Patents

Literature

40results about How to "Uniform finish" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Release agent delivery system for use in printer devices

InactiveUS6449455B1Improve uniformityUniform deliveryElectrographic process apparatusFiberBiomedical engineering

A release agent delivery system for an electrophotographic printing process utilizes a web which is a non-woven textile comprised of substantially all sub-denier fibers. The release agent delivery system using the textile produced with predominantly sub-denier fibers, creates finer oil flow patterns which yield improved print quality though decreased microscopic streaking.

Owner:BMP AMERICA

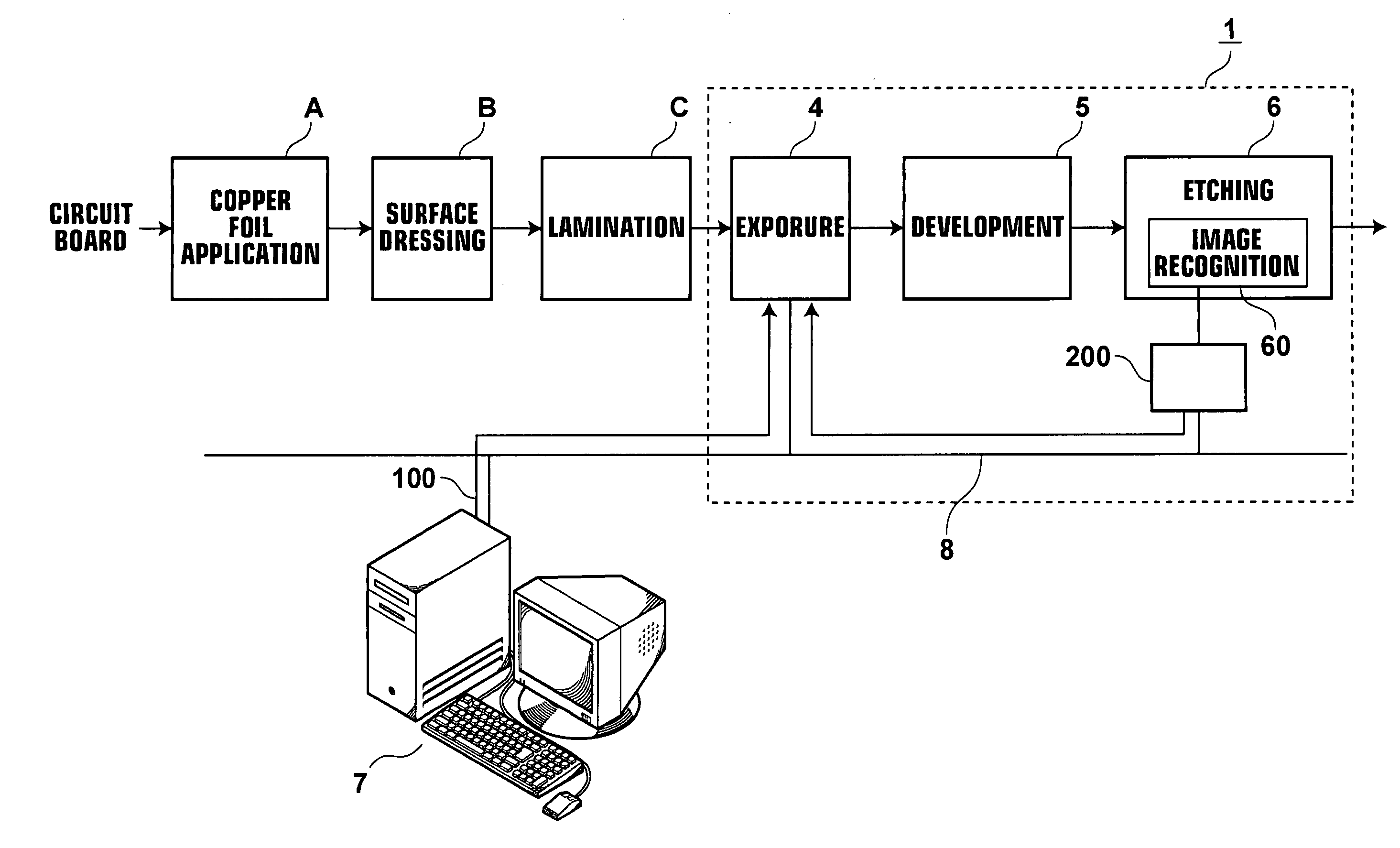

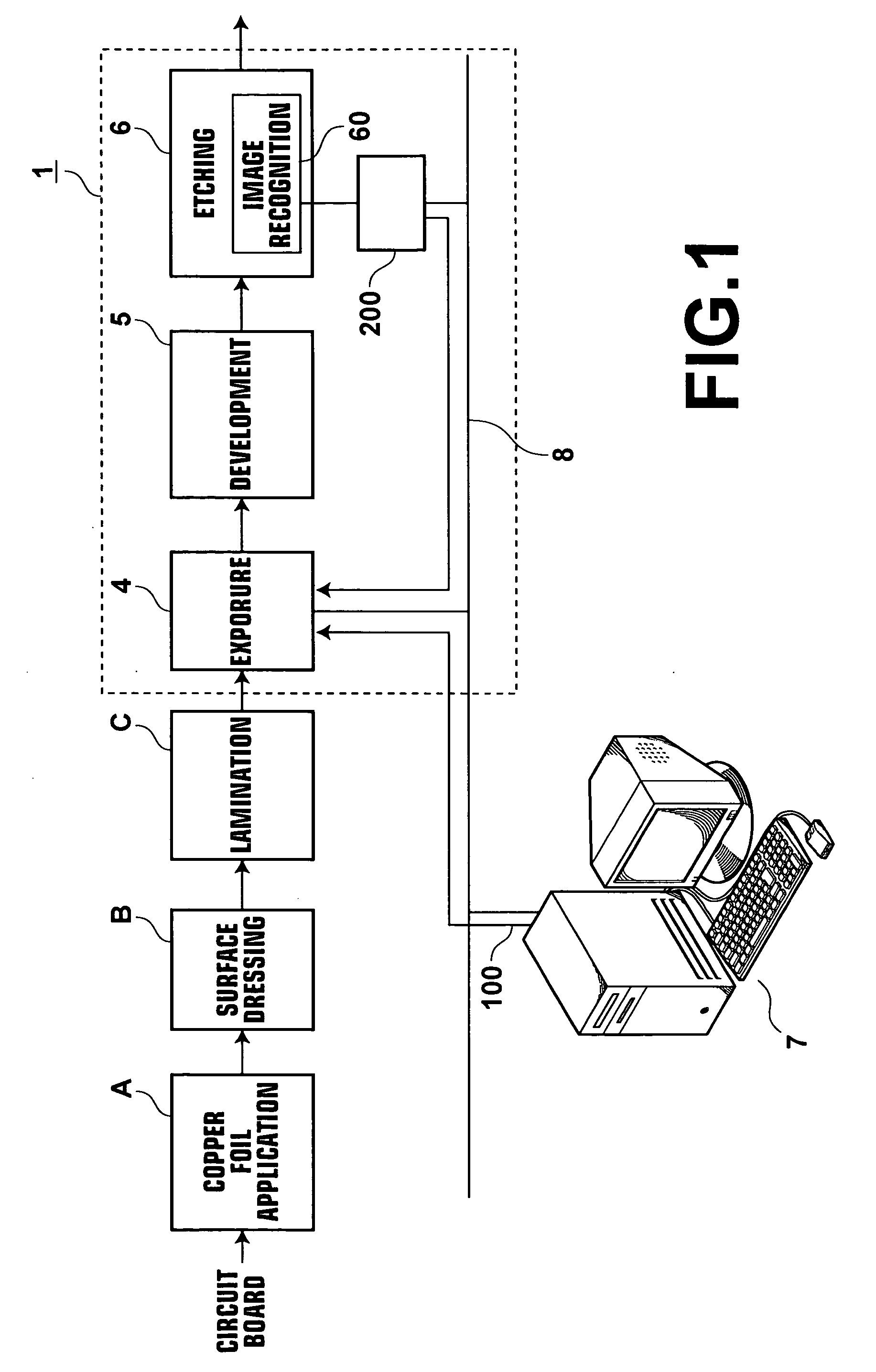

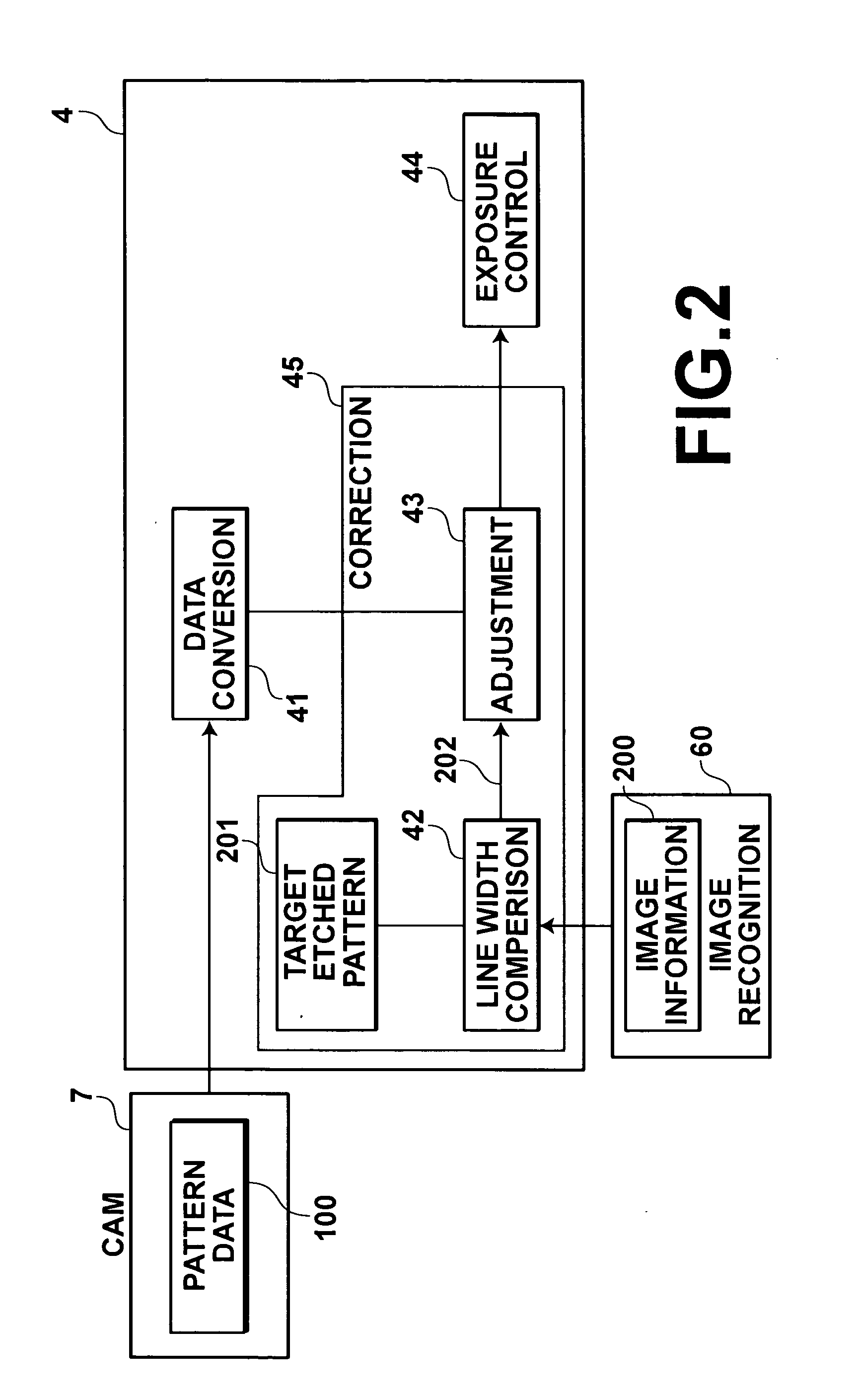

Pattern production system, exposure system, and exposure method

InactiveUS20050036783A1Improve the finishLow costLiquid processingSemiconductor/solid-state device manufacturingResistLine width

In a pattern production system, resist coated on copper foil on the substrate is exposed to light, by direct drawing, on the basis of a width of a line forming a pattern designated by processing pattern data at a predetermined exposure, the exposed resist is developed to form a resist pattern, and the copper foil is etched to form an etched pattern. An image of the etched pattern is scanned and image information of the etched pattern is obtained. The width of the line forming the pattern represented by the image information and the width of the line forming the pattern of the target etched pattern are compared, and the width of the line forming the pattern designated by the processing pattern data is adjusted on the basis of the result of comparison. The resist is exposed to light, by direct drawing, with the adjusted line width on the basis of the result of comparison.

Owner:FUJIFILM CORP +1

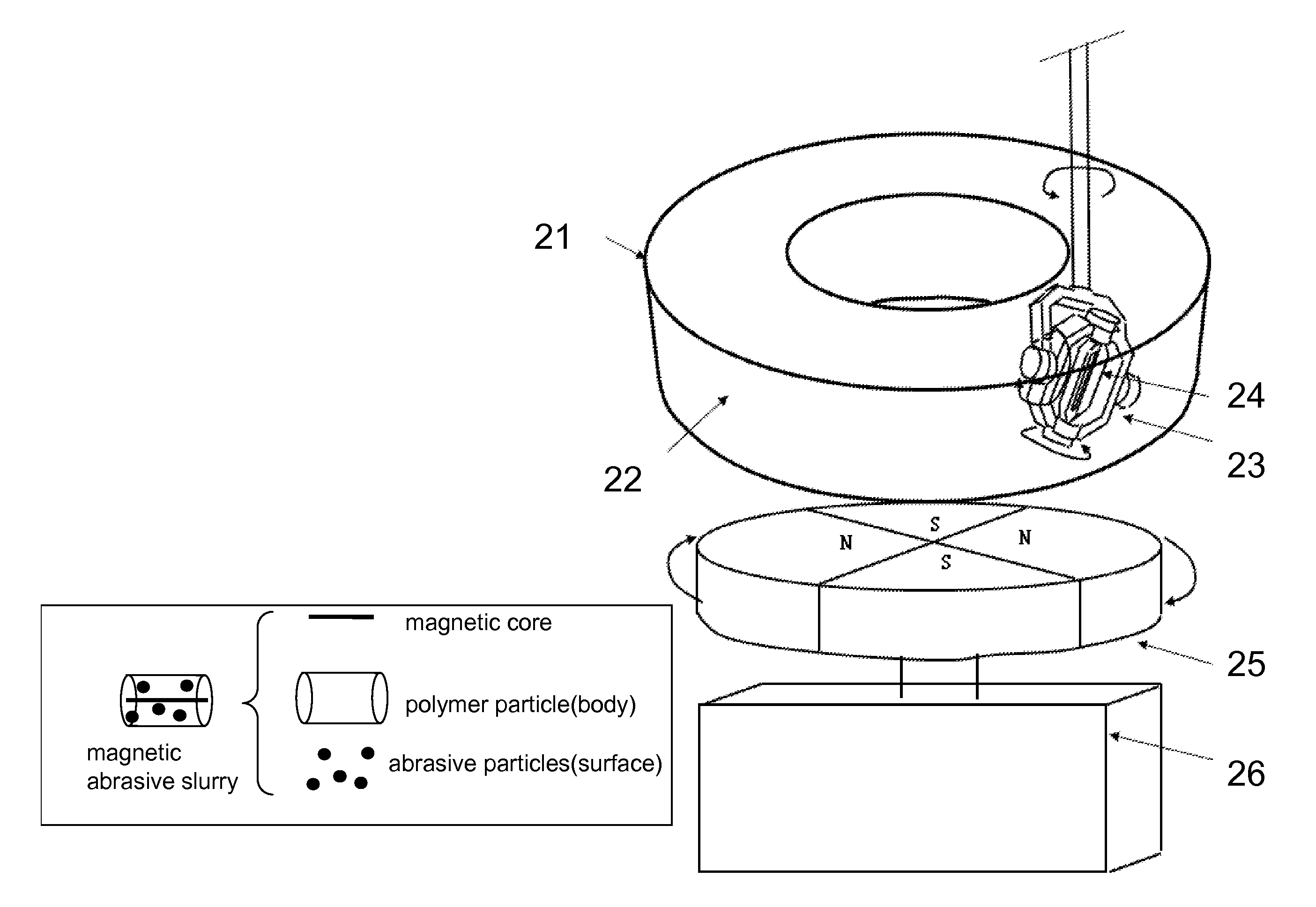

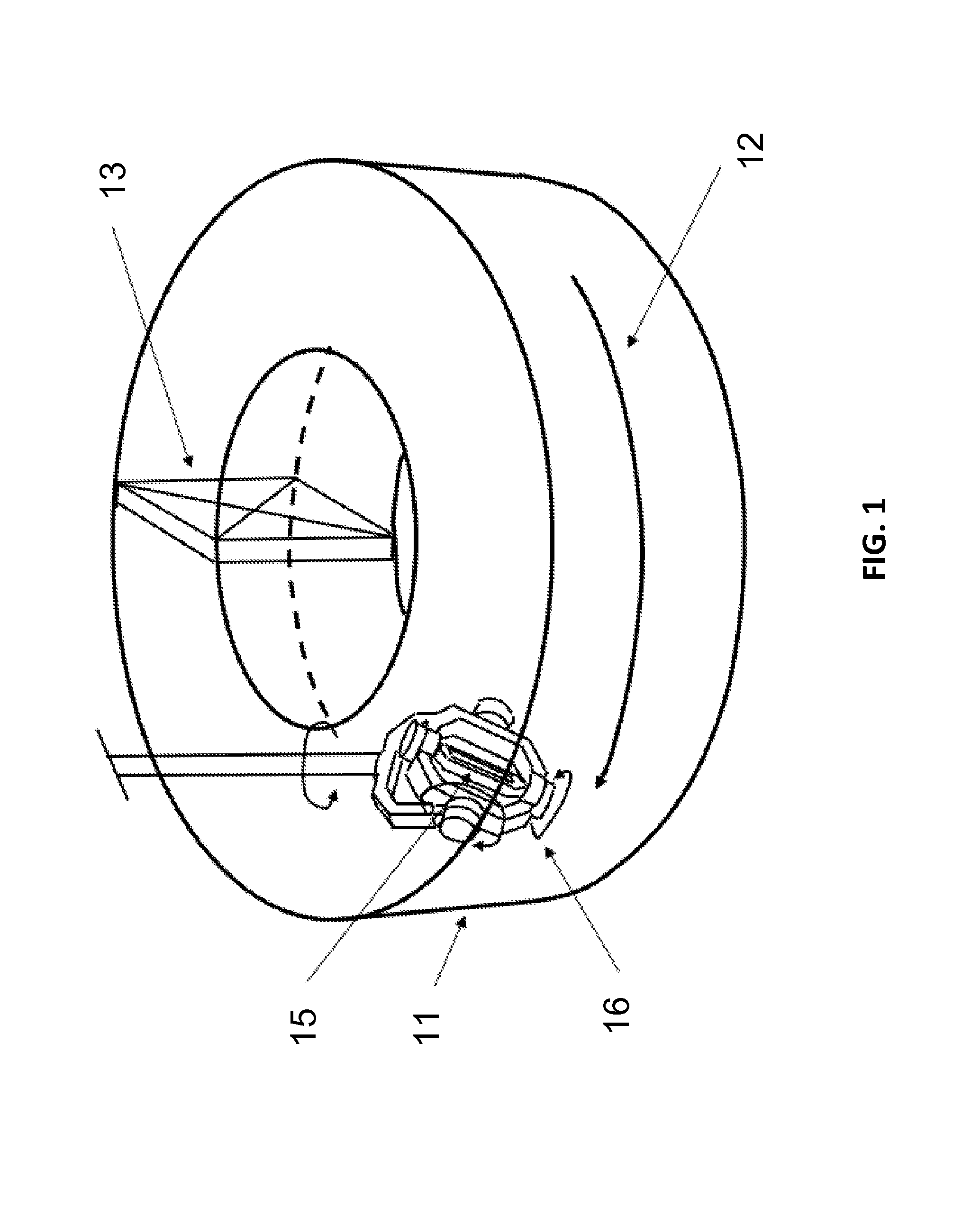

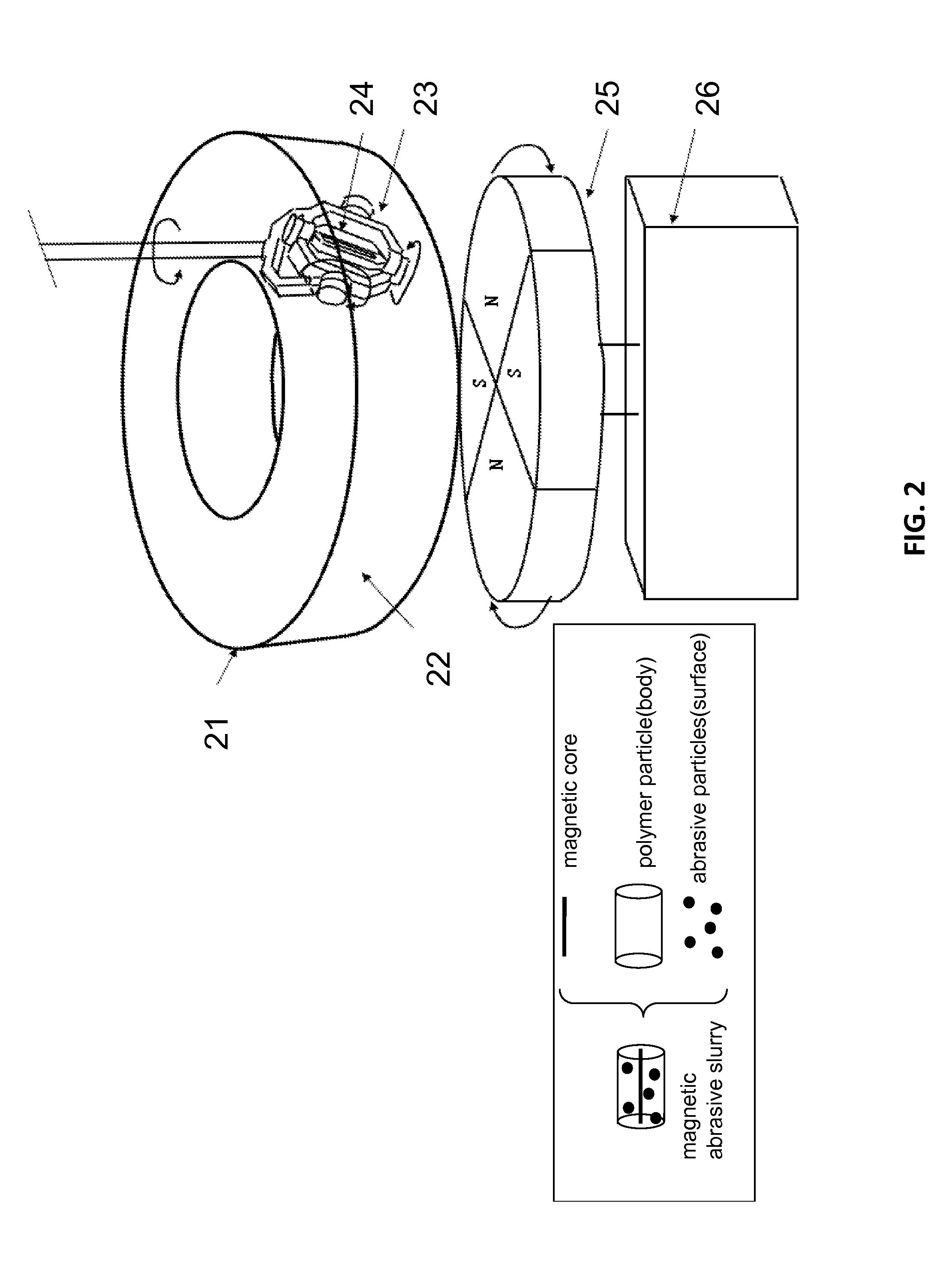

Automatic polishing device for surface finishing of complex-curved-profile parts

InactiveUS20130273816A1Easy to moveLow costPolishing machinesGrinding feed controlNon destructiveFree form

The present invention discloses an automatic polishing device and the method of using the device for the surface finishing of a workpiece such as complex-curved-profile parts. Automatic polishing is performed by mounting the workpiece on an apparatus which enables different orientations along multiple axes and immerging the workpiece in a controlled flow of abrasive slurry. The device of the present invention provides a uniform finish on free form surface. It is also precise, low cost, non-destructive, and non-polluting.

Owner:NANO & ADVANCED MATERIALS INST

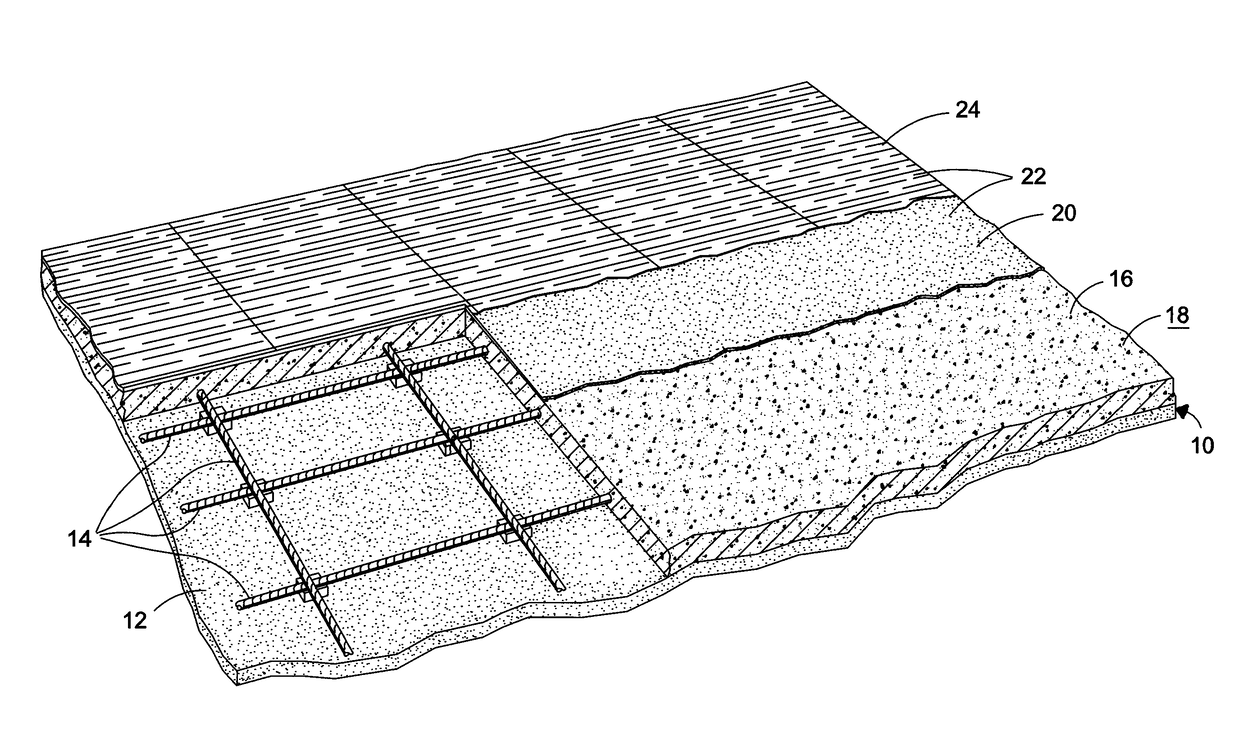

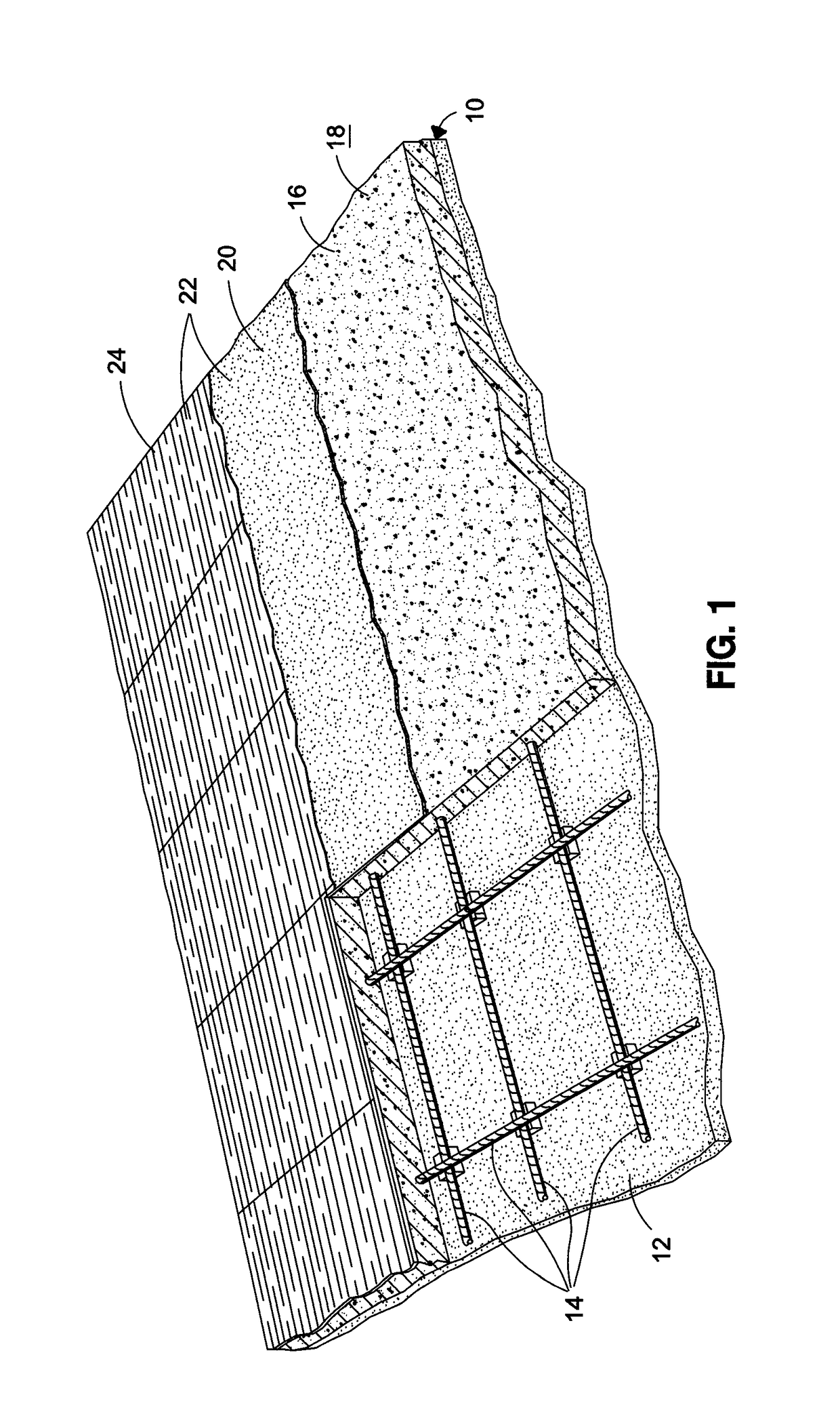

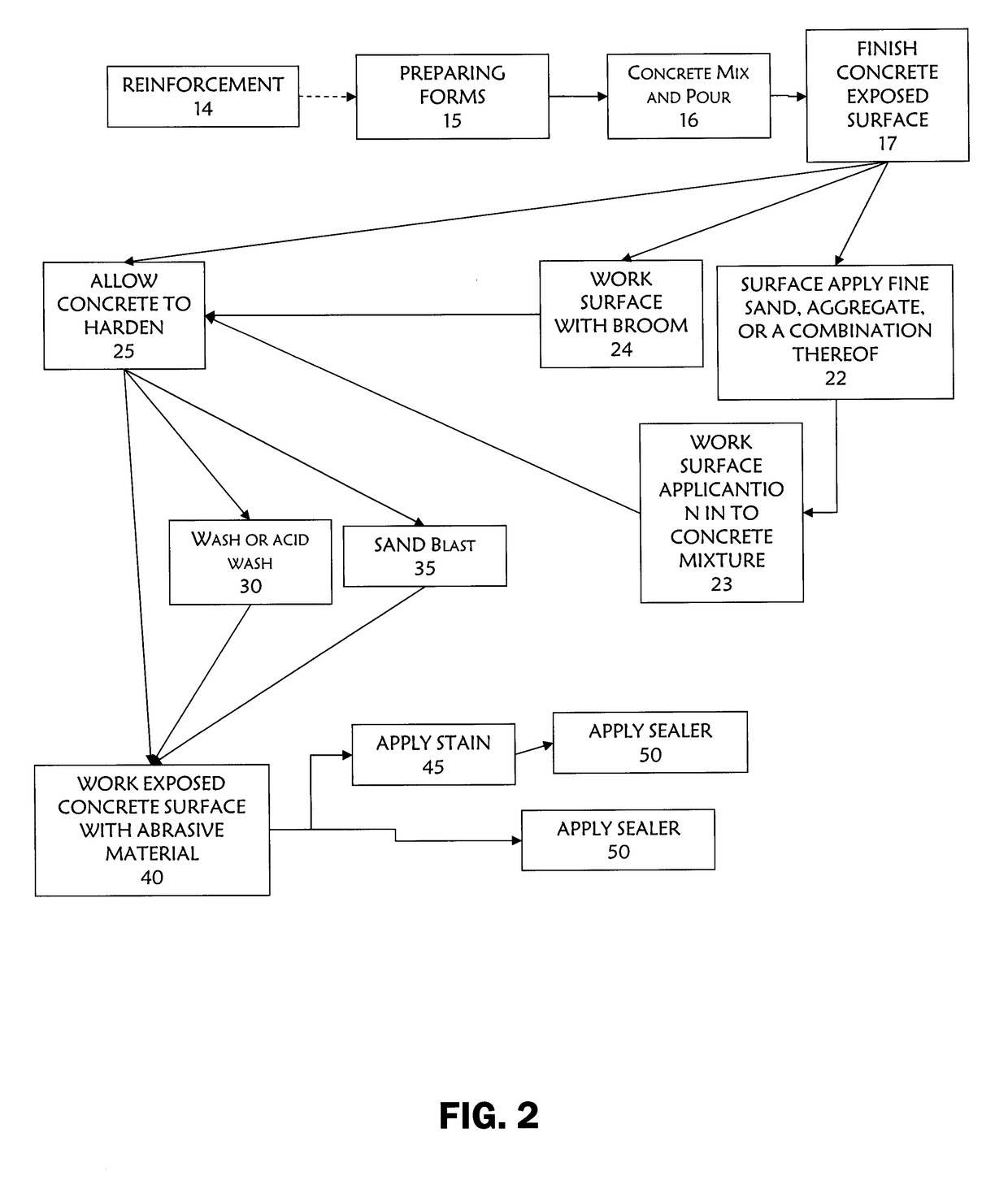

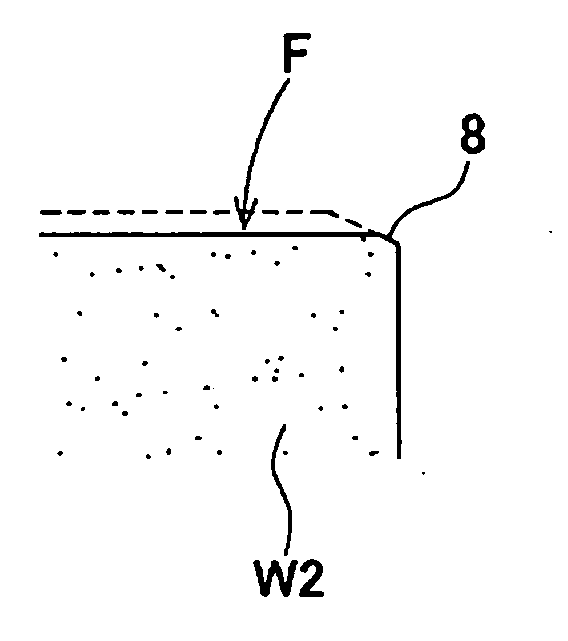

Decorative concrete with uniform surface and method of forming the same

InactiveUS20170298626A1Uniform finishImprove uniformityConstruction materialDomestic articlesMachined surfaceMaterials science

A decorative concrete with a very uniform finish surface and a method of fabricating the same is disclosed. A concrete mixture is poured over a subgrade which defines an exposed surface. The exposed surface is finished with any of several techniques, and the surface is then worked with an abrasive material, and additional techniques are used to color and seal the concrete.

Owner:SHAW & SONS

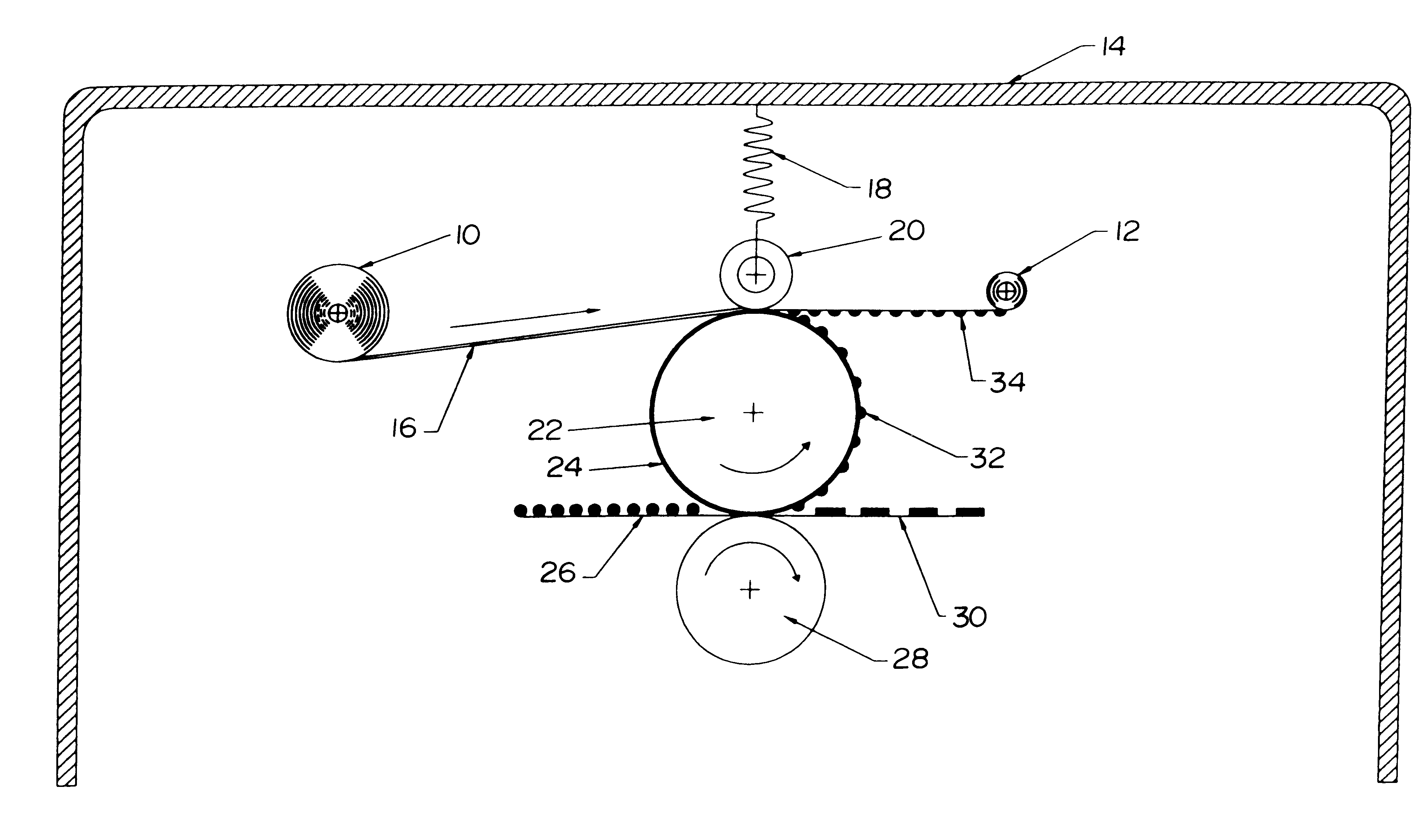

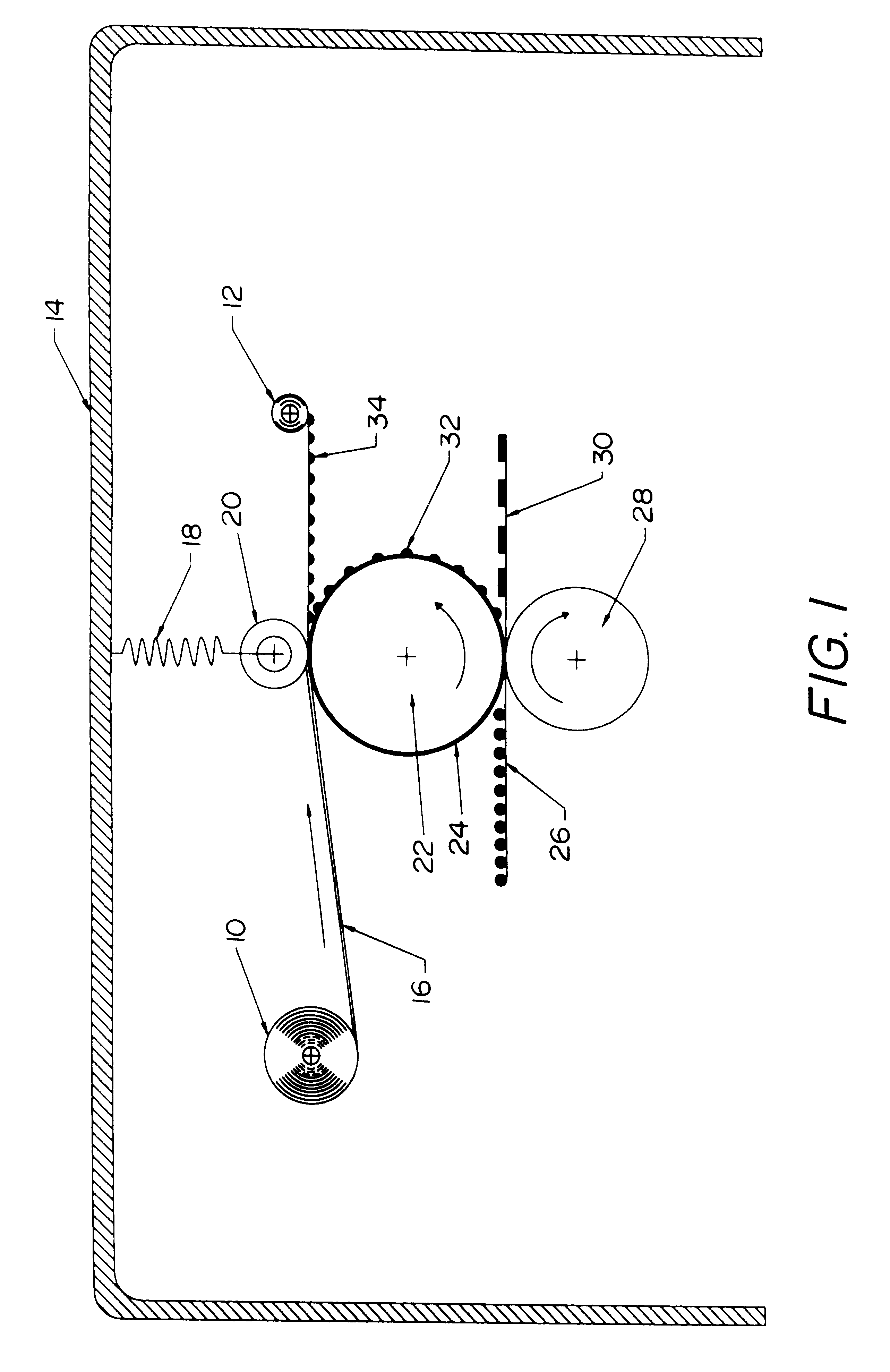

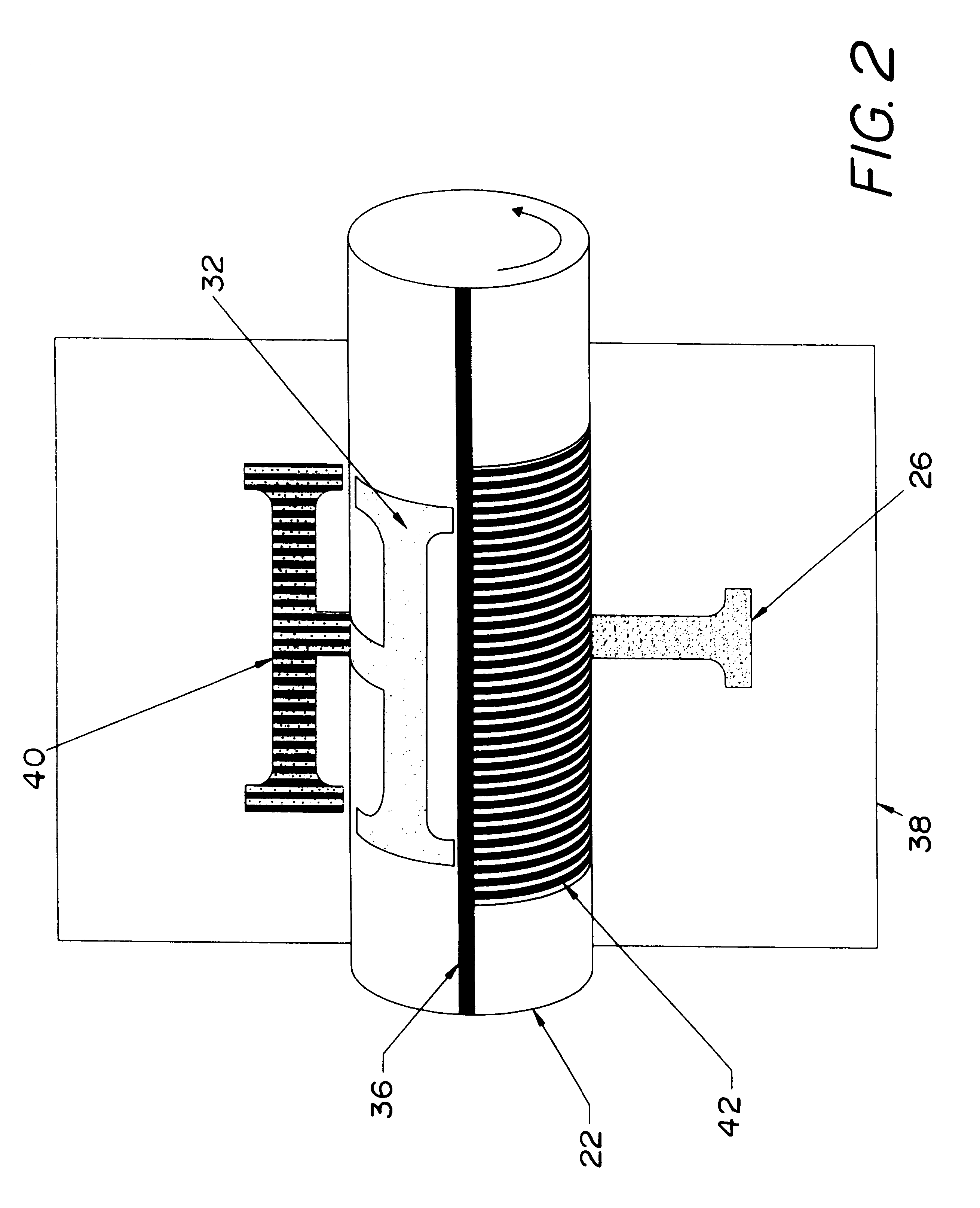

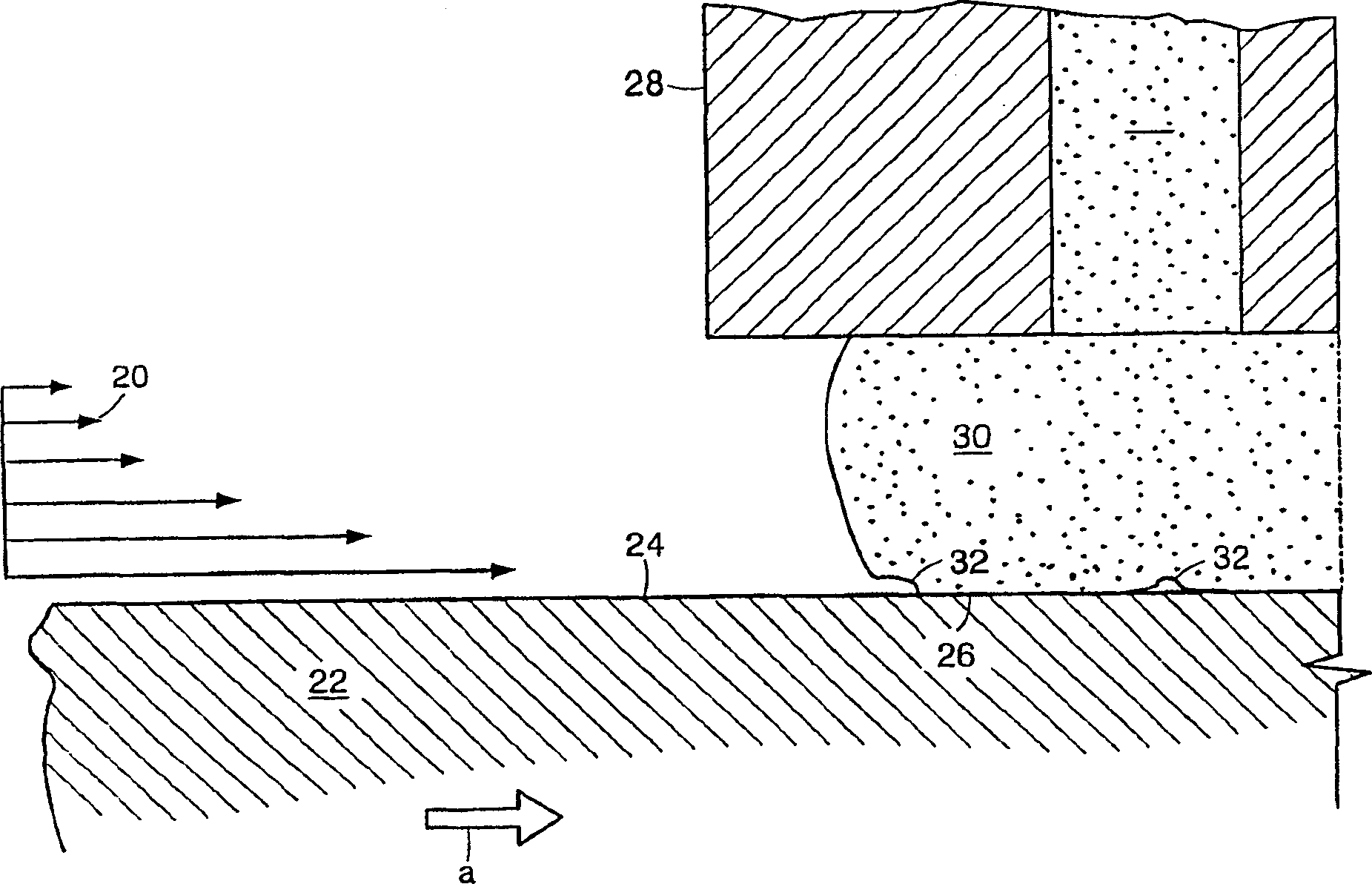

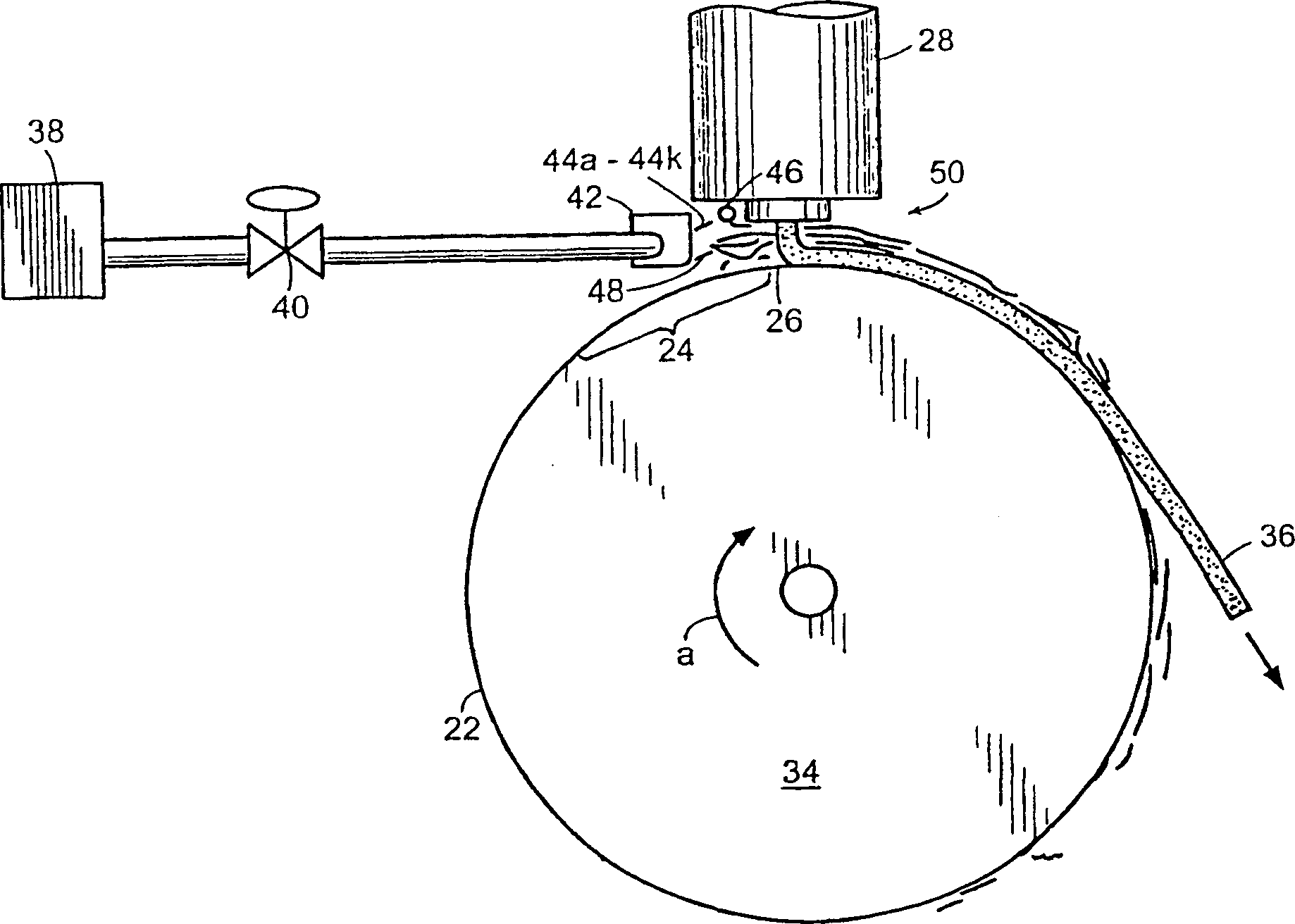

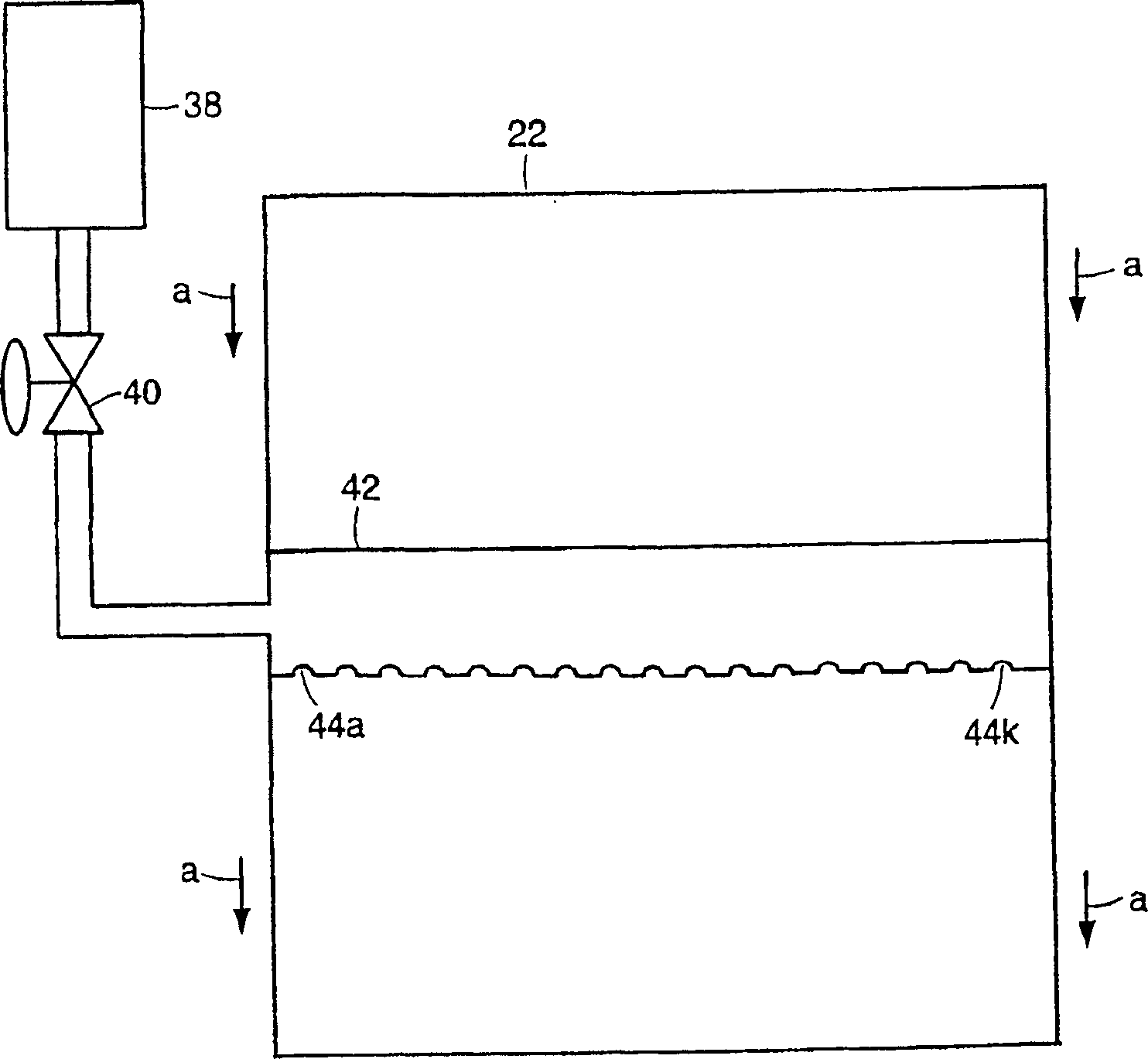

Apparatus and method for hydroenhancing fabric

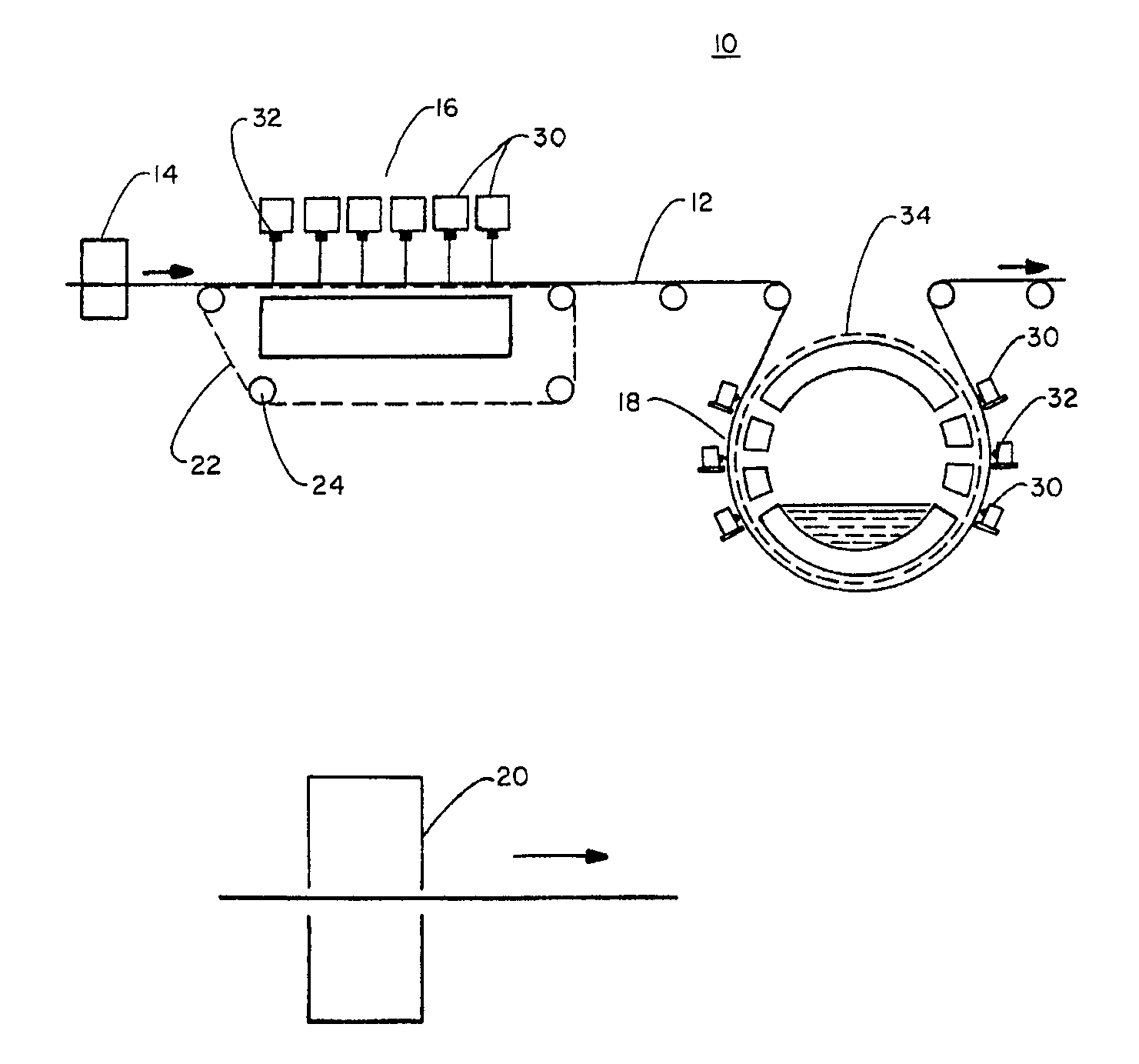

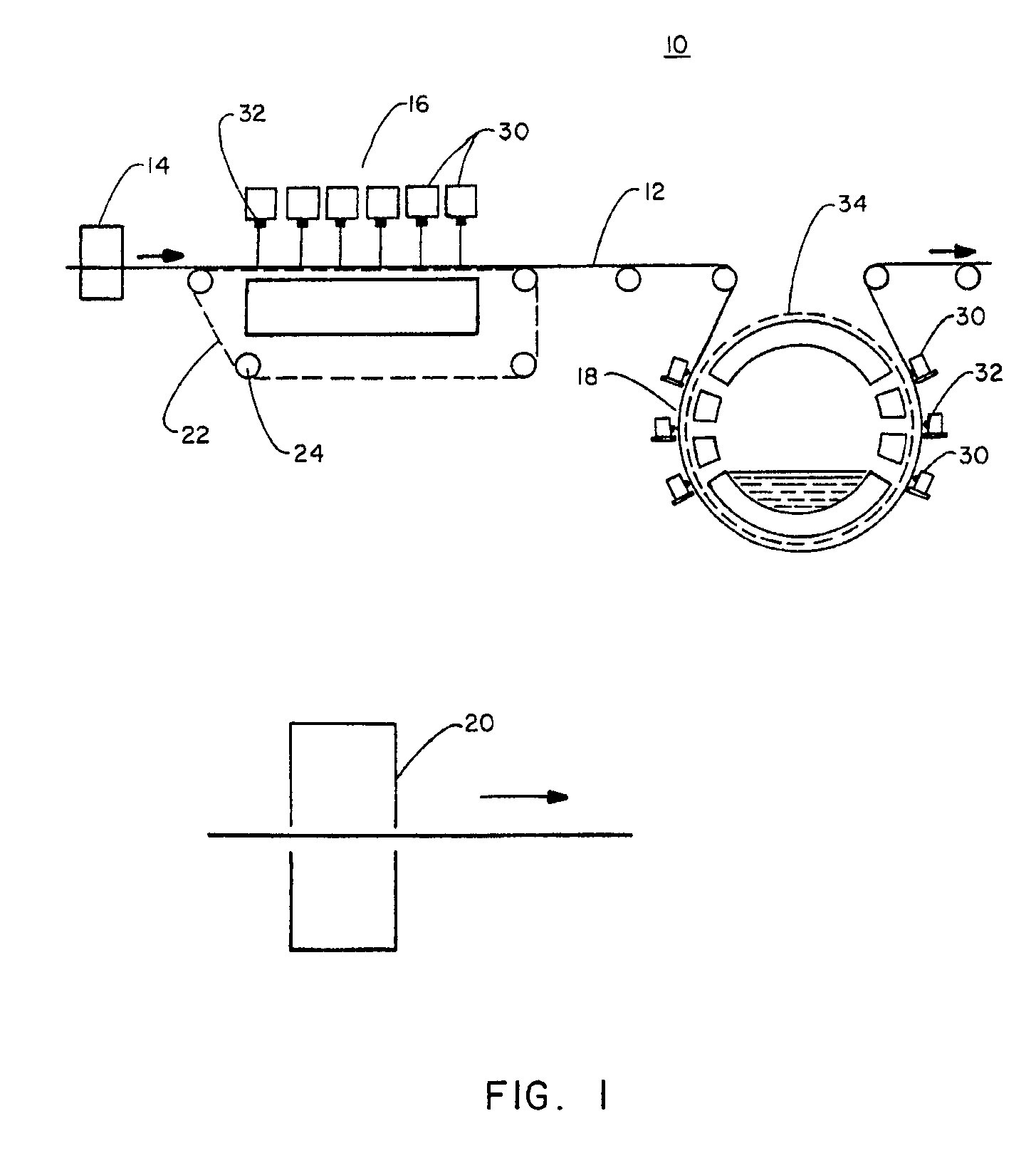

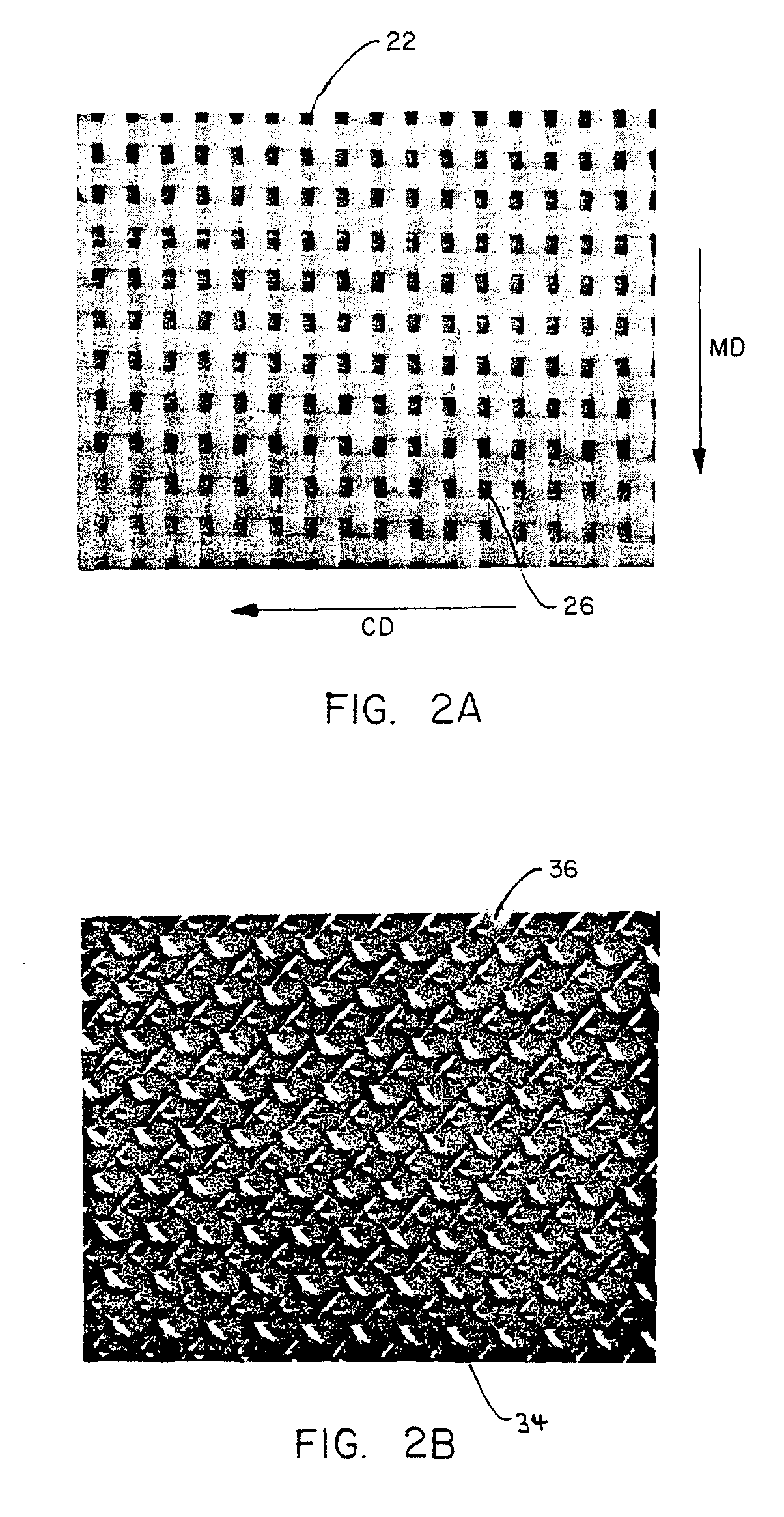

InactiveUSRE40362E1Uniform finishImprove featuresPattern makingOther washing machinesYarnHigh pressure

An apparatus 10 and related process for enhancement of woven and knit fabrics through use of dynamic fluids which entangle and bloom fabric yarns. A two stage enhancement process is employed in which top and bottom sides of the fabric are respectively supported on members 22, 34 and impacted with a fluid curtain including high pressure jet streams. Controlled process energies and use of support members 22, 34 having open areas 26, 36 which are aligned in offset relation to the process line produces fabrics having a uniform finish and improved characteristics including, edge fray, drape, stability, abrasion resistance, fabric weight and thickness.

Owner:BBA NONWOVENS SIMPSONVILLE

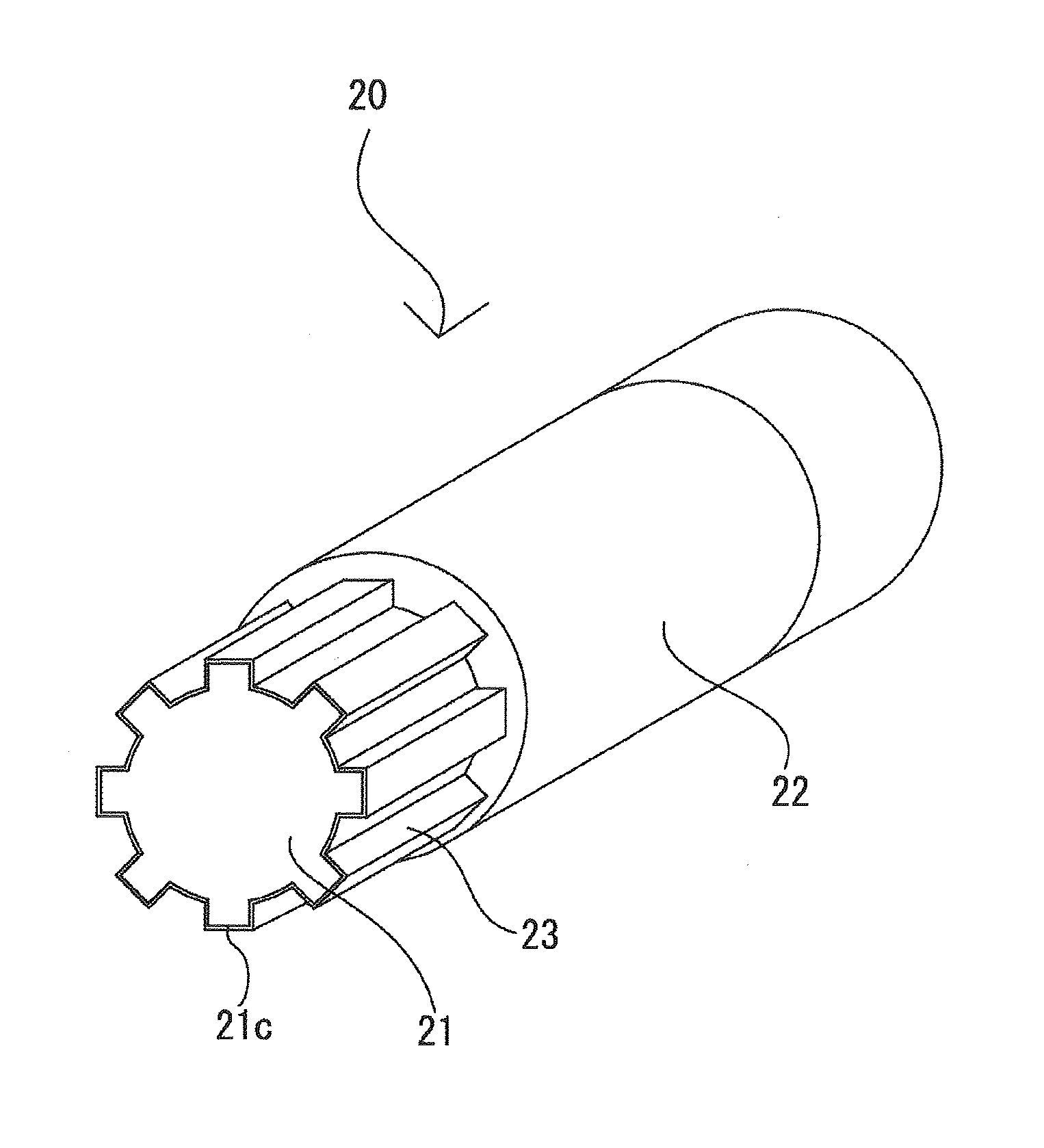

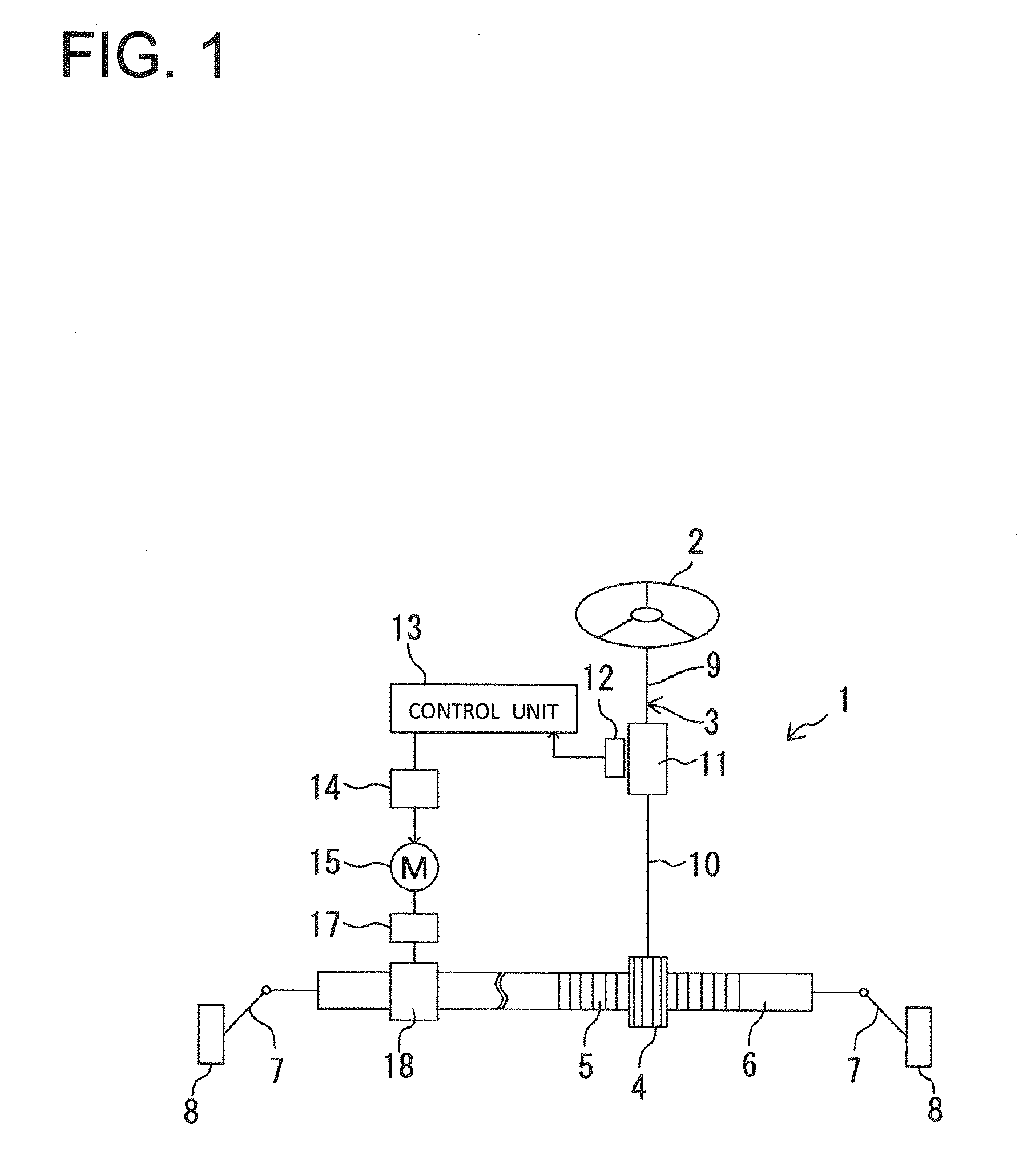

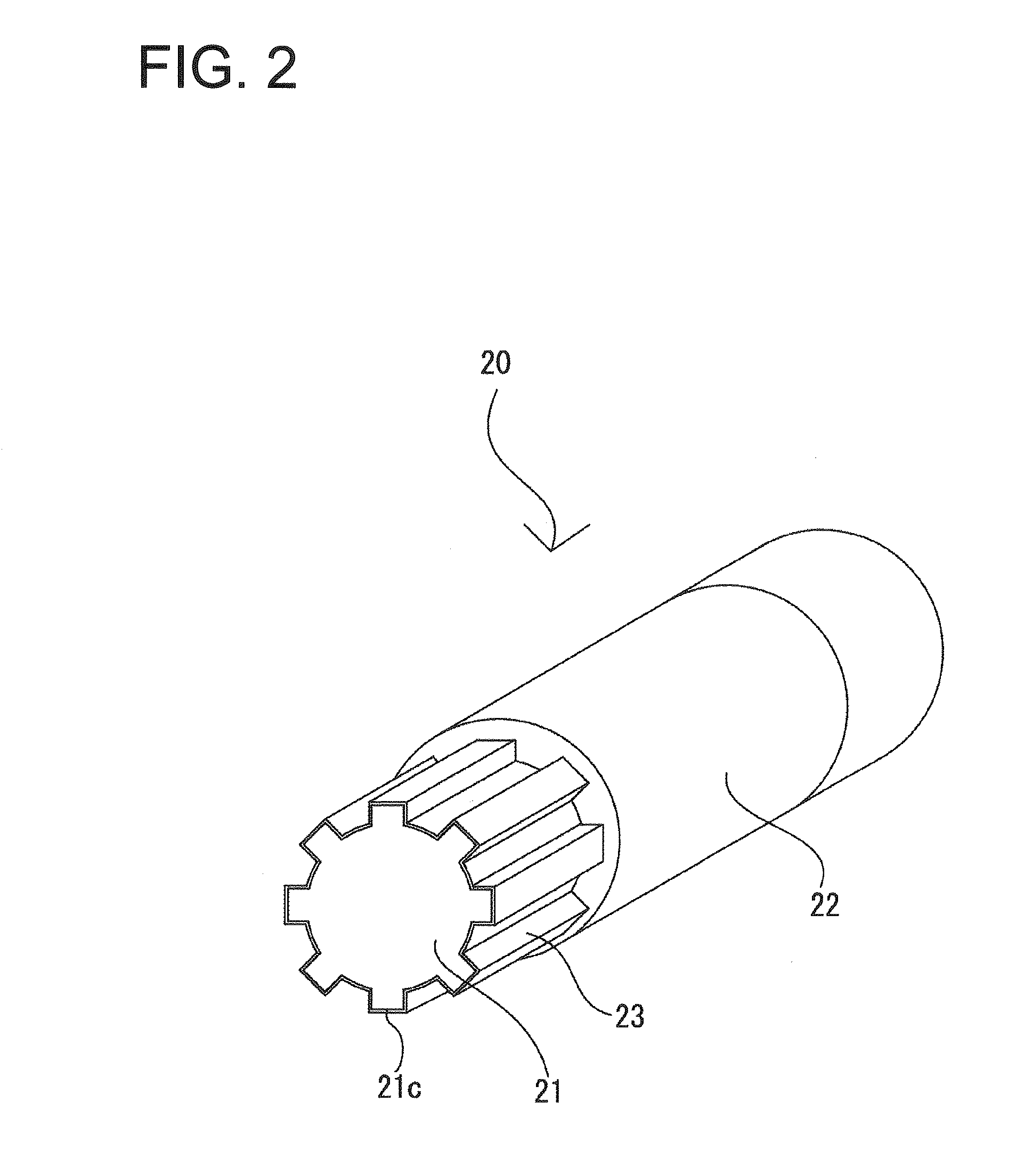

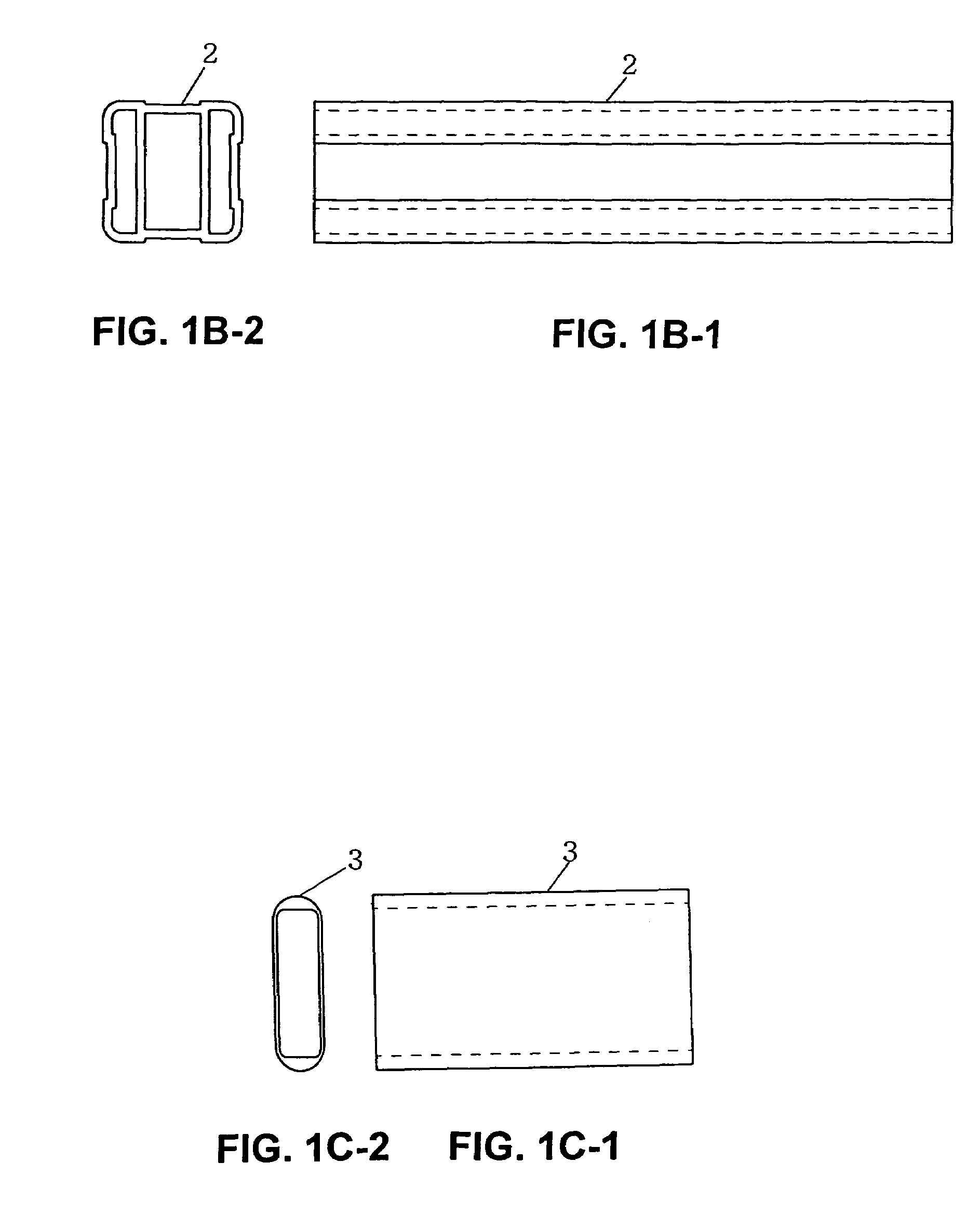

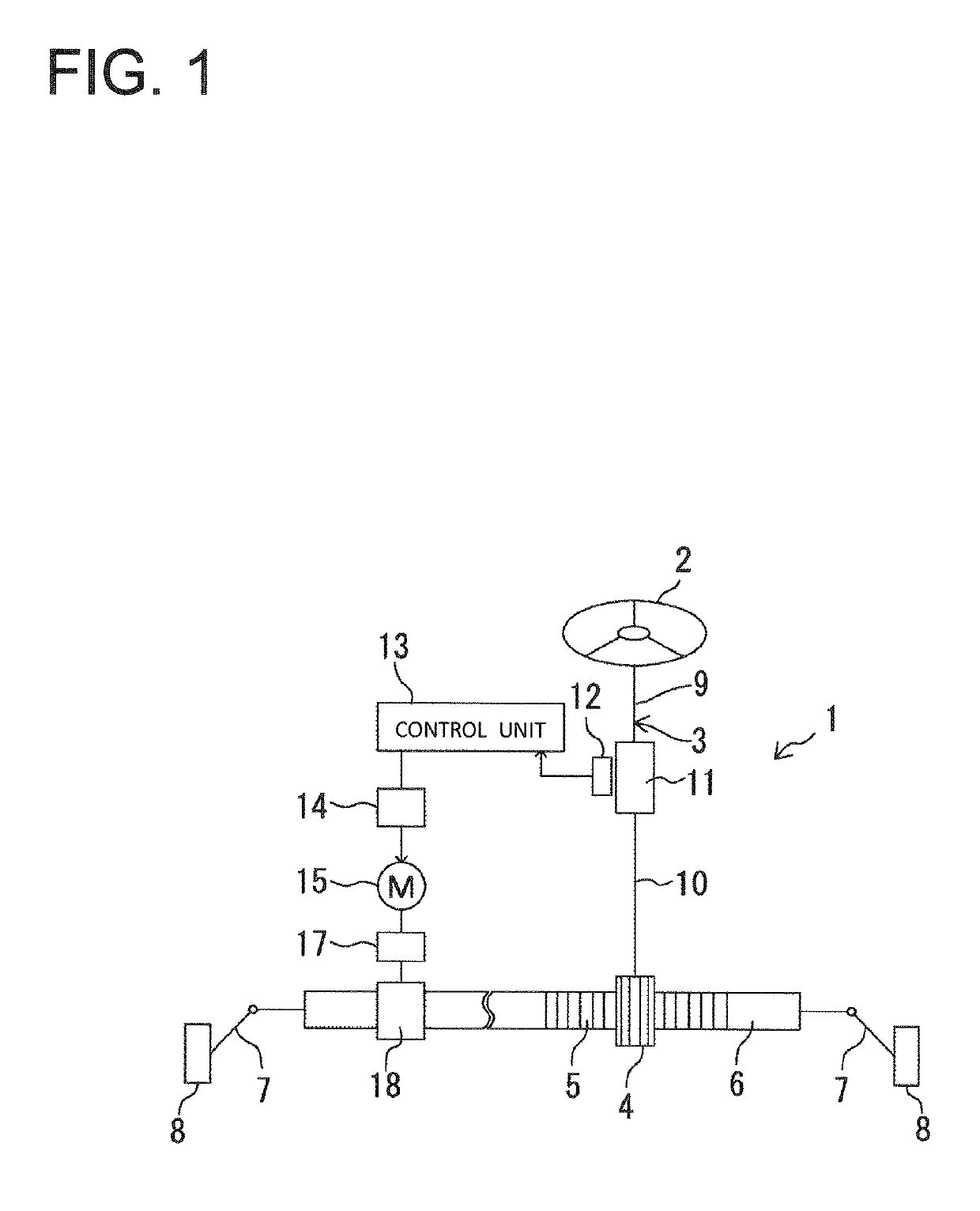

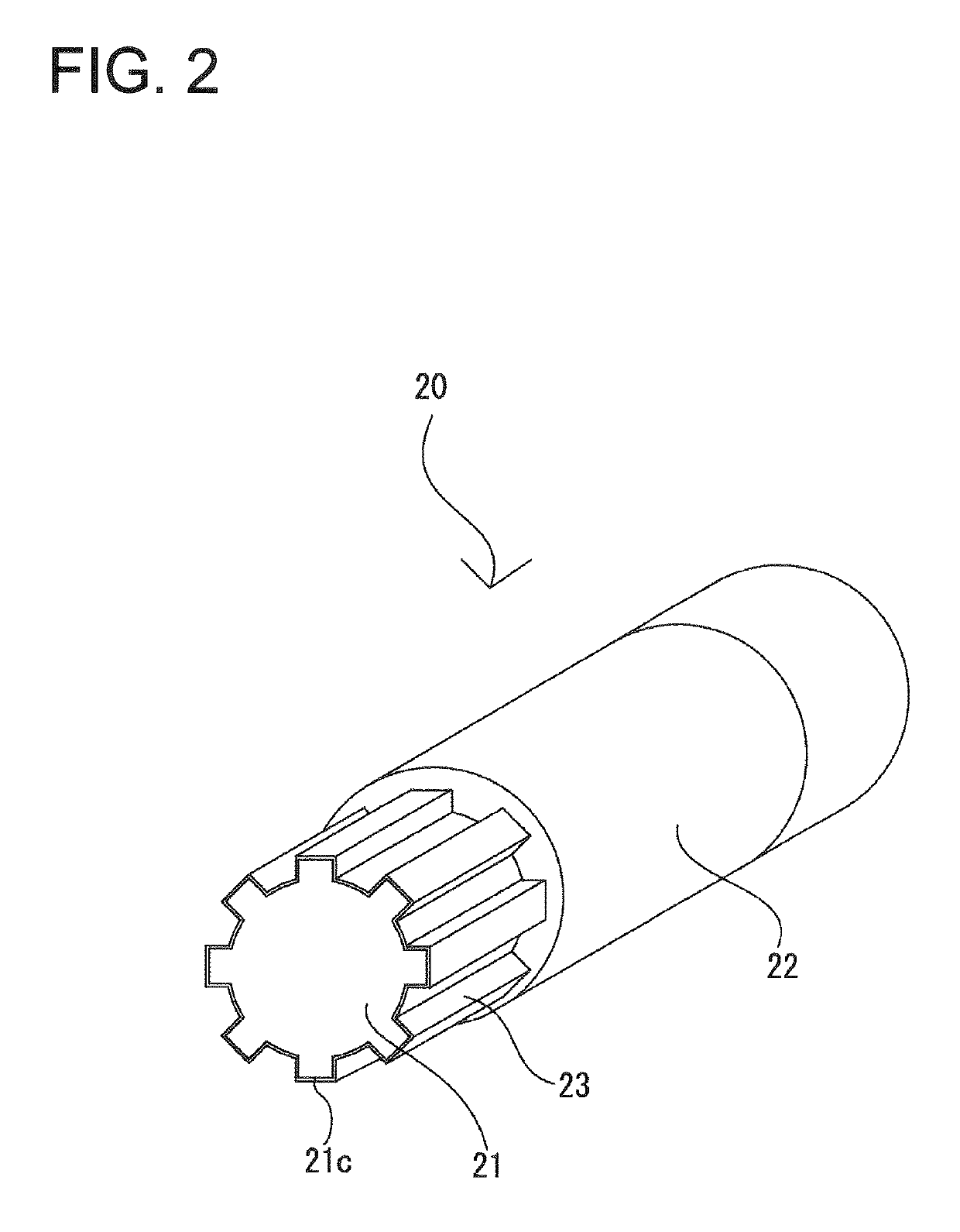

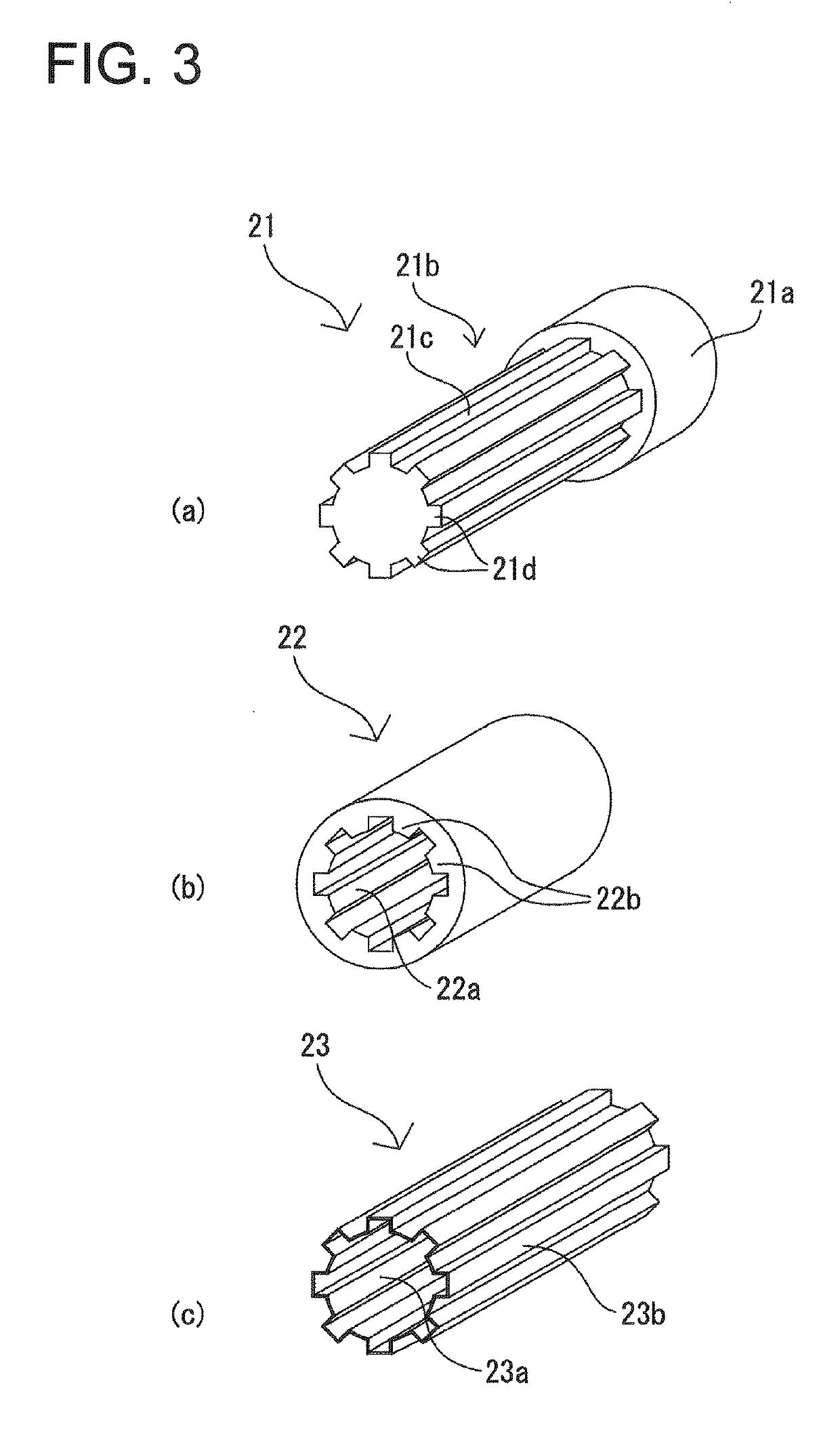

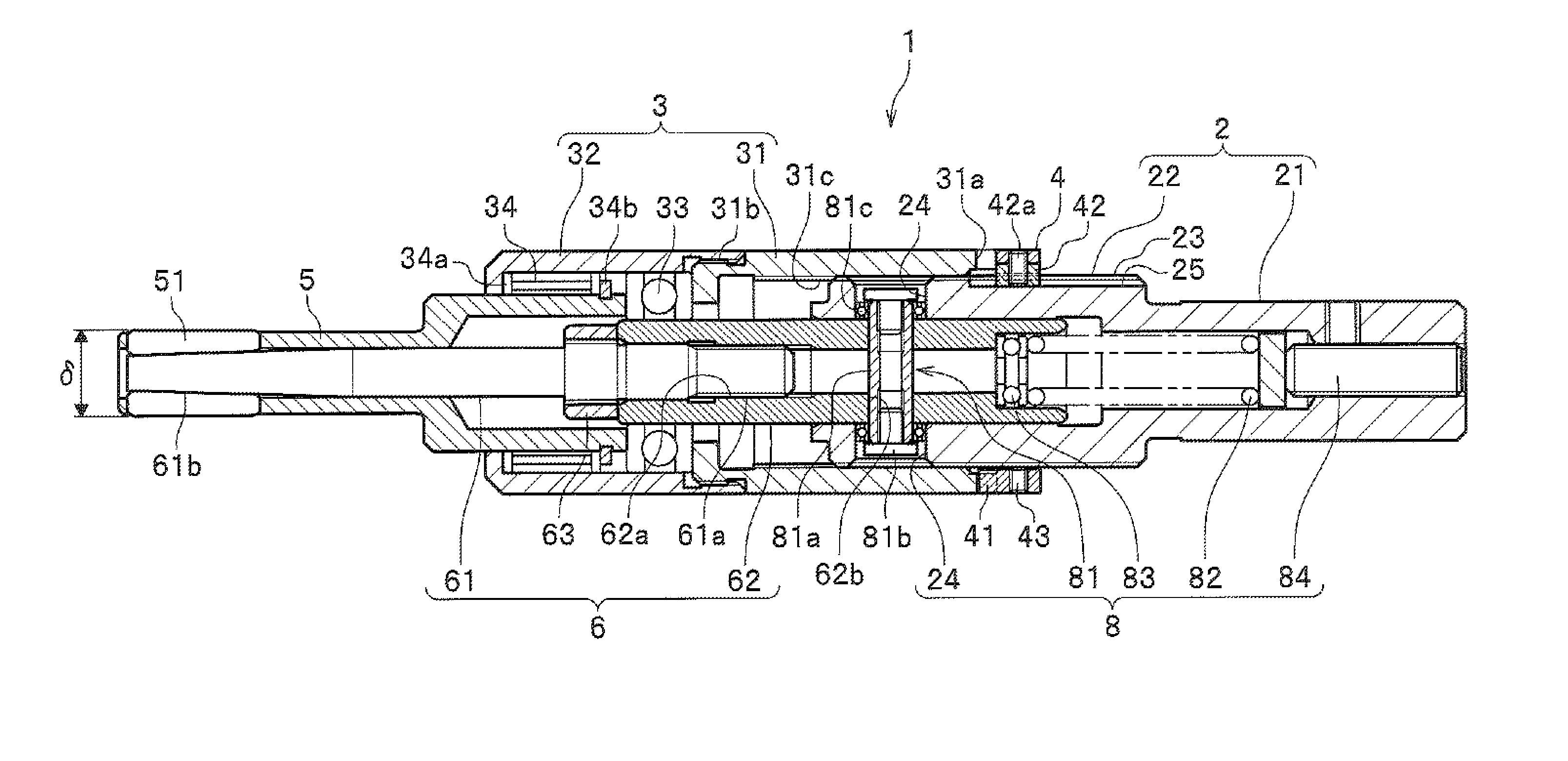

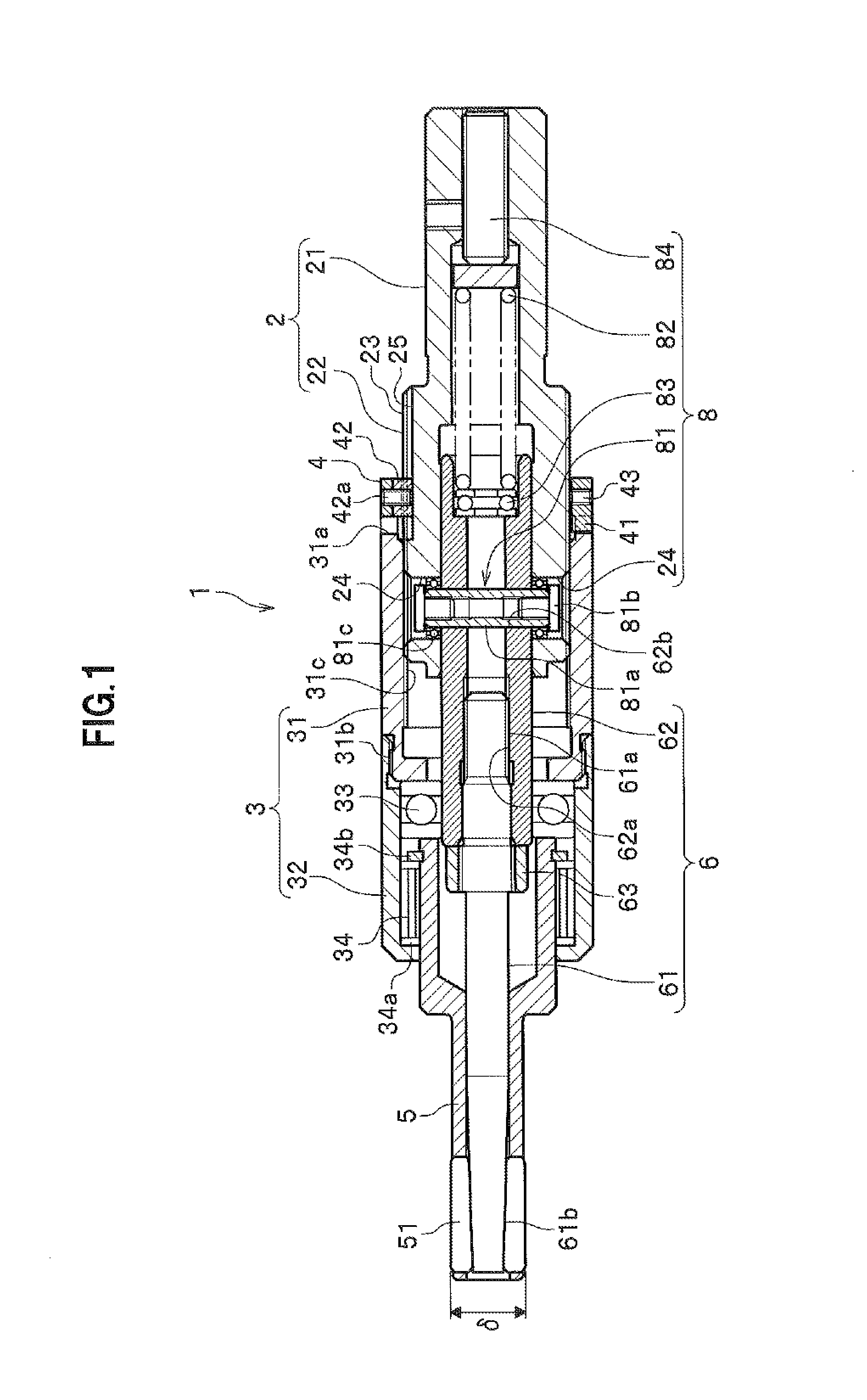

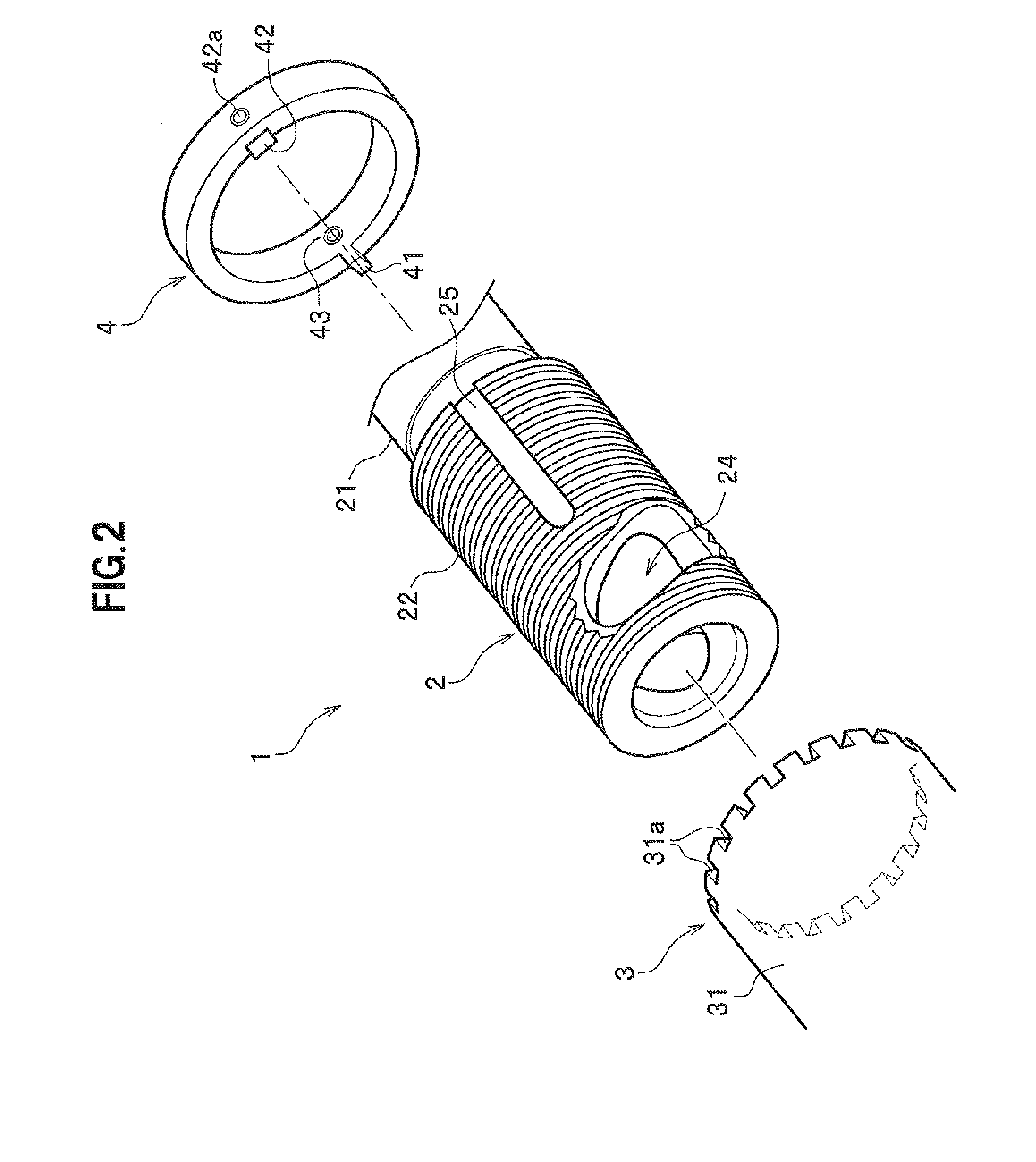

Structural body for shaft, male member, and female member

ActiveUS20150110551A1Reduced sliding resistanceReduce generationClutchesYielding couplingEngineeringPower transmission

A shaft structure installed in a shaft capable of making a power-transmission, the shaft structure including: a male component having a plurality of male splines formed on an outer peripheral part thereof; and a female component having a plurality of female splines formed on an inner peripheral part thereof, the inner peripheral part configured to allow the outer peripheral part of the male component to be engaged therein so that the male component and the female component can be slidably fitted with respect to each other in an axial direction thereby making up said shaft structure, wherein the outer peripheral part of the male component and the inner peripheral part of the female component have a fabric impregnated with rubber or resin interposed therebetween.

Owner:NITTA CORP

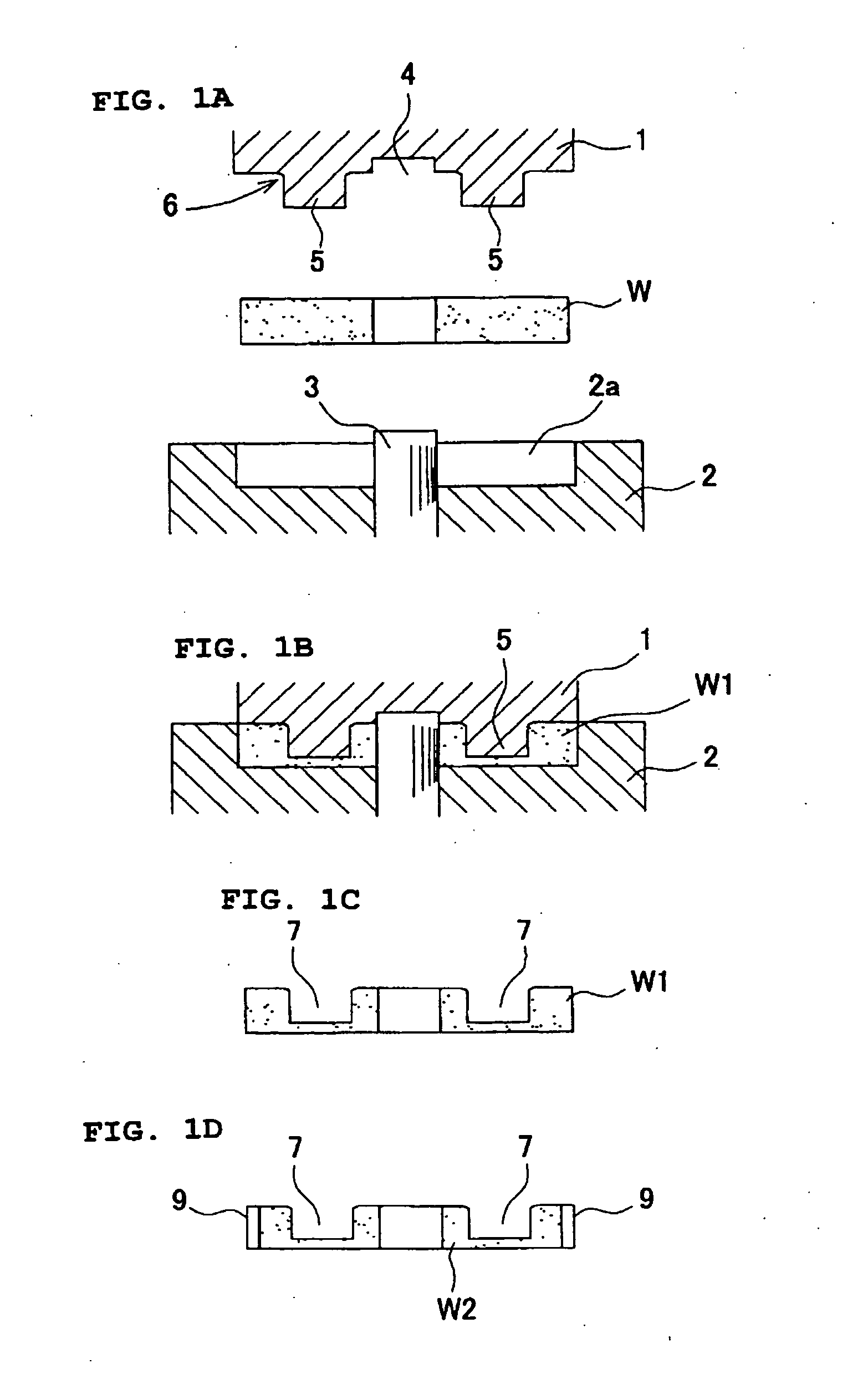

Chamfering method, forging device used in the chamfering method, and chamfered product

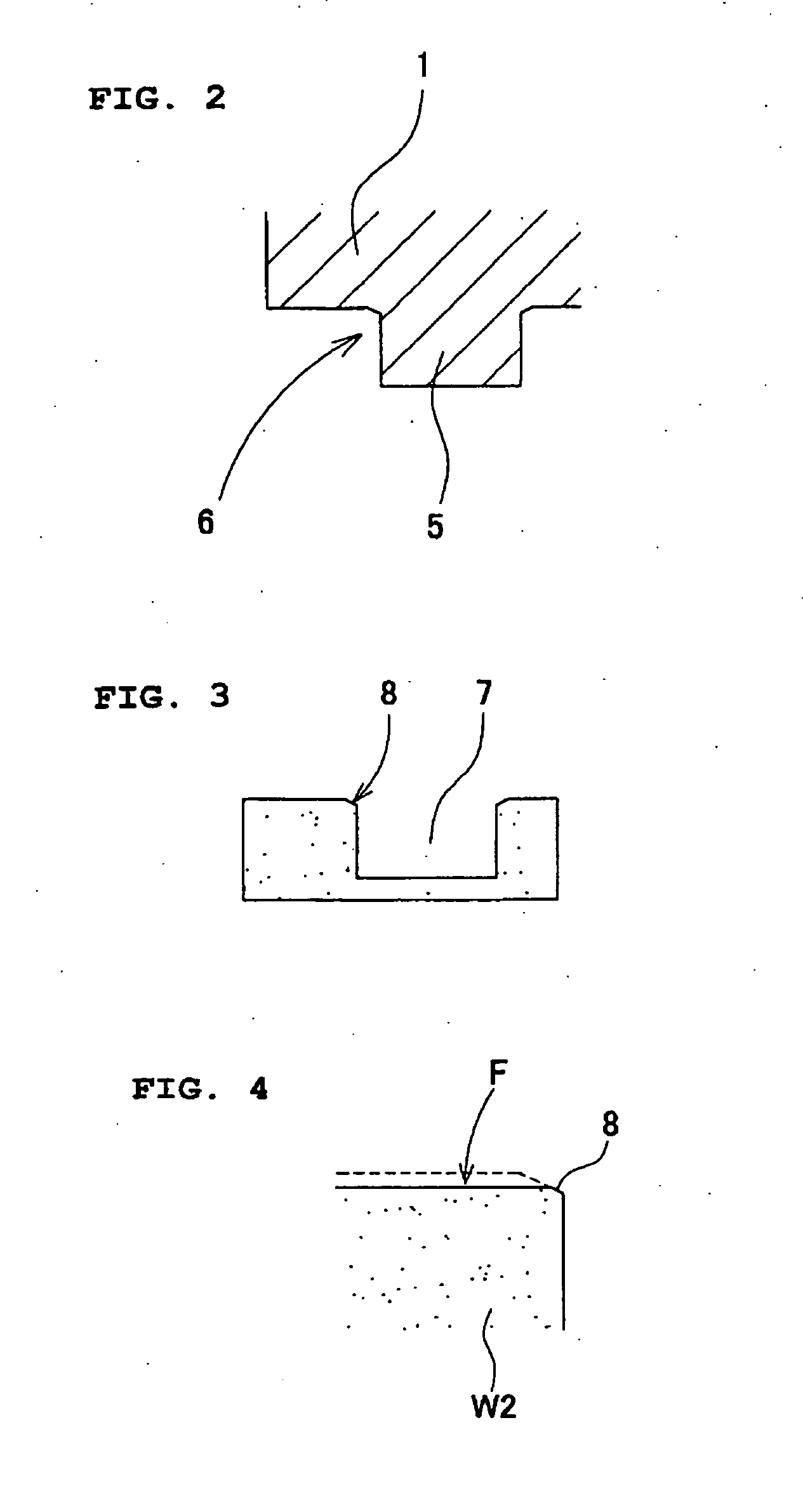

InactiveUS20050136223A1Reduced form requirementsAccurate UniformityLayered productsConfectioneryEngineeringMechanical engineering

A chamfer processing method for forming a chamfer part in a producing method for molding a product which has a cut-finished surface by cutting and penetrated hole or concave portion opening to said cut-finished surface, wherein chamfer processing step for chamfer processing previously the chamfer part by press molding at a corner part between the cut-finished surface and the penetrated hole or concave portion, and cutting step for cut-finishing the cut-finished surface in order to remain the chamfer part on the corner part between the cut-finished surface and the penetrated hole or concave portion.

Owner:O OKA CORP

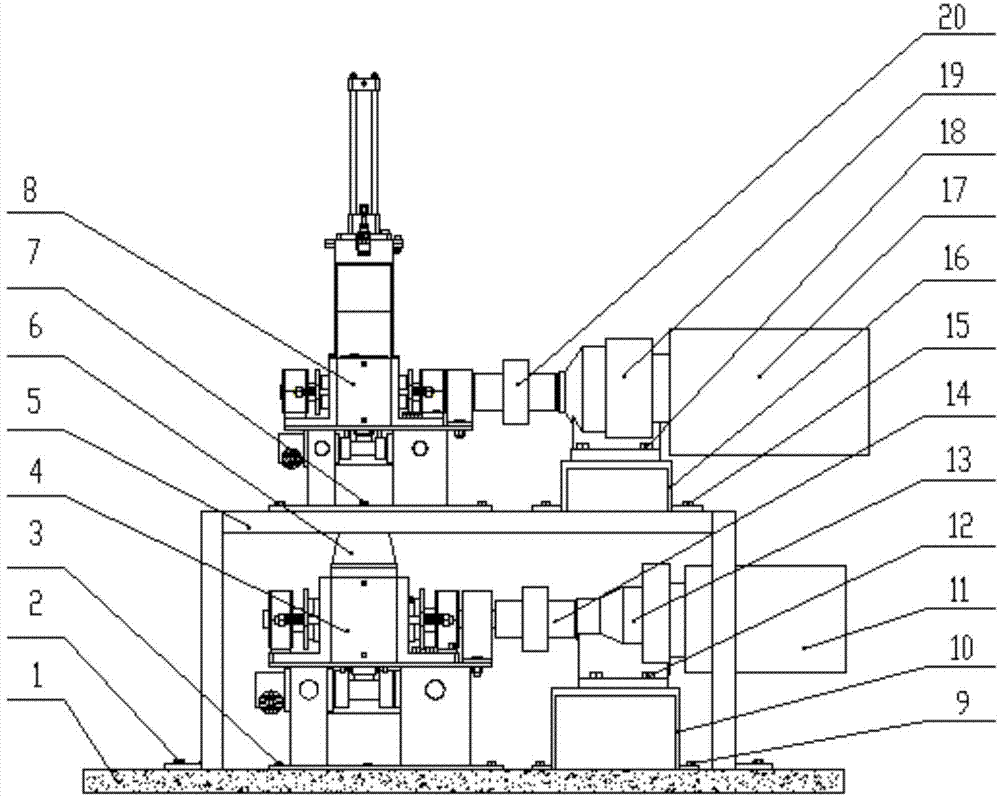

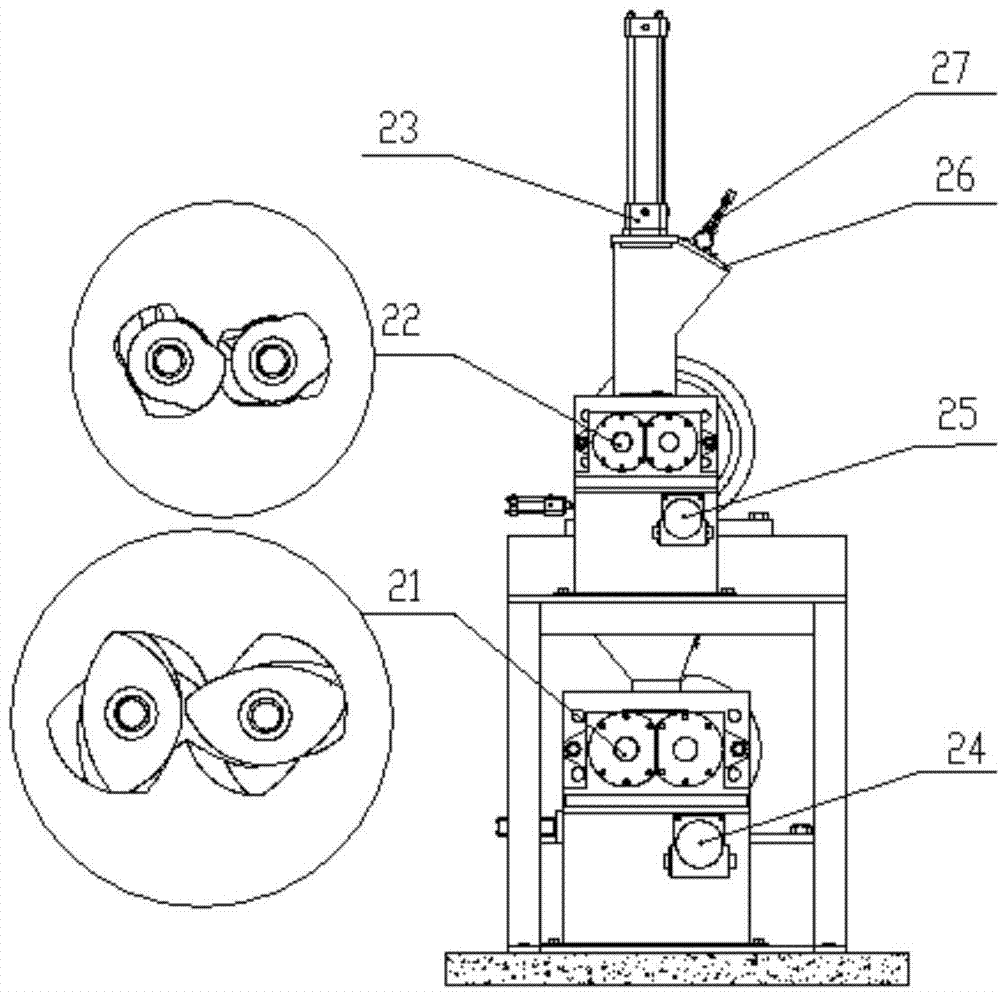

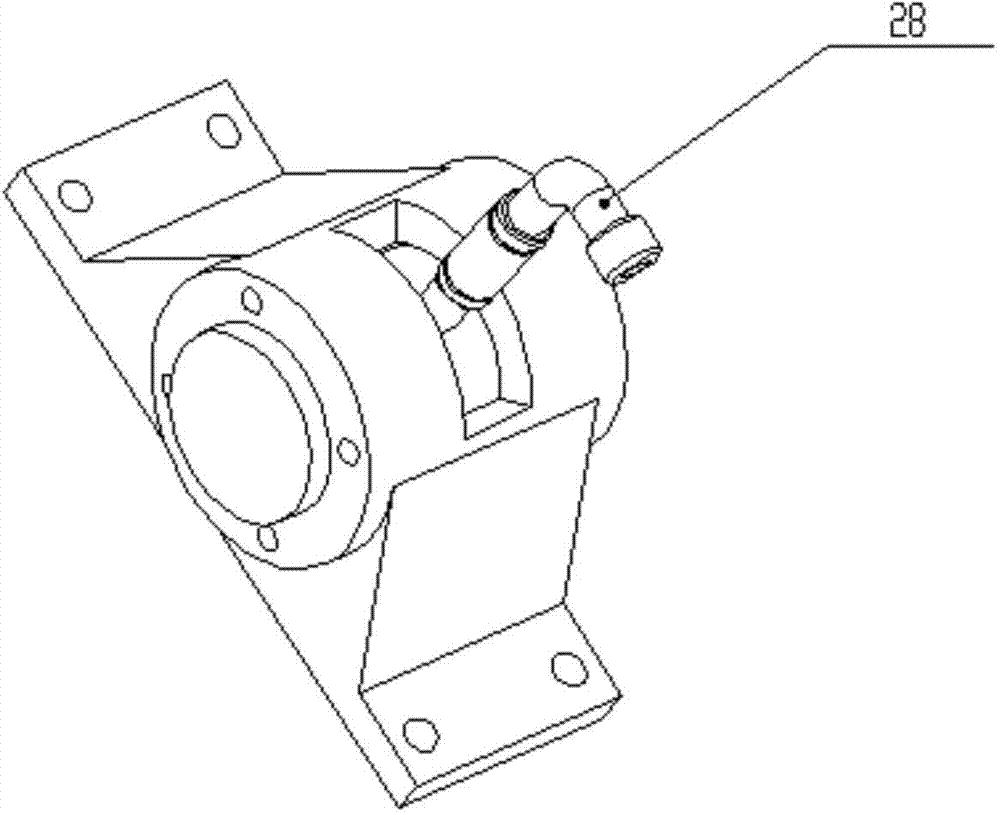

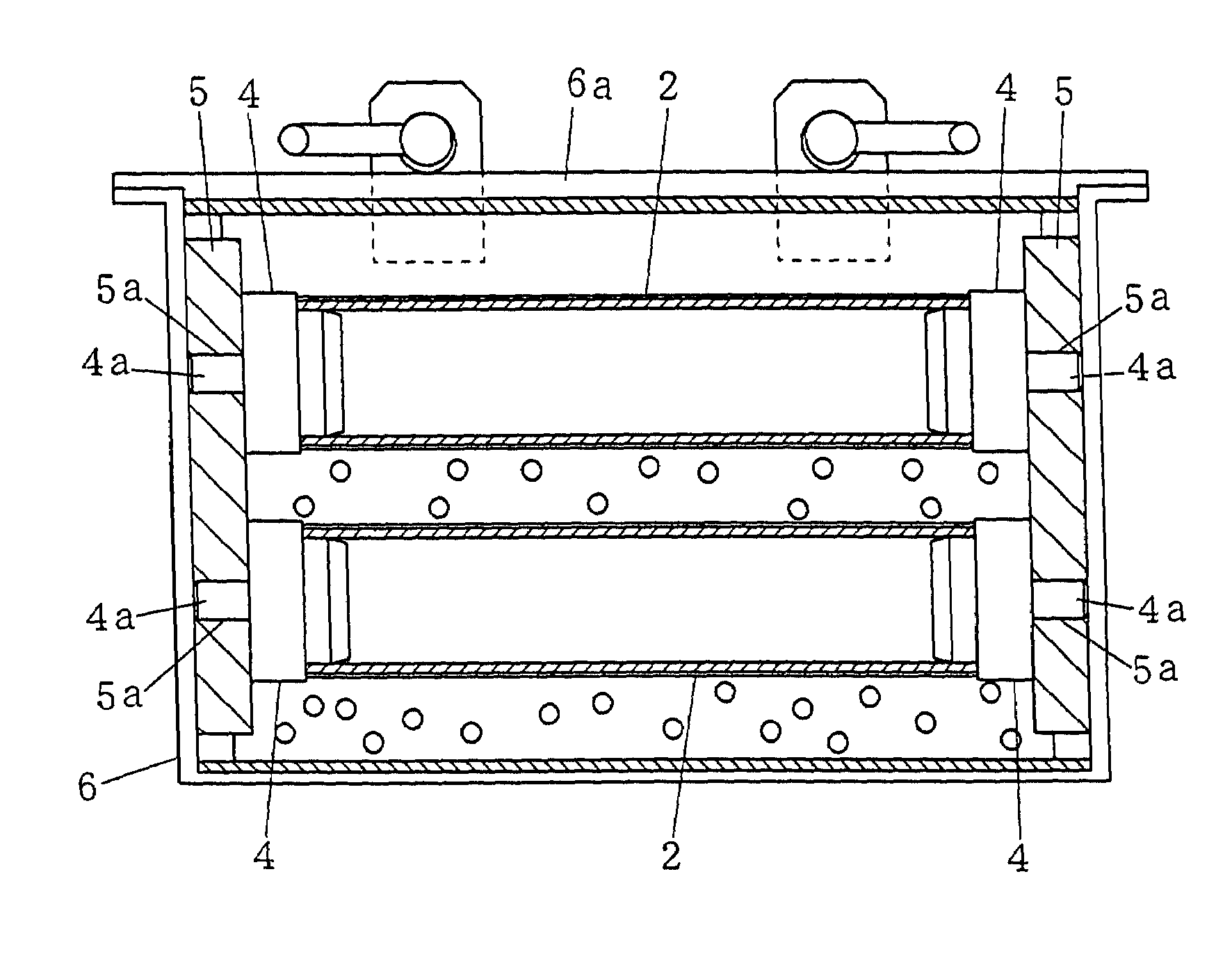

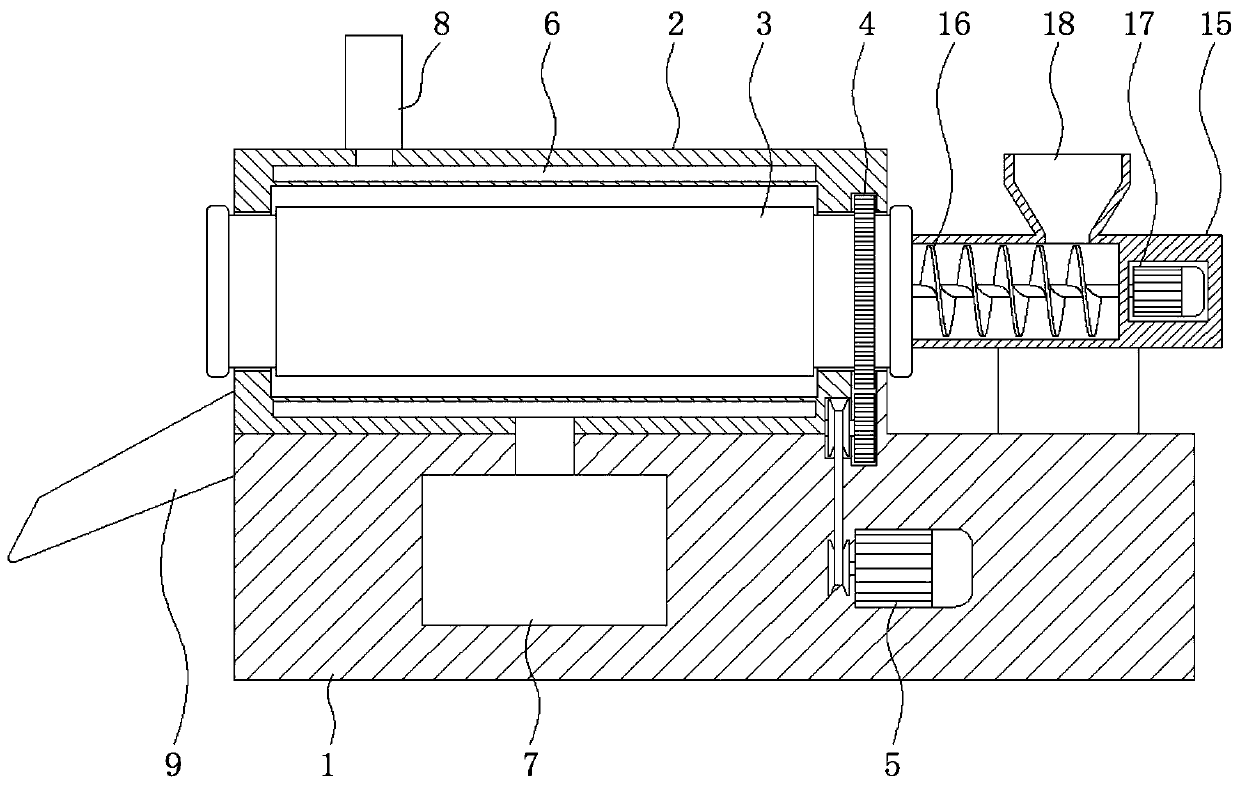

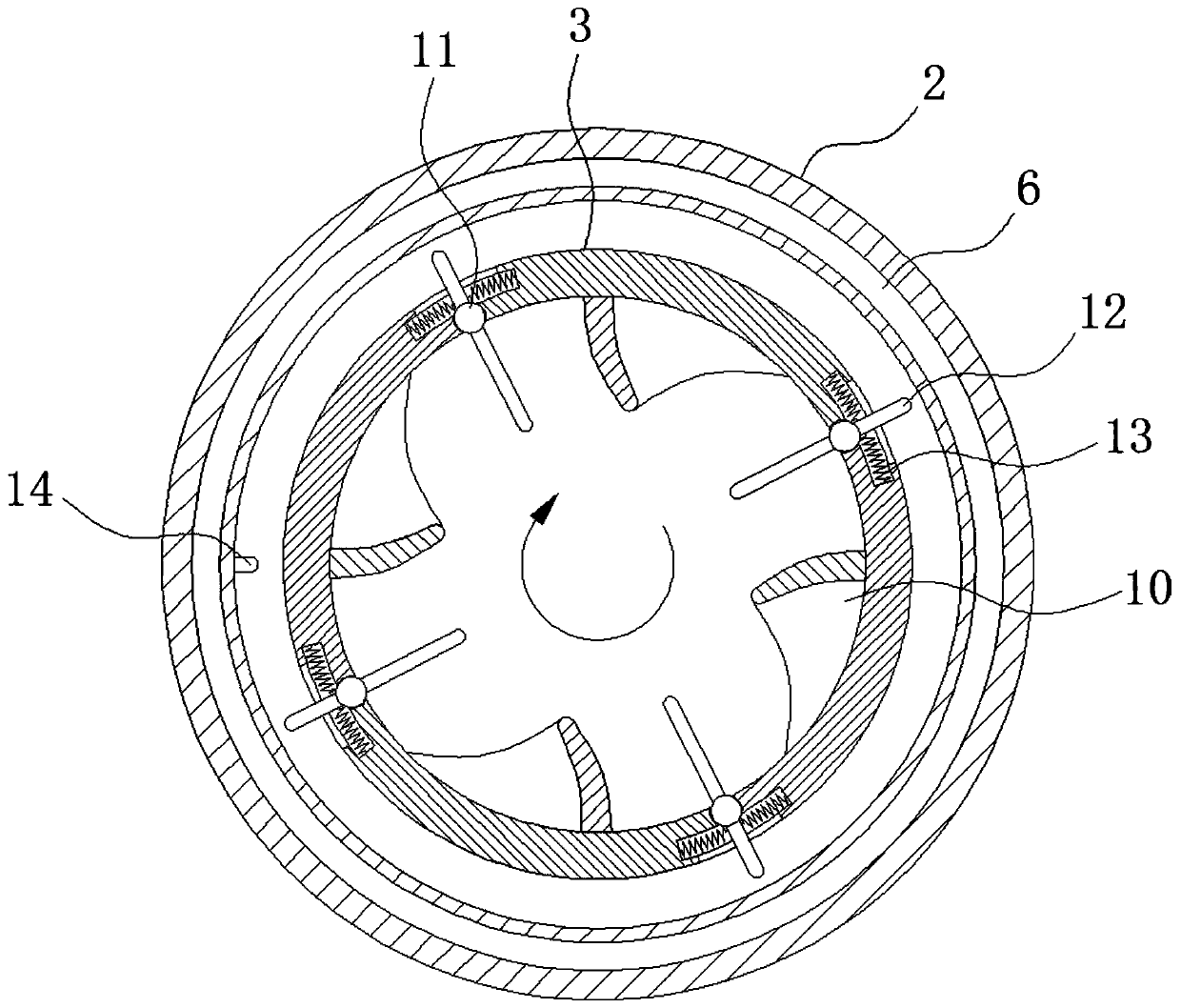

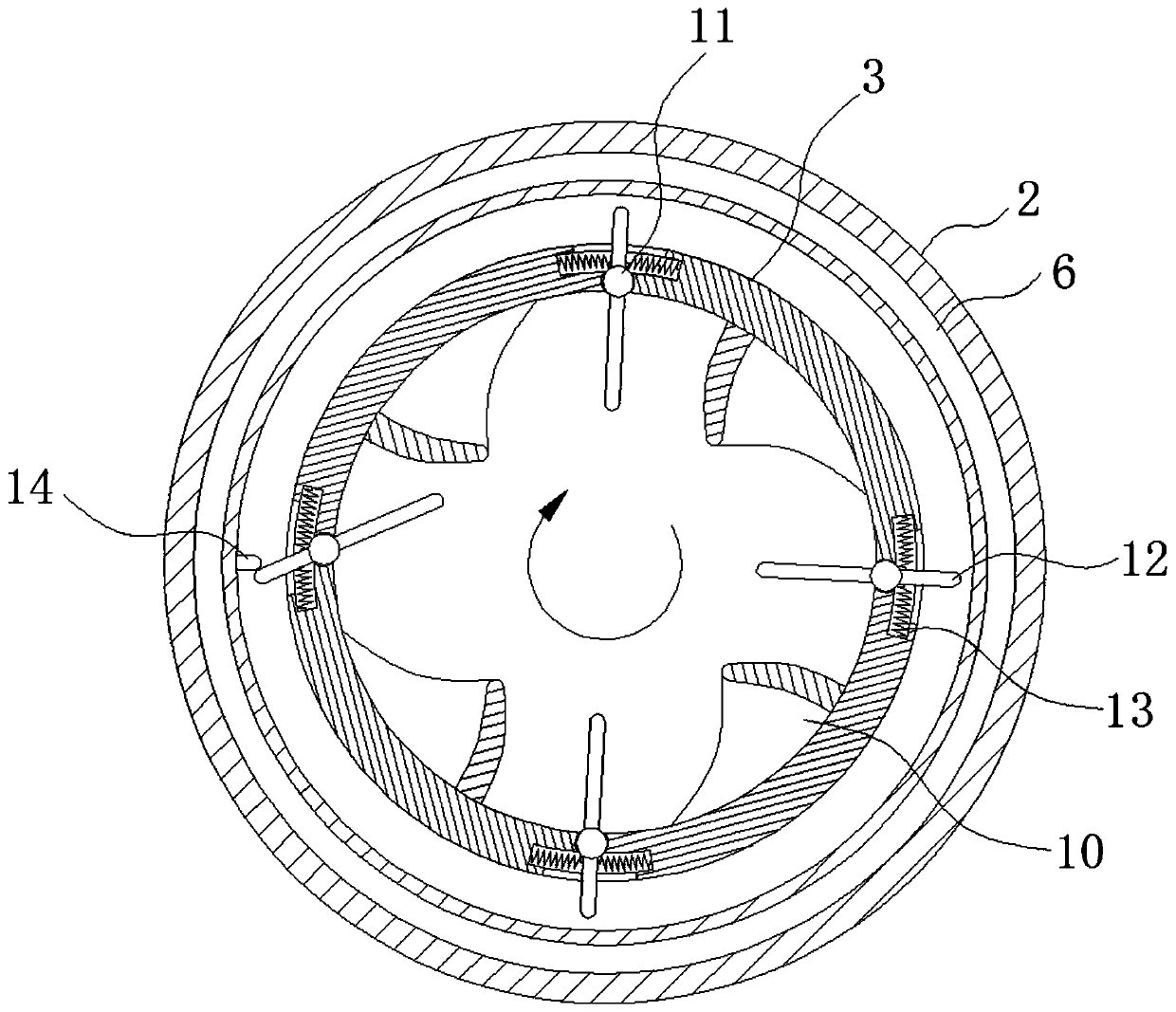

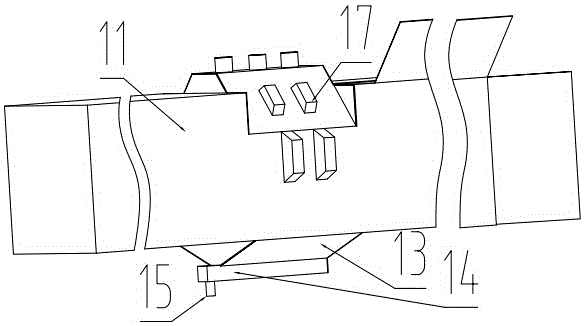

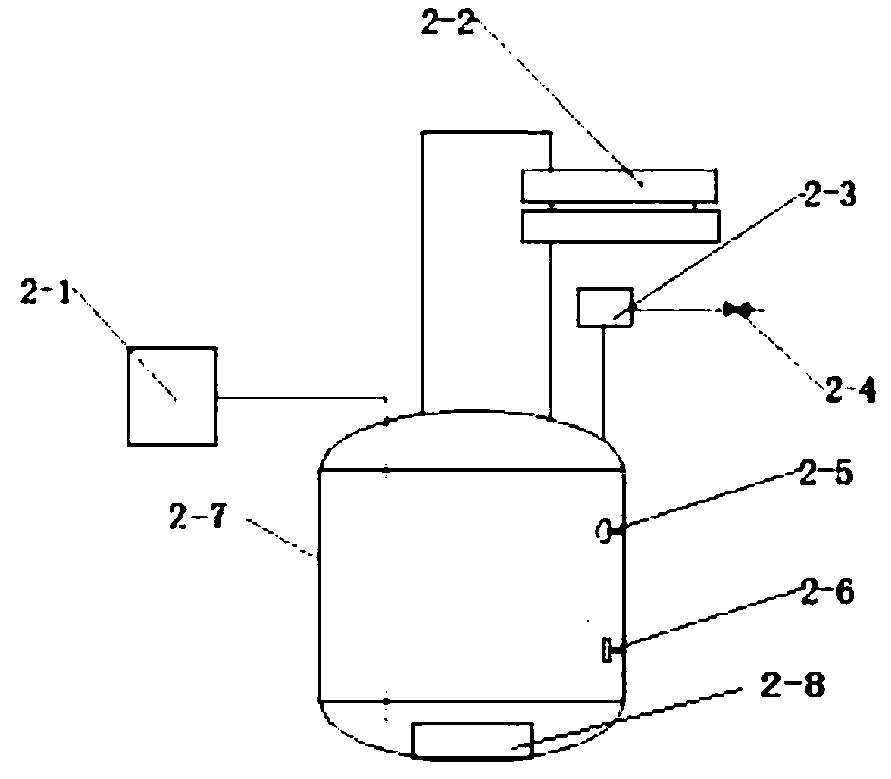

Rotor combined mixer

The invention belongs to the technical field of rubber mixing and in particular relates to a rotor combined mixer, comprising an upper internal mixer and a lower internal mixer connected in series and equal in size. The upper internal mixer is a small maternal mixer equipped with an automatic cleaner and a meshing rotor of high dispersion and low temperature; the lower internal mixer is a large internal mixer with no top bolt and is equipped with a reaction four-edged rotor having shearing effect of a shearing rotor and distributed mixing action of the meshing rotor. During mixing, the meshing rotor of the upper internal mixer quickly disperses rubber material by high-speed shearing and kneading; the lower internal mixer secondarily mixes the rubber material through a large internal mixing chamber and the reaction four-edged rotor, and thus silylation reactions are ensured being fully and evenly completed at constant temperature. The rotor combined mixer is scientific in design, simple in structure, simple to assemble, easy to temperature-control, safe to operate, good in mixing effect and good in product quality.

Owner:QINGDAO UNIV OF SCI & TECH

Apparatus and method for casting amorphous metal alloys in an adjustable low density atmosphere

Owner:METGLAS INC

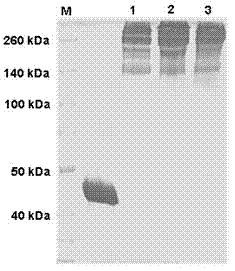

PEG (polyethylene glycol) modified recombinant arginine deiminase (ADI) as well as preparation method and application thereof

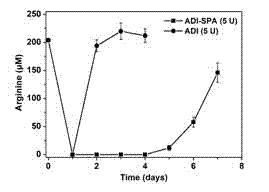

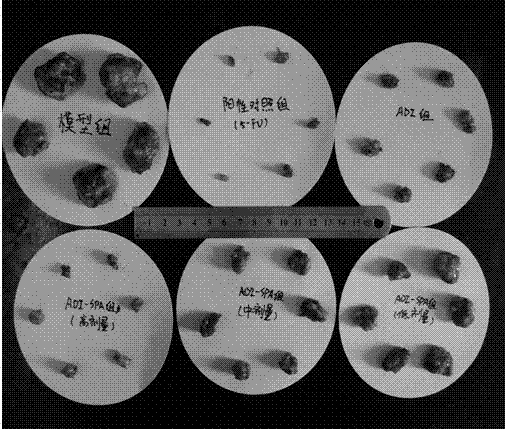

InactiveCN103923898AUniform finishGood stability in vitroHydrolasesAntineoplastic agentsCancer cellPolyethylene glycol

The invention discloses a PEG (polyethylene glycol) modified recombinant arginine deiminase (ADI) as well as a preparation method and application thereof, belonging to the technical field of biomedical engineering. The stability of ADI-PEG obtained by modifying ADI with PEG in vitro and in mouse plasma is remarkably improved. A pharmacokinetics / pharmacodynamics study shows that compared with free ADI before modification, the half-life period of ADI-PEG in a mouse is prolonged by more than 11 times; the concentration of arginine in the plasma can be reduced and maintained for more than 5 days in the limiting level through single injection of 5U ADI-PEG and can be maintained for 1 day only through injection of unmodified ADI; an H22 liver cancer model mouse is treated for 15 days, and the cancer cell inhibition rate of ADI-PEG (15U) is 95.02% close to 98.34% (the inhibition rate) of a positive control group treated with 5-fluorouracil. PEG modified recombinant arginine deiminase is relatively long in in-vivo half-life period and relatively low in immunogenicity, and serves as an excellent tumor treating or inhibiting drug.

Owner:JIANGNAN UNIV

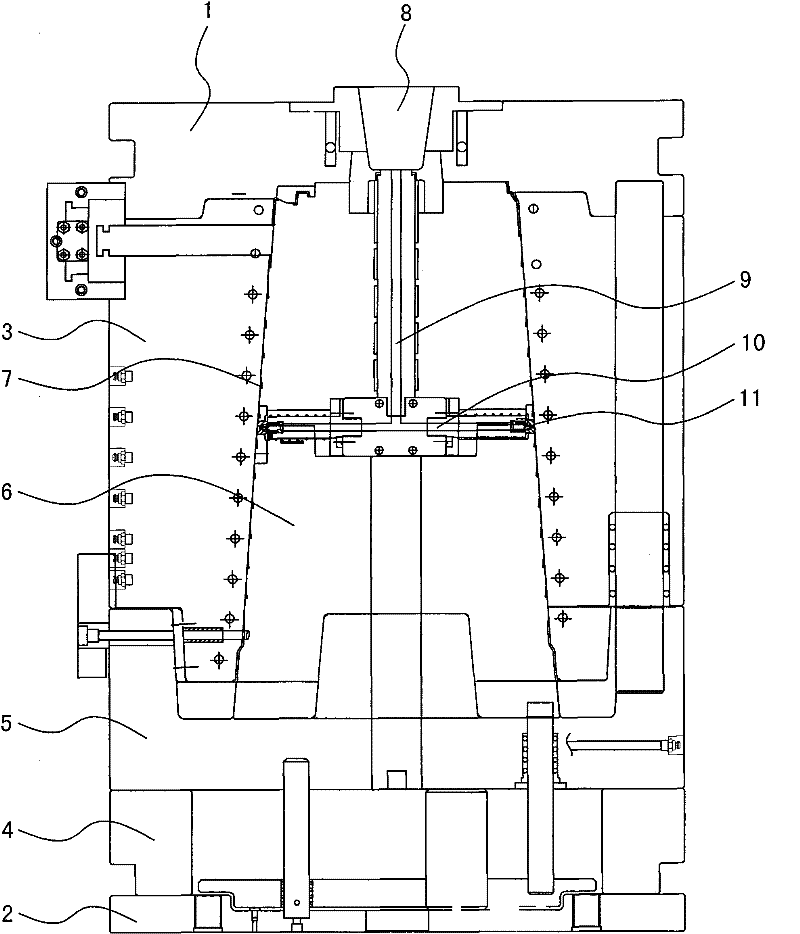

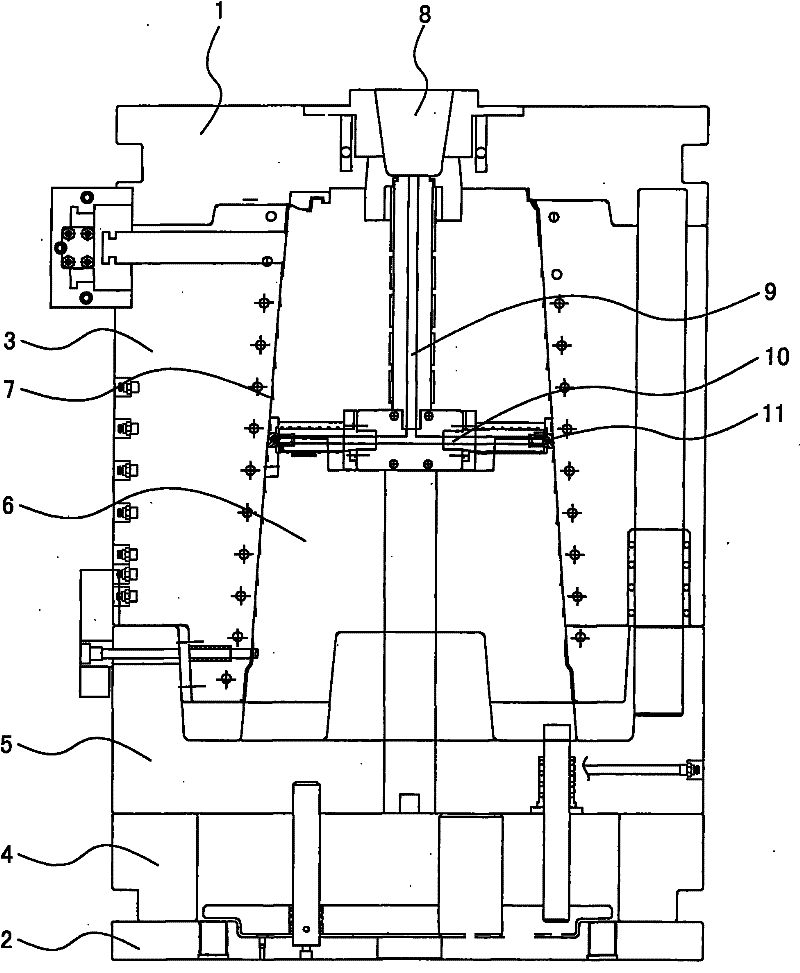

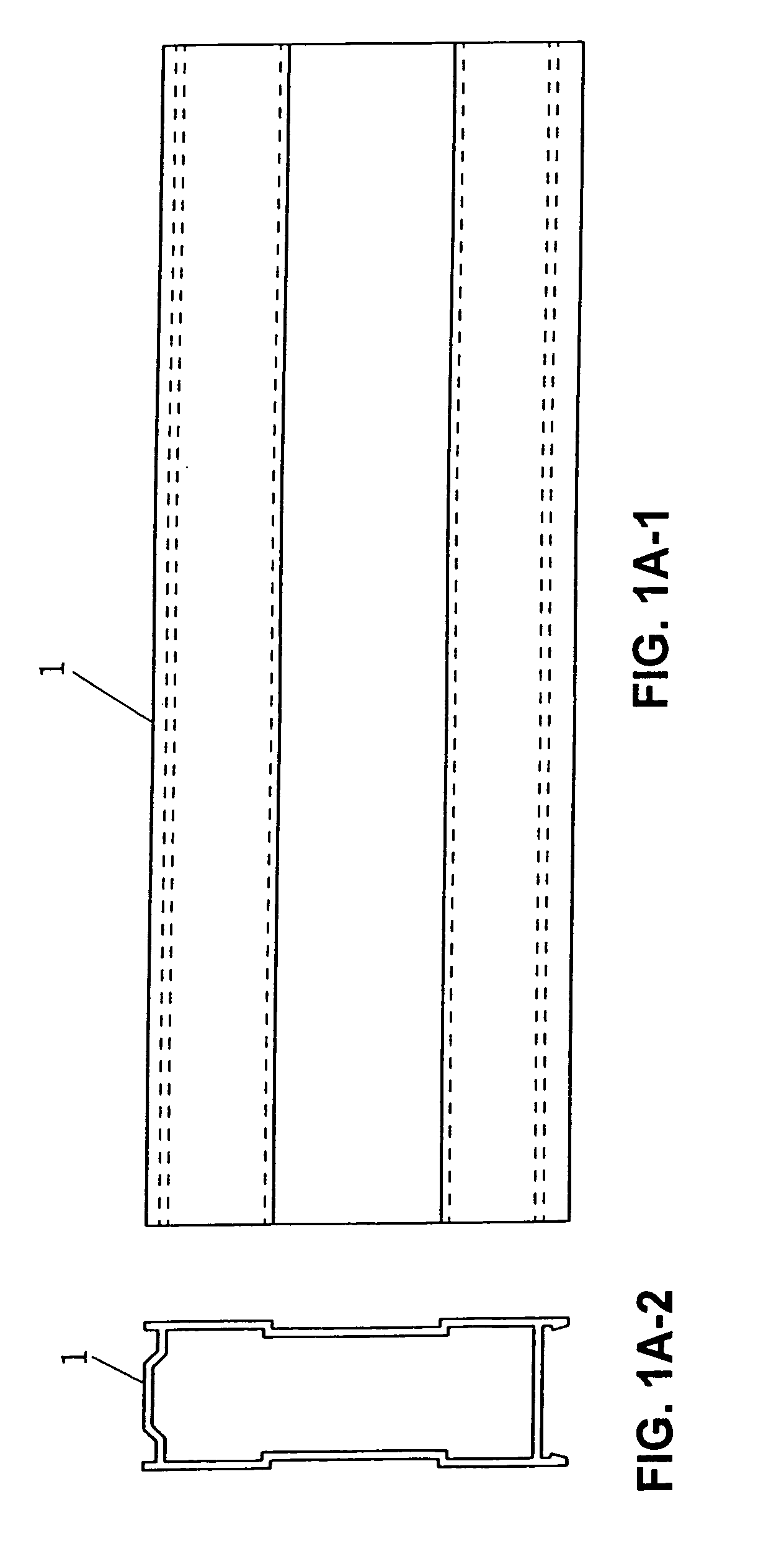

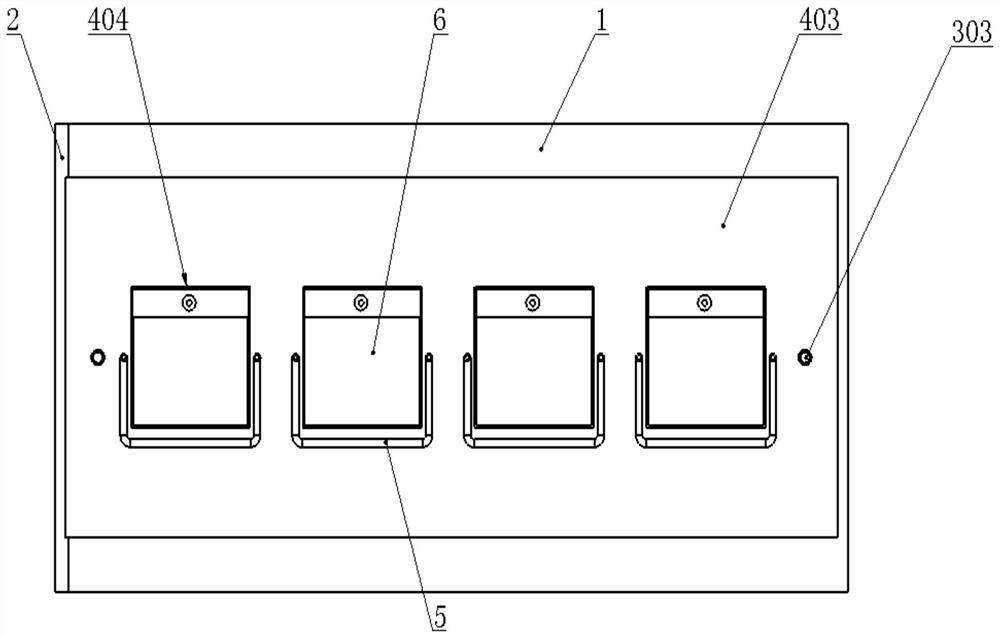

Plastic bucket mold multi-point pouring mechanism

The multi-point pouring mechanism of the plastic barrel mold includes an upper template and a lower template. The upper template is connected to the fixed mold cavity. The movable template is installed on the movable template, and the movable mold core is installed on the movable template. The mold cavity is formed between the movable mold core, the movable template and the fixed mold cavity. The channel is connected to the main channel, and each branch channel is made with pouring points, and each pouring point is connected to the mold cavity. In this scheme, the pouring point of the mold runner is placed in the middle of the barrel, so that the molten plastic is evenly injected into the plastic raw material from the middle of the product, so that it can complete the injection molding better, faster and more uniformly during the molding process. Molding makes the product look beautiful, reduces the scrap rate of injection molding products, and overcomes the restriction that the barrel of the existing product is too high to be injection molded.

Owner:浙江荣信模具塑料有限公司

Production method for base paper of latex sandpaper

InactiveCN102660905AUniform finishGood sandblasting adhesionNatural cellulose pulp/paperSpecial paperPulp and paper industryCrusher

The invention discloses a production method for base paper of latex sandpaper. The production method comprises the following steps of: firstly, diluting wood pulp; secondly, sequentially crushing pulp by using a crusher and pulping by a disc mill; thirdly, mixing; fourthly, carrying out forming on a paper making mesh part, dehydration by squeezing, preliminary drying in a large vat, drying and calendaring in a second vat, drying a group of vats, winding, rewinding and splitting; and fifthly, coating, drying, winding, rewinding and splitting. The production method for the base paper of the latex sandpaper has the advantages of reasonable design, simple process steps and easiness in operation; and in addition, the base paper of the latex sandpaper, which is obtained by the production method disclosed by the invention, has the advantages of uniformity in paper surface smoothness, favorable sandblasting adhesion, folding strength and flexibility as well as tensile strength of paper of over 95N / cm.

Owner:杭州新兴纸业有限公司

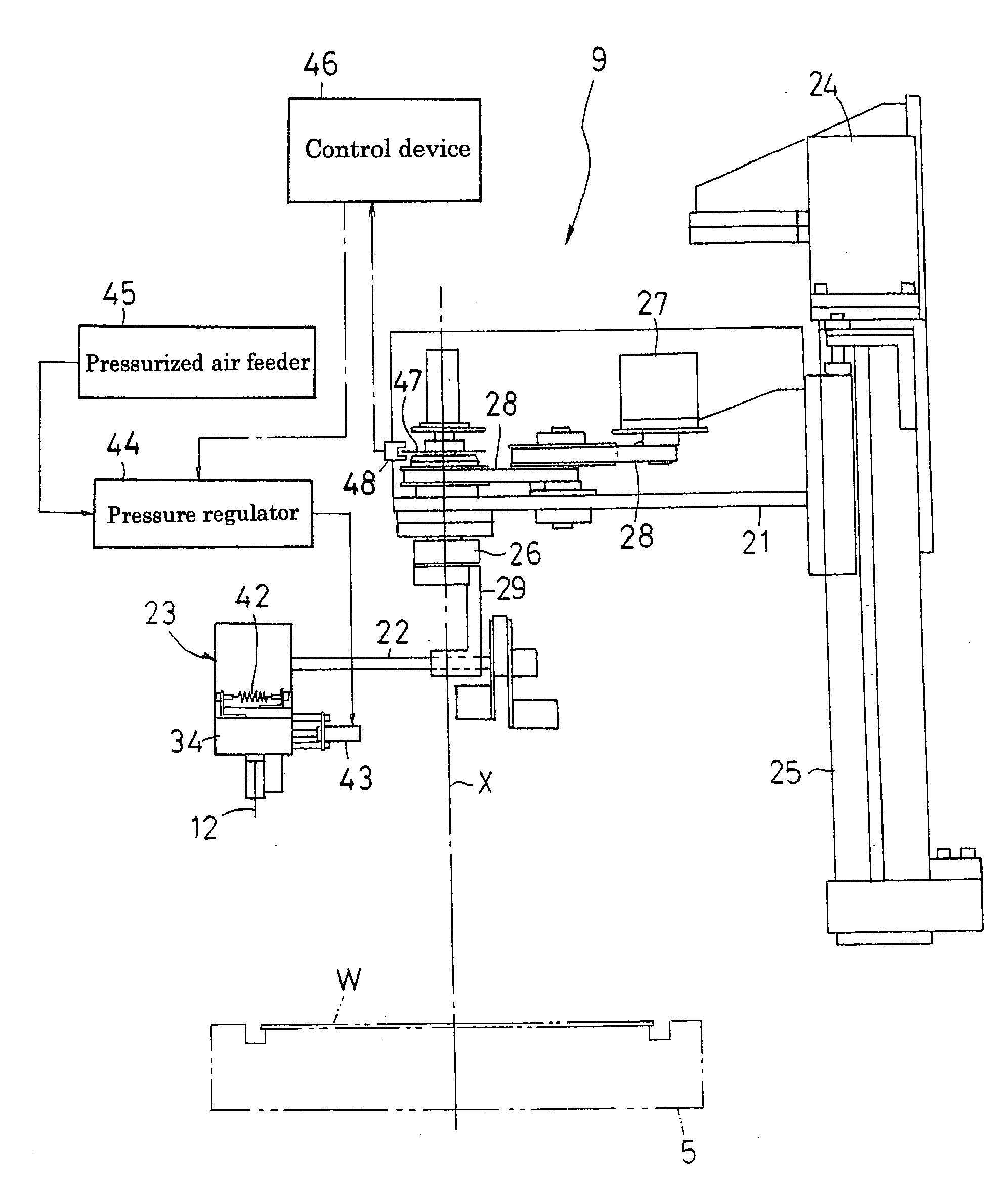

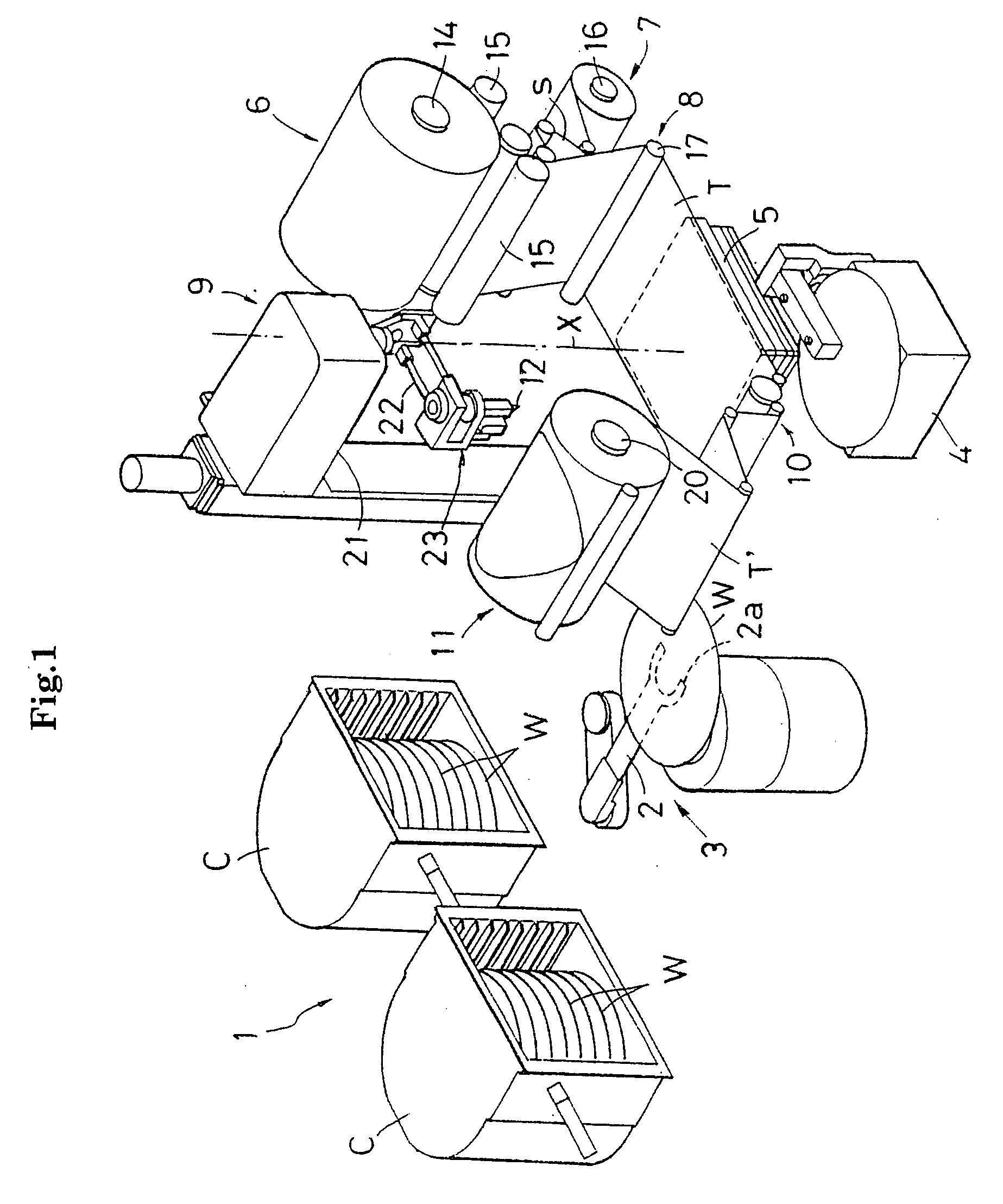

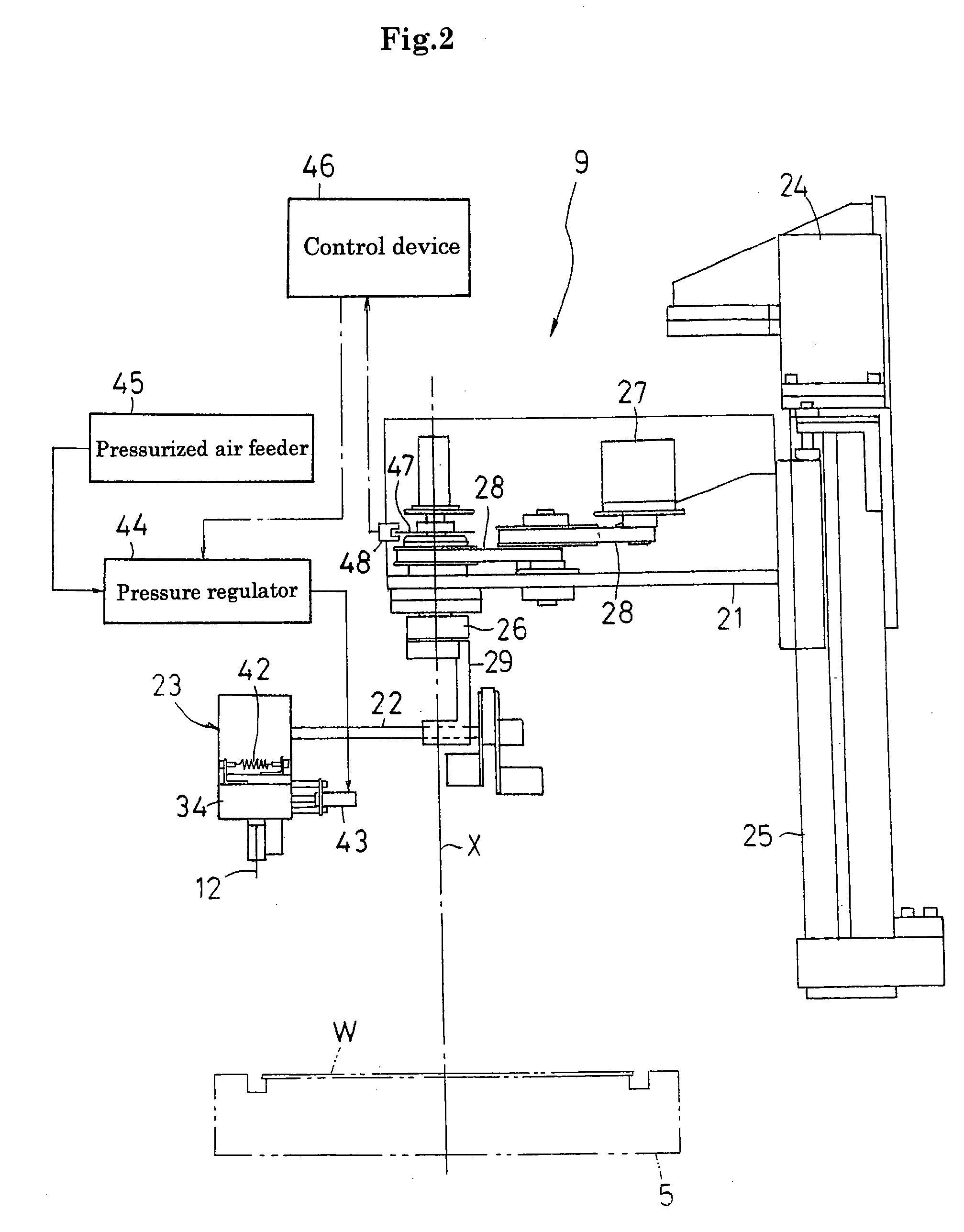

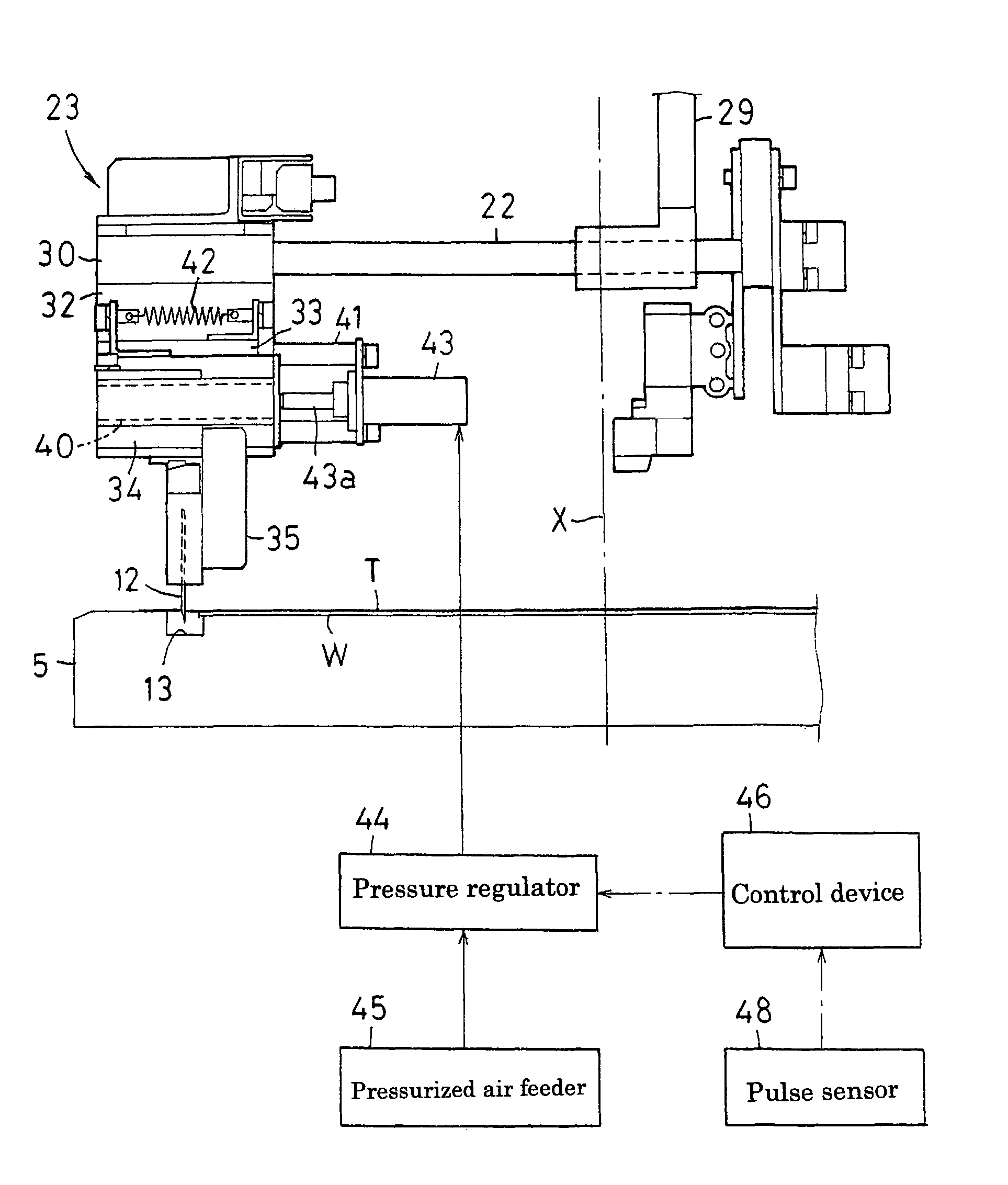

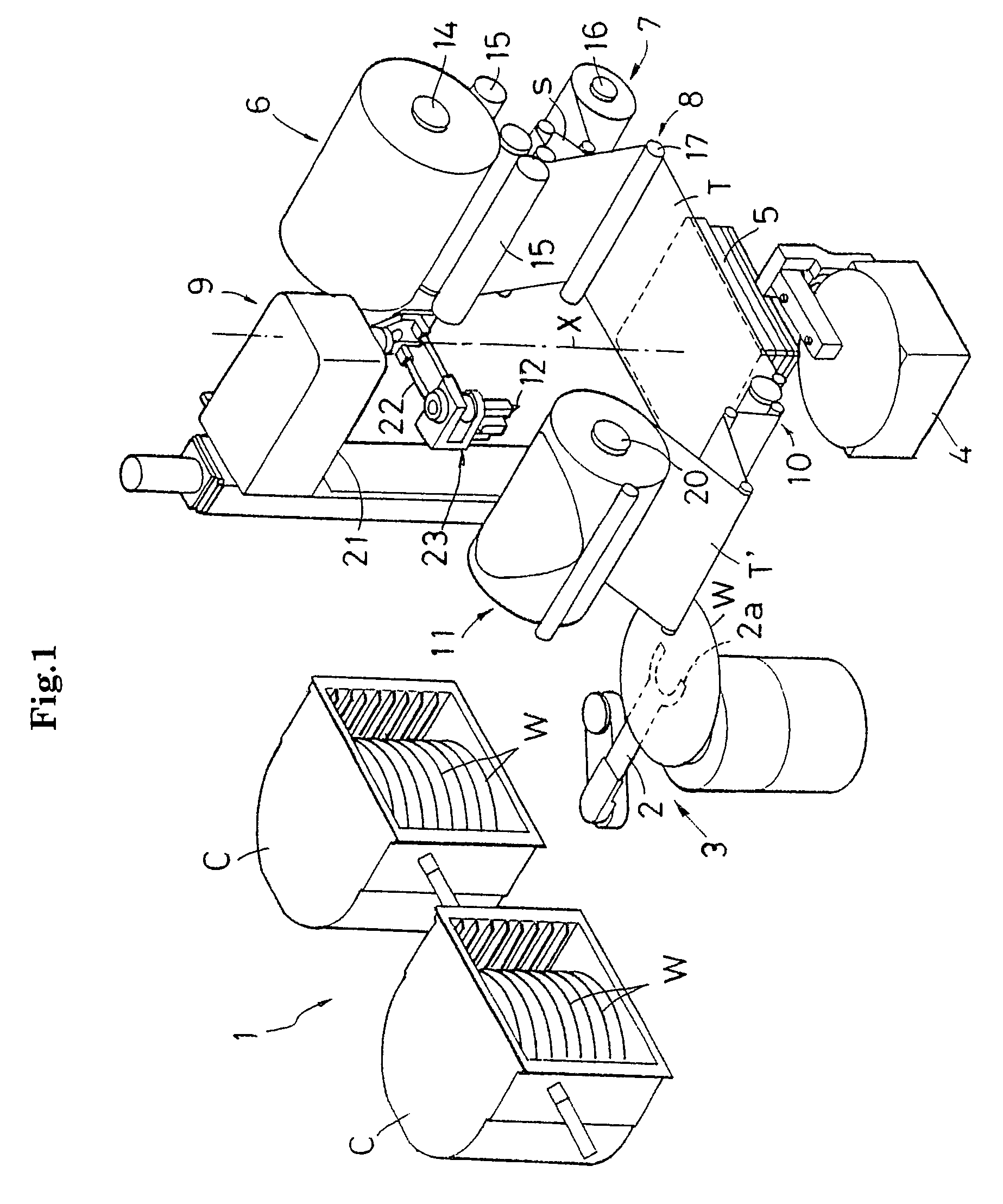

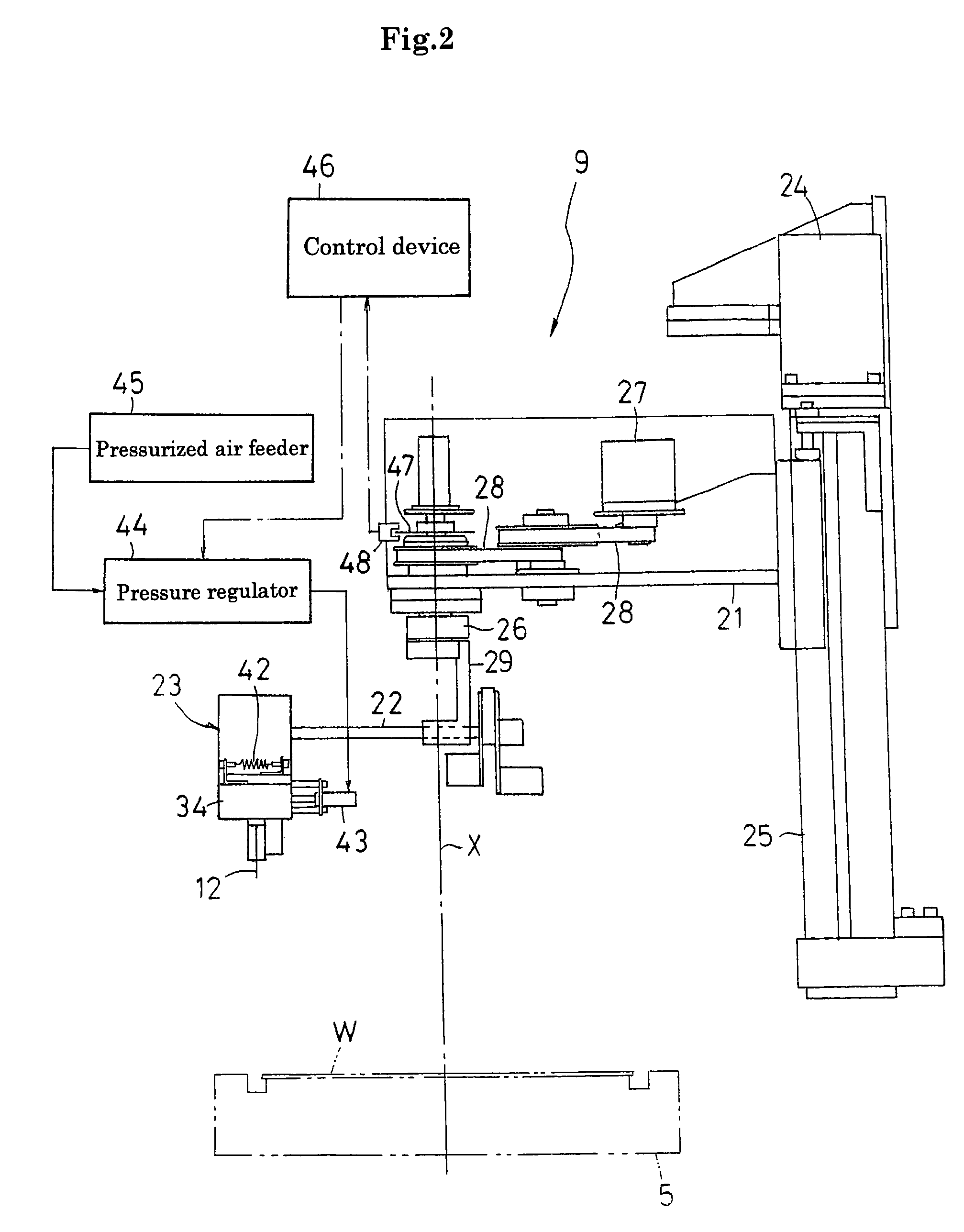

Method for cutting protective tape of semiconductor wafer and apparatus for cutting the protective tape

InactiveUS20080113492A1Improve accuracyGood precisionAutomatic control devicesSemiconductor/solid-state device manufacturingContact pressureEngineering

A cutter blade movably in a radial direction of a wafer is pressed for biasing to an outer circumferential edge of the semiconductor wafer. Simultaneously, the pushing biasing force of the cutter blade is controlled constant with automatic regulation corresponding to a traveling speed variation of the cutter blade, so that effect of a centrifugal force that works at the time of rotating travel of the cutter blade may not vary a pushing biasing force of the cutter blade. As a result, a contact pressure of the cutter blade to the outer circumferential edge of the semiconductor wafer is maintained stable.

Owner:NITTO DENKO CORP

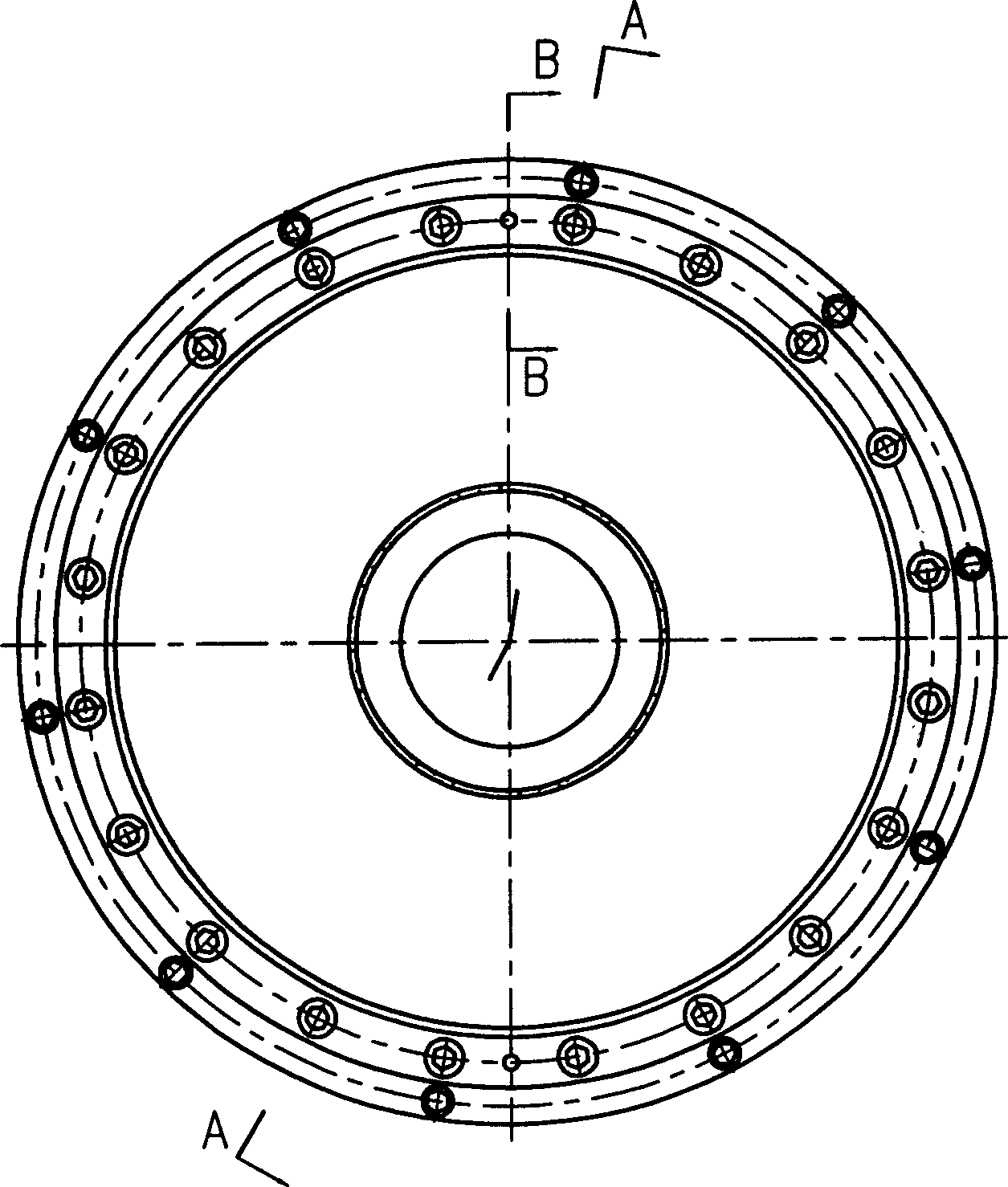

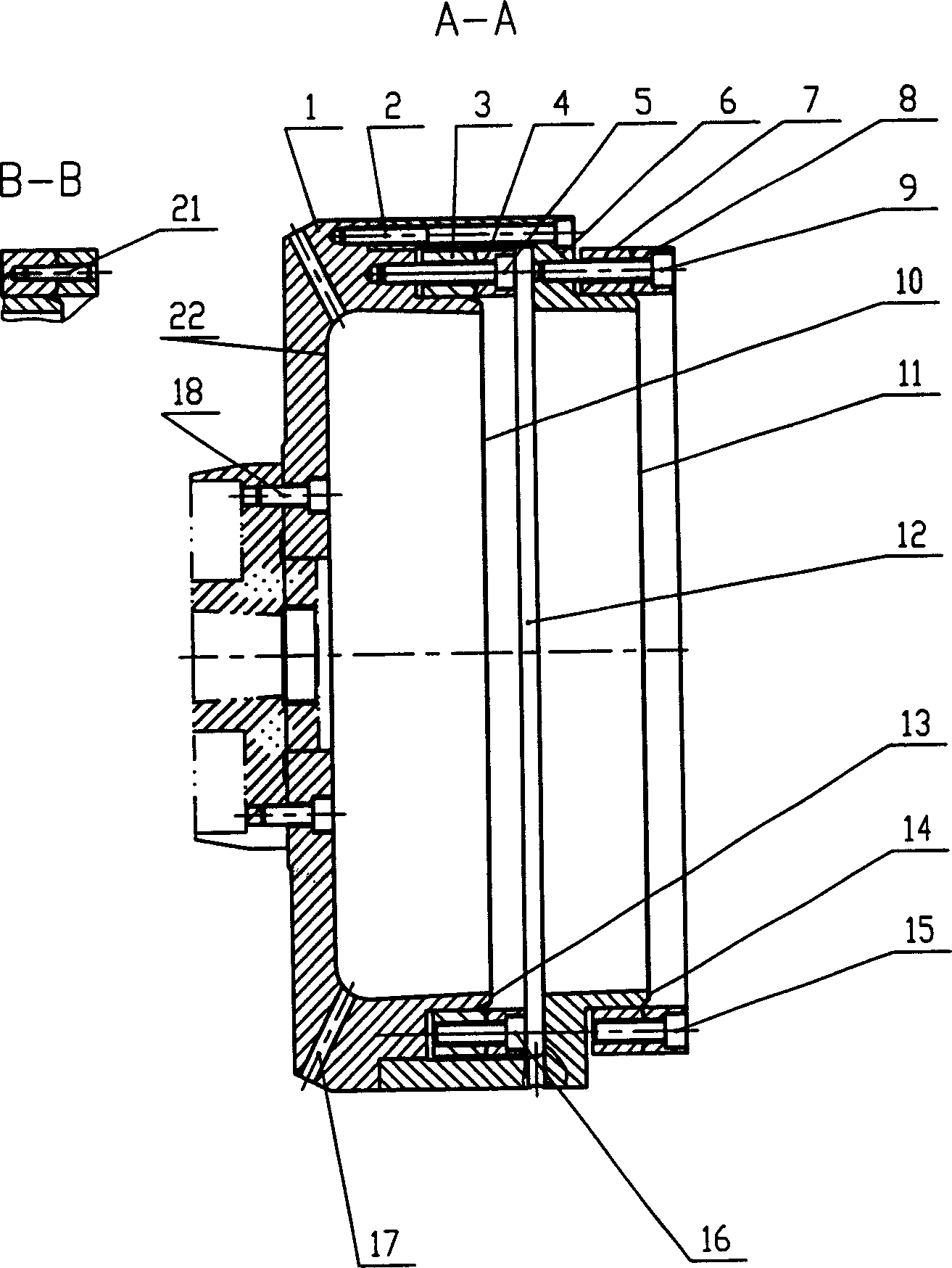

Multicutter technique for cutting inner circle and device

ActiveCN1562544AUniform radial tensionEasy to achieve adjustment accuracyMetal sawing devicesShearing machinesEngineeringMechanical engineering

A technology and apparatus for multi-cutter machining of intenal circle is disclosed. Said apparatus is composed of a capstan, a fastening ring matched with capstan for fastening cutters, a medium ring between capstan and fastening ring, left and right cutter fastening rings between capstan and medium ring, the first internal-circle cutter and the second internal-circle cutter.

Owner:NINGBO YUNSHENG

Surface finishing method for aluminum shapes by barrel polishing

ActiveUS7238086B1Prevent be damageUniform finishEdge grinding machinesPolishing machinesSurface finishingAluminium

A surface finishing method for aluminum shapes by barrel polishing, wherein caps are mounted at both open ends of a hollow aluminum shape, and two aluminum shapes each mounted with the caps are set on two right and left holders so as not to interfere with each other, the two aluminum shapes held above and below by the two right and left holders are next put in a barrel pot, and water, a compound, and a medium are put in the barrel pot, and then the barrel pot is closed by a lid. A plurality of barrel pots are installed on a centrifugal barreling machine, and the centrifugal barreling machine is operated so that the aluminum shapes are rotated and revolved.

Owner:ZENIYA ARUMINIUMU SEISAKUSHO K

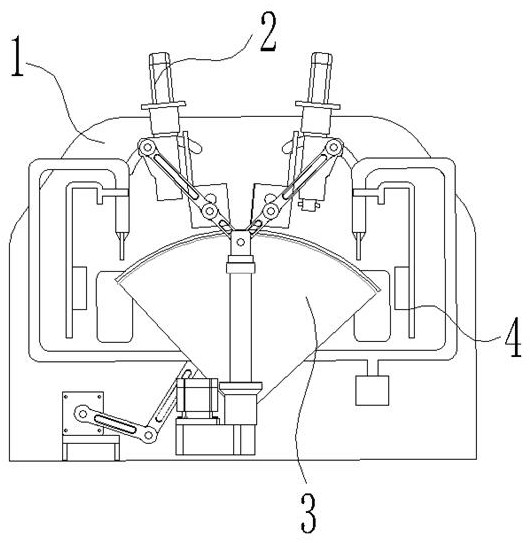

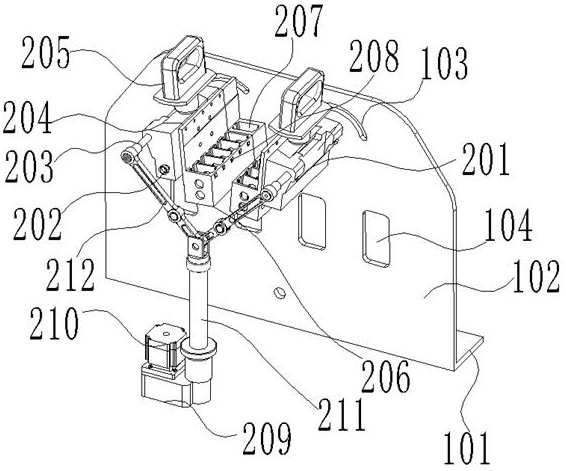

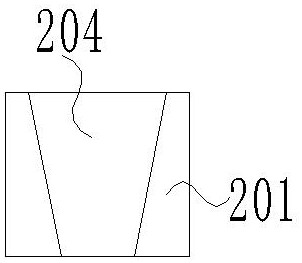

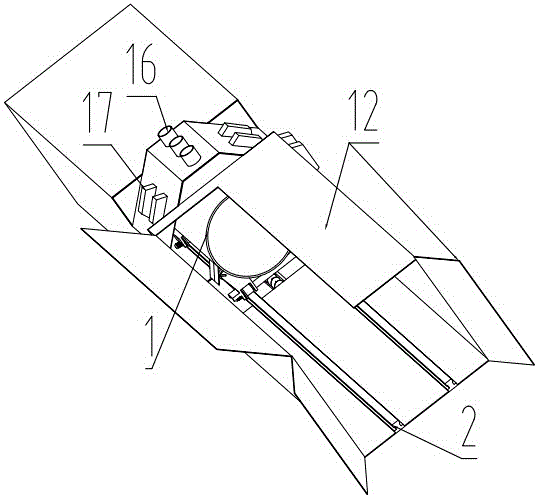

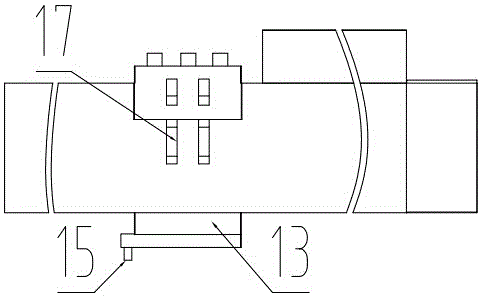

Carbon brush cambered surface automatic grinding tool and using method thereof

PendingCN112276739AImprove work efficiencyPrecise processingGrinding carriagesGrinding drivesElectric machineryBrush

The invention relates to a tool for machining a cambered surface of a motor carbon brush contact surface, in particular to a carbon brush cambered surface automatic grinding tool and a using method thereof. The tool comprises supports, a positioning and clamping mechanism and a grinding mechanism. The supports comprise supporting tables, wherein supporting plates are vertically arranged on the supporting tables. The two supports are symmetrically arranged, the grinding mechanism is arranged between the two supports, the grinding mechanism comprises two sector-shaped supporting plates, a grinding wheel plate is connected to the arc surfaces of the tops of the two sector-shaped supporting plates, and the sector-shaped supporting plates are arranged on the two sides of the grinding wheel plate. A rotating shaft is fixedly connected to the lower ends of the sector-shaped supporting plates, the two ends of the rotating shaft are rotationally connected between the two supporting plates, a connecting rod is arranged above the rotating shaft, the connecting rod is arranged between the sector-shaped supporting plates, the connecting rod is fixedly connected to the central axis positions ofthe sector-shaped supporting plates, a fixing seat is arranged on the inner sides of the supports, and a grinding motor is arranged on the fixing seat; and the output end of the grinding motor is fixedly connected with one end of a rotating arm, the other end of the rotating arm is rotatably connected with one end of a rocker arm, and the other end of the rocker arm is rotationally connected to the connecting rod.

Owner:国网甘肃省电力公司超高压公司

Method for cutting protective tape of semiconductor wafer and apparatus for cutting the protective tape

InactiveUS8042441B2Good accuracy and precisionStable maintenanceAutomatic control devicesSemiconductor/solid-state device manufacturingContact pressureEngineering

A cutter blade movably in a radial direction of a wafer is pressed for biasing to an outer circumferential edge of the semiconductor wafer. Simultaneously, the pushing biasing force of the cutter blade is controlled constant with automatic regulation corresponding to a traveling speed variation of the cutter blade, so that effect of a centrifugal force that works at the time of rotating travel of the cutter blade may not vary a pushing biasing force of the cutter blade. As a result, a contact pressure of the cutter blade to the outer circumferential edge of the semiconductor wafer is maintained stable.

Owner:NITTO DENKO CORP

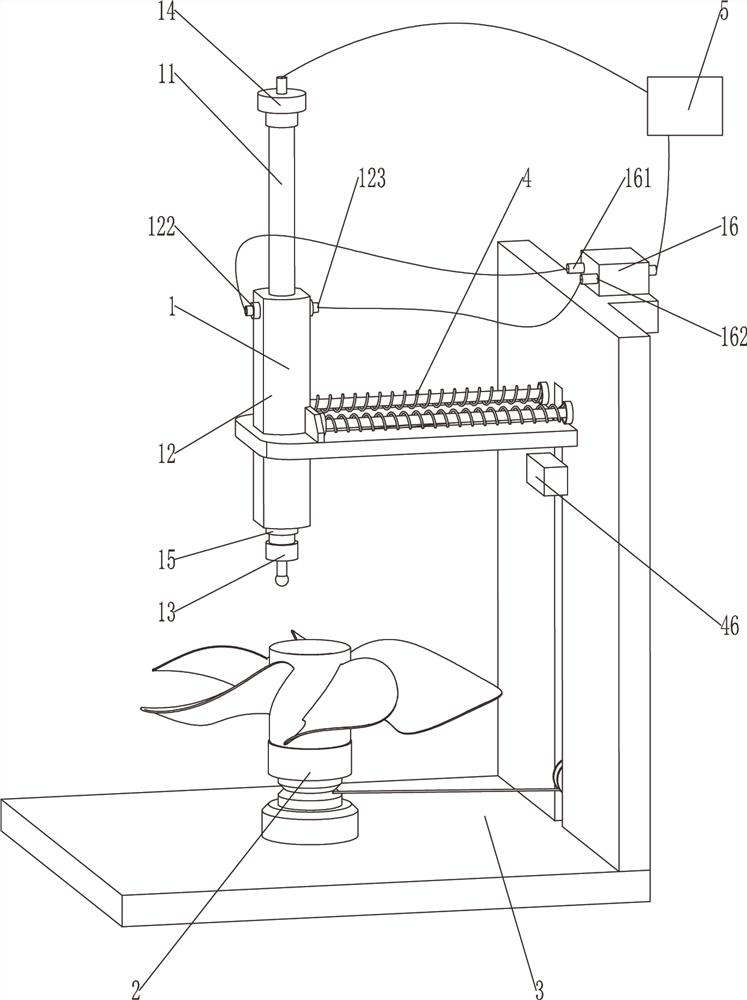

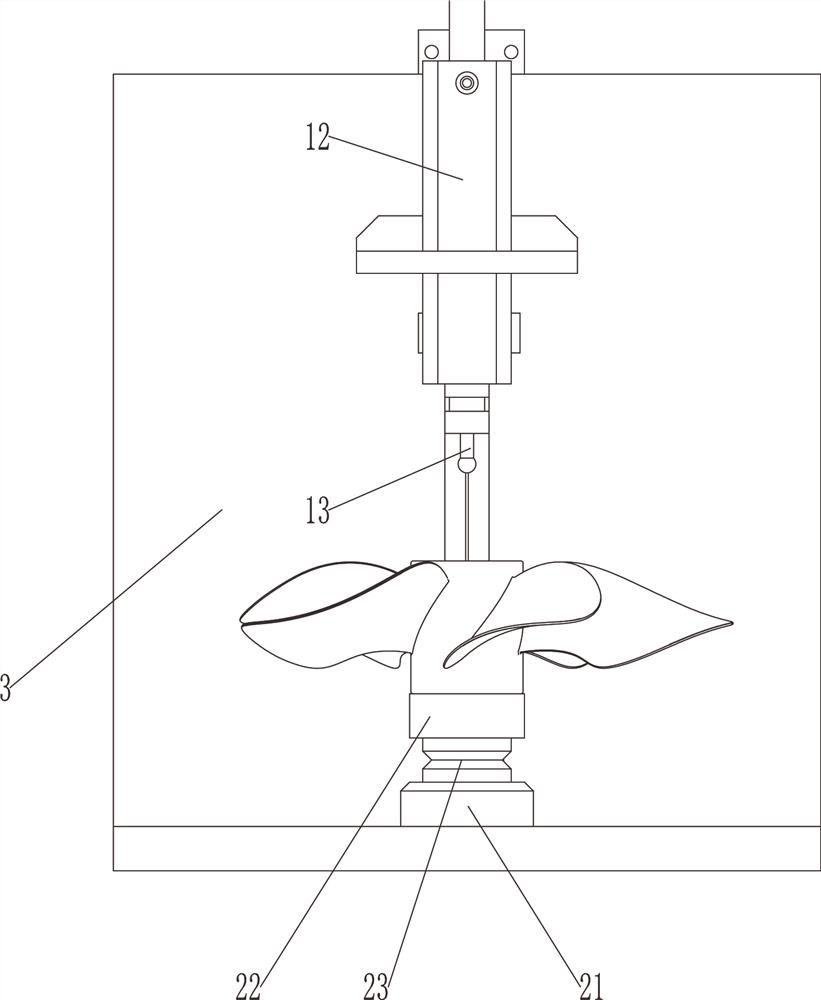

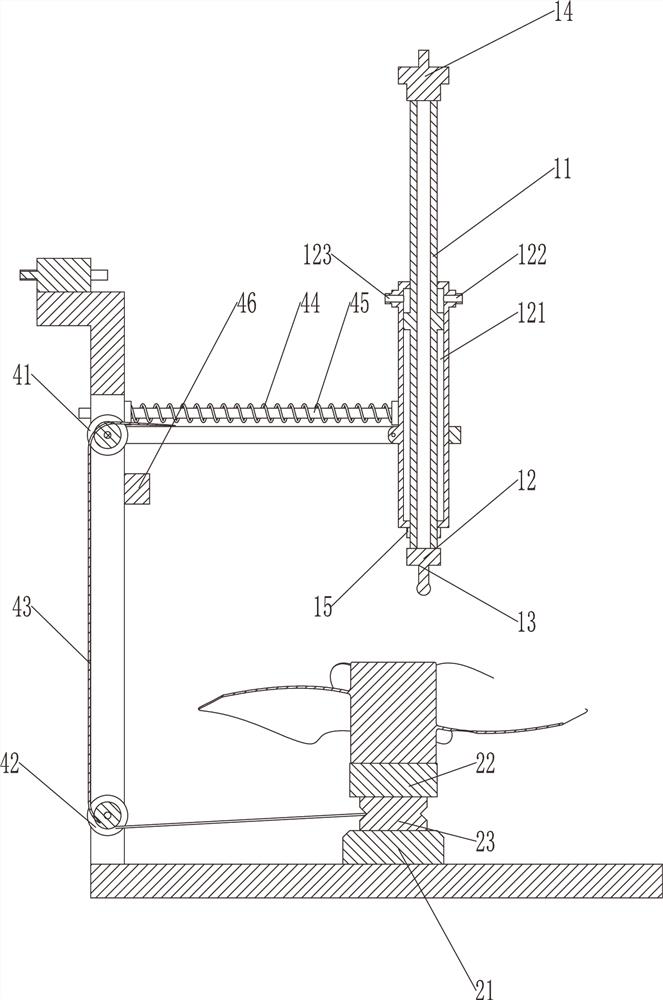

Device for producing ship propeller

PendingCN113182981AConsistent pressureUniform finishGrinding drivesGrinding machinesPropellerEngineering

The invention discloses a device for producing a ship propeller. The device for producing the ship propeller comprises a constant-pressure floating grinding head, a bottom rotating device, a rack, a left-right moving device and an air source, wherein the bottom rotating device is arranged at the bottom of the rack, and the constant-pressure floating grinding head is arranged on the rack and can float up and down along with the curved surface of the propeller for grinding; and the left-right moving device is connected with the constant-pressure floating grinding head and the bottom rotating device in a matched mode, so that the bottom rotating device drives the constant-pressure floating grinding head to slowly move backwards while rotating. According to the device for producing the ship propeller, the blade surface of the propeller is automatically ground by a machine, the pressure of the grinding head is always kept consistent, and the grinding depth and the surface smoothness are kept uniform, so that the labor cost is greatly saved, and the grinding quality is controllable.

Owner:浙江元鼎船舶设备有限公司

Structural body for shaft, male member, and female member

InactiveUS10344795B2Reduce resistanceEasy to shapeClutchesYielding couplingEngineeringMechanical engineering

A shaft structure installed in a shaft capable of making a power-transmission, the shaft structure including: a male component having a plurality of male splines formed on an outer peripheral part thereof; and a female component having a plurality of female splines formed on an inner peripheral part thereof, the inner peripheral part configured to allow the outer peripheral part of the male component to be engaged therein so that the male component and the female component can be slidably fitted with respect to each other in an axial direction thereby making up said shaft structure, wherein the outer peripheral part of the male component and the inner peripheral part of the female component have a fabric impregnated with rubber or resin interposed therebetween.

Owner:NITTA CORP

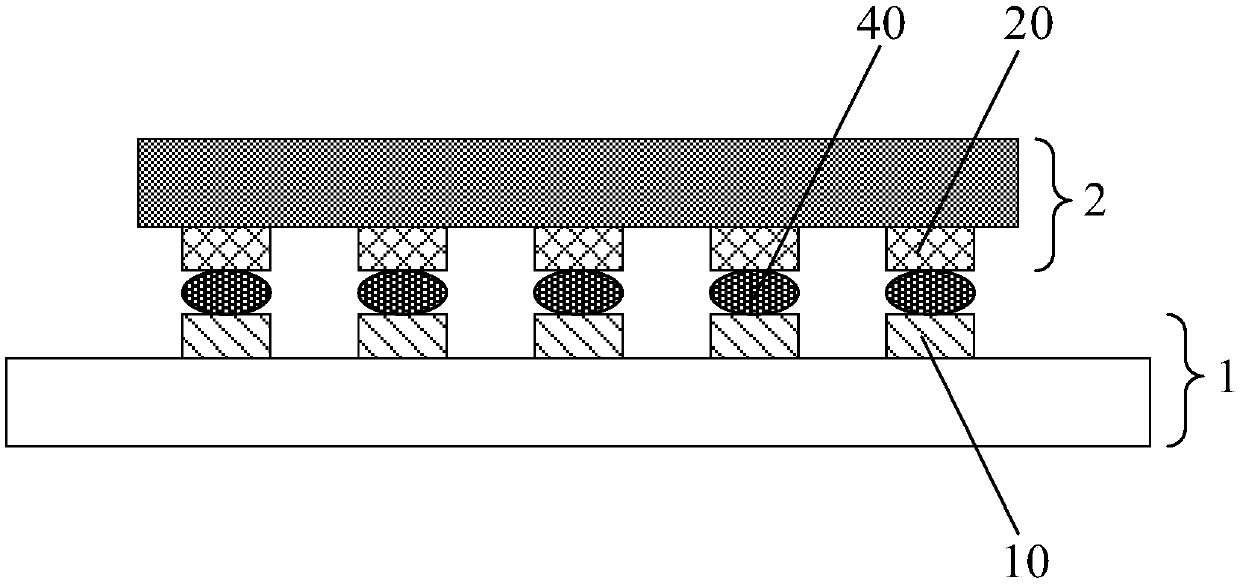

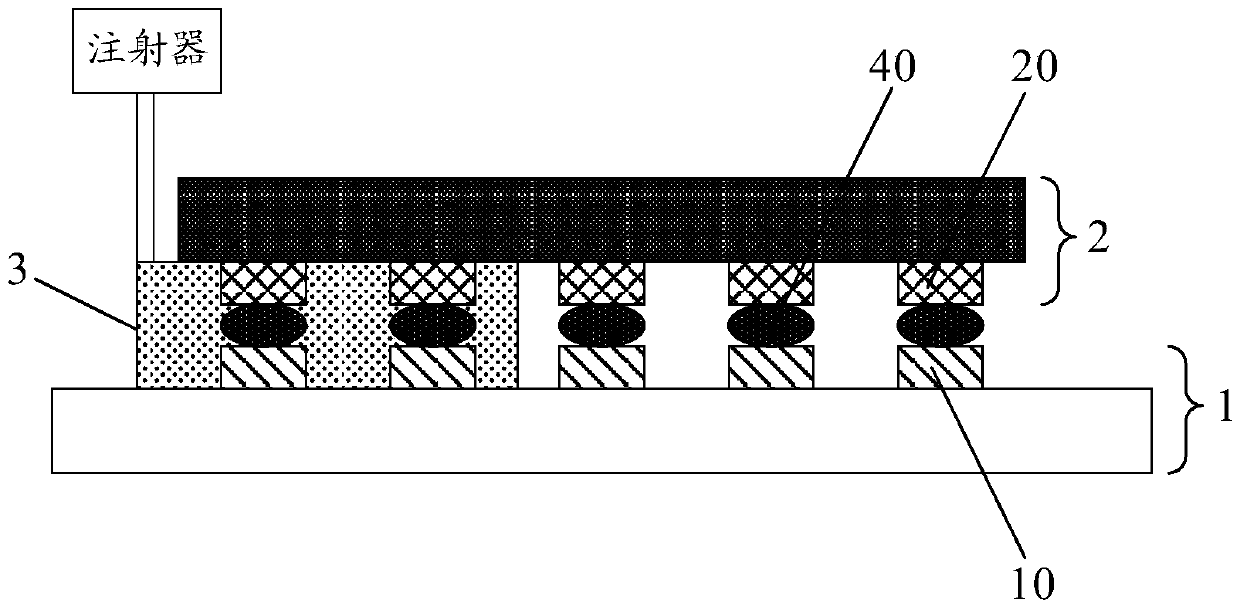

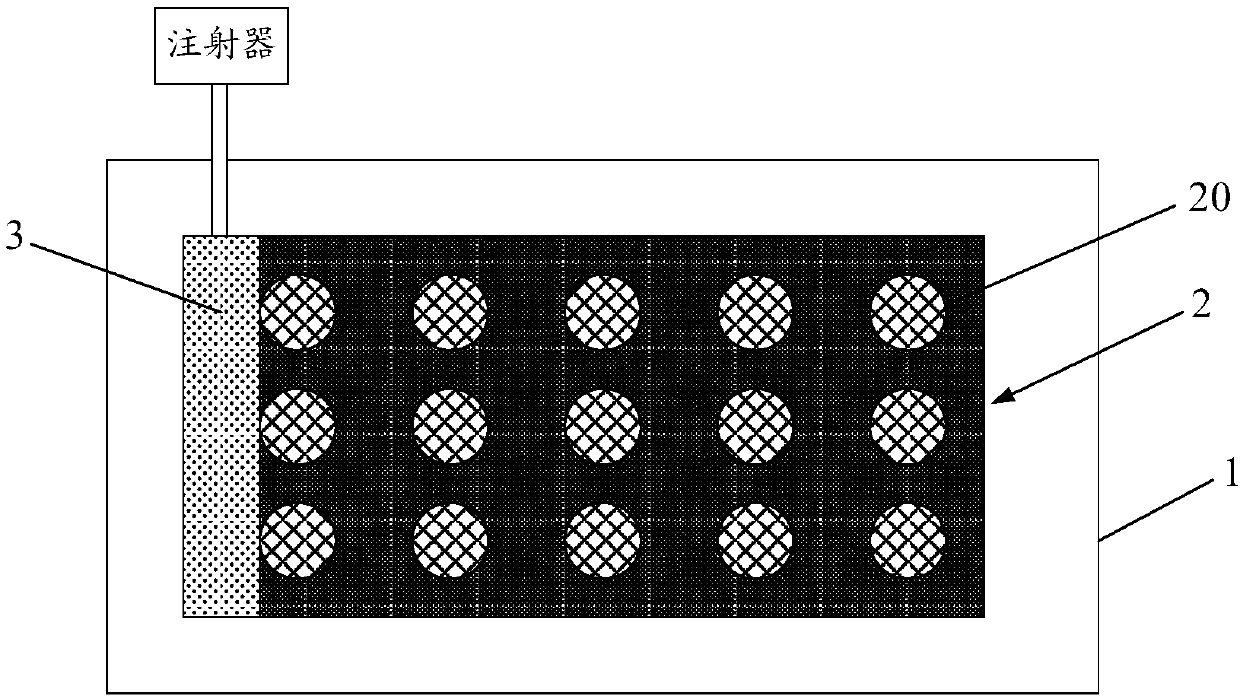

Chip packaging structure, chip packaging method, and display device

ActiveCN109545754AGuaranteed reliabilityFast flowSemiconductor/solid-state device detailsSolid-state devicesFilling materialsDisplay device

The invention discloses a chip packaging structure, a chip packaging method and a display device, relates to the technical field of packaging, and aims to solve the problem that when a chip is packaged, a hole phenomenon is easily generated between the chip and a circuit board after bottom filling operation is carried out, so that the chip packaging reliability is reduced. The chip packaging structure comprises a circuit board, a chip arranged in a chip packaging area and a filling material filled between the chip and the circuit board, wherein the chip comprises a plurality of pins which arein one-to-one correspondence with a plurality of bonding pads on the circuit board, and the pins are electrically connected with the corresponding bonding pads to form conductive parts. The circuit board is corresponding disposed in the region of a gap between the adjacent conductive parts, and at least a part of the region is provided with a first groove; and / or at least a part of the area, corresponding to the gap between the adjacent conductive parts, of the chip is provided with a second groove. The chip packaging structure provided by the invention is used for providing a driving signal.

Owner:BOE TECH GRP CO LTD +1

Tea leaf enzyme deactivating pot capable of timely separating tea leaves adhered to each other

PendingCN110742141AAvoid uneven heatingQuality improvementPre-extraction tea treatmentElectric machineryEngineering

The present invention provides a tea leaf enzyme deactivating pot capable of timely separating tea leaves adhered to each other and relates to the technical field of tea leaf enzyme deactivating. Thetea leaf enzyme deactivating pot capable of timely separating the tea leaves comprises a base seat, a top end of the base seat is fixedly provided with a heating cylinder, an inside of the heating cylinder is rotatably connected with a roller, a periphery of a right side of the roller is fixedly provided with a gear, a bottom part of the gear is in a transmission connection with a first motor, a heat conduction chamber is arranged inside the heating cylinder, and a boiler is arranged inside the base seat. During a rolling process of the roller and through up and down shaking of shaking plates,the tea leaf enzyme deactivating pot capable of timely separating the tea leaves adhered to each other can pat the tea leaves of a top side loose, avoids uneven heating of the tea leaves due to adhesion, improves quality of enzyme deactivating, can enable putting amount of the tea leaves to keep a uniform speed, can carry out stable regulation on the putting amount of the tea leaves, and enablesan enzyme-deactivating degree of the tea leaves to be more even.

Owner:遂川县安村茶厂(有限合伙)

Shot-blast cleaning device for outer wall of wind power tower drum

InactiveCN104999377AReduce pollutionAvoid pollutionAbrasive machine appurtenancesAbrasive blasting machinesStress concentrationLow speed

The invention discloses a shot-blast cleaning device for the outer wall of a wind power tower drum, and belongs to the technical field of shot-blast treatment. The shot-blast cleaning device is mainly used for shot-blast treatment of the outer wall of the wind power tower drum and solves the problems of relatively low efficiency in cleaning rust, welding slag and other attachments on the outer wall of the wind power tower drum and stress concentration caused in the reeling process of the tower drum. The shot-blast cleaning device comprises a shot-blasting device, a shot-blasting room, a shot-collecting pool, a spiral conveying device, a load bearing vehicle and connecting openings. A motor provides power, the tower drum slowly moves and rotates at a low speed around the axis per se, shots blasted by the shot-blasting device continually impact the moving tower drum to finish shot-blast treatment, and scattered shots and generated dust are conveyed to other equipment connected with the connecting openings to be effectively processed. The shot-blast cleaning device for the outer wall of the wind power tower drum is high in cleaning efficiency and automation degree, low in dust pollution and improved in surface quality, reduces stress concentration, relieves the labor intensity of workers and improves the work environment of the workers.

Owner:UNIV OF JINAN

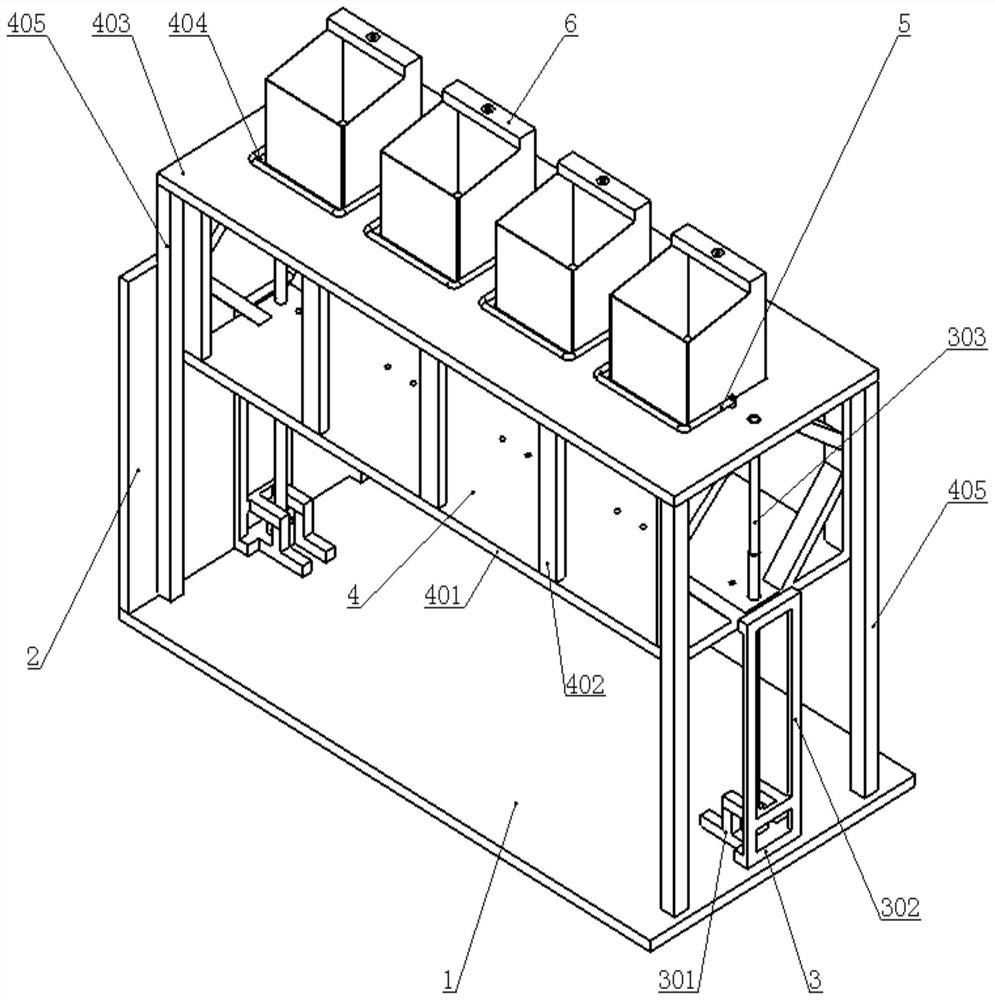

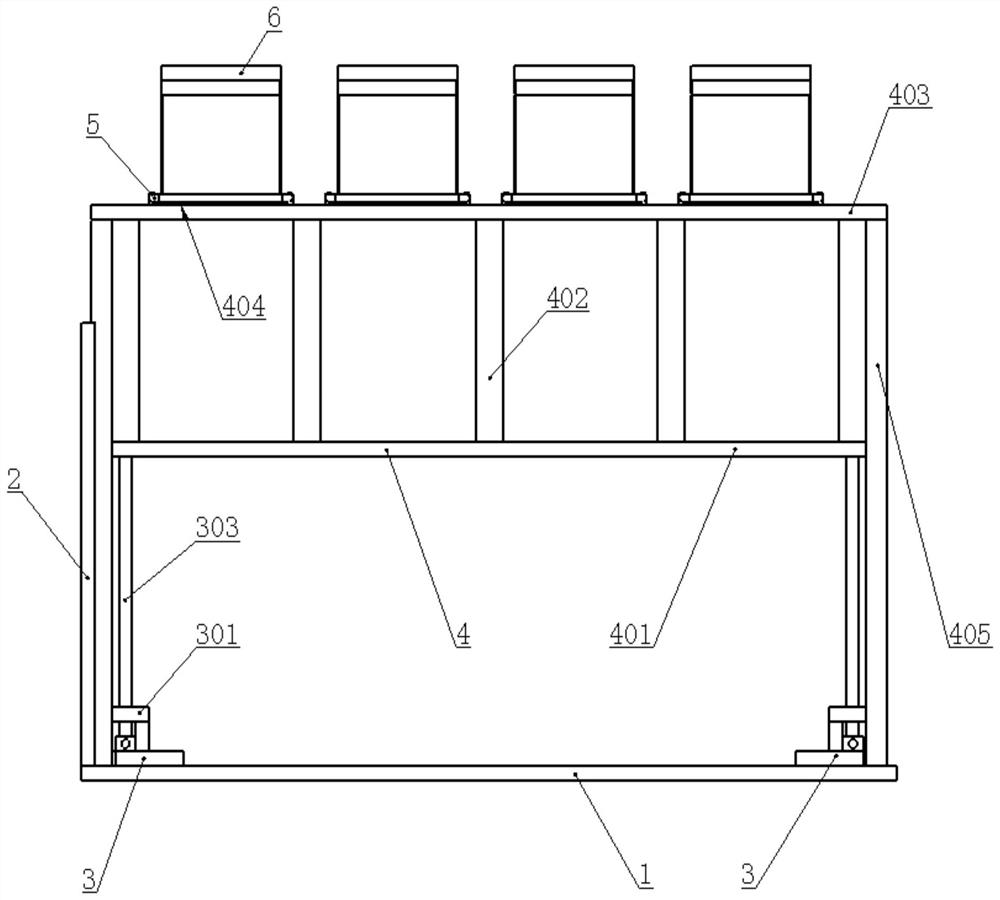

Buried garbage station

PendingCN112849841ACompact and stable structureConvenient and beautiful facilitiesRefuse receptaclesRefuse cleaningEnvironmental resource managementControl system

The invention discloses a buried garbage station. The buried garbage station comprises a base, a reinforcing wall body, a hydraulic lifting system, a platform assembly, a spraying and flushing system, intelligent garbage cans and a power control box, the reinforcing wall body is arranged on the left side of the base, the reinforcing wall body is arranged on the left side of the top of the base, the hydraulic lifting system is arranged on the top of the base, the platform assembly is arranged in the center of an inner cavity of the hydraulic lifting system, the spraying and flushing system is arranged at the top of the platform assembly, and the intelligent garbage cans are arranged at the top of the platform assembly at equal intervals. The buried garbage station is a closed structural body, and compact and firm in structure, a top cover of an integrated garbage lifting platform is flat and tidy, through cooperation of the power control box and an electrical control system, the effects of automatically detecting whether a bin is full of garbage, automatic extrusion, full sewage and the like, timely treatment, environmental protection and sanitation are achieved, and the problems that whether the bin is full of garbage or not, automatic extrusion is not achieved, and the surrounding environment is affected due to full sewage are solved.

Owner:青州华平环保科技有限公司

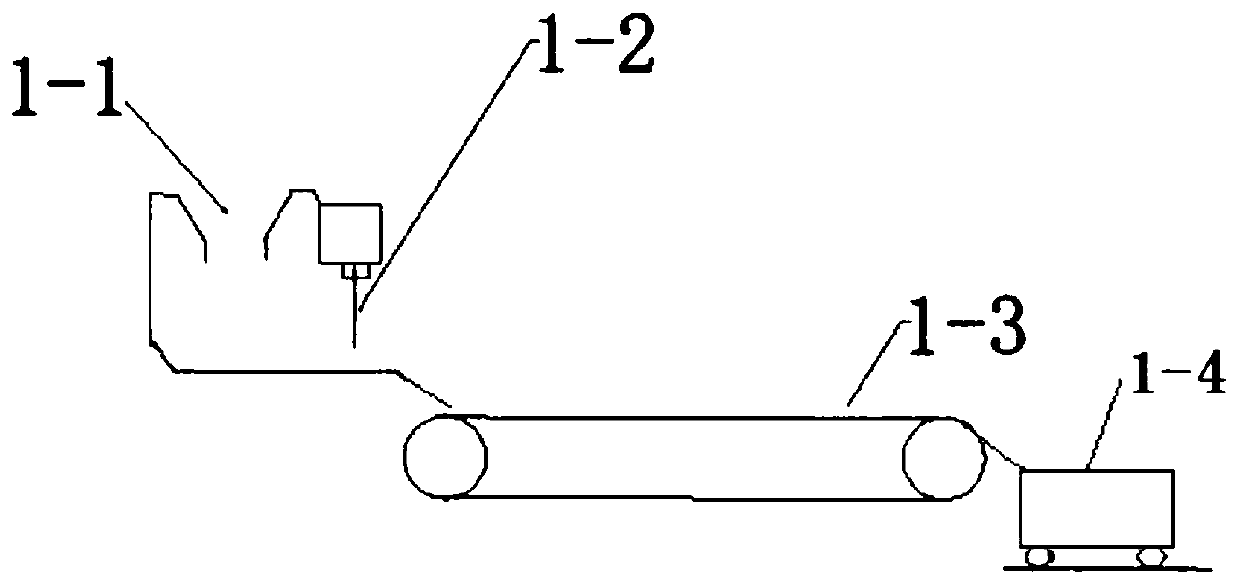

Fresh kale slicing, enzyme-deactivation and green-maintaining processing equipment

InactiveCN109793041ASolve wasteImprove the finishFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by heatingMultienzyme complexesLipoxidase activity

The invention relates to fresh kale slicing, enzyme-deactivation and green-maintaining processing equipment, comprising a slicing device, a conveying belt, an enzyme-linked ultrasonic decompressing processing device, a high-temperature high-pressure saturated vapor jet tunnel type thermostatic enzyme-deactivation device and a low-temperature high-pressure saturated vapor jet tunnel type thermostatic quenching device. The processing includes the steps of slicing fresh kale through the slicing device, sending the sliced kale in the enzyme-linked ultrasonic decompressing processing device throughthe conveying belt to perform green-taste removal, performing green-maintaining enzyme-deactivation in the high-temperature high-pressure saturated vapor jet tunnel type thermostatic enzyme-deactivation device and then performing green-maintaining browning-proof treatment through the low-temperature high-pressure saturated vapor jet tunnel type thermostatic quenching device. Since the sliced kaleis processed through a lipase activity composite inhibitor by the multienzyme complex combined ultrasonic decompressing technology, green-taste substance of kale can be removed and degraded effectively, lipoxidase activity can be deactivated, green taste of kale can be reduced greatly, and the problem of strong green taste of sliced fresh kale after processing is solved.

Owner:SDIC ZHONGLU FRUIT JUICE

Underground pressure release valve and hydraulic shaping pipe column

ActiveCN112576221AImprove shaping efficiencyConvenient multi-levelWell/borehole valve arrangementsSealing/packingPressure riseStructural engineering

The invention discloses an underground pressure release valve and a hydraulic shaping pipe column. The underground pressure release valve comprises an outer sleeve, a valve seat, a valve element and apiston connecting piece, wherein a liquid outlet hole is formed in the outer sleeve, the valve seat is fixed in the outer sleeve and is in sealing fit with the outer sleeve, a pressurizing channel and a pressure release channel are formed in the valve seat, the piston connecting piece can move downwards along with a piston of a hydraulic booster when pressurizing the interior of the outer sleeve,a transmission relation is established between the piston connecting piece and the valve element when the piston connecting piece moves downwards by a certain distance, and the valve element is disengaged from the valve seat to communicate the pressure relief channel. According to the underground pressure release valve, when the piston connecting piece descends to a certain position, the valve element can be automatically driven to be disengaged from the valve seat, the pressure release channel is connected, then the hydraulic shaping column automatically releases pressure, the whole pressurerelease process is conducted underground, frequent pressure rising and releasing on the ground manually are not needed, the pressure release speed is high, the process is safe and reliable, manpowerand material resources can be saved, and pipe column shaping efficiency can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

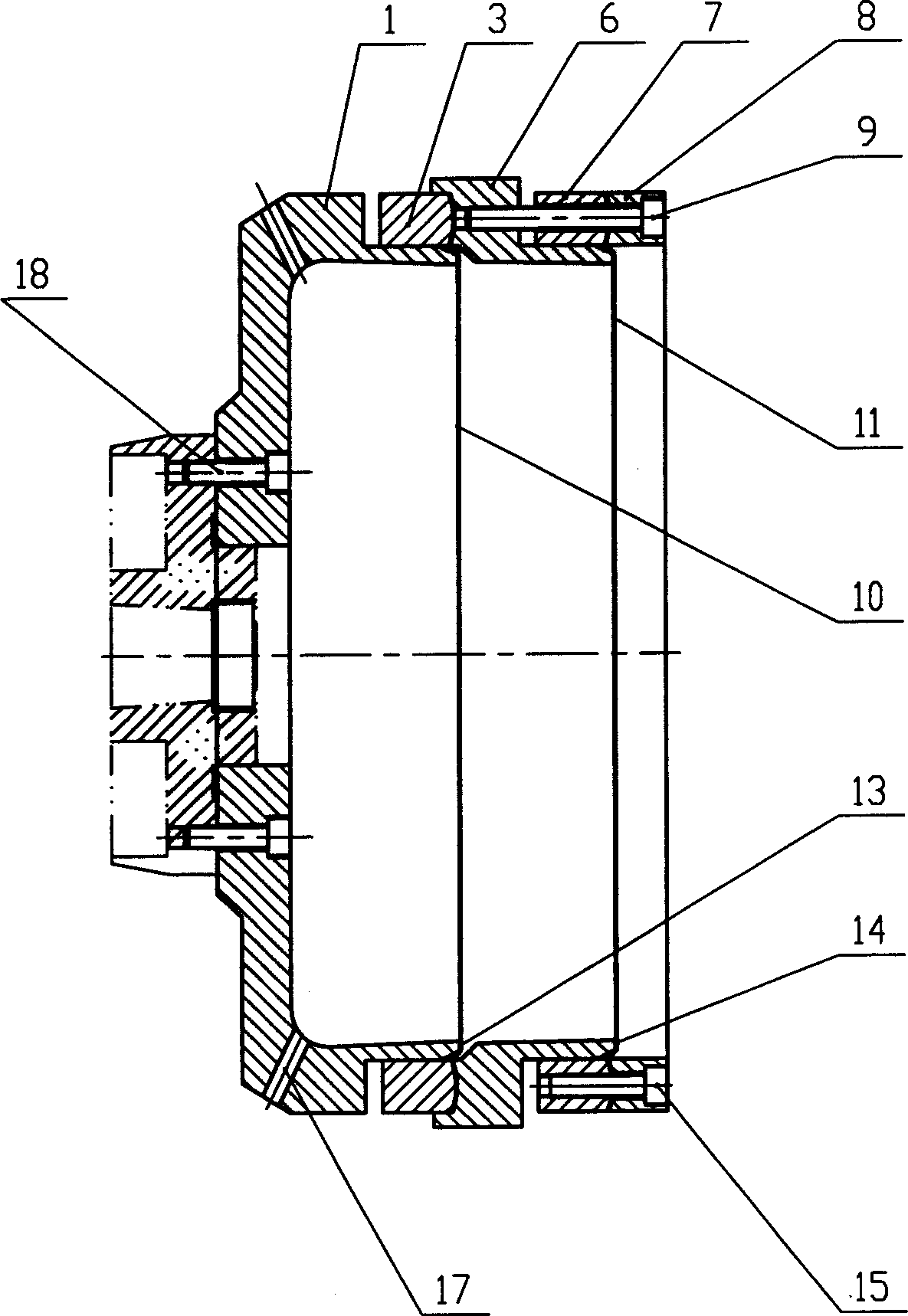

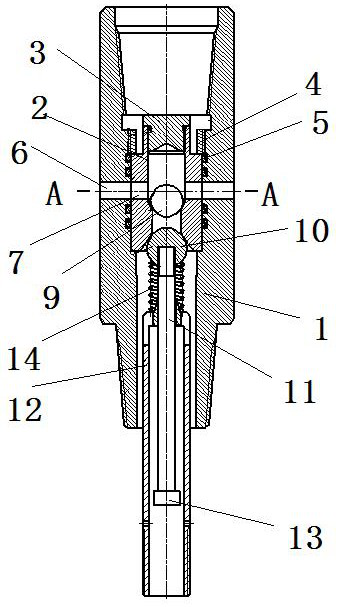

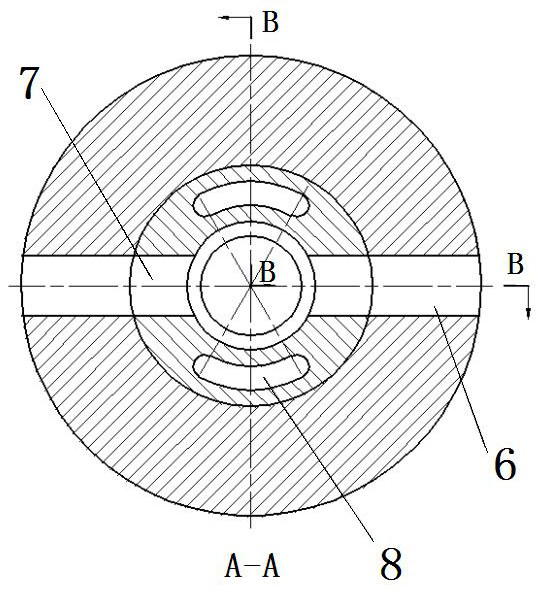

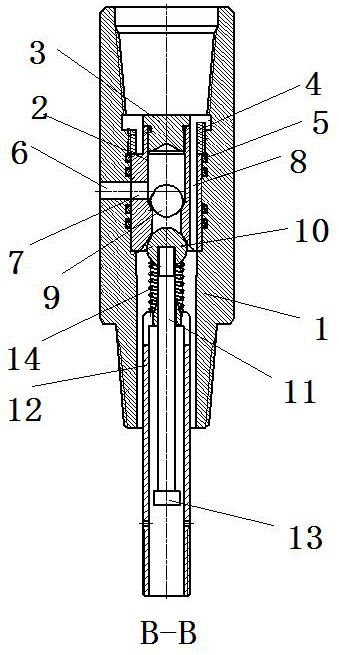

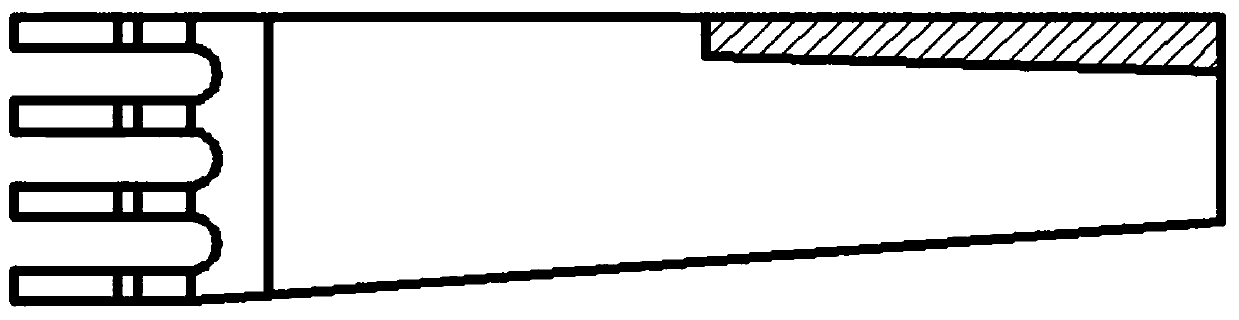

Roller burnishing tool device

ActiveUS20150367479A1Uniform finishSimple constitutionBurnishing machinesEngineeringMechanical engineering

Provided is a roller burnishing tool device including a shank; a housing connected to the shank, a connected position of the housing relative to the shank being adjustable; a roller support member supported to be capable of rotating relative to the housing and attached to follow a movement of the housing in a case of adjusting the connected position; tapered rollers supported by the roller support member; a mandrel having a tapered portion matched with the tapered rollers and movable relative to the roller support member; and a tool diameter following mechanism connecting the shank and the mandrel, having a lead groove formed spirally in a front portion of the shank, a pin member capable of moving along the lead groove, a pin member insertion hole formed in the mandrel to insert the pin member therein, and a biasing unit biasing the mandrel forward.

Owner:SUGINO MACHINE

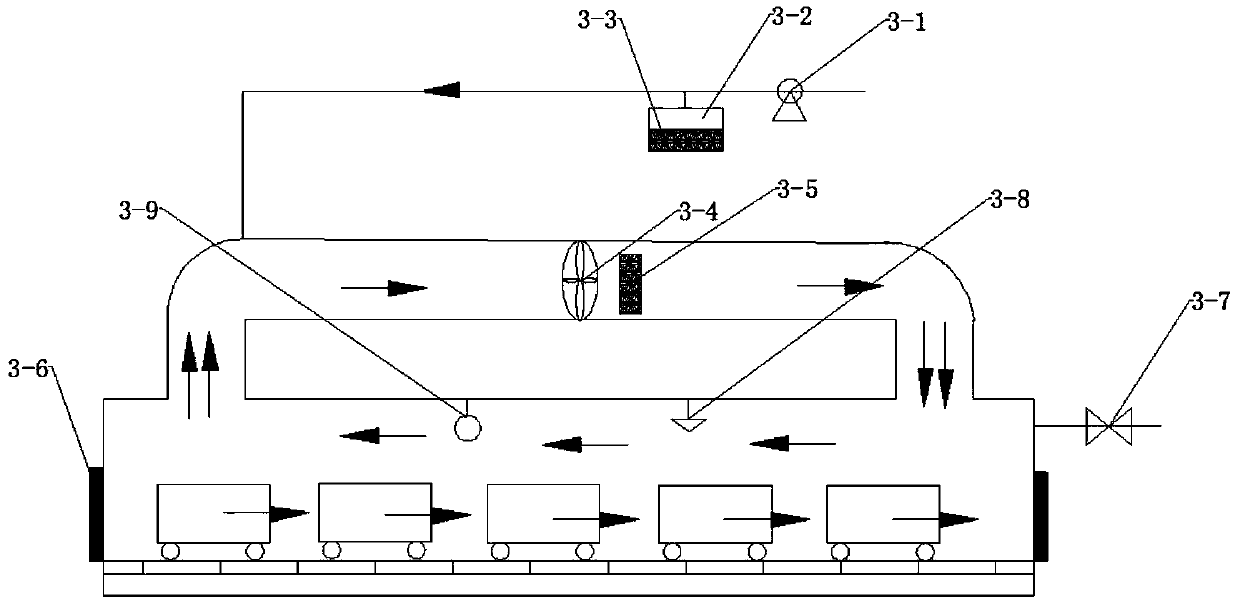

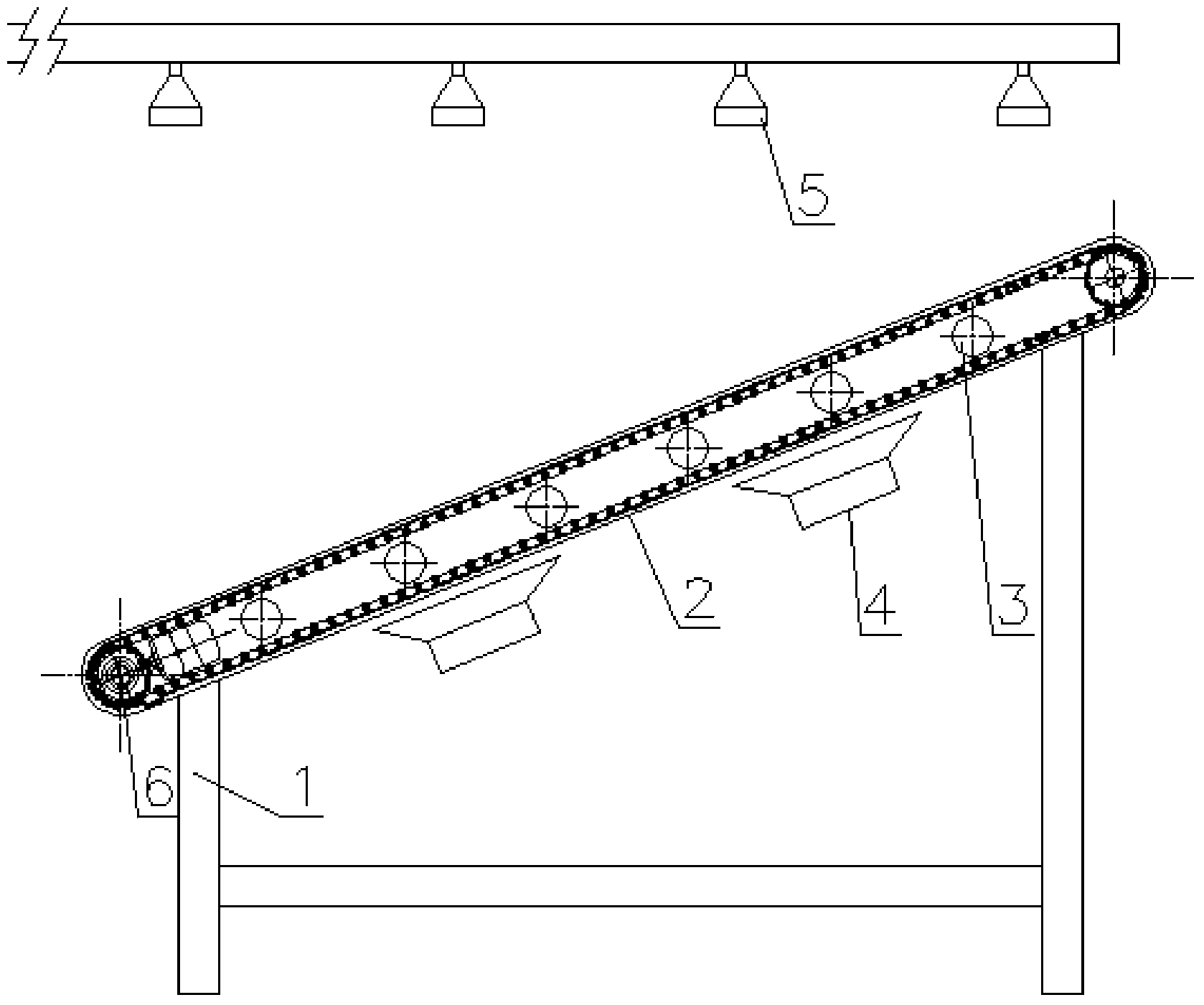

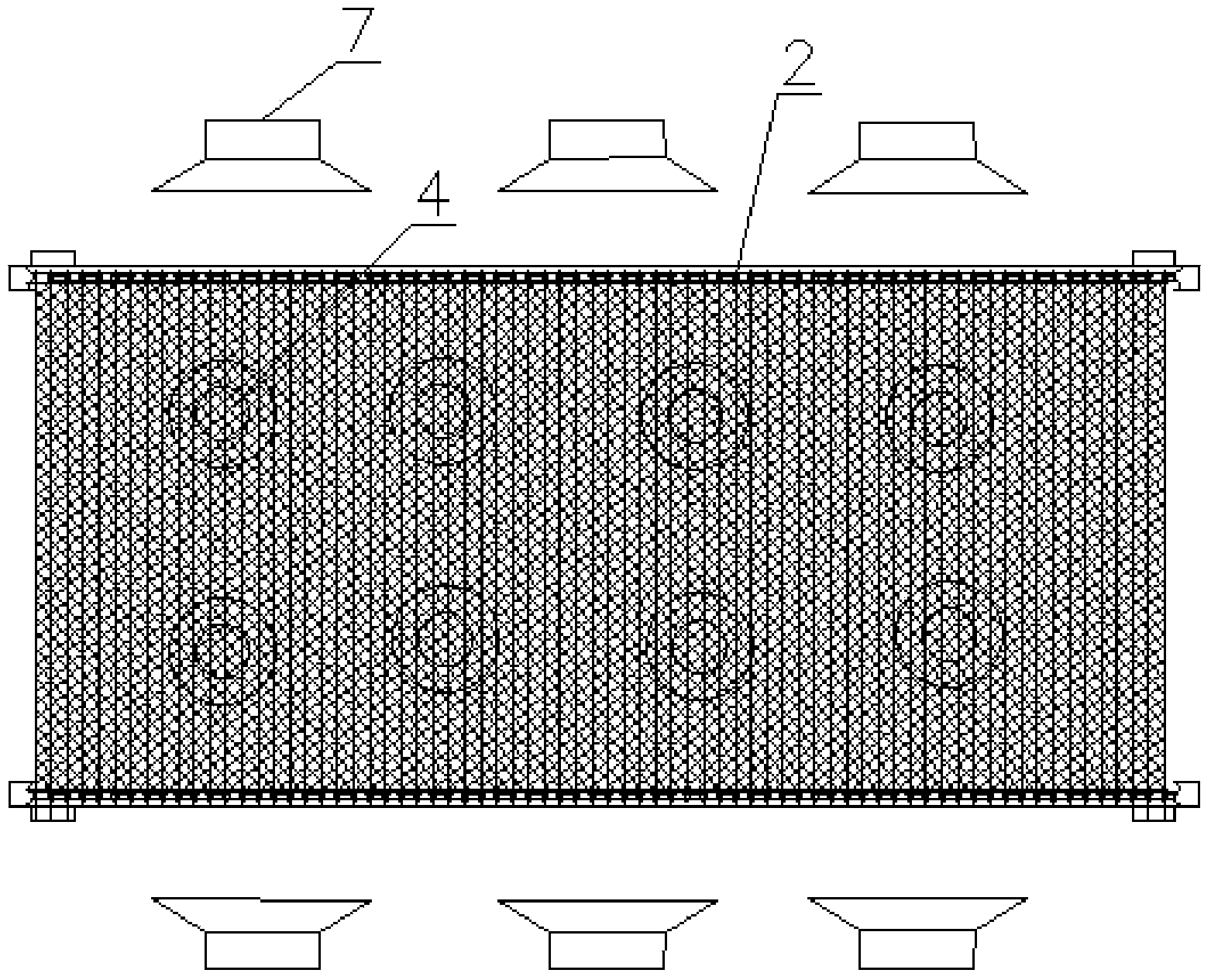

Quenching device with conveying function

InactiveCN103509923ARapid quenchingImprove processing efficiencyQuenching devicesQuenchingMaterials science

The invention relates to casting processing equipment, in particular to a quenching device with a conveying function. The quenching device comprises a conveying mechanism used for storing and moving a casting, wherein a quenching mechanism used for quenching the casting is arranged on the conveying mechanism in a moving direction of the casting. According to the quenching device, the quenching mechanism used for quenching the casting is arranged on the conveying mechanism in the moving direction of the casting, and comprises an air blowing mechanism arranged at the lower part and / or on the side surface of a net-shaped conveying chain and used for blowing air to the casting and a spraying mechanism arranged above the net-shaped conveying chain and used for spraying a quenching medium to the casting; the air blowing mechanism and the spraying mechanism work at the same time, so that the casting can be quickly quenched while conveyed on the net-shaped conveying chain, the processing efficiency is high and the problem that complex quenching device and quenching process are required for quenching in a traditional processing process is avoided.

Owner:滁州汽车与家电技术及装备研究院

Preparation process of a structured anti-corrosion layer for titanium alloy blades

InactiveCN105568213BWater corrosion resistance hasHigh hardnessSolid state diffusion coatingRare-earth elementAfter treatment

The invention discloses a preparation process for a structuralized water erosion preventing layer of a titanium alloy blade. The preparation process includes the following steps that (1) carburizing treatment is carried out, specifically, a carburized layer is prepared on the surface of the titanium alloy blade through the method that rare earth elements are doped into solid powder in a vacuum tube furnace to carry out carburizing treatment; (2) laser structuralizing nitriding treatment is carried out, specifically, laser scanning is carried out on an admission edge back arc of the carburized titanium alloy blade through a multifunctional laser generator, a discrete structuralized array area is obtained, and a discrete structuralized nitrided modified layer is obtained after treatment; and (3) fusing treatment is carried out, specifically, fusing is carried out on the discrete structuralized nitrided modified layer of the titanium alloy blade through the multifunctional laser generator, the structuralized water erosion preventing protecting layer which is in graded distribution both in the axis layer depth direction of the titanium alloy blade and the axis radius direction of the whole titanium alloy blade and with good surface quality is obtained. The abrasion resistance of the whole blade is obviously improved, and the overall hardness and abrasion resistance of the structuralized nitrided admission edge water erosion preventing modified layer are higher than those of base materials.

Owner:ZHONGYUAN ENGINEERING COLLEGE

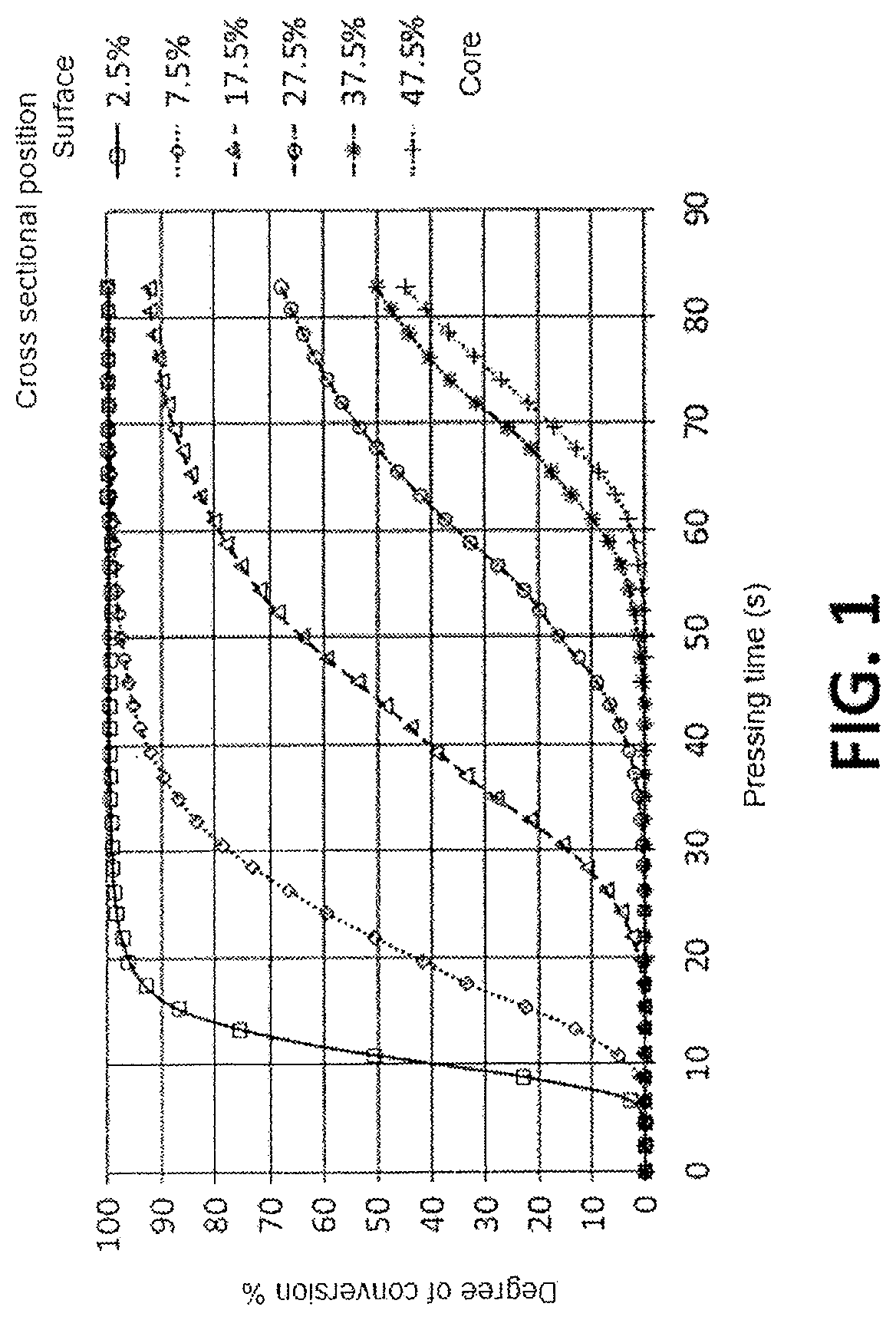

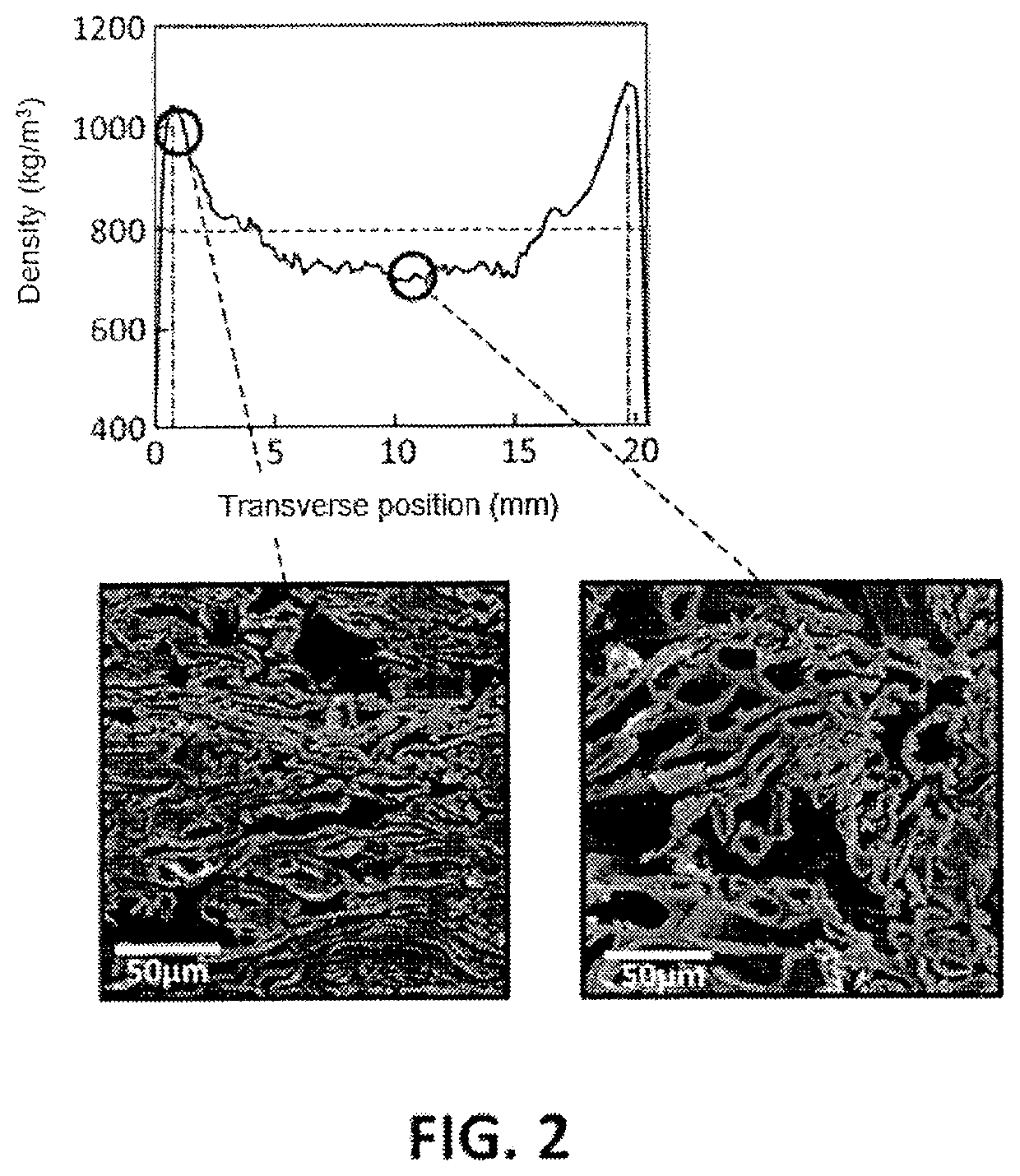

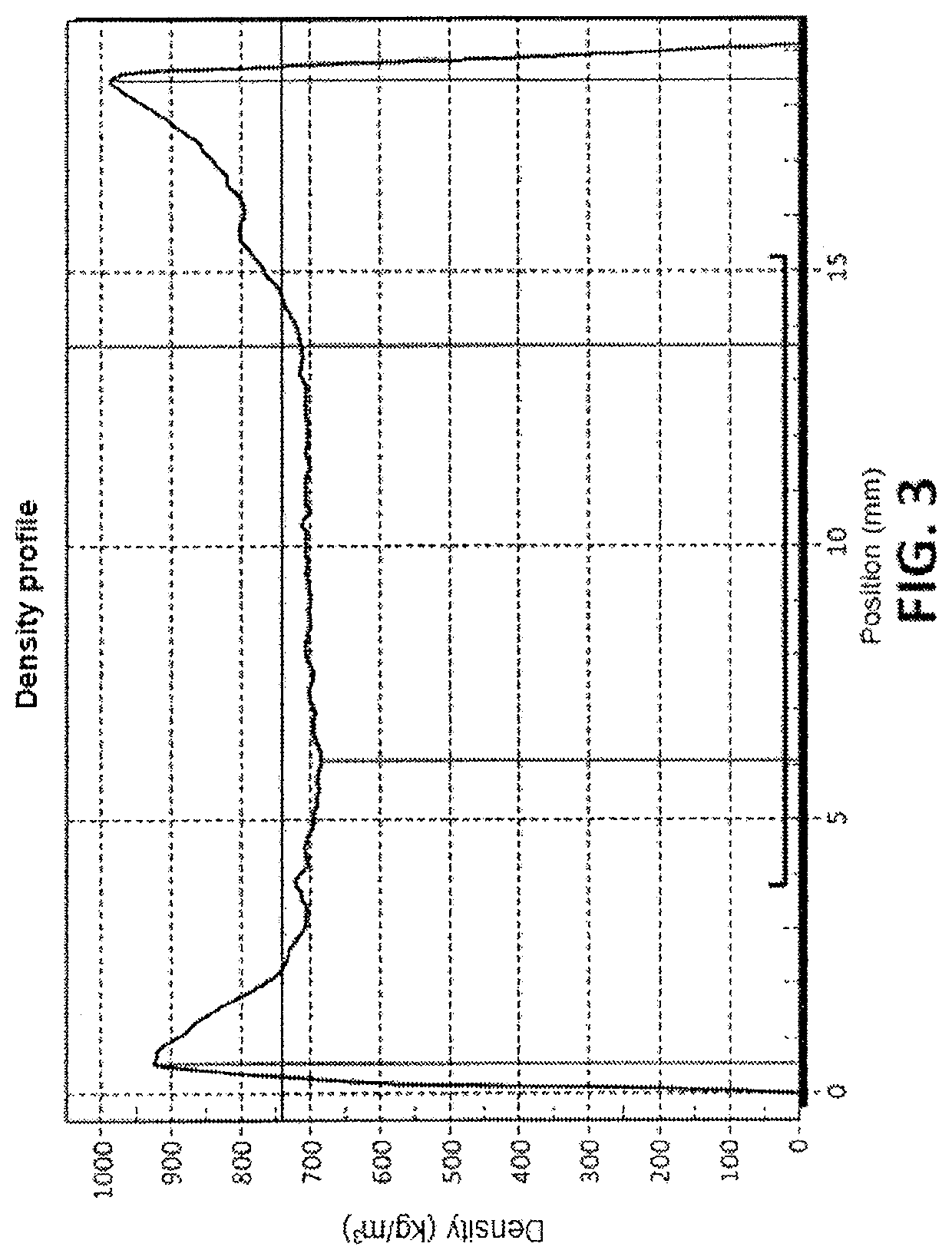

Method for the production of multilayer laminated board and resulting board

ActiveUS11065847B2Prevent movementUniform finishWood working apparatusFlat articlesFiberThermodynamics

The method is carried out by means of the stacked deposition of a series of layers of fibers and / or particles with a binder material and / or other chemical additives on a conveyor belt until a multilayer mat is produced, in which the layers are physically different from one another. The method comprises:defining the final thickness and density of the board;defining the number of layers forming the board and the type of material to be used for each layer;selecting and preparing the constituent material of each layer to be formed;depositing, in a stacked and staggered manner, the layers previously defined according to weight per m2 of each layer;pre-compacting and, optionally, pre-heating the mat;compacting the mat using pressure and heat.The invention also relates to the board produced using said method for the production of a symmetrical or asymmetrical, stable board.

Owner:FINANCIERA MADERERA

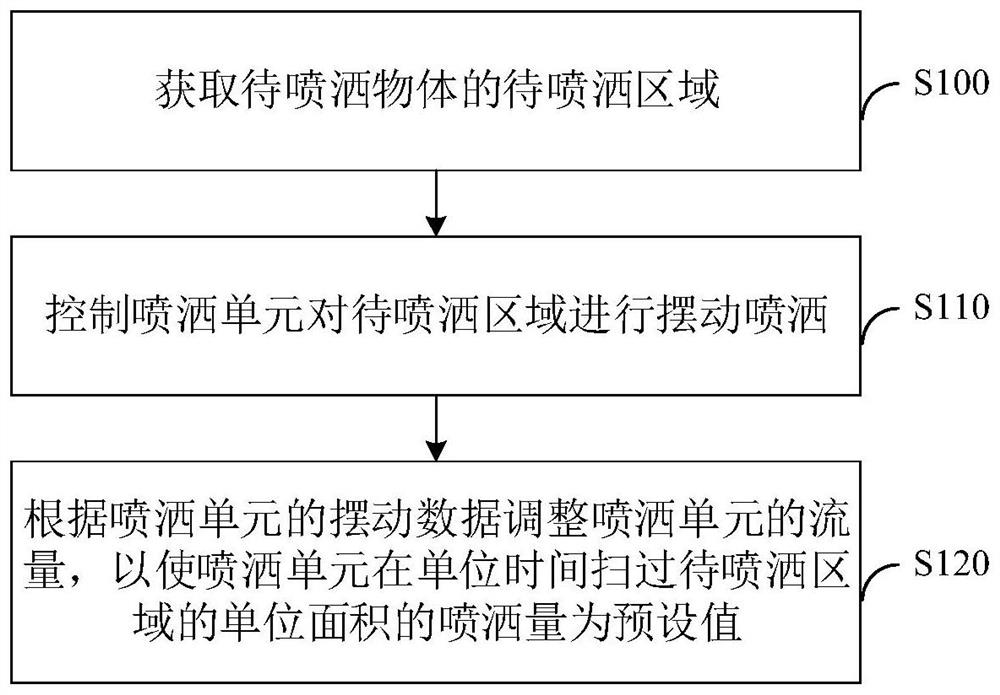

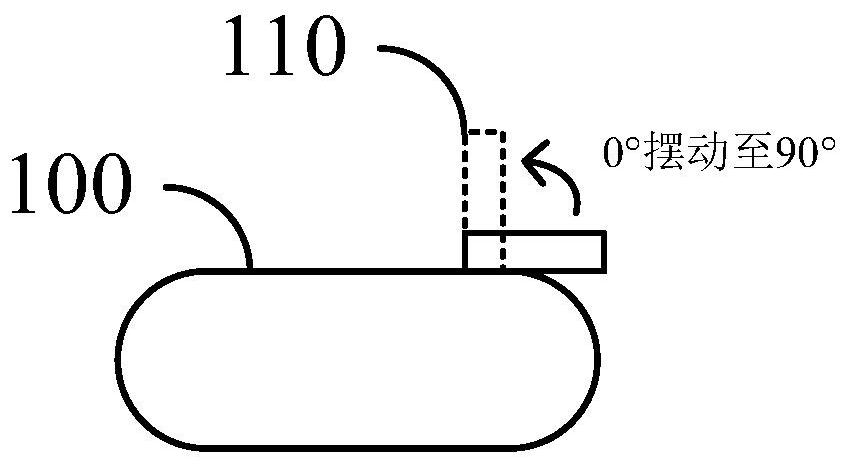

Even sprinkling operation method and relevant device

ActiveCN111744688AUniform finishImprove work efficiencyMovable spraying apparatusLiquid fertiliser regulation systemsProcess engineeringMechanical engineering

The embodiment of the invention provides an even sprinkling operation method and a relevant device, and relates to the field of intelligent equipment control. The method comprises the following stepsof: obtaining a to-be-sprinkled area of a to-be-sprinkled object; controlling a sprinkling unit to carry out swinging sprinkling on the to-be-sprinkled area; and according to the swinging angular velocity of the sprinkling unit, regulating the flow of the sprinkling unit to enable the sprinkling quantity of the sprinkling unit on the unit area of the to-be-sprinkled area swept in unit time to be as a preset value. Since the sprinkling quantity of the sprinkling unit on the unit area of the to-be-sprinkled area swept in unit time is the preset value, i.e., the sprinkling quantity for the to-be-sprinkled area of the unit area by the sprinkling unit is fixed, the sprinkling quantity for the unit area of the to-be-sprinkled area can be the same, and therefore, a sprinkling operation task can be evenly finished to improve operation efficiency, save resources and protect the environment.

Owner:GUANGZHOU XAIRCRAFT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com