Patents

Literature

168results about "Artificial filament support" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

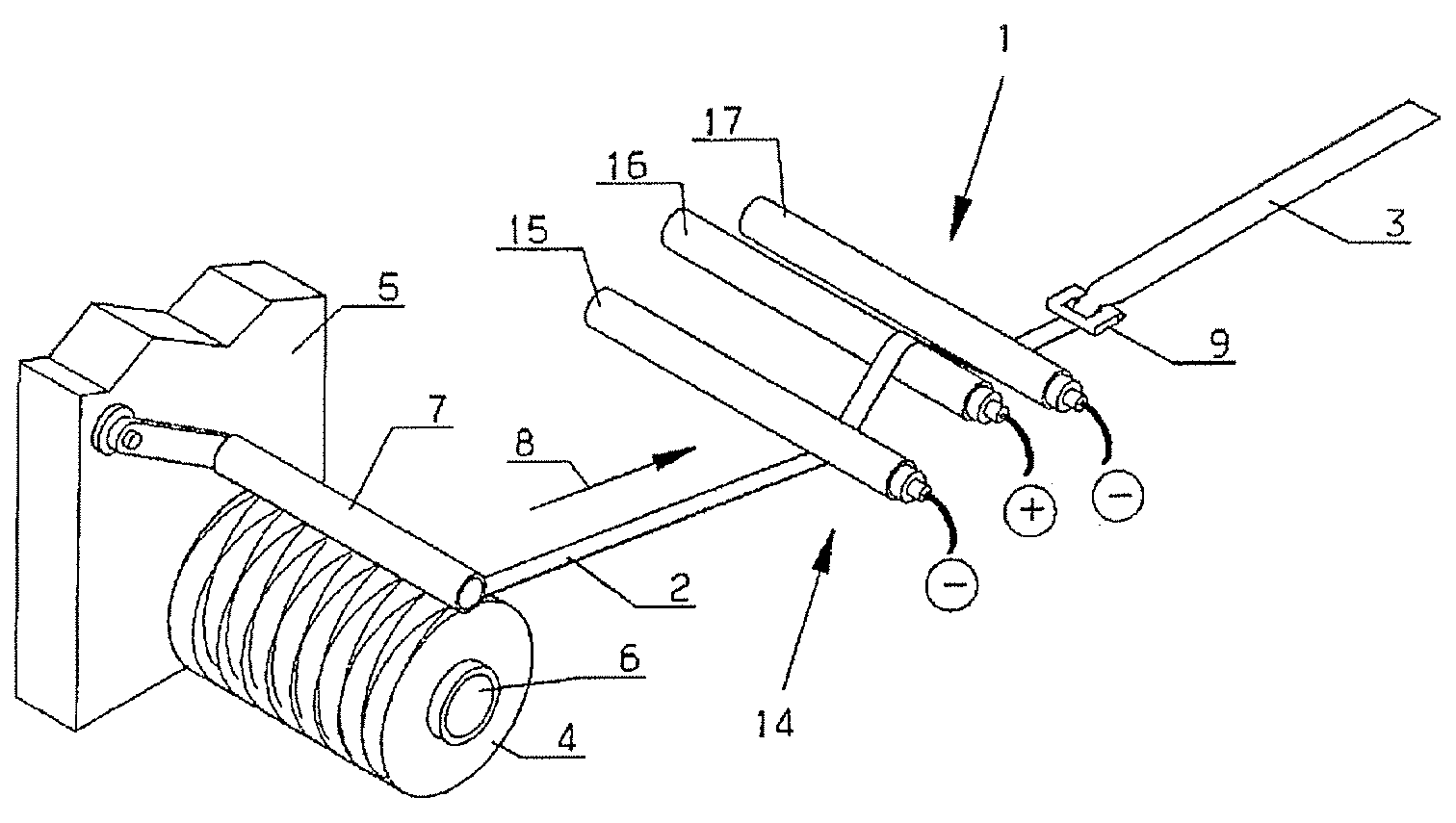

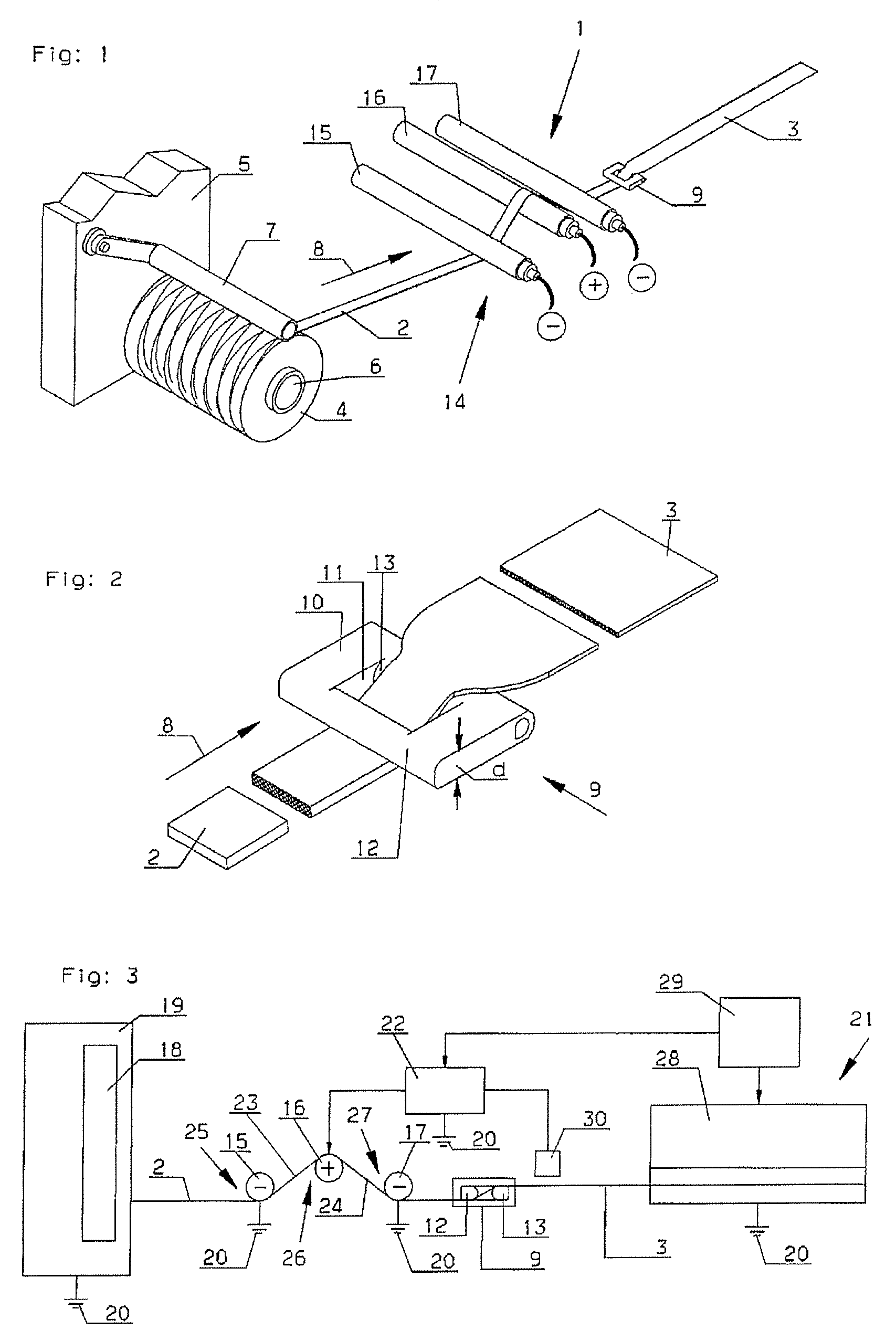

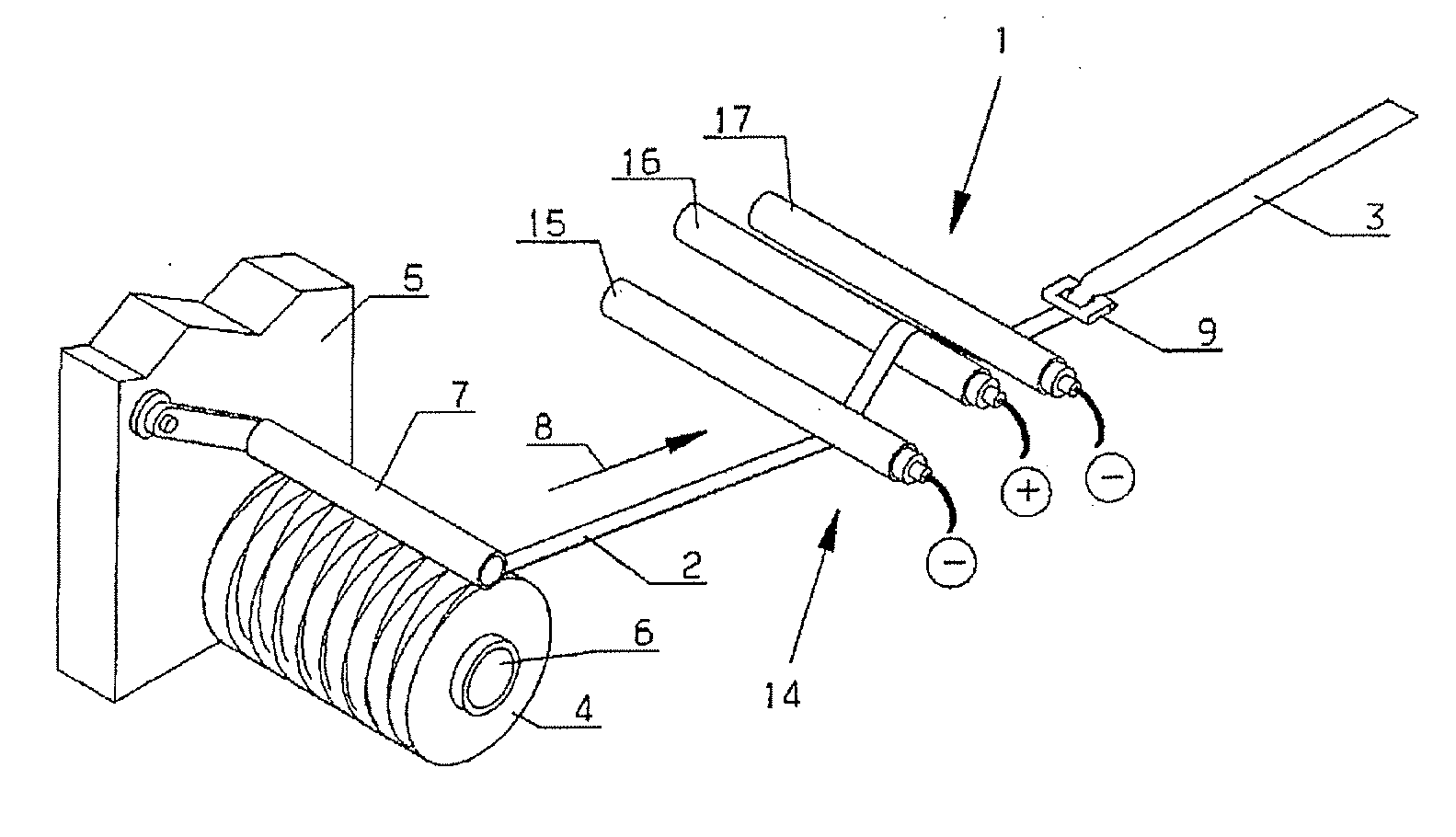

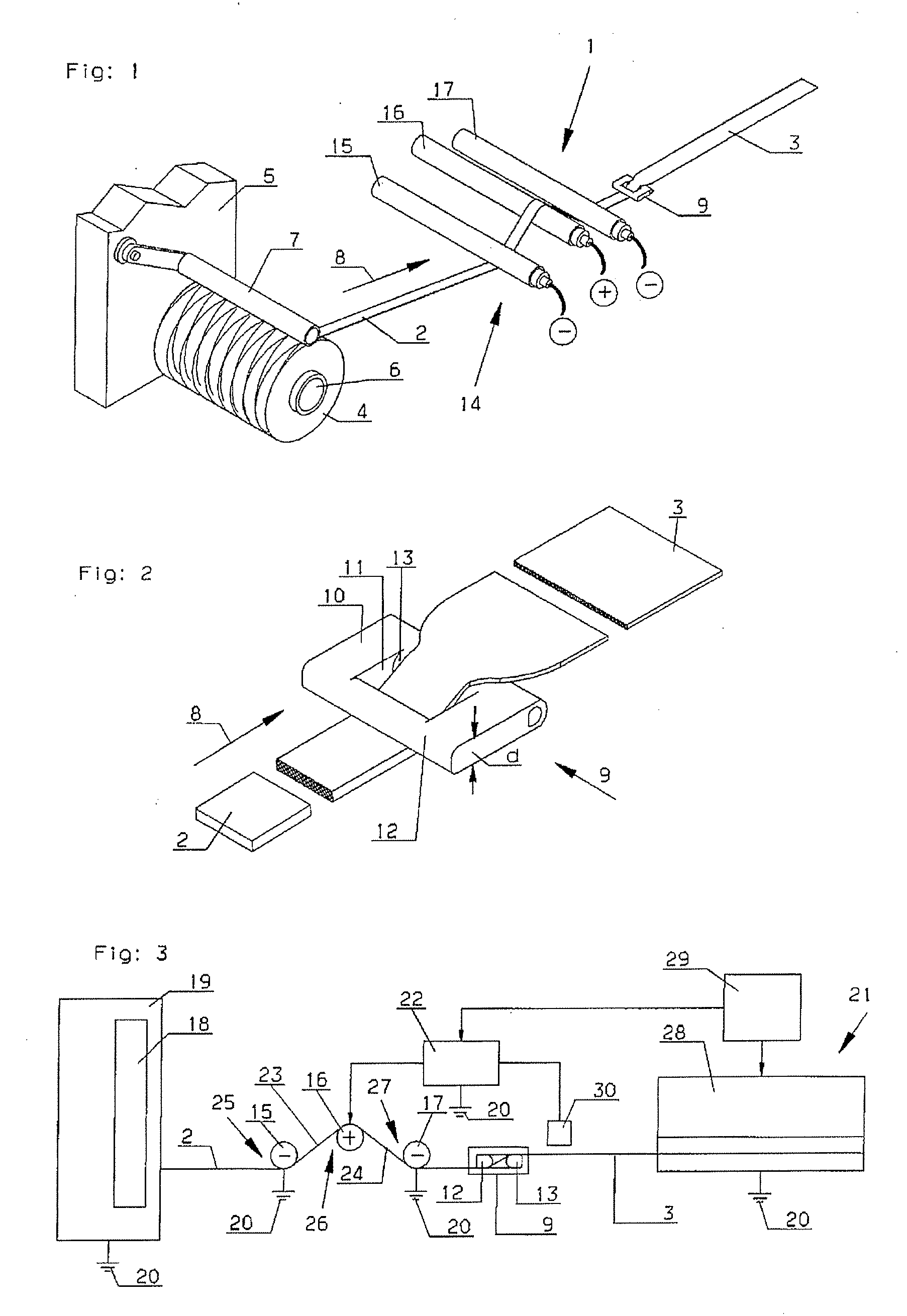

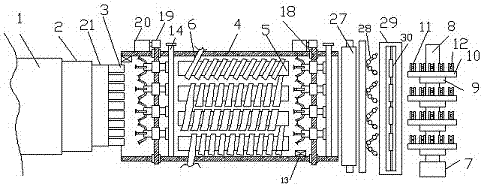

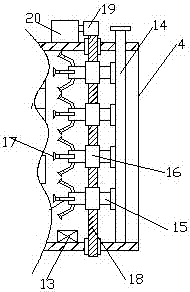

Device and method for spreading a carbon fiber hank

InactiveUS7536761B2Spread carbon fiber hanksSimple wayFilament manufactureArtificial filament supportFiberCarbon fibers

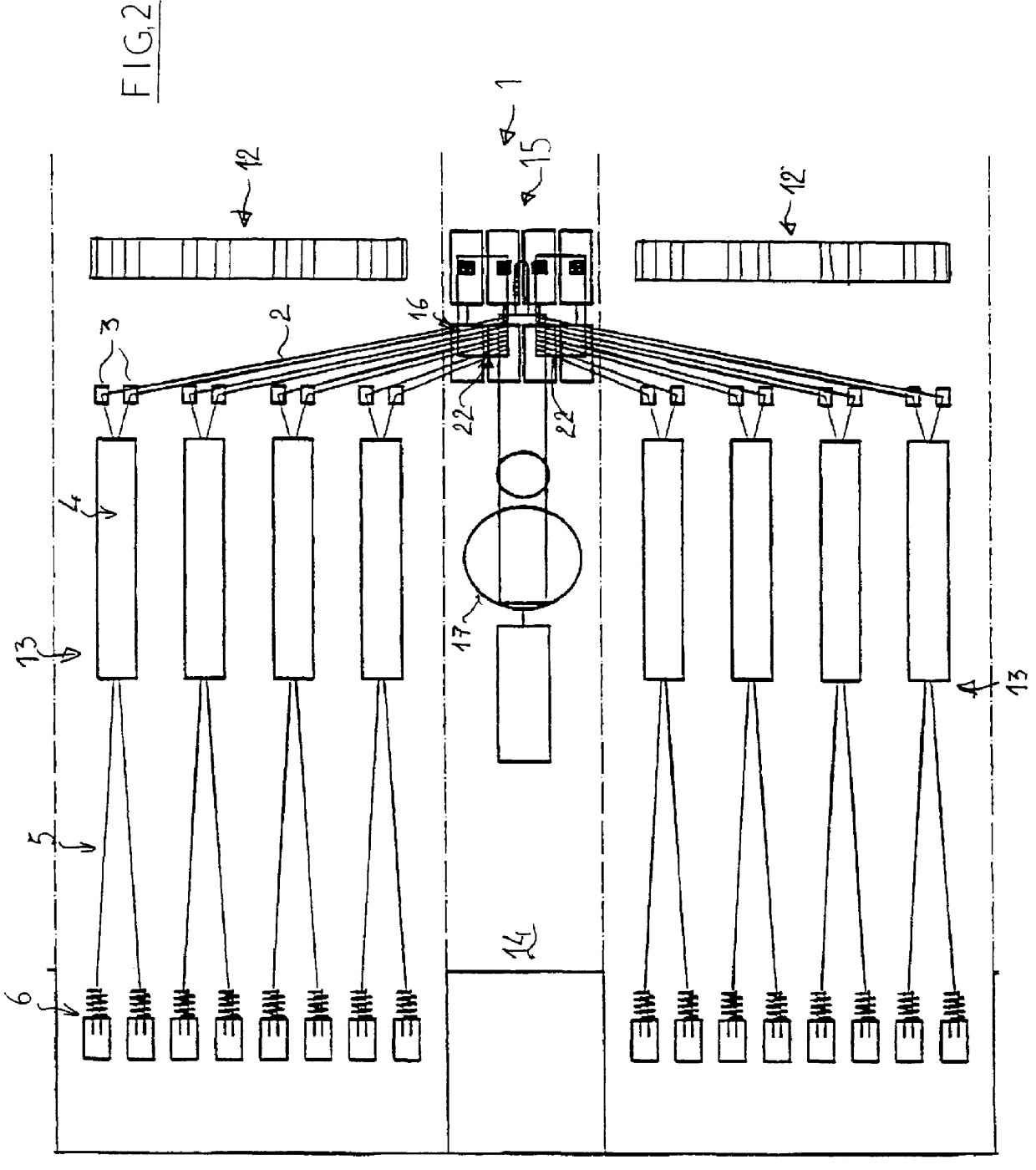

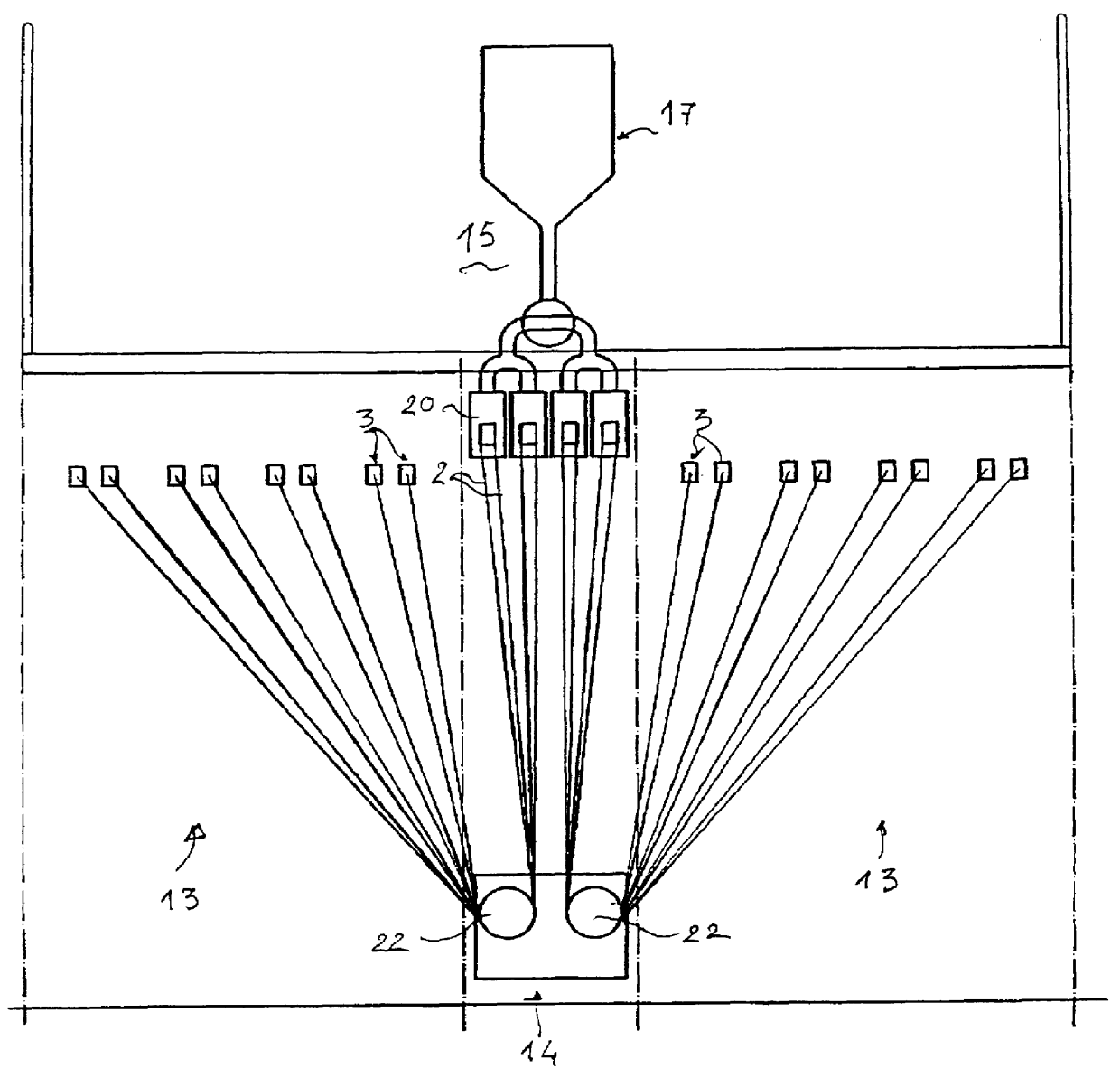

Device and method for spreading a carbon fiber hank into a carbon fiber band. The device includes a heating device having at least two electrodes that are spaced apart from each other and coupled to a power supply, and a spreading device arranged after the heating device in the traveling direction of the carbon fiber hank.

Owner:KARL MAYER MALIMO TEXTILMASCHFAB

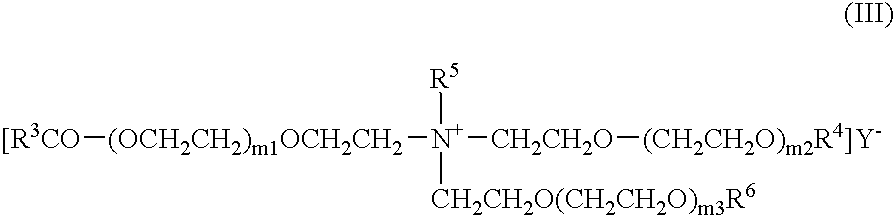

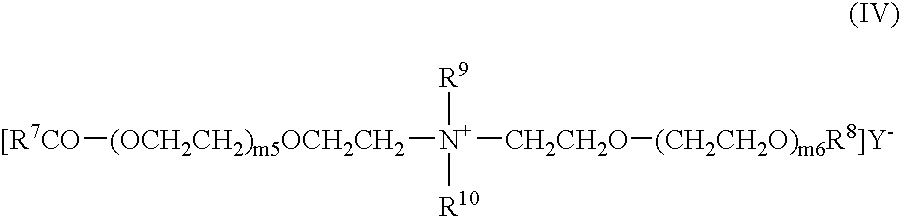

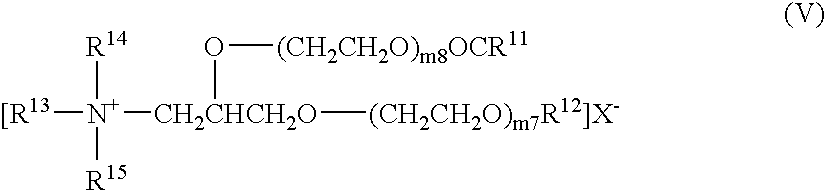

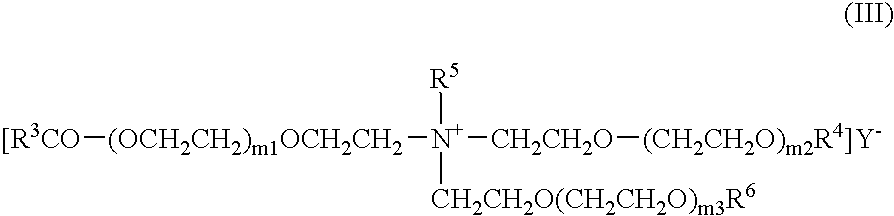

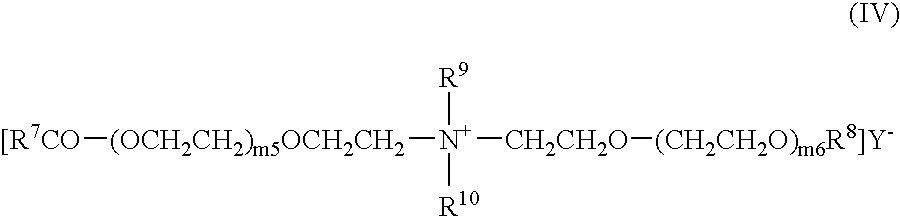

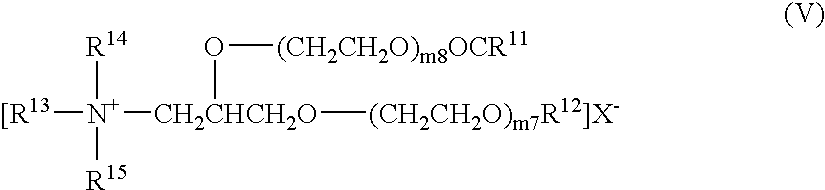

Textile finishing agents

InactiveUS20060258558A1Organic detergent compounding agentsNon-ionic surface-active compoundsFiberYarn

A method for treating fibers, yarns or textiles to improve the sensory effect for a user or weaver of a fabric article. The method treats the fiber, yarns or textiles with an emulsion containing 15-30% by weight of a mixture of waxes having melting points in the range of 35° C. to 60° C. including a lipophilic wax matrix; 10%-20% by weight of emulsifier which are at least one of alkyl or alkenyl oligoglycosides or alkyl ether sulfates, 1%-10% by weight of a crystal regulator which can be partial esters of C12-22 fatty acids with at least one of glycerol, polyglycerol and sorbitan. The mean particle size of the wax crystals is not greater than 6 μm. The emulsion includes water and auxiliaries and additives.

Owner:COGNIS IP MANAGEMENT GMBH

Device and method for spreading a carbon fiber hank

InactiveUS20070101564A1Spread carbon fiber hanksSimple wayFilament manufactureArtificial filament supportFiberCarbon fibers

Device and method for spreading a carbon fiber hank into a carbon fiber band. The device includes a heating device having at least two electrodes that are spaced apart from each other and coupled to a power supply, and a spreading device arranged after the heating device in the traveling direction of the carbon fiber hank.

Owner:KARL MAYER MALIMO TEXTILMASCHFAB

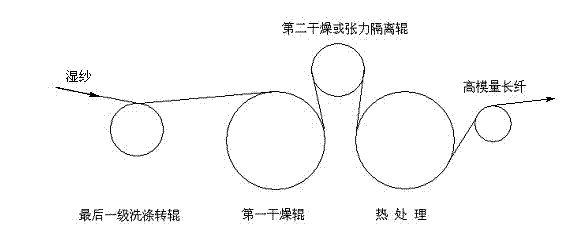

High-modulus poly(p-phenylene terephthalamide) (PPTA) fiber and preparation method thereof

ActiveCN102251306AImprove performanceLow spinning efficiencyArtificial filament heat treatmentArtificial filament supportPolymer scienceYarn strength

The invention discloses a high-modulus PPTA fiber which is prepared from PPTA polymers with inherent viscosity of 5.5 to 8.0 dL / g obtained through the method of low-temperature solution polycondensation by drawing undried wet strands in the procedures of washing, neutralizing and drying in the process of dry-jet wet spinning and carrying out heat treatment under high temperature and high tension on dry strands in the procedure of drying or after drying; the modulus of the PPTA fiber is 800 to 1000 g / denier and the inherent viscosity of 5.0 to 7.5 dL / g. The fiber product obtained through the method provided in the invention has excellent yarn strength, high modulus, luster of high crystallinity, a bright color, little fuzziness, superior properties and a wider application scope, and fills in gaps in market.

Owner:BLUESTAR CHENGDU NEW MATERIALS

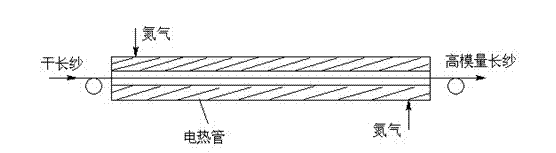

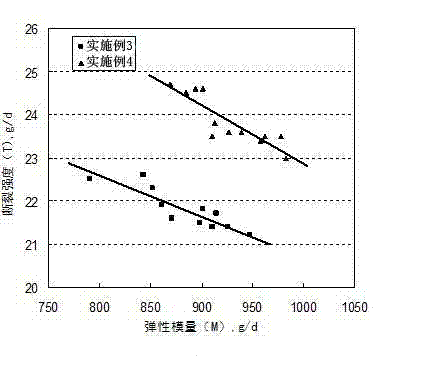

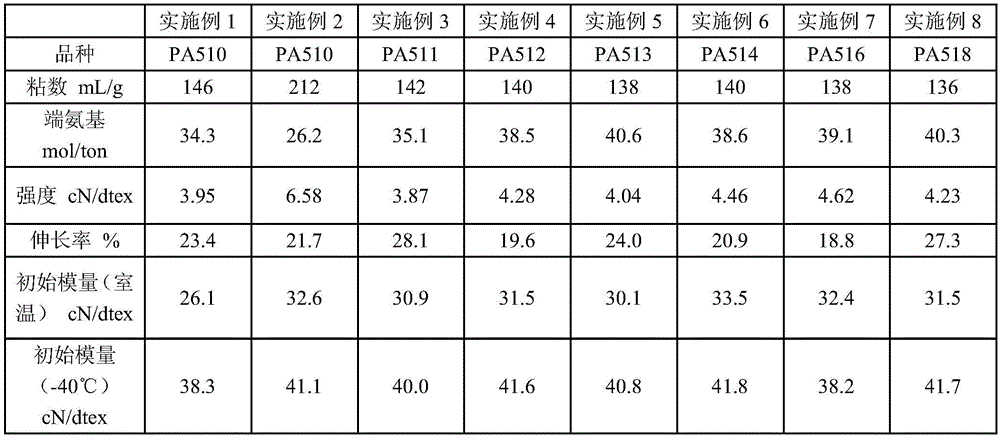

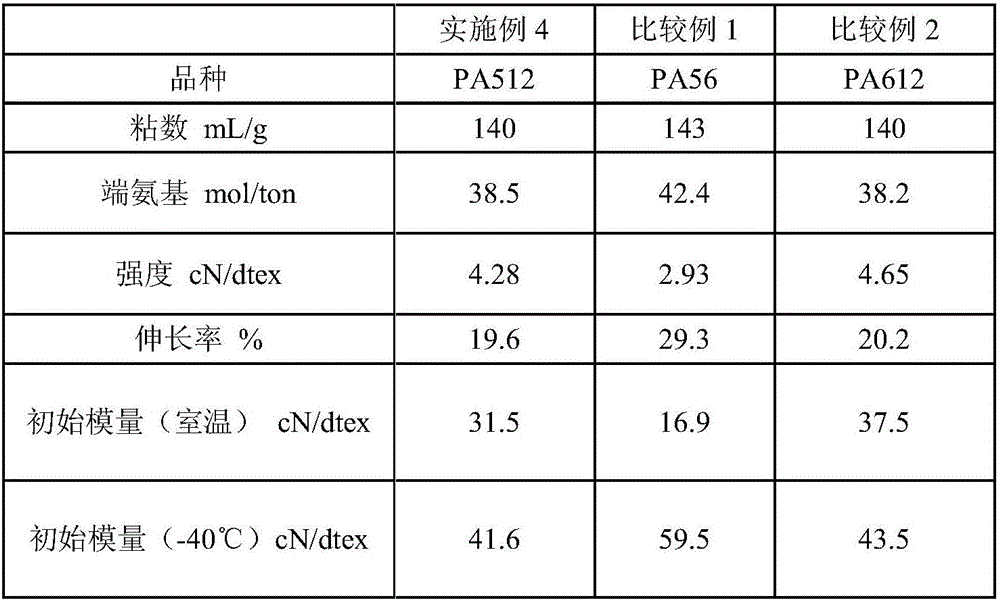

Long-carbon chain polyamide fiber and preparation method thereof

ActiveCN106555250AImprove performanceOvercoming the disadvantages of low temperature hardeningArtificial filament heat treatmentArtificial filament supportPolymer scienceCarbon chain

The invention provides a long-carbon chain polyamide fiber and a preparation method thereof. The long-carbon chain polyamide fiber is prepared at least from long-carbon chain polyamide resin as a raw material. The raw materials of the long-carbon chain polyamide resin comprise 1, 5-pentamethylene diamine and a dibasic acid. The long-carbon chain polyamide fiber has an initial modulus of 20-60 cN / dtex at -40 DEG C. The preparation method comprises introducing long-carbon chain polyamide resin slices or melt into a spinning box, carrying out spraying by a spinneret plate to obtain fine melt flows, blowing the fine melt flows to obtain cured wires, coating the wires with oil, and carrying out drawing and post-processing on the wires to obtain long-carbon chain polyamide fibers, wherein a spinning speed is 800-6000m / min and the temperature of a later godet is less than 200 DEG C. The preparation method is simple and realizes a low cost. The long-carbon chain polyamide fiber has low temperature resistance, excellent mechanical properties and a good application prospect.

Owner:CATHAY R&D CENT CO LTD +2

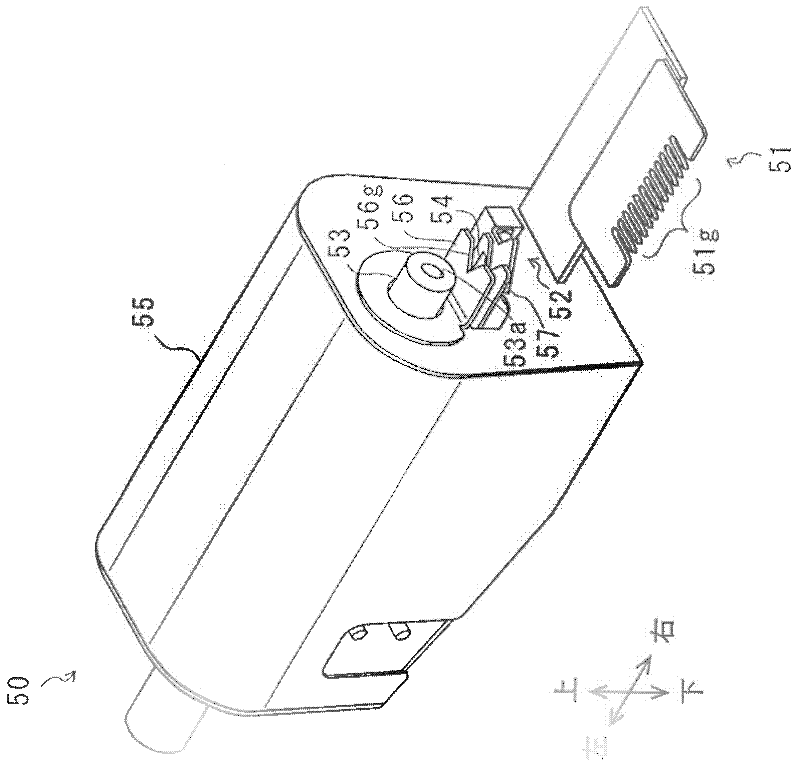

Yarn cutting apparatus

ActiveCN102560711AEasy to cutWon't relaxArtificial thread manufacturing machinesFilament manufactureYarnEngineering

A yarn cutting apparatus is provided that improves the workability of the yarn threading operation while securely cutting a plurality of yarns. A yarn cutting apparatus (50) is configured to cut a plurality of yarns (Y) and includes a yarn path regulating guide (51) configured to guide the plurality of yarns (Y), a yarn shift guide (52) disposed further upstream than the yarn path regulating guide (51) so as to shift the yarns (Y) fed onto the yarn path regulating guide (51) to one direction, an aspirator (53) disposed further upstream than the yarn shift guide (52) so as to suck the yarns Y shifted by the yarn shift guide, and a cutter (54) disposed between the yarn shift guide (52) and the aspirator (53) so as to cut the yarns Y sucked by the aspirator (53).

Owner:TMT MACHINERY INC

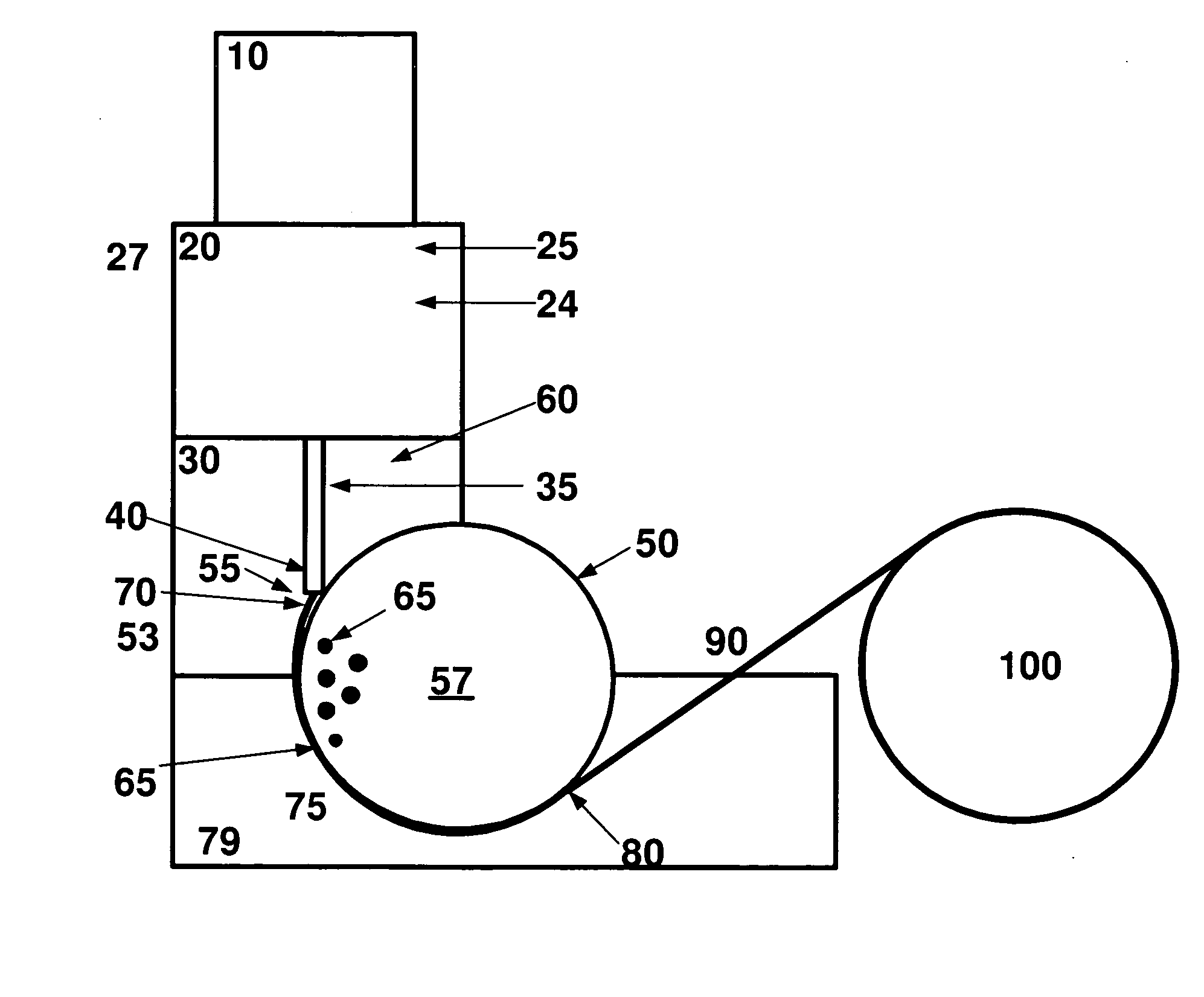

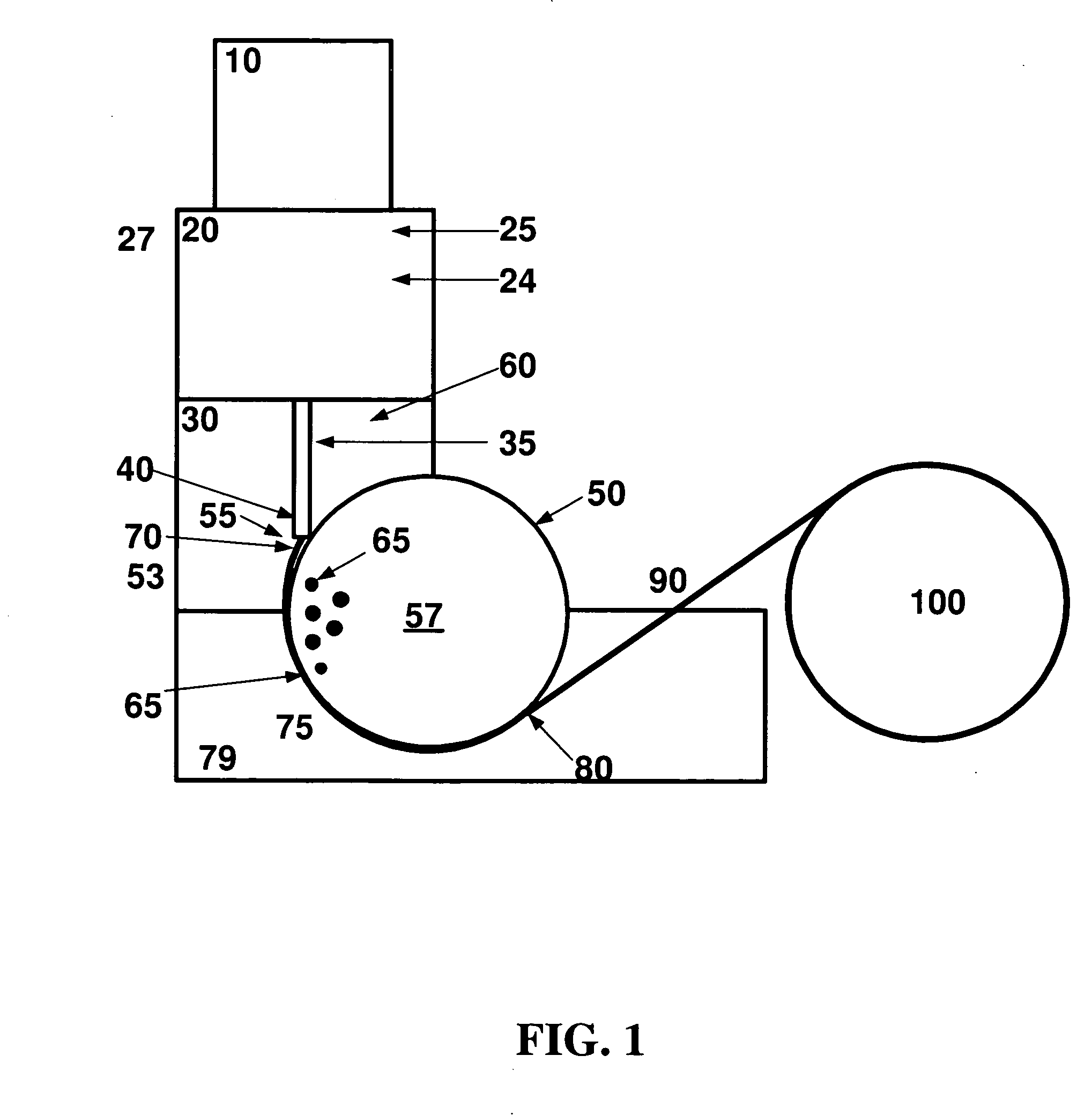

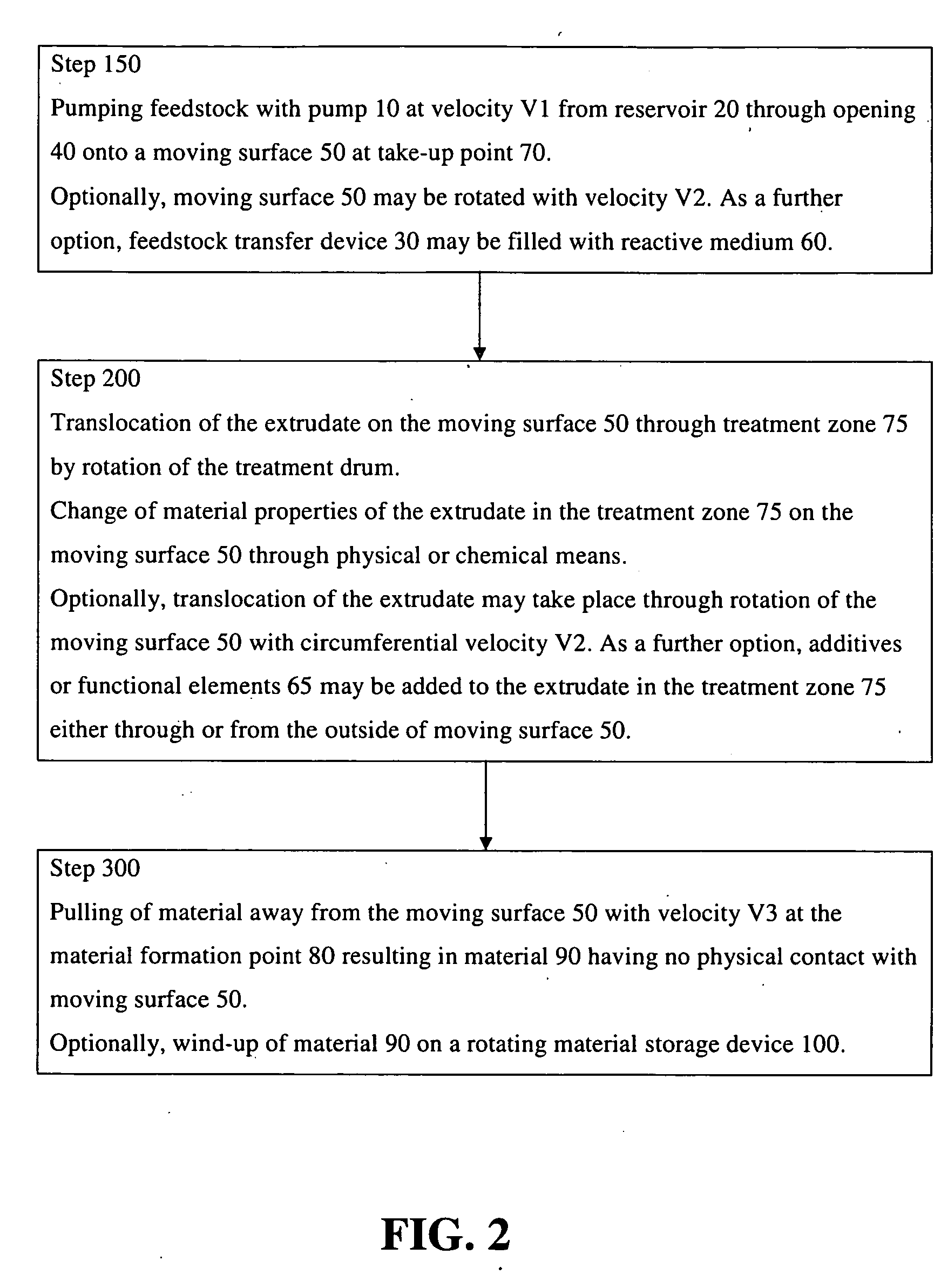

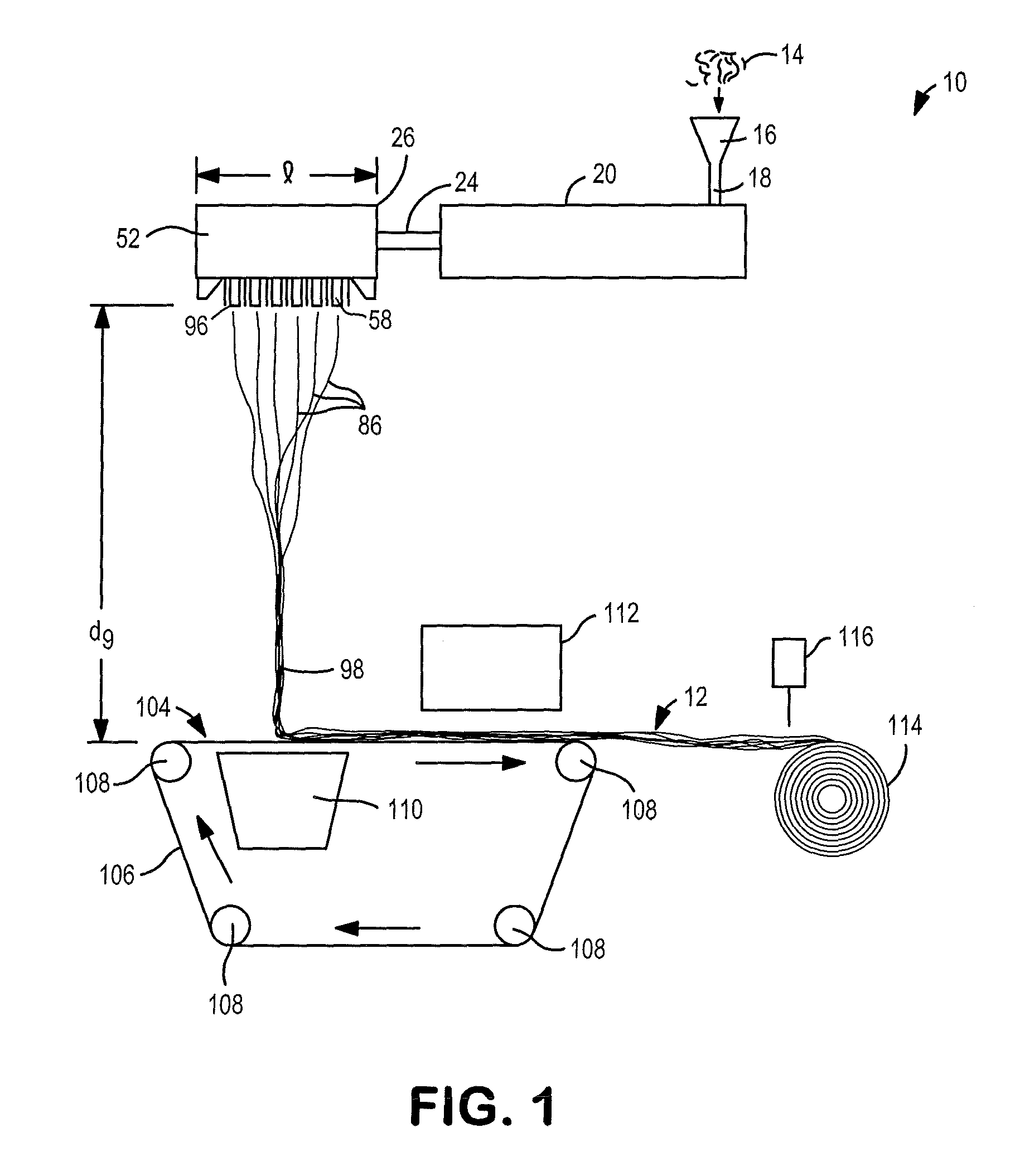

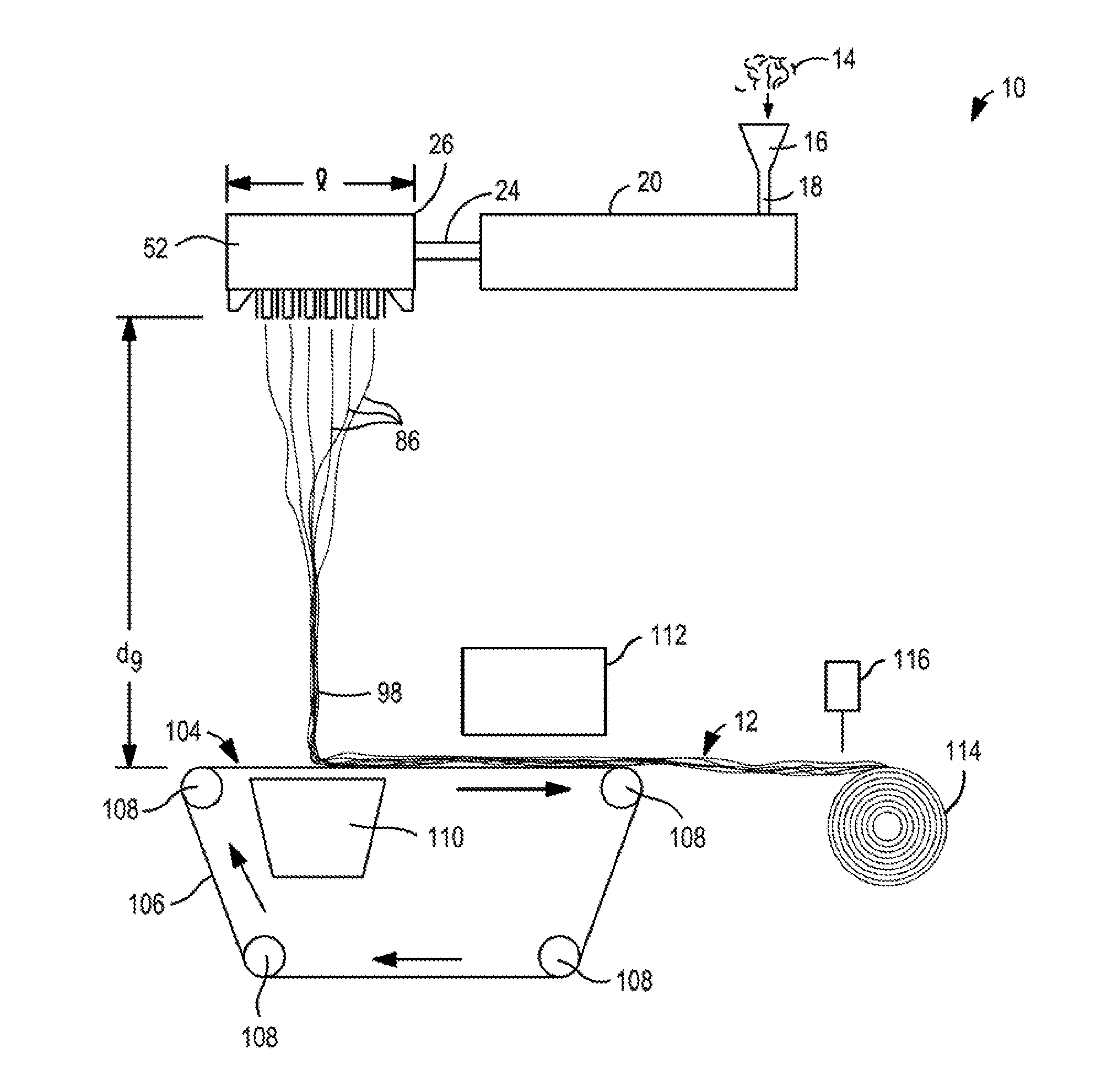

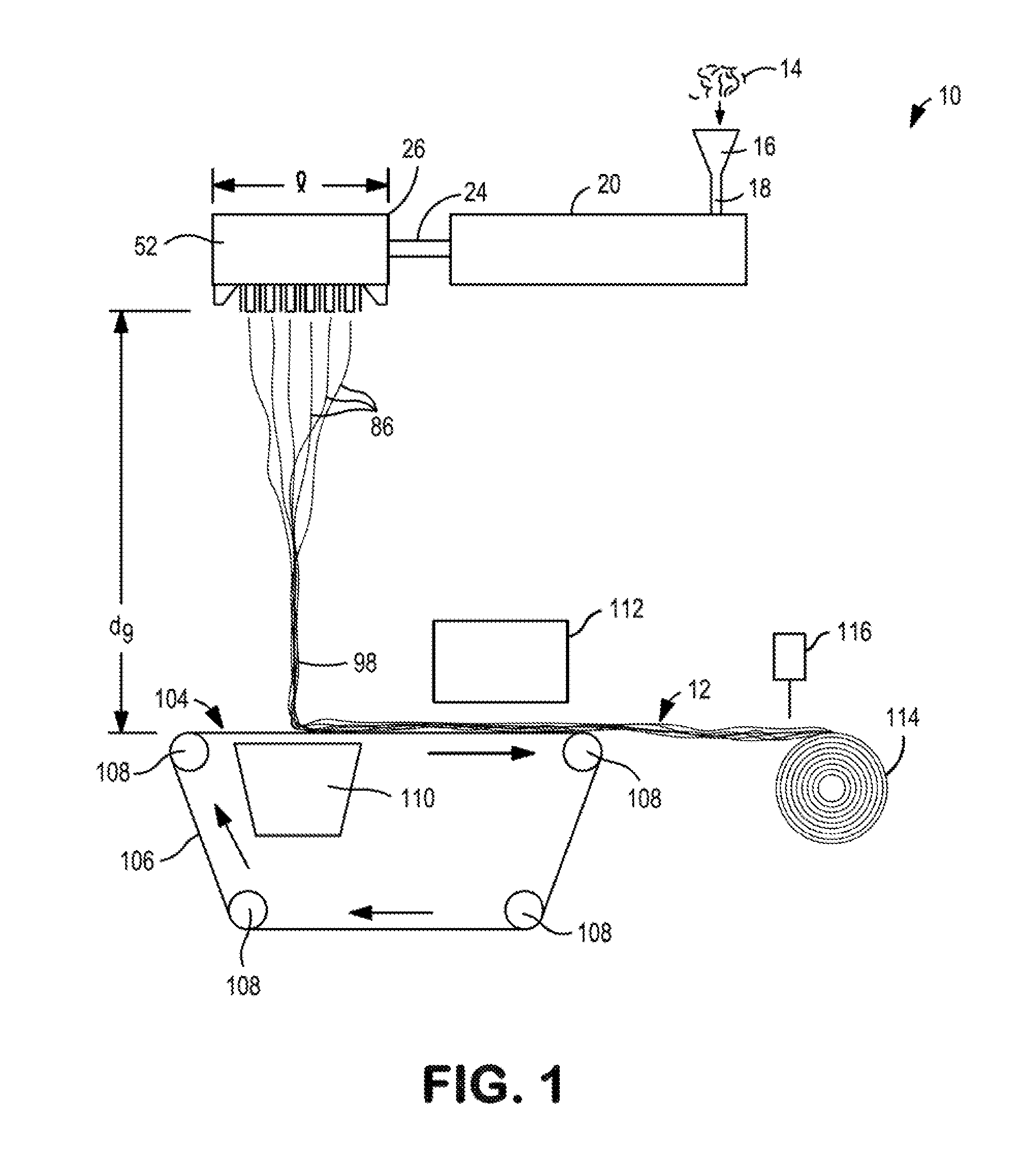

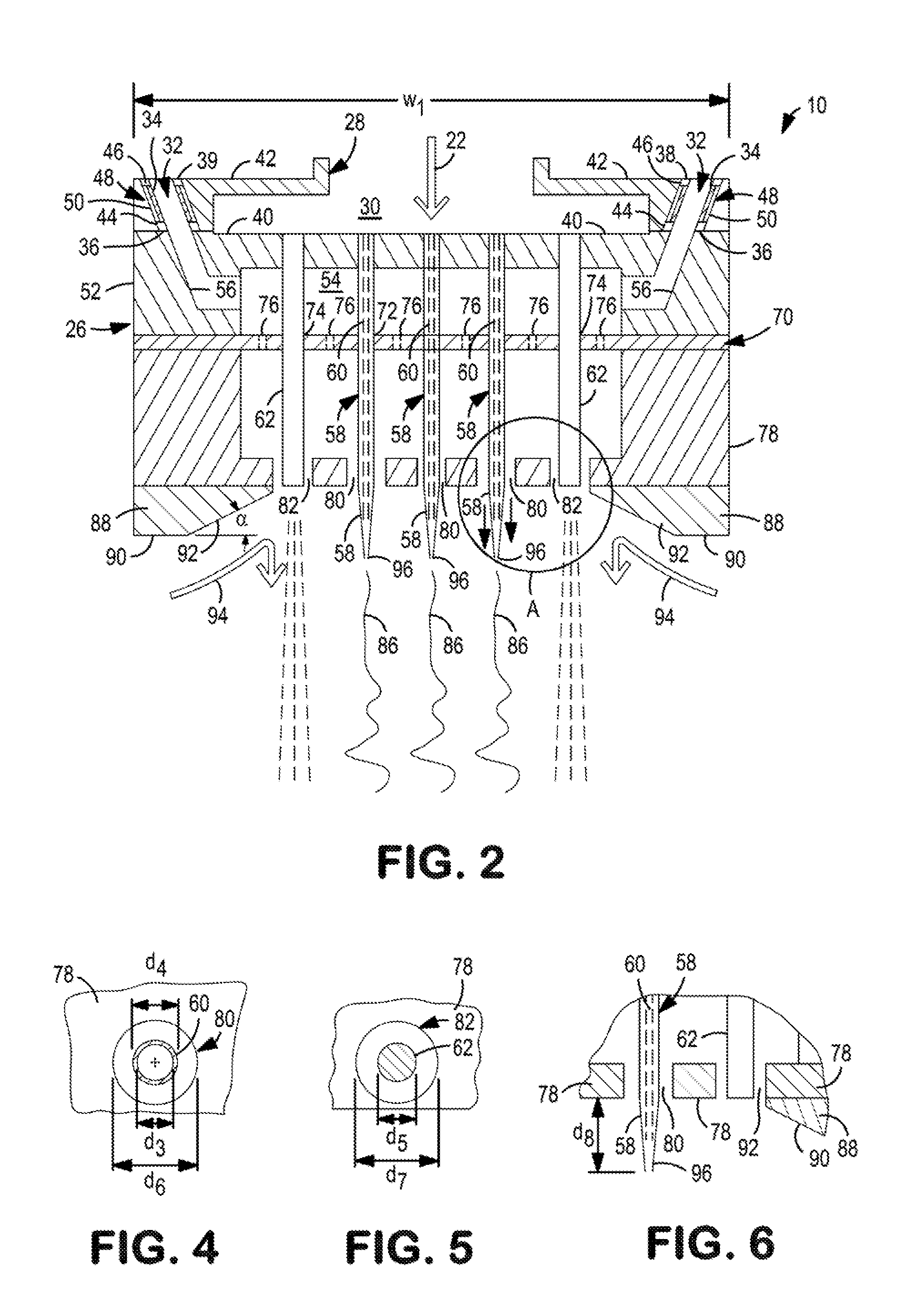

Method and apparatus for the manufacture of a fiber

InactiveUS20090261498A1Monocomponent fibroin artificial filamentArtificial filament supportFiberEngineering

An apparatus for the manufacture of extruded material. The apparatus includes a material supplier which supplies a material and has an opening, through which the material is extruded to form extruded material. A moving surface is positioned adjacent to the opening to receive the extruded material from the opening. The method for the extrusion of the material which comprises providing the material in a liquid form, extruding the material through an opening to form extruded material and receiving the extruded material on the moving surface.

Owner:SPINTECH ENG

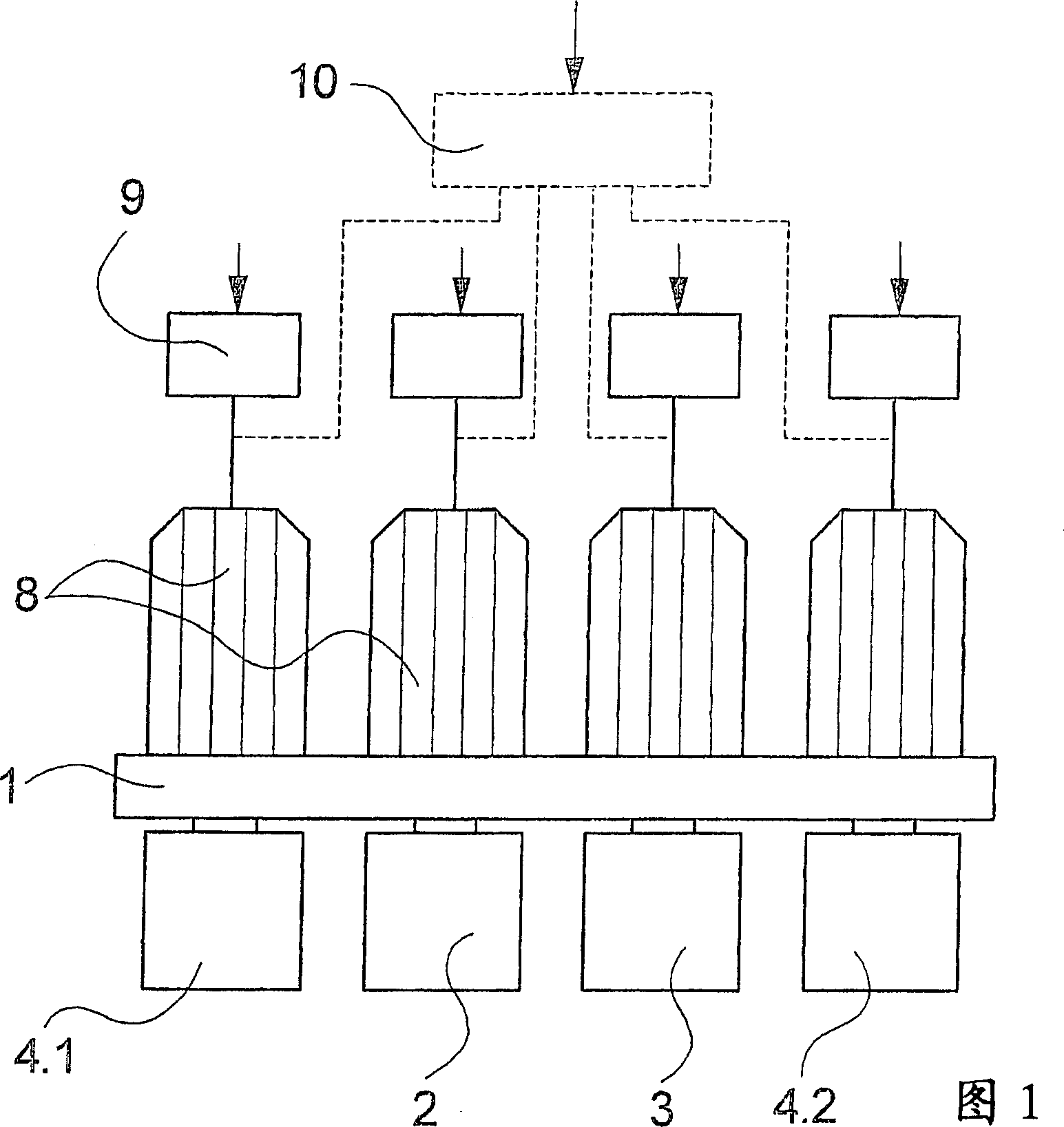

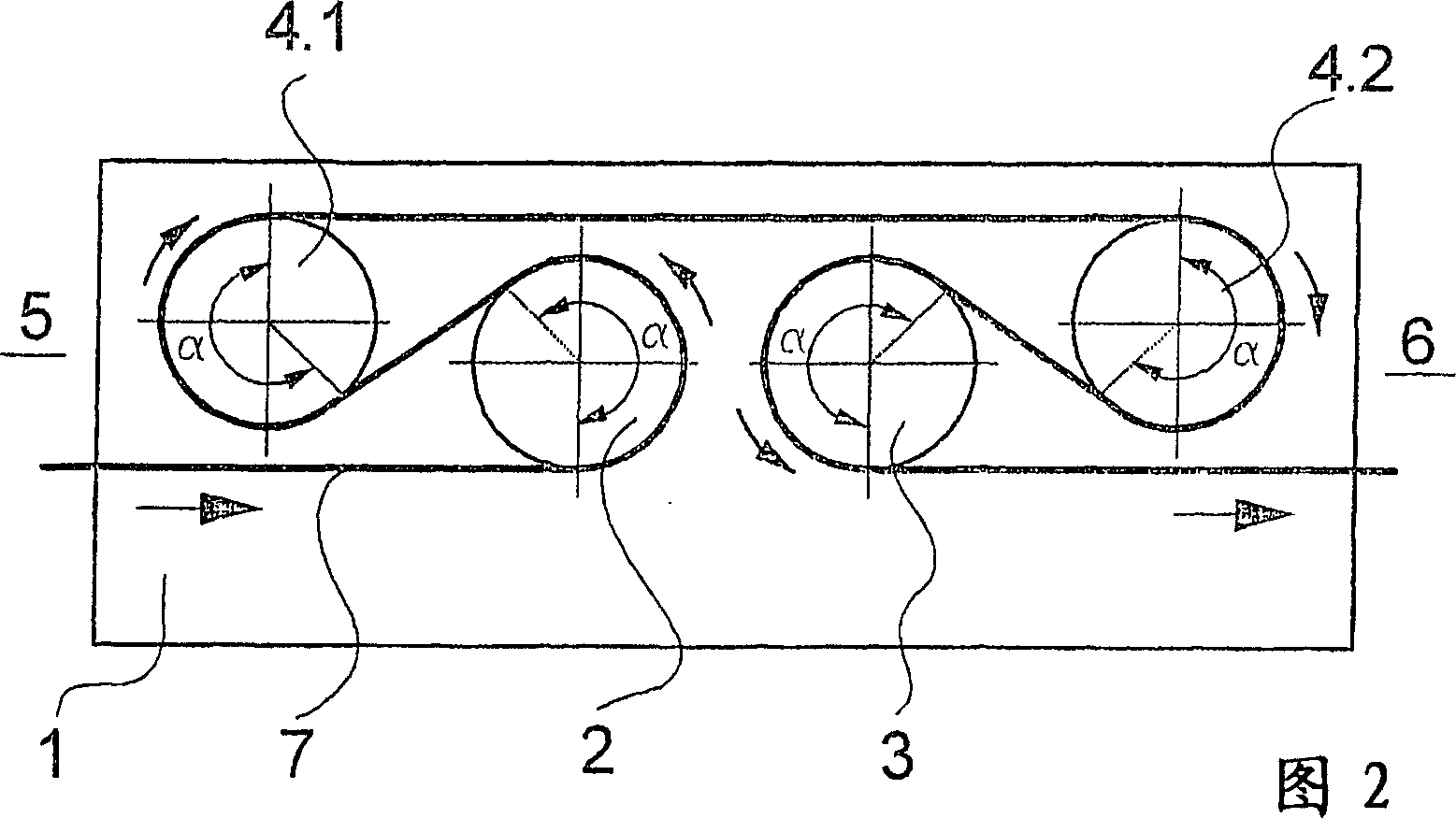

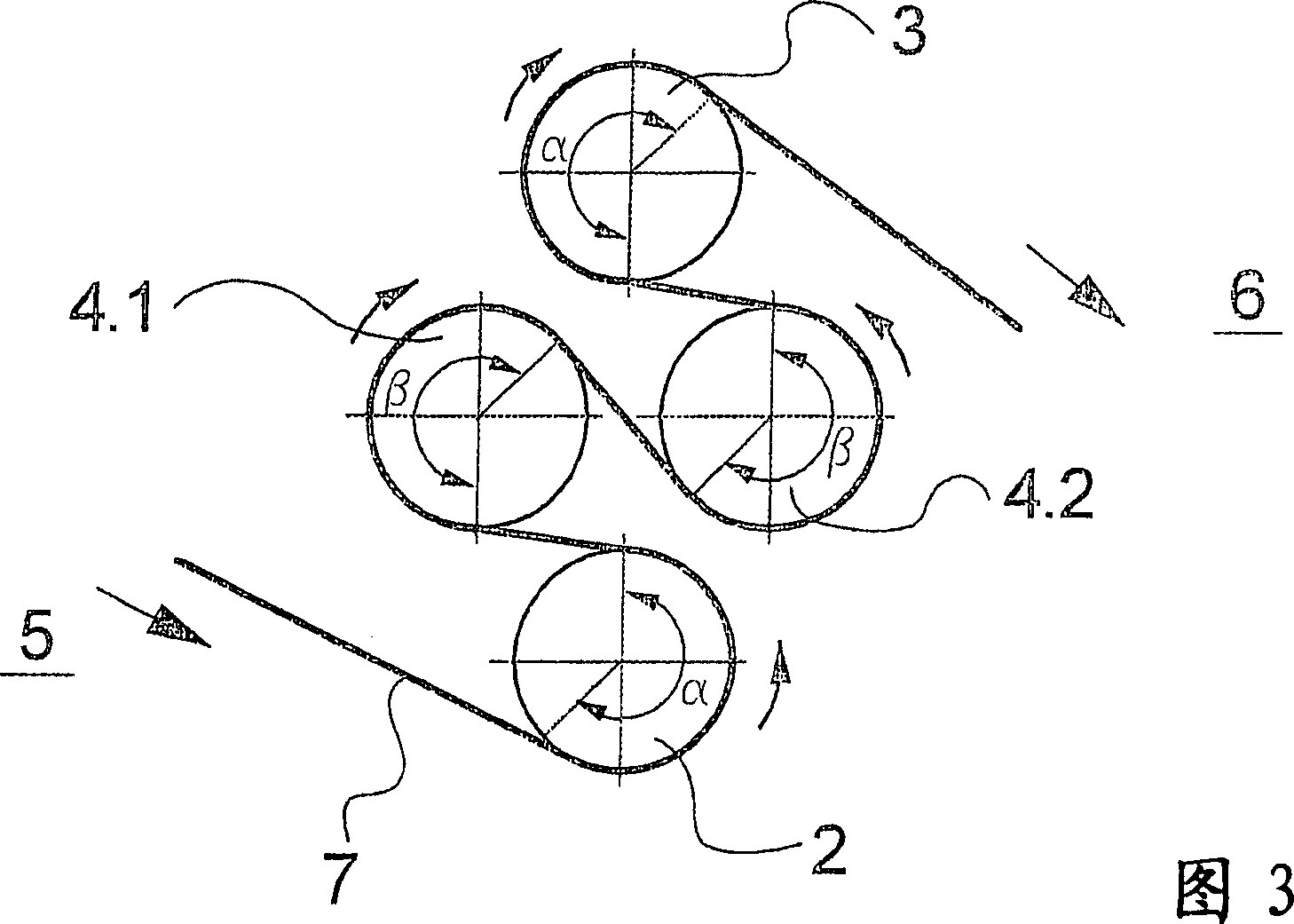

Device for guiding, conveying, or treating a fiber cable

Disclosed is a device for guiding, conveying, or treating a fiber cable (7), comprising several driven rollers (2, 3, 4.1, 4.2, 4.3, 4.3, 4.4), the fiber cable being guided along the circumference of the rollers so as to partly wrap therearound. The rollers encompass a roller (2) for feeding the fiber cable and a roller (3) for discharging the fiber cable. The remaining rollers (4.1, 4.2, 4.3, 4.4) are disposed relative to the feeding roller and the discharging roller in such a way that the fiber cable can be guided on the rollers at a respective angle of contact of >180 DEG . In order to involve all rollers to the same extent for guiding, conveying, and treating the fiber cable, the feeding roller and the inlet of the fiber cable as well as the discharging roller and the outlet of the fiber cable are arranged relative to each other such that the fiber cable can be guided along the circumference of the feeding roller and the circumference of the discharging roller so as to partly wrap therearound at a respective angle of contact of >180 DEG .

Owner:SAURER GMBH & CO KG

Method for preparing radiation protection polyester fiber on basis of mechanically exfoliated graphene and method for spinning radiation protection polyester fiber

InactiveCN107794591AGood dispersionGood radiation protectionArtificial filament supportMelt spinning methodsPolyesterIn situ polymerization

The invention relates to a radiation protection polyester fiber on the basis of mechanically exfoliated graphene. The radiation protection polyester fiber is characterized in that flake graphite is exfoliated in ethylene glycol by the aid of micro-mechanical exfoliation processes to obtain graphene, dispersing agents are added into the graphene to form uniform, stable and dispersed graphene / ethylene glycol solution, then the graphene / ethylene glycol solution which is used is a raw material is polymerized in an in-situ manner to obtain high-dispersibility graphene / polyester, and melt spinning is ultimately carried out to obtain the radiation protection polyester fiber on the basis of the mechanically exfoliated graphene. According to the scheme, the radiation protection polyester fiber hasthe advantages that processes for synthesizing the radiation protection polyester fiber are simple, the radiation protection polyester fiber is low in cost, dispersion effects can be realized while the graphene is mechanically exfoliated, the problem of uneven dispersion of graphene in polyester melt at present can be solved, and the radiation protection polyester fiber has antistatic, far-infrared and anti-ultraviolet functionality and the like; the modified radiation protection polyester fiber is excellent in radiation protection performance; the prepared radiation protection polyester fiberon the basis of the mechanically exfoliated graphene can be widely applied to the fields of home textiles, dressing clothes, armies and the like.

Owner:江苏双良低碳产业技术研究院有限公司 +1

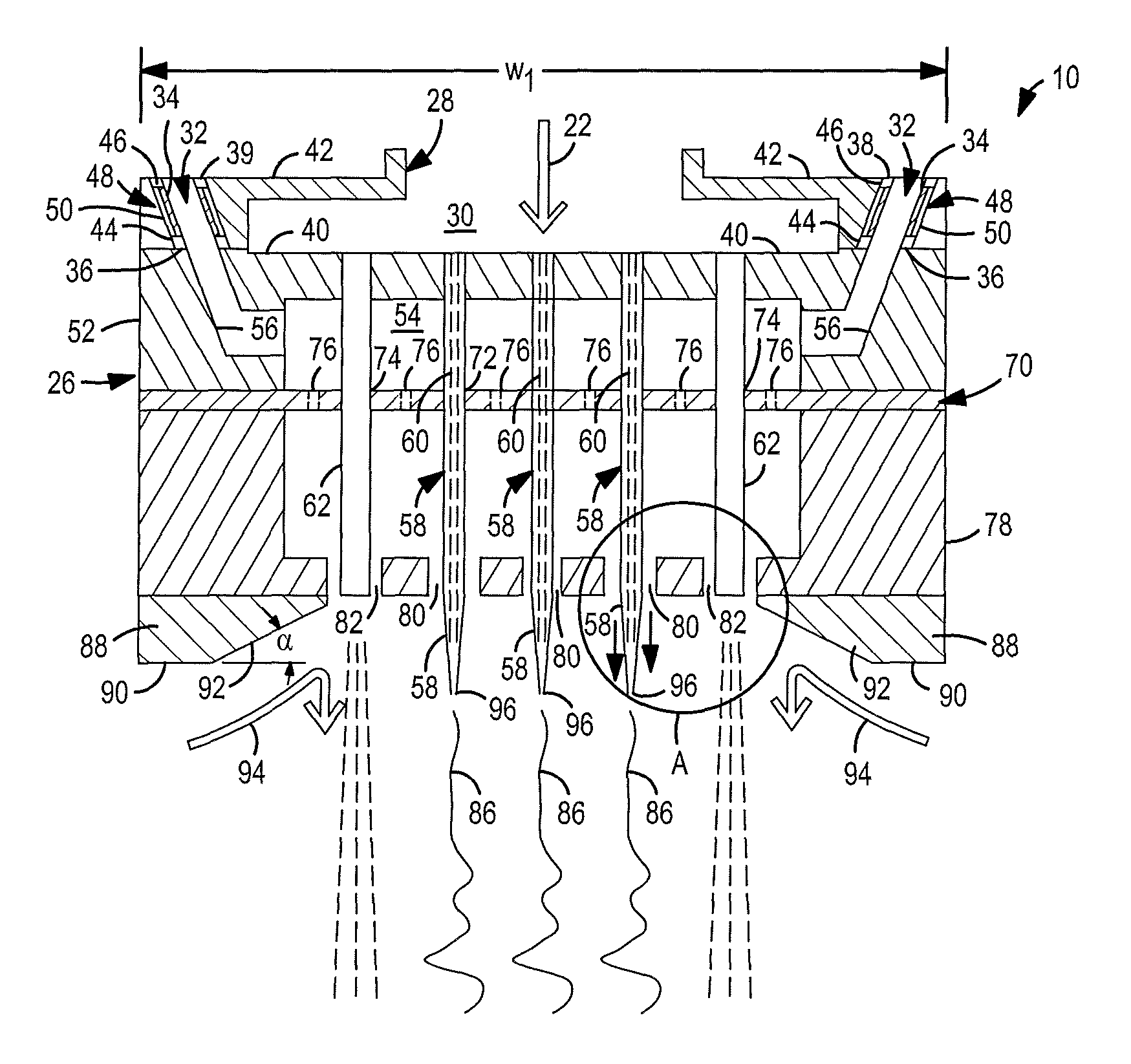

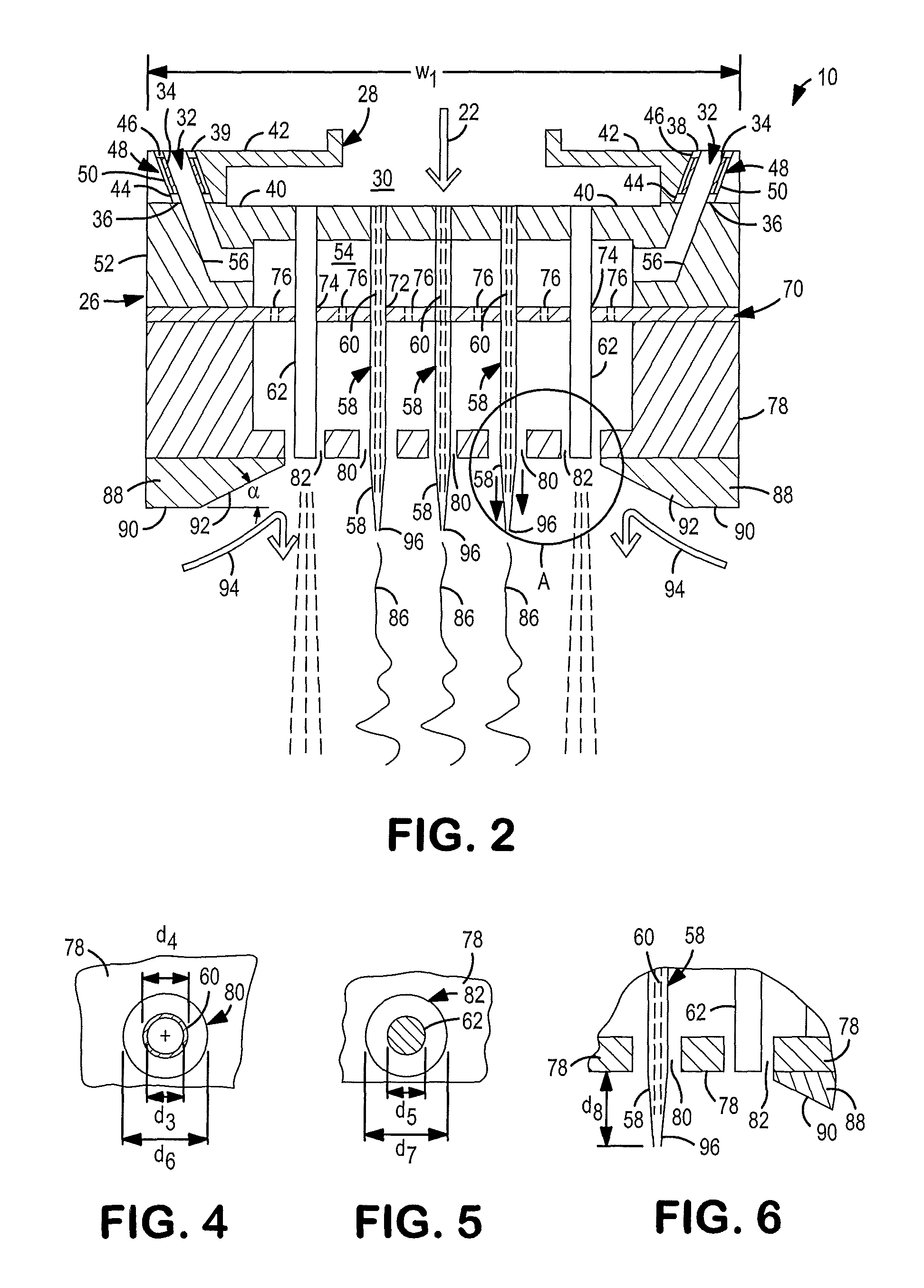

Apparatus for forming a non-woven web

ActiveUS9303334B2Spinnerette packsArtificial thread manufacturing machinesMechanical engineeringEngineering

Owner:BIAX FIBERFILM CORP

Apparatus for forming a non-woven web

ActiveUS20150322592A1Spinnerette packsArtificial thread manufacturing machinesEngineeringMechanical engineering

Owner:BIAX FIBERFILM CORP

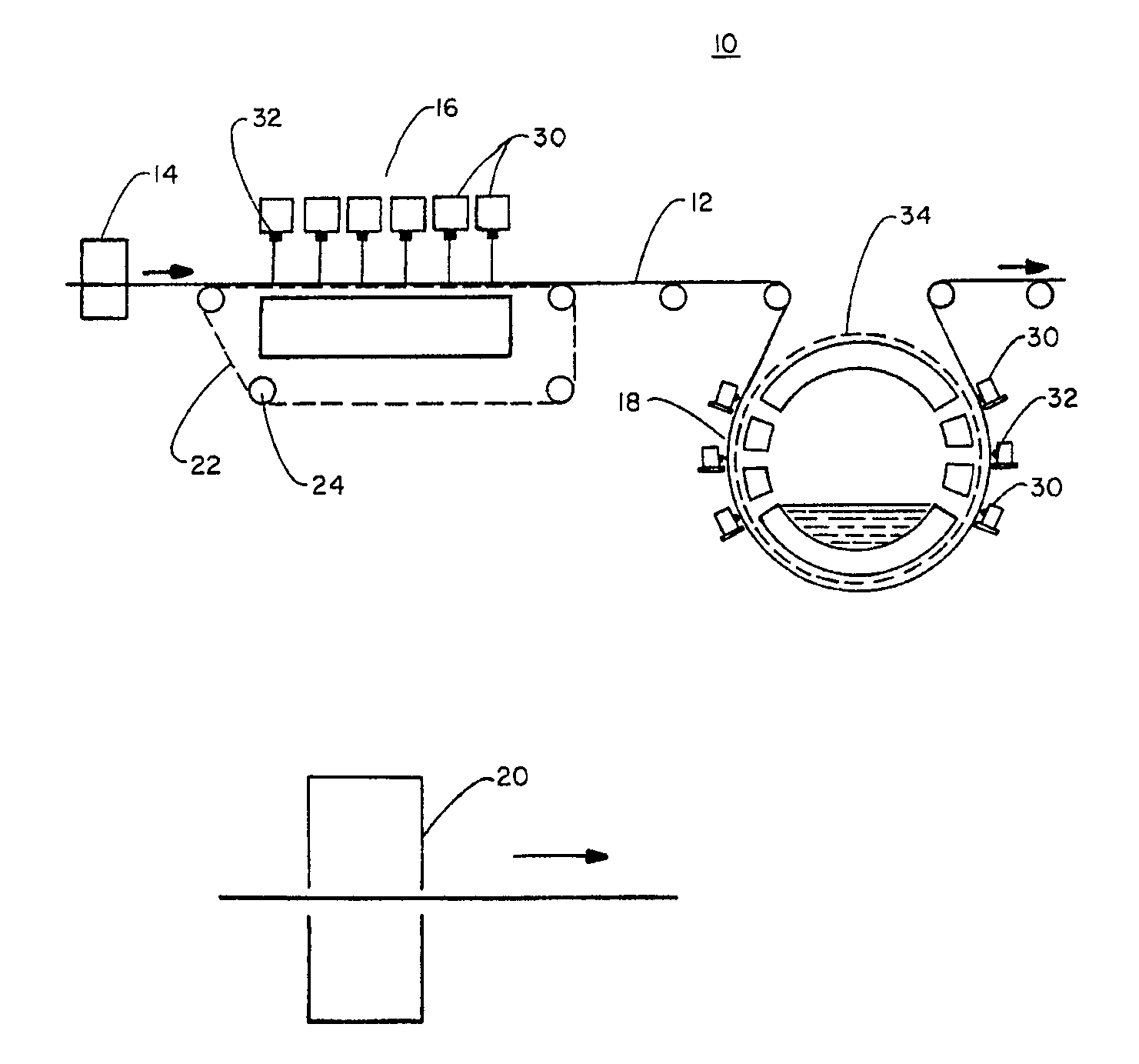

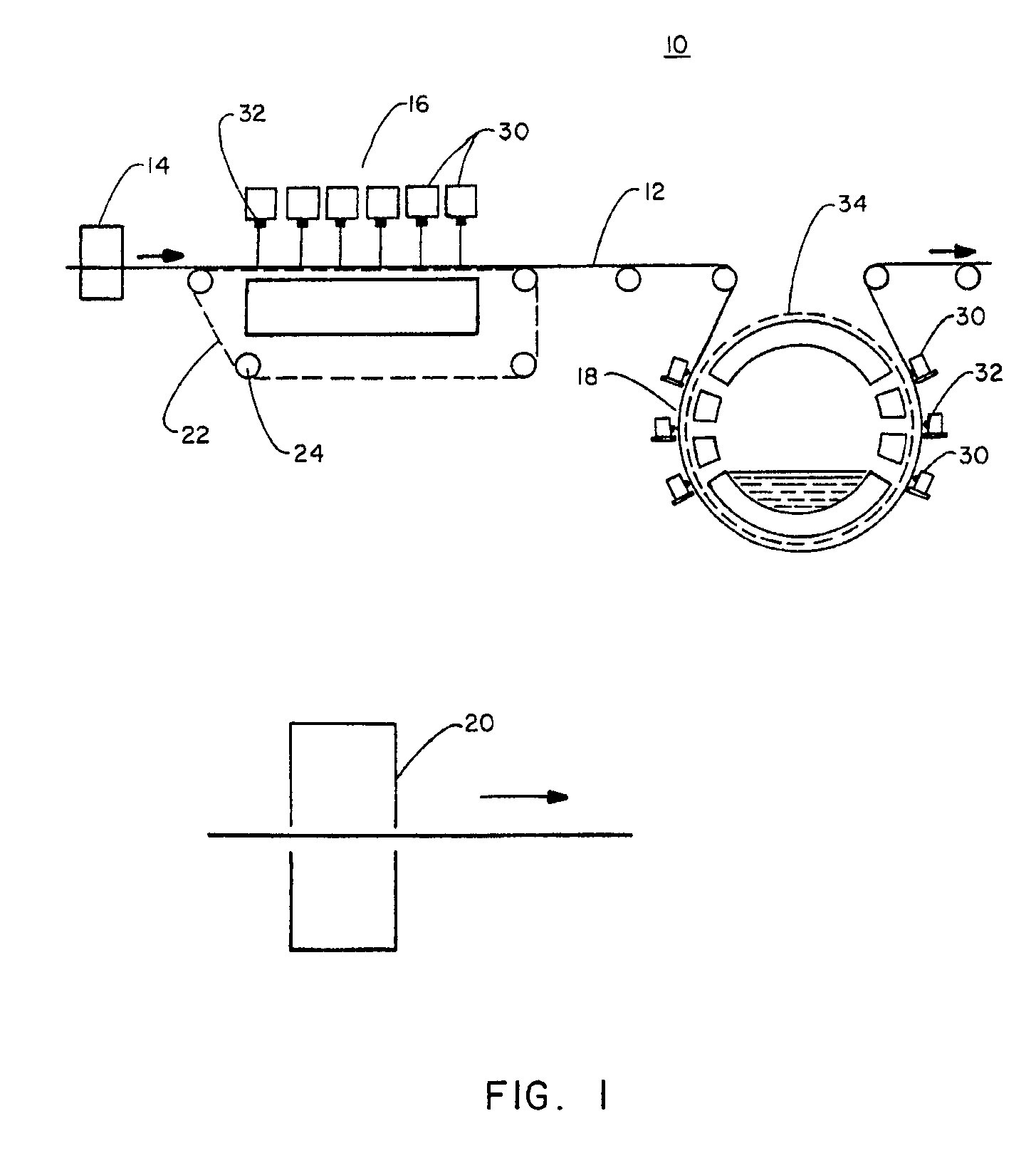

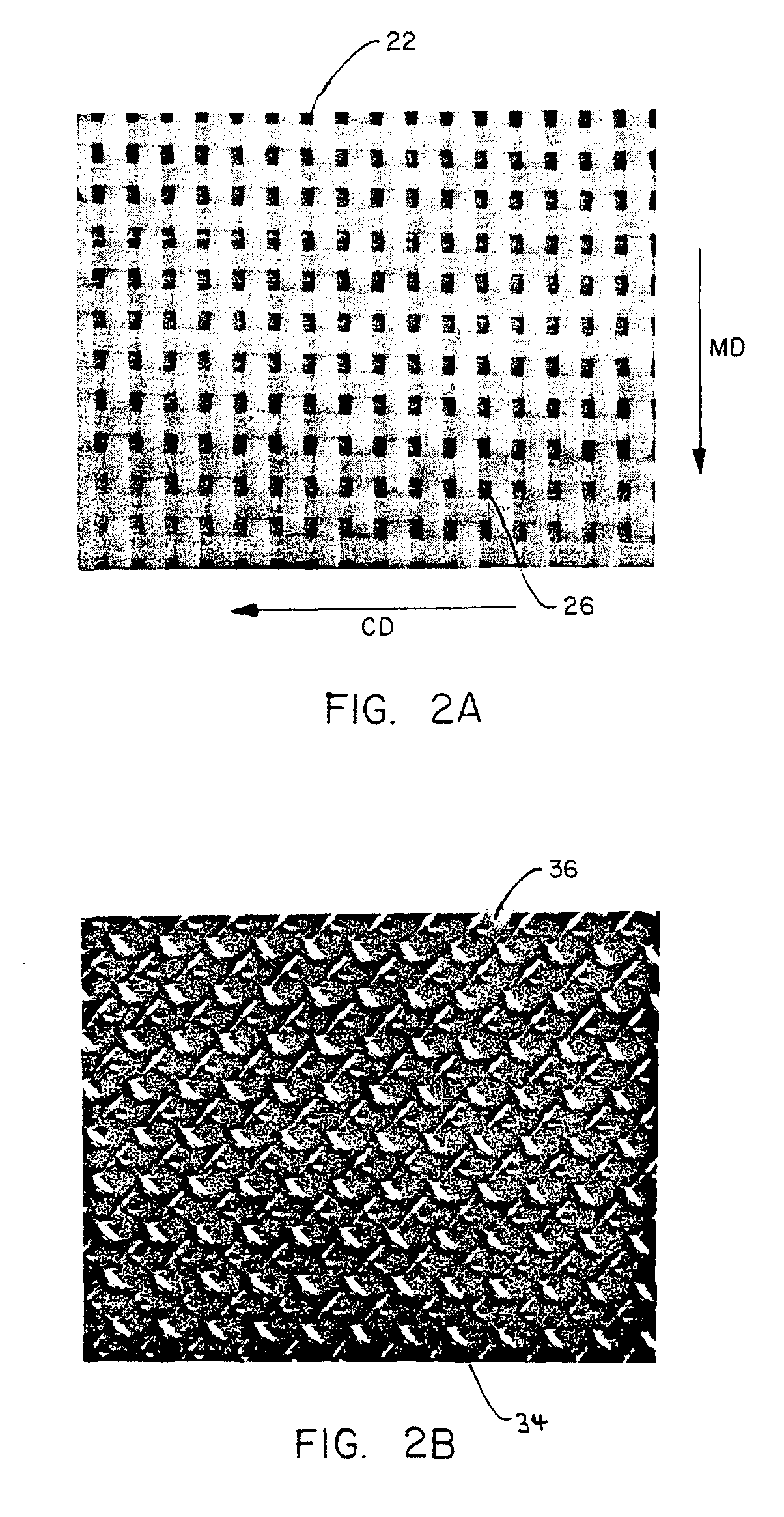

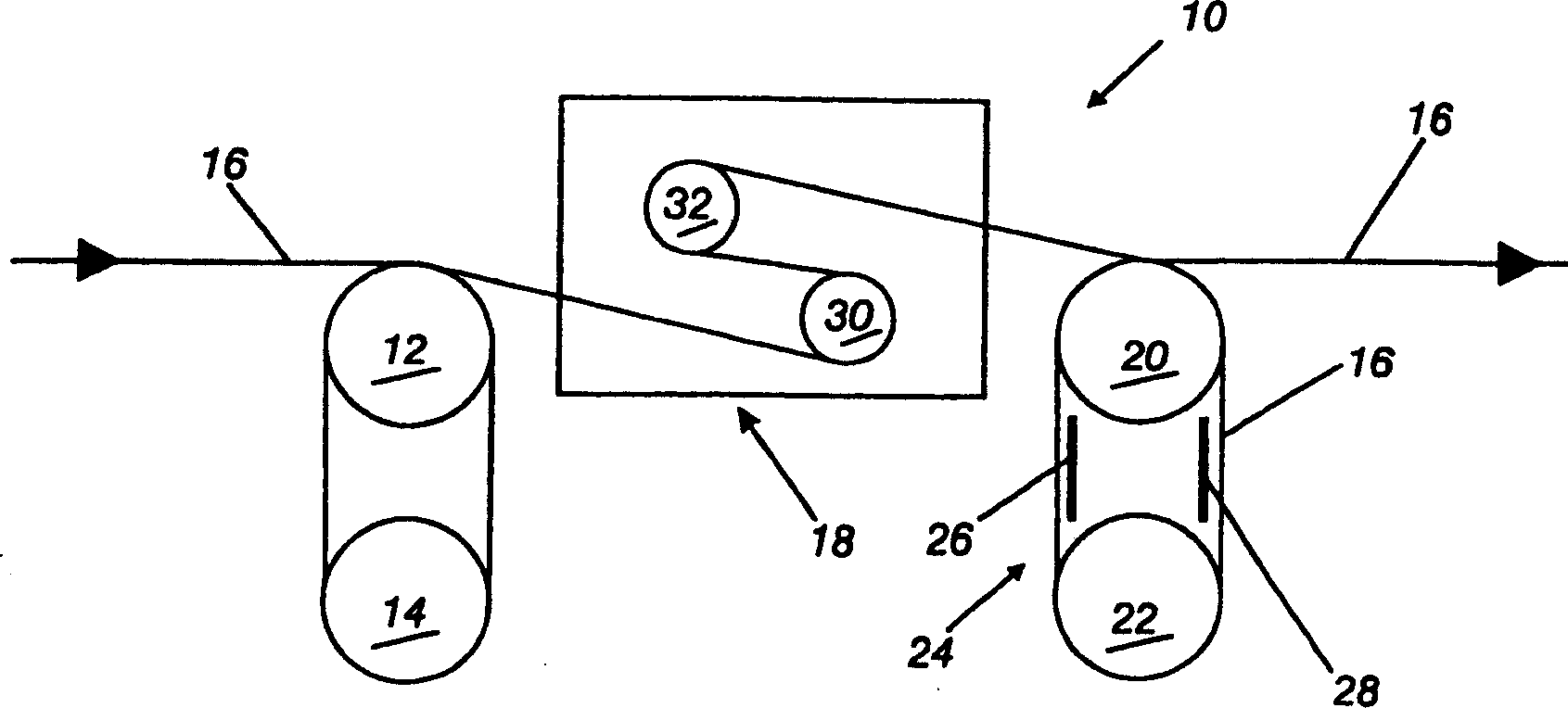

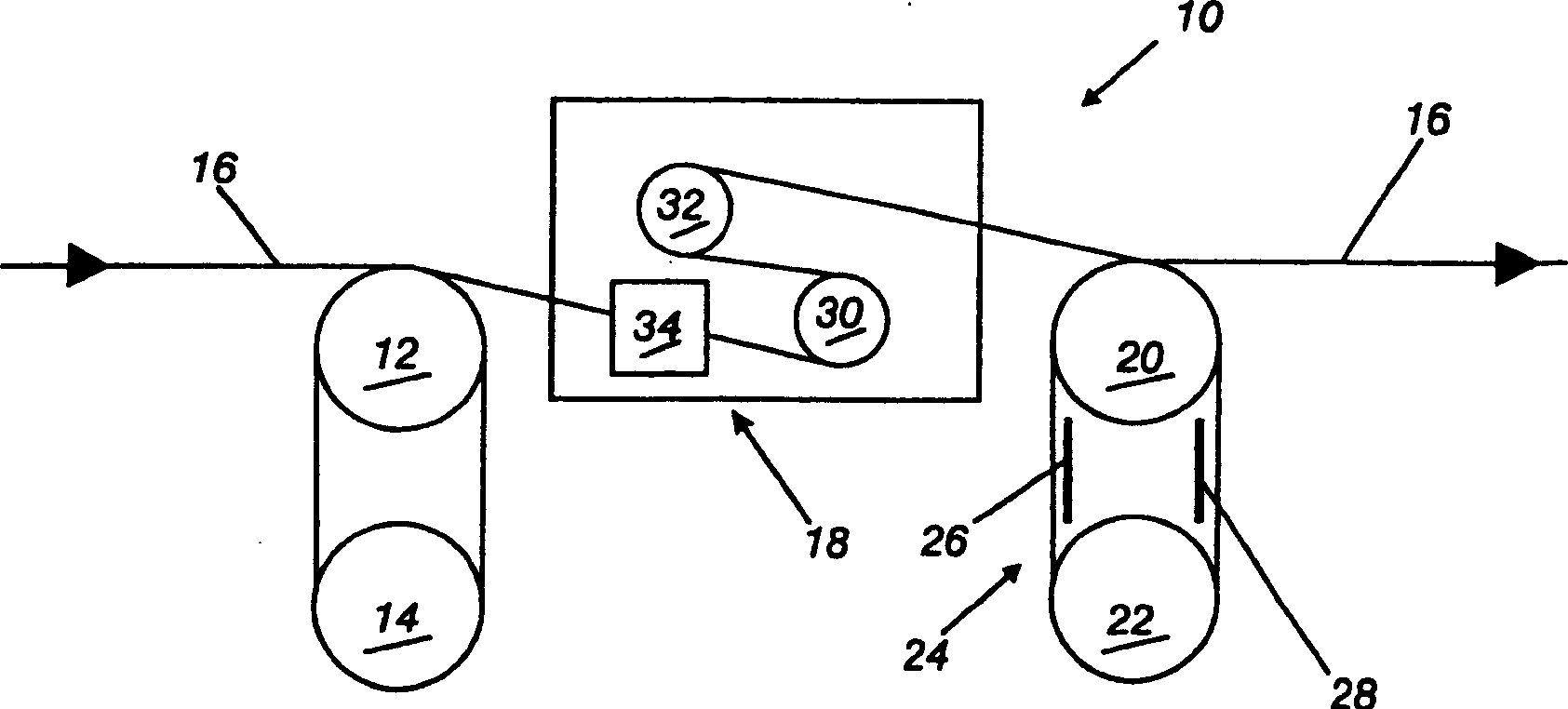

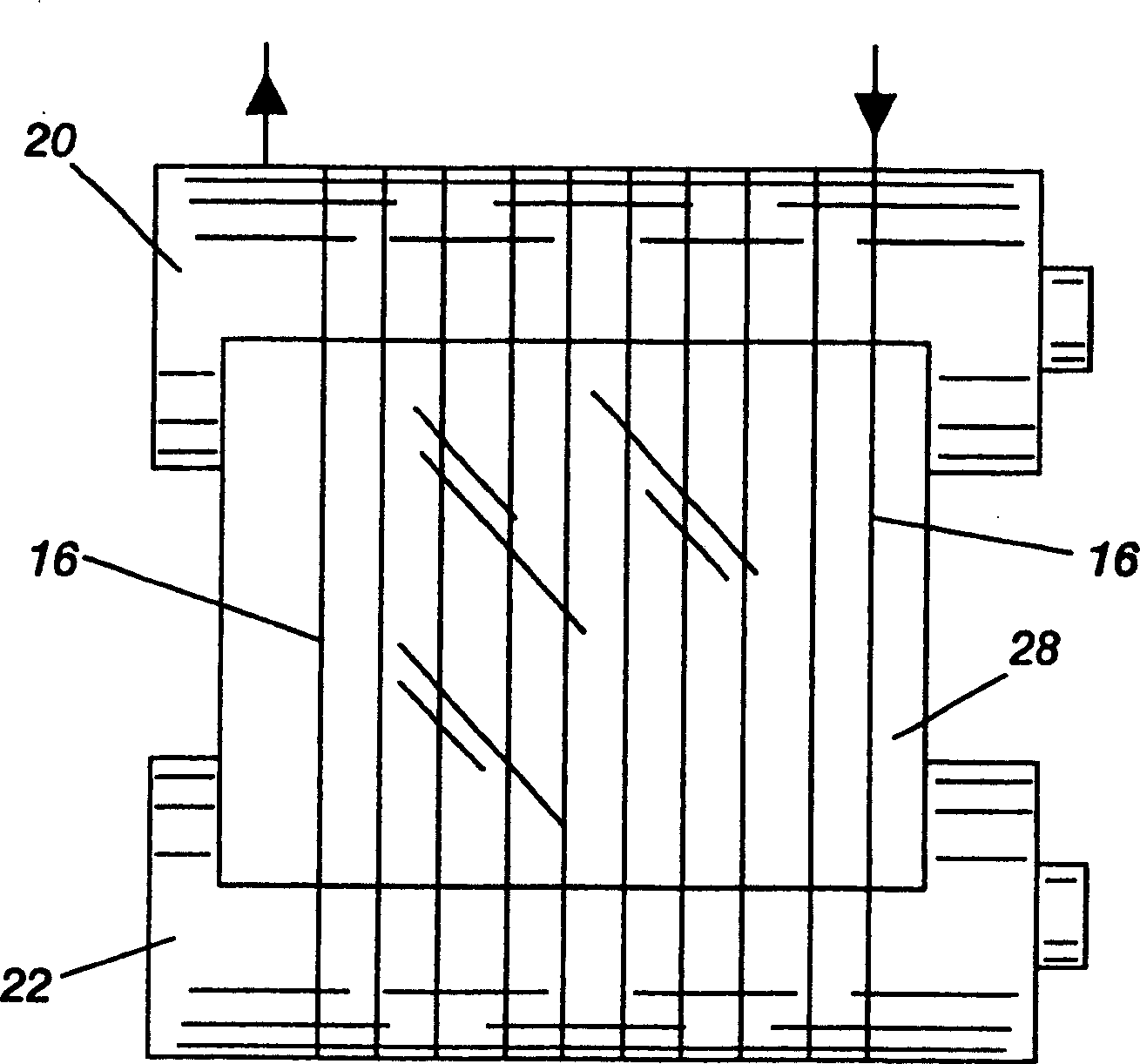

Apparatus and method for hydroenhancing fabric

InactiveUSRE40362E1Uniform finishImprove featuresPattern makingOther washing machinesYarnHigh pressure

An apparatus 10 and related process for enhancement of woven and knit fabrics through use of dynamic fluids which entangle and bloom fabric yarns. A two stage enhancement process is employed in which top and bottom sides of the fabric are respectively supported on members 22, 34 and impacted with a fluid curtain including high pressure jet streams. Controlled process energies and use of support members 22, 34 having open areas 26, 36 which are aligned in offset relation to the process line produces fabrics having a uniform finish and improved characteristics including, edge fray, drape, stability, abrasion resistance, fabric weight and thickness.

Owner:BBA NONWOVENS SIMPSONVILLE

Textile finishing agents for imparting a sensory effect during use

A method for treating fibers, yarns or textiles to improve the sensory effect for a user or weaver of a fabric article. The method treats the fiber, yarns or textiles with an emulsion containing 15-30% by weight of a mixture of waxes having melting points in the range of 35° C. to 60° C. including a lipophilic wax matrix; 10%-20% by weight of emulsifier which are at least one of alkyl or alkenyl oligoglycosides or alkyl ether sulfates, 1%-10% by weight of a crystal regulator which can be partial esters of C12-22 fatty acids with at least one of glycerol, polyglycerol and sorbitan. The mean particle size of the wax crystals is not greater than 6 μm. The emulsion includes water and auxiliaries and additives.

Owner:COGNIS IP MANAGEMENT GMBH

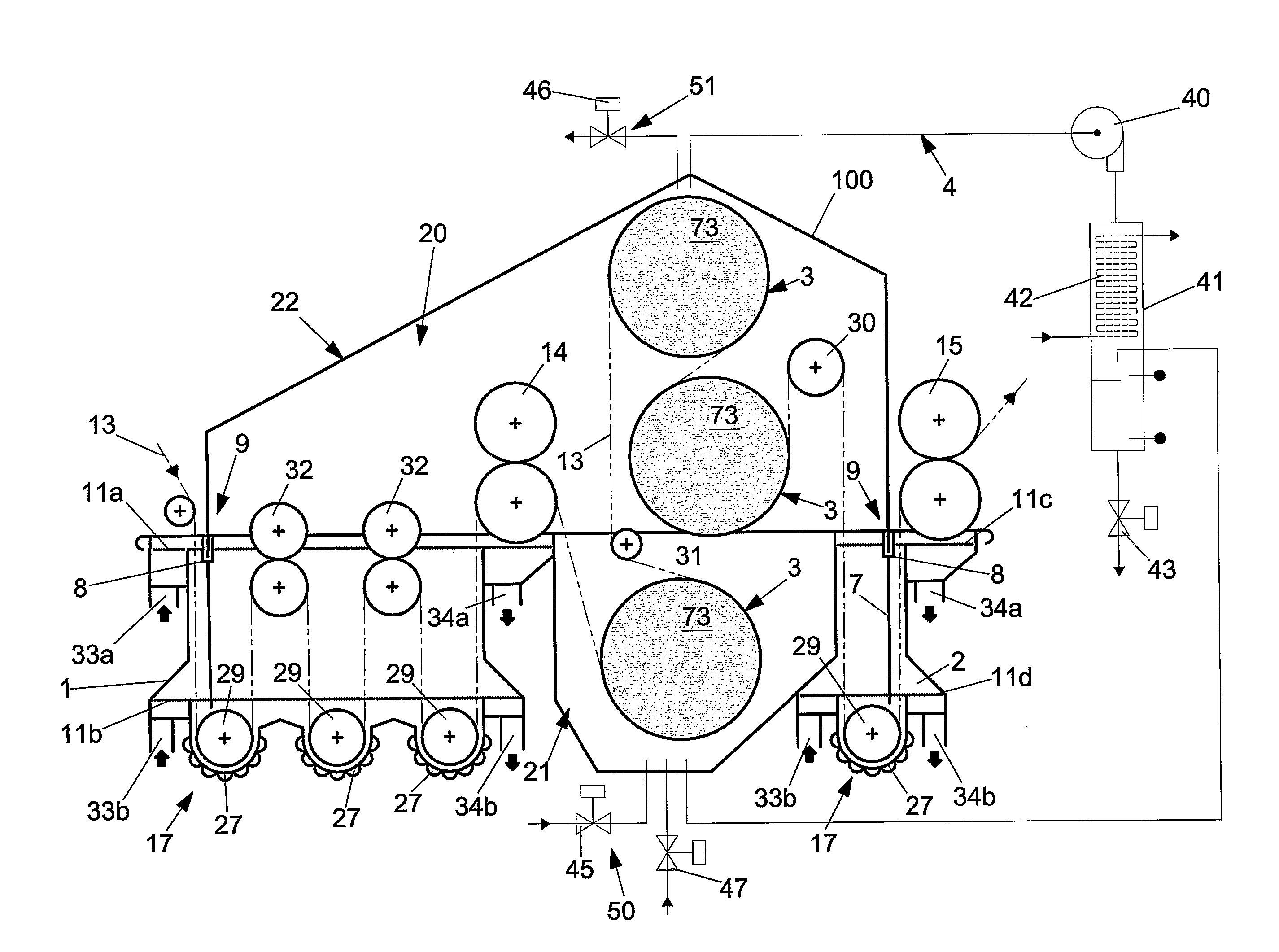

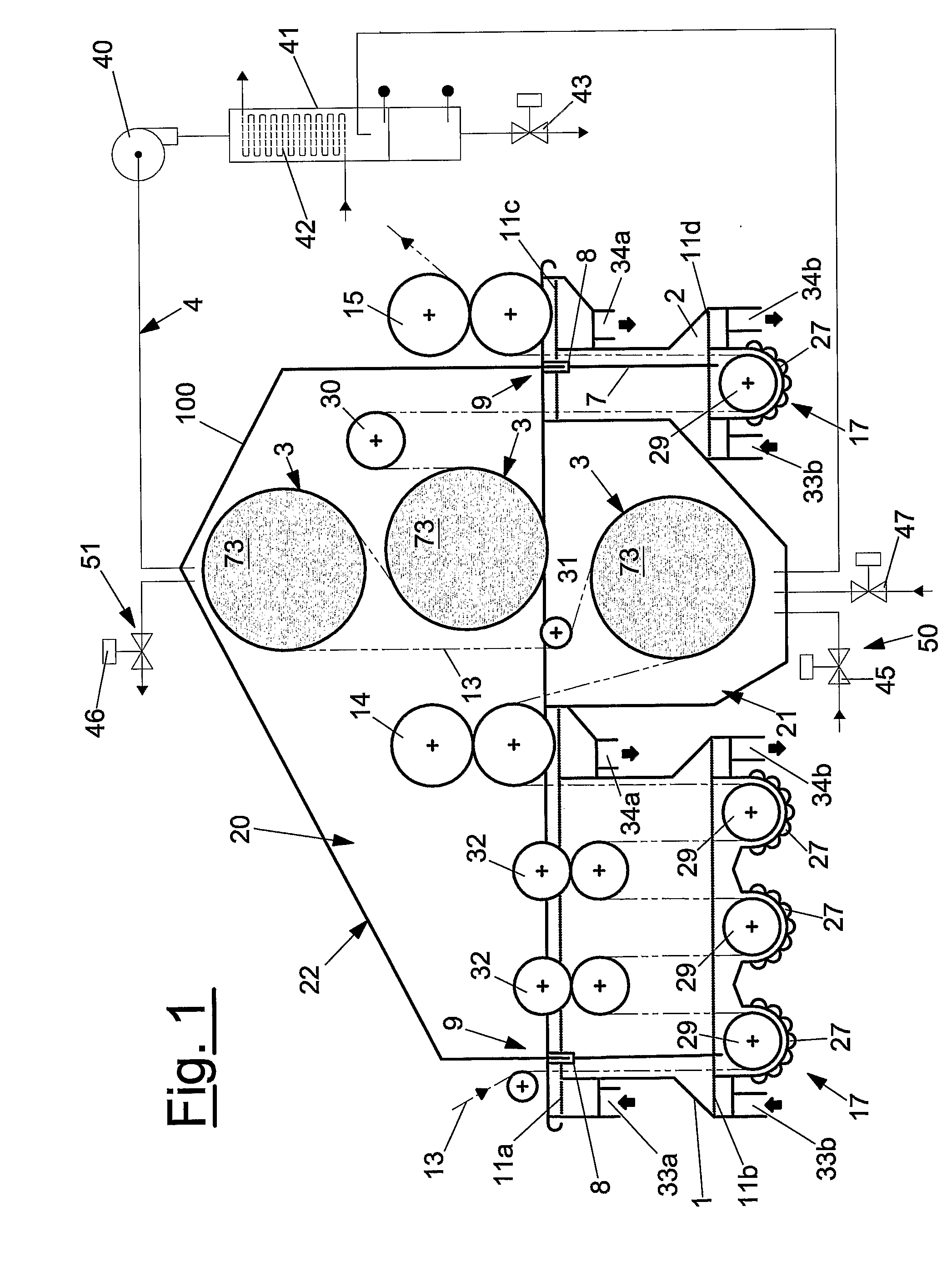

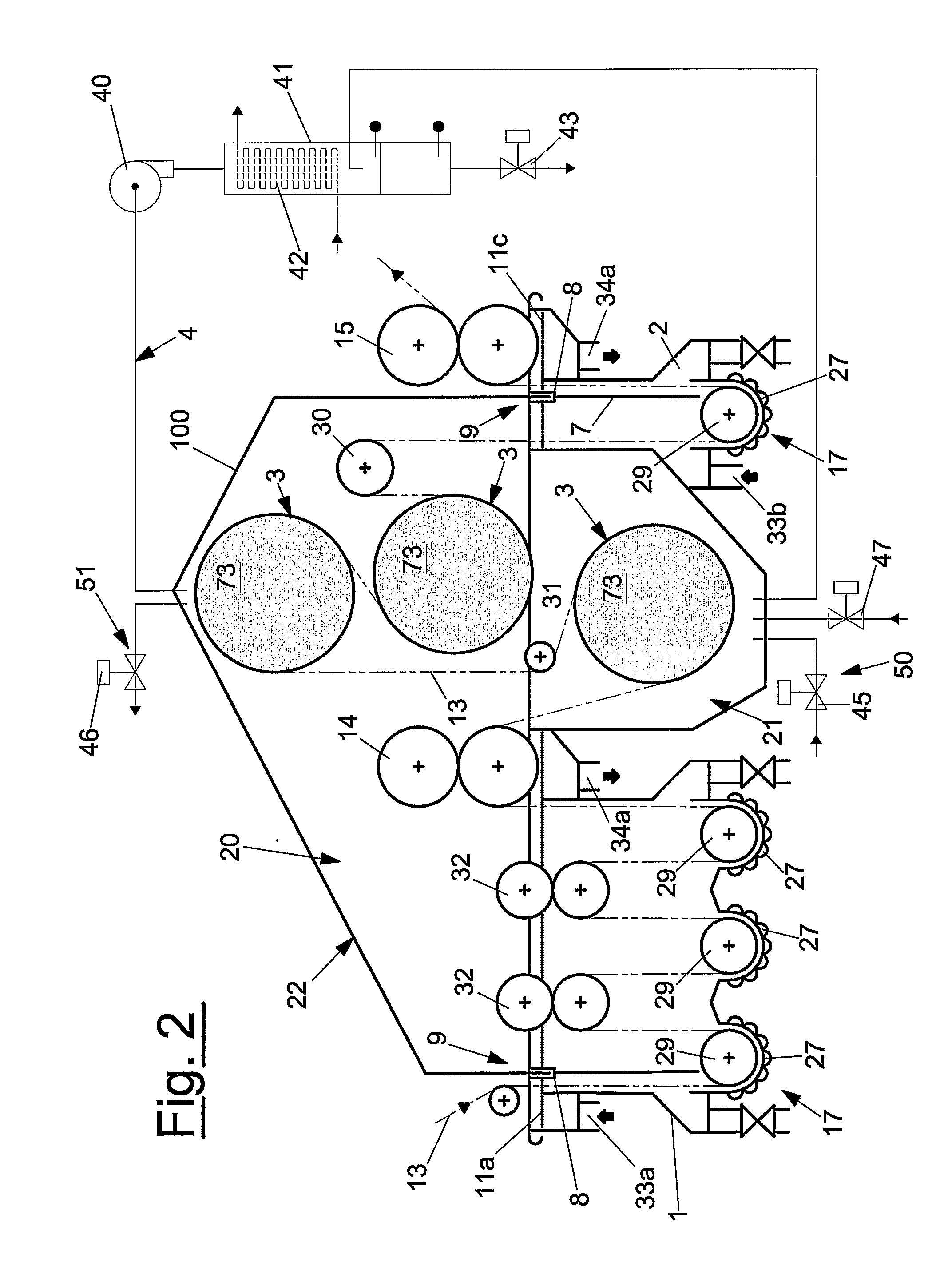

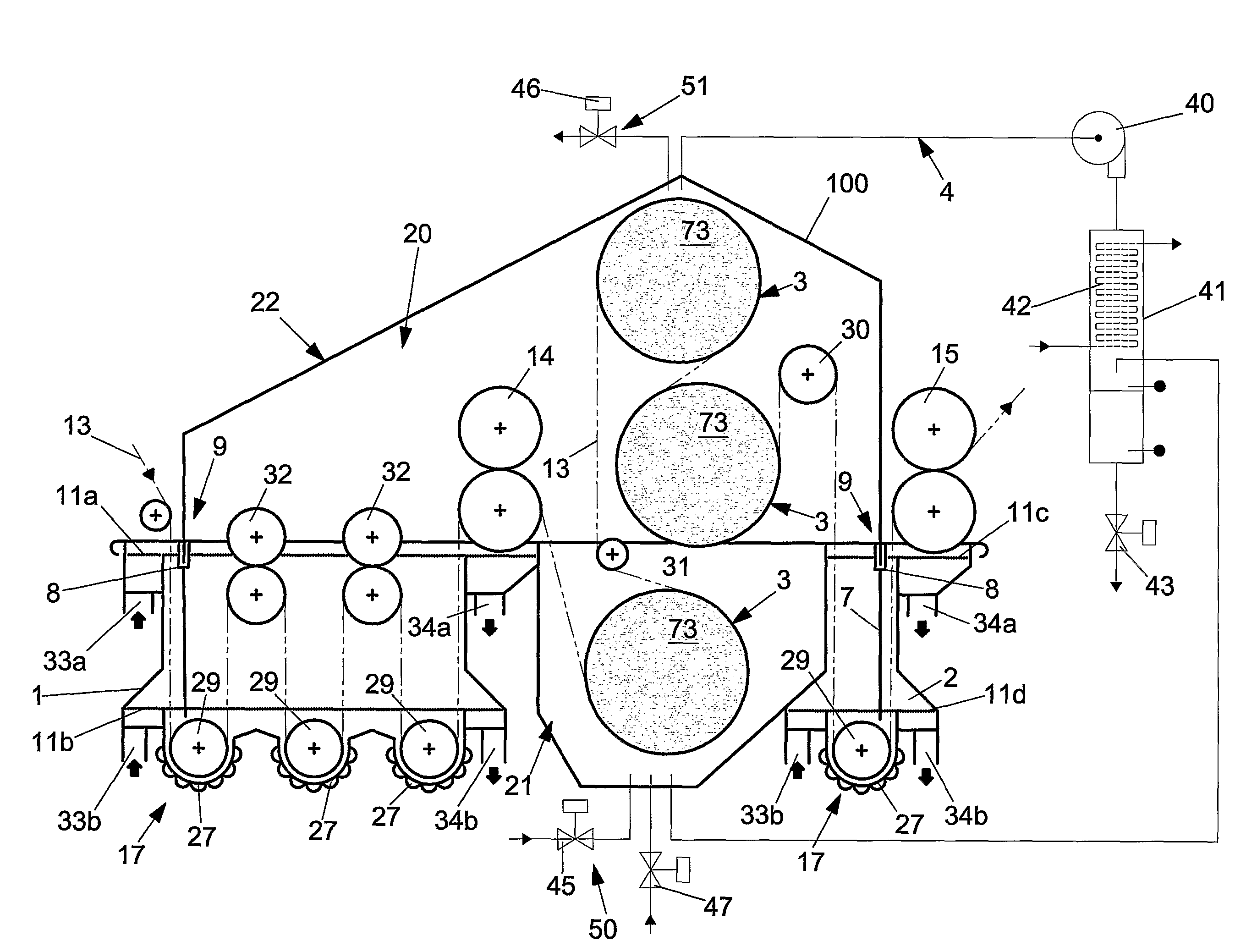

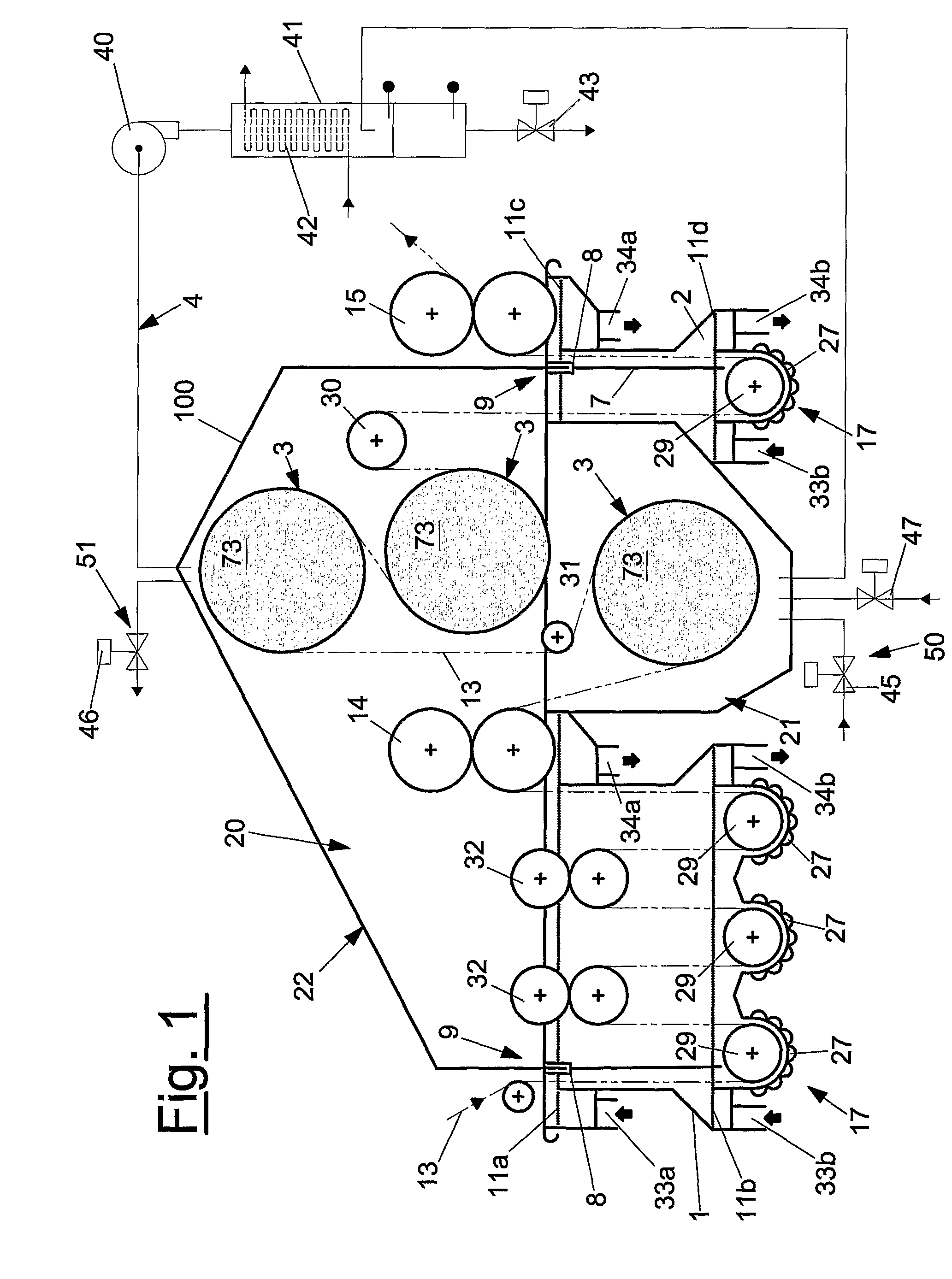

Dyeing Device And Process Using Indigo And Other Colorants

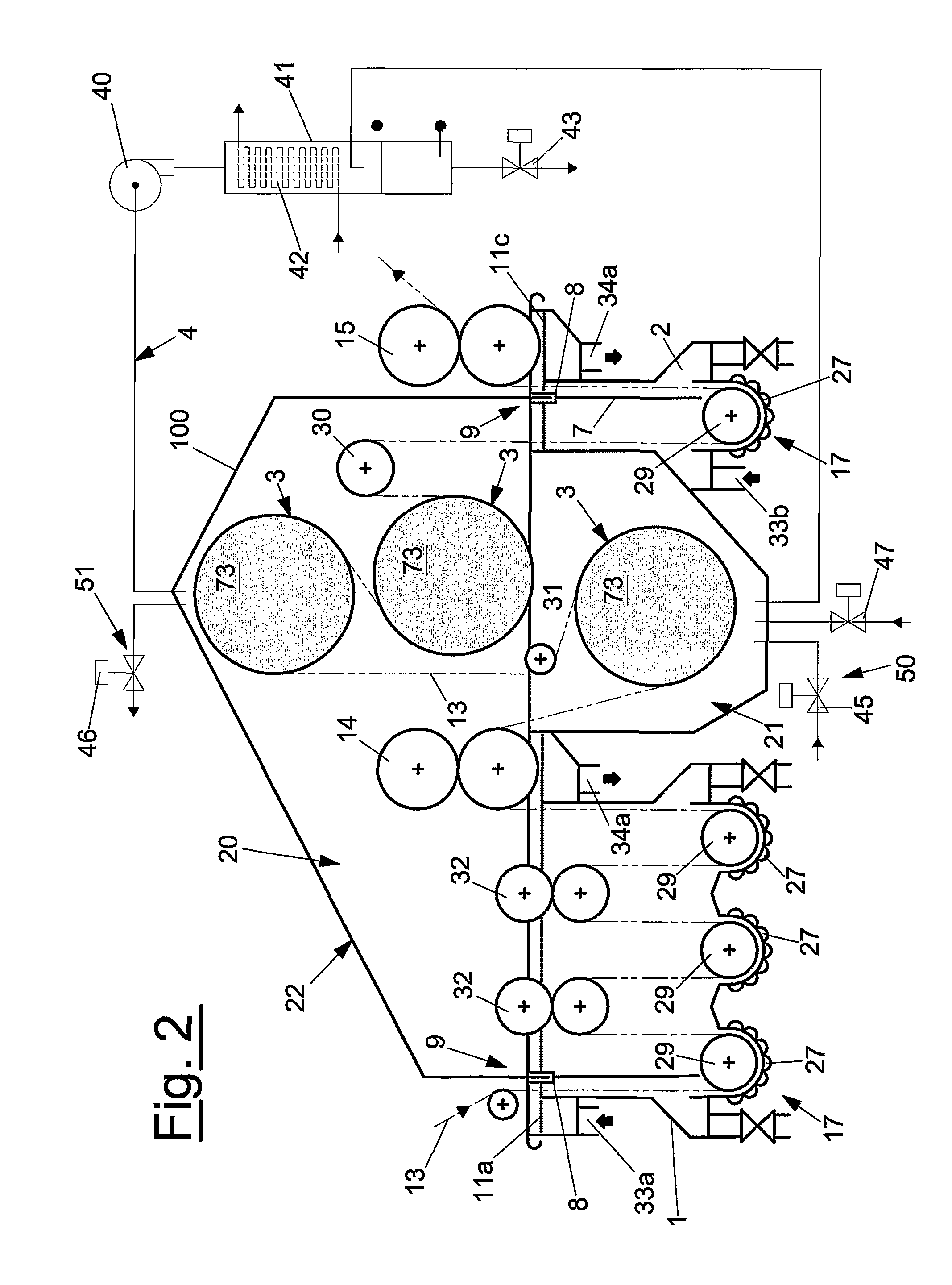

ActiveUS20080040870A1Reduction in the yarn rejectsLow costArtificial filament supportLiquid/gas/vapor treatment of definite length materialsYarnEngineering

A continuous dyeing device (100) and related processes using indigo and / or other colorants for warp yarn chains and / or for fabrics (13), equipped with at least a first (1) and a second (2) dyeing compartments containing dyeing baths (11a, 11b, 11c, 11d), the first and second dyeing compartments (1, 2) being enclosed, at least partially, in a hermetically sealed chamber (20). The device (100) also includes at least one squeezing element (14) interposed between the two dyeing compartments (1, 2) and a plurality of cylinders (3) for heating and / or dehydrating the yarn and / or the fabric (13), thereby increasing the diffusion and the absorption of the colorant. The cylinders (3) are positioned downstream of the first dyeing compartment (1) and squeezing element (14).

Owner:KARL MAYER STOLL R&D GMBH

Production method for complete extinction modified polyester

InactiveCN106757406AIncrease stressWell mixedSpinnerette packsArtificial thread manufacturing machinesPolyesterExtinction

The invention discloses a production method for complete extinction modified polyester. The production method comprises the following steps: conveying master batch to a drying system for crystal drying, feeding through a master batch high-level cabin, a screw rod melting extrusion machine, a master batch metering pump, a melt dynamic mixer and a melt static mixer in sequence, feeding into a spinning manifold, and performing a polymerization reaction on polyester melt in the spinning manifold, wherein the polyester melt is cooled by a melt cooler; feeding through a metering pump and a spinneret plate, performing annular air-blowing cooling, and feeding oil through a nozzle, feeding through a wire guide and a pre-network, performing GR1 and GR2 coiling molding, inspecting a finished product, and packaging and storing in a warehouse in sequence. By adoption of the production method, production situations can be relatively stable, a product is excellent in appearance and high in dyeing property, and later weaving can be performed smoothly.

Owner:TONGKUN GRP

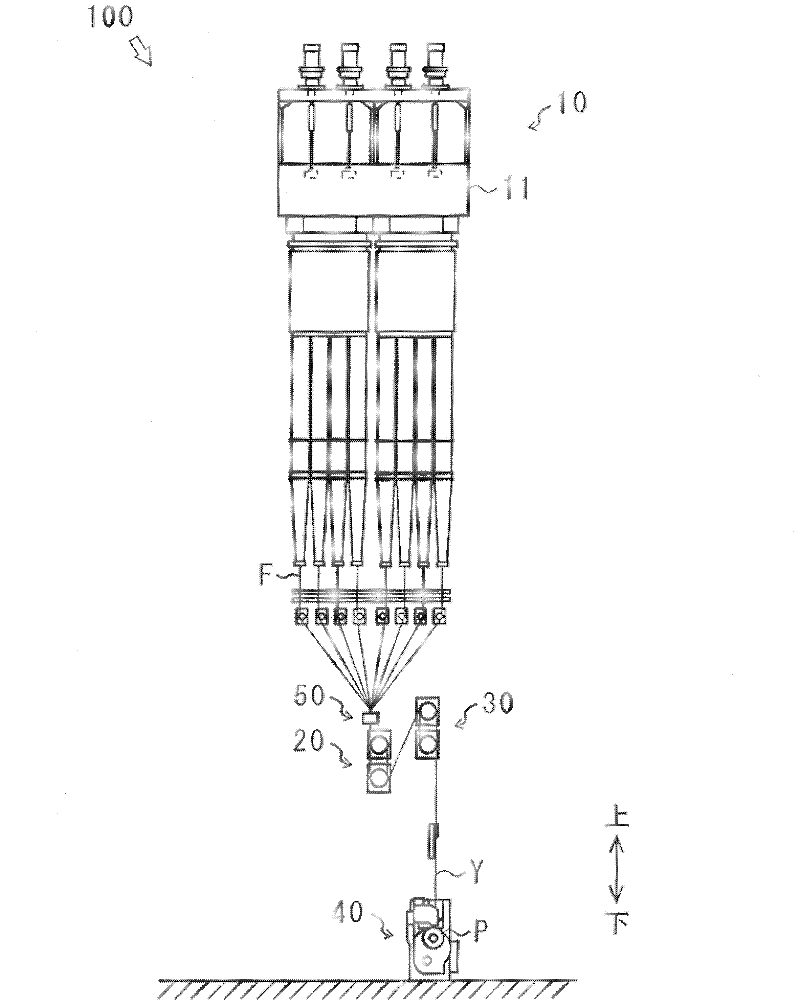

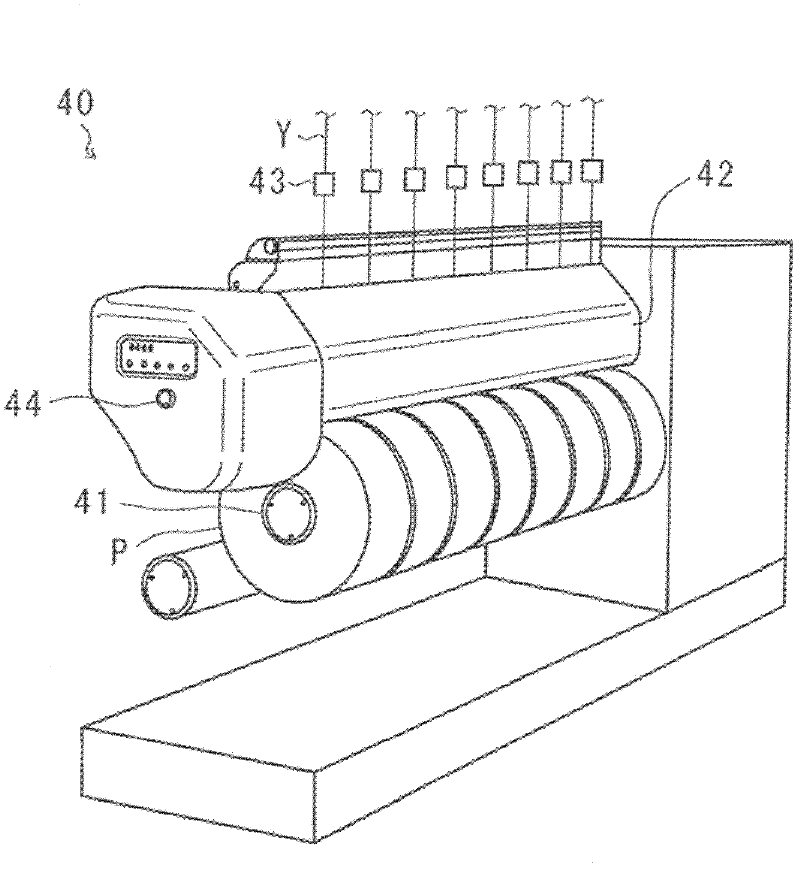

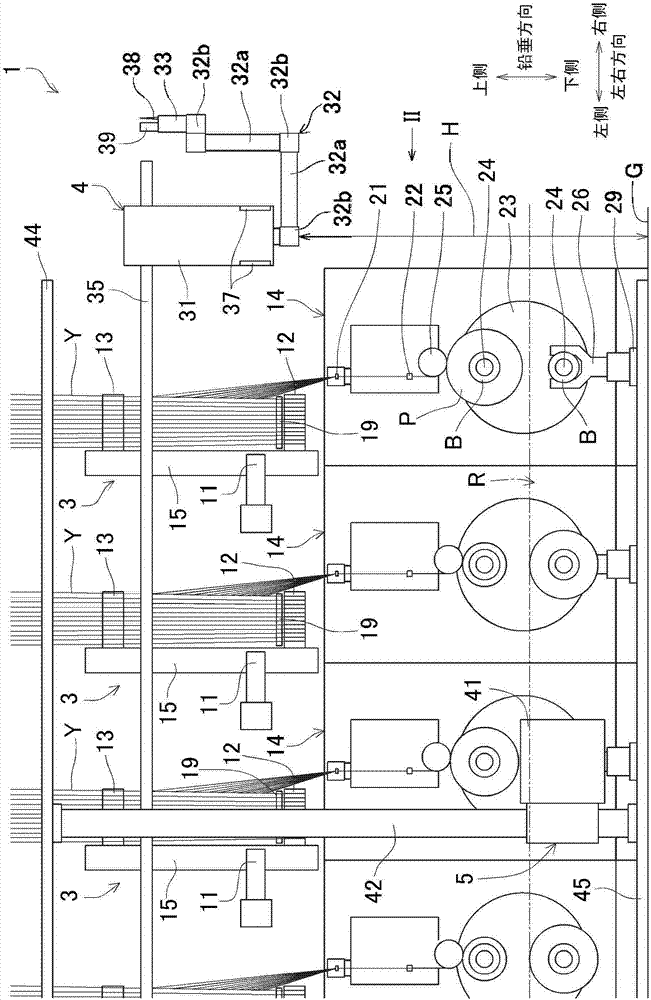

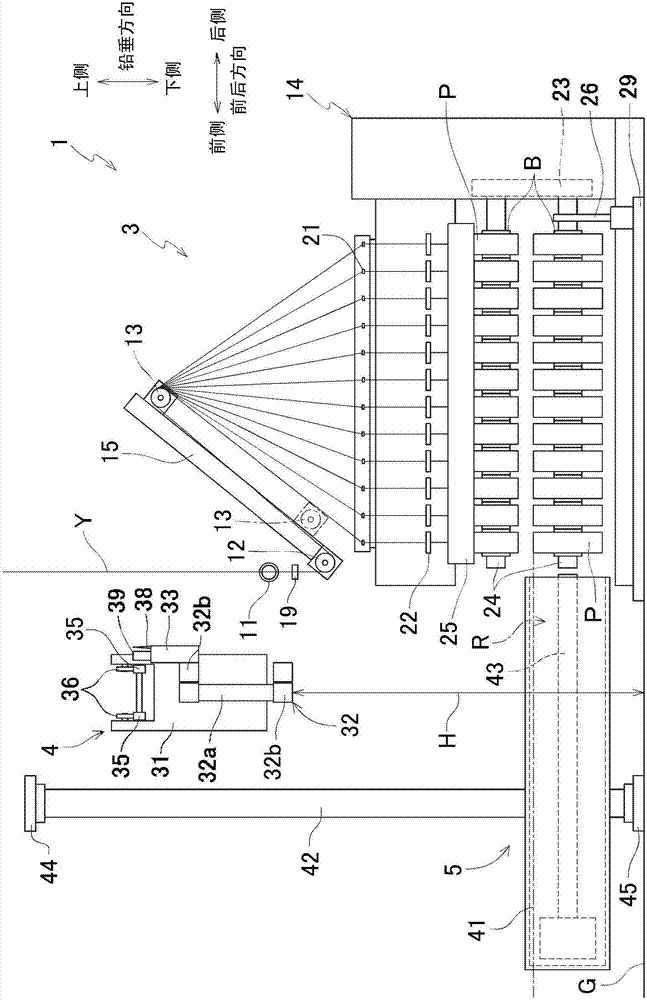

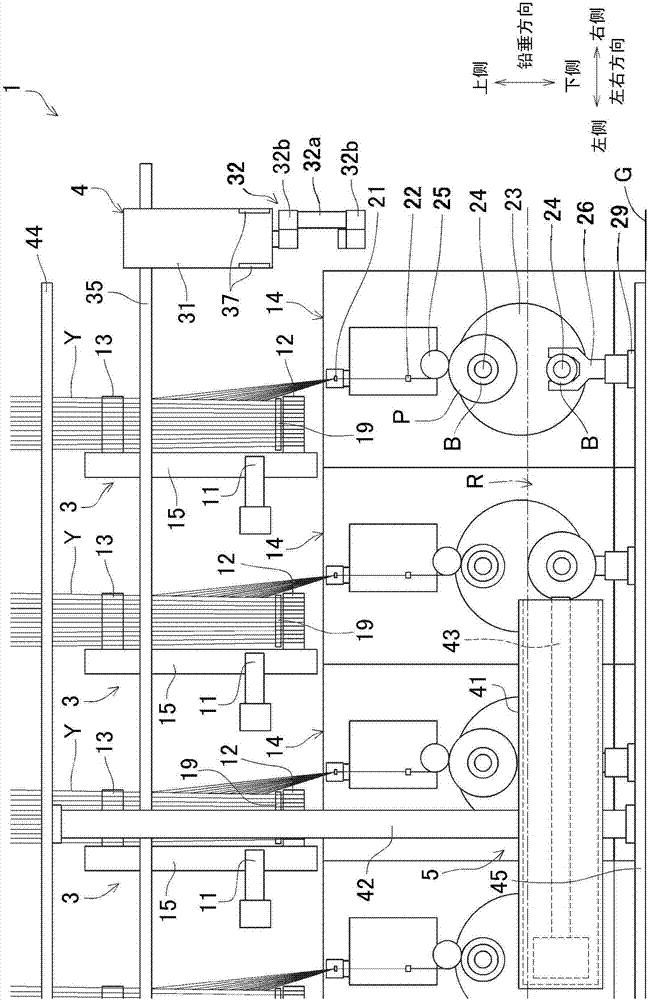

Spun yarn winding system

In a spun yarn winding system, a yarn threading robot is less likely to interfere with an operator or an apparatus which collects packages. Take-up units 3 are lined up in the left-right direction. Each take-up unit 3 is configured to take up yarns Y spun out from a spinning apparatus and form packages by winding the yarns Y into bobbins B. A yarn threading robot 4 is provided above a winding unit 14 of the take-up unit 3, and hangs down from a guide rail 35 extending in the left-right direction over the take-up units 3 and moves in the left-right direction along the guide rail 35. At least when moving along the guide rail 35, the yarn threading robot 4 is positioned above the upper end of a fully-wound package P attached to a bobbin holder 24.

Owner:TMT MACHINERY INC

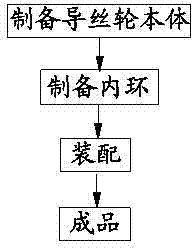

Preparation method of novel thread guide wheel

InactiveCN102443907AImprove wear resistanceImprove corrosion resistanceArtificial filament supportYarnHeat resistance

The invention discloses a preparation method of a novel thread guide wheel. The preparation method mainly comprises the following steps of: a) preparing a thread guide wheel body; b) preparing an inner ring; and c) assembling. In the preparation method, the arrangement of the working procedures is reasonable, the implementation is convenient, the prepared thread guide wheel has good performances such as wear resistance, corrosion resistance, heat resistance and self lubrication, and has good stability and excellent yarn guide performance in the operation process, the preparation cost is low, the assembly is convenient and the service life is long.

Owner:WUJIANG YILANJI TEXTILE PROD

Method for producing fine denier bright flame-retardant polyester FDY filament

ActiveCN107338490APromote solidification and crystallizationPromote crystallizationFlame-proof filament manufactureArtificial filament heat treatmentCompanion animalMetering pump

The invention discloses a method for producing fine denier bright flame-retardant polyester FDY filament, and the method comprises the steps of (1) weighing 70%-80% bright PET slice, 6%-8% black master batch and 8%-10% flame-retardant master batch, 6%-10% crystallization-promoting agent, 1%-3% electromagnetic stress particles; (2) mixing the bright PET slice with the black master batch and the flame-retardant master batch to obtain a mixed PET melt; (3)filtering and pressurizing the mixed PET melt, and then distributing the melt to each filament-spraying assembly through a metering pump to generate nascent fiber; (4) blowing and cooling the nascent fiber in a spinning path; (5) applying a controllable pulse magnetic field in the PET melt fusion process, the nascent fiber cooling process and the process that the PET melt is sprayed from the filament-spraying assembly to form the nascent fiber; and (6) subjecting the cooled fiber to oil applying by an oil nozzle, stretching and shaping, gridding and winding successively.

Owner:青岛威达体育用品有限公司

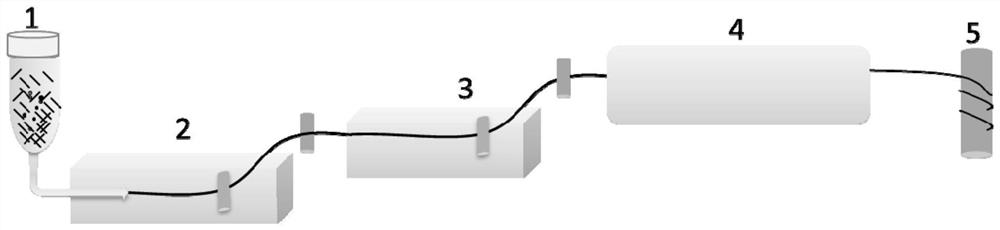

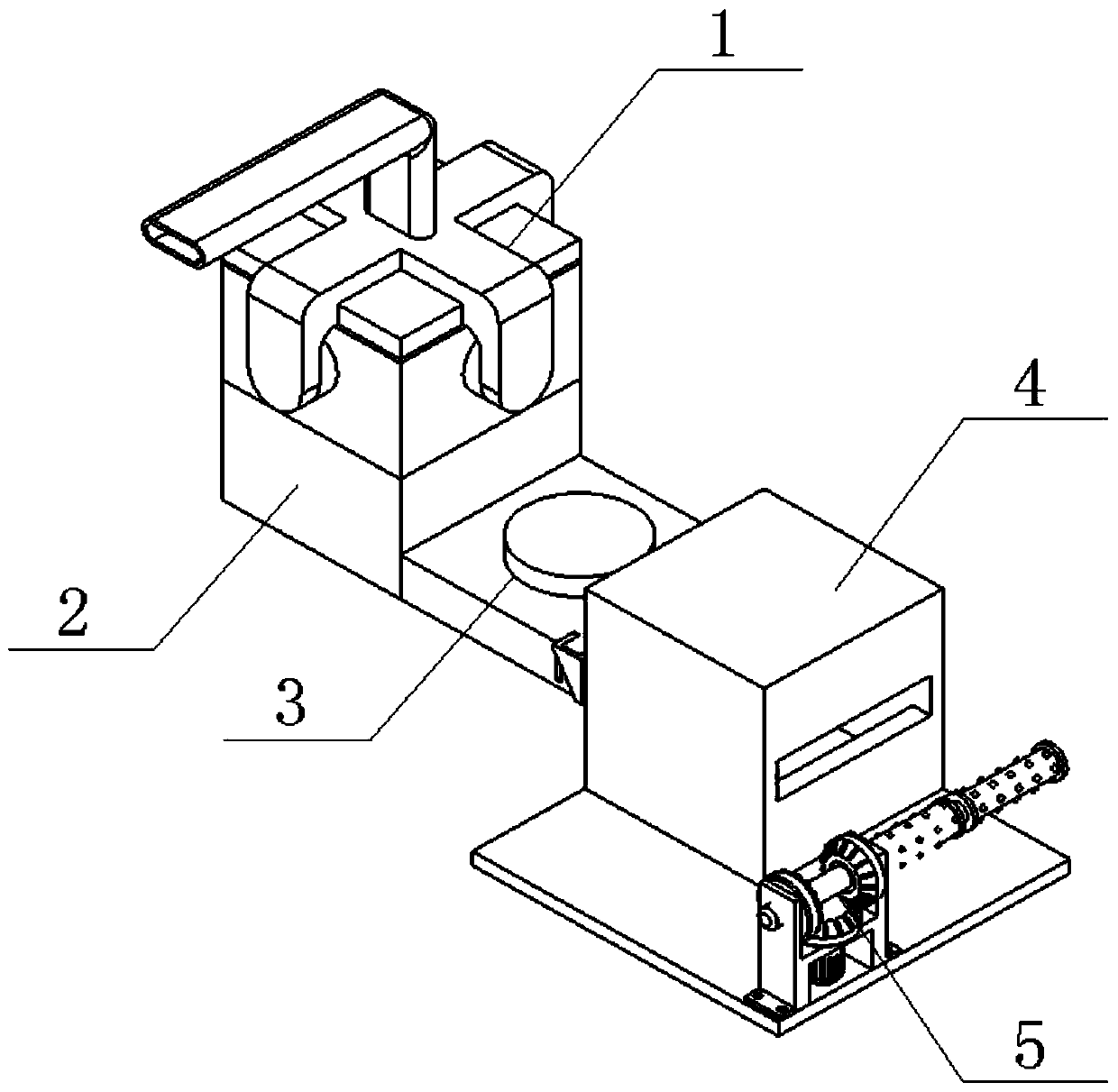

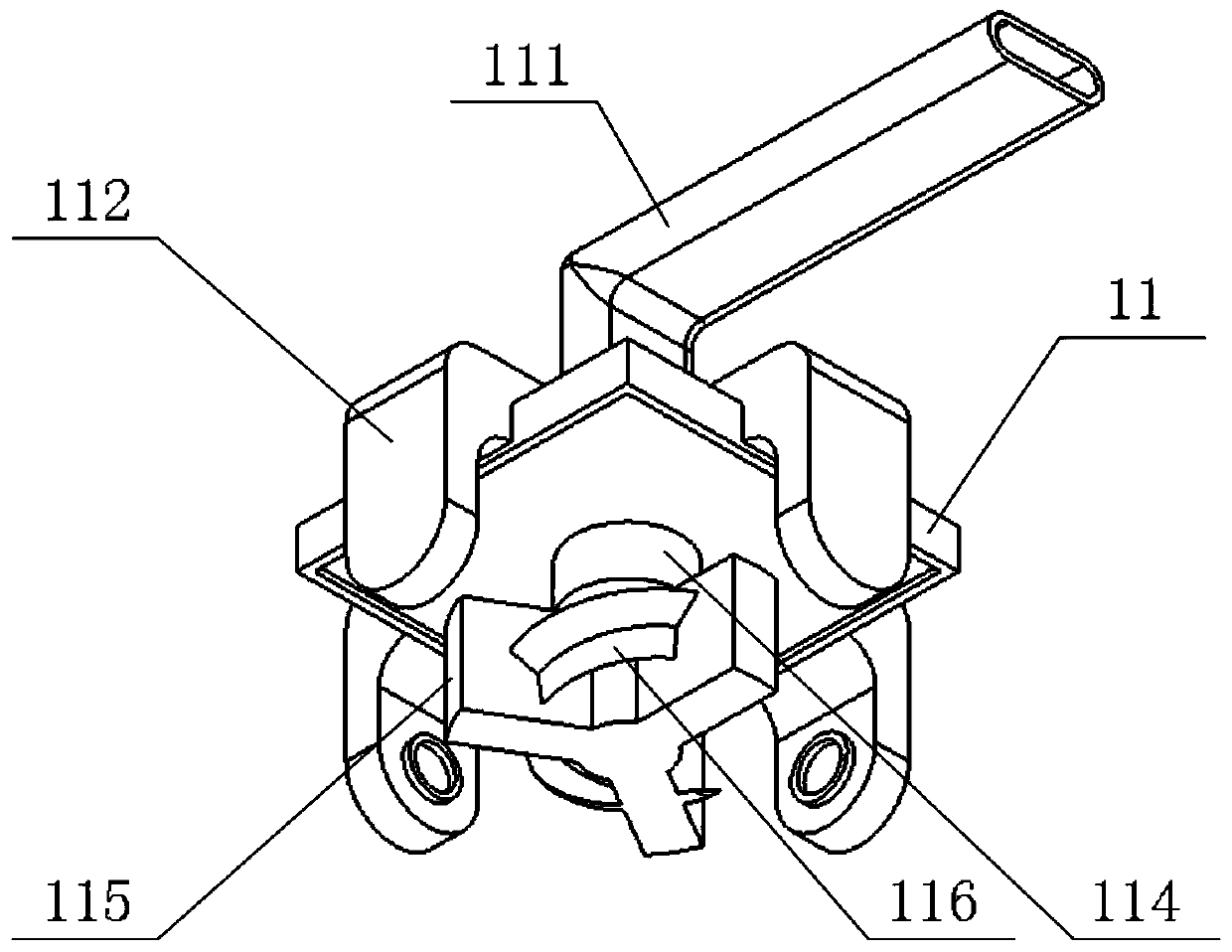

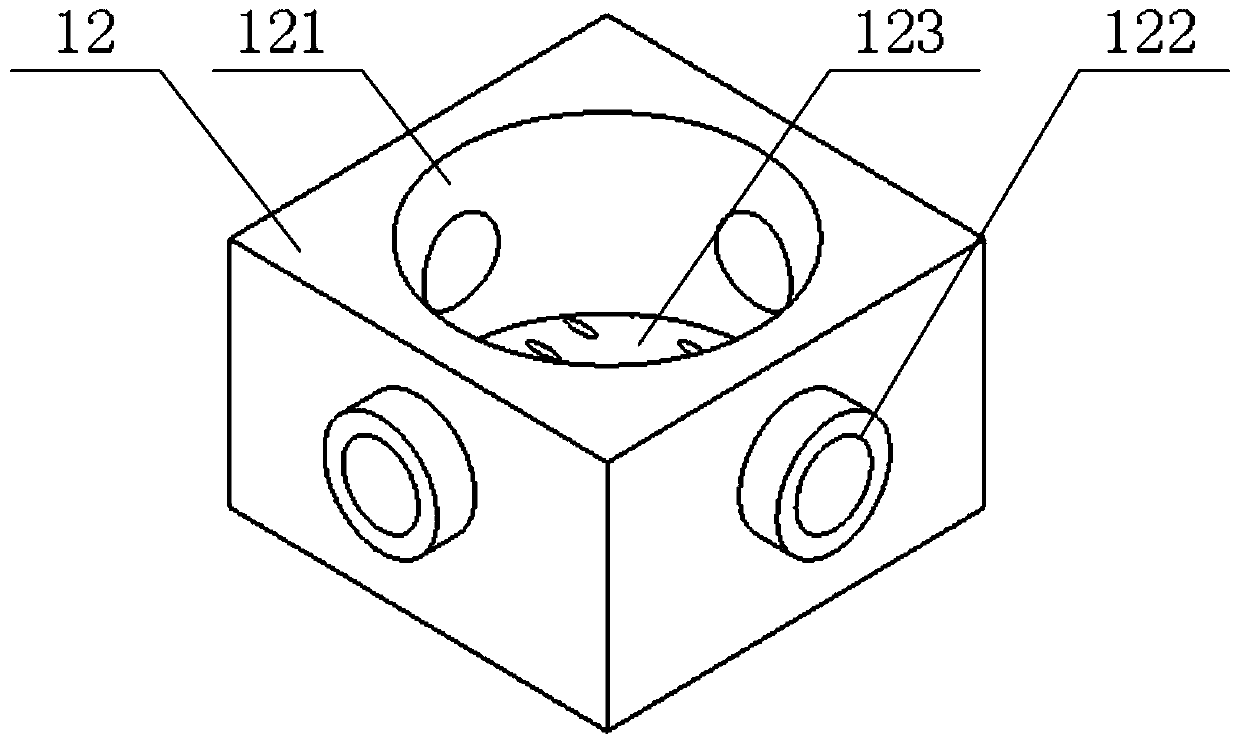

Complex fiber processing follow-up production device

InactiveCN107460555AAvoid mixingEnsure claritySpinnerette packsFilament/thread formingFiberEngineering

The invention provides a complex fiber processing follow-up production device which comprises a spinning machine, a cooling device, a pre-shaping mechanism and a winding mechanism which are sequentially arranged. A spinning assembly is arranged on the spinning machine. The spinning assembly comprises a vertical spraying frame, a protecting device and a nozzle. The cooling device comprises a cooling box. Channel pipes are arranged inside the cooling box. A cooling water pipe is wound around each channel pipe. A feeding inlet and a discharging outlet of the cooling box are each provided with an induction air cooling device. The technological steps are coherent, and the product quality is ensured.

Owner:缪爱国

Dyeing device and process using indigo and other colorants

ActiveUS8060963B2Reduction in the yarn rejectsLow costOther washing machinesArtificial filament supportYarnEngineering

A continuous dyeing device and related processes using indigo and / or other colorants for warp yarn chains and / or for fabrics, equipped with at least a first and a second dyeing compartments containing dyeing baths, the first and second dyeing compartments being enclosed, at least partially, in a hermetically sealed chamber. The device also includes at least one squeezing element interposed between the two dyeing compartments and a plurality of cylinders for heating and / or dehydrating the yarn and or the fabric, thereby increasing the diffusion and the absorption of the colorant. The cylinders are positioned downstream of the first dyeing compartment and squeezing element.

Owner:KARL MAYER STOLL R&D GMBH

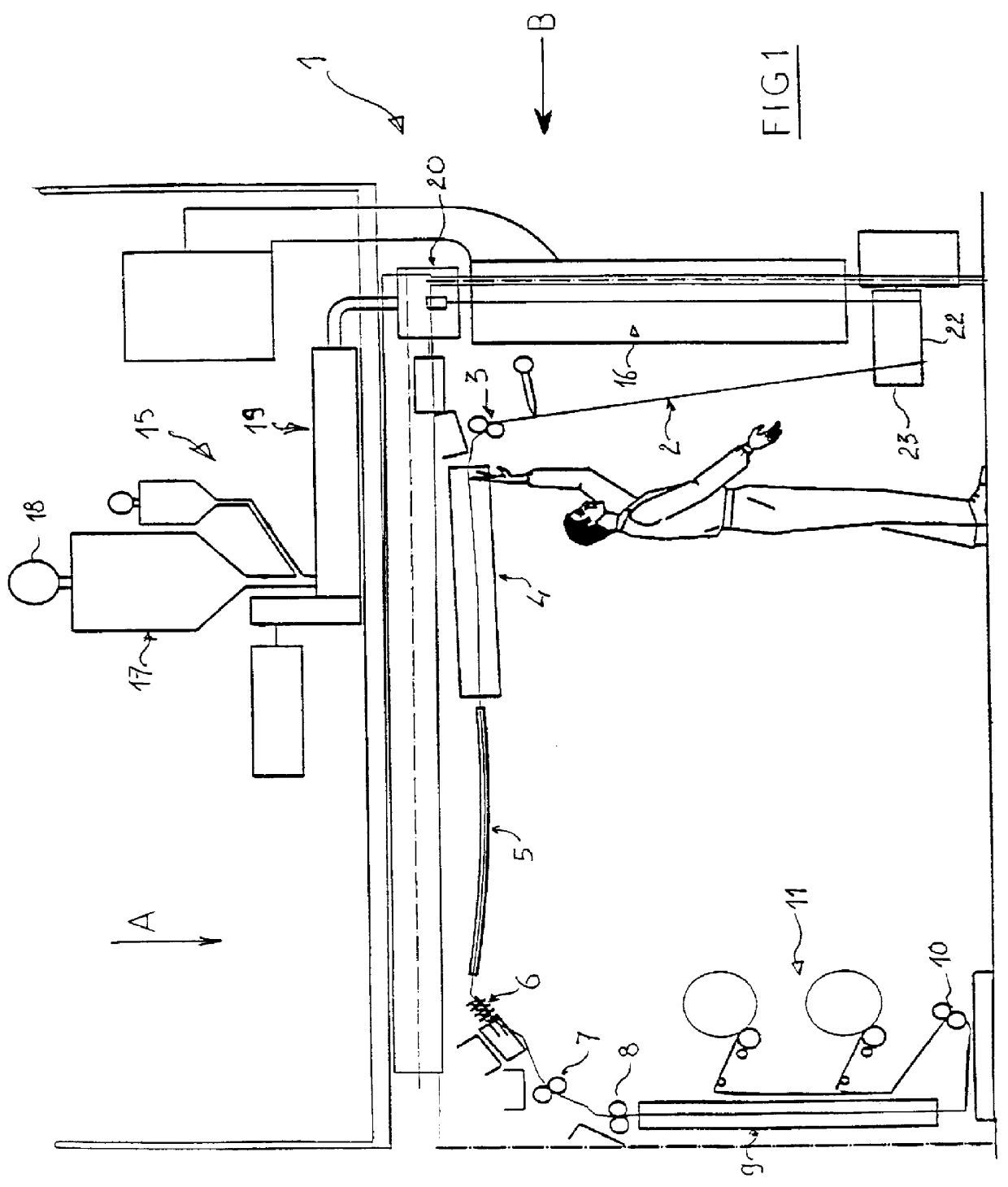

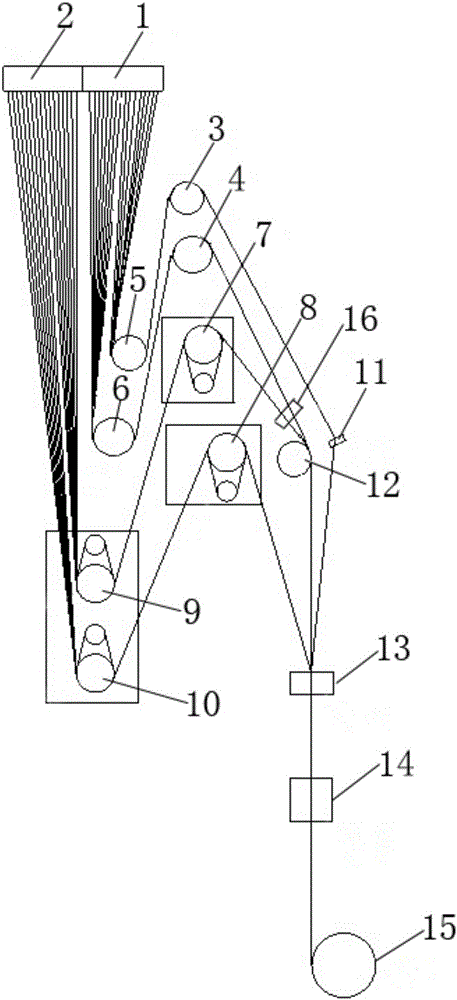

Machine for the spinning and texturing of threads by false twisting

Machine for spinning and texturing by false twisting, in which the false-twist zone comprises a plurality of identical texturing stations arranged side by side on a common frame, each station comprising in order, with regard to the displacement of the thread (2) during its texturing treatment: a first delivery (3) associated, if appropriate, with a system for drawing the thread (2) and making it possible to deliver the thread to be textured; a heating device (4) followed by a cooling zone (5) for the heated thread; a false-twist spindle (6); a second take-up (7) for the textured thread emerging from the false-twist spindle (6); if appropriate, a third take-up (8) of the thread, downstream of which is arranged a second thermal treatment zone (9), and; a final take-up arranged immediately in front of the receiving members, wherein the feed of threads to all the texturing stations is carried out from means for the spinning and drawing of chemical threads, which means are mounted on said texturing machine, the threads produced being introduced directly into the first deliveries (3) of the texturing zone after they have emerged from the spinning / drawing assembly.

Owner:ICBT YARN

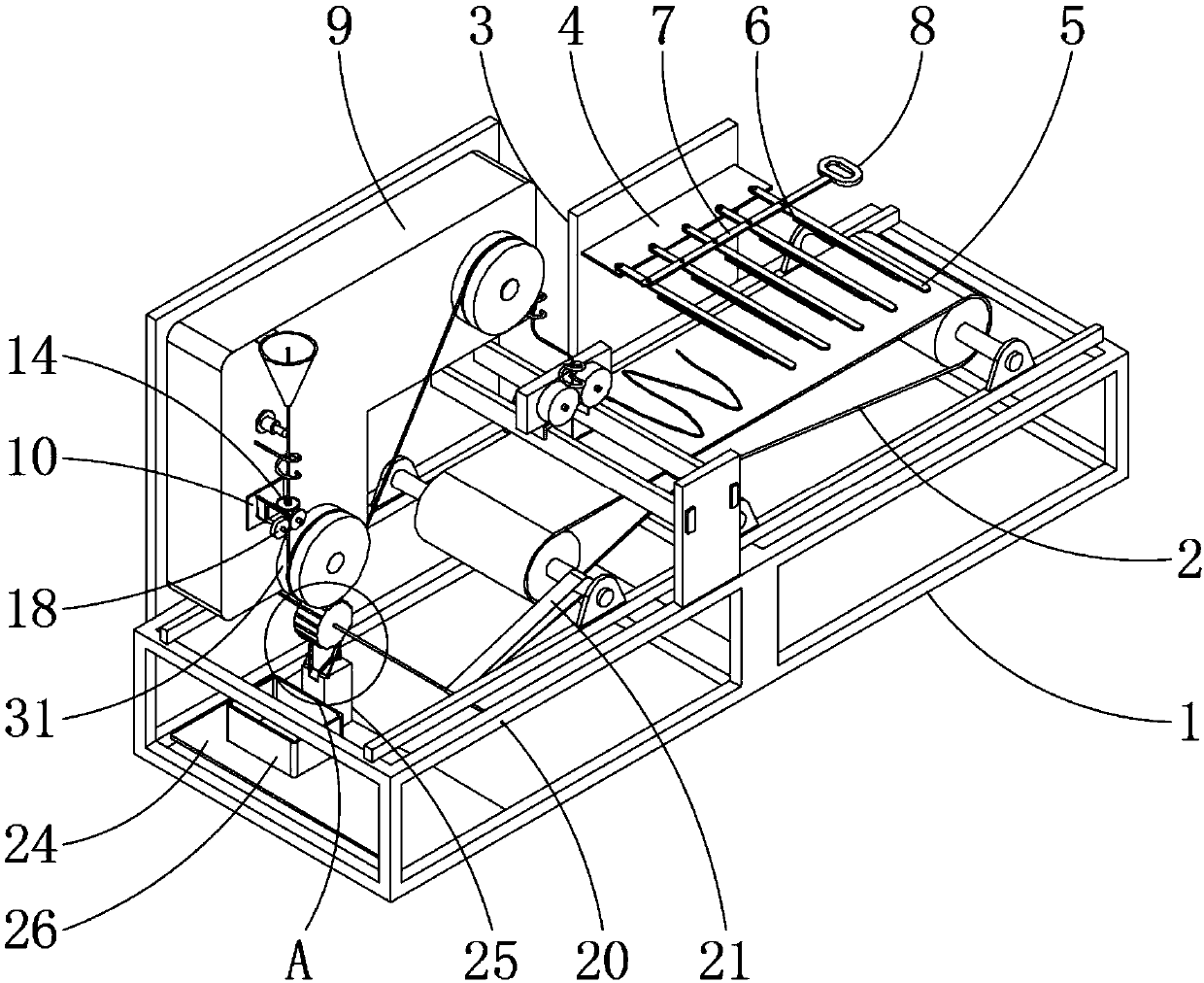

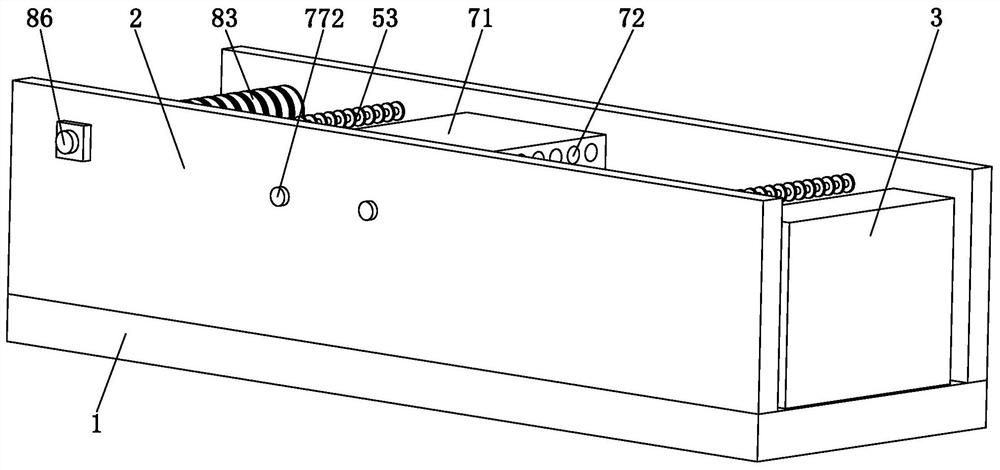

Multi-differential shrinkage combined filament yarn preparation device and method

InactiveCN105803600AGood shaping effectEasy to bundleArtificial thread manufacturing machinesArtificial filament heat treatmentGuide wiresFilament yarn

The invention relates to a multi-differential shrinkage combined filament yarn preparation device and method. The device comprises a first spinning assembly, a second spinning assembly, a first godet, a second godet, a third godet, a four godet, a first heat roller, a second heat roller, a third heat roller, a fourth heat roller, a steering gear, a setting heat roller, a humidifying device, a doubling device, a wire stitching machine and a winding roller. The preparation method comprises the following steps of spinning with a first spinning solution and splitting into first pre-oriented yarns and second pre-oriented yarns; spinning with a second spinning solution and splitting into first fully drawn yarns and second fully drawn yarns; allowing the second pre-oriented yarns and the second fully drawn yarns to pass through the humidifying device and the setting heat roller and then pass through the doubling device, the wire stitching machine and the winding roller together with the first pre-oriented yarns and the first fully drawn yarns to obtain multi-differential shrinkage combined filament yarns. The multi-differential shrinkage combined filament yarn prepared by the invention has a multi-crimping three-dimensional effect, has a plump appearance and hand feeling, flexible adjustment of multi-differential shrinkage effect of combined filament yarns, and improvement on processing stability.

Owner:DONGHUA UNIV +1

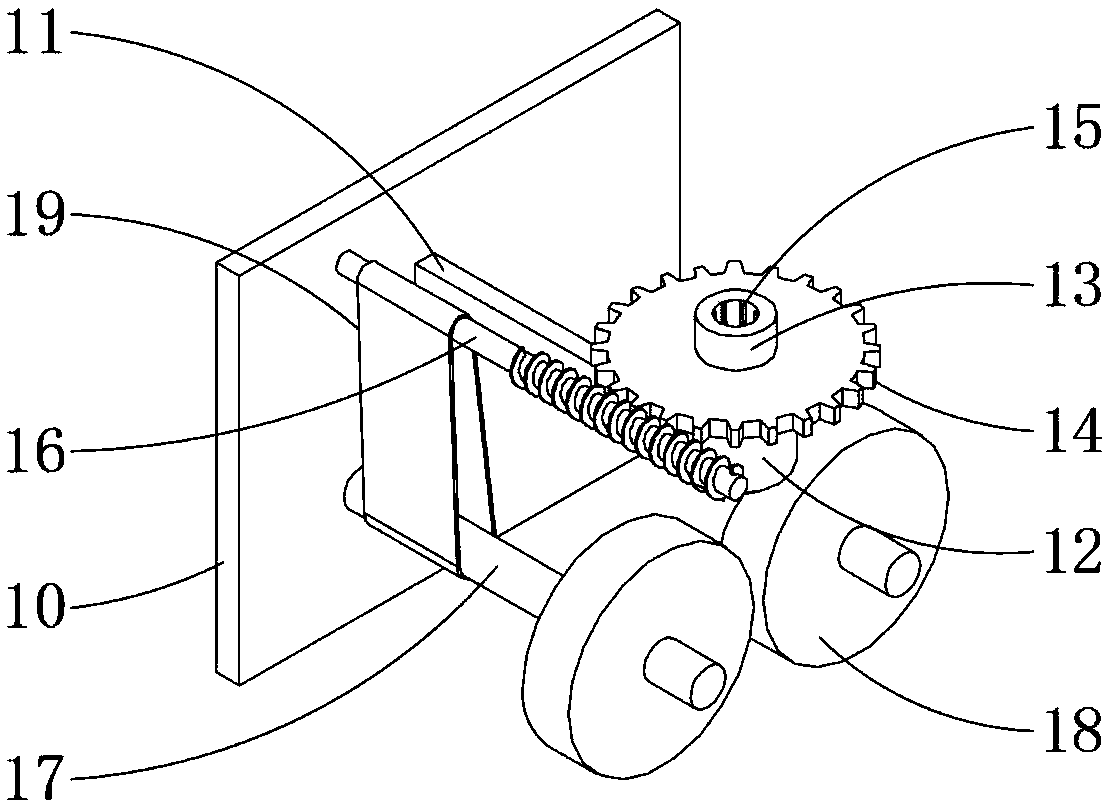

Chemical fiber yarn transferring traction device

InactiveCN109097845AScientific and reasonable structureEasy to useArtificial thread manufacturing machinesArtificial filament heat treatmentYarnFiber

The invention discloses a chemical fiber yarn transferring traction device which comprises a frame. The top of the frame is rotationally connected with a mounting shaft corresponding to the lower portion of a yarn guide roller, and the middle of the mounting roller is provided with a clearing roller corresponding to the lower portion of the yarn guide roller. The chemical fiber yarn transferring traction device is scientific and reasonable in structure and safe and convenient to use; by arrangement of a twisting sleeve, a worm drives a worm gear to rotate to enable the twisting sleeve to rotate in a fixed sleeve; chemical fiber yarns are effectively driven to rotate through twisting ribs, coagulation of fiber yarns in chemical fiber threads is improved, bonding area of solvent oil and fiber yarns can be increased conveniently, and bonding strength of the chemical fiber yarns is effectively improved; by arrangement of the clearing roller and clearing cushion blocks, a rotating shaft isdriven to rotate through a power roller of a transmission mesh belt, the clearing cushion blocks are effectively driven to clear the surface of the yarn guide roller, solvent oil is prevented from continuing moving backwards along with the chemical fiber yarns, and bonding damages of the chemical fiber yarns and the yarn guide roller due to the solvent oil can be reduced.

Owner:长兴一盛纺织有限公司

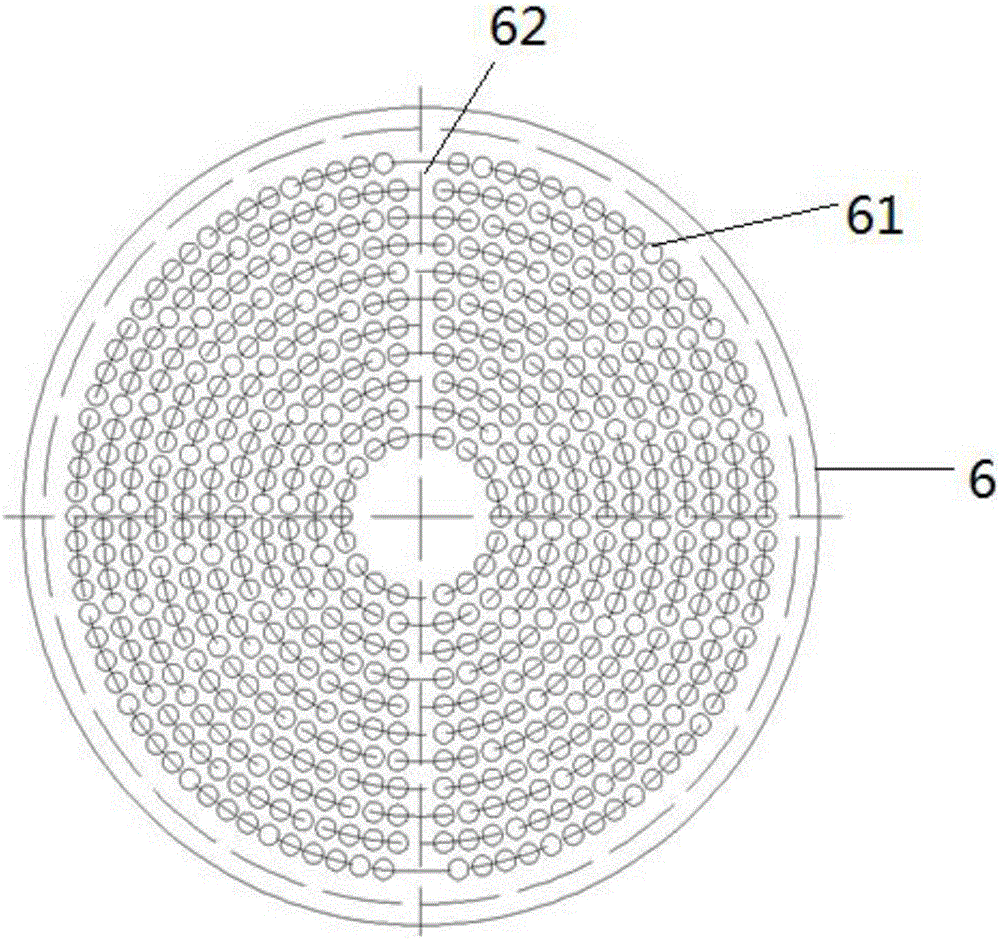

High-performance carbon nano/MXene composite fiber and preparation method thereof

InactiveCN112458553AGood orientationMeet the applicable conditionsElectroconductive/antistatic filament manufactureInorganic material artificial filamentsFiberMetallic aluminum

The invention discloses a high-performance carbon nano / MXene composite fiber and a preparation method thereof, and belongs to the technical field of novel functional fiber materials. The preparation method comprises the following steps of dispersing MXene powder without a metal aluminum component in water to obtain a two-dimensional lamellar MXene aqueous dispersion liquid, and uniformly dispersing a carbon nano material in the two-dimensional lamellar MXene aqueous dispersion liquid to obtain carbon nano / MXene dispersion slurry; and carrying out wet spinning on the obtained carbon nano / MXenedispersion slurry to obtain the high-performance carbon nano / MXene composite fiber. The invention discloses the carbon nano / MXene composite fiber which can be simply, rapidly, continuously and easilyprepared on a large scale, and the carbon nano / MXene composite fiber with high conductivity and high mechanical strength can be obtained by the preparation method, so that the obtained material can bewell applied to a flexible electrode material.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

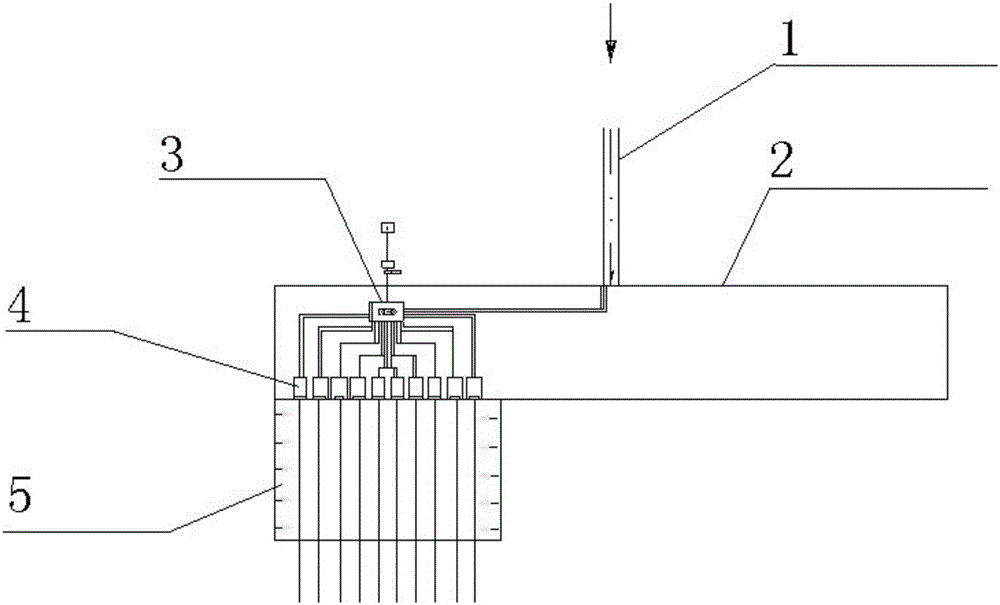

Production method of single-cake 576f super-multihole POY (pre-oriented yarn)

InactiveCN106087085AReduce exposureReduce generationSpinnerette packsArtificial thread manufacturing machinesWinding machineFiber

The invention discloses a production method of a single-cake 576f super-multihole POY (pre-oriented yarn). The production method comprises the following steps: S1. firstly feeding a semi-gloss polyester melt as a raw material into a melt cooler after the semi-gloss polyester melt passes through a melt delivery pipeline and is pressurized to 150-200Pa by a booster pump, cooling the semi-gloss polyester melt to 275-278 DEG C by the melt cooler and then feeding the semi-gloss polyester melt to a spinning manifold; S2. metering the melt entering the spinning manifold by a metering pump, then delivering the melt to a spinning pack in the spinning manifold by a thin pipeline to be filtered, then extruding the melt by a spinneret plate and then cooling and solidifying the melt into as-formed fibers by a circular air blow device; S3. after applying oil to the as-formed fibers in the step S2 by a double-passage nozzle and increasing the saturability of the as-formed fibers by a nozzle in sequence, controlling the tension till the tension required by the process by a godet integrated on a winding machine and then guiding tows into the winding machine to undergo package shaping. The production method can achieve production of the single-cake 576f super-multihole POY, thus greatly improving the production efficiency and effectively reducing the production cost.

Owner:TONGXIANG ZHONGCHEN CHEM FIBER

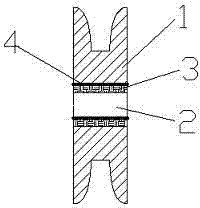

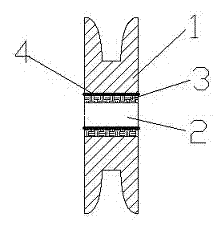

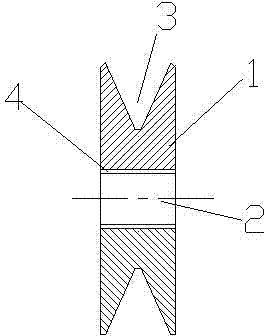

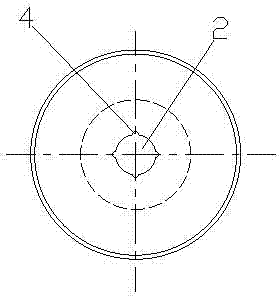

Novel yarn guiding wheel

InactiveCN102409457AImprove wear resistanceImprove heat resistanceArtificial filament supportInterference fitYarn

The invention discloses a novel yarn guiding wheel which comprises a yarn guiding wheel body, wherein the middle part of the yarn guiding wheel body is provided with a shaft hole; an inner ring is arranged in the shaft hole; the shaft hole is in interference fit with the inner ring; the yarn guiding wheel body is made of a high-temperature sintered ceramic material; and the inner ring is made of a graphite material. In the invention, the novel yarn guiding wheel is disclosed; the yarn guiding wheel has reasonable material selection and excellent performance; the yarn guiding wheel body is made of the ceramic material, thus the wear resistance and thermal resistance of the yarn guiding wheel can be effectively improved; the inner ring arranged in the shaft hole is made of the graphite material, thus the friction between the shaft hole and a fixed shaft of the yarn guiding wheel is effectively reduced, and the running of the yarn guiding wheel is more stable; and the yarn guiding wheel has low cost, convenience in assembly, and long service life.

Owner:WUJIANG YILANJI TEXTILE PROD

Method for producing yarn and apparatus thereof

The present invention relates to the combination of a tension gate and an air shield in the relax zone of a fiber production process. The combination provides a synergistic effect over an air shield alone, or a tension gate alone, or the added effect of both a tension gate and an air shield. The air shield is a plate like structure with or without perforations. The air shield plates are placed in close proximity to a pair of rolls following the tension gate. The tension gate can be one or more air drag devices, one or more liquid drag devices, or one or more solid surface contact devices, or a combination of any of the above. The apparatus and the process for using the apparatus is disclosed and claimed.

Owner:INVISTA TECHNOLOG IES S A R L

Spinning process equipment for polyester production

PendingCN110273187AWill not hinder normal opening and closingReasonable designSpinning solution de-aeratingSpinnerette packsWinding function

The invention discloses spinning process equipment for polyester production. The spinning process equipment comprises a grading box, a melting furnace, a spinneret device, a condensing box and a bidirectional winding device. The grading box comprises a pulverizing cover and a filtering box. The pulverizing cover is fixedly arranged at the head of the filtering box, and is hermetically connected with the filtering box. The spinning process equipment has the advantages that the structure of conventional spinning equipment for polyester production is improved to solve the problems of non-thorough melting and inconvenience in separation between spinneret plates and silks after spinning due to insufficiently disperse feeding and no cutting and screening structure of existing polyester production equipment, and the problem that winding structures do not have bidirectional winding functions; through the bidirectional winding device, users can conveniently and timely wind the spun silks; a motor is used for winding the silks in both forward and backward directions, so that intertwining during winding is effectively avoided, and the working efficiency is greatly improved.

Owner:福建省长乐市天梭纺织实业有限公司

Yarn guiding wheel convenient for lubrication

The invention discloses a yarn guiding wheel convenient for lubrication. The yarn guiding wheel comprises a yarn guiding wheel body, wherein the middle part of the yarn guiding wheel body is a shaft hole, a circular yarn guiding groove is formed along the circumferential direction of yarn guiding wheel body, the shaft hole is shaped by casting, and oil grooves are formed on the inner wall of the shaft hole. In the invention, the yarn guiding wheel convenient for lubrication is disclosed; the yarn guiding wheel has unique structure design; multiple oil grooves are formed on the inner wall of the shaft hole of the yarn guiding wheel, thus the lubrication of a fixed shaft is convenient; and meanwhile, the oil grooves can be used for storing quantitative lubricating oil, thus the addition frequency of the lubricating oil is reduced, the use performance of the yarn guiding wheel is effectively improved, and the service life of the yarn guiding wheel is effectively prolonged.

Owner:WUJIANG QINBANG TEXTILE

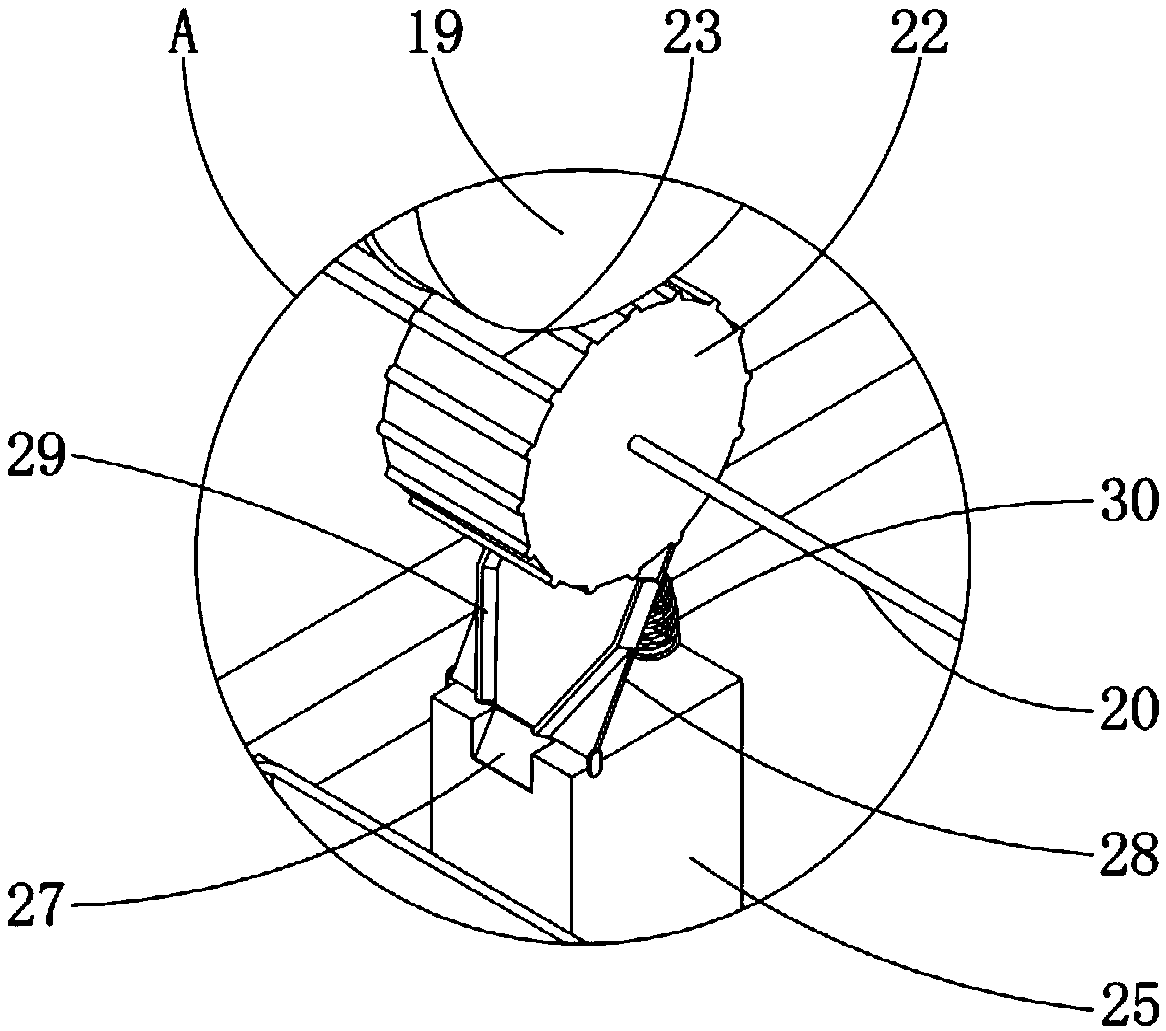

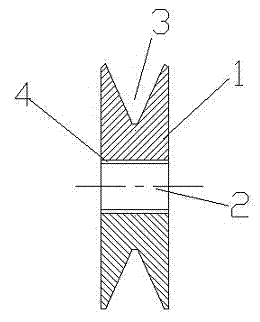

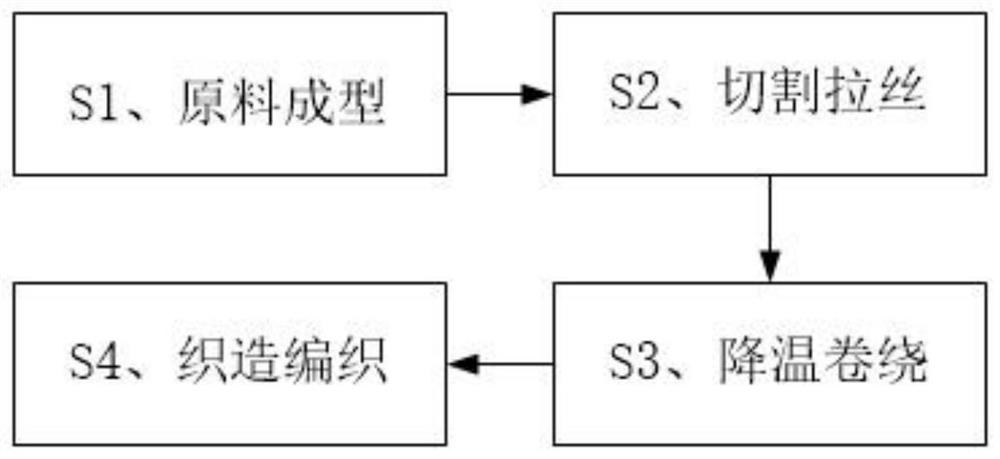

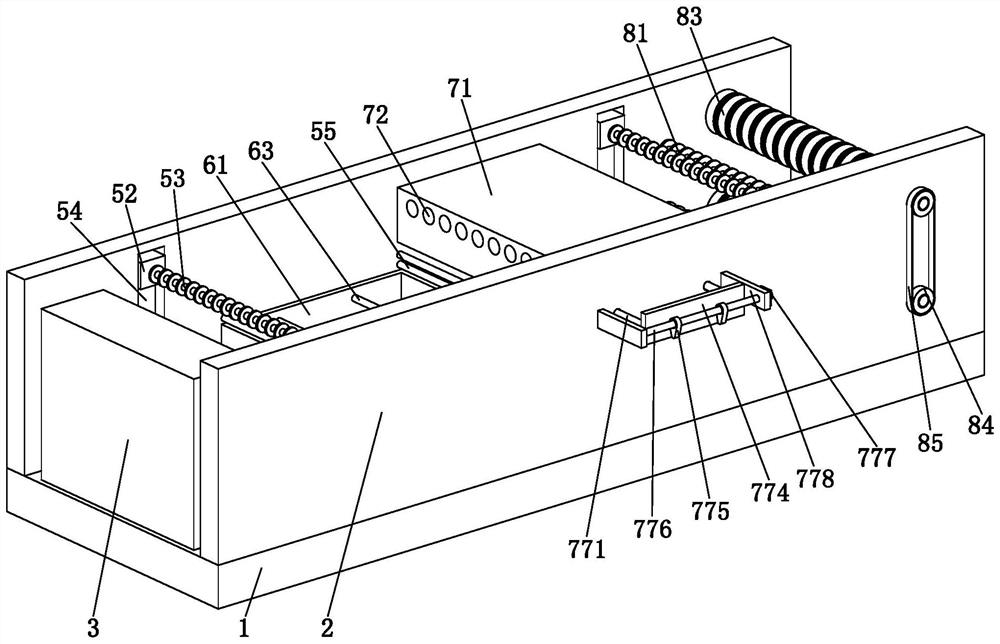

Plastic woven bag manufacturing and forming method

ActiveCN112853516AIncrease temperatureAvoid deformationArtificial thread manufacturing machinesFilament/thread formingForming processesAir drying

The invention provides a plastic woven bag manufacturing and forming method. The plastic woven bag manufacturing and forming method adopts a plastic woven bag manufacturing and forming device, wherein the plastic woven bag manufacturing and forming device comprises a base, a mounting plate, a flat filament forming machine, a pull-out mechanism, a tensioning mechanism, a circulating cooling mechanism, an air drying mechanism and a winding and collecting mechanism. The invention provides the plastic woven bag manufacturing and forming method which can solve the following problems existing in the plastic woven bag manufacturing and forming process: a, after a plastic raw material is heated and stretched to form flat filaments, the flat filaments have a certain high temperature, and the flat filaments need to be cooled when being wound and collected; b, the flat filaments are pulled by a winding mechanism after being extruded out of the flat filament forming machine, and the just formed flat filaments are prone to tensile deformation in the pulling process, so that the flat filaments need to be pulled to a certain degree when being extruded out, and the deformation phenomenon of the flat filaments is prevented; and c, required water drops exist on the flat filaments after the flat filaments are subjected to water cooling, and the water drops are difficult to be thoroughly air-dried after being air-dried for a short time.

Owner:温州国宏新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com