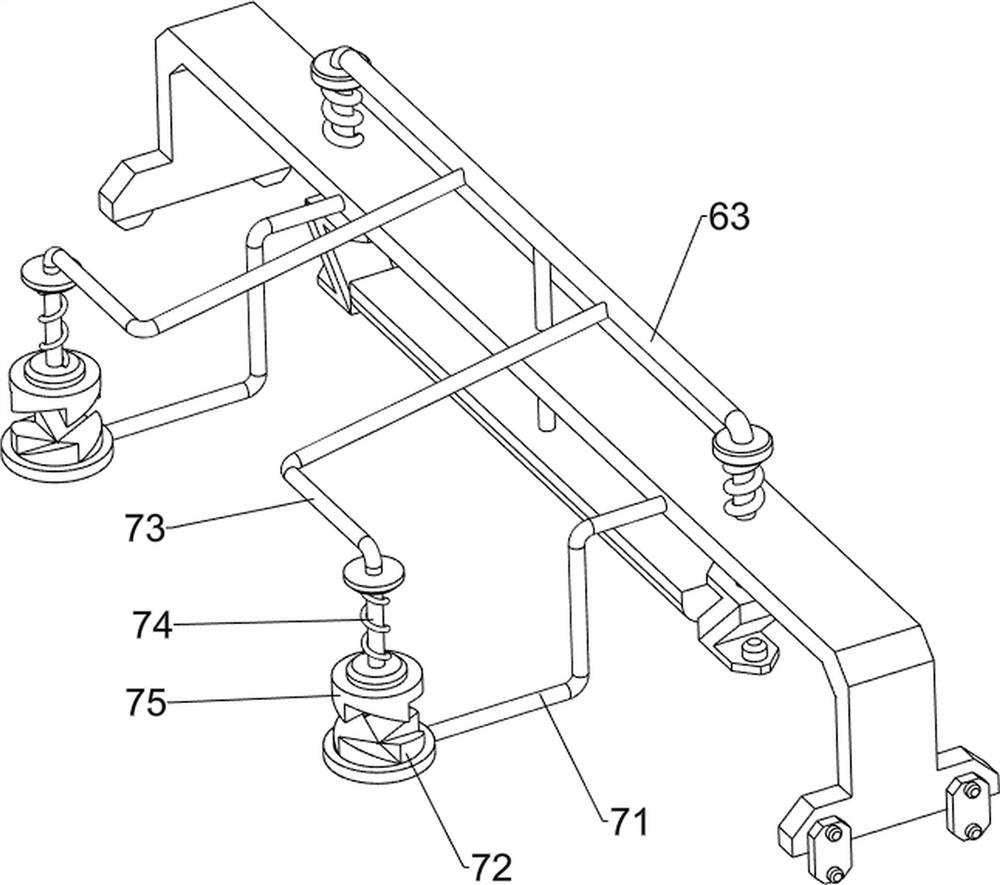

High-efficiency complete-set splicing degumming process for electroplating roller

PendingCN114392949AResidue reductionEasy to remove glueCellsCleaning using toolsProcess engineeringRefrigerated temperature

The invention provides a high-efficiency complete-set splicing degumming process for electroplating rollers, and relates to the technical field of roller degumming, the degumming process comprises the following steps: S1, a preparation step: firstly, splicing rollers needing degumming together and fixing, thereby facilitating batch high-efficiency complete-set degumming; and S2, a freezing step: then putting the roller needing to be degummed into an industrial refrigerator to be frozen, the freezing temperature range is-40 DEG C to-50 DEG C, the freezing time is 1-2 hours, and at the moment, the frozen roller is obtained, so that subsequent degumming can be facilitated. According to the electroplating roller, when glue needs to be removed, the rollers are spliced, so that complete-set glue removing is conveniently conducted on the rollers, the glue removing efficiency is improved, meanwhile, glue can be frozen through the freezing step so that the glue can be hardened, the glue scraping step is further facilitated, the glue scraping efficiency is improved, and the production cost is reduced. And the glue can be bulked through the bulking step, so that the glue removal operation of the glue removal liquid is facilitated.

Owner:扬州景如源电镀设备配件有限公司

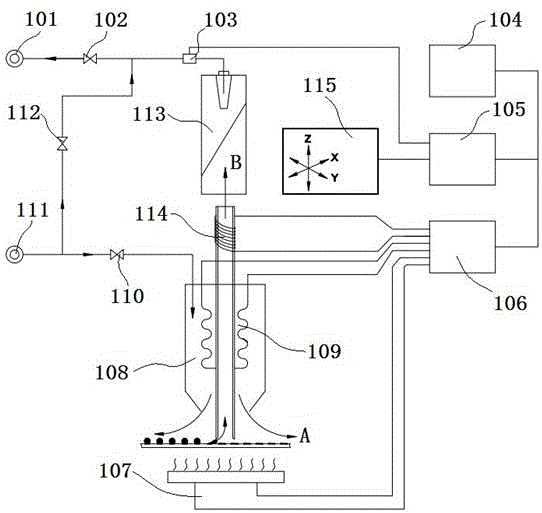

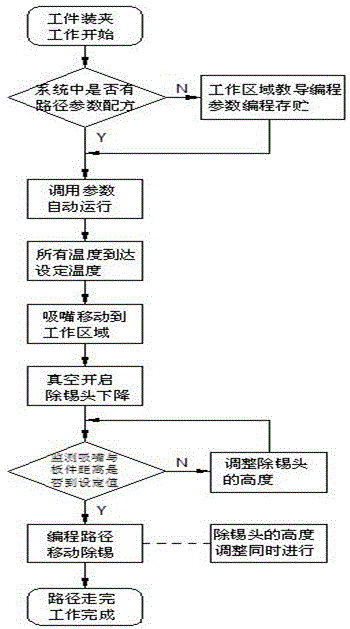

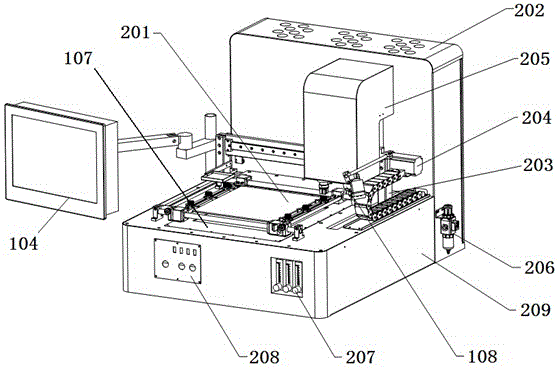

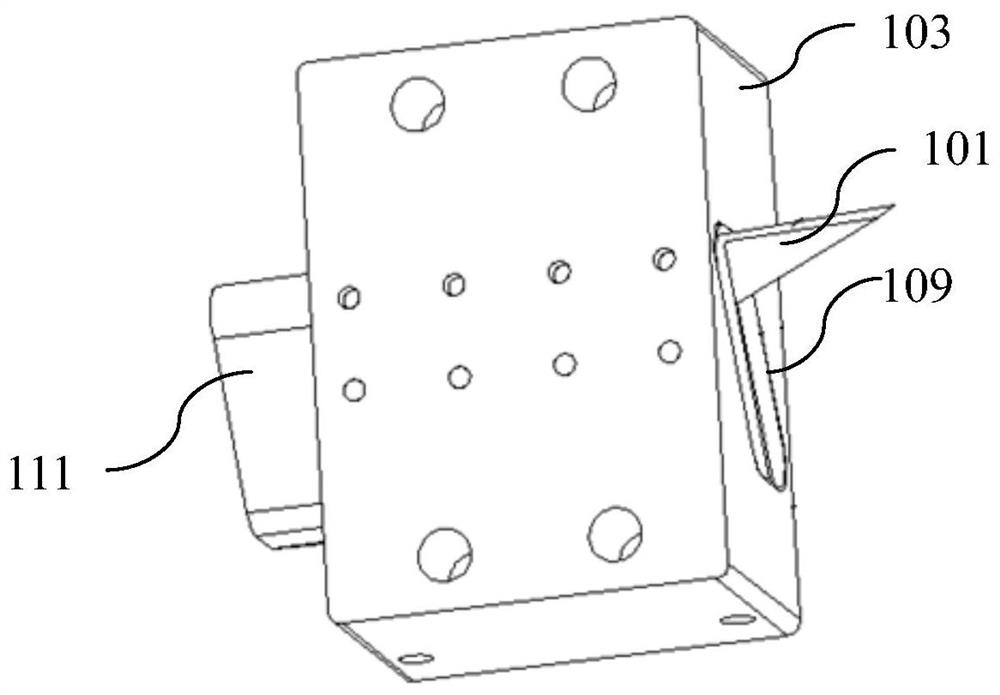

Equipment and method for removing tin and glue from printed circuit boards and electronic components

ActiveCN104690387BAvoid overall overheatingInhibit sheddingSoldering apparatusPrinted circuitsMolten stateHuman–machine interface

The invention relates to auxiliary equipment used in repair of printed circuit boards (PCBs) and electronic elements, in particular to detinning and degumming equipment for the printed circuit boards and the electronic elements as well as a use method of the detinning and degumming equipment. According to the equipment, manual operation is directly replaced and accurate motion control is adopted, so that the repair processing quality of a product is greatly improved; accurate temperature control is adopted, so that the elements are prevented from being overheated and the product safety is guaranteed; vacuum adsorption is adopted during detinning and a suction nozzle is not contacted with a workpiece, so that a welding plate is prevented from falling off; the combination of a complete system enables the whole processing batch quality to be unified; the equipment is suitable for repair of PCBs and BGA (ball grid array) elements of various electronic products from low end to high end. A tin suction pipe heater assembly is further arranged at an upper part of a detinning and degumming head, so that after tin or gum is sucked, blockage of a pipeline caused by re-solidification of tin due to cooling is prevented; the heating temperature is higher than the melting point of tin, so that tin is always in a molten state. A man-machine interaction module is connected with the equipment, so that man-machine interface operation is realized and the equipment is started for automatic operation after parameter setting.

Owner:深圳市新迪精密科技有限公司

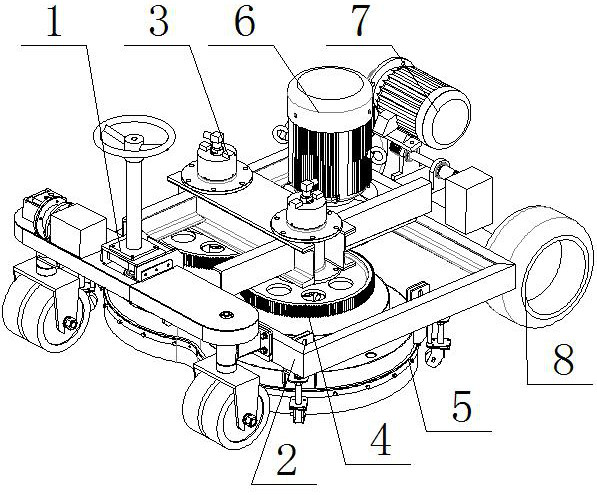

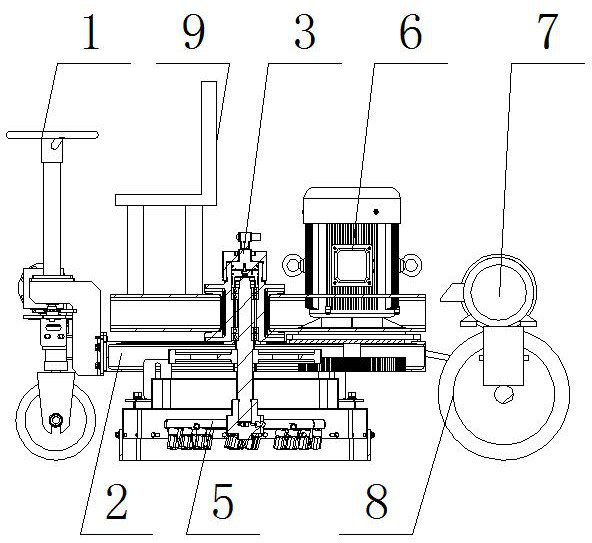

Special degumming vehicle for airport runway pavement

PendingCN113186862AFlexible useImprove transmission efficiencyRoad cleaningElectric machineryTransaxle

The invention discloses a special degumming vehicle for an airfield runway pavement. The vehicle comprises a steering assembly, a vehicle frame, rotating assemblies, driven wheels, degumming discs, a degumming driving motor, a driving motor and a driving axle, the steering assembly is fixedly connected with one side surface of the vehicle frame through a connecting piece, the vehicle frame is connected with bearing chambers in the two rotating assemblies through I-shaped steel, the lower ends of main shafts in the two rotating assemblies are provided with glue removing discs, driven wheels are arranged between the two rotating assemblies and the two glue removing discs and connected with a driving wheel in a glue removing driving motor, a driving motor is arranged on the right side of the glue removing driving motor, a rotating gear on an output shaft of the driving motor is connected with a driving pinion on a driving axle, the driving axle is fixedly connected with the right side of the vehicle frame through a connecting rod, the driving motor serves as a power source to drive the whole vehicle to move, the steering assembly conducts multi-angle free movement, and the two sets of degumming discs have good high-pressure glue removing effect, so that the degumming vehicle conducts full-automatic efficient degumming.

Owner:河南新路航交通科技有限公司

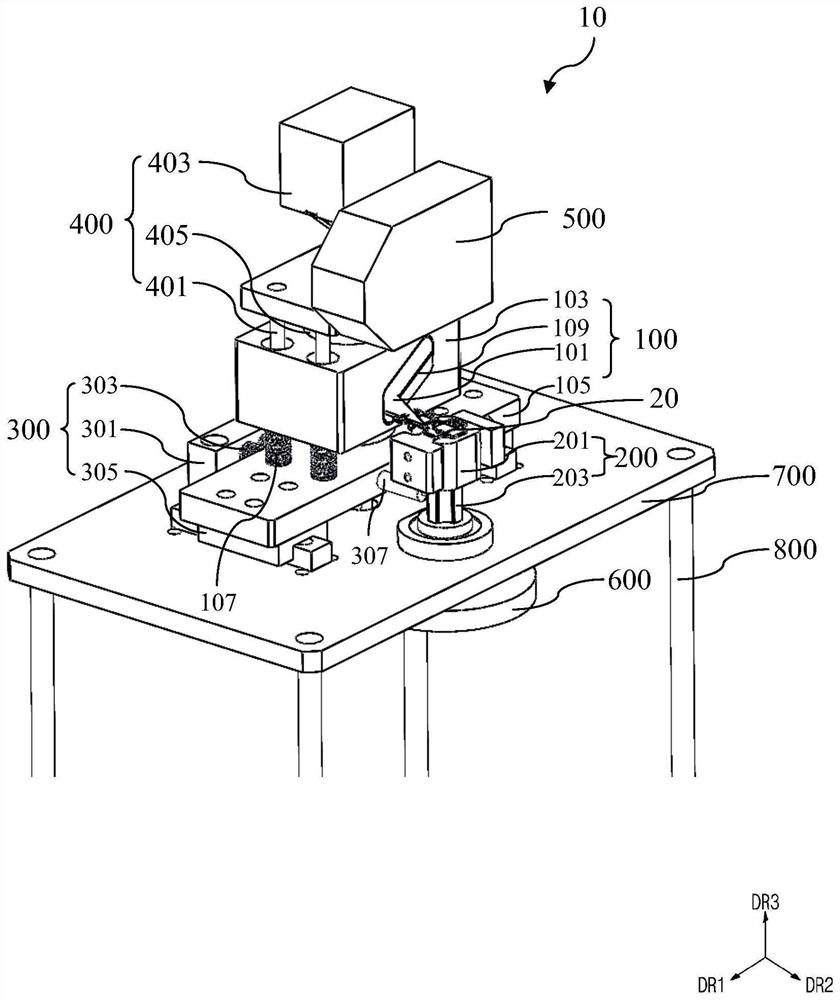

Device for removing glue and method for removing glue by using same

PendingCN114682535AHigh glue removal efficiencyHigh degree of automationCleaning using toolsRubber materialStructural engineering

The invention provides a device for removing glue and a method for removing glue by using the device. The device for removing the glue comprises a blade assembly which comprises a blade for removing the glue material and a blade fixing part configured to fix the blade; the rotatable assembly comprises a glue removing operation table and a track limiting part located below the glue removing operation table, the device to be subjected to glue removing is fixed to the glue removing operation table, a glue material to be removed arranged on the device to be subjected to glue removing is exposed, and the rotatable assembly is configured to rotate relative to the blade assembly so that the glue material to be removed can be aligned with the blade and removed; and a coupling device configured to be coupled to the blade fixing portion and abut against an outer edge of the trajectory defining portion, the blade fixing portion moving along a trajectory corresponding to a shape of the outer edge of the trajectory defining portion through the coupling device. When observed from the top, the outer edge of the track limiting part is aligned with the outer edge of the to-be-removed rubber material and has the same shape as the to-be-removed rubber material.

Owner:YUYAO SUNNY OPTICAL INTELLIGENCE TECH CO LTD

Glue washing machine for stainless steel template processing and production

ActiveCN113485077AEasy to assemble and disassembleReduce use costCleaning using toolsPhotosensitive material processingElectric machineryStructural engineering

The invention relates to the technical field of stainless steel template processing equipment, in particular to a glue washing machine for stainless steel template processing and production, which comprises a main frame, an internal transmission roller, a driving motor, an electric hydraulic support rod, a cooling water delivery pipe, a heating water delivery pipe and a high-pressure water delivery pipe. The glue washing machine for stainless steel template processing and production is composed of the main machine frame and a position-adjustable top glue removing and cleaning device which are installed in a split mode, disassembly and assembly are convenient, and the later use cost is reduced; and lateral supporting limiting plates used for supporting the position-adjustable top glue removing and cleaning device are symmetrically fixed to the outer side face of the main machine frame, and the position-adjustable top glue removing and cleaning device is laterally locked and fixed through lateral locking screws on the outer side faces of the lateral supporting limiting plates. The bottom supporting force and the stability are improved while the glue washing position is conveniently adjusted, and the adjusting and locking operation is simple and convenient; and the inner top face of the main machine frame is fixedly connected with an inner heating pipe of a U-shaped structure.

Owner:摩泰金属科技常州有限公司

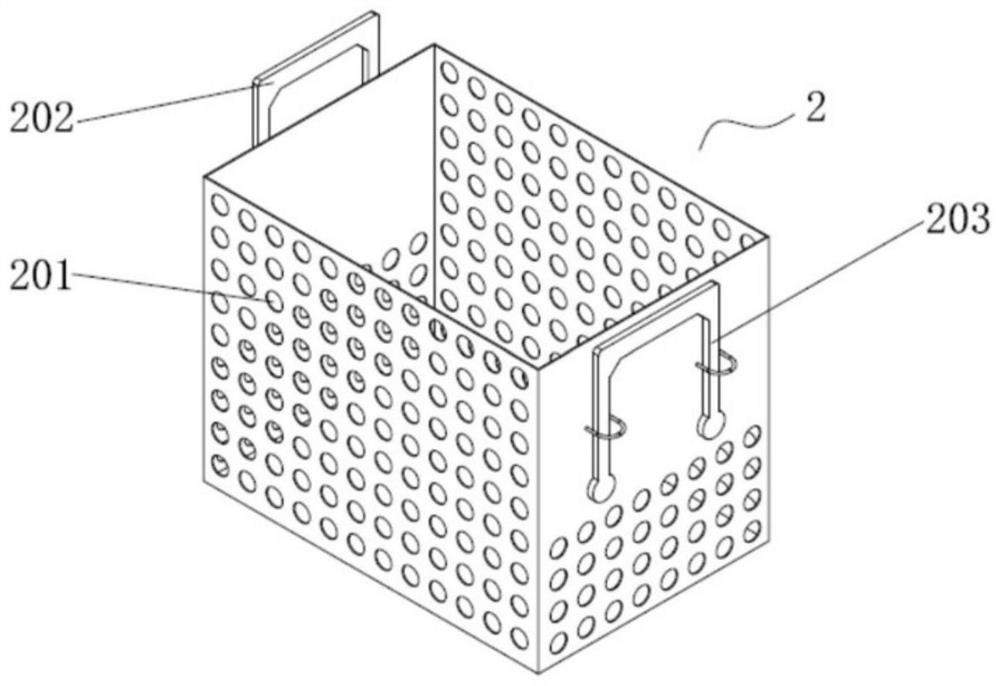

Glue-removing soaking material box for semiconductor packaging product

PendingCN114130750AImprove glue removalEasy to cleanSemiconductor/solid-state device manufacturingCleaning using liquidsSemiconductor packageStructural engineering

The invention provides a degumming soaking material box for semiconductor packaging products, which comprises a material box body which is enclosed by an upper side plate, a lower side plate, a left side plate, a right side plate and a bottom plate and is in a cube or cuboid overall shape, and further comprises a cover plate, one side of the cover plate is hinged with the right side plate, and the cover plate can be opened or covered on the material box body by rotating the cover plate; permeable structures are arranged on the upper side plate, the lower side plate, the left side plate, the right side plate, the cover plate and the bottom plate; and the bottom plate is also provided with a separating and positioning device for semiconductor packaging products. The device and the method are not only suitable for degumming treatment of traditional electronic packaging products, but also suitable for degumming treatment of novel electronic packaging products such as QFN and DFN, not only effectively solve the problem that the surfaces of novel packaging bodies are prone to being scratched or generate liquid medicine marks in the degumming process, but also remarkably improve the degumming efficiency and save liquid medicine.

Owner:FOSHAN BLUE ROCKET ELECTRONICS

Device and method for automatically removing glue from mobile phone

PendingCN114392943ASo as not to damageSolve the problem of reduced glue removal efficiencyCleaning using toolsControl engineeringElectric machinery

The invention discloses equipment and a method for automatically removing glue from a mobile phone. The equipment comprises a glue removing module, a feeding module, a pressure sensing module, a laser sensing module, a control module, a brush cleaning module and a rack, wherein a stepping motor in the glue removing module is fixed on the lower side of a Z-axis part of a feeding module, and the feeding module is fixed on a rack bracket; the pressure sensing module is fixed on one side of the rack; the control module is fixed on one side of the rack and below the pressure display; the laser sensing module is fixed on one side of a brush rotating main shaft on the degumming module so as to conveniently scan the surface of the mobile phone; the degumming module is a chemical degumming module or a mechanical degumming module; hot melt adhesive attached to a vertical shaft damping brush and a transverse shaft roller brush is cleaned up through a brush cleaning module, and then the cutter is fed to continue to clean the mobile phone; the problem that the recovery rate of mobile phone parts is low due to the fact that hot melt adhesive remains in the disassembly and recovery process of the mobile phone parts is solved. The degumming device is high in degumming efficiency, good in effect, simple in structure, low in operation cost, energy-saving and environment-friendly.

Owner:QINGDAO UNIV OF SCI & TECH

A kind of plasma degumming equipment for airport runway

ActiveCN113106903BClean up thoroughlyReduce neutralizationDispersed particle separationDirt cleaningDirect couplingRoad surface

The invention provides a plasma degumming equipment for an airport runway, comprising: a carrying vehicle body, a rolling electrode installed at the bottom of the carrying vehicle body, and a discharge electrode assembly; and an oxygen generator, a radio frequency power supply and a control unit installed in the carrying vehicle body; The rolling ground electrode is connected to the negative pole of the radio frequency power supply. When it is used, the road surface rubber layer of the airport runway is in rolling contact, and is used to temporarily polarize the road surface rubber layer of the airport runway to form a temporary discharge electrode of the discharge electrode assembly; the discharge electrode assembly and the airport The pavement rubber layer of the runway is directly coupled with discharge and excites the oxygen ejected from the oxygen generator to generate high-concentration plasma to gasify the pavement rubber layer; the oxygen generator is used to produce oxygen from air; the radio frequency power supply is used to Provide high-voltage and high-frequency power for the discharge electrode assembly; the control unit is used to control the operation of the ground electrode, the discharge electrode assembly, the oxygen generator, and the radio frequency power supply. The direct-coupled discharge is used to generate plasma, and the glue removal efficiency is high and thorough without losing the road surface.

Owner:林强

A quick glue removal device for positioning holes of PCB boards for electrical engineering

ActiveCN112620029BQuick clearAutomatic take outLiquid surface applicatorsCoatingsAdhesive glueEngineering

The invention relates to a glue removing device, in particular to a fast glue removing device for positioning holes of PCB boards used in electrical engineering. The invention provides a fast degumming device for PCB board positioning holes for electrical engineering with high degumming efficiency of PCB board and relatively convenient loading. A quick glue removal device for positioning holes of a PCB board for electrical engineering, comprising: a base and a clamping mechanism, the base is provided with a clamping mechanism; a glue removal mechanism, the clamping mechanism is provided with a glue removal mechanism. The invention achieves the effect of quickly removing excess glue in the positioning holes of the PCB board. Through the cooperation of the glue removing mechanism, the glue scraping mechanism and the adsorption mechanism, the invention can automatically remove the excess glue on the surface of the PCB board and in the positioning holes, and improve the glue removal efficiency. , It also achieves the effect of convenient loading. Through the cooperation of the clamping mechanism, the pushing mechanism and the guiding and positioning mechanism, the PCB boards that need to be glued can be placed uniformly, and then loaded gradually, reducing the number of manual loading and making the loading easier. Material is more convenient.

Owner:普科(清新)电路板有限公司

A corrugated paper bonding press roll for carton production

ActiveCN108790280BNot easy to damageHigh glue removal efficiencyPaper-makingBox making operationsInterference fitCarton

Owner:义乌市义心科技有限责任公司

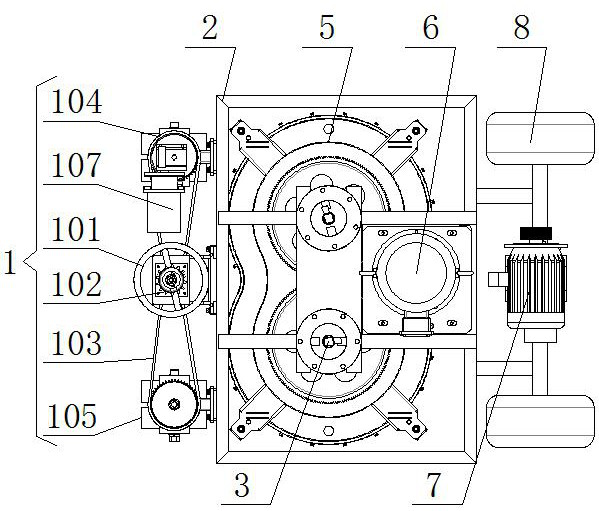

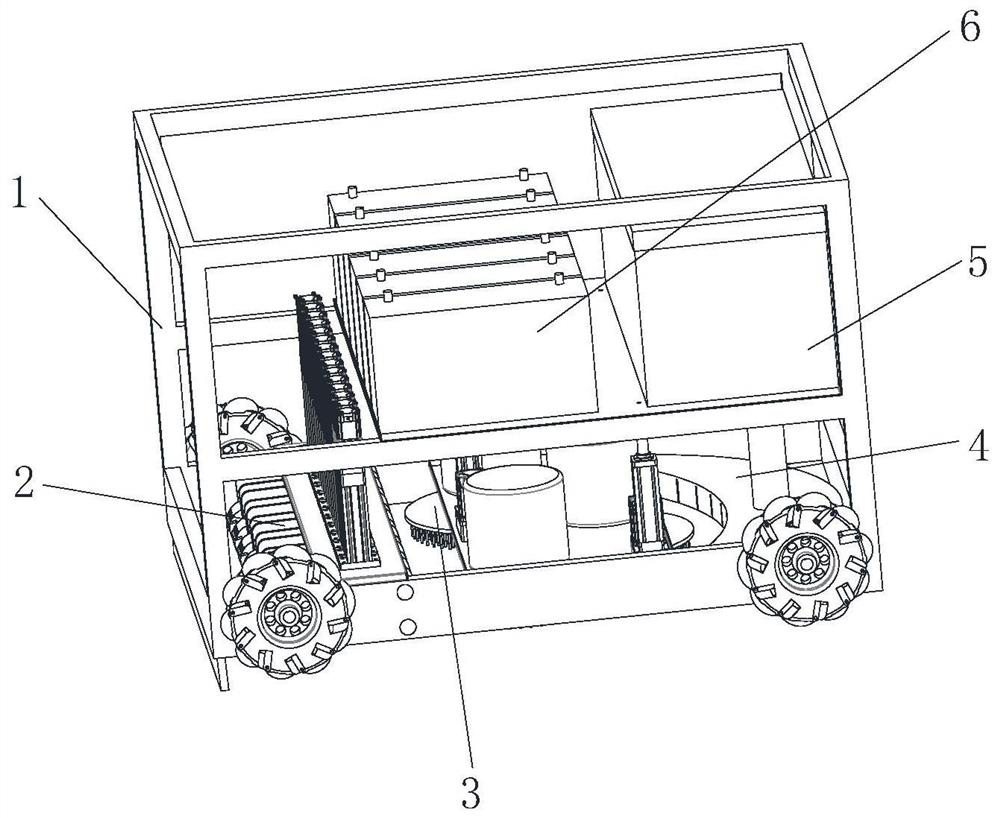

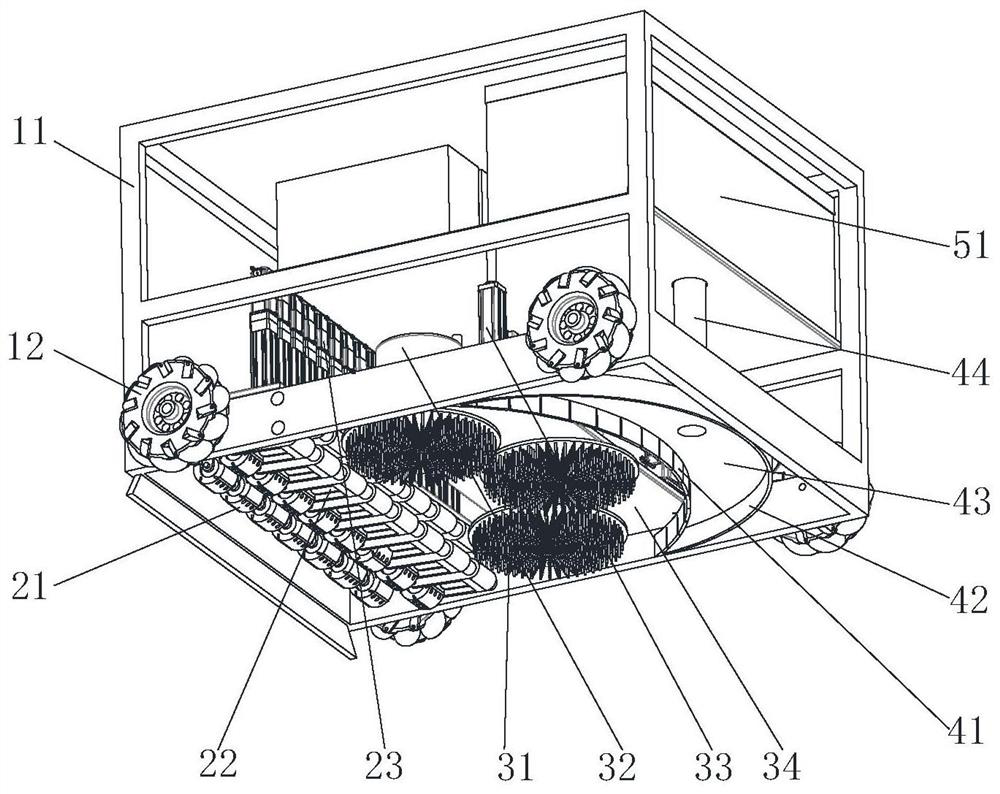

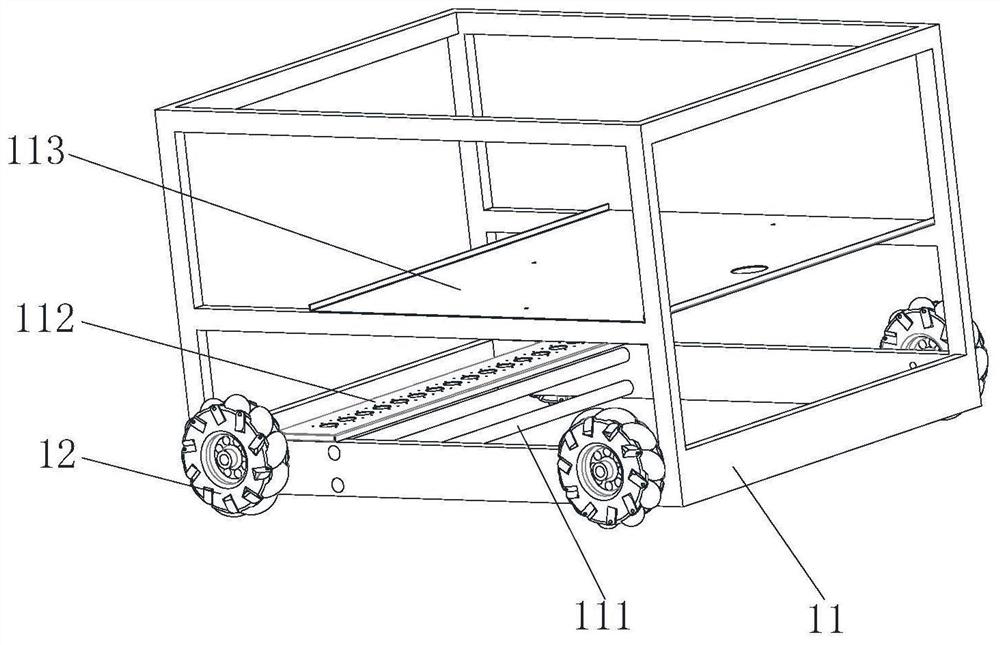

An intelligent deglue equipment for airport runways

ActiveCN111996886BImprove work efficiencyHigh glue removal efficiencyRoads maintainenceWater flowProcess engineering

The invention discloses an intelligent degumming device for an airport runway, which comprises an omnidirectional mobile frame, an adhesive black scraper mechanism, a granular colloidal particle scouring mechanism, a colloidal one-way adsorption mechanism, a colloidal particle storage and detection device, and a power supply Module and intelligent control system; an airport runway intelligent degumming device disclosed in the present invention can realize efficient and intelligent removal and storage functions for the adhesive black and granular colloidal particles of the airport runway, thereby avoiding the use of traditional high-pressure water flow in the prior art Non-uniform glue removal in the work area, cumbersome operation, and increased safety hazards have been caused by technologies such as manual glue removal.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com