Rounded zipper tooth

A technology of zipper teeth and arc segments, which is applied in the field of zippers, can solve the problems of reducing the reliability of zippers, zipper bursting, etc., and achieve the effects of not easy to disengage, firm meshing, and unique structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

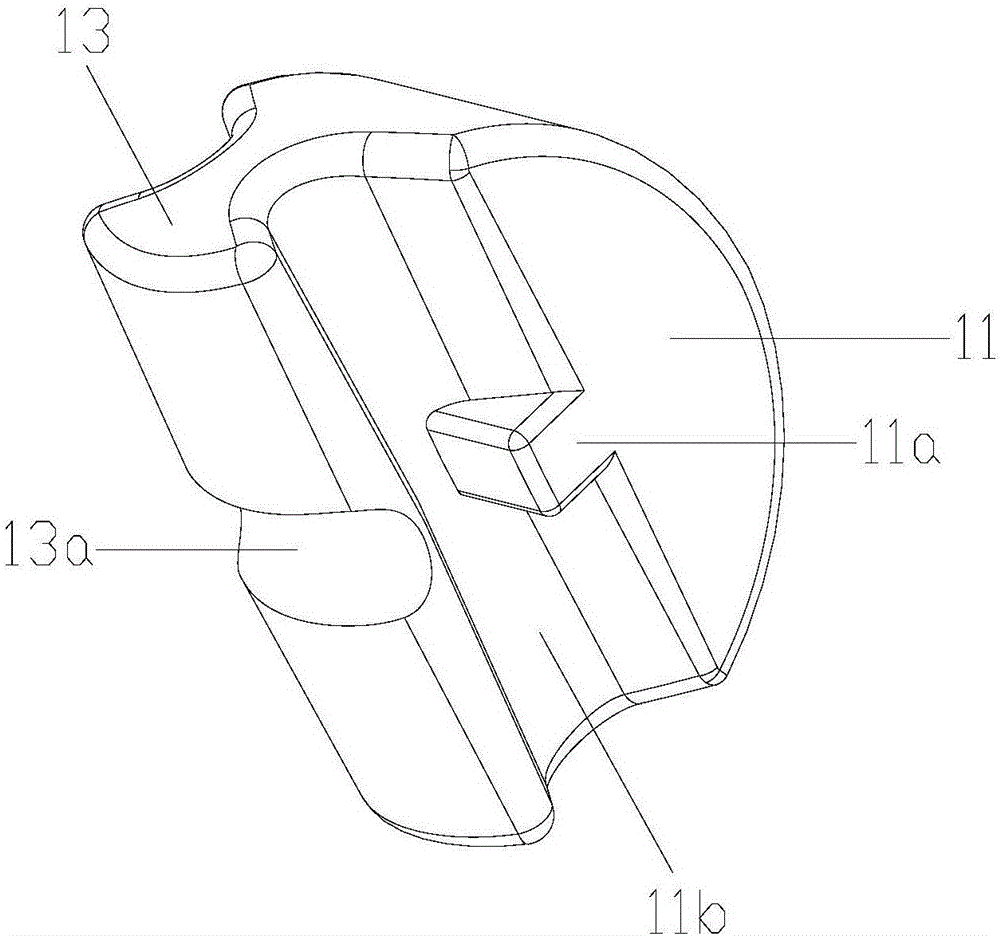

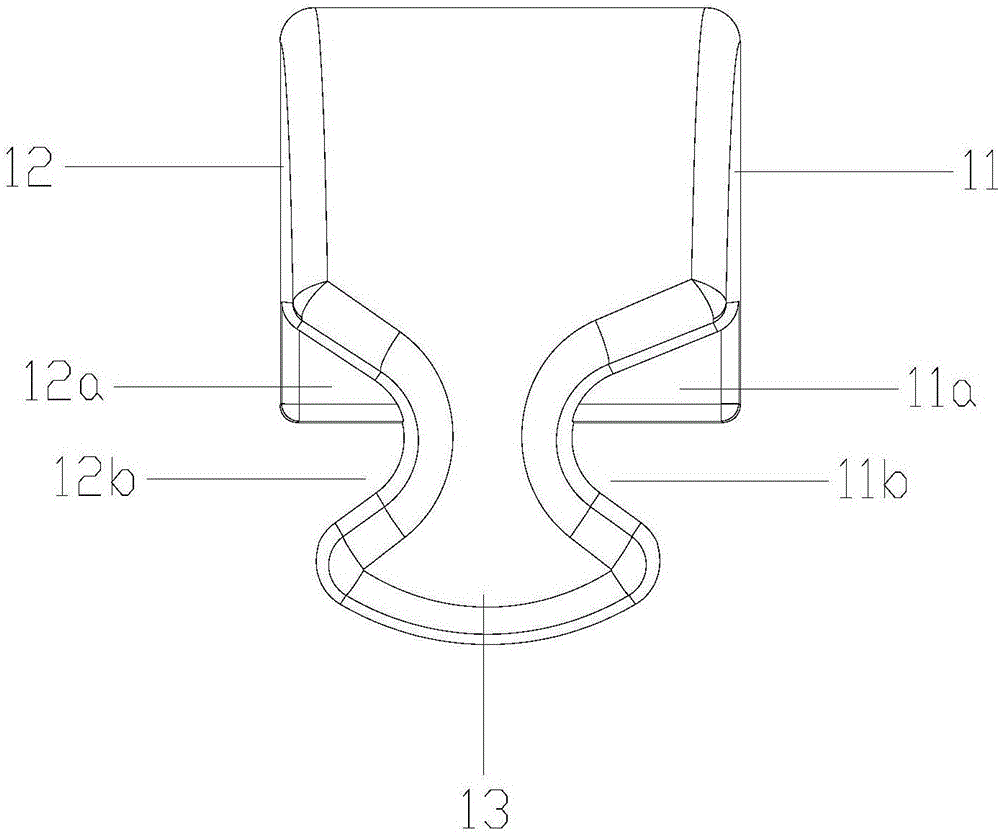

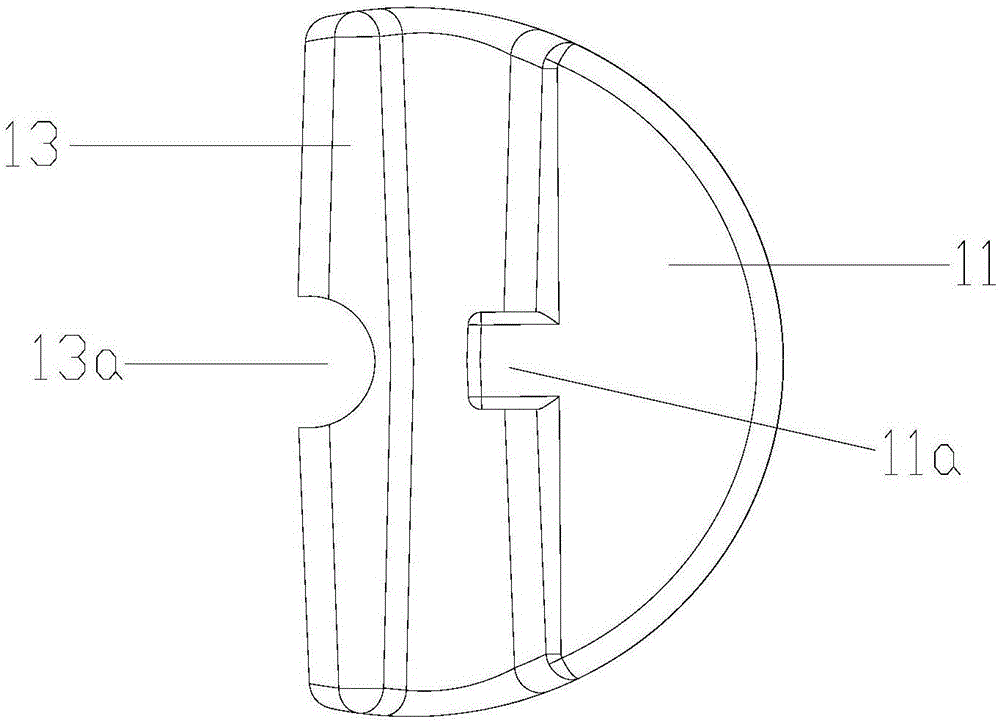

[0026] see Figure 1 to Figure 3 , a round zipper element of the present invention, comprising a zipper element body 1, the zipper element body 1 includes a first engaging surface 11 and a second engaging surface 12, the first engaging surface 11 and the second engaging surface 12 are semicircular, the second The arc angle of the arc segment on the first engaging surface 11 and the arc segment on the second engaging surface 12 is greater than 180°;

[0027] One end of the first engaging surface 11 and one end of the second engaging surface 12 are recessed into the fastener element body to form a first engaging recess 11b, a second engaging recess 12b and an engaging portion 13; One end is provided with at least one protruding first positioning portion 11a, and the second engaging concave portion 12b is provided with at least one protruding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com