Decorative concrete with uniform surface and method of forming the same

a decorative concrete and uniform surface technology, applied in the field of decorative concrete with a highly uniform surface, can solve the problems of difficult installation or difficult or costly installation, and the use of conventional techniques that do not provide the desired effect, and achieve the effect of improving the uniformity and aesthetics of the top surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

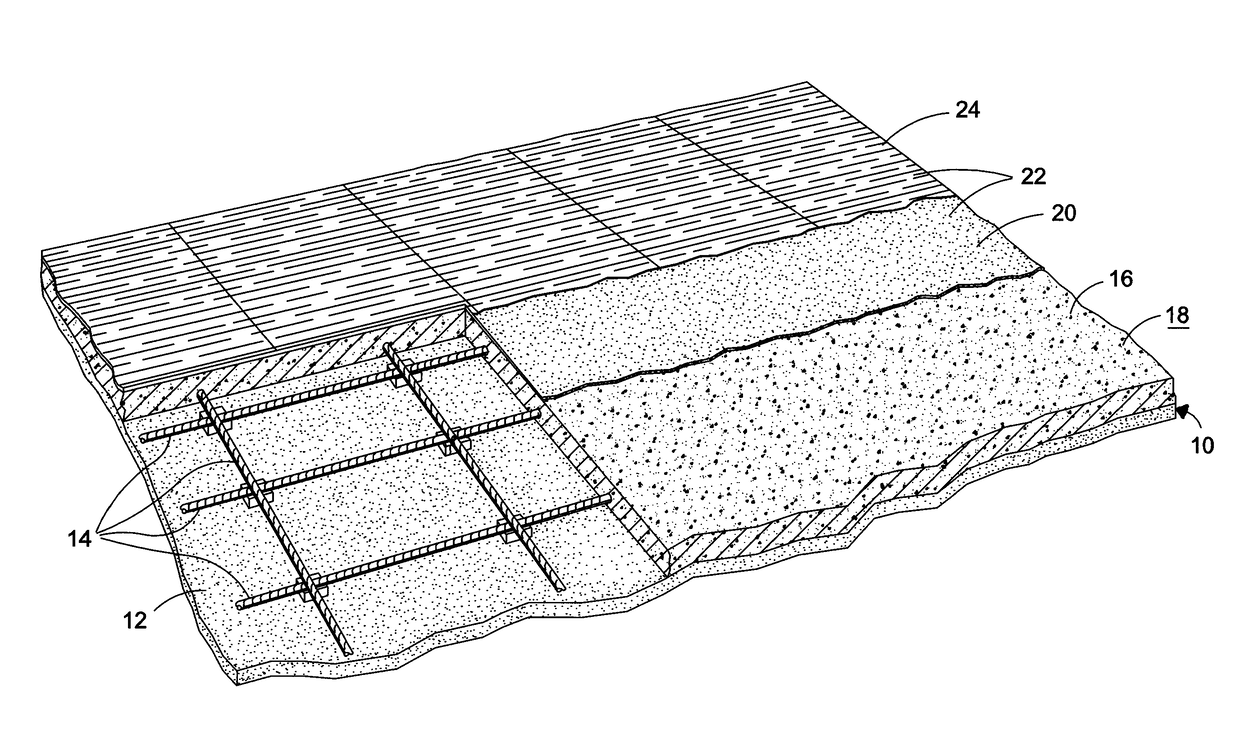

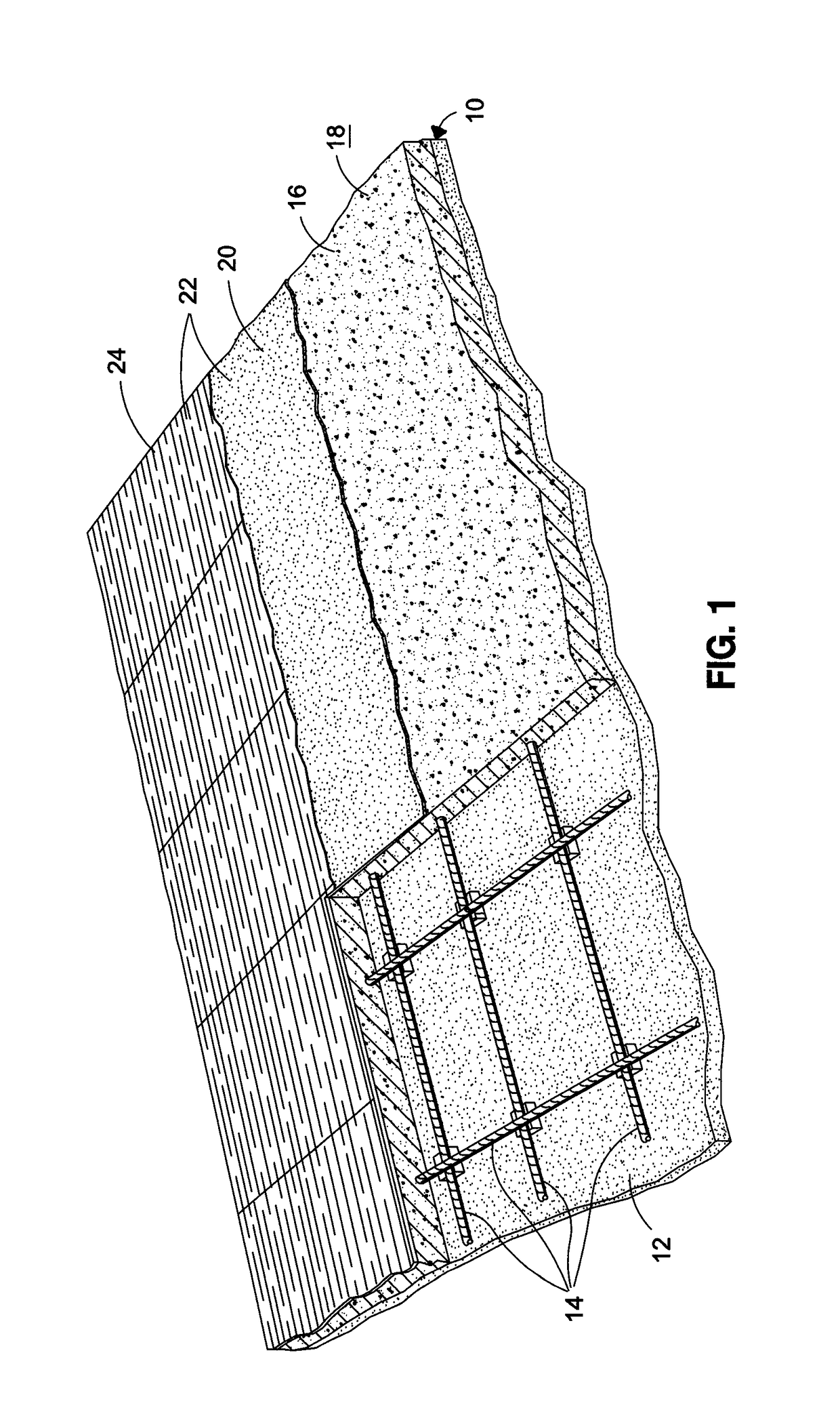

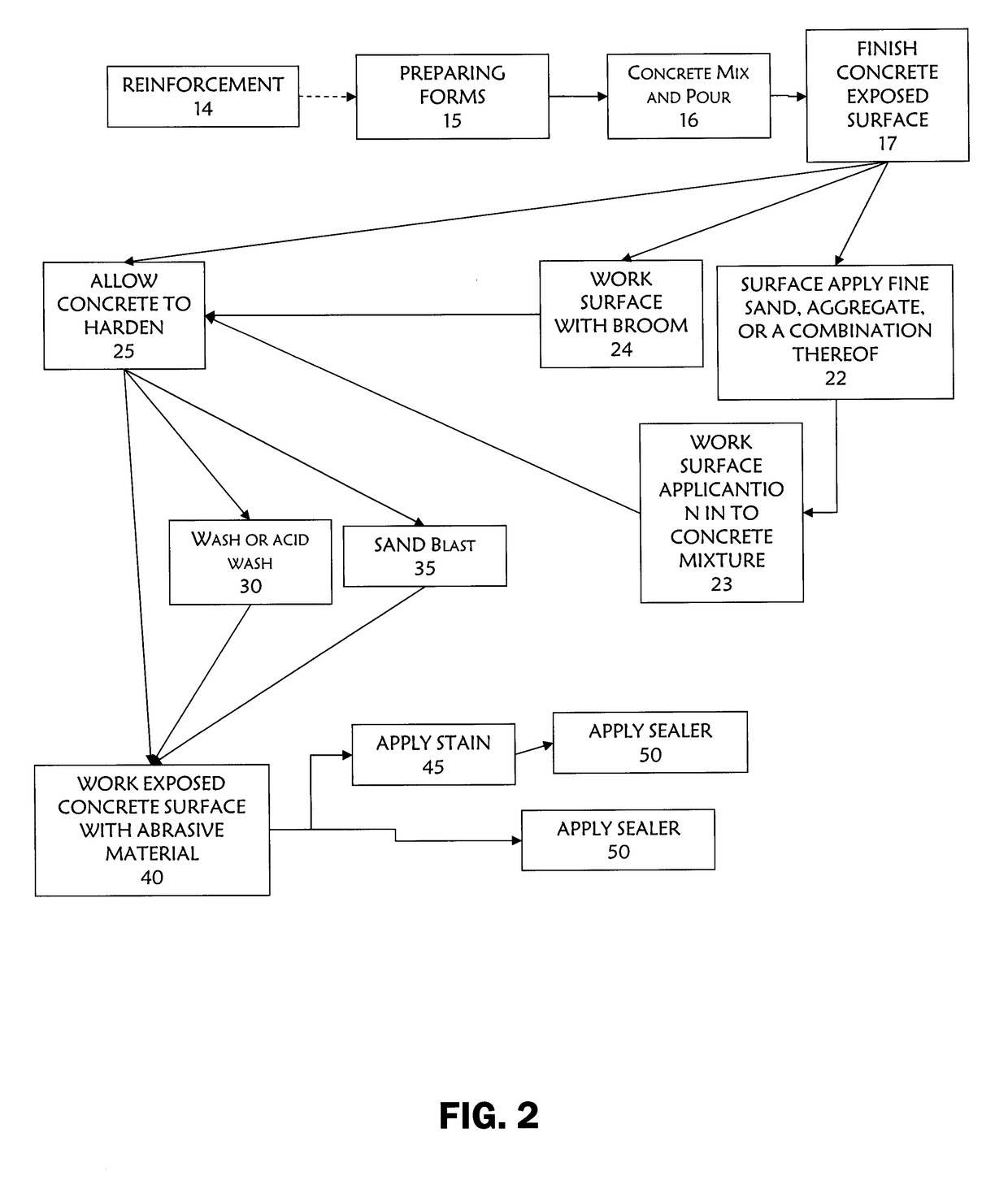

[0016]Referring first to FIGS. 1 and 2, the decorative concrete structure 10 of the present invention providing a highly uniform surface and the method for preparing a decorative concrete structure 10 is shown. Various aspects of preparing the decorative concrete structure 10 result in a decorative concrete structure 10 which provides a highly uniform surface of the concrete.

[0017]An initial step in forming the decorative concrete structure 10 may optionally comprise preparing a subgrade 8. The subgrade 8 may provide uniform support for the decorative concrete structure 10. Typically, the initial step involves excavating the ground to a desired elevation and compacting the ground preferably to 90% compaction to ensure a uniform and stable support. After compacting the subgrade 8, the subgrade may be covered with a layer of clean, moist, fill sand 12 which preferably defines a minimum thickness of approximately four inches. Although the fill sand 12 is not necessary for the method of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| abrasive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com