Yarn guiding wheel convenient for lubrication

A technology of wire guide wheel and wire guide groove, which is applied in the direction of artificial filament support, textiles and papermaking, etc. It can solve the problems of wear of the inner hole and fixed shaft of the wire guide wheel, complicated preparation process, loss, etc., so as to improve the use performance and The effect of service life, unique structural design, and reducing the number of additions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

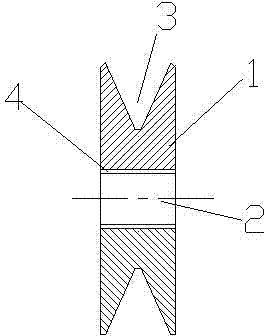

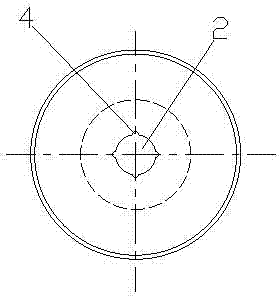

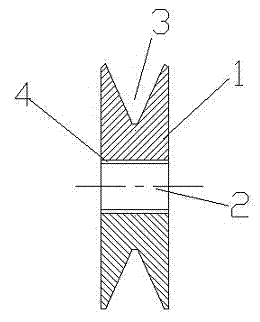

[0017] figure 1 It is a structural schematic diagram of a godet wheel that is convenient for lubrication according to an embodiment of the present invention; figure 2 It is the left view of the godet wheel which is easy to lubricate according to the embodiment of the present invention; the godet wheel includes a godet wheel body 1, and the middle part of the godet wheel body 1 is a shaft hole 2, and an annular guide wire groove is arranged along its circumferential direction 3. The shaft hole 2 is formed by casting, and the inner wall of the shaft hole 2 is provided with an oil groove 4 .

[0018] The oil groove 4 in the godet wheel that is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com