Spun yarn winding system

A kind of equipment and spinning technology, which is applied in the production of complete sets of equipment for artificial threads, filament production, textiles and papermaking, etc., and can solve problems such as delays in the end of hanging silk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Hereinafter, preferred embodiments of the present invention will be described.

[0060] (Overall configuration of spinning winding equipment)

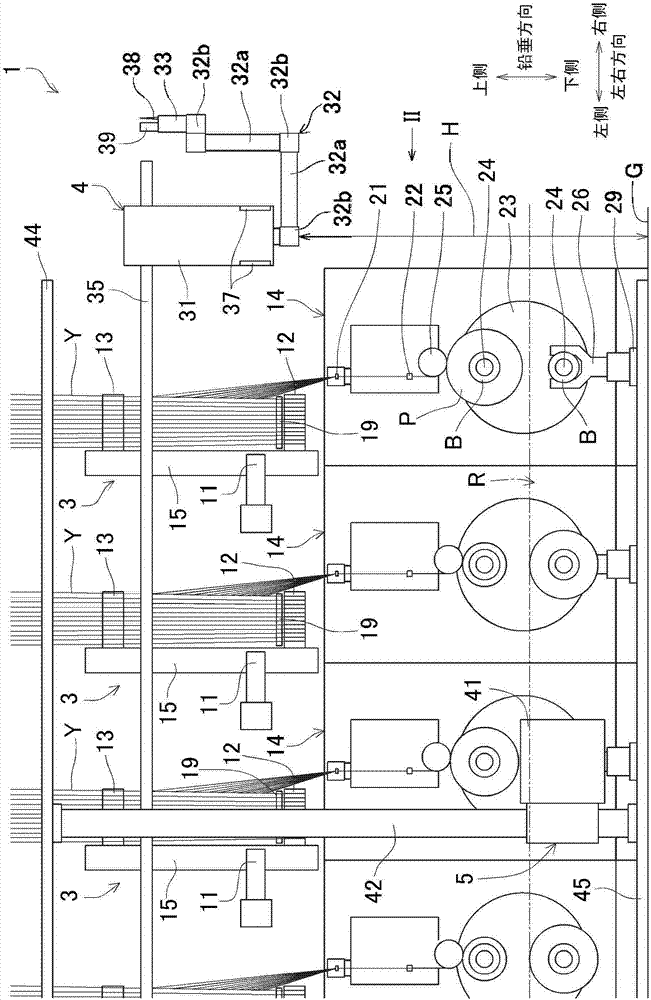

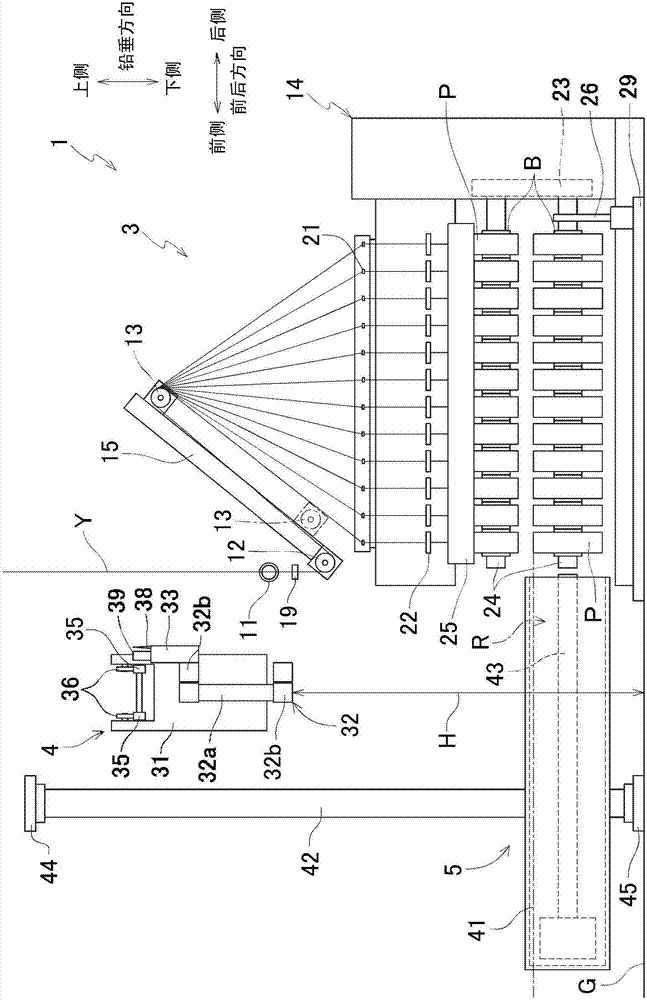

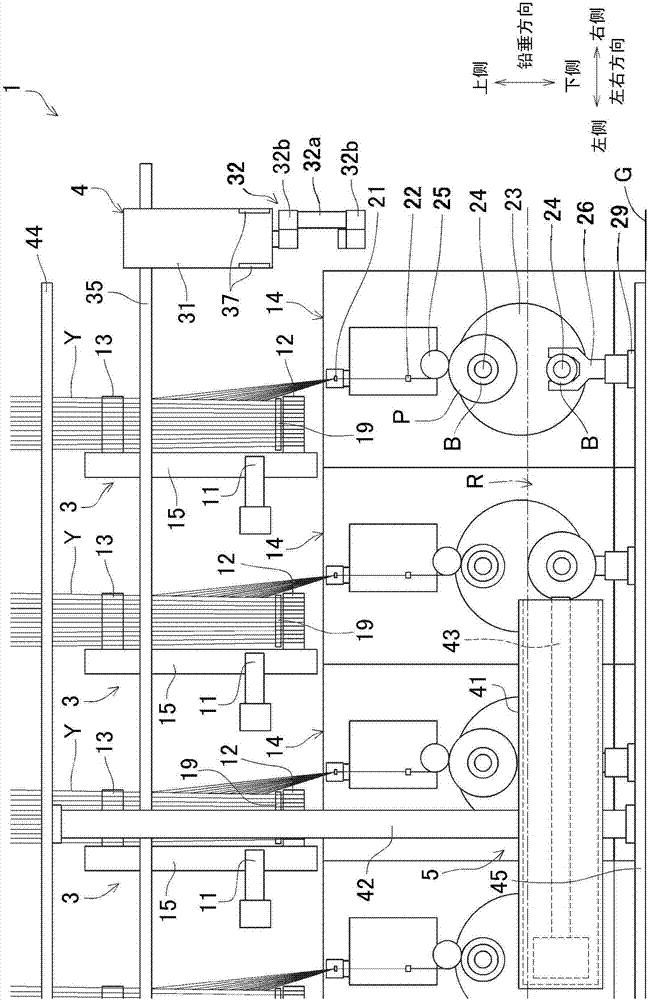

[0061] The spinning winding device 1 of the present embodiment draws a plurality of yarns Y spun from a spinning device (not shown), and winds them on a plurality of bobbins B to form a plurality of packages P. Such as Figure 1 ~ Figure 4 As shown, the spinning winding equipment 1 includes a plurality of pulling units 3 , a spinning robot 4 and a package collecting device 5 provided in common with the plurality of pulling units 3 .

[0062] A plurality of traction units 3 are arranged along one horizontal direction. In addition, in the following, the direction in which a plurality of traction units 3 are arranged is referred to as the left-right direction (the "second direction" in the present invention), and the direction that is horizontal and perpendicular to the left-right direction is referred to as the front-rear direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com