Carbon fibre composite damping well cover and manufacturing process thereof

A composite material and carbon fiber technology, applied in artificial islands, water conservancy projects, infrastructure engineering and other directions, can solve problems such as engineering, environment, energy problems, difficulty in opening, and sinking of manhole covers, and achieve high creep resistance, safety and stability. Good environmental aging resistance and unique effect of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

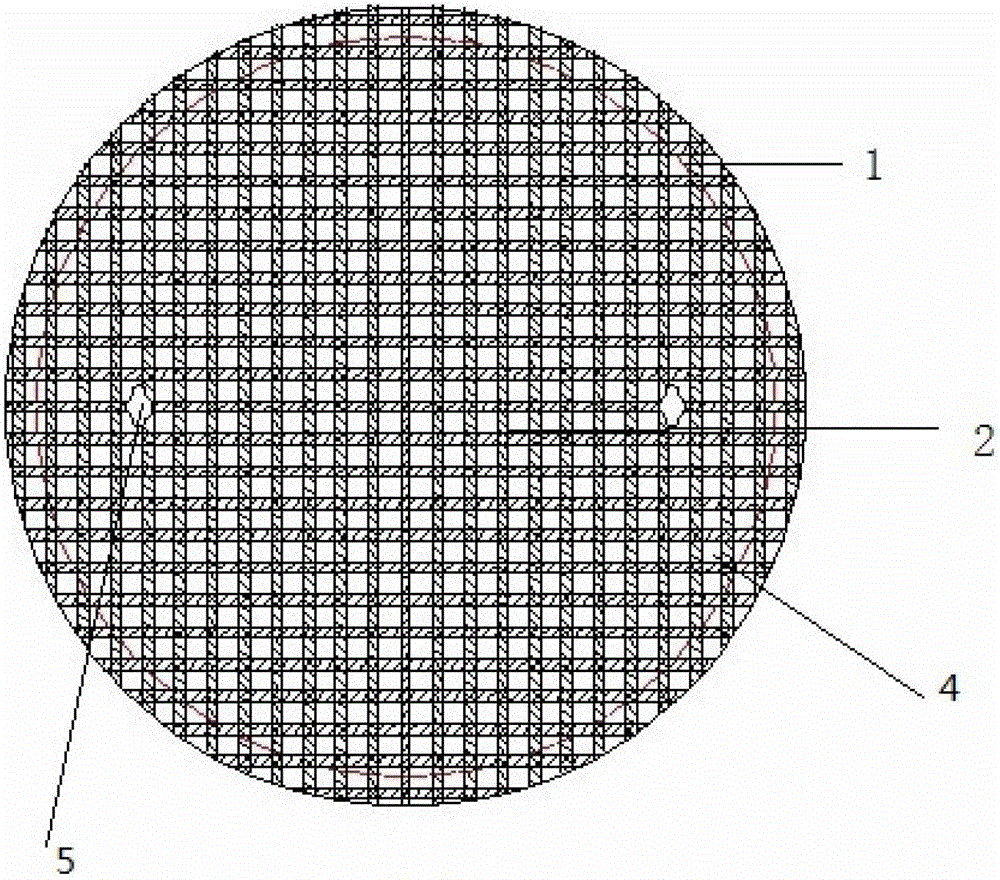

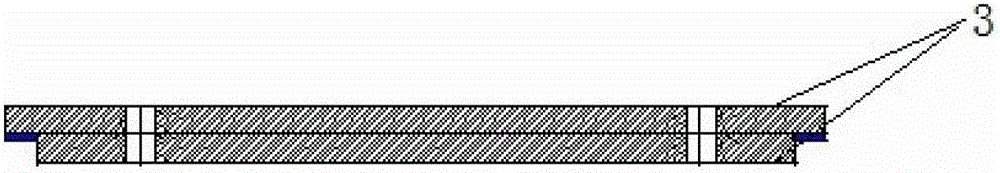

[0025] Processing carbon fiber composite shock-absorbing manhole covers, the major diameter is 625mm, the minor diameter is 575mm, the thickness is 30mm, and the step thickness is 17mm.

[0026] Multi-layer 6K carbon fiber cloth 3 is spread on the upper and lower surfaces of the manhole cover, and two layers of carbon fiber reinforcement layers 2 are arranged in 90?? in the middle, evenly embedded in epoxy resin mixed filler, compacted and applied a certain load to cure at room temperature. , After fully cured, paste a layer of rubber ring with a width of 20mm and a thickness of 4mm on the outer side of the bottom of the well cover and the contact part of the well seat. The material is aging-resistant silicone rubber.

[0027] The carbon fiber reinforcement is made of Mitsubishi T700 carbon fiber from Japan, and the high temperature resistant thermosetting epoxy resin is used as a matrix to prepare a rod-shaped material by continuous pultrusion molding. Its specific gravity is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com