High-precision silicon carbide lens rapid clamping device for polishing

A clamping device, high-precision technology, used in grinding/polishing equipment, grinding machines, optical surface grinders, etc., can solve the problems of production and processing personnel injury, splash, silicon carbide lens damage, etc., to achieve low cost, easy automation, Good precision and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

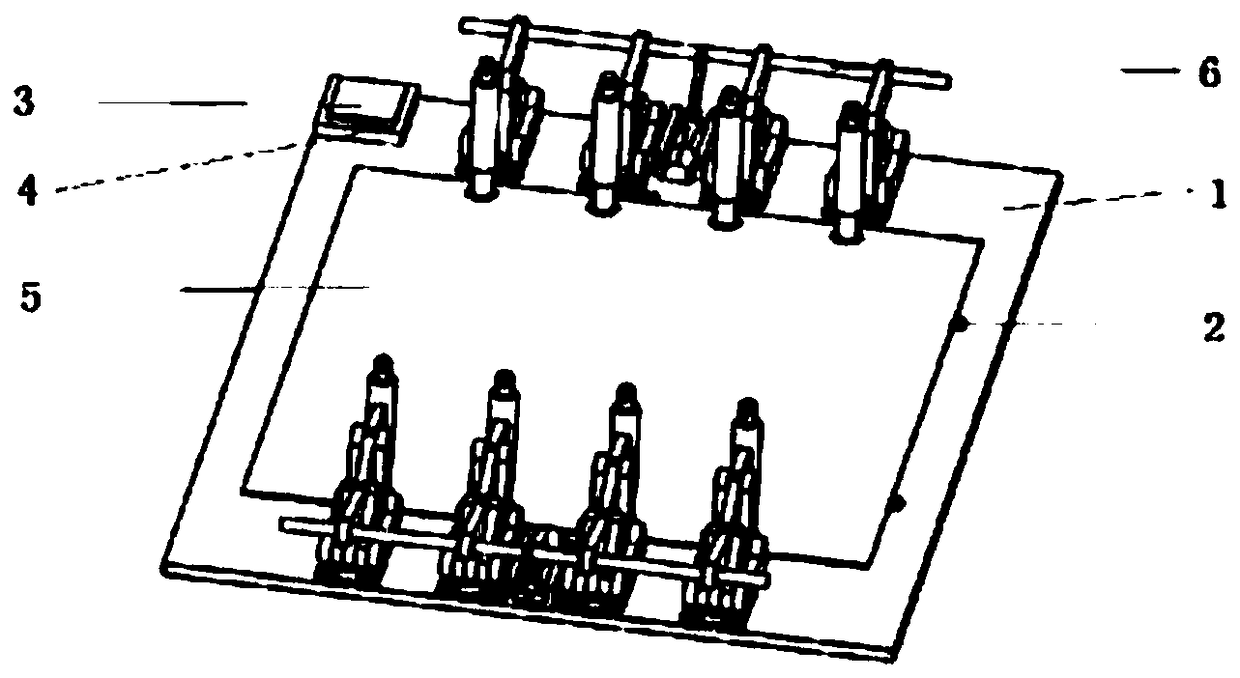

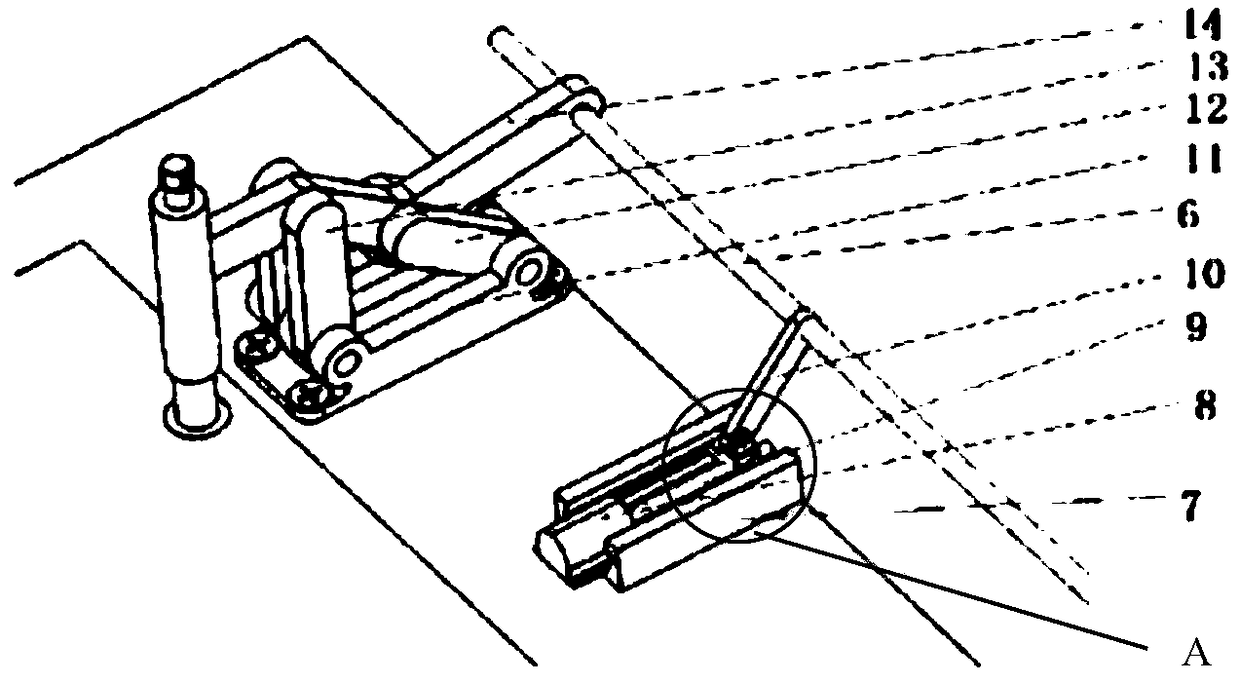

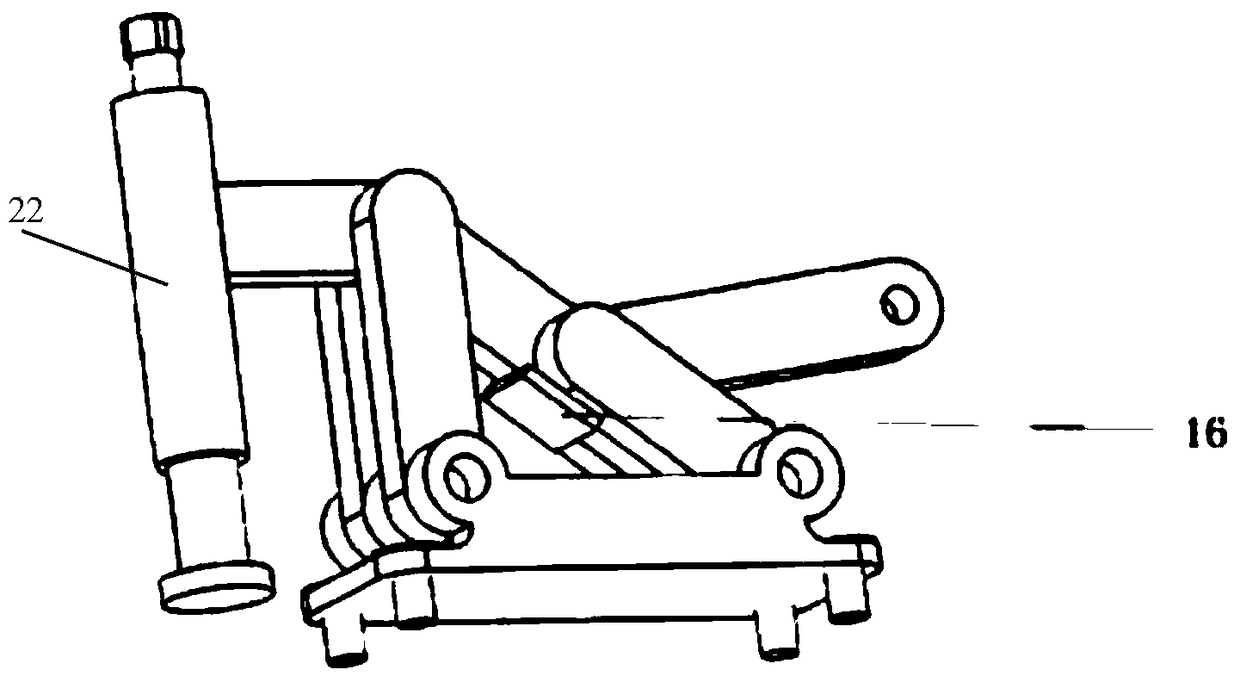

[0030] Such as figure 1 As shown, the high-precision silicon carbide lens quick clamping device for grinding provided by the present invention includes a placement table 1, a display screen 3 and a single-chip microcomputer 4 are arranged at a corner of the placement table 1, and the surface of the placement table 1 is along the lateral direction The positioning block 2 is symmetrically installed on the center line, and the upper and lower sides of the surface of the placing table 1 are symmetrically provided with linkage clamping devices, and the linkage clamping devices include linkage devices and several clamping devices, such as figure 2 with Figure 5 As shown, the linkage device includes a chute 7, the chute 7 is arranged in the middle of the side end of the placement table 1, a motor 8 is installed in the chute 7, and the output end of the motor 8 is connected to a screw 9 , the screw 9 is provided with a slider 15 that slides along the chute 7, the screw 9 rotates un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com