Gripper

A technology of mechanical claws and clamping arms, applied in the field of semiconductor production, can solve problems such as high cost, cumbersome work, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation of this patent will be described below in conjunction with the accompanying drawings. It should be noted that this specific implementation is only an example of the preferred technical solution of this patent, and should not be understood as limiting the scope of protection of this patent.

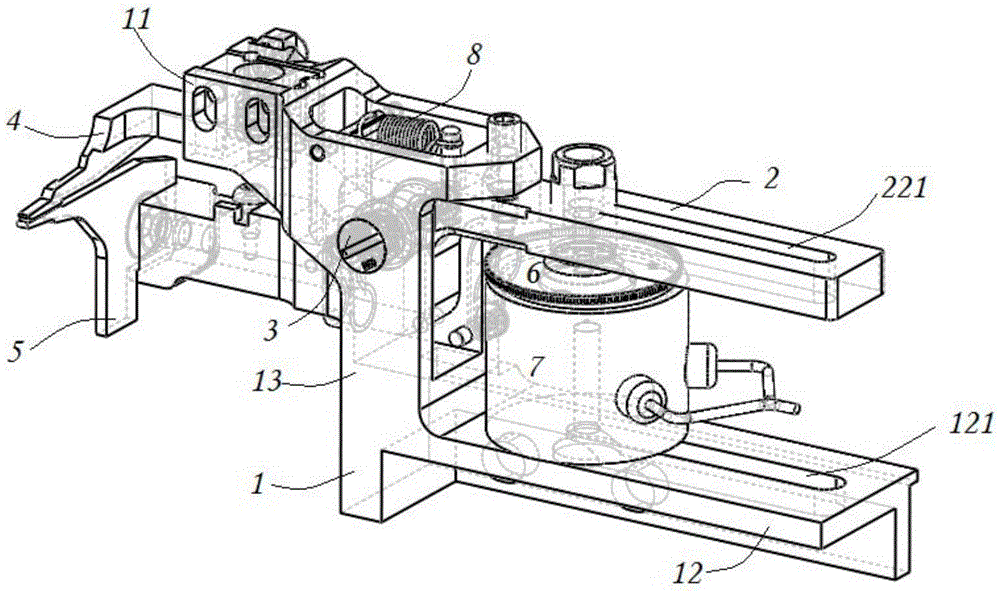

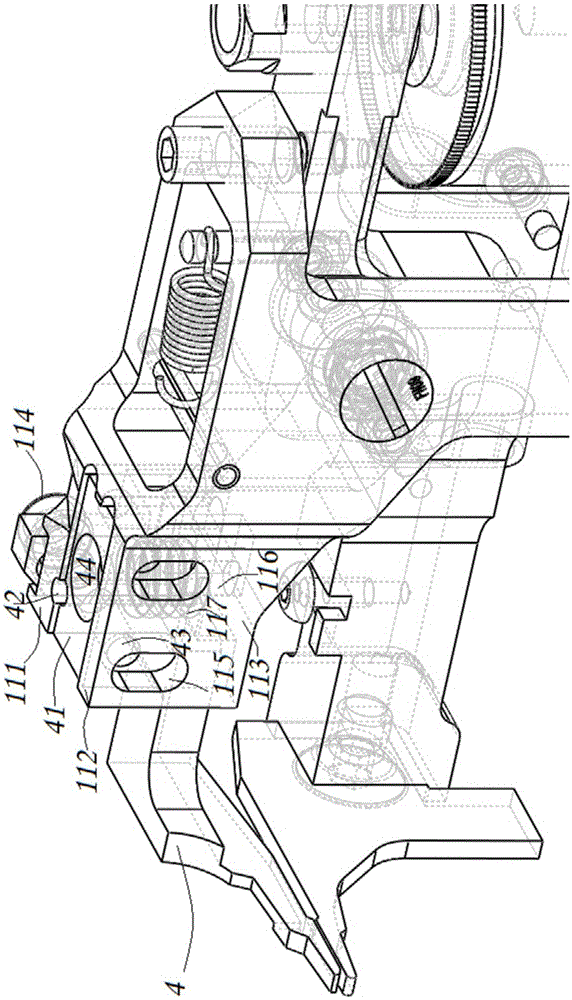

[0021] The overall structure of the mechanical gripper of this embodiment is as follows: figure 1 shown. Place

[0022] The mechanical gripper includes a base 1. The base 1 can be fixedly arranged, and the base is formed in a substantially Z-shape, including two horizontal parts arranged in parallel, that is, a left horizontal part 11 and a right horizontal part 12, and the adjacent ends of the two horizontal parts pass through a vertical The straight part 13 is connected.

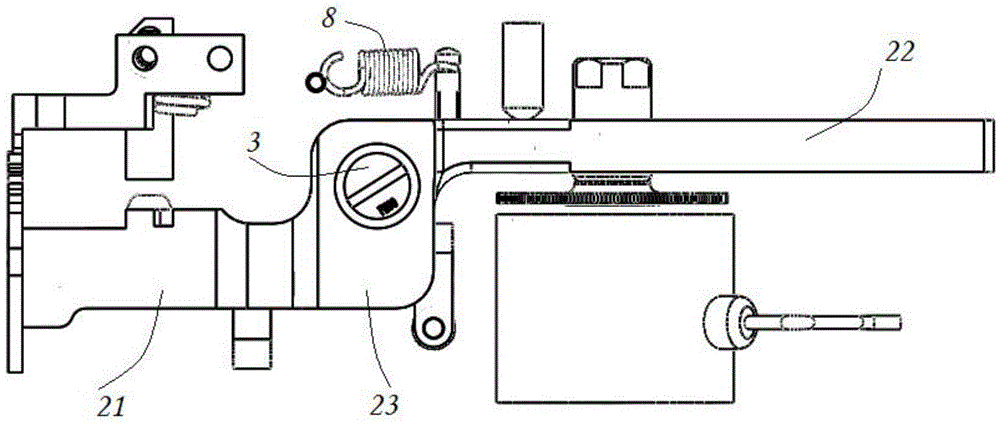

[0023] The gripper also has a clamping arm 2, such as figure 2 As shown, horizontal portions parallel to each other are also formed on the left and right sides of the clamping ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com