Fastening base for iron core of dry-type transformer

A dry-type transformer and iron core technology, used in the manufacture of inductors/transformers/magnets, transformers/inductor cores, electrical components, etc. Reasonable force point, reduce vibration, reduce noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

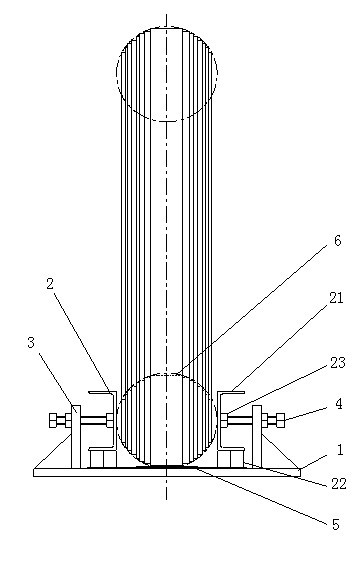

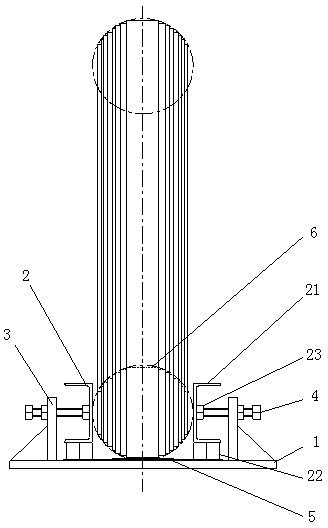

[0009] The dry-type transformer core fastening base of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0010] see figure 1 , The dry-type transformer core fastening base of the present invention includes a base 1 , a lower clip 2 , a fixing part 3 , a nut 23 , a fastener 4 and an insulating part 5 . There are two fixing parts 3, which are respectively fixed on the two ends of the base 1, and can be designed in one piece. There are two lower clamping parts 2 , the middle clamps the iron core, and the two lower clamping parts 2 are both arranged between the two fixing parts 3 . Each lower clip 2 includes a half-frame foot 21 and a spacer 22 . The cushion block 22 is arranged at the lower end of the semi-frame-shaped foot 21, which can relieve the vibration of the iron core piece. The opening of the semi-frame-shaped foot 21 faces outwards, and a nut 23 is welded at the opening. Through holes are provided at cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com