Glue-removing soaking material box for semiconductor packaging product

A semiconductor and material box technology, which is applied in the manufacture of semiconductor/solid-state devices, cleaning methods using liquids, electrical components, etc., can solve the problems of poor glue removal and cleaning effect, residual liquid medicine, and excessive consumption of liquid medicine, so as to save liquid medicine. , Improve fluidity and improve the effect of removing glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

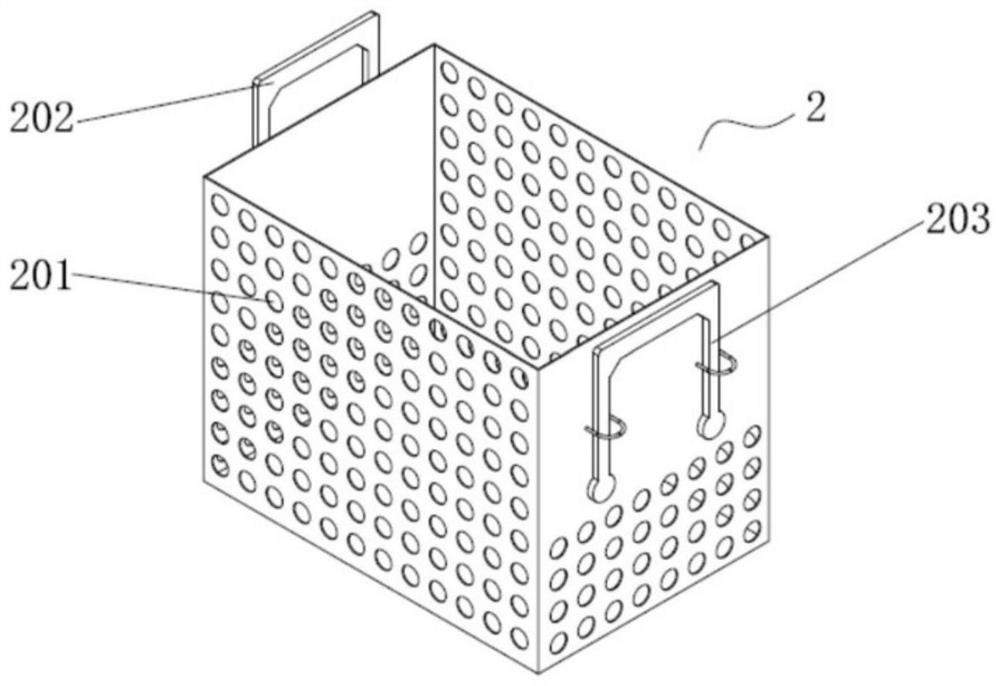

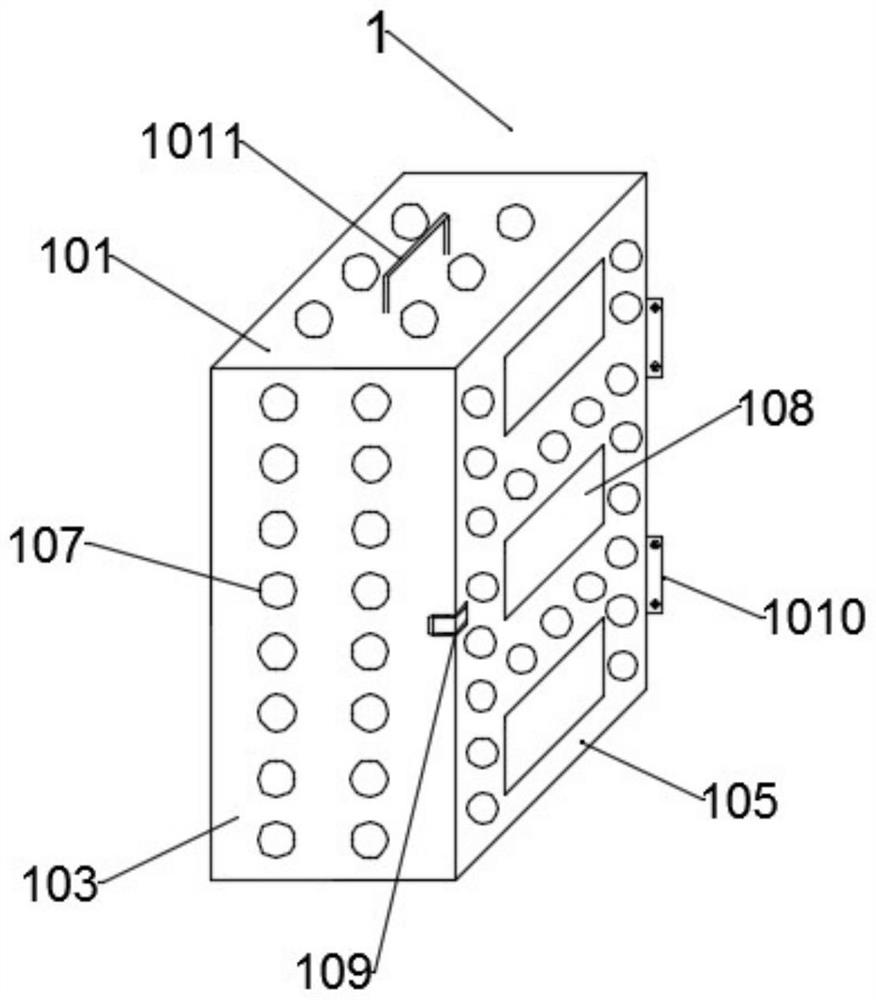

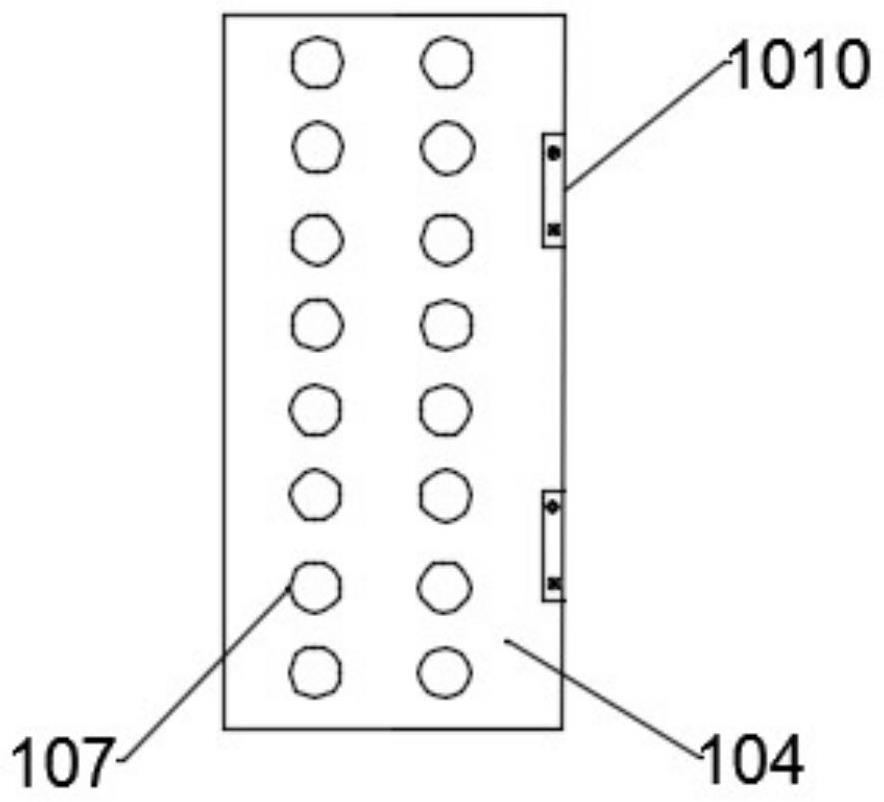

[0039] Such as figure 2 and combine image 3 , Figure 4 , Figure 5 As shown, a glue-removing soaking box 1 for semiconductor packaging products includes a box surrounded by an upper side plate 101, a lower side plate 102, a left side plate 103, a right side plate 104 and a bottom plate 106, and the overall shape is a cube or The magazine body of cuboid also comprises cover plate 105, and one side of cover plate 105 is hingedly connected with right side plate 104 by hinge 1010, and rotating cover plate 105 can make cover plate 105 open or cover on the magazine body, The upper side plate 101, the lower side plate 102, the left side plate 103, the right side plate 104, the cover plate 105 and the bottom plate 106 are all provided with water-permeable structures; the bottom plate 106 is also provided with a separation and positioning device for semiconductor packaging products, and the upper side plate The middle part of 101 is also provided with handle 1011.

[0040]It sho...

Embodiment 2

[0045] The basic shape and structure of this embodiment are the same as those of Embodiment 1, the difference is that, as Figure 7 As shown, in this embodiment, the upper side plate, the lower side plate (not shown in the figure), the left side plate, the right side plate (not shown in the figure), the bottom plate ( (not shown in the figure) and the cover plate are both criss-crossed and combined screen plates made of stainless steel wires, and the meshes of the screen plates constitute the permeable structure. In addition, whether it is this embodiment or embodiment 1, parallel barriers can be set on the bottom plate to separate and position the semiconductor packaging products to be deglue-treated. Of course, in terms of product processing and use, two rows The technical scheme in which the stainless steel rake teeth 1012 are used as the separation positioning device is more optimal.

[0046] Above, the shape and structural features of the two embodiments of the present i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com