Strip-lattice cell combined type positioning grid

A positioning grid and combined technology, which is applied in the direction of reactor fuel elements, reactors, and reduction of greenhouse gases, can solve the problems of increasing work load, etc., and achieve the effect of less molds, simple assembly, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

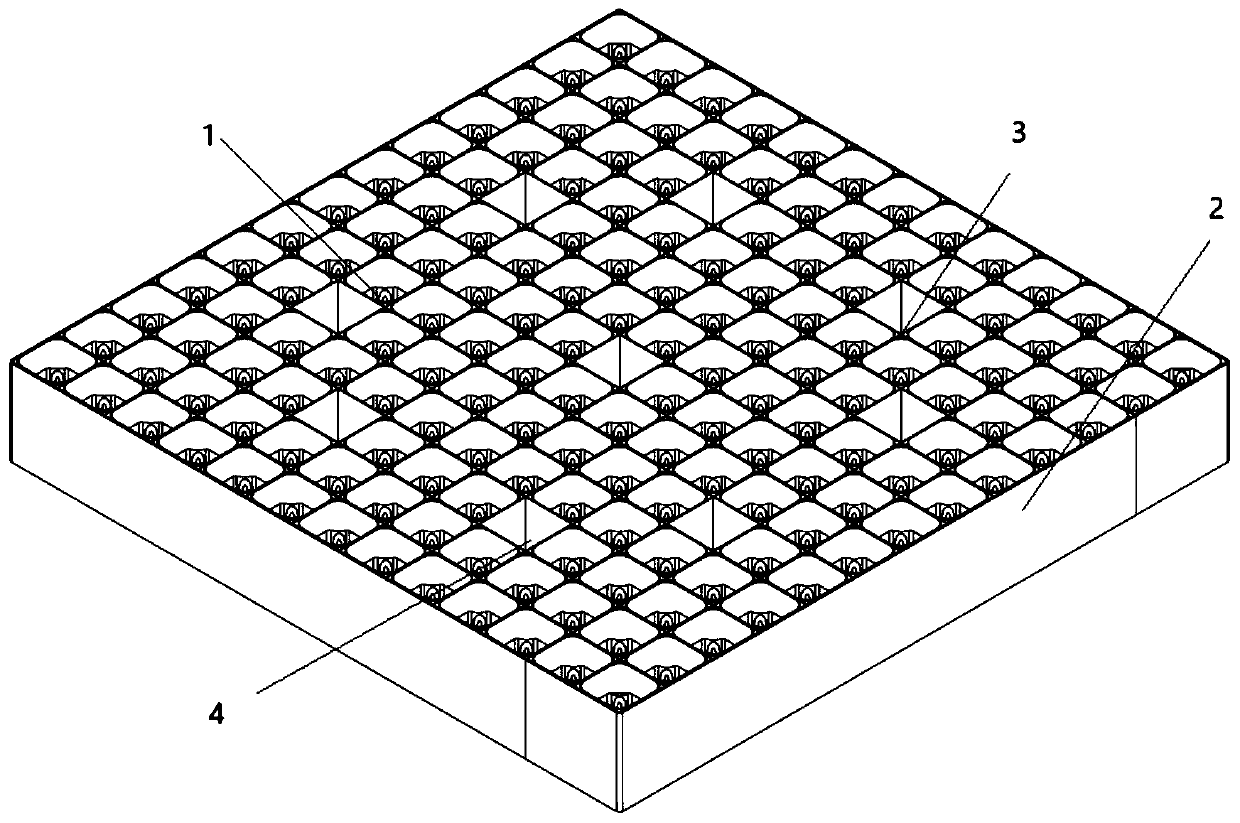

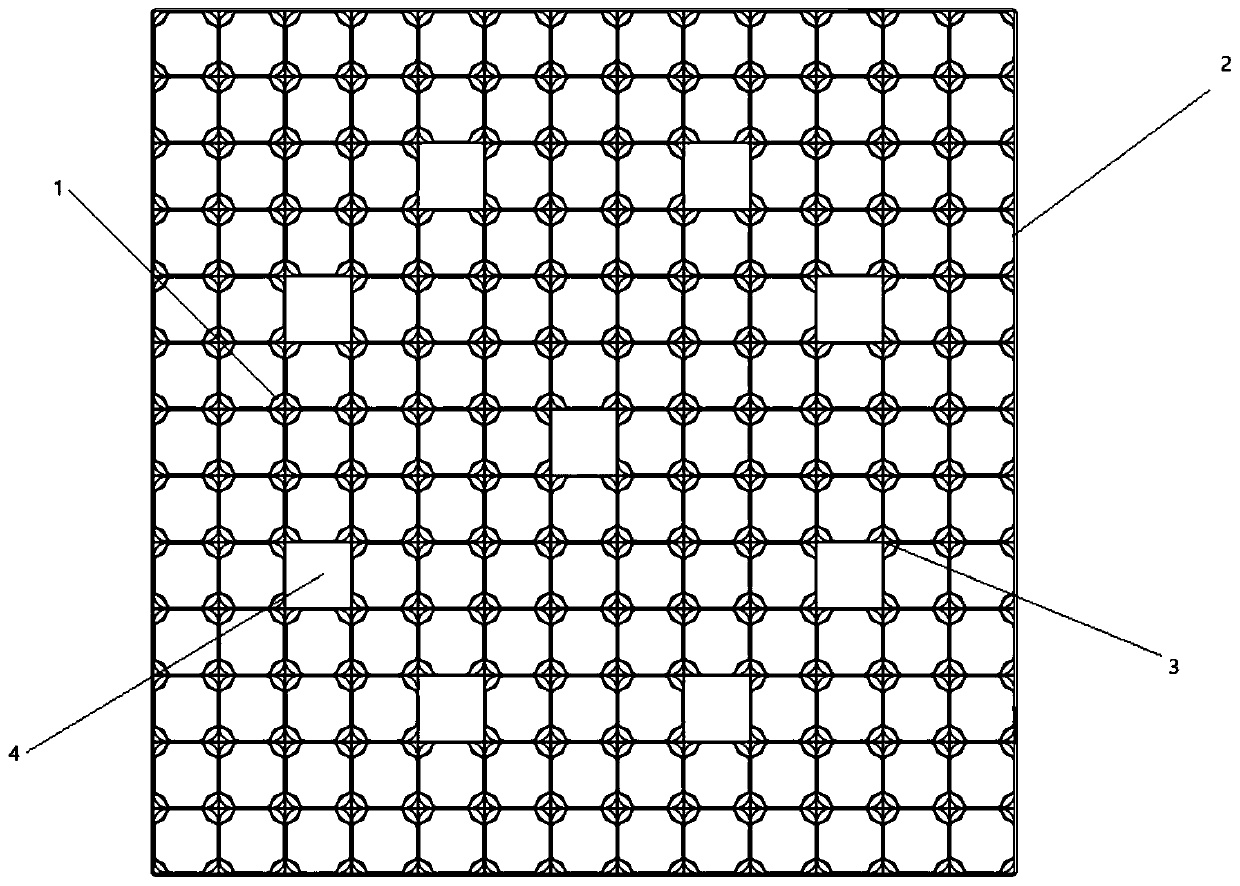

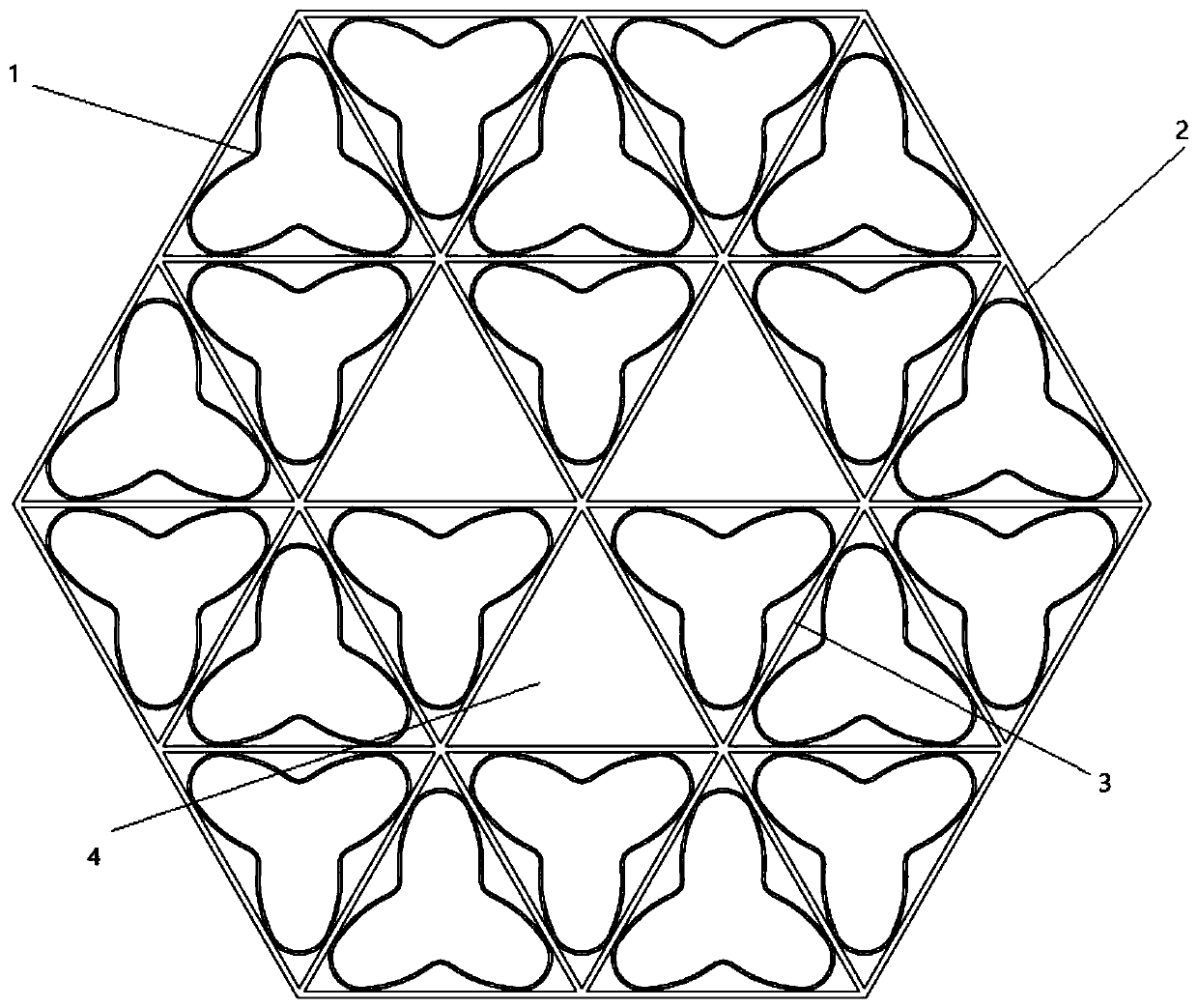

[0031] Such as figure 1 As shown in -5, the strip cell combined positioning grid of the present invention includes a cell 1, an outer strip 2, an inner strip 3, and a guide tube channel 4;

[0032] Several inner strips 3 are inserted and arranged to form a square or hexagonal structure, and a circle of outer strips 2 is welded and fixed around the square or hexagonal structure; cells 1 are welded to form a grid formed by intersecting inner strips 3 in space. According to the actual design requirements of the fuel assembly, several cells 1 are taken out as guide tube channels 4 , and the guide tubes are arranged in the guide tube channels 4 and fixed with the inner strip 3 .

[0033] When the inner strips 3 are inserted and arranged to form a square shape, the structure of the cells 1 can be a cylinder or a four-sided cylinder according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com