A corrugated paper bonding press roll for carton production

A corrugated paper and press roller technology, which is applied in the manufacture of paper/cardboard containers, papermaking, rigid/semi-rigid containers, etc., can solve the problems of low efficiency of manual degumming and easily damaged paper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

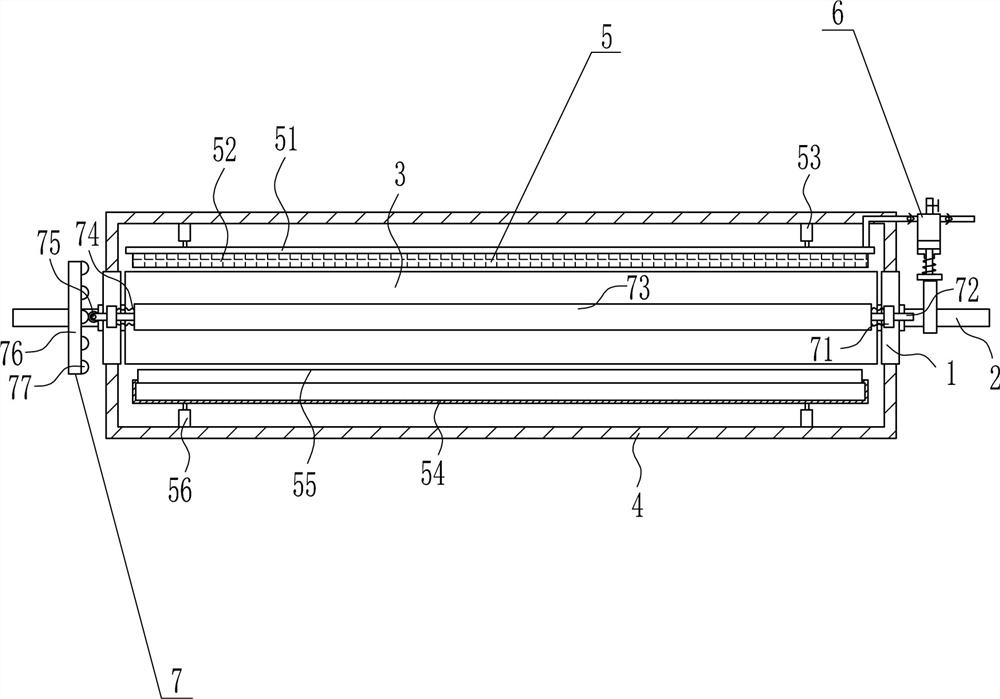

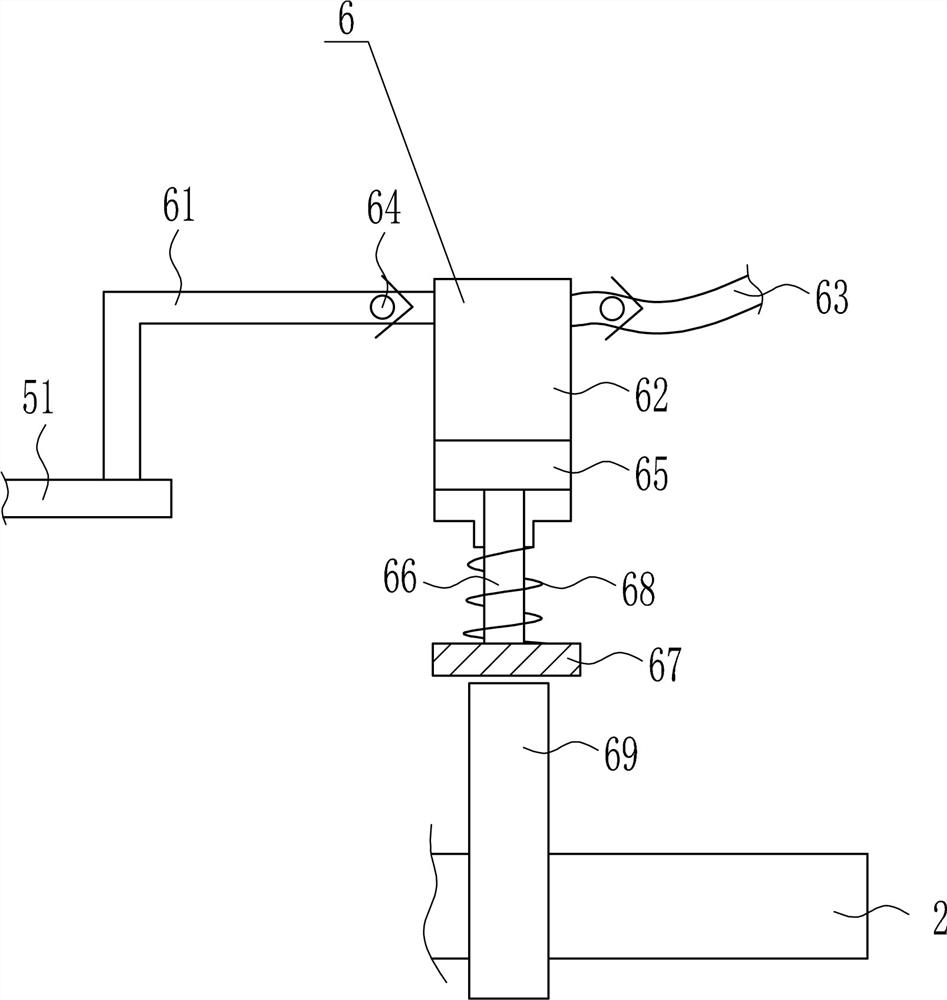

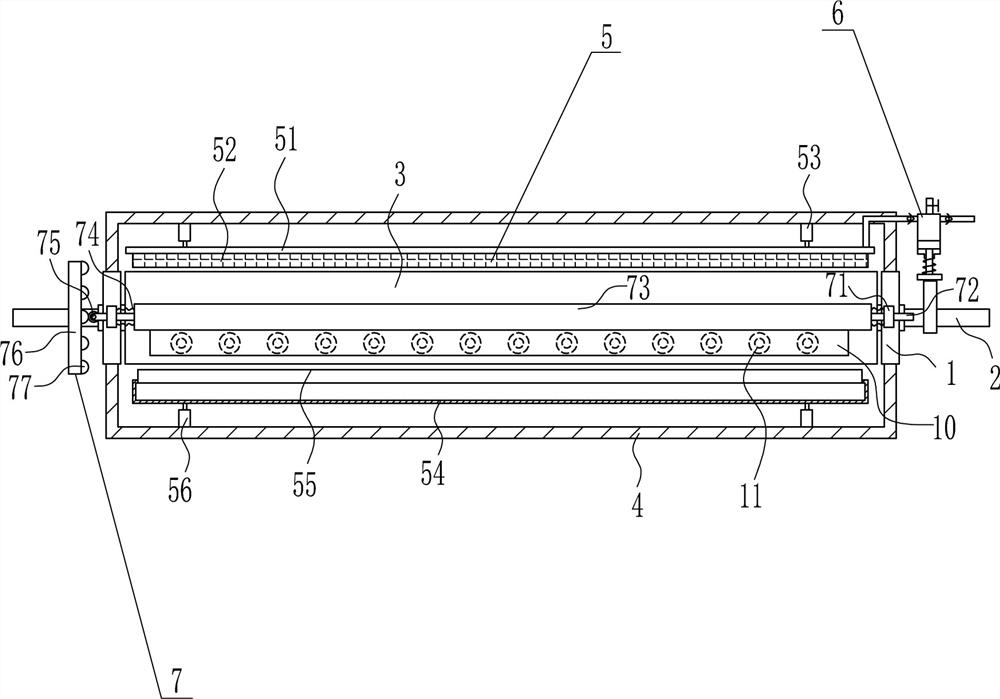

[0028]A corrugated bonding press roll for carton production such as Figure 1-7 As shown, it includes a bearing seat 1, a first rotating shaft 2, a pressure roller 3, an n-shaped frame 4, a glue removing device 5 and a liquid spraying device 6, and the left and right sides of the first rotating shaft 2 are connected by an interference fit connection. Bearing housing 1, the left and right bearing housings 1 are equipped with n-shaped frames 4 on the upper and lower sides, the middle part of the first rotating shaft 2 is equipped with pressure roller 3, and the pressure roller 3 is located between the two n-shaped frames 4, and the inner side of n-shaped frame 4 is provided with Glue removing device 5, liquid spraying device 6 is arranged on the moving part of glue removing device 5.

Embodiment 2

[0030] A corrugated bonding press roll for carton production such as Figure 1-7 As shown, it includes a bearing seat 1, a first rotating shaft 2, a pressure roller 3, an n-shaped frame 4, a glue removing device 5 and a liquid spraying device 6, and the left and right sides of the first rotating shaft 2 are connected by an interference fit connection. Bearing housing 1, the left and right bearing housings 1 are equipped with n-shaped frames 4 on the upper and lower sides, the middle part of the first rotating shaft 2 is equipped with pressure roller 3, and the pressure roller 3 is located between the two n-shaped frames 4, and the inner side of n-shaped frame 4 is provided with Glue removing device 5, liquid spraying device 6 is arranged on the moving part of glue removing device 5.

[0031] Glue removing device 5 comprises hollow tube 51, anti-corrosion sponge block 52, first cylinder 53, loading hopper 54, scraper blade 55 and second cylinder 56, and the left and right sides...

Embodiment 3

[0033] A corrugated bonding press roll for carton production such as Figure 1-7 As shown, it includes a bearing seat 1, a first rotating shaft 2, a pressure roller 3, an n-shaped frame 4, a glue removing device 5 and a liquid spraying device 6, and the left and right sides of the first rotating shaft 2 are connected by an interference fit connection. Bearing housing 1, the left and right bearing housings 1 are equipped with n-shaped frames 4 on the upper and lower sides, the middle part of the first rotating shaft 2 is equipped with pressure roller 3, and the pressure roller 3 is located between the two n-shaped frames 4, and the inner side of n-shaped frame 4 is provided with Glue removing device 5, liquid spraying device 6 is arranged on the moving part of glue removing device 5.

[0034] Glue removing device 5 comprises hollow tube 51, anti-corrosion sponge block 52, first cylinder 53, loading hopper 54, scraper blade 55 and second cylinder 56, and the left and right sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com