Skid positioning and clamping device of roller bed conveyor

A technology for positioning, clamping and conveyors, applied in the field of conveyors, can solve the problems of difficult to control the clamping force, difficult to clamp the skid beam, easy to damage the skid beam, etc., to achieve simple structure, long service life and easy adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

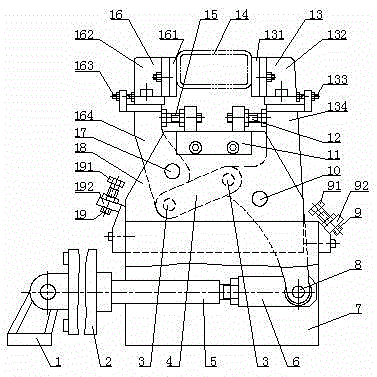

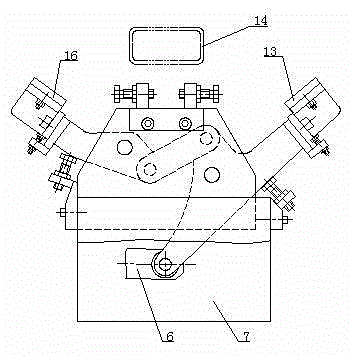

[0008] see Figure 1 to Figure 2 , the skid positioning and clamping device of the roller bed conveyor of the present invention includes a single clevis support 1, a cylinder 2, an intermediate rotating shaft 3, an intermediate connecting plate 4, an extending shaft 5 of the cylinder, a connecting rod 6, a fixed base 7, a lower rotating shaft 8, Right lower limit assembly 9, right shaft 10, upper limit seat 11, right upper limit screw 12, right clamping assembly 13, left upper limit screw 15, left clamping assembly 16, left rotating shaft 17, outer orifice plate 18 and left lower limit Position assembly 19, the lower right limit assembly 9 includes a lower right limit screw 91 and a lower right limit seat 92, and the right clamping assembly 13 includes a right splint 131, a right clamp 132, a right clamp adjustment screw 133 and a right clamp Arm 134, the left lower limiting assembly 19 includes a left lower limiting screw 191 and a left lower limiting seat 192, and the left c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com