Patents

Literature

385 results about "Pillow block bearing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A pillow block (or plummer block) is a pedestal used to provide support for a rotating shaft with the help of compatible bearings & various accessories. Housing material for a pillow block is typically made of cast iron or cast steel.

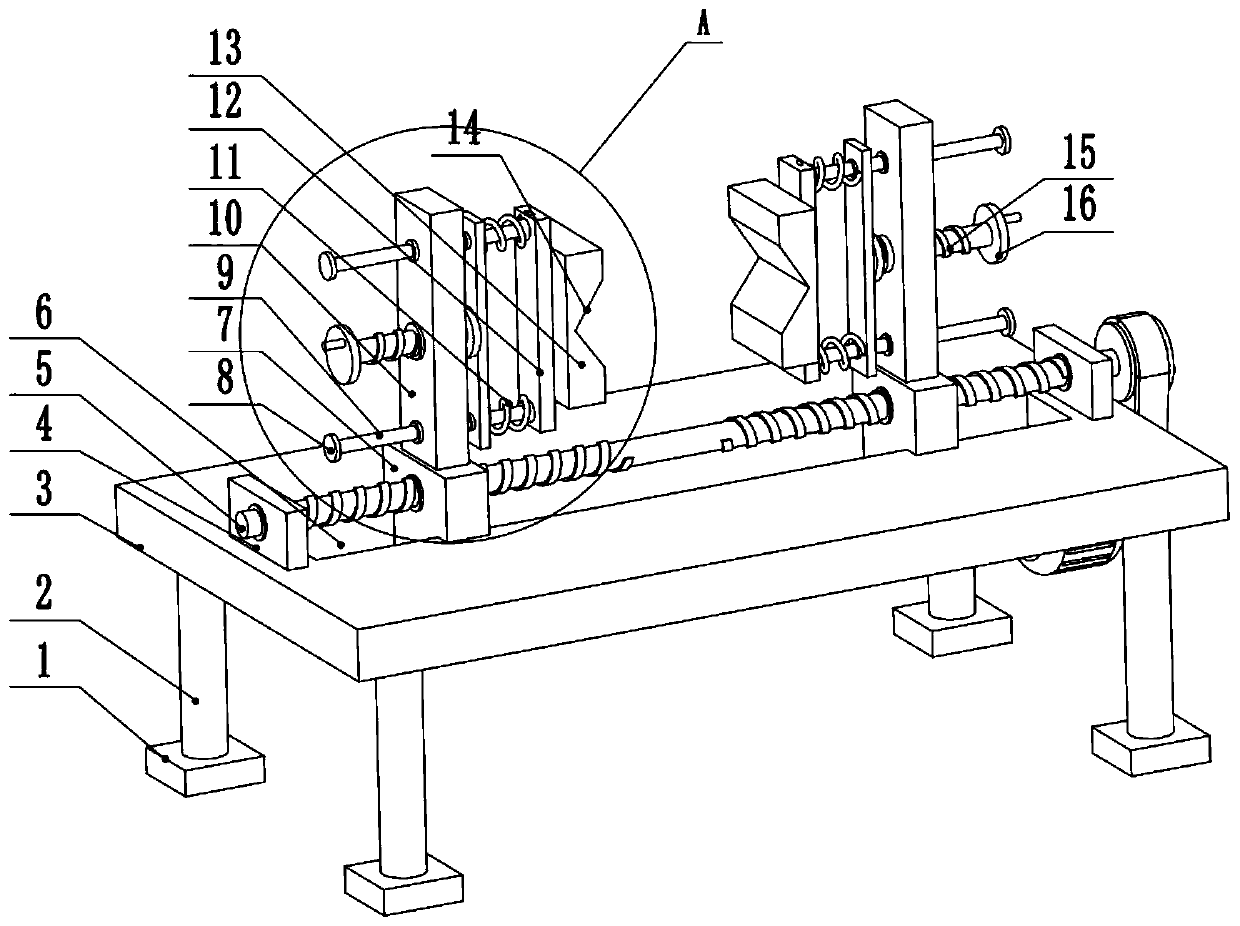

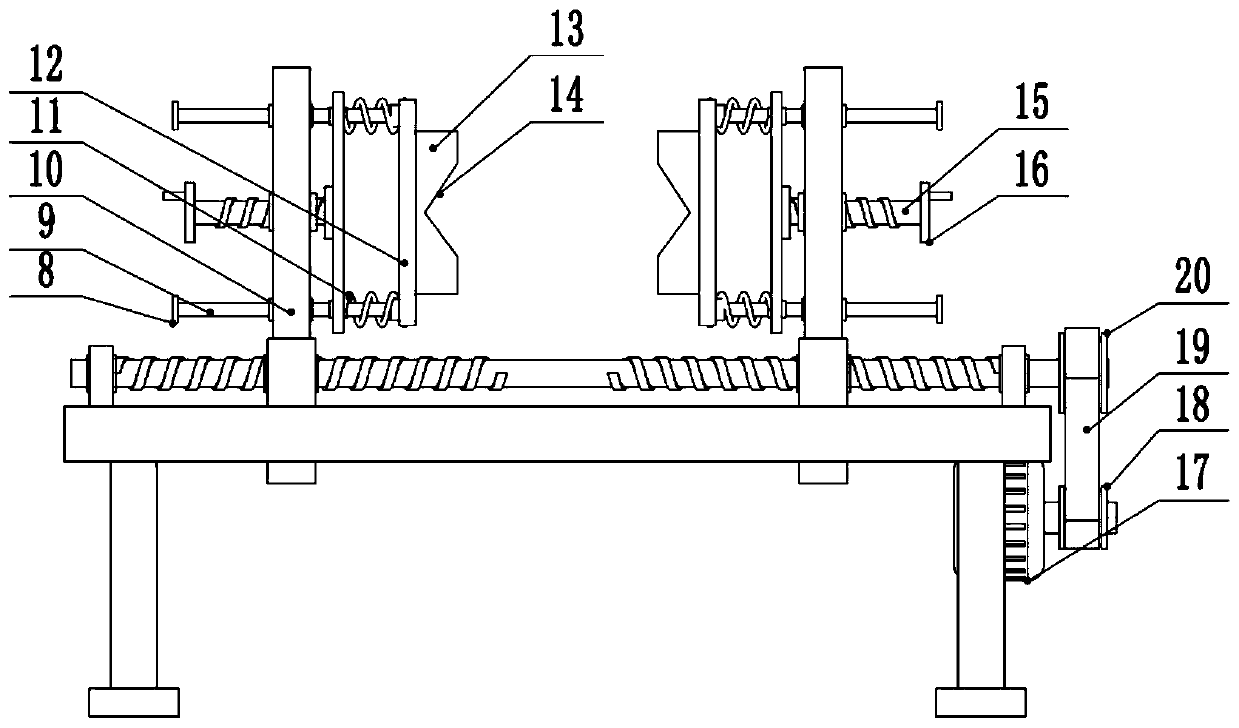

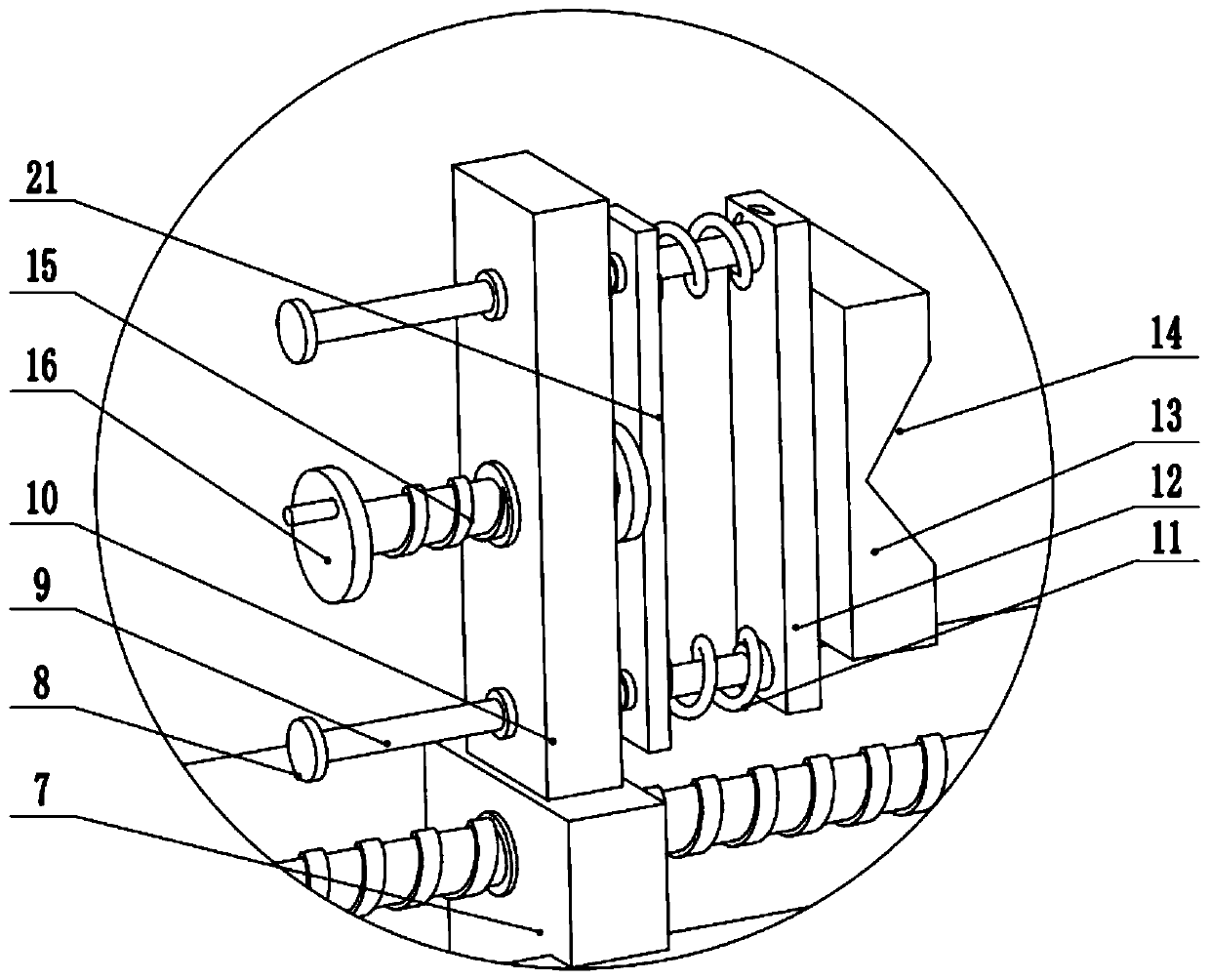

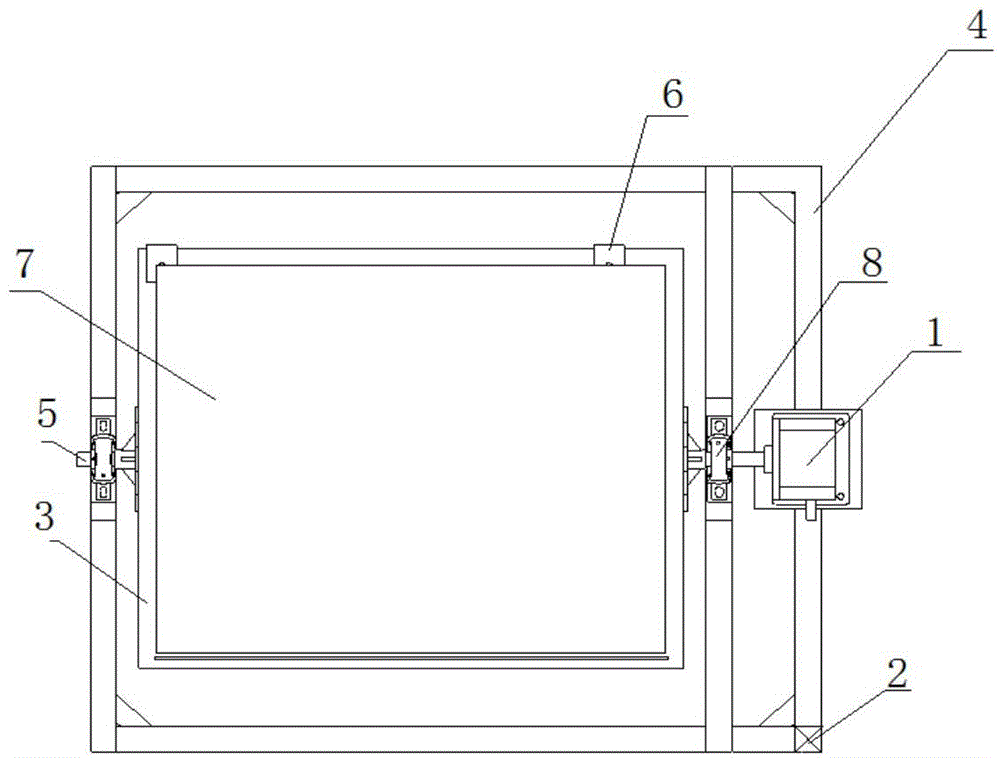

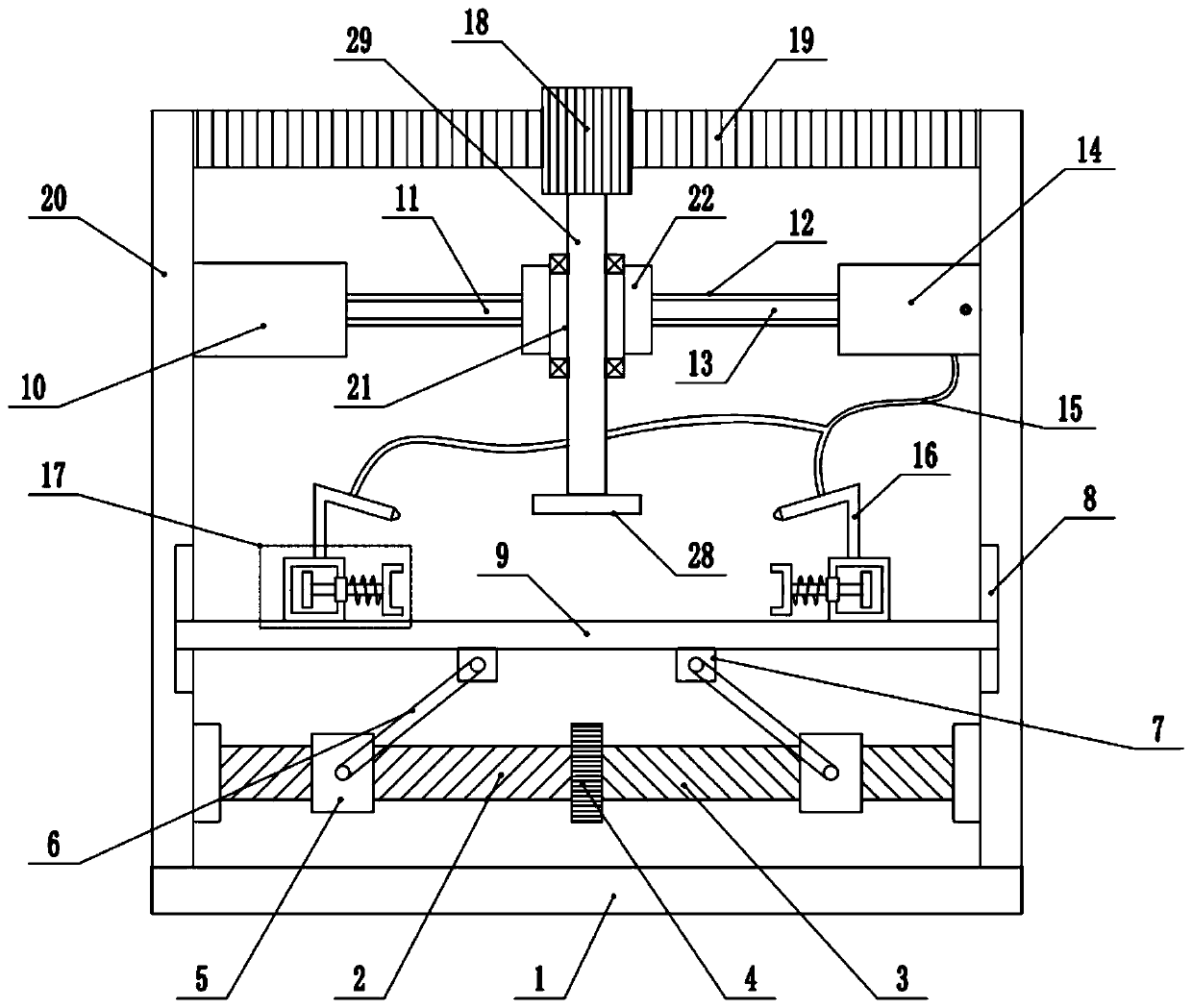

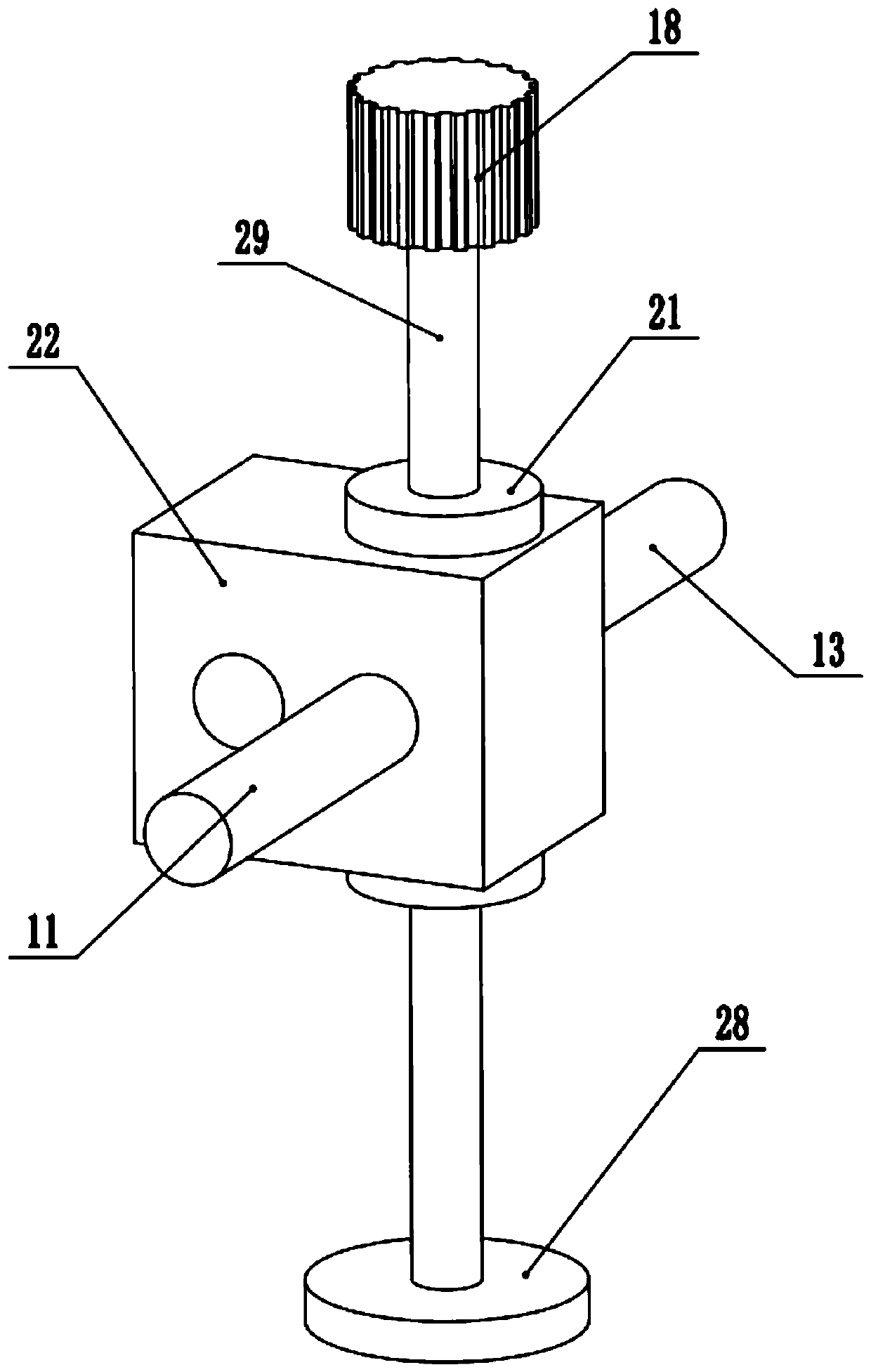

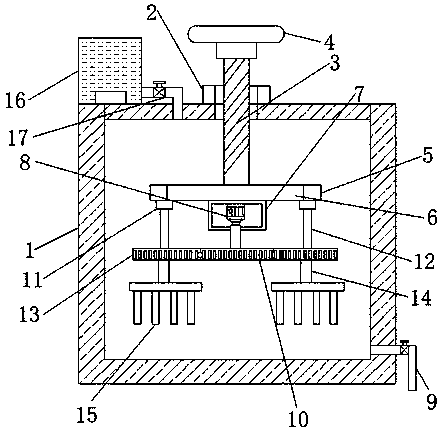

Clamping device with pressure sensor

InactiveCN110774196AQuick clamping workAdjust clamping forceWork holdersPillow block bearingElectric machinery

The invention relates to the technical field of clamping, and discloses a clamping device with a pressure sensor. The clamping device comprises a workbench, wherein a sliding groove is formed in the middle of the workbench, a sliding block is slidably connected to the sliding groove, a fixing seat is arranged on the upper portion of the sliding block, bearing seats are arranged at the left end andthe right end of the workbench, first screw rods are rotationally connected to the middle of the bearing seats, the left ends and the right ends of the first screw rods are in threaded connection with the middle of the sliding block, guide rods are connected to the upper end and the lower end of the fixing seats in a sliding mode, pressure sensors are connected to the sides, close to the center of the device, of the guide rods, and clamping blocks are connected to the sides, close to the center of the device, of the pressure sensors. According to the clamping device with the pressure sensor,a driving motor is arranged to drive the first screw rods to rotate, so that rapid clamping work of a workpiece can be achieved, meanwhile, second screw rods are arranged to adjust the distance between push plates and clamping blocks, so that the clamping force is accurately adjusted, the whole device is simple to operate, and the clamping device is suitable for popularization and application.

Owner:湖南绚丽新材料科技有限公司

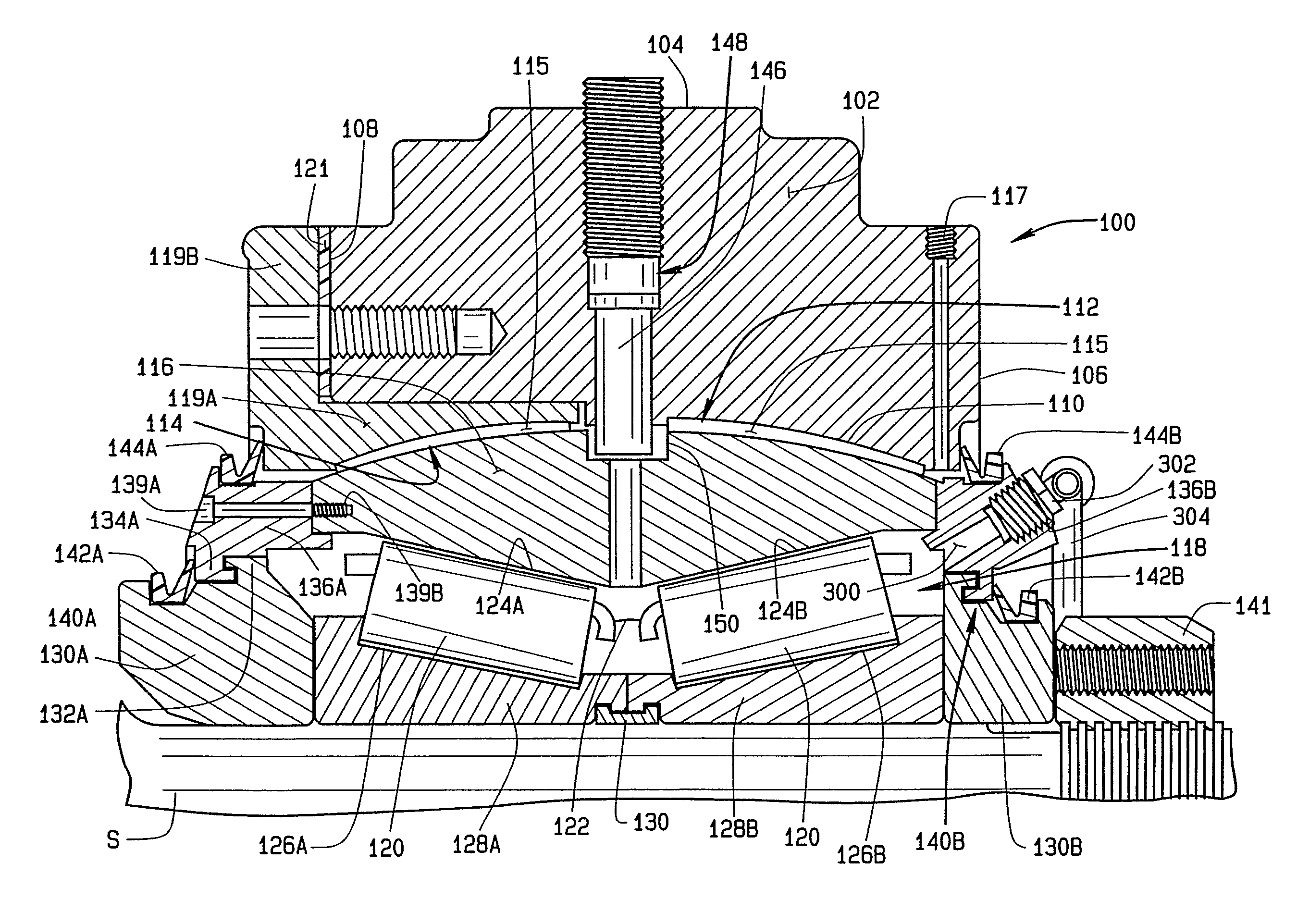

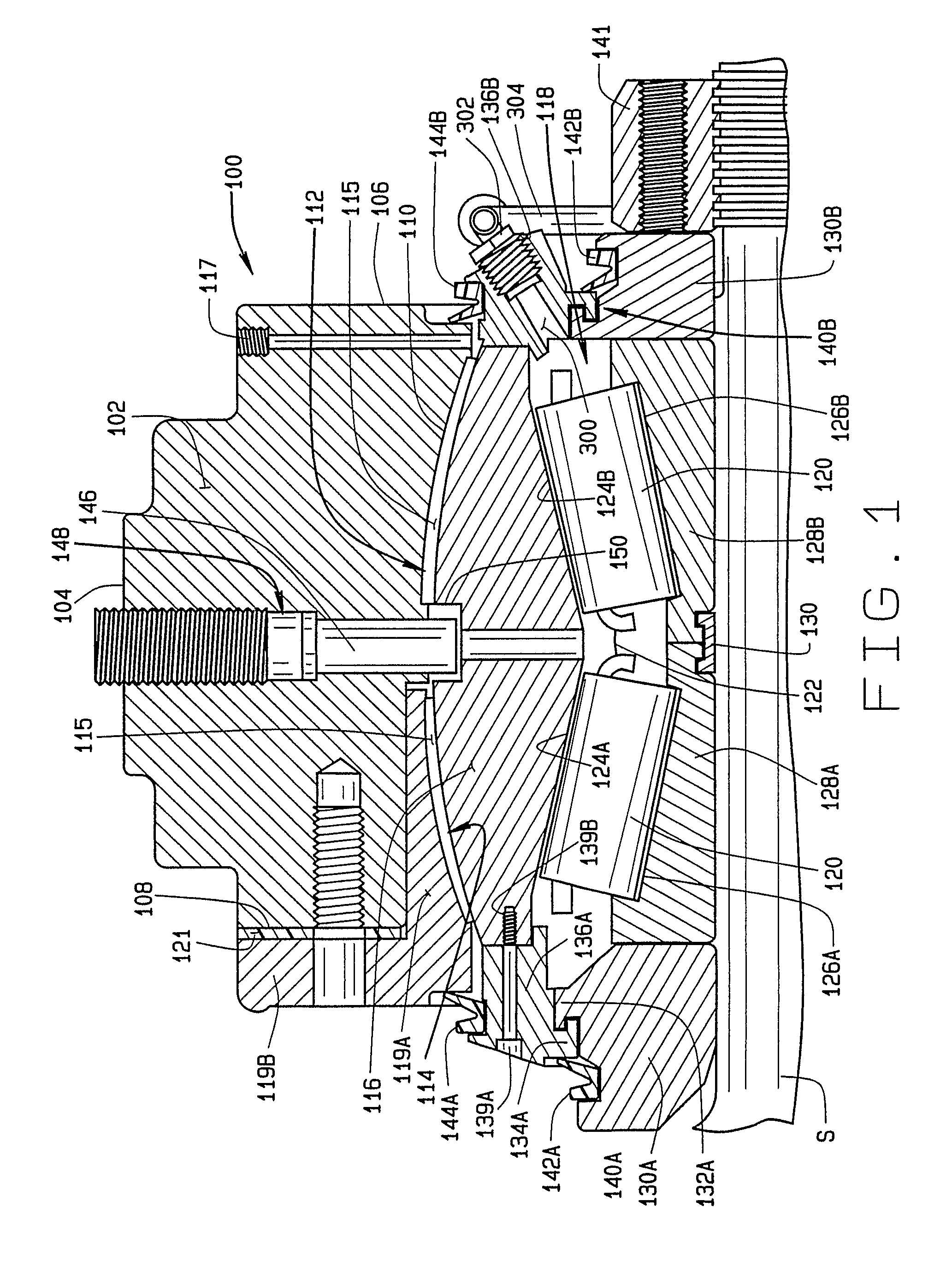

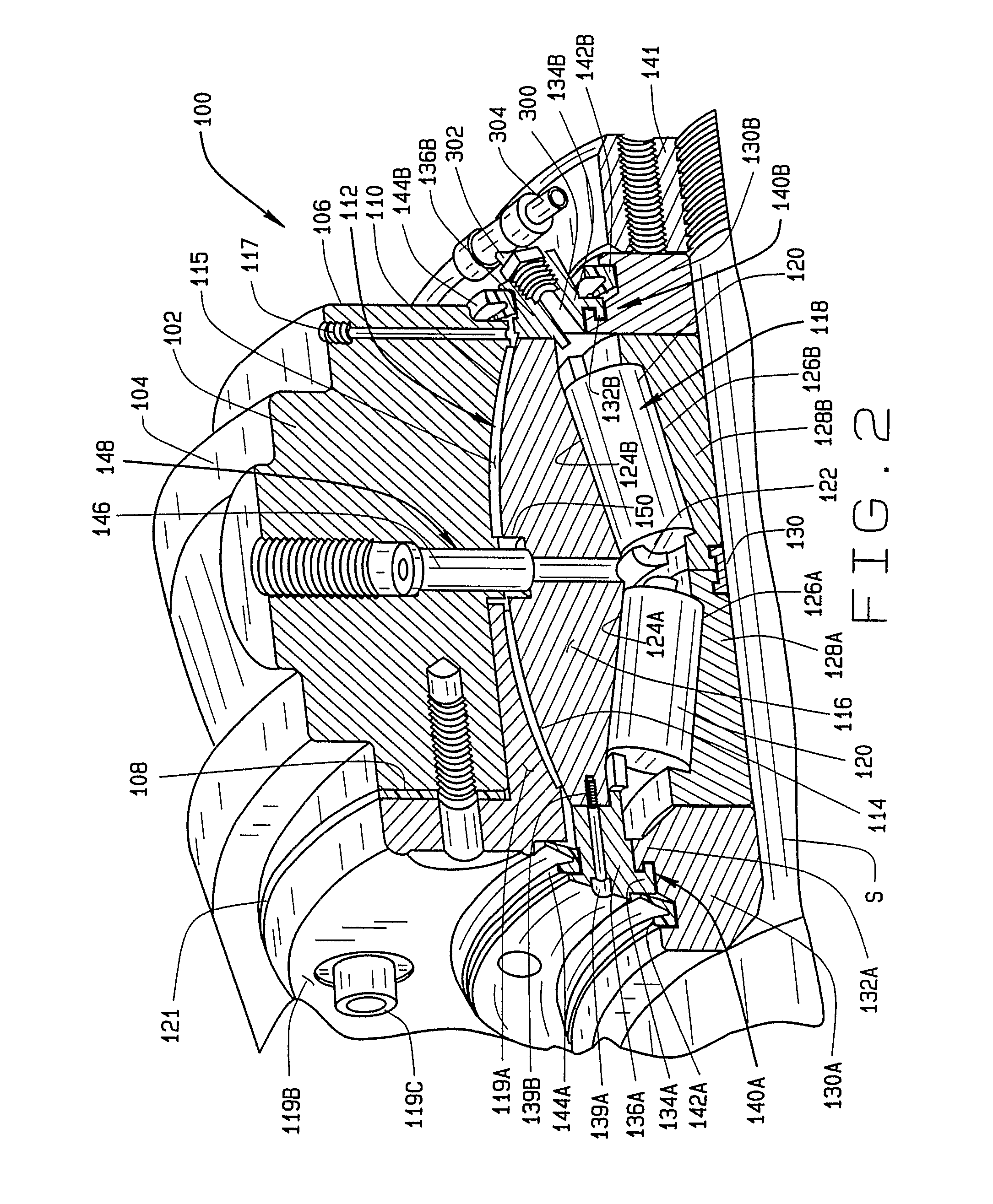

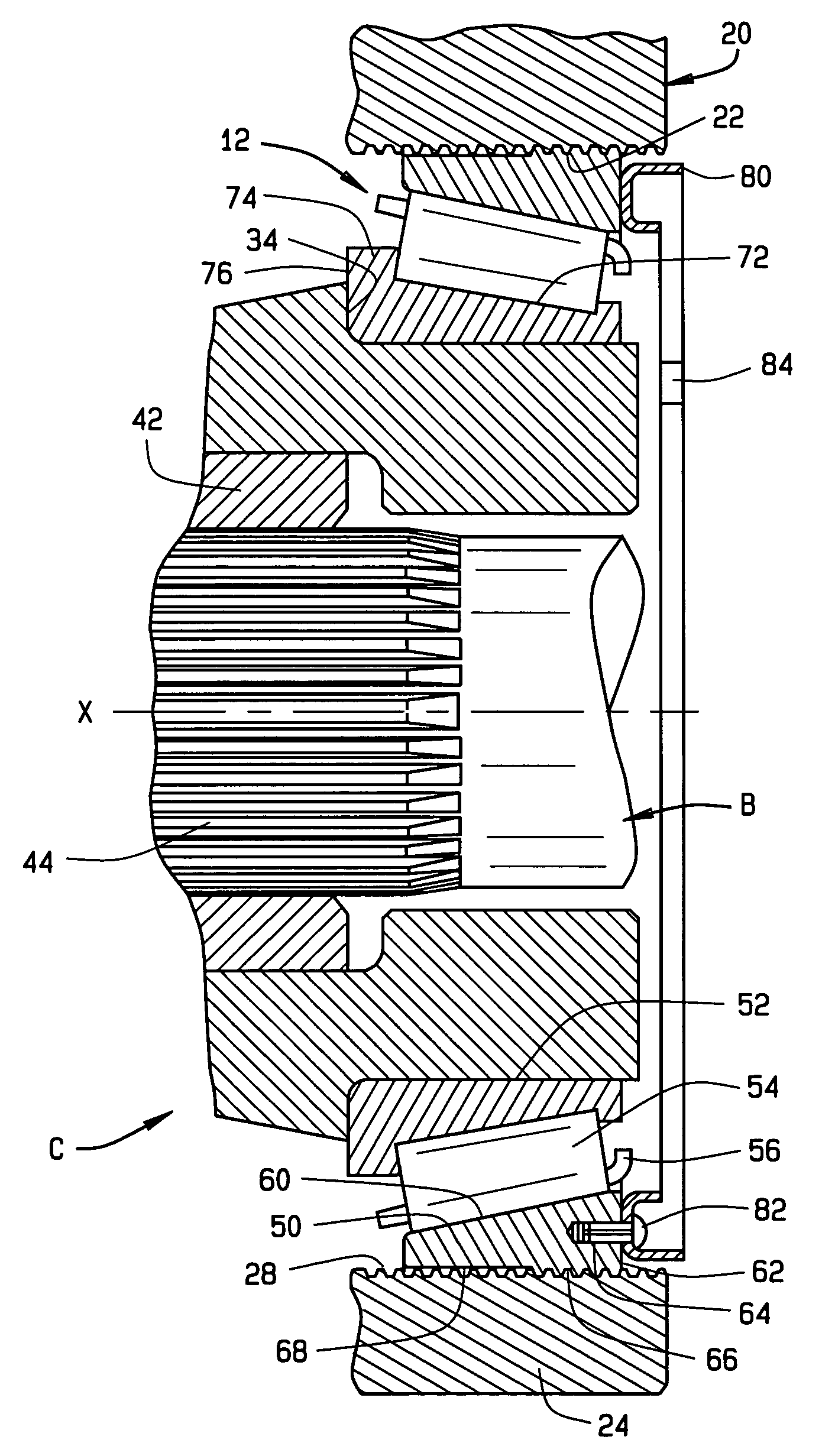

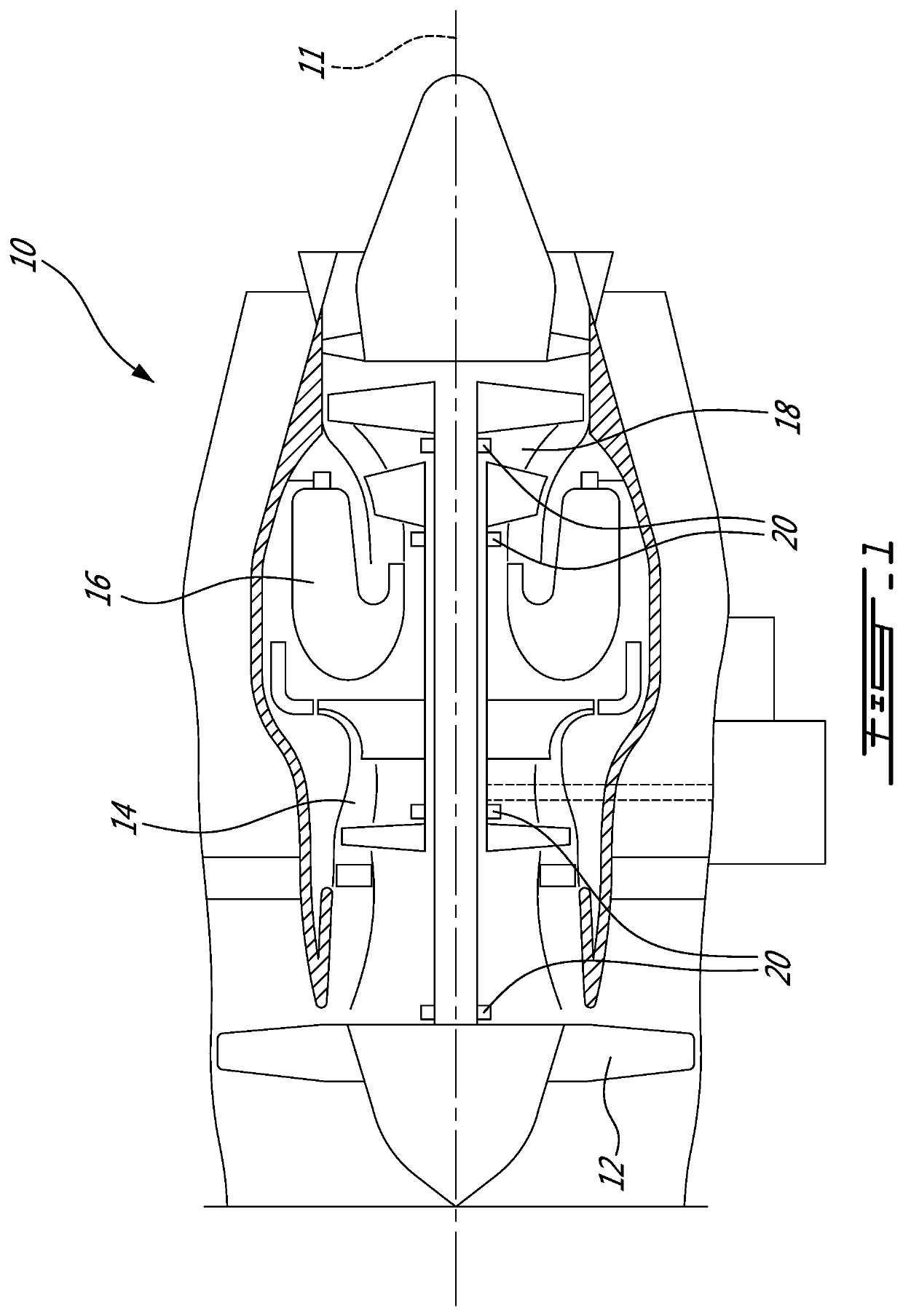

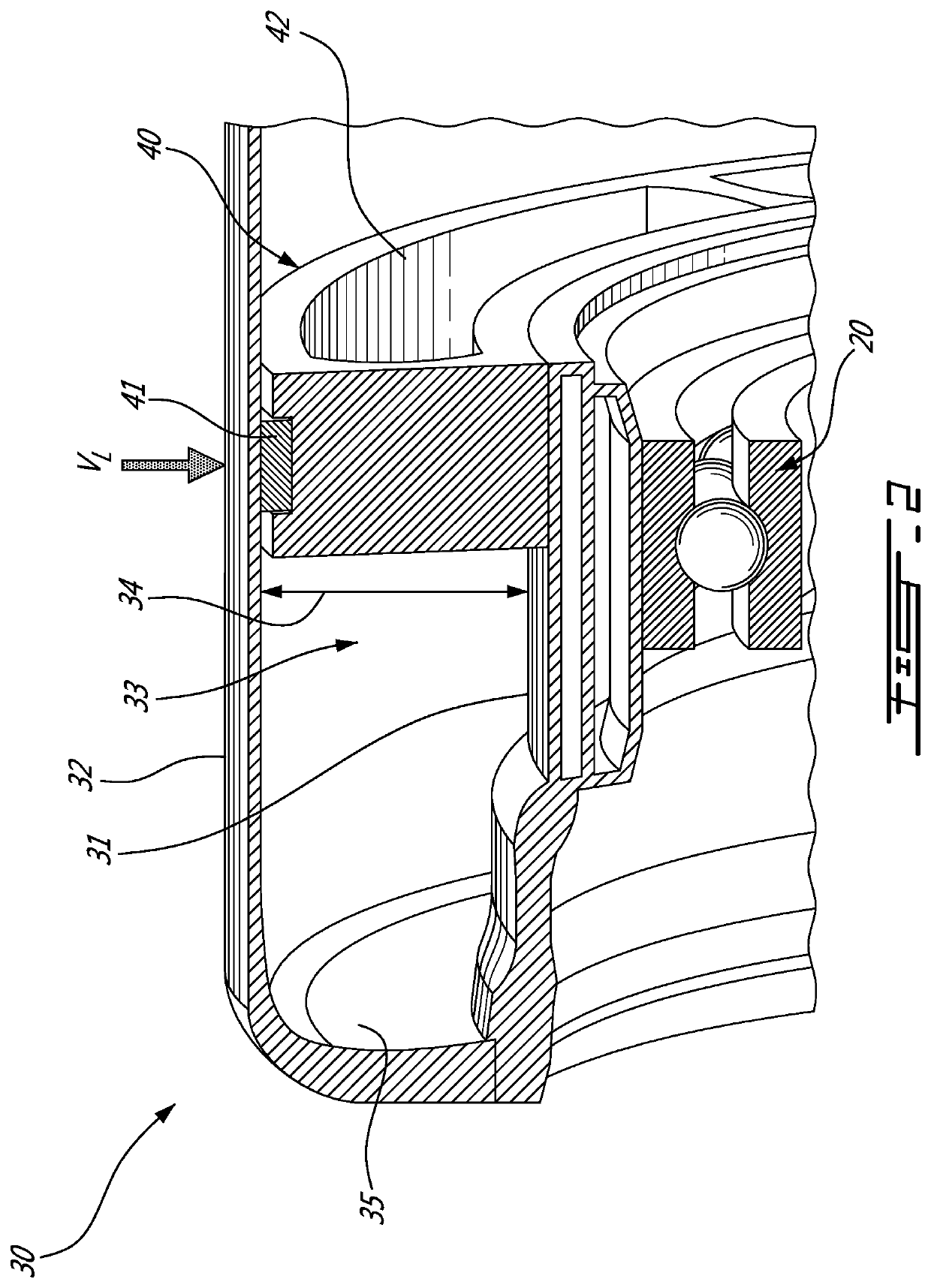

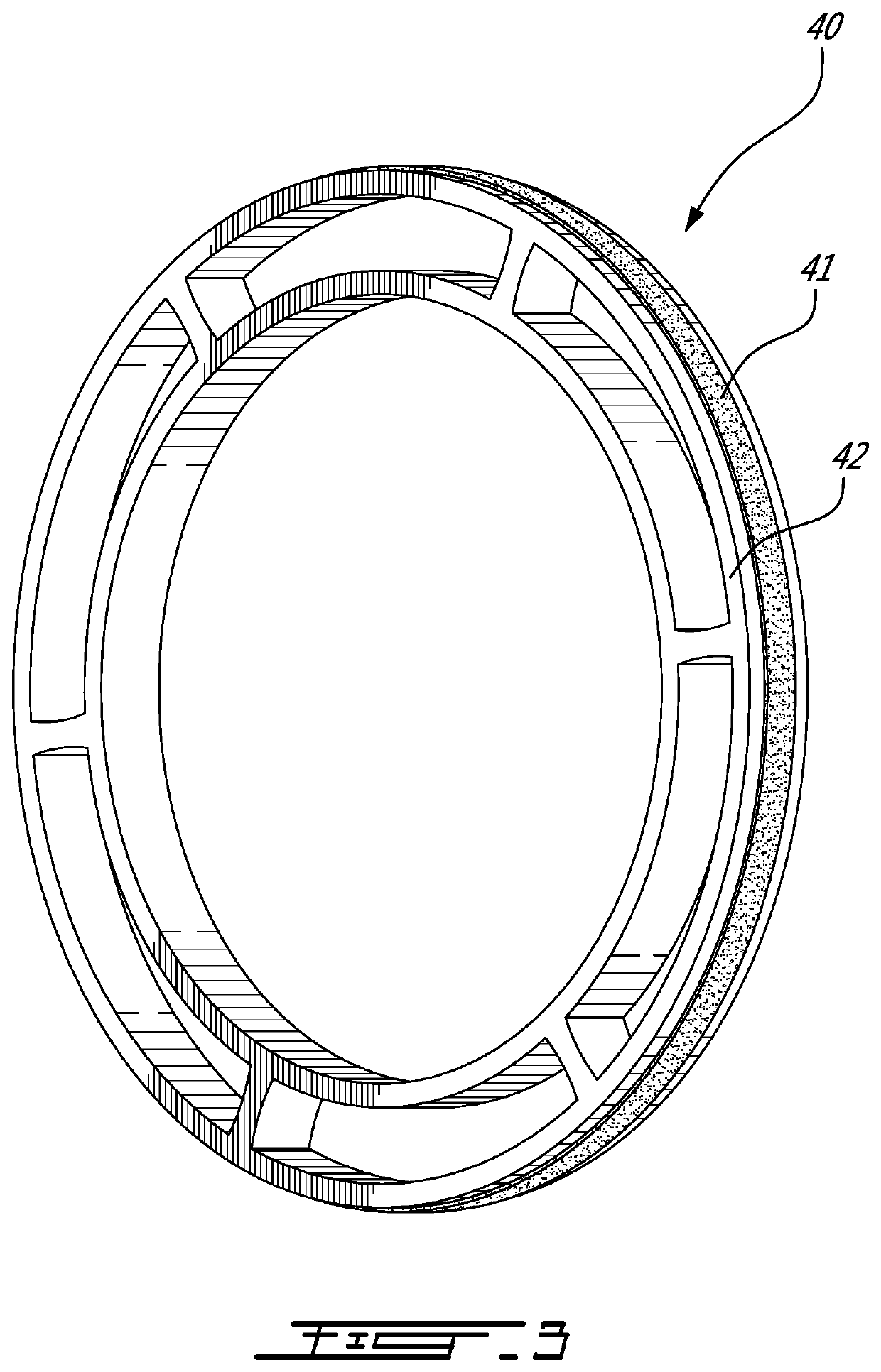

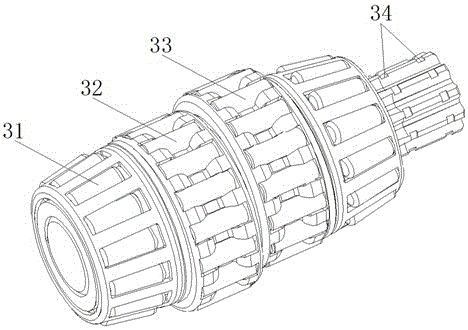

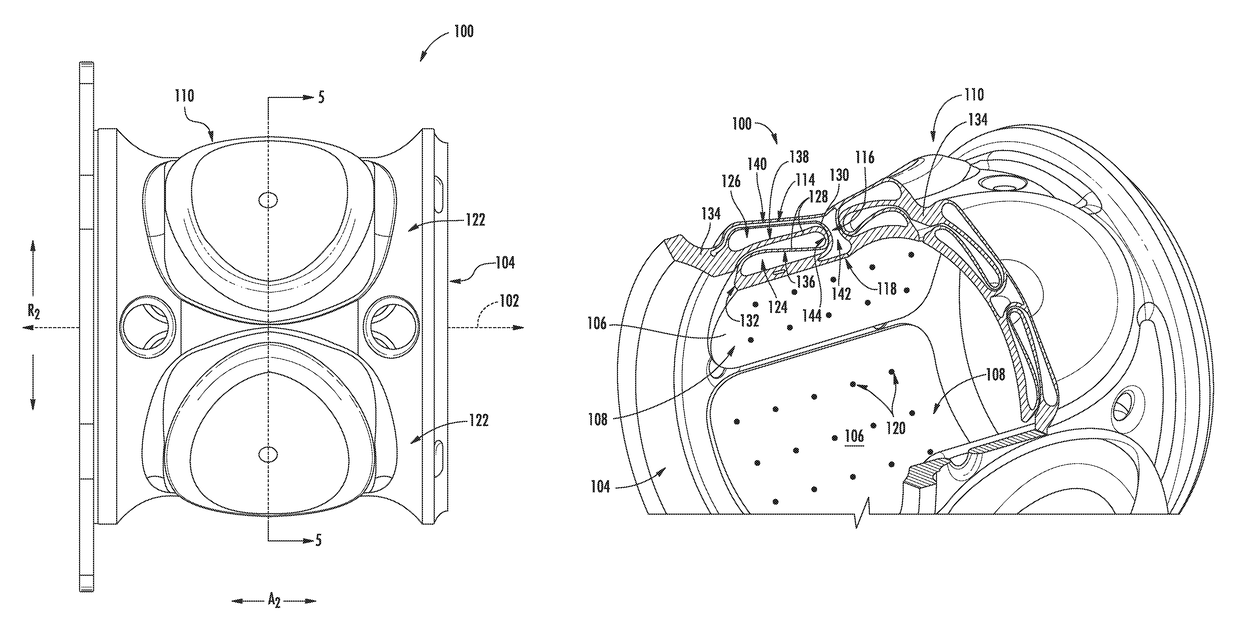

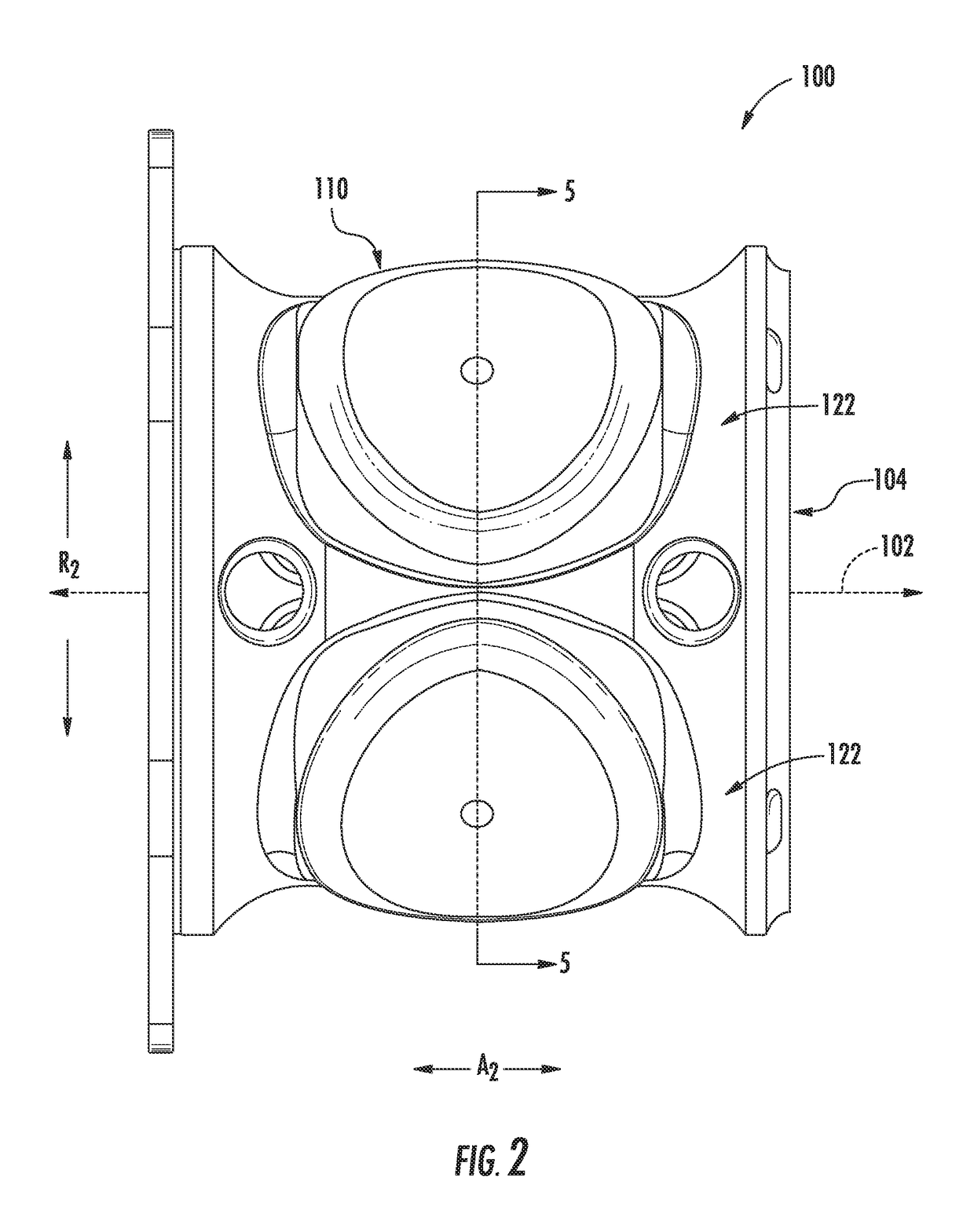

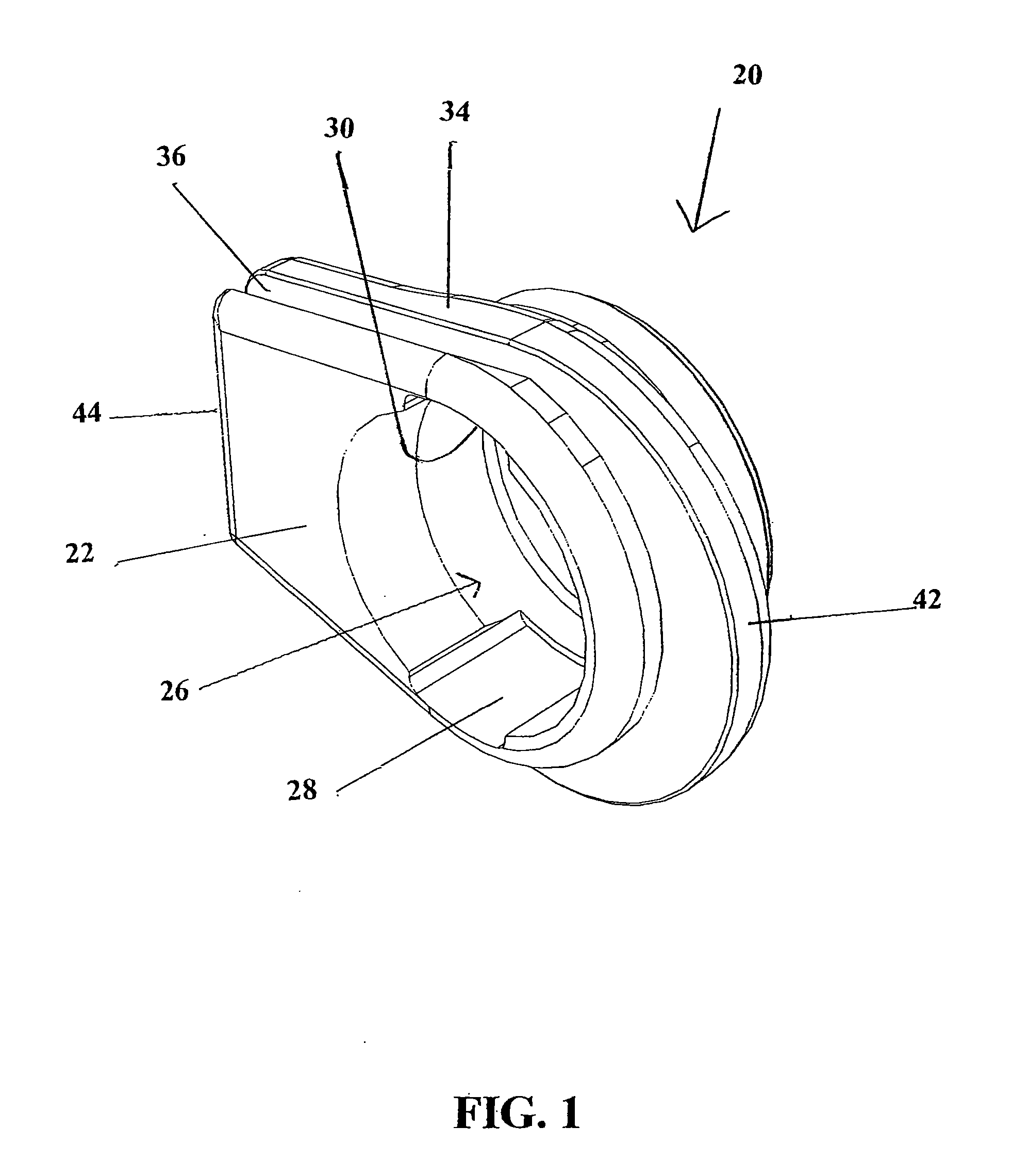

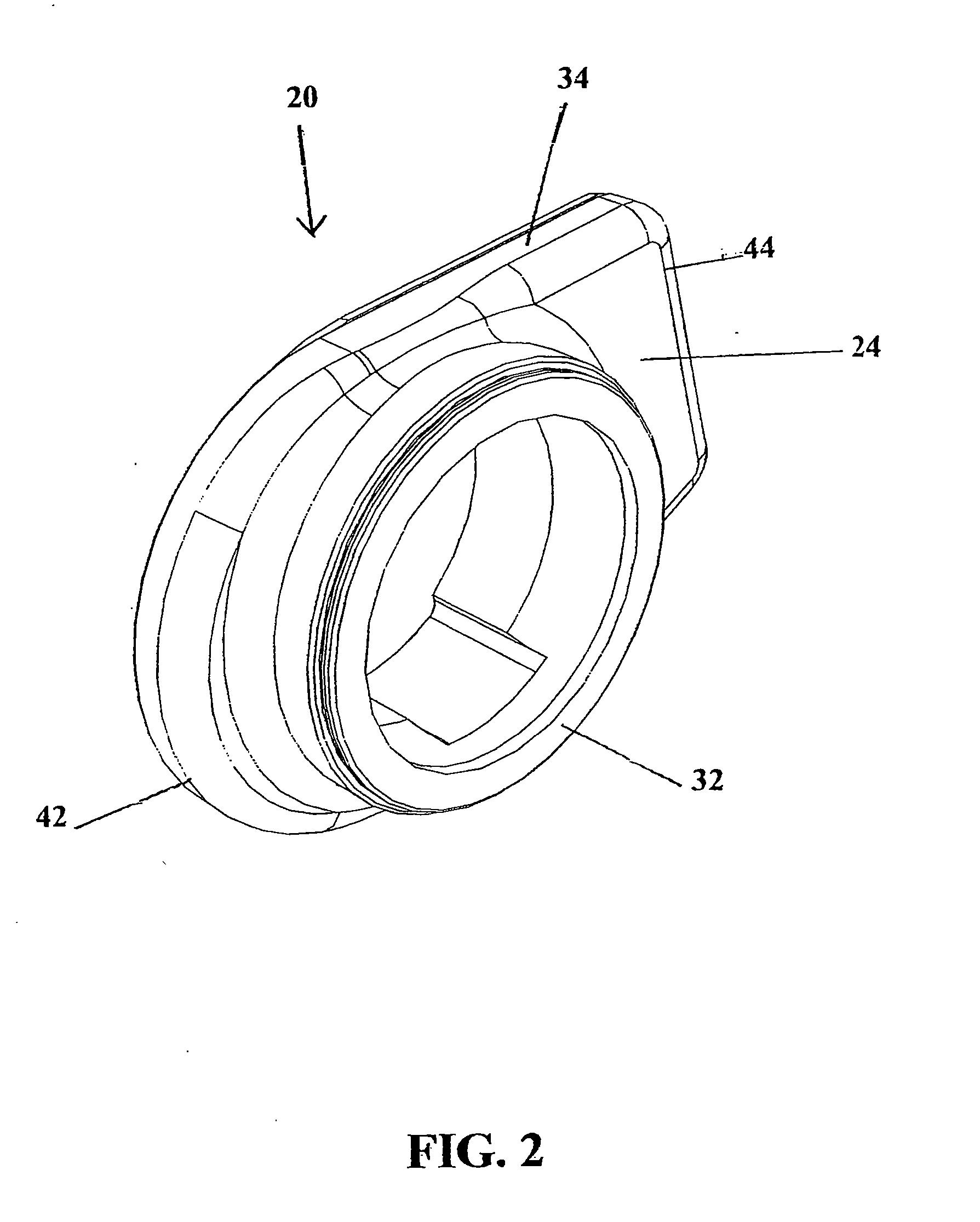

Pillow block housing with tapered roller bearings

ActiveUS8075196B2Reduce exerciseReduced responseEngine sealsRolling contact bearingsPillow block bearingTurbine

A spherical outer diameter tapered roller bearing pillow block system (100) for supporting the rotating main shaft of a wind turbine. The bearing system is configured with a unitized construction and factory set preload bearing settings to facilitate installation and setup. A spherical outer diameter surface (114) is formed on the outer race (116) of a tapered roller bearing assembly disposed about the rotating main shaft of the wind turbine. The bearing assembly is secured to a stationary support structure of the wind turbine through a pillow block housing assembly (102) providing a matching spherical housing seat (112) to form a ball and socket interface between the tapered roller bearing assembly (118) and the pillow block housing assembly (102). The ball and socket interface accommodates static and dynamic misalignments between the wind turbine main shaft and the supporting structure, while the bearing assembly (118) accommodates radial and axial loads.

Owner:THE TIMKEN CO

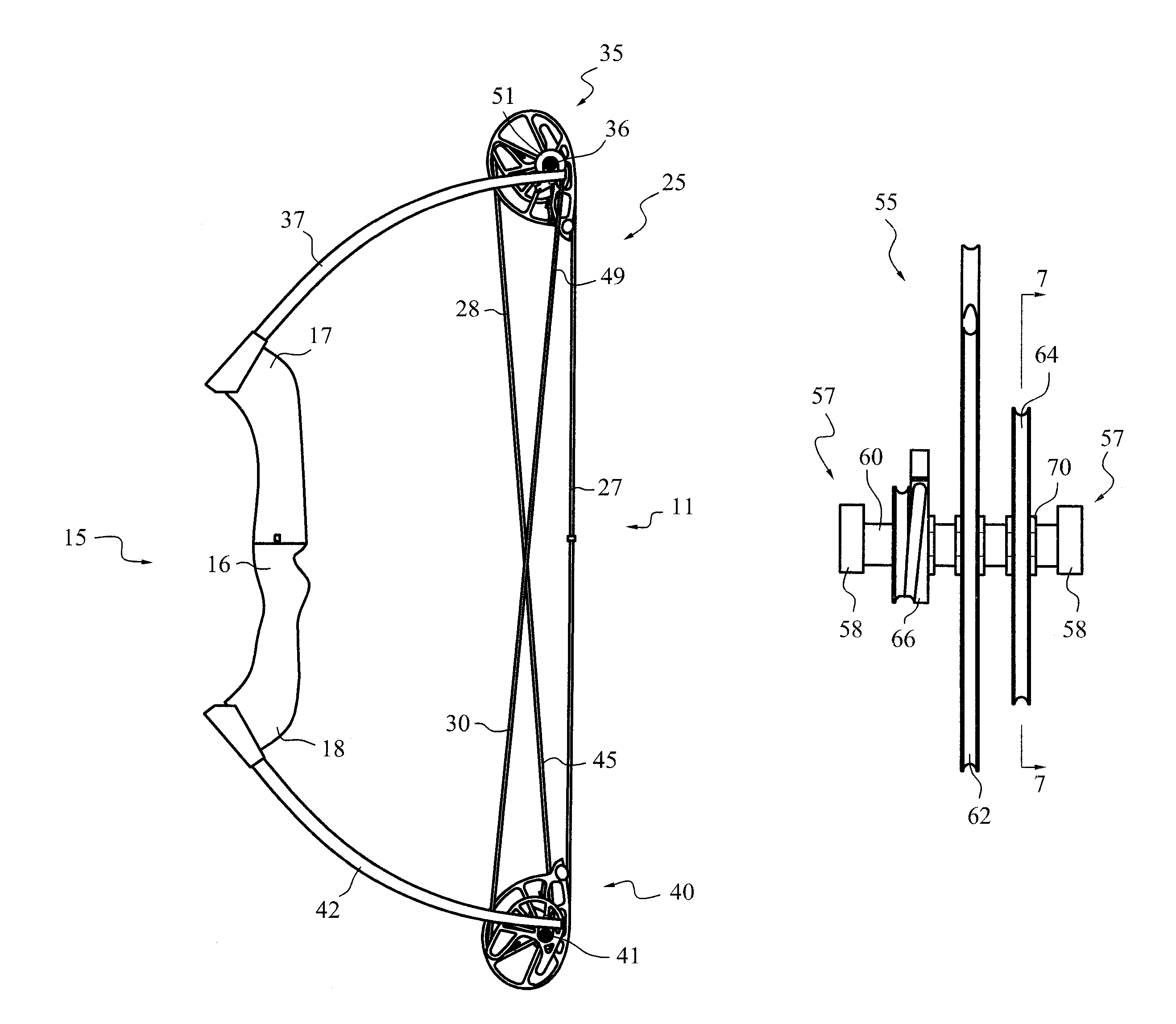

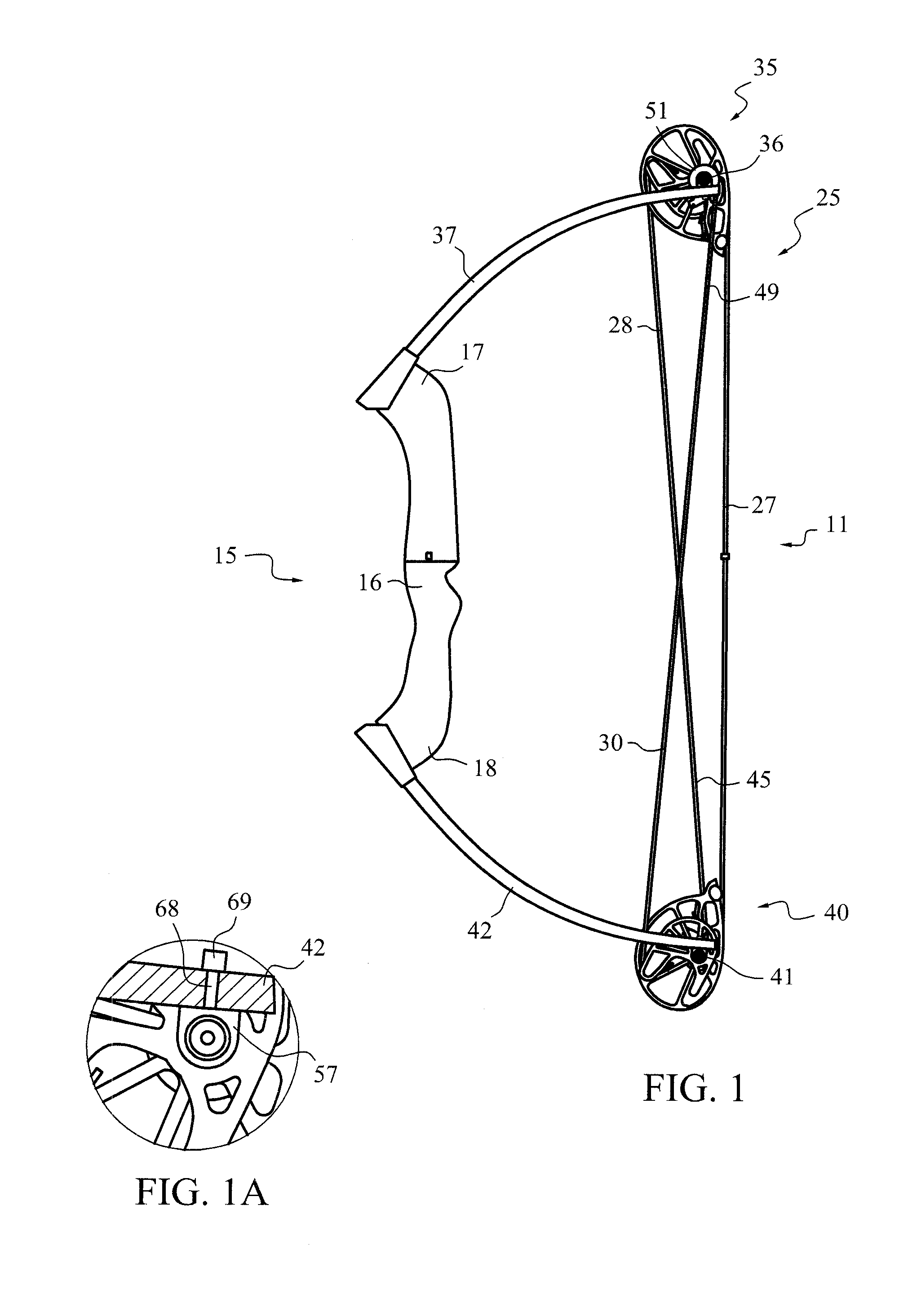

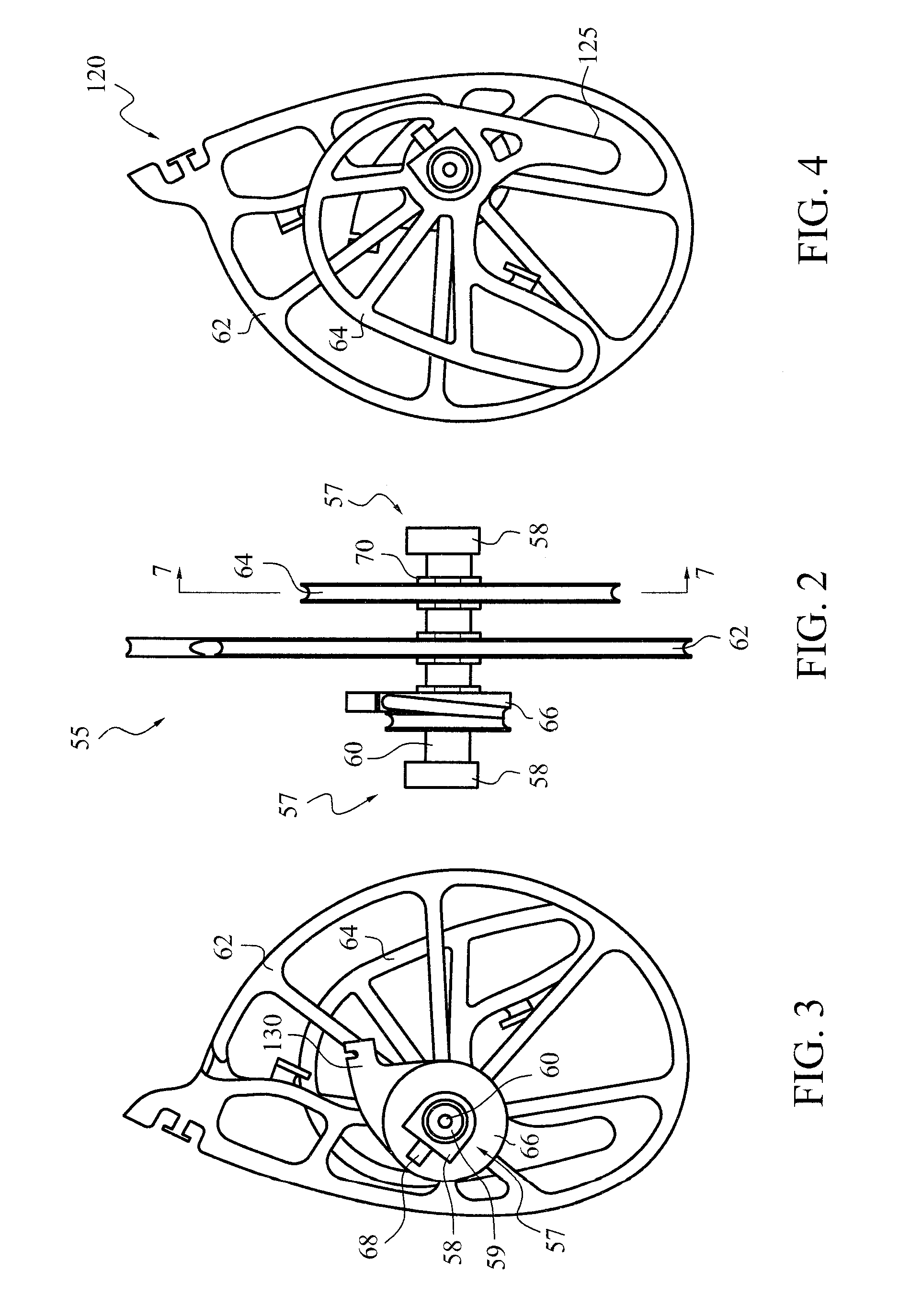

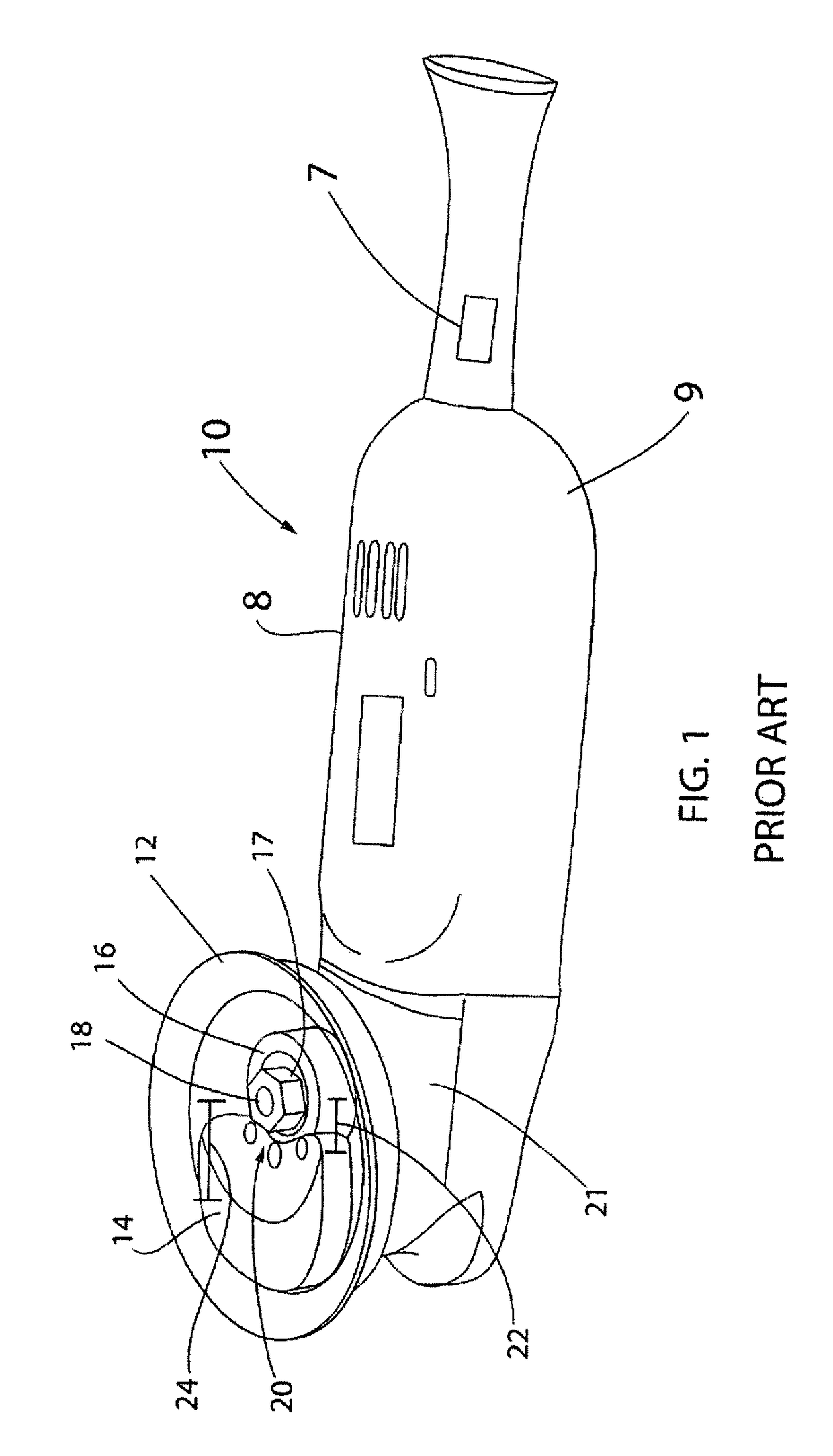

Pillow block bearing assembly for compound bows

The axles of the eccentric pulley assemblies of a compound bow are journal mounted in pillow blocks carried by the limbs of the bow.

Owner:BOWTECH INC

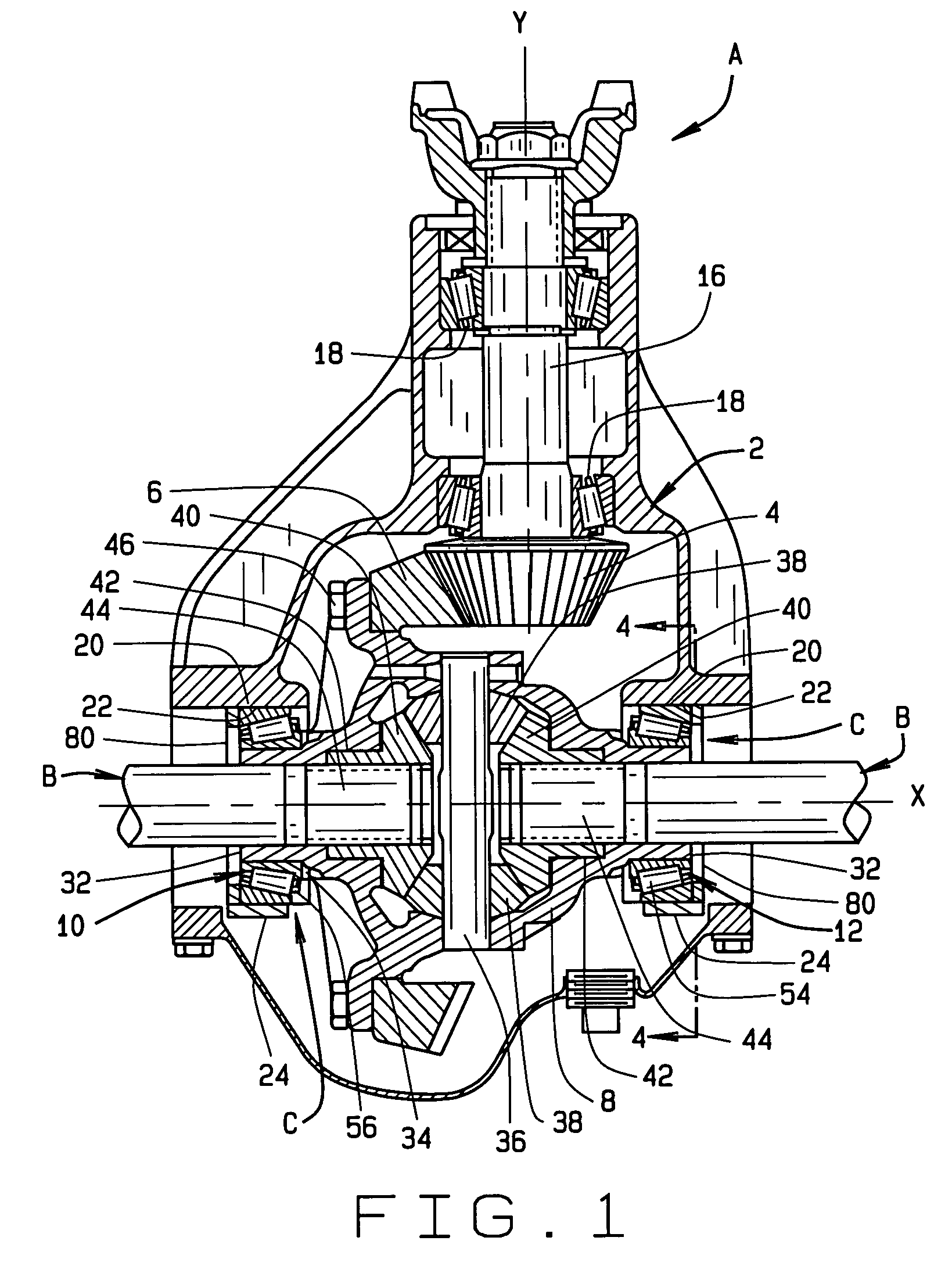

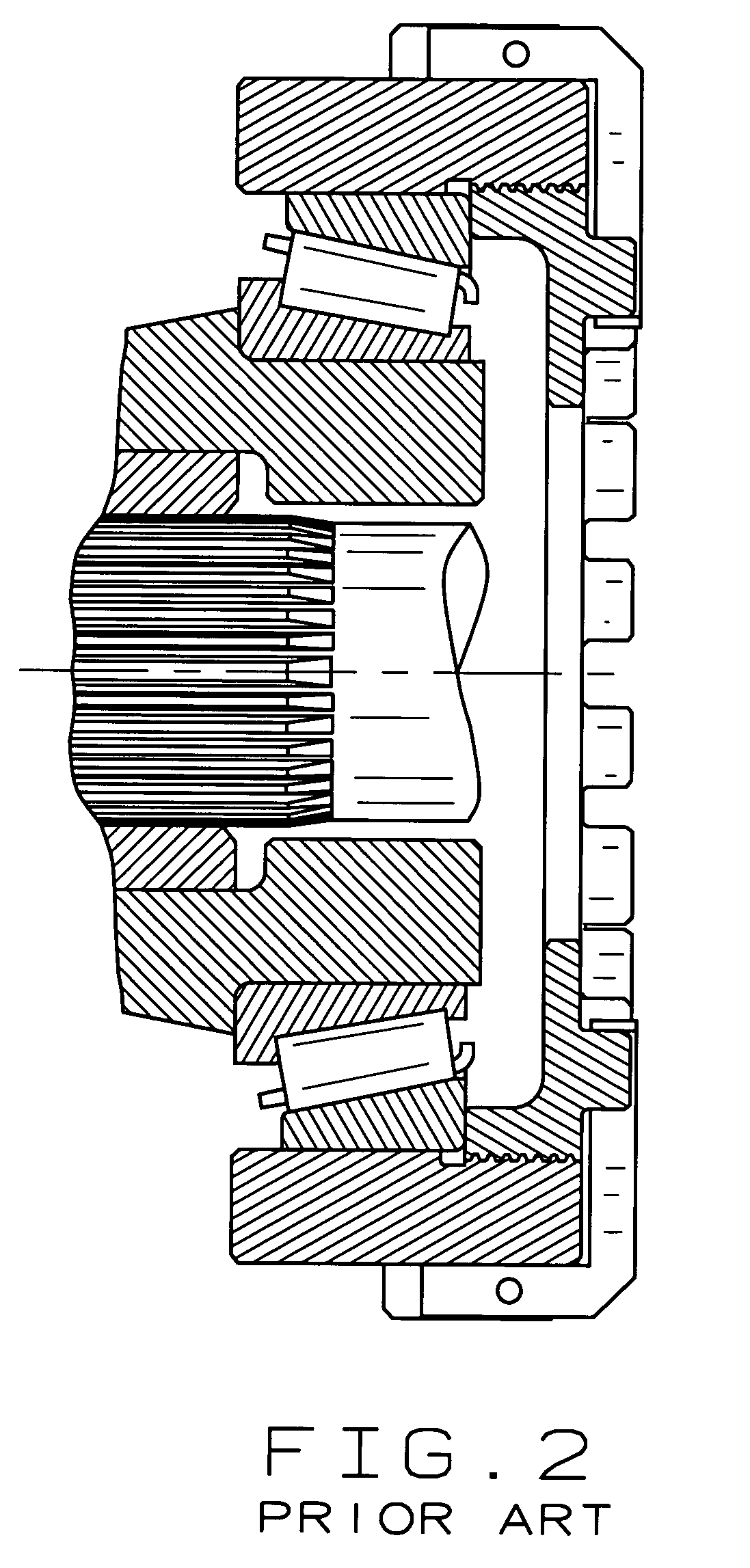

Bearing arrangement for a vehicle differential

A vehicle differential includes a housing having bearing seats and a carrier provided with stub shafts which project into the bearing seats. The carrier is supported in the housing on two single row tapered roller bearings which allow the carrier to rotate, but confine it radially and axially. The housing also contains a beveled pinion which meshes with a beveled ring gear that is attached to the carrier. The two bearings are mounted in opposition and each includes a cup that is located in the bearing seat for that bearing, a cone that fits around the stub axle that projects into that bearing seat, and tapered rollers located between the cup and cone. Each bearing seat contains an internal thread and the bearing cup which fits into the seat has an external thread that engages the internal thread. Each cup also carries a locking ring which is engaged by an adjustment tool to turn the cup, but is later deformed into the housing to secure the cup against rotation. By rotating the cups in their bearing seats, one can adjust the setting of the bearings and the mesh setting of the pinion and ring gear.

Owner:THE TIMKEN CO

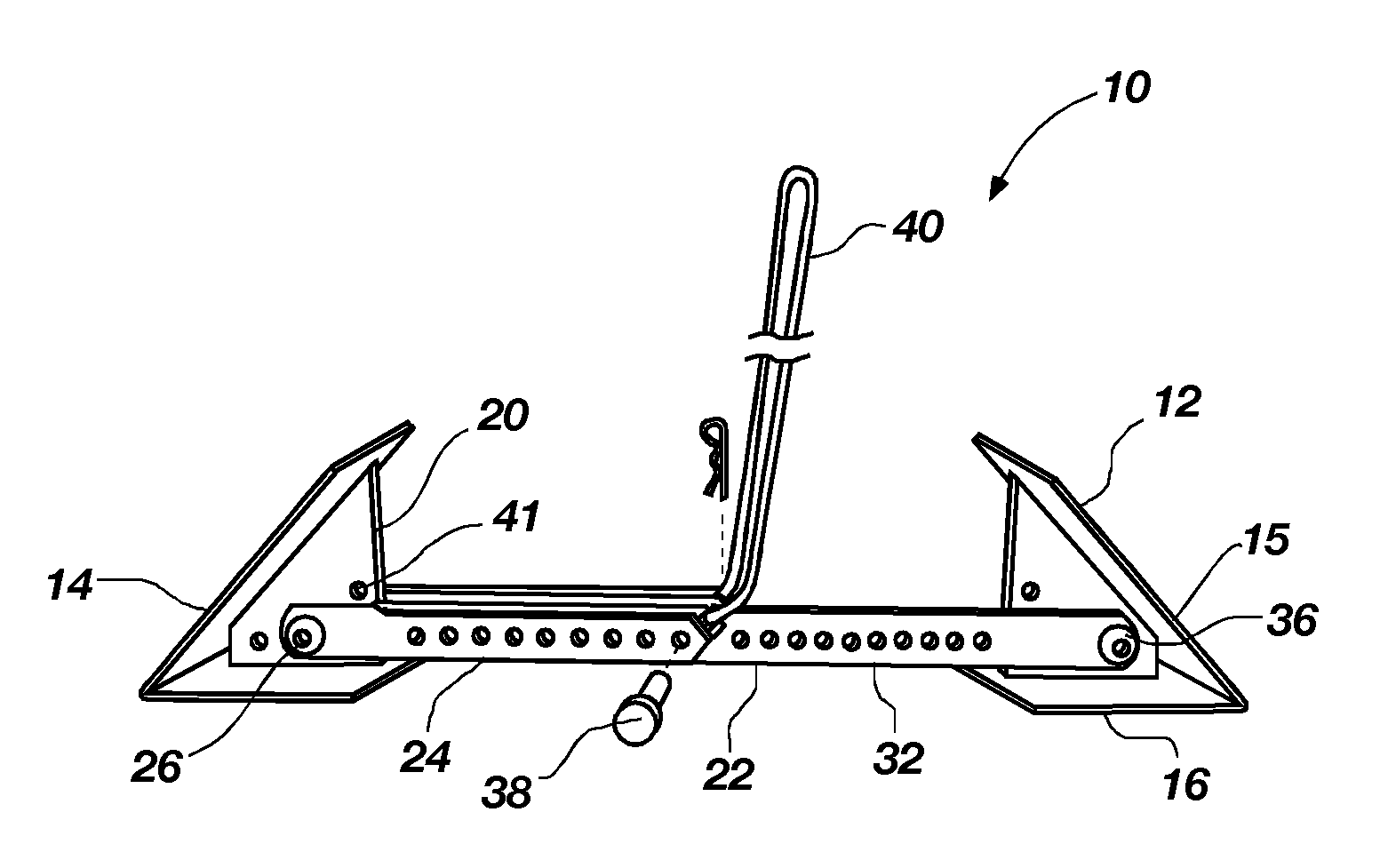

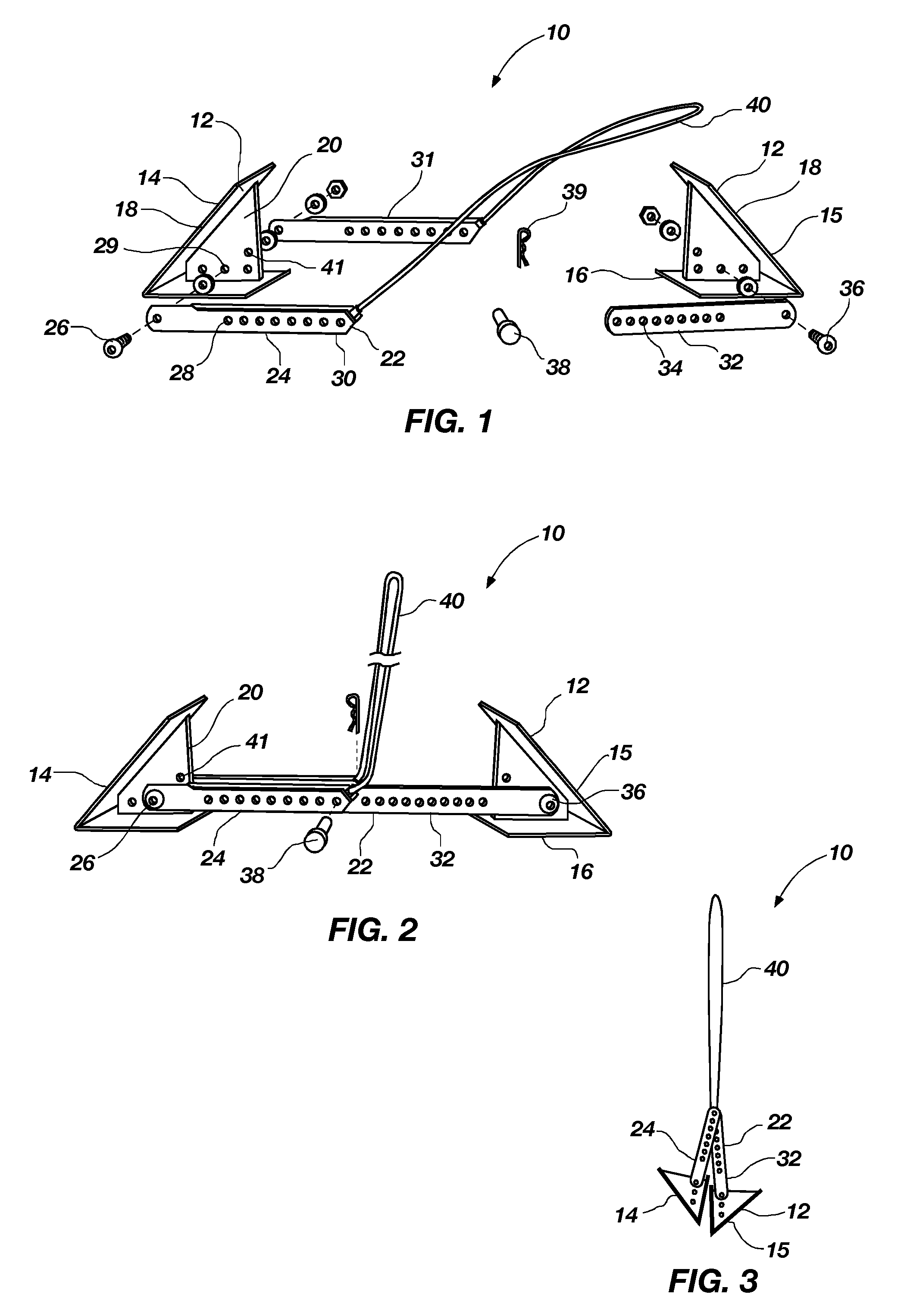

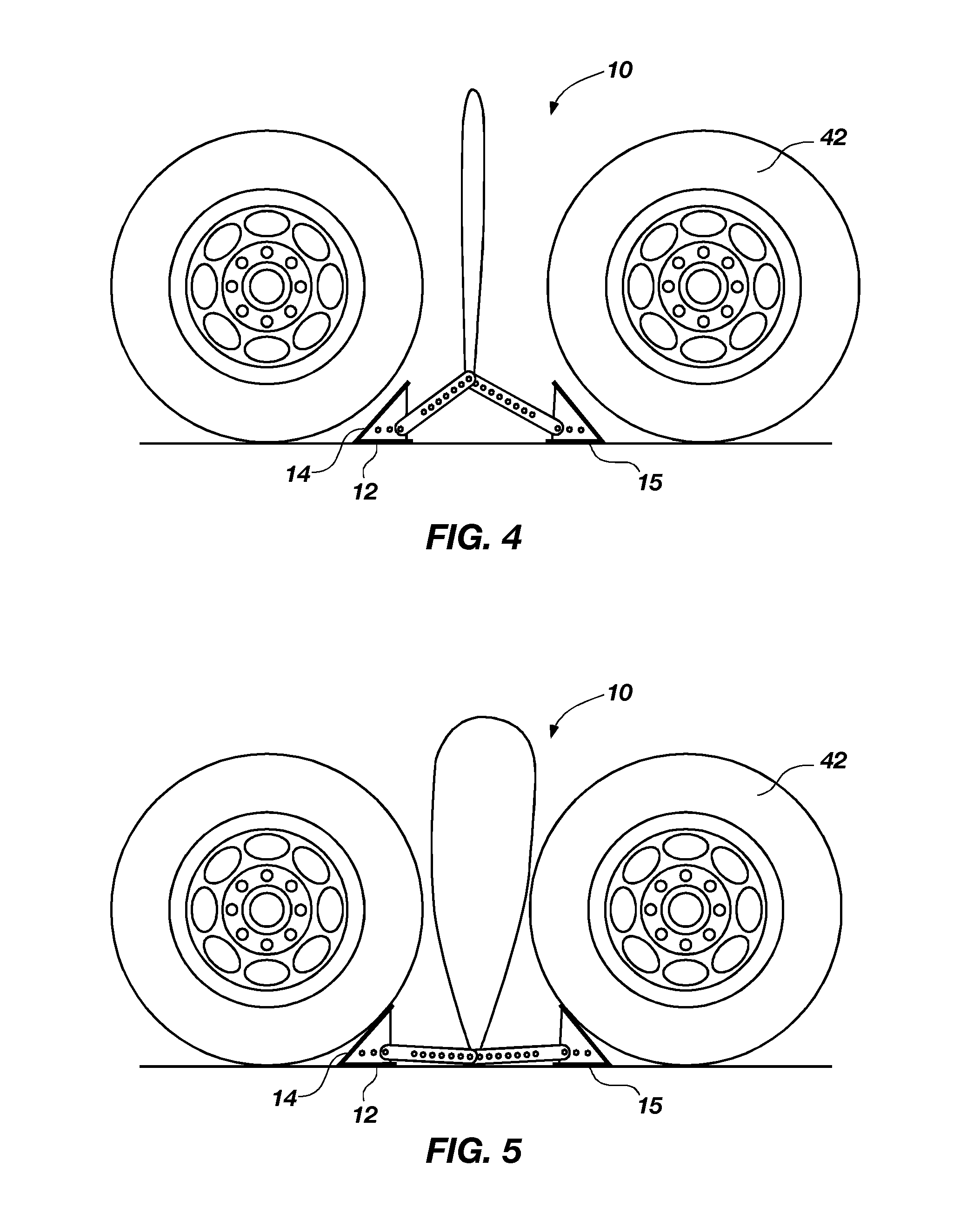

Over-center clamping wheel chocks

A wheel chock system for preventing movement of one or more wheels. The system may include a pair of chocks for clamping onto one or more wheels. The chocks may be connected through a linkage mechanism that can be rotated to draw the chocks together or move the chocks further apart. A handle may be attached to the linkage mechanism for moving the chock system from a blocking position to a released position. The handle may be configured to stand upright such that the chock system can be installed and removed by a user in a standing position without the need to bend or crouch. One embodiment of the chock system may be attachable to two different wheels in a tandem wheel arrangement, whereas another embodiment of the chock system may be configured to clamp onto a single wheel.

Owner:PROGRESS MFG LLC

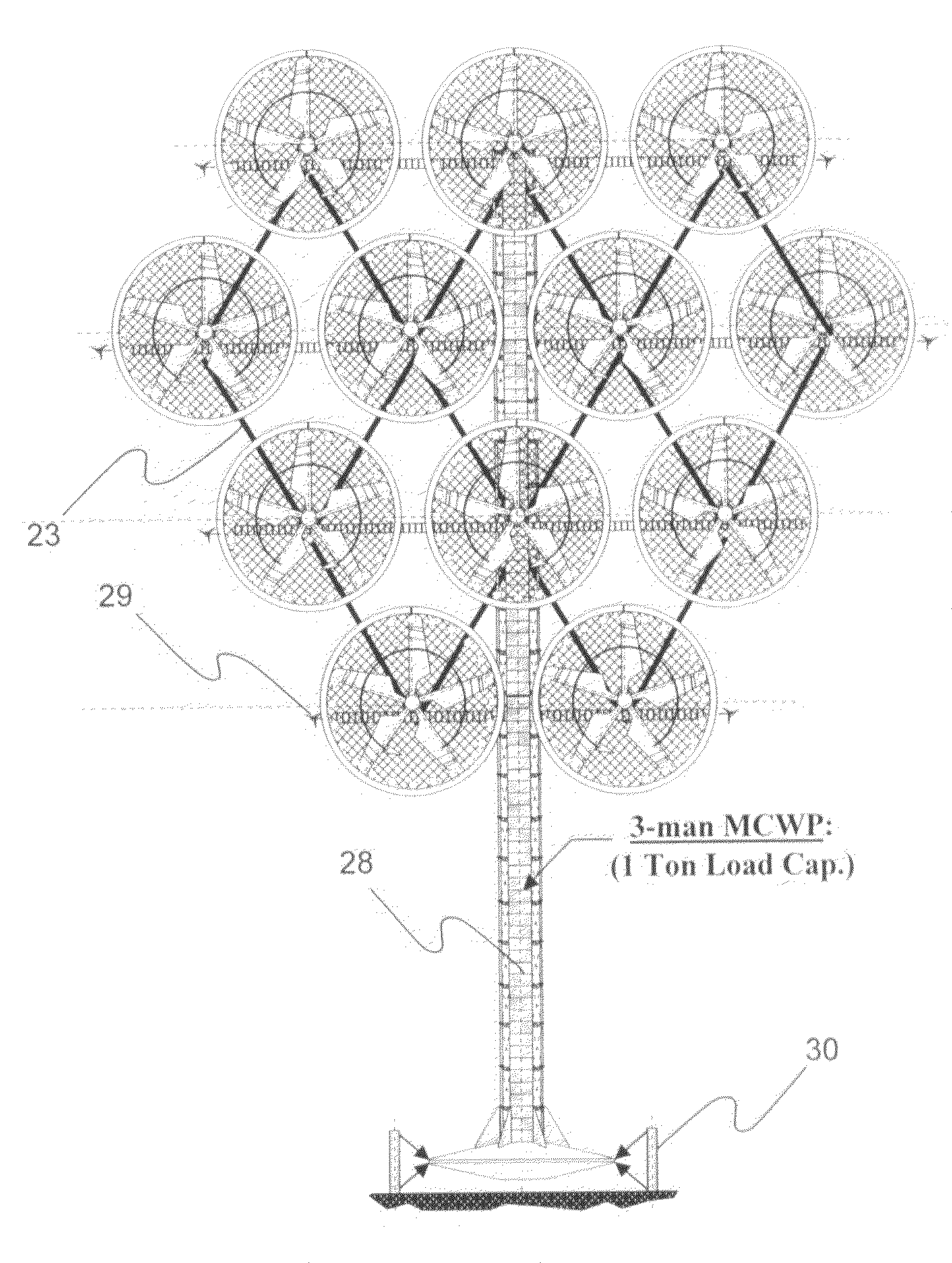

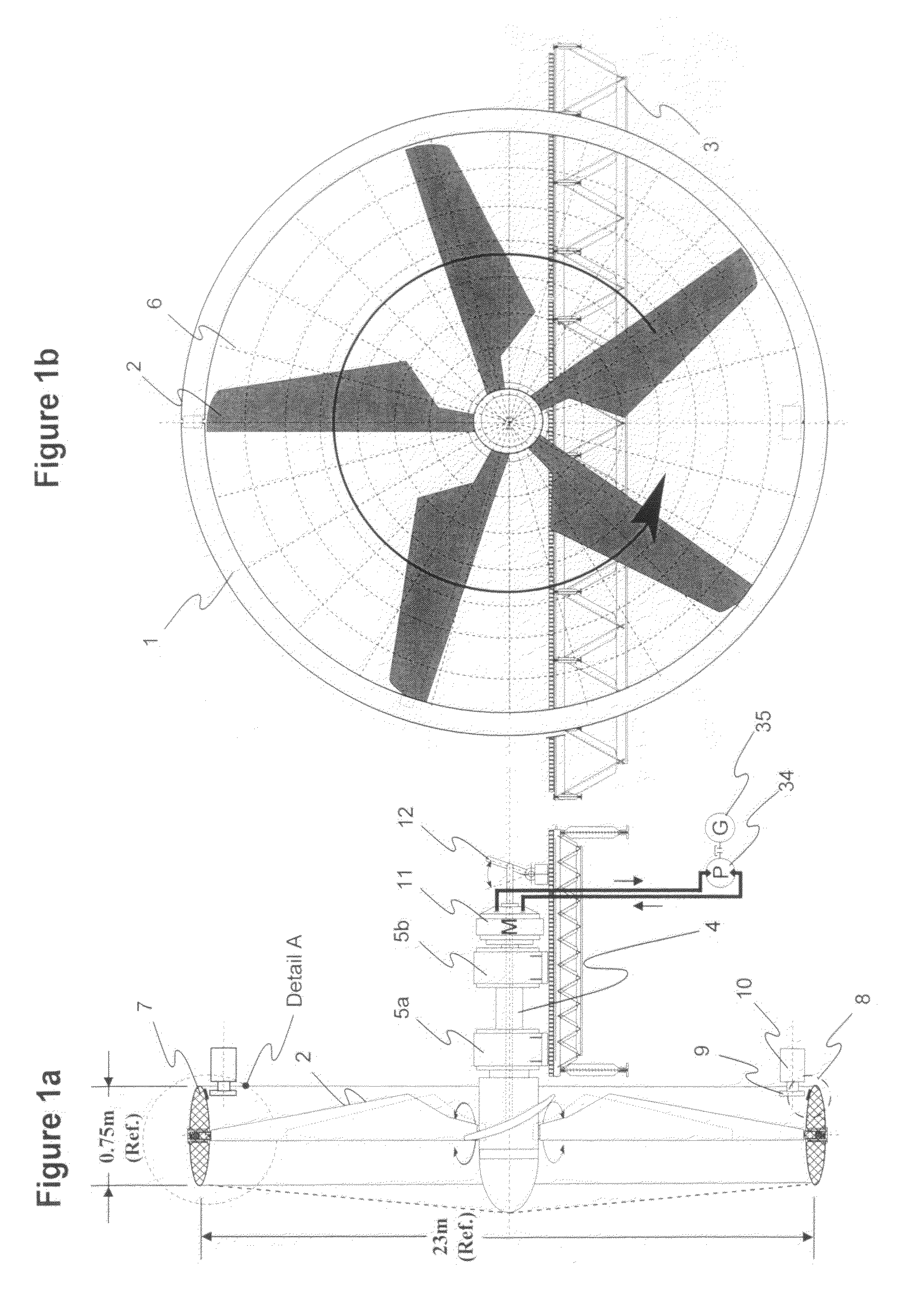

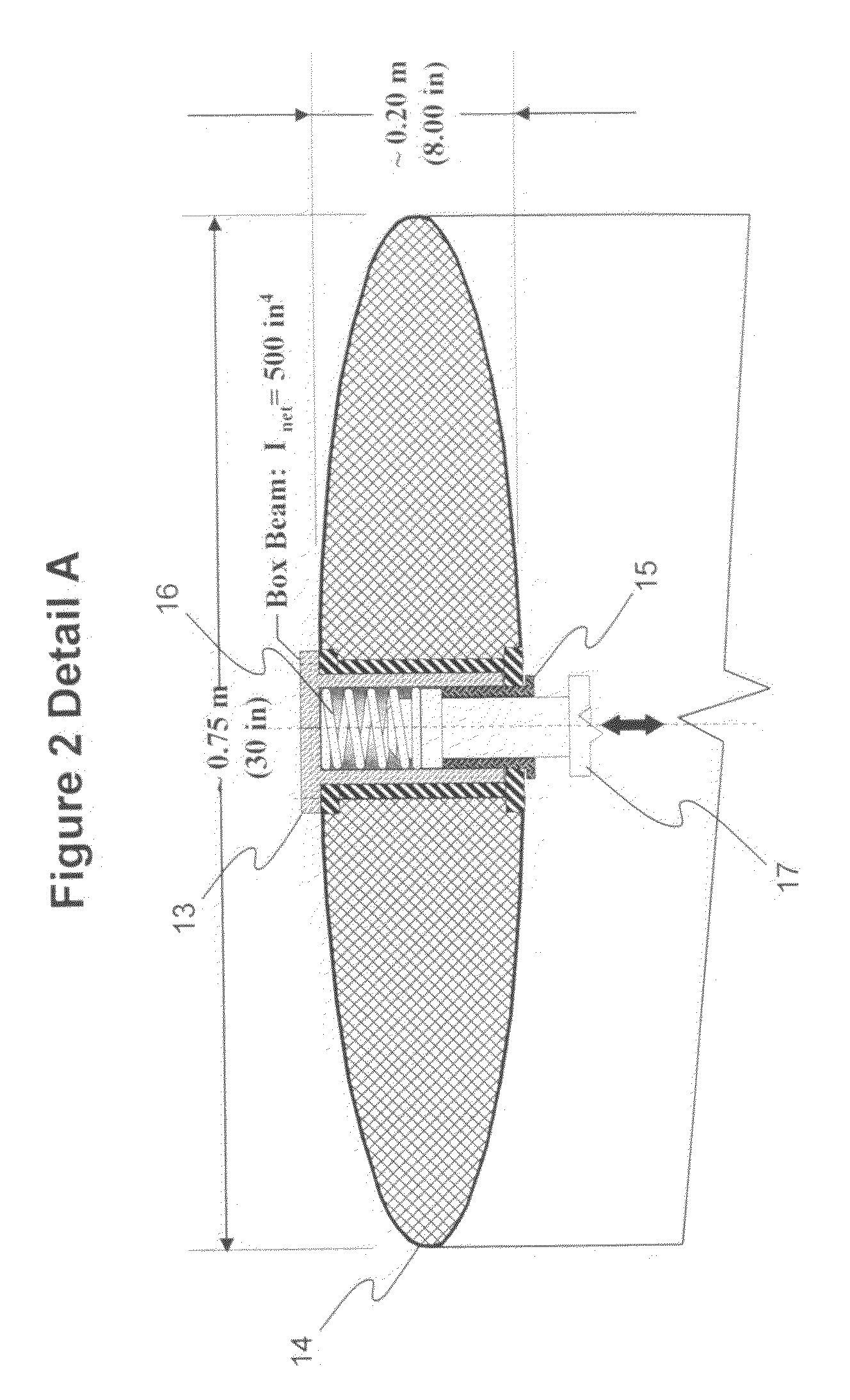

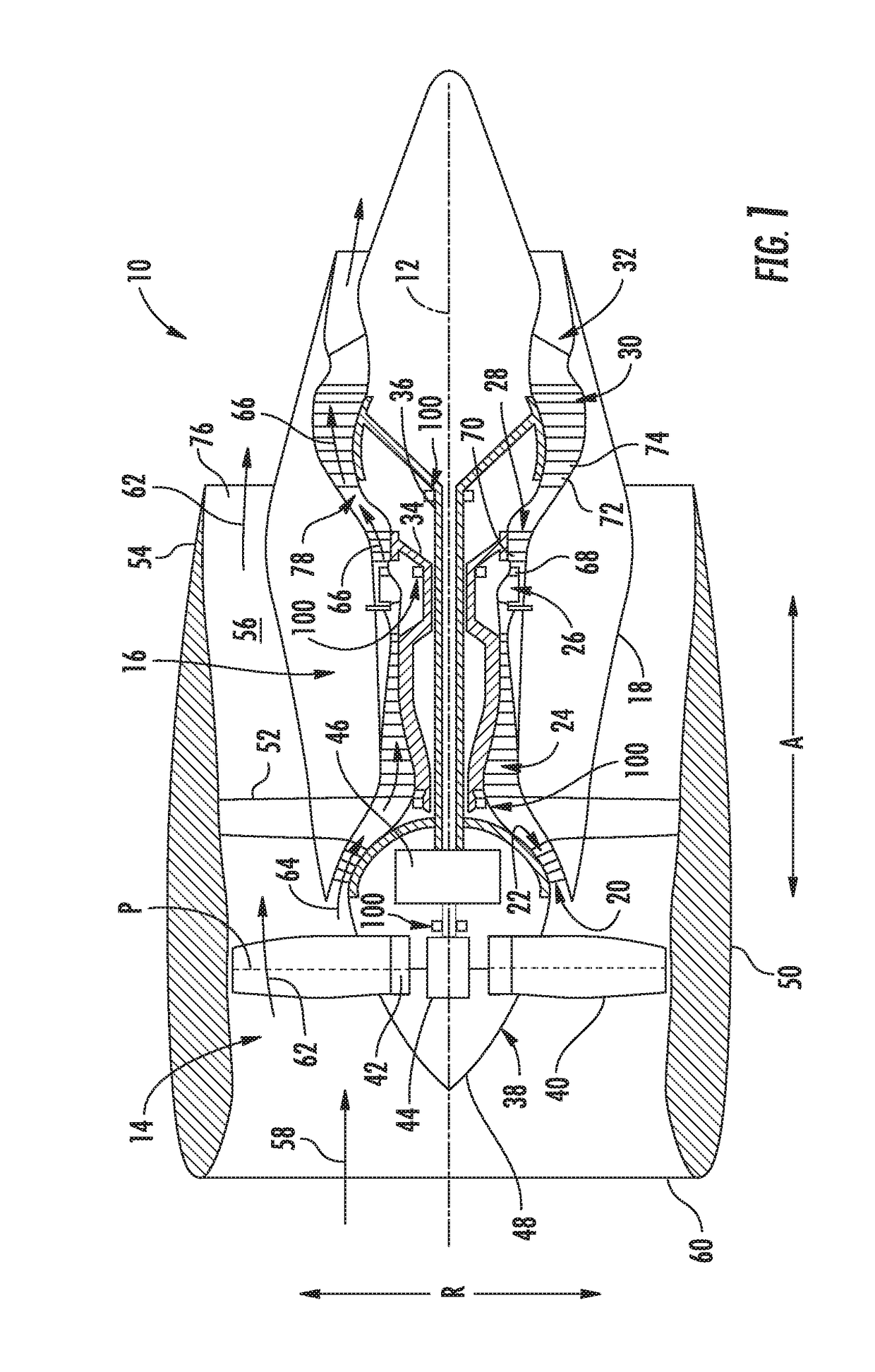

Banded turbine

InactiveUS20090311099A1Low costImprove efficiencyPropellersPump componentsPillow block bearingAlternator

A banded turbine configuration has an integral outer band support structure capable of providing two point simple support for a multiplicity of blades. A large scale vertical array has a set of twelve 23 m-diameter banded turbines with up to nine blades and resting on an Open Web Steel Joist (OWSJ) platform. The banded turbine configuration is supported off of a main shaft hub assembly, which is supported by forward and aft pillow block bearing assemblies. The banded turbine allows for a protective screen for bird- and bat-kill prevention. Each banded turbine employs DC alternators to provide a switchable output which is subsequently fed to a dedicated set of high efficiency grid-compatible solid state invertors or, alternatively, to energy storage.

Owner:RICHARDS WILLIAM R

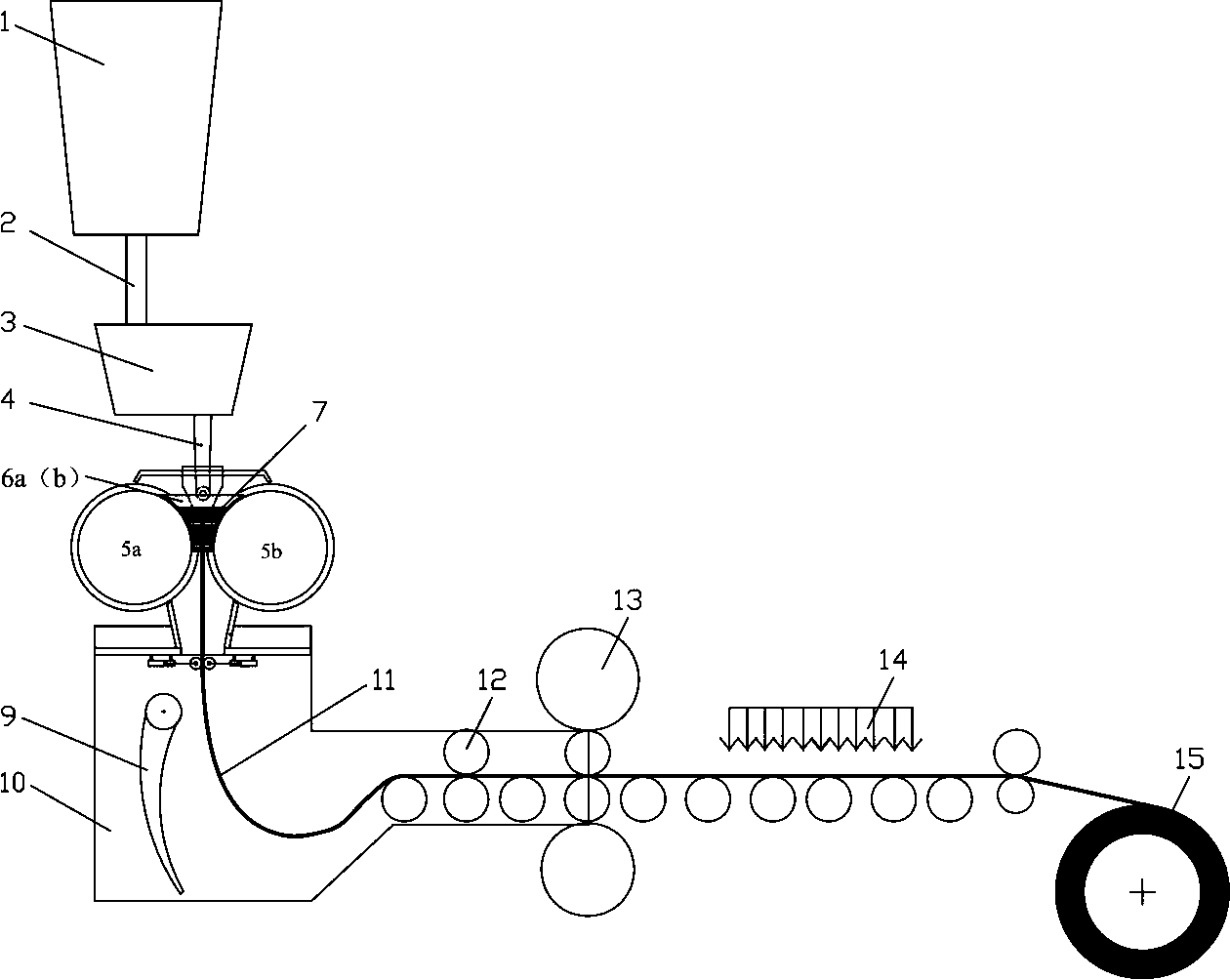

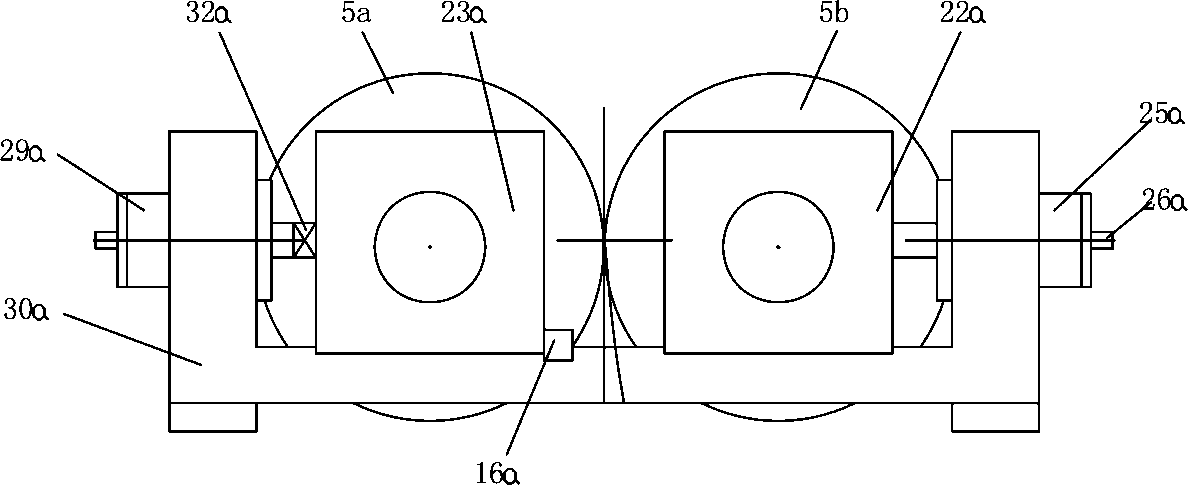

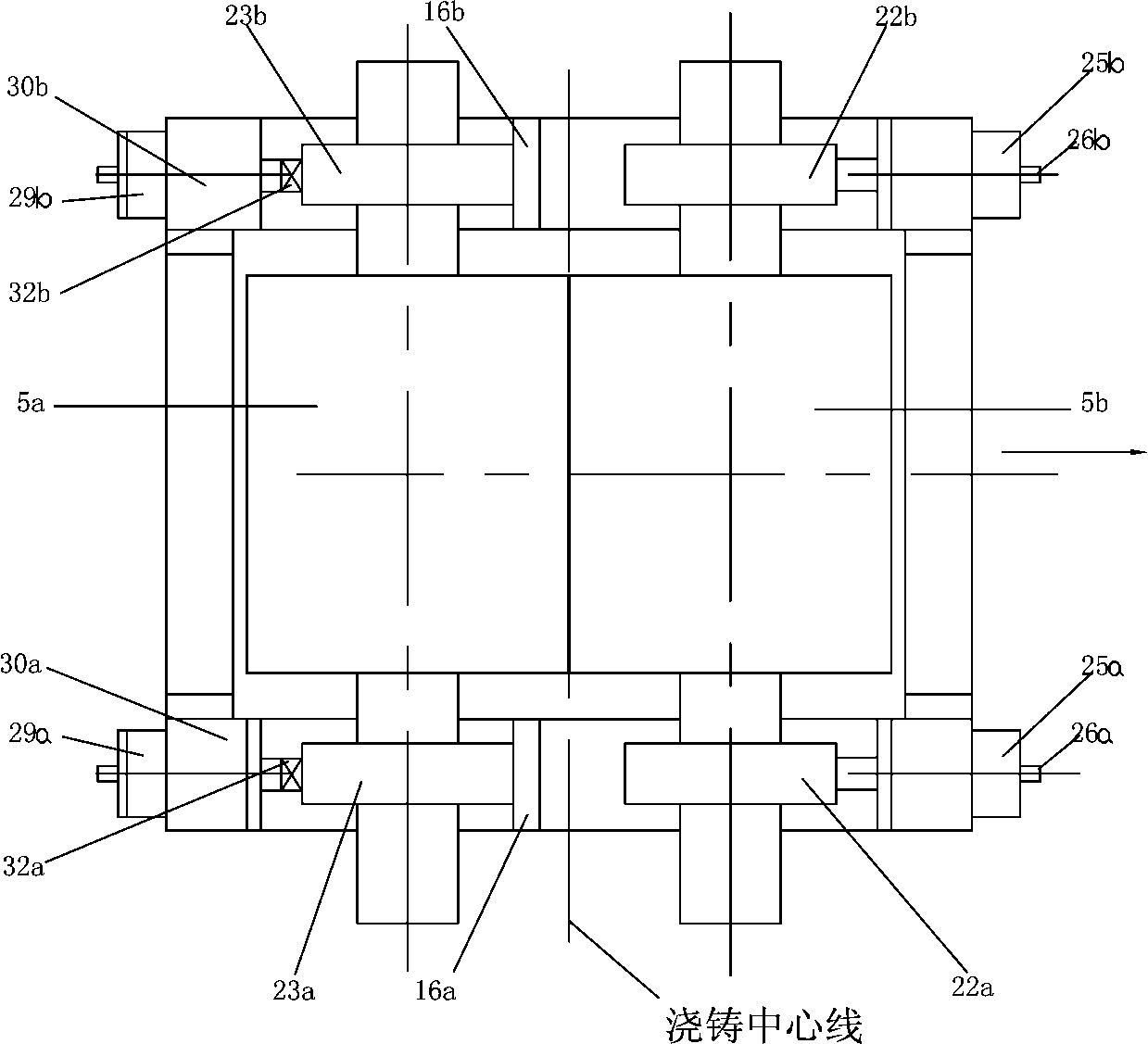

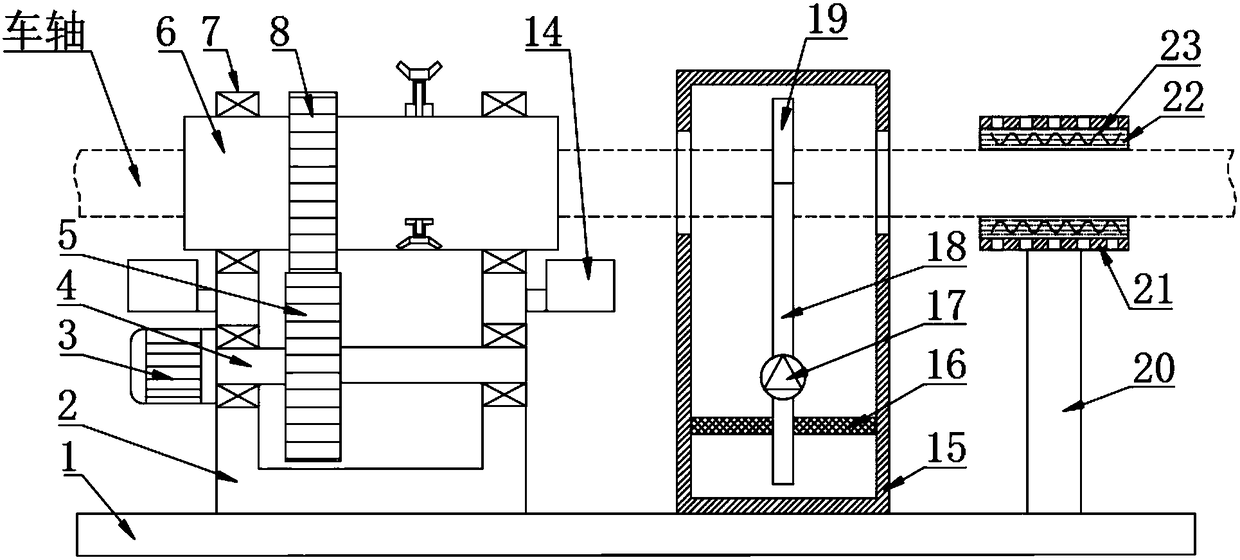

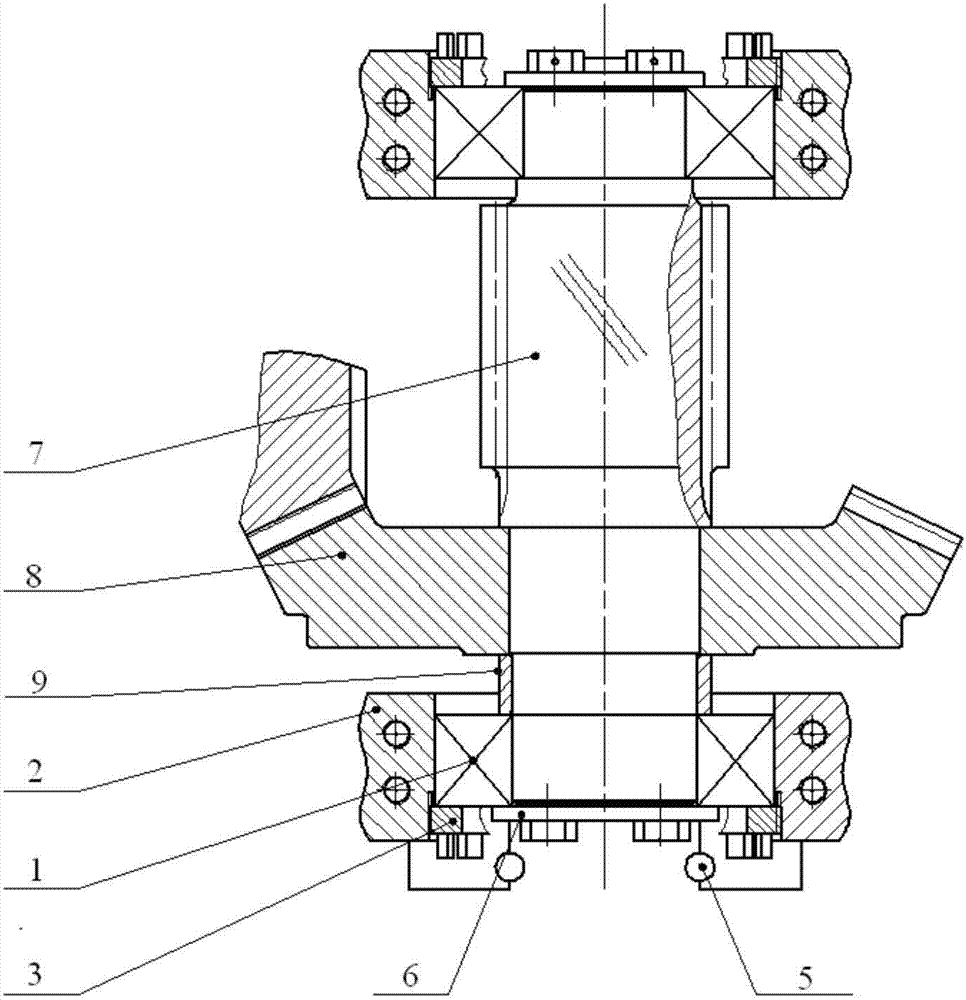

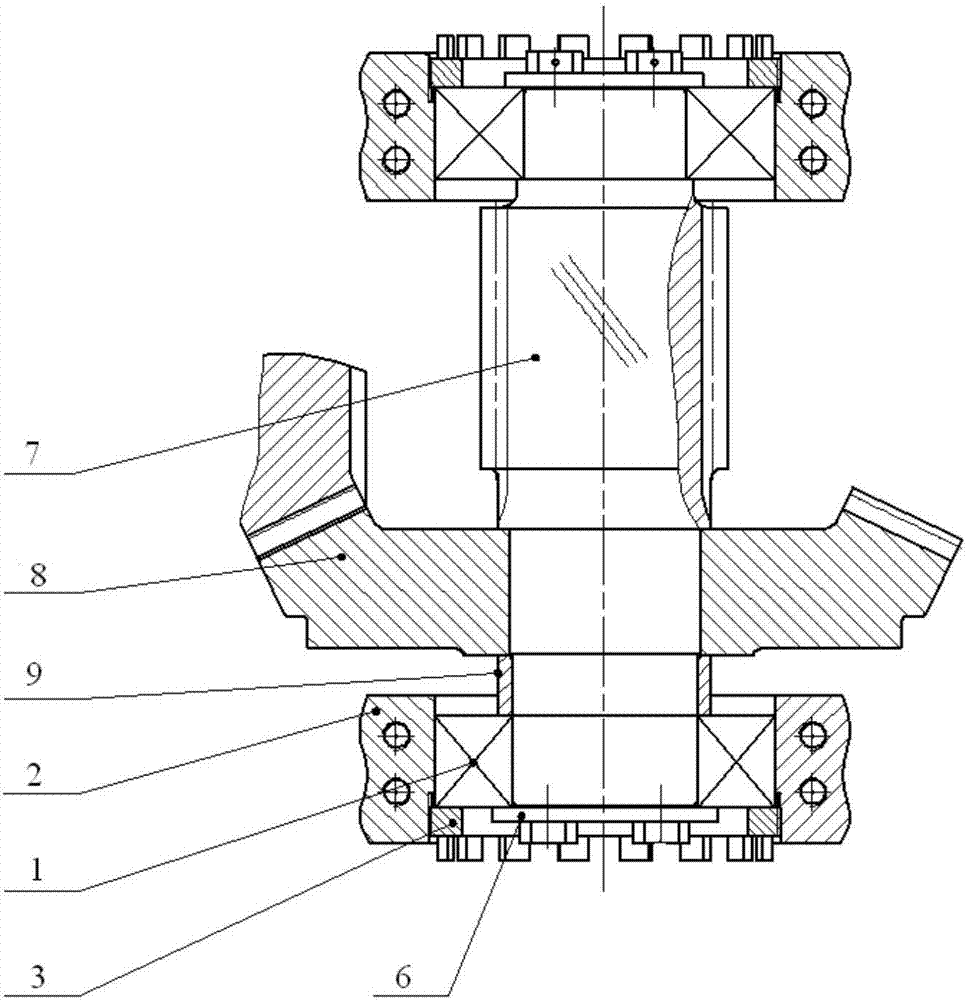

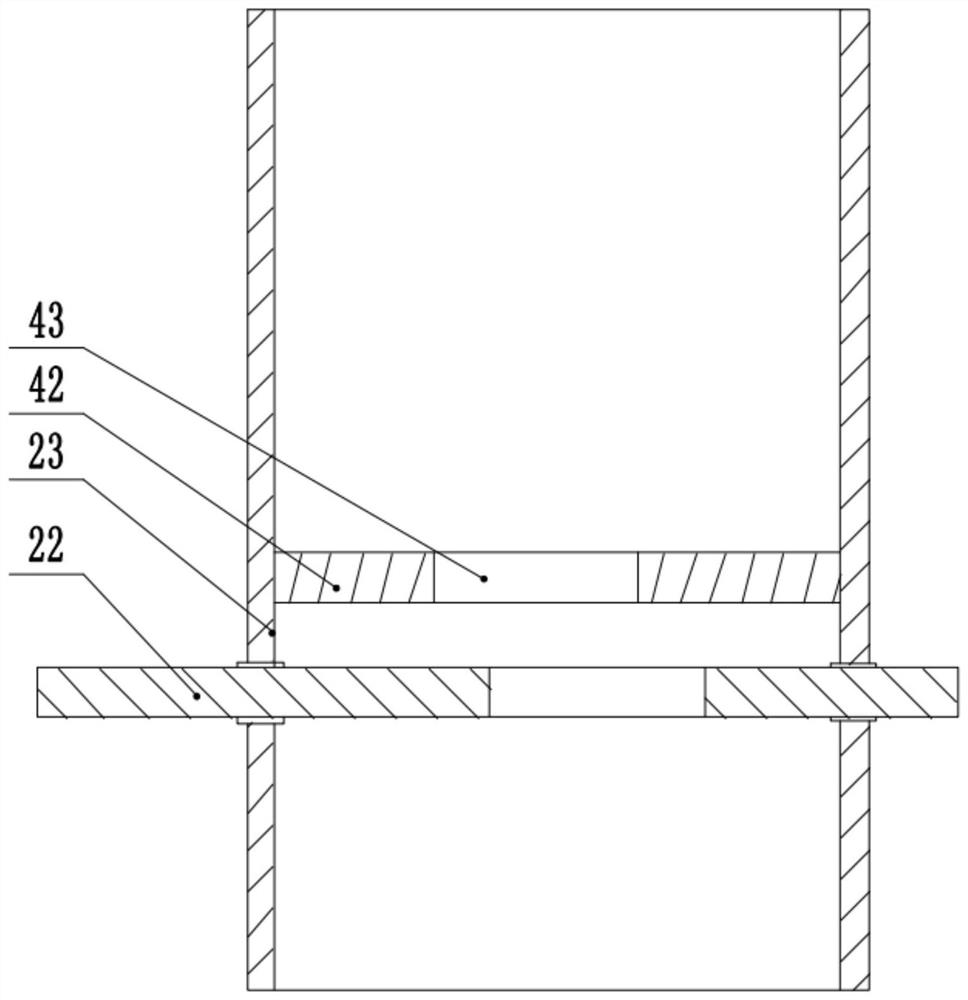

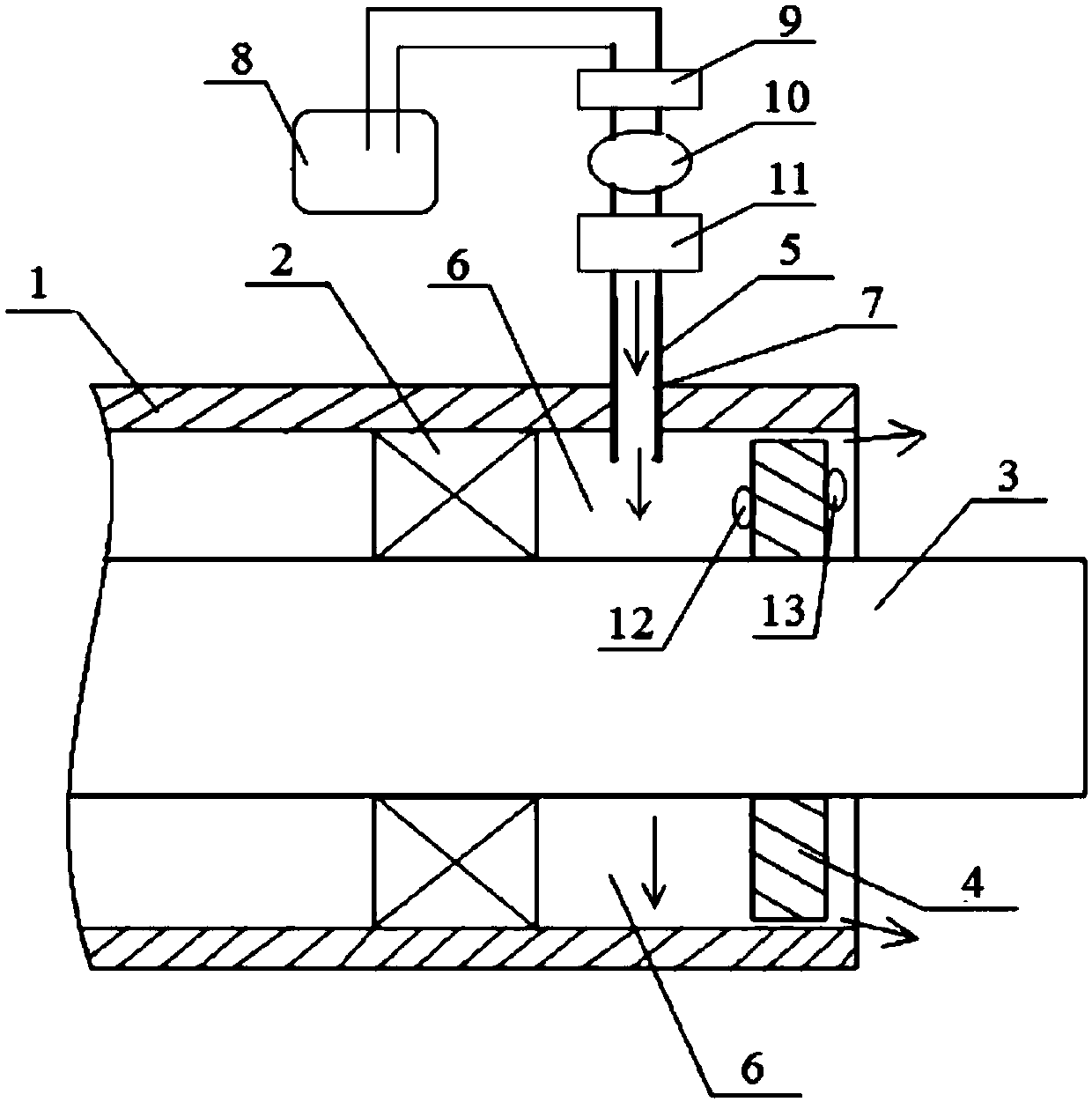

Method and device for positioning double-roller thin-strip continuous casting roller and adjusting roller gap

The invention discloses a method and a device for positioning a double-roller thin-strip continuous casting roller and adjusting a roller gap. A stand of a thin-strip continuous casting roller is a memorial arch with a U-shaped structure and is used for supporting bearing blocks on two sides of each casting roller; the bearing blocks can drive the casting roller to slide on a guide rail of the memorial arch; a hydraulic cylinder fixed on the U-shaped memorial arch of a casing machine can drive a movable roller to move relative to a fixed roller in a close or away manner; the size of a parallel gap, namely the size of the roller gap between the movable roller and the fixed roller is adjusted; a fixed stop block is arranged on one side, which corresponds to the bearing roller of the fixed roller and is close to a casting center line, on the stand; after the casting roller is replaced for each time, the casting center line of the casting machine is calibrated; the axis of the casting roller is adjusted to be parallel to the casting center line by adjusting the thickness of the fixed stop block on the stand; and meanwhile, the distance between two casting rollers is limited by the fixed stop block. According to the method and the device disclosed by the invention, the position of the fixed roller can be correspondingly adjusted along with the change of the diameter of the casting roller, so that the axis of the casting roller is parallel to the casting center line of the casting machine; and on the other hand, the detection precision of a casting and rolling force can be improved and the casting stability is improved.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Trolley and chock assembly

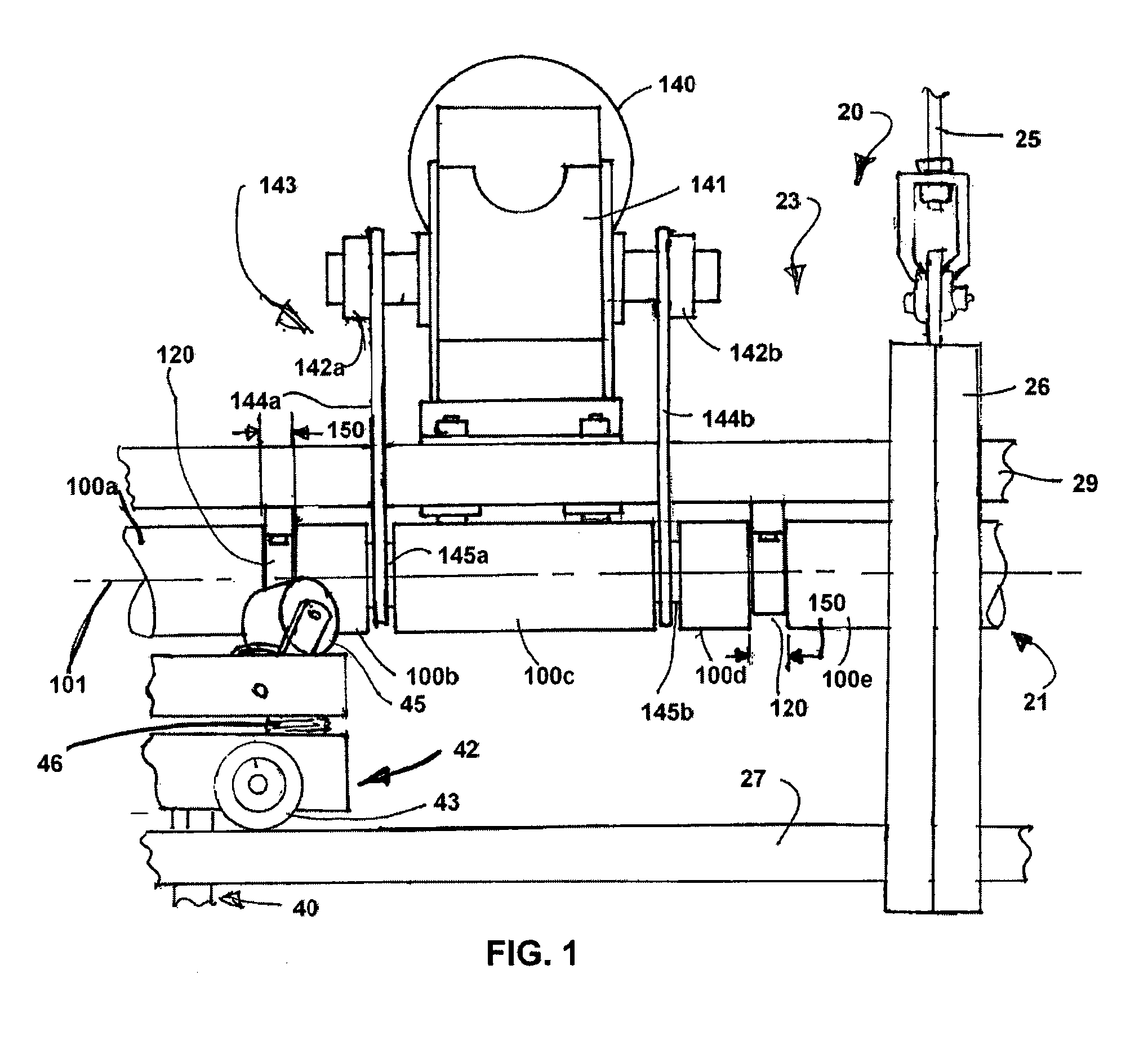

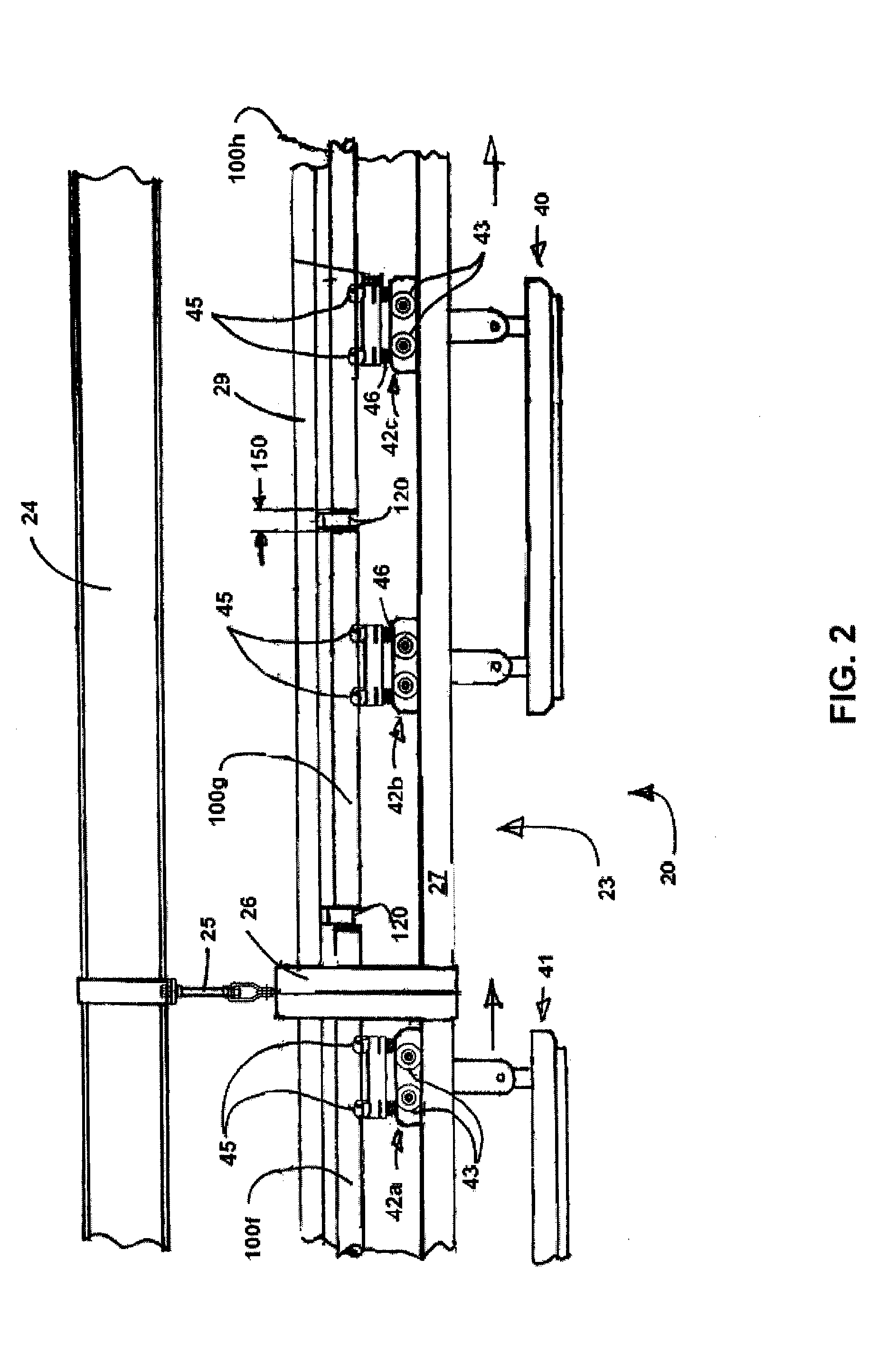

ActiveUS20050135895A1Reduce obstaclesReduce cloggingFlexible elementsAmmunition loadingPillow block bearingMechanical engineering

A trolley and chock assembly including a trolley and a chock shaped to be slidably coupled to the trolley such that the chock can slide in a sliding direction along the trolley. The chock includes a side opening on a side surface thereof. The trolley and chock assembly further includes an attachment mechanism for releasably coupling the chock to the trolley, and the side opening of the chock provides access to the attachment mechanism in a direction generally perpendicular to the sliding direction.

Owner:VALENTIN SA

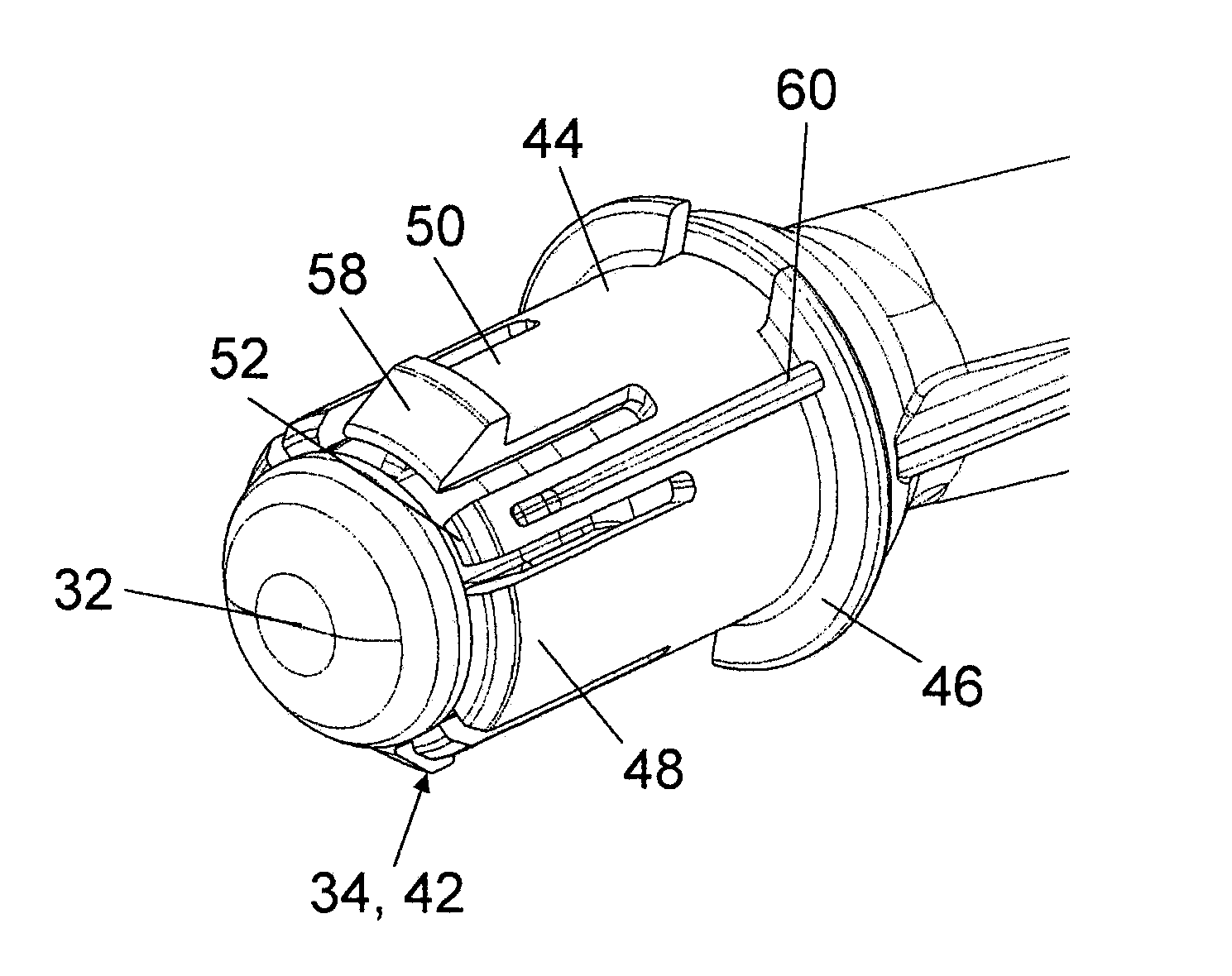

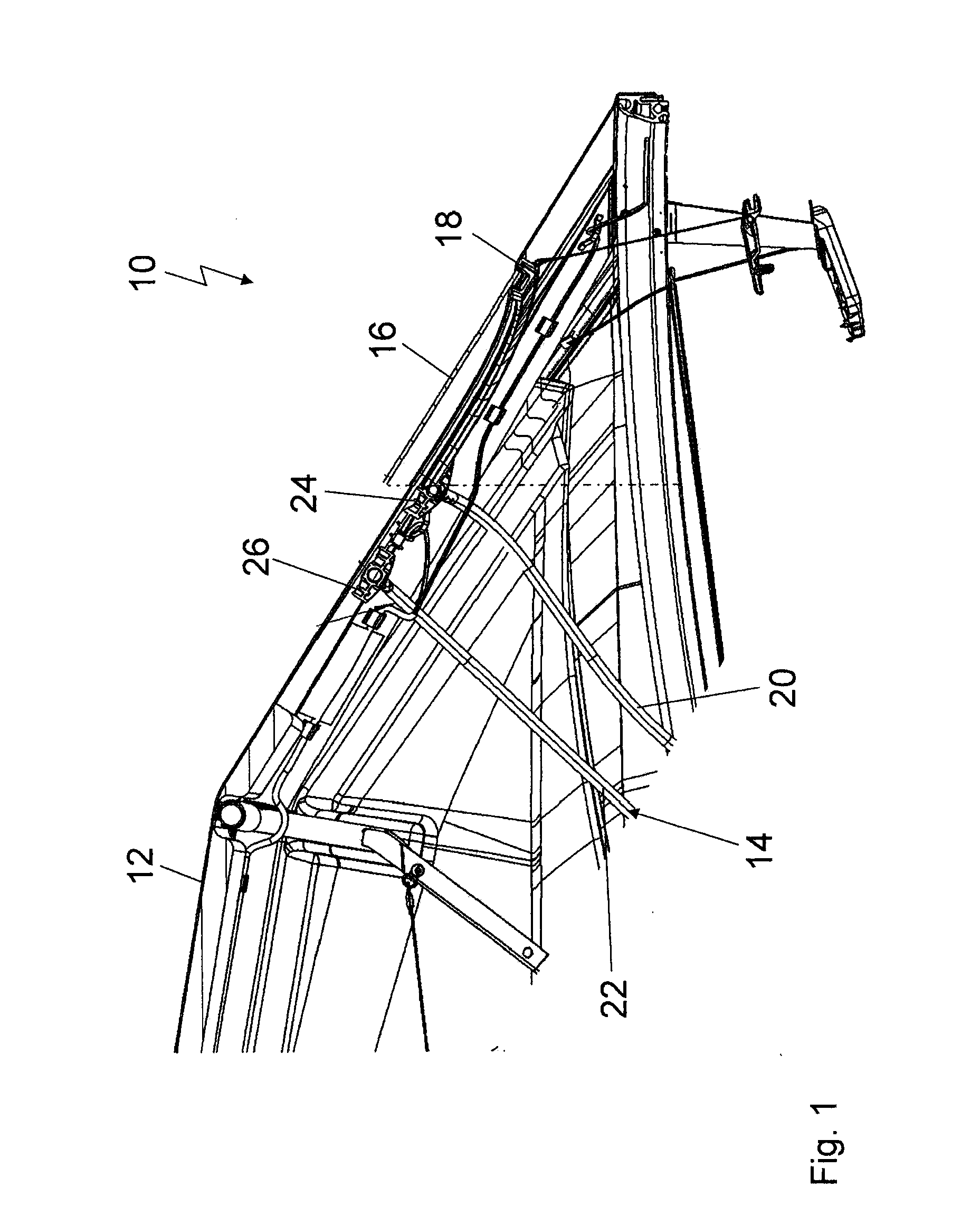

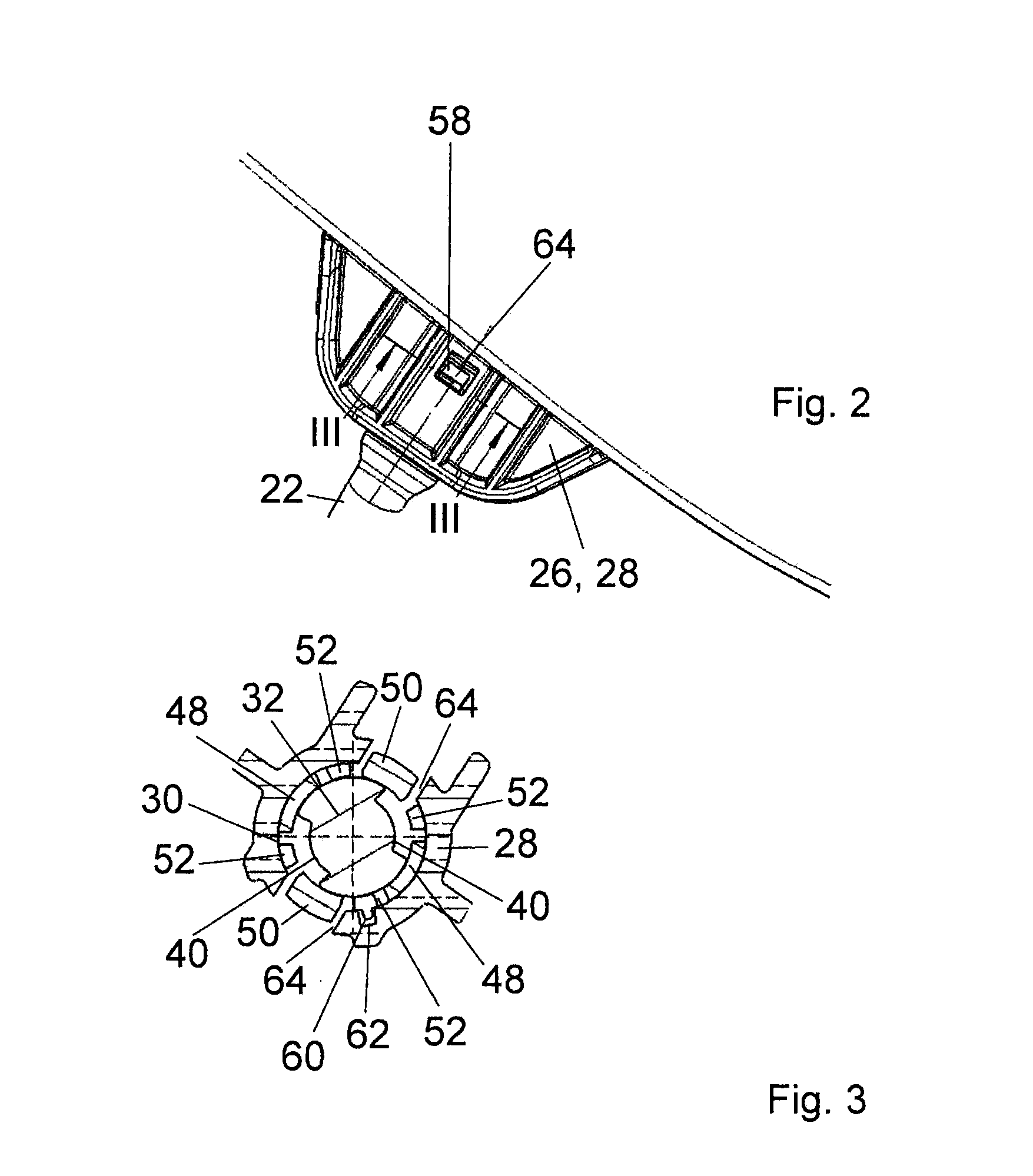

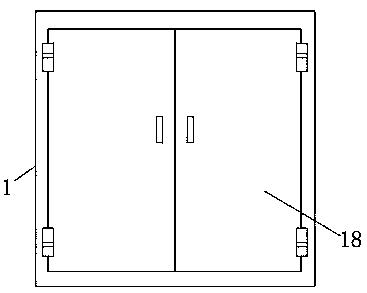

Bearing Arrangement Having A Bearing Socket

ActiveUS20140099156A1Simple wayPrevent undesirable releaseWindowsYielding couplingPillow block bearingInterior space

A bearing arrangement includes a carrier device and a bearing socket for rotatably supporting a component. The bearing socket includes a sleeve fixed in a recess of the carrier device. A peripheral wall of the sleeve delimits an inner space for receiving a bearing journal of a component. The sleeve includes at least a first, inner catch element securing the bearing journal in the sleeve and a second, outer catch element securing the sleeve in the recess of the carrier device. The second catch element is formed from a catch tongue which is a portion of the peripheral wall of the sleeve and which has a hooked portion for engagement in a catch receiving member of the recess of the carrier device.

Owner:WEBASTO EDSCHA CABRIO

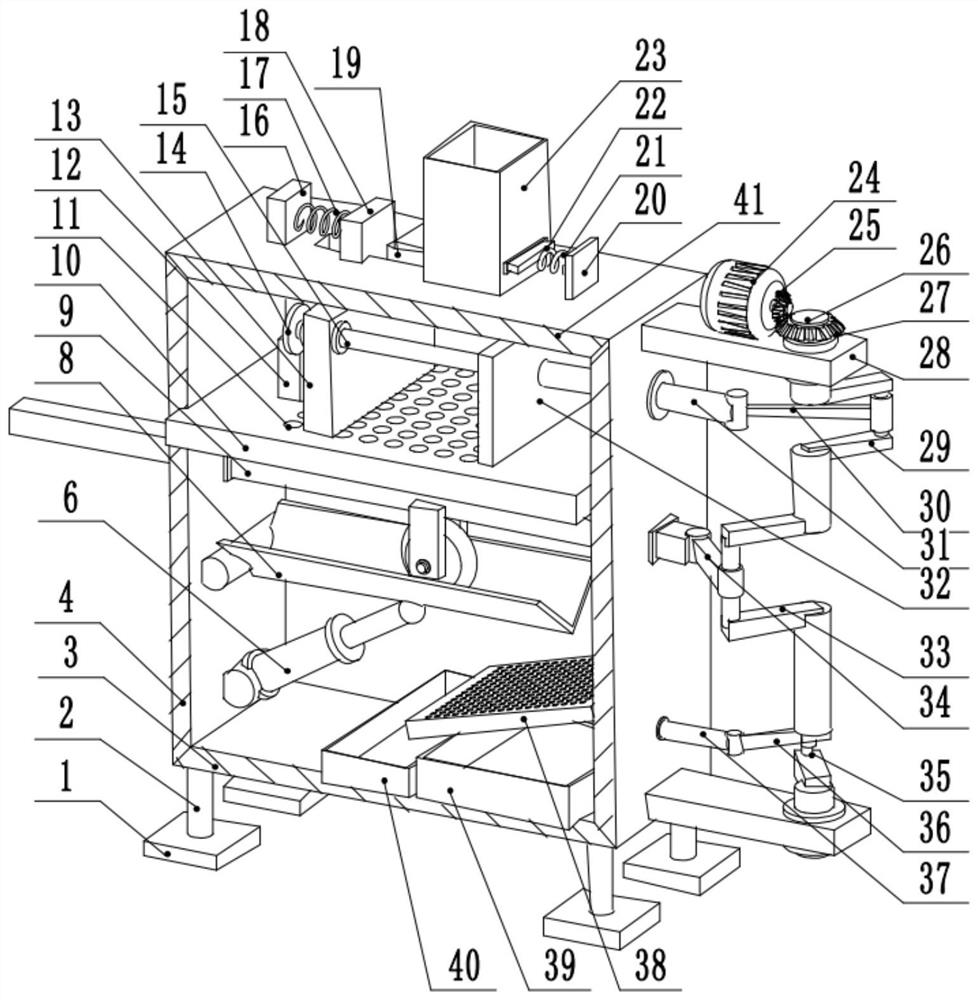

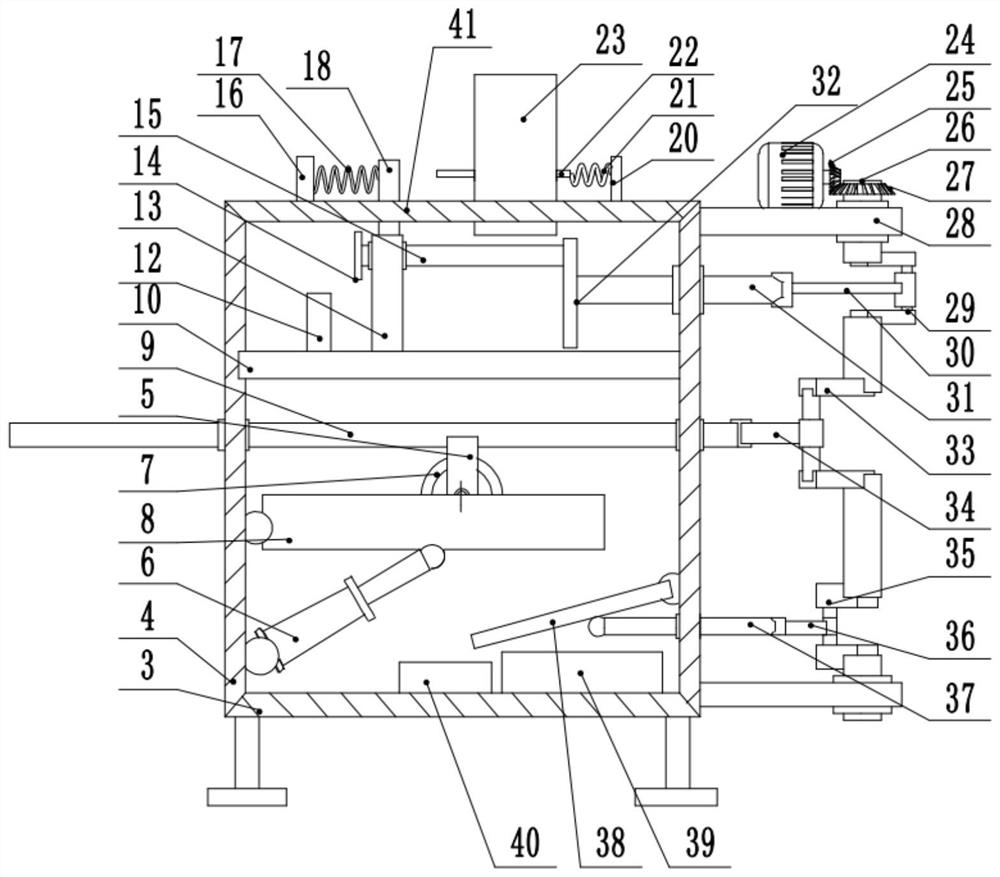

Multi-specification axle polishing device with cleaning and drying functions

InactiveCN108274376APrevent rustAbsorb moreGrinding carriagesPolishing machinesPillow block bearingBristle

The invention discloses a multi-specification axle polishing device with cleaning and drying functions. The device comprises a base, a U-shaped seat is fixedly arranged on the left side of the top ofthe base, the top of the U-shaped seat is rotationally connected with a polishing barrel through a pillow block bearing, a gear ring is further installed on the polishing barrel, a motor is further arranged on the left side wall of the U-shaped seat, a rotating shaft is connected to a motor shaft at the right end of the motor, a gear is installed on the rotating shaft, and the gear is located in the U-shaped seat and is meshed with the gear ring; and the side wall of the polishing barrel is uniformly and fixedly connected with nuts, the nuts are connected with split bolts, the tail ends of thesplit bolts penetrate through the side wall of the polishing barrel to be rotationally connected with arc-shaped plates, polishing brush bristles are uniformly and fixedly connected to the inner walls of the arc-shaped plates, the outer walls of the arc-shaped plates are further fixedly connected with guide rods, and the guide rods penetrate through the side wall of the polishing barrel and are in sliding connection with the polishing barrel. According to the device, the polishing brush bristles are driven to rotate through the polishing barrel to polish an axle, and the polishing efficiencyis high; and the arc-shaped plates can move inwards or outwards by rotating the split bolts so that the device can adapt to polishing of axles with different diameters.

Owner:周佳裕

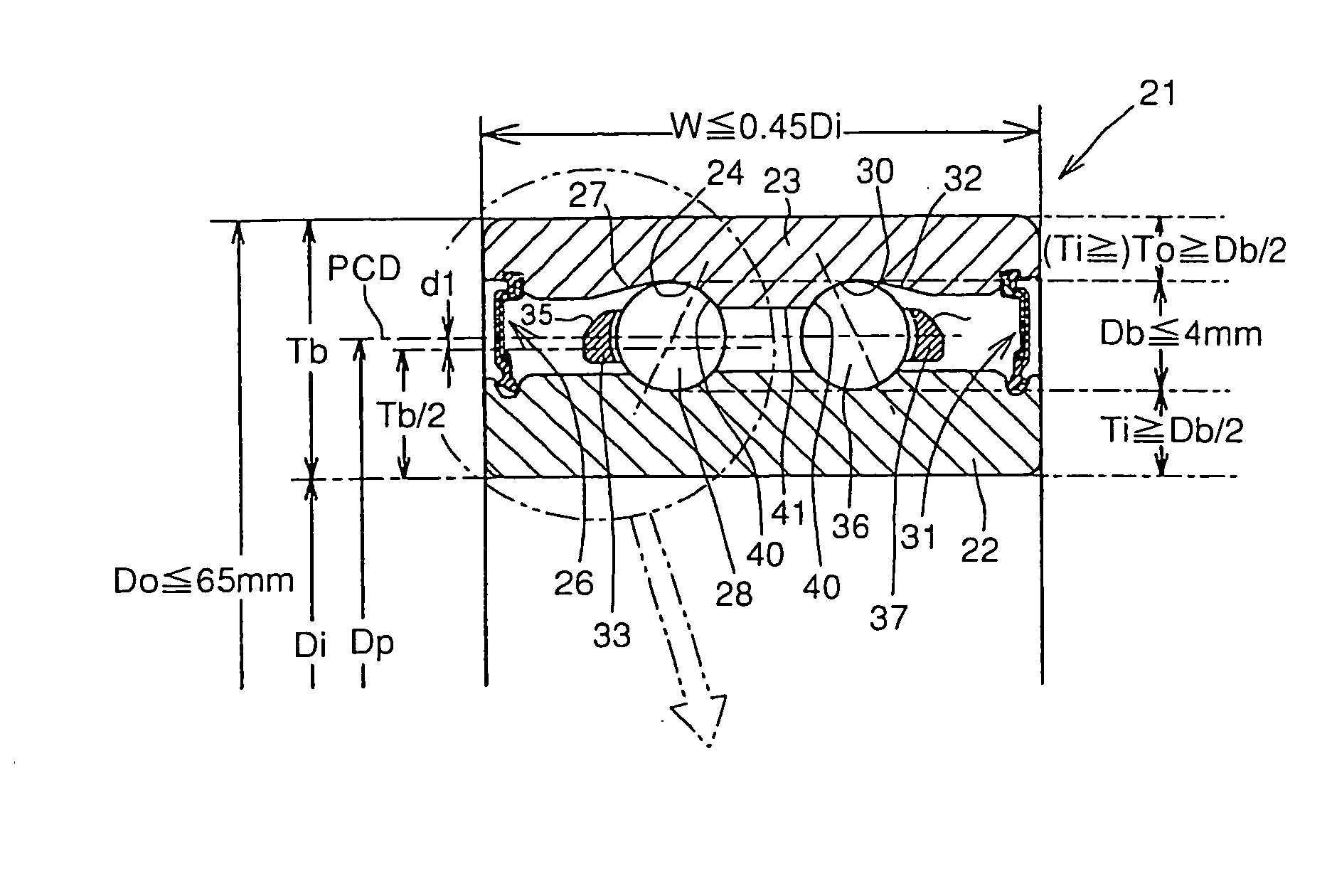

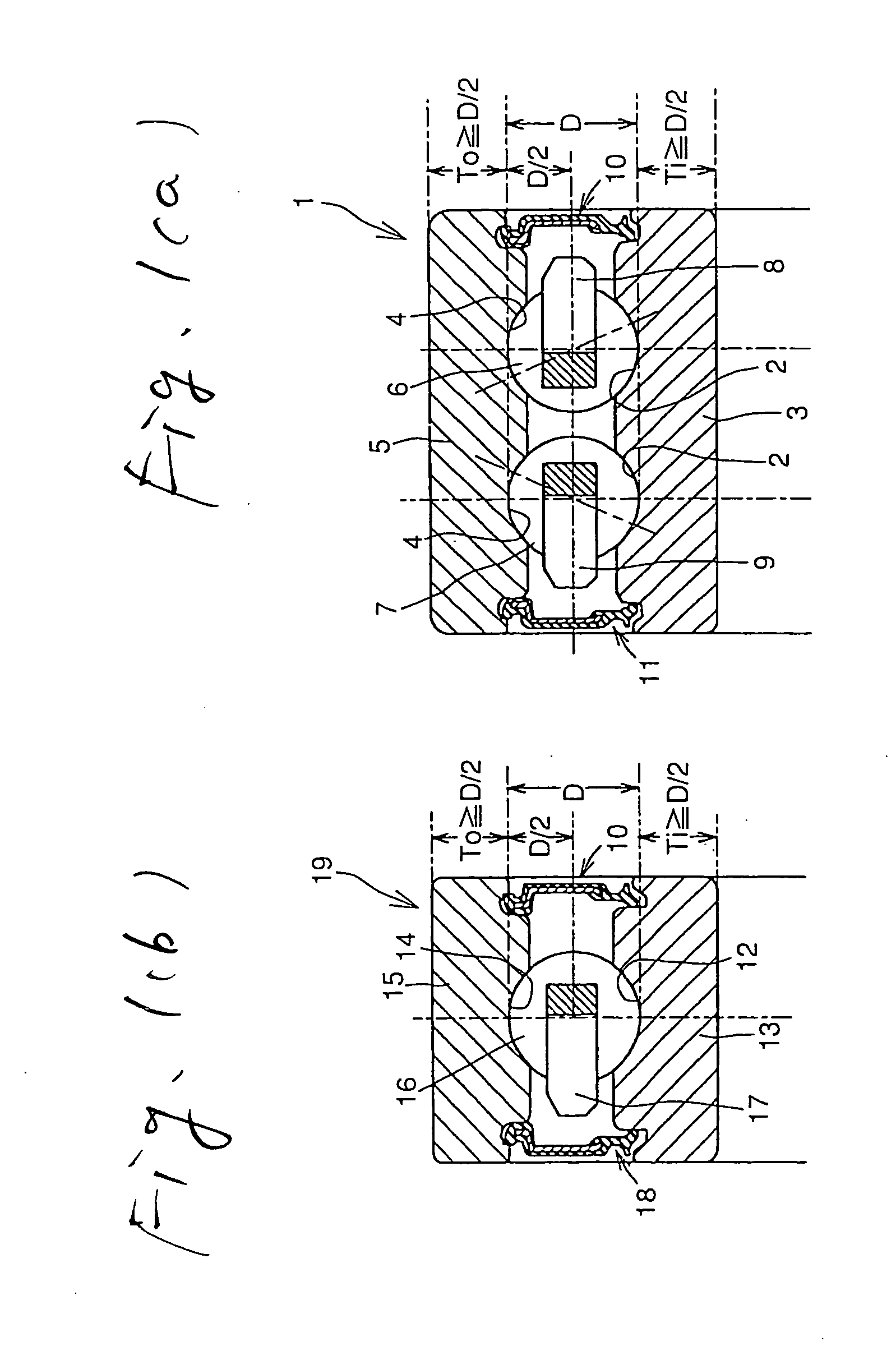

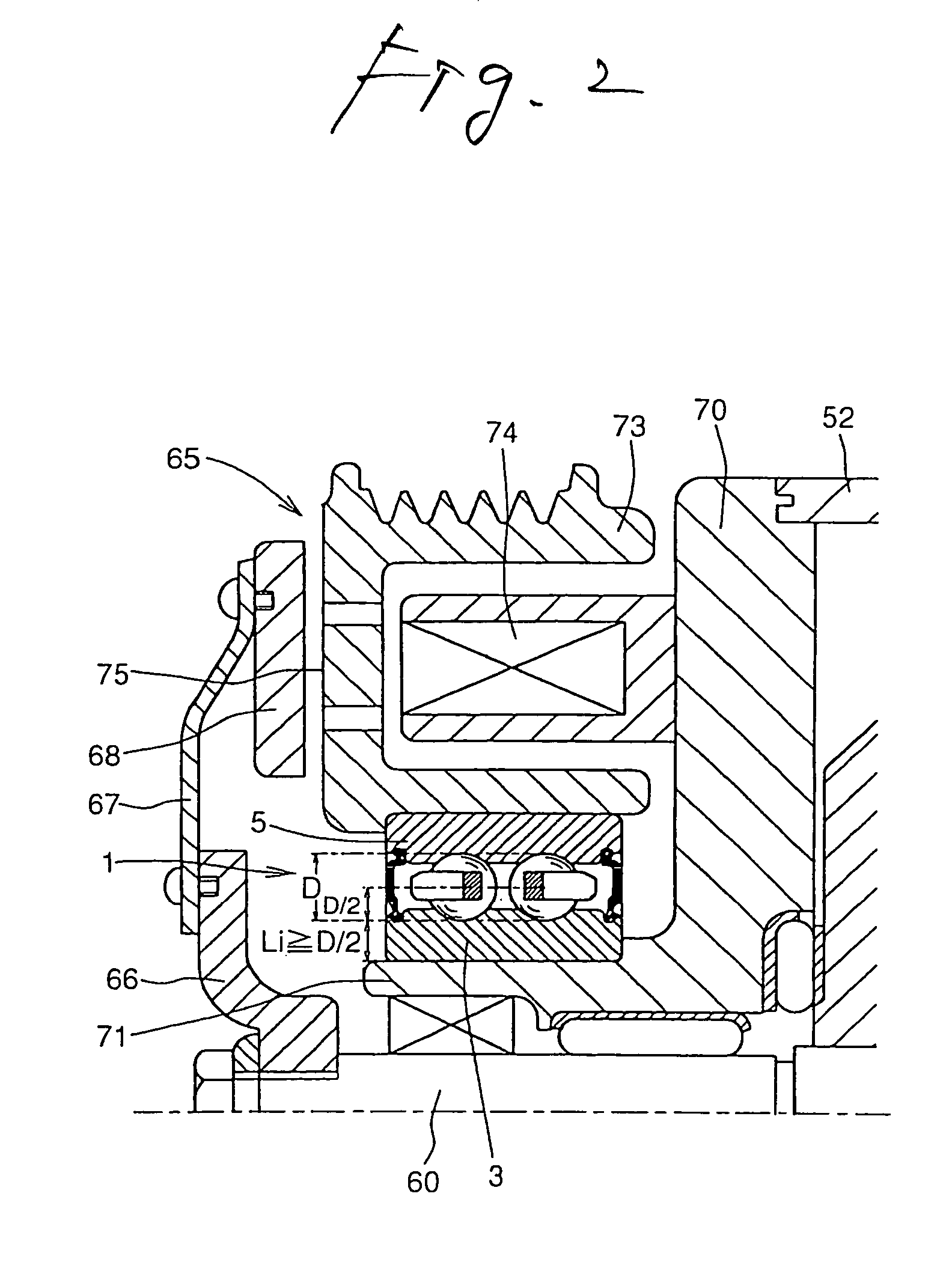

Pulley bearing for engine auxiliares

In the bearing of the present invention, the thickness of the bottom of at least one of the inner ring and the outer ring is 50% or more of the diameter of said balls. Further, the bearing comprises an outer ring having an outer diameter of 65 mm or less and balls having a diameter of 4 mm or less and has a width dimension of 45% or less of the inner diameter dimension thereof wherein the pitch diameter of the balls is closer to the outer side of the bearing than to the center of the section of the bearing, EP steel is used, the outer side of the outer raceway grooves is tapered, the inner side of angularly arranged outer raceway grooves is positioned closer to the central axis of the bearing than to the outer side of the outer raceway grooves, beveling or the like of the outer back side of the retainer is greater than half the section width or a seal having a plurality of lips fitted in an inner ring seal groove is provided.

Owner:NSK LTD

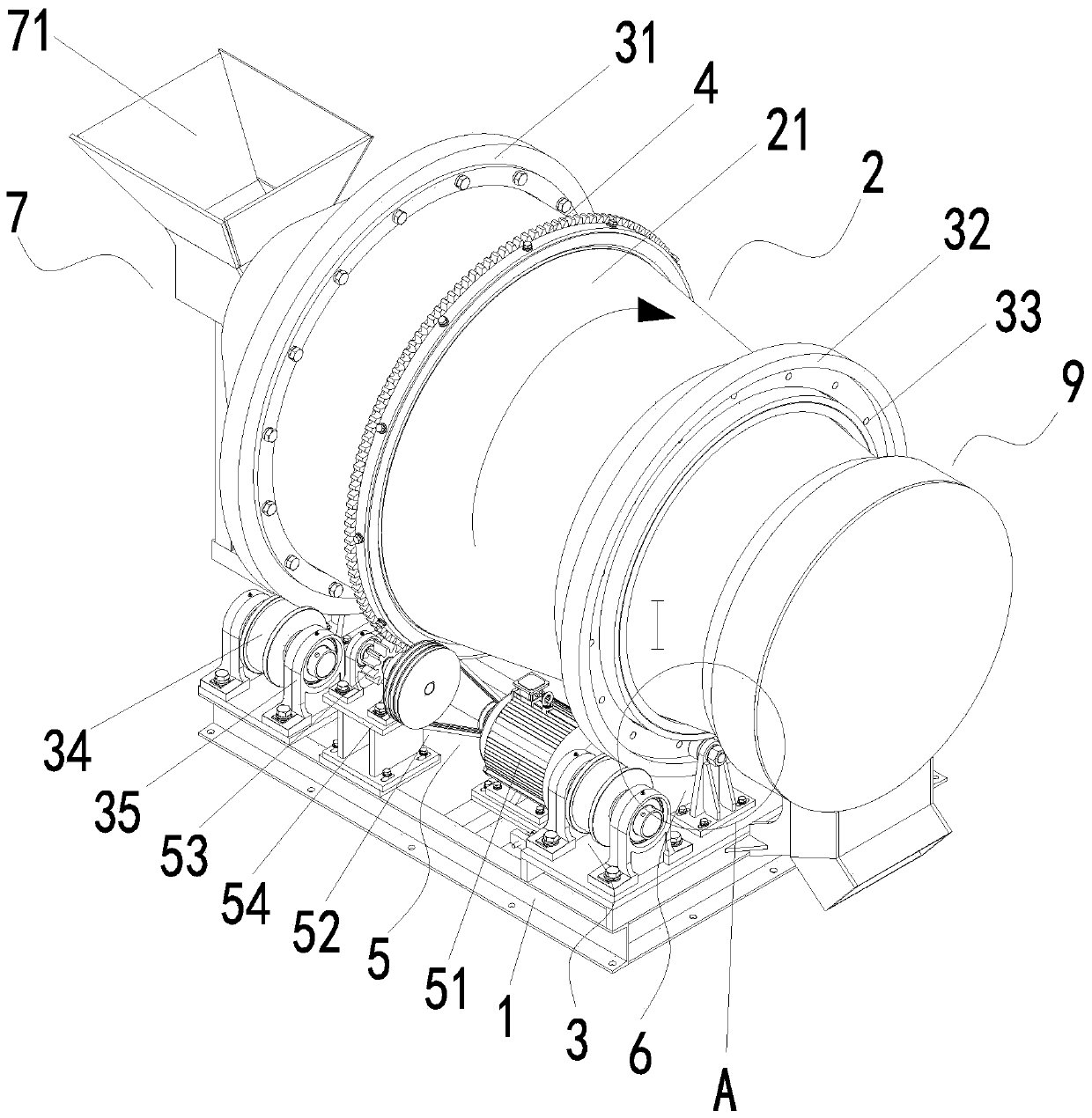

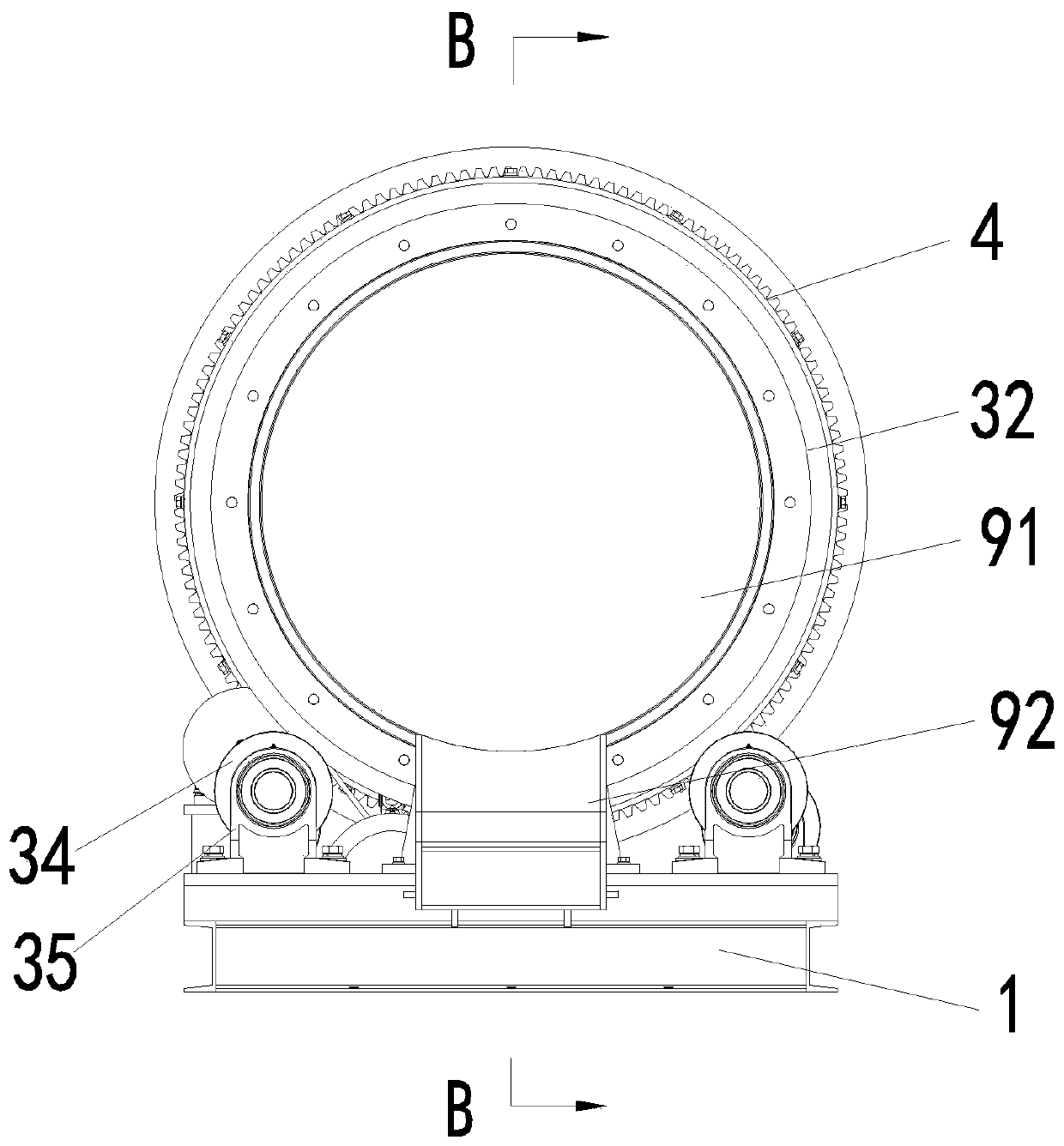

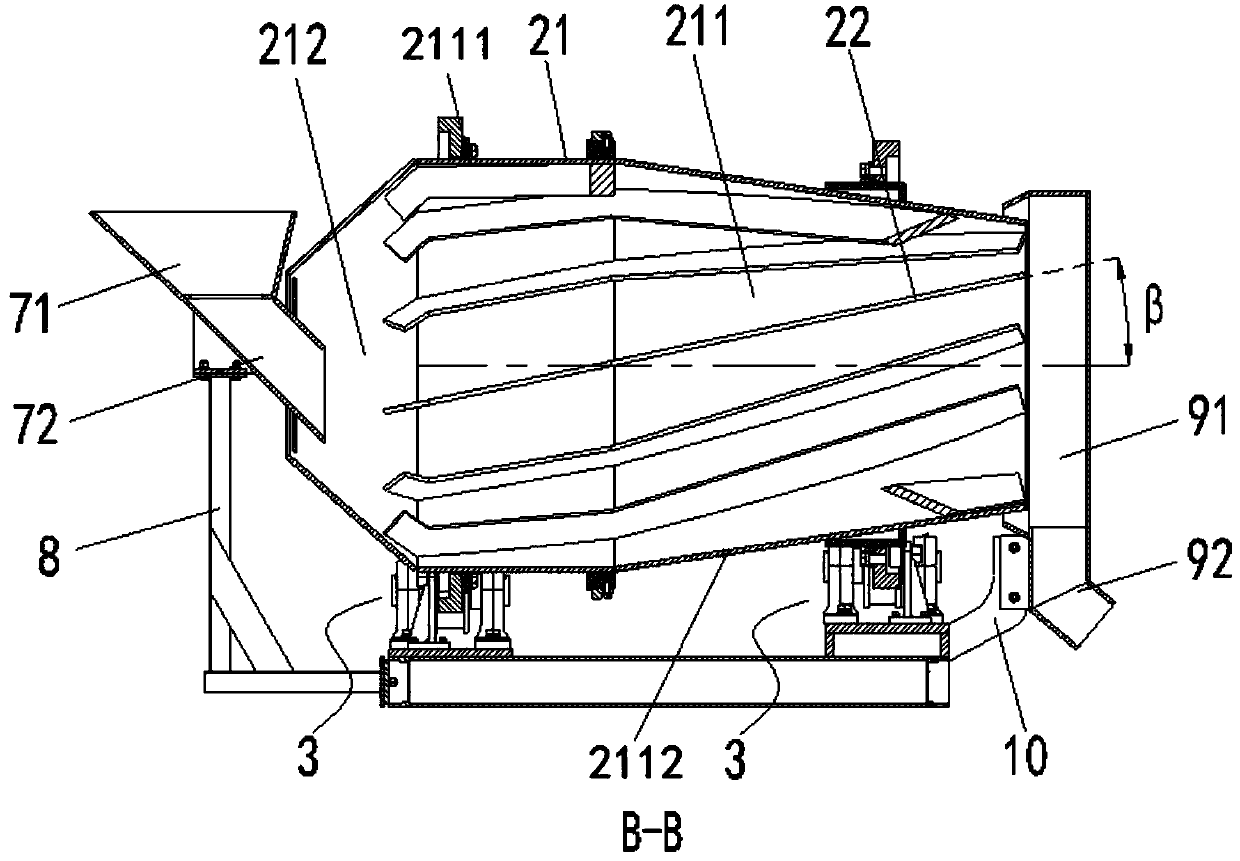

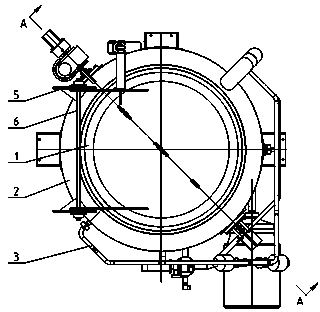

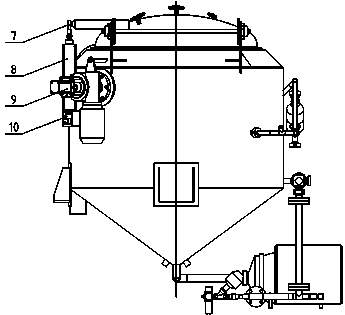

Continuous type material mixing device

PendingCN110027113AWell mixedImprove mixing efficiencyClay mixing apparatusPillow block bearingEngineering

The invention relates to the technical field of material processing equipment, in particular to a continuous type material mixing device. The continuous type material mixing device includes a base, amaterial mixing barrel, a rolling supporting mechanism, a drive gear and a drive mechanism; the material mixing barrel includes a barrel body and mixing blades, a material mixing cavity is formed in the barrel body and includes a material mixing section and a material sending section, the diameters of the material sending section are gradually decreased from the side close to the feed end of the material mixing cavity to the side of the discharge end, and the mixing blades are distributed along the inner wall of the material mixing cavity in a circumferential mode; the rolling supporting mechanism includes a first rolling ring, a second rolling ring, carrier rollers and pillow block bearings, the first rolling ring and the second rolling ring correspondingly sleeve the two ends of the outer barrel wall of the material mixing cavity and are correspondingly mounted on the carrier rollers on the two sides of the barrel body, the carrier rollers are fixed to the base through the pillow block bearings; and the drive gear sleeves the side wall of the barrel body, and the drive mechanism is connected with the drive gear in a transmission mode. According to the material premixing device, the mixing efficiency of materials is high, the materials are mixed more uniformly, and the mixing effect is very good.

Owner:福建龙亿粉体装备制造有限公司

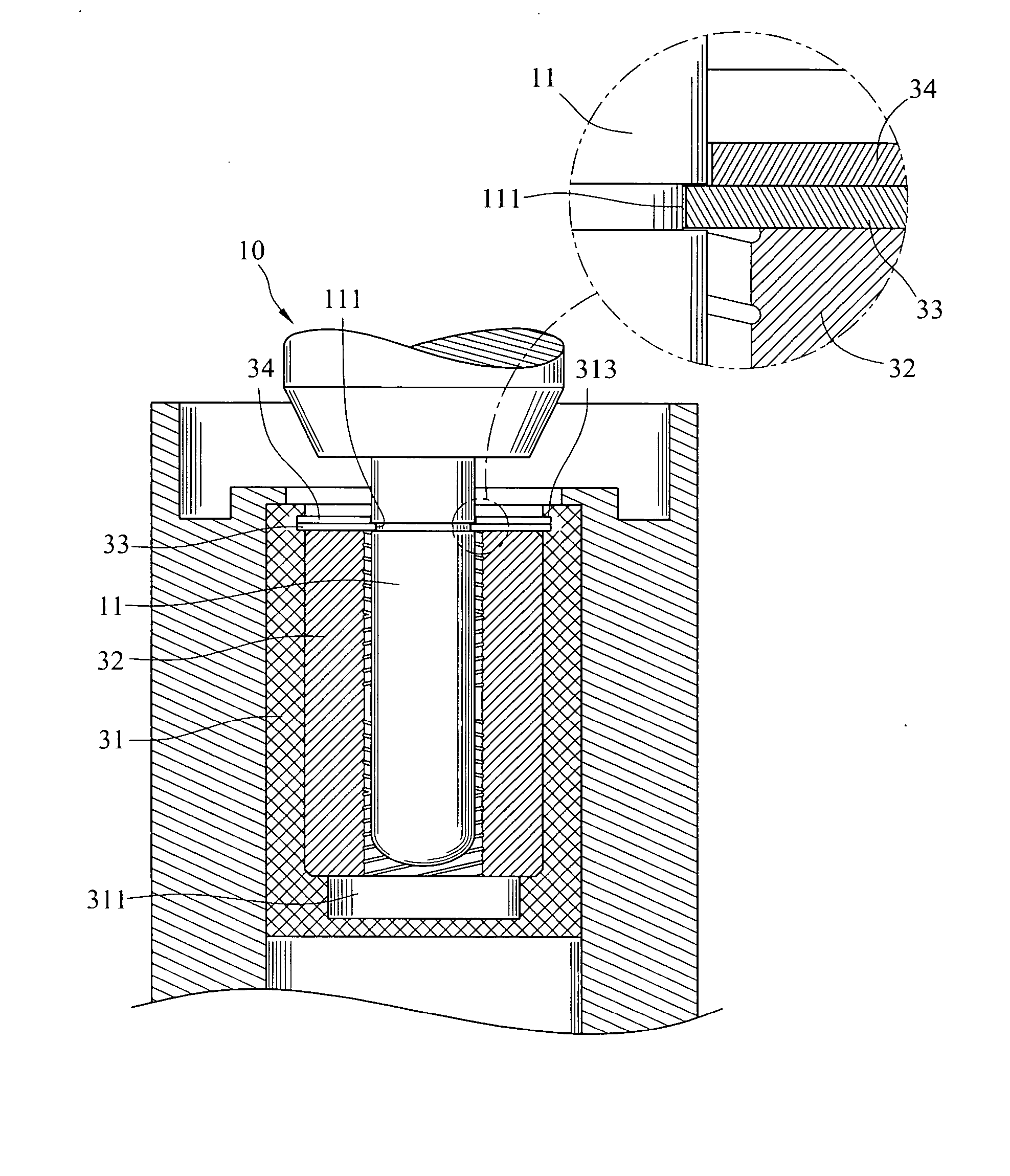

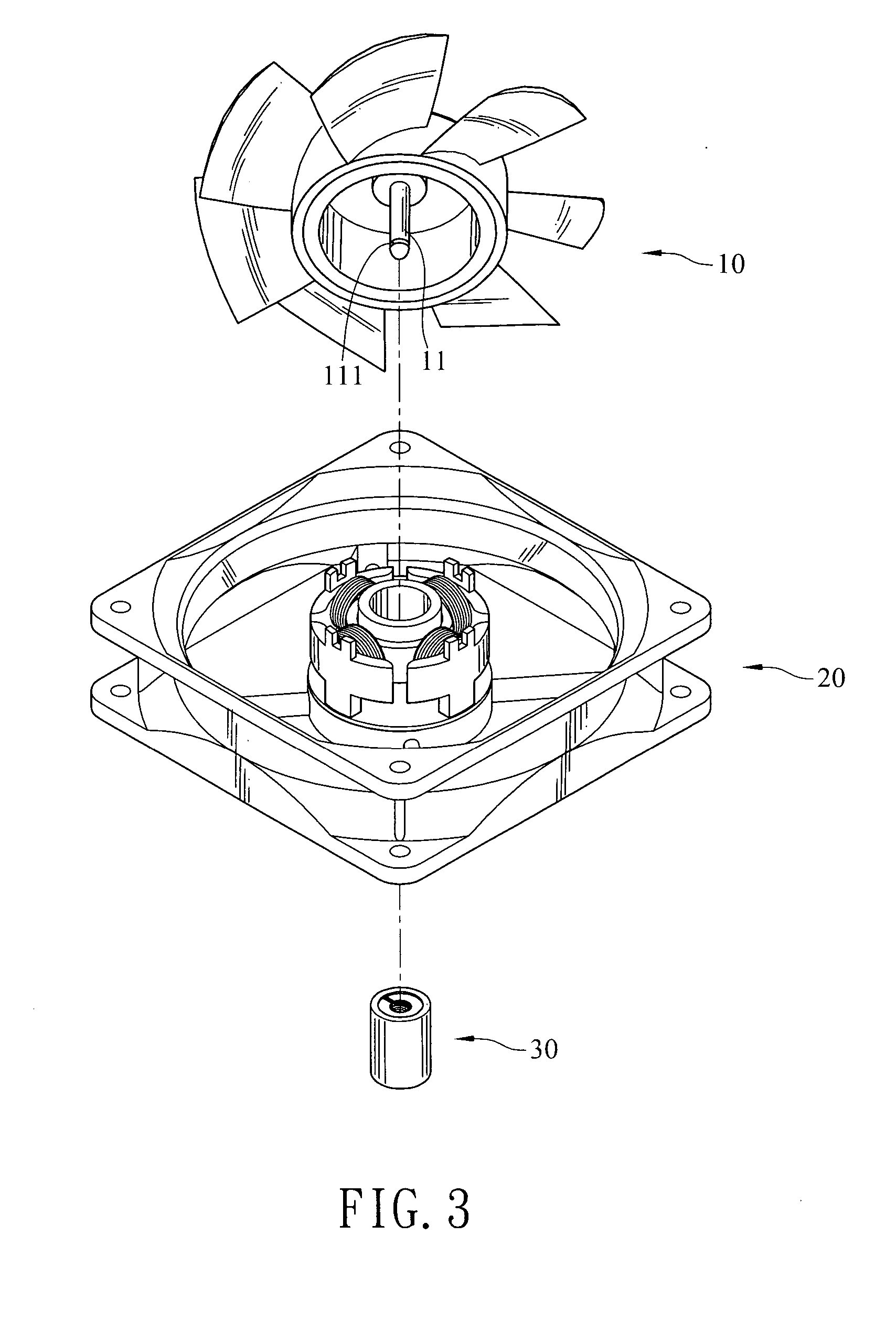

Fluid bearing module

InactiveUS20050069235A1Prevent leakagePump componentsRopes and cables for vehicles/pulleyPillow block bearingEngineering

A fluid bearing module has a bearing seat, a bearing, a deflecting member, and an impediment. The bearing seat has a capacity with an opening. The bearing in the capacity has a hollow space for the axis of a rotor to go through, and a lubricant medium is filled in between. The deflecting member protruding from the side near the opening of the bearing seat bends toward the capacity and clips on the rotor axis. The impediment protrudes from the side near the opening of the bearing seat for preventing the deflecting member from bending toward the opening and departing from the rotor. Moreover, the deflecting member and the impediment form a maze to keep the lubricant medium within.

Owner:IND TECH RES INST

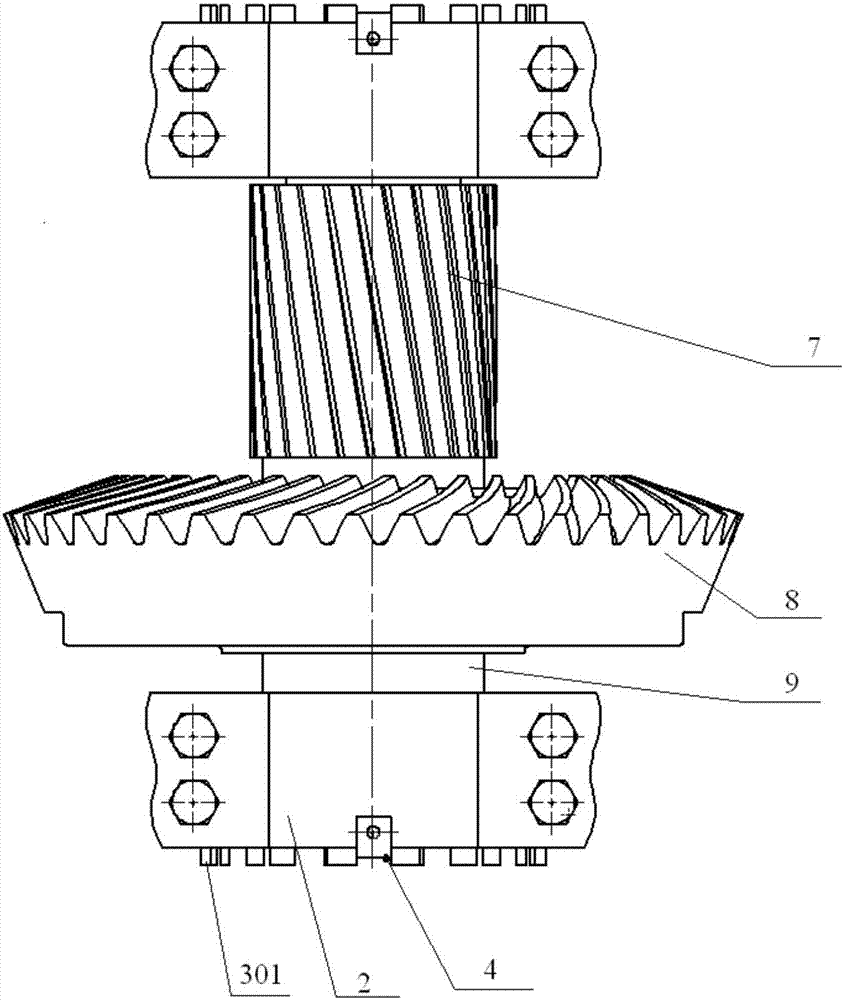

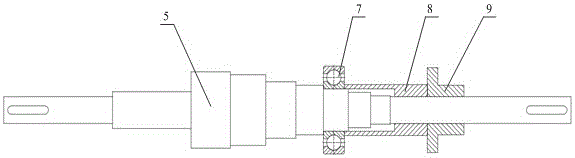

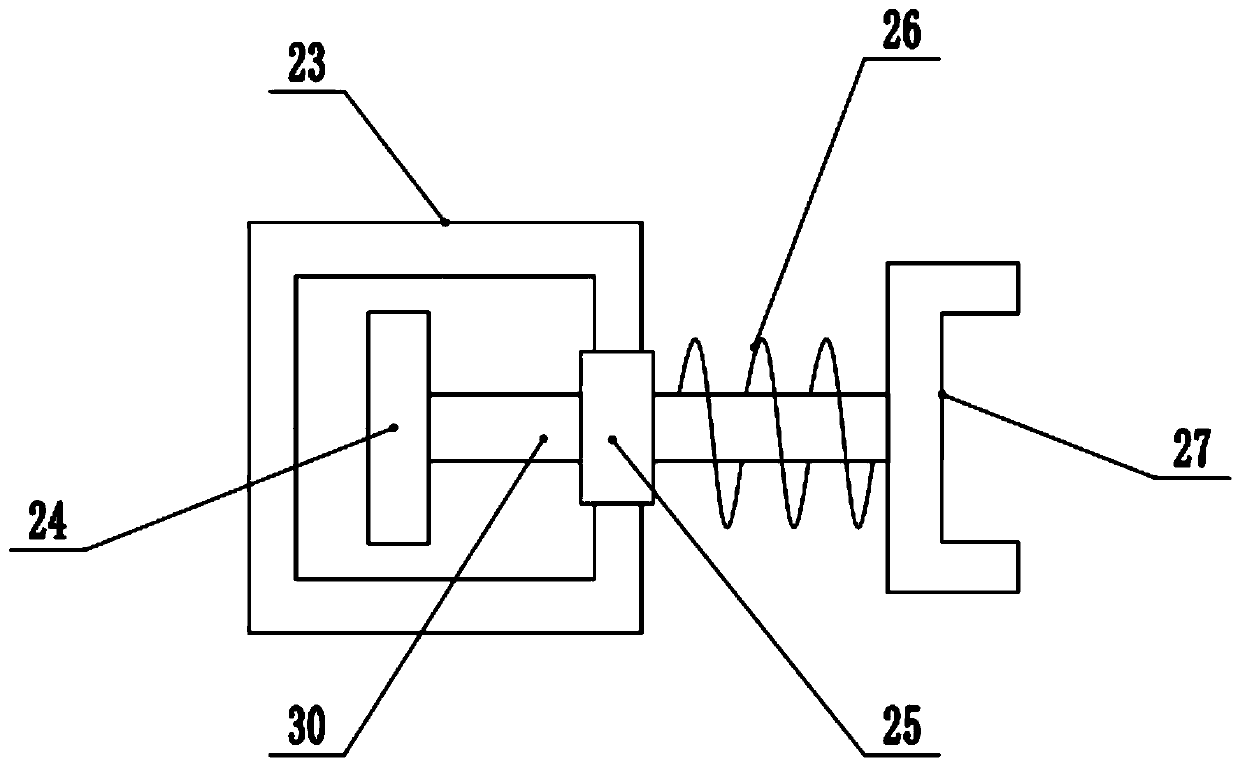

Roller-bearing preloading adjustment structure and method

InactiveCN107289030AEnsure clearanceEnsure preloadGearing detailsBearing unit rigid supportGear wheelDrive shaft

The invention discloses a roller bearing preload adjustment structure and method. The roller bearing preload adjustment structure includes: a roller bearing capable of being installed on a transmission shaft; a bearing seat supporting the roller bearing, and the bearing seat is installed in a box On the body, and the inner ring of the bearing seat is provided with an internal thread; the bearing lock nut is provided with an external thread that engages with the internal thread on the bearing seat, and the inner side of the bearing lock nut is in contact with the roller bearing the outer ring abutment. The roller bearing preload adjustment structure disclosed in the present invention adjusts the bearing lock nut when adjusting the axial positioning of the roller bearing. Since the bearing lock nut and the bearing seat are threaded, the bearing lock nut rotates One turn, forward or backward by one pitch, so as to ensure that the clearance and preload of the roller bearing meet the technical requirements, and realize the axial position adjustment of the transmission parts such as the gear on the transmission shaft. The use of grinding parts is reduced, and the adjustment can be realized only by rotating the bearing lock nut, which has high efficiency.

Owner:CHONGQING GEARBOX

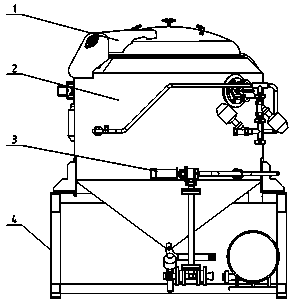

Fully-automatic powder dye solving, conveying and cleaning device

InactiveCN103736701ACircular stirringAvoid contactHollow article cleaningPillow block bearingWorking environment

The invention discloses a fully-automatic powder dye solving, conveying and cleaning device. The fully-automatic powder dye solving, conveying and cleaning device comprises a cylinder body assembly, the cylinder body assembly is arranged on a frame assembly, the top of the cylinder body assembly is provided with a cylinder cover assembly, and the cylinder cover assembly is fixed onto the cylinder body assembly through a pillow block bearing and a connecting rod; the cylinder body assembly is provided with an uncovering air cylinder which is fixed onto the cylinder body assembly through an air cylinder seat, the top of the air cylinder rod of the uncovering air cylinder is provided with an S-type spherical surface connecting rod, and the S-type spherical surface connecting rod is connected with the cylinder body assembly; the outside of the cylinder body assembly is provided with a pipe assembly, and the pipe assembly plays a role of dye solution circular mixing, dye solution conveying and cylinder body, melting barrel and conveying pipe cleaning. The fully-automatic powder dye solving, conveying and cleaning device achieves automation of a whole power dye solving, conveying and cleaning process, avoids the contact between operating personnel and powder dye and reduces the pollution of the powder dye to human bodies and working environments and the labor intensity of the operating personnel.

Owner:TAIAN COMPANION MACHINERY

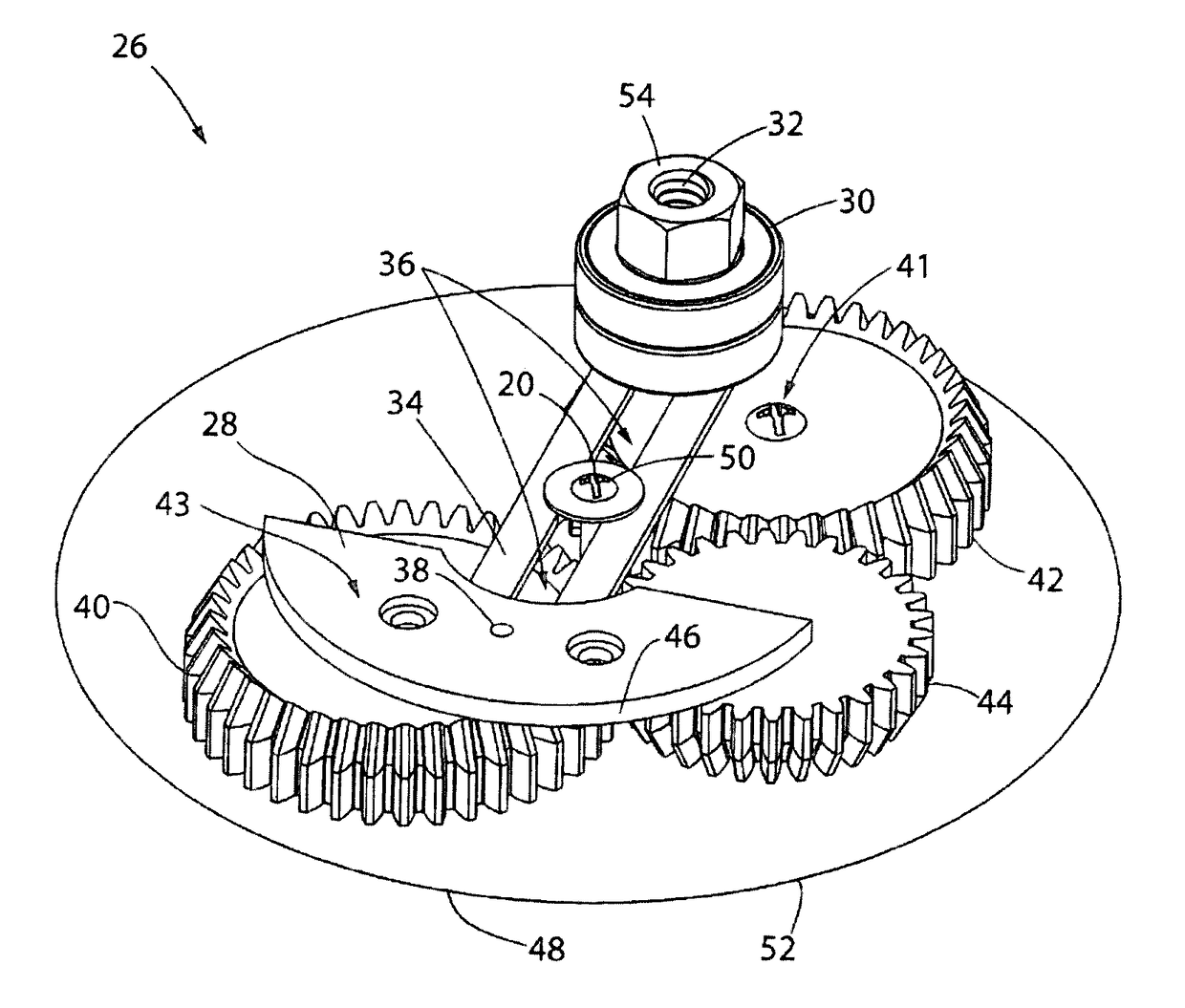

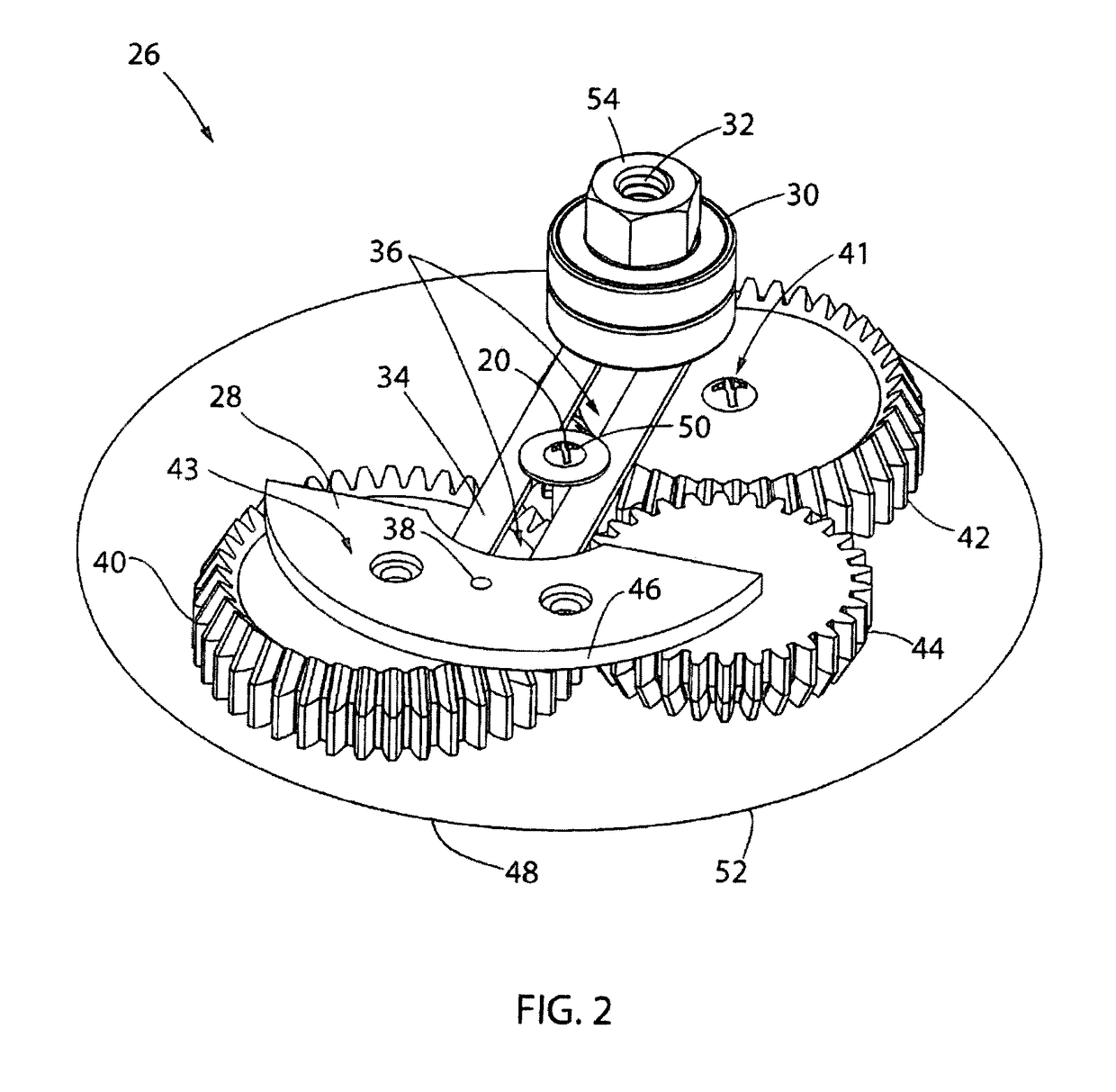

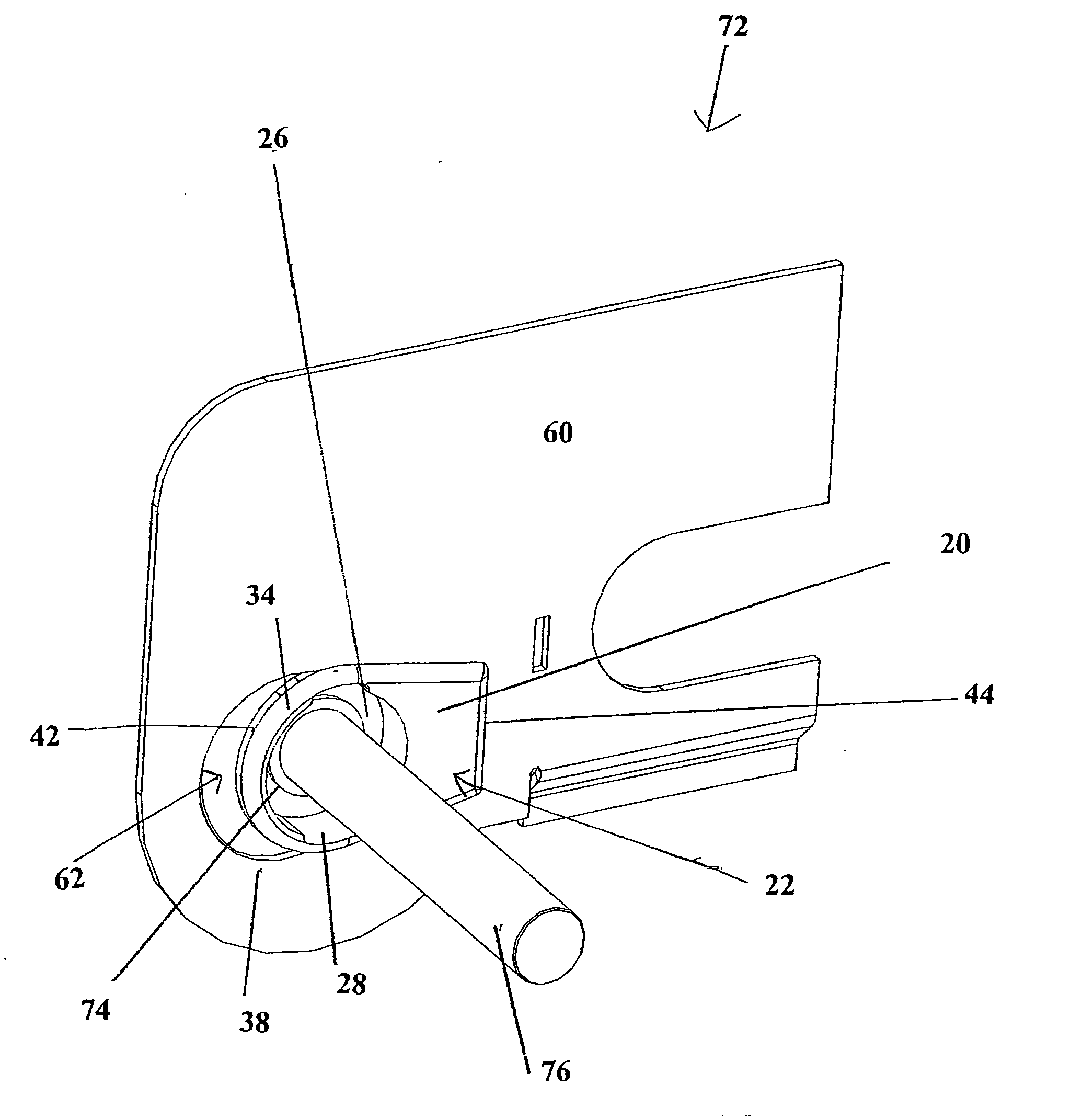

Adjustable Stroke Mechanism for Random Orbital Machine

An adjustable stroke mechanism for a random orbital machine including a housing having a wall enclosing a cavity, an adjuster ring surrounding the housing and having a first set of gear teeth along a first portion of an inner surface, and a second set of gear teeth along a second portion of the inner surface, a counterweight having gear teeth on an exterior surface disposed within the housing, and a bearing carriage having gear teeth disposed within the housing. At least one counterweight gear that meshes with the gear teeth of the counterweight and the first set of gear teeth of the adjuster ring, and at least one bearing carriage gear that meshes with the gear teeth of the bearing carriage and the second set of gear teeth of the adjuster ring, so that movement of the adjuster ring causes movement of both the counterweight and the bearing carriage.

Owner:LAKE COUNTRY TOOL LLC

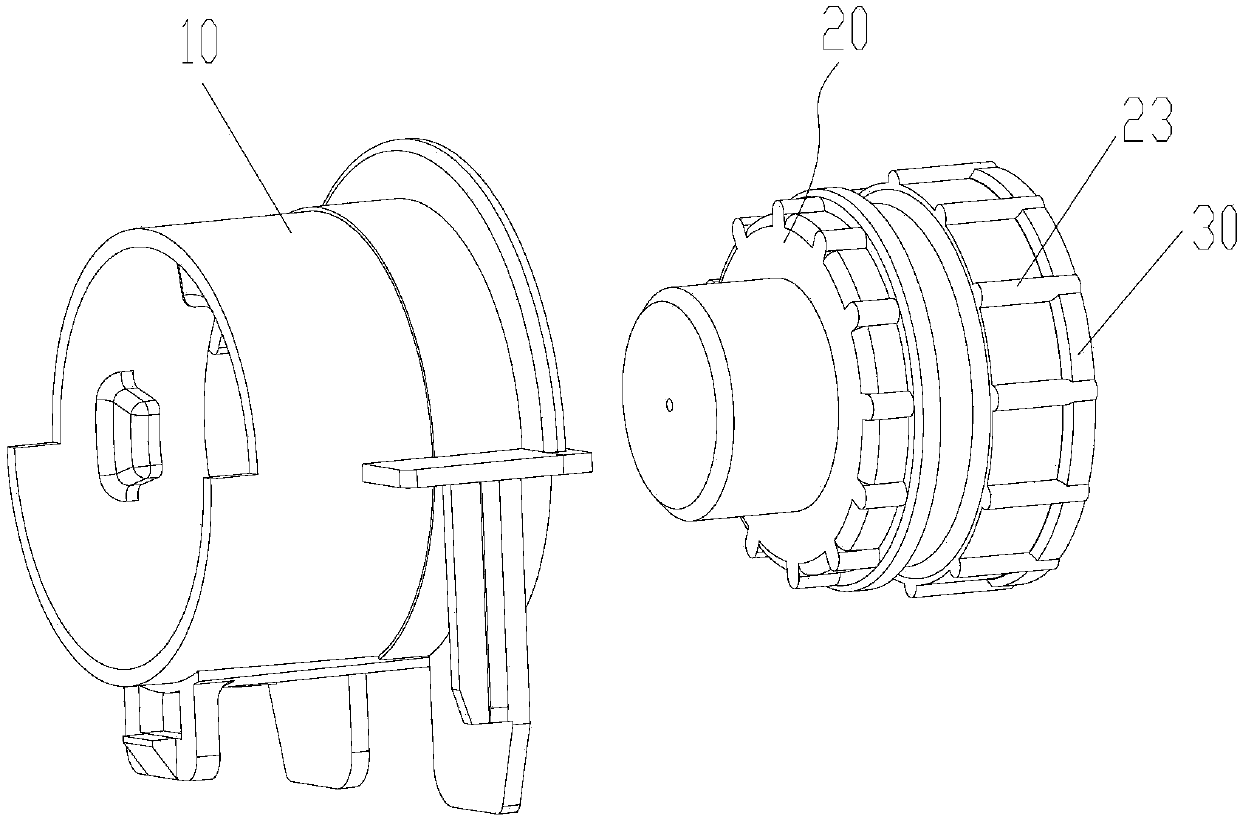

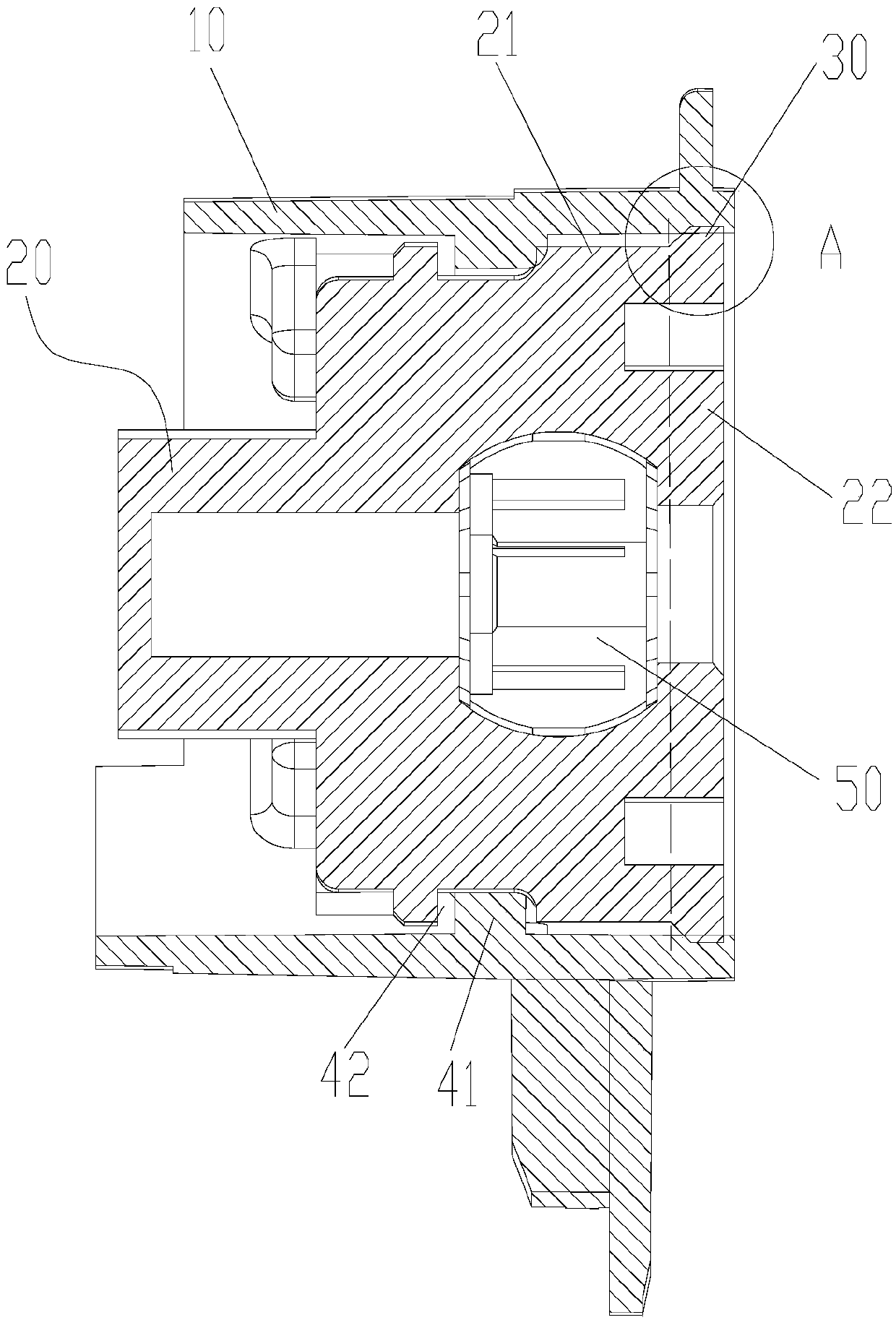

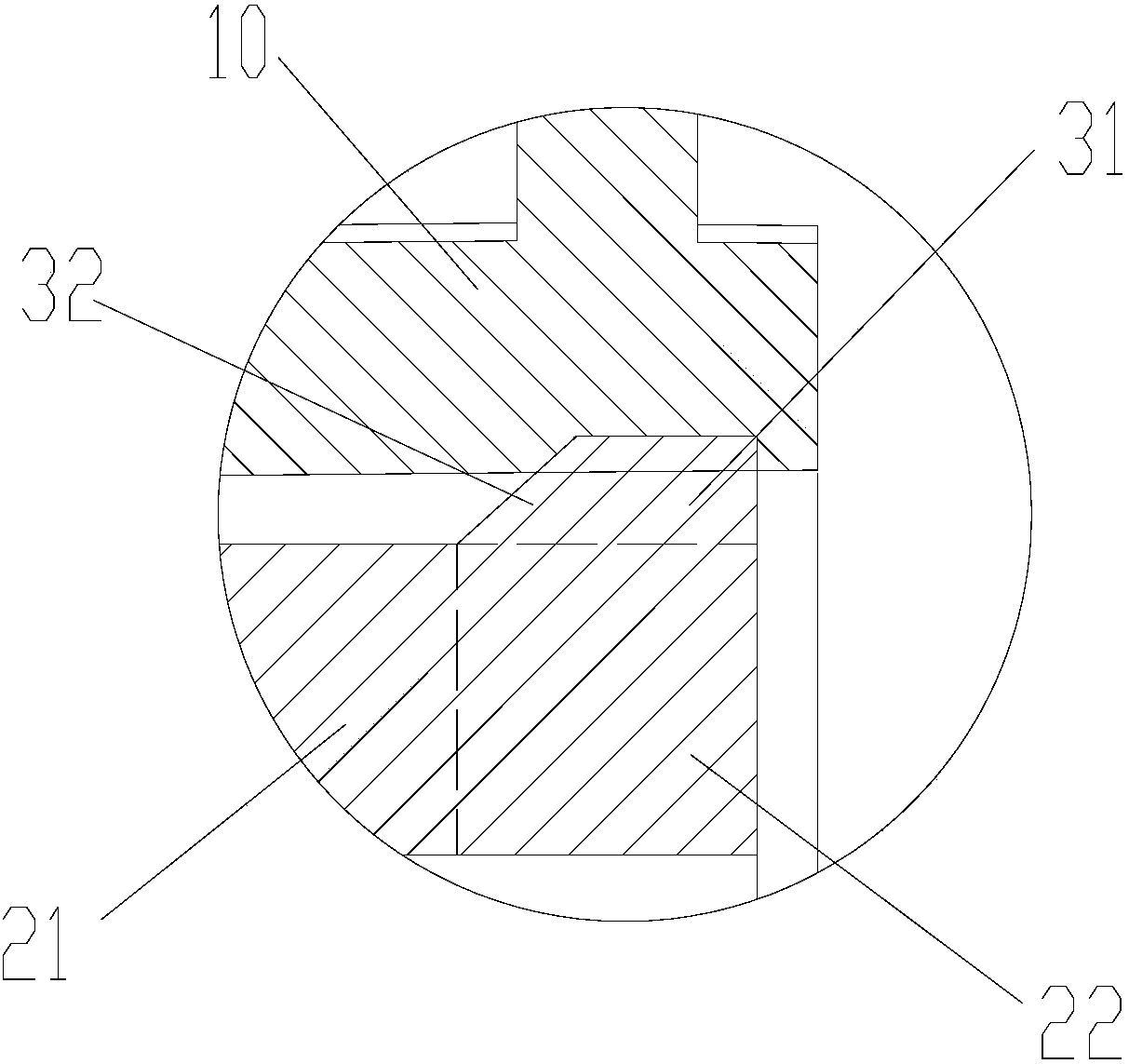

Bearing assembly and air conditioner provided with same

ActiveCN107631453AEasy to insertSolve the problem of air leakageCondensate preventionAir-flow control membersEngineeringMechanical engineering

The invention provides a bearing assembly and an air conditioner provided with the same. The bearing assembly comprises a bearing pedestal, a bearing sleeve and a sealing structure, wherein the bearing sleeve is arranged in the bearing pedestal and comprises a first sleeve section and a second sleeve section connected to each other, and a gap is reserved between the first sleeve section and the bearing pedestal; and the sealing structure is arranged between the second sleeve section and the bearing pedestal. According to the technical scheme provided by the invention, the problem that the bearing assembly leaks air in the prior art can be solved.

Owner:GREE ELECTRIC APPLIANCES INC

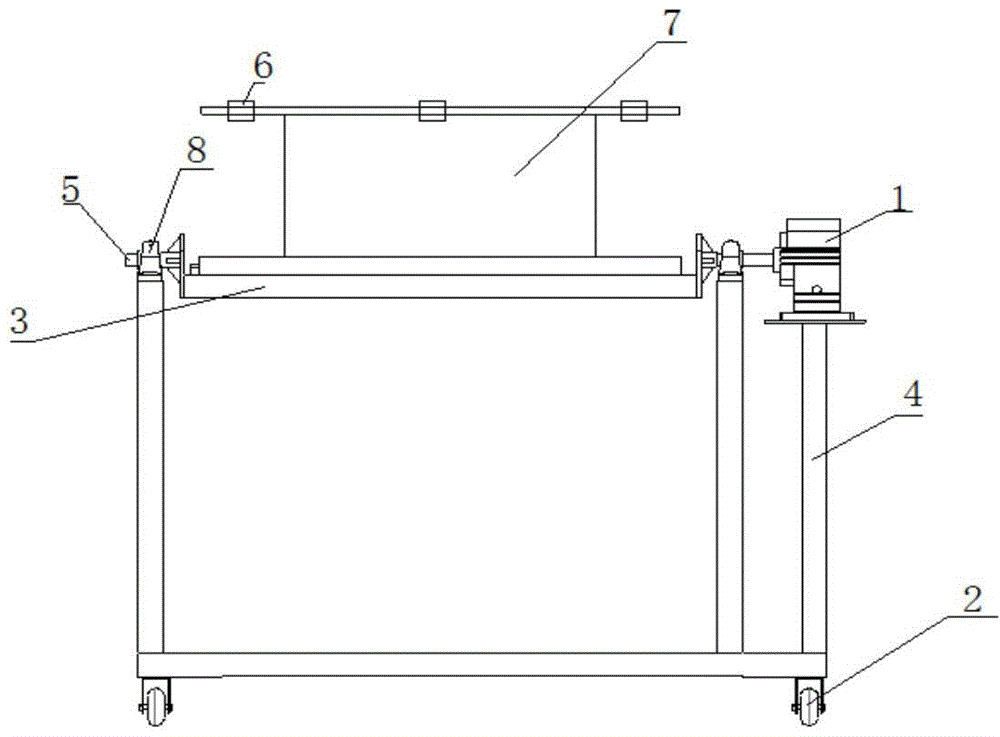

Turnover trolley for loading and unloading of moulds

InactiveCN104310290AUnique structureTo achieve the matching effectLifting devicesHoisting equipmentsPillow block bearingReducer

The invention relates to a turnover trolley, in particular to a turnover trolley for loading and unloading of moulds. The turnover trolley is characterized by comprising a machine frame, wherein the left side of the upper part of the machine frame is fixedly provided with a worm and gear speed reducer, the left side of the speed reducer and the right side of the machine frame are correspondingly and fixedly provided with a pair of linkage shafts, a mould fixing framework is fixedly arranged between the two linkage shafts through a clamp, and the linkage shaft near the speed reducer is matched with a pillow block bearing. The turnover trolley has the advantages that the structure is particular, the labor intensity is decreased, the mould turnover trolley can be freely moved, the fixed installation in designated positions is not needed, the moulds can be turned over with any angle on the trolley, and the mould overhauling without dead area is realized.

Owner:KOCEL EQUIP

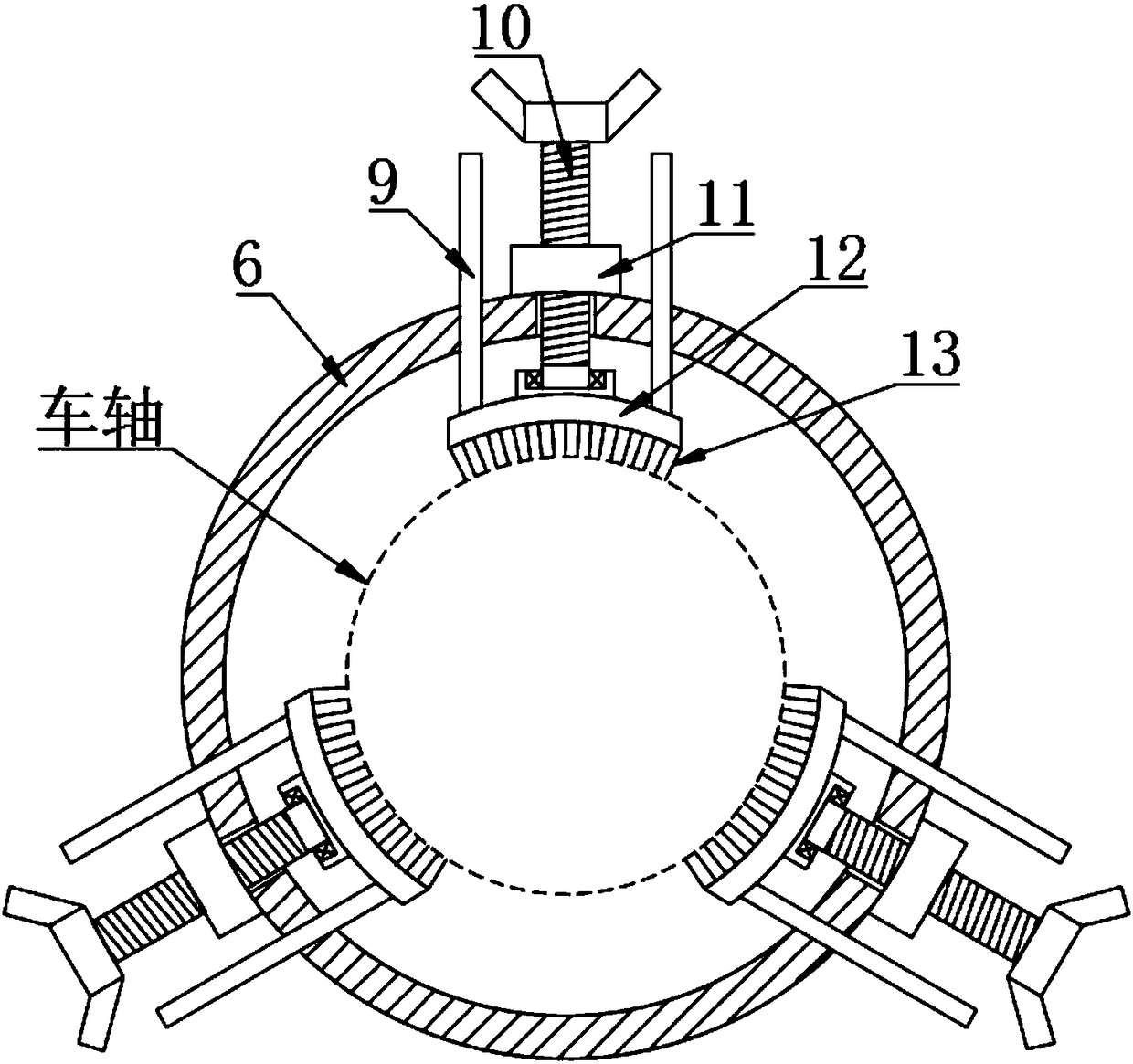

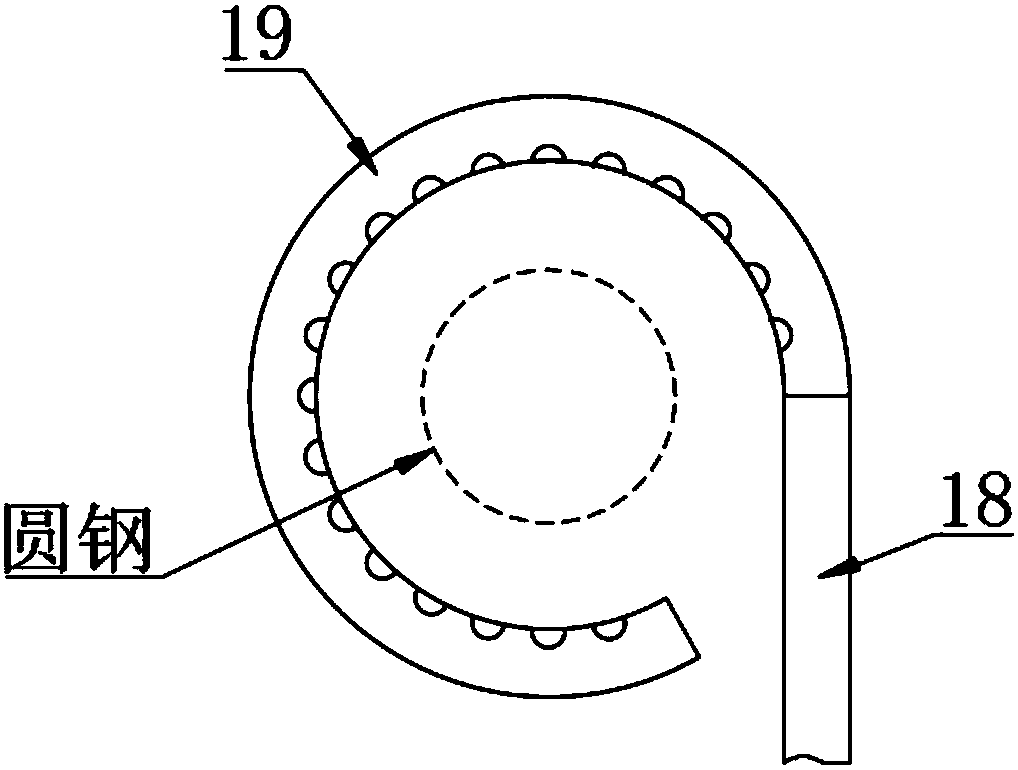

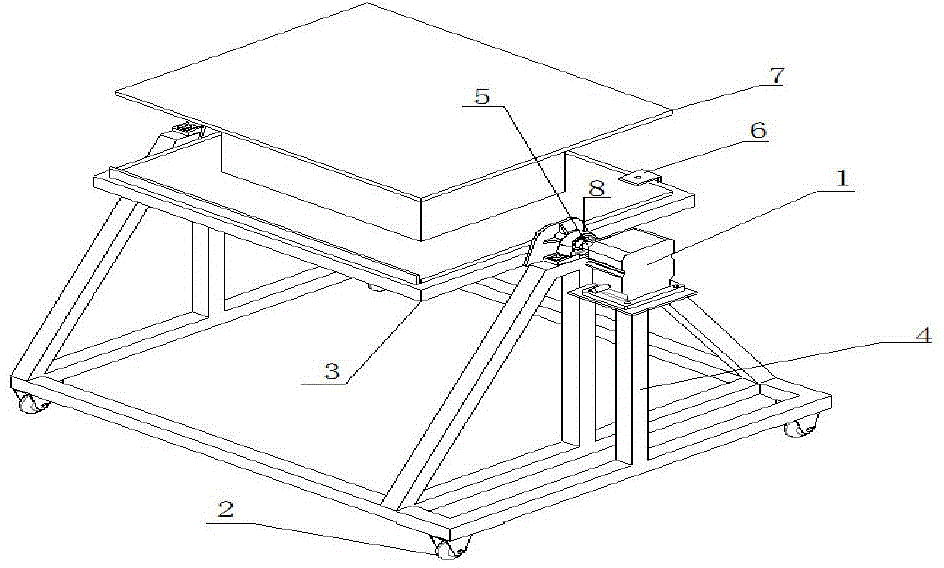

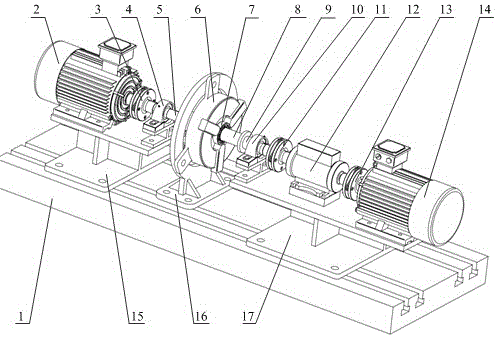

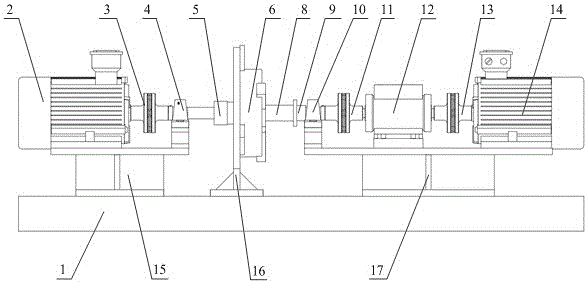

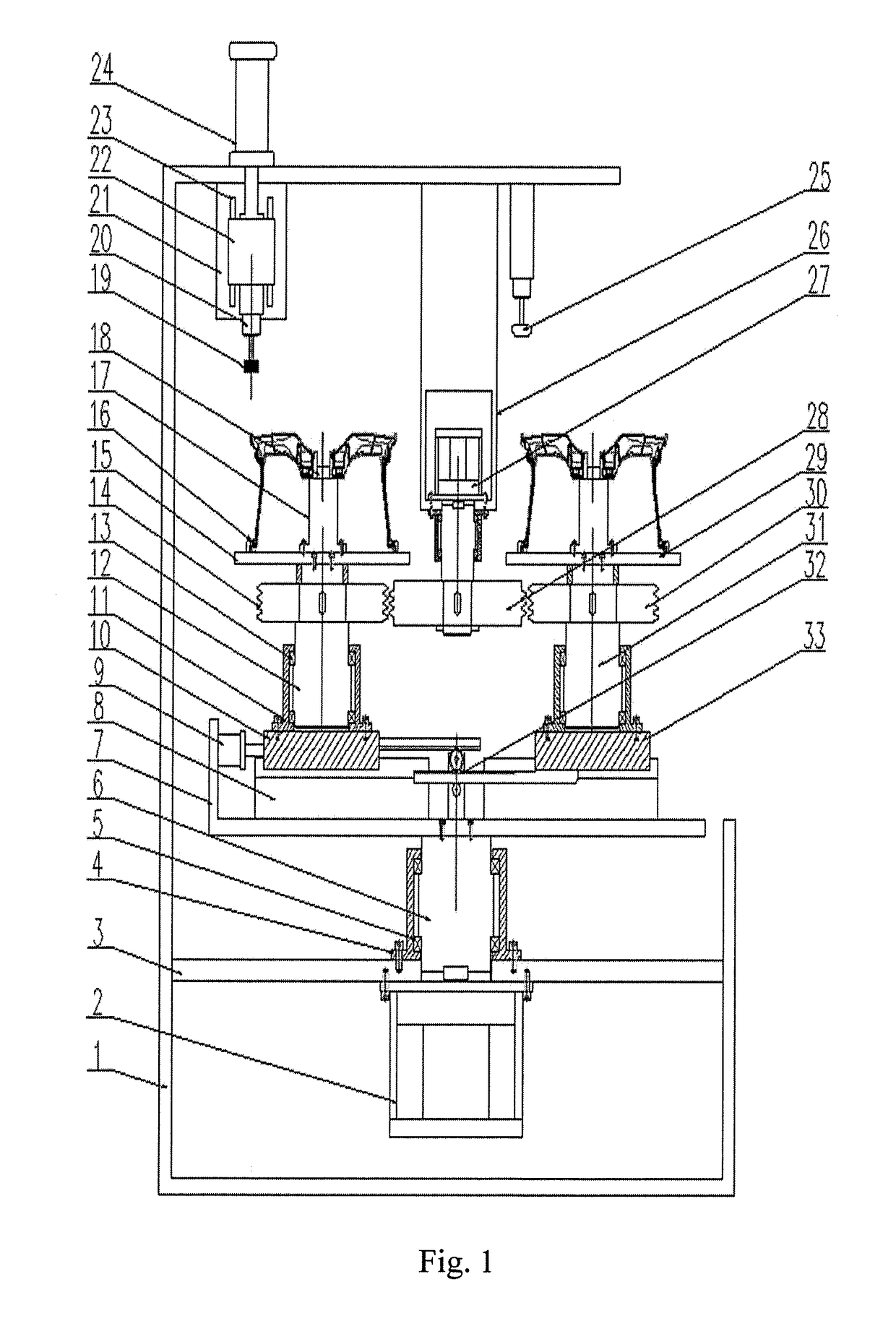

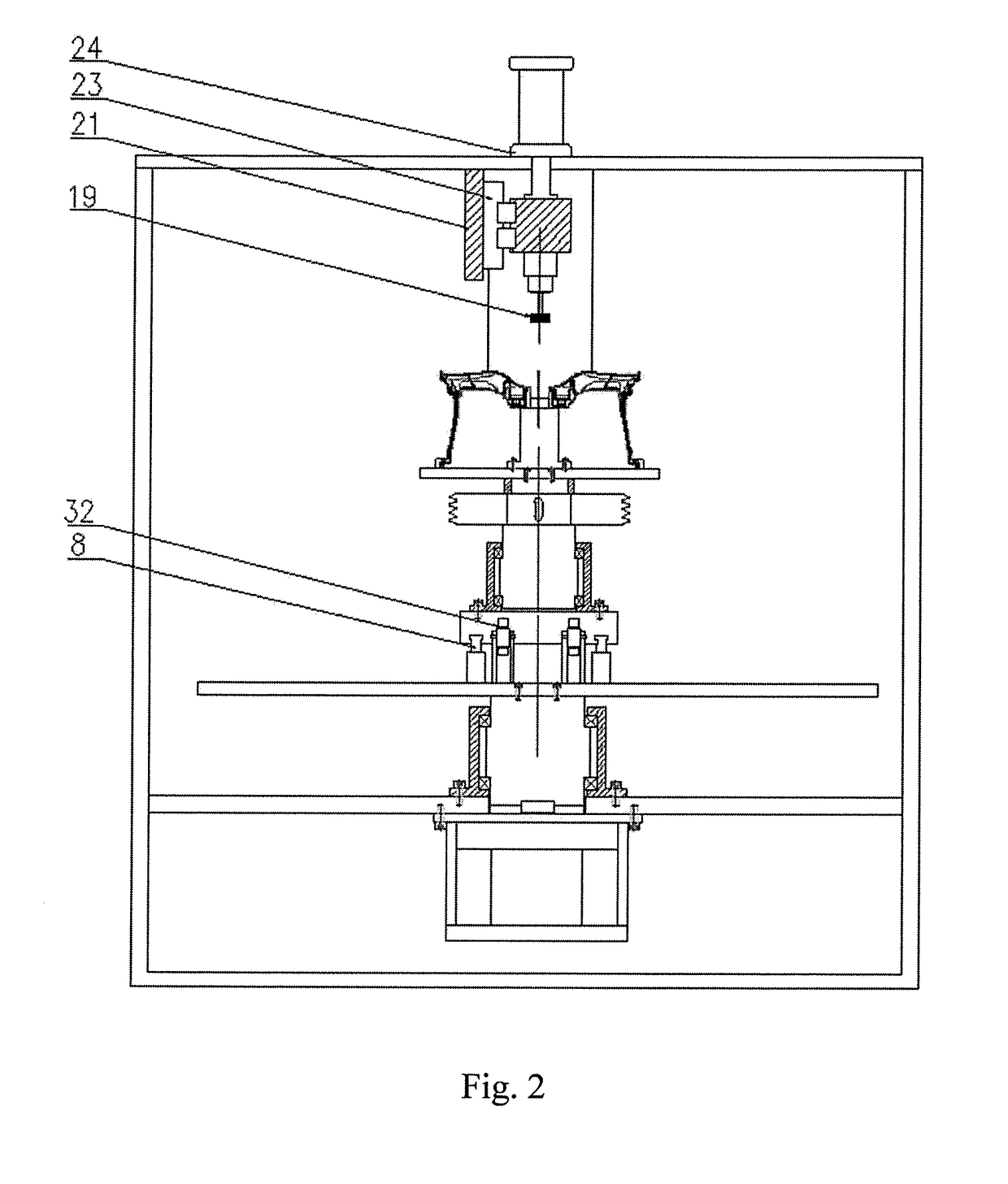

Chuck clamping type multi-specification rolling bearing fault simulation experiment platform mounted on basis of stepped shaft

InactiveCN106840677AEasy to installEasy to disassembleMachine bearings testingComplete dataPillow block bearing

The invention discloses a chuck-clamping multi-standard rolling bearing fault simulation test bench installed on the basis of stepped shafts. One end of the multi-level stepped shaft is connected to a driving motor, the other end is connected to one end of a torque tachometer, and the other end of the torque tachometer is connected. Connected with the loading motor; the inner ring of the experimental rolling bearing is sleeved on a step in the middle of the multi-step stepped shaft, one end of the straight sleeve withstands the end face of the inner ring of the experimental rolling bearing, and the other end withstands the flange end face of the flanged sleeve; three-jaw clamp The jaws of the disk clamp the outer ring of the experimental rolling bearing. The driving motor and the first bearing with a seat are installed on the base of the driving end. The second bearing with a seat, the torque tachometer and the loading motor are installed on the base of the loading end. The base of the driving end , the chuck frame and the loading end base are installed on the base table. The invention realizes the installation of multi-standard rolling bearings, can carry out failure simulation experiments on multi-standard rolling bearings, is convenient for disassembly and assembly, and has reliable and complete data collection.

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

Wheel blank positioning end face correction device

ActiveUS20190022822A1Flexible structureGood precisionEdge grinding machinesGrinding carriagesPillow block bearingGear wheel

The present application disclose a wheel blank positioning end face correction device, comprising a frame, a servo motor I, a support frame, a bearing seat, a bearing, a shaft, a rotating platform, a guide rail, a cylinder, a left slide plate, a left bearing seat, a left shaft, a left bearing, a left driven grooved friction wheel, a left workbench, corner cylinder pressure claws, mandrel seats, mandrels, a grinding wheel, a grinding wheel drive motor, a support plate, a feeding slide plate, feeding guide rails, a linear motor, a distance measuring sensor, a fixed plate, a servo motor II, a driving grooved friction wheel, a right workbench, a right driven grooved friction wheel, a right shaft, a gear rack structure and a right slide plate.

Owner:CITIC DICASTAL

Bearing housing with damping arrangement

ActiveUS20200096041A1Improve radial stiffnessRolling contact bearingsEngine fuctionsPillow block bearingStructural engineering

A bearing housing for connecting a bearing to a supporting structure of a gas turbine engine is discussed. The bearing housing has an inner wall and an outer wall radially spaced apart from the inner wall between which an annular space is defined. A device extends from the inner wall toward the outer wall and includes at least a first and a second member in series between the inner and outer walls, the second member having a radial stiffness greater than a radial stiffness of the first member. The device may operate in multiple operating stages, where in a first stage the first member of the device deforms to absorb at least partially a vibration load over a given range of vibration amplitude when the bearing housing deflects, and where in a subsequent second stage the second member of the device increases a total radial stiffness of the assembly of the bearing housing and device over the bearing housing alone.

Owner:PRATT & WHITNEY CANADA CORP

Dispensing subsequent glue removing device for electronic component

ActiveCN110936276AHigh glue removal efficiencyReasonable structureGrinding drivesGrinding machinesPillow block bearingGear wheel

The invention relates to a machining device for electronic components and discloses a dispensing subsequent glue removing device for an electronic component, which comprises a fixed bottom plate. Support frames are mounted on two sides of the upper end of the fixed bottom plate; a fixed rack is installed at the top of the support frame; a guide column is arranged between the upper ends of the support frames; a sliding block is slidably connected to the middle of the guide column; a bearing seat is arranged in the sliding block; a rotating shaft is mounted in the bearing seat; a movable gear meshed with the fixed rack is mounted at the upper end of the rotating shaft; a glue removing grinding wheel is arranged at the bottom end of the rotating shaft; an air guiding box is installed in the middle of the left end of the support frame on the right side; a piston plate is installed in the air guiding box; an air guiding rod is installed on the left side of the piston plate; a sliding blockis connected to the left side of the air guiding rod; a lifting plate is installed between the inner sides of the support frames; and positioning clamping mechanisms are installed on the two sides ofthe upper end of the lifting plate. Reciprocating rotation of the glue removing grinding wheel is achieved, the glue removing efficiency of the electronic components is greatly improved, meanwhile, glue residues obtained after glue removing can be better blown away, and the glue removing efficiency is further improved.

Owner:肇庆益华电子科技有限公司

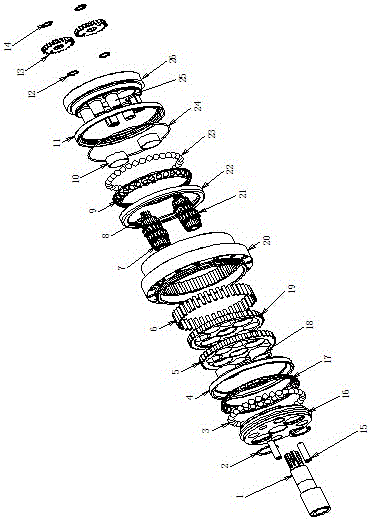

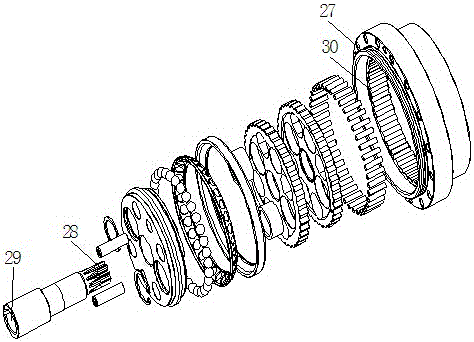

Bearing type RV speed reducer

InactiveCN105041985AStable structureSmooth driveToothed gearingsGearing detailsEngineeringPower transmission

Disclosed in the invention is a bearing type RV speed reducer. The structure of the speed reducer is stable and the power transmission process is smooth and reliable. The bearing type RV speed reducer comprises a body; and a through hole is formed in the center of the body. In addition, the speed reducer also includes a bearing seat and a foot-contained bearing seat, wherein the bearing seat and the foot-contained bearing seat are installed at the wall of the through hole of the body in a rotating mode. Two cycloidal gears are arranged between the bearing seat and the foot-contained bearing seat in parallel; and roller pins are arranged between the cycloidal gears and the wall of the through hole. Input shaft holes located at the centers as well as eccentric shaft holes symmetrically formed in the two sides of the input shaft holes are correspondingly formed in the bearing seat, the foot-contained bearing seat, and the cycloidal gears; and are symmetrically formed in the two sides of the input shaft hole. An input shaft is installed at the walls of the input shaft holes in a rotating mode. Eccentric shafts contain eccentric wheels cooperating with the eccentric shaft holes of the two cycloidal gears. Gear wheels engaged with each other are installed at end portions, approaching the foot-contained bearing seat, of the eccentric shafts and the input shaft. The diameter of the gear wheel of the input shaft is smaller than the gear wheel diameters of the eccentric shafts. A blind hole for assembling a power shaft is formed in one end, far away from the foot-contained bearing seat, of the input shaft; and a key groove is formed in the wall of the blind hole.

Owner:FUJIAN LIDONG PRECISION MACHINERY

Plate cleaning device

InactiveCN107931227AEasy to cleanFully cleanedCleaning using toolsCleaning using liquidsArchitectural engineeringUltimate tensile strength

The invention discloses a plate cleaning device. The plate cleaning device comprises a cleaning box. A sleeve is arranged in the middle position of the top of the cleaning box. The sleeve is in threaded connection with a threaded column. A handle is fixed to the top of the threaded column. The lower end of the threaded column extends into the cleaning box. The lower end of the threaded column is rotatably connected with a supporting plate. The top of the supporting plate is provided with a mounting groove. A motor seat is fixed to the middle position of the bottom of the supporting plate. A motor is mounted on the inner top wall of the motor seat. A first gear is fixedly connected to an output shaft of the motor. The two sides of the first gear are both fixedly provided with bearing pedestals. Bearings are mounted in the bearing pedestals. The bearing pedestals are both fixedly connected with the bottom of the supporting plate. Inner rings of the bearings in the two bearing pedestals are both fixedly connected with rotary shafts. Two second gears are fixedly mounted on the two rotary shafts correspondingly. The plate cleaning device is simple in structure and reasonable in design.The labor intensity of workers is reduced. The cleaning efficiency is improved. The plate cleaning device is suitable for application and popularization.

Owner:新昌县永亿科技有限公司

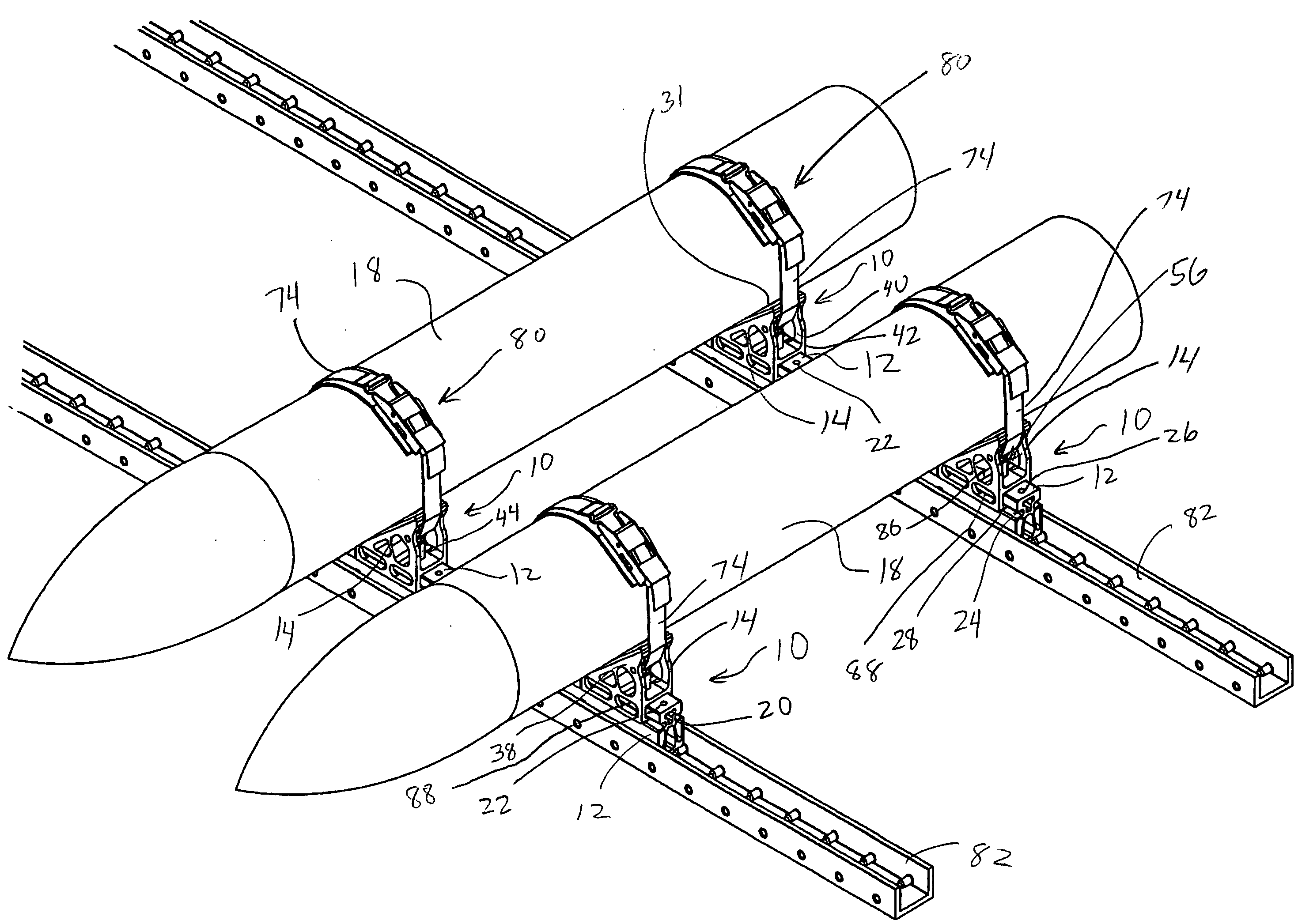

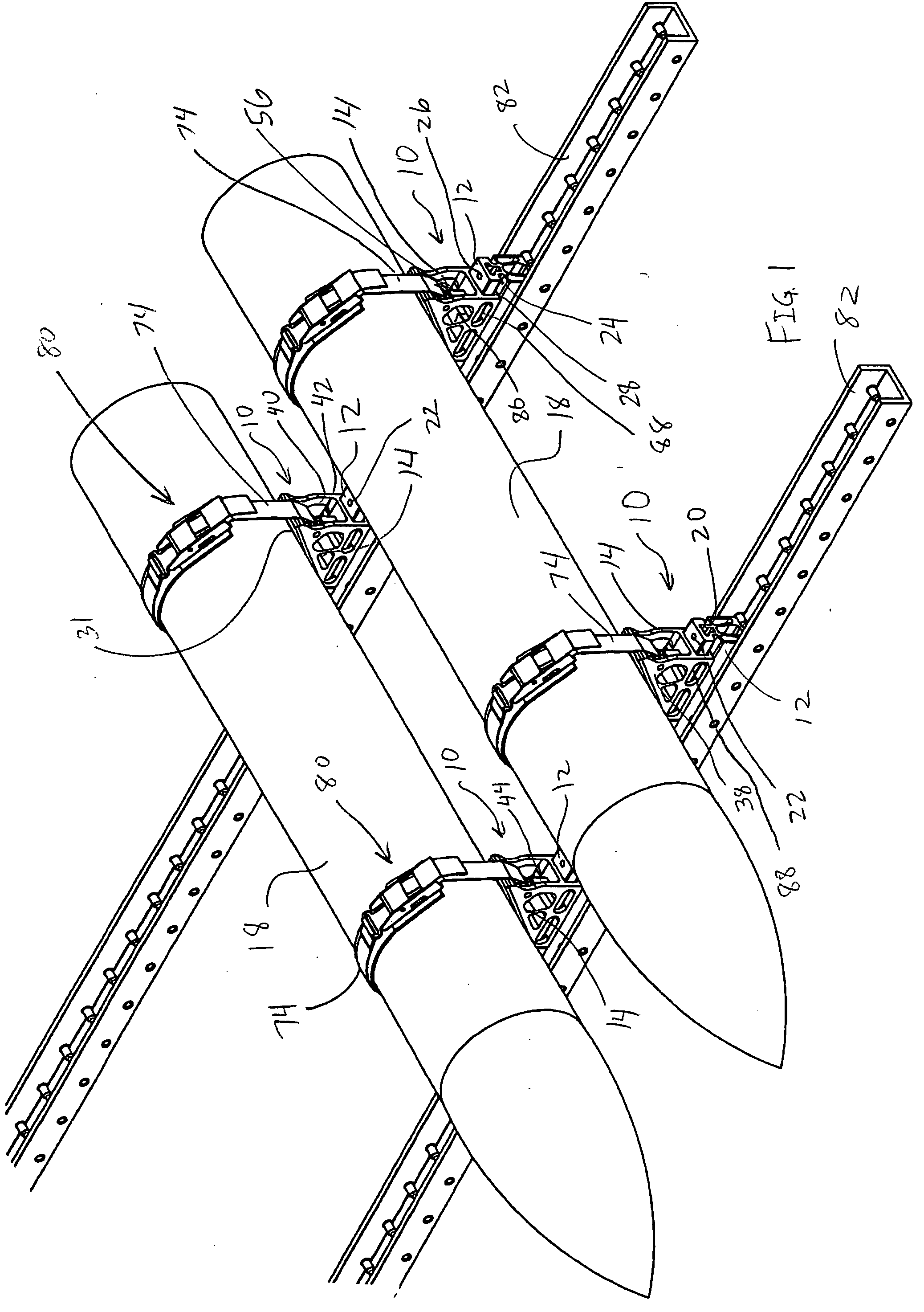

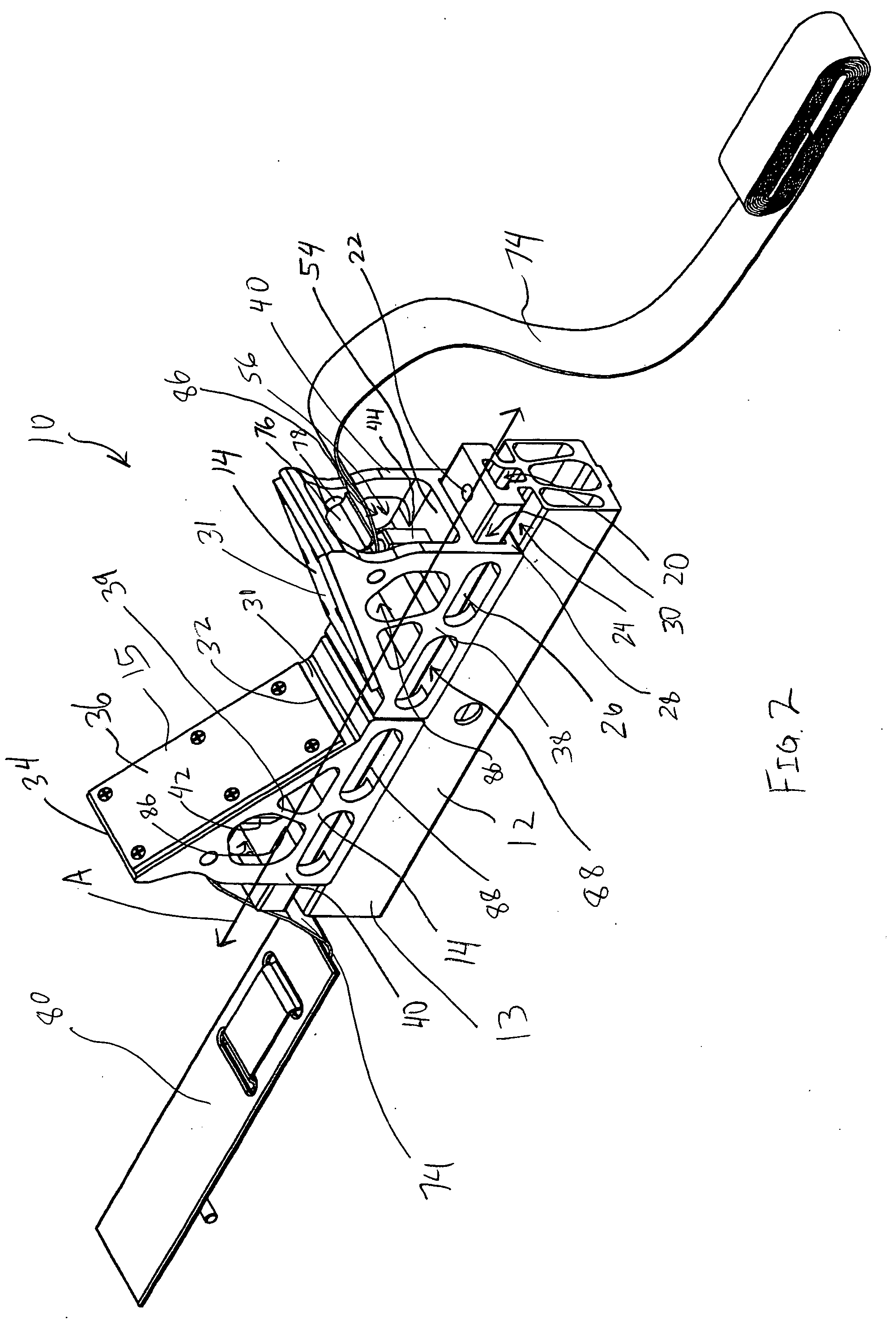

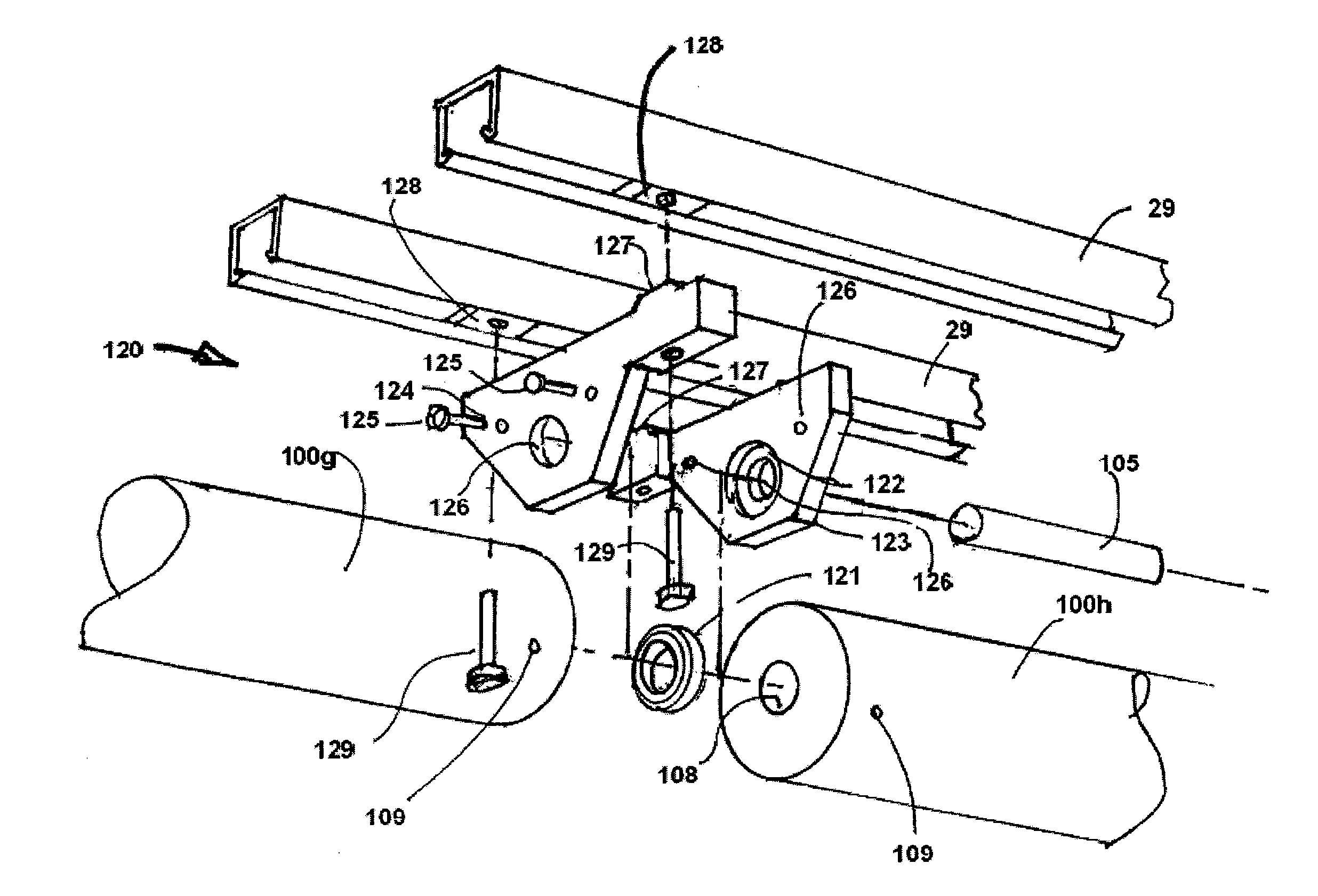

Pillow Block Bearing for Shaft Driven Conveyor System with Self Aligning Feature

A rotating shaft drive system is configured to propel a load along a conveying path of an overhead conveyor system. A stationary frame extends along the conveying path and supports the rotating shaft drive system. A movable carriage is suspended from the stationary frame and engages with a rotating shaft of the shaft drive system to propel the carriage and the load. The rotating shaft comprises a plurality of shaft segments supported pillow blocks at each end of the rotating shaft segments, and the pillow blocks create a gap between adjacent shaft segments. The movable carriage has at least one canted driven roller configured to engage with adjacent rotating shaft segments and to create a helical loci of tractional engagement that provides sufficient drive force to propel the carriage and the load along the conveying path. The drive system is further configured to provide continuous propulsion as the canted driven roller moves across the gap between adjacent shaft segments.

Owner:OCS INTELLITRAK

Fluid-filled damper for gas bearing assembly

ActiveUS10066505B2SpringsSprings/dampers functional characteristicsPillow block bearingGas lubrication

The present disclosure is directed to a gas-lubricated bearing assembly for a gas turbine engine and method of damping same. The bearing assembly includes a bearing pad for supporting a rotary component and a bearing housing attached to or formed integrally with the bearing pad. The bearing housing includes a first fluid damper cavity, a second fluid damper cavity in restrictive flow communication with the first fluid damper cavity via a restrictive channel configured as a clearance gap, and a damper fluid configured within the first and second fluid damper cavities. More specifically, the damper fluid of the present disclosure is configured to withstand the high temperature environment of the engine. Thus, the bearing housing is configured to transfer the damper fluid from the first fluid damper cavity to the second fluid damper cavity via the restrictive channel in response to a force acting on the bearing pad.

Owner:GENERAL ELECTRIC CO

Tablet grinding device for medical care department

InactiveCN111686847ANo human intervention requiredGrain treatmentsPillow block bearingMedical equipment

The invention relates to the technical field of medical equipment and discloses a tablet grinding device for medical care department. The tablet grinding device for medical care department comprises abottom plate, wherein supporting columns are arranged on the left and right sides of the lower surface of the bottom plate, cushion blocks are arranged at the lower ends of the supporting columns, side plates are arranged on the left and right sides of the upper surface of the bottom plate, a top plate is arranged on the tops of the side plates, a storage box is arranged on the right side of thetop plate, a partition plate is arranged in the middle of the storage box, the lower part of the storage box is slidably connected to a sliding plate, bearing pedestals are arranged at the upper and lower ends of the side plate on the right side, the right ends of the bearing pedestal bearings are rotatably connected to the upper and lower ends of a spindle, and a first crank is arranged on the upper part of the spindle. The invention provides the tablet grinding device for medical care department. The tablet grinding device crushes tablets preliminarily through an extrusion plate and a scraper blade and then grinds the tablets through a grinding roller and a grinding groove. By means of grinding and crushing treatment for many times, finally formed drug powder is smoother.

Owner:李新雨

Bearing Housing for a Conveyor Assembly and Bearing Assembly System

InactiveUS20070248294A1Easy to assembleEasy to removeConveyorsBearing componentsPillow block bearingFastener

An easy to clean, assemble and disassemble bearing assembly is provided. The assembly comprises a bearing housing for removably securing a bearing in a conveyor assembly. The bearing housing comprises a means for attaching same to a conveyor assembly without fasteners and a means for attaching a bearing within the bearing housing without fasteners. A bearing assembly having a bearing housing attached to a panel, a bearing, and a shaft, as well as a method of assembling a bearing assembly are also disclosed.

Owner:INDAL DESIGN FABTION & INSTALLATION

Positive pressure dust-proof structure for bearing

PendingCN107830176AAvoid lubricationAvoid abnormal wearEngine sealsBearing coolingInterference fitRelative pressure

The invention discloses a positive pressure dust-proof structure for a bearing. The positive pressure dust-proof structure comprises a bearing block, the bearing, a shaft and a spacer bush; the spacerbush is arranged on the shaft in an interference fit mode and is in clearance fit with the bearing block; a bearing chamber cavity is formed between the spacer bush and the bearing; a hole matched with a compressed air injection pipe is formed in the bearing block; and the length of the part, inserted into the bearing chamber cavity, of the compressed air injection pipe is larger than the lengthof a clearance between the spacer bush and the bearing block. According to the positive pressure dust-proof structure, the compressed air injection pipe communicates with the bearing chamber cavity, clean compressed air is injected into the bearing chamber cavity through the compressed air injection pipe at the relative pressure of 3kPa-5kPa and forms the positive pressure, the compressed air flows out of the clearance between the spacer bush and the bearing block due to the positive pressure existing in the bearing chamber cavity, dust, mud and the like can be prevented from entering the bearing chamber cavity due to the action of air flow, and therefore the purpose of dust prevention can be achieved; and the continuously flowing compressed air enhances the heat dissipation function of abearing chamber, and therefore the temperature of the bearing can be decreased, the operation environment of the bearing can be improved, and the service life of the bearing can be prolonged.

Owner:Y & C ENGINE

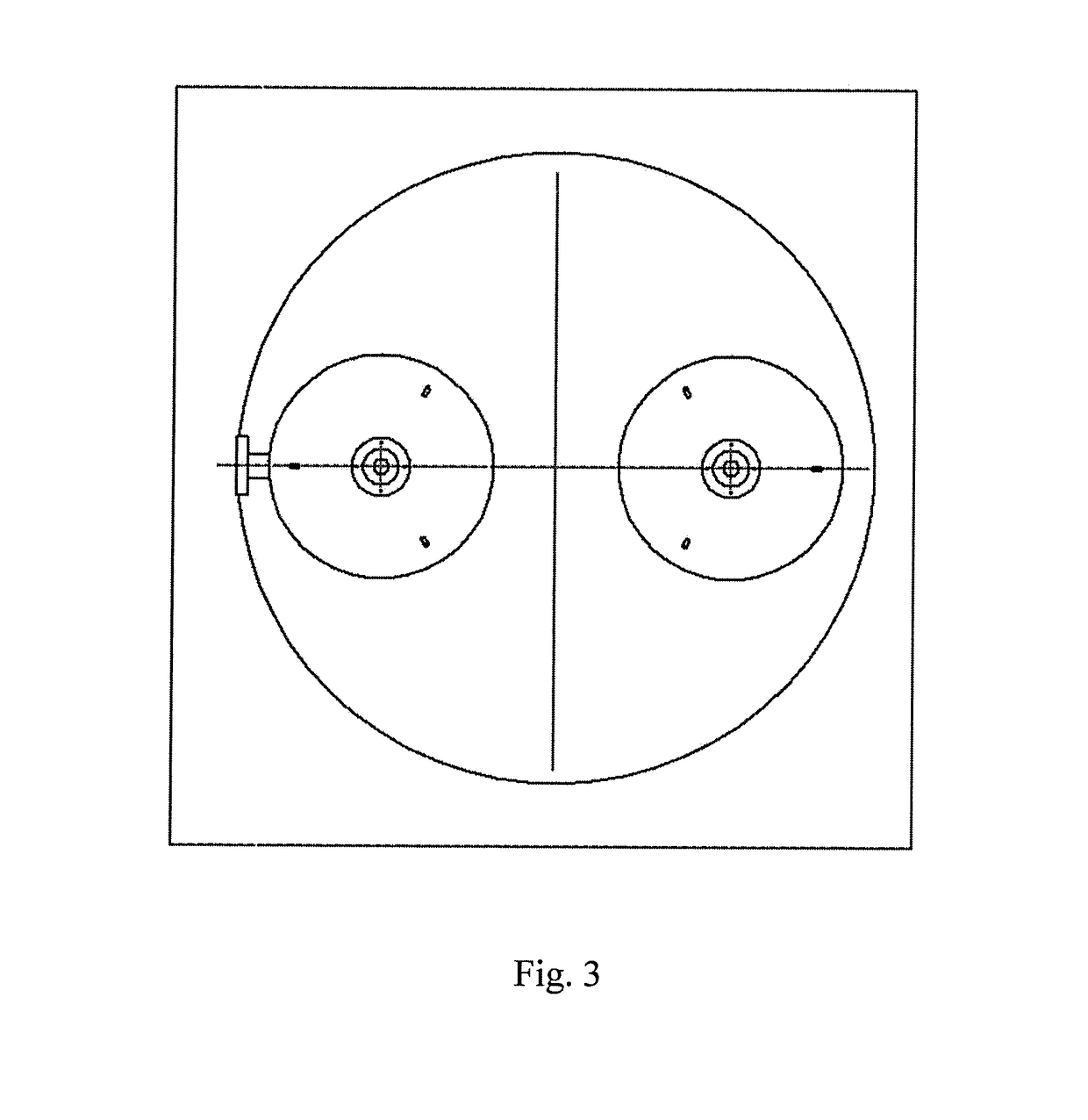

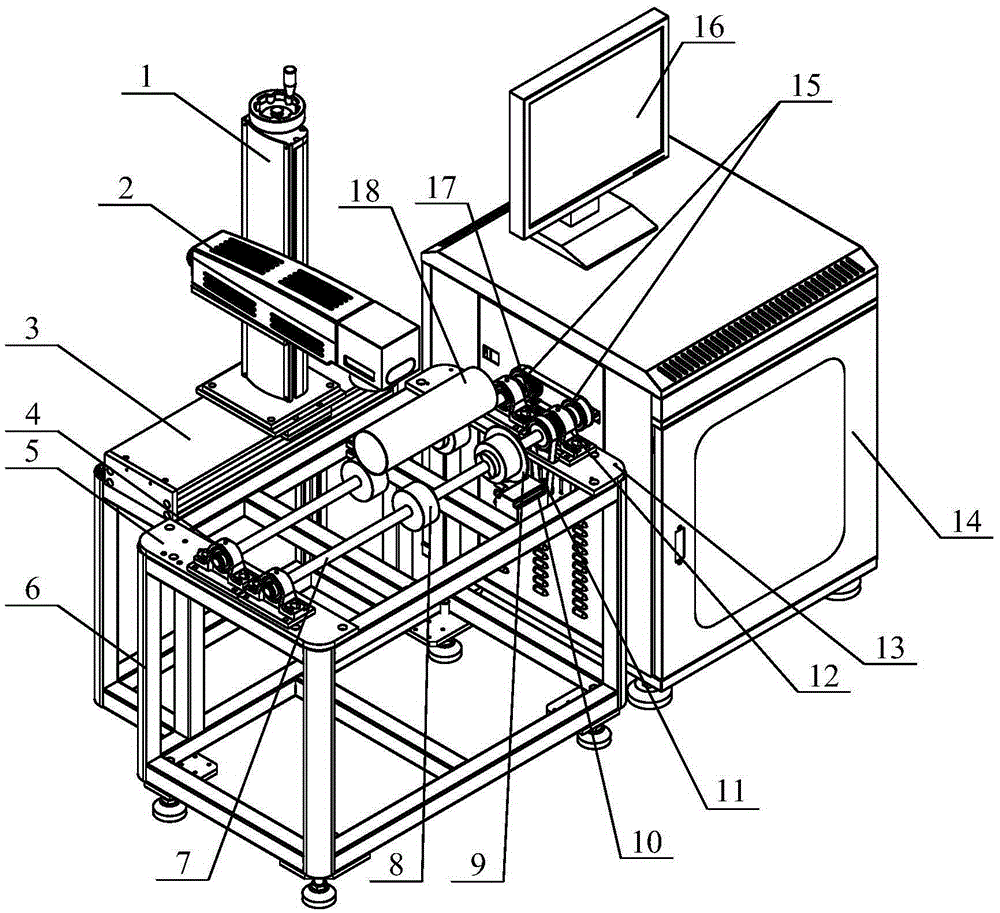

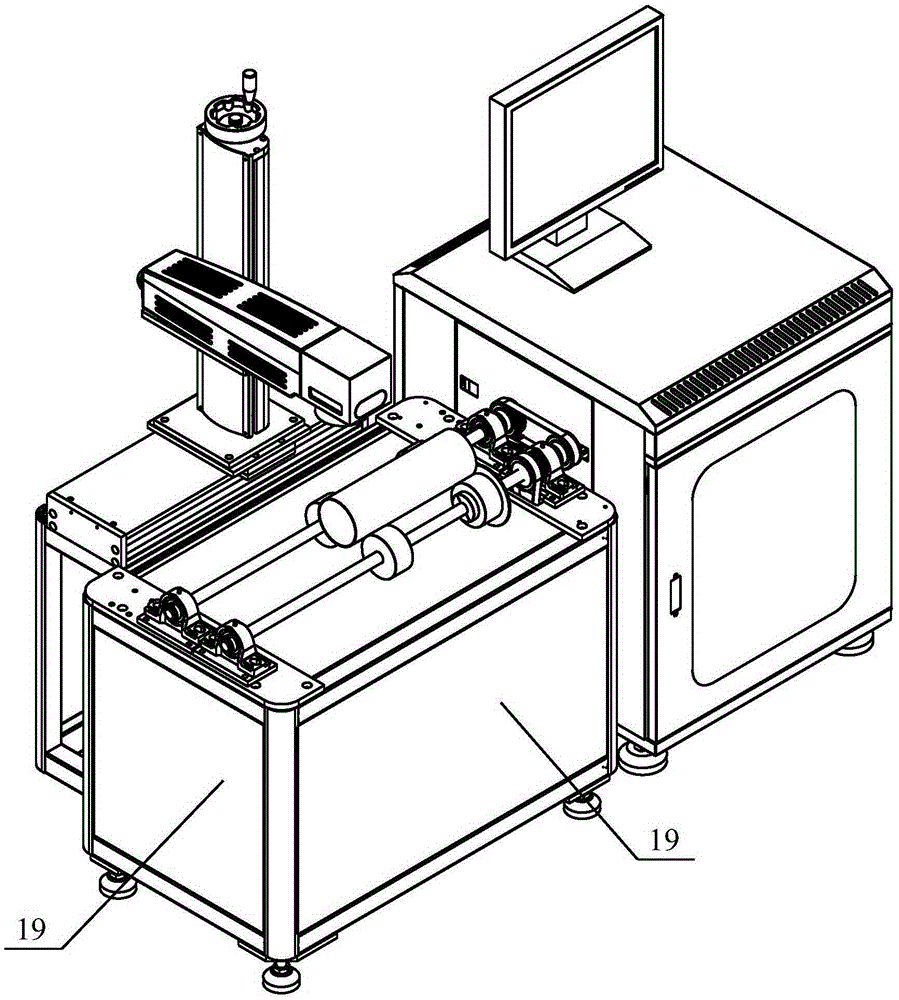

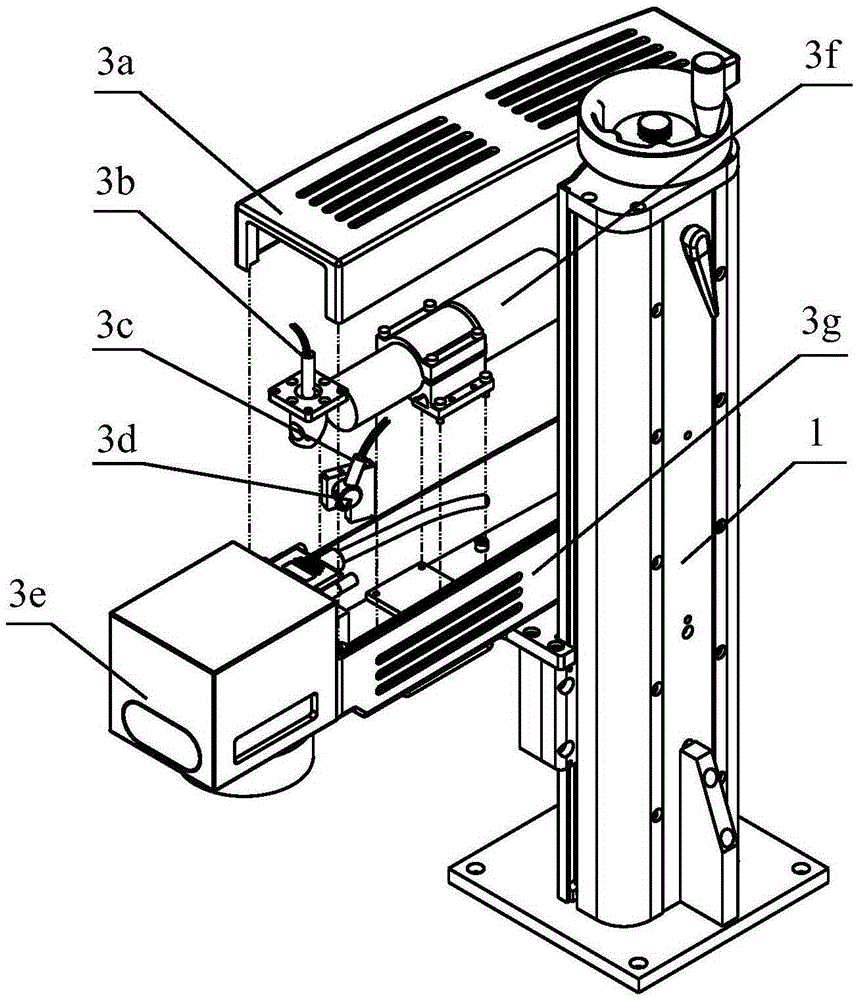

Laser marking machine with rotary marking function for processing water pump identifications

ActiveCN105383186AEnables rotary machiningWide range of processingTypewritersPillow block bearingEngineering

The invention discloses a laser marking machine with a rotary marking function for processing water pump identifications, wherein the laser marking machine relates to the field of water pump marking processing. The laser marking machine comprises a body frame. The top of a body bracket is provided with a left supporting base board and a right supporting base board. Two rotary marking assemblies are parallelly arranged between the left supporting base board and the right supporting base board. Each rotary marking assembly comprises a left pillow block bearing and a right pillow block bearing. A rotating shaft penetrates through the left pillow block bearing and the right pillow block bearing. A friction wheel and a baffle plate sleeve the rotating shaft. The right pillow block bearings of the two rotary marking assemblies rotate in a same direction through an electric transmission assembly. The laser marking machine further comprises a marking head translation mechanism, a marking head elevating mechanism, a laser marking head, and a control system which is used for marking the electric transmission assembly work. The laser marking machine can realize 360-DEG rotation processing on the circumferential surface of a cylindrical water pump product and furthermore can machine a plurality of positions of the circumferential surface of the product. The laser marking machine has relatively wide machining range and facilitates use by the people.

Owner:武汉创恒世纪激光科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com