Chemical fiber yarn transferring traction device

A pulling device and a technology for chemical filaments, which are applied in the field of chemical filaments, can solve the problems of splitting and breaking of godet rollers, adhesion of threads and godet rollers, and easy to leave solvent oil, etc., so as to achieve safe and convenient use, ensure stable rotation, avoid problems such as mutual bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

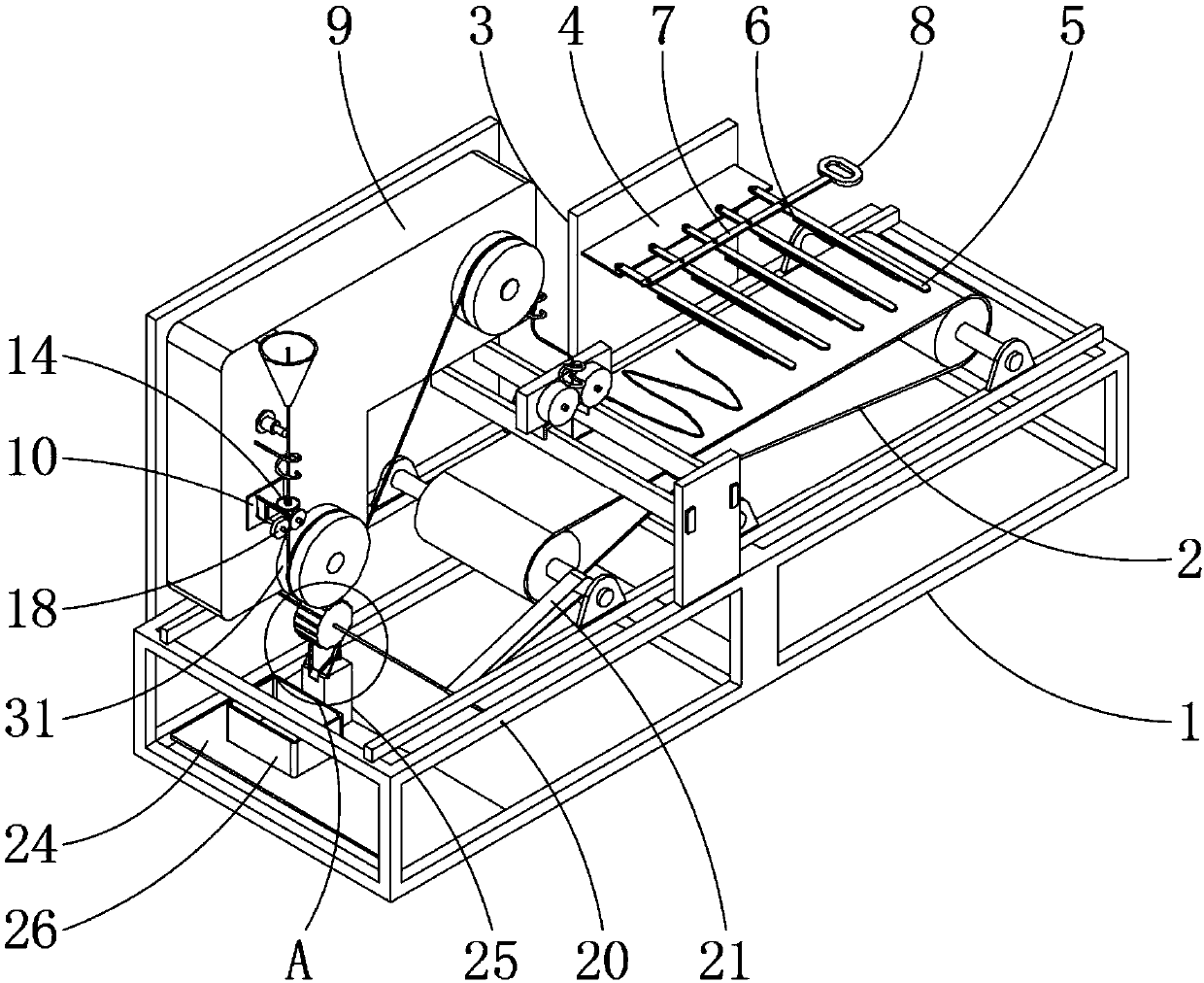

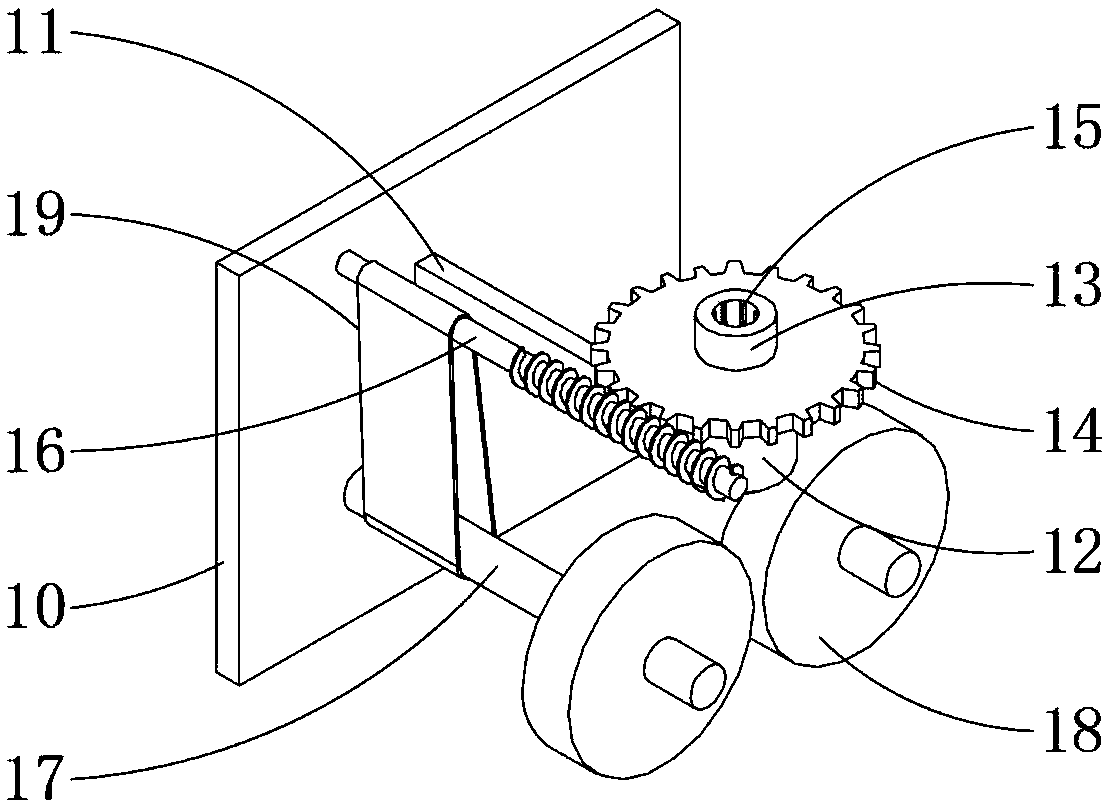

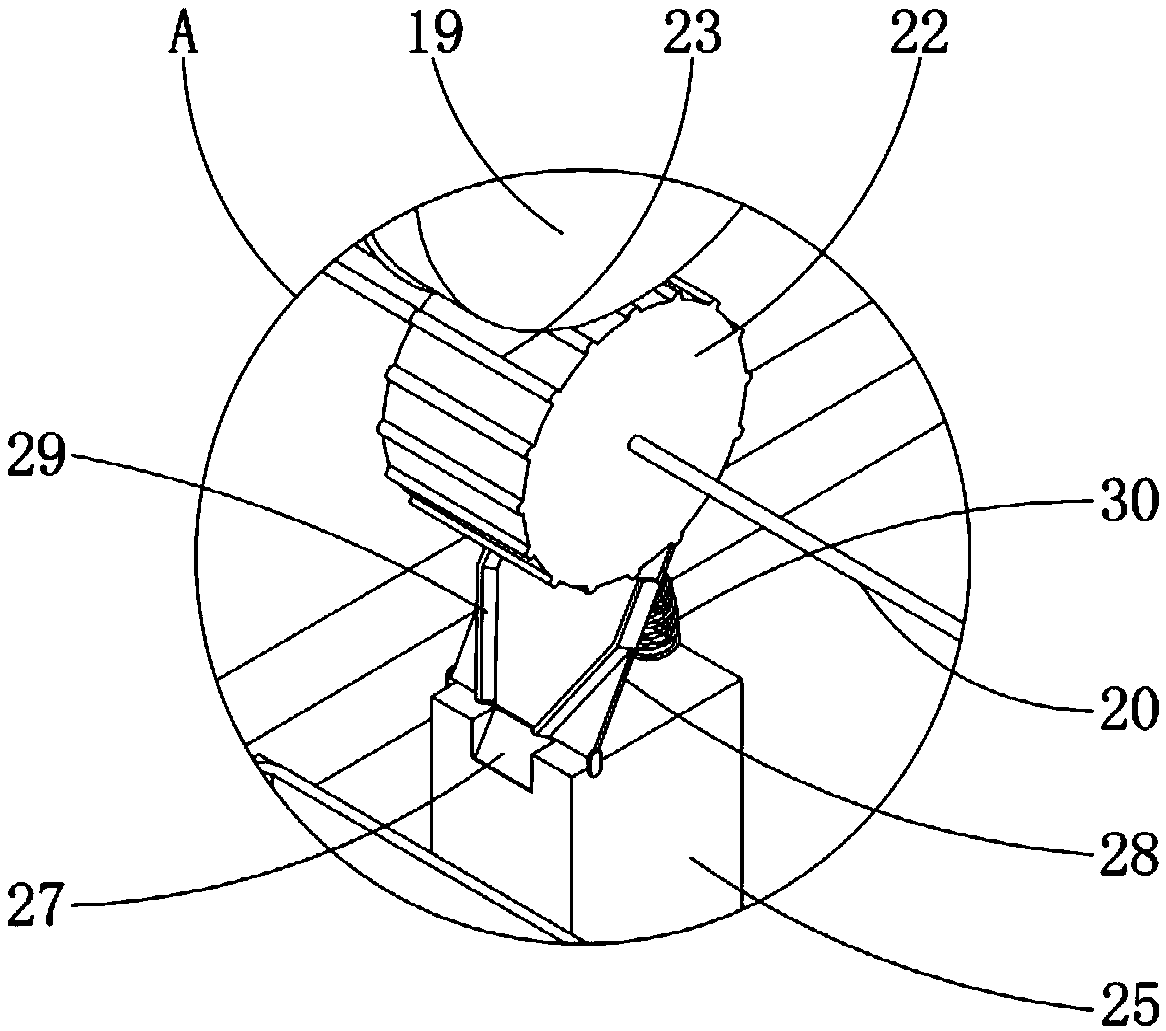

[0022] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, a transmission and traction device for chemical fiber filaments, comprising a frame 1, a transmission mesh belt 2 is installed on the top of the frame 1, and a boss 9 is arranged on one side of the frame 1, and the boss 9 A godet roller 31 is installed at the bottom, a back plate 3 is welded on the side surface of the frame 1 corresponding to the side of the boss 9, a mounting plate 4 is welded on the top of the back plate 3, and a rotating plate is mounted on one side of the top of the mounting plate 4 to rotate equidistantly 5. A heating plate 6 is installed at the bottom of the rotating plate 5. The model of the heating plate 6 is JT-G. The input end of the heating plate 6 is electrically connected to the output end of the power supply. A handle 8 is installed at one end. In order to improve the comfort of the handle 8 in use, the outer surface of the handle 8 is sleeved with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com