Patents

Literature

97results about How to "Adjust clamping force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

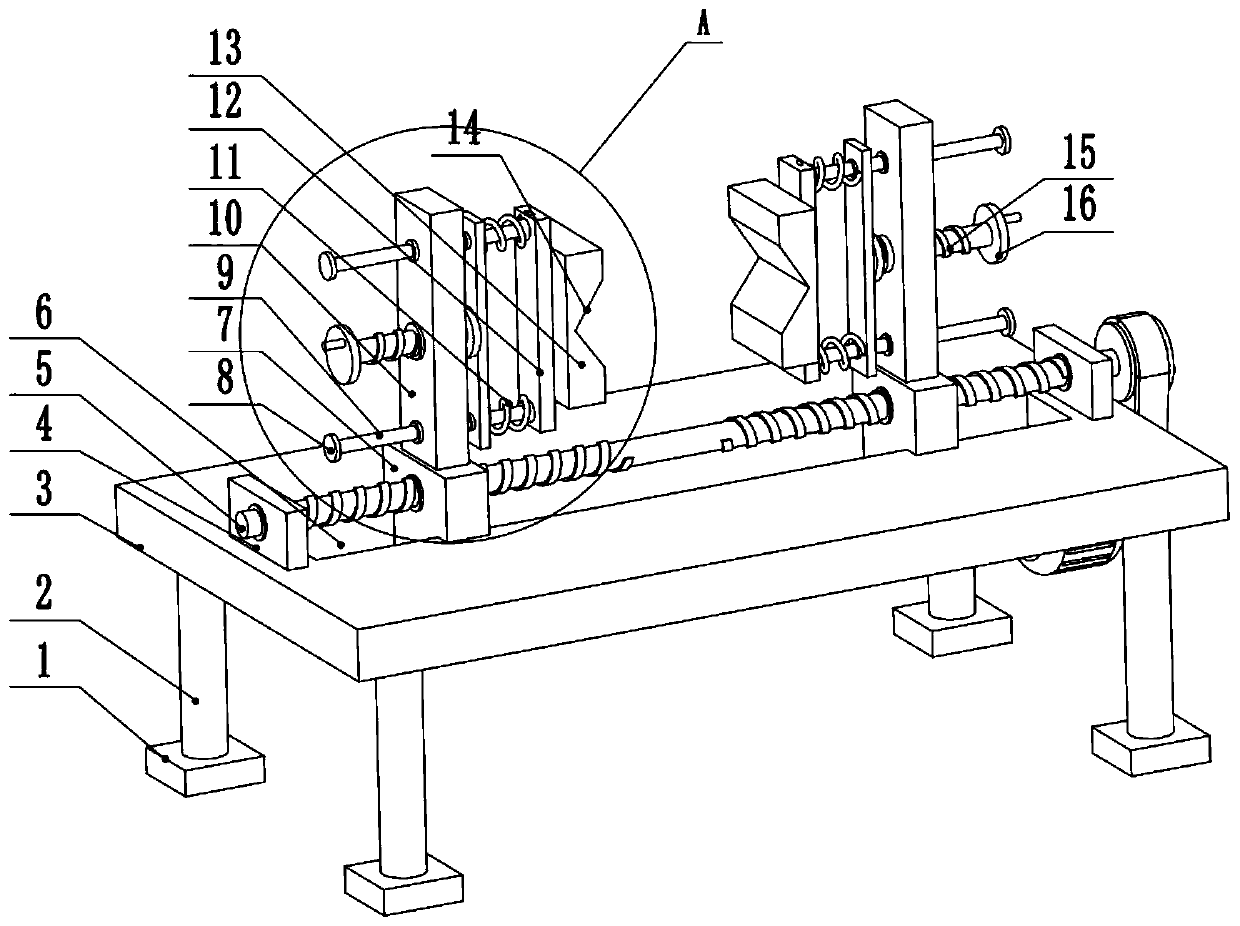

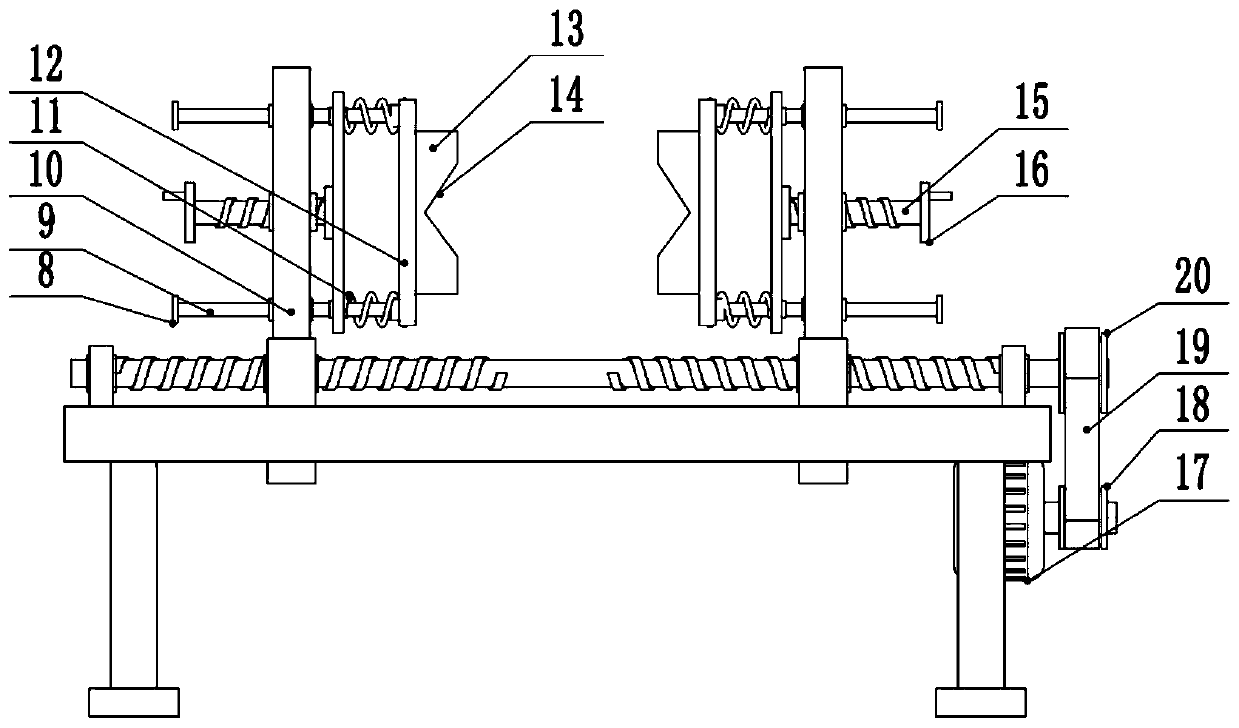

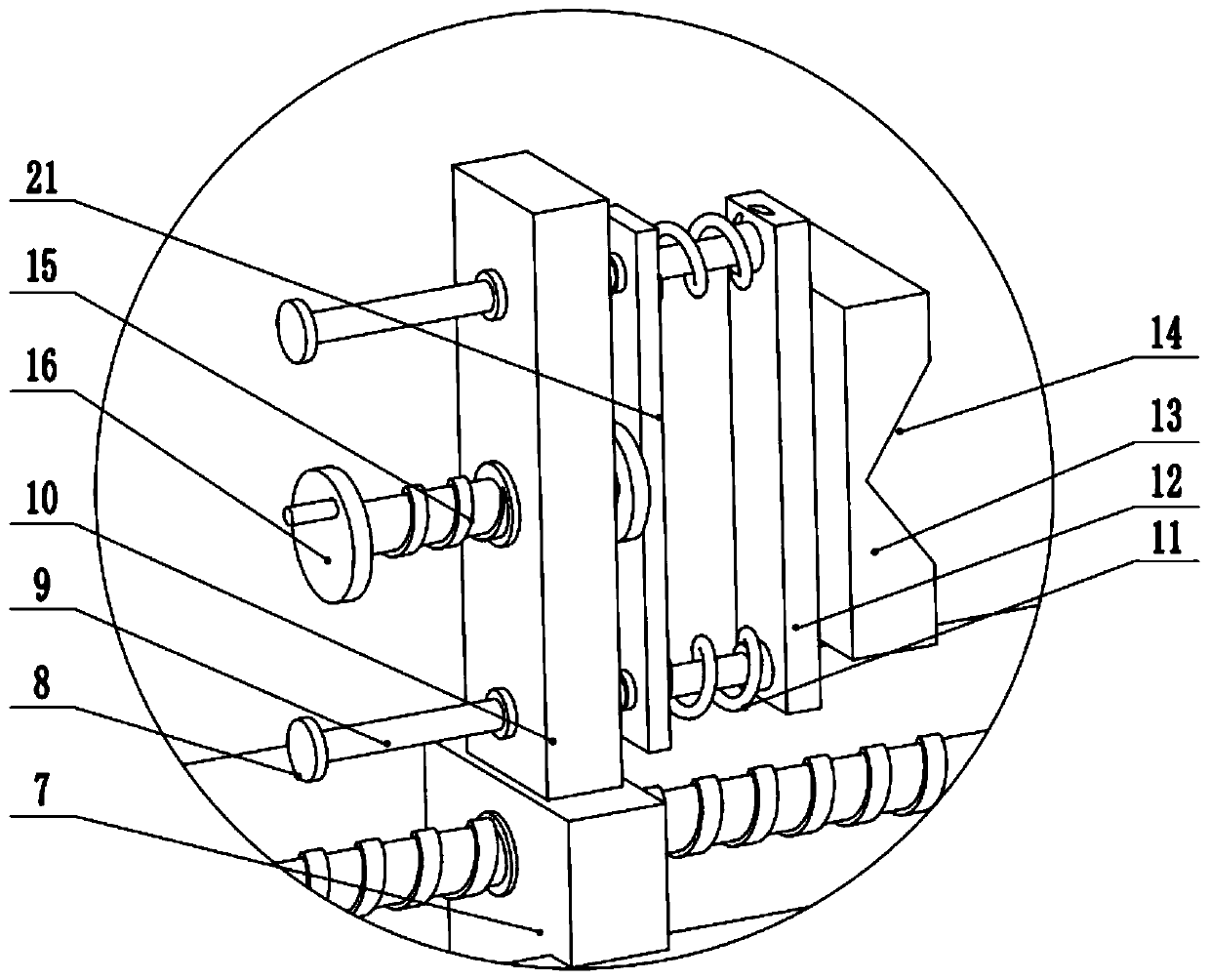

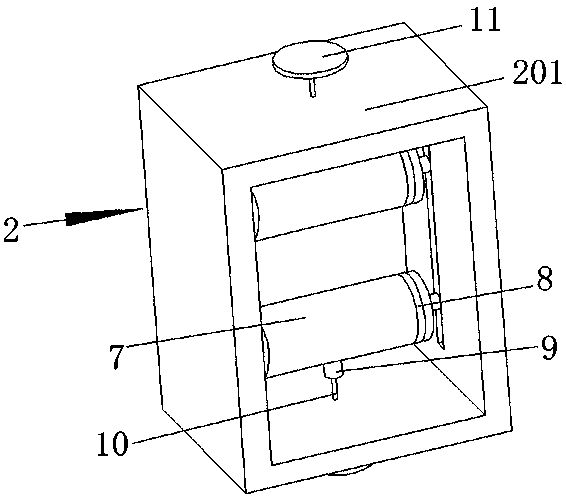

Clamping device with pressure sensor

InactiveCN110774196AQuick clamping workAdjust clamping forceWork holdersPillow block bearingElectric machinery

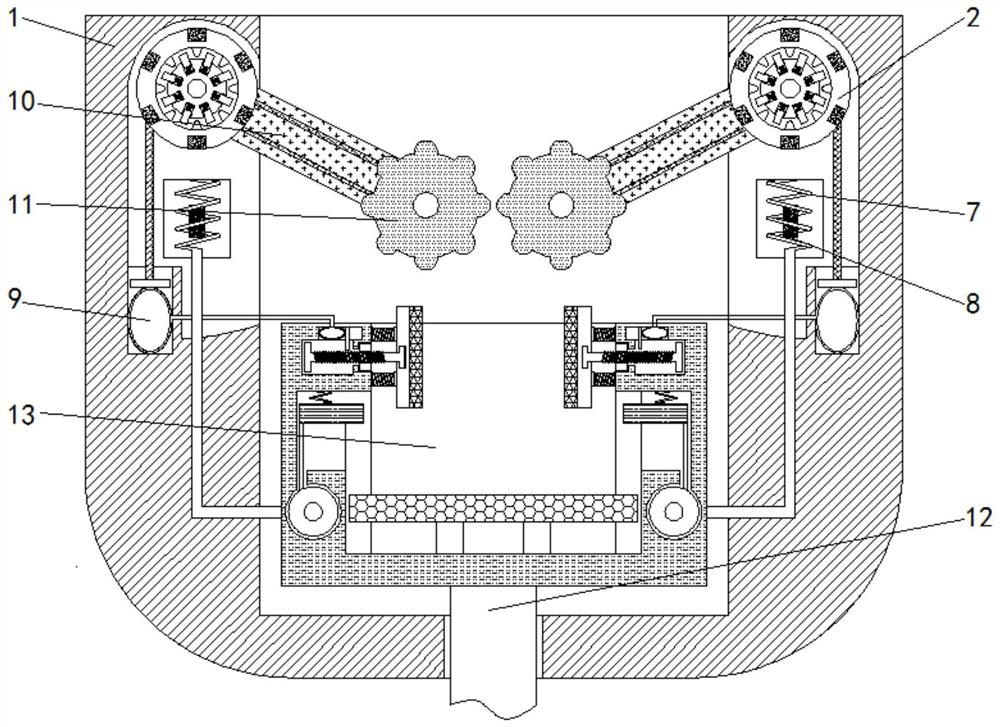

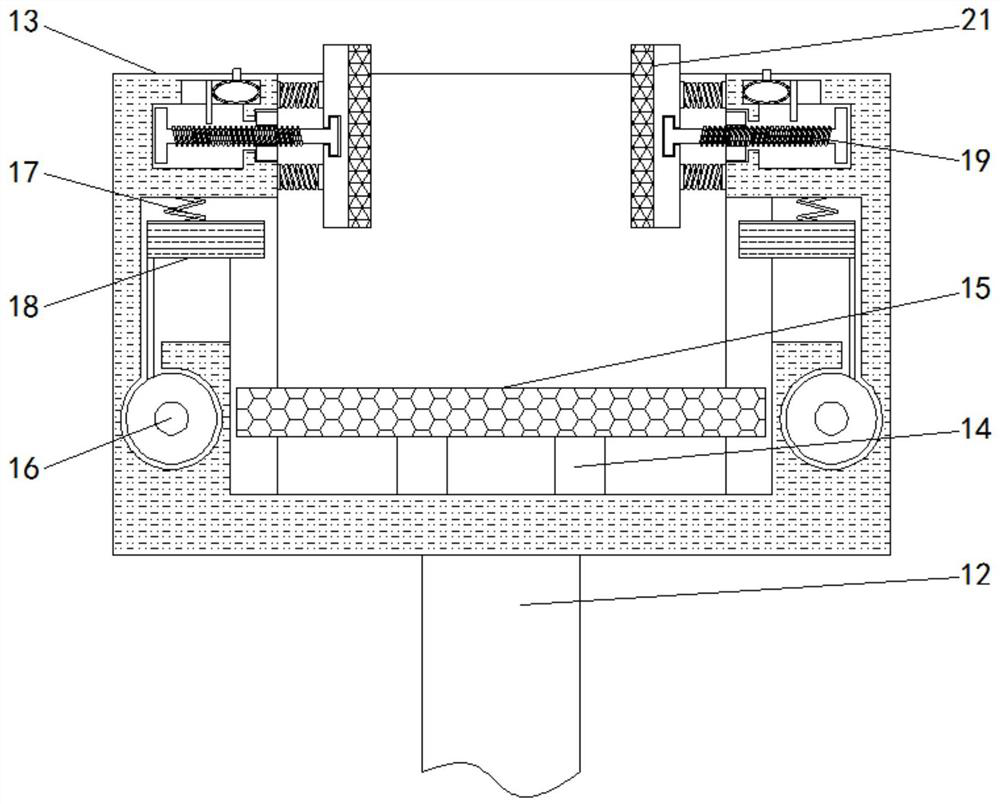

The invention relates to the technical field of clamping, and discloses a clamping device with a pressure sensor. The clamping device comprises a workbench, wherein a sliding groove is formed in the middle of the workbench, a sliding block is slidably connected to the sliding groove, a fixing seat is arranged on the upper portion of the sliding block, bearing seats are arranged at the left end andthe right end of the workbench, first screw rods are rotationally connected to the middle of the bearing seats, the left ends and the right ends of the first screw rods are in threaded connection with the middle of the sliding block, guide rods are connected to the upper end and the lower end of the fixing seats in a sliding mode, pressure sensors are connected to the sides, close to the center of the device, of the guide rods, and clamping blocks are connected to the sides, close to the center of the device, of the pressure sensors. According to the clamping device with the pressure sensor,a driving motor is arranged to drive the first screw rods to rotate, so that rapid clamping work of a workpiece can be achieved, meanwhile, second screw rods are arranged to adjust the distance between push plates and clamping blocks, so that the clamping force is accurately adjusted, the whole device is simple to operate, and the clamping device is suitable for popularization and application.

Owner:湖南绚丽新材料科技有限公司

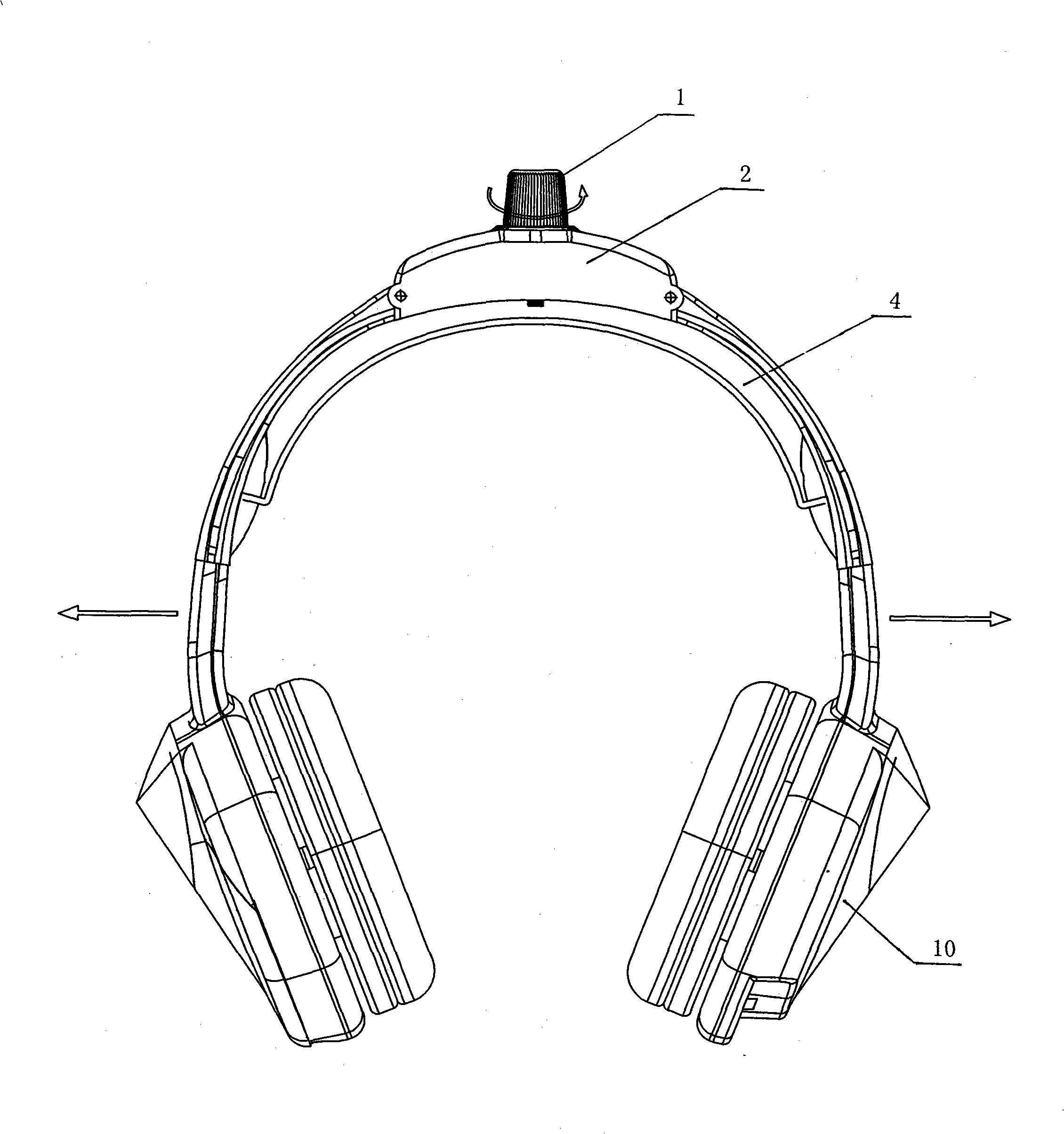

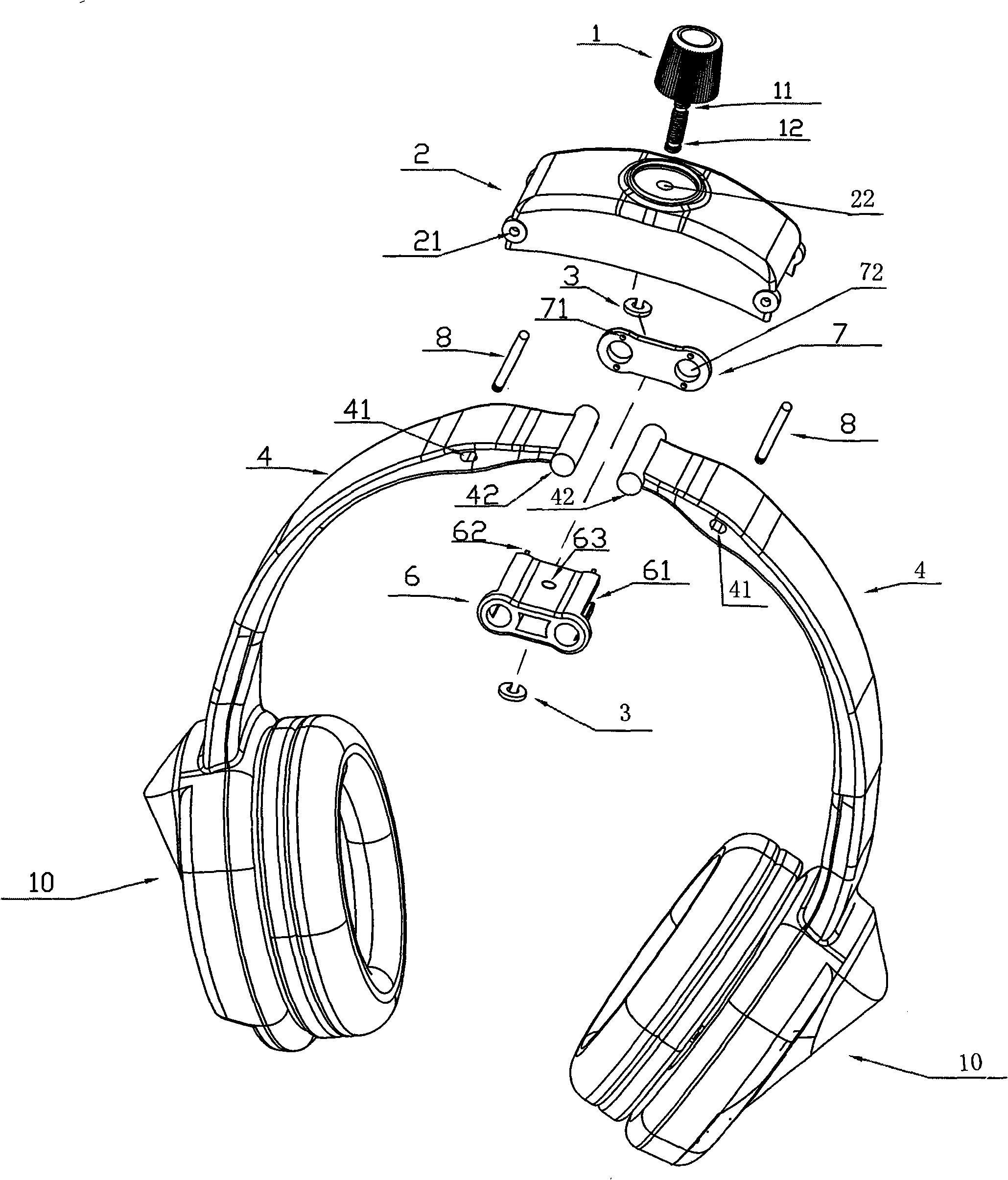

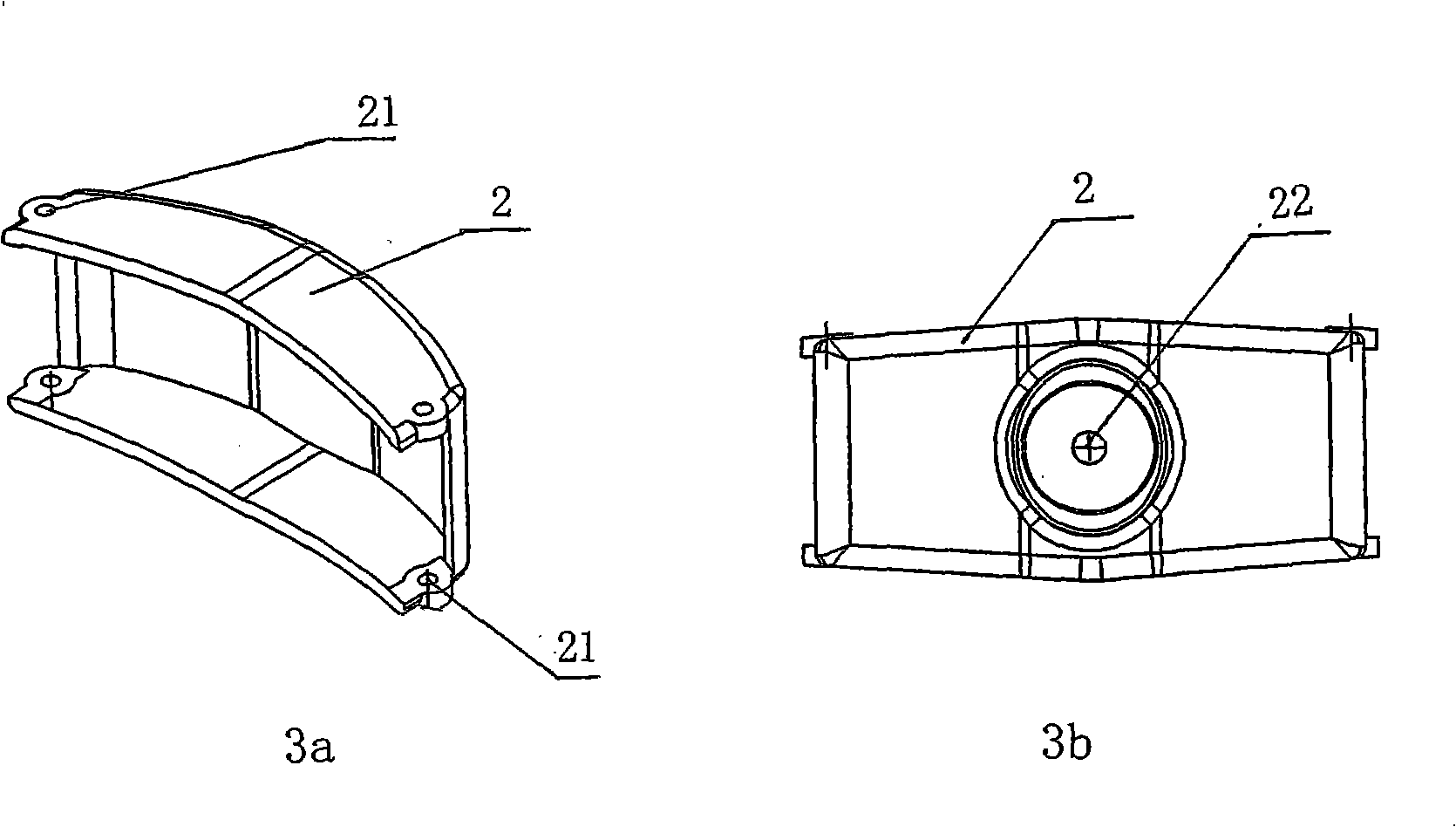

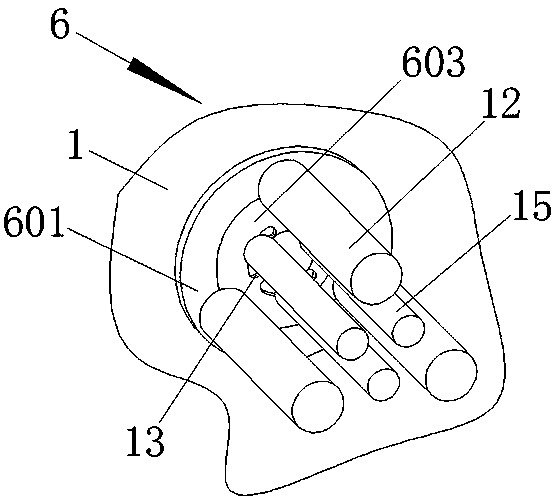

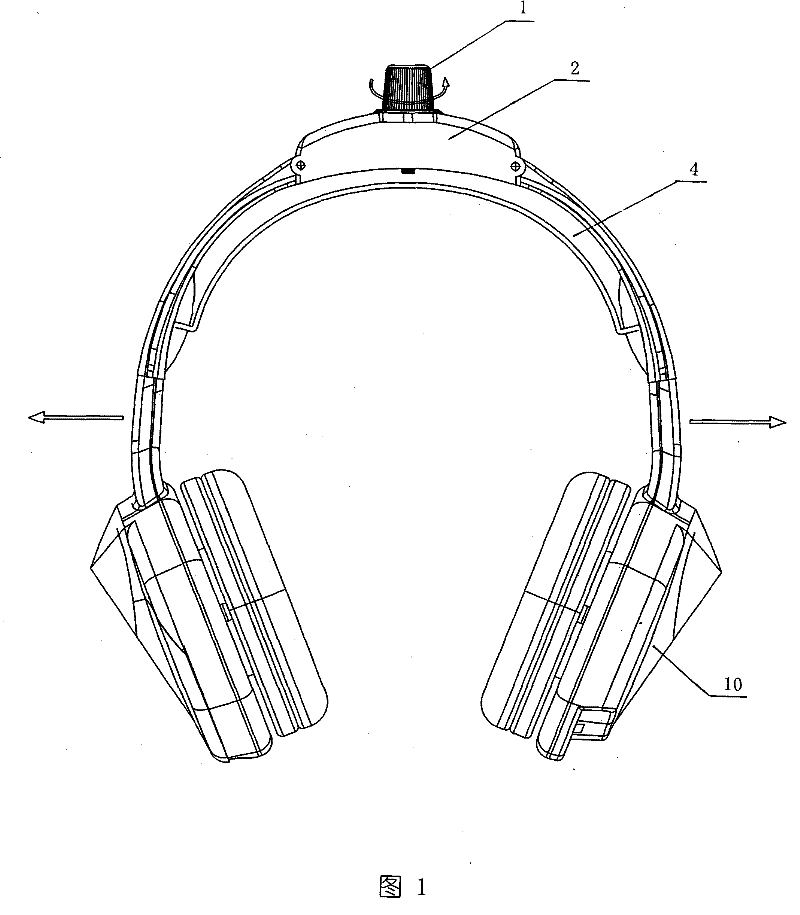

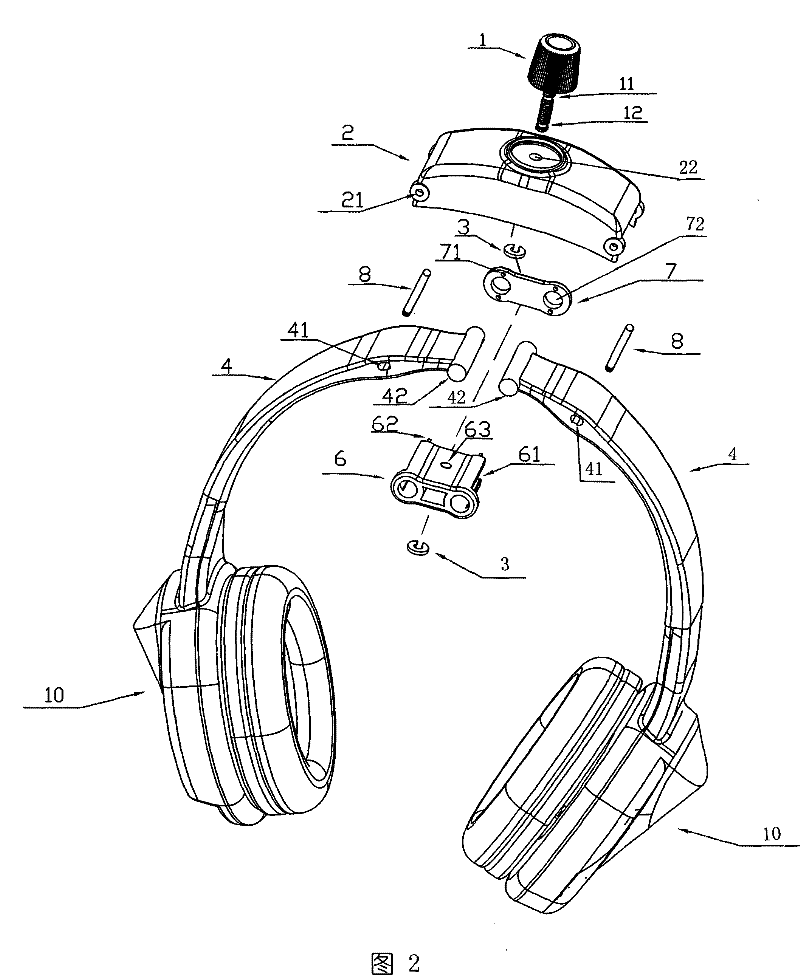

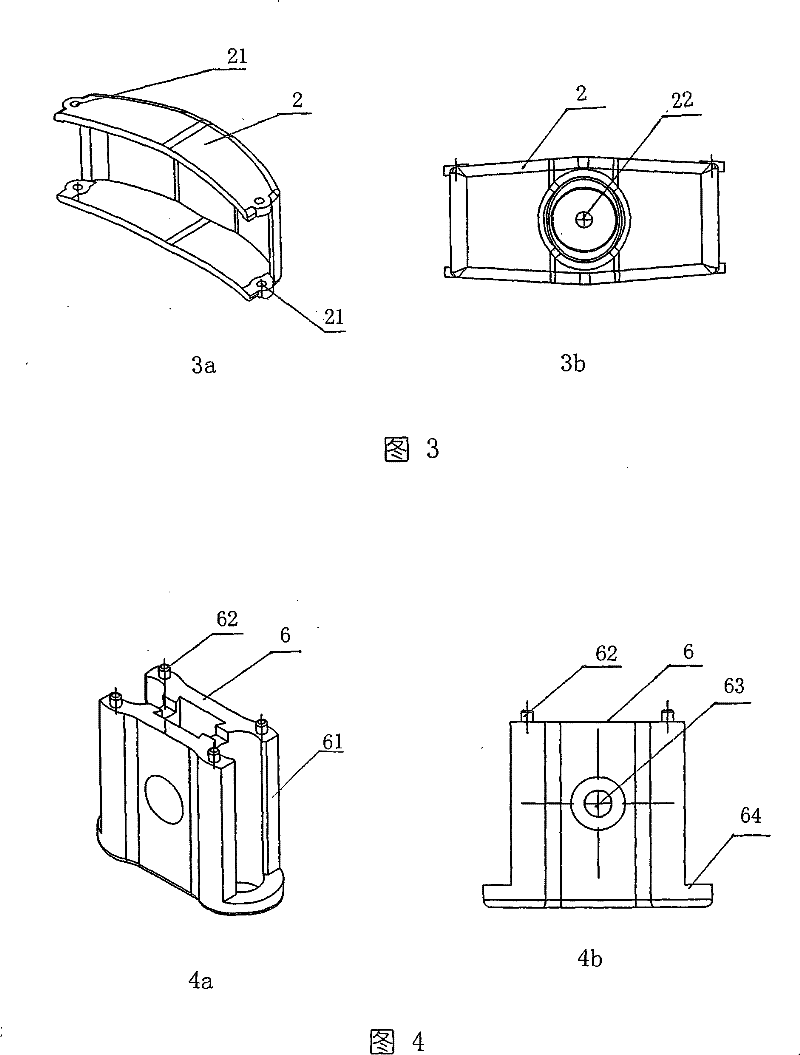

Earphone microphone capable of adjusting clamping force

InactiveCN101330766AAdjust clamping forceSimple structureEarpiece/earphone attachmentsMouthpiece/microphone attachmentsEngineeringMicrophone

The invention discloses an earphone microphone which can adjust clamping force. The earphone microphone is provided with earphones and a connecting rod connected with the earphones; the connecting rod connected with the earphones is divided into a left part and a right part; the left part is hinged with the right part; a clamping force adjusting mechanism is arranged in the middle of the connecting rod; the clamping force adjusting mechanism comprises a supporting frame, a connecting rod fixing seat and an adjusting screw rod, wherein the supporting frame is articulated with the left connecting rod and the right connecting rod; the connecting rod fixing seat is hinged with the ends of the left connecting rod and the right connecting rod; the adjusting screw rod is positioned between the supporting frame and the connecting rod fixing seat, and used for adjusting the distance between the supporting frame and the connecting rod fixing seat. Because the adjusting mechanism which can adjust the opening between the left earphone and the right earphone is arranged on the connecting rod between the two earphones, the purpose of adjusting the clamping force between the two earphones is achieved; furthermore, the earphone microphone has the advantages of simple structure, convenient use and comfortable wear.

Owner:NINGBO EXCEL ELECTRONICS

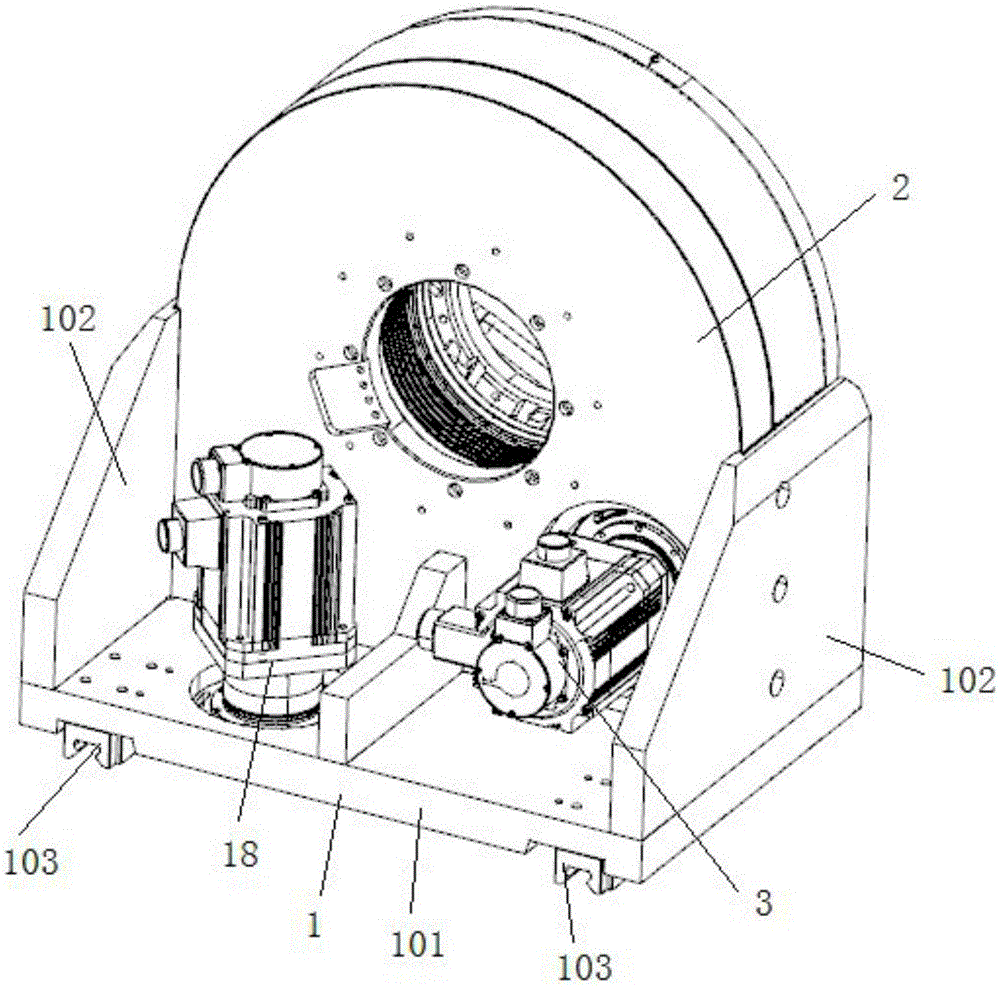

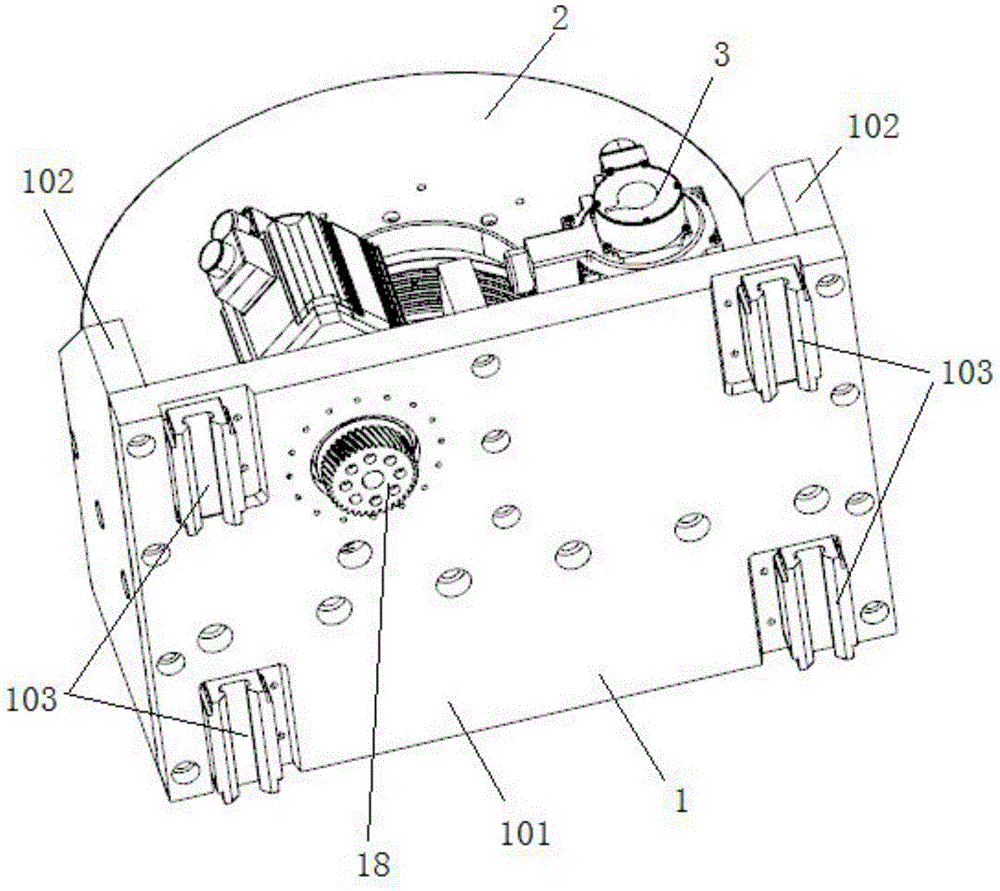

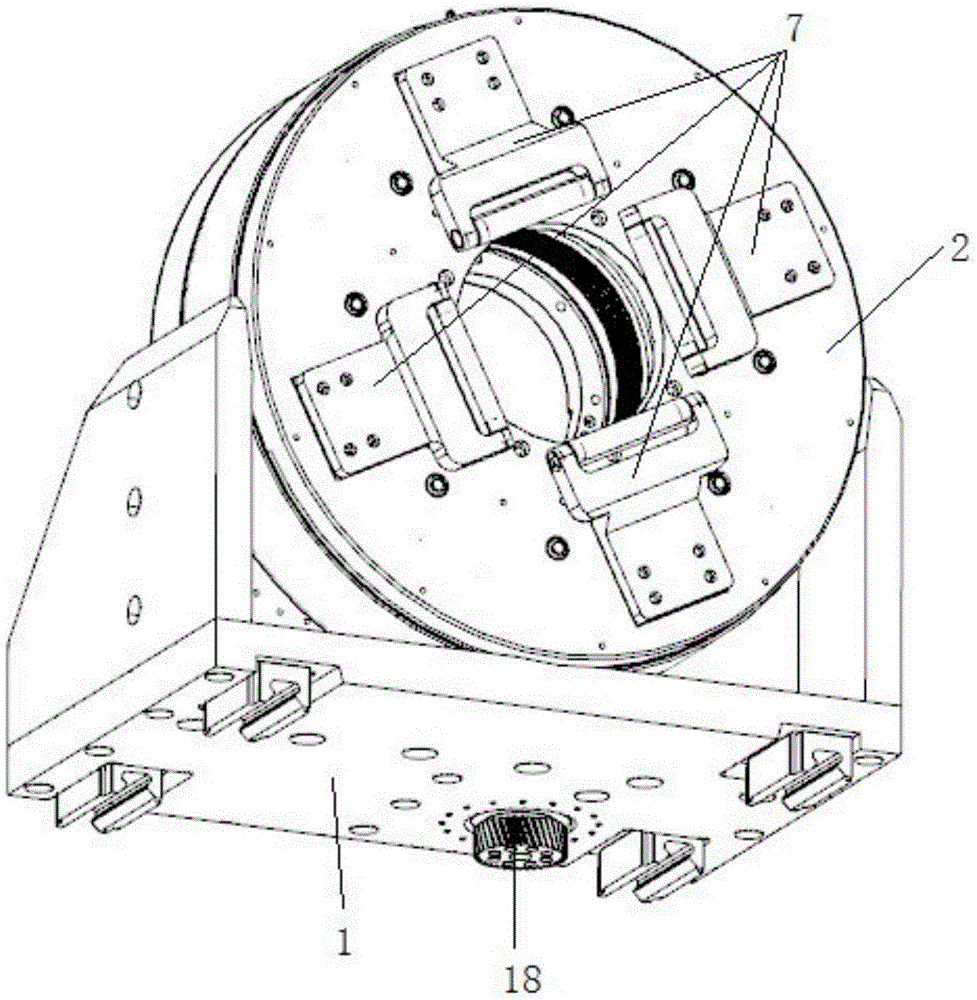

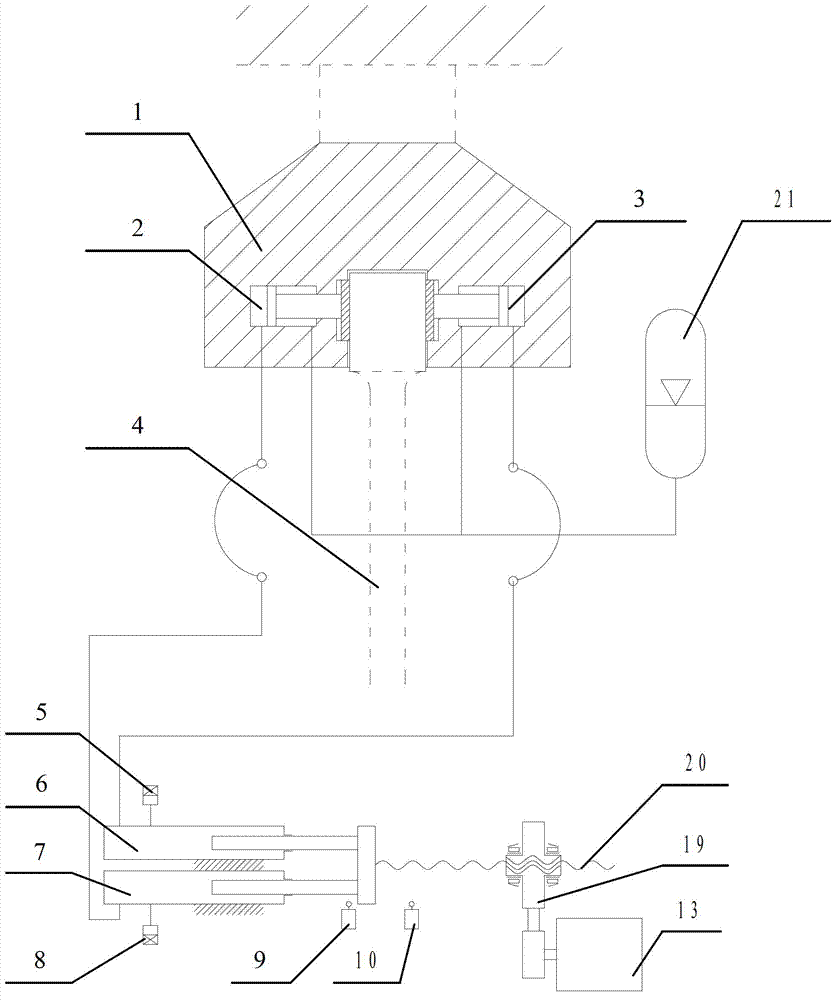

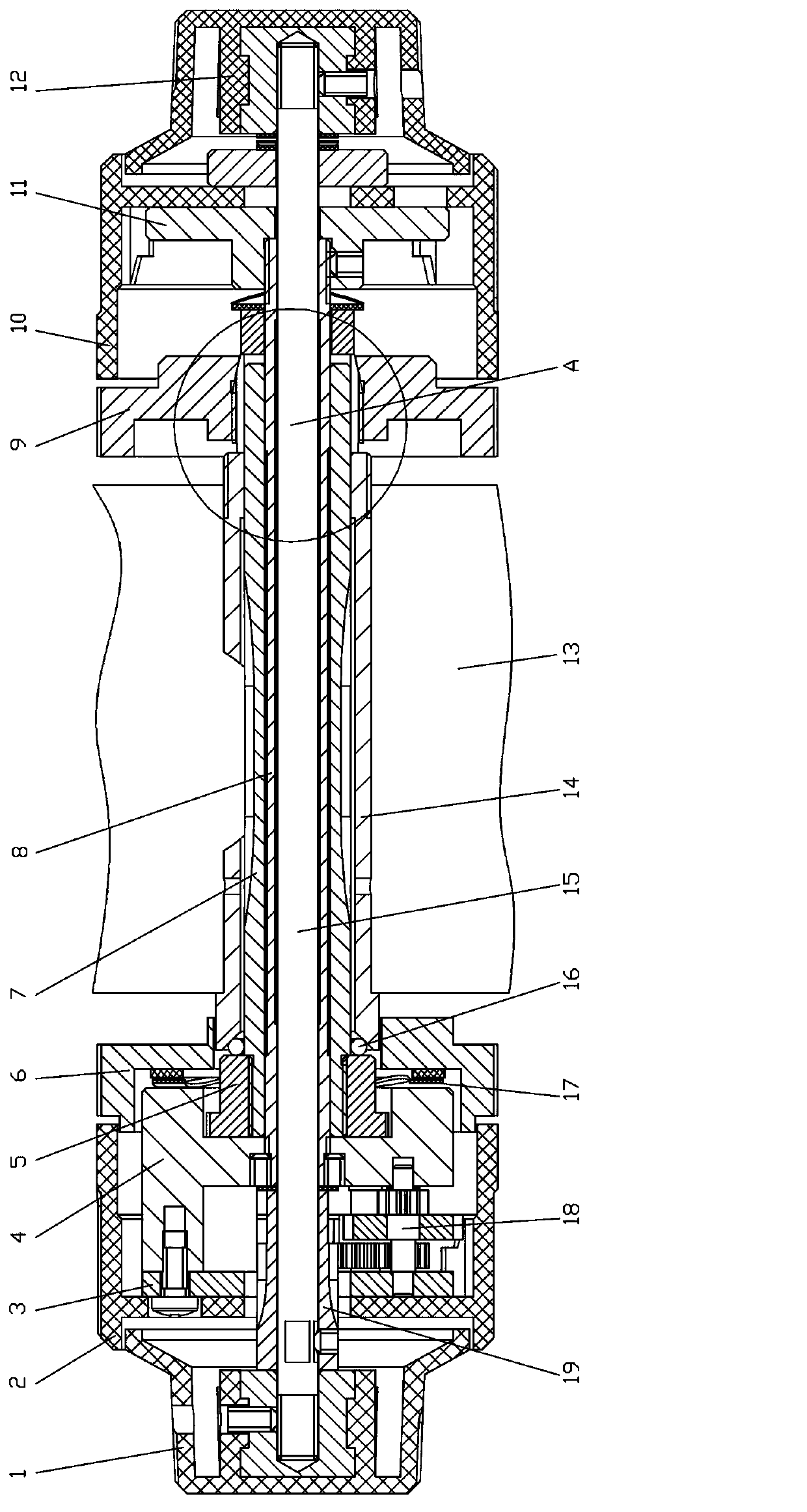

Pneumatic chuck for laser cutting machine

ActiveCN105522285AAvoid damaging the productClamping products are firm and reliableLaser beam welding apparatusLaser cuttingEngineering

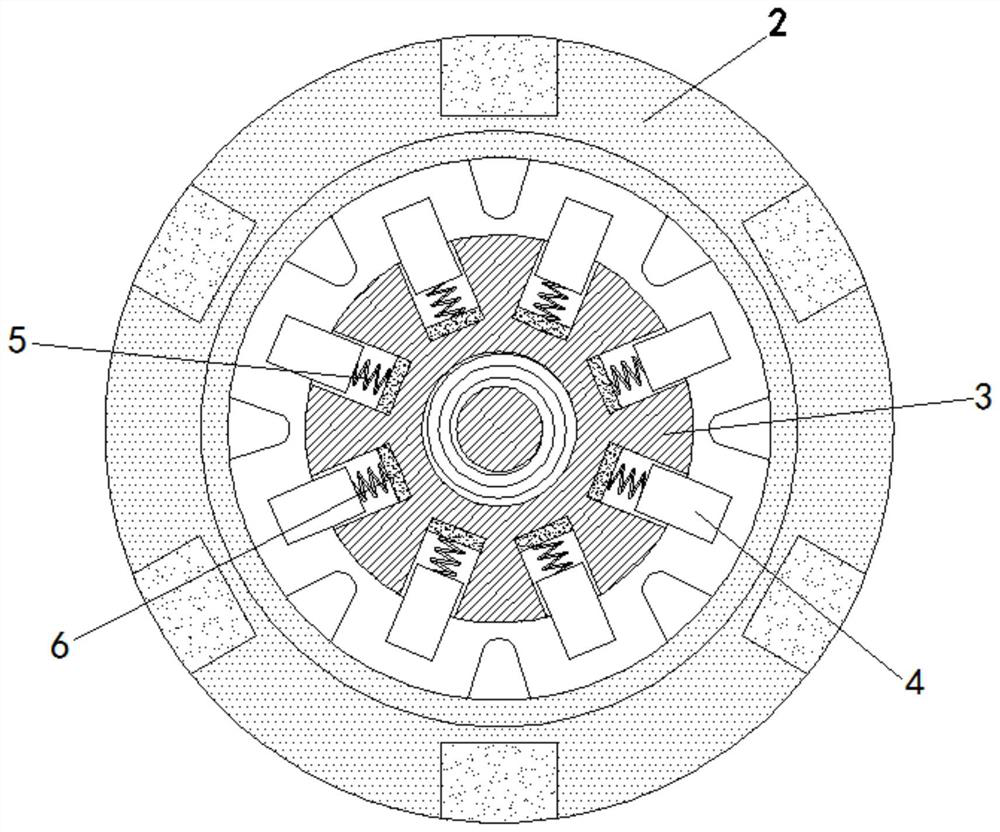

The invention discloses a pneumatic chuck for a laser cutting machine. The pneumatic chuck for the laser cutting machine comprises a base and a clamping device. The clamping device comprises a shell and a first motor. A first gear is installed on the first motor. A first installation disc is arranged in the shell. A second gear is fixed to the first installation disc and engaged with the first gear. The clamping device further comprises at least two sets of clamping jaws, a second installation disc, an air cylinder, a third installation disc and a first transmission mechanism. The first installation disc, the third installation disc and the second installation disc are connected in sequence. The clamping jaws and the first transmission mechanism are installed on the side, backing onto the third installation disc, of the second installation disc. The air cylinder is installed on the side, backing onto the second installation disc, of the third installation disc. The first transmission mechanism is connected with the clamping jaws and the air cylinder. According to the pneumatic chuck for the laser cutting machine, the clamping jaws can be controlled by the air cylinder to clamp a product, and the product is prevented from being damaged by adjusting the clamping force; the first motor can drive the clamping device to rotate for position adjustment; the second motor can drive the pneumatic chuck to move on a machine tool; manual operation is not needed in the whole process, and the production efficiency is improved.

Owner:SUZHOU QUICK LASER TECH

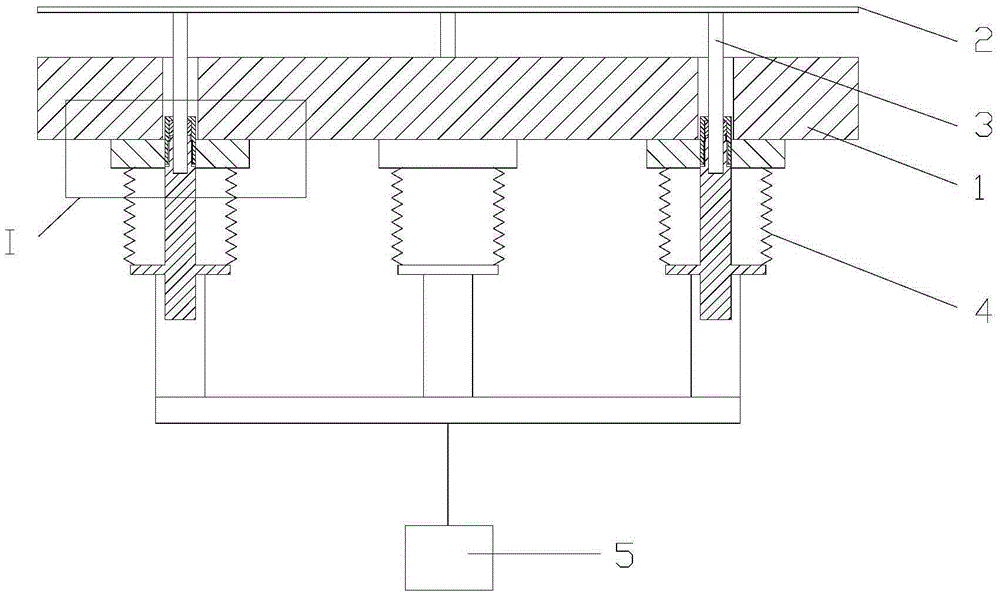

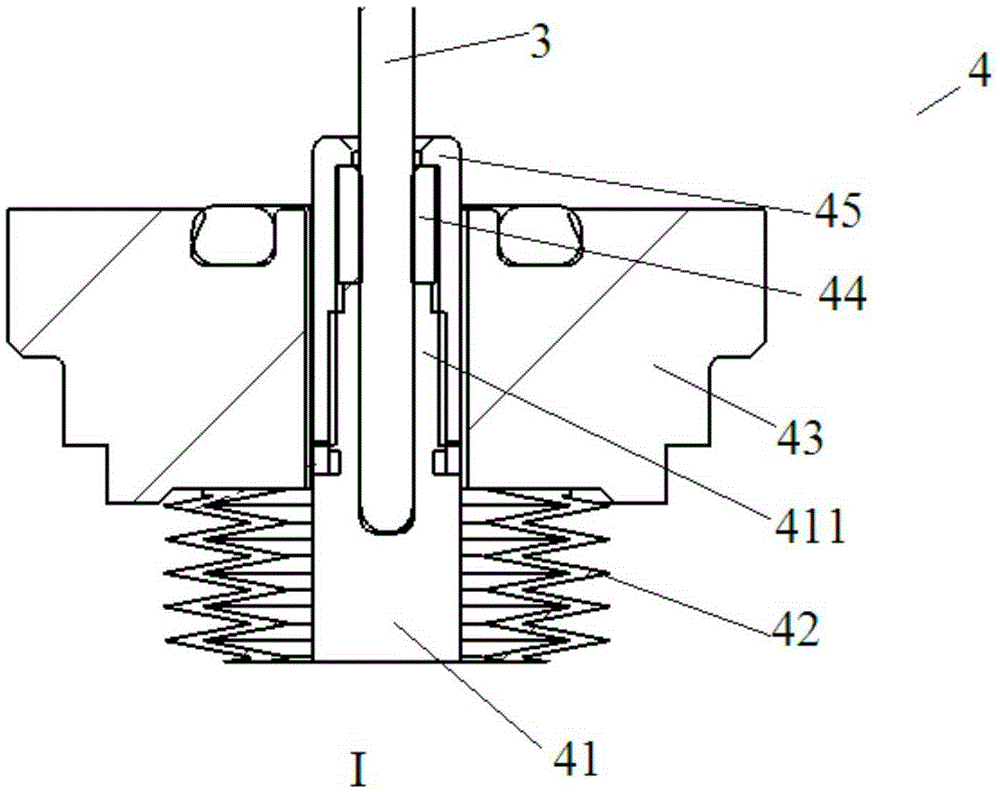

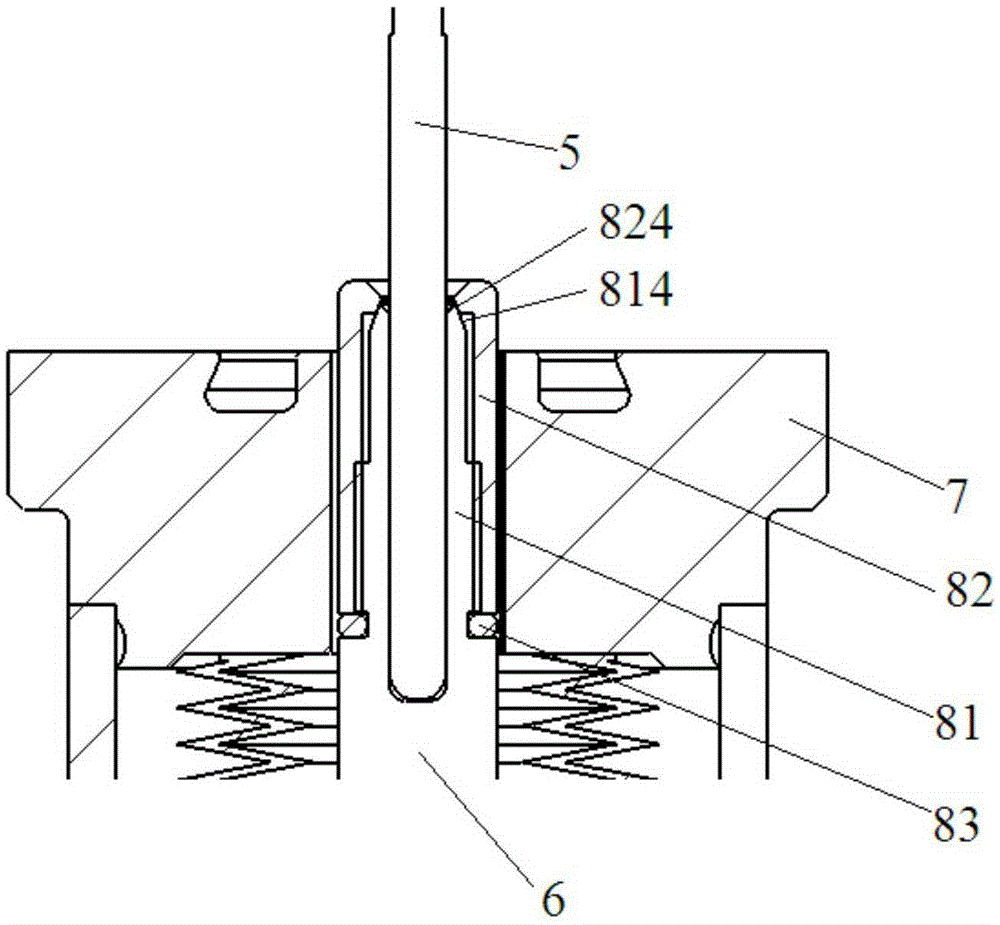

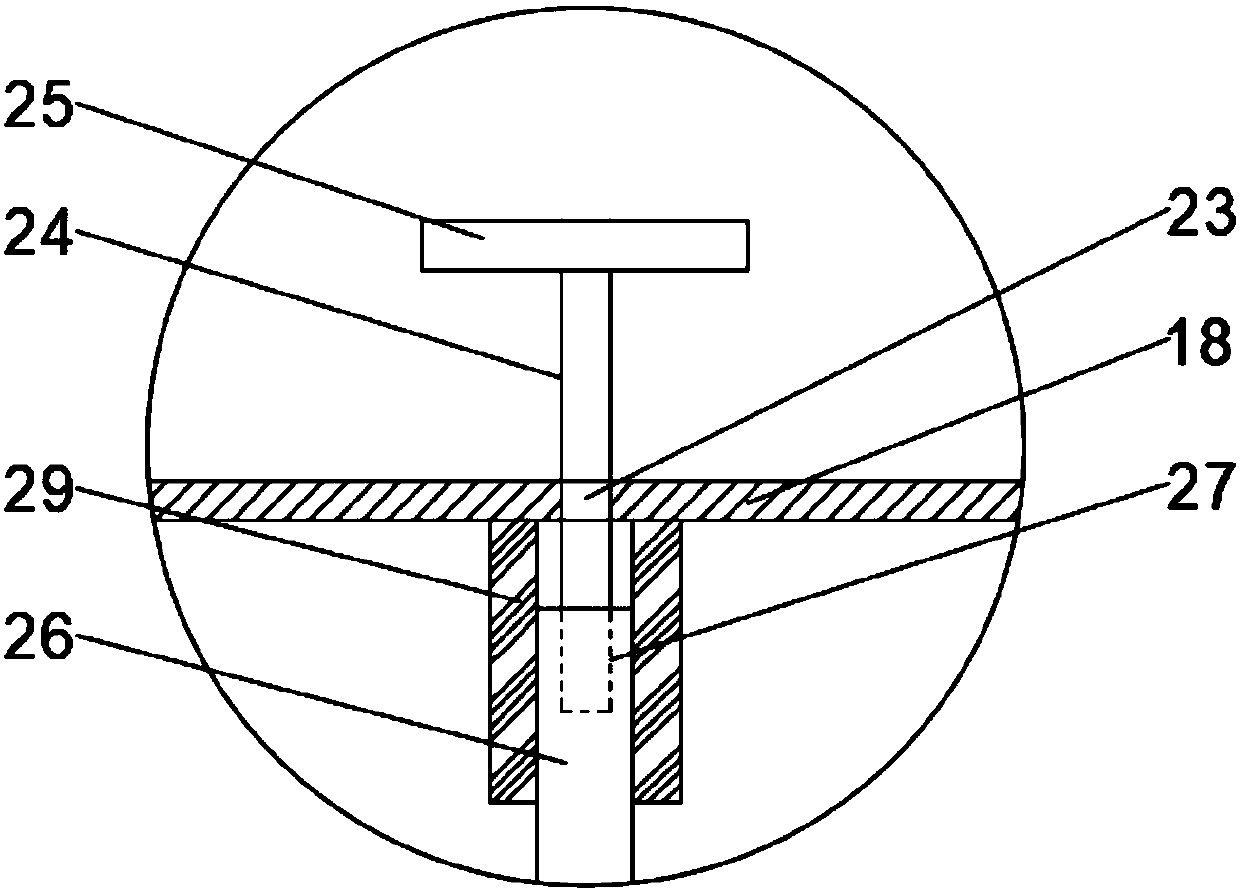

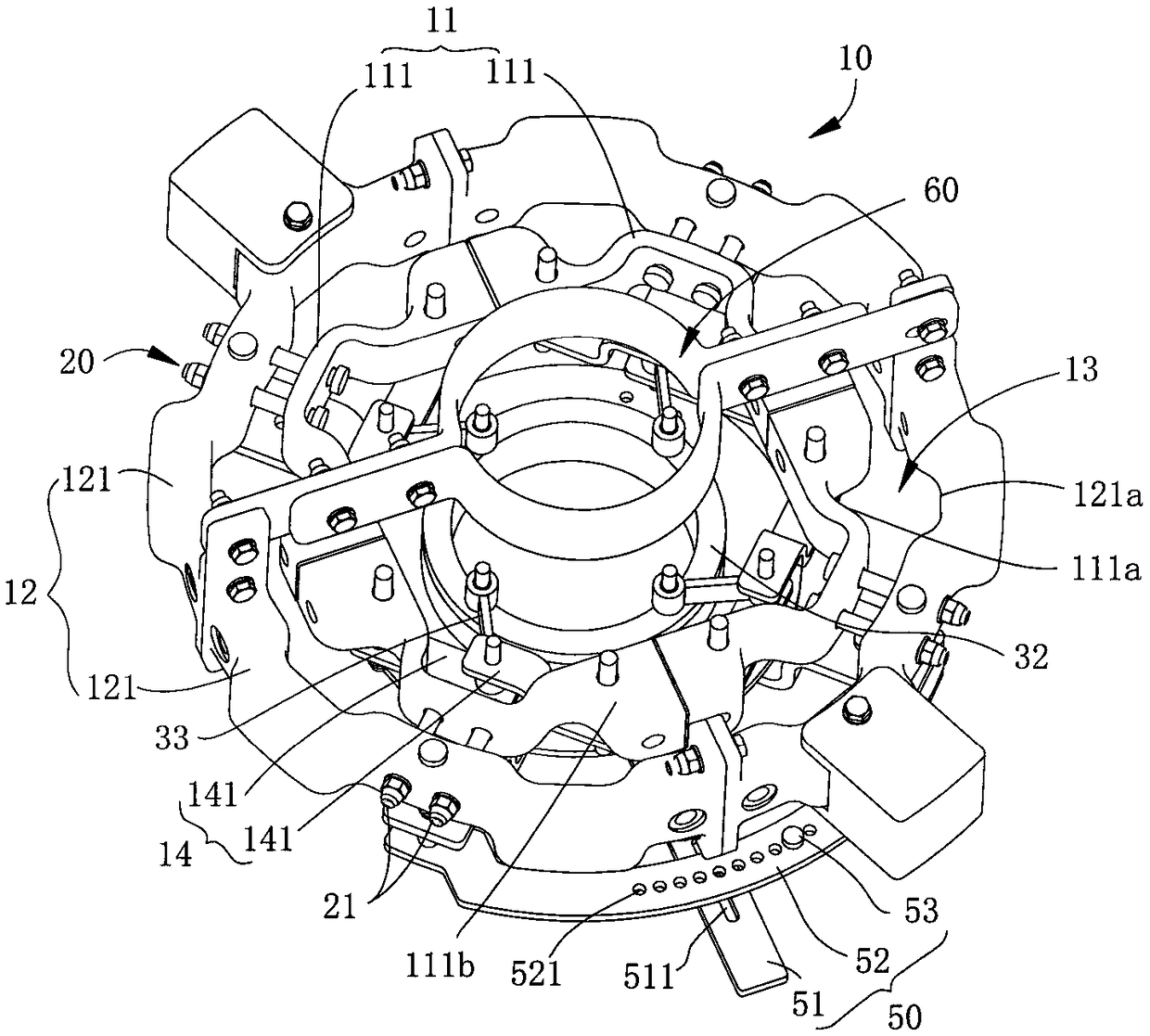

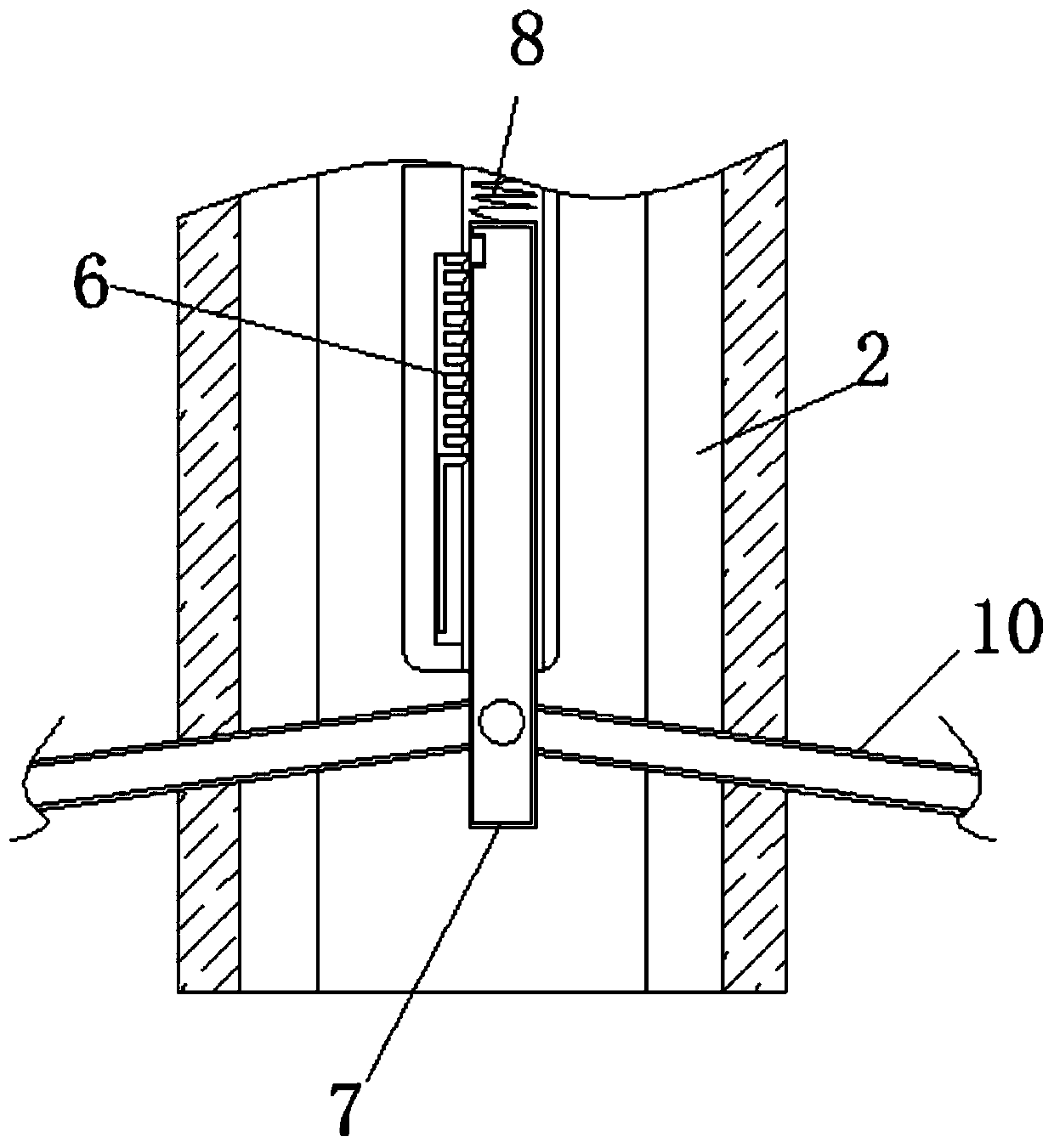

A centre mechanism and a semiconductor processing device

ActiveCN106611736AAdjust clamping forceAvoid Loose FaultsSemiconductor/solid-state device manufacturingEngineeringScrew thread

The invention provides a centre mechanism and a semiconductor processing device. A centre, a center shaft and a fixing component used for connecting the centre and the center shaft are comprised. The fixing component includes a clamping deformation member and a lock nut, wherein the clamping deformation member is provided at the top of the central shaft and is fitted in the lower portion of the centre in a sleeving mode. The locking nut is provided on the clamping deformation member in a sleeving mode and matched with threads of the clamping deformation member. A first mating surface and a second mating surface are respectively provided on the clamping deformation member and the locking nut. The first mating surface and the second mating surface cooperate with each other while the locking nut is simultaneously tightened or loosened to elastically deform the clamping deformation member to adjust the clamping force to the centre. According to the centre mechanism provided by the invention, the clamping force applied to the centre can be adjusted, thereby raising the assembling efficiency and avoiding the fault of centre loosening.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

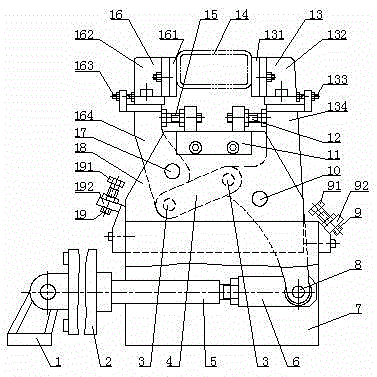

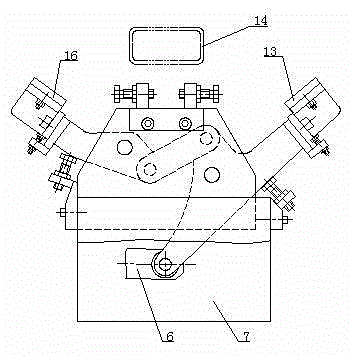

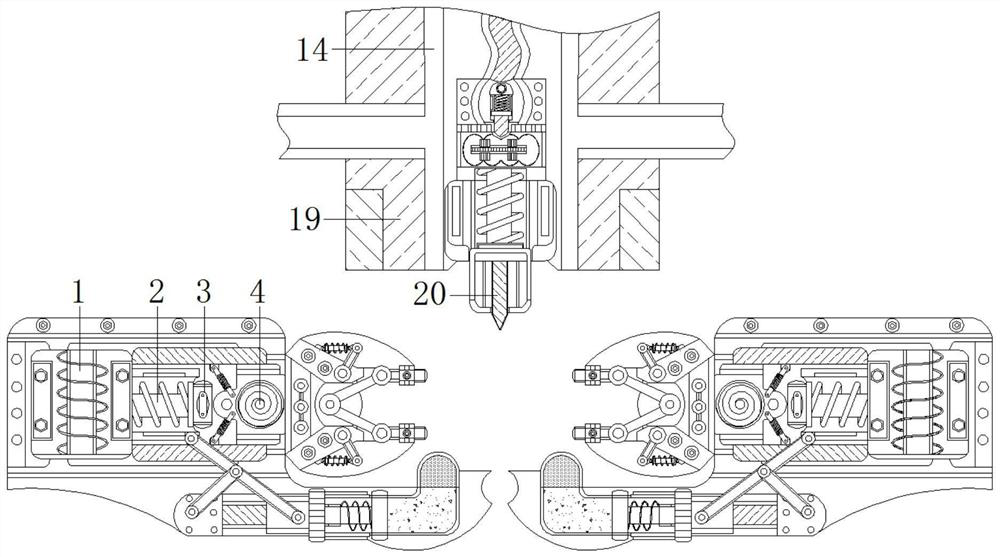

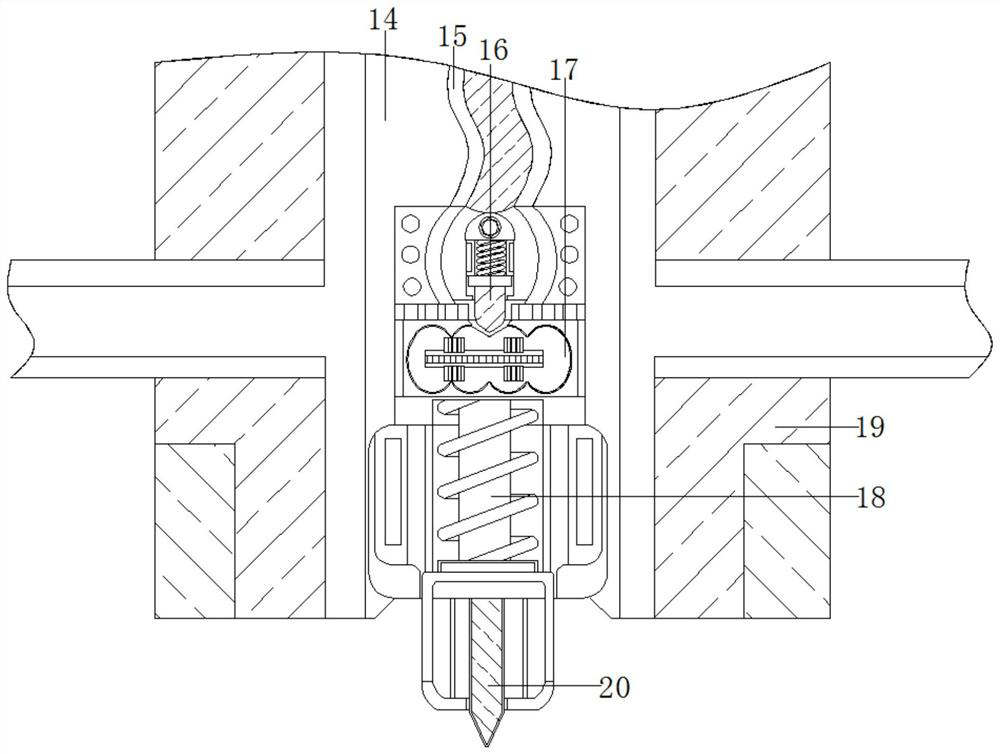

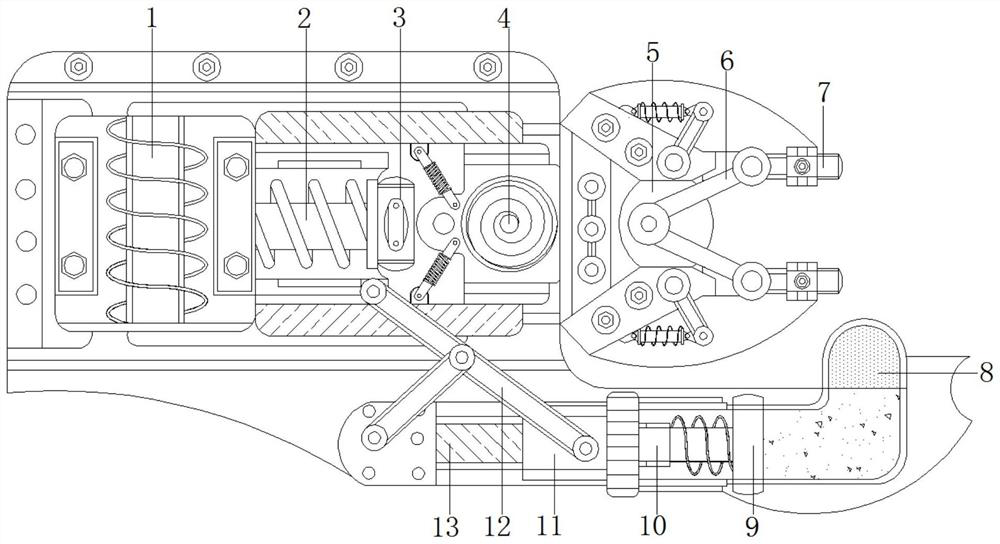

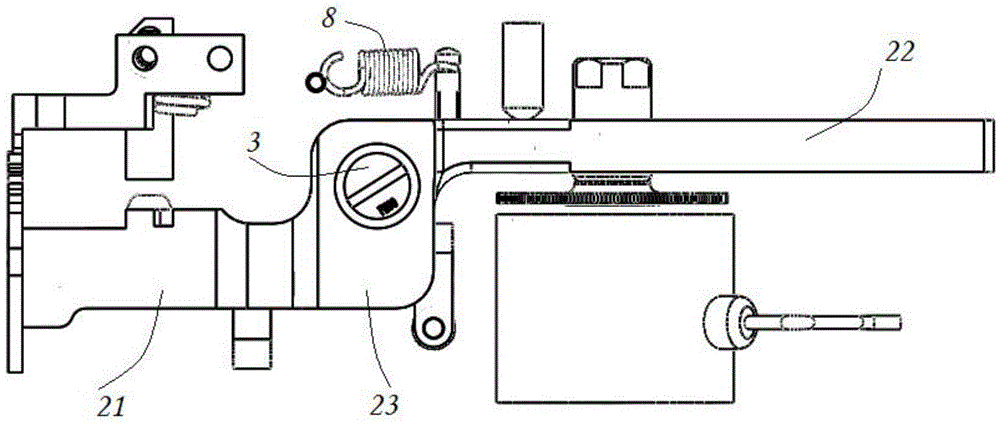

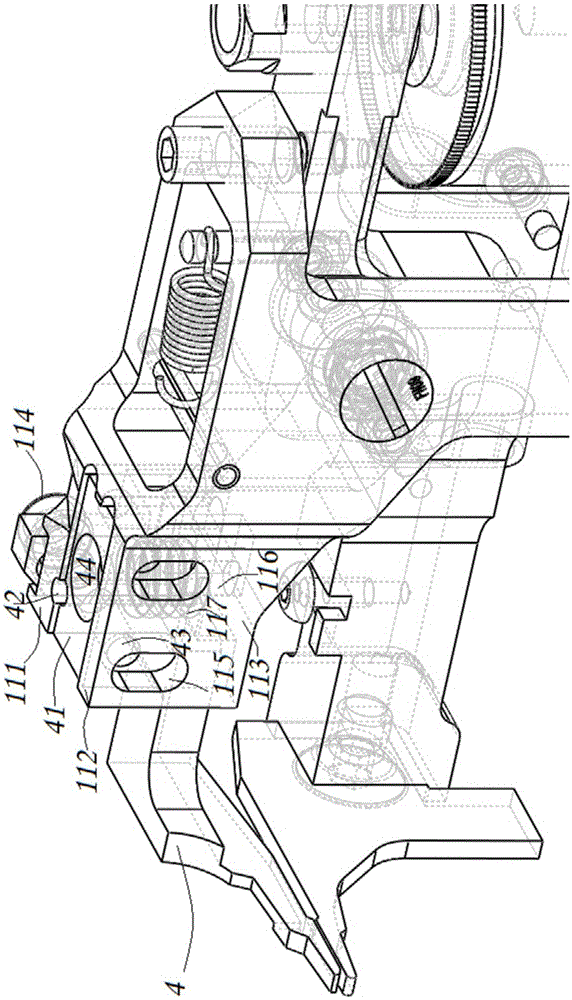

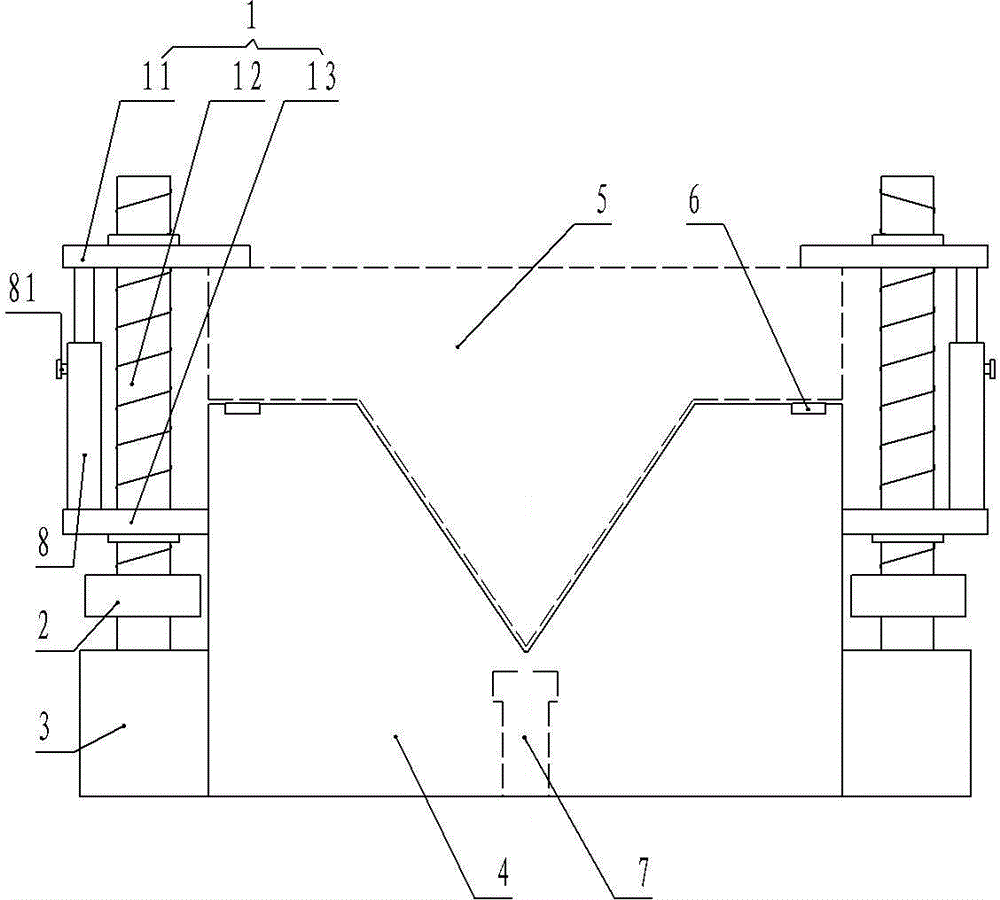

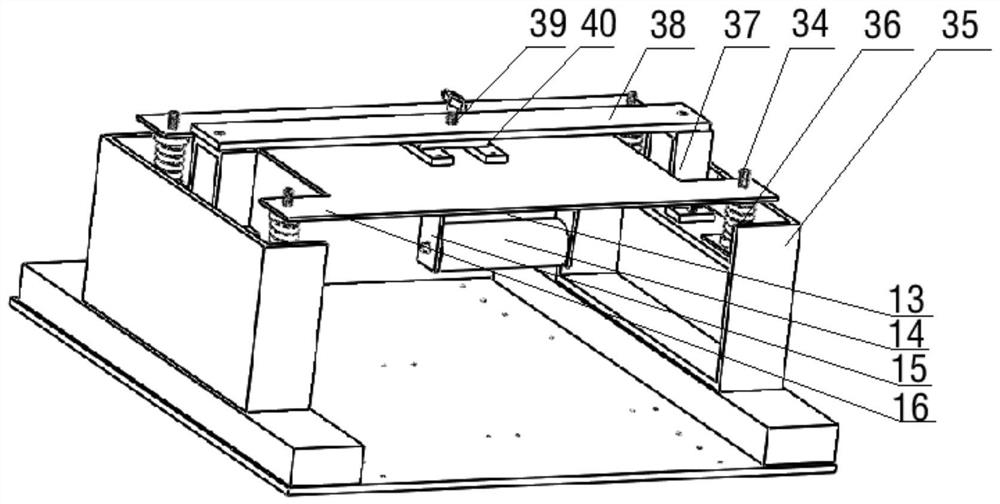

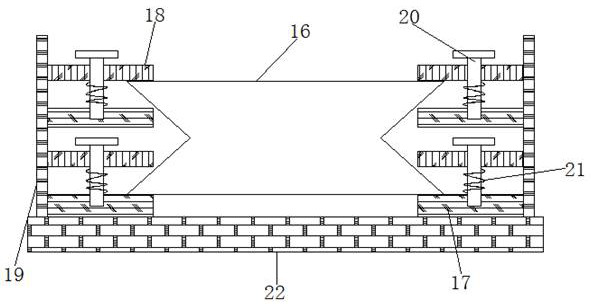

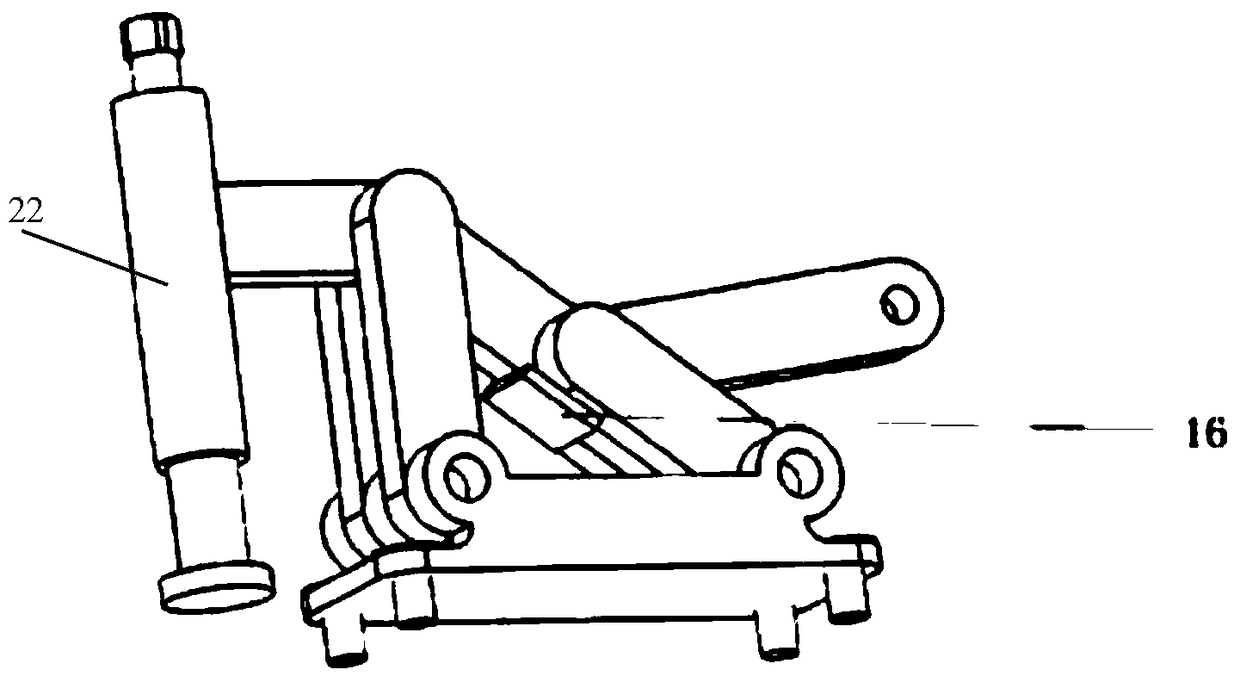

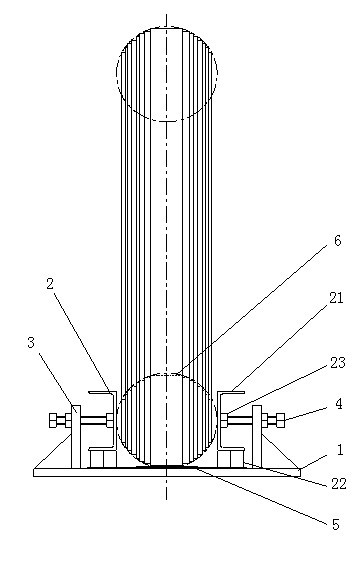

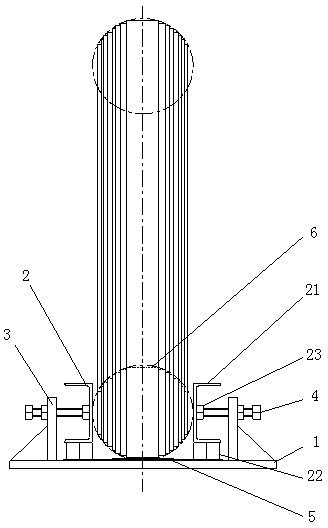

Skid positioning and clamping device of roller bed conveyor

The invention discloses a skid positioning and clamping device of a roller bed conveyor. The skid positioning and clamping device is characterized in that the skid positioning and clamping device comprises a single-lug ring support, an air cylinder, a middle rotating shaft, a middle connecting plate, an air cylinder stretching shaft, a connecting rod, a fixed base, a lower rotating shaft, a lower right limiting assembly, a right rotating shaft, an upper limiting base, an upper right limiting screw, a right clamping assembly, an upper left limiting screw, a left clamping assembly, a left rotating shaft, an outer hole plate and a lower left limiting assembly, the lower right limiting assembly comprises a lower right limiting screw and a lower right limiting base, the right claming assembly comprises a right clamping plate, a right chuck, a right chuck regulating screw and a right clamping arm, the lower left limiting assembly comprises a lower left limiting screw and a lower left limiting base, and the left clamping assembly comprises a left clamping plate, a left chuck, a left chuck regulating screw and a left clamping arm. The skid positioning and clamping device is simple in structure, easy to regulate, accurate in clamping action, controllable in clamping force, safe, reliable and long in service life.

Owner:HUANGSHI HUATIAN AUTOMATION EQUIP

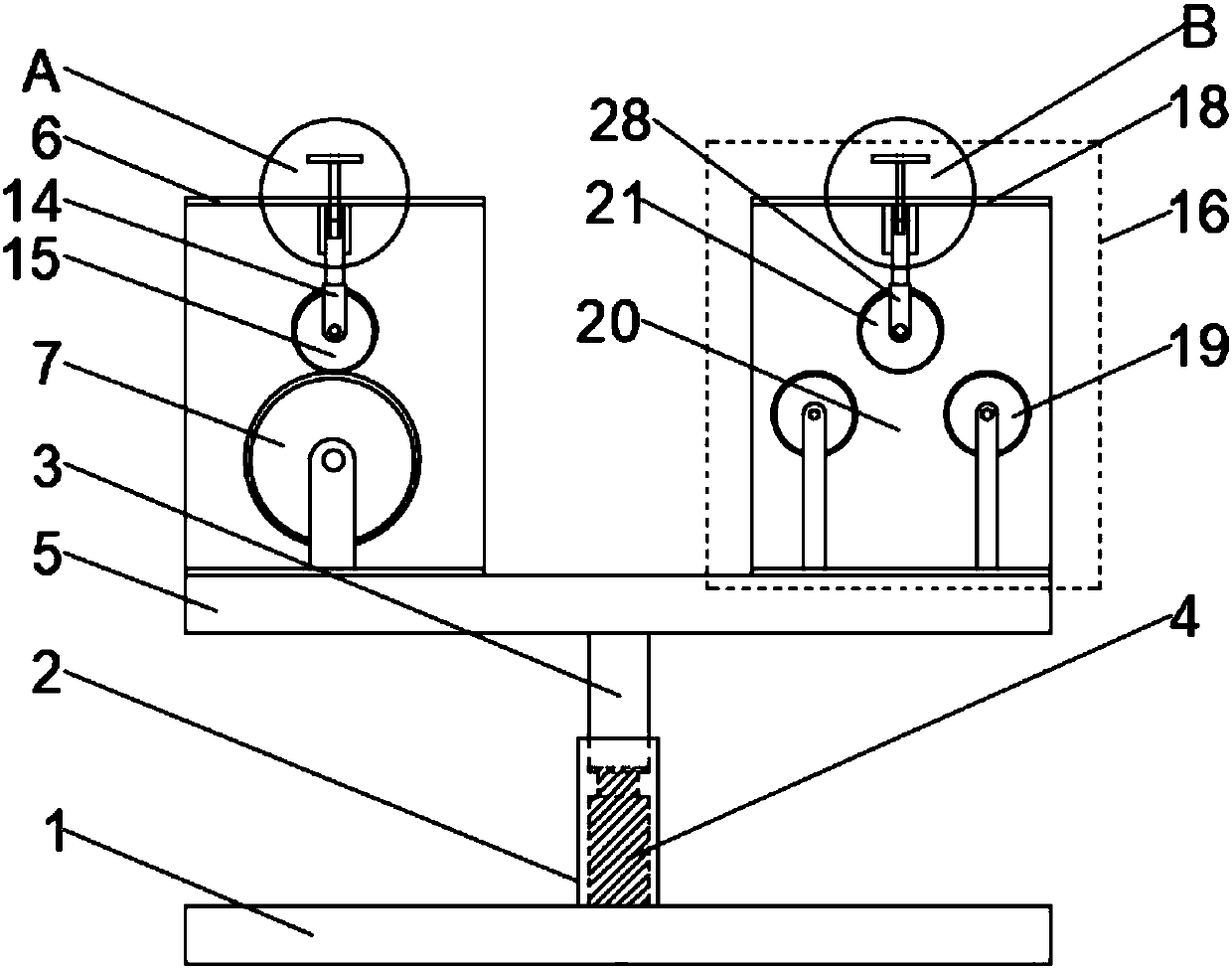

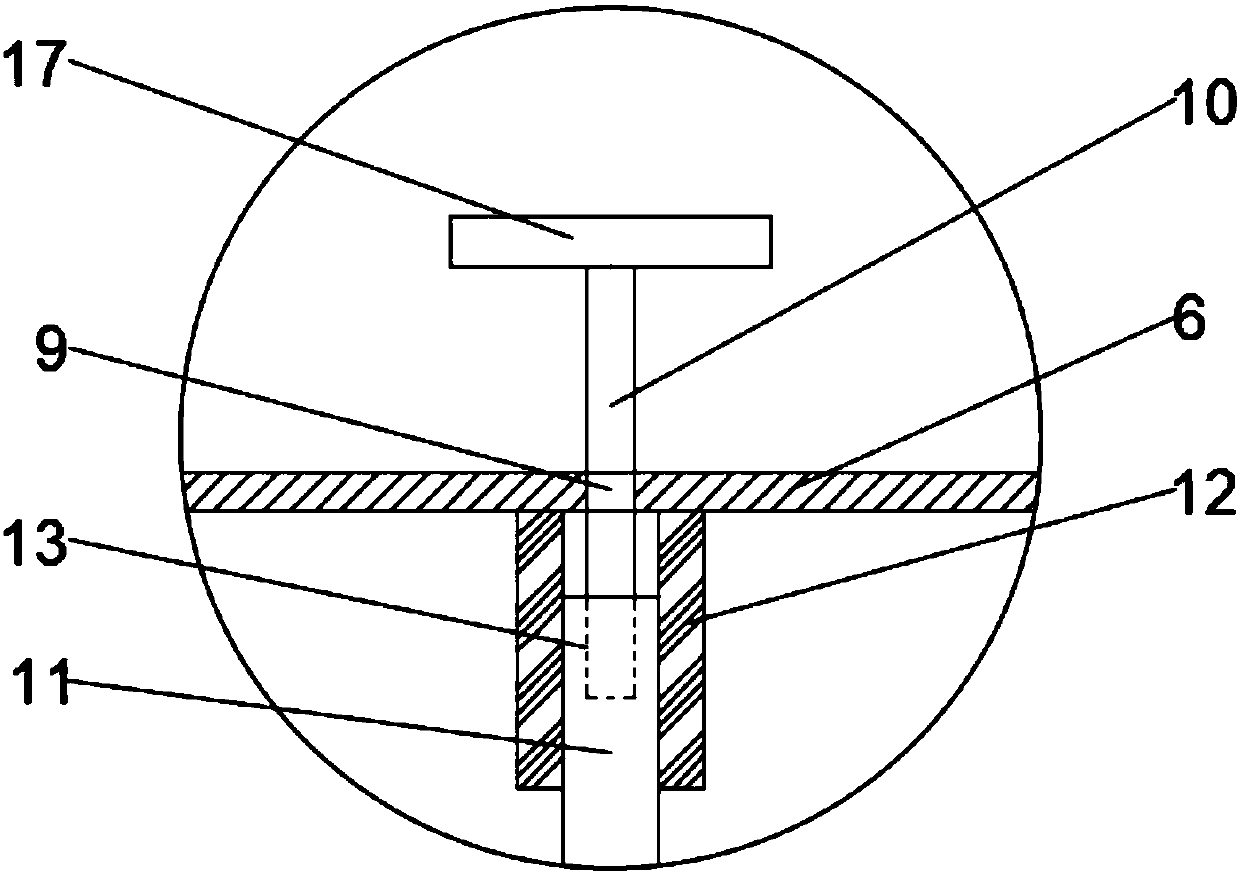

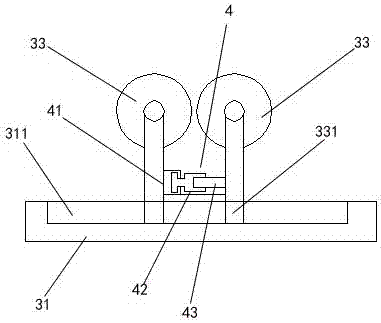

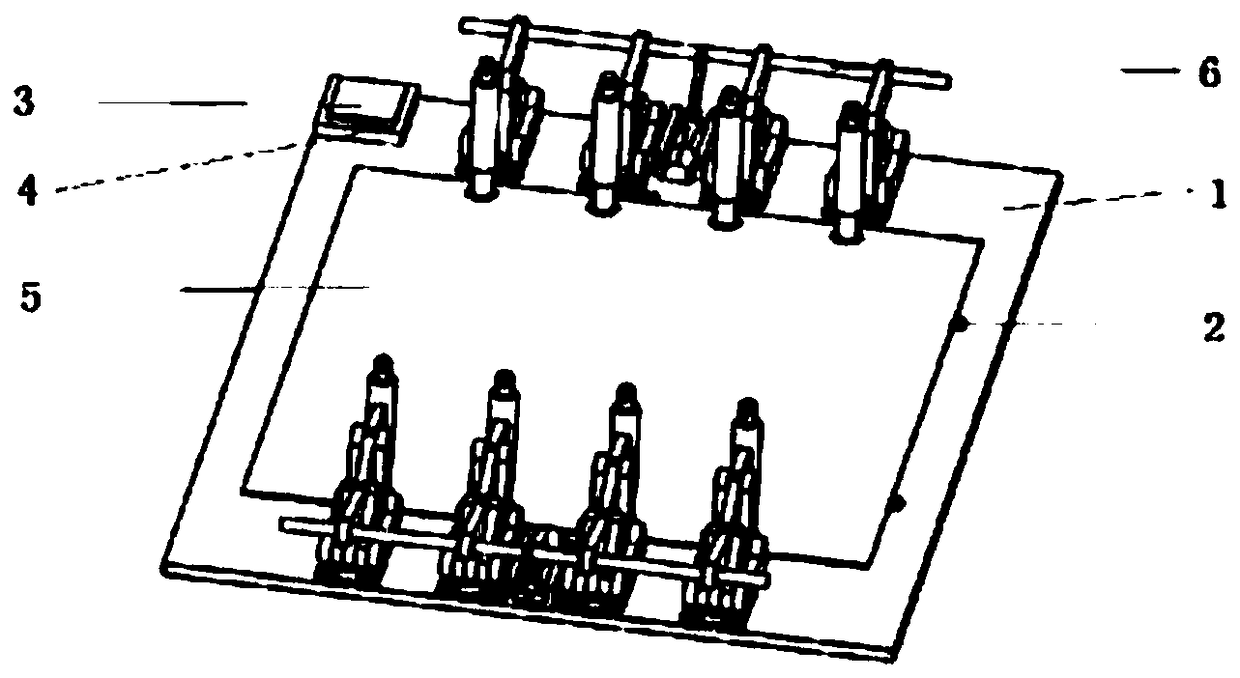

Yarn clamping mechanism for spinning machine

The invention discloses a yarn clamping mechanism for a spinning machine. The mechanism comprises a base, a lifting cylinder is arranged on the base, a lifting column is arranged in the lifting cylinder, a hydraulic cylinder is arranged at the lower end of the lifting column, a foundation bed is arranged at the upper end of the lifting column, a clamping frame with the hollow inner portion is arranged on the foundation bed, a yarn passing wheel is arranged in the clamping frame, a yarn passing groove is formed in the wheel surface of the yarn passing wheel, a yarn clamping lifting hole with threads is formed in the upper end surface of the clamping frame, a yarn clamping lifting rod is internally connected with the yarn clamping lifting hole through the threads, a yarn clamping sliding rodis arranged at the lower end of the yarn clamping lifting rod, a yarn clamping installation hole is formed in the upper end of the yarn clamping sliding rod, the lower end of the yarn clamping lifting rod is fixed into the yarn clamping installation hole through a bearing, yarn clamping lifting grooves fixed to the clamping frame are formed in the two sides of the yarn clamping sliding rod, a yarn clamping support is arranged at the lower end of the yarn clamping sliding rod, a yarn clamping wheel is arranged at the lower end of the yarn clamping support, and a tensioning device is arranged on the foundation bed. By means of the yarn clamping mechanism, yarn can be effectively clamped all the time, the use ratio of the machine is improved, machine halts are reduced, and clamping force onthe yarn and the tensioning degree of the yarn can be adjusted.

Owner:阜阳恒泰纺织有限公司

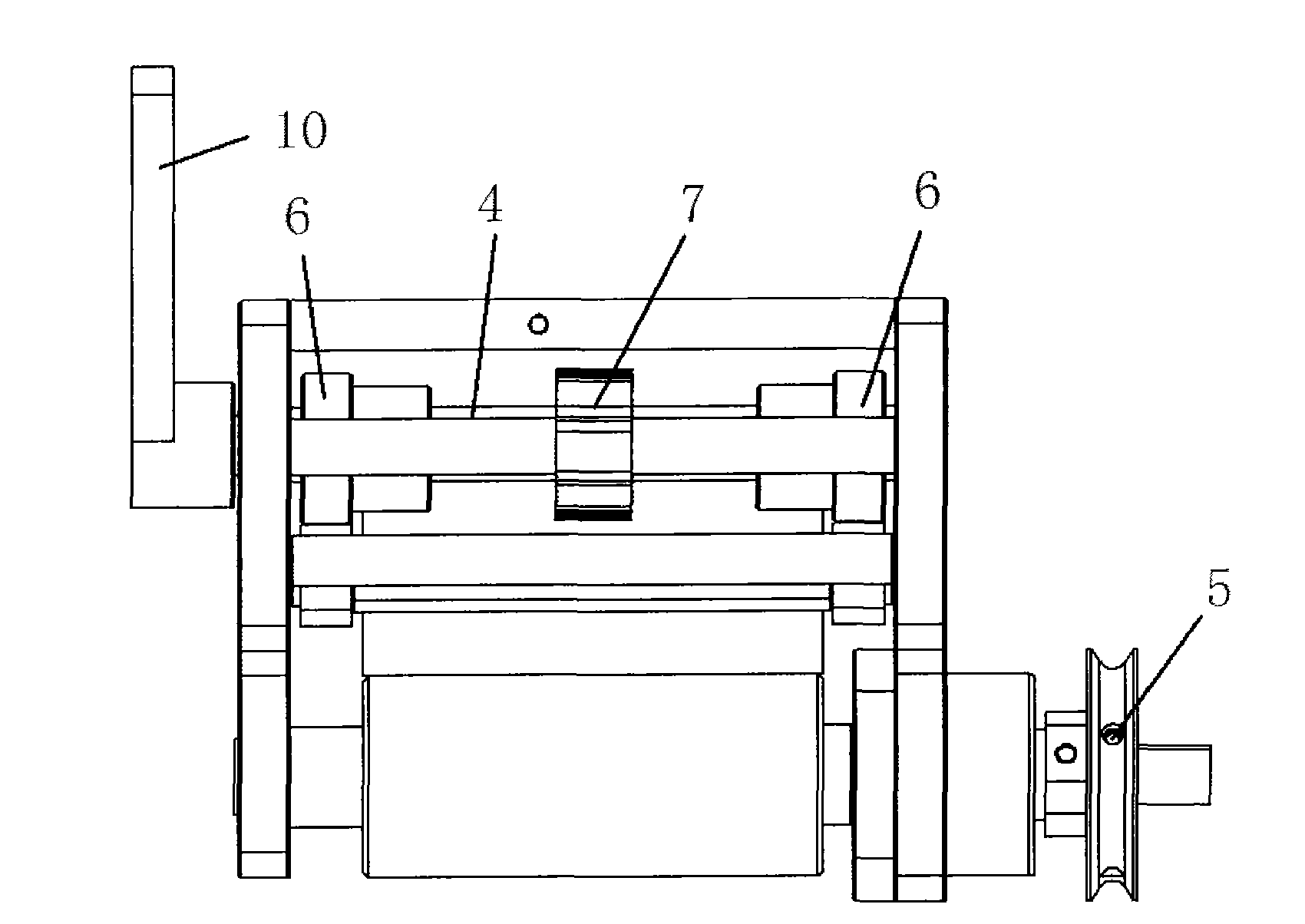

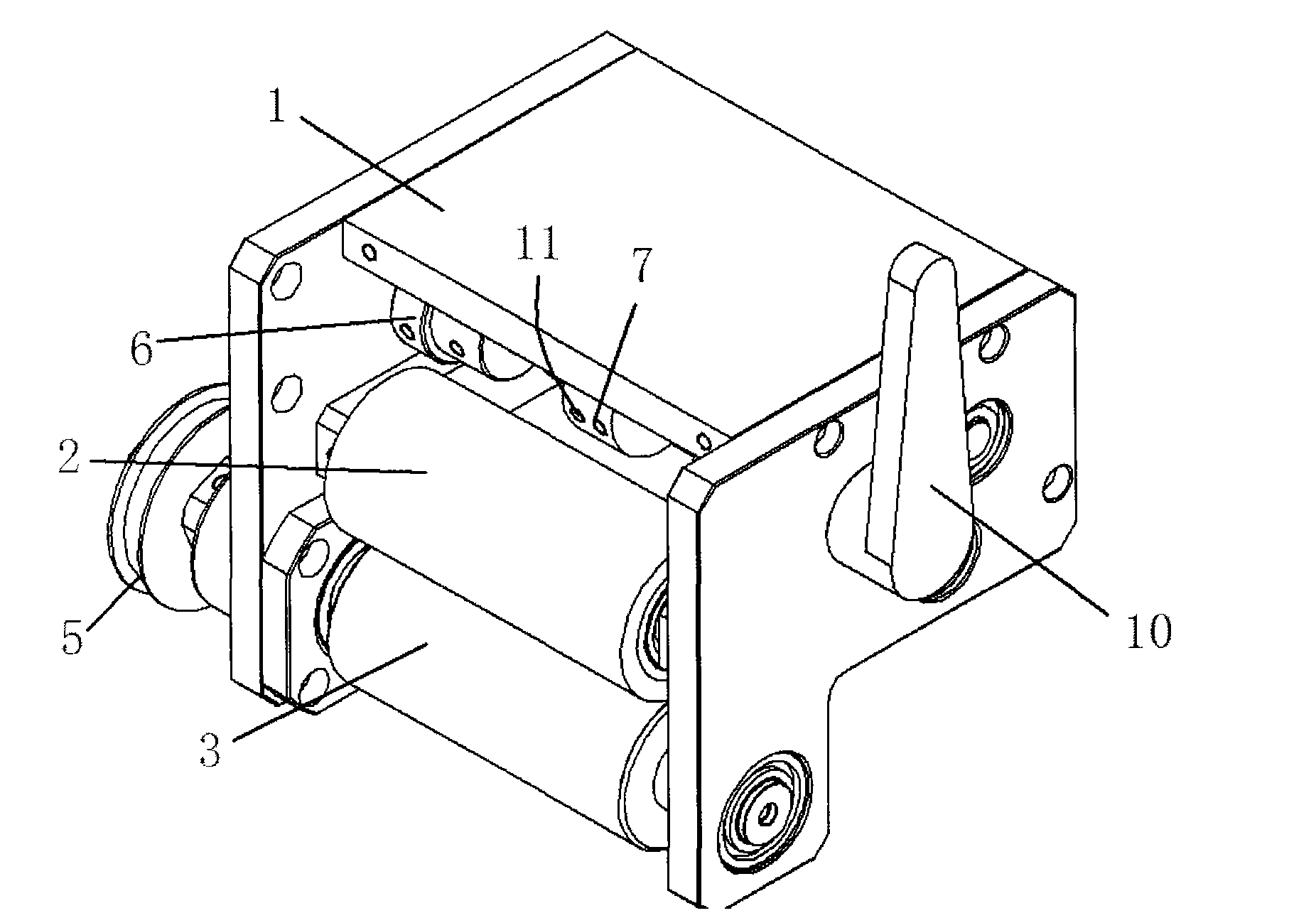

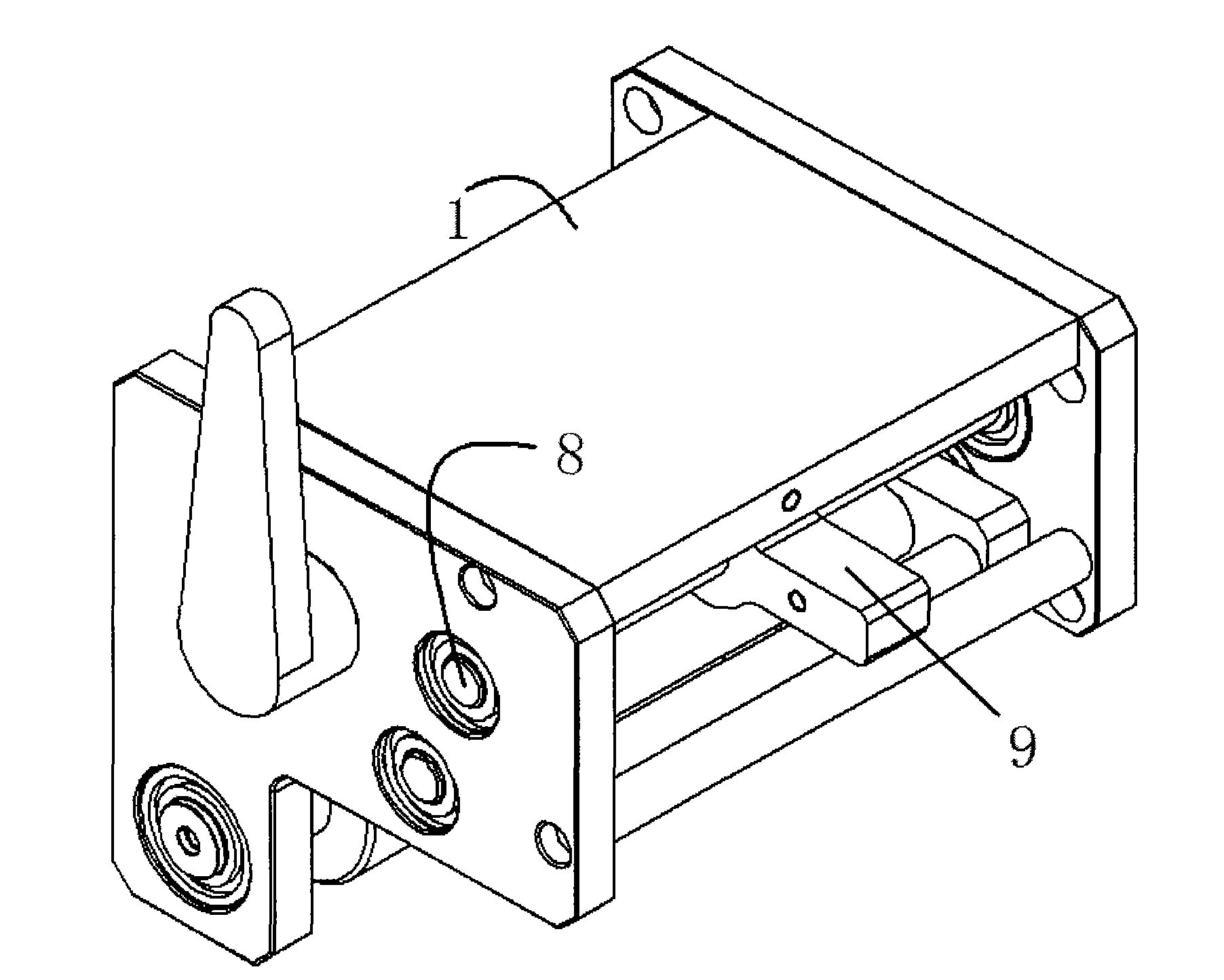

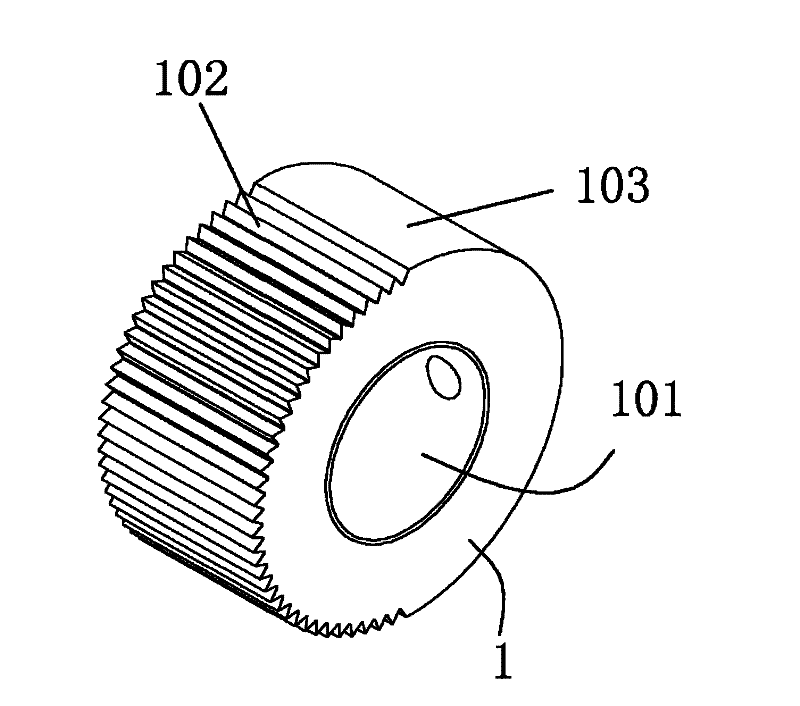

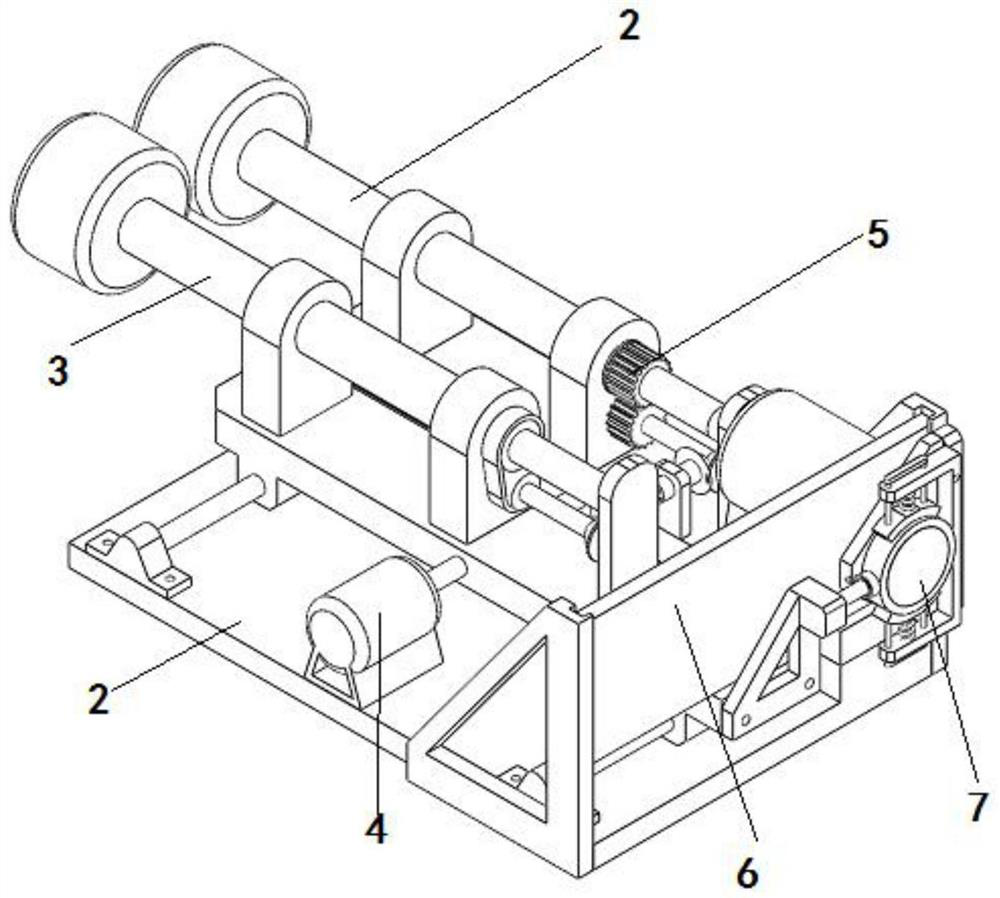

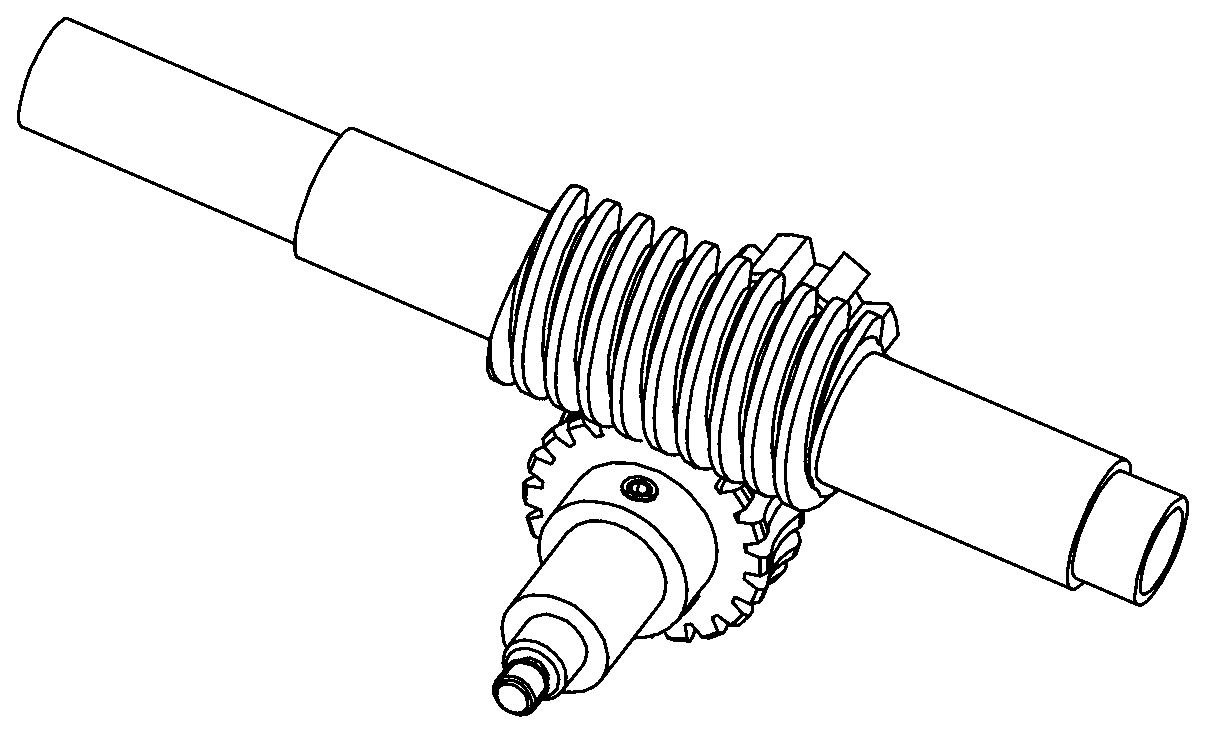

Semi-gear tension conveying device

The invention discloses a semi-gear tension conveying device comprising a shell. A driven roll, a driving roll and a transmission shaft are mounted in the shell; a transmission belt pulley is fixed at the end of the driving roll, two eccentric wheels are fixed on the transmission shaft; the two eccentric wheels can contact to the driven roll with the rolling of the transmission shaft, and allows the driven roll and the driving roll to be a compaction state; a semi-gear with a semi-tooth on the outer circumferential surface is also fixed on the transmission shaft; the shell is also provided with a rotating shaft, a semi-gear clamping stem is mounted on the rotating shaft in a clearance fit way, a protrusion capable of being inserted into the tooth of the semi-gear is arranged at the front end of the semi-gear clamping stem; and the upper surface of the protrusion is an inclined surface. The tension conveying device disclosed by the invention not only can be adjusted in the tension force, but also can keep the position in the use process without loosing phenomenon.

Owner:BOZHON PRECISION IND TECH CO LTD

Self-adaptive auxiliary device for safety protection of engraving clamping force of glasses frame

InactiveCN112171331ASolve the difficult problem that affects the engraving effectImprove magnetismMilling equipment detailsPositioning apparatusProtective glassesStructural engineering

The invention relates to the technical field of safety protection, and discloses a self-adaptive auxiliary device for safety protection of engraving clamping force of a glasses frame. The self-adaptive auxiliary device comprises an electrified coil, wherein a reset spring is movably connected to the right side of the electrified coil, a clamping magnet is movably connected to the right side of thereset spring, a pushing block is movably connected to the right side of the clamping magnet, a clamping block is movably connected to the right side of the pushing block, a pull rod is movably connected to the middle of the clamping block, and a clamping jaw is movably connected to the right side of the pull rod. An upward counter-acting force is applied to a graver through a material, so that the magnitude of current in the electrified coil is adjusted, and the clamping jaw is driven to clamp the material; and after the material is graved, the pressure applied to a piezoelectric material disappears, and the current of the electrified coil returns to normal at the moment, so that the clamping block is driven to move in the direction away from the material, the clamping jaw is driven to loosen the material, and the effect of automatically adjusting the clamping force to the material according to a graving state is achieved.

Owner:广州零尚电商贸易有限公司

Gripper

Owner:SHENZHEN DEVOL ADVANCED AUTOMATION CO LTD

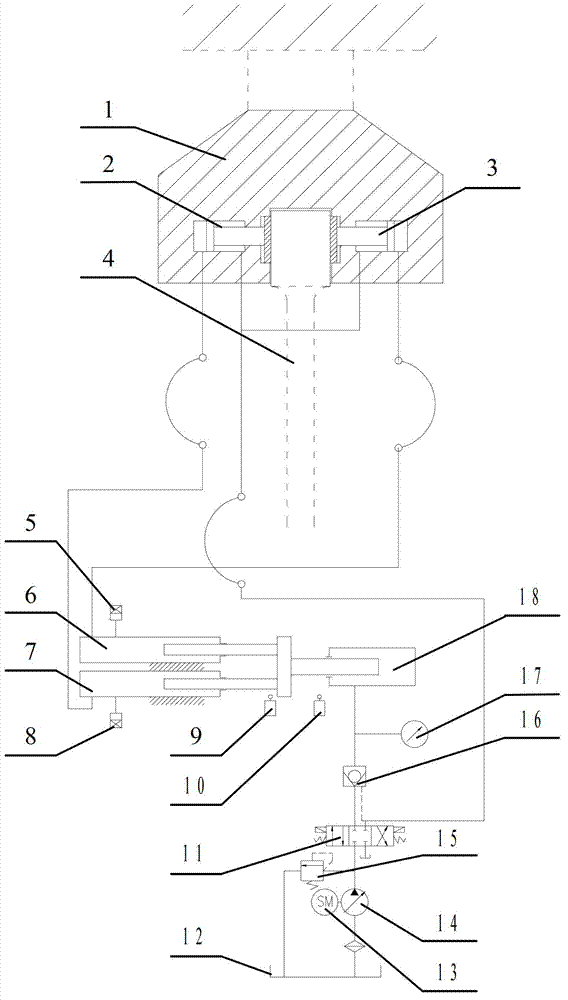

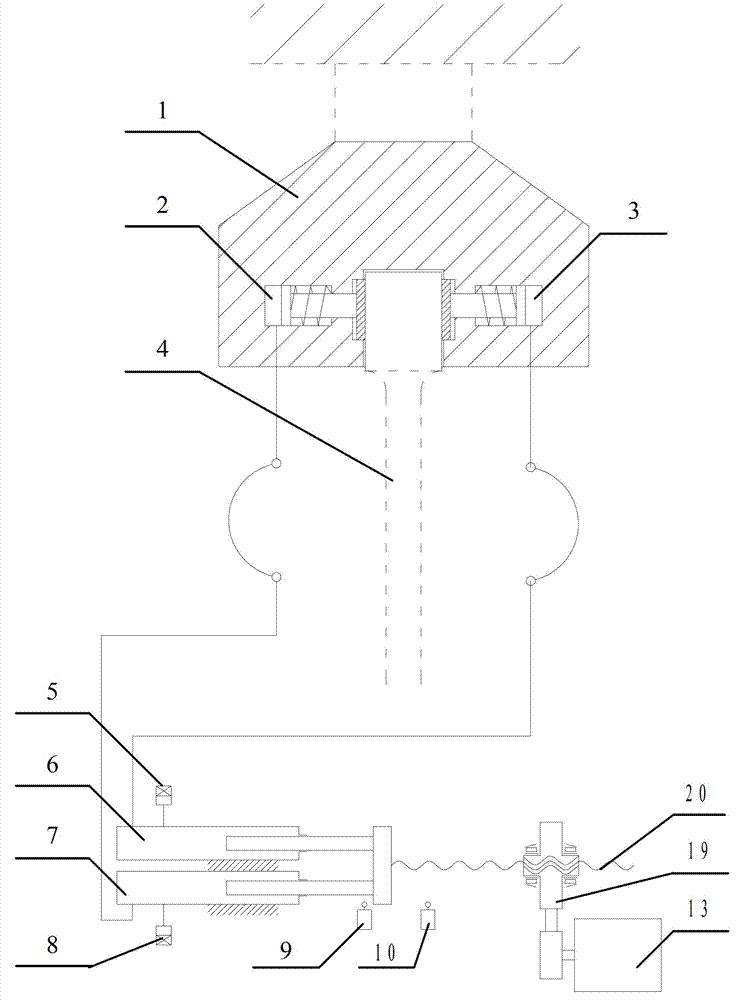

Electro-hydraulic flat-pushing clamping device

The invention discloses an electro-hydraulic flat-pushing clamping device, and belongs to the technical field of fixtures. The electro-hydraulic flat-pushing clamping device solves problems of poor synchronization performance and uncontrollability in clamping force when an existing bidirectional flat-pushing clamping device is used for clamping. The electro-hydraulic flat-pushing clamping device comprises a chuck, a piston cylinder A, a piston cylinder B, a plunger type cylinder A, a plunger type cylinder B and a driving device, a piston rod of the piston cylinder A and a piston rod of the piston cylinder B are respectively fixedly connected with clamp splices in the chuck, the piston cylinder A, the piston cylinder B, the plunger type cylinder A and the plunger cylinder B form a communicating vessel, an extending end of a plunger rod of the plunger type cylinder A is fixedly connected with an extending end of a plunger rod of the plunger type cylinder B, and the plunger rod of the plunger type cylinder A and the plunger rod of the plunger type cylinder B are driven by the driving device to move. As the piston cylinder A, the piston cylinder B, the plunger type piston A and the plunger type cylinder B form the communicating vessel, the clamping synchronization performance of the clamp splices is good, and clamping force can be adjusted by controlling rotation of the motor to adjust pressure.

Owner:CHANGCHUN NEW TESTING MACHINE

Welding fixture for automobile part machining

InactiveCN107398668APrevent sideslipAvoid offsetWelding/cutting auxillary devicesAuxillary welding devicesCompression deviceEngineering

The invention discloses a welding fixture for automobile part machining. The welding fixture for automobile part machining comprises a fixture bottom plate, a fixture body and a base, wherein the fixture body is fixed above the fixture bottom plate through a screw; the base is welded below the fixture bottom plate; the fixture body comprises a compression device, a transition block and a support seat; the support seat is L-shaped; the transition block is fixed to a side of the support seat through a plurality of location pins, and the compression device is arranged at the other side of the support seat; a location block is installed above a left side of the transition block through a location pin; an adjustment gasket is placed between the transition block and the location block, and a press block is arranged above the location block; a limit block is fixed to a left side of the transition block through a location pin; the limit block is as high as the location block; and an upper end of the location block faces the press block. The welding fixture for automobile part machining is high in location accuracy, and flexibility degree is remarkably increased; and the structures are relatively independent, simple in structure and convenient to replace, and production and machining costs are remarkably lowered.

Owner:安徽特斯艾尔机电设备有限公司

Gantry milling workpiece clamp

InactiveCN104669007AImprove machining accuracyAdjust clamping forceMeasurement/indication equipmentsMetal working apparatusReduction driveElectric machinery

The invention discloses a gantry milling workpiece clamp, and belongs to the technical field of a tooling clamp. The clamp comprises a base, wherein the bottom surface of the base is a plane, the upper end of the base is provided with a concave cavity corresponding to a bulge arranged at the bottom of a workpiece, the two sides of the base are respectively provided with a workpiece clamp which can clamp the workpiece through being driven by a power machine, each workpiece clamp comprises a first clamping seat and a second clamping seat which are connected with a screw rod through screw threads, the second clamping seat is fixedly connected with the side wall of the base, a telescopic guide post is arranged between the first clamping seat and the second clamping seat, a locking screw is arranged on the telescopic guide post, the power machine is a motor, and one end of the screw thread is connected with an output shaft of the motor through a speed reducer. The gantry milling workpiece clamp can solve the problem that the workpiece provided with the bulge at the bottom surface cannot be processed by the gantry milling.

Owner:LIUZHOU YONGYI MACHINERY MFG

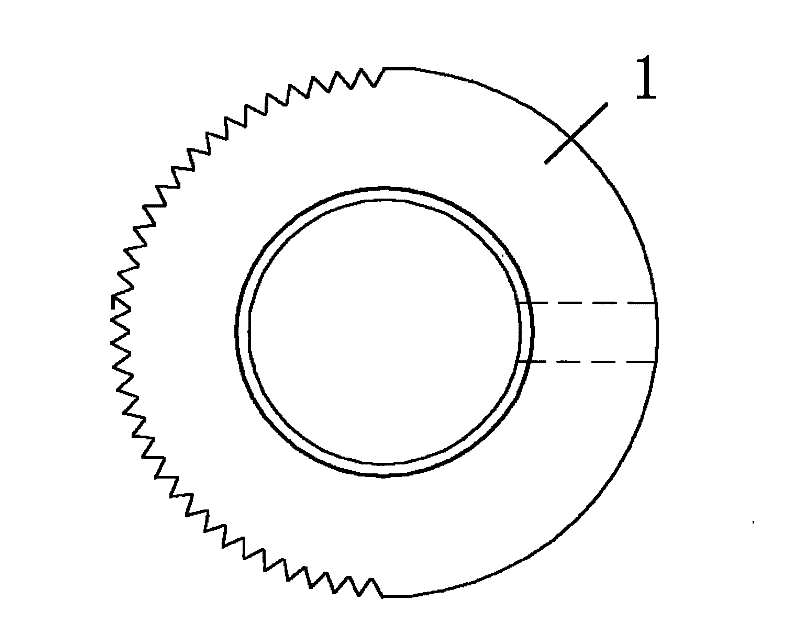

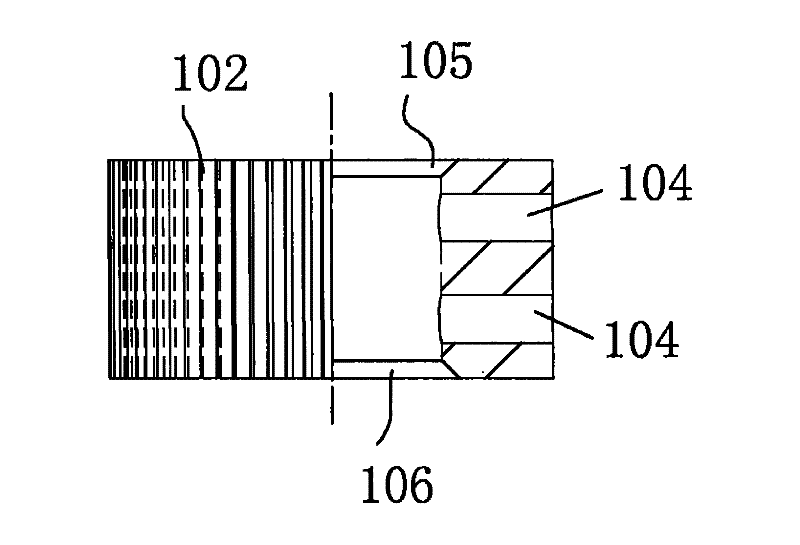

Semi-gear

The invention discloses a semi-gear which comprises a cylinder which is provided with a through hole. Teeth are arranged at the periphery of the cylinder. Half of the periphery of cylinder is provided with teeth while the other half thereof is a smooth surface. Pin holes are arranged at the smooth surface, the pin holes are communicated with the through hole. Teeth are arranged at the other half of periphery of the cylinder, so that a transmission shaft can be fixed at any position within the scope of 180 degrees. With the function of the transmission shaft, rotation positions of an eccentric wheel can be adjusted so as to adjust clamp force of two roller wheels.

Owner:BOZHON PRECISION IND TECH CO LTD

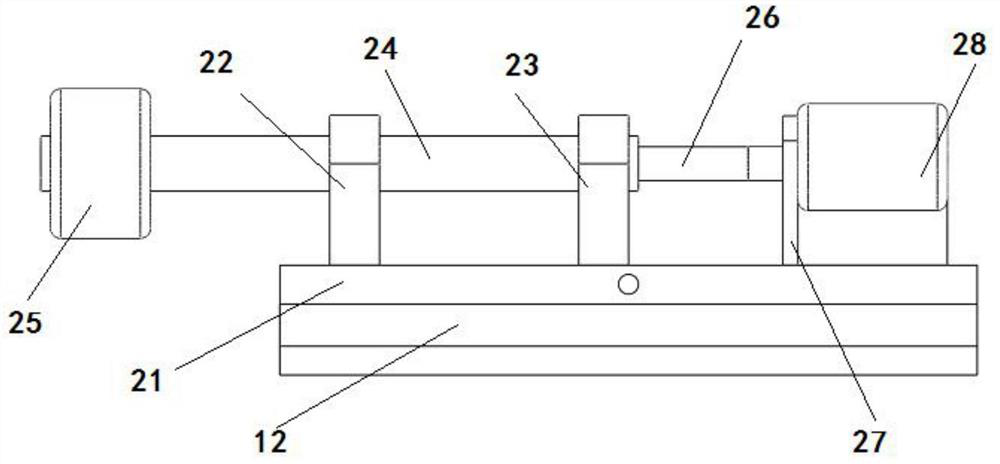

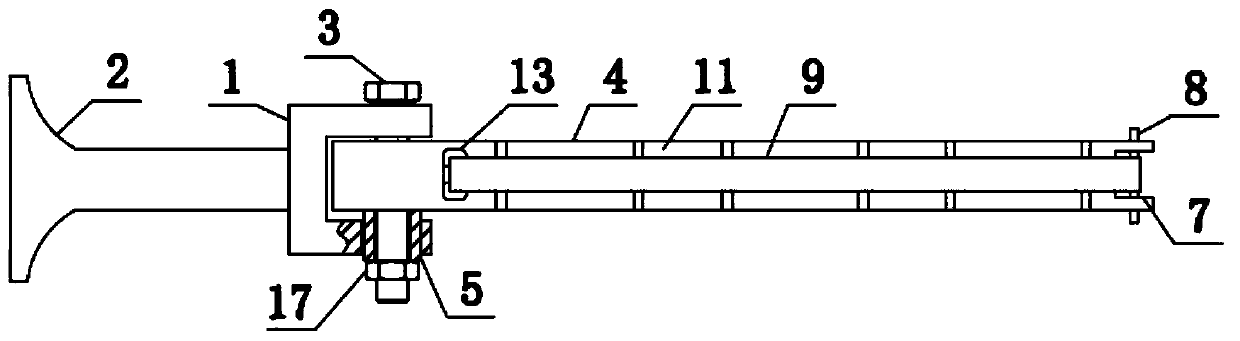

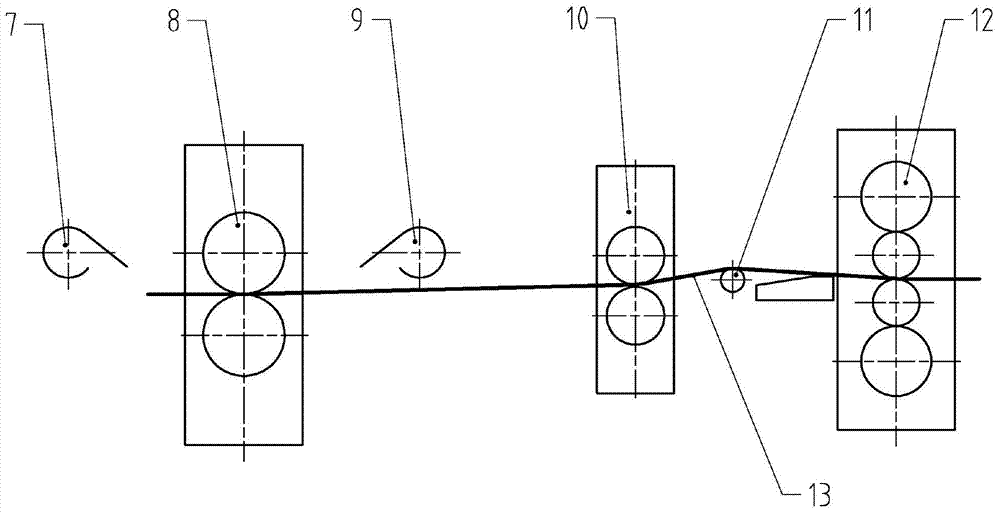

Traction mechanism for glass substrate production

ActiveCN113548473AAdjust clamping forceAvoid clampingControl devices for conveyorsCharge manipulationEngineeringMechanical engineering

The invention discloses a traction mechanism for glass substrate production. The traction mechanism comprises a mounting base, a floating traction structure and a fixed traction structure are respectively mounted at the front side and the rear side of the upper end of the mounting base, and an adjusting driving mechanism for moving the floating traction structure is further mounted at the front side of the upper end of the mounting base; and the floating traction structure is connected with the fixed traction structure through a transmission mechanism, a heat insulation assembly is installed at the right side of the upper end of the fixed traction structure, and a clamping force display structure is installed at the right side of the heat insulation assembly. According to the traction mechanism, the floating traction structure, the fixed traction structure and the transmission mechanism are jointly matched to perform traction forming on a glass tape, and the clamping force of the floating traction structure and the fixed traction structure on a glass plate can be accurately adjusted through the adjusting driving mechanism and the clamping force display structure, so that the clamping force of the floating traction structure is effectively prevented from being too large or too small, the stability of the production state and the warping grade of a glass substrate can be ensured, and the forming quality of the glass substrate is ensured.

Owner:RAINBOW (HEFEI) LIQUID CRYSTAL GLASS CO LTD

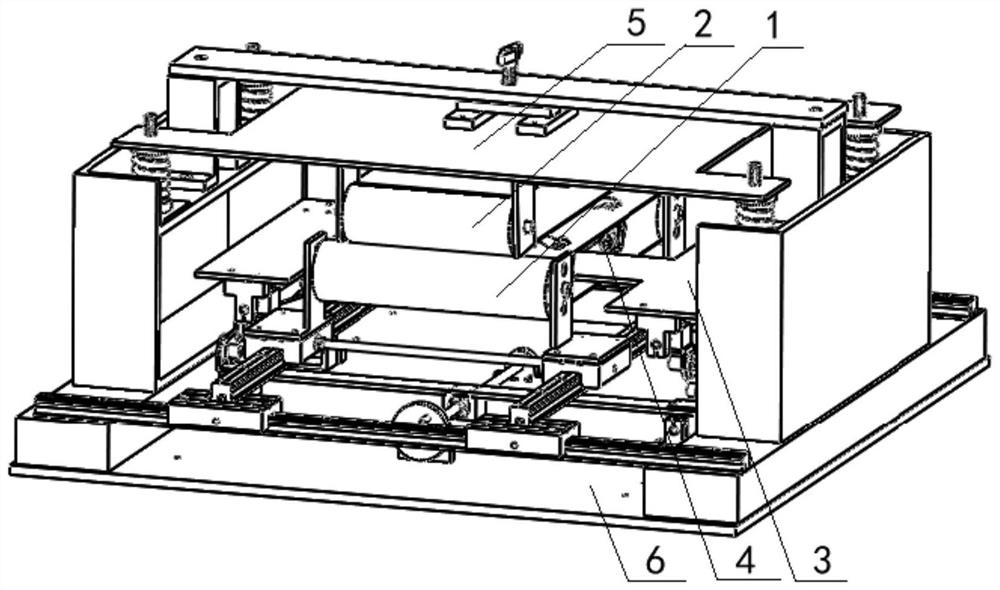

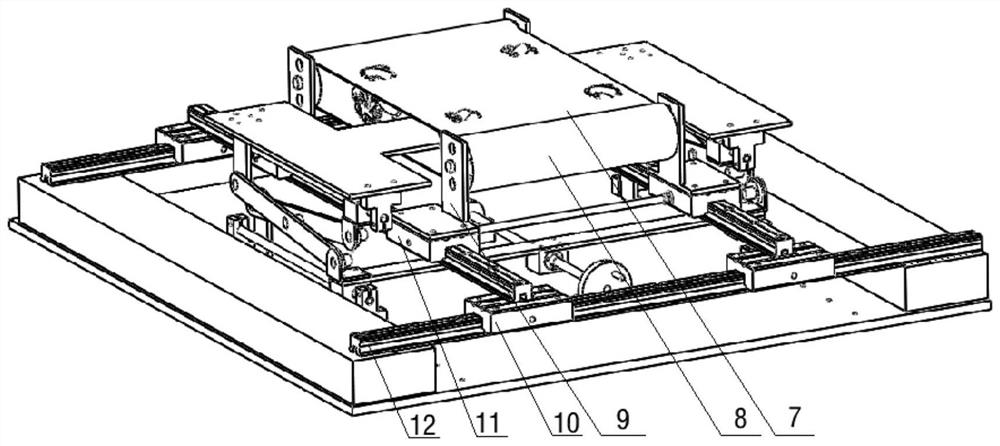

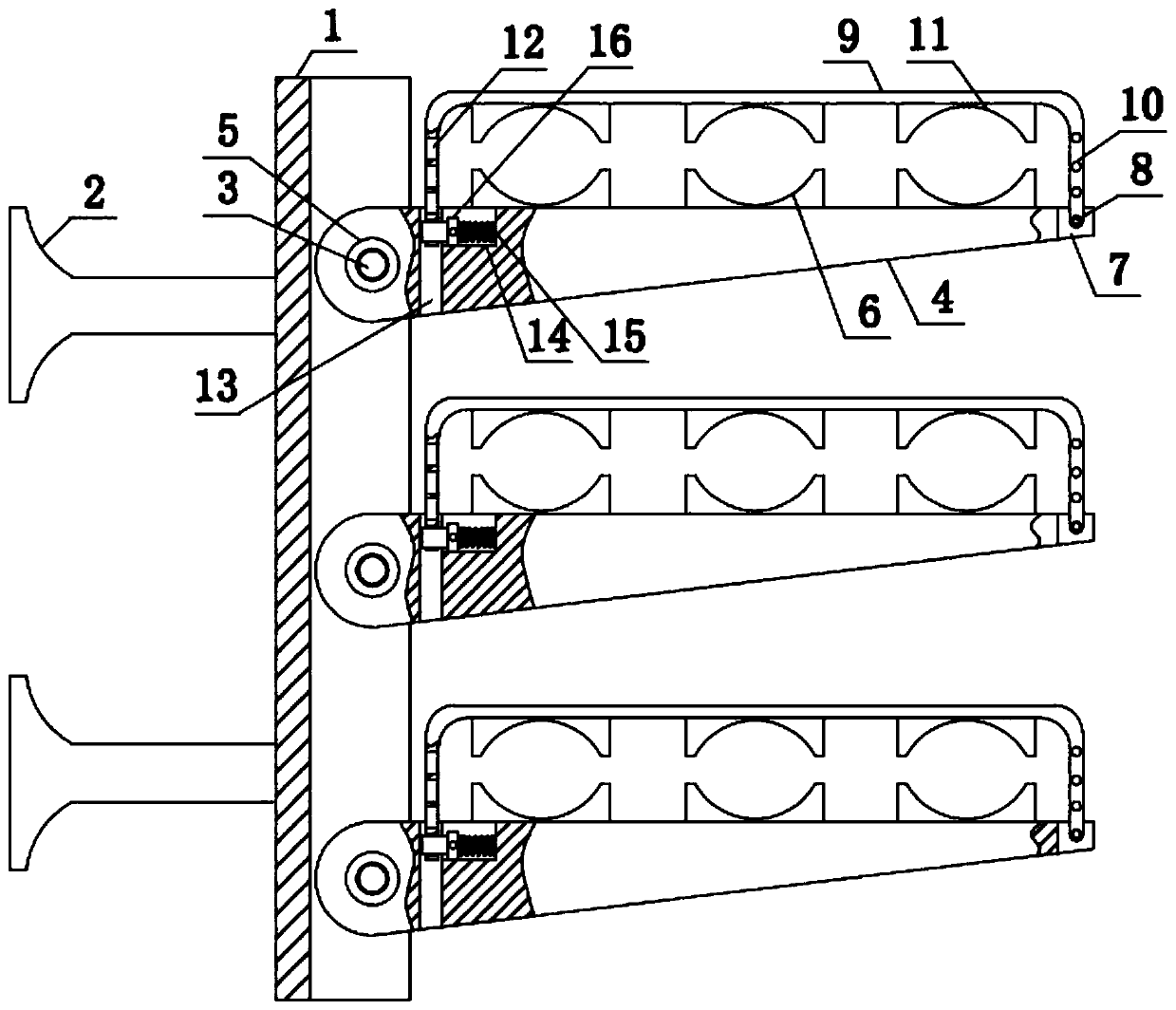

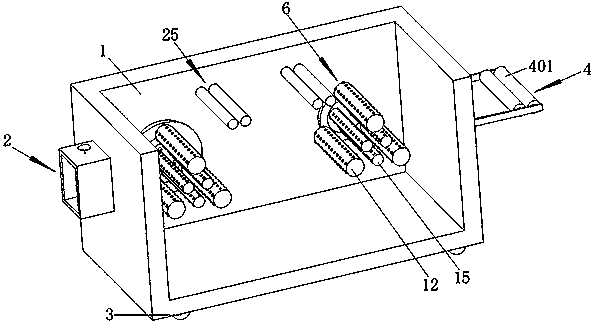

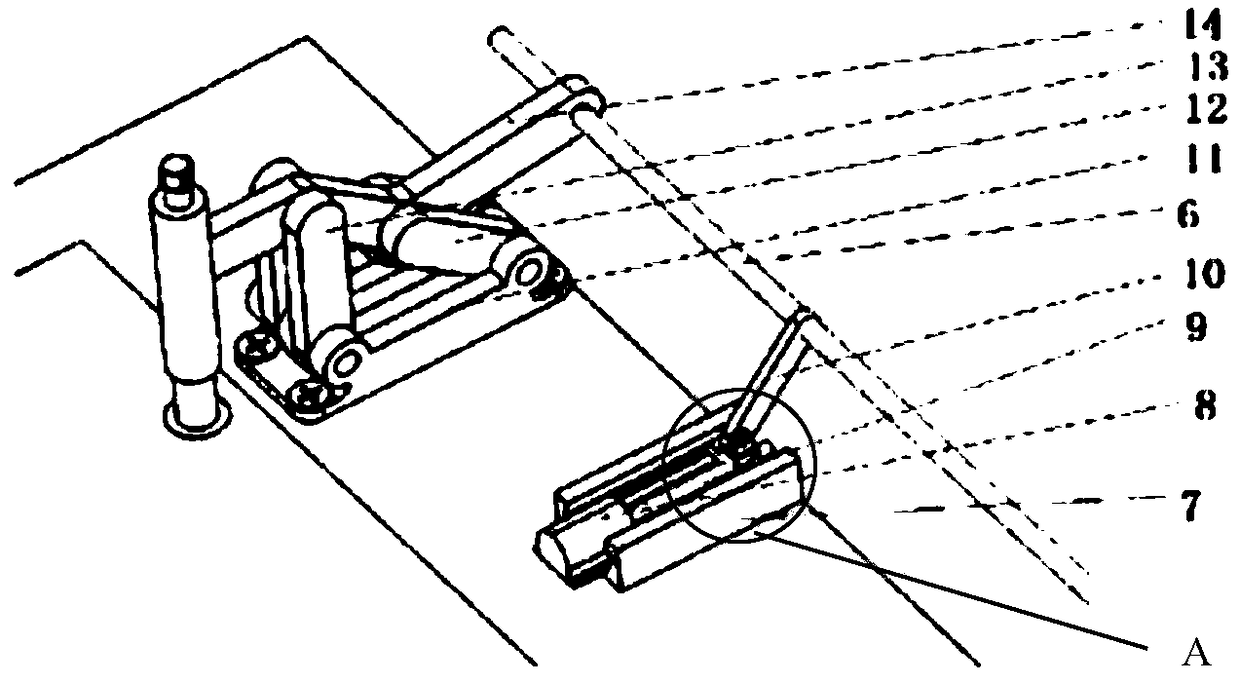

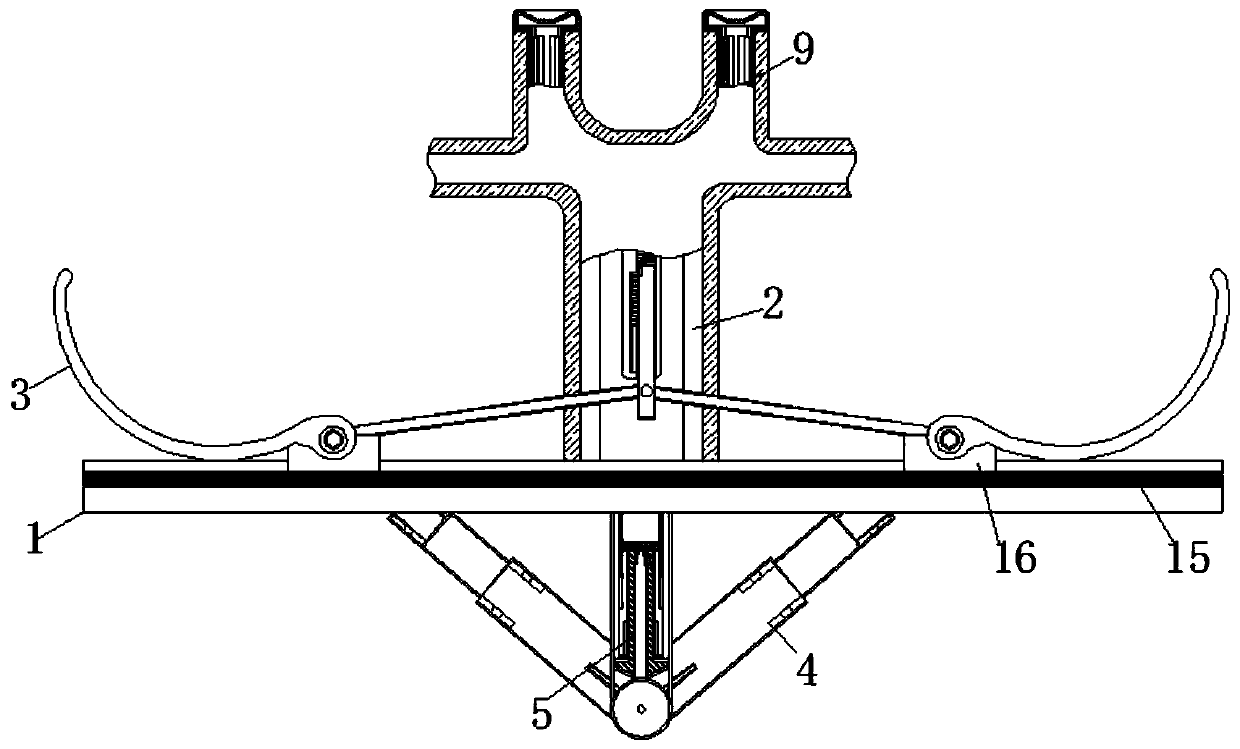

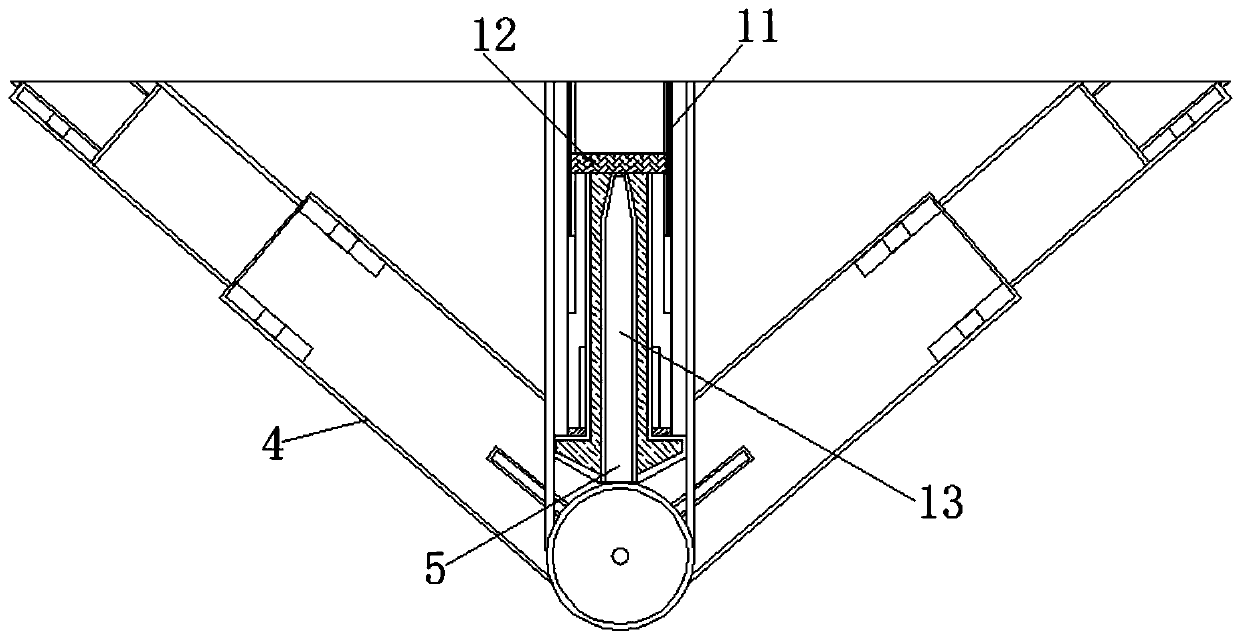

Vascular interventional instrument twisting device and method

ActiveCN113974787AAdjust clamping forceEffective Twisting ForceSurgical needlesFilament handlingControl engineeringStructural engineering

The invention relates to the technical field of surgical robots, and provides a blood vessel interventional instrument twisting device and method. The blood vessel interventional instrument twisting device comprises a supporting table on which two parallel first guide rails are arranged; a driving wire feeding mechanism which comprises a first support assembly, a driving conveying belt and a driving carrier roller belt wheel, the first support assembly being arranged on the first guide rail in a sliding mode, and the driving conveying belt being matched with the driving carrier roller belt wheel in a tensioning mode; a pressing mechanism which comprises a second support assembly, an adjusting assembly and a pressing plate; a driven wire feeding mechanism which comprises a driven conveying belt and a driven carrier roller belt wheel. The gap between the driven conveying belt and the driving conveying belt is adjusted through an adjusting assembly to adjust the clamping force on a guide wire, so that the slipping phenomenon in the twisting process is prevented, relative movement between the driving conveying belt and the driven conveying belt is guaranteed, effective twisting force is generated on the guide wire, and the twisting efficiency, the operation efficiency and the safety are improved.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

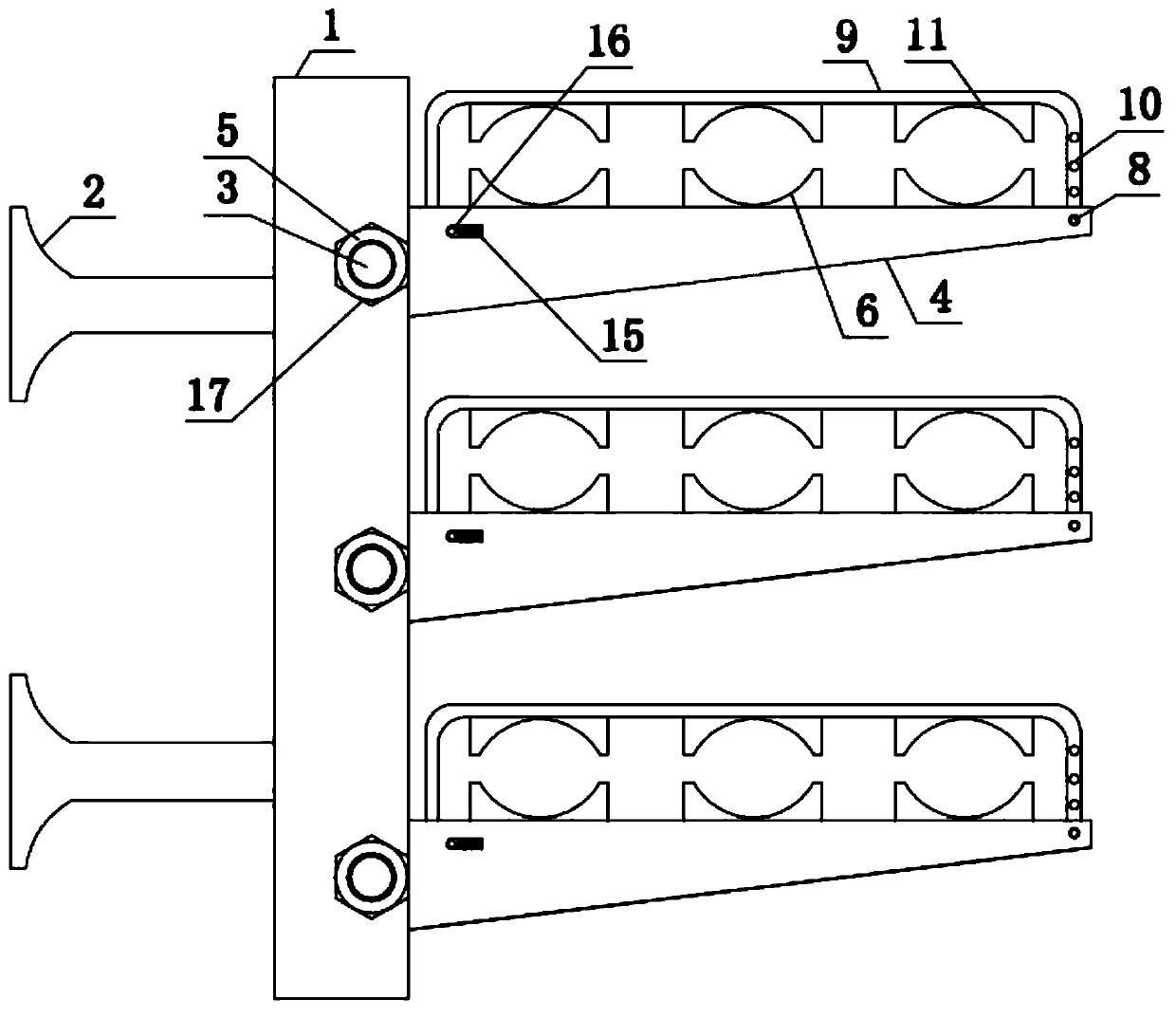

Cable rack pre-buried fixing device for electric power construction

ActiveCN109861157AEasy to fixIncrease swingCable installations in tunnelsElectric powerPetroleum engineering

The present invention discloses a cable rack pre-buried fixing device for electric power construction, and relates to the technical field of cable laying. The device comprises a mounting support, theleft side of the mounting support is provided with a pre-buried fixing head, and the side wall of the mounting support is sleeved with a pin rod, and is hinged with a cable rack plate through the pinrod. The device is provided with the pin rod and a sleeve to achieve convenient regulation, the mounting support and the cable rack plate are hinged, the cable rack plate can swing in a fan shape in and can perform regulation the mounting support through loosening nuts, the sleeve is used as a fastener, the cable rack support forms a certain distance in the mounting support to facilitate swing, one side of the sleeve is attached to the cable rack plate and is fastened by nuts to fasten the sleeve on the cable rack plate to fasten and connect with the cable rack plate to facilitate fixing of the cable rack plate, and according to the actual usage condition, the position of the cable rack plate which allows the cable to be put on is regulated, and the flexibility is high.

Owner:国网山东省电力公司建设公司 +2

Clamping device capable of being automatically adjusted according to workpiece and used for vertical machining center

InactiveCN112475993AAutomatically adjust the placement heightAdjust clamping forceLarge fixed membersPositioning apparatusDrive wheelPull force

The invention relates to the technical field of vertical machining centers, and discloses a clamping device capable of being automatically adjusted according to a workpiece and used for a vertical machining center. The clamping device comprises a rack and is characterized in that a rotating wheel is fixedly connected to the top of the rack, wherein a rolling wheel is fixedly connected into the rotating wheel, a clamping block is connected into the rolling wheel in a sliding manner, a tension spring is fixedly connected to the side, away from the rotating wheel, of the clamping block, a push ball is fixedly connected into a carrying frame, and a baffle is fixedly connected to the side, away from a clamping plate, of the push ball. According to the clamping device capable of being automatically adjusted according to the workpiece and used for the vertical machining center, the workpiece descends to drive a measuring wheel to rotate, the measuring wheel drives the rotating wheel to rotate, the rotating wheel drives a suction block to rotate, the suction block drives a magnetic block to move, the magnetic block enables a coil to be powered on, the coil enables a driving wheel to rotate, the driving wheel drives a pressing block to descend through a pull rope, the pressing block and a sliding plate are used in cooperation, and therefore the effect of automatically adjusting the containing height according to the height of the workpiece is achieved.

Owner:厦门语芙涵机械有限公司

Cable-clamping device and method method for using the same

ActiveCN109244974AEasy to operateImprove work efficiencyElectrical apparatusEngineeringMechanical engineering

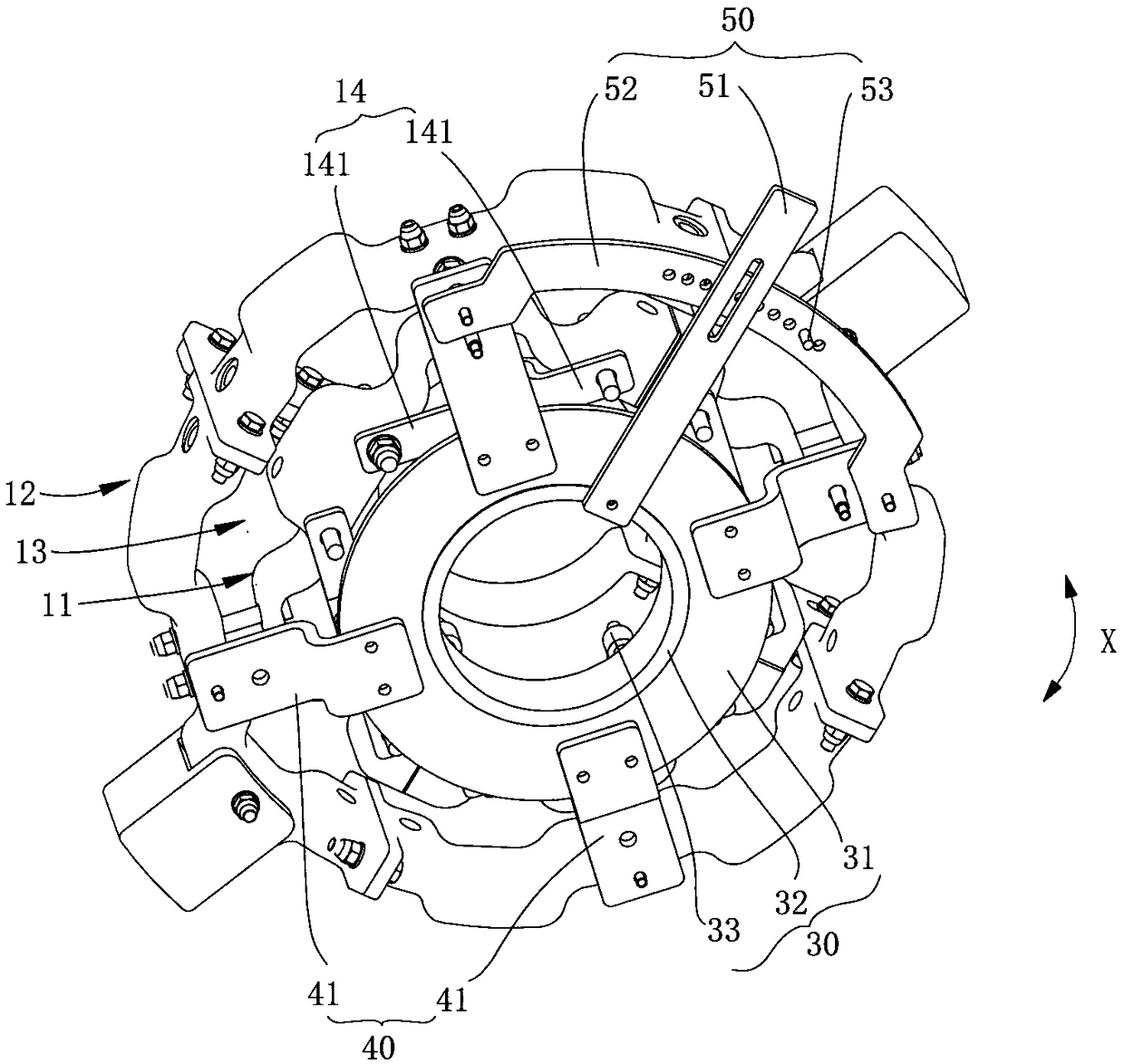

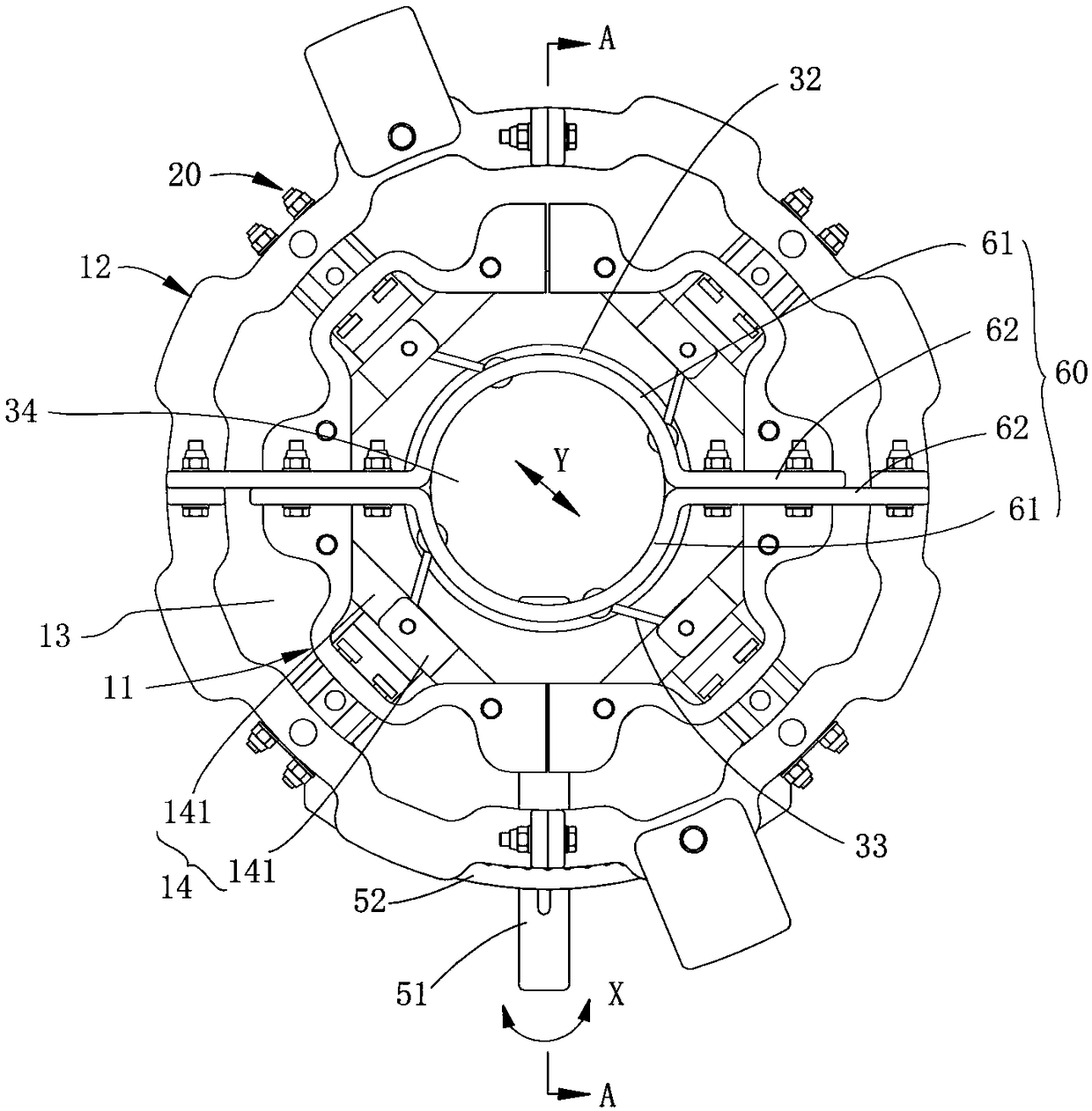

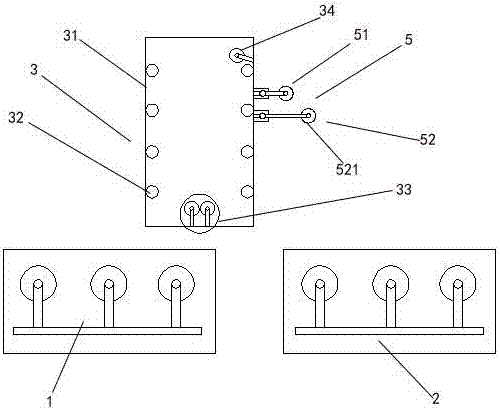

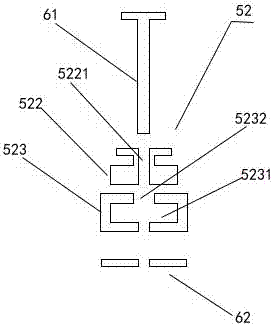

The invention relates to a cable clamping device and a method for using the same. The cable clamping device comprises a clamping assembly including an inner ring, an outer ring and a cable clamping groove formed between the inner ring and the outer ring, which are spaced apart from each other. a connecting assembly connecting inner ring and outer ring; The adjusting assembly comprises a fixed partand a rotating part sleeved with each other and two or more adjusting levers movably connected to the rotating part; The fixing part is fixedly connected with the outer ring, two or more adjusting levers are arranged at intervals around the axis of the inner ring and are both rotatably connected with the inner ring, and the rotating part is rotatably connected with the fixing part and can drive the adjusting lever to swing so as to drive the inner ring to expand in the direction close to the outer ring or contract in the direction far from the outer ring along the connecting assembly. The cable clamping device and the use method thereof provided by the embodiment of the invention can meet the clamping requirements of the cable, can simultaneously complete the adjustment of the clamping force of each cable clamped by the clamping device at one time, and can effectively improve the work efficiency of the operator.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP

Tension-adjusting type shrink film heating mechanism

InactiveCN107021270AEasy to useGuaranteed stabilityWrappers shrinkageWrapping material feeding apparatusEngineeringMechanical engineering

The invention discloses a tension-adjusting type shrink film heating mechanism which comprises a feeding device, a discharging device, a heating device, a clamping mechanism and a tension adjusting mechanism. The tension adjusting mechanism comprises an upper adjusting mechanism and a lower adjusting mechanism. The upper adjusting mechanism and the lower adjusting mechanism each comprise a feeding roller, a sliding rod, a locating plate and a locating assembly, wherein the sliding rod is installed on one side of the feeding roller, a moving groove is formed in the locating plate, the sliding rod is connected into the moving groove of the locating plate in a sliding manner, the sliding rod in the upper adjusting mechanism is shorter than the sliding rod in the lower adjusting mechanism, and the sliding rod and the locating plate are fixed through the locating assembly. By means of telescopic moving of the sliding rods in the upper adjusting mechanism and the lower adjusting mechanism, the length of the upper sliding rod and the length of the lower sliding rod are adjusted to be different, so that the purpose of adjusting tension of shrink films is achieved.

Owner:JIANGSU ZHONGDA PACKING MATERIAL CO LTD

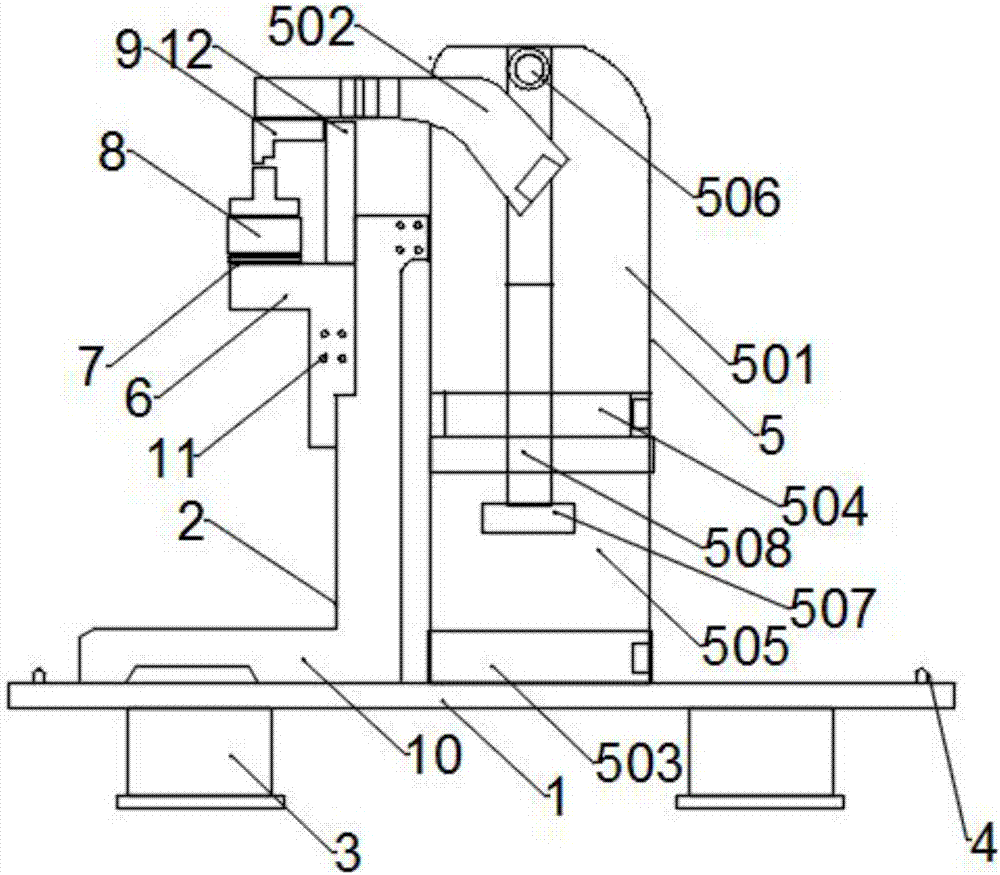

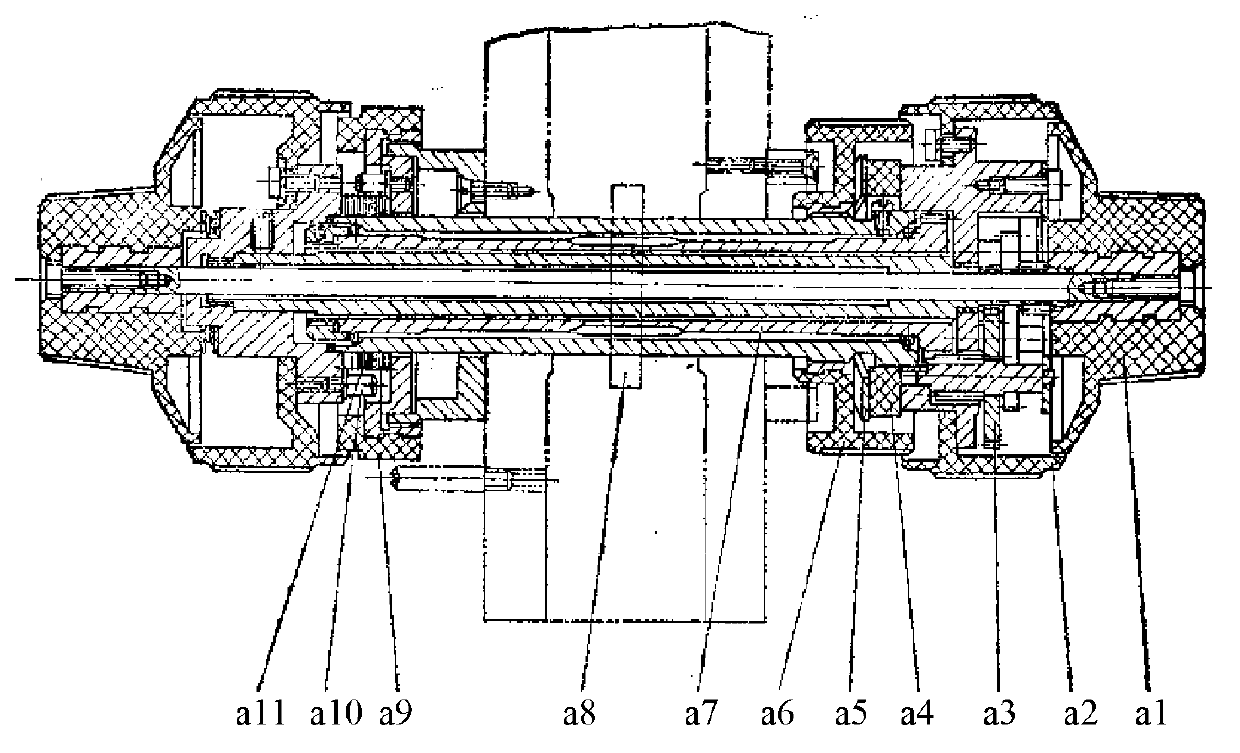

Pinch roll in front of rolling mill

InactiveCN103658198AResolve connection jobsAvoid damageMetal rolling arrangementsHydraulic cylinderSlide plate

The invention discloses a pinch roll in front of a rolling mill. The pinch roll comprises a frame, rolls, transmission devices, hydraulic cylinders and a mill body auxiliary tube, wherein the frame comprises a left side frame sheet, a right side frame sheet, and an upper transverse beam and a lower transverse beam which are fixedly connected between the left side frame sheet and the right side frame sheet; a frame window is enclosed by the left and right side frame sheets and the upper and lower transverse beams; the inner side wall of the frame window is provided with a slide plate; two hydraulic cylinders are fixed on the tops of the left side frame sheet and the right side frame sheet respectively; the two ends of a lower pinch roll are supported on lower pinch roll bearing bases of the left and right side frame sheets respectively through bearings; the two ends of an upper pinch roll are supported on bearing bases respectively through bearings; the two bearing bases are connected with piston rods of the two hydraulic cylinders on the tops of the left and right side frame sheets; the upper and lower pinch rolls are driven by the respective transmission device respectively. The pinch roll has the beneficial effects that the technical problem of pinching of strip steel into a finishing mill during connection operation between a steekle mill unit and the finishing mill is solved, tension can be borne, and the strip steel can be prevented from tilting and damaging the shell of a coiler furnace.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

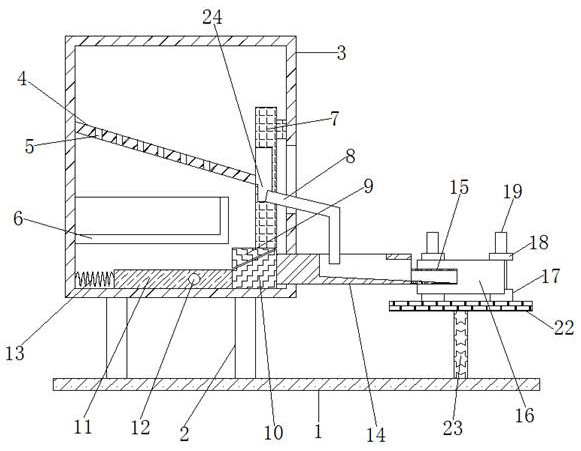

Vacuum packaging device with integrity of tea guaranteed

InactiveCN112572849AIntegrity guaranteedPrevent fallingWrapper twisting/gatheringSolid materialStructural engineeringTea leaf

The invention relates to the technical field of tea packaging, and discloses a vacuum packaging device with integrity of tea guaranteed. The device comprises a bottom plate and a shell, wherein a sliding plate is fixedly connected to the interior of the shell, a movable plate is movably connected to the right wall of the shell, a conveying pipe is fixedly connected to the interior of the movable plate, a pressed block is fixedly connected to the lower side of the movable plate, a pressing block is arranged below the pressed block, the right side of the pressing block is fixedly connected witha material receiving barrel, the right end of the material receiving barrel is fixedly connected with a flat-port pipe, the flat-port pipe extends into a packaging bag, the four corners of the packaging bag are each provided with a fixed clamping plate and a movable clamping plate, an adjusting bolt is connected between each fixed clamping plate and the corresponding movable clamping plate, and asecond spring is arranged on the outer ring of each adjusting bolt. According to the vacuum packaging device capable of guaranteeing the integrity of the tea leaves, during working, the flat-port pipecan move outwards from the innermost end of the packaging bag, tea leaves can be stably laid in the packaging bag, it is avoided that the tea leaves are impacted and broken due to gravity, and an alarm can be given out in the vacuumizing process.

Owner:HUNAN UNIV OF TECH

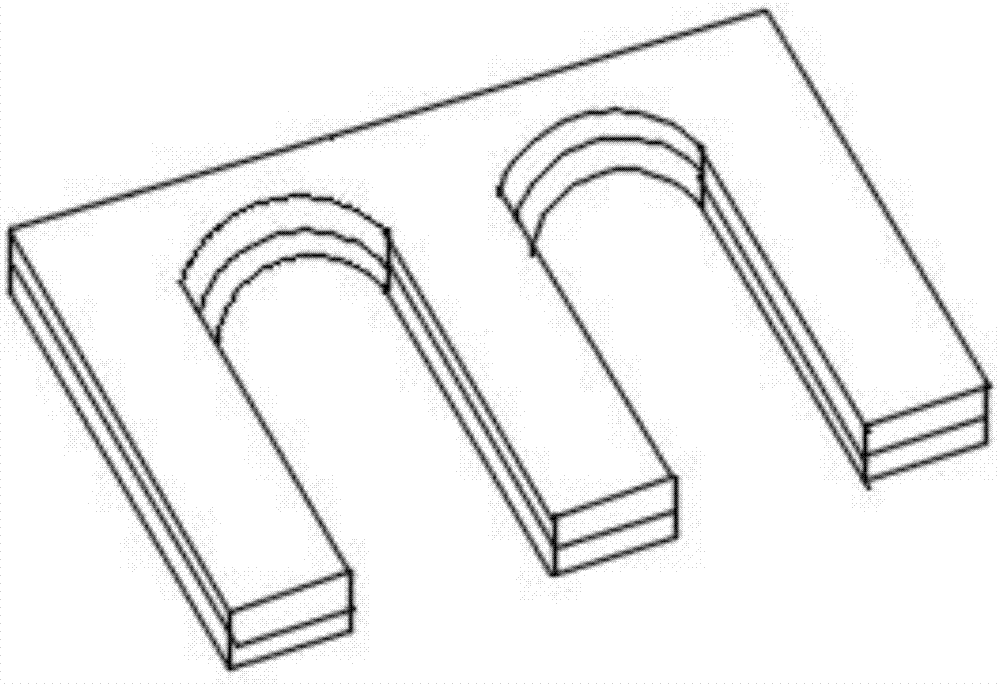

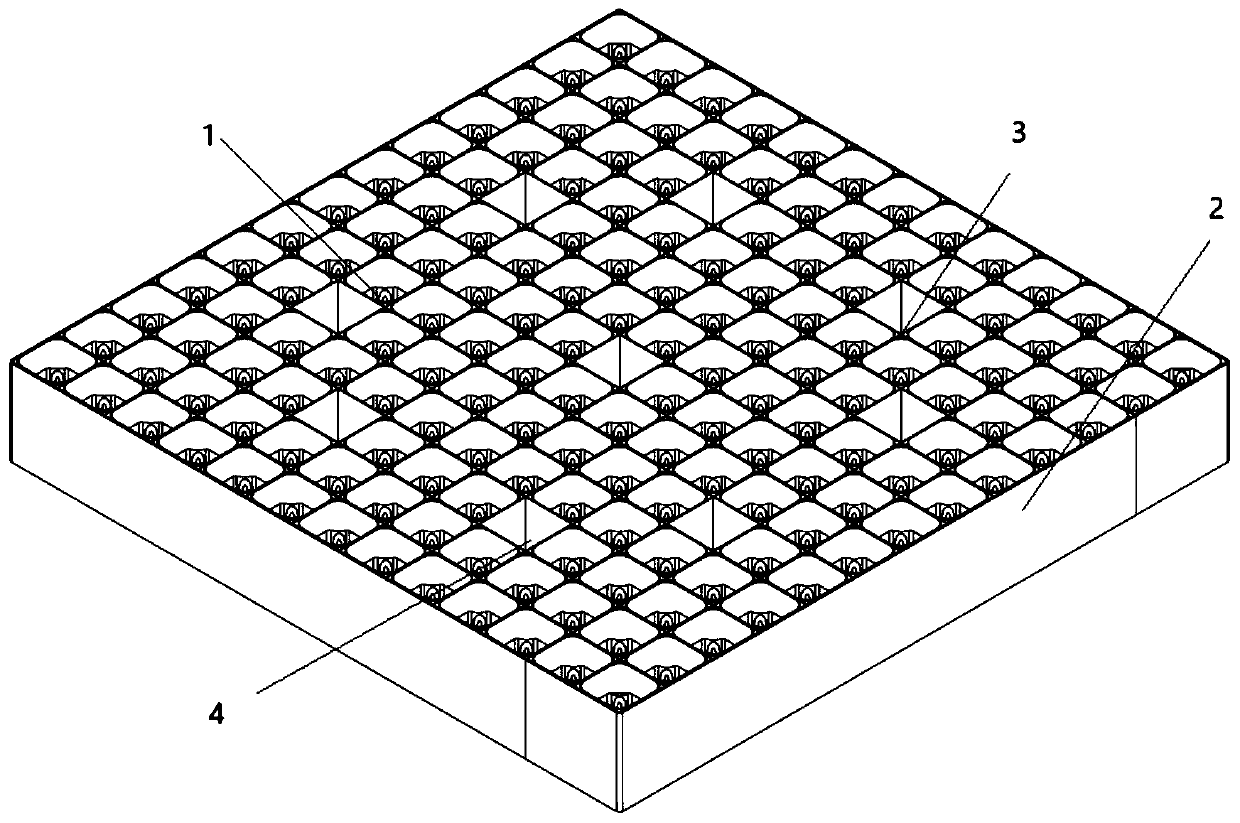

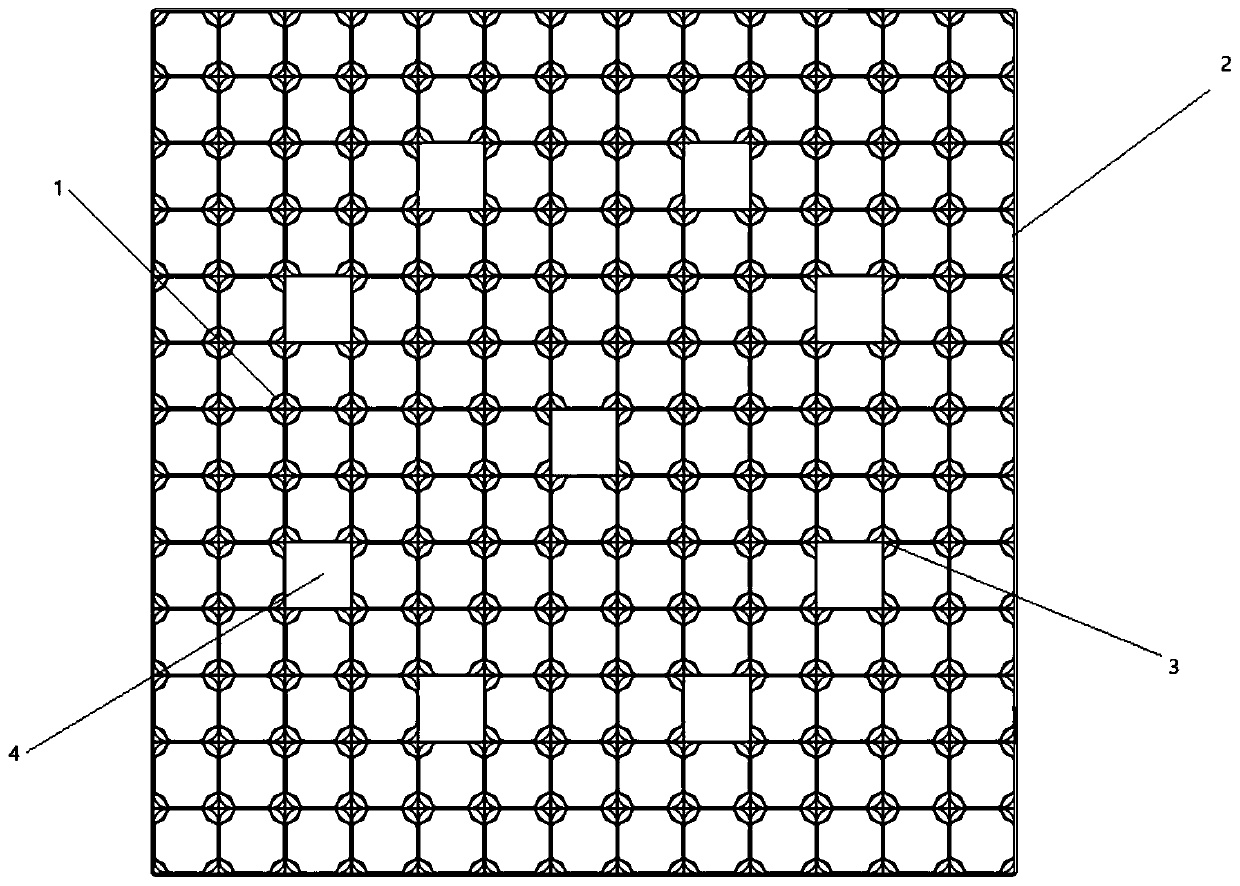

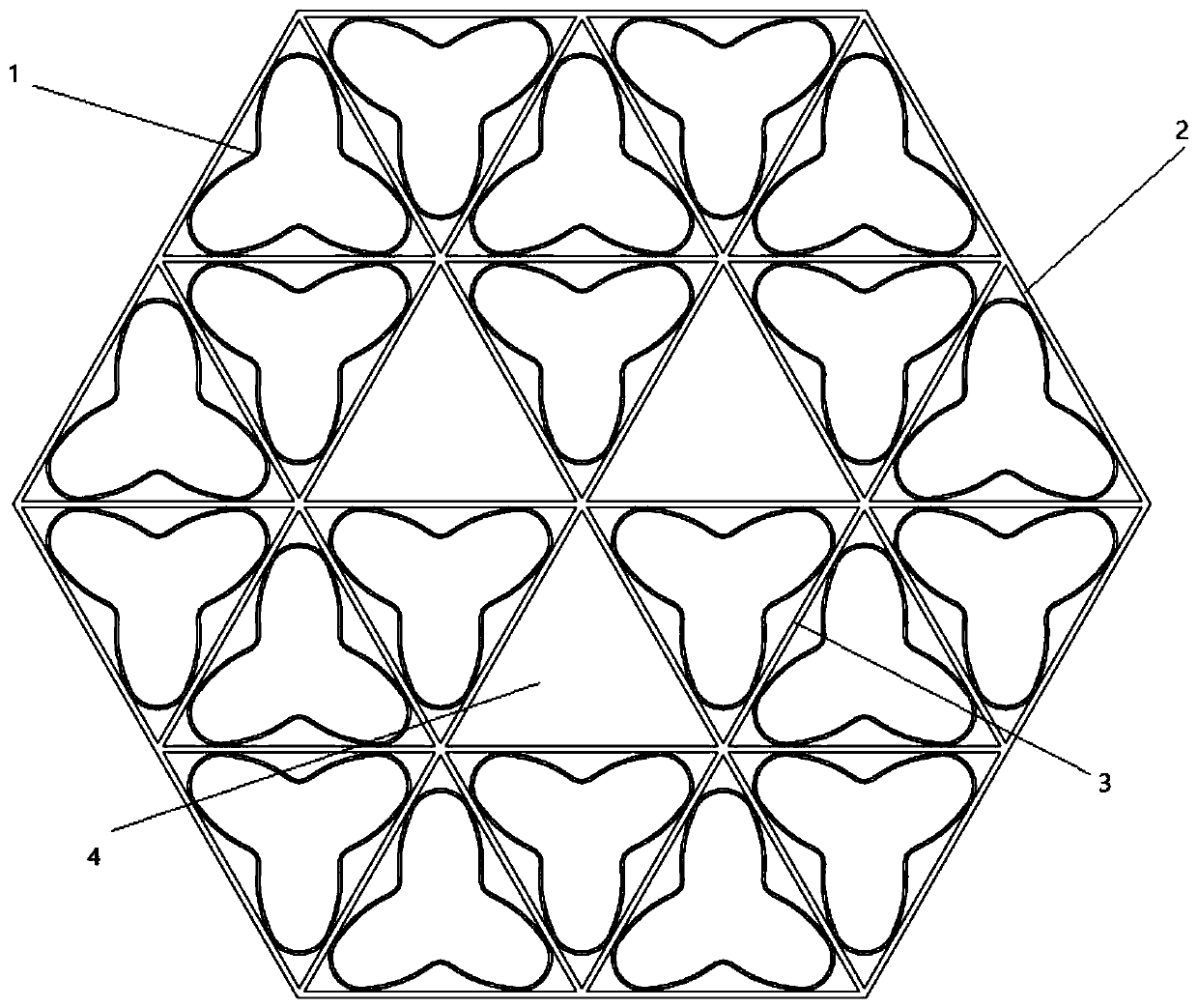

Strip-lattice cell combined type positioning grid

PendingCN111477358AAdjust clamping forceSimple structureNuclear energy generationReactor fuel elementsEngineeringMechanical engineering

The invention belongs to the technical field of fuel assemblies, and particularly relates to a strip-lattice cell combined type positioning grid. The positioning grid comprises lattice cells, an outerstrip and inner strips, wherein the plurality of inner strips are mutually spliced and arranged to form a square or hexagonal structure, and the outer strip in a circle form is welded and fixed around the square or hexagonal structure; and the lattice cells are welded in grid spaces formed by mutually inserting the inner strips. Planes or protrusions are machined at the cylinder corners of the lattice cell structure to serve as supporting structures to be used for supporting fuel rods at the opposite corners of grids, and the lattice cell structure is suitable for fuel assemblies with large rod diameters and small grid distances of the fuel rods. The clamping force of the supporting structure on fuel rods can be adjusted according to the design requirements of the fuel assembly by adjusting planes or bulges at the cylinder corners of the lattice cell structures; due to the adoption of the structural form that the inner strips are used as the frame, different lattice cell forms can beadopted in different lattices of the same positioning lattice frame, and the positioning grid is suitable for a situation that fuel rods with different rod diameters are adopted in the same fuel assembly.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

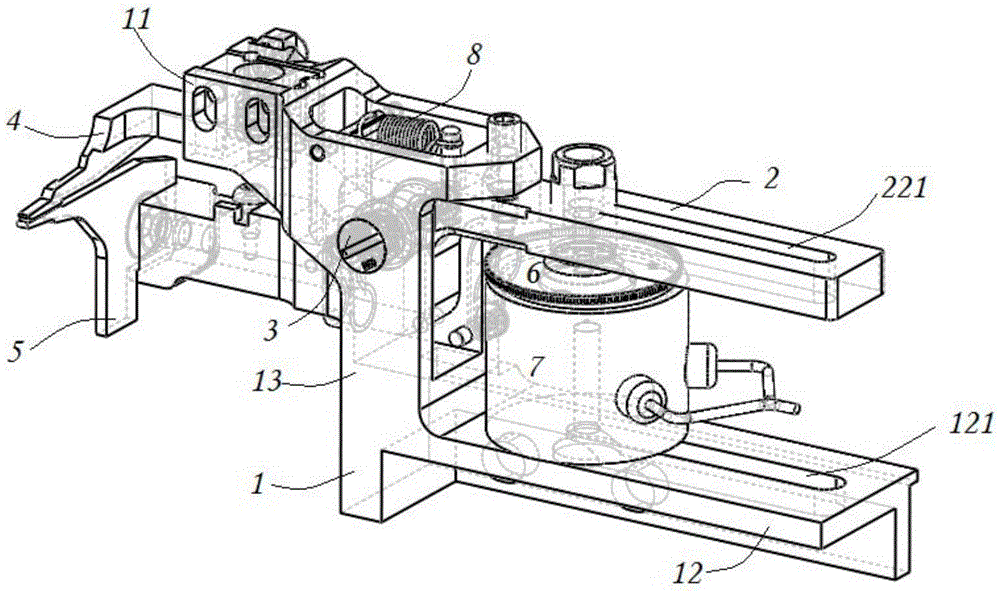

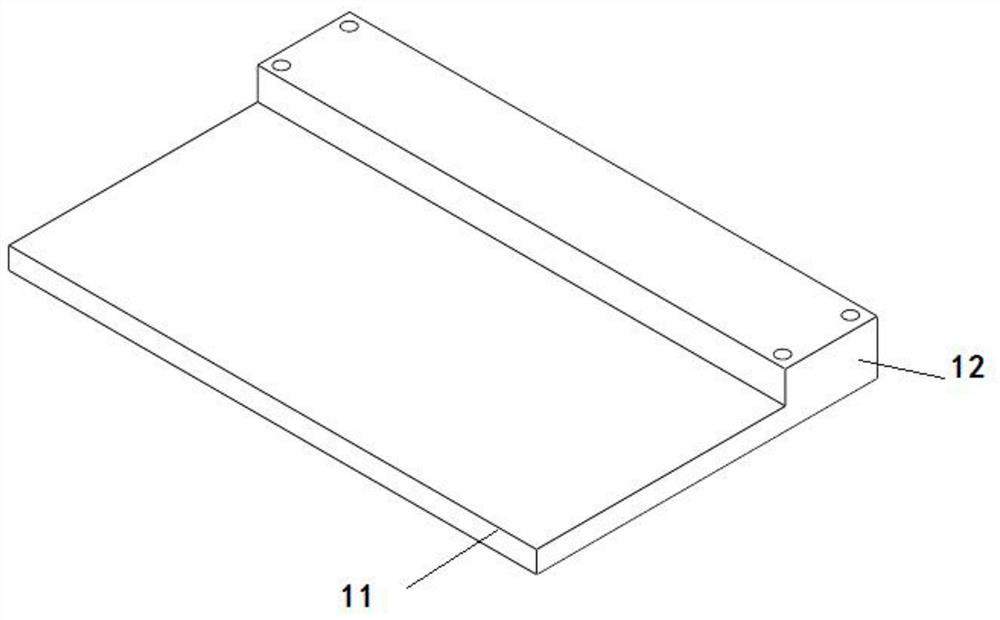

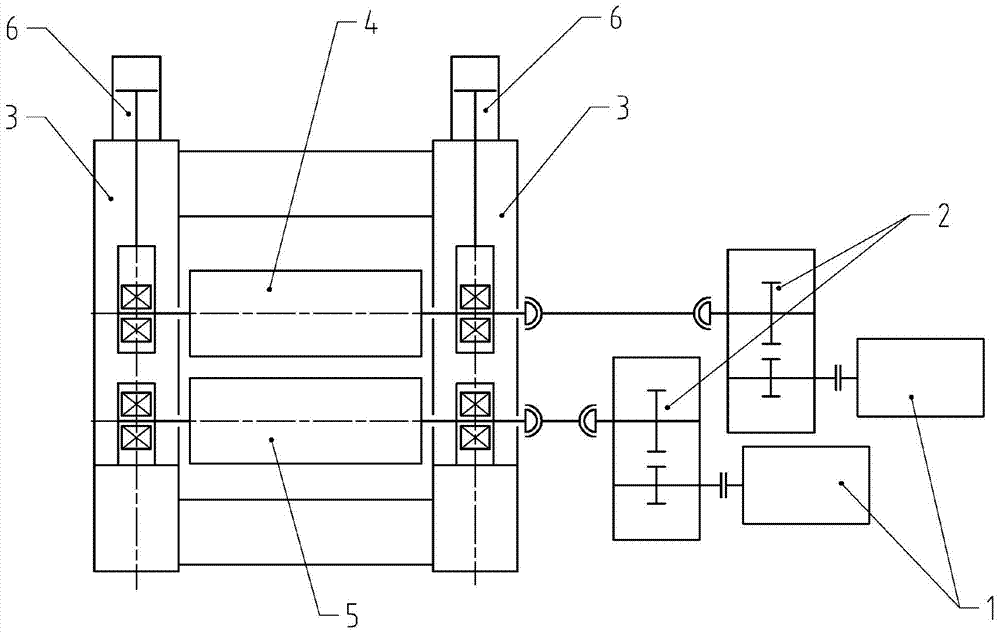

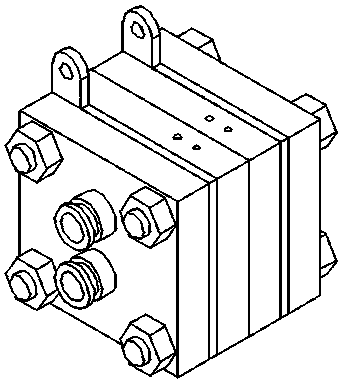

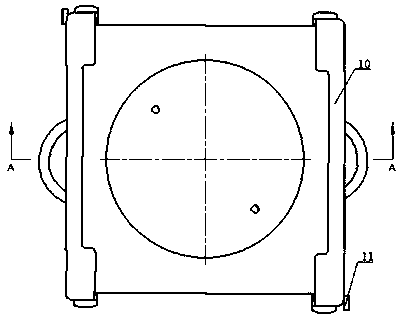

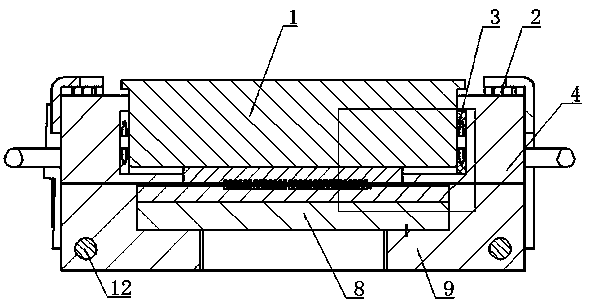

Fuel cell fixture convenient for quick disassembly and assembly

ActiveCN110289433AImprove work efficiencyEasy to assemble and disassembleFinal product manufactureFuel cellsFuel cellsBiochemical engineering

The invention discloses a fuel cell fixture convenient for quick disassembly and assembly. The fuel cell fixture convenient for quick disassembly and assembly comprises a membrane electrode; two sides of the membrane electrode are provided with a cathode plate and an anode plate respectively; one side, far away from the membrane electrode, of the cathode plate is provided with a gas guiding piston; a cathode frame is arranged outside the gas guiding piston and the cathode plate; one side, far away from the membrane electrode, of the anode plate is provided with an anode pad plate; an anode frame is arranged outside the anode pad plate and the anode plate; one side, far away from the cathode plate, of the cathode frame is provided with multiple adjustable screws; the anode frame is hinged with a fixing frame for tightly pressing the cathode frame; and after the fixing frame and the cathode plate are clamped, the outer plane of the adjustable screw is contacted with the inner plane of the fixing frame. The fixture solves the problems of assembly and clamping during the fuel cell testing and production process, and the air tightness of the fixture is improved.

Owner:SHANDONG JIANZHU UNIV

Filament winding tension adjusting device for moisture absorption and sweat releasing polyester filament feeding and winding machine

PendingCN108977904AAdjustable tensionRealize the winding processNew-spun product collectionArtificial filament supportWinding machinePolyester

The invention discloses a filament winding tension adjusting device for a moisture absorption and sweat releasing polyester filament feeding and winding machine, belonging to the technical field of filament winding and tension adjustment. The device comprises a box body, a pre-traction mechanism, a rotary wheel, a traction mechanism and a polyester filament. The pre-traction mechanism is fixedly connected to the side wall of the box body. The rotary wheel is rotatably connected to the bottom of the box body. The traction mechanism is arranged on one end, away from the pre-traction mechanism, outside the box body. The interior of the box body is connected with symmetrically-distributed winding mechanisms. Adjusting assemblies are arranged in the winding mechanisms. The polyester filament orderly bypasses the pre-traction mechanism, the winding mechanisms and the traction mechanism. The device is convenient to operate. When fixing filament-guide rollers remain relatively fixed positions,adjusting filament-guide rollers of the winding mechanism can adjust tension during winding of polyester filaments.

Owner:HUAXIANG (CHINA) HIGH FIBER CO LTD

High-precision silicon carbide lens rapid clamping device for polishing

ActiveCN108942515AReduce deformationAvoid damageOptical surface grinding machinesOptoelectronicsSelf locking

The invention belongs to the technical field of machining clamps, and particularly relates to a high-precision silicon carbide lens rapid clamping device for polishing. The clamping force of the high-precision silicon carbide lens rapid clamping device is adjustable; the clamping force is very small after being distributed to each clamping device, and damage to a precise silicon carbide lens is correspondingly reduced; deformation of the lens caused by the clamping force is small, or the integral deformation is in the same direction and is uniform, so that precision controllability at a clamping part is good; clamping devices on the same side of the placement table are driven by a linkage device, and clamping and releasing can be controlled with a very small force; resisting blocks of theclamping devices abut against corresponding first rockers during clamping, so that self-locking of the clamping devices on the same side is realized, and damage to the silicon carbide lens caused by overlarge pressure is avoided; screws are arranged on parts, which are above pressure sensors, in round barrels, so that clamping forces of different clamping devices can be adjusted; and optimum clamping forces at different positions of the silicon carbide lens are provided.

Owner:YANGZHOU XIAGUANG OPTICAL ELECTRONICS CO LTD

Earphone microphone capable of adjusting clamping force

InactiveCN101330766BAdjust clamping forceSimple structureEarpiece/earphone attachmentsMouthpiece/microphone attachmentsEngineeringHeadphones

The invention discloses an earphone microphone the clamping force of which is adjustable. The earphone microphone is provided with earphones and a connecting rod connected with the earphones; the connecting rod connected with the earphones is divided into a left part and a right part; the left part is hinged with the right part; a clamping force adjusting mechanism is arranged in the middle of the connecting rod; the clamping force adjusting mechanism comprises a supporting frame, a connecting rod fixing seat and an adjusting screw rod, wherein the supporting frame is articulated with the left connecting rod and the right connecting rod; the connecting rod fixing seat is hinged with the ends of the left connecting rod and the right connecting rod; the adjusting screw rod is positioned between the supporting frame and the connecting rod fixing seat, and used for adjusting the distance between the supporting frame and the connecting rod fixing seat. Because the adjusting mechanism whichcan adjust the opening between the left earphone and the right earphone is arranged on the connecting rod between the two earphones, the purpose of adjusting the clamping force between the two earphones is achieved; furthermore, the earphone microphone has the advantages of simple structure, convenient use and comfortable wear.

Owner:NINGBO EXCEL ELECTRONICS

Fastening base for iron core of dry-type transformer

InactiveCN102682965AThe force point is reasonableReduce vibrationTransformers/inductances magnetic coresInductances/transformers/magnets manufactureFastenerEngineering

The invention provides a fastening base for an iron core of a dry-type transformer. The fastening base comprises a base, two lower clamping parts and fastening parts, fixing parts are respectively arranged at two ends of the base, the two lower clamping parts are disposed between the two fixing parts, a nut is fixedly disposed on the outer side of each lower clamping part, through holes corresponding to the nuts are arranged on the fixing parts, and the nuts penetrate through the through holes, so that the lower clamping parts are connected with the fastening parts and connected with the corresponding fixing parts. The fastening base can uniformly and effectively clamp the iron core, accordingly, vibration of an iron core plate is reduced, and noise is effectively lowered.

Owner:ZHENJIANG TIANLI TRANSFORMER

Dental extraction oral cavity supporting device for children

ActiveCN110353847AAdjust clamping forcePrevent tamperingDentistryInstruments for stereotaxic surgeryDental extractionEngineering

The invention relates to the technical field of oral cavity supporting frames and discloses a dental extraction oral cavity supporting device for children. The device comprises a support frame, wherein the upper part of the support frame is fixedly connected with a hollow channel, both sides of the hollow channel are movably connected with arc plates respectively, and the lower part of the supportframe is movably connected with a retractable rod; a pushing mechanism is fixedly connected to the junction between the retractable rod and the support frame, a clamping groove is movably connected into the hollow channel, and the surface of the clamping groove is slidably connected with a clamping block; the upper part of the clamping block is movably connected with a spring, so that a push rodmoves downwards in a sliding way and is discharged from an exhaust pipe; meanwhile, the retractable rod is stretched in the process of moving downwards, and the retractable rod and the pushing mechanism are positioned in the oral cavity of a patient. When the retractable rod is stretched out, the tongue of the patient can be pressed, air flow can be continuously blown to the tongue of the patient,and once the tongue is interfered with the air flow, the patient can intentionally shorten the nasal breathing process, so that the effects of preventing children from coughing and moving the tonguesat will are achieved.

Owner:HEILONGJIANG UNIV OF CHINESE MEDICINE

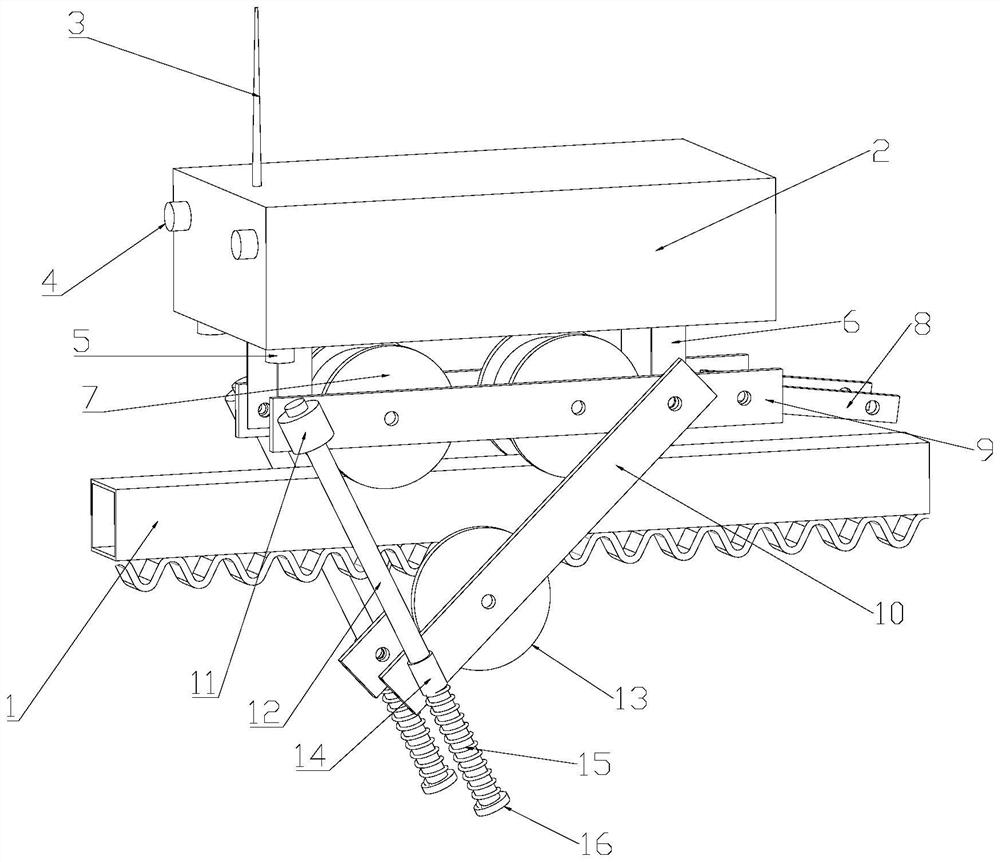

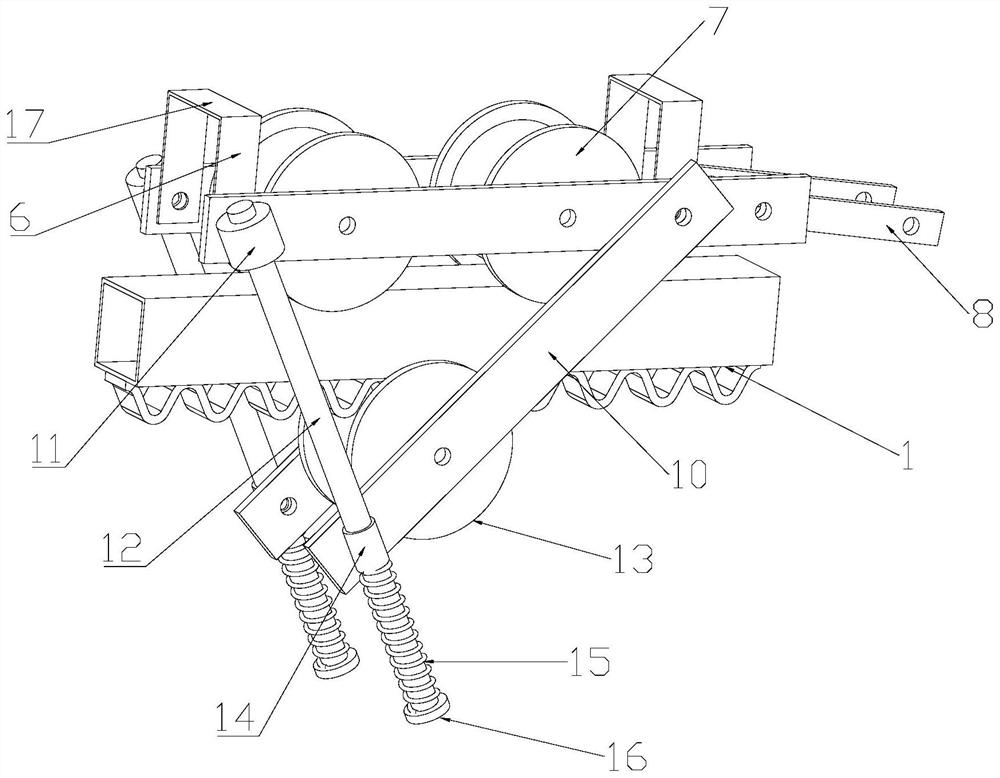

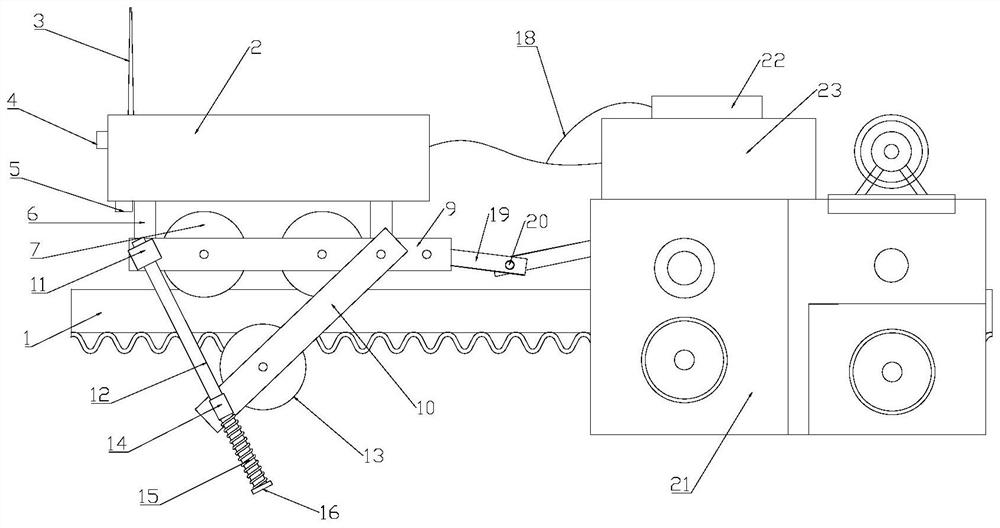

Remote-control obstacle avoidance device suitable for electric monorail transporter and transporter

PendingCN114715202AReduce maintenance costsProtection securityMonorailsRailway transportRemote controlObstacle avoidance

The invention relates to a remote-control obstacle avoidance device suitable for an electric monorail conveyor, and the obstacle avoidance device is connected with the conveyor and moves on a track; the obstacle avoidance device comprises a control box, a communication antenna, a diffuse reflection sensor, a distance sensor, a connecting part, a tightness adjusting part, a movement mechanism and a clamping mechanism; the control box is installed on the movement mechanism, the movement mechanism is connected with the track, the clamping mechanism is connected with the track, and the clamping mechanism is connected with the movement mechanism; the connecting part is connected with the end of the moving mechanism, and the tightness adjusting part is installed on the clamping mechanism. The diffuse reflection sensor is installed in the control box, and the distance sensor is installed in the control box, located at the bottom of the control box and arranged towards the ground. The communication antenna is connected with the control box, and the control box is electrically connected with the conveyor. The invention also relates to a transport vehicle. The robot is high in obstacle avoidance capacity and capable of achieving remote control and belongs to the technical field of hillside orchard transportation equipment.

Owner:SOUTH CHINA AGRI UNIV

Eccentric sleeve and heavy load rough-fine adjustment coaxial microscope

The invention relates to an eccentric sleeve used in a heavy load rough-fine adjustment coaxial microscope. The eccentric sleeve is provided with two or more than two opened grooves along the radial direction, and the opened grooves are used for installation of a shaft gear. The shaft gear penetrates through the eccentric sleeve, and adjusting nuts are arranged at one end of the eccentric sleeve and used for adjusting tightening and loosening of the opened grooves. The heavy load rough-fine adjustment coaxial microscope comprises the eccentric sleeve. An opened-groove structure is adopted in the eccentric sleeve and used for changing clamping force on the shaft gear by the eccentric sleeve in the mode matching with the adjusting nuts, consequently friction force between the eccentric sleeve and the shaft gear can be changed, and therefore hand feel of a hand wheel can be adjusted. With the method, the clamping force on the shaft gear is greatly improved compared with the prior art, load of a rough-fine coaxial adjustment mechanism is improved, and the problem of low load of the rough-fine coaxial adjustment mechanism is solved. In addition, a focusing mechanism is long in stroke, compact in structure and small in occupied space, low cost manufacturing can be achieved, and therefore the eccentric sleeve can be used in small-scale tools like microscopes.

Owner:MOTIC CHINA GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com